Preparation method of nano-cellulose-based oxygen isolation composite film

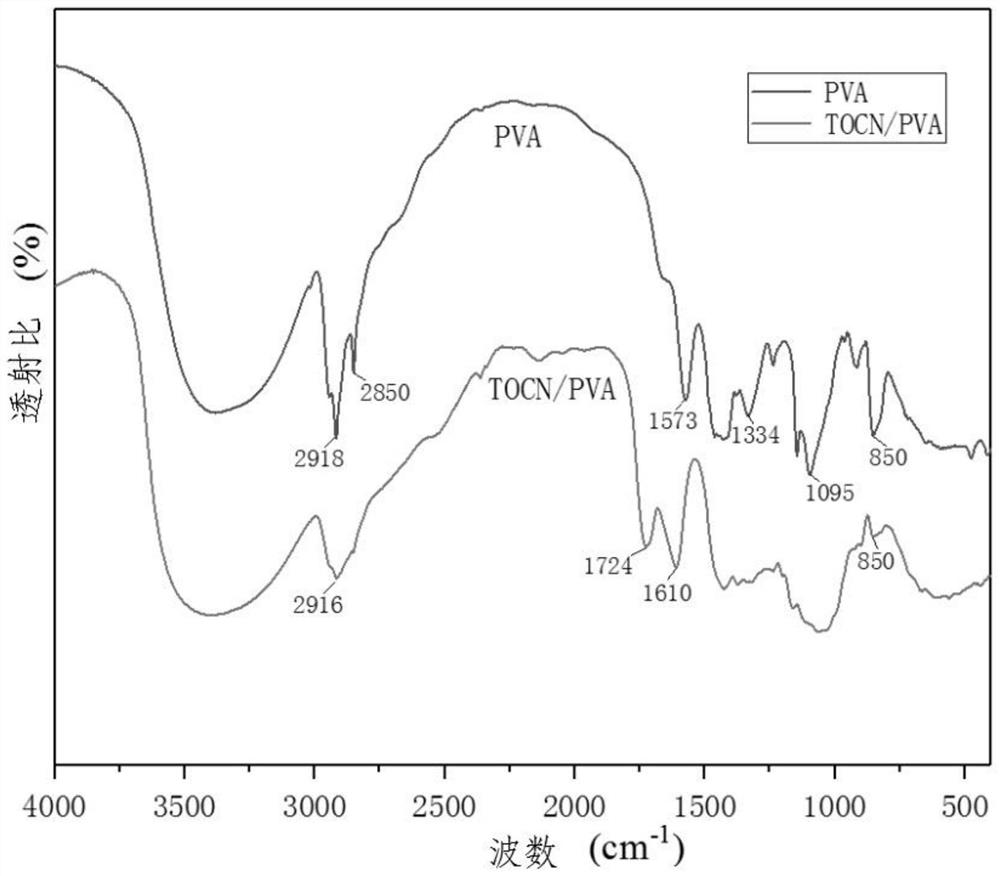

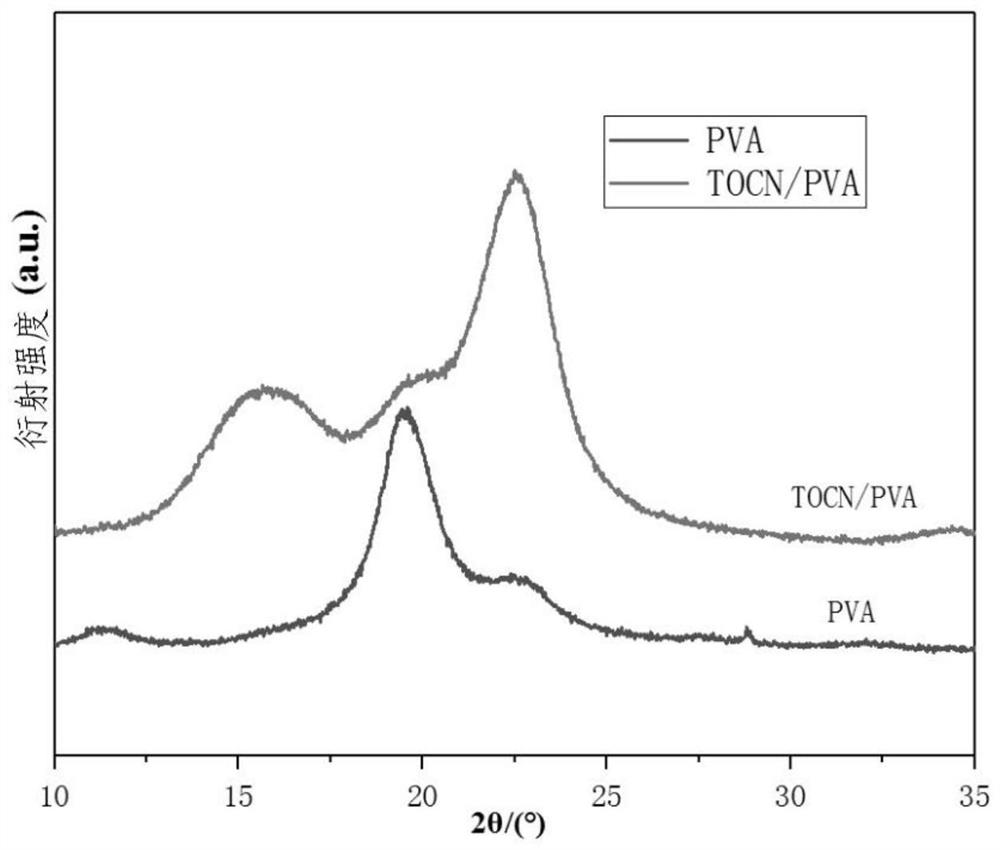

A technology of nanocellulose and composite film, which is applied in the field of preparation of nanocellulose-based oxygen-barrier composite film, which can solve the problems of poor water resistance, easy shrinkage of TOCN film, decline in mechanical properties and oxygen barrier performance, and achieve excellent water resistance and The effect of mechanical properties and excellent oxygen barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the nanocellulose-based oxygen-barrier composite film of the present embodiment, the method is:

[0028] S1. Add sodium chlorite a, glacial acetic acid a and distilled water to the larch pulp powder to obtain a pre-extraction solution, perform delignification treatment in a water bath at a temperature of 75°C, and add sodium chlorite b every 1 hour and glacial acetic acid b, add a total of 2 times, carry out delignification treatment for 4 hours, and obtain the initial lignocellulose extract, and then vacuum filter, wash with deionized water until neutral, wash with acetone, and store at a temperature of 30°C dry under the condition of dry, obtain the lignocellulose of water content≤10%; The addition amount of described sodium chlorite b every time is the same as the addition amount of sodium chlorite a in the described pre-extract; The glacial acetic acid b The supplementary amount each time is the same as the addition amount of glacial acetic...

Embodiment 2

[0055] The preparation method of the nanocellulose-based oxygen-barrier composite film of the present embodiment, the method is:

[0056] S1. Add sodium chlorite a, glacial acetic acid a and distilled water to the larch pulp powder to obtain a pre-extraction solution, perform delignification treatment in a water bath at a temperature of 75°C, and add sodium chlorite b every 1 hour And glacial acetic acid b, add 2 times in total, carry out delignification treatment for 4 hours, obtain the lignocellulose primary extract, then vacuum filter, wash with deionized water until neutral, wash with acetone, at a temperature of 25 ℃ dry under the condition of dry, obtain the lignocellulose of water content≤10%; The addition amount of described sodium chlorite b every time is the same as the addition amount of sodium chlorite a in the described pre-extract; The glacial acetic acid b The supplementary amount each time is the same as the addition amount of glacial acetic acid a in the pre-e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com