Water-based two-component polyurethane paint

A two-component polyurethane and water-based polyurethane technology, which is applied in the field of coatings and paints, can solve the problems of easy aging of the coating film, cracking of the wall surface, and affecting the appearance of buildings, etc., to achieve enhanced application range, water resistance and good mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

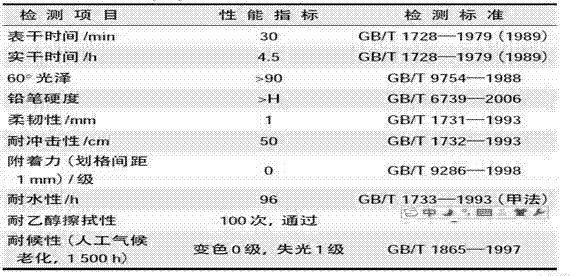

Image

Examples

Embodiment 1

[0035] A water-based two-component polyurethane coating is characterized in that the coating is configured by A component and B component, wherein the formula of A component is as follows:

[0036] 60 parts of hydroxyl polyacrylate dispersion

[0037] Leveling wetting agent 0.2 parts

[0038] 12 parts polyacrylic acid

[0039] 20 parts polyisocyanate

[0040] 30 parts of crosslinking agent

[0041] Filling 10 parts

[0042] 1 part of N,N-dimethylethanolamine

[0043] Co-solvent 0.2 parts

[0044] 1 part antifreeze

[0045] Wetting agent 0.2 parts

[0046] 0.2 part of defoamer

[0047] Thickener 0.1 parts

[0048] Wetting agent 0.1 part

[0049] 1 part preservative

[0050] pH regulator

[0051] 30 parts of deionized water; 6 parts of B component polyisocyanate curing agent, add component A into the container according to the above formula, add deionized water, leveling wetting agent, co-solvent, and defoamer in sequence under medium-speed stirring , Thickener, dis...

Embodiment 2

[0057] A water-based two-component polyurethane coating is characterized in that the coating is configured by A component and B component, wherein the formula of A component is as follows:

[0058] 80 parts of hydroxyl polyacrylate dispersion

[0059] 0.3 parts of leveling wetting agent

[0060] 25 parts polyacrylic acid

[0061] 30 parts polyisocyanate

[0062] 40 parts of crosslinking agent

[0063] Filling 15 parts

[0064] N,N-Dimethylethanolamine 2 parts

[0065] Co-solvent 0.5 parts

[0066] Antifreeze 2 parts

[0067] Wetting agent 0.5 parts

[0068] 0.5 parts of defoamer

[0069] Thickener 0.3 parts

[0070] Wetting agent 0.3 parts

[0071] 2 parts preservative

[0072] pH regulator

[0073] 40 parts of deionized water; 9 parts of B component polyisocyanate curing agent, add component A into the container according to the above formula, and add deionized water, leveling wetting agent, cosolvent, and defoamer in sequence under medium speed stirring , Thickene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com