High-strength normal-temperature-insoluble PVA shopping bag

A shopping bag and high-strength technology, which is applied in the field of high-strength insoluble PVA shopping bags at room temperature, can solve the problems of poor water resistance and cannot be hydrolyzed quickly, achieve good water resistance and mechanical properties, and ensure the effect of green environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

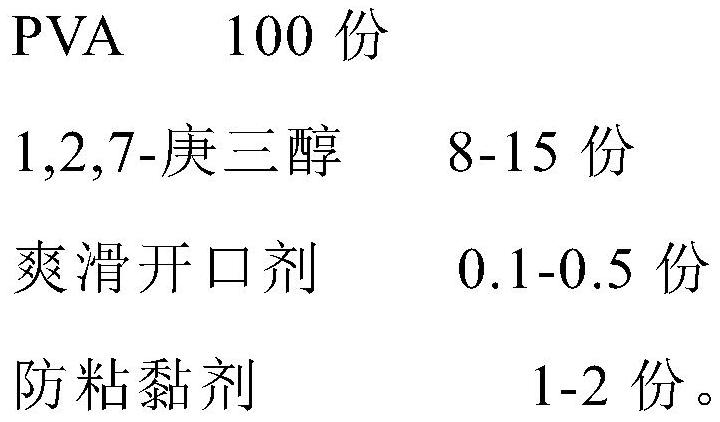

[0033] (1) Put 100 parts by weight of PVA into a high-speed mixer, stir and heat up to 70°C, and slowly add 8 parts by weight of 1,2,7-heptanetriol;

[0034] (2) Stir at low speed for 120 minutes, and control the temperature at 80°C until PVA fully absorbs 1,2,7-heptanetriol;

[0035] (3) Add 0.1 parts by weight of smooth opening agent and 1 part by weight of anti-adhesive agent and mix well;

[0036] (4) The uniformly mixed material is extruded and granulated by a twin-screw extruder. ℃ / 180℃ / 180℃, and then blown into a film by a thermoplastic extrusion blown film machine. The temperature of blown film is 140℃ / 160℃ / 180℃ / 185℃ / 185℃ / 180℃, and then the Machine prepared PVA shopping bags with a thickness of 10 μm.

Embodiment 2

[0038] (1) Put 100 parts by weight of PVA into a high-speed mixer, stir and heat up to 75°C, and slowly add 12 parts by weight of 1,2,7-heptanetriol;

[0039] (2) Stir at low speed for 80 minutes, and control the temperature at 90°C until PVA fully absorbs 1,2,7-heptanetriol;

[0040] (3) Add 0.3 parts by weight of smooth opening agent and 1.5 parts by weight of anti-adhesive agent and mix well;

[0041] (4) The uniformly mixed material is extruded and granulated by a twin-screw extruder. ℃ / 180℃ / 180℃, and then blown into a film by a thermoplastic extrusion blown film machine. The temperature of blown film is 140℃ / 160℃ / 180℃ / 185℃ / 185℃ / 180℃, and then the Machine prepared PVA shopping bags with a thickness of 40 μm.

Embodiment 3

[0043] (1) Put 100 parts by weight of PVA into a high-speed mixer, stir and heat up to 80°C, and slowly add 15 parts by weight of 1,2,7-heptanetriol;

[0044] (2) Stir at low speed for 50 minutes, and control the temperature at 100°C until PVA fully absorbs 1,2,7-heptanetriol;

[0045] (3) Add 0.5 parts by weight of smooth opening agent and 2 parts by weight of anti-sticking agent and mix well;

[0046] (4) The uniformly mixed material is extruded and granulated by a twin-screw extruder. ℃ / 180℃ / 180℃, and then blown into a film by a thermoplastic extrusion blown film machine. The temperature of blown film is 140℃ / 160℃ / 180℃ / 185℃ / 185℃ / 180℃, and then the Machine prepared PVA shopping bags with a thickness of 80 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com