Plastic film

A plastic film and mixing technology, which is applied in the field of plastic film, can solve the problems that the physical and mechanical properties of the product, that is, the elongation at break of the tensile properties cannot meet the requirements of physical properties, and achieve easy industrialization, high production efficiency, and simple process. Effect

Inactive Publication Date: 2014-11-19

TIANJIN KAIXUAN PLASTIC PROD

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, there are many materials in the degradable material market, but they are roughly divided into photothermal degradable plastics and pure biodegradable plastics. However, the existing degradable products only consider one aspect of the degradation environment, and the physical and mechanical properties of the products are The length, etc. cannot meet the actual physical performance requirements of the final product

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

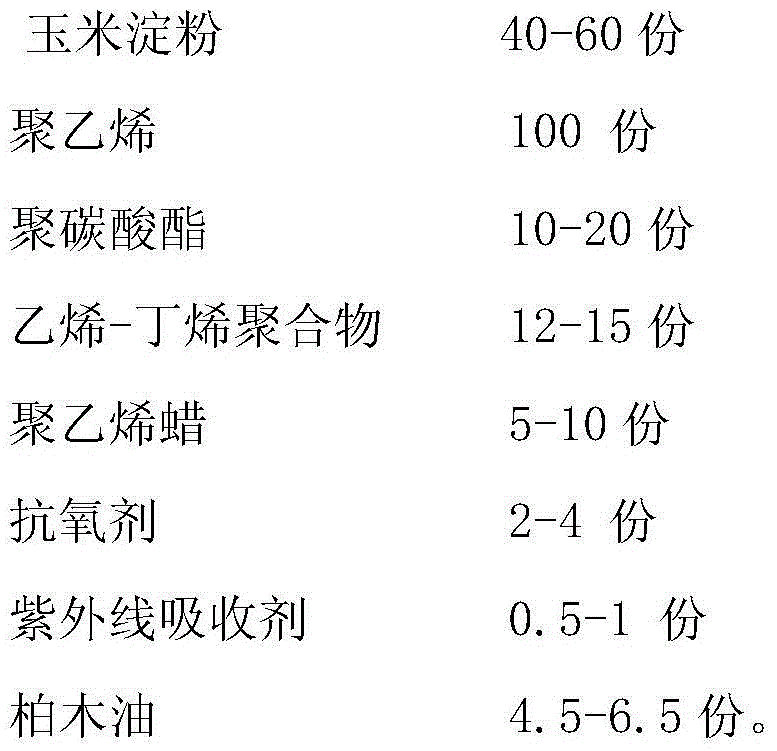

[0017] A kind of plastic film, its component and weight number are:

[0018]

Embodiment 2

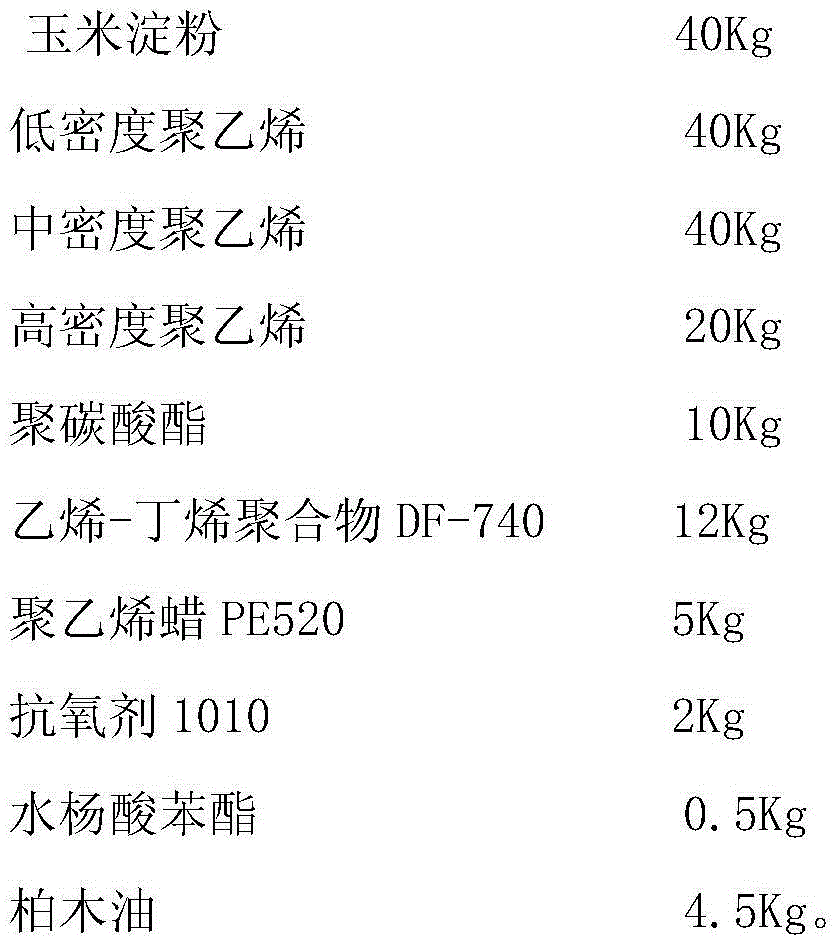

[0020] A kind of plastic film, its component and weight number are:

[0021]

[0022]

Embodiment 3

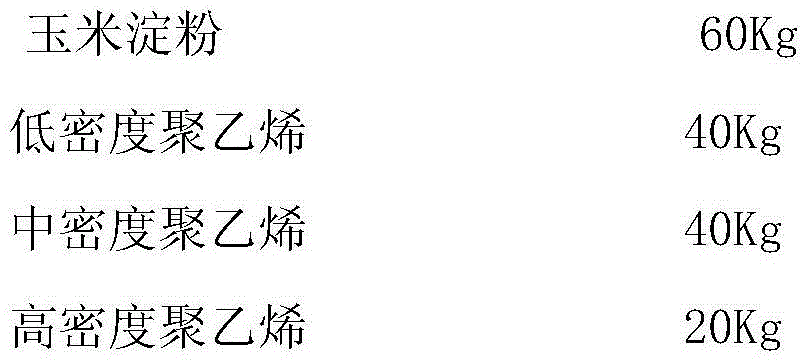

[0024] A kind of plastic film, its component and weight number are:

[0025]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a plastic film. The plastic film comprises the following components in parts by weight: 40-60 parts of corn starch, 100 parts of polyethylene, 10-20 parts of polycarbonates, 12-15 parts of thylene-butylene polymers, 5-10 parts of polyethylene wax, 2-4 parts of an anti-oxygen, 0.5-1 part of an ultraviolet light absorber and 4.5-6.5 parts of cedarwood oil. The oxygen isolating and degradable plastic film provided by the invention can be decomposed automatically under the influences of oxygen enrichment and microorganisms, the abandoned film can be degraded and digested completely through the microorganisms in nature to generate carbon dioxide and water ultimately, and compared with LDPE (low-density polyethylene) plastic film with same thicknesses, the oxygen isolating property can be improved by 40%. The preparation method of the plastic film provided by the invention has the advantages that the process is simple, the production efficiency is high, the implementations of the industrialization is easy and the plastic film can be produced through common plastic film blasting machines.

Description

technical field [0001] The invention belongs to the field of plastic film materials, in particular to a plastic film. Background technique [0002] Degradable films not only have the functions and characteristics of traditional plastics, but also can be split and degraded in the natural environment through the action of microorganisms in soil and water or ultraviolet rays in sunlight after reaching the end of their service life, and finally re-enter the ecology in a reduced form. environment, back to nature. Domestically developed varieties have covered photodegradation, photobiodegradation, photooxidative biodegradation, high starch content biodegradation, high calcium carbonate filled photooxygen degradation, and full biodegradation. At present, there are many materials in the degradable material market, but they are roughly divided into photothermal degradable plastics and pure biodegradable plastics. Length, etc. cannot meet the actual physical performance requirements...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/06C08L3/02C08L69/00C08L23/08C08L91/00

CPCC08L23/06C08J5/18C08J2303/02C08J2323/06C08J2423/06C08L3/02C08L2201/06C08L2201/14C08L2203/162C08L2205/025C08L2205/035C08L2207/062C08L2207/066

Inventor 郝永强

Owner TIANJIN KAIXUAN PLASTIC PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com