Agricultural insect killing and oxygen isolating environment-friendly degradable plastic film

A plastic film and environmental protection technology, applied in the direction of insecticide, application, biocide, etc., can solve the problems of lack of mechanical properties of film materials, poor oxygen barrier properties of films, and affecting packaging quality, etc., to achieve easy industrial implementation and high production efficiency The effect of high and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

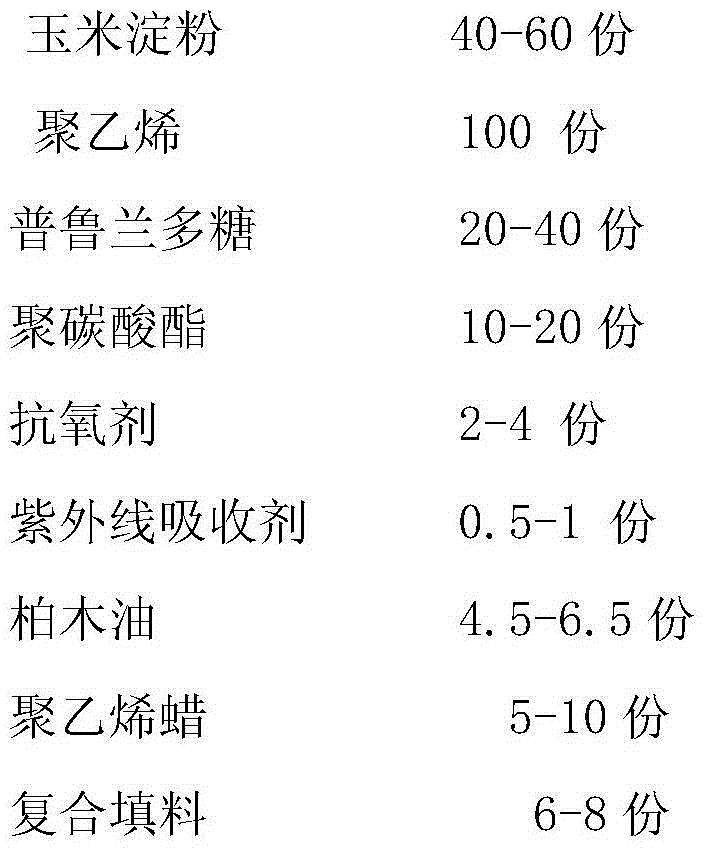

[0025] (1) A kind of degradable plastic film of agricultural desinsection environmental protection oxygen barrier, it adopts the double-sided coating insecticide at plastic film to make, and described plastic film is made by the raw material of following weight (kg):

[0026]

[0027]

[0028] Coat insecticide slurry 4g on every square meter of film.

[0029] (2) The insecticide slurry is prepared by mixing the raw materials of the following parts by weight:

[0030] Polyvinyl alcohol 65,

[0031] Chinese medicine deworming extract 3,

[0032] Cross-linking agent TAIC 1,

[0033] Chlorinated paraffin 0.3,

[0034] Alcohol ether glycoside 0.3;

[0035] (3) The described Chinese medicine deworming extract is made from the following raw materials in parts by weight:

[0036] Safflower 1,

[0037] Shantou root 2,

[0038] Soil wattle bark 1,

[0039] 100 parts 3,

[0040] wolf poison 1,

[0041] hibiscus flower 1,

[0042] Pyrethrum 1;

[0043] (4) The preparatio...

Embodiment 2

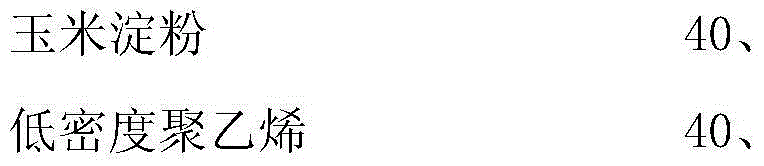

[0053] (1) A kind of degradable plastic film of agricultural desinsection environmental protection oxygen barrier, it adopts the double-sided coating insecticide at plastic film to make, and described plastic film is made by the raw material of following weight (kg):

[0054]

[0055] Coating 5g of insecticide slurry on every square meter of film;

[0056] (2) The insecticide slurry is prepared by mixing the raw materials of the following parts by weight:

[0057] Polyvinyl alcohol 70,

[0058] Chinese medicine deworming extract 4,

[0059] Cross-linking agent TAIC 1.5,

[0060] Chlorinated paraffin 0.4,

[0061] Alcohol ether glycoside 0.4;

[0062] (3) The described Chinese medicine deworming extract is made from the following raw materials in parts by weight:

[0063] Safflower 1.5,

[0064] Shantou root 3,

[0065] Soil wattle skin 1.5,

[0066] 100 parts 4,

[0067] wolfbane 1.5,

[0068] Hibiscus 2,

[0069] Pyrethrum 1.5;

[0070] (4) The preparation method...

Embodiment 3

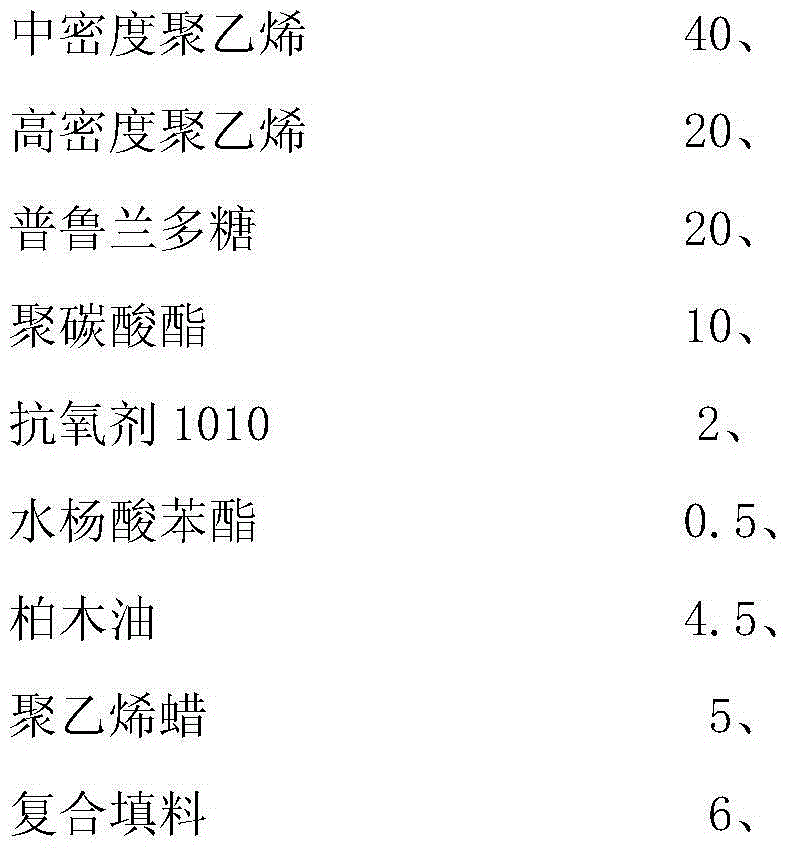

[0080] (1) A kind of degradable plastic film of agricultural desinsection environmental protection oxygen barrier, it is to adopt the double-sided coating desinsection agent of plastic film to make, and described plastic film is made by the raw material of following weight (kg):

[0081]

[0082] Coat insecticide slurry 6g on every square meter of film.

[0083] (2) The insecticide slurry is prepared by mixing the raw materials of the following parts by weight:

[0084] Polyvinyl alcohol 75,

[0085] Chinese medicine deworming extract 5,

[0086] Cross-linking agent TAIC 2,

[0087] Chlorinated paraffin 0.5,

[0088] Alcohol ether glycoside 0.5;

[0089] (3) The described Chinese medicine deworming extract is made from the following raw materials in parts by weight:

[0090] Safflower 2,

[0091] Shantou root 4,

[0092] Soil thorn skin 2,

[0093] 100 parts 5,

[0094] wolf poison 2,

[0095] Hibiscus 3,

[0096] Pyrethrum 2;

[0097] (4) The preparation method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com