Method for preventing browning in production of konjak powder

A technology of konjac flour and konjac flying flour is applied in the field of konjac flour processing, which can solve the problem of poor adhesion between starch or cellulose and fresh konjac slices, achieve good color protection effect, prevent browning, and reduce equipment investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

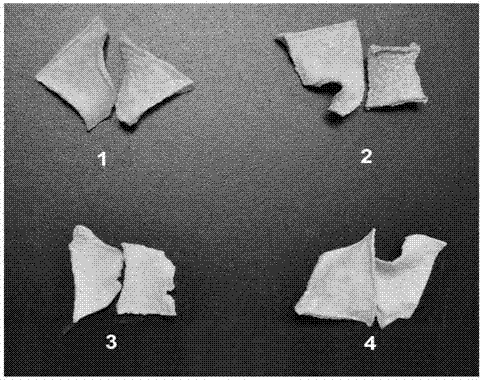

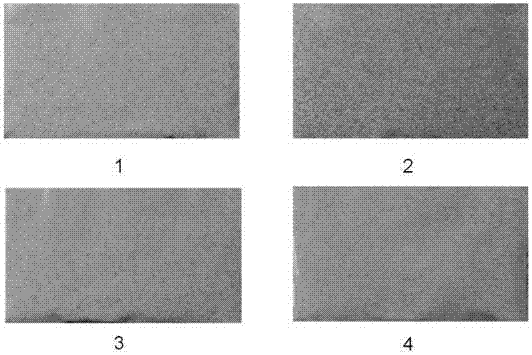

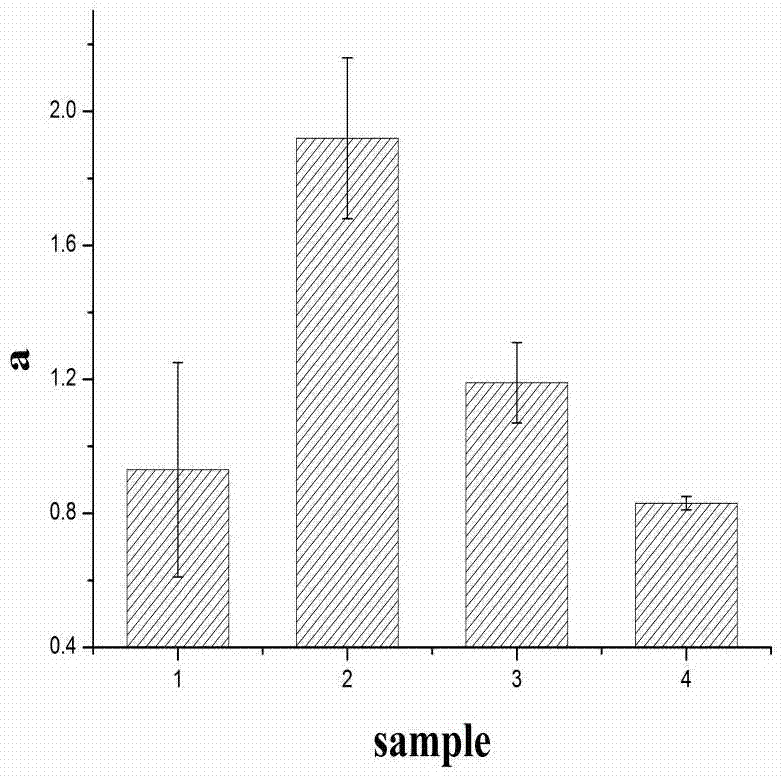

[0029] Example 2 Take 30 kg of fresh konjac and put it into a brush-type cleaning and peeling machine for cleaning to remove the skin and remove the terminal buds; cut the cleaned fresh konjac into slices with a slicer. Weigh 2 kg of starch, as group No. 1; weigh and weigh 2 kg of starch, 2 million activity units of papain 2g, mix into color-protecting powder, as group No. 2; weigh 2 kg of konjac flying powder, as group No. 3; Weigh 2 kg of konjac powder and 0.2 g of 2 million activity units of papain, and mix them into color-protecting powder as No. 4 group. Sprinkle the mixed color-protecting agent on the fresh-cut konjac slices with a powder sprinkler; put the color-protected konjac slices into the belt drying equipment and dry at 60°C for 6 hours until the moisture content reaches 13%-15%; dry The konjac chips after are pulverized by pulverizer; Grinding konjac flour after pulverizing by grinder; The konjac flour after grinding is placed on vibrating sieving machine 40 mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com