Patents

Literature

33results about How to "Achieve environmental friendliness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing acrylate-modified anionic polyurethane composite emulsion

The invention discloses a method for preparing an acrylate-modified anionic polyurethane composite emulsion, belonging to the technical field of adhesive preparation. The method disclosed by the invention comprises the following steps: carrying out polymerization on isocyanate and polymer dihydric alcohol through replacing an organic cosolvent used in the traditional polyurethane preparation process with an acrylate monomer so as to obtain a hydroxyl-obtaining polyurethane prepolymer; after cooling, introducing a proper amount of acrylate monomer and an initiator; and further initiating the polymerization of the acrylate monomer under the action of the initiator after neutralization and water dispersion so as to prepare the acrylate-modified anionic polyurethane composite emulsion. The method disclosed by the invention has the advantages that through taking the acrylate monomer as a solvent in the process of reaction without any organic cosolvent, the real environmental friendliness is achieved; the cost is lowered, and the adhesive performance of a water-gel and the appearance performance of a coating are improved; and no emulsifying agent is required to be added in the process of emulsion preparation, and the prepared product is excellent in performance, can be used in the field of composite adhesives and can also be used in fabric coatings.

Owner:NANTONG GAOMENG NEW MATERIAL

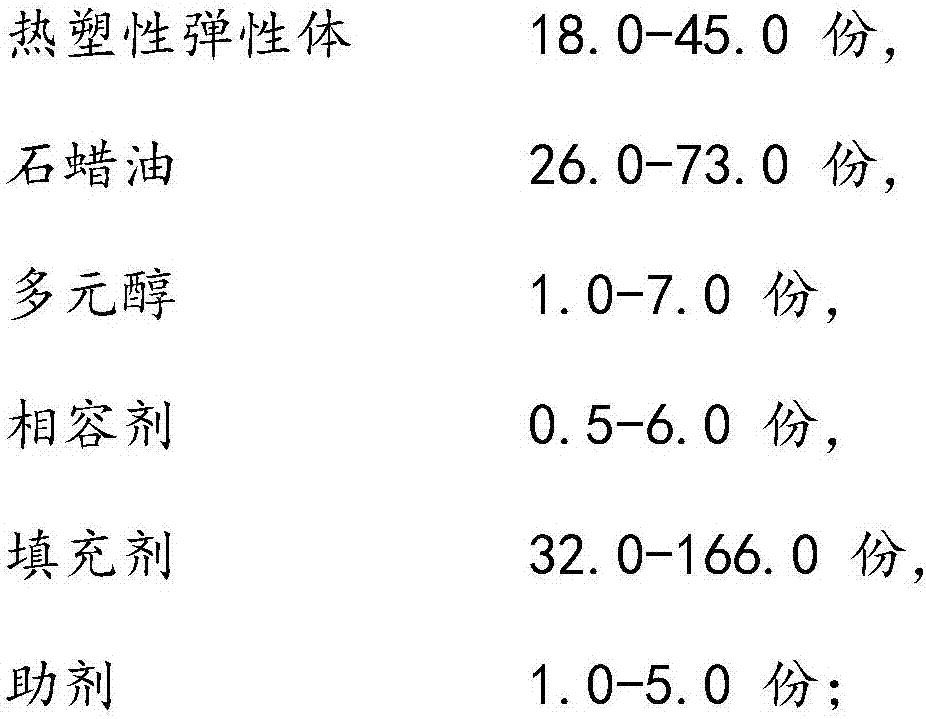

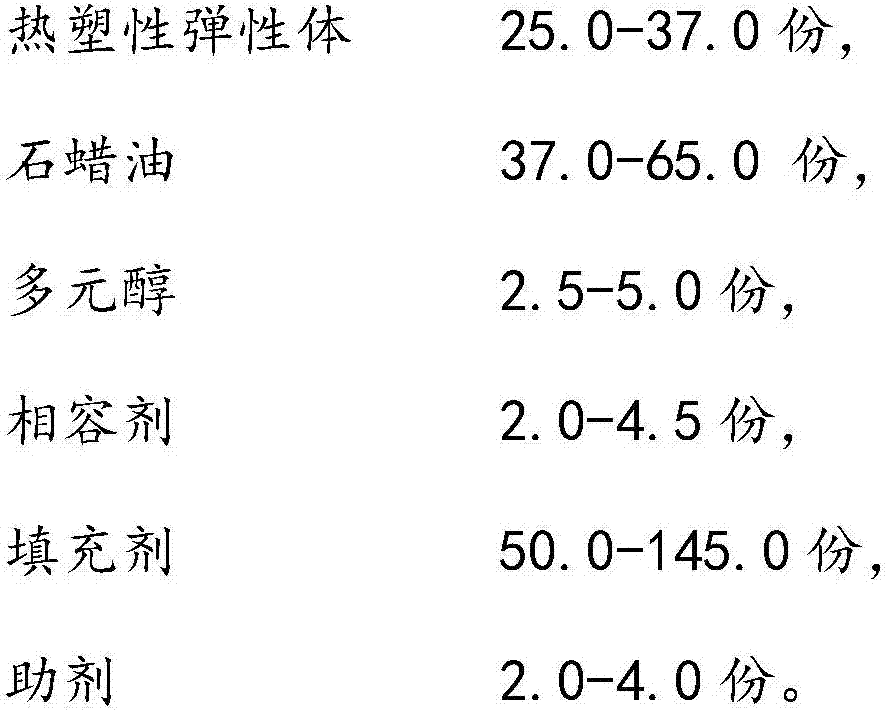

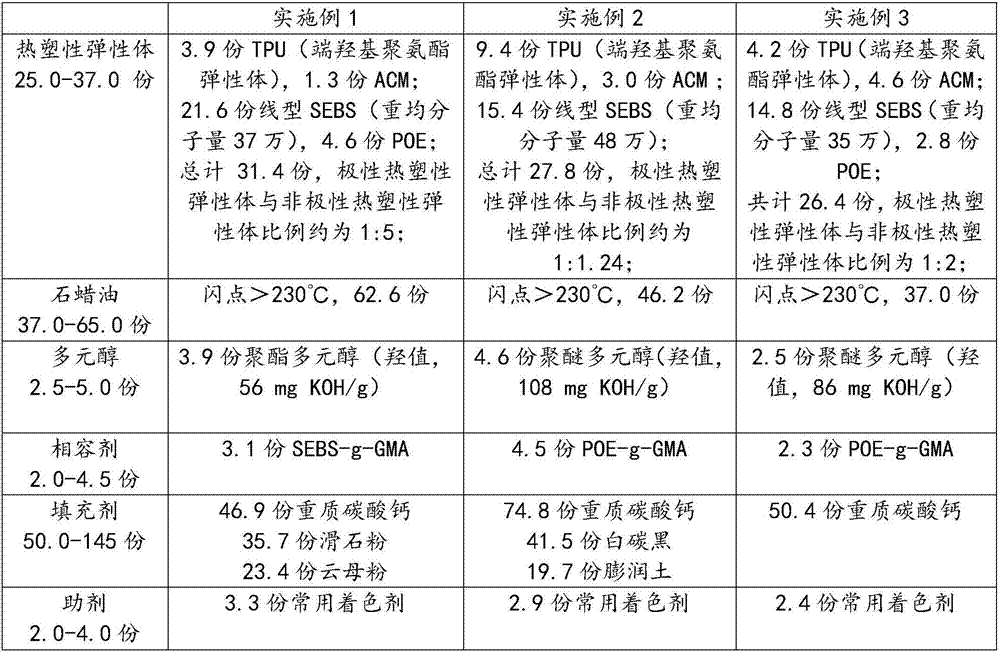

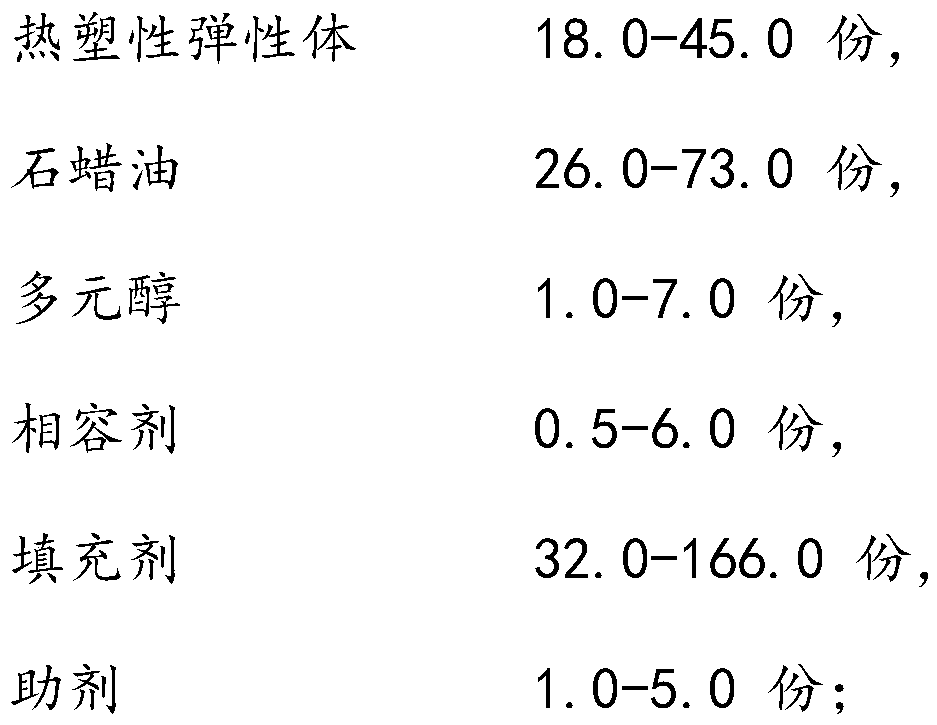

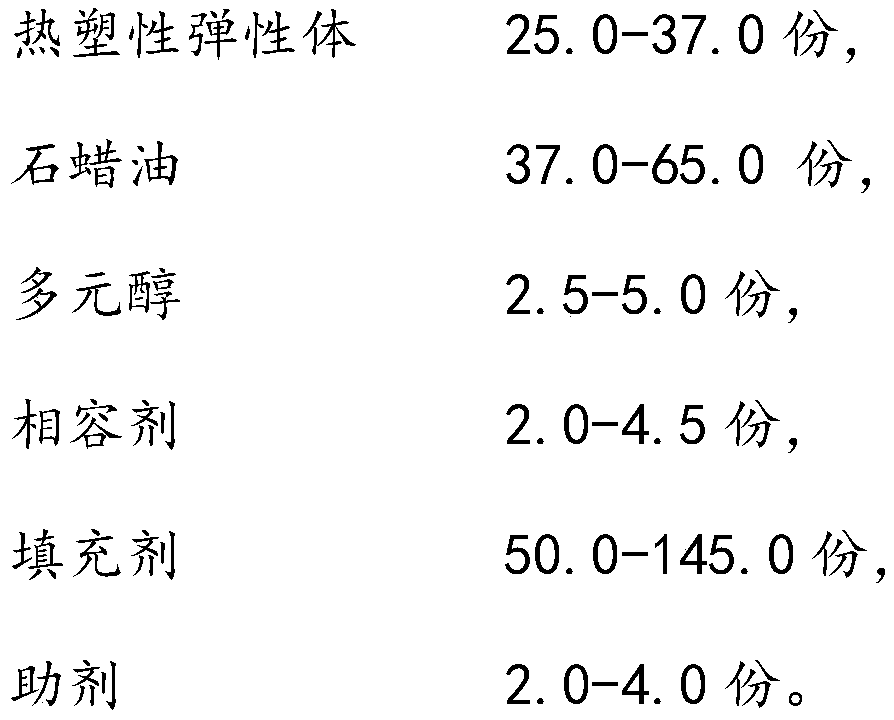

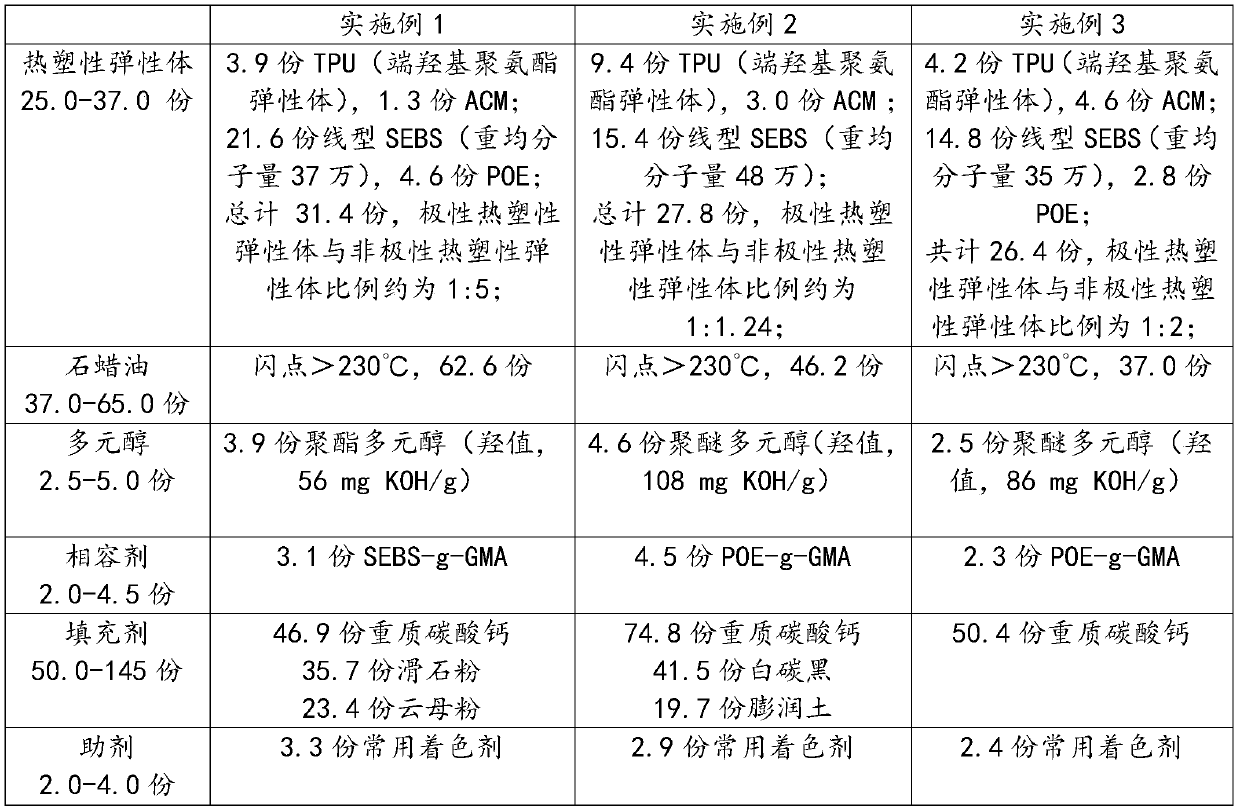

Thermoplastic composite elastomer, and preparation method and application of thermoplastic composite elastomer

ActiveCN107227027ATo achieve environmental friendlinessHigh bonding strengthGround pavingsPolyolefinAcrylic rubber

The invention discloses a thermoplastic composite elastomer, and a preparation method and application of the elastomer. The thermoplastic composite elastomer comprises the following raw materials in parts by weight: 18.0-45.0 parts of thermoplastic elastomer, 26.0-73.0 parts of paraffin oil, 1.0-7.0 parts of polyhydric alcohol, 0.5-6.0 parts of a compatilizer, 32.0-166.0 parts of a filler and 1.0-5.0 parts of an assistant, wherein the thermoplastic elastomer is a composite of a polar thermoplastic elastomer and a nonpolar thermoplastic elastomer; the polar thermoplastic elastomer is one or two of acrylic rubber and a thermoplastic polyurethane elastomer; the nonpolar thermoplastic elastomer is one or two of a hydrogenated styrene-butadiene segmented copolymer and a polyolefin elastomer. Compared with the prior art, the thermoplastic composite elastomer achieves overall effects of environment friendliness, high bonding strength and excellent mechanical properties and is a preferable material of a plastic track.

Owner:广东杰锐新材料有限公司

Environment-friendly water-based nail polish and preparation method thereof

ActiveCN104546550AImprove water resistanceGood solvent resistanceCosmetic preparationsToilet preparationsWater basedCross-link

The invention discloses environment-friendly water-based nail polish and a preparation method thereof. The nail polish comprises waterborne polyurethane emulsion, an antifoaming agent, an accelerant, a thickening agent and pigments, wherein the waterborne polyurethane emulsion comprises the following components in parts by weight: 4-18 parts of an inert vinyl monomer, 9.48-13.35 parts of polymer polyol, 8.5-14 parts of a diisocyanate compound, 0.8-2 parts of a chain extender, 1.66-2.95 parts of a hydrophilic chain extender, 0.15-0.3 part of a cross-linking agent, 0-0.095 part of a catalyst, 0.5-2 parts of a vinyl monomer containing activated hydrogen, 1.3-3.2 parts of volatile alkali, 60-100 parts of water and initiator solution; and the initiator solution is prepared by dissolving 0.2-0.8 part of an initiator in 10-40 parts of water. The water-based nail polish disclosed by the invention is simple in preparation process, environmentally friendly and pollution-free and has environmental-friendly, non-toxicity and odorless performances.

Owner:上海高庄生物科技有限公司

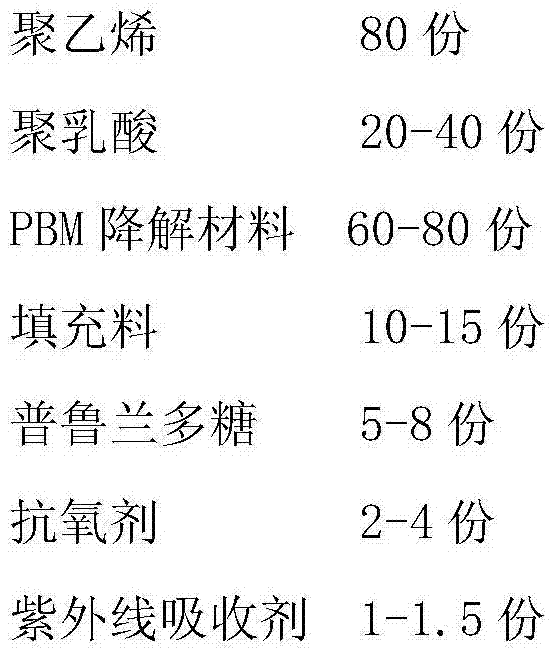

Biological nano plastic

The invention discloses a biological nano plastic, which is characterized in that the plastic comprises the following raw material components in parts by weight: 45-60 parts of plant fiber starch, 4-6 parts of glycerine, 40 parts of polyethylene, 20-40 parts of a polylactic acid, 60-80 parts of synthetic resin, 10-15 parts of additives, 5-8 parts of Pulullan, 2-4 parts of an antioxidant, 1-1.5 parts of an ultraviolet light absorber, and the like.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

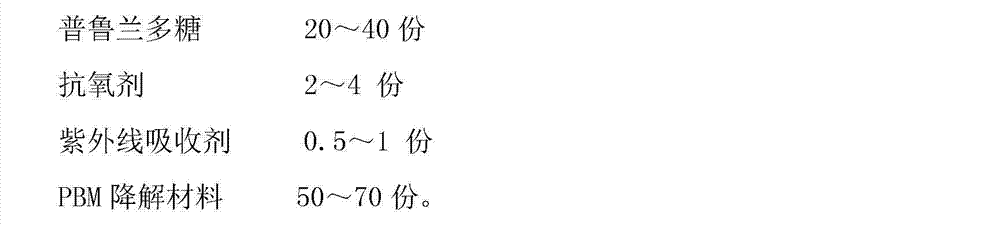

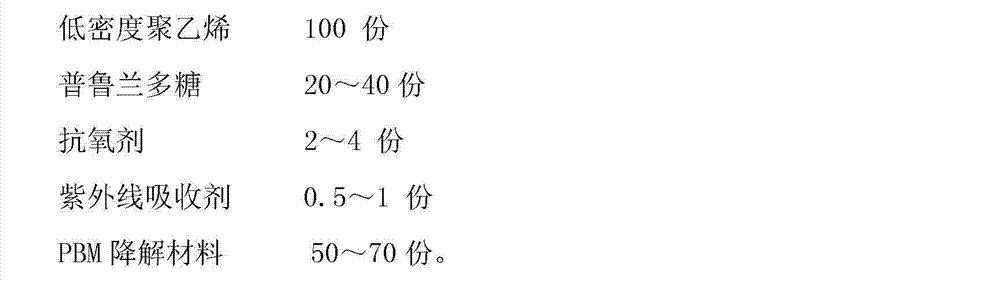

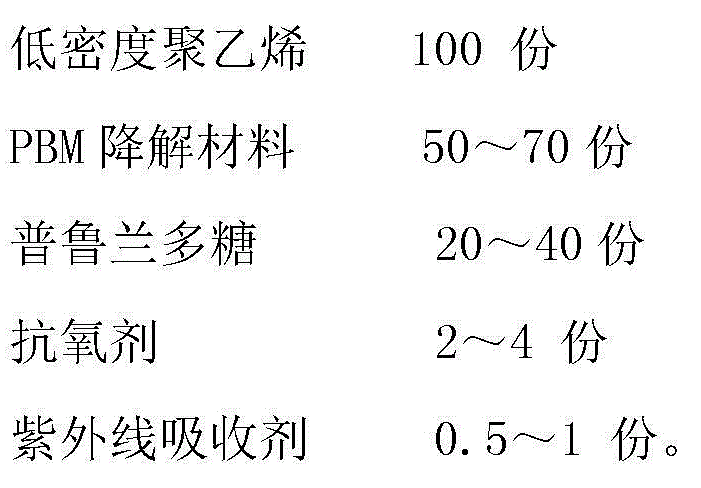

Preparation method for oxygen separating degradable plastic thin film

InactiveCN103205045AImprove mechanical propertiesAchieve environmental friendlinessLow-density polyethylenePullulan

The invention relates to a preparation method for an oxygen separating degradable plastic thin film. The method comprises the following steps of: (1) preparing a PBM (Plastic Master Batch) degradable material which is composited by full degradable natural high polymer material synthesized by main raw materials such as starch, plant grease and the like through special treatment with water soluble high polymer material and small amount of resin for later use; (2) mixing low density polyethylene, Pulullan and an antioxygen and an ultraviolet light absorber in a high speed mixer for 25-35 minutes; then, extruding and prilling in a twin-screw extruder to obtain master batch; and (3) mixing the master batch obtained by the step (1) with the PBM degradable material, and extruding and blowing by a plastic film blowing machine to obtain the product. According to the preparation method of the oxygen separating degradable plastic thin film, marketed mature modified starch degradable plastic master batch PBM and Pullulan and thin film grade LDPE are co-mixed, extruded and blown, so that the thin film has good mechanical property and degradability, and meanwhile has higher oxygen separating property.

Owner:天津超平新材料科技有限公司

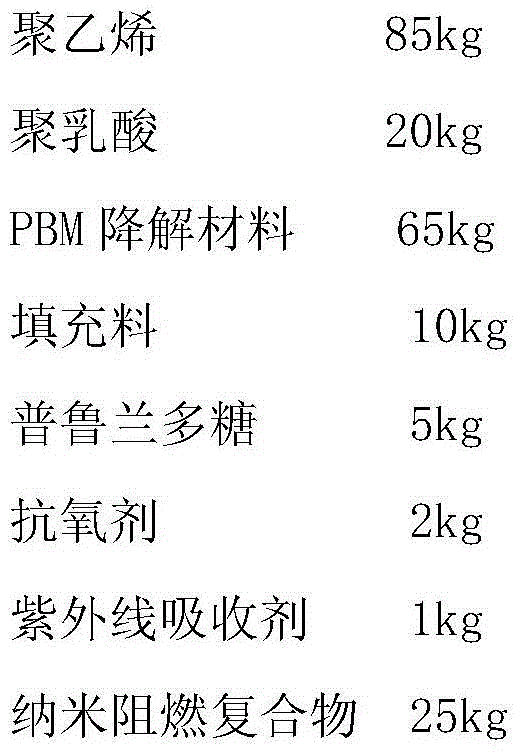

Biodegradable flame-retardant plastic film and preparation method thereof

InactiveCN104448495AGood mechanical propertiesAchieve environmental friendlinessPolymer sciencePullulan

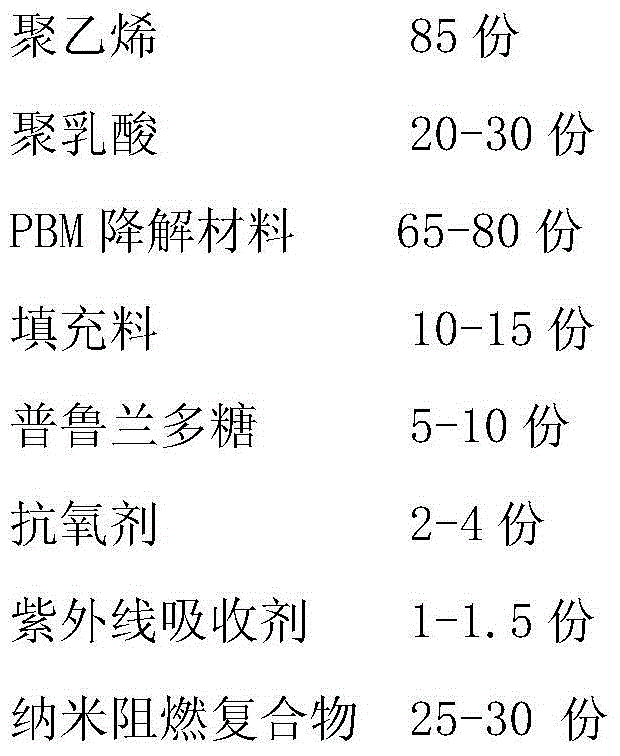

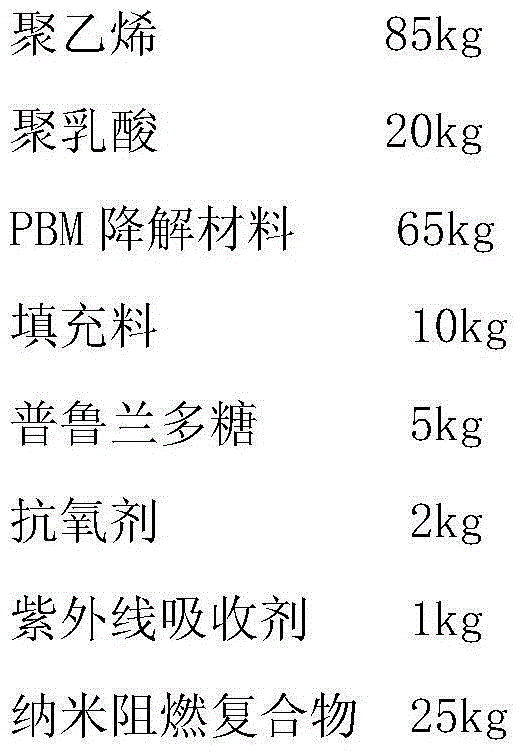

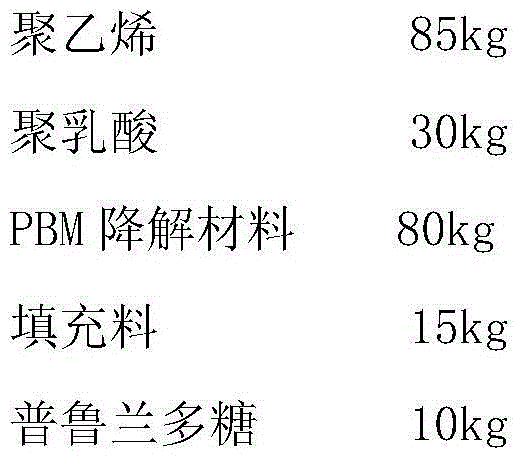

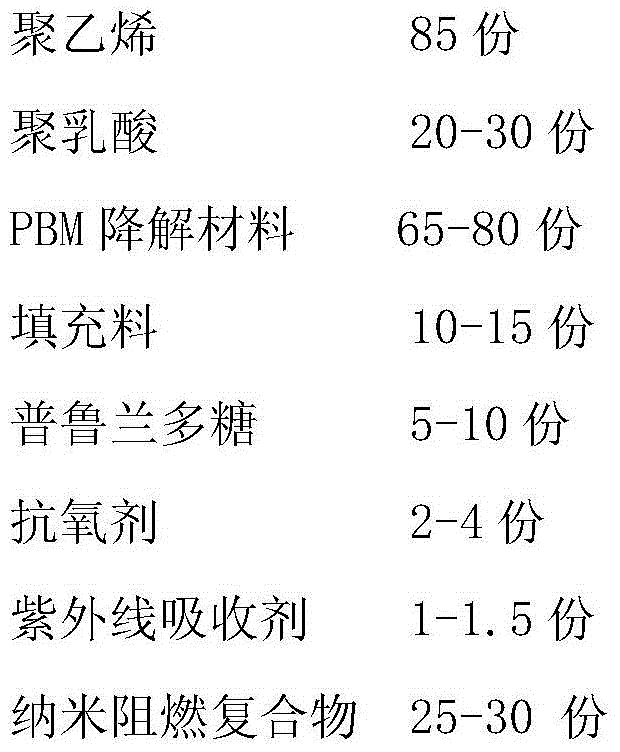

The invention discloses a biodegradable flame-retardant plastic film, which is prepared from the following raw materials in parts by weight: 85 parts of polyethylene, 20-30 parts of polylactic acid, 65-80 parts of a PBM degradable material, 10-15 parts of packing, 5-10 parts of pullulan, 2-4 parts of an antioxidant, 1-1.5 parts of an ultraviolet light absorber and 25-30 parts of nano flame-retardant composites. The oxygen-isolating biodegradable plastic film disclosed by the invention is prepared by blending extrusion and film blowing of mature modified starch biodegradable plastic master batches PBM and pullulan and film-grade LDPE in the market at present in the preparation method; good mechanical property of the film is ensured by using the characteristics of the LDPE; the environment friendliness of the film material is achieved by using the biodegradability of the PBM and the pullulan; the oxygen isolating property of the film material is improved by using high oxygen isolating property of the pullulan; the overall compatibility of the plastic film material is improved by using the structure similarity of the starch and the pullulan as carbohydrates; and regulation and control of the oxygen isolating property, the biodegradability and the like can be achieved by controlling the blending ratio of the LDPE / PBM / Pullulan system.

Owner:TIANJIN KAIXUAN PLASTIC PROD

Biodegradable plastic

ActiveCN103483850AGood mechanical propertiesAchieve environmental friendlinessFiberUltraviolet lights

Biodegradable plastic is characterized by including the following raw materials in parts by weight: 45-60 parts of plant fiber starch, 4-6 parts of glycerinum, 40 parts of polyethylene, 20-40 parts of polylactic acid, 60-80 parts of synthetic resin, 10-15 parts of auxiliaries, 5-8 parts of pulullan, 2-4 parts of an antioxidant and 1-1.5 parts of an ultraviolet light absorbent.

Owner:江苏湘园化工有限公司

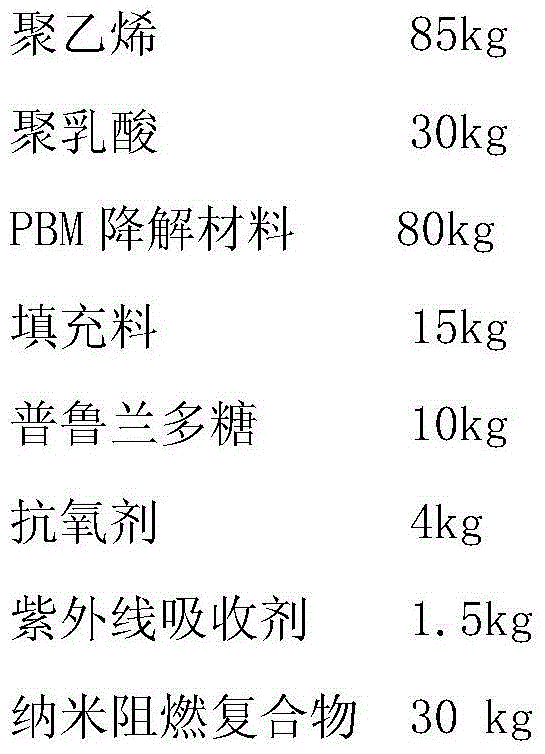

Biodegradable flame-retardant plastic film

InactiveCN104448502AImprove mechanical propertiesAchieve environmental friendlinessPullulanAntioxidant

The invention discloses a biodegradable flame-retardant plastic film, which is prepared from the following raw materials in parts by weight: 85 parts of polyethylene, 20-30 parts of polylactic acid, 65-80 parts of a PBM degradable material, 10-15 parts of packing, 5-10 parts of pullulan, 2-4 parts of an antioxidant, 1-1.5 parts of an ultraviolet light absorber and 25-30 parts of nano flame-retardant composites. The oxygen-isolating biodegradable plastic film disclosed by the invention is prepared by blending extrusion and film blowing of mature modified starch biodegradable plastic master batches PBM and pullulan and film-grade LDPE in the market at present in the preparation method; good mechanical property of the film is ensured by using the characteristics of the LDPE; the environment friendliness of the film material is achieved by using the biodegradability of the PBM and the pullulan; the oxygen isolating property of the film material is improved by using high oxygen isolating property of the pullulan; the overall compatibility of the plastic film material is improved by using the structure similarity of starch and the pullulan as carbohydrates; and regulation and control of the oxygen isolating property, the biodegradability and the like can be achieved by controlling the blending ratio of the LDPE / PBM / Pullulan system.

Owner:TIANJIN KAIXUAN PLASTIC PROD

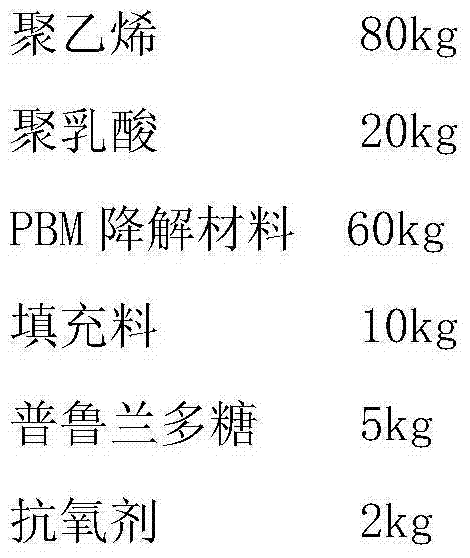

Biodegradable plastic film

InactiveCN104497398AGood mechanical propertiesAchieve environmental friendlinessPullulanUltraviolet lights

The invention discloses a biodegradable plastic film which respectively comprises the following raw material components in parts by weight: 80 parts of polyethylene, 20-40 parts of polylactic acid, 60-80 parts of a PBM degradable material, 10-15 parts of a filling material, 5-8 parts of Pullulan, 2-4 parts of an antioxidant and 1-1.5 parts of an ultraviolet light absorber. The oxygen-isolating and biodegradable plastic film provided by the invention has the advantages that the mature modified starch biodegradable plastic master batch PBM, the Pullulan and film-level LDPE in the market are selected to be subjected to blending extrusion and film blowing in the preparation method at present, the characteristics of LDPE are utilized, and good mechanical property of the film is guaranteed; by utilizing the biodegradability of PBM and Pullulan, the environment friendliness of the film material is realized; by utilizing high oxygen isolating property of the Pullulan, the oxygen isolation property of the film material is improved; by utilizing the structural similarity of the starch and Pullulan serving as saccharides, the overall compatibility of the plastic film material is improved; and moreover, the blending ratio of the LDPE / PBM / Pullulan system is controlled, so that the oxygen isolation property, the biodegradability and the like can be regulated.

Owner:TIANJIN KAIXUAN PLASTIC PROD

Preparation method for regenerated nanometer flame retardant plastic

ActiveCN103483623AImprove mechanical propertiesAchieve environmental friendlinessFiberUltraviolet lights

The invention discloses a preparation method for a regenerated nanometer flame retardant plastic, wherein the regenerated nanometer flame retardant plastic is characterized by comprising the following raw materials in parts by weight: 45-60 parts of plant fiber starch, 4-6 parts of glycerinum, 40 parts of polyethylene, 20-40 parts of polylactic acid, 60-80 parts of synthetic resin, 10-15 parts of an additive, 5-8 parts of pulullan, 2-4 parts of an antioxygen agent, 1-1.5 parts of an ultraviolet light absorber and the like.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

Preparation method for degradable plastic composite film with oxygen separation performance

ActiveCN104861246AImprove mechanical propertiesAchieve environmental friendlinessPullulanComposite film

The invention discloses a preparation method for a degradable plastic composite film with an oxygen separation performance. In the preparation method, degradable plastic master batch PBM mature in the present market, Pullulan polysaccharide and film-level LDPE are employed as raw material with addition of anti-oxidants and ultraviolet ray absorbers, tannic acid is employed for modifying Pullulan polysaccharide, further the plastic film three-layer co-extrusion film blowing technology is employed, and a three-layer plastic composite film with good oxygen separation performance, degradability and mechanical properties is prepared. The inner layer, the middle layer and the outer layer of the composite film are LDPE / PBM / Pullulan, PBM / Pullulan and LDPE / PBM / Pullulan respectively. The composite film can decompose automatically under action of oxygen enrichment and microbes, a wasted film can be degraded and digested completely by microbes in nature, the oxygen separation performance of the composite film can be raised by 70%-80% compared with the oxygen separation performance of an LDPE film with the same thickness, and the mechanical properties of the composite film are almost the same as mechanical properties of an LDPE film with the same thickness. The composite film is advantaged by simple production technology, high production efficiency and easy industrial enforcement.

Owner:TIANJIN JINSHENGYU PLASTIC PROD SCI & TECH CO LTD

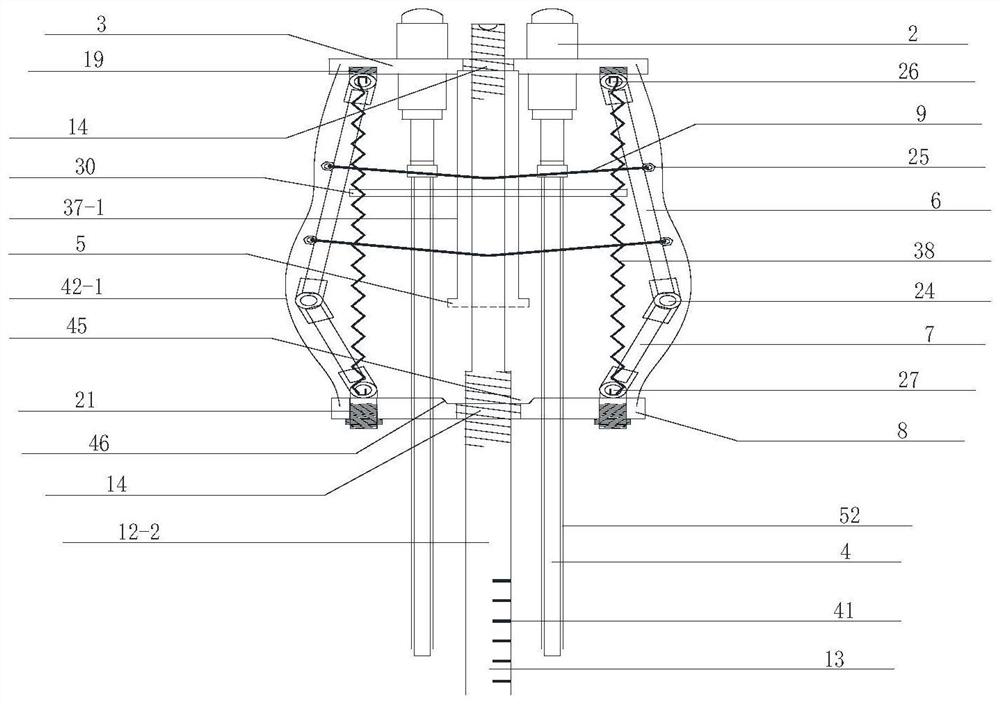

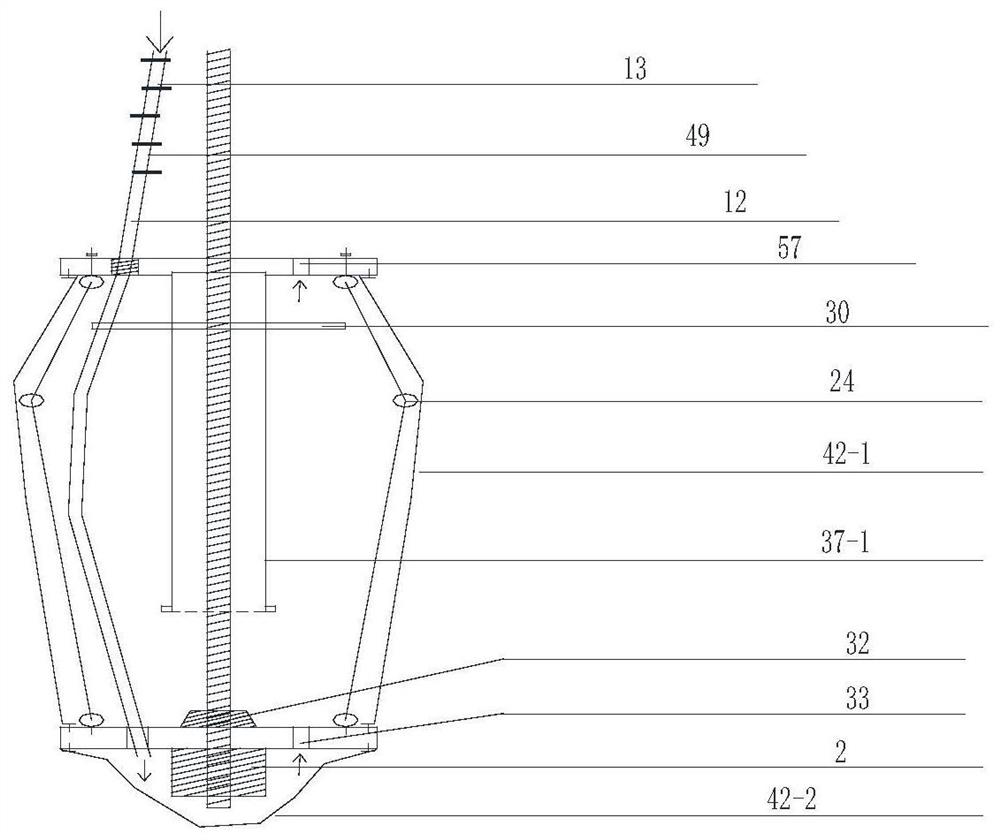

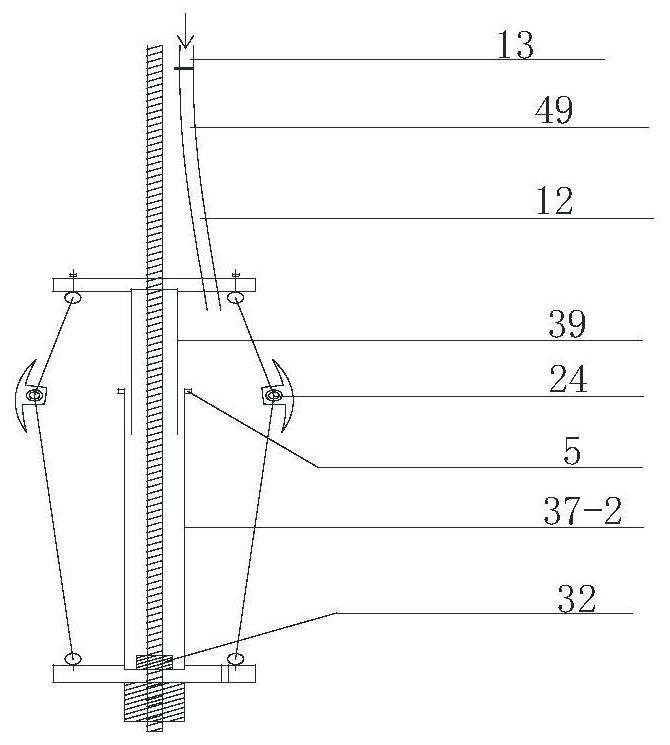

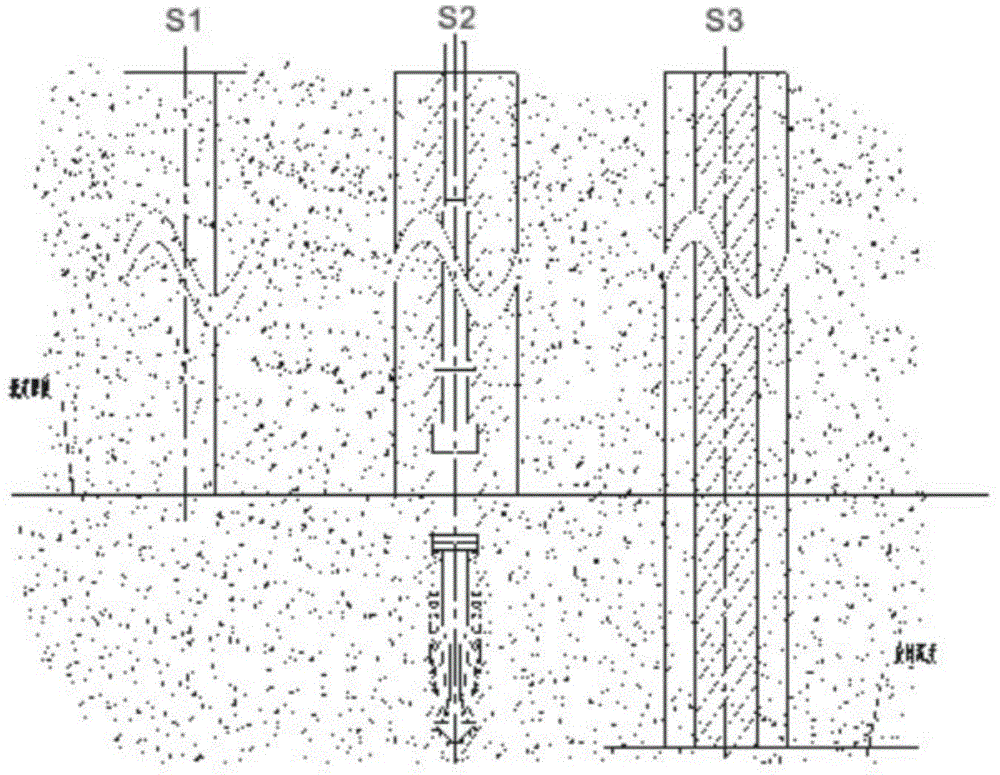

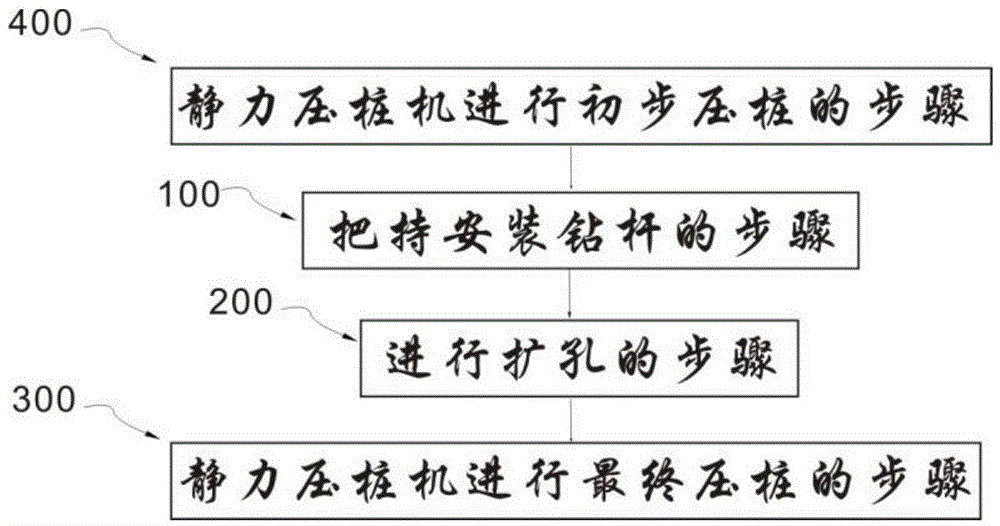

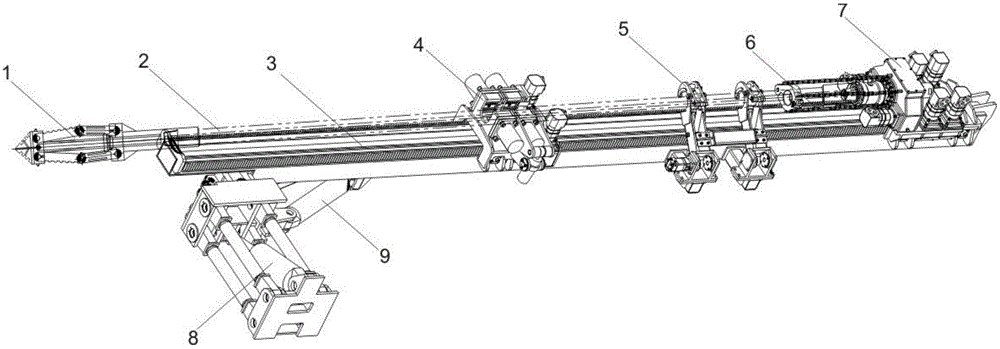

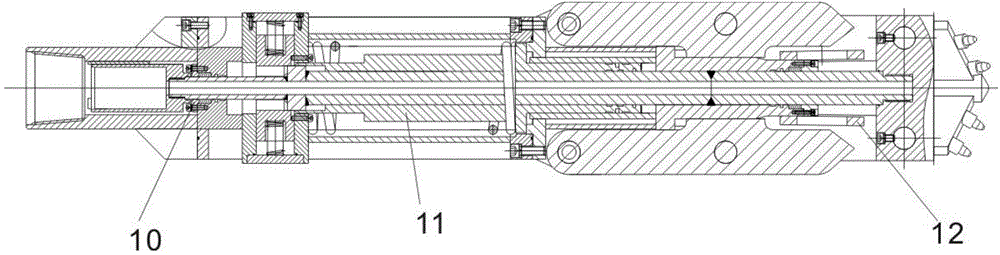

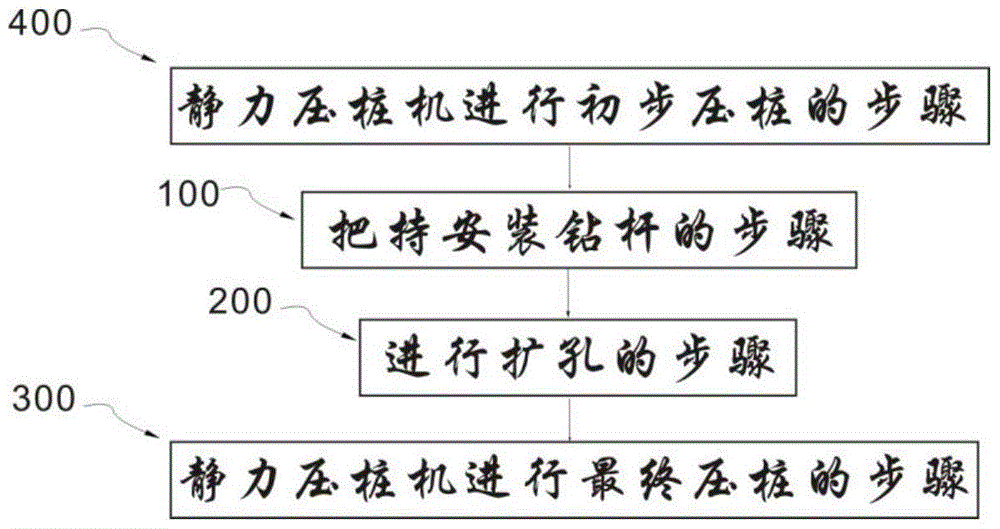

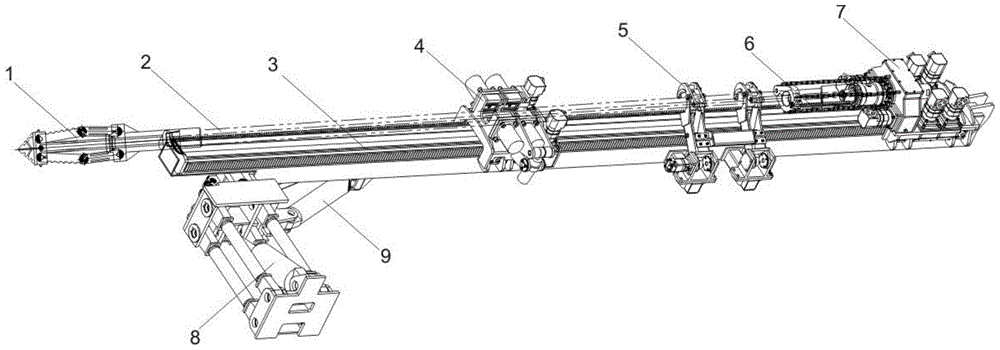

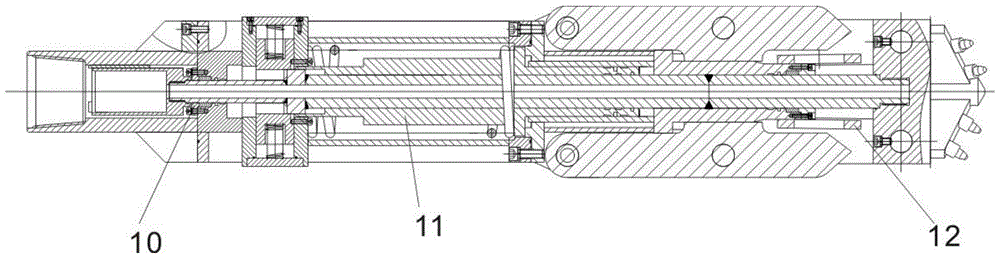

Hole reaming and pile sinking method for static pile driver

InactiveCN104929112AGood construction performanceAchieve reliabilityBulkheads/pilesStructural engineeringPile driver

The invention discloses a hole reaming and pile sinking method for a static pile driver. The method comprises following steps that the static pile driver presses a pile to reach the preset depth; a drill of the static pile driver enters a drill hole from a pile inner hole so as to finish drilling; and the static pile driver presses the pile to the designed depth. By employing the method, a problem that piles are difficult to sink in sand layers, hard soil layers, differentiation layers and some soil layers in which piles cannot be easily pressed is solved. According to the method, the hole is reamed firstly, and then the pile is sunk. The method is characterized in that the noise is low, the counterweight is small, less soil is extruded, the operation is easy, and the structure is simple and reliable.

Owner:JIANGSU GOODENG ENG MACHINERY ASSEMBLING

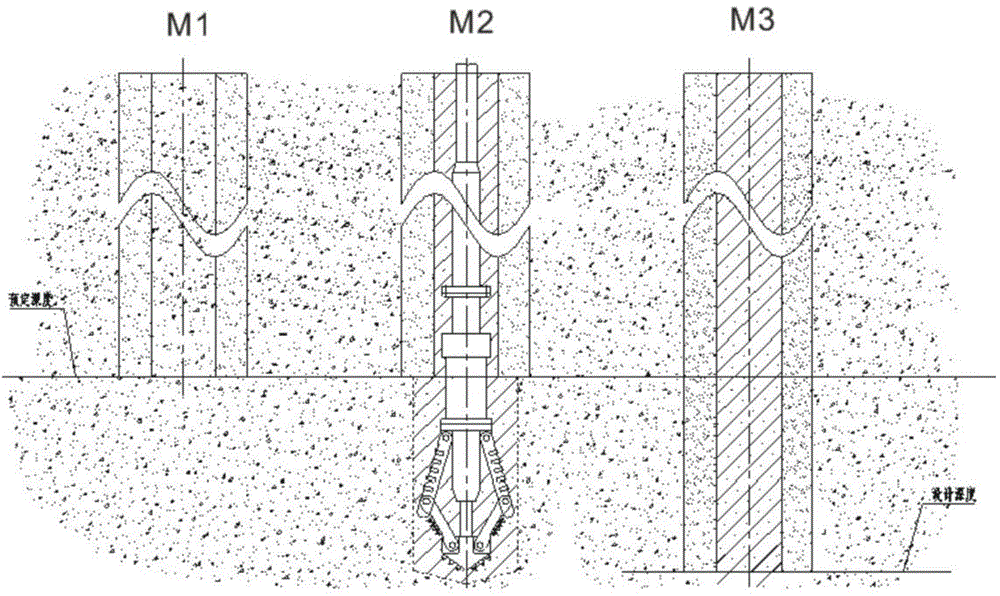

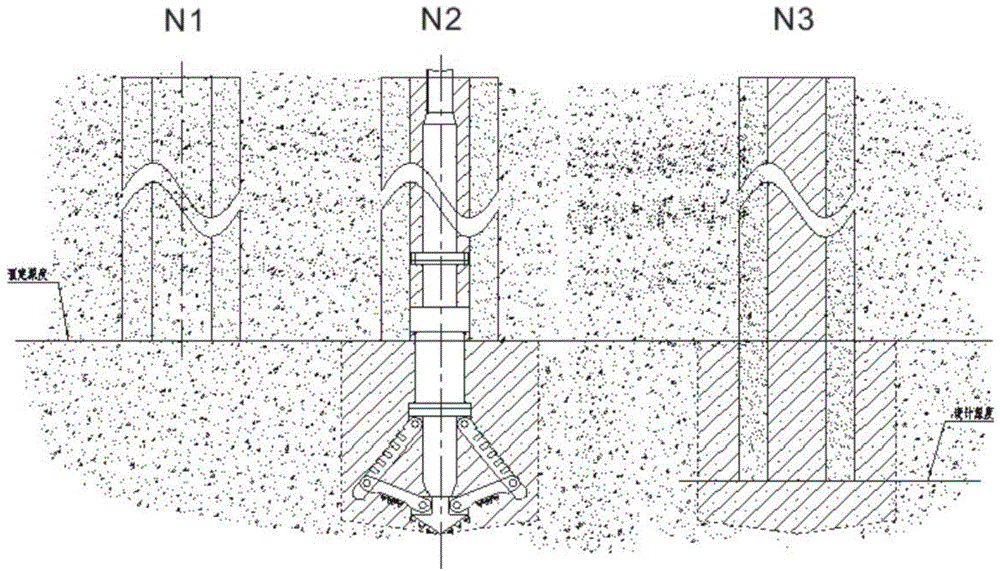

Chambering and pile sinking construction method for static pile driver

ActiveCN104631458AGood construction performanceAchieve reliabilityBulkheads/pilesStructural engineeringPile driver

The invention discloses a chambering and pile sinking construction method for a static pile driver. The method comprises the steps that the static pile driver carries out primary pile pressing, drill pile holding and mounting are carried out, chambering is carried out, and the static pile driver carries out final pile pressing. The chambering and pile sinking construction method for the static pile driver solves the problem that pile sinking is difficult in a sand layer, a hard soil layer, a differentiation layer and other soil layers where piles cannot be pressed easily. According to the method, chambering is carried out first, then pile sinking is carried out, and the method has the advantages of being small in noise, small in additional weight, little in squeezed soil, simple in operation and simple and reliable in structure.

Owner:江苏谷登重型机械装备科技有限公司

Natural polymer modified coated controlled release fertilizer and preparation method thereof

ActiveCN102295491BImproved controlled releaseFully Environmentally DegradableAgriculture gas emission reductionFertilizer mixturesCellulosePetrochemical

Owner:大项生态建设有限公司

Preparation method of oxygen-insulation and degradable plastic film

InactiveCN107955242AGood mechanical propertiesAchieve environmental friendlinessFlexible coversWrappersLow-density polyethylenePullulan

The invention belongs to the field of plastic film materials, and particularly relates to a preparation method of an oxygen-insulation and degradable plastic film. The preparation method is characterized by comprising the following steps: (1) mixing low-density polyethylene, pullulan, an antioxidant and an ultraviolet absorbent in a high-speed mixer for 25-35 minutes, and carrying out extruding granulation in a twin-screw extruder to obtain a master batch; and (2) mixing the master batch with a PBM degradation material, and carrying out extruding film blowing by adopting a plastic film blowingmachine to obtain the product. The oxygen-insulation and degradable plastic film provided by the invention can automatically decompose under the action of enriched oxygen and microorganisms, so thatdiscarded films can be completely degraded and digested by microorganisms in natural, and finally, carbon dioxide and water are generated. Compared with a LDPE film with a same thickness, the oxygen-insulation and degradable plastic film provided by the invention has an oxygen-insulation property improved by 40%. The preparation method provided by the invention has a simple process, high production efficiency and easy industrialization, and can be produced by using a common plastic film blowing machine.

Owner:天津市宝宏塑胶制品有限公司

Novel plastic film and preparation method thereof

InactiveCN109503927AImprove mechanical propertiesAchieve environmental friendlinessPullulanUltraviolet lights

The invention discloses a novel plastic film. The novel plastic film comprises the following raw material components in parts by weight: 100 parts of polyethylene, 20-30 parts of polylactic acid, 65-80 parts of a PBM degradable material, 10-15 parts of filler, 5-10 parts of lignocellulose, 3-5 parts of an anti-oxidant, 1-1.5 parts of an ultraviolet light absorber, and 25-30 parts of a nano flame retardant compound. The invention further provides a preparation method for the plastic film. According to the method, a mature modified starch degradable plastic master batch PBM in the current marketis selected to be mixed with Pullulan polysaccharide and film-level LDPE for extruding and film-blowing, with the features of the LDPE, good mechanical properties of the film is ensured; with biodegradability of the PBM and the Pullulan, environment friendliness of the film material is realized; with high oxygen insulation of the Pullulan, the oxygen insulation of the film material is improved; with similarity of the starch and the Pullulan as carbohydrates in structure, entire compatibility of the plastic film material is improved; and through controlling a blending matching ratio of a LDPE / PBM / Pullulan system, the control on the oxygen insulation and the biodegradability and the like is realized.

Owner:嘉兴市竹林塑料泡沫有限公司

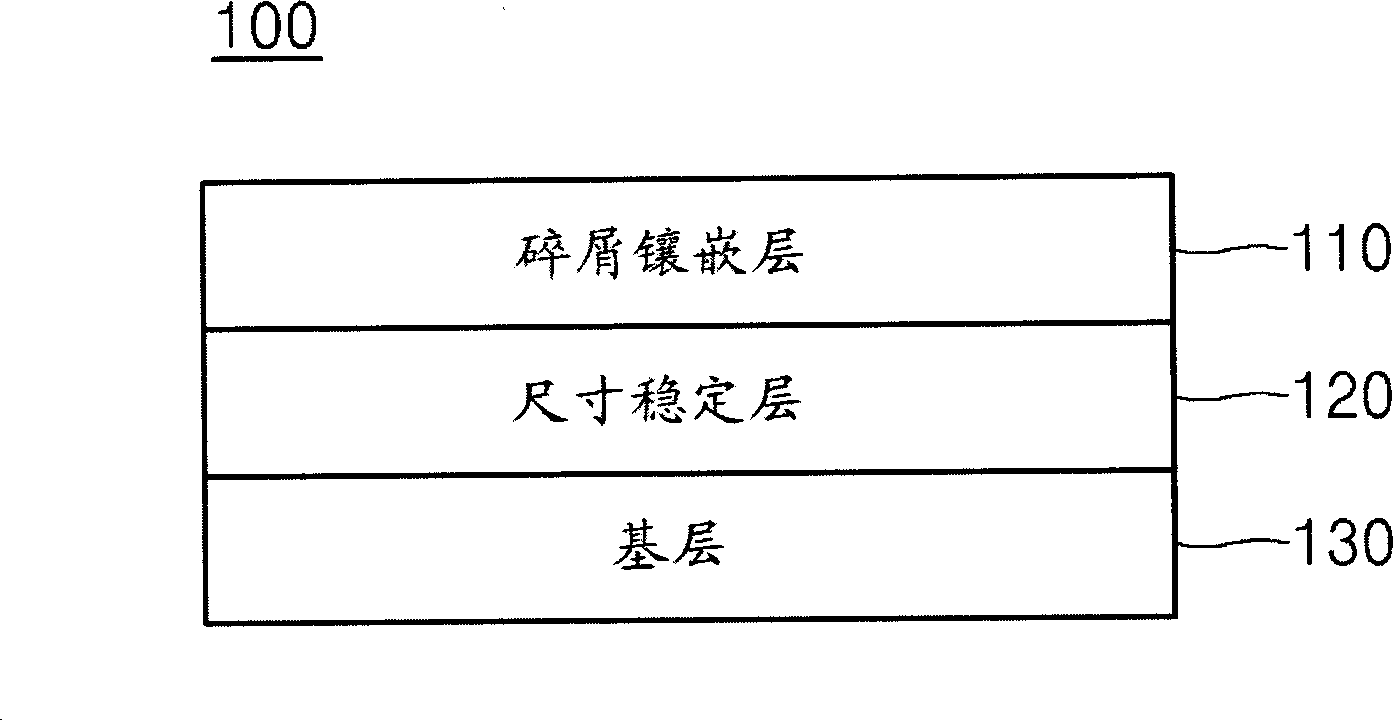

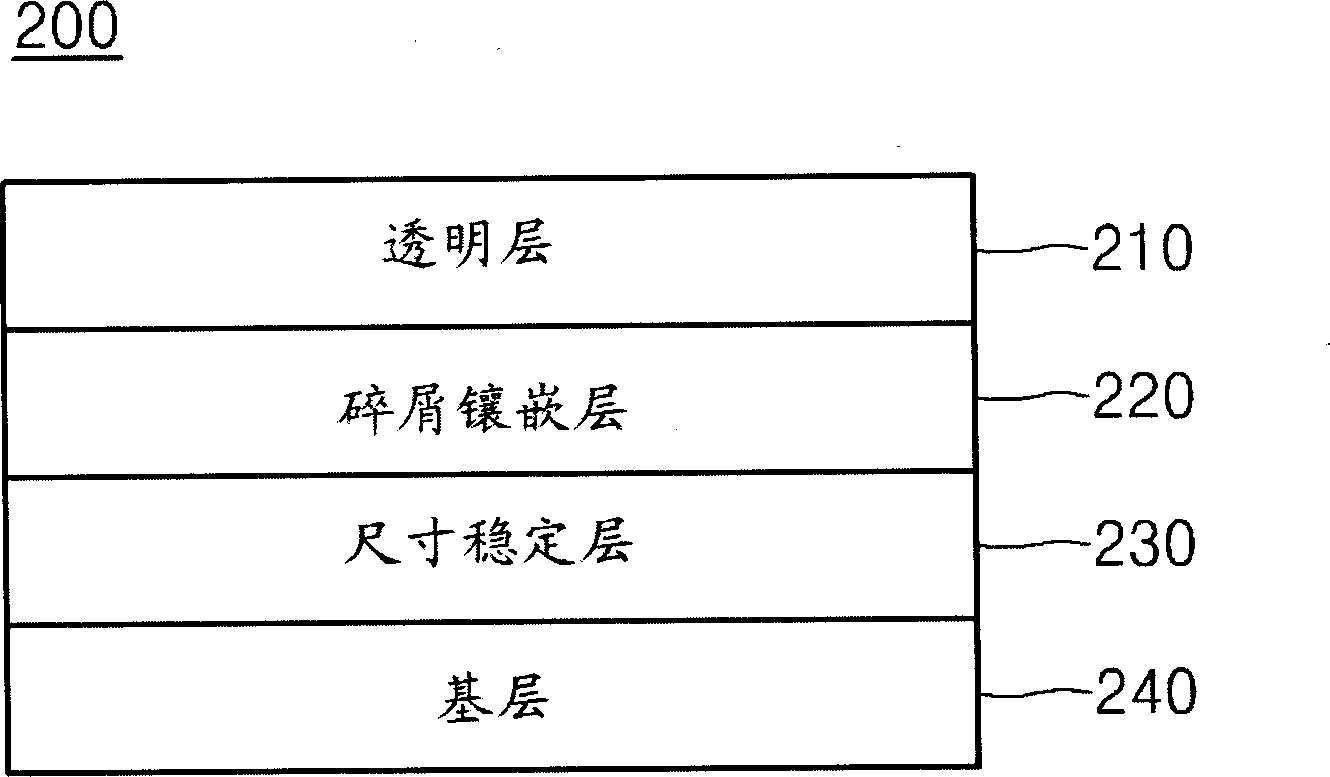

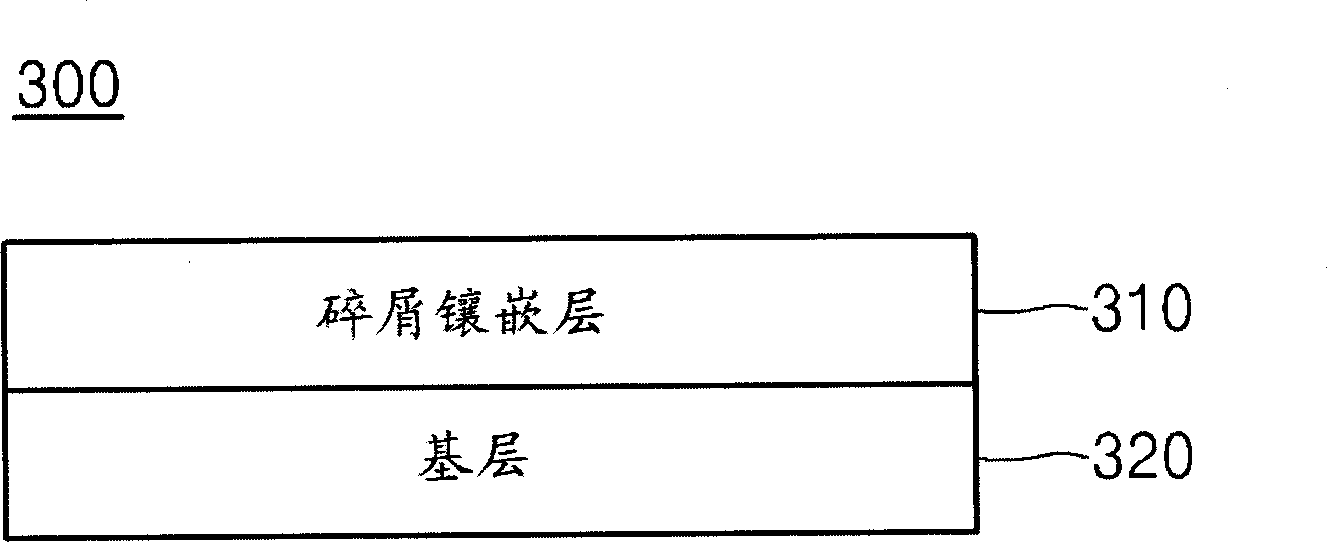

Chip-inlaid flooring material using pla resin

InactiveCN103282589AAchieve environmental friendlinessGuaranteed dimensional stabilitySynthetic resin layered productsFloor coveringsPolyresinPolylactic acid

According to one embodiment of the present invention, a chip-inlaid flooring material using a PLA (polylactic acid) resin comprises: from the top, a chip-inlaid layer, a dimensional-stability layer, and a base material layer. One of the chip-inlaid layer and the base material layer includes PLA as a binder.

Owner:LG HAUSYS LTD

Degradable fresh-keeping plastic thin film and preparation method thereof

InactiveCN107298789AImprove mechanical propertiesAchieve environmental friendlinessFlexible coversWrappersLow-density polyethylenePullulan

The invention provides a degradable fresh-keeping plastic film and a preparation method thereof. The degradable fresh-keeping plastic film is prepared from the following raw materials in parts by weight: 40 to 80 parts of high density polyethylene, 30 to 50 parts of low density polyethylene, 50 to 70 parts of PBM degradable material, 10 to 40 parts of pulullan, 3 to 8 parts of poly(dipropylene glycol) phenyl phosphate, and 2 to 5 parts of phenyl salicylate. According to the preparation method of the degradable plastic film, the mature modified starch degradable plastic master batch PBM on the market is blended with pullulan and film-grade LDPE to be extruded and to blow a film, and good mechanical performance of the film is ensured by utilizing the characteristics of the LDPE; by utilizing the degradability of the PBM and Pullulan, the environment friendliness of the film material can be realized; and by utilizing the high oxygen insulation performance of the Pullulan, the oxygen insulation performance of the film material is improved.

Owner:安徽华猫软包装有限公司

Recycling method of fine dust and free formaldehyde

InactiveCN102514077ASolve wasteAchieve environmental friendlinessWood working apparatusDomestic articlesProcess engineeringParticle board

The invention relates to a recycling method of fine dust and free formaldehyde generated in an artificial board production process. In the method, the discharged fine dust and free formaldehyde are collected in a thermal pressing and board cooling working procedure of the production process of fiberboards and particle boards, and then treated to be used for manufacturing of the fiberboards and the particle boards, wherein the fine dust is collected and conveyed to a sizing bin to be paved on the surface layers of the slabs of the particle boards or fiberboards, and free formaldehyde is dissolved, filtered, condensed and concentrated to obtain formaldehyde solution with concentration more than 10% to be used for manufacturing an urea-formaldehyde resin adhesive. By implementing the method, the reutilization rates of the fine dust and free formaldehyde achieve more than 90%, the shop working environment is significantly improved, the working efficiency is improved, and the environmental friendliness and resource saving of the production process of the fiberboards and particle boards are realized.

Owner:广西新凯骅实业集团股份有限公司

A kind of environment-friendly water-based nail polish and preparation method thereof

ActiveCN104546550BImprove water resistanceGood solvent resistanceCosmetic preparationsToilet preparationsPtru catalystPolyol

The invention discloses an environment-friendly water-based nail polish and a preparation method thereof. The nail polish includes aqueous polyurethane emulsion, defoamer, accelerator, thickener and pigment. The water-based polyurethane emulsion is made of the following components by weight: 4-18 parts of inert vinyl monomer, 9.48-13.35 parts of polymer polyol, 8.5-14 parts of diisocyanate compound, 0.8-2 parts of chain extender, 1.66-1 2.95 parts of hydrophilic chain extender, 0.15-0.3 parts of cross-linking agent and 0-0.095 parts of catalyst, 0.5-2 parts of vinyl monomer containing active hydrogen, 1.3-3.2 parts of volatile base, 60-100 parts of water and The initiator solution is prepared by dissolving 0.2-0.8 parts of initiator in 10-40 parts of water. The preparation process of the water-based nail polish of the present invention is simple, environment-friendly and pollution-free, and embodies the performances of being green, environment-friendly, non-toxic and tasteless.

Owner:上海高庄生物科技有限公司

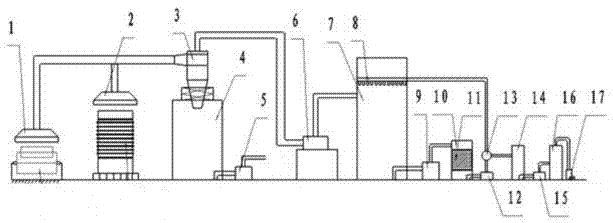

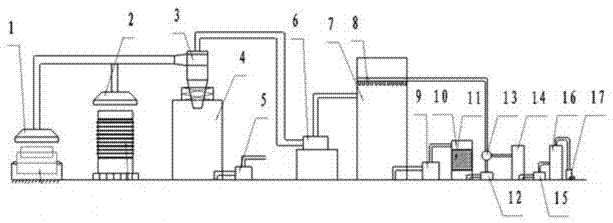

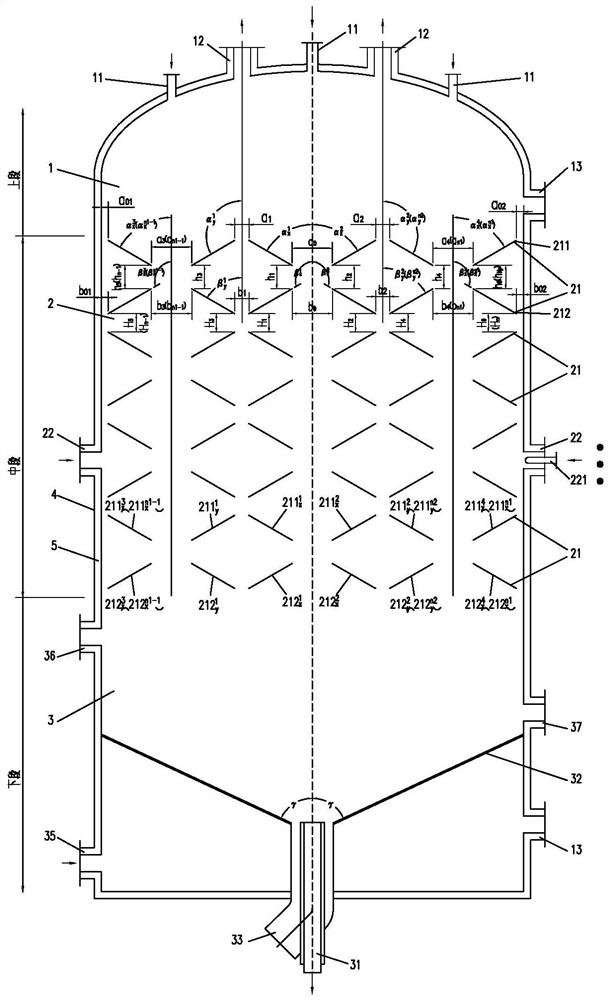

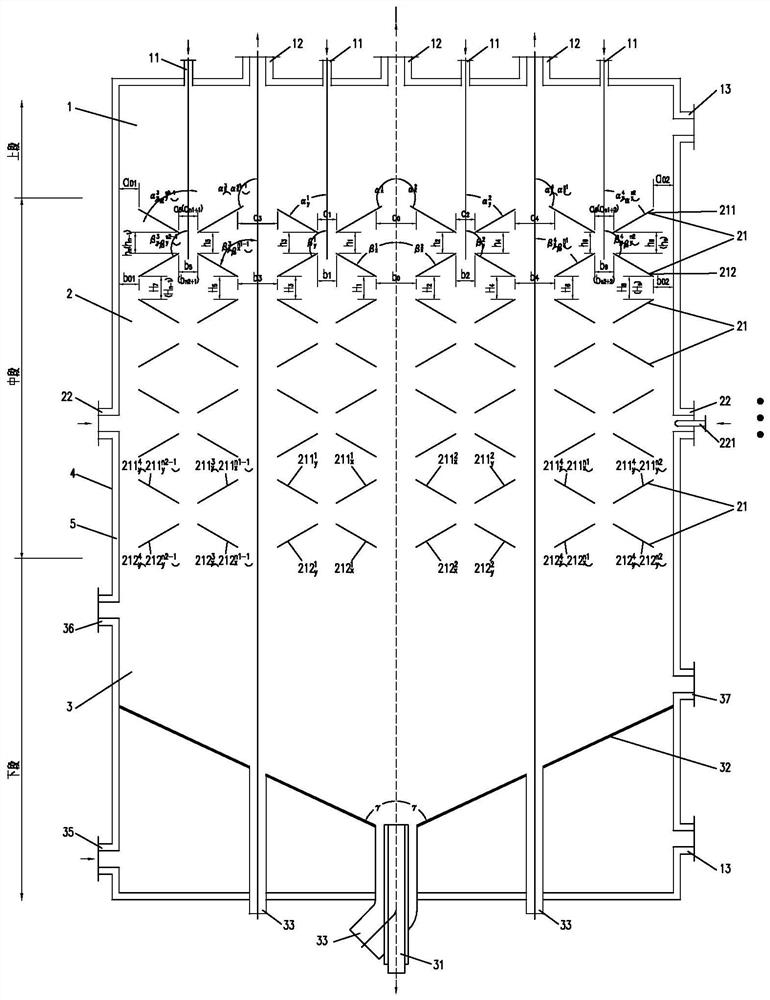

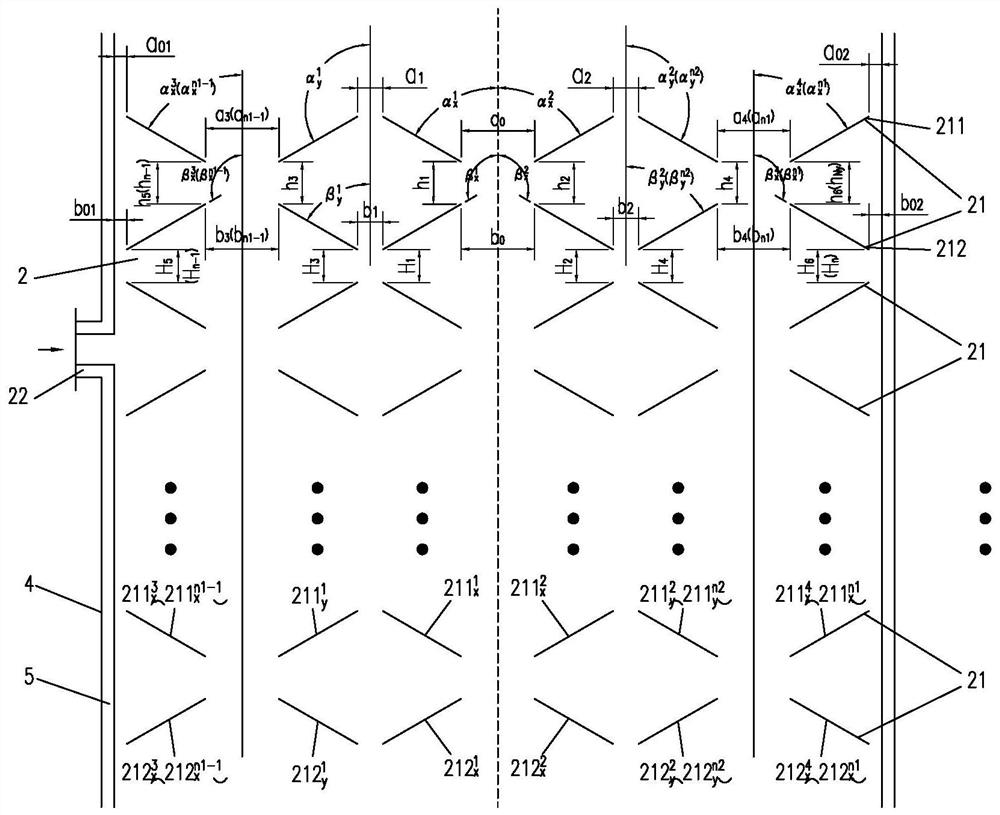

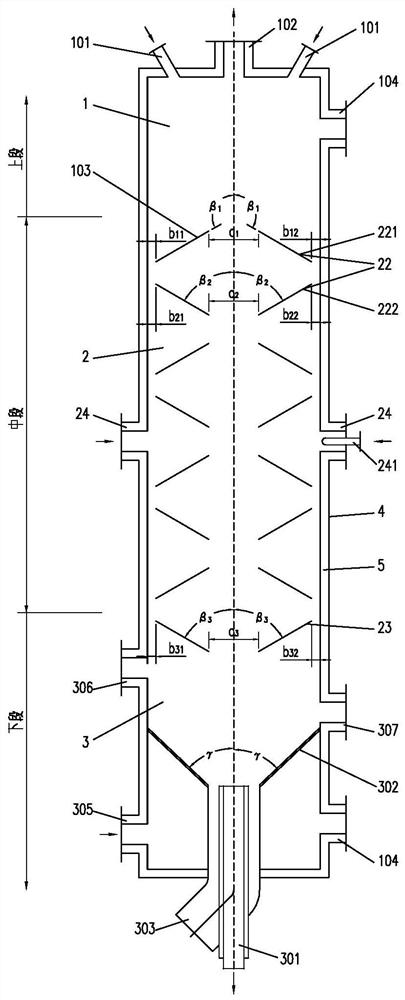

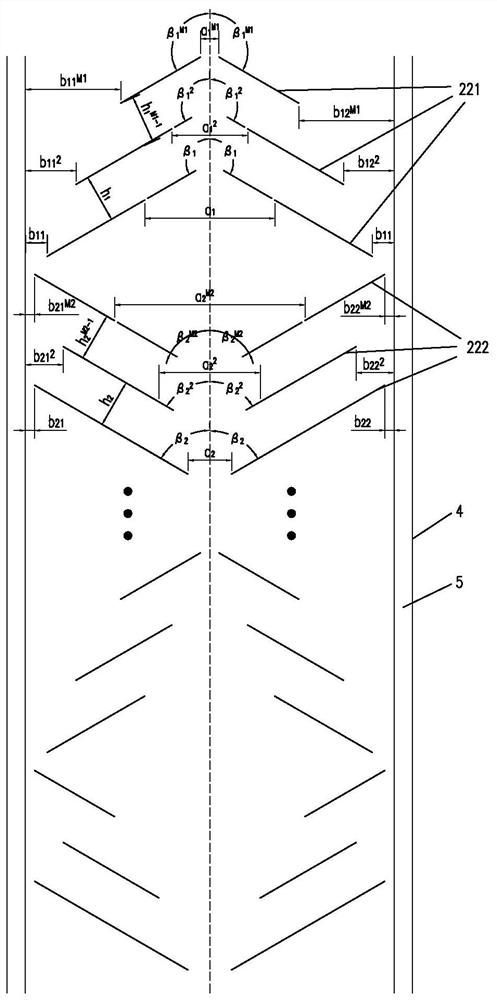

Direct heat supply type multi-stage series-parallel turbulent bed pyrolysis stripping furnace in combustion flame furnace

PendingCN113088304ALow costLess investmentDirect heating destructive distillationSpecial form destructive distillationCombustorFlue gas

The invention relates to the field of pyrolysis stripping reactors, in particular to a direct heat supply type multi-stage series-parallel turbulent bed pyrolysis stripping furnace in a combustion flame furnace. The direct heat supply type multi-stage series-parallel turbulent bed pyrolysis stripping furnace comprises a furnace shell, and the furnace shell comprises an upper section furnace, a middle section furnace and a lower section furnace which communicate with one another; the upper section furnace is provided with an organic solid waste inlet and a gaseous mixture outlet; the middle section furnace is provided with a plurality of serially-connected groups of parallel turbulent micro-reaction beds; the lower section furnace is provided with a fuel burner, a pressure-temperature gas inlet and a residue outlet; and fuel is combusted through a fuel combustor to generate high-temperature flue gas which flows from bottom to top and is in direct contact with organic solid waste to provide heat. The direct heat supply type multi-stage series-parallel turbulent bed pyrolysis stripping furnace has the effects of improving the heat supply efficiency and the heat absorption efficiency of the organic solid waste pyrolysis stripping process and reducing the energy consumption.

Owner:NINGBO LIANTONG EQUIP MFG

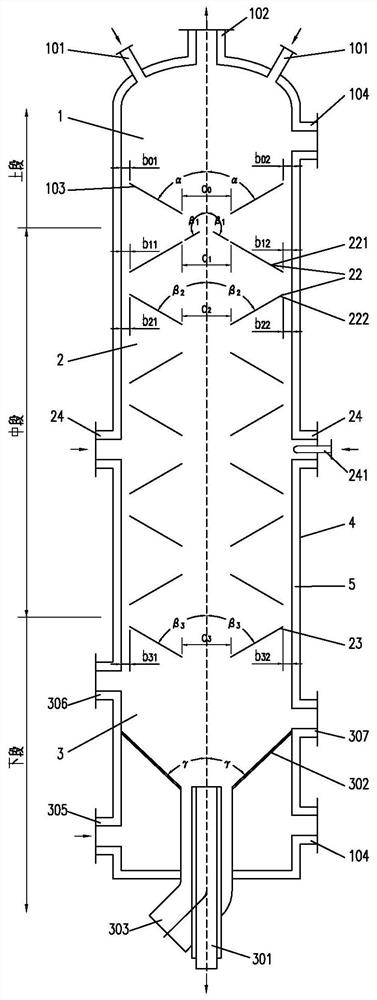

Direct heat supply type multi-stage series turbulent bed pyrolysis stripping furnace in combustion flame furnace

ActiveCN113088306AImprove efficiencyImprove heat absorption efficiencyBiofuelsSpecial form destructive distillationThermodynamicsCombustor

The invention relates to the field of solid waste treatment, in particular to a direct heat supply type multi-stage series turbulent bed pyrolysis stripping furnace in a combustion flame furnace. The direct heat supply type multi-stage series turbulent bed pyrolysis stripping furnace comprises a furnace shell, and the furnace shell comprises an upper section furnace, a middle section furnace, a lower section furnace and a fire-resistant heat insulation lining which communicate with one another; the upper section furnace is provided with an organic solid waste material inlet and a gaseous mixture outlet; the middle section furnace is provided with a plurality of groups of turbulent micro reaction beds which are connected in series; the lower section furnace is provided with a fuel burner, a pressure and temperature gas inlet and a residue outlet; and fuel is combusted through the fuel burner to generate high-temperature flue gas which flows from bottom to top and is in direct contact with organic solid waste to provide heat. The direct heat supply type multi-stage series turbulent bed pyrolysis stripping furnace has the effect of improving the pyrolysis efficiency of the reactor.

Owner:NINGBO LIANTONG EQUIP MFG

Aqueous acrylate electrostatic flocking bonding agent and preparation method thereof

InactiveCN102516470BPromote environmental protectionImprove performanceLiquid surface applicatorsCoatingsEpoxyCooking & baking

The invention discloses an aqueous acrylate electrostatic flocking binder and a preparation method thereof, belonging to the field of the preparation of macromolecular binders. The environment-friendly and excellent-performance aqueous acrylate electrostatic flocking binder is prepared by taking a soft monomer, a hard monomer, a functional monomer, a crosslinking monomer, epoxy resin, an initiator, an emulsifier, a buffering agent, a pH regulator and deionized water as raw materials, adopting an alkylphenol ethoxylates (APEO)-excluding emulsifier to carry out prophase pre-emulsification, taking acrylic monomers and the epoxy resin as main raw materials, and using a hemicontinuous emulsion polymerization manner that monomers and the initiator are dual-dropwise added, wherein the monomers are monomers with functional groups which are not hydroxylmethyl, the functional groups can crosslink with fiber only during the baking process of an electrostatic flocking fabric, and free formaldehyde can be produced. The aqueous acrylate electrostatic flocking binder has the advantages of simplicity in process, higher conversion ratio and stable performance, the flocking fabric made from the binder complies with the standards of no formaldehyde, APEO excluding, abrasion resistance and soft hand feeling, and the service requirements of ecologic clothing fabrics can be effectively met.

Owner:BEIJING COMENS NEW MATERIALS

An oxygen-barrier and biodegradable plastic film

InactiveCN103160012BImprove mechanical propertiesAchieve environmental friendlinessLow-density polyethylenePullulan

The invention relates to an oxygen-separating and degradable thin plastic film which contains the following raw constituents in parts by weight: 100 parts of low-density polyethylene, 50-70 parts of PBM (Plant Base Master batch), 20-40 parts of pullulan, 2-4 parts of antioxidant, and 0.5-1 part of ultraviolet light absorber. The excellent mechanical property of the thin film is guaranteed by utilizing the characteristics of LDPE (Low-Density Polyethylene), the environment friendliness of the thin film material is realized by utilizing the degradability of the PBM and the pullulan; the oxygen separating property of the thin film material is increased by utilizing the high oxygen separating property of the pullulan; the whole compatibility of the thin film material is increased by utilizing the structural similarity of starch and the pullulan as carbohydrates; and the oxygen separating property, the degradability and the like can be adjusted and controlled by controlling the blending proportion of LDPE / PBM / Pullulan systems.

Owner:TIANJIN JINSHENGYU PLASTIC PROD SCI & TECH CO LTD

A method of hole reaming and sinking with static pile driver

ActiveCN104631458BGood construction performanceAchieve reliabilityBulkheads/pilesStructural engineeringPile driver

The invention discloses a chambering and pile sinking construction method for a static pile driver. The method comprises the steps that the static pile driver carries out primary pile pressing, drill pile holding and mounting are carried out, chambering is carried out, and the static pile driver carries out final pile pressing. The chambering and pile sinking construction method for the static pile driver solves the problem that pile sinking is difficult in a sand layer, a hard soil layer, a differentiation layer and other soil layers where piles cannot be pressed easily. According to the method, chambering is carried out first, then pile sinking is carried out, and the method has the advantages of being small in noise, small in additional weight, little in squeezed soil, simple in operation and simple and reliable in structure.

Owner:江苏谷登重型机械科技股份有限公司

A kind of non-voc high solid content water-based epoxy polyurethane primer and preparation method thereof

The invention discloses VOC (volatile organic compound)-free high-solid-content water-borne epoxy PU (polyurethane) primer and a preparation method thereof. A vinyl monomer mixture is used as a dispersion phase, polymer polyol and a polyisocyanate compound are polymerized with trimethylolpropane serving as a self-crosslinking monomer under the action of a carboxyl and sulfonyl mixed hydrophilic chain extender, PU prepolymers capped with the vinyl monomers are obtained through end capping by vinyl monomers containing active hydrogen, after neutralization by an alkaline salt-forming agent, a PU micro-emulsion is obtained through dispersion with water, the polymerization of the vinyl monomers is further triggered under the action of a water-soluble initiator, meanwhile, epoxy functional groups are introduced into the polymer, and the epoxy modified PU-polyacrylate micro-emulsion which is free of VOCs and high in solid content is obtained with an in-situ emulsion polymerization method. Compared with traditional PU primer, the water-borne PU primer is lower in cost and high in curing speed and has excellent adhesive force, alkali resistance, wear resistance, weather resistance and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Thermoplastic composite elastomer and its preparation method and use

ActiveCN107227027BAchieve environmental friendlinessHigh bonding strengthGround pavingsPolymer sciencePolyolefin

The invention discloses a thermoplastic composite elastomer, and a preparation method and application of the elastomer. The thermoplastic composite elastomer comprises the following raw materials in parts by weight: 18.0-45.0 parts of thermoplastic elastomer, 26.0-73.0 parts of paraffin oil, 1.0-7.0 parts of polyhydric alcohol, 0.5-6.0 parts of a compatilizer, 32.0-166.0 parts of a filler and 1.0-5.0 parts of an assistant, wherein the thermoplastic elastomer is a composite of a polar thermoplastic elastomer and a nonpolar thermoplastic elastomer; the polar thermoplastic elastomer is one or two of acrylic rubber and a thermoplastic polyurethane elastomer; the nonpolar thermoplastic elastomer is one or two of a hydrogenated styrene-butadiene segmented copolymer and a polyolefin elastomer. Compared with the prior art, the thermoplastic composite elastomer achieves overall effects of environment friendliness, high bonding strength and excellent mechanical properties and is a preferable material of a plastic track.

Owner:广东杰锐新材料有限公司

A kind of preparation method of degradable plastic composite film with oxygen barrier property

ActiveCN104861246BImprove mechanical propertiesAchieve environmental friendlinessPullulanComposite film

The invention discloses a preparation method for a degradable plastic composite film with an oxygen separation performance. In the preparation method, degradable plastic master batch PBM mature in the present market, Pullulan polysaccharide and film-level LDPE are employed as raw material with addition of anti-oxidants and ultraviolet ray absorbers, tannic acid is employed for modifying Pullulan polysaccharide, further the plastic film three-layer co-extrusion film blowing technology is employed, and a three-layer plastic composite film with good oxygen separation performance, degradability and mechanical properties is prepared. The inner layer, the middle layer and the outer layer of the composite film are LDPE / PBM / Pullulan, PBM / Pullulan and LDPE / PBM / Pullulan respectively. The composite film can decompose automatically under action of oxygen enrichment and microbes, a wasted film can be degraded and digested completely by microbes in nature, the oxygen separation performance of the composite film can be raised by 70%-80% compared with the oxygen separation performance of an LDPE film with the same thickness, and the mechanical properties of the composite film are almost the same as mechanical properties of an LDPE film with the same thickness. The composite film is advantaged by simple production technology, high production efficiency and easy industrial enforcement.

Owner:TIANJIN JINSHENGYU PLASTIC PROD SCI & TECH CO LTD

A degradable three-layer co-extruded plastic composite film with oxygen barrier properties

ActiveCN104859237BImprove mechanical propertiesAchieve environmental friendlinessFlexible coversWrappersPullulanComposite film

The invention discloses a degradable three-layer co-extrusion plastic composite film with an oxygen separation performance. Degradable plastic master batch PBM mature in the present market, Pullulan polysaccharide and film-level LDPE are employed as raw material with addition of anti-oxidants and ultraviolet ray absorbers, tannic acid is employed for modifying Pullulan polysaccharide, further the plastic film three-layer co-extrusion film blowing technology is employed, and a three-layer plastic composite film with good oxygen separation performance, degradability and mechanical properties is prepared. The inner layer, the middle layer and the outer layer of the composite film are LDPE / PBM / Pullulan, PBM / Pullulan and LDPE / PBM / Pullulan respectively. The composite film can decompose automatically under action of oxygen enrichment and microbes, a wasted film can be degraded and digested completely by microbes in nature, the oxygen separation performance of the composite film can be raised by 70%-80% compared with the oxygen separation performance of an LDPE film with the same thickness, and the mechanical properties of the composite film are almost the same as mechanical properties of an LDPE film with the same thickness. The composite film is advantaged by simple production technology, high production efficiency and easy industrial enforcement.

Owner:TIANJIN JINSHENGYU PLASTIC PROD SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com