Patents

Literature

42results about How to "Good bonding strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water based copolymer adhesive for artificial board and its preparation method

InactiveCN1410498AExcellent performanceGood bonding strengthNitrile polymer adhesivesEster polymer adhesivesDisperserAdhesive

A water-base copolymer adhesive for artificial board is prepared from soft monomer (10-60 wt.%), hard monomer (35-65), unsaturated carboxylic acid (2-10), hydroxy acrylate (2-10), polymer-type emulsifier monomer (1-5) through dispersing in water with special water disperser and polymerization at 30-120 deg.c. Its advantages are high performance, no release of formaldehyde, and low cost.

Owner:南京元初科技有限公司

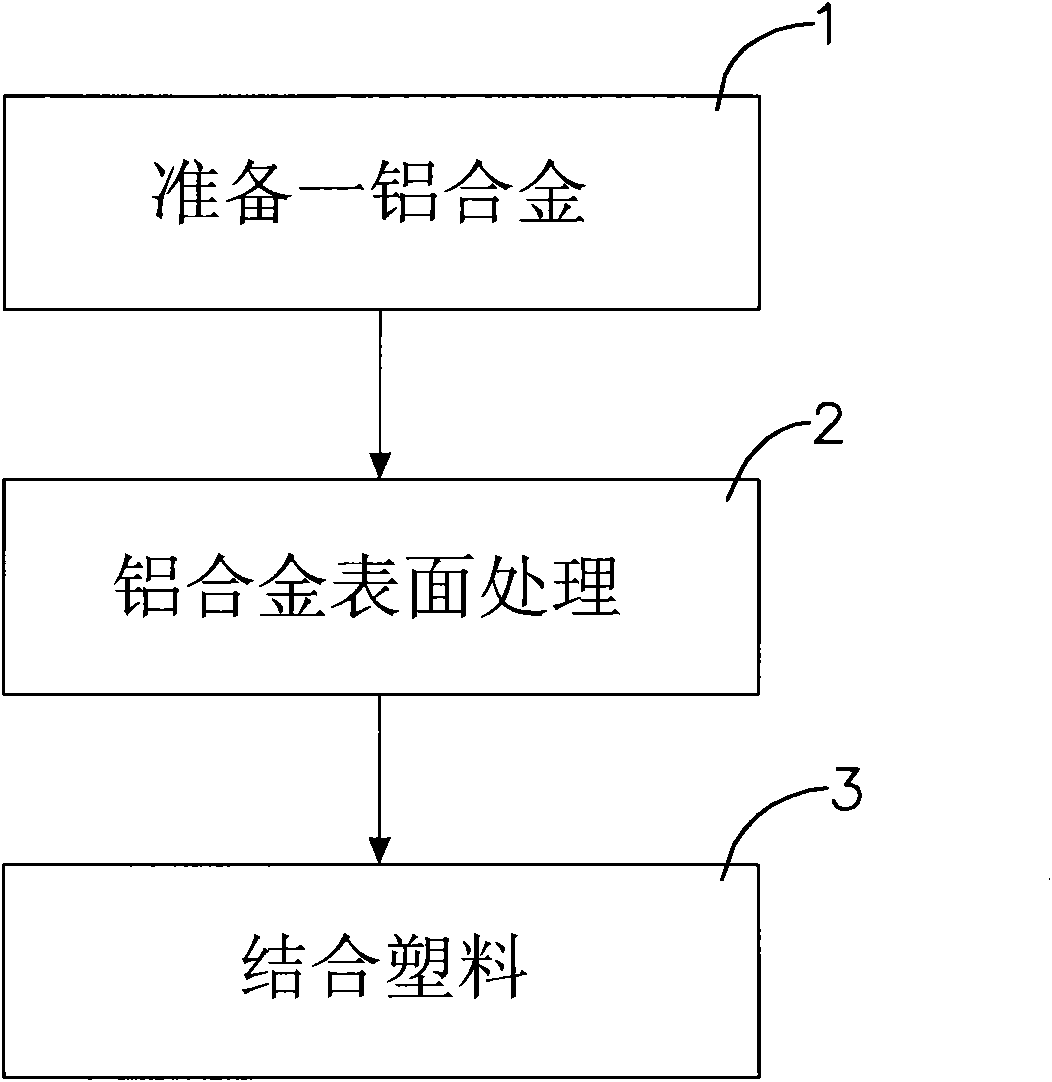

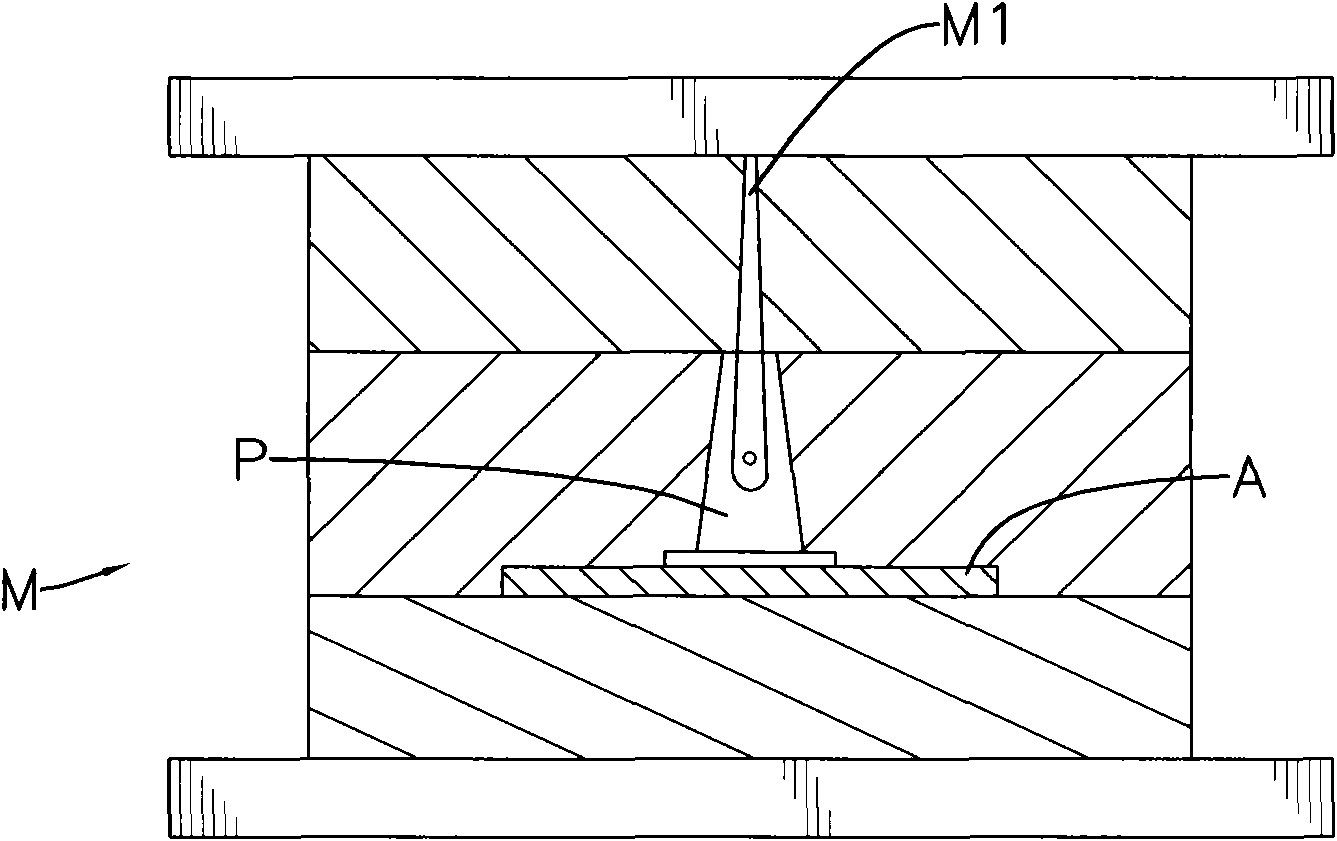

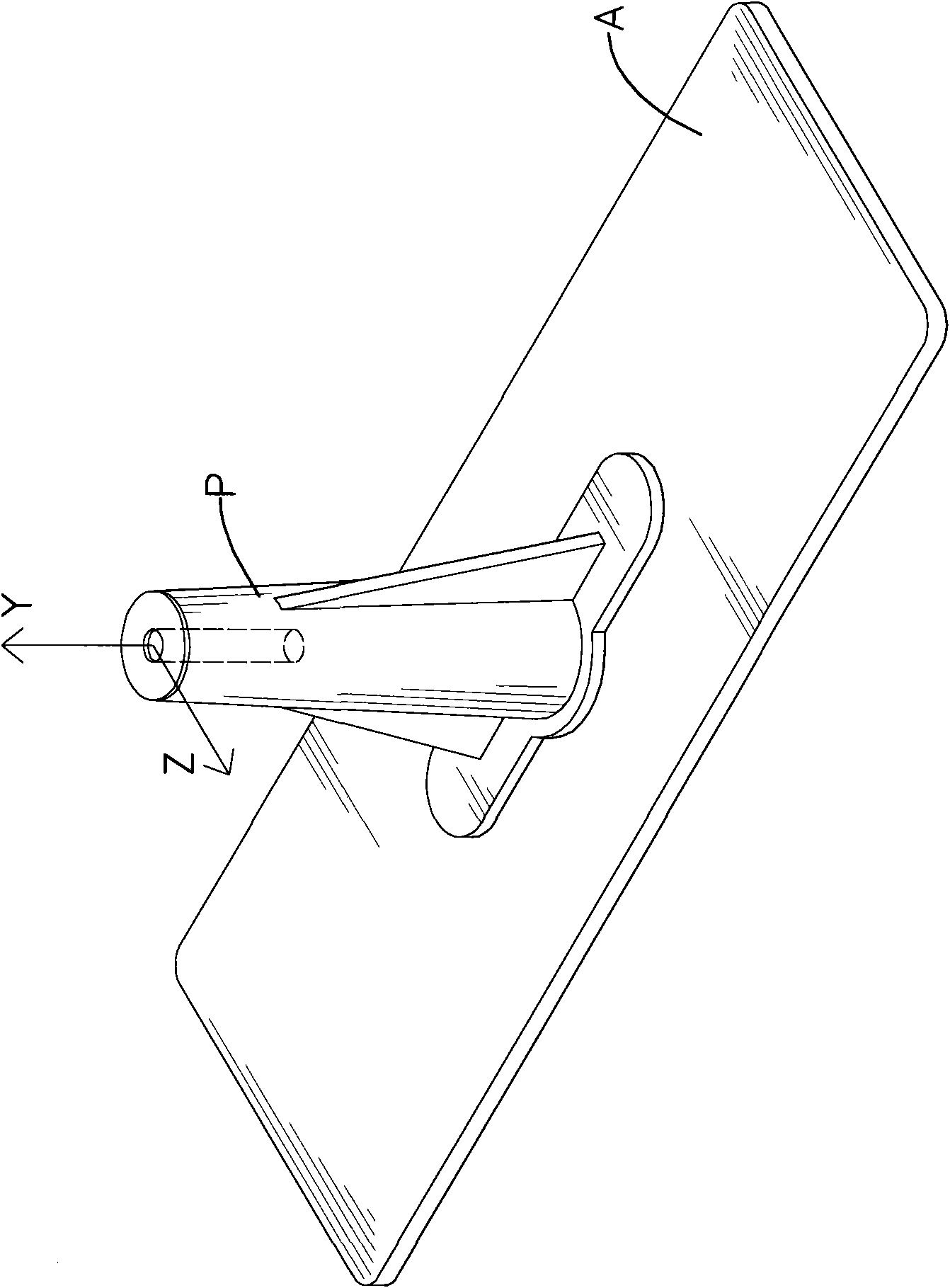

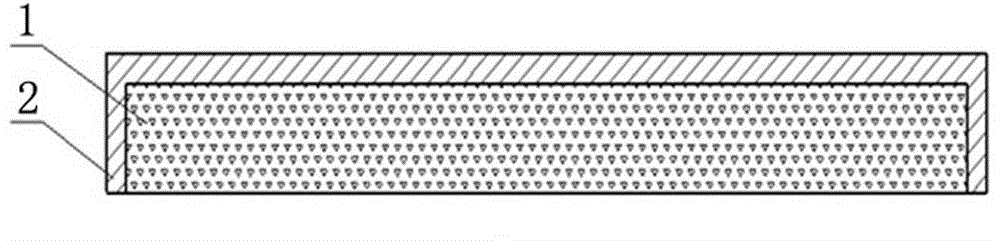

Combination method of alloy and plastic

InactiveCN102373499AGood bonding strengthSafe to useSurface reaction electrolytic coatingAlloy surfaceMaterials science

The invention relates to a combination method of alloy and plastic. According to the invention, first, alloy is subject to an electrochemical treatment, such that micropores are formed on the surface of the alloy; and plastic is formed on the surface of the alloy through an injection molding method. Because molten plastic can enter the micropores, when the plastic is cooled and cured, the plastic can be attached to the surface of the alloy.

Owner:CATCHER TECH

Magnesium alloy differential arc electrophoresis composite surface treating method

InactiveCN1908246AGood bonding strengthLow costAnodisationElectrophoretic coatingsMicro arc oxidationSurface finishing

the invention discloses a compound surface disposing method of Mg-alloy micro-arc electrophoresis, which comprises the following steps: placing the disposed Mg-alloy working piece in the silicate electrolytic solution to proceed micro-arc oxidizing disposal; forming Mg-alloy ceramic layer; immersing in the deionized water; cleaning through ultrasonic wave cleaner; proceeding electrophoretic disposal for Mg-alloy working piece; forming compound film on the surface.

Owner:XIAN UNIV OF TECH

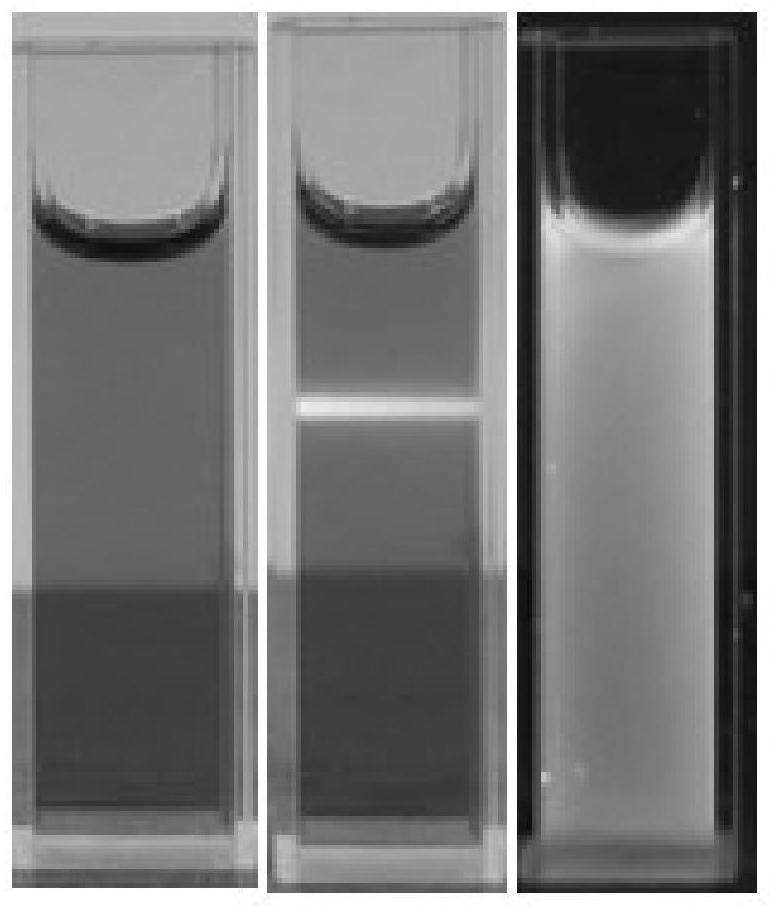

Method for preparing self-supporting diamond film

ActiveCN104561925AGood bonding strengthAvoid cracksChemical vapor deposition coatingTitaniumAcid corrosion

The invention discloses a method for preparing a self-supporting diamond film and belongs to the technical field of chemical vapor deposition diamond films. The method disclosed by the invention comprises the following steps: pre-depositing a titanium metal coating on the upper surface and side surface of a silicon substrate; depositing a molybdenum metal coating on the upper surface of the silicon substrate containing the titanium metal coating; depositing a diamond film on the upper surface of the silicon substrate which is pre-deposited with the titanium / molybdenum metal coating by adopting a chemical vapor deposition method; and finally, obtaining the self-supporting diamond film by using an oxalic acid solution corroding sample, and recycling the silicon substrate. Compared with the prior art, the method disclosed by the invention has the advantages that the diamond film is fast in nucleation, and the deposition time can be shortened; the silicon substrate can be repeatedly used, and the production cost can be reduced; and the environmental pollution caused by conventional acid corrosion of the silicon substrate can be avoided.

Owner:山西新碳超硬材料科技有限公司

Alcohol-soluble decorative adhesive and preparation method thereof

InactiveCN101818034AWide range of bondingGood bonding strengthMonocarboxylic acid ester polymer adhesivesMineral oil hydrocarbon copolymer adhesivesSolventFunctional monomer

The invention discloses an alcohol-soluble decorative adhesive and a preparation method thereof, belonging to the field of an adhesive. The adhesive is prepared from the following components in percentage by weight: acrylate polymer, tackifying resin and solvent, wherein the acrylate polymer is polymerized from 20-50wt% of acrylate hard monomer, 40-70wt% of acrylate soft monomer and 1-10wt% of acrylate functional monomer by a solution polymerizing method under the actions of an initiator and the solvent. The glass transition temperature of the acrylate polymer is -10 to -40 DEG C. As the acrylate hard monomer and the acrylate soft monomer are reasonably matched, and a certain acrylate functional monomer is matched to participate into the polymer, the molecular chain of the acrylate polymer in the decorative adhesive has multiple chemical bond structures of -COH, -OH, -NH and the like, multiple intermolecular action force can be formed, the adhesive can be adhered to various composite materials with good adhesion property and wide adhesion range. The decorative adhesive can use the alcohol as the main solvent and has the advantages of little toxicity and low cost.

Owner:BEIJING COMENS NEW MATERIALS

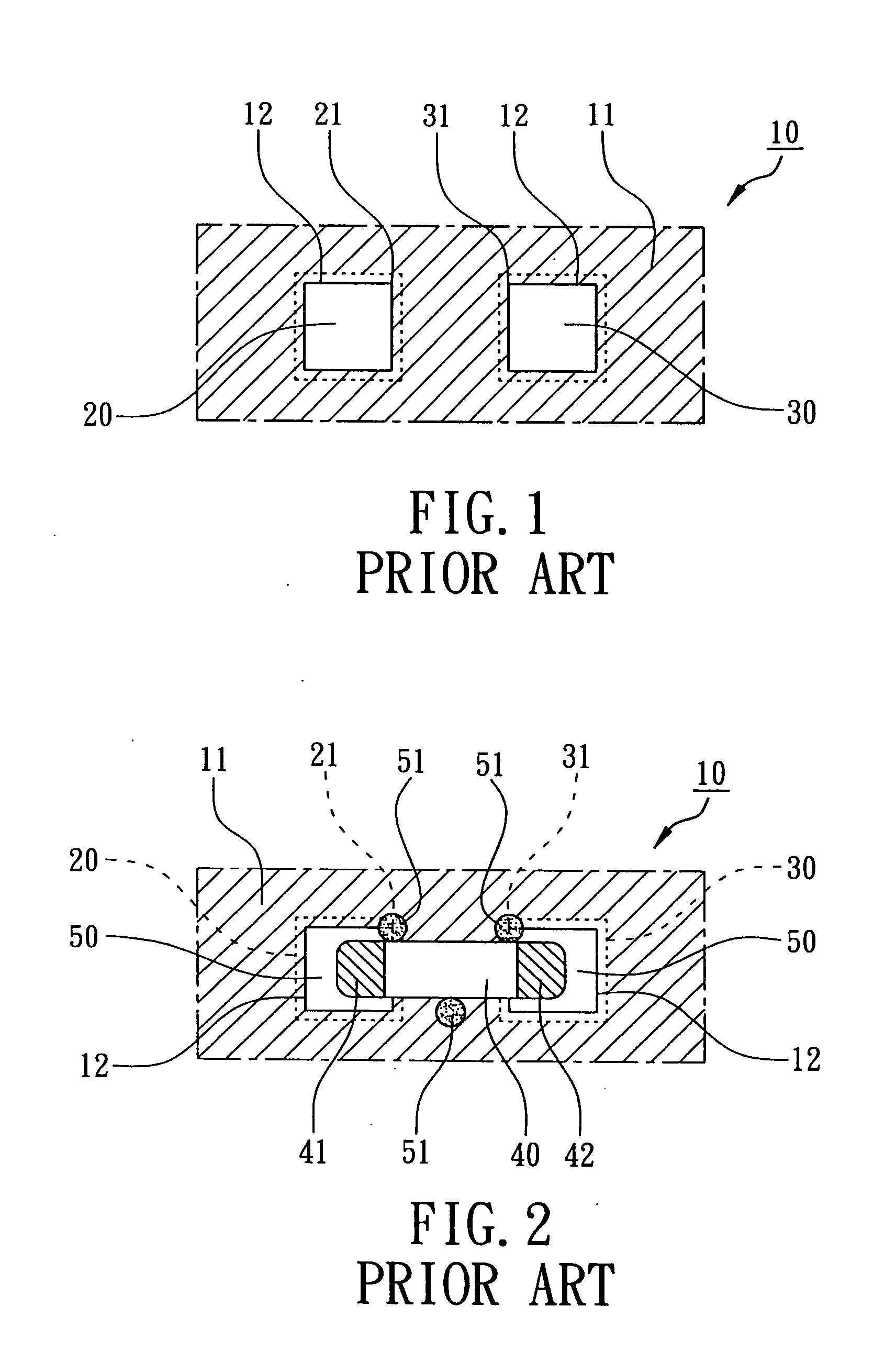

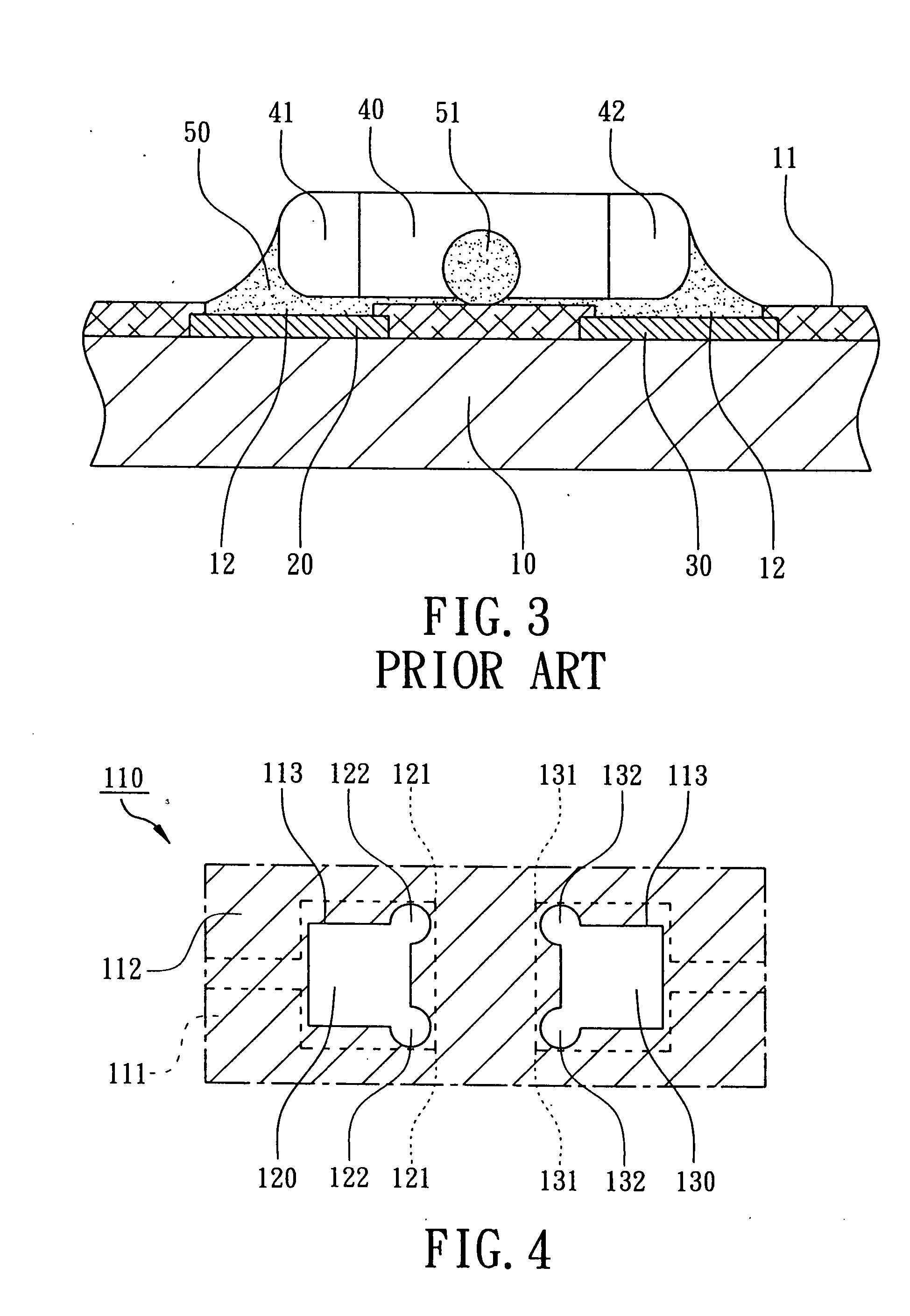

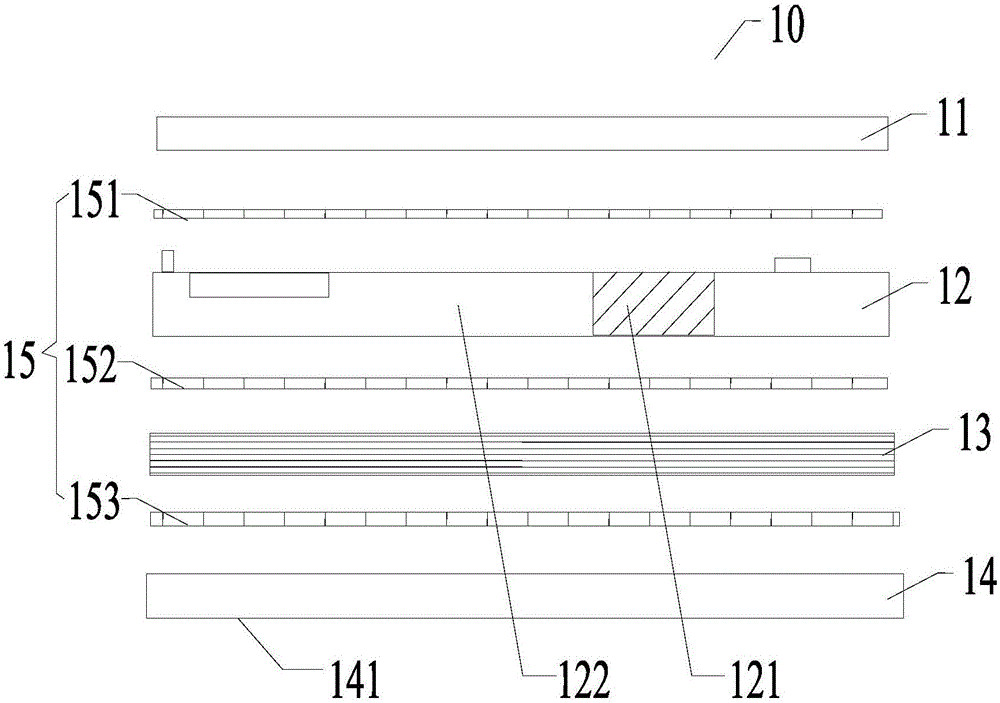

Circuitized substrate for fixing solder beads on pads

ActiveUS20050082686A1Good bonding strengthHigh bonding strengthFinal product manufactureSemiconductor/solid-state device detailsContact padSolder paste

A circuitized substrate has contact pads for mounting a Surface Mount Device (SMD). First and second contact pads are located on a surface of the substrate corresponding to a first terminal and a second terminal of the SMD. The first and the second contact pads have a plurality of expanded portion or diminished portions to form bead receptacles at the facing corners thereof. When solder paste is reflowed to electrically connect the SMD, solder beads formed from the solder paste can be fixed on the bead receptacles. Therefore, there is no free solder bead on the substrate causing short circuit for semiconductor packages.

Owner:ADVANCED SEMICON ENG INC

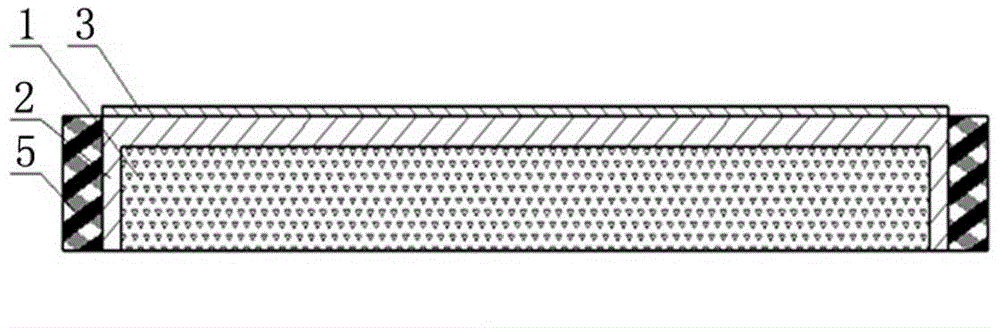

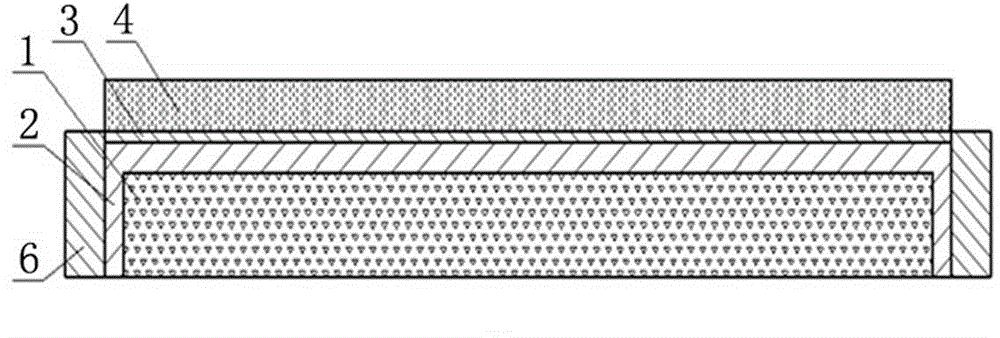

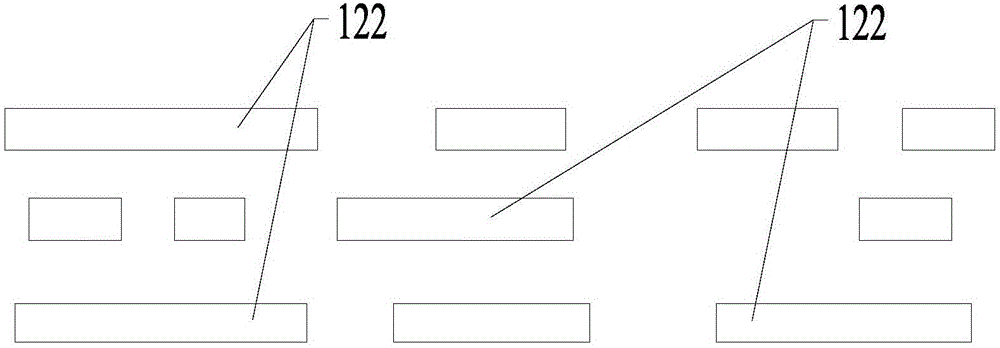

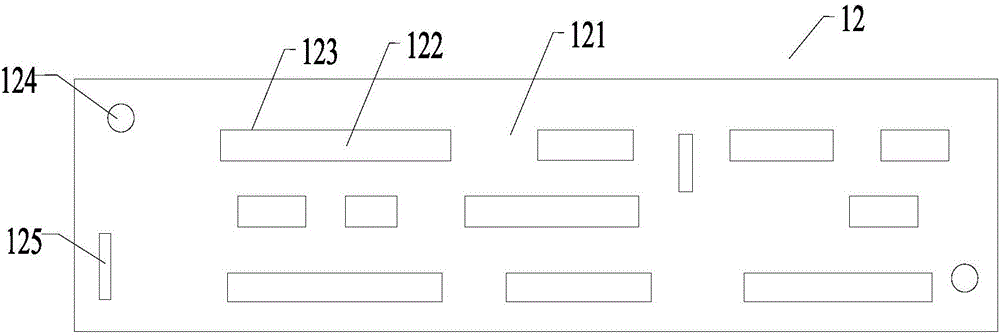

Novel busbar and manufacturing method thereof

InactiveCN106231810AReduce electromagnetic interferenceGood bonding strengthPrinted circuit assemblingSynthetic resin layered productsBusbarElectricity

The invention discloses a novel busbar, which comprises an insulating layer, a busbar (busbar), an insulating material and a printed board (PCB) which are sequentially laminated into a whole, wherein a bonding sheet is arranged between any two adjacent layers of the insulating layer, the busbar, the insulating material and the PCB; the busbar is formed by inlaying an insulating plate and a copper bar; and the busbar is electrically connected with the PCB through an interlayer conduction structure. The embodiment of the invention further provides a manufacturing method of the novel busbar. The novel busbar disclosed by the technical scheme is of an integrally laminated molded structure; and a plurality of disadvantages due to the fact that the PCB and the busbar are installed together in a bracket fixing manner in the prior art can be overcome.

Owner:深圳众力新能源科技有限公司

GF/PEEK composite artificial tooth with novel BGC coating and preparation method of artificial tooth

ActiveCN106725945AAccelerate early fixesImprove adhesionArtificial teethTissue regenerationCell adhesionBiocompatibility Testing

The invention provides a GF / PEEK composite artificial tooth with a novel BGC coating and a preparation method of the artificial tooth. A blank of the artificial tooth is prepared from a GF / PEEK composite; the elastic modulus and an expansion coefficient of the composite are close to those of a human bone; the toughness and the fatigue reliability of the composite are good; the blank and the novel BGC coating sprayed on the surface of an implantation part have higher cohesion and close expansion coefficients, and are securely combined. Therefore, compared with the conventional titanium artificial tooth, the mechanical property, the biocompatibility and the bone bonding strength of the artificial tooth are better; the coating cannot easily fall. The novel BGC coating is sprayed on the surface of the implantation part of the artificial tooth, and a micro / nano porous groove structure and an exposed nano hydroxyapatite particle rough surface are presented, so that cell adhesion can be facilitated; early repair of the bone is accelerated. The artificial tooth is low in material price, simple in preparation technology, easy to produce, cheap and fine, and is worthy of popularization.

Owner:NANNING YUEYANG TECH

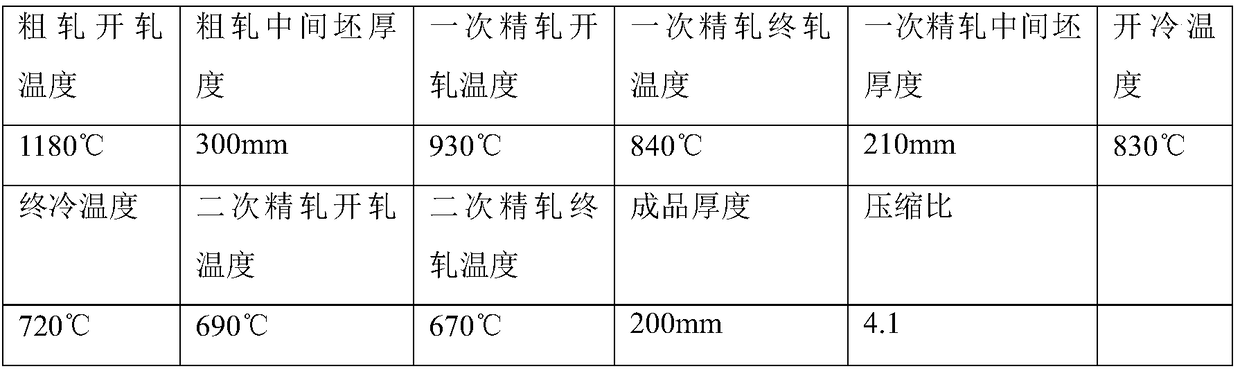

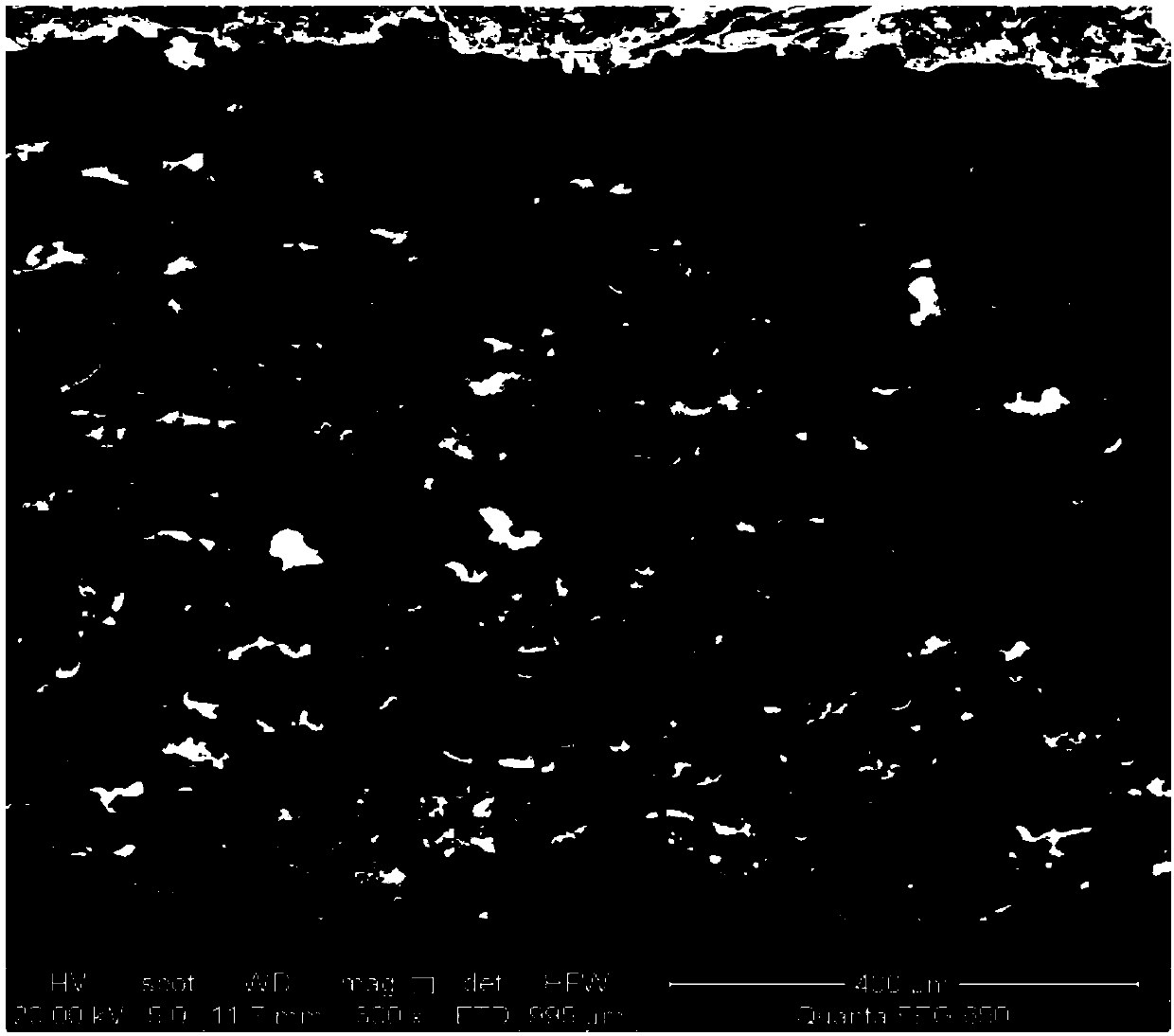

Ultrathick normalizing high-intensity pressure container steel plate and production method thereof

The invention discloses an ultrathick normalizing high-intensity pressure container steel plate and a production method thereof. The ultrathick normalizing high-intensity pressure container steel plate is prepared from 0.19 to 0.22 percent of C, 0.25 to 0.60 percent of Si, 1.45 to 1.60 percent of Mn, smaller than and equal to 0.010 percent of P, smaller than and equal to 0.005 percent of S, 0.030to 0.040 percent of Nb, 0.20 to 0.30 percent of Ni, 0.020 to 0.030 percent of Ti, 0.010 to 0.020 percent of V, 0.20 to 0.30 percent of Cr, 0.015 to 0.3 percent of Cu, 0.020 to 0.045 percent of Alt andthe balance of Fe and unavoidable impurities. The thickness of the steel plate is 180 to 250 mm; the normalizing state thickness 1 / 2 position tensile intensity Rm is greater than or equal to 600 Mpa;the simulated post-welding heat treatment state steel plate thickness 1 / 2 tensile intensity Rm is greater than or equal to 550 Mpa.

Owner:ANGANG STEEL CO LTD

Cermet composite material and coating preparation method thereof

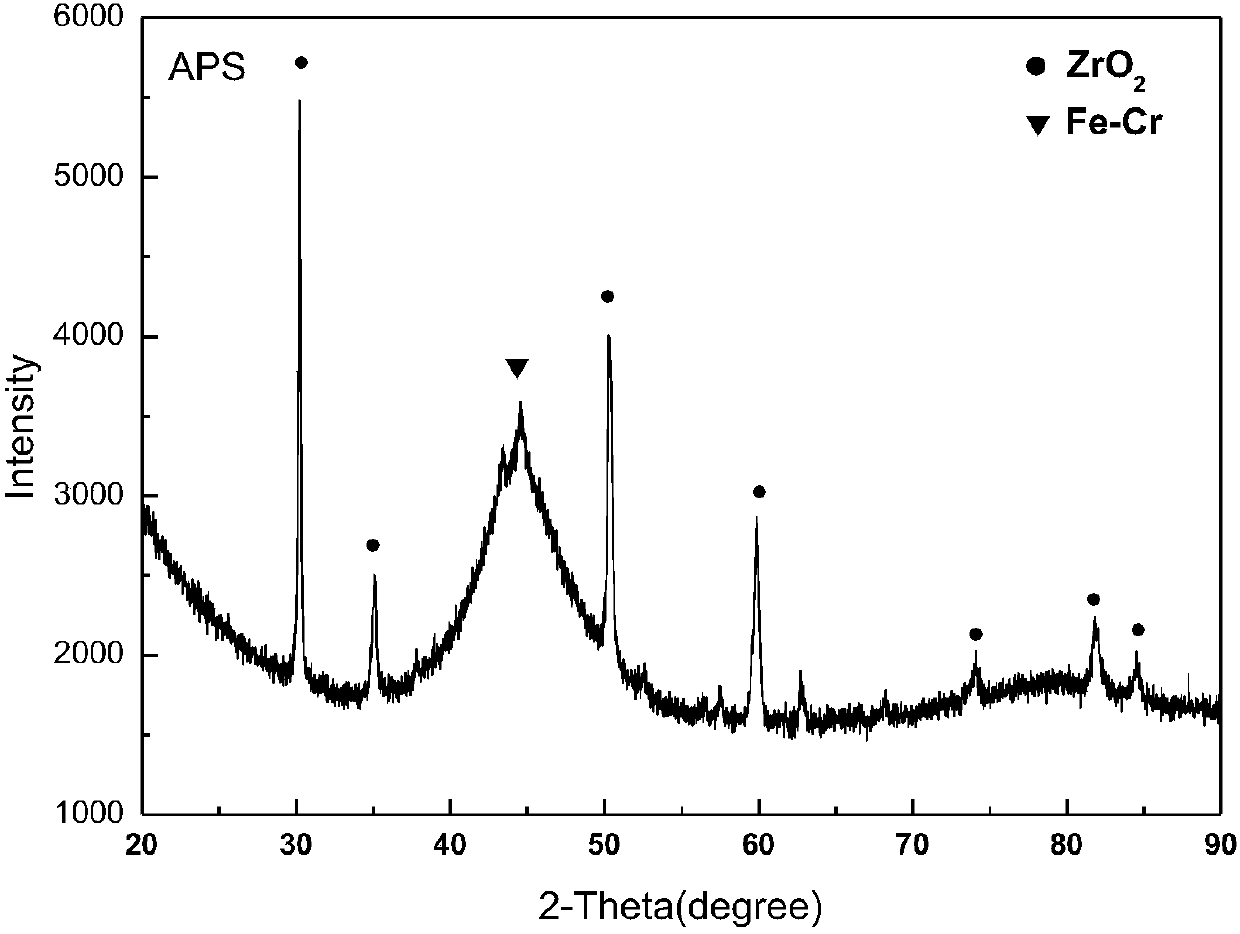

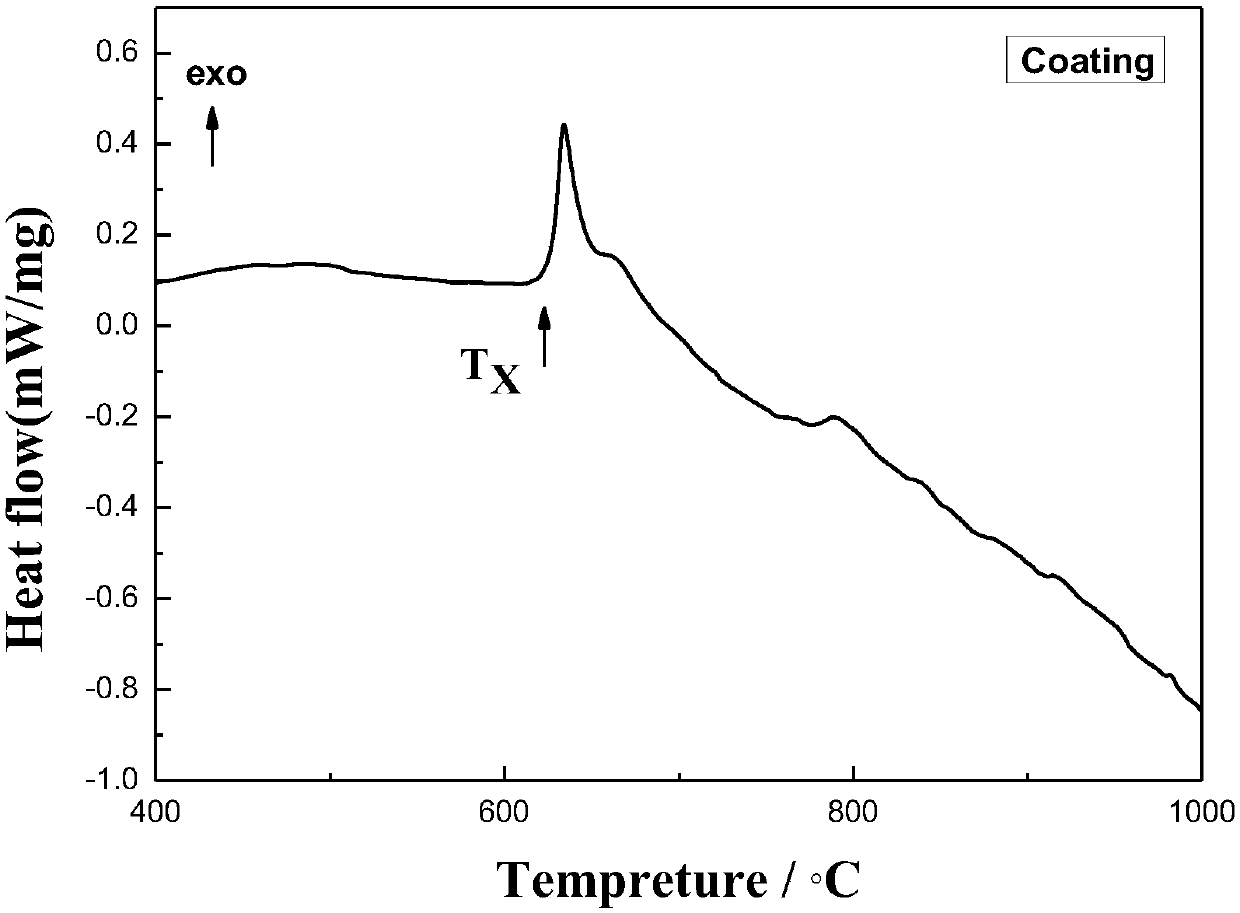

InactiveCN107653430AGood matching of thermal expansionGood bonding strengthMolten spray coatingSurface engineeringNitrogen gas

The invention provides a cermet composite material and a coating preparation method thereof, belongs to the field of thermal spraying in composite materials and surface engineering, and particularly relates to a preparation method for metal-based composite powder with low thermal conductivity and a coating thereof by atmospheric plasma spraying. The method comprises the following steps that iron-based amorphous powder prepared by the high pressure nitrogen gas atomization method is mixed with zirconia powder prepared by the agglomeration sintering method according to a certain mass ratio, andfinally the composite powder with a better sphericity and a particle size of 25-75 [mu]m is obtained. The iron-based-ceramic composite coating is prepared by adopting the atmospheric plasma spraying mode, and the composite coating prepared has relatively low thermal conductivity, and can be used for insulation protection for hot end parts of a diesel engine.

Owner:BEIJING UNIV OF TECH

Chrome electroplating solution

The invention discloses a chrome electroplating solution which comprises 5-20 g / L chromic sulfate, 10-50 g / L potassium phosphate, 1-10 g / L ammonium bromide, 15-50 g / L oxalic acid, 5-30 g / L sodium hypophosphite, 0.5-2 g / L stannous sulfate, 5-40 g / L acetic acid, 1-10 g / L citric acid and the balance of water. The invention has the advantages of reasonable formula, high binding strength (due to the adoption of the citric acid as a stabilizer for preventing the coating from shedding), and high surface smoothness; and the sodium hypophosphite can effectively prevent the component in the solution from being converted into toxic substance hexavalent chrome ions.

Owner:赵春美

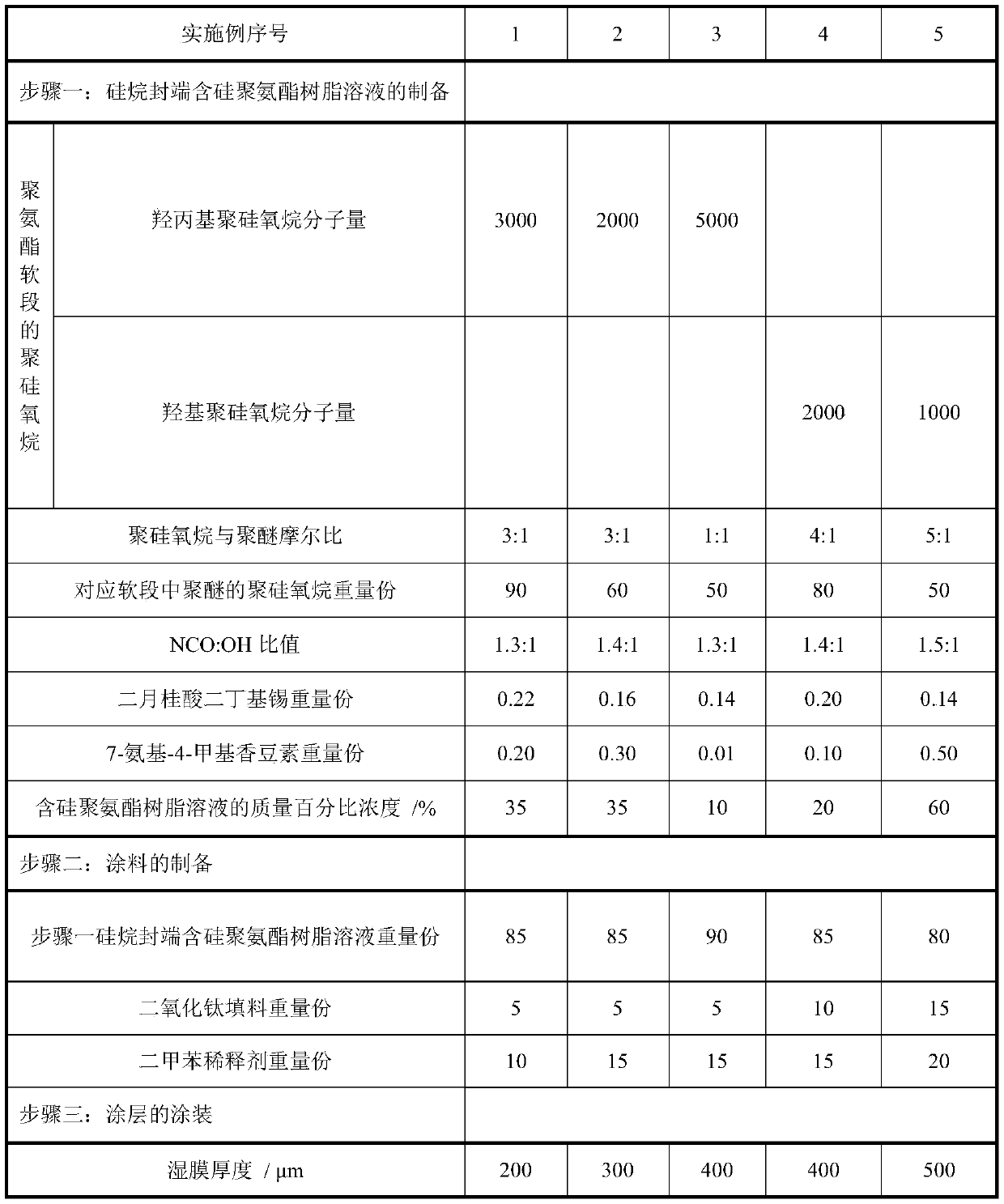

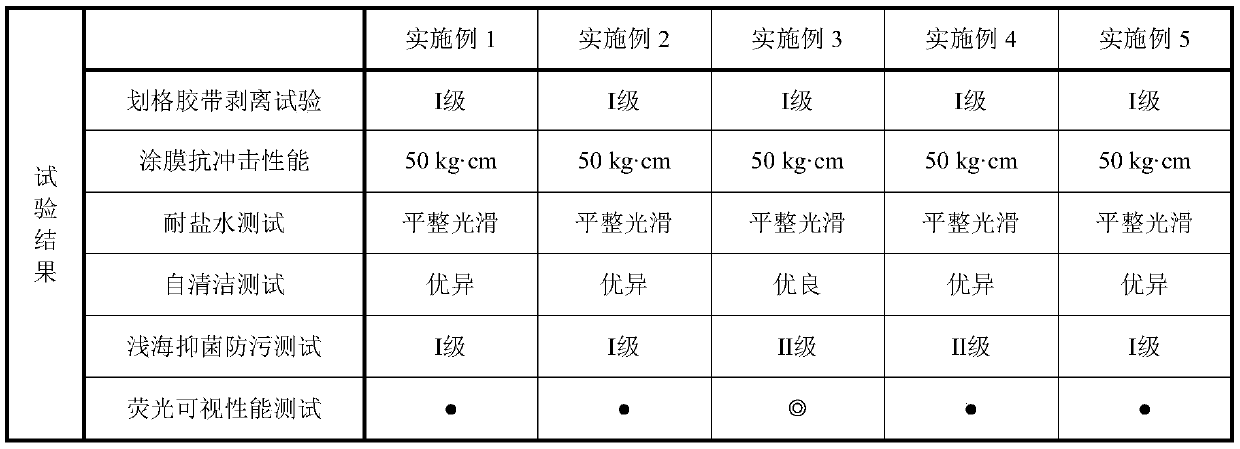

Fluorescent low-surface-energy marine antifouling paint and preparation method thereof

ActiveCN111393983AGood bonding strengthImprove adhesionAntifouling/underwater paintsPaints with biocidesSilane couplingPolymer chemistry

The invention relates to a marine antifouling coating technology, and aims to provide a fluorescent low-surface-energy marine antifouling coating and a preparation method thereof. The coating comprises a silane coupling agent-terminated silicon-containing polyurethane resin solution, a pigment filler and a diluent, wherein the silicon-containing polyurethane resin solution is a mixture of silicon-containing polyurethane resin and the diluent. The invention is applicable to the technical field of marine antifouling paint, the antifouling coating can be directly coated on an epoxy substrate, good adhesion performance can be achieved without additionally adding a connecting coating or an adhesive coating, and the problem of poor adhesion of a polysiloxane-containing low-surface-energy antifouling finish paint coating on substrates such as epoxy primer and the like is solved. The coating has excellent bonding strength and high adhesive force with a base material related to maritime work equipment and can be applied to various ships, ocean engineering equipment and structural facilities, marine ranching breeding nets and the like. The surface energy of the surface of the base material can be reduced, aquatic organisms are not easily attached and a long-acting antifouling effect can be achieved.

Owner:ZHEJIANG UNIV

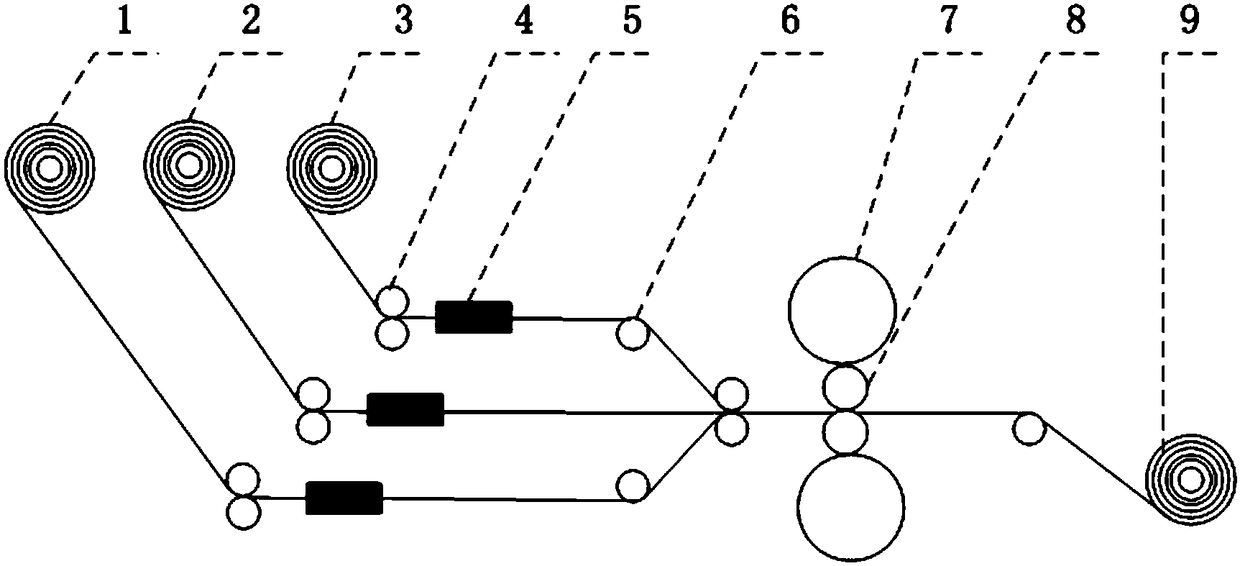

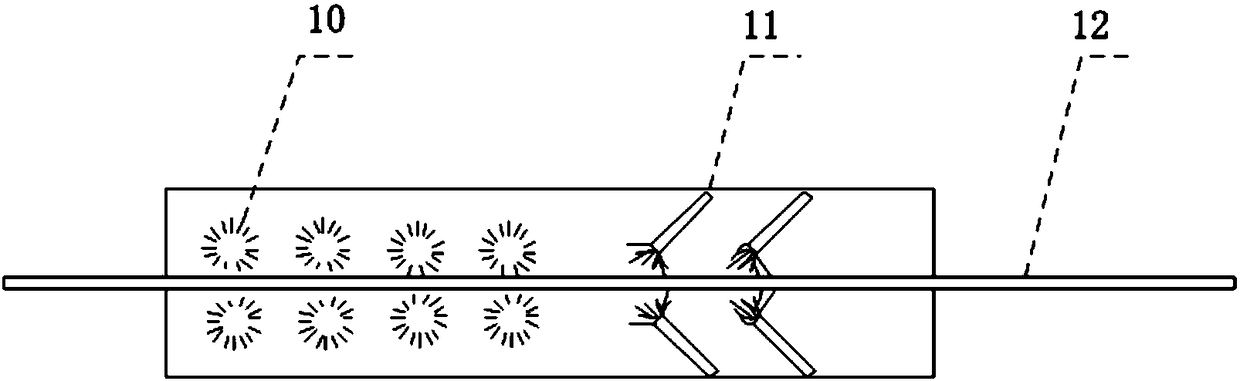

Production process of decorative base paper

InactiveCN102330378AGood bonding strengthHigh surface finenessNon-fibrous pulp additionPulp beating methodsPulp treatmentChemical pulp

The invention relates to a production process of decorative base paper. The process comprises the following steps: carrying out pulping treatment on wood pulp, thus rough pulp is prepared; carrying out pulping treatment on the rough pulp, defibering fiber in paper pulp, cutting off moderately and brooming, thus mechanical pulp after knocking and needle leaf and broad leaf mixed chemical pulp after knocking are prepared; mixing the mechanical pulp and the chemical pulp, and adding starch and auxiliary chemicals in the pulp, thus pulp is prepared; and adding auxiliary chemicals such as glue, filler after dilution, and preparing the high-grade decorative base paper after the treatment of screening, processing of a wet end, processing of a pressing section, press polishing, paper winding and rewinding and packaging. According to the invention, through the improvement of production technology and devices in the production technology, the ratio of expansion and contraction, thickness, bubble points and other using performances are improved.

Owner:五洲特种纸业集团股份有限公司

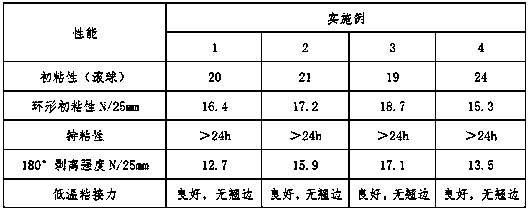

Ultrahigh-viscosity acrylate emulsion pressure-sensitive adhesive and preparation method thereof

ActiveCN111187586AGood initial tackGood bonding strengthPressure sensitive film/foil adhesivesGraft polymer adhesivesPolymer scienceFunctional monomer

The invention relates to an ultrahigh-viscosity acrylate emulsion pressure-sensitive adhesive. The ultrahigh-viscosity acrylate emulsion pressure-sensitive adhesive is prepared from the following rawmaterials in parts by weight: 70-120 parts of an acrylate monomer, 1-5 parts of a functional monomer, 1-5 parts of an internal crosslinking monomer, 1-15 parts of liquid tackifying resin, 0.3-2 partsof an emulsifier, 0.2-1 part of an initiator, 0.05-0.3 part of a reducing agent, 0.05-1 part of a wetting agent, 0.05-1 part of a defoaming agent and 70-130 parts of deionized water. According to theinvention, the submicron liquid tackifying resin is creatively prepared and is used as a seed for emulsion polymerization, and the tackifying resin is wrapped in latex particles, so a special core-shell structure is formed, with a core being the tackifying resin and a shell being polyacrylate; the core and the shell are fused with each other in the process of film forming, so a formed adhesive film has excellent initial adhesion, bonding strength and temperature resistance; and a ratio of the core to the shell is adjustable, a performance range is wide, a new idea is provided for solving the defect of poor comprehensive performance of water-based acrylate pressure-sensitive adhesives, and the adhesive can be popularized and used in a large range.

Owner:JIANGSU JINGHONG NEW MATERIAL TECH

EVA edge-sealing hot melt adhesive with no adhesive line and low adhesive coating amount and preparation method of EVA edge-sealing hot melt adhesive

ActiveCN111944456AGood bonding strengthThin glue layerNon-macromolecular adhesive additivesMacromolecular adhesive additivesAnoxomerPetroleum resin

The invention relates to the technical field of hot melt adhesives, in particular to an EVA edge-sealing hot melt adhesive with no adhesive line and low adhesive coating amount and a preparation method of the EVA edge-sealing hot melt adhesive. The EVA edge-sealing hot melt adhesive is prepared from, by weight, at least 25-45 parts of ethylene-vinyl acetate copolymer, 15-30 parts of petroleum resin, 2-10 parts of tackifying resin, 5-10 parts of viscosity modifier, 20-55 parts of filler and 0.01-0.05 part of antioxidant. The hot melt adhesive provided by the invention has the advantages of goodstrength, thin adhesive layer, adhesive saving, good flexibility of the adhesive layer, environmental protection, no harmful substances such as formaldehyde and toluene, no phthalate, no heavy metalsand the like, and compared with the color of a plate and a furniture edge banding, the adhesive line cannot be seen, and the effect of no stranded line is achieved.

Owner:上海路嘉胶粘剂有限公司

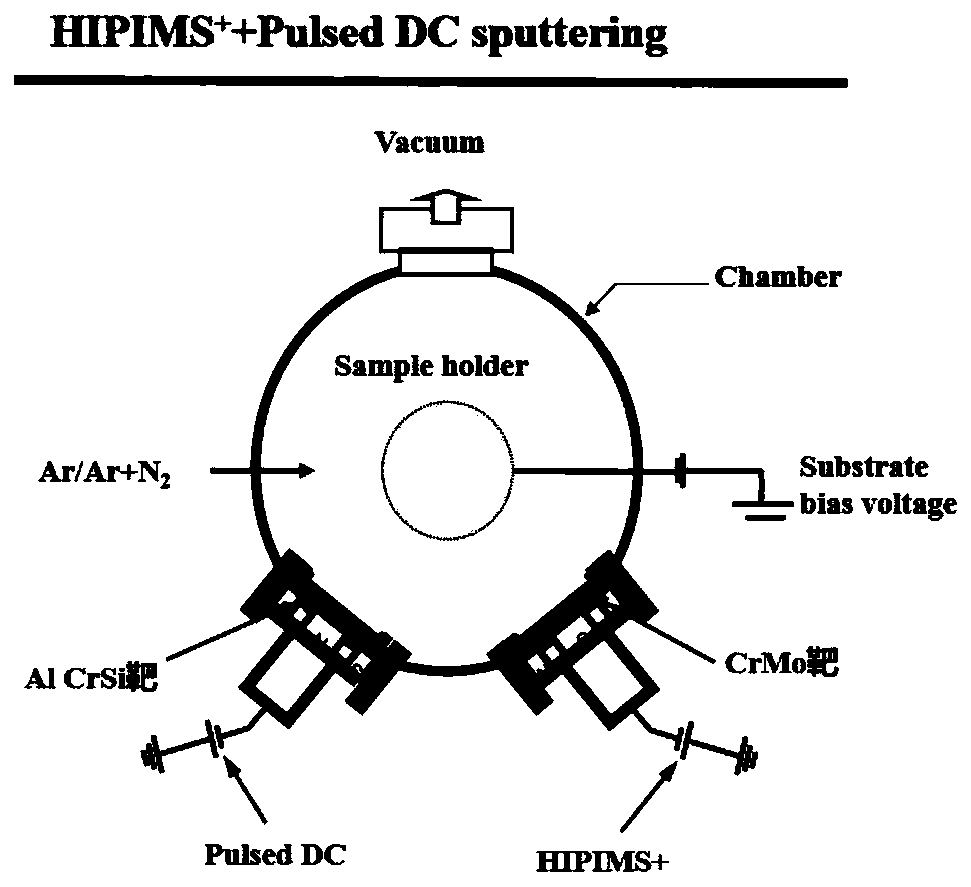

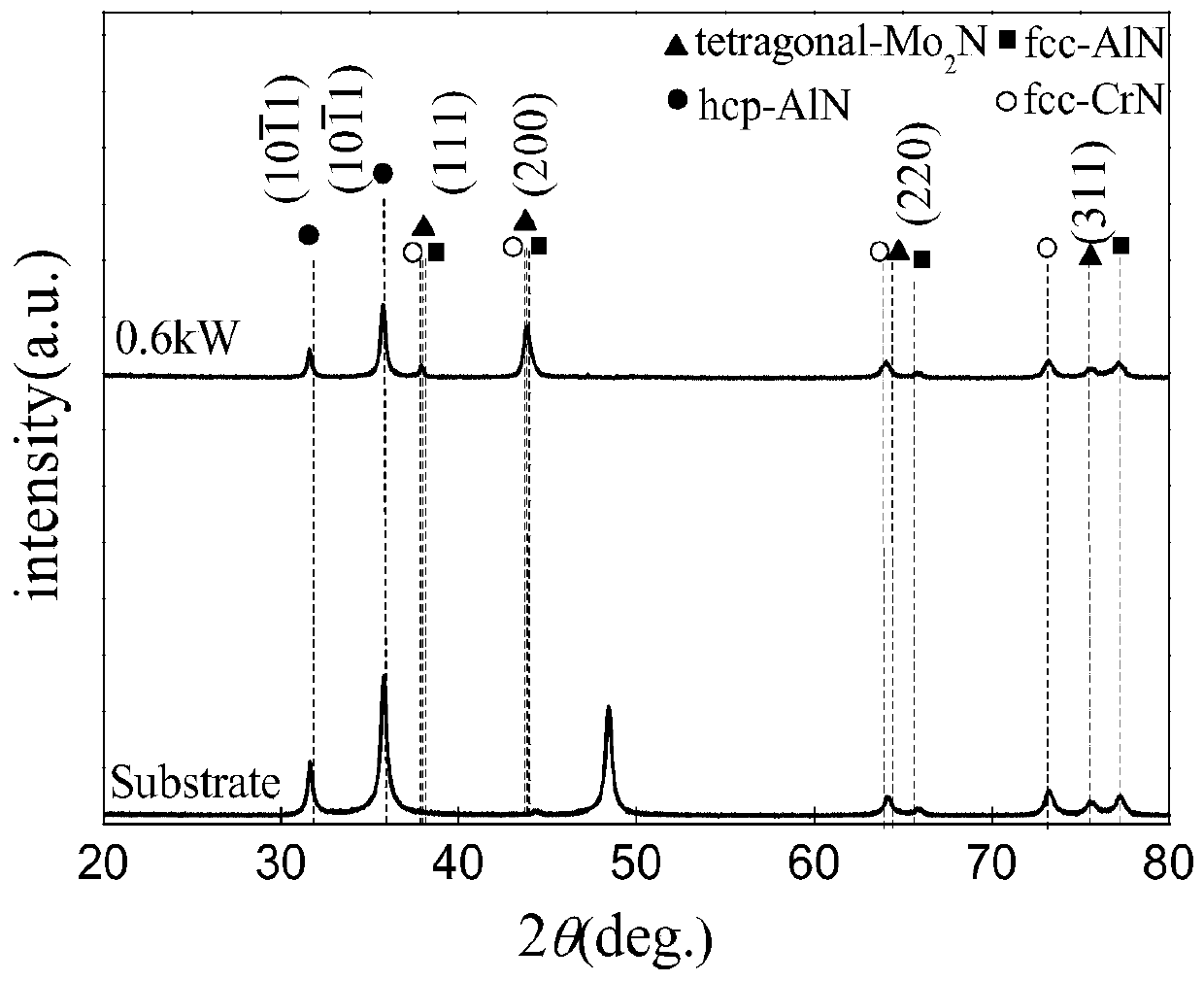

Composite magnetron sputtering preparation method for AlCrSiN/Mo self-lubricating film

ActiveCN110453190AReduce friction coefficient and cutting heatGood bonding strengthVacuum evaporation coatingSputtering coatingHigh-power impulse magnetron sputteringLubrication

The invention discloses a composite magnetron sputtering preparation method for an AlCrSiN / Mo self-lubricating film and belongs to the technical field of film preparation. The AlCrSiN / Mo self-lubricating film is prepared on a base body through a high-power pulse magnetron sputtering technology and a pulse direct current magnetron coating technology. The preparation process comprises the steps thatbias voltage is reduced to -50 V--150 V, N2 flow is 50 sccm-150 sccm, Ar flow is 50 sccm-250 sccm, the total flow of N2 and Ar is 300 sccm, the deposition intensity of pressure is 1.0 Pa-2.5 Pa, theCrMo target sputtering power is 0.1 Kw-0.9 Kw, and the AlCrSi target power is 0.2 kW-1.5 kW. The prepared AlCrSiN / Mo self-lubricating film is high in hardness, good in tenacity and excellent in anti-attrition character, the friction between a cutter and chip can be remarkably reduced, and relatively good chemical stability and a shear susceptible lubrication character are achieved.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Characteristic coating

The invention discloses a characteristic coating. The coating is prepared from the following raw materials in percentage by weight: 20 to 30 percent of dimethyl benzene, 8 to 20 percent of styrene, 0.5 to 1 percent of antioxidant, 0.5 to 2 percent of dispersant, 2 to 3 percent of thixotropic agent, 1 to 1.5 percent of cobalt naphthenate, 4 to 5 percent of butanol, 15 to 17 percent of linoleic acid and 10 to 13 percent of oxalic acid polyester. The coating is prepared through the following steps of: mixing the styrene, the antioxidant, the dispersant, the thixotropic agent, the cobalt naphthenate and the butanol, adding the dimethyl benzene, the linoleic acid and the oxalic acid polyester while stirring, stirring uniformly, adding water and stirring uniformly. The coating has the advantages of simple structure, high bonding strength, high hardness, excellent waterproof and steam-proof performance, good insulating effect, low production cost, convenience in use, simplicity in operation, safety and reliability.

Owner:NINGBO SANLI NEW MATERIALS

Soilless culture substrate formula used for vertical greening, and production method therefor

The invention discloses a soilless culture substrate formula used for vertical greening, and a production method therefor. The production method comprises: weighing and adding a mixture of multi-hydroxyl ethers and a plasticizer, namely dibutyl phthalate into a high-pressure reaction kettle; then, adding a natural binder and a catalyst into the high-temperature reaction kettle with stirring, and introducing inert gas for shielding; finally adding an adosrbent with sufficiently and uniformly stirring, and discharging, thereby preparing a binder for later use; in the presence of an adhesive added in a wet state, uniformly stirring decomposed straws, grass carbon, coconut tree peel, coconut shells, branches and tree leaves at high speed to obtain a mixture, then, standing the mixture, adding a self-made binder into the mixture with stirring, pouring the mixture into a mould to form, and discharging the mixture out of mould. Polyethylene glycol 600 with molecular weight of 570-630, polypropylene glycol 200 with molecular weight of 180-220, and polymer polyol are matched in proportion, so that the soilless culture substrate formula can be suitable for splicing most of cellulose with different molecular weights; pores of a formed three-dimensional net-shaped structure are especially suitable for storing water molecules, so that water absorbing capacity of the whole substrate can be greatly improved, the gravity action can be overcome to certain extent, and the substrate is suitable for vertical greening.

Owner:BEIJING LVSHUNYUAN AGRI TECH CO LTD

Screen waterborne ink for air inflation toy

The invention belongs to the technical field of waterborne ink, and particularly relates to a screen waterborne ink for an air inflation toy. The screen waterborne ink is prepared from the following raw materials in percentage by weight according to a formula: 30 to 35% of waterborne polyurethane dispersant, 30 to 35% of waterborne acrylic resin, 0.5 to 1% of wetting agent, 0.5 to 1% of flatting agent, 1 to 2% of polymer dispersant, 1 to 2% of defoamer, 0.5 to 2% of thickener, 0 to 1% of pH (potential of hydrogen) adjuster, 4 to 6% of filler, 3 to 5% of thixotropic agent, 0 to 5% of pigment, and 15 to 25% of water. The screen waterborne ink has the advantages that the adhesion force is excellent, the adhering strength is better, the flexibility of an ink film is strong, and the cracking isavoided; the screen waterborne ink is directly diluted by pure water, so that the construction and operation are easy, the releasing of volatile organic matters is avoided, and the pollution to environment is reduced.

Owner:昆山大世界油墨涂料有限公司

Method for remedying water-eroded defects on surface of engine cylinder block

The invention discloses a method for remedying water-eroded defects on the surface of an engine cylinder block and belongs to the technical field of engine cylinder refabrication. The method includes: polishing the defective surface to expose a cylinder block body; polishing sharp corners or edges of the cylinder block body; removing oil at defective positions; re-polishing; cleaning the defective positions; remedying the defective positions by electric spark ionic microwelding to make the welded positions higher than the surface of the cylinder block; and polishing the welded positions to make the welded positions level to the surface of the cylinder block. The method effectively guarantees fine bonding of welding material and the cylinder block body during welding. The cylinder block body is not heated, deformed or undercut, and the welding material is metallurgically combined with the cylinder block body under fine intensity. The shape and precision of the defective positions are restored fully, original properties of a workpiece are restored, and the water-eroded defects on the surface of the engine cylinder block are remedied.

Owner:WEICHAI POWER CO LTD

Adhesive for industrial-washing-resistant bright silver reflective fabric and preparation method thereof

PendingCN111253899AGood bonding strengthFlexibleNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesIsocyanatePolyester

The invention relates to an adhesive for an industrial-washing-resistant bright silver reflective fabric and a preparation method thereof. The adhesive is prepared by compounding polyurethane matrix resin, which is prepared from polyester and / or polyether polyol and isocyanate through a reaction, a coupling agent, a catalyst, an anti-hydrolysis additive and a solvent. The adhesive comprises the following components in percentage by mass: 20-40% of polyester polyol with a molecular weight of 1000 to 3000, 0-15% of polyether polyol, 3-5% of isocyanate, 50-60% of the solvent, 0.4-2% of the coupling agent, 0.01-0.1% of the catalyst and 0.5-2% of the anti-hydrolysis additive, wherein the catalyst is one or a combination of bismuth iso-octoate and bismuth neodecanoate. The adhesive has the advantages of favorable bonding strength, flexible hand feeling, excellent hydrolysis resistance, simple process, energy saving performance, environment friendliness and high initial adhesion, and is suitable for popularization.

Owner:泰安聚仁新材料有限公司

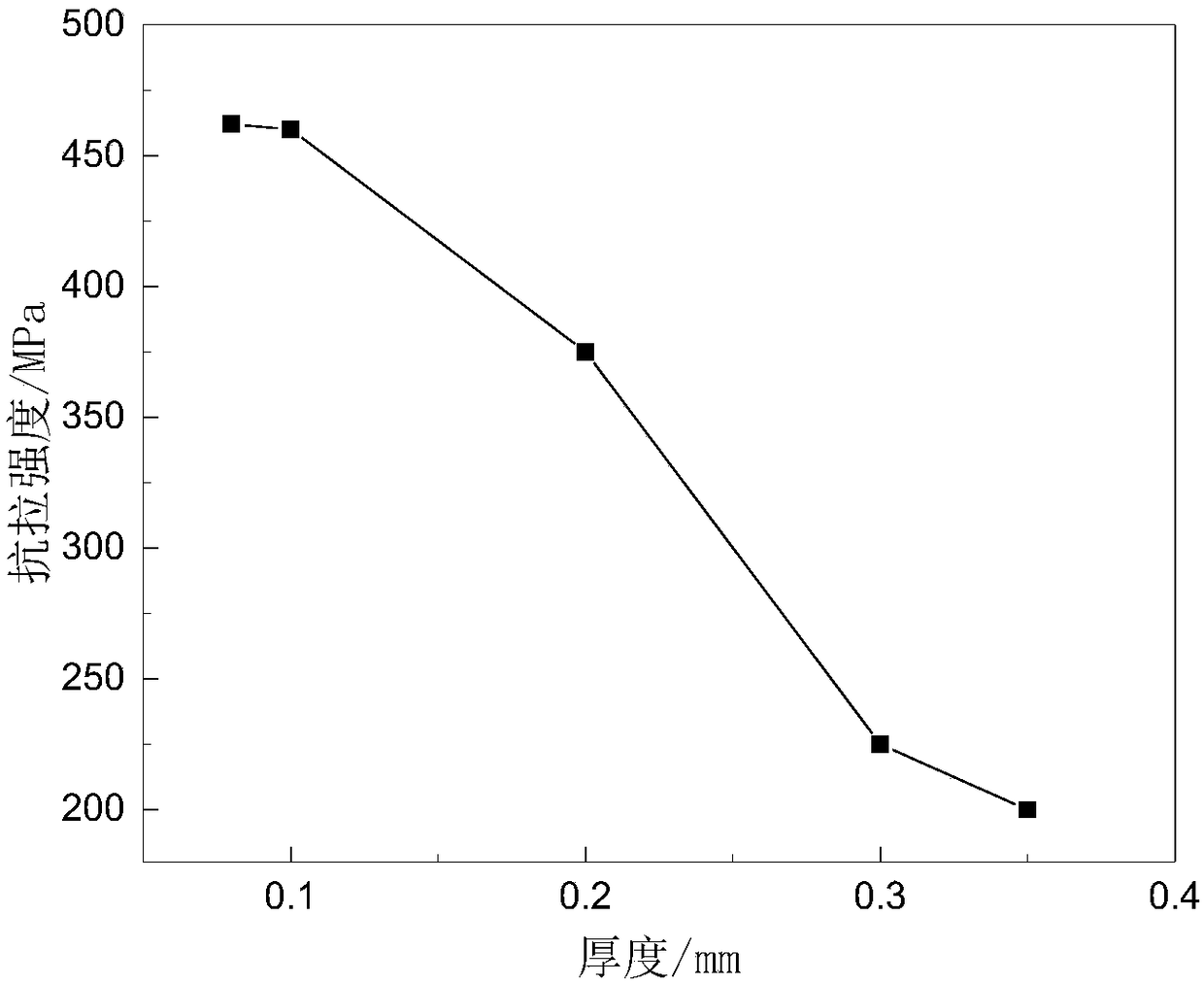

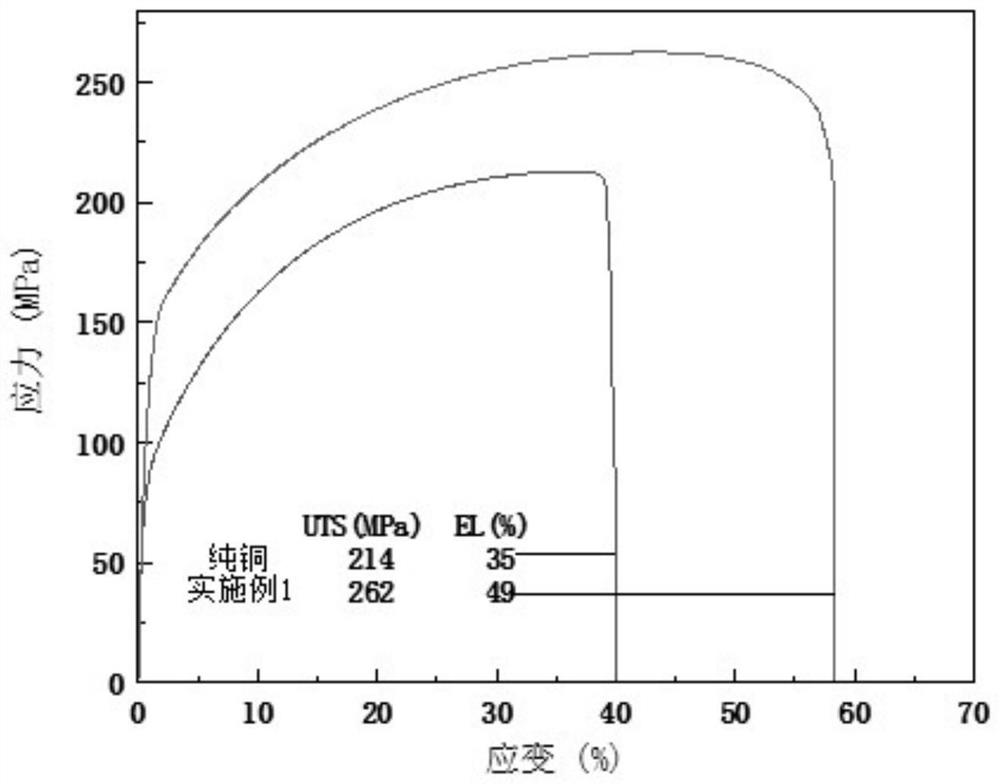

Copper-steel-copper composite material for thin gauge electrical connector terminal and preparation method thereof

InactiveCN108162564AGood bonding strengthReduce processLamination ancillary operationsLaminationSurface finishingBonding strength

The invention relates to the field of electronic device materials and discloses a copper-steel-copper composite material for a thin gauge electrical connector terminal and a preparation method of thecopper-steel-copper composite material for the thin gauge electrical connector terminal. The preparation method comprises the following steps: using a steel strip of Q195, Q235, Q345 or stainless steel and the like as a substrate and pure copper T3 as a coating material, utilizing a cold-rolling composite process, performing surface treatment-cold rolling compounding-diffusion annealing-cold rolling thinning to compound three layers of metal strips of copper, steel and copper, thus preparing the copper-steel-copper composite material of which the finished product thickness is 0.01 to 0.3mm, wherein the thickness ratio of various layers of the metal strips, namely copper to steel to copper is equal to (30% to 45%): (10% to 40%): (30% to 45%). The steel layer in the composite material mainlybears external loads, and the copper layer plays a role of conduction. The material prepared by the invention has good bonding strength and excellent mechanical properties and conductivity, thereby providing a feasible solution to solve the problem that copper alloy is difficult to take account of the conductivity and high strength.

Owner:NORTHEASTERN UNIV

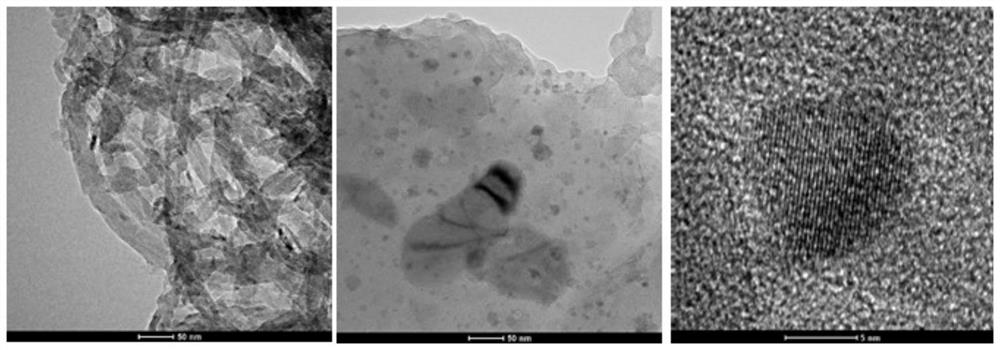

Preparation method of multi-dimensional carbon material composite reinforced copper-based material

ActiveCN113278838AEvenly dispersedGood bonding strengthMaterial nanotechnologyGrapheneCarbon nanotubeGraphene quantum dot

The invention discloses a preparation method of a multi-dimensional carbon material composite reinforced copper-based material, which comprises the following steps: uniformly mixing a carbon precursor with concentrated acid, heating, stirring and refluxing, neutralizing a product with an alkaline substance, dialyzing in ultrapure water, carrying out rotary evaporation, and freeze-drying to obtain mixed powder of carbon nanotube-graphene-graphene quantum dots; performing ball milling and reduction on copper powder and the mixed powder to obtain copper and carbon nano tube-graphene-graphene quantum dot composite powder, and sintering to obtain a composite material. The method disclosed by the invention is simple to operate and easy for industrial preparation, the obtained composite reinforcements are uniformly distributed, the relative proportion of the three-dimensional reinforcements is controllable, and a remarkable effect of multi-dimensional reinforcement on a matrix material can be achieved.

Owner:KUNMING UNIV OF SCI & TECH

Non-occupying coating and using method thereof

InactiveCN102974753AGood bonding strengthCuring time controllableFoundry mouldsFoundry coresPolymer chemistryGlycerol

The invention discloses a non-occupying coating and a using method thereof. The non-occupying coating consists of a component A and a component B, wherein the component A and the component B are independently stored; the component A is formed by mixing the following components in percentage by weight: 35-40 percent of graphite powder, 2-5 percent of attapulgite, 10-15 percent of water glass and 43-50 percent of water; the component B is a curing agent and is an organic ester formed by mixing 60 percent of glycerol diacetate and 40 percent of glycerol triacetate; and the amount of the component B is 15-22 percent of mass of the water glass. According to the non-occupying coating, because the component A and the component B are independently stored, the available time of the non-occupying coating is not limited, and when the non-occupying coating is further used, the curing time of the coating layer formed from the component A can be adjusted by controlling the coating amount of the curing agent in the component B; and therefore, the non-occupying coating is controllable in curing time.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

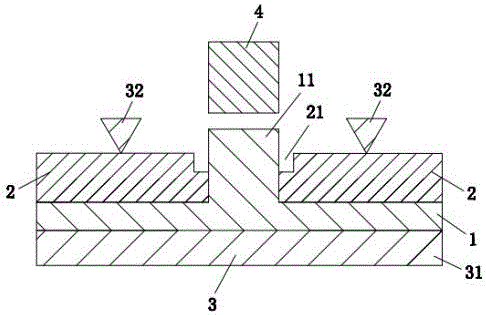

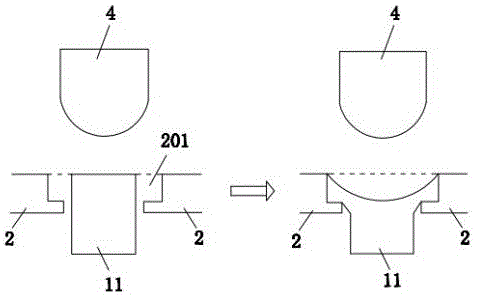

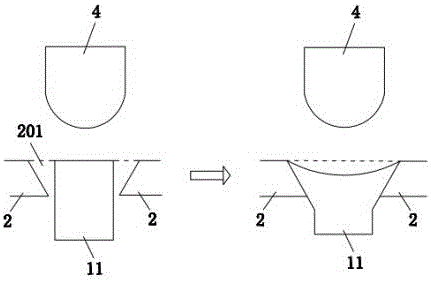

Joining method of amorphous alloy electronic productshell and middle plate

InactiveCN106659008AIncrease the joint surfaceGood bonding strengthElectrical apparatus casings/cabinets/drawersSizingBonding strength

The inventionrelates to the technical field of the production of an amorphous alloy product, and in particular relates to a joining method of an amorphous alloy electronic product shell and a middle plate. The method comprises the following steps: step one, pre-bonding; step two, heating; step three, pressing according to a molten-state gravity effect; and step four, cooling and sizing. By use of the joining method disclosed by the invention, a convex column structure of the amorphous alloy electronic product shell is heated to Tg and more, wherein the Tg is the glass transformationtemperature, and the heating process is controlled according to a TTT graph so as to prevent convex column structure of the amorphous alloy electronic product shell from generating the crystallization. Furthermore, a chamfer structure or a circular concave structure region can be filled with amorphous alloy in the bonding so as to form an inverted buckling structure, thereby enhancing the bonding strength performance by increasing the bonding surface in the bonding. The bonding strength of theamorphous alloy electronic product shell and the middle plate is good, and the method has the advantages of being mass in production, high in production efficiency and low in production cost.

Owner:DONGGUAN PROMETAL TECH CO LTD

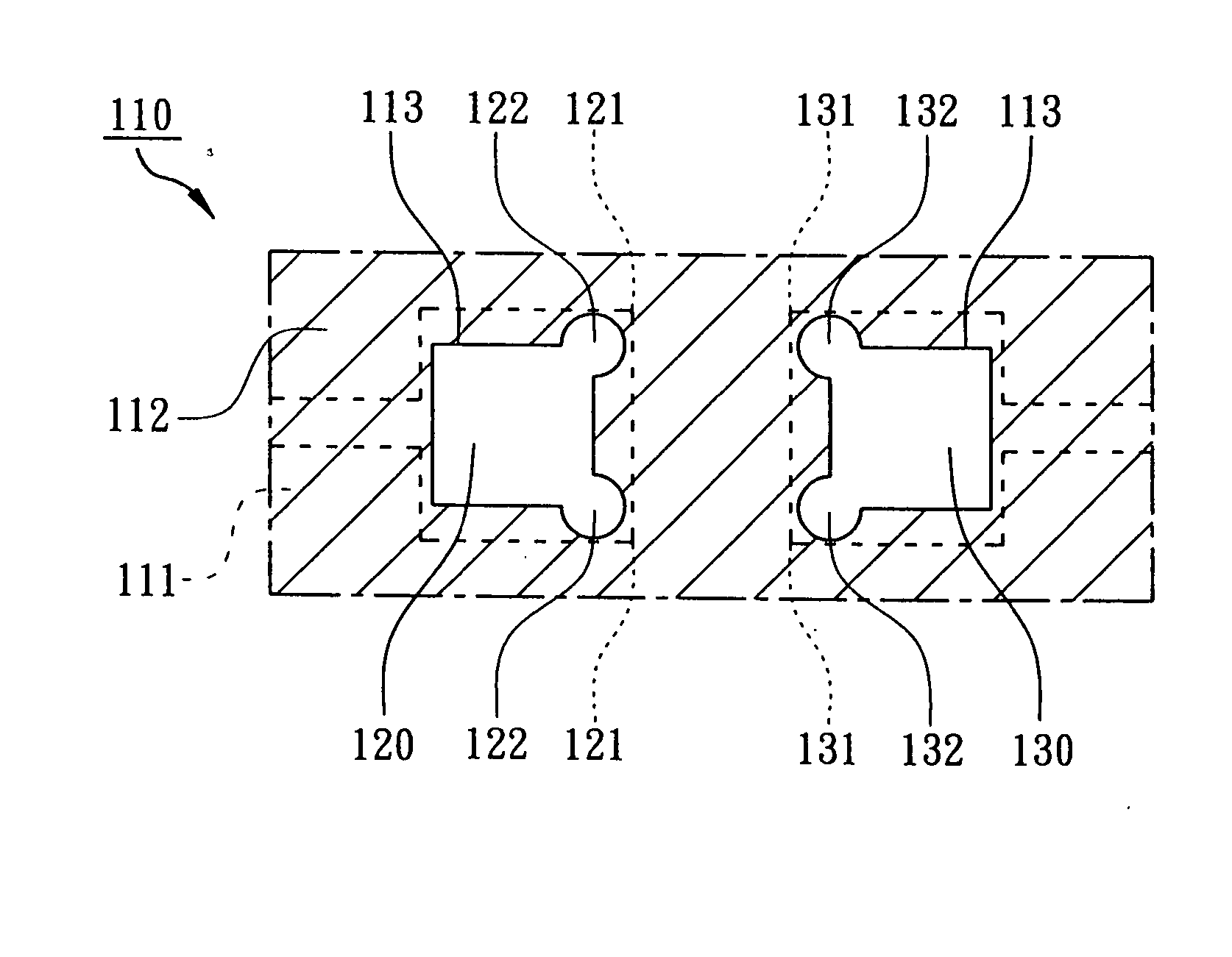

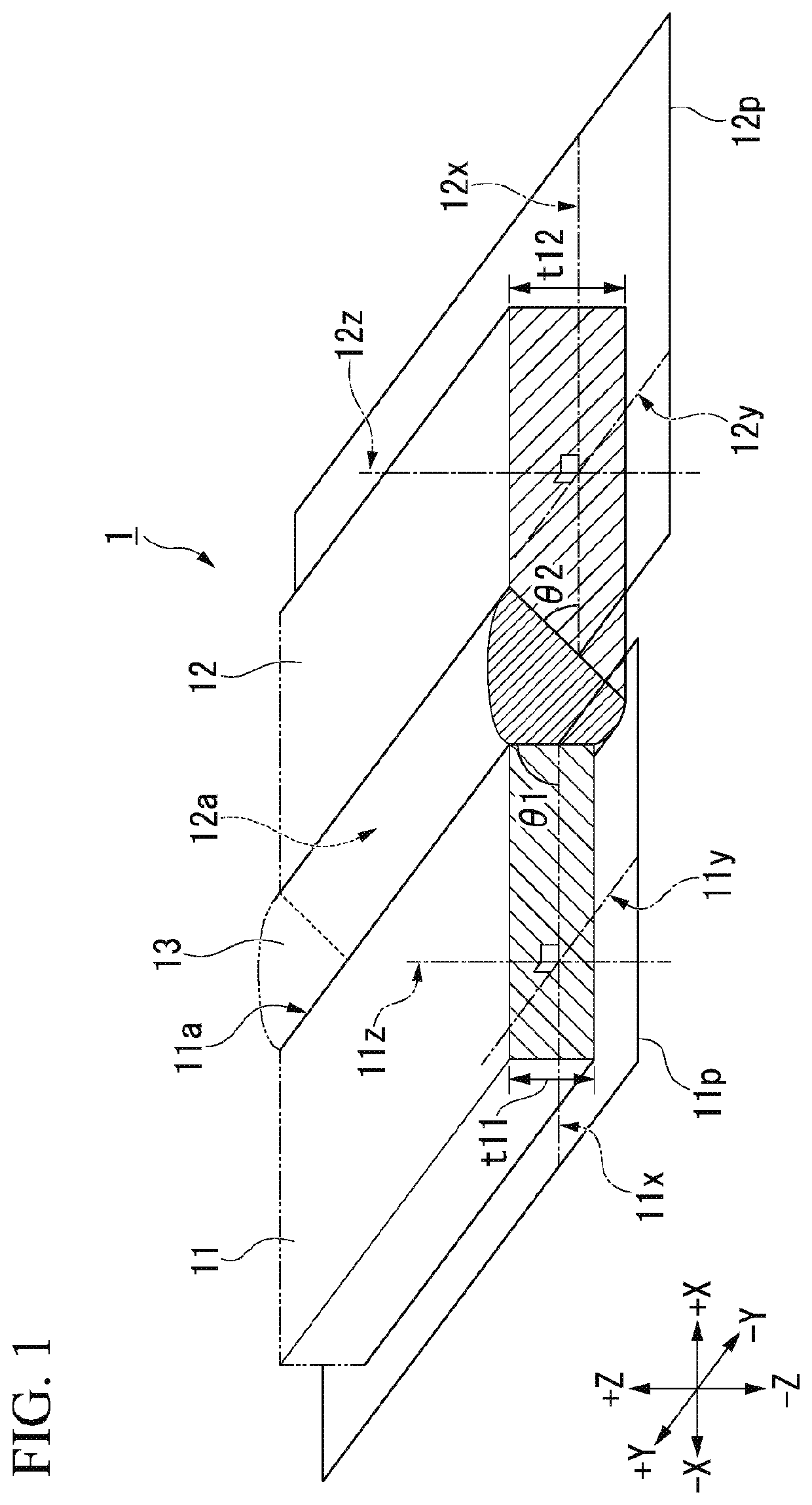

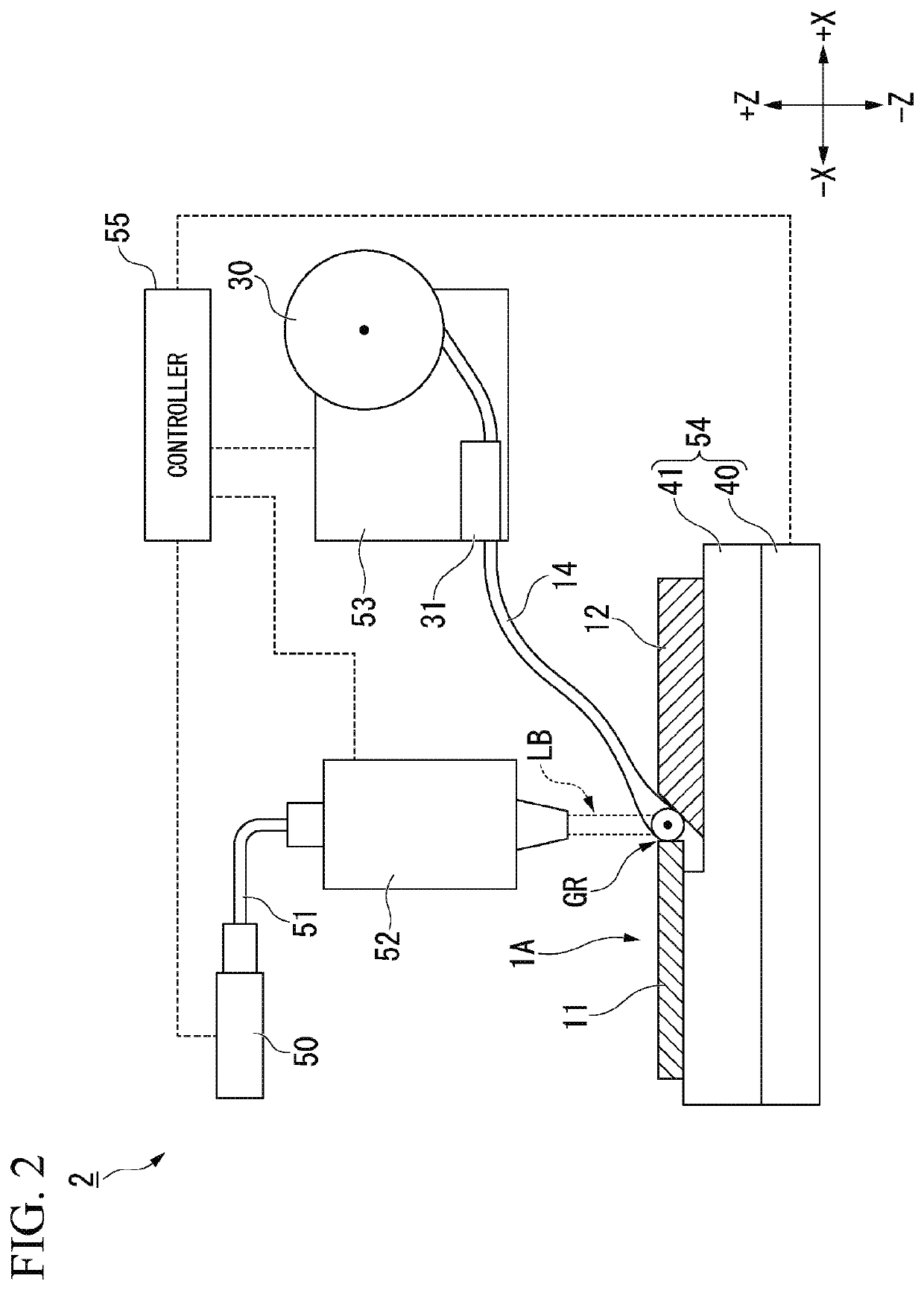

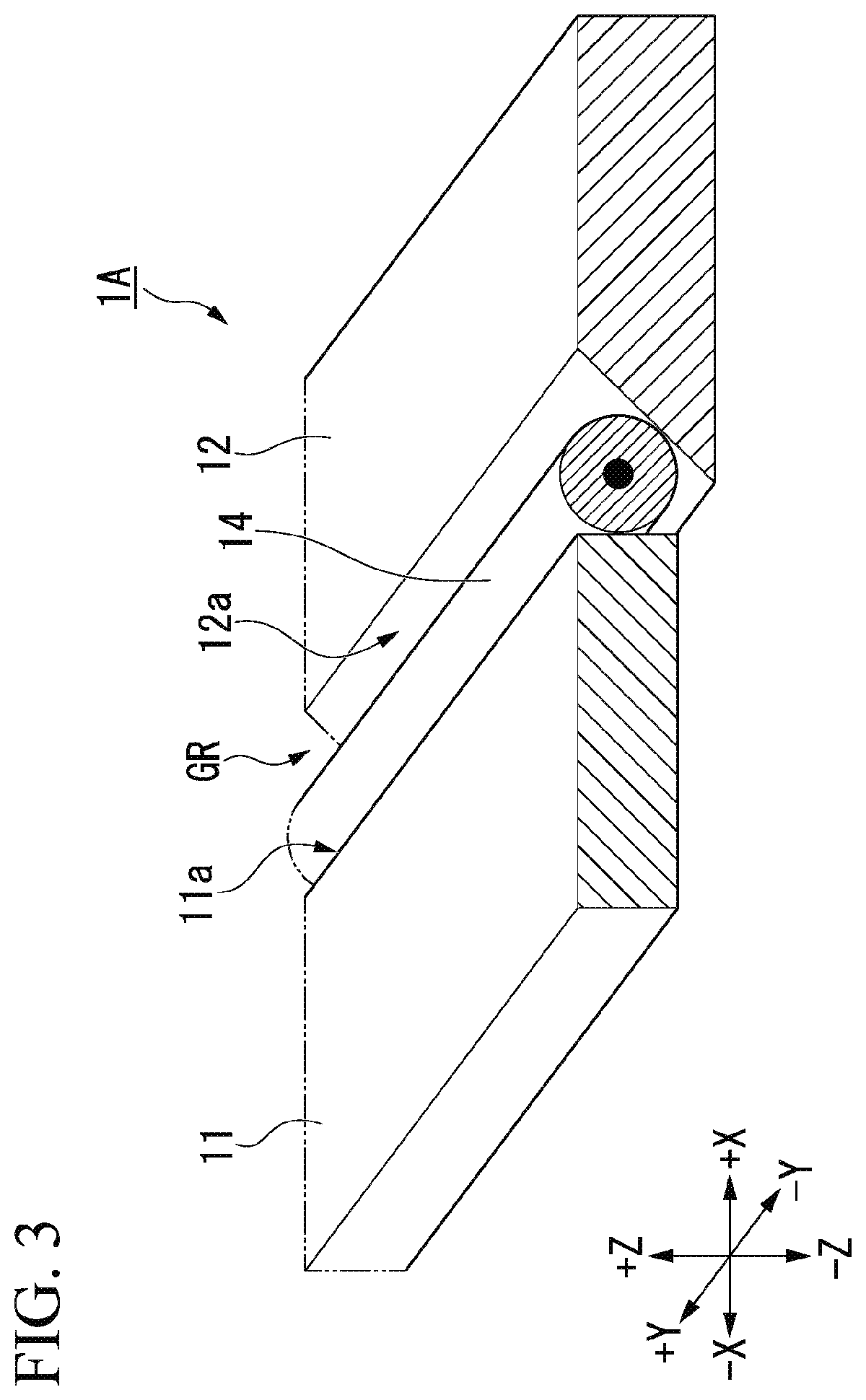

Bonding structure of dissimilar metal members and precursor thereof

PendingUS20210046568A1Good bonding strengthEasily positionWelding/soldering/cutting articlesLaser beam welding apparatusComposite materialDissimilar metal

A bonding structure of dissimilar metal members, including a first metal member, a second metal member, and a brazing filler metal, wherein the brazing filler metal bonds a bonding end surface of the first metal member and a bonding end surface of the second metal member, and any one or both of the following conditions (1) and (2) are satisfied: (1) at least a part of the bonding end surface of the first metal member in a thickness direction of the first metal member is an inclined surface inclined with respect to a plane perpendicular to the thickness direction of the first metal member, and (2) at least a part of the bonding end surface of the second metal member in a thickness direction of the second metal member is an inclined surface inclined with respect to a plane perpendicular to the thickness direction of the second metal member.

Owner:HONDA MOTOR CO LTD

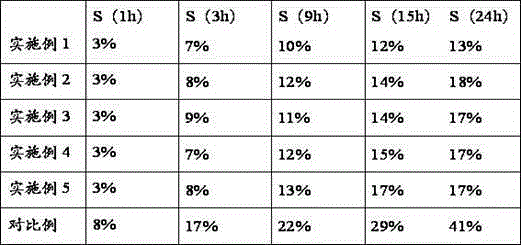

Formaldehyde-free artificial wood board and preparation method thereof

ActiveCN112895028AGood bonding strengthReduce pollutionPlywood pressesNon-macromolecular adhesive additivesPolyurethane adhesiveActive carbon

The invention relates to the field of artificial wood boards, and particularly discloses a formaldehyde-free artificial wood board and a preparation method thereof. The formaldehyde-free artificial wood board comprises a plurality of layers of veneers, a waterborne polyurethane adhesive is compounded between the adjacent veneers, and the waterborne polyurethane adhesive is prepared from the following raw materials including, by weight: 50 to 65 parts of compound waterborne polyurethane, 25 to 35 parts of polyacrylate, 0.1 to 2 parts of allyl polyoxyethylene ether, 1 to 2 parts of composite filler and 100 to 150 parts of water, wherein the composite filler comprises 0.1 to 0.2 part of modified polyacrylonitrile-based active carbon fiber. The formaldehyde-free artificial wood board has the advantage of reducing the pollution of the artificial board to the environment.

Owner:浙江创通木业有限公司

Waterproof adhesive tape

InactiveCN109796888AGood bonding strengthGood water resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesEmulsionSilane coupling

The invention discloses waterproof adhesive tape and relates to the technical field of adhesive tape. The adhesive tape is formed by combining a PE substrate with an adhesive layer. The adhesive layeris prepared from sodium alginate / a hybrid-silica-modified acrylic emulsion, a silane coupling agent, nano-calcium carbonate, butyl rubber powder, sodium tripolyphosphate, diethanolamide cocoate, hydroxypropyl starch sodium phosphate and deionized water.

Owner:王秀云

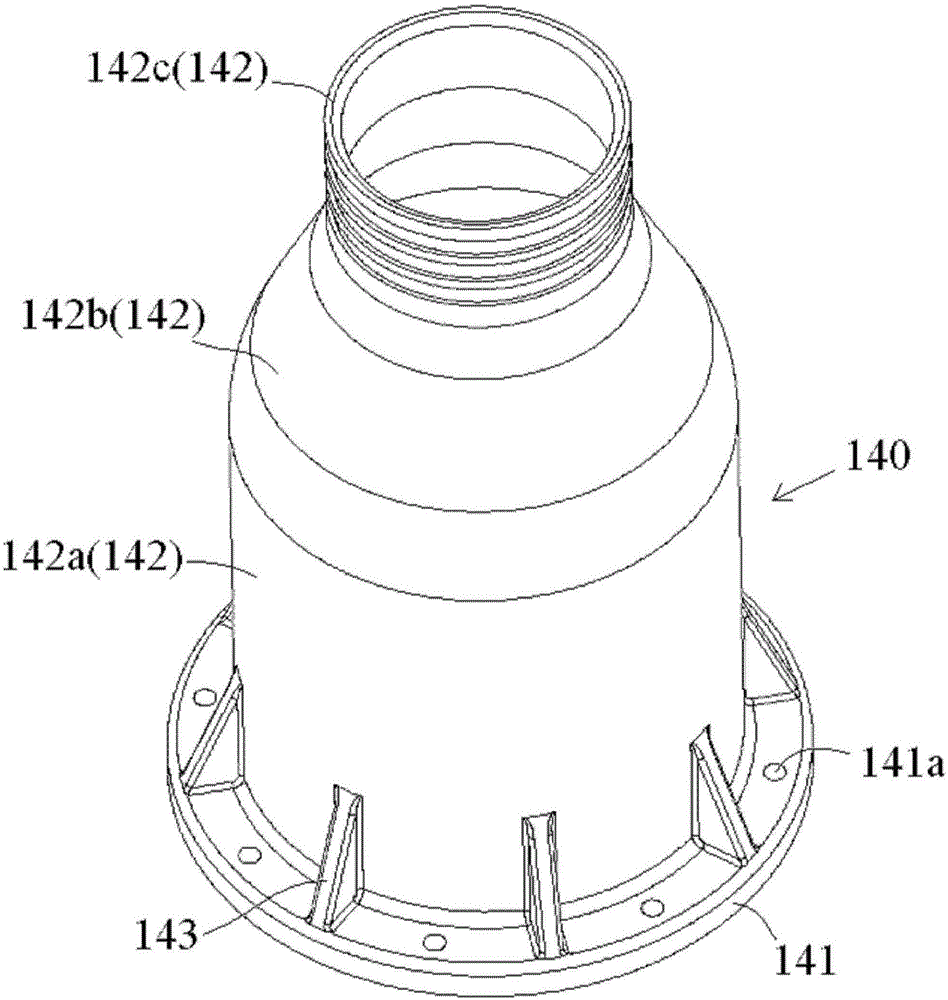

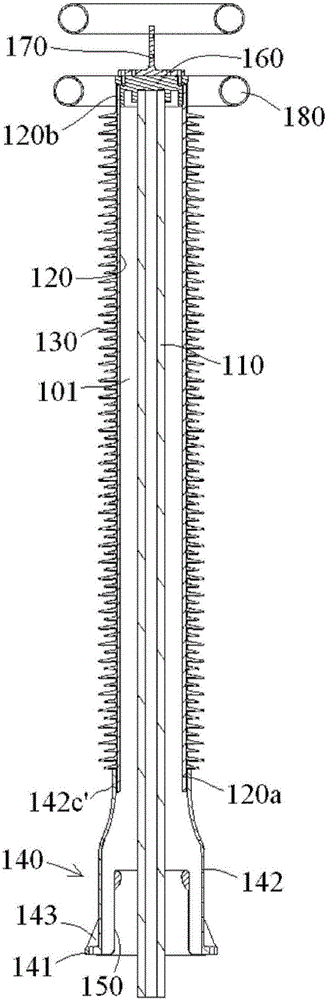

Insulation assembly

InactiveCN106169342AGood bonding strengthImprove sealingRubber insulatorsPlastic/resin/waxes insulatorsElectric fieldEngineering

The invention discloses an insulation assembly. The insulation assembly comprises an insulation sleeve which is provided with a first end and a second end opposite to the first end; and an insulation umbrella skirt which is formed on the outer wall of the insulation sleeve. The insulation assembly further comprises an insulation pedestal made of an insulation material, and the insulation pedestal is connected to the first end of the insulation sleeve. According to the invention, a conventional metal flange is replaced by the insulation pedestal, and thus the manufacturing cost of the insulation assembly is decreased. Besides, the boning strength between the insulation pedestal and the insulation sleeve is good, slits are not easily generated between the two, and the sealing performance of the insulation assembly is improved. Furthermore, the insulation pedestal can effectively prolongs the creepage distance and dry-arc distance of the insulation assembly, can substantially improve the electric field distribution of the insulation assembly and optimizes the electrical performance of the insulation assembly.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD

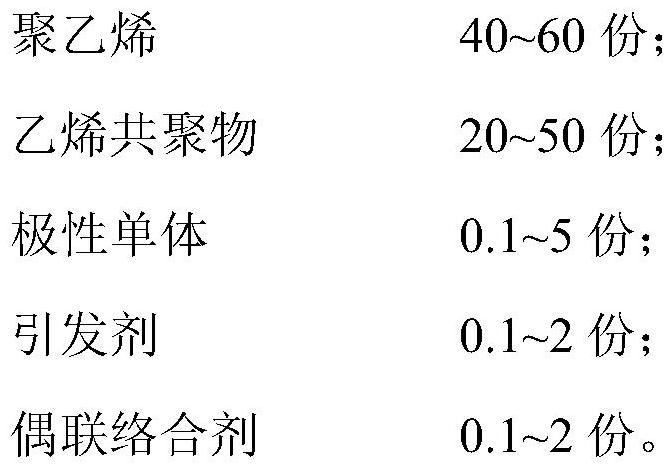

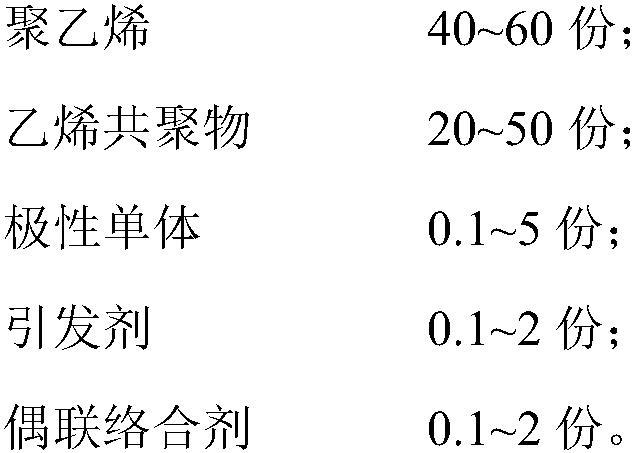

Compatible adhesive resin for PE and PA and preparation method of compatible adhesive resin

The invention provides compatible adhesive resin for PE and PA and a preparation method of the compatible adhesive resin. The adhesive resin comprises the following components in parts by weight: 40-60 parts of polyethylene, 20-50 parts of ethylene copolymer, 0.1-5 parts of polar monomer, 0.1-2 parts of initiator and 0.1-2 parts of coupling adhesive. According to the compatible bonding resin for PE and PA provided by the invention, the polyethylene, the ethylene copolymer, the polar monomer, the initiator and the coupling bonding agent are mixed in parts by mass according to precise compatibility and are processed through an extruder, so that the prepared compatible bonding resin is relatively good in peel strength, tensile strength and tensile property, the problem of compatibility of PE and PA is well solved, the compatibility of nylon and PE is improved, and the tensile strength and impact strength of nylon are improved.

Owner:SHANGHAI BANGZHONG NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com