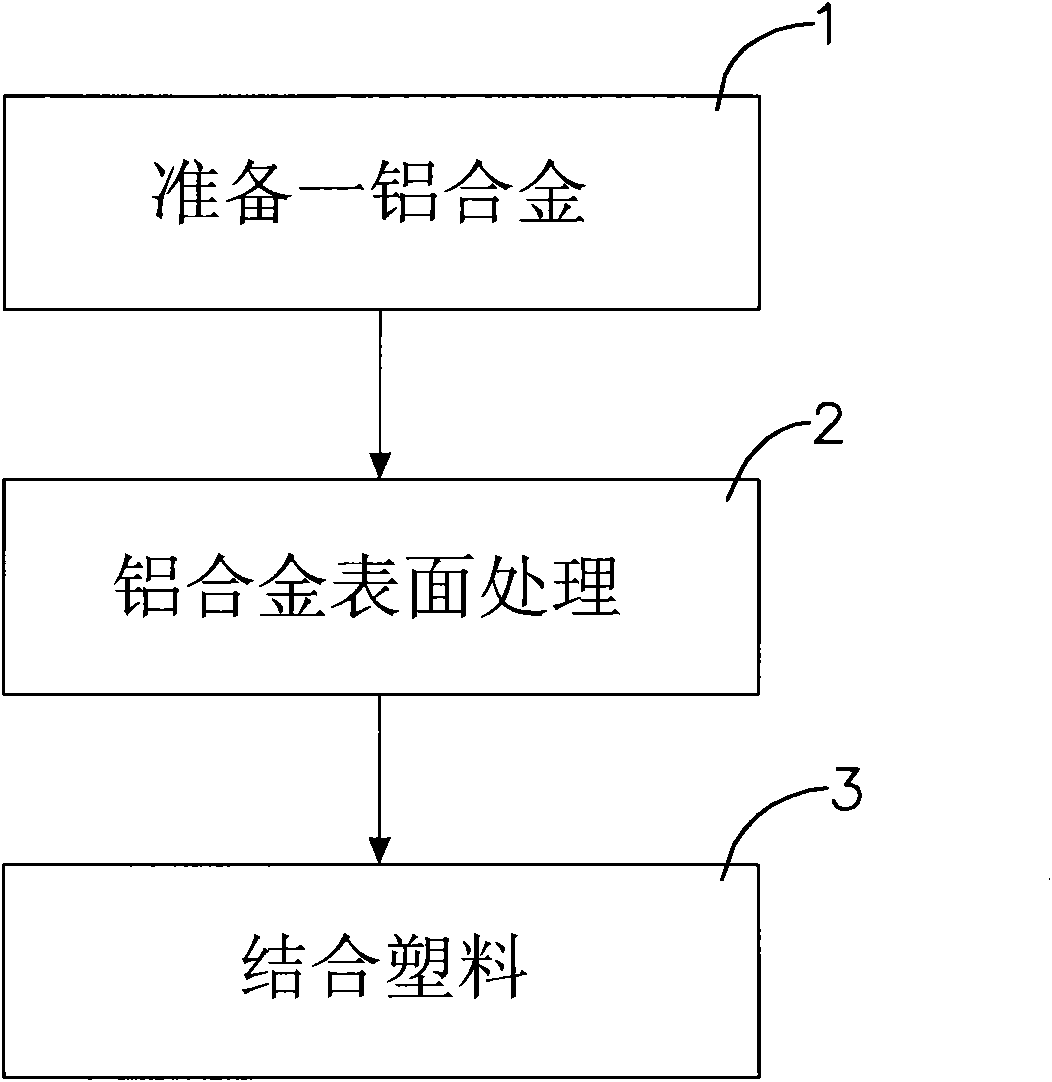

Combination method of alloy and plastic

An alloy and plastic technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of stress concentration, rising production costs, low bonding strength, etc., to save safety maintenance, recycling, and production costs. The effect of drop, good bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

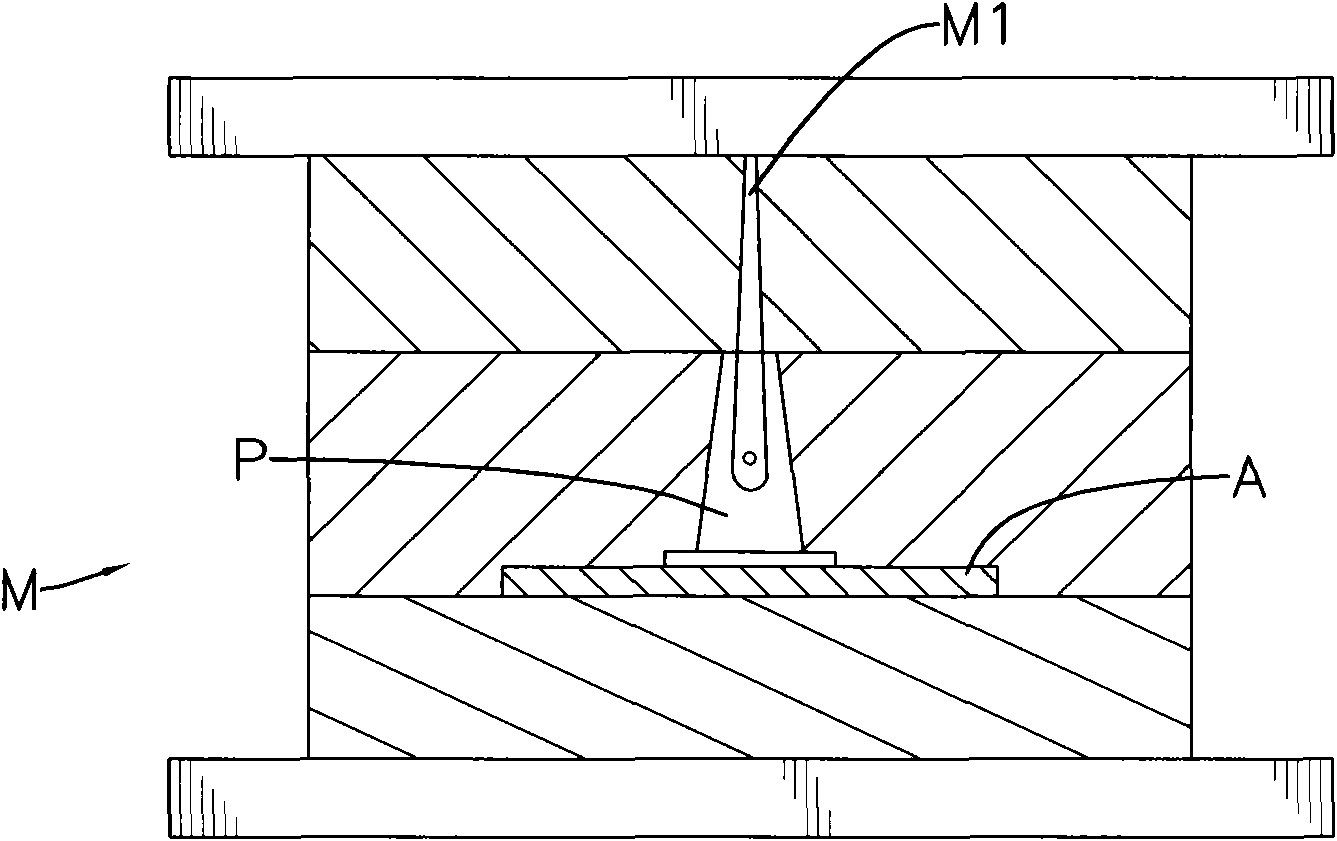

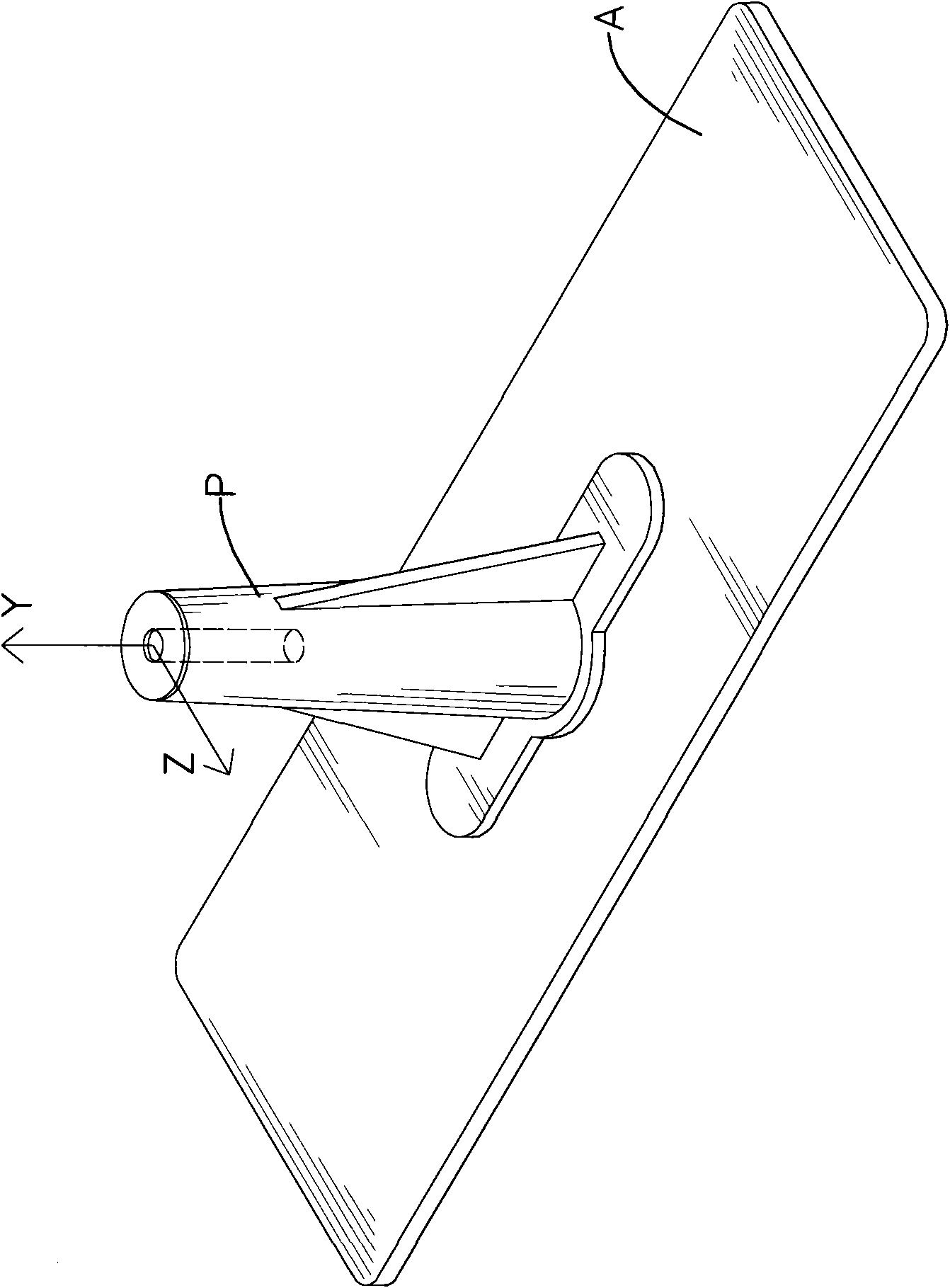

Embodiment 1

[0052] Embodiment 1: The alloy type is AA5052 aluminum alloy, immersed in a mixed aqueous solution of 0.15wt% of organic salts, 1.4wt% of inorganic salts and 0.35wt% of nonionic surfactant for 60 seconds to degrease. Soak in the mixed aqueous solution of 250g / L and sodium gluconate 10g / L for 10 seconds for alkali washing, soak for 30 seconds in the mixed solution of phosphoric acid 98% and glycine 2% for chemical polishing, and soak in nitric acid aqueous solution for 30 seconds Pickling, followed by sulfuric acid 175g / L aqueous solution as electrolyte at 0.6A / dm 2 The current density was treated for 70 minutes. After the treatment, the surface of the aluminum alloy was combined with polyphenylene sulfide (PPS) by injection molding, and 50wt% of glass fibers were added to the polyphenylene sulfide (PPS). The strength measured by tensile test and lateral tensile test is 14.4 and 3.3Kgf / cm respectively 2 .

Embodiment 2

[0053] Embodiment 2: The alloy type is AA5052 aluminum alloy, immersed in a mixed aqueous solution of 0.15wt% of organic salts, 1.4wt% of inorganic salts and 0.35wt% of nonionic surfactant for 60 seconds to degrease. Soak in the mixed aqueous solution of 250g / L and sodium gluconate 10g / L for 10 seconds for alkaline cleaning, soak in the mixed solution of 98% phosphoric acid and 2% glycine for 30 seconds for chemical polishing, and soak in aqueous solution of nitric acid for 30 seconds Pickling, followed by sulfuric acid 175g / L aqueous solution as electrolyte at 0.6A / dm 2 The current density was treated for 70 minutes. After the treatment, the surface of the aluminum alloy was combined with polypropylene (PP) by injection molding, and 30wt% glass fibers were added to the polypropylene (PP). This embodiment was tested in the forward tensile test and The strength measured by the lateral tensile test is 30.8 and 6.2Kg / cm respectively 2 .

Embodiment 3

[0054] Embodiment 3: The alloy type is AA6061 aluminum alloy, immersed in a mixed aqueous solution of 0.15wt% of organic salts, 1.4wt% of inorganic salts and 0.35wt% of nonionic surfactant for 60 seconds to degrease. Soak in the mixed aqueous solution of 250g / L and sodium gluconate 10g / L for 10 seconds for alkali washing, soak for 30 seconds in the mixed solution of phosphoric acid 98% and glycine 2% for chemical polishing, and soak in nitric acid aqueous solution for 30 seconds Pickling, followed by sulfuric acid 175g / L aqueous solution as electrolyte at 0.8A / dm 2 The current density was treated for 53 minutes. After the treatment, the surface of the aluminum alloy was combined with polypropylene (PP) by injection molding, and 30wt% glass fibers were added to the polypropylene (PP). This embodiment was tested in the forward tensile test and The strength measured by the lateral tensile test is 50.7 and 5.2Kgf / cm respectively 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com