Compatible adhesive resin for PE and PA and preparation method of compatible adhesive resin

A technology for bonding resin and polyethylene, applied in the field of bonding resin, can solve the problems of poor compatibilization effect, increase the user's production cost, and reduce the physical properties of the compatibilizer, and achieve the effect of good bonding strength and tensile performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

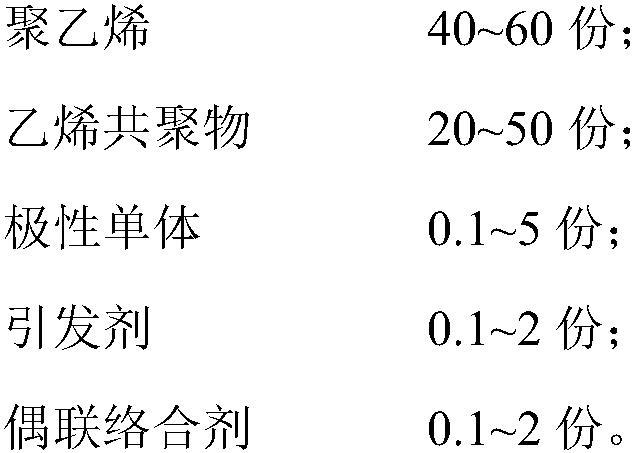

[0030] A kind of preparation method as above-mentioned compatible adhesive resin, comprises the steps:

[0031] Step 1, weighing polyethylene, ethylene copolymer, polar monomer, initiator and coupling agent, adding the above components into a high-speed mixer, and mixing uniformly to obtain materials;

[0032] Step 2: Put the material into a twin-screw extruder to extrude a strip, cool the strip through a circulating water tank to room temperature, dry it with a blower, and then enter the pelletizer for granulation, and the preparation is completed.

[0033] In a specific embodiment of the present invention, the temperature of each temperature zone of the twin-screw extruder is 160-190°C.

Embodiment 1

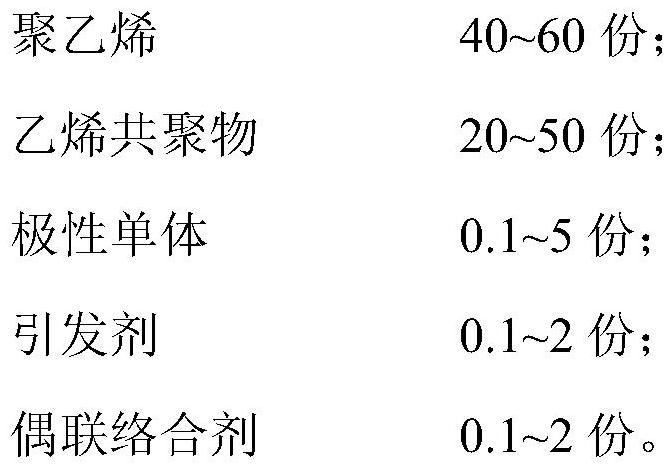

[0036] This embodiment provides a compatible adhesive resin for PE and PA, including the following components in parts by mass:

[0037]

[0038] Among them, polyethylene is high-density polyethylene with a density of 0.952g / cm 3 , the melt index is 8.0g / 10min (190°C, under 2.16kg pressure), and the tensile strength is 26MPa;

[0039] The ethylene copolymer is an ethylene-vinyl acetate copolymer, wherein the monomer content of vinyl acetate is 33%, and the melt index is 12g / 10min;

[0040] The polar monomer is maleic anhydride; the initiator is benzoyl peroxide; the coupling agent is a silane coupling agent.

[0041] The preparation method of compatible adhesive resin for above-mentioned PE and PA comprises the following steps:

[0042] Step 1, weighing polyethylene, ethylene copolymer, polar monomer, initiator and coupling agent according to the above-mentioned parts by mass, adding the above components into a high-speed mixer, and mixing uniformly to obtain materials; ...

Embodiment 2

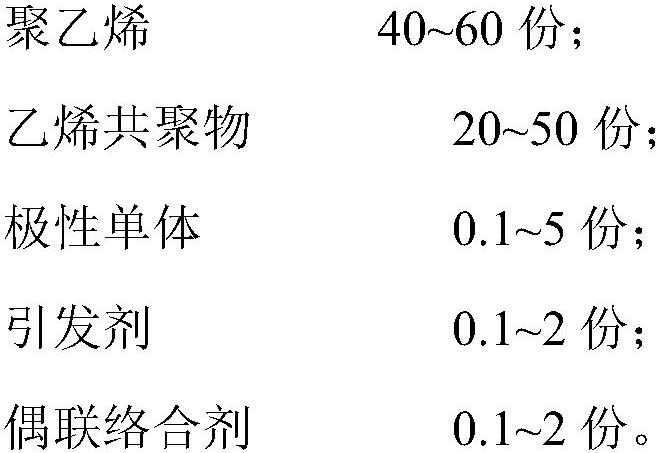

[0045] This embodiment provides a compatible adhesive resin for PE and PA, including the following components in parts by mass:

[0046]

[0047]

[0048] Among them, polyethylene is high-density polyethylene and linear low-density polyethylene, and the density of high-density polyethylene is 0.952g / cm 3 , the melt index is 8.0g / 10min (190°C, under 2.16kg pressure), the tensile strength is 26MPa; the density of linear low density polyethylene is 0.940g / cm 3 , the melt index is 4.0g / 10min (190°C, under 2.16kg pressure), and the tensile strength is 20MPa;

[0049] The ethylene copolymer is an ethylene-vinyl acetate copolymer, wherein the monomer content of vinyl acetate is 18%, and the melt index is 3g / 10min;

[0050] The polar monomer is acrylic acid; the initiator is cumene hydroperoxide; the coupling agent is a compound of silane coupling agent and ethylenediamine tetraacetate, and the ratio of the two is 1:1.

[0051] The preparation method of compatible adhesive res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com