Joining method of amorphous alloy electronic productshell and middle plate

A technology of electronic products and amorphous alloys, which is applied in the direction of electrical equipment shell/cabinet/drawer, electrical components, etc., can solve the problems of crystallization, increased production cost, aging, etc. Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

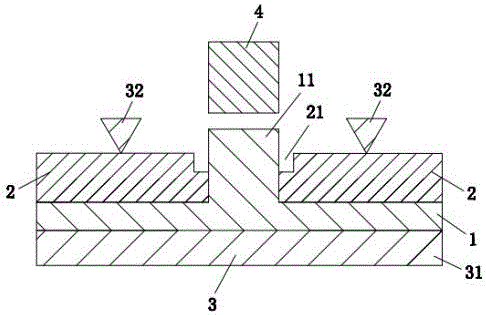

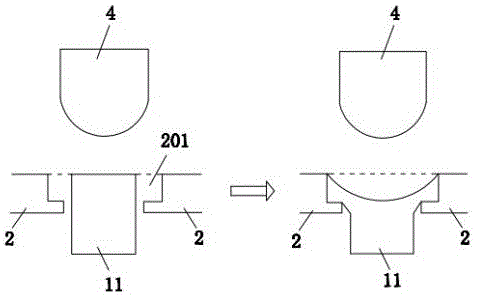

[0049] see figure 1 with figure 2 . A method for joining an amorphous alloy electronic product casing and a middle plate, comprising the following steps:

[0050] Step 1, pre-bonding: Pre-bonding the shell 1 of the amorphous alloy electronic product with the middle plate 2, wherein the shell 1 of the amorphous alloy electronic product has a convex column structure 11, and the middle plate 2 is provided with a through hole 21; the amorphous alloy electronic product The protrusion structure 11 of the product shell 1 is inserted into the through hole 21 of the middle plate 2, and locked by the clamp 3 so that the amorphous alloy electronic product shell 1 and the middle plate 2 are pre-bonded to obtain a pre-bonded whole; In this embodiment, the protrusion structure 11 is a solid cylinder; wherein, the upper part of the through hole of the middle plate 2 is provided with a chamfer structure 201;

[0051] In this embodiment, when pre-combined, the height of the protrusion stru...

Embodiment 2

[0059] See image 3 . A method for joining an amorphous alloy electronic product casing and a middle plate, comprising the following steps:

[0060] Step 1, pre-bonding: pre-bonding the shell of the amorphous alloy electronic product with the middle plate 2, wherein the shell of the amorphous alloy electronic product has a convex column structure 11, and the middle plate 2 is provided with a through hole 21; the shell of the amorphous alloy electronic product The convex post structure 11 is inserted into the through hole 21 of the middle plate 2, and is locked by the clamp 3 so that the shell of the amorphous alloy electronic product and the middle plate 2 are pre-bonded to obtain a pre-bonded whole; in this embodiment , the convex column structure 11 is a solid cylinder; wherein, the upper part of the through hole of the middle plate 2 is provided with a chamfering structure 201;

[0061] In this embodiment, when pre-combined, the height of the protrusion structure 11 of th...

Embodiment 3

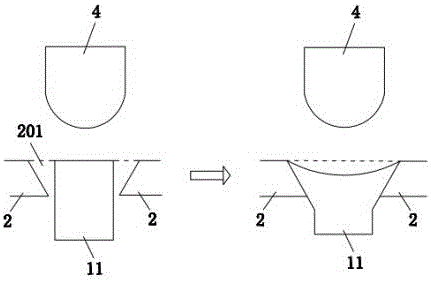

[0069] See Figure 4 . A method for joining an amorphous alloy electronic product casing and a middle plate, comprising the following steps:

[0070] Step 1, pre-bonding: pre-bonding the shell of the amorphous alloy electronic product with the middle plate 2, wherein the shell of the amorphous alloy electronic product has a convex column structure 11, and the middle plate 2 is provided with a through hole 21; the shell of the amorphous alloy electronic product The convex post structure 11 is inserted into the through hole 21 of the middle plate 2, and is locked by a clamp so that the shell of the amorphous alloy electronic product and the middle plate 2 are pre-bonded to obtain a pre-bonded whole; in this embodiment, The convex column structure 11 is a solid circular platform; wherein, the upper part of the through hole of the middle plate 2 is provided with a chamfering structure 201;

[0071] In this embodiment, when pre-combined, the height of the protrusion structure 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com