Vinyl resin easily adhered with concrete

A vinyl resin and concrete technology, applied in the field of polymers, can solve problems such as poor durability, insufficient firmness, and reduced lifespan, and achieve the effects of long durability, excellent mechanical properties, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

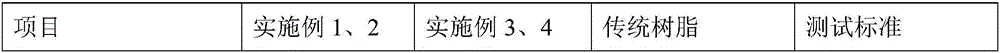

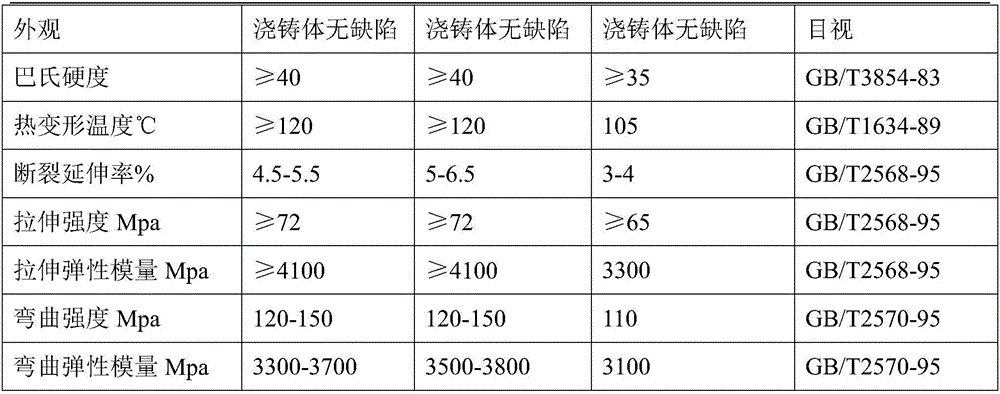

Examples

Embodiment 1

[0022] A vinyl resin that is easy to bond with concrete, and its specific ratio is as follows: bisphenol A formaldehyde epoxy resin 38kg, polyurethane modified epoxy resin 7kg, butanol etherified melamine formaldehyde resin 6kg, methacrylic acid 8kg, acrylic acid 16kg, fumaric acid 15kg, maleic anhydride 16kg, triphenylethylphosphonium bromide 1kg, hydroquinone 0.6kg, styrene 50kg, itaconic anhydride 13kg, adhesion modifier 8kg.

[0023] The ratio of the bonding modifier is calculated by weight in kg: 2 kg of cellulose acetate, 8 kg of itaconic acid, 0.3 kg of nanometer zinc oxide, and 0.2 kg of cesium hydroxide.

Embodiment 2

[0025] A vinyl resin that is easy to bond with concrete, and its specific proportions are as follows: bisphenol A formaldehyde epoxy resin 41kg, polyurethane modified epoxy resin 5kg, butanol etherified melamine formaldehyde resin 9kg, methacrylic acid 5kg, acrylic acid 18kg, fumaric acid 12kg, maleic anhydride 20kg, triphenylethylphosphonium bromide 0.5kg, hydroquinone 0.9kg, styrene 48kg, itaconic anhydride 15kg, bond modifier 3kg.

[0026] The ratio of the bonding modifier is calculated by weight in kg: 5 kg of cellulose acetate, 12 kg of itaconic acid, 0.5 kg of nanometer zinc oxide, and 0.1 kg of cesium hydroxide.

Embodiment 3

[0028] On the basis of Example 1, 2kg of nano-titanium dioxide and some bonding compounding agents were added, and the bonding compounding agents included 5kg of methyl methacrylate, 4kg of ethylene glycol ethyl ether acetate, 4kg of dichlorodiphenylsilane, cis Butenedioic acid 4kg, ethylene glycol 5kg, N-bromosuccinimide 1kg, 4,4'-diaminodiphenyl sulfone 2kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com