Patents

Literature

150 results about "Butenedioic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Random ethylene/alkyl acrylate copolymers, compounds and elastomeric compositions thereof with improved low temperature properties

Disclosed are random copolymers derived from ethylene and at least two different alkyl acrylate comonomers, with or without an acid cure site-containing comonomer. In particular, disclosed are copolymers derived from copolymerization of (a) from 10 to 50 weight % of ethylene; (b) from 5 to 55 weight % of a first alkyl acrylate; (b) from 15 to 80 weight % of a second alkyl acrylate; and (d) from 0 to 7 weight % of a monoalkyl ester of 1,4-butene-dioic acid. Such copolymers exhibit lower glass transition temperatures (Tg) relative to previous ethylene copolymers comprising a single alkyl acrylate comonomer and maintain the good heat and fluid resistance when employed to produce cured elastomeric compositions as well as the improved low temperature properties. This invention also provides compounded compositions comprising these copolymers, and cured compositions (i.e., vulcanizates) as well as rubber articles formed from these compounded compositions, such as hoses, dampers, seals, gaskets, constant velocity joint (CVJ) boots and shaft boots.

Owner:DUPONT POLYMERS INC

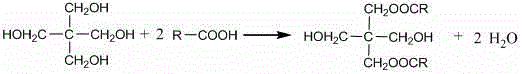

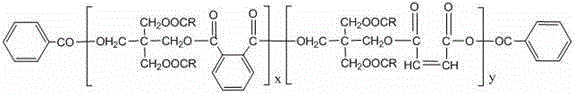

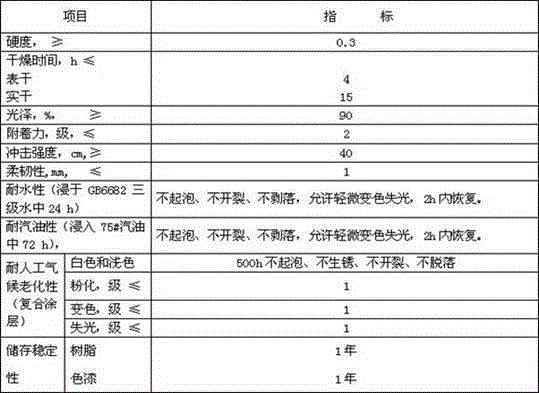

Aqueous acrylic acid-modified alkyd resin and preparation method thereof

ActiveCN103554379AImprove water resistanceImprove aging resistanceCoatingsBenzoic acidPolymer science

The invention discloses aqueous acrylic acid-modified alkyd resin and a preparation method thereof. Basic alkyd resin of the aqueous acrylic acid-modified alkyd resin is prepared from an unsaturated fatty acid, benzoic acid, trimethylolpropane, pentaerythritol, maleic anhydride, isophthalic acid, ethylene glycol monobutyl ether and butanol. The aqueous acrylic acid-modified alkyd resin is prepared by adding styrene, methyl methacrylate, butyl acrylate, acrylic acid, a silane coupling agent, benzoyl peroxide, tert-butyl hydroperoxide, ethylene glycol monobutyl ether and a mixing neutralizer into the basic alkyd resin. According to the aqueous acrylic acid-modified alkyd resin and the preparation method thereof, the advantages of alkyd resin and acrylic resin are integrated, and a product has high gloss retention, color retention and weather resistance; a production process is simple, the raw materials are readily available, and the production cost is low; a paint production process is simple, water is used as a diluting agent, and safety and convenience in construction are ensured.

Owner:西北永新涂料有限公司

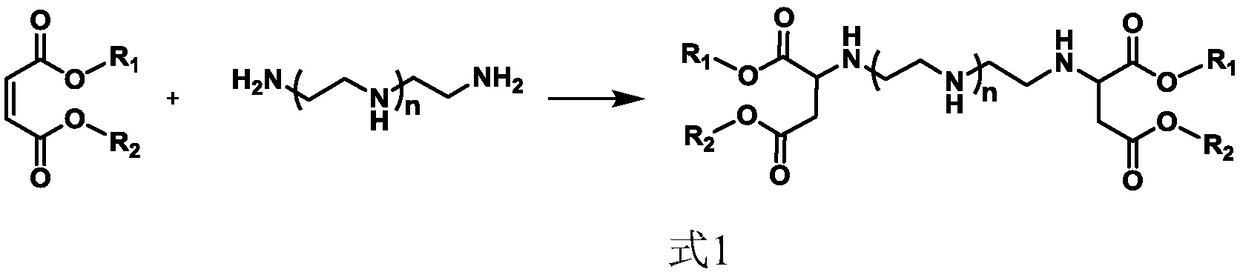

Siloxane-modified aspartic ester as well as preparation method and application thereof

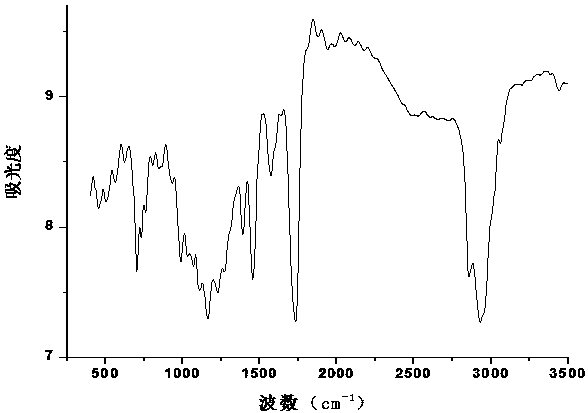

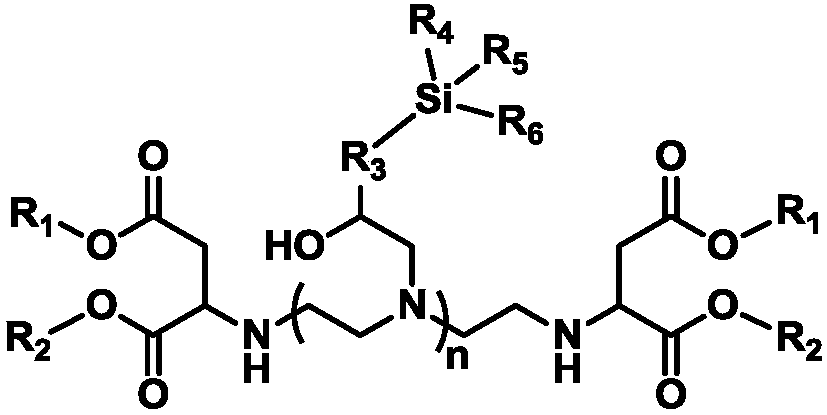

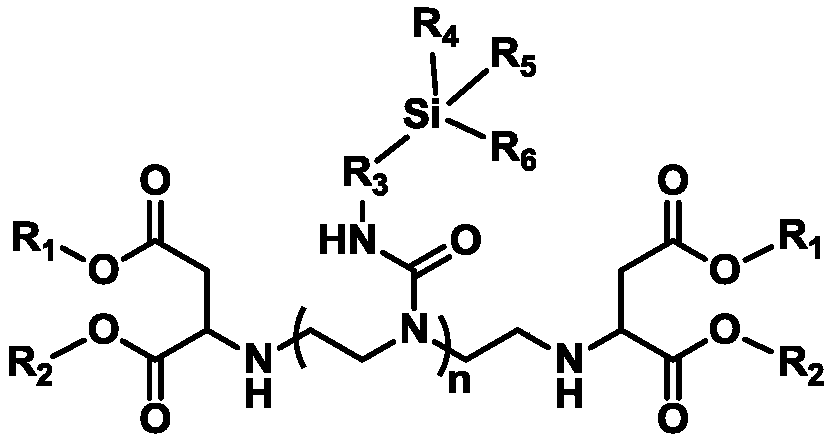

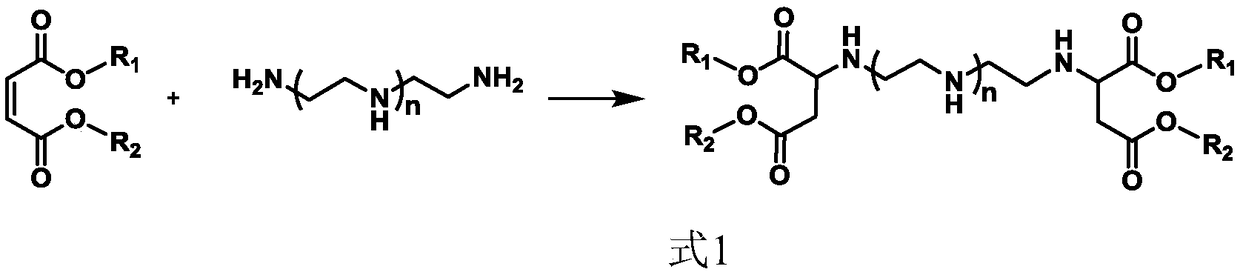

PendingCN109467571AIncrease crosslink densityGood substrate adhesionGroup 4/14 element organic compoundsPolyurethane coatingPolyamine

The invention provides siloxane-modified aspartic ester as well as a preparation method and application thereof. The aspartic ester has a siloxane structure and can enhance the adhesive force of a prepared coating layer onto inorganic and metal base materials. The preparation method comprises the following steps: during synthesis, firstly obtaining aspartate polyamines with un-reacted secondary amine groups through the reaction between diester butenediate and polyvinyl polyamine; then adding a silane coupling agent capable of reacting with an amine group to obtain the siloxane-modified aspartic ester. The siloxane-modified aspartic ester provided by the invention can be used as a two-component polyurea / polyurethane coating resin monomer to improve the adhesive force of the coating layer onto the base materials.

Owner:WANHUA CHEM GRP CO LTD

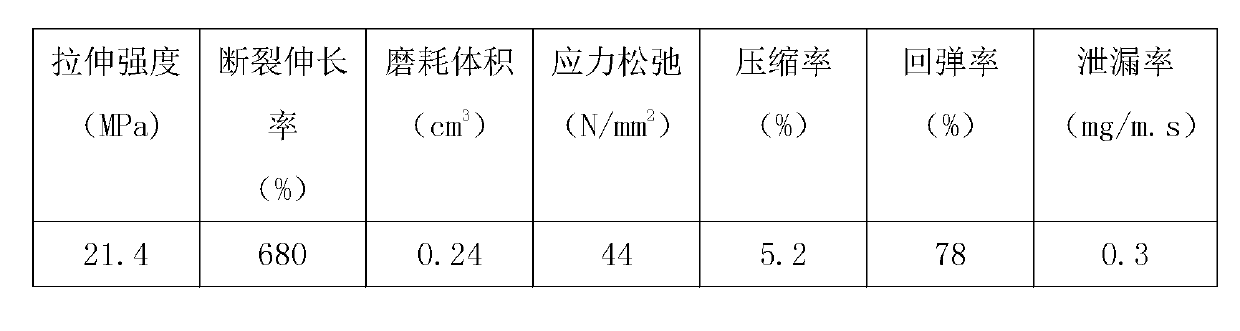

Chloroprene rubber gasket with high abrasion resistance and preparation method thereof

InactiveCN102993517AImprove flame retardant performanceAccelerated corrosionLow-density polyethylenePolymer science

The invention discloses a chloroprene rubber gasket with high abrasion resistance. The chloroprene rubber gasket comprises the following raw materials in parts by weight: 135-145 parts of chloroprene rubber (CR)121, 10-15 parts of butyl rubber CBK139, 20-25 parts of low density polyethylene, 3-5 parts of acetyl triethyl citrate, 2-5 parts of dibutyl maleate, 1-2 parts of isooctyl dimercaptoacetate di-n-octyl tin and the like. The chloroprene rubber gasket has the beneficial effects that the gasket has good high temperature resistance, sealability, flame retardance and corrosion resistance and can work in such medias as acid, alkali and oil for a long time; the volume and hardness of the gasket are small in variation; the gasket does not adhere to metal surfaces; and the gasket has small friction coefficient and good abrasion resistance and has the advantages of softness of bonding with sealing surfaces, good weathering aging and ozone aging resistance, durability and the like.

Owner:ANHUI RONGDA VALVE

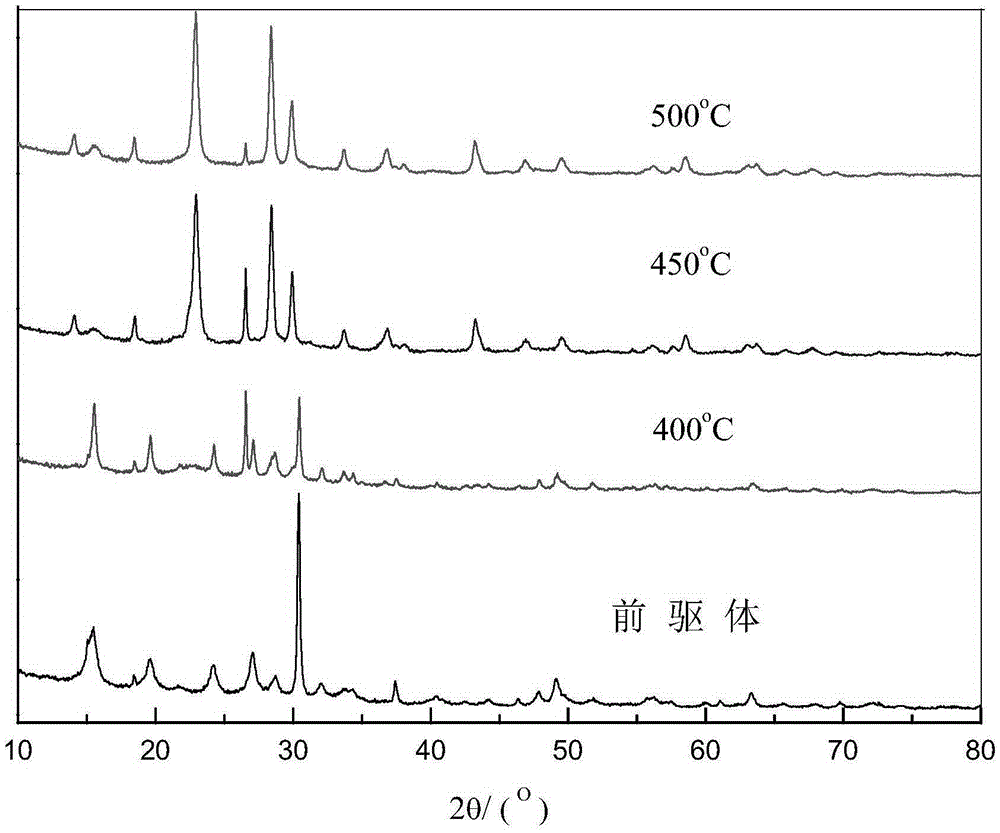

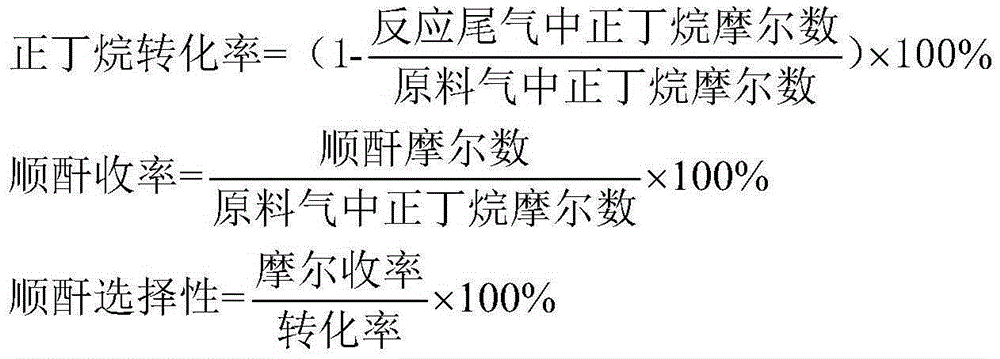

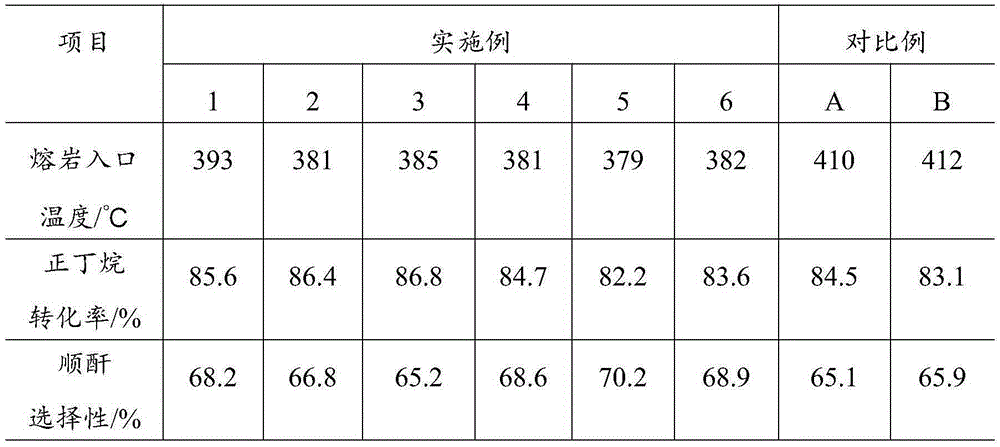

Vanadium phosphorus oxide catalyst for producing maleic anhydride and preparation method for catalyst

ActiveCN105289743AHigh activityHigh selectivityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsMaleic anhydridePhosphorus oxide

The present invention relates to a vanadium phosphorus oxide catalyst for producing maleic anhydride and a preparation method for the catalyst. The preparation method comprises the steps of: preparing a heteropoly acid solution; preparing a catalyst precursor; shaping; baking and the like. For the preparation method for the VPO catalyst provided by the invention, heteropoly acid is added to prepare the catalyst precursor for the first time, thereby effectively increasing the activity and the selectivity of the catalyst. Compared with the prior art, the conversion rate of n-butane is improved by 1-2% and the selectivity of maleic anhydride is increased by 2-3%. The preparation method for the catalyst provided by the invention simplifies the preparation process, and solves the problem that the bed temperature is difficult to control when the VPO catalyst is activated. The VPO catalyst prepared by the preparation method provided by the invention has a reaction temperature which is about 30 DEG C lower than that of an existing commercial catalyst and has a good application prospect.

Owner:XIAN ORIGIN CHEM TECH

Unsaturated polyester resin compositions containing 2,2,2,4-tetramethyl-1,3-cyclobutanediol and articles made therefrom

Disclosed are unsaturated polyester resins comprising residues of 1,2-propanediol, 2,2,4,4-tetramethyl-1,3-cyclobutanediol, an aliphatic, cycloaliphatic, or aromatic diacid, and 2-butenedioic acid. Also disclosed are curable compositions containing admixtures of the unsaturated polyesters and aromatic vinyl compounds copolymerizable with the unsaturated polyesters, and coatings and casted and molded articles obtained from the curable compositions. The curable compositions are useful for coatings and casted and molded articles that have at least one surface that is persistently exposed to organic or aqueous liquids.

Owner:EASTMAN CHEM CO

Degradable unsaturated carbamide resin of polyester amide, and synthetic method

A degradable unsaturated polyester-amidourea resin used for disposable food container, packing material, plastic bag, medicinal coating, capsule and slow-releasing material, etc is prepared from C2-C4 binary alcohol, anti-butenedioic acid or maleic anhydride, and urea through fusing and polycondensating. It can be modified by starch or calcium carbonate powder.

Owner:郭文迅

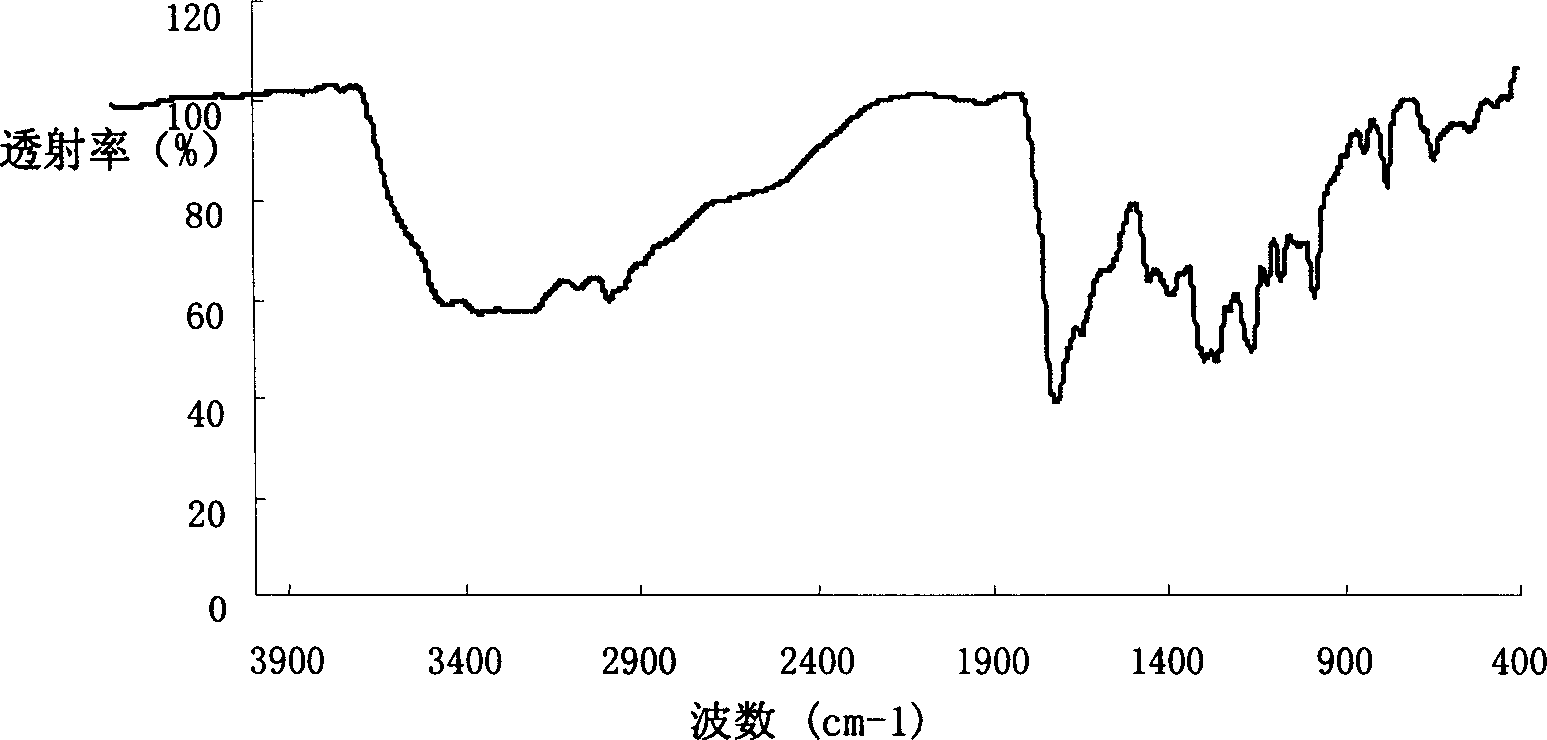

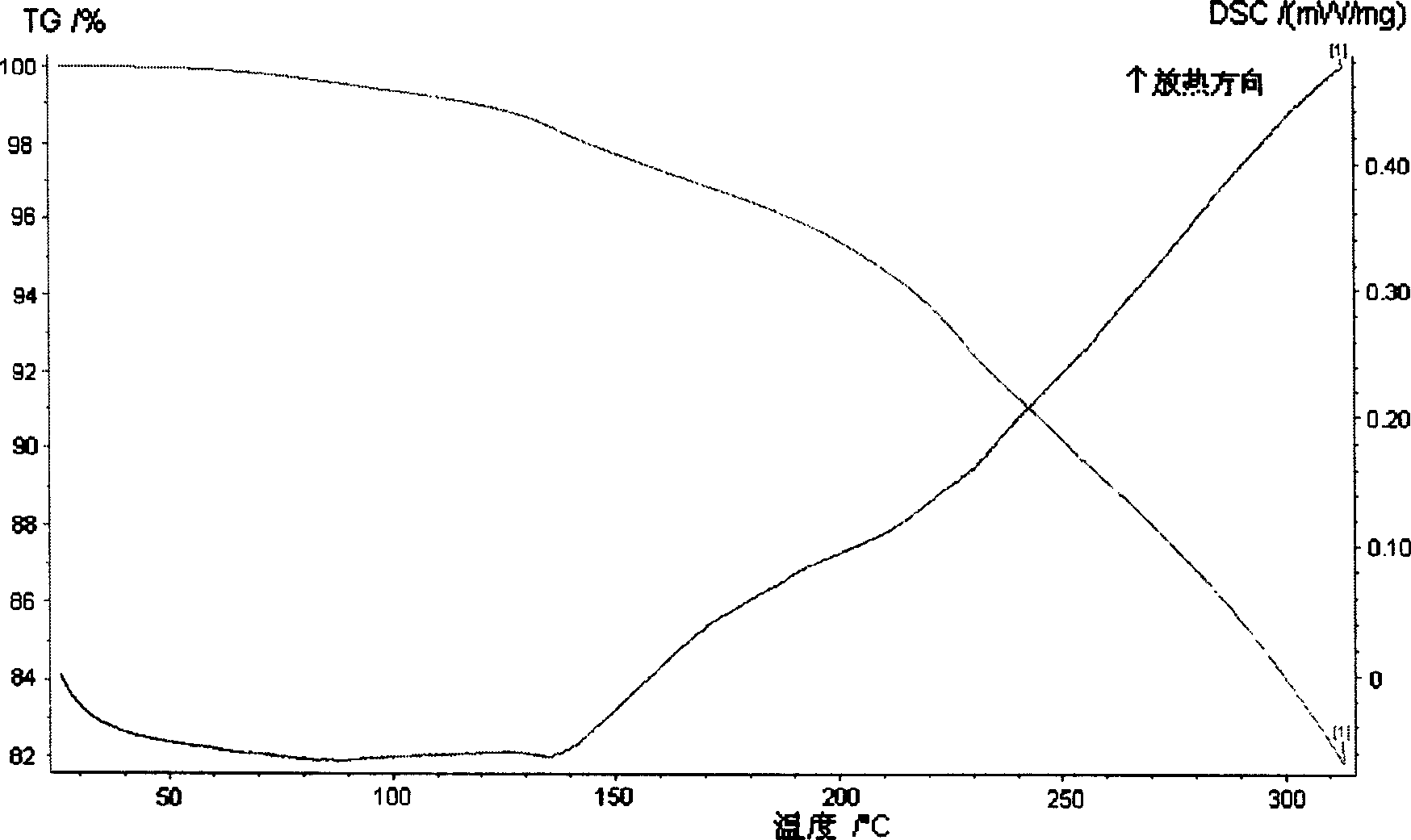

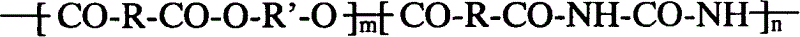

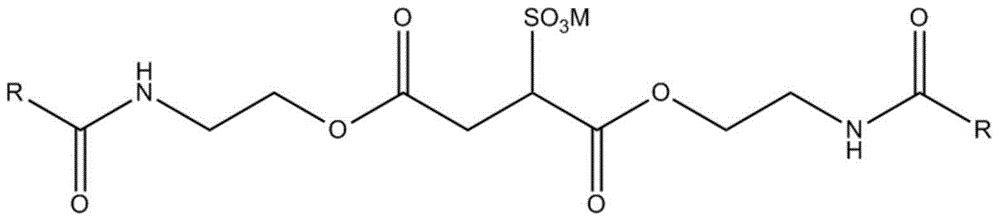

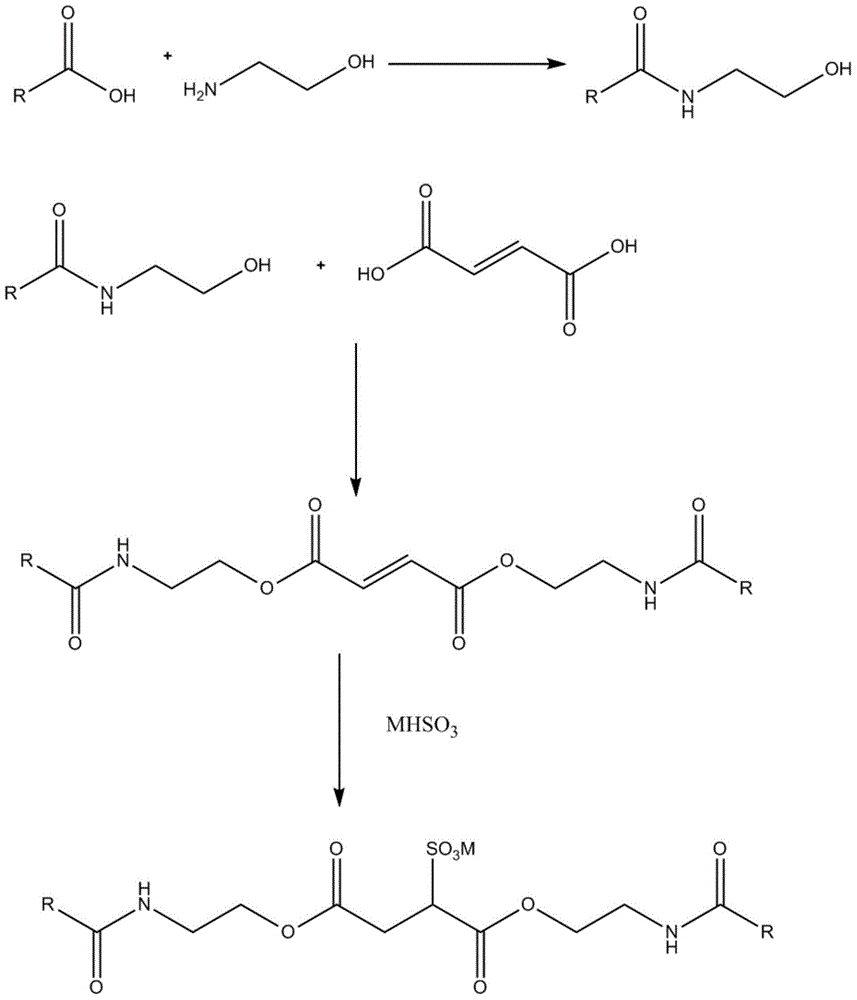

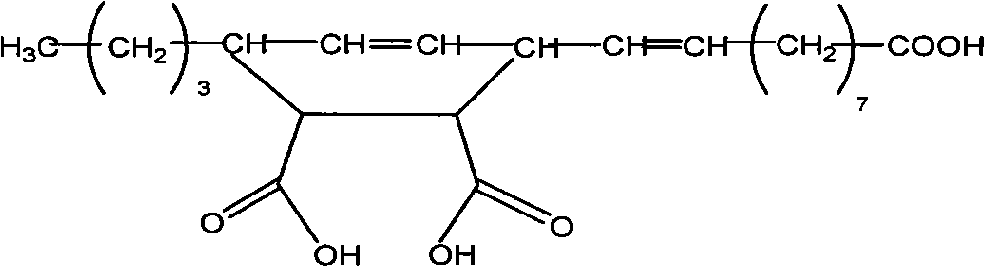

Fatty acid monoethanolamide succinate sulfonate and preparation method and application thereof

ActiveCN103819370AImprove the lubrication effectImprove rust resistanceTransportation and packagingSulfonic acids salts preparationSulfonateButenedioic acid

The invention provides a preparation method for fatty acid monoethanolamide succinate sulfonate. The preparation method is characterized by comprising the steps of generating amidation reaction by fatty acid and monoethanolamide to generate fatty acid monoethanolamide which is reacted with butenedioic acid or maleic anhydride to generate fatty acid monoethanolamide butenedioic acid ester, and generating salt formation reaction of the fatty acid monoethanolamide butenedioic acid ester and hydrosulphite to generate the fatty acid monoethanolamide succinate sulfonate. Compared with the prior art, trace cutting liquid prepared from the fatty acid monoethanolamide succinate sulfonate provided by the invention has high lubricating property, extreme pressure antiwear property and biological degradability; a high-end requirement on metal processing can be met only by using an extremely small amount of the trace cutting liquid; therefore, harm to the environment and workers is alleviated, and the pollution to the environment is reduced to the maximum extent.

Owner:深圳市泓丰科技有限公司

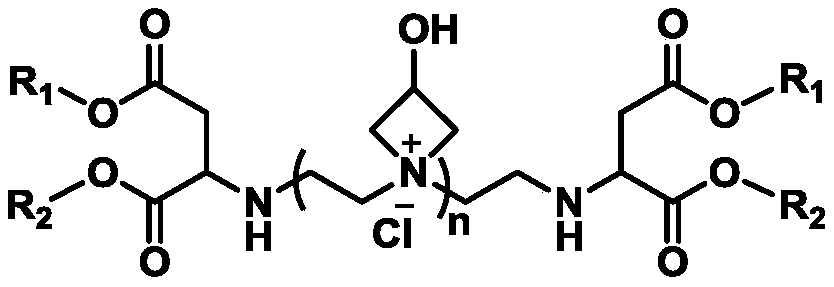

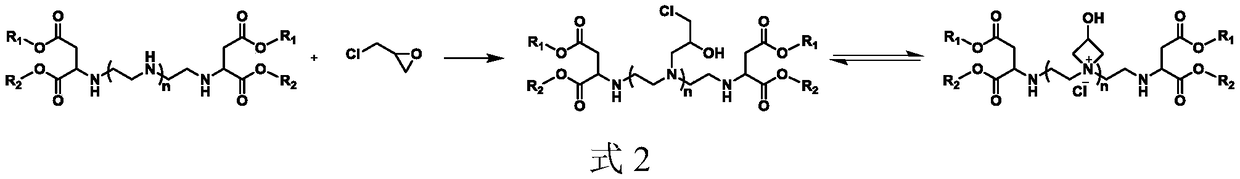

Water-soluble cationic polyaspartic ester, preparation method and application thereof

ActiveCN109020859AImprove stabilityHigh mechanical strengthOrganic chemistryPolyurea/polyurethane coatingsSynthesis methodsPolyaspartic

The invention provides a water-soluble cationic polyaspartic ester and a synthesis method thereof. The substance has a 3-hydroxyazetidine structure. During synthesis, firstly butene diacid diester reacts with polyethylene polyamine to obtain polyaspartic ester polyamine with unreacted secondary amine group, and then adding epoxy chloropropane for reaction with the secondary amine group so as to obtain water-soluble polyaspartic ester with azetidine cationic group. The cationic polyaspartic ester monomer can be compounded with isocyanate to develop water-soluble polyurea or polyurea / polyurethane coating resin.

Owner:WANHUA CHEM GRP CO LTD

Pesticide residue degradation agent

InactiveCN104342161AImprove fat retentionPromote growth and developmentAgriculture tools and machinesOrganic fertilisersButenedioic acidPesticide residue

The invention relates to a pesticide residue degradation agent which is characterized in comprising the following components: 8 parts of butenedioic acid, 15 parts of butenedioic acid, 12 parts of alkylbenzene sulfonic acid, 15 parts of sodium carbonate, 10 parts of sodium sulfate, 56 parts of water, 5 parts of glutathione, 1 part of borax, and 4 parts of calcium sulfate. The degradation agent also includes 6 parts of phenyl ring and 18 parts of amino acid. The pesticide residue degradation agent assists in effectively improving soil. When the pesticide residue degradation agent provided by the invention is applied, beneficial microbes in a disinfectant bloom at the roots of crops, and a large amount of secondary metabolites are produced during the reproductive processes. Therefore, soil aggregate structure formation can be accelerated.

Owner:QINGDAO AIHUALONG BIOTECH

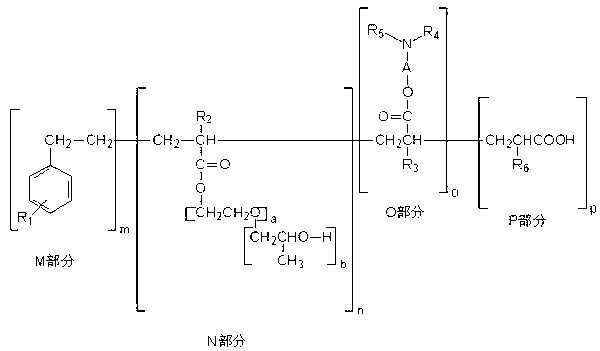

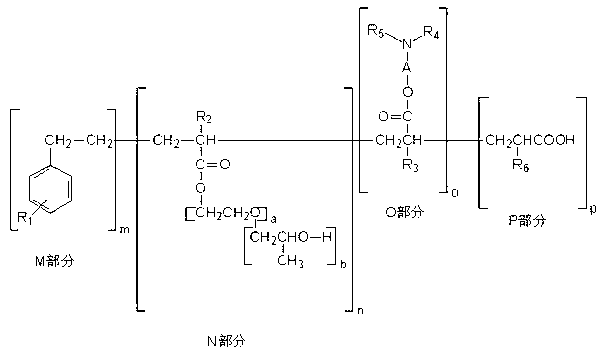

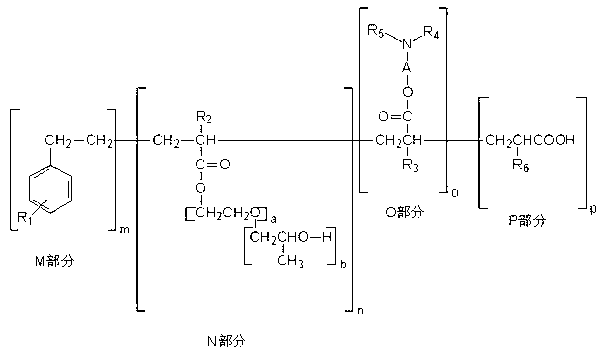

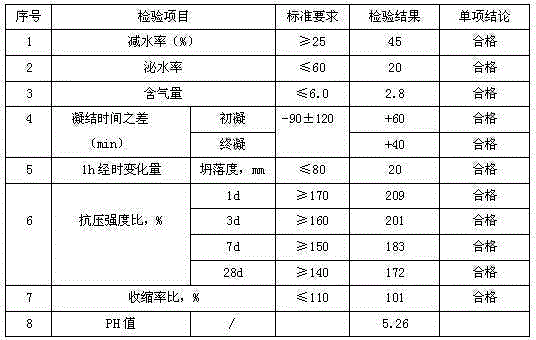

An early-strength type polycarboxylic acid water reducer and a preparing method thereof

The invention discloses an early-strength type polycarboxylic acid water reducer and a preparing method thereof in the technical field of concrete additives. The preparing method adopts methyl allyl polyethenoxy ether, maleic anhydride and acrylamide as monomers and includes adding an oxidant, a reductant and a chain transfer agent, and performing copolymerization in water. The prepared water reducer has characteristics of good slump loss resistance and good cement adaptability, and has obvious early-strength reinforcing effects. Adjustment of the pH value by using an alkaline solution is not needed in a preparing process. The process is simple and easy in operation.

Owner:NORTHEASTERN UNIV

Alkyd acrylic graft copolymer and preparation method thereof

The invention relates to an alkyd acrylic graft copolymer and a preparation method thereof. According to the invention, high-molecular alkyd resin with main chain containing unsaturated double bond is synthesized through molecular design. The copolymer comprises the components of: soybean oil acid 55%-65%, pentaerythritol 17%-19%, maleic anhydride 1.07%-1.24%, phthalic anhydride 15.54%-17.92%, xylene 7.5%, and benzoic acid 1.55%-1.79%. Synthesized alkyd resin is subjected to free radical graft copolymerization with acrylic monomer, such that the alkyd acrylic graft copolymer is obtained. The copolymer monomer comprises the components of: acrylic acid 0.2%-0.9%, methyl methacrylate 2.7%-10.1%, styrene 2.6%-9.5%, butyl acrylate 4.0%-14.8%, alkyd resin 9.0%-35.0%, an initiator 0.15%-0.30%, and xylene 60.0%.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Hyperdispersant for pesticide, and preparation method and application thereof

Owner:LIANYUNGANG TIANLIRUN CHEM

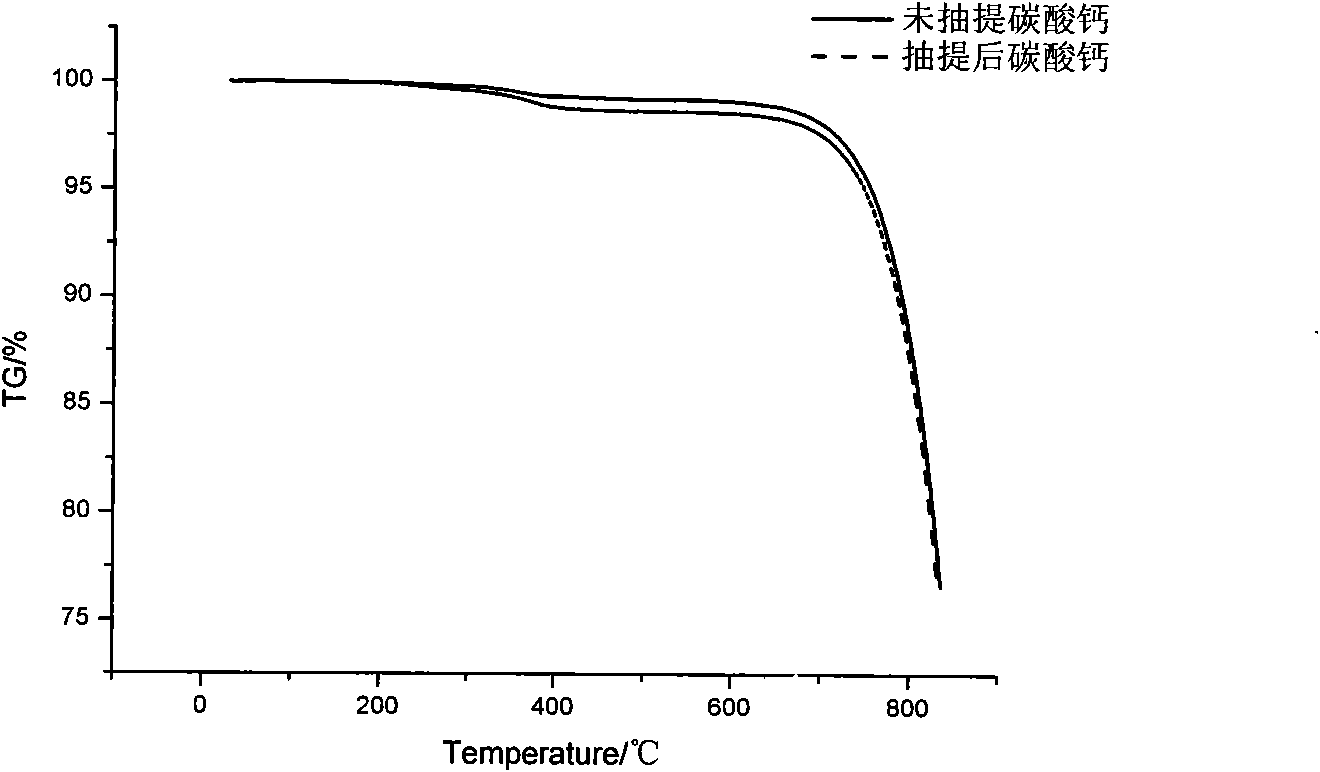

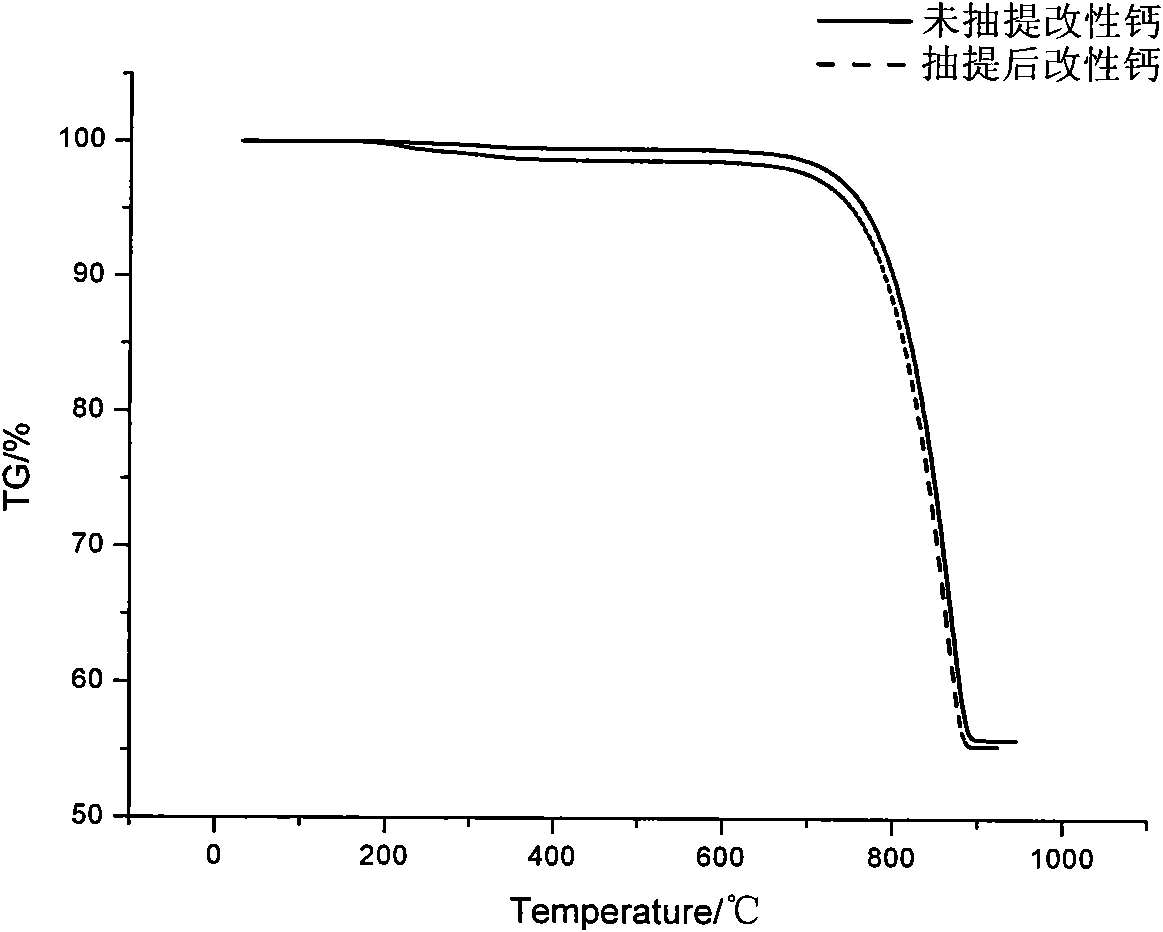

Calcium carbonate modifier and preparation method thereof

InactiveCN101671495AGood compatibilityImprove interface performancePreparation from carboxylic acid anhydridesPigment treatment with non-polymer organic compoundsHydrolysateStearic acid

The invention provides a calcium carbonate modifier and a preparation method thereof. The calcium carbonate modifier is eleostearic acid estolide hydrolysate, which is prepared by taking eleostearic acid and maleic anhydride as materials to directly synthesize eleostearic acid estolide by one-step procedure and using a proper amount of water to hydrolyze the eleostearic acid estolide. The invention has the advantages of simple production process, low production cost, high yield, easy popularization and the like. The calcium carbonate modifier has more action points and can chemically react with calcium carbonate, thereby having better effect than the traditional stearic acid modifier.

Owner:ZHANGJIAJIE HENGLIANG MINING

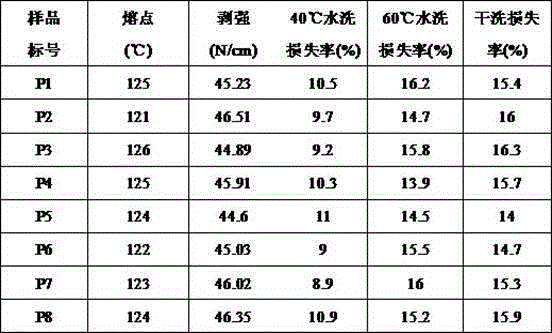

Novel copolyster hot melt adhesive and preparation method thereof

ActiveCN105348497ALow costImproves dry cleaning resistanceNon-macromolecular adhesive additivesPolymer scienceButenedioic acid

The invention discloses a novel copolyster hot melt adhesive and a preparation method thereof. The preparation method is mainly characterized by comprising the following steps: selecting raw materials (including bisphenol A, maleic acid, terephthalic acid, other binary acids, 1,4-butanediol, other dihydric alcohols, a catalyst and a stabilizer) at a preset ratio; performing negative-pressure generation of a prepolymer at the low-temperature section; then completing normal-pressure esterification at the low-temperature section; after that, completing negative-pressure polycondensation at the high-temperature section; finally, preparing the novel copolyster hot melt adhesive product. The prepared novel copolyster hot melt adhesive product is greatly improved in dry cleaning resistance and not inferior to the washing resistance of a polyamide hot melt adhesive, on the basis of maintaining the comprehensive performance of a conventional copolyster hot melt adhesive product, and the integral cost of the prepared novel copolyster hot melt adhesive product is lower than that of the conventional polyamide hot melt adhesive.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +1

Special quenching agent for large shaft and preparation method of quenching agent

The invention discloses a special quenching agent for a large shaft and a preparation method of the quenching agent, belonging to the field of quenching agents. The quenching agent is prepared from the following components: sodium chloride, sodium hydroxide, sodium citrate, cis-butenedioic acid, mesotrione, lotus root starch, acrylic acid, p-cresol, metribuzin and water. Through adding reasonable components and strictly controlling the component proportion, when used for quenching a shaft which is made of 45# steel and has the diameter of 1.8-3.5m, the quenching agent has the following advantages that the workpiece cooling speed is high within the temperature range of 650-450 DEG C, and the cooling speed is low at the temperature of below 400 DEG C, so that a favorable quenching effect can be obtained, and a quenching crack condition can also be avoided. The preparation method of the quenching agent has the advantages that all components in the quenching agent are completely dispersed and uniformly distributed by controlling temperatures and adding sequences of raw materials, the quenching agent is similar to a colloid in shape, and the cooling speed at the temperature of below 400 DEG C is lowered.

Owner:深圳市新元特钢有限公司

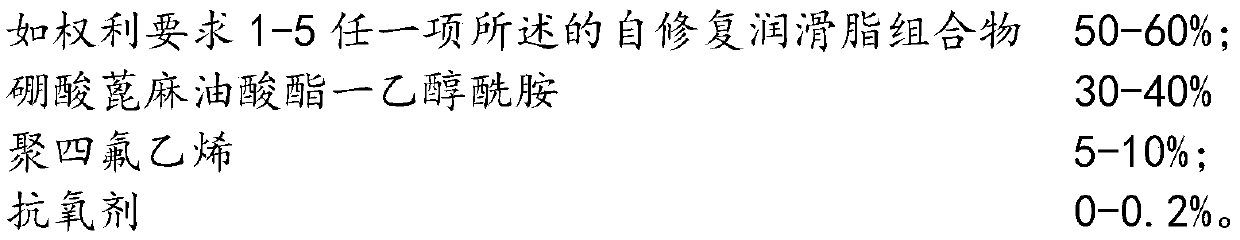

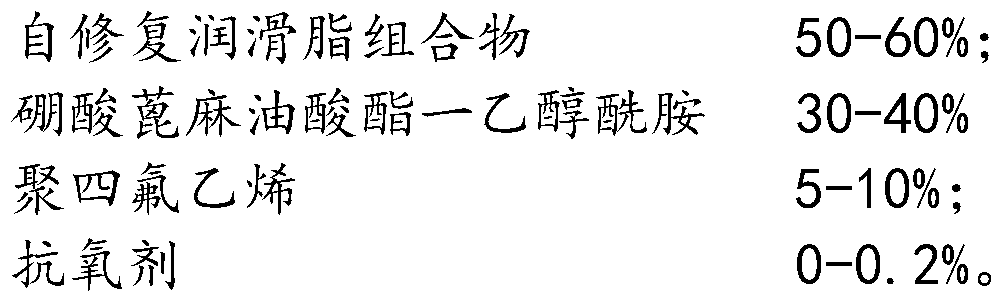

Environment-friendly self-repairing lubricating grease and preparation method thereof

ActiveCN110257141AGood extreme pressure and anti-wear propertiesGood chemical stabilityLubricant compositionPolytetrafluoroethyleneAntioxidant

The invention provides a self-repairing lubricating grease composition, which is characterized by comprising castor oil and butenedioic acid, and the molar ratio of castor oil to butenedioic acid is 1:1-1.5. The self-repairing lubricating grease composition also comprises a rare earth oxide, wherein the rare earth oxide accounts for 0.1-0.5 wt% of the components. The self-repairing lubricating grease composition has a complex cross-linked structure, relatively large molecular weight and good lubricity and extreme pressure wear resistance; wherein the rare earth oxide not only can be used as a catalyst in the reaction process, but also exists in the composition in the form of organic neodymium, can form an iron-neodymium compound with certain magnetism with metal iron in the use process, and can automatically fill and repair tiny cracks on the surface of a friction pair. The invention further discloses the environment-friendly self-repairing lubricating grease prepared from the self-repairing lubricating grease composition, boric acid ricinoleate monoethanolamide, polytetrafluoroethylene, an antioxidant and the like.

Owner:上海源育节能环保科技有限公司

Polycarboxylate water reducing agent and preparation method thereof

The invention discloses a polycarboxylate water reducing agent and a preparation method thereof. The water reducing agent is prepared from the following main components in parts by weight: methyl allyl polyethenoxy ether, sodium methallyl sulfonate, maleic anhydride, acrylamide, propenoic acid, hydrogen peroxide, mercaptoacetic acid and purified water. The polycarboxylate water reducing agent has the advantages that the water reducing rate reaches up to 45%, the high water reducing and slump loss resisting requirements of concrete can be better met, the sensitivity to temperature is low, the adaptability to cement is strong, the preparation process is simple, and the preparation is easy.

Owner:贵州省瓮安新源新材料有限公司

Acrylic rubber, crosslinkable acrylic rubber composition and moldings

An acrylic rubber comprised of a copolymer comprising 0.1 to 20% by weight of (A) units of a butenedioic acid monoester monomer having an alicyclic structure and 50 to 99.9% by weight of (B) units of at least one kind of monomer selected from acrylic acid ester monomers and methacrylic acid ester monomers. A crosslinkable acrylic rubber composition comprising the acrylic rubber and a crosslinking agent, especially a polyamine crosslinking agent, has good process-stability and good shapability and gives a shaped article having high heat resistance and exhibiting reduced permanent set.

Owner:ZEON CORP

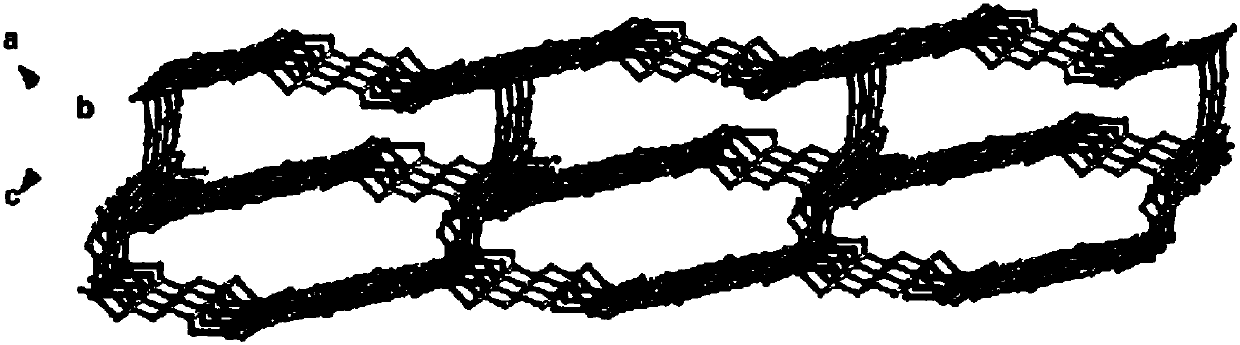

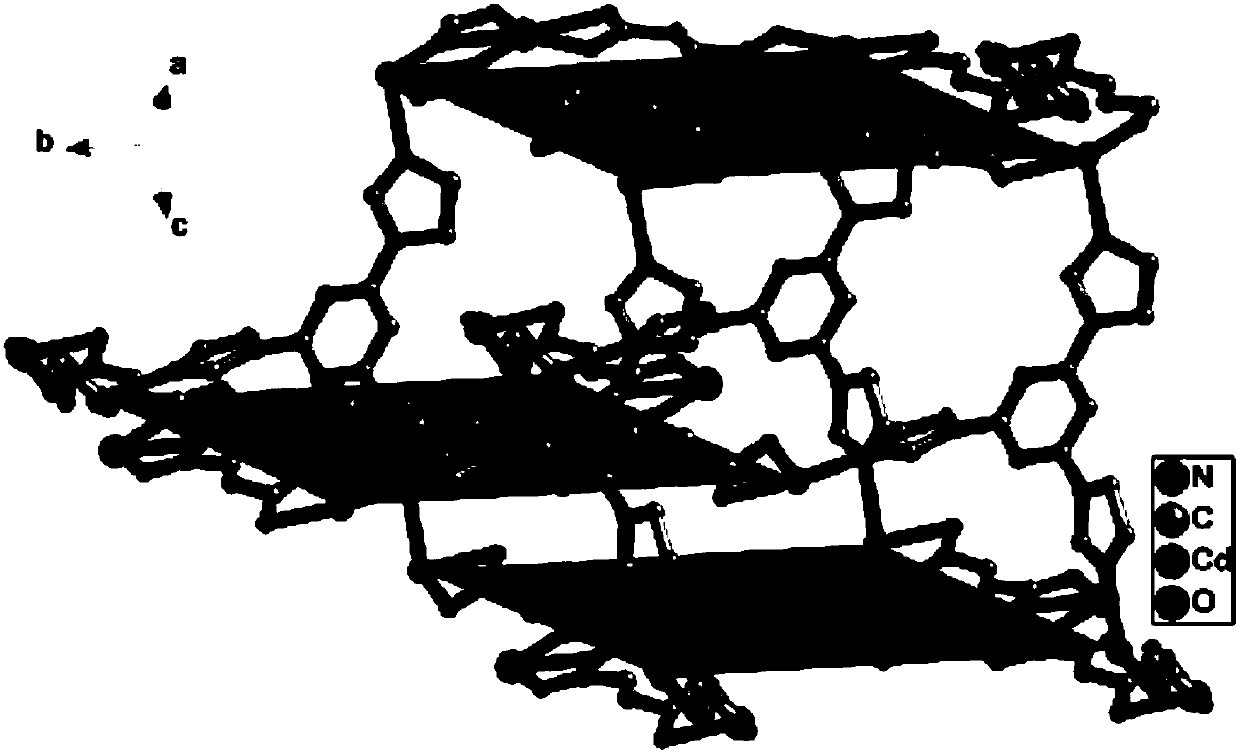

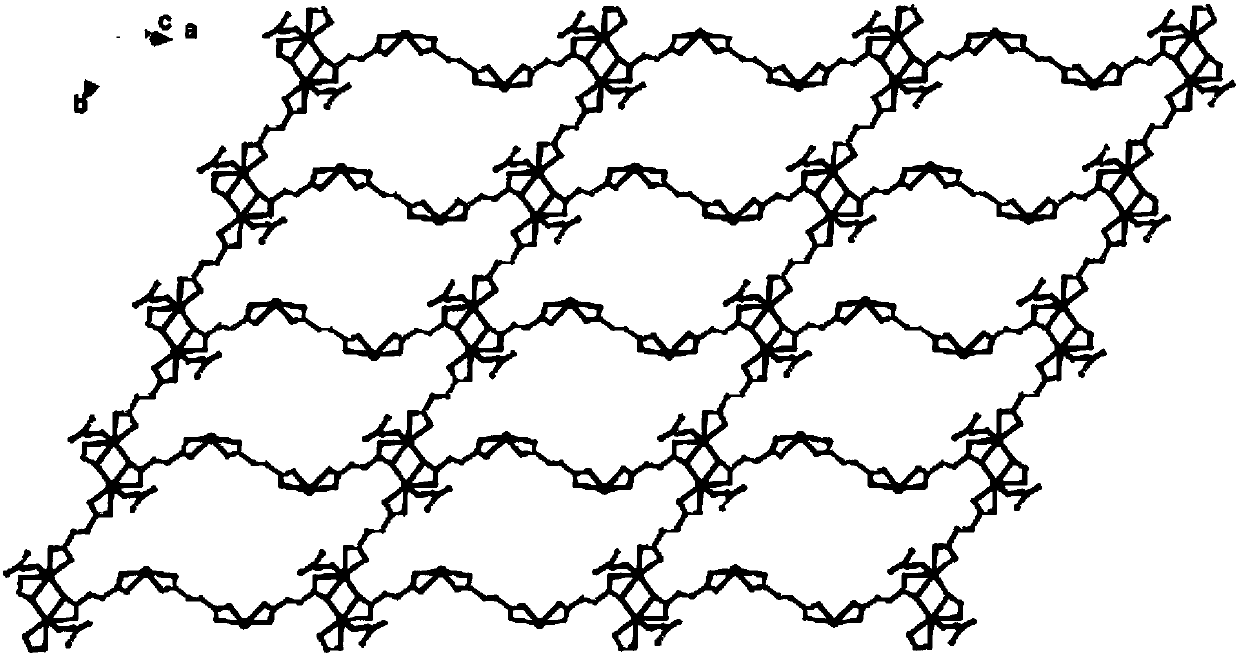

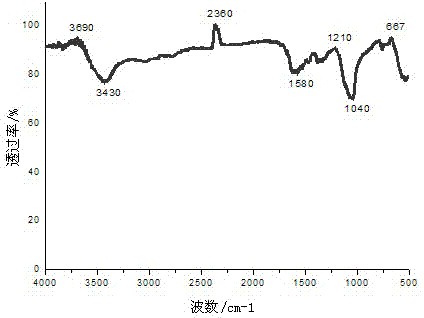

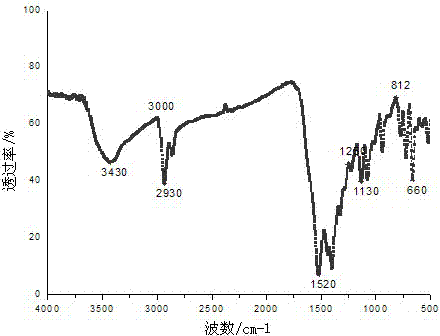

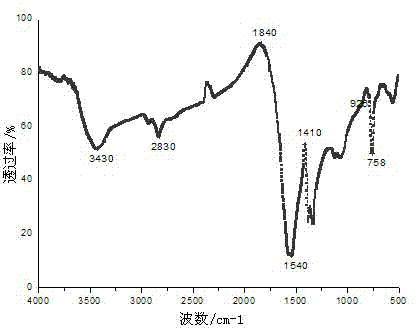

Fluorescent porous material as well as synthetic method and application thereof

ActiveCN107793440ASimple ingredientsEasy to manufactureFluorescence/phosphorescenceGroup 2/12 organic compounds without C-metal linkagesBenzeneN dimethylformamide

The invention relates to the technical field of fluorescent porous materials, and particularly relates to a fluorescent porous material as well as a synthetic method and application thereof. A chemical formula of the fluorescent porous material disclosed by the invention is C26H16N7O9Cd2; a main ligand is 1,3,5-tri-benzene imidazolyl, an auxiliary ligand is butene diacid, and a solvent is N,N-dimethylformamide; the fluorescent porous material is prepared through a heating method of the solvent. The fluorescent porous material disclosed by the invention has simple raw materials, a preparation process is simple and easy, and the fluorescent porous material has higher heat stability and fluorescence emission property. In a process of detecting pesticide paraquat by adopting the material, thesensitivity is high, the detection selectivity is good, and the fluorescent porous material has good application prospects in the field of material science.

Owner:秦皇岛天大环保研究院有限公司

Synthesis method and application of flexible carboxylic acid and transition metal complex

InactiveCN103588819AOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsButenedioic acidButanedioic acid

The invention discloses a method for synthesizing a flexible carboxylic acid and transition metal complex by taking Fe<3+>, Pb<2+> or Ba<2+> as a metal center and the 5-amino-1,2,4-triazole-3-carboxylic acid, succinic acid, malonic acid, adipic acid, butenedioic acid (cis, trans), 2,3-quinoline dicarboxylic acid or 2,5-dicarboxythiophene as an organic ligand, and provides an application of the complex serving as a catalyst to catalyze a phenol hydroxylation reaction. Through the method and application disclosed by the invention, by taking the synthesized complex as a catalyst to catalyze the phenol hydroxylation to obtain benzenediol, the yield can approach 74%; and the catalysis reaction is green and environment-friendly, and the catalyst is expected to become a novel catalyst for catalyzing phenol hydroxylation.

Owner:宣城明美蓝莓科技有限公司

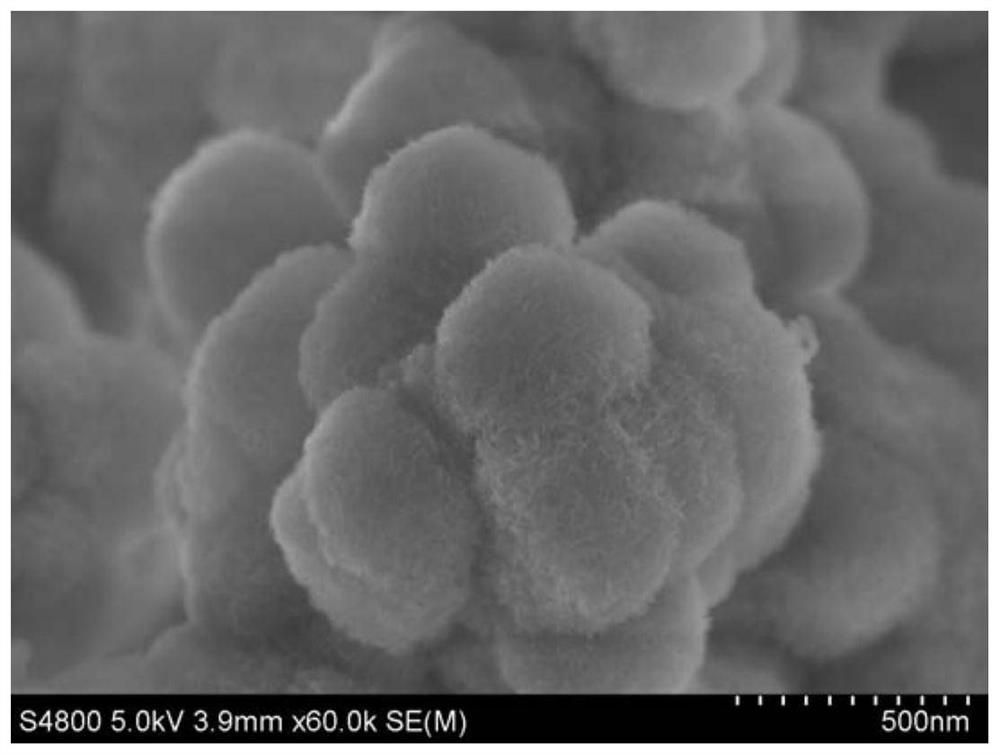

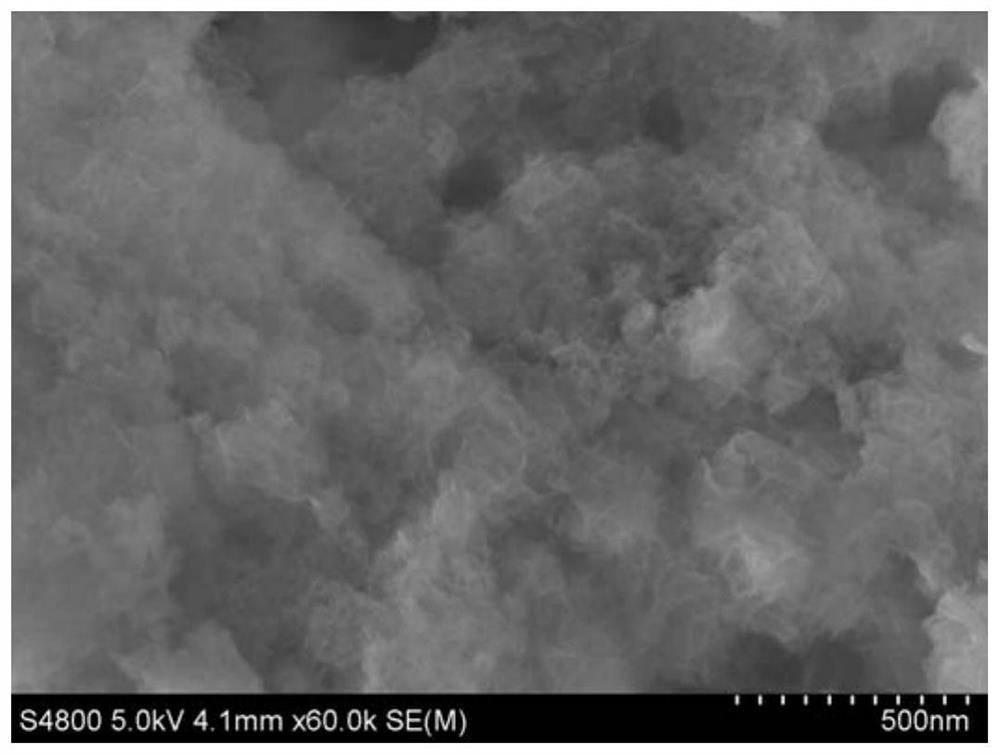

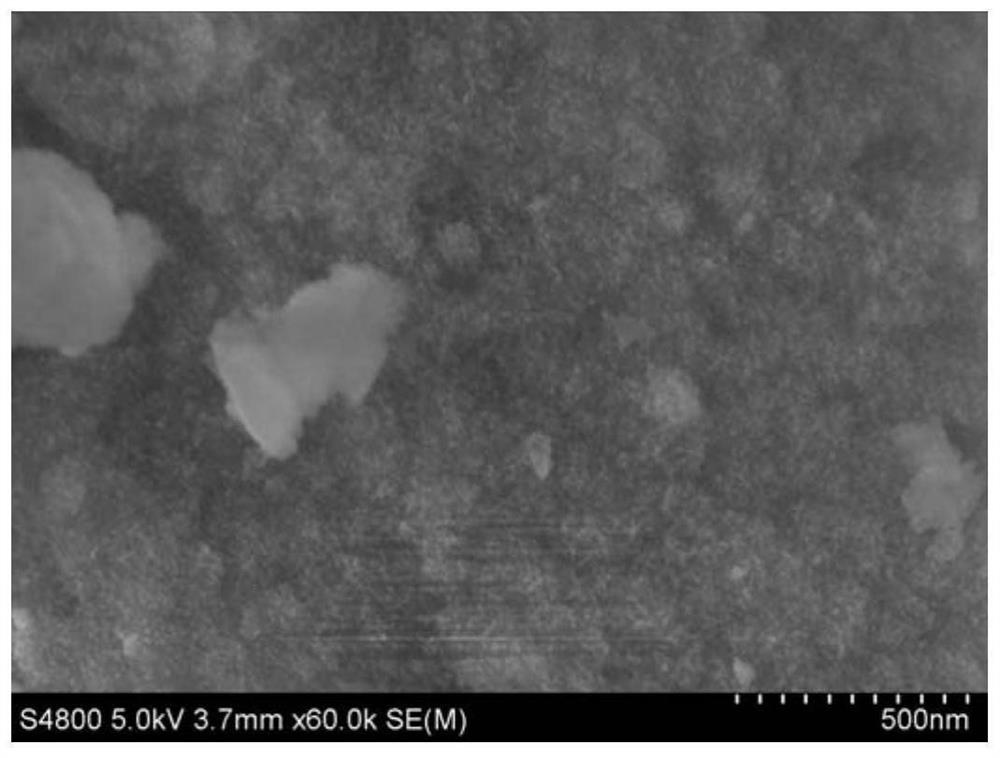

Reaction catalyst for preparing gamma-butyrolactone through maleic anhydride hydrogenation, and preparation method and application thereof

ActiveCN113731480AImprove hydrogenation activityImprove stabilityOrganic chemistryMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a reaction catalyst for preparing gamma-butyrolactone through maleic anhydride hydrogenation, and a preparation method and application thereof. The catalyst has a hierarchical pore structure and relates to two transition metals A and B and a silicon-based MFI molecular sieve. The micropore diameter of the MFI molecular sieve is 0.6 to 0.8 nm; and the component A of the catalyst metal part mainly refers to one or more than two of transition metal elements Fe, Co, Ni, Cu and Zn, the component B refers to one or more than two of metals Zr, Y, Hf, La, Ce, Sn and Ti, and active metal components are loaded in an in-situ synthesis or post-treatment mode. The invention provides the high-stability and high-efficiency catalyst for catalyzing maleic anhydride hydrogenation to prepare gamma-butyrolactone, and the preparation method thereof. Compared with a noble metal catalyst, the catalyst is cheaper in cost, can be comparable with the catalytic performance of the noble metal catalyst in the reaction, and has an industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Cleaning agent for calcium sulfate scale

ActiveCN102703233BWash thoroughlyNo hydrogen embrittlementCationic surface-active compoundsScale removal and water softeningButenedioic acidReverse osmosis

The invention provides a cleaning agent for cleaning calcium sulfate scale. The cleaning agent comprises the following components in percentage by weight: 10 to 30 percent of sodium citrate, 0.5 to 5 percent of dodecyl dimethyl benzyl ammonium chloride, 0.5 to 5 percent of sodium di-iso-octyl maleate sulfonate, 5 to 15 percent of absolute ethanol and 45 to 85 percent of reverse osmosis water. The cleaning agent for the calcium sulfate scale is particularly used for removing insoluble calcium sulfate scale, can completely remove the scale, does not corrode metals, is nontoxic to human bodies and is efficient and safe, a medicament is a neutral solution, waste liquid can be safely discharged, and a phenomenon of hydrogen embrittlement can be avoided.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

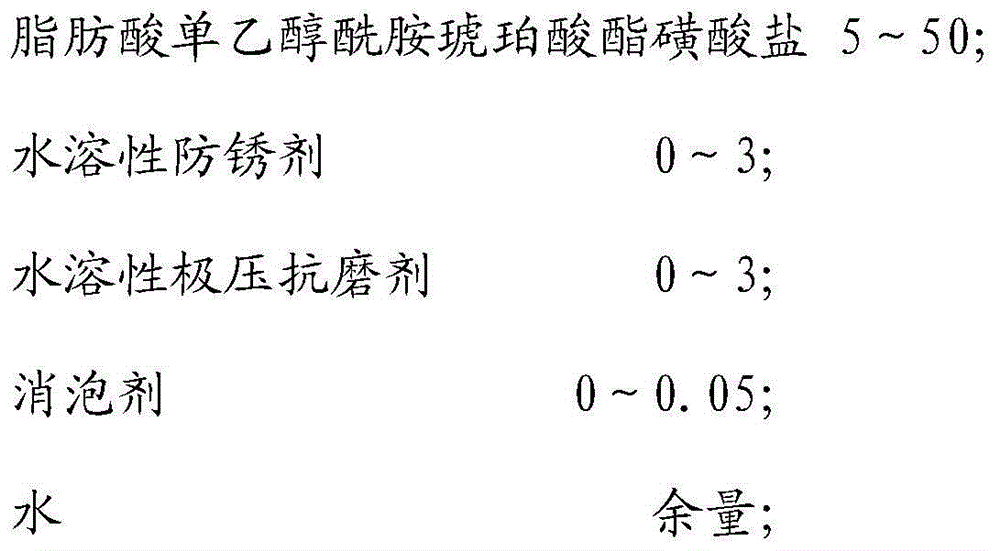

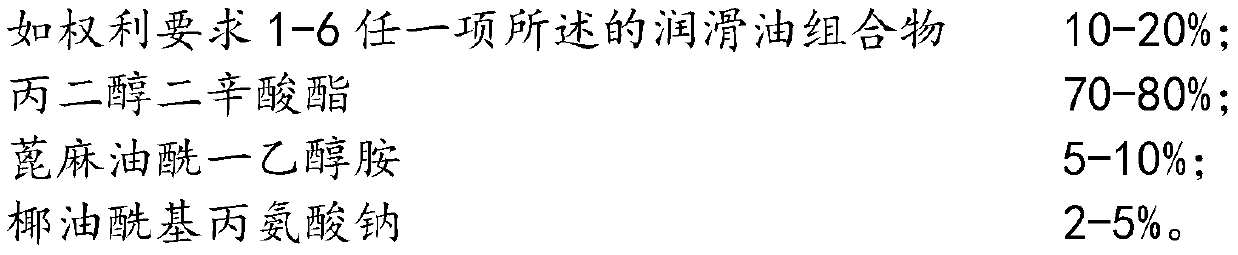

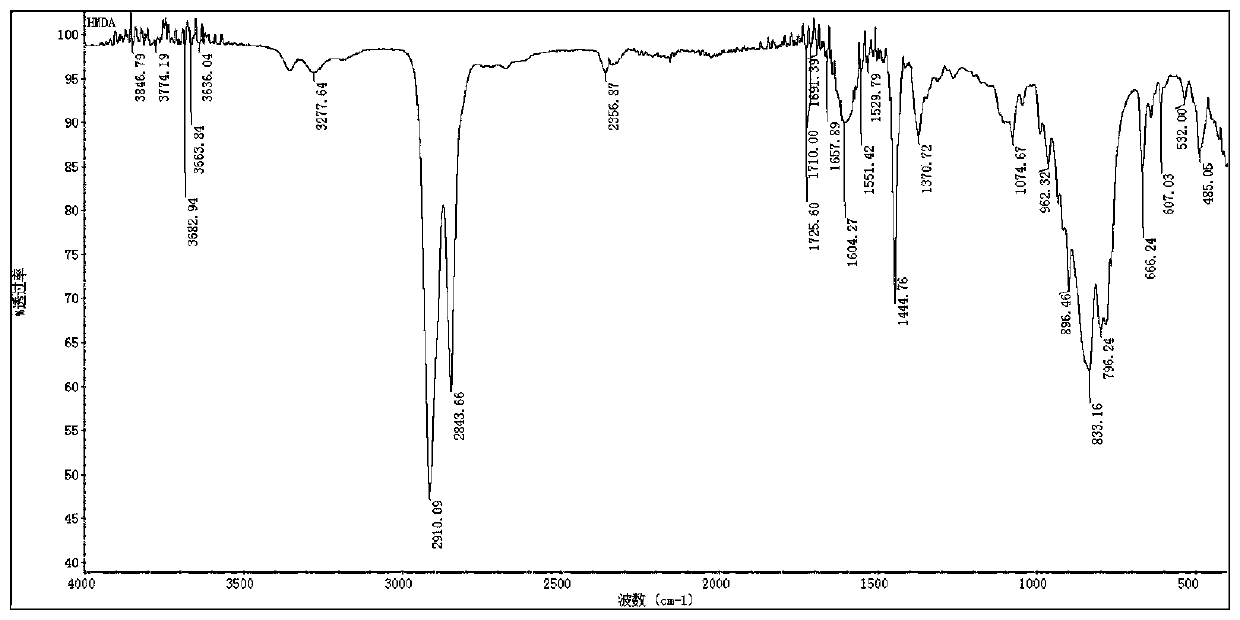

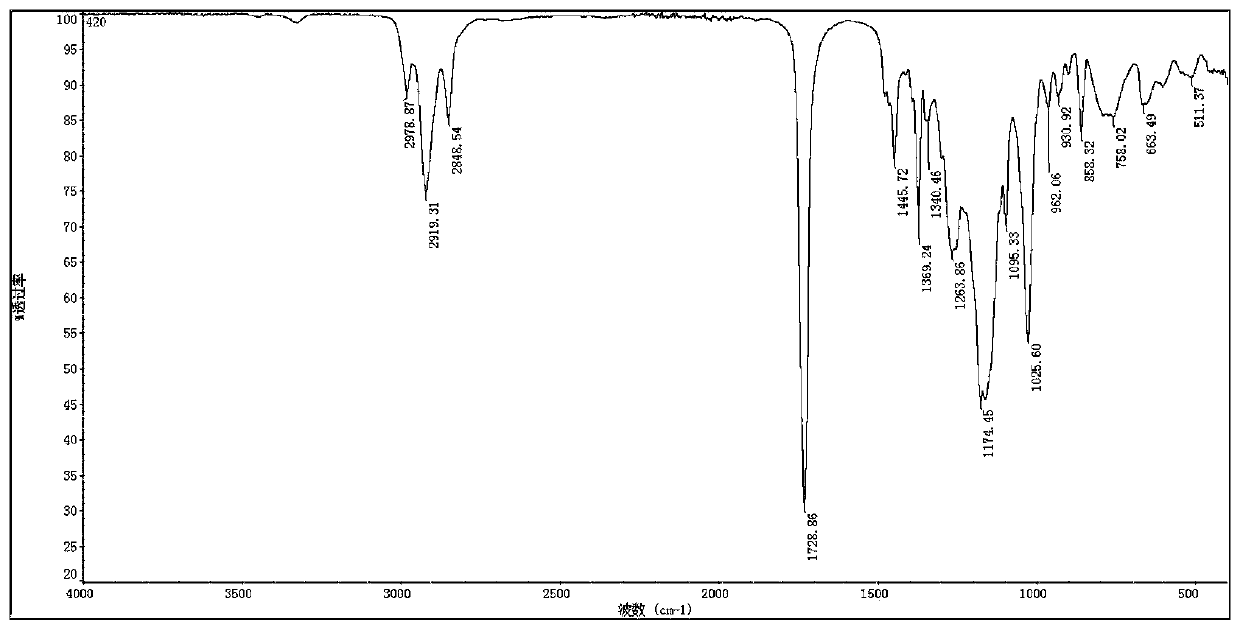

Lubricating oil composition, preparing method thereof and near-dry processing lubricating oil prepared from composition

ActiveCN110205189AExtended service lifeHigh molecular weightLubricant compositionMetalworkingButenedioic acid

The invention provides a lubricating oil composition. The lubricating oil composition is characterized by being prepared from castor oil, butenedioic acid and rare earth oxide, wherein the mole ratioof the castor oil to the butenedioic acid is 1:1-1:1.5, and the rare earth oxide accounts for 0.1-0.5% of the weight of the composition, and is preferably one of lanthanum oxide and cerium oxide or amixture of the lanthanum oxide and cerium oxide. The invention provides a near-dry processing lubricating oil containing the lubricating oil composition. The near-dry processing lubricating oil is characterized by being prepared from, by weight, 10-20% of the lubricating oil composition, 70-80% of propylene glycol dicaprylate, 5-10% of ricinoleic acid-glycollic amide and 2-5% of sodium cocoyl alaninate. The near-dry processing lubricating oil prepared from the lubricating oil composition can meet the requirements of metal processing for lubricating cooling, extreme-pressure wear resistance andrust prevention. When the near-dry processing lubricating oil is used in cooperation with a near-dry cutting lubricating device, the use quantity of a lubricant can be saved by 95% or above, and theeffects of energy conservation and emission reduction and environmental protection are significant.

Owner:上海贝能环保科技有限公司

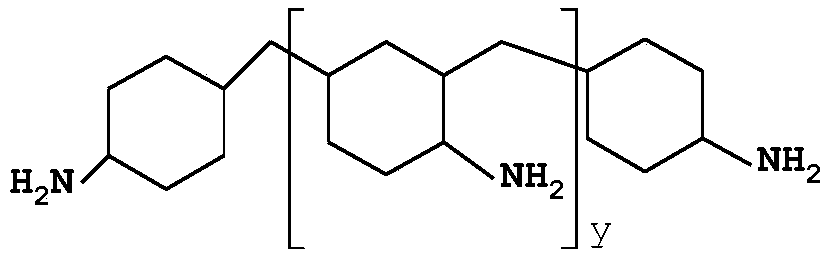

Polyfunctional polyaspartic acid ester mixture and preparation method and application thereof

ActiveCN111454413AGood solvent resistanceIncrease crosslink densityCarboxylic acid nitrile preparationOrganic compound preparationButenedioic acidPolyaspartic acid

The invention provides a multifunctional polyaspartic acid ester mixture and a preparation method and application thereof. The preparation method of the polyaspartic acid ester mixture comprises the following steps: reacting mixtures of diaminodicyclohexylmethane and polyaminopolycyclohexylmethane in different mixing ratios with butenedioic acid diester to prepare a polyfunctional polyaspartic acid ester mixture; and after the reaction is finished, adding acrylonitrile into a system to eliminate unreacted primary amine. The method of the invention can solve the technical problems of uncontrollable operation time of polyaspartic acid ester, residual primary amine in reaction products and the like in the prior art; and the multifunctional polyaspartic acid ester mixture has the advantages ofadjustable operation time, improvement of solvent resistance of a two-component polyurea / polyurethane coating and the like when used as a component of the coating.

Owner:WANHUA CHEM GRP CO LTD

Composite scale inhibitor and preparation method thereof

PendingCN111517487AImprove performanceSolve the problems of easy hydrolysis and poor effect of inhibiting calcium sulfate scaleScale removal and water softeningButenedioic acidActive agent

The invention relates to the technical field of scale inhibitors, particularly relates to a phosphorus-free and environment-friendly novel composite scale inhibitor which has stable performance and can solve the problem that the traditional polyphosphate scale inhibitor is easy to hydrolyze and has a poor calcium sulfate scale inhibition effect, and specifically relates to a composite scale inhibitor and a preparation method thereof. The composite scale inhibitor comprises the following raw material components in parts by weight: 12-20 parts of an itaconic acid-polyaspartic acid copolymer, 12-18 parts of an ethylene glycol itaconic acid-acrylamide-2-methyl propanesulfonic acid-maleic acid copolymer, 2-8 parts of sulfamic acid, 8-15 parts of sodium hydroxide, 1-5 parts of a surfactant and 46-52 parts of water. The compound scale inhibitor is small in dosage, not prone to scaling after being used and high in scale inhibition rate, the itaconic acid-polyaspartic acid copolymer in the compound scale inhibitor has very high temperature resistance and has scale inhibition and corrosion inhibition effects, itaconic acid is inserted into polymer molecules, and therefore, the scale inhibition and removal performances of the compound scale inhibitor are greatly superior to those of polyphosphate scale inhibitors.

Owner:SCI GREEN SHANDONG ENVIRONMENT TECH CO LTD

Food acidity regulator and preparing method thereof

InactiveCN104543900AStrong chelating abilityMild sourFood ingredient as antioxidantAcidic food ingredientsSolubilityPropanoic acid

Owner:NANTONG SHUANGHE FOOD

Method for producing maleic acid disooctyl sodium sulfonate

InactiveCN110526838AIncrease reaction rateEasy to recycleOrganic compound preparationCarboxylic acid esters preparationIsooctyl alcoholSulfonate

The invention provides a method for producing maleic acid disooctyl sodium sulfonate. The method adopts maleic anhydride and isooctanol as raw materials and comprises the following steps: (1) by taking a halogen-containing strong-acidity resin and a sulfonic acid agent as catalysts, synthesizing maleic acid disooctyl; and (2) performing sulfonation by using a liquid sulfonation agent. By adoptingthe process method provided by the invention, the esterification reaction velocity can be increased, energy conservation and consumption reduction can be achieved, meanwhile, the chromaticity of a product can be reduced, the catalysts are easy to recycle and reuse, and the effective utilization rate of the sulfonation agent can be increased. The method is simple and easy to operate, is safe and environment-friendly and is good in permeability, stable in quality and easy in on-scale industrial production, and the chromaticity of the product is less than or equal to 20Hazen.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

Epoxy resin carton adhesive and preparation method thereof

ActiveCN103396751AImprove heat resistanceImprove aging resistanceEpoxy resin adhesivesGraft polymer adhesivesCyclohexanonePolymer science

The invention discloses an epoxy resin carton adhesive. The epoxy resin carton adhesive is characterized by being prepared from the following raw materials in parts by weight: 10-12 parts of E-42 epoxy resin, 3-4 parts of methylene bis-cyclohexaneamine, 4-5 parts of 2,4-toluene diisocynate, 2-3 parts of maleic anhydride, 40-45 parts of ethyl acetate, 3-4 parts of dibutyltin dilaurate, 5-6 parts of acrylic acid, 3-4 parts of butadiene, 4-5 parts of styrene, 6-8 parts of diglycol, 1-2 parts of morpholine, 4-5 parts of acetone, 4-5 parts of chloroform, 2-3 parts of cyclohexanone peroxide, 3-4 parts of neopentyl glycol, 1-2 parts of catechol, and 2-3 parts of polyisobutene. The epoxy resin carton adhesive disclosed by the invention is good in adhesive property, excellent in stretching performance, peel resistance and ageing resistance, high in adhesive strength, and better in the comprehensive performances of heat resistance, ageing resistance, and the like.

Owner:重庆理想包装有限责任公司

ABS (acrylonitrile butadiene styrene) antibacterial plastic

InactiveCN103524992ALong-term antimicrobial propertiesGood antibacterial functionAntimicrobial actionFiber

The invention discloses ABS (acrylonitrile butadiene styrene) antibacterial plastic. The ABS antibacterial plastic comprises the following components in parts by mass: 200-208 parts of ABS, 8-9 parts of metastannic acid, 11-12 parts of antimonous oxide, 10-15 parts of ammonium polyphosphate, 10-15 parts of montmorillonite, 10 parts of magnesium salt crystal whiskers, 10 parts of cis-butenedioic acid acidified PP (propene polymer), 10-13 parts of wollastonite fibers, 5-7 parts of silver-loaded zirconium phosphate, 7-8 parts of copper-loaded zirconium phosphate and 8-10 parts of zinc oxide crystal whiskers. The prepared ABS antibacterial plastic has a good antibacterial function, an obvious antibacterial effect can be achieved with low dosage; meanwhile, mechanical strength of the plastic is not influenced, especially a thermal deformation temperature, a mechanical temperature and electrical insulation property of a plastic product are not reduced; the ABS antibacterial plastic is uniform in dispersion, good in weatherability and good in durability, so that the ABS antibacterial plastic has long-term antibacterial property.

Owner:WUJIANG TIANYUAN PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com