Polyfunctional polyaspartic acid ester mixture and preparation method and application thereof

A technology for aspartic acid esters and mixtures, which is applied in the field of multifunctional polyaspartic acid ester mixtures and its preparation, can solve the problems of primary amine residues and uncontrollable operation time of polyaspartic acid esters, and achieve improved Effects of crosslink density, mechanical properties, and good solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

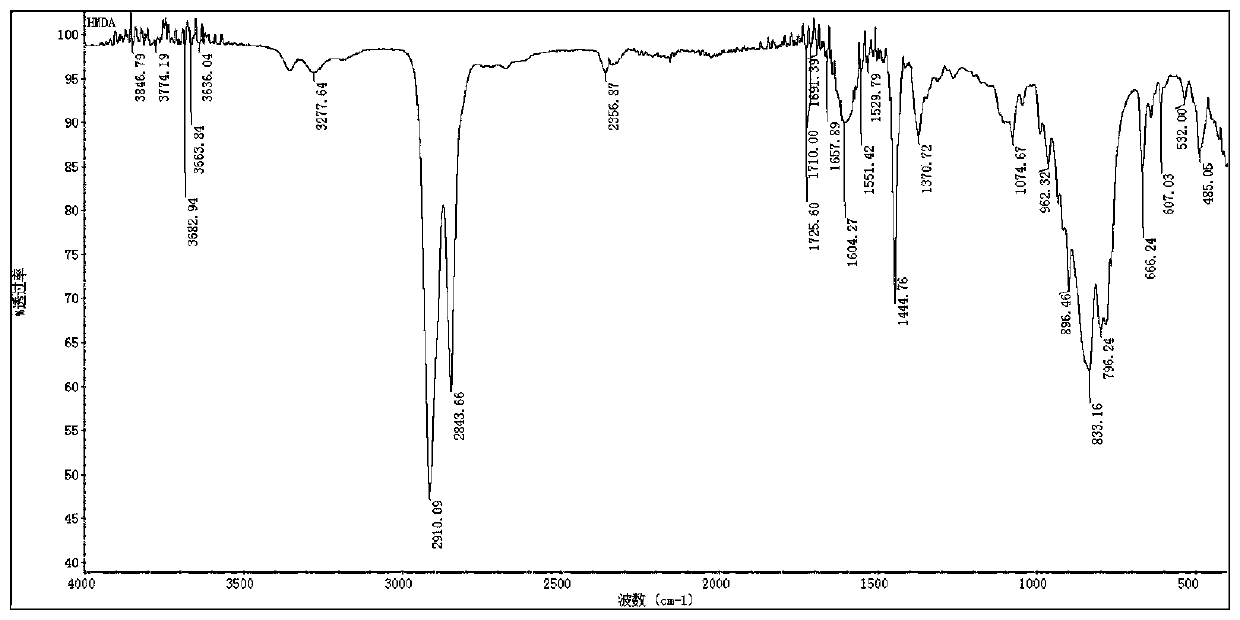

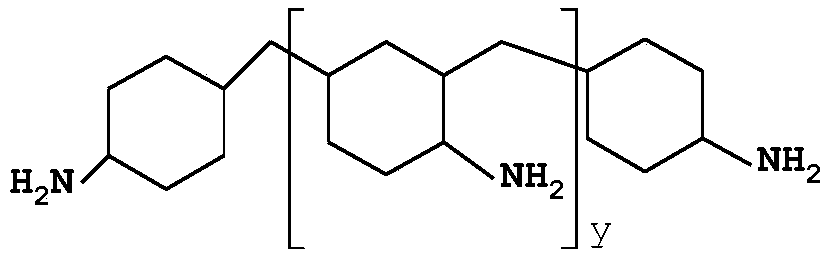

[0043] Preparation of diaminodicyclohexylmethane (55wt%), triaminotricyclohexylmethane (25wt%), tetraaminotetracyclohexylmethane (20wt%) mixture:

[0044] In a 2L volume autoclave with built-in filter, add 5g Rh / Al 2 o 3 and 0.125g Ru / Al2 o 3 Catalyst, add 500g MDA-45 raw material and 500g tetrahydrofuran simultaneously, use N 2 and H 2 After three replacements, H 2 The pressure was increased to 7MPa (absolute pressure), and the temperature was raised to 210°C. During the reaction, H was continuously fed into the reactor through the hydrogen flow controller. 2 , to ensure that the reaction pressure is maintained at 7MPa (absolute pressure), when the hydrogen flow rate indication of the hydrogen flow controller is lower than 100sccm, stop feeding H 2 , when the pressure drop of the reactor is less than 0.1bar / min, stop the reaction, cool down the reactor and release the pressure, and when the temperature of the reactor drops to 30°C, use N 2 The product liquid and the cat...

Embodiment 2

[0049] The method in Example 1 was used to prepare a mixture of 90wt% diaminodicyclohexylmethane, 5wt% triaminotricyclohexylmethane, and 5wt% tetraaminotetracyclohexylmethane, the only difference being that the hydrogenation raw material selection was MDA-85, Mixture B was prepared.

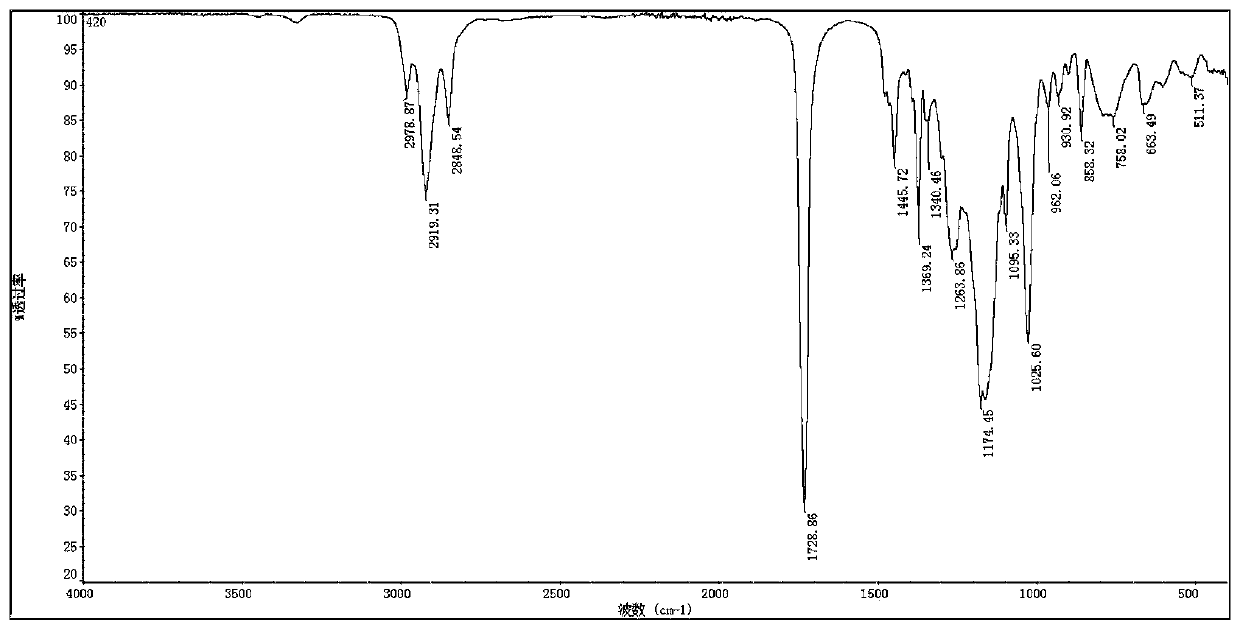

[0050] Preparation of acrylonitrile-modified multifunctional polyaspartic ester mixture:

[0051] Weigh 1000g of mixture B (wherein -NH 2 9.5 mol) into the reaction vessel equipped with mechanical agitation, feed nitrogen into the reactor for 8 minutes, replace the air in the reactor, control the system temperature to 35°C, and the stirrer speed to 250r / min , Weighed 2212.03g (9.69mol) dibutyl maleate and added it to the constant pressure dropping funnel, then slowly added it dropwise to the reaction vessel, and the dropping time was controlled at 25min. After the dropping was completed, the temperature of the system was raised High to 120 ° C, and then continue to react for 3h.

[0052] Cool ...

Embodiment 3

[0054] Using the method in Example 1 to prepare a mixture of 75wt% diaminodicyclohexylmethane, 15wt% triaminotricyclohexylmethane, and 10wt% tetraaminotetracyclohexylmethane, the only difference is that the hydrogenation raw material selection is MDA-75, Compound C was prepared.

[0055] Preparation of acrylonitrile-modified multifunctional polyaspartic ester mixture:

[0056] Weigh 1000g of mixture C (wherein -NH 2 9.47mol) was added to the reaction vessel equipped with mechanical stirring, and nitrogen gas was passed into the reactor for 7 minutes to replace the air in the reactor. , Weigh 689.28g (4.78mol) dimethyl maleate and 823.42g (4.78mol) diethyl maleate and add them to the constant pressure dropping funnel, then slowly add them dropwise to the reaction vessel. The temperature was controlled at 22 minutes. After the dropwise addition was completed, the temperature of the system was raised to 115° C., and then the reaction was continued for 2.5 hours.

[0057] Cool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com