Patents

Literature

57 results about "Dimethyl maleate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimethyl maleate is an organic compound with the formula C₆H₈O₄. It is the dimethyl ester of maleic acid.

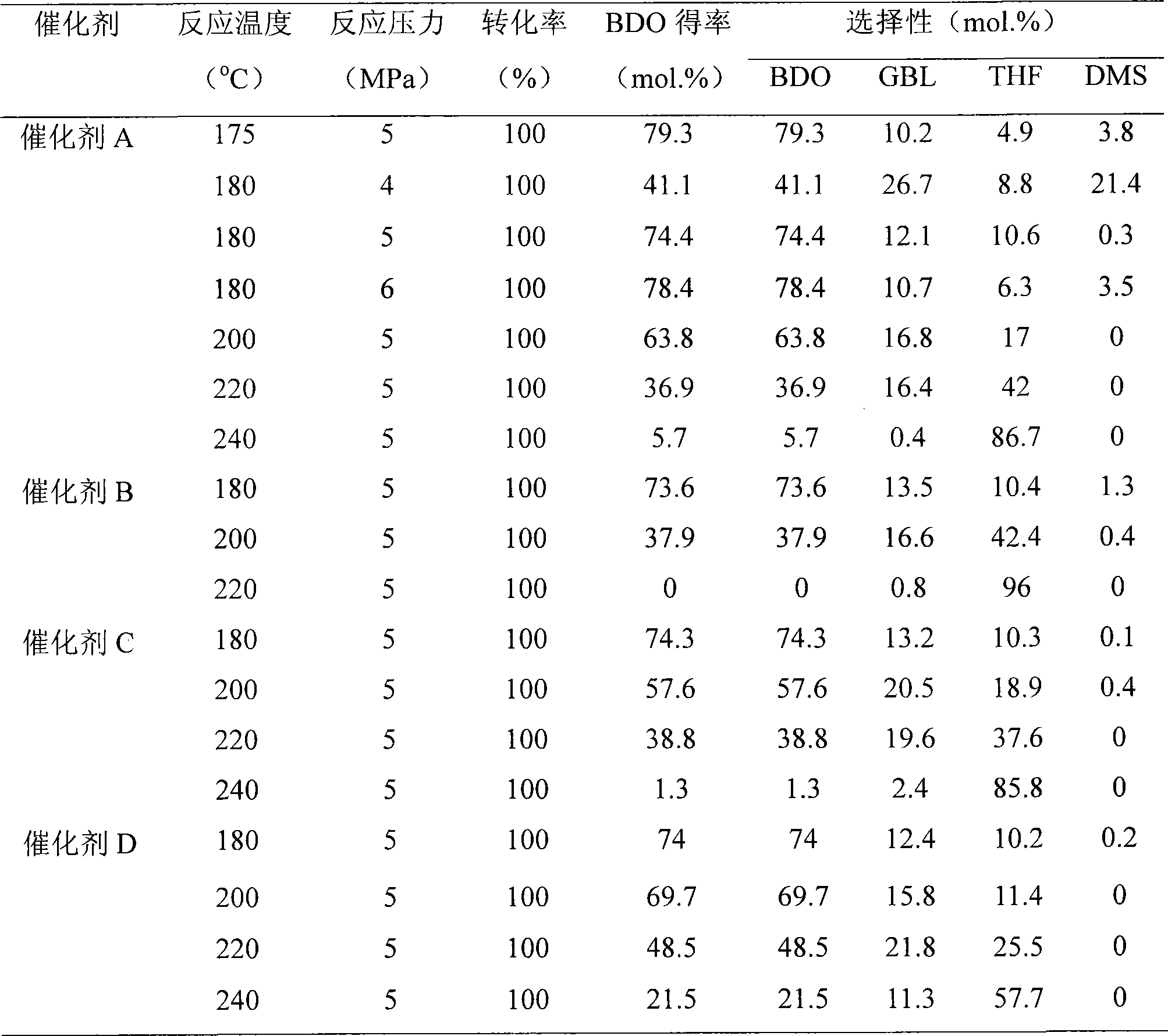

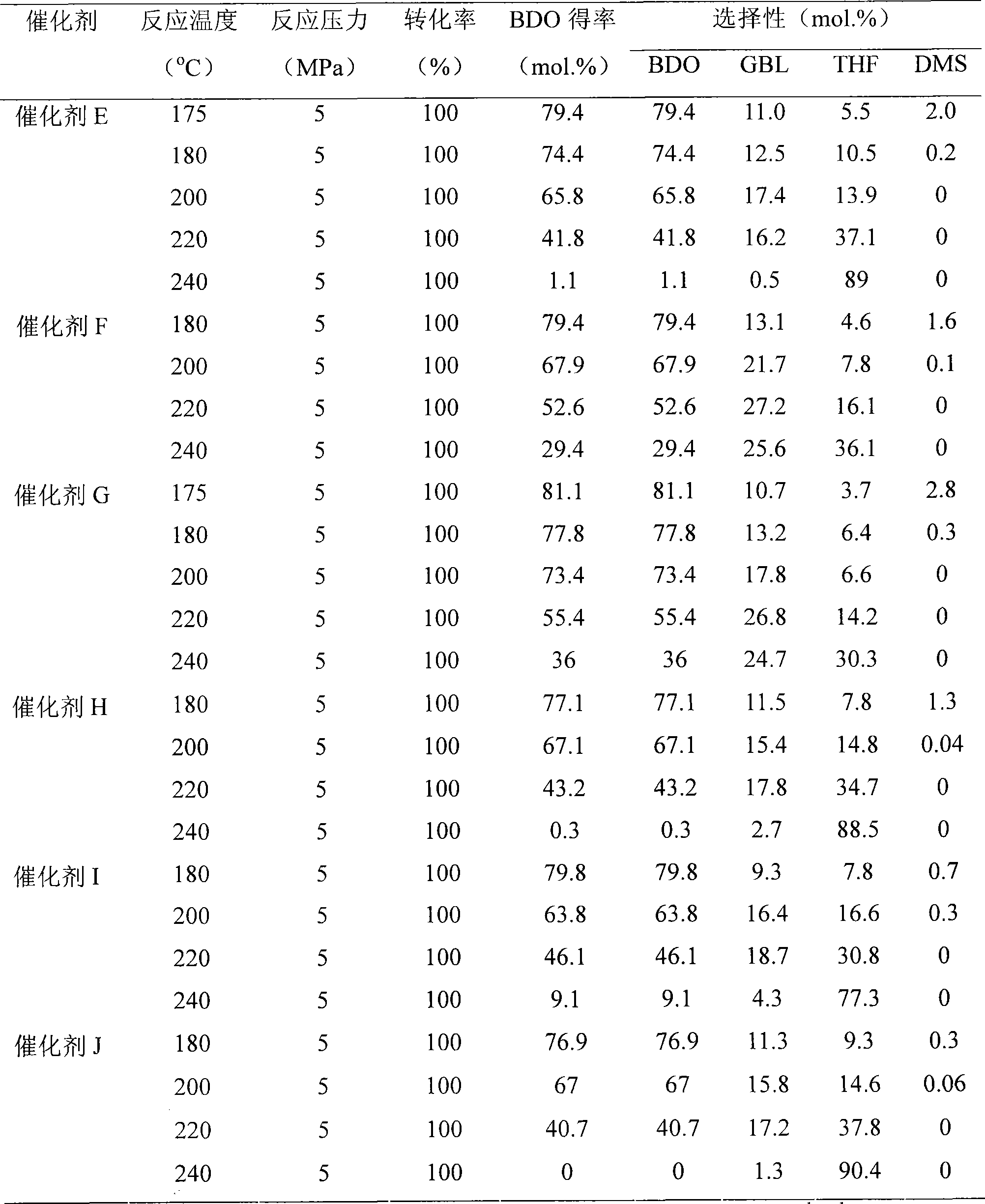

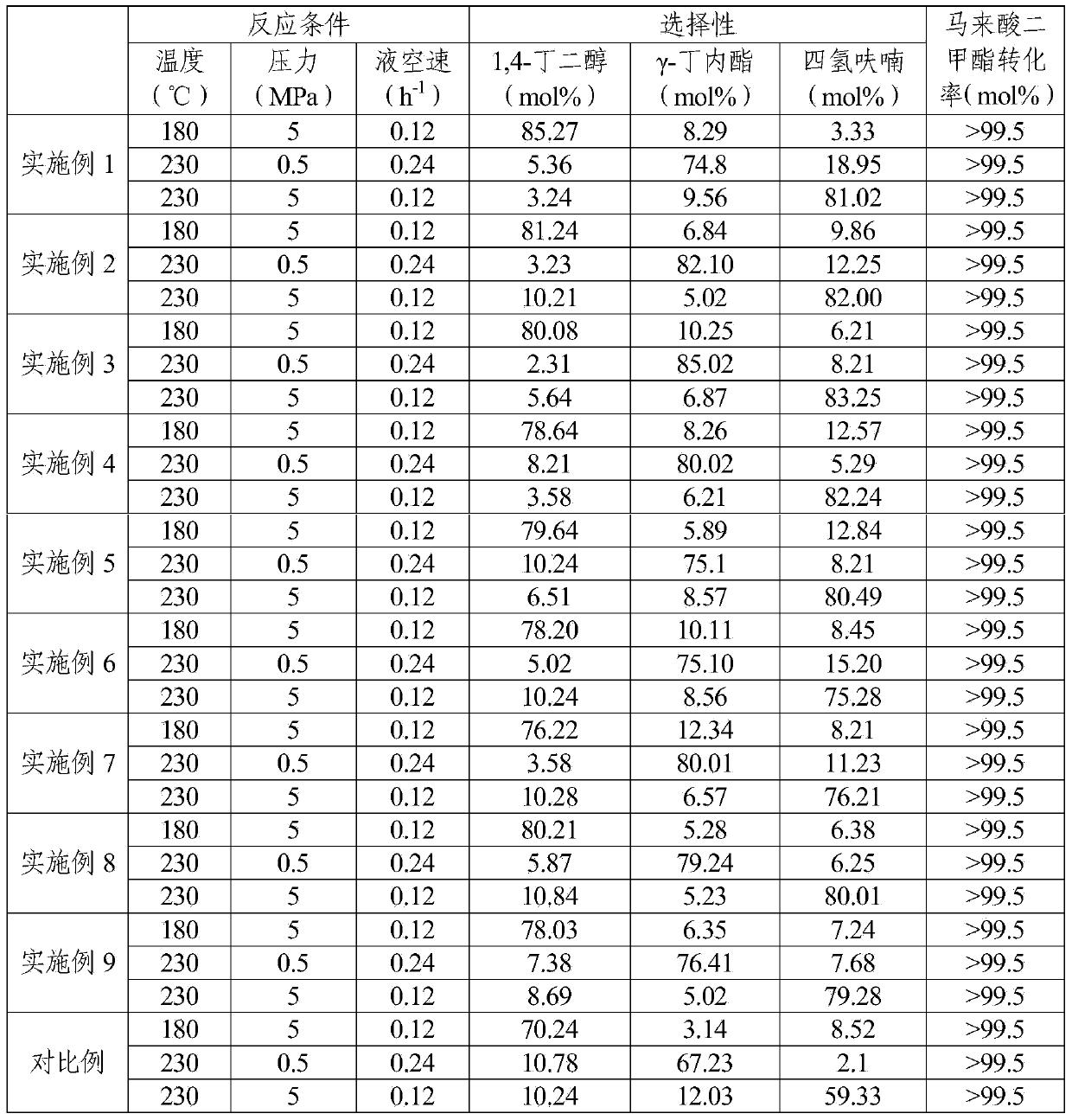

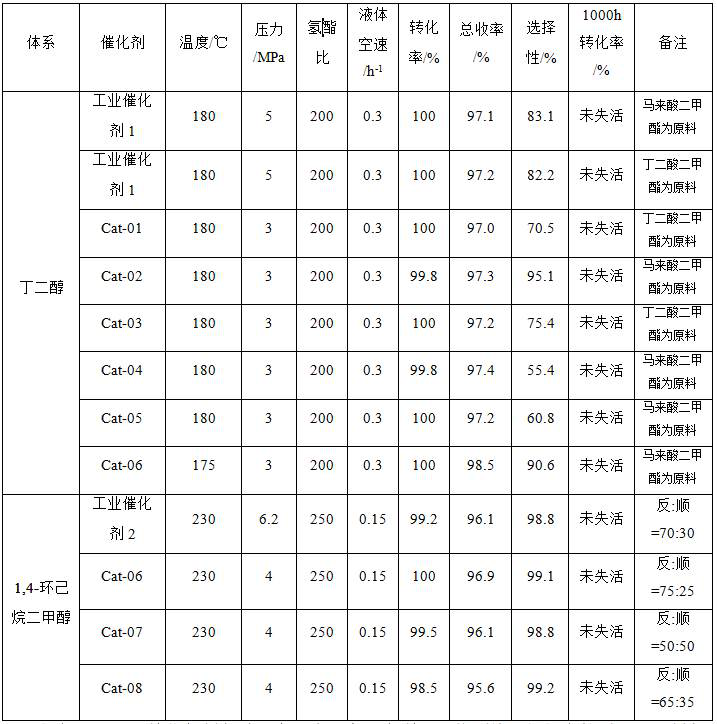

Catalyst for preparing 1,4-butanediol or tetrahydrofuran from selective hydrogenation of dimethyl maleate and preparation method thereof

ActiveCN101502803AHigh selectivitySolve filterabilityOrganic compound preparationHydroxy compound preparationMonoethyl maleateHydrogenation reaction

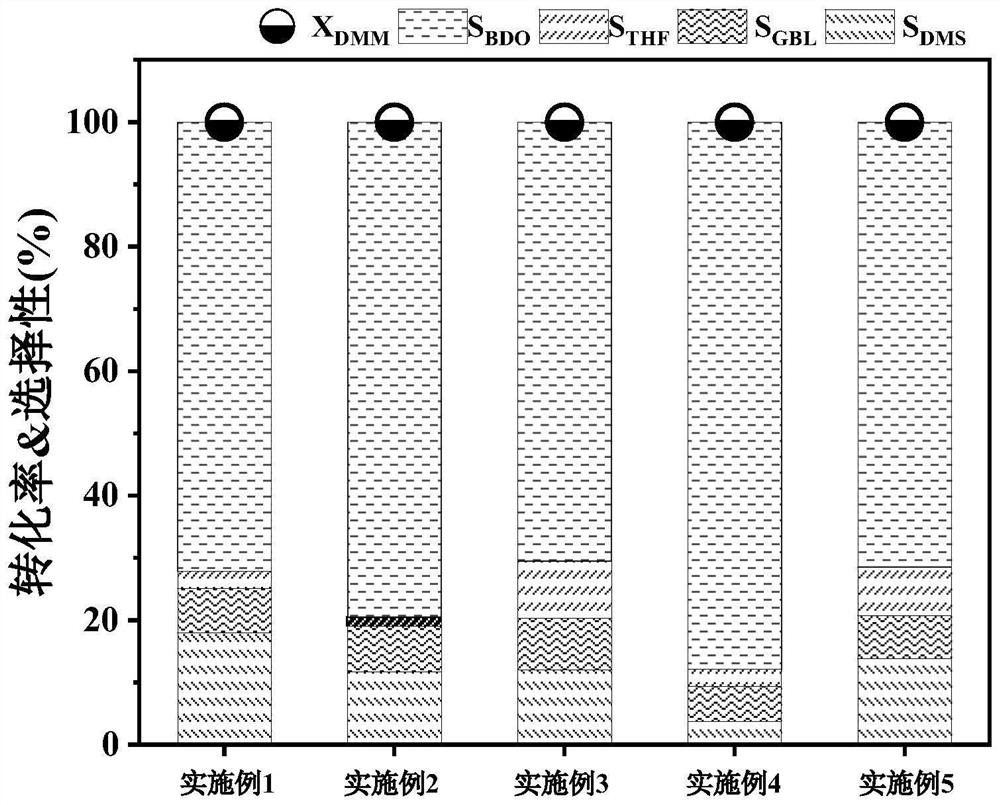

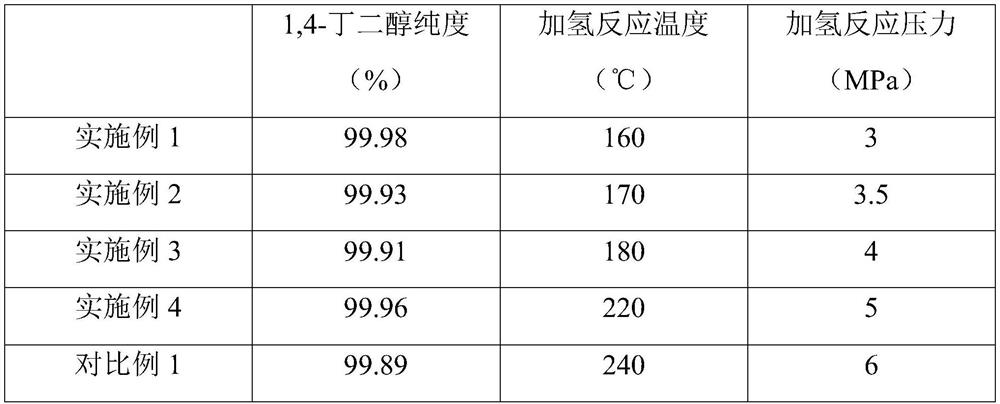

The invention belongs to the field of chemical technology, and in particular relates to a catalyst for preparing 1, 4-butanediol or tetrahydrofuran by selective hydrogenation of dimethyl maleate and a preparation method thereof. The catalyst consists of Cu, Zn, Al, M and O, and the mol content of each metal element is as follows: 30 to 60 percent of Cu, 10 to 50 percent of Zn, 5 to 20 percent of Al and 0 to 10 percent of M, wherein M is any one of Mn, Mg and Cr. The preparation method for the catalyst comprises precipitation, ageing, washing, drying and baking of a catalyst precursor, and reduction activation before use. The catalyst is applied to the hydrogenation reaction of the dimethyl maleate, and the yield of the 1, 4-butanediol at a reaction temperature of 180 DEG C is 73.6 percent; and the yield of the tetrahydrofuran is 96 percent at a reaction temperature of 220 DEG C. Product composition of the catalyst can be well adjusted by changing the reaction condition to adapt to different market demands, and the catalyst has extremely high industrial application value.

Owner:FUDAN UNIV +1

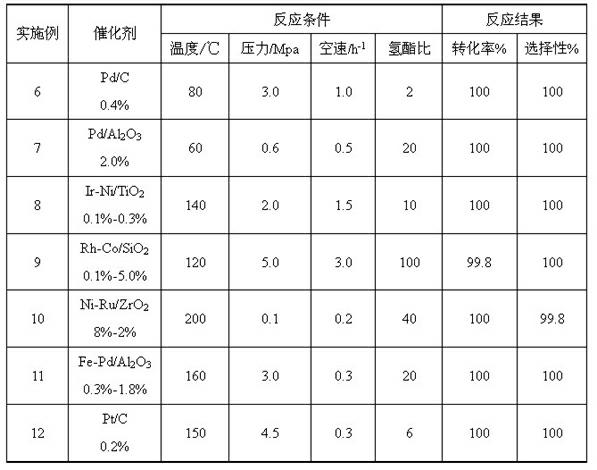

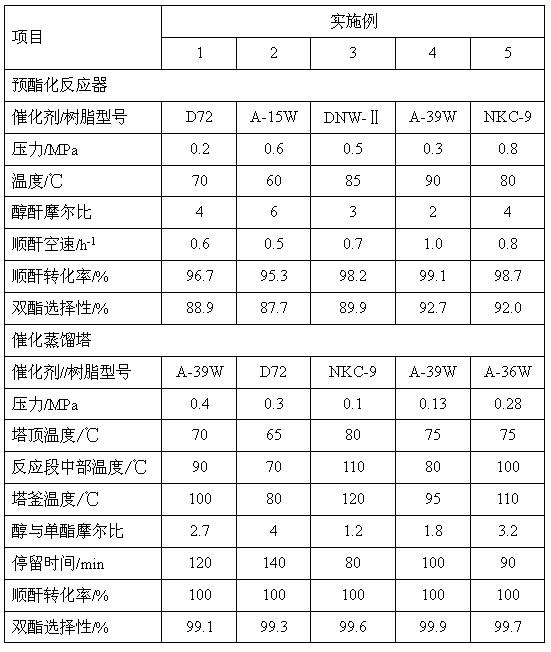

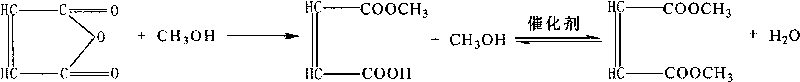

Method for preparing dimethyl succinate

ActiveCN102070448ASimple separation processImprove responseOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystSolid acid

The invention discloses a method for preparing dimethyl succinate. The method comprises two reaction processes of esterification and hydrogenation and the reaction processes are as follows: (1) after pre-esterification reaction, maleic anhydride-methanol solution enters a catalytic distillation tower from the upper rectifying section of the tower, methanol enters the tower from the lower stripping section of the catalytic distillation tower, the reaction section is filled with solid acid catalyst, the two material flows perform countercurrent contact on the surface of the catalyst to perform esterification reaction and synthetize dimethyl maleate; and (2) dimethyl maleate and hydrogen are placed in a fixed bed reactor to perform hydrogenation reaction and generate the dimethyl succinate product in the presence of hydrogenation catalyst under a certain reaction condition. The method of the invention has the advantages of high raw material conversion rate and good product selectivity; and the process flow is simple, the energy consumption is low, no pollution can be caused and the scale production of dimethyl succinate can be realized.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Preparation method of hydrogenation catalyst

ActiveCN103769158AOrganic compound preparationHydroxy compound preparation1,4-ButanediolMonoethyl maleate

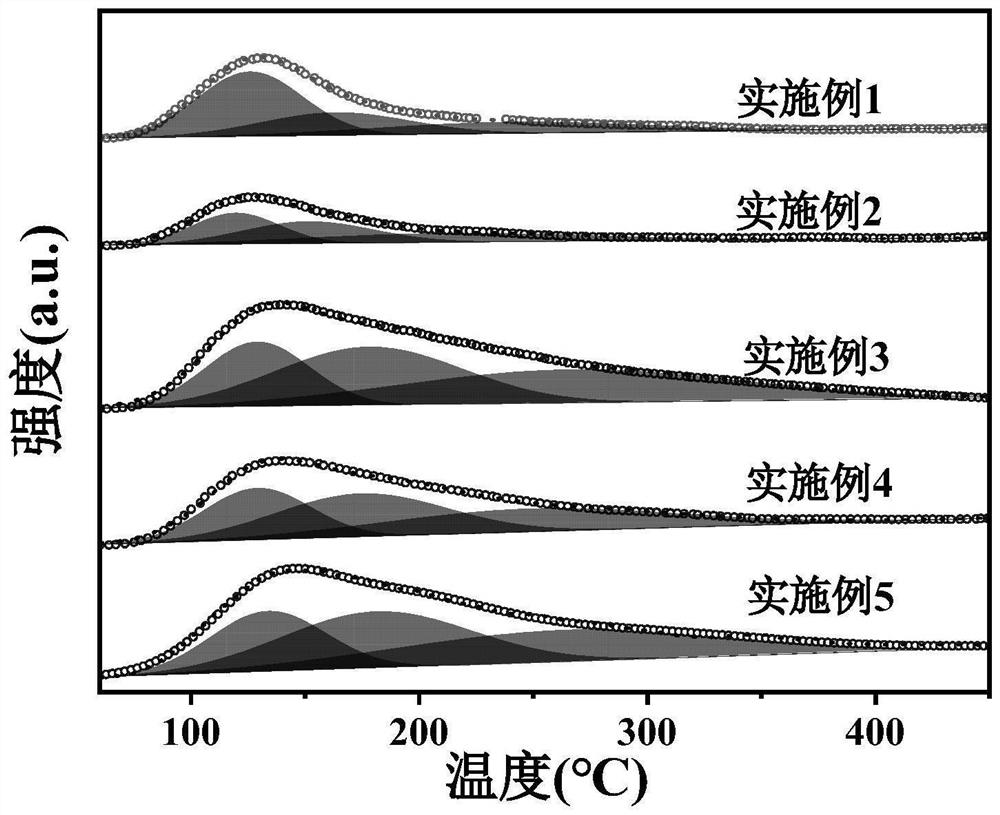

The invention discloses a preparation method of a hydrogenation catalyst. The catalyst is a Cu-Al-Zn-M-O catalyst, wherein the M represents one or more components selected from: Ba, Mn, Mg, Ti, and Cr. The hydrogenation catalyst is prepared through a two-step parallel-flow precipitation method, namely subjecting a solution containing Cu, Al and a precipitant and a solution containing Cu, Zn, M, and a precipitant to a parallel-flow precipitation treatment under different conditions so as to obtain the hydrogenation catalyst. The hydrogenation catalyst is suitable for being used during the process of hydrogenation preparation of 1,4-butanediol from dimethyl maleate, and the reaction activity, reaction selectivity and stability of the catalyst are all improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing dimethyl succinate

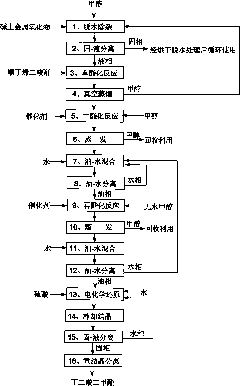

ActiveCN101824627AThorough responseLow production costElectrolysis componentsOrganic compound preparationEvaporationCis-Butenedioic Acid

The invention relates to a method for preparing dimethyl succinate, which comprises the following steps that: (1) dehydration and decontamination: methanol and alkali-earth metal oxide are mixed, dehydrated and decontaminated; (2) separation of solid and liquid; (3) monoesterification reaction: maleic anhydride is added in the liquid-phase material which is obtained in the previous step; (4) vacuum distillation; (5) 2-esterification reaction; (6) evaporation; (7) mixing of oil and water; (8) separation of oil and water; (9) re-eesterification; (10) evaporation; (11) mixing of oil and water; (12)separation of oil and water; (13) electrochemical reduction: hydrogen is introduced to reduce dimethyl maleate to dimethyl succinate; (14) cooling and crystallization; (15) separation of solid and liquid: solid material enters the next step; (6) re-crystallization and separation: the product dimethyl succinate is obtained. The method is simple, and has reasonable process, low preparation cost, high product purity and good quality.

Owner:RUNTAI CHEM CO LTD

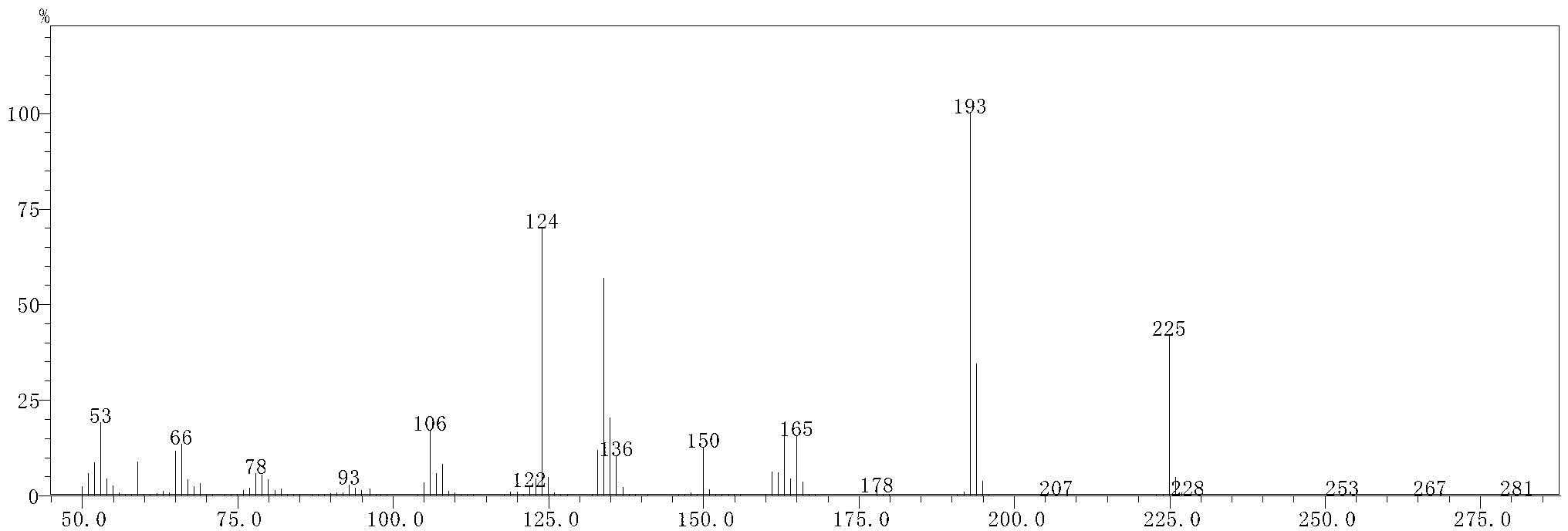

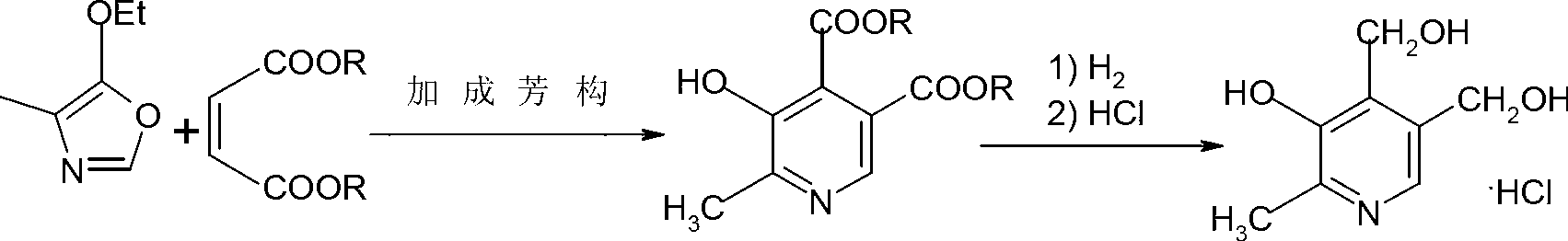

One-pot preparation method of vitamin B6

The invention relates to a new one-pot preparation method of vitamin B6. The method includes that 5-ethoxy-4-methyloxazole which is a key intermediate of vitamin B6 and dimethyl maleate or diethyl maleate are subjected to Diels-Alder addition reaction and aromatization to further form pyridine rings, and then the pyridine rings undergo hydrogenation to be catalytically reduced to vitamin B6. The one-pot method is adopted, so that the intermediates can directly react without separation. The period of technological processes is shortened, and the one-pot preparation method of vitamin B6 is simple in operation, environment-friendly and low in cost. Moreover, the selectivity, the yield and the purity of the product are high, and the method is more suitable for being used for large-scale industrial production.

Owner:XINFA PHARMA

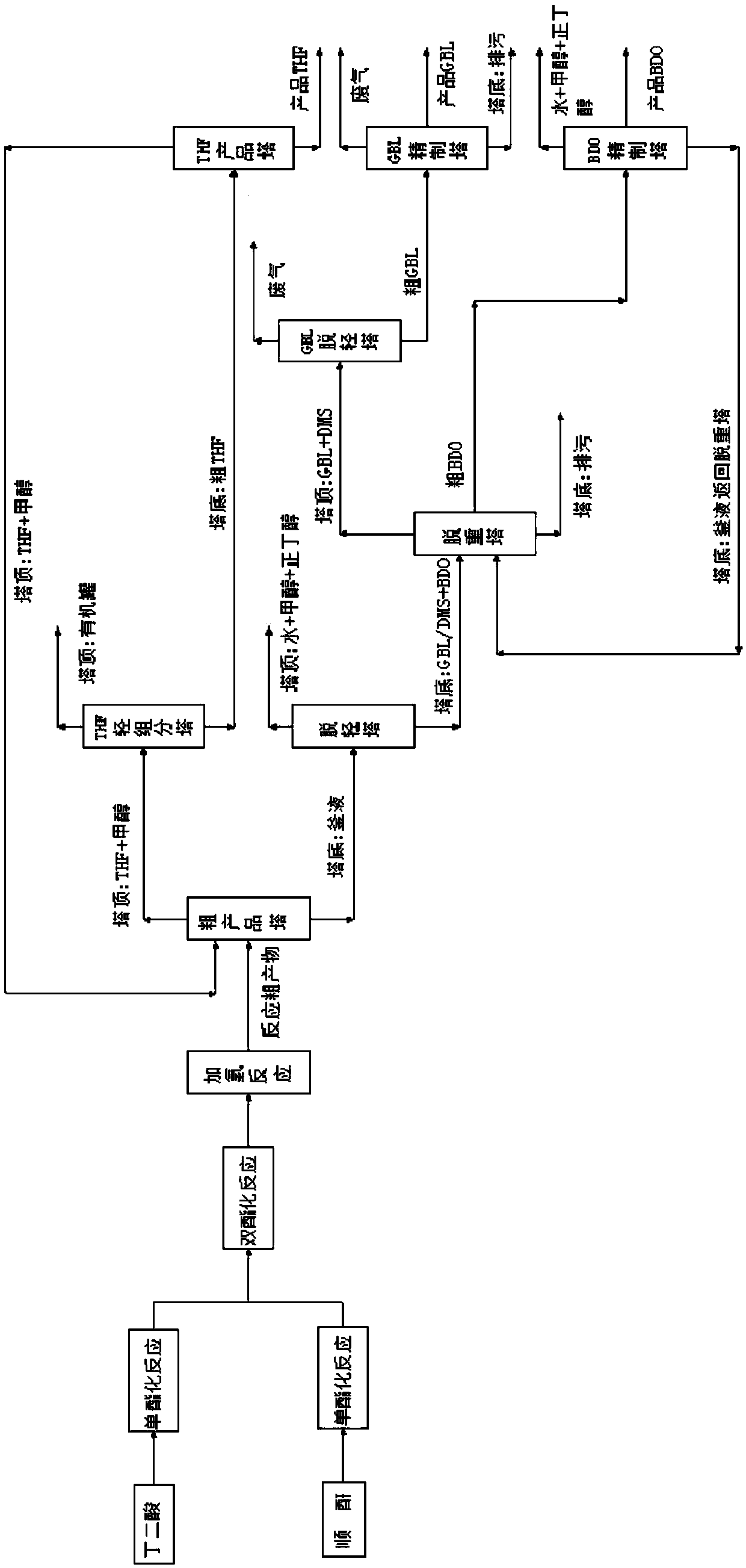

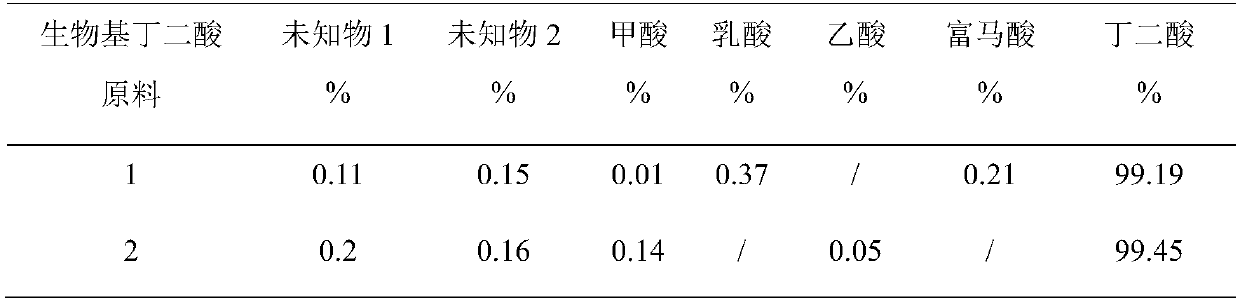

Continuous preparation method of 1,4-butanediol

ActiveCN111018669AAvoid mutual influence of co-monoesterificationAvoid interactionOrganic compound preparationCarboxylic acid esters preparationSuccinic acid monomethyl esterButanedioic acid

The invention discloses a continuous preparation method of 1,4-butanediol. The method comprises the following steps: carrying out a monoesterification reaction on bio-based succinic acid and methanolto obtain a succinic acid monoesterification liquid containing succinic acid monomethyl ester; mixing with monomethyl maleate to obtain a mixed esterification liquid; feeding into a double esterification reaction tower, and carrying out a double esterification reaction to generate a mixture of dimethyl succinate and dimethyl maleate; feeding the mixture into a hydrogenation reactor, and carrying out a hydrogenation reaction, wherein the the dimethyl maleate in the mixture is hydrogenated to generate dimethyl succinate; and performing a cascade reaction to convert into an intermediate product gamma-butyrolactone, and then generating 1,4-butanediol and tetrahydrofuran. According to the method, the bio-based succinic acid is adopted to partially replace monomethyl maleate to produce 1,4-butanediol, so that the consumption of petroleum chemicals is reduced, and the production cost of 1, 4-butanediol is reduced; and bio-based succinic acid and methanol are subjected to a monoesterificationreaction, and then mixing is performed with monomethyl maleate, so that the mutual influence caused by co-monoesterification of succinic acid and maleic anhydride is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

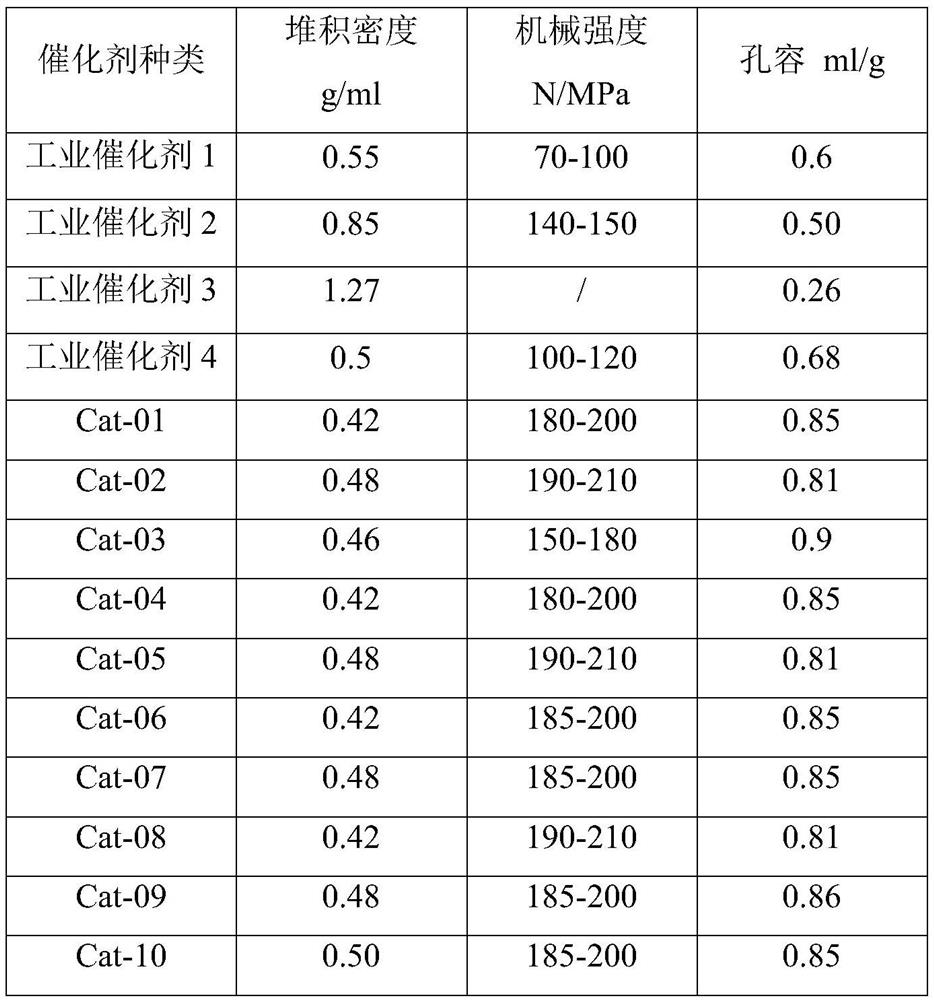

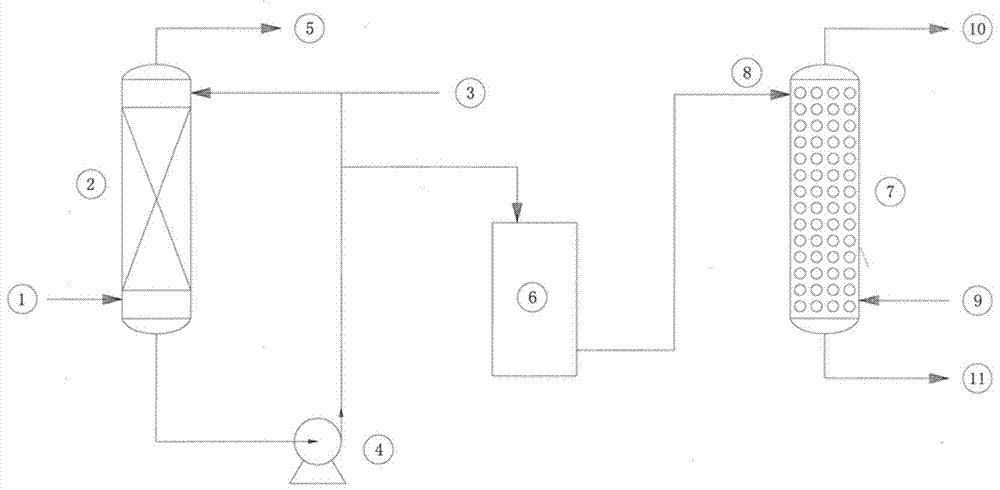

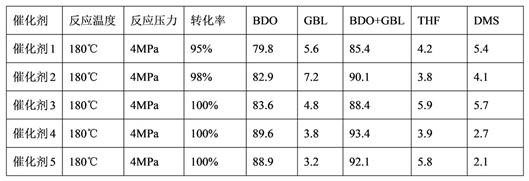

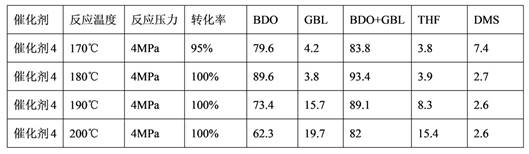

Preparation methods and catalysis method of dimethyl maleate hydrogenation catalyst

InactiveCN103551154AHigh strengthLow firing temperatureOrganic compound preparationHydroxy compound preparationMonoethyl maleateCoprecipitation

The invention discloses a preparation method of a dimethyl maleate hydrogenation catalyst, which comprises the following steps: 1, preparing a copper and zinc coprecipitation material; 2, preparing pseudo-boehmite colloidal sol; 3, preparing a catalyst precursor from the coprecipitation material and the pseudo-boehmite colloidal sol or from the coprecipitation material, the pseudo-boehmite colloidal sol and pseudo-boehmite powder; and 4, drying, roasting, and tabletting to obtain the catalyst. The invention also discloses another preparation method which comprises the following steps: preparing a catalyst precursor by mixing a coprecipitation material and pseudo-boehmite colloidal sol, drying, roasting, then mixing with pseudo-boehmite powder, and tabletting or granulating to obtain the catalyst. Besides, the invention also discloses a method for realizing catalytic dimethyl maleate hydrogenation by using the catalyst. The proportion of the product can be adjusted according to market demands. According to the invention, the prepared catalyst is good in strength and low in roasting temperature, has favorable catalytic property and can effectively reduce occurrence of polymerization reaction in the reaction process at the same time.

Owner:THE NORTHWEST RES INST OF CHEM IND

Preparation method of hydrogenation

ActiveCN103769111AGood dispersionHigh activityOrganic compound preparationHydroxy compound preparationLiquid ratioDiluent

The invention discloses a preparation method of a hydrogenation catalyst. The preparation method comprises the following steps: subjecting an active metal solution and a precipitant to a parallel flow precipitation reaction, adding a diluent solution during the reaction process through a parallel flow method, and controlling a certain solid-to-liquid ratio during the reaction process to guarantee stable precipitation environment so as to generate crystal particles with a uniform size; thus the pore diameter distribution is more concentrated, and furthermore, the diluent is added to assist the dispersion of active metal so as to improve the activity and selectivity of the catalyst. The catalyst obtained through the method mentioned above is suitable for selective hydrogenation preparation of 1,4-butadiol from dimethyl maleate.

Owner:CHINA PETROLEUM & CHEM CORP +1

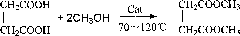

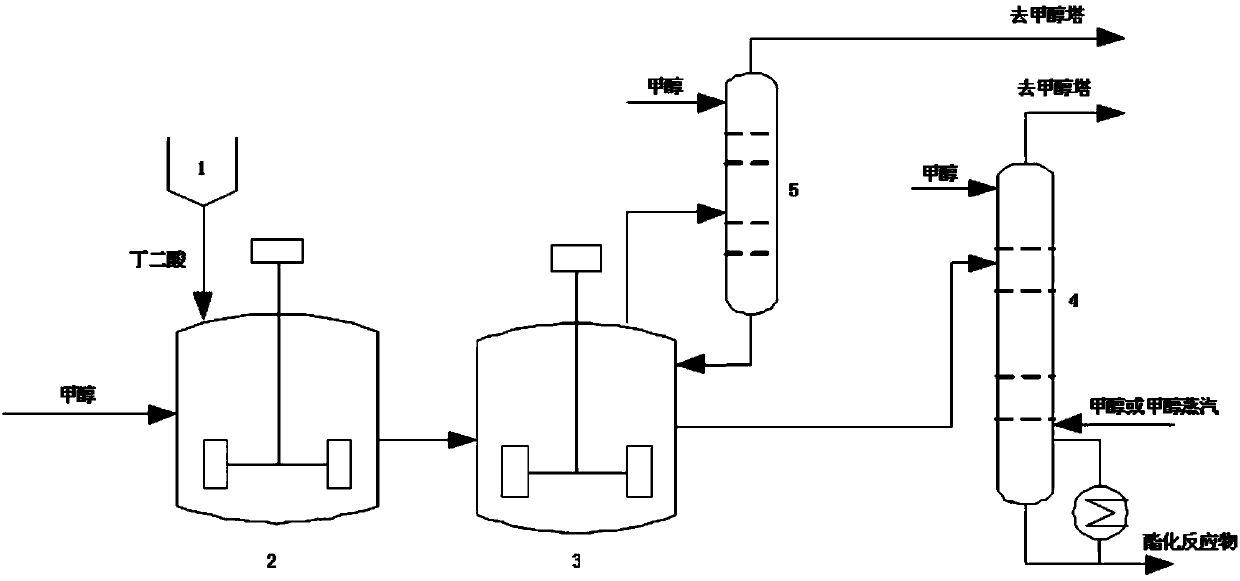

Synthesis process of dimethyl maleate

InactiveCN106631784AIncrease contact areaExtension of timeOrganic compound preparationCarboxylic acid esters preparationAlcoholContact time

The invention discloses a synthesis process of dimethyl maleate. The synthesis process comprises steps as follows: maleic anhydride and methanol are subjected to a reaction in a mono-esterification reaction kettle at the temperature of 70-100 DEG C, and monomethyl maleate is generated; monomethyl maleate enters a catalytic esterification tower from a tower, methanol steam enters the catalytic esterification tower from the position below upper liquid level of each layer of tower plate and is contacted with monomethyl maleate and a solid catalyst on the tower plate, and dimethyl maleate is generated. With the adoption of continuous production, energy utilization rate is increased by full use of waste heat of the esterification reaction; with the adoption of multiple methanol steam inputs, methanol steam is distributed on each tower plate, each tower plate forms one small reactor in a boiling state, the contact area of monomethyl maleate and methyl alcohol is increased, the contact time of monomethyl maleate and methyl alcohol is prolonged, the problem of uneven distribution of methanol in the tower due to liquefied reflow of the methyl alcohol steam in a rising process is solved, the reaction efficiency and the esterification rate are increased, the methanol utilization rate is increased, the production cost is reduced while the yield is increased, and the synthesis process is suitable for industrial application.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

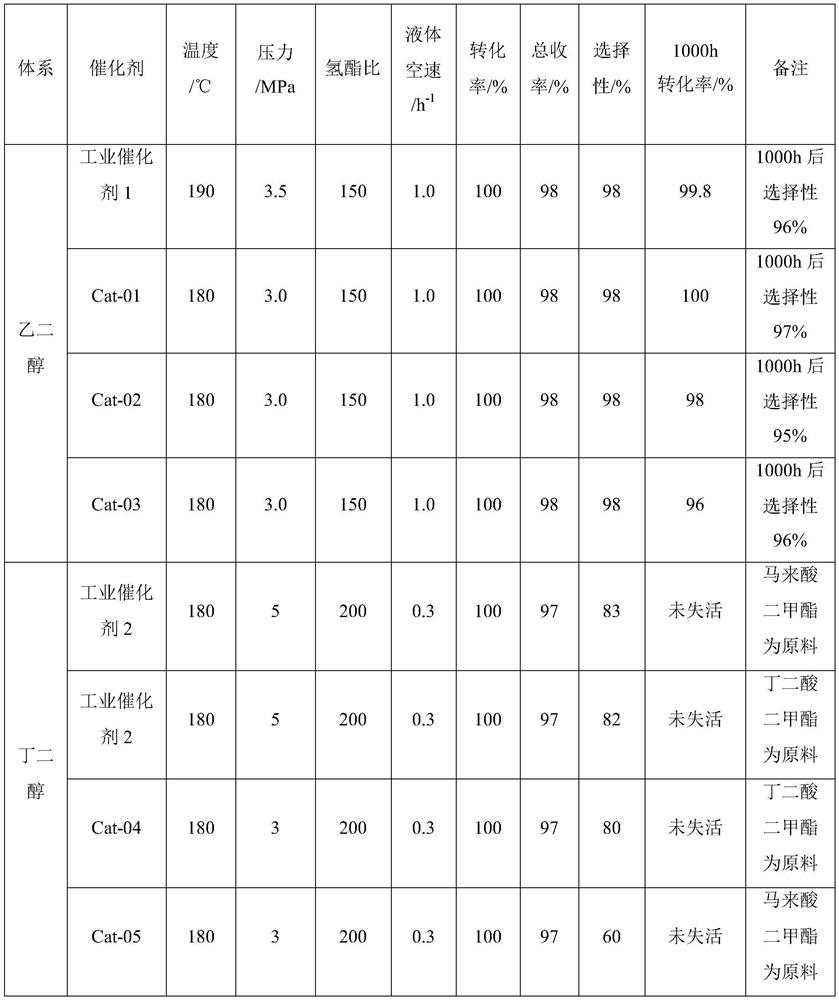

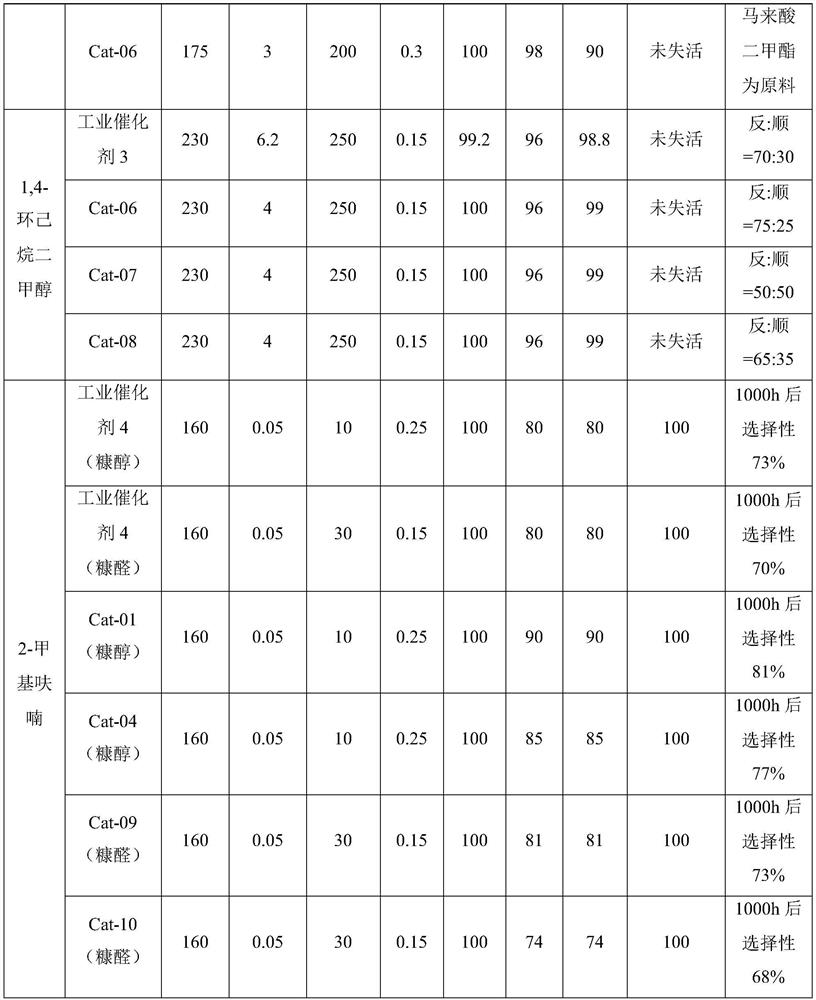

Preparation method of copper hydrogenation catalyst

PendingCN113649021AHigh porositySize porosityOrganic compound preparationHydroxy compound preparationPtru catalystWarm water

The invention relates to a preparation method of a copper hydrogenation catalyst, which comprises the following steps: adding a mixed salt solution of soluble copper salt and other metal soluble salts into an alkali solution to prepare corresponding hydroxide precipitate, filtering, washing with water, uniformly mixing with a sodium hydroxide solid phase, adding warm water and aluminum powder paste into the mixed material, and uniformly stirring, and maintaining for a certain time at a certain temperature, then transferring into a still kettle for treatment, then replacing sodium ions in the system through hydrothermal treatment, and finally drying and roasting to obtain the copper-based catalyst. The copper-based catalyst prepared by the method has the characteristics of small stacking density, large porosity, high activity and multiple catalytic functions, and is particularly suitable for and simultaneously used as a catalyst for preparing ethylene glycol by hydrogenation of dimethyl oxalate, preparing butanediol by hydrogenation of dimethyl maleate / dimethyl succinate, preparing 1, 4-cyclohexanedimethanol by hydrogenation of 1, 4-cyclohexanedicarboxylic acid dimethyl ester, preparing 2-methyl furan by hydrogenation of furfural / furfuryl alcohol, and the like.

Owner:濮阳圣恺环保新材料科技股份有限公司 +1

Method for preparing aspartate

InactiveCN101024618AIncrease elasticityElastomer has high hardness and highOrganic compound preparationAmino-carboxyl compound preparationDimethyl maleateCrystallization

The invention relates to a manufacturing method for asparagic acid ester that has simple producing technology. And the dimethyl maleate occupies 88.3% of total maleic acid ester. The method includes the following steps: dimethyl maleate taking reaction with 2-primary amines, after reacting, the dimethyl maleate would be totally crystallized, adding other dimethyl maleate, mixing fully, adding 2-primary amines to take reaction until non crystal; or shortfall dimethyl maleate taking reaction with excessive 2-primary amines, after reacting, the dimethyl maleate not reacted would be fully crystallized, adding other dimethyl maleate until no crystal.

Owner:JIANGSU CHEM RES INST

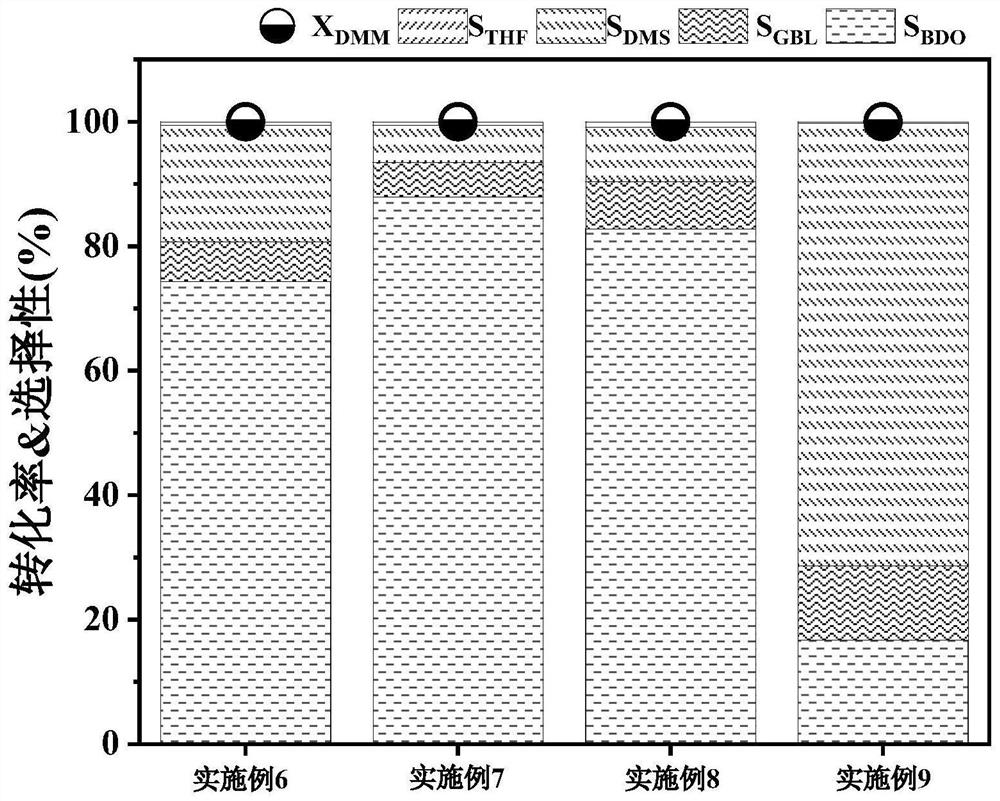

Catalyst for [gamma]-butyrolactone preparation through dimethyl maleate hydrogenation, and preparation method thereof

ActiveCN104399484AReduce pollutionEasy to prepareOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsManganeseCis-Butenedioic Acid

The present invention discloses a catalyst for [gamma]-butyrolactone preparation through dimethyl maleate hydrogenation, and a preparation method thereof, wherein the active components of the catalyst comprise CuO, SiO2 and MnO2, and the mass contents of CuO, SiO2 and MnO2 in the catalyst are respectively 51-56%, 41-46% and 1.0-3.0%. The catalyst preparation method comprises: (1) respectively preparing a soluble salt solution of copper, a soluble salt solution of manganese and an acid silica sol solution, and mixing to obtain a mixed solution; (2) adding an alkaline precipitating agent to the mixed solution, and carrying out cocurrent flow co-precipitation; and (3) aging after completing the cocurrent flow co-precipitation, filtering to obtain the precipitate, sequentially drying and calcinating the precipitate, and then adding graphite powder to form so as to obtain the finished product. Compared with the catalyst in the prior art, the catalyst of the present invention has advantages of no chromium, low environmental pollution, simple preparation method, high activity and high selectivity, wherein the dimethyl maleate conversion rate is up to 100%, and the [gamma]-butyrolactone selectivity is up to 92-93%.

Owner:中科合成油内蒙古技术研究院有限公司

Production method of dimethyl maleate

ActiveCN107473966AImprove solubilityPromote absorptionOrganic compound preparationCarboxylic acid esters separation/purificationMonoethyl maleateDistillation

The invention provides a production method of dimethyl maleate, and in particular relates to a method used for producing the dimethyl maleate by enabling mixed liquid, which is obtained by using dimethyl maleate as a solvent to absorb maleic anhydride in maleic anhydride-containing mixed gas and is taken as a raw material, and methanol to be subjected to an esterification reaction. The production method comprises the following steps: enabling the maleic anhydride-containing mixed gas to be subjected to heat exchange and preliminary cooling, and then enabling the maleic anhydride-containing mixed gas to enter the bottom of an absorption tower and be in counter-current contact with the dimethyl maleate sprayed from the top of the tower so as to obtain absorption liquid; filling an esterification tower with solid acid esterification catalyst filler, pumping the absorption liquid from the top of the esterification tower, and enabling the pumped absorption liquid and the methanol at the bottom of the esterification tower to be subjected to a contact type reaction; obtaining a dimethyl maleate crude product at the bottom of the tower, distilling to obtain the dimethyl maleate product, and returning part of the dimethyl maleate product for absorbing the maleic anhydride in a spraying way; carrying out distillation and separation on water-containing methanol steam on the top of the tower to obtain methanol and water, and returning the methanol for the esterification reaction.

Owner:南京雪郎化工科技有限公司

Method for preparing dimethyl succinate

ActiveCN102070448BSimple separation processImprove responseOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystSolid acid

The invention discloses a method for preparing dimethyl succinate. The method comprises two reaction processes of esterification and hydrogenation and the reaction processes are as follows: (1) after pre-esterification reaction, maleic anhydride-methanol solution enters a catalytic distillation tower from the upper rectifying section of the tower, methanol enters the tower from the lower stripping section of the catalytic distillation tower, the reaction section is filled with solid acid catalyst, the two material flows perform countercurrent contact on the surface of the catalyst to perform esterification reaction and synthetize dimethyl maleate; and (2) dimethyl maleate and hydrogen are placed in a fixed bed reactor to perform hydrogenation reaction and generate the dimethyl succinate product in the presence of hydrogenation catalyst under a certain reaction condition. The method of the invention has the advantages of high raw material conversion rate and good product selectivity; and the process flow is simple, the energy consumption is low, no pollution can be caused and the scale production of dimethyl succinate can be realized.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

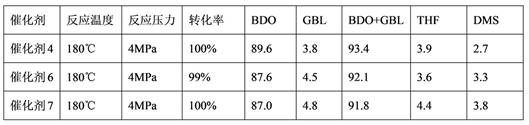

Dimethyl maleate hydrogenation reaction catalyst as well as preparation method and application thereof

PendingCN113731442AEasy to prepareLow costOrganic compound preparationHydroxy compound preparationMonoethyl maleatePtru catalyst

The invention belongs to the technical field of chemical products, and particularly relates to a dimethyl maleate hydrogenation reaction catalyst as well as a preparation method and an application thereof. The catalyst comprises the following elements in percentage by mole: 30 to 40 percent of Cu, 20 to 30 percent of Mn, 10 to 20 percent of Al, 10 to 20 percent of Zn, 0 to 5 percent of Ag and 0 to 5 percent of Ru. The Al element, the Ag element and the Ru element are added into the catalyst, so that dispersion and modification of active components in the catalyst are realized, the total selectivity of BDO and gamma-butyrolactone can reach 93%, the cost can be effectively reduced, and the catalyst is green and environment-friendly. According to the present invention, with the catalyst, the 1, 4-butanediol and / or gamma-butyrolactone can be prepared with high selectivity by changing the reaction conditions during the 1, 4-butanediol preparation process through the dimethyl maleate hydrogenation reaction catalyst; the preparation method of the catalyst is simple and low in cost, and the prepared catalyst is environmentally friendly and has long service life.

Owner:河南省生物基材料产业研究院有限公司

Preparation method of inorganic solid catalyst for synthesizing dimethyl maleate

InactiveCN101716521AEasy to separateImprove heat resistanceMolecular sieve catalystsOrganic compound preparationMolecular sieveHeat resistance

The invention discloses a preparation method of an inorganic solid catalyst, which is used for synthesizing dimethyl maleate and belongs to a catalyst synthesis technology. The method comprises the following steps of: firstly heating and activating a zeolite molecular sieve, then processing with an ammonium chloride solution, a ferric chloride solution or a magnesium chloride solution, and then calcining and activating to obtain the inorganic solid catalyst with selective catalytic activity. The catalyst can be used for a continuous reaction rectifying production process, is easy to separate, can be recycled, has good heat resisting property, high activity, good selectivity and less side reaction, can be used under the conditions of pressurized high temperature, is not easy to age or deteriorate and can not pollute products, and the single pass yield of the dimethyl maleate reaches more than 90 percent.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Leather used flame retardant and preparation method thereof

InactiveCN103045774ASimple preparation processRaw materials are easy to getLeather impregnationSodium acetatePolyvinyl chloride

The invention discloses leather used flame retardant and a preparation method thereof. The leather used flame retardant is composed of the following components in weight part: 10-20 parts of PVC (polyvinyl chloride) resin, 20-30 parts of tricresyl phosphate, 3-8 parts of chlorinated paraffin, 2-5 parts of orthophthalic dimethyl formamide, 10-20 parts of dimethyl maleate, 2-6 parts of calcium chloride, 1-3 parts of sodium acetate, 4-8 parts of triethanolamine, 30-50 parts of butyl acetate and 400-600 parts of water. Compared with the prior art, the leather used flame retardant has the benefits as follows: (1) good flame retardant effect, no damage to leather surface; and (2) simple preparation process, easy-to-obtain raw materials and low cost.

Owner:吴江市钱氏纺织有限公司

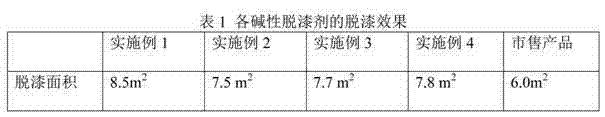

Alkaline paint remover and preparation method thereof

The invention discloses an alkaline paint remover and a preparation method thereof. The alkaline paint remover comprises the following components in part by weight: 30 to 40 parts of sodium hydroxide, 20 to 30 parts of benzyl alcohol, 5 to 8 parts of water-soluble cellulose, 1 to 3 parts of alkylphenol polyoxyethylene, 1 to 3 parts of benzotriazole, 3 to 6 parts of dimethyl maleate, 1 to 3 parts of polyethylene glycol and 10 to 15 parts of water. The alkaline paint remover is low in cost and toxicity, high in paint removing speed and environment-friendly and sewage is easy to discharge and treat. Different raw materials, proportioning ratios and preparation processes are adopted, so that the alkaline paint remover is safely used, the paint removing effect is enhanced, the using period is prolonged, the working efficiency is effectively improved, and the production cost is obviously saved.

Owner:GUANGDONG REDSUNSTAR IND

Oxidation resisting calcium carbonate filler and preparation method thereof

An oxidation resisting calcium carbonate filler is prepared from the following raw materials in parts by weight: 1-2 parts of ammonium polyphosphate, 1-2 parts of ASA, 1-2 parts of cyclohexanone, 0.4-0.8 part of epoxy soja bean oil, 0.8-1.1 parts of zinc diricinoleate, 1.5-1.8 parts of dimethyl maleate, 1.5-1.8 parts of bismaleimide resin, 0.1-0.2 part of lauric acid polyoxyethylene esters, 2.6-2.9 parts of dibutylhydroxytoluene, 3-5 parts of alcohol, 20-30 parts of modified wood meal, 180-200 parts of light calcium carbonate, and 60-80 parts of water. The oxidation resisting calcium carbonate filler provided by the invention has excellent oxidation resistance, and can reinforce oxidation resistance and weather resistance of a plastic; through adoption of the modified wood meal, the oxidation resisting calcium carbonate filler is compatible with PVC, and can reinforce heat preservation performance, shock resistance and coloration properties of the plastic; the oxidation resisting calcium carbonate filler is suitable for manufacturing of doors and windows of PVC and other plastics, can reduce the cost, improve machining property, and prolong service life, is recycled easily, and can protect the environment.

Owner:ANHUI SANLE DOOR & WINDOW CURTAIN WALL ENG

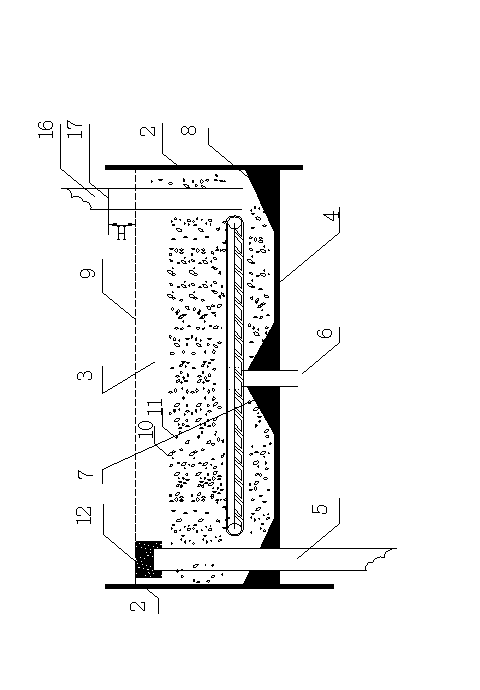

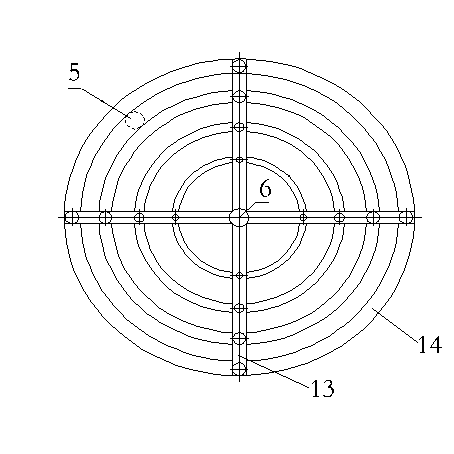

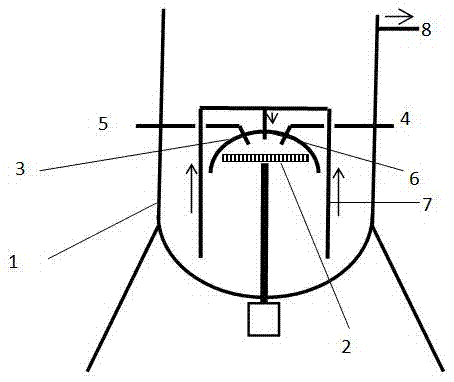

Esterification reactor and production method of dimethyl maleate

ActiveCN102908956AImprove capacity utilizationEasy to handleOrganic compound preparationCarboxylic acid esters preparationAlcoholCarboxylic acid

The invention relates to an esterification reactor and a production method of dimethyl maleate. The esterification reactor is suitable for esterification reactions of carboxylic acids and alcohols. The reactor is composed of a plurality of tower plates; each tower plate is provided with a downtake pipe and an ascension pipe, wherein the ascension pipe is connected with a gill type gas distributor; each tower plate reserves a certain liquid level liquid, wherein the liquid contains a solid catalyst; and the liquid phase is a component containing a carboxylic acid, flows downward from an esterification tower plate to the following tower plate in the reactor, and reacts with rising alcohol steam countercurrent. The esterification reactor has the advantages of adequate contact of three phases (gas, liquid and solid), high reaction efficiency, high volume utilization rate of the reactor, and the like; and is suitable for various esterification reaction processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

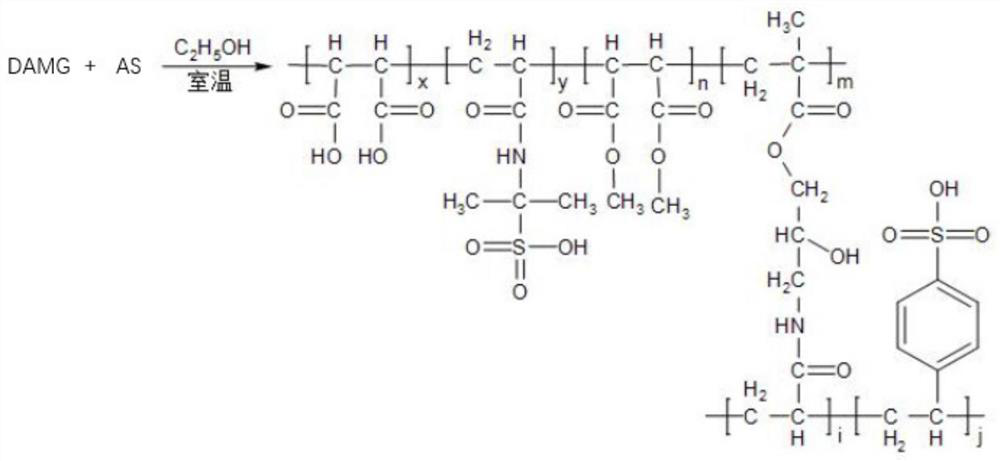

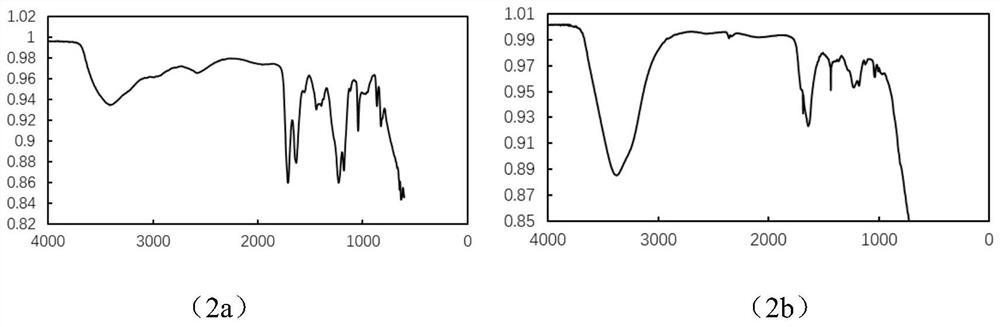

High-molecular polymer oil displacement surfactant for oil field and preparation method of high-molecular polymer oil displacement surfactant

ActiveCN111808594AImprove development efficiencyImprove performanceDrilling compositionMeth-Active agent

The invention discloses a high-molecular polymer oil displacement surfactant for an oil field and a preparation method of the high-molecular polymer oil displacement surfactant and belongs to the technical field of oil field development. The high-molecular polymer oil displacement surfactant is prepared from a DMAG quaternary polymer and an AS polymer; the DMAG quaternary polymer is composed of areaction monomer, an initiator and distilled water; the reaction monomer is composed of dimethyl maleate, maleic anhydride, 2-acrylamide-2-methylpropanesulfonic acid and dehydrated glyceryl methacrylate; the initiator is azodiisopropylimidazoline acid salt; the AS polymer is polymerized in distilled water by taking acrylamide and vinylbenzene sulfonic acid as reaction monomers, 2,2'-Azobis[2-(2-imidazolin-2-yl)propane] dihydrochloride(AIBI) as an initiator and mercaptoethylamine sulfonate as a chain transfer agent. The prepared oil displacement surfactant and crude oil form emulsion, the viscosity of the crude oil can be effectively reduced, remaining oil in stratum gaps can be effectively exploited, and the exploitation requirement of an oil field for thick oil and pore remaining oil is met.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

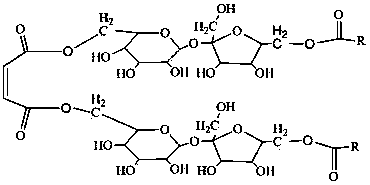

Gemini surfactant and preparation method thereof

ActiveCN103357345AImprove surface activityGuaranteed conversion rateEsterified saccharide compoundsSugar derivativesSolubilitySucrose

The invention discloses a gemini surfactant and a preparation method thereof. The preparation method comprises following steps: adding maleic anhydride and methanol in a mol ratio of 1:3 of maleic anhydride to methanol in a reaction device, where the mixture has catalytic reactions in the presence of catalysts to obtain dimethyl maleate; then mixing dimethyl maleate with fatty acid sucrose ester in a ratio of 1:2 of dimethyl maleate to fatty acid sucrose ester , dimethyl maleate and fatty acid sucrose ester have catalytic reactions in the presence of catalysts so as to obtain malelic sucrose aliphatic diester. The gemini surfactant has a dimerization surface activity structure, and has the advantages of good low temperature solubility and compounding property and excellent surface activity.

Owner:ADANA FOOD TECH LIUZHOU

Hydrogenation catalyst precursor, hydrogenation catalyst, and preparation methods of hydrogenation catalyst precursor and hydrogenation catalyst

ActiveCN106944051AAvoid gatheringGood dispersionOrganic compound preparationHeterogenous catalyst chemical elementsMonoethyl maleatePtru catalyst

The present invention discloses a hydrogenation catalyst precursor, a hydrogenation catalyst, and preparation methods of the hydrogenation catalyst precursor and the hydrogenation catalyst. The hydrogenation catalyst precursor is the mixture of the following metal hydroxides, wherein the metal is Cu, Al and M, M is one or a plurality of materials selected from Ba, Mn, Mg, Ti and Cr, and the particle size distribution (calculated as the volume fraction) of the hydrogenation catalyst precursor is that the particles having a particle size of less than 20 [mu]m account for less than 10%, the particles having a particle size of 20-50 [mu]m account for 65-90%, and the particles having a particle size of more than 50 [mu]m account for less than 25%. According to the present invention, the hydrogenation catalyst prepared from the hydrogenation catalyst precursor is particularly suitable for the 1,4-butanediol preparation through hydrogenation of dimethyl maleate, has characteristics of has high activity and good stability, and is particularly suitable for the method for producing 1,4-butanediol and co-producing tetrahydrofuran and gamma-butyrolactone.

Owner:CHINA PETROLEUM & CHEM CORP +1

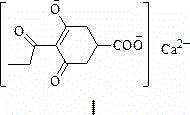

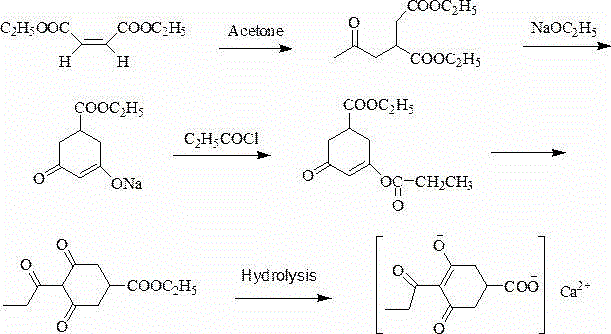

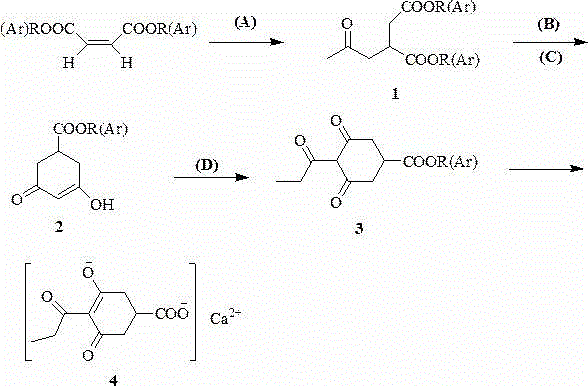

Preparation method of prohexadione calcium

InactiveCN104478707AIncrease fat solubilityReduced fat solubilityOrganic compound preparationCarboxylic acid esters preparationChromatographic separationOrganic base

Owner:JIANGXI AGRICULTURAL UNIVERSITY

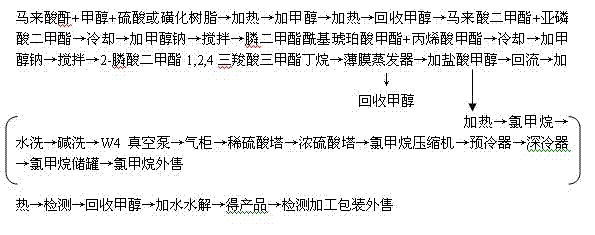

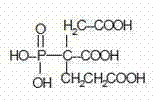

Batch method for producing 2-phosphonobutane-1, 2, 4-tricarboxylic acid and byproduct methyl chloride

ActiveCN102731567AReduce phosphorous acid contentWill not polluteGroup 5/15 element organic compoundsHalogenated hydrocarbon separation/purificationAcyl groupTricarboxylic acid

The present invention relates to a batch method for producing 2-phosphonobutane-1, 2, 4-tricarboxylic acid (PBTCA) and a byproduct methyl chloride. The method comprises the following steps: (1) reacting Dimethyl maleate with dimethyl phosphite in the presence of alkaline catalyst to synthesize dimethyl phosphonate acyl methyl succinate; (2) adding methyl acrylate into the product from the step (1) under cooling condition to synthesize 2-phosphono-1, 2, 4-trimethyl butane tricarboxylic acid in the presence of alkaline catalyst; and (3) adding hydrochloric acid methanol into the product from the step (2) to start an acidolysis reaction, collecting methyl chloride gas generated by the reaction, and recycling methanol; then adding water into the reaction kettle for dilution, hydrolyzing, and cooling to obtain a PBTCA product. The method has advantages of simple operation, easy operation on control point, improvement on the working environment of workers and high safety; and the prepared PBTCA has good scale and corrosion inhibition effect.

Owner:南通联膦化工有限公司

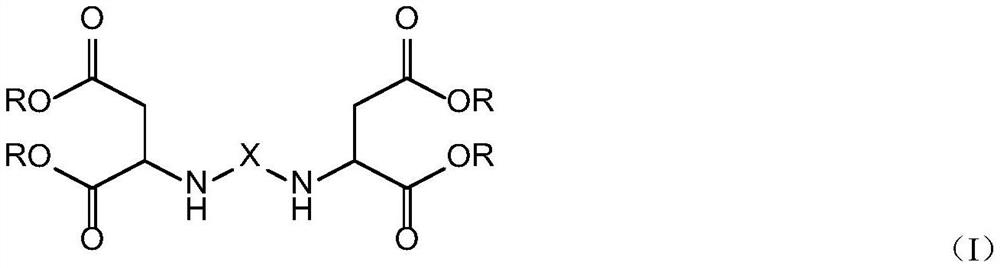

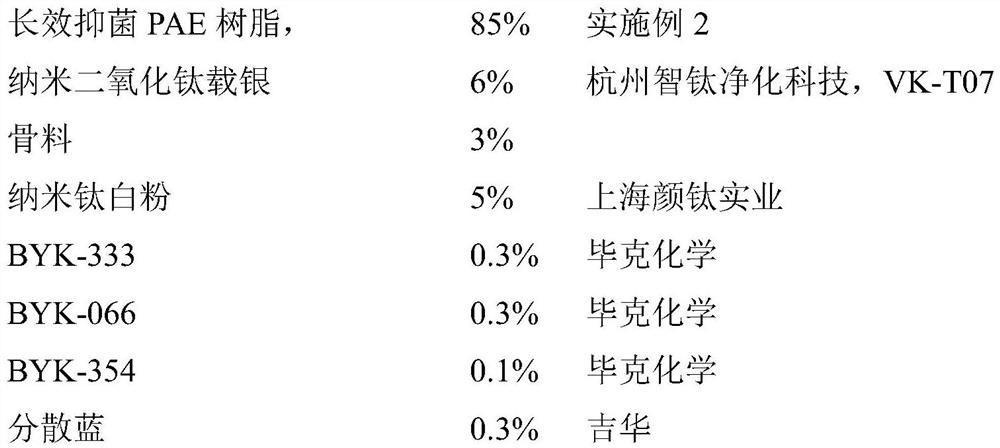

Long-acting antibacterial PAE resin, preparation method thereof and coating composition

ActiveCN112778145APlenty of time to operateImprove stabilityAntifouling/underwater paintsOrganic compound preparationMonoethyl maleatePolymer science

The invention discloses long-acting antibacterial PAE resin, a preparation method thereof and a coating composition. Dimethyl maleate and hydroxyl quaternary ammonium salt are subjected to transesterification, the obtained maleate quaternary ammonium salt and aliphatic diamine are subjected to Michael addition reaction, and the long-acting antibacterial PAE resin is obtained. Due to the high branching characteristic of the resin, the flowability of the resin is better, and the resin has sufficient operation time during polyurea double-component floor construction by adjusting the proportion; and meanwhile, the dendritic macromolecular structure contains a large number of cavities and has a good effect on stabilizing and dispersing the nano-silver, and the antibacterial effect does not decline remarkably along with long-time use or aging of the terrace.

Owner:浙江艾特普科技有限公司

Method for one-step production of 1, 4-butanediol through dimethyl maleate liquid phase hydrogenation

ActiveCN114685242ASave heatLow investment costOrganic compound preparationPreparation by hydrogenationMonoethyl maleatePtru catalyst

The invention relates to a method for one-step production of 1, 4-butanediol through liquid phase hydrogenation of dimethyl maleate. The method comprises the following steps: adding dimethyl maleate, a catalyst and a solvent dioxane into a high-pressure reaction kettle, sealing, introducing hydrogen until the pressure is 5-7MPa, and reacting for 7-12 hours at 140-220 DEG C while stirring to obtain 1, 4-butanediol, the catalyst is a copper-zinc-magnesium catalyst or a silylation reagent modified copper-zinc-silicon catalyst; according to the invention, 1, 4-butanediol with the yield of 97.8% can be obtained under the temperature and pressure condition equivalent to or milder than that of gas phase hydrogenation, which is higher than that of most hydrogenation in the prior art, and heat and hydrogen consumption required by raw material gasification are saved.

Owner:TIANJIN UNIV

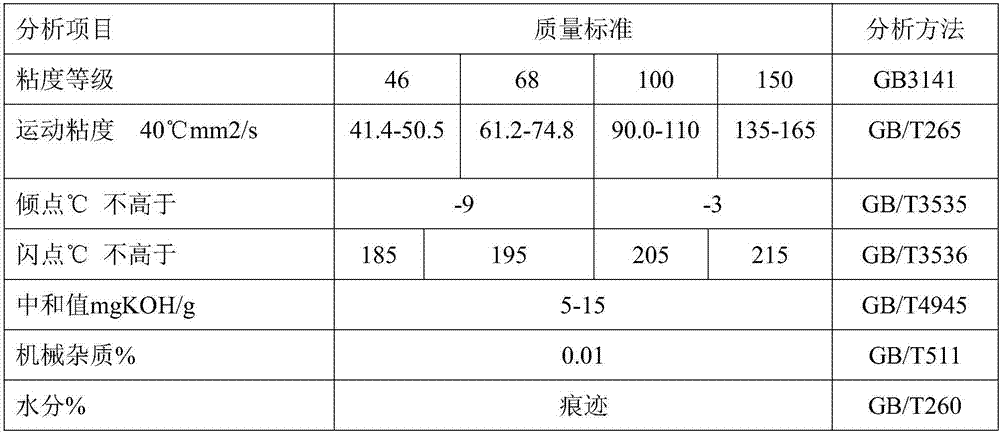

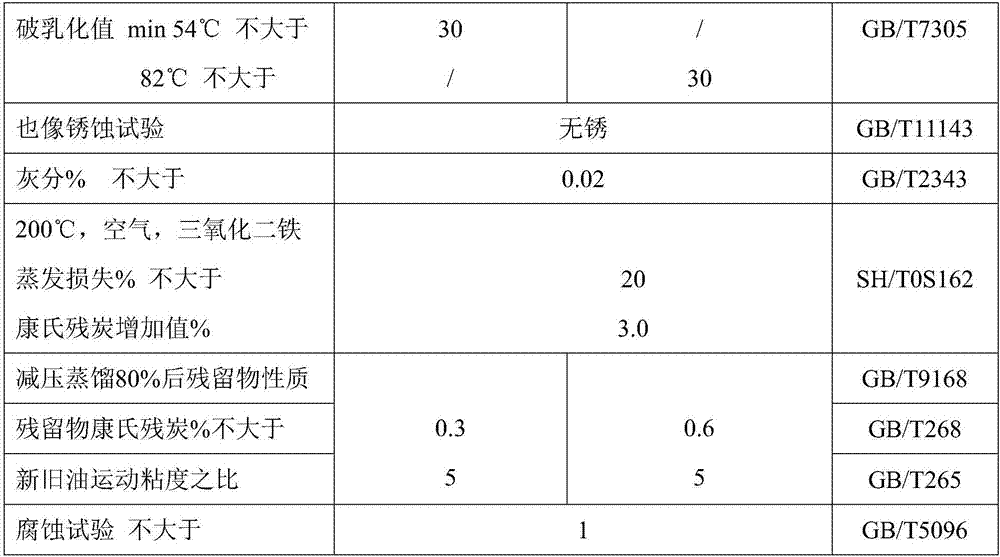

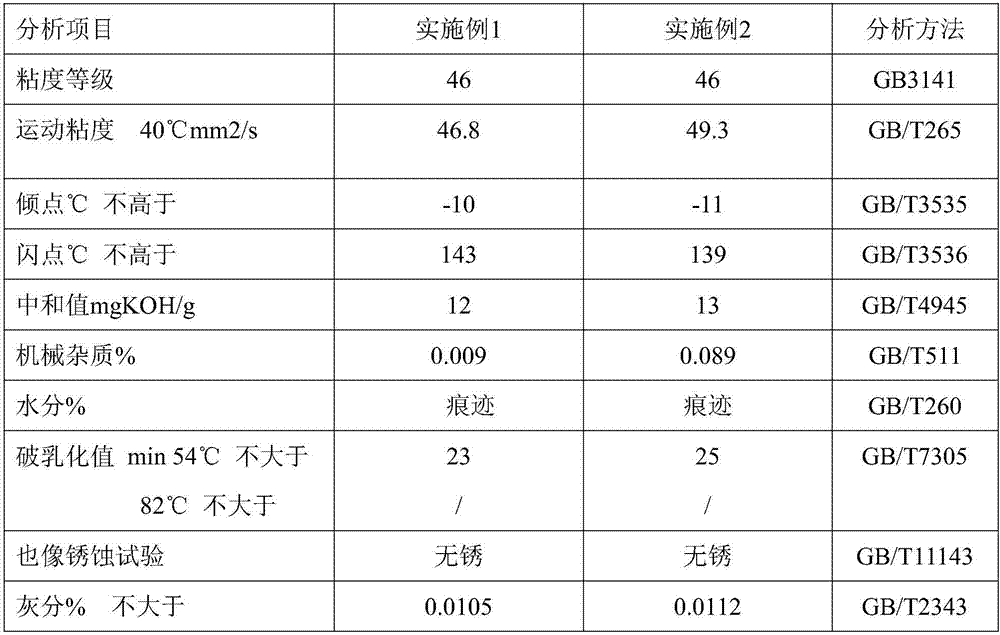

Corrugated roller bearing lubricating oil

The invention discloses corrugated roller bearing lubricating oil and relates to the technical field of lubricating oil. The corrugated roller bearing lubricating oil is prepared from, by weight, basic oil, dimethyl maleate, alkyl polyglucoside, kukui nut oil, modified methyl acrylate, sodium formate, carboxymethyl chitosan, an antioxidant, polyvinyl pyridine, nano Fe3O4 micro-spheres, polyvinyl acetate, SiO2 powder, a beeswax matrix, and plant extract oil. The corrugated roller bearing lubricating oil is made from safe and toxic-free raw materials and is free of environment pollution. The lubricating oil contains surface epoxidation groups, so that the lubricating oil is improved in reaction activity and is acid-resistant, alkali-resistant, heat-resistant, weather-resistant and high-stability, is easy to store and is free of corrosion. The lubricating oil fully fills a cavity of the corrugated roller bearing so as to reduce friction between parts and reduce the noise generated due to the friction in the interior of the corrugated roller bearing, thereby prolonging the service life of a corrugated machine bearing and reducing wear.

Owner:马鞍山市康辉纸箱纸品有限公司

Preparation method of high-mechanical-strength copper-based hydrogenation catalyst

PendingCN113600186AHigh reactivityImprove stabilityOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystButanedioic acid

The invention relates to a preparation method of a high-mechanical-strength copper-based hydrogenation catalyst, which comprises the following steps: pumping a mixed salt solution of soluble copper salt and other metal soluble salts and an alkali solution in parallel into a seed crystal-containing high-temperature saturated hydroxide solution, carrying out high-temperature reaction crystallization to prepare hydroxide, cooling, filtering, washing, drying and roasting to obtain the high-mechanical-strength copper-based catalyst. The copper-based catalyst prepared by the method has the characteristics of uniform particles, large particle size, high mechanical strength, high activity and high selectivity, is especially suitable for being used as a hydrogenation catalyst for preparing butanediol by hydrogenation of dimethyl maleate / dimethyl succinate and for preparing 1, 4-cyclohexanedimethanol by hydrogenation of dimethyl 1, 4-cyclohexanedicarboxylate, and is especially suitable for fluidized bed hydrogenation reaction processes.

Owner:濮阳圣恺环保新材料科技股份有限公司

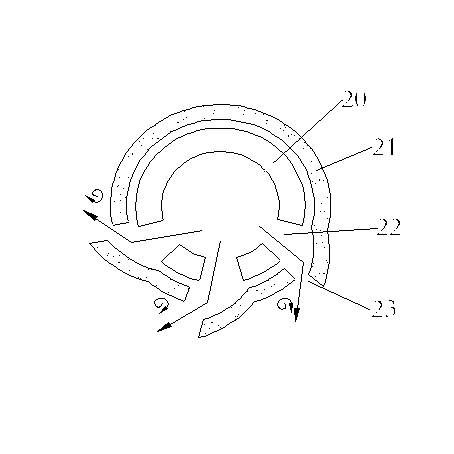

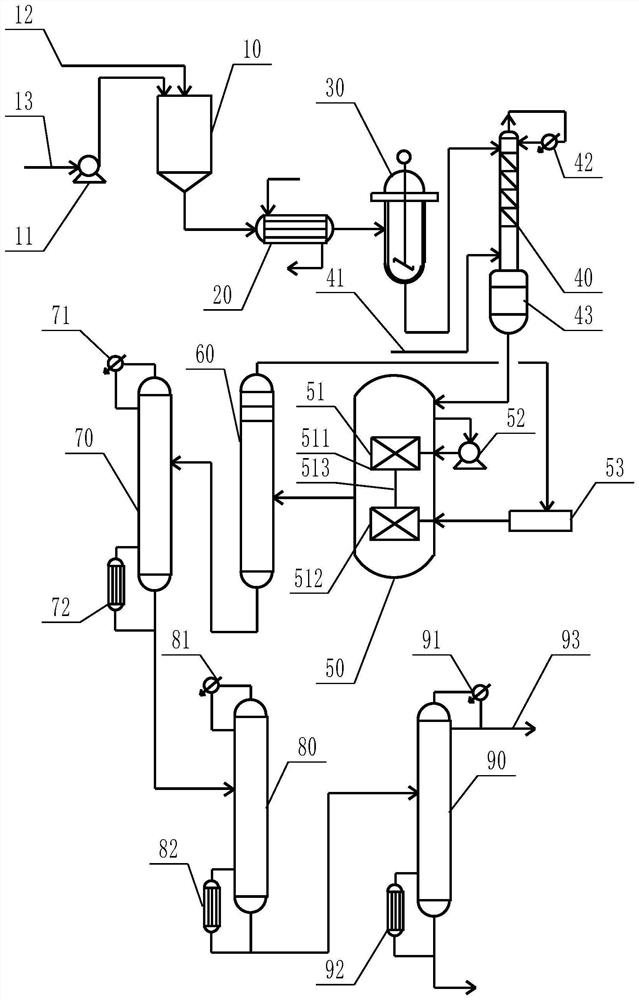

Micro-interface preparation system and method of 1, 4-butanediol

PendingCN114505027AIncrease the mass transfer area of the phase boundaryImprove reaction efficiencyOrganic compound preparationChemical industryMonoethyl maleateHydrogenation reaction

The invention provides a micro-interface preparation system of 1, 4-butanediol, which comprises a mixing tank, the mixing tank is connected with a methanol feeding pipeline and a maleic anhydride feeding pipeline, and the mixing tank is sequentially connected with a heat exchanger, a single esterification reactor, a double esterification reactor, a hydrogenation reactor, a flash tower, a methanol rectifying tower, a dimethyl maleate rectifying tower and a 1, 4-butanediol rectifying tower. A product outlet is formed in the 1, 4-butanediol rectifying tower, a gas-liquid linkage type micro-interface generator is arranged in the hydrogenation reactor, and the gas-liquid linkage type micro-interface generator is connected with a hydrogen inlet pipeline and a circulating pump. Hydrogen is dispersed and broken into hydrogen microbubbles through the gas-liquid linkage type micro-interface generator, the gas-liquid two-phase mass transfer area is increased, and due to the fact that the gas-liquid linkage type micro-interface generator has the circulating stirring function, the hydrogen can better react with mixed liquid in the hydrogenation reaction process, and the hydrogenation reaction is more sufficient.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com