Hydrogenation catalyst precursor, hydrogenation catalyst, and preparation methods of hydrogenation catalyst precursor and hydrogenation catalyst

A hydrogenation catalyst and hydroxide technology, applied in the preparation of hydroxyl compounds, the preparation of organic compounds, chemical elements of heterogeneous catalysts, etc., can solve the problems of easy aggregation of active metals, affecting catalyst activity and product conversion rate, etc. The effect of short reaction time, prevention of agglomeration and uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

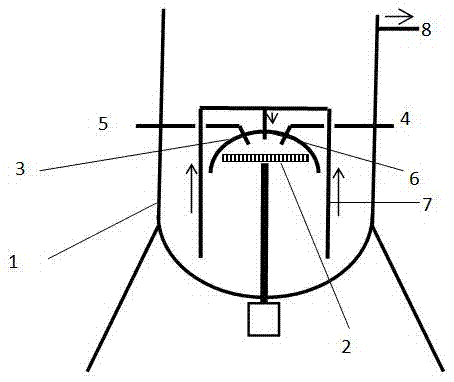

[0032] The preparation process of the hydrogenation catalyst precursor of the present invention is as follows: ammonia gas and metal hydrochloric acid mixed solution are respectively sprayed continuously on the impeller 2 rotating at high speed from the feed ports 4 and 5 provided on the impeller cover, and the slurry produced by the reaction is fed by the impeller 2 The surroundings fall into the reactor, and the generated part of the slurry enters the circulation line 7 through the circulation pipe inlet 6, and the circulating material enters the high-speed rotating impeller 2 from the circulating material outlet 6 provided on the impeller cover 3, and the slurry generated by the reaction flows from the upper part of the reactor. The overflow port 8 is continuously discharged, and the discharged slurry is filtered, washed, and dried to obtain a hydrogenation catalyst precursor, wherein the reaction temperature is controlled at 20~35°C, the residence time is 5~20min, and the pH...

Embodiment 1

[0036] Take 362.4g Cu(NO 3 ) 2 . 3H 2 O, 371.5g Al(NO 3 ) 3 . 9H 2 O, 51.3g Mg(NO 3 ) 2 . 6H 2 O and 80.6g Mn(NO 3 ) 3 . 6H 2 O was prepared into 2800mL of mixed acidic aqueous solution of metal hydrochlorides. The mixed ammonia gas and the acidic mixed aqueous solution of metal hydrochloride are continuously sprayed into the high-speed rotating impeller 2 from the feed ports 4 and 5 provided on the impeller cover respectively, and the resulting slurry falls into the reactor from around the impeller 2, and the resulting part The slurry enters the circulation pipe 7 through the circulation pipe inlet 6, and the circulating material enters the high-speed rotating impeller 2 from the circulating material outlet 6 provided on the impeller cover 3, and the slurry generated by the reaction is continuously discharged from the overflow port 8 at the top of the reactor. The slurry is filtered, and the filtered samples are taken at the reaction 1h and the reaction 7h resp...

Embodiment 2

[0038] Other conditions are the same as in Example 1, except that the diameter of the nozzle is changed to 15 μm, the volume ratio of the circulation amount of the slurry to the feed amount of the acidic mixed solution is 3:1, the pH value of the slurry at the overflow port is 6.5, and the sample is taken for 1 hour of reaction to obtain the catalyst Prebody a 2 and Catalyst A 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com