Organic electrolyte, method for extracting non-metallic inclusions from steel and electrolyzer

A technology of non-metallic inclusions and organic electrolyte, applied in the field of metallurgical physical chemistry research, can solve the problems affecting the total amount of inclusions in steel and the detection precision and accuracy of size, loss of non-metallic inclusions, slow electrolysis speed, etc. Achieve the effect of shortening electrolysis time and detection cycle, improving conductivity, and accelerating corrosion electrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention are described in detail as follows:

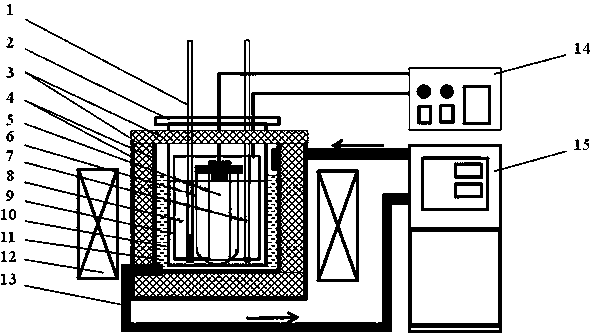

[0033] In this example, see figure 1 , a kind of electrolysis device, comprises electrolyzer 10, power supply 14, anode 5, negative electrode 9, fixed frame 2 and lead wire, electrolyzer 10 is an electrolysis beaker, cathode 9 is a stainless steel sheet, anode 5 and cathode 9 each have an end and fix respectively The frame 2 is fixedly connected, the fixed frame 2 is a plexiglass plate, the electrolyte 8 is stored in the electrolytic cell 10, the anode 5 and the negative electrode 9 are respectively connected to the positive pole and the negative electrode of the power supply 14 through wires, and the electrolytic cell 10 is controlled by adjusting the voltage of the power supply 14 The current density in the electrolyte solution 8 inside, the electrolytic cell 10 is arranged in the insulation box that is made of stainless steel and insulation material board 3, and the insulation materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com