Patents

Literature

104results about How to "Eliminate Concentration Polarization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic filter film of rare-earth modified attapulgite with nano coating and preparation method thereof

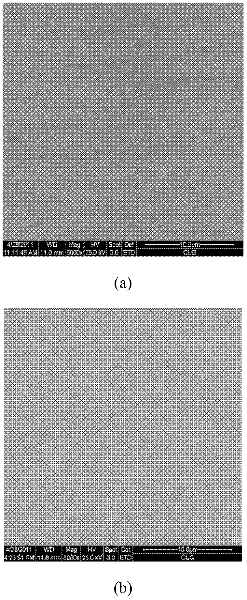

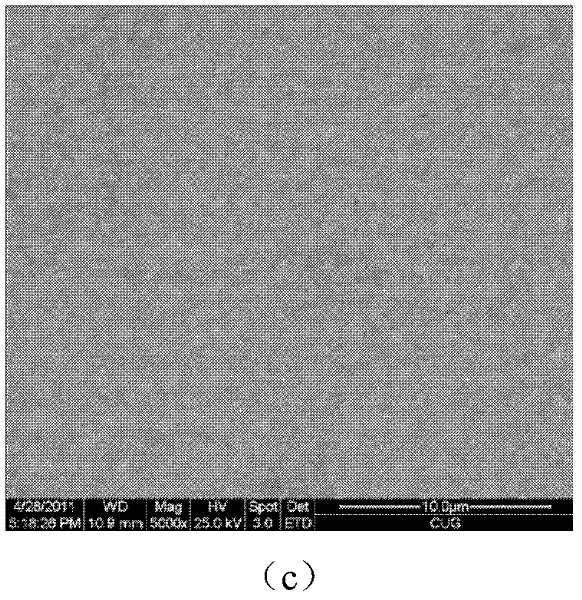

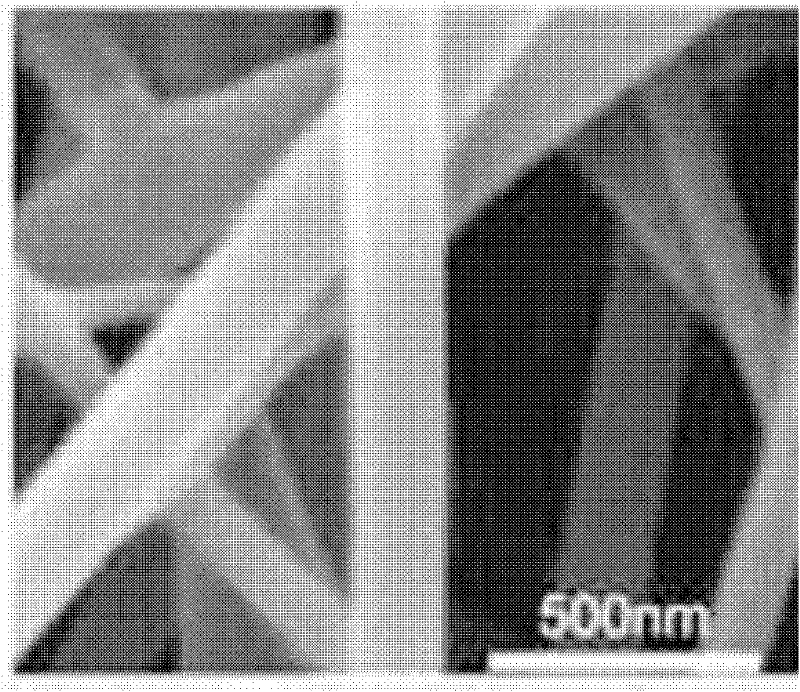

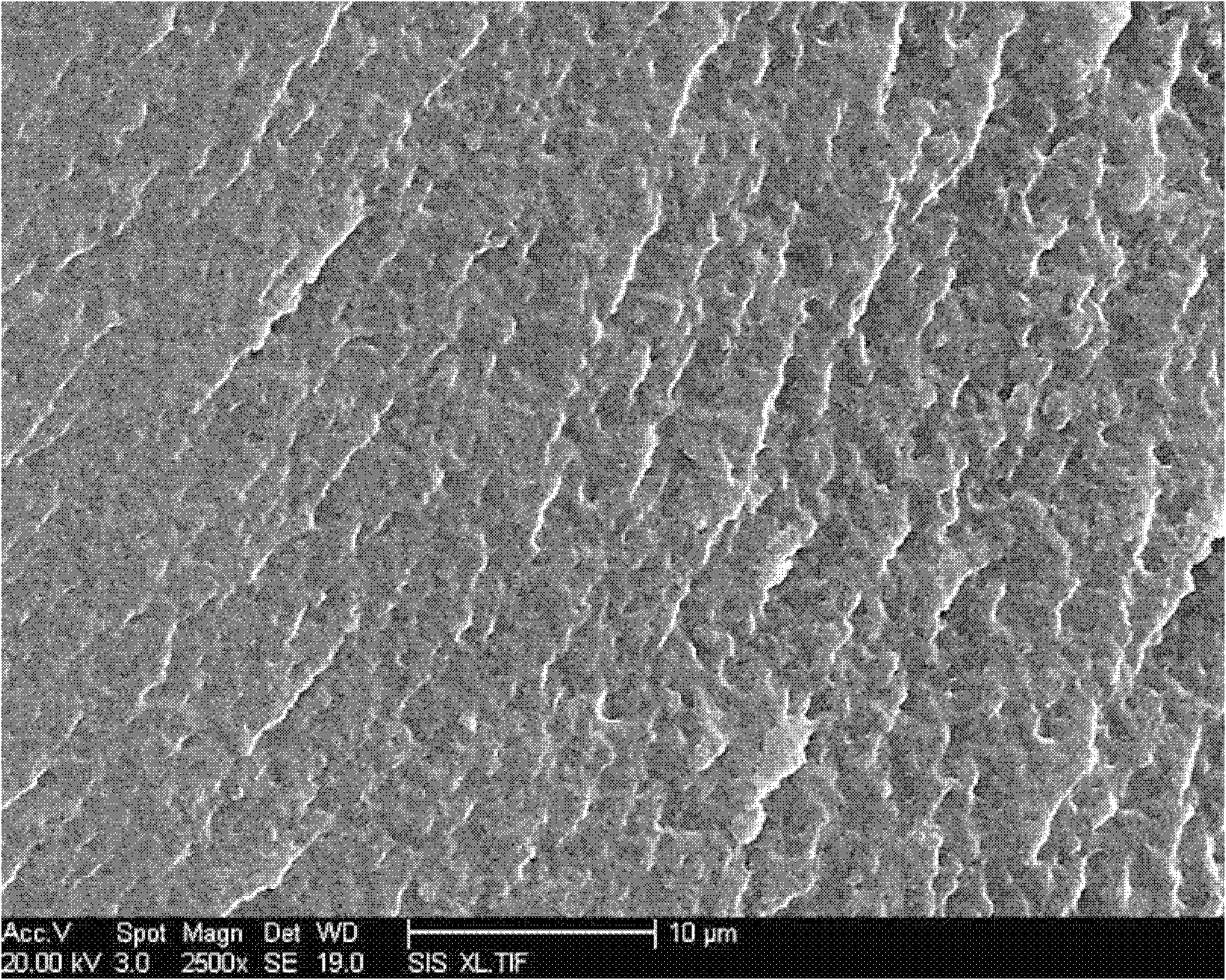

InactiveCN102614782AUniform pore size distributionLight in massSemi-permeable membranesCeramicwareRare earthPore diameter

Owner:SHANGHAI MARITIME UNIVERSITY

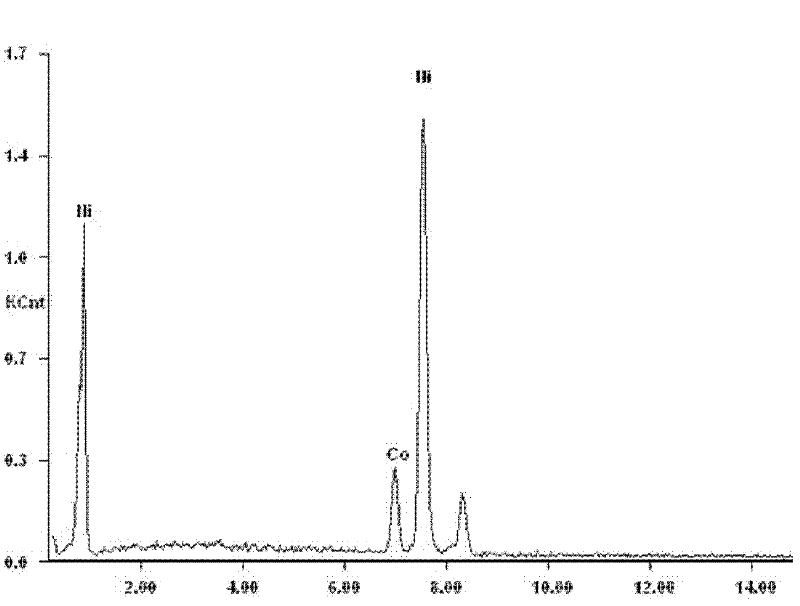

Method for double-pulse electrodeposition of nanocrystalline nickel-cobalt alloy

InactiveCN102260891AUniform crystallizationCrystal fineMaterial nanotechnologyPhotography auxillary processesElectroplatingNickel ions

The invention relates to a method for electrodepositing a nanocrystalline nickel-cobalt alloy by double-pulse. The method for electrodepositing the nanocrystalline nickel-cobalt alloy by double-pulse is characterized by comprising the following processing steps: in a plating solution with a pH value of 5-6, a nickel ion concentration of 0.68-0.95 mol / L and a cobalt ion concentration of 1.9*10<-2>to 3.8*10<-2> mol / L, taking a soluble nickel plate after the soluble nickel plate is subjected to surface treating as a anode, taking an iron sheet after the iron sheet is subjected to surface treating as a cathode and electroplating a nanocrystalline nickel-cobalt alloy layer by using double-pulse electrodepositing technology, wherein the time for electrodepositing is 15-20 min, the positive-going pulse current density is 1.0-2.0 A / dm<2>, the positive-going duty ratio is 60-80%, the working time of the positive-going pulse is 50-100 ms and the positive-going cycle is 40-60 ms; and the negative-going pulse current density is 0.1-0.2 A / dm<2>, the negative-going duty ratio is 60-80%, the working time of the negative-going pulse is 10-20 ms, the negative-going cycle is 1-2 ms and the workingtime of the positive-going pulse is 5-10 times of that of the negative-going pulse. The nickel-cobalt alloy coating prepared by the method has the advantages of smooth surface, compact structure, fine and even crystal, good smoothness, no crack and excellent corrosion resistance.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

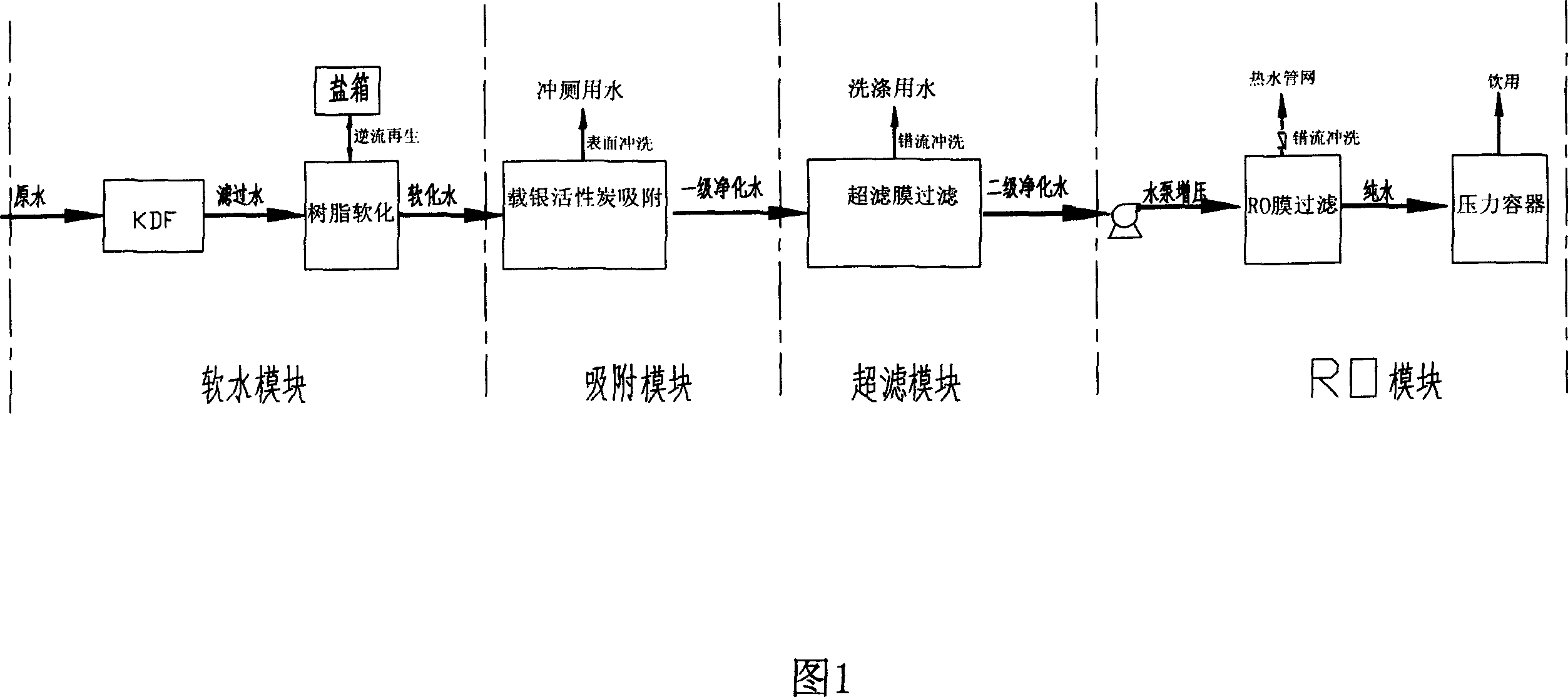

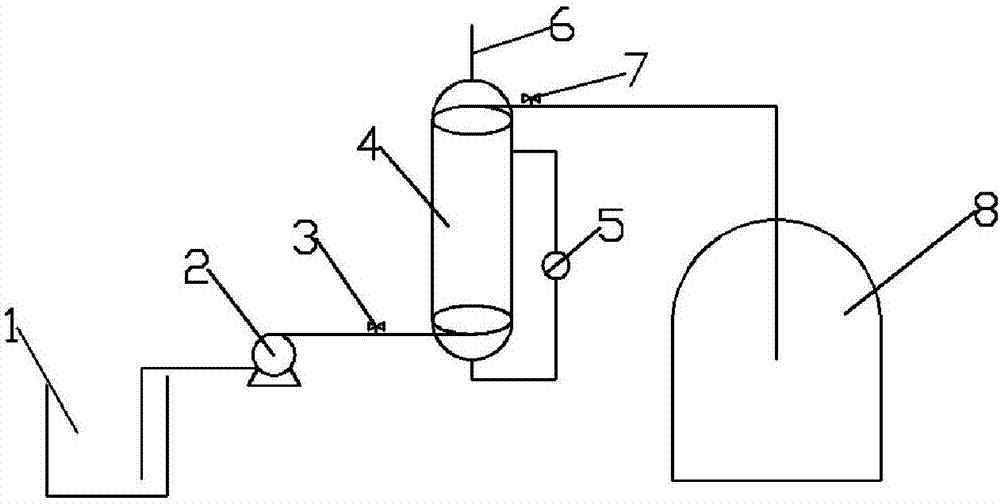

Household different water supply system

ActiveCN1944816AEliminate Concentration PolarizationExtend your lifeGeneral water supply conservationMultistage water/sewage treatmentWater softeningActivated carbon

The dual water supply system for household includes a soft water module with KDF filter connected to the raw water pipeline, a water softening resin device with salt box and resin jar, an adsorbing module with active carbon with water outlet connected to toilet water pipeline, an ultrafilter module, an RO module with pressurizing water pump, a bath water inlet pipeline, and a pressure container connected to the pure water outlet of the RO module. The dual water supply system makes the drinking water and the living use water flow separately, and has reverse resin regeneration, active carbon surface flushing and ultrafiltering membrane cross flow filtering to complete the timely system washing for eliminating pollutant and prolonging service life.

Owner:ZHEJIANG QINYUAN WATER TREATMENT S T

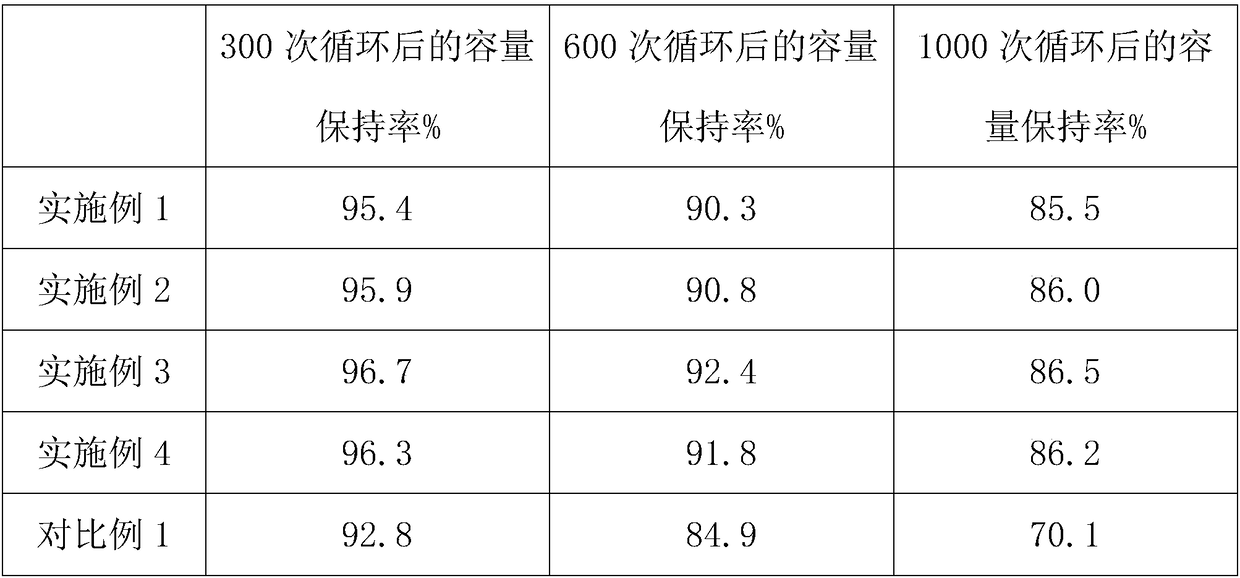

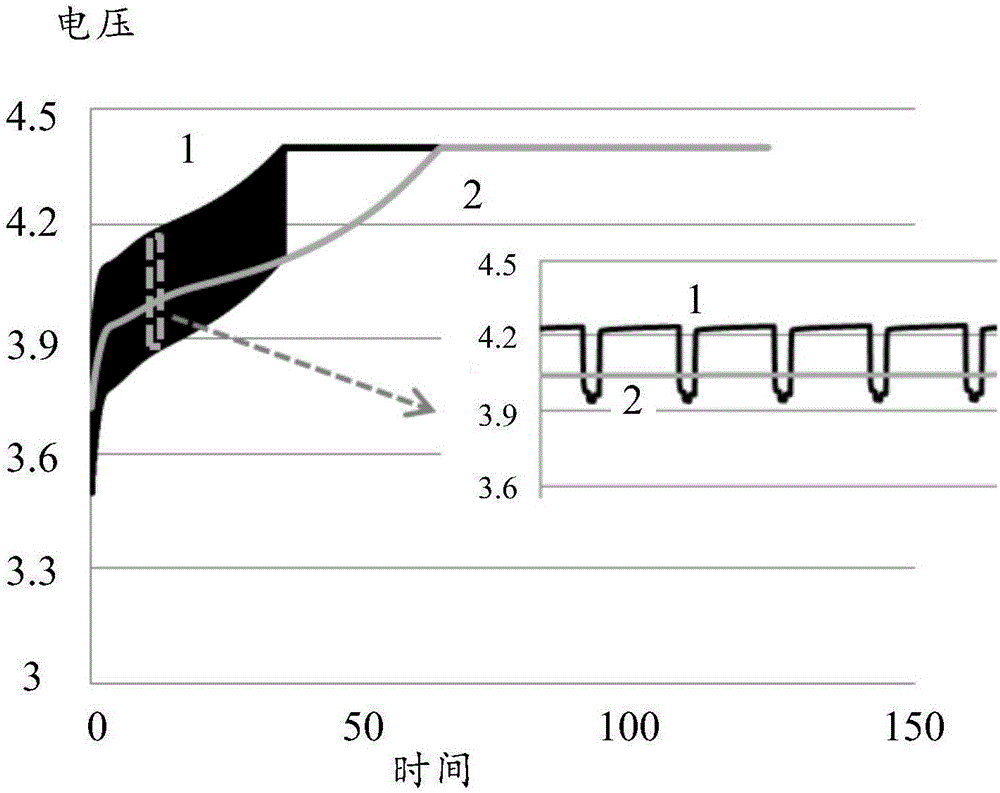

Formation technology of flexible package lithium ion battery

ActiveCN108808144AImprove permeabilityEasy dischargeSecondary cells charging/dischargingEngineeringLithium-ion battery

The invention provides a formation technology of a flexible package lithium ion battery. The formation technology comprises the following steps: heating and pressing the lithium ion battery in the formation process, and controlling the atmosphere to form current and voltage, so that a compact SEI film is formed on the electrode surface of the flexible package lithium ion battery, the cycle life ofthe battery is prolonged, and the capacity retentivity of the battery is improved.

Owner:JIANGXI DIBIKE

Preparation method of flaky metal powder

ActiveCN103122465AThe process is reasonable and convenientPrepared products of good qualityElectrochemical responseElectrochemistry

The invention relates to a preparation method of flaky metal powder. The preparation method comprises the following steps in sequence: machining a metal to be prepared into flaky powder into a flake and using the flake as a soluble anode; in an anode chamber of an electrochemical reactor, taking sulfate of the metal and sulfuric acid water solution as an electrolyte, oxidizing the soluble anode into corresponding metal ions and enabling the metal ions to enter anolyte; and after solid-liquid separation and anolyte impurity removal, adding an alkyl glycoside surfactant to the anolyte and adjusting the pH value to 5.0-6.5, then injecting the electrolyte into a cathode chamber of the electrochemical reactor, carrying out electrochemical reduction reaction on the cathode and separating out the metal to be prepared through deposition, simultaneously starting an ultrasonic generating device to strip the metal to be prepared on the cathode and deposit the metal to be prepared in the electrolyte below the cathode and then obtaining the qualified flaky metal powder through solid-liquid separation, washing, vacuum drying, screening and packaging. The preparation method has the advantages of reasonable and convenient process, safe and reliable preparation course and good prepared product quality.

Owner:YANGZHOU SHUANGSHENG ZINC IND

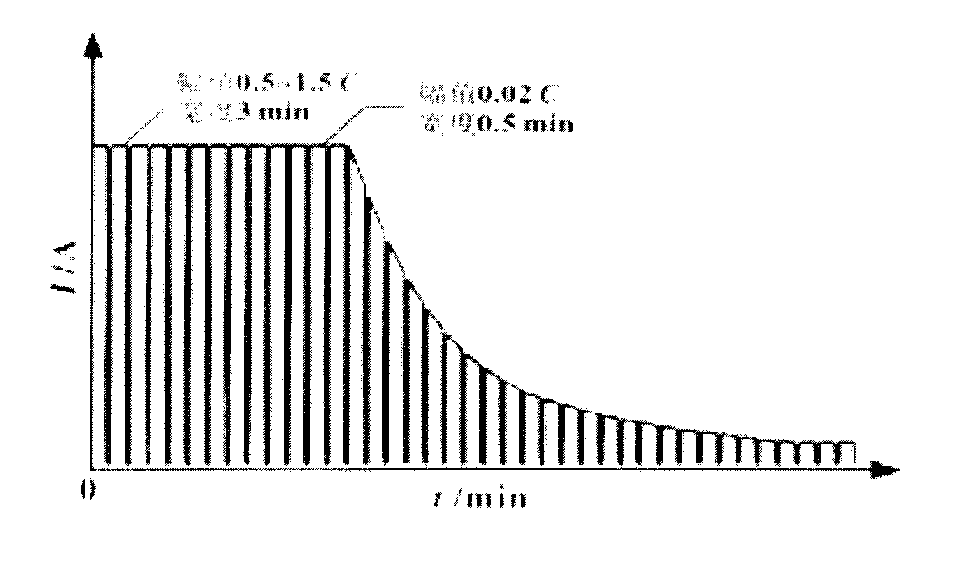

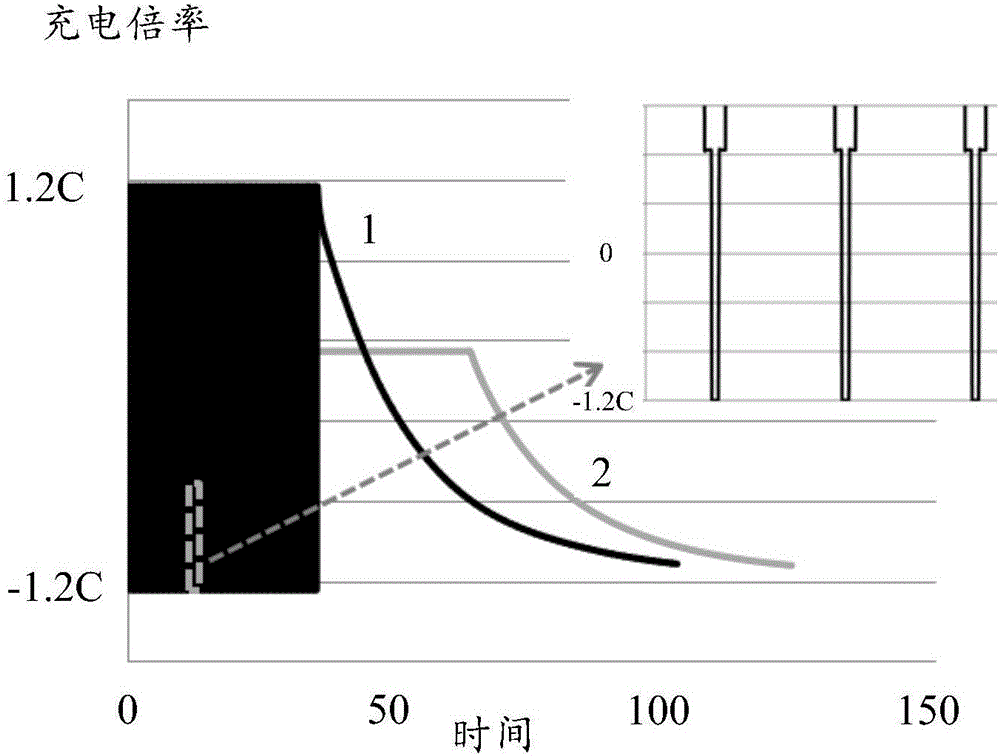

Formation and matching method for lithium ion battery

ActiveCN107293812AEliminate Concentration PolarizationExtended storage lifeSecondary cells charging/dischargingConcentration polarizationElectrical battery

The invention provides a formation and matching method for a lithium ion battery. For forming a stable and uniform SEI film and screening out batteries with similar performances, a low-current pulse and high-current charging-discharging circulation mode is adopted; concentration polarization on the surface of an electrode is eliminated by low-current pulse charging, so as to form the stable and uniform SEI film; the active material of the electrode is activated by the high-current charging-discharging circulation so as to balance the rate capacity of the battery; by increasing current, the heating amount among different batteries can be increased; and therefore, the batteries with similar capacity and same heat dissipation can be matched into a battery pack more accurately according to the capacity and the heating amount of the batteries, thereby improving the uniformity of the battery pack.

Owner:青岛恒金源电子科技有限公司

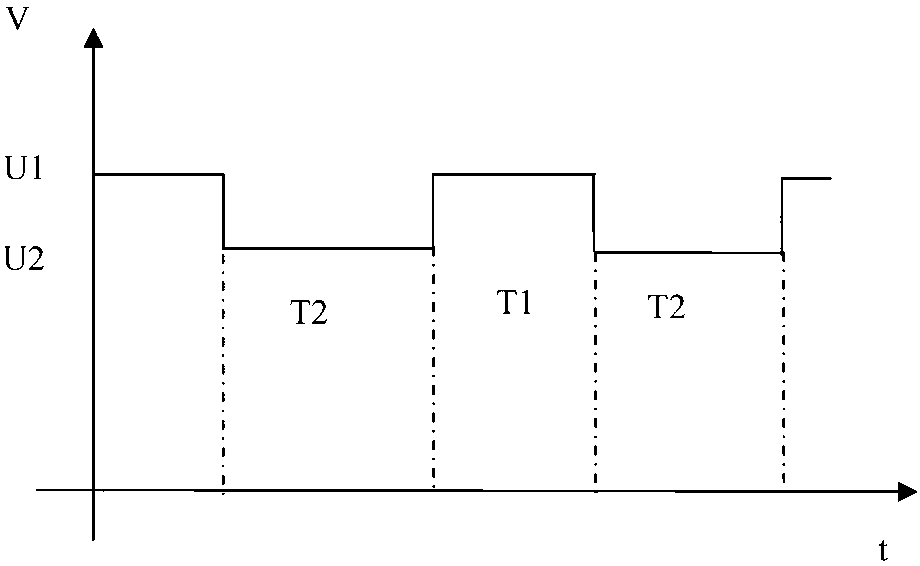

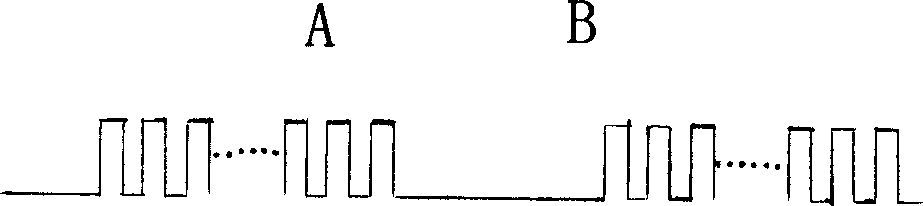

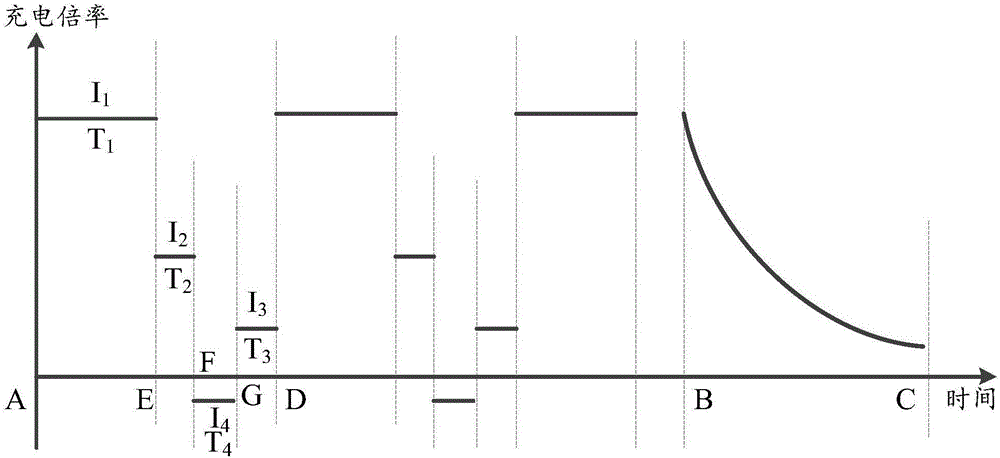

Pulse charging method used for prolonging VRLA battery service life

ActiveCN103227351AHigh porositySmall particle sizeSecondary cells charging/dischargingElectrical batteryPulse charge

The invention relates to a pulse charging method used for prolonging VRLA battery service life. The invention aims at provides a pulse charging method used for prolonging VRLA battery service life, such that the service life of a valve-regulated lead acid battery is prolonged. The invention adopts a technical scheme that, a VRLA battery has an output voltage of U and a capacity of C. The method is characterized in that the method is preceded in three sections which are a section A, a section B, and a section C. In the section A, constant-current charging is carried out with a charging limited current I. In the section B, periodic-change charging is carried out with constant current of the limited current I and constant-voltage of a second charging voltage U2. In the section C, periodic-change charging is carried out with constant-voltage of a first charging voltage U1 and constant-voltage of the charging voltage U2. In the section A, when a voltage is increased to U1, the process turns to the section B. In the section B, when the battery is charged to almost full, the process turns to the section C. The invention is suitable to be used in a field of storage battery charger.

Owner:杭州优联新能源科技有限公司

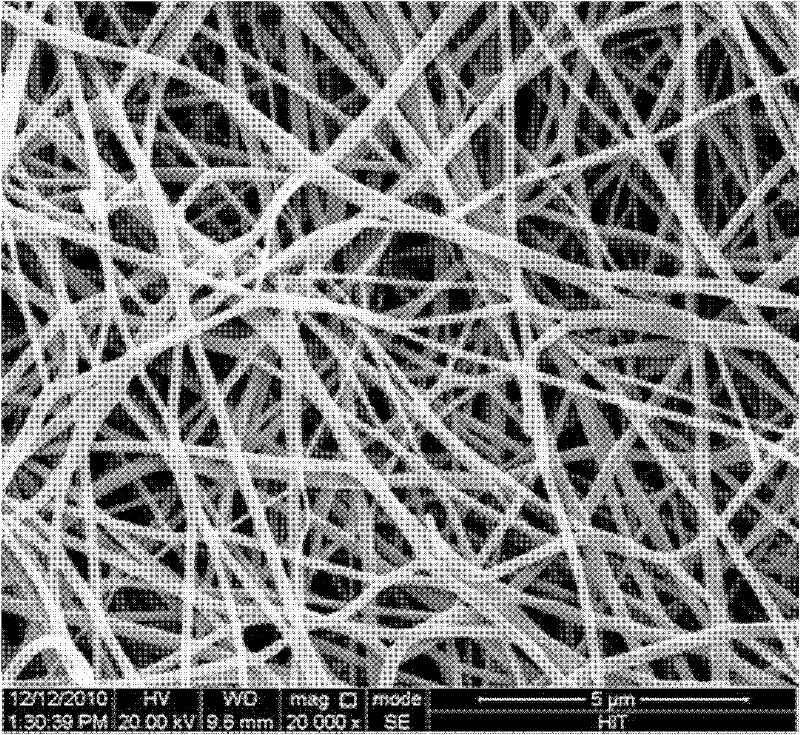

PAMPSLi fiber based polymer electrolyte membrane preparation method utilizing electrospinning method

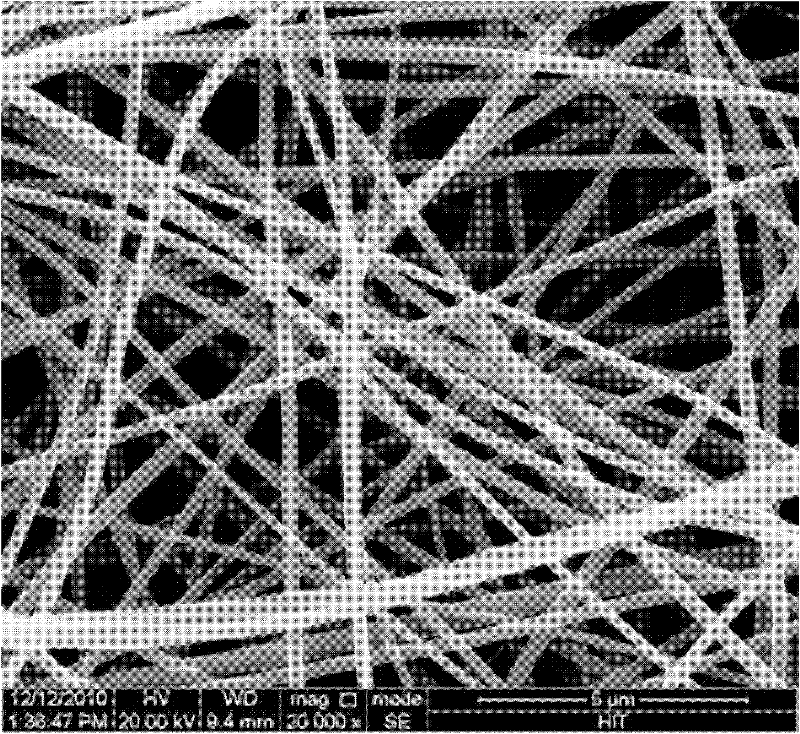

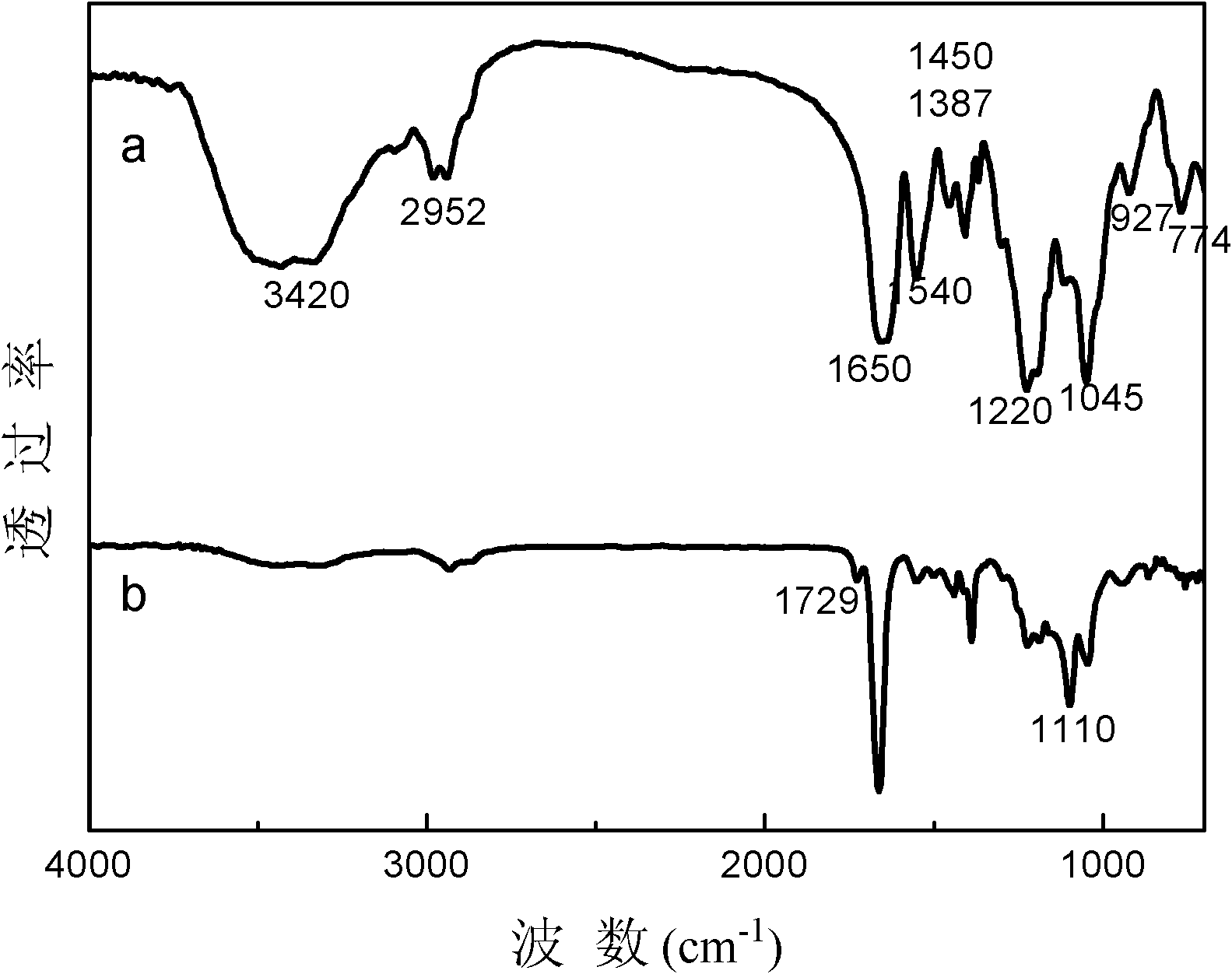

ActiveCN102255106ALarge specific surface areaImprove liquid absorption capacityFinal product manufactureFilament/thread formingFiberPolymer science

A PAMPSLi (poly-vinylacetate-methyl methacrylate acid lithium) fiber based polymer electrolyte membrane preparation method utilizing an electrospinning method. The method belongs to the field of preparation of polymer electrolyte for polymer lithium ion battery. The invention mainly solves problems of concentration polarization phenomenon and low ion transport number in a salt polymer electrolytesystem. The PAMPSLi fiber based polymer electrolyte of the invention is prepared by employing a polymer electrolyte PAMPSLi as a polymer matrix and a lithium ion source to eliminate the concentrationpolarization phenomenon effectively, and the prepared membrane has a submicron pore structure, large specific surface area and high imbibition rate. In addition, a dual solvent system is employed to prepare a spinning liquid, so that shape and dimension of fiber can be controlled by adjusting the dual solvent composition. The PAMPSLi fiber based single ion polymer electrolyte has a conductivity reaching 2.12*10<-5>S / cm at room temperature, good electrochemical stability and an electrochemical window reaching 4.4V vs Li, so as to satisfy application requirements of a lithium ion battery. The preparation technology of the invention is simple, does not require a large consumption of solvents, has little environmental pollution, and is suitable for industrialized scale production.

Owner:HARBIN INST OF TECH

Preparation method of interpenetrating network structure p(liamps)-based single ion transport gel polymer electrolyte film

InactiveCN102276860AIncrease the number of transfersGood dimensional stabilityCell component detailsCross-linkMethacrylate

The invention relates to a preparation method of a gel polymer dielectric film by conveying an interpenetrating network structure P (LiAMPS) single ion, which belongs to a preparation method of polymer electrolyte films. The present invention solves the problems of low transport numbers and dimension stability of the present gel polymer electrolyte ions. The invention employs 2-acrylamide-2-methyl propanesulfonic acid lithium (LiAMPS) and vinyltriethoxysilane free radical polymerization to obtain a linear polymer P (LiAMPS-co-VTES), P (LiAMPS-co-VTES) containing an ethoxy functional group enables hydrolysis and polycondensation to form a net structure, simultaneously a cross-linking agent monomer polyethylene glycol dimethyl methacrylate is performed a free radical polymerization to form another net structure. The invention is capable of raising the dimension stability of the polymer electrolyte. Through heat weightlessness analysis, the polymer electrolyte films have good heat stability, the initial weightless temperature of the films is more than 200 DEG C, so that the requirement of lithium ion battery can be satisfied.

Owner:HARBIN INST OF TECH

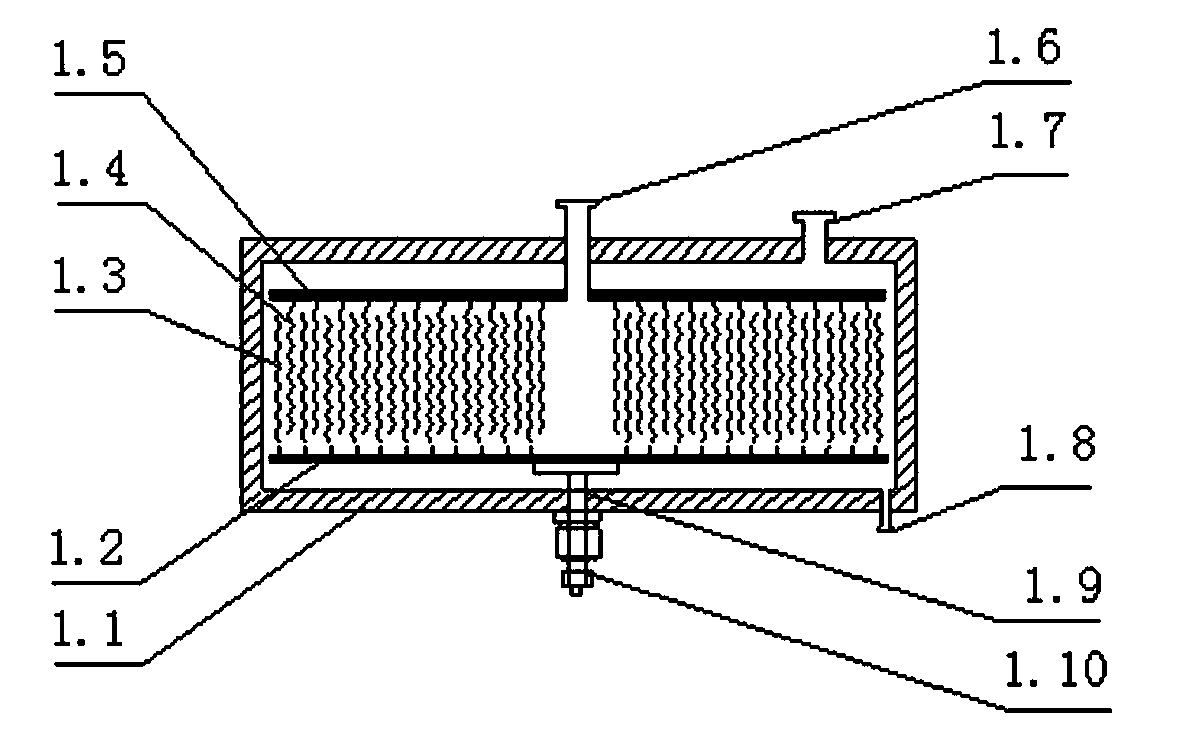

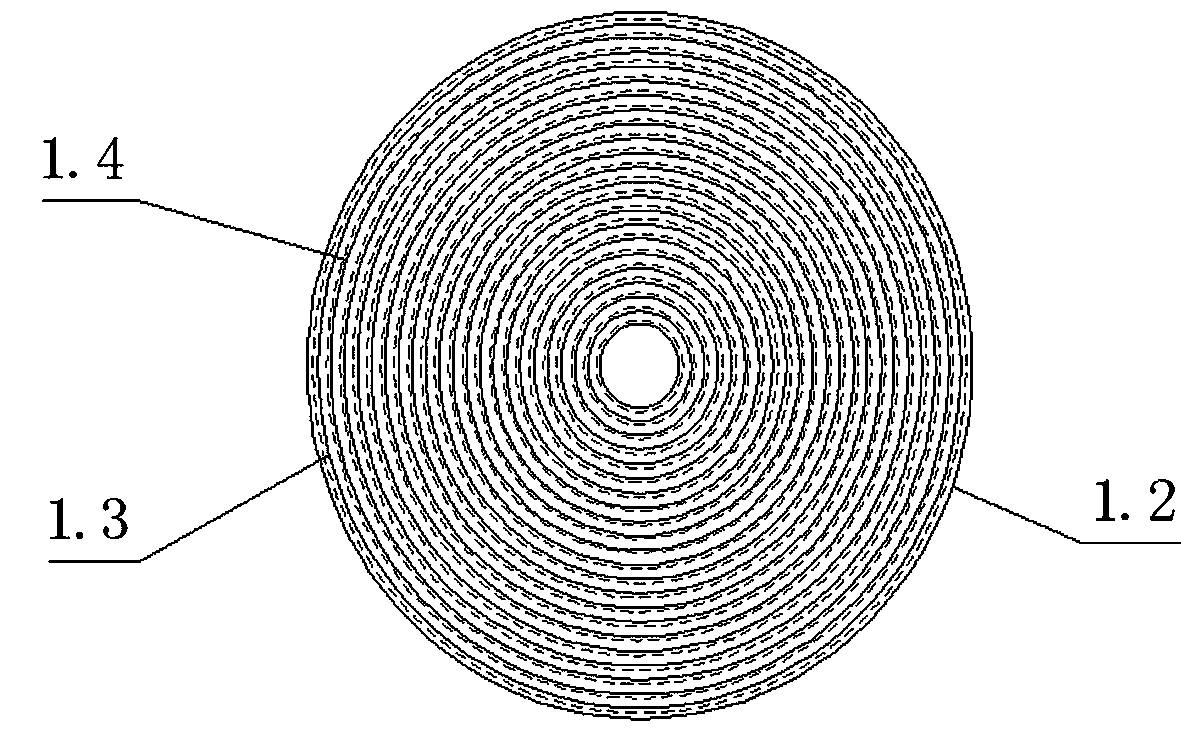

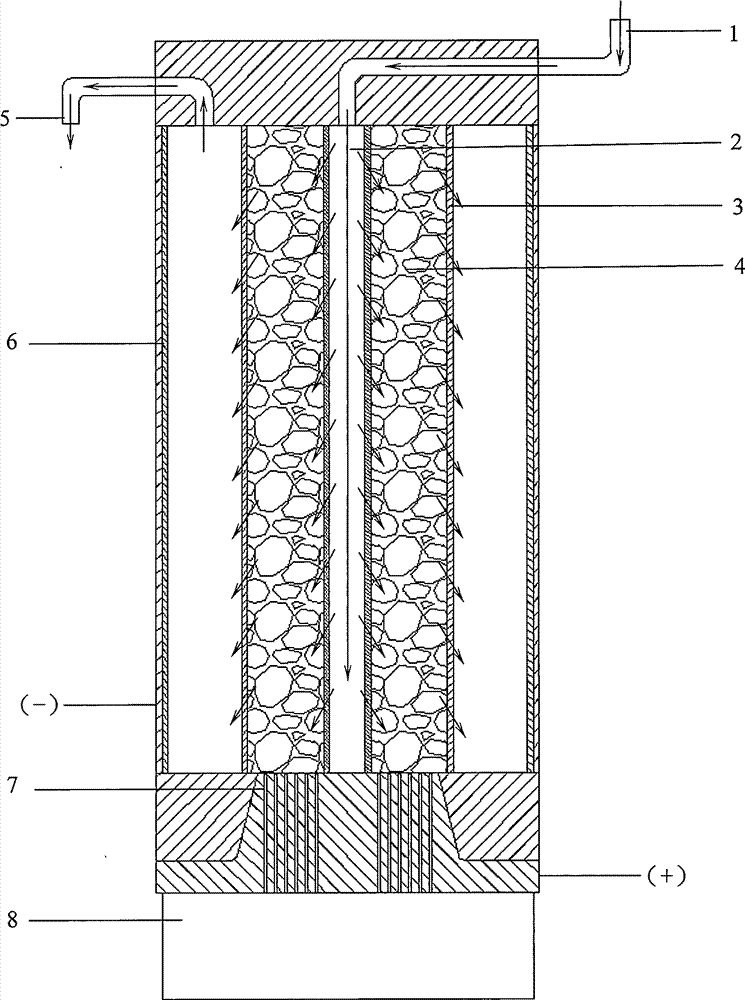

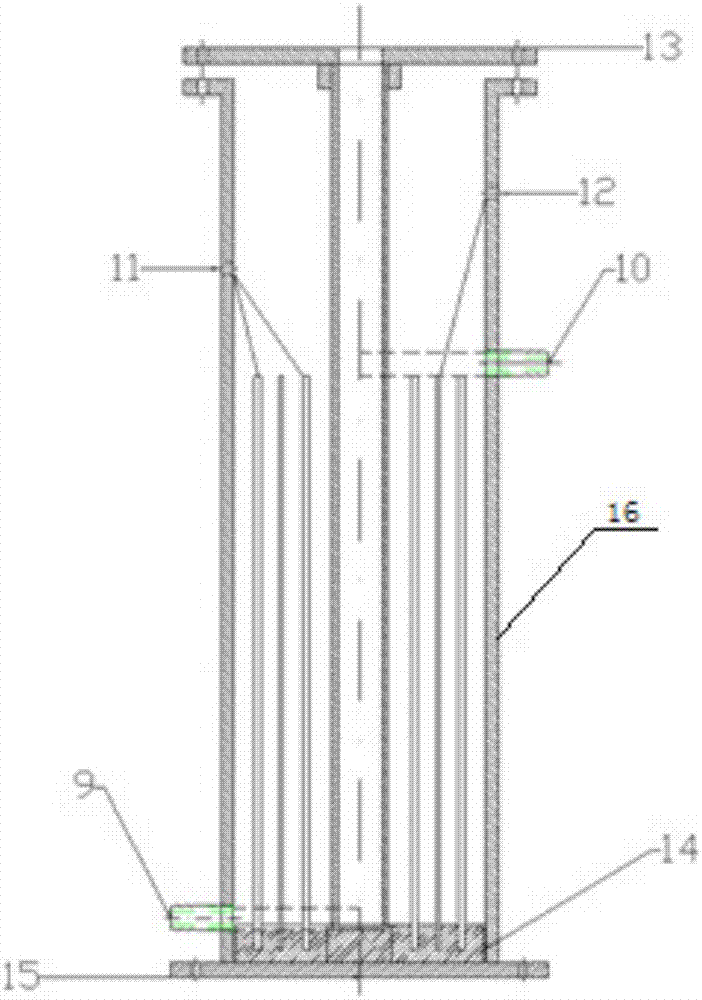

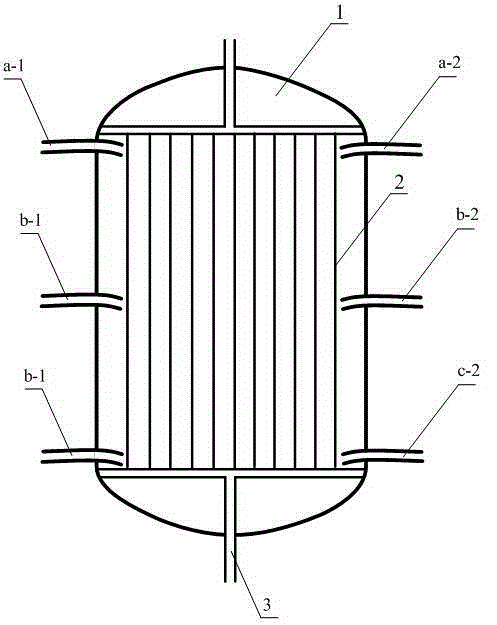

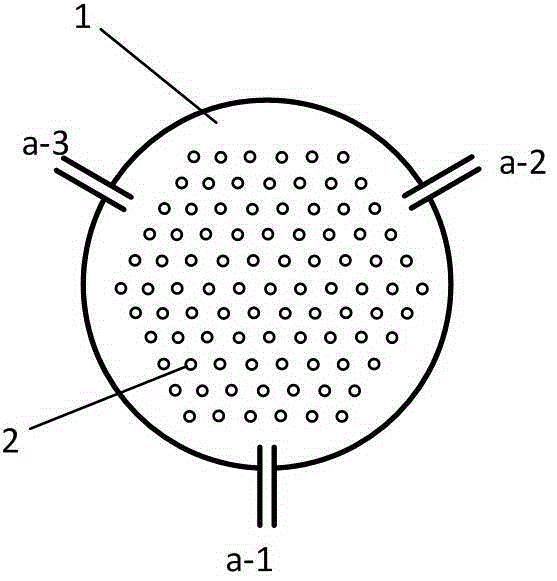

Device and technology for processing degradation-resistant waste water through hypergravity multistage sacrificial anode electro-Fenton method

ActiveCN103613169AImprove processing efficiencyIncrease electrode areaWater/sewage treatment by electrochemical methodsWater/sewage treatment by oxidationOxygen utilization rateWastewater

The invention belongs to the water processing technology field, concretely provides a device and a technology for processing degradation-resistant waste water through a hypergravity multistage sacrificial anode electro-Fenton method, and solves the problem of mass transfer limitation in processing degradation-resistant waste water through a sacrificial anode electro-Fenton method. The device comprises a plurality of corrugated cylindrical anodes and anode connection disks and a plurality of corrugated cylindrical cathodes and cathode connection disks. The corrugated cylindrical cathodes and the cathode connection disks are stationary relative to a shell. The centers of the anode connection disks are connected with a rotating shaft. In the technology, the rotary corrugated cylindrical anodes and anode connection disks, the stationary corrugated cylindrical cathodes and cathode connection disks and a H2O2 solution form a hypergravity multistage sacrificial anode electro-Fenton reaction system. The device and the technology can reinforce the mass transfer process of the electro-Fenton reaction. The electrode area utilization rate, the oxygen utilization rate, the H2O2 production rate and the processing efficiency are all raised. The device has advantages of small size, low load and low energy consumption, and is suitable for continuous operation and scale processing.

Owner:ZHONGBEI UNIV

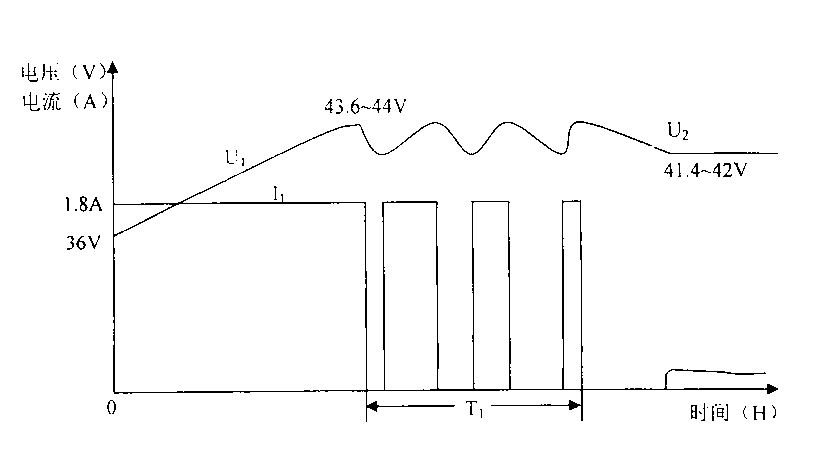

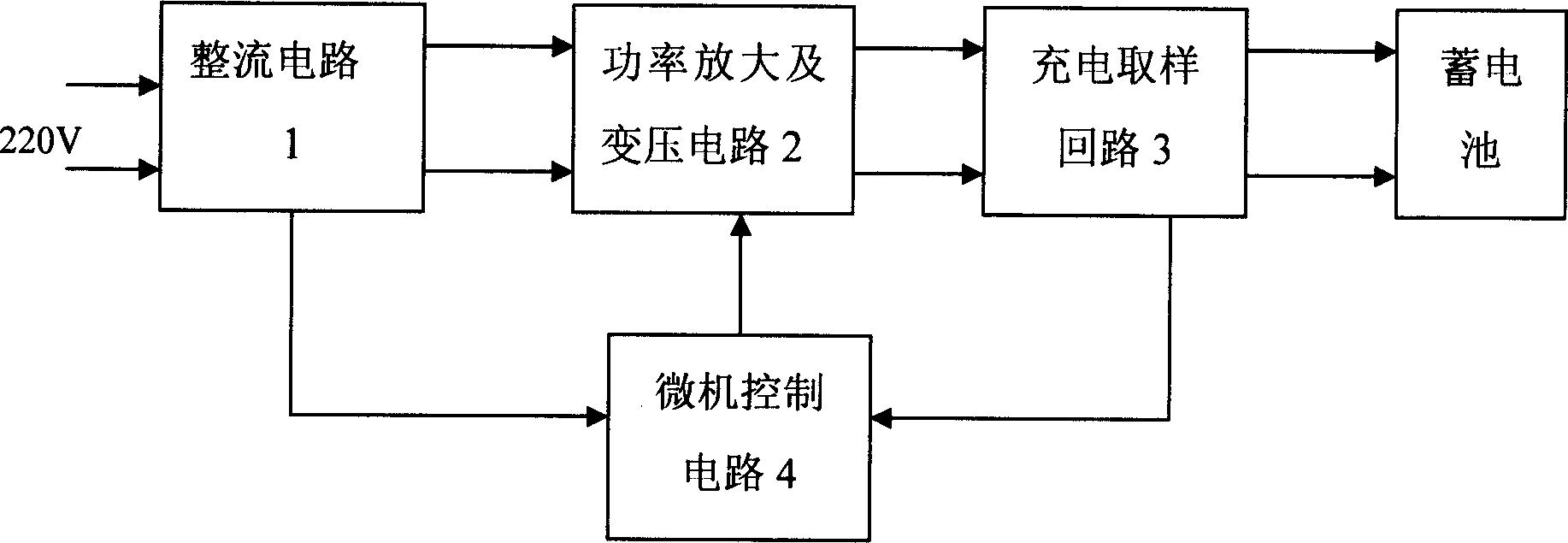

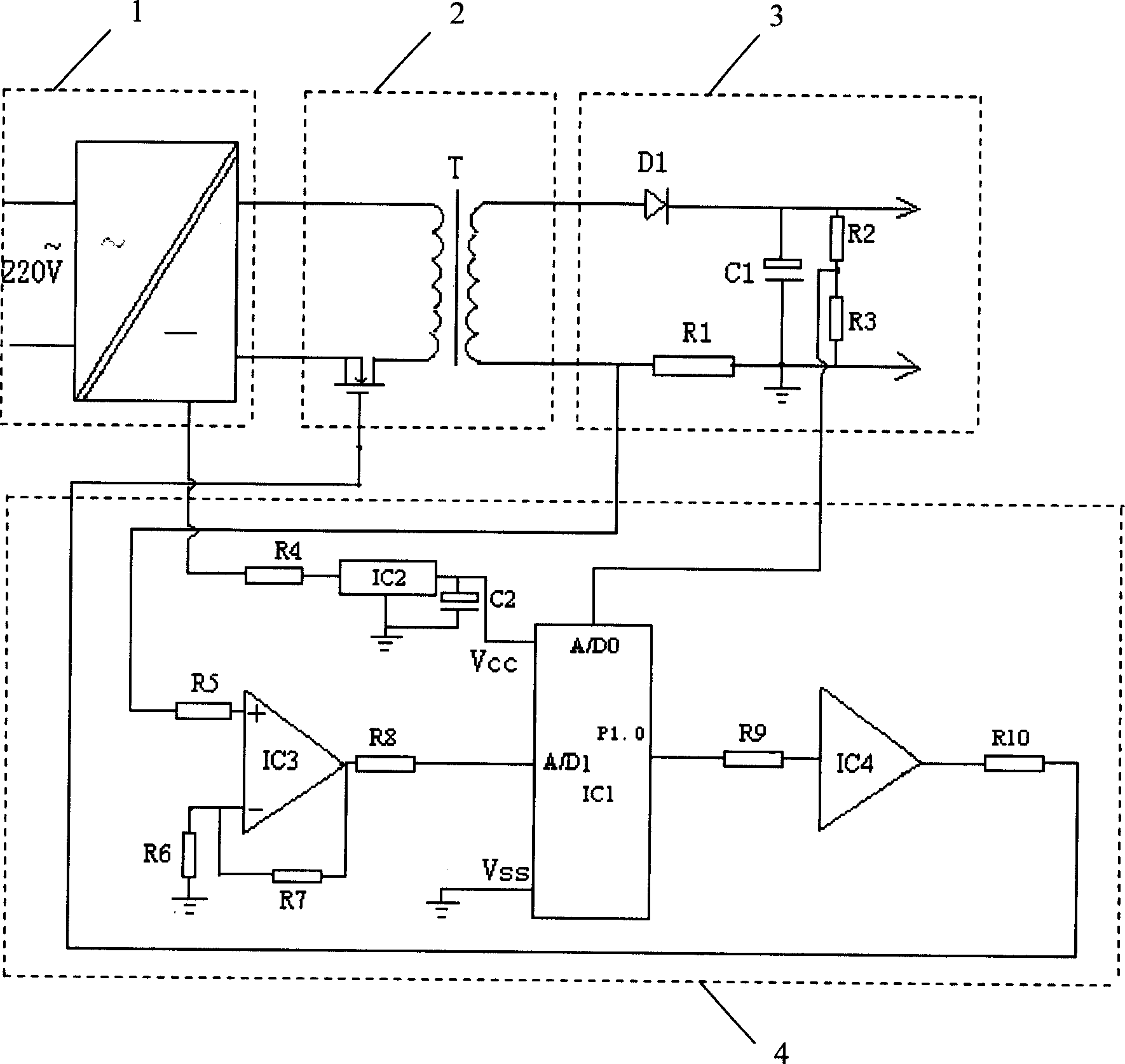

Accumulator charger and charging method thereof

InactiveCN1866664AFull recovery cooling timeEliminate Concentration PolarizationBatteries circuit arrangementsSecondary cells charging/dischargingPeak valuePeak current

The invention discloses an accumulator charger and charging method, which comprises the following parts: commutating circuit, pulse power amplification and transformation circuit, charging sampling circuit and microcomputer control circuit. The charger uses down rectangular wave pulse charging to produce segment charging peak current within ideal curved scale, which eliminates accumulator resistance polarization and concentration polarization of common intelligent charger. When the pulse down segment stops charging, the accumulator possesses enough cooling restoring time. The invention realizes rapid charging, which lengthens utility lifetime of accumulator.

Owner:JIANGSU TEACHERS UNIV OF TECH

Method for separating and recovering metal compound waste materials

ActiveCN104498992AHigh purityHigh recovery ratePhotography auxillary processesProcess efficiency improvementInlet channelWaste material

The invention relates to a method for separating and recovering metal compound waste materials. The method comprises the following steps: putting the metal compound waste materials in an anode basket as an anode for cyclonal electrolysis to obtain metals needed to be electrolyzed and purified; and feeding an electrolyte from a liquid inlet in an electrolytic process, flowing at a certain speed among a liquid inlet channel, the metal compound waste materials and two poles, finally flowing out from a liquid outlet at the upper end, and recycling the electrolyte after certain treatment; and after certain treatment of anode mud, separating and recovering metals. The method provided by the invention can be used for achieving separation and recovery with high efficiency, zero pollution and low cost.

Owner:温州宏丰特种材料有限公司

Method for recovering tellurium through cyclone electrolysis of solution containing tellurium

InactiveCN105862059AShorten the electrolysis cycleAvoid Concentration RequirementsElectrolysis componentsCycloneHigh current density

The invention discloses a method for recovering tellurium by swirl electrolysis of a tellurium-containing solution, which comprises the following steps: adding concentrated sulfuric acid into the tellurium-containing solution until the pH value of the tellurium-containing solution is 5.7-6.5, controlling the temperature of the tellurium-containing solution to be higher than React at 90°C for 2 to 4 hours, filter; leach the filter residue obtained after filtration with sodium hydroxide solution; perform swirl electrolysis on the leaching solution obtained after leaching, and take out the cathode after swirl electrolysis; The solution is boiled, washed, and dried to obtain high-purity tellurium. The invention adopts swirl electrolysis to recover tellurium in the tellurium-containing solution, which avoids the influence of unfavorable factors on electrowinning such as the decrease of current efficiency and the increase of concentration polarization caused by the slow flow of the solution in the traditional electrolysis process, and shortens the electrolysis cycle of tellurium , which reduces the concentration requirements of impurity elements in the electrolyte, and has many advantages such as high selectivity, high current density, and high product purity.

Owner:CENT SOUTH UNIV

Free-standing internal formation charging process for storage battery

ActiveCN104134827AQuality assuranceIncrease productivitySecondary cells charging/dischargingConcentration polarizationVoltage stability

The invention aims to provide a free-standing internal formation charging process for a storage battery. Through the adoption of the internal formation process in which charging is performed for six times and discharging is performed for four times, an original acid extraction step is advanced to the time after the fifth charging, so that the storage battery is unnecessary to stand for 24 hours, battery quality is guaranteed while production efficiency is improved, in addition, concentration polarization can be eliminated, and voltage stability can be ensured.

Owner:TIANNENG BATTERY WUHU

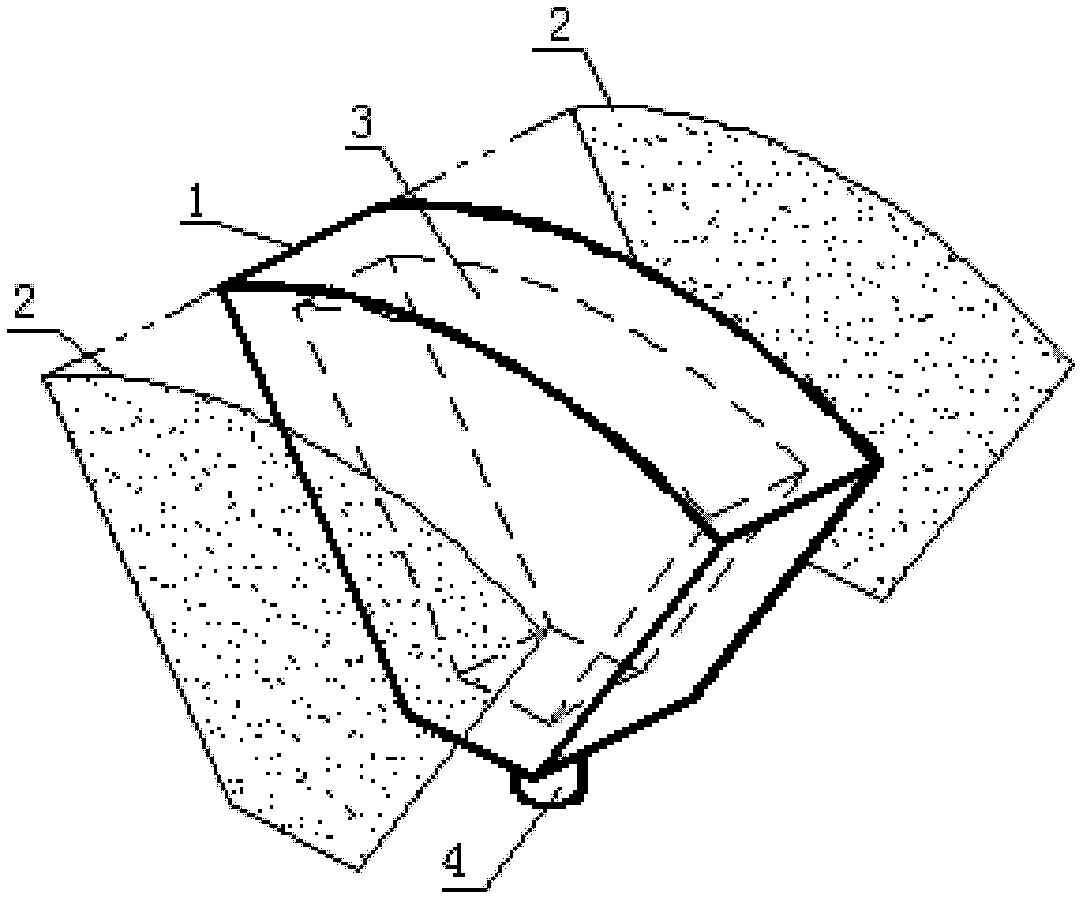

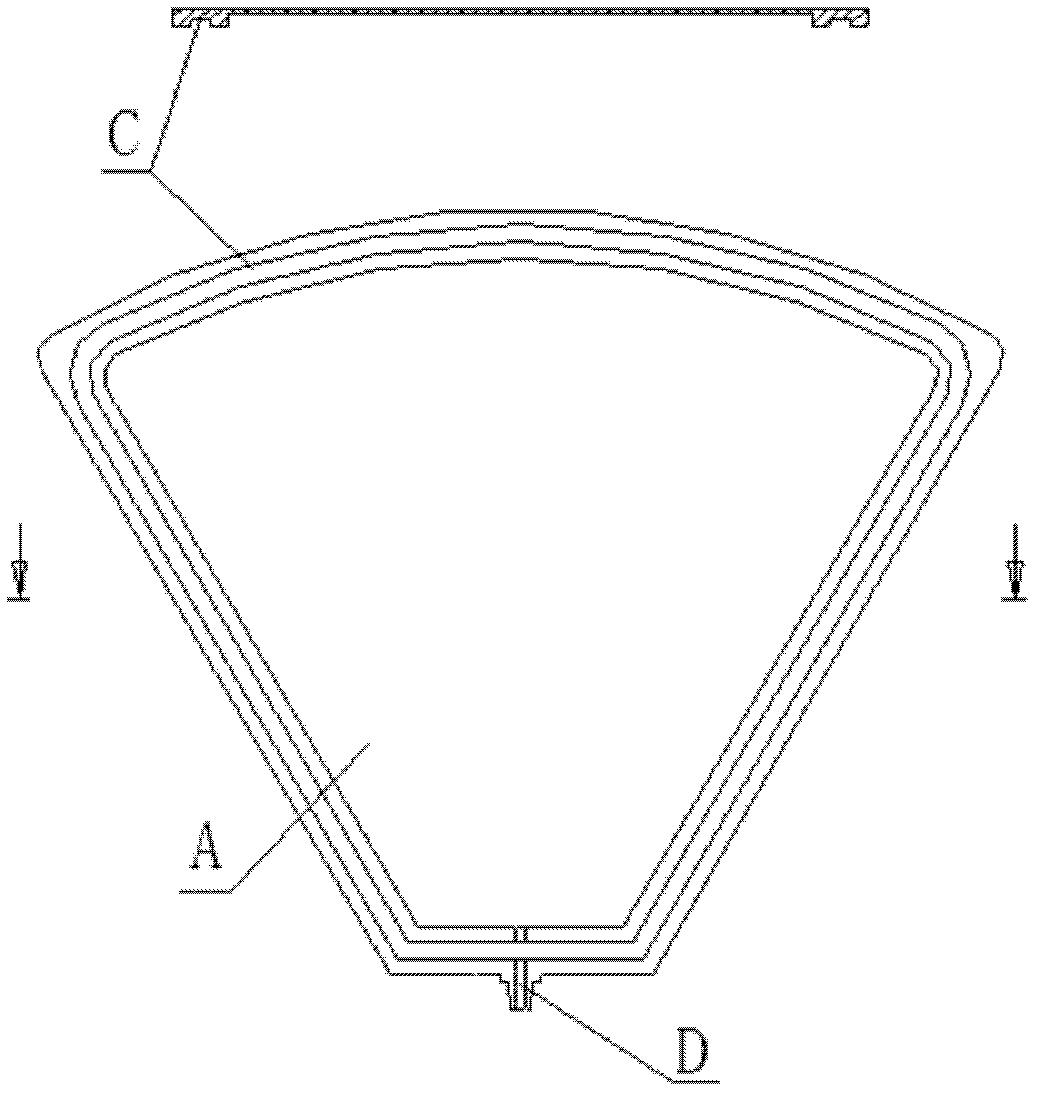

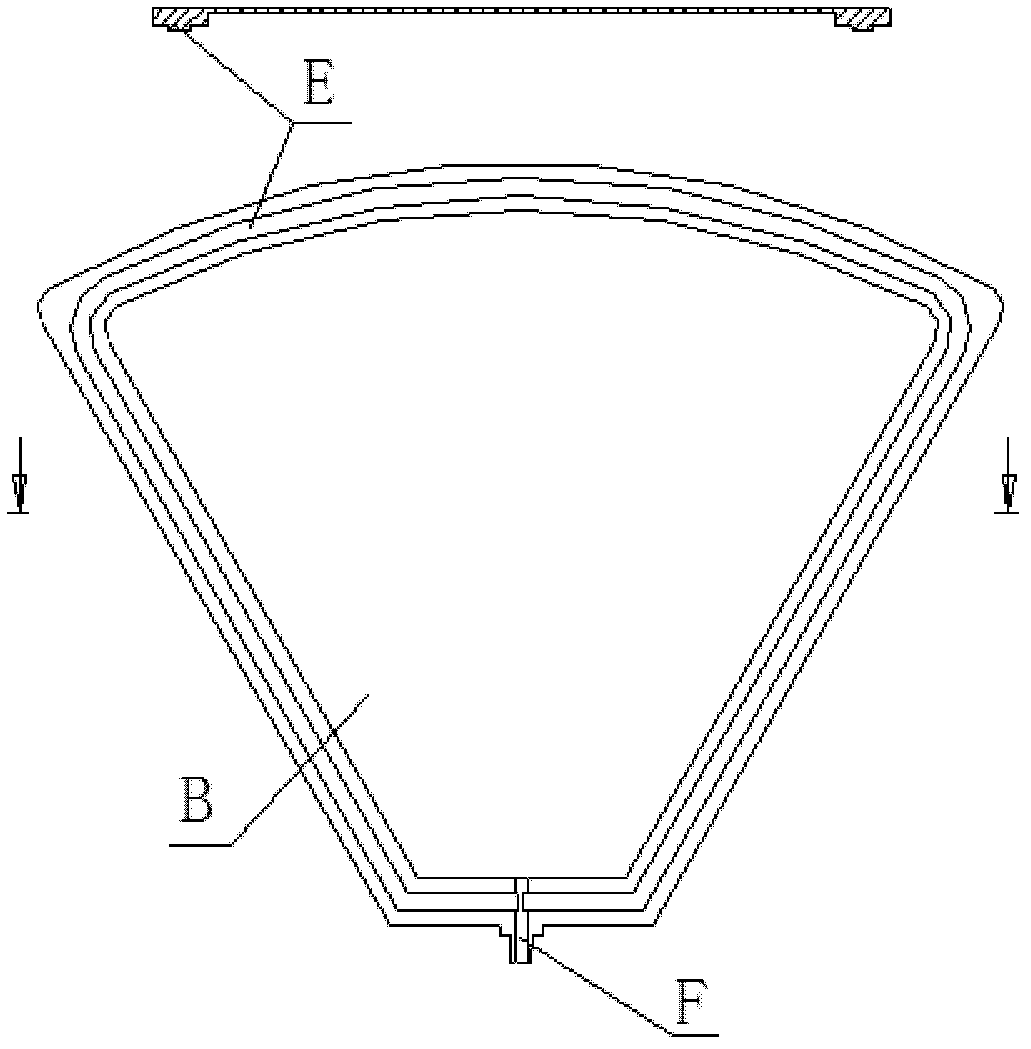

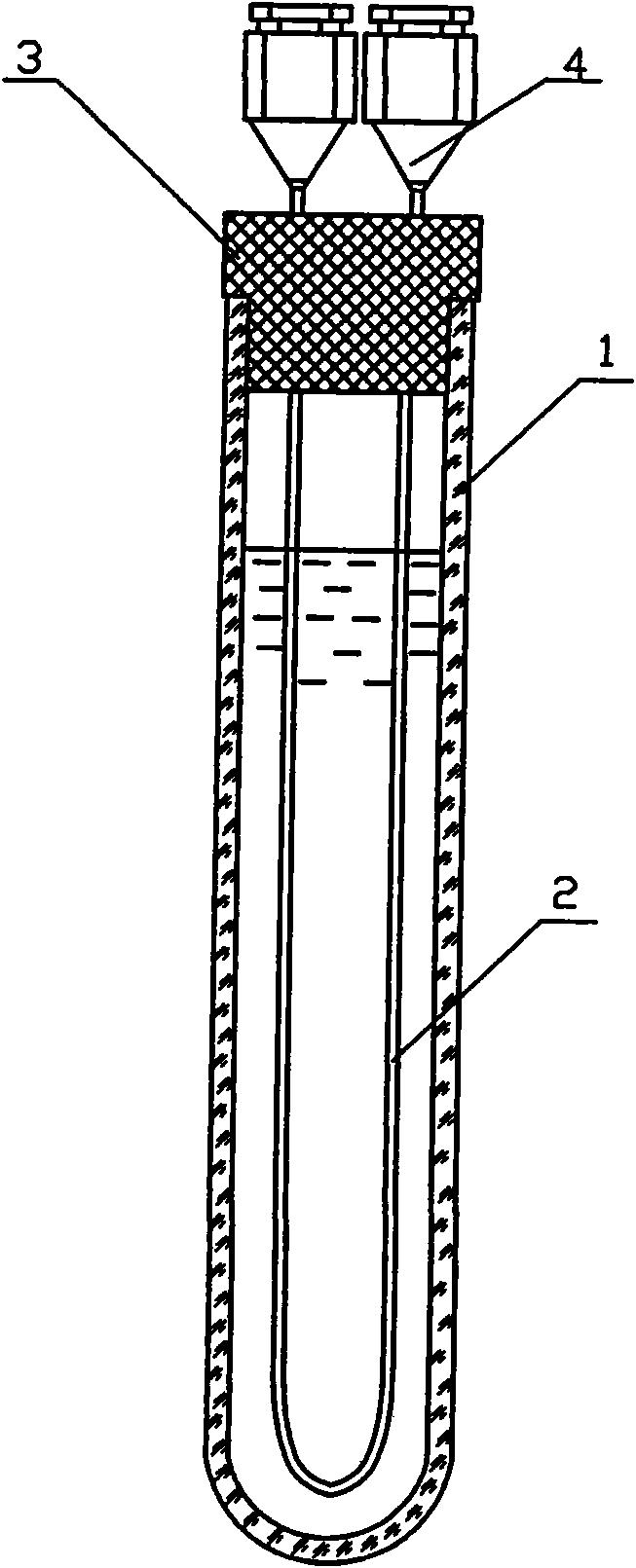

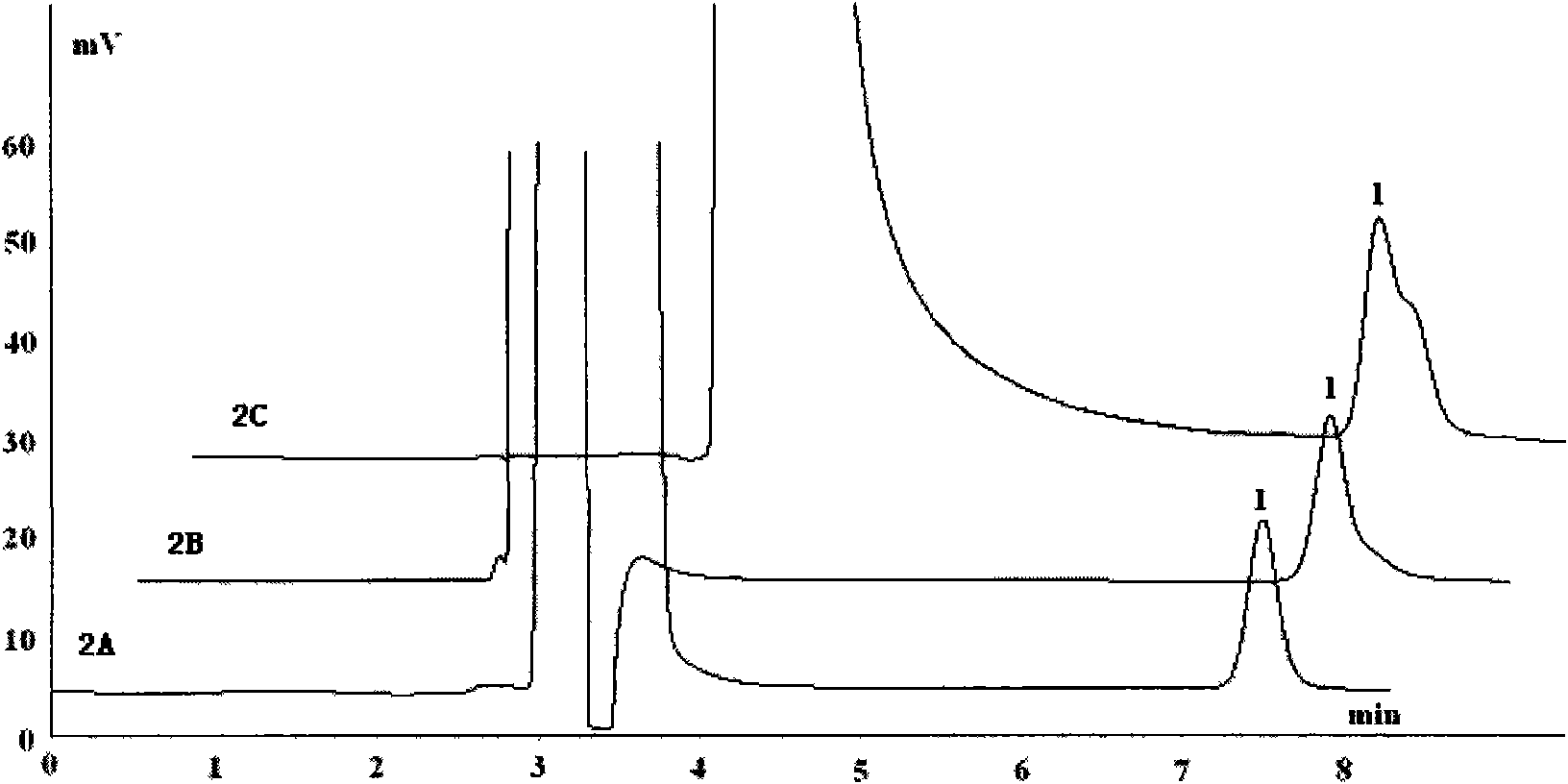

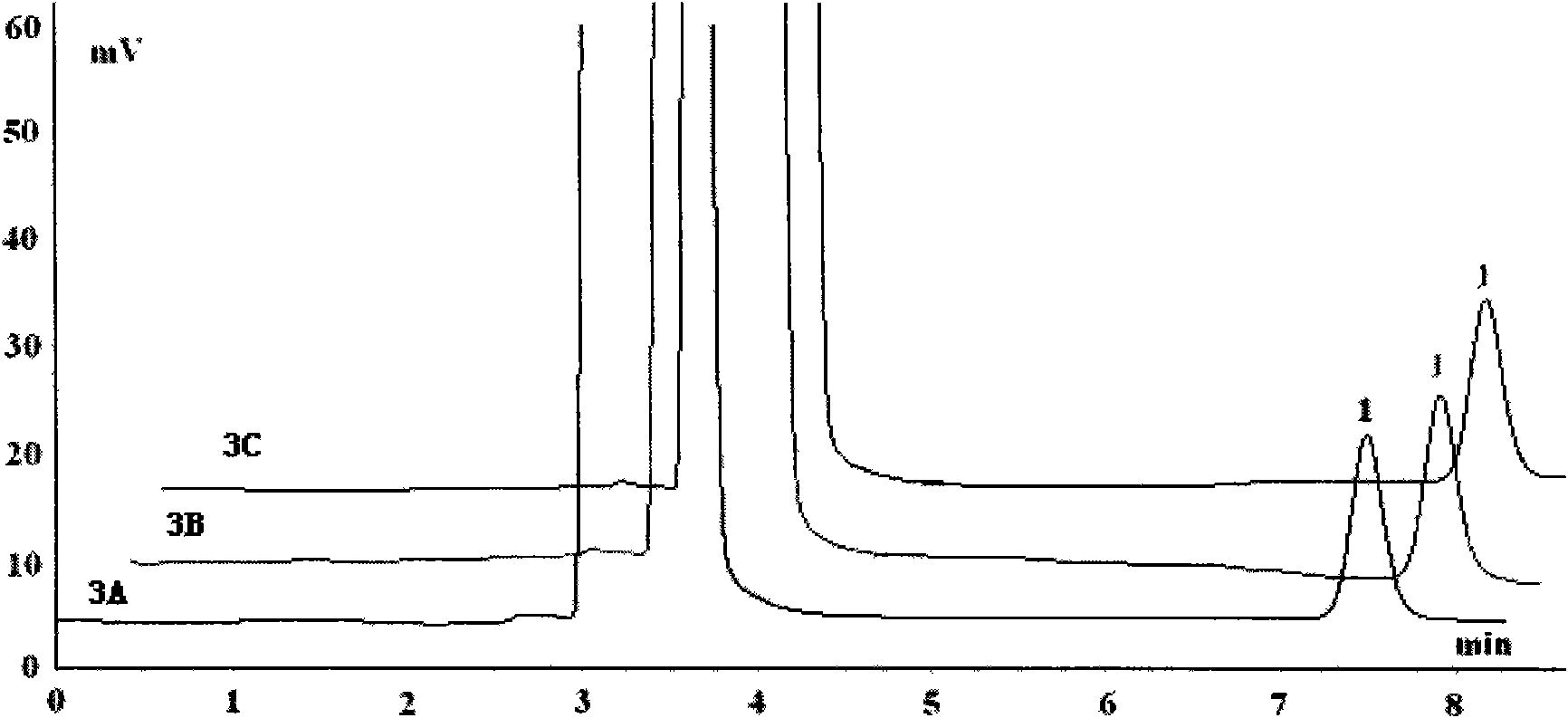

Centrifugal ultrafiltration device suitable to be used in preprocessing of micro sample

InactiveCN101898088AEasy to manufactureTo achieve the purpose of separationSemi-permeable membranesPreparing sample for investigationFiberUltrafiltration

The invention discloses a centrifugal ultrafiltration device suitable to be used in the preprocessing of a micro sample, which comprises a centrifuge tube, and is characterized in that a hollow fiber film which is parallel to the axis of the centrifuge tube and of which the outlet extends out of the centrifuge tube are arranged in the centrifuge tube. The centrifugal ultrafiltration device can bewidely used in the preprocessing of the micro sample as well as the separation, purification and concentration of micro biological samples. The use of the device is simple, quick and convenient; the processed sample suffers little interference and has high sensitivity; and, the service life of a chromatographic column is prolonged effectively.

Owner:HEBEI MEDICAL UNIVERSITY

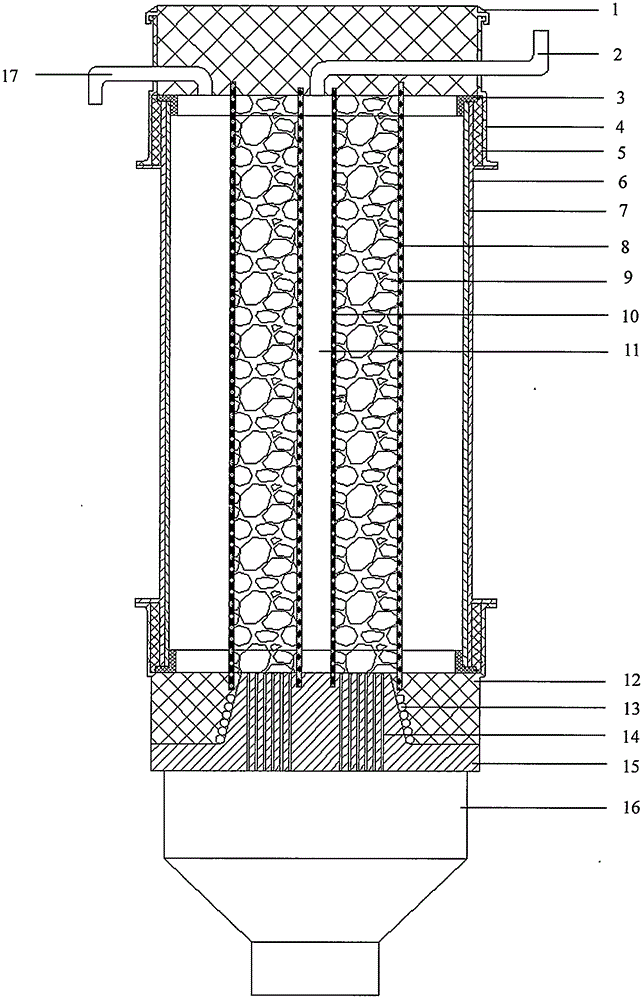

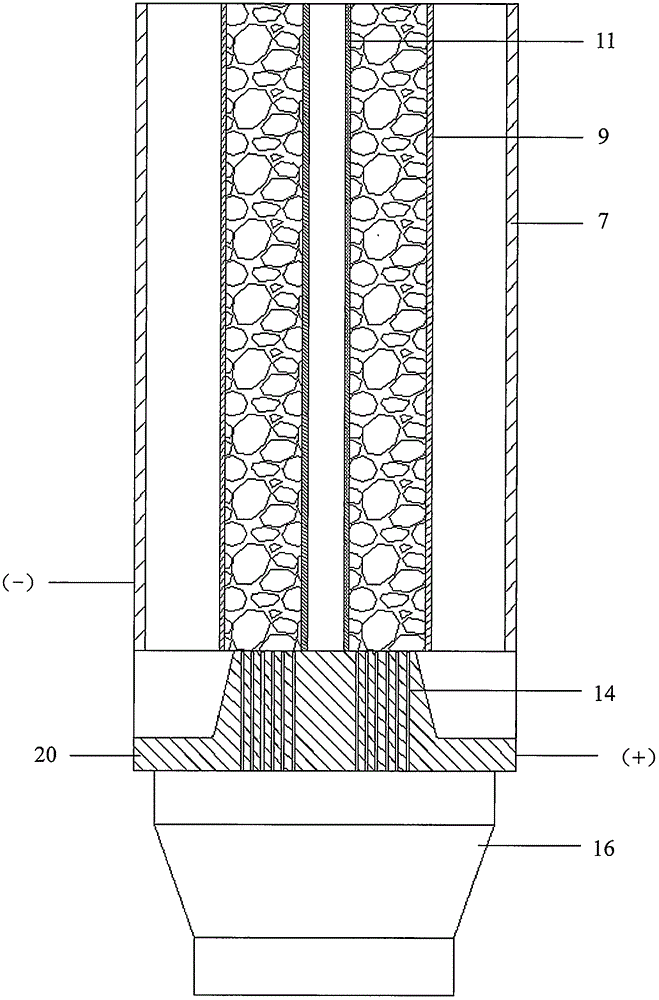

Rotational flow electrolyzing device for separating and recycling metal composite waste material

InactiveCN104451784ARealize direct electrolytic purificationAchieve high efficiencyElectrodesElectrode potentialElectrolysis

The invention relates to a rotational flow electrolyzing device for separating and recycling a metal composite waste material. The rotational flow electrolyzing device comprises an anode basket, a liquid intake channel, a power supply, an anode mud channel, an anode mud collecting tank and a cathode, wherein the cathode is internally provided with the anode basket and a clearance is formed between the cathode and the anode basket; the anode basket is internally filled with a metal composite waste material so as to form an anode integrally; the anode basket is internally provided with a liquid intake channel; electrolyte flows into a metal composite waste material outside the channel via the liquid intake channel, is in full contact with the metal composite waste material for reacting, further penetrates through the anode basket to enter the clearance between the anode and the cathode, and then flows out; metal required to be electrolyzed and purified in the metal composite waste material is dissolved in an ion mode under the specific electrode potential and is separated out from the cathode; although metal with low electrode potential is dissolved at the anode, the metal cannot be separated out at the cathode, and metal with high electrode potential is remained at the anode as anode mud, and flows into an anode mud collecting tank via the anode mud channel. According to the invention, metal can be separated and recycled efficiently with zero pollution and low cost.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Charging method and device

InactiveCN106785144AReduce polarizationDepolarizationSecondary cells charging/dischargingElectronConstant current

The embodiment of the invention provides a charging method and device. The charging method is characterized in that the charging for a battery includes a first charging stage and a second charging state, wherein the first charging state comprises at least two charging sub-steps; the battery is sequentially subjected to first constant-current charging, second constant-current charging, constant-current discharging and third constant-current discharging in each charging sub-step; the battery is subjected to constant-voltage charging in the second charging state. According to the technical scheme provided by the embodiment of the invention, the charging method and device can solve the problem of high safety risk, caused by the increase of the charging speed, of the battery in an existing charging method, can be solved.

Owner:NINGDE AMPEREX TECH

Spent solution treatment method of silver electrolyte

InactiveCN106048659AReduce outputIncrease production capacityPhotography auxillary processesProcess efficiency improvementElectricitySolution treatment

The invention discloses a spent solution treatment method of a silver electrolyte. A silver electrolyte spent solution, as a silver electro-deposition liquid, is fed into a whirl-flow electro-deposition system to perform primary electro-deposition; and then metal copper is added to a low-silver liquid to replace crude silver powder; a desilverized solution, as a copper electro-deposition mother liquid, is fed into the whirl-flow electro-deposition system to perform secondary electro-deposition; and finally, a part of a low-copper liquid is fed back to a sliver liquid preparing system, while the rest part of the low-copper liquid is sent to an environmental protection workshop for treatment. The spent solution treatment method of the silver electrolyte is simple in processes, convenient to carry out and low in cost, can be used for directly recycling valuable metal, such as silver, copper and the like, in a high-effective, low-cost and high-recovery-rate manner.

Owner:ZIJIN MINING GROUP

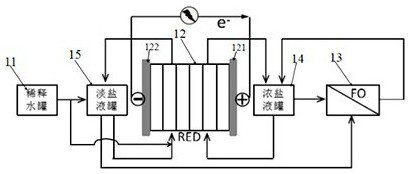

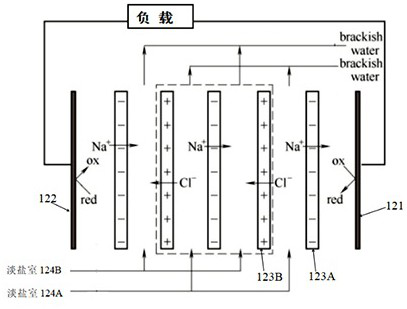

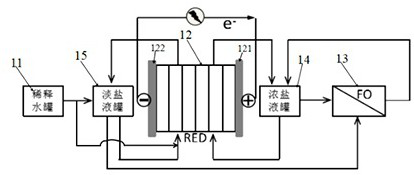

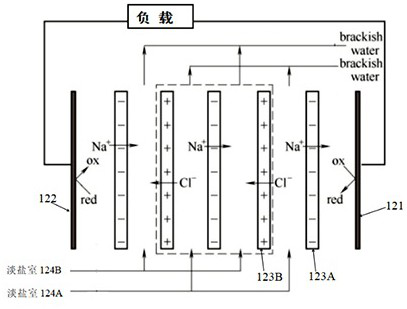

Continuous salinity gradient power generation device and method

ActiveCN112713808AImprove concentration efficiencyLower resistanceKinetic-electric generatorEngineeringReversed electrodialysis

The invention relates to a continuous salinity gradient power generation device. The device comprises a dilution device, a reverse electrodialyzer, a forward osmosis device, a concentrated salt liquid tank and a light salt liquid tank; the concentrated salt solution tank contains a concentrated salt solution, the light salt solution tank contains a light salt solution, and the concentration of the concentrated salt solution is greater than that of the light salt solution; the reverse electrodialyzer is provided with a cathode and an anode, and a cation exchange membrane, an anion exchange membrane, a thick liquid chamber and a thin liquid chamber are alternately arranged between the cathode and the anode; a potential difference is formed between the cathode and the anode of the reverse electrodialyzer; the concentrated salt solution circulates between a concentrated solution chamber and a concentrated salt solution tank of the reverse electrodialyzer, the light salt solution circulates between a light solution chamber and a light salt solution tank of the reverse electrodialyzer, the dilution device provides a diluent to maintain the light salt solution at a low concentration, the forward osmosis device provides a concentration effect to maintain the concentrated salt solution at a high concentration, and part of the light salt solution is concentrated and then is used for supplementing the strong salt solution. The device disclosed by the invention can realize cyclic continuous power generation by utilizing the salt concentration difference and has the characteristic of high power generation efficiency.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

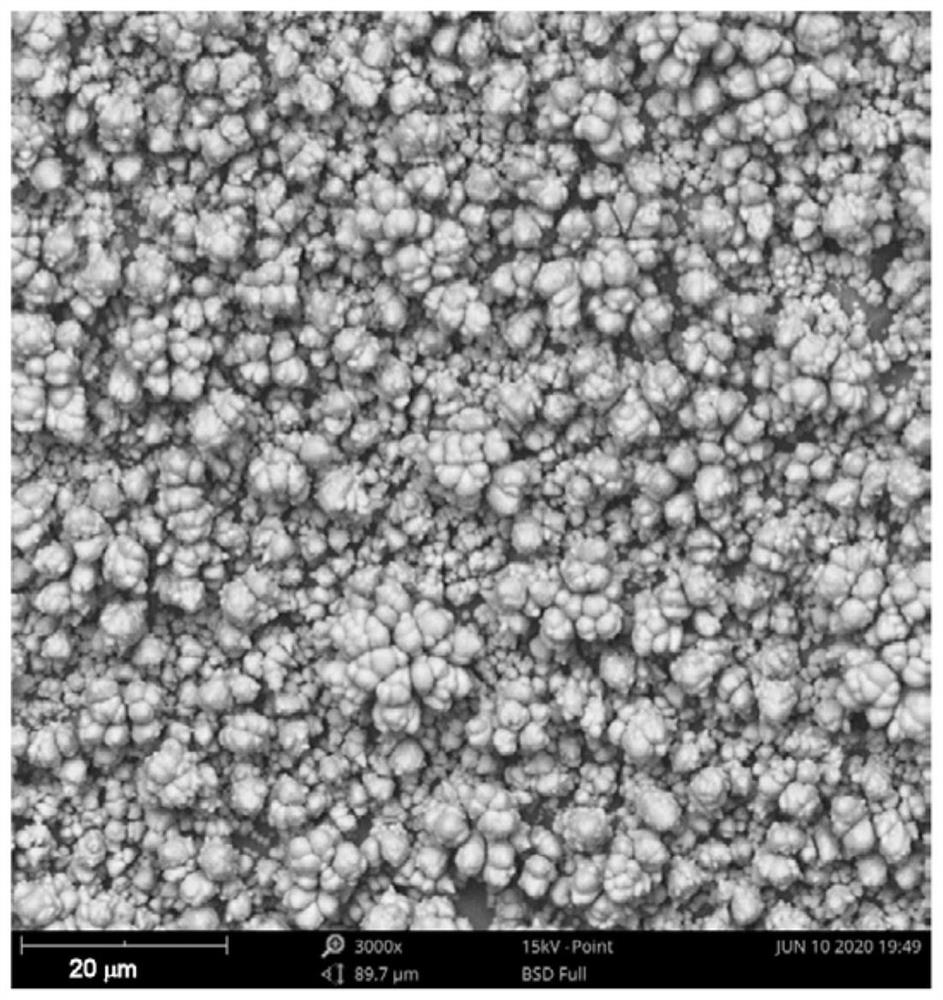

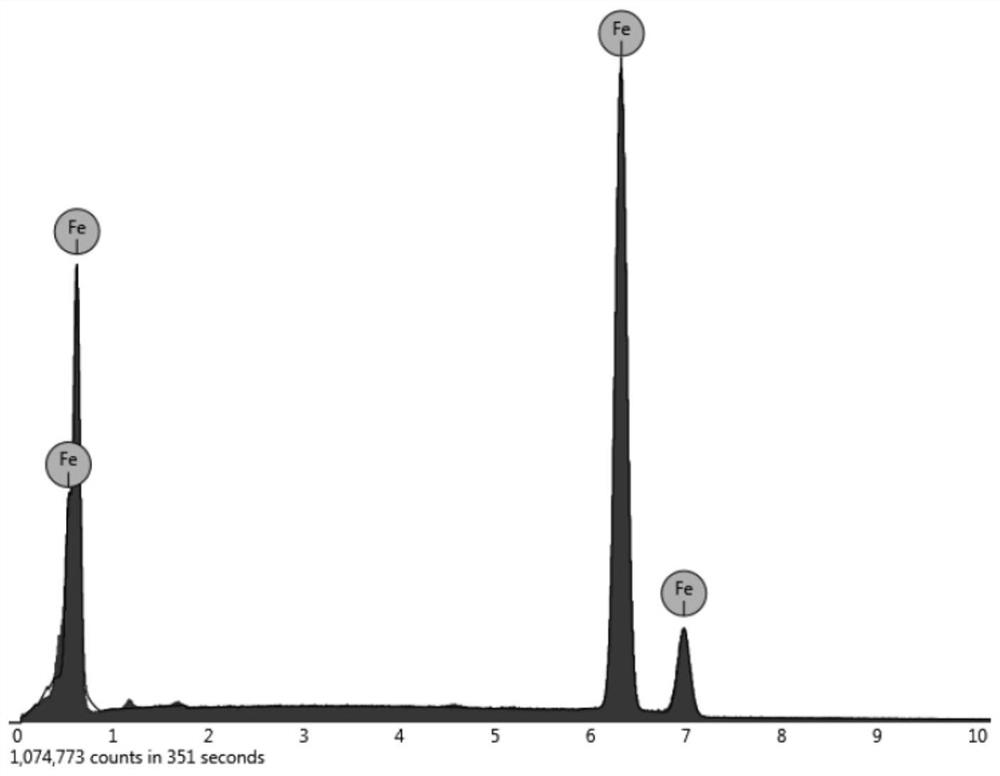

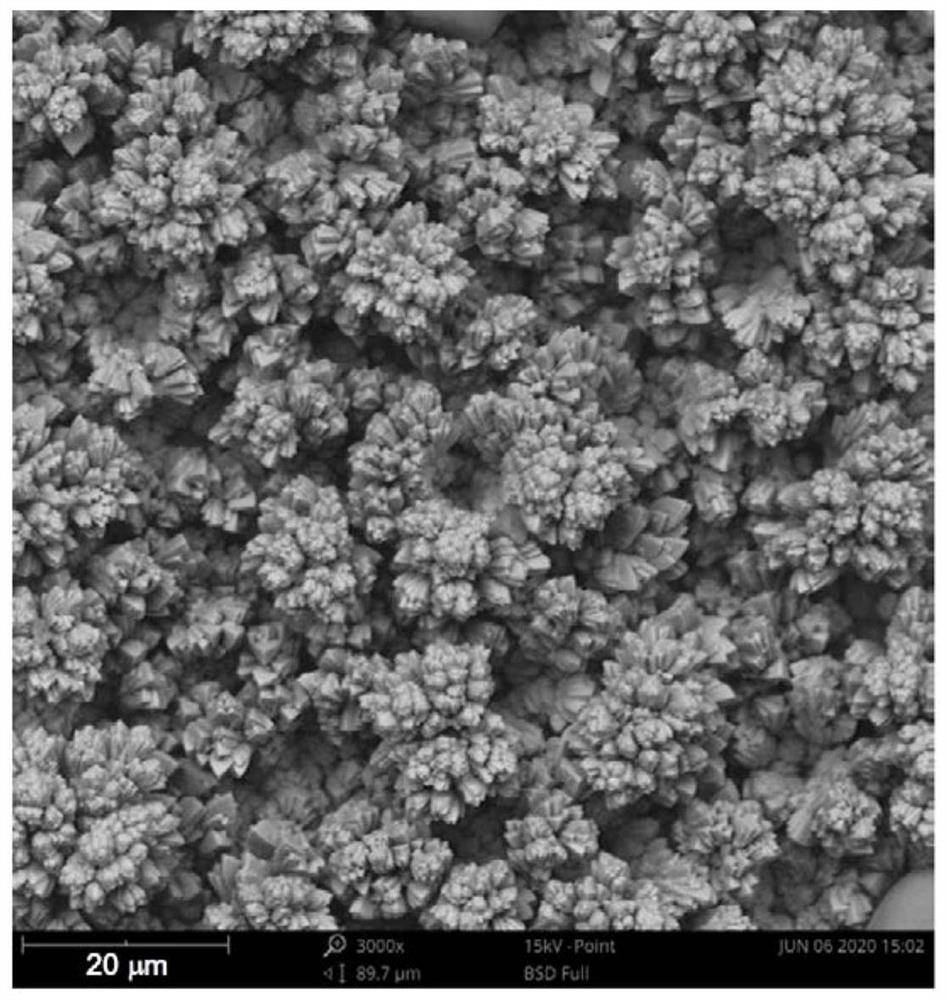

Electroplating solution for directly electrodepositing iron on surface of magnesium alloy and electroplating process thereof

The invention belongs to the technical field of surface engineering and surface treatment, and discloses an electroplating solution for directly electrodepositing iron on the surface of a magnesium alloy and an electroplating process thereof. The electroplating solution comprises the following components in concentration of 1-300 g / L of water soluble iron / ferrous salt, 1-1000 g / L of citric acid and / or citrate, 1-50 g / L of sodium fluoride, 0.01-200 g / L of a surfactant, 0.1-500 g / L of a co-complexing agent and 1-1000 mL / L of ammonia, and water is used as a solvent. The electroplating solution can be used for electrodepositing the iron on the surface of the magnesium alloy in a one-step method, and a prepared pure iron coating is compact, uniform, good in binding force, good in biocompatibility, degradable and stable in effect, can provide effective corrosion protection for a magnesium alloy matrix, and can also realize controllable preparation of coating morphology, grain size and thickness and the like. The electroplating solution and the electroplating process thereof have the advantages of low cost, simple operation and easiness in large-scale production.

Owner:JINAN UNIVERSITY

Device for treating refractory wastewater through electrocatalytic oxidation and method

PendingCN107973457AEffective contactEliminate Concentration PolarizationWater treatment parameter controlWater treatment compoundsCycloneChemical oxygen demand

The invention relates to a device for treating refractory wastewater through electrocatalytic oxidation and a method. The device comprises a cylindrical cyclone electrocatalytic oxidation device, wherein a liquid outlet and a liquid inlet are formed in the upper and lower ends of the device and are separately located at tangent planes of a cylindrical device body, and the wastewater enters along acylindrical tangent line direction through a magnetic driving pump and forms cyclone along the internal wall of a cylinder. An electrode assembly consists of a DSA anode, stainless steel and a titanium cathode, and the DSA anode is lead dioxide, iridic oxide, ruthenium dioxide or a titanium-plated platinum anode. The core of the device is that the cyclone is formed by using forced water flow, a concentration polarization phenomenon inside an electrocatalytic reactor is eliminated, the mass transfer efficiency of the reactor is increased, and the reaction efficiency is increased. Proven by treatment of high-salinity wastewater of coal chemical industry, the device has good electrocatalytic oxidation capacity, the chromaticity and COD (chemical oxygen demand) of the high-salinity wastewatercan be obviously lowered, effluent can enter an evaporation crystallizing system, produced salts are qualified through detection by national salt product quality testing center, and the purity of sodium chloride and sodium sulfate reaches 99.5%.

Owner:XIAN TAIJIN NEW ENERGY & MATERIALS SCI TECH CO LTD

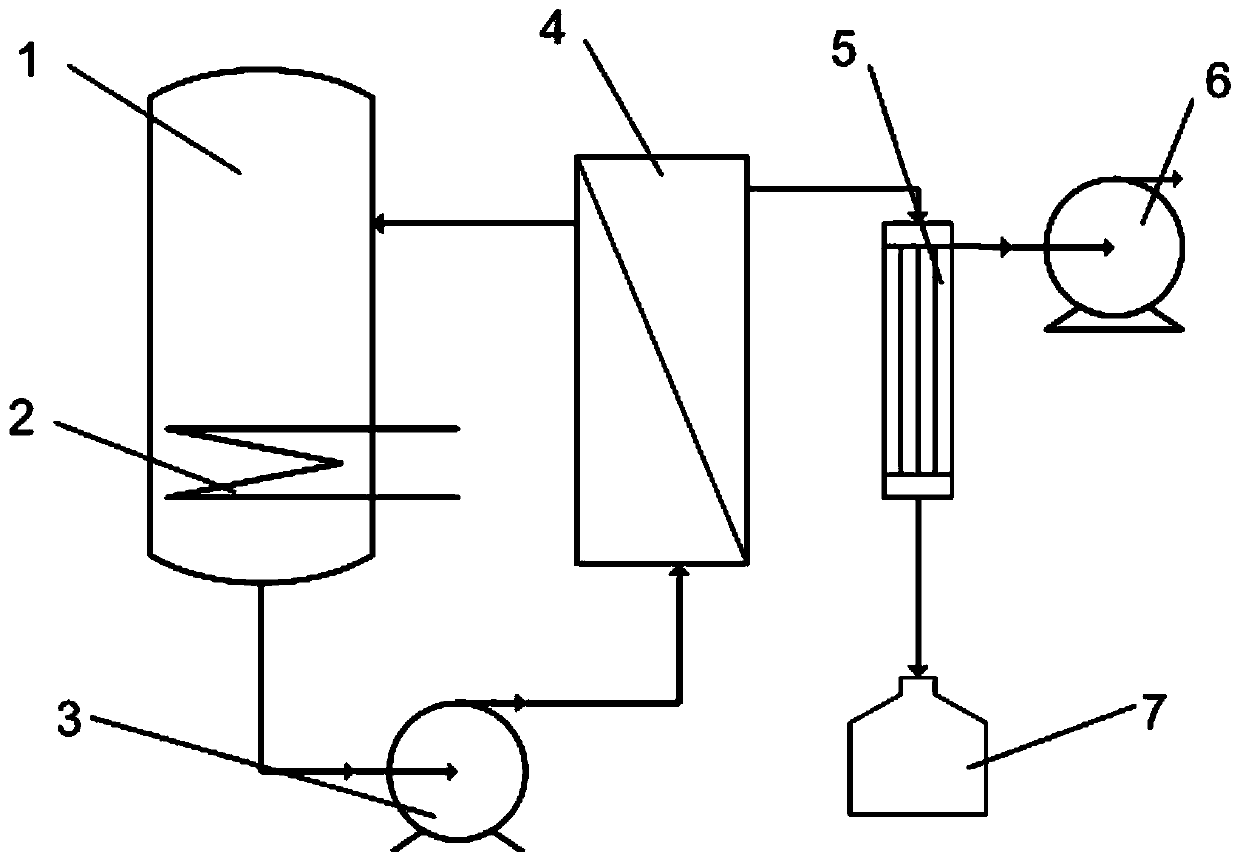

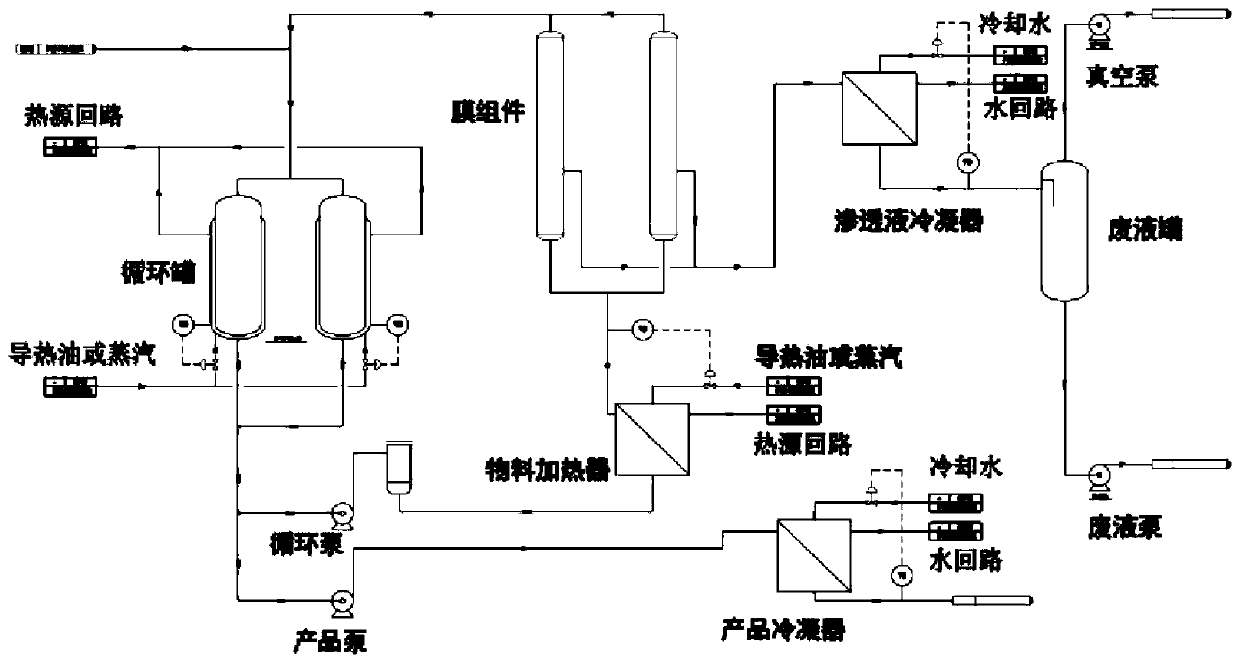

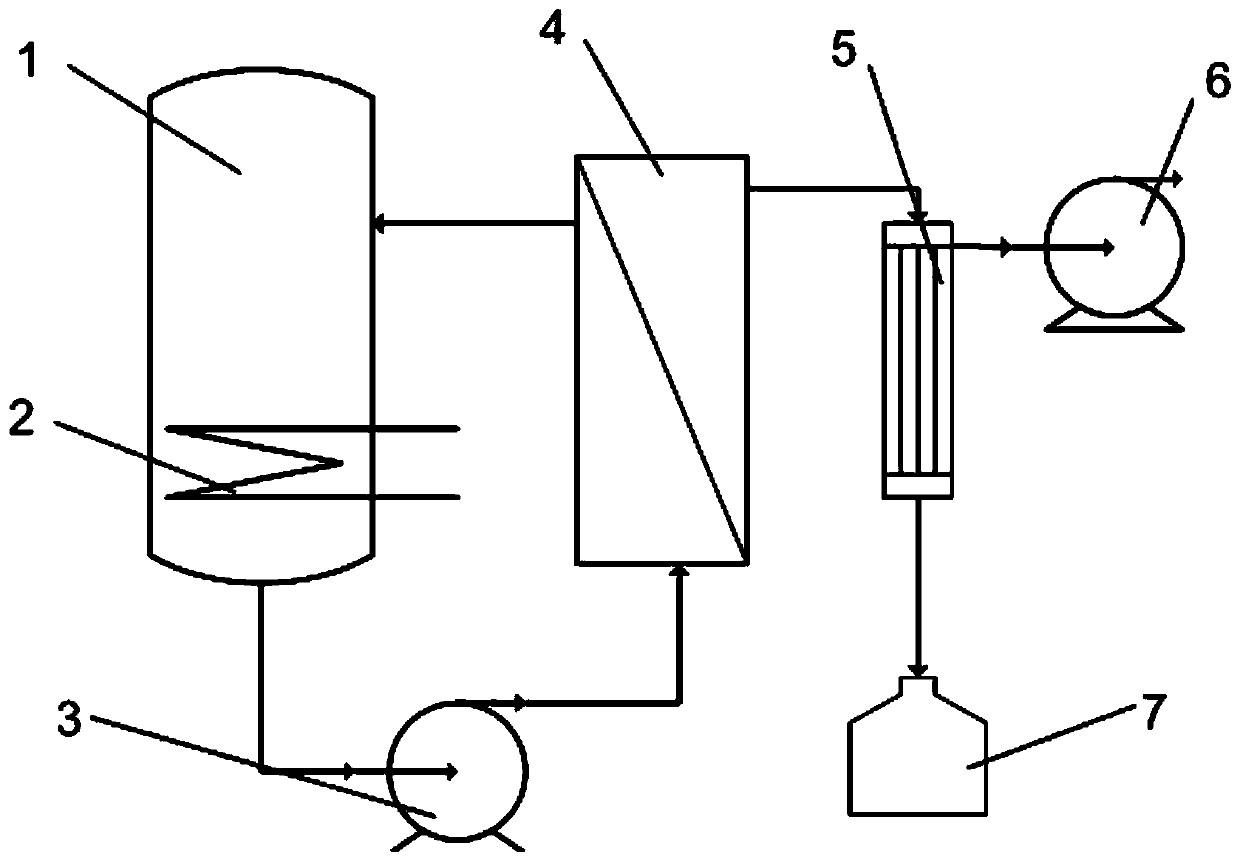

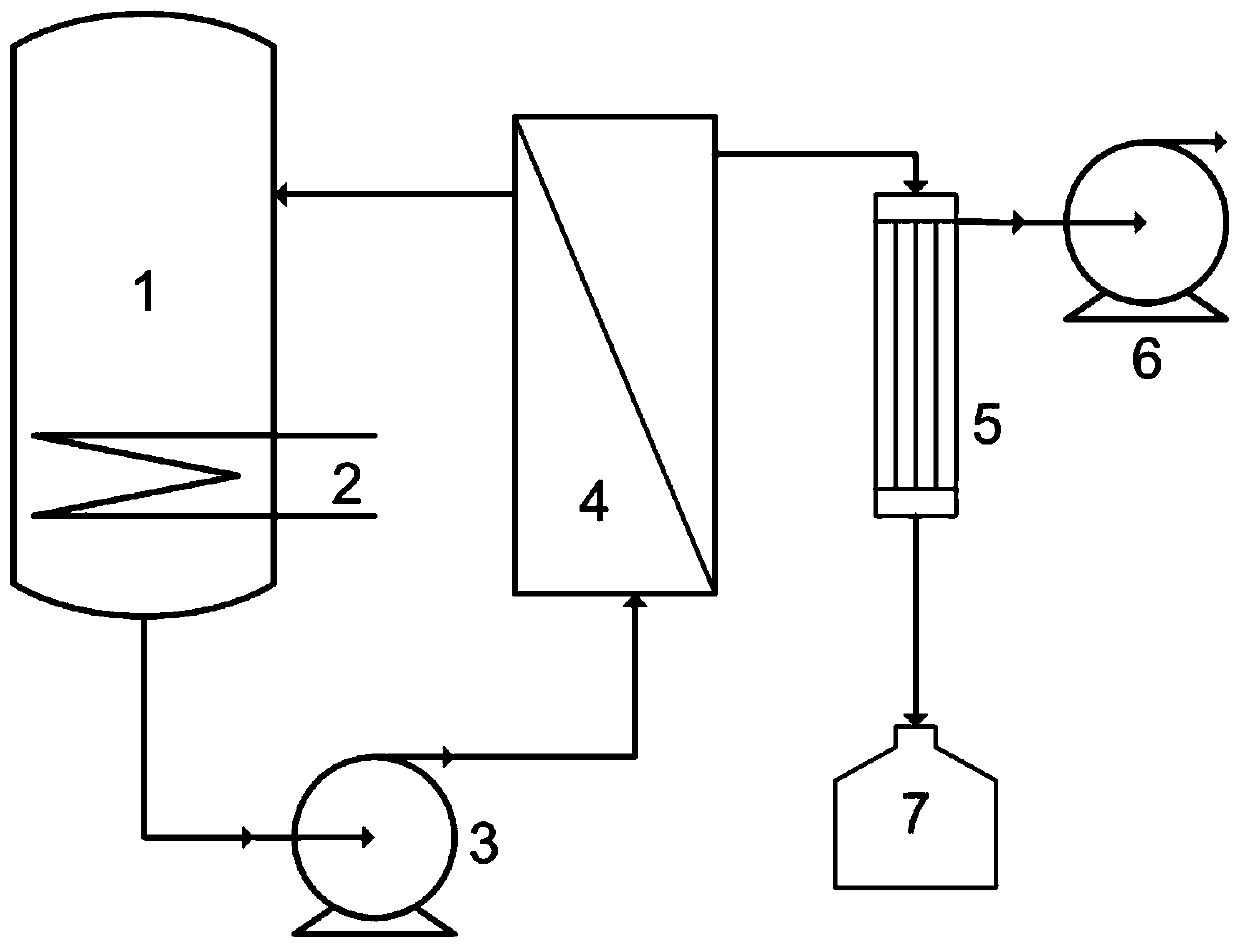

Quick, efficient and flexible pervaporation dehydration system and dehydration extraction method based on pervaporation dehydration system

PendingCN109999669AImprove separation efficiencyIncrease the Reynolds numberDistillationConcentration polarizationEngineering

The invention discloses a quick, efficient and flexible pervaporation dehydration system and a dehydration extraction method based on the pervaporation dehydration system. The system comprises a circulation tank, a heater, a material and liquid pump and a pervaporation membrane separator, the heater is installed in a raw material liquid tank and located below the raw material liquid level of the circulation tank, and an outlet of the circulation tank is connected with an inlet of the material and liquid pump; an outlet of the material and liquid pump is connected with an inlet of the pervaporation membrane separator, a lateral raw material outlet of the pervaporation membrane separator is connected with an inlet in the upper end of the circulation tank, a lateral permeation outlet of the pervaporation membrane separator is connected with a condenser, and the other outlet of the condenser is connected with a vacuum pump. The designed membrane pervaporation separation system is wider andmore flexible in application range and suitable for dehydration purification of multiple materials and reduces the equipment investment cost, commercial popularization is convenient, the concentration polarization phenomenon generally existing at the raw material side in a traditional pervaporation technology is greatly reduced and even completely eliminated, the separation efficiency of a membrane assembly is improved, and the application range is wider and more flexible.

Owner:HYLEIN ENERGY & ENVIRONMENT TECH CO LTD

Recovery method of N-methyl pyrrolidone

PendingCN110759844AReduce concentration polarizationReduce or even eliminate concentration polarizationOrganic chemistryPyrrolidinonesMethyl palmoxirate

The invention provides a recovery method of N-methyl pyrrolidone. The method is characterized by comprising the following steps: heating an N-methyl pyrrolidone material liquid with the water contentof 1-50 wt.% in a circulating tank to 30-190 DEG C; introducing the heated N-methyl pyrrolidone material liquid into a pervaporation membrane assembly to make water in the material liquid be separatedfrom the material liquid side of the pervaporation membrane and enter the permeation side, wherein the pervaporation membrane assembly comprises 1-3000 organic-inorganic or inorganic-organic hybrid membrane single-pass pipes or multi-pass pipes, an absolute pressure of the permeation side is set to be 100-15000 Pa, and a membrane feeding speed of the material liquid is set to be 0.15-1.6 m / s; after the material liquid passes through the pervaporation membrane assembly, making the material liquid on the material liquid side return to the circulating tank, and making the water on the permeationside be condensed and recovered; and performing circulation for multiple times on the material liquid in the circulating tank to obtain recovered N-methyl pyrrolidone.

Owner:HYLEIN ENERGY & ENVIRONMENT TECH CO LTD

A continuous salt difference power generation device and method

ActiveCN112713808BImprove concentration efficiencyLower resistanceKinetic-electric generatorReversed electrodialysisSalt solution

The invention relates to a continuous salt difference power generation device, which includes a dilution device, a reverse electrodialyzer, a forward osmosis device, a concentrated salt liquid tank and a light salt liquid tank; the concentrated salt liquid tank contains the concentrated salt liquid, and the light salt liquid tank contains Light salt solution, the concentration of the concentrated salt solution is greater than that of the light salt solution; the reverse electrodialyzer is provided with a cathode and an anode, and between the cathode and the anode are alternately arranged cation exchange membranes and anion exchange membranes and alternately distributed concentrated solution chambers and Dilute liquid chamber; a potential difference is formed between the cathode and anode of the reverse electrodialyzer; the concentrated salt solution circulates between the concentrated liquid chamber of the reverse electrodialyzer and the concentrated salt liquid tank, and the light salt solution is circulated in the reverse electrodialyzer Circulation between the light liquid chamber and the light salt liquid tank, the dilution device provides diluent to maintain the light salt solution at a low concentration, the forward osmosis device provides concentration to maintain the concentrated salt solution at a high concentration, and concentrates part of the light salt solution Used to replenish concentrated brine. The device of the invention can utilize the salt concentration difference to realize cycle continuous power generation, and has the characteristics of high power generation efficiency.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

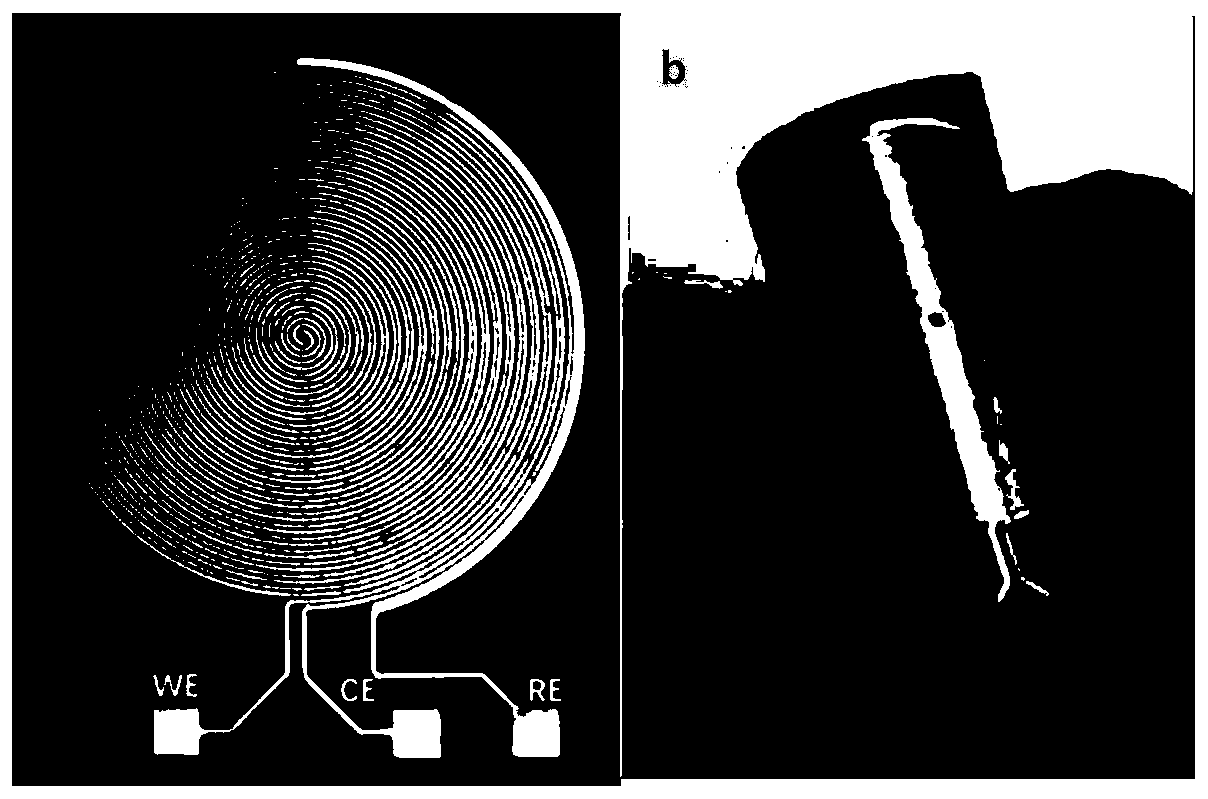

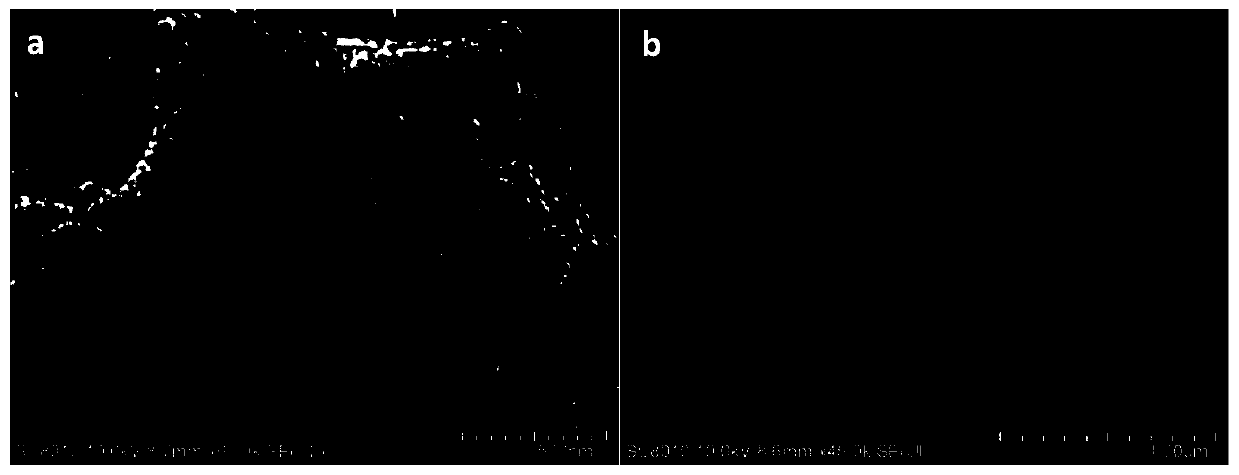

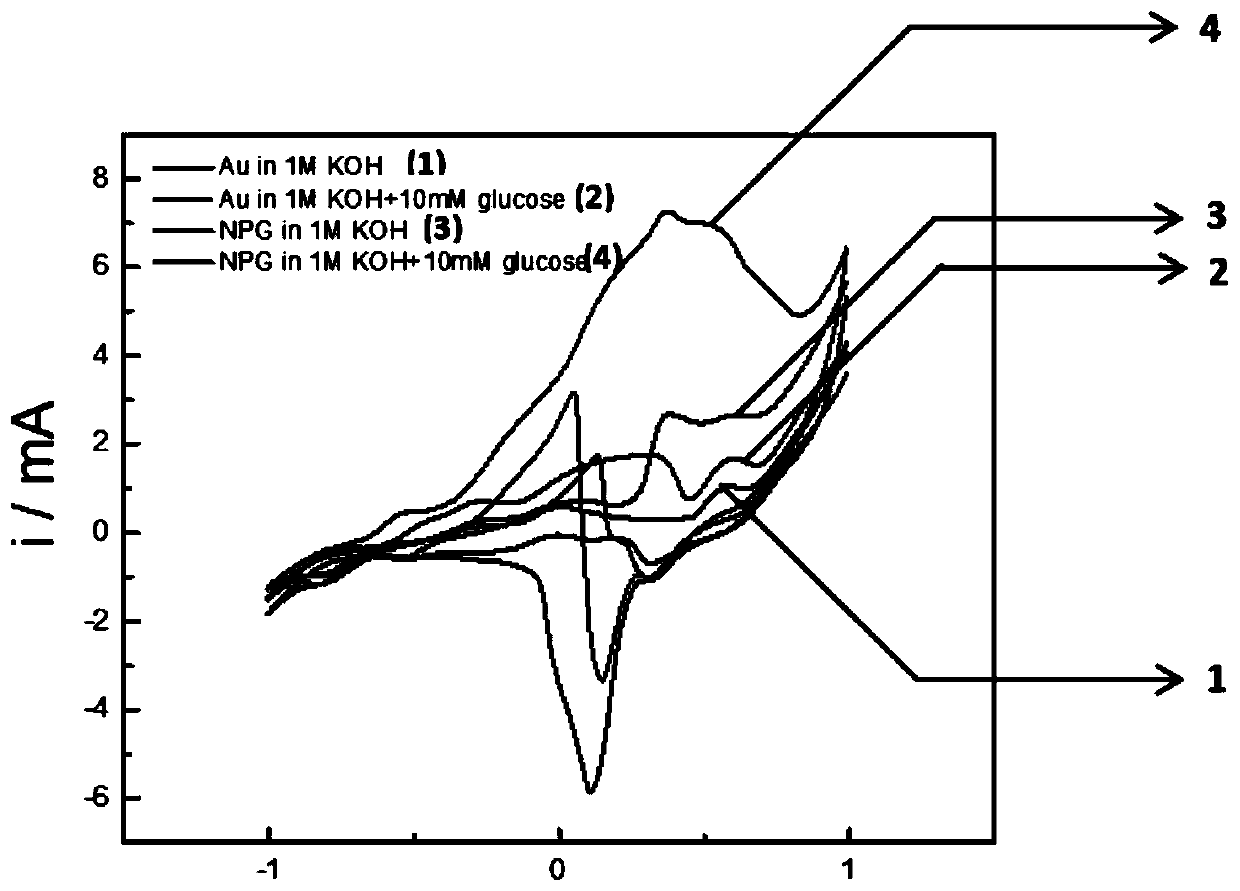

Nano porous gold enzyme-free flexible sensing electrode for detecting glucose through sweat, and preparation method and application thereof

InactiveCN110455894ASolving problems that cannot be applied to tiny sensorsSolving technical problems in modifying nanoporous goldMaterial electrochemical variablesMicrometerD-Glucose

The invention provides a nano porous gold enzyme-free flexible sensing electrode for detecting glucose through sweat, and a preparation method and application thereof. The invention provides a three-electrode coplanar integrated enzyme-free glucose sensing electrode, nano porous gold with high catalytic activity is combined with a fine interdigital electrode through electrodeposition, and a feasible method for electrodeposition of a nano material in a microelectrode area is provided. The nano porous gold modified flexible sensing electrode provided by the invention has higher sensitivity, extremely low detection limit, wider detection range and excellent stability and anti-interference performance, wherein the detection limit is 0.55 micrometers, in the detection ranges of 0.001-2.50mM and2.50-10.0mM, the electrode respectively has high sensitivity of 1297 mu A / mM.cm2 AND 854.7 mu A / mM.cm2.

Owner:HUIZHOU LEADAO ELECTRONICS MATERIAL

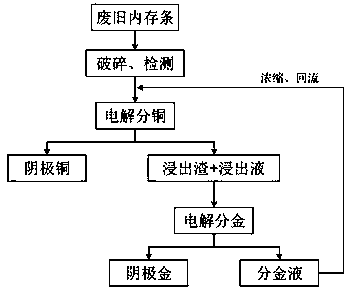

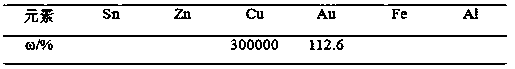

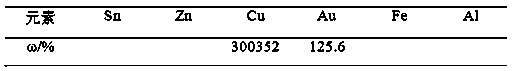

Method of selective electrolytic leaching recycling gold and copper from waste memory strips

ActiveCN109797407ASimple processLower requirementPhotography auxillary processesProcess efficiency improvementPregnant leach solutionElectrolysis

The invention belongs to the technical field of electrolytic recycling of metallic copper and gold, and particularly relates to a method of selective electrolytic leaching recycling gold and copper from waste memory strips. The method comprises the following specific steps that (1) a broken abandoned golden finger is put into an electrolytic bath containing an electrolytic solution I and an annexing agent I for electrolysis; (2) after reaction is finished, the broken abandoned golden finger is taken out and is replaced with a cathode plate, crude copper is recycled, and filtering and washing are carried out; (3) an electrolytic solution II and an annexing agent II are supplied in the electrolytic bath for re-electrolysis; (4) crude gold powder on a cathode is recycled after reaction is finished; and (5) a leaching solution is recycled and subjected to concentration and enrichment, and re-electrolysis and recycling are carried out. According to the method of selective electrolytic leaching recycling gold and copper from the waste memory strips, the recycling cost is low, the purpose of selective resource recycling the gold and copper is realized by adding different annexing agents in a same electrolytic solution system, and the recycling rates of the gold and the copper both can reach more than 98.5%.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

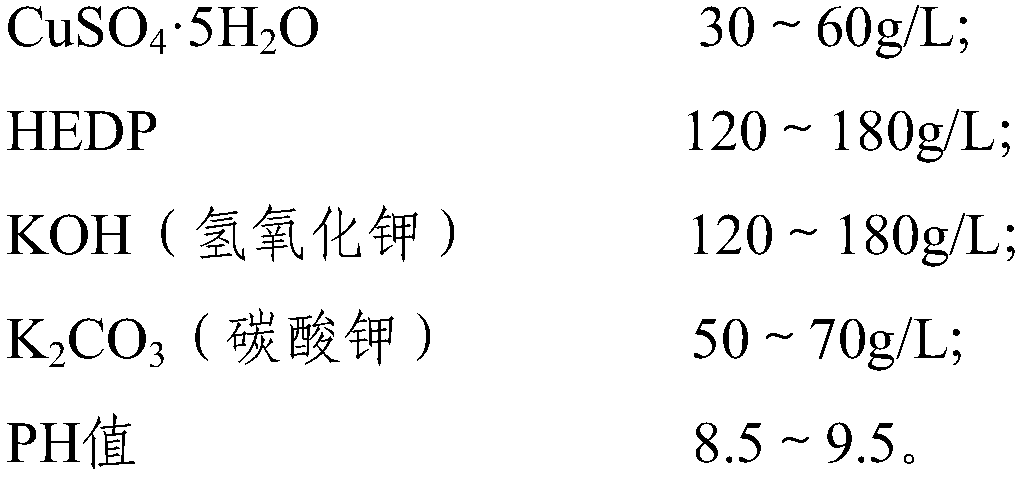

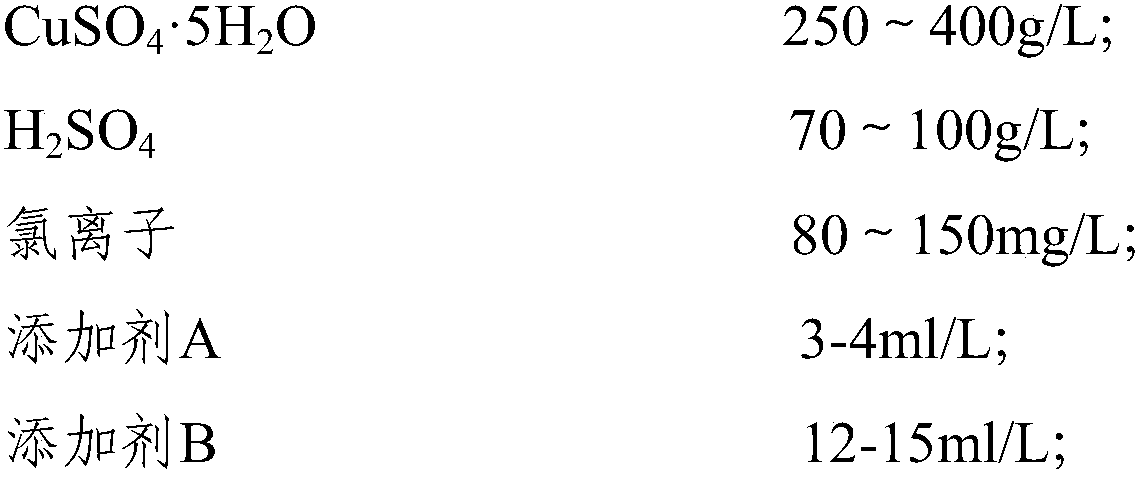

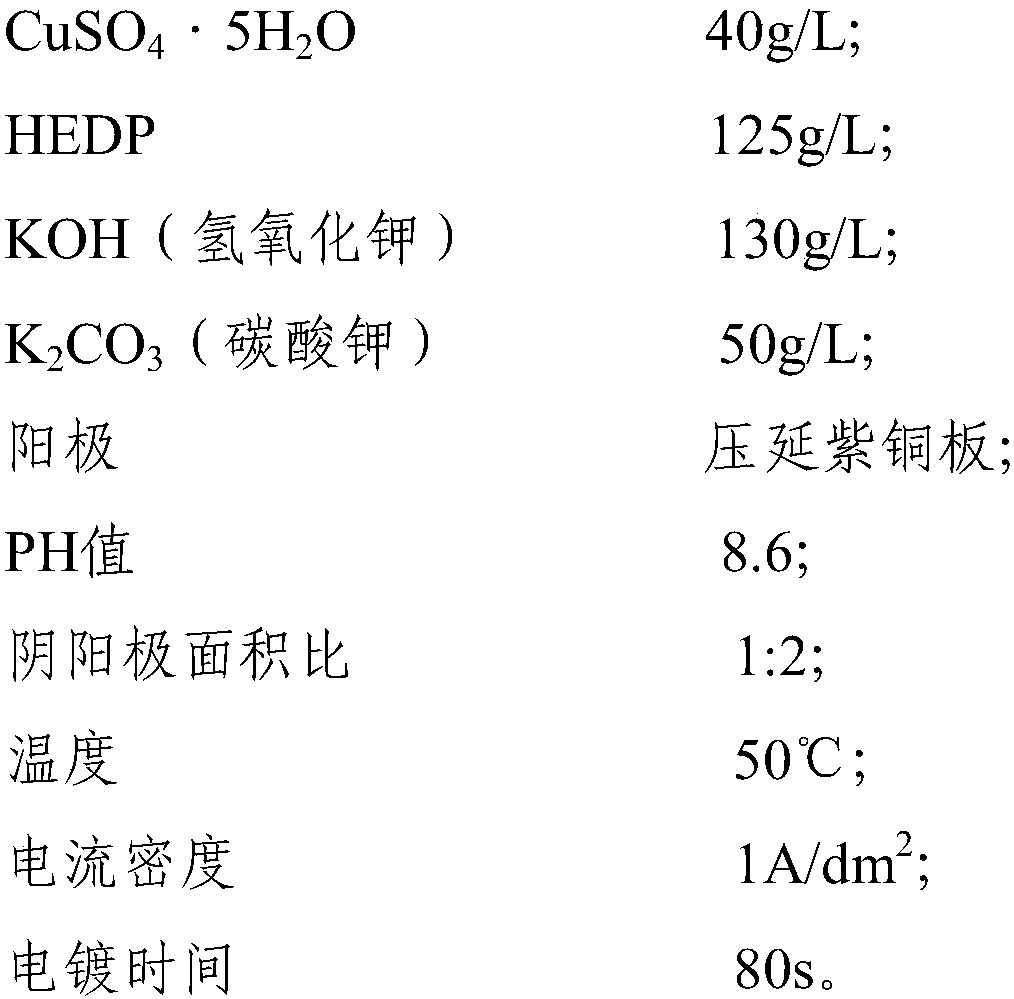

Copper-plated steel wire and production method thereof

The invention relates to a copper-plated steel wire and a production method thereof. The production method for the copper-plated steel wire comprises the following steps of pre-treating low-carbon steel, carrying out copper pre-plating, carrying out copper preliminary activating after carrying out water washing, carrying out acid thick copper plating and then carrying out post-treatment so as to obtain the copper-plated steel wire. According to the copper-plated steel wire and the production method thereof, an existing process for a copper-plated steel wire is improved, and therefore the working procedures taking the three modes, namely oil removing-copper pre-plating-acid thick copper plating as the principal things are determined; an HEDP solution is adopted for activating and pre-plating a copper layer, and therefore the copper-steel binding force can be greatly enhanced; and meanwhile, high-temperature, high-current-density and high-speed air agitation is adopted for electroplating, and a compact and smooth coating can be quickly achieved by means of the synergistic effect of multiple aspects.

Owner:BEIJING ALLDAY SCI & TECH

Membrane distillation device and membrane distillation system

ActiveCN105233695AIncreased turbulence intensityEliminate concentration polarizationDistillationProduction rateChemistry

The invention provides a membrane distillation device and a membrane distillation system. The membrane distillation device comprises a membrane assembly and at least three sets of liquid delivery assemblies. The sets of liquid delivery assemblies are sequentially connected in the membrane assembly along the axial direction of the membrane assembly, and are used for inputting and / or outputting liquid into and / or out of the membrane assembly. According to the invention, feed liquid inlet / outlet numbers in the membrane assembly are increased; inlet / outlet positions are changed; and different inlets / outlets are switched during working, such that turbulence intensity of the feed liquid in the membrane assembly is enhanced; a membrane outer surface feed liquid concentration polarization phenomenon is reduced and eliminated; a temperature polarization phenomenon on two sides of the membrane is reduced and eliminated; a steam productivity in the membrane is improved; and membrane assembly anti-pollution capacity and service life are improved.

Owner:ENN ENVIROTECH CO LTD

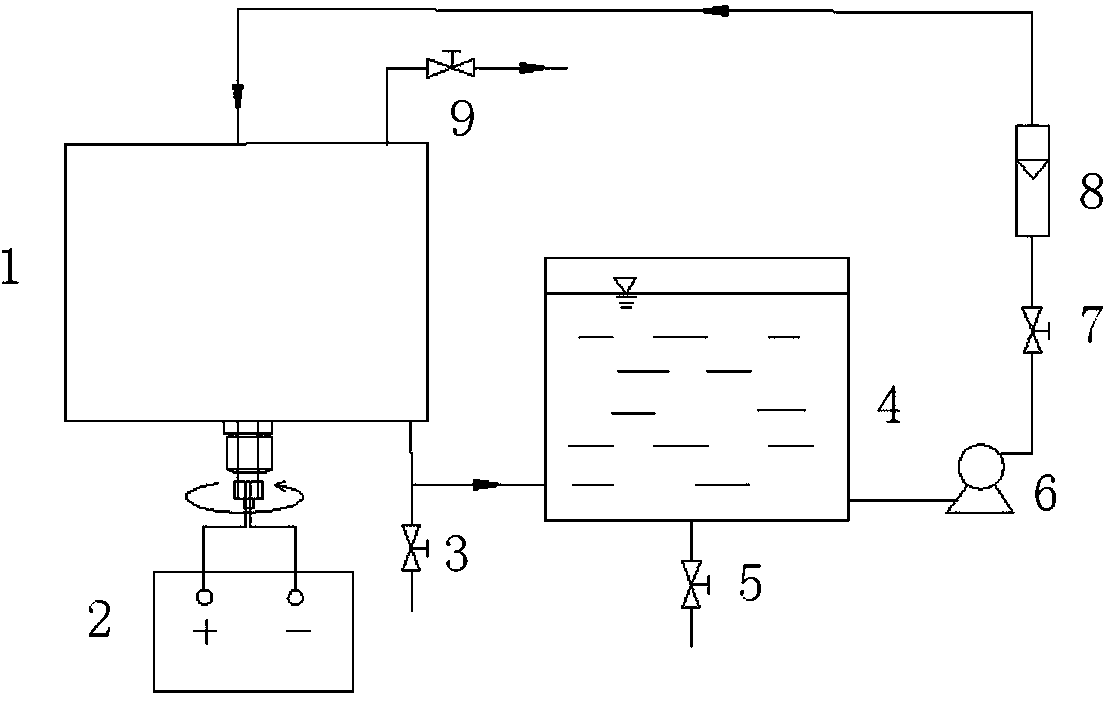

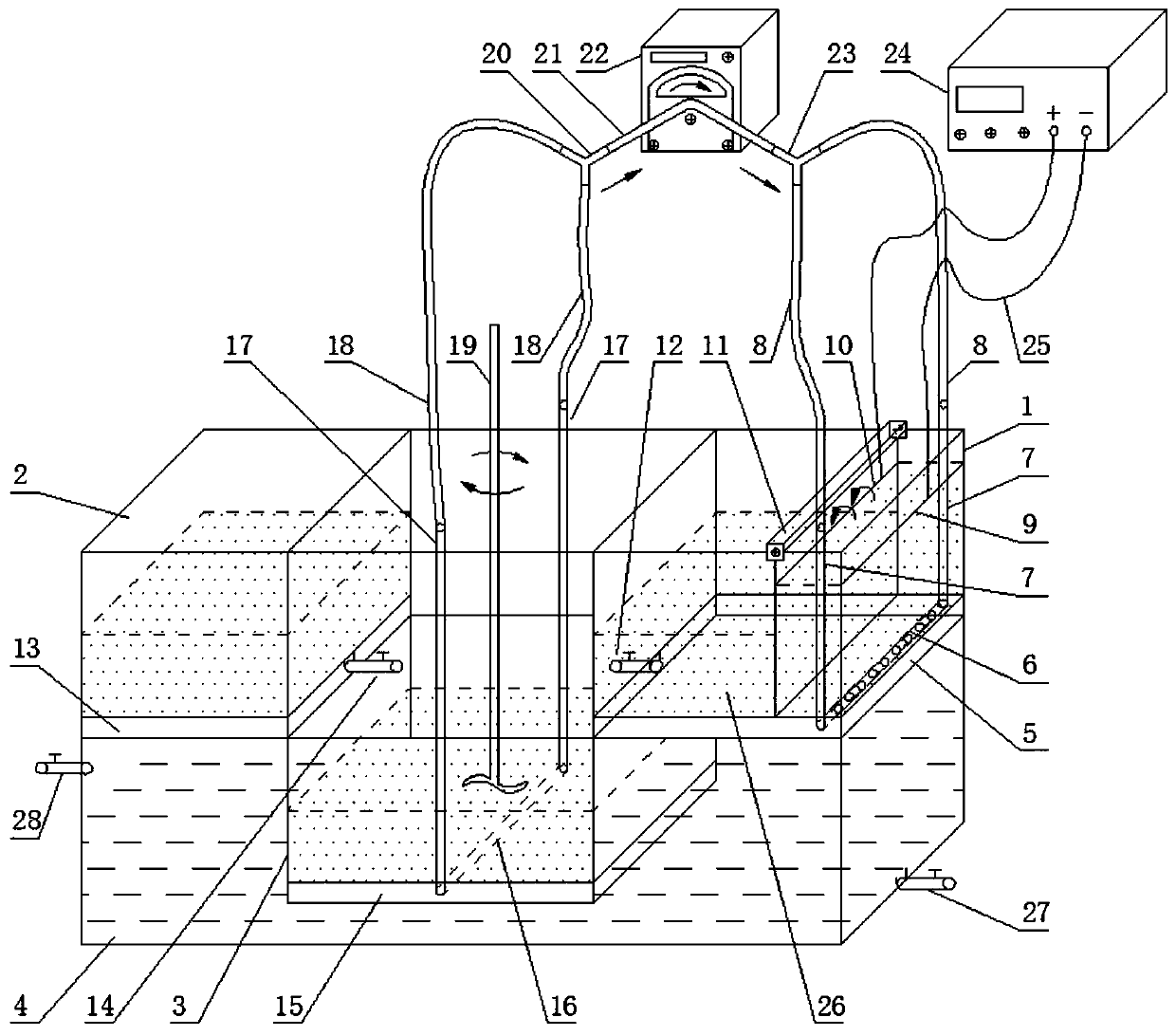

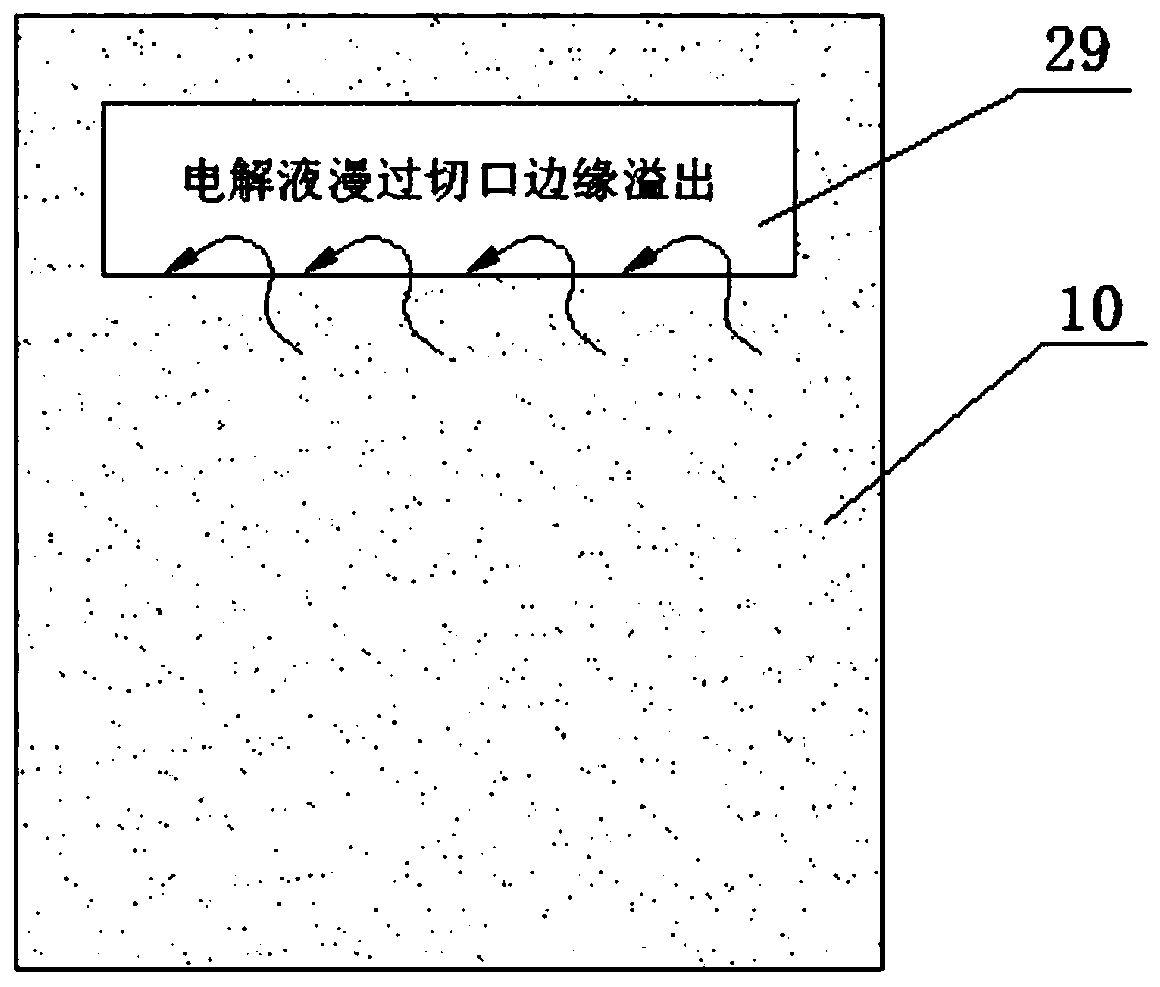

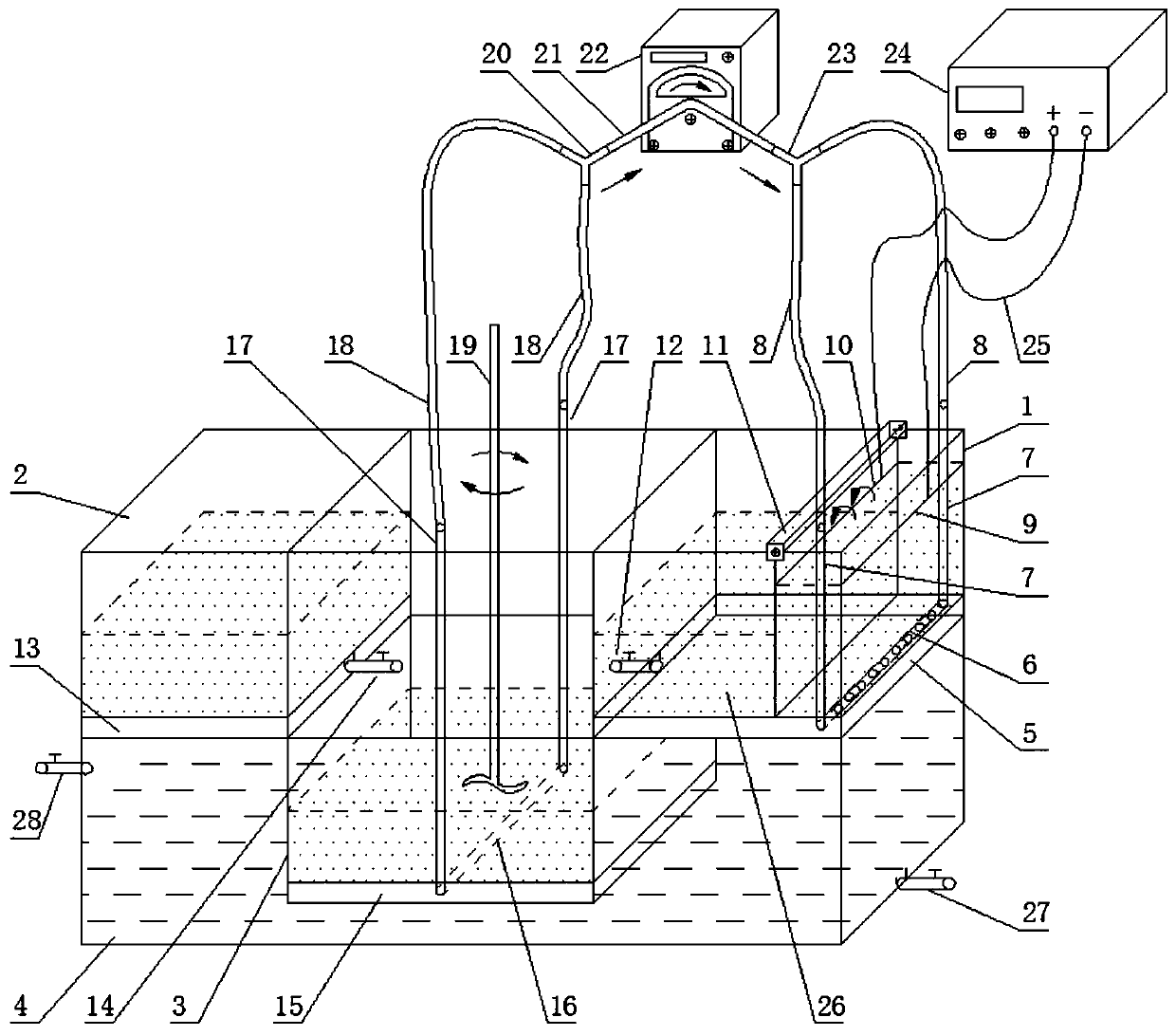

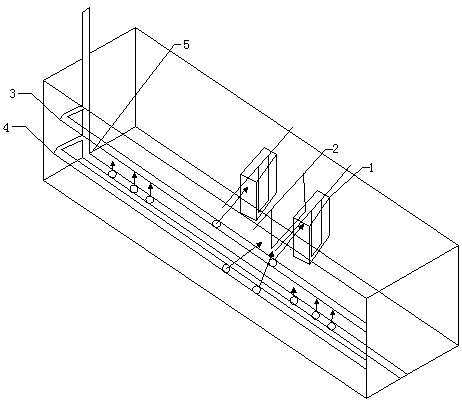

Experiment research system for electrolytic copper foil and using method thereof

ActiveCN111172565AEliminate Cathode Concentration PolarizationMeet the actual production auxiliary requirementsCellsElectroforming processesElectrolytic agentConcentration polarization

The invention discloses an experiment research system for an electrolytic copper foil and a using method thereof, and belongs to the technical field of electrolytic copper foil experiment. The systemcomprises an electrolytic cell, a constant-current rectifier, a solution supplementing slot, a solution mixing slot, a heating slot, a cathode plate and an anode plate, wherein the upper edge of the electrolytic cell is slidably connected to an anode slide block for mounting the anode plate; an overflow hole is formed in the anode plate; the solution mixing slot and the solution supplementing slotare formed in one side of the electrolytic cell; solution discharge valves are arranged on the bottom of the electrolytic cell and the bottom of the solution supplementing slot; the solution mixing slot communicates with the electrolytic cell through a pipeline; and one heating slot is co-formed below the electrolytic cell and the solution supplementing slot. The using method comprises electrolytic solution preparation, temperature control, parameter setting, copper consumption calculating, electrolytic solution supplementing, copper foil sample obtaining and the like. The experiment researchsystem can eliminate the concentration polarization problem, supplements electrolytic solution components, keeps temperature constant, meets practical production auxiliary requirements, can simplifytest operations, quickens test development efficiency, and reduces new product development and production cost.

Owner:JIANGXI UNIV OF SCI & TECH

Direct scrap copper electrolysis method

InactiveCN111304694AReduce voltageQuality improvementElectrolysis componentsPhotography auxillary processesElectrolytic agentConductive materials

The invention discloses a direct scrap copper electrolysis method. The direct scrap copper electrolysis method comprises the following steps that firstly, a non-conductive anode frame is adopted, a copper sheet serves as a conductive material for the anode frame, scrap copper is arranged on the two sides of the copper sheet, the non-conductive anode frame is loaded on a conductive bar, a permanentstainless steel cathode plate serves as a cathode, and an acid copper sulfate solution serves as an electrolyte; secondly, gelatin, albumen powder, thiourea, acitretin and an additive A are added inan electrolytic cell to serve as an electrolysis additive; and thirdly, electrolysis is conducted, scrap copper in the non-conductive anode frame is constantly dissolved, and A-level copper standard electrolytic copper is obtained through stainless steel cathode deposition. The direct scrap copper electrolysis method has the beneficial effects that through electrolysis additive optimization improvement and electrolysis process electrolyte filter quality control, the double-spraying-flow collaborative bottom liquid inflow manner is adopted, concentration polarization is eliminated, the voltageof the electrolytic cell and the electrolytic copper impurity content are greatly reduced, the electrolytic copper product quality is improved, and the electrolytic product economic additional value is increased.

Owner:TONGLING NON FERROUS METAL GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com