Direct scrap copper electrolysis method

A waste miscellaneous copper, direct technology, applied in the field of recycling of renewable resources, can solve problems such as the increase of electrolyzer cell voltage, achieve the effects of eliminating concentration polarization, increasing economic added value, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

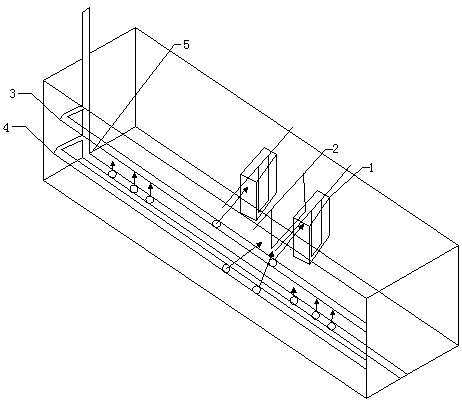

Image

Examples

Embodiment 1

[0020] Scrap copper raw material composition (%): Cu 95.71, Zn 0.079, Sn 0.00019, Sb 0.00016, Bi 0.0001, Pb0.00019, As 0.00071. The anode frame 1 is a non-conductive anode frame, the copper sheet is a conductive material, and the opening ratio of the conductive anode frame is 30%; the composition of the electrolyte: Cu 2+ 48g / L, H 2 SO4 190g / L, As 8g / L, Sb 0.3g / L, Bi 0.3g / L, Cl - 0.05g / L; current density 260A / m 2 ;Electrolysis temperature 60°C; Homopolar distance 12cm; Circulation speed per cathode area of electrolyte 50L / min.m 2; Electrolysis additives: gelatin dosage 120g / tCu, protein powder dosage 10g / tCu, thiourea dosage 100g / tCu, additive A polyethylene glycol dosage 20g / tCu, avi common dosage 15g / tCu; electrolysis process electrolytic tank liquid inlet The suspended matter content is less than 5ppm, and the suspended matter content in the overflow port is less than 10ppm. Electrolysis is carried out under the above conditions, and the waste copper in the anode fra...

Embodiment 2

[0022] Scrap copper raw material composition (%): Cu 95.34, Zn 0.058, Sn 0.27, Sb 0.0041, Bi 0.022, Pb 0.0021, As 0.0031. The anode frame is a non-conductive anode frame, the copper sheet is a conductive material, and the opening ratio of the conductive anode frame is 15%; the electrolyte composition: Cu 2+ 40g / L, H 2 SO4 180g / L, As 2g / L, Sb 0.2g / L, Bi 0.2g / L, Cl - 0.08g / L; current density 200A / m2; electrolysis temperature 45°C; homopolar distance 12cm; electrolyte circulation rate per unit cathode area 25L / min.m2; electrolysis additives: gelatin dosage 100g / tCu, protein powder dosage 30g / tCu, The dosage of thiourea is 80g / tCu, the dosage of additive A polyvinyl alcohol is 30g / tCu, and the dosage of Avi is 10g / tCu; during the electrolysis process, the suspended solids content in the liquid inlet of the electrolytic cell is less than 10ppm, and the suspended solids content in the overflow port is less than 15ppm. Electrolysis is carried out under the above conditions, and th...

Embodiment 3

[0024] Scrap copper raw material composition (%): Cu 96.58, Zn 0.096, Sn 0.12, Sb 0.0087, Bi 0.015, Pb 0.0095, As 0.0086. The anode frame is a non-conductive anode frame, the copper sheet is a conductive material, and the opening ratio of the conductive anode frame is 25%; the electrolyte composition: Cu 2+ 55g / L, H 2 SO4 200g / L, As 5g / L, Sb 0.5g / L, Bi 0.5g / L, Cl - 0.1g / L; current density 220A / m2; electrolysis temperature 65°C; homopolar distance 12cm; electrolyte circulation rate per cathode area 35L / min.m2; electrolysis additives: gelatin dosage 110g / tCu, protein powder dosage 20g / tCu, The dosage of thiourea is 120g / tCu, the dosage of additive A polyoxyethylene naphthalene ether is 25g / tCu, and the dosage of Avi is 20g / tCu; the content of suspended solids in the liquid inlet of the electrolytic cell during electrolysis is less than 8ppm, and the content of suspended solids in the overflow port is less than 12ppm. Under the above conditions, the electrolysis is carried out,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com