Patents

Literature

84results about How to "Increase the Reynolds number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

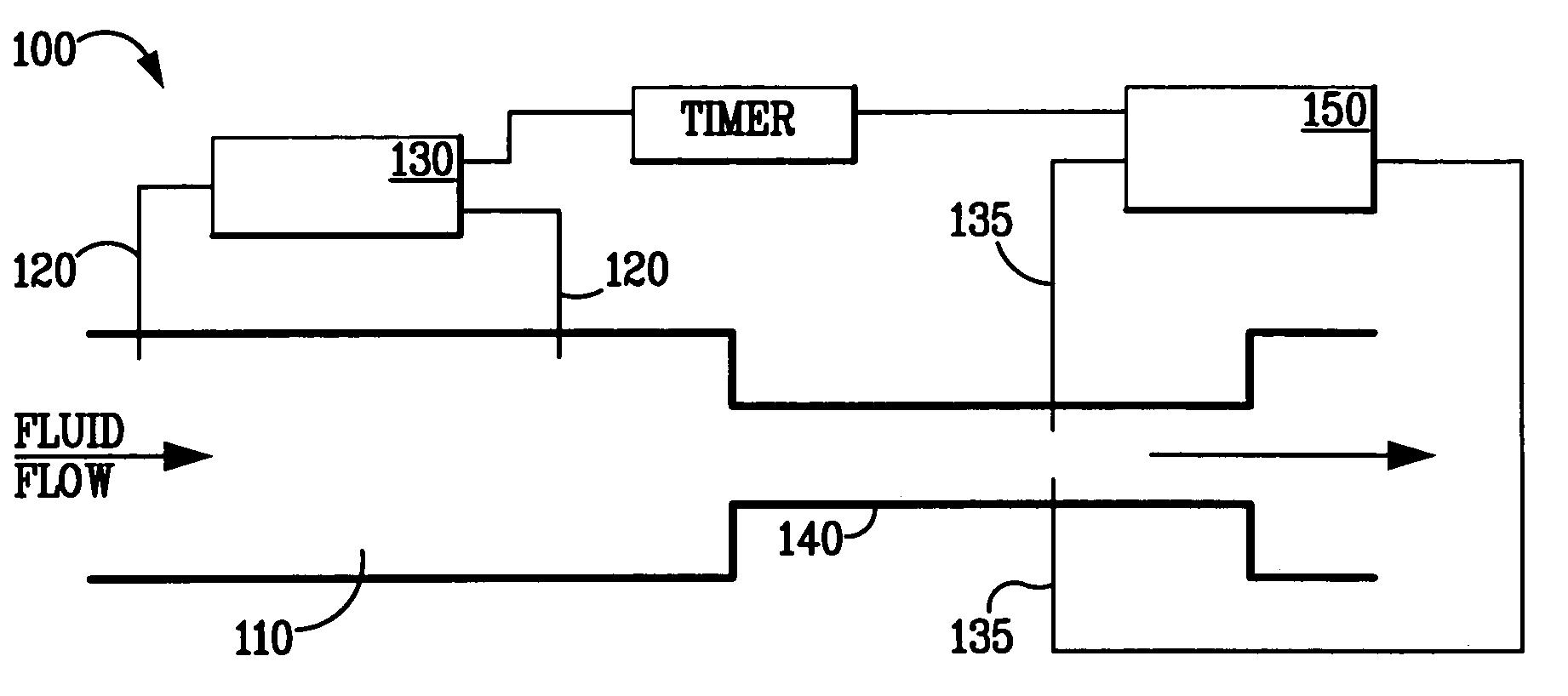

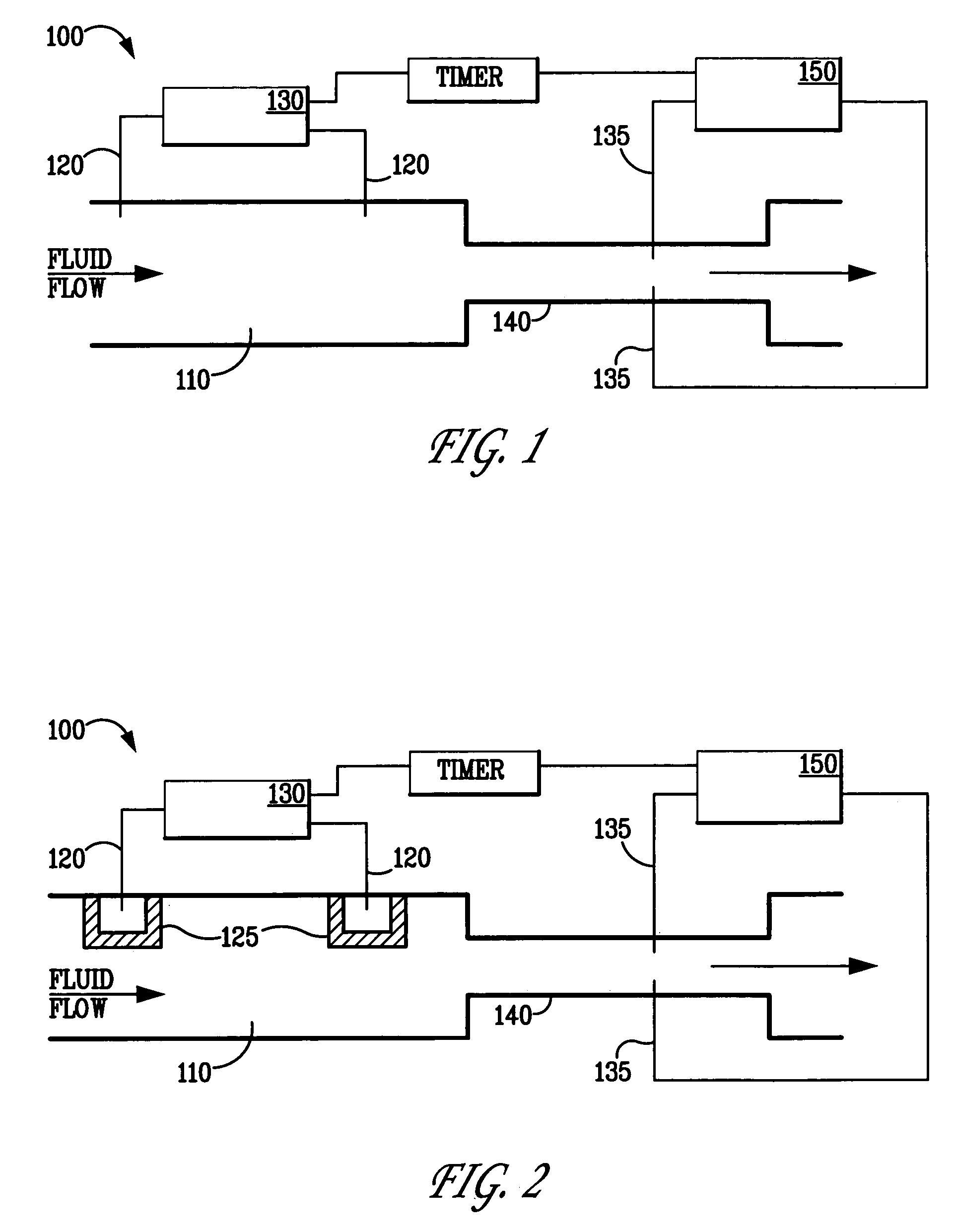

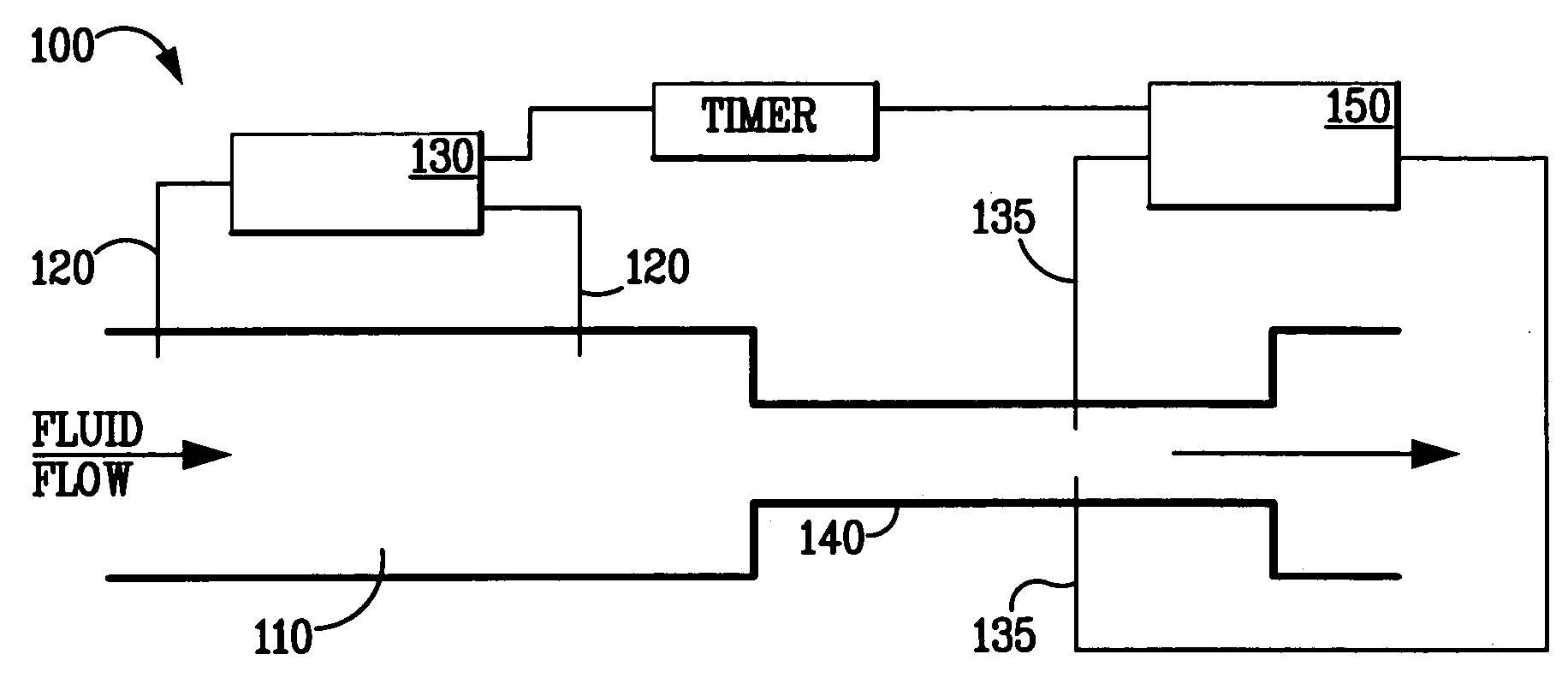

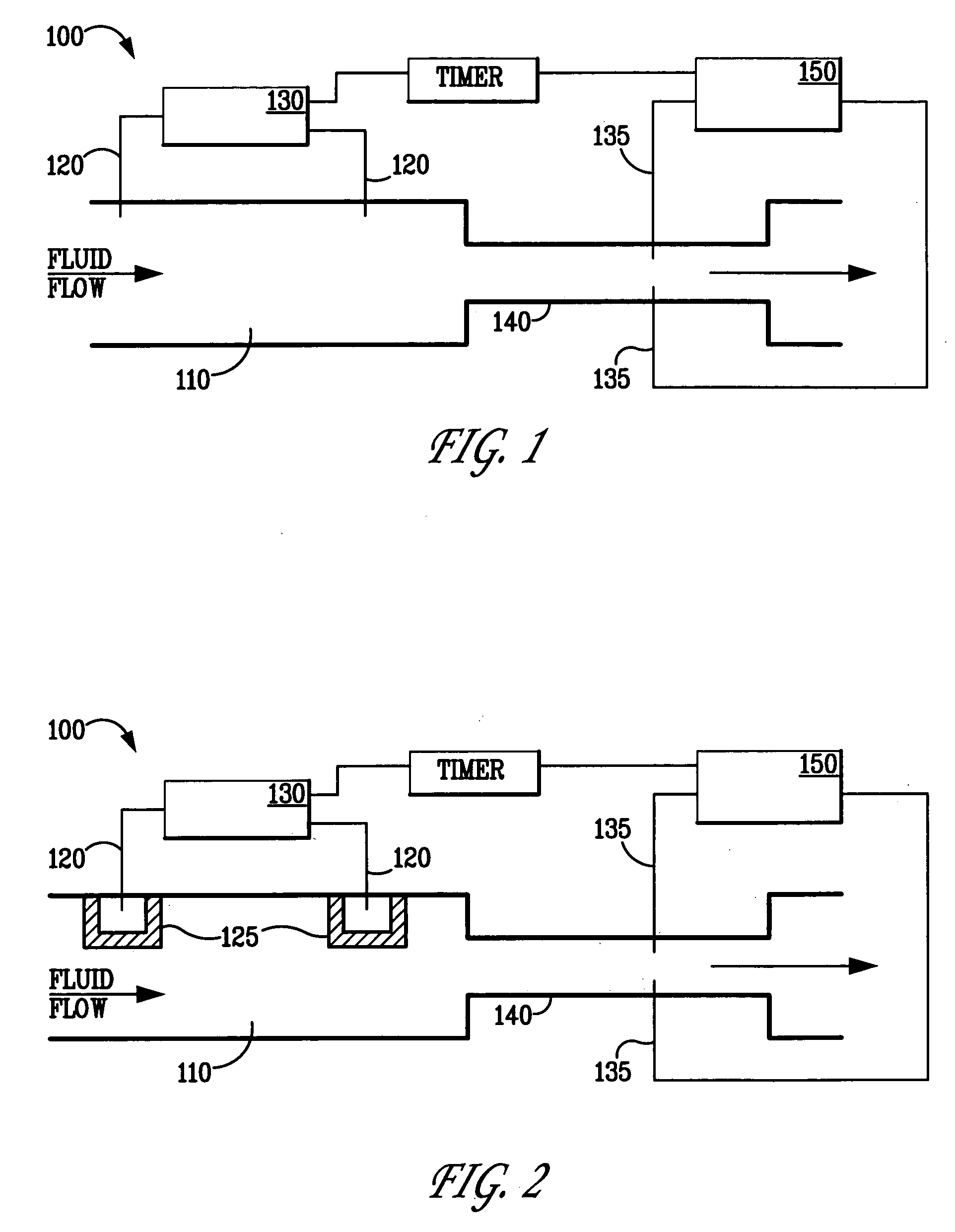

Composition pulse time-of-flight mass flow sensor

InactiveUS7225683B2Increase heat transfer rateHigh sensitivityVolume/mass flow by electromagnetic flowmetersElectrolysisSolvent

Owner:SANDIA NAT LAB

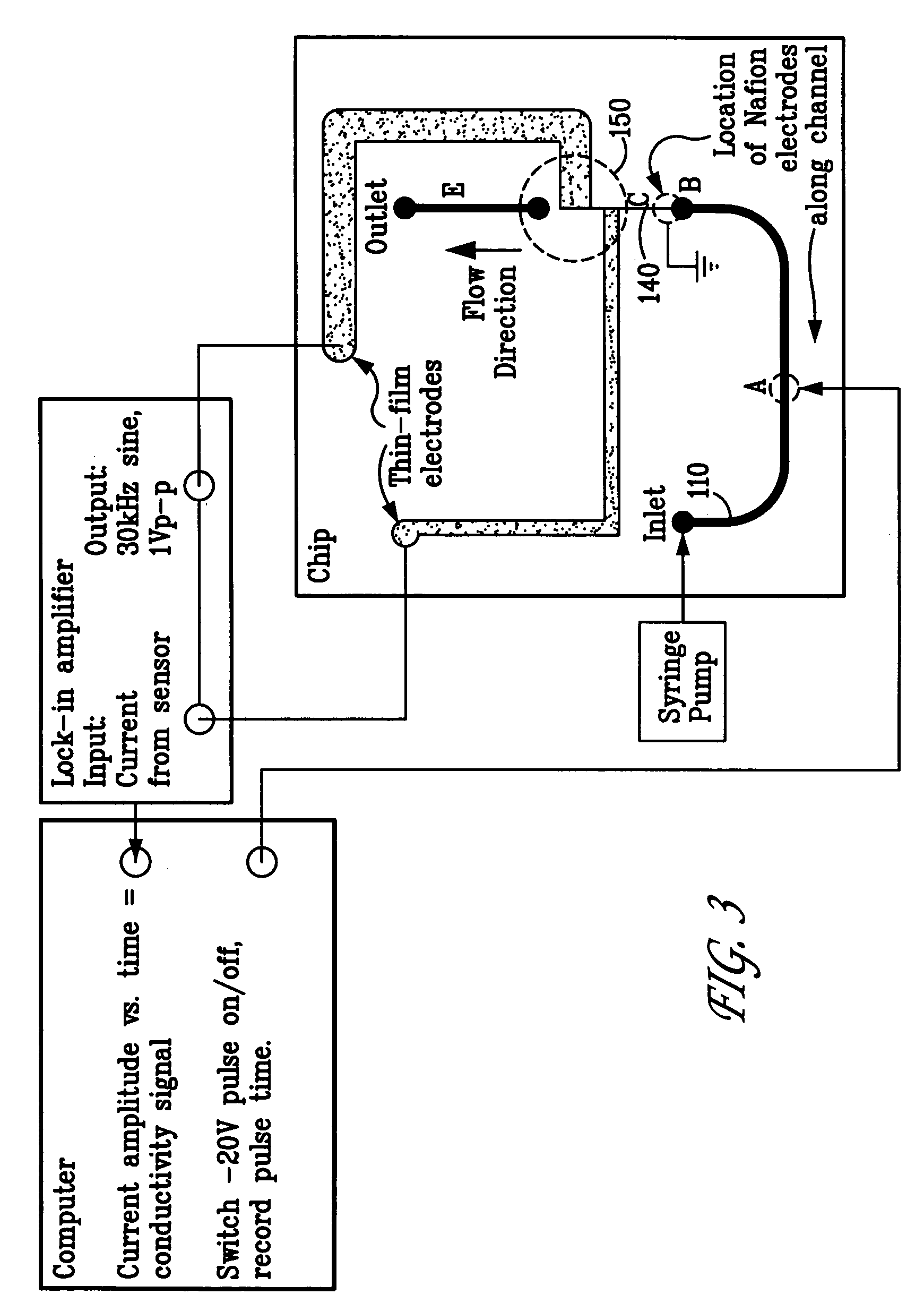

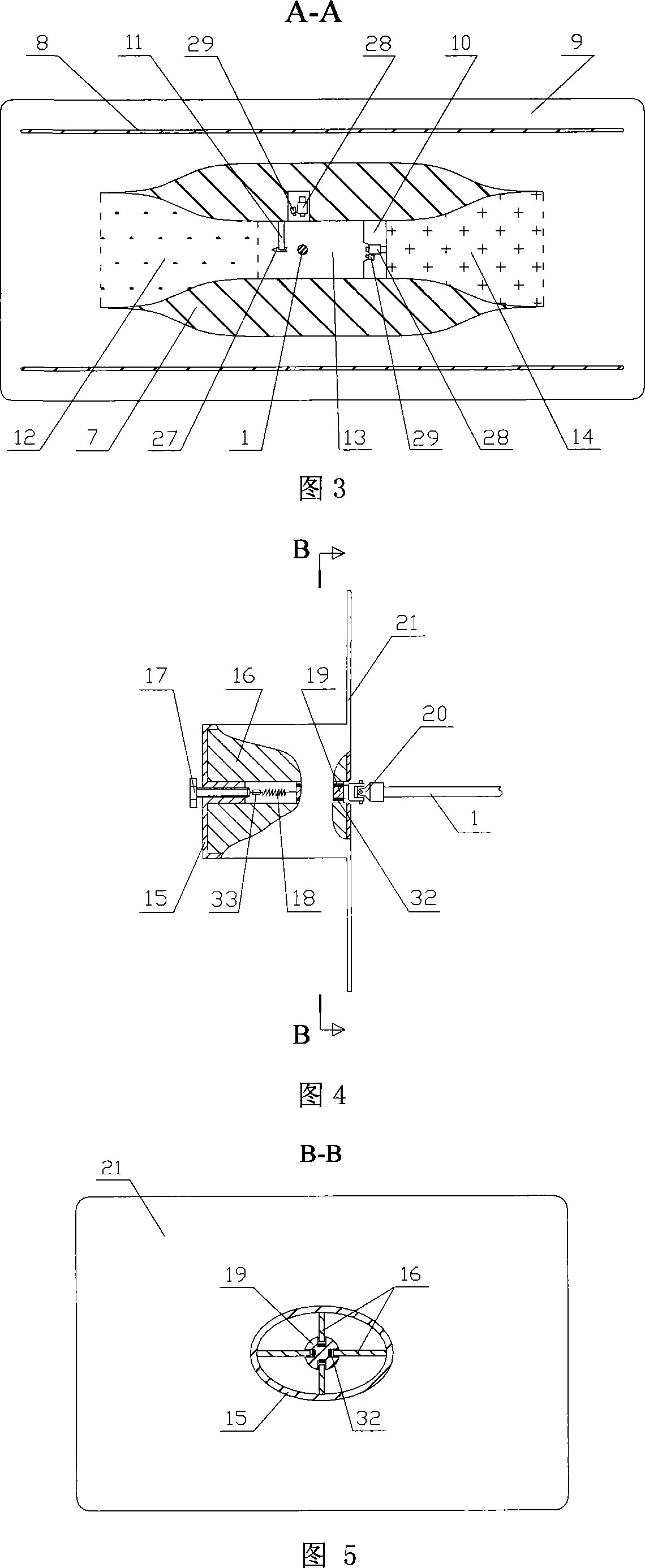

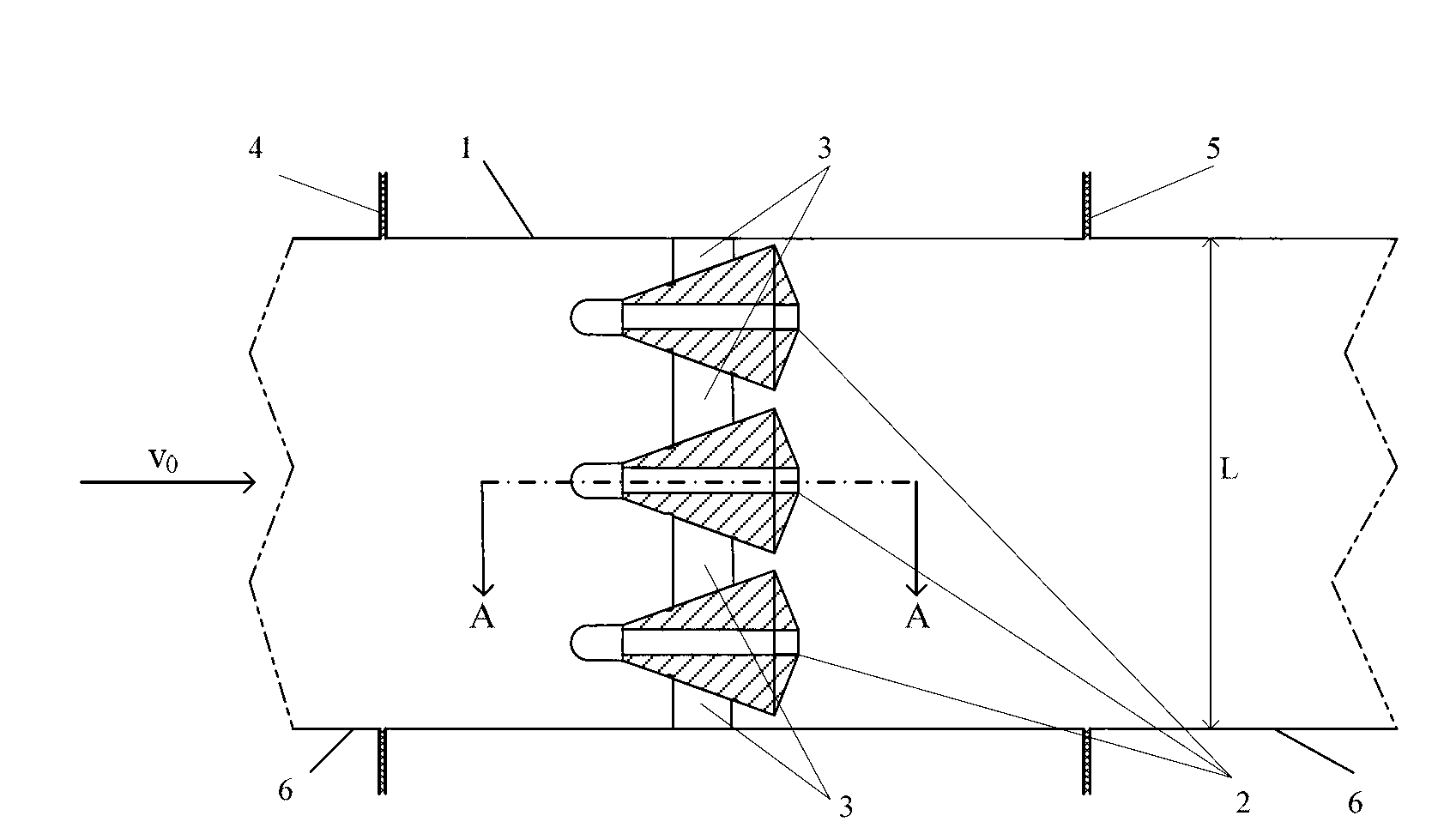

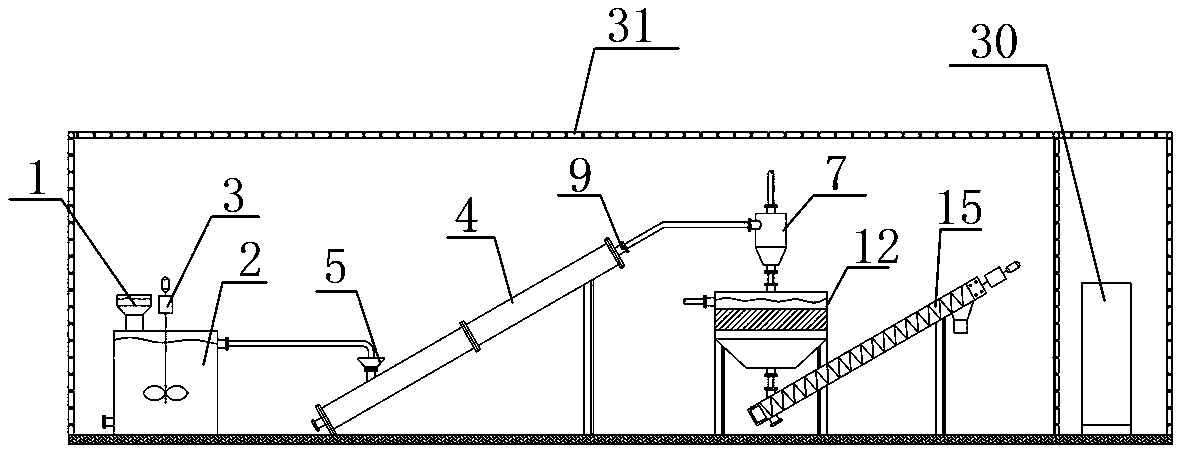

Vortex vibration testing device for flexible pipe mould vertical in towing pool

ActiveCN101089578AIncrease the Reynolds numberImprove flow uniformityVibration testingPipe fittingEngineering

A vortex-exciting vibration test device of flexible pipe fittings mode set horizontally in pull water pool is prepared as passing pipe fittings model through flow-speed increasing unit; setting said model and said unit vertically in pull water pool; supporting two ends of said model by support mechanism; using horizontal test support to connect said unit and support mechanism with trailer and distributing various instruments of measurement-analysis system in said model, said units, said mechanism, said support and said trailer.

Owner:SHANGHAI JIAO TONG UNIV

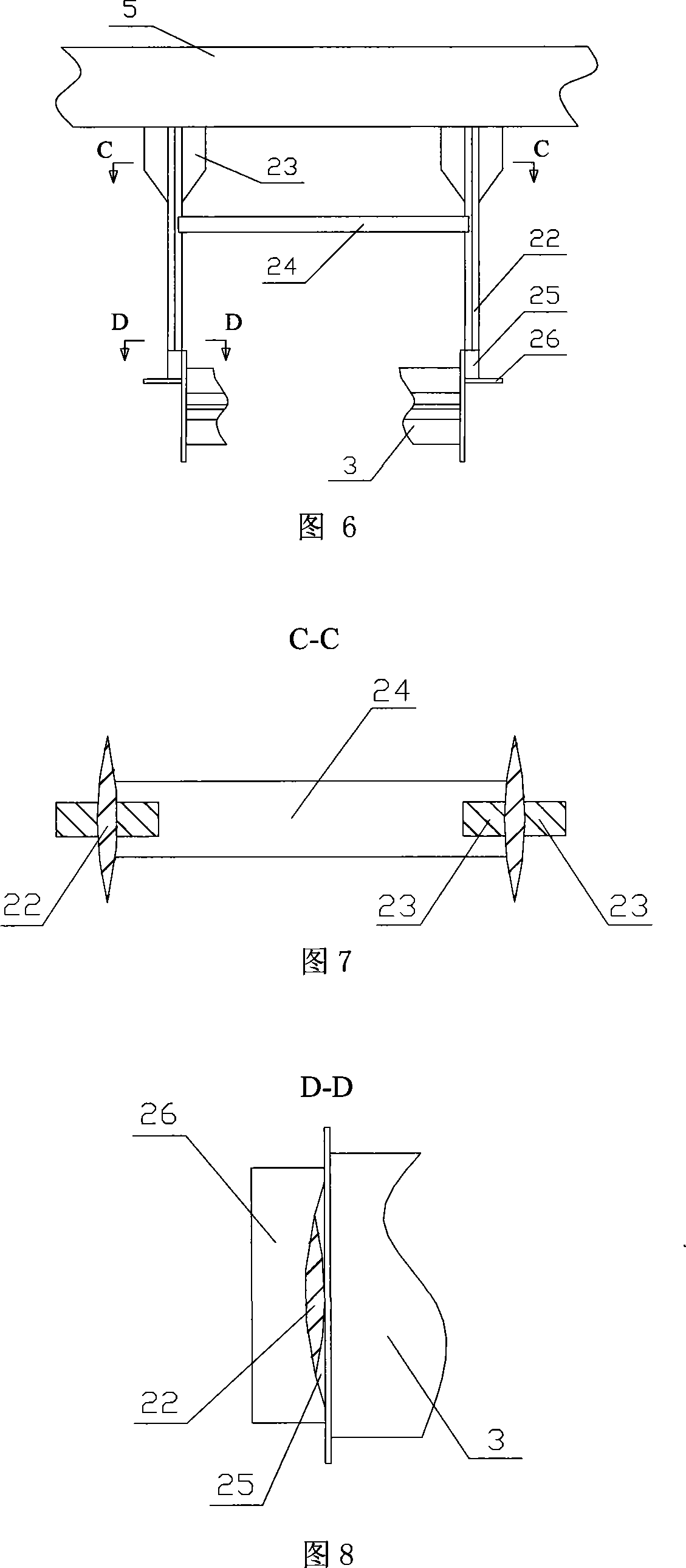

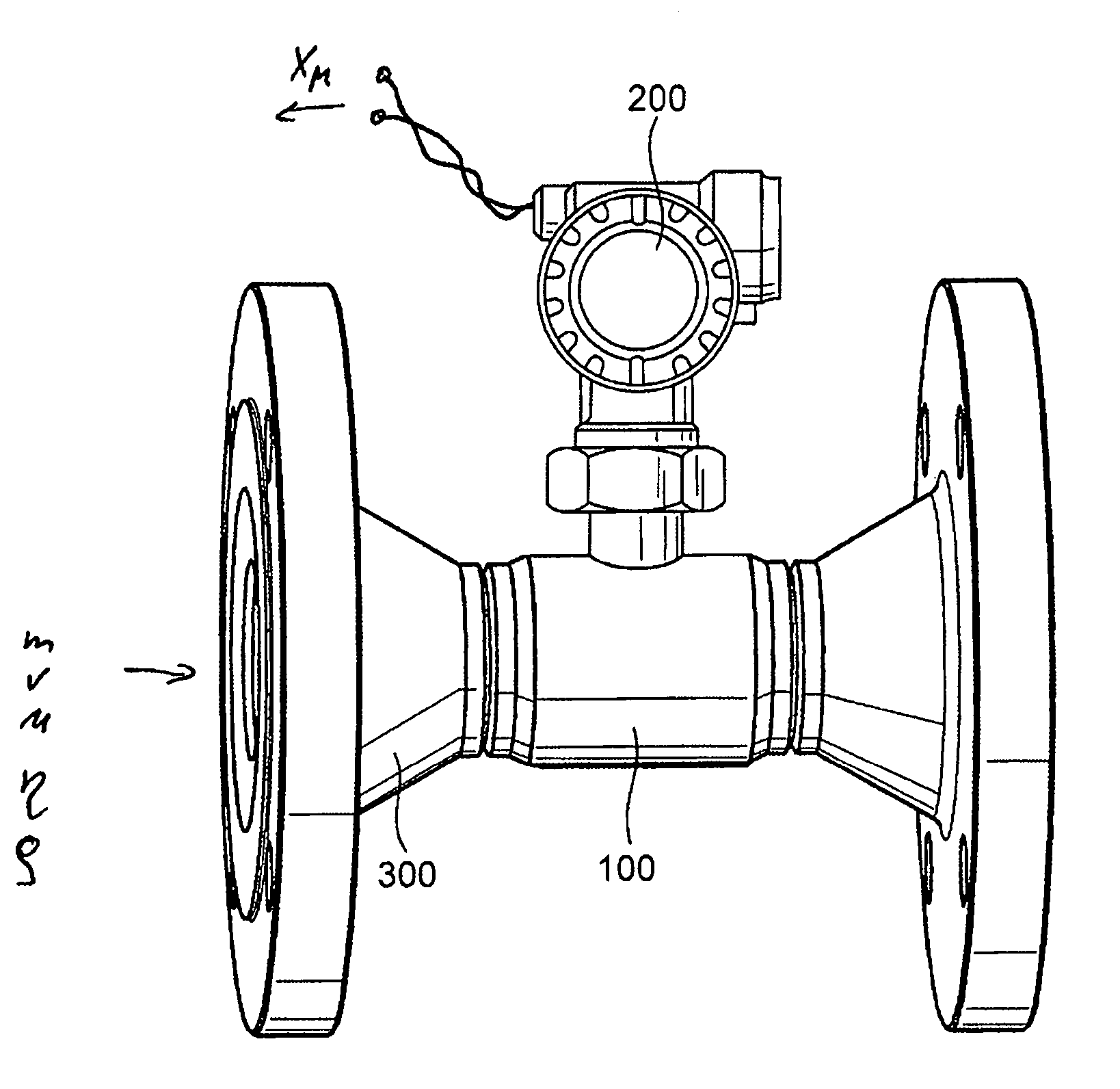

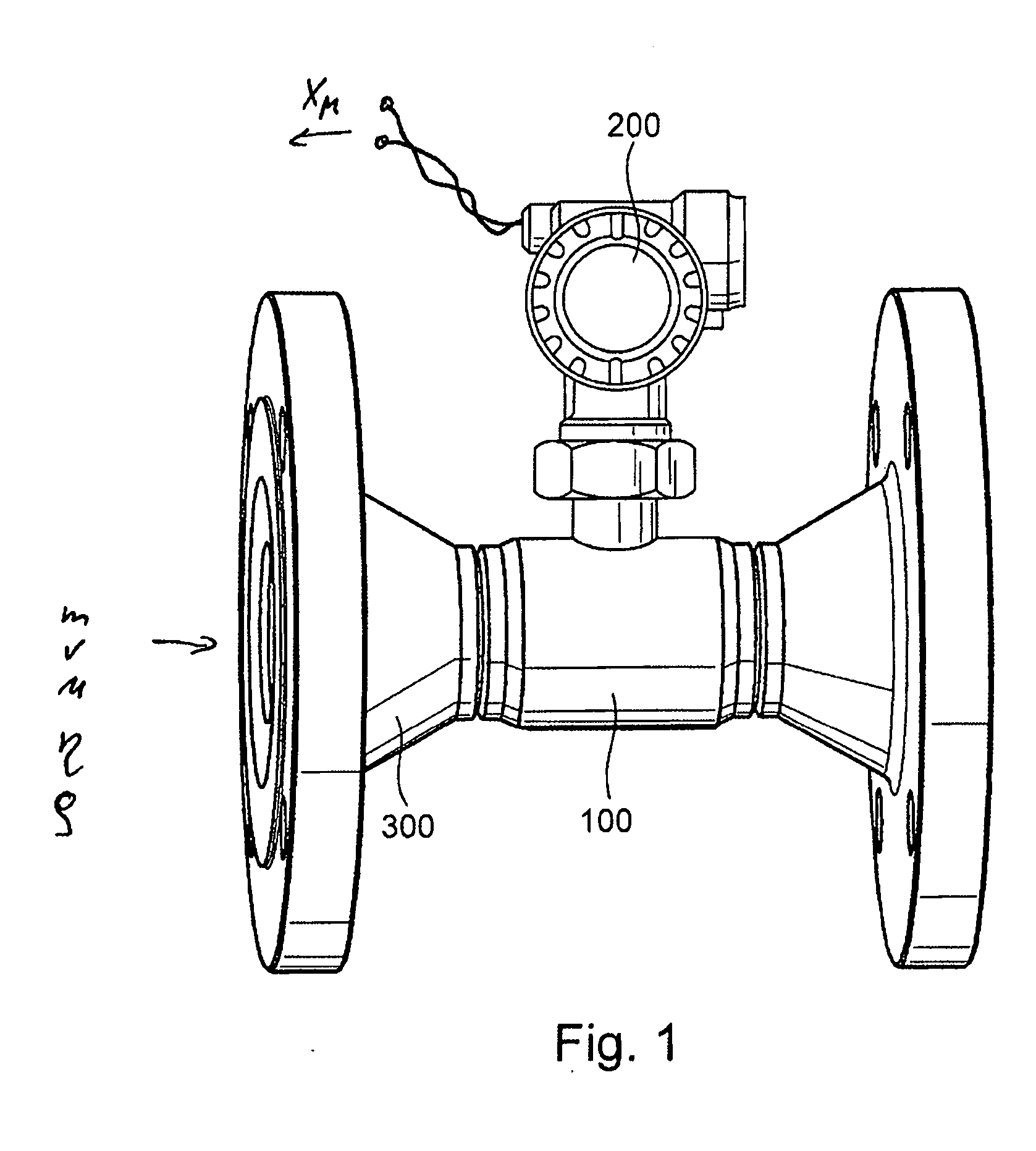

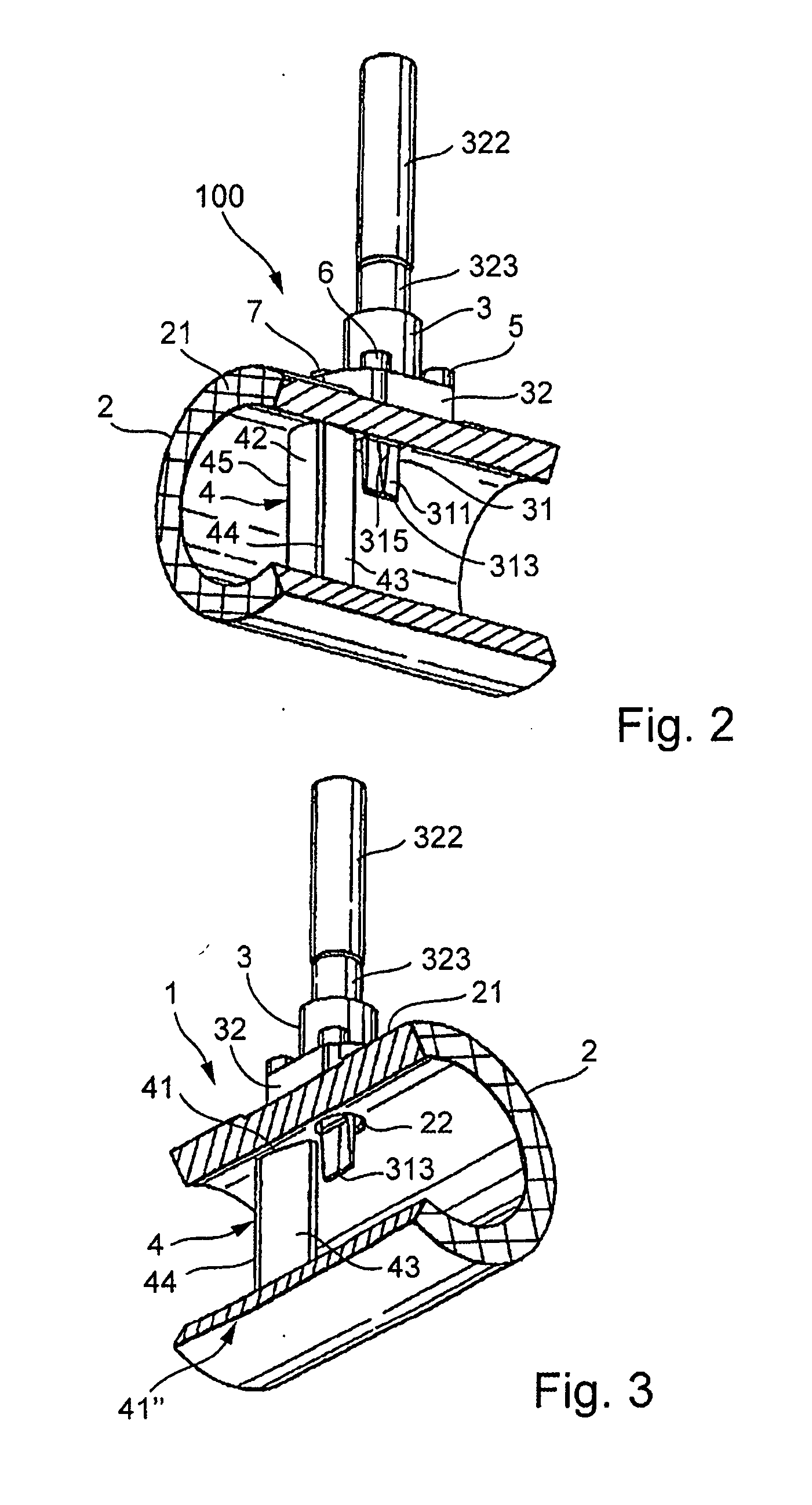

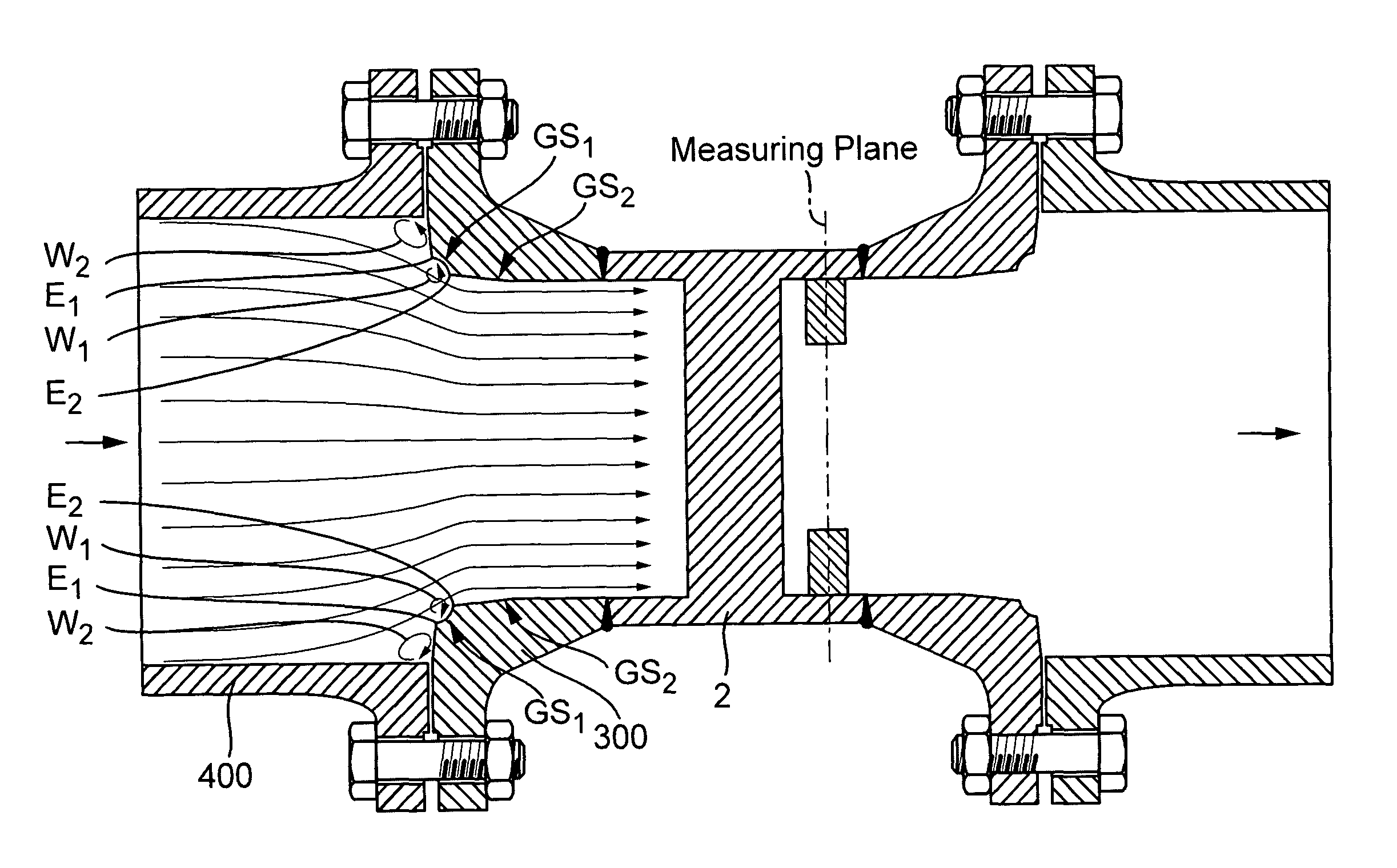

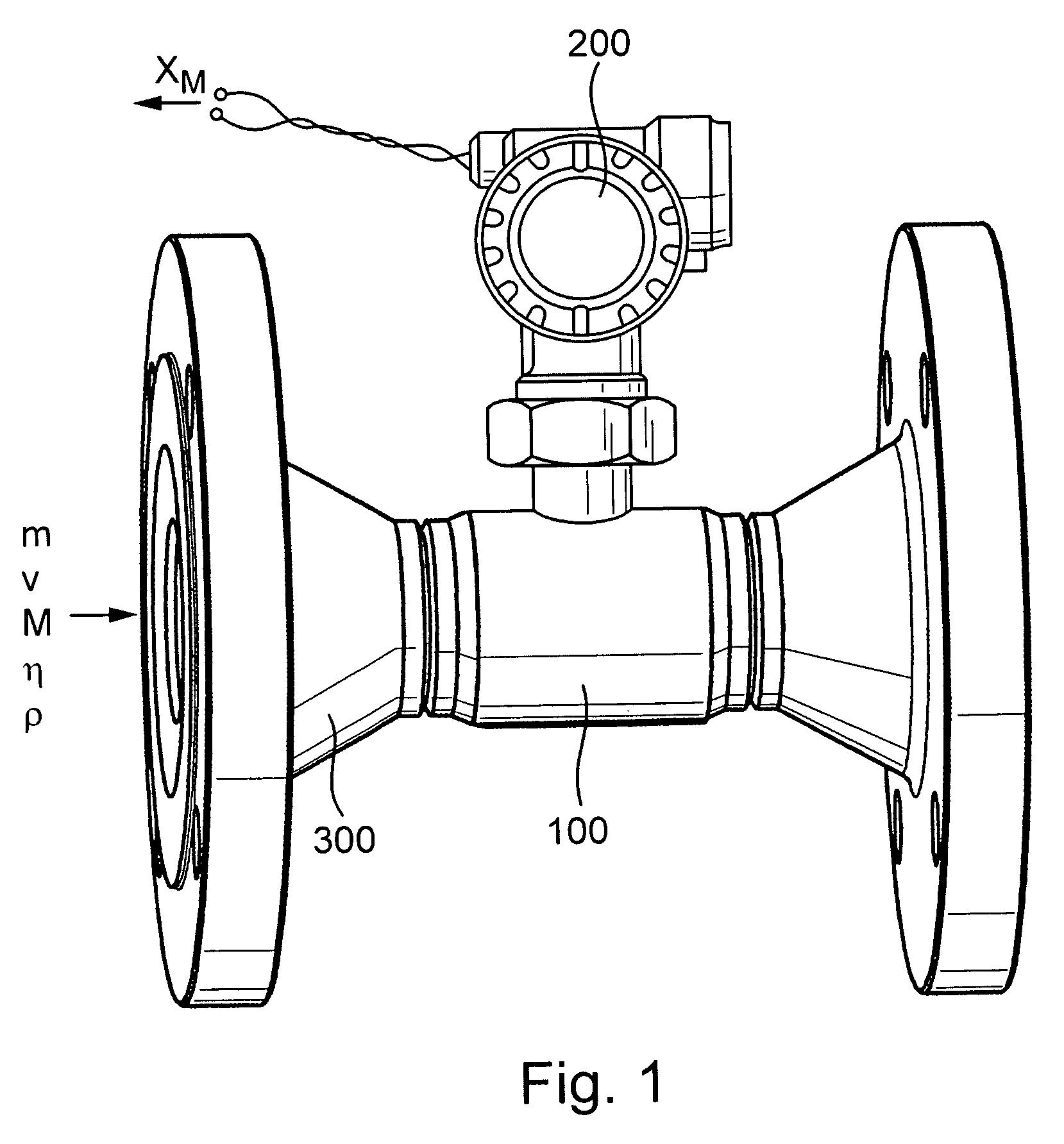

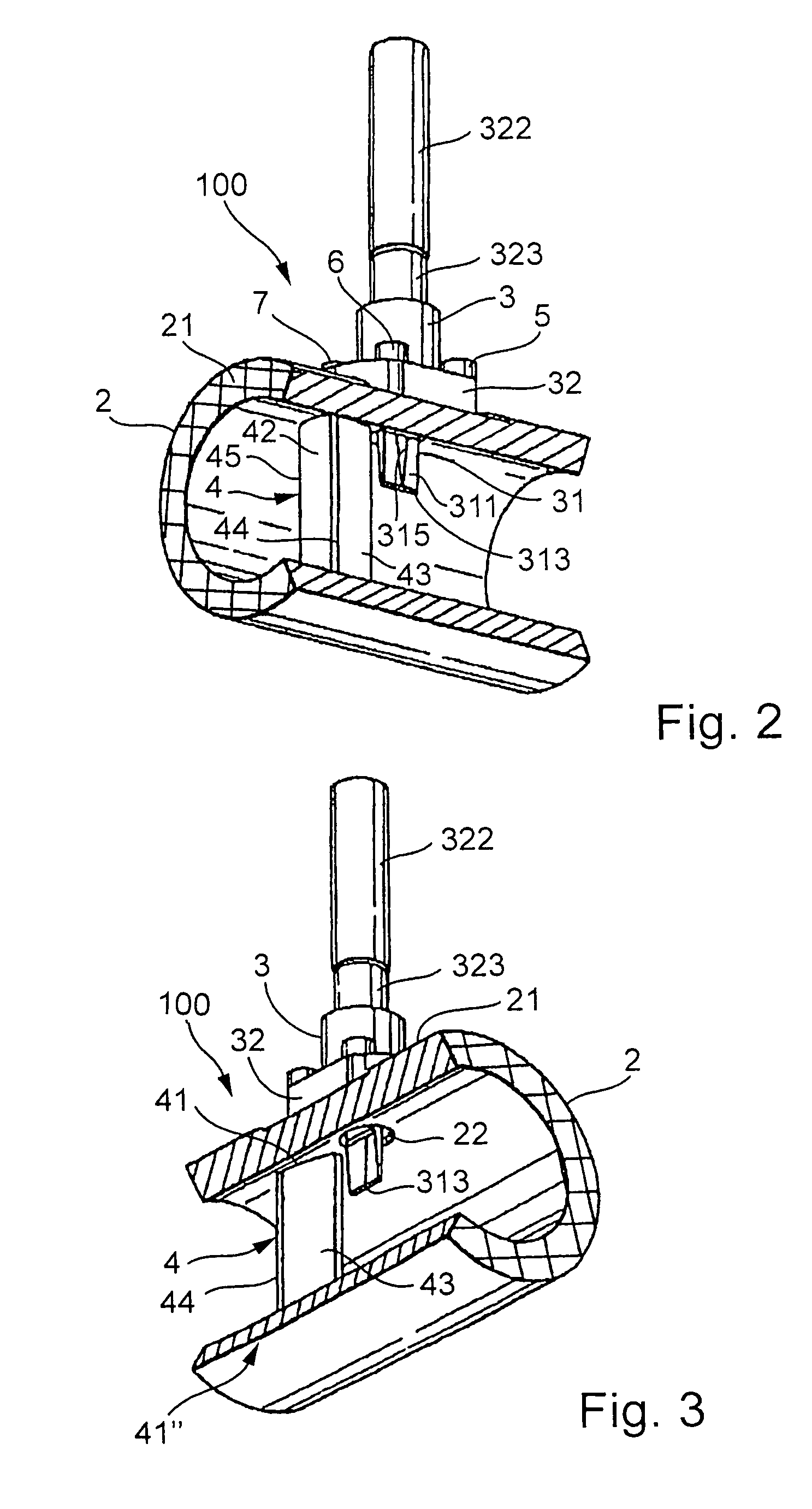

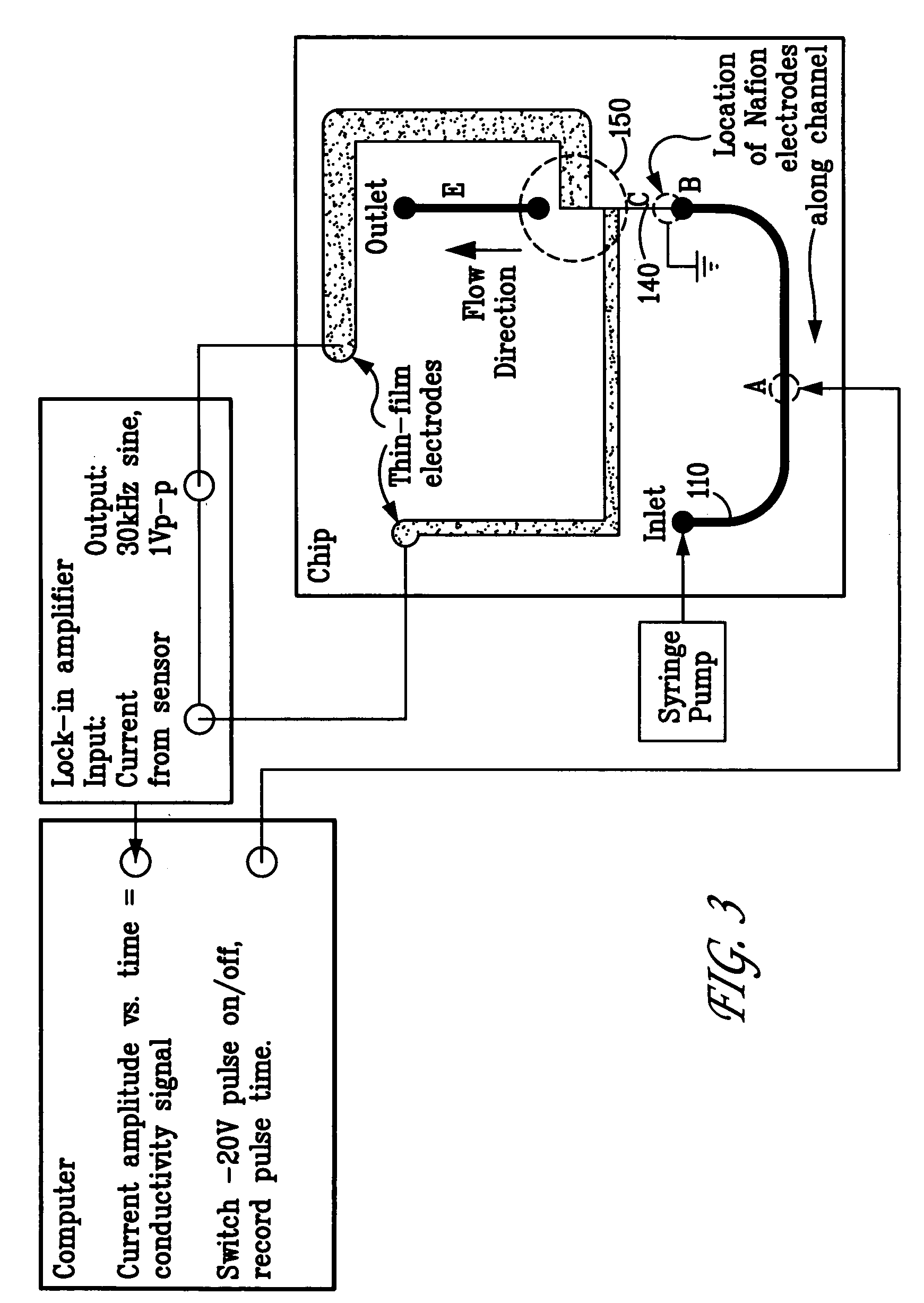

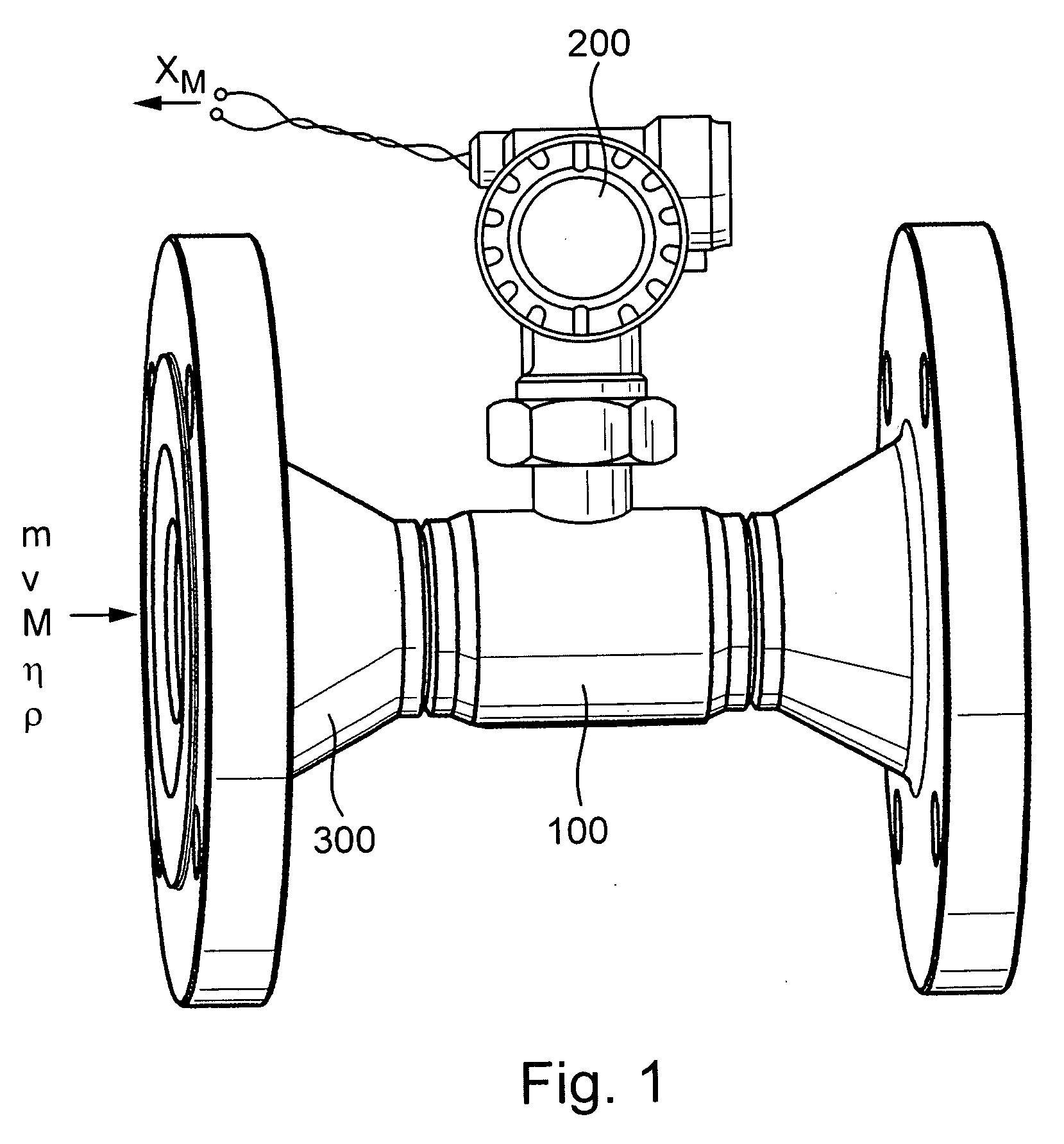

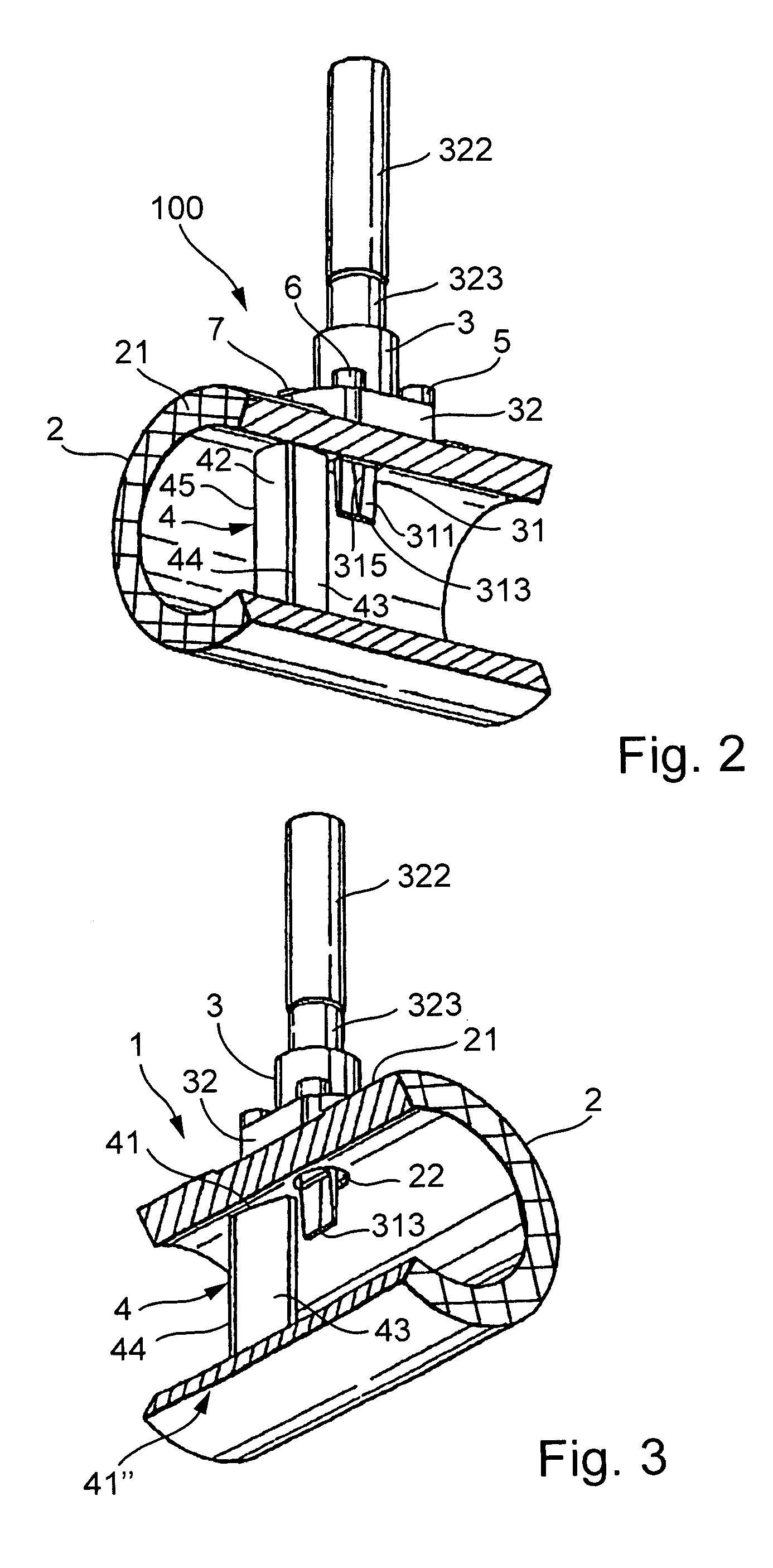

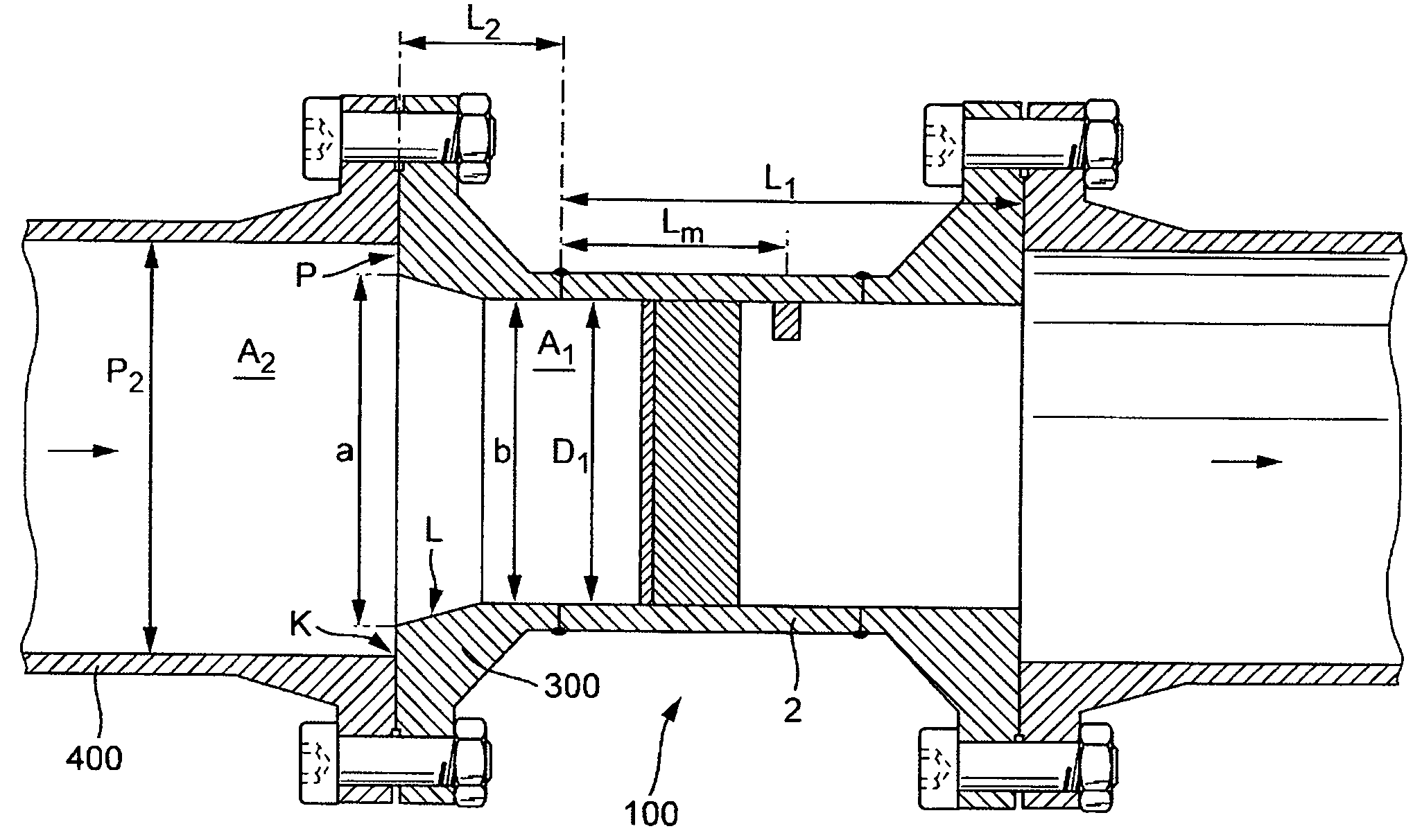

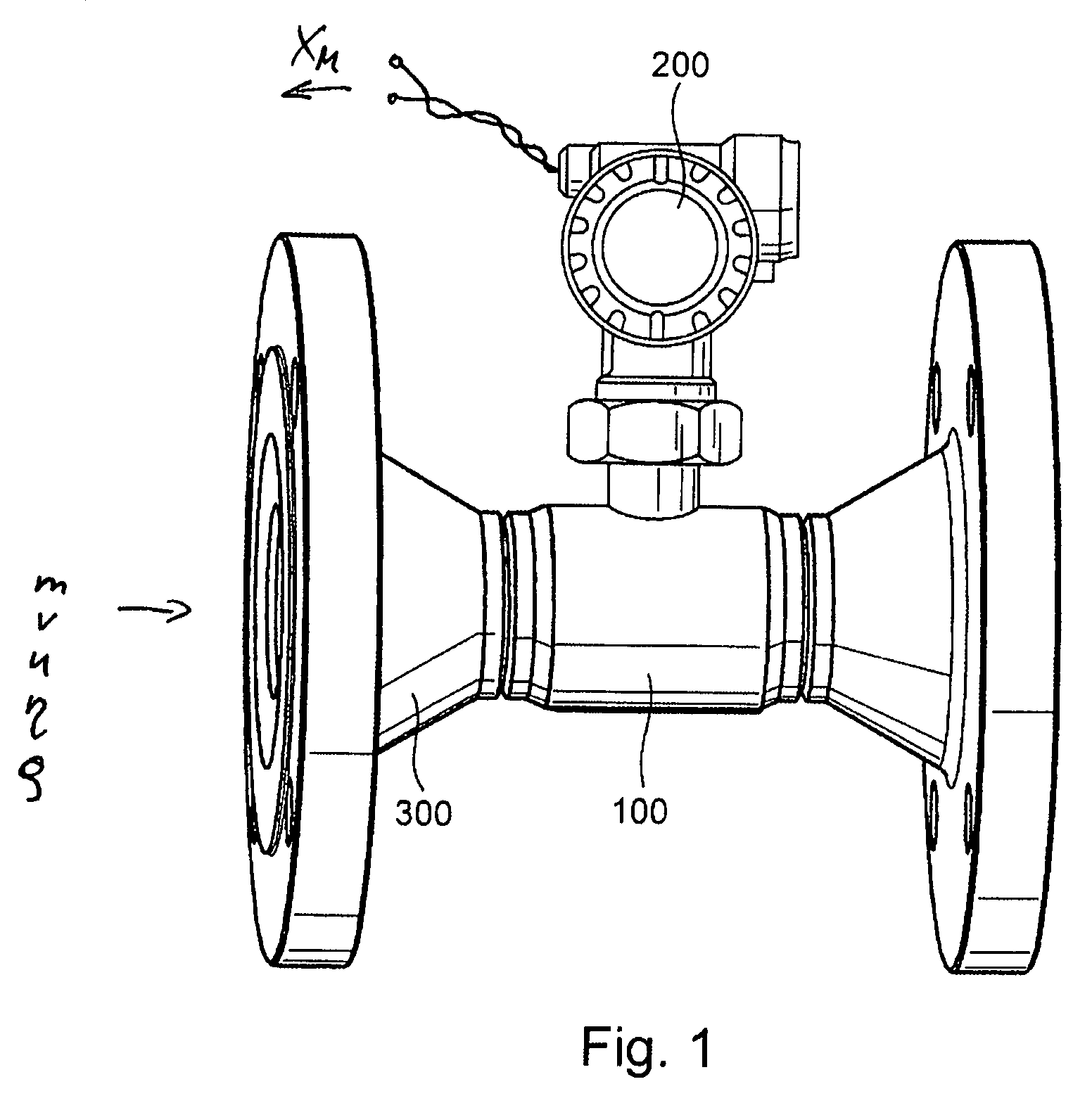

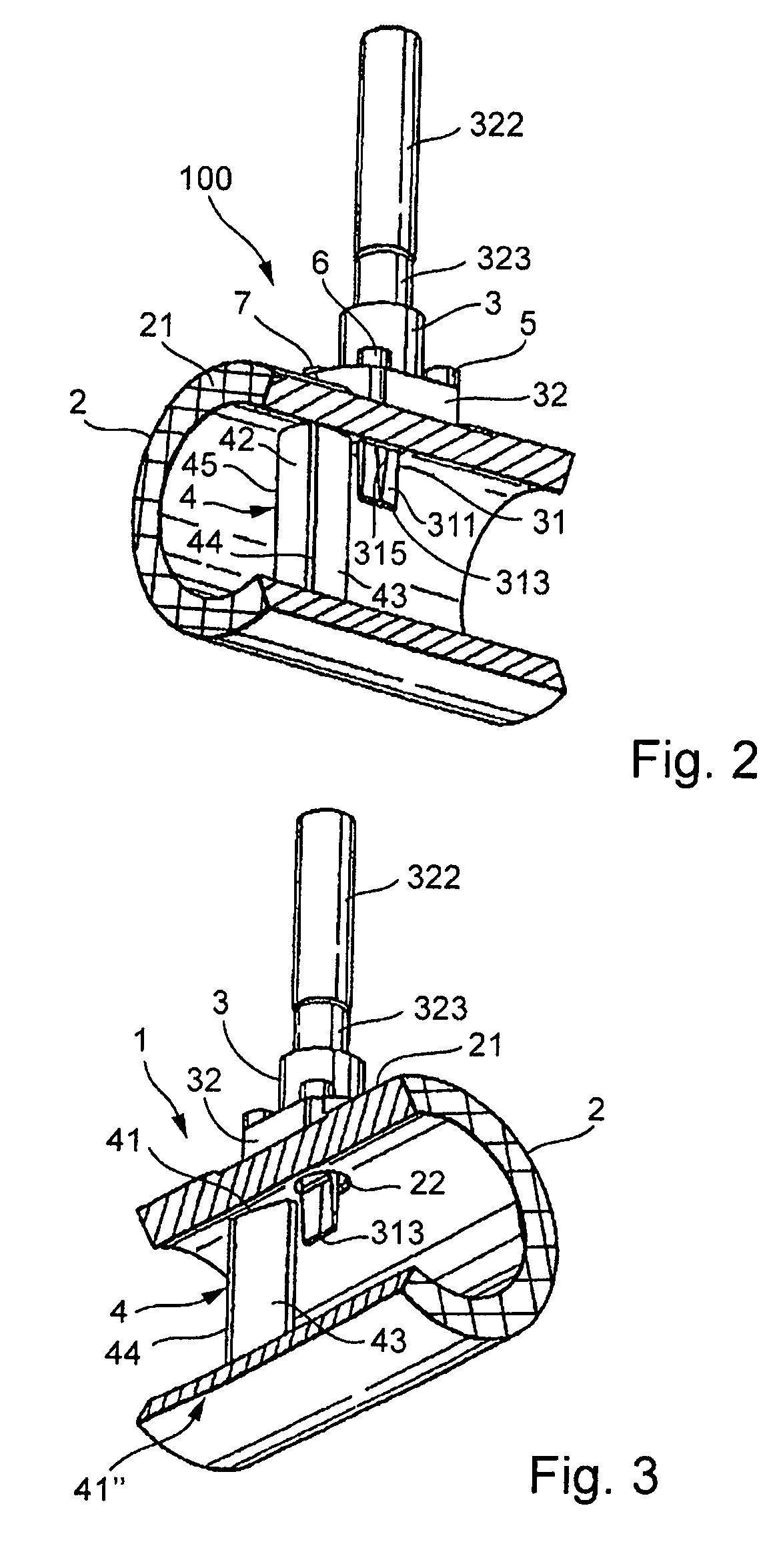

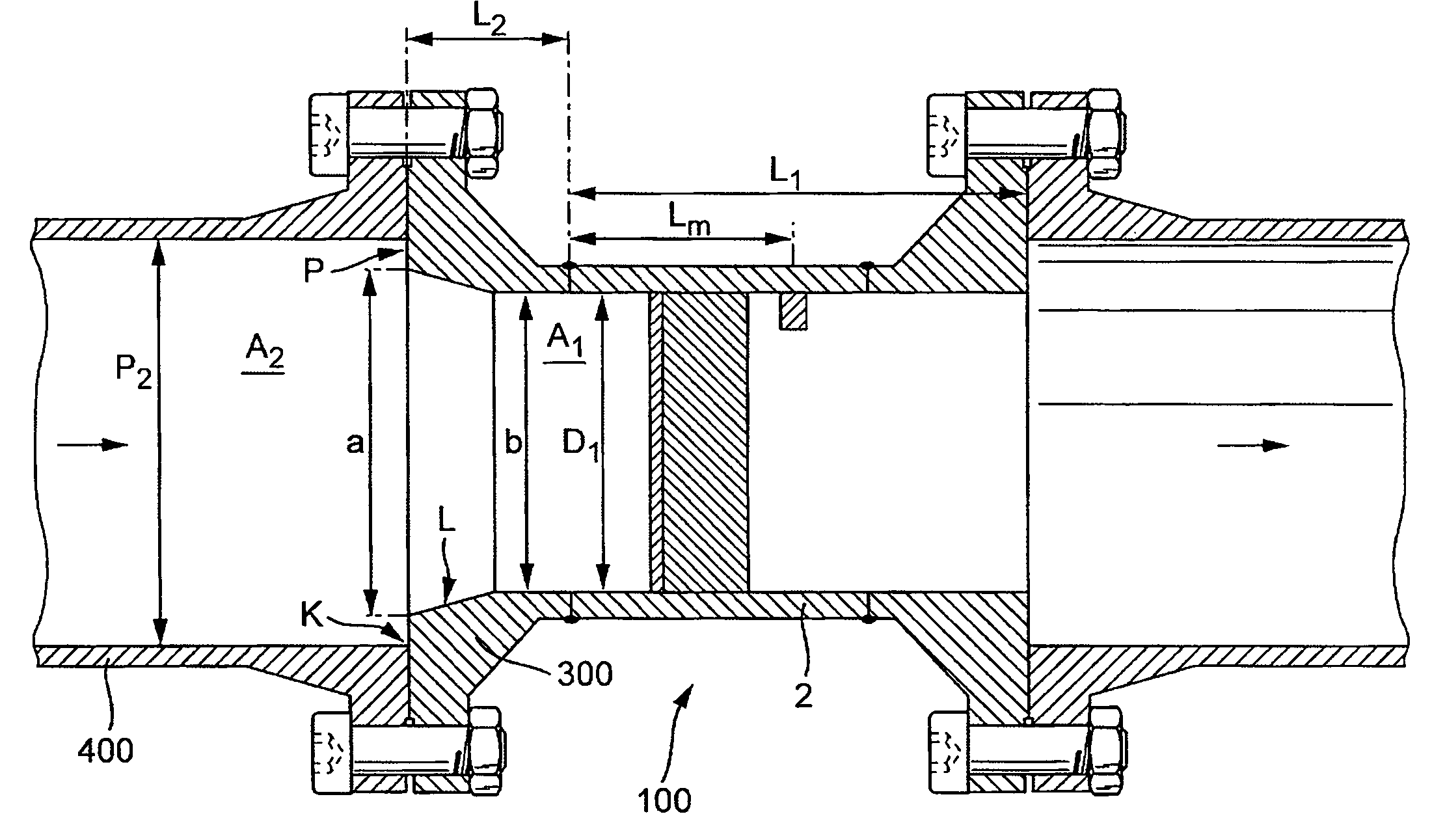

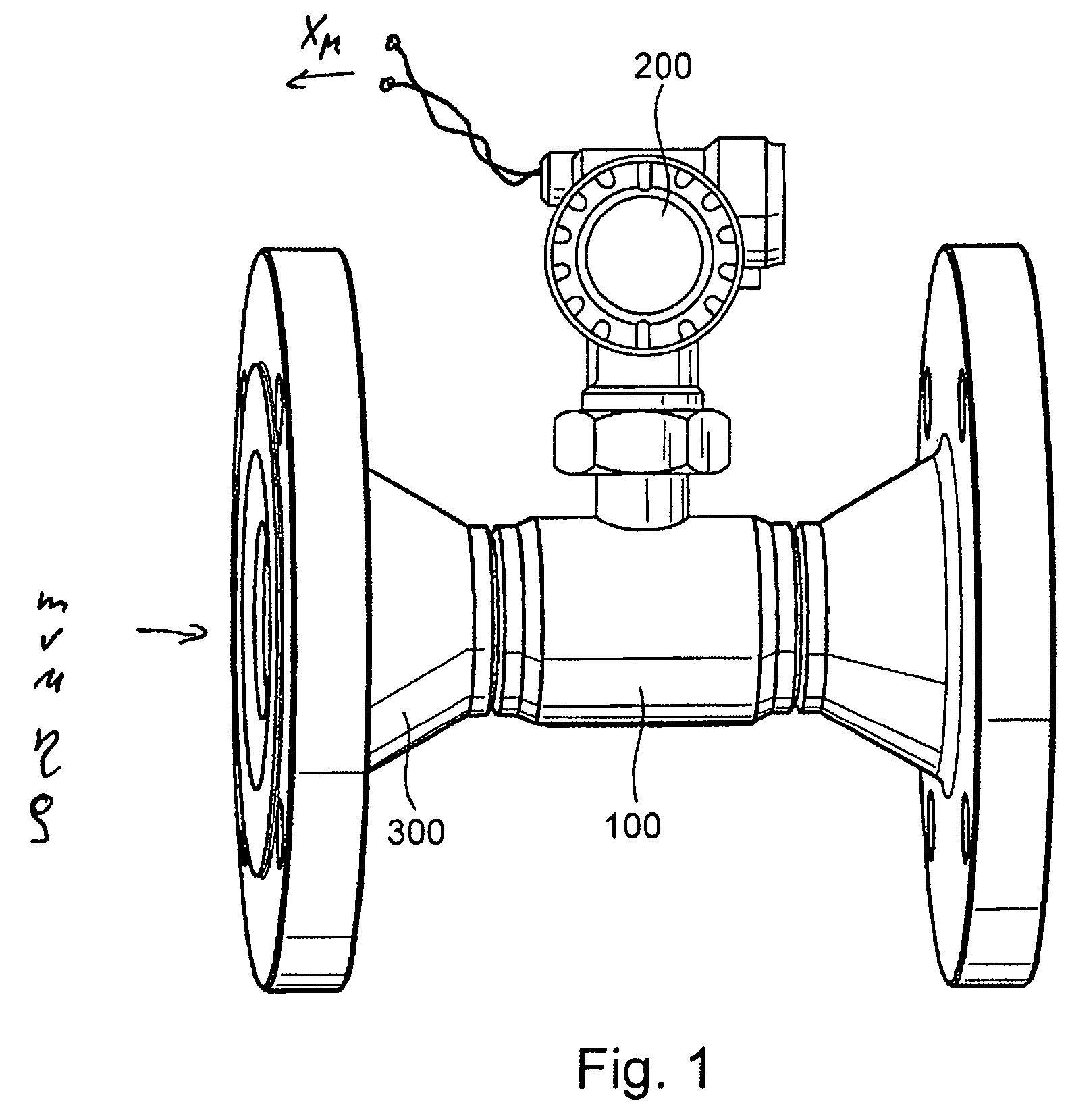

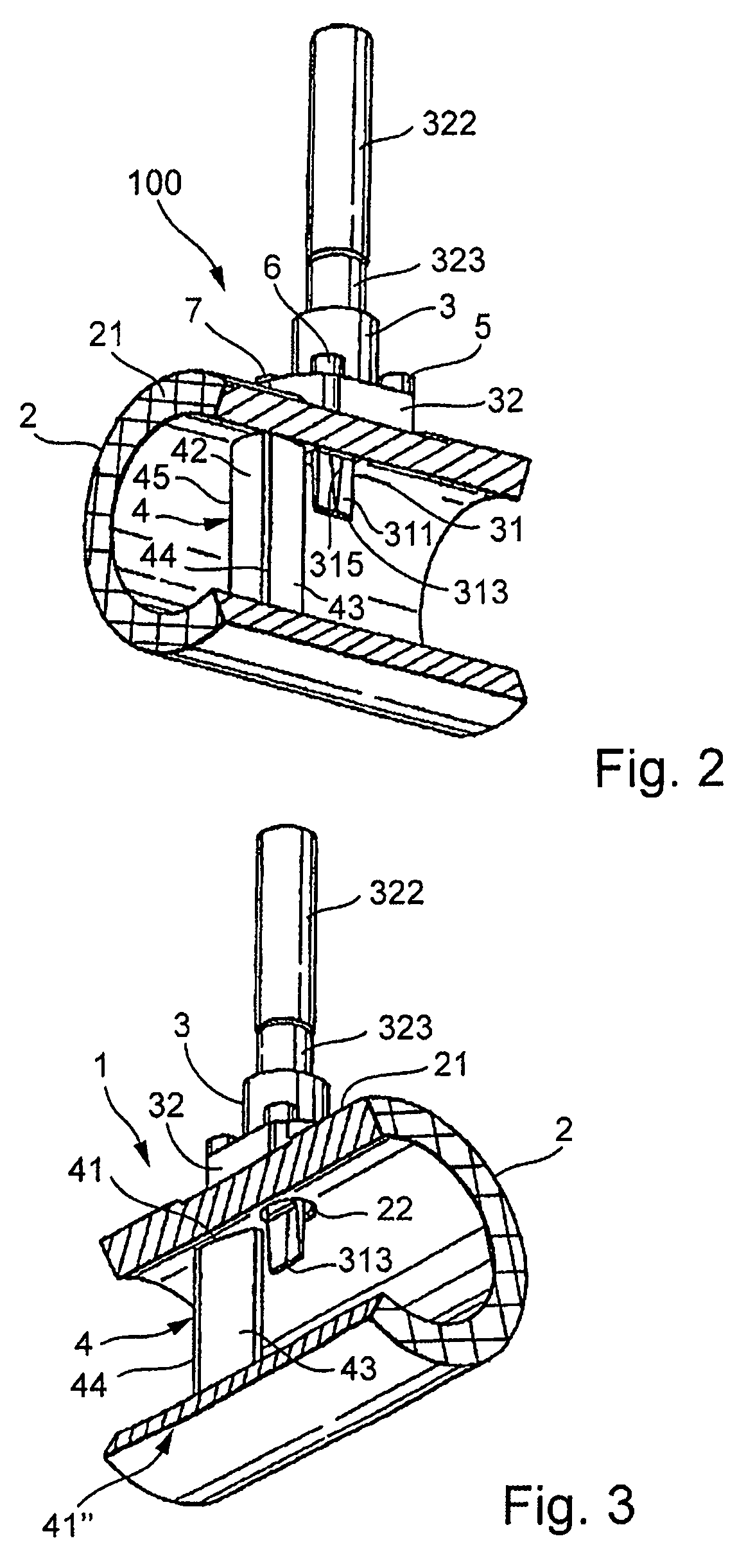

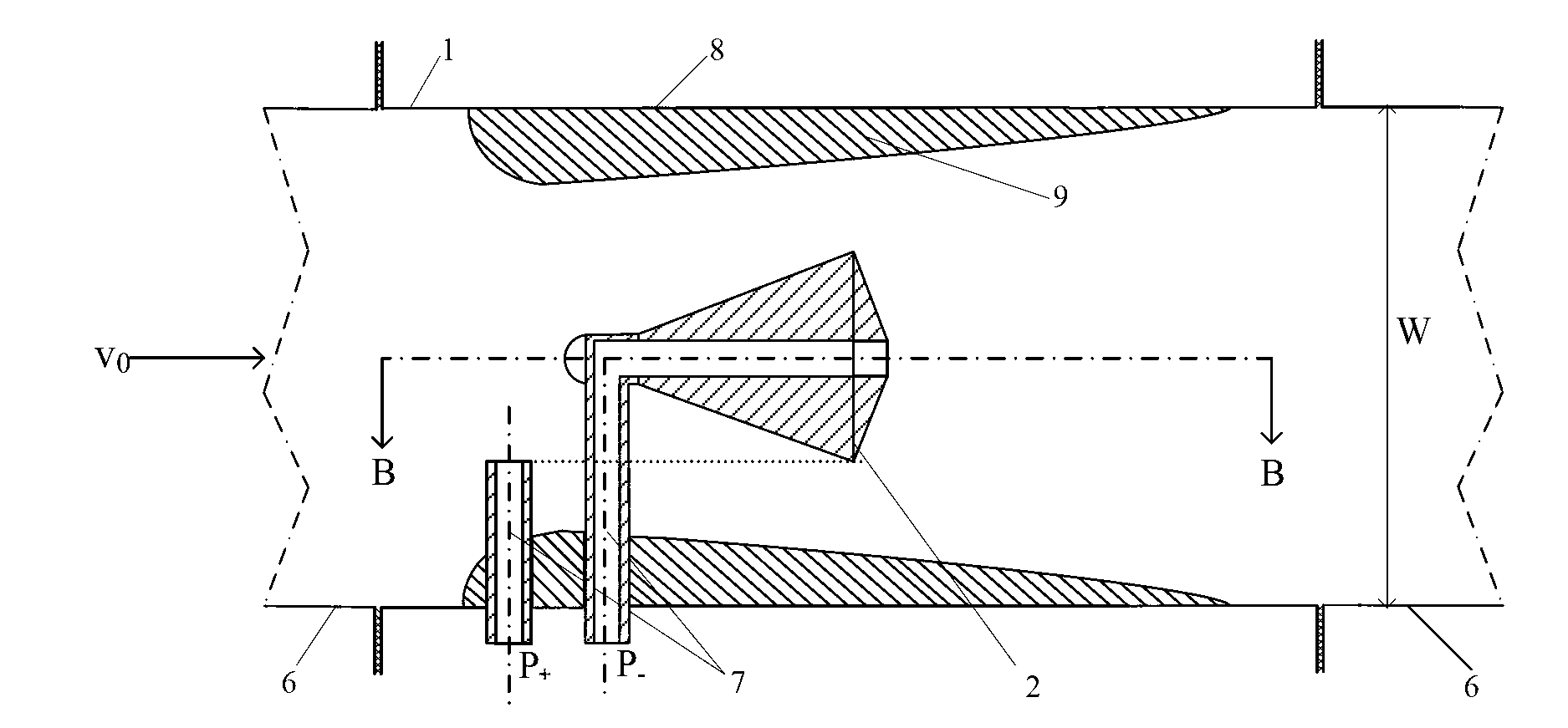

Measuring system for a medium flowing in a process line

ActiveUS20080072686A1Increase Reynolds numberIncrease the Reynolds numberVolume/mass flow by dynamic fluid flow effectVolume meteringEngineeringElectronics

The measuring system is inserted into the course of a process line and serves for registering at least one measured variable of a medium flowing in the process line. The measuring system includes for such purpose a measuring transducer having a measuring tube serving for conveying medium being measured and a sensor arrangement, which has at least one sensor element reacting primarily to the measured variable to be registered, and which delivers by means of at least one sensor element at least one measurement signal influenced by the measured variable. Further, the measuring system includes a measuring electronics communicating with the measuring transducer and using the at least one measurement signal for producing, at least at times, at least one measured value instantaneously representing the measured variable. The measuring tube has, in the case of the measuring system of the invention, a smaller flow cross section than a supply segment of the process line connected to the inlet end of the measuring system. To this end, the measuring system further includes a flow conditioner arranged at the inlet end of the measuring tube and mediating between the measuring tube and the supply segment of the process line. The flow conditioner has a lumen tapering in the direction of the measuring tube. During operation, medium flows through the lumen of the flow conditioner. The flow conditioner includes at least one inner edge arranged upstream of its outlet end and protruding into the lumen of the flow conditioner. During operation, medium conveyed in the flow conditioner flows against the inner edge.

Owner:ENDRESS HAUSER FLOWTEC AG

Measuring system with a flow conditioner for flow profile stabilization

ActiveUS7882751B2Increase the Reynolds numberVolume meteringVolume/mass flow by dynamic fluid flow effectTransducerEngineering

Owner:ENDRESS HAUSER FLOWTEC AG

Composition pulse time-of-flight mass flow sensor

InactiveUS20050034534A1Increase the Reynolds numberFast shippingFluid speed measurementVolume/mass flow by electromagnetic flowmetersElectrolysisSolvent

A device for measuring fluid flow rates over a wide range of flow rates (<1 nL / min to >10 μL / min) and at pressures at least as great as 2,000 psi. The invention is particularly adapted for use in microfluidic systems. The device operates by producing compositional variations in the fluid, or pulses, that are subsequently detected downstream from the point of creation to derive a flow rate. Each pulse, comprising a small fluid volume, whose composition is different from the mean composition of the fluid, can be created by electrochemical means, such as by electrolysis of a solvent, electrolysis of a dissolved species, or electrodialysis of a dissolved ionic species. Measurements of the conductivity of the fluid can be used to detect the arrival time of the pulses, from which the fluid flow rate can be determined. A pair of spaced apart electrodes can be used to produce the electrochemical pulse. In those instances where it is desired to measure a wide range of fluid flow rates a three electrode configuration in which the electrodes are spaced at unequal distances has been found to be desirable.

Owner:SANDIA NAT LAB

Measuring system for a medium flowing in a process line

ActiveUS20090217771A1Increase the Reynolds numberVolume/mass flow by dynamic fluid flow effectVolume meteringTransducerEngineering

The measuring system is inserted into the course of a process line and serves for registering at least one measured variable of a medium flowing in the process line. The measuring system includes for such purpose a measuring transducer having a measuring tube serving for conveying medium being measured and a sensor arrangement, which has at least one sensor element reacting primarily to the measured variable to be registered, and which delivers by means of at least one sensor element at least one measurement signal influenced by the measured variable. Further, the measuring system includes a measuring electronics communicating with the measuring transducer and using the at least one measurement signal for producing, at least at times, at least one measured value instantaneously representing the measured variable.The measuring tube has, in the case of the measuring system of the invention, a smaller flow cross section than a supply segment of the process line connected to the inlet end of the measuring system. The measuring system further includes a flow conditioner arranged at the inlet end of the measuring tube and mediating between the measuring tube and the supply segment of the process line. The flow conditioner has a lumen tapering in the direction of the measuring tube. During operation, medium flows through the lumen of the flow conditioner. The flow conditioner includes at least two inner edges arranged upstream of its outlet end and protruding into the lumen of the flow conditioner. During operation, medium conveyed within the flow conditioner flows against each of the inner edges. Between the first inner edge and the second inner edge, there extends, additionally, a first guide surface of the flow conditioner. Moreover, the second inner edge bounds a second guide surface of the flow conditioner extending in the direction of the outlet end of the flow conditioner and serving for guiding medium flowing in the flow conditioner.

Owner:ENDRESS HAUSER FLOWTEC AG

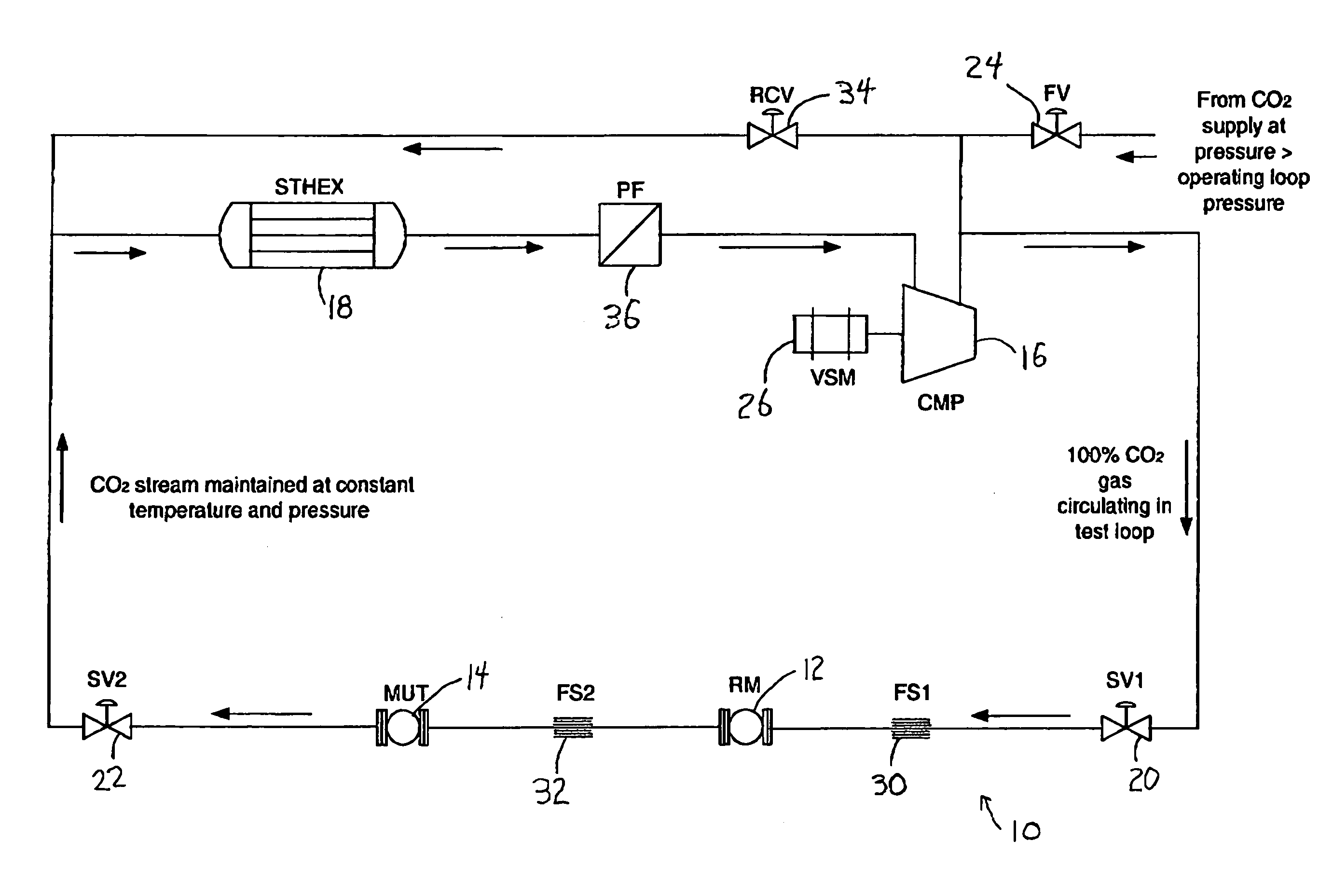

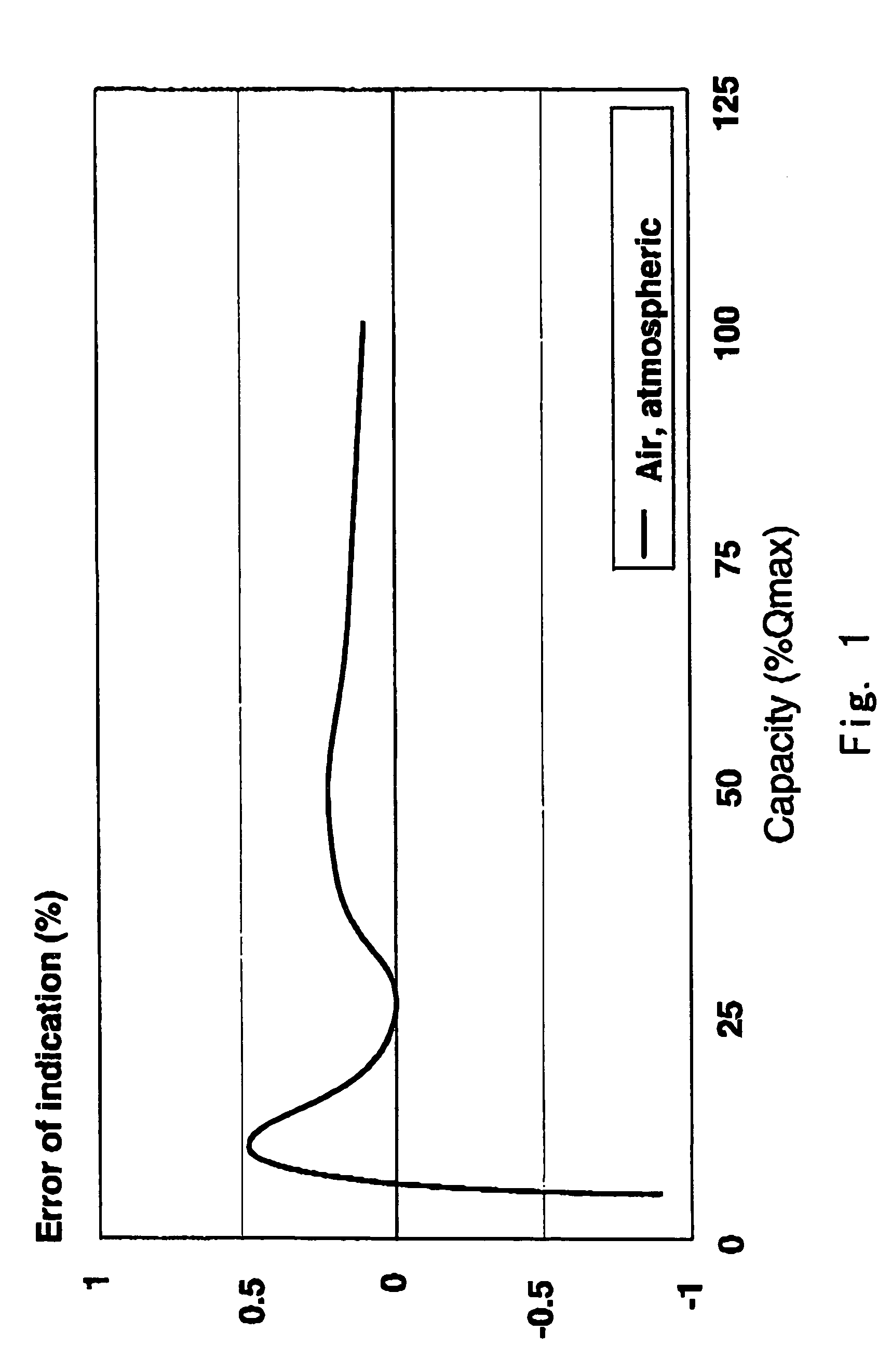

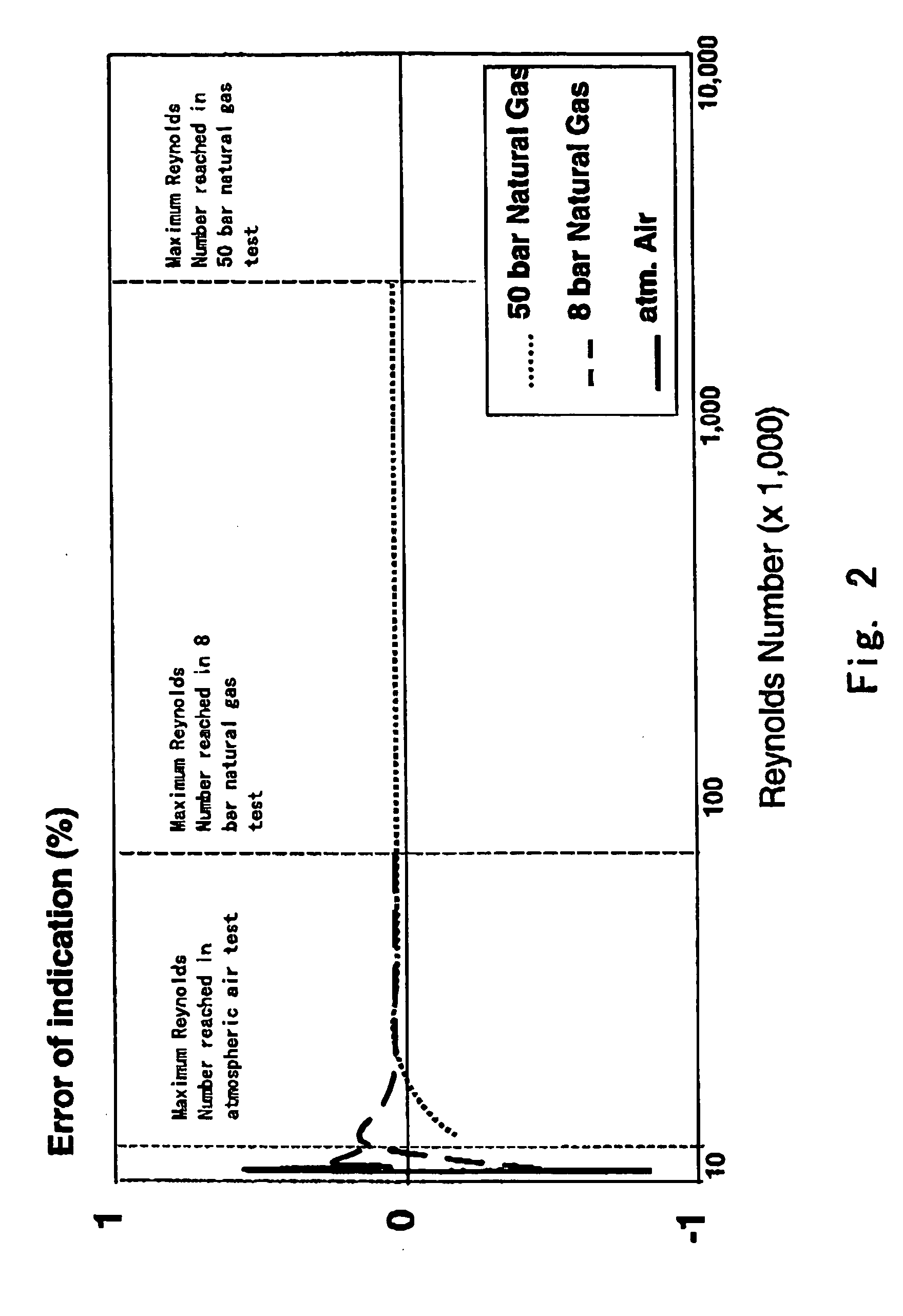

Medium, method and system for proving a turbine meter

ActiveUS20050160784A1Efficiently and accurately test and calibrateThe result is accurateFluid pressure measurementTesting/calibration of speed/acceleration/shock measurement devicesCyclic testNatural gas

A novel medium, method and system for proving a turbine meter for use with natural gas. The novel test medium is a gas having the following characteristics: (a) Density >2×Density of Natural Gas; (b) Dynamic Viscosity < Dynamic Viscosity of Natural Gas; and (c) Ideal gas behavior for approximately 15° C.<T<25° C. and 1 bar<P<50 bar. The method and system make use of the novel test medium. Also disclosed is a novel method and system for cooling a test medium circulating in a turbine meter prover system involving injecting liquefied test medium into said circulating test medium.

Owner:FORTISBC ENERGY

Measuring system with a flow conditioner arranged at an inlet of a measuring tube

ActiveUS7600436B2Increase the Reynolds numberVolume meteringVolume/mass flow by dynamic fluid flow effectTransducerEngineering

The measuring system is inserted into the course of a process line and serves for registering at least one measured variable of a medium flowing in the process line. The measuring system includes for such purpose a measuring transducer having a measuring tube serving for conveying medium being measured and a sensor arrangement, which has at least one sensor element reacting primarily to the measured variable to be registered, and which delivers by means of at least one sensor element at least one measurement signal influenced by the measured variable. Further, the measuring system includes a measuring electronics communicating with the measuring transducer and using the at least one measurement signal for producing, at least at times, at least one measured value instantaneously representing the measured variable. The measuring tube has, in the case of the measuring system of the invention, a smaller flow cross section than a supply segment of the process line connected to the inlet end of the measuring system. To this end, the measuring system further includes a flow conditioner arranged at the inlet end of the measuring tube and mediating between the measuring tube and the supply segment of the process line. The flow conditioner has a lumen tapering in the direction of the measuring tube. During operation, medium flows through the lumen of the flow conditioner. The flow conditioner includes at least one impingement surface arranged upstream of its outlet end and protruding into the lumen of the flow conditioner. During operation, medium conveyed in the flow conditioner flows against the impingement surface.

Owner:ENDRESS HAUSER FLOWTEC AG

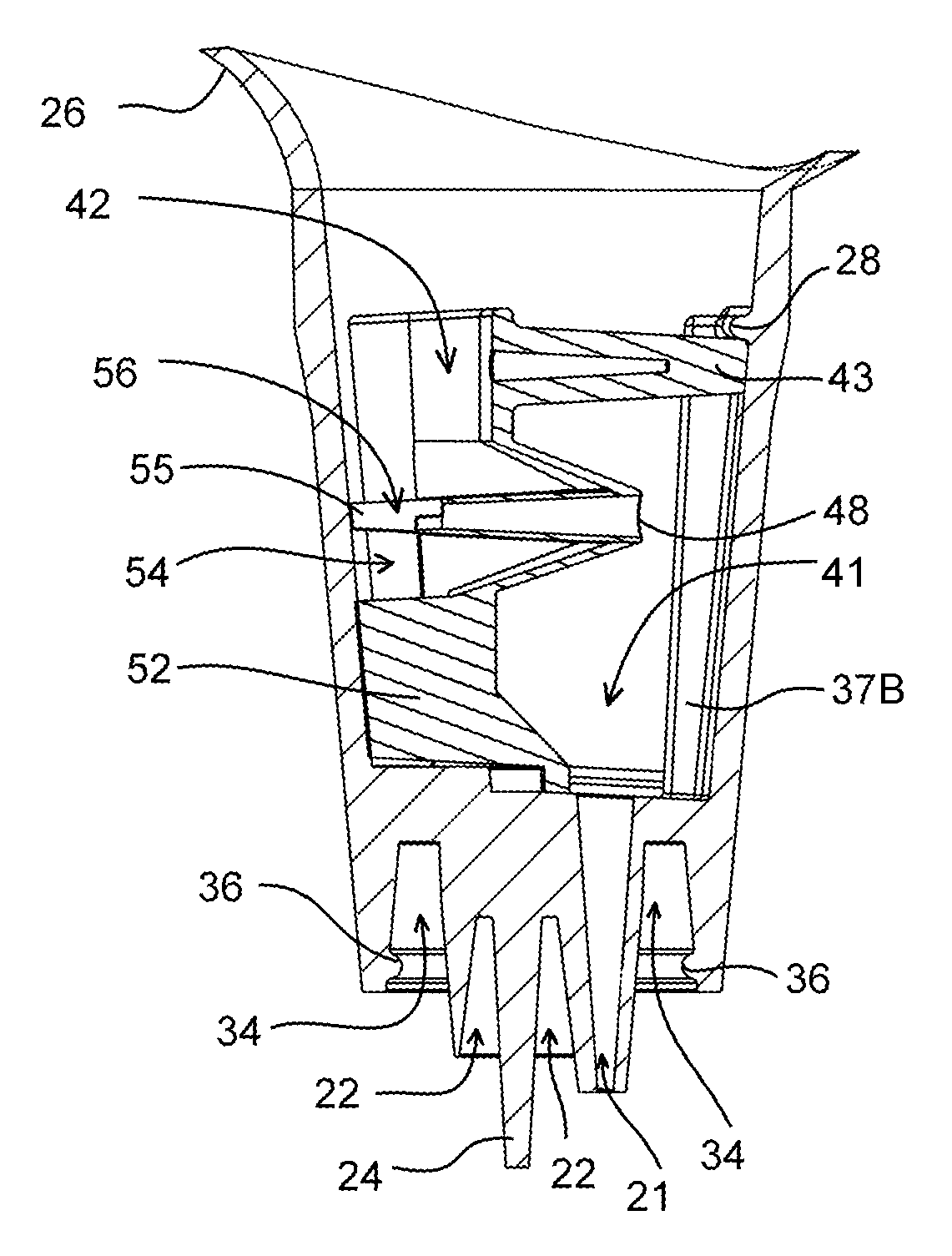

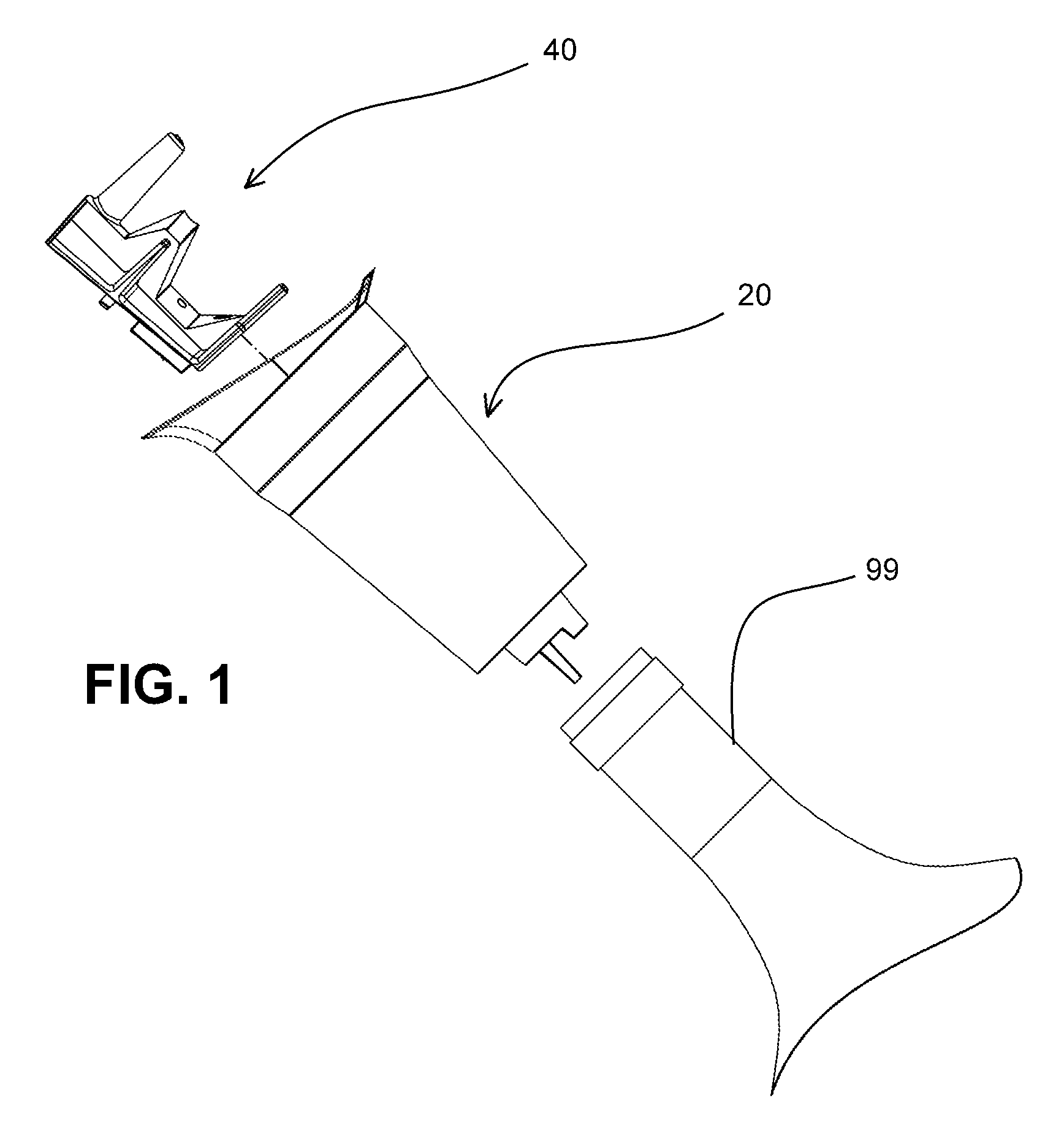

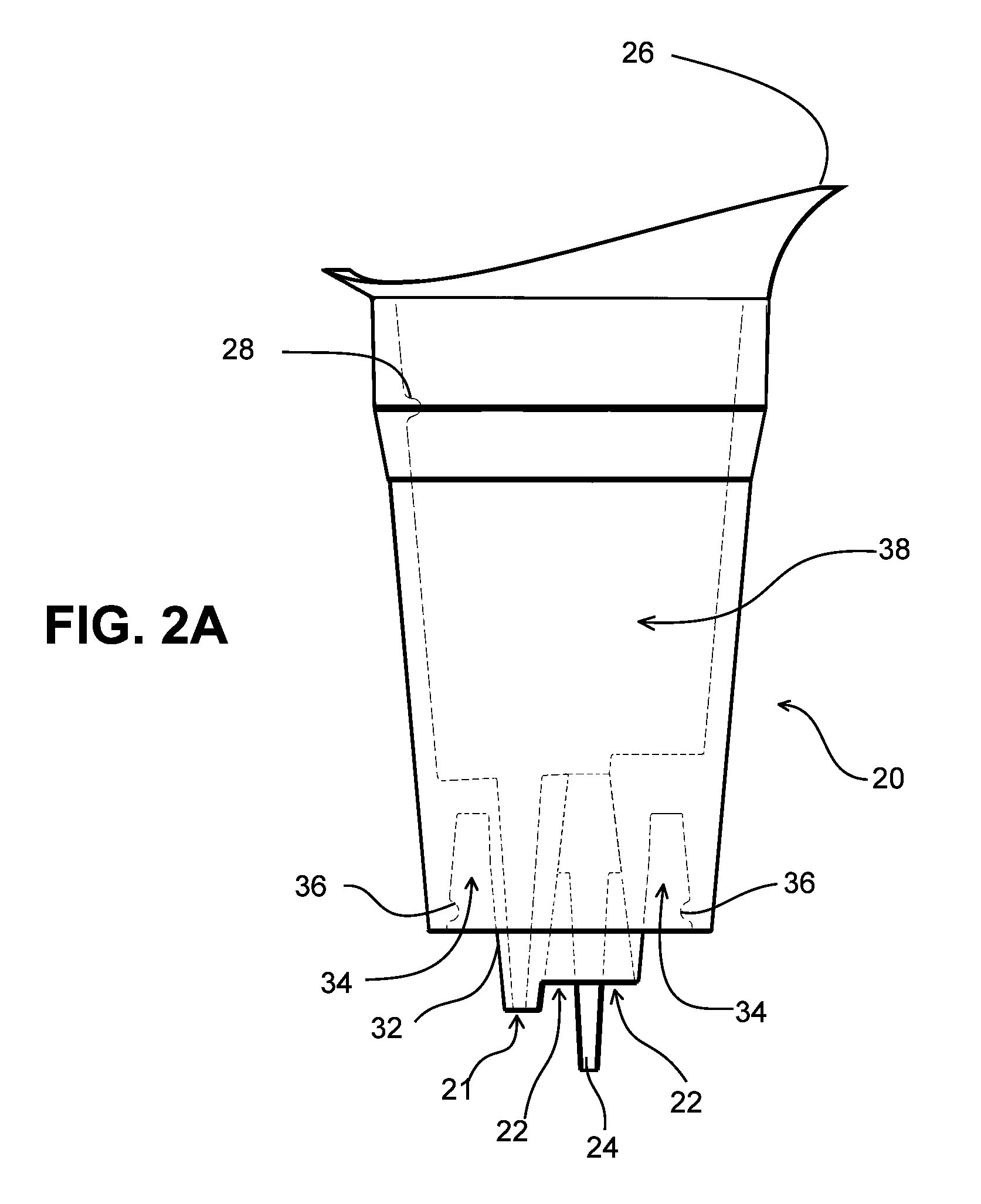

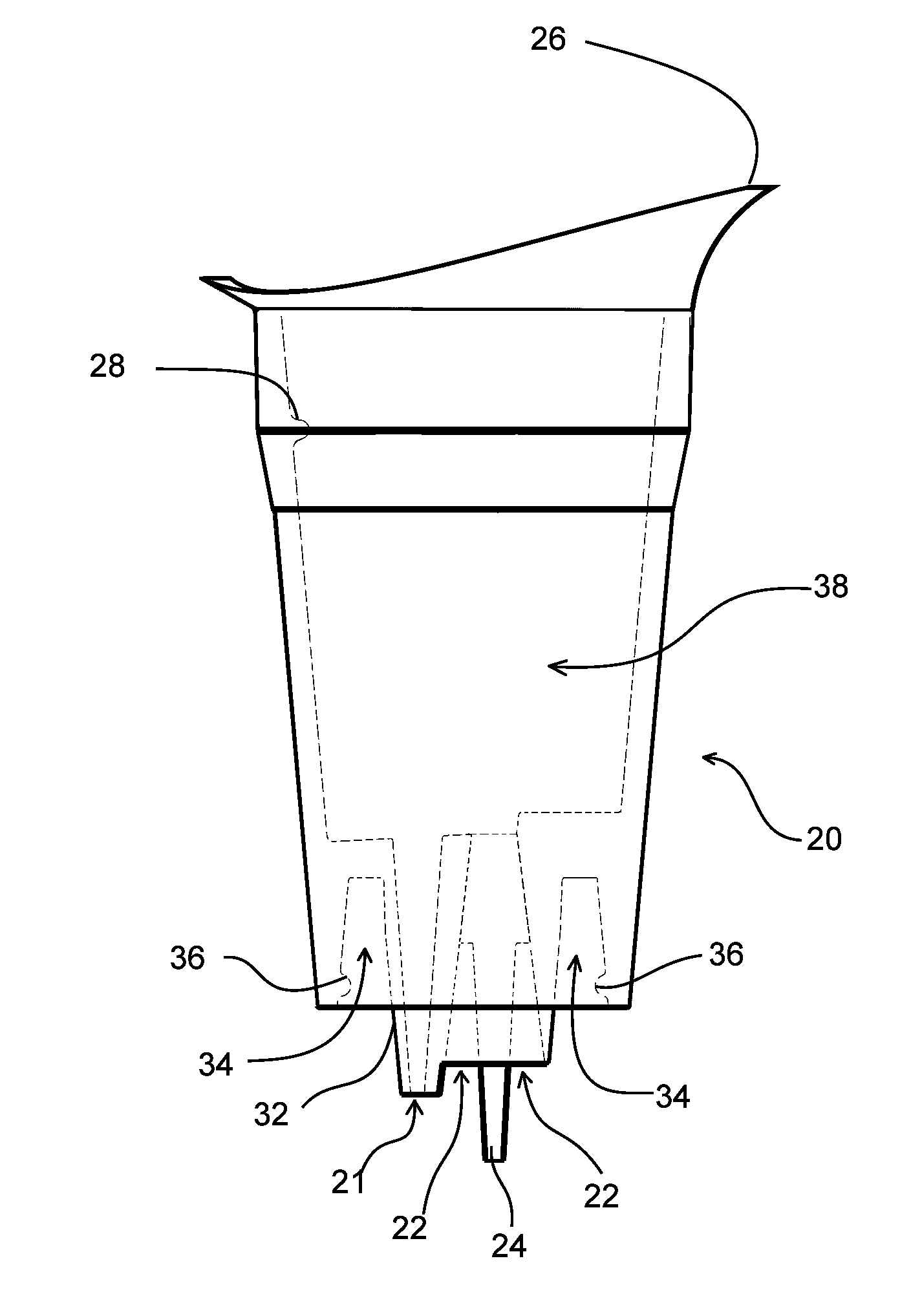

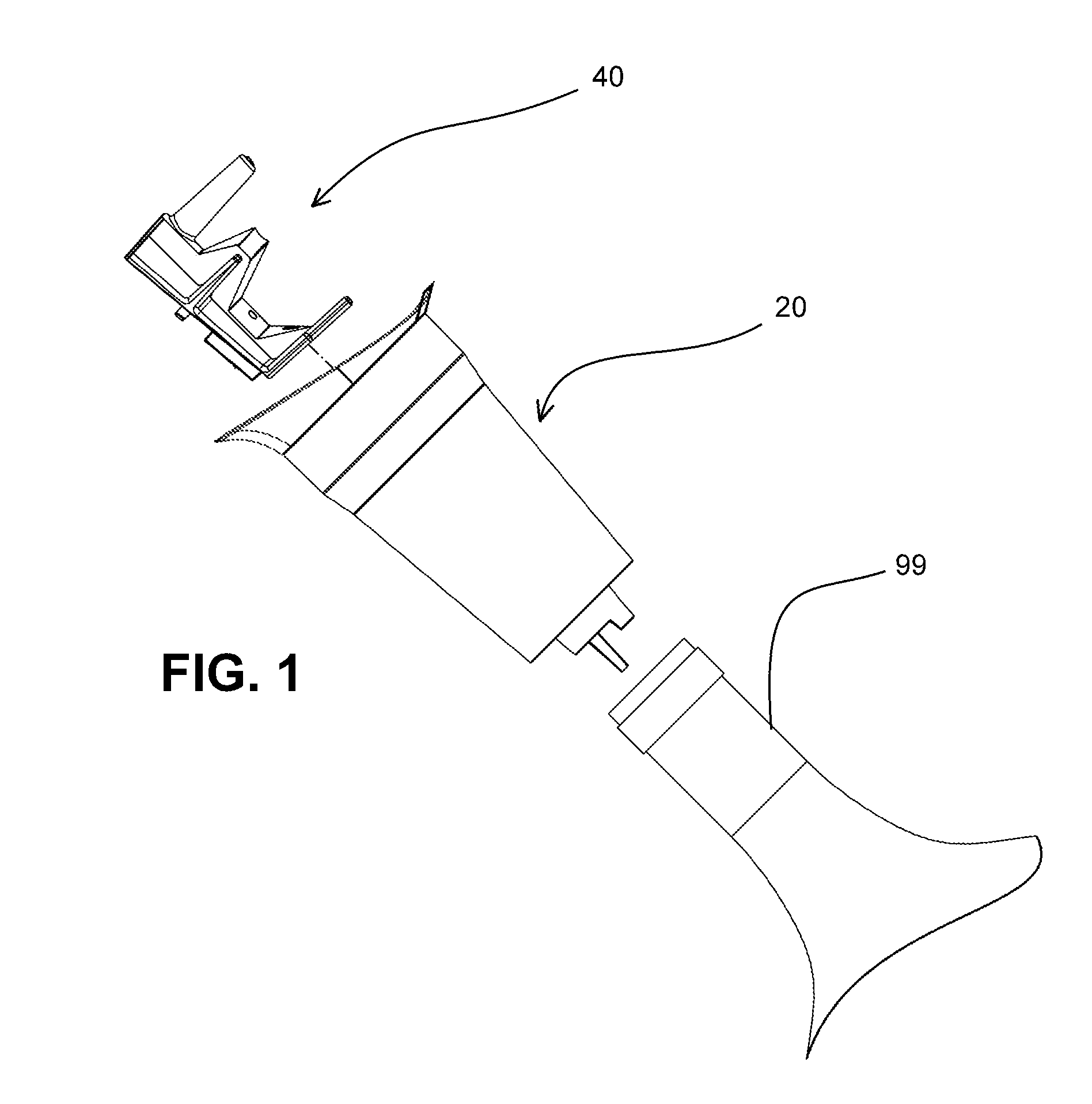

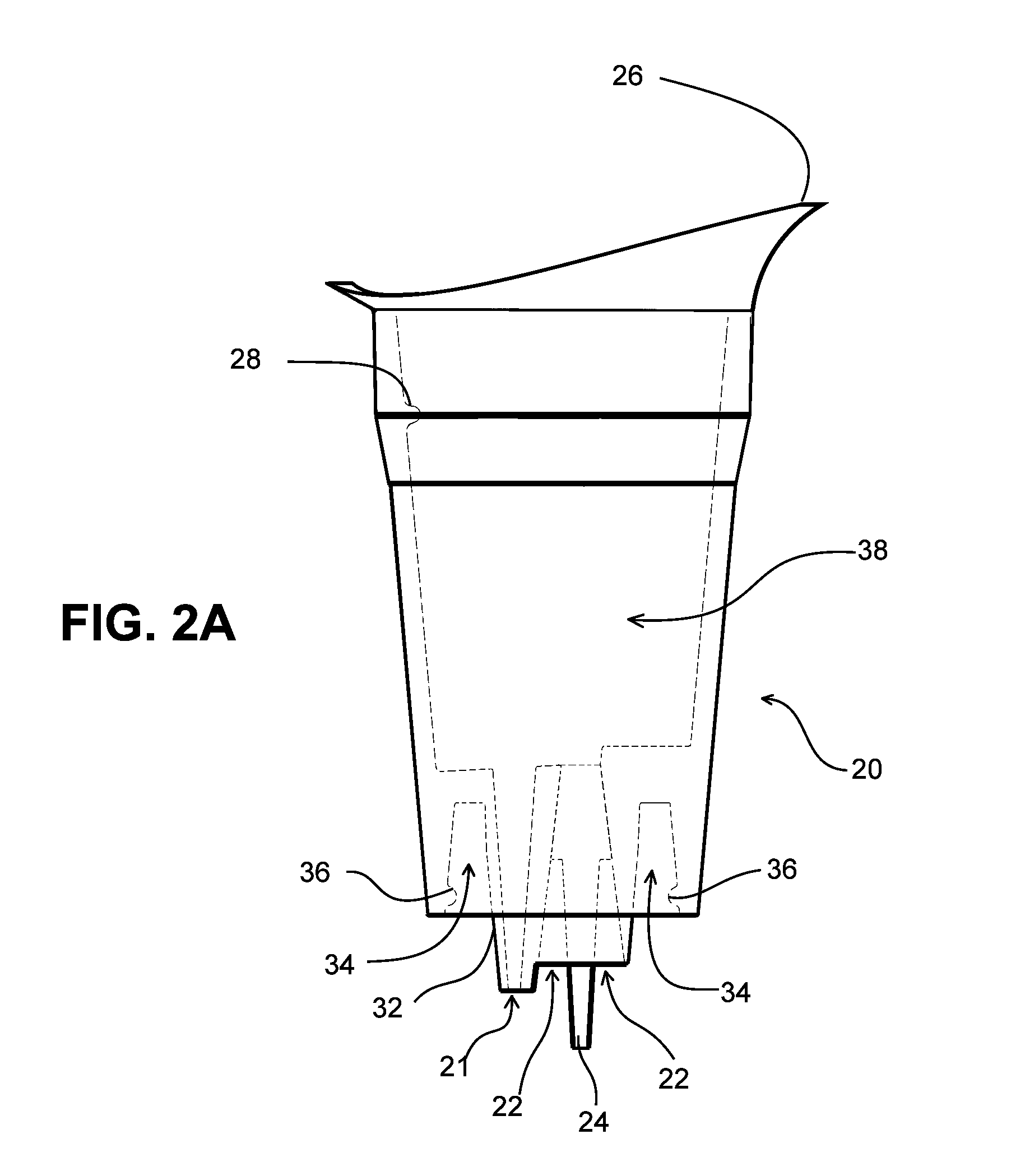

Interchangeable bottletop aerator

InactiveUS8783665B2Introduce turbulenceFaster and more homogeneous mixingMilk preservationFlow mixersEngineeringBottle

An interchangeable bottletop aerator for controllably mixing air with a liquid contained in a bottle. The apparatus includes a receptacle and an interchangeable aerator module that is inserted into the receptacle. The receptacle engages and seals the bottle through a multi lumen cylinder that extends inside the narrow neck of the bottle. It has internal structures to adjust flow characteristics of the liquid and encapsulates the module. The module has multiple channels and sections to apply predetermined aeration and flow speed to the contained liquid. The inserted module can be replaced on demand with a different module to change the aeration parameters and adapt the aeration characteristics to various liquids. The interchangeable bottletop aerator presents a solution to the changing aeration requirements of different liquids like wine in a compact, easy to use, and easy to produce package by means of simply replacing and employing different modules inside the receptacle.

Owner:KURU MURAT +1

Measuring system with a flow conditioner arranged at an inlet of a measuring tube

ActiveUS7603914B2Increase the Reynolds numberVolume/mass flow by dynamic fluid flow effectVolume meteringTransducerEngineering

The measuring system is inserted into the course of a process line and serves for registering at least one measured variable of a medium flowing in the process line. The measuring system includes for such purpose a measuring transducer having a measuring tube serving for conveying medium being measured and a sensor arrangement, which has at least one sensor element reacting primarily to the measured variable to be registered, and which delivers by means of at least one sensor element at least one measurement signal influenced by the measured variable. Further, the measuring system includes a measuring electronics communicating with the measuring transducer and using the at least one measurement signal for producing, at least at times, at least one measured value instantaneously representing the measured variable. The measuring tube has, in the case of the measuring system of the invention, a smaller flow cross section than a supply segment of the process line connected to the inlet end of the measuring system. To this end, the measuring system further includes a flow conditioner arranged at the inlet end of the measuring tube and mediating between the measuring tube and the supply segment of the process line. The flow conditioner has a lumen tapering in the direction of the measuring tube. During operation, medium flows through the lumen of the flow conditioner. The flow conditioner includes at least one inner edge arranged upstream of its outlet end and protruding into the lumen of the flow conditioner. During operation, medium conveyed in the flow conditioner flows against the inner edge.

Owner:ENDRESS HAUSER FLOWTEC AG

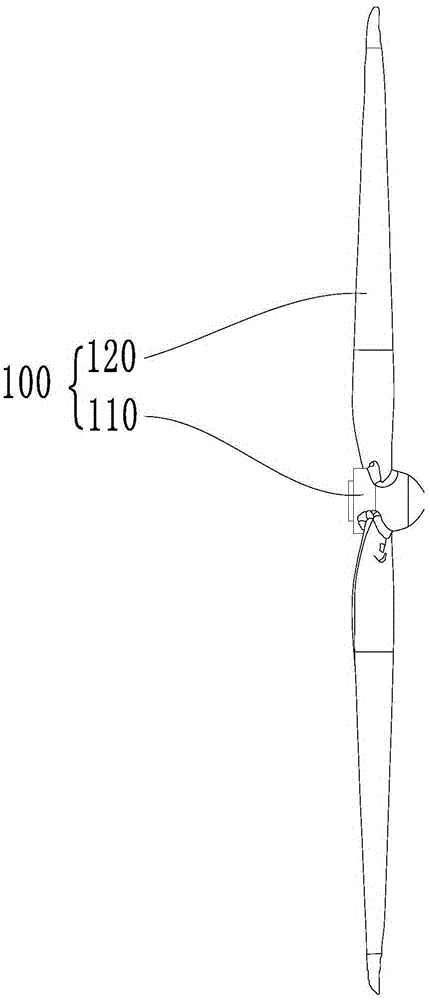

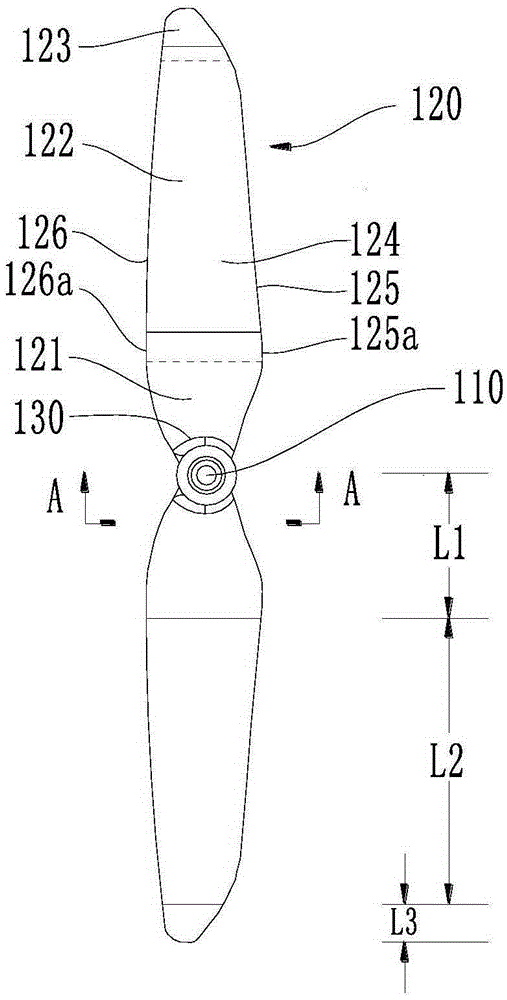

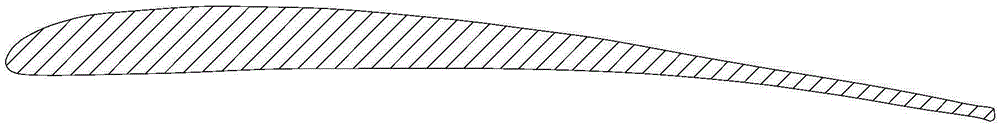

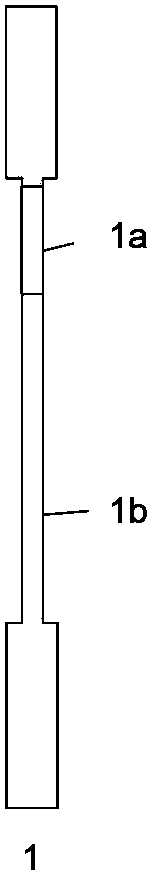

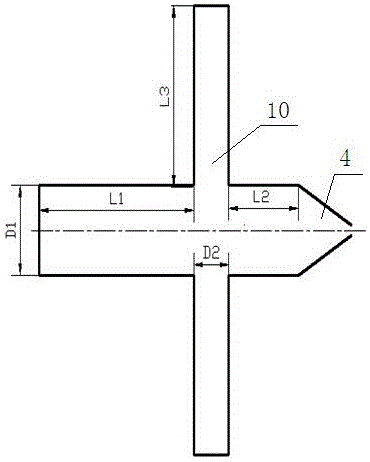

Propeller and aircraft

ActiveCN105235893AIncrease the Reynolds numberReduce resistancePropellersRotocraftAerodynamic dragPropeller

The invention relates to the technical field of unmanned aerial vehicles, and particularly discloses a propeller and an aircraft. The propeller comprises a propeller hoop and at least two propeller blades connected with the propeller hoop. The wing type of the propeller blades is ARA-D, and each propeller blade is composed of a root portion, a main body portion and a blade tip portion which are sequentially connected. The length L1 of the root portion accounts for 20% to 30% of the length L of the propeller blades, and the length L of the propeller blades is the length, in the first direction from the center of the propeller hoop to the farthest end of the blade tip portions, of the propeller blades; the installing inclined angle of the root portions ranges from 10 degrees to 15 degrees, and the blade widths of the root portions are gradually increased in the first direction; the length L2 of the main body portions accounts for 60% to 70% of the length of the paddle blades, and the blade widths of the main body portions are gradually decreased in the first direction; the minimum blade width of the main body portions accounts for 55% to 65% of the maximum blade width of the main body portions; and the length L3 of the blade tip portions is equal to L-L1-L2, and the blade widths of the blade tip portions are gradually decreased in the first direction. According to the propeller, the air resistance is reduced, efficiency is improved, and therefore the flying speed and the flying distance of the aircraft are increased.

Owner:SHENZHEN AUTEL INTELLIGENT AVIATION TECH CO LTD

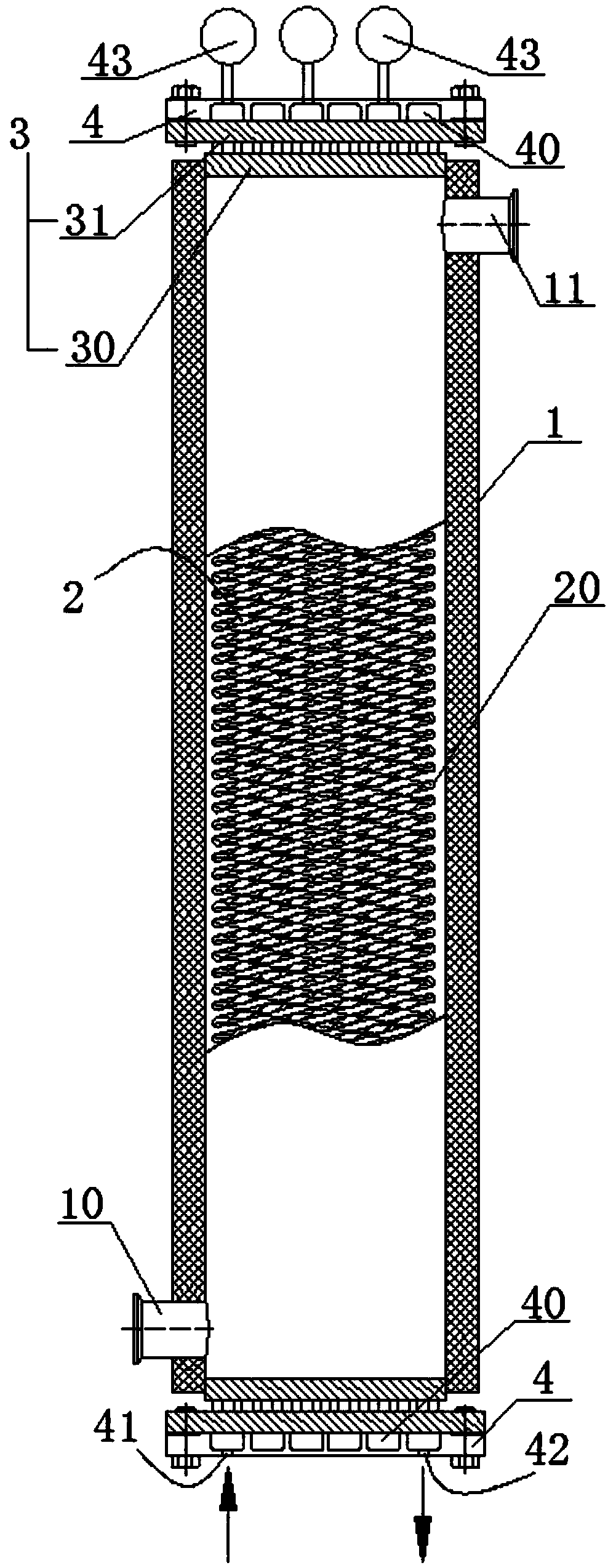

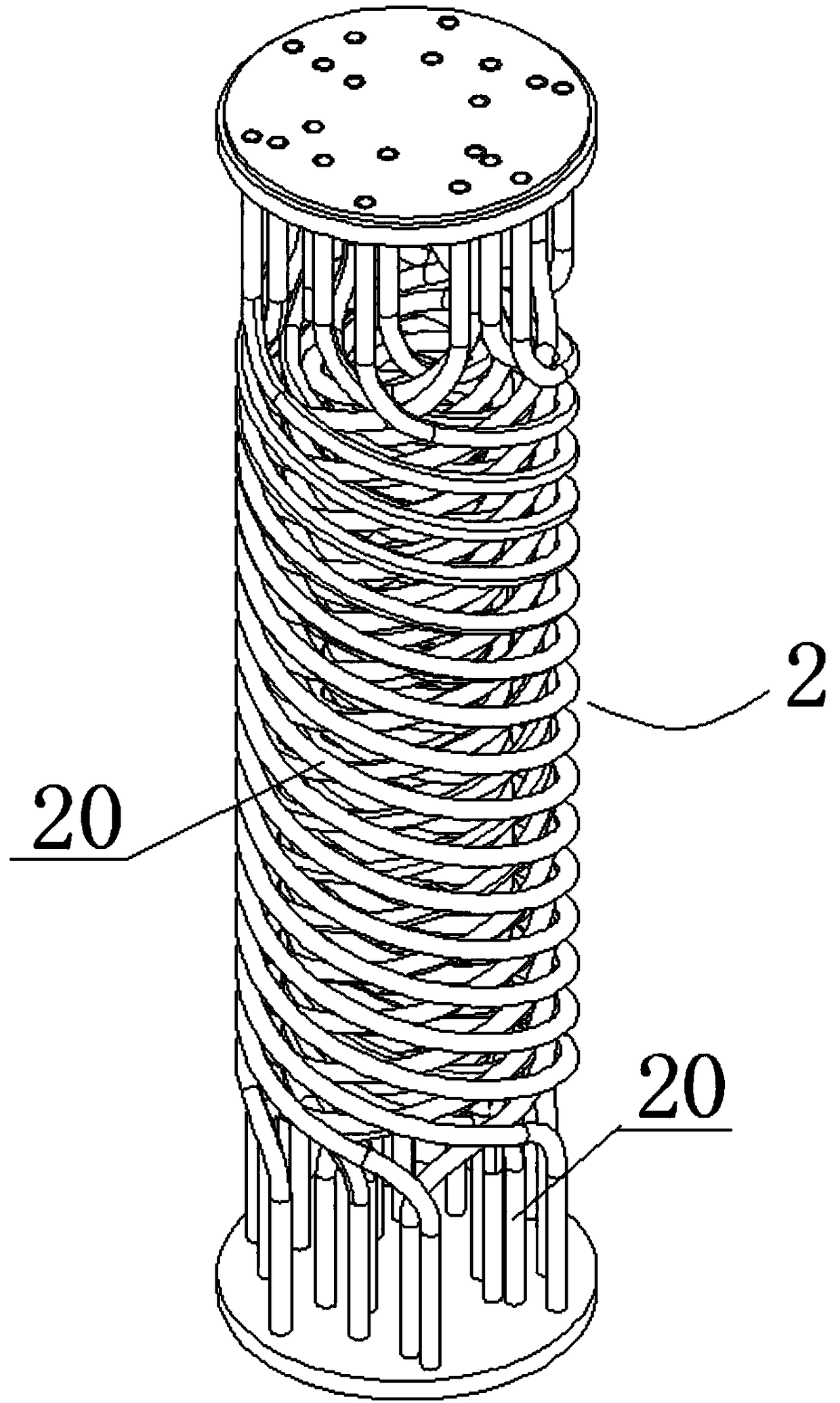

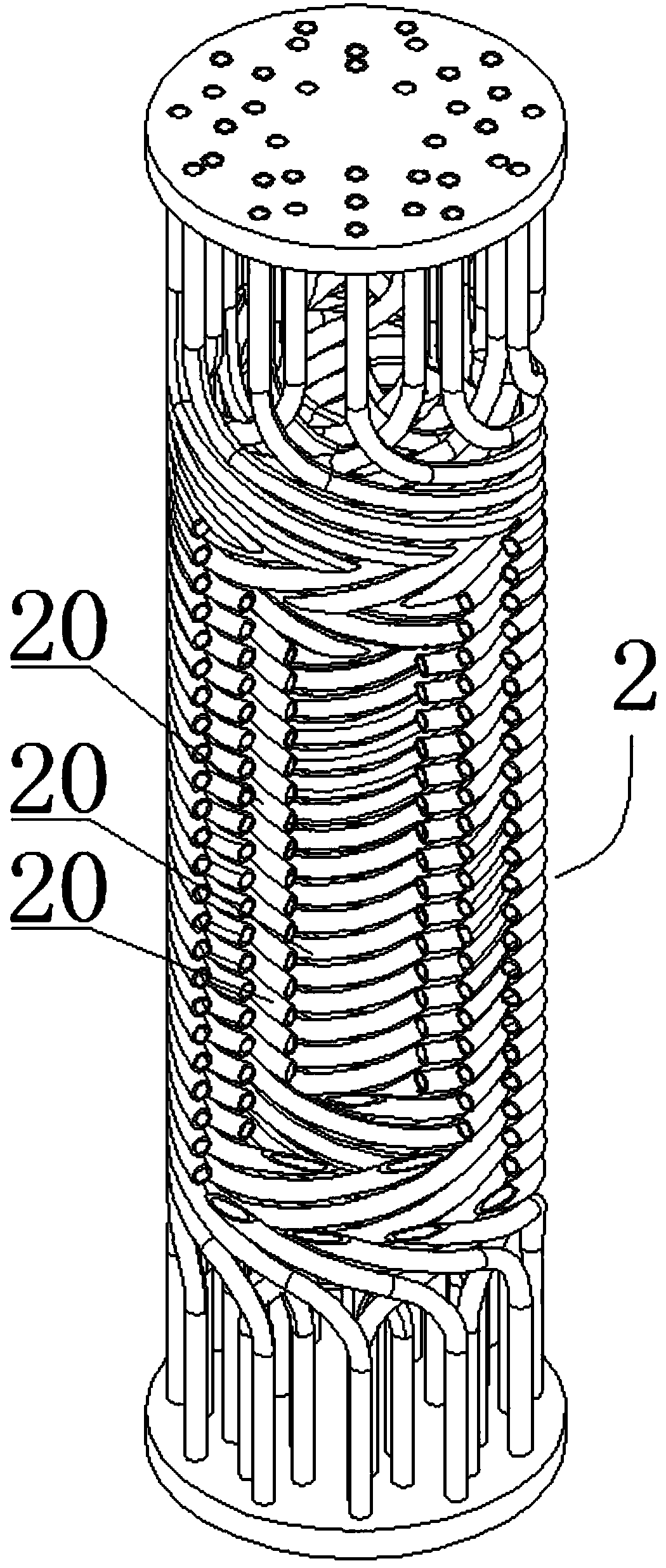

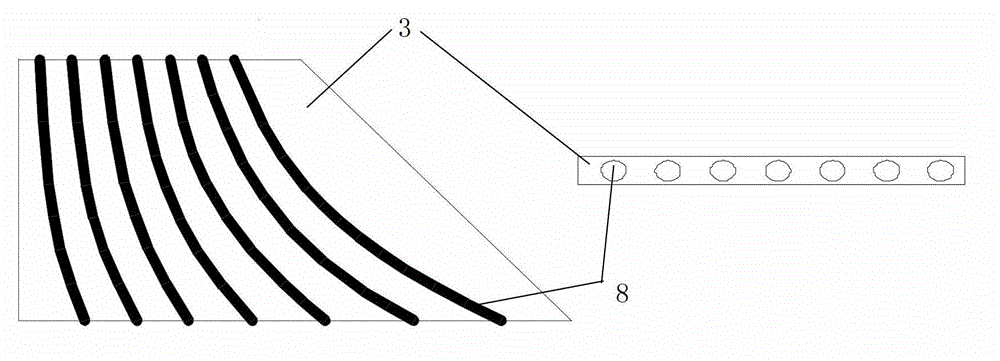

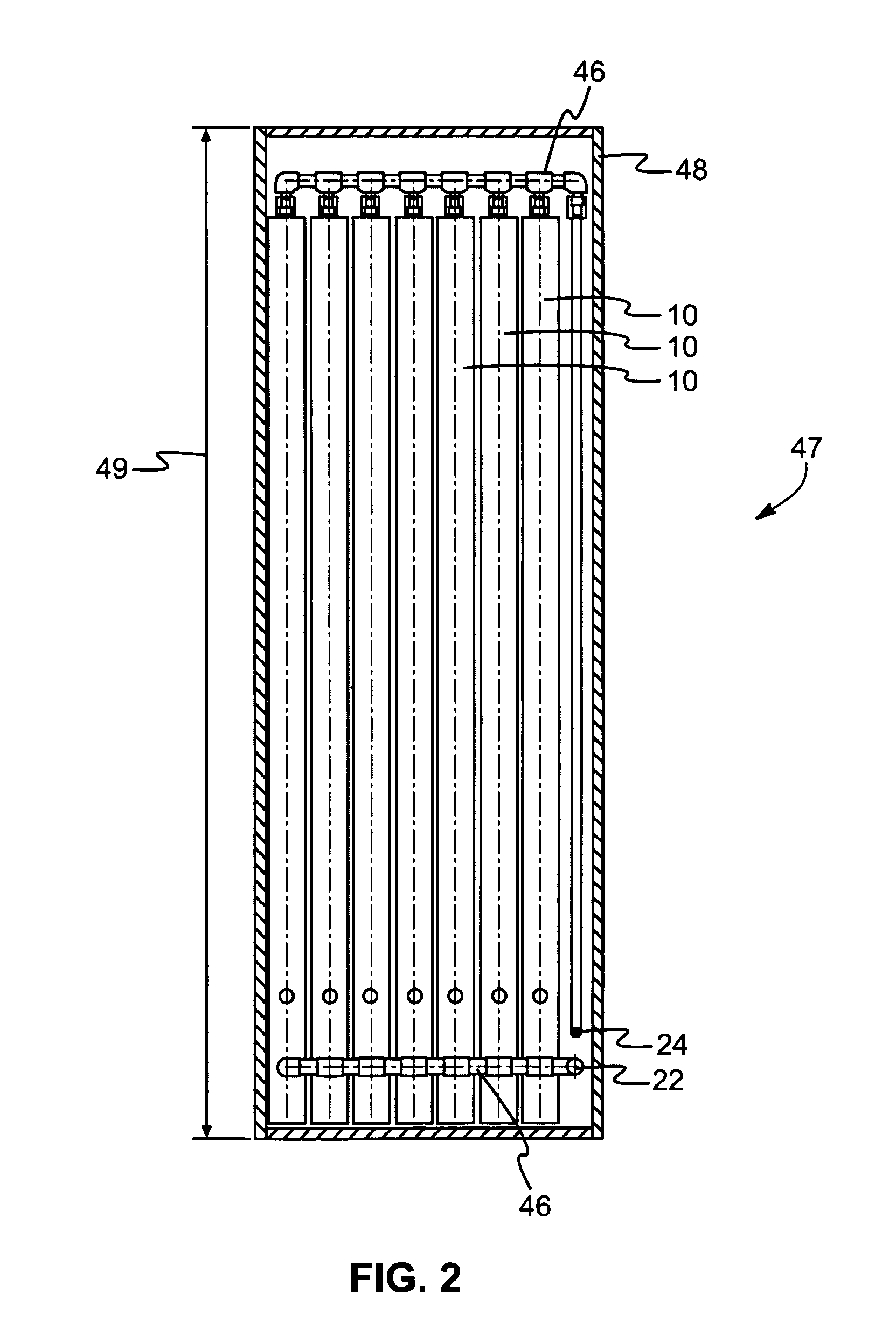

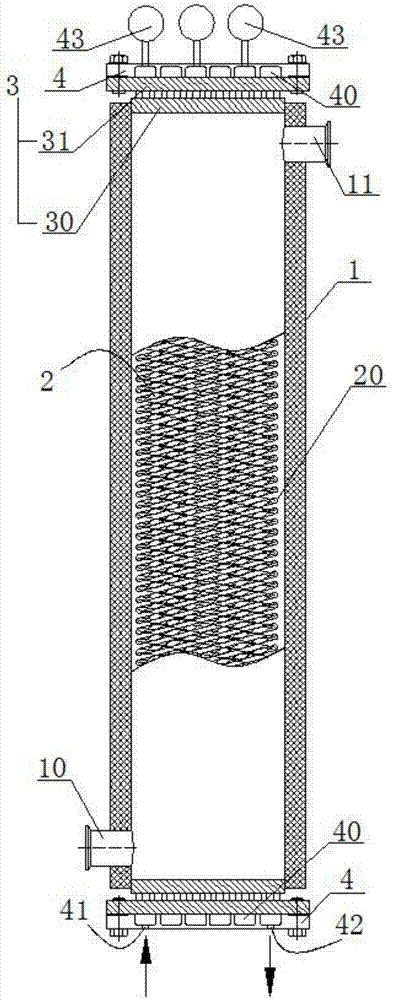

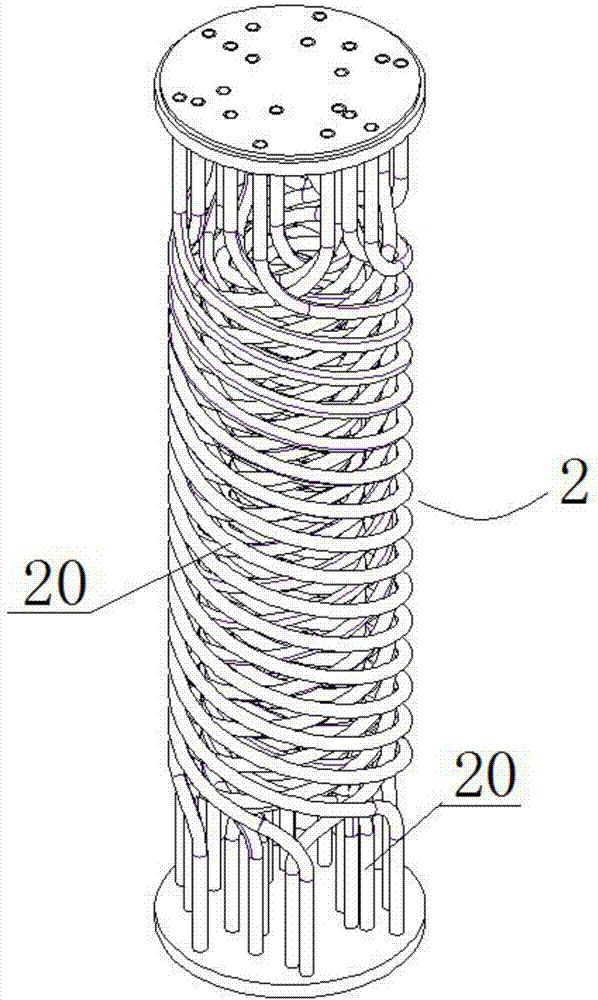

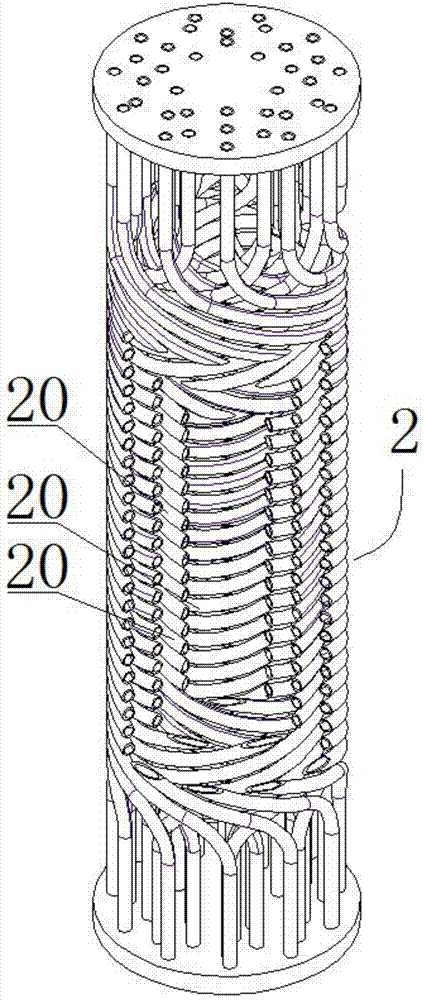

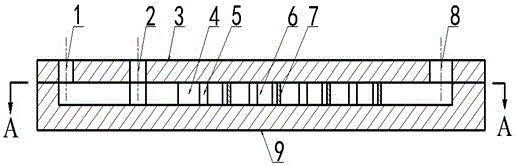

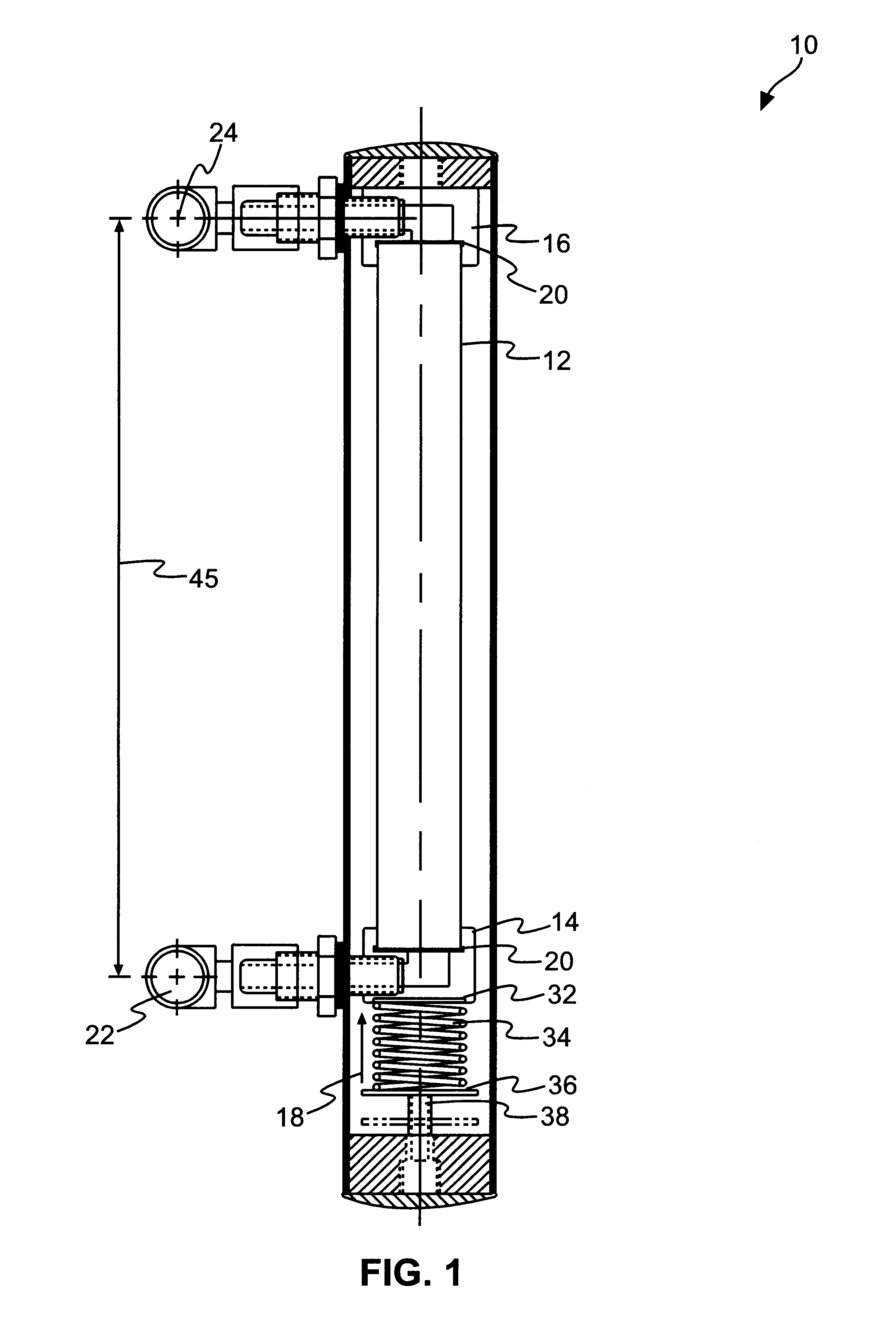

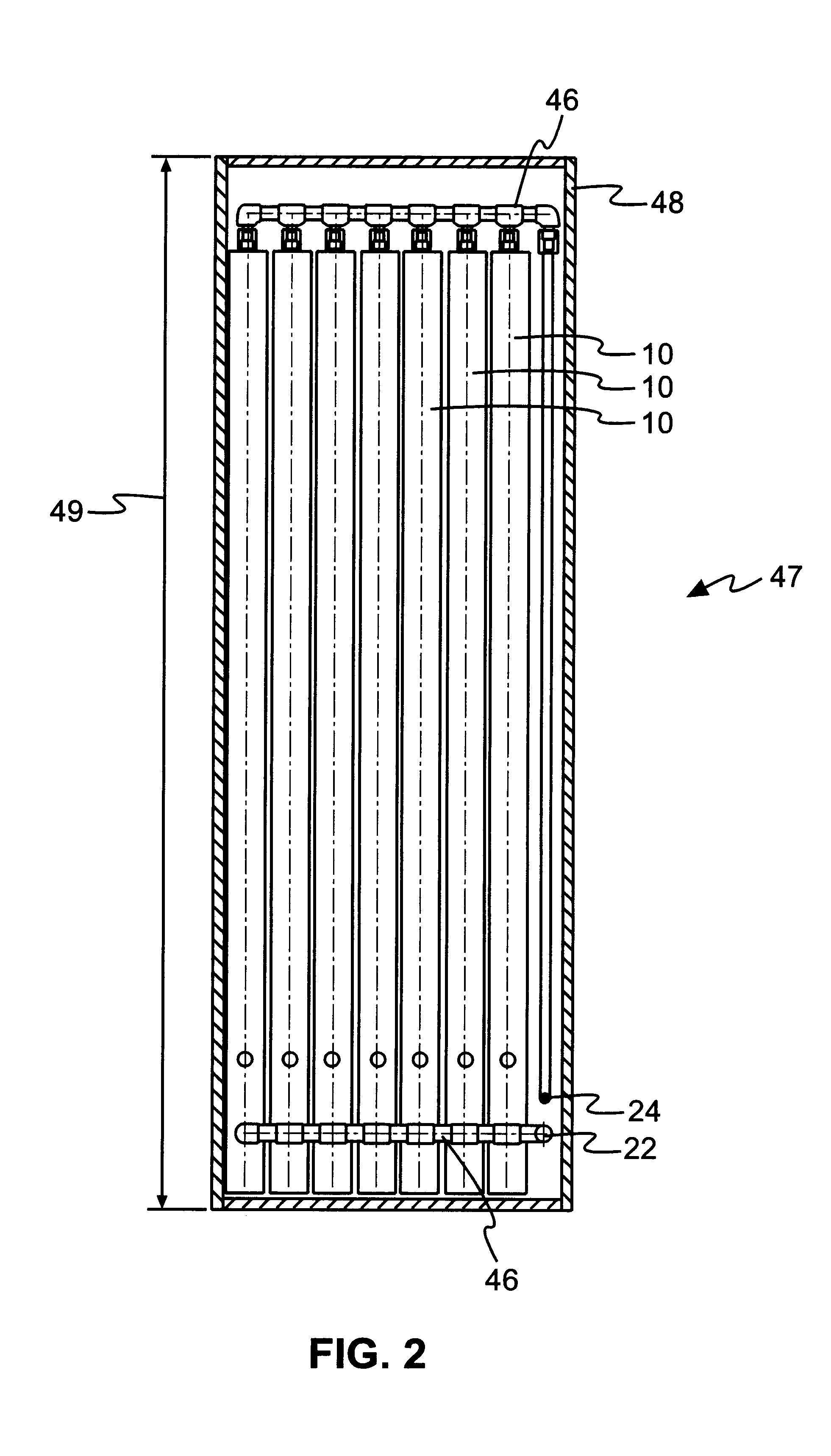

A continuous flow reactor

ActiveCN107442061BImprove responseIncrease the Reynolds numberChemical/physical/physico-chemical stationary reactorsBiochemical engineeringContinuous flow

The invention relates to the technical field of chemical and pharmaceutical equipment, in particular to a continuous flow reactor. The continuous flow reactor comprises a shell, wherein a shell side inlet and a shell side outlet which are communicated with an inner cavity of the casing are arranged on the shell; each of the upper end and the lower end of the shell is connected with a tube plate and a communicating device, a reaction tube stack is arranged in the shell and comprises multiple reaction tubes, the upper end and the lower end of each reaction tube penetrate through and are fixedly connected on the tube plates, and all the reaction tubes are sequentially connected in series through the communicating devices. By comparison with a traditional reactor, the reaction process is greatly improved under the condition of the same volume, reactants have high reynolds numbers under the condition of a low flow speed, the turbulence effect is greatly improved, unintermittent mixing is performed during constant flowing reactions, states of reaction stages can be detected in real time, and mounting and assembly are simplified.

Owner:SHANDONG NERVE PHARMA FLUID SYST CO LTD

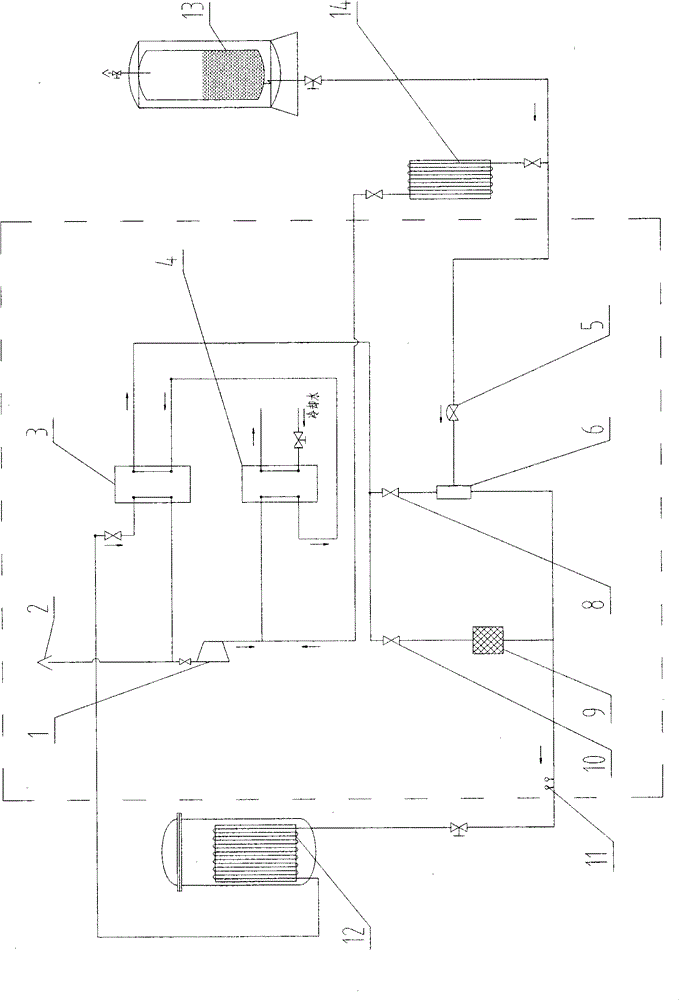

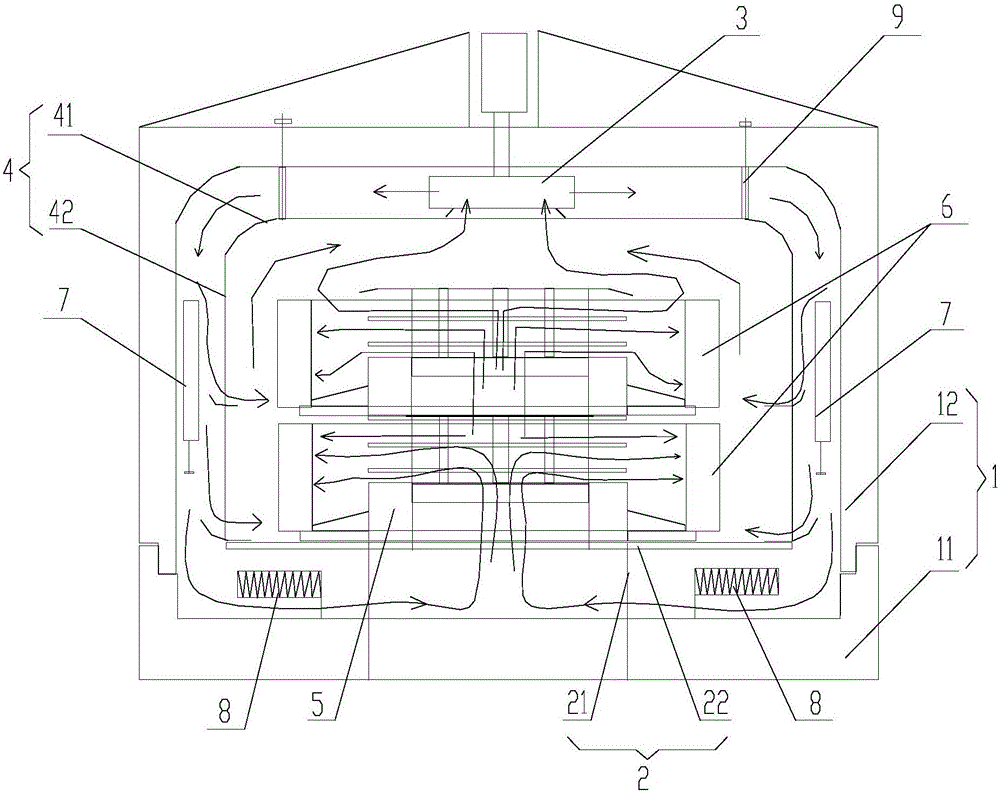

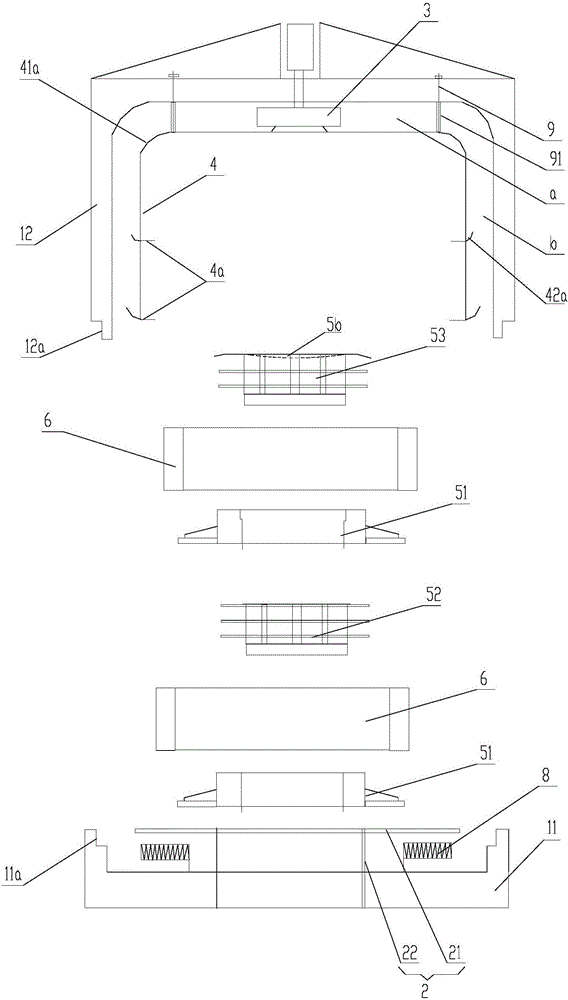

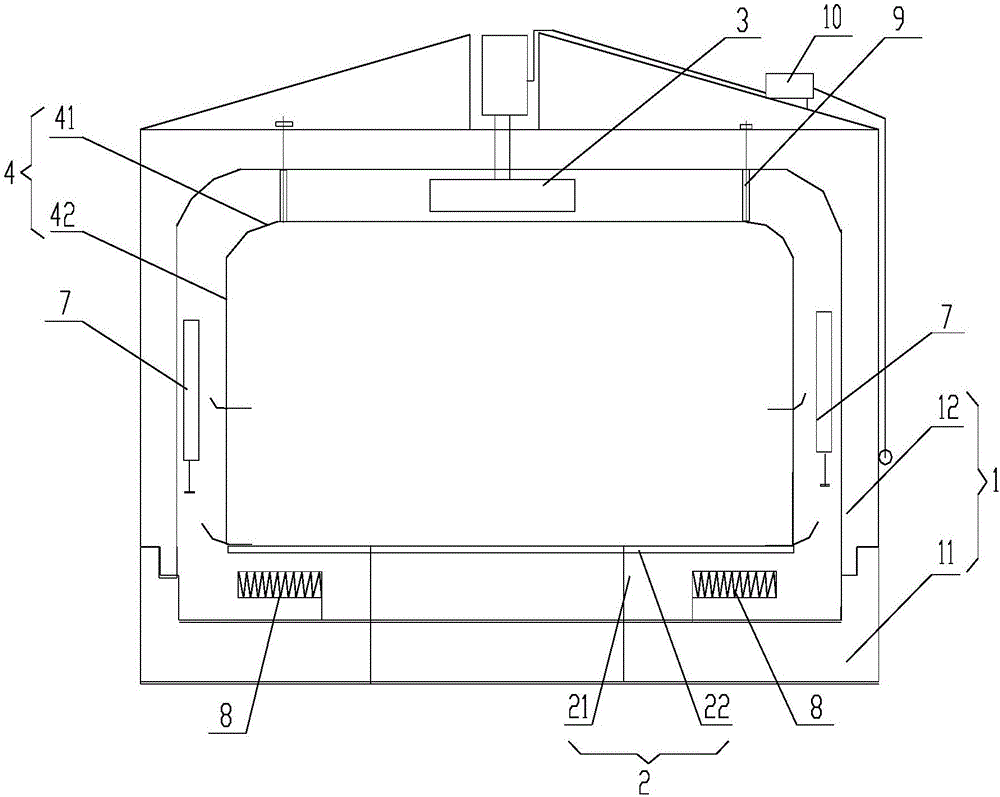

Backheating gas mixed circulating refrigeration, heating and temperature adjustment system

ActiveCN104571183AImprove the use environmentImprove operational reliabilityTemperature control using electric meansNitrogen gasEnvironmental simulation

The invention relates to a backheating gas mixed circulating refrigeration, heating and temperature adjustment system which comprises a circulating fan, a gas exhaust port, a two-channel regenerator, a water-cooling heat exchanger, a liquid nitrogen flow control valve, a liquid nitrogen storage tank, a liquid nitrogen mixer, a heater, a heating stop valve, a refrigeration stop valve, a universal stop valve, a vaporizer, a heat sink, a sensor and pipelines. Gas such as nitrogen or air serves as a circulating working medium, the circulating fan circulates the gas in the pipelines, and the circulating gas cools or heats the heat sink; during high-temperature circulating, heating temperature control is performed on the gas via the heater; during low-temperature circulating, cooling temperature control is performed on the gas via liquid nitrogen; and the cooling or heating quantity of the gas flowing out of the heat sink is recovered via the two-channel regenerator. Therefore, the flow energy consumption is reduced; the circulating fan can operate at a room temperature; the operation reliability of the fan is improved; and precise temperature control can be performed on environmental simulation equipment, namely the heat sink from -173 DEG C to 200 DEG C.

Owner:杭州华宇航天科技有限公司 +1

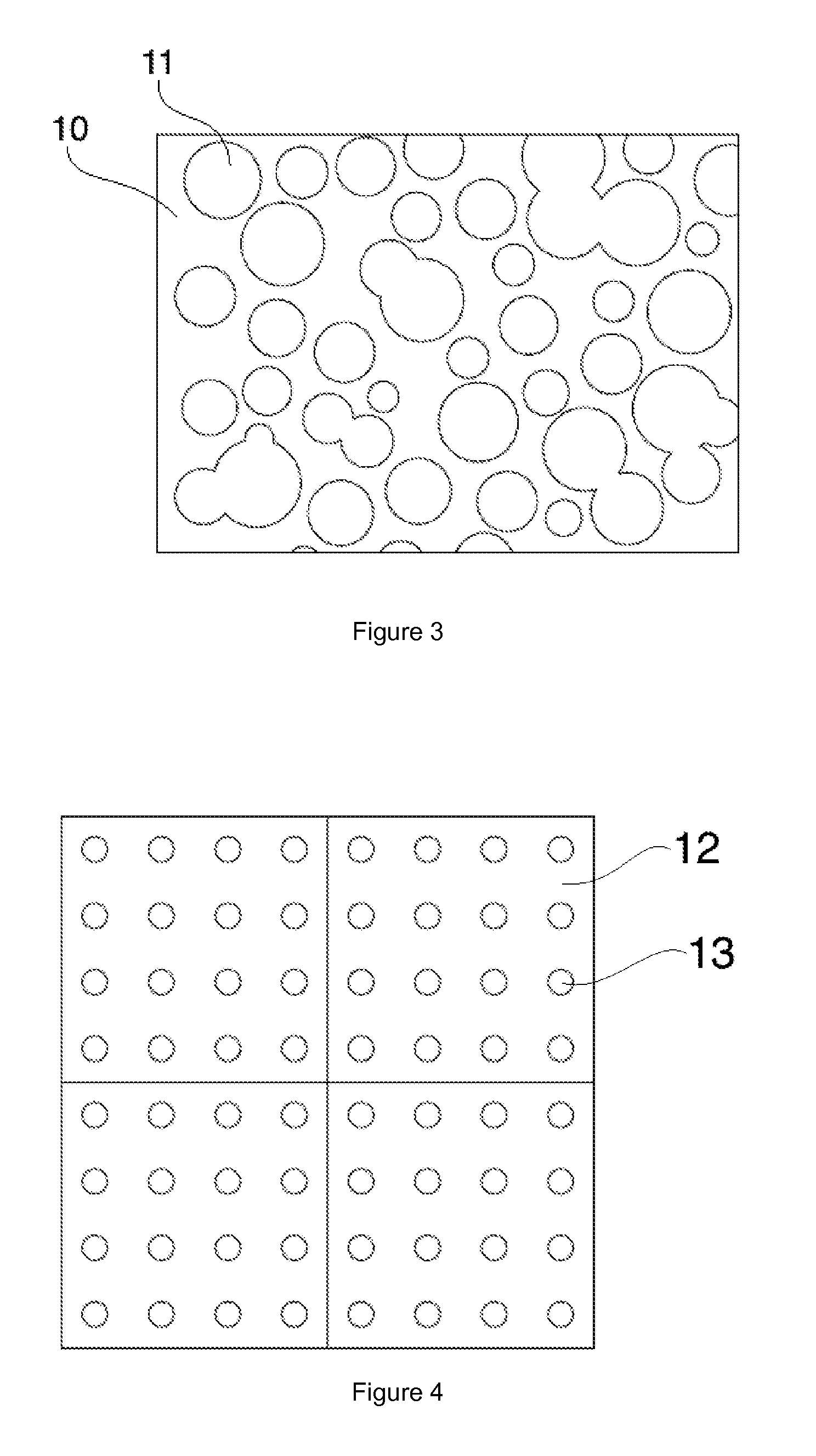

Electrodialysis spacer

InactiveCN102910713APrecise processing sizeFlat processing sizeDispersed particle separationElectricityOrganic solvent

The invention discloses the technical field of water treatment, and particularly relates to a spacer member in an electrodialysis device. An electrodialysis spacer comprises a board frame, a water distribution flow passage, liquid guide holes and a board-core grid, wherein half of the liquid guide holes are elliptical, and half of the liquid guide holes are semi-elliptical, connected with the water distribution flow passage and communicated with the inner cavity of the board frame; the elliptical liquid guide holes are arranged at one end of the board frame; and the board-core grid is distributed in the inner cavity of the board frame. The electrodialysis spacer has the advantages that the flow capacity can be improved and the resistance is reduced in the water flow process; and the electrodialysis spacer has the characteristics of being good in elasticity, resistant to strong acid, strong base and organic solvent, easy to seal and good in leak tightness.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

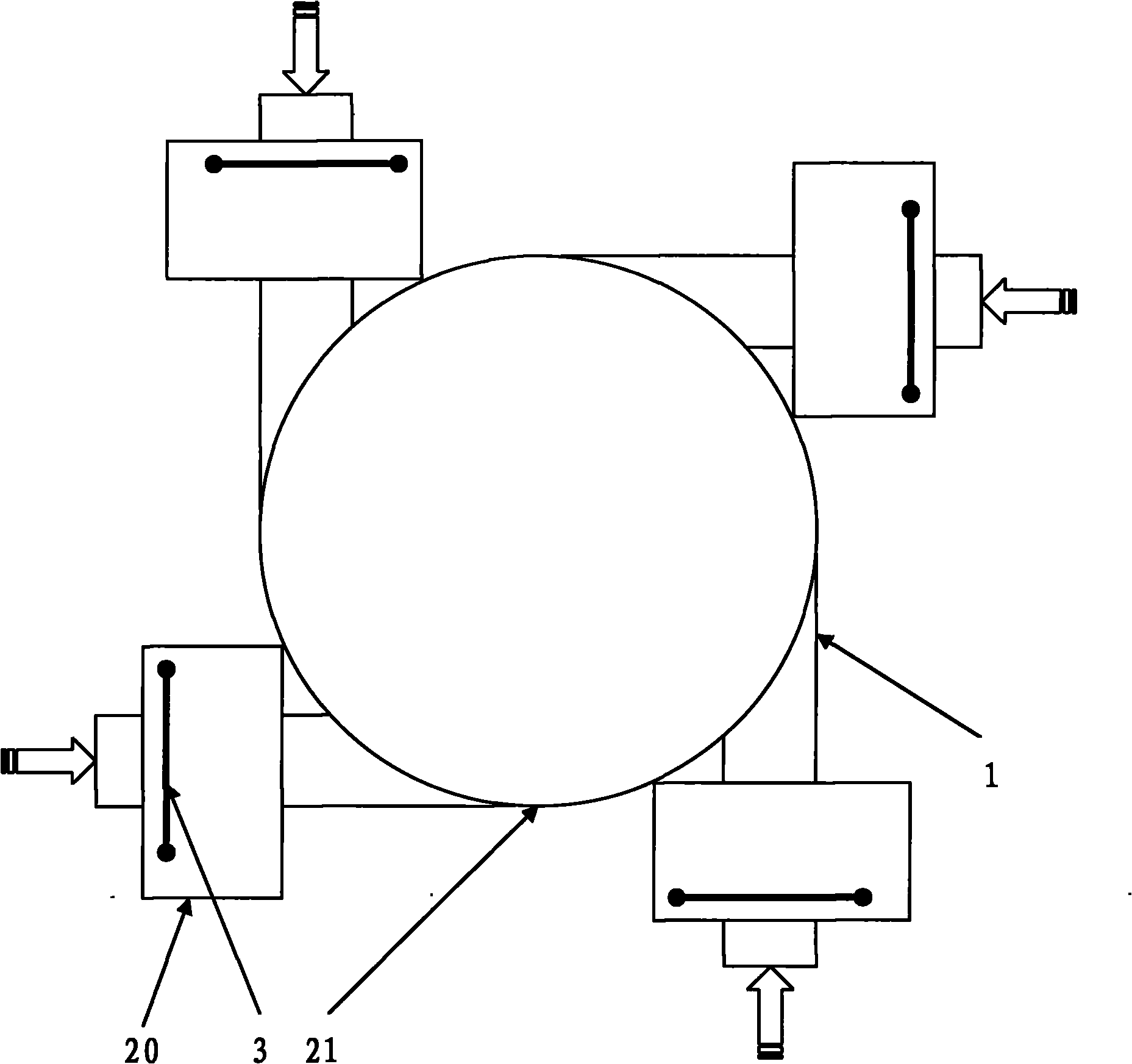

Method for preparing stratiform hydrotalcite PVC (Poly Vinyl Chloride) heat stabilizer by using rotary liquid membrane reactor

ActiveCN102633294ASmall sizeAvoid mixed reactionsAluminium compoundsZinc compoundsGeneration rateChemical physics

The invention provides a rotary liquid membrane reactor, belonging to the technical field of an inorganic functional material and used for preparing the stratiform hydrotalcite PVC heat stabilizer. Starting from a basic technique of a coprecipitation method and based on a crystal chemical principle, the invention designs the rotary liquid membrane reactor through calculation and analysis of fluid mechanics, so that two fluids flow in a turbulence manner within a confinement space. Therefore, the supersaturation degree is uniform, the nucleation rate of a system is improved, and the crystallization generation rate is reduced; alamellar hydrotalcite PVC heat stabilizer with smaller grain size and narrower grain size distribution is obtained. The grain size of the product can be controlled within a range of 10-150 nm, and the size distribution range can be reduced to 20-50 nm.

Owner:青海西部镁业新材料有限公司

Wind tunnel aircraft model with truncated wing

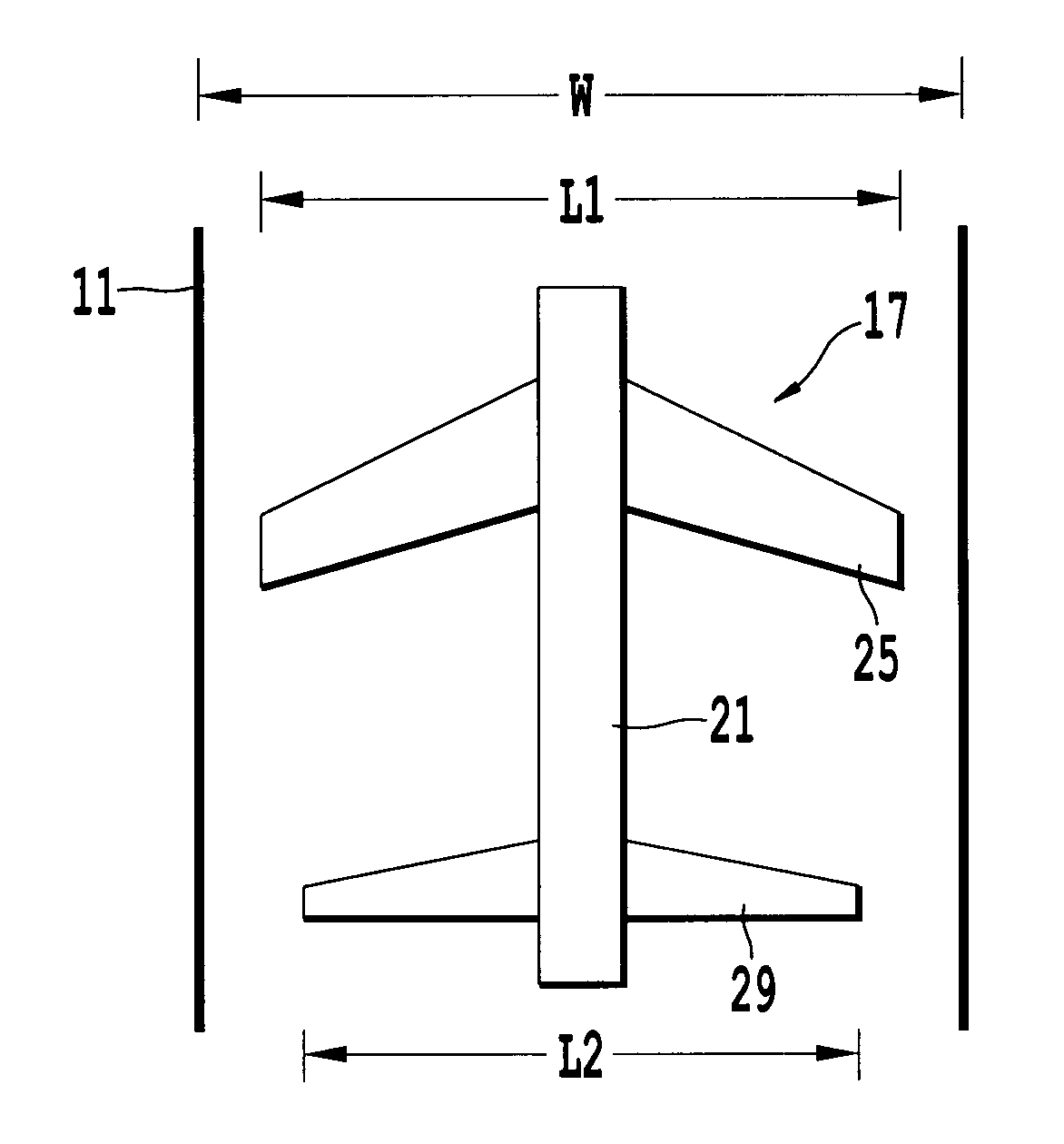

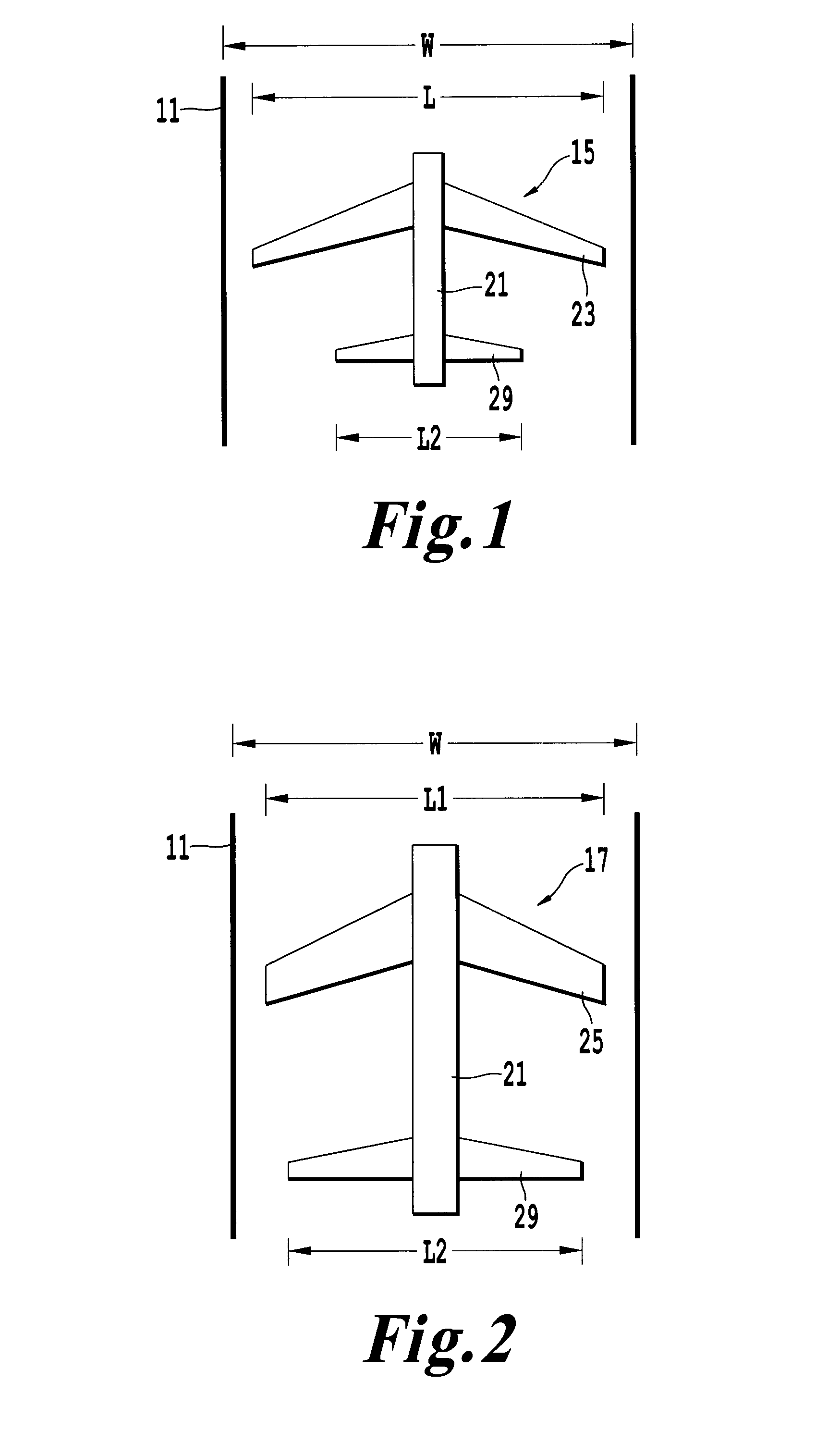

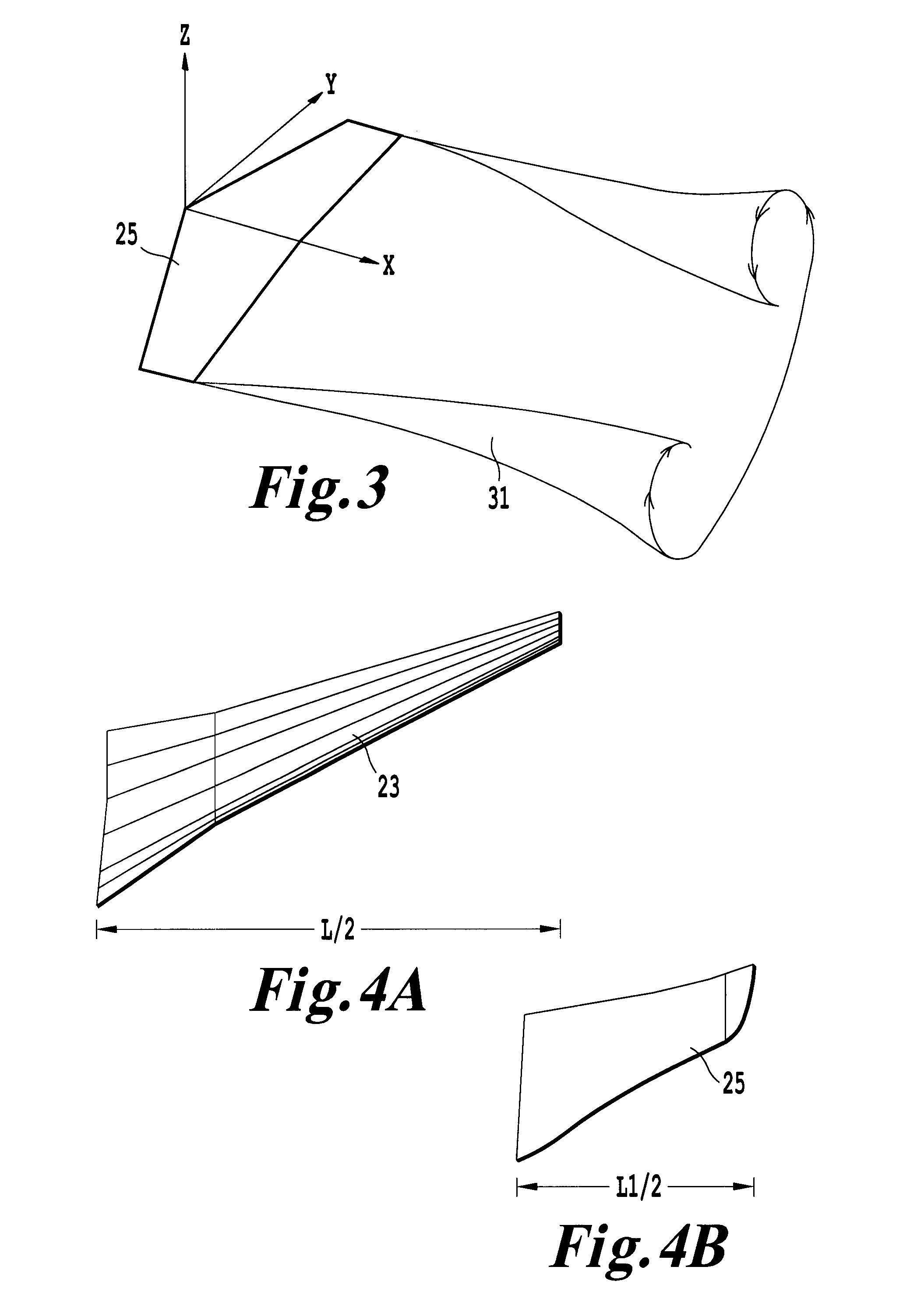

InactiveUS20110106503A1Increase maximum scaleSmall spanAircraft stabilisationAerodynamic testingAirplaneTailplane

An aircraft model (17) for testing in a wind tunnel (11) of width W comprising a fuselage (21), a truncated wing (25) whose length L1 is lesser than the length L of a full scaled wing (23) and additional components in the rear aircraft as, in particular, an horizontal tail plane (29), that produces the same downwash arriving to said additional components than in a full scaled model. The shape of said truncated wing (25) may be designed for having a similar lift distribution (35) to the lift distribution (37) of a full scaled wing (23) along at least the maximum length L2 in the Y-axis of any component in the rear aircraft. The invention also relates to a method for designing said truncated wing (25).

Owner:AIRBUS OPERATIONS SL

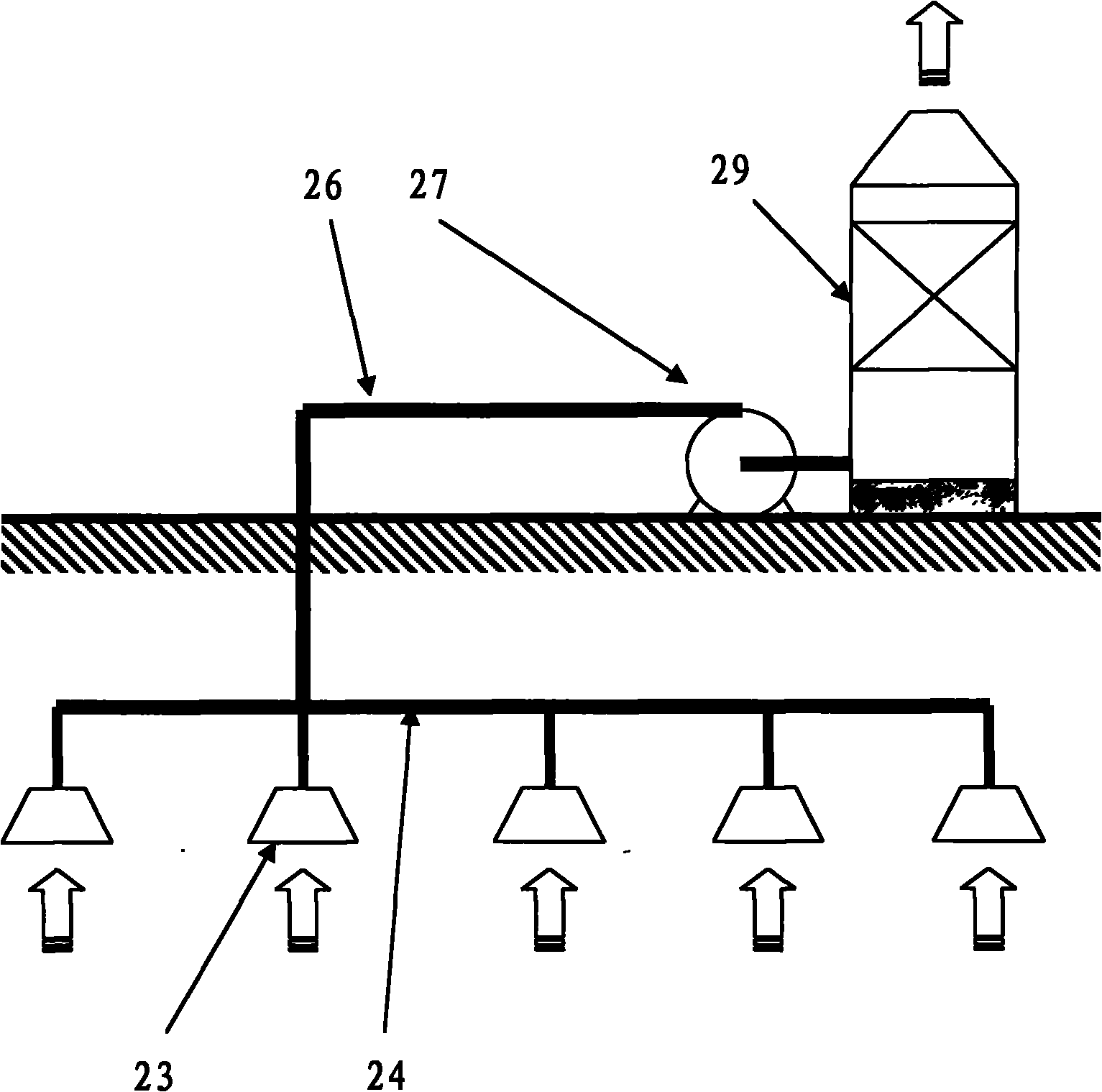

Waste gas central treating system

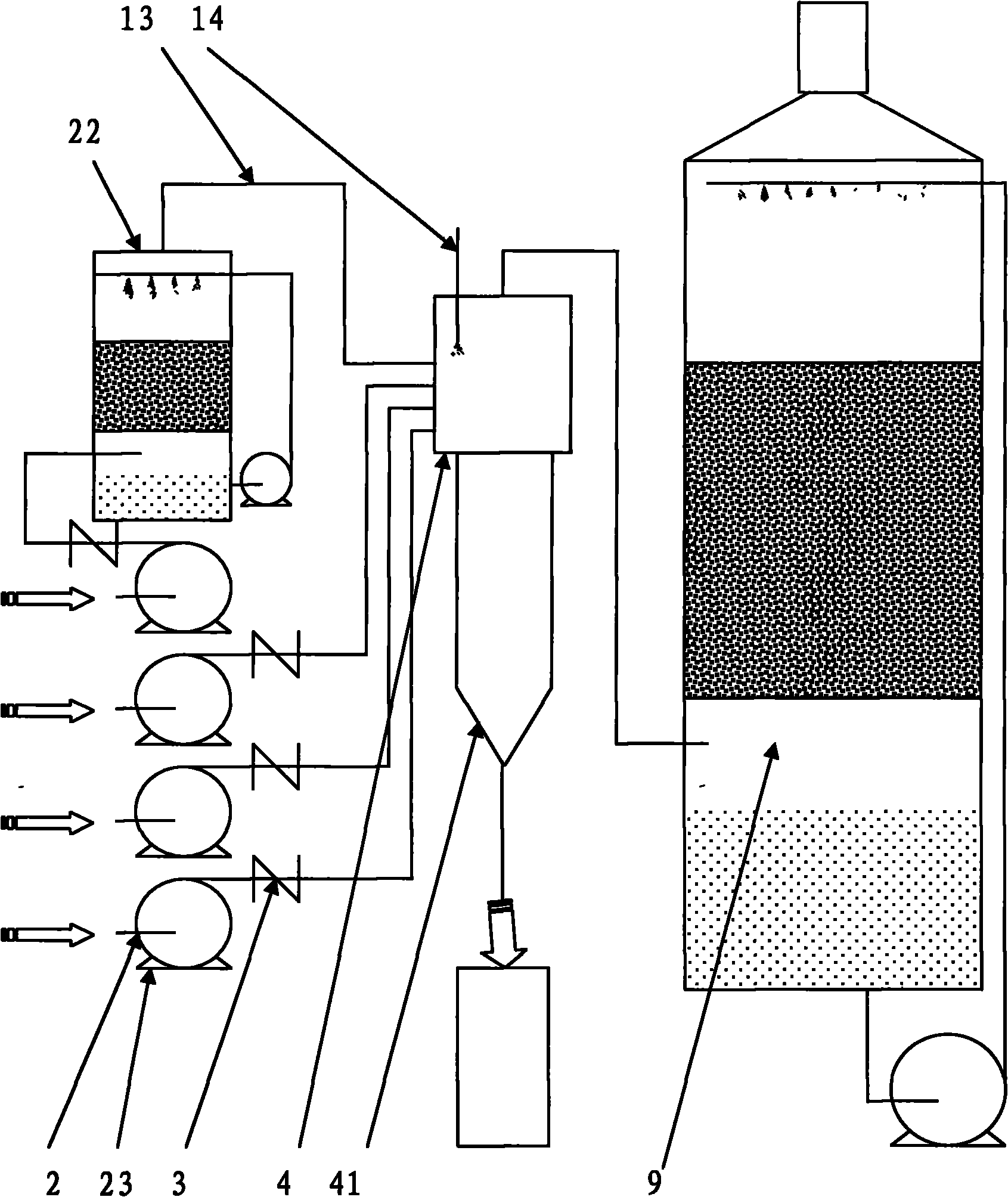

InactiveCN101791516AReduce intake air temperatureImprove acid removal effectCellsDispersed particle separationAmine gas treatingCyclone

The invention relates to the waste gas treating field of electroplating industry, in particular to a waste gas treating system. The waste gas treating system comprises a gas scrubbing tower. The front end of the gas scrubbing tower is provided with a cyclone separating tower, an air inlet part of which is provided with a plurality of gas inlet pipelines, and each gas inlet pipeline is respectively provided with a suction fan and an air suction cover. By taking the air inlet part of the cyclone separating tower as a connecting part, the gas inlet pipelines are counterclockwise arranged in the circumferential tangential direction of the air inlet pipeline. The gas inlet pipeline is respectively provided with a check baffle plate. At least one gas inlet pipeline at the front end of the cyclone separating tower is provided with equipment for pretreating special waste gas. The cyclone separating tower is provided with a cooling device. The system is provided with switches for flexibly adjusting the suction fans according to the treating requirement, therefore, the operation cost can be controlled, and the waste gas of different sources and properties can be flexibly treated; the gas inlet temperature of the gas scrubbing tower is decreased, the Reynolds number is increased, the acid removing effect of the gas scrubbing tower is enhanced, the usable waste acid can be recycled, and the resources are sufficiently saved.

Owner:惠州益伸电子有限公司

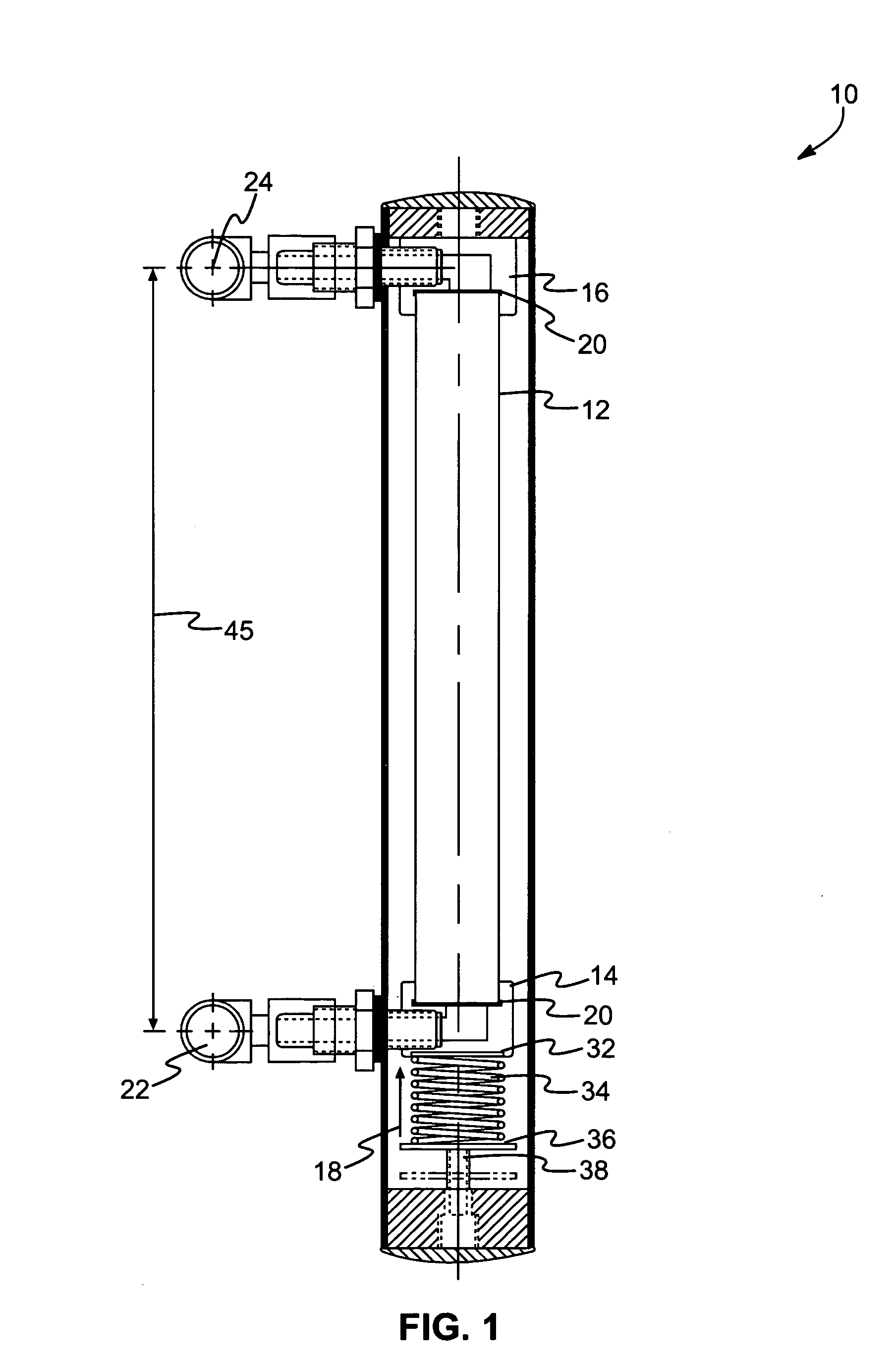

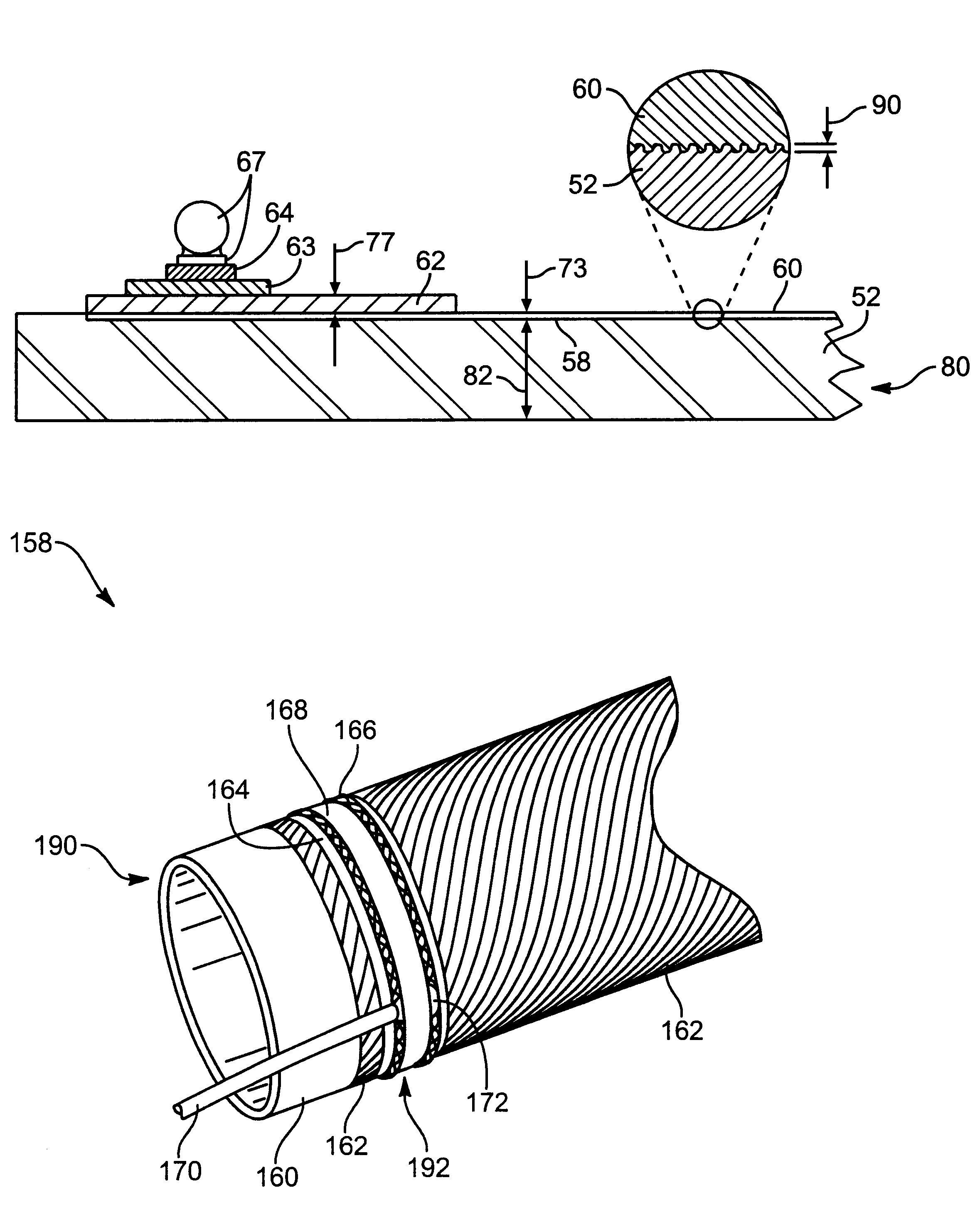

Fail-safe, resistive-film, immersion heater

InactiveUS7081602B1Equally distributedAcceptable densityHeater elementsImmersion heating arrangementsEngineeringFail-safe

A heater comprising a conduit made of corundum (e.g. synthetic sapphire) and having a wall forming a closed cross-section with an interior surface, and an exterior surface. At least one of the interior and exterior surfaces may have a roughened portion comprising inclusions and corresponding protrusions formed substantially continuously therethroughout. An electrically resistive coating may extend substantially continuously over, in, and around the inclusions and protrusions of at least a part of the roughened portion to form a conformal cross-section having a thickness selected to promote bending thereof to accommodate annular expansion and contraction occurring in response to a differential in the coefficients of expansion between the electrically resistive coating and the conduit.

Owner:TREBOR INT

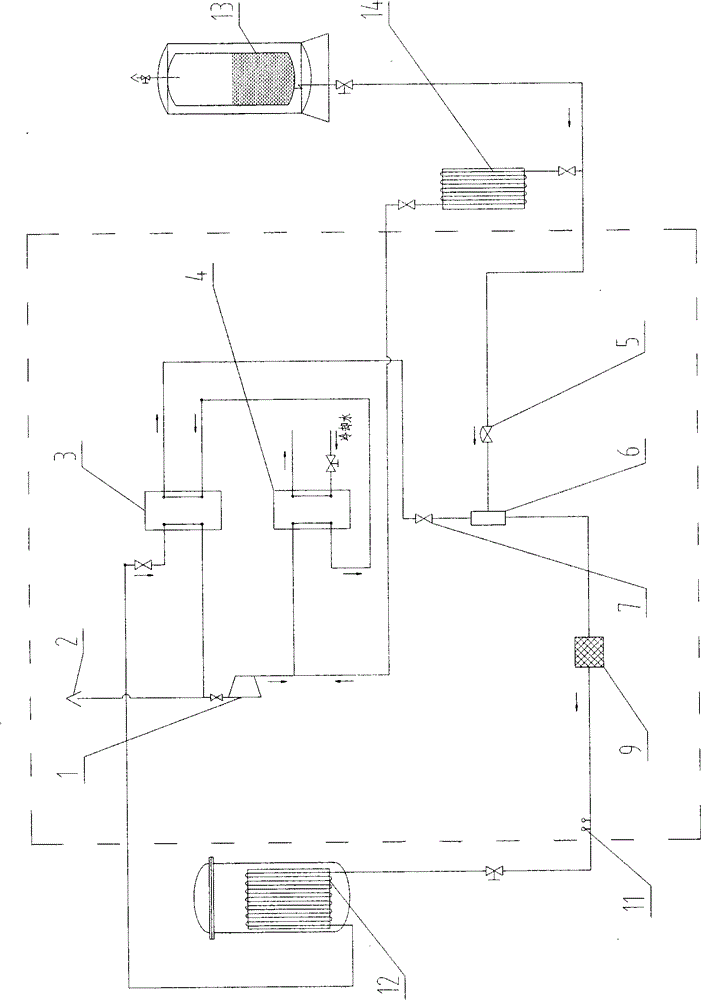

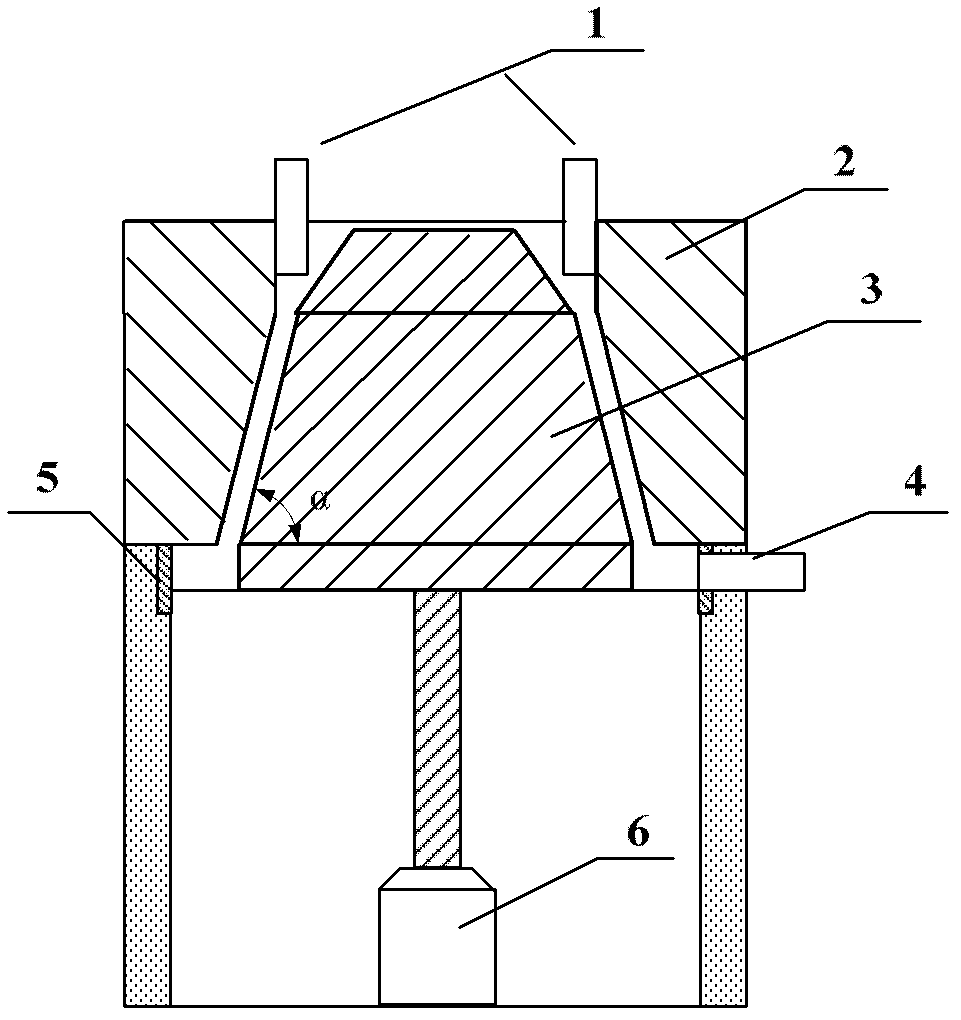

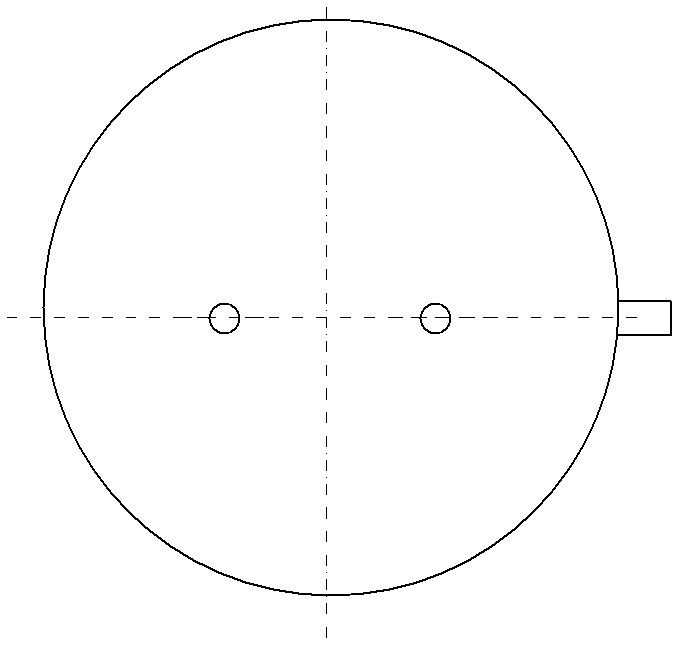

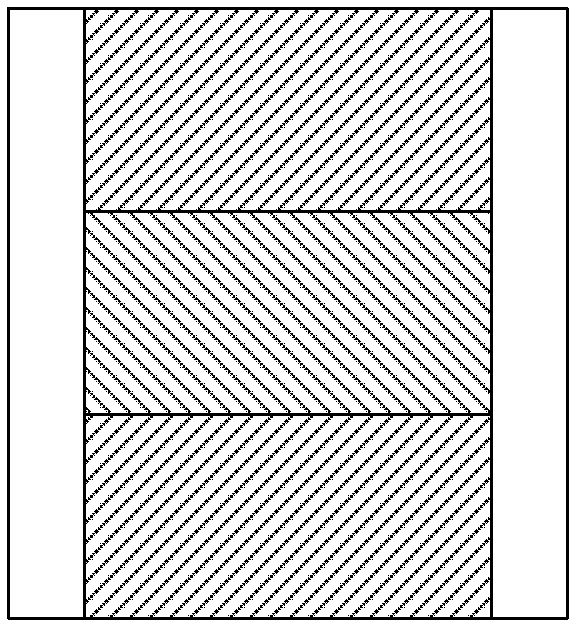

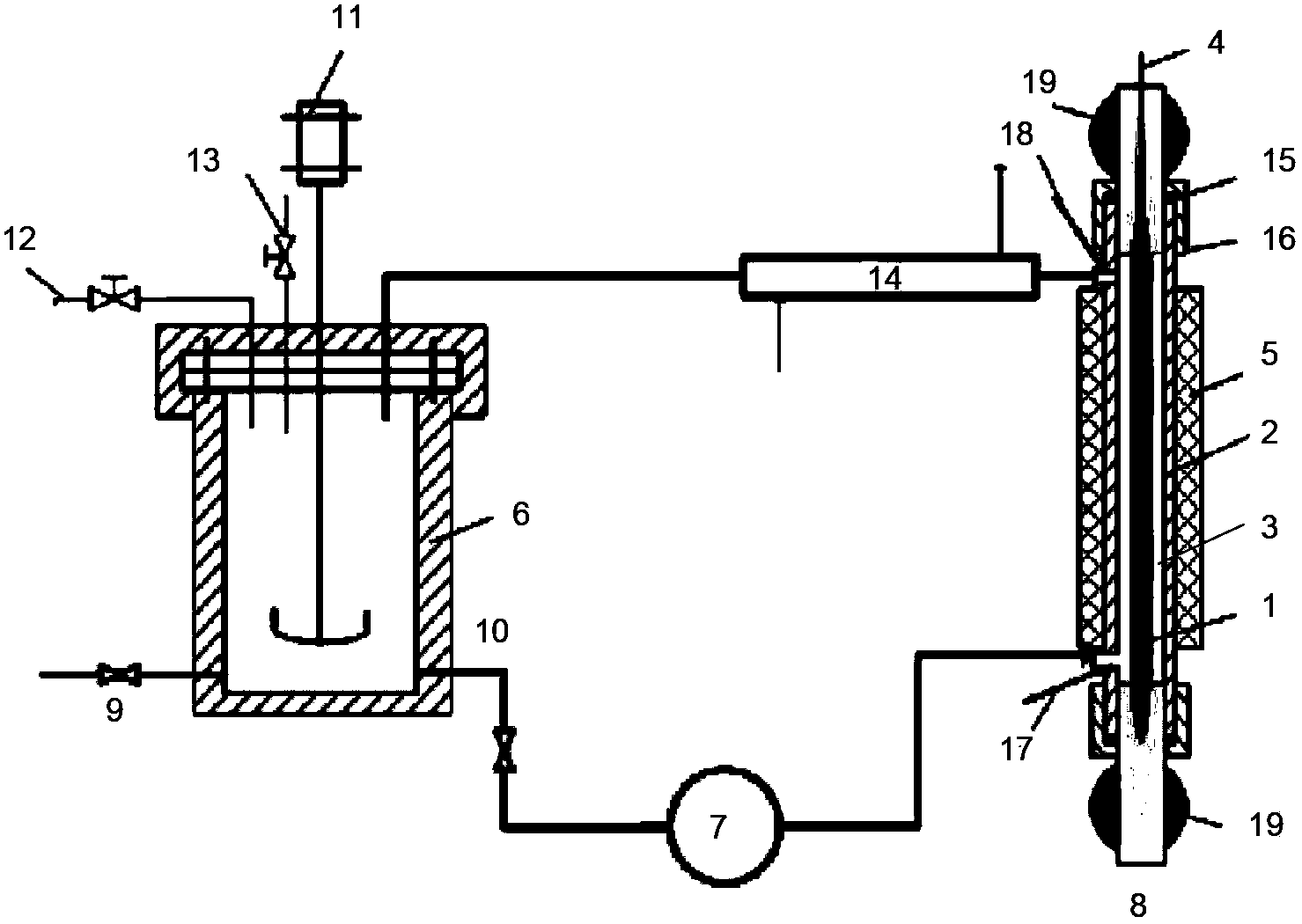

Corrosion reaction tester, corrosion evaluation device and corrosion evaluation method

ActiveCN103487363AThere is no phenomenon of overheatingEasy to assemble and disassembleWeather/light/corrosion resistanceTemperature controlCorrosion reaction

The invention discloses a corrosion reaction tester. The corrosion reaction tester comprises an electric heating rod (1) and a tester coat (2) sleevedly arranged outside the electric heating rod; a cavity (3) having an inlet at one end and an outlet at the other end is formed between the outer wall of the electric heating rod (1) and the inner wall of the tester coat (2), and the interior of the electric heating rod (1) is insertedly provided with a temperature control thermocouple (4). The invention also provides a corrosion evaluation device comprising the corrosion reaction tester and a corrosion evaluation method implemented by utilizing the corrosion evaluation device. The corrosion evaluation device provided by the invention is a corrosion evaluation device which not only has less used oil sample, simple operation and small occupied area of the device, but also has small acid loss amount and high corrosion speed, and is rapid, convenient and accurate during a testing process; and the corrosion evaluation method implemented by utilizing the device has high precision and good parallelism.

Owner:CHINA PETROLEUM & CHEM CORP +1

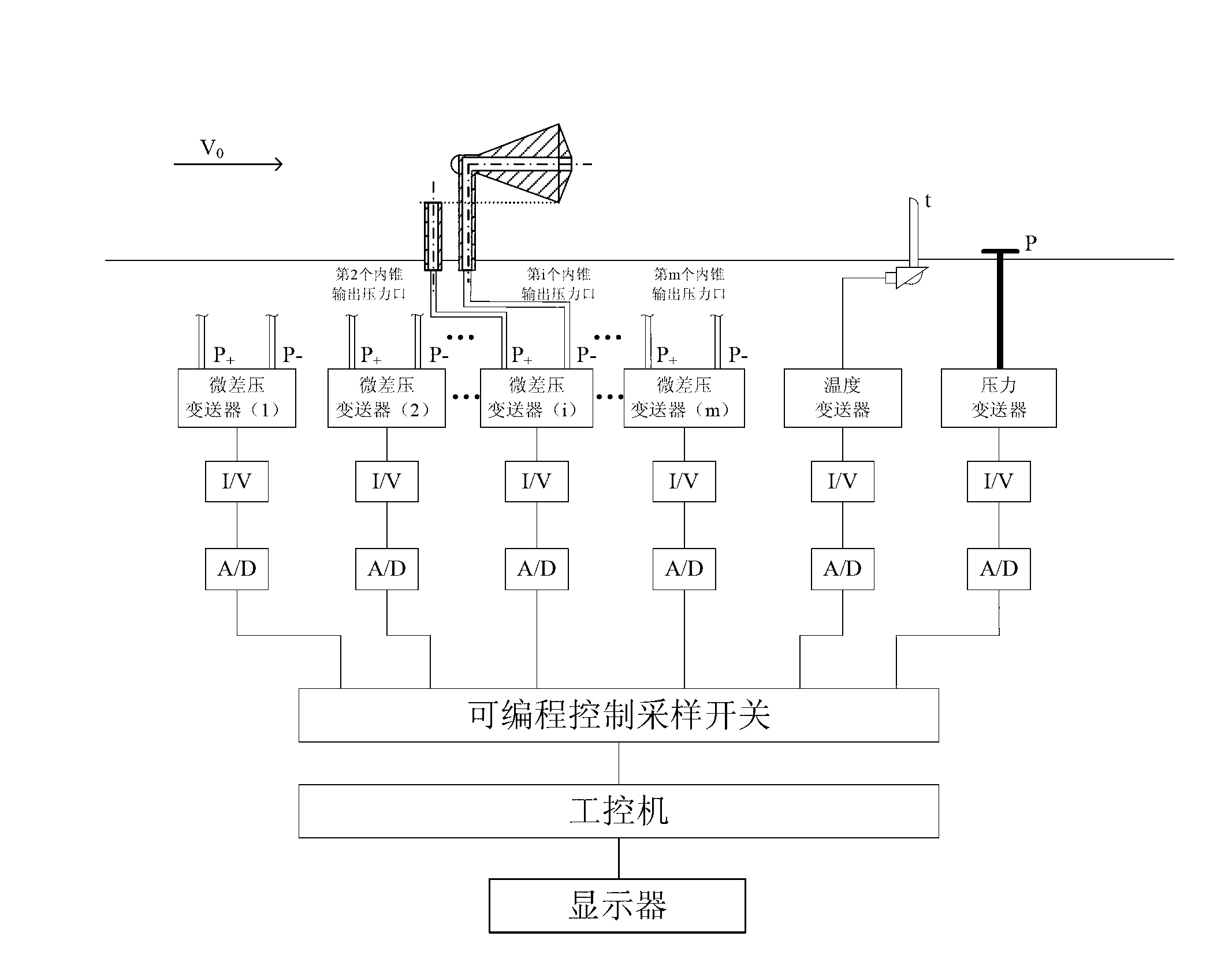

Blowing flow real time measuring device and method for pipeline with rectangular section

InactiveCN102997967AHigh measurement sensitivityImprove effectivenessAerodynamic testingVolume/mass flow by differential pressureMicrocomputerDifferential pressure

The invention discloses a blowing flow real time measuring device and a method for a pipeline with rectangular section, and belongs to the field of process parameter detection. The real time measuring device consists of a measuring pipe section, a sensor assembly, a micro differential pressure transmitter, an I / V (Current to Voltage) converter, an A / D (Analogue to Digital) converter, a temperature transmitter, a pressure transmitter, a programmable control sampling switch and a microcomputer signal processing system. The measuring pipe section is hermetically connected with the blowing pipeline through upstream and downstream flanges. According to the invention, with the adoption of m inner cones which are completely the same in structure and size and are arranged on the cross section of the pipeline with rectangular section of the measuring pipe section, a sensor module formed by the cross section of the measuring pipe section is equally divided. A flow rate-area flow measuring scheme by a multi-point inner cone method is designed to overcome the deficiencies that the inner cone method is commonly suitable for pipelines with circular sections, and exert the advantages of the inner core method. The invention provides a solution which is high in efficiency and robustness for the blowing flow of a power generating boiler through feasible practice.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

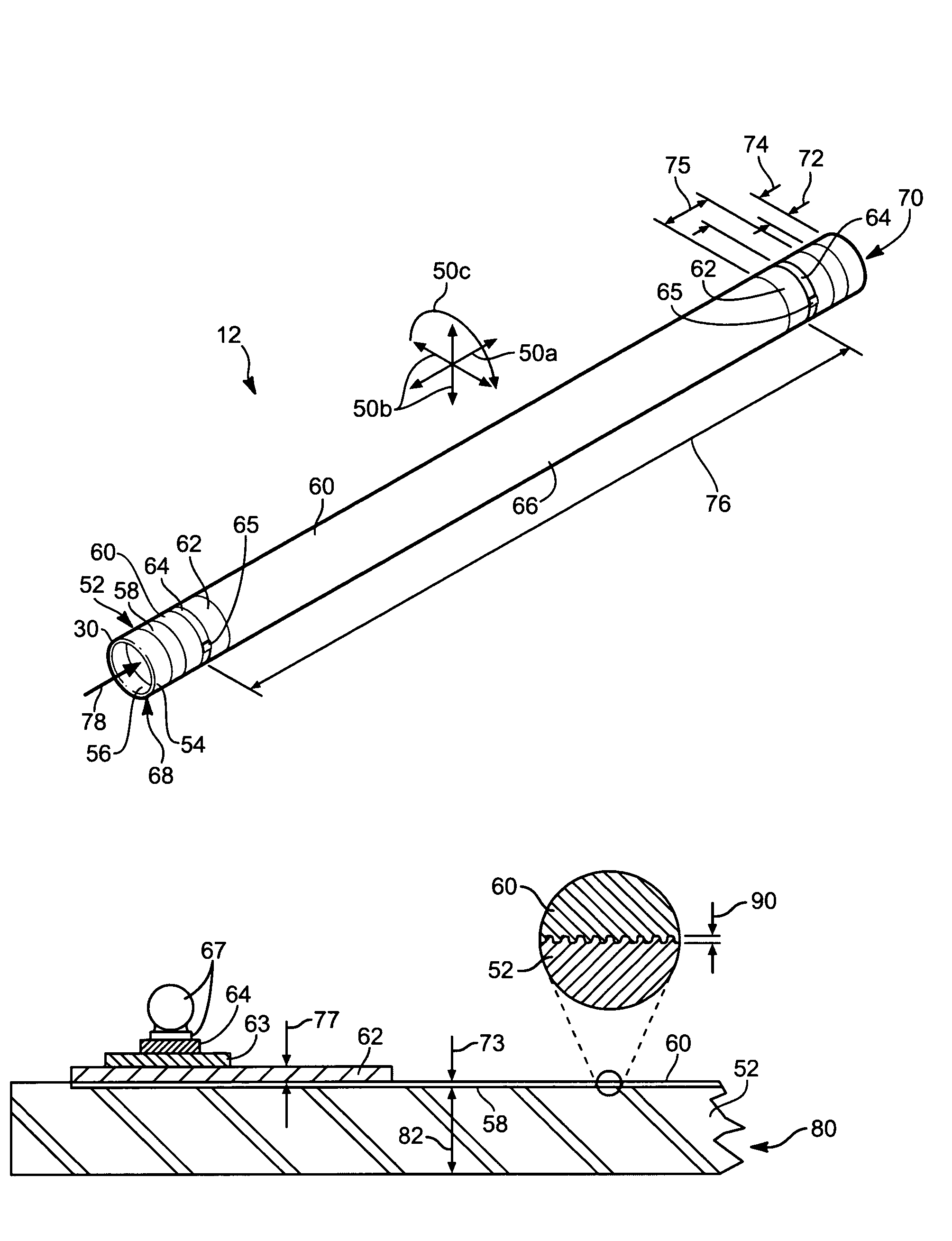

Interchangeable bottletop aerator

InactiveUS20140120226A1Introduce turbulenceFaster and more homogeneous mixingCarburetting airMilk preservationComputer moduleEngineering

An interchangeable bottletop aerator for controllably mixing air with a liquid contained in a bottle. The apparatus includes a receptacle and an interchangeable aerator module that is inserted into the receptacle. The receptacle engages and seals the bottle through a multi lumen cylinder that extends inside the narrow neck of the bottle. It has internal structures to adjust flow characteristics of the liquid and encapsulates the module. The module has multiple channels and sections to apply predetermined aeration and flow speed to the contained liquid. The inserted module can be replaced on demand with a different module to change the aeration parameters and adapt the aeration characteristics to various liquids. The interchangeable bottletop aerator presents a solution to the changing aeration requirements of different liquids like wine in a compact, easy to use, and easy to produce package by means of simply replacing and employing different modules inside the receptacle.

Owner:KURU MURAT +1

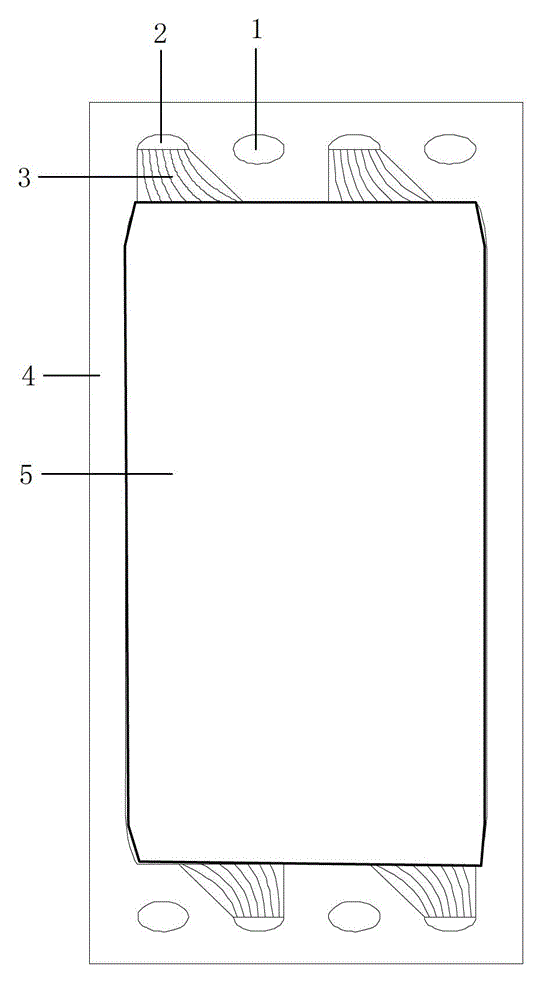

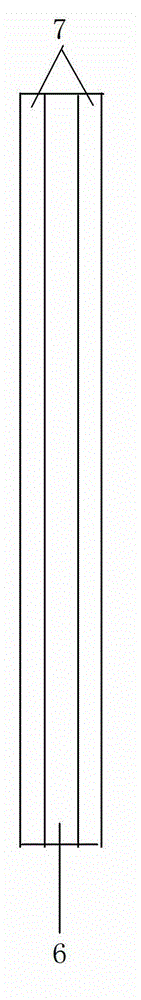

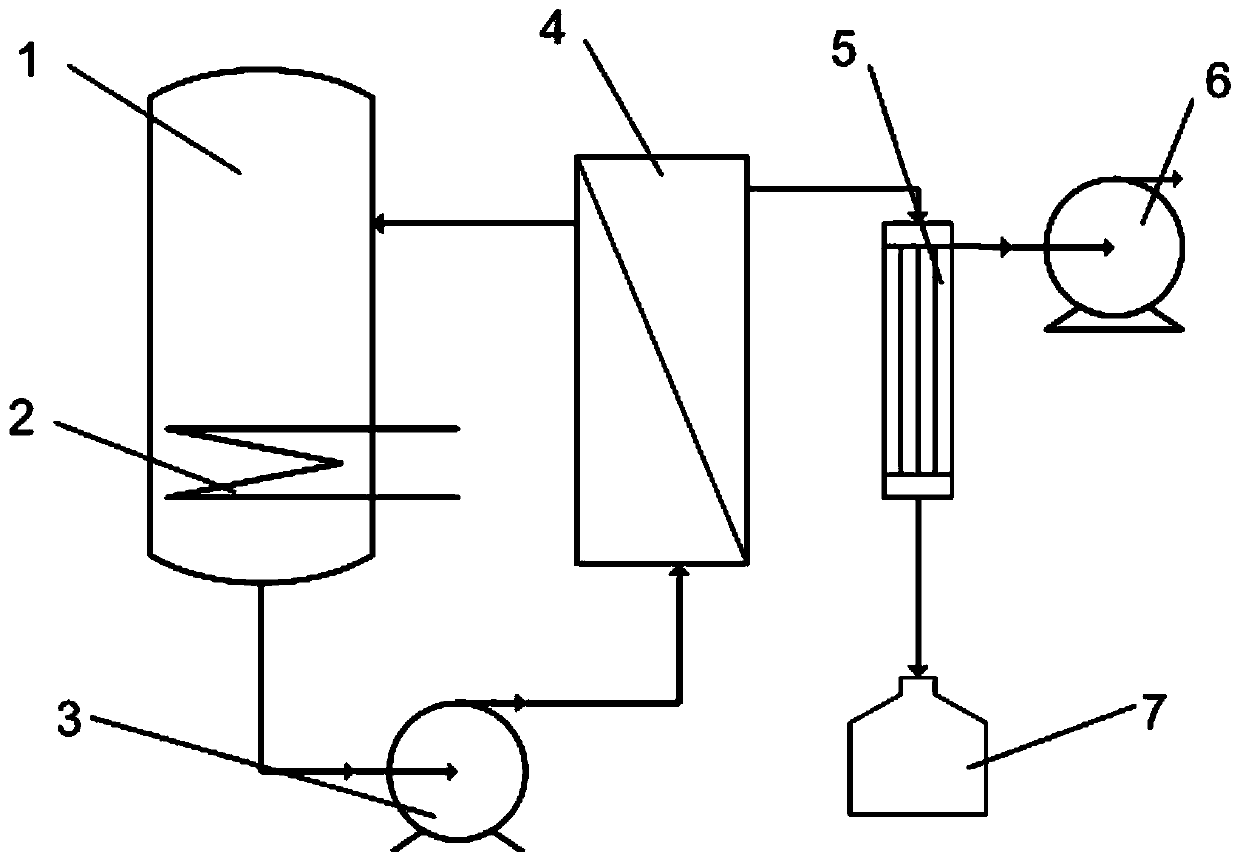

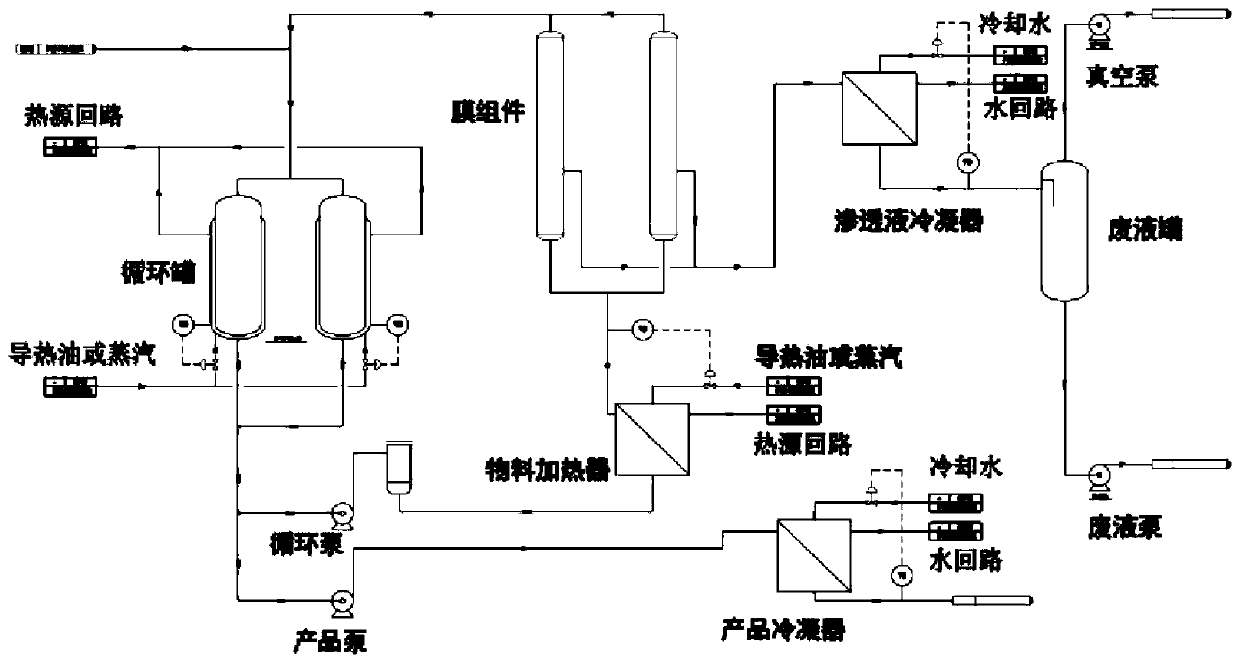

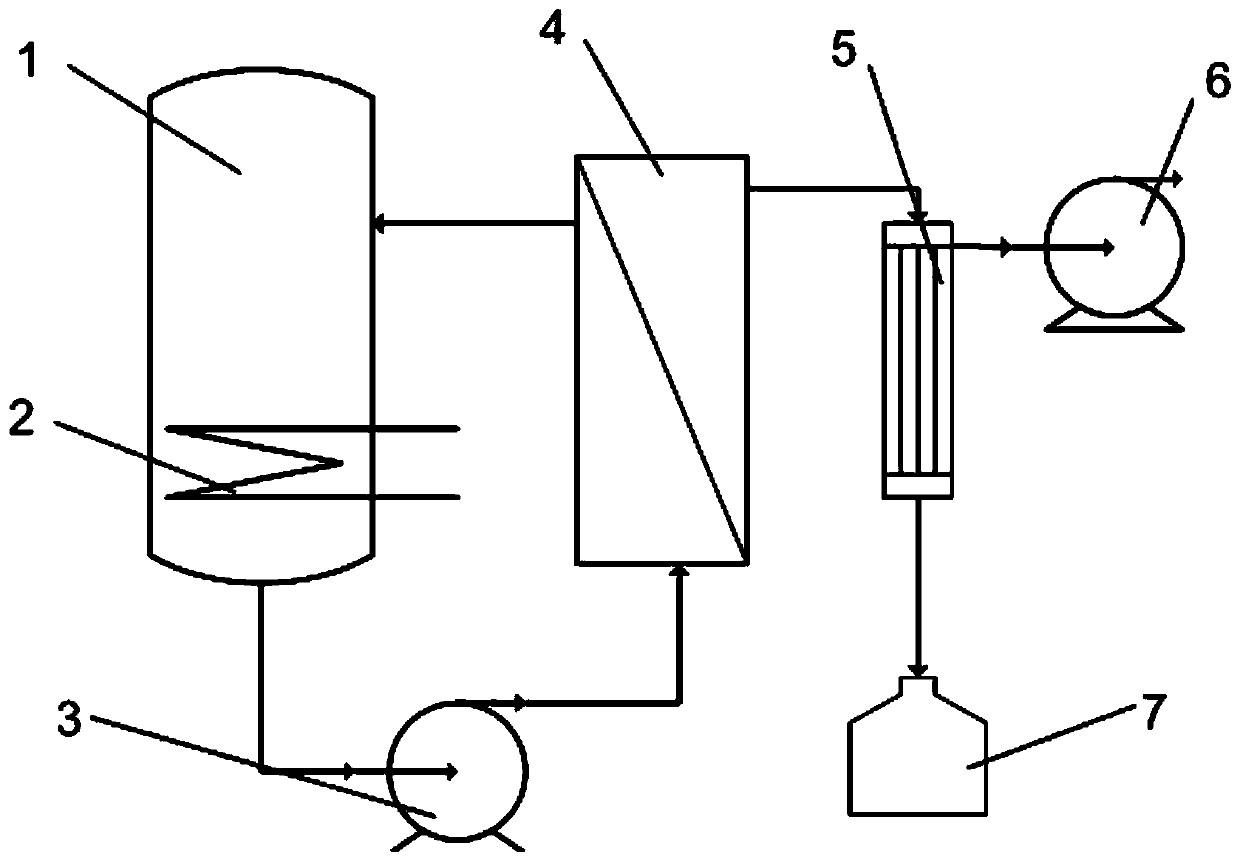

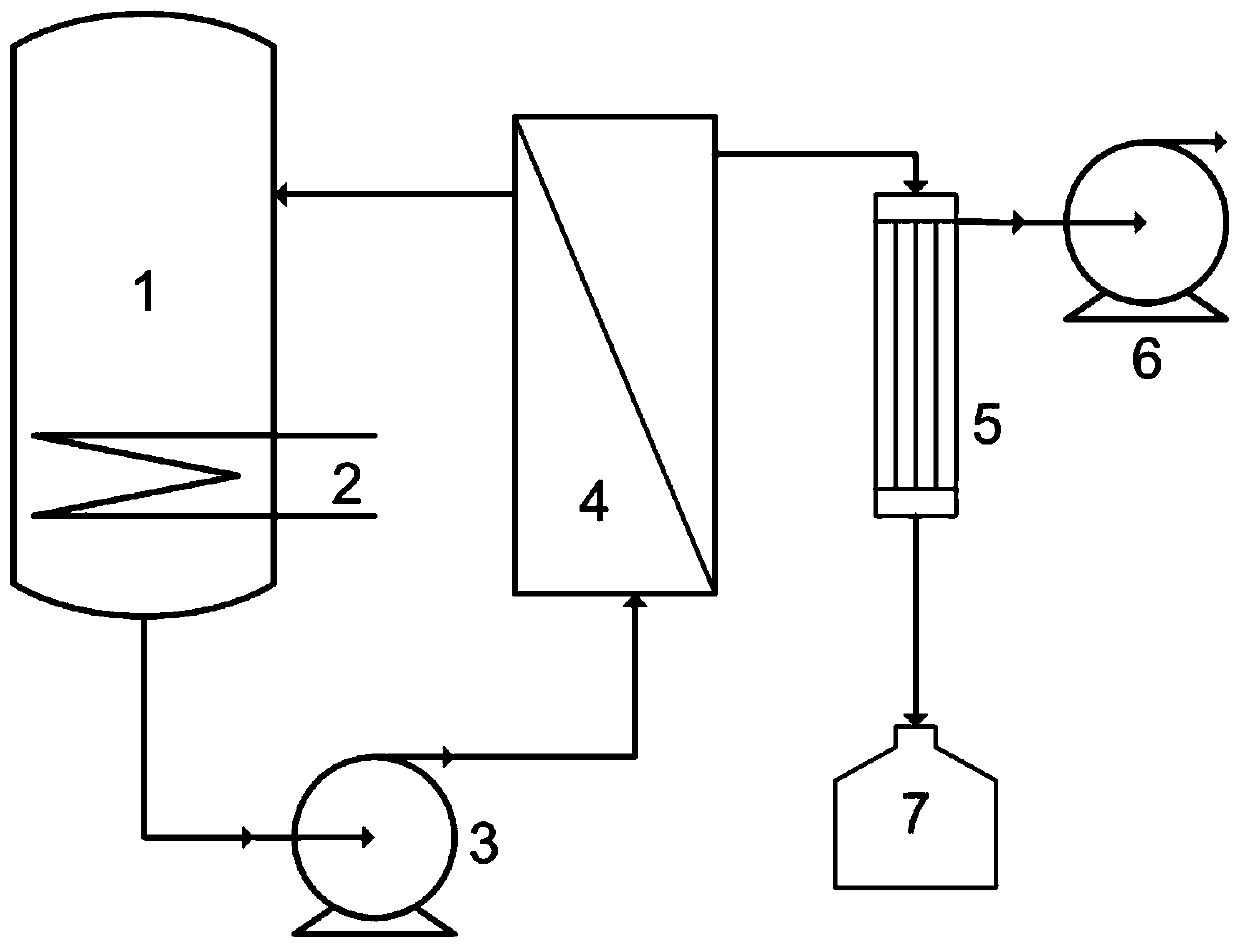

Quick, efficient and flexible pervaporation dehydration system and dehydration extraction method based on pervaporation dehydration system

PendingCN109999669AImprove separation efficiencyIncrease the Reynolds numberDistillationConcentration polarizationEngineering

The invention discloses a quick, efficient and flexible pervaporation dehydration system and a dehydration extraction method based on the pervaporation dehydration system. The system comprises a circulation tank, a heater, a material and liquid pump and a pervaporation membrane separator, the heater is installed in a raw material liquid tank and located below the raw material liquid level of the circulation tank, and an outlet of the circulation tank is connected with an inlet of the material and liquid pump; an outlet of the material and liquid pump is connected with an inlet of the pervaporation membrane separator, a lateral raw material outlet of the pervaporation membrane separator is connected with an inlet in the upper end of the circulation tank, a lateral permeation outlet of the pervaporation membrane separator is connected with a condenser, and the other outlet of the condenser is connected with a vacuum pump. The designed membrane pervaporation separation system is wider andmore flexible in application range and suitable for dehydration purification of multiple materials and reduces the equipment investment cost, commercial popularization is convenient, the concentration polarization phenomenon generally existing at the raw material side in a traditional pervaporation technology is greatly reduced and even completely eliminated, the separation efficiency of a membrane assembly is improved, and the application range is wider and more flexible.

Owner:HYLEIN ENERGY & ENVIRONMENT TECH CO LTD

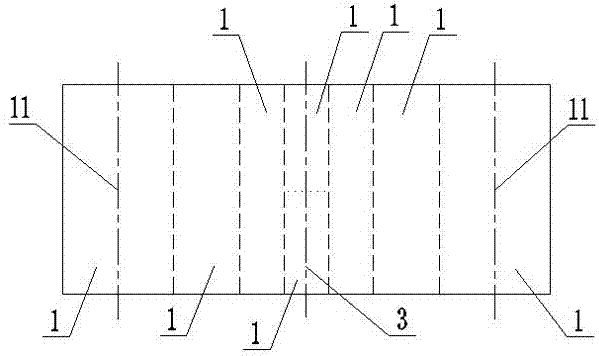

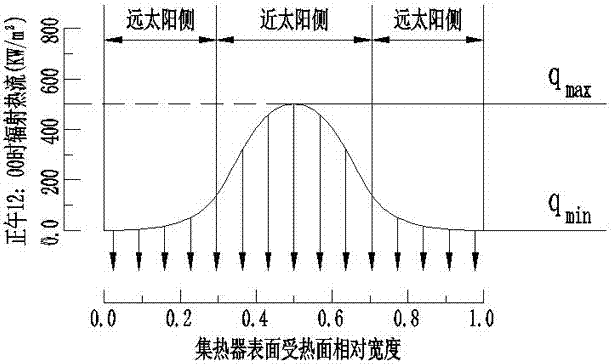

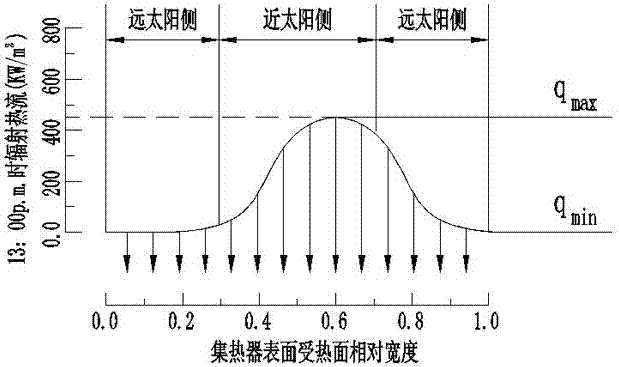

High-efficiency tower solar power station heat collector system with diameter gradually varied heat absorbing tubes

ActiveCN107084536AReduce surface temperatureIncrease flow rateSolar heating energySolar heat devicesHeat flowEngineering

The invention provides a high-efficiency tower solar power station heat collector system with diameter gradually varied heat absorbing tubes. By adoption of the high-efficiency tower solar power station heat collector system with the diameter gradually varied heat absorbing tubes, the surface temperature of the heat absorbing tubes in a radiant heat flux concentration area can be decreased, the degree of superheat of partial surface of a heat collector can be reduced, and the service life of the heat absorbing tubes can be prolonged. Each heat absorber module is attached against and arranged on the surface of the heat collector in the horizontal direction; heat absorbing tubes in a same heat absorber module have the same tube diameter and specification; the diameter and the specification of heat absorbing tubes in different heat absorber modules are different; heat absorber modules composed of the heat absorbing tubes with the same tube diameter and the specification are symmetrically arranged on the heat collector, the symmetry axis is the straight line where the density maximum value of the radiant heat flux of the surface of the heat collector is located, and the straight line is in the same direction as the self central axis of each heat absorbing tube; and the heat absorber modules are sequentially arranged from small to large according to the tube diameter and the specification of the heat absorbing tubes, the heat absorbing tube in the heat absorber module, closest to the symmetry axis, has the smallest tube diameter, and the heat absorbing tube in the heat absorber module, furthest way from the symmetry axis, has the largest tube diameter.

Owner:CHINA UNITED ENG

Recovery method of N-methyl pyrrolidone

PendingCN110759844AReduce concentration polarizationReduce or even eliminate concentration polarizationOrganic chemistryPyrrolidinonesMethyl palmoxirate

The invention provides a recovery method of N-methyl pyrrolidone. The method is characterized by comprising the following steps: heating an N-methyl pyrrolidone material liquid with the water contentof 1-50 wt.% in a circulating tank to 30-190 DEG C; introducing the heated N-methyl pyrrolidone material liquid into a pervaporation membrane assembly to make water in the material liquid be separatedfrom the material liquid side of the pervaporation membrane and enter the permeation side, wherein the pervaporation membrane assembly comprises 1-3000 organic-inorganic or inorganic-organic hybrid membrane single-pass pipes or multi-pass pipes, an absolute pressure of the permeation side is set to be 100-15000 Pa, and a membrane feeding speed of the material liquid is set to be 0.15-1.6 m / s; after the material liquid passes through the pervaporation membrane assembly, making the material liquid on the material liquid side return to the circulating tank, and making the water on the permeationside be condensed and recovered; and performing circulation for multiple times on the material liquid in the circulating tank to obtain recovered N-methyl pyrrolidone.

Owner:HYLEIN ENERGY & ENVIRONMENT TECH CO LTD

Continuous flow reactor

ActiveCN107442061AImprove responseIncrease the Reynolds numberChemical/physical/physico-chemical stationary reactorsBiochemical engineeringContinuous flow

The invention relates to the technical field of chemical and pharmaceutical equipment, in particular to a continuous flow reactor. The continuous flow reactor comprises a shell, wherein a shell side inlet and a shell side outlet which are communicated with an inner cavity of the casing are arranged on the shell; each of the upper end and the lower end of the shell is connected with a tube plate and a communicating device, a reaction tube stack is arranged in the shell and comprises multiple reaction tubes, the upper end and the lower end of each reaction tube penetrate through and are fixedly connected on the tube plates, and all the reaction tubes are sequentially connected in series through the communicating devices. By comparison with a traditional reactor, the reaction process is greatly improved under the condition of the same volume, reactants have high reynolds numbers under the condition of a low flow speed, the turbulence effect is greatly improved, unintermittent mixing is performed during constant flowing reactions, states of reaction stages can be detected in real time, and mounting and assembly are simplified.

Owner:SHANDONG NERVE PHARMA FLUID SYST CO LTD

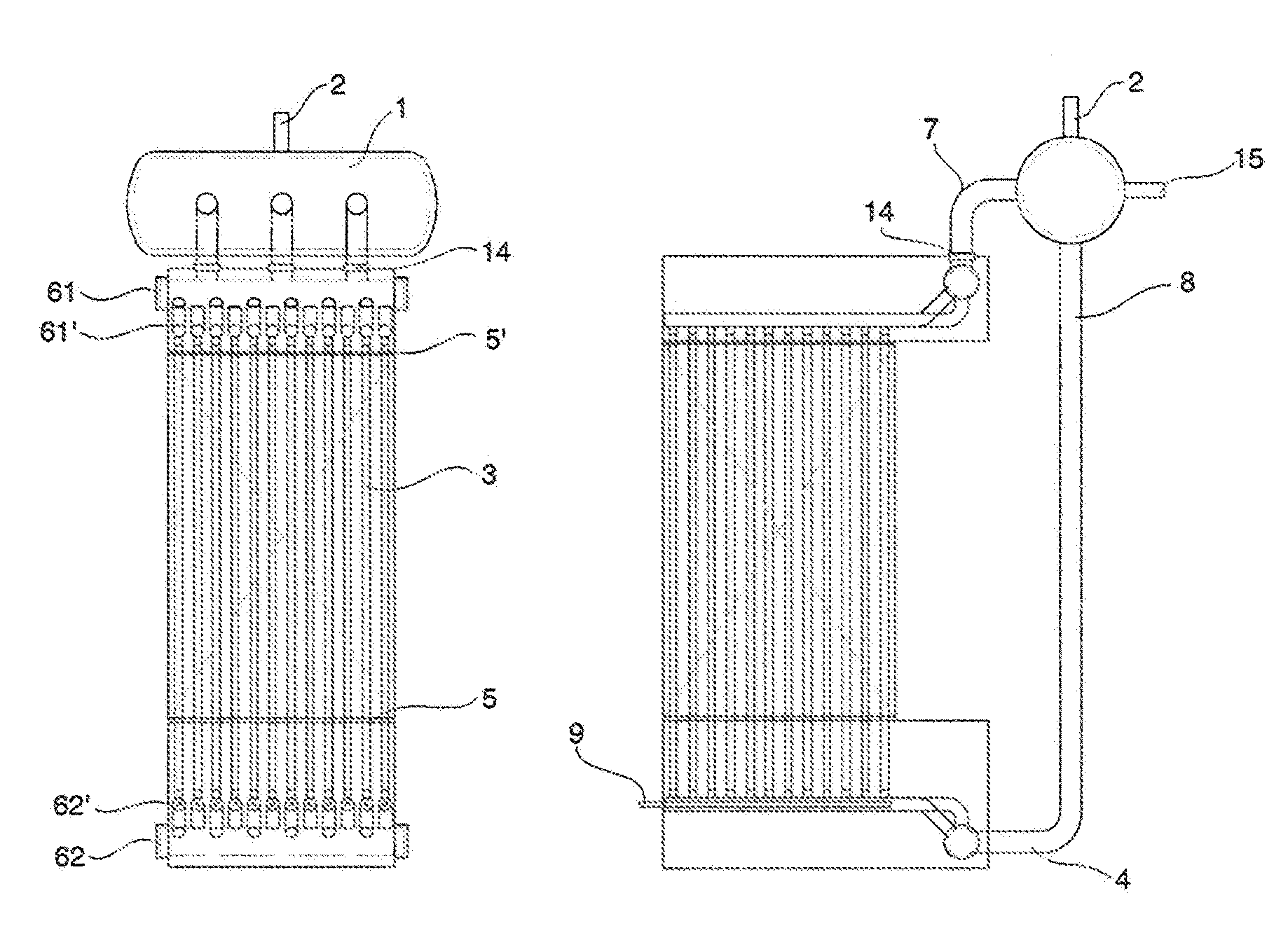

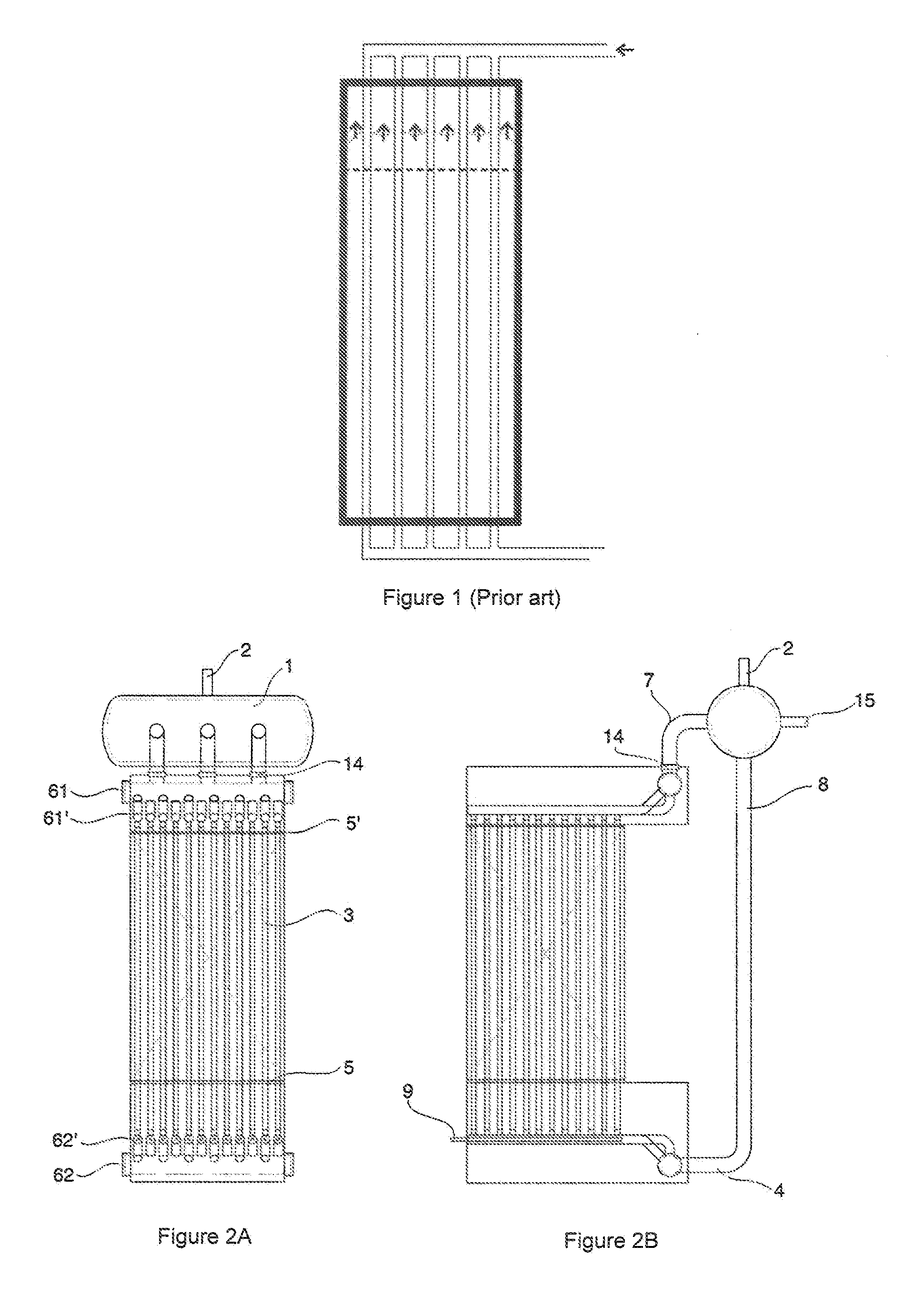

Heat storage system and method for the charging and discharging thereof

InactiveUS20150241135A1Speed up heat transferIncrease the Reynolds numberHeat storage plantsSteam generation plantsEngineeringPhase change

Thermal storage system and its charging and discharging process using a heat-transfer fluid. The system includes a phase change storage material contained in a casing that is penetrated by heat exchanger tubes (3), preferably vertical ones, connected at their lower end with at least one lower chamber (62) via lower sub-chambers (62′) which include a series of injectors (9) for enabling the heat-transfer fluid to be inserted in gas form; at the upper end, these tubes (3) connect via upper sub-chambers (61′) with at least one upper chamber (61) which in turn is connected to a boiler (1) from which downpipes (8) extend via which heat-transfer fluid in liquid form circulates, located outside of the casing, connecting the aforementioned boiler (1) to the lower chamber (62), which enables the natural circulation of the heat-transfer fluid within the system.

Owner:ABENGOA SOLAR NEW TECH SA

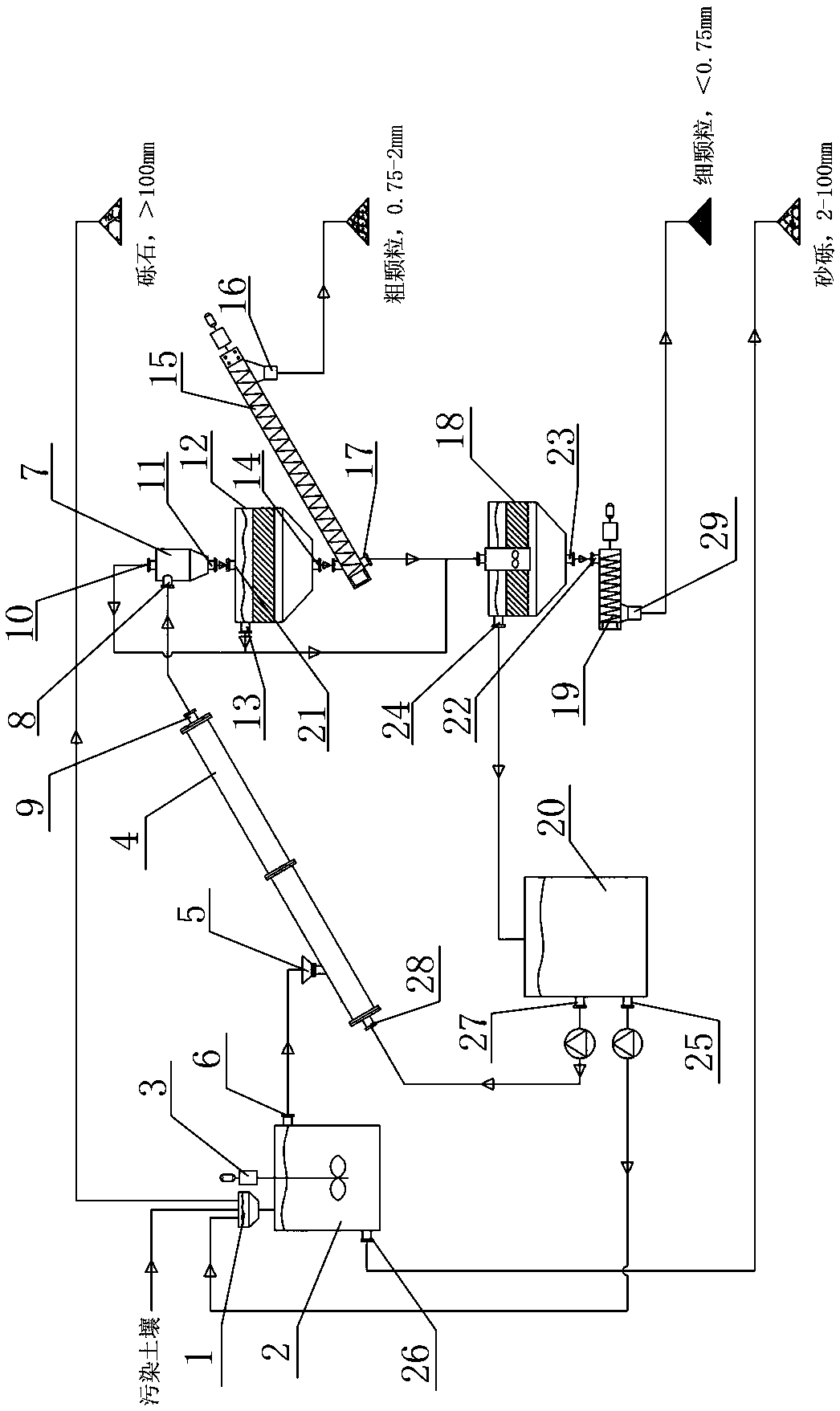

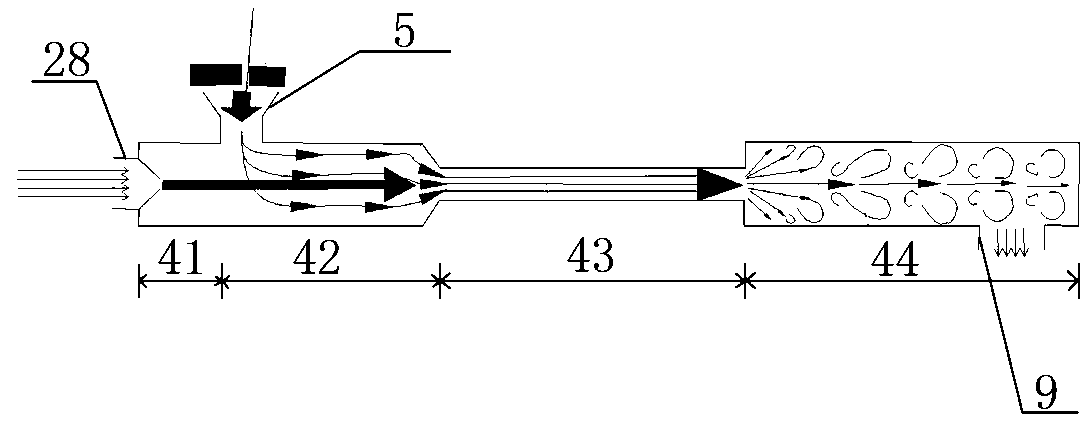

Soil leaching remediation reduction system and construction method thereof

ActiveCN111167846AReduce fluid velocityIncrease the Reynolds numberContaminated soil reclamationFiltration circuitsSoil treatmentSoil remediation

The invention discloses a soil leaching remediation reduction system and a construction method thereof, and belongs to the technical field of soil remediation. The soil leaching remediation reductionsystem comprises a feeding primary grading unit, a high-pressure jet separation unit, a secondary grading unit, a slurry settling concentration unit, a filter pressing unit, a sewage treatment unit, adust tail gas treatment unit and an instrument electrical control unit which are connected in sequence. According to the system, the grading quantity and the equipment quantity are greatly reduced, and for soil treatment of small-sized polluted sites, the whole system can adopt modularized container equipment or skid-mounted equipment which is convenient to move, so that the on-site constructioncost can be greatly reduced, the construction period can be greatly shortened, and the remediation efficiency is improved. The system is simple and ingenious in structure, easy and convenient to operate, low in equipment investment cost, small in occupied area, particularly suitable for remediation projects of small contaminated sites, capable of achieving multi-equipment parallel operation, suitable for treatment of medium and large sites, wide in application range, good in effect and wider in application prospect.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

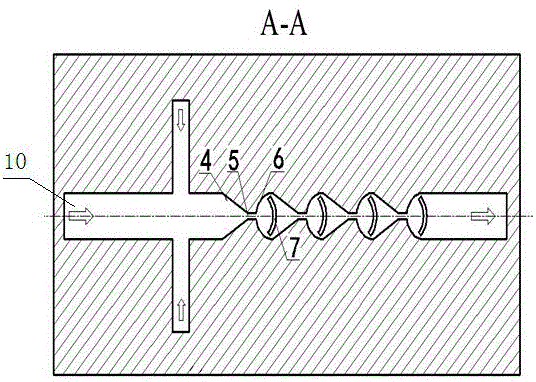

Cross micromixer of symmetrical fan shaped annular baffle

InactiveCN105107401AIncrease flow rateIncrease the Reynolds numberFlow mixersMixing methodsConvex sideMixing effect

The invention discloses a cross micromixer of a symmetrical fan annular baffle. A cross flow channel and a plurality of sequentially connected mixing units are arranged between a cover plate and a substrate. Each mixing unit is composed of a shrinking flow channel, a narrow direct current channel, a circular arc flow channel and a fan-shaped annular baffle which is located near the outlet of the circular arc flow channel in sequential connection. The outlet of the cross flow channel is connected to and communicated with a first shrinking flow channel inlet, and a last circular arc flow channel is connected to and communicated with the flow channel outlet. A gap is formed between the outer edge of the fan-shaped annular baffle and the inner wall of the circular arc flow channel; concave surfaces of the fan-shaped annular baffle and the circular arc flow channel face each other, and the fan-shaped annular baffle is symmetrical in respect to a central axis. According to the cross micromixer disclosed by the invention, a jet can be formed after a fluid passes the shrinking flow channel and the narrow direct current channel, so that the flow velocity of the fluid is increased; when the fluid passes the fan-shaped annular baffle, jet attached flow is formed on the convex surface of the fan-shaped annular baffle, and secondary flow phenomenon occurs, so that a relatively high mixing effect is achieved under the condition that the flow channel length is relatively short.

Owner:JIANGSU UNIV

Heating furnace for heating annular component

ActiveCN106282527APlay the role of diverting gasReduce heating rateCharge supportsMaintainance of heating chambersAirflowHeating furnace

The invention discloses a heating furnace for heating an annular component. The heating furnace comprises a furnace body, a heating medium driving component, a supporting piece, a flow guiding component and a hollow cylindrical body. A part of heat media in the heating furnace is sprayed on the outer peripheral surface of the annular component through the flow guiding component, and the other part of the heat media flows through an inner cavity of the hollow cylindrical body and is blown to the inner peripheral surfaces of bearings through a second heat medium channel on the hollow cylindrical body so that the inner peripheral surfaces of the bearings can be heated. Thus, the hollow cylindrical body has an effect of dividing a gas flow to a certain extent, and the upper end surface of the hollow cylindrical body is of a sealed structure, so that the flowing gas flow is completely converted into an effective heat exchange gas flow and limited in heat exchange spaces on the surfaces of the bearings. The high reynolds number of the gas flow in heat exchange areas of the bearings as well as the high heat exchange speed of the surfaces of the bearings and the gas flow are obtained, the flow speed is multiplied at the same volume flow rate, and the flowing gas flow is completely converted into the effective heat exchange gas flow; and at the same flow speed, the volume flow rate is decreased substantially, the temperature raising speed of the gas flow is multiplied, thus, the heating efficacy is improved, and the power of a electric heater is decreased greatly.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

Electrical, thin film termination

InactiveUS6674053B2Improve temperature distributionIncrease the Reynolds numberPrinted circuit assemblingHeater elementsElectricityConductive coating

An apparatus for operably connecting an electrical source to a conductive coating or film. The apparatus may include a substrate made of a structural material. A conductive coating or thin film may be applied to the substrate. An interface layer may be applied over the conductive coating and conduct electricity thereto while transferring insufficient force to separate the conductive coating from the substrate. A conductor, for providing electricity to the interface layer comprising strands configured to be separable and electrically conductive, may be positioned in contact with the interface layer. A clamping mechanism may apply a clamping load urging the conductor toward the conductive coating. The strands of the conductor may be formed to distribute mechanical stress and strain induced by thermal expansion and the clamping load sufficiently to substantially reduce damage to the mechanical and electrical integrity of the conductive coating.

Owner:TREBOR INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com