Blowing flow real time measuring device and method for pipeline with rectangular section

A real-time measurement, rectangular cross-section technology, applied in measuring devices, detecting fluid flow by measuring differential pressure, volume/mass flow generated by mechanical effects, etc. Uneven distribution, etc., to achieve the effect of increasing Reynolds number, eliminating uneven distribution of flow velocity, and improving measurement sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

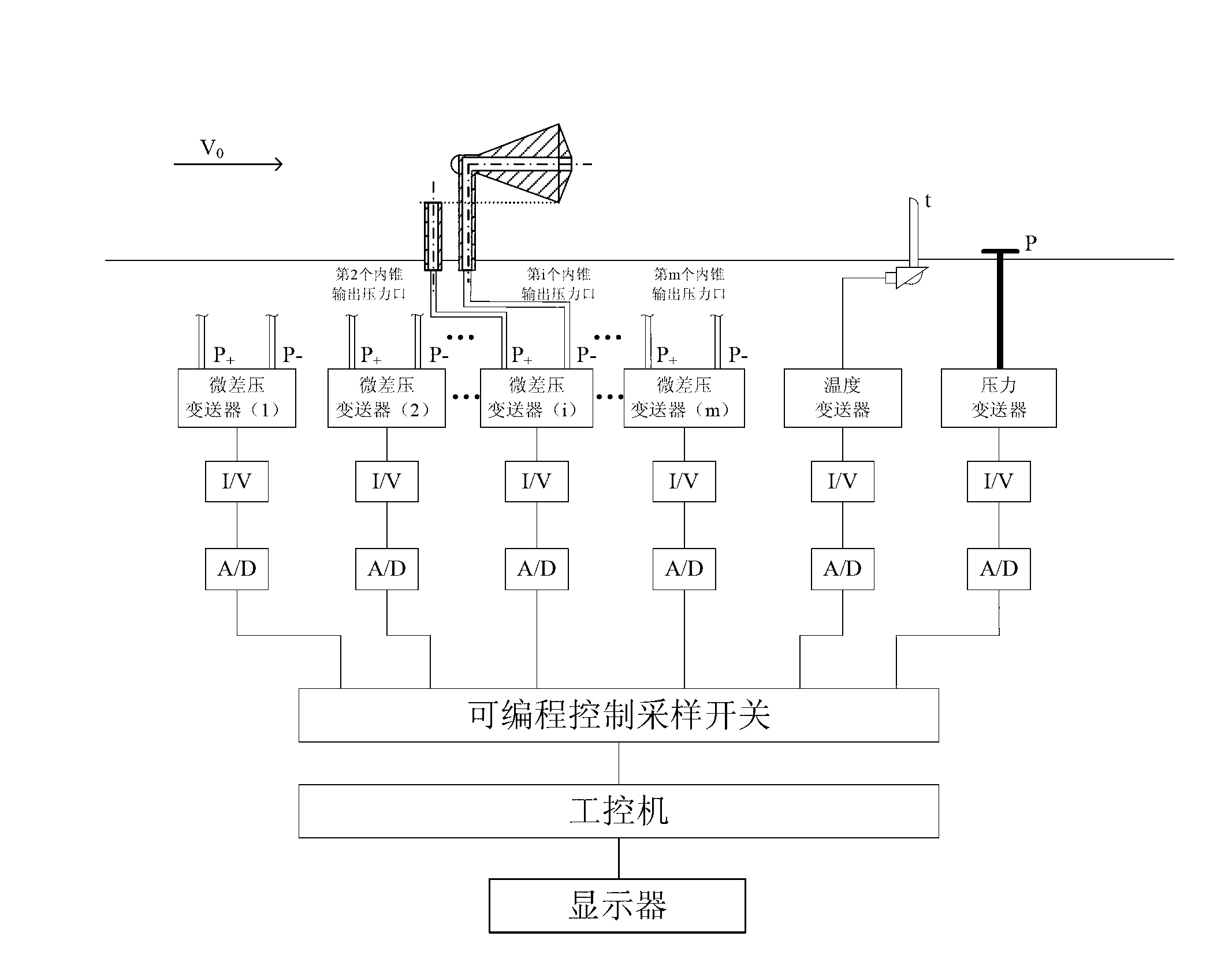

[0025] The invention provides a real-time measuring device and method for the air supply flow rate of a rectangular section duct. Compared with the prior art, the device has higher sensitivity and a larger output differential pressure signal even at low flow rates, and the effectiveness of flow measurement is significantly improved. Further explanation.

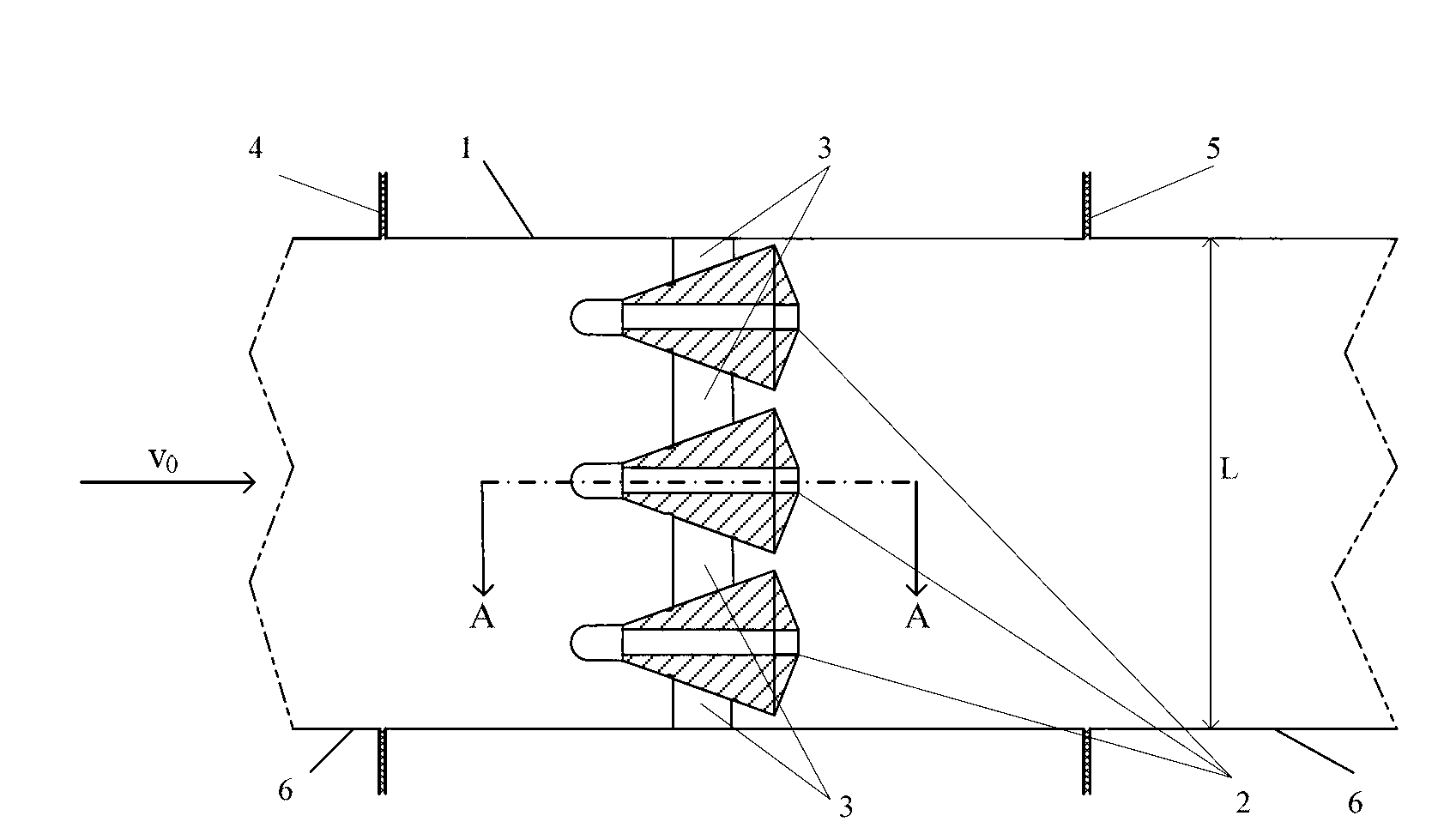

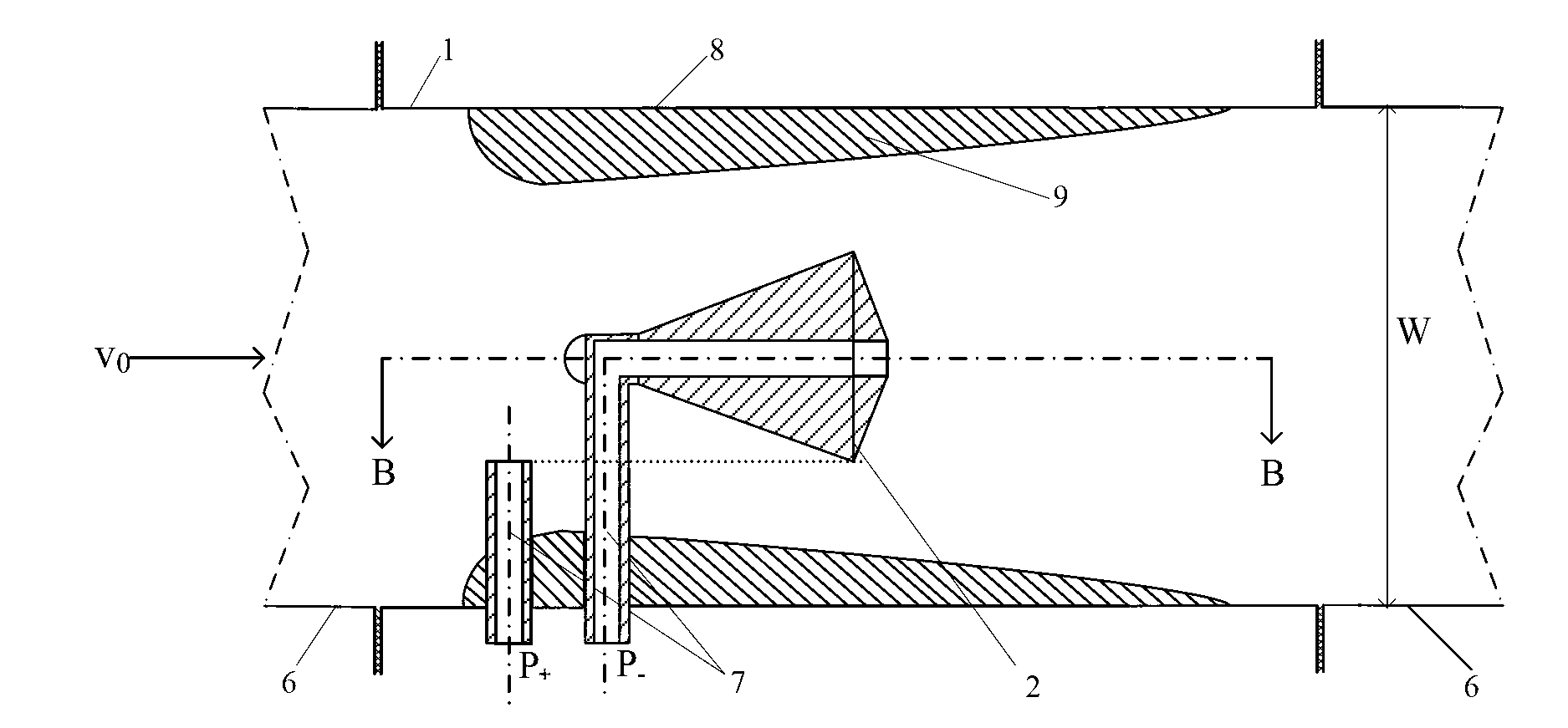

[0026] Let the length of the long side of the cross section of the rectangular air supply duct be L and the length of the short side be W.

[0027] exist figure 1 , 2 In the above, the air supply flow measurement pipe section 1 is sealed with the air supply pipe 6 through the upstream side flange 4 and the downstream side flange 5, and the cross section in the measurement pipe section 1 is facing the incoming flow υ 0 Arrange m inner cones 2 with exactly the same structural size in the direction, m is a positive integer greater than or equal to 3, and m inner cones equally divide the cross-section of the measuring pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com