Patents

Literature

46 results about "Electrical integrity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and morphologically adaptable apparatus for altering the charge distribution upon living membranes with functional stabilization of the membrane physical electrical integrity

ActiveUS7608035B2Relieve painShorten wound healing timeElectrotherapySurgeryEnergy balancingMagnetic field gradient

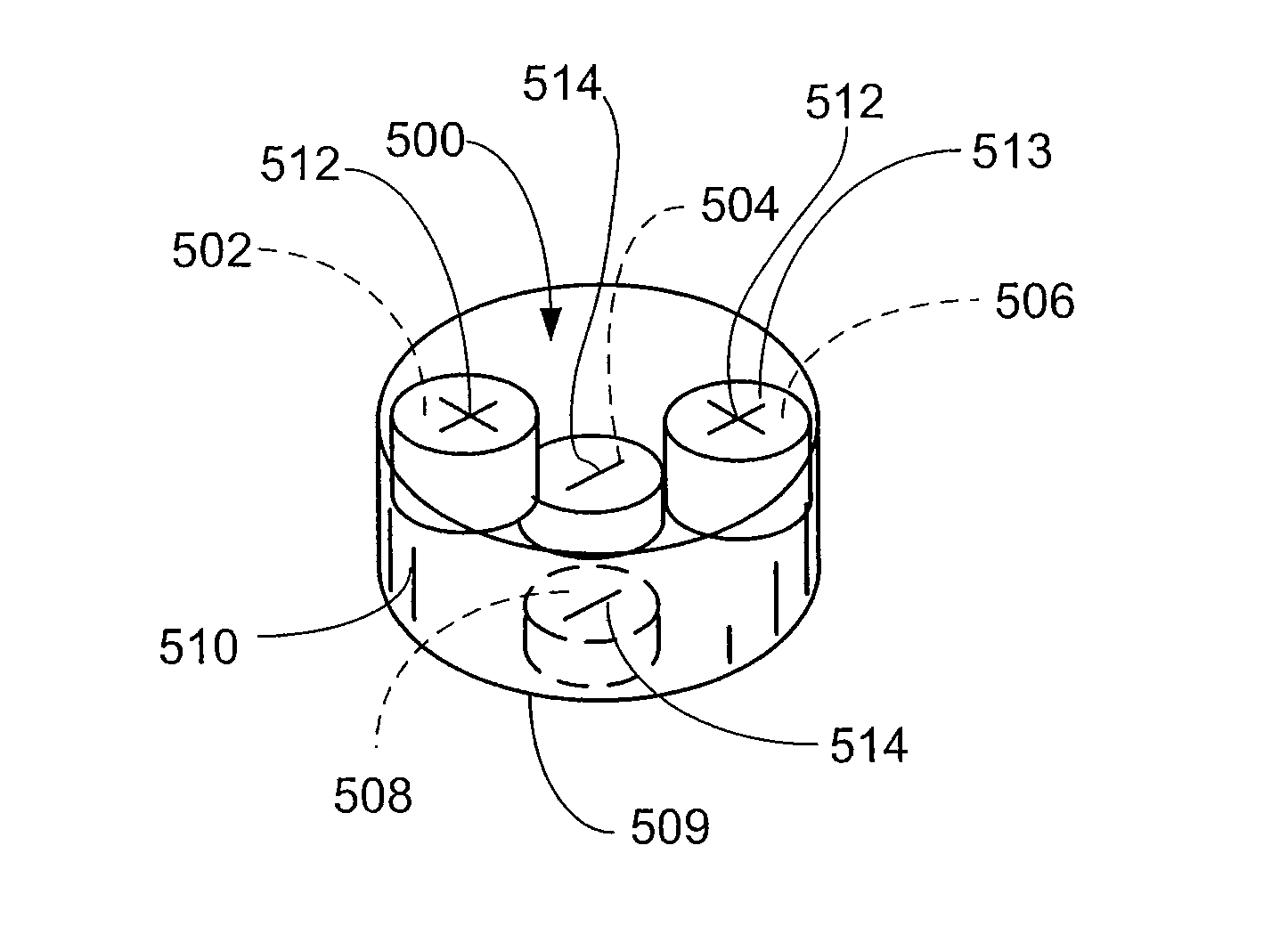

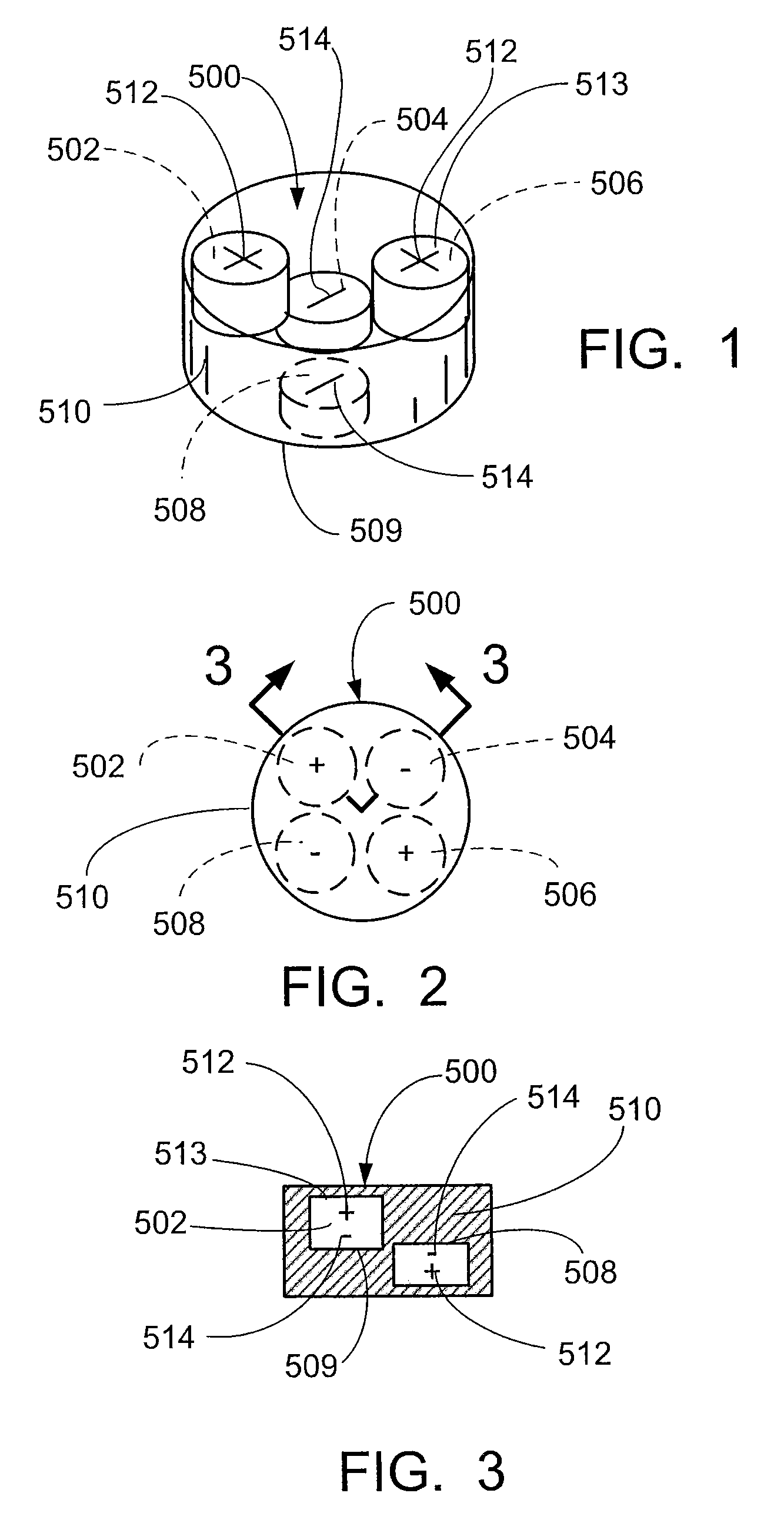

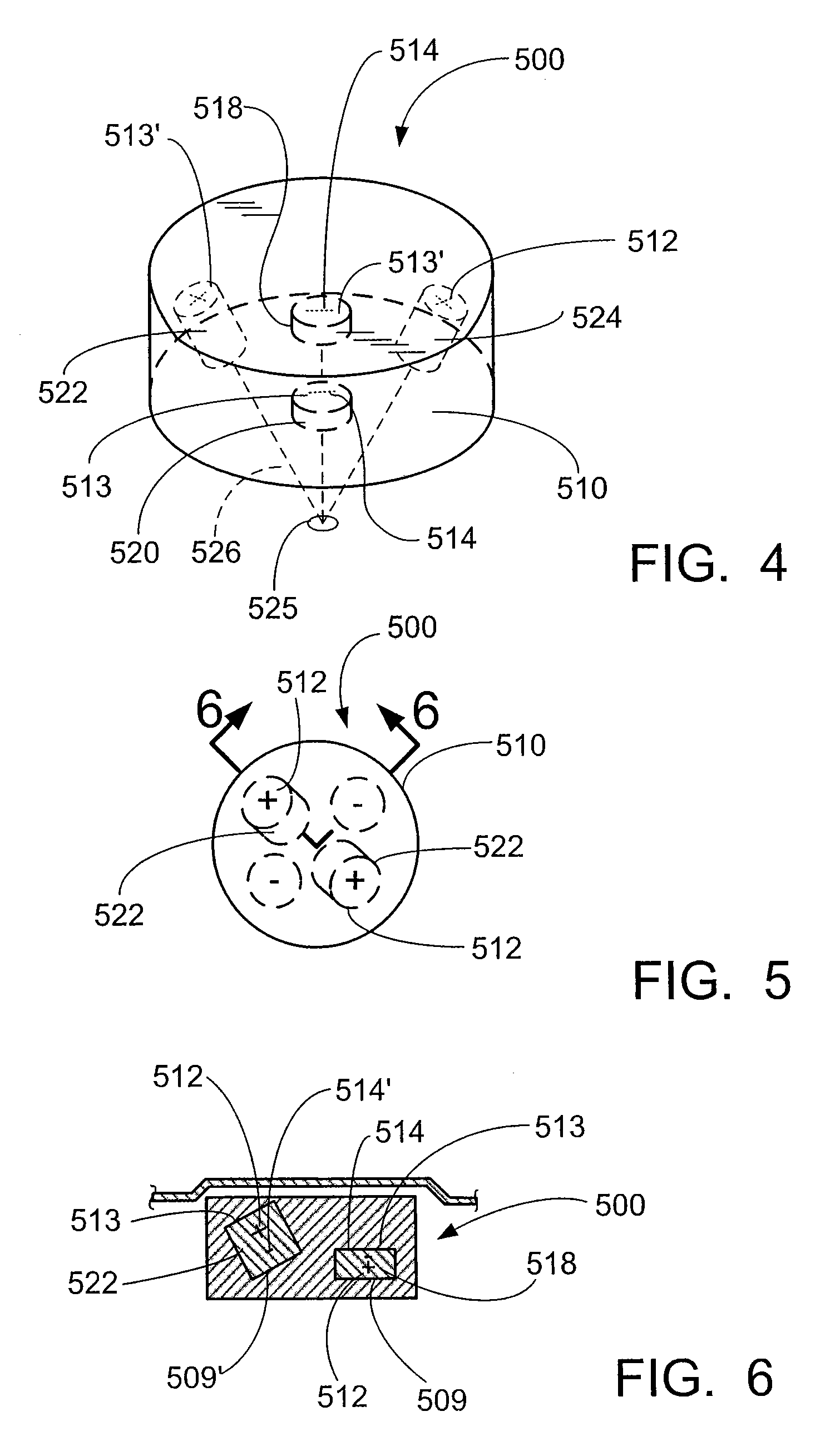

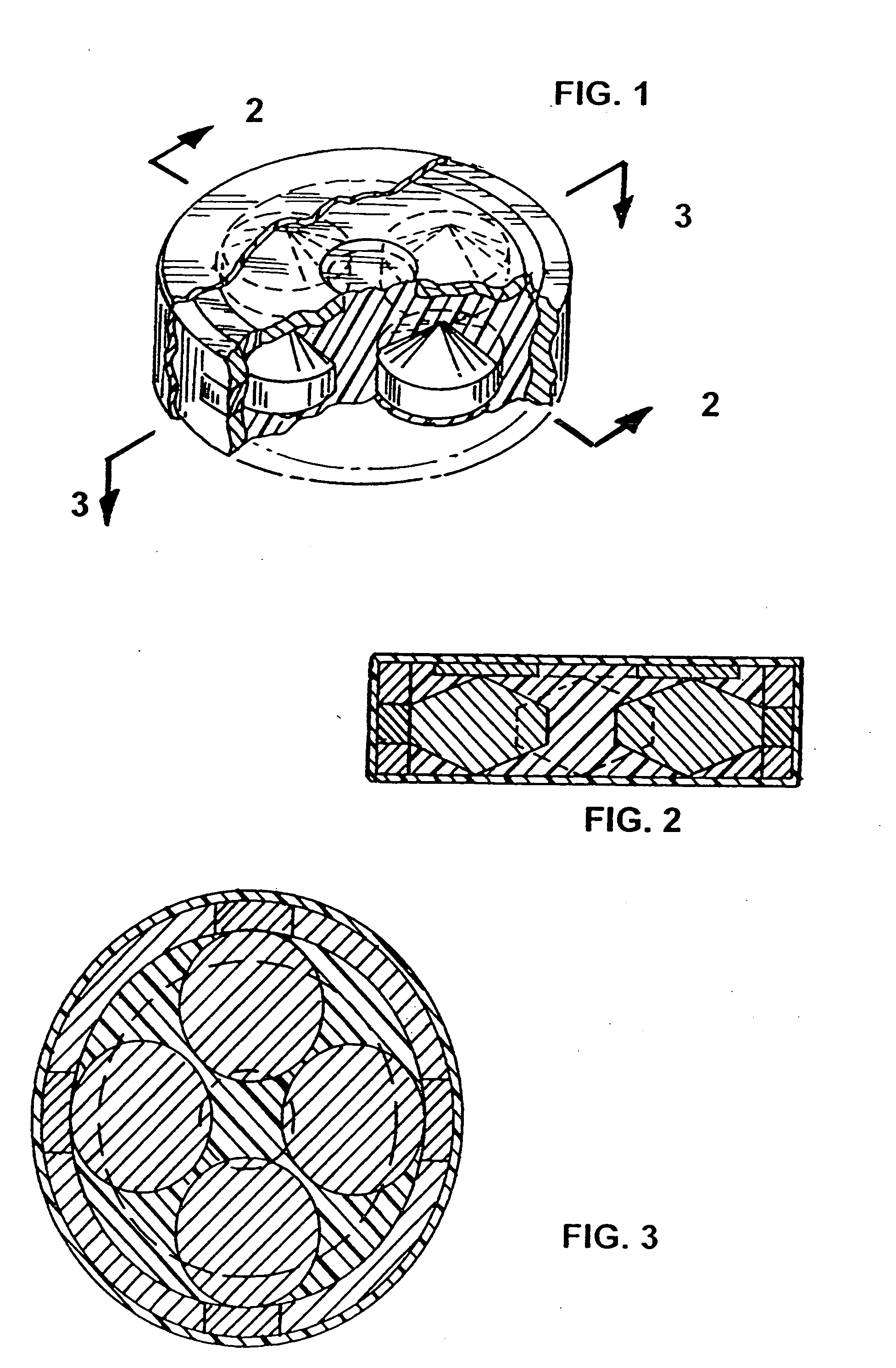

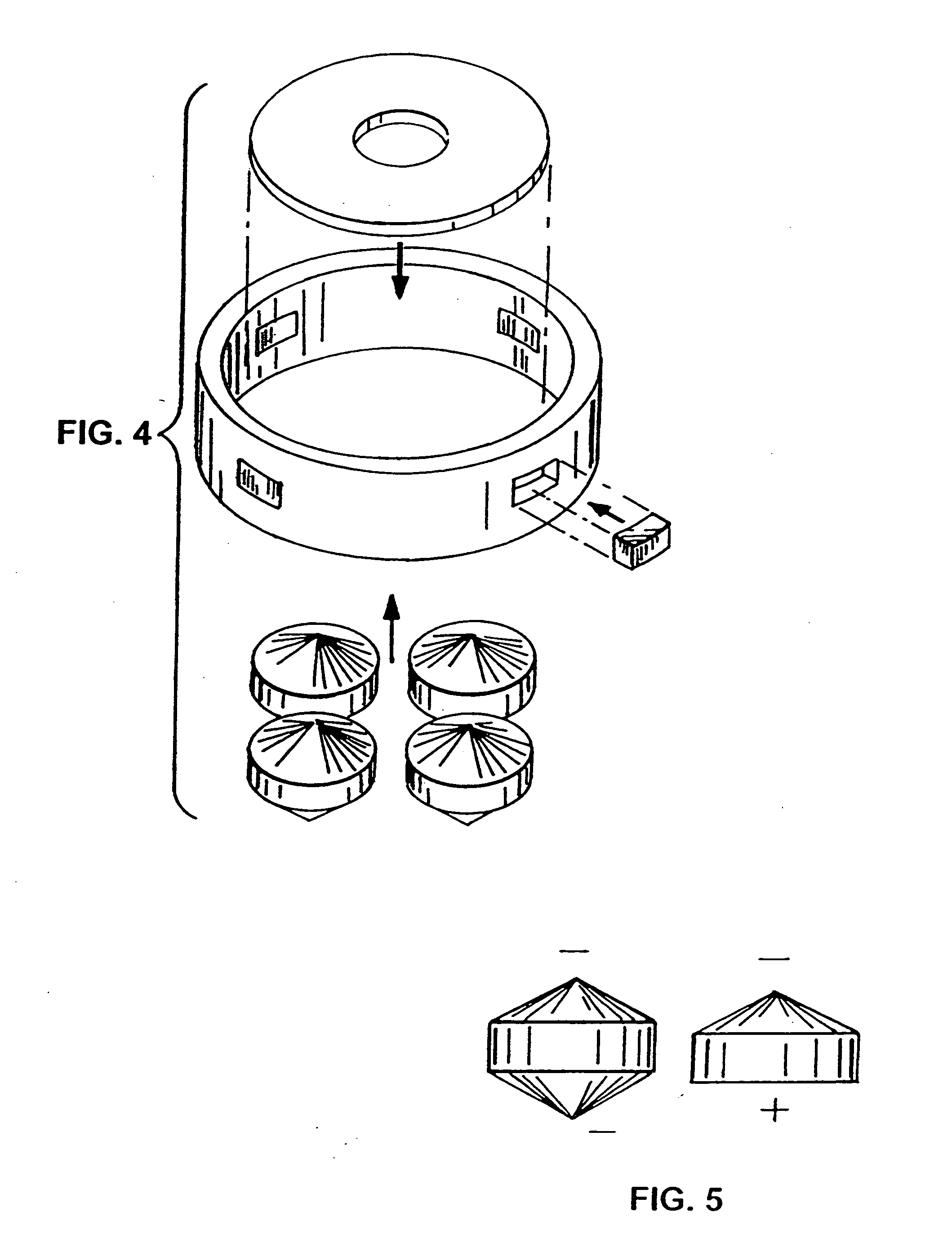

A method and morphologically adaptable apparatus for altering the charge distribution upon living membranes with functional stabilization of the membrane physical electrical integrity further comprising a method for using quadripolar, circular, center charged, energy balanced magnetic device in a four (4) magnet array of alternating polarity in which the magnetic poles are in multiple planes and are separated by a predetermined distance which provide an effective magnetic sphere of influence on all adjacent poles to suppress the firing of action potentials of mammalian sensory neurons. The method and apparatus further provides a static magnetic device for production of a magnetic field for treatment of various disorders that can be focused at the site of pain or edema to deliver a gradient in the magnetic field to prevent or reduce charge flow. Further there is provided a static magnetic device for production of a magnetic field for treatment of disorders wherein the device provides a static magnetic field such that the focused magnetic field gradient is oriented To be perpendicular to the neuron or membrane charge flow providing maximum deflection of the ion or charge flow.

Owner:GRADIENT TECH

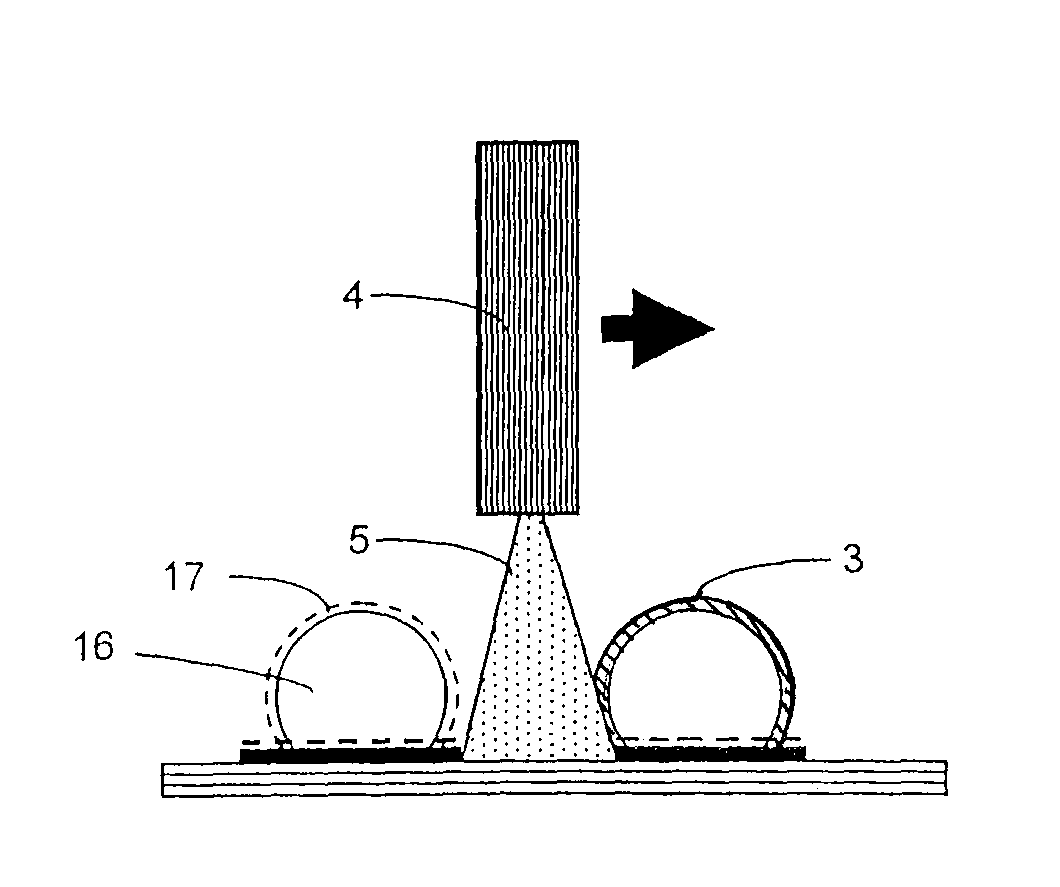

Method and materials for bonding electrodes to interconnect layers in solid oxide fuel cell stacks

ActiveUS20070111069A1Reliable electrical connectionStrong adhesive bondFuel cells groupingFuel cell auxillariesBond propertiesElectrical integrity

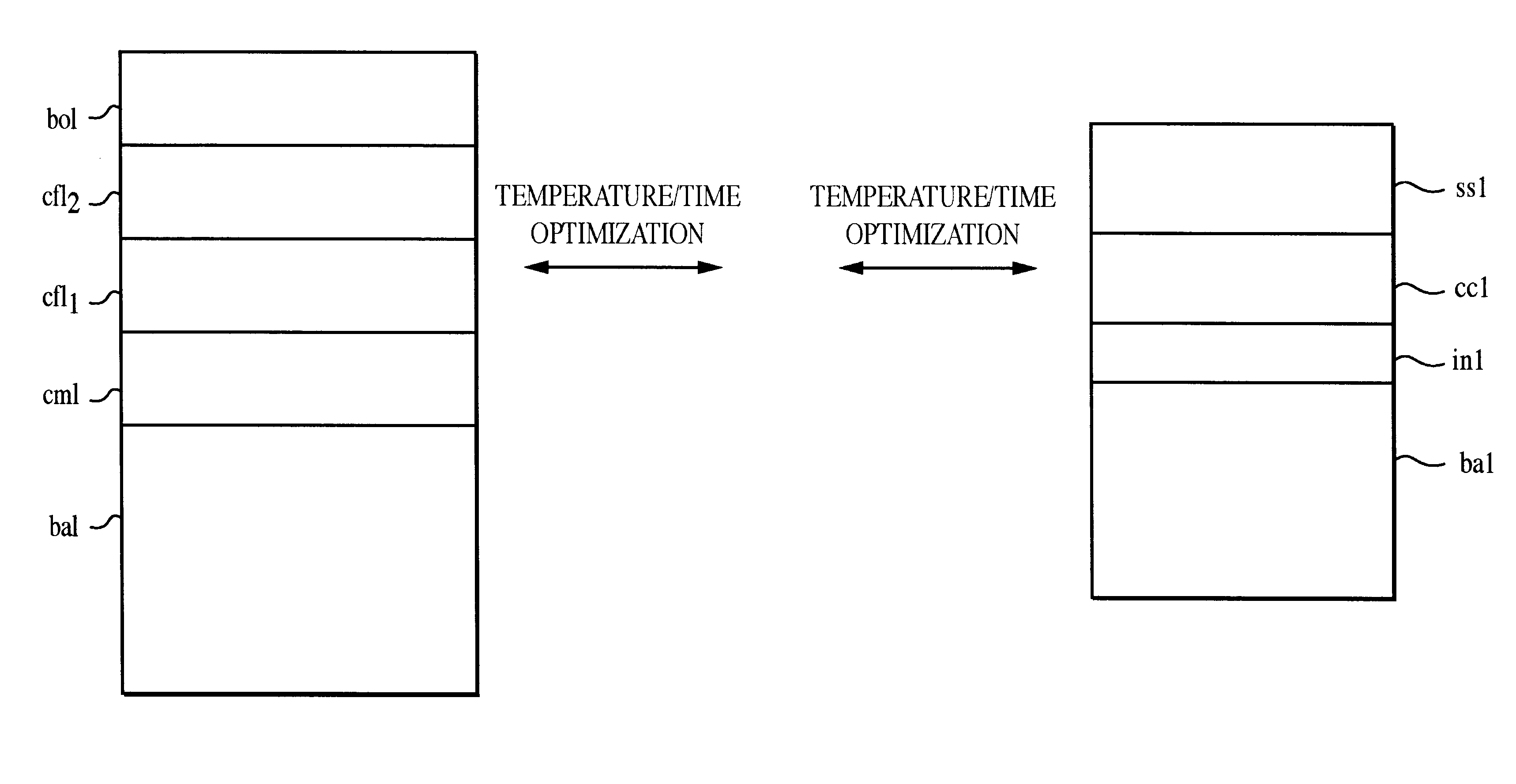

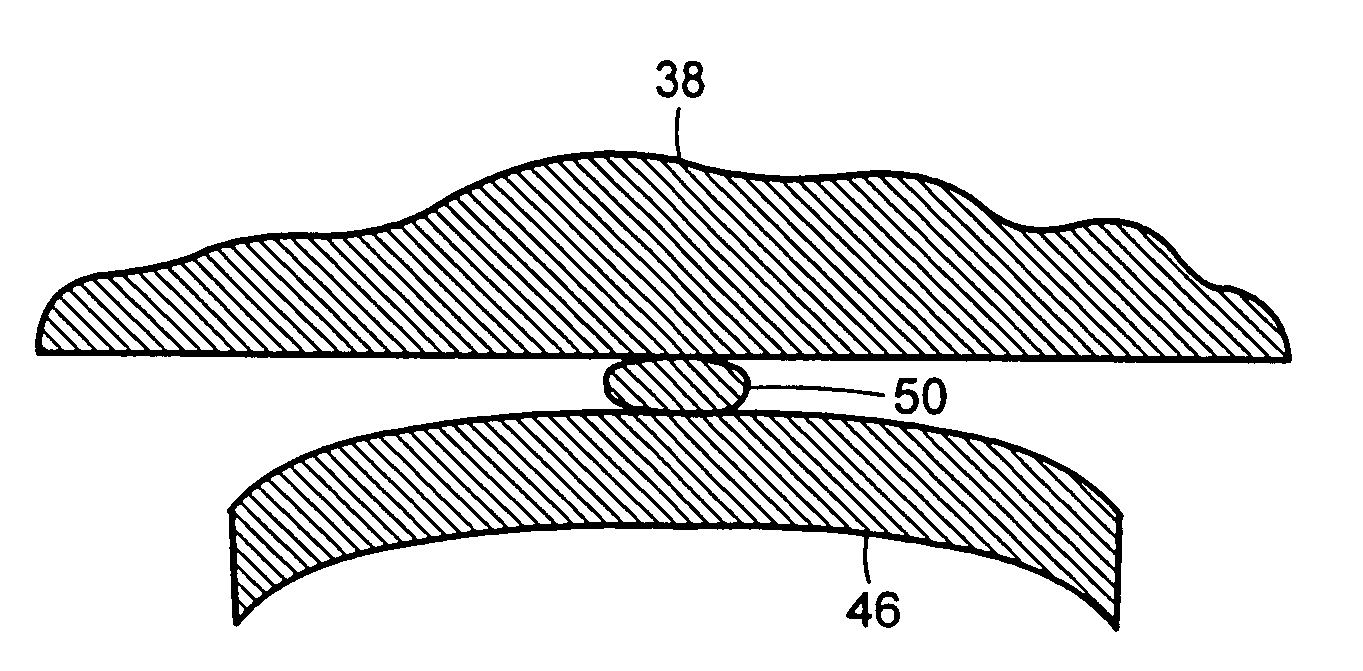

A method and related bonding compositions for use in assembling a solid oxide fuel cell (“SOFC”) stack having thermally and chemically stable and electrically conductive bonds between alternating fuel cells and interconnect components in the stack. The improved method and materials allow for the assembly of solid oxide fuel cells having a stronger and more reliable bond with good electrical contact in situ between the SOFC interconnect layers (plates) and the electrodes. The bonding materials and method according to the invention provide good electrical performance while maintaining the mechanical and electrical integrity of SOFC stacks without requiring excessive mechanical compression of the stack as exemplified by prior art systems. The preferred bonding agents comprise a primary phase that provides the electrical conduction path during fuel cell operation, as well as the mechanical strength necessary to insure a reliable connection between the interconnect and the relevant anode or cathode surfaces of the fuel cell. Secondary phases can be added in small amounts to the primary phase to improve adhesion. An exemplary method according to the invention also contemplates various different steps for pre-treating the surfaces of the interconnect plates and electrodes to improve their surface bonding properties.

Owner:CUMMINS ENTERPRISE LLC

Method and apparatus for altering the charge distribution upon living membranes with functional stabilization of the membrane physical electrical integrity

A method and apparatus for altering the charge distribution upon living membranes with functional stabilizational of the membrane physical electrical integrity further comprising a method for using submicroscopic, quadripolar, circular, center charged, energy balanced magnetic device in a four (4) magnet array of alternating polarity in which the magnetic poles are separated only by a distance which will allow a magnetic sphere of influence on all adjacent poles to suppress the firing of action potentials of mammalian sensory neurons. The method and apparatus further provides a static magnetic device for production of a magnetic field for treatment of various disorders. Further there is provided a static magnetic device for production of a magnetic field for treatment of disorders wherein the device provides a static magnetic pole of like polarity on the outer surface of the flux focusing ring adjacent to each of the 4 poles of the invention (focusing magnet) such that the end r top of the focusing magnet is oriented to the geometric side of the pole such that the a six of the two magnets form a 45 to 90 degree angle.

Owner:WILSON SPENCE L

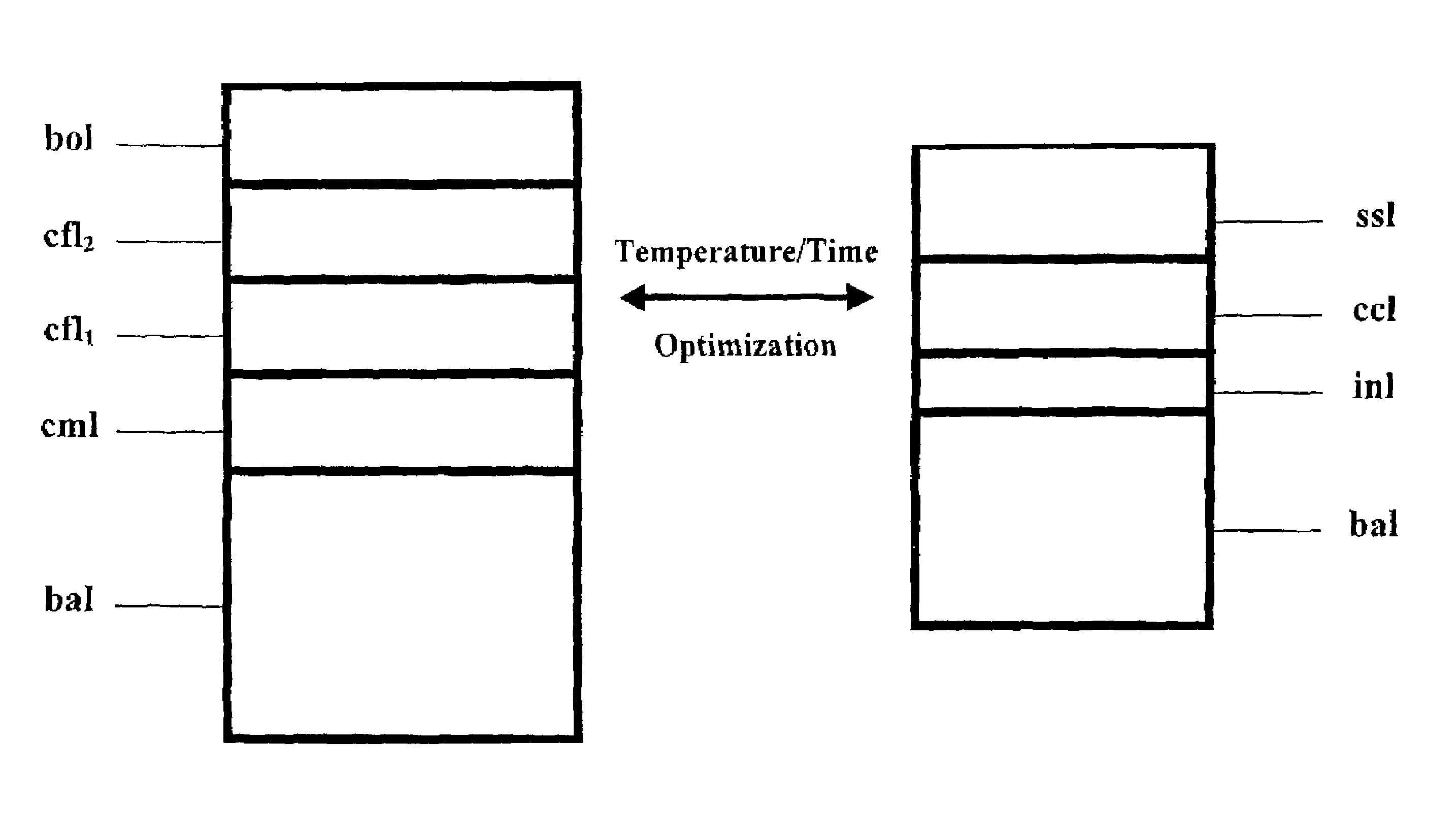

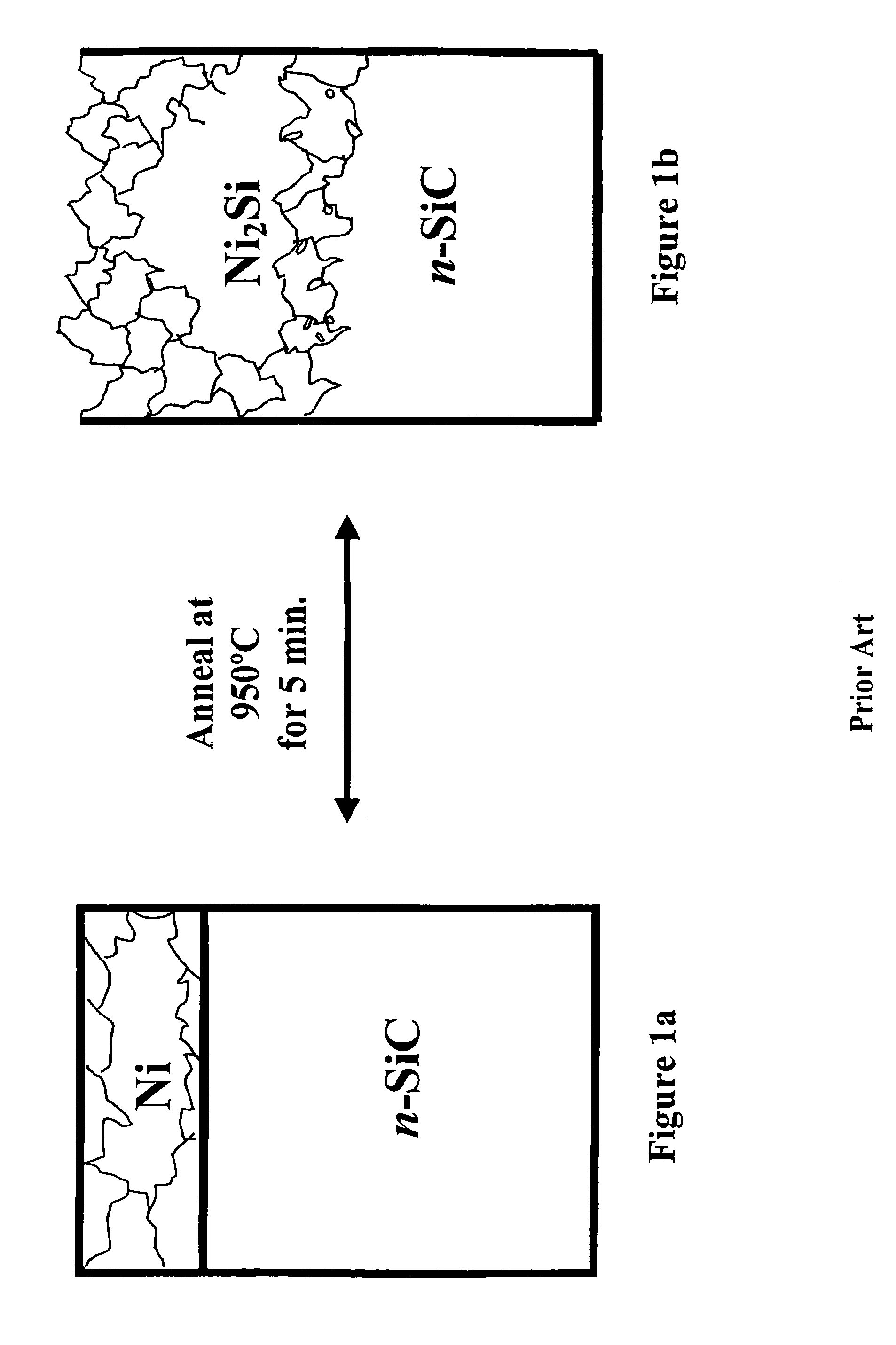

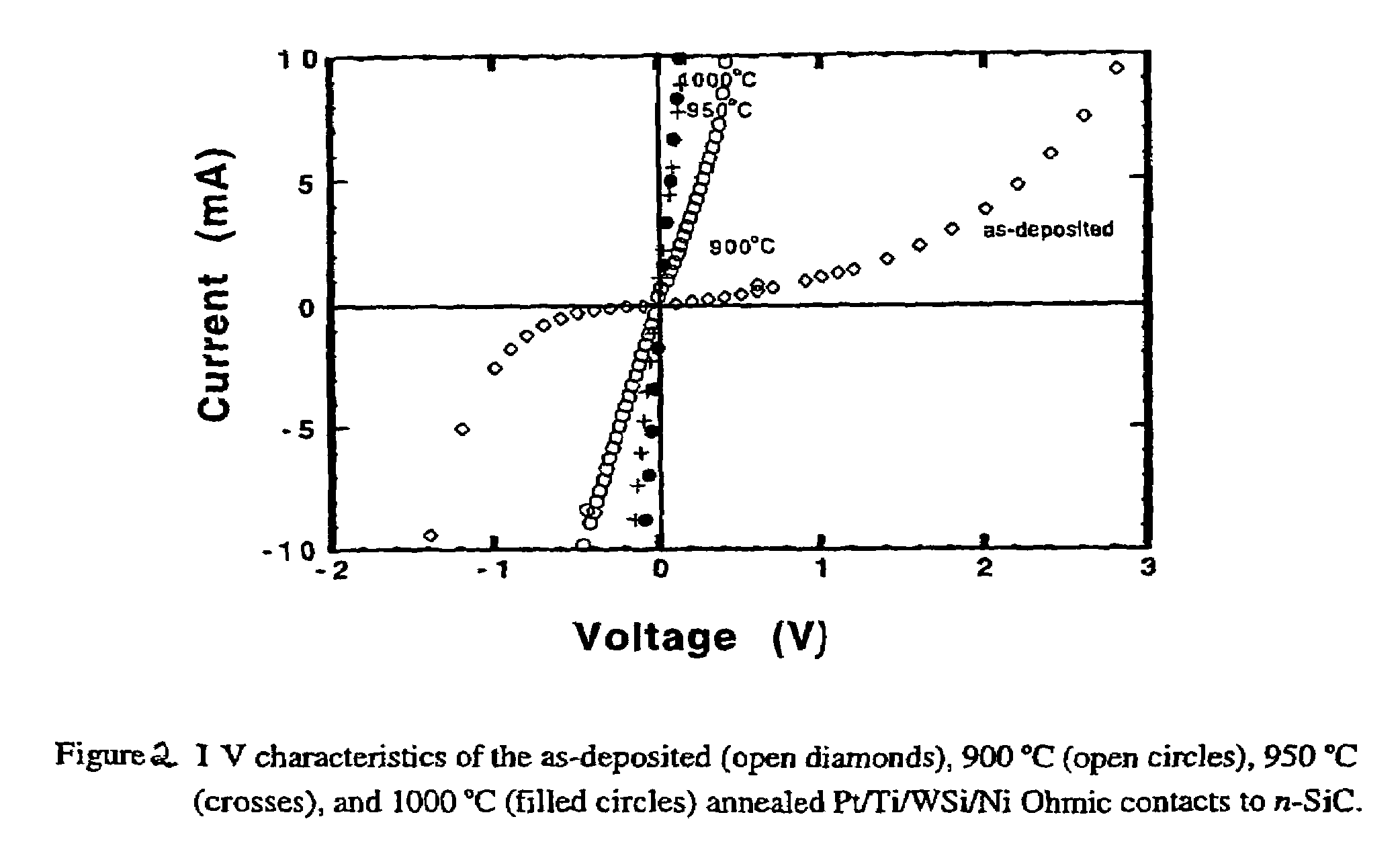

Formulation and fabrication of an improved Ni based composite Ohmic contact to n-SiC for high temperature and high power device applications

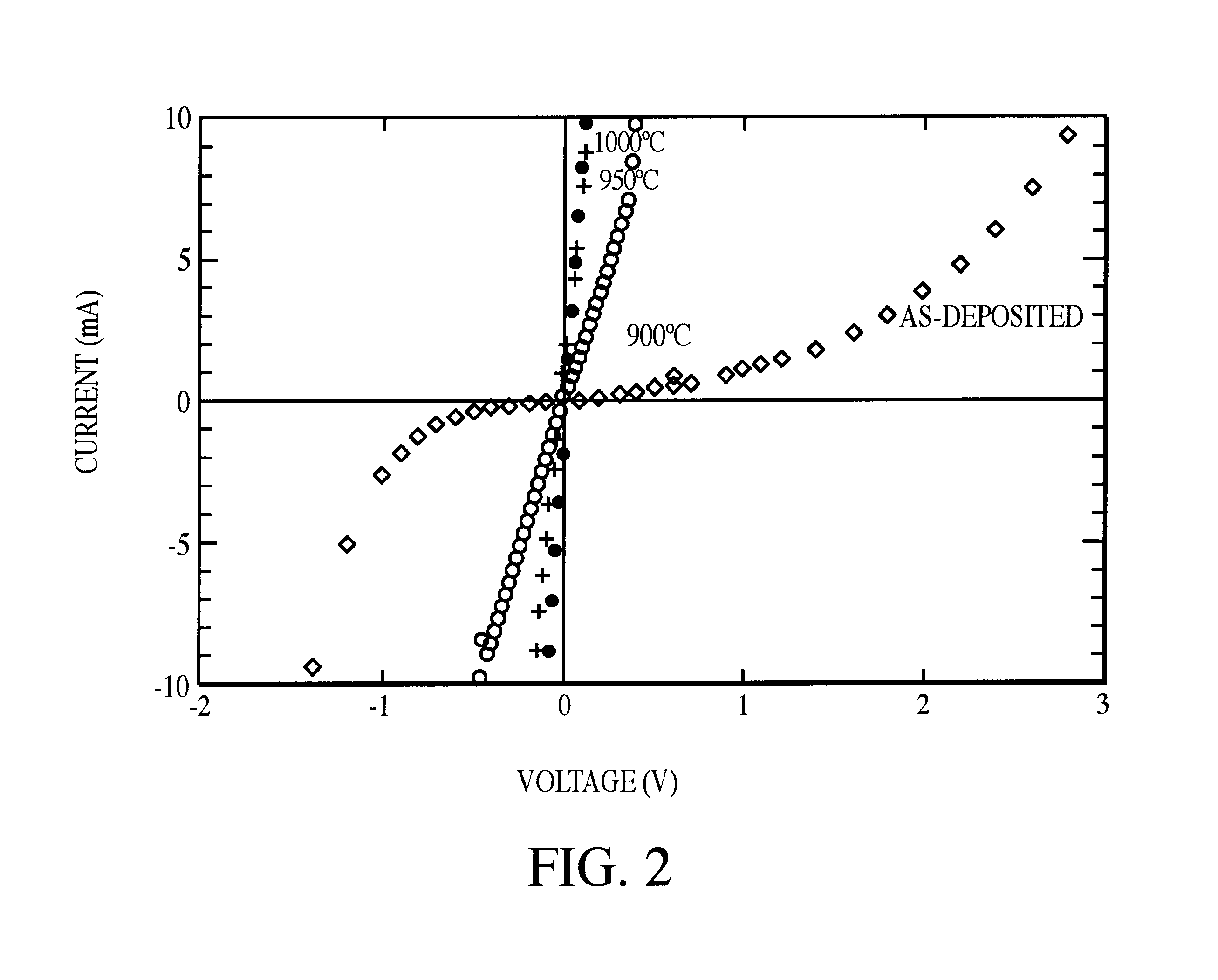

InactiveUS6759683B1Semiconductor/solid-state device detailsSolid-state devicesMetallurgyElectrical instability

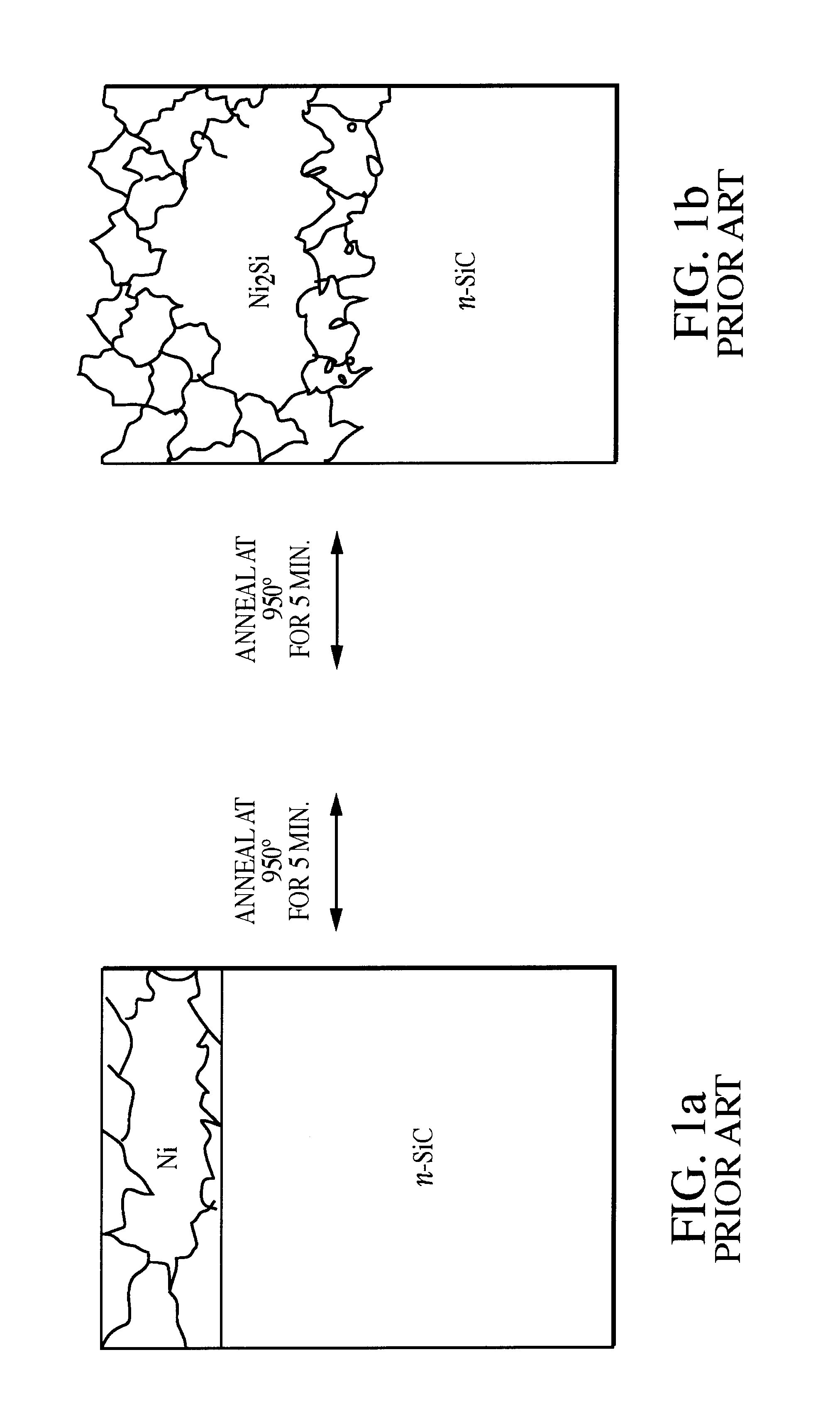

A composite Pt / Ti / WSi / Ni Ohmic contact has been fabricated by a physical deposition process which uses electron beam evaporation and dc-sputter deposition. The Ni based composite Ohmic contact on n-SiC is rapid thermally annealed (RTA) at 950° C. to 1000° C. for 30s to provide excellent current-voltage characteristics, an abrupt, void free contact-SiC interface, retention of the as-deposited contact layer width, smooth surface morphology and an absence of residual carbon within the contact layer and / or at the Ohmic contact-SiC interface. The annealed produced Ni2Si interfacial phase is responsible for the superior electrical integrity of the Ohmic contact to n-SiC. The effects of contact delamination due to stress associated with interfacial voiding has been eliminated. Wire bonding failure, non-uniform current flow and SiC polytype alteration due to extreme surface roughness have also been abolished. The Ohmic contact also avoids electrical instability associated with carbon inclusions within the contact metallization and / or at the contact-SiC interface, that occur under prolonged high temperature and power device operations. Overall, this contact is reliable for high temperature and high power operations and the stresses inclusive of use under those conditions.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

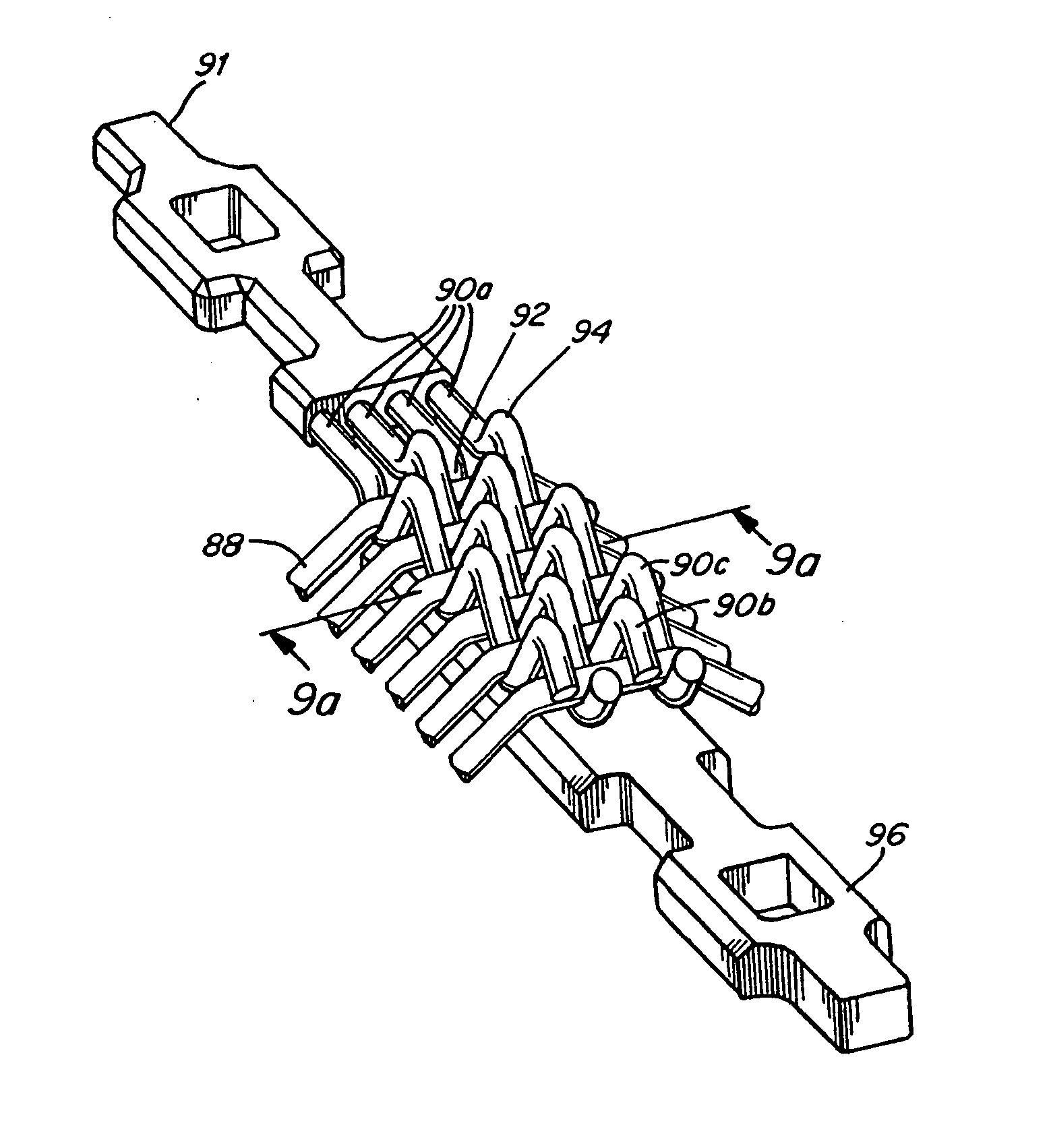

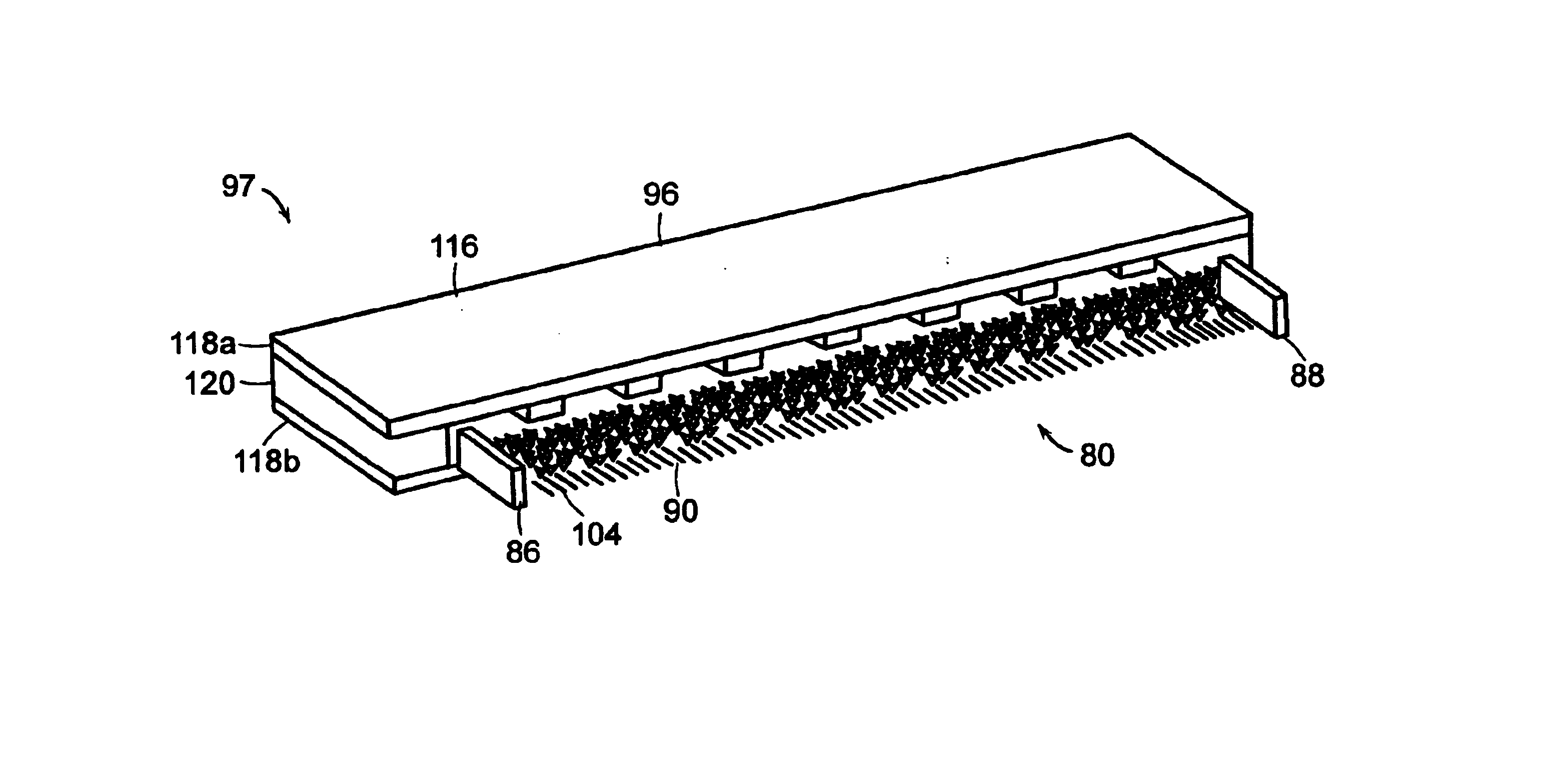

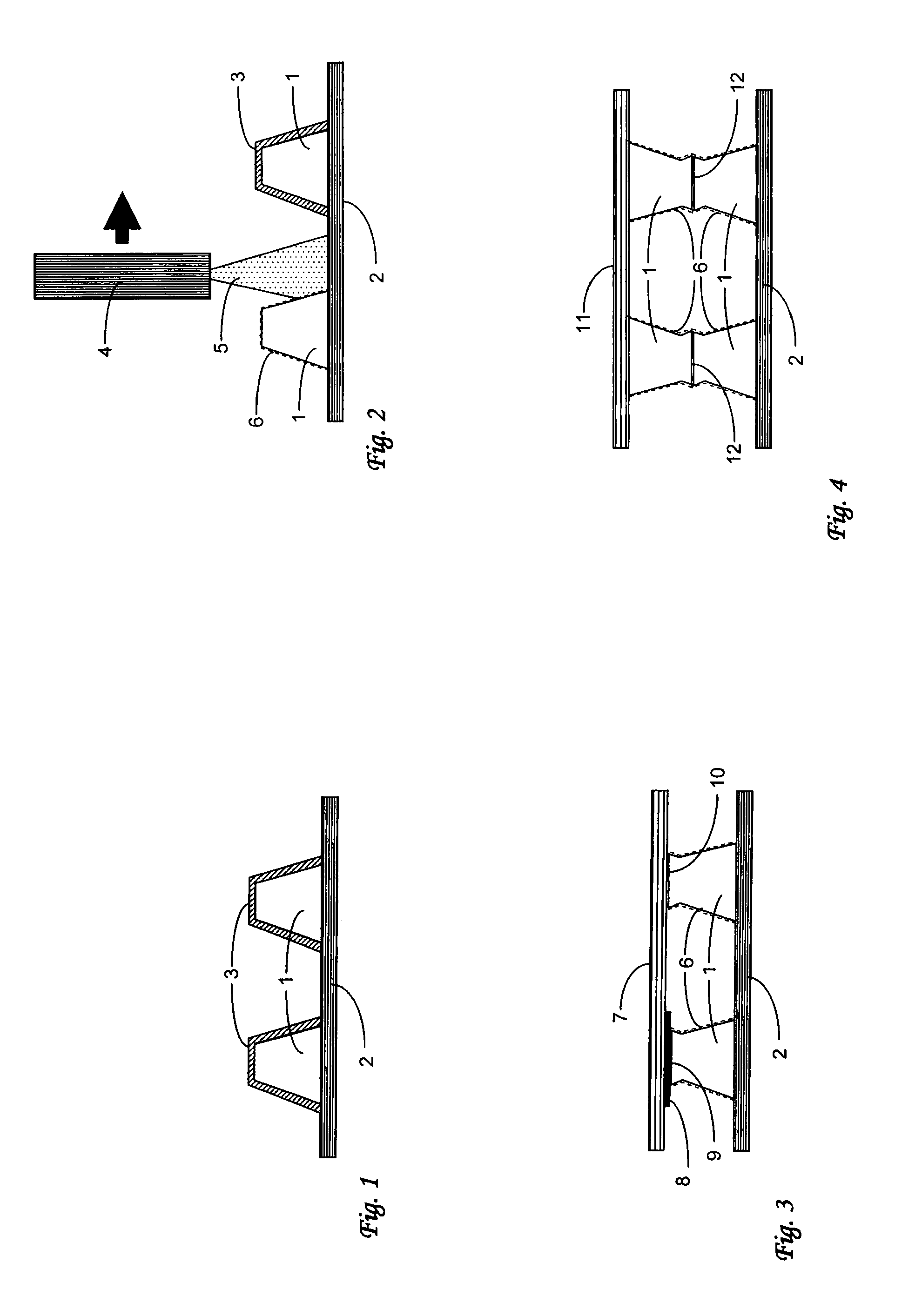

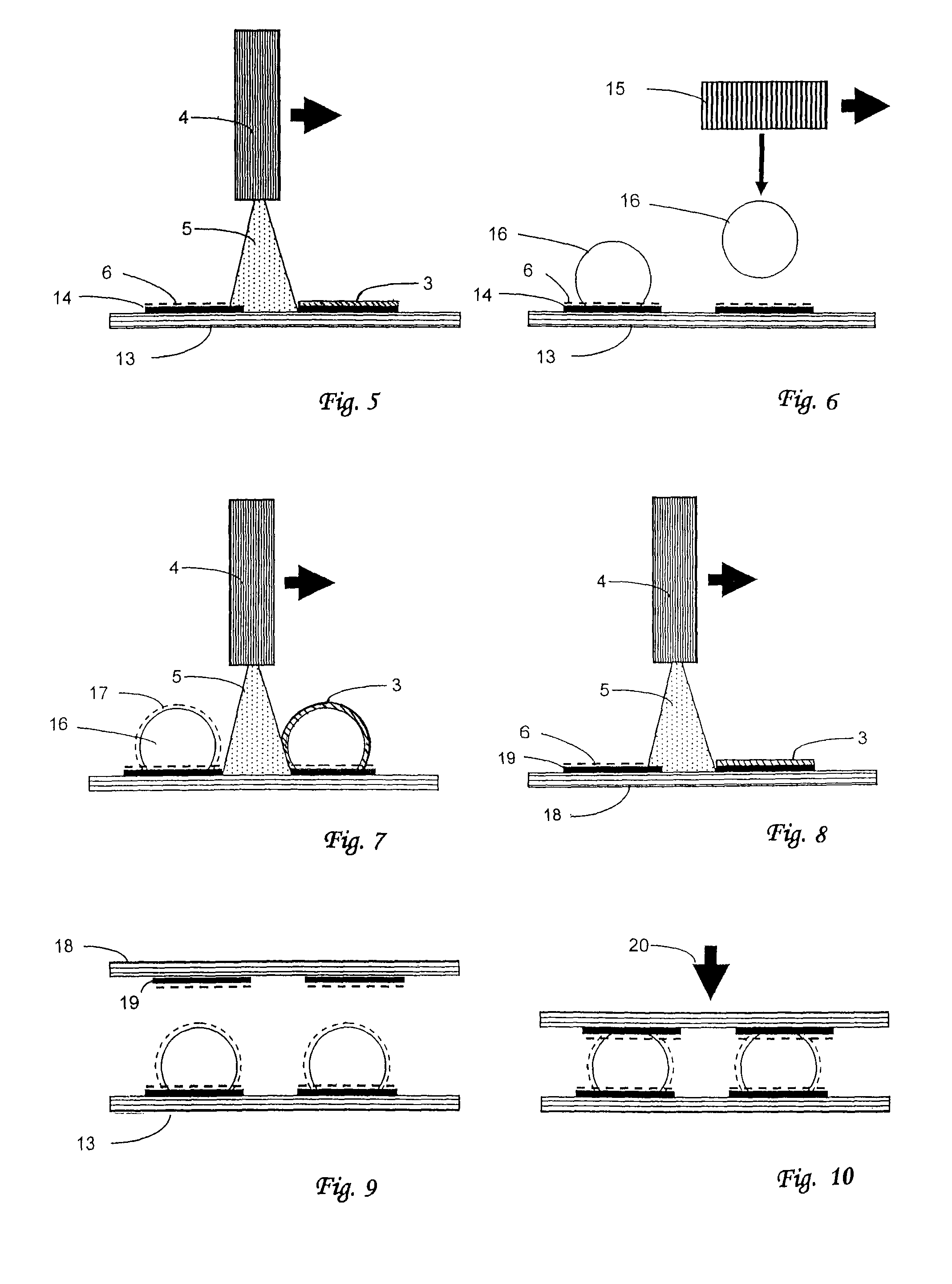

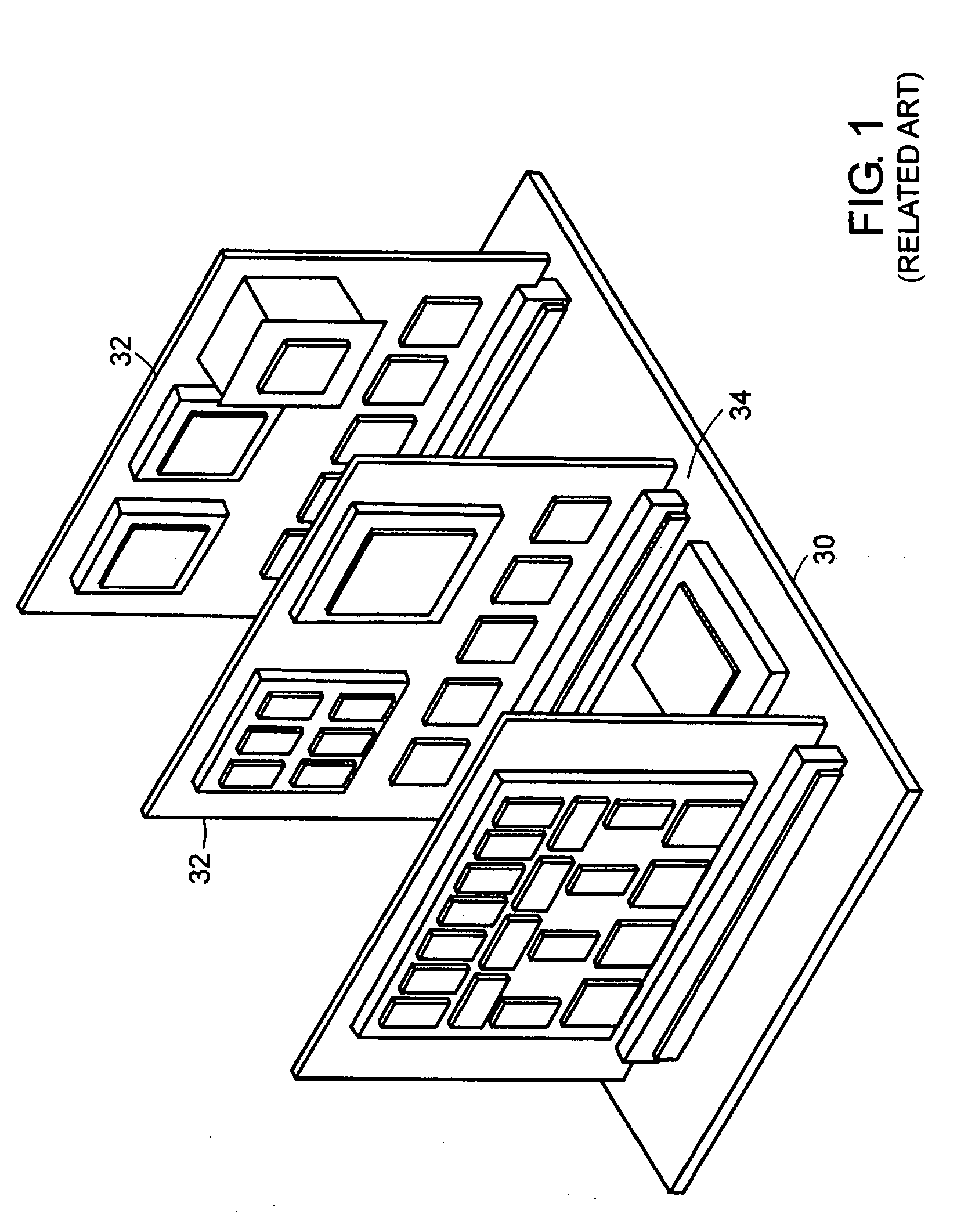

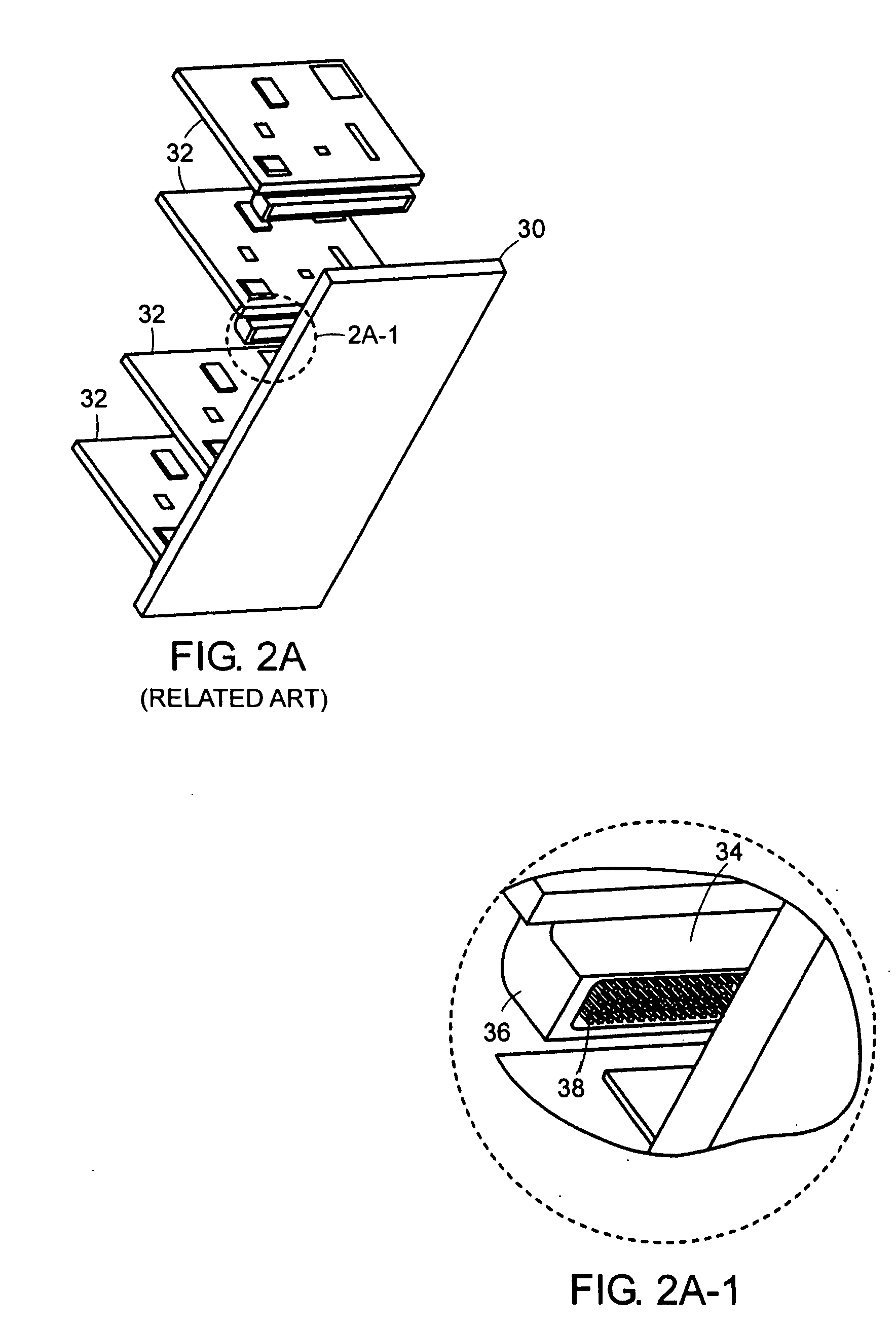

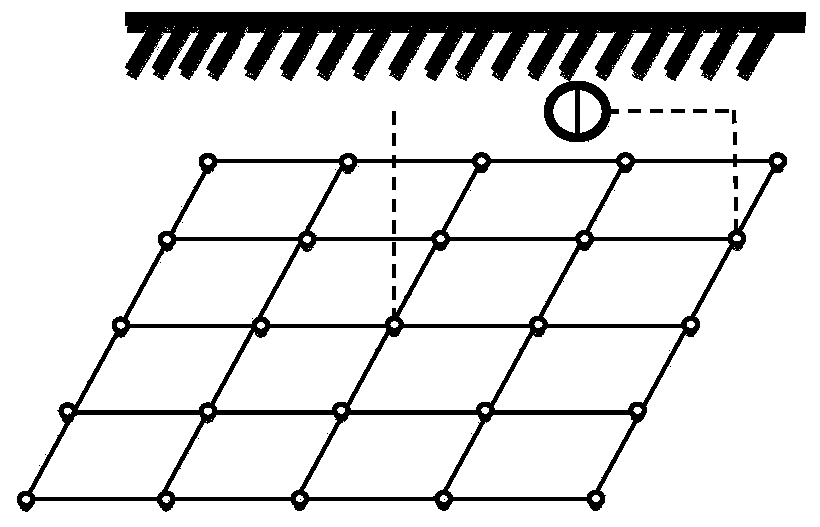

System and methods for connecting electrical components

The present disclosure is directed to methods and devices that use a contact interface for establishing an electrical connection with an electrical component. In certain exemplary embodiments, the contact interface of a device includes at least one loading fiber and at least one conductor having at least one contact point. The conductor(s) is coupled to a loading fiber so that an electrical connection can be established between the contact point(s) of the conductor(s) and the electrical component when the device is engaged with the electrical component. In certain exemplary embodiments, a conductor is woven with, or wound around, a loading fiber. In some exemplary embodiments, the conductor is comprised of a shaped contact and a conductive lead. The present disclosure is also directed to methods and devices for testing the electrical integrity or functionality of an electrical component. In certain exemplary embodiments, the device includes a plurality of loading fibers, a plurality of conductors and a plurality of tensioning guides. Each conductor can be coupled to at least one loading fiber. The tensioning guides can be disposed on at least one side of each said conductor. In such embodiments, electrical connections can be established between at least a portion of the plurality of conductors and the electrical component when the device is engaged with the electrical component. At least a portion of the plurality of loading fibers may come into contact with the plurality of tensioning guides when the device is engaged with the electrical component. In one exemplary embodiment, the device comprises a burn-in socket device. In another exemplary embodiment, the device comprises a test socket device.

Owner:METHODE ELETRONICS INC

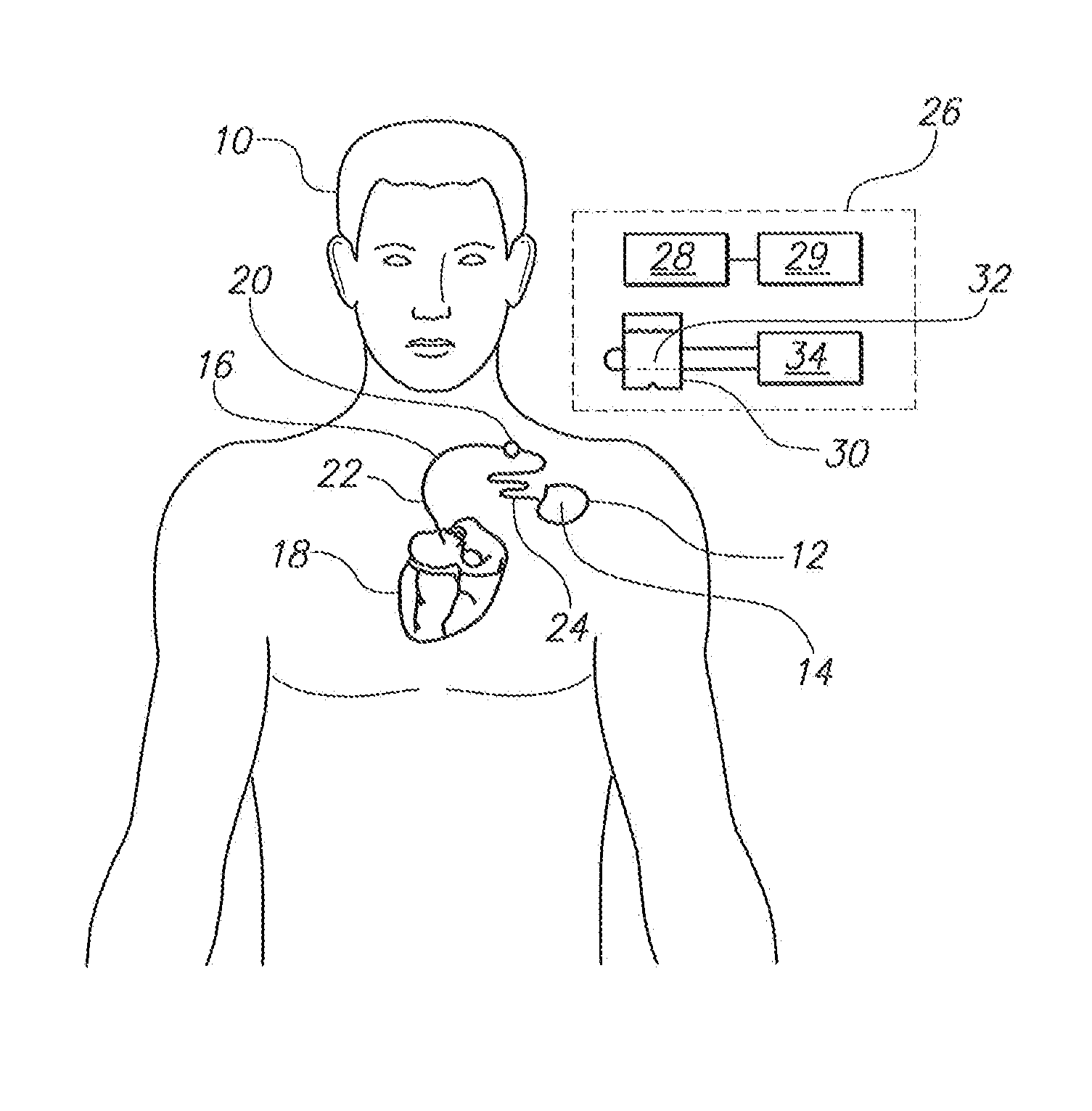

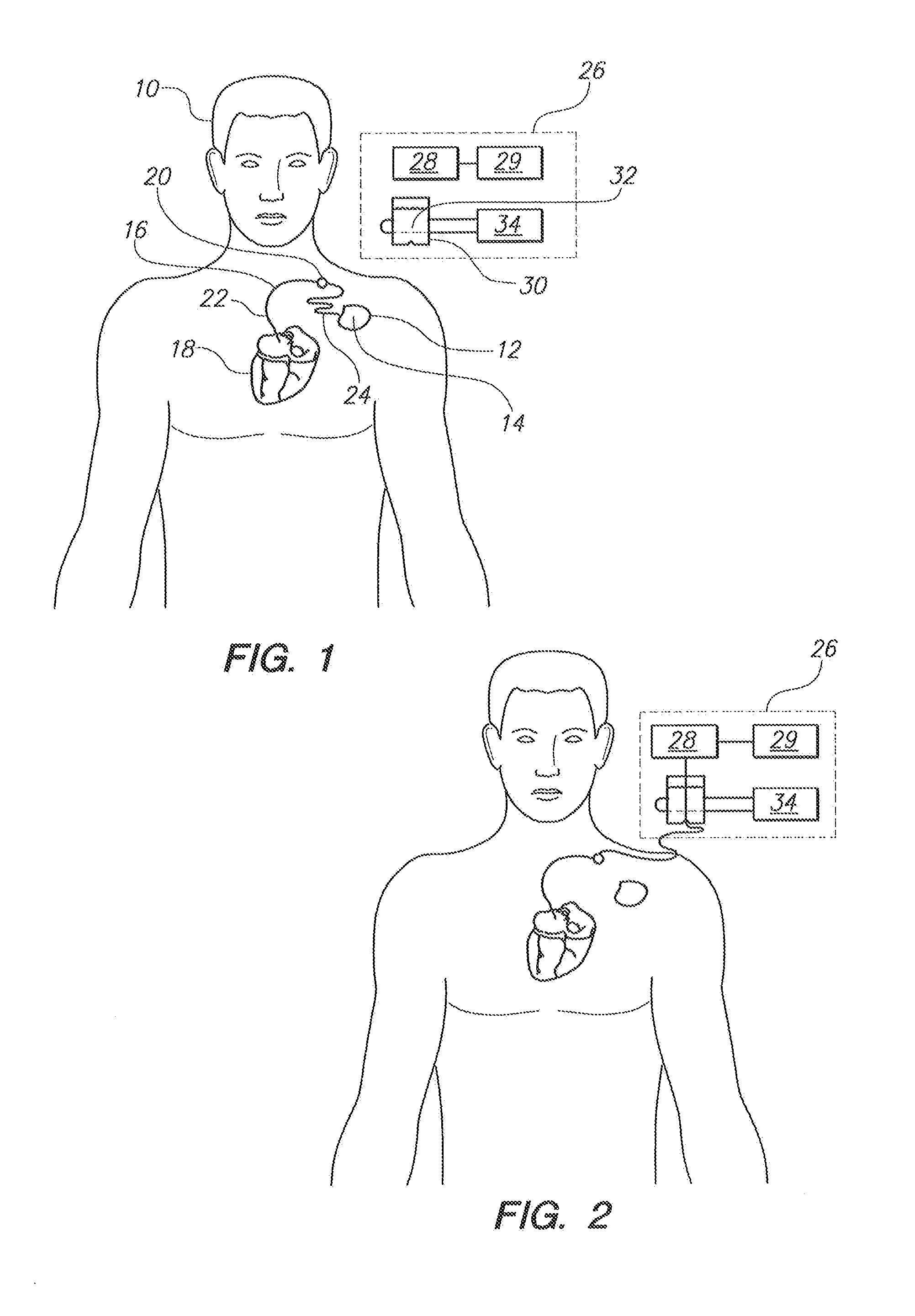

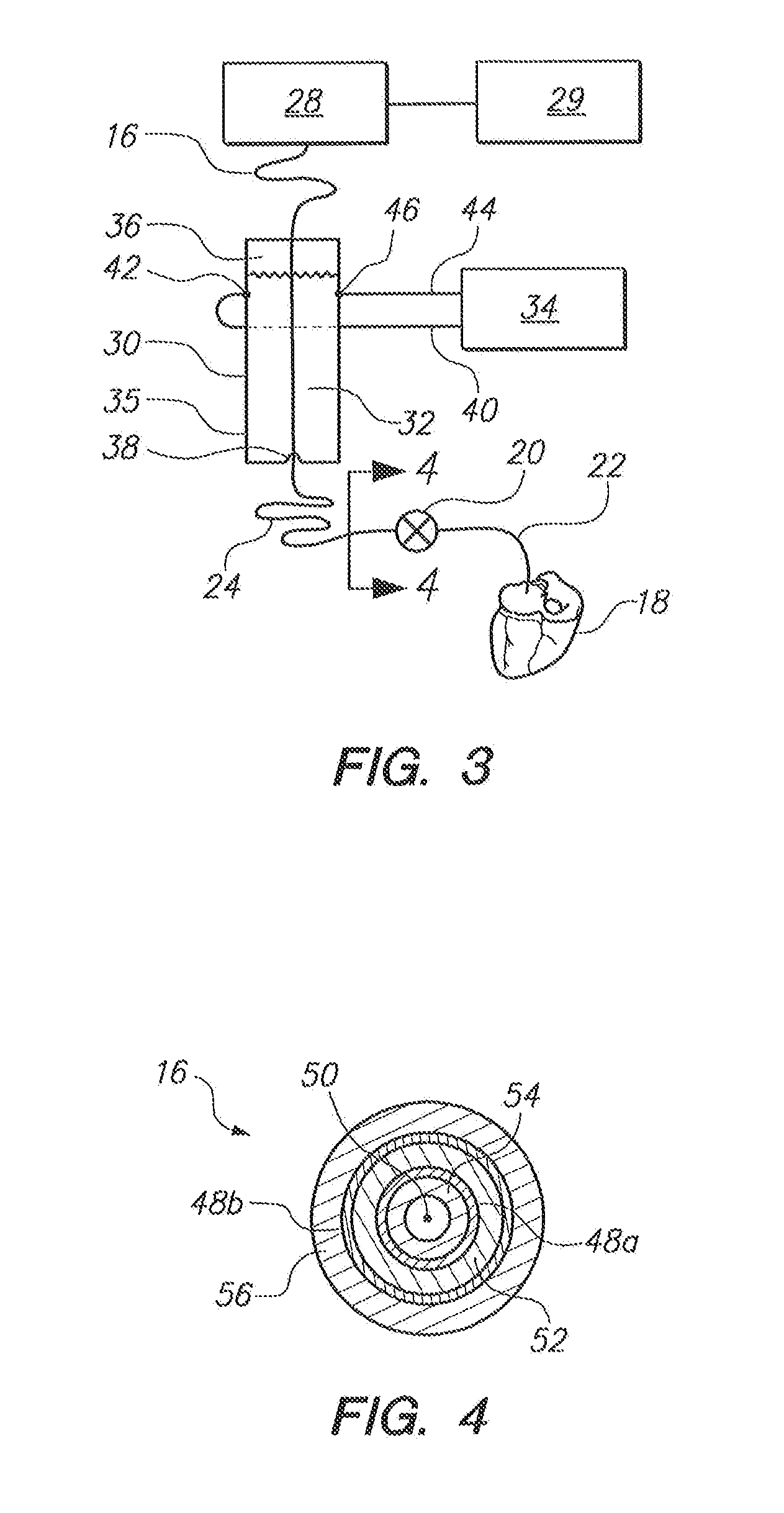

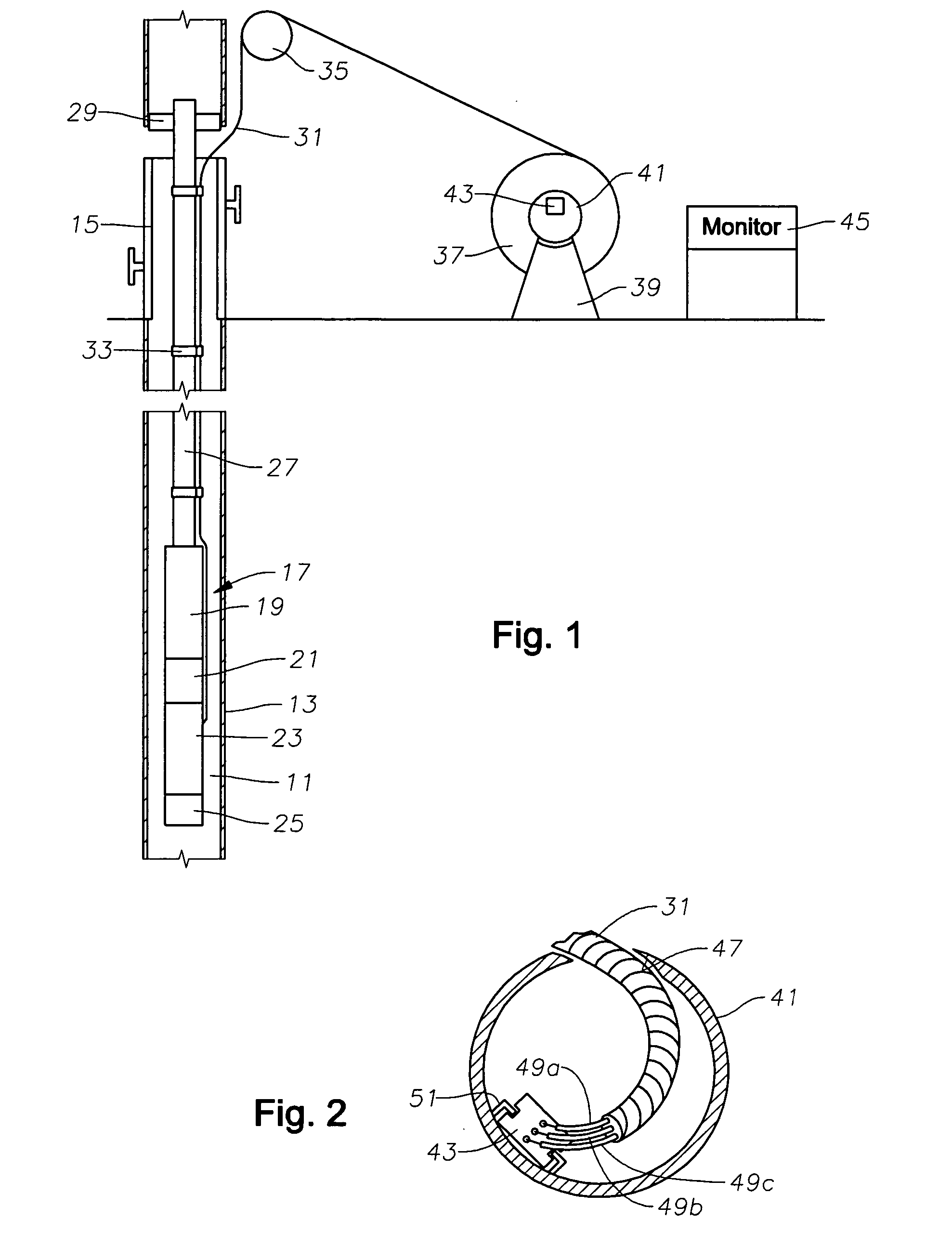

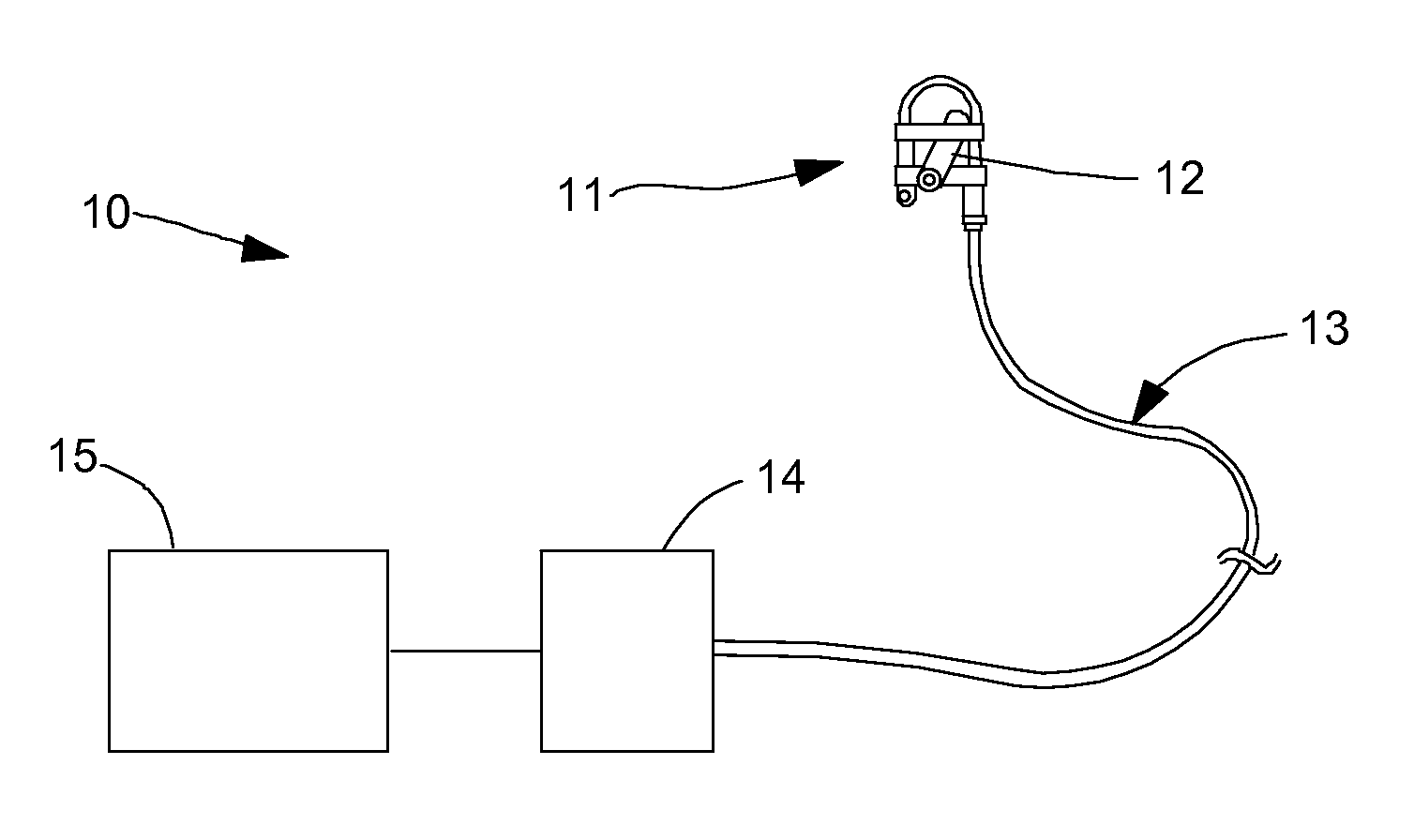

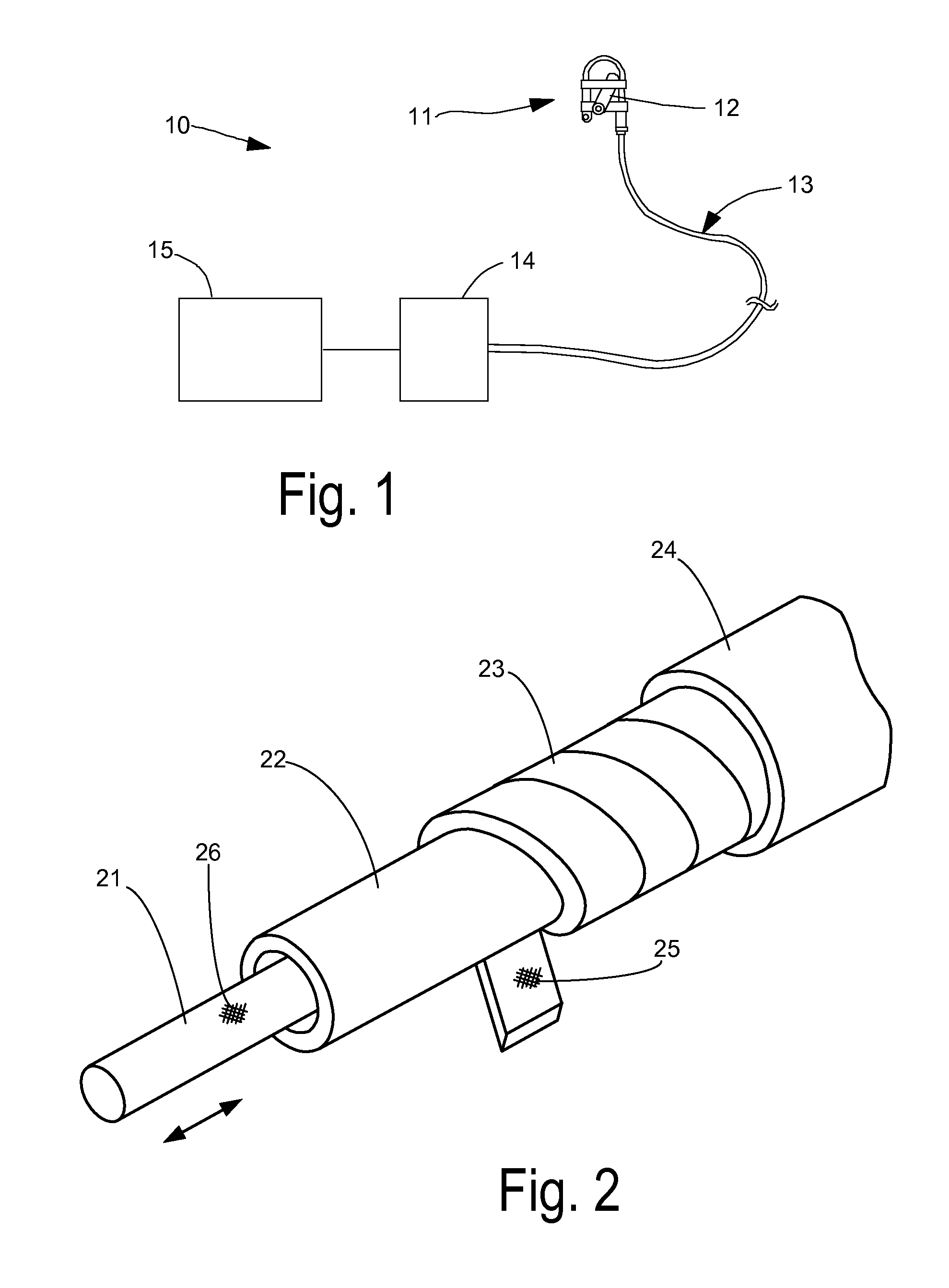

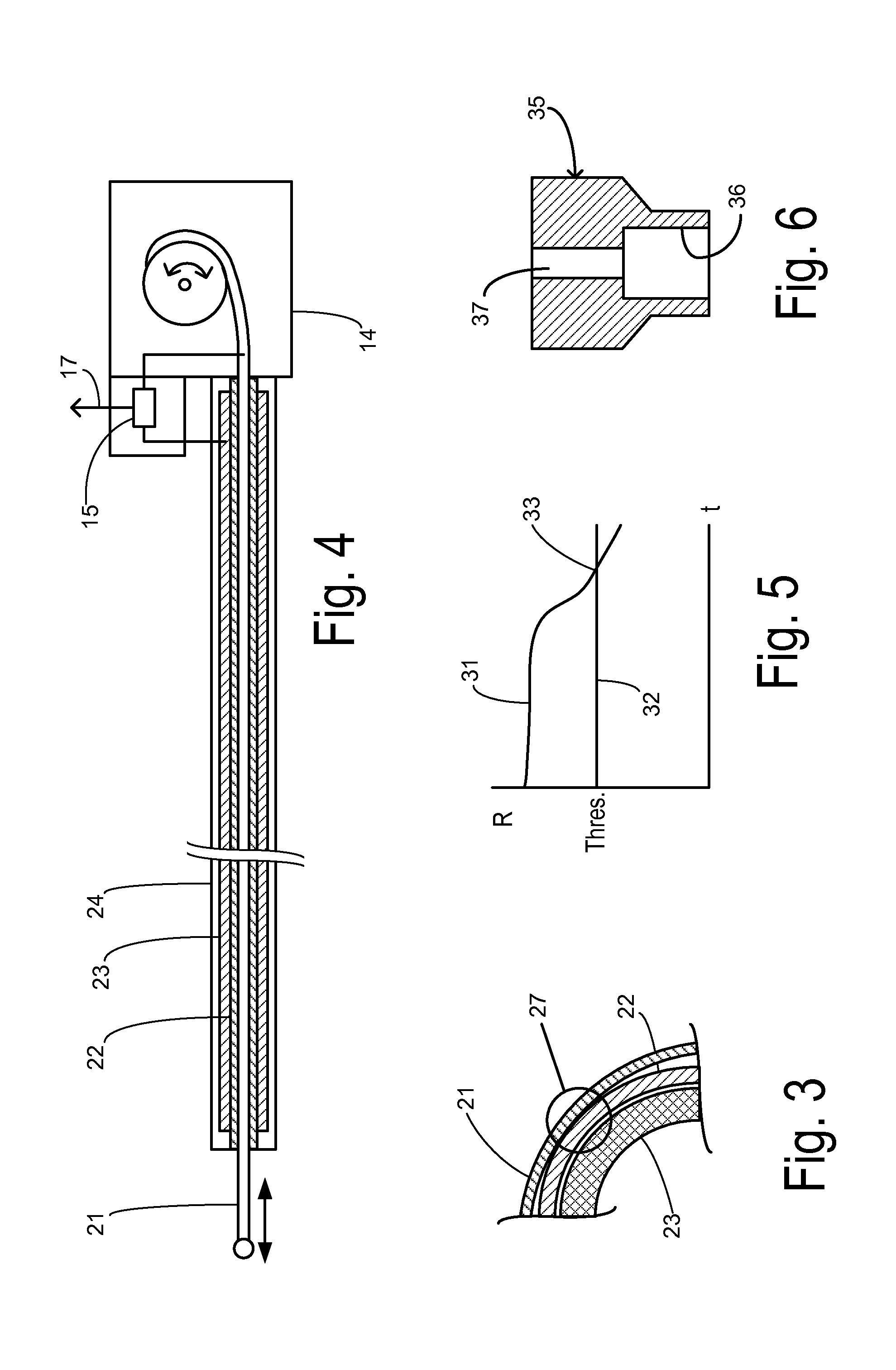

Extracorporeal Unit for Inspecting the Insulation of an Electrical Wire of an Implanted Medical Device

ActiveUS20130310887A1Increase electrical couplingHeart defibrillatorsElectrical testingImplanted pacemakerEngineering

A system is provided for testing the electrical integrity of an implanted pacemaker or defibrillator lead. The system includes a container holding an electrically conductive solution, such as a saline solution. A voltage source and two electrodes are provided to pass an electrical current through the solution. To use the system, the proximal end of the electrical lead is disconnected from the implanted electronic device, passed through the saline solution and then electrically connected to a device / monitor. During testing, the device / monitor sends a test pulse through the lead and monitors electrical activity in the lead. To test sequential locations along the length of the proximal segment, the segment is drawn through the saline solution and between the electrodes while test pulses are sent and monitored. The monitor detects abnormal electrical activity in the lead indicative of a break in lead insulation.

Owner:THE GUY P CURTIS & FRANCES L CURTIS TRUST

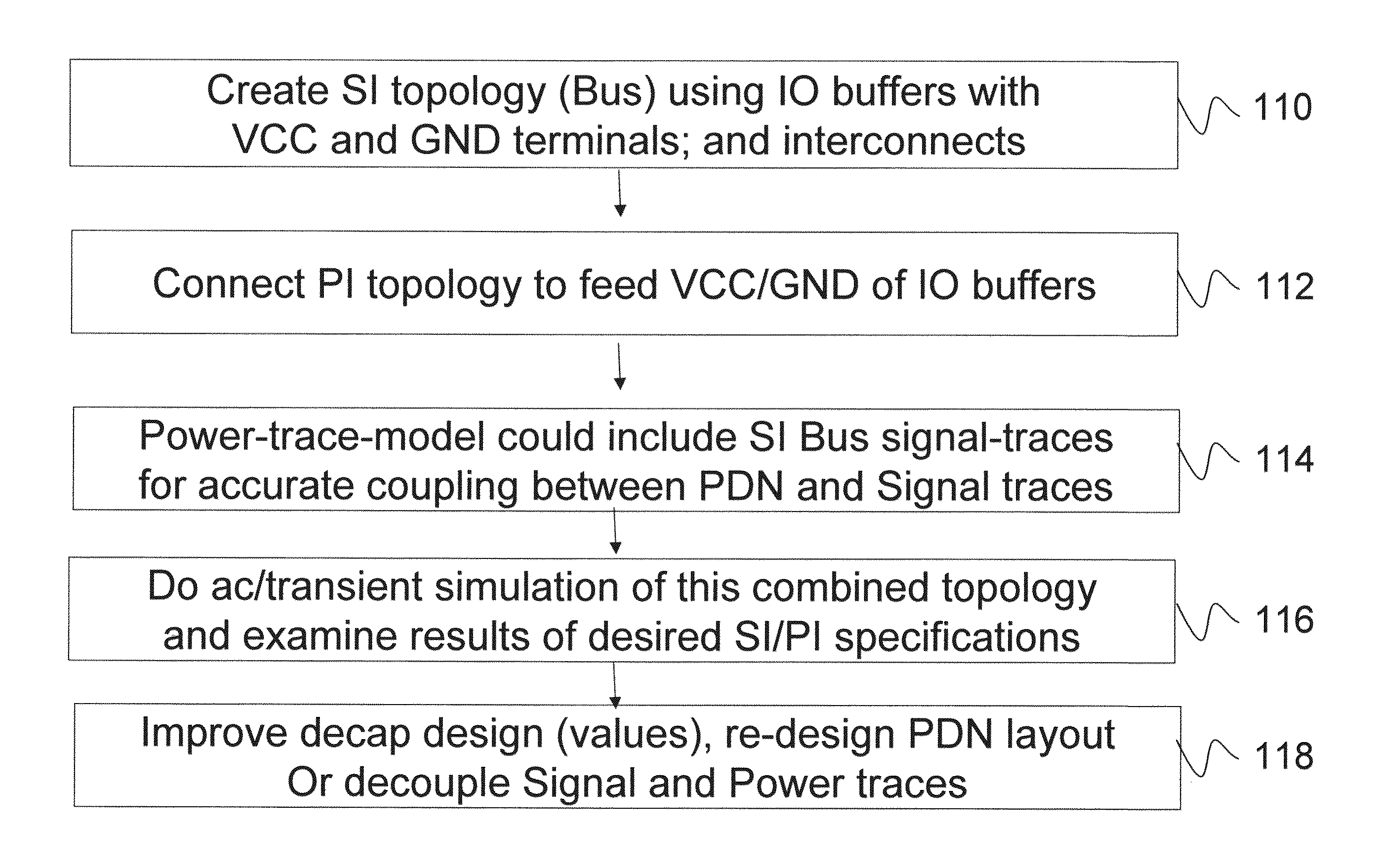

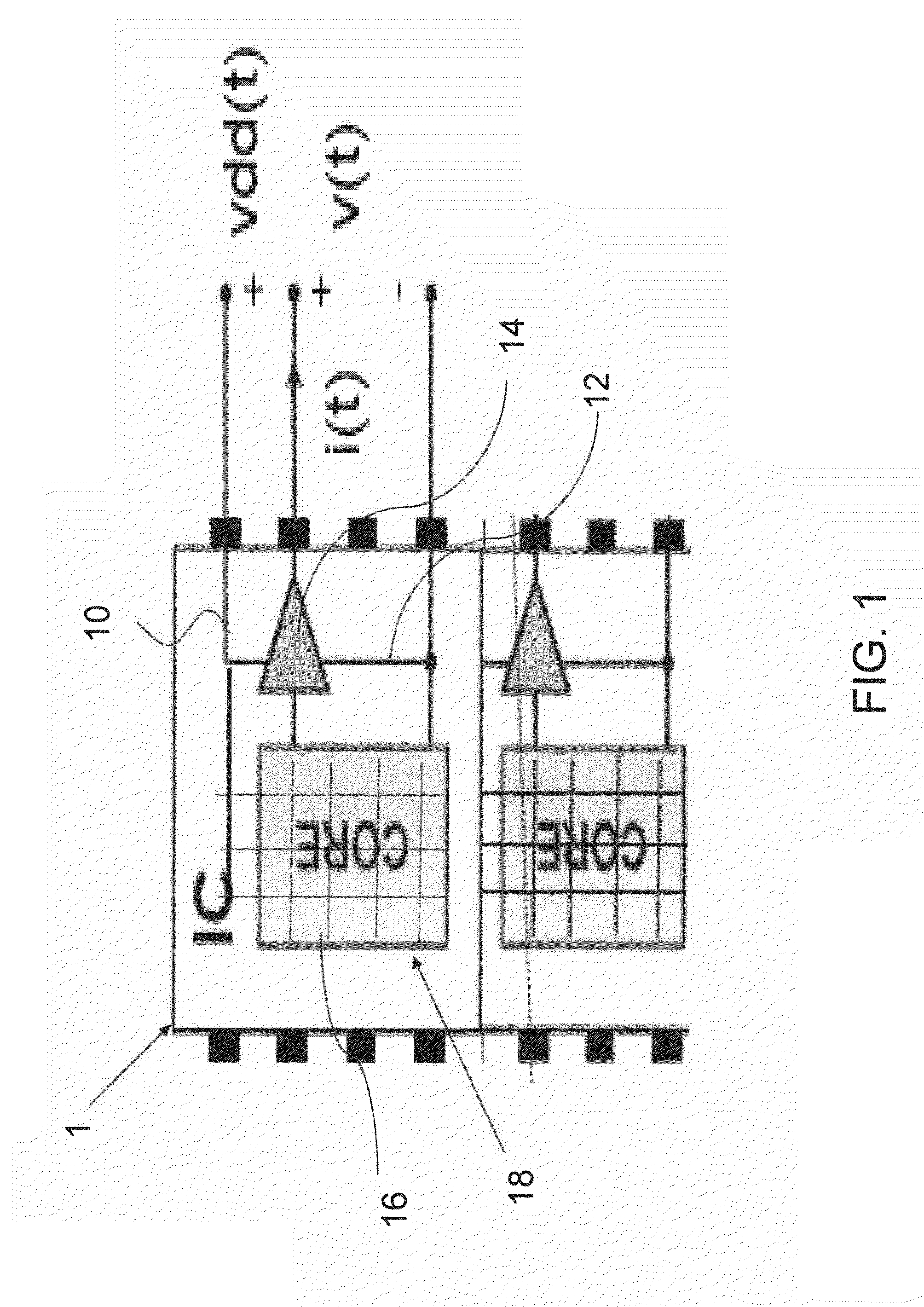

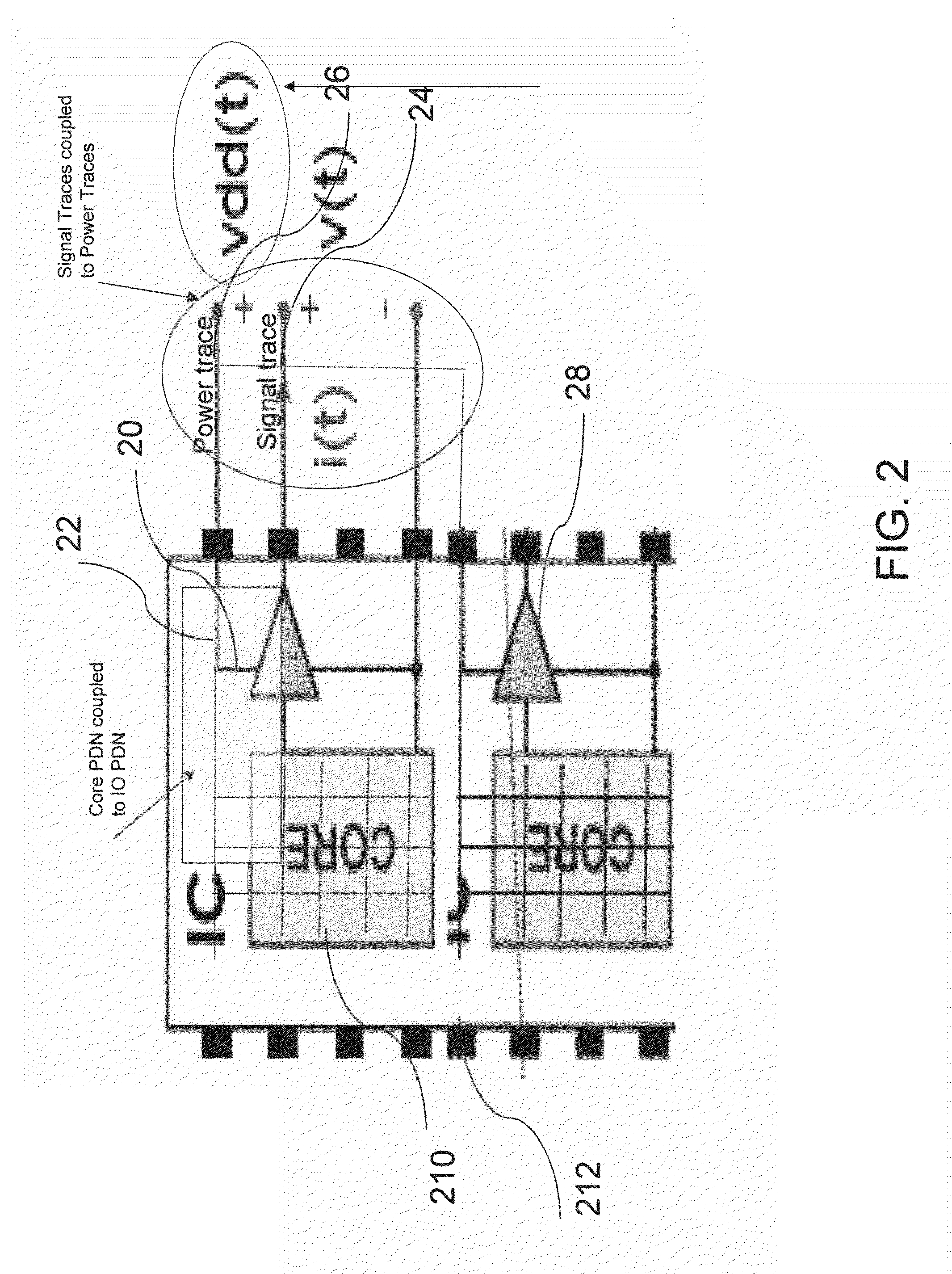

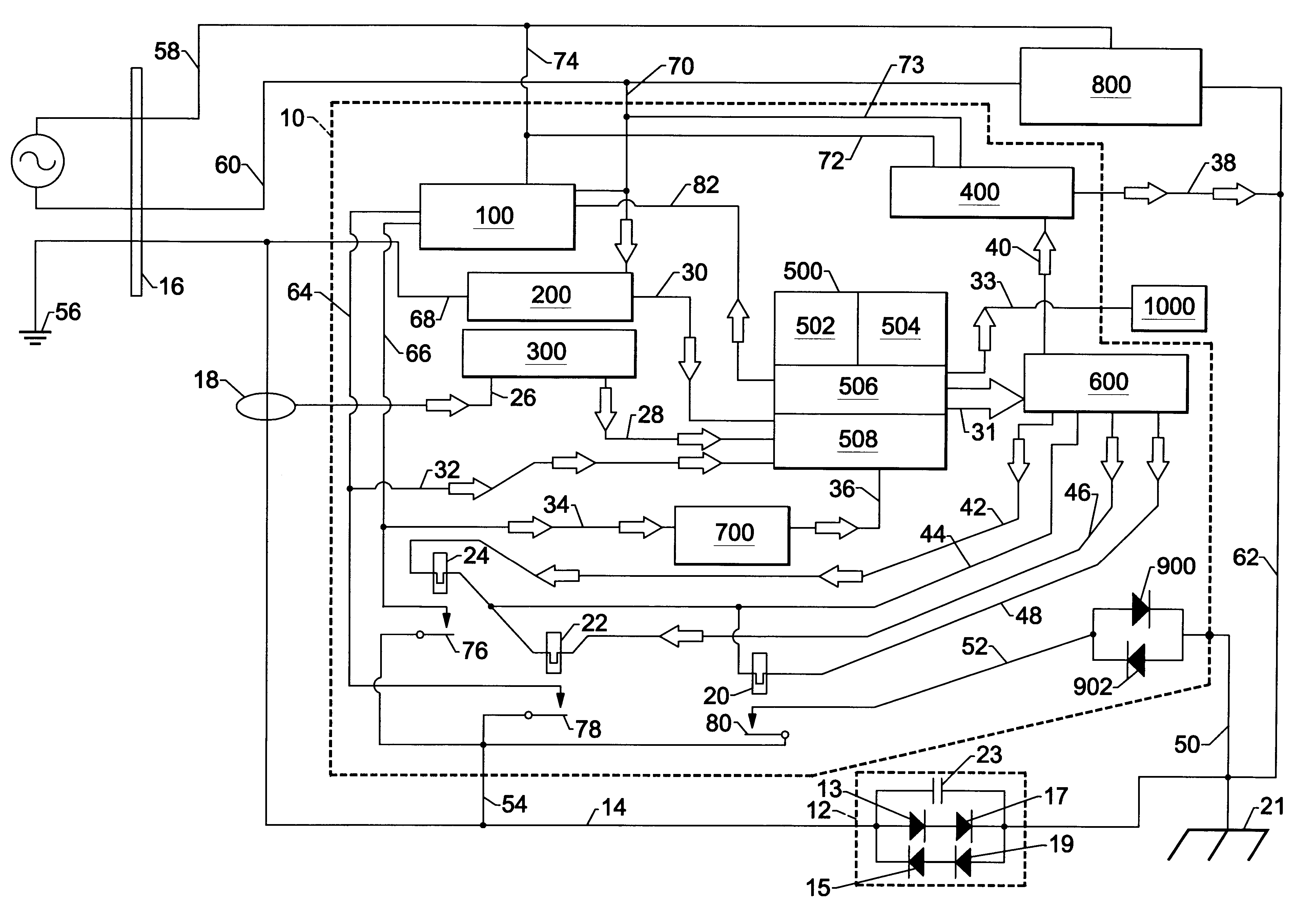

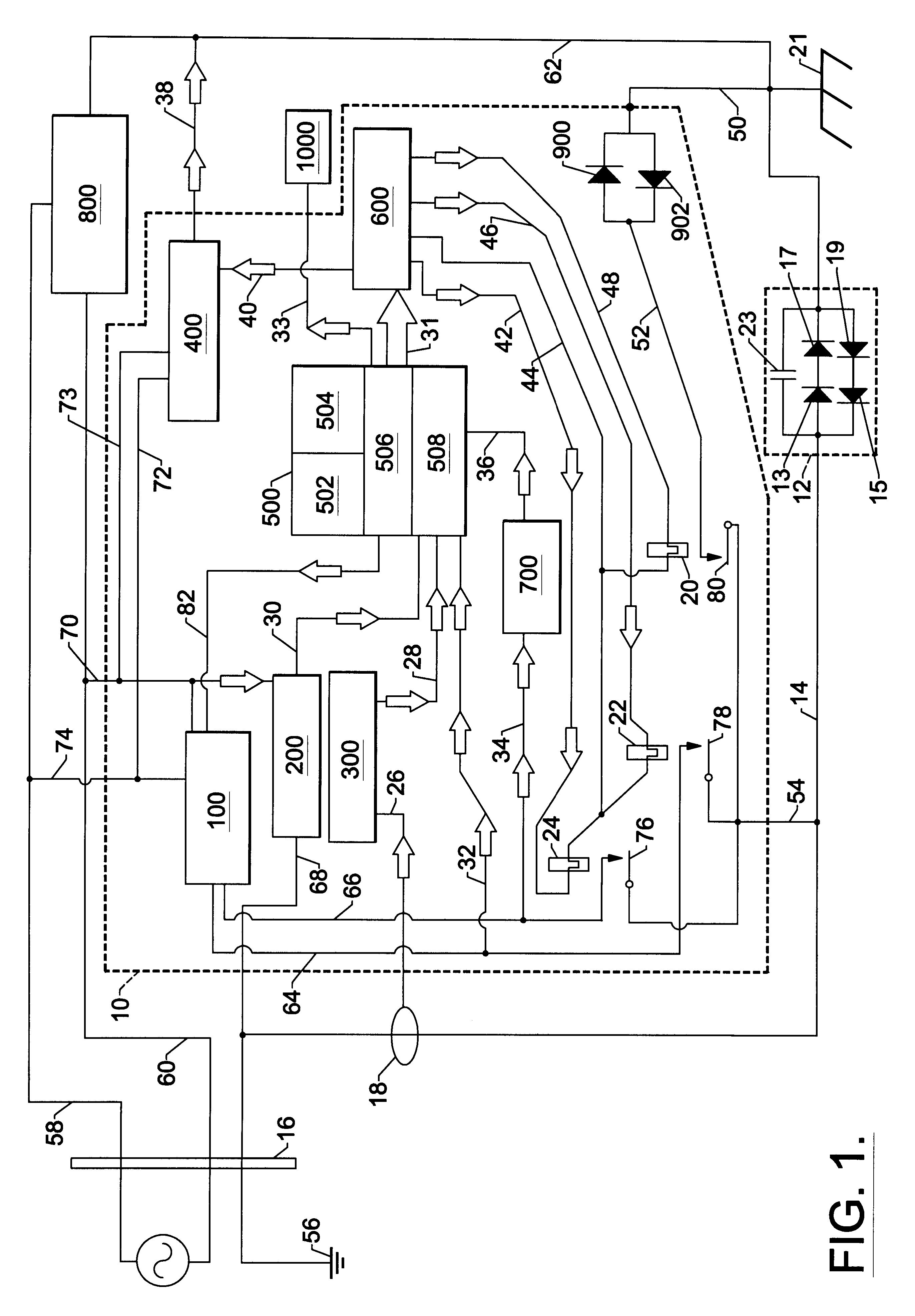

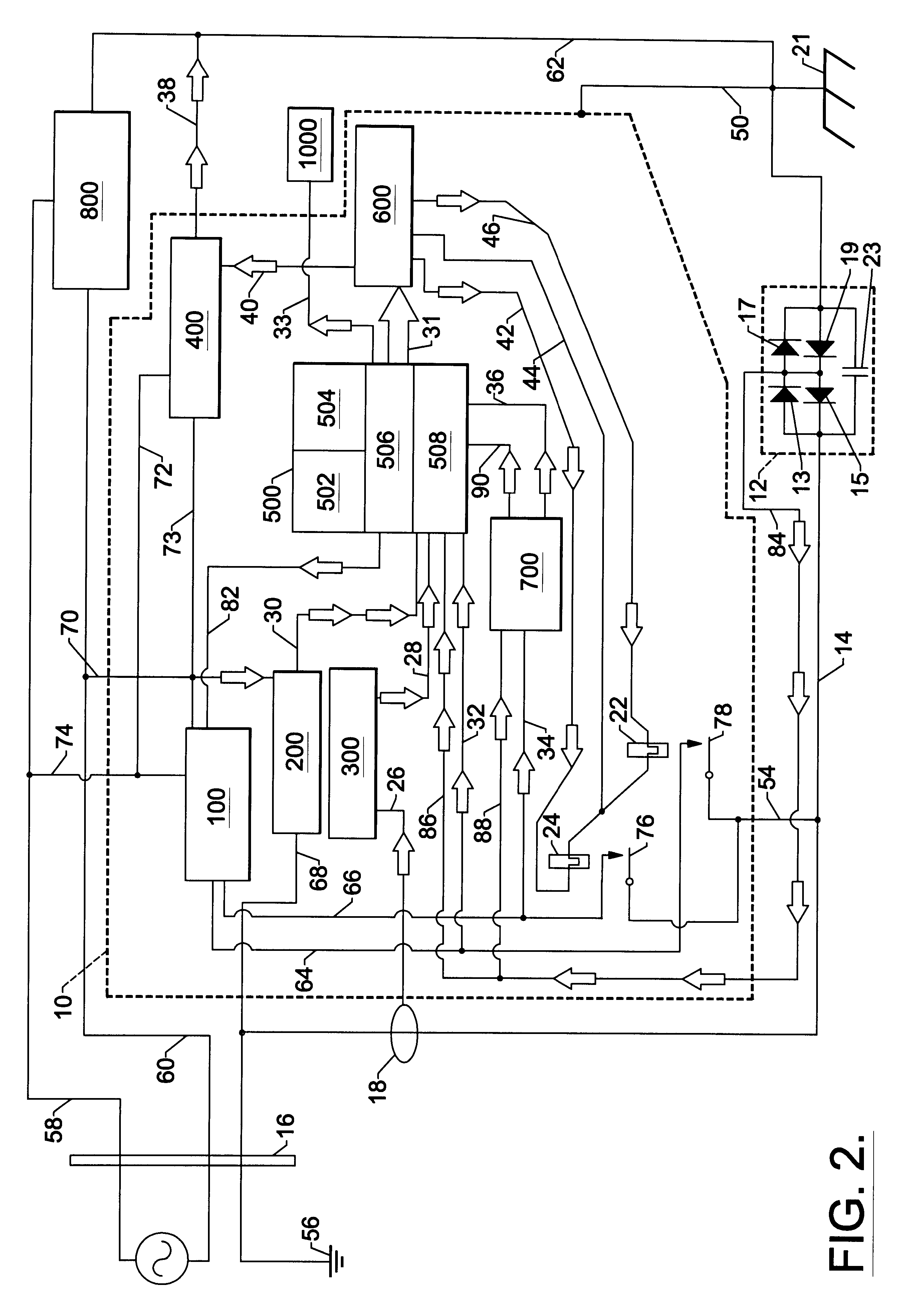

System and method for adapting electrical integrity analysis to parametrically integrated environment

ActiveUS8286110B1Detecting faulty computer hardwareComputer aided designVoltage regulator moduleElectronic systems

A system and method is provided for generating a programmably implemented model which emulates a power delivery network serving an integrated circuit (IC) core in an electronic system. The system and method generally comprise measures for establishing a power integrity (PI) topology including models for a voltage regulator module that generates at least one predetermined supply voltage level, and for a conductive power rail portion of the power delivery network (PDN). The system and method further comprise measures for interconnecting to the conductive power rail portion model a first behavioral model indicative of the current consumption characteristics of the IC core, and a second behavioral model indicative of the current consumption of an IO interface buffer driving an output signal of the electronic system.

Owner:CADENCE DESIGN SYST INC

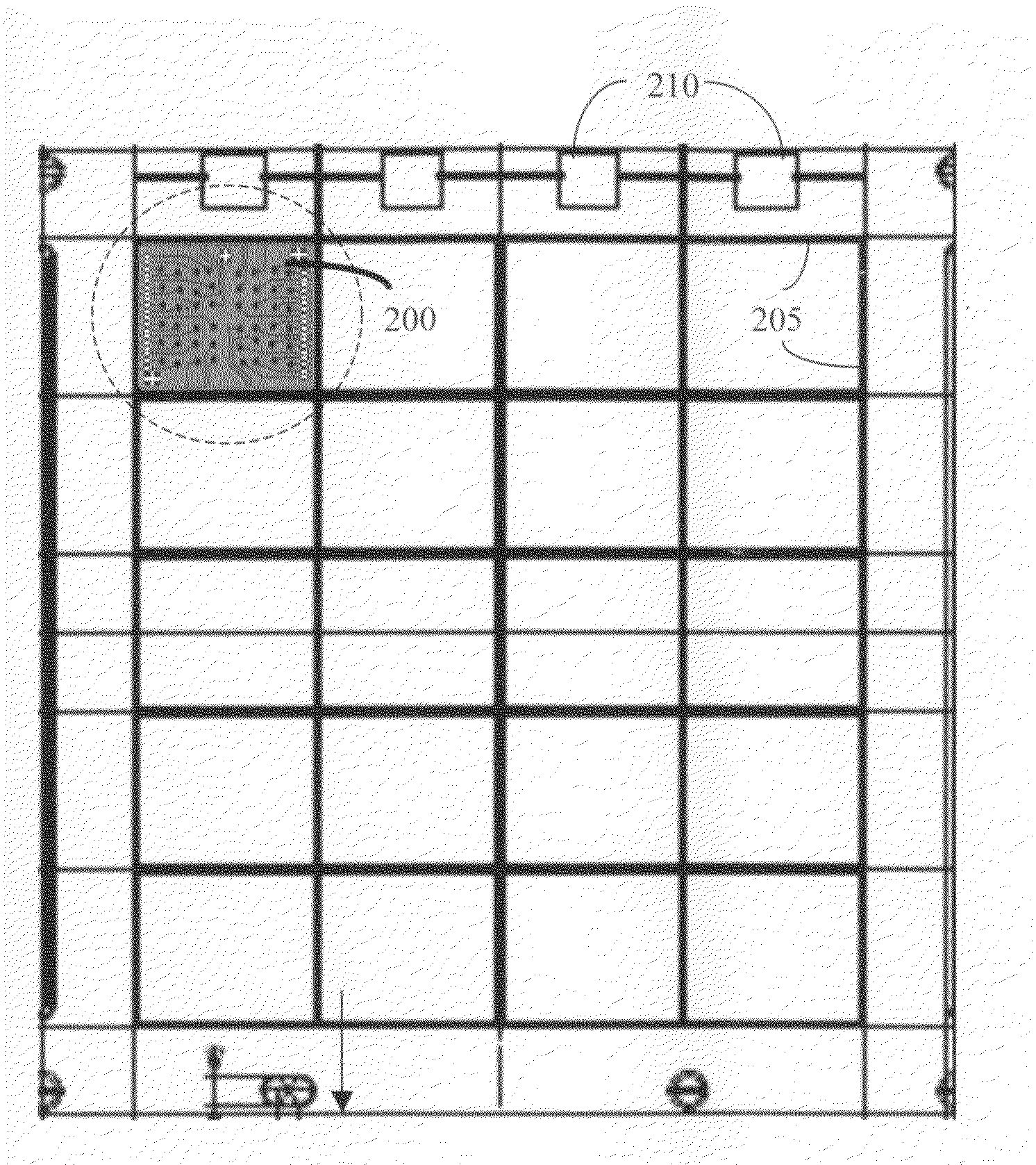

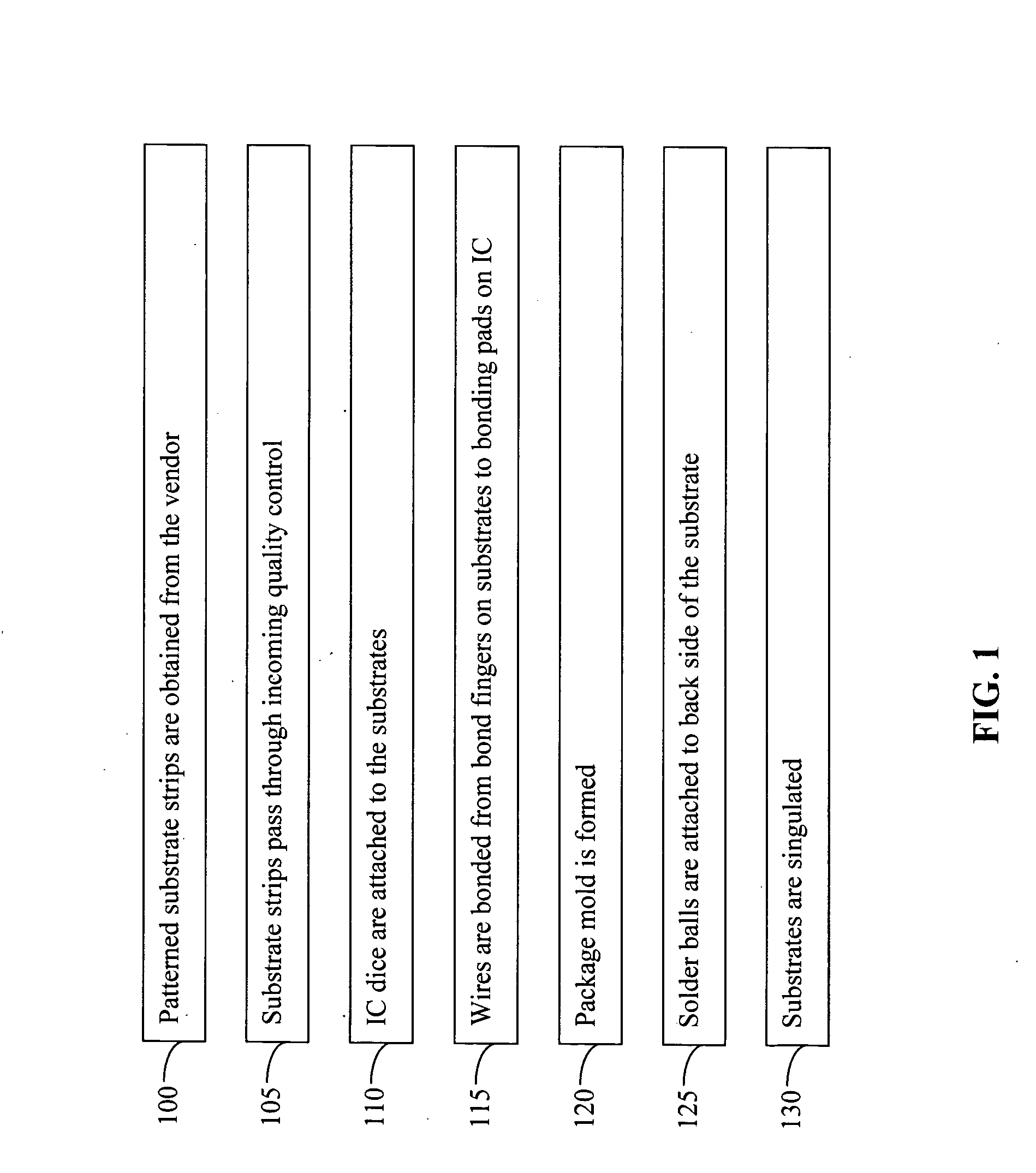

Structure and method for wire bond integrity check on BGA substrates using indirect electrical interconnectivity pathway between wire bonds and ground

InactiveUS20090001573A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsElectricityInterconnectivity

An invention providing improvement in integrity testing of wire bonds between an IC die and a BGA substrate.The invention includes a BGA integrated circuit package comprising:1) a BGA substrate having conducting bond fingers and a grounded feature on a first side thereof; 2) an IC die electrically connected to the conducting bond fingers with wire bonds; the BGA substrate configured to be formed into a singulated unit with the IC die; wherein the BGA substrate does not have direct electrical connection on the first side thereof between the bond fingers and the grounded feature; 4) the BGA substrate including an indirect electrical connection pathway from each wire bond to the grounded feature that enables electrical integrity testing for the wire bonds; the indirect electrical connection pathway configured so that at least a portion of each indirect electrical connection pathway is not present on the singulated unit.The invention further includes a method for bonding an integrated circuit (IC) die to a BGA substrate, said BGA substrate configured to be formed into a singulated unit with said IC die, said method including testing electrical integrity of a wire bond between a) a bond finger on a first side of said BGA substrate and b) a bonding pad on said IC die, wherein said substrate does not have direct electrical connections on said first side between said bond fingers and a grounded feature on said first side; the method comprising the steps of:applying a voltage through said wire bond on said BGA substrate to said grounded feature, through an indirect electrical connection pathway at least a portion of which is not present on said singulated unit; andmeasuring if there is current flow through said pathway.The invention further includes an integrated circuit (IC) die mounted on and packaged with the BGA substrate, formed by a method comprising the steps of:making electrical connections between the IC die and the substrate, including forming bond finger wire bonds;testing the electrical integrity of each bond finger wire bond according to the method of this invention;forming a package mold on the substrate;attaching solder balls to the bottom side of the substrate; andsingulating the substrate.

Owner:CYPRESS SEMICON CORP

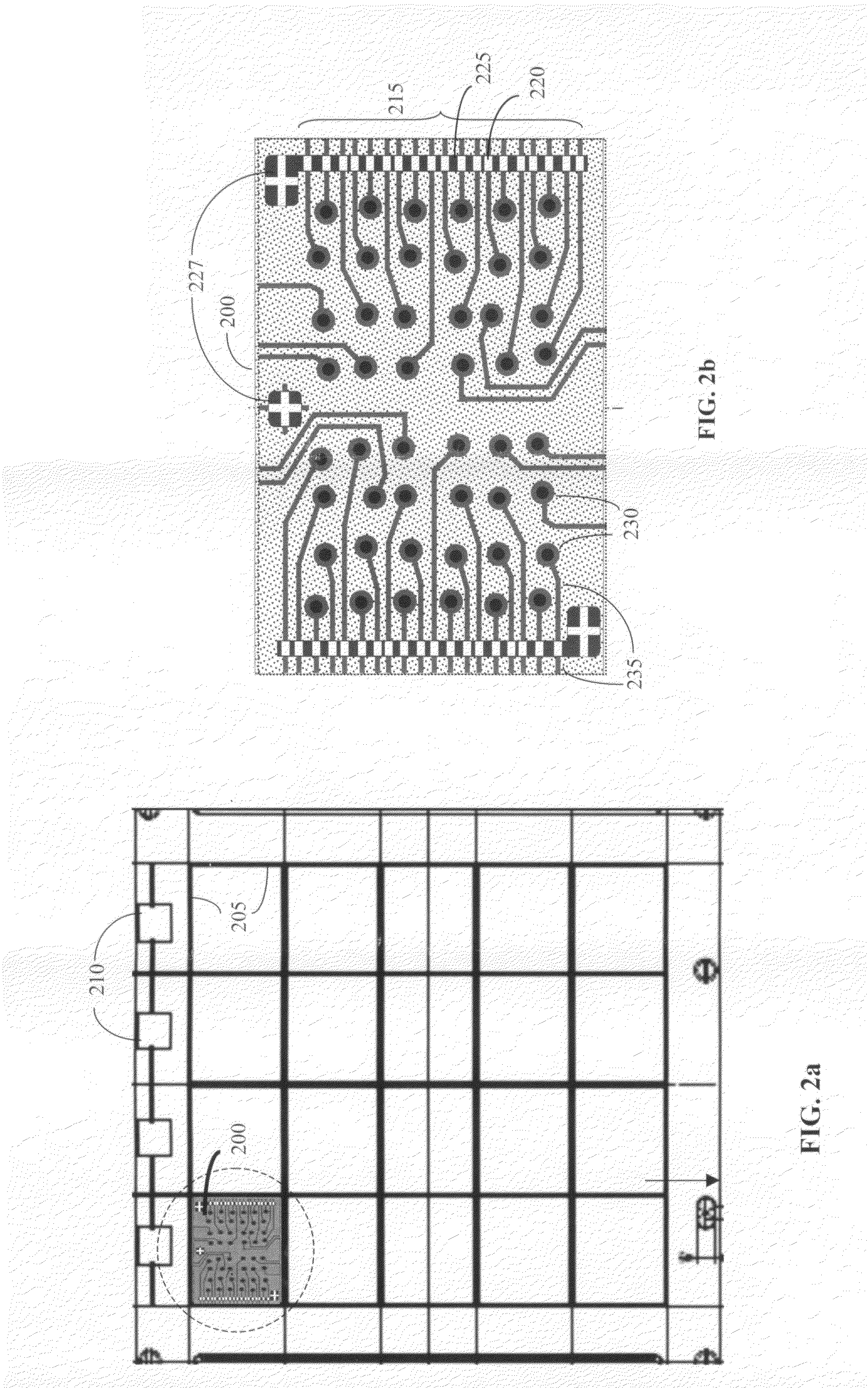

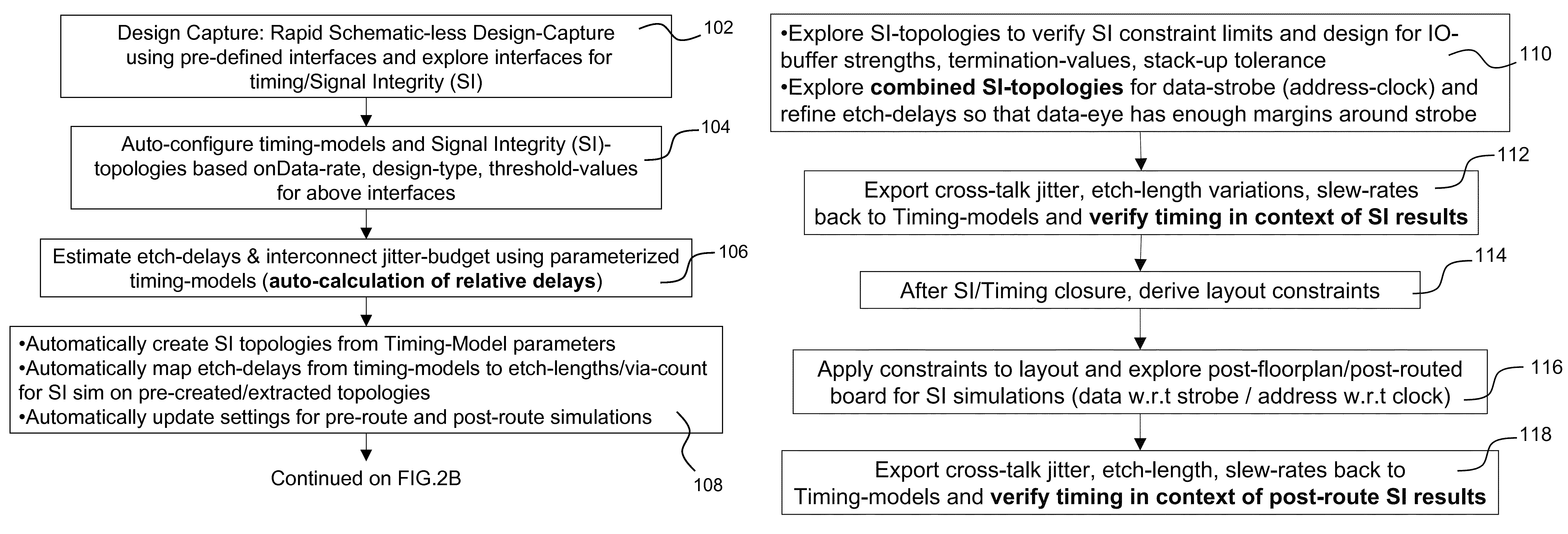

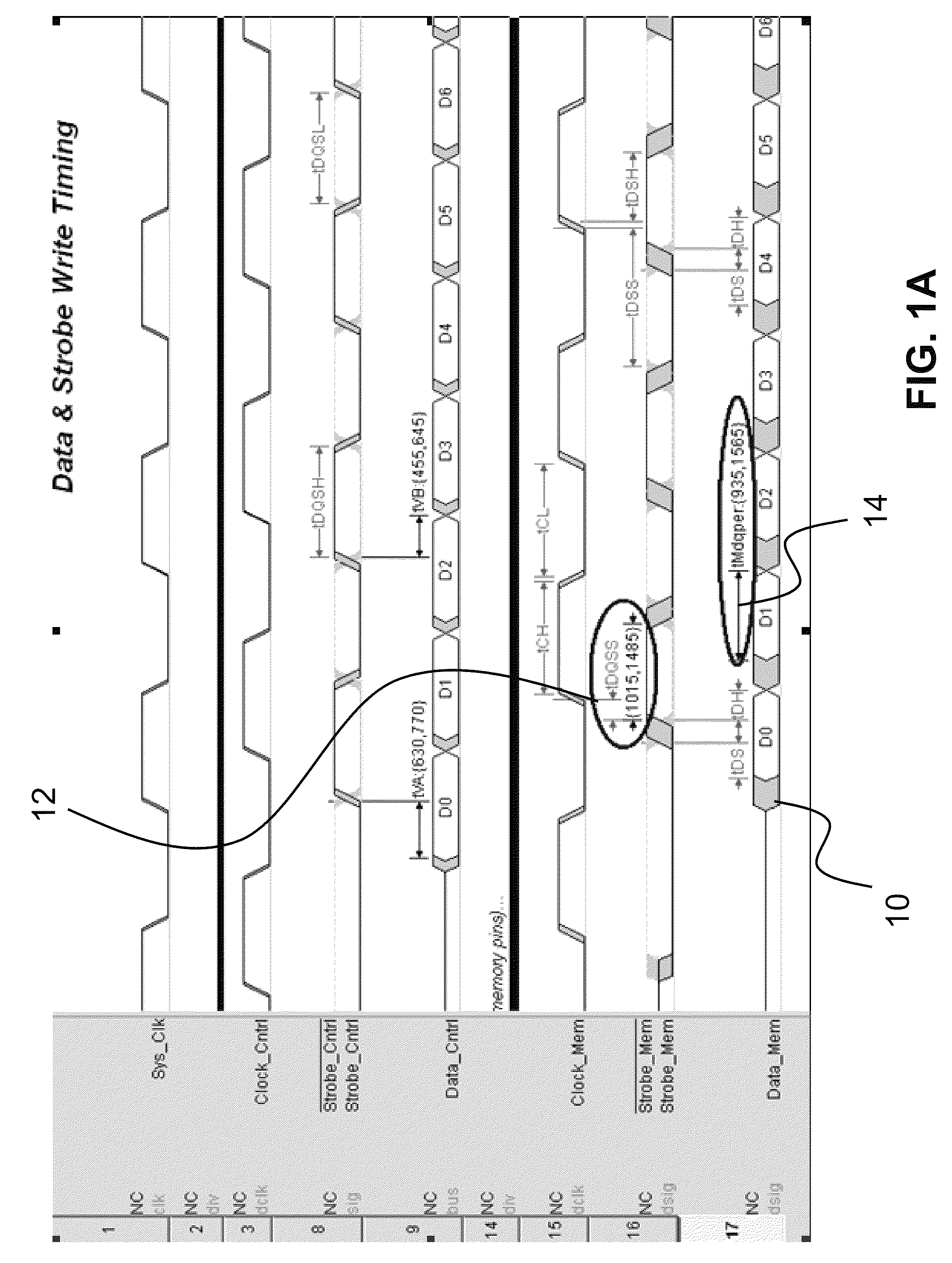

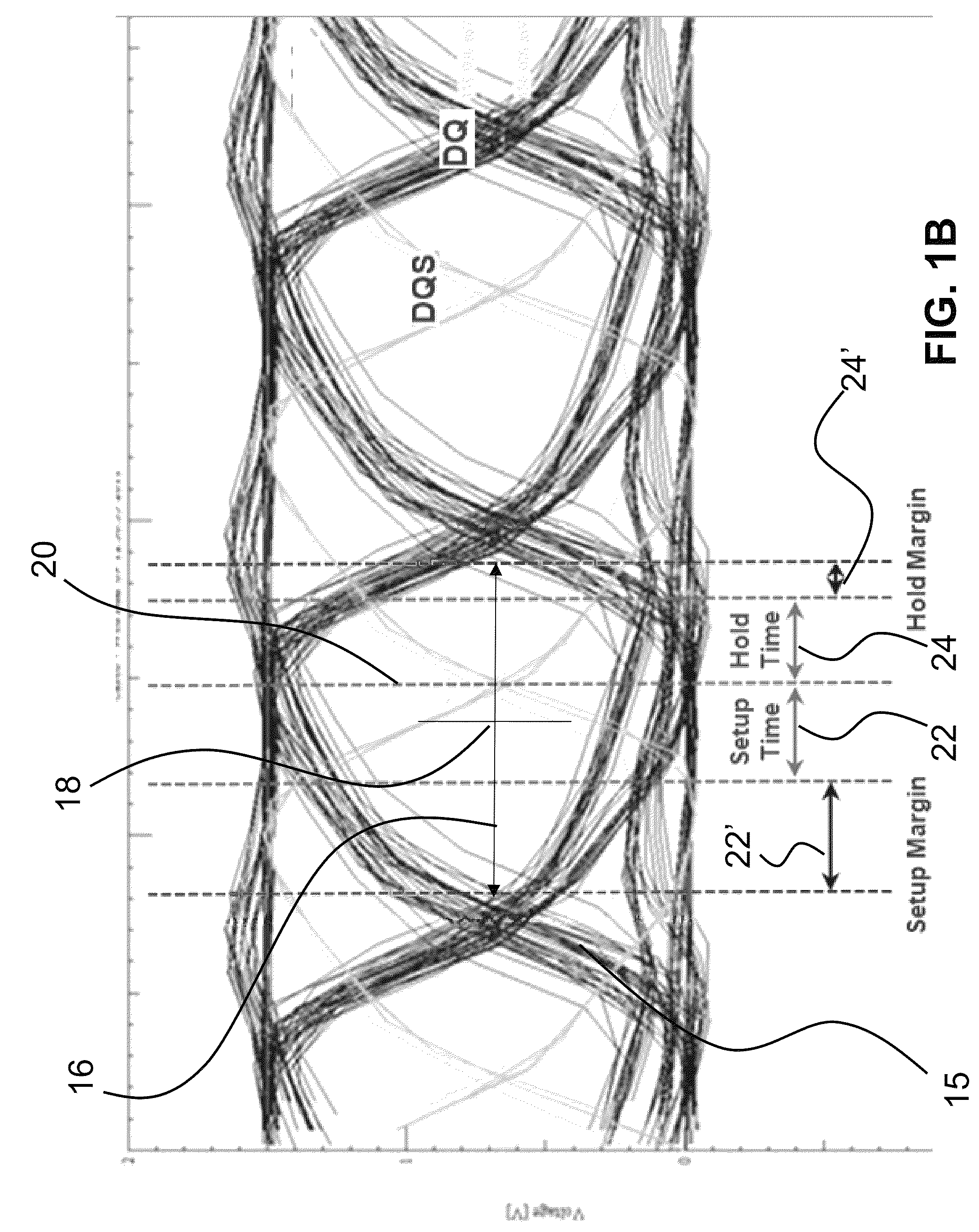

System and method for parametric intercoupling of static and dynamic analyses for synergistic integration in electronic design automation

InactiveUS8566767B1Shorten the timeImprove design flexibilityAnalogue computers for electric apparatusDetecting faulty computer hardwareElectronic systemsAnalysis tools

A system and method are provided for actuating static and dynamic analysis tools in parametrically intercoupled manner for synergistic optimization of an electronic system design. The system and method execute a timing designer process for selectively actuating the static analysis tool to conduct timing analysis based on at least one predetermined timing model and generate a plurality of estimated values for certain signal parameters to be in compliance with predetermined timing constraints. A signal exploration process is executed to receive the estimated values from the timing designer process and configure the resources of the dynamic analysis tool responsive thereto. The signal exploration process actuates the dynamic analysis tool to conduct electrical integrity analysis based on transient simulation and generate a plurality of simulated values for signal parameters. The simulated values are back annotated to the timing designer process for timing closure.

Owner:CADENCE DESIGN SYST INC

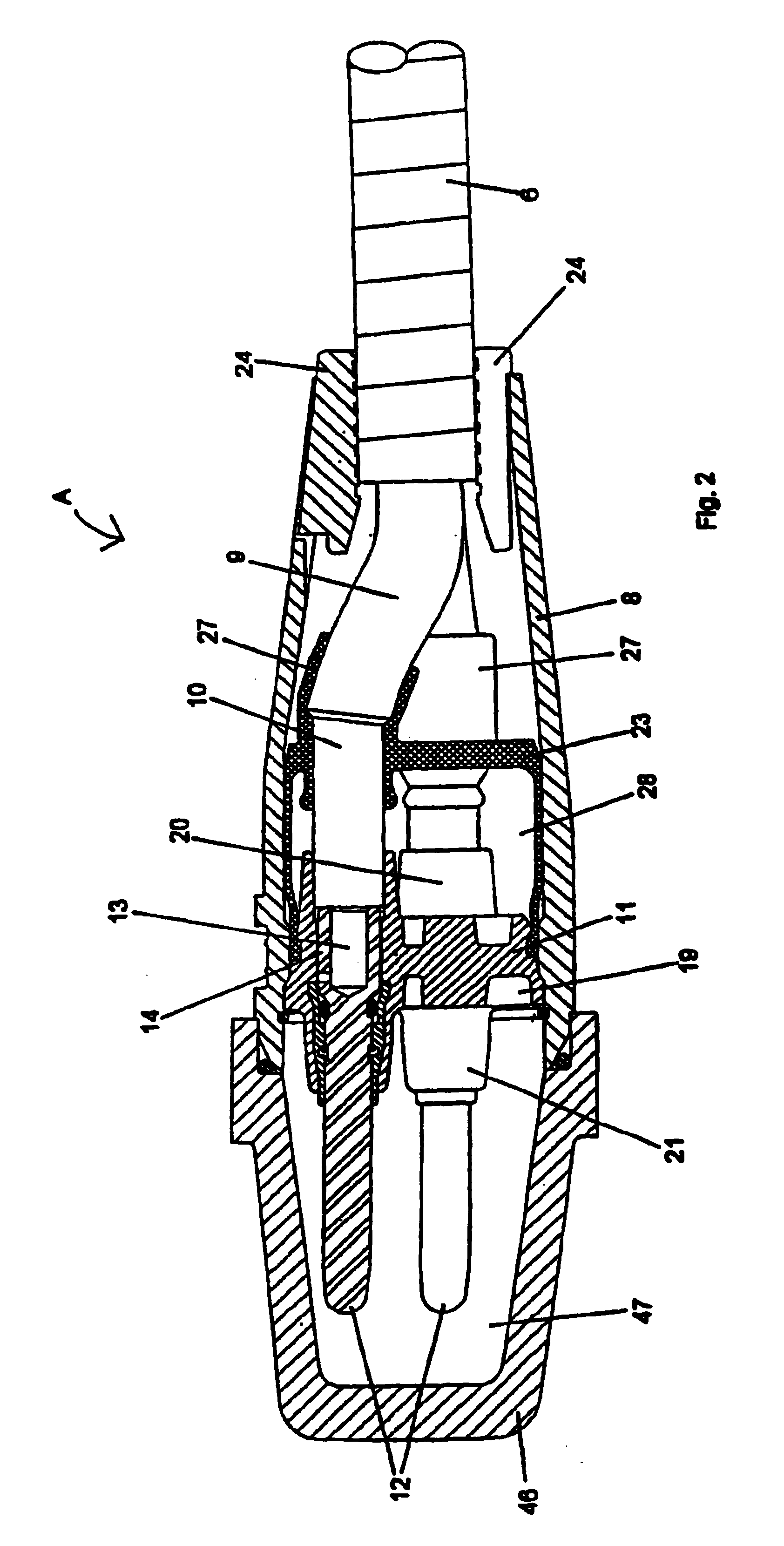

Electrical connectors

InactiveUS6943298B2Accurate fitMechanical forceLine/current collector detailsCouplings bases/casesCushioningElectricity

An electrical connector and method of making the electrical connection are disclosed for use in particularly arduous conditions, such as down hole oil production applications. The invention provides high electrical integrity with an ability to accommodate steady and / or fluctuating mechanical forces placed via the cable into the connector. Synergy between the mechanical and electrical aspects of the design is taught in which an insulating member, fitted with annular upstands, co-operates with a mechanically soft, essentially incompressible, insulating substance (gel) to cause vibrations in the cable to be dissipated over a length of the insulated cores inside the connector rather that at a single point where it would cause the core to fracture. In addition, annular collars of the gel are provided between the insulating member and the crimped pin-core connections and between the annular upstands and insulated cores to give further cushioning. Because the core insulation sits deep inside the annular upstand of the insulating member and gel collars, this creates a good electrical interface with a long creepage distance. The method covers the creation of the gel collars, alignment of contact pins and insulated cores and assembly of the connector.

Owner:DIAMOLD

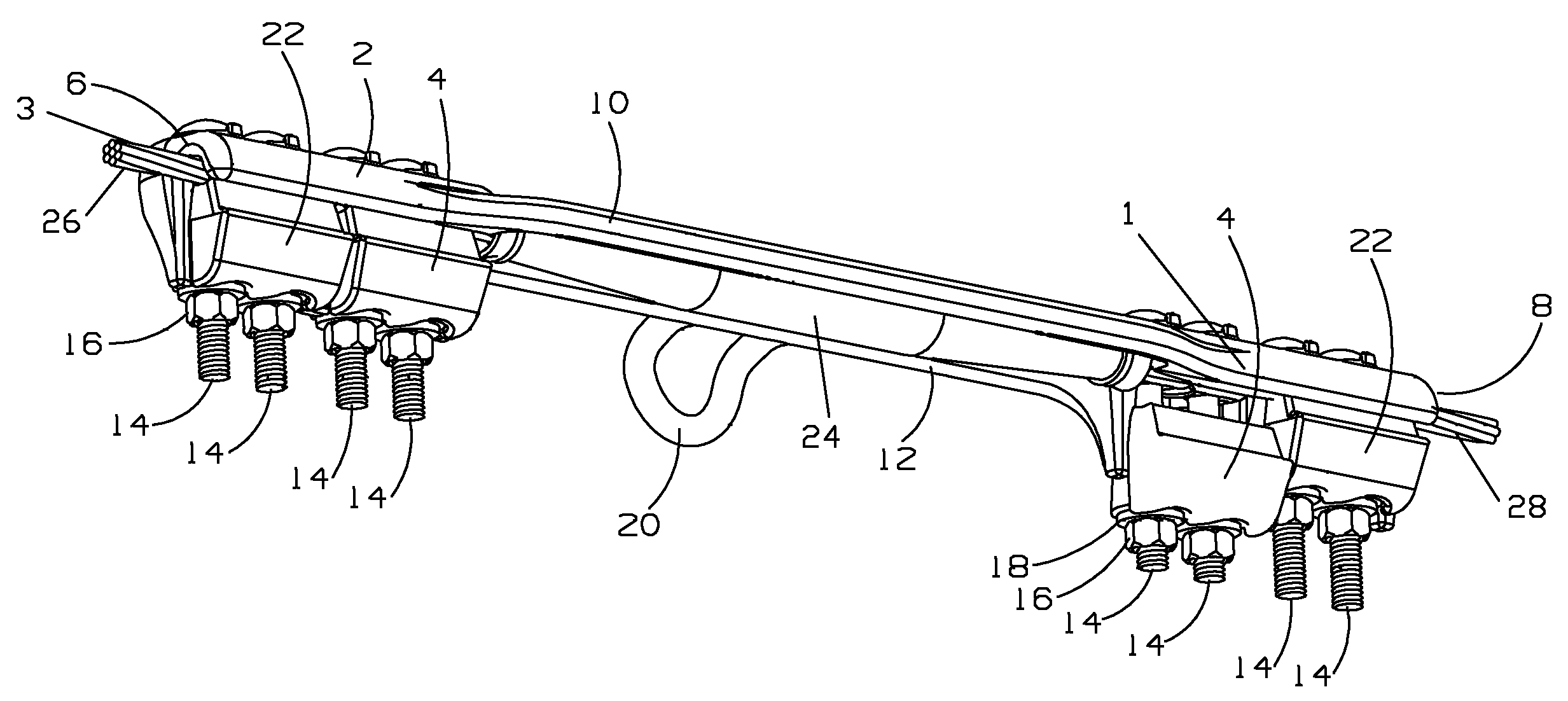

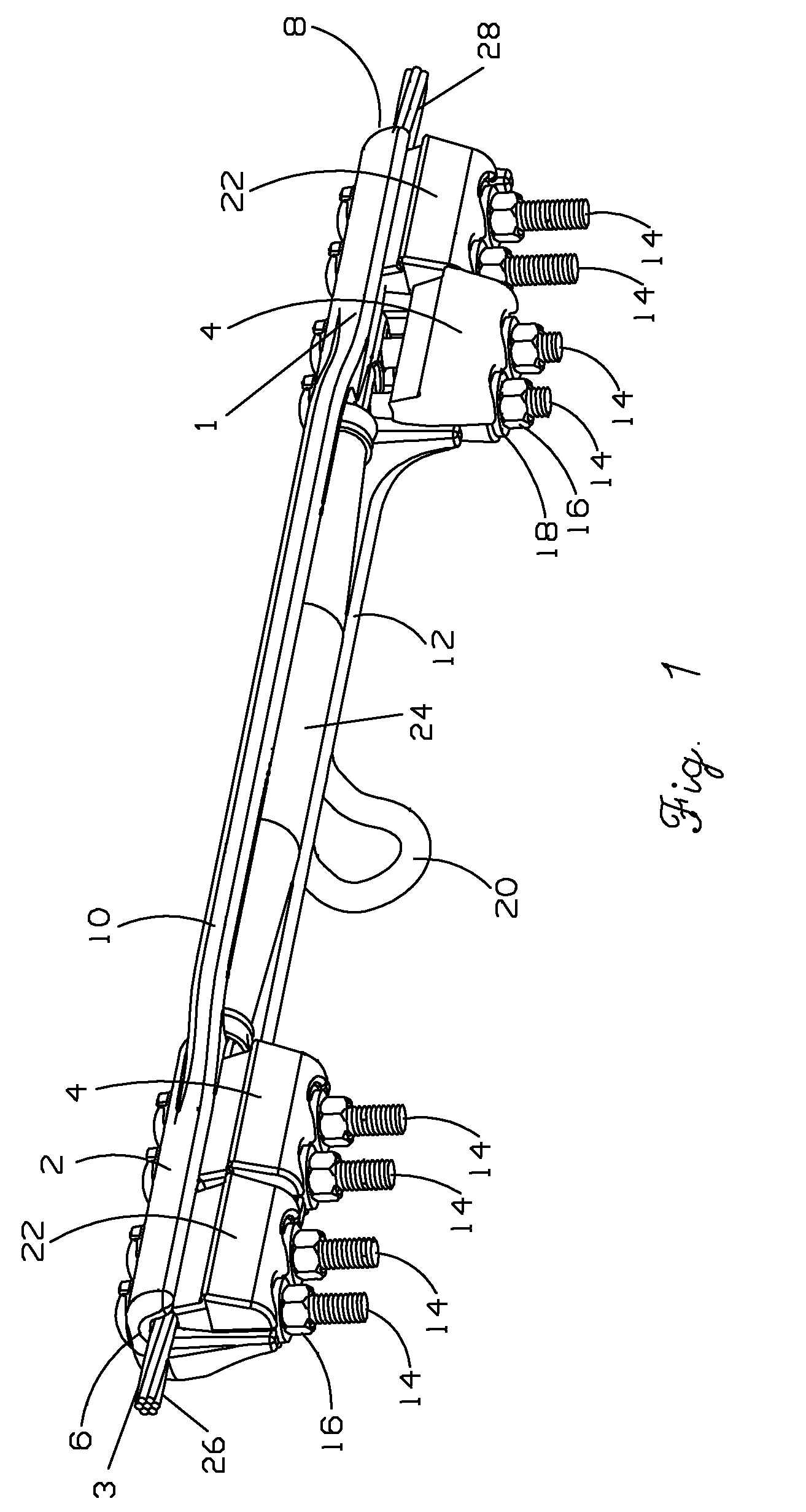

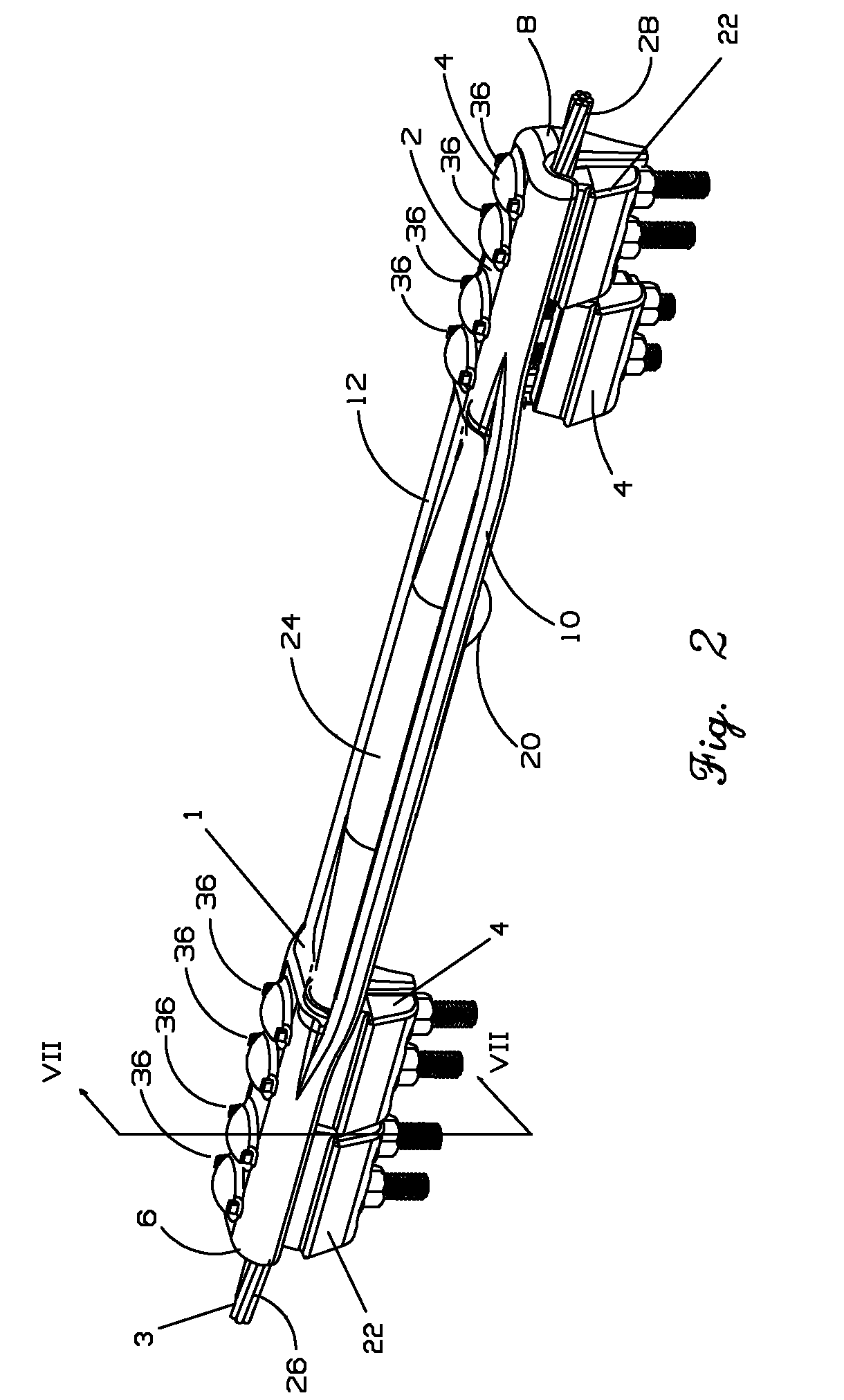

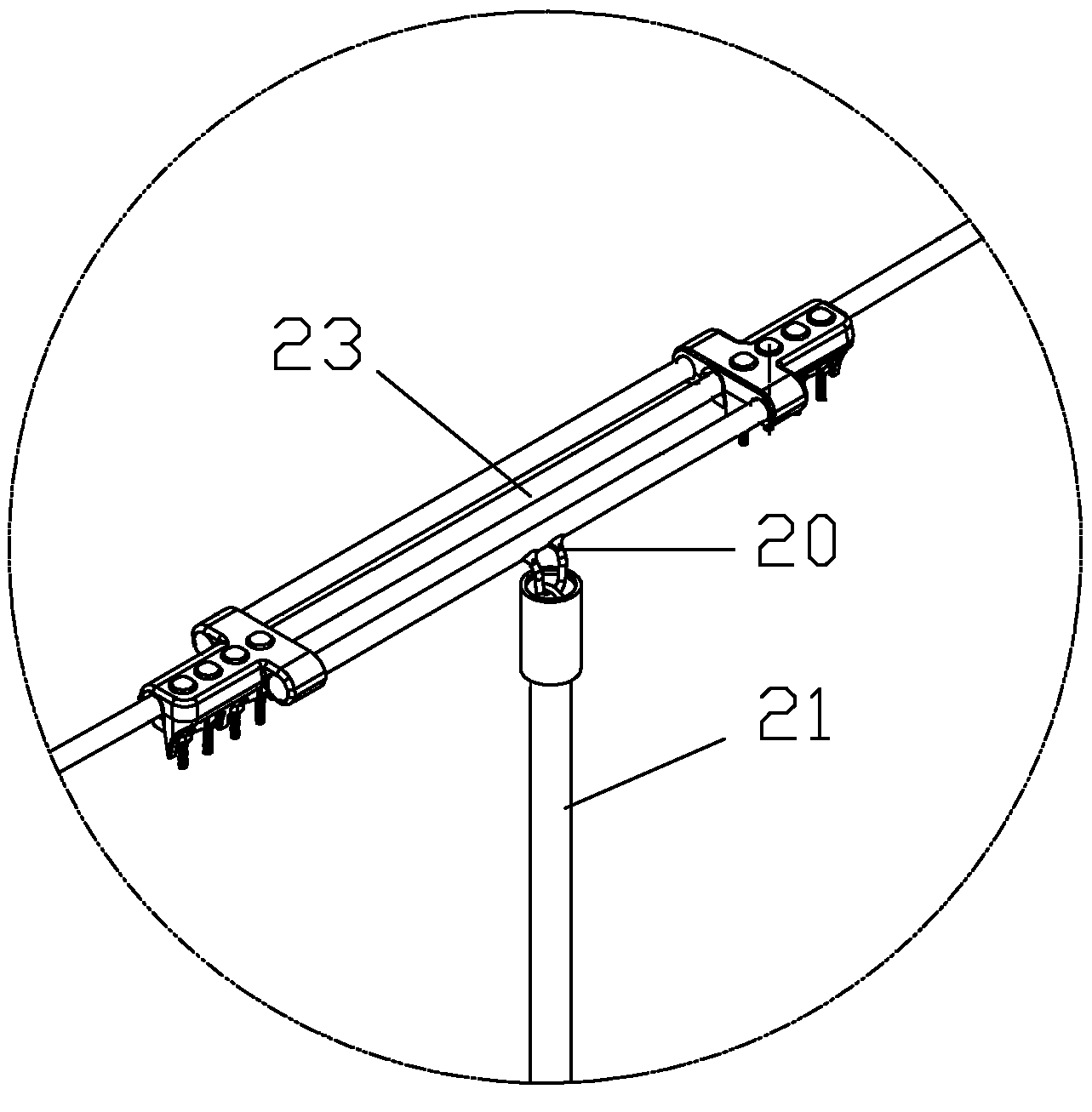

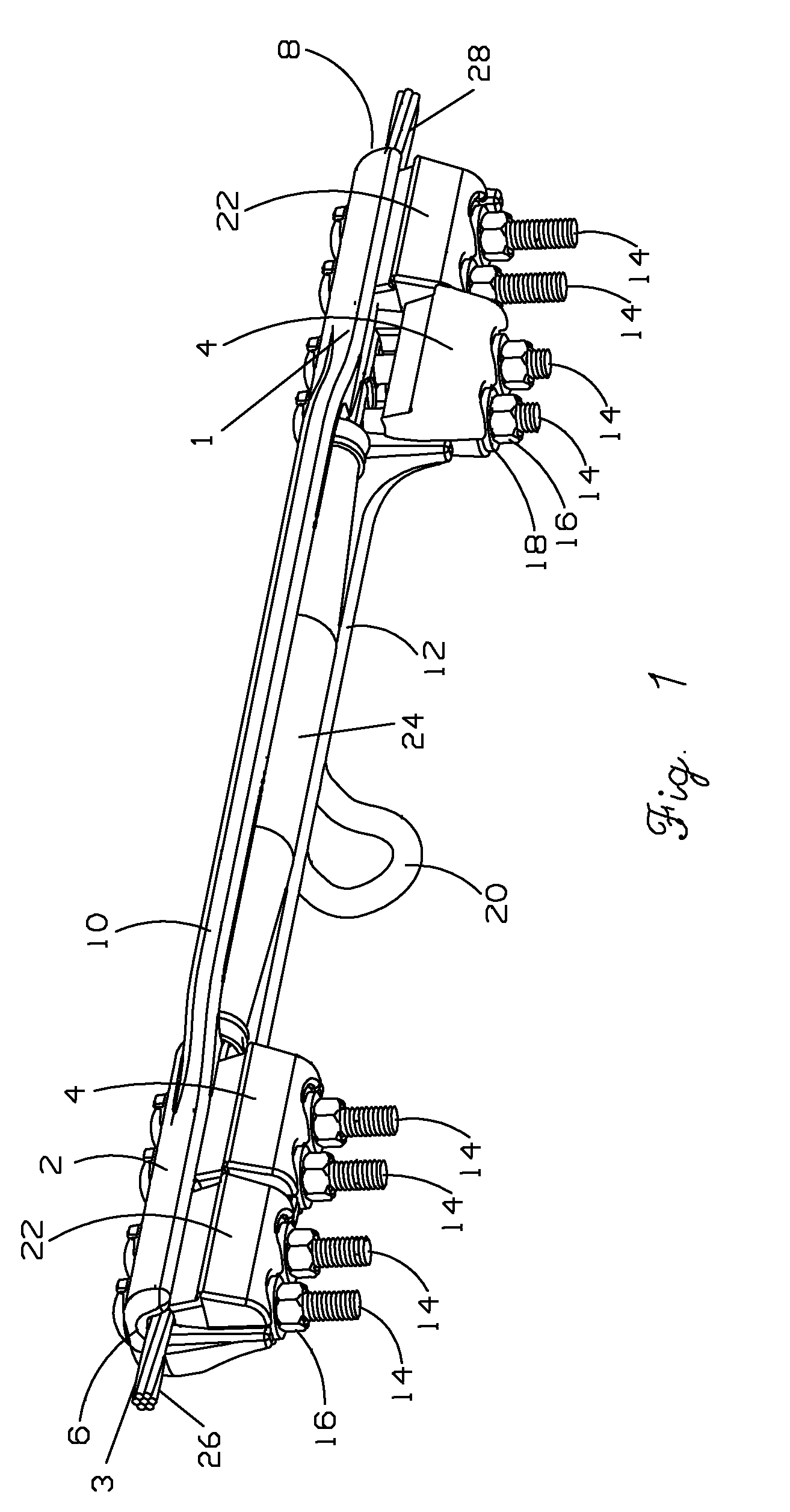

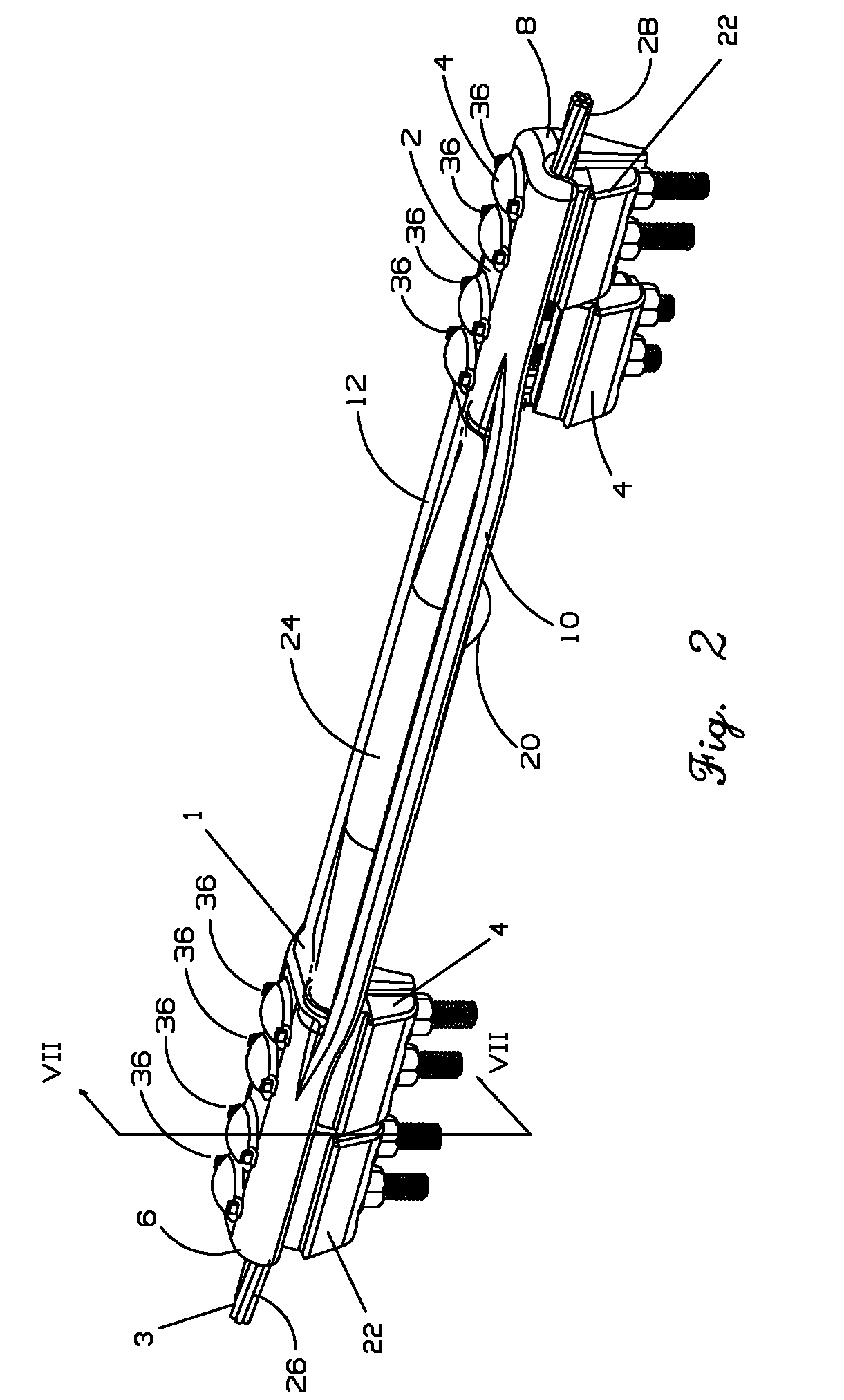

Electrical transmission line repair device

ActiveUS7794291B2High strengthEasy to installLine/current collector detailsElectric connection structural associationsElectric power transmissionElectrical conductor

An electrical conductor repair device for restoring mechanical and electrical integrity to a compromised section of an electrical conductor. The device includes a body that serves as an electrical shunt and a mechanical support. The body includes a first end section for attachment to the conductor at a location on one side of the compromised section, and a second end section for attachment to the conductor at a location on the other side of the compromised section. The end sections are connected by an intermediate section.

Owner:CLASSIC CONNECTORS

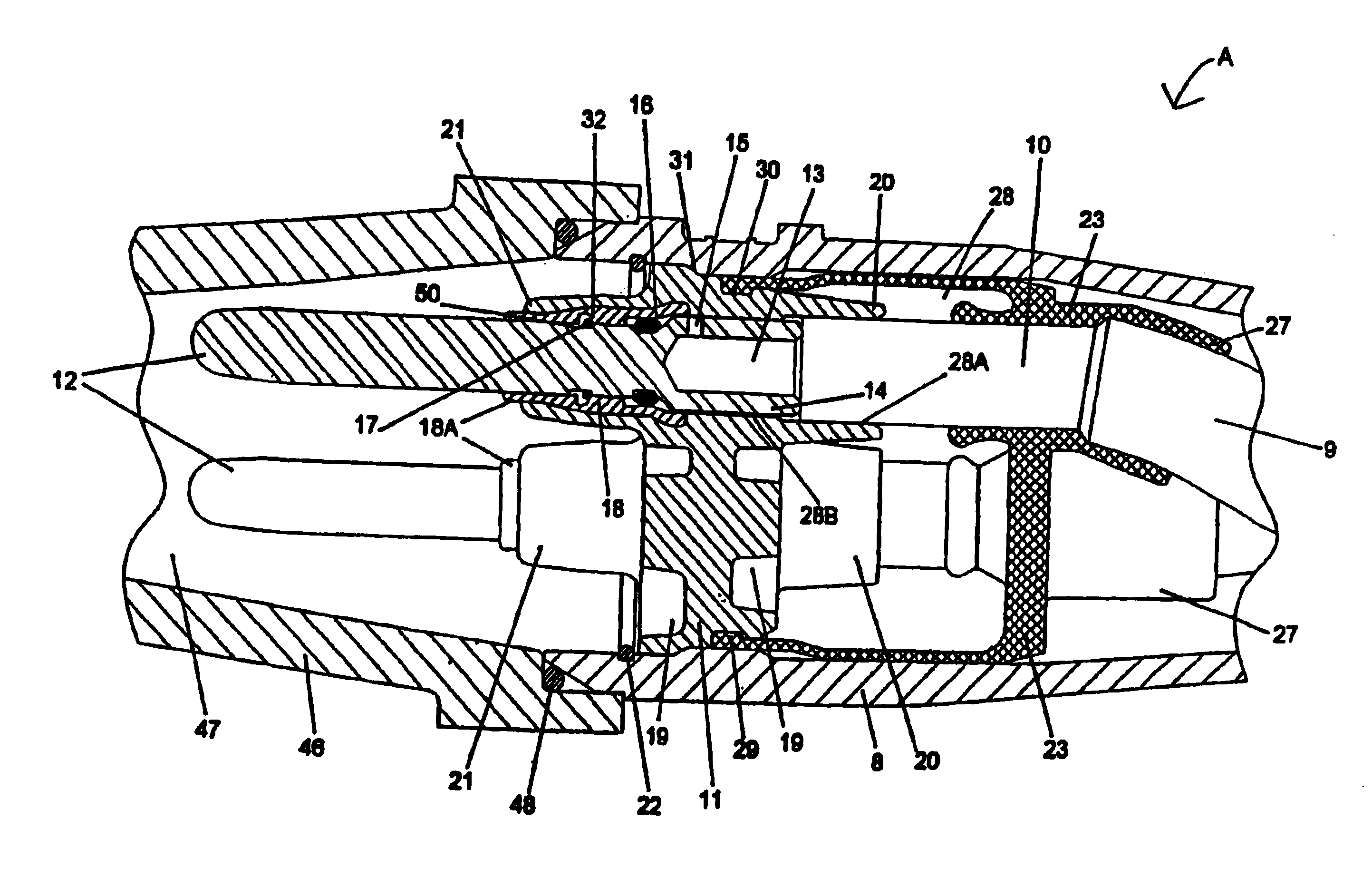

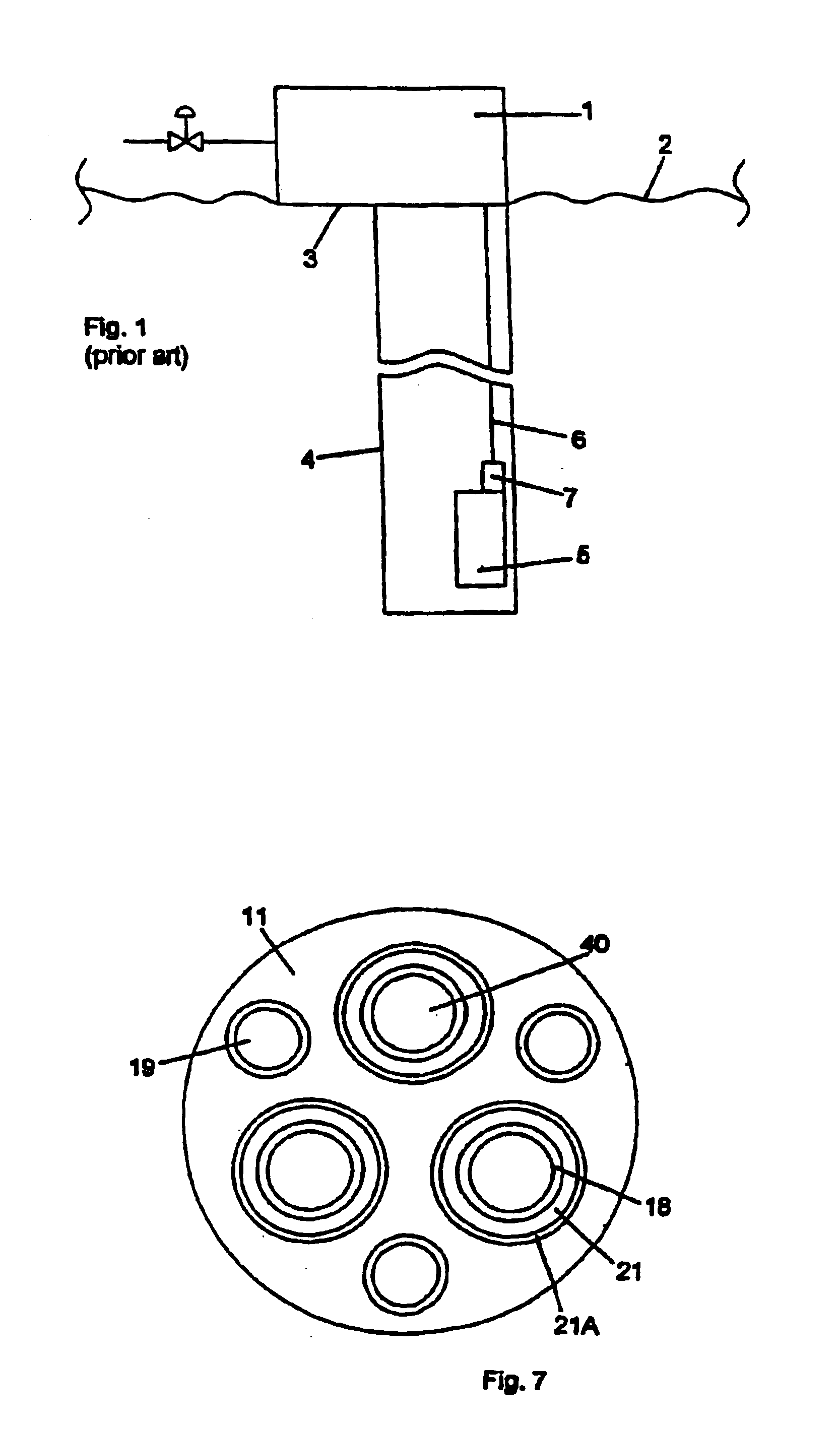

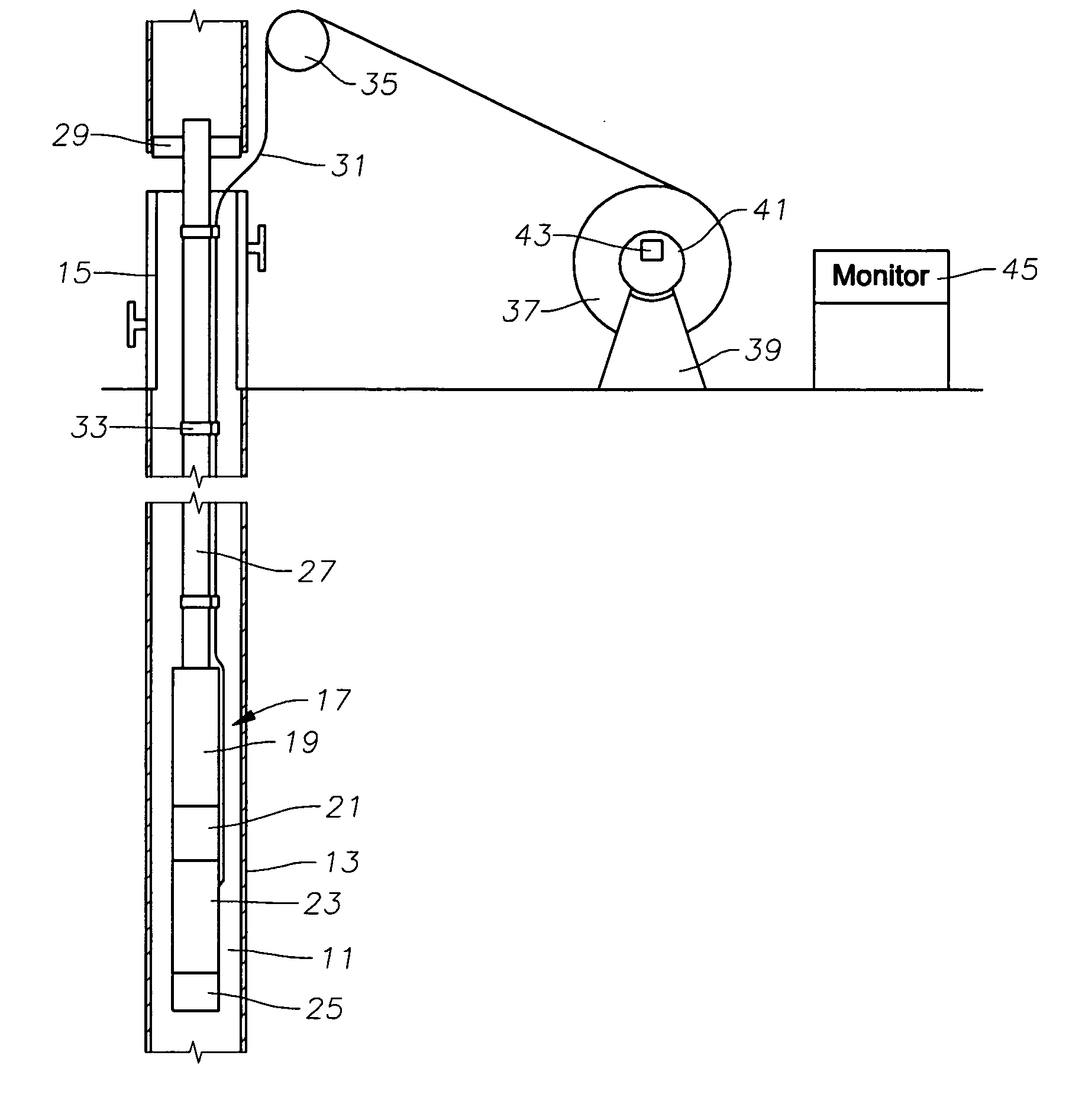

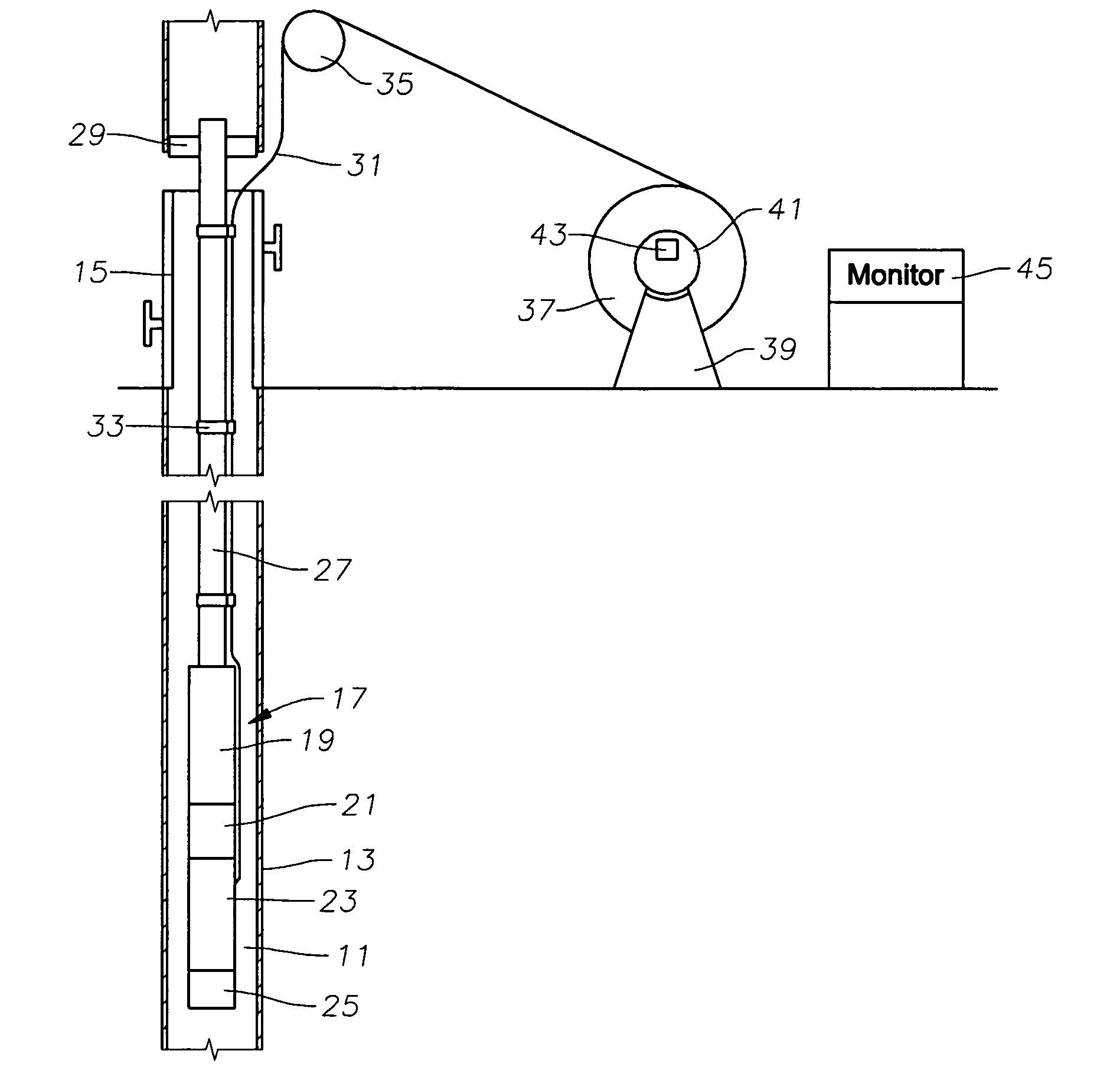

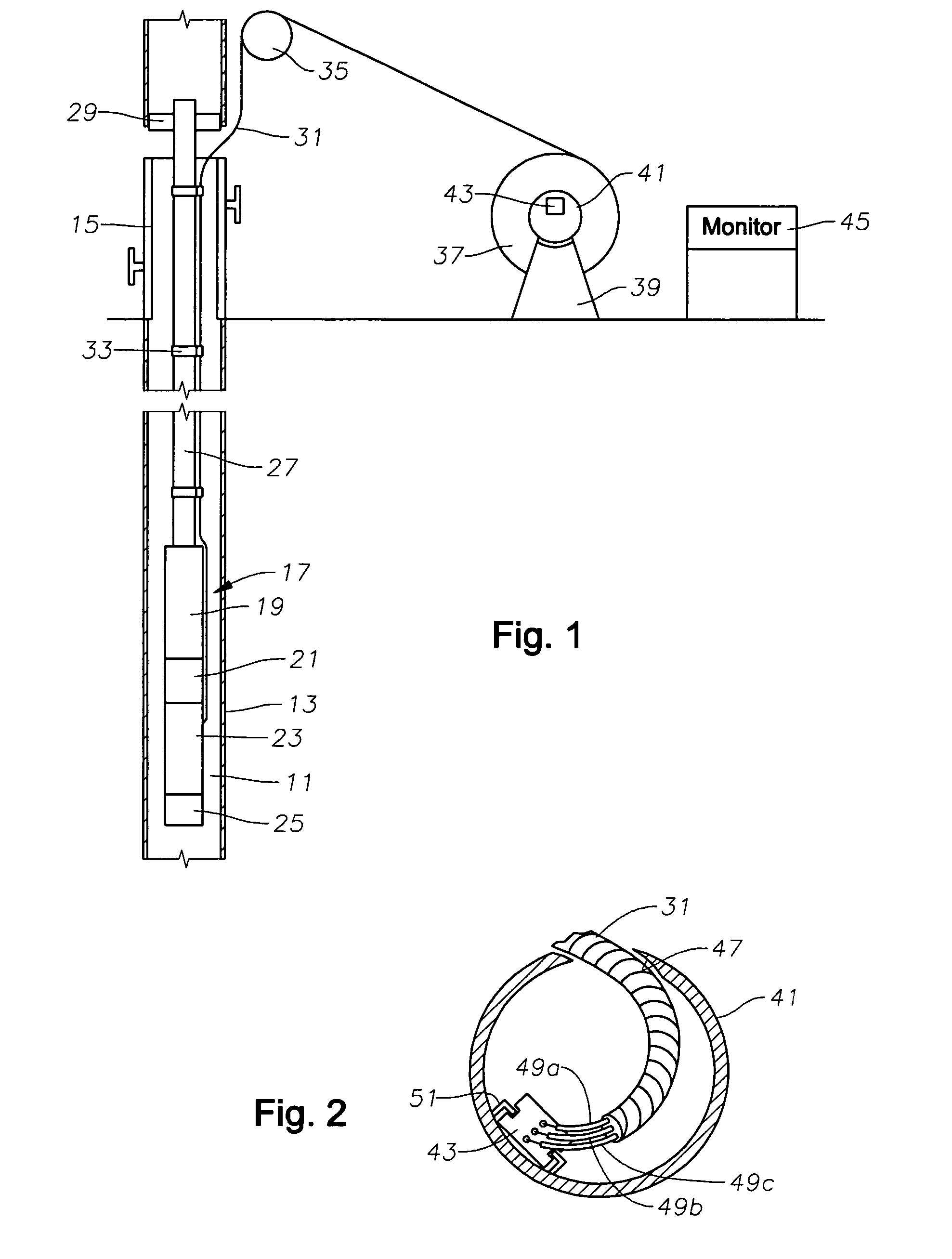

Method for installing well completion equipment while monitoring electrical integrity

A method of installing a submersible electrical pump assembly in a well monitors the integrity of the pump assembly and electrical cable while the pump assembly is being run. The pump assembly has at least one sensor that measures a parameter in the environment of the pump assembly. A battery-powered test unit is mounted to the reel of cable, and a lead of the unit is connected to the power cable. While lowering the completion equipment, test voltage is supplied from the unit via the power cable through the motor to the sensor. The unit transmits an indication to a remote monitor that the sensor is operational.

Owner:BAKER HUGHES INC

System and methods for connecting electrical components

The present disclosure is directed to methods and devices that use a contact interface for establishing an electrical connection with an electrical component. In certain exemplary embodiments, the contact interface of a device includes at least one loading fiber and at least one conductor having at least one contact point. The conductor(s) is coupled to a loading fiber so that an electrical connection can be established between the contact point(s) of the conductor(s) and the electrical component when the device is engaged with the electrical component. In certain exemplary embodiments, a conductor is woven with, or wound around, a loading fiber. In some exemplary embodiments, the conductor is comprised of a shaped contact and a conductive lead.The present disclosure is also directed to methods and devices for testing the electrical integrity or functionality of an electrical component. In certain exemplary embodiments, the device includes a plurality of loading fibers, a plurality of conductors and a plurality of tensioning guides. Each conductor can be coupled to at least one loading fiber. The tensioning guides can be disposed on at least one side of each said conductor. In such embodiments, electrical connections can be established between at least a portion of the plurality of conductors and the electrical component when the device is engaged with the electrical component. At least a portion of the plurality of loading fibers may come into contact with the plurality of tensioning guides when the device is engaged with the electrical component. In one exemplary embodiment, the device comprises a burn-in socket device. In another exemplary embodiment, the device comprises a test socket device.

Owner:METHODE ELETRONICS INC

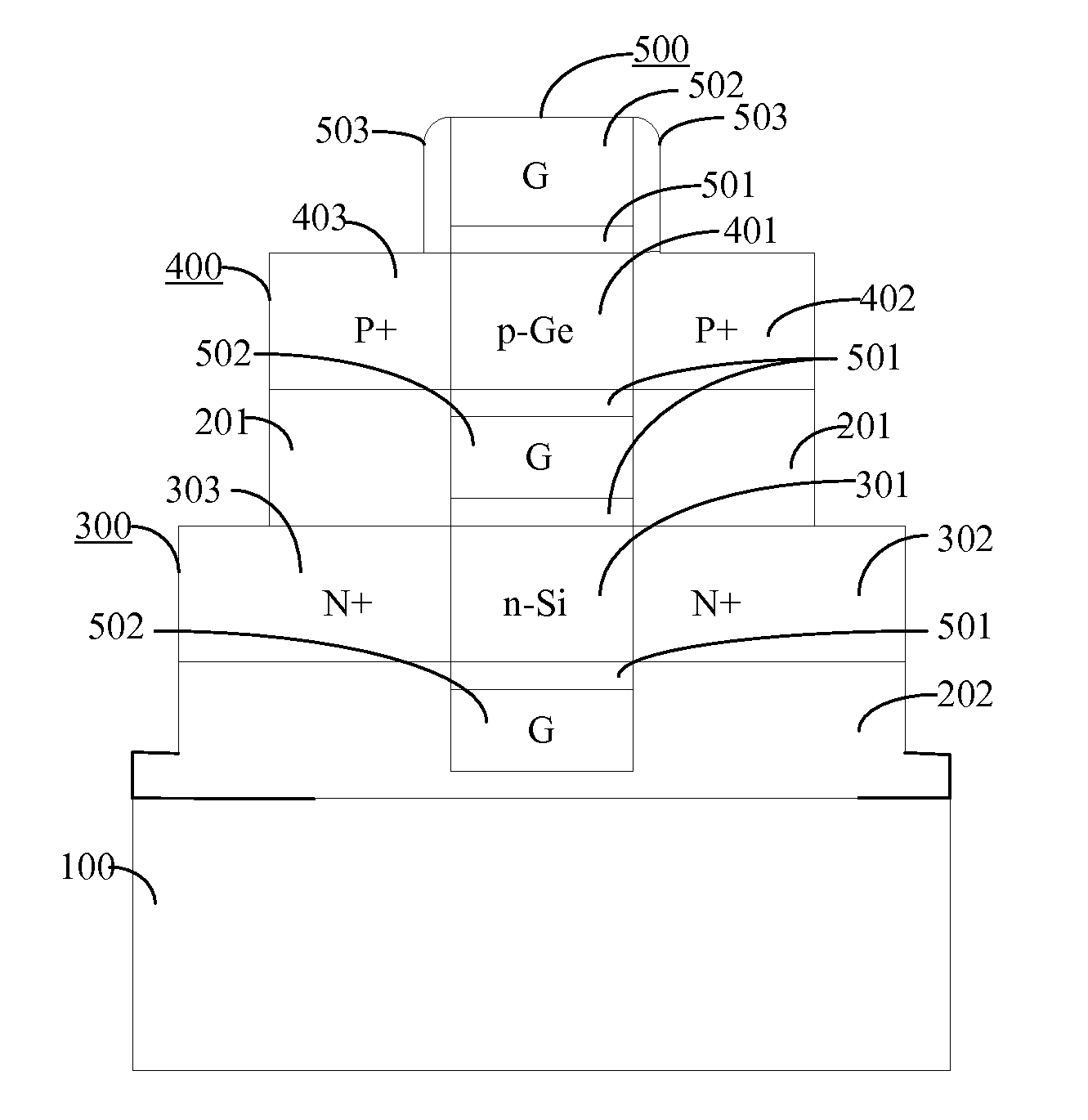

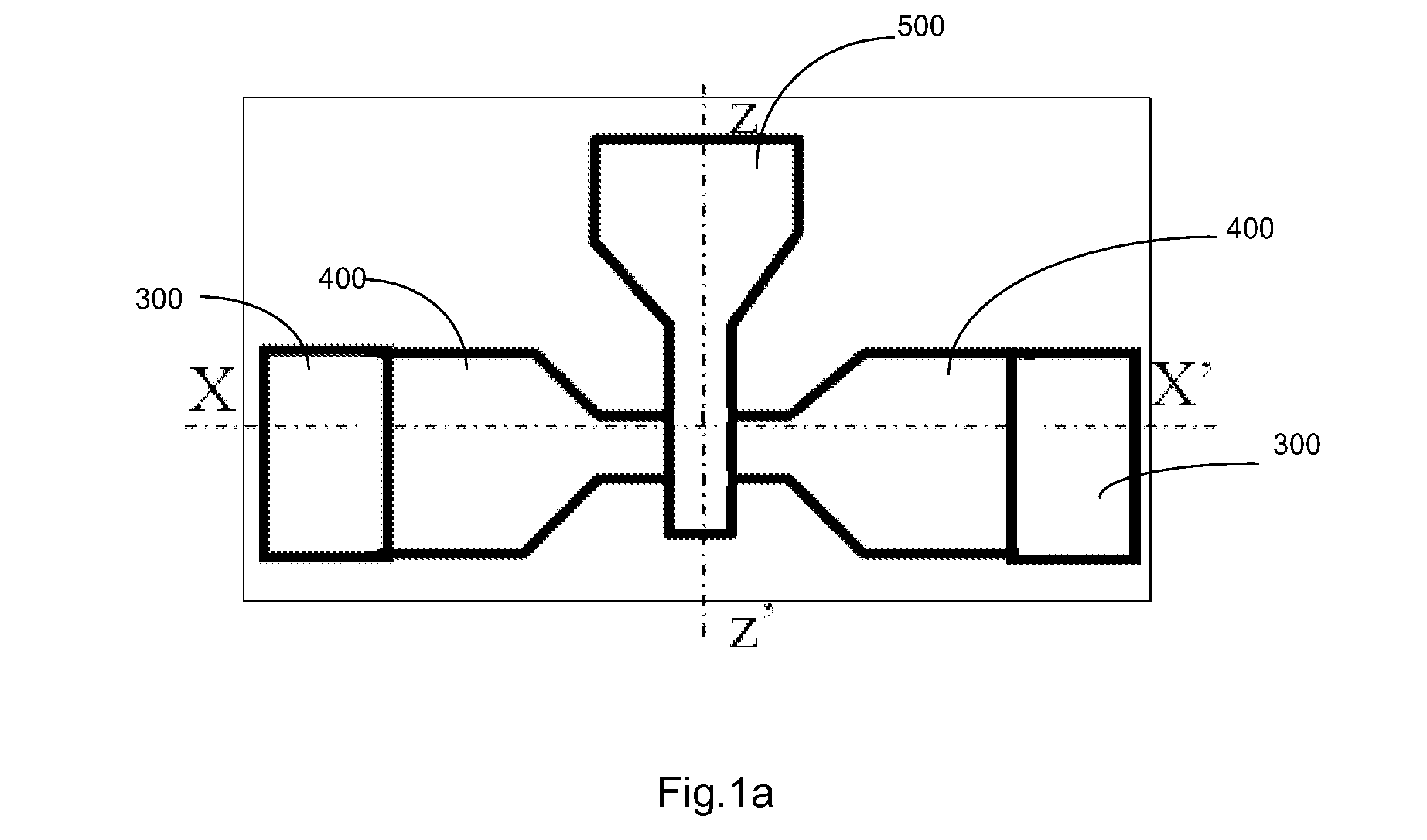

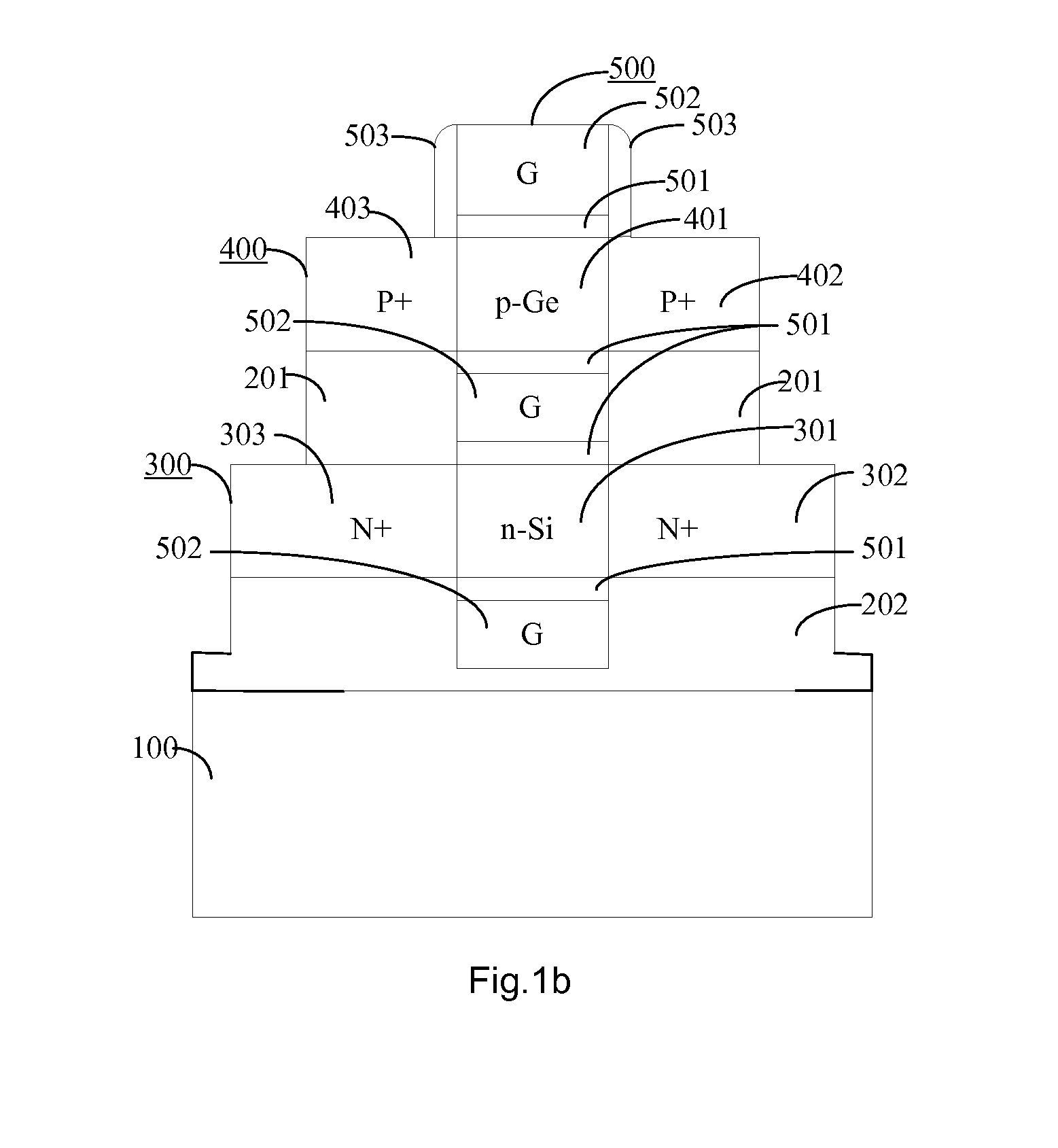

Hybrid material accumulation mode gaa cmosfet

InactiveUS20110254100A1Easy to integrateReduce low frequency noiseTransistorSolid-state devicesDriving currentCharge carrier mobility

A Ge and Si hybrid material accumulation mode GAA (Gate-All-Around) CMOSFET includes a PMOS region having a first channel, an NMOS region having a second channel and a gate region. The first channel and the second channel have a racetrack-shaped cross section and are formed of p-type Ge and n-type Si, respectively; the surfaces of the first channel and the second channel are substantially surrounded by the gate region; a buried oxide layer is disposed between the PMOS region and the NMOS region and between the PMOS or NMOS region and the Si substrate to isolate them from one another. In an accumulation mode, current flows through the overall racetrack-shaped channel. The disclosed device has high carrier mobility, high device drive current, and maintains the electrical integrity of the device. Meanwhile, polysilicon gate depletion and short channel effects are prevented.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

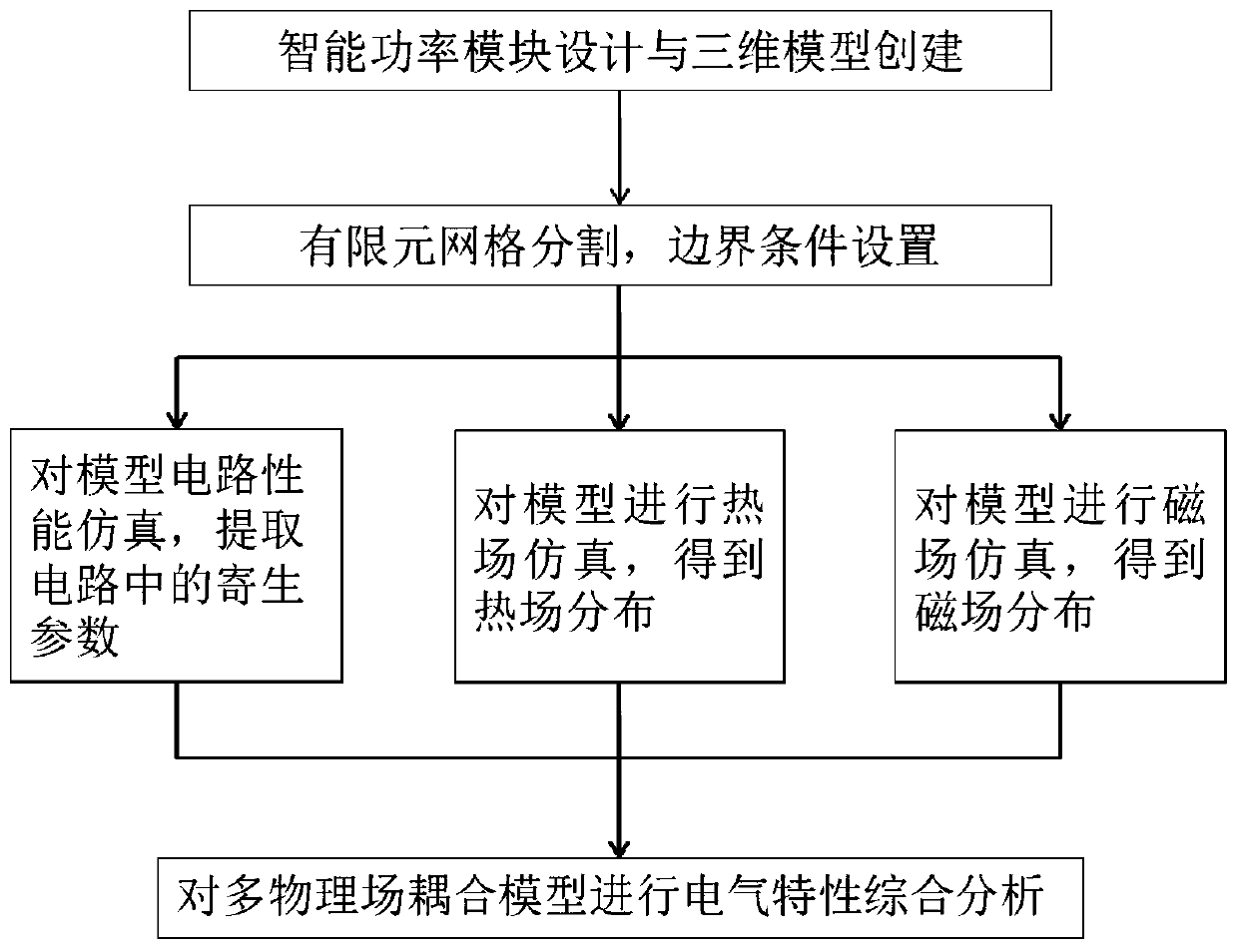

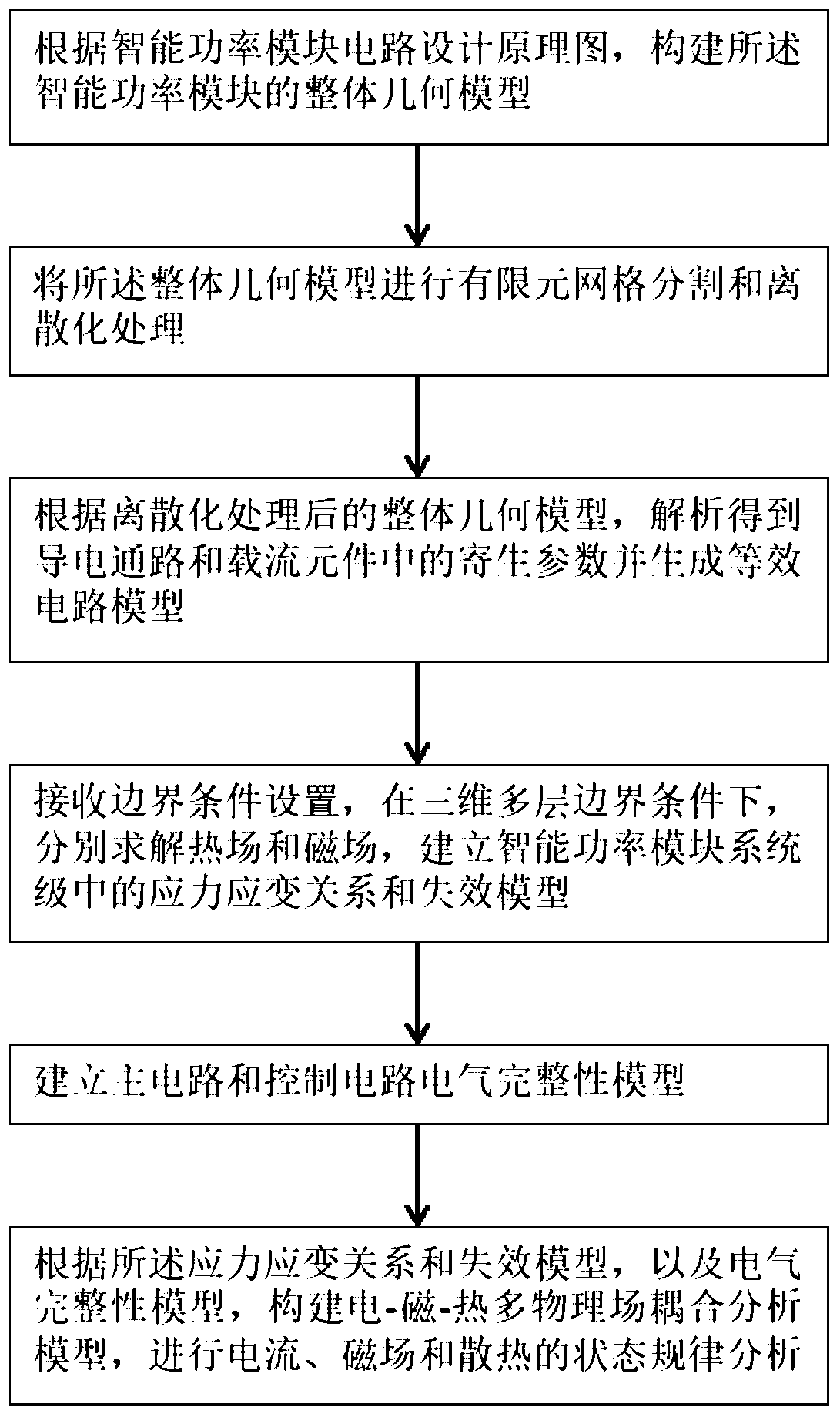

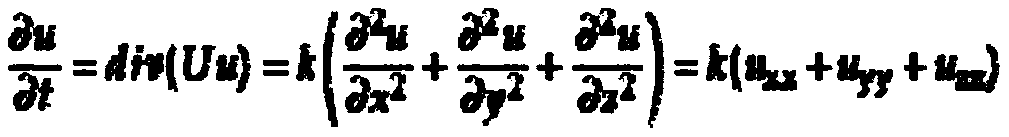

An intelligent power module multi-physical field coupling simulation analysis method and system

ActiveCN109783885AOptimizing electro-magnetic-thermal designImprove performanceSpecial data processing applicationsElement analysisPhysical field

The invention discloses an intelligent power module multi-physical field coupling simulation analysis method and system, and the method comprises the steps: building an overall geometric model of an intelligent power module according to an intelligent power module circuit design schematic diagram; Performing finite element grid segmentation and discretization processing on the overall geometric model, performing analyzing to obtain parasitic parameters in a conductive path and a current-carrying element, and generating an equivalent circuit model; Establishing an electrical integrity model ofthe main circuit and the control circuit; Respectively solving the thermal field and the magnetic field, and establishing a stress-strain relationship and a failure model in the system level; Constructing a physical field coupling analysis model according to the stress-strain relationship, the failure model and the electrical integrity model; And based on the coupling analysis model, carrying outcurrent, magnetic field and heat dissipation state rule analysis. Parameter extraction, field distribution and coupling calculation of multi-physical field analysis can be carried out across differentfinite element analysis software, and multi-physical field coupling analysis under complex boundary conditions is completed.

Owner:SHANDONG NORMAL UNIV

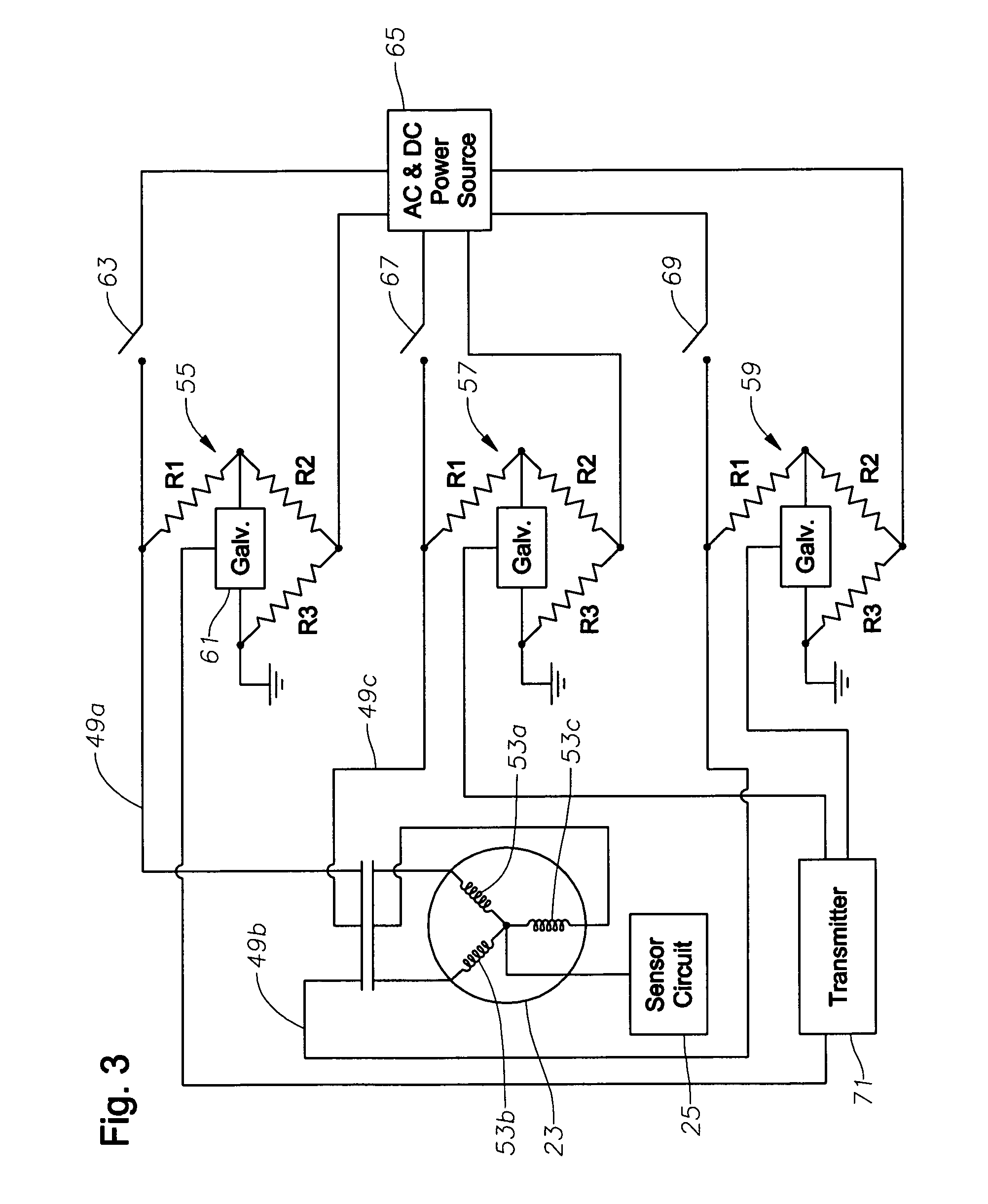

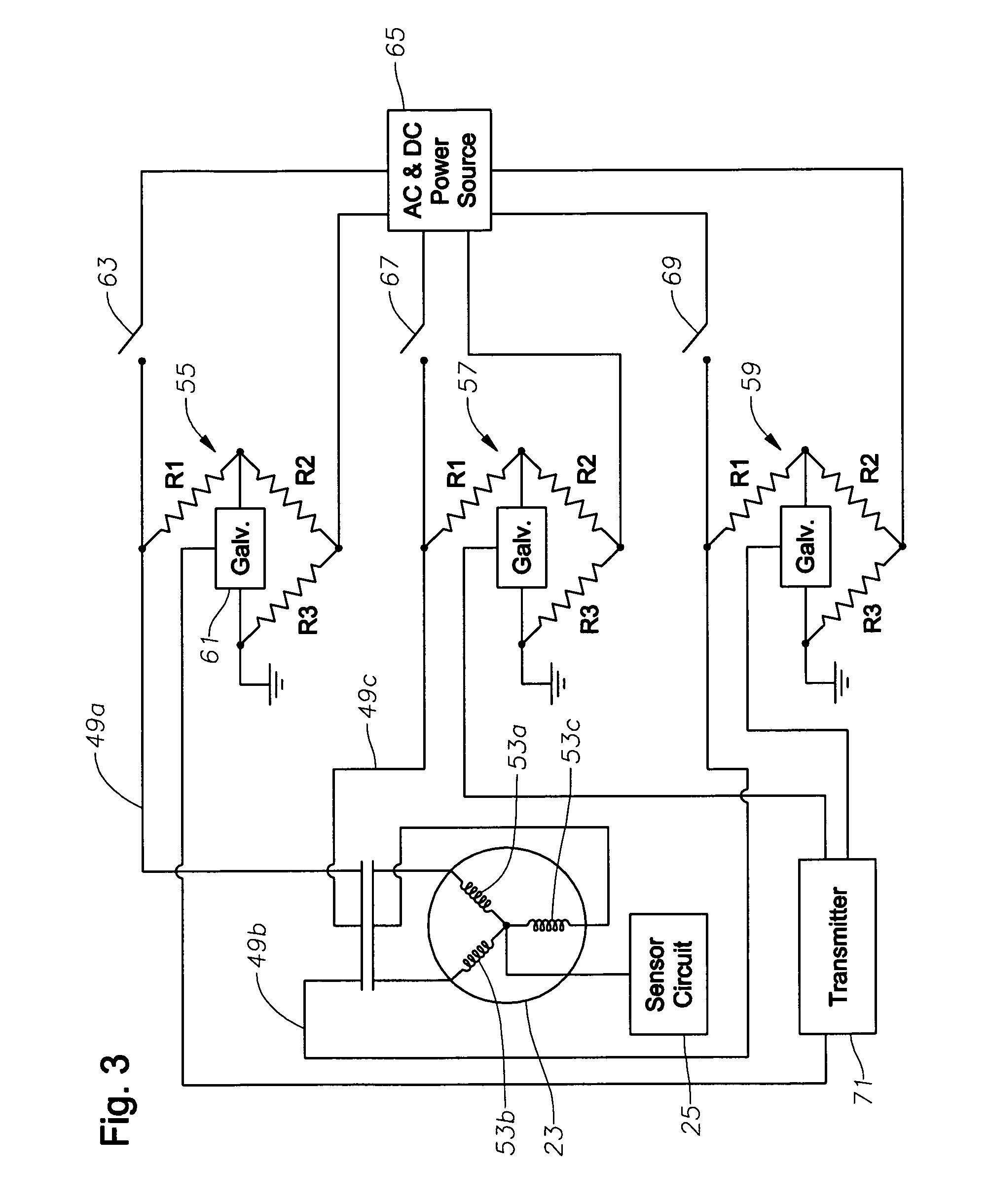

Electrical integrity test system for boats

InactiveUS6265879B1Weather/light/corrosion resistanceElectric connection testingVoltage dropEngineering

An electrical integrity test system for boats provides circuitry for evaluating the integrity of the boat's galvanic isolator. The integrity test system includes two single reference diodes and a circuit for applying DC voltages across said reference diodes and said galvanic isolator. Another micro-controller stores the values of the voltage drops across the galvanic isolator and the voltage drops across each reference diode and subsequently determines if the voltage drop across the galvanic isolator is that to be normally expected. If it is not, then the system informs the operator that the boat's galvanic isolator is not operating properly.

Owner:LANDRETH KEITH W

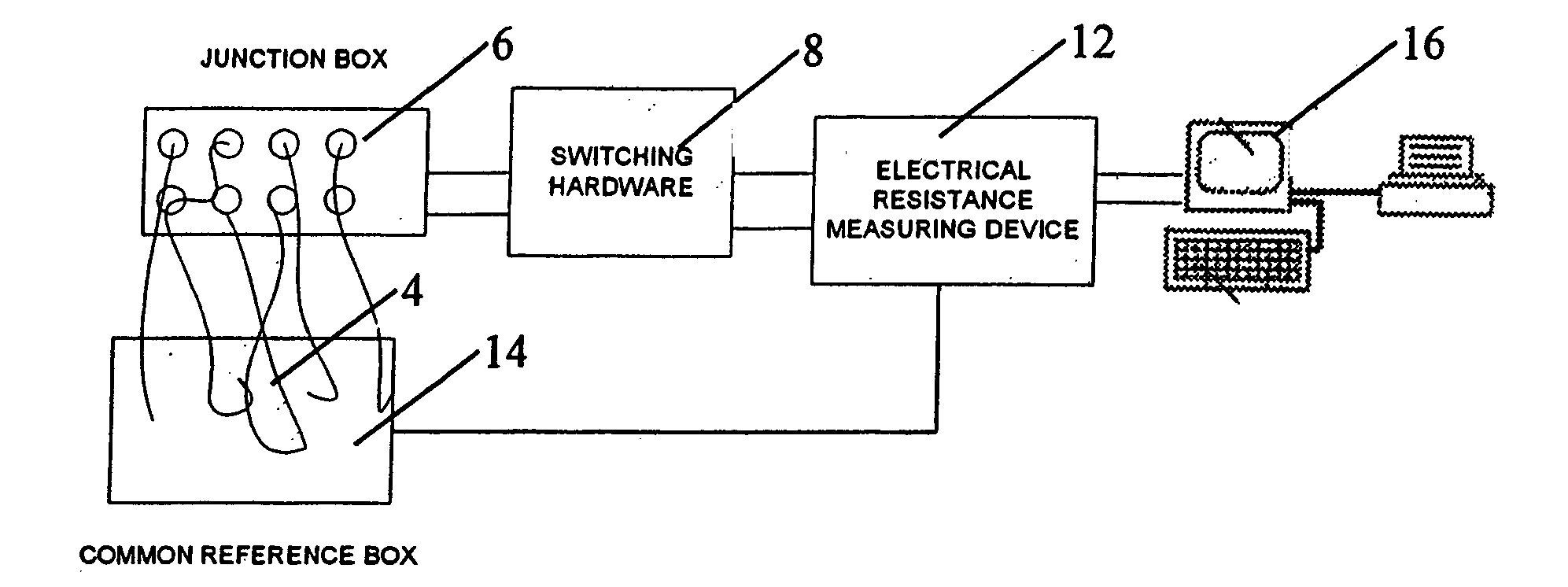

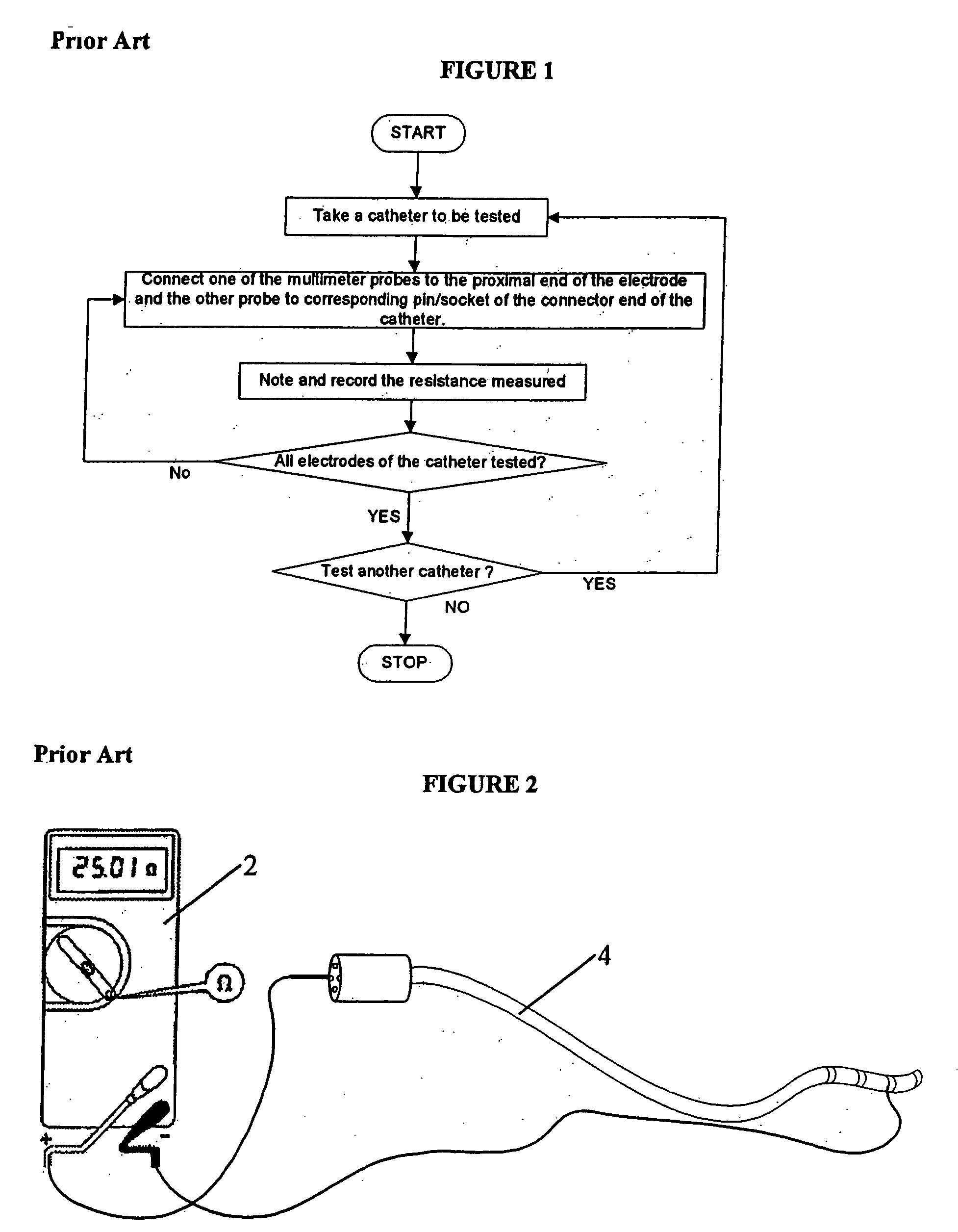

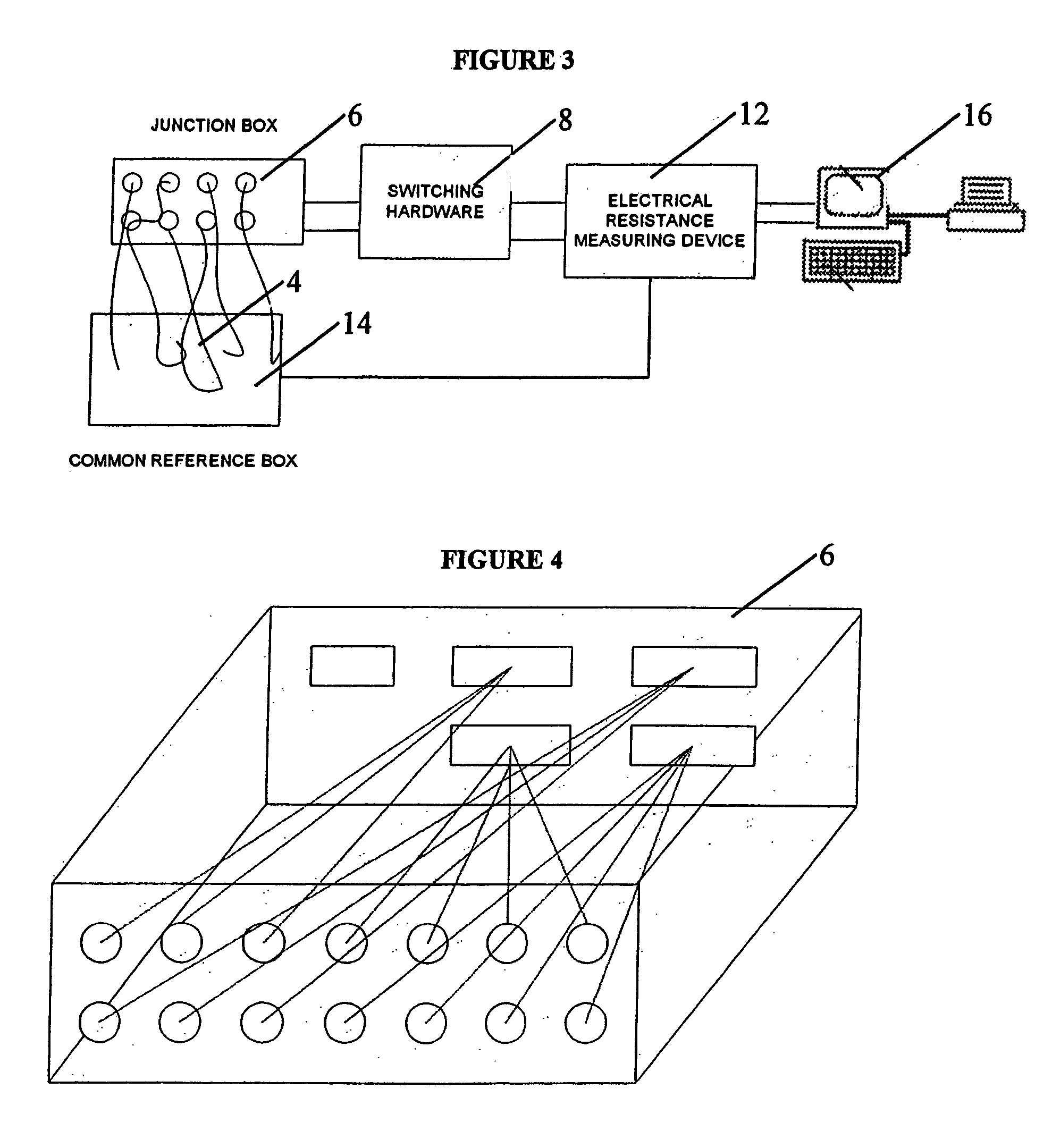

Catheter and cable inspection system and method

InactiveUS20050182466A1Improve automationInternal electrodesDiagnostic recording/measuringElectricityEngineering

The invention includes an automated inspection system, which automates the evaluation of electrical integrity to determine whether electrode catheters and / or cables are functioning properly. An exemplary embodiment of the system is to provide a system and method for automating the testing of various electrical parameters of several electrode catheters and / or cables so that its performance can be evaluated. The automated inspection system also automates, for example, catheter / cable identification, analysis to known specifications, and report printing and recording of the data analyses.

Owner:ALLIANCE MEDICAL

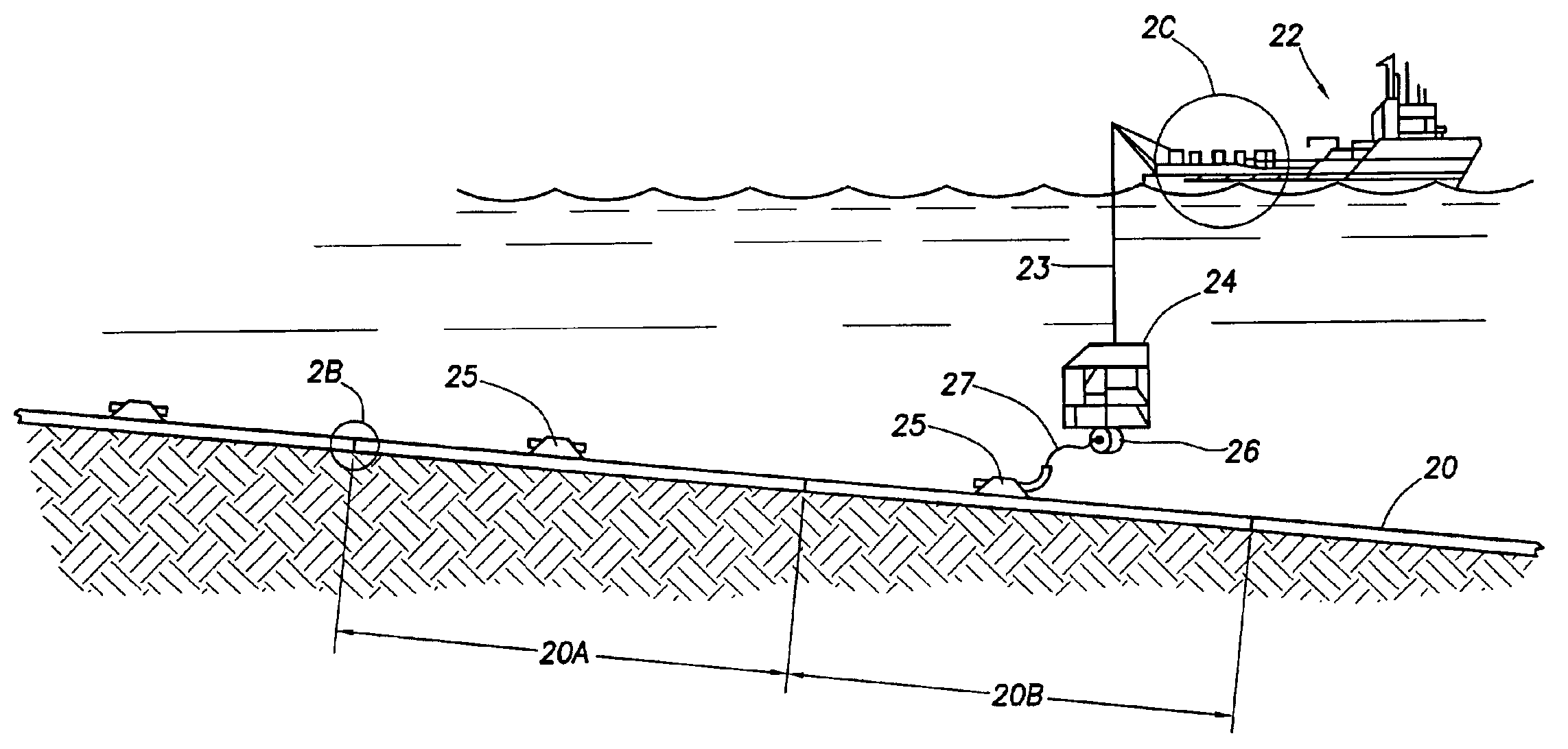

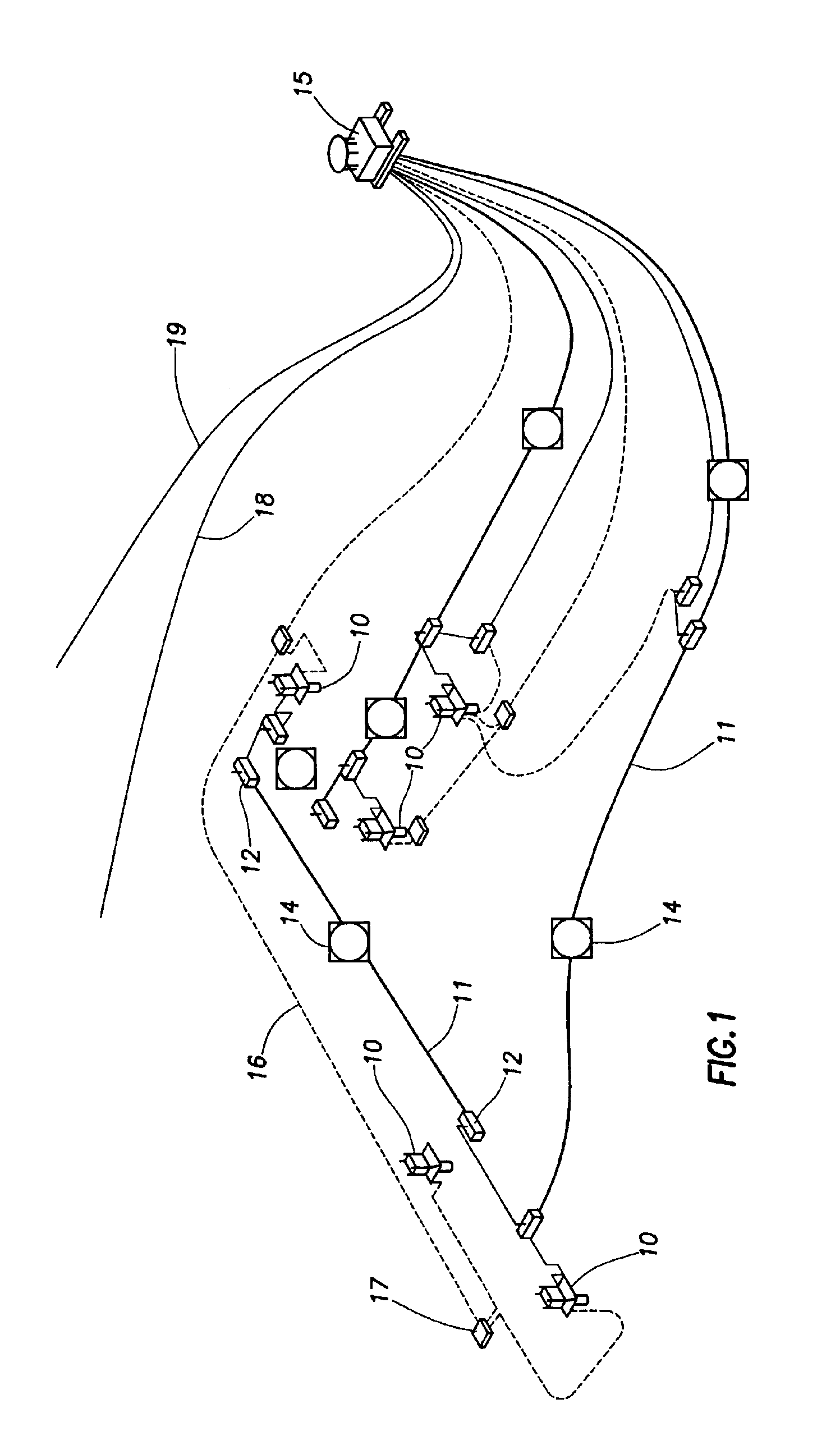

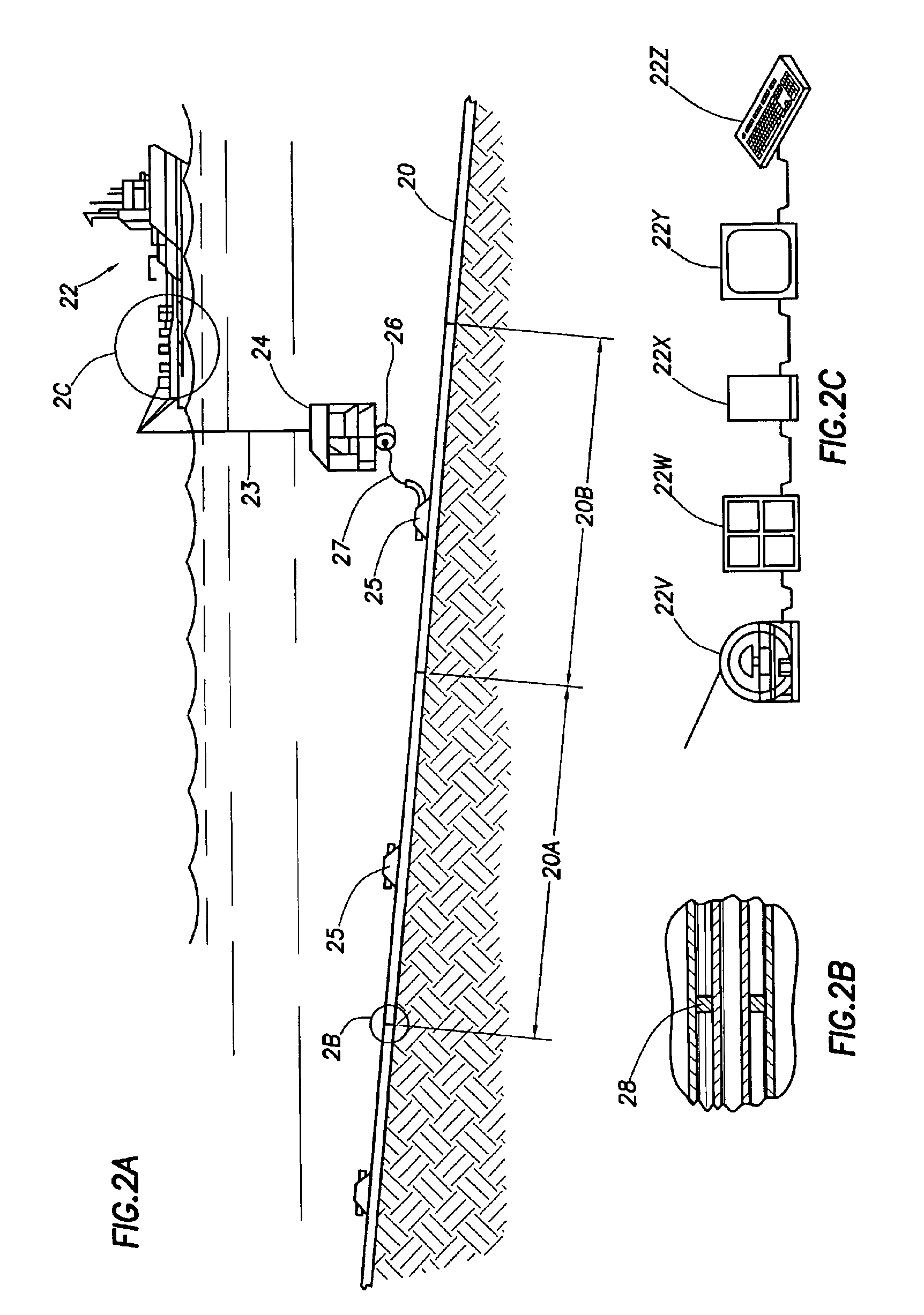

Testing electrical integrity of electrically heated subsea pipelines

InactiveUS6937030B2Resistance/reactance/impedencePipe heating/coolingTime domainTime-domain reflectometer

Method is provided for testing electrically heated subsea pipelines that are “electrical-ready,” that is, equipped for applying electrical power when it is needed for heating the pipeline at any time during the life of the pipeline. Time domain reflectometer apparatus in a water-tight enclosure can be deployed subsea. Electrical connections are made with the pipeline using wet-mateable connectors. Reflected signals from the segment of the pipeline being tested are transmitted to an interface at the surface, where the time domain reflectometer is controlled to send a selected pulse. Reflected signals may be interpreted by observing pulse form and time of receipt or by comparison of pulse forms received at different times during the life of a pipeline. Apparatus for electrically connecting a time domain reflectometer to an electrical-ready pipeline is provided.

Owner:SHELL USA INC

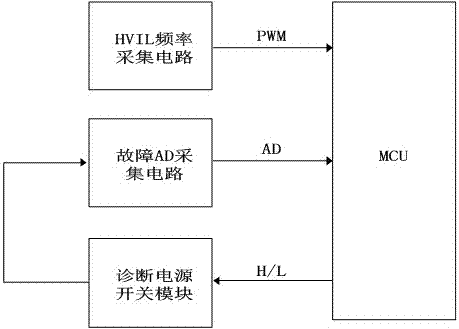

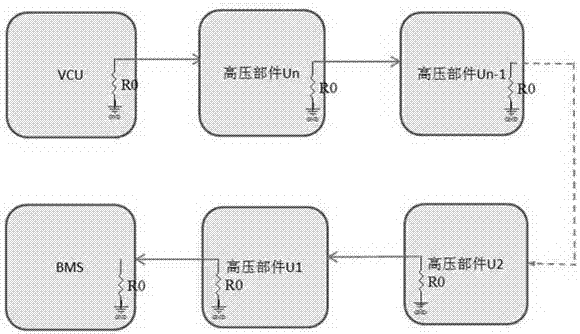

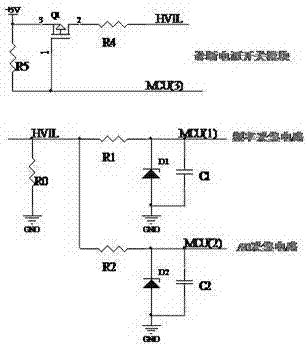

Diagnostic circuit and method for hazardous voltage interlock loop (HVIL)

InactiveCN107310395ARapid positioningSave time and costElectric devicesVoltage amplitudeHigh pressure

The invention discloses a loop interlock diagnosis circuit and method. Loop interlock is a common method for electric vehicles to check the electrical integrity of all high-voltage components, high-voltage wires and connectors by using small electrical signals to connect all high-voltage components in series. By detecting the frequency and voltage amplitude of the loop interlock signal, the invention can accurately judge three faults of the loop interlock: open circuit, short circuit to power supply and short circuit to ground. Cooperating with the pull-down resistors of each high-voltage component node of the loop interlock, it can quickly and quickly locate which high-voltage component disconnection causes the loop interlock (HVIL, the same below) to disconnect, saving time and cost for maintenance.

Owner:东营俊通汽车有限公司

Method for installing well completion equipment while monitoring electrical integrity

A method of installing a submersible electrical pump assembly in a well monitors the integrity of the pump assembly and electrical cable while the pump assembly is being run. The pump assembly has at least one sensor that measures a parameter in the environment of the pump assembly. A battery-powered test unit is mounted to the reel of cable, and a lead of the unit is connected to the power cable. While lowering the completion equipment, test voltage is supplied from the unit via the power cable through the motor to the sensor. The unit transmits an indication to a remote monitor that the sensor is operational.

Owner:BAKER HUGHES HLDG LLC

Method and materials for bonding electrodes to interconnect layers in solid oxide fuel cell stacks

ActiveUS7645535B2Reliable electrical connectionFuel cells groupingFuel cell auxillariesEngineeringBond properties

A method and related bonding compositions for use in assembling a solid oxide fuel cell (“SOFC”) stack having thermally and chemically stable and electrically conductive bonds between alternating fuel cells and interconnect components in the stack. The improved method and materials allow for the assembly of solid oxide fuel cells having a stronger and more reliable bond with good electrical contact in situ between the SOFC interconnect layers (plates) and the electrodes. The bonding materials and method according to the invention provide good electrical performance while maintaining the mechanical and electrical integrity of SOFC stacks without requiring excessive mechanical compression of the stack as exemplified by prior art systems. The preferred bonding agents comprise a primary phase that provides the electrical conduction path during fuel cell operation, as well as the mechanical strength necessary to insure a reliable connection between the interconnect and the relevant anode or cathode surfaces of the fuel cell. Secondary phases can be added in small amounts to the primary phase to improve adhesion. An exemplary method according to the invention also contemplates various different steps for pre-treating the surfaces of the interconnect plates and electrodes to improve their surface bonding properties.

Owner:CUMMINS ENTERPRISE LLC

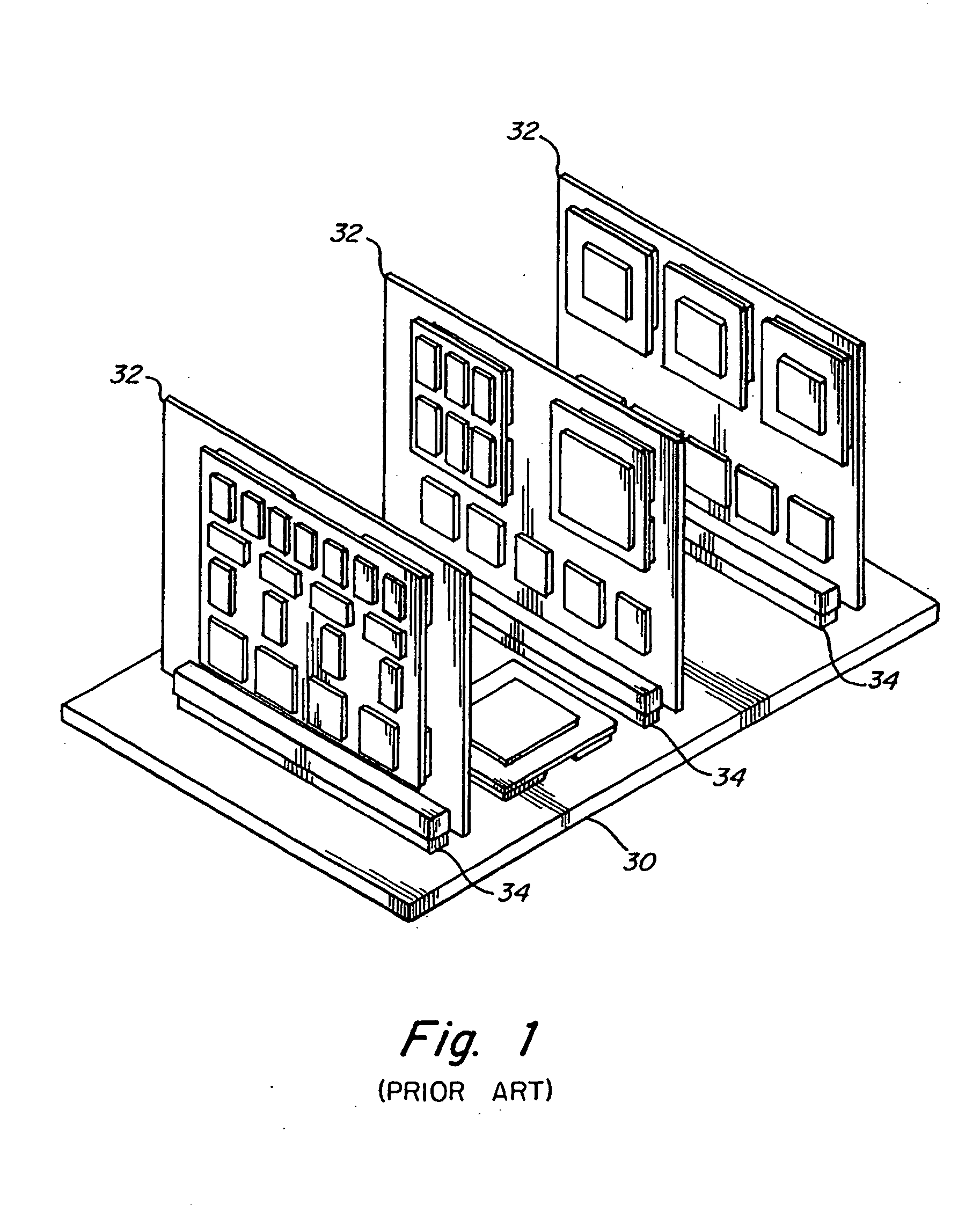

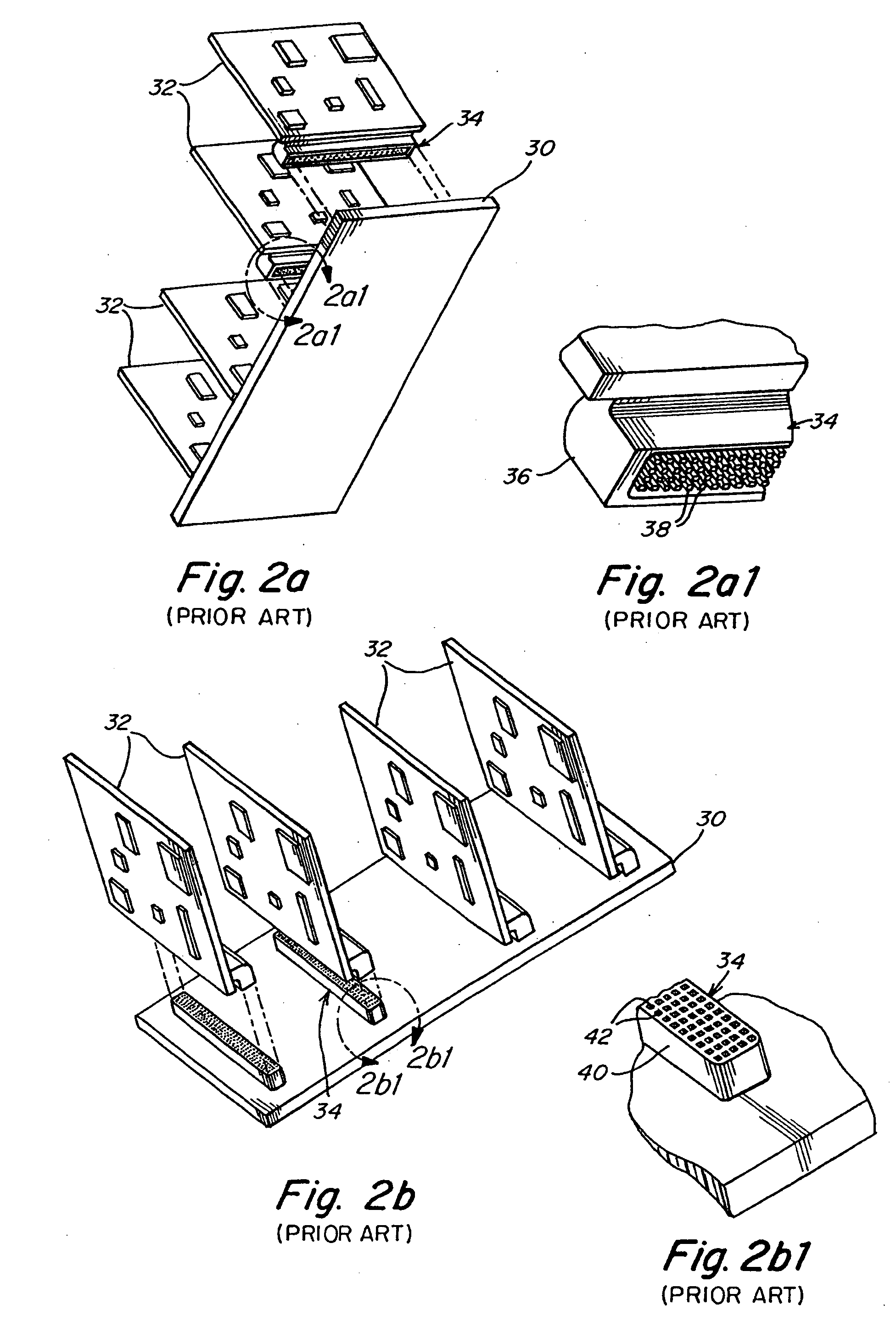

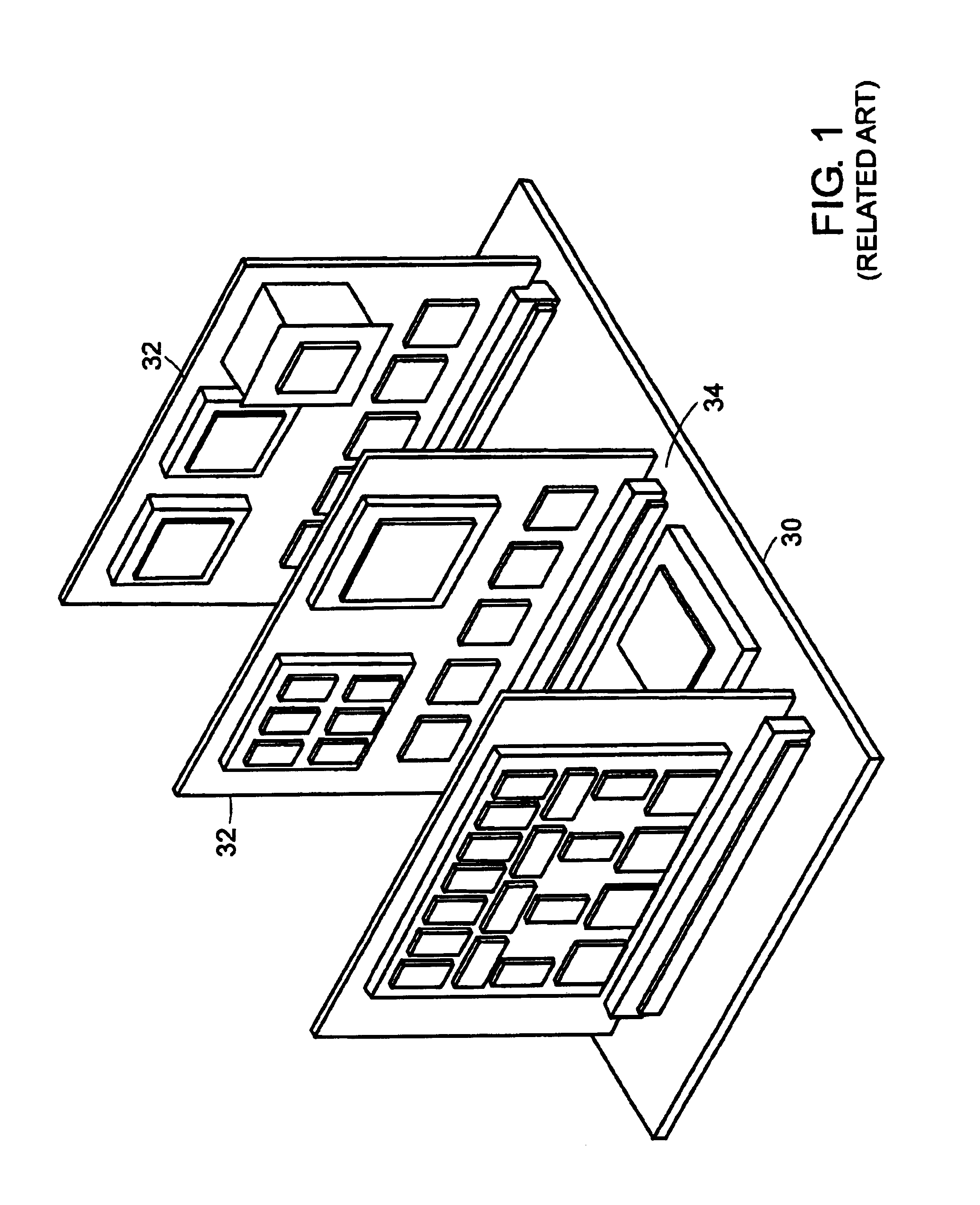

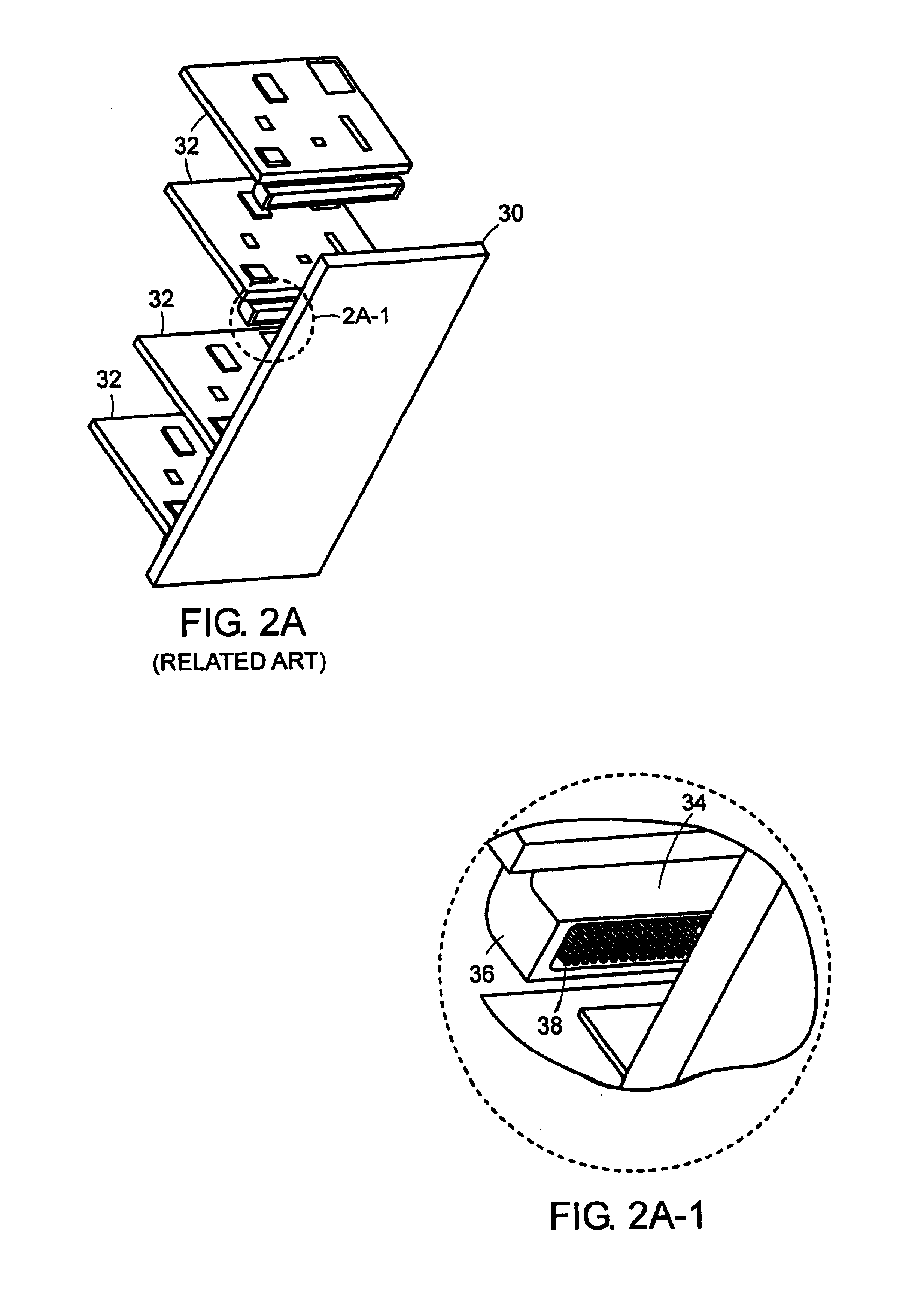

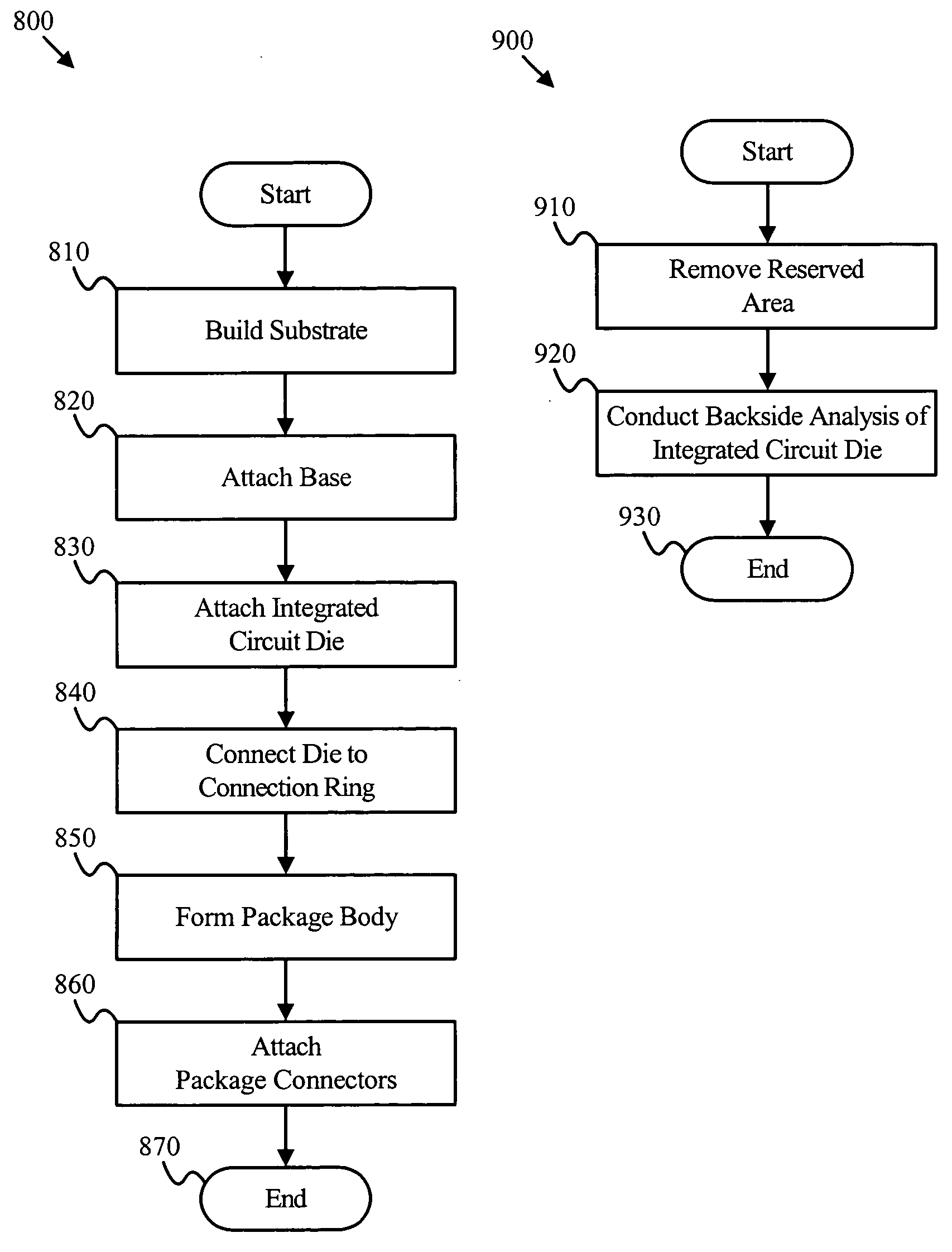

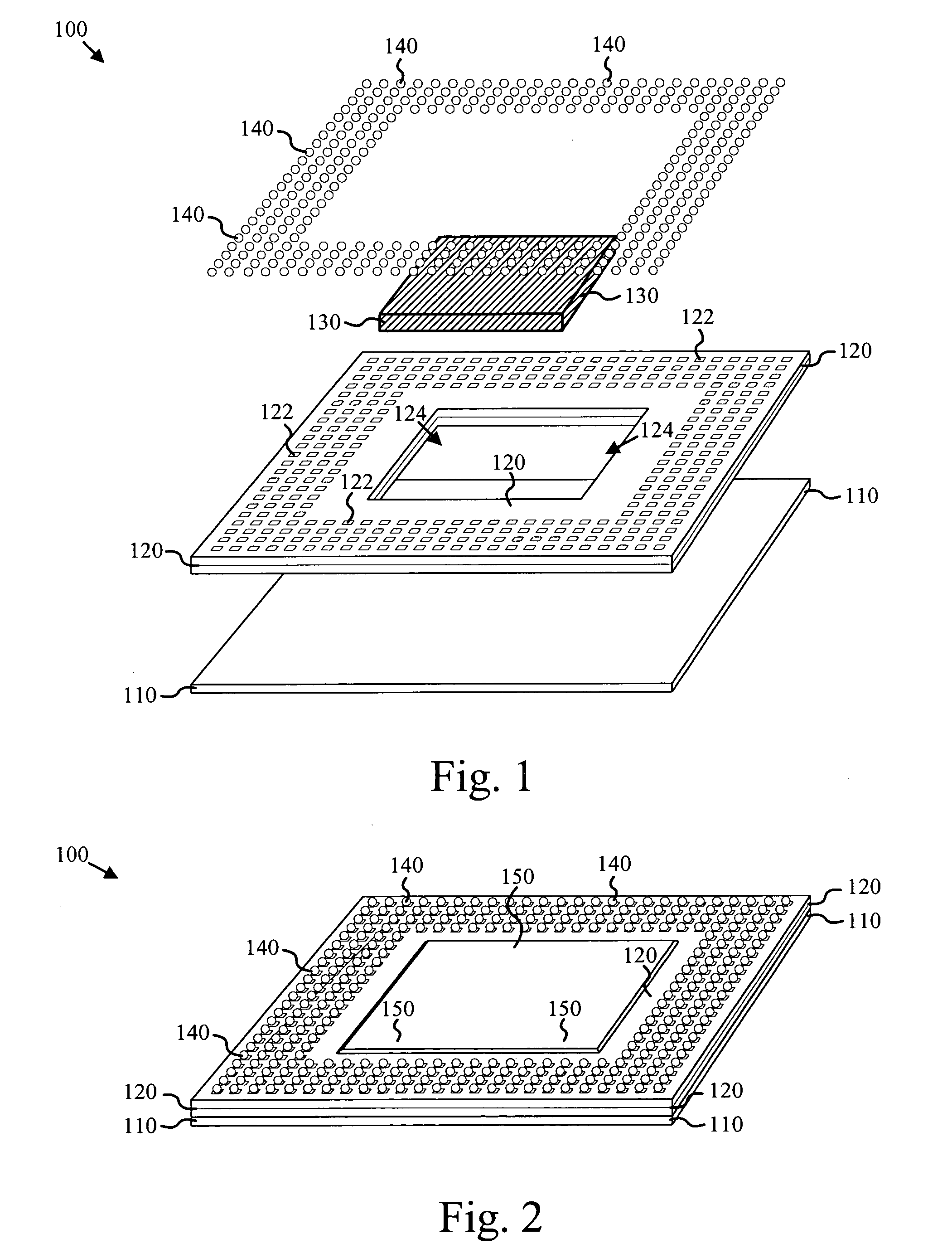

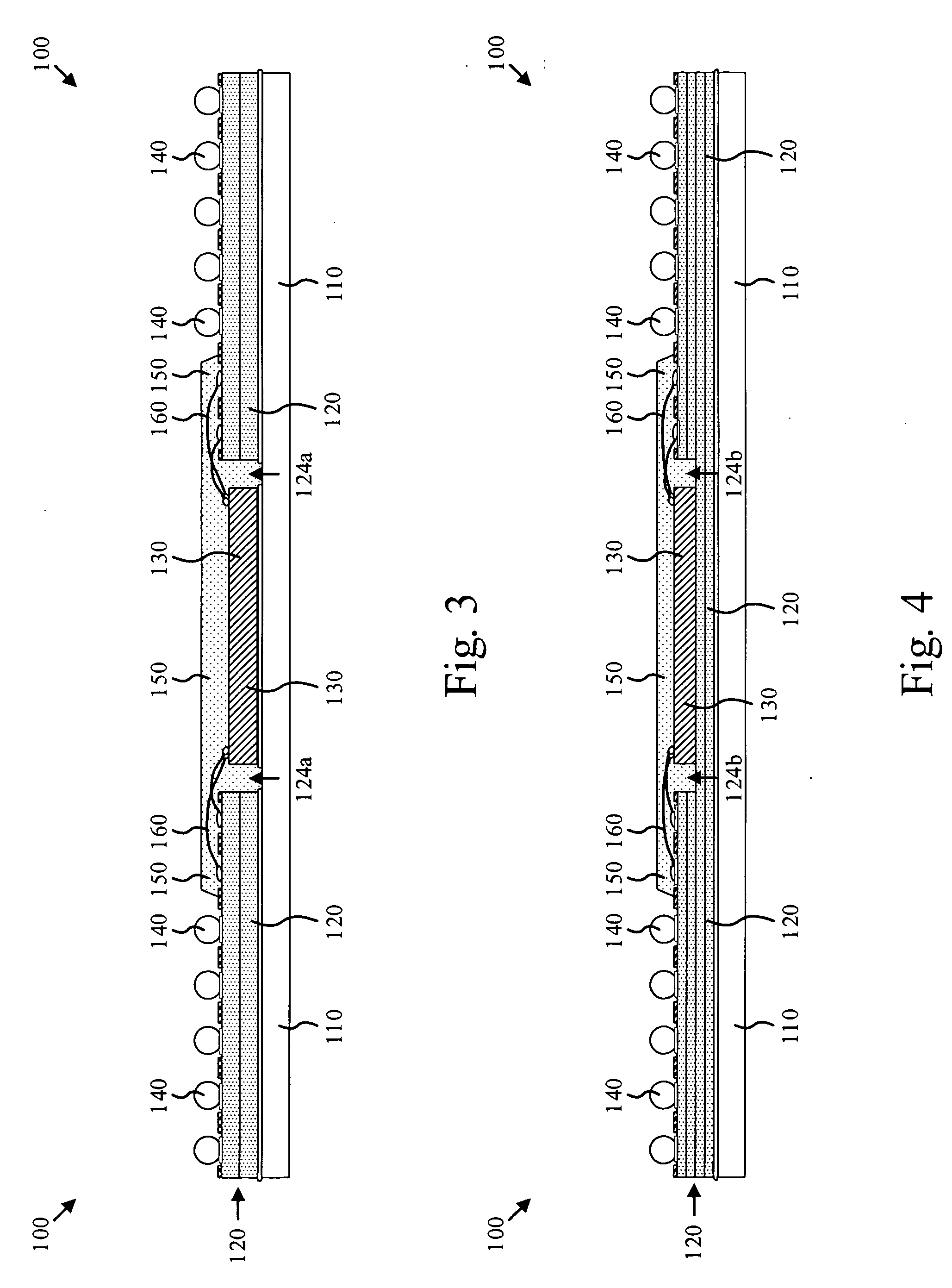

Integrated circuit carrier apparatus method and system

ActiveUS20050104172A1Designing can be facilitatedEasy to analyzeSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitElectrical integrity

A carrier substrate includes an access region placed within the interior of the substrate that facilitates backside access to an integrated circuit die without damaging electrical integrity of the carrier substrate, a ring of die connection pads placed around the access region, and an array of package connection pads positioned around the perimeter of the top surface of the carrier substrate. In one embodiment, the perimeter depth of the array of package connections pads is selected to correspond to the number of electrical traces routable between minimally spaced package connection pads. The basic carrier substrate design is used to create an integrated circuit carrier family with each particular circuit carrier configured to receive a range of integrated circuit sizes and I / O counts such that each circuit carrier overlaps in size range with at least one other circuit carrier.

Owner:BELL SEMICON LLC

Formulation and fabrication of an improved Ni based composite Ohmic contact to n-SiC for high temperature and high power device applications

InactiveUS7163882B1Improve electrical performanceEliminate the effects ofSemiconductor/solid-state device manufacturingSemiconductor devicesMetallurgyElectrical instability

A composite Pt / Ti / WSi / Ni Ohmic contact has been fabricated by a physical deposition process which uses electron beam evaporation and dc-sputter deposition. The Ni based composite Ohmic contact on n-Sic is rapid thermally annealed (RTA) at 950° C. to 1000° C. for 30 s to provide excellent current-voltage characteristics, an abrupt, void free contact-SiC interface, retention of the as-deposited contact layer width, smooth surface morphology and an absence of residual carbon within the contact layer and / or at the Ohmic contact-SiC interface. The annealed produced Ni2Si interfacial phase is responsible for the superior electrical integrity of the Ohmic contact to n-SiC. The effects of contact delamination due to stress associated with interfacial voiding has been eliminated. Wire bonding failure, non-uniform current flow and SiC polytype alteration due to extreme surface roughness have also been abolished. The Ohmic contact also avoids electrical instability associated with carbon inclusions within the contact metallization and / or at the contact-SiC interface, that occur under prolonged high temperature and power device operations. Overall, this contact is reliable for high temperature and high power operations and the stresses inclusive of use under those conditions.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

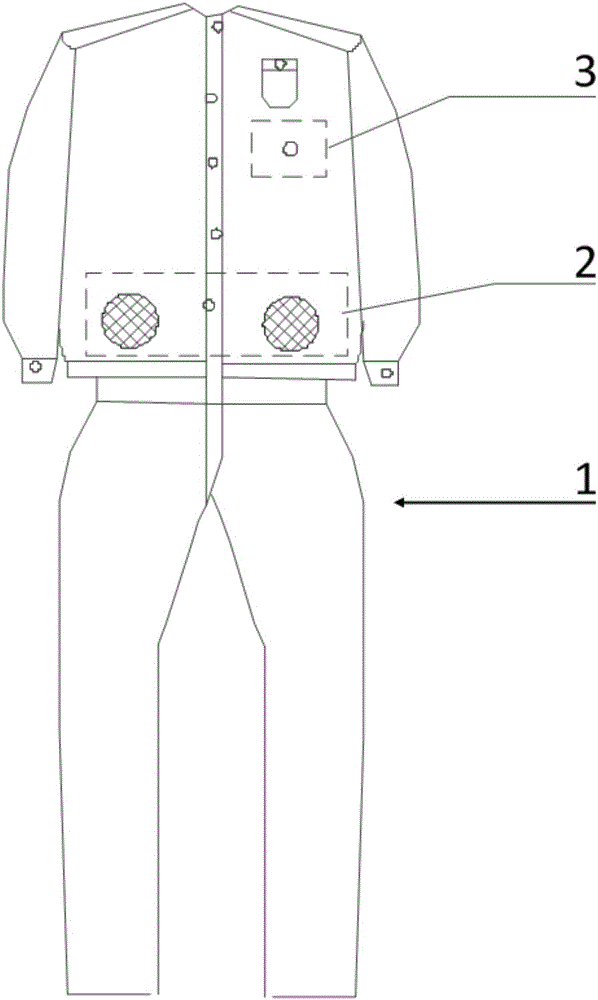

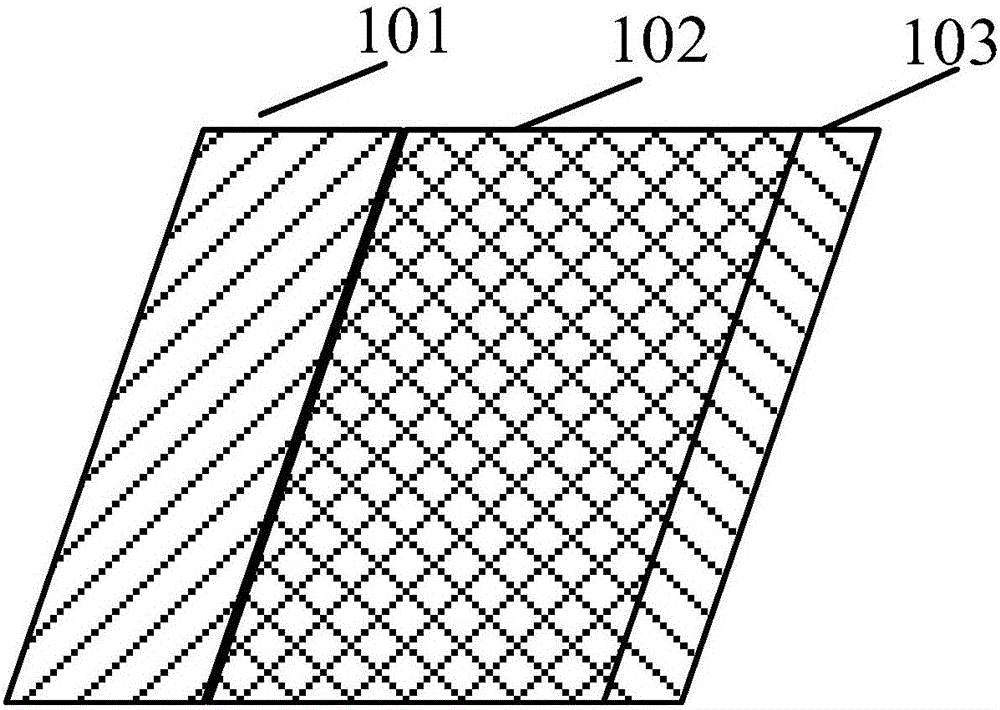

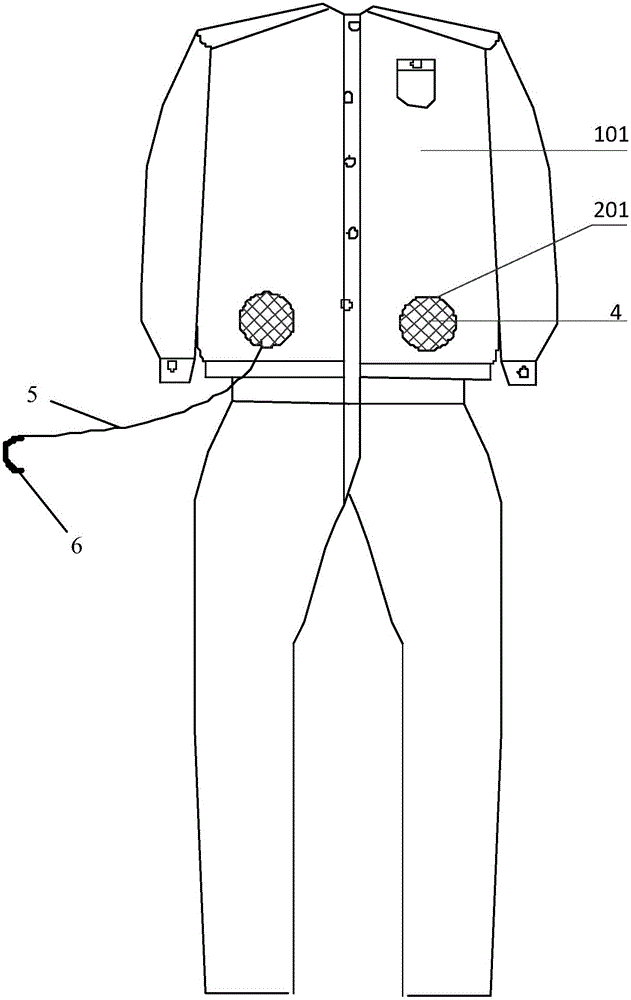

Extra-high-voltage cooling shielding clothes for live working

ActiveCN105054390AWill not affect normal useEasy to removeProtective garmentSpecial outerwear garmentsAir volumeEvaporation

The invention provides extra-high-voltage cooling shielding clothes for live working. The shielding clothes comprise a shielding clothes body, cooling assemblies arranged on the shielding clothes body, and a detecting unit. The shielding clothes body comprises a conduction outer lining, a cooling inner lining, and a ventilating layer sandwiched between the conduction outer lining and the cooling inner lining. The number of the cooling assemblies is at least four. Each cooling assembly comprises one air guide opening and a minitype fan connected with the air guide opening, and the air guide openings are formed in the same position on the shielding clothes body. The shielding clothes are convenient to assemble and disassemble without damaging the whole shielding efficiency of the shielding clothes; while the electric integrity of the shielding clothes is ensured, air volume is conveyed uniformly, and effective cooling is ensured; meanwhile, mobility of airflow is improved, the coverage area is increased, and the temperature of the human body under the high-temperature condition is reduced effectively by means of evaporation of sweat; the situation that due to the unsmooth airflow, the clothes are fluffy and swell, and inconvenience is brought to operation of an operator is avoided, and the safety of equipment and the personal safety of the operator are ensured.

Owner:CHINA ELECTRIC POWER RES INST +2

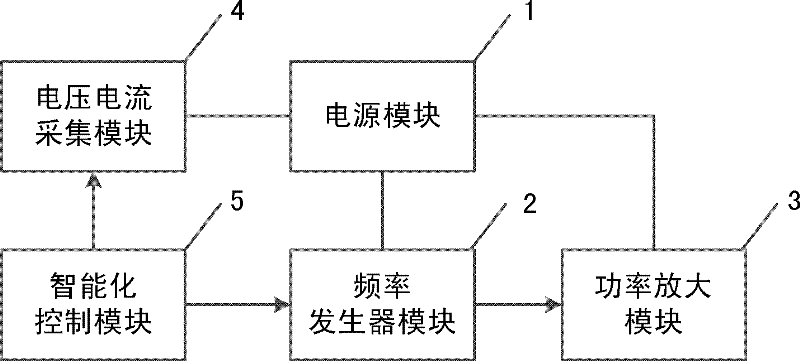

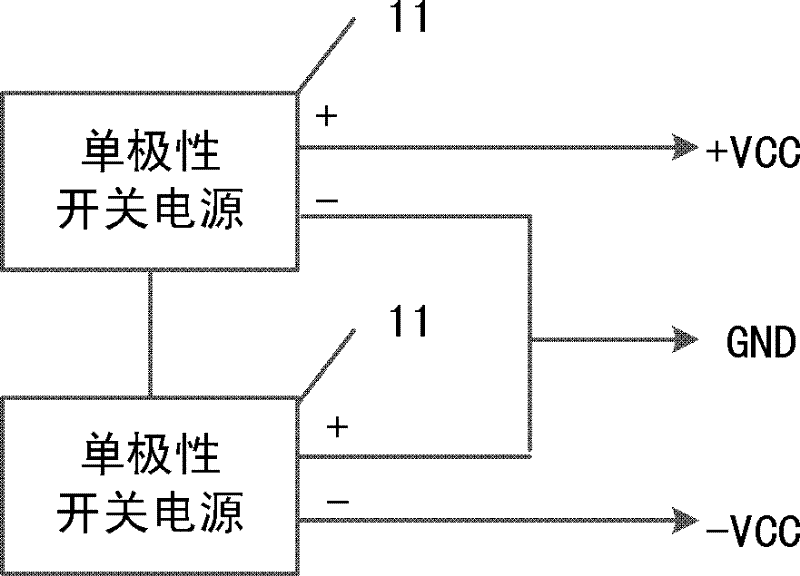

Transformer substation grounding network frequency response test device

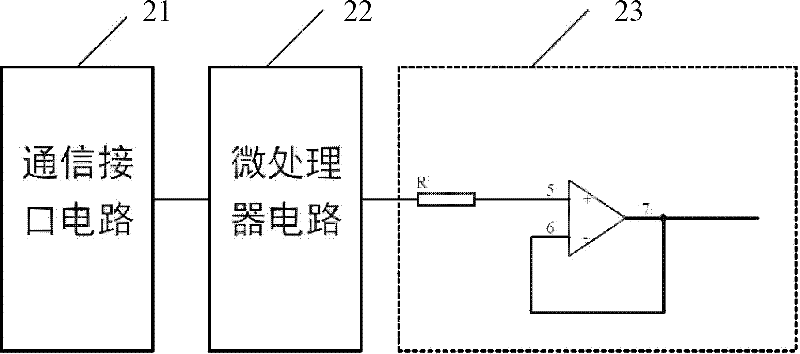

ActiveCN102540013AGuaranteed stabilityEnsure reliabilityFrequency measurement arrangementFault locationComputer moduleEngineering

The invention discloses a transformer substation grounding network frequency response test device, which comprises a power supply module, a frequency generator module, a power amplification module, a voltage and current collecting module and an intelligent control module, wherein the voltage and current collecting module, the intelligent control module, the frequency generator module and the power amplification module are sequentially connected, the power supply module provides the power supply for each module of the test device, the intelligent control module controls the frequency generator module to output sine wave voltage signals at different frequencies in different times, the corresponding sine wave voltage signals are amplified and loaded onto a grounding network to be tested by the power amplification module, and then, the voltage and the current of the grounding network to be tested are collected through the voltage and current collection module, so the impedance of the grounding network to be tested under the signal loading at the different frequencies is calculated by the intelligent control module. The device can be used for conveniently testing the electric completeness of the grounding network.

Owner:广东电网有限责任公司韶关供电局

Method of plasma preparation of metallic contacts to enhance mechanical and electrical integrity of subsequent interconnect bonds

A method of removing oxidation from certain metallic contact surfaces utilizing a combination of relatively simple and inexpensive off-the-shelf equipment and specific chemistry. The method being a very rapid dry process which does not require a vacuum or containment chamber, or toxic gasses / chemicals, and does not damage sensitive electronic circuits or components. Additionally, the process creates a passivation layer on the surface of the metallic contact which inhibits further oxidation while allowing rapid and complete bonding, even many hours after surface treatment, without having to remove the passivation layer. The process utilizes a room-ambient plasma applicator with hydrogen, nitrogen, and inert gasses.

Owner:ONTOS EQUIP SYST

Systems and methods for connecting electrical components

InactiveUS20050239329A1Electrical measurement instrument detailsPrinted circuit aspectsFiberElectricity

Owner:METHODE ELETRONICS INC

Electrical transmission line repair device

ActiveUS20090081909A1Restore mechanical integrityEasy to installLine/current collector detailsElectric connection structural associationsElectric power transmissionElectrical conductor

An electrical conductor repair device for restoring mechanical and electrical integrity to a compromised section of an electrical conductor. The device includes a body that serves as an electrical shunt and a mechanical support. The body includes a first end section for attachment to the conductor at a location on one side of the compromised section, and a second end section for attachment to the conductor at a location on the other side of the compromised section. The end sections are connected by an intermediate section.

Owner:CLASSIC CONNECTORS

Bowden cable wear detection in a tube clamp system for medical fluids

A system for clamping a flexible tube containing medical fluids includes a cable assembly coupled to a remote driver and a slidable clamp that imparts a clamping force to the flexible tube. An electrical continuity detector is included to measure the wear of an internal insulating layer of the cable between a sliding inner wire and a cable casing member. An indication of the wear to the cable is generated in response to a comparison of the electrical integrity of the insulating layer with a threshold. The wear indication enables the cable to be repaired or replaced prior to a malfunction of the overall tube clamp system.

Owner:TERUMO CARDIOVASCULAR SYST CORP

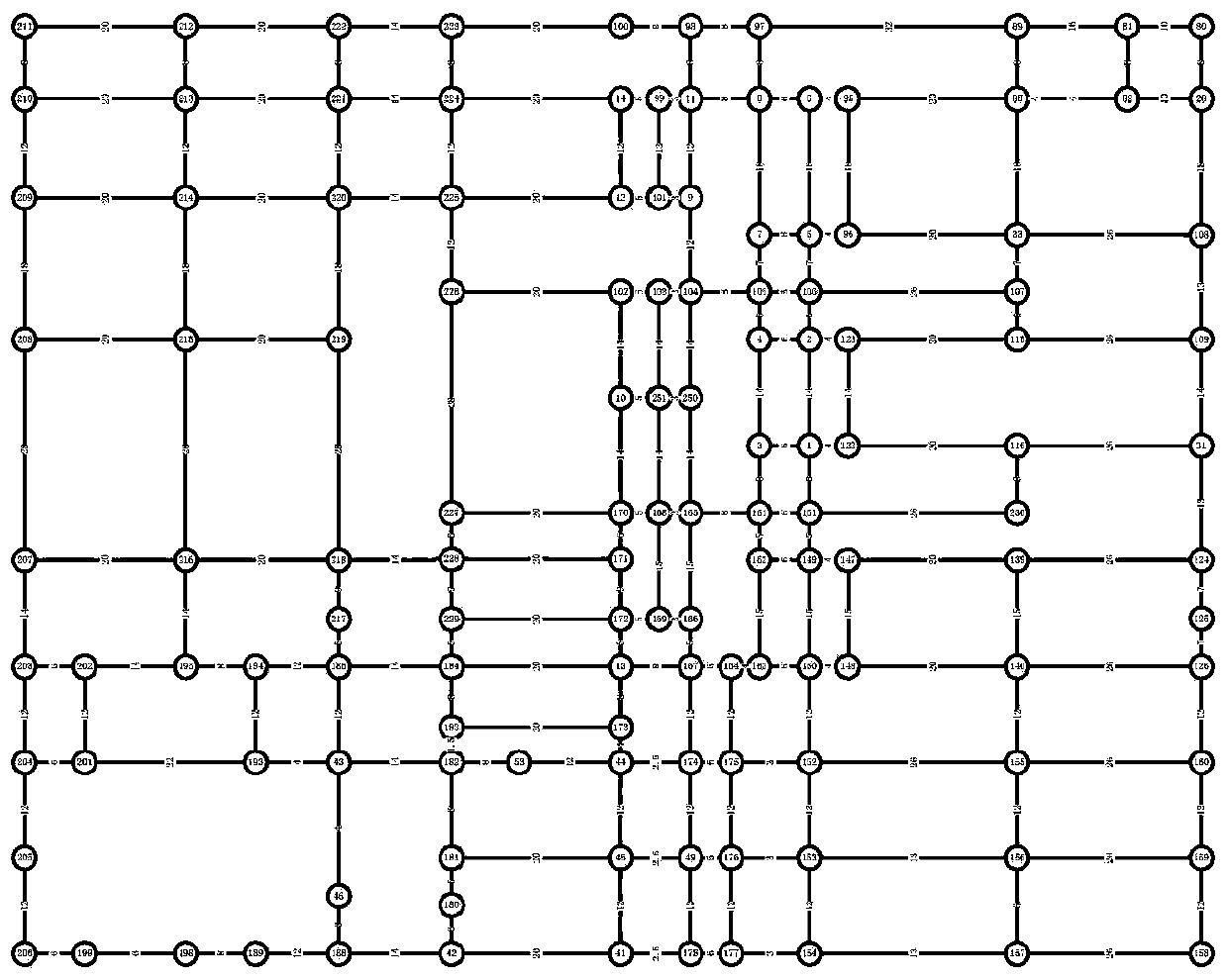

Rapid model establishment and accurate corrosion diagnosis method for transformer substation grounding grid

PendingCN111262246AEfficient modelingAccurate modelingFault location by conductor typesShort-circuit testingGrounding gridTransformer

The invention relates to a rapid model establishment and accurate corrosion diagnosis method for a transformer substation grounding grid, which is technically characterized by comprising the steps ofobtaining a drawing of the transformer substation grounding grid according to the electrical integrity test condition of a transformer substation; establishing a VISIO-based transformer substation grounding grid rapid model according to the drawing of the transformer substation grounding grid; and accurately diagnosing the corrosion according to the established model. According to the invention, VISIO software is used to carry out rapid and efficient modeling on the grounding grid, the model is processed by using a Tellegen's theorem, an epsilon-dimensional fault diagnosis equation set is constructed, and finally, the underdetermined equation set is solved by using a particle swarm algorithm for local optimization by using a least square method, so that the grounding grid can be accuratelyand quickly modeled, and the corrosion fault position and the corrosion fault degree of the grounding grid can be accurately positioned and judged through calculation.

Owner:ELECTRIC POWER SCI & RES INST OF STATE GRID TIANJIN ELECTRIC POWER CO +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com