Corrosion reaction tester, corrosion evaluation device and corrosion evaluation method

A corrosion reaction and corrosion evaluation technology, which is applied to measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as increased research costs and work intensity, incomparable corrosion rates, and complex simulation equipment construction, etc., to achieve High accuracy of test results, inhibition of corrosion, and small footprint of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

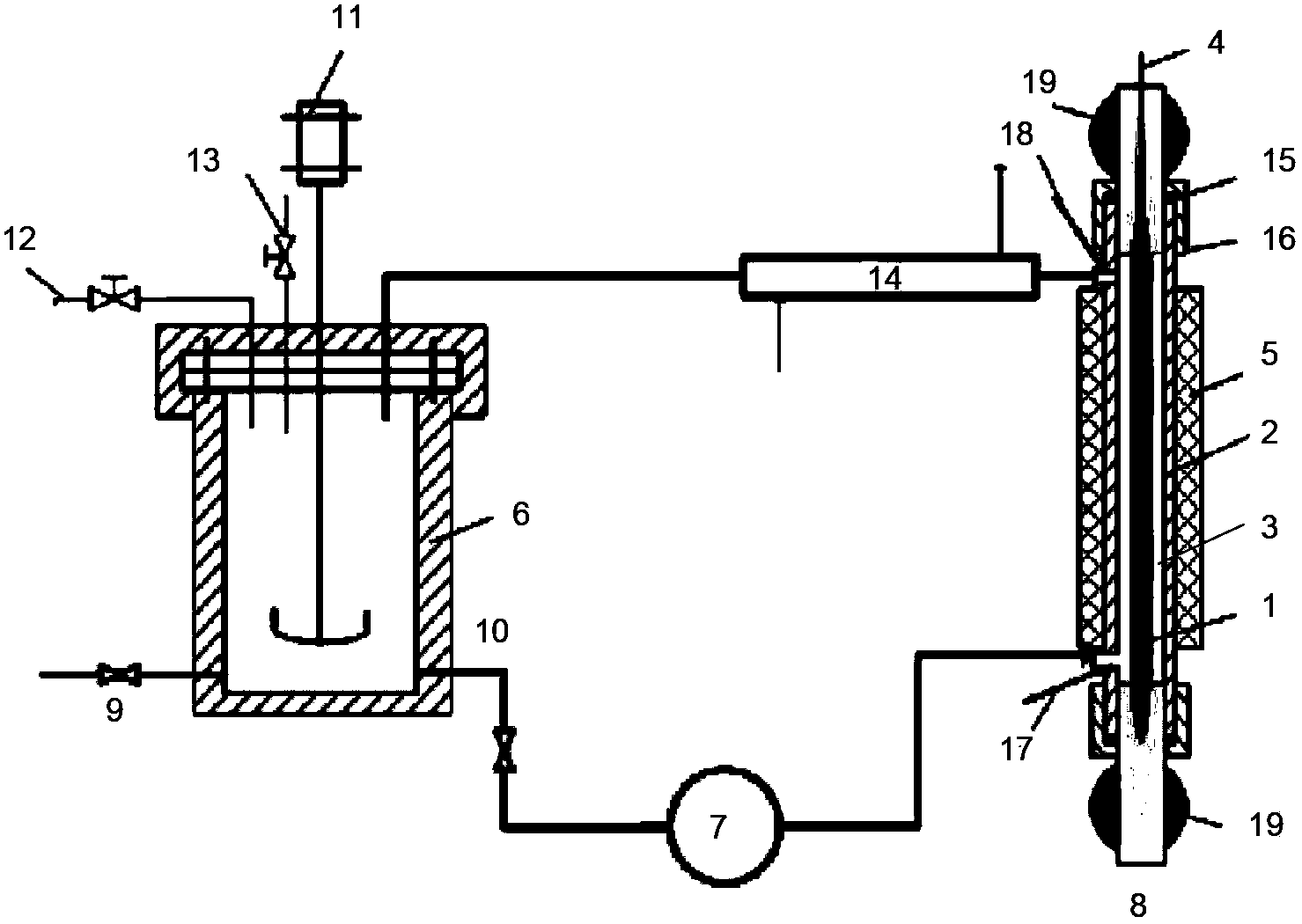

[0050] According to a preferred embodiment of the present invention, the outlet of the cavity 3 of the corrosion reaction tester 8 communicates with the oil sample container 6, so that the oil sample can circulate in the entire corrosion evaluation device. That is, the oil sample to be tested is poured into the oil sample container 6, and the oil sample is transported from the oil sample container 6 to the corrosion reaction tester 8 through the high-precision gear pump 7, from the outlet of the cavity 3 of the corrosion reaction tester 8 (upper end opening), and after passing through the condenser 14, the oil sample flows back to the oil sample container 6 for recycling.

[0051] In order to reduce the impact of high-temperature oil samples on oil sample containers, pumps and pipelines, preferably, such as figure 1 As shown, the outlet of the cavity 3 of the corrosion reaction tester 8 communicates with the oil sample container 6 through a condenser 14 .

[0052] In addition...

Embodiment 1

[0058] (1) Pour 200mL of petroleum acid simulated oil A (prepared from diesel fraction petroleum acid and hydrogenated white oil, with an acid value TAN of 10.1mgKOH / kg) to be tested into the oil sample container 6.

[0059] (2) Introduce nitrogen to purge for 5 minutes, and the test process is under normal pressure, but use a small flow of nitrogen to purge for protection.

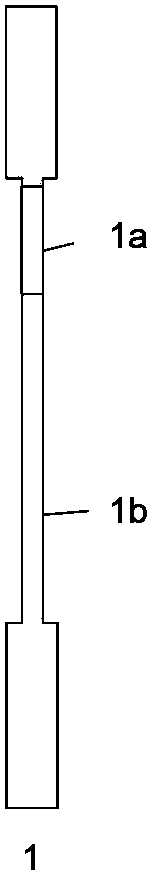

[0060] (3) Let the oil sample to be tested enter the corrosion reaction tester 8 through the pump 7 for corrosion testing, then flow out from the outlet of the corrosion reaction tester 8 and condense in the condenser 14, and then flow back to the oil sample container 6 for recycling. Among them, the pump speed of the pump 7 is 10mL / min, the temperature control program of the corrosion reaction tester 8 is set, the temperature of the electric heating rod 1 is 280°C, the heating time is 6min, and the constant temperature time is 3 hours, and the corrosion reaction test is recorded The temperature at the in...

Embodiment 2

[0063] (1) Pour petroleum acid simulated oil A (prepared from diesel fraction petroleum acid and hydrogenated white oil, with an acid value TAN of 10.1 mgKOH / kg) to be tested into the oil sample container 6 .

[0064] (2) Introduce nitrogen to purge for 5 minutes, and the test process is under normal pressure, but use a small flow of nitrogen to purge for protection.

[0065] (3) Let the oil sample to be tested enter the corrosion reaction tester 8 through the pump 7 for corrosion testing, then flow out from the outlet of the corrosion reaction tester 8 and condense in the condenser 14, and then flow back to the oil sample container 6 for recycling. Among them, the pump speed of the pump 7 is 10mL / min, the temperature control program of the corrosion reaction tester 8 is set, the temperature of the electric heating rod 1 is 320°C, the heating time is 6min, and the constant temperature time is 3 hours, and the corrosion reaction test is recorded The temperature at the inlet and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com