Patents

Literature

373 results about "Corrosion reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion is an electrochemical reaction that appears in several forms, such as chemical corrosion and atmospheric corrosion, the latter of which is the most common form. When acidic substances (including water) come in contact with metals, such as iron and/or steel, rust begins to form.

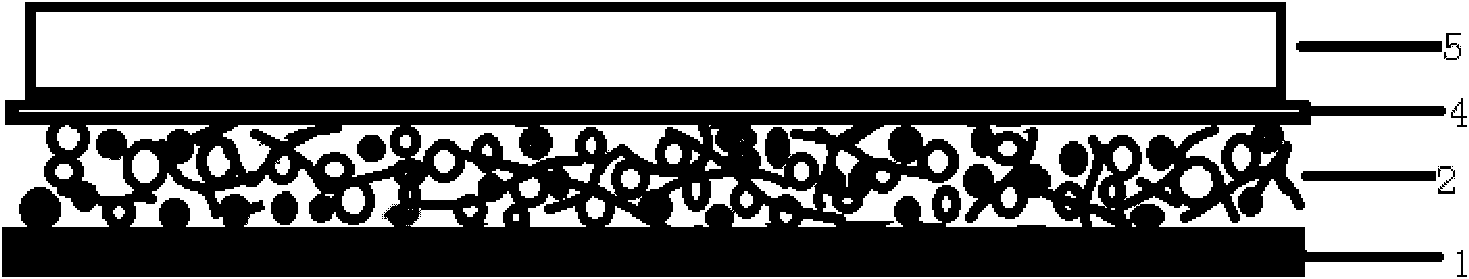

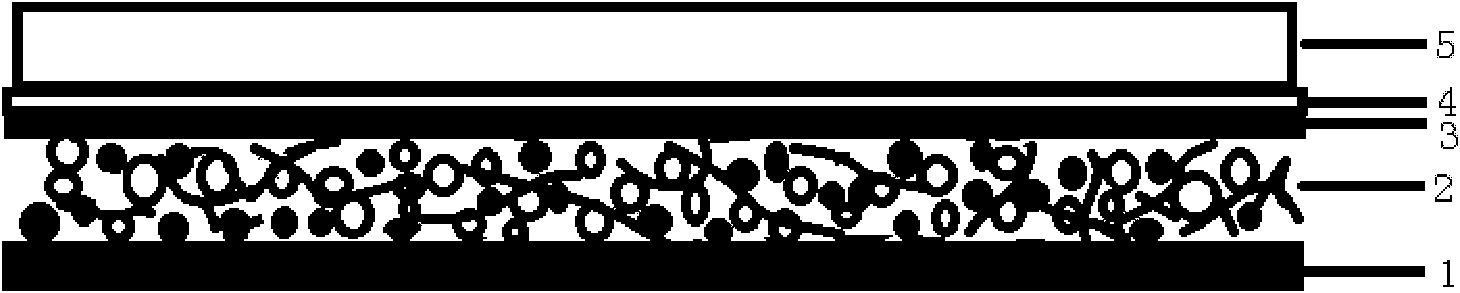

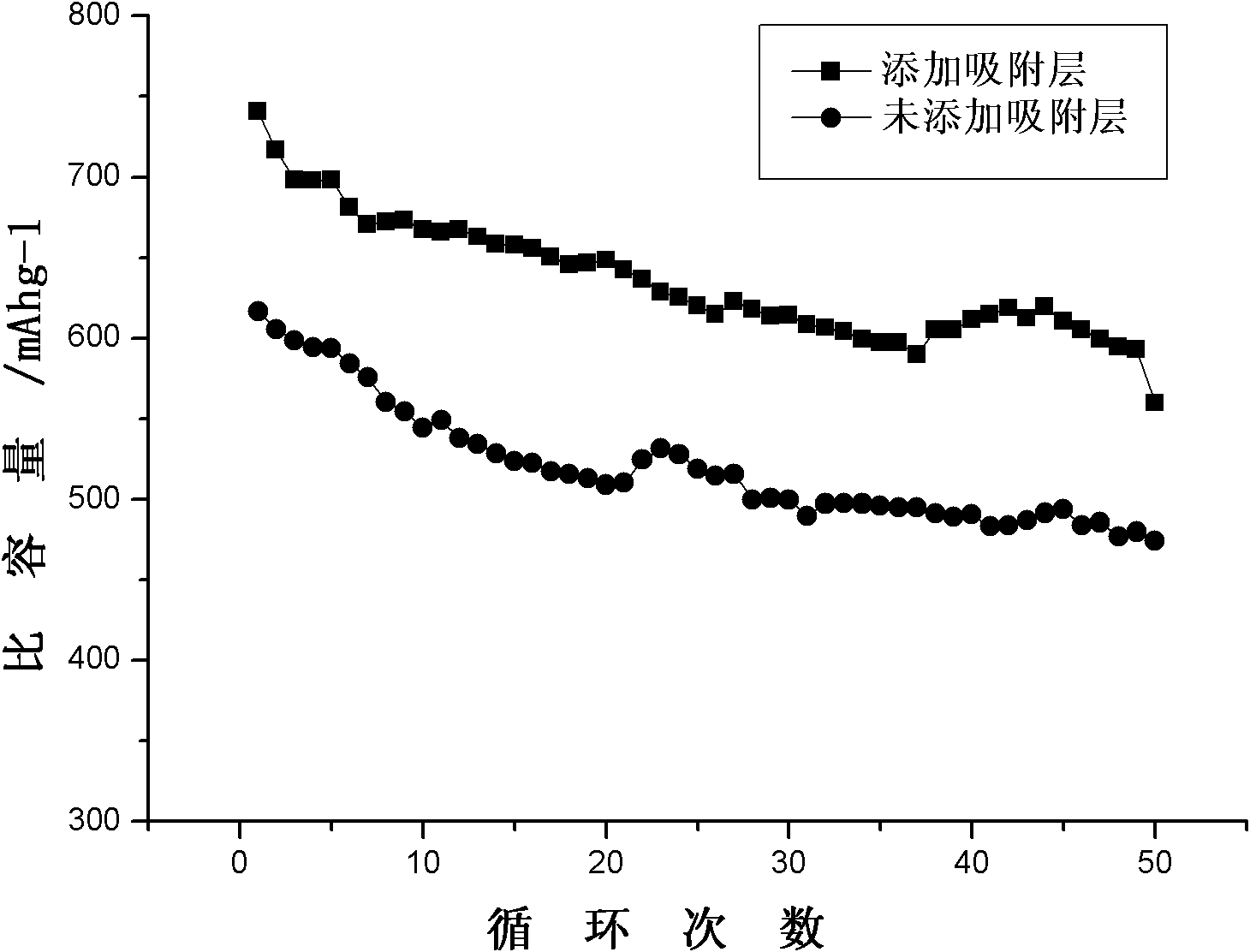

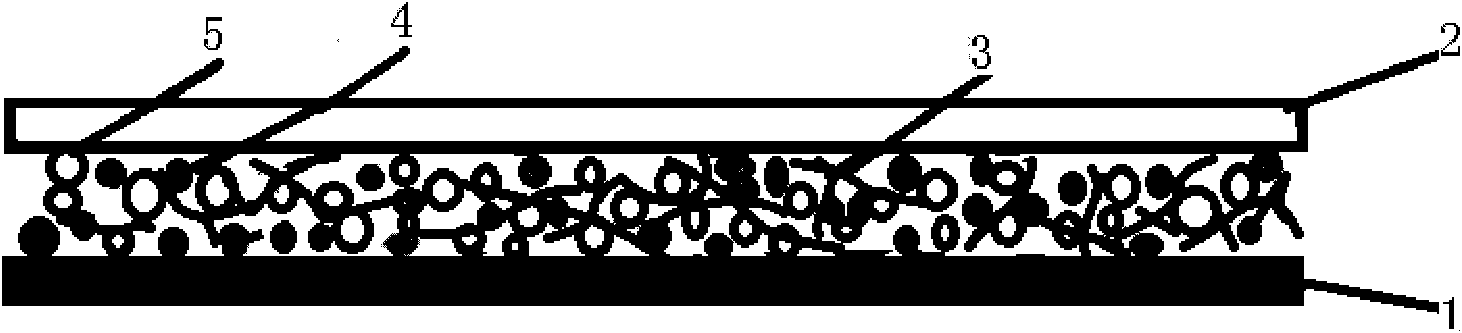

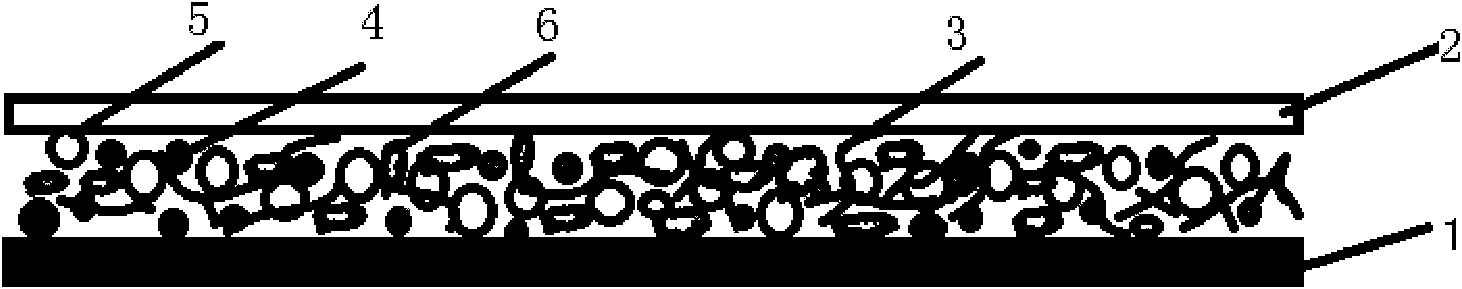

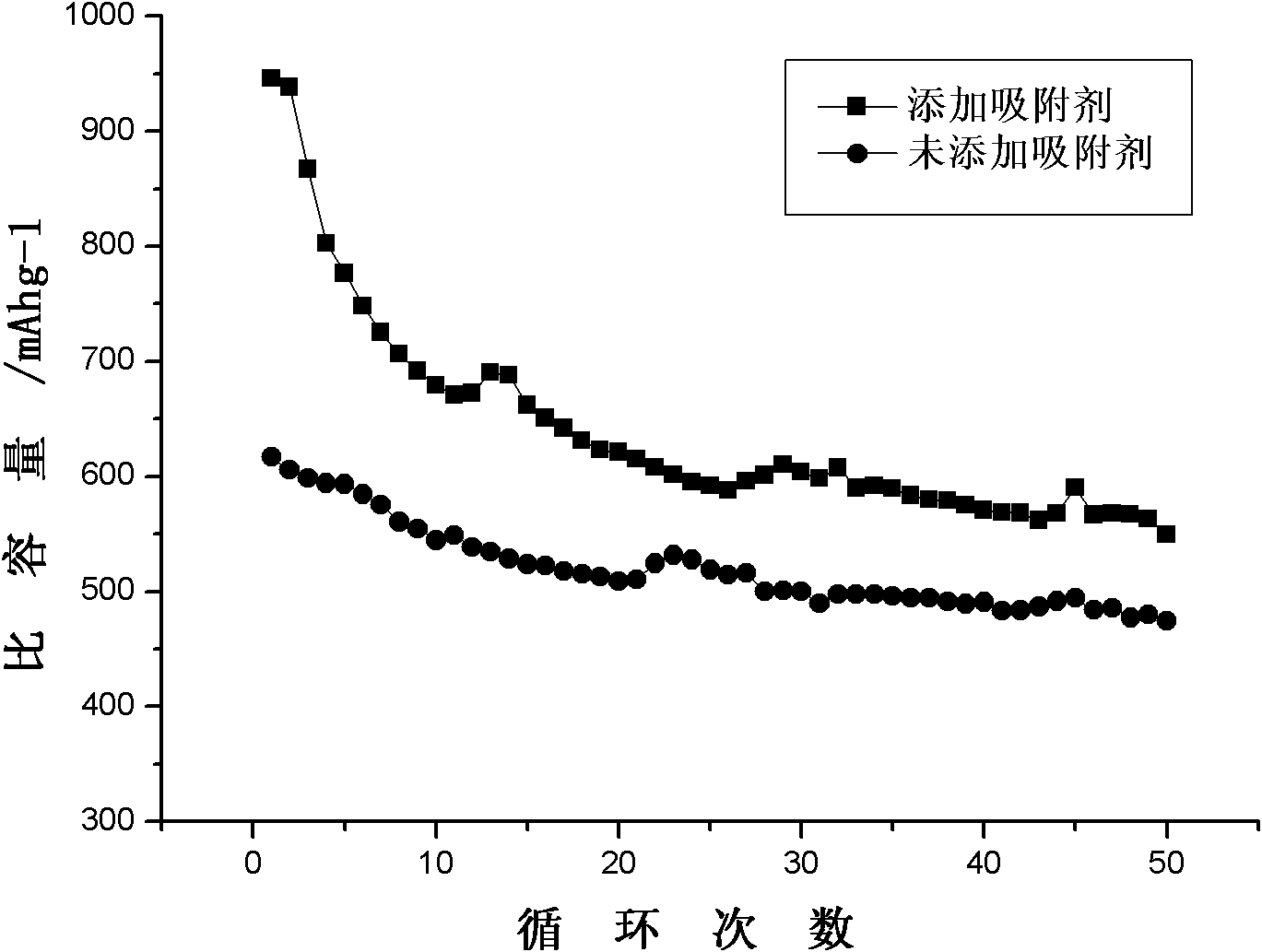

Lithium sulfur battery provided with adsorption layer

The invention relates to a lithium sulfur battery provided with an adsorption layer. The adsorption layer is added in the lithium sulfur battery, is made of a strong-adsorption material with a high specific surface area and a porous structure, and is positioned between an anode pole piece and a porous diaphragm. The adsorption layer can adsorb polysulfide formed in charging and discharging processes of the lithium sulfur battery and prevent the polysulfide dissolved in electrolytic solution from scattering to the surface of a cathode to generate corrosion reaction with lithium and cause irreversible capacity losses of the battery. Therefore, the adsorption layer can improve the performance of the lithium sulfur battery.

Owner:WUHAN UNIV OF TECH

Lithium sulphur battery anode piece added with absorbent and lithium sulphur battery

InactiveCN102185127ALi-accumulatorsNon-aqueous electrolyte accumulator electrodesCapacity lossCorrosion reaction

The invention relates to a lithium sulphur battery anode piece added with an absorbent and a lithium sulphur battery. In the invention, a material which has the characteristics of high specific surface area and strong absorption performance is used as the absorbent; the absorbent is added into the anode piece of the lithium sulphur battery; and the addition amount of the absorbent is more than 5% of the mass of the anode piece. The added absorbent can absorb the polysulfide of the lithium sulphur battery in the charge and discharge courses, thereby avoiding the polysulfide from being absorbed on the surface of a sulfhydryl composite material to reduce the electrical conductivity, and can simultaneously prevent the polysulfide from being scattered on the surface of the cathode and generating a corrosion reaction with lithium to further cause the irreversible capacity loss of the battery. Thus, the added absorbent can be used for improving the performance of the lithium sulphur battery provided by the invention.

Owner:WUHAN UNIV OF TECH

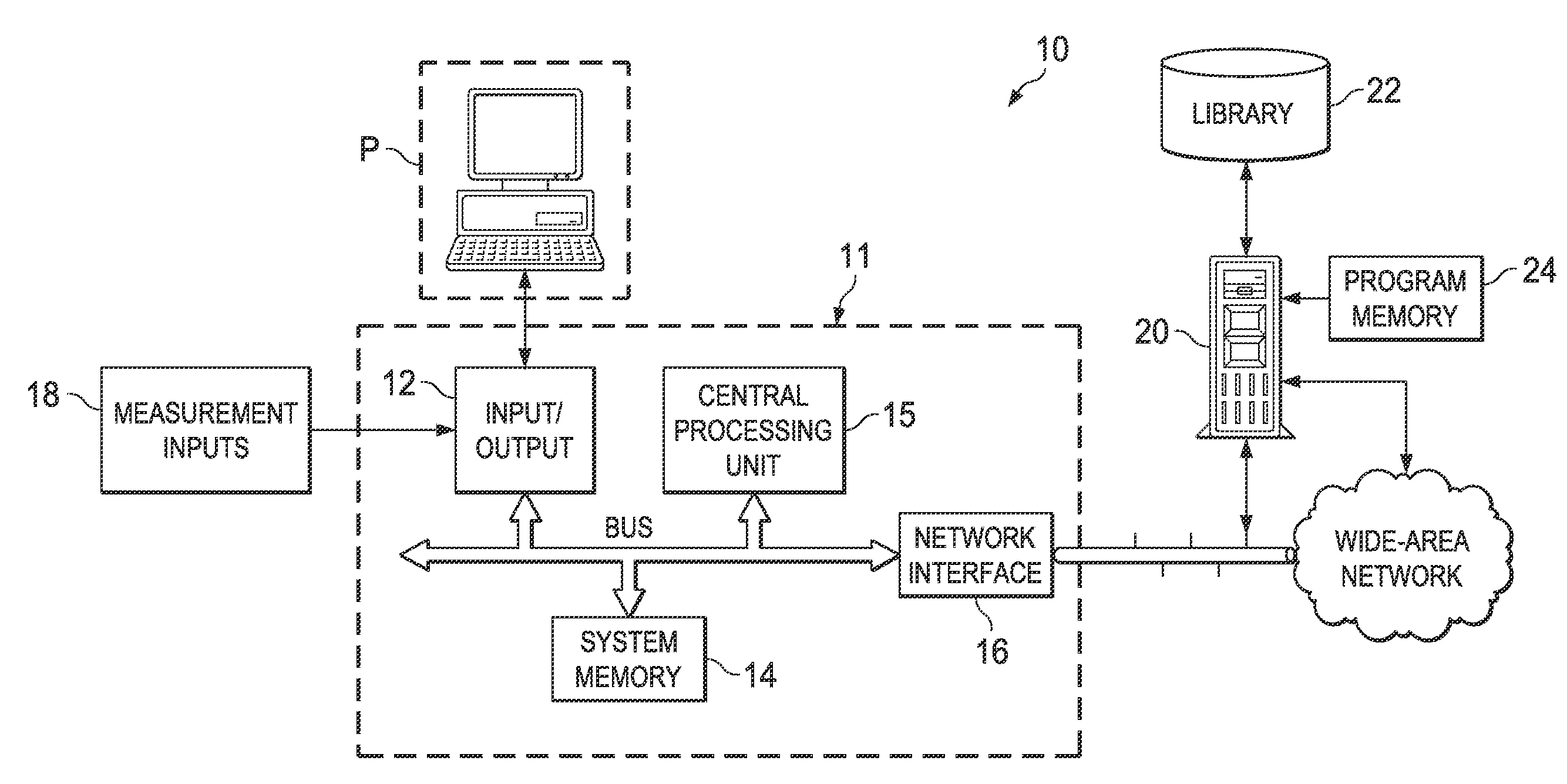

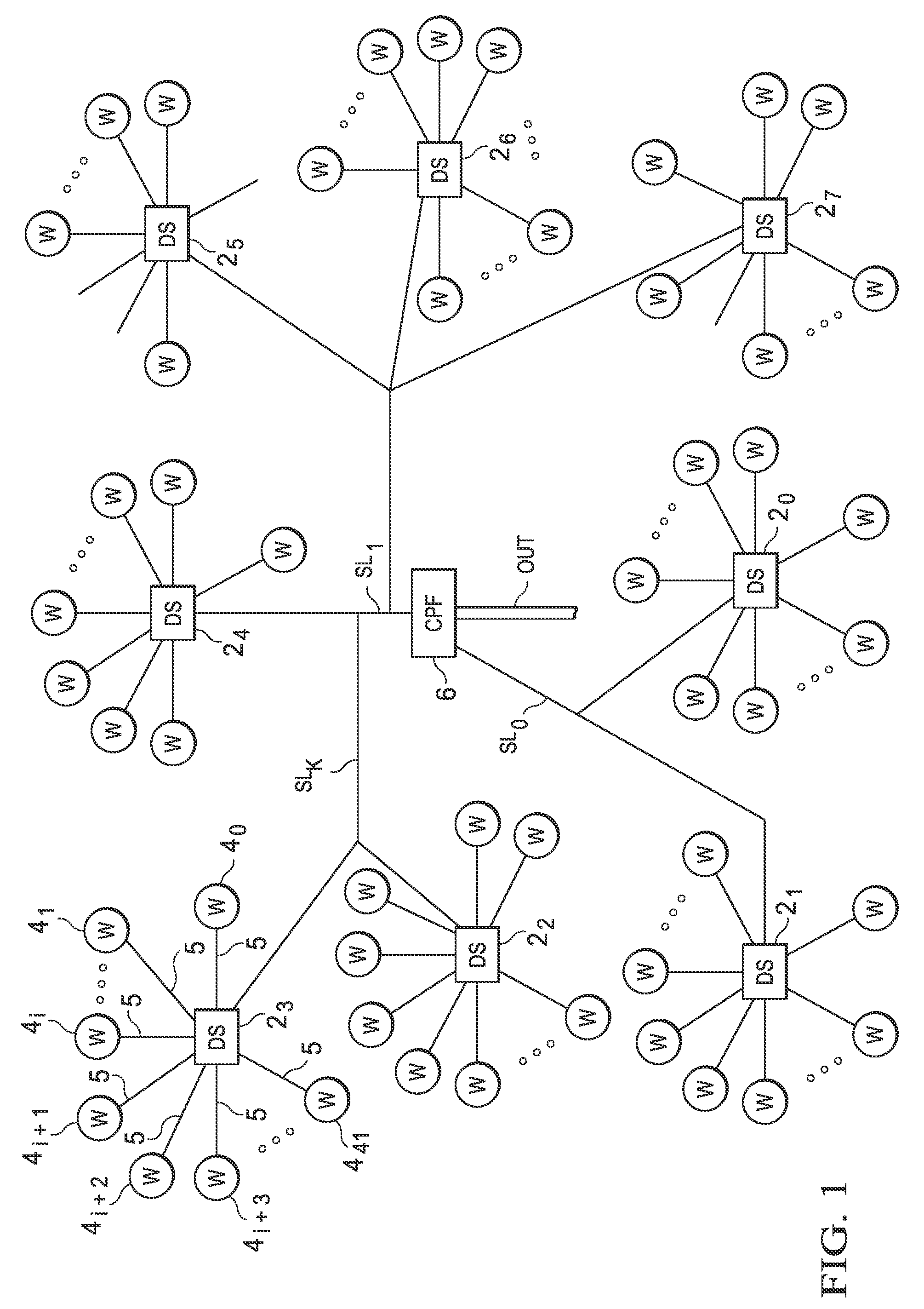

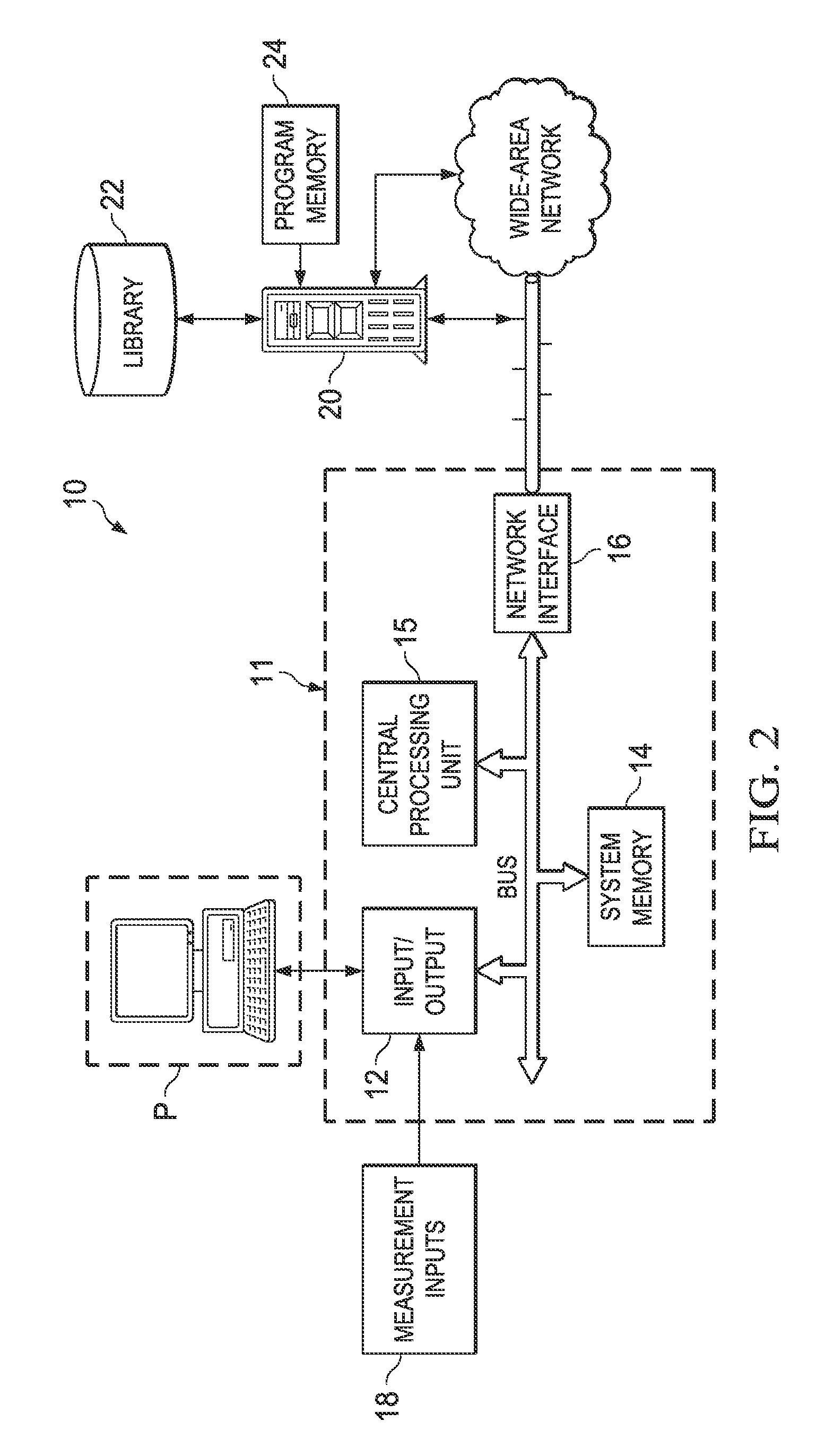

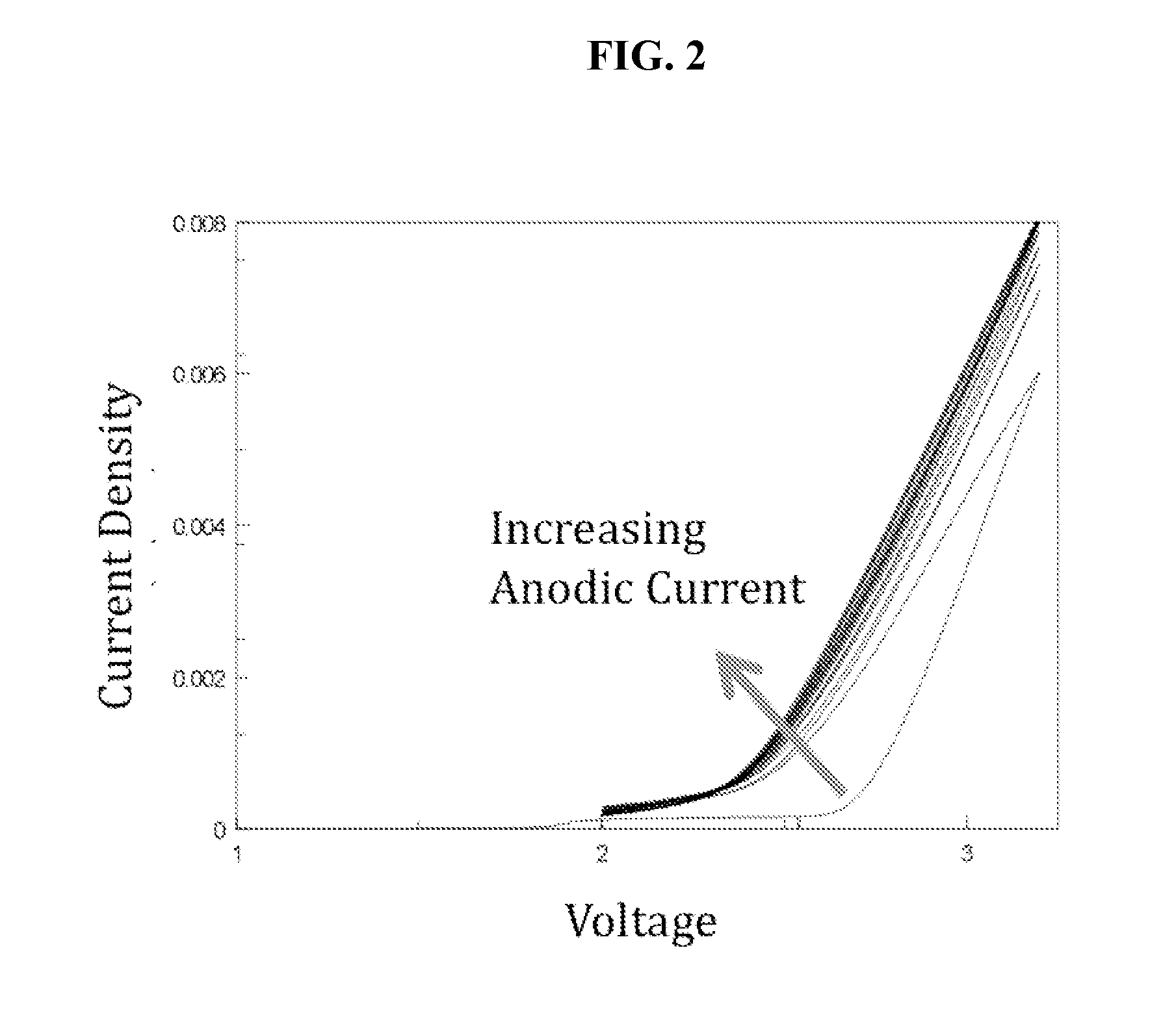

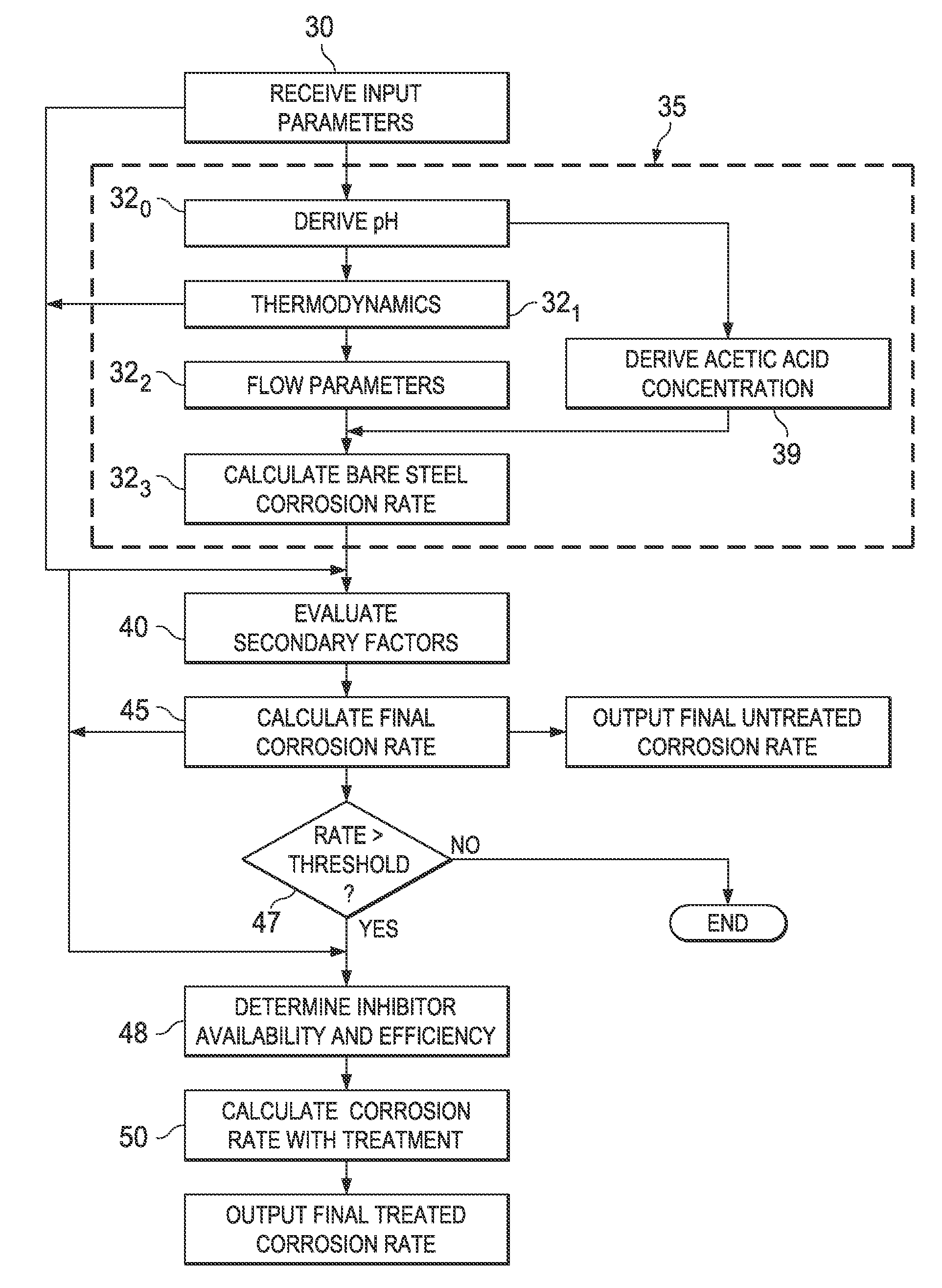

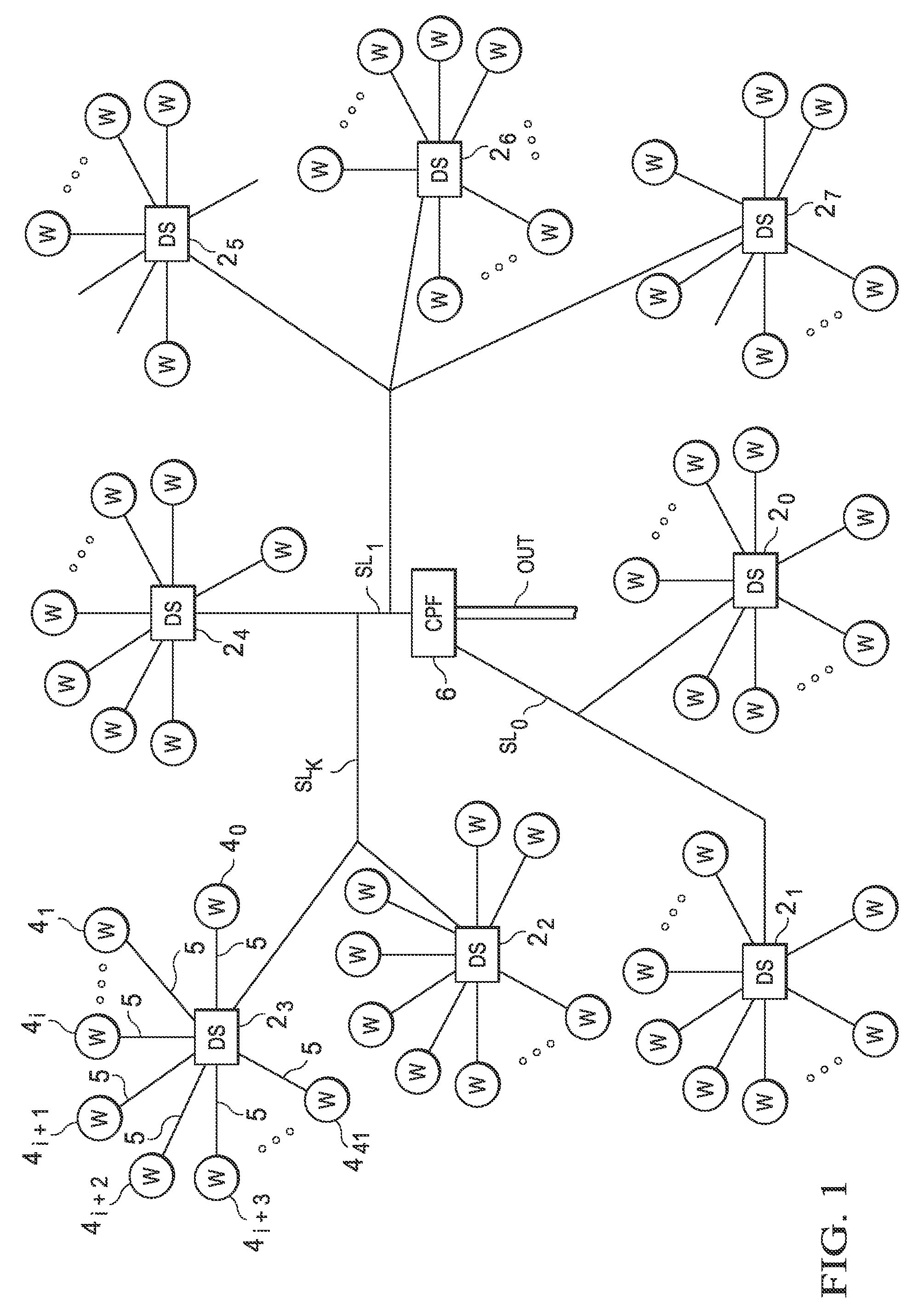

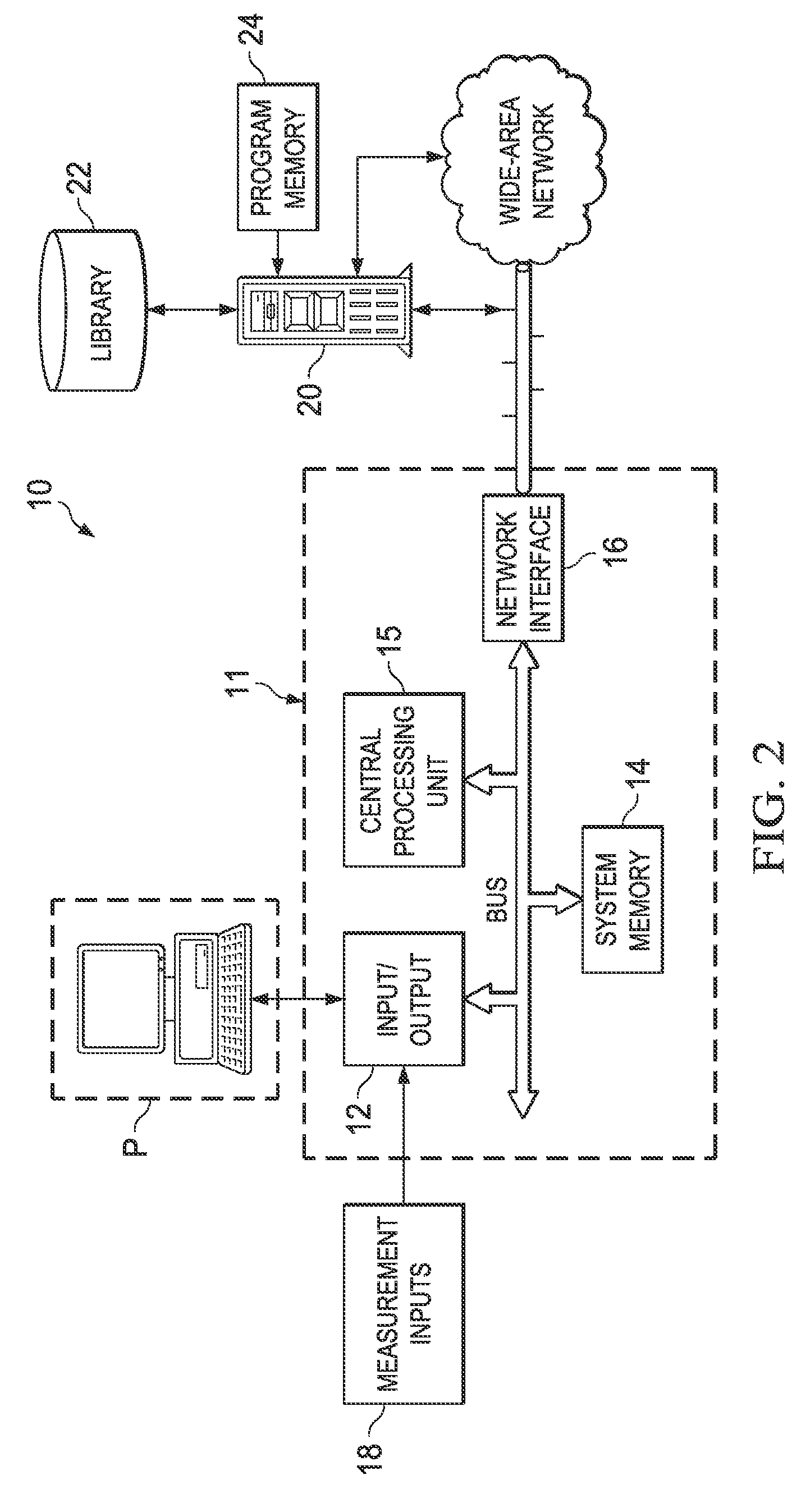

Method and system for predicting corrosion rates using mechanistic models

InactiveUS20100185401A1Efficient designPlug gaugesWeather/light/corrosion resistanceCorrosion reactionMechanical models

A computer system and method for predicting the aqueous phase CO2 corrosion rate of a pipe useful in the production and transportation of oil and gas. Input parameter values corresponding to water chemistry and physical fluid and pipe properties are received. Based on these input parameter values, the system and method derive current-voltage relationships for multiple cathodic reduction reactions according to an electrochemical model of the corrosion reaction, and a current-voltage relationship for the anodic oxidation reaction of iron dissolution. A current density is obtained, at the intersection of an extrapolation of the anodic current-voltage relationship and an extrapolation of the summed cathodic current-voltage relationships. The predicted corrosion rate is then calculated from the obtained current density. The effects of secondary parameters such as scale and flow regime, and the efficacy of a corrosion inhibitor, can also be evaluated.

Owner:BP CORP NORTH AMERICA INC

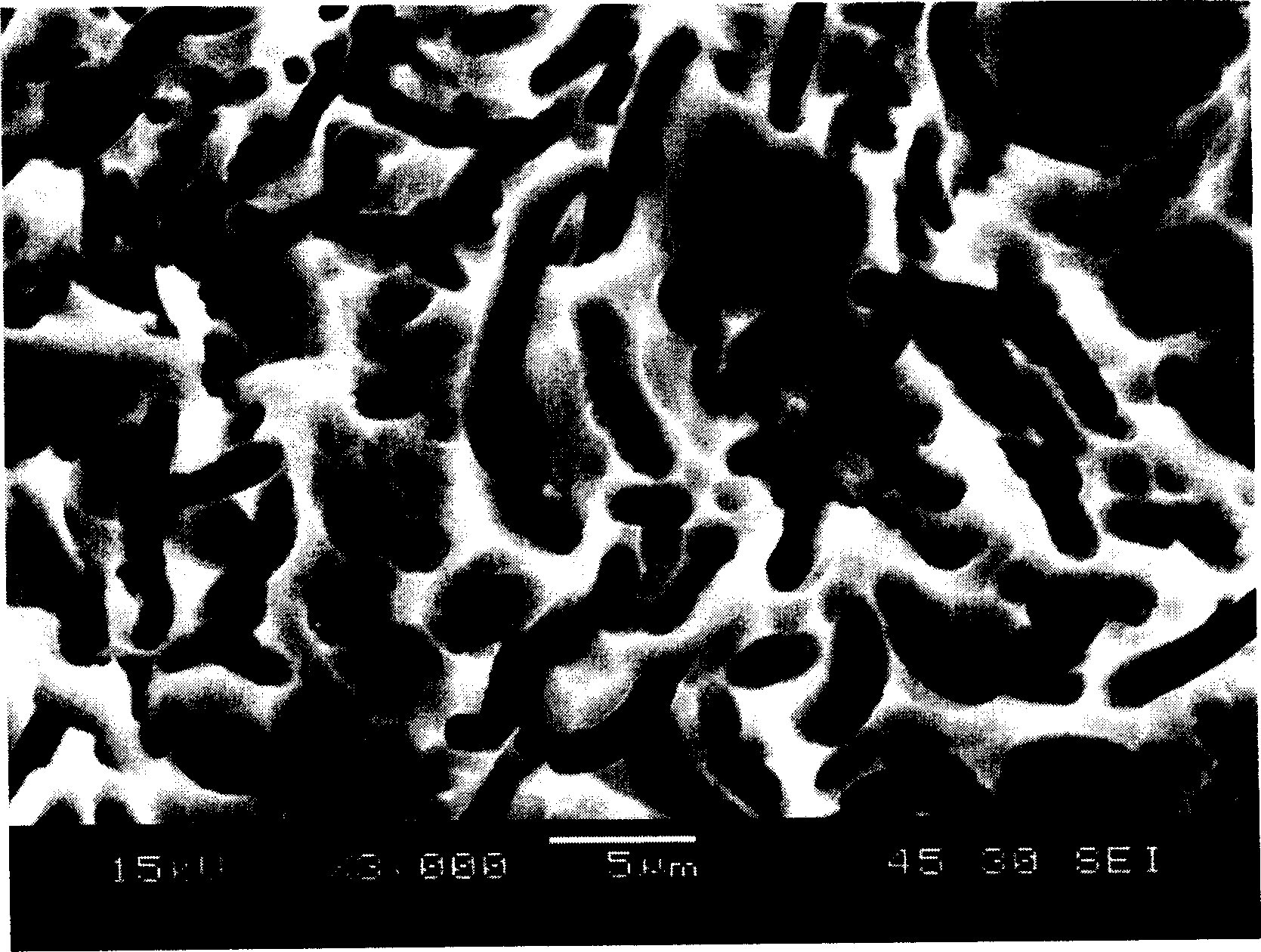

Acid corrosion solution for preparing multicrystal silicon pile surface and its using method

ActiveCN1821446AEliminate hazardsSuitable for mass productionSemiconductor/solid-state device manufacturingPhotovoltaic energy generationCorrosion reactionHydrofluoric acid

The present invention discloses acid corrosion solution for preparing polycrystalline silicon pile surface and its usage. The solution is compounded with oxidant and hydrofluoric acid and through mixing, and the oxidant is nitrate or nitrite. During use, the cut polycrystalline silicon chip is set inside the corrosion solution for corrosion at the temperature of -10 to +25 deg.c for 0.5-20 min to eliminate damage surface caused by wire electrode cutting, with the acid corrosion time and temperature being dependent on the solution concentration. The present invention is suitable for both intermittent production and continuous production, and has easy treatment of the produced waste acid.

Owner:WUXI SUNTECH POWER CO LTD

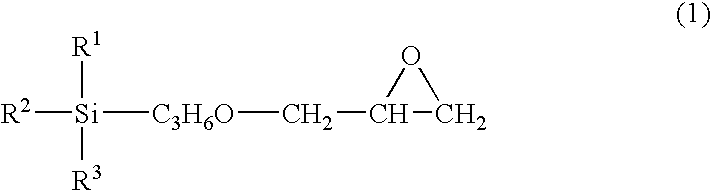

Clear coating composition, method of forming multilayer coating film and inmold decoration product

InactiveUS20060014024A1Design value is deterioratedBeautiful designSynthetic resin layered productsPolyurea/polyurethane coatingsClear LayerCorrosion reaction

It is an object of the present invention to provide a clear coating composition which inhibits a corrosion reaction by containing a rust preventive agent in a clear layer on a silver-plating layer and preventing a corrosive substance such as chlorine ion from contacting with the surface of the silver-plating layer, and develops beautiful silver-plating design for a long time, and an inmold decoration product comprising a silver-plating layer. A clear coating composition used in forming a multilayer coating film comprising a silver-plating layer, said multilayer coating film being obtainable by forming a base coating film layer, a silver-plating layer and a clear coating film layer in succession on a plastic substrate, wherein said clear coating composition is a two-package polyurethane coating composition comprising a main material containing acrylic polyol and a curing agent containing a polyisocyanate compound, the equivalence ratio of an NCO group in said polyisocyanate compound to an OH group in said acrylic polyol (NCO / OH) ranges from 0.8 / 1 to 1.2 / 1, and the clear coating composition contains a rust preventive agent in the proportions of 1.0 to 13.0 parts (on a basis of solids weight) with respect to 100 parts by weight of the total of the acrylic polyol and the rust preventive agent.

Owner:HONDA MOTOR CO LTD +1

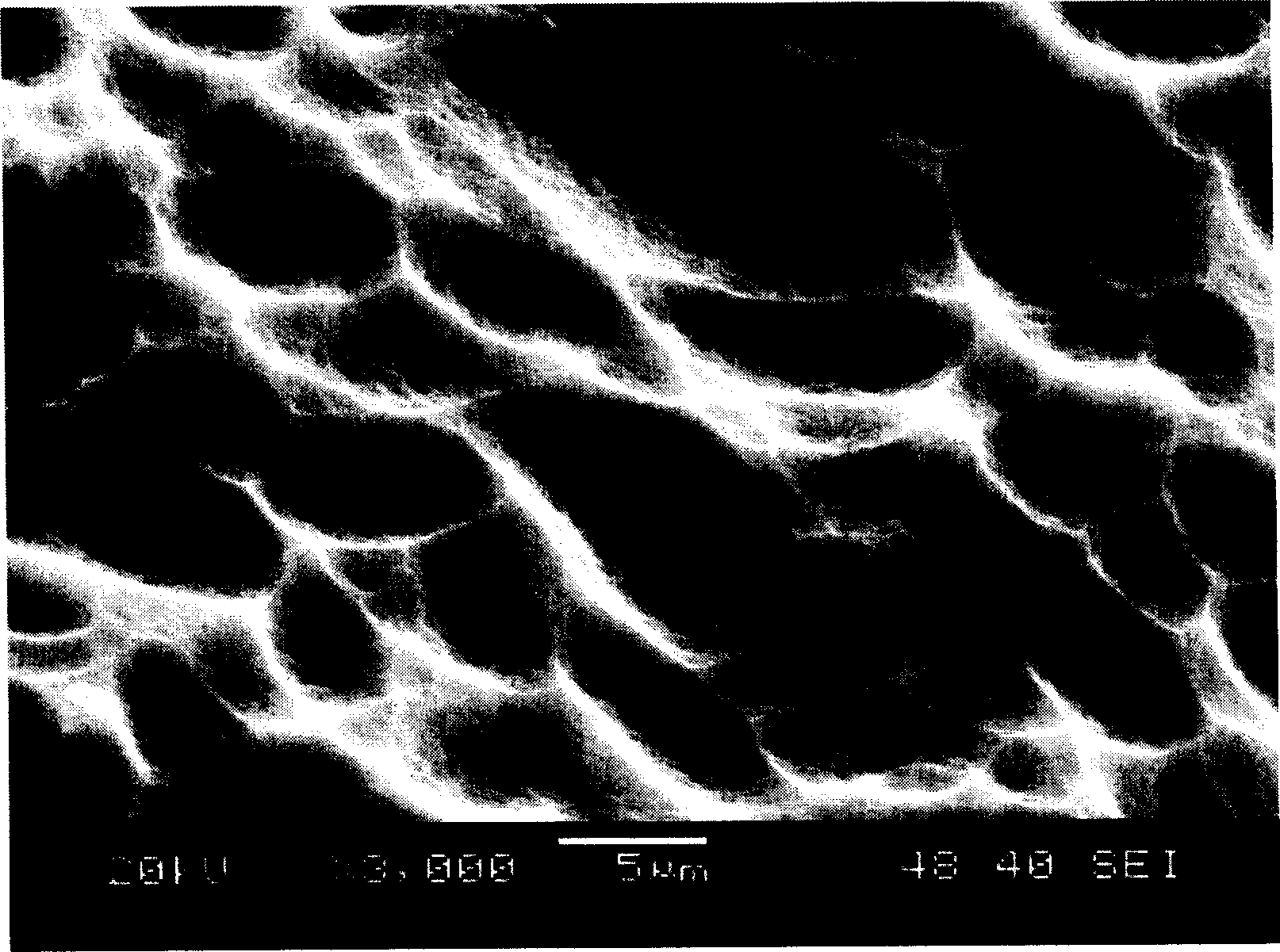

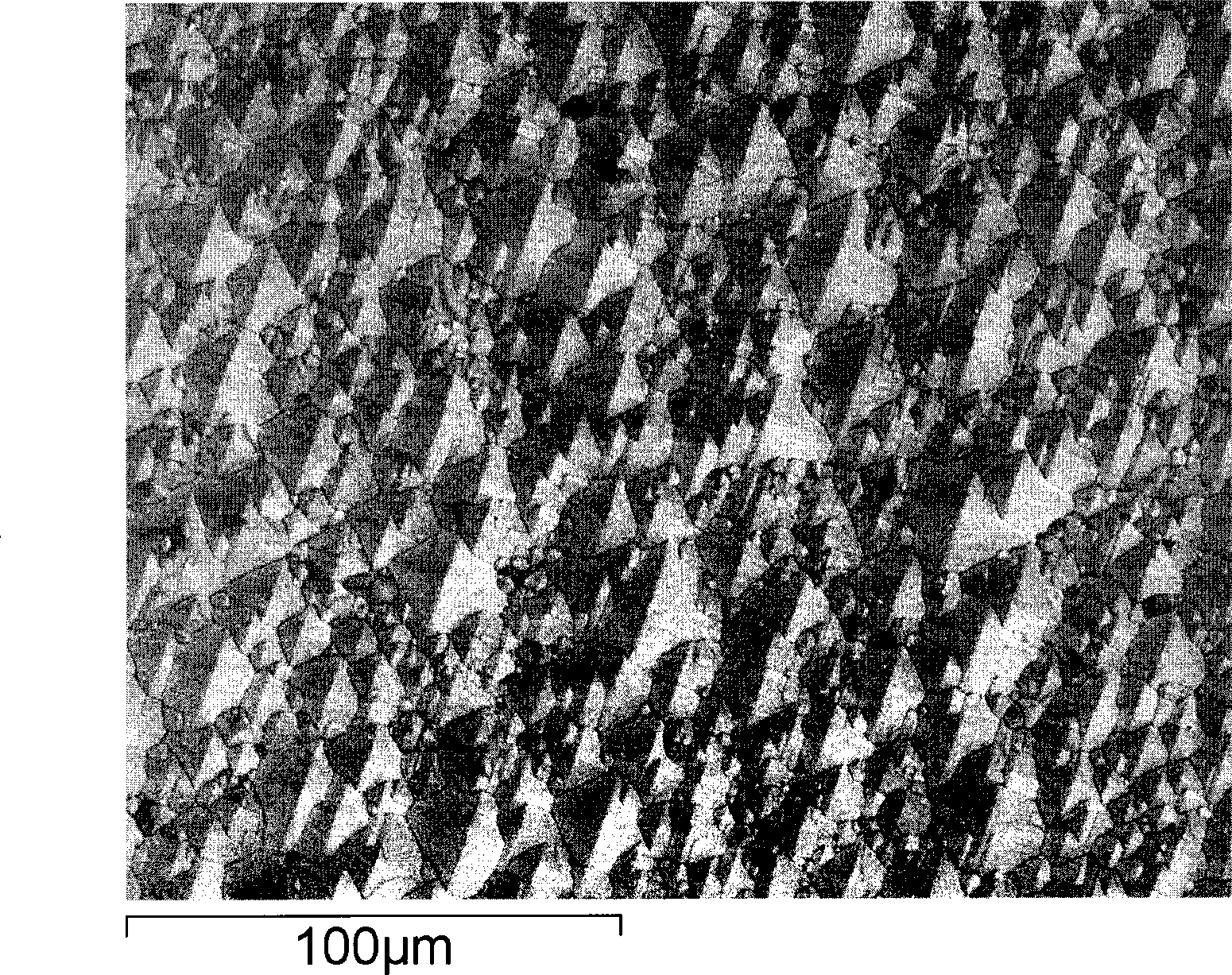

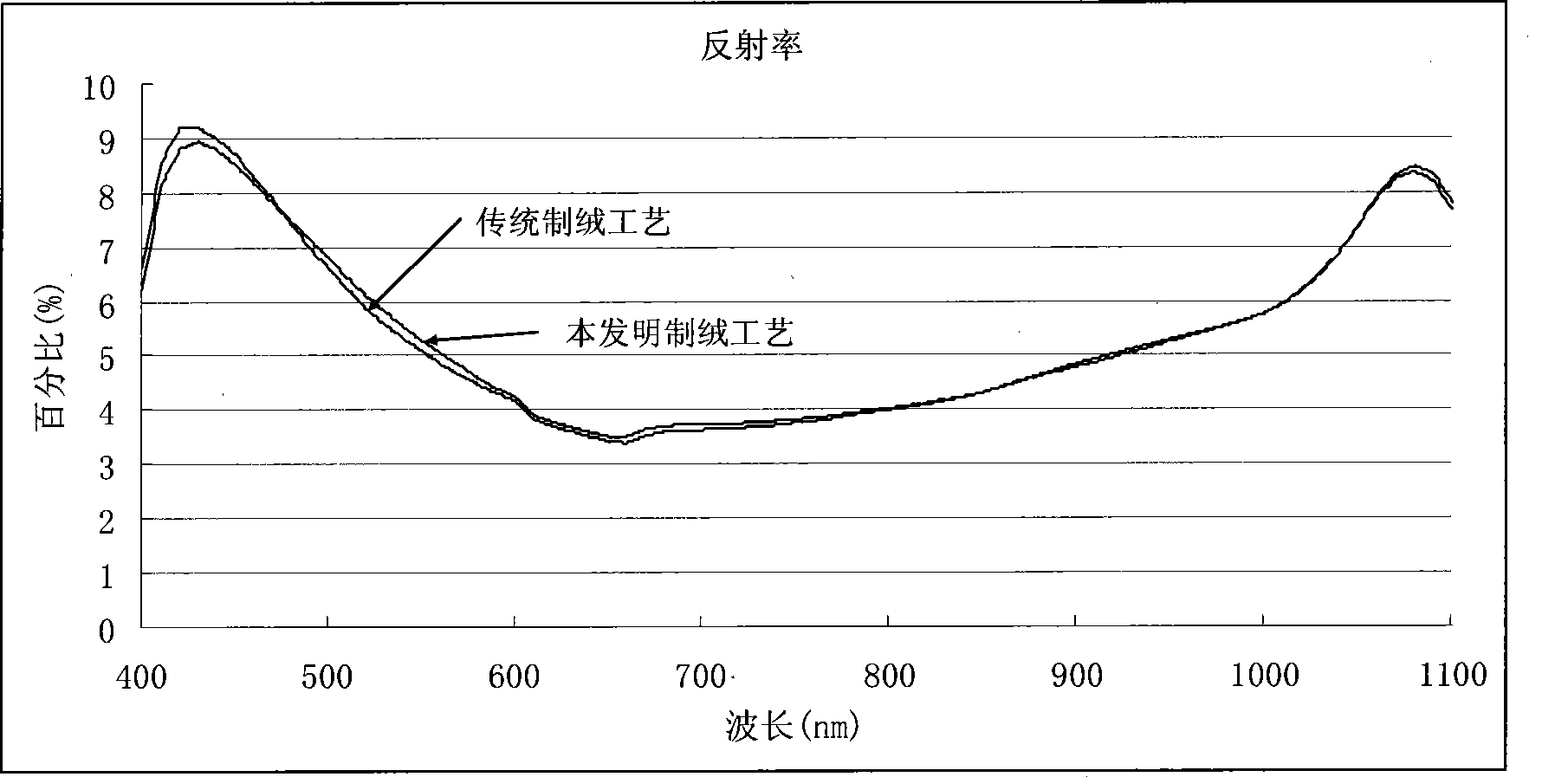

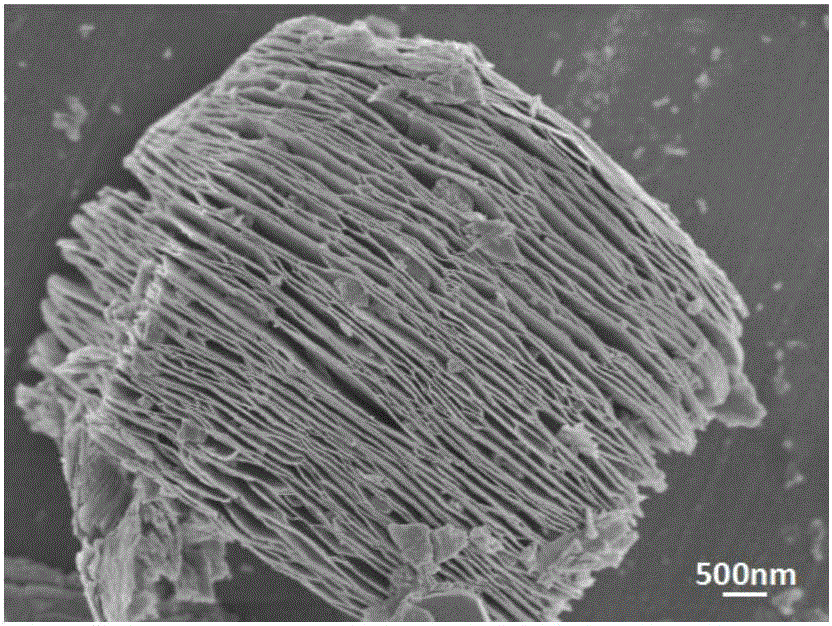

Method for texturing silicon wafer cut by diamond wire

ActiveCN102220645AReduce reflectivityAfter-treatment detailsFinal product manufactureCorrosion reactionProcess manufacturing

The invention belongs to the technical field of the texturing of silicon wafers, and particularly relates to a method for texturing a silicon wafer cut by a diamond wire, which comprises the following steps of: 1, cleaning the silicon wafer cut by the diamond wire; 2, performing acidic corrosion reaction on the cleaned silicon wafer in H2SO4 or H3PO4-HF-HNO3 mixed acidic solution for 30 to 70 seconds, wherein a volume ratio of the H2SO4 or the H3PO4 to the HF to the HNO3 is (2-10):(1-4):(1-4), the concentration of the H2SO4 is 98 percent, the concentration of the HF is 49 percent, the concentration of the HNO3 is 63 percent, and the concentration of the H3PO4 is 85 percent; 3, soaking the silicon wafer which reacts with the acids in alkali texturing liquid, and reacting for 10 to 30 seconds; 4, soaking the silicon wafer which reacts with alkali in HCL-HF solution for 30 to 120 seconds; and 5, drying the reacted silicon wafer, and performing subsequent cell process manufacturing. Compared with the conventional texturing process, the optimized method for texturing the silicon wafer cut by the diamond wire has the advantages that: the reflectivity of the textured silicon wafer is reduced by about 6 percent, and the cell efficiency is improved greatly.

Owner:TRINA SOLAR CO LTD

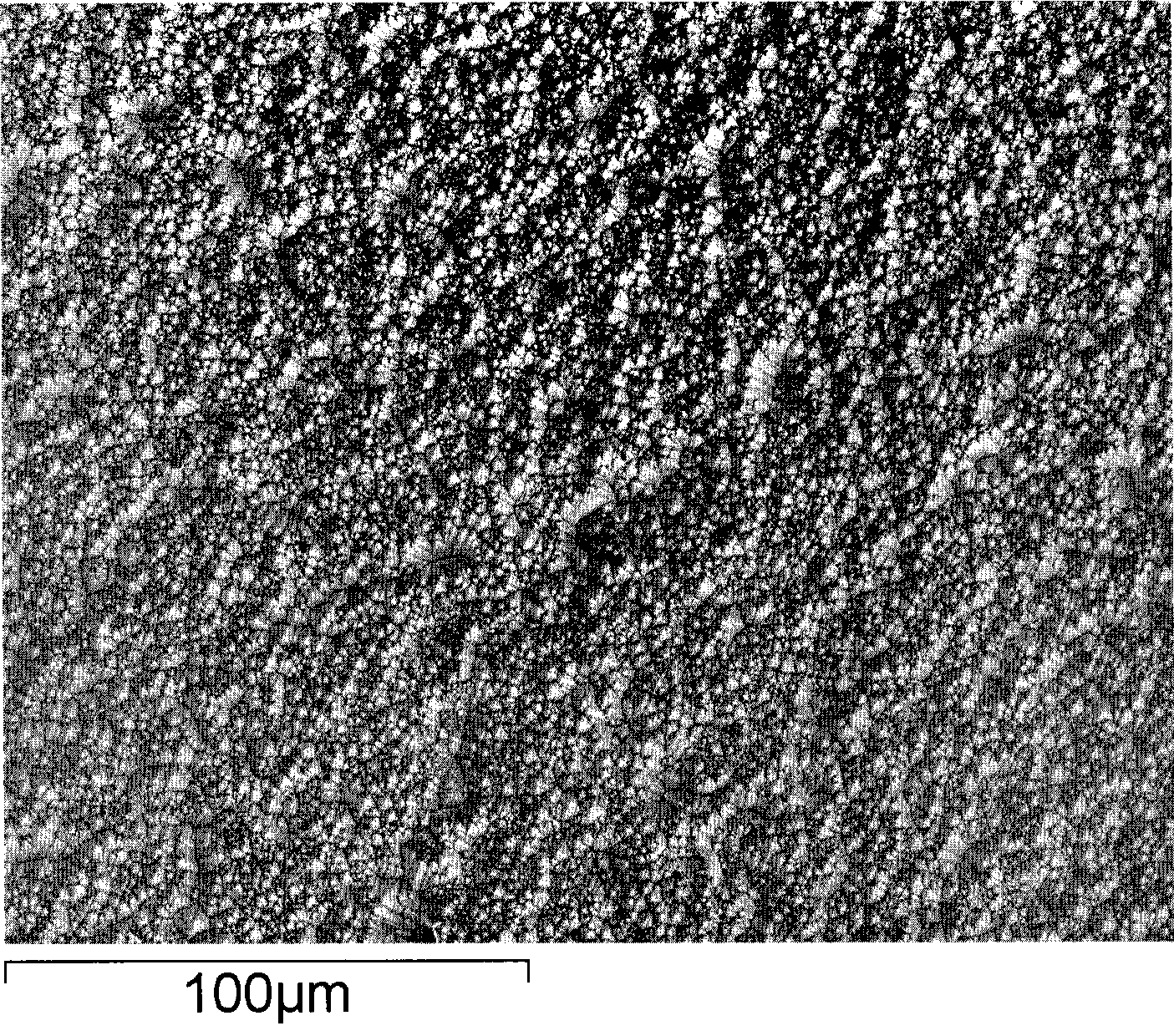

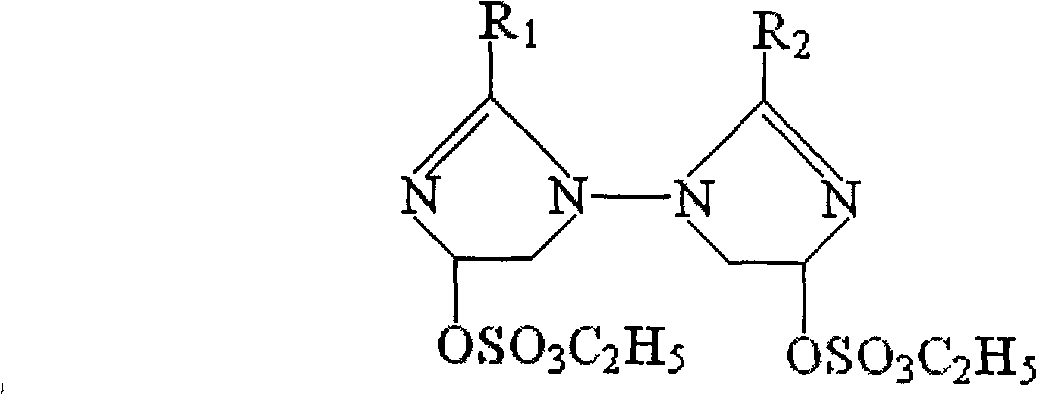

Method for preparing monocrystal silicon textured surface

InactiveCN101634027AReduce dosageHigh thermodynamic stabilityAfter-treatment detailsSemiconductor devicesCorrosion reactionSulfonate

The invention relates to a method for preparing monocrystal silicon textured surfaces, which comprises the following steps: (1). preparing alkali corrosive liquid comprising an alkali solution, sodium silicate and isopropanol in a thermostatic bath at the temperature of 75-85DEG C, wherein the alkali solution has the volume percent of 1-2.5 percent, the sodium silicate has the mass percent of 0.1-2 percent, and the isopropanol has the mass percent of 0.5-3 percent; (2). adding a perfluorooctyl sulfonate solution with the concentration of 5*10<-5>-5*10<-3>mol / L into the thermostatic bath filled with the alkali corrosive liquid in step 1 such that the volume percent of perfluorooctyl sulfonate solution is 0.2-1 percent, simultaneously putting monocrystal silicon into the thermostatic bath for corrosion reaction, taking out the monocrystal silicon after 10-20 minutes, flushing with deionized water and drying. Pyramids formed on the prepared monocrystal silicon textured surfaces have small and uniform sizes, and the method is favorable for improving the efficiency of solar batteries and can be used for the large-scale production of the solar batteries.

Owner:BEIJING SOLAR ENERGY INST +1

Alkali etch solution and method for preparing monocrystalline silicon pile fabrics

InactiveCN101423942AReduce dosageImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationCorrosion reactionSolar cell

The invention belongs to the field of monocrystalline silicon solar battery production and discloses an alkaline corrosion solution and a method for preparing monocrystalline silicon texture. The solution is a mixed liquor of an alkaline solution, isopropanol and Na2SiO3, and is structurally characterized in containing 0.002 to 0.01 weight percent of Pb(NO3)2 or Pb. The weigh percentage of the alkaline solution is 1 to 3.5 percent, the weight percentage of the isopropanol is 5 to 7 percent, and the weight percentage of Na2SiO3 is 0.2 to 2 percent. The method is to soak a monocrystalline silicon piece in the alkaline solution to perform a corrosion reaction for 20 to 30 minutes under a condition that the alkaline corrosion solution is at a temperature of between 75 and 80 DEG C. The alkaline corrosion solution and the method have the advantages of reducing surface reflectivity of the monocrystalline silicon piece, preparing a fine texturing 'pyramid', along with low cost, simple operation and stable and effective preparation of the monocrystalline silicon texture.

Owner:蒋冬 +1

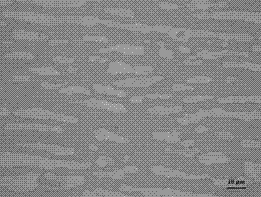

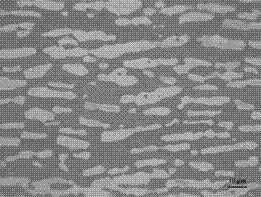

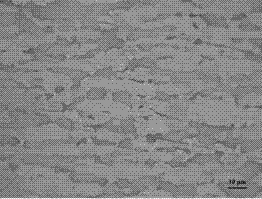

Tin electrodeposits having properties or characteristics that minimize tin whisker growth

InactiveUS20070007144A1Minimizing and preventing tin whisker formationMinimizing and preventing and growthSemiconductor/solid-state device detailsPrinted circuit aspectsCorrosion reactionMaterials science

A method of reducing tin whisker formation by creating a tin deposit which is inherently less prone to tin whisker formation or growth facilitated by oxide presence or corrosion reactions on the tin deposit surface. This is obtained by one or more of: (i) the deposition of a fine-grained tin deposit having an average grain diameter in the range of 0.05 to 5 microns; (ii) a phosphorous compound in the solution that is used to electroplate the tin deposit so that that the deposit incorporates trace amounts of phosphorous which in turn reduces tin whisker formation by preventing surface oxides even when exposed to heat or humidity; or (iii) a phosphorous compound, mercaptan, or organic or organo-metallic compound in a solution that applies a protective coating to the surface of a previously electroplated tin deposit, wherein the protective coating acts to minimize or prevent oxide formation or corrosion of the tin deposit during exposure to heat or humidity. Such tin deposits containing 80% to 100% by weight of tin exhibit minimal to no tin whisker growth.

Owner:TECHNIC INC

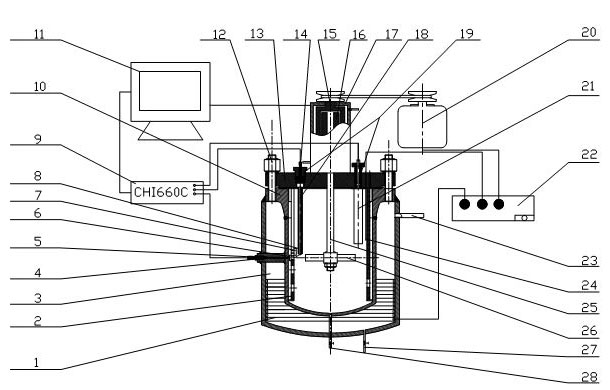

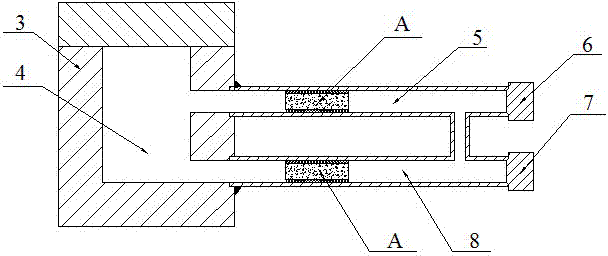

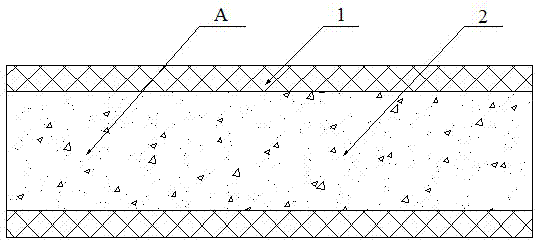

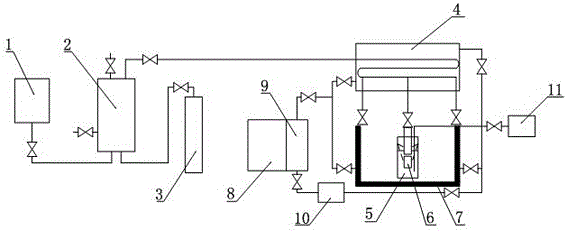

Vapour-liquid two-phase flow accelerated corrosion test device

InactiveCN101900664ASimple structureEasy to operateWeather/light/corrosion resistanceCorrosion reactionGas phase

The invention relates to a vapour-liquid two-phase flow accelerated corrosion test device which is characterized by comprising a testing autoclave body, an oil bath heating jacket, an autoclave body cover, a magnetic rotating device, a high-temperature reference electrode, a graphite auxiliary electrode, a working electrode, a variable frequency motor, a potentiostat, a corrosion measurement computer, an equipment control cabinet, an inner lining, a gas-phase generator, an electric heater and a thermocouple sensor. In the invention, an electrochemical measurement method is adopted to carry out experimental study on the relevant properties of vapour-liquid two-phase flow accelerated corrosion, including the measurement of relevant coefficients of the transient corrosion property, the corrosion impedance and the corrosion reaction, the relation between mass transfer and corrosion reaction, the relation between the vapour-liquid two-phase flow pattern and the corrosion rate and production and breakage mechanism of a corrosion product membrane and the critical characteristic of the breakage. The high-speed rotation is realized and meanwhile, and the good sealing property is ensured by adopting the magnetic rotating device.

Owner:NANJING UNIV OF TECH

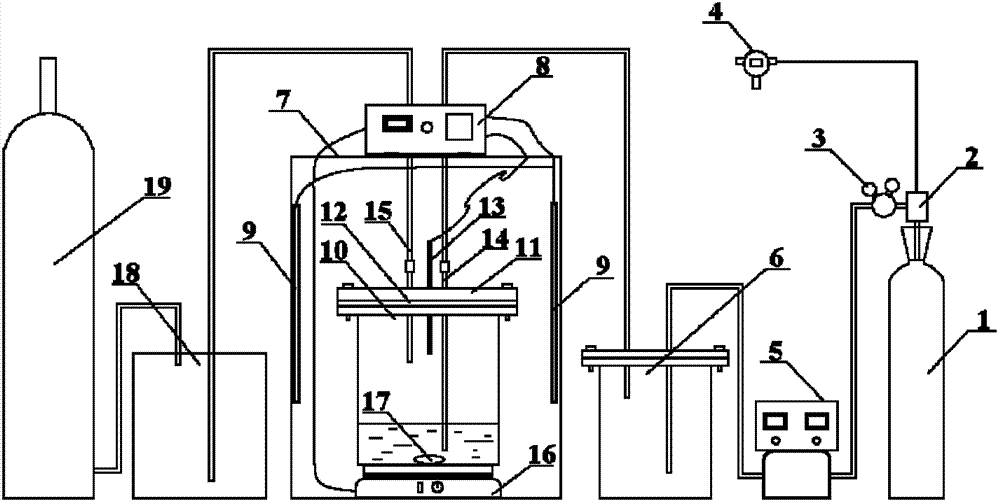

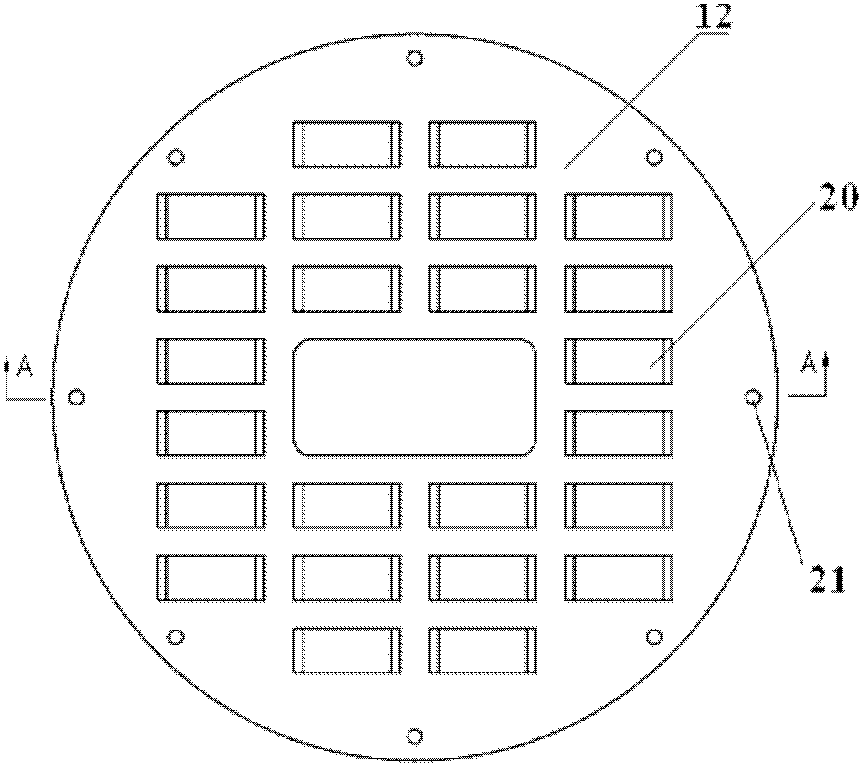

Gas/liquid corrosion simulation test device and test method

InactiveCN103364328ASimple structureEasy maintenanceWeather/light/corrosion resistanceCorrosion reactionGas cylinder

The invention provides a gas / liquid corrosion simulation test device and a test method. The device is formed by a gas supply system, a corrosion reaction pot, a temperature control system, a medium flow-state control system, a safety alarm system and a tail gas treatment system, wherein the gas supply system is used for conveying corrosive gas into the corrosion reaction pot through a gas inlet pipe; tail gas exhausted by the corrosion reaction pot is conveyed to the tail gas treatment system through a gas outlet pipe; the gas supply system is formed by sequentially connecting a gas bottle, a decompressor, a gas flow controller and a gas mixing pot; the upper part of the corrosion reaction pot is provided with a test sample frame and an upper cover; the temperature control system comprises a heating pipe and a thermoelectric couple and is controlled by a programmable controller; the medium flow-state control system is a magnetic stirrer and is located at the bottom of the corrosion reaction pot. The device disclosed by the invention can simulate a plurality of corrosion environments of gas, liquid, static gas-liquid coexistence, laminar flow gas-liquid coexistence and the like, and is simple in structure, easy to maintain, good in safety and small in environmental pollution; the device does not need to be guarded by a specially-assigned person in a use process.

Owner:ANGANG STEEL CO LTD

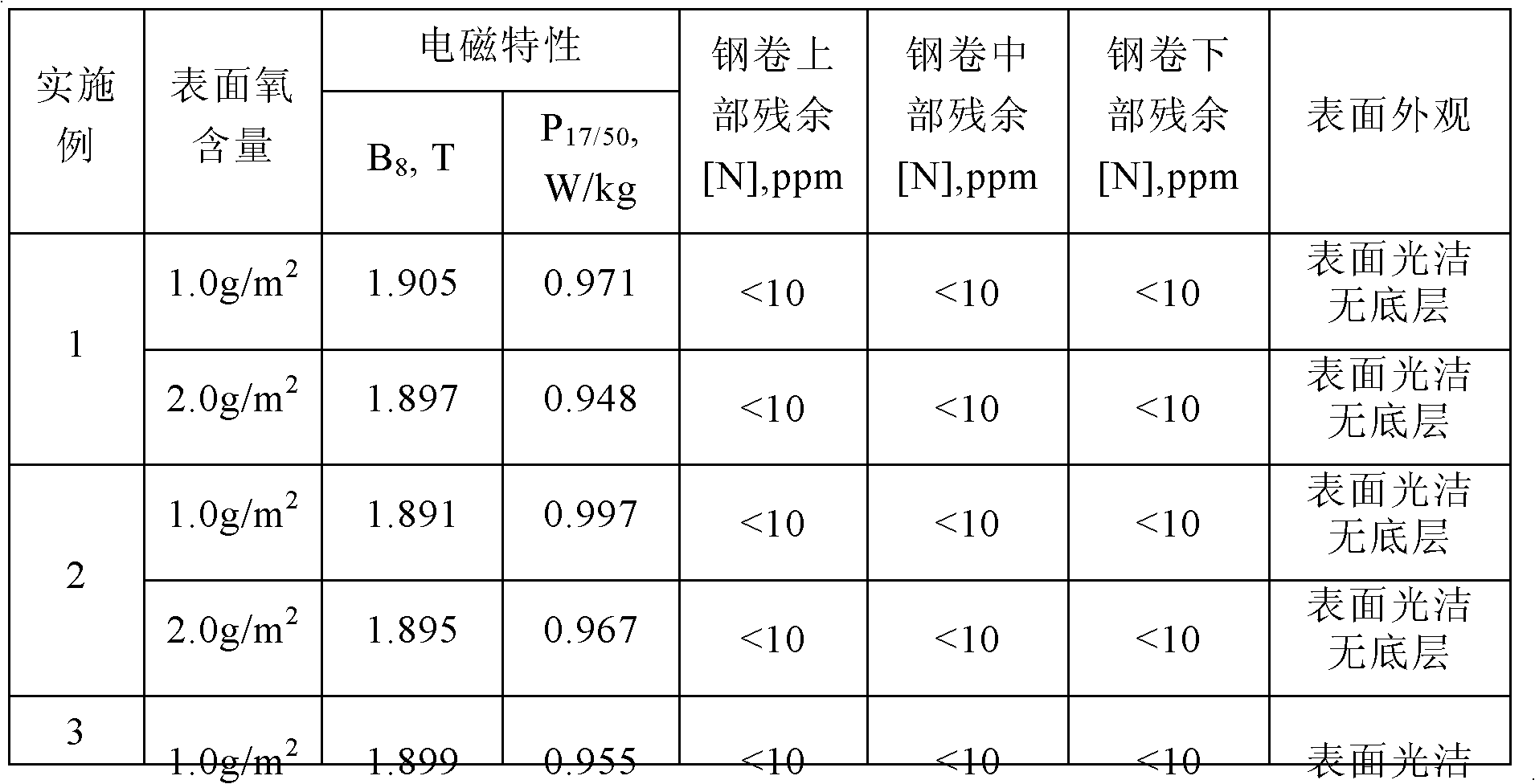

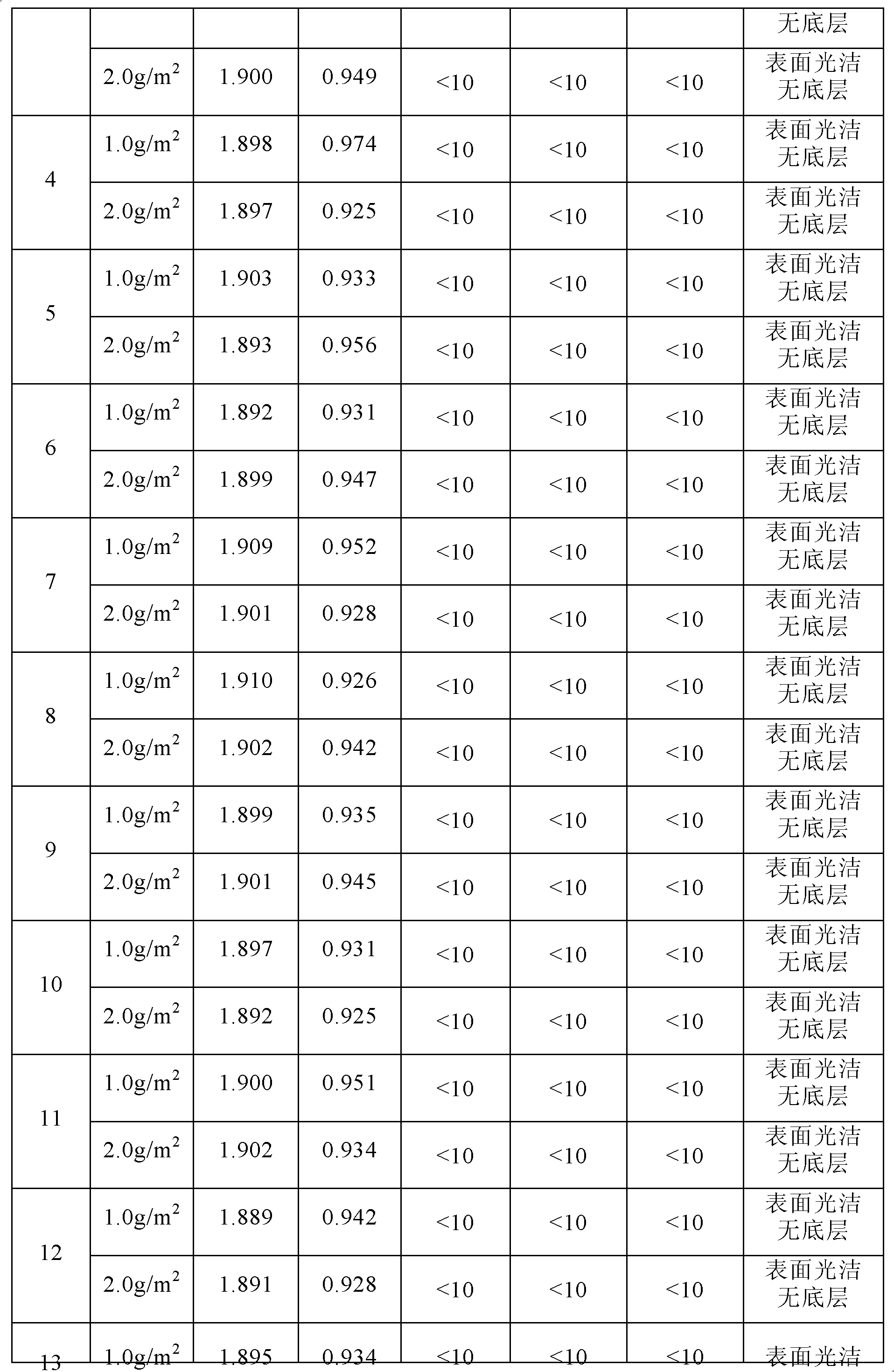

Manufacturing method of mirror surface oriented silicon steel with good magnetic performance and annealing parting agent

ActiveCN103014285AStrong magnetismFlat surfaceFurnace typesHeat treatment furnacesCorrosion reactionMetal chloride

The invention discloses a manufacturing method of mirror surface oriented silicon steel with good magnetic performance and an annealing parting agent. The manufacturing method comprises the following steps of: 1) smelting; 2) hot rolling and normalizing; 3) cold rolling; 4) decarbonization and nitriding; and 5) parting agent coating and high-temperature annealing. The annealing parting agent comprises the following components in parts by mass: 65-96 parts of Al2O3 powder, 2-15 parts of silicate powder with a particle size of 0.1-100 microns, 1-10 parts of alkaline earth metal oxide and 1-10 parts of metal chloride. According to the invention, through the annealing parting agent consisting of Al2O3 powder, silicate powder, alkaline earth metal oxide and metal chloride, a glass film bottom layer is not formed on the surface of a steel plate in a high-temperature annealing process, and the steel can be effectively purified; and meanwhile, the embedded oxide on the near surface of a substrate is removed through the corrosion reaction of chloride so as to obtain a product with a smooth and clean surface and stable magnetic performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Metallographic corrosion method for clearly displaying 9-12% Cr heat-resistant steel original austenite grain boundary

InactiveCN103983502AIncrease the strength of the electrochemical reactionAvoid corrosionPreparing sample for investigationCorrosion reactionElectrochemical response

The invention provides a metallographic corrosion method for clearly displaying a 9-12% Cr heat-resistant steel original austenite grain boundary, solving the difficult problems that 9-12% Cr heat-resistant steel original austenite crystal grains subjected to quenching and tempering treatment are hardly displayed can be solved by adopting the metallographic corrosion method. By adopting corrosive liquid, on one hand, full acidification effects can be realized, and the electrochemical reaction intensity of a dissolved solution can be improved, and on the other hand, the corrosive liquid can be in chemical reaction with a matrix to generate Fe<3+>, wherein Fe<3+> can be used for inhibiting an intragranular corrosion reaction to a certain extent when heating so as to ensure that the corrosion degree of an intragranular structure is significantly slower than that of a grain boundary. Meanwhile, a certain amount of precipitates exist on the grain boundary to ensure that the corrosion of the grain boundary is relatively strong and can generate a relatively large difference from the intragranular corrosion degree in a certain time, thus obtaining an original austenite grain boundary with a clear outline.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

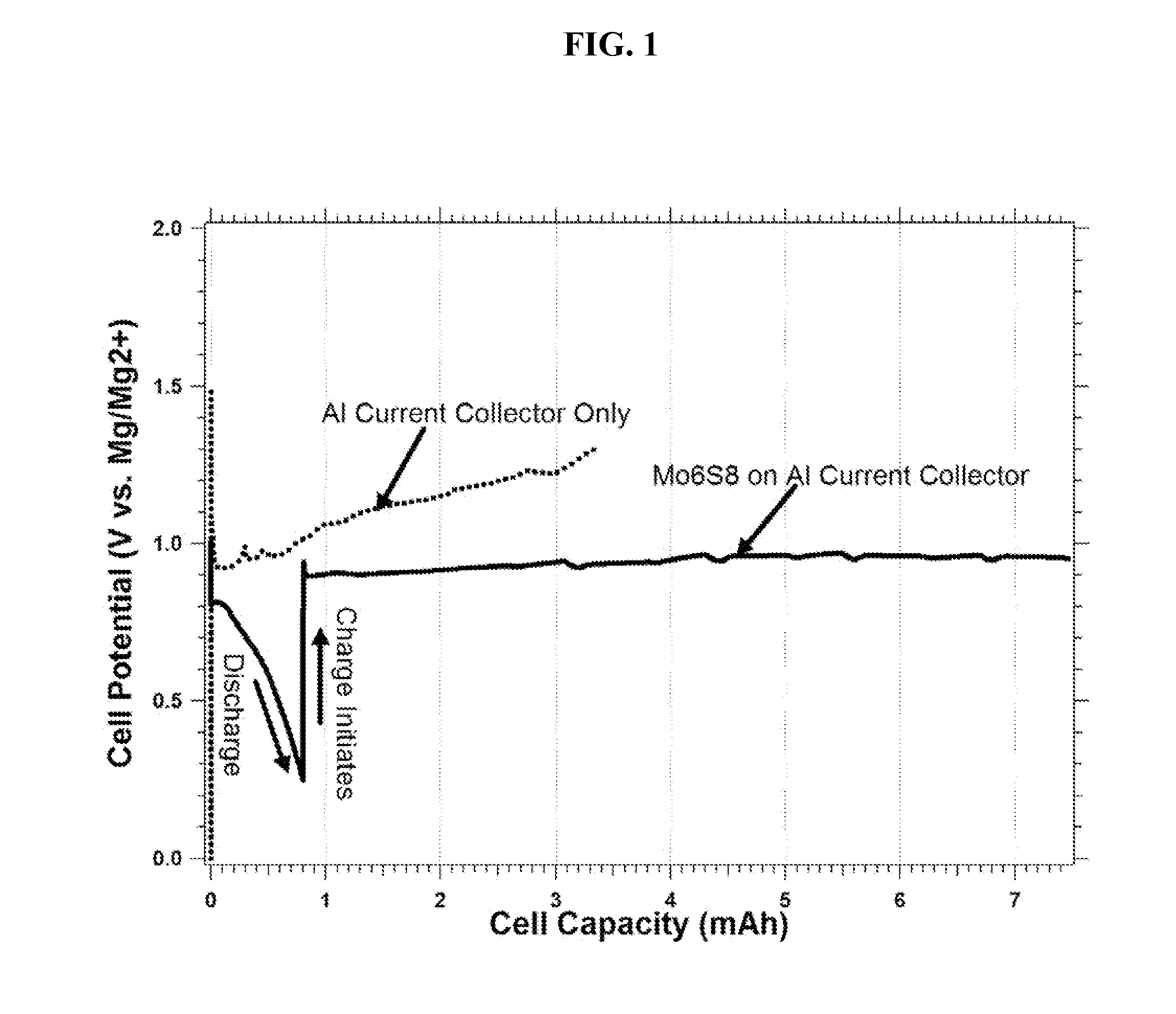

Rechargeable magnesium ion cell components and assembly

InactiveUS20130115521A1Improve chemical inertnessImproves anodic stabilityElectrode carriers/collectorsOrganic electrolyte cellsCorrosion reactionMagnesium ion

A magnesium battery electrode assembly is described, including a current collector comprising a metal, an overlayer material on the metal and an electrode layer comprising an electrode active material disposed on the current collector. The overlayer material passivates the metal, or inhibits a corrosion reaction that would occur between the metal and an electrolyte in the absence of the overlayer material.

Owner:PELLION TECH

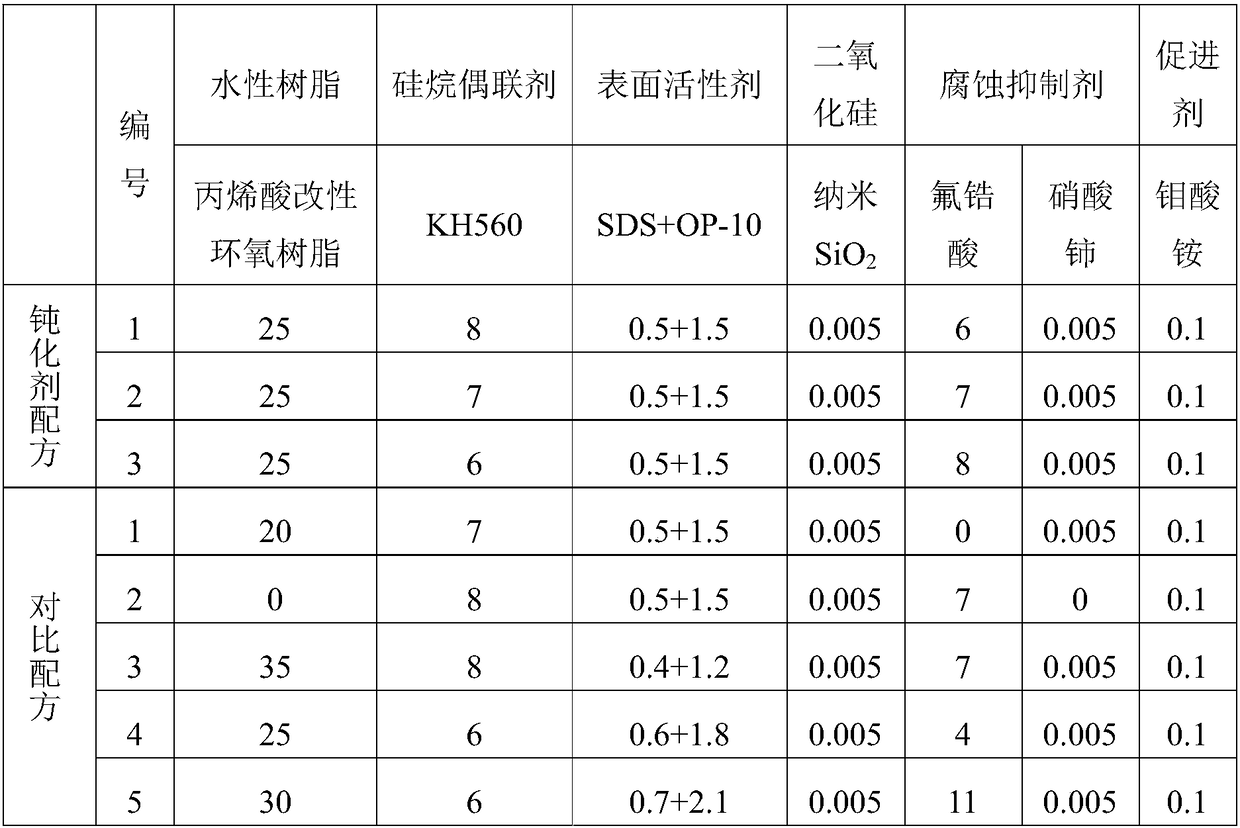

Compound chromate-free passivator capable of forming films rapidly and preparation method

InactiveCN108300988ANo pollution in the processClean manufacturingMetallic material coating processesCorrosion reactionPhosphoric acid

The invention provides a compound chromate-free passivator capable of forming films rapidly. The compound chromate-free passivator comprises water-dilutable resin, silicon dioxide, a surfactant, a corrosion inhibitor, an accelerant and water. The chromate-free passivator provided by the invention does not contain poisonous and harmful ingredients such as heavy metal, sodium nitrite, phosphoric acid and the like, is environment-friendly, pollution-free and clean in production, and is close to passivation effect of hexavalent chromate in the aspect of comprehensive performance such as corrosionresistance and reprocessing; and the passivator sufficiently utilizes the diversity of organic high-molecular polymers and the rapid forming characteristic of inorganic salt, so that a high-performance resin and zirconium-based oxide layer compound coating can be provided for metal surfaces, compound passivation film provides a double protection function for protection of metal surfaces, and the organic coating has a clear advantage of delaying initial-stage corrosion on the metal surfaces, so as to ensure that the metal surfaces have excellent corrosion resistance and then the adhesive forceof coating is improved.

Owner:长沙艾森设备维护技术有限公司

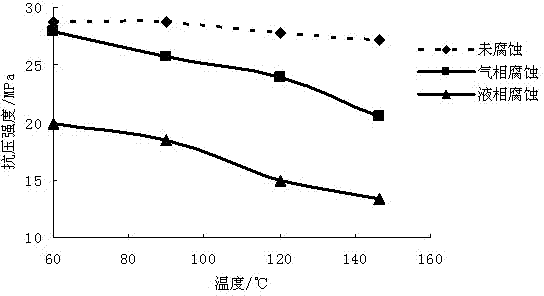

Evaluating method for corrosion of well-reinforcing cement stone

InactiveCN102830057AReliable resultsWeather/light/corrosion resistanceCorrosion reactionElectron microscope

The invention provides an evaluating method for corrosion of well-reinforcing cement stone, which comprises the following steps: firstly, preparing cement paste for reinforcing a well; filling the prepared cement paste into a mould; sealing the mould, placing into a high-temperature high-pressure curing kettle and curing for a period of time, thereby solidifying the cement paste and forming the cement stone; placing a cement stone sample with the mould into a corrosion reaction kettle, pouring into a corrosive medium, and controlling the conditions of temperature, pressure and corrosion time, thereby carrying out a corrosion test; and finally, taking the cement stone sample out of the corrosion reaction kettle, removing the mould, performing electron microscope scanning on the cement stone, measuring the performance parameters, such as compression strength and permeability, of the cement stone, and analyzing and evaluating a corroded cement stone structure. According to the evaluating method provided by the invention, the dynamic corrosion condition of the well-reinforcing cement stone being in one-way contact with the corrosive medium in the well is truly simulated, and a measured result is true and reliable.

Owner:SOUTHWEST PETROLEUM UNIV

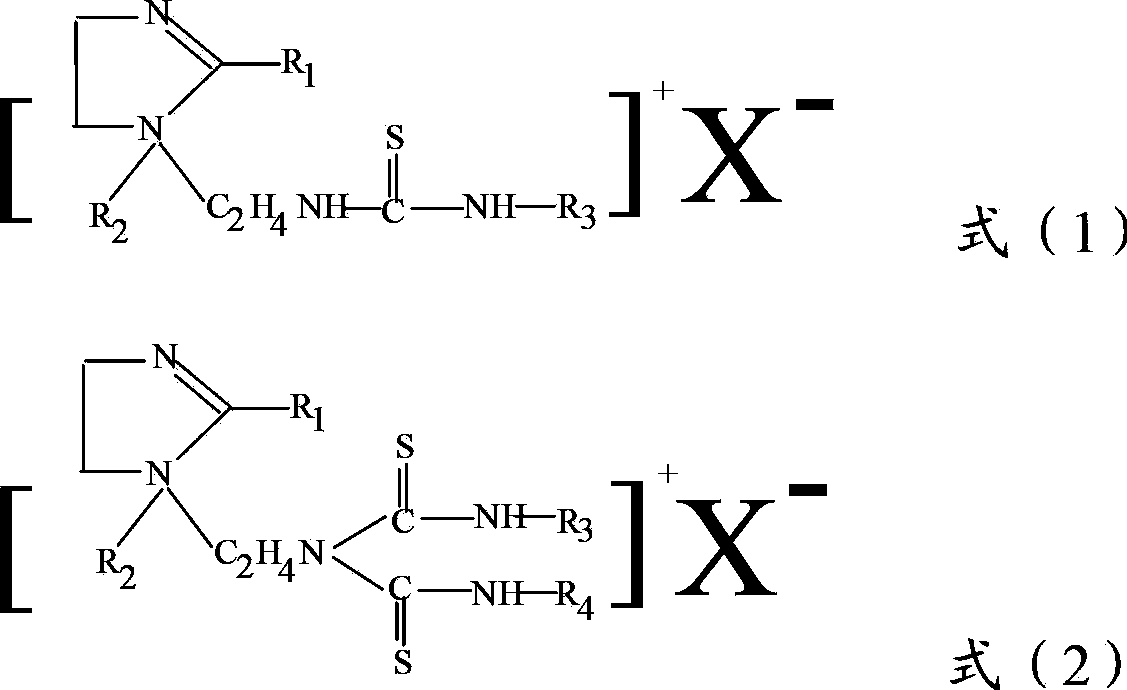

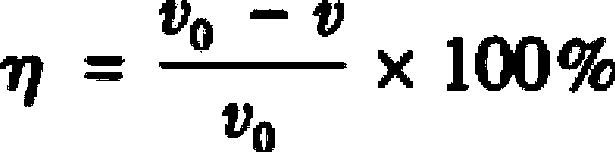

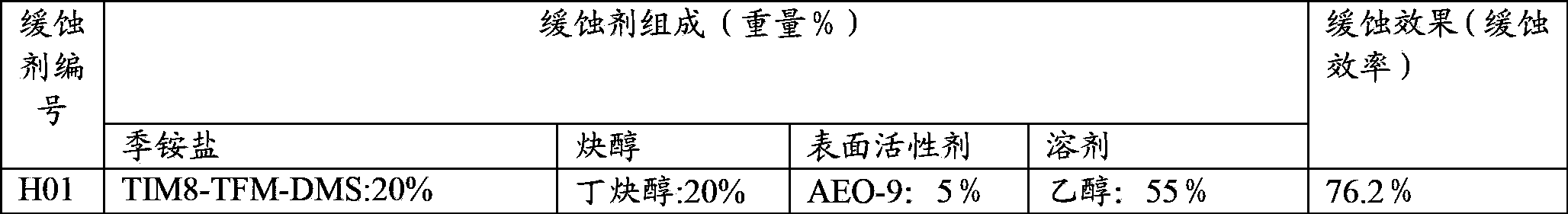

Corrosion inhibitor for gas field and preparation method thereof

ActiveCN103898515AImprove distribution balanceGood chemical stabilityOrganic chemistryBorehole/well accessoriesCorrosion reactionSolubility

The invention discloses a corrosion inhibitor for a gas field and a preparation method thereof, belonging to the fields of corrosion and protection. The corrosion inhibitor is composed of the following components in percentage by weight: 20-60% of fluorine-containing thioureidoimidazoline quaternary ammonium salt, 10-20% of alkynol, 1-5% of nonionic surfactant and 20-60% of solvent. By using the fluorine-containing thioureidoimidazoline quaternary ammonium salt as the main component of the corrosion inhibitor, a polycentric chemical adsorption action can be generated, so that the corrosion inhibitor is adsorbed to the metal surface, and the corrosion reaction is inhibited. the fluorine substituent group is introduced to lower the surface tension of the water solution, enhance the wettability and permeability of the water solution, improve the solubility of the corrosion inhibitor in a water solution and the distribution proportionality in an oil-gas-water multiphase flow, and enhance the chemical stability of the corrosion inhibitor in high-temperature high-pressure corrosive media containing H2S, CO2 and Cl<-> and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

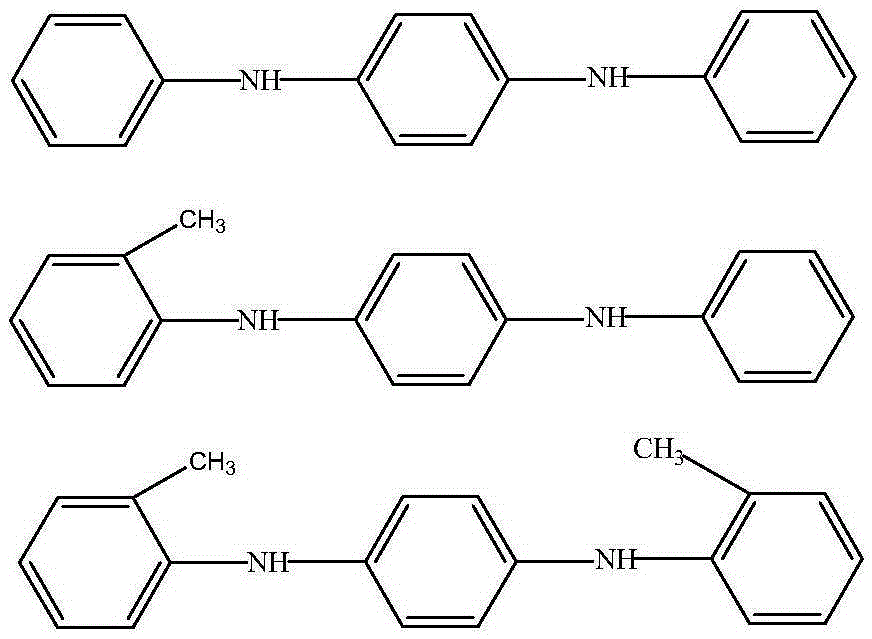

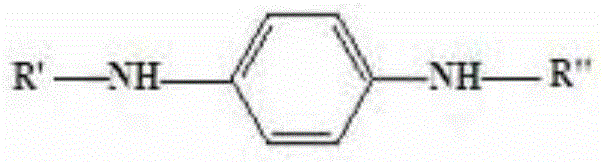

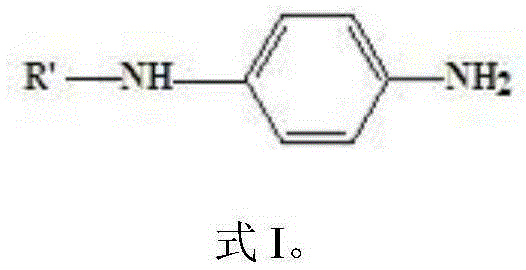

Preparation method for aryl substituted p-phenylenediamine substance

InactiveCN106608827AReduce the amount addedWill not corrodeAmino compound purification/separationAmino preparation from aminesCyclohexanoneCorrosion reaction

The invention provides a preparation method for an aryl substituted p-phenylenediamine substance. The aryl substituted p-phenylenediamine substance has the following structural formula defined in the specification, wherein R'' is phenyl or o-methyl phenyl, and R' and R'' are the same or different. The preparation method comprises the steps of carrying out a reaction of a raw material A and a raw materials B under the action of a hydrogen acceptor and a catalyst, to form the aryl substituted p-phenylenediamine substance, wherein the raw material A has the structural formula defined in the specification, the raw material B is cyclohexanone and / or o-methylcyclohexanone, and the hydrogen acceptor is a hydrogen acceptor which can accept hydrogen to be converted into the raw material B. The preparation method provided by invention has the advantages that the raw materials are cheap and easy to obtain, and reaction post-processing has no need of use of a lot of water. At the same time, the reaction conditions are mild, and equipment cannot be corroded. Therefore, the preparation method has the advantages of environmental protection and less pollution and can obtain better economic benefits.

Owner:JIANGSU SINORGCHEM TECH CO LTD

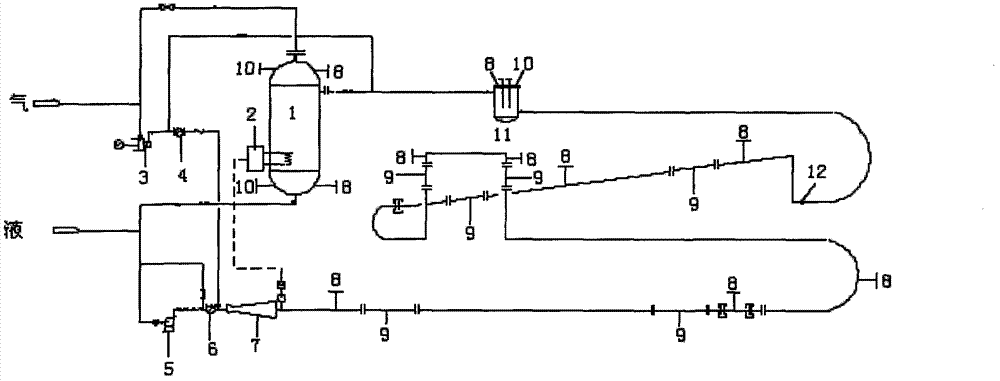

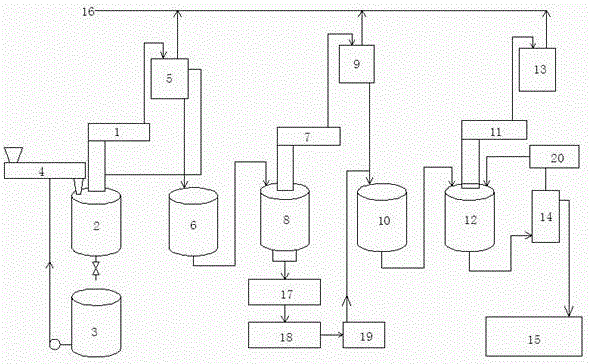

Multifunctional annular oil-gas-water multiphase flow corrosion simulation test device

ActiveCN102854122AAvoid disadvantagesAvoid interferenceWeather/light/corrosion resistanceCorrosion reactionVapor–liquid separator

A multifunctional annular oil-gas-water multiphase flow corrosion simulation test device comprises a control cabinet, a gas-liquid separator, an electric heater, a gas supercharger, a gas flowmeter, a screw pump, a fluid flowmeter, a static mixer, a corrosion detection probe, a rotatable joint, a corrosion detection pipe section, a corrosion hanging device, and a corrosion reaction vessel. Both a gas source pipeline and a gas outlet pipeline of the gas-liquid separator are connected with an inlet of the gas supercharger; an outlet pipeline of the gas supercharger is connected with an outlet of the static mixer; both a liquid source pipeline and a liquid outlet pipeline of the gas-liquid separator are connected with an inlet of the screw pump; an outlet pipeline of the screw pump is horizontally connected with an inlet of the static mixer through the fluid flowmeter; a temperature sensor is disposed at the outlet of the static mixer; an outlet pipeline of the static mixer is connected with the corrosion reaction vessel through the corrosion detection pipe section; an outlet pipeline of the corrosion reaction vessel is connected with a gas-liquid inlet of the gas-liquid separator; the corrosion detection probe is disposed at the front end or the back end of the corrosion detection pipe section.

Owner:中石化石油工程技术服务有限公司 +1

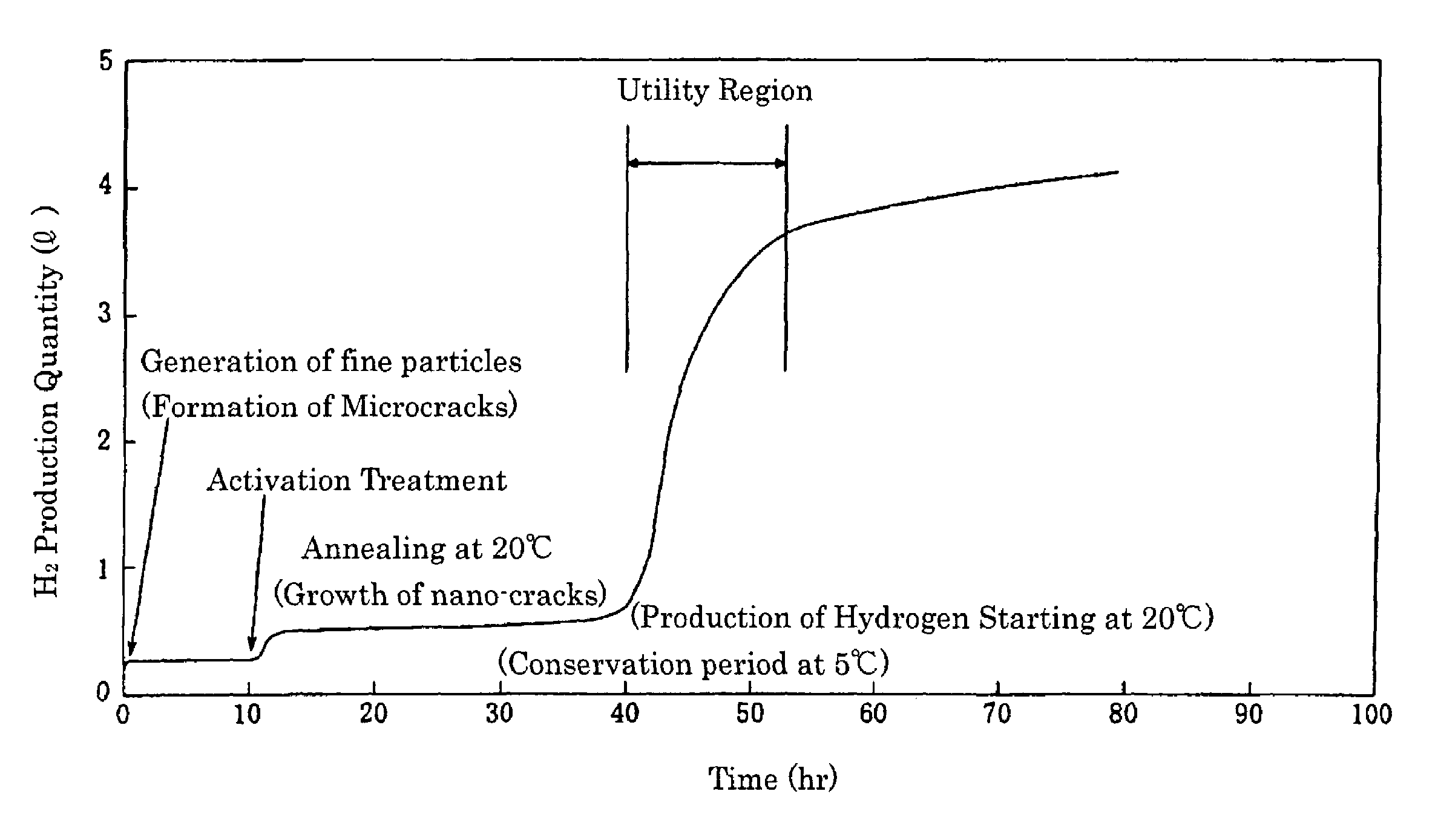

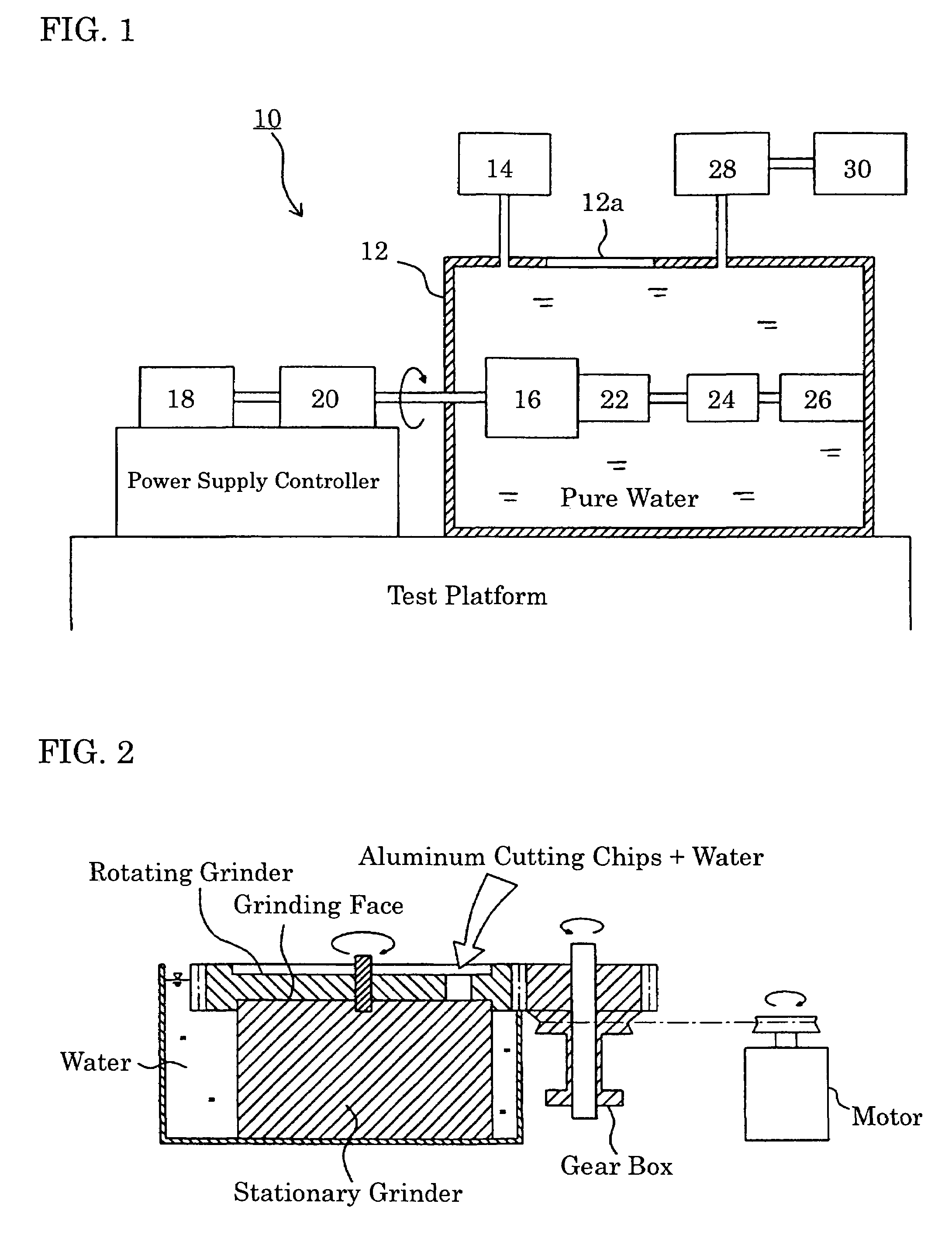

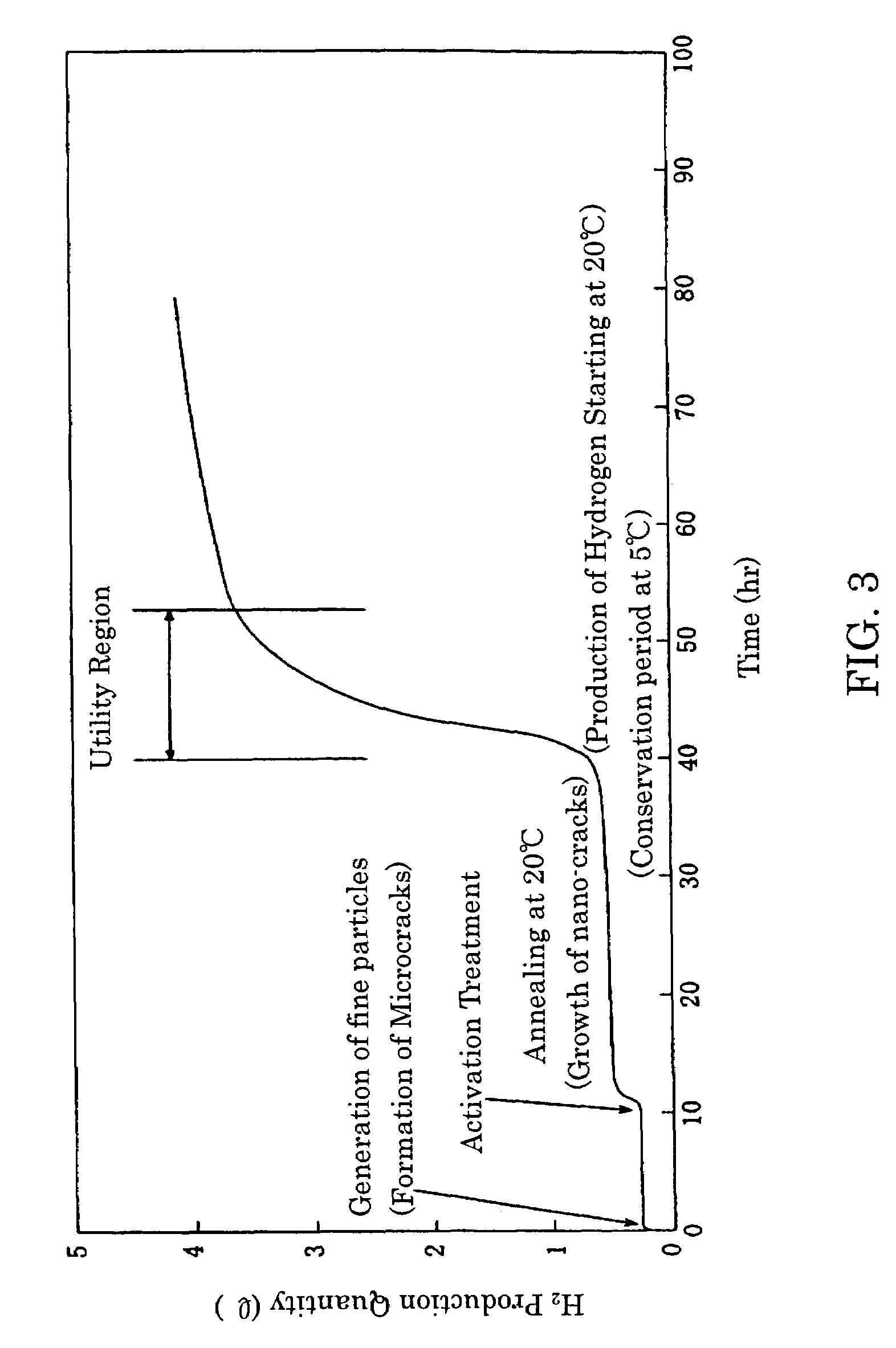

Method for producing hydrogen gas utilizing mechano-corrosive reaction

InactiveUS7008609B2Low costSimple and safe processAluminium oxide/hydroxide preparationHydrogen productionCorrosion reactionChemical reaction

There is provided a method of producing hydrogen gas serving as fuel for a portable fuel cell, whereby hydrogen gas can be provided easily, safely, and at a low cost. To that end, the method of producing hydrogen gas comprises the steps of causing friction and mechanical fracture accompanying the friction to occur to a metallic material under water and increasing thereby chemical reactivity of atoms of the metallic material, in close proximity of the surface thereof; wherein water molecules are decomposed by accelerating corrosion reaction of water with the metallic material. Further, for the metallic material, an aluminum or aluminum alloy material is used as industrial waste including refuse and cutting chips (curls) of an industrial aluminum material. Meanwhile, pure water not substantially containing ionic impurities and organic molecules is used for the water.

Owner:HYDRO DEVICE

Double-phase stainless steel microstructure and sigma mesophase chromatic corrosive and corrosion method

InactiveCN102766869AResponse is smooth and safeEasy to operatePreparing sample for investigationCorrosion reactionHydrofluoric acid

The present invention relates to a double-phase stainless steel microstructure and sigma mesophase chromatic corrosive and a corrosion method, and is suitable for the detection of double-phase stainless steel. The corrosive comprises components of: 0.1-2g of potassium metabisulfite, 5-25ml of hydrochloric acid with mass percent concentration of 40%, 5-15ml of nitric acid with mass percent concentration of 68%, 5-15ml of hydrofluoric acid with mass percent concentration of 40% and 150-300 ml of deionized water. The invention has advantages of good corrosion effect, good display effect of structure of a corroded specimen, no pollution, stable corrosion reaction, and easy configuration.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

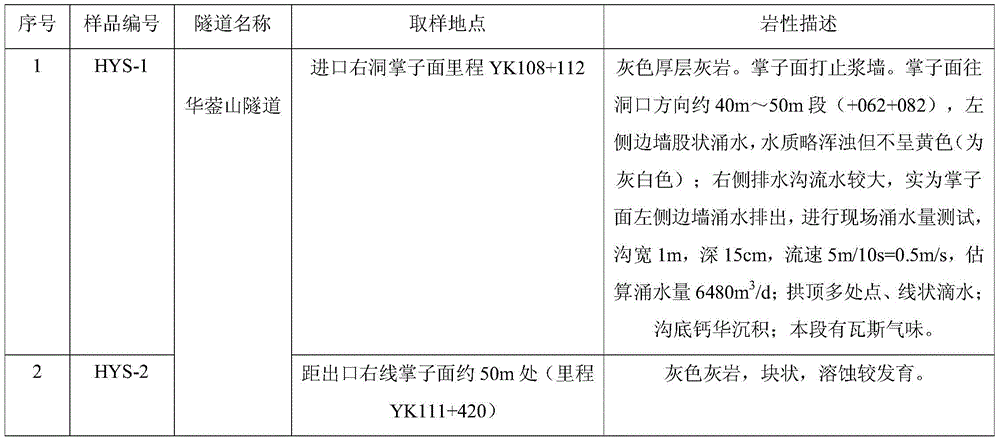

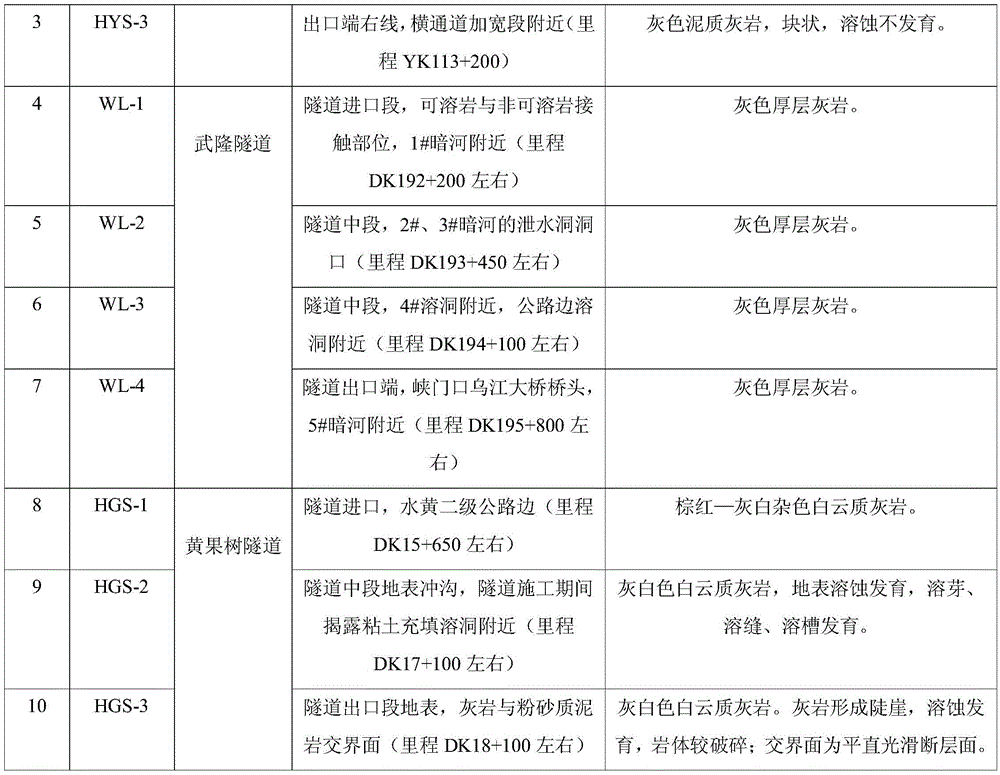

Corrosion testing apparatus and implementing method thereof

ActiveCN105628596AReasonable designHigh simulation fidelityWeather/light/corrosion resistanceWater bathsCorrosion reaction

The invention discloses a corrosion testing apparatus which comprises a corrosion water supply device, a constant-temperature water bath bed, a corrosion tube, a constant-temperature water bath and a constant-temperature water supply device. The corrosion water supply device is used for providing corrosion water; the constant-temperature water bath bed is used for heating (or cooling) the corrosion water and keeping a constant-temperature state; the corrosion tube is placed in the constant-temperature water bath and is used for placing a rock sample so as to perform a corrosion reaction on the heated (or cooled) the constant-temperature corrosion water and the rock sample and collecting corrosion liquid after the reaction; the constant-temperature water bath is used for heating (or cooling) the corrosion tube to the same temperature with the temperature of the corrosion water, and keeping a constant-temperature state; the constant-temperature water supply device is used for respectively supplying constant-temperature water to the constant-temperature water bath bed and the constant-temperature water bath so as to enable the constant-temperature water bath bed to heat (or cooling) the corrosion water and enable the constant-temperature water bath to heat (or cooling) the corrosion tube. The corrosion testing apparatus lays a theoretical foundation for establishing a hydrochemical dynamics-fractal exponent evaluation mathematical model of karst development intensity.

Owner:中铁西南科学研究院有限公司

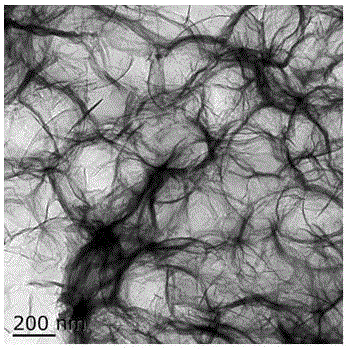

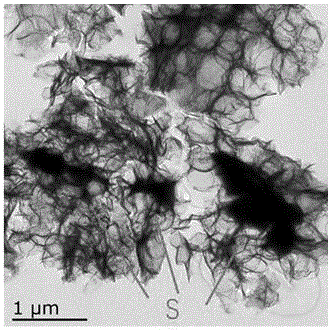

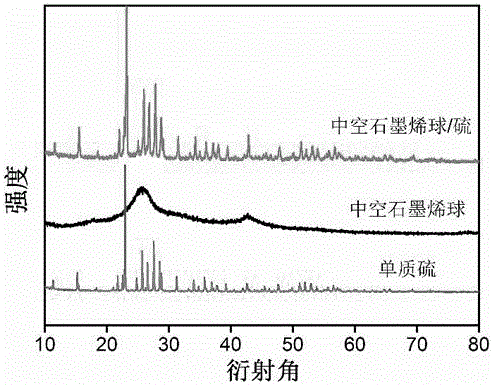

Preparation method of hollow graphene ball/sulfur composite material

ActiveCN106025231AReduce manufacturing costLiquidityMaterial nanotechnologyCell electrodesCorrosion reactionSilicon dioxide

The invention discloses a preparation method of a hollow graphene ball / sulfur composite material and belongs to the technical field of chemical batteries. The preparation method comprises the following steps: an ethanol solution of tetraethyl orthosilicate is mixed with and reacts with the ethanol solution of ammonia water and the ammonia water, so as to obtain silica nanospheres; silica nanospheres and cetyltrimethylammonium bromide are dispersed in deionized water; an aqueous solution of graphene oxide is added; a mixture is centrifuged after stirring and reaction; a solid phase is taken to be washed, dried and placed in a vacuum tube furnace for reduction at a high temperature; an HF aqueous solution is added to perform corrosion reaction, so as to obtain the hollow graphene ball; finally, the hollow graphene ball and sulfur are mixed and subjected to the thermal melting and sulfur volatilization reaction so as to obtain the hollow graphene / sulfur composite material. The preparation method provided by the invention is low in production cost; the prepared product is favorable for forming a conductive network and improving the conductivity.

Owner:YANGZHOU UNIV

Production method of environmental friendly plasticizer DOTP and production system

ActiveCN105130804ARealize resourcesReduce corrosionOrganic compound preparationCarboxylic acid esters separation/purificationPlasticizerOctanol

The invention relates to the technical field of plasticizer production, particularly to a production method of an environmental friendly plasticizer DOTP and a production system. The production method comprises the following steps: feeding a wet material into a twin-screw counter and adding octanol for mixing, then putting into an esterification reactor after preimpregnating, adding an alkaline solution for stirring and washing, controlling a PH value to be neutral, and heating up to evaporate the moisture; utilizing a vacuum effect to continuously add materials; adding a decolorizing agent to improve a decoloring effect; heating up under the vacuum effect, and adding siliceousearth and kaolin into a filter, and filtering to obtain the product. According to the production method, two major raw materials are charged by metering and matching; equipment corrosion is reduced by neutralized water washing; esterification and dealcoholization of the reactor are realized in one reactor; continuous production is realized; the continuous production of material transfer and material charge is realized under the vacuum effect; residues are recycled through processing equipment; the reclamation is realized; the cost is saved, and environment is improved.

Owner:SHANDONG CHENGWU YIXIN ENVIRONMENTAL TECH CO LTD

S-SnO2/Ti3C2 two-dimensional nano lithium ion battery cathode material and preparation method thereof

InactiveCN106025236ARelieve the phenomenon of pulverization and agglomerationIncrease capacityMaterial nanotechnologyCell electrodesTin dioxideCorrosion reaction

The invention discloses an S-SnO2 / Ti3C2 two-dimensional nano lithium ion battery cathode material and a preparation method thereof. The preparation method includes: preparing a high-purity ternary layered Ti3AlC2 ceramic block by vacuum sintering, and subjecting the ceramic block to high-energy ball milling to obtain Ti3AlC2 ceramic powder with grain size of 8-75 microns; immersing the Ti3AlC2 ceramic powder in a hydrofluoric acid solution, stirring, carrying out corrosion reaction, and centrifugally washing to obtain a two-dimensional layered nano material Mxene-ti3C2; loading granular tin dioxide among layers and on the surface of the two-dimensional layered material Ti3C2, and coating the surface of the two-dimensional layered material with sulfur; adopting a one-step hydrothermal method to utilize thioacetamide to provide a sulfur source so as to successfully prepare the S-SnO2 / Ti3C2 nano composite material. The material has the advantages of simple preparation process, controllable process and low cost and has two-dimensional layered characteristics like graphene; MXene-ti3C2 is uniform in layering, large in specific surface area and high in conductivity, SnO2 particles are fine and uniform in distribution, a sulfur layer is uniform in coating, photocatalytic performance is good, and biological affinity is high; accordingly, the material is applicable to the fields of photocatalysis, wastewater treatment, lithium ion batteries, supercapacitors and biological sensors.

Owner:SHAANXI UNIV OF SCI & TECH

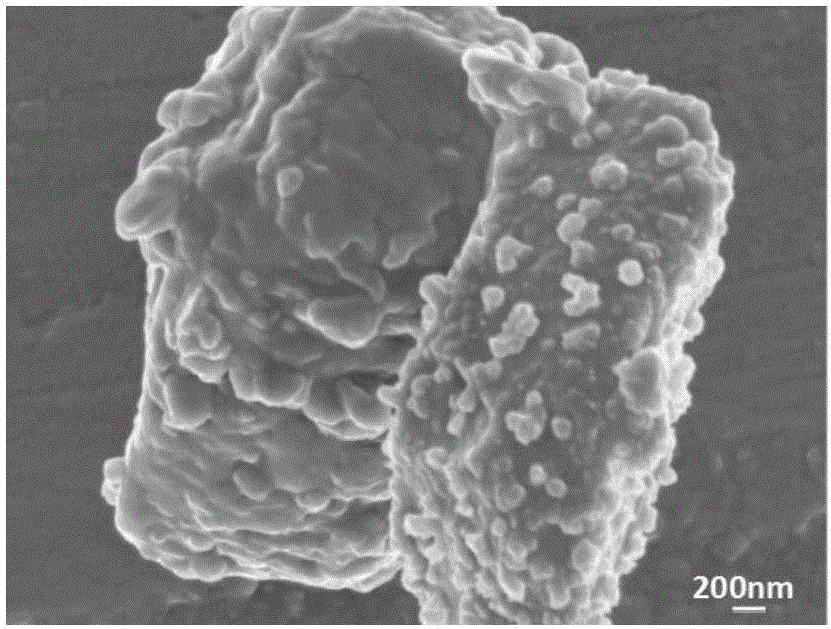

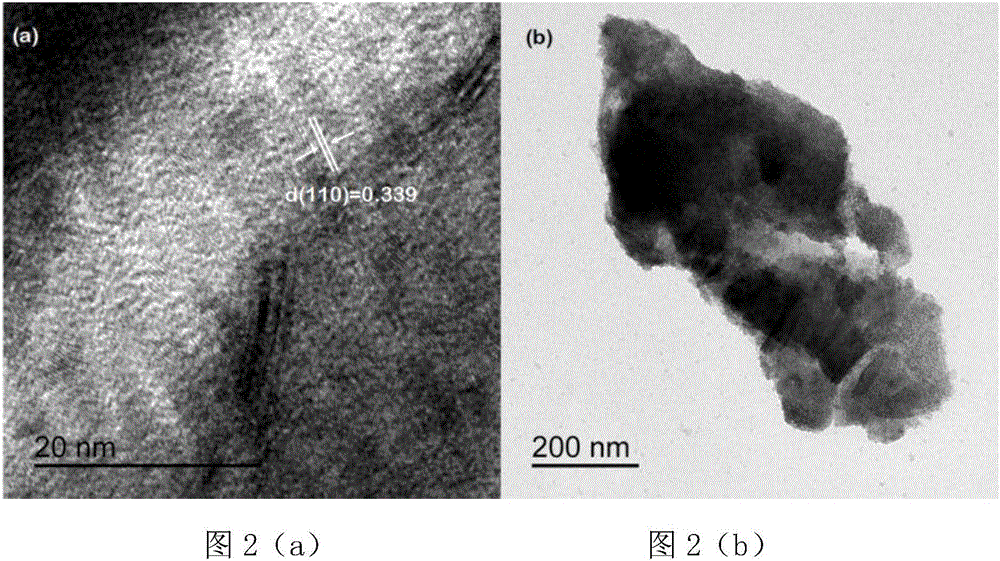

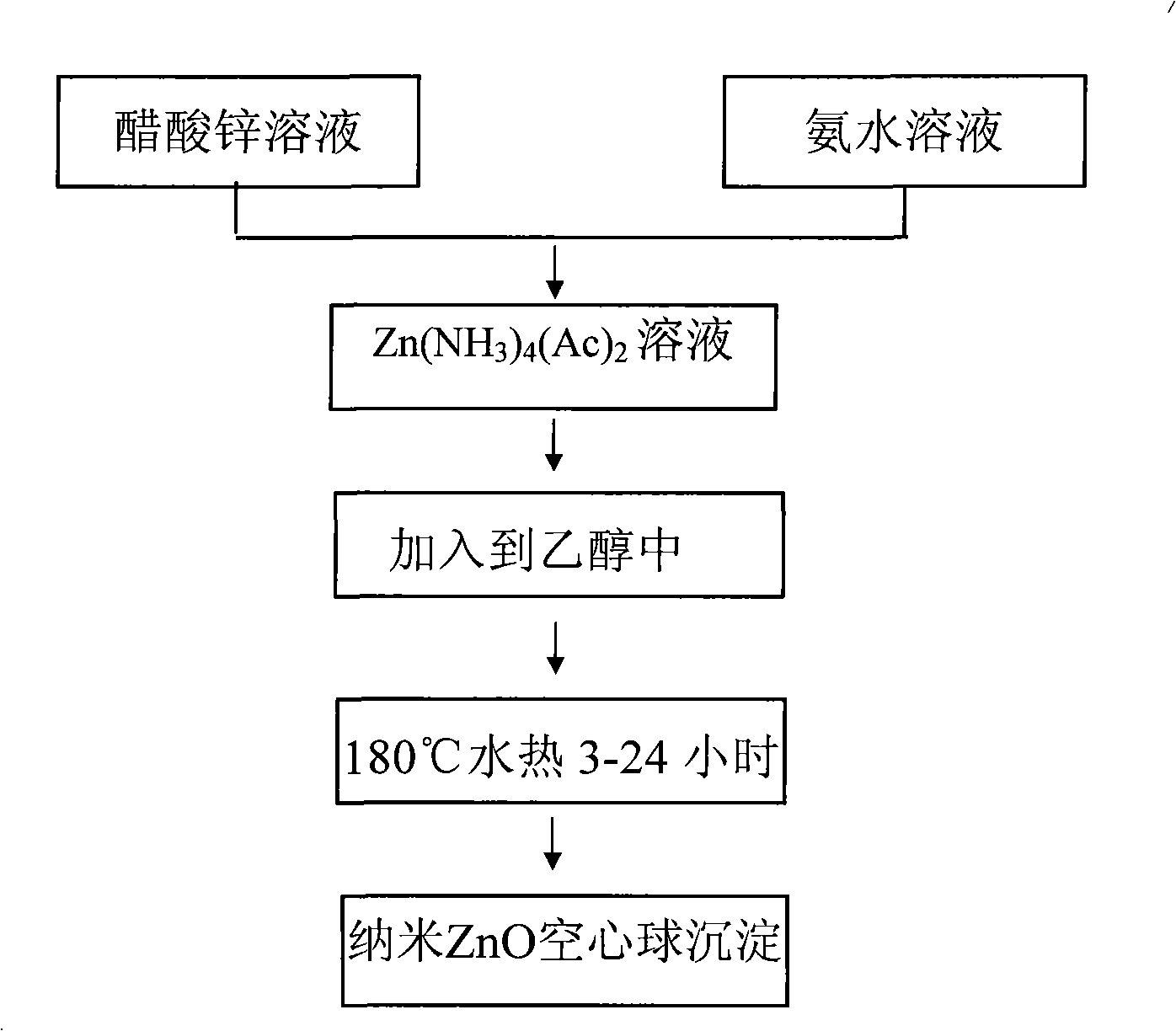

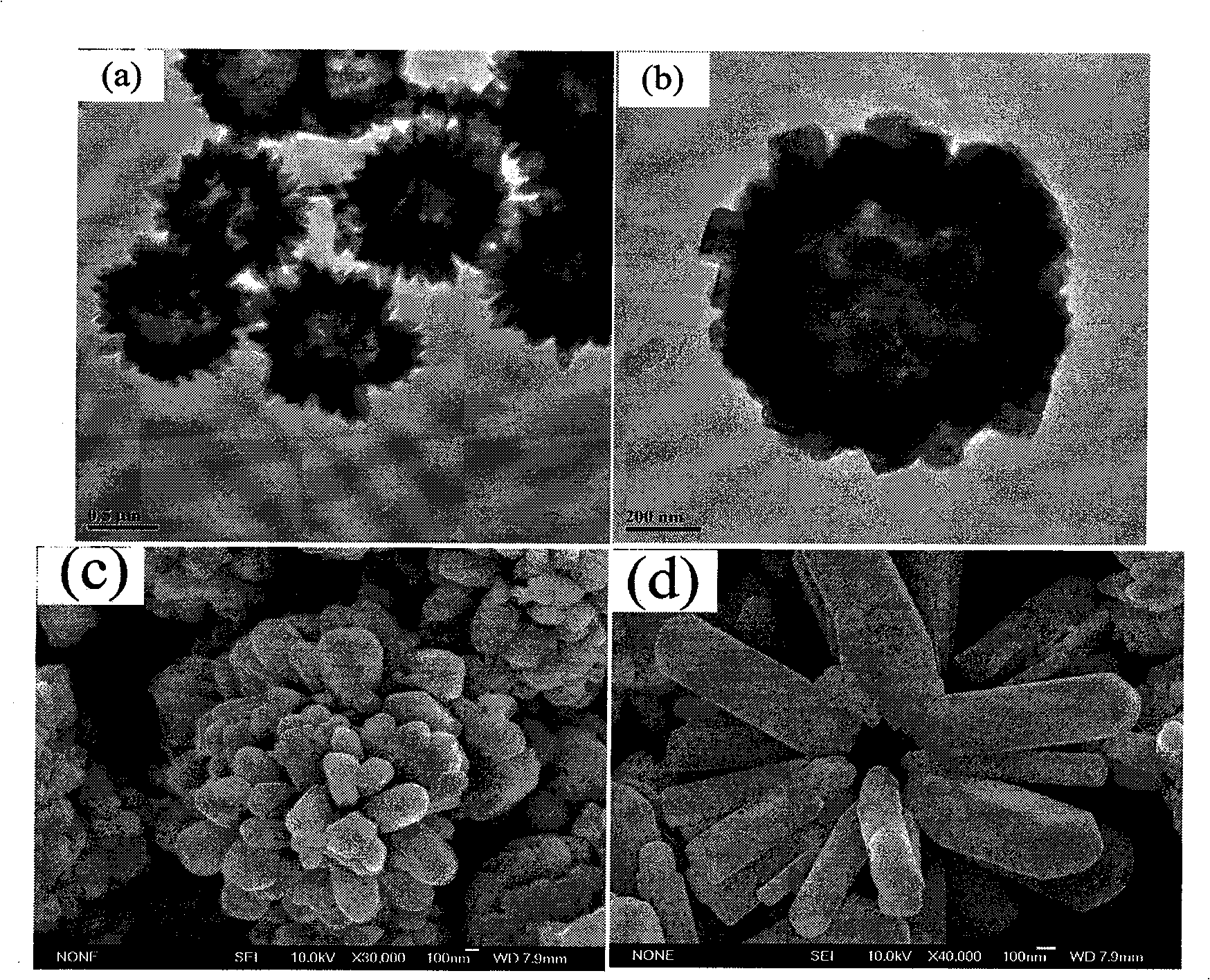

Method for preparing zinc oxide nano hollow spheres by caustic corrosion reaction

InactiveCN101254939AAdd less typesAvoid introducingNanostructure manufactureZinc oxides/hydroxidesCorrosion reactionProduction rate

The invention provides a method for preparing zinc oxide nanometer hollow spheres in caustic corrosion reaction. The method is mainly characterized in including using the solution of Zn(Ac)2 as the initial reactant first, adjusting the pH value to 11.5-14 by adding ammonia, using ethanol as the solvent, finally forming the nanometer hollow spheres in the hydrothermal reaction between Zn(NH3)4<2+> and excessive ammonia at a high temperature. The entire reaction has simple material, easy operation, no need for any complex instrument processing, convenience and rapidness, which is a method of rapidly preparing the zinc oxide nanometer hollow spheres. The obtained hollow spheres have narrow size distribution and good dispersibility with an external diameter of 600 nm and an internal diameter of 200-300 nm. The caustic corrosion reaction is adopted to synthesize zinc oxide nanometer hollow spheres in the method, thus agglomeration phenomenon caused by an aging machine is obviated, complex operation steps of organic reaction synthesis, contamination and disturbance to objective material zinc oxide caused by the complex operation steps are obviated. The method is obviously characterized in high production rate, rapidness, easiness, convenient operation, low cost and environment friendliness.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

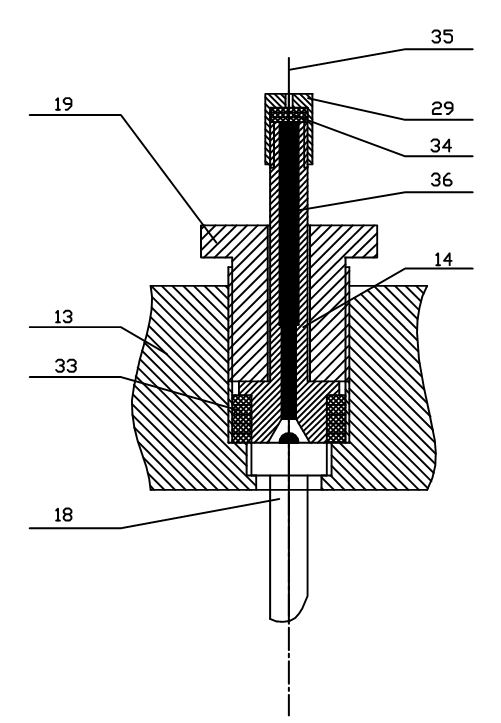

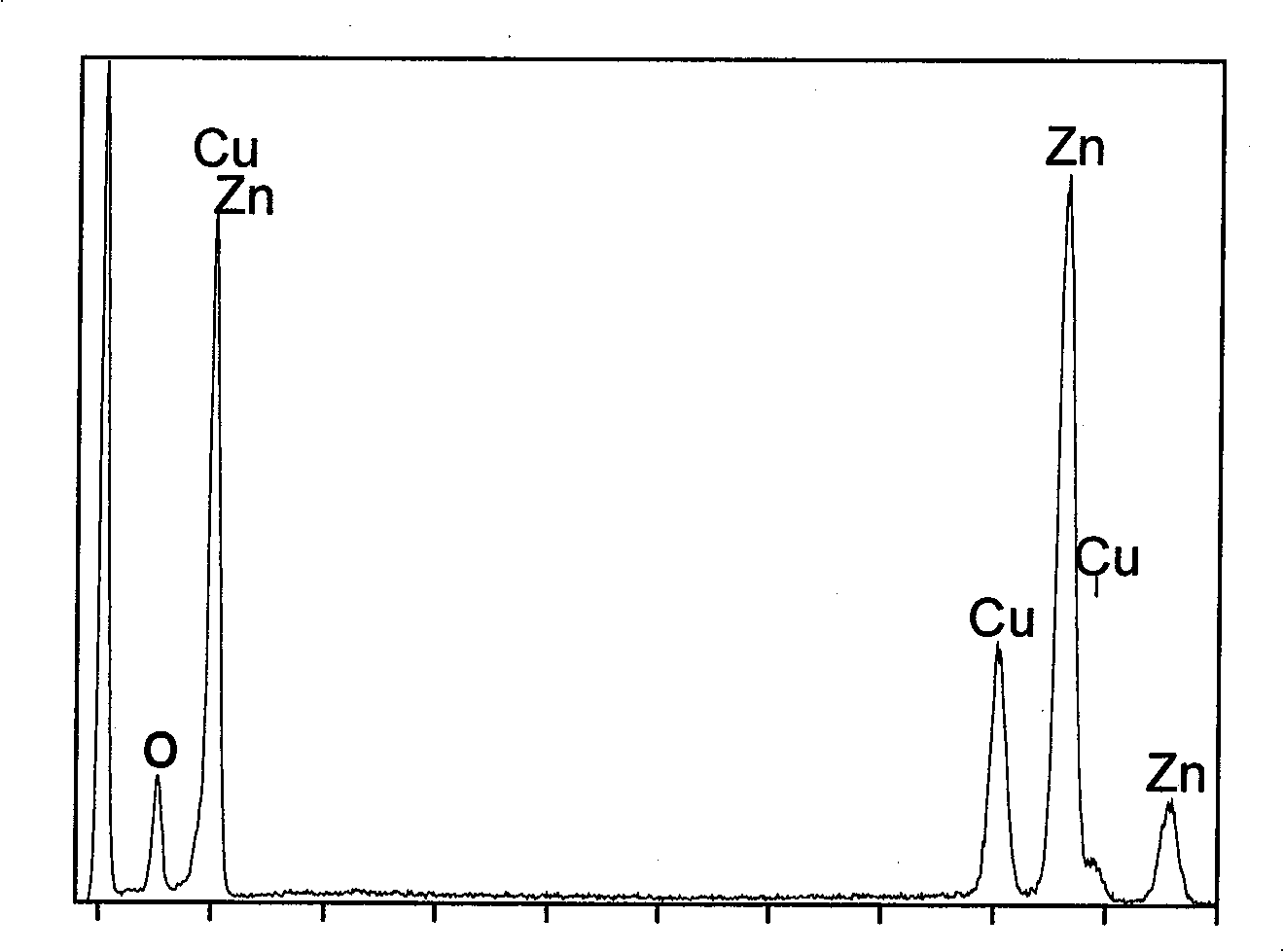

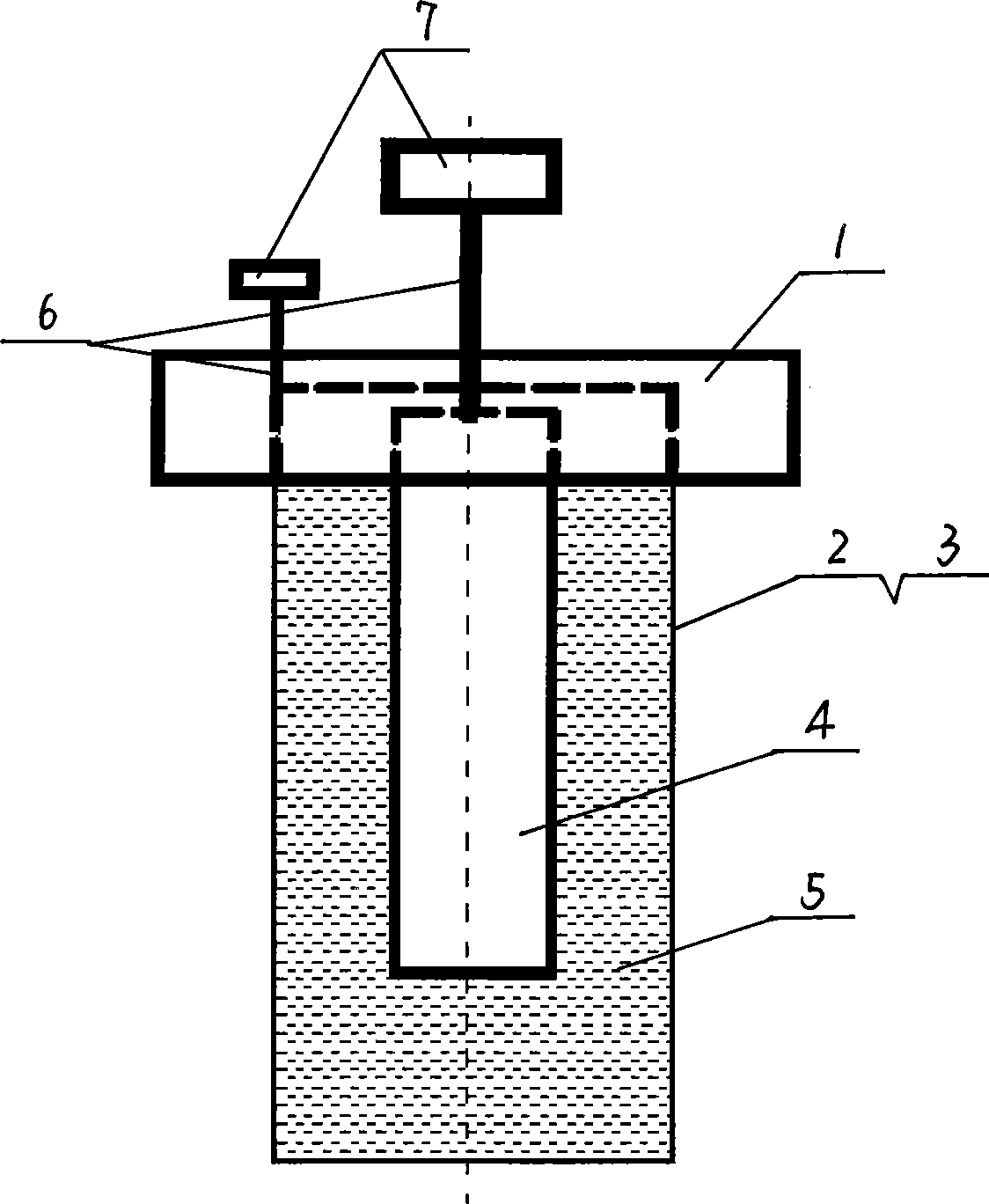

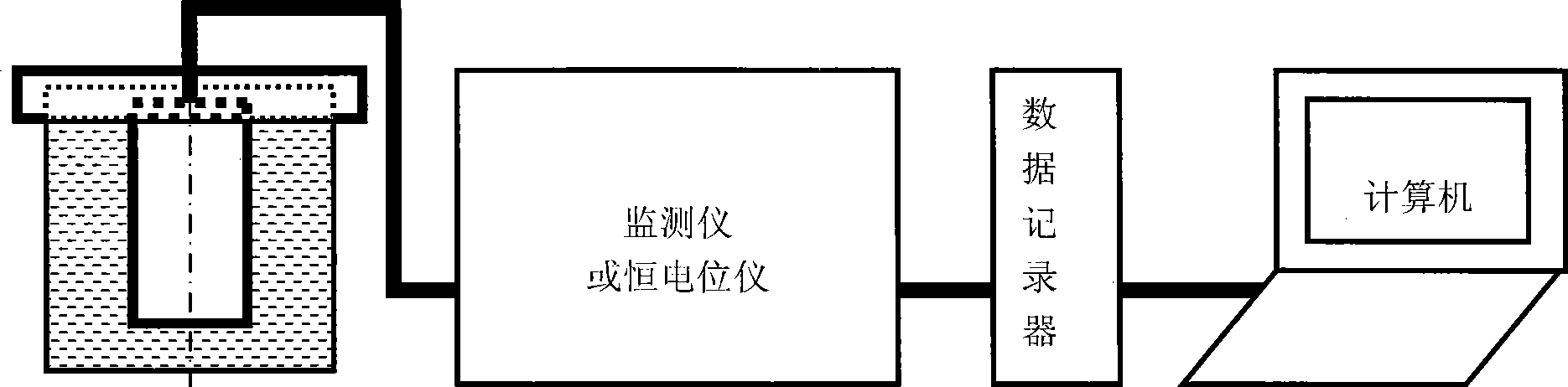

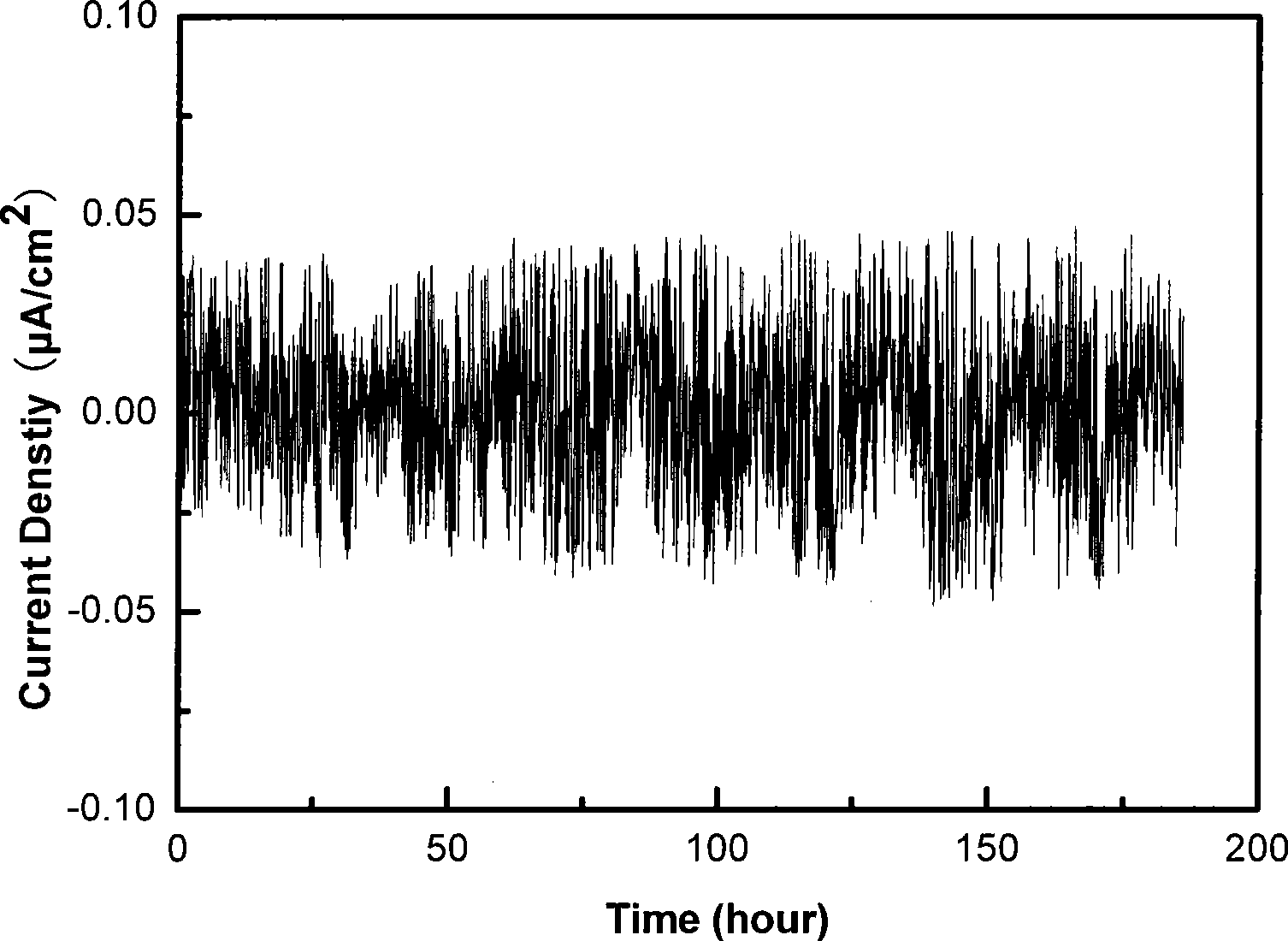

Apparatus and method for monitoring metal corrosion under organic coating

InactiveCN101430271AMonitor the degree of corrosionMonitor Corrosion RateWeather/light/corrosion resistanceMaterial electrochemical variablesCorrosion reactionMetallic materials

The invention relates to a device for monitoring metallic corrosion, in particular to a device for monitoring the metallic corrosion under an organic coat and a monitoring method thereof. The device comprises an electrolytic cell cap, a barrel made from the material same as metallic material to be monitored, a nickel bar and a socket connector. The nickel bar which is equipped with a shielded conductor is connected with the electrolytic cell cap. The internal wall of the barrel is plated with nickel, the external surface is coated with a coat uniformly, then electrolyte is put in the barrel, and the nickel bar is inserted in the barrel. The shielded conductor at the barrel and the nickel bar is led out by the electrolytic cell cap. The led-out shielded conductor is connected with a potentiostat by the socket connector. The inside of the barrel is provided with a corrosion signal monitoring working electrolytic cell. A nickel-plated surface on the internal wall of the barrel is a signal detection working face. The external wall of the barrel and a coat surface on the external wall are corrosion reaction faces. A signal output end of the potentiostat is connected with a data collector and a computer for collecting a monitoring device signal and realizing the monitoring towards the metallic corrosion degree and the corrosion speed under the coat. The invention can monitor the metallic corrosion status under the coat fast and continuously for a long time.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

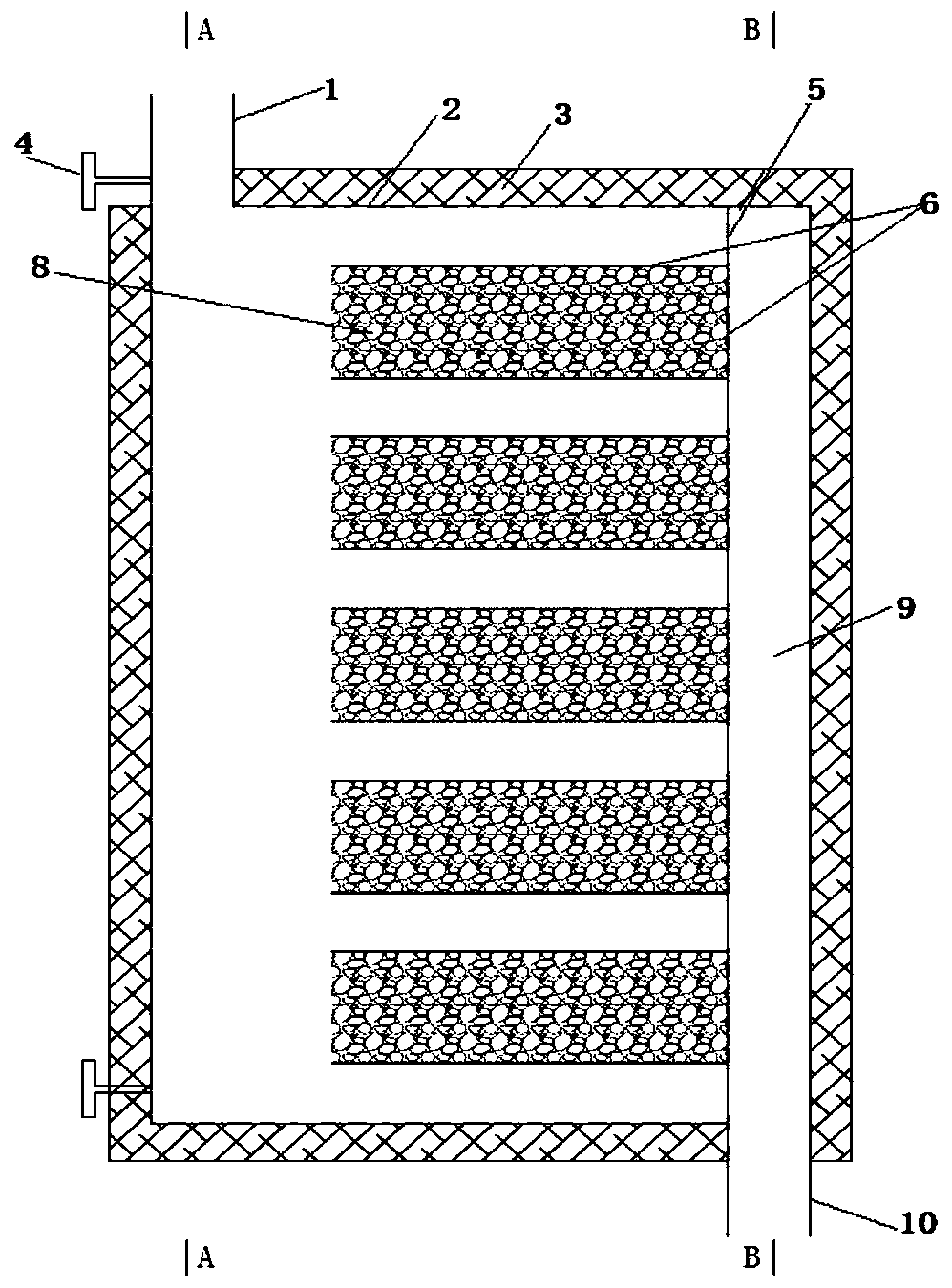

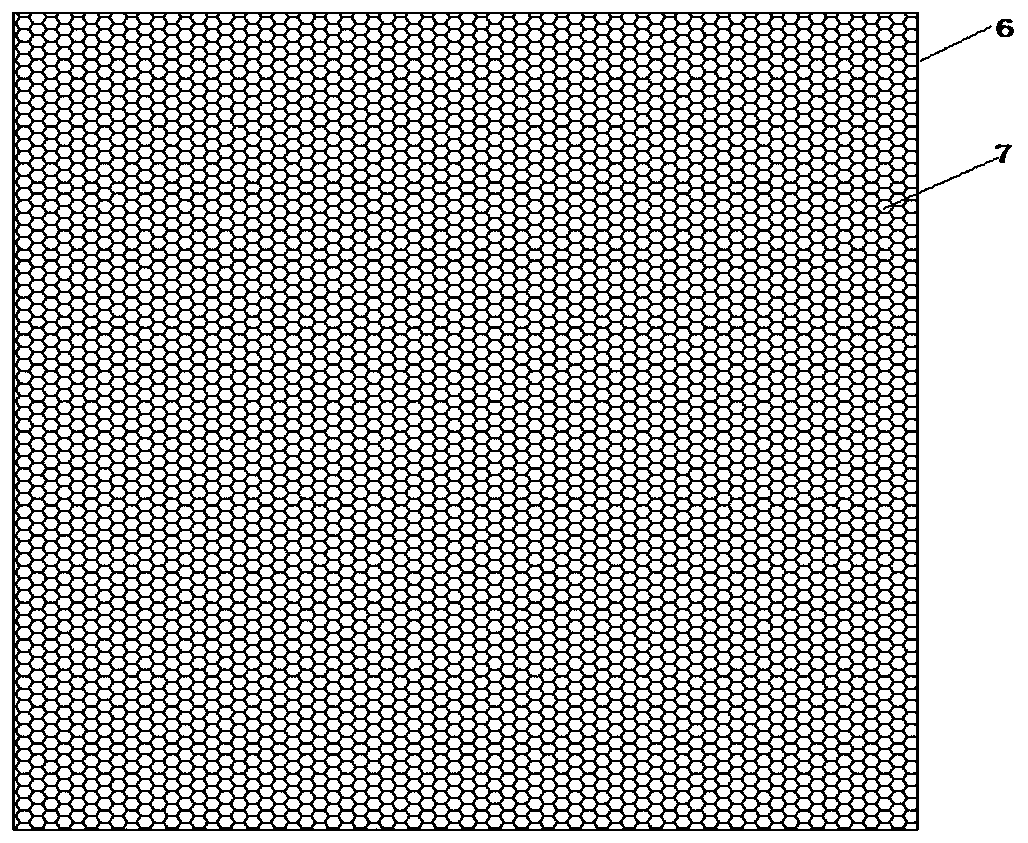

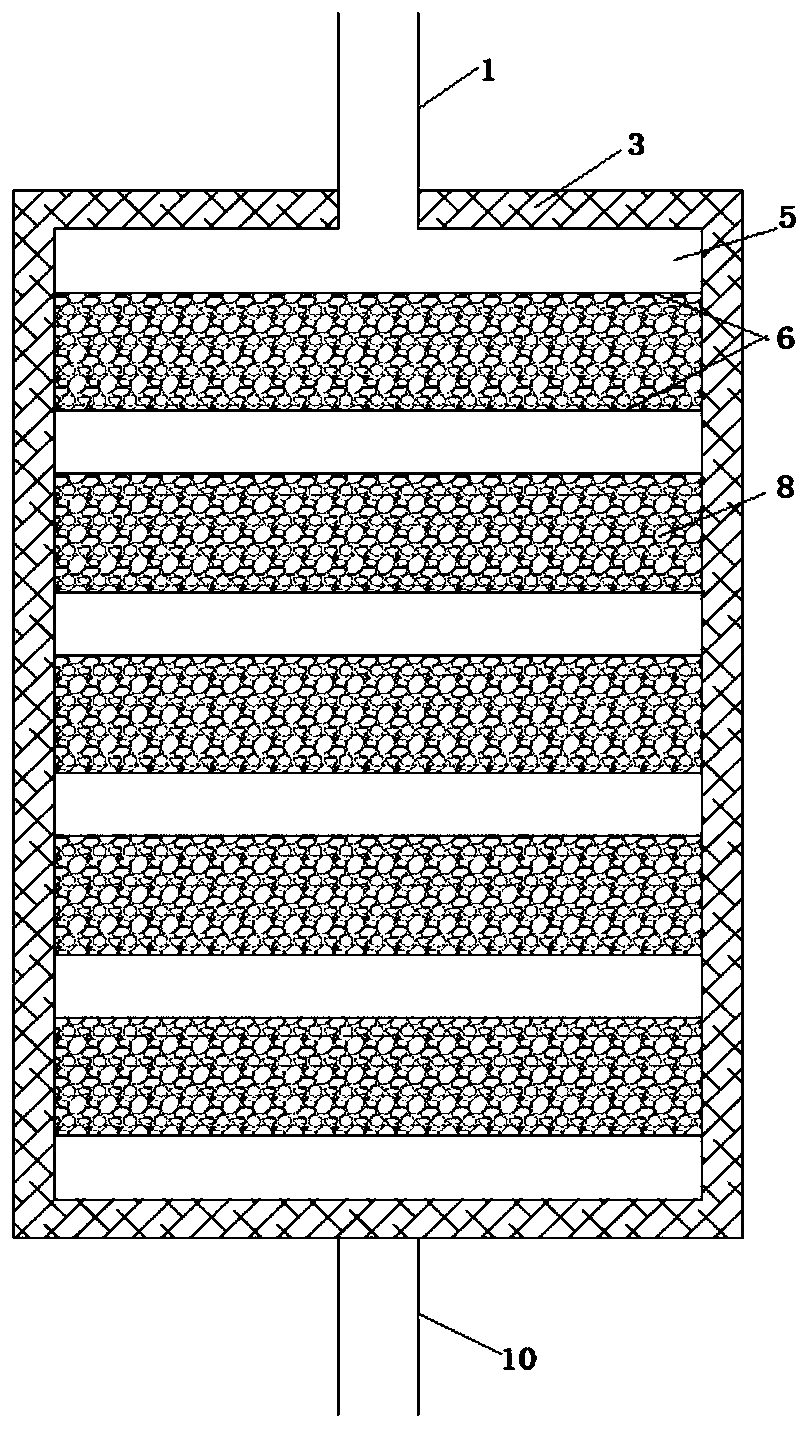

Layered unit type reactor used for hydrated salt heat storage

InactiveCN110193336AAvoid local deliquescenceAvoid cakingHeat storage plantsChemical/physical/physico-chemical stationary reactorsCorrosion reactionParticulates

The invention relates to a layered unit type reactor used for hydrated salt heat storage. The layered unit type reactor is used for desorption / adsorption reaction process heat energy storage and release of hydrated salts or other particular matters; in the reactor, metal sieve screens are adopted as packed beds of a hydrate reactant, the end of each metal sieve screen close to a gas inlet segmentis fixed by a pair of bolts arranged up and down, so that dismounting can be realized, and it is convenient for filling and taking out of reaction particular salts; the periphery and the upper and lower surfaces of the reactors are coated with a thermal insulation material, so that heat loss in reaction process is prevented. The reactor can be used for high efficiency full hydrated salt desorption / adsorption reaction, is not only capable of improving heat and mass transfer effect in reaction process, but also capable of preventing hydrated salt deliquescence because of excess adsorption on moisture; reactor corrosion and heat storage density reduction caused by deliquescence of hydrated salt are avoided, heat storage material circulation operation period is prolonged, and the service lifeis prolonged.

Owner:XI AN JIAOTONG UNIV

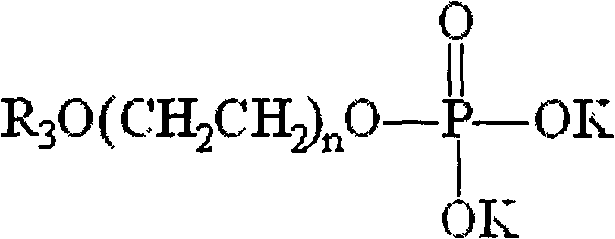

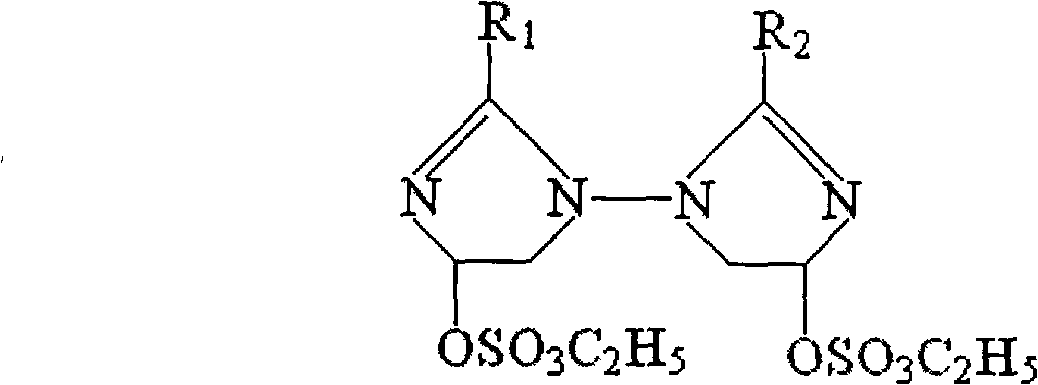

Gas well corrosion inhibitor and preparation method thereof

InactiveCN102020978AUniform corrosionEnhanced inhibitory effectBorehole/well accessoriesCorrosion reactionPhosphate

The invention discloses a gas well corrosion inhibitor and a preparation method thereof. The gas well corrosion inhibitor comprises the following components in percentage by mass: 20-30% of gemini-imidazoline surfactant, 10-15% of fatty alcohol polyoxyethylene ether phosphate, 5-10% of polyether demulsifier, 10-25% of fatty acid amide borate and 20-30% of solvent. The preparation method comprises the following steps: A, adding the gemini-imidazoline surfactant and fatty alcohol polyoxyethylene ether phosphate into a stainless steel agitated reactor, heating to about 75 DEG C, stirring for 30-40 minutes; B, adding the fatty acid amide borate and the polyether demulsifier to the agitated reactor, and stirring for 20-30 minutes; and C, finally adding the solvent to the agitated reactor and stirring for 30 minutes. The gas well corrosion inhibitor can form a firm adsorbed film and drainage protecting film on the surface of the metal so as to prevent the transferring of charges or substances related to corrosion reaction, has excellent capability of overcoming local corrosion and inhibiting pitting corrosion, and can solve the problem of oil-water emulsification and compatibility of the demulsifier, fungicide and an antisludging agent.

Owner:JIAJIANG LONGXING INVESTMENT

Method and system for predicting corrosion rates using mechanistic models

InactiveUS8447529B2Efficient designPlug gaugesWeather/light/corrosion resistanceCorrosion reactionMechanical models

A computer system and method for predicting the aqueous phase CO2 corrosion rate of a pipe useful in the production and transportation of oil and gas. Input parameter values corresponding to water chemistry and physical fluid and pipe properties are received. Based on these input parameter values, the system and method derive current-voltage relationships for multiple cathodic reduction reactions according to an electrochemical model of the corrosion reaction, and a current-voltage relationship for the anodic oxidation reaction of iron dissolution. A current density is obtained, at the intersection of an extrapolation of the anodic current-voltage relationship and an extrapolation of the summed cathodic current-voltage relationships. The predicted corrosion rate is then calculated from the obtained current density. The effects of secondary parameters such as scale and flow regime, and the efficacy of a corrosion inhibitor, can also be evaluated.

Owner:BP CORP NORTH AMERICA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com