Layered unit type reactor used for hydrated salt heat storage

A hydrated salt heat storage and layered unit technology, applied in the field of thermochemical heat storage, can solve problems such as thermal efficiency limitation, and achieve the effects of easy processing, improved thermal efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

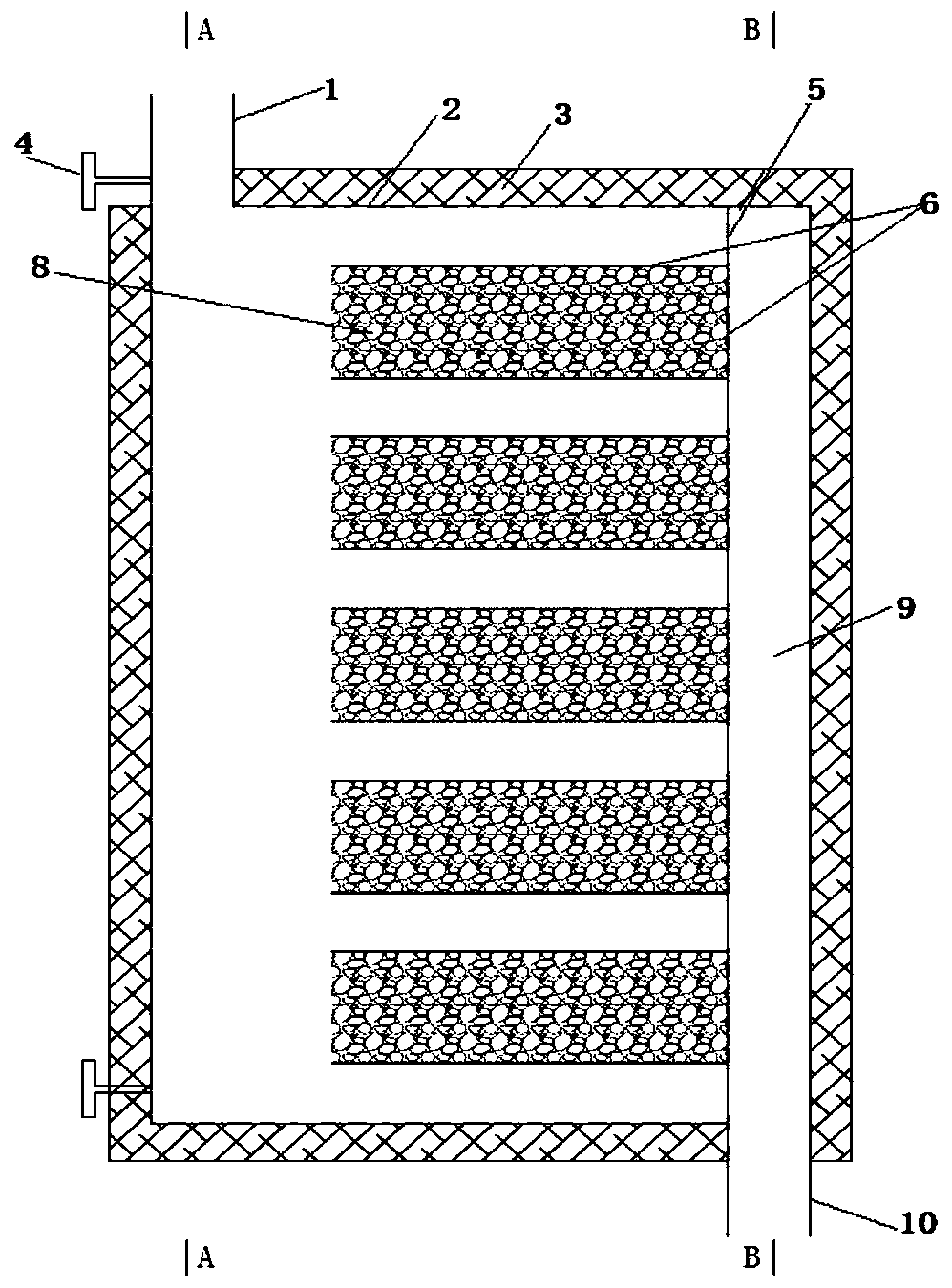

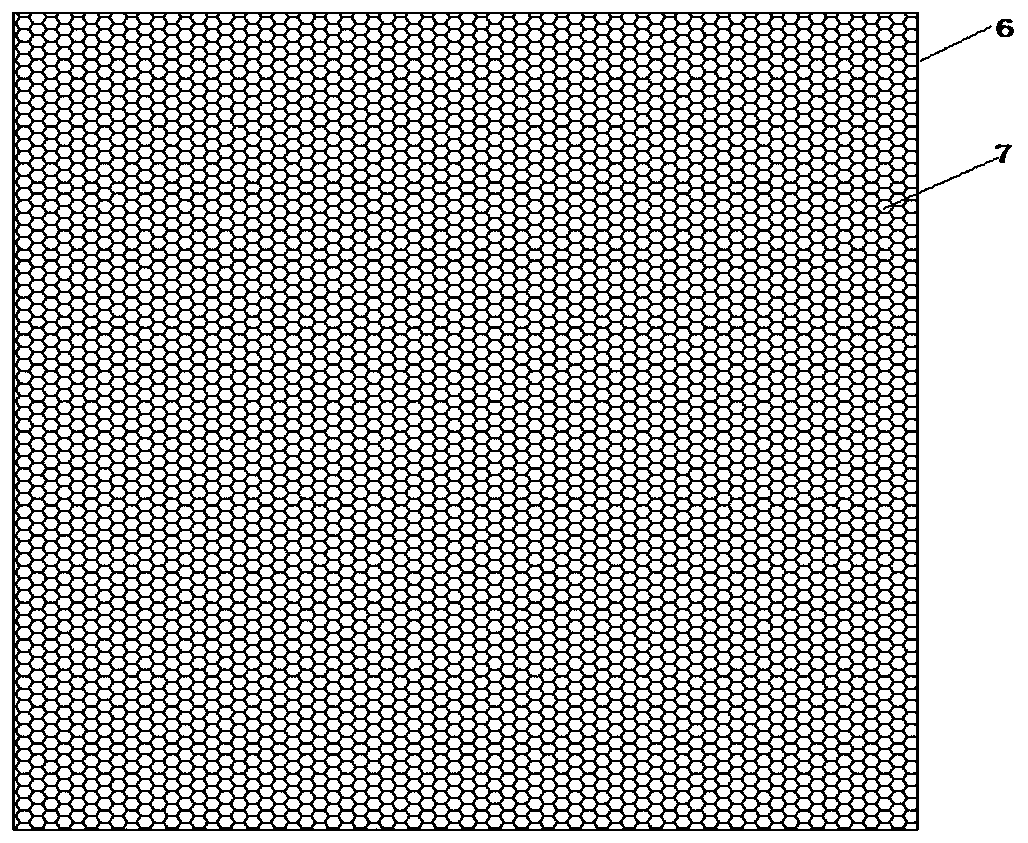

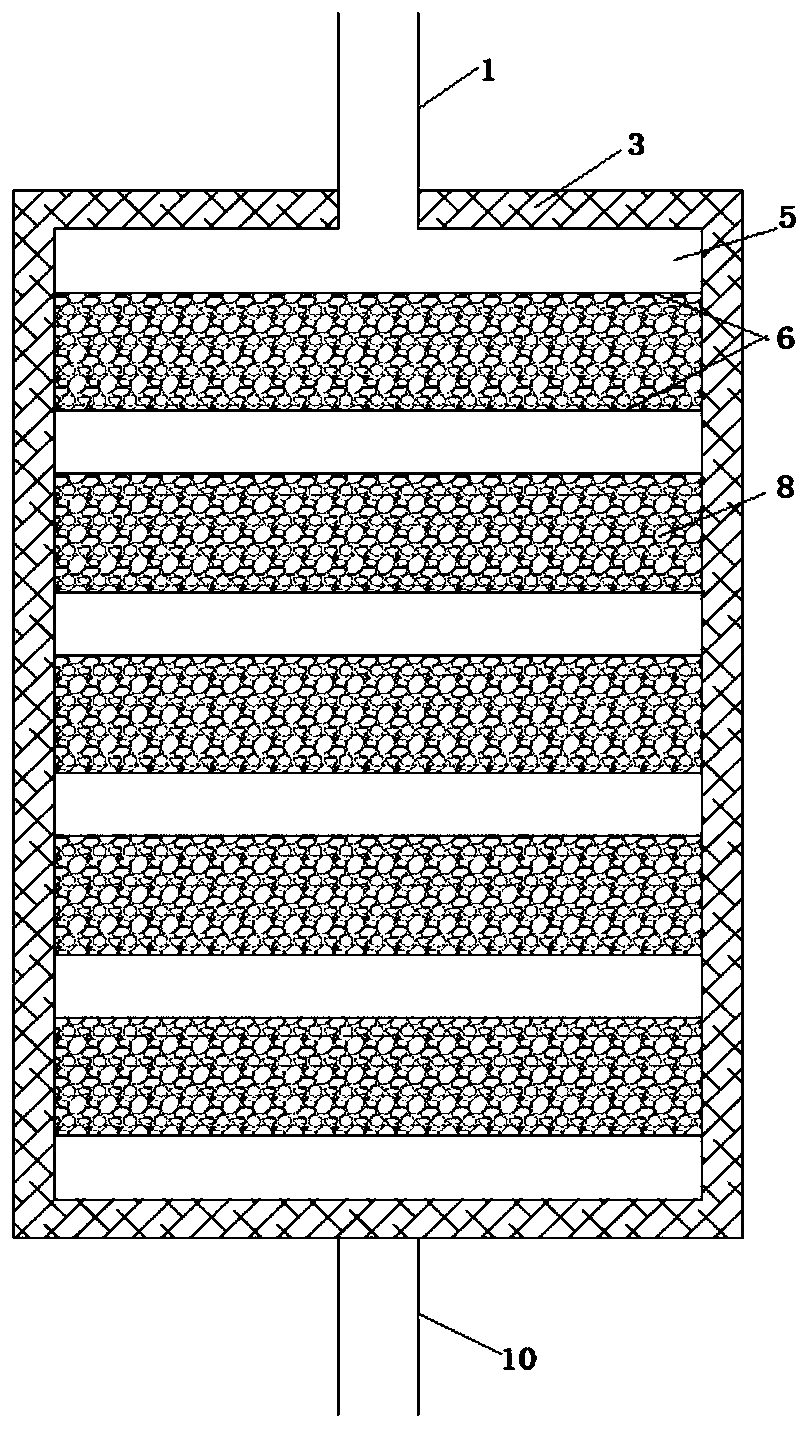

[0030] like figure 1 and figure 2 , a layered unit reactor for heat storage of hydrated salts, comprising a gas inlet section 1, a shell 2, a thermal insulation coating, 3, bolts 4, partitions 5, metal screens 6, meshes 7, hydration Salt 8, gas collection channel 9, gas outlet section 10; the gas inlet section 1 is a cylindrical pipe used to connect the dry hot air or wet cold air pipe provided externally. The metal screen 4 arranged in the direction of the vertical partition 5 is used as the reaction bed of the hydrated salt 6, and the middle third of the partition 5 section occupied by the layer thickness of each reaction unit is also composed of the metal screen 6, All metal screens 6 have the characteristics of thin thickness, small pore size, and large porosity. In this way, the leakage of the filled hydrated salt can be prevented, and the normal reaction between the incoming gas and the hydrated salt 8 particles is not hindered; With multiple reaction bed units, under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com