Patents

Literature

2310results about How to "Avoid caking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

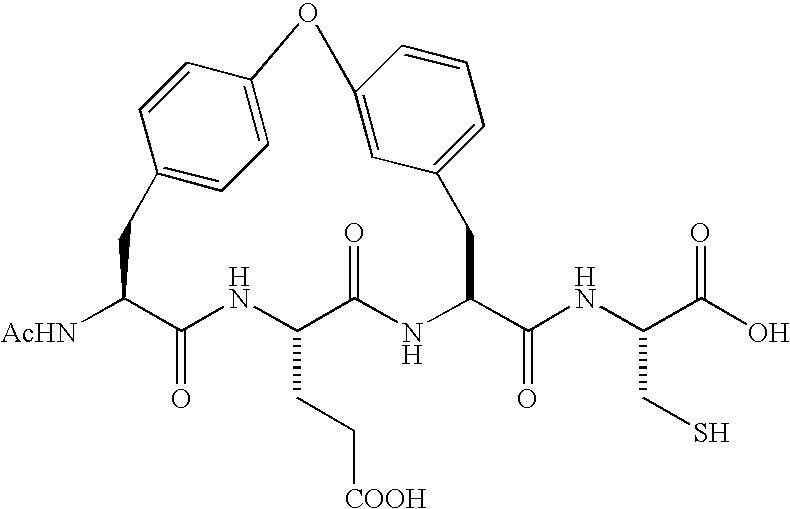

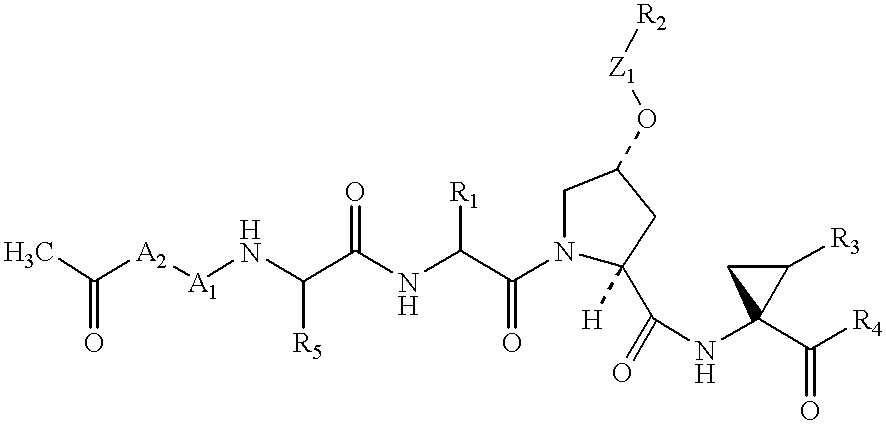

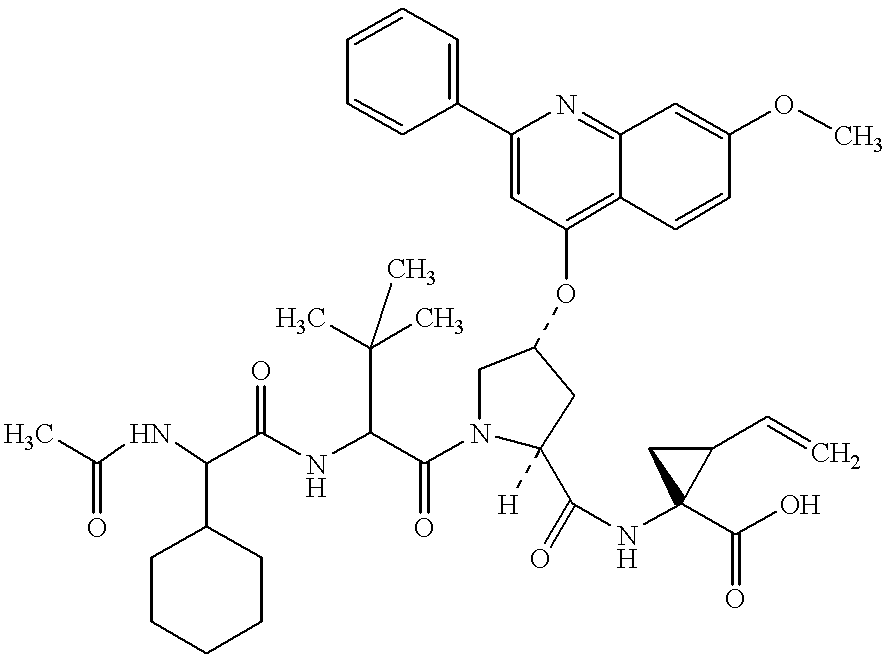

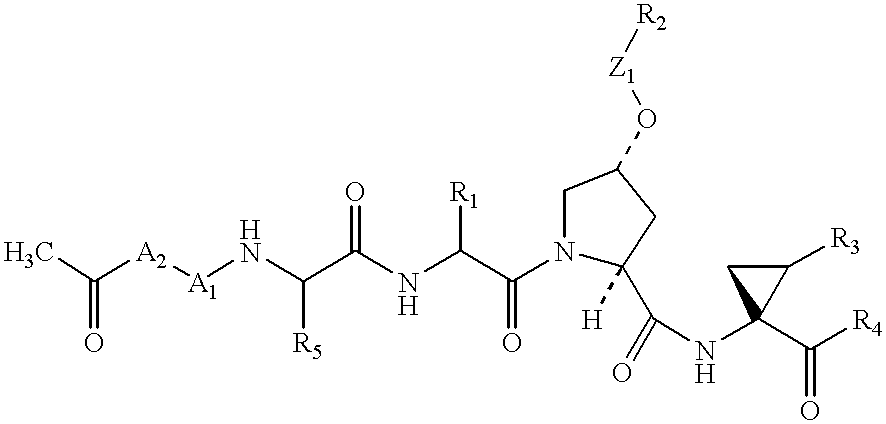

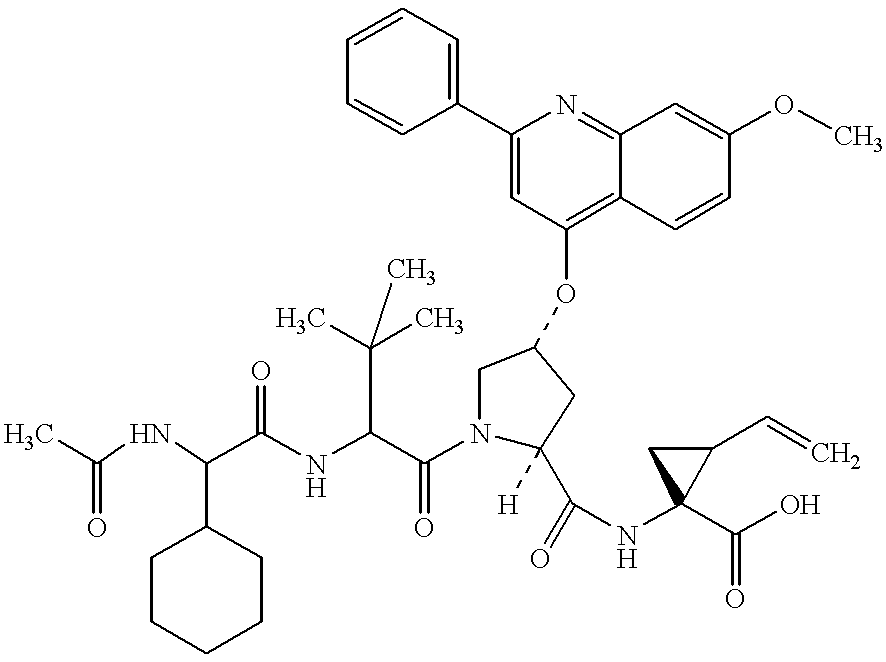

Imidazolidinones as NS3-serine protease inhibitors of hepatitis C virus

InactiveUS6838475B2Reduce frictionReduce wearBiocideOrganic active ingredientsSerine Protease InhibitorsHepacivirus

The present invention discloses novel imidazolidinones which have HCV protease inhibitory activity as well as methods for preparing such compounds. In another embodiment, the invention discloses pharmaceutical compositions comprising such imidazolidinones as well as methods of using them to treat disorders associated with the HCV protease.

Owner:SCHERING CORP

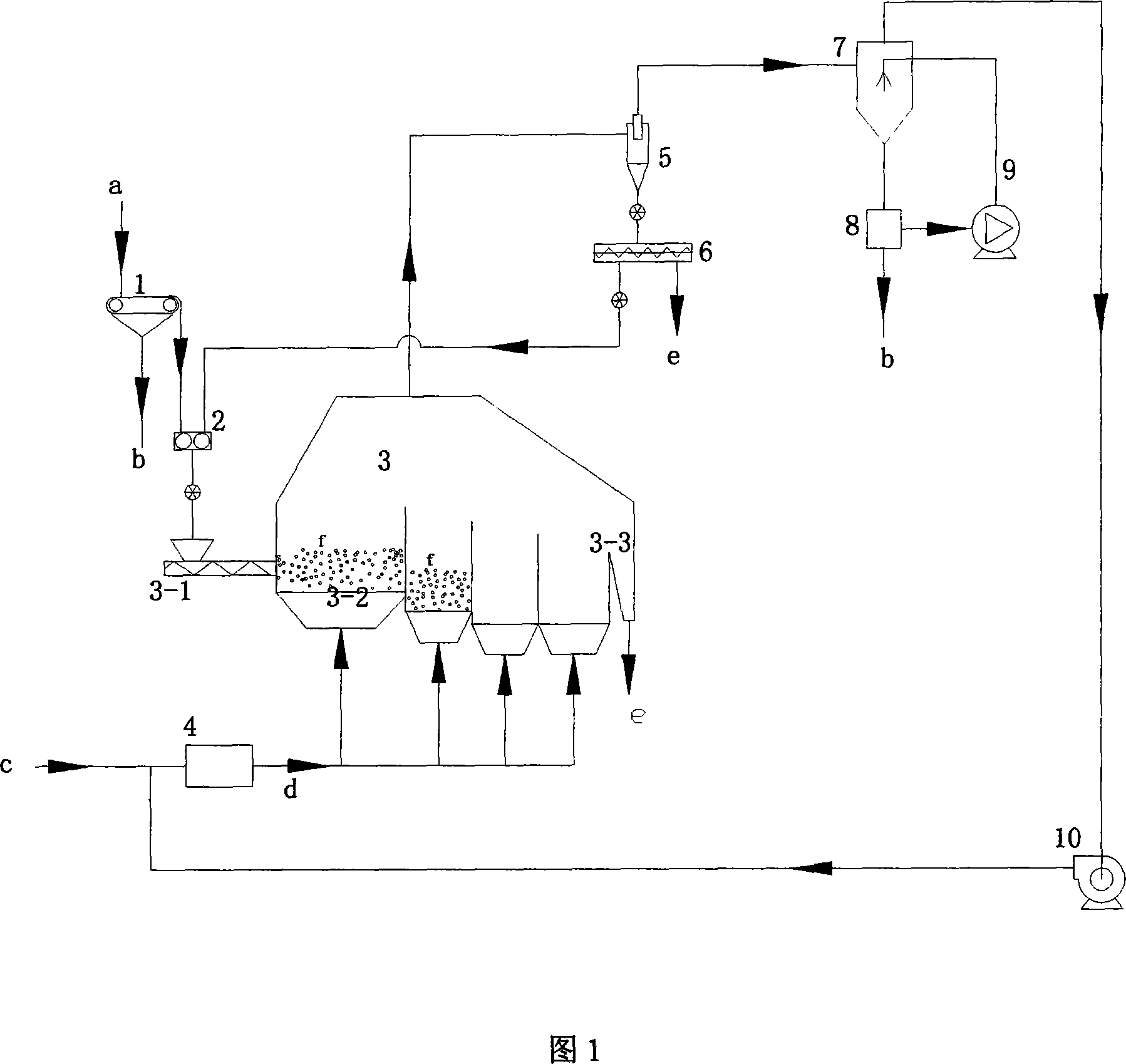

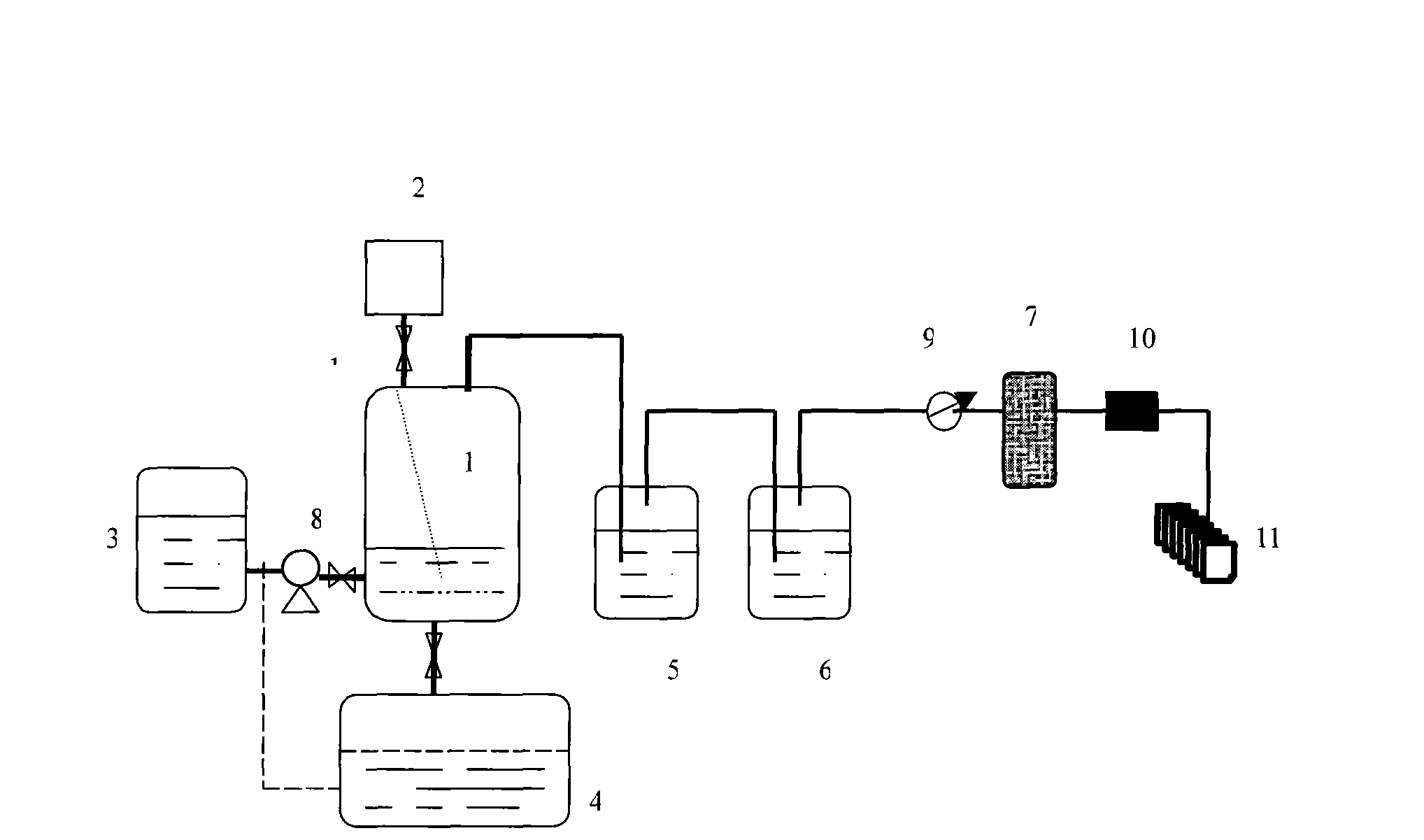

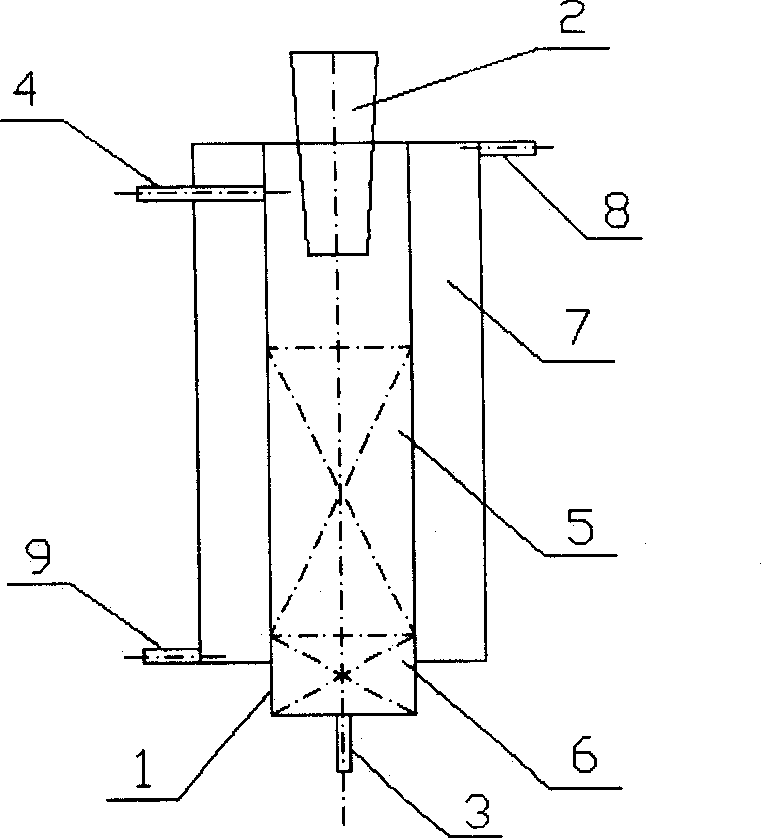

Enclosed multi-chamber fluidized bed drying method for sludge

InactiveCN101186422AUniform humidityReduce breakageSludge treatment by de-watering/drying/thickeningLiquid wasteFluidized bed drying

A closed multi-room fluidized bed sludge drying method is provided, which is a sludge drying method having the advantages of simple equipment structure, convenient operation, strong sludge adaptability, high thermal efficiency, safety, continuity, stability, etc. After the mechanically dewatered sludge is mixed with the back-mixed sludge, the mixture is dried room by room in an inert particles multi-room fluidized bed dryer (3). The first room and the second room of the inert particles multi-room fluidized bed dryer (3) adopt inert particles (f) as heat storage medium. Gas from a cyclone separator (5) goes through a spray tower (7) and returns into an air heating unit (4) through a circulating fan (10). Part of dried sludge (e) at the lower part of the cyclone separator (5) enters the inert particles multi-room fluidized bed dryer (3) through the back-mixing in a mixer (2). Waste liquid from the bottom of the spray tower (7) enters a waste liquid circulating pool (8), with part of waste liquid circulating into the spray tower (7) and part into a sewage treatment system.

Owner:SOUTHEAST UNIV

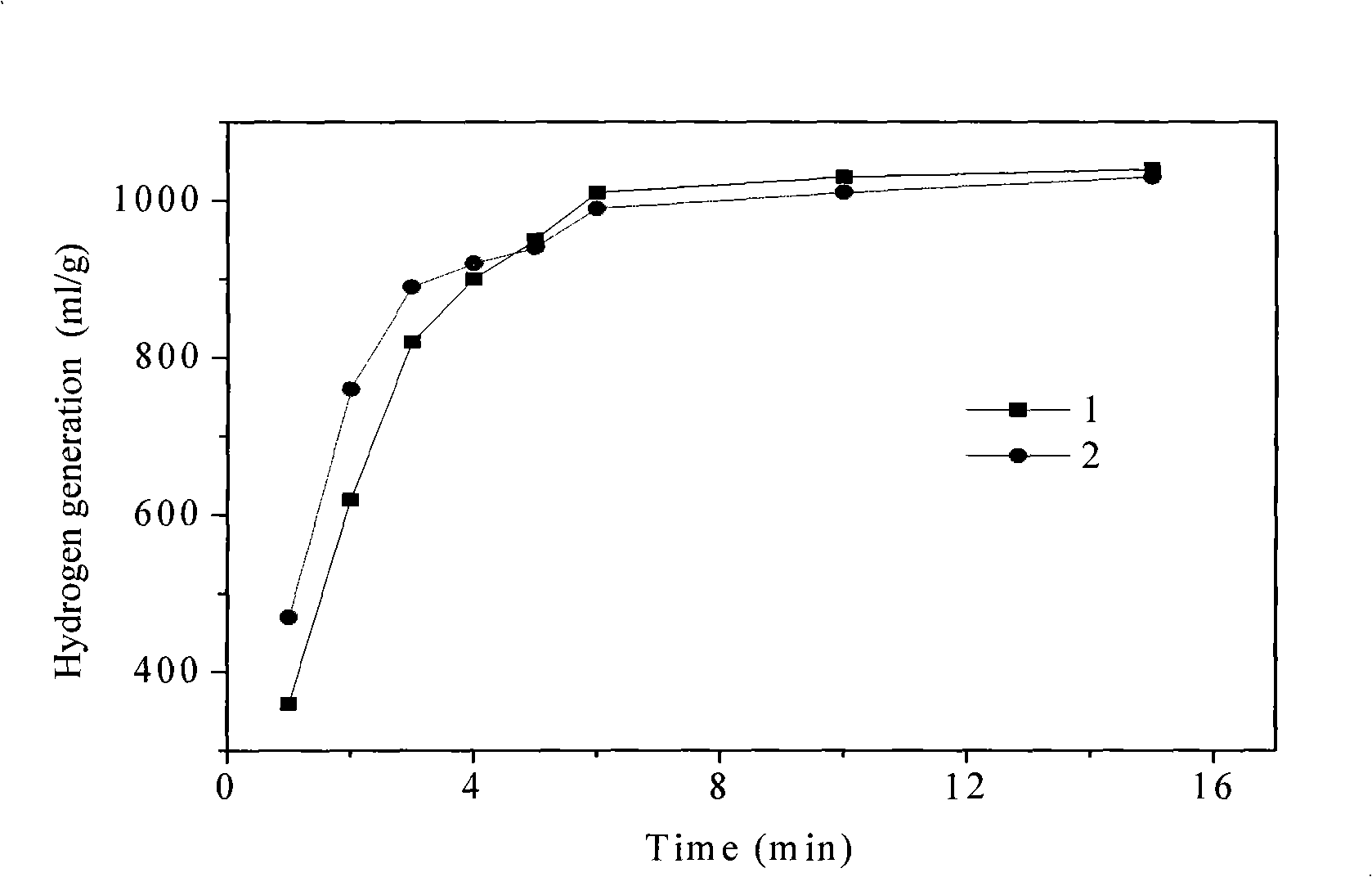

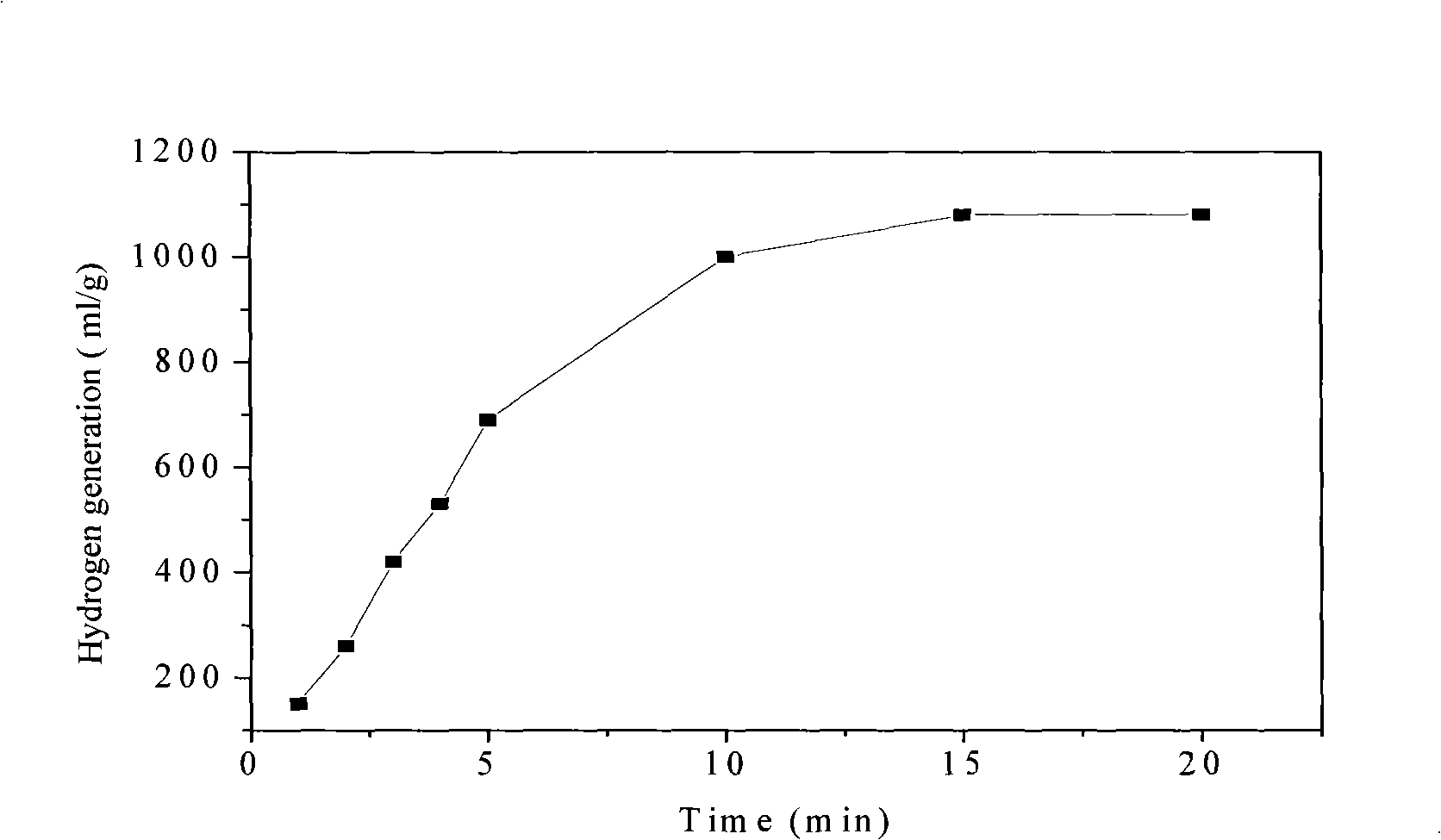

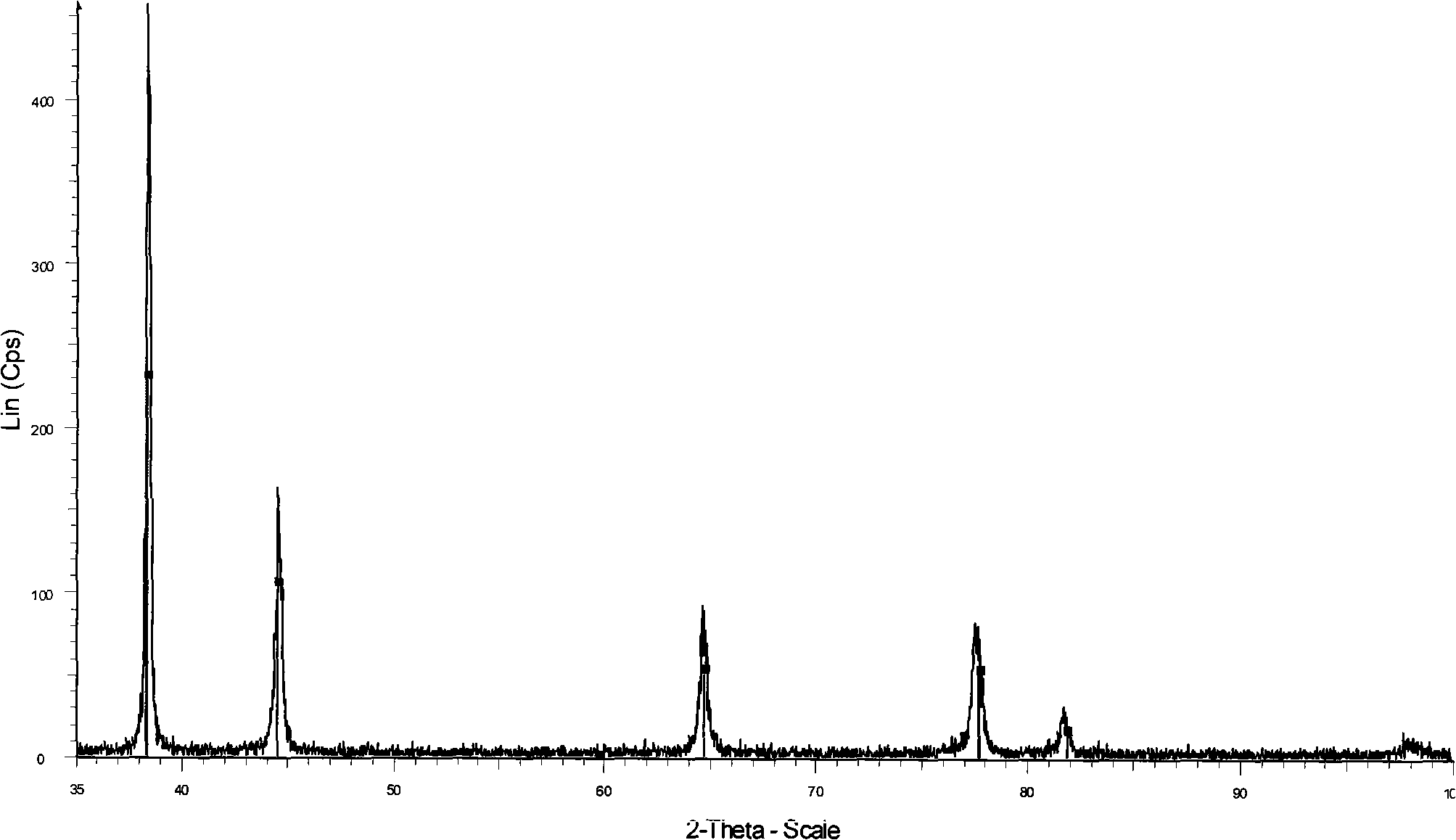

Aluminum alloy for preparing hydrogen by hydrolytic decomposition and preparation thereof

InactiveCN101289163ALower the hydrolysis reaction temperatureImprove electrochemical activityHydrogen productionDecompositionReaction rate

The invention relates to a hydrogen preparation method by hydrolyzing aluminum alloy, in particular to an aluminum alloy which can be hydrolyzed to make hydrogen and a preparation method thereof. The alloy consists of simple-substance metal aluminum, metal bismuth, metals with low melting point and water-soluble compound; according to weight percentage, the content of the metal bismuth is 8 to 50 percent, low melting point metal is 0 to 15 percent, water soluble compound is 1 to 40 percent and metal aluminum is 40 to 90 percent. The method of the invention reduces reaction temperature of aluminum hydrolysis, speeds up reaction rate of aluminum hydrolysis, enhances hydrogen yield rate, simplifies reaction devices as well as reduces hydrogen storage cost. The aluminum alloy prepared by the method of the invention is portable easily, is capable of preparing and providing hydrogen at any time and is applicable to providing humid hydrogen for fuel cells.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

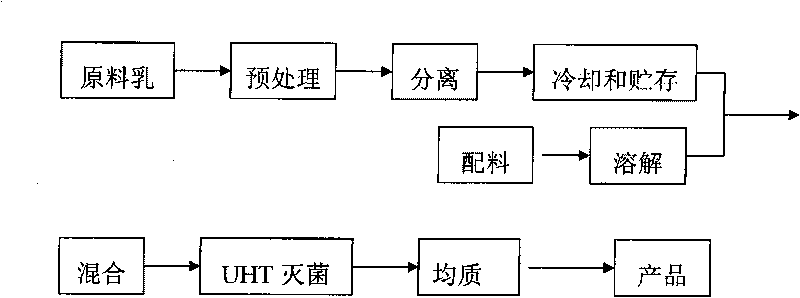

Cream and making method and use thereof

The invention discloses a cream which contains 20-45% of fat, 1-3% of protein, 0.1-0.55% of stabilizer, 0.05-0.35% of emulsifier, 0.005-0.15% of buffer salt and the balance water, and the percent is the weight percent of each component in the total weight of the cream. The invention further provides a making method of the cream. The making method can overcome the defects of short shelf life, strict preservation conditions and further limitation of the sales regions of the cream prepared by the conventional method, and the invention provides the cream and the making method thereof by improvingthe formula and the process of the cream. The cream produced and prepared by the method can be stored at room temperature, the use is convenient and fast, and the shelf life is long, thereby being suitable for long-distance transportation and being conductive to construction of a national sales network; meanwhile, the cream product has the advantages of uniformity, stability, no water separation,good whipability and thermal stability, thereby being applicable to making egg tarts, candies, cakes or cream soup.

Owner:BRIGHT DAIRY & FOOD

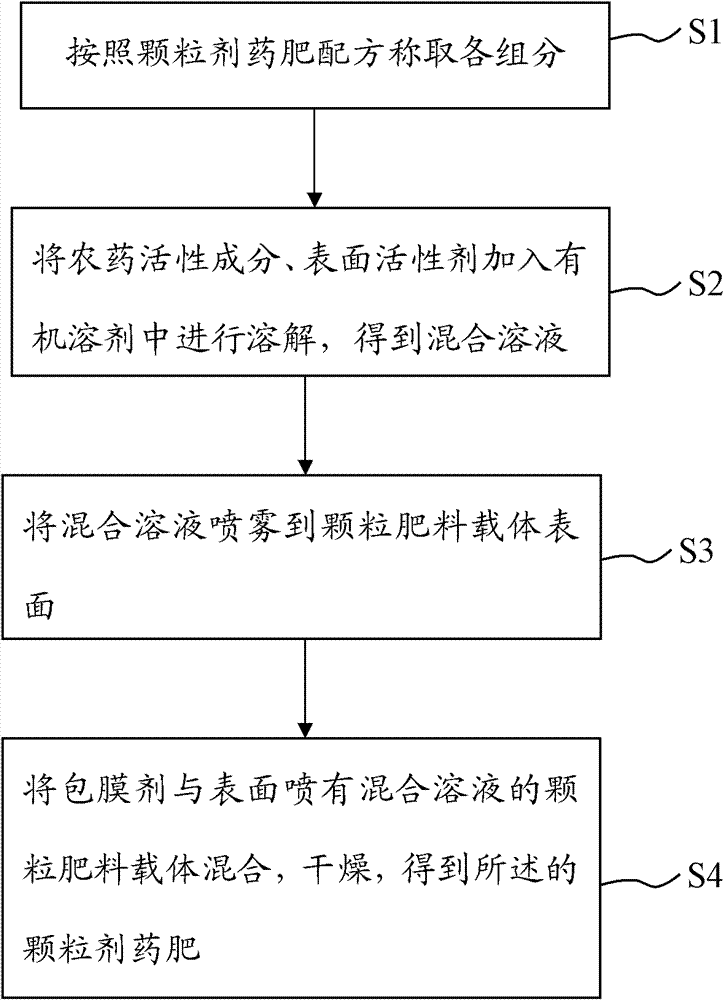

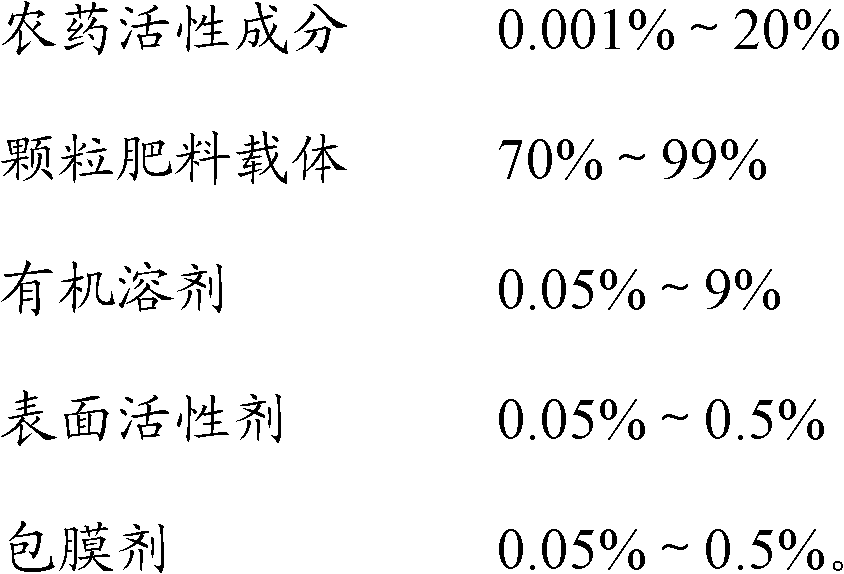

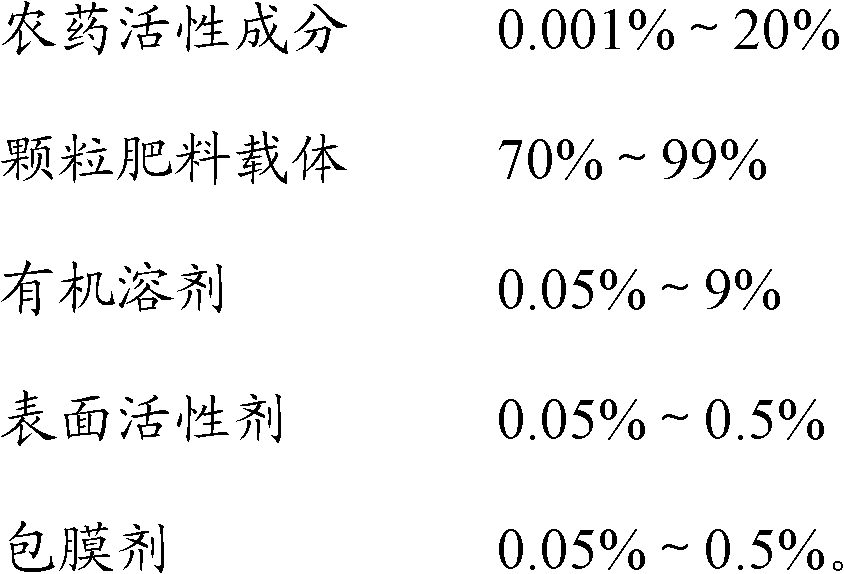

Granular pesticide fertilizer, and preparation method and application thereof

InactiveCN102775241AReduce stress on the farm environmentSave resourcesFertiliser formsFertilizer mixturesFertilizerPesticide

The invention provides a granular pesticide fertilizer, and a preparation method and application thereof. The granular pesticide fertilizer comprises the following components expressed in mass percent: on the basis that the total mass of the granular pesticide fertilizer is 100%, 0.001 to 20% of a pesticide active component, 70 to 99% of a granular fertilizer carrier, 0.05 to 9% of an organic solvent, 0.05 to 0.5% of a surfactant and 0.05 to 0.5% of a coating agent. According to embodiments in the invention, the pesticide active component and the granular fertilizer carrier in the granular pesticide fertilizer are reasonably combined, which allows the problem of damage by diseases and insects to soil in agricultural production to be effectively overcome and enables soil fertility to be improved and labor and time to be saved. The granular pesticide fertilizer is produced by using a normal temperature spraying adsorption process and a cladding process, so the preparation method for the granular pesticide fertilizer has the advantages of a simple process, low energy consumption, reduction in production cost, easiness in controlling and operating and suitability for industrial production.

Owner:SHENZHEN NOPOSION AGROCHEM

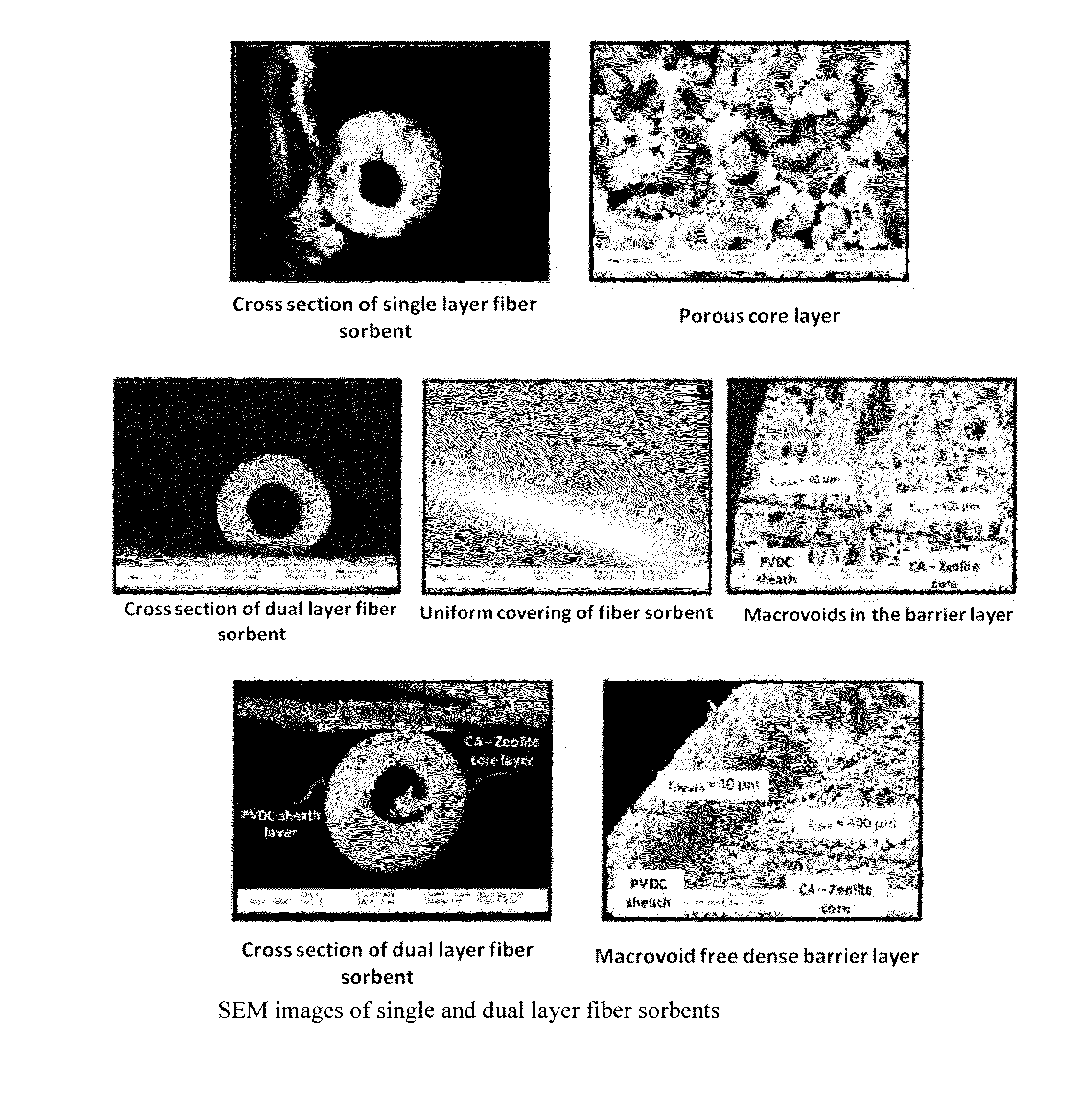

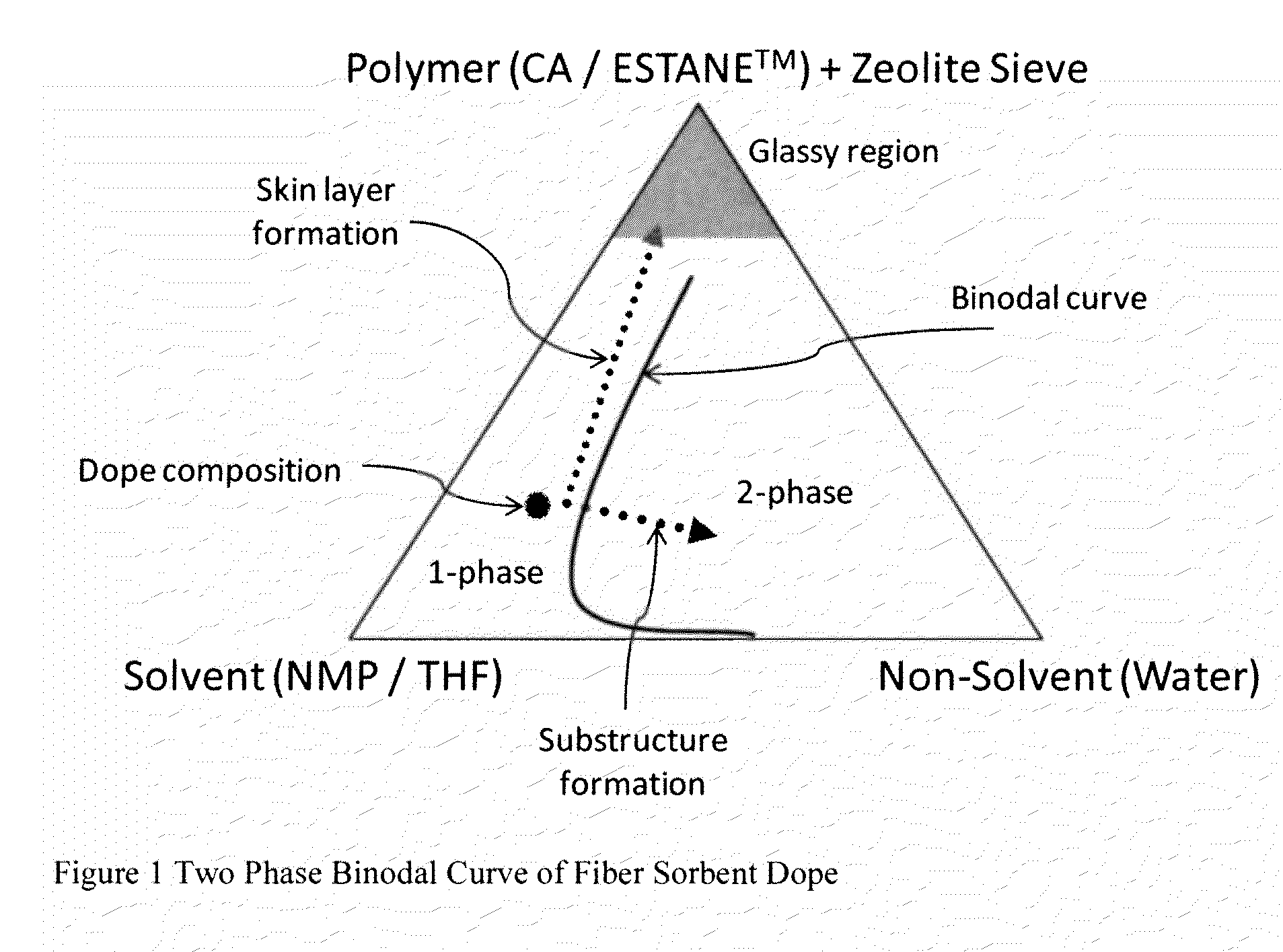

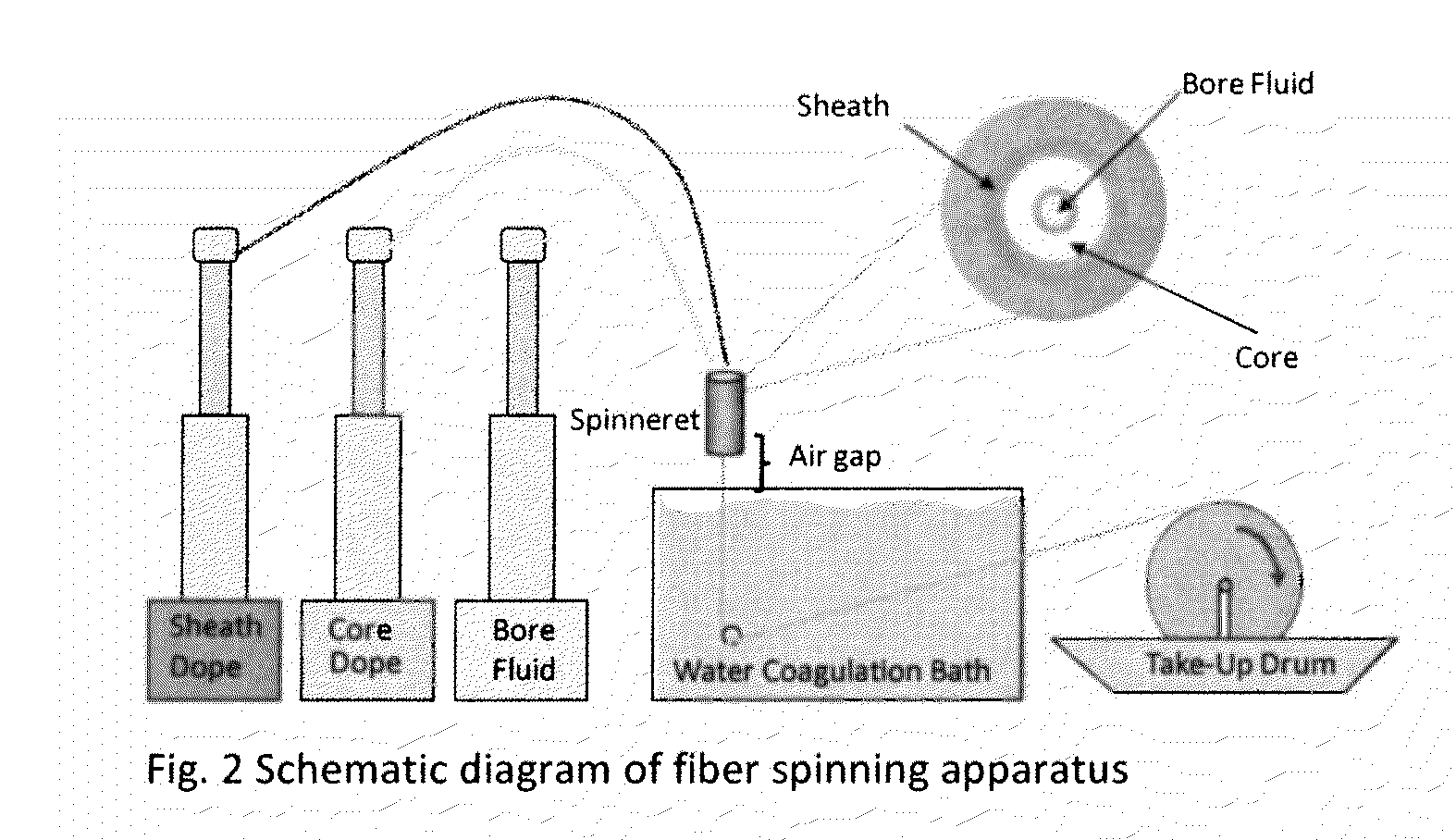

Fiber sorbents

InactiveUS20100313755A1Efficiently and effectively removedRemoving low level contaminants from a gas stream both effectively and efficientlyGas treatmentMolecular sieve catalystsFiberSulfur

The present invention relates to new fibers, new processes of using said fibers, and new sheath dope compositions for multi-layer spinning processes. The fibers comprise a porous core and a sheath surrounding said porous core. The fibers may be useful in, for example, processes for removing low level contaminants like sulfur compounds from a gas stream like natural gas.

Owner:GEORGIA TECH RES CORP

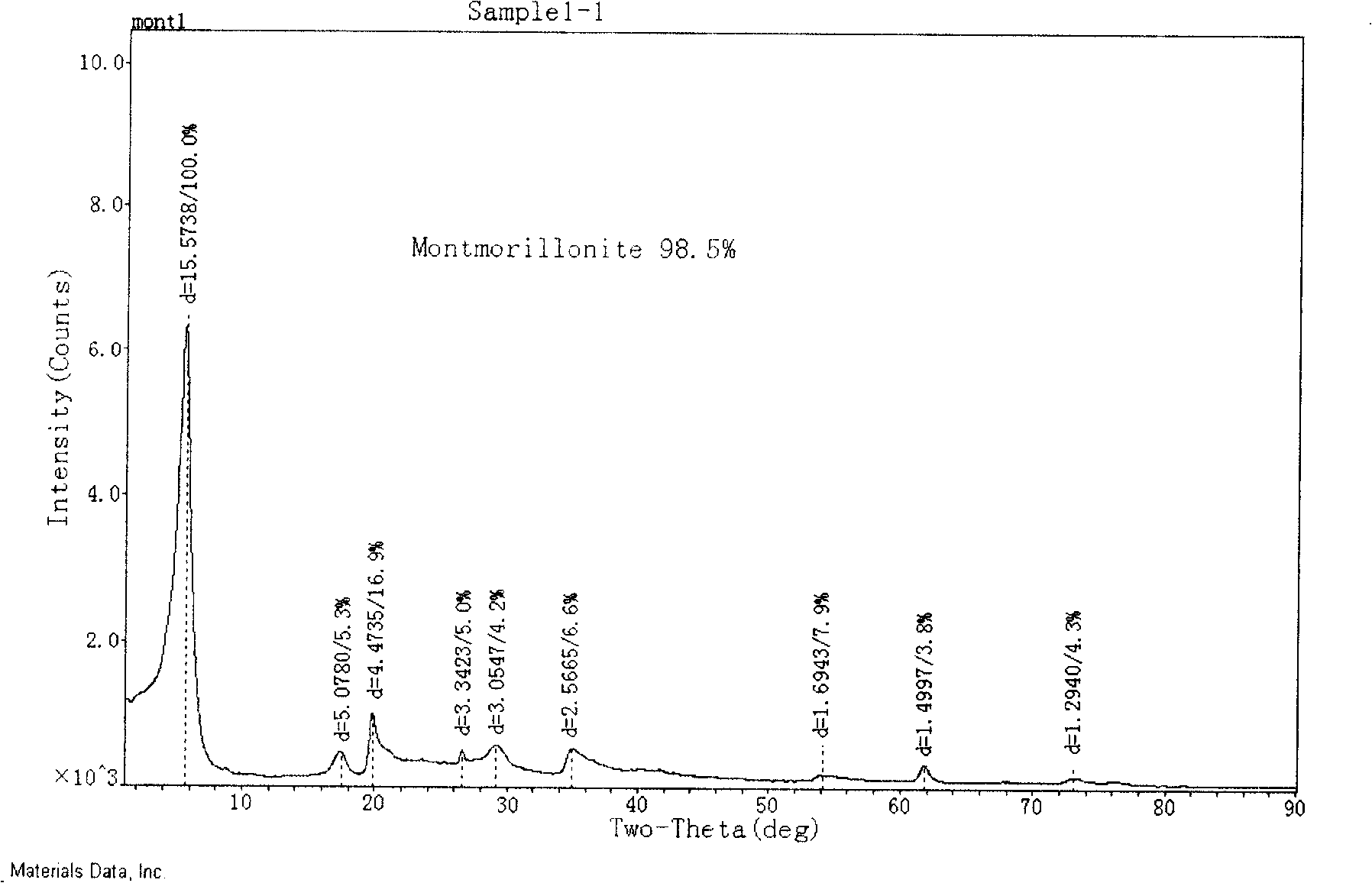

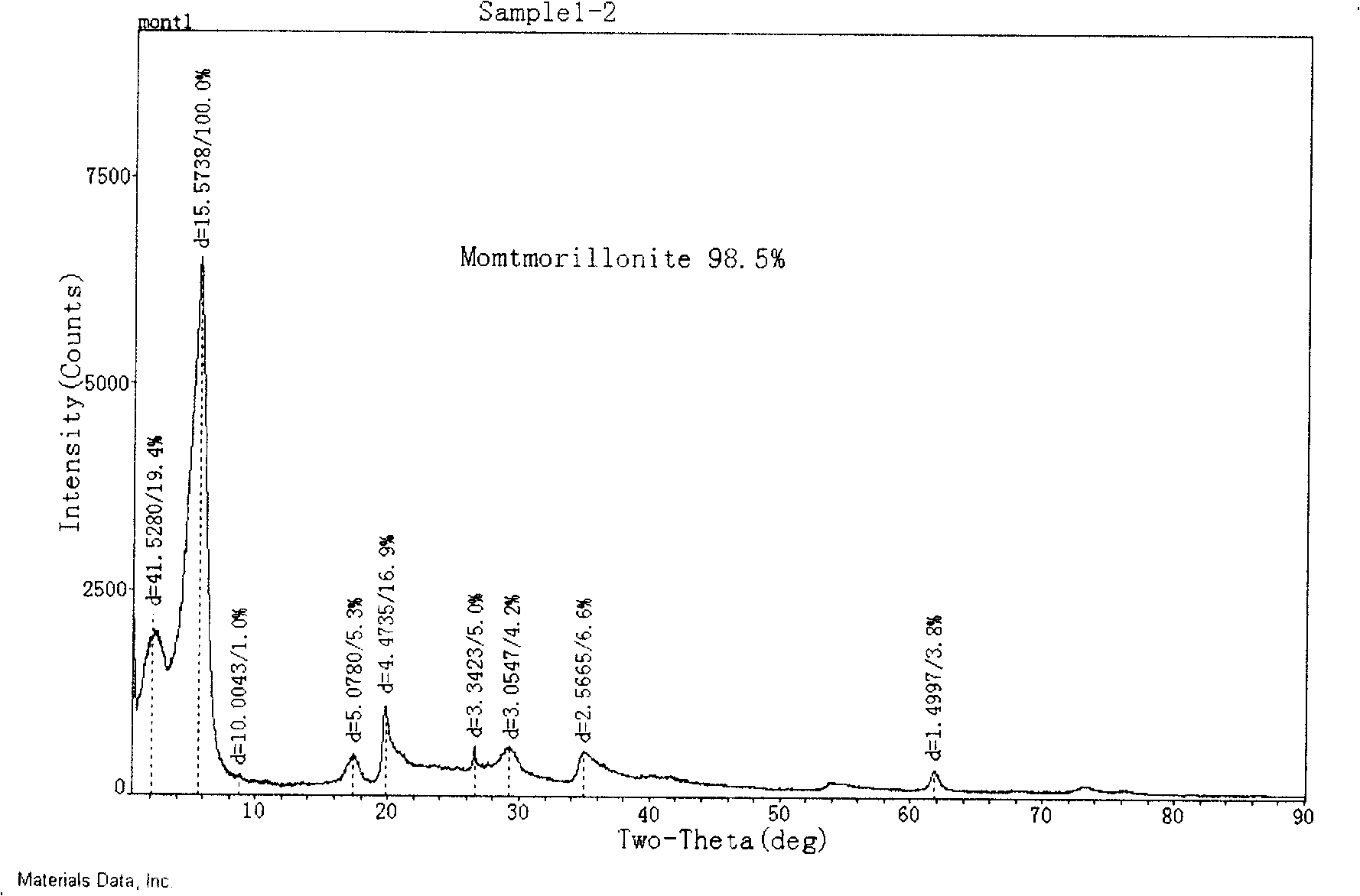

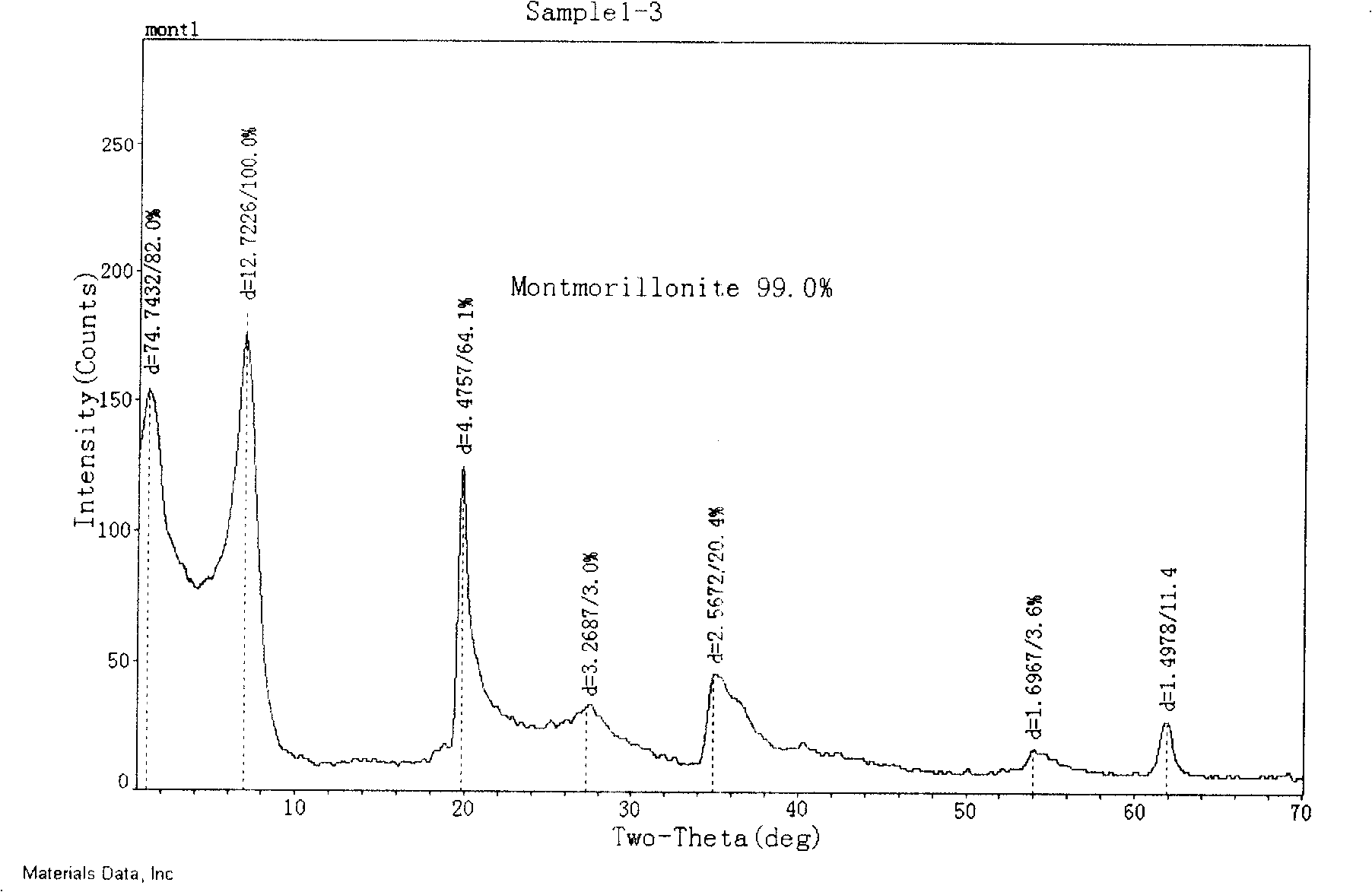

Modified smectite and method for producing the same and its application

ActiveCN101272986ANot easy to raise dustReduce moisture contentCosmetic preparationsOther chemical processesChemical compositionMontmorillonite

Disclosed is an inorganic medicine, particularly modified montmorillonite, method for preparing the same and use thereof. The said modified montmorillonite means that dioctahedron of natural montmorillonite is not destroyed and basic chemical composition for the same is not changed, and the microstructure stacked from dioctahedron layer is changed to decrease the thickness of stacking layer and to expose and increase the end face charge and the interlayer charge of montmorillonite, thereby resulting in its lower degree of C axis order. The present medical use of montmorillonite is thus significantly strengthened, particularly the reversal treatment effect on chronic atrophic gastritis. Also disclosed are a medicine composition containing modified montmorillonite and the reversal treatment effect of natural montmorillonite on chronic atrophic gastritis.

Owner:ZHEJIANG HAILISHENG PHARM CO LTD

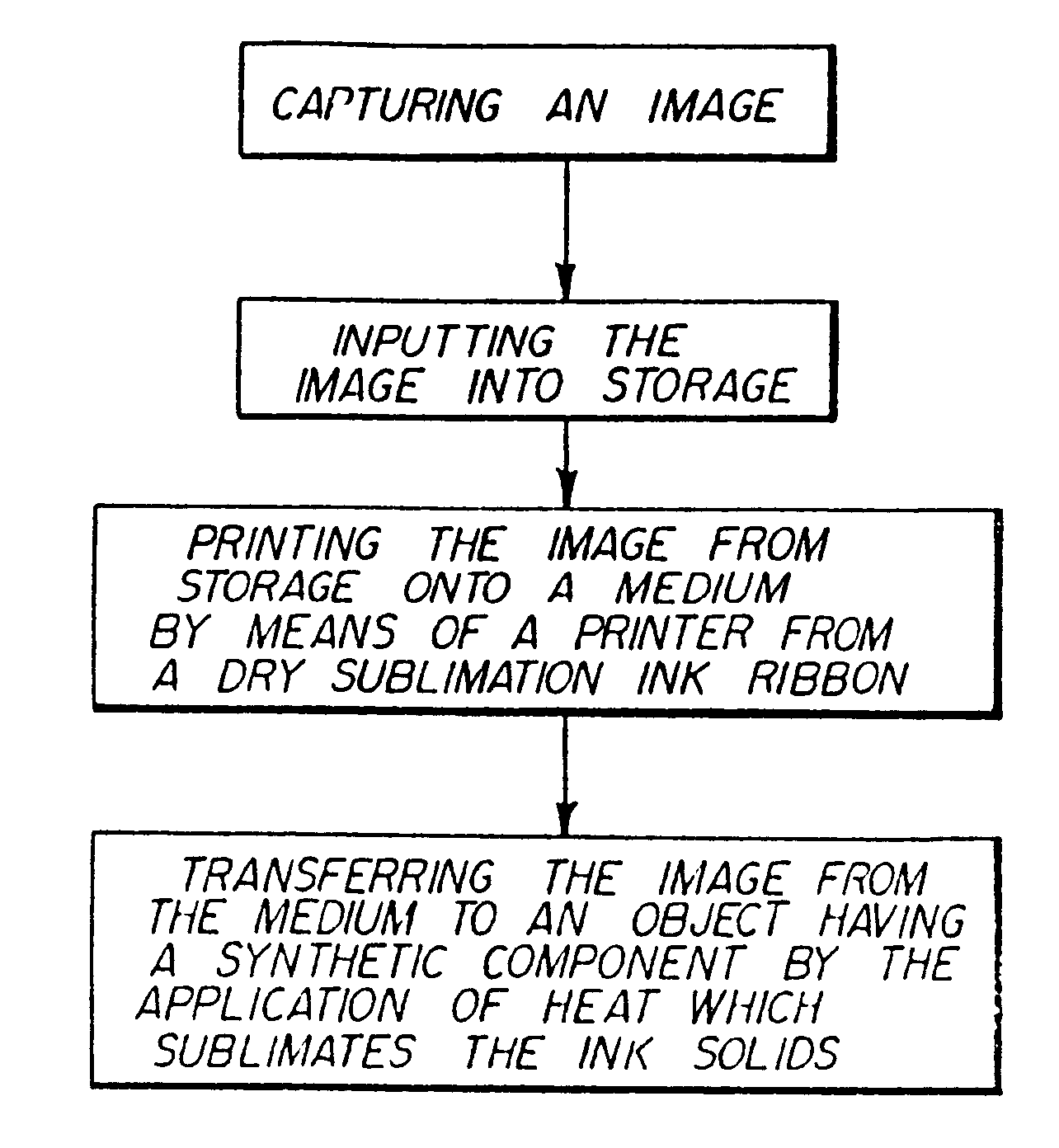

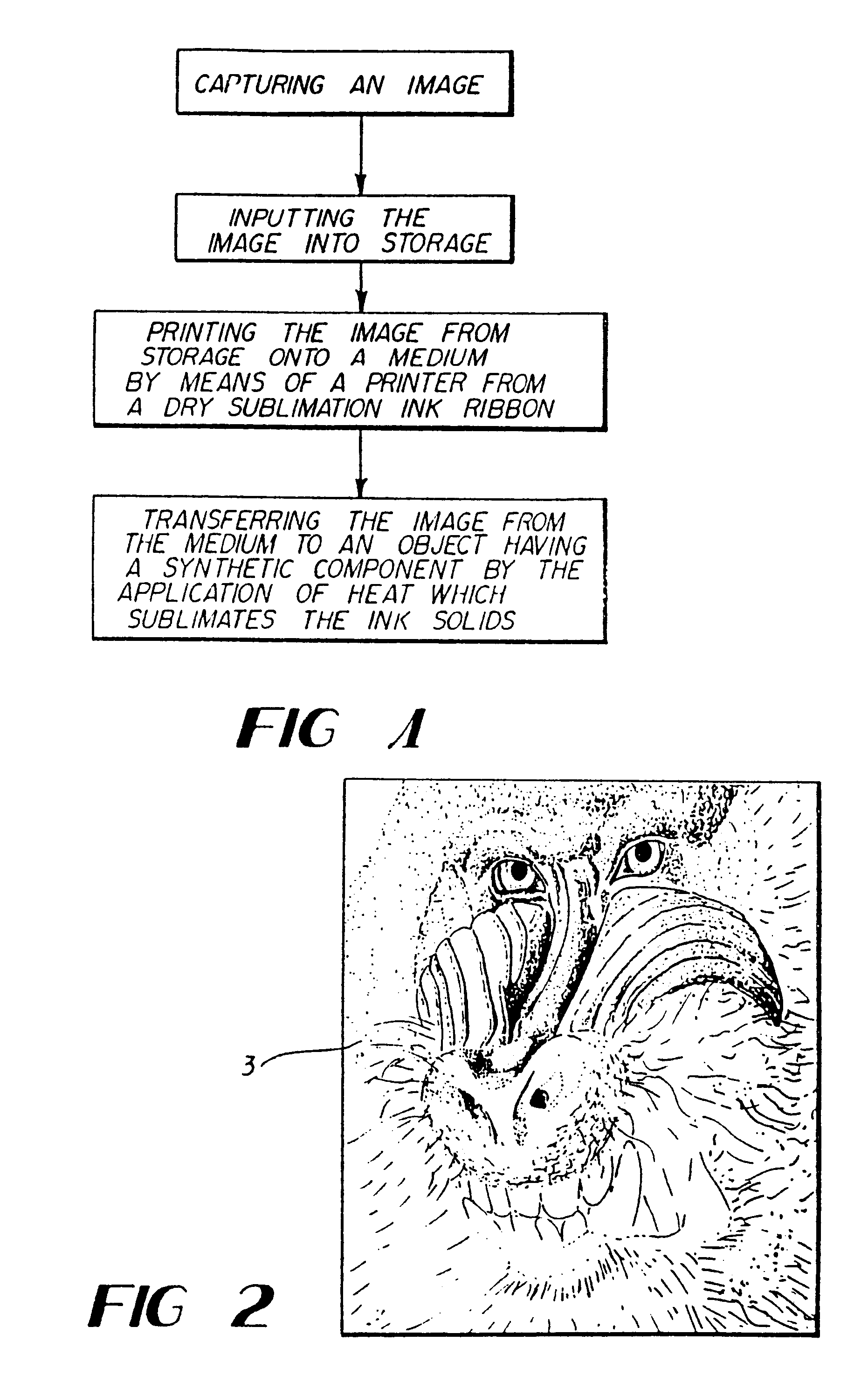

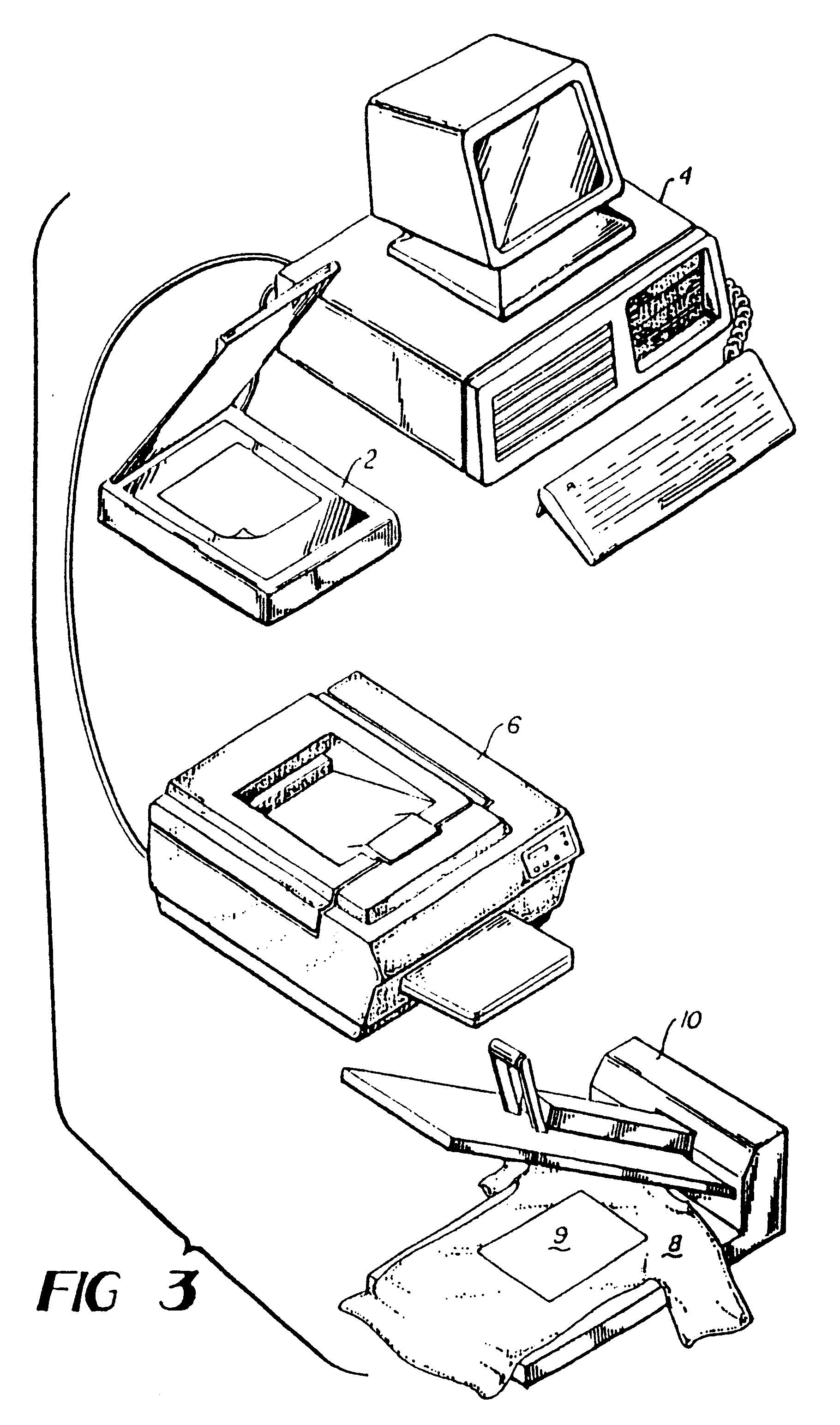

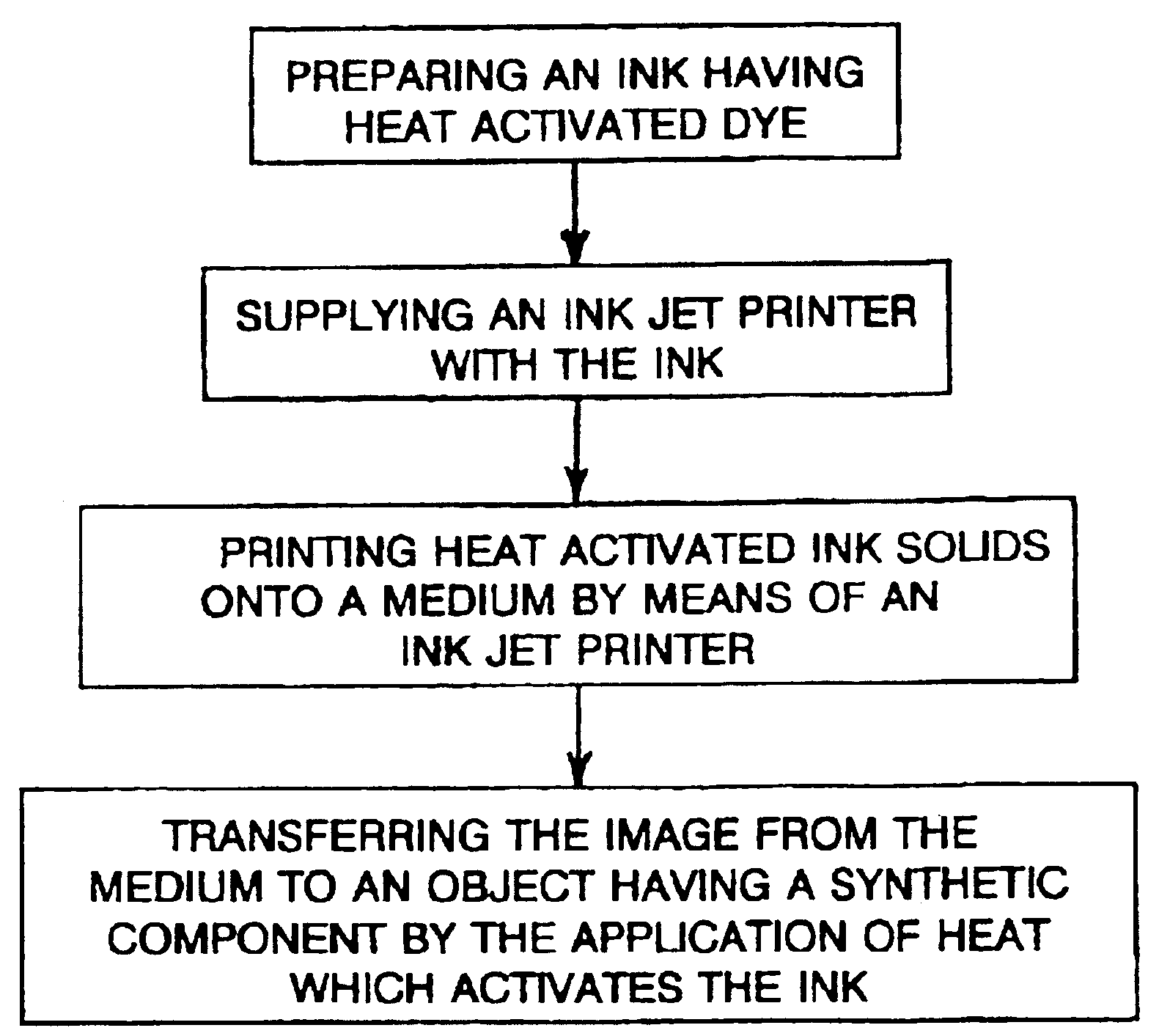

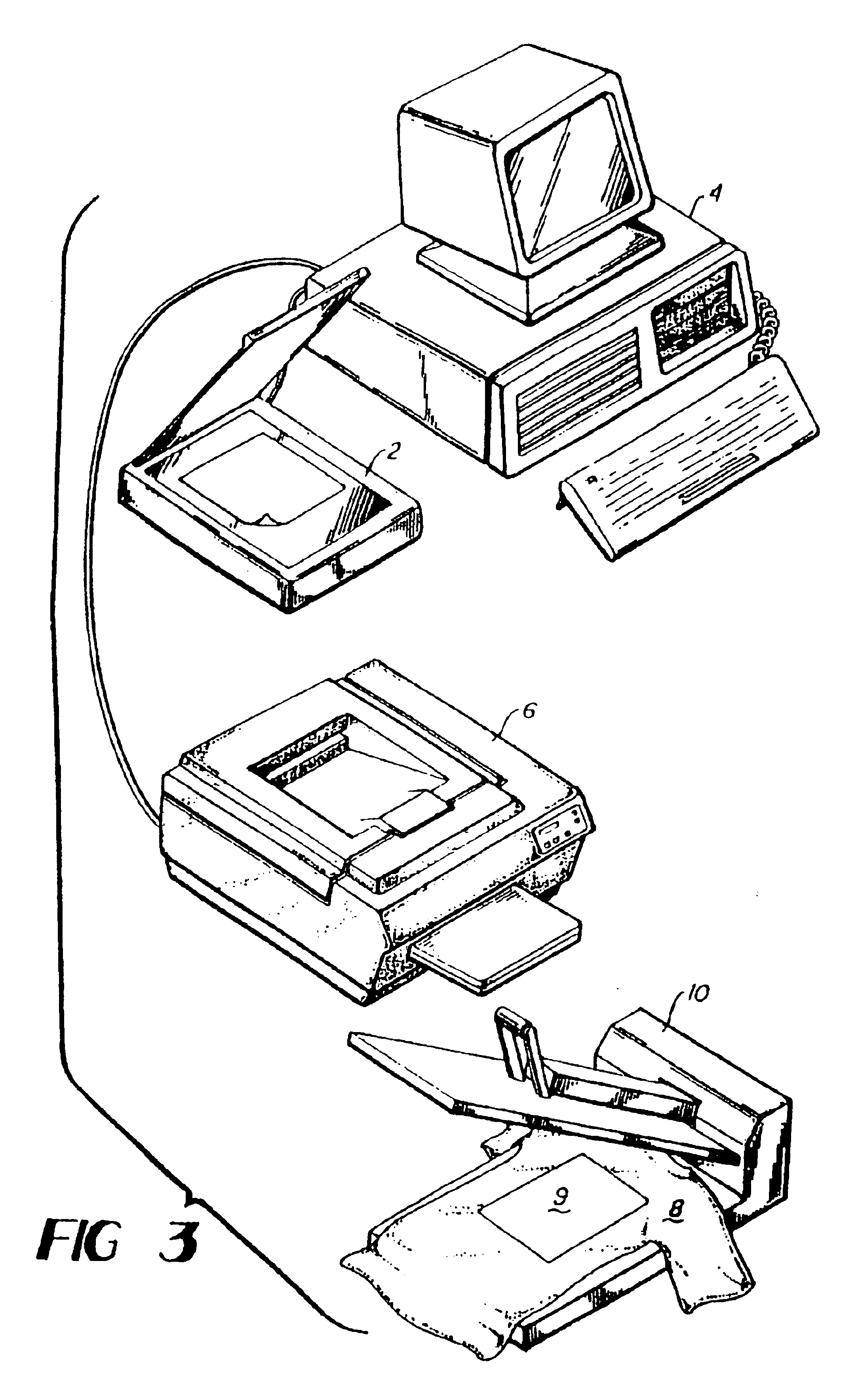

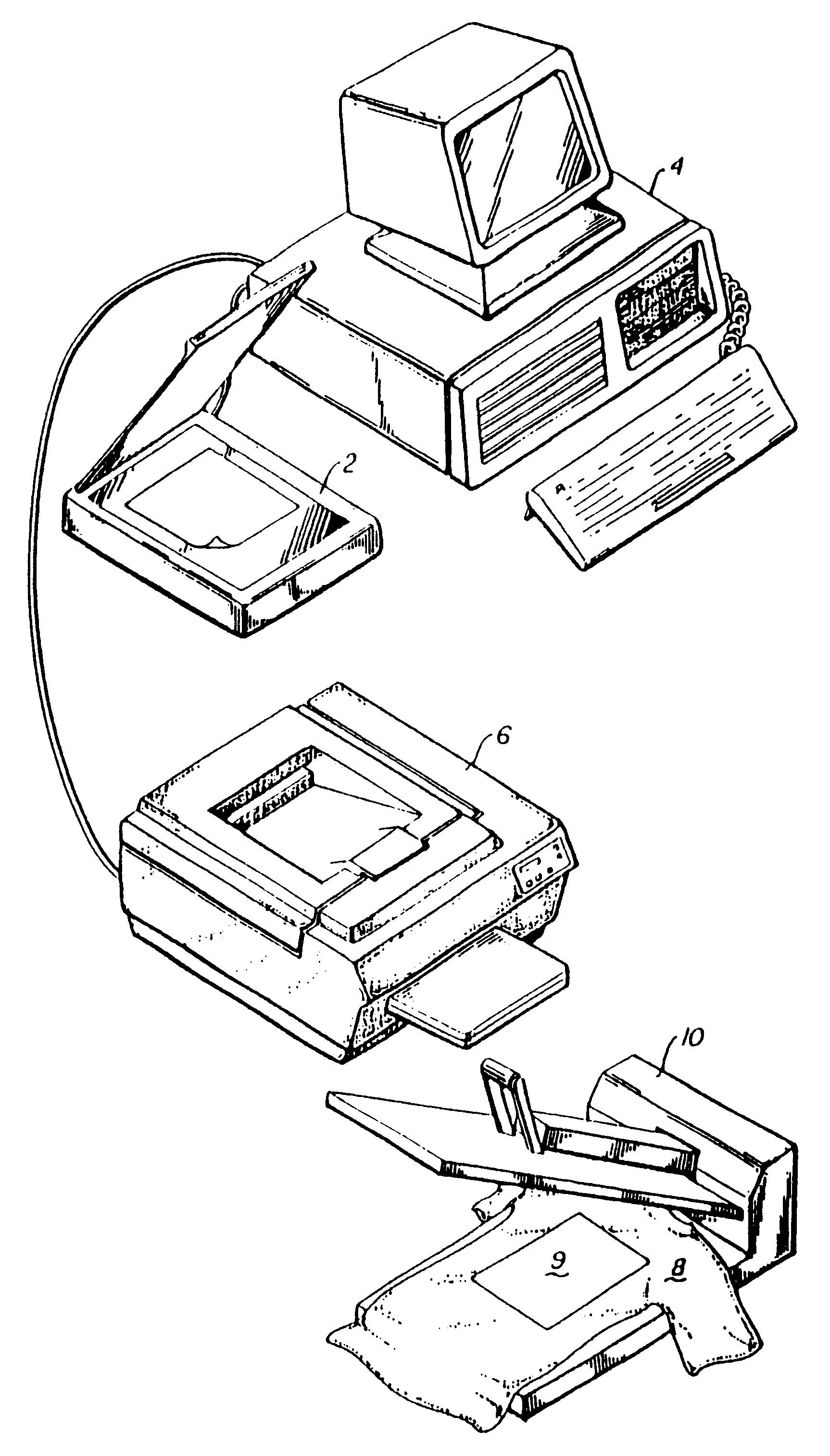

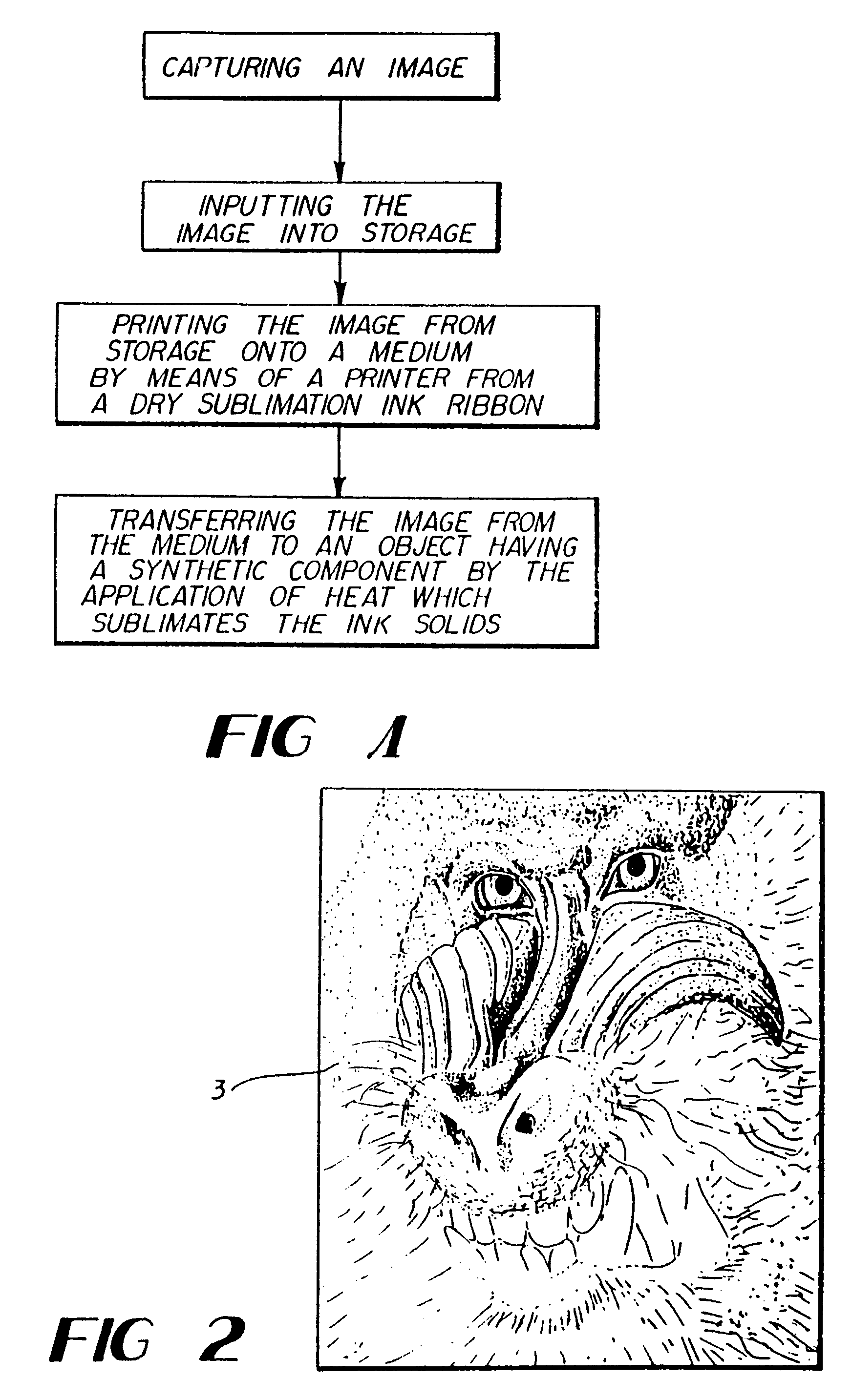

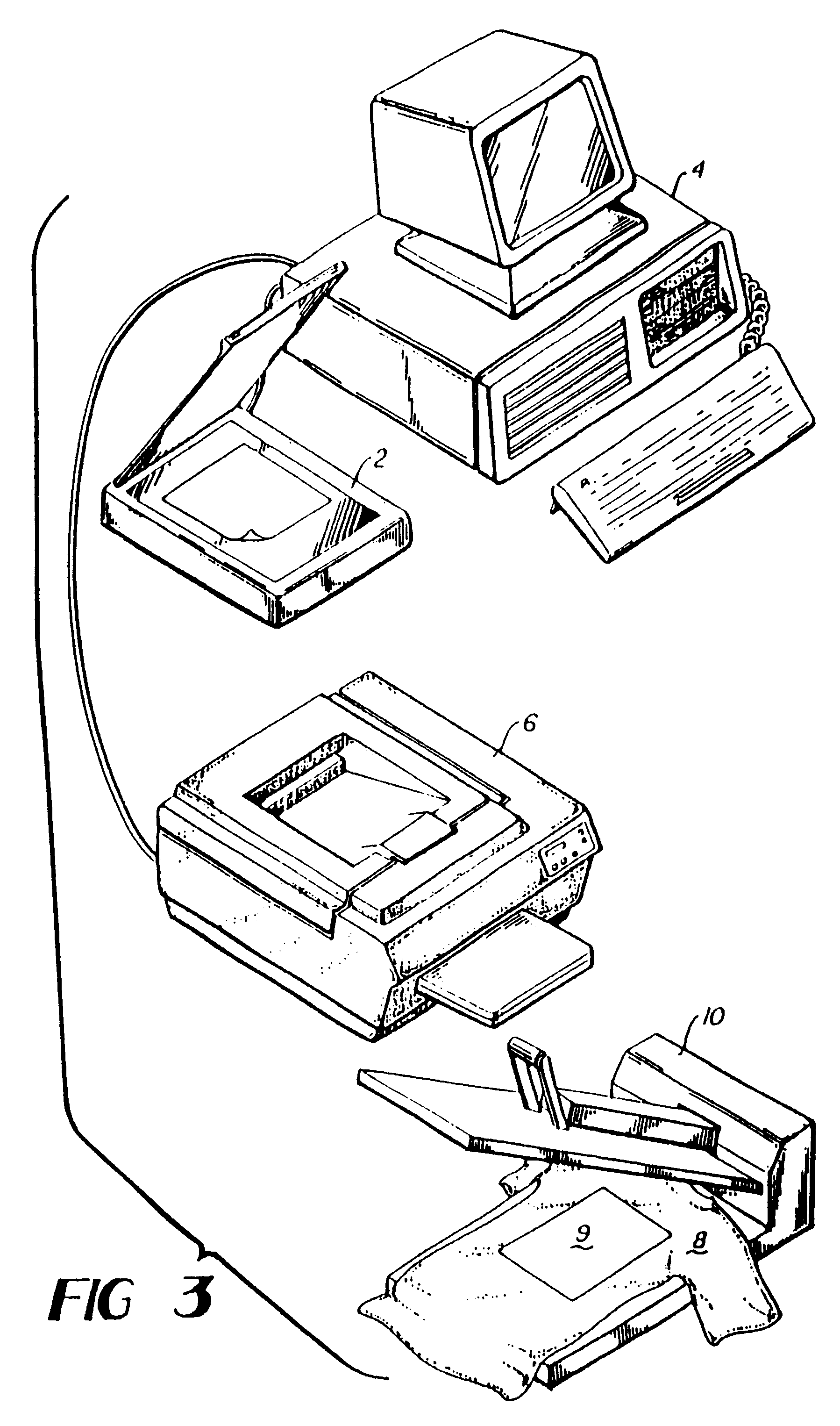

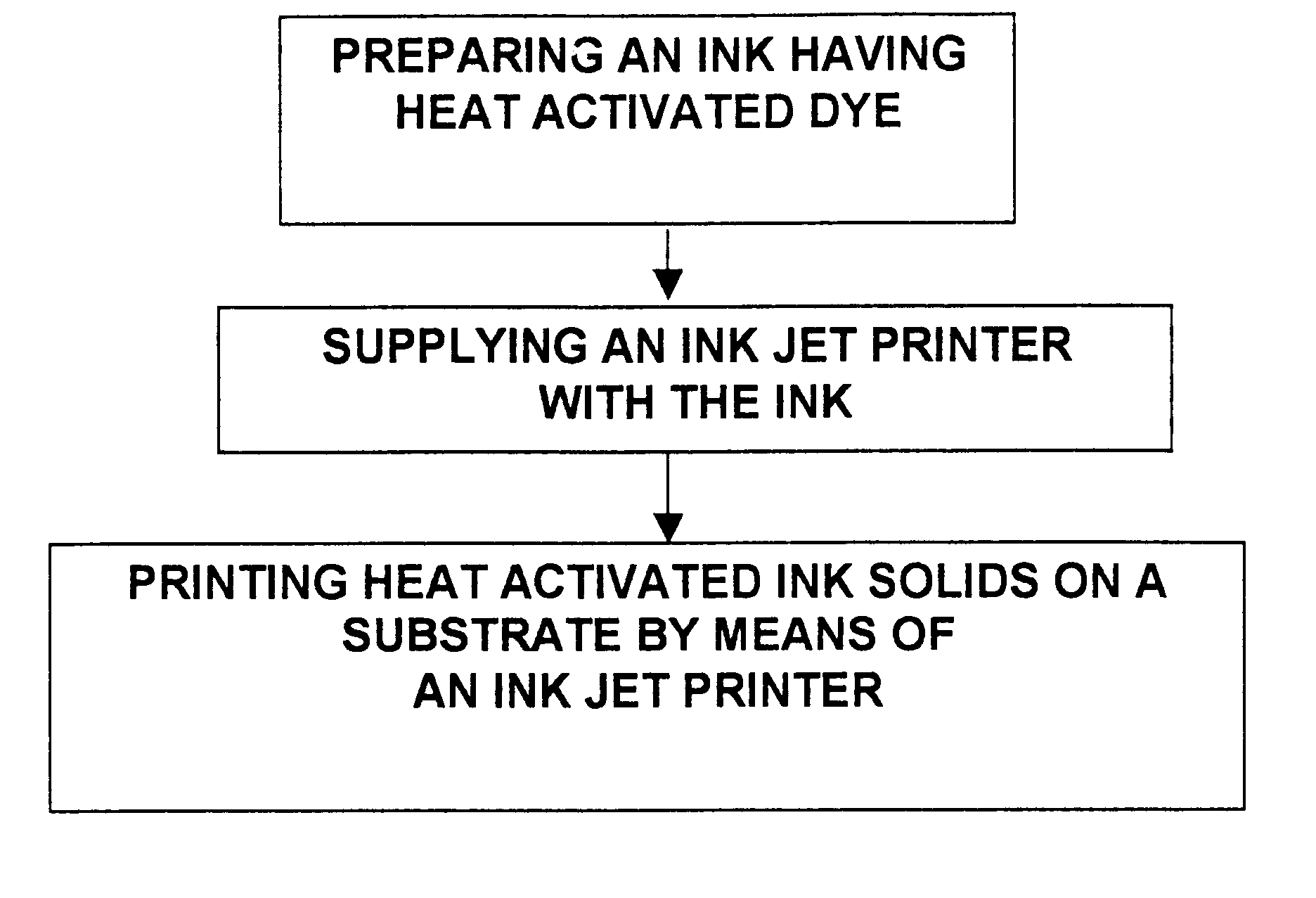

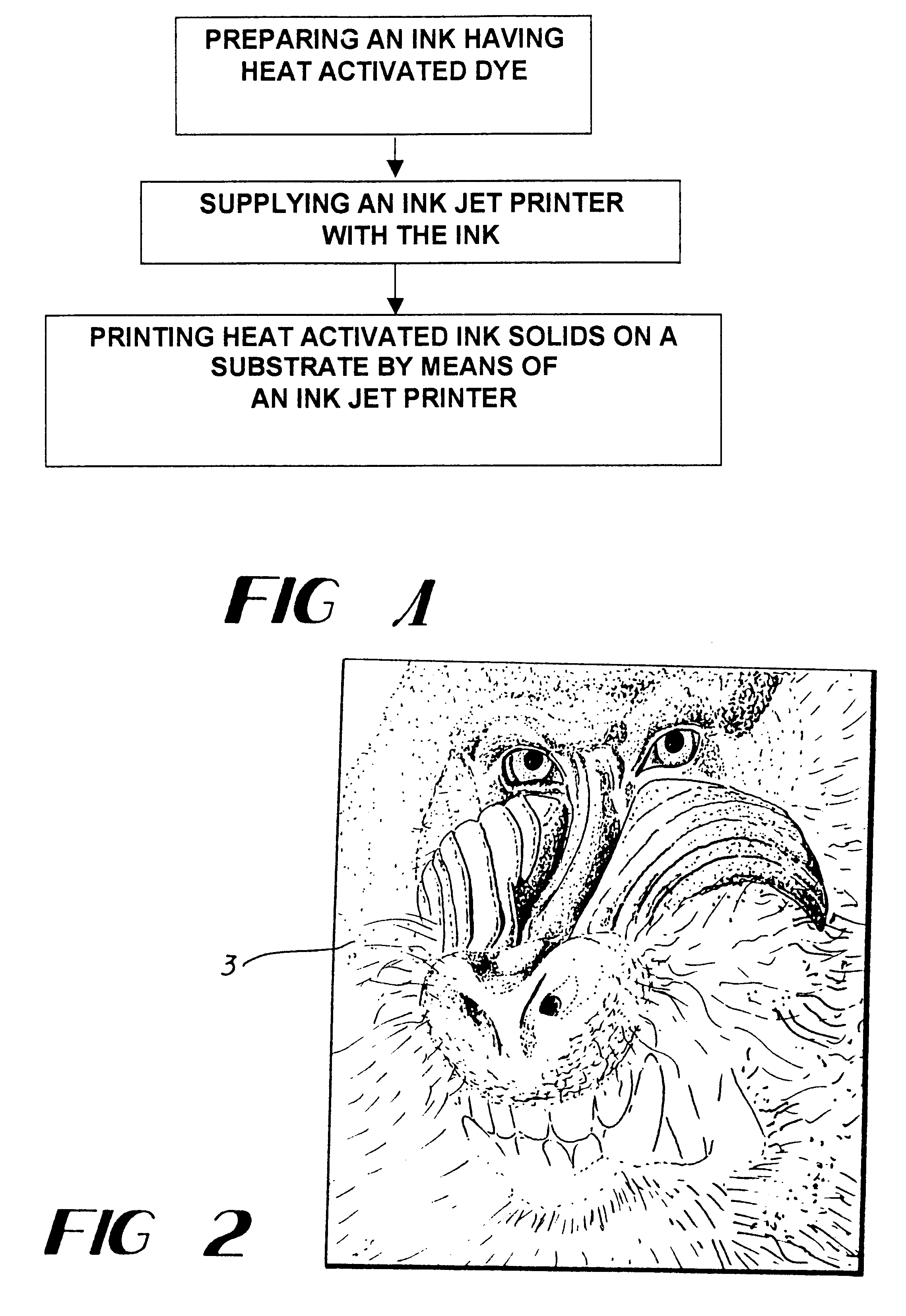

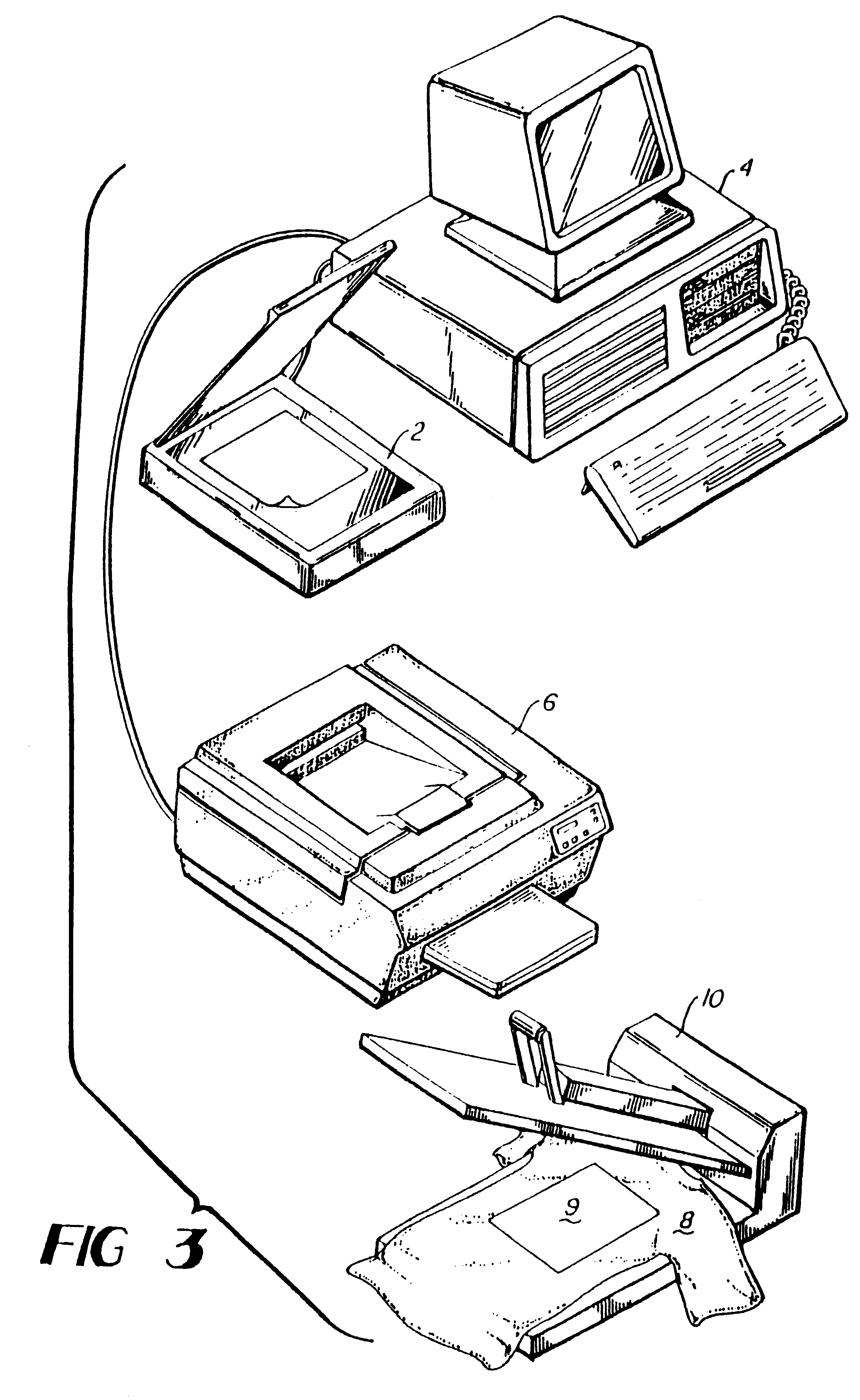

Permanent heat activated ink jet printing process

InactiveUS6450098B1Improve bindingFacilitate and withstand temperatureTransfer printingMeasurement apparatus componentsEngineeringComputer drive

Owner:SAWGRASS SYST INC

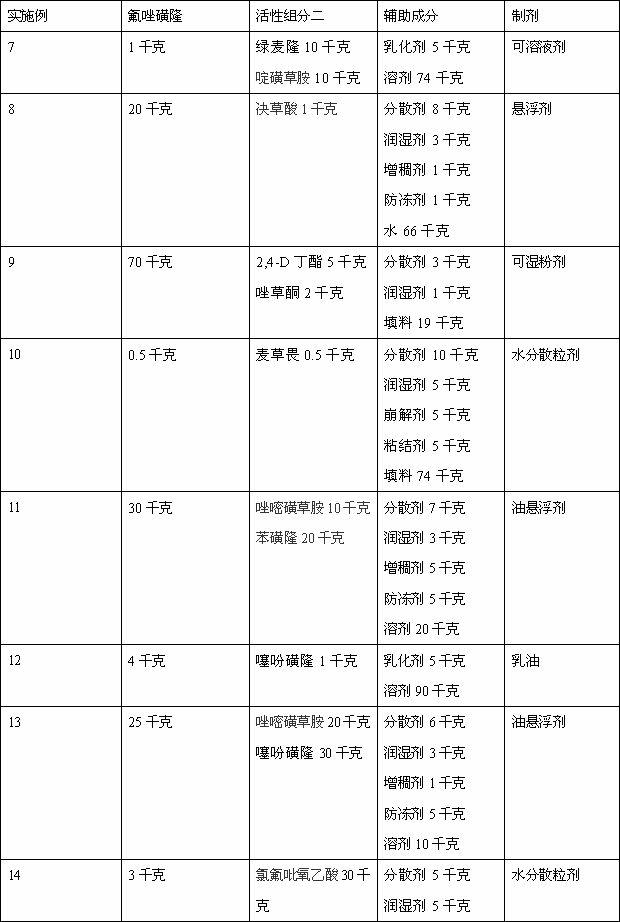

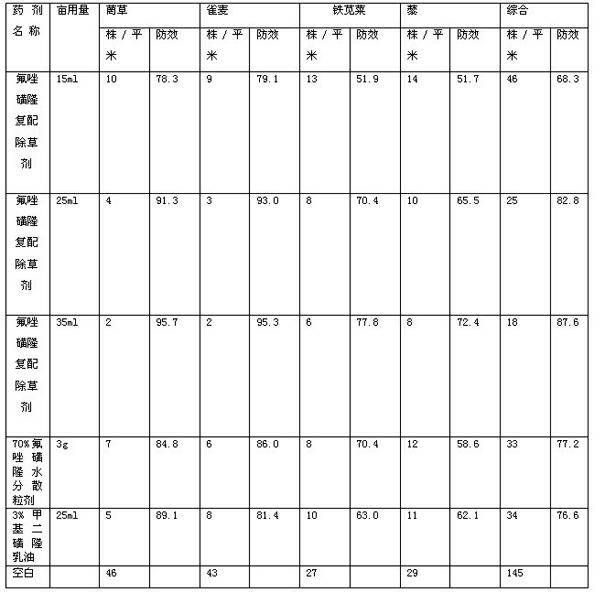

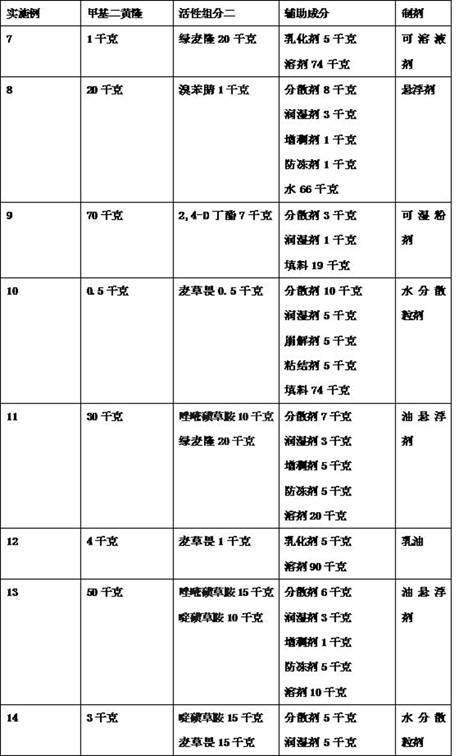

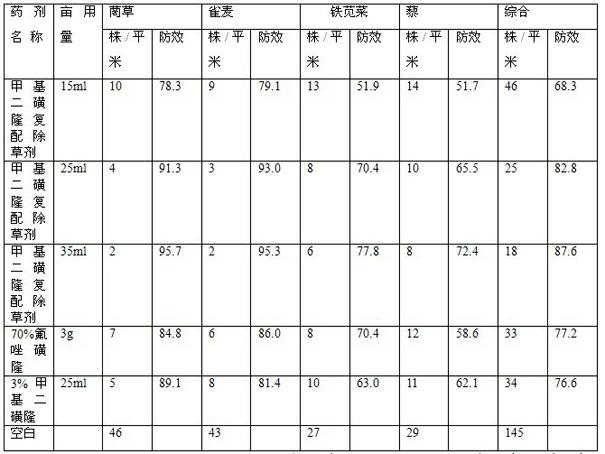

Flucarbazone-Na compounded herbicide

InactiveCN102428945APrevent flocculationAvoid layeringBiocideAnimal repellantsFluroxypyrFluoroglycofen-ethyl

The invention discloses a flucarbazone-Na compounded herbicide which comprises an active component I (flucarbazone-Na), an active component II and auxiliary components, wherein the active component II is one or a combination of several of mesosulfuron methyl, isoproturon, chlortoluron, pyroxsulam, Clodinafop-propargyl, carfentrazone-ethyl, tribenuron-methyl, fluroxypyr, methoxone, 2,4-D-butyl ester, dicamba, bromoxynil, thifensulfuron methyl, amidosulfuron, bensulfuron-methyl, flumetsulam, fluoroglycofen-ethyl and florasulam; the auxiliary components comprise an auxiliary agent and also comprise one of a filler and a solvent; the auxiliary agent is one or a combination of two of an emulsifying agent, a dispersant, a wetting agent, a disintegrant, an agglomerant, an antifreezing agent and a thickening agent; the mass sum of the active component I (flucarbazone-Na) and the active component II is 1%-85% of the total mass of the flucarbazone-Na compounded herbicide; and the mass ratio of the active component I to the active component II is (1:20)-(20:1). The flucarbazone-Na compounded herbicide disclosed by the invention is a novel herbicide for preventing and removing weeds in a wheatland.

Owner:河北博嘉农业有限公司

Frozen confectionery product with layered structure and apparatus for manufacturing same

Owner:SOC DES PROD NESTLE SA

Digital film grain

ActiveUS7015479B2Reduce lossesReduces and prevents signalTelevision system detailsSolid-state devicesSheet filmRadiation flux

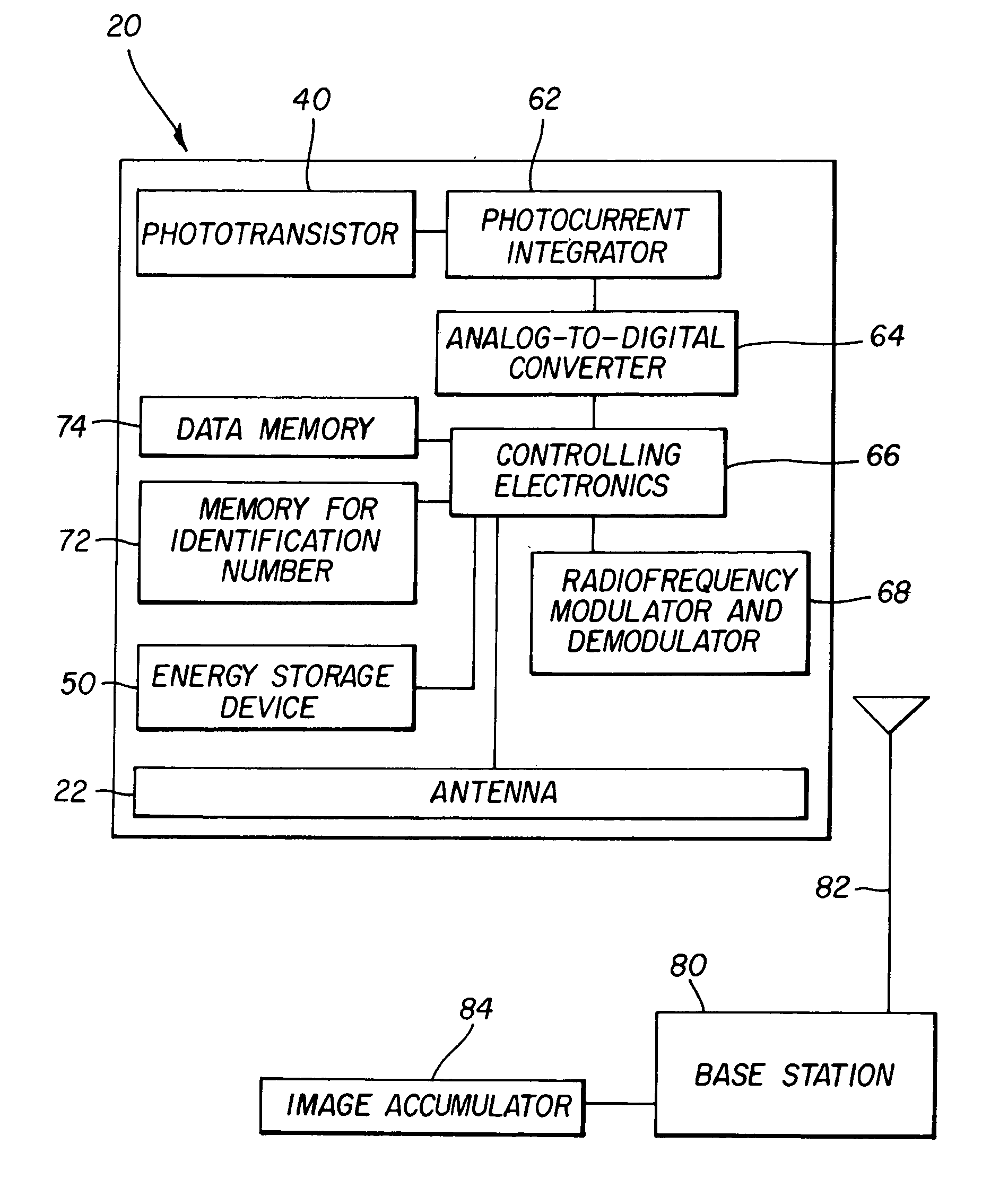

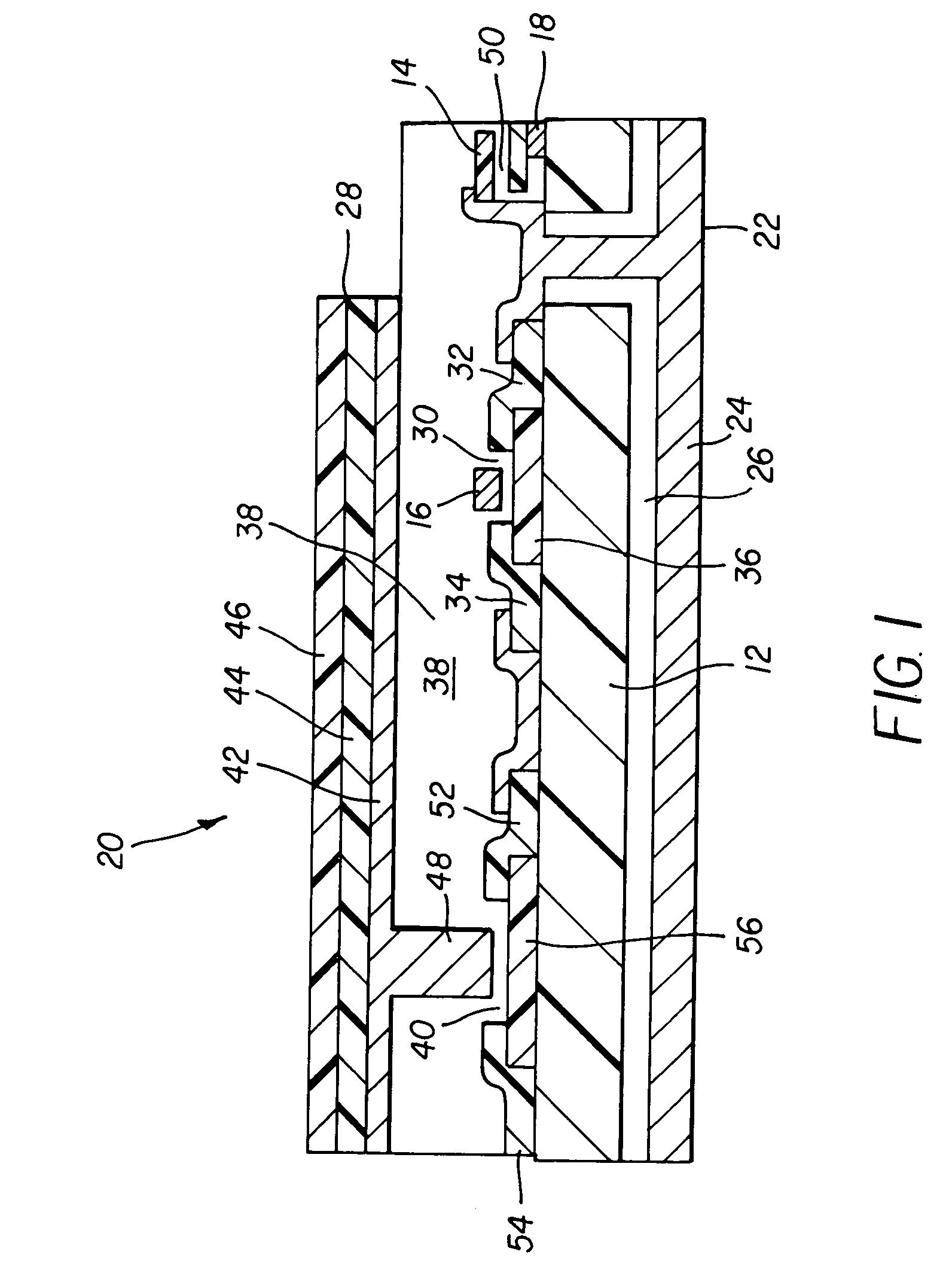

A digital film grain (20) comprises a phototransistor (40) which produces an electrical signal having a strength which is related to an input radiation flux. A transponder receives commands and power from a base station (80) and transmits information quantifying the radiation observed by that digital film grain. An image accumulator (84) connected to the base station (80) assembles an image from the profile of radiation reported by a distribution of digital film grains correlated to the locations of those grains.

Owner:CARESTREAM HEALTH INC

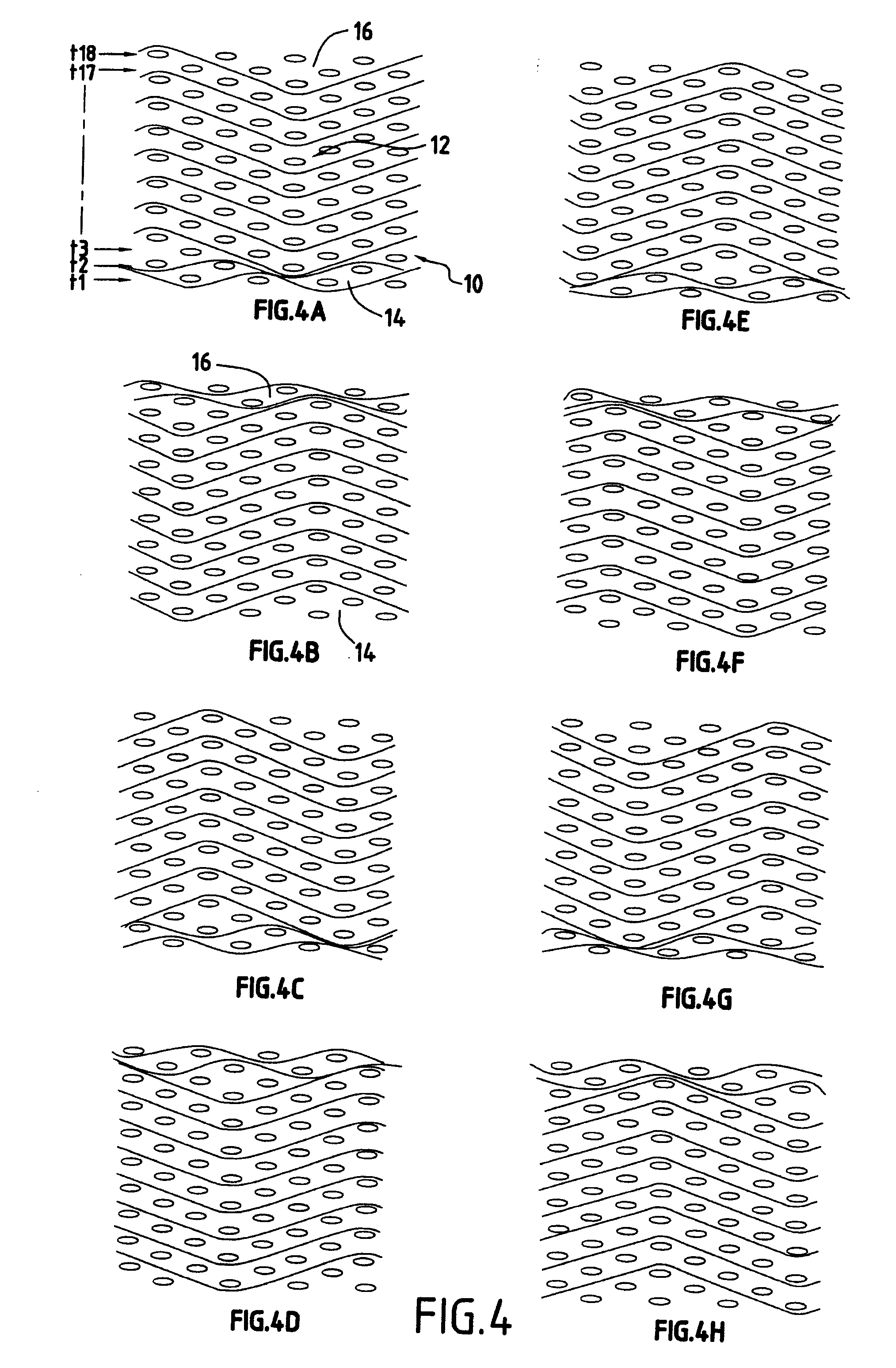

Reinforcing fibrous structure for a composite material and a part containing said structure

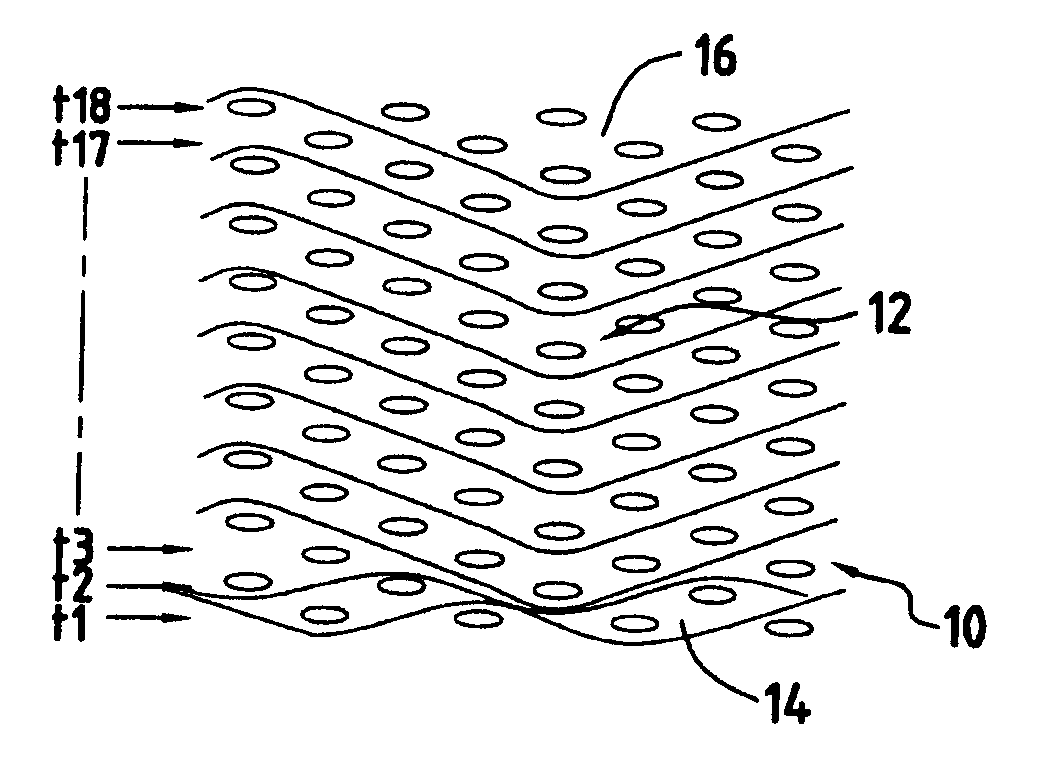

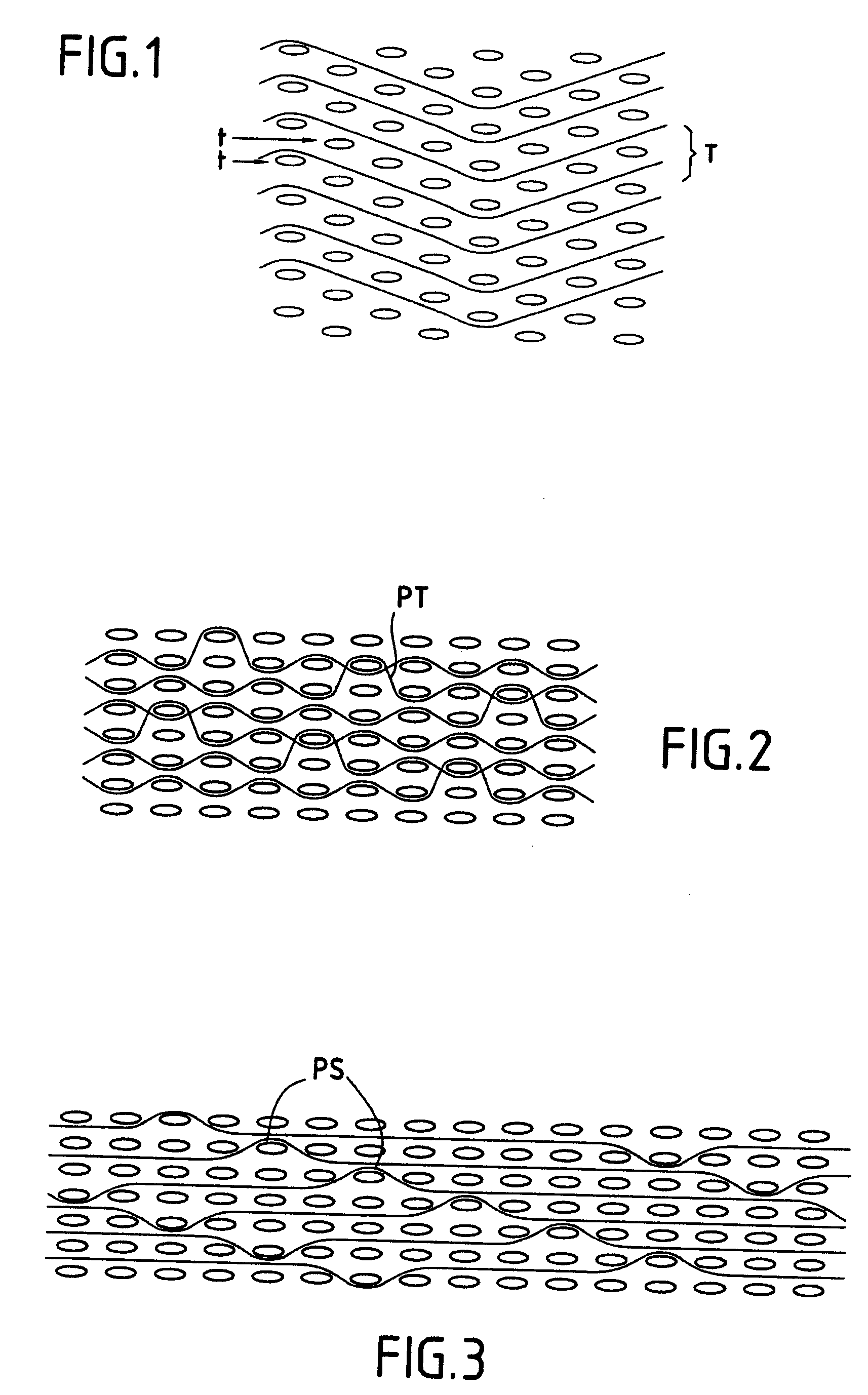

ActiveUS20100144227A1Easy accessReduce irregularitiesConnecting rodsMulti-ply fabricsBiomedical engineeringFiber structure

A woven fibrous structure embodied in one piece, used for producing a composite material part and comprising an internal part or a core (72) and a part adjacent to the external surface thereof or a skin (74, 76), is formed by three-dimensional core weaving with at least one weave selected from interlock and multilayer weaves and by skin weaving with a weave which differs from the core weave and selected from a multilayer weave and a two-dimensional weave. It can be also formed by three-dimensional weaving with at least one core interlock weave (72) and weaving with a fabric-, satin or skin twill-type weave, wherein skin weaving is of a multilayer or two-dimensional type.

Owner:GERAKL

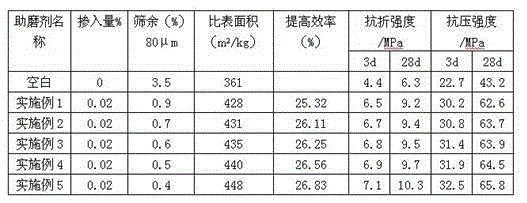

Silicate cement grinding aid and preparation method thereof

The invention discloses a silicate cement grinding aid and a preparation method thereof. The silicate cement grinding aid is prepared from the following main raw materials by weight: 3-6 parts of sodium hexametaphosphate, 2-5 parts of aluminum sulfate, 5-8 parts of tetra sodium salt of amino trimethylene phosphonic acid (ATMP.Na4), 4-6 parts of ethylene diamine tetra (methylene phosphonic acid) sodium, 38-45 parts of polymeric alkylol amine, 34-42 parts of triisopropanolamine, 8-12 parts of waste engine oil, 2-5 parts of sodium alpha-olefin sulfonate, 10-16 parts of sorbitol, 15-20 parts of diethylene glycol, 8-13 parts of polypropylene wax, 6-10 parts of oxidized polyethlene wax, 4-8 parts of lignite wax, 20-30 parts of odium thiosulfate, 12-18 parts of sodium thiosulfate and 15-20 parts of quicklime powder. The prepared silicate cement grinding aid has the advantages that the quality is stable, the effect is remarkable, the adding amount is small, the use is simple, and the adding is more convenient and reliable to control.

Owner:王金奎

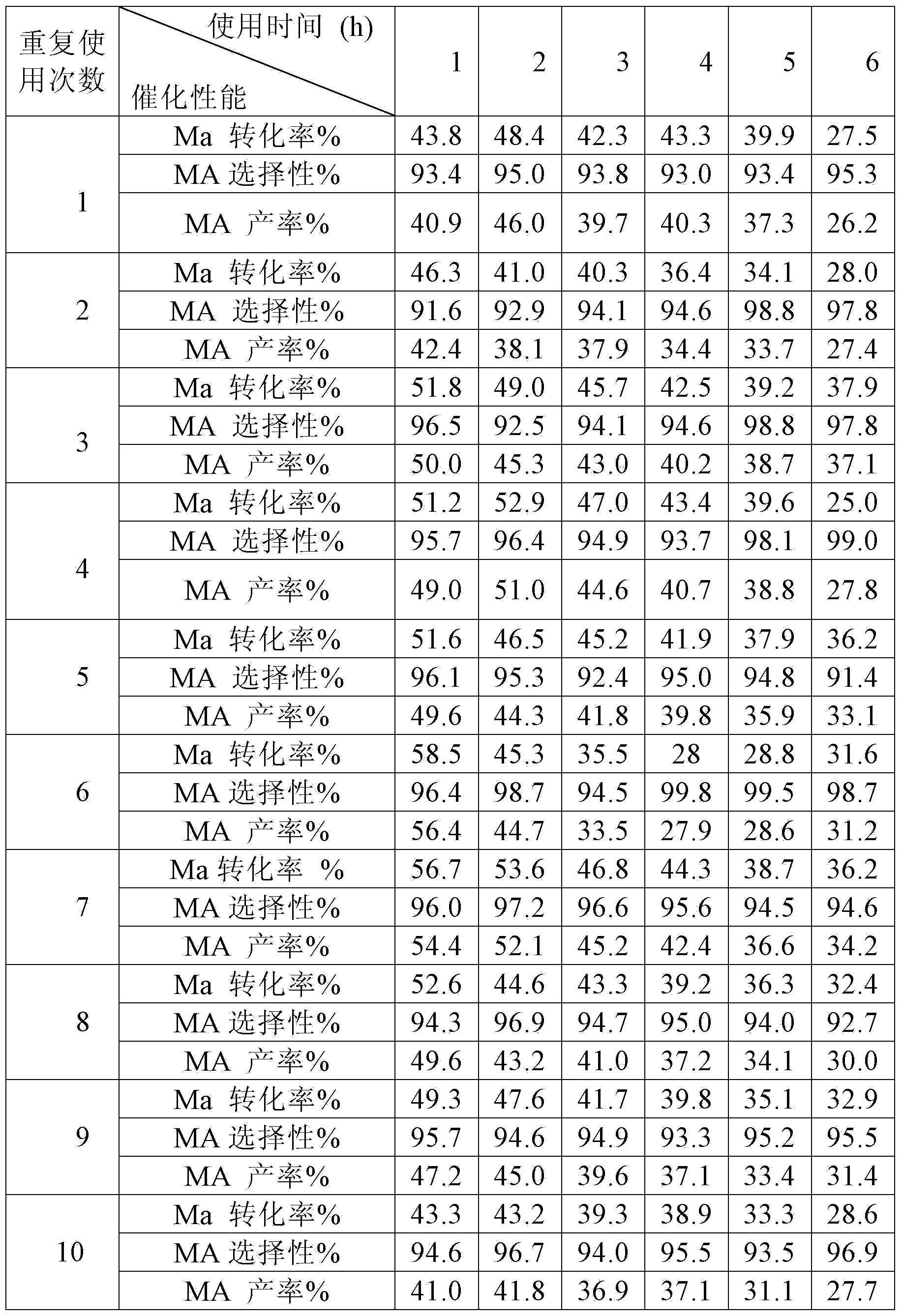

Cs-supported silica-based catalyst and preparation method and application thereof

InactiveCN103801280AImprove stabilityContinuous productionMolecular sieve catalystsOrganic compound preparationGas phaseMethyl acetate

The invention provides a Cs-supported silica-based catalyst. One of SBA-15, SiO2 or silicon dioxide prepared by a silica sol method is used as a carrier, the support is selected from one of Cs salt and a mixture of Cs and modified elements, the catalyst is prepared by a dipping method, the Cs content is 0.1wt%-10wt%, and the content of the modified elements is 0-2wt%. Meanwhile, the invention further provides a preparation method of the Cs-supported silica-based catalyst and application of the Cs-supported silica-based catalyst to the process of preparing methyl acrylate by catalyzing condensation reaction of methyl acetate and a methanal gas phase. The prepared catalyst is capable of realizing the aldol condensation of the methyl acetate and the methanal gas phase under proper conditions so as to prepare the methyl acrylate, wherein the activity of the Cs / SBA-15 catalyst is higher than that of other Cs-supported silica-based catalysts, and the selectivity on the methyl acrylate is good.

Owner:SHANGHAI HUAYI GRP CO

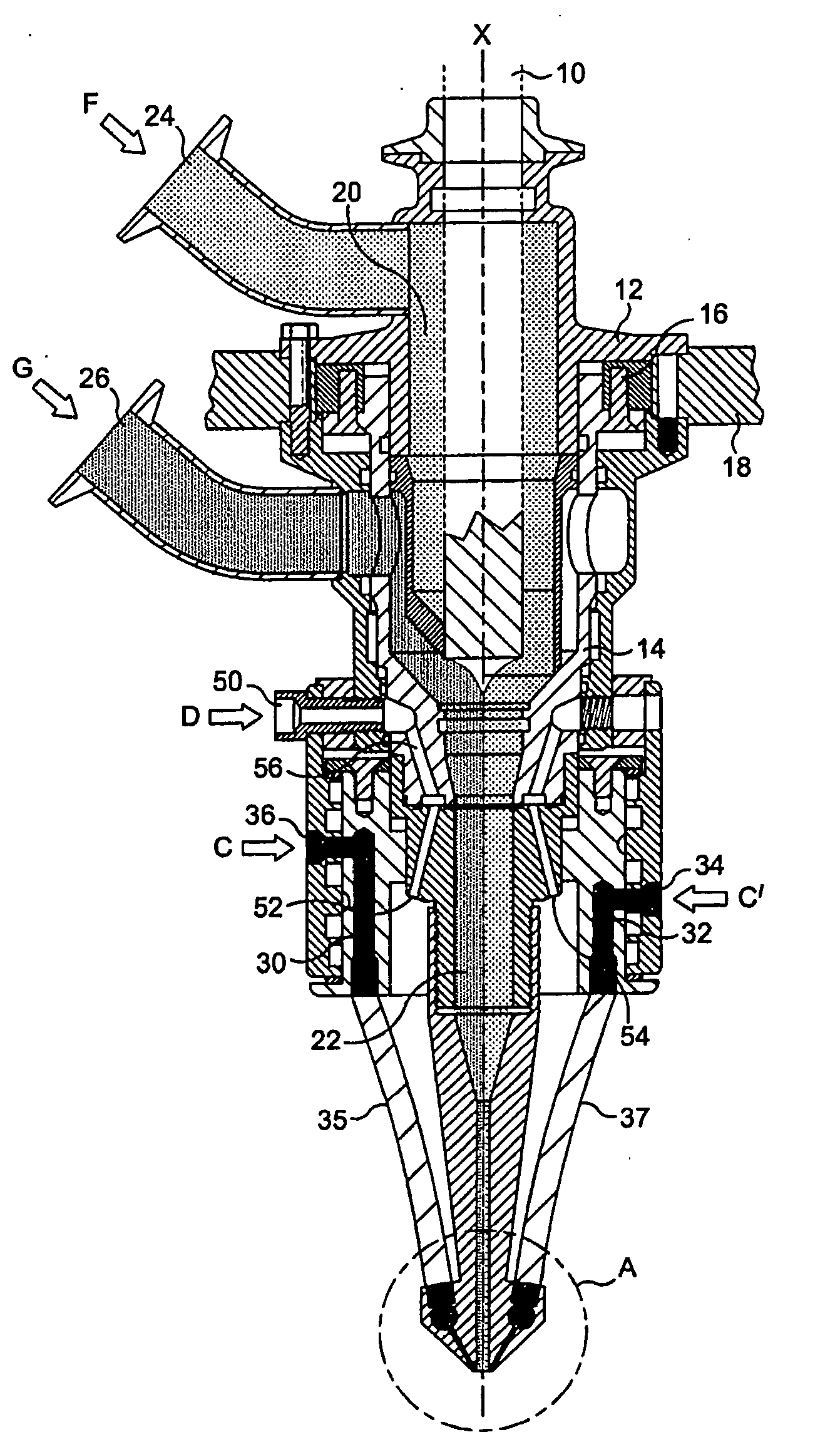

Frozen confectionery product with layered structure and apparatus for manufacturing same

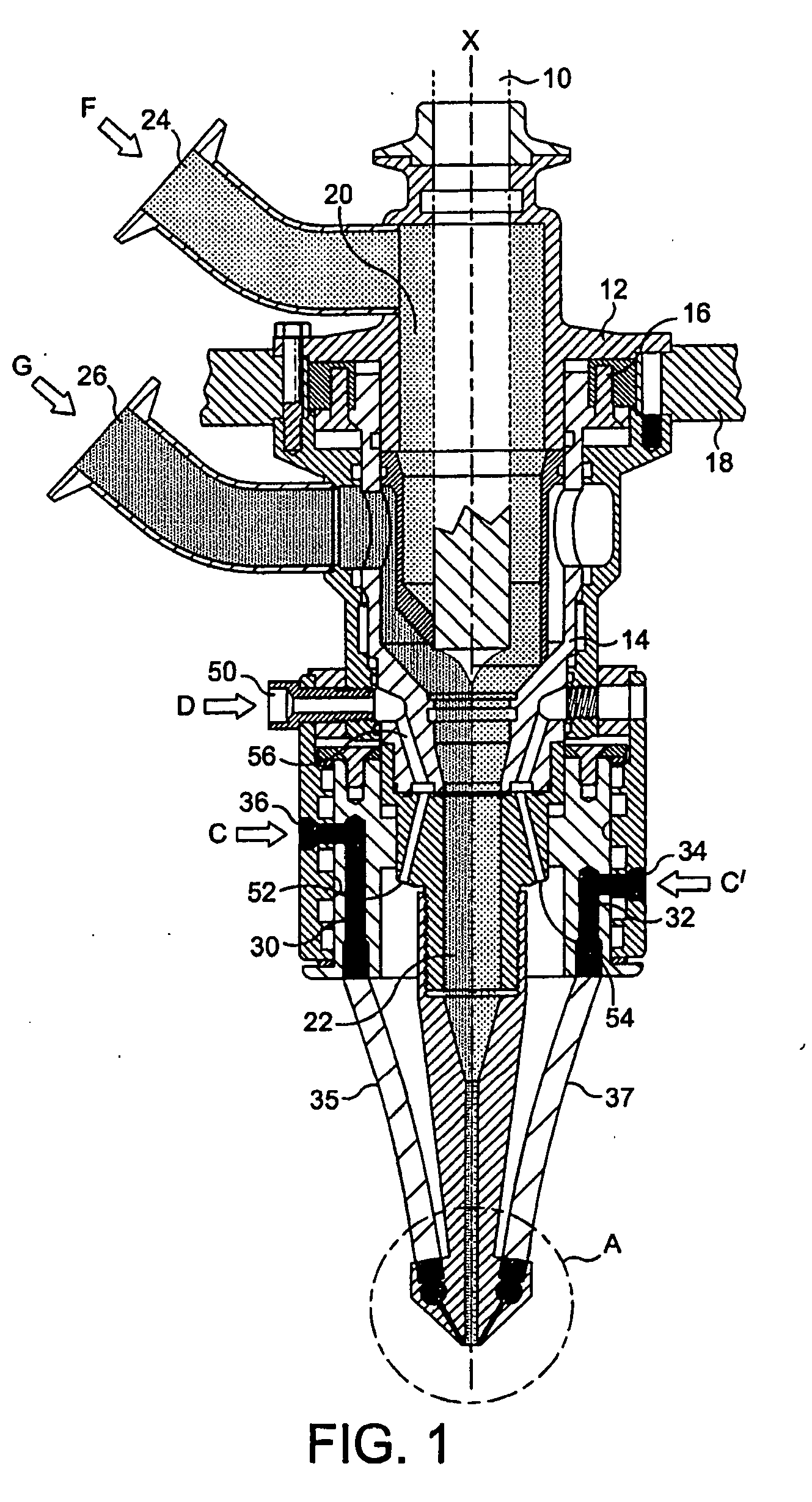

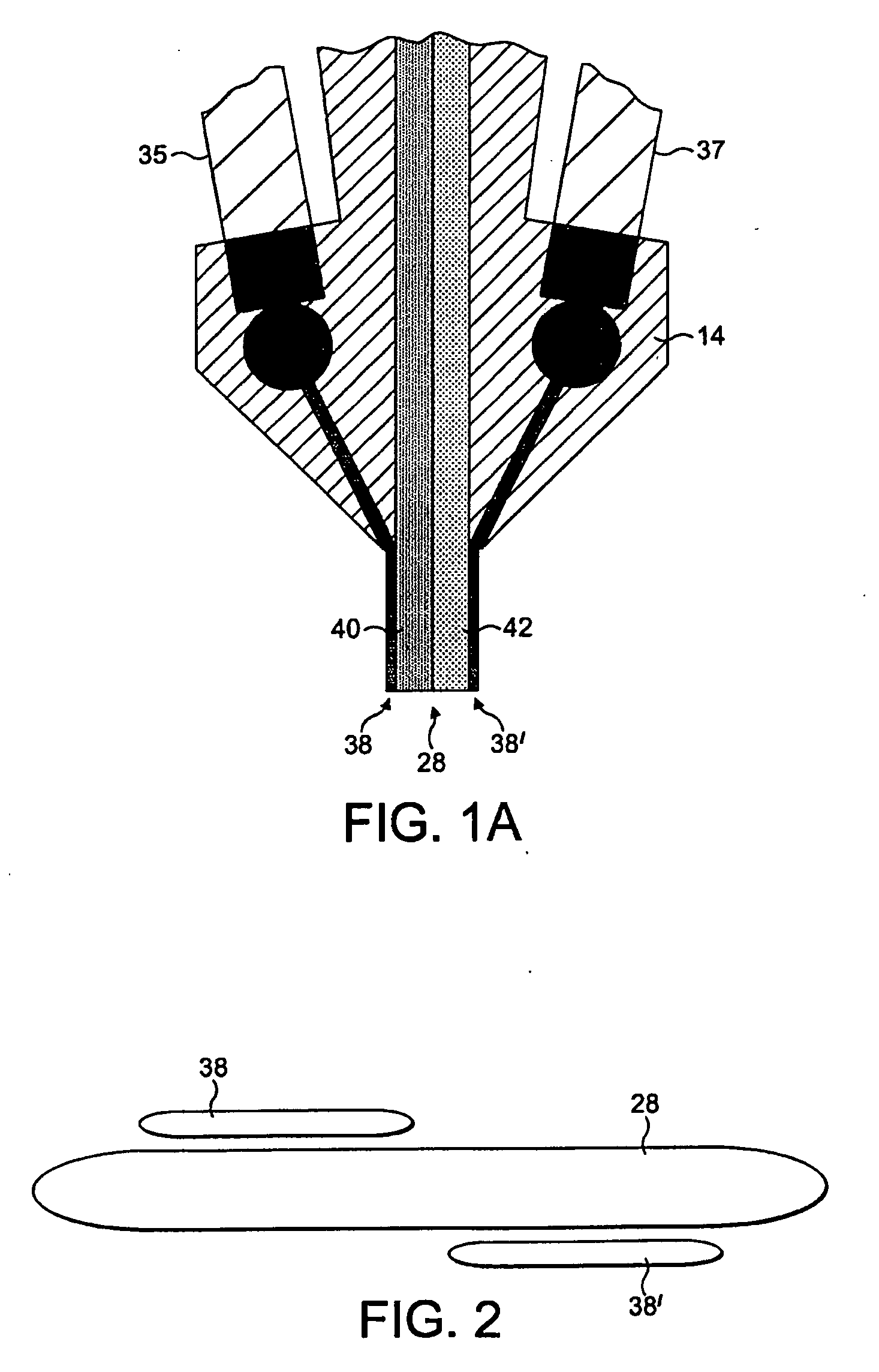

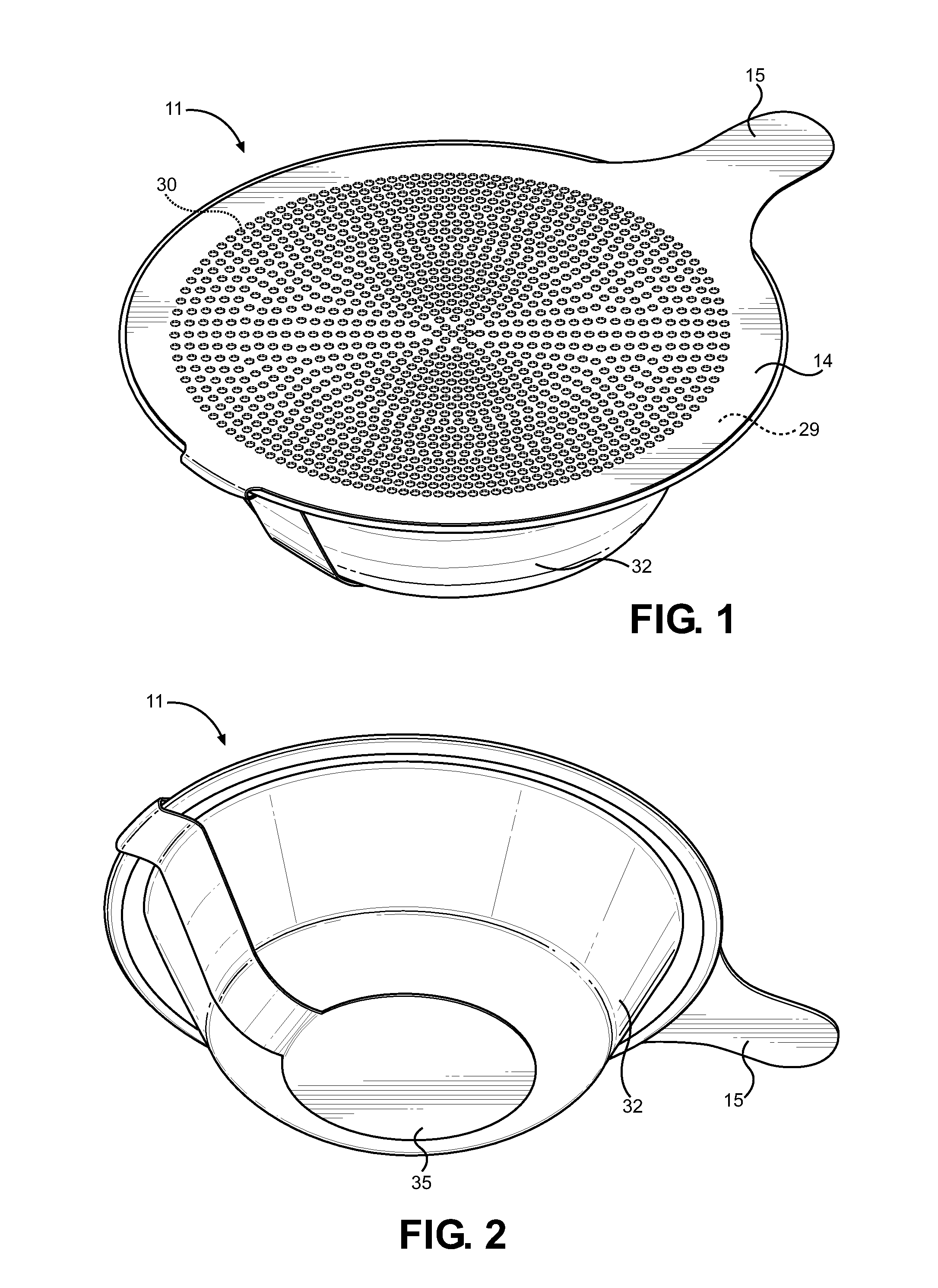

ActiveUS20130045310A1Overcomes drawbackAvoid cakingMilk treatmentFrozen sweetsLayered structureEngineering

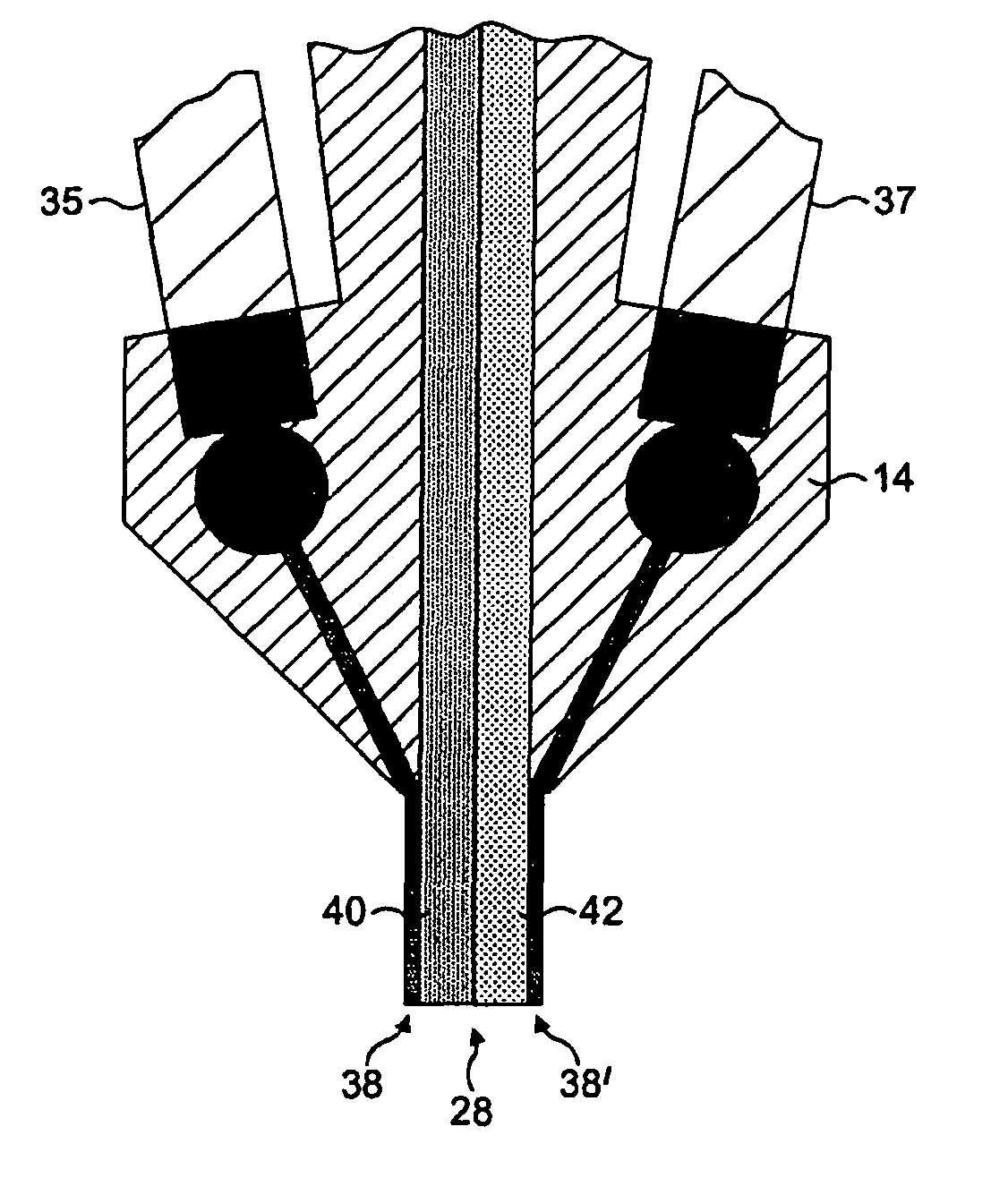

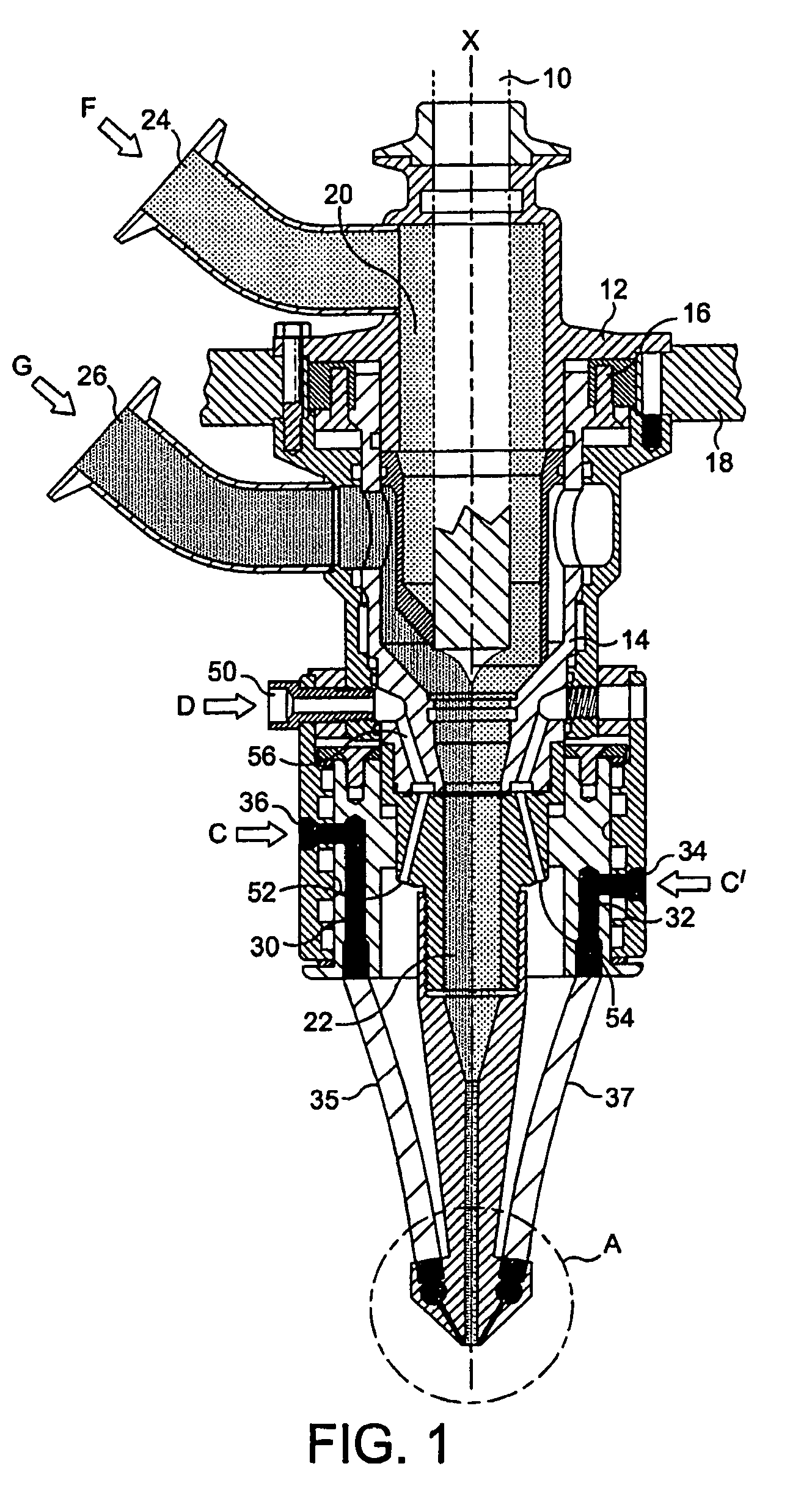

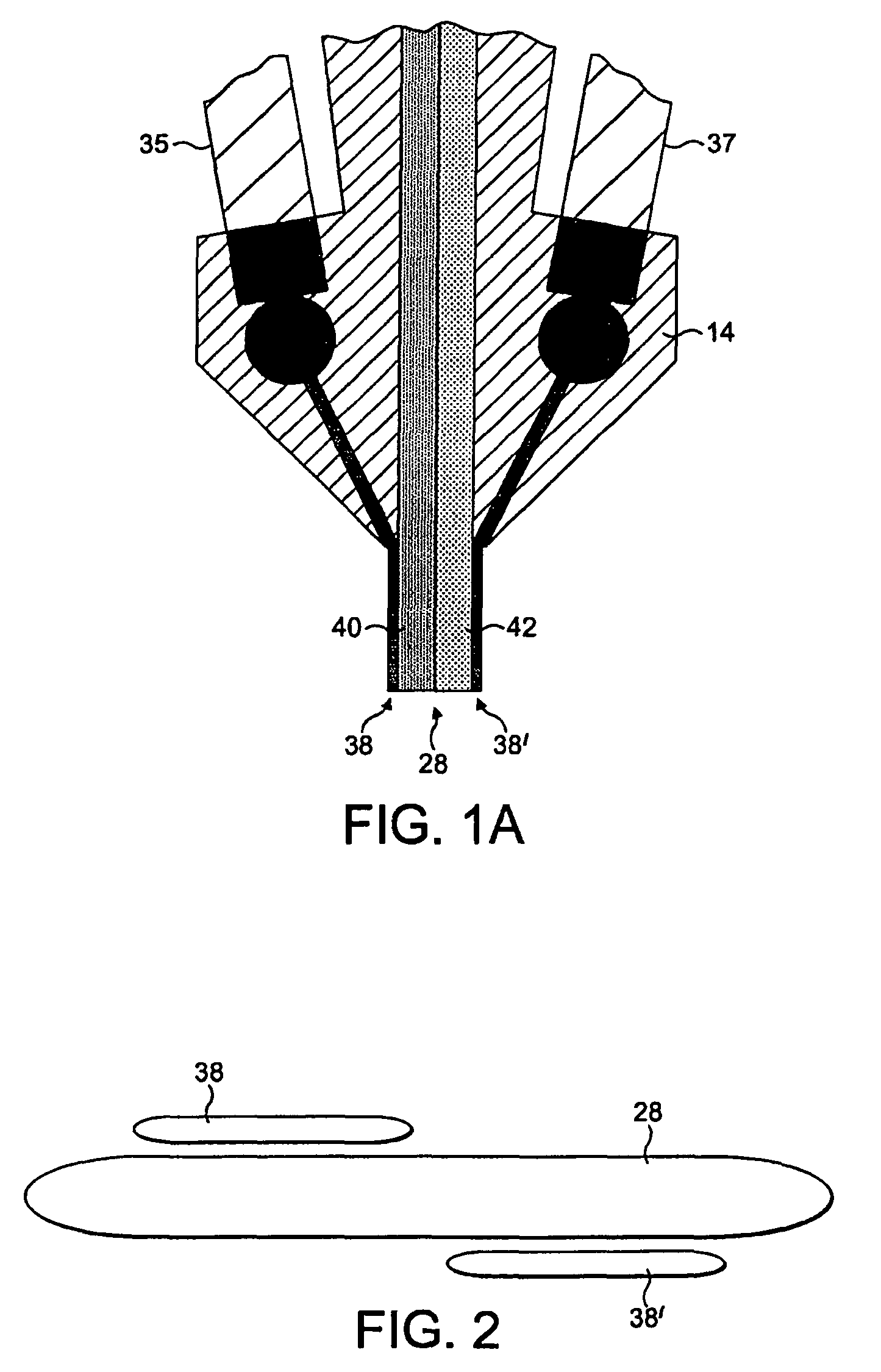

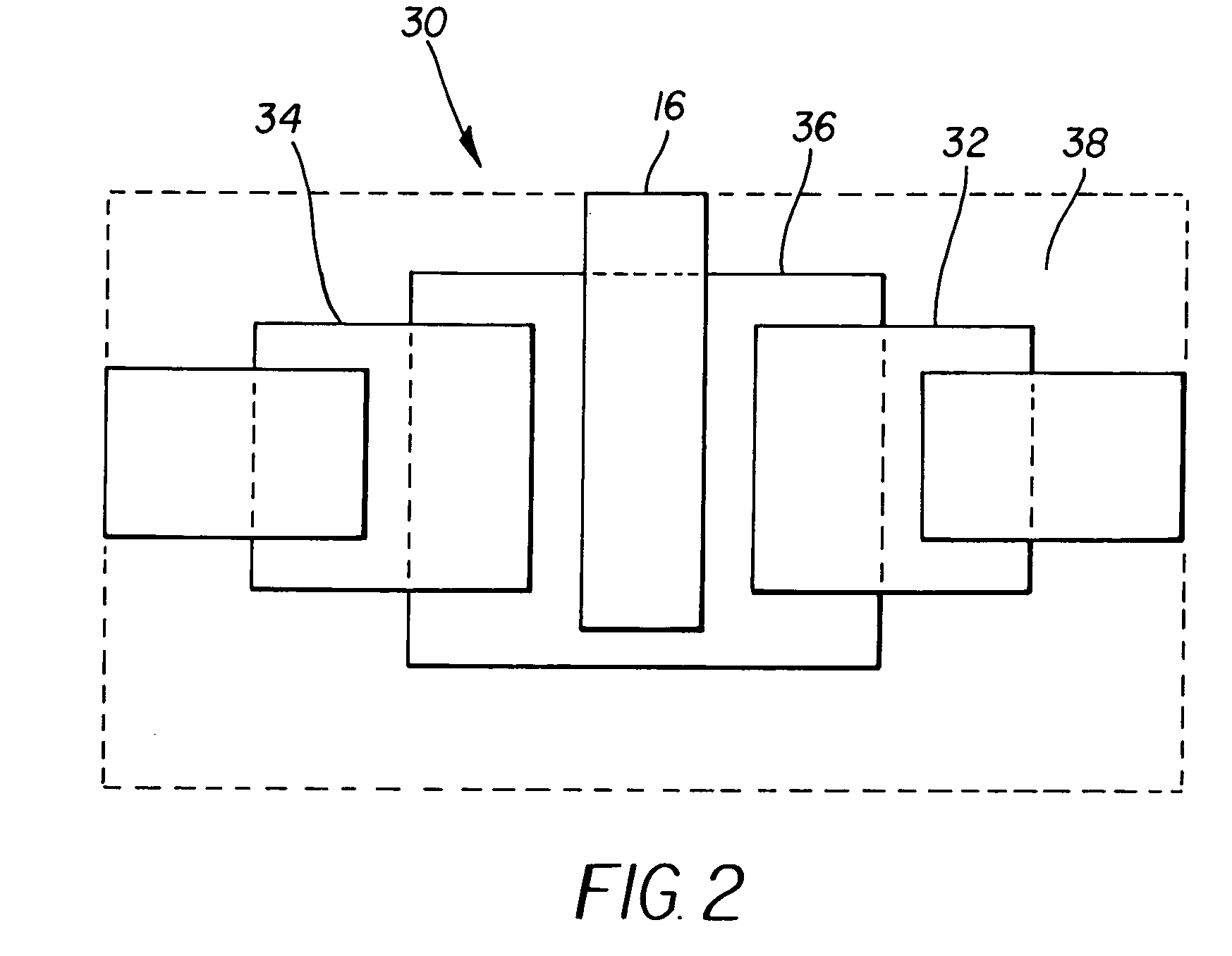

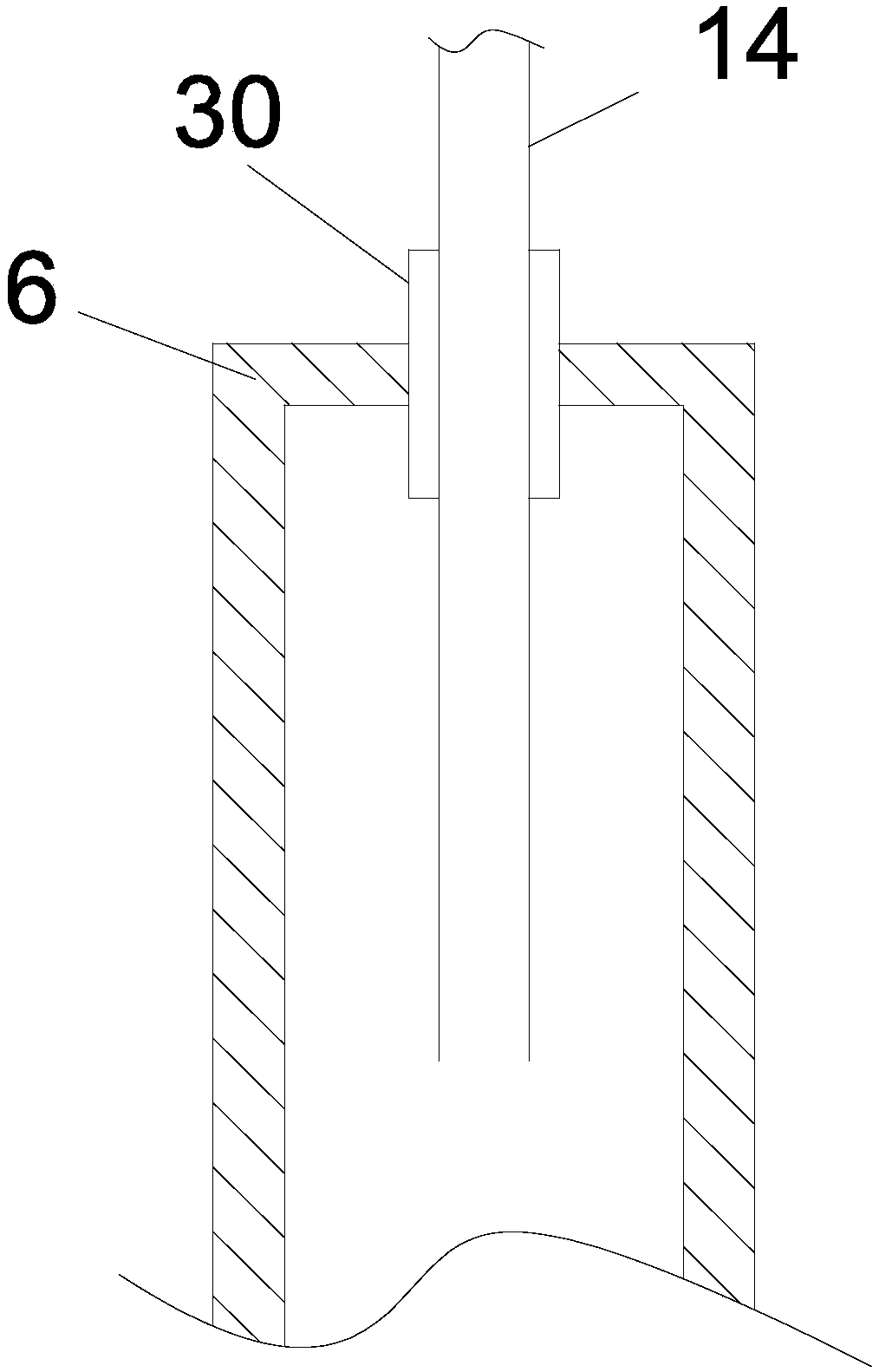

The present invention relates to a frozen confectionery product and to a method of manufacturing same. It furthermore relates to an apparatus for manufacturing a frozen confectionery product by rotary vertical extrusion. Said apparatus comprises a nozzle (14) at least one ice-cream passage (20, 22) with at least one inlet port (24, 26) and an outlet port (28), and at least one chocolate passage (30, 32) with respectively an inlet port (34, 36) and an outlet port (38, 38′). The outlet ports are provided in the nozzle (14) and have elongated cross-sections, and each chocolate outlet port (38, 38′) extends in parallel to an ice cream outlet port (28), so as to form annular or helical chocolate layers upon rotation of the nozzle and the container with respect to each other.

Owner:SOC DES PROD NESTLE SA

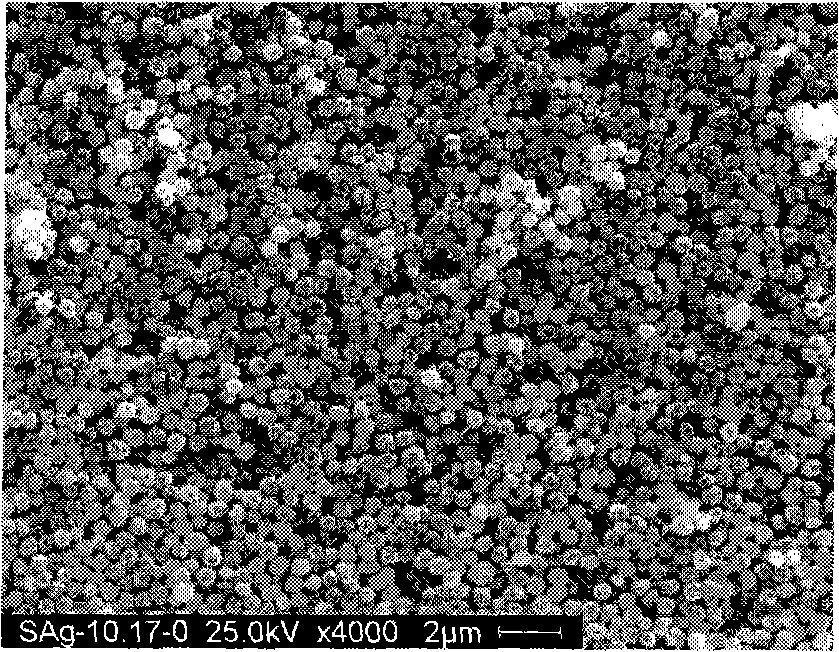

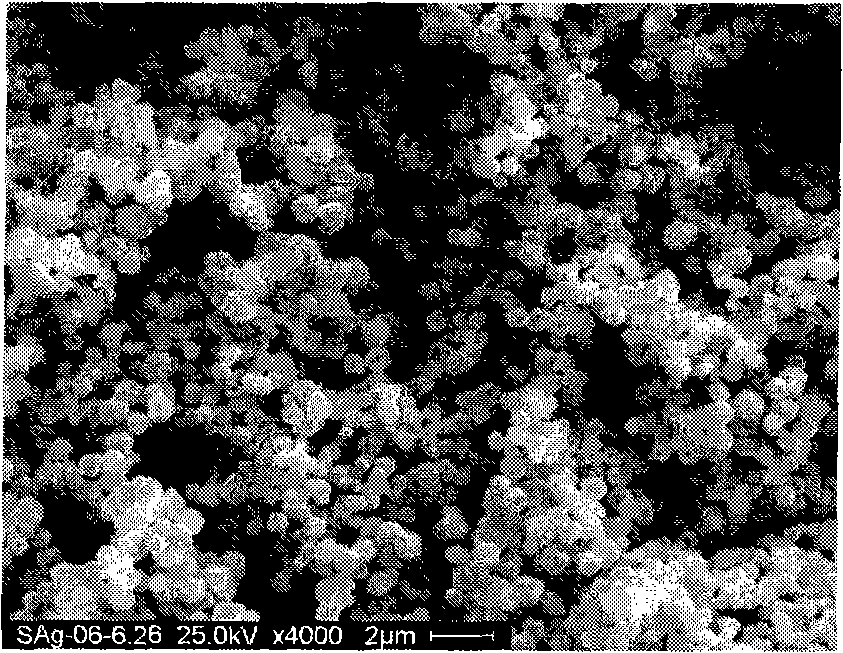

Preparation of high dispersed superfine spherical silver powder for conductive silver slurry

A preparation method of high-dispersion ultra-fine spherical silver powder used for conductive silver paste relates to a preparation method of ultra-fine spherical silver powder, in particular to the preparation method of the high-dispersion ultra-fine spherical silver powder for the conductive silver paste in the electronic industry. The preparation method is characterized in that silver ammonia solution is dropped in a reduction system which consists of a reducing agent of formaldehyde, a dispersant of polyvinyl alcohol PVA and sodium hydroxide solution, thus obtaining high-dispersion ultra-fine silver powder slurry, and the high-dispersion ultra-fine spherical silver powder with the particle size range of 0.3 to 1.0Mum can be obtained by solid-liquid separation and drying. The method of the invention has simple and feasible process flow, low production cost, less equipment investment, stable and reliable process conditions, small particle size of the product silver powder, narrow distribution range, high yield and easy realization of industrial mass production.

Owner:JINCHUAN GROUP LIMITED

Permanent heat activated ink jet printing process

InactiveUS6966643B2Prevent undesired activationAvoid cakingTransfer printingMeasurement apparatus componentsComputer printingEngineering

Owner:HALE NATHAN +1

Permanent heat activated printing process

InactiveUS6425331B1Improve bindingFacilitate and withstand temperatureTransfer printingMeasurement apparatus componentsComputer printingEngineering

Owner:SAWGRASS SYST INC

Anti-caking agent for fertilizer and preparation method thereof

The invention relates to an anti-caking agent for fertilizer and a preparation method thereof. The anti-caking agent comprises the following components in percentage by weight: 5-10% of hydrogenized bovine fatty amine, 15-25% of solid paraffin, 5-15% of stearic acid and 50-75% of oil. The method comprises the following steps: adding the hydrogenized bovine fatty amine, the solid paraffin and the stearic acid to a pulverizer according to the percentage by weight for pulverizing to 80-100 meshes; and then, dispersing the pulverized particles into the oil while being stirred to prepare the anti-caking agent for the fertilizer. The invention has the advantages that high melting-point matters such as the paraffin, the hydrogenized bovine fatty amine, the stearic acid and the like need not to be molten into a liquid state; after the high melting-point matters such as the paraffin, the hydrogenized bovine fatty amine, the stearic acid and the like are uniformly dispersed in the oil, the high melting-point matters have good flowability, heating again for melting in the canning process and in the using process are omitted; and all the steps of the invention are carried out at normal temperature.

Owner:HUBEI FORBON TECH

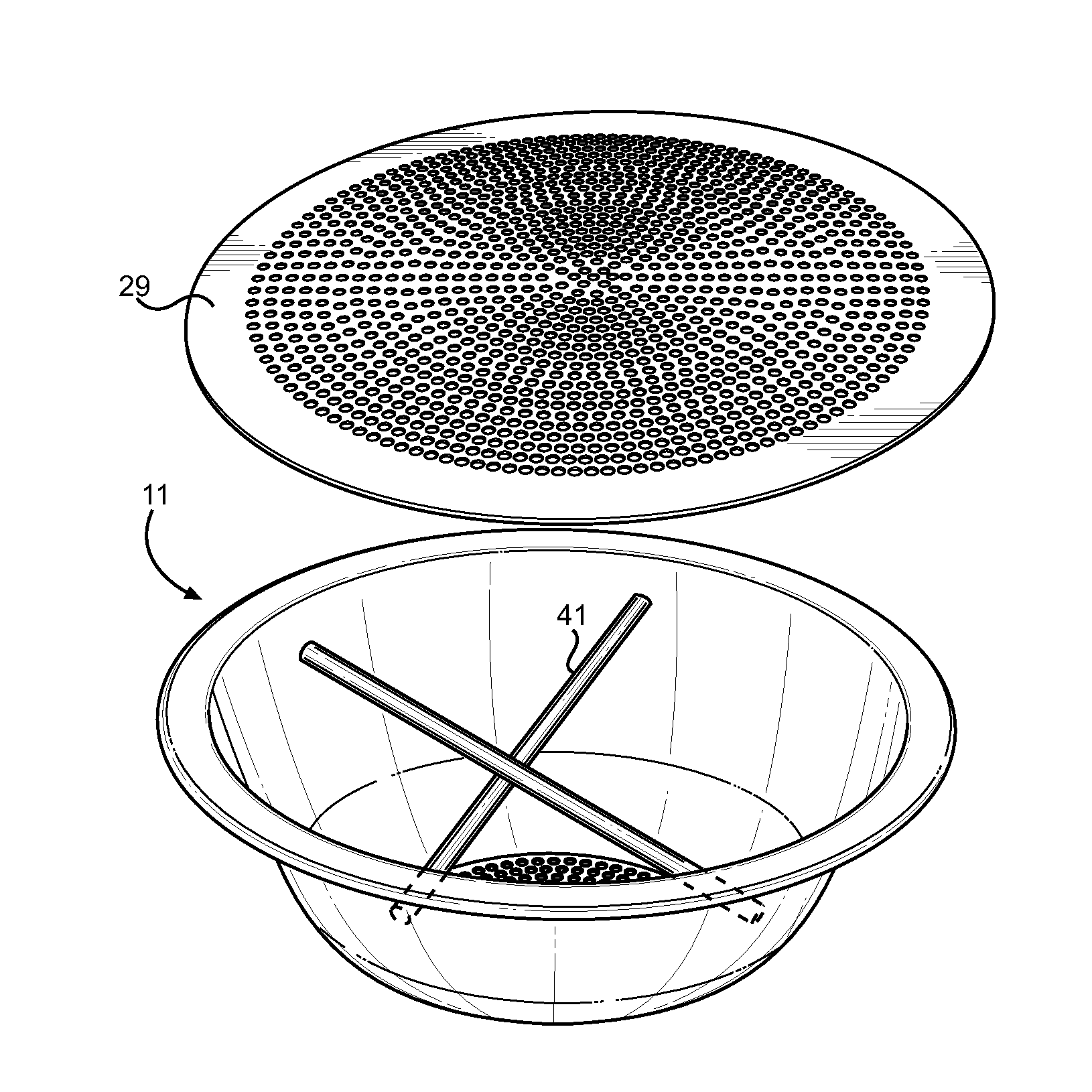

Prepackaged Smokable Material Capsule

InactiveUS20140326257A1Avoid cakingEasy transferCigar manufactureTobacco pipesTobacco productBiomedical engineering

Disclosed is a prepackaged smokable material capsule, comprising a container having an internal volume that allows a user to place a packaged amount of shisha or similar tobacco product into a hookah bowl without physical contact therewith. The capsule has a removable seal, an inlet, outlet and an internal agitator means within the capsule. The seal removably covers its upper inlet and lower outlet prior to use. Once removed, the inlet and outlet are preferably pre-perforated, or alternatively may then be perforated by a user, prior to a layer of coals be placed thereonto for burning the capsule contents and allowing smoke to be drawn therefrom. The imbedded agitator provides a means to control the density of the capsule contents and prevent clumping to ensure free flowing passage of air therethrough. Also disclosed is a capsule retainment system comprising a hookah bowl and capsule clamp.

Owner:SHISHAPRESSO S A L

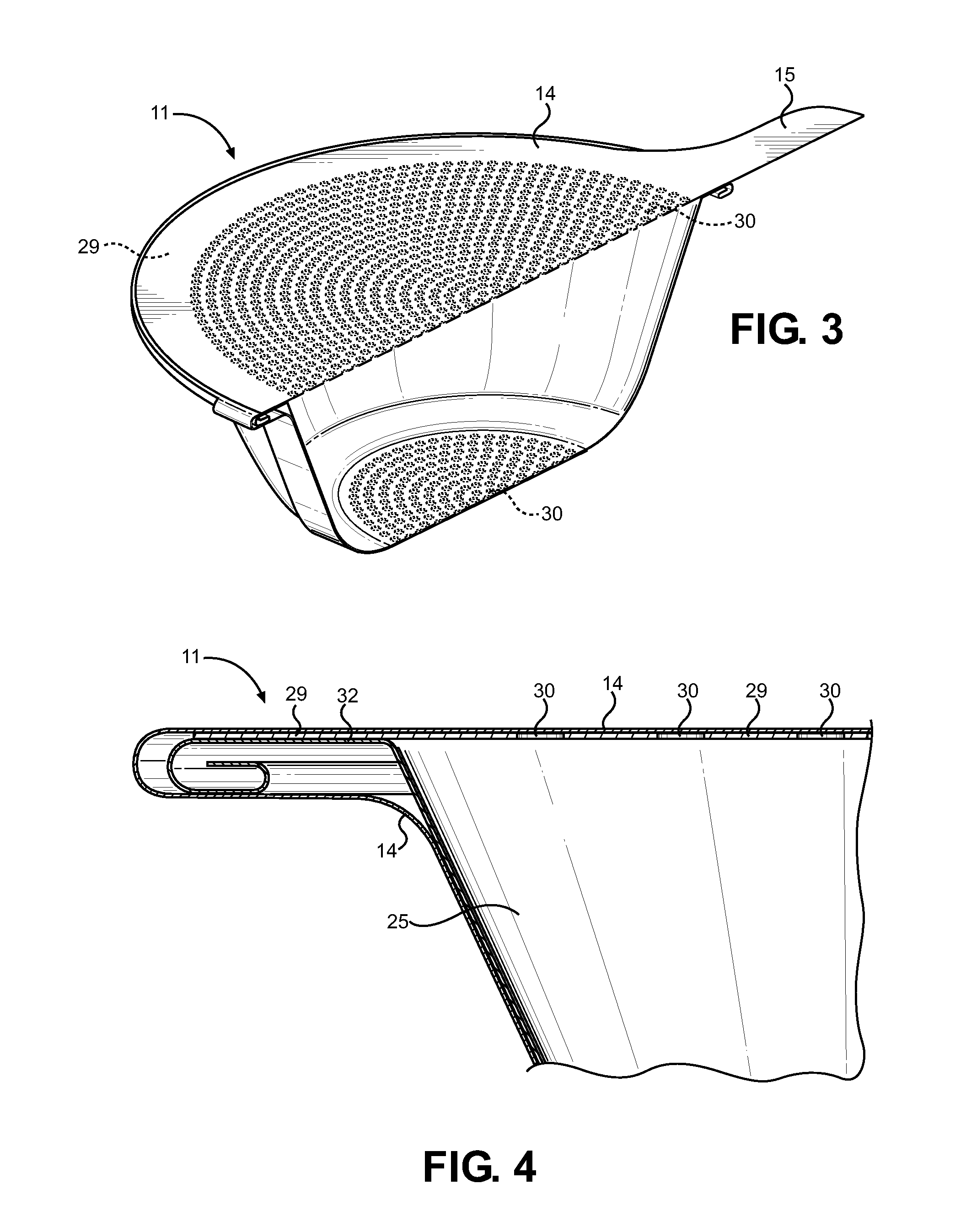

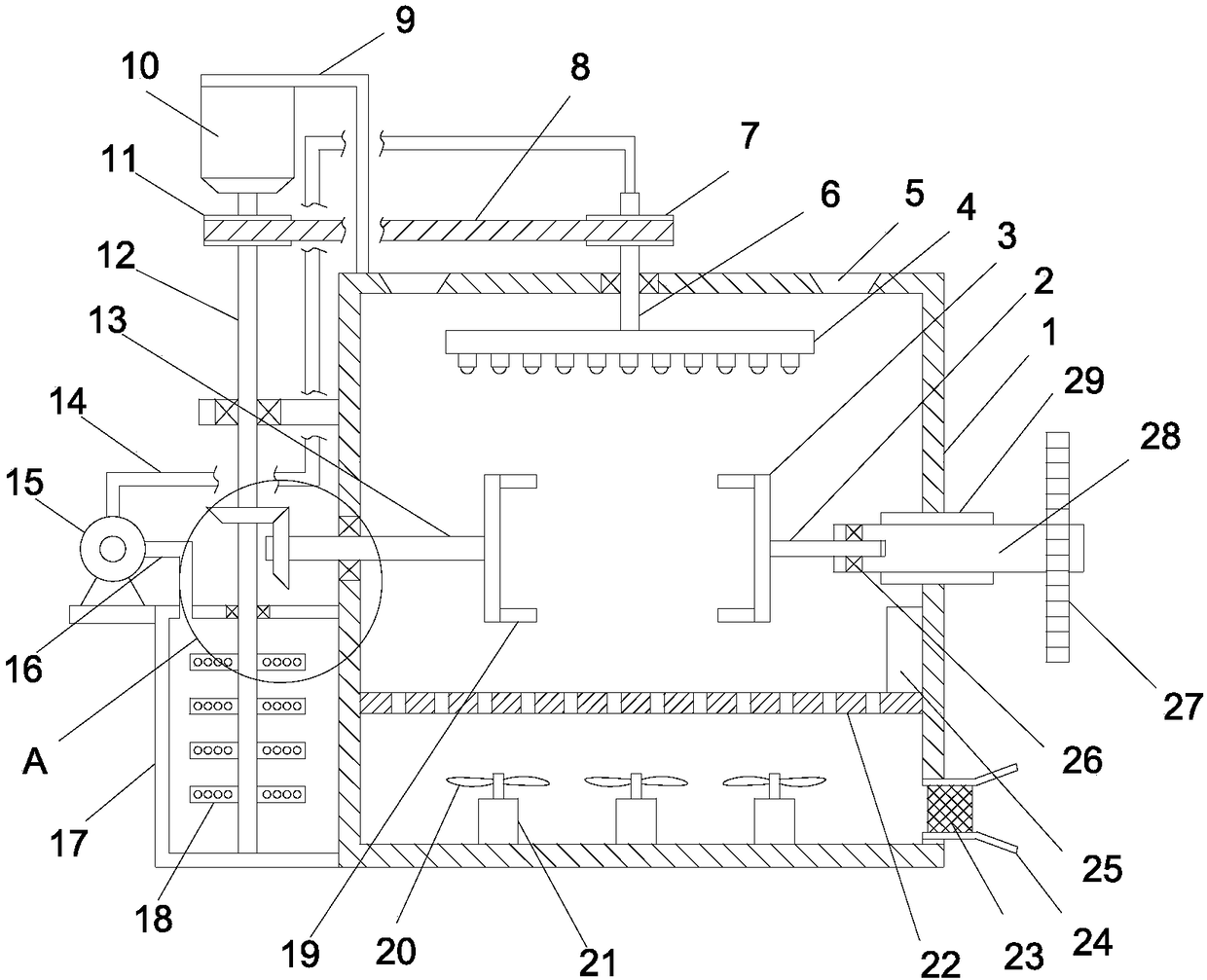

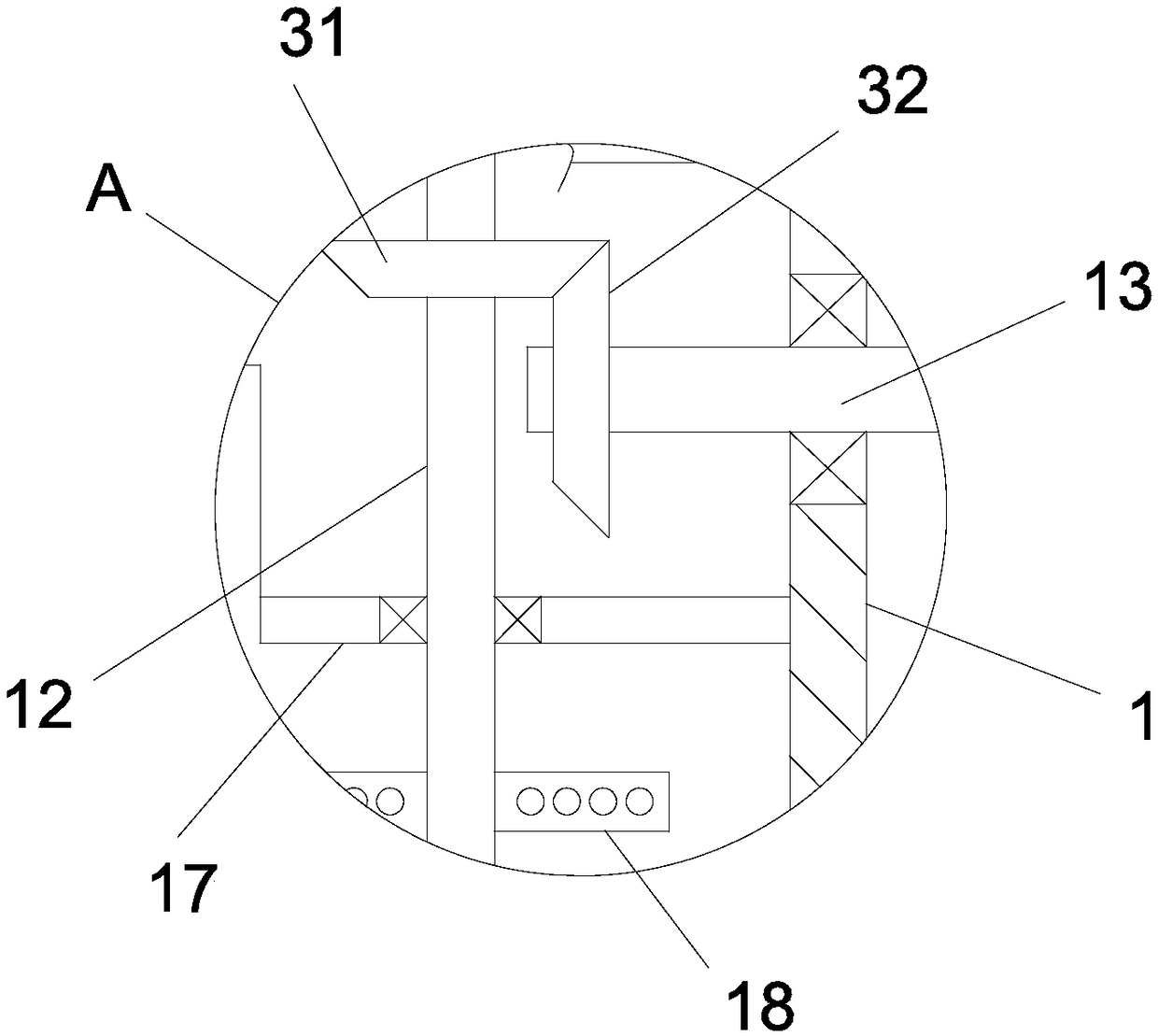

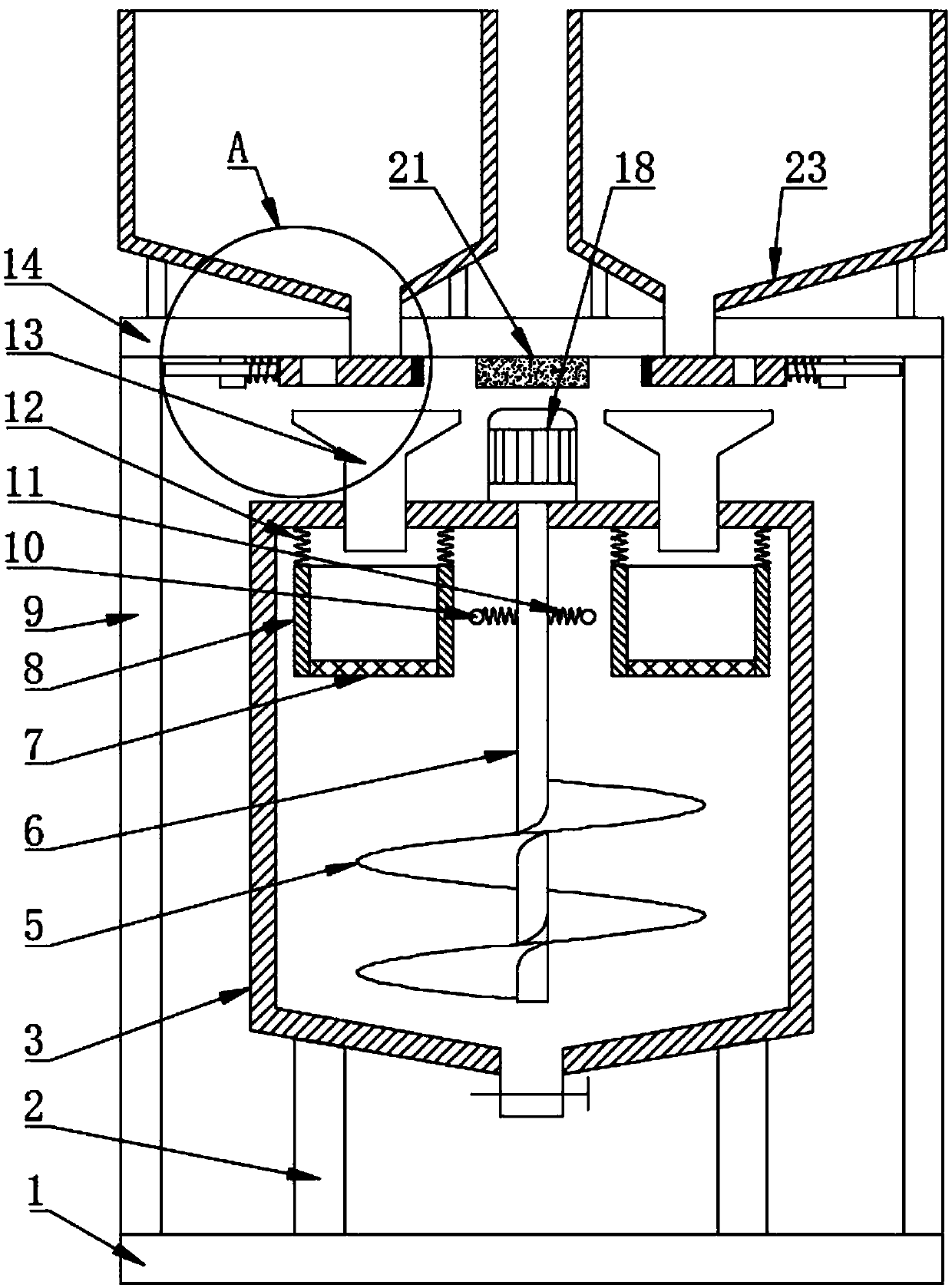

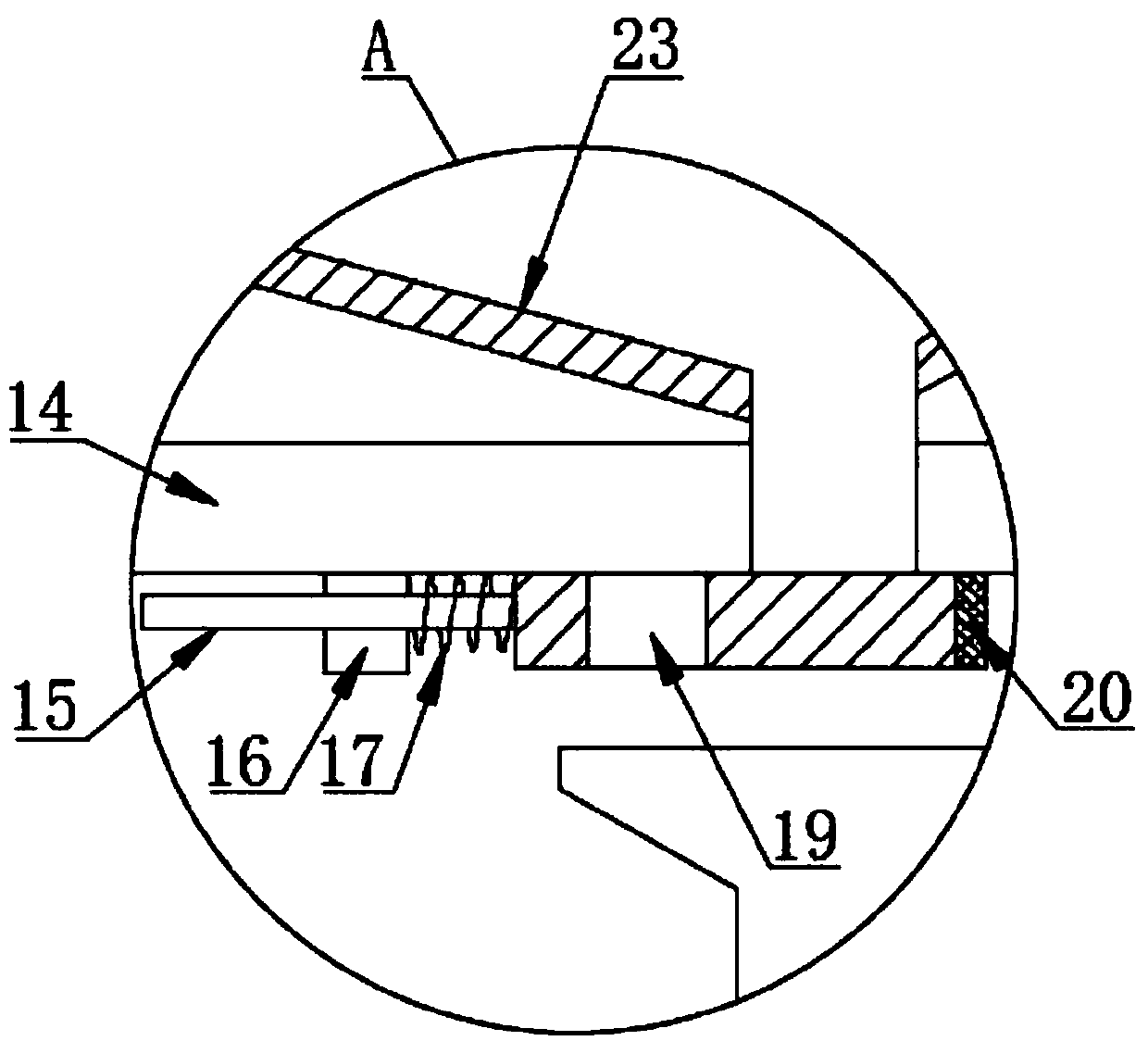

Crushing device for chemical industry production

InactiveCN106733113AQuality assuranceImprove work efficiencyGrain treatmentsChemical industryHydraulic cylinder

The invention discloses a crushing device for chemical industry production. The crushing device for chemical industry production comprises a crushing machine body. The crushing machine body is divided into a crushing cavity and a smashing cavity in an upper-lower mode. The bottom end of the left side of the crushing cavity is connected with a feeding pipe, a feeding hopper is arranged on the upper side of the feeding pipe, and an iron removing rotary shaft is horizontally arranged in the center in the feeding hopper. Permanent magnet sheets are arranged on the outer wall of the iron removing rotary shaft in a vertically symmetrical mode. A telescopic column is vertically arranged in the center in the crushing cavity, the top end of the telescopic column stretches out of the crushing cavity and is connected with a hydraulic cylinder fixed on the outer wall of the upper side of the crushing machine body, and the bottom end of the telescopic column is connected with a crushing hammer arranged horizontally. The crushing device for chemical industry production can conduct iron removing on materials twice, thereby being good in iron removing effect and sufficient in iron removing; two crushing mechanisms arranged up and down are adopted for sufficiently crushing materials, gears are engaged to conduct crushing, and thus the crushing effect is good, and crushing is sufficient; and besides, effective shock absorption can be achieved, and the service life of the machine body is prolonged.

Owner:GUANGXI UNIV

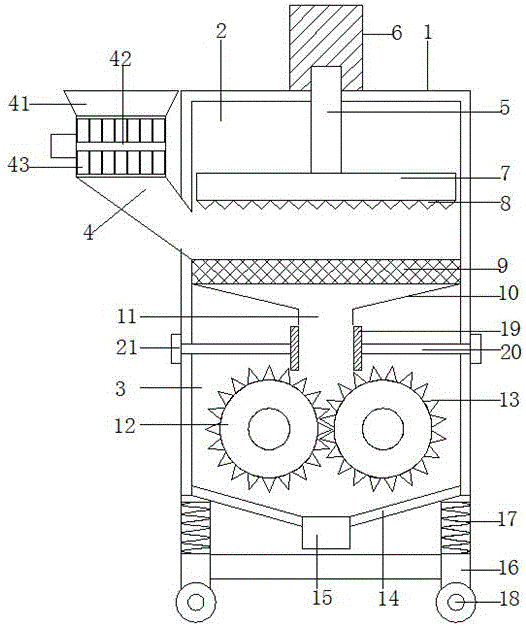

Novel imidazolidinones as NS3-serine protease inhibitors of hepatitis C virus

InactiveUS20020102235A1Reduce friction and wearHigh melting pointOrganic active ingredientsBiocideDrugHcv protease

The present invention discloses novel imidazolidinones which have HCV protease inhibitory activity as well as methods for preparing such compounds. In another embodiment, the invention discloses pharmaceutical compositions comprising such imidazolidinones as well as methods of using them to treat disorders associated with the HCV protease.

Owner:SCHERING CORP

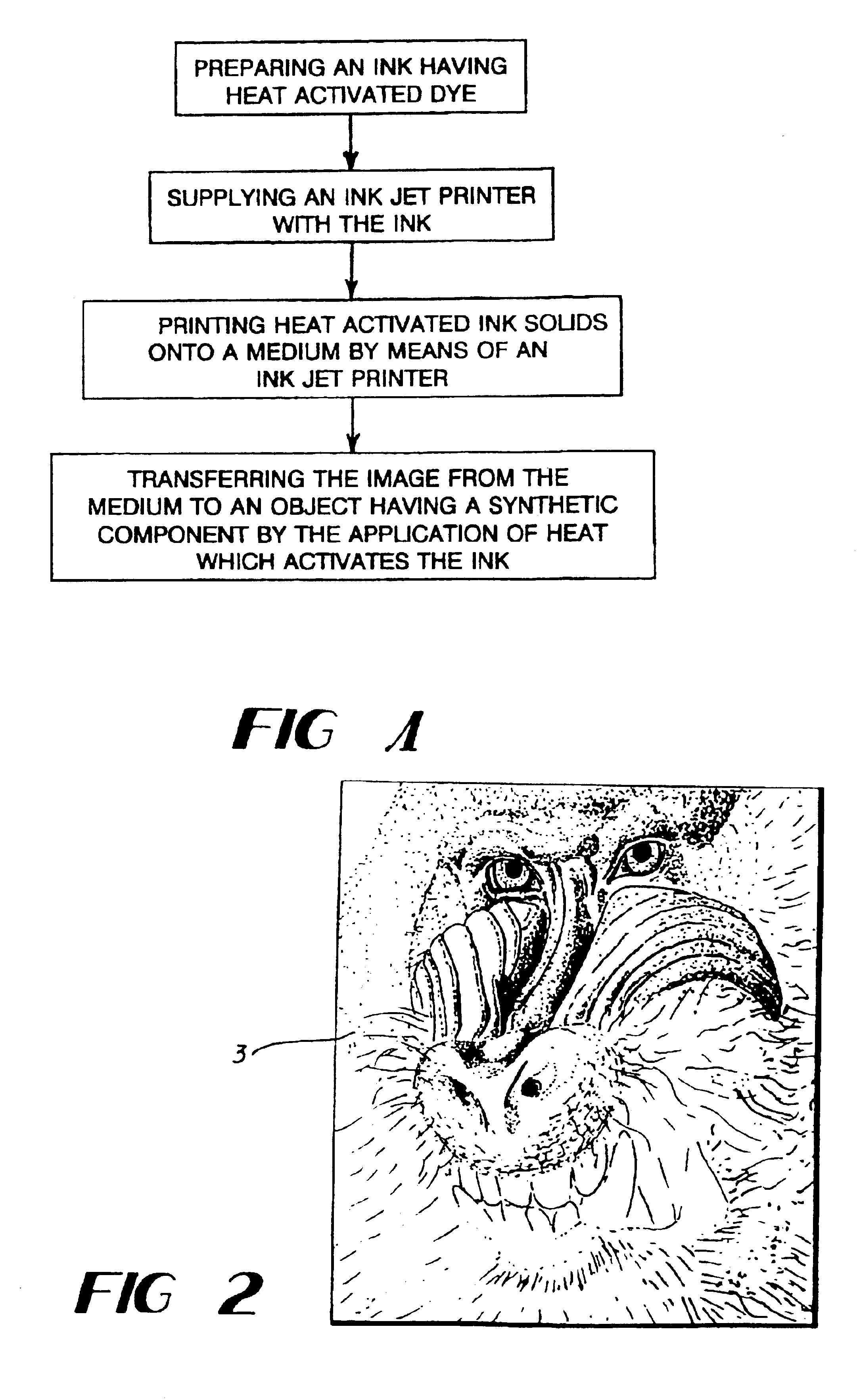

Printed media produced by permanent heat activated printing process

InactiveUS6439710B1Prevent undesired activationAvoid cakingTransfer printingMeasurement apparatus componentsEmulsionEngineering

The present invention is a method of producing a printed a by printing heat activated ink solids in a non activated form onto a medium in a desired image by means of an ink jet printer. The invention is printed using ink or dye compositions comprising heat activated ink or dye solids. The ink compositions used to print the medium are solid at ambient temperature when used with phase change ink jet printers, and are emulsions when used with liquid ink jet printers such as free flow and bubble jet printers. The dye solids are printed in the desired design by means of a printer onto a substrate, which becomes the printed medium. The substrate may be paper, or it may be other material.

Owner:SAWGRASS SYST INC

Method and equipment for processing wastewater of internal electrolysis based on supersound function

InactiveCN1958469APrevent rust and agglomerationAvoid cloggingWater/sewage treatment with mechanical oscillationsShock waveCavitation

This invention relates to method and apparatus for treating interior electrolytic wastewater based on ultrasonication. The method utilizes low-intensity ultrasonic wave to intensify the electrolytic process and improve the treatment effect. Microfluidization effect of ultrasonication, shock wave damage, and H2O2 produced by cavitation during the ultrasonication process can activate the surface of iron chips, thus can effectively prevent the rust and agglomeration of iron chips, clean the surface of iron chips, and accelerate the reaction speed of interior electrolysis. The reaction apparatus is uniformly filled with iron chips and activated carbon particles. Besides, ultrasonication is used as an auxiliary. Ultrasonic cleaning can effectively prevent the blockage of iron and carbon bed. The method and apparatus are simple and rational, and have low cost. The method and apparatus can be widely used for treating organic pollutants in wastewater that are difficult to degrade, improving the ability of wastewater for biochemical treatment, and having high removing rates of color degree and COD of pigment wastewater.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Motor shell paint spraying device with drying function

InactiveCN108339702AImprove spraying effectImprove spraying efficiencySpray boothsDrive shaftEngineering

The invention discloses a motor shell paint spraying device with a drying function. The device comprises an operating box, wherein an oil pant box is fixedly mounted on the left side wall of the operating box; a motor supporting rack is fixedly mounted on the top of the operating box; a reducing motor is fixedly mounted on the motor supporting rack; a plurality of rotating motors are fixedly mounted in the bottom of the operating box; and a plurality of fan blades are fixedly mounted on an output shaft of each rotating motor. The device disclosed by the invention sprays the oil paint uniformlyby means of rotary paint spray of a paint spray disc and attaches the oil paint uniformly to the surface of the motor shell by clamping and rotating the motor shell by means of a first clamp and a second clamp, so that the oil paint spraying effect and efficiency are improved; the oil paint in the oil paint box is uniformly stirred as the stirring blades rotate along with a driving shaft, so thatthe uniform degree of the oil paint is improved effectively, agglomeration of the oil paint is avoided, and the oil paint spraying quality is improved. The device also has a very good oil paint drying function, accelerates quick drying of the oil paint on the surface of the motor shell, and improves the work efficiency.

Owner:ZHEJIANG OUDAO AUTOMATION EQUIP CO LTD

Tone dependent plane dependent error diffusion halftoning

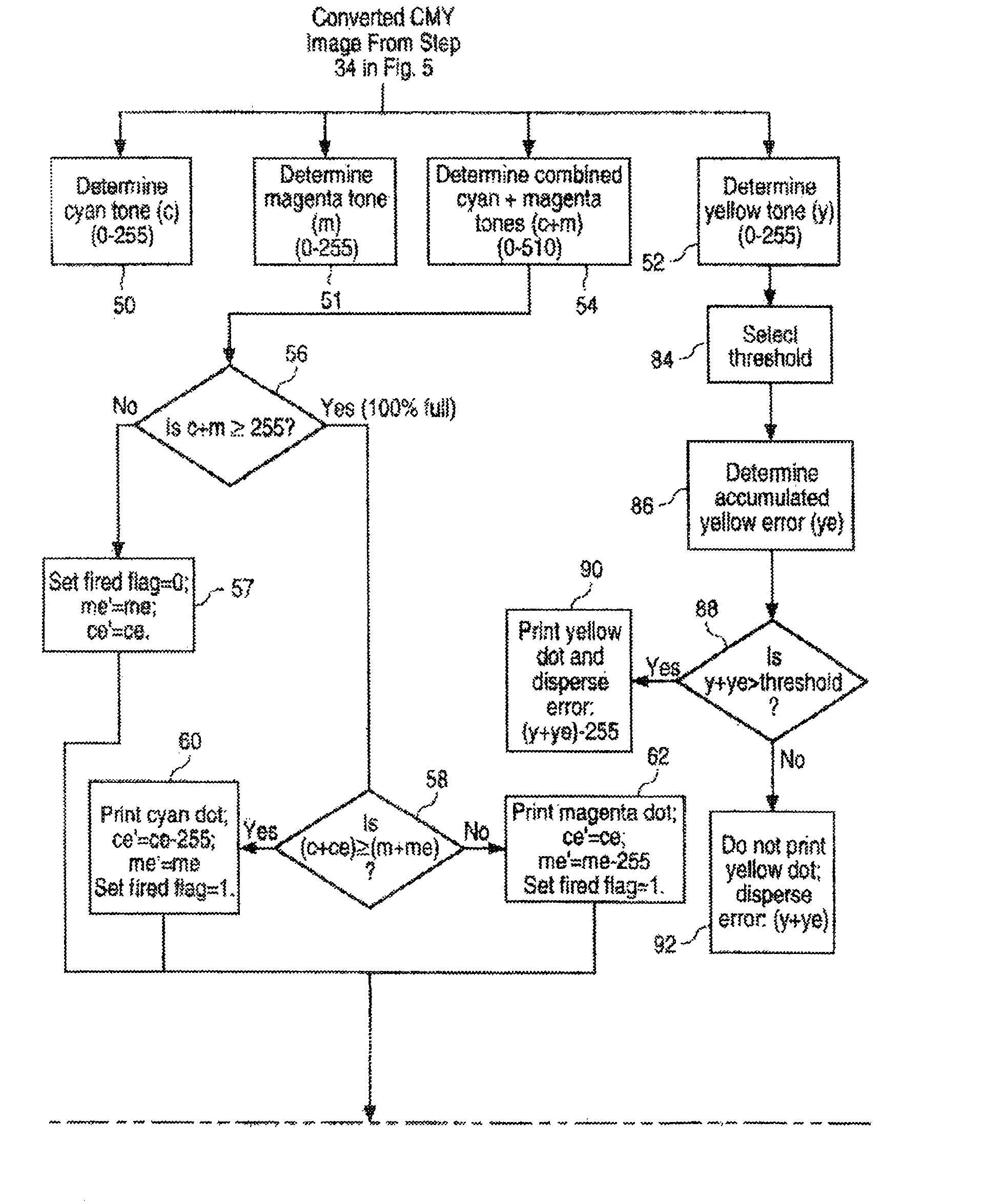

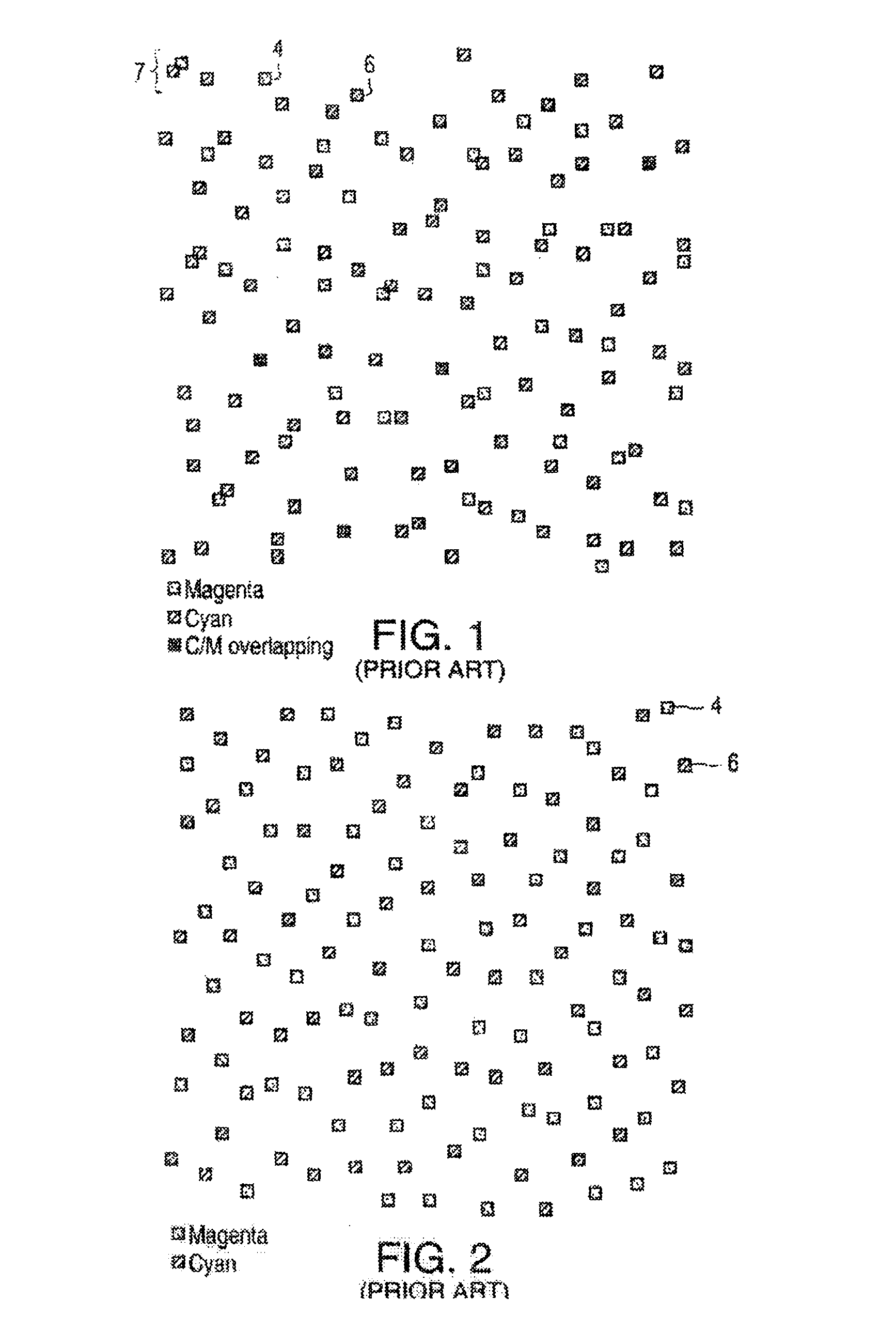

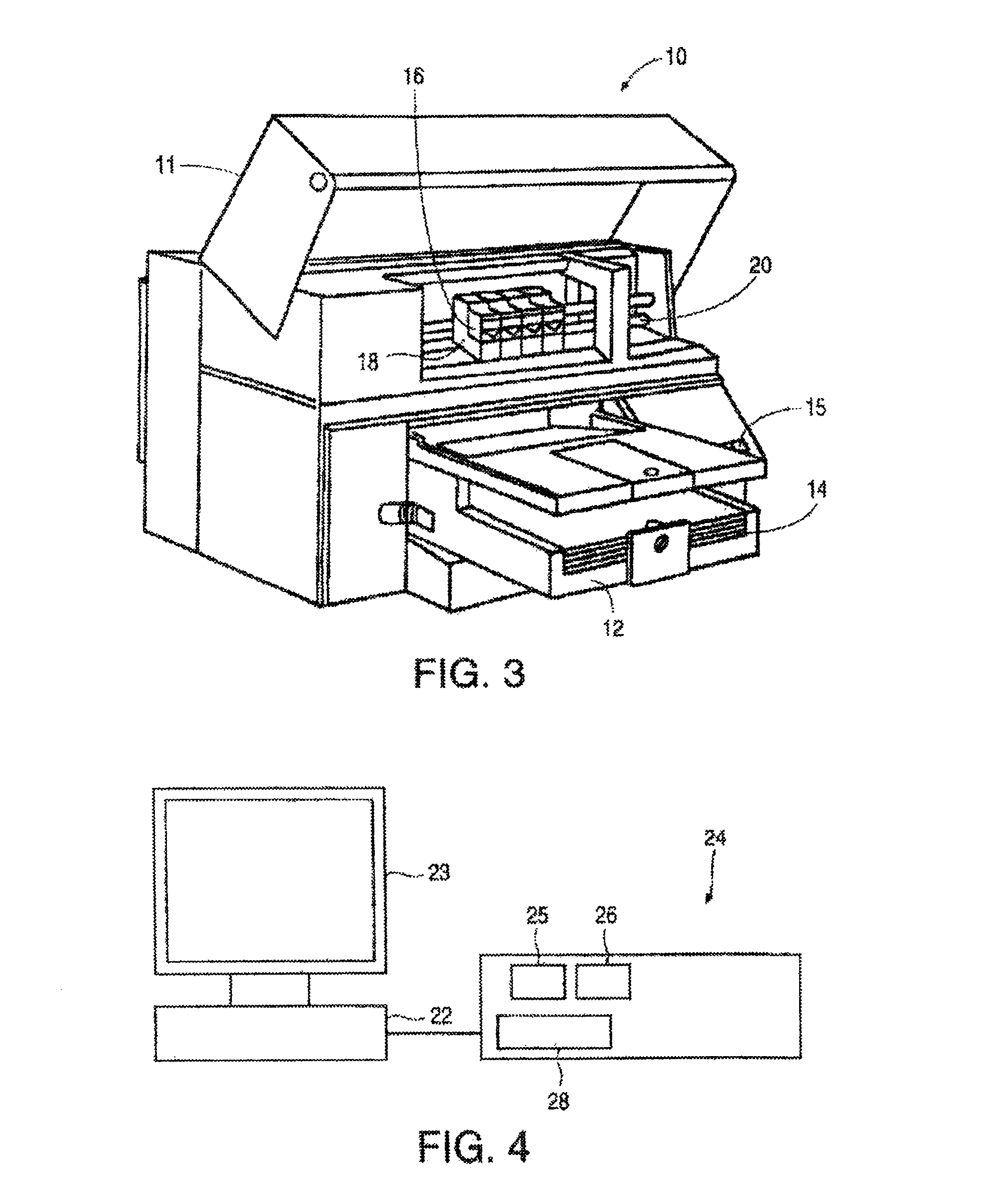

InactiveUS6870644B2Avoid cakingAvoid unintentional overlappingImage enhancementDigitally marking record carriersError diffusionColor plane

Tone dependent plane dependent error diffusion halftoning takes into account multiple color planes, such as cyan and magenta, when determining the placement of a dot in any of the color planes. The combined tones of the correlated color planes is used to determine the threshold levels against which the combined tones and the accumulated errors for the correlated color planes is compared. Further, tone dependent error weightings are determined based on the combined tones of the correlated color planes. The tone dependent error weightings are used to diffuse the final accumulated errors for each color plane. A prerendered mid-tone bitmap may be used to break up any structured patterns that occur in the mid-tones. Using this technique, printed dots of two or more colors are dispersed so as to avoid noticeable clumping of dots of two or more colors to provide a more uniform pattern and to avoid the unintentional overlapping of colors. This technique can be used to augment any existing error diffusion method.

Owner:HEWLETT PACKARD DEV CO LP

Mesosulfuron-methyl compound herbicide

InactiveCN102550585APrevent flocculationAvoid layeringBiocideAnimal repellantsAdjuvantAdditive ingredient

The invention discloses a mesosulfuron-methyl compound herbicide which consists of mesosulfuron-methyl as active ingredient I, active ingredient II and auxiliary ingredients; the active ingredient II is the combination of one or more of flucarbazone-Na, isoproturon, chlortoluron, pyroxsulam, 2-methyl-4-chlorophenoxy acetic acid, 2,4-D butyl ester, dicamba, bromoxynil, amidosulfuron, bensulfuron-methyl, flumetsulam, fluoroglycofen-ethyl and florasulam; the auxiliary ingredients consists of adjuvant and one of filler and solvent, and the adjuvant is the combination of one or more of emulsifying agent, dispersing agent, wetting agent, disintegrant, binding agent, antifreezing agent and thickening agent; the sum of the weight of the mesosulfuron-methyl as the active ingredient I and the weight of the active ingredient II is 1 to 85 percent of the total weight of the mesosulfuron-methyl compound herbicide; and the weight ratio of the active ingredient I to the active ingredient II is 1:20 to 20:1. The mesosulfuron-methyl mixed herbicide is novel herbicide for wheatlands.

Owner:河北博嘉农业有限公司

Feed uniform mixing device with constant proportion

InactiveCN107837727APrevent feed cakingMix well and evenlyFeeding-stuffRotary stirring mixersAgricultural engineeringMaterial storage

The invention discloses a feed uniform mixing device with constant proportion. The feed uniform mixing device comprises a base, wherein support rods are fixedly arranged at the left side and right side of the top part of the base; a top plate is fixedly arranged at the top part of each support rod; a left material storage box and a right material storage box are fixedly arranged at the top part ofthe top plate through brackets; a left guide sleeve and a right guide sleeve are fixedly arranged at the bottom part of the top plate, and are slidingly connected with guide rods, one end of each guide rod is fixedly connected with a blocking plate, and the left blocking plate and right blocking plate are respectively provided with a material discharge port which is matched with a material outlet; a reset spring is sheathed on a guide rod between each guide sleeve and the corresponding blocking plate, and both ends of each reset spring are respectively connected with the corresponding guide sleeve and the blocking plate; an electromagnet is fixedly arranged at the center of the bottom part of the top plate; an iron block is fixedly arranged at the end surface, near the electromagnet, of each blocking plate. The feed uniform mixing device has the advantages that the electromagnet is used for intermittently supplying power, the blocking plates are driven to move left and right, and thematerial outlet of each material storage box is intermittently coincided with the material discharge port of the corresponding blocking plate, so that the feed is discharged at constant proportion, the artificial weighing for proportion is not needed, and more convenience in use is realized.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

Method for wet stabilization of material or waste to reduce selenium leaching potential

InactiveUS20040018130A1Avoid cakingSmooth connectionContaminated soil reclamationSolid sorbent liquid separationSe elementMaterials science

This invention provides a method for chemical stabilization of selenium bearing materials and wastes subject to acid and water leaching tests or leach conditions by addition of water and selenium stabilizing agents such that the leaching potential is inhibited to desired levels. The resultant material or waste after stabilization is deemed suitable for on-site reuse, off-site reuse or disposal as RCRA non-hazardous waste.

Owner:FORRESTER KEITH EDWARD

Preparation method of naturally-degradable compound fertilizer anti-blocking agent and application thereof

The invention discloses a preparation method of a naturally-degradable compound fertilizer anti-blocking agent and an application thereof. The naturally-degradable compound fertilizer anti-blocking agent comprises the following components in percentage by mass: 10-20 percent of fatty amine or salt thereof, 20-25 percent of stearic acid, 15-20 percent of oleic acid, 5-15 percent of refined glycerin and 20-50 percent of waste edible oil and fat, and the sum of all the components is 100 percent according to the percentage. The preparation method comprises the following steps of: mixing all the components according to the proportion, heating to be 70 DEG C -85 DEG C, and stirring and reacting for 15 minutes-30 minutes. The used amount of the compound fertilizer anti-blocking agent is 05-2.0kg / t (compound fertilizer), and a granulation mode of a high air-cooling crystallization tower of an all-molten compound fertilizer is adopted to mix the naturally-degradable compound fertilizer anti-blocking agent with the compound fertilizer. In the preparation method and the application thereof, the processing is simple, the use cost is low, the anti-blocking performance is good, the purely natural and environmentally-friendly performances are achieved, the absorption of crops is convenient, the fertilizer effect is enhanced, and the soil is protected.

Owner:福建达安能源实业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com