Cs-supported silica-based catalyst and preparation method and application thereof

A catalyst, supported technology, applied in molecular sieve catalysts, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of high equipment requirements, easy corrosion, high price of propylene, etc., achieve simple preparation process, maintain catalytic activity, The effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

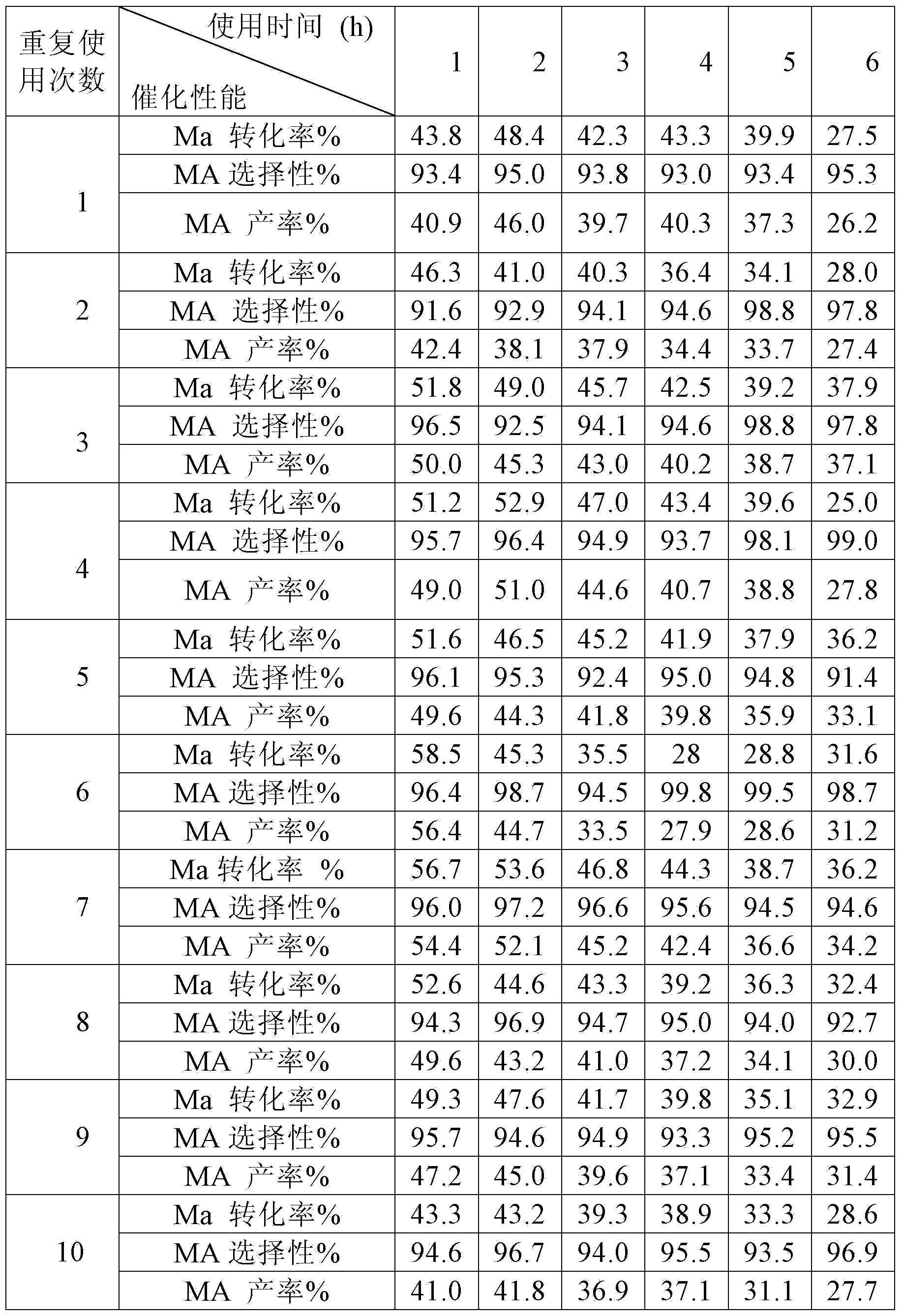

Examples

Embodiment 1

[0035] Weigh 0.7280g CsNO 3 Dissolve in 12ml of deionized water, and evenly impregnate the solution in 10g of 40-60 mesh SiO 2 Put it on, stir, let it stand for 1 hour, and evaporate excess water in a 60°C water bath. Transfer to a vacuum drying oven, dry at 50°C for 12 hours, and then bake at 450°C for 5 hours in an air atmosphere to prepare the catalyst 5 (wt%) Cs / SiO 2 .

[0036] In a fixed bed reactor, at 390°C, carrier gas flow 50ml / min, methyl acetate: formaldehyde: methanol molar ratio 1:2:2, space velocity 5h -1 , Feed volume 0.03ml / min, catalyst dosage is under the condition of 0.5000g, prepare methyl acrylate, the one-pass conversion rate of methyl acetate is 43.2%, the selectivity of methyl acrylate is 92.1%, the one-pass yield of methyl acrylate was 39.8%.

Embodiment 2

[0038] Weigh 0.7280g CsNO 3 Dissolve in 12ml of deionized water, dip the solution evenly on 10g of 40-60 mesh SBA-15, stir, let it stand for 1 hour, and evaporate excess water in a 60°C water bath. Transfer to a vacuum drying oven, dry at 50°C for 12 hours, and then bake at 450°C for 5 hours in an air atmosphere to prepare catalyst 5 (wt%) Cs / SBA-15.

[0039] In a fixed bed reactor, at 390°C, carrier gas flow 50ml / min, methyl acetate: formaldehyde: methanol molar ratio 1:2:2, space velocity 5h -1 , feed volume 0.03ml / min, catalyst dosage is under the condition of 0.5000g, prepare methyl acrylate, the one-pass conversion rate of methyl acetate is 48.4%, the selectivity of methyl acrylate is 95.0%, the one-pass yield of methyl acrylate was 46.0%.

Embodiment 3

[0041] Weigh 0.7280g CsNO 3 Dissolve in 12ml of deionized water, evenly impregnate the solution on 10g of 40-60 mesh silica prepared by the silica sol method, stir, let stand for 1 hour, and evaporate excess water in a 60°C water bath. Transfer to a vacuum drying oven, dry at 50°C for 12 hours, and then bake at 450°C for 5 hours in an air atmosphere to prepare catalyst 5 (wt%) Cs / Silica gel (silicon dioxide prepared by silica sol method).

[0042] In a fixed bed reactor, at 390°C, carrier gas flow 50ml / min, methyl acetate: formaldehyde: methanol molar ratio 1:2:2, space velocity 5h -1 , feed volume 0.03ml / min, catalyst dosage is under the condition of 0.5000g, prepare methyl acrylate, the one-pass conversion rate of methyl acetate is 28.9%, the selectivity of methyl acrylate is 94.8%, the one-pass yield of methyl acrylate was 27.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com