Patents

Literature

227results about How to "More exposure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

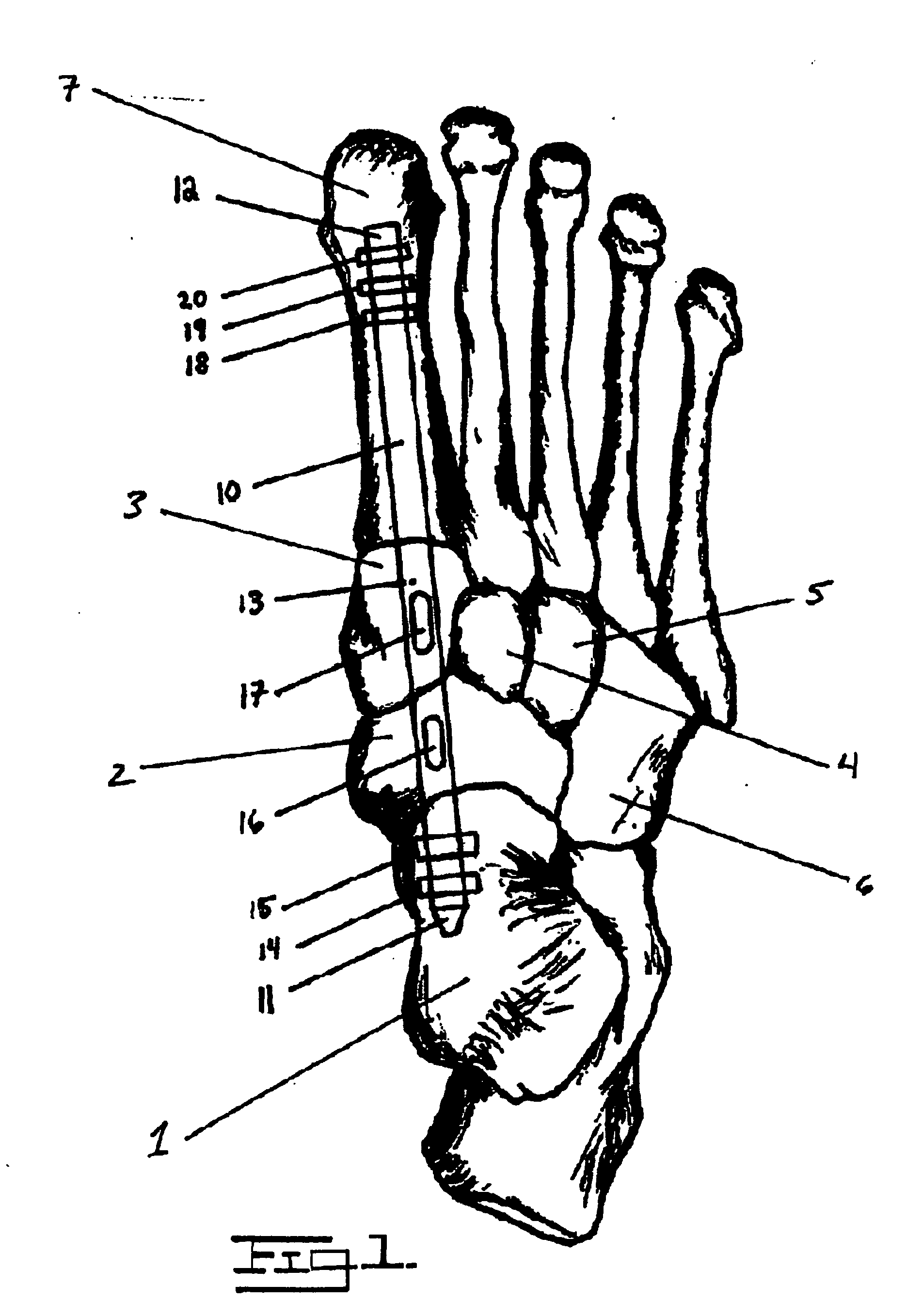

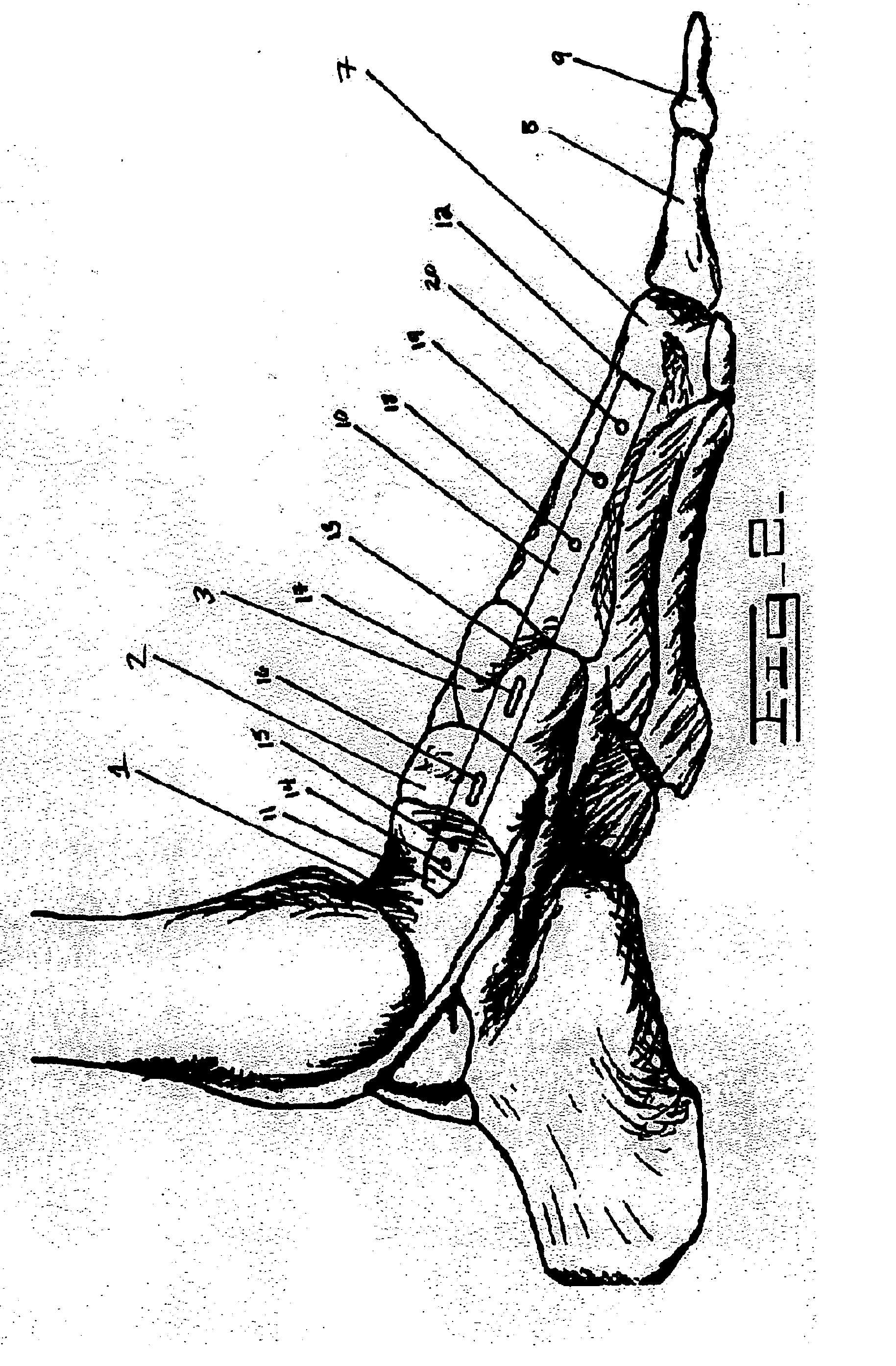

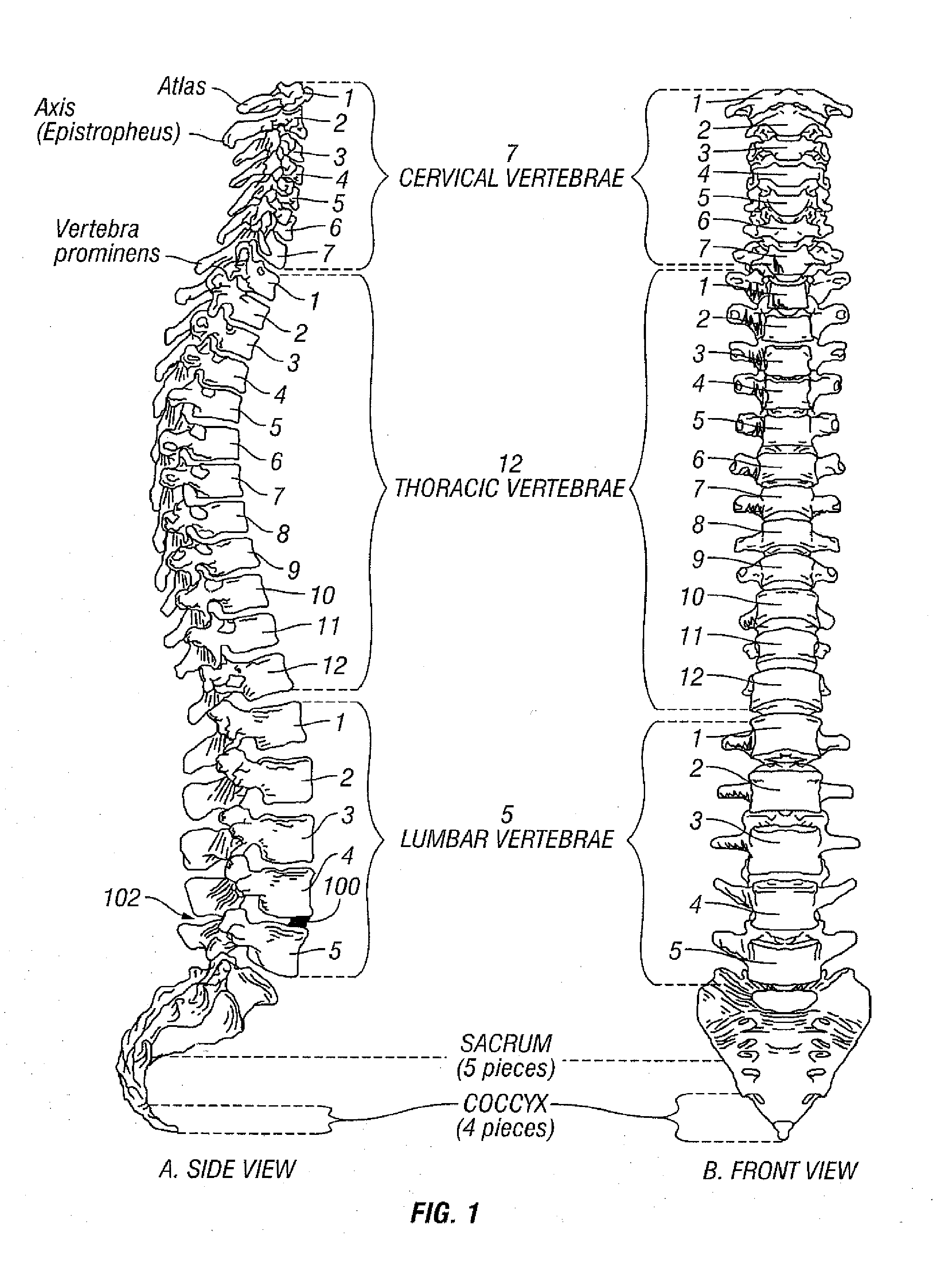

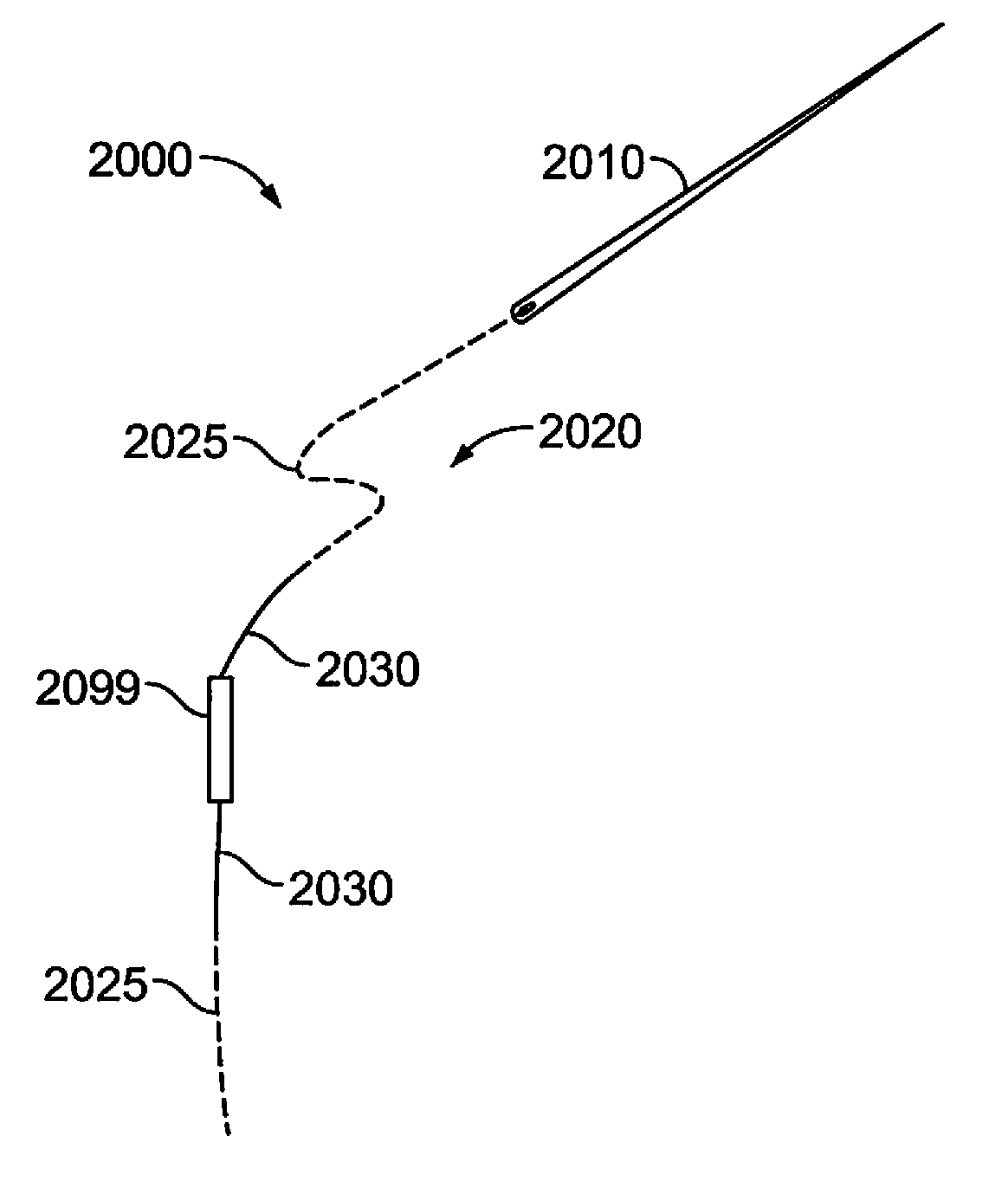

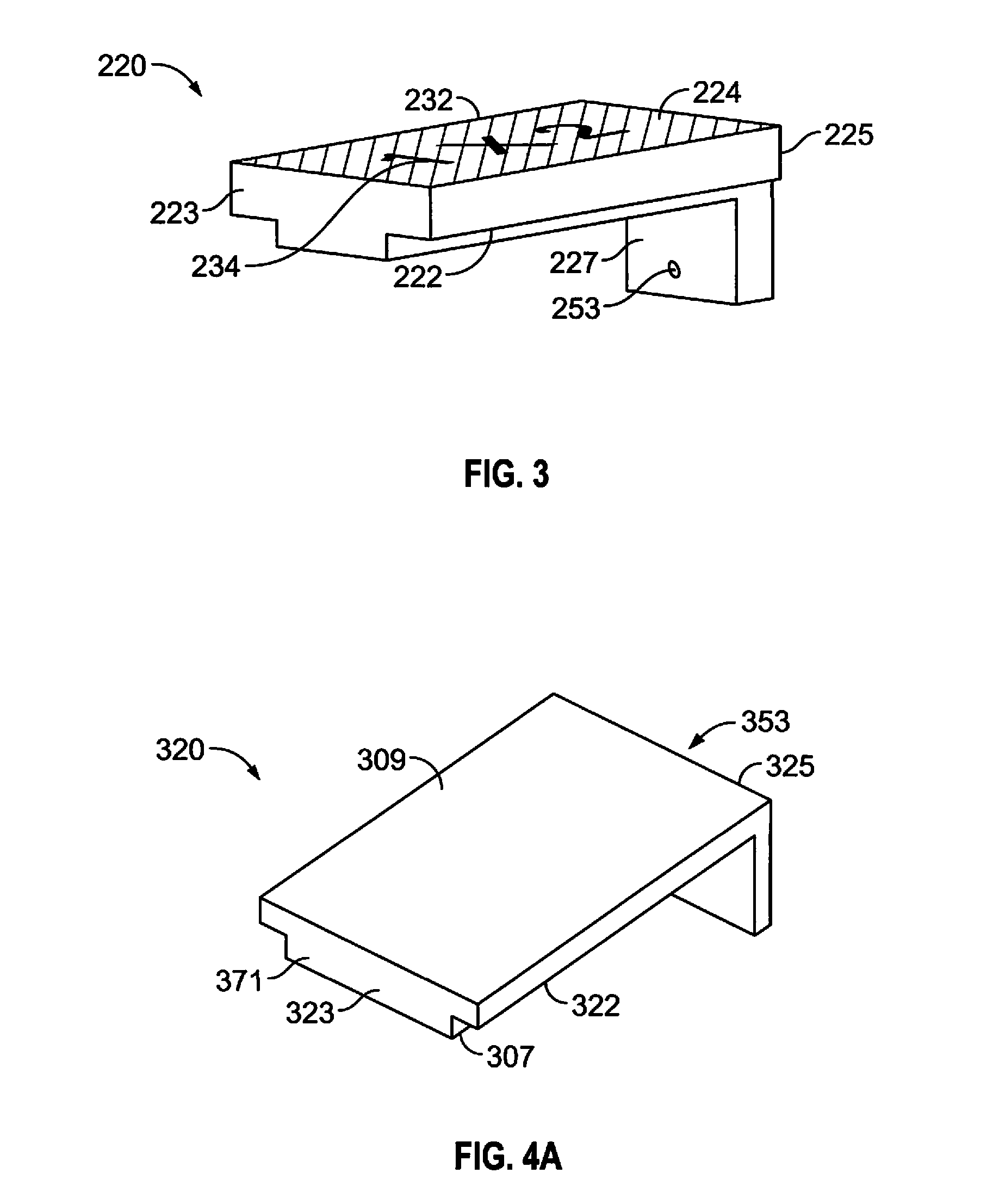

Method and apparatus for repairing the mid-food region via an intramedullary nail

InactiveUS20060206044A1Eliminate needPreventing future mid-foot collapse and ultimate limb lossInternal osteosythesisNon-surgical orthopedic devicesFoot regionMetatarsal bones

A device, method, and system for treatment or fixation of a fractured, damaged, or deteriorating bone or bones in a mid-foot region. The device comprising an implant with both proximal and distal fastener holes, along with fastener slots in a central elongated body, for securing the implant to the appropriate osseous cortical structures of the foot. The method for treatment or fixation of fractured, damaged, or deteriorating bones in the medial column of the foot with use of a device such as an intramedullary nail that attaches to either the talus or first metatarsal bones to secure the medial cuneiform and navicular bones in place.

Owner:HOWMEDICA OSTEONICS CORP

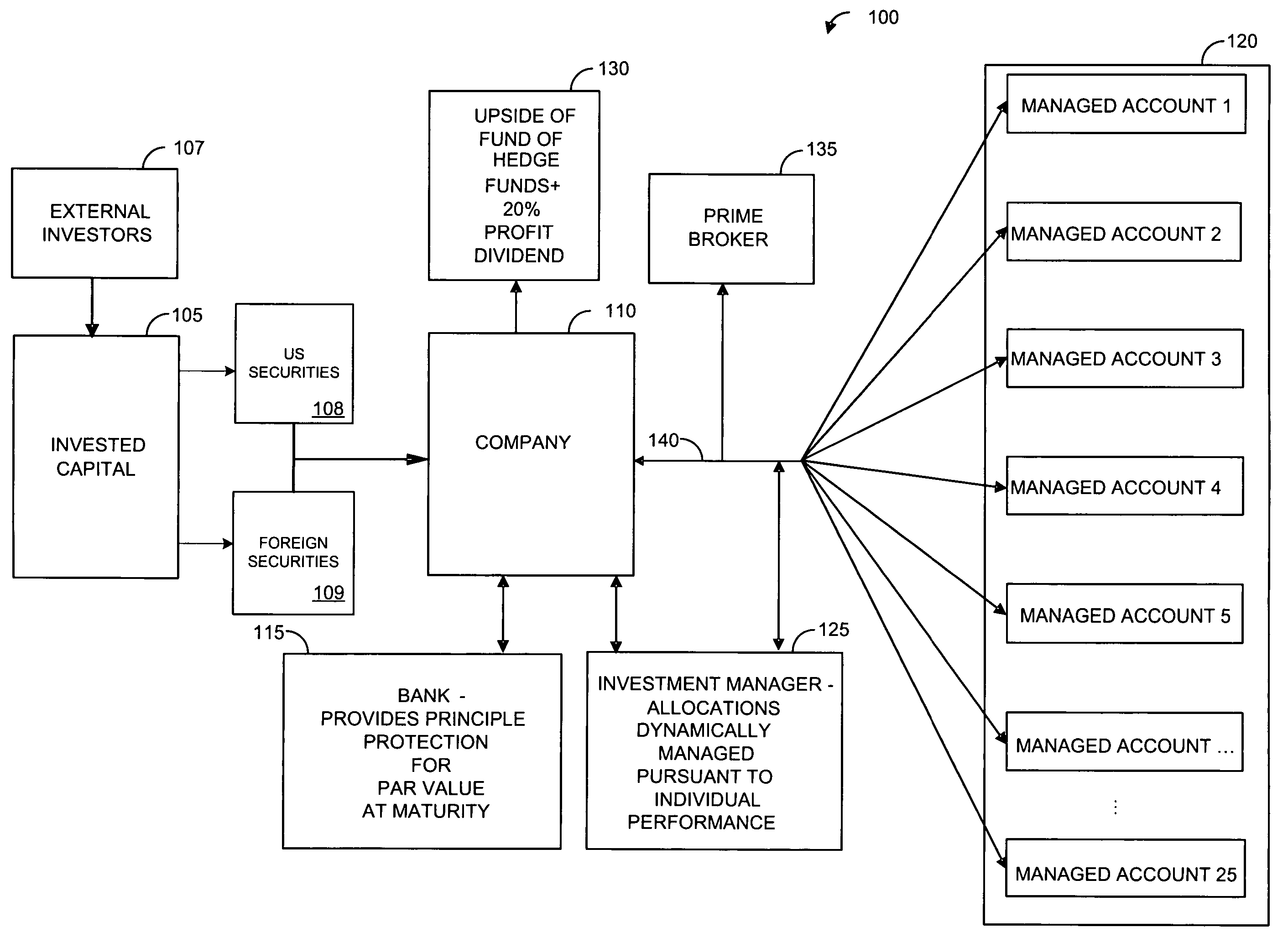

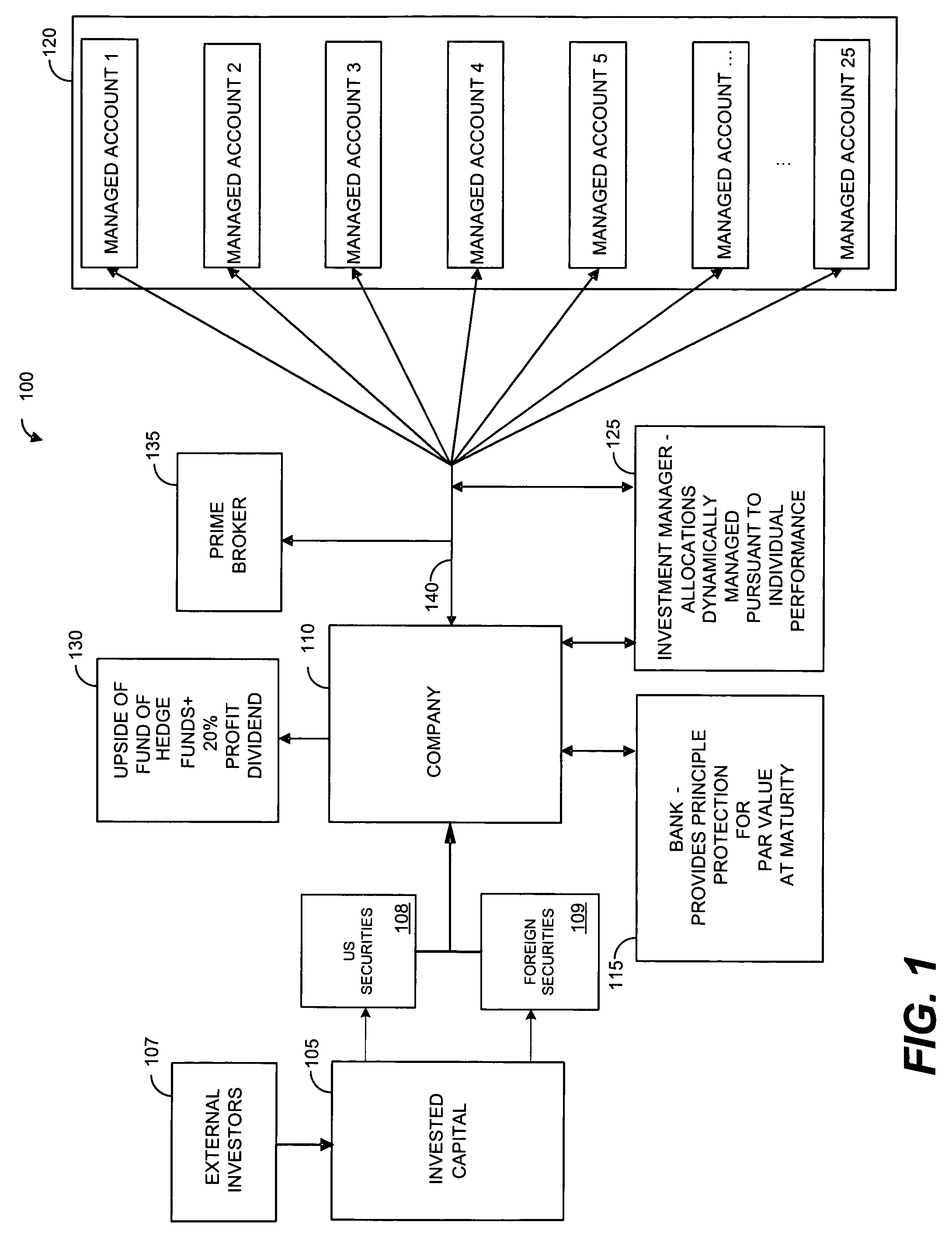

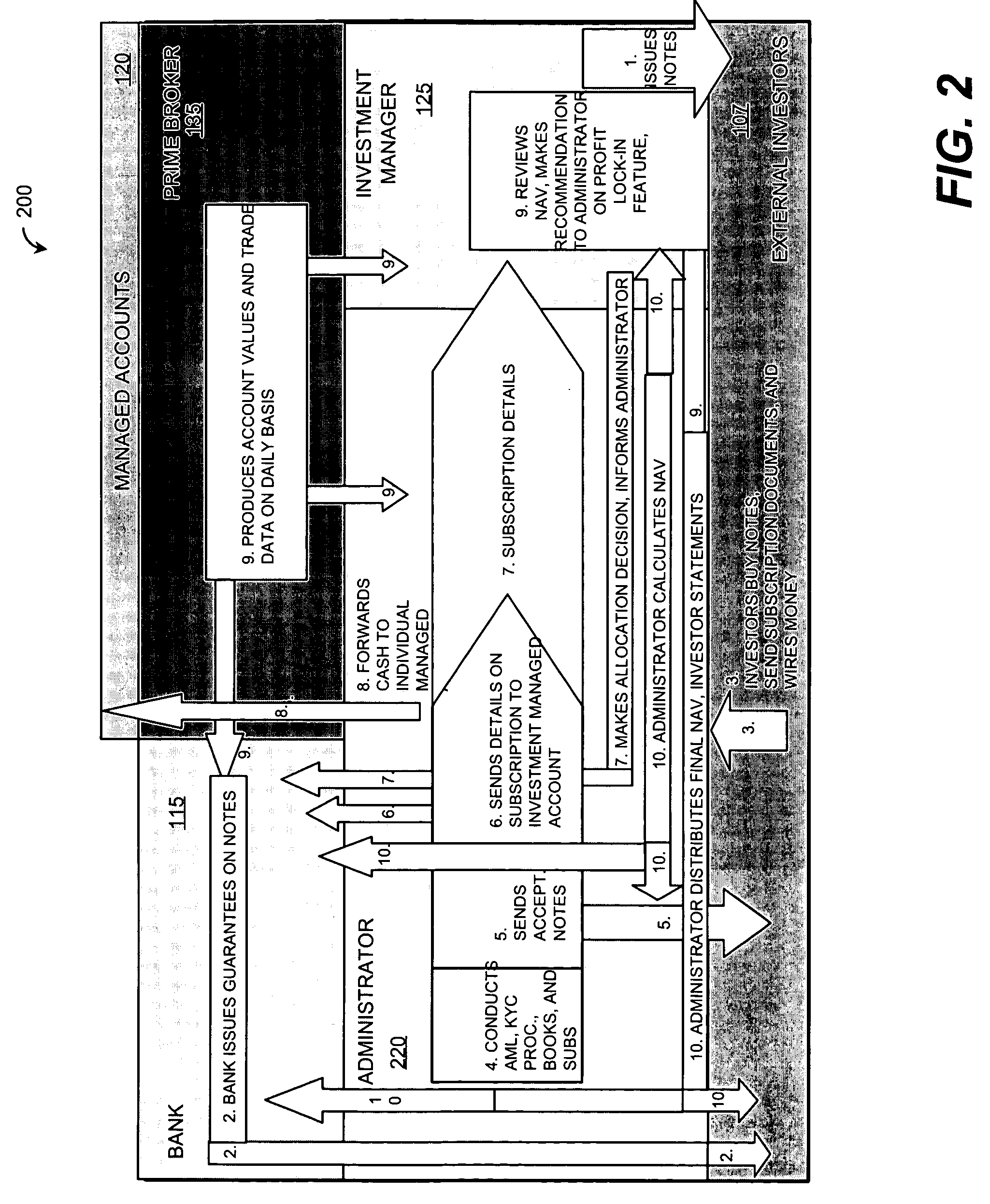

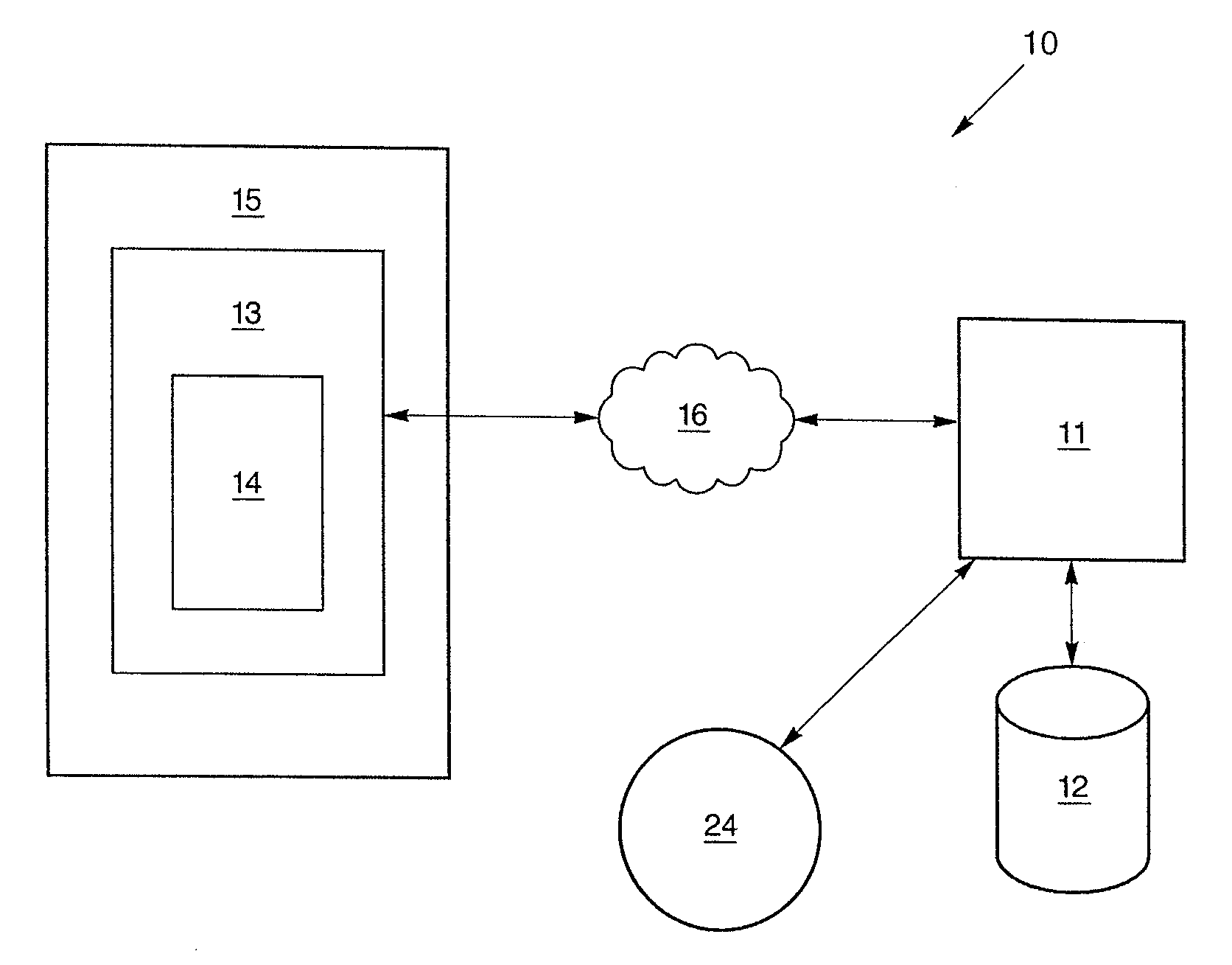

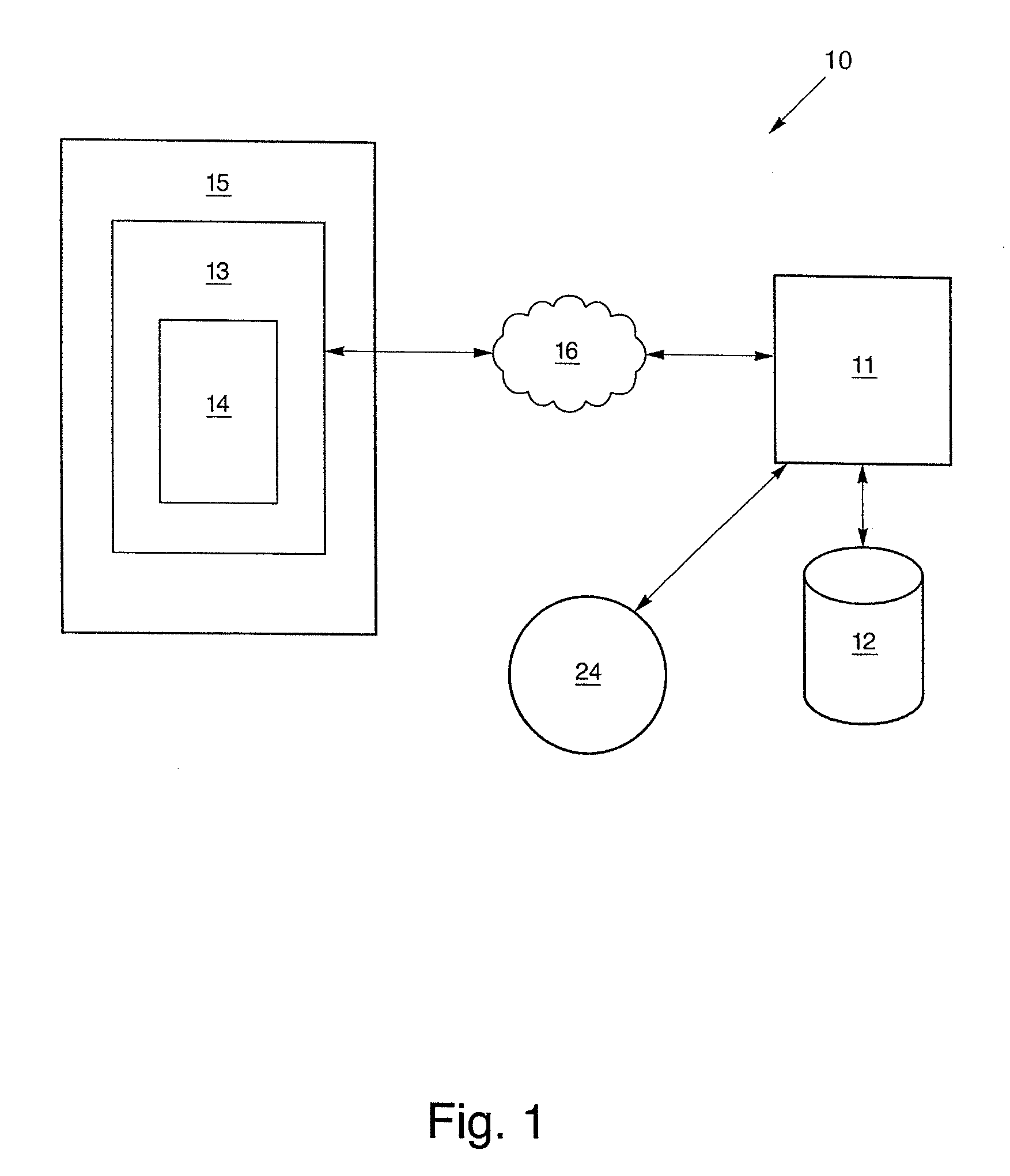

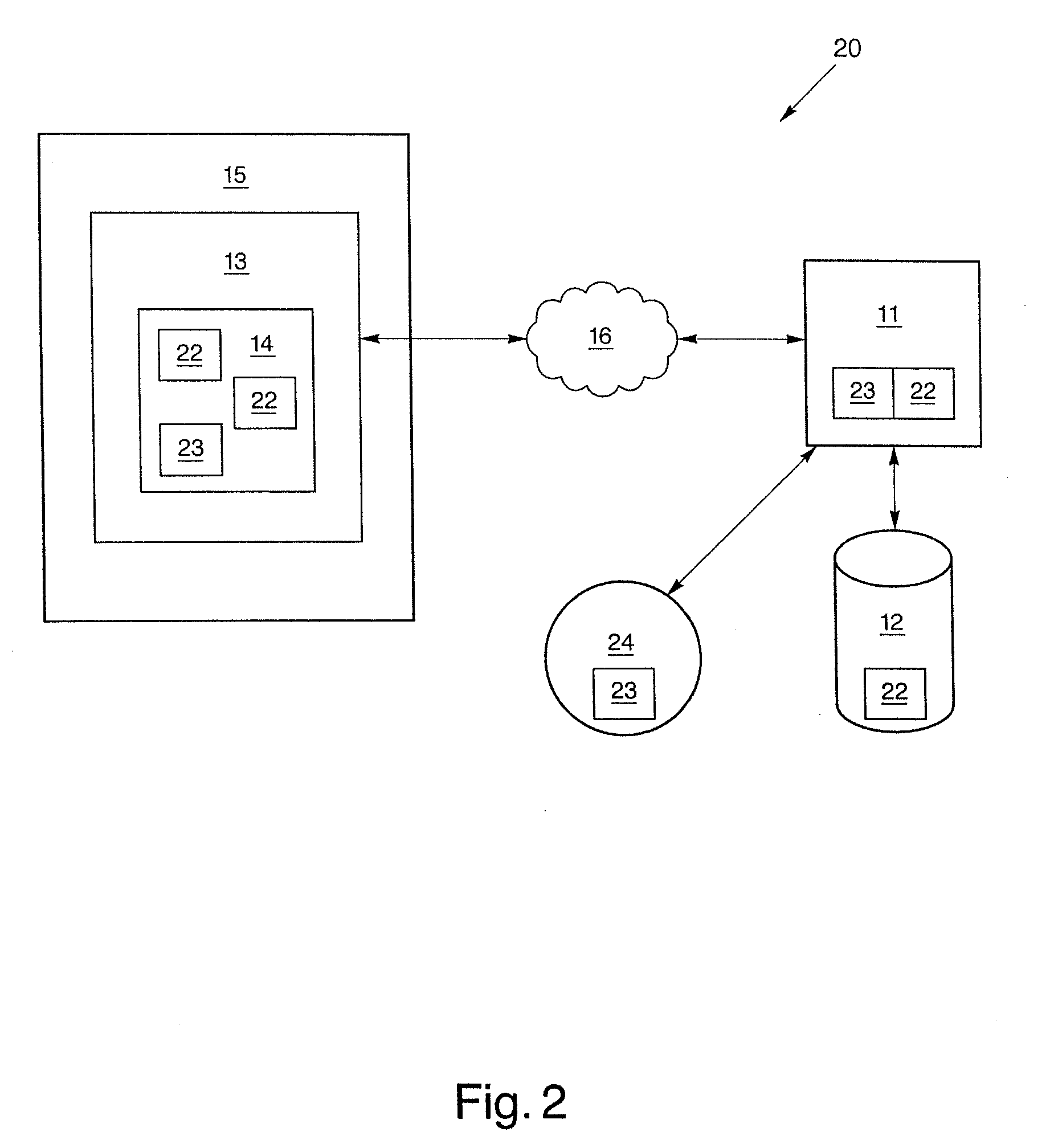

System and method for managing a stable of managed accounts over a distributed network

InactiveUS20050044035A1Minimize excessive exposureManage riskFinanceSpecial data processing applicationsDistributed computingNetwork method

Method and system that allows External Investors to participate in an Investment Fund consisting of a portfolio of Managed Accounts, such as hedge funds, with the security and liquidity provided by guaranteed securities. The guaranteed securities are provided to external investors in exchange for cash. An Investment Manager then selects a number of Trading Advisors from a list of emerging hedge fund managers to manage the individual hedge funds and distributes the assets among the hedge funds according to set of allocation rules. The Investment Manager dynamically monitors the trading activities of each Trading Advisor through a computer system over a disturbed network. Investment Manager also determines a lock-in dividend rate for the issued securities based on the daily activity of each of the hedge funds, which is paid to the External Investors at the end of the year.

Owner:CIRCLE T EXPLORER ASSET MANAGEMENT

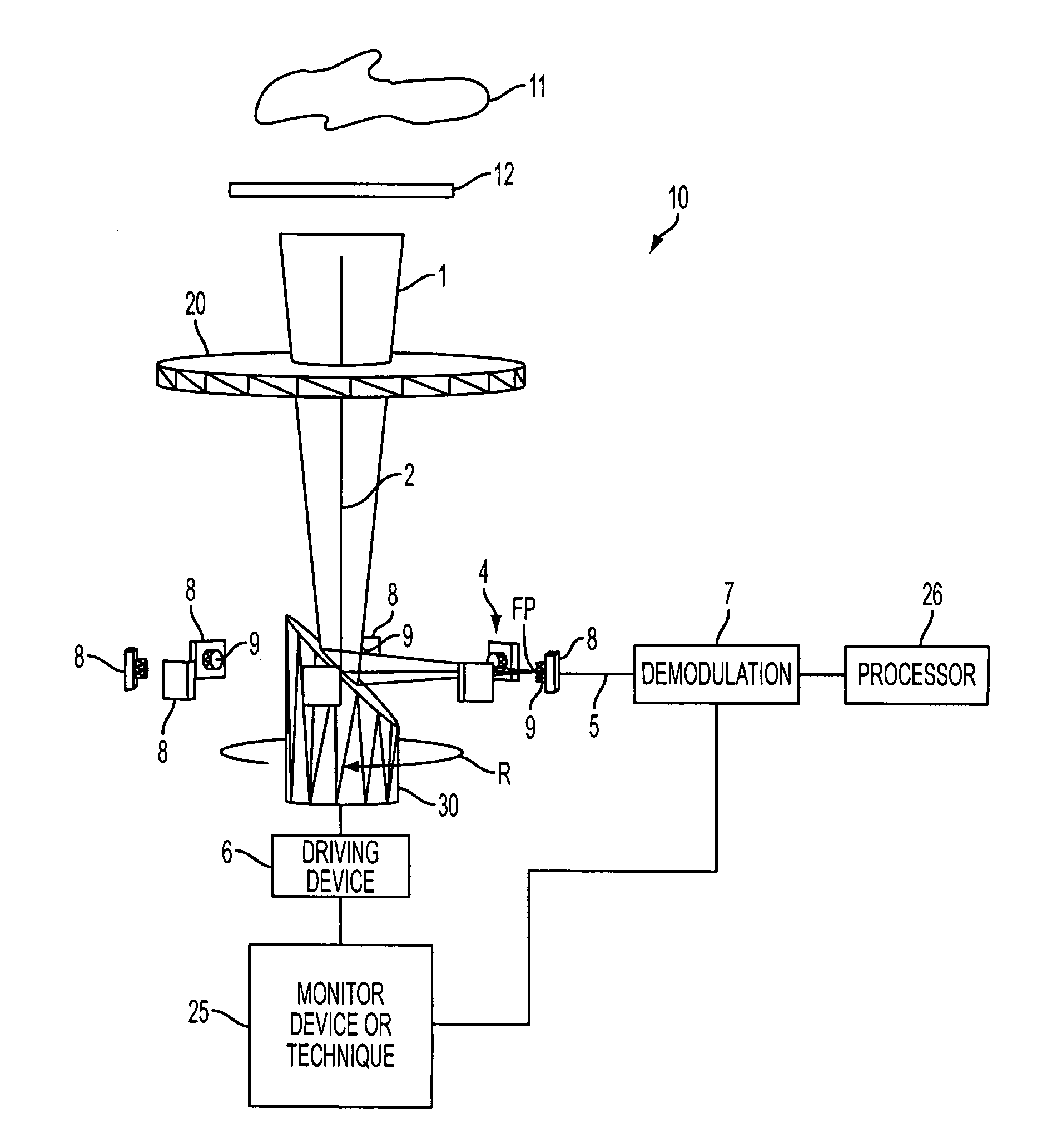

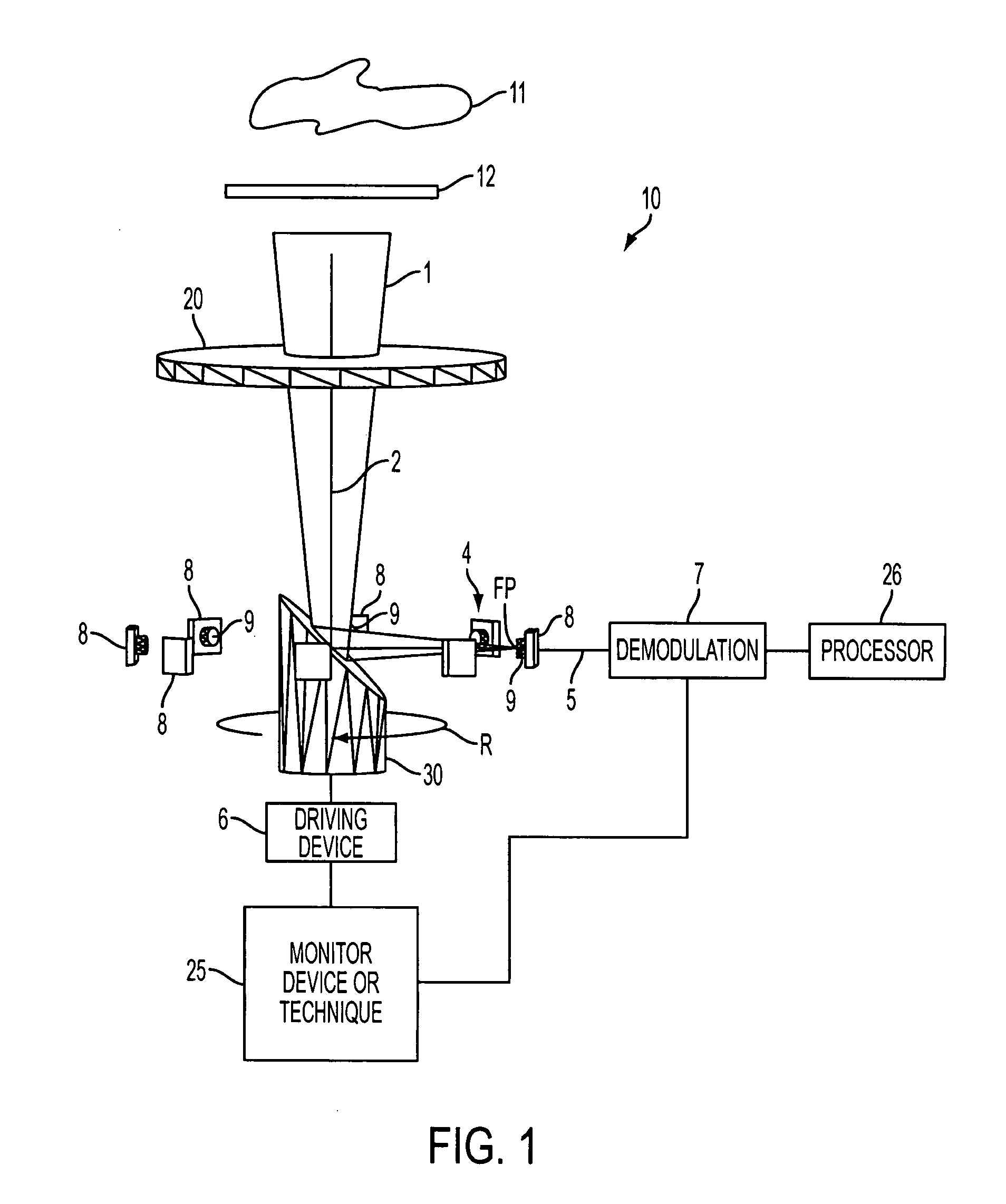

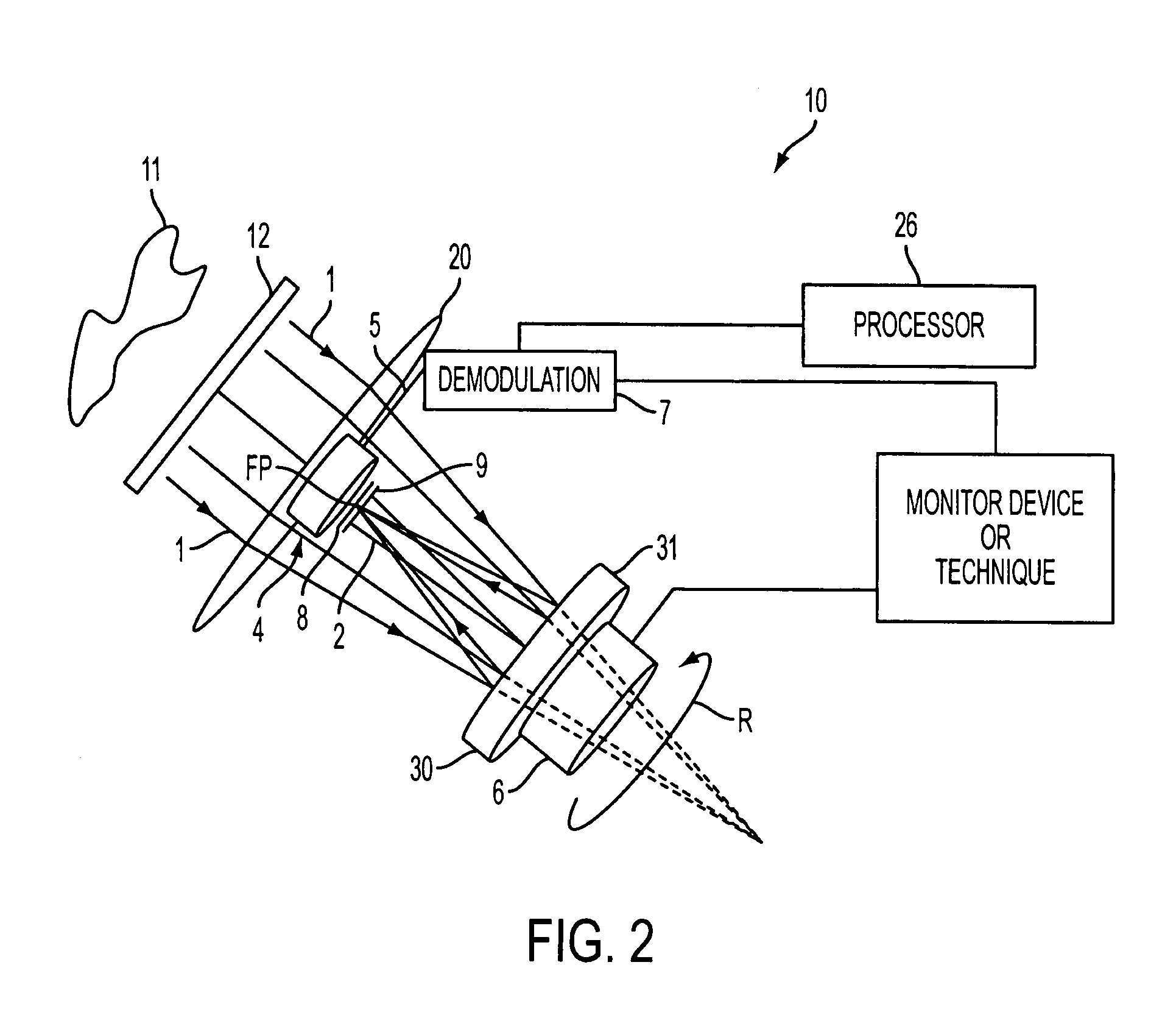

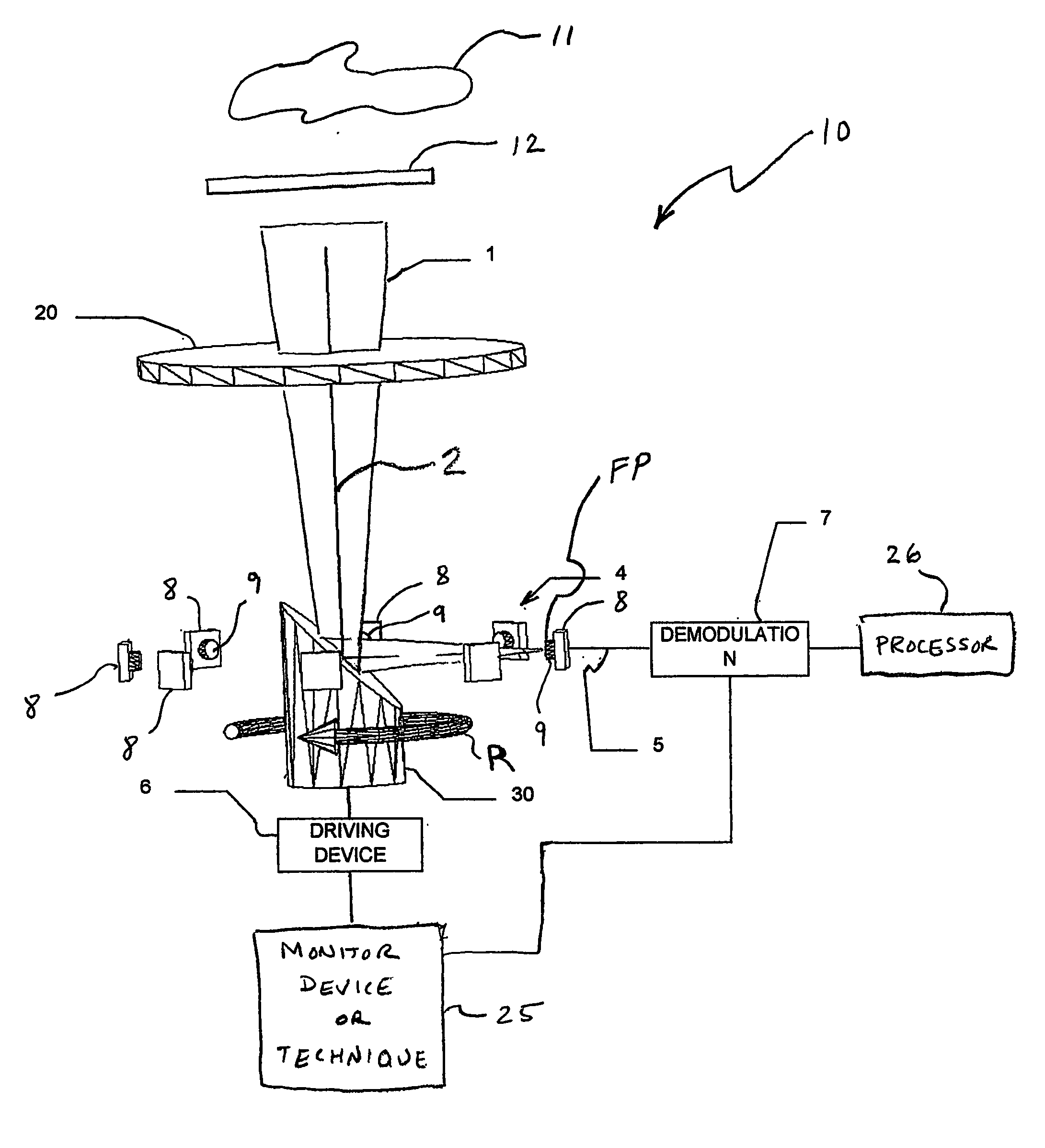

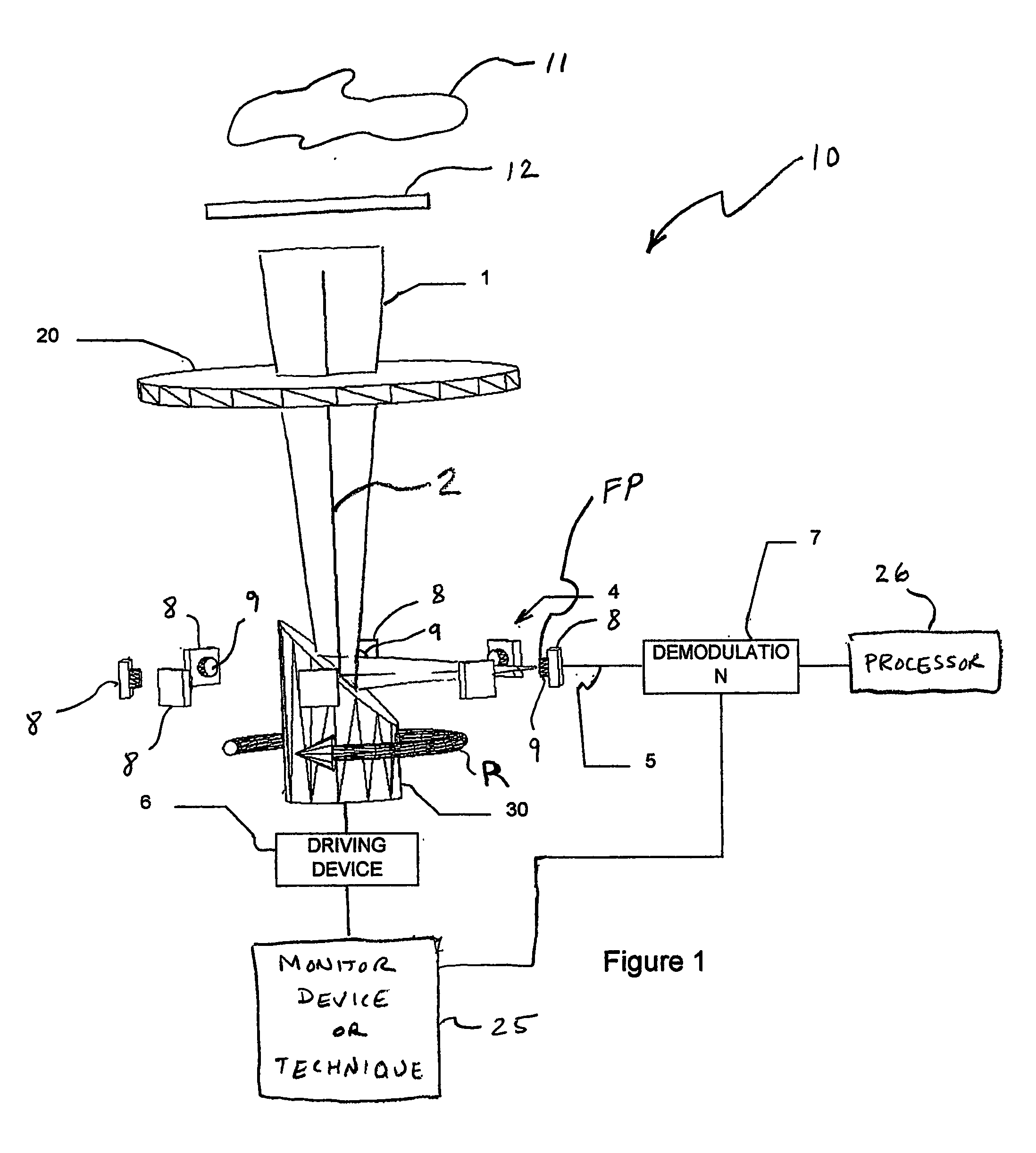

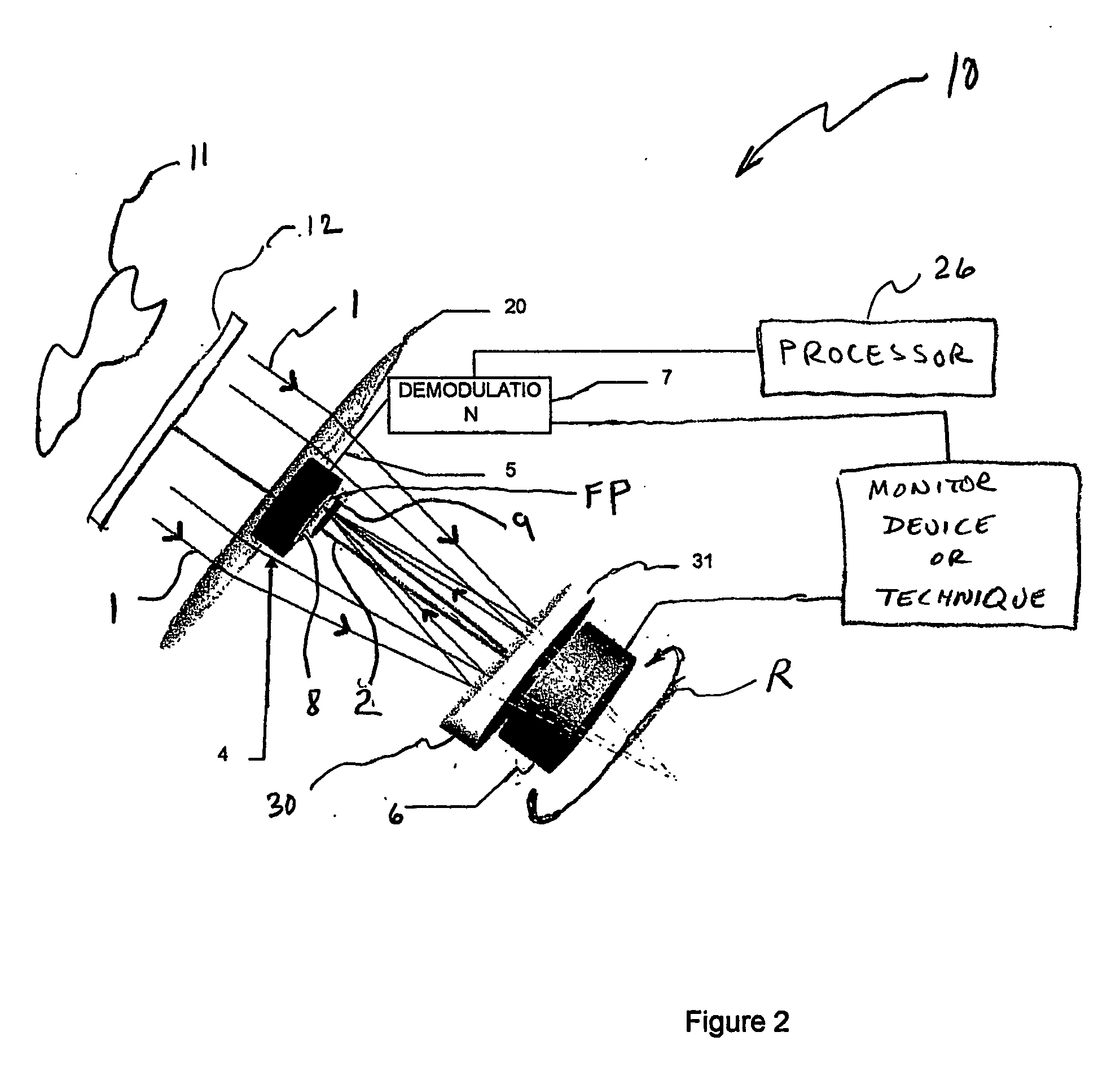

System and method for remote sensing and/or analyzing spectral properties of targets and/or chemical species for detection and identification thereof

A method and a low-cost, robust and simple system for remote sensing and analyzing spectral properties of targets as a means to detect and identify them is introduced. The system can be highly portable but is usable in fixed locations or combination thereof. An aspect of the method and system includes the capability to distribute, modulate, aperture and spectrally analyze radiation emitted or absorbed by a volumetric target chemical species (solid, liquid or gas) or a target surface. Radiation is first collected by a single light gathering device, such as a lens, telescope, or mirror, and then distributed to multiple detectors through spectrally discriminating components and if desired through apertures to achieve this desired detection and identification.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

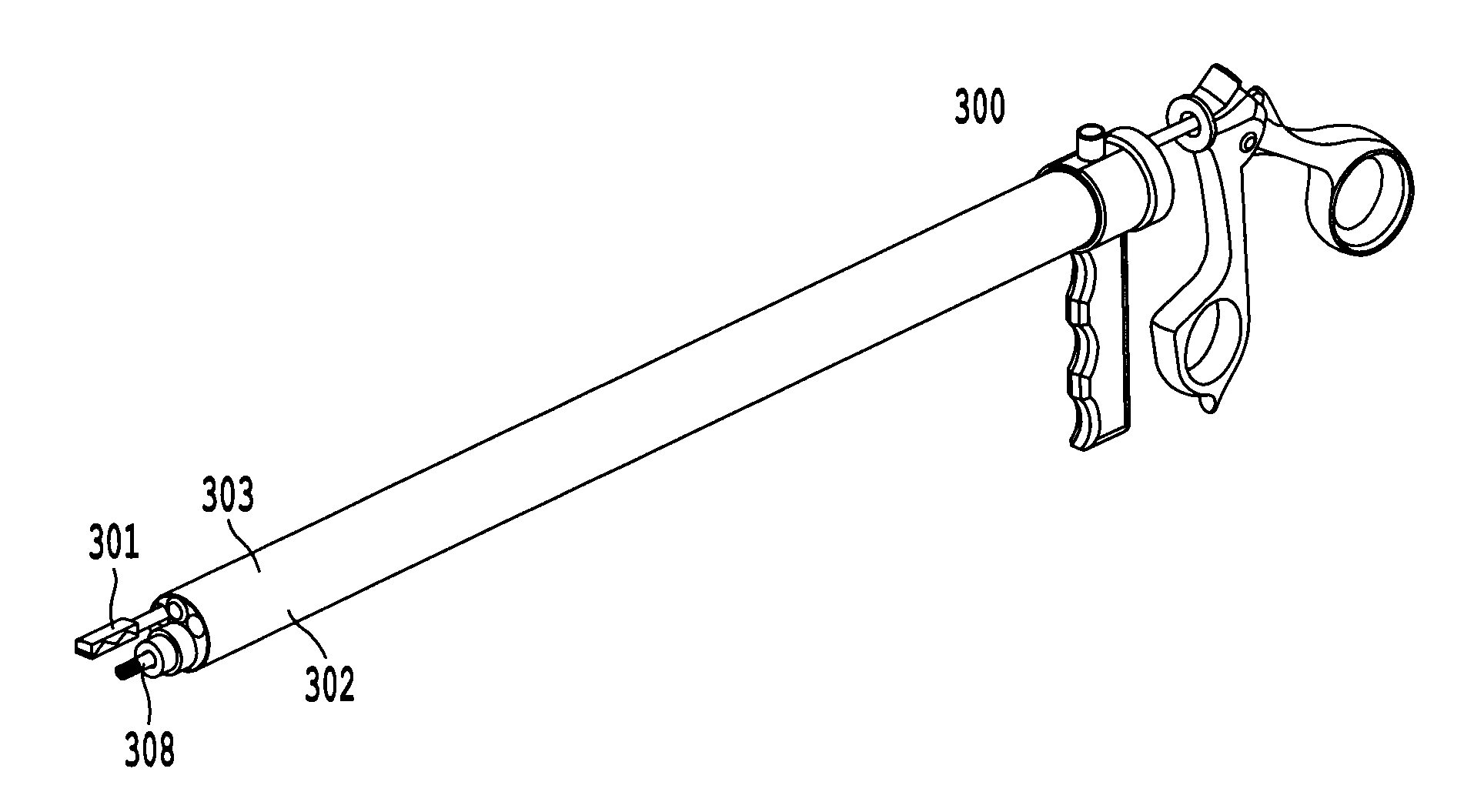

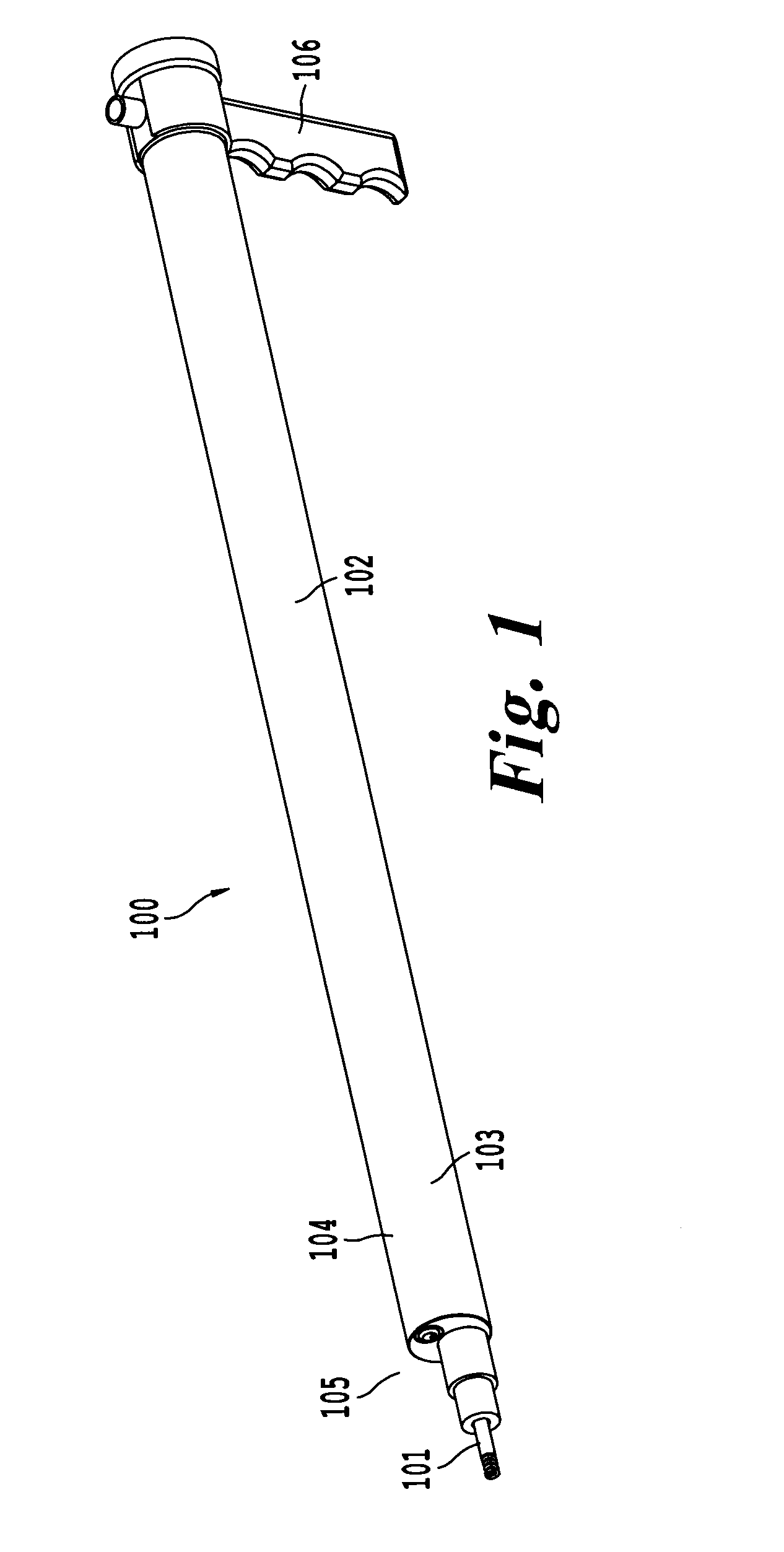

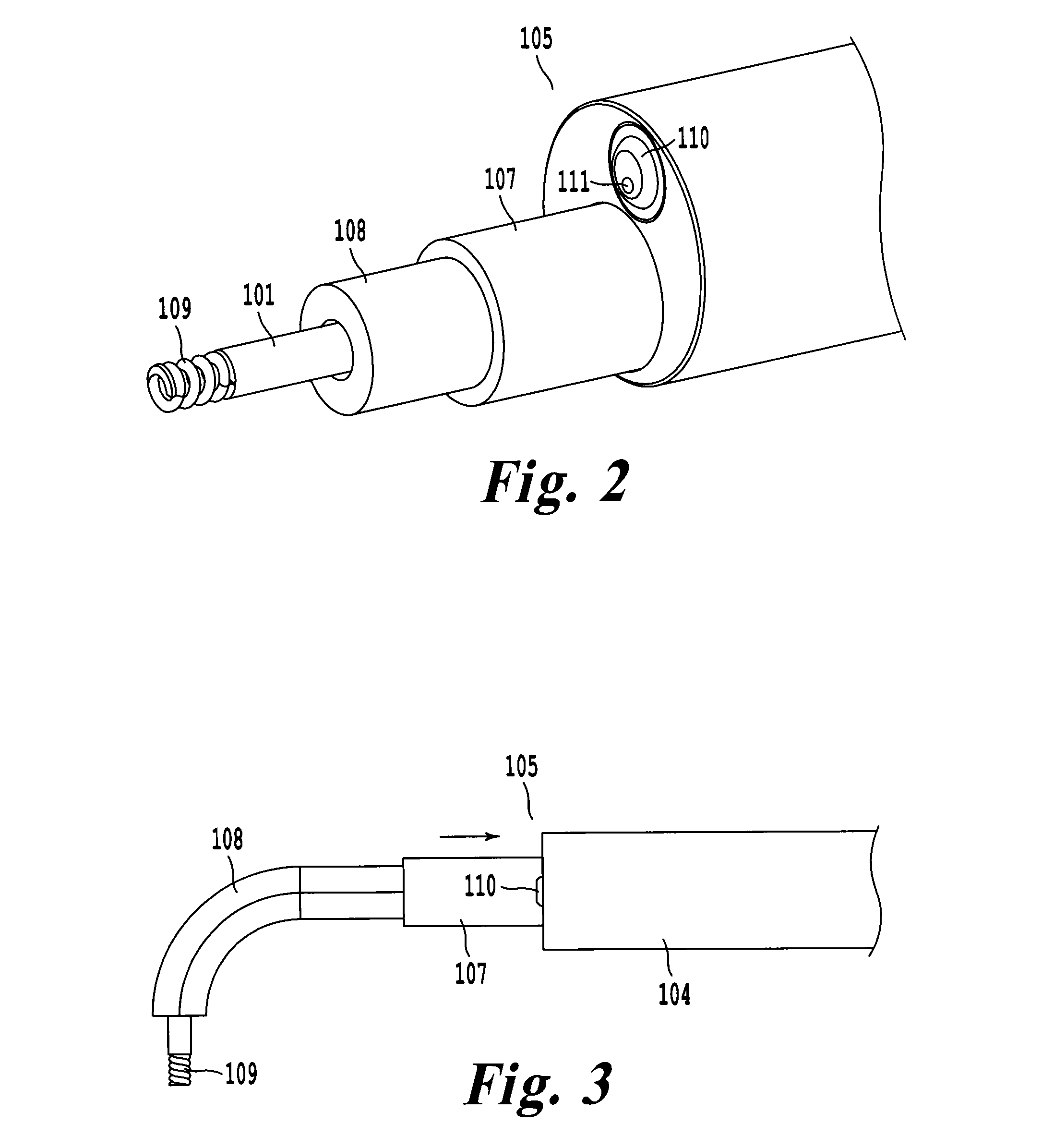

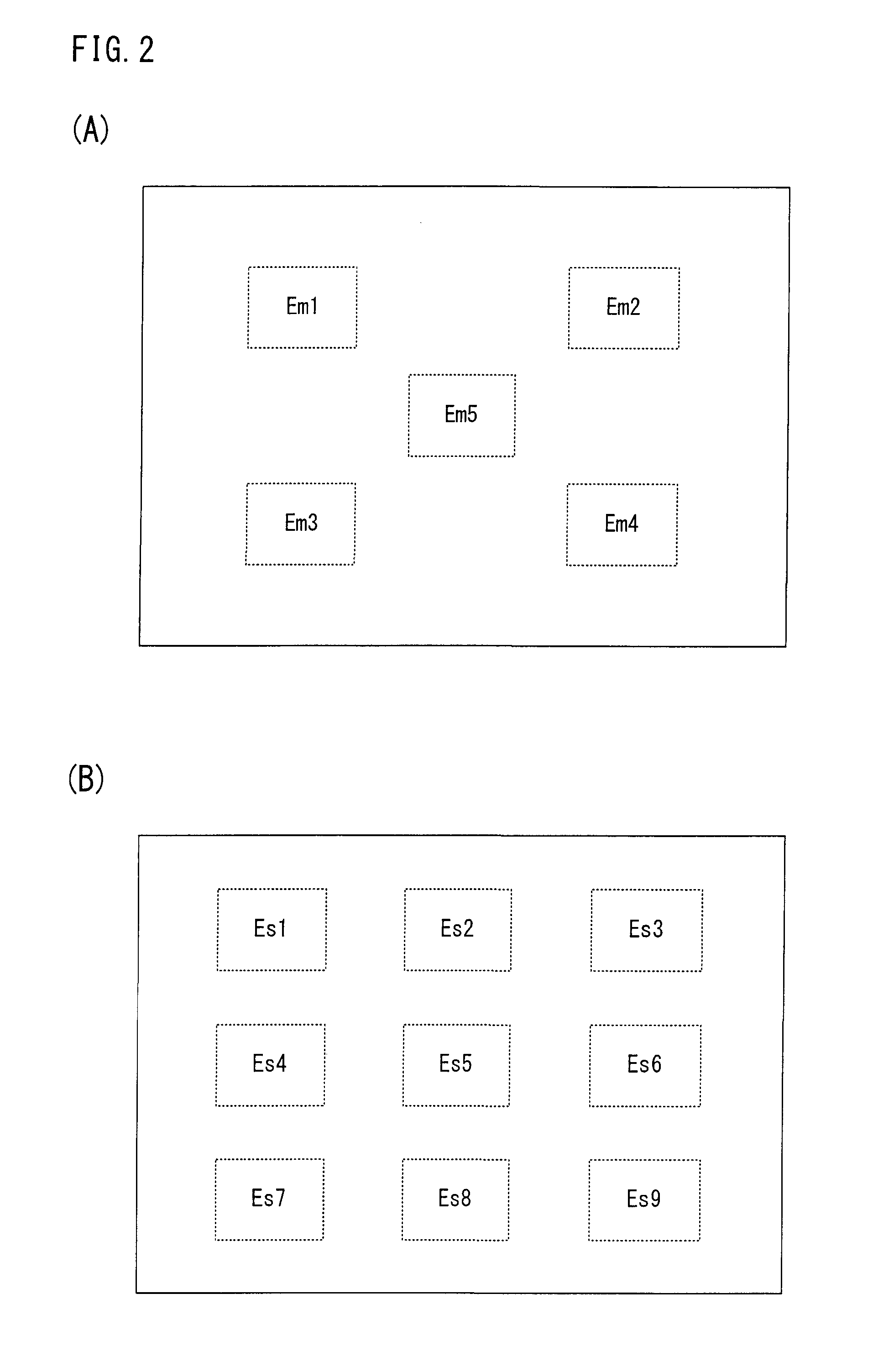

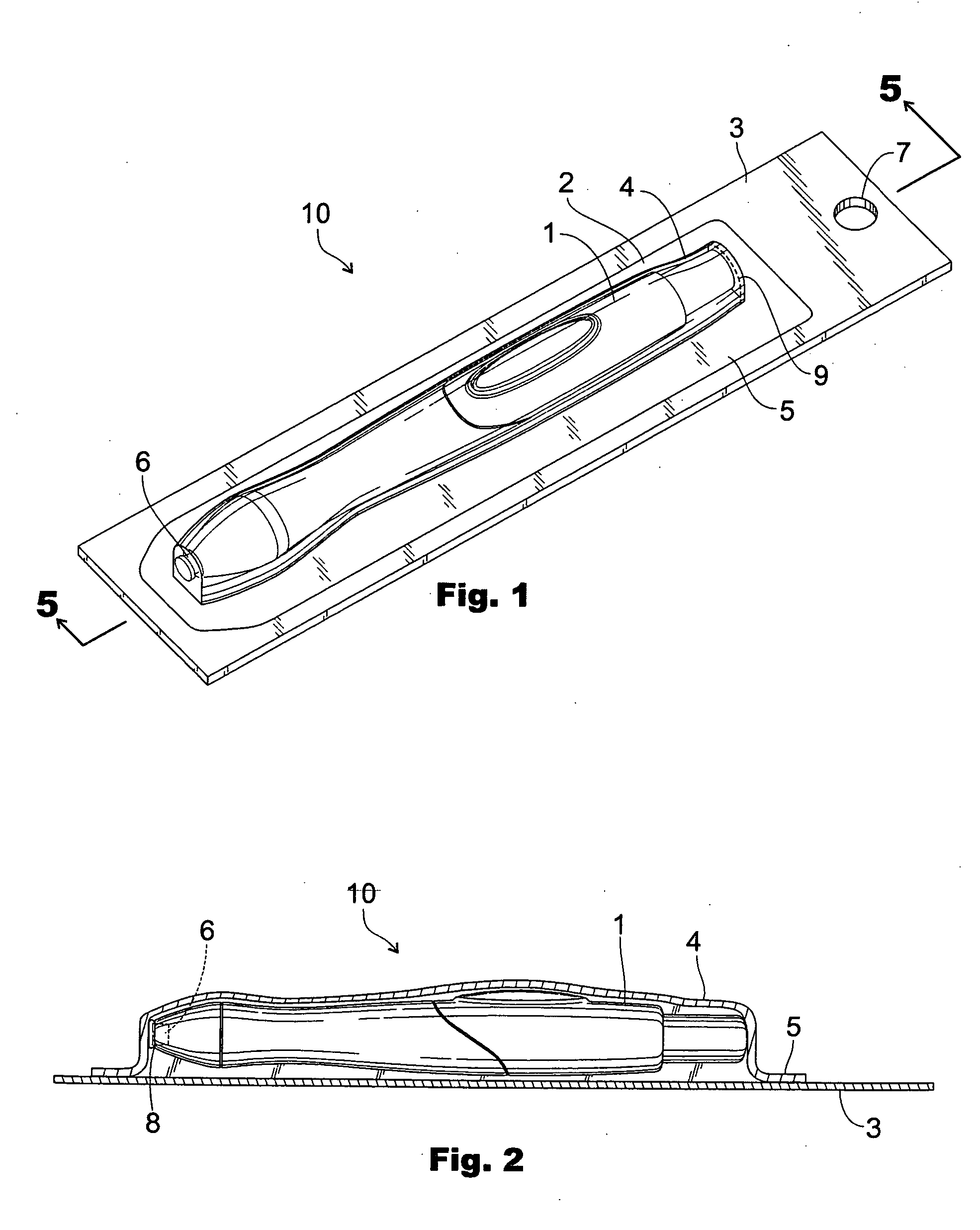

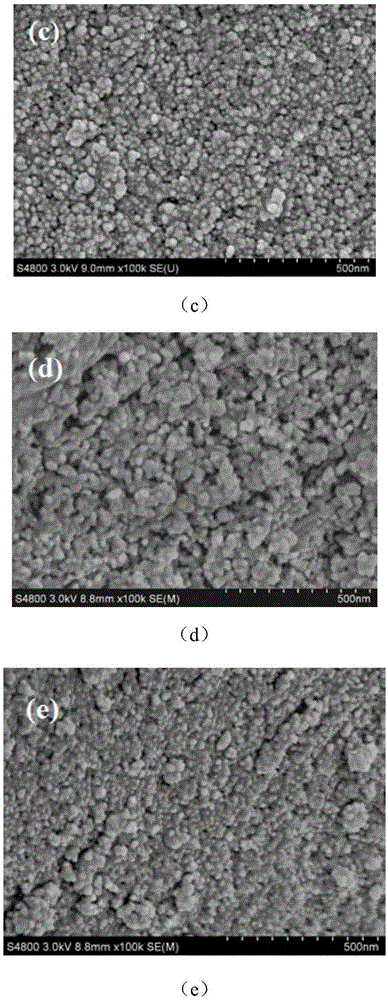

Delivery tool and method for devices in the pericardial space

ActiveUS20150230699A1More exposureRisk of excessEpicardial electrodesEndoscopesPericardial spaceCardiac pacemaker electrode

The present disclosure is a device and method associated with the delivery of medical devices in the pericardial space using a minimally invasive approach with direct visualization. More specifically, the device can be used to deliver permanent pacing, defibrillation and cardiac resynchronization leads, as well as leadless pacemakers for cardiac rhythm management to the epicardial surface of the heart. A subxiphoid procedure is proposed as a minimally invasive alternative to thoracotomy, while the delivery tool incorporates a camera for direct visualization of the procedure. The tool also incorporates a steerable catheter to provide selective control of the placement and orientation of the medical device in the pericardial space.

Owner:CHILDRENS NAT MEDICAL CENT

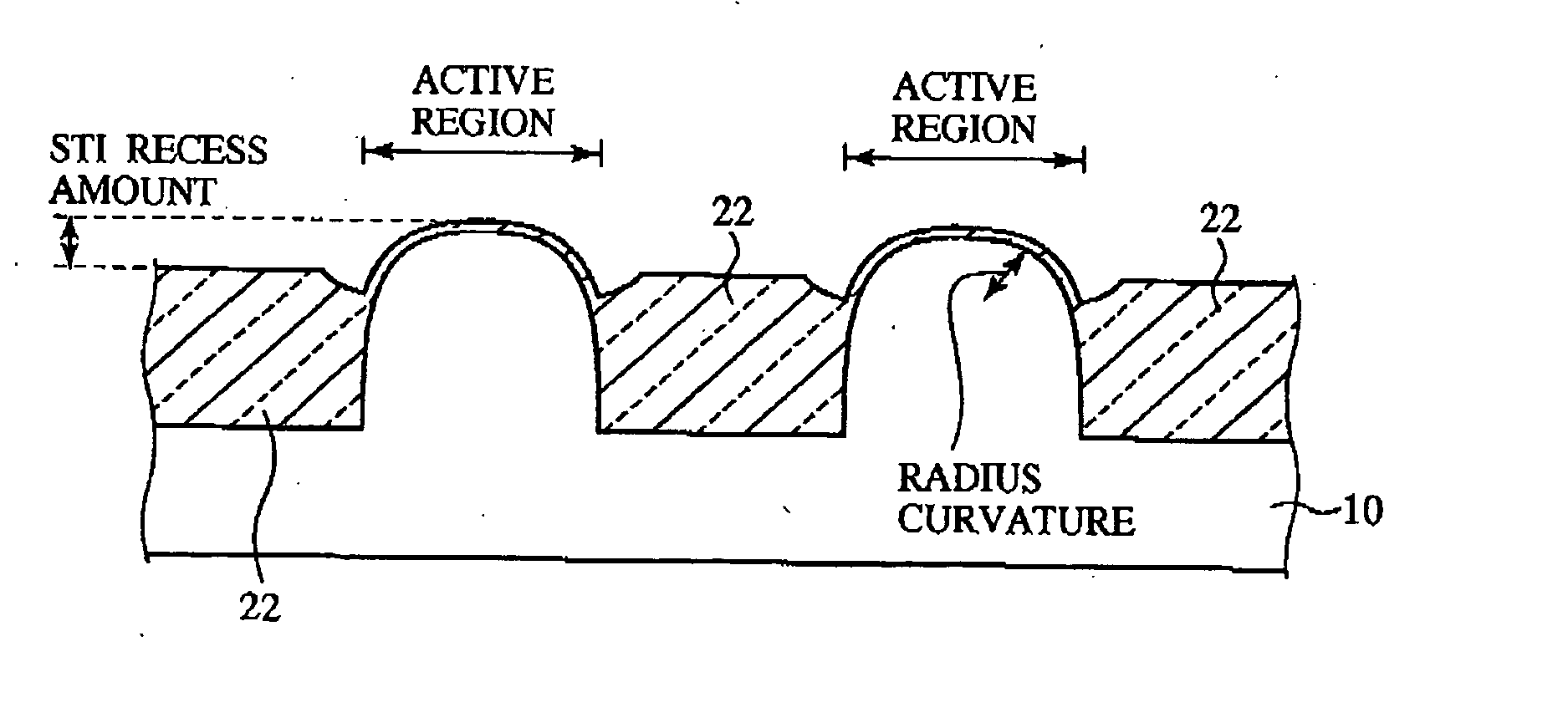

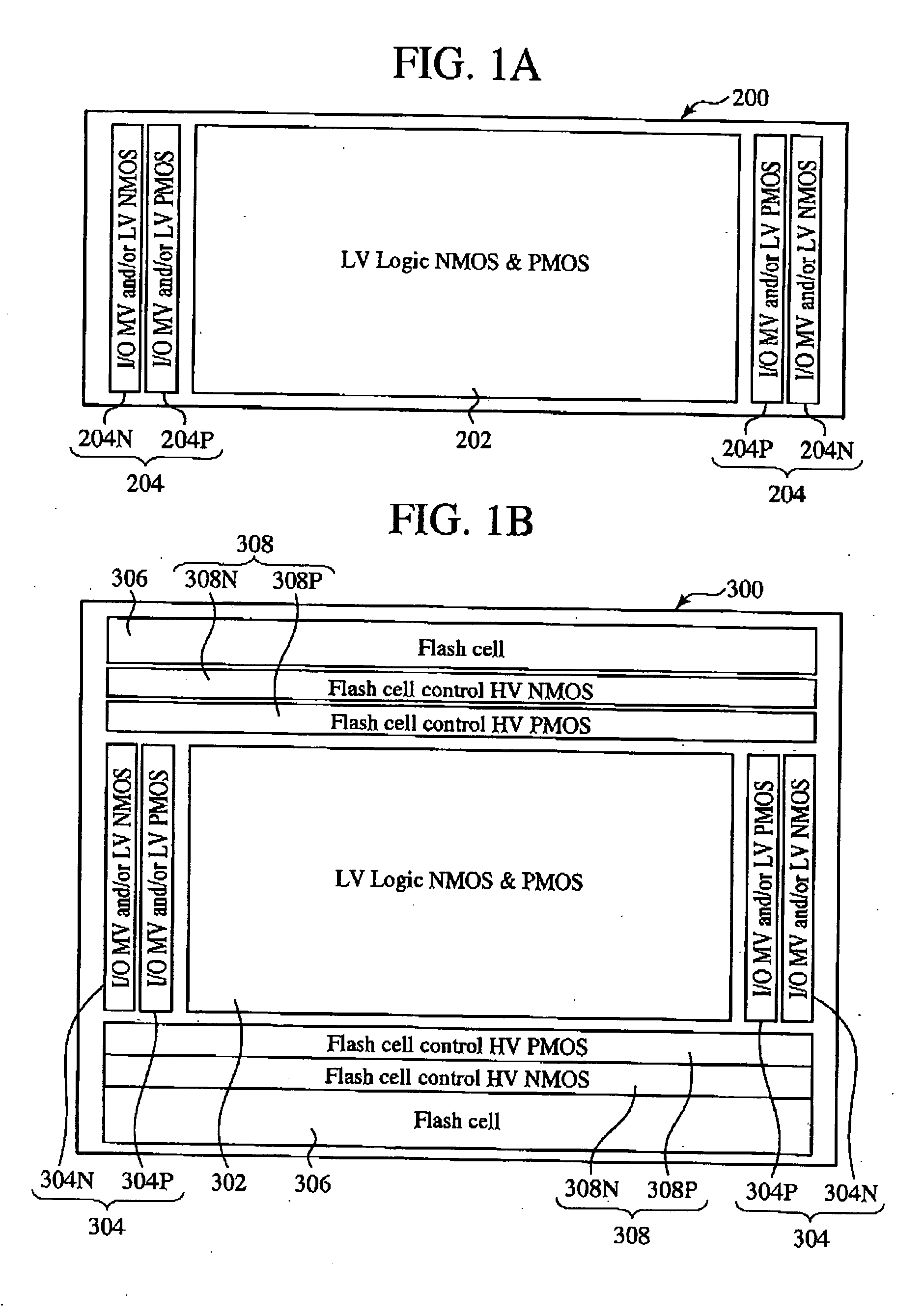

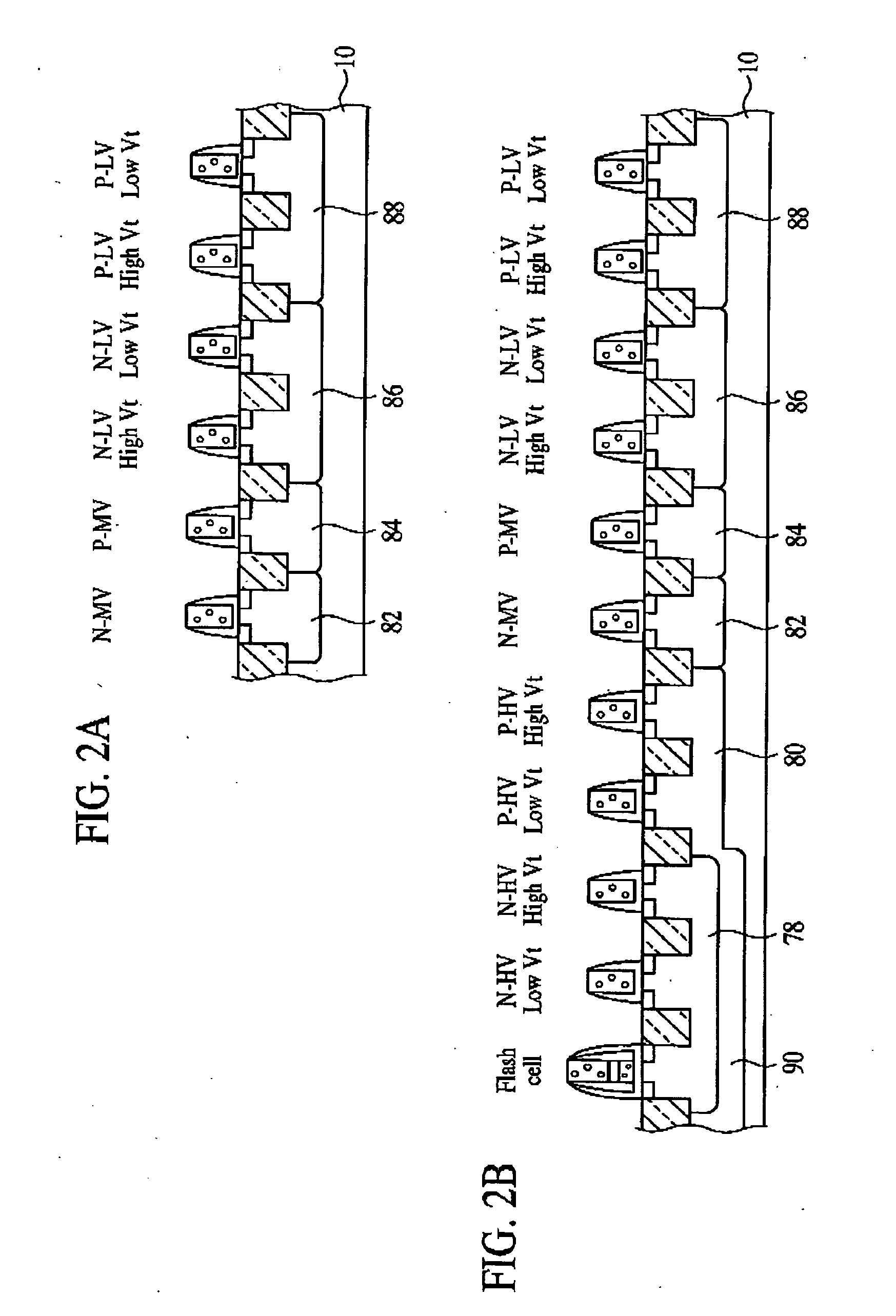

Semiconductor device group and method for fabricating the same, and semiconductor device and method for fabricating the same

ActiveUS20050110071A1High purityMore exposureSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialEngineering

The semiconductor group comprises a first semiconductor device including a first design macro and a nonvolatile memory, and a second semiconductor device including a second design macro having identity with the first design macro and including no nonvolatile memory. The first design macro includes a first active region and a first device isolation region formed on a first semiconductor substrate. The second design macro includes a second active region and a second device isolation region formed on a second semiconductor substrate. A curvature radius of an upper end of the first active region in a cross section is larger than a curvature radius of an upper end of the second active region in a cross section. A difference in height between a surface of the first active region and a surface of the first device isolation region is larger than a difference in height between a surface of the second active region and a surface of the device isolation region.

Owner:FUJITSU SEMICON LTD

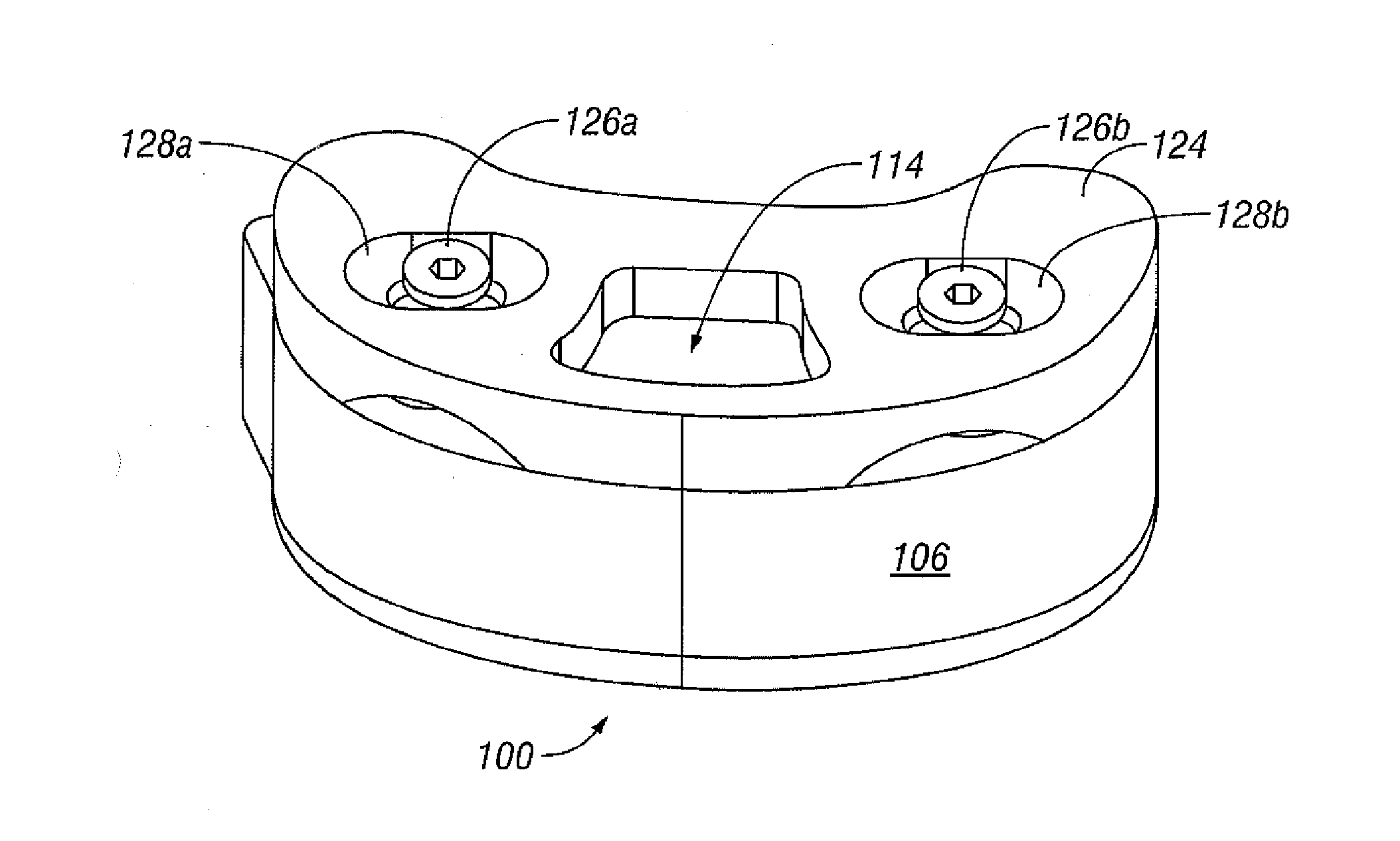

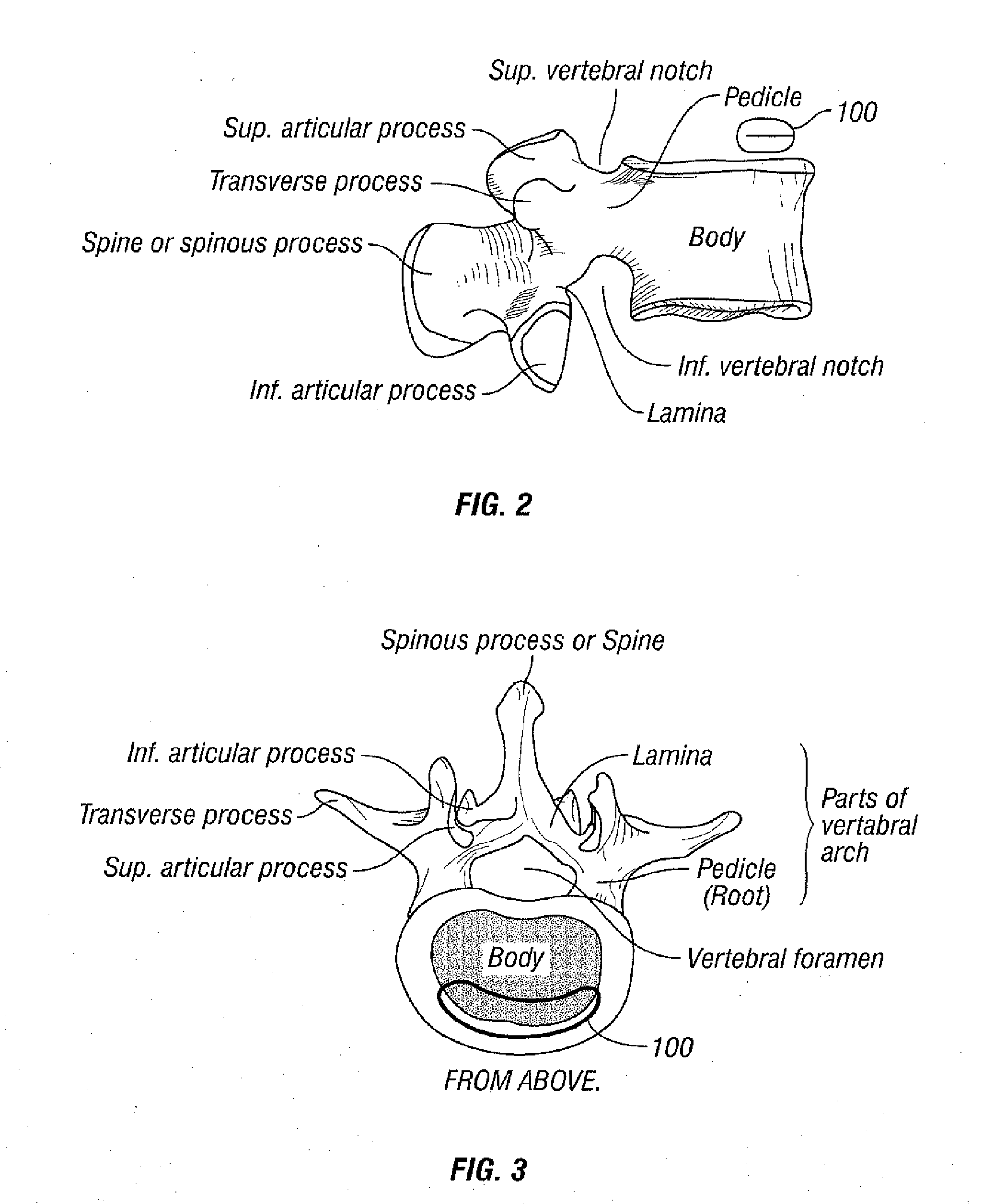

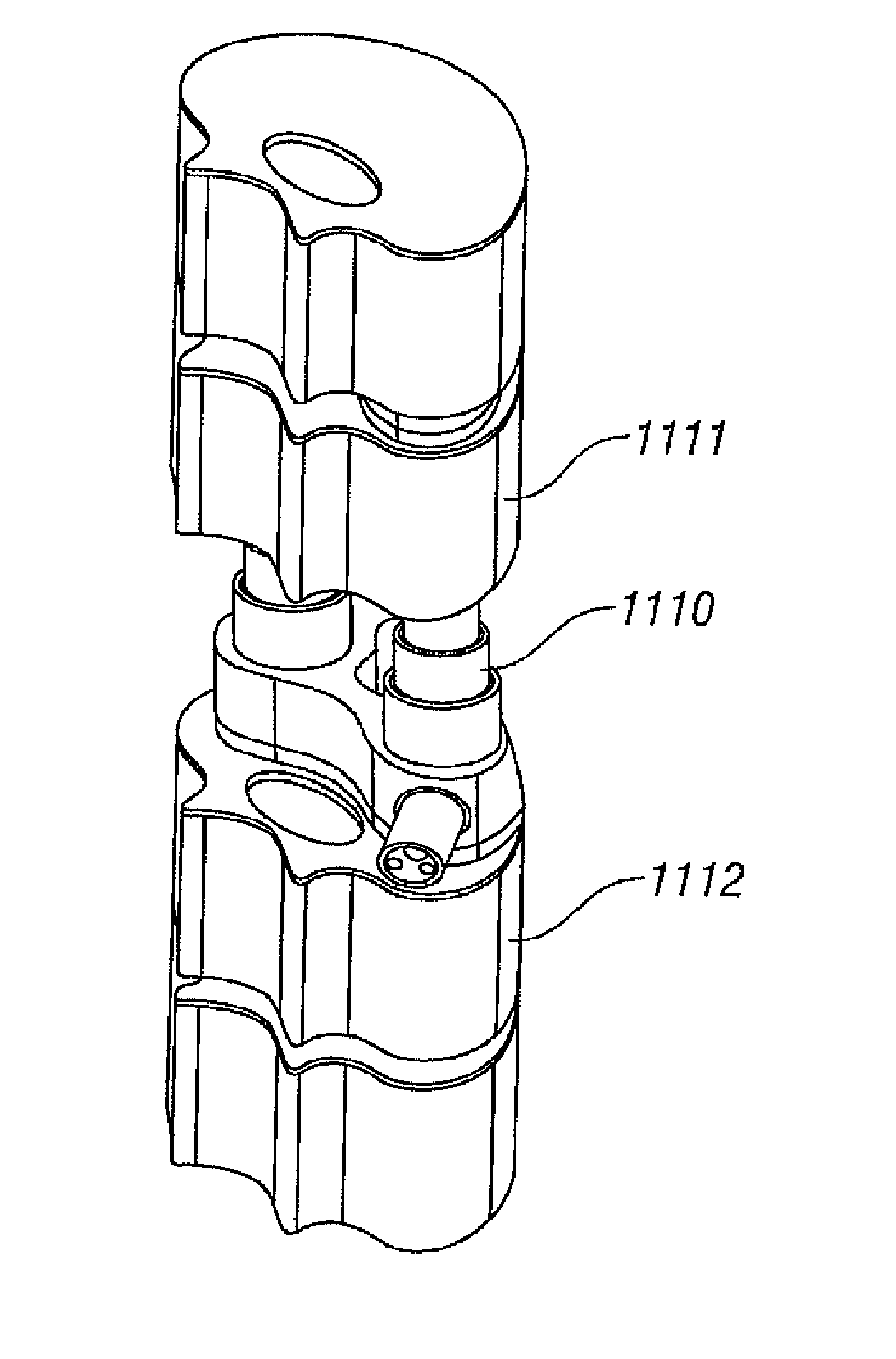

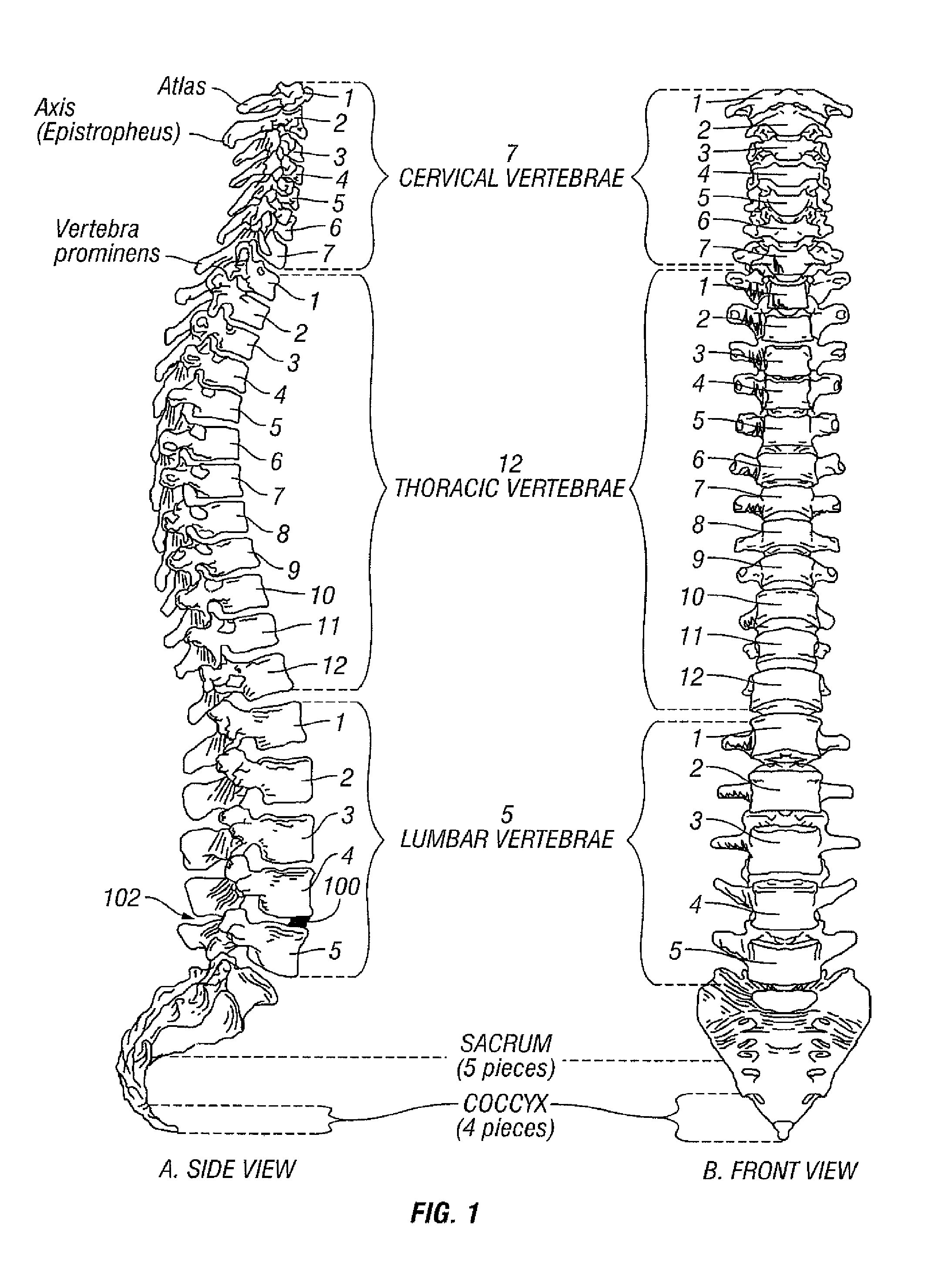

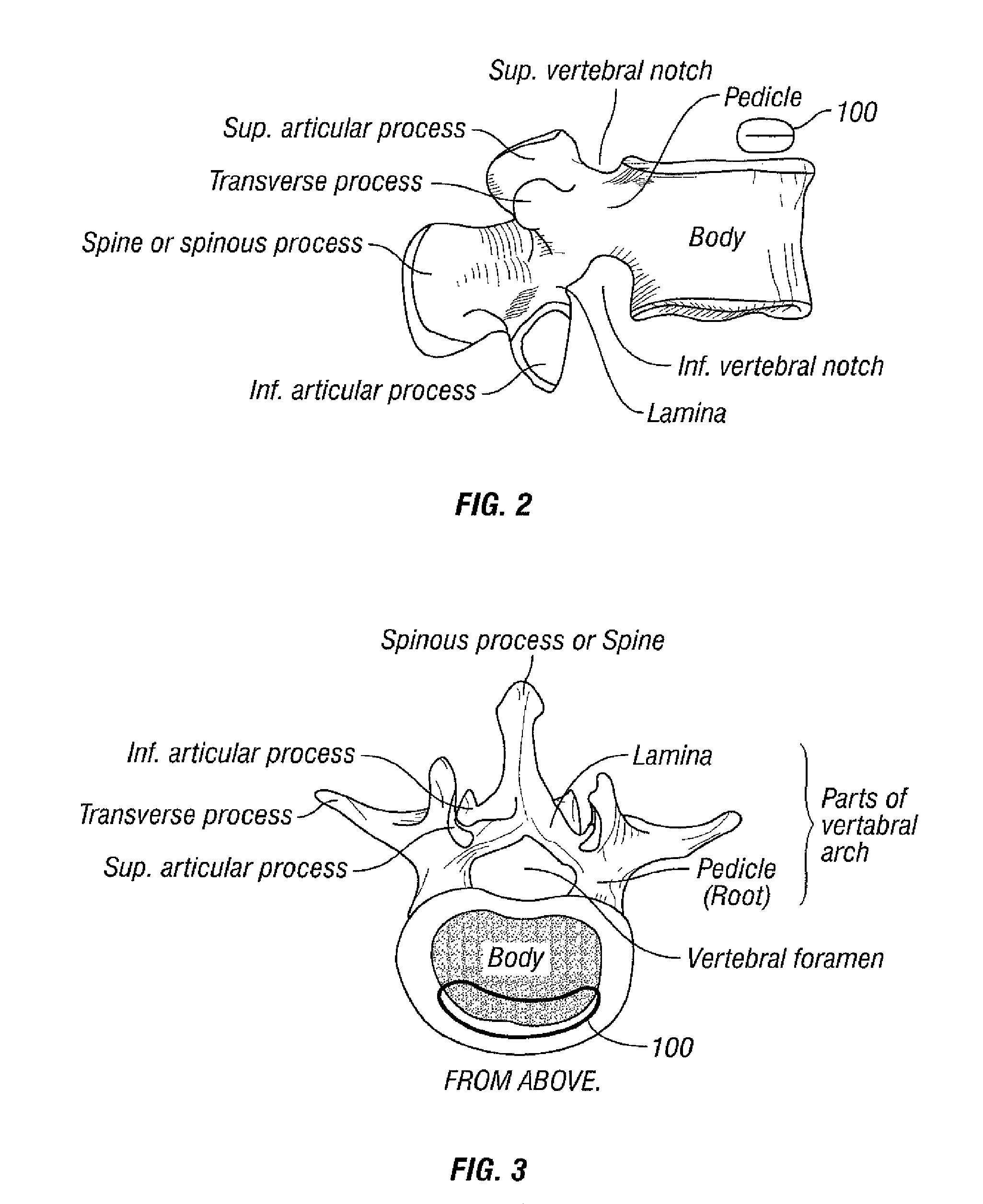

Selectively Expanding Spine Cage, Hydraulically Controllable In Three Dimensions for Vertebral Body Replacement

ActiveUS20120116518A1Minimally invasive riskRelieve painInternal osteosythesisBone implantVertical axisSpinal locomotion

A selectively expanding spine cage has a minimized diameter in its unexpanded state that is smaller than the diameter of the neuroforamen through which it passes in the distracted spine. The cage conformably engages between the endplates of vertebrae to effectively distract the anterior disc space, stabilize the motion segments, eliminate pathologic spine motion, or effect vertebral body replacement. Expanding selectively (anteriorly, along the vertical axis of the spine) rather than uniformly, the cage height increases and holds the vertebrae with fixation forces greater than adjacent bone and soft tissue failure forces in natural lordosis. Stability is thus achieved immediately, enabling patient function by eliminating painful motion. The cage shape intends to rest proximate to the anterior column cortices securing the desired spread and fixation, allowing for bone graft in, around, and through the implant for arthrodesis whereas for arthroplasty it fixes to endpoints but cushions the spine naturally.

Owner:HOWMEDICA OSTEONICS CORP

Selectively expanding spine cage, hydraulically controllable in three dimensions for vertebral body replacement

ActiveUS8480741B2Deterioration of over timeStrong implantInternal osteosythesisBone implantDistractionSpinal locomotion

A selectively expanding spine cage has a minimized diameter in its unexpanded state that is smaller than the diameter of the neuroforamen through which it passes in the distracted spine. The cage conformably engages between the endplates of the adjacent vertebrae to effectively distract the anterior disc space, stabilize the motion segments and eliminate pathologic spine motion. The cage enhances spinal arthrodesis by creating a rigid spine segment. Expanding selectively, the cage height increases and holds the vertebrae with fixation forces greater than adjacent bone and soft tissue failure forces in natural lordosis. Stability is thus achieved immediately, enabling patient function by eliminating painful motion. Greater distraction height is achieved without an increase in implant size through the use of interfitted stages.

Owner:HOWMEDICA OSTEONICS CORP

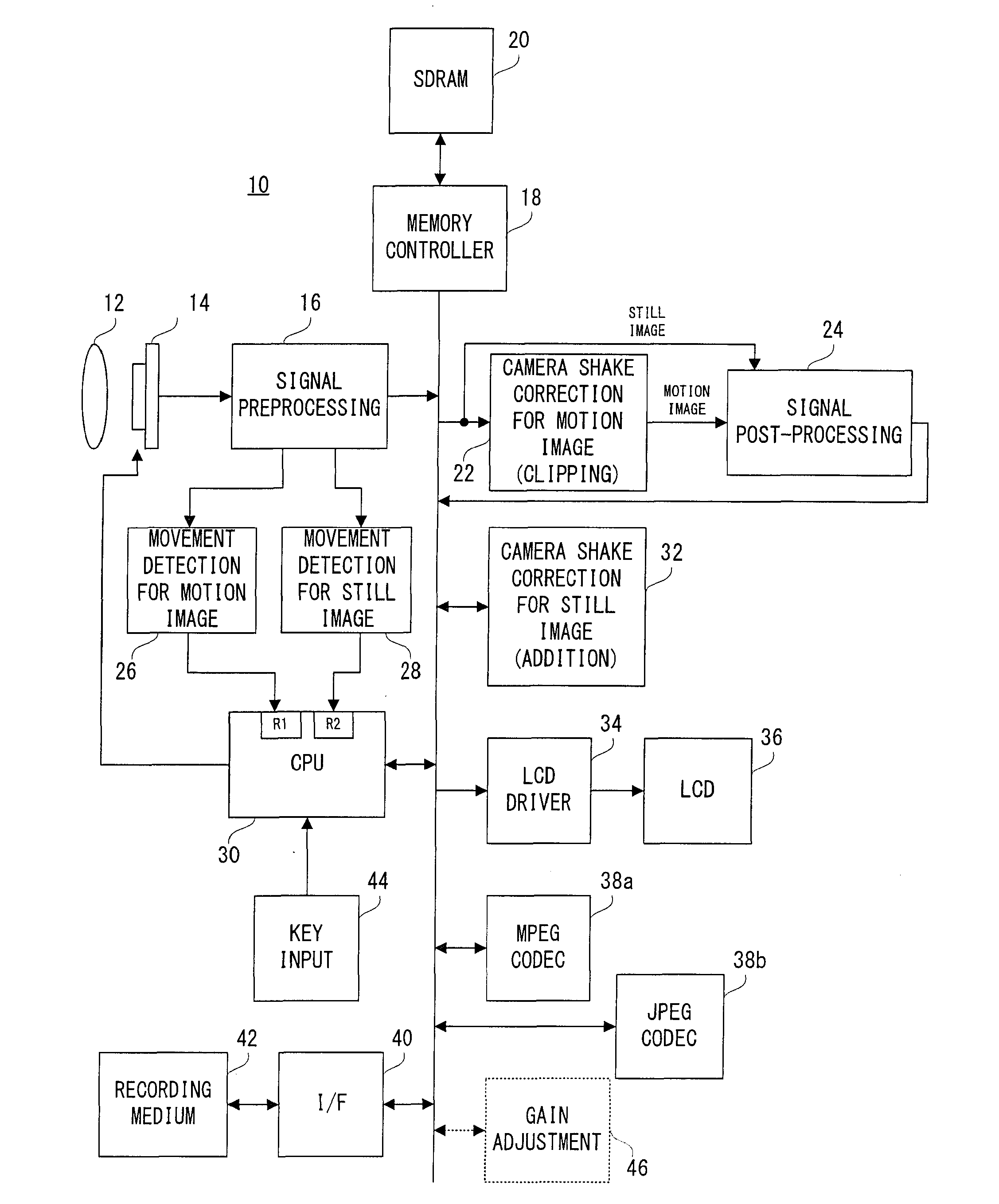

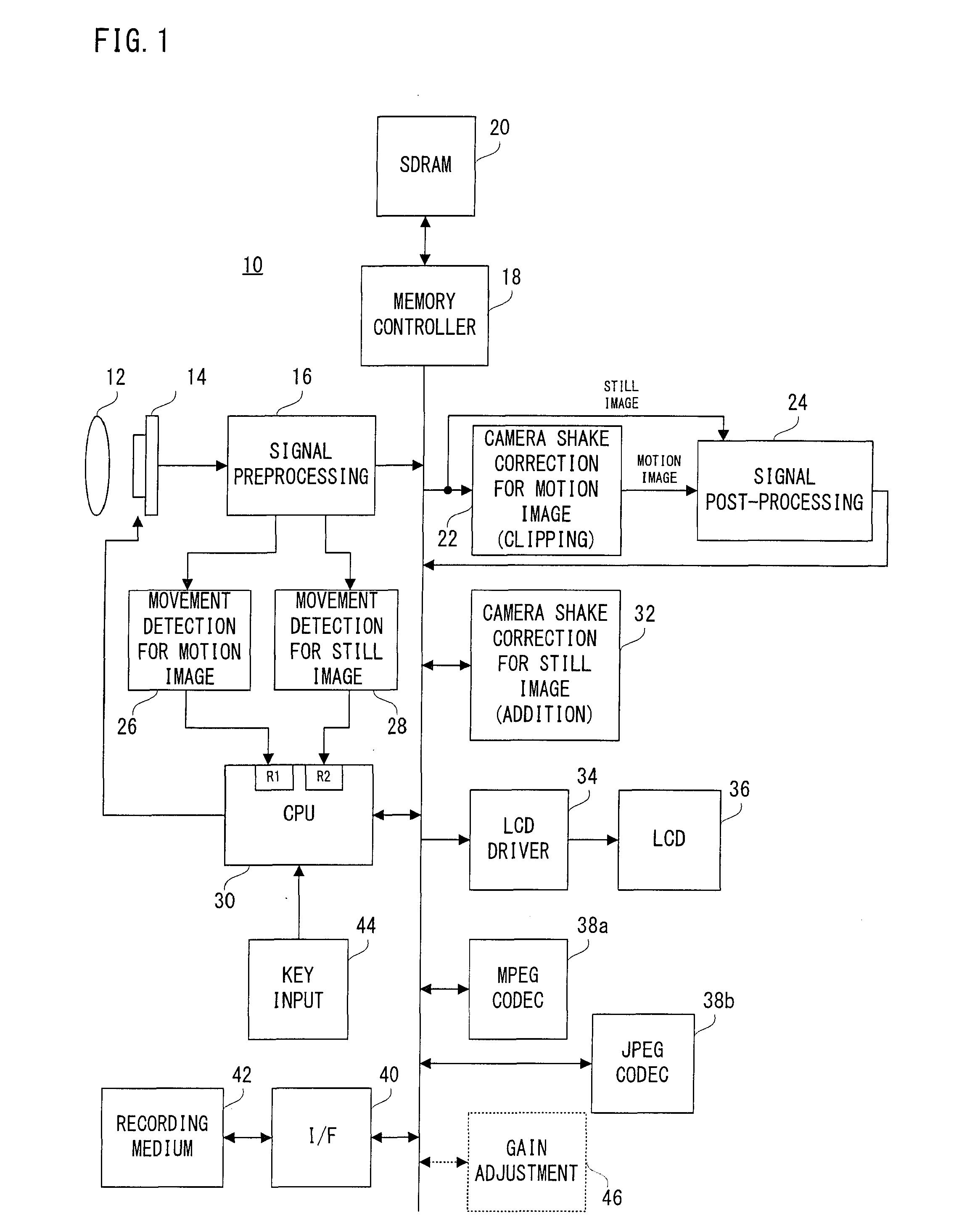

Imaging device and image processing apparatus

InactiveUS20090059017A1Reduce exerciseSuppress random noiseTelevision system detailsColor television detailsImaging processingImage recording

An imaging device includes an imager, with which an optical image of an object scene is repetitively captured. A first movement detector detects, as to each of a plurality of object scene images according to a time series output from the imager, a movement of a first feature point between the object scene image and the object scene images immediately before, and a clipper performs clipping processing on each of the plurality of object scene images on the basis of the detection result. When a still image recording operation is performed, a CPU changes an exposure time of the imager in such a direction as to shorten the time, and a second movement detector detects a movement of a second feature point between the object scene image immediately after the recording operation (reference object scene image) and the three object scene images being successive thereto out of a plurality of object scene images, and an adder adds the respective three object scene images to the reference object scene image while displacing the same on the basis of the detection result.

Owner:XACTI CORP

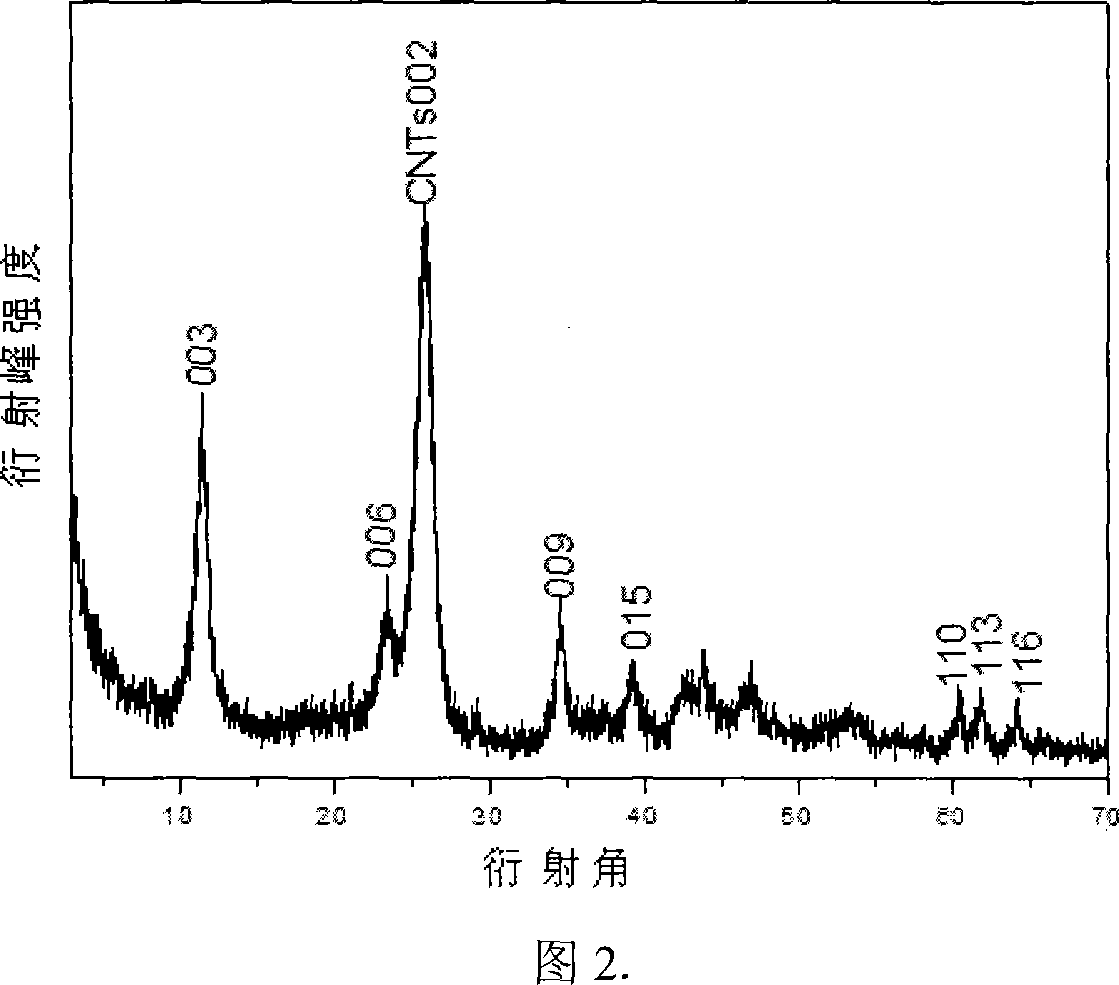

Package with integral plug

InactiveUS20050218027A1Extended shelf lifeEasy to removeOther accessoriesContainer/bottle contructionHermetic packagingEngineering

A package is disclosed having integral means to seal an opening in a packaged product, such as a capless writing instrument, in order to protect material within the packaged product, such as ink, from excessive exposure to air while stored in the package. The package may be of any type used to contain articles of merchandise, including, without limitation, a blister package, a clamshell package, a closed tube, or a box. A plug portion attached to or molded into the interior of the package is sized and positioned so that it fits sealingly in an opening of a product contained within said package in order to prevent or minimize passage of air through said opening. Also disclosed is a package insert for holding an article of merchandise securely within a package while sealing an opening in the merchandise.

Owner:INNODESK

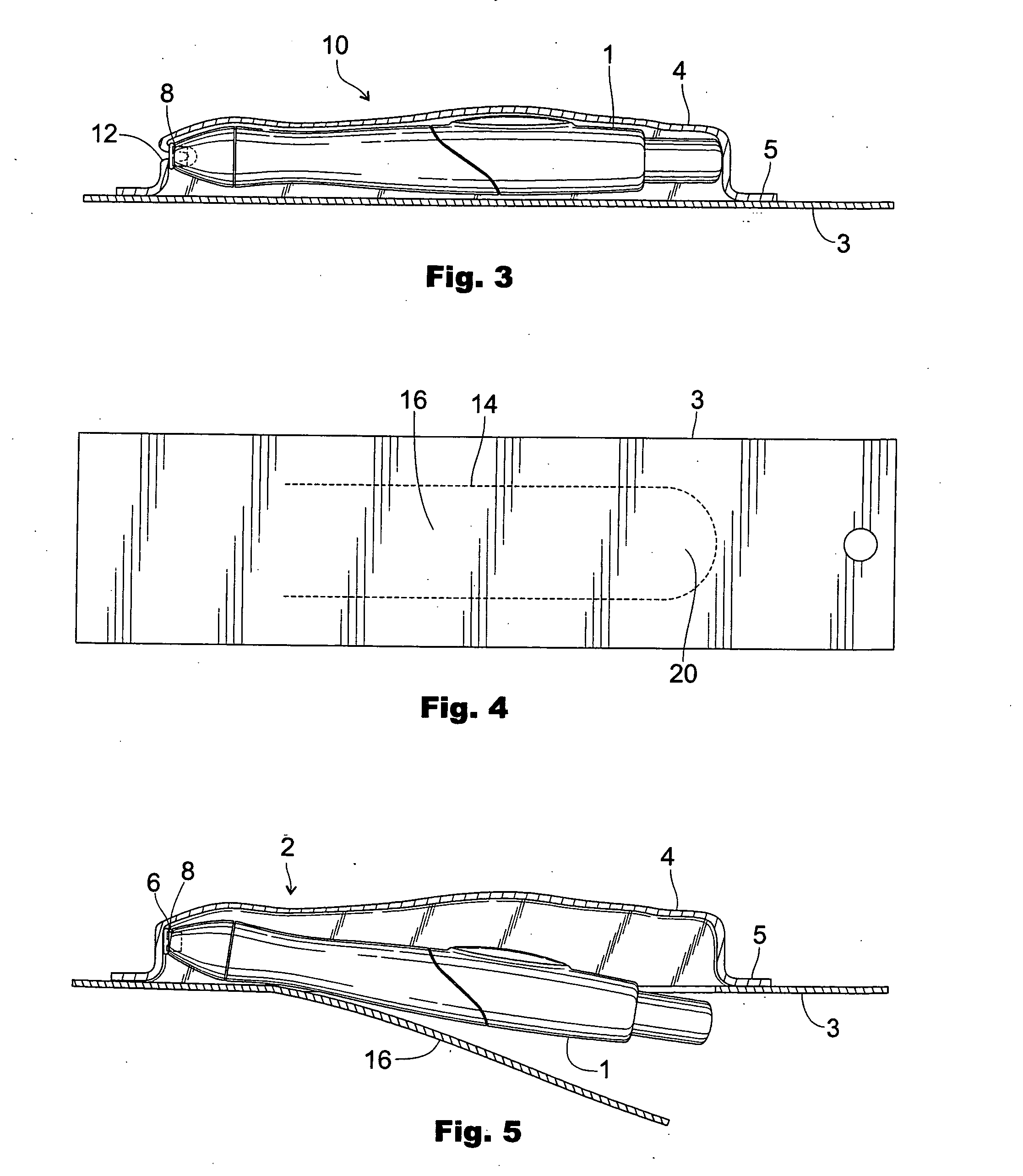

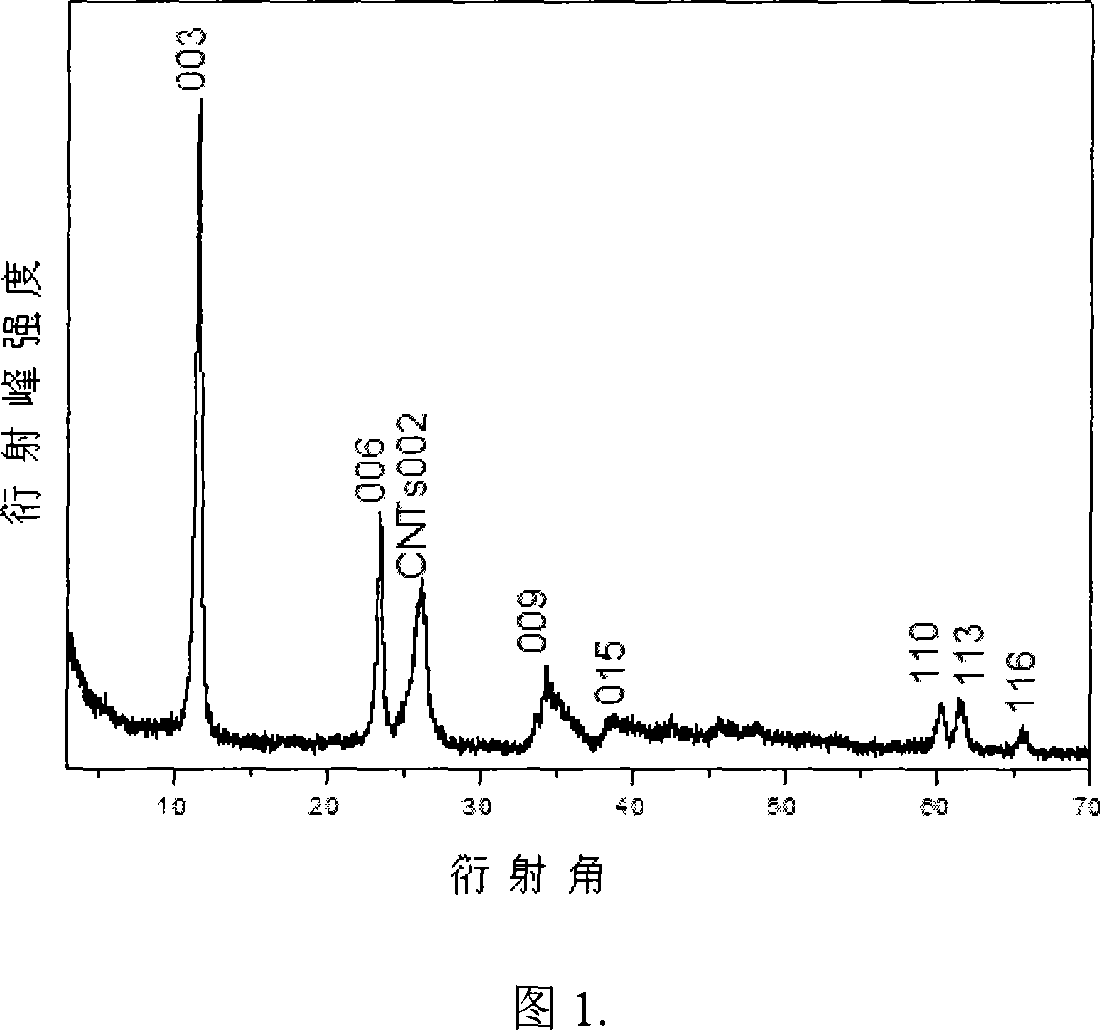

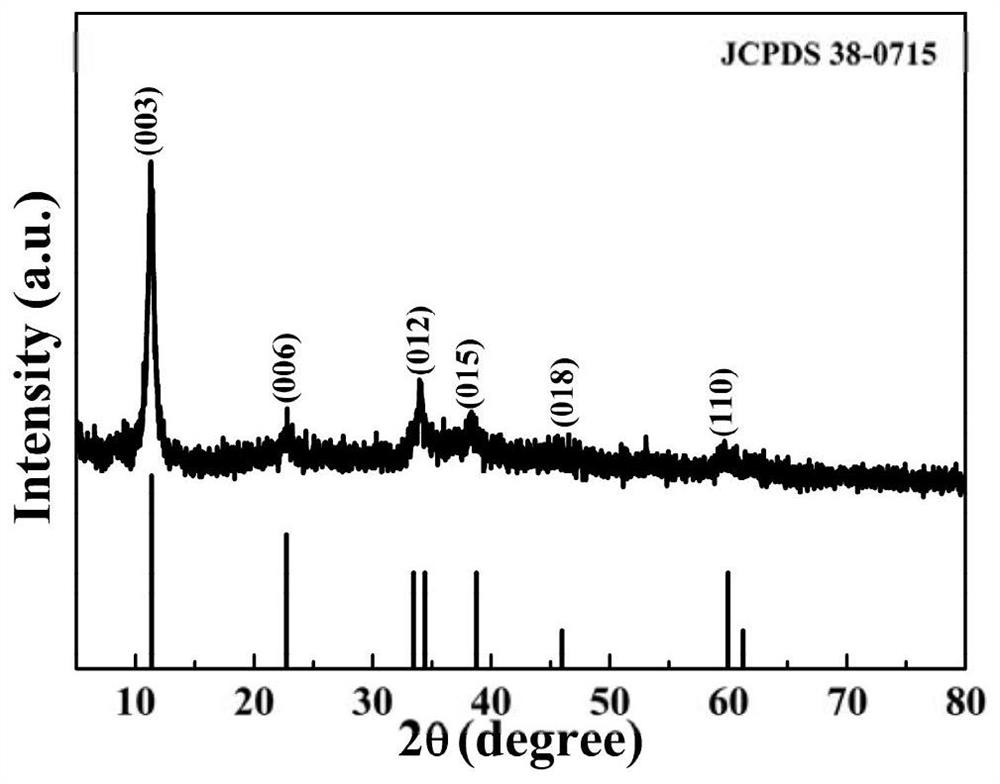

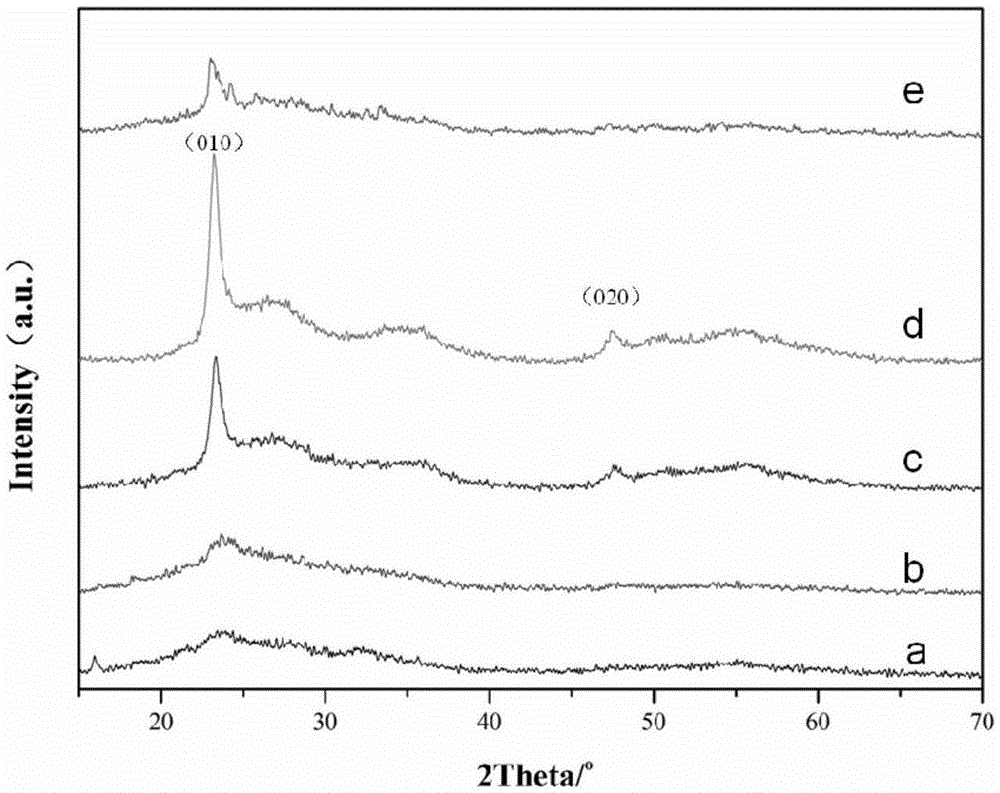

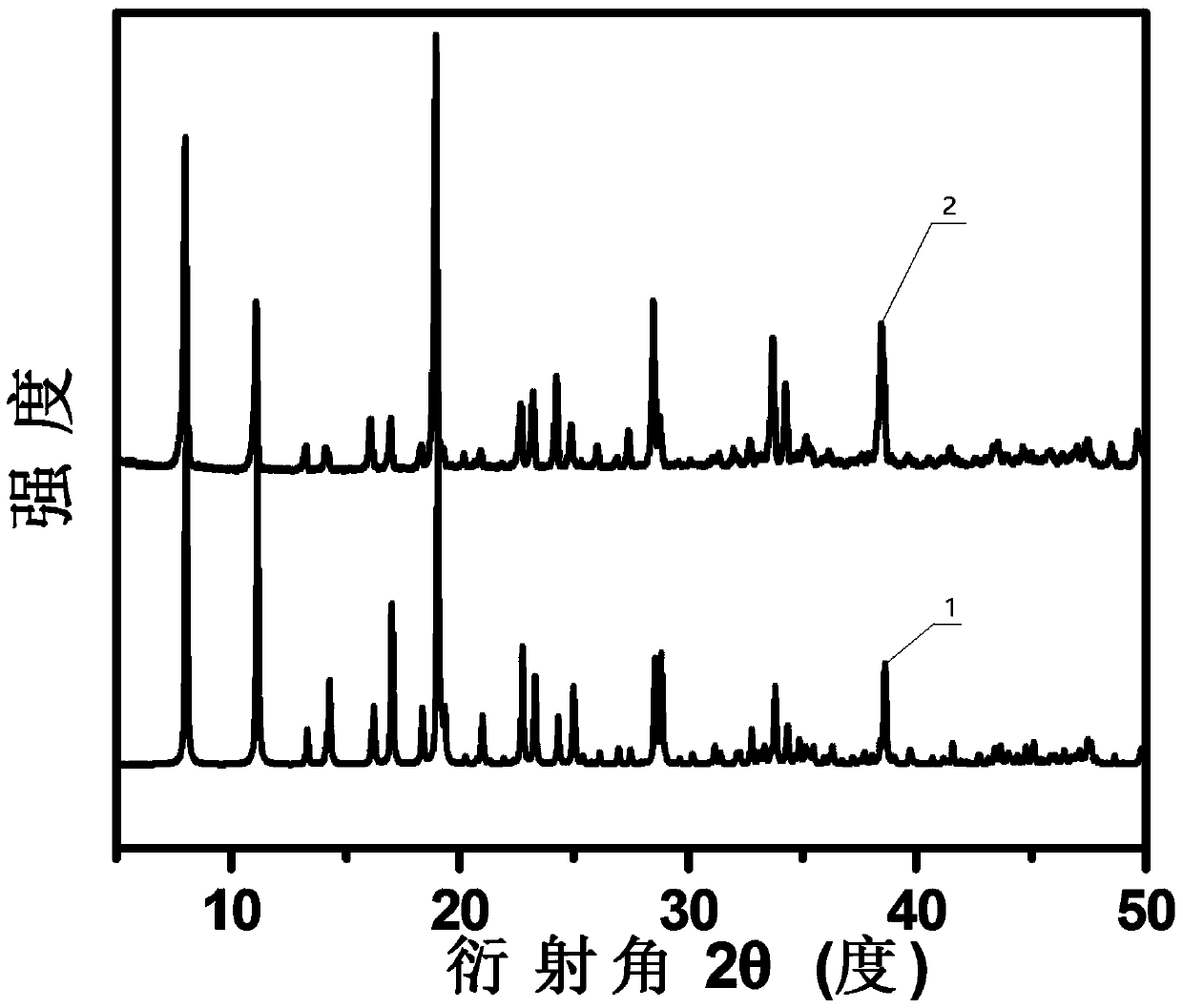

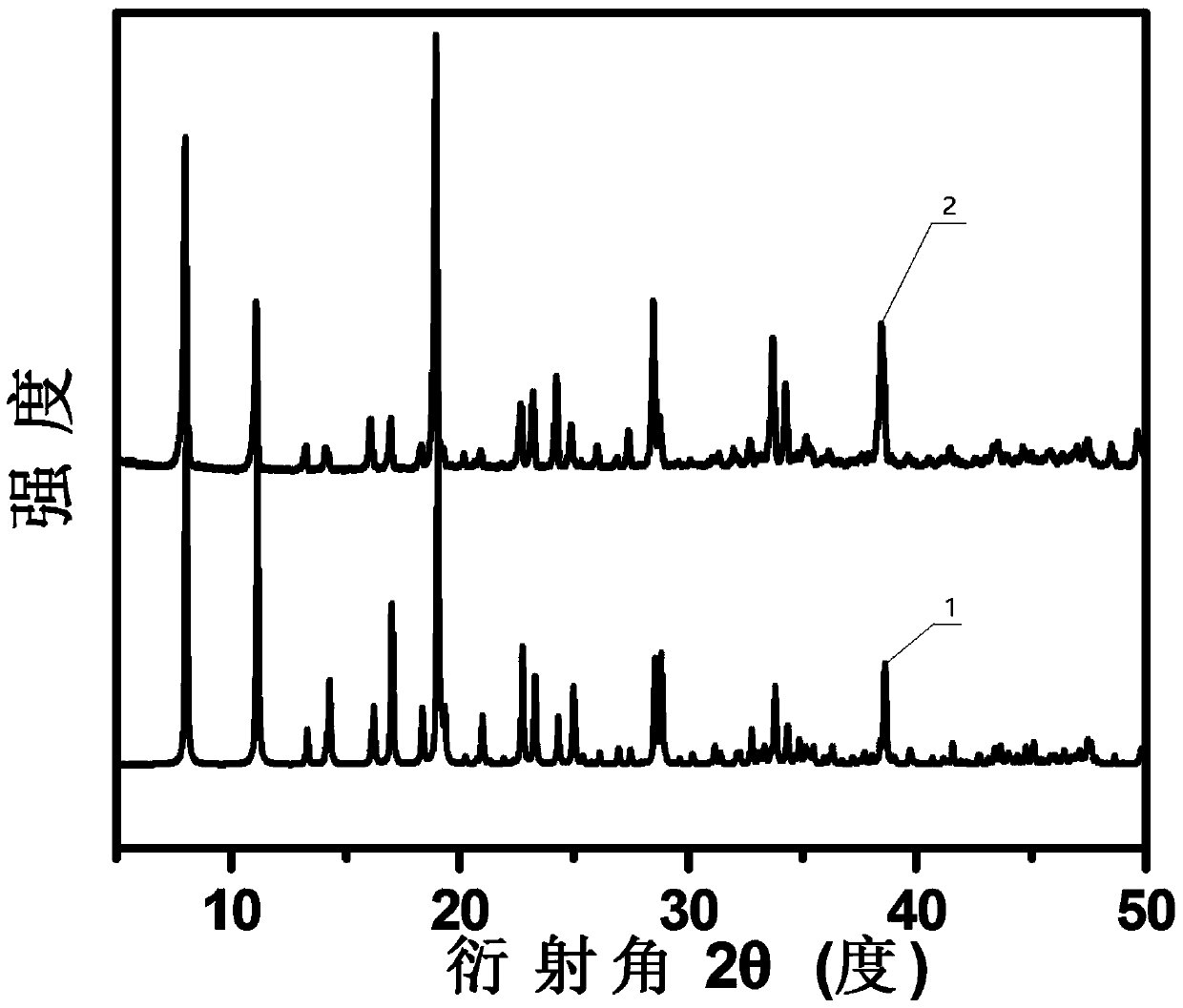

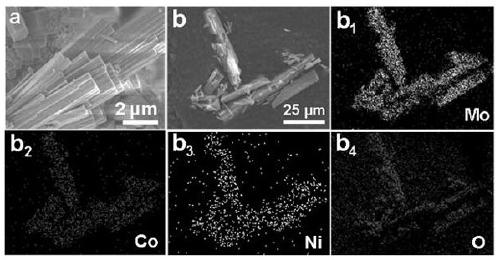

Heterostructure material of hydrotalcite and carbon nanotube and its prepn process

InactiveCN101066526AEfficient assemblyThe amount of assembly can be adjustedPhysical/chemical process catalystsCarbon nanotubeHydrotalcite

The present invention provides one kind of heterostructure material of hydrotalcite and carbon nanotube and its preparation process. Carbon nanotube and bridging molecule L-cysteine are first added into alkali solution and the mixture solution of soluble bivalent metal salt and trivalent metal salt is then added to produce co-precipitation reaction to prepare hydrotalcite. During the reaction, the -NH2 end of L-cysteine existing in positively charged -NH3+ combines stably with the negatively charged -COO- and -O- radicals in the surface of carbon nanotube while the -SH end of L-cysteine and the metal ion in the hydrotalcite layer form coordinate bond, so that hydrotalcite is assembled onto carbon nanotube by means of the bridging effect. The present invention can raise the dispersivity of hydrotalcite particle and the active center, and the obtained heterostructure material is homogeneous, stable, strong in binding force and adjustable in assembled amount.

Owner:BEIJING UNIV OF CHEM TECH

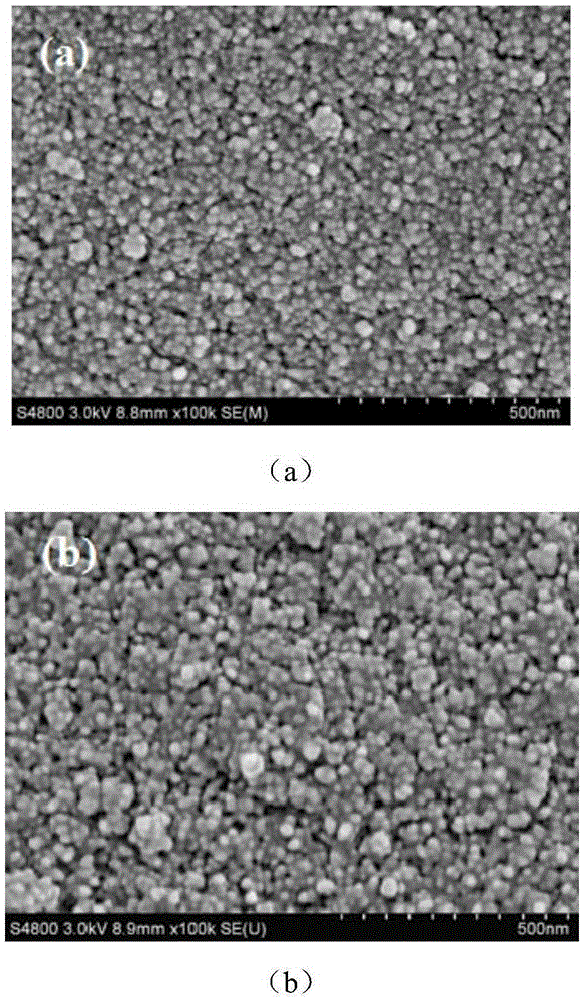

Nickel foam-loaded silver-doped nickel-based bimetallic hydroxide electrocatalytic hydrogen evolution catalyst and preparation method thereof

The invention relates to a nickel foam-loaded silver-doped nickel-based bimetallic hydroxide electrocatalytic hydrogen evolution catalyst and a preparation method thereof. The catalyst takes foam nickel as a carrier, nickel-based bimetallic hydroxide of a laminated structure is uniformly arranged and grows on the surface of foam nickel, and nano-silver particles are uniformly attached to the surface of the nickel-based bimetallic hydroxide. The nickel foam-loaded silver-doped nickel-based bimetallic hydroxide electrocatalytic hydrogen evolution catalyst takes three-dimensional porous foam nickel of a net structure as a carrier, the nickel-based bimetallic is combined with the carrier firmly, distribution is uniform, the catalyst has the good catalytic hydrogen evolution effect under the alkaline condition, and the stable catalytic activity can be kept in a long time.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

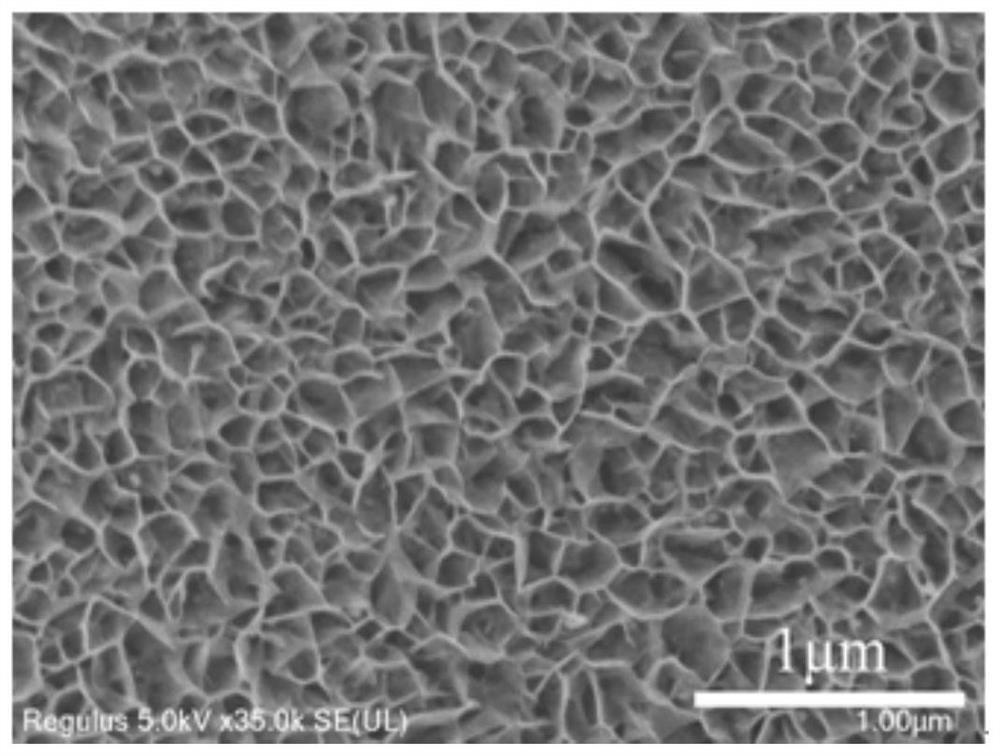

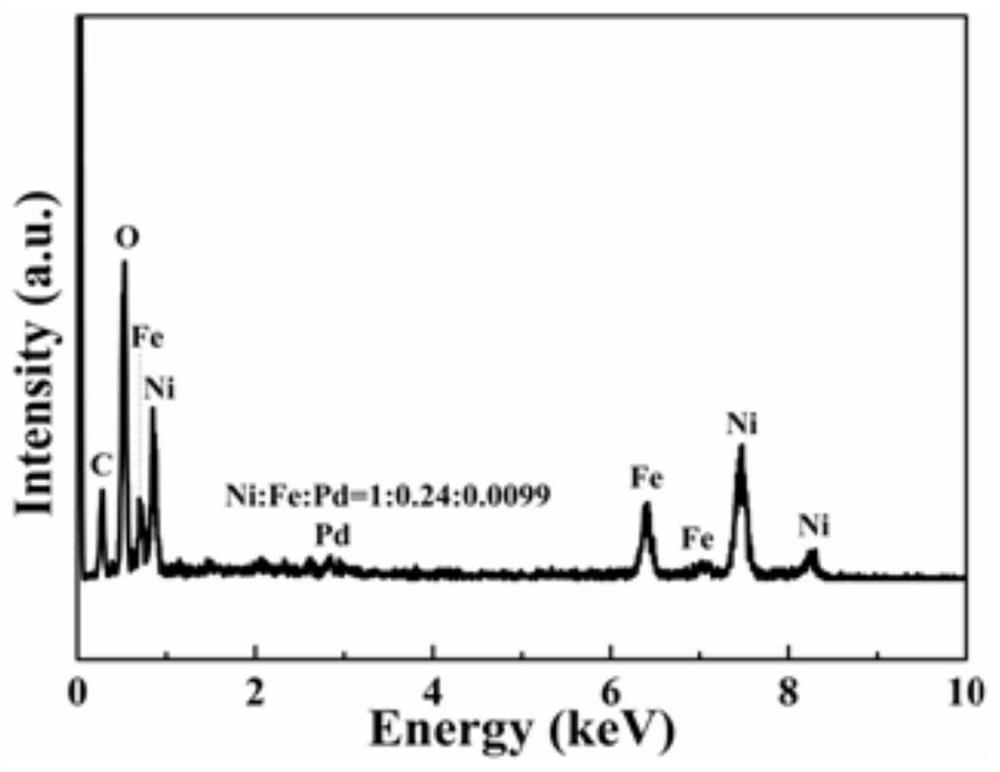

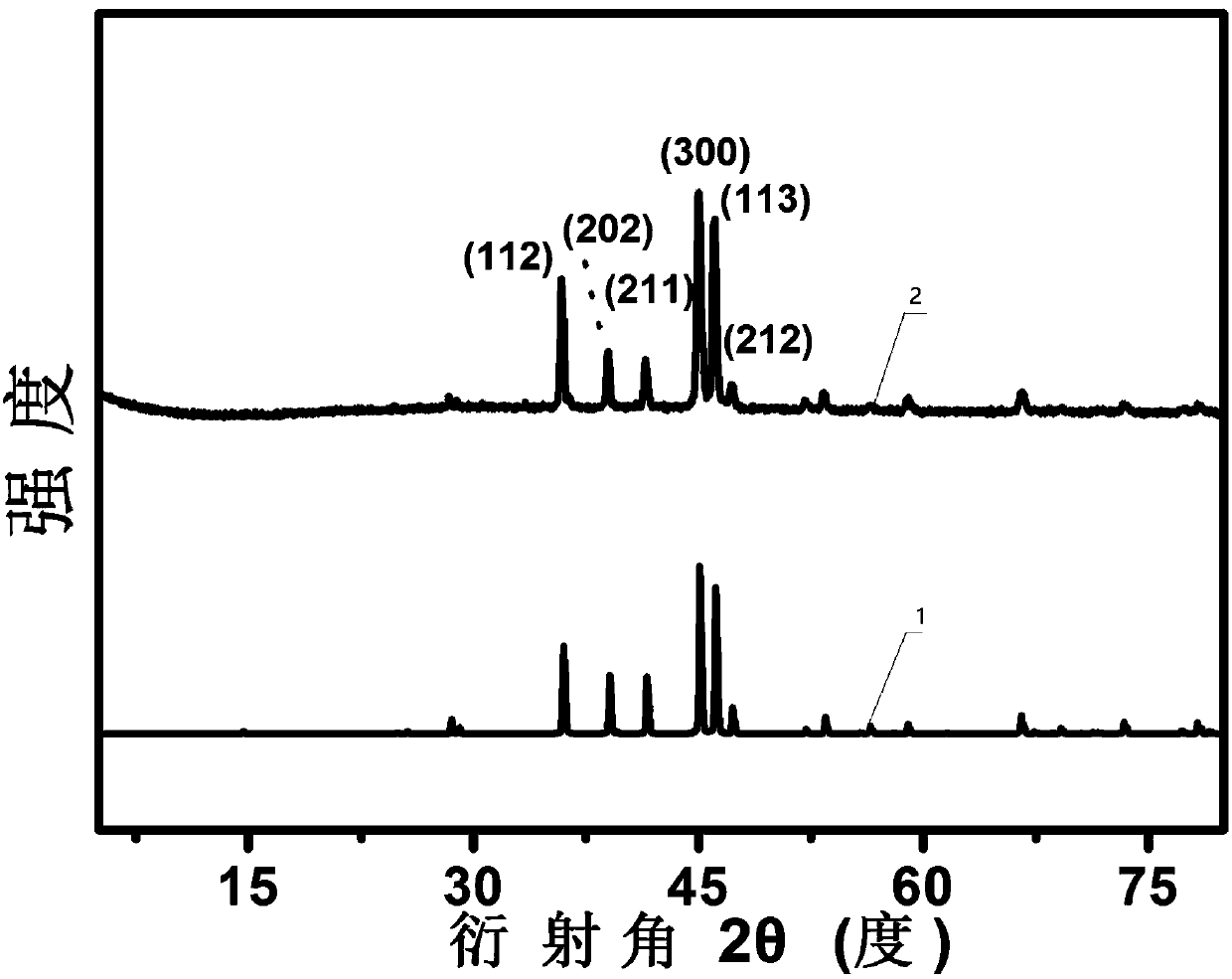

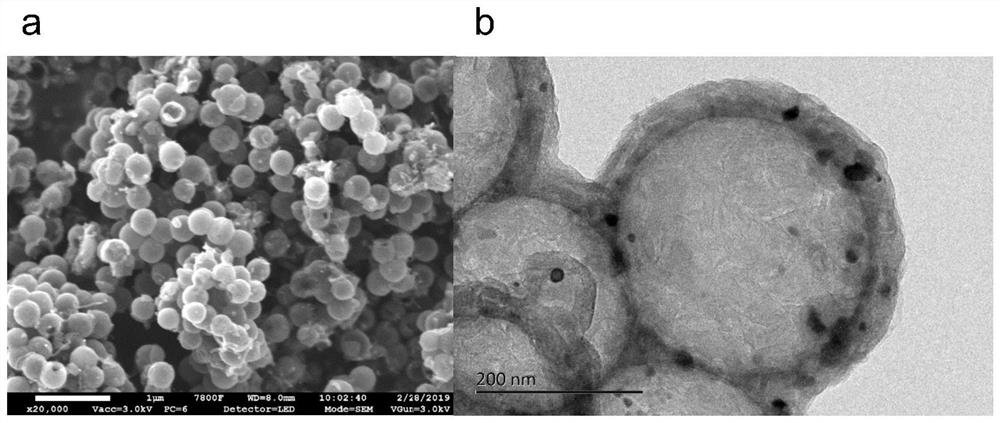

Pd nanoparticle-loaded ferronickel double hydroxide nanosheet array structure material, preparation method and application thereof

ActiveCN111871426AIncrease electron densityImprove adsorption capacityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNickel saltWater methanol

The invention discloses a Pd nano-particle loaded ferronickel double hydroxide nanosheet array structure material, a preparation method and application thereof. The preparation method comprises the following steps: adding nickel salt, ferric salt, urea and quaternary ammonium salt into absolute methanol, ultrasonically dissolving the components, adding a palladium source solution, uniformly mixingthe components, transferring the mixed solution into a reaction kettle, obliquely placing foamed nickel into the mixed solution, carrying out solvothermal reaction, naturally cooling the reaction product to room temperature, and washing and drying the reaction product to obtain the Pd nanoparticle loaded NiFe LDH nanosheet array structure material. The material has the advantages of high activity, good durability, simple preparation process and low cost in alkaline electrolyte, shows excellent activity and stability for oxygen evolution reaction, hydrogen evolution reaction and total hydrolysis reaction, and has very high value in practical application of electro-catalytic water decomposition materials.

Owner:ANHUI NORMAL UNIV

Method for preparing nanoscale granular W18O49 material

ActiveCN105271420AMore exposureEvenly dispersedMaterial nanotechnologyTungsten oxides/hydroxidesOxalateAlcohol

The invention provides a method for preparing a nanoscale granular W18O49 material. The method comprises the steps of adding WC16 into absolute ethyl alcohol to prepare a solution A; adding oxalic acid into the solution A to obtain a solution B, wherein the mass ratio of the oxalic acid to the WC16 to is (5 to 10) to 1; sealing the solution B, stirring, and then performing ultrasonic treatment, so as to obtain a solution C; enabling the solution C to react in a homogeneous reactor, and obtaining the nanoscale granular W18O49 material after the reaction. The prepared homogeneously dispersed nanoscale granular W18O49 material is uniform in chemical constitution, high in purity, and uniform in shape, and the W18O49 is a nano-particle with the diameter being 20nm. The W18O49 material has relatively large specific surface area, and more active crystal faces are enabled to exposed at the same time, so that catalytic efficiency is greatly improved. The reaction temperature is low, the condition is mild, the energy consumption is less, the preparation process is simple, the cost is lower, the process is easy to control, the preparation period is short, and the method is easy to implement and is friendly to environment.

Owner:广西自贸区见炬科技有限公司 +1

Apparatus for loading dosimetrically customizable brachytherapy carriers

ActiveUS20130338423A1Provide dimensional stabilityMaintain positionX-ray/gamma-ray/particle-irradiation therapyBrachytherapyEngineering

A device for loading and customizing brachytherapy carriers based on the principles of optimizing a more precise and predictable dosimetry, and adaptable to the geometric challenges of a tumor bed in a real-time setting. The present invention relates to a specialized loading device designed to enable a medical team to create a radionuclide carrier for each patient and tumor reliably, reproducibly and efficiently.

Owner:GT MEDICAL TECH INC

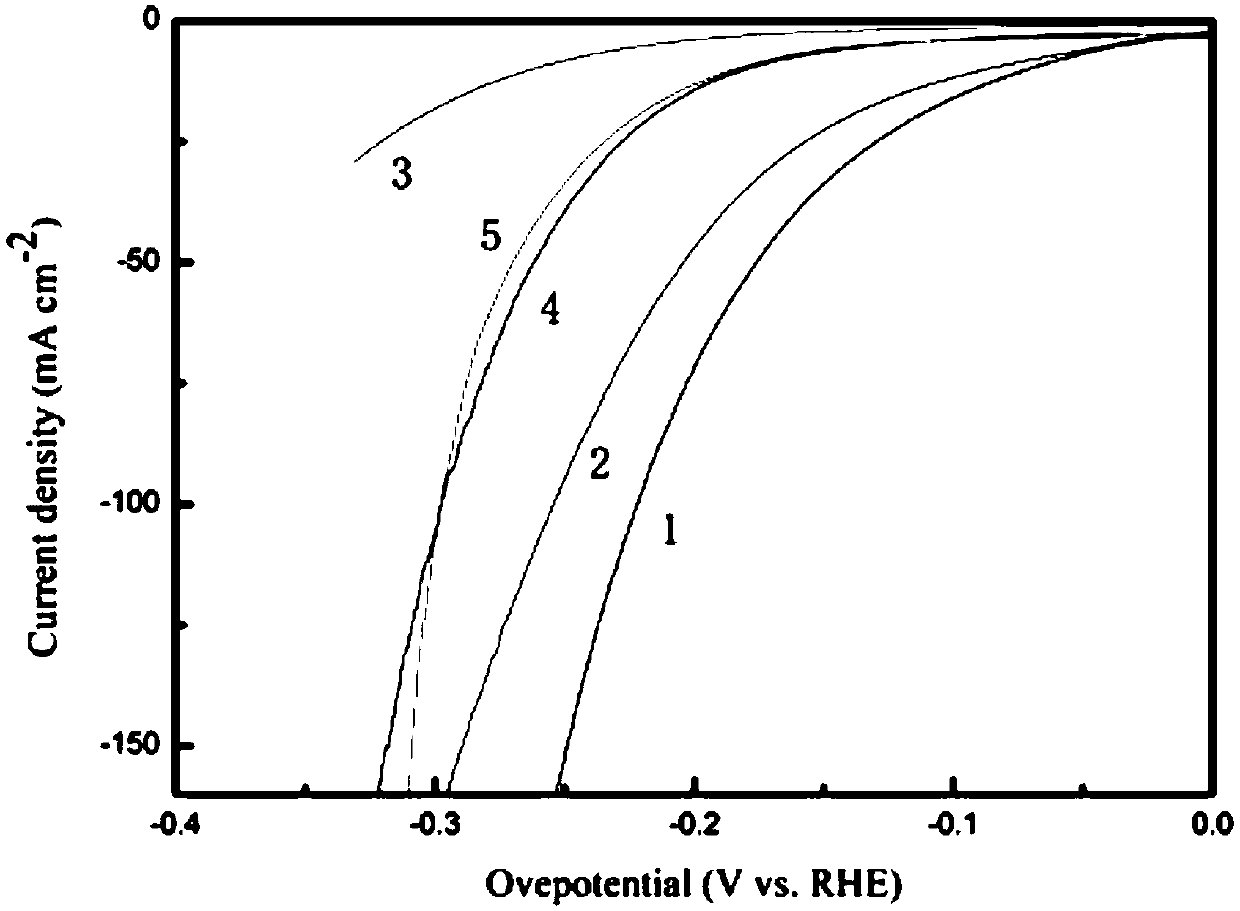

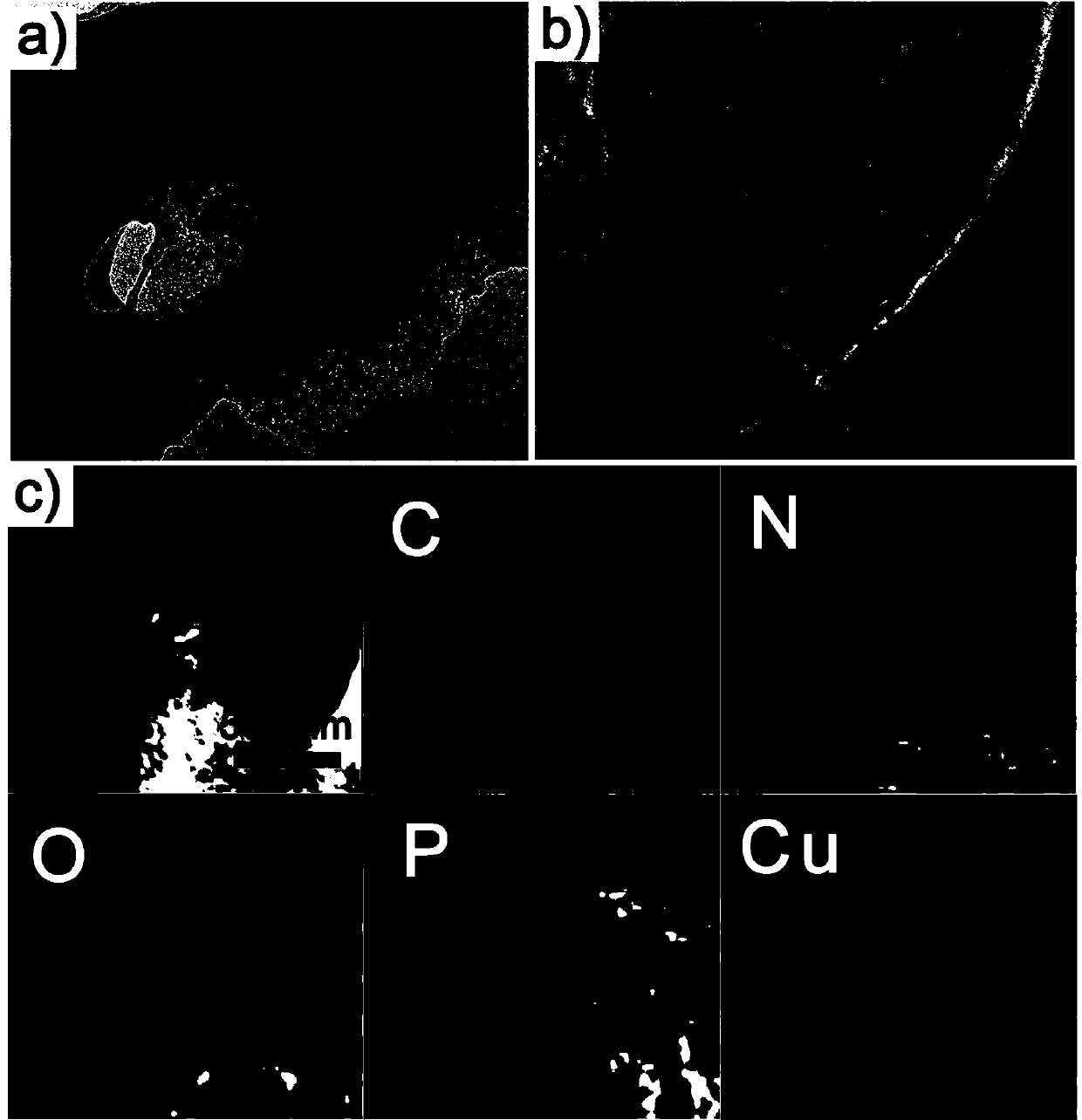

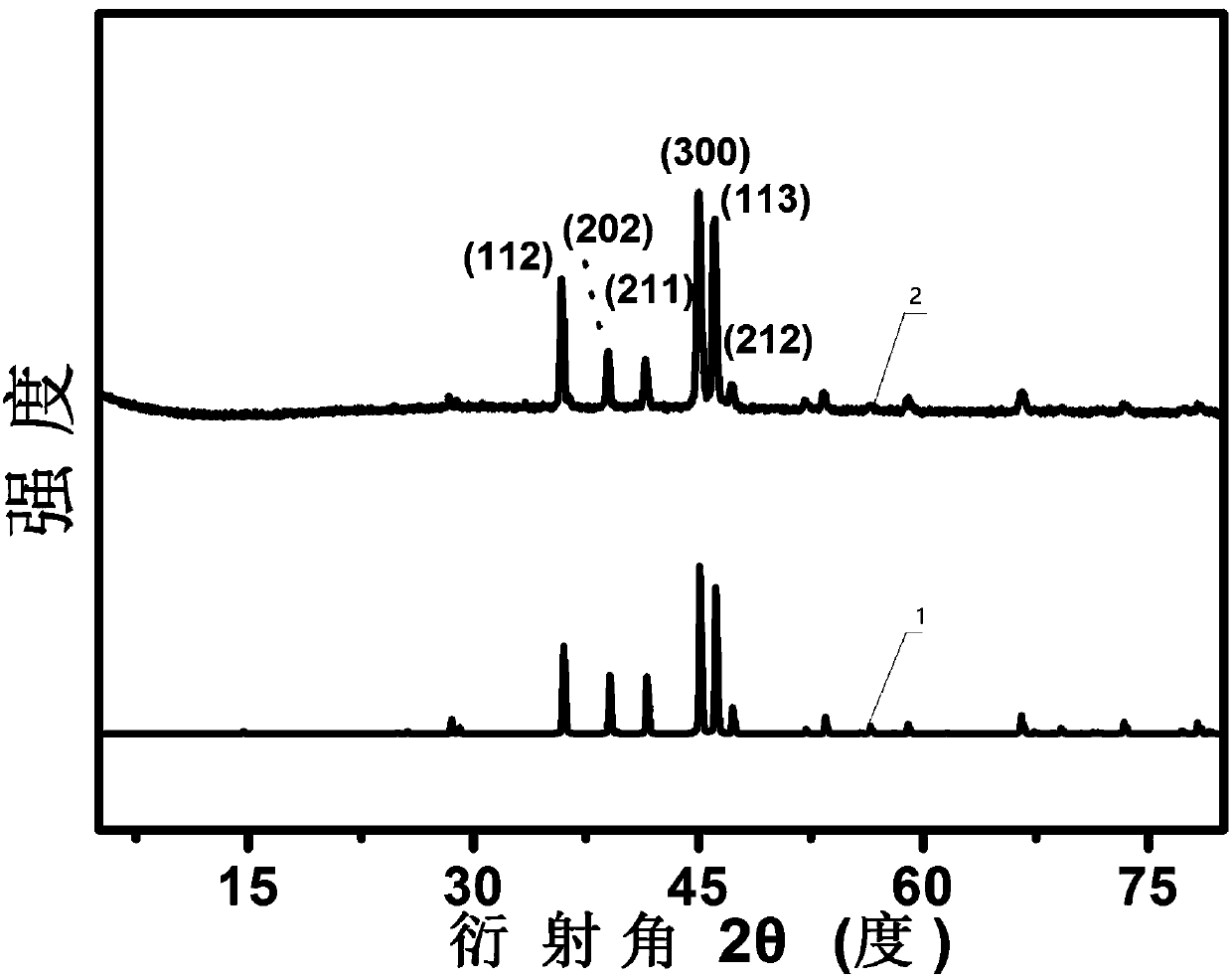

Nitrogen phosphorus co-doped porous carbon-coated copper phosphide composite catalyst and its preparation method

ActiveCN107790164AImprove electrocatalytic activityLarge specific surface areaCatalyst activation/preparationElectrodesOvervoltageElectrolysis

The invention discloses nitrogen phosphorus co-doped porous carbon-coated copper phosphide composite catalyst and its preparation method, and relates to the technical field of composite catalyst and electro-catalysis. The of composite catalyst prepares the composite nitrogen phosphorus co-doped porous carbon-coated copper phosphide hydrogen-producing catalyst by taking a nitrogen phosphorus double-heteroatom mixing type copper based metal-organic framework material (Cu-NPMOF for short) as a precursor, and is used for producing hydrogen efficiently by brine electrolysis. In the .05 mol-L-1 sulfate electrolyte, the overpotential of hydrogen evolution is 0-89mV when the current density is 10mAcm-2, and the nitrogen phosphorus co-doped porous carbon-coated copper phosphide composite catalyst has low hydrogen overvoltage. Through circular tests for many times, the catalyst keeps good catalytic activity, and has strong stability, and high actual application value.

Owner:ZHENGZHOU UNIV

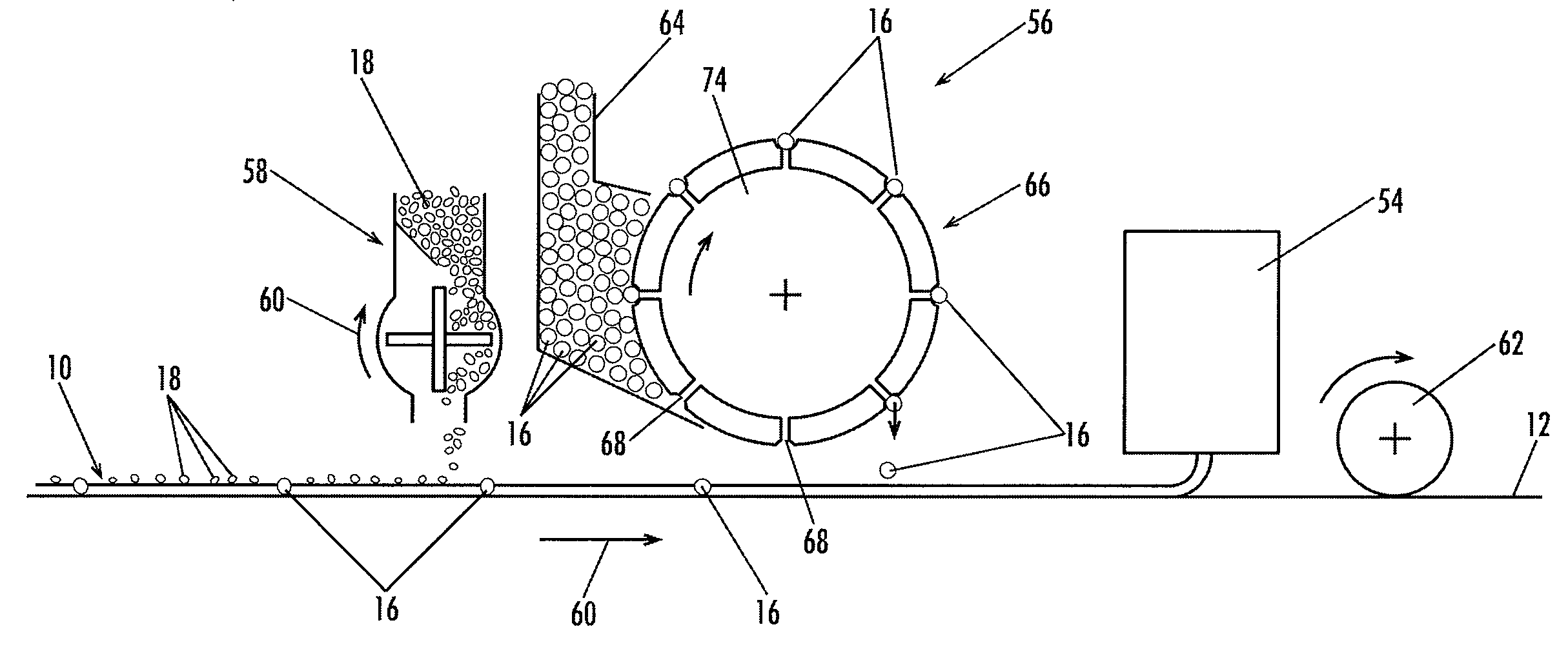

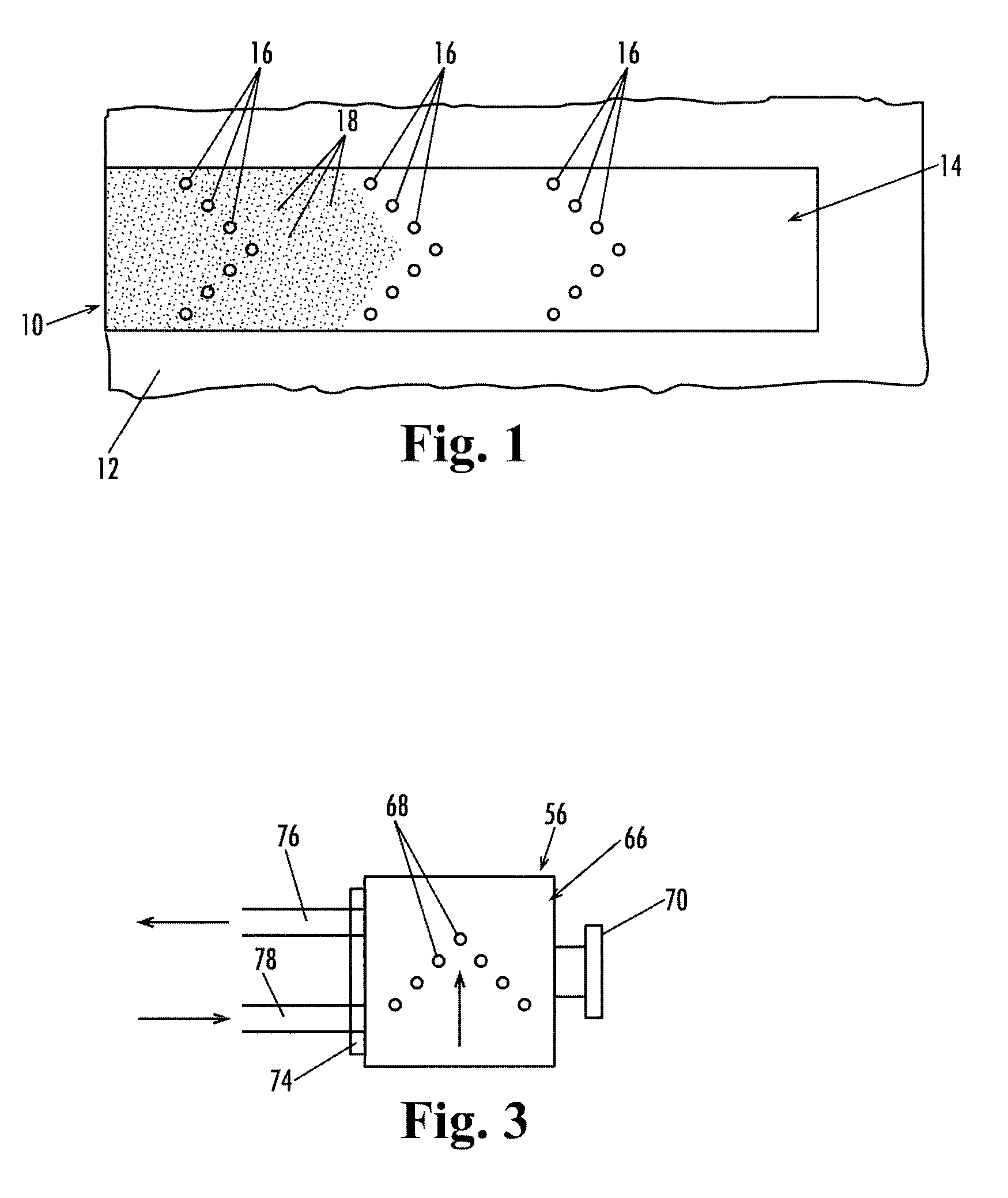

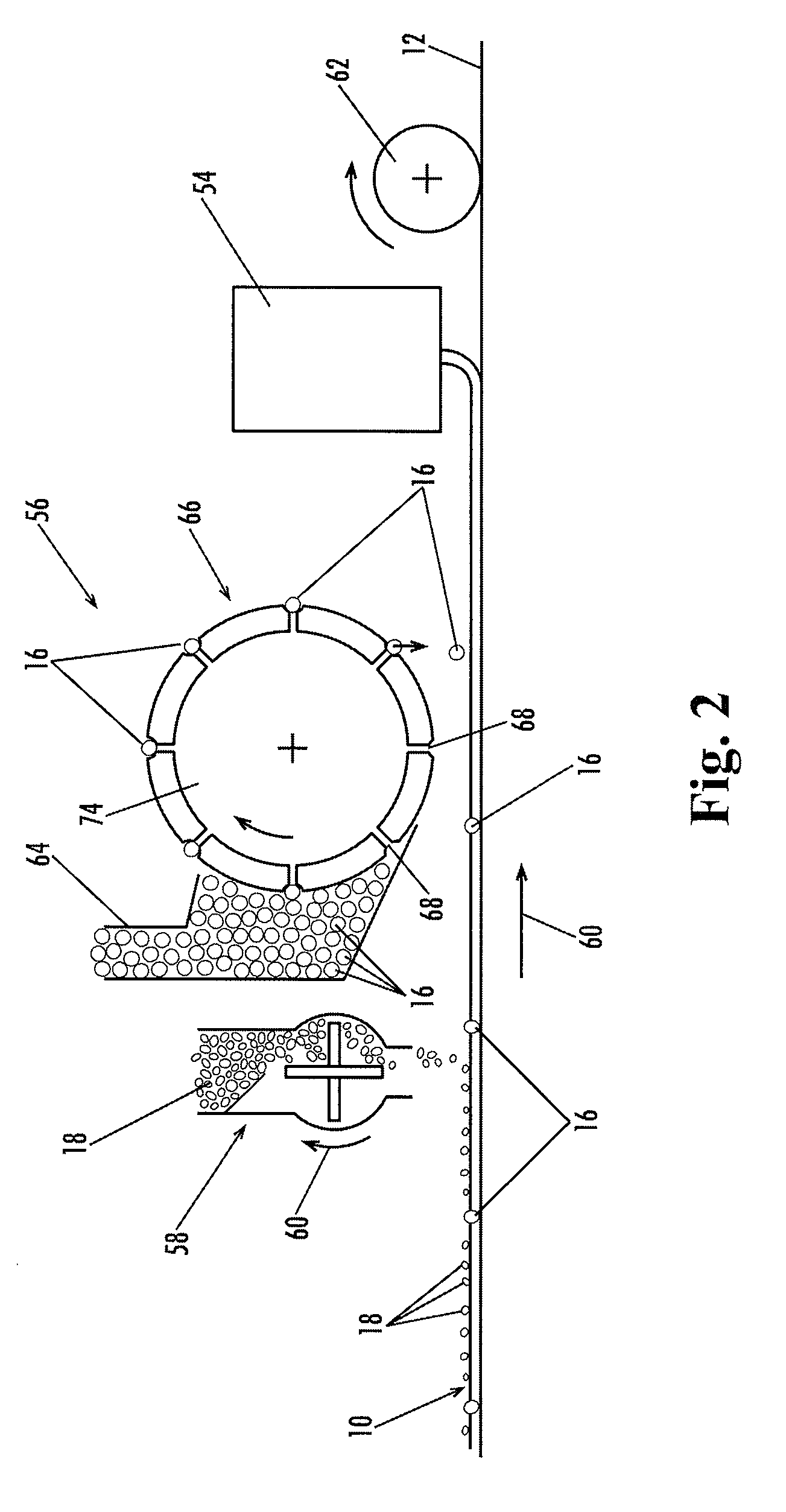

Wet Reflective Pavement Marking and Method

ActiveUS20090202298A1Increase reflectionLong maintenance periodOptical articlesReflex reflectorsThermoplasticOptoelectronics

Reflective pellets (16) are formed by extrusion of reflective micro beads (26) in a thermoplastic (20), removal of the surface layer of the pellets so as to expose the reflective beads at the surface of the pellets and applying the reflective pellets to the base line (14) of the striping applied to a paved road.

Owner:CROWN USA INC

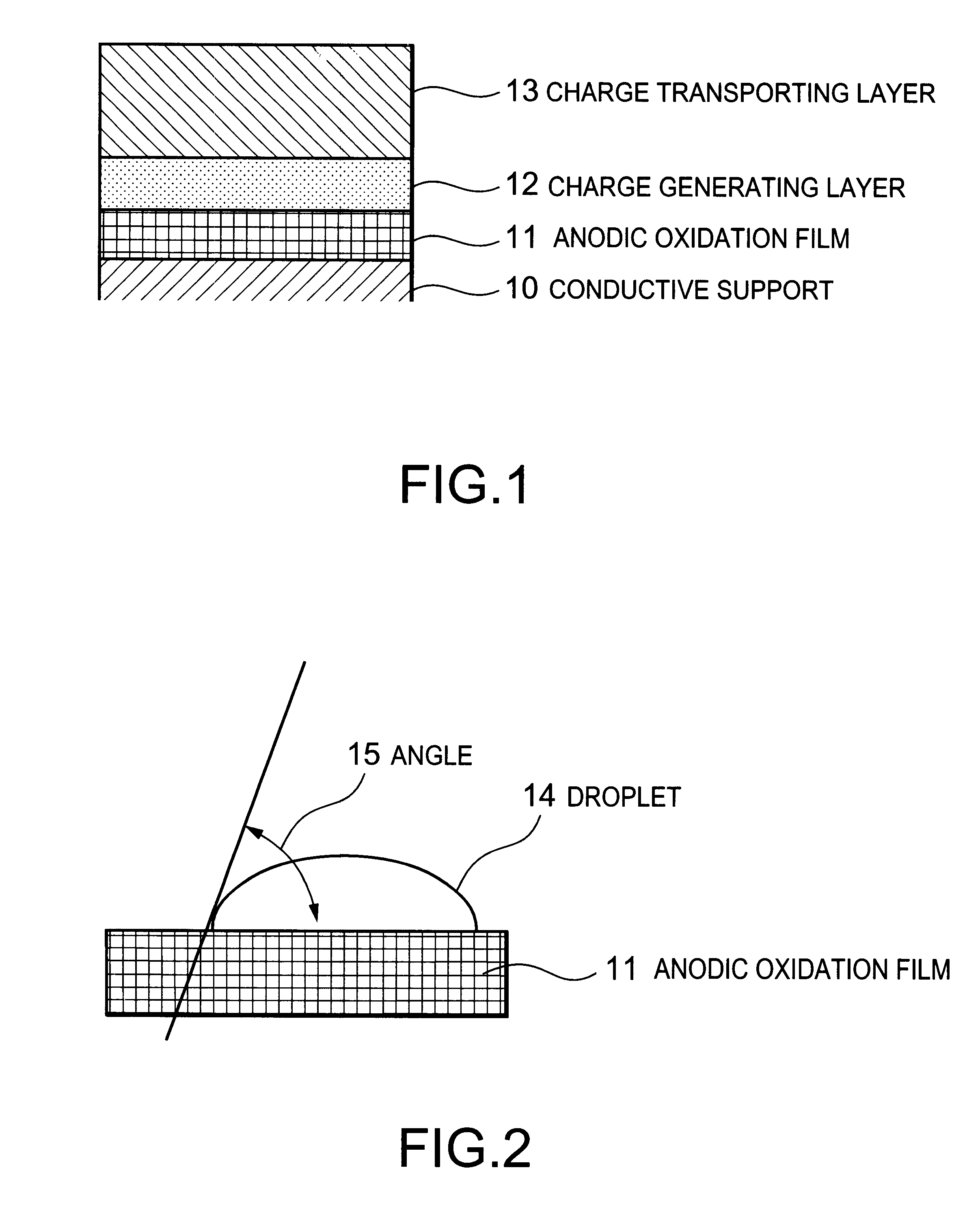

Electrophotographic photoreceptor and its manufacturing method

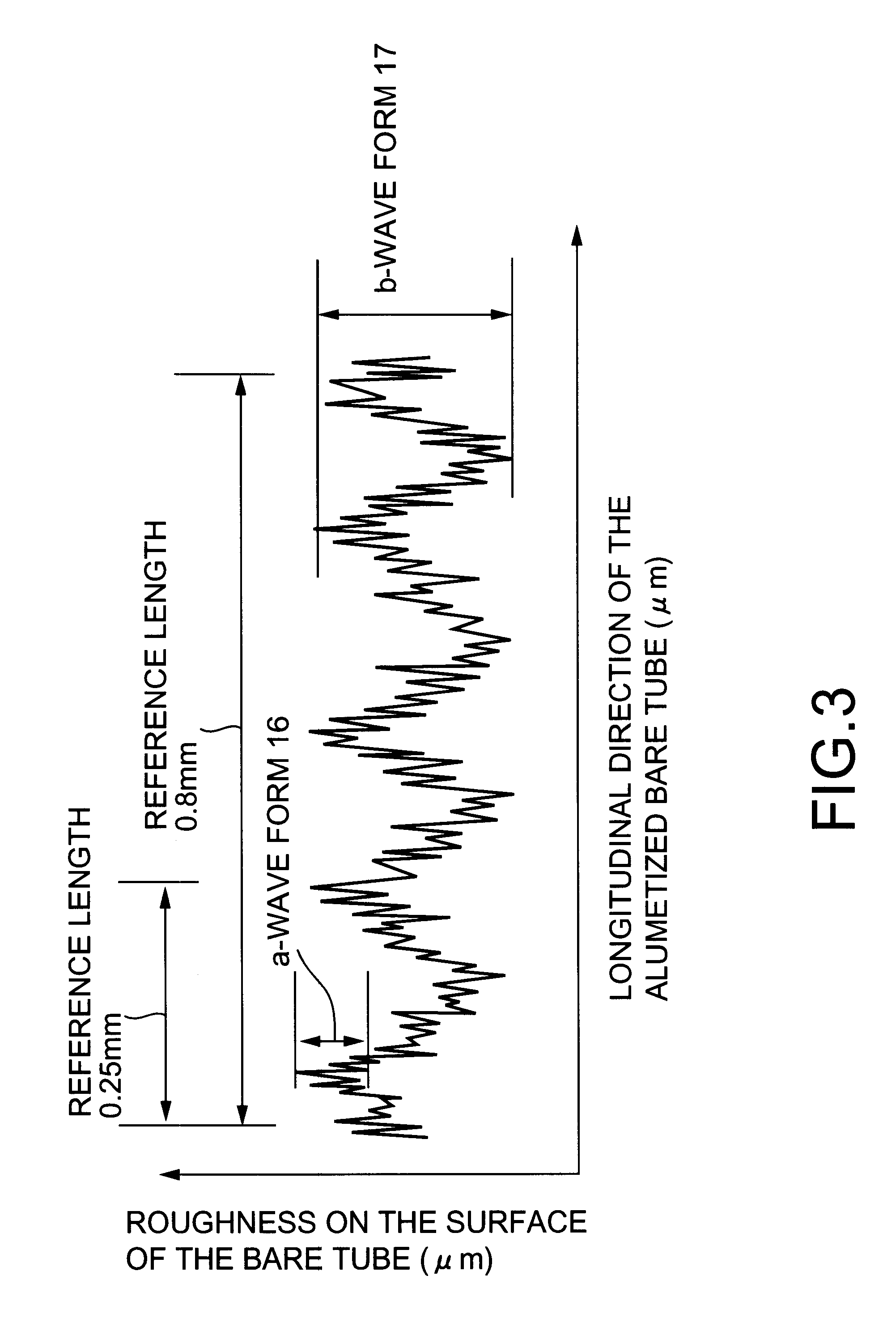

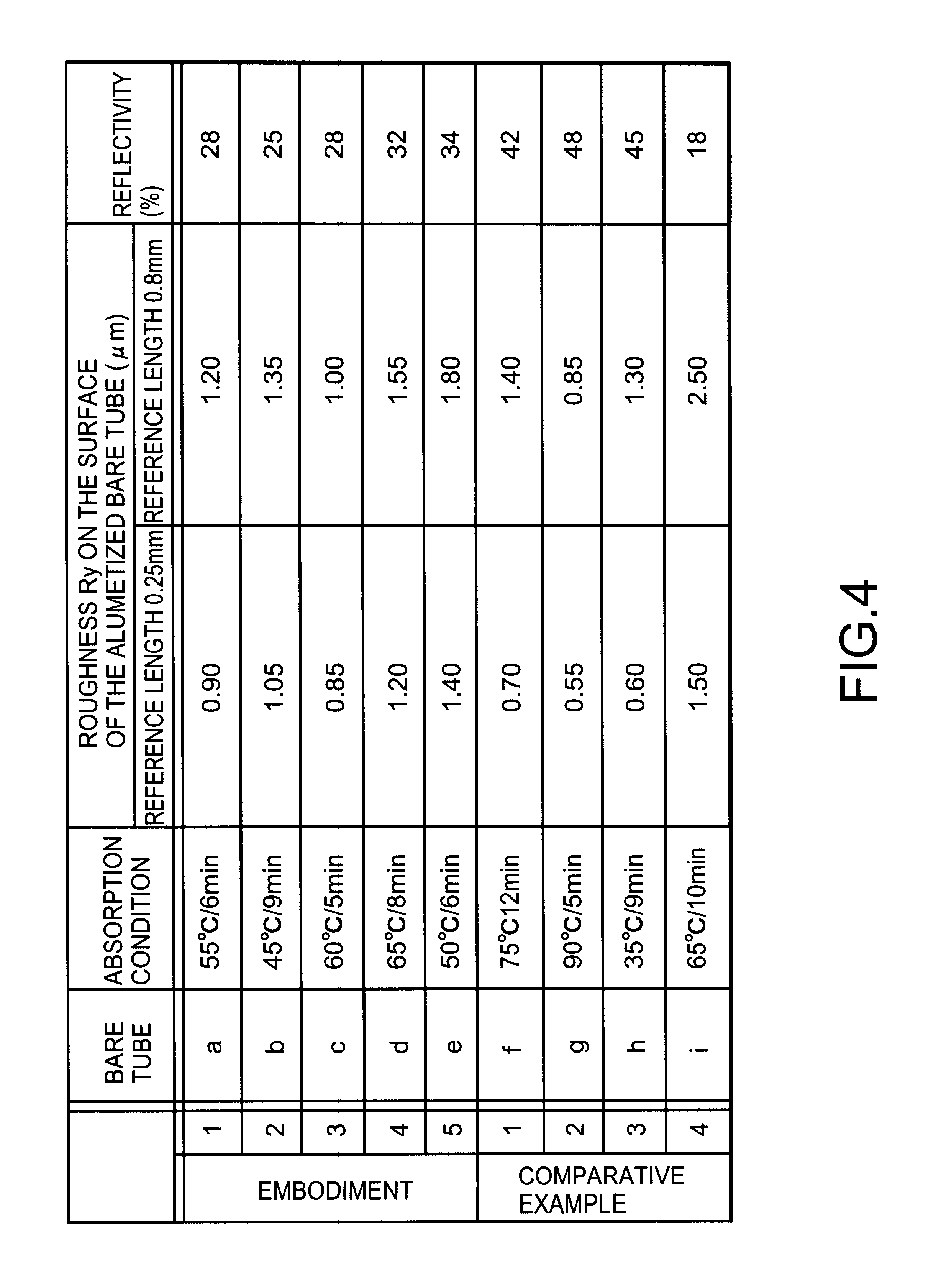

InactiveUS6331371B1More exposureOccurrence of black spots and fogs was able to be suppressedElectrographic process apparatusSurface roughnessAlloy

The electrophotographic photoreceptor according to the present invention has a conductive support (10) and a photoconductive layer laminated on the conductive support. The conductive layer is characterized by making a quantity of reflected lights with respect to exposure of a coherent light as a light source to be small and by having a short wavelength surface roughness in order to suppress a quantity of interference lights produced by the reflected lights and reflected lights from or incident lights on the photoconductive layer. Specifically, the conductive support (10) has aluminum or aluminum based alloy, and the maximum height (Ry) of the surface roughness of the conductive support is 0.8 mum or more and 2.0 mum or less. Further, the reflectivity of the light on the surface of the conductive support is equal to or less than 35% of a quantity of exposure light of a light source of a coherent light. This is able to prevent generation of the interference fringes.The surface of the conductive support is preferably processed for an anodic oxidation film. In this case, the surface roughness subjected to the anode oxidation treatment has a roughness waveform composed of two components shown in the following equation: 1.0a<=b<==2.5a, wherein, a is the roughness of the short waveform (fine roughness) component, and b is the roughness of the long waveform (coarse roughness) component.

Owner:FUJIFILM BUSINESS INNOVATION CORP

System and method for remote sensing and/or analyzing spectral properties of targets and/or chemical speicies for detection and identification thereof

InactiveUS20060132780A1Low-cost and robust and simpleLow costRadiation pyrometrySamplingTarget surfaceChemical species

A method and a low-cost, robust and simple system for remote sensing and analyzing spectral properties of targets as a means to detect and identify them is introduced. The system can be highly portable but is usable in fixed locations or combination thereof. An aspect of the method and system includes the capability to distribute, modulate, aperture and spectrally analyze radiation emitted or absorbed by a volumetric target chemical species (solid, liquid or gas) or a target surface. Radiation is first collected by a single light gathering device, such as a lens, telescope, or mirror, and then distributed to multiple detectors through spectrally discriminating components and if desired through apertures to achieve this desired detection and identification.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Increasing Website Revenue Generation Through Distribution of Interactive Web Content

InactiveUS20090055405A1Increasing website revenueIncrease incomeMarketingSpecial data processing applicationsWeb siteInternet privacy

A system and method of presenting web content on a webpage to increase website revenue generation. The method includes generating a data module by coupling an advertisement to specific data content, providing at least one link in the data module to allow a viewer of the webpage to manipulate the data content, displaying the data module on a webpage at one or more websites, identifying selections of the link made by the viewer, and refreshing the webpage, in response to each selection of the link, to generate a page view corresponding to each selection. Refreshing the webpage can further include displaying the manipulated data content and additional advertisements in the data module on the webpage.

Owner:TINBU

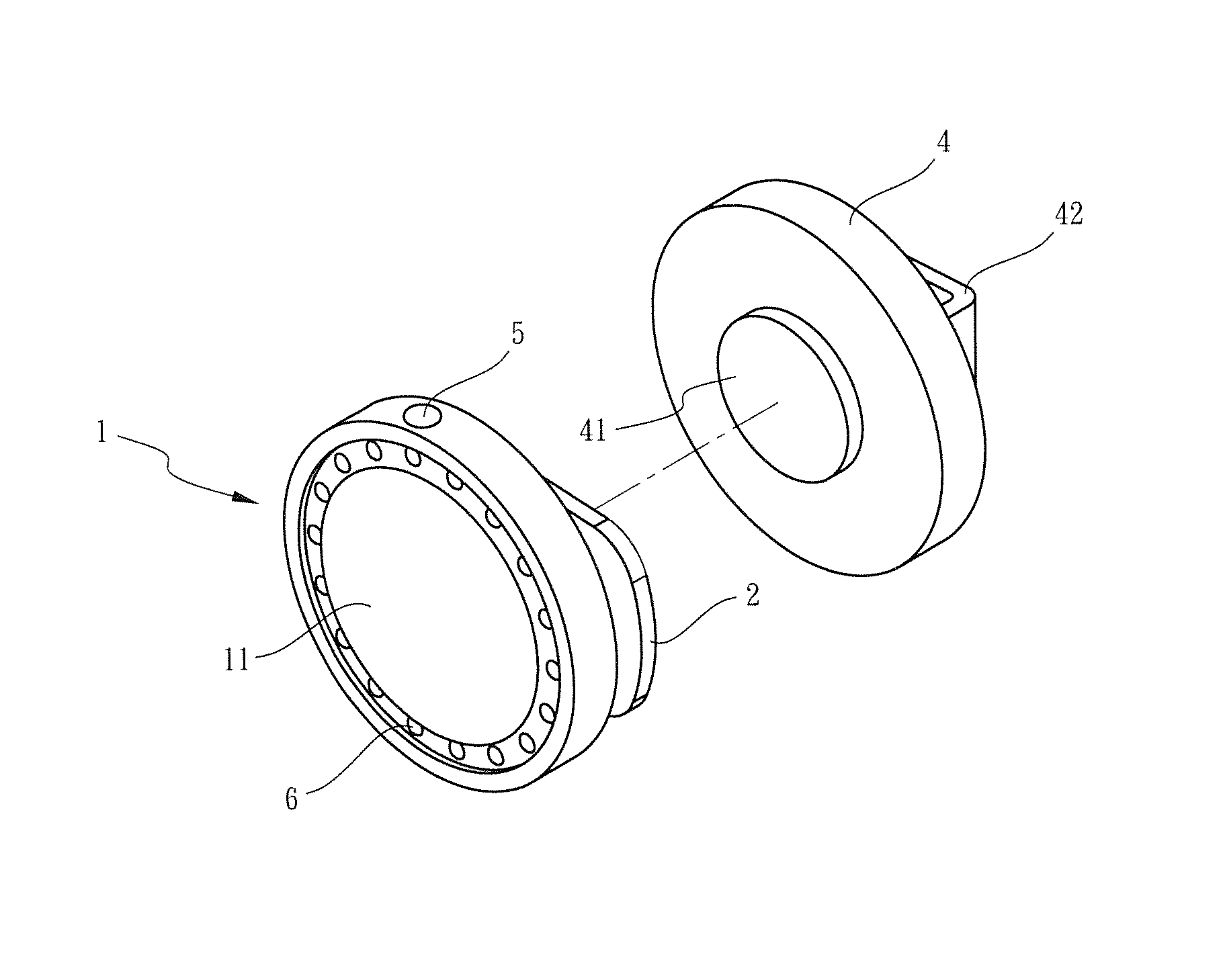

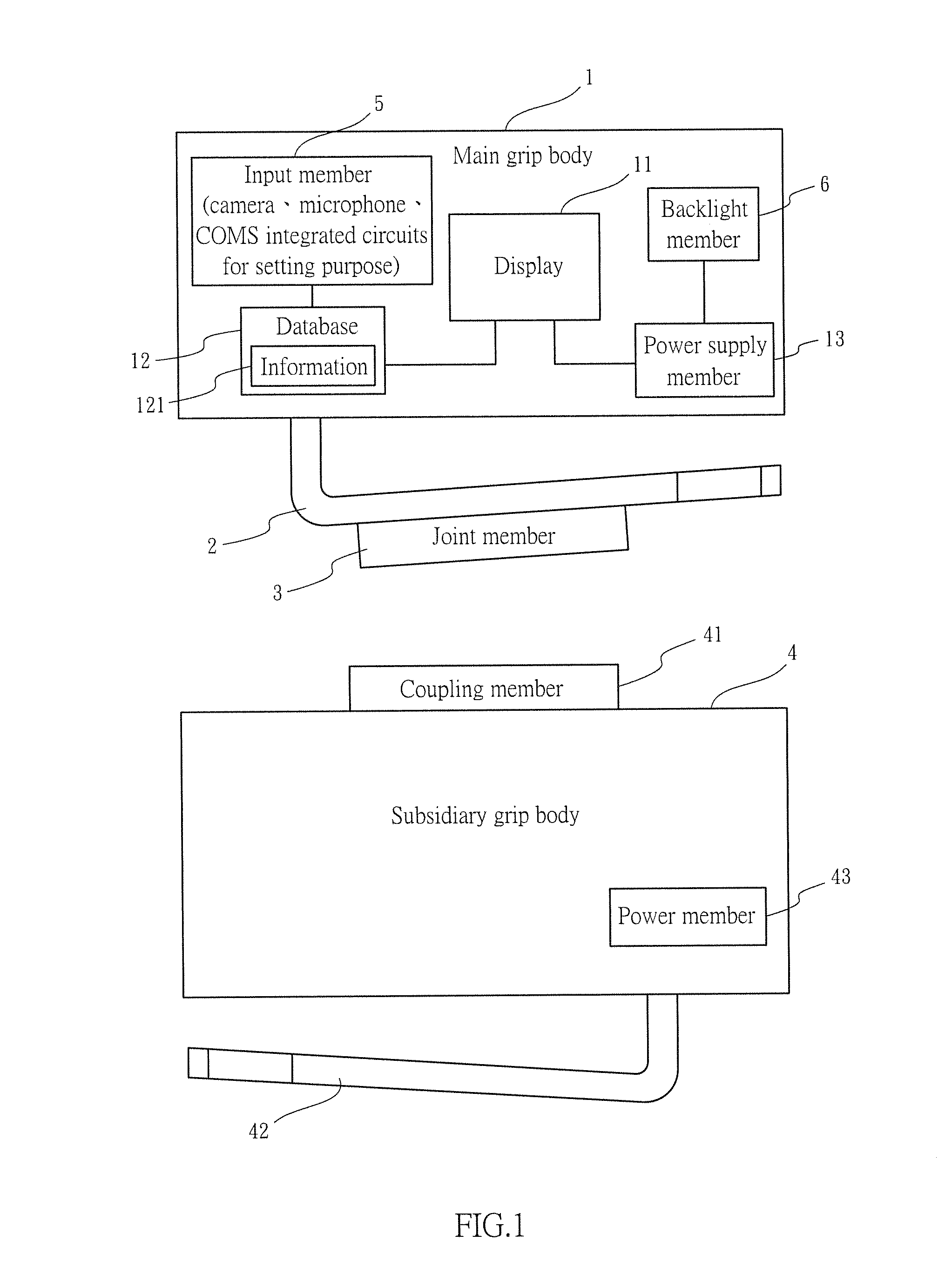

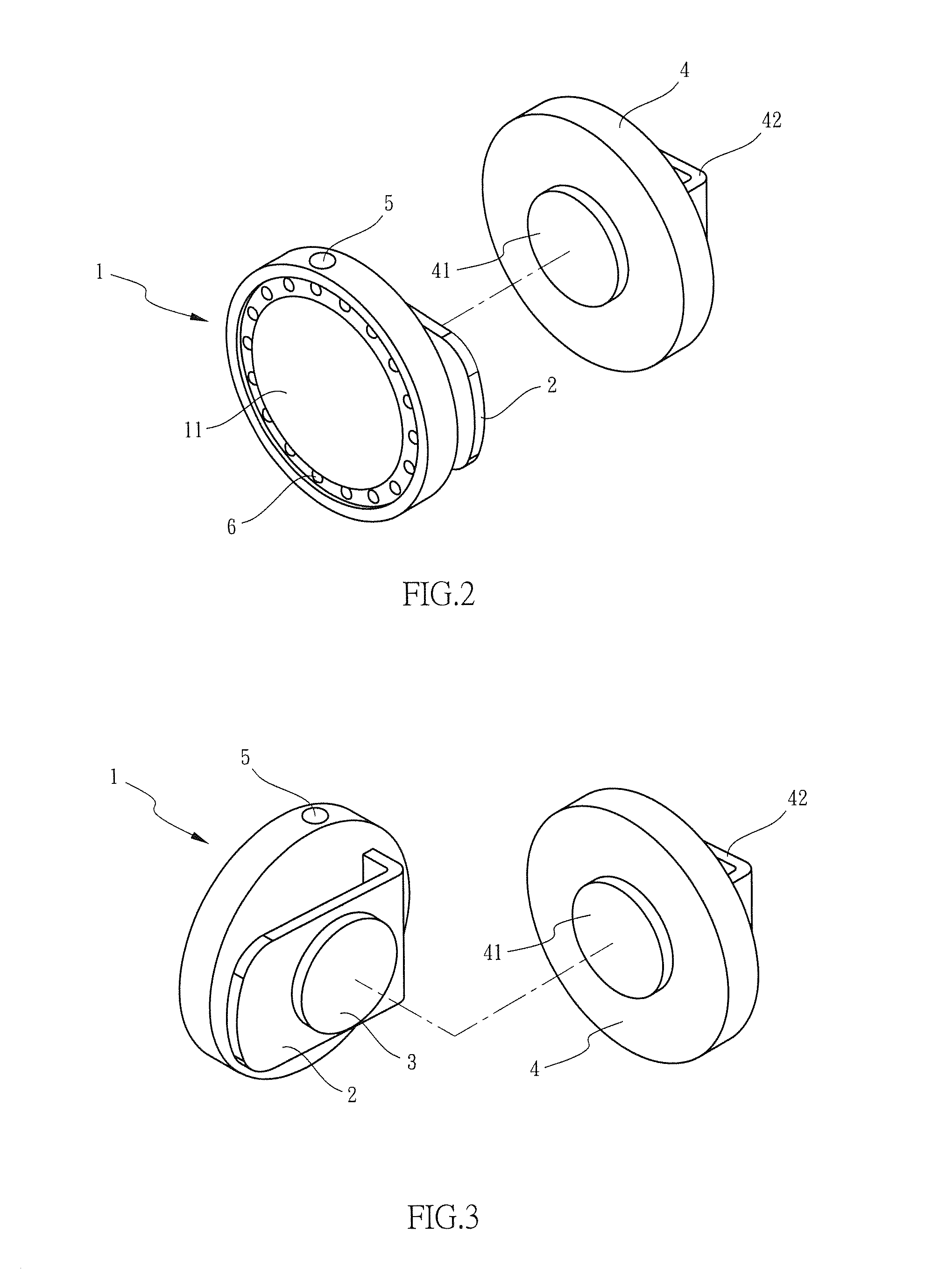

Button device

ActiveUS9220321B1More exposureImproves aforesaid drawbackClothes buttonsSensing by electromagnetic radiationEngineeringMutual engagement

The invention relates to a button device, attachable to the clothing, comprising: a main grip body, having a clip member for attaching to the clothing; and a subsidiary grip body, attaching to the clothing and being buckled with the main grip body, where the position of the subsidiary grip body on the clothing is in the same height to that of the main grip body. The subsidiary grip body is provided with a coupling member corresponding to the joint member for mutual engagement, and is provided with a latch member for attaching to the clothing. Accordingly, once the main grip body and the subsidiary grip body are attached to the clothing, and the joint member and the coupling member are engaged one with the other, the dressing is then aesthetic and the new button device is functional, which saves time and efforts for the replacement.

Owner:NAT CENT UNIV

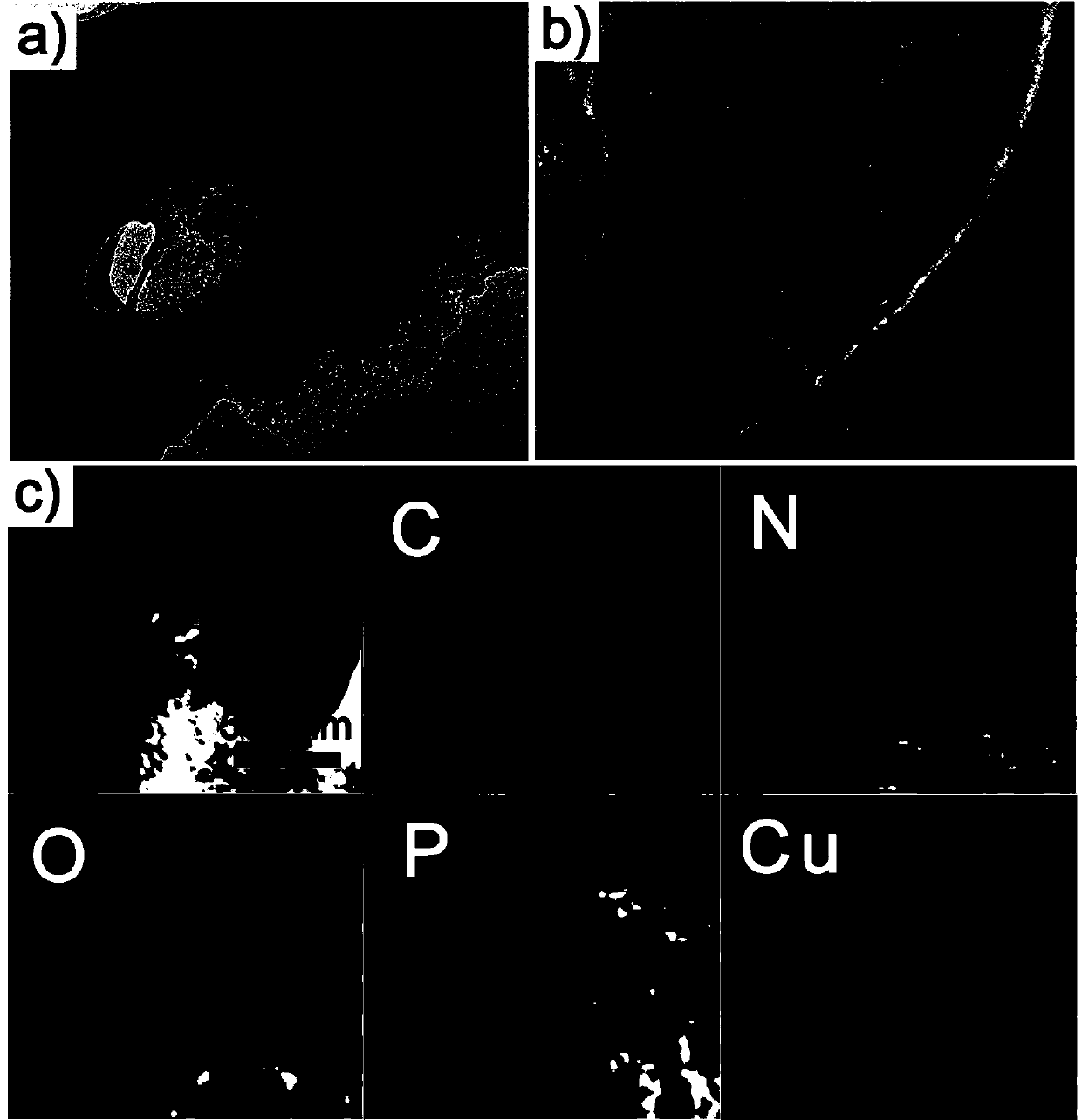

Application of heteroatom-doped porous carbon coated cuprous phosphide composite catalyst

ActiveCN107694581AIncrease contact areaGood mass transfer channelPhysical/chemical process catalystsCell electrodesChemistryCopper

The invention discloses application of a heteroatom-doped porous carbon coated cuprous phosphide composite catalyst in electrocatalytic oxygen reduction reaction and belongs to the technical field ofcomposite catalysts, electrocatalytic oxygen reduction and zinc air cells. The composite catalyst is obtained by using a nitrogen-phosphorus double-heteroatom mixed copper-based metal-organic frame material (Cu-NPMOF for short) as a precursor and carbonizing and phosphorizing, and is used for efficient electrocatalytic oxygen reduction. In potassium hydroxide electrolyte of 0.1 mol L-1, oxygen reduction semiwave potential of the catalyst is 0.78 V, and extreme diffusion current is 5.57 mA cm-2. 38 h's circular charging and discharging tests of zinc air batteries assembled by using the catalystshow that charging and discharging voltage difference has no obvious change, this indicates that the catalyst has quite high stability and high actual application value.

Owner:ZHENGZHOU UNIV

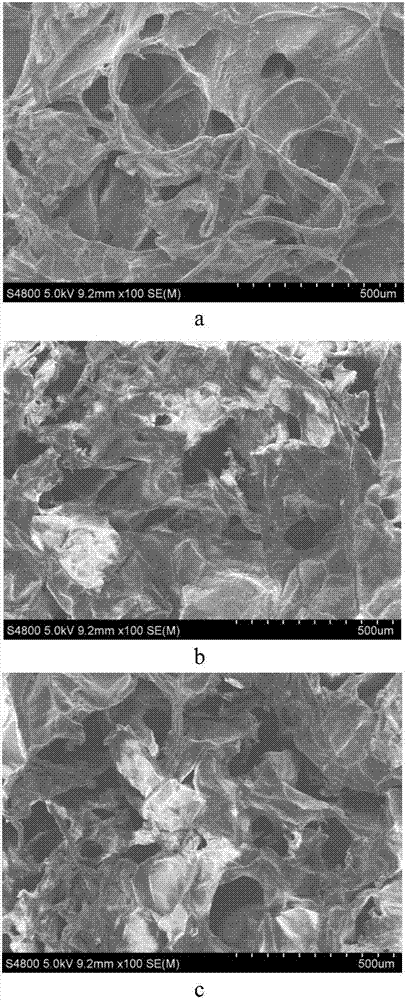

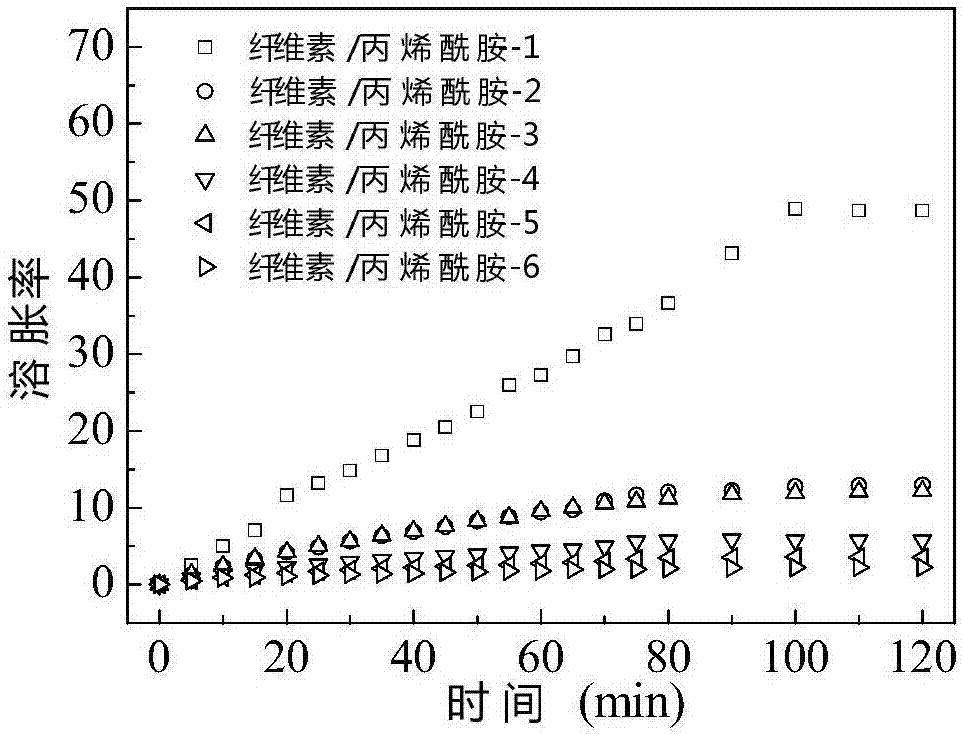

Dual-network hydrogel adsorbent and preparation method thereof and application of dual-network hydrogel adsorbent as heavy metal absorbent

ActiveCN107082894ARealize comprehensive utilizationWide variety of sourcesOther chemical processesAlkali metal oxides/hydroxidesCelluloseCross-link

The invention discloses a dual-network hydrogel adsorbent and a preparation method thereof and an application of the dual-network hydrogel adsorbent as a heavy metal absorbent. The preparation method of the dual-network hydrogel adsorbent comprises the steps of dissolving abandoned cotton cloth into a sodium hydroxide / urea solvent system to obtain a cellulose solution; and mixing the cellulose solution with a solution containing acrylamide, a cross-linking agent and an initiator evenly and carrying out cross-linking and polymerization reaction to obtain the hydrogel which is good in mechanical property and rich in active functional group, and has a crosslinked cellulose and polyacrylamide dual network and a three-dimensional porous structure. The method is simple in operation, low in cost and beneficial to large-scale production; and the prepared dual-network hydrogel adsorbent is used for adsorbing heavy metal ions in water, has the advantages of being small in additive amount, high in adsorption rate and large in adsorbing capacity, and can be applied to treatment of various wastewater containing heavy metal ions.

Owner:HUNAN UNIV

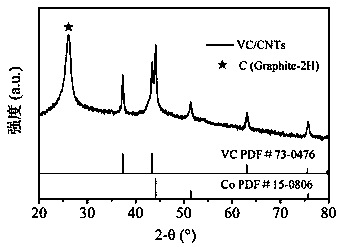

An ultra-small vanadium carbide embedded carbon nanotube material, a preparing method thereof and an application thereof in a water cracking hydrogen production aspect

ActiveCN108837838AShort reaction cycleSynthesis temperature is lowCatalyst activation/preparationElectrodesCarbon nanotubeAmmonium metavanadate

The invention discloses an ultra-small vanadium carbide embedded carbon nanotube material. A structure includes a carbon nanotube with a tube wall thickness which not exceeds 3 nm and vanadium nitrideultra-small crystal grains dispersing in the tube wall of the carbon nanotube, and the ultra-small vanadium carbide embedded carbon nanotube material has a nanometer-size tubular morphology. The preparing method for the ultra-small vanadium carbide embedded carbon nanotube material includes the following steps: dicyandiamide, ammonium metavanadate and a metal catalyst are mixed and then fully grinded; heat treatment is performed on a mixture at 500-1200 DEG C under atmosphere protection; after completing the heat treatment, a product is placed into an acidic environment and then impurity is removed; and a target product is obtained after cleaning, drying and griding. The invention also provides the application of the material in a water cracking hydrogen production aspect. A VC / CNTs hydrogen production electrocatalyst which is low in synthesizing temperature, is short in reaction period, uniform in material chemical composition, uniform in morphology size, high electrocatalytic activity and stability in an all pH electrolyte environment can be obtain through a single-step calcination method.

Owner:SHAANXI UNIV OF SCI & TECH

Dealership inventory display through interactive banner ads

An electronic advertisement method and system for delivering, via the Internet, a fully interactive database of vehicle inventory contained within a Banner Advertisement. A key strength of the invention is that it takes an existing commercial infrastructure—the banner ad—and it greatly enhances its value to the marketplace. The invention makes it possible for a user to easily and efficiently browse inventory of cars for sale, including photos, within the banner advertisement itself without obstructing the viewing and reading of other website content. This benefits both the viewer as well as the advertiser. The Interactive Inventory banner advertisement system provides a novel method of inserting inventory into any web page banner as well as a novel method for consumers to interact with car classifieds.

Owner:DUMOND DAVID I +1

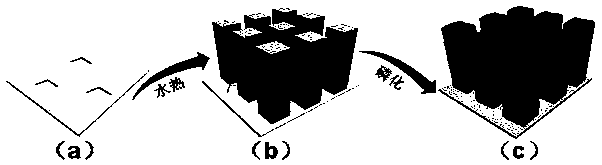

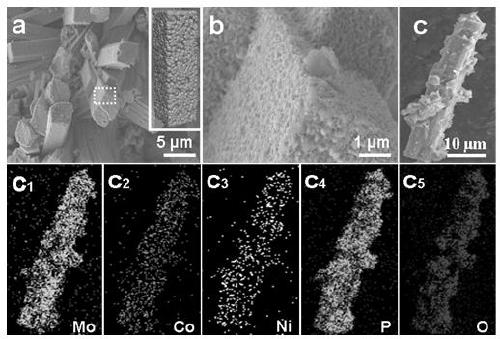

Binary metal phosphide controlled by molybdenum trioxide (tungsten), preparation method and application

The invention relates to a binary metal phosphide controlled by molybdenum trioxide (tungsten), a preparation method and application. According to the method, foam nickel is used as a matrix, a columnar precursor is prepared by means of a hydrothermal method at first, and then a MoO3-x-controlled columnar array structure with multiple pores in the surface is formed by means of a low-temperature phosphorization method. Amorphous MoO3-x and CoP / Ni5P4 heterojunctions exist in the structure and are beneficial to the activation of water molecules and the precipitation of hydrogen. In addition, thevertical porous columnar array structure can accelerate electrolyte permeation, facilitate exposure of more electrochemically active areas and promote gas desorption from the surface of a catalyst. The structure has a great potential application value in the field of electrocatalysis.

Owner:NANKAI UNIV

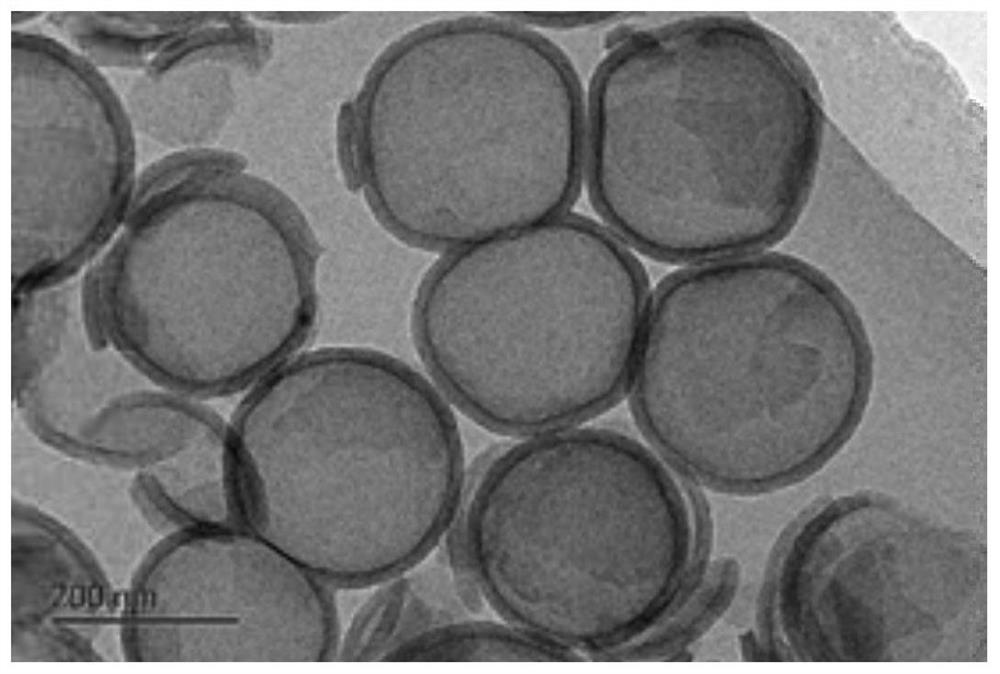

Preparation and application of carbon dioxide electrochemical reduction catalyst

InactiveCN112791739AReduce reunionActs as an ion bufferCatalyst activation/preparationElectrodesPtru catalystFaraday efficiency

The invention relates to preparation and application of a carbon dioxide electrochemical reduction catalyst. The preparation method of the catalyst comprises the following steps of by taking carbon spheres rich in microporous structures as a precursor, limiting adsorbed transition metal ions into a pore structure of the carbon spheres by utilizing the microporous structures of the carbon spheres through a liquid-phase impregnation process, and introducing a nitrogen source into later-stage high-temperature calcination carbonization treatment, generating a nitrogen-rich sheet structure at a high temperature to further anchor the transition metal monatomic. Therefore, the high-dispersion and high-load monatomic catalyst is prepared. The preparation method of the catalyst provided by the invention is simple / easy to control, has excellent Faraday efficiency, catalytic activity and stability for preparing CO through CO2 electrochemical reduction, and is expected to realize large-scale commercial production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

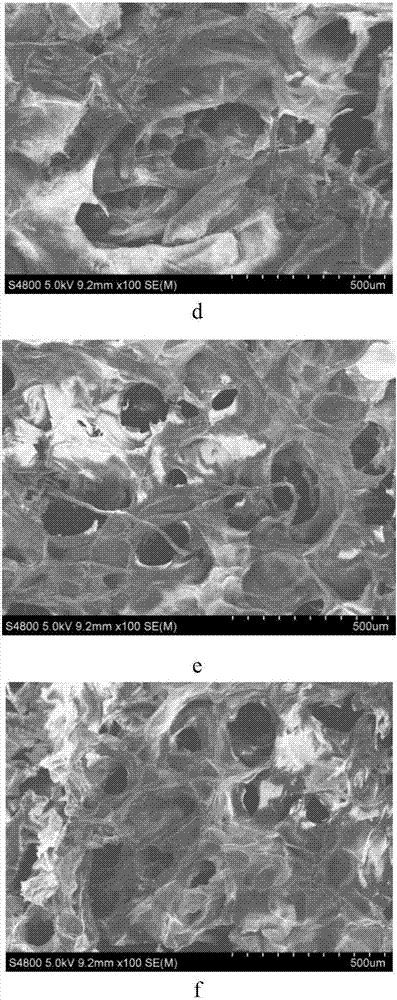

Transition metal phosphide hydrogen-evolution composite material as well as preparation method and application thereof

InactiveCN109590002ALarge specific surface areaRegular structureElectrolysis componentsPhysical/chemical process catalystsHydrogenDouble network

The invention belongs to the hydrogen-evolution material field and particularly discloses a transition metal phosphide hydrogen-evolution composite material as well as a preparation method and application thereof. The preparation method comprises the following steps: dissolving a phosphorus source into water, and adding a certain amount of an organic amine alkali compound, so as to obtain a solution A, wherein the phosphorus source is at least one of a polymer containing phosphonic acid groups and a monomer containing phosphonic acid groups; adding a transition metal source into the solution A, and stirring to obtain dispersion liquid B; adding agar into the dispersion liquid B, and stirring, so as to obtain double-network hydrogel; cooling the double-network hydrogel, and drying, so as toobtain dried gel; and calcining the dried gel at 750-1000 DEG C in a protective atmosphere, so as to obtain the transition metal phosphide hydrogen-evolution composite material. The preparation method is wide in raw material source and low in cost, obtained transition metal phosphide has excellent electro-catalytic property, and the preparation method is hopefully applied to the industrial production.

Owner:CENT SOUTH UNIV

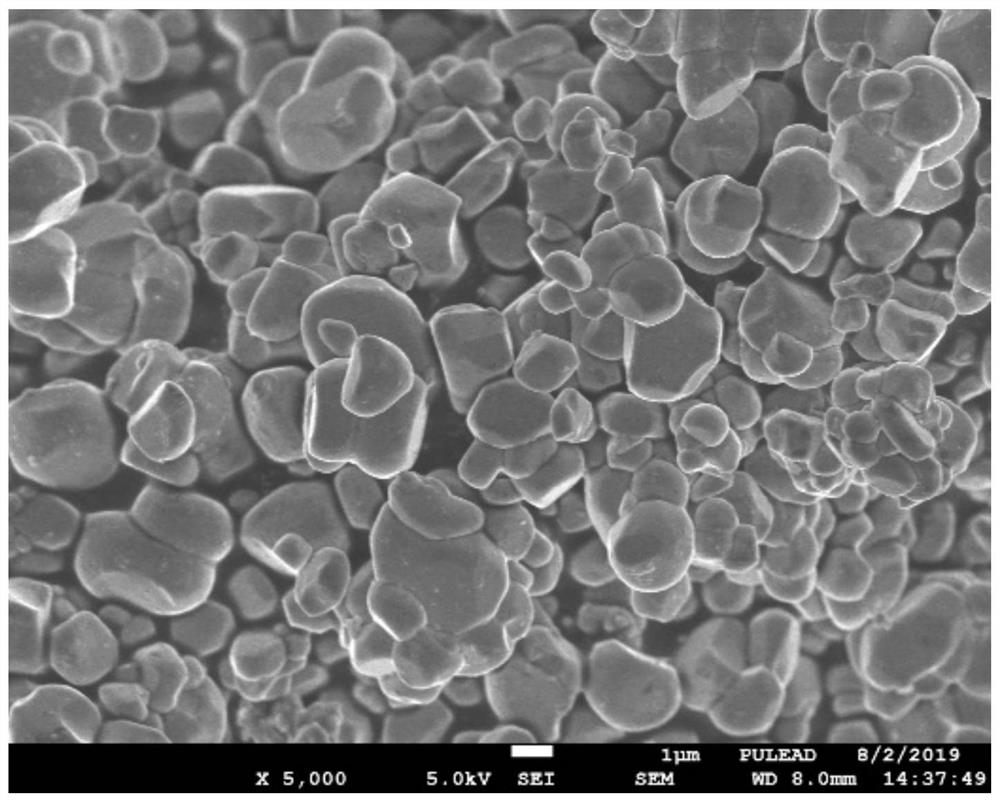

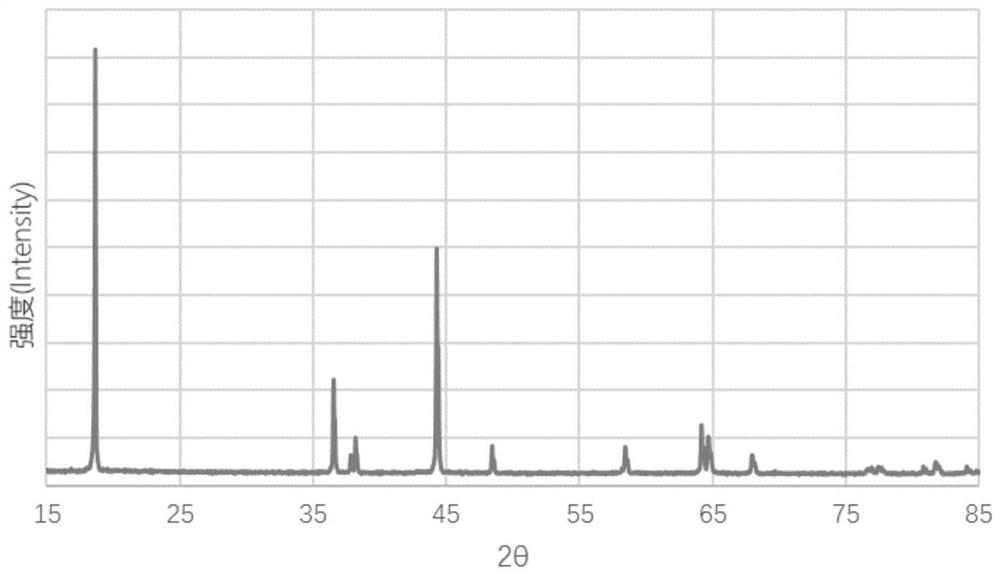

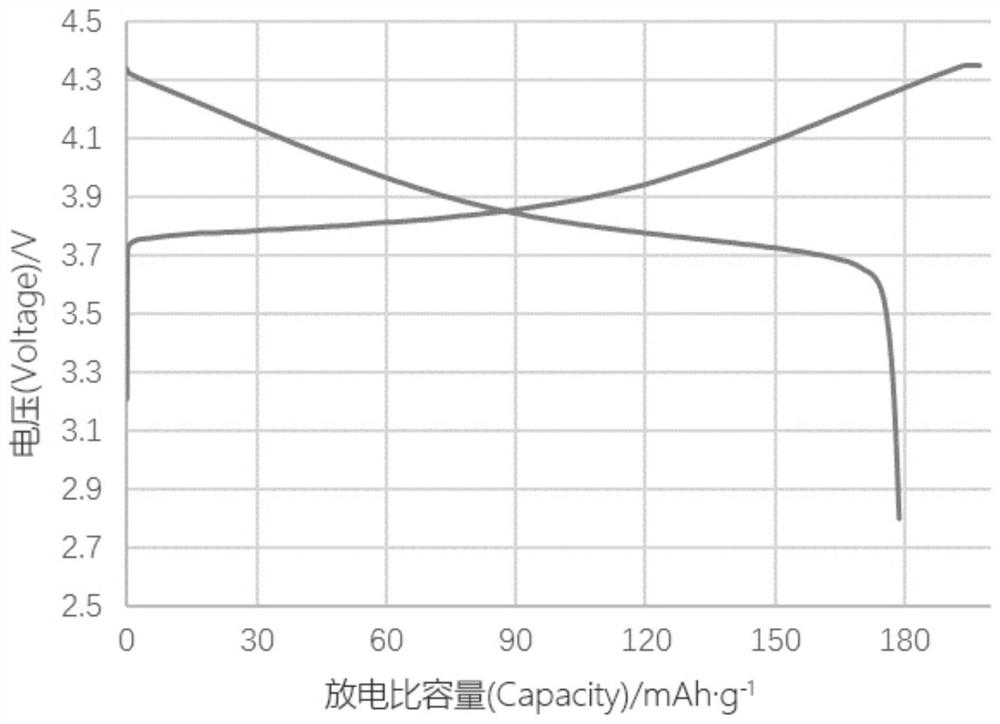

Single-crystal ternary positive electrode material, preparation method thereof and lithium ion battery

PendingCN112018372ADoes not affect rate performanceMore exposureCell electrodesSecondary cellsPhysical chemistrySingle crystal

The invention provides a single-crystal ternary positive electrode material, a preparation method thereof and a lithium ion battery, and belongs to the technical field of lithium-ion batteries. Aimedat the problem that low-cobalt high-manganese ternary material single crystal particles are difficult to grow up, the preparation method of the single-crystal ternary positive electrode material provided by the invention can promote crystal growth and preferred directional growth of the low-cobalt / cobalt-free high-manganese material. The single-crystal ternary positive electrode material providedby the invention has relatively good single-crystal morphology, the [003] crystal face in single-crystal particles grows directionally, more layered structures can be exposed, a lithium ion diffusionpath can be effectively shortened, the electrochemical performance of the material is improved, and meanwhile, the preparation method is simple and easy for large-scale production.

Owner:BEIJING TAIFENG XIANXING NEW ENERGY TECH CO LTD +2

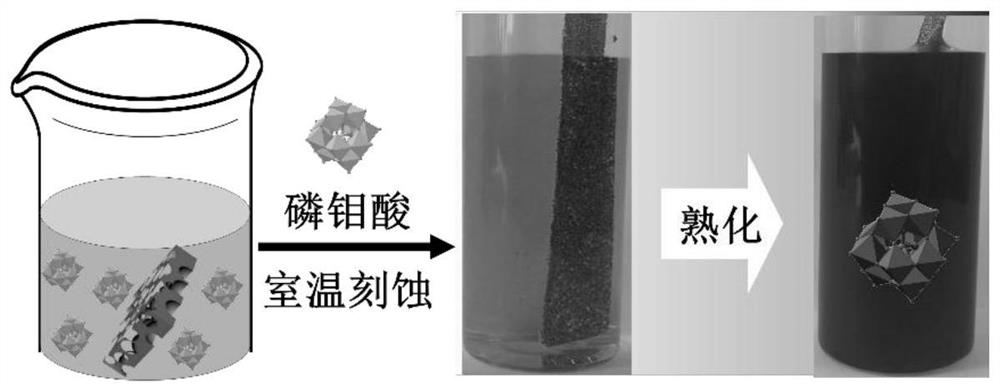

Preparation method of foamed nickel-loaded amorphous phosphorus-doped nickel molybdate bifunctional electrocatalytic electrode and application thereof

ActiveCN111663152ASimple preparation processMild conditionsCatalyst activation/preparationElectrolytic organic productionPhosphomolybdic acidElectrolysis

The invention provides a preparation method of a foamed nickel-loaded amorphous phosphorus doped nickel molybdate bifunctional electrocatalytic electrode and an application thereof, and belongs to thetechnical field of hydrogen energy and fuel cells. The preparation method comprises the following steps: soaking foamed nickel into an HCl solution, removing metal oxide on the surface, soaking the pickled foamed nickel into a phosphomolybdic acid aqueous solution, carrying out a spontaneous oxidation-reduction reaction, taking out, washing with deionized water, and drying for later use, therebyobtaining the foamed nickel-loaded amorphous phosphorus-doped nickel molybdate nanostructure. The foamed nickel is etched by using the phosphomolybdic acid aqueous solution, and can be directly used after drying, the material can be used as a bifunctional electrode material for urea electrooxidation and water and electricity reduction; a urea electrooxidation reaction with low oxidation potentialis used for replacing an electrocatalytic oxygen evolution reaction, a two-electrode urea auxiliary electrolysis hydrogen production system based on a bifunctional electrocatalyst is constructed in analkaline solution, low-cost, low-energy-consumption and stable electrochemical hydrogen production is achieved, and the method is suitable for large-scale industrial electrochemical hydrogen production application.

Owner:HARBIN INST OF TECH

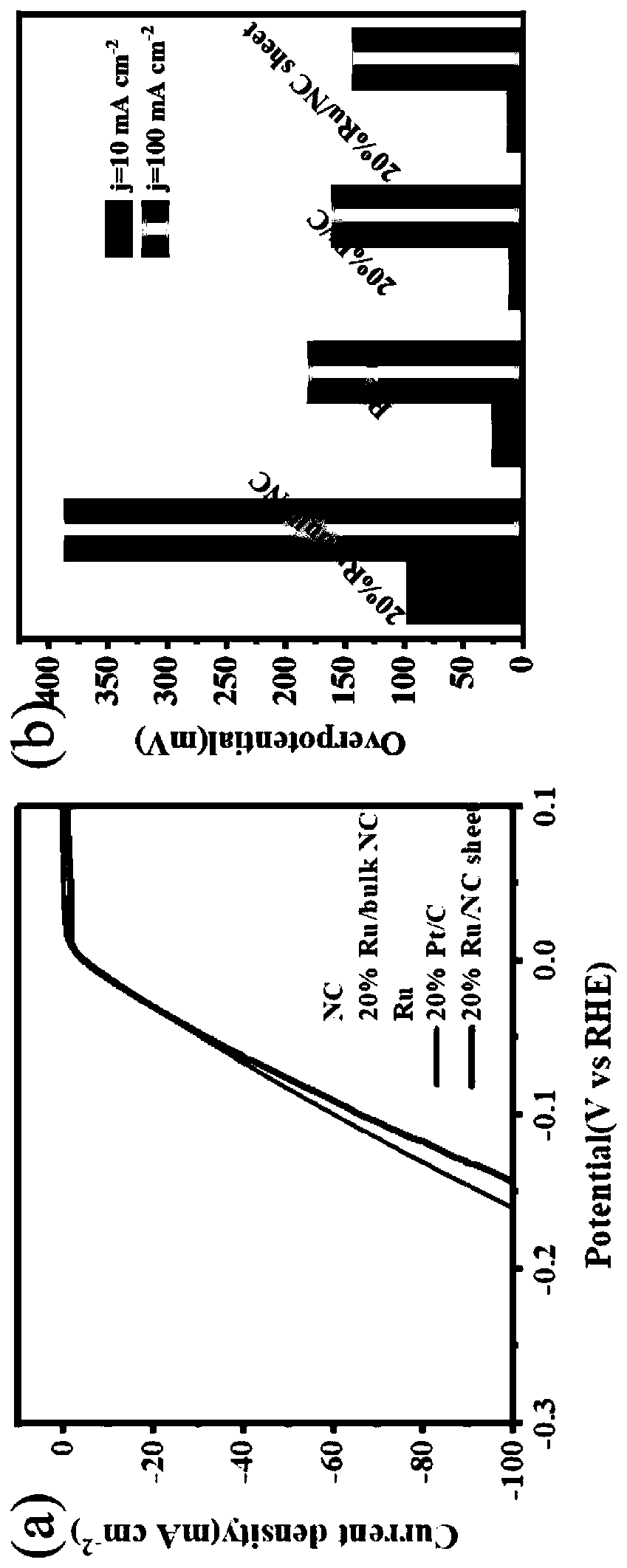

Carbon-based composite electrocatalyst, preparation method and applications thereof

ActiveCN110813350ASimple stepsShort reaction timePhysical/chemical process catalystsElectrodesPtru catalystElectrochemical decomposition

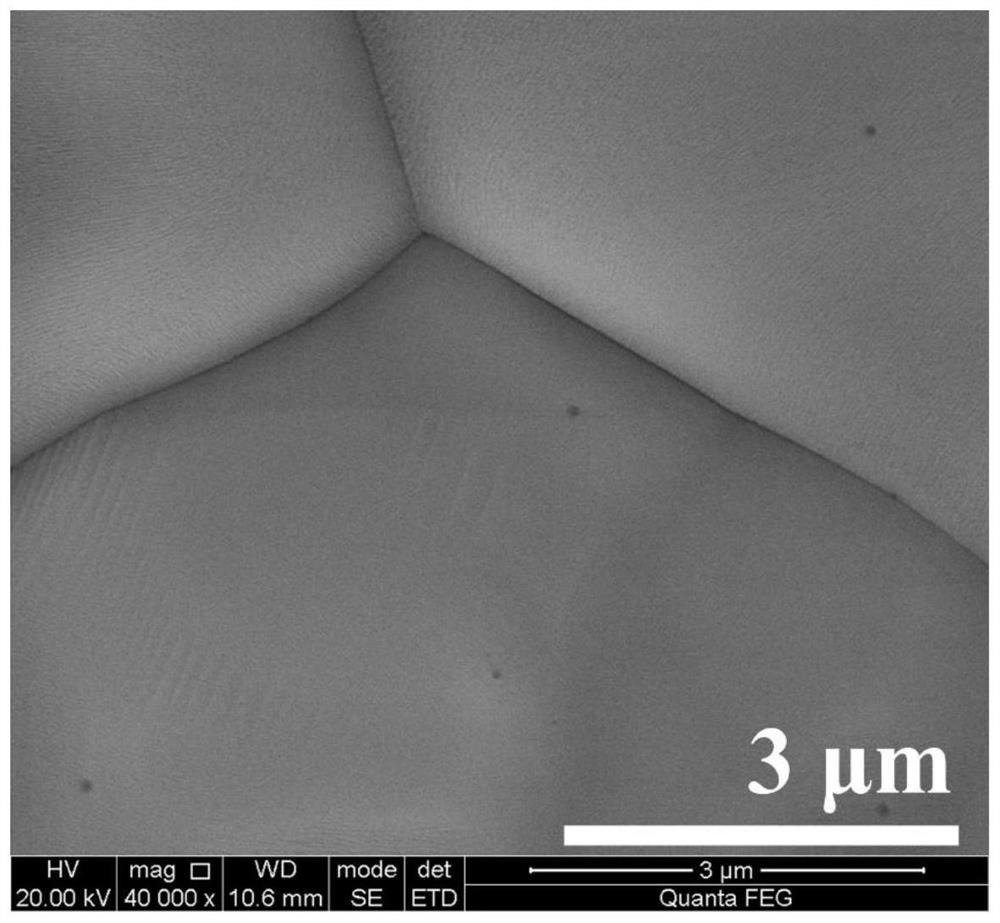

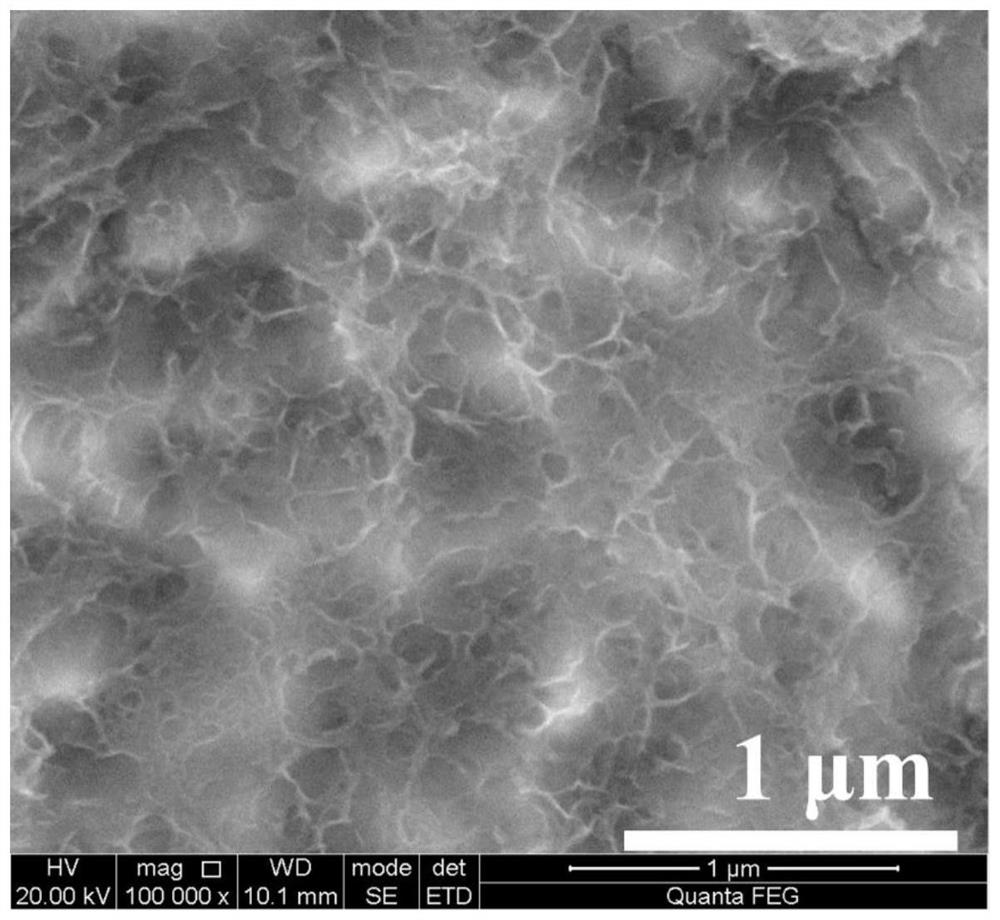

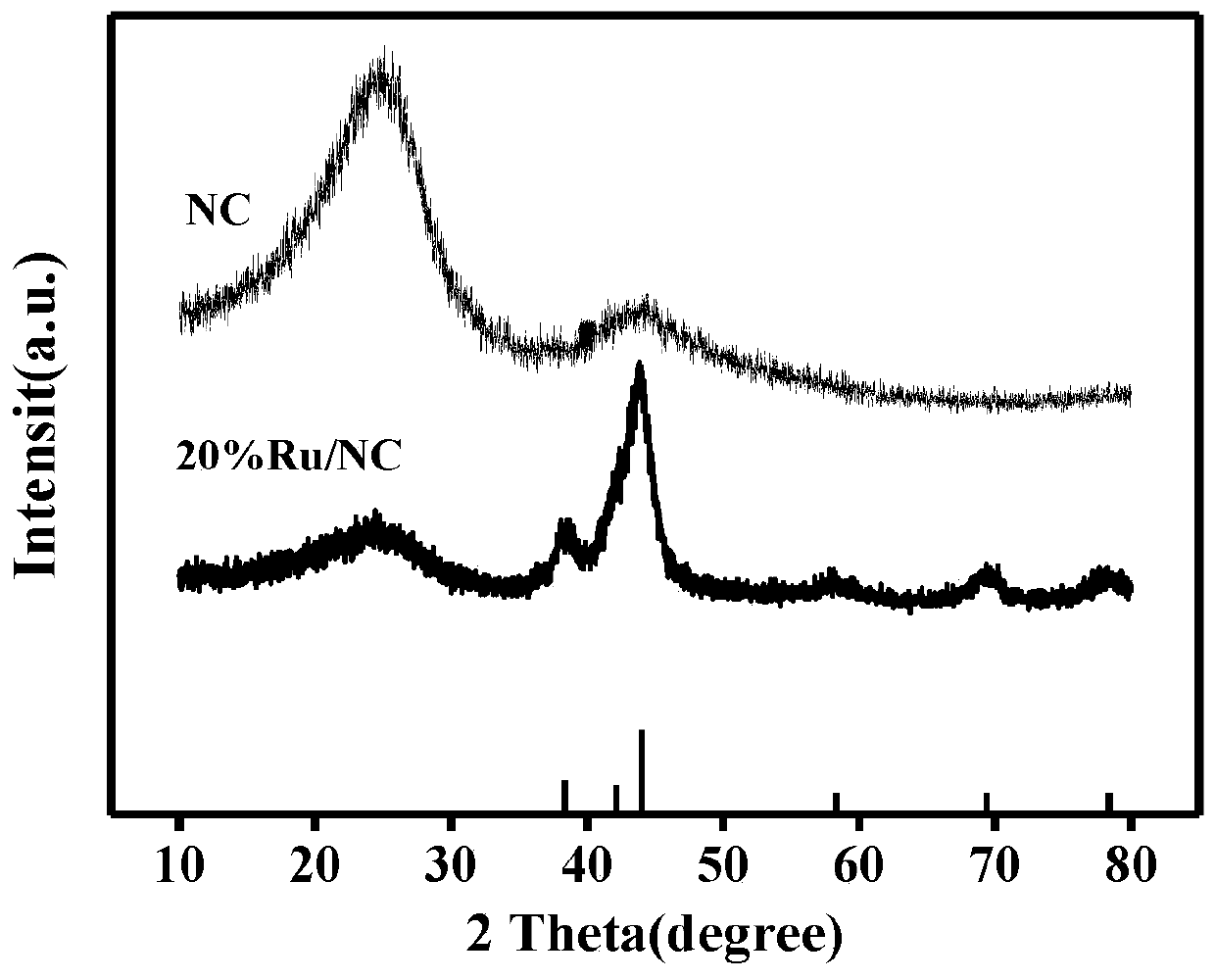

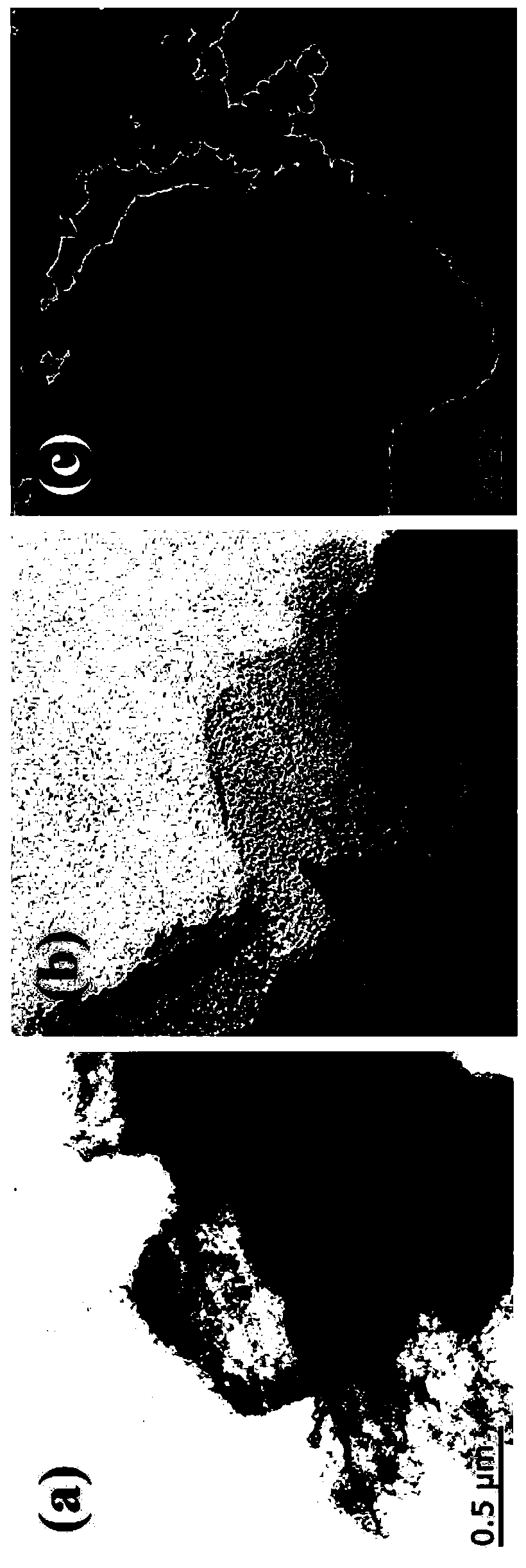

The invention belongs to the field of electrocatalysts, and particularly relates to a preparation method and applications of a high-performance carbon-based composite catalyst for producing hydrogen by electrochemically decomposing water, wherein the Ru / NC electrocatalyst is obtained by using nitrogen-doped carbon (NC) synthesized through complexing, calcining and acid washing as a substrate material and using ethylene glycol as a reducing agent under a reflux condition. According to the invention, the electrocatalyst material has low charge transfer resistance and reaction barrier of hydrogenevolution reaction, and has excellent performance in electrocatalytic hydrogen evolution reactions; Ru has the lowest price in Pt series precious metal materials, so that the catalyst is low in cost;and the obtained catalyst is simple and convenient in experimental operation, simple in process and excellent in catalytic performance, and provides the basic application research for the materials in the field of electro-catalysis.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com