Method for preparing nanoscale granular W18O49 material

A W18O49, granular technology, applied in the field of preparation of nano-scale granular W18O49 materials, can solve the problems of not much research on exposed active crystal planes, the influence of physical and chemical properties, and difficulty, and achieve good photocatalytic performance and short preparation period. , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

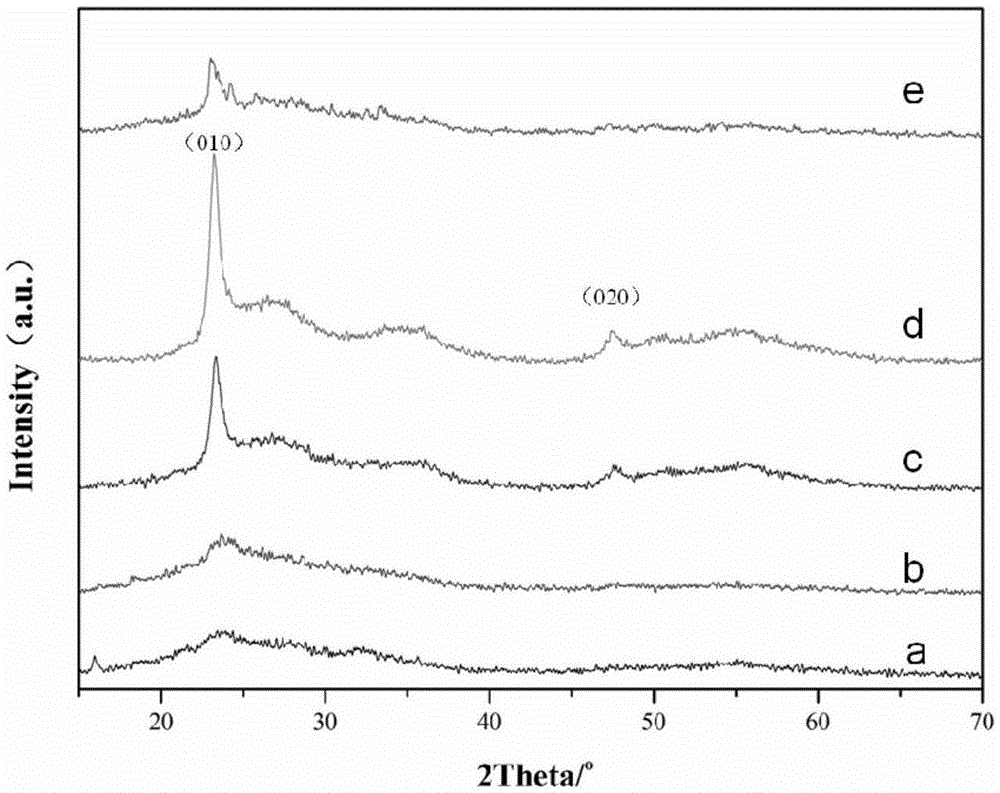

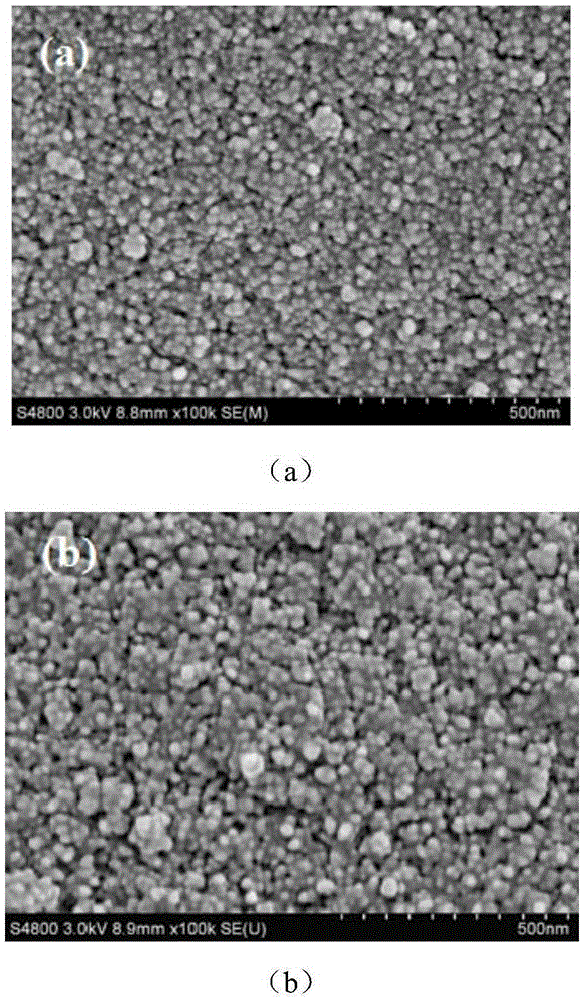

Embodiment 1

[0026] 1) Weigh 0.7931g analytically pure WCl 6 , Prepare 0.05mol / L solution A with 40mL absolute ethanol.

[0027] 2) Add 0.9004g analytically pure oxalic acid (H 2 C 2 o 4 ), making oxalic acid (H 2 C 2 o 4 ) and WCl 6 The ratio of the amounts of the substances is 10:1 to obtain solution B.

[0028] 3) Seal solution B with a plastic wrap to avoid contact with air, stir with a magnetic stirrer for 30 minutes, and treat with ultrasonic (50 Hz) for 20 minutes to obtain solution C.

[0029] 4) Pour solution C into a 100mL polytetrafluoroethylene-lined autoclave, keeping the volume filling ratio at 40%.

[0030] 5) Put the sealed reactor into a homogeneous hydrothermal reactor, and react at 100° C. for 24 hours.

[0031] 6) After the reaction is completed, cool down to room temperature with the furnace, centrifuge the final reactant, and wash with absolute ethanol 3 times. The centrifuged material was dried in a vacuum oven at 50°C to obtain nanoscale granular W 18 o ...

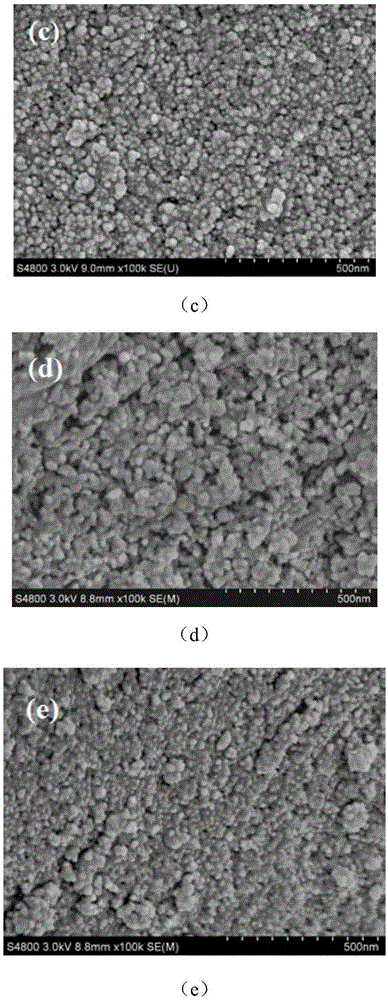

Embodiment 2

[0033] The difference from Example 1 is that in step 5), the reaction was carried out at 120° C. for 24 h. Other steps are all identical with embodiment 1.

Embodiment 3

[0035] The difference from Example 1 is that in step 5), the reaction was carried out at 140° C. for 24 h. Other steps are all identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com