Preparation method of foamed nickel-loaded amorphous phosphorus-doped nickel molybdate bifunctional electrocatalytic electrode and application thereof

A foamed nickel, amorphous technology, applied in catalyst activation/preparation, chemical instruments and methods, electrodes, etc., can solve the problems of high energy consumption, unfavorable large-scale industrialization, cumbersome preparation process, etc., and achieves simple preparation process and convenient industrialization. The effect of simple application and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

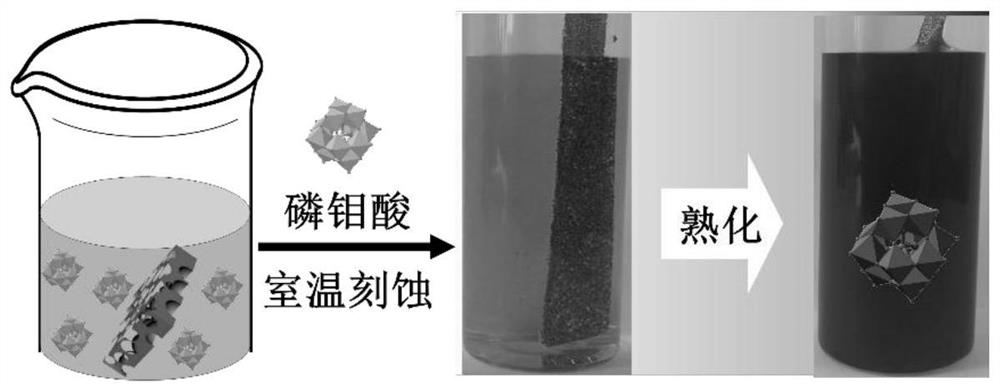

[0052] Such as Figure 1 to Figure 15 As shown, the preparation method of a foam nickel-loaded amorphous phosphorus-doped nickel molybdate bifunctional electrocatalytic electrode involved in this embodiment, the specific steps of the preparation method are as follows:

[0053] Step 1. Soak the nickel foam in 0.5-5mol / L hydrochloric acid aqueous solution at room temperature to remove the metal oxides on the surface. The soaking time is 10-60 minutes. Take out the nickel foam and rinse it with deionized water;

[0054] Step 2. Immerse the pickled nickel foam into 10-100mg / mL phosphomolybdic acid aqueous solution, the reaction temperature is room temperature, and the soaking time is between 12-48 hours. Take out the foam nickel and rinse it with deionized water, dry it for later use. Amorphous phosphorus-doped nickel molybdate nanostructures supported by nickel foam were prepared.

[0055] Application of an amorphous phosphorus-doped nickel molybdate nanostructure bifunctional e...

Embodiment 1

[0059] The concentration of phosphomolybdic acid in this example is 20mg / mL, and concrete preparation steps are as follows:

[0060] First, immerse a nickel foam with a size of 2cm×5cm in 3mol / L HCl for 10min to remove the oxides on the surface. After finishing, rinse the nickel foam with deionized water. At room temperature, soak the above-mentioned nickel foam from which surface metal oxides have been removed in 10 milliliters of phosphomolybdic acid aqueous solution, the concentration of phosphomolybdic acid is 20 mg / mL, and the soaking time is 24 hours. After the reaction, rinse it with deionized water and dry it for later use.

[0061] In the embodiment, the schematic diagram of redox reaction is as figure 1 shown.

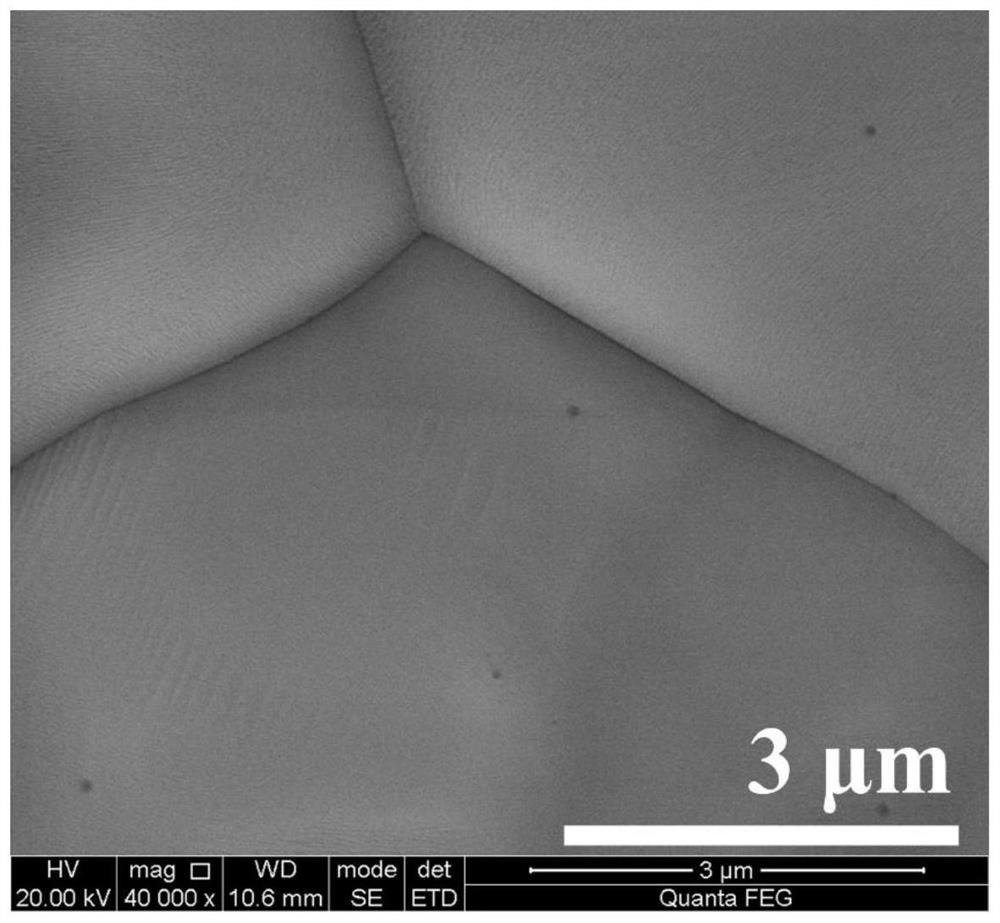

[0062] In the embodiment, the surface morphology of the metal oxide on the surface of nickel foam is removed and analyzed by FEI Quanta 200 scanning electron microscope, such as figure 2 , showing a smooth surface.

[0063] In the embodiment, the surfac...

Embodiment 2

[0069] The concentration of phosphomolybdic acid in this example is 10mg / mL, and concrete preparation steps are as follows:

[0070] First, immerse a nickel foam with a size of 2cm×5cm in 3mol / L HCl for 10min to remove the oxides on the surface. After finishing, rinse the nickel foam with deionized water. At room temperature, soak the above-mentioned nickel foam from which the surface metal oxide has been removed in 10 ml of phosphomolybdic acid aqueous solution, the concentration of phosphomolybdic acid is 10 mg / mL, and the soaking time is 24 hours. After the reaction, rinse it with deionized water and dry it for later use.

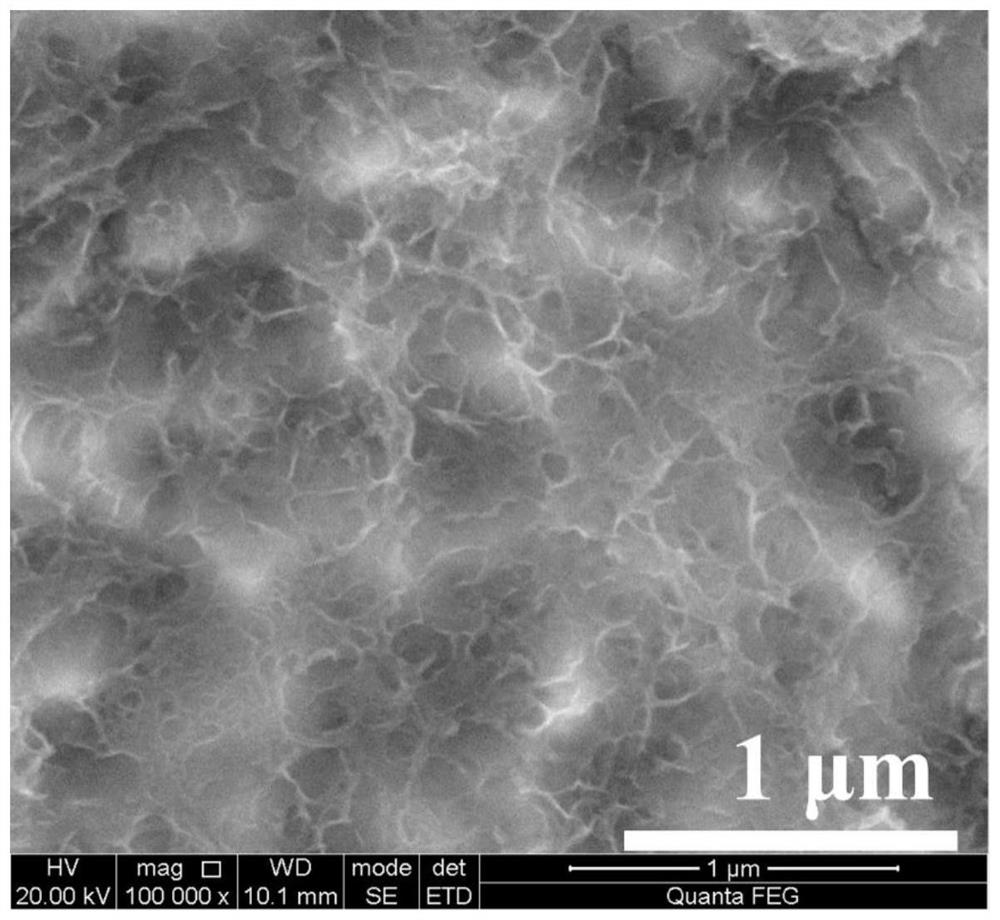

[0071] In the embodiment, the surface morphology of the metal oxide on the surface of nickel foam is removed and analyzed by FEI Quanta 200 scanning electron microscope, such as Figure 9 As shown, a grid-like nanostructure is displayed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com