Patents

Literature

1812 results about "Molybdic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molybdic acid refers to hydrated forms of molybdenum trioxide and related species. The monohydrate is MoO₃·H₂O and the dihydrate (MoO₃·2H₂O) are well characterized. They are yellow diamagnetic solids.

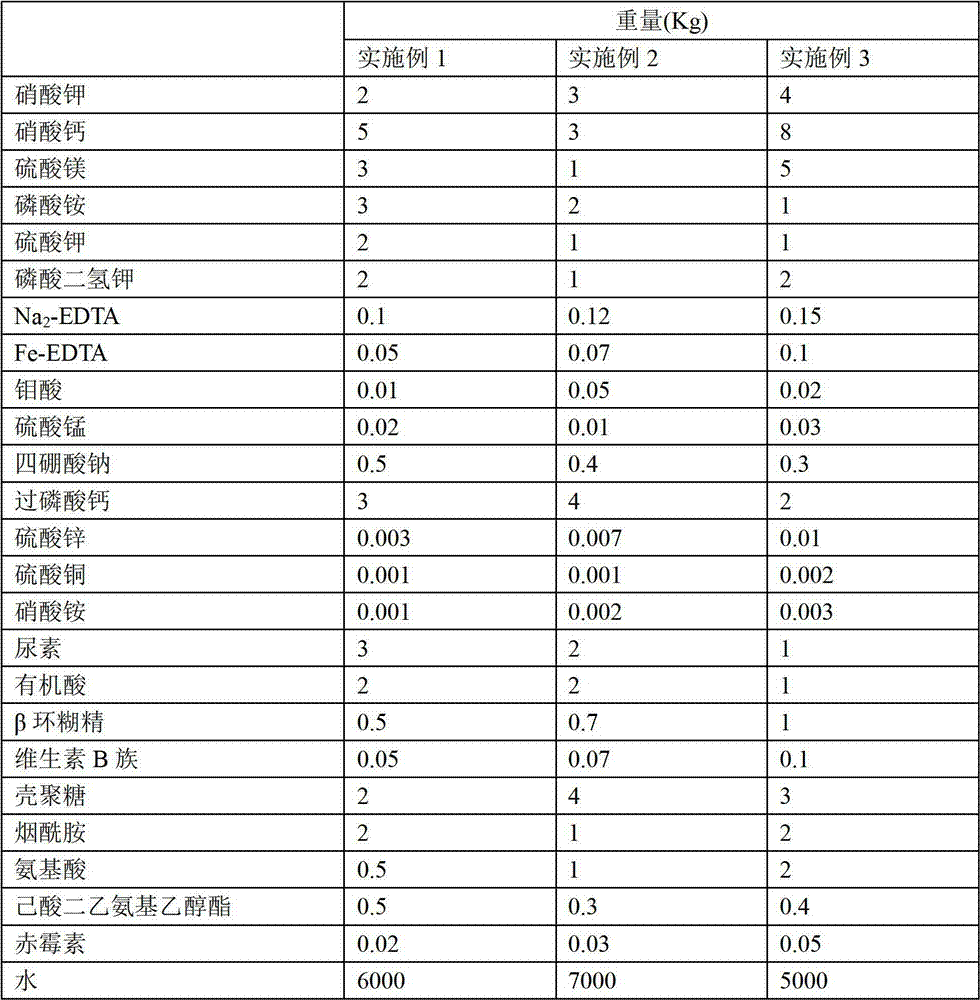

Plant nutrient solution for soilless culture of tomato

The invention provides a plant nutrient solution for soilless culture of tomato. The plant nutrient solution is prepared by the following raw materials in part by weight: 2 to 4 parts of potassium nitrate, 3 to 8 parts of calcium nitrate, 1 to 5 parts of magnesium sulfate, 1 to 3 parts of potassium phosphate, 1 to 2 parts of potassium sulphate, 1 to 2 parts of monopotassium phosphate, 0.1 to 0.15 part of Na2-EDTA, 0.05 to 0.1 part of Fe-EDTA, 0.01 to 0.05 part of molybdic acid, 0.01 to 0.03 part of manganese sulfate, 0.3 to 0.5 part of sodium tetraborate, 2 to 4 parts of superphosphate, 0.003 to 0.01 part of zinc sulfate, 0.001 to 0.002 part of copper sulfate, 0.001 to 0.003 part of ammonium nitrate, 1 to 3 parts of urea, 1 to 2 parts of organic acid, 0.5 to 1 part of beta cyclodextrin, 0.05 to 0.1 part of vitamin B, 2 to 4 parts of chitosan, 1 to 2 parts of nicotinamide, 0.5 to 2 parts of amino acid, 0.3 to 0.5 part of diethyl aminoethyl hexanoate, 0.02 to 0.5 part of gibberellin, and 5,000 to 7,000 parts of water. According to experiment, the plant nutrient solution provided by the invention can be used for carrying out soilless culture of tomato, and the tomato has high plant height, thick stem, high cluster and high output.

Owner:山西田森杜氏番茄科技有限公司

Aqueous dispersion for chemical mechanical polishing

InactiveUS6527818B2Pigmenting treatmentOther chemical processesColloidal silicaOXALIC ACID DIHYDRATE

There is provided an aqueous dispersion for CMP with an excellent balance between chemical etching and mechanical polishing performance. The aqueous dispersion for CMP of the invention is characterized by comprising an abrasive, water and a heteropolyacid. Another aqueous dispersion for CMP according to the invention is characterized by comprising an abrasive, water, a heteropolyacid and an organic acid. Yet another aqueous dispersion for CMP according to the invention is characterized by comprising colloidal silica with a primary particle size of 5-100 nm, water and a heteropolyacid. Preferred for the heteropolyacid is at least one type selected from among silicomolybdic acid, phosphorotungstic acid, silicotungstic acid, phosphoromolybdic acid and silicotungstomolybdic acid. Preferred for the organic acid is at least one selected from among oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, maleic acid, fumaric acid, phthalic acid, malic acid, tartaric acid and citric acid.

Owner:JSR CORPORATIOON

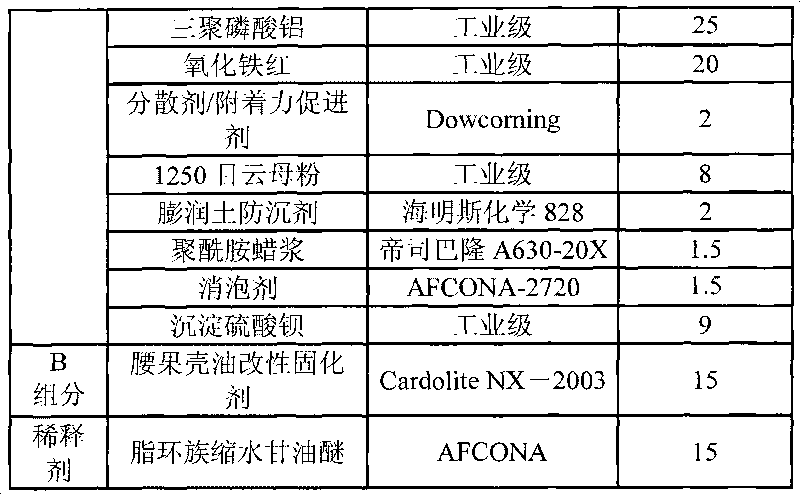

Coating composition and article coated therewith

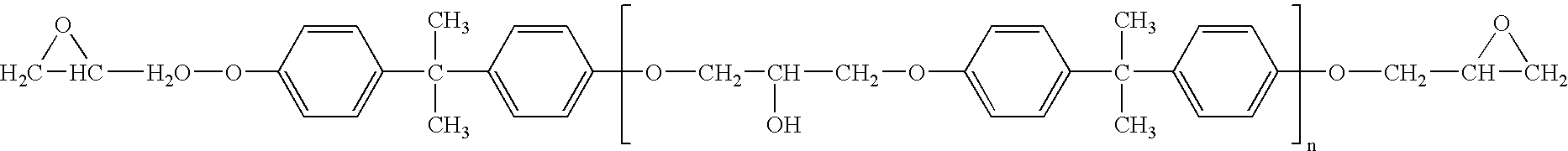

InactiveUS20050215670A1Improve corrosion resistancePlastic/resin/waxes insulatorsAnti-corrosive paintsEpoxyTriazole antifungals

A coating composition used for coating of a steel material and / or aluminum material comprises a corrosion inhibitor, a base resin and a curing agent. The corrosion inhibitor may be selected from cerium compounds, lanthanum compounds, molybdate salt compounds, gluconic acid derivative salts, porous base materials, triazole compounds, thiazole compounds, tetracyclines, and metal phosphate salt compounds of ascorbic acid. The base resin may include a xylene-formaldehyde-resin-modified amino-containing epoxy resins obtained by reacting an epoxy resin having an epoxy equivalent of from 180 to 2500 with a xylene formaldehyde resin and an amino-containing compound. The curing agent may be a blocked polyisocyanate compound obtained by blocking an isocyanate group of a polyisocyanate compound with a blocking agent.

Owner:KANSAI PAINT CO LTD

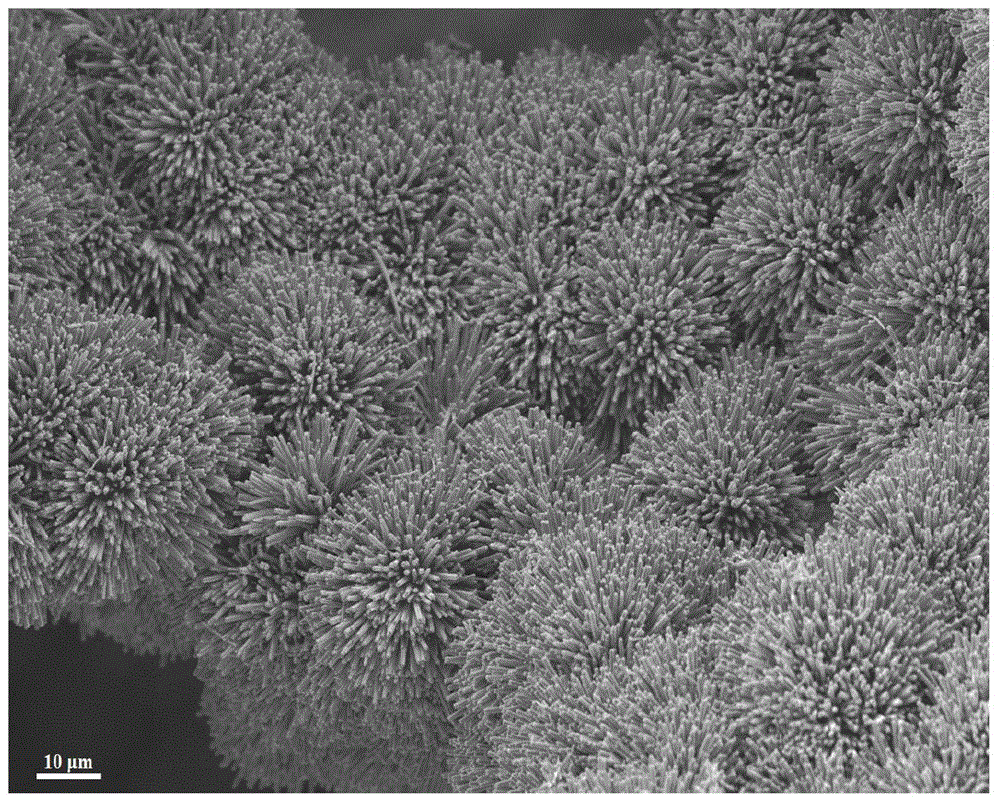

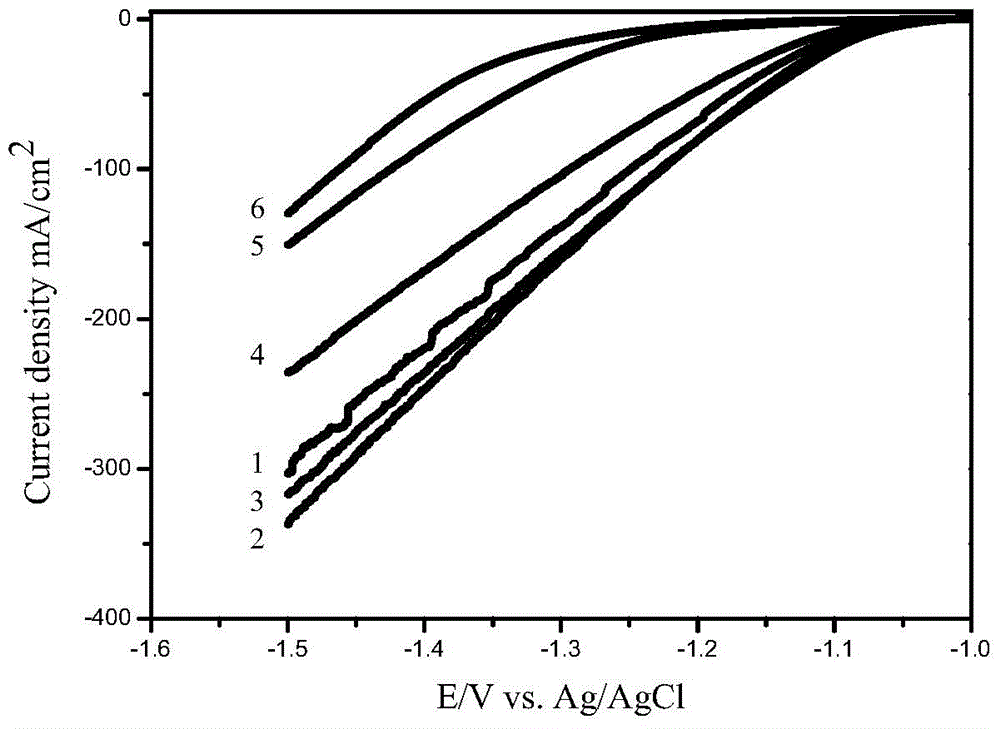

Method for preparing high-performance molybdenum-based hydrogen evolution electrode by phosphatizing molybdate precursor

The invention provides a method for preparing a high-performance molybdenum-based hydrogen evolution electrode by phosphatizing a molybdate precursor and belongs to the fields of water electrolysis and electric catalytic hydrogen evolution in the chlor-alkali industry. The method comprises the steps of pre-processing foamed nickel, growing the molybdate precursor in situ on the surface of a pre-processed foamed nickel base with the hydrothermal synthesis method, and finally placing the prepared precursor and a phosphorus source into a rube furnace together for phosphating of the molybdate precursor so that the high-performance molybdenum-based hydrogen evolution electrode can be prepared. The method is novel, the technology adopted is simple, production cost is low, the requirement for equipment is low, and the method is suitable for industrial production. Furthermore, the electrode is large in specific area, can be combined with the base firmly, has excellent hydrogen evolution activity and stability, and can be widely applied to the fields of water electrolysis and hydrogen evolution in the chlor-alkali industry.

Owner:CHONGQING UNIV

Non-Phosphorus composite anti incrustation eorrosion snhibiter and its application in water treatment

ActiveCN1785853AImprove performanceExcellent resistance to CaCO

<sub>3</sub>

Dirt performanceScale removal and water softeningMolybdatePolyaspartic acid

The present invention relates to a phosphorus-free composite antiincrustation corrosion inhibitor. It includes polyaspartic acid and / or polyepoxysuccinic acid and at least one kind of scale inhibition and dispersion agent, in which the scale inbibition and dispersion agent is polymer containing carboxylic acid group, or it includes polyaspartic acid and / or polyepoxysuccinic acid, zinc salt, molybdate or tungstate and polymer containing carboxylic acid group. Said invention is applicable to treatment of circulating cooling water.

Owner:BEIJING YANHUA PETRO CHEM

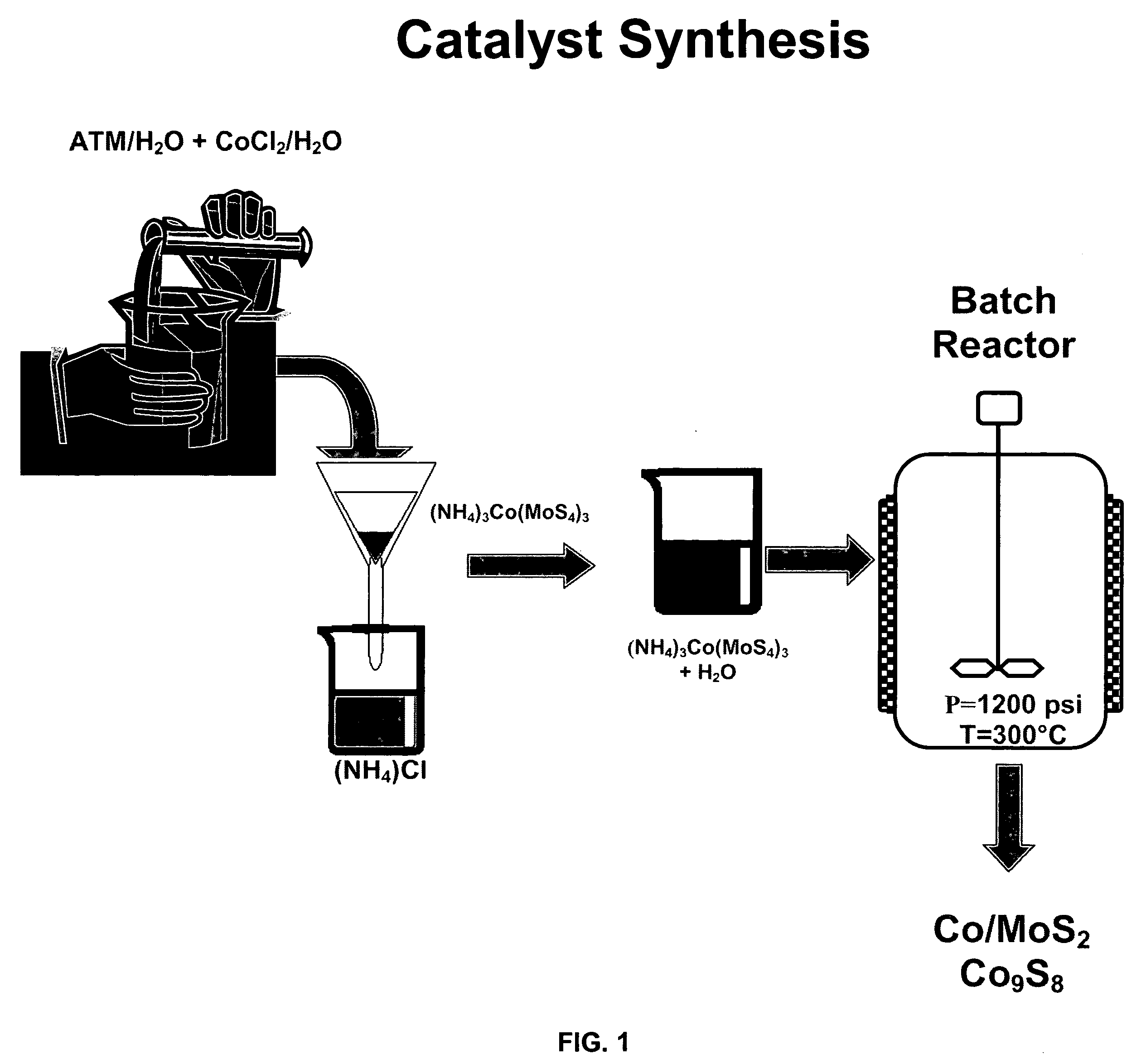

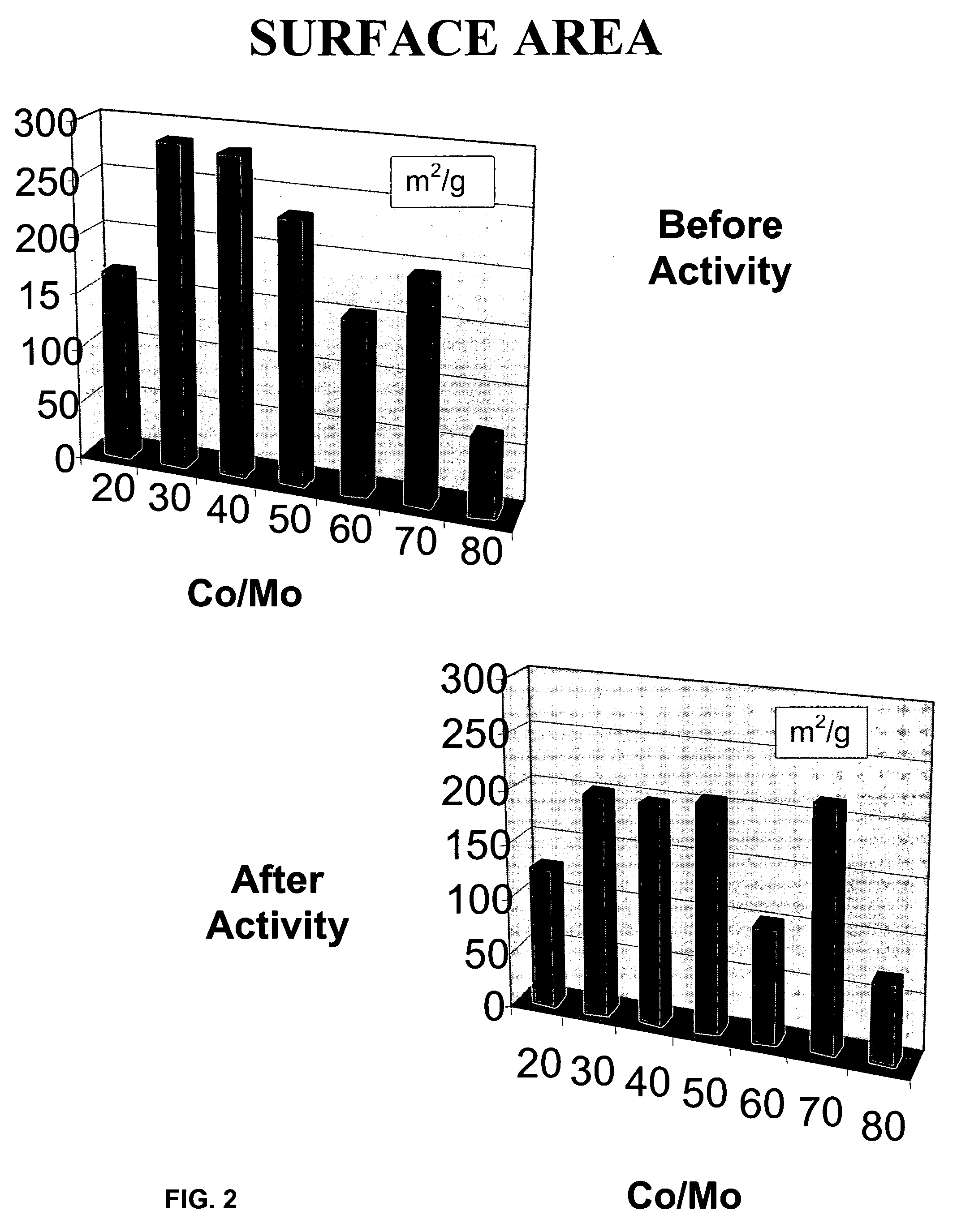

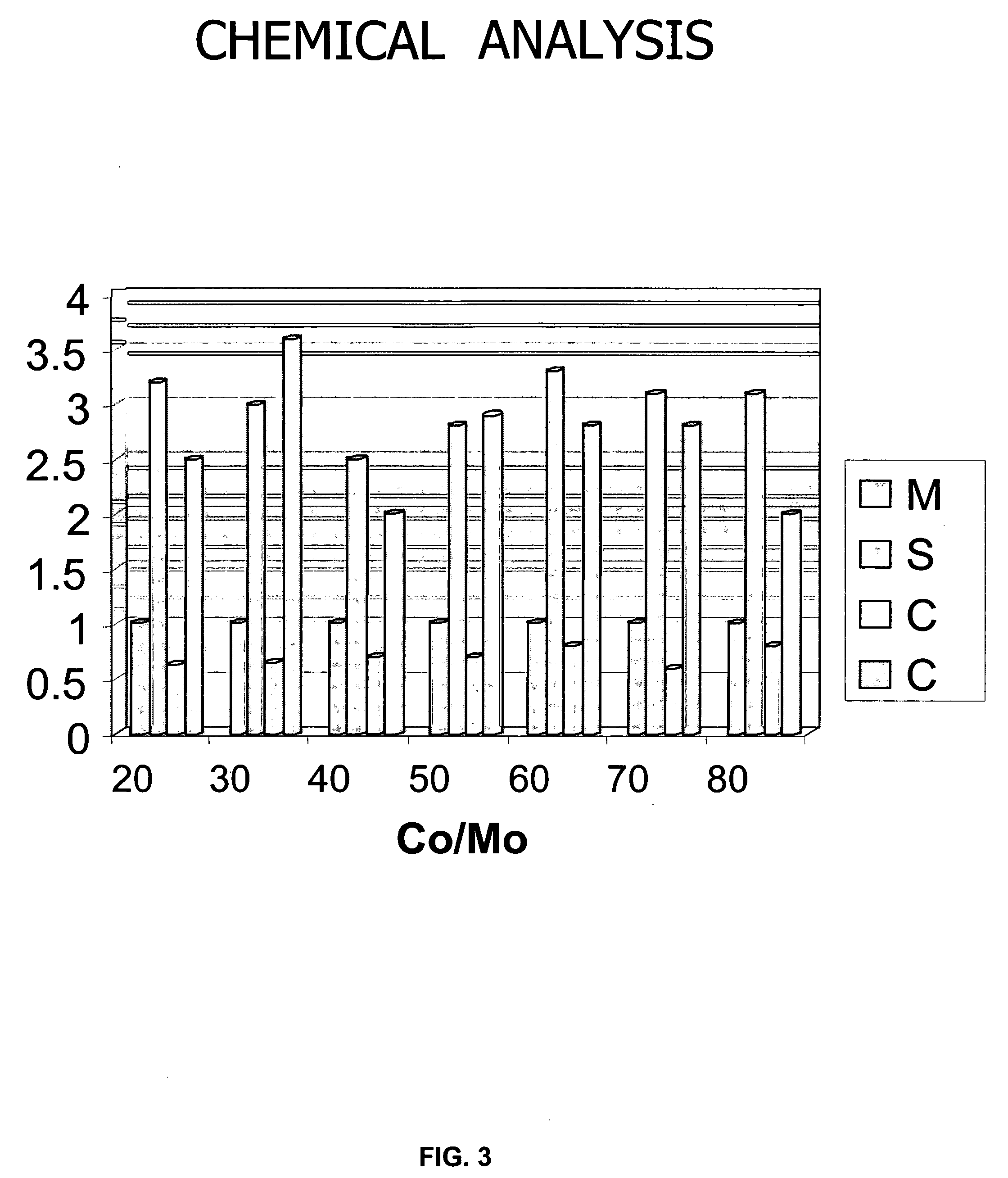

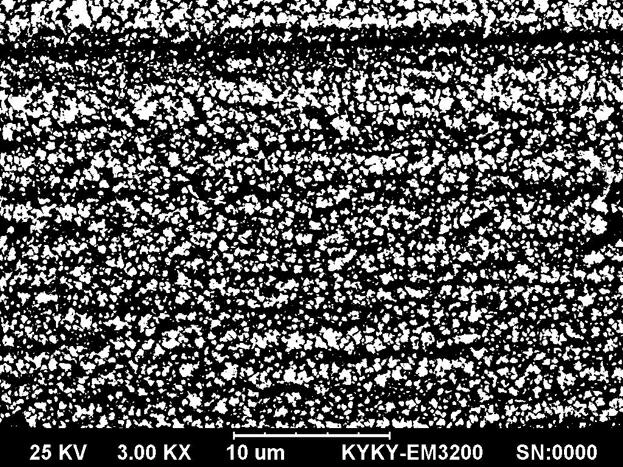

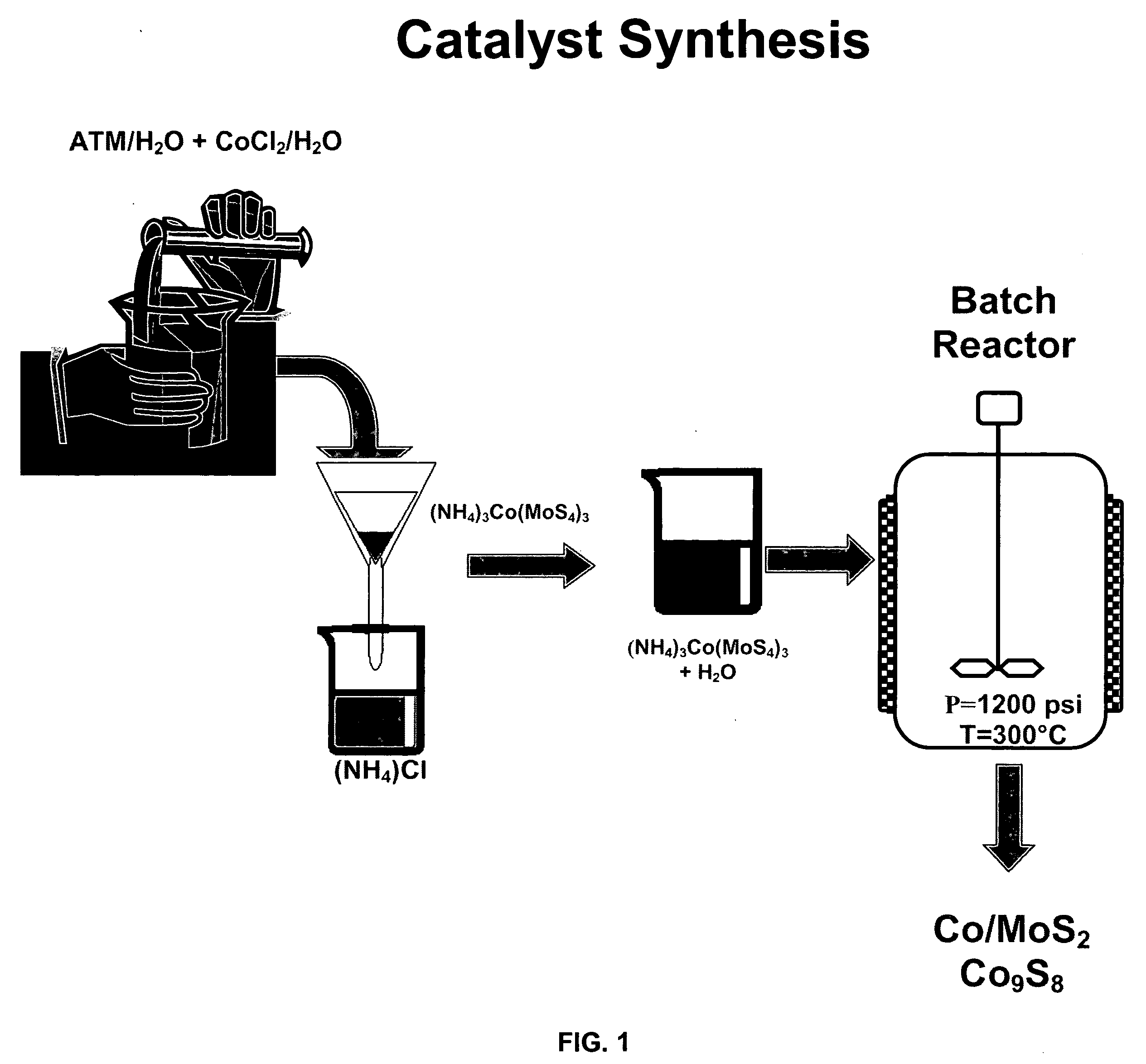

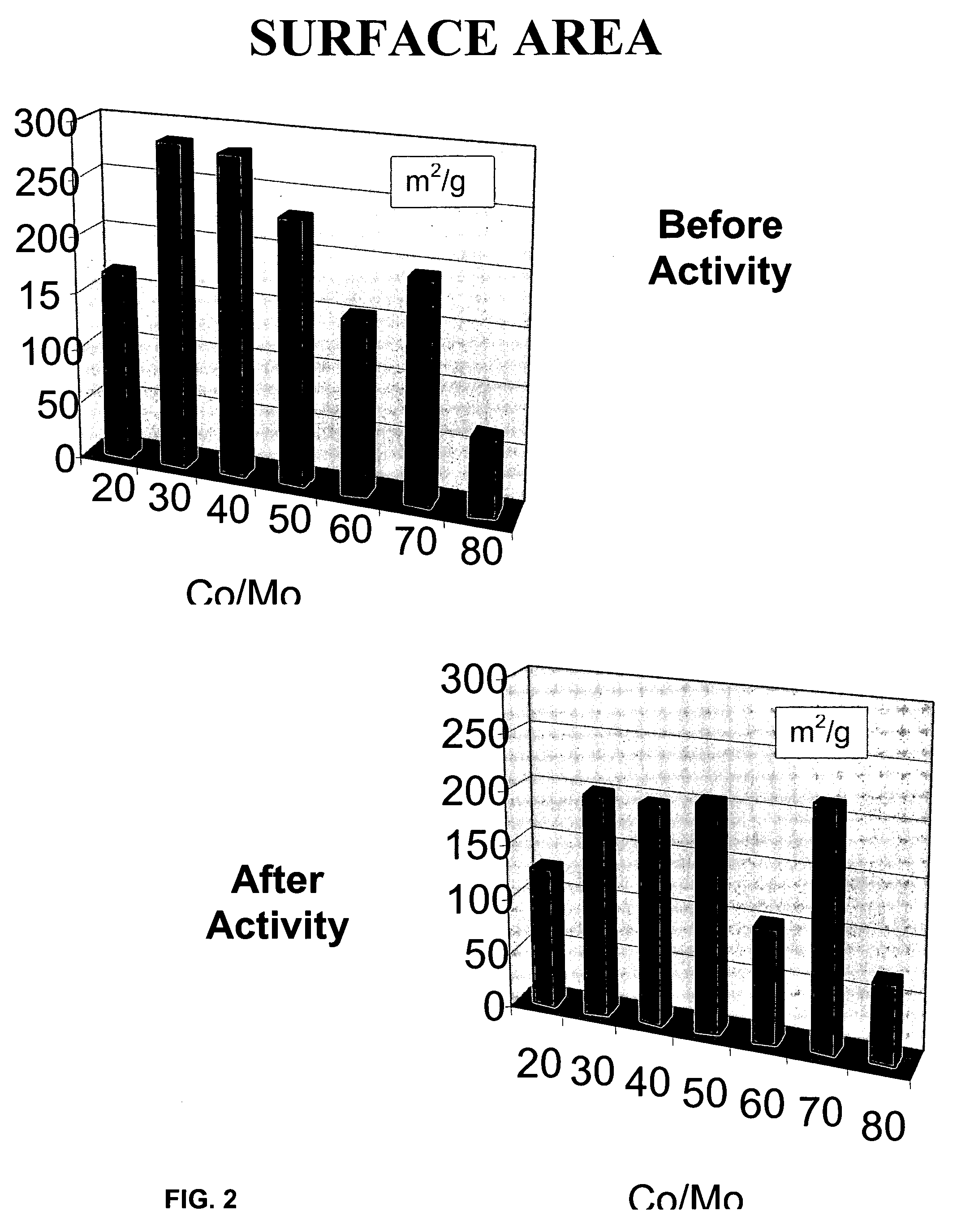

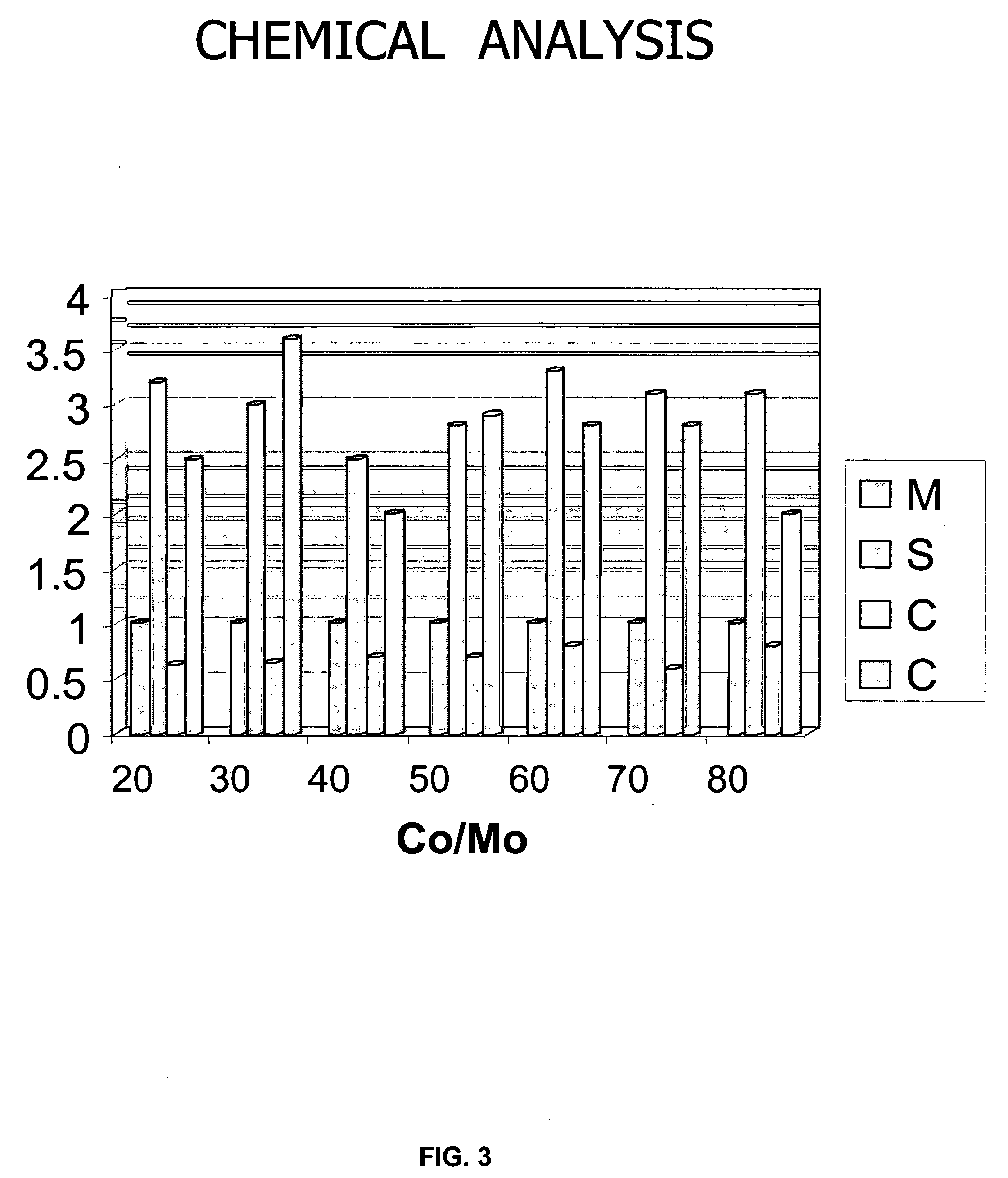

Molybdenum sulfide/carbide catalysts

InactiveUS7223713B2High activityImprove stabilityCell electrodesCatalyst activation/preparationMolybdateNitrogen

The present invention provides methods of synthesizing molybdenum disulfide (MoS2) and carbon-containing molybdenum disulfide (MoS2-xCx) catalysts that exhibit improved catalytic activity for hydrotreating reactions involving hydrodesulfurization, hydrodenitrogenation, and hydrogenation. The present invention also concerns the resulting catalysts. Furthermore, the invention concerns the promotion of these catalysts with Co, Ni, Fe, and / or Ru sulfides to create catalysts with greater activity, for hydrotreating reactions, than conventional catalysts such as cobalt molybdate on alumina support.

Owner:GABRIEL ALONSO +2

Multifunctional concrete structure endurance protective agent, preparation and application method thereof

The invention discloses a multifunctional concrete structure endurance protective agent as well as the preparation and application method thereof. The protective agent provided by the invention contains the following ingredients of: an organic / inorganic composite fluorosilicone-acrylate copolymer, lithium silicate, sodium silicate, lithium molybdate, sodium tetraborate, sal glauberi, 1,2-aminoazophenylene, nanometer titanium dioxide, anhydrous ethanol and water. The protective agent can penetrate inside concrete, wherein a densification ingredient can minimize internal holes and cracks to raise the compactness of concrete, and a rust-resistant ingredient can penetrate into concrete and be adsorbed on the surface of steel bar so as to passivate and protect the steel bar; the low-surface energy silicon fluoride ingredient can be solidified to form a cured film on the surface of concrete so as to endow the protective agent with the hydrophobic performance; a nanometer ingredient can endow the cured film layer with properties of resisting ultraviolet and ageing and improving the organic polymer performance as well as the self-cleaning performance. In addition, hydroxy generated from the hydrolysis of siloxane group can perform a condensation reaction with hydroxy on the surface of concrete to produce chemical bond, so as to raise the anchoring strength between the film and concrete and improve the interface combination. The protective agent provided by the invention can be widely applied in various concrete structure engineering protections to raise the service life of concrete.

Owner:CENT SOUTH UNIV +1

Boiler coal combustion-improving desulfurizing and denitrifying agent composition and preparation method thereof

The invention provides a boiler coal combustion-improving desulfurizing and denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-7 parts of sodium carbonate, 1-3 parts of alumina, 2-8 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 2-6 parts of ferric oxide, 3-10 parts of potassium permanganate, 3-10 parts of potassium chlorate, 10-35 parts of activated attapulgite clay, 15-30 parts of urea, 2-4 parts of ammonium formate, 2-4 parts of ammonium chloride, 6-23 parts of ammonium acetate, 3-9 parts of manganese oxide, 9-12 parts of copper chloride, 1-3 parts of copper oxide, 2-4 parts of zinc sulfate, 1-3 parts of zinc nitrate, 7-18 parts of potassium dichromate, 1.0-1.5 parts of titanium dioxide, 0.5-1.0 part of barium molybdate, 0.5-1.5 parts of cobalt sulfate, 0.5-1.5 parts of vanadium pentoxide, 0.3-0.7 part of cerium oxide, 0.1-0.2 part of sodium dodecyl benzene sulfonate and 0.1-0.2 part of alkyl glyceryl ether. The composition is convenient to use, has stable properties, plays roles of combustion improving, desulfurization and denitrification, has coal saving rate of 8-25% and can remove fixed sulfur by 50-70%.

Owner:兰州熙瑞化工科技有限公司

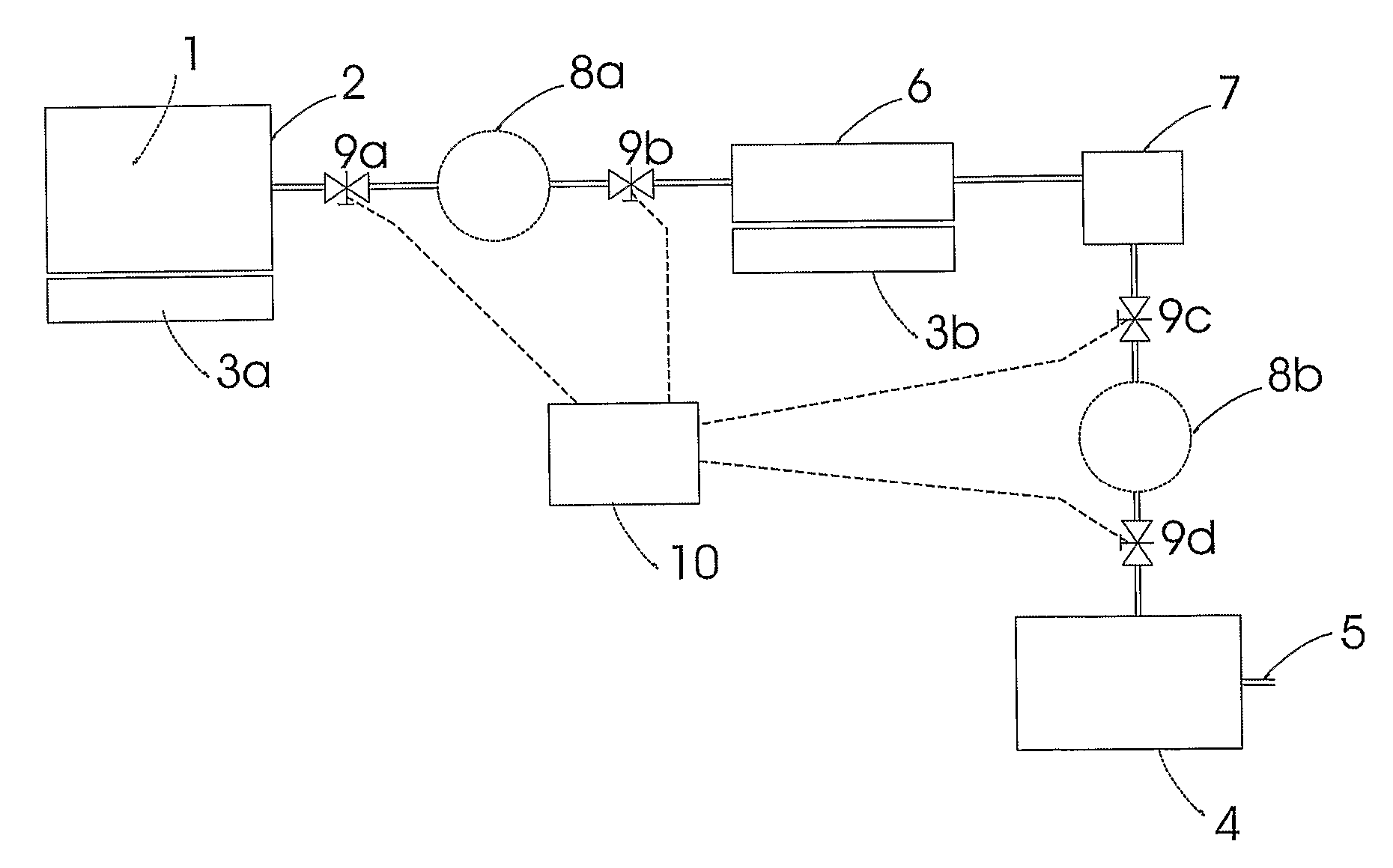

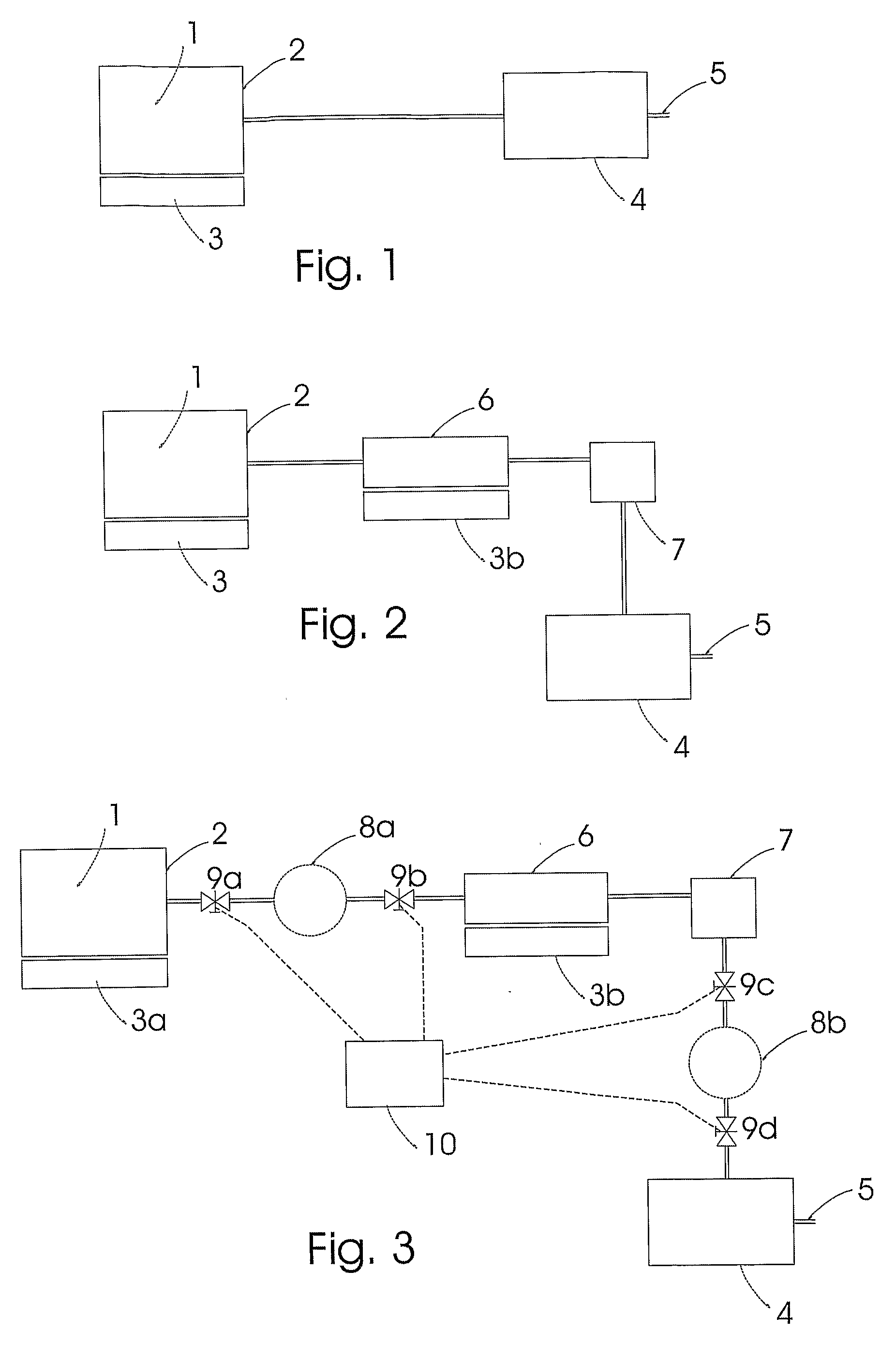

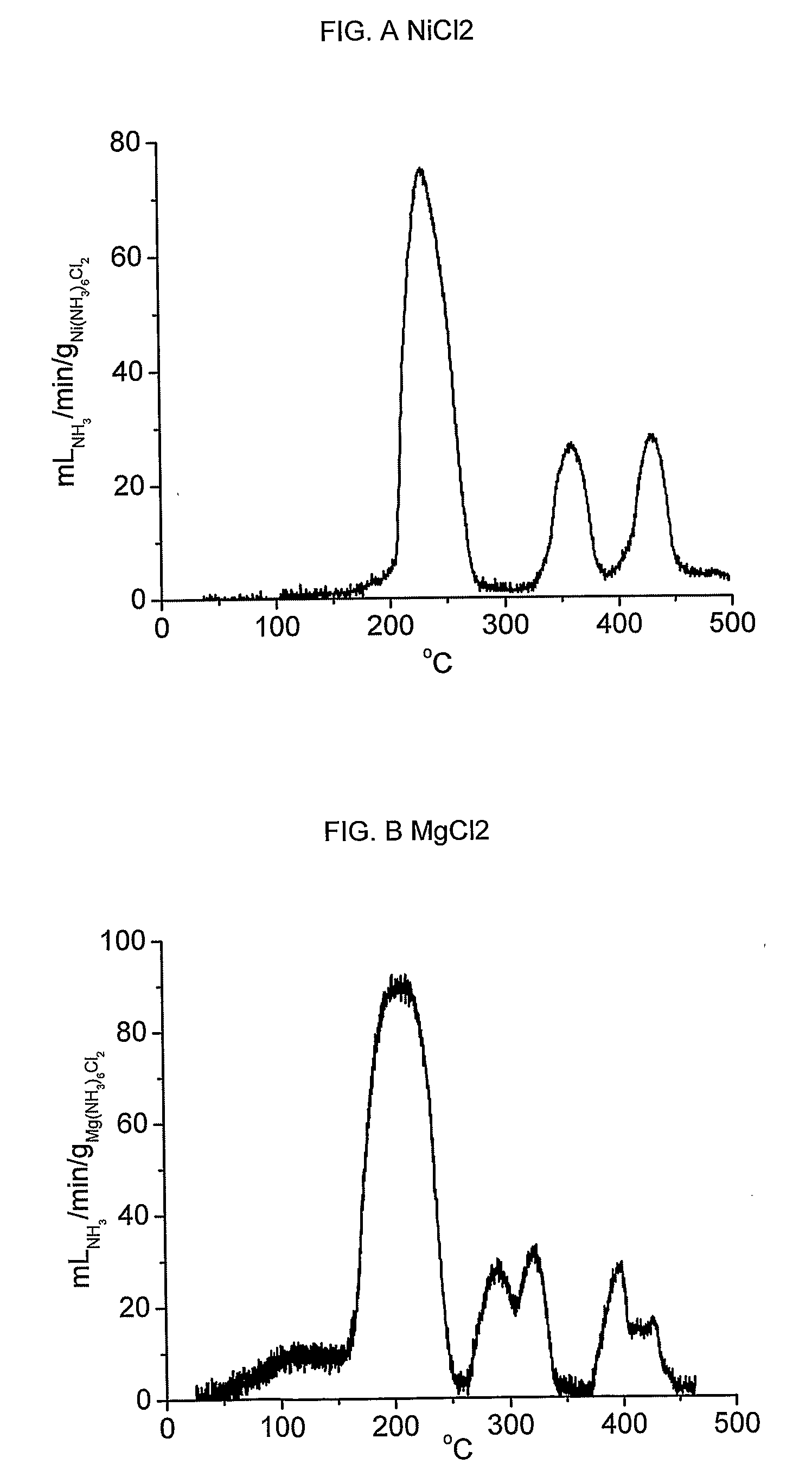

Use Of An Ammonia Storage Device In Production Of Energy

InactiveUS20070207351A1Reactant parameters controlMagnesium halidesAlkaline earth metalAmmonia storage

An electric power generating unit comprising (i) an ammonia storage device in the form of a container comprising an ammonia absorbing and releasing salt of the general formula: Ma(NH3)nXz, wherein M is one or more cations selected from alkali metals, alkaline earth metals, and transition metals such as Li, K, Mg, Ca, V, Cr, Mn, Fe, Co, Ni, Cu or Zn, X is one or more anions selected from fluoride, chloride, bromide, iodide, nitrate, thiocyanate, sulphate, molybdate, phosphate, and chlorate ions, a is the number of cations per salt molecule, Z is the number of anions per salt molecule, and n is the coordination number of 2 to 12. (ii) means for heating said container and ammonia absorbing and releasing salt for releasing ammonia gas and (iiia) a fuel cell for converting ammonia directly into electric power; or (iiib1) a reactor for dissociating ammonia into hydrogen and nitrogen and (iiib2) a fuel cell for converting hydrogen into electric power is useful for large stationary energy producing facilities, but also for use for is useful for large stationary energy producing facilities, but also for use for small rechargeable and / or replaceable power supply units for micro-fabricated or miniaturized ammonia decomposition reactors for use in mobile units and portable devices may be used for large energy producing facilities, and by use of small rechargeable and / or replaceable ammonia storage decomposition reactors, it is also possible to provide energy for mobile units and portable devices.

Owner:AMMINEX

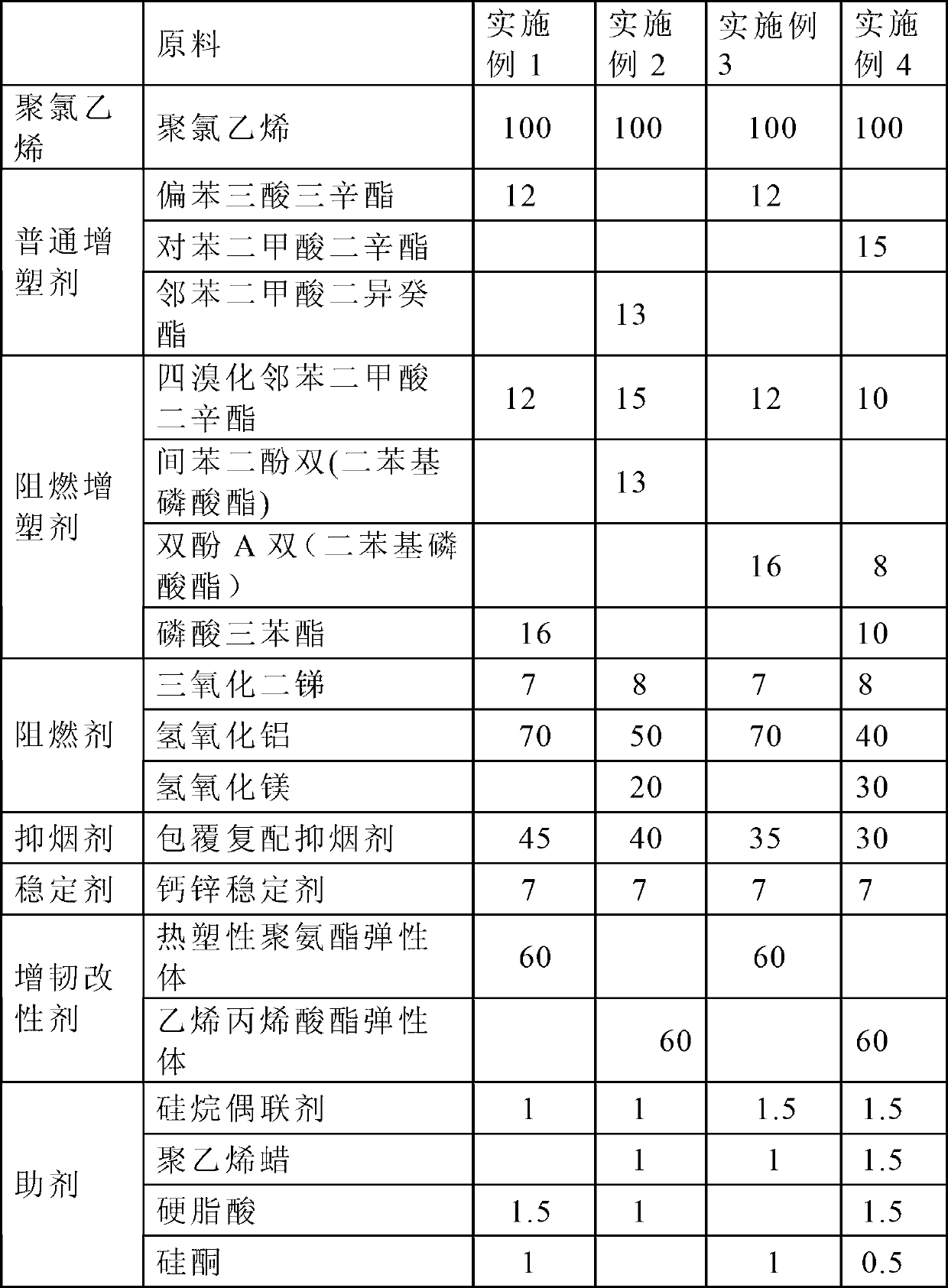

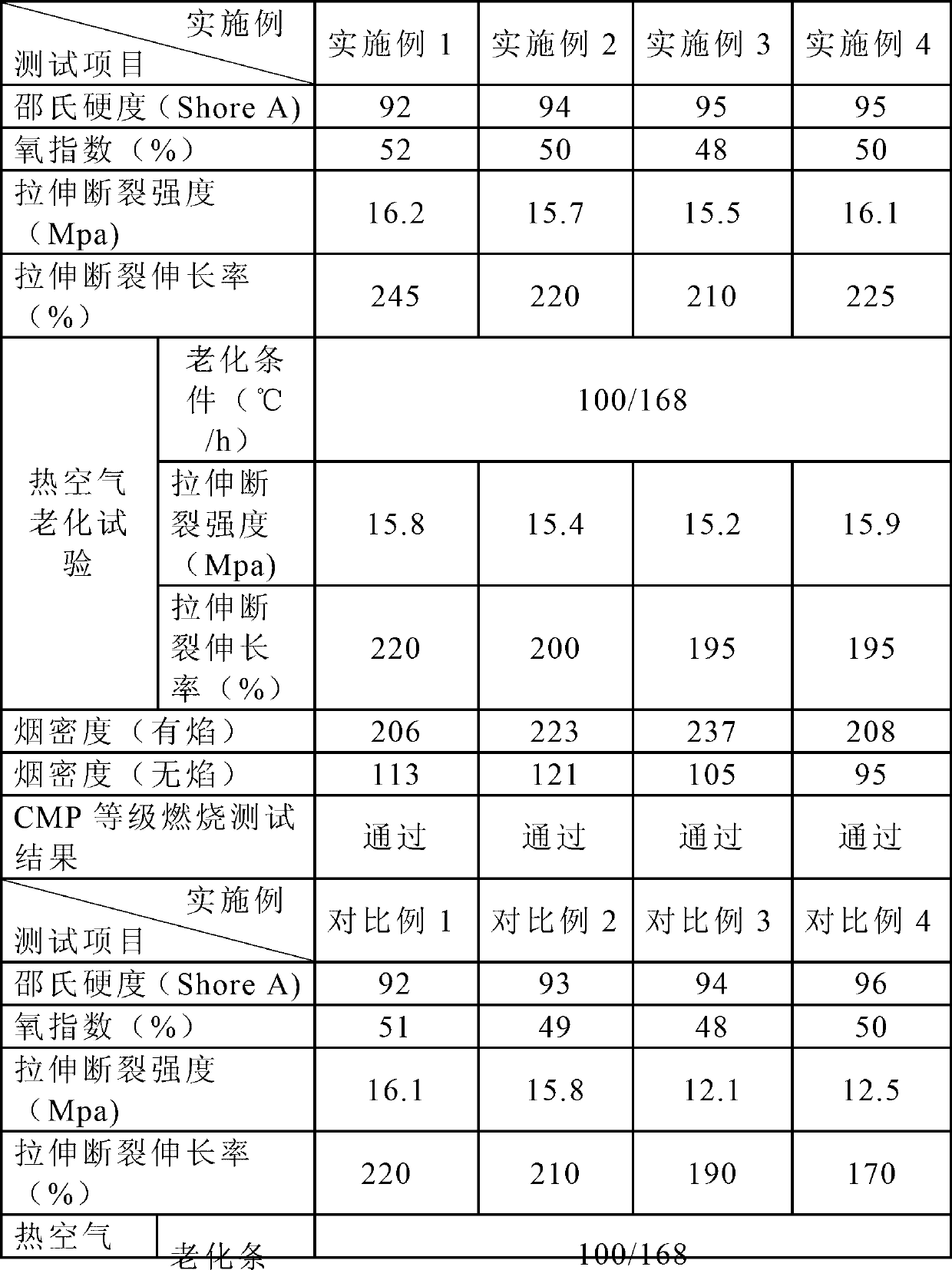

Corrugated metal pipe (CMP) grade flame-retardant smoke-suppressing polyvinyl chloride cable sheath material and preparation method thereof

ActiveCN102993602AReasonable cooperationImprove flame retardant and smoke suppression performanceInsulated cablesInsulated conductorsAluminium hydroxidePolyvinyl chloride

The invention provides a corrugated metal pipe (CMP) grade flame-retardant smoke-suppressing polyvinyl chloride cable sheath material and a preparation method thereof and belongs to the technical field of material. The invention solves the problem that in the prior art, the flame-retardant and smoke-suppressing effects and the mechanical property and the physical property of the cable sheath material are all good. The raw materials thereof comprise the following components in parts by weight: 100 parts of polyvinyl chloride, 5-15 parts of common plasticizer, 20-50 parts of flame-retardant plasticizer, 40-100 parts of fire retardant, 20-50 parts of smoke-suppressing agent, 5-10 parts of stabilizer, 40-80 parts of toughening modification agent and 1-5 parts of promoter; wherein the smoke-suppressing agent comprises ammonium octamolybdate, zinc molybdate and zinc borate which are compounded according to the proportion of 1:1 to 3:1 to 3 and coated by aluminium hydroxide the grain size of which is 1-5mu m according to the proportion of 1:1 to 3. The CMP grade flame-retardant smoke-suppressing polyvinyl chloride cable sheath material has the advantages of good flame-retardant and smoke-suppressing effect, mechanical property and physical property.

Owner:江西一舟数据技术有限公司

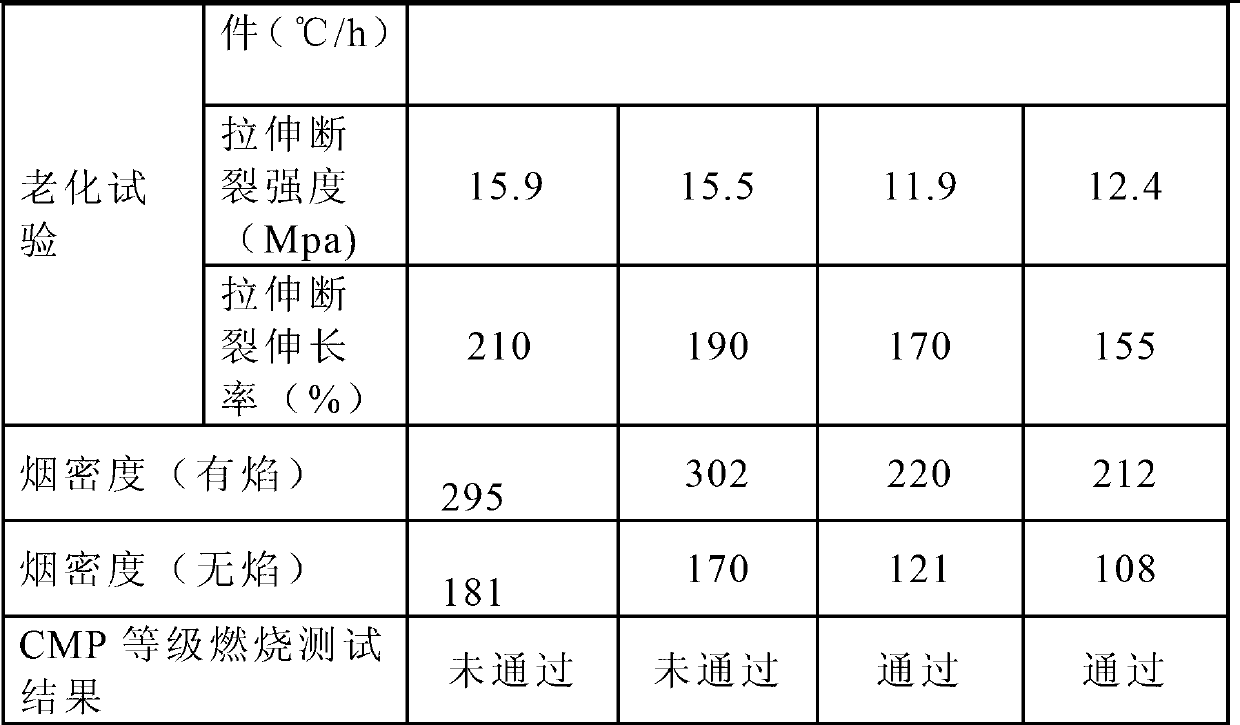

Method for preparing 1,3-butadiene as high yield

ActiveUS20130281748A1Excellent catalytic performanceHigh dehydrogenation activityDistillation purification/separationCatalystsButenePolymer science

Disclosed is a method for producing 1,3-butadiene through oxidative dehydrogenation of normal-butene using a parallel reactor in which catalysts are charged into fixed bed reactors and are not physically mixed. More specifically, disclosed is a method for efficiently producing 1,3-butadiene through oxidative dehydrogenation of normal-butene using the parallel reactor containing multi-component bismuth molybdate-based catalysts exhibiting different activities to oxidative dehydrogenation for normal-butene isomers (1-butene, trans-2-butene and cis-2-butene), and butene separated from a C4 mixture containing normal-butene and normal-butane, as a reactant.

Owner:LG CHEM LTD

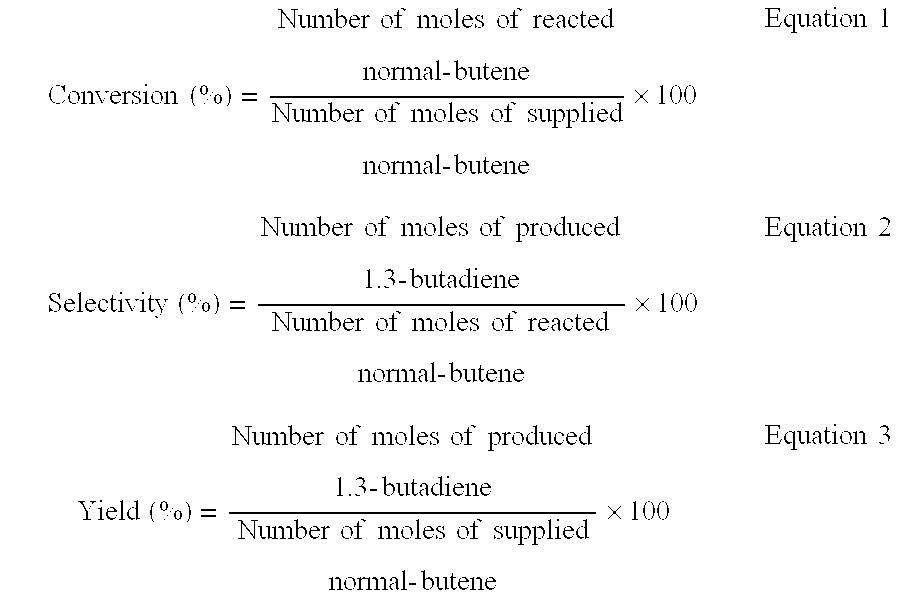

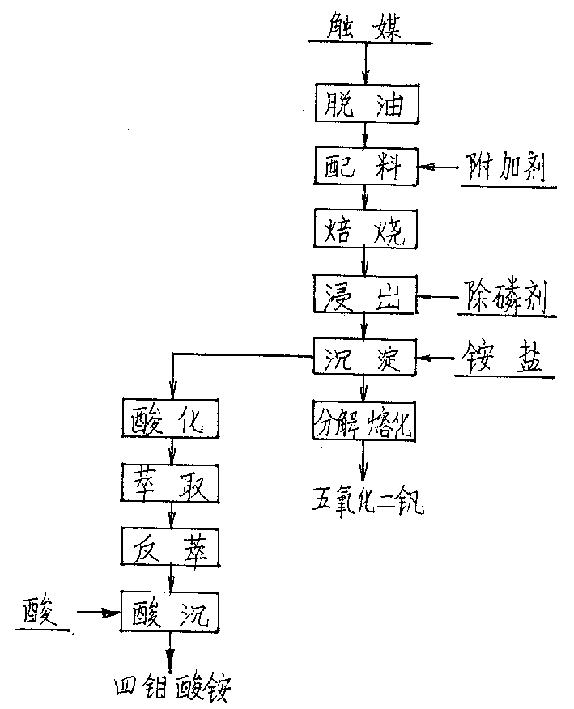

Wet process of extracting vanadium and/or molybdenum from waste catalyst

InactiveCN1453379ALess investmentReduce consumptionProcess efficiency improvementMagnesium saltAmmonium metavanadate

The present invention is wet process of extracting vanadium and / or molybdenum form waste petrochemical catalyst alumina carrier containing V, Mo and other elements. The wet process includes high-temperature deoiling the catalyst in natural granularity, mixing with sodium carbonate, high-temperature oxidation and roasting in a kiln or furnace to obtain water soluble sodium vanadate and sodium molybdate; countercurrent water soaking of the chamotte to obtain solution containing V and Mo in certain concentration, adding calcium salt and magnesium salt to eliminate P and other impurities, addingammonium salt solution into the clear solution to obtain ammonium metavanadate, decomposing and melting ammonium metavanadate to obtain V2O5 product; adding acid to the supernatant and organic phase extraction of Mo, ammonia water reverse extraction to obtain ammonium molybdate, and adding acid to precipitate ammonium tetramolybdate or molybdate product.

Owner:CITIC JINZHOU METAL

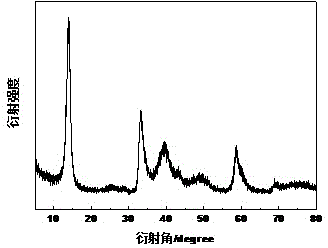

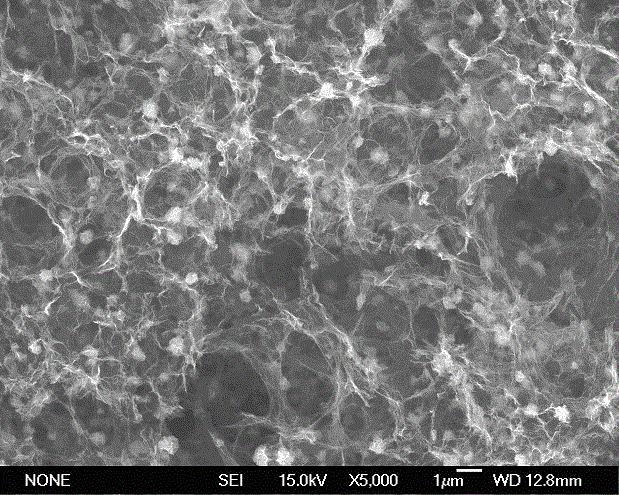

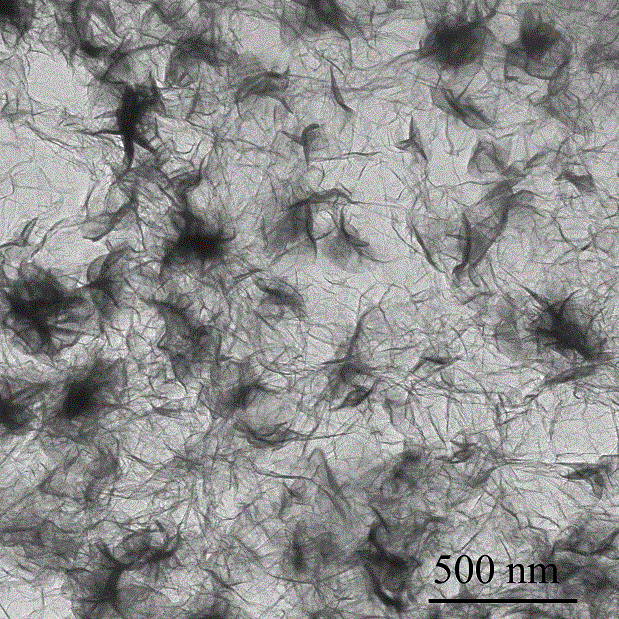

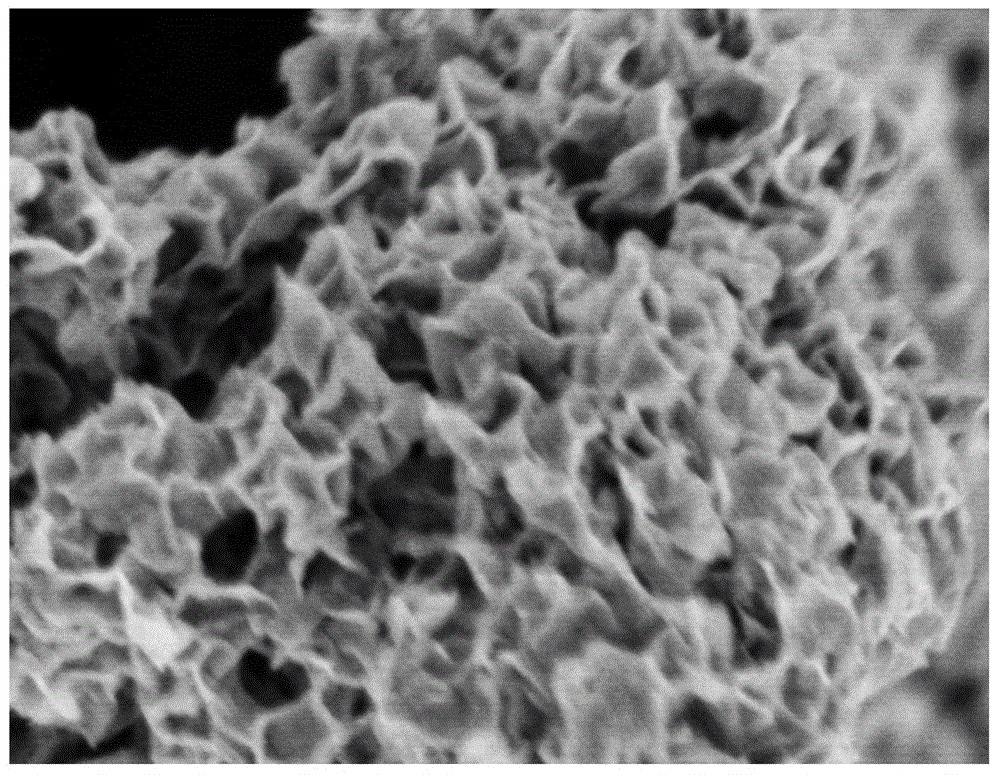

Flake MoS2/graphene composite aerogel and preparation method thereof

InactiveCN104600315AHigh electrical conductivityDeformation stableCell electrodesThioureaFreeze-drying

The invention relates to a flake MoS2 / graphene composite aerogel and a preparation method thereof and belongs to the technical field of anode materials of lithium ion batteries. The preparation method comprises the following steps: ultrasonically dispersing a certain quantity of graphene oxide solution into deionized water, adding a certain quantity of water-soluble molybdate and thiourea, then adding 0.1-3mL organic amine solution, taking out a cylindrical product after hydrothermal reaction at the temperature of 160-240 DEG C, freeze-drying, and then carrying out thermal treatment for 2h in the mixed atmosphere of argon and hydrogen at the temperature of 800 DEG C to obtain the flake MoS2 / graphene composite aerogel. According to the flake MoS2 / graphene composite aerogel and the preparation method thereof disclosed by the invention, thin layers of graphene are connected with one another in a staggering mode to form a three-dimensional ordered conductive network and form micron pore canals, MoS2 is uniformly dispersed on the ultra-large superficial area, and thus, the problems of volume expansion and crushing materials are effectively solved; meanwhile, the structure stability and the cycle performance of the flake MoS2 / graphene composite aerogel, serving as the anode material, are improved.

Owner:SHANGHAI UNIV

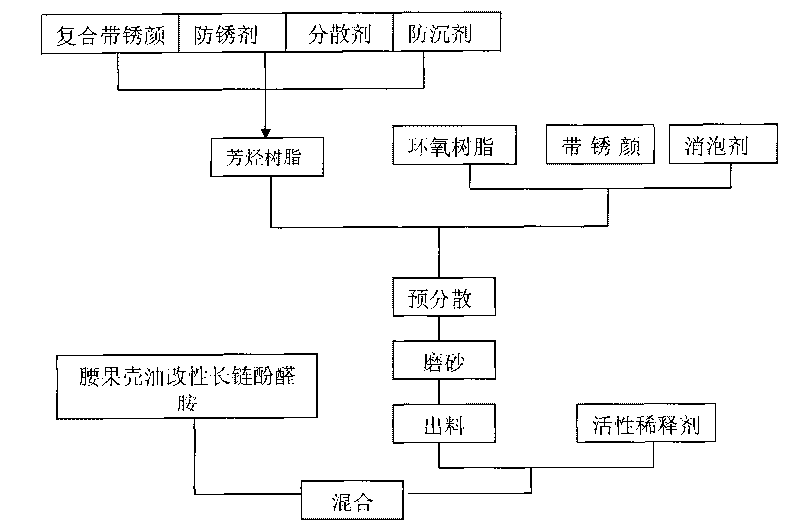

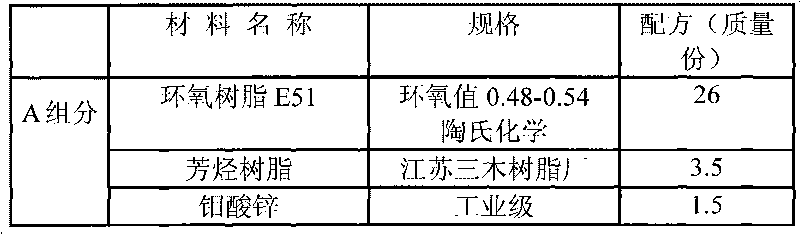

Environment-friendly solvent-free humidified and rusted anticorrosive paint

InactiveCN101747825AEasy pretreatmentConvenient anti-corrosion solutionAnti-corrosive paintsEpoxy resin coatingsOrganic filmSolvent free

The invention relates to a paint material with formed organic film, in particular to an epoxy solvent-free anticorrosive paint applied to low surface treatment steel structure. The anticorrosive paint is prepared by efficiently compounding rusted coating pigments such as zinc molybdate, zinc phosphate, aluminium trippolyhosphate, iron oxide red and the like, using cashew nut oil modified long-chain amine phenolic aldehyde as, alicyclic glycidyl ether as active diluent, thus overcoming the problems that surface treatment technique in coating construction costs high and heavy anticorrosive paint with high solvent content pollutes the environment, having easy preparation and construction, low cost, fast solidification at high temperature, good mechanical and anticorrosive performance, solvent-free and environment-friendly properties, and being applicable to heavy anticorrosive projects of steel structures such as ship, train, bridge and the like.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Surface treated steel plate excellent in corrosion resitance electroconductivity and appearance of coating film

ActiveUS20060177685A1Hot-dipping/immersion processesRecord information storageO-Phosphoric AcidPhosphate

The present invention provides a surface-treated steel sheet including a steel sheet; a plating layer provided on at least one of the surfaces of the steel sheet, the plating layer containing at least one metal selected from the group consisting of zinc and aluminum; a first layer film provided on the surface of the plating layer and containing (α) 1 to 2000 mg / m2 of silica in terms of SiO2, (β) a total of 1 to 1000 mg / m2 of phosphoric acid groups in terms of P, (γ) a total of 0.5 to 800 mg / m2 of at least one metal selected from the group consisting of Mg, Mn, and Al in terms of a metal element, and (δ) 0.1 to 50 mg / m2 of a tetravalent vanadium compound in terms of V; and a second layer film formed to a thickness of 0.1 to 5 μm on the first layer film and containing a resin (A) having at least one type of functional group selected from the group consisting of OH and COOH groups, and at least one rust-proofing additive (B) selected from the group consisting of (a) a phosphate, (b) Ca ion-exchanged silica, (c) a molybdate, (d) silicon oxide, and (e) at least one organic compound selected from the group consisting of triazoles, thiols, thiadiazoles, thiazoles, and thiurams. The surface-treated steel sheet has excellent corrosion resistance without containing hexavalent chromium in a coating, and also has excellent conductivity and coating appearance.

Owner:JFE STEEL CORP

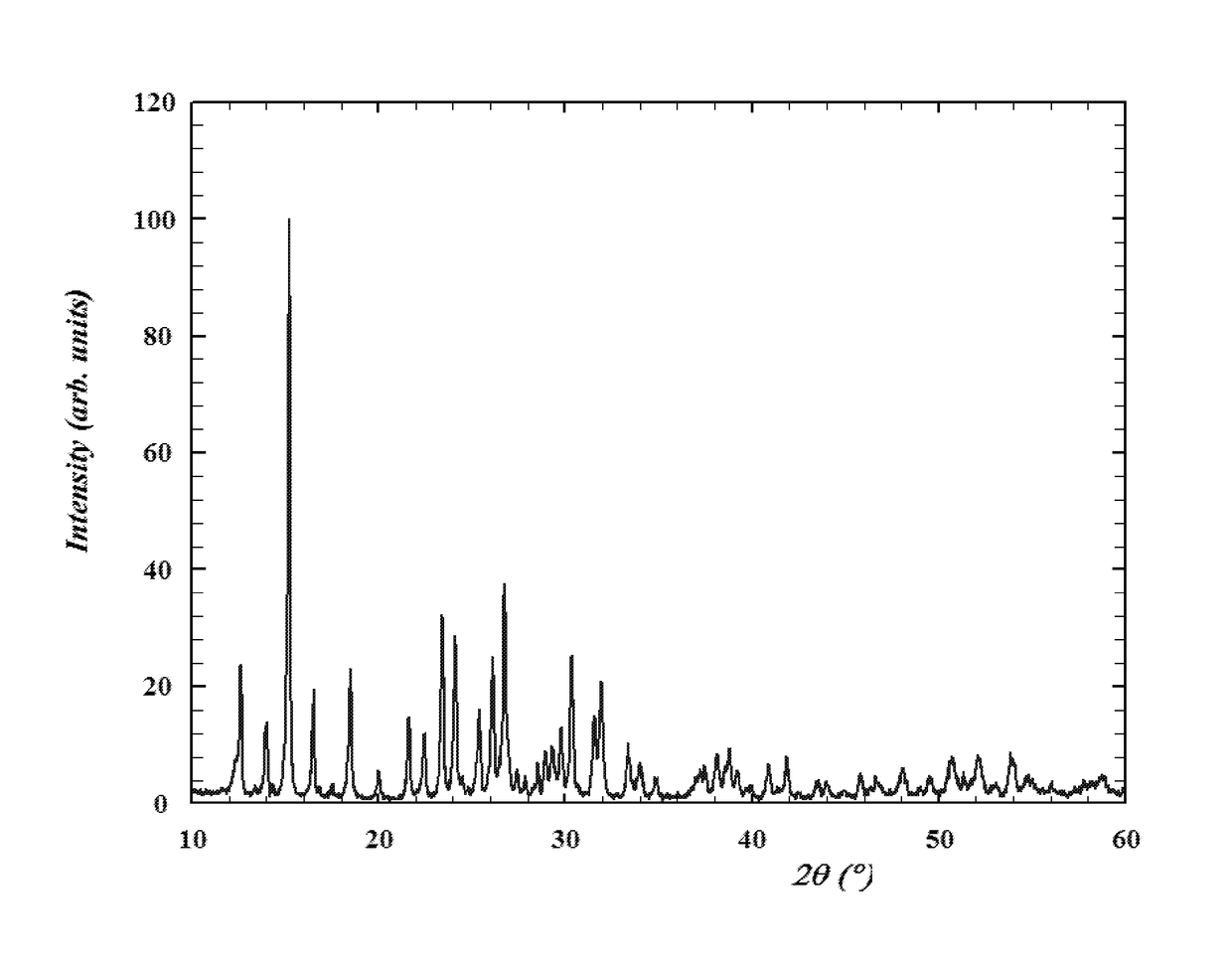

Crystalline ammonia transition metal molybdate

ActiveUS20170165649A1Catalyst activation/preparationHydrocarbon oil crackingMolybdateHydrodesulfurization

A hydroprocessing catalyst has been developed. The catalyst is a unique crystalline ammonia transition metal molybdate material. The hydroprocessing using the crystalline ammonia transition metal molybdate material may include hydrodenitrification, hydrodesulfurization, hydrodemetallation, hydrodesilication, hydrodearomatization, hydroisomerization, hydrotreating, hydrofining, and hydrocracking.

Owner:UOP LLC

Method for preparing 2,5-furandicarboxylic acid from 5-hydroxymethyl furfural

ActiveCN105037303AEffective control of selectivityEffective regulation of catalyst activityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsTungstateHydroxymethylfurfural

The invention discloses a method for preparing 2,5-furandicarboxylic acid from 5-hydroxymethyl furfural. Quaternary ammonium molybdate and quaternary ammonium tungstate are taken as a catalyst; oxygen gas, hydrogen peroxide or air is taken as an oxidant; the catalyst and the oxidant are heated to 80-120 DEG C under an alkali environment so as to carry out selective oxidization on 5-hydroxymethyl furfural. According to the method, ammonium salt and molybdic acid or tungstic acidis utilized to structurally regulate the activity of the catalyst and the selectivity of a product; the used catalyst is high in activity, easy to recycle and good in stability; the oxidant adopted in the oxidization process is environmentally-friendly, green and pollution-free; high yield and high selectivity of the 2,5-furandicarboxylic acid can be obtained at a low temperature; and a conversion rate of the 5-hydroxymethyl furfural is higher than 90%.

Owner:TIANJIN POLYTECHNIC UNIV

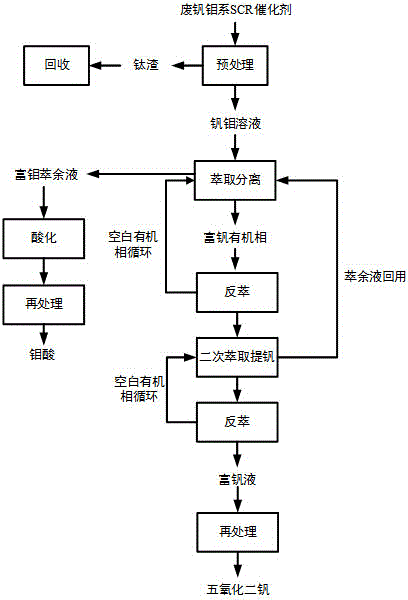

Method for separating and purifying vanadium and molybdenum of waste vanadium-molybdenum SCR (selective catalytic reduction) catalyst

ActiveCN104831075ARealize separation and recoveryReduce consumptionProcess efficiency improvementPtru catalystPhysical chemistry

The invention discloses a method for separating and purifying vanadium and molybdenum of a waste vanadium-molybdenum SCR (selective catalytic reduction) catalyst. The method comprises the following steps: firstly, carrying out pretreatment on a catalyst to obtain a titanium slag and a vanadium-molybdenum solution; extracting and separating the vanadium-molybdenum solution, acidifying the obtained molybdenum-rich raffinate, and reprocessing to prepare a molybdenic acid product; carrying out reverse extraction on the obtained molybdenum-rich organic phase, then carrying out a two-stage extraction and vanadium purification process, and carrying out reverse extraction again to obtain a vanadium-rich solution; and reprocessing the vanadium-rich solution to prepare vanadium pentoxide. According to the method disclosed by the invention, the problem of difficult vanadium and molybdenum separation, recovery and purification of the waste vanadium-molybdenum SCR catalyst in industry is thoroughly solved; in addition, the recovery rates of vanadium and molybdenum exceed 95%; a high-purity (greater than 99%) molybdenic acid product and a vanadium pentoxide product of which the purity exceeds 99.5% can be respectively obtained; recycling of resources is really realized; and the method has good environmental and economic benefits, and is suitable for industrial popularization and application.

Owner:BOTREE CYCLING SCI & TECH CO LTD

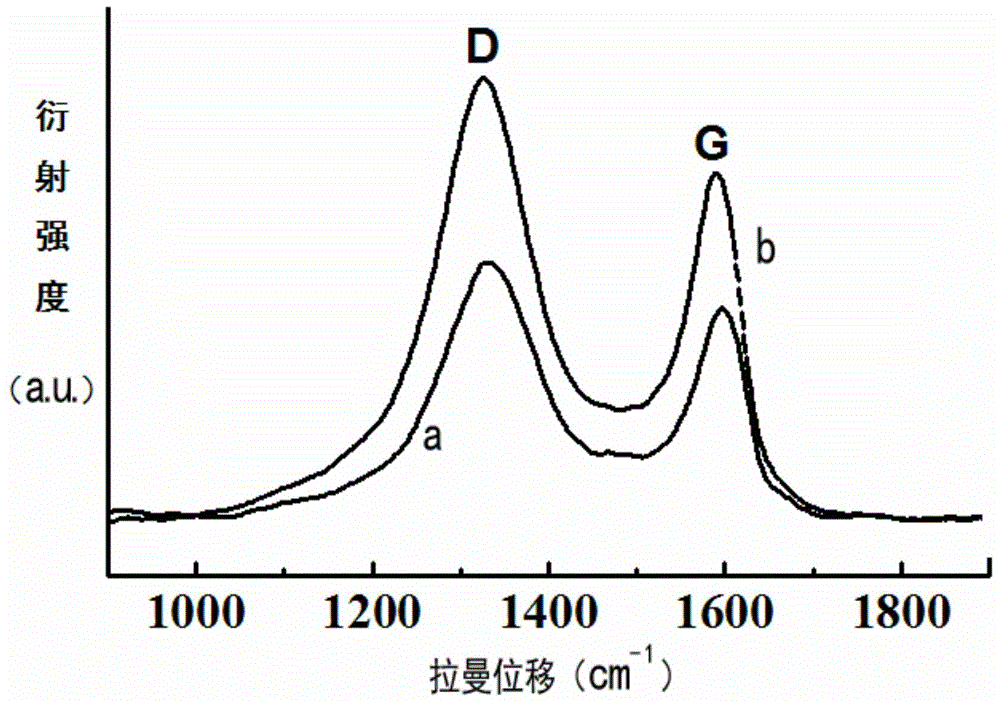

Method for preparing three-dimensional flower-shaped graphene/molybdenum disulfide composite loaded fibrous counter electrode

InactiveCN104319102ASimple processMild reaction conditionsLight-sensitive devicesFinal product manufactureFiberCarbon fibers

The invention discloses a method for preparing a three-dimensional flower-shaped graphene / molybdenum disulfide composite loaded fibrous counter electrode. The method for preparing the three-dimensional flower-shaped graphene / molybdenum disulfide composite loaded fibrous counter electrode uses a one-step hydrothermal reduction method, to be specific, adding molybdic acid or the water solution of molybdenum oxide, ammonium thiocyanate and graphene oxide in a hydrothermal reactor, vertically immersing carbon fiber in the reaction liquid, carrying out hydrothermal reduction reaction for 12 to 36 hours under 160 to 200 degrees centigrade, taking out the carbon fiber after ending reacting, using deionized water and absolute ethyl alcohol to wash, and drying. The method for preparing the three-dimensional flower-shaped graphene / molybdenum disulfide composite loaded fibrous counter electrode has advantages of simple technique, moderate reaction condition, high yield, good reproducibility, easiness in scale production and the like; the photoelectric conversion rate of a dye-sensitized solar cell composed of the prepared fibrous counter electrode is obviously higher than that of a dye-sensitized solar cell composed of an MoS2 or platinum loaded fibrous counter electrode, and the method for preparing the three-dimensional flower-shaped graphene / molybdenum disulfide composite loaded fibrous counter electrode is important for promoting the commercial application of the dye-sensitized solar cell.

Owner:SHANGHAI UNIV OF ENG SCI

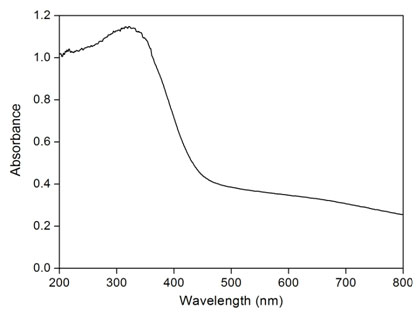

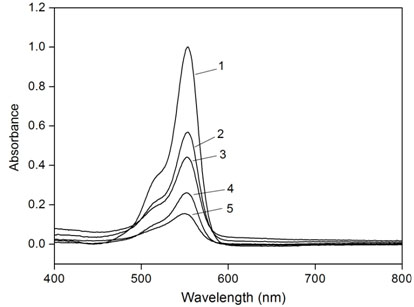

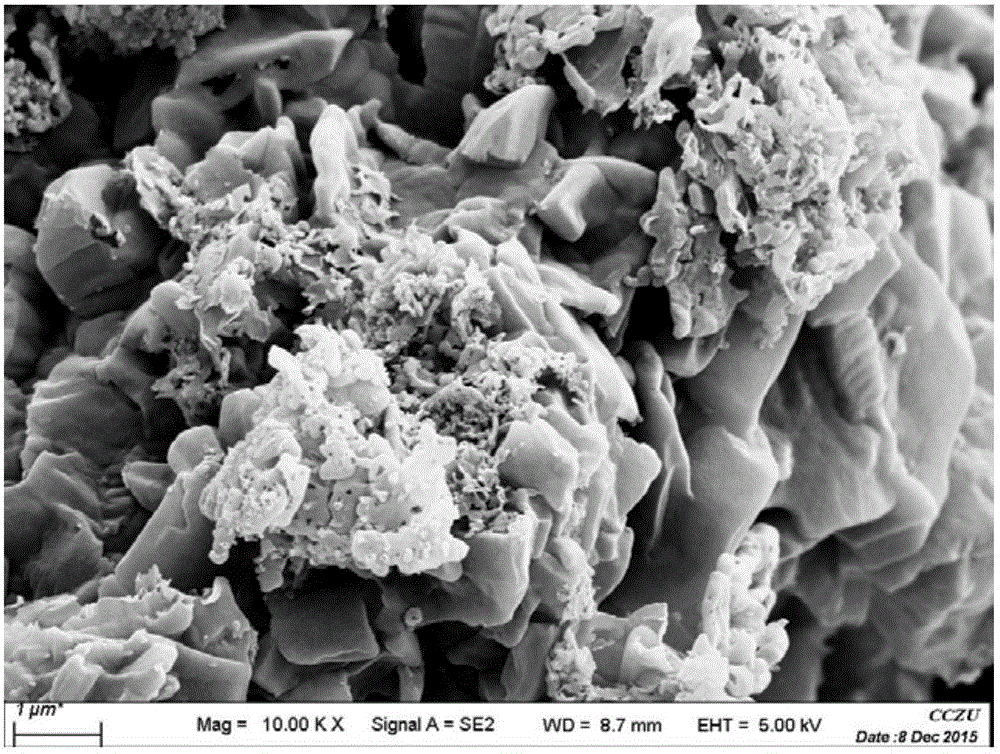

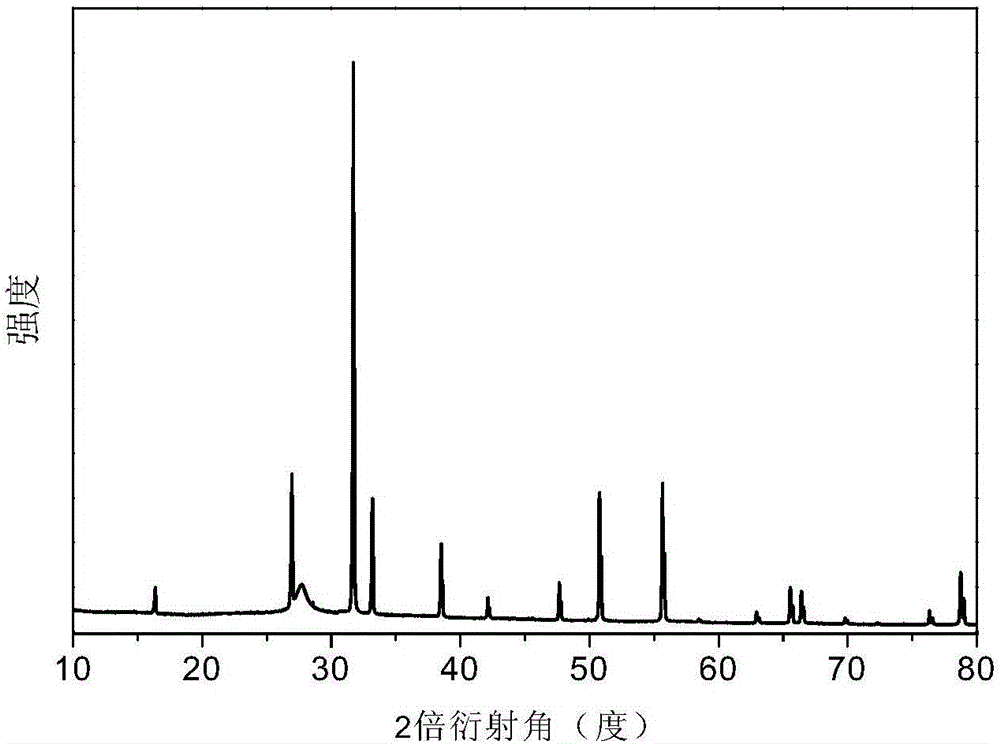

Graphene/silver molybdenum oxide compound visible-light catalyst and preparation method thereof

InactiveCN102580739AUniform sizeHigh purityMetal/metal-oxides/metal-hydroxide catalystsPtru catalystAmmonium heptamolybdate

The invention relates to a graphene / silver molybdenum oxide compound visible-light catalyst and a preparation method thereof, in particular to a method for preparing the graphene / silver molybdenum oxide-combined visible-light catalyst by water and heat, belonging to the technical field of compound materials and photocatalysis. The preparation method comprises the following steps: taking graphene oxide, silver nitrate and ammonium heptamolybdate as raw materials according to certain proportion, mechanically stirring and mixing the raw materials uniformly in sequence, adjusting the pH value of solution, and then utilizing hydro-thermal reaction to prepare the graphene / silver molybdenum oxide compound visible-light catalyst. The photocatalytic degradation experiment shows that the graphene / silver molybdenum oxide compound visible-light catalyst prepared by the method has a good phtocatalytic degradation effect on rhodamine B due to the irradiation of the visible light and is ideal.

Owner:JIANGSU UNIV

Preparation method of antibacterial silver molybdate and graphite-phase carbon nitride composite visible-light-induced photocatalyst

InactiveCN105728010AImprove antibacterial propertiesNo secondary pollutionBiocidePhysical/chemical process catalystsEfficient catalystCatalytic efficiency

The invention relates to a preparation method of an antibacterial silver molybdate and graphite-phase carbon nitride composite visible-light-induced photocatalyst.The method comprises the following steps of preparing lamellar graphite-phase carbon nitride and preparing the silver molybdate doped graphite-phase carbon nitride composite photocatalyst.The preparation method of the antibacterial silver molybdate and graphite-phase carbon nitride composite visible-light-induced photocatalyst has the advantages that the preparation method is simple, and the preparation conditions are easy to control; the prepared silver molybdate doped graphite-phase carbon nitride composite photocatalyst is a green and environment-friendly efficient catalyst, has the advantages of being excellent in antibacterial property, free of secondary pollution, high in catalytic efficiency and the like and has practical application value.

Owner:CHANGZHOU UNIV

Method for manufacturing metal surface self-cleaning high-protection film

ActiveCN104213112AGuaranteed protective effectWith self-cleaning functionMetallic material coating processesComposite filmMolybdate

The invention provides a method for manufacturing a metal surface self-cleaning high-protection film. The method comprises two steps of molybdate solution soaking treatment and plant corrosion inhibitor-low-surface-energy material collaborative modification treatment. According to the molybdate solution soaking treatment step, a composite film which is of a specific micro / nano coarse structure, has the good protection effect and is composed of metallic oxides, molybdenum oxide and metal molybdate can be formed on a metal surface, and therefore according to the plant corrosion inhibitor-low-surface-energy material collaborative modification treatment step, efficient green plant corrosion inhibitors can be introduced into the film, and the protection effect can be obviously improved. Due to the hydrophobization effect of the low-surface-energy material on the film, the film has the self-cleaning function, the pollution can be avoided, the probability of direct contact of metal materials and corrosive media can be reduced, and the protection effect of the film can be further improved. The method has the advantages of being environmentally friendly, simple in process, convenient to operate, capable of being easily and industrially produced in a large-scale mode and the like.

Owner:重庆中昆新材料科技有限公司

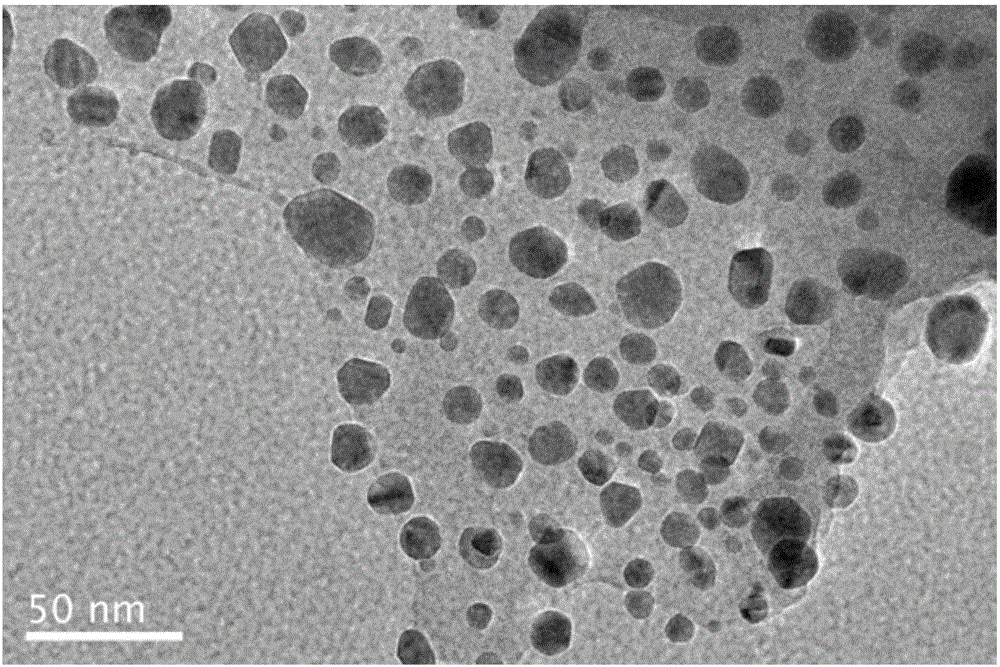

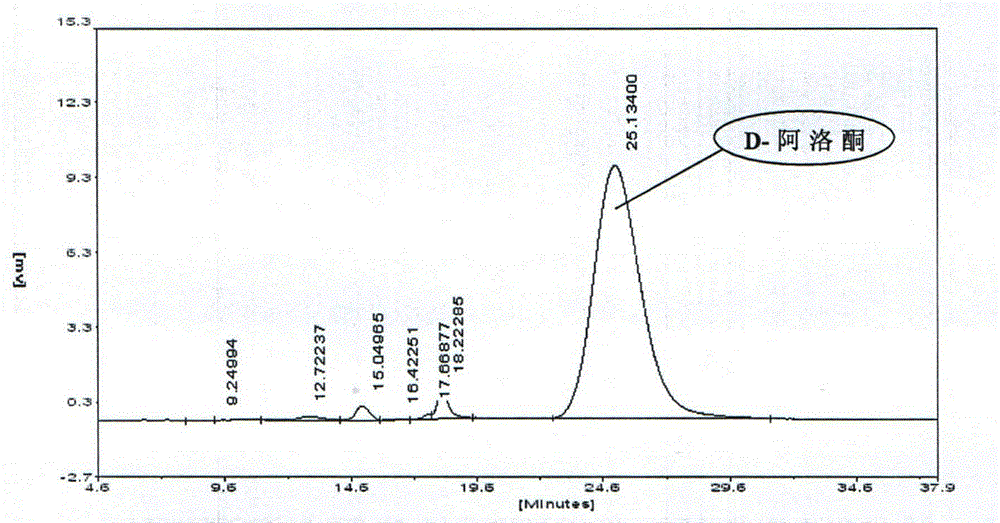

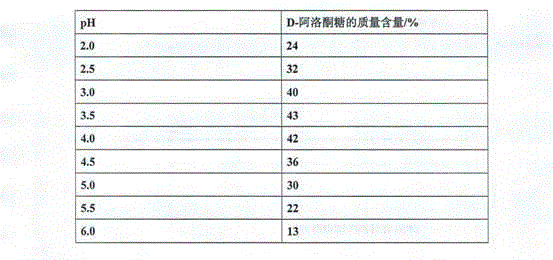

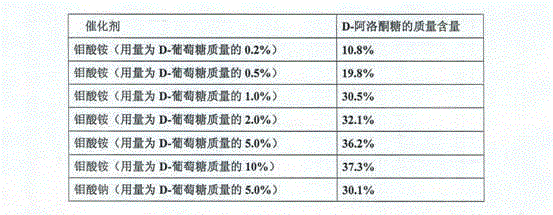

Preparation method and application of allulose

ActiveCN104447888AIncrease profitSimple processSugar derivativesSugar derivatives preparationMolybdateDifferential phase

The invention provides a preparation method and application of allulose. The preparation method comprises the following step: by adopting glucose as a raw material and adopting molybdate as a catalyst, performing catalytic conversion, separation and purification to obtain allulose with corresponding configuration. The method provided by the invention mainly comprises the following step: by adopting a chemical method, preparing a crystal allulose product by virtue of working procedures such as chemical differential phase isomerism, refined chromatography separation and purification, concentration and crystallization and the like by adopting glucose as the raw material. The preparation method provided by the invention is simple in process, short in time consumption, high in reaction speed and high in efficiency, and the problems that a conventional enzymatic method for preparing D-allulose products is poor in enzyme stability and low in efficiency and the like can be solved.

Owner:SHANDONG FUTASTE

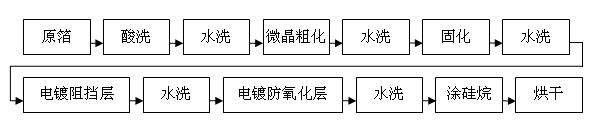

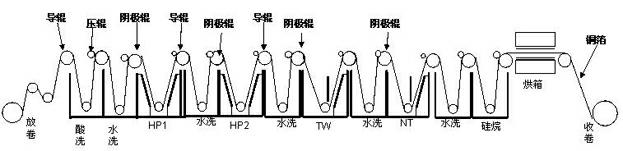

Additive for electrolytic copper foil and surface treatment process of very low profile electrolytic copper foil

ActiveCN102560584AEnhanced depth capabilitiesMicrocrystalline effectInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentElectrolysisMolybdate

The invention belongs to the technical field of electronic materials, particularly relates to a surface treatment process of a very low profile electrolytic copper foil, in particular to an additive used during the surface treatment of the very low profile electrolytic copper foil. The additive is composed of three components: titanous sulfate, titanium sulfate and molybdate, wherein the contents of the three components in the electroplate liquid are respectively 50-150mg / L, 150-250mg / L and 70-118mg / L (molybdate radical). The additive is used to be added into a microcrystalline coarsening slot; and the three components are used cooperatively, so that the treated copper foil coarse layer crystalline grains are small and dense, achieving a microcrystalline effect. In the invention, the addition amount of each additive and proper electroplating process conditions such as content of cuprate, temperature and current density are found out in the coarsening slot for the surface treatment, so that the treated 18-micron very-low profile electrolytic copper foil can meet the following technical indicators: the anti-stripping strength is equal to or greater than 1.0kg / cm and the value of surface roughness Rz is smaller than or equal to 5.1 microns.

Owner:惠州联合铜箔电子材料有限公司

Molybdenum sulfide/carbide catalysts

InactiveUS20050059545A1High activityImprove stabilityCell electrodesCatalyst activation/preparationChemistryMolybdenum disulfide

The present invention provides methods of synthesizing molybdenum disulfide (MoS2) and carbon-containing molybdenum disulfide (MoS2-xCx) catalysts that exhibit improved catalytic activity for hydrotreating reactions involving hydrodesulfurization, hydrodenitrogenation, and hydrogenation. The present invention also concerns the resulting catalysts. Furthermore, the invention concerns the promotion of these catalysts with Co, Ni, Fe, and / or Ru sulfides to create catalysts with greater activity, for hydrotreating reactions, than conventional catalysts such as cobalt molybdate on alumina support.

Owner:GABRIEL ALONSO +2

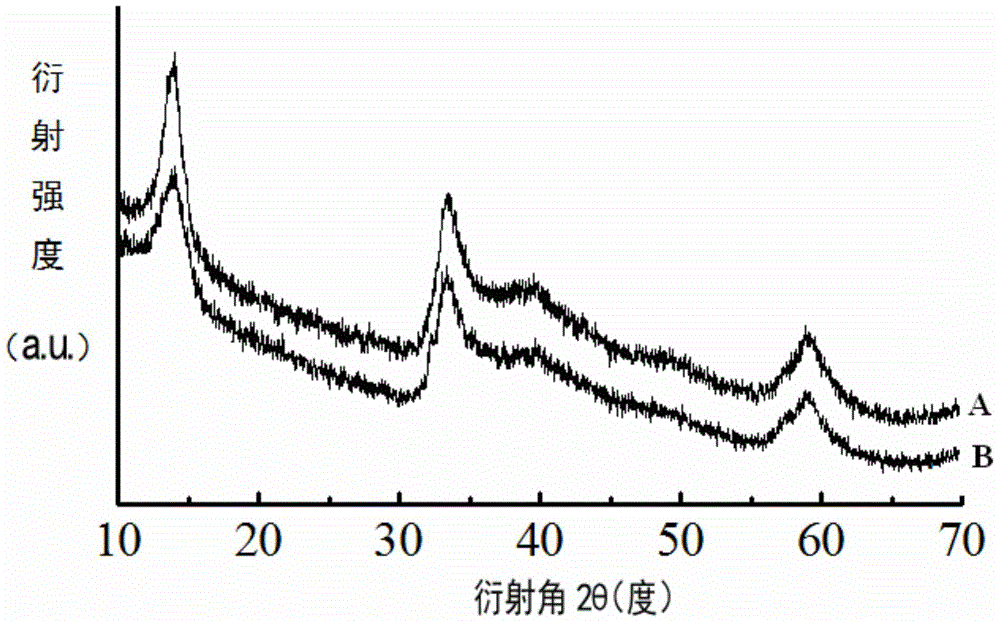

Method for preparing orthorhombic phase molybdenum trioxide nano wire

InactiveCN101423254ASimple reaction conditionsHigh selectivityMolybdenum oxides/hydroxidesEthylenediamineMolybdate

The invention discloses a method for preparing an orthorhombic phase molybdenum trioxide nano wire, which is characterized in that molybdate, molybdic acid or molybdenum trioxide is dissolved in aqueous solution with quadrol concentration of 0.2-6 mol / L to cause the mol ratio of molybdenum atom and quadrol to be 1:1-6; and then strong acid solution with hydrogen ion concentration of 0.5-3.0 mol / L is dropwise added under the condition of stirring till the pH value is within 4 to 5; the solution is unceasingly stirred for 10 to 30 min; then the white precipitation is sucked, filtered, washed and dried to obtain white orthorhombic phase single crystal nano wires with the diameter of 100 to 400 nm and the length of 10-40 Mum. In the method, the raw materials are easily obtained; the needed device is simple; the technique is convenient; the reaction can be finished in an hour in the normal temperature and pressure; the method is safe and easy to be controlled; the productive rate reaches more than 99 percent; the mother solution can be reused; and the method is applicable to large-scale industry production.

Owner:UNIV OF SCI & TECH OF CHINA

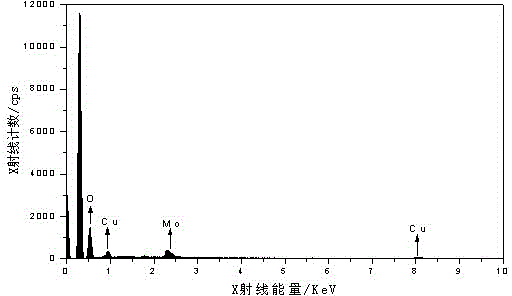

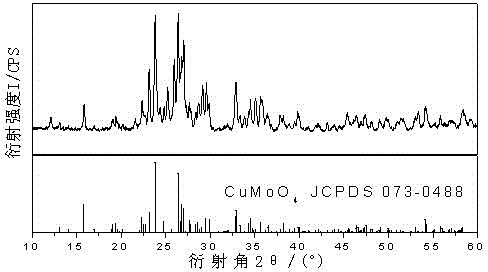

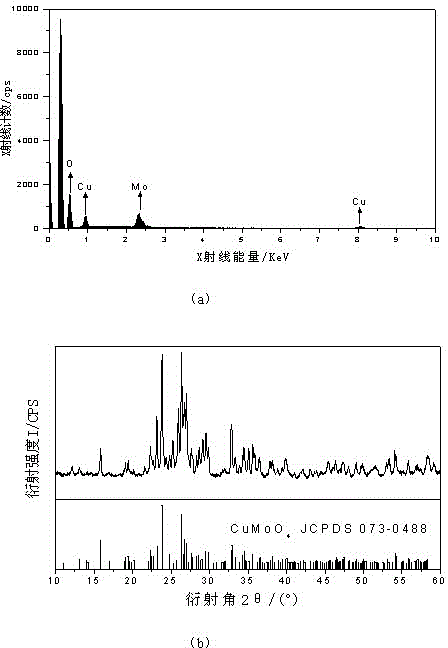

Method for preparing copper molybdate by using cation membrane electrolysis method

The invention discloses a method for preparing copper molybdate by using a cation membrane electrolysis method. A copper sheet serves as an anode; an inert electrode serves as a cathode; Na2MoO4.2H2O solution serves as anolyte; and solution with the pH range of 0-14 serves as catholyte. A cation membrane is adopted to electrolyze sodium molybdate solution, and the obtained product is dried after being cleaned. The dried product is roasted in high temperature to obtain pure copper molybdate crystals. The method uses the optimal effect of ion-exchange membrane electrolysis to transfer Na+ into a cathode chamber; the reaction time is short; no additive is added; the pure copper molybdate can be obtained; no impurity or impurity ion exist; and the subsequent treatment is simple. The method has the advantages of simplicity, easy operation and low investment cost, and can be directly applied to the industrialized batch production.

Owner:SHANGHAI INST OF TECH

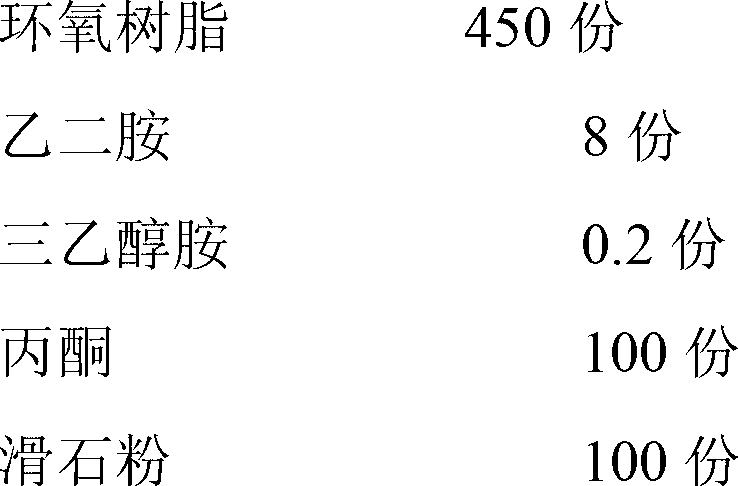

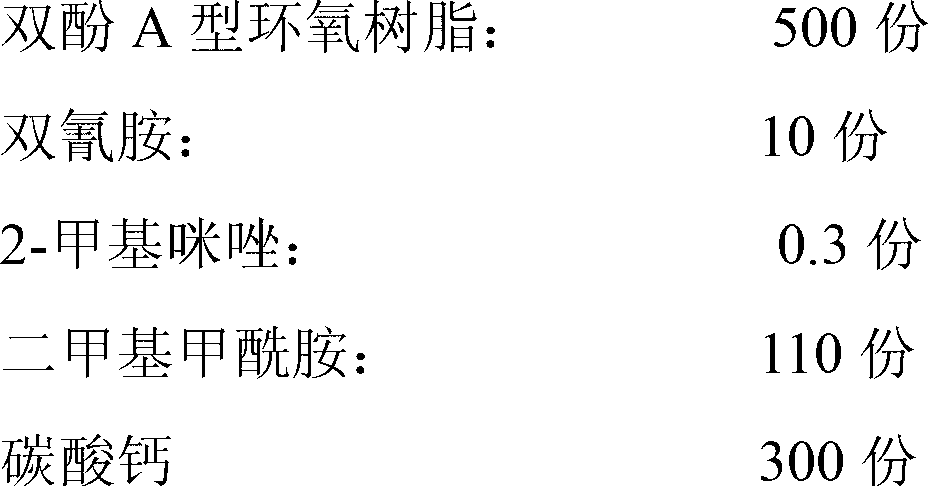

Environment-friendly copper clad laminate for LED monochrome display, glue solution and preparation method

ActiveCN103057213AImprove cooling effectImprove heat resistanceSynthetic resin layered productsLaminationSolventScrap

The invention discloses an environment-friendly copper clad laminate (CCL) for an LED (Light-Emitting Diode) monochrome display, a glue solution and a preparation method. The glue solution for a CCL comprises the following raw materials by mass: 400-500 parts of resin, 8-12 parts of curing agent, 0.2-0.3 part of curing accelerator, 100-120 parts of solvent, and an inorganic filler that includes one or more of talc powder, kaolin, magnesium hydroxide, aluminum hydroxide, zinc borate, zinc molybdate, magnesium oxide, calcium carbonate, calcium silicate, barium sulfate and boron nitride, wherein the inorganic filler accounts for 10%-70% of the total mass of the raw materials. According to the invention, the CCL is good in heat resistance, high in heat dissipation performance, low in organic content, environment-friendly during waste treatment, low in production cost, and suitable for industrial production.

Owner:SHANGHAI GUOJI ELECTRONICS MATERIALS CO LTD

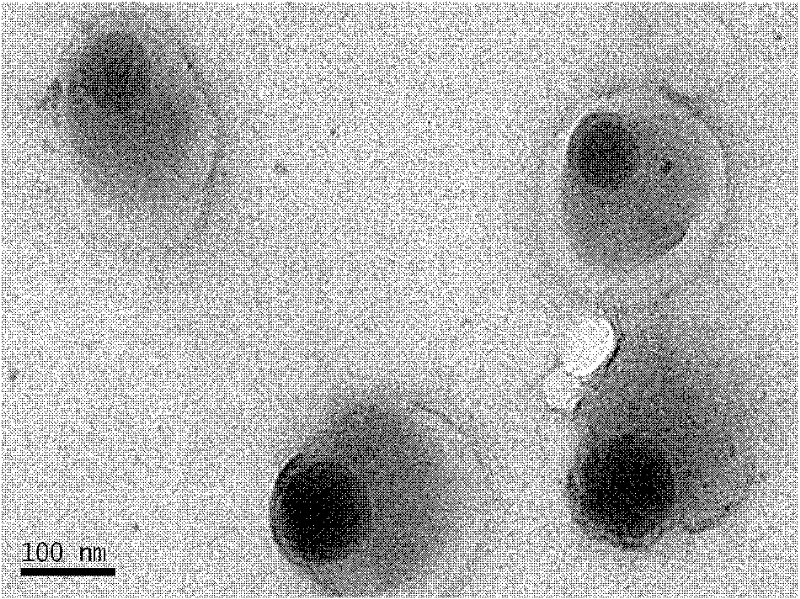

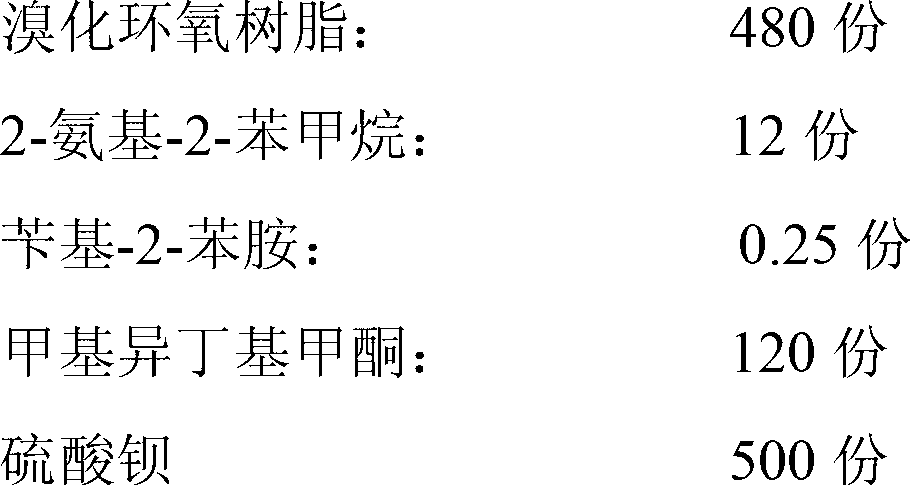

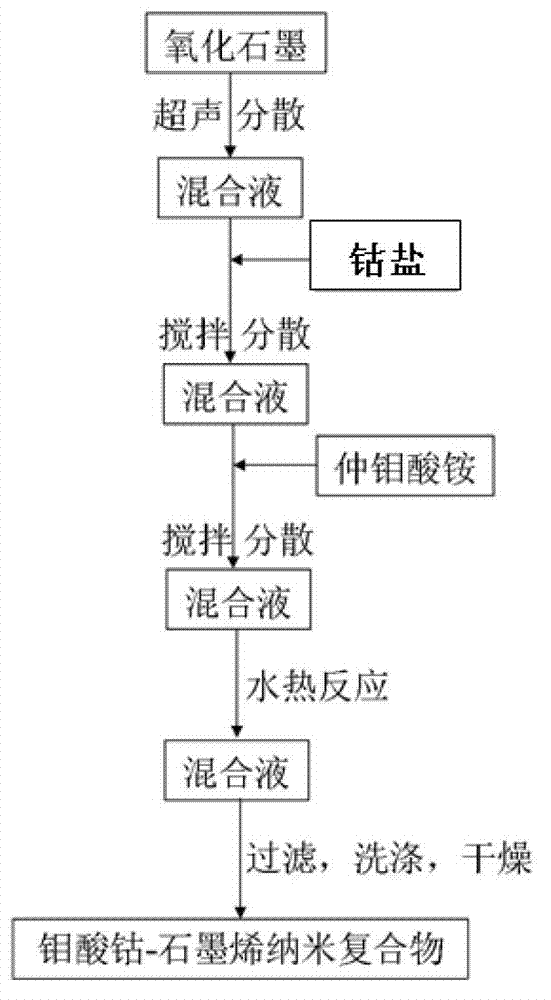

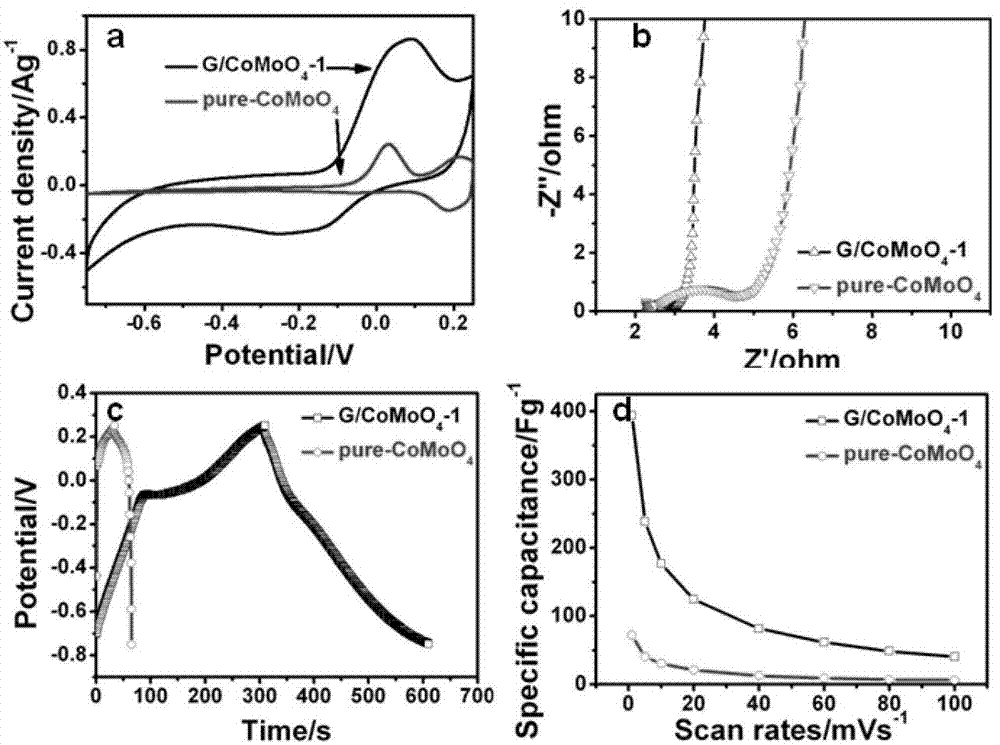

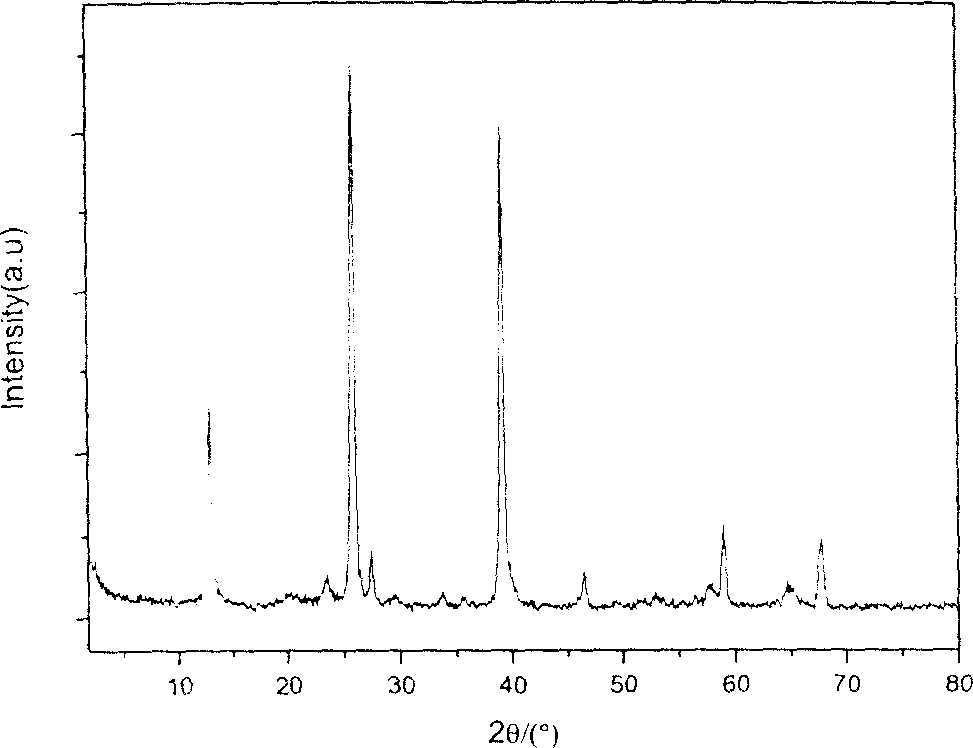

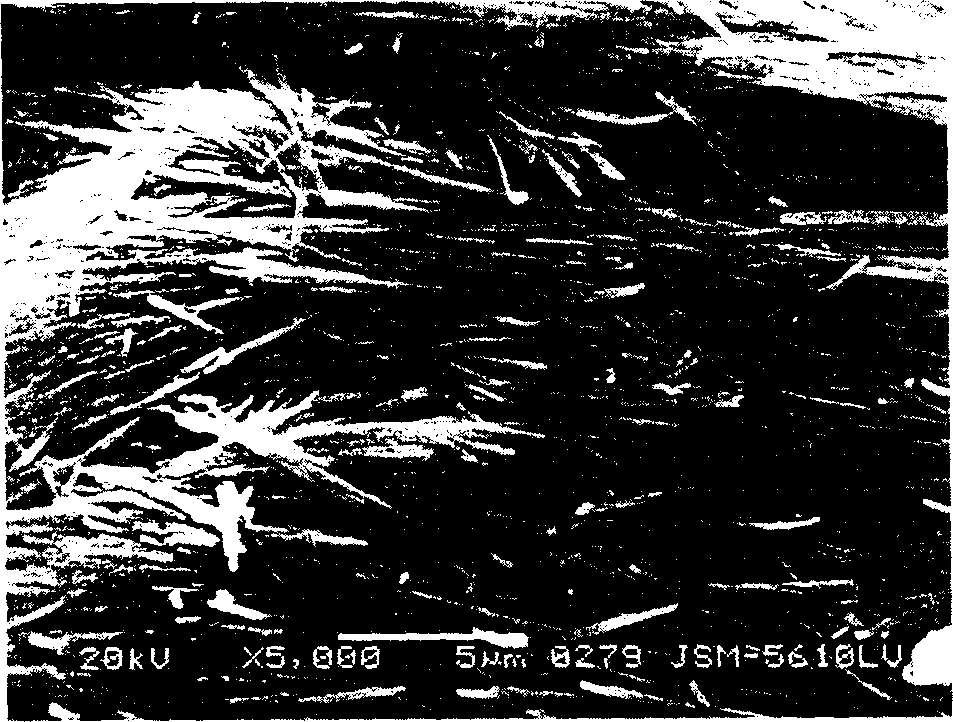

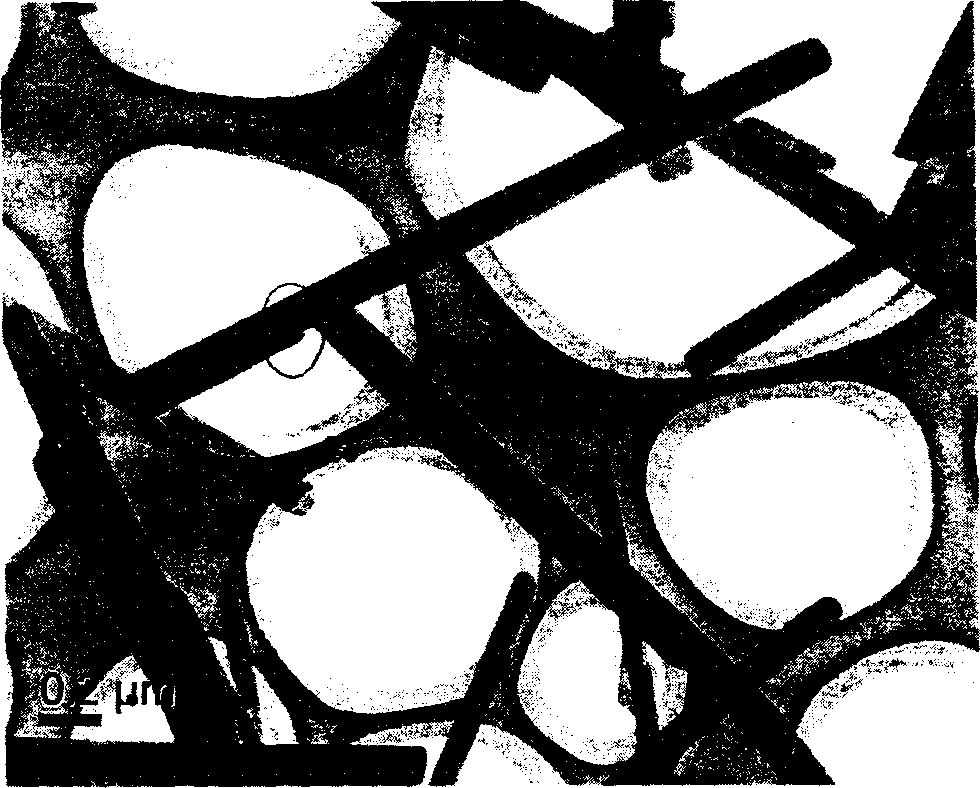

Cobalt molybdate-graphene nano compound and preparation method thereof

ActiveCN103043729ANo pollution in the processIncrease surface areaMaterial nanotechnologyCarbon compoundsMolybdatePhysical chemistry

The invention discloses a cobalt molybdate-graphene nano compound and a preparation method thereof. The method comprises steps of putting the oxidation graphite into water and ultrasonic dispersing; putting the cobalt salt into the system, stirring and dissolving; later putting the ammonium molybdate into the system and adjusting the pH; then transferring the mixture system into a water heating kettle to perform reaction; and when the reaction is ended, the product passes through separation, washing and dryness, and the cobalt molybdate-graphene nano compound is gained. The material is provided with broad application prospects in the field of energy and other electronic device fields.

Owner:NANJING UNIV OF SCI & TECH

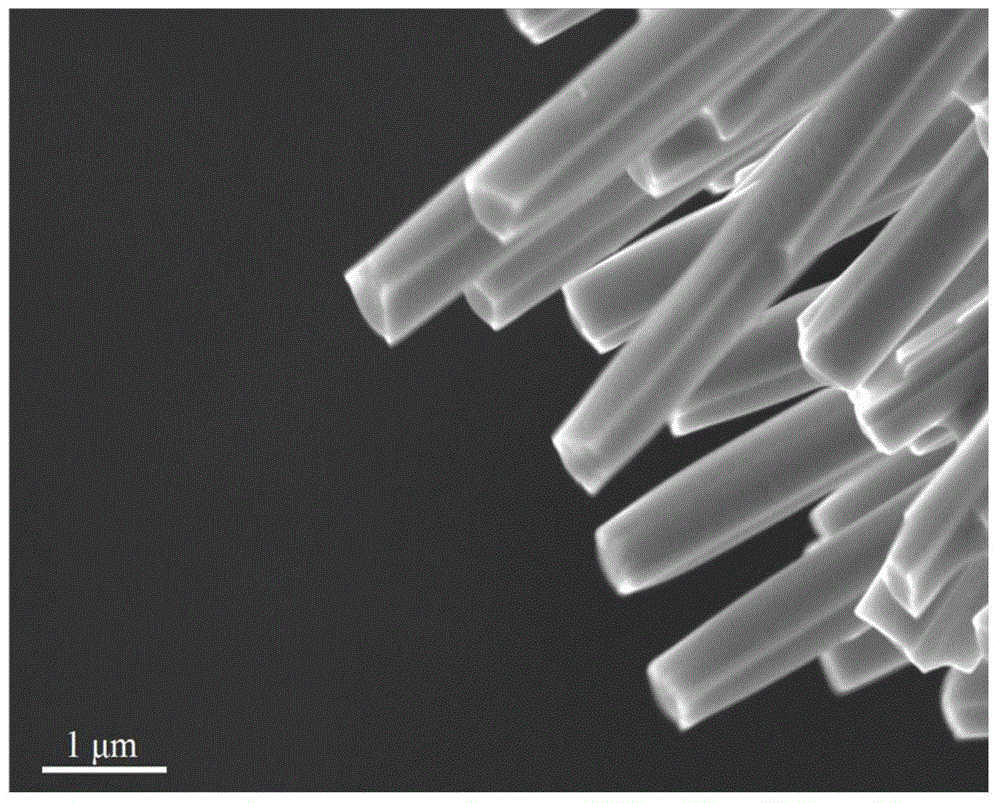

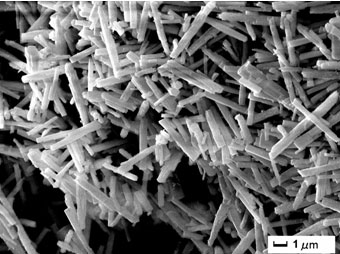

Molybdenum trioxide laminated nanometer bar and preparation method

InactiveCN1762831ASimple methodGood reproducibilityMolybdenum oxides/hydroxidesPolytetrafluoroethyleneOxide

The present invention provides one kind of nanometer MoO3 stick and its preparation process. The laminated nanometer MoO3 stick in orthorhombic system has length 1-10 microns, 3-9 laminated MoO3 layers, thickness 50-200 nm and width 60-120 nm. The preparation process includes dissolving molybdenum oxide or molybdate in hydrogen peroxide solution via intense stirring for 30-50 hr to form sol, transferring the sol into stainless steel reaction tank with PTFE lining, hydrothermal treatment at 150-180 deg.c for 4-6 days, naturally cooling to room temperature to obtain hydrothermal product, anhydrous ethyl alcohol washing and water washing, and drying. The preparation process is simple, high in reproducibility, controllable, and environment friendly. The prepared nanometer MoO3 stick has high surface activity and may be filmed via brushing or spraying and prepared into electrochemical and optical devices directly or after being mixed with other superfine powder.

Owner:武汉理工力强能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com