Method for preparing three-dimensional flower-shaped graphene/molybdenum disulfide composite loaded fibrous counter electrode

A technology of molybdenum disulfide and composite materials, which is applied in the field of solar cells, can solve the problems of weak bonding between materials and conductive substrates, low stability of electrodes, and influence on popularization and application, so as to promote commercial application, high yield, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] 1. Graphene oxide was synthesized by Hummers oxidation method

[0022] Put 46mL concentrated sulfuric acid in a 250mL beaker, slowly add 2.0g graphite powder and 1.0g NaNO under ice bath and magnetic stirring 3 , after stirring evenly, slowly add 6.0g potassium permanganate, continue to stir evenly, then transfer to 35°C oil bath for 30 minutes, then slowly add deionized water to dilute to 250mL, then add 30% H 2 o 2 The solution neutralizes the unreacted potassium permanganate, centrifuges the finally obtained khaki solution, repeatedly washes with deionized water until the solution is neutral, centrifuges, and dries to obtain graphene oxide.

[0023] 2. Ultrasonically disperse the graphene oxide in deionized water to prepare a graphene oxide aqueous solution with a concentration of 0.01-0.2 mg / mL for use.

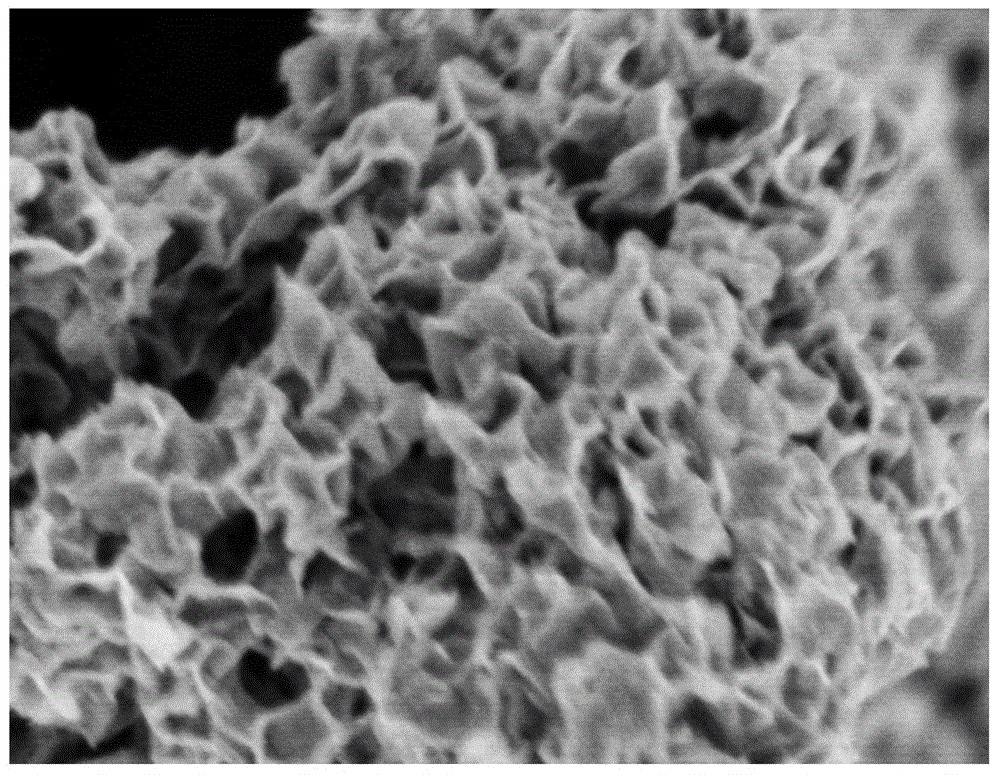

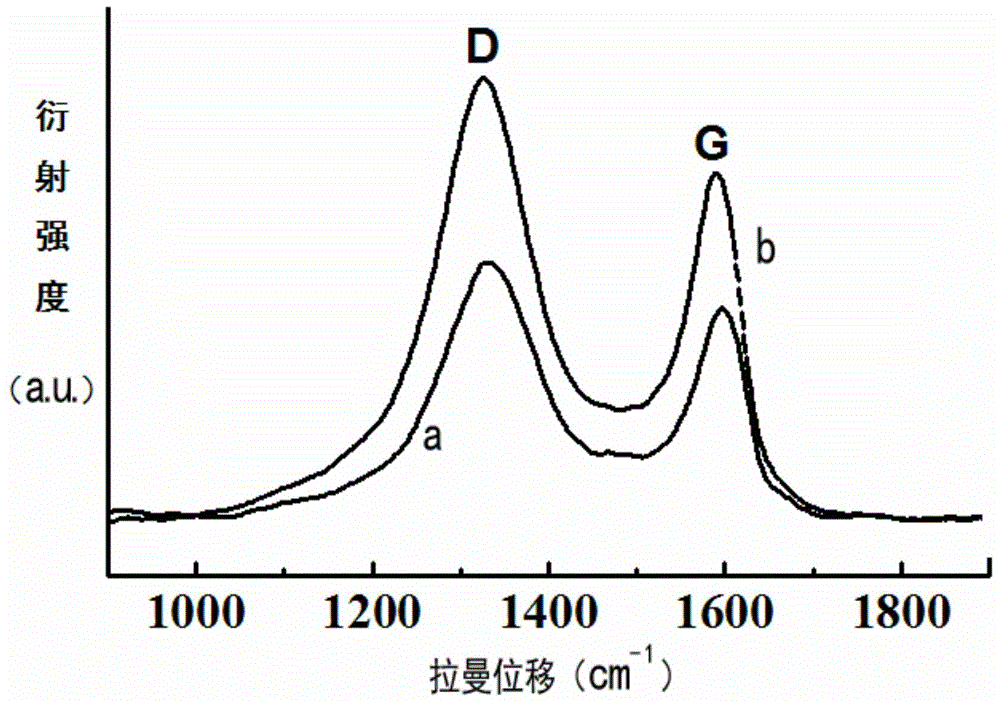

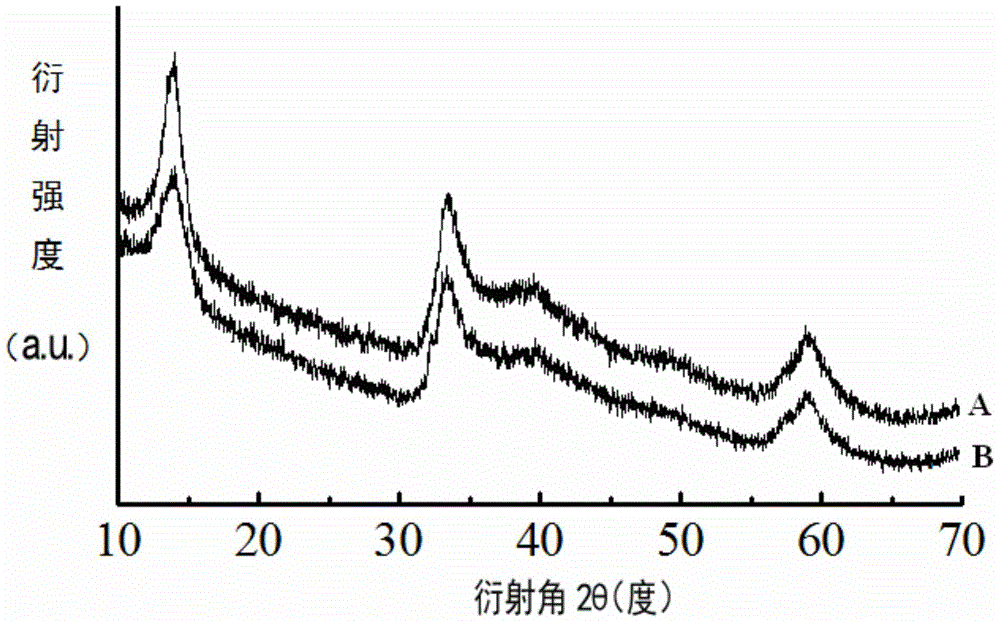

[0024] 3. Fabrication of fibrous counter electrode loaded with three-dimensional flower-like graphene / molybdenum disulfide composites by one-step hydrothermal re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com