Patents

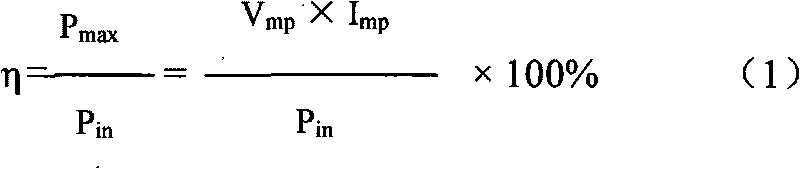

Literature

440results about How to "Improve photoelectric conversion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethylene-vinyl acetate copolymer adhesive film for packaging solar energy battery and preparation method thereof

InactiveCN101240157AImproves UV resistanceImprove thermal conductivityOther chemical processesFilm/foil adhesivesAcetic acidPolymer science

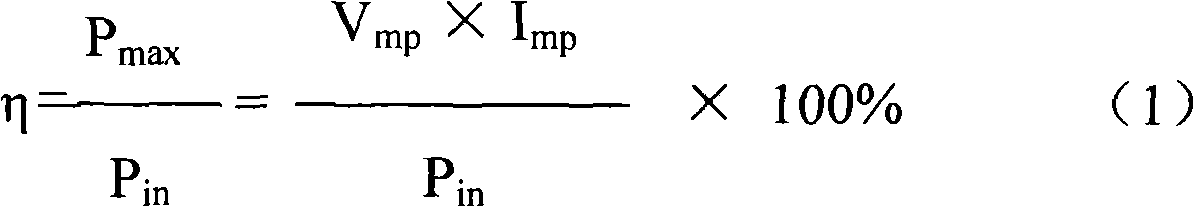

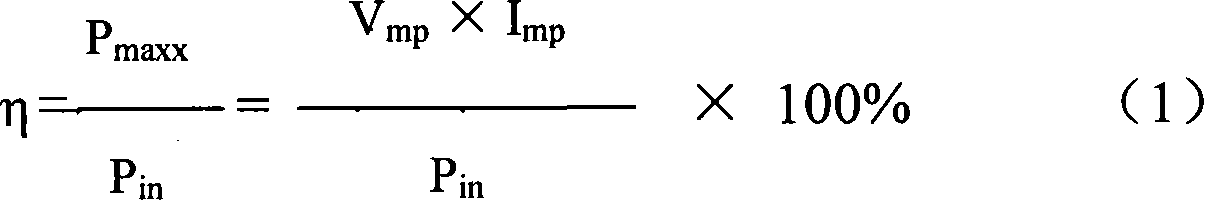

The invention discloses an ethylene-acetic acid polymer rubber film for solar energy battery packaging and preparation method thereof. The rubber film is composed of ethylene-acetic acid polymer granular materials, solidifier, heat-conducting filler, antioxidant, UV stabilizer, and coupling agent according to certain mass parts; the preparation method is: 1, mixing heat-conducting filler and coupling agent, drying and dispersing the mixture by grinding, to obtain active heat-conducting filer; 2, mixing ethylene-acetic acid polymer granular materials and solidifier; 3, mixing antioxidant, UV stabilizer and said active heat-conducting filler; 4, adding mixture of said step 3 into mixture of step 2, mixing the mixture and extruding the mixture, casting, cooling, towing, coiling the extrusion, obtain rubber film of the invention. Compared with current products, the rubber film of the invention has a higher heat-conducting coefficient which is increased by more than 3 times, and properties of improved photo-electric conversion ratio of solar energy battery, and prolonged useful life.

Owner:HOHAI UNIV

Silver coated copper conductor slurry for front electrode of solar battery and preparation method of silver coated copper conductor slurry

ActiveCN102610297ALow costImprove electrical performanceNon-conductive material with dispersed conductive materialCable/conductor manufactureCopper conductorMetallurgy

The invention provides silver coated copper conductor slurry for a front electrode of a solar battery and a preparation method of the silver coated copper conductor slurry for the front electrode of the solar battery. The silver coated copper conductor slurry for the front electrode of the solar battery comprises a conductive phase, glass powder and an organic carrier, wherein the conductive phase is silver coated copper powder and silver powder which account for 68-85% of the total weight of the slurry, the glass powder is Bi-B-Zn-Si-Ti-Ba-Al-O glass powder which accounts for 5-10% of the total weight of the slurry, and the organic carrier accounts for 10-22% of the total weight of the slurry. The preparation method comprises the steps: mixing the silver coated copper powder, the silver powder and the glass powder; weighing the organic carrier to agitate adequately; then mixing the silver coated copper powder, the silver powder and the glass powder with the organic carrier; and then rolling the mixture to obtain the silver coated copper conductor slurry for the front electrode of the solar battery. According to the silver coated copper conductor slurry for the front electrode of the solar battery, the electric properties of the electrode greatly is improved, and the photoelectric conversion rate of the battery is enhanced. The maximum fineness of the silver coated copper conductor slurry for the front electrode of the solar battery is 15 microns, the average fineness of the silver coated copper conductor slurry is less than 7 microns, the solid content is 80-87%, and the viscosity is 200-100keps. The solar battery printed and sintered by the silver coated copper slurry has higher photoelectric conversion rate and low cost.

Owner:昆明高聚科技有限公司

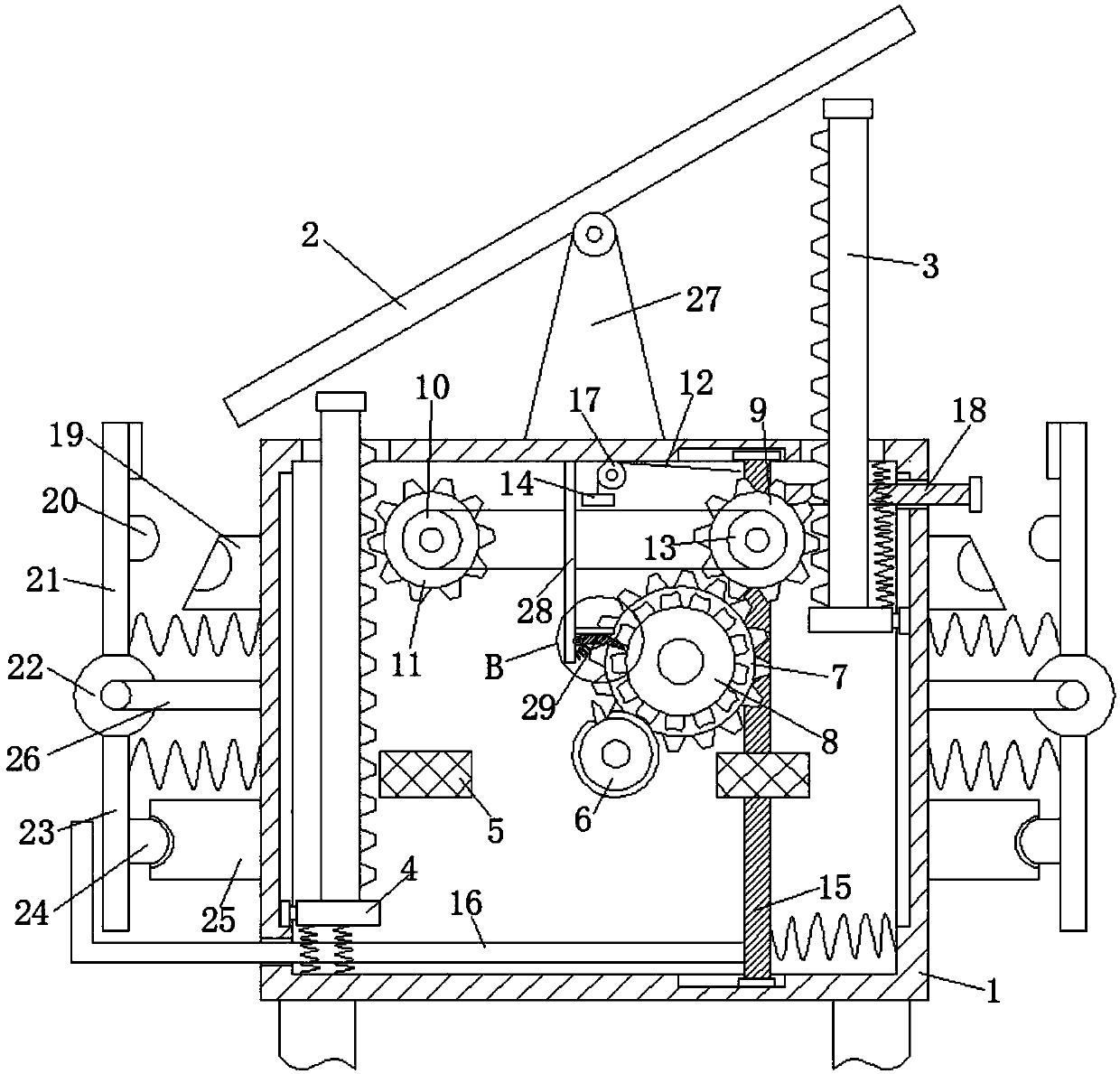

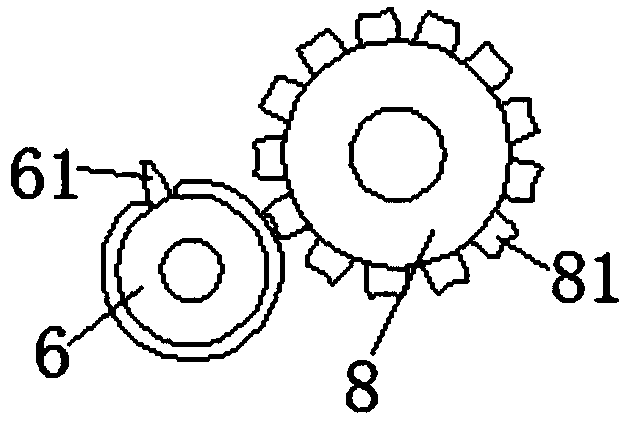

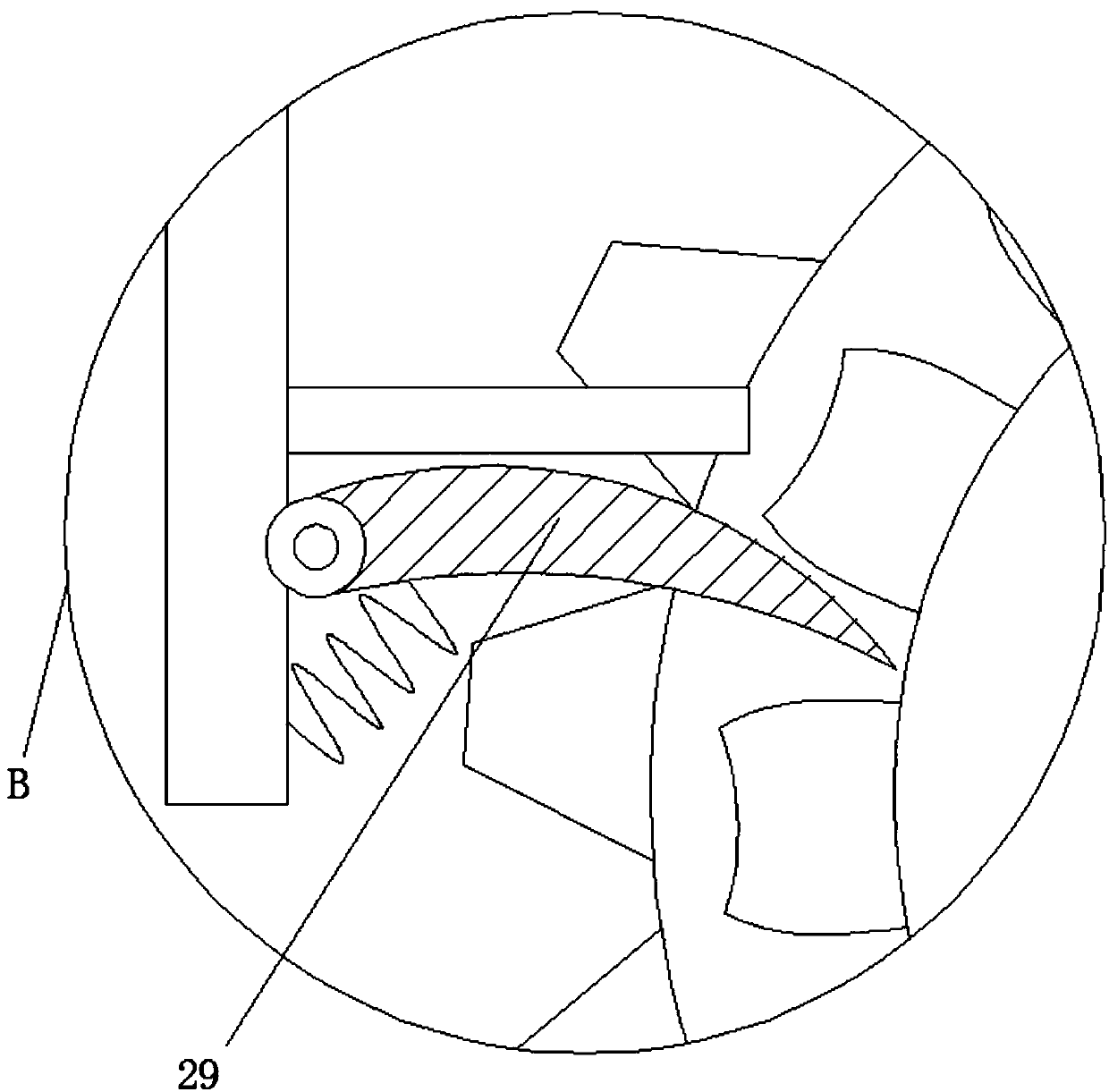

Automatically-adjusted windproof solar panel

ActiveCN110138324AReduce windEnsure stabilityPhotovoltaic supportsSolar heating energyWind forceSUN LIGHT EXPOSURE

The invention discloses an automatically-adjusted windproof solar panel. The bottom portion of an adjustment box is fixedly connected with a plurality of support rods, the bottom end face of the solarpanel is hinged with a base, the base is fixedly connected at the top wall of the adjustment box, and the bottom surface of the solar panel is provided with two symmetrically arranged rack rods. through combination of the rack rods, a rotating table and a ratchet wheel, the angle of the solar panel can be automatically adjusted to adapt the change of the irradiation angle of sunlight to achieve the maximum photoelectric conversion rate, the pawl on the rotating table is meshed with the ratchet wheel on the turntable in a clearance way for rotation to make the speed of the rack rod moving up and down and the speed of the azimuthal shift of the sun the same, when the automatically-adjusted windproof solar panel is blown by wind, an electromagnet can attract an iron plate to be located at same horizontal plane so that the two rack rods are arranged in the horizontal direction to ensure the horizontal arrangement of the solar panel, reduce the wind force of the solar panel and ensure thesteadiness of the solar panel.

Owner:中国电力工程顾问集团新能源有限公司

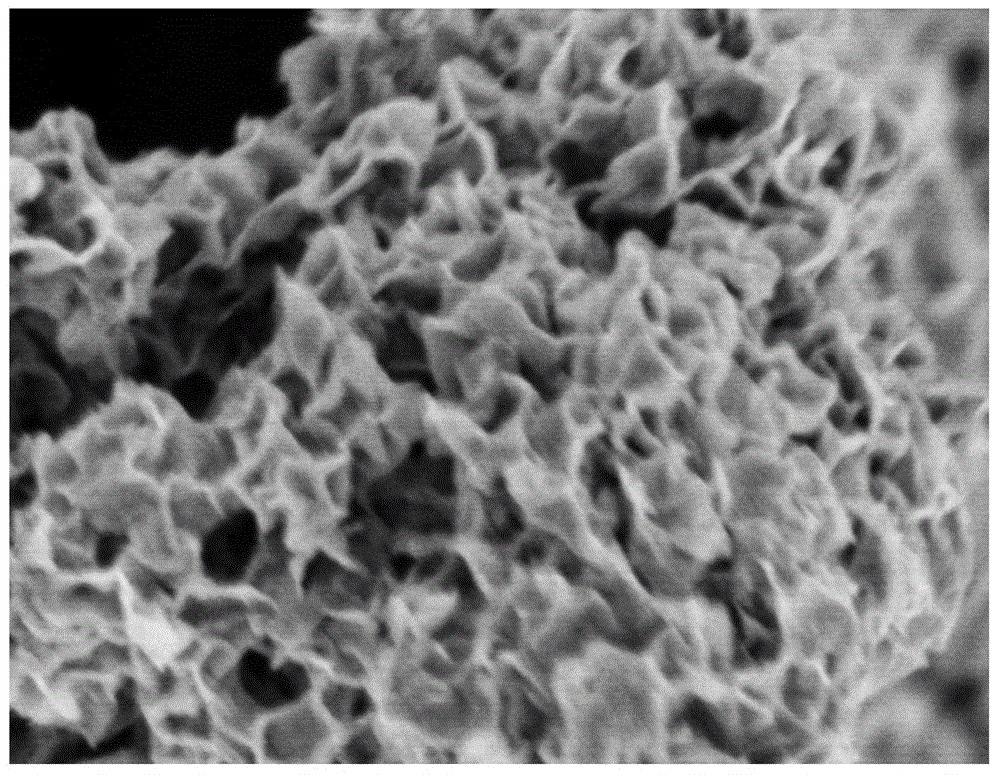

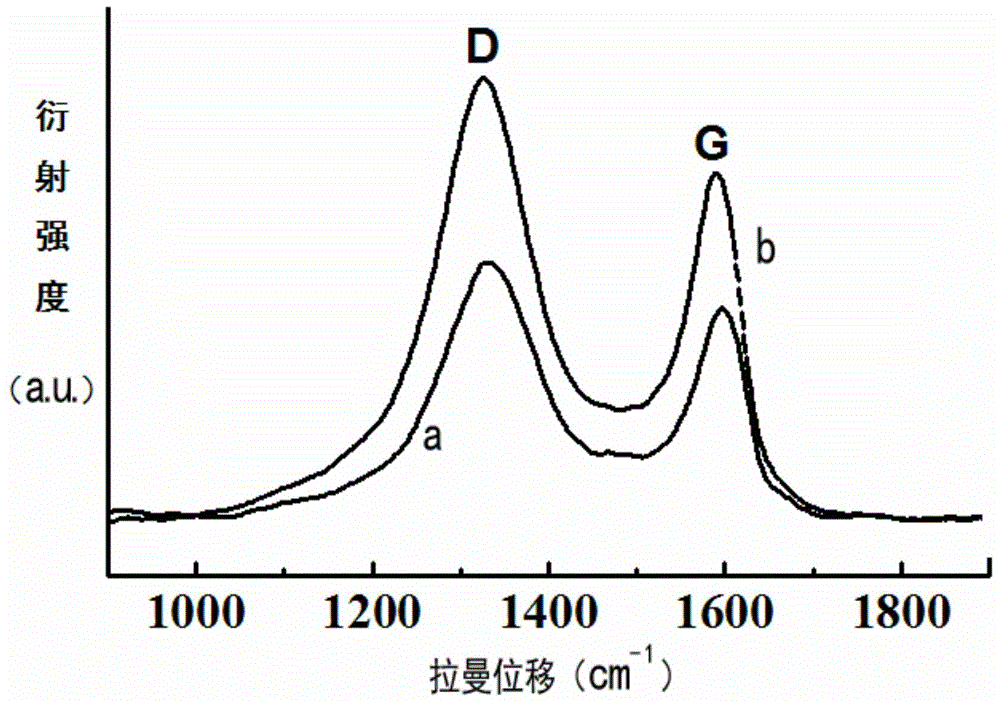

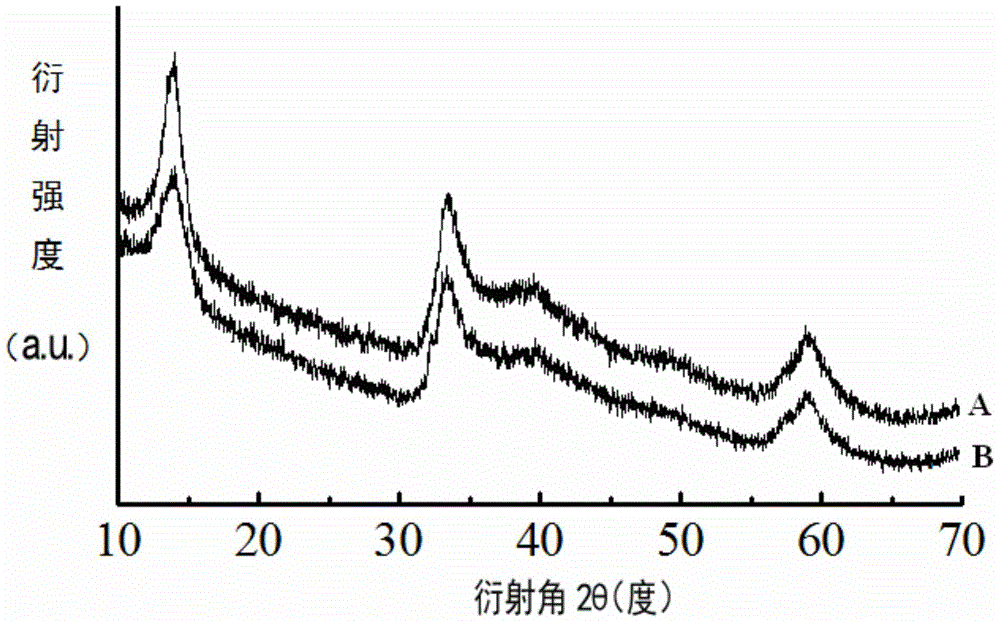

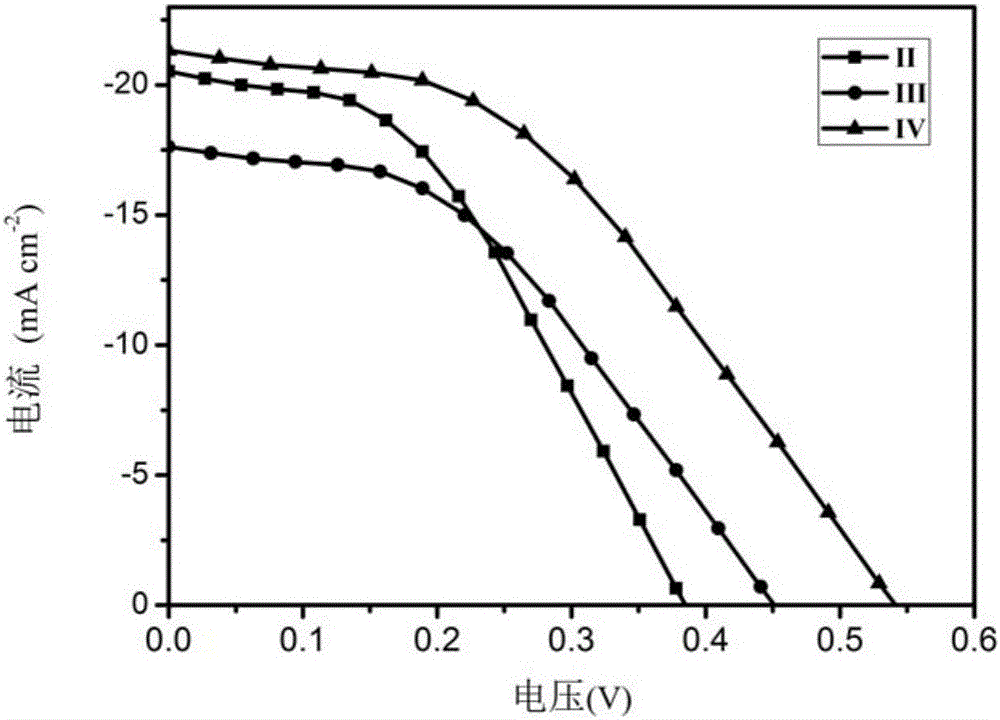

Method for preparing three-dimensional flower-shaped graphene/molybdenum disulfide composite loaded fibrous counter electrode

InactiveCN104319102ASimple processMild reaction conditionsLight-sensitive devicesFinal product manufactureFiberCarbon fibers

The invention discloses a method for preparing a three-dimensional flower-shaped graphene / molybdenum disulfide composite loaded fibrous counter electrode. The method for preparing the three-dimensional flower-shaped graphene / molybdenum disulfide composite loaded fibrous counter electrode uses a one-step hydrothermal reduction method, to be specific, adding molybdic acid or the water solution of molybdenum oxide, ammonium thiocyanate and graphene oxide in a hydrothermal reactor, vertically immersing carbon fiber in the reaction liquid, carrying out hydrothermal reduction reaction for 12 to 36 hours under 160 to 200 degrees centigrade, taking out the carbon fiber after ending reacting, using deionized water and absolute ethyl alcohol to wash, and drying. The method for preparing the three-dimensional flower-shaped graphene / molybdenum disulfide composite loaded fibrous counter electrode has advantages of simple technique, moderate reaction condition, high yield, good reproducibility, easiness in scale production and the like; the photoelectric conversion rate of a dye-sensitized solar cell composed of the prepared fibrous counter electrode is obviously higher than that of a dye-sensitized solar cell composed of an MoS2 or platinum loaded fibrous counter electrode, and the method for preparing the three-dimensional flower-shaped graphene / molybdenum disulfide composite loaded fibrous counter electrode is important for promoting the commercial application of the dye-sensitized solar cell.

Owner:SHANGHAI UNIV OF ENG SCI

Fourth generation alcohol-free additive not additionally added in suede preparation of monocrystalline silicon

InactiveCN103290484AReduce pollutionImprove photoelectric conversion rateAfter-treatment detailsAlcohol freeGlycerol

The invention relates to a fourth generation alcohol-free additive not additionally added in suede preparation of monocrystalline silicon. The fourth generation alcohol-free additive comprises the following main components: a dispersing agent, a humectant and deionized water, wherein the dispersing agent is one of or a combination of more of styrene sodium sulfonate, benzyl naphthalenesulfonate formaldehyde condensate, sodium polyaluminate, sodium hexametahposphate, sodium methylene dinaphthalenesulfonate, sodium polysilicate, sodium lignin sulfonate and sodium polyacrylate; and the humectant is one of or a combination of more of sodium hyaluronate, D5-panthenol, glycerol, propanediol, polyethylene glycol, polypropylene glycol, honey and collagen. When the suede preparation additive is added into a suede preparation solution, clean and uniform monocrystalline silicon suede can be quickly prepared, the photoelectric conversion rate is improved, the production cost is reduced, and the environmental pollution is reduced.

Owner:JINGJIANG JINGYI CHEM CO LTD

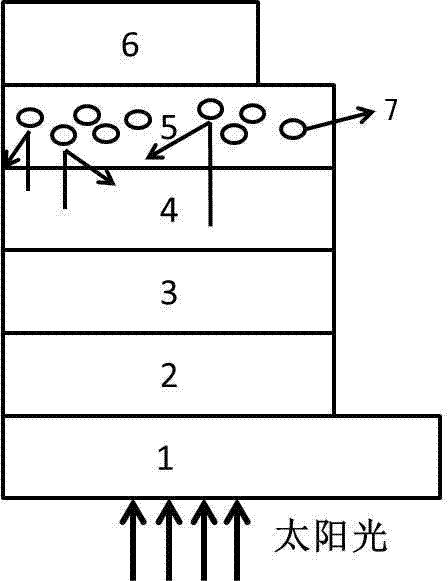

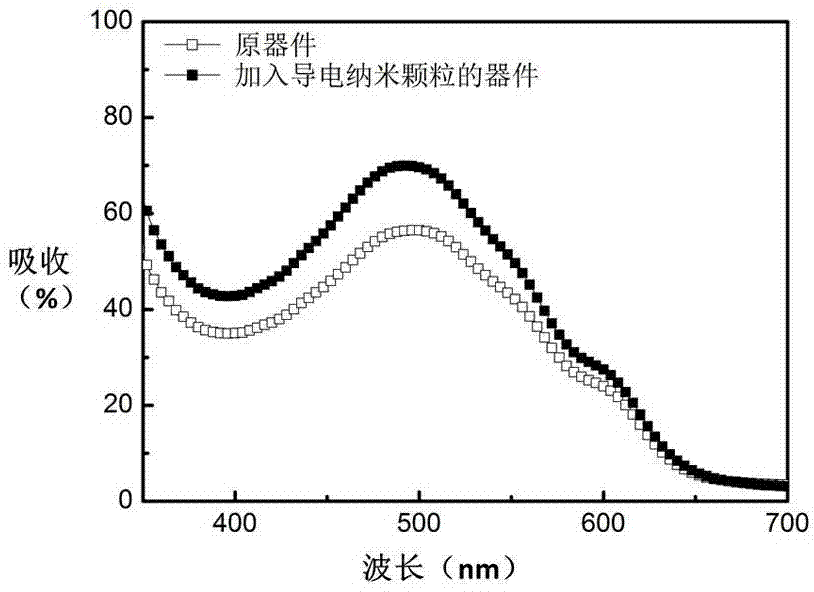

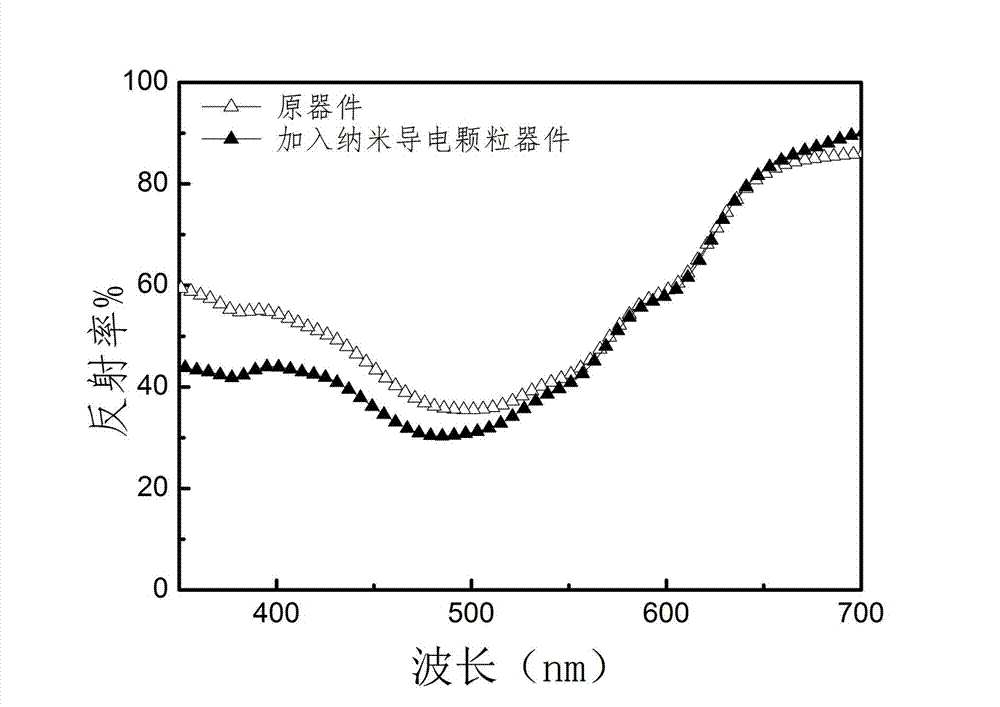

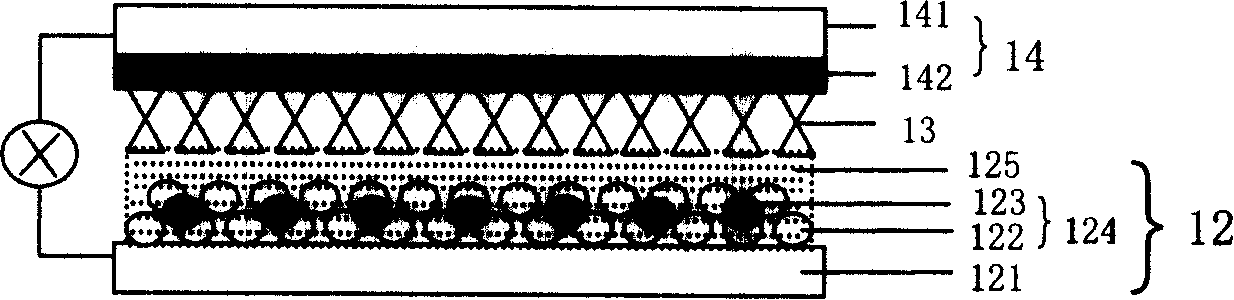

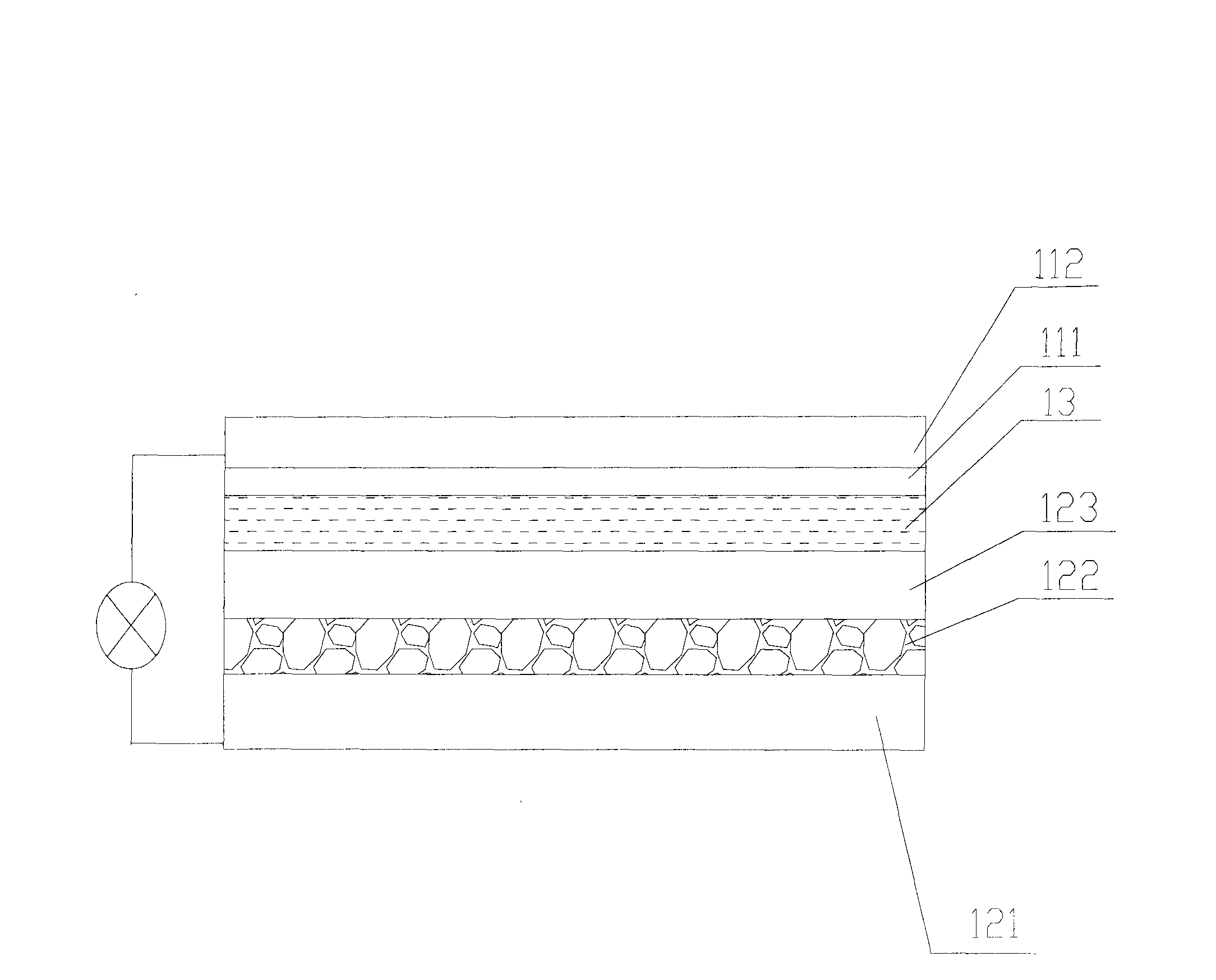

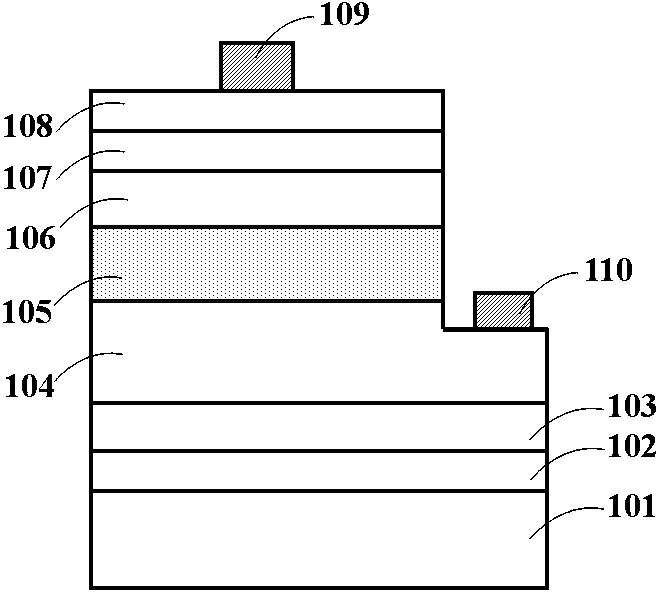

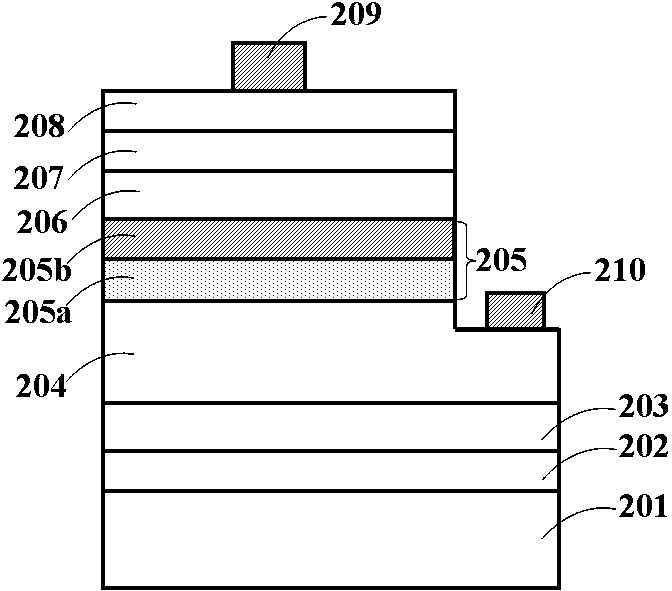

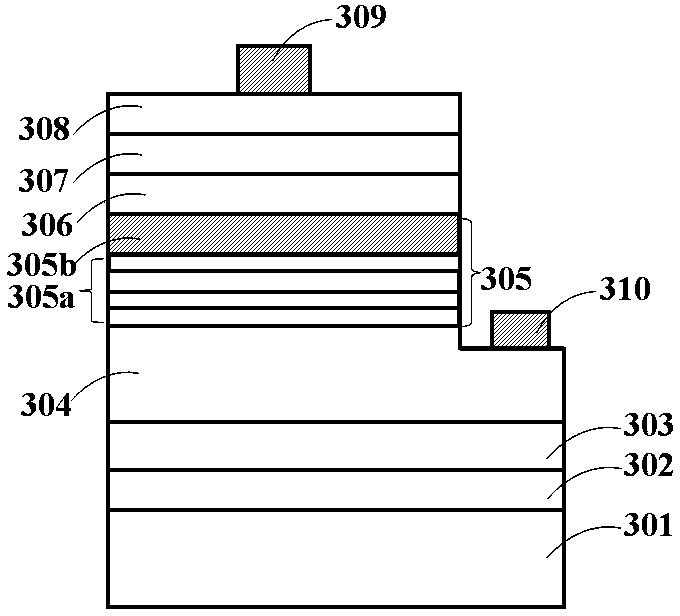

Inversed organic thin-film solar cell and manufacturing method of inversed organic thin-film solar cell

InactiveCN103594627AIncrease the rate of electron transferEasy to stackSolid-state devicesSemiconductor/solid-state device manufacturingEvaporationHigh reflectivity

The invention discloses an inversed organic thin-film solar cell and a manufacturing method of the inversed organic thin-film solar cell. The inversed organic thin-film solar cell structurally and sequentially comprises a substrate, a transparent electric conduction cathode ITO, a cathode buffer layer, an optical activity layer, an anode buffer layer and a metallic cathode from bottom top top. Transparent electric conduction nano-particles are added in the anode buffer layer. The manufacturing method includes the steps of forming a substrate body through the substrate and the transparent electric conduction cathode ITO, washing and drying the base plate, manufacturing the cathode buffer layer on the surface of the transparent electric conduction cathode ITO, manufacturing and baking the optical activity layer on the surface of the cathode buffer layer, manufacturing the anode buffer layer on the surface of the optical activity layer, conducting annealing on the substrate body, and plating the anode buffer layer with the metallic cathode in an evaporation mode. High conductivity and high reflectivity of the transparent electric conduction nano-particles are used, the electron transmission rate and the light reflection rate of a traditional anode buffer layer are strengthened, the absorptivity of the optical activity layer to sunlight is improved, the light current density and the carrier transmission efficiency of the organic thin-film solar cell are accordingly improved, the series resistance of the cell is reduced, and the photoelectric conversion efficiency of a device is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

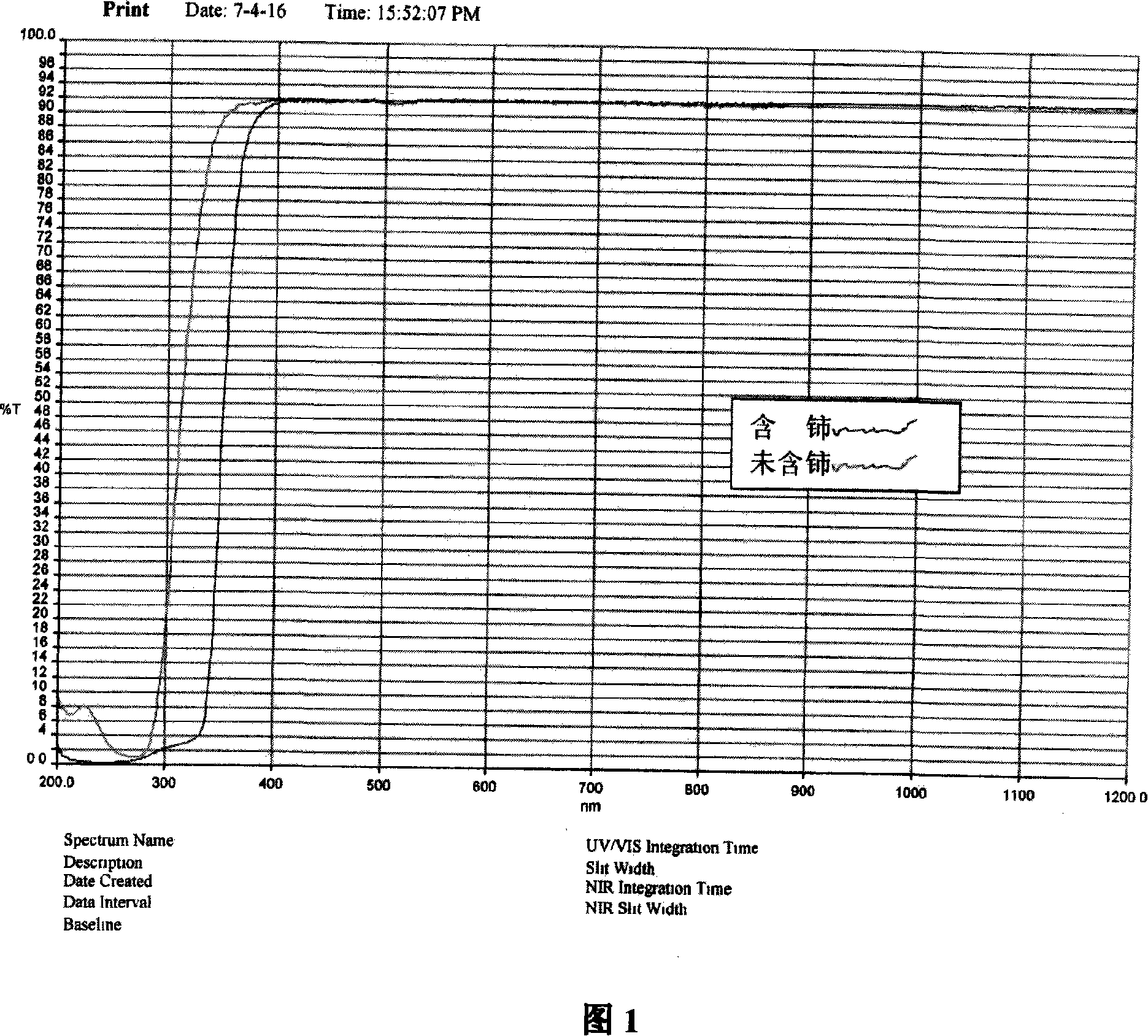

Ultraviolet blocking-up solar energy ultra-white configurated glass and method for manufacturing the same

The present invention is one kind of white figured glass capable of blocking ultraviolet ray for solar photovoltaic cell assembly with crystalline silicon cell and non-crystalline silicon electrode plates and its production process. The white figured glass is made of material with very low Fe element content and added CeO2, and has very low ultraviolet ray transmittance. Its production process includes sorting material, compounding material, mixing, smelting, rolling, annealing and other steps.

Owner:ZHEJIANG JIAFU GLASS CO LTD

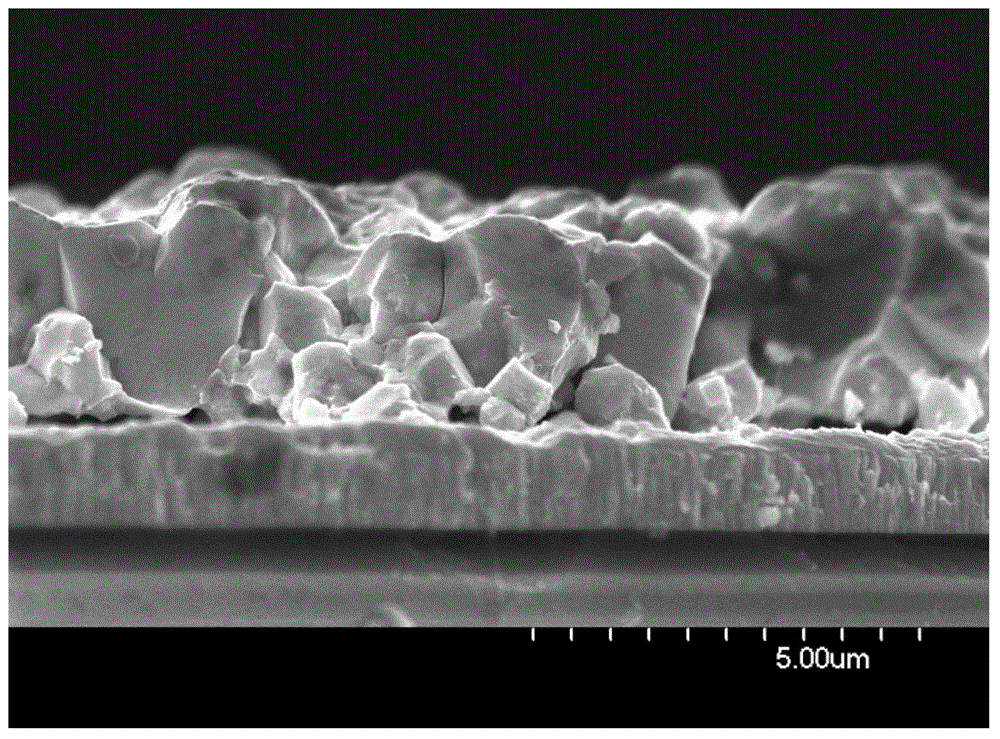

Method for electrochemical codeposition of CZTS (Se) films in deep eutectic solution

The invention discloses a method for electrochemical codeposition of CZTS (Se) films in deep eutectic solution. The method adds any one or two of sulfide and selenide, copper salt, zinc salt and tin salt in the deep eutectic solution as electroplating solution for electric deposition of CZTS (Se) prefabricated layer films. The method uses the deep eutectic solution system as the electroplating solution without additionally adding a complexing agent and an additive; and the obtained CZTS (Se) films are compact, level, uniform, few in impurity residues and not liable to be oxidized, are excellent solar cell absorption layer materials, and have higher photoelectric conversion rate.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

Photovoltaic module production process

InactiveCN106098837AReduce the phenomenon of air bubblesImprove photoelectric conversion rateFinal product manufacturePhotovoltaic energy generationTest batteryElectrical battery

The invention relates to the technical field of photovoltaic module production, in particular to a photovoltaic module production process. The photovoltaic module production process comprises the following steps of screening, in which batteries and separated and classified by testing current and voltage output parameters of the batteries; welding, in which screened battery pieces are welded to a solar cell module; stacking, in which cover plate glass, an EVA membrane, solar cells which are connected to one another, an EVA membrane and a back plate are stacked together for lamination; laminating; trimming; carrying out EL detection; framing; packaging a junction box; and finally, testing, in which module test and high-voltage test are performed on the packaged battery module. After the adoption of the above process, the phenomenon that air bubbles are generated in an EVA photovoltaic module after lamination in the photovoltaic module production process due to very short extraction time is effectively reduced, the photoelectric conversion rate of the photovoltaic module is improved, and the service lifetime of the photovoltaic module is prolonged.

Owner:ZNSHINE PV TECH

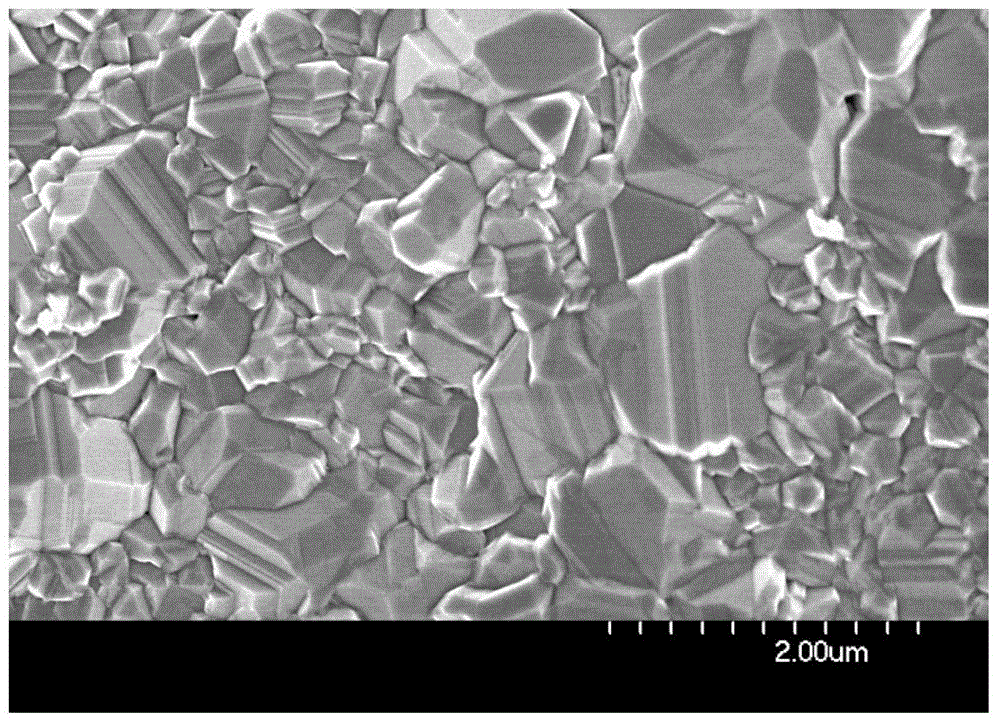

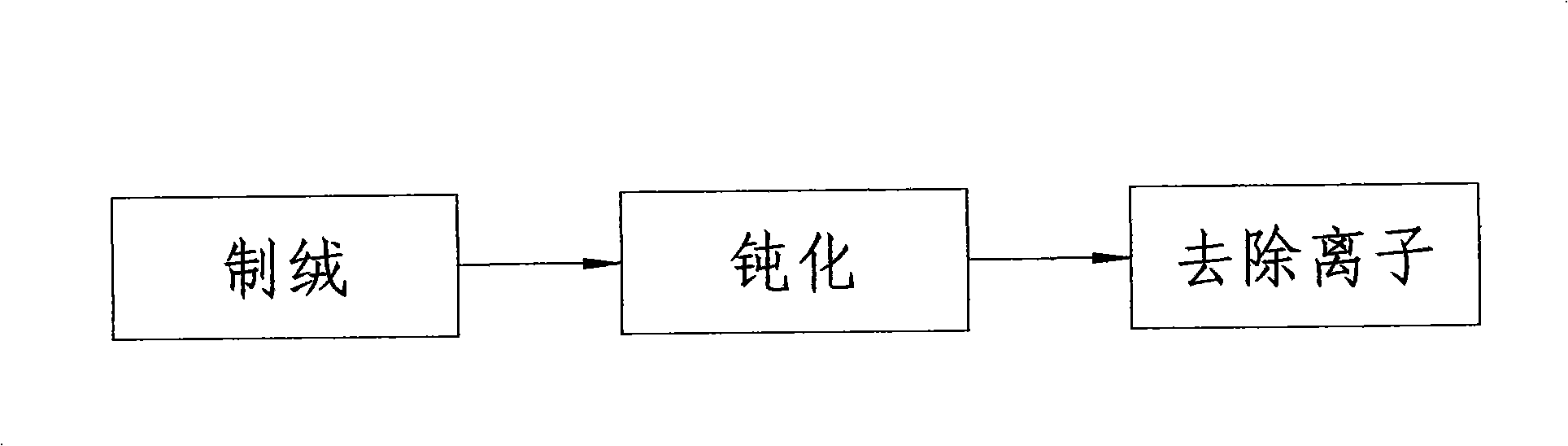

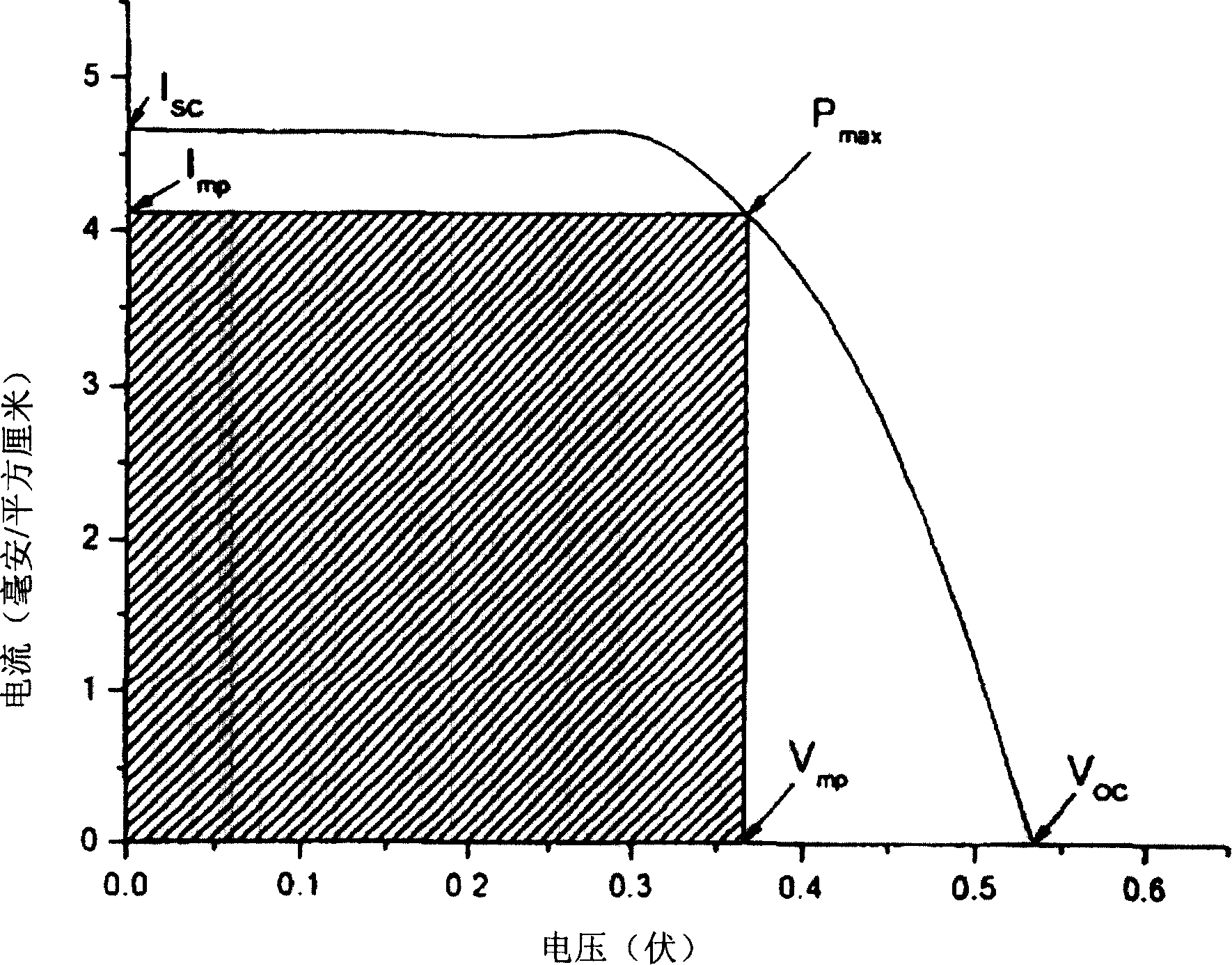

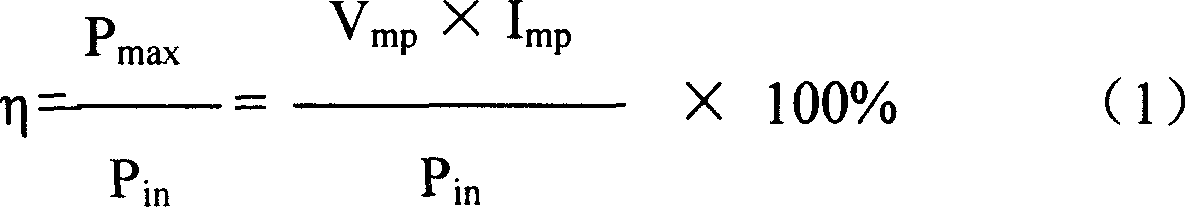

Method for fine-hair maring using monocrystalline silicon slice

InactiveCN101409312AUnbreakableUniform and fine suedeFinal product manufactureSemiconductor devicesHigh reflectivitySteady state

The invention discloses a method for texturing a monocrystalline silicon wafer. The method comprises the steps of texturing by corrosion, passivation and deionization. By the technical scheme of cancelling rough polishing, and changing a formula, reaction conditions and treatment flow, the method overcomes the problems and the disadvantages of the prior art that the texturing technological process is difficult to be controlled, the thickness reduction of the monocrystalline silicon wafer is greater, the silicon wafer is easily cracked during the treatment process, the textures formed on the silicon wafer is uneven, and bulky dimension of a cone structure leads to high reflectivity of the silicon wafer, lower short circuit current (Isc) and lower photoelectric conversion rate. The method provided for texturing the monocrystalline silicon wafer realizes that corrosive liquid is in a steady state which is easy to be controlled, the thickness reduction of the silicon wafer is reduced, the formed textures are even and the dimension of the cone structure is compact; the method reaches the purposes of reducing the reflectivity of the silicon wafer, increasing the short circuit current (Isc), and improving the photoelectric conversion rate, meanwhile, the method improves the quality and the qualification rate of the product on the whole, reduces the consumption of chemical reagents and lowers the cost.

Owner:SHANGHAI CHAORI (LUOYANG) SOLAR ENERGY CO LTD

Semi-conductor electrode and method for making and solar cell containing the semiconductor electrode

ActiveCN101192628AImprove photoelectric conversion rateImprove utilization efficiencyLight-sensitive devicesFinal product manufactureSemiconductor electrodeMetal particle

A semiconductor electrode for a dye-sensitized solar cell comprises a conductive bottom layer, a semiconductor nanometer crystal membrane formed on the conductive bottom layer, and a dye layer formed on the semiconductor nanometer crystal membrane. The semiconductor nanometer crystal membrane contains semiconductor particles and conductive particles; the conductive particles are composite conductive particles which contain metal particles and carbon particles, and the metal particles are loaded on the surface of the carbon particles. The invention also provides a method for preparing the semiconductor electrode and the dye-sensitized solar cell which contains the semiconductor electrode. The semiconductor nanometer crystal membrane contains the composite conductive particles which contain the carbon particles and the metal particles which are loaded on the surface of the carbon particles, thus improving the use efficiency of the metal particles. The metal particles can be used as capture wells for electrons, so that the electrons and cavities in the semiconductor are separated effectively, and the life of the electronic-cavity is prolonged and the photo-generated current is increased, thus enhancing the photoelectric conversion rate of the dye-sensitized solar cell.

Owner:BYD CO LTD

Semiconductor electrode, manufacture method thereof and solar cell containing same

InactiveCN101635203AImprove adsorption capacityImprove photoelectric conversion rateAlkaline accumulatorsLight-sensitive devicesPorositySemiconductor electrode

The invention provides a semiconductor electrode for a dye-sensitized solar cell, comprising a conductive bottom layer, a porous semiconductor layer formed on the conductive bottom layer and a dye layer formed on the porous semiconductor layer, wherein the porosity of the porous semiconductor layer is 40-85% and the thickness of the porous semiconductor layer is 6-20 microns. The invention also provides a preparation method of the semiconductor electrode and the dye-sensitized solar cell containing same, wherein the preparation method comprises the following steps: paving sizing agent which contains semiconductor grains, pore-forming agent and dispersing agent on the conductive bottom layer, calcining the sizing agent to obtain a solid film, putting the solid film in solution to be dipped into pores and obtain a porous solid film, calcining the porous solid film, and forming the porous semiconductor layer on the conductive bottom layer. The porosity of the porous semiconductor layer is high, can improve the absorption load quantity of the dye on the porous semiconductor layer, increases light generated current, and improves opto-electrical conversion rate.

Owner:BYD CO LTD

Ultra clear float solar battery glass production process and product thereof

ActiveCN103253864AHigh light transmittanceReduce reflectivityGlass severing apparatusPhotovoltaic industryEngineering

The invention belongs to the technical field of special glass production, and provides an ultra clear float solar battery glass production process and a product thereof. The process comprises the following steps: (1) preparing raw materials, (2) feeding and melting, (3) carrying out clarification, (4) carrying out homogenization, (5) carrying out tin stripping molding, (6) annealing, and (7) cutting. With the ultra clear float solar battery glass production process, ultra clear float solar battery glass with a thickness of 2.5 mm can be produced, wherein the glass has characteristics of high transmittance, low reflectivity and light unit weight, and is applicable for photovoltaic industry to be adopted as a photoelectric conversion substrate and a light-heat conversion panel so as to be used for solar battery manufacturing. In addition, with application of the process to produce the ultra clear float solar battery glass, the production cost is low so as to reduce a production cost of the whole photovoltaic industry chain.

Owner:XINYI PHOTOVOLTAIC IND (ANHUI) HLDG CO LTD

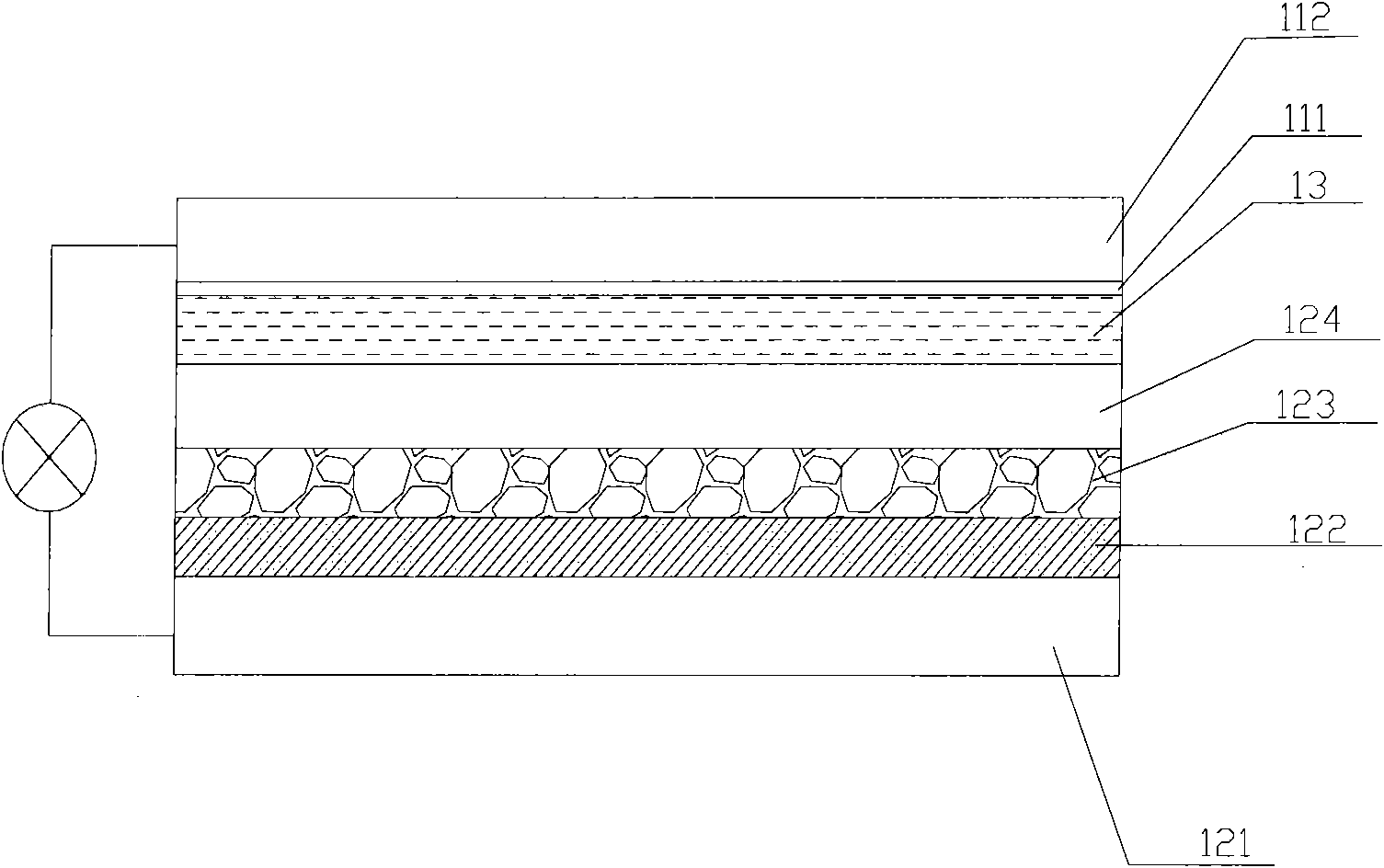

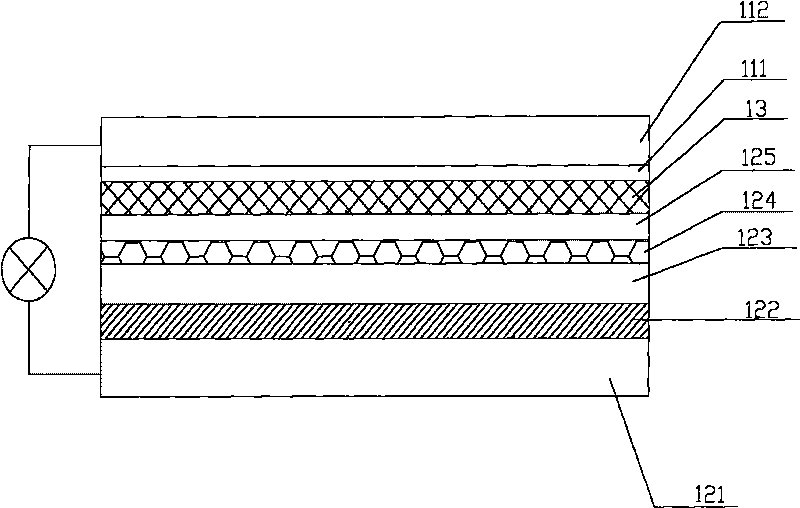

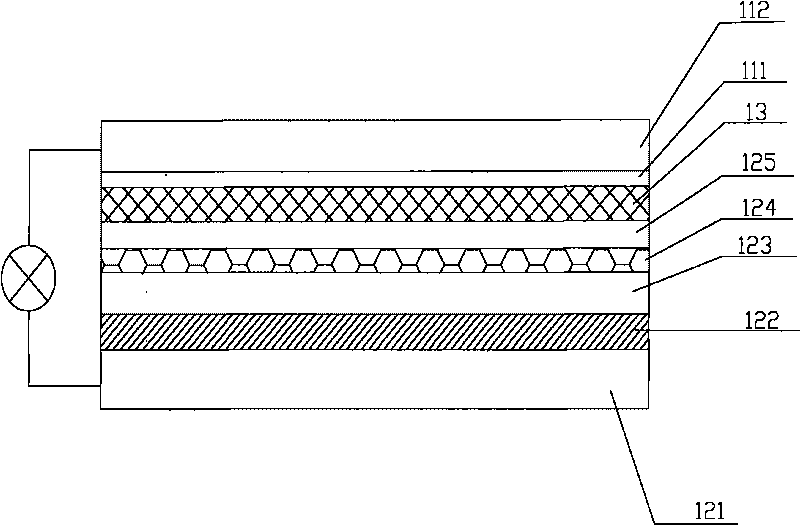

Backboard for high heat dissipation photovoltaic module and preparation method

ActiveCN104393084AProtection lifeGood resistance to water vapor transmissionFinal product manufacturePhotovoltaic energy generationPolyolefinUltraviolet lights

The invention relates to the technical field of solar cell backboard, and in particular relates to a backboard for high heat dissipation photovoltaic module and a preparation method, the backboard comprises a high thermal conductivity weather-proof layer, an aluminum foil layer, a bonding layer and a lower weather-proof layer orderly formed, the underside of the high thermal conductivity weather-proof layer is pasted to the aluminum foil layer, two sides of the bonding layer are respectively pasted to the aluminum foil layer and the lower weather-proof layer, the lower weather-proof layer is the fluorine resin modified polyolefin film provided with the concave-convex grid structure on the surface, wherein the high thermal conductivity weather-proof layer is prepared by the fluorocarbon coating, the raw material of the fluorocarbon coating comprises the fluorocarbon resin, isocyanate, inorganic filler, ultraviolet light absorber, light stabilizer and butyl acetate; the raw material of fluorine resin modified polyolefin film comprises the polypropylene resin, fluorinated ethylene-propylene resin, filler, anti-ultraviolet agent and antioxygen. The backboard for high heat dissipation photovoltaic module is good in heat dissipation effect, high in photoelectric conversion rate and simple in structure. The preparation method for the backboard for high heat dissipation photovoltaic module is simple in process, convenient in operation control, stable in quality and high in production efficiency.

Owner:MING CROWN ADVANCED MATERIAL CO LTD

Nano titanium dioxide coated carbon nanotube reinforced carbon nanofiber and preparation method thereof

InactiveCN102634873AOne-dimensional continuityLarge specific surface areaArtificial filament chemical after-treatmentArtifical filament manufactureFiberSensitized cell

The invention discloses a nano titanium dioxide coated carbon nanotube reinforced carbon nanofiber which is characterized in that the surface layer is uniformly coated with anatase titanium dioxide particles with diameters of 1-100nm, the inside contains single-wall or multi-wall carbon nanotubes with diameters of 0.9-100nm, and the diameter of the carbon nanofiber is 30-700nm. The nano titanium dioxide coated carbon nanotube reinforced carbon nanofiber is prepared from the following components in percentage by mass: 0.05-25% of nano titanium dioxide, 0.05-30% of carbon nanotube and 45-99.9% of carbon fiber. With the features one-dimension continuity, high specific area and the like, the fiber has higher solution absorptivity and incident light diffuse reflection effect, has the characteristics of higher softness, higher conductivity and stronger workability than the titanium dioxide nanowire and nanofiber, and can effectively enhance the photoelectric conversion rate of the solar dye-sensitized cells.

Owner:JIANGNAN UNIV

Semiconductor electrode, preparation method thereof and solar cell comprising semiconductor electrode

InactiveCN101620939AImprove photoelectric conversion rateEfficient separationLight-sensitive devicesFinal product manufactureSemiconductor electrodeElectron hole

The invention discloses a semiconductor electrode for a dye-sensitized solar cell, which comprises a conductive bottom layer, a compact semiconductor layer formed on the conductive bottom layer, a porous semiconductor layer formed on the compact semiconductor layer, and a dye layer formed on the porous semiconductor layer, wherein the compact semiconductor layer and the porous semiconductor layer comprise semiconductor particles and conductive particles; and the conductive particles can be used as electron traps, so that electrons and holes in a semiconductor are effectively separated, the electron-hole service life is prolonged, and the light generated current is increased so as to improve the photo-electro transition rate of the dye-sensitized solar cell.

Owner:BYD CO LTD

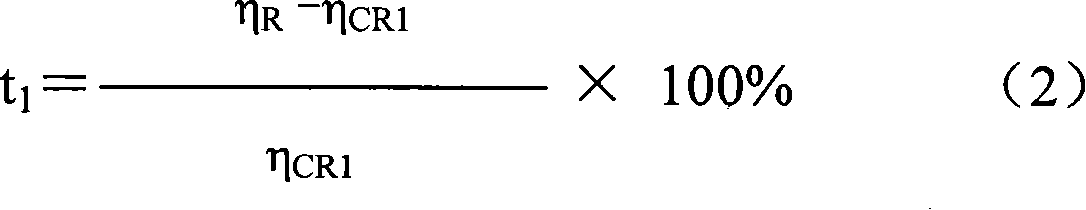

Solar cell encapsulating EVA (ethylene vinyl acetate copolymer) adhesive film with high light transmittance and preparation method of adhesive film

ActiveCN107502232AHigh transparencyGood flexibilityNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkMechanical property

The invention relates to a solar cell encapsulating EVA (ethylene vinyl acetate copolymer) adhesive film with high light transmittance. The solar cell encapsulating EVA adhesive film is characterized in that the thickness of the EVA adhesive film is 0.8 mm-1.1 mm, and the EVA adhesive film is prepared from raw materials in parts by weight as follows: 100 parts of EVA resin, 0.5-2.5 parts of a plasticizer, 0.1-0.3 parts of a photoelectric conversion rate enhancer, 1-4 parts of an anti-aging agent, 1.5-2.5 parts of a blocking agent, 1-2 parts of a dispersing agent, 1-3 parts of a coupling agent and 1-3 parts of a cross-linking agent. Firstly, the raw materials are added to a mixer proportionally and mixed into uniform components, the components are subjected to melt mixing by a banbury mixer and then subjected to extrusion and pelletizing, and the EVA adhesive film is obtained. According to the prepared EVA adhesive film, the light transmittance of the adhesive film is not influenced and the mechanical properties are greatly improved while properties and photoelectric conversion efficiency of the adhesive film are improved with addition of multiple additives.

Owner:NINGBO HUASHUN SOLAR ENERGY TECH

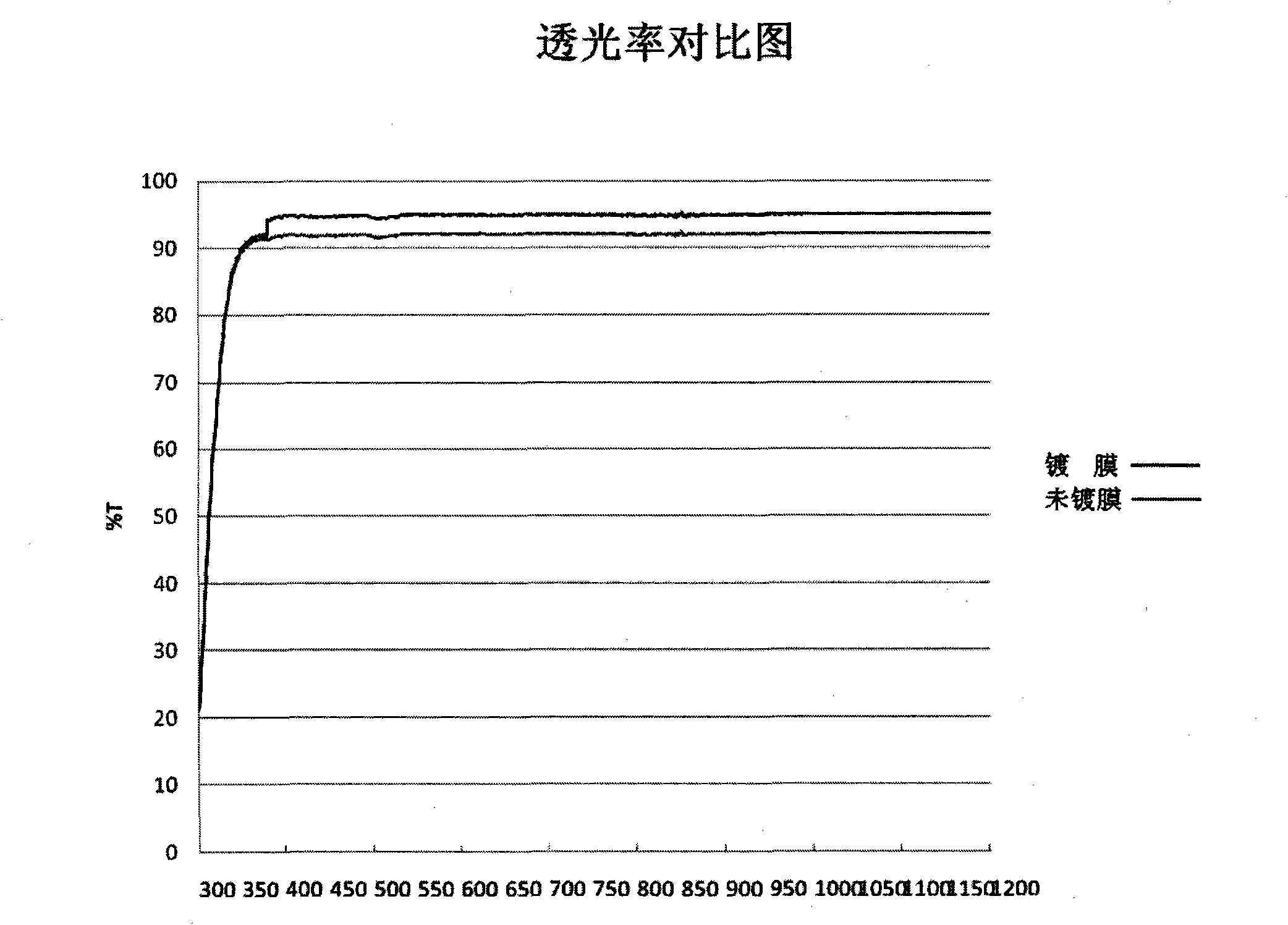

Anti-reflection high-transmittance coated solar super-white embossed glass and manufacturing method thereof

ActiveCN101967041AHigh solar transmittanceThermal effect reductionHigh transmittanceCrystalline silicon

The invention relates to anti-reflection high-transmittance coated solar super-white embossed glass and a manufacturing method thereof. The glass comprises a glass base layer and a coating layer. The manufacturing method comprises the following steps of: selection of raw materials, proportioning, mixing, melting, calendaring, annealing, sheet collection with specified size, deep processing of appearance, coating processing and toughening. The reflected rays of the glass are reduced; and the glass is treated by double-sided coating technology so as to improve the effective sunlight section transmittance of the glass and fulfill the purposes of controlling the crystalline silicon used by a photovoltaic assembly to be relative reduced and improving the power of a solar power generation assembly.

Owner:FLAT GLASS GROUP CO LTD

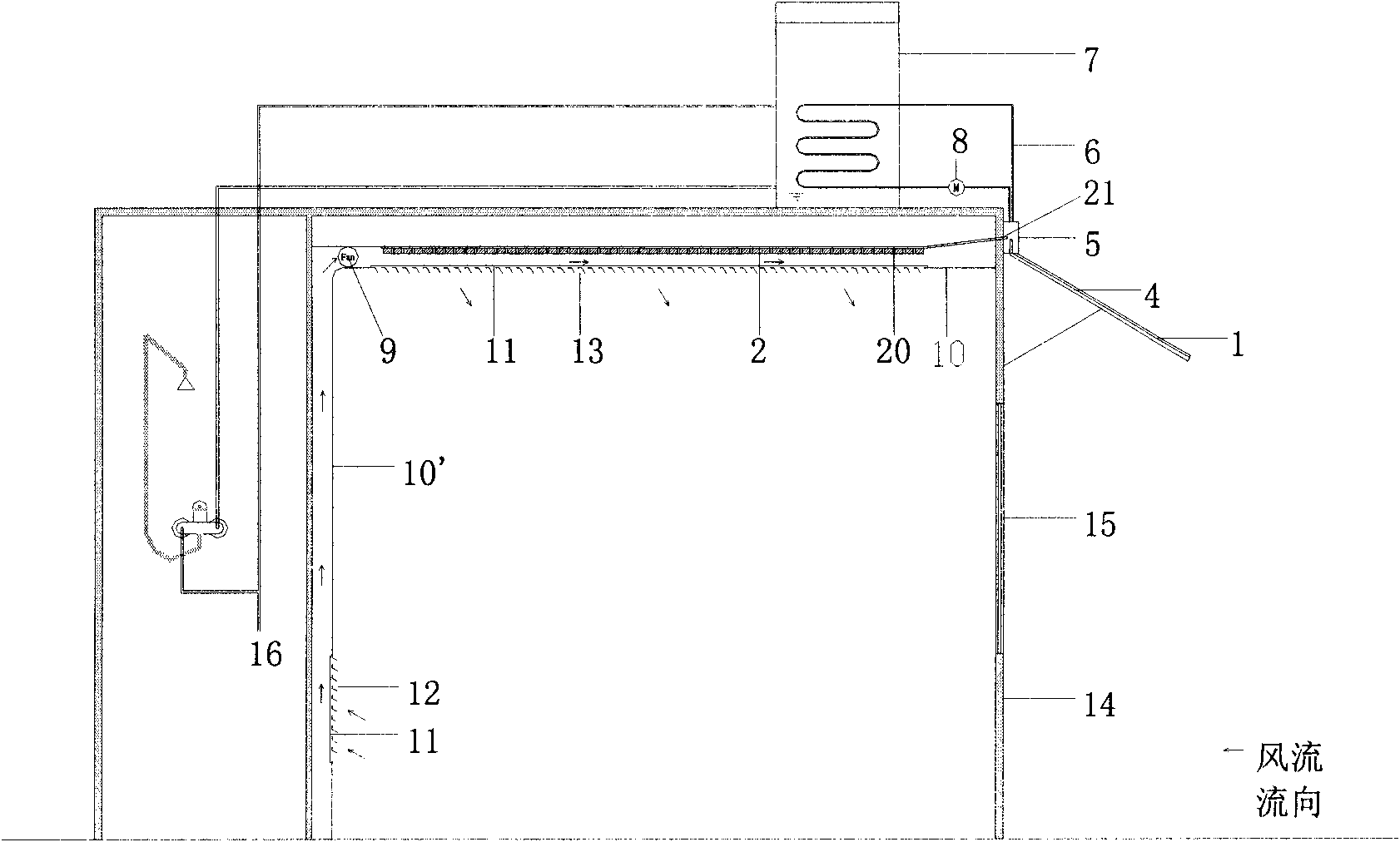

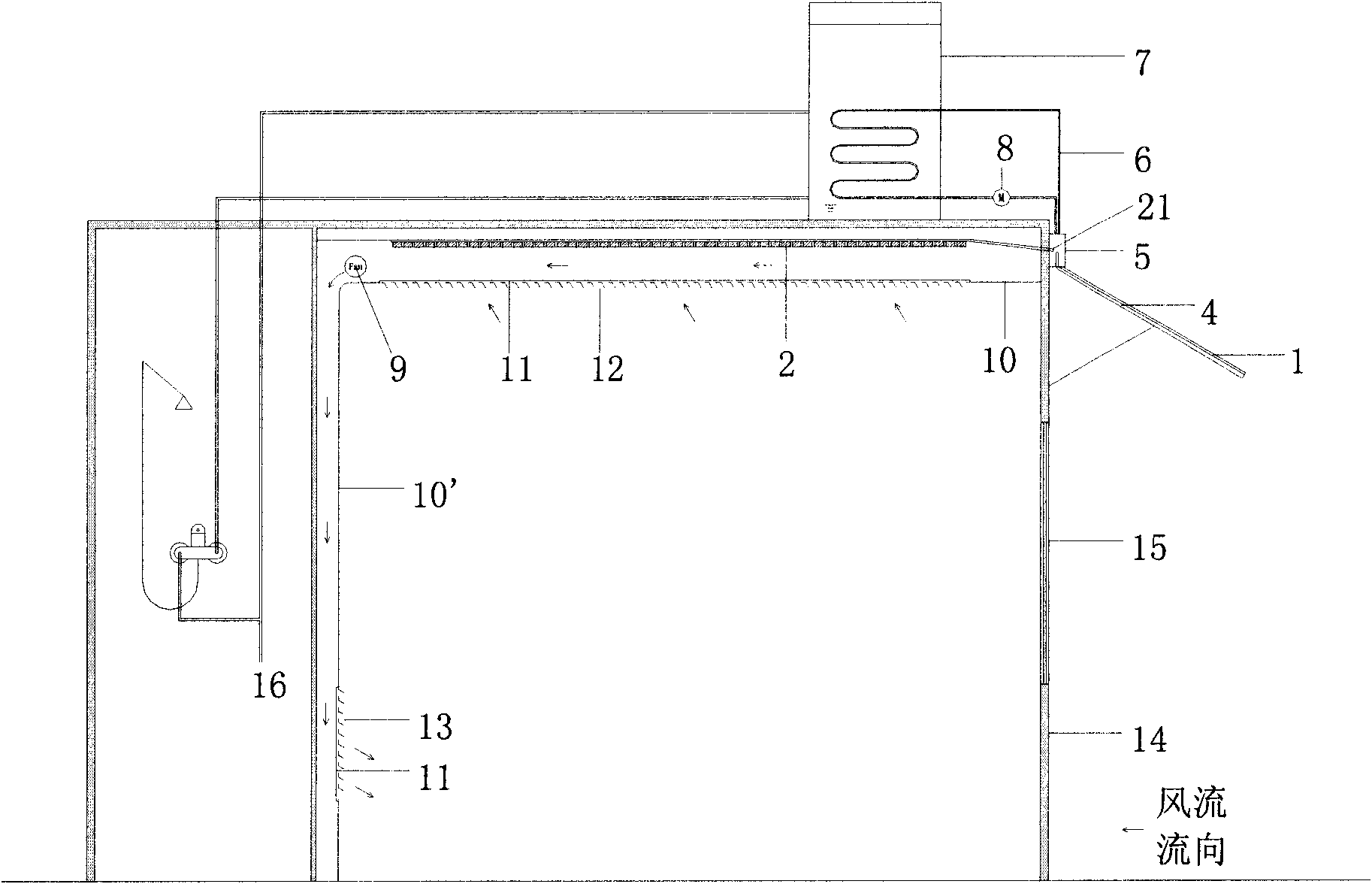

Composite solar photovoltaic hot-water cold supply and heating system for building

InactiveCN101806514ATake advantage ofVersatileSolar heating energySolar heat devicesEngineeringSolar power

The invention discloses a composite solar photovoltaic hot-water cold supply and heating system for a building, which mainly comprises a solar photovoltaic hot water sunshade plate, a semiconductor refrigerating assembly, a separate heat pipe with a short pipe bundle, an integral gravity heat pipe, a heat exchange header and the like. The system is characterized in that the solar photovoltaic hot water sunshade plate and the semiconductor refrigerating assembly form a loop to realize indoor refrigeration and heat supply in summer and in winter by using solar power generation respectively; and the separate heat pipe, the integral gravity heat pipe, the heat exchange header, a coil pipe, a water tank and the like form a hot water system to generate hot water when cooling and heating of the semiconductor refrigerating assembly are realized in summer and in winter respectively. The system solves the problem that heating and hot water generation cannot be realized at the same time in the combined application of the traditional solar photovoltaic power generation and semiconductor refrigerating assemblies; and the introduction of the separate heat pipe and the gravity heat pipe improves the refrigerating and heating efficiency and enlarges the application range.

Owner:UNIV OF SCI & TECH OF CHINA

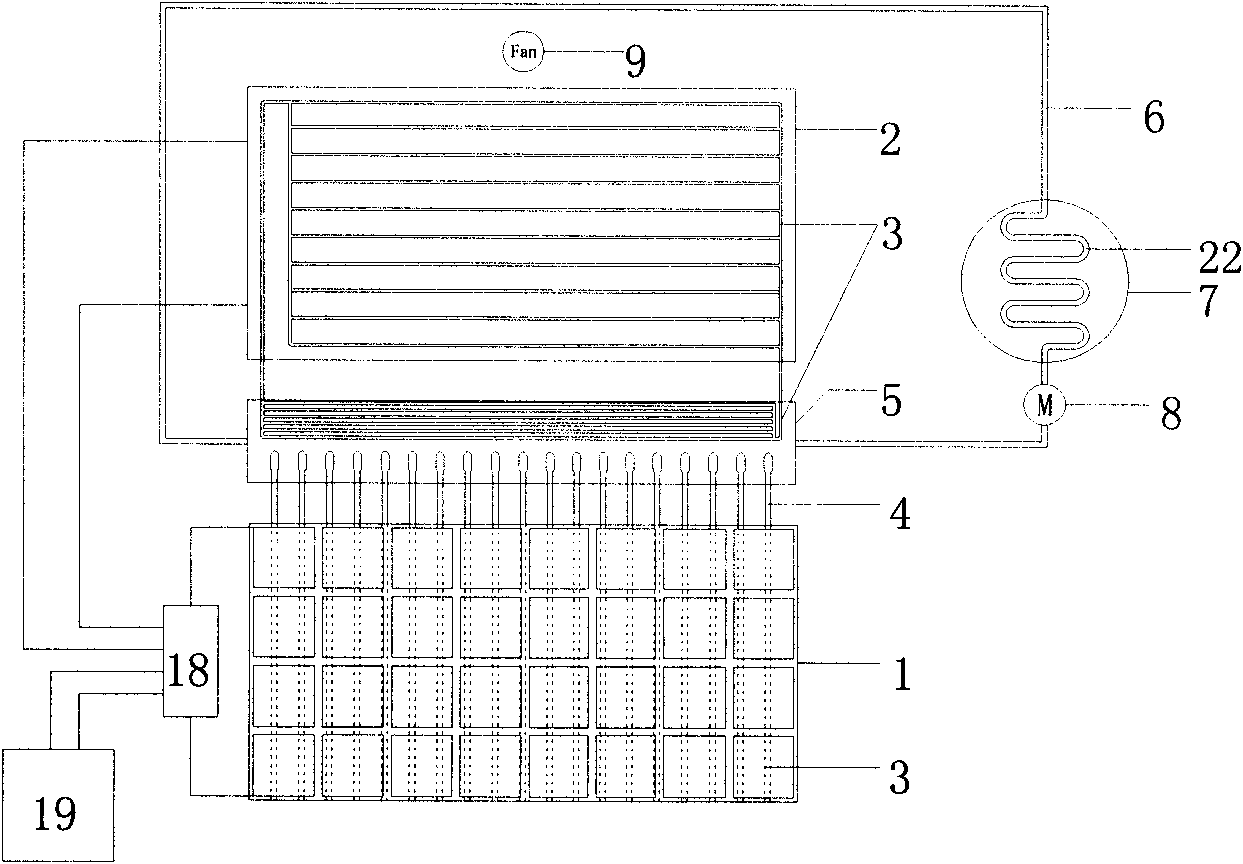

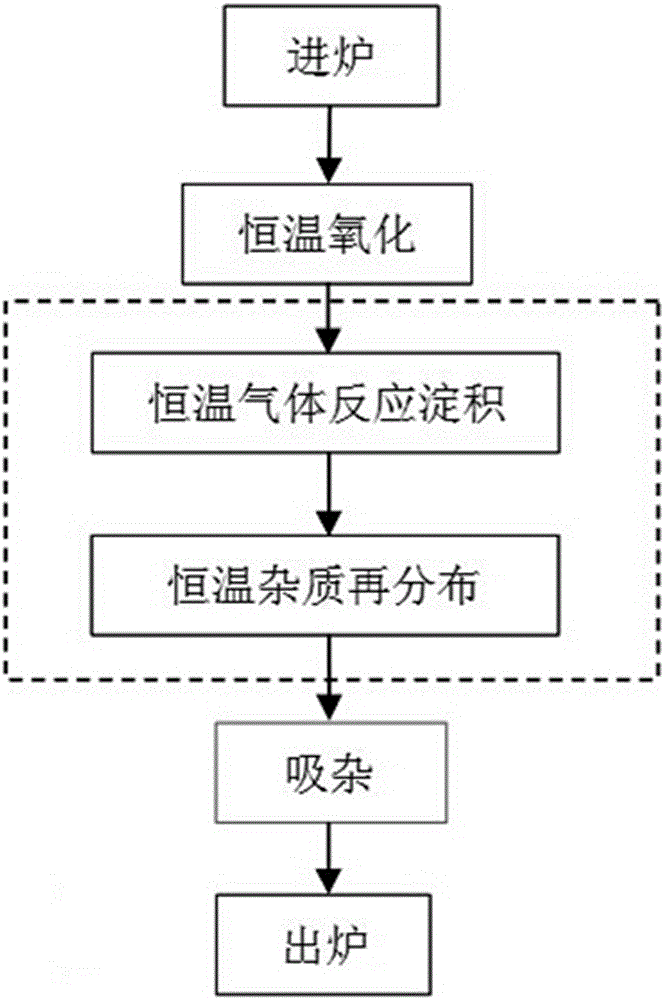

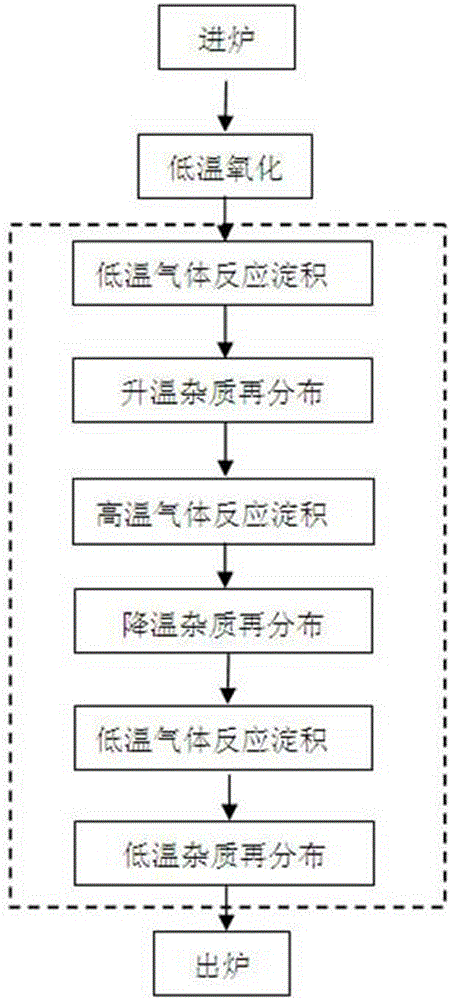

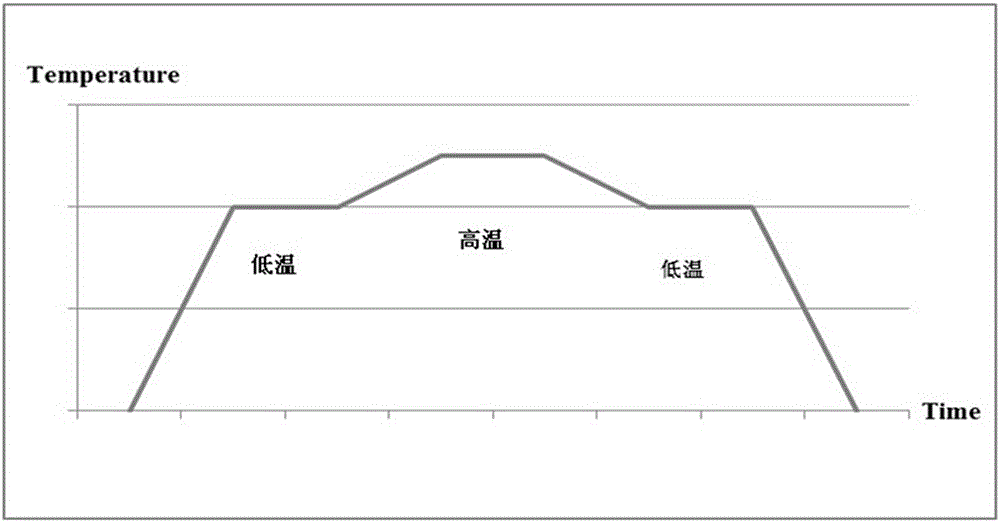

Diffusion technique of crystal-silicon efficient high-sheet-resistance battery piece

ActiveCN105280484AImprove photoelectric conversion rateReduce surface recombinationFinal product manufactureSemiconductor/solid-state device manufacturingDopantEngineering

The present invention relates to a diffusion technique of a crystal-silicon efficient high-sheet-resistance battery piece. The diffusion technique comprises the steps of furnace entering, low-temperature oxidation, low temperature gas reaction deposition, low temperature dopant redistribution, high temperature gas reaction deposition, cooling dopant redistribution, low temperature gas reaction deposition, low temperature dopant redistribution and discharge. With adoption of the diffusion technique provided by the present invention, photoelectric conversion efficiency of the battery pieces can be raised, the production time is shortened, and the production efficiency is raised.

Owner:TRINA SOLAR CO LTD +1

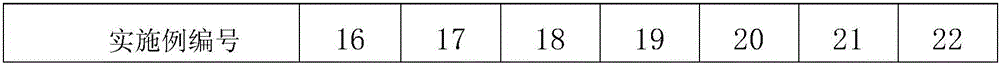

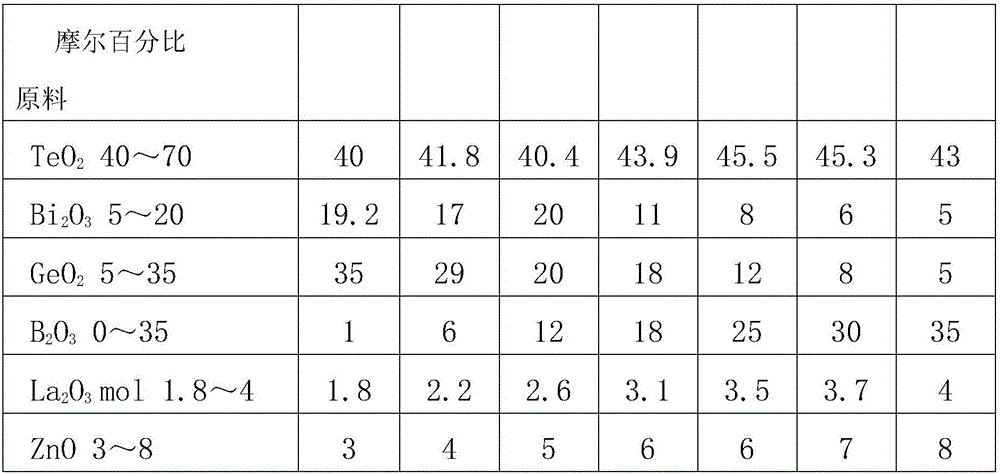

Preparation method of tellurite glass powder for silicon solar battery positive electrode silver paste

InactiveCN105800942ALower melting temperatureLow viscosityPhotovoltaic energy generationCable/conductor manufactureSilver pasteSilicon solar cell

The invention discloses a preparation method of tellurite glass powder for silicon solar battery positive electrode silver paste.The preparation method is characterized in that by molar percentage, 40-70% of TeO2, 5-20% of Bi2O3, 5-35% of GeO2, 0-30% of V2O5, 0-35% of B2O3, 1.8-4% of La2O3 and 3-8% of ZnO are weighed and blended, postprocessing steps including mixed material fine grinding and drying, glass melting, secondary fine grinding and the like are conducted, and the tellurite glass powder for silicon solar battery positive electrode silver paste is obtained.By the adoption of the prepared tellurite glass powder, no lead is contained, and it is beneficial to protect the environment and the human health; the tellurite glass powder is good in adaptation to a silicon substrate and silver, is matched with the silicon substrate and silver in coefficient of thermal expansion and is good in chemical stability, moderate in softening temperature and particularly suitable for a binding phase of the silicon solar battery positive electrode silver paste.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

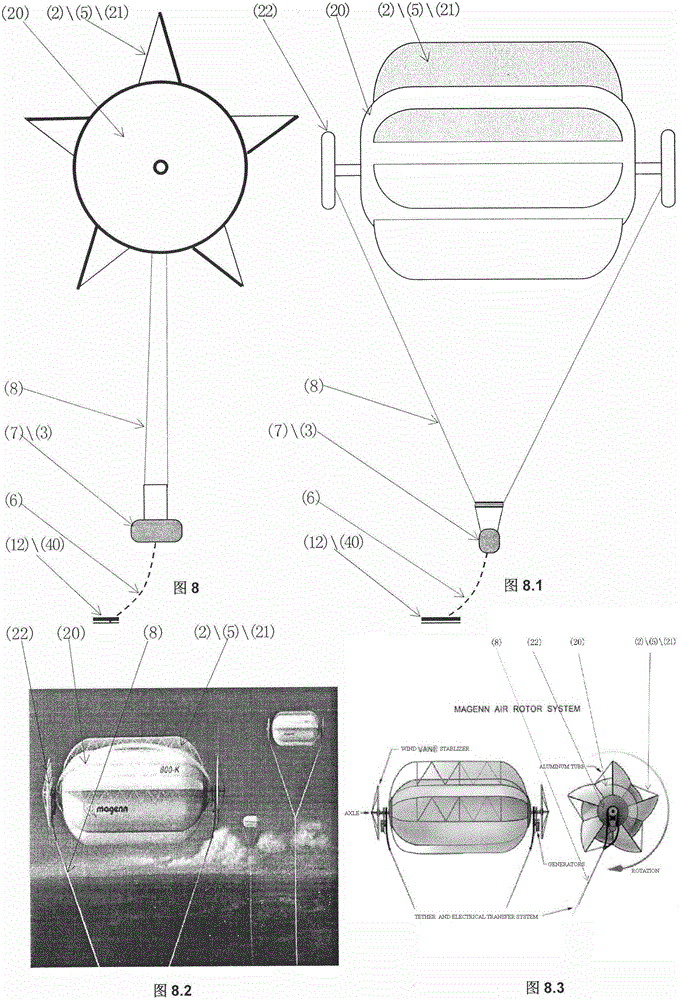

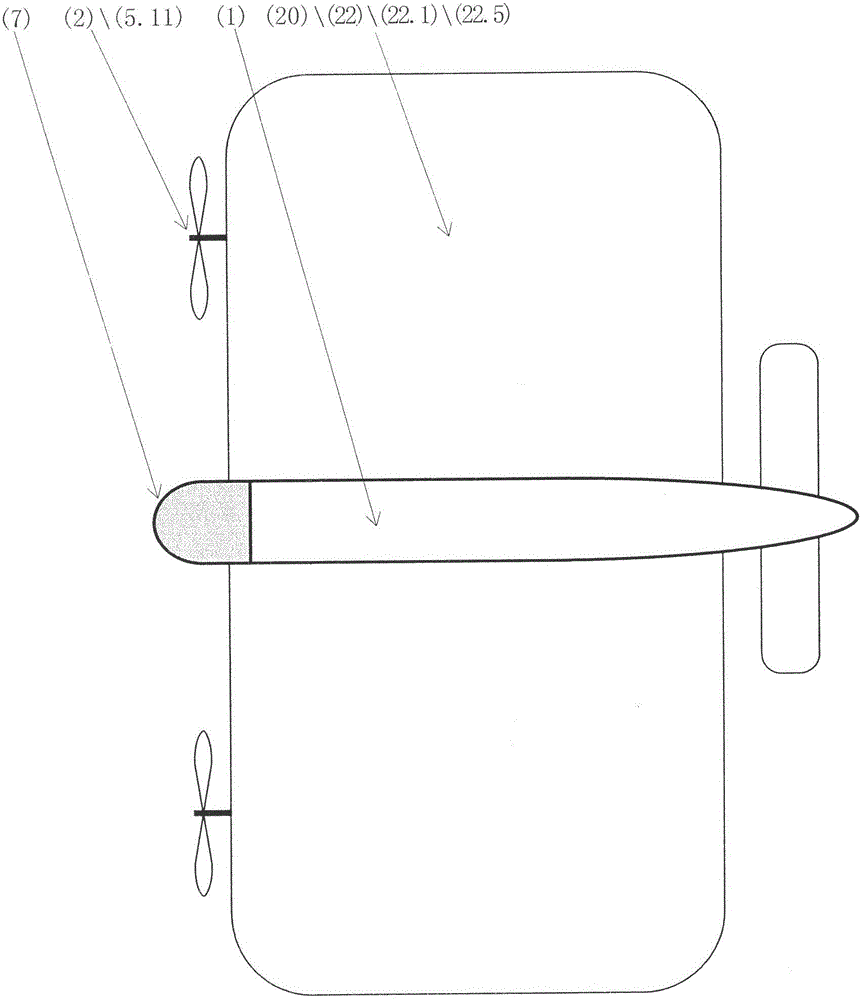

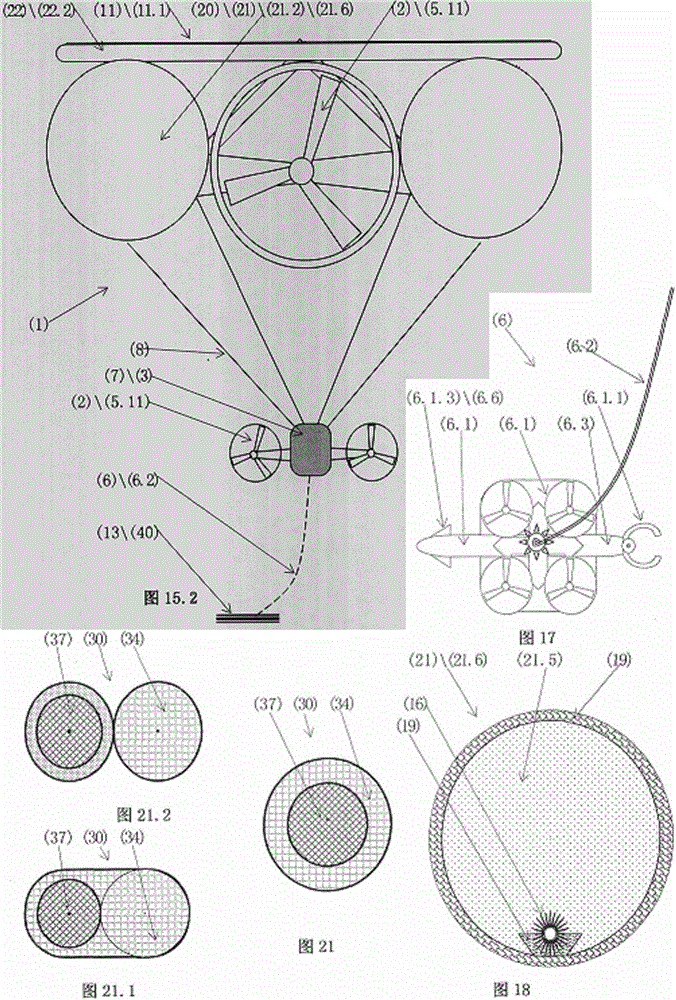

Aerial wind-energy power-station aircraft and aerial fixation aircraft device

InactiveCN106218849ASave energyReduce volumeBatteries circuit arrangementsEfficient propulsion technologiesElectricityPower station

An aerial wind-energy power-station aircraft relates to the technical field of engineering such as manufacture of power-driven aircrafts, aerial wind power and photoelectricity, aerial transportation and military affairs. The aircraft comprises an aircraft body (1) or a buoyancy lift body (20), a control system (4) and a propelling system (5). The aircraft is characterized in that the aerial wind-energy aircraft also comprises an aerial wind power generation system (2), a storage system (3) of power electric energy and a grounding and water-connecting system (6), wherein the power propelling system (5) comprises an electric propelling flight system (5.1). When the grounding and water-connecting system (6) is connected to an easy-to-connect ground object (12), an aerial fixation aircraft device (13) and a water body (14), the system stays at a stationary state and can start aerial wind-power generation. When the storage system (3) of the power electric energy is filled with aerial wind electricity, the electricity can then be supplied to the electric propelling flight system (5.1), so that flight can be driven. In this way, no fuel is consumed, and the flight can be implemented by ''aerial wind energy and wind electricity''. The aircraft has a very low cost; and by the storage system (3) of the power electric energy or the aerial fixation aircraft device (13), the aerial wind electricity with the very low cost can also be conveyed to the ground for utilization.

Owner:吕怀民 +1

Semiconductor electrode, manufacturing method thereof and solar cell having semiconductor electrode

InactiveCN101728092AImprove bindingEfficient separationLight-sensitive devicesFinal product manufactureSemiconductor electrodeSolar cell

The invention discloses a semiconductor electrode for a dye-sensitized solar cell, which comprises a conductive bottom layer, a compact semiconductor layer, a transitional semiconductor layer, a porous semiconductor layer and a dye layer, wherein the compact semiconductor layer, the transitional semiconductor layer, the porous semiconductor layer and the dye layer are sequentially formed on the conductive bottom layer; the compact semiconductor layer is obtained by vacuum evaporation; the transitional semiconductor layer is obtained by a sol-gel method; the porous semiconductor layer is obtained by a powder coating method; and the transitional semiconductor layer is formed between the compact semiconductor layer and the porous semiconductor layer, so the bonding force between the semiconductor electrode and the semiconductor layers is improved, and consequently the photoelectric conversion rate of the dye-sensitized solar cell is improved.

Owner:BYD CO LTD

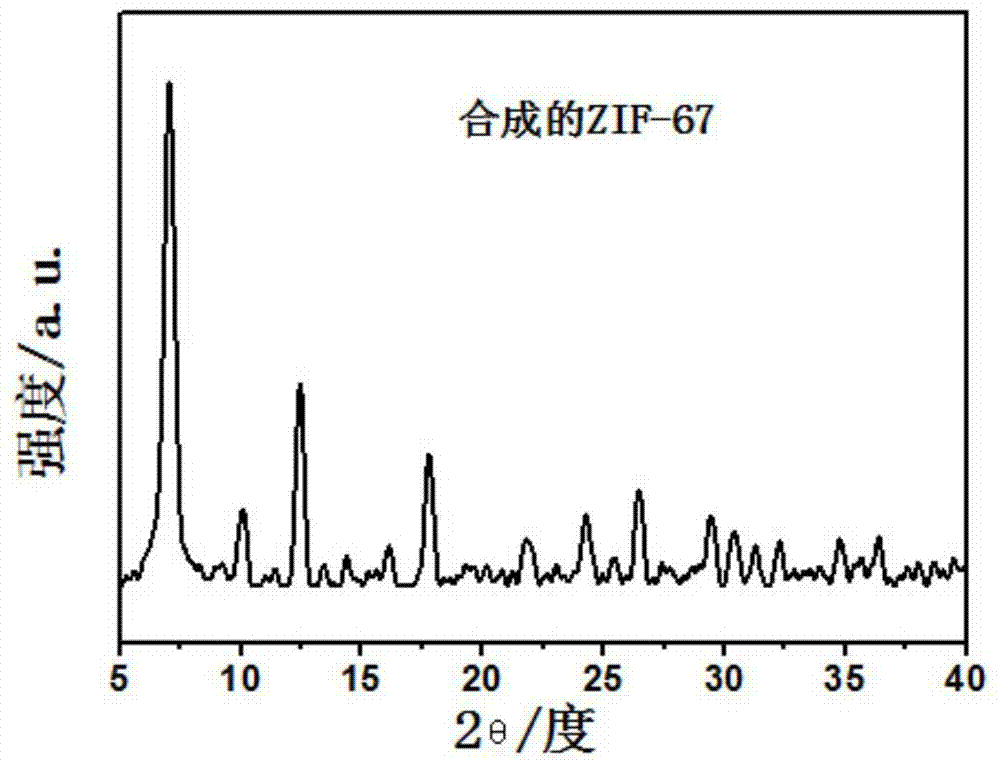

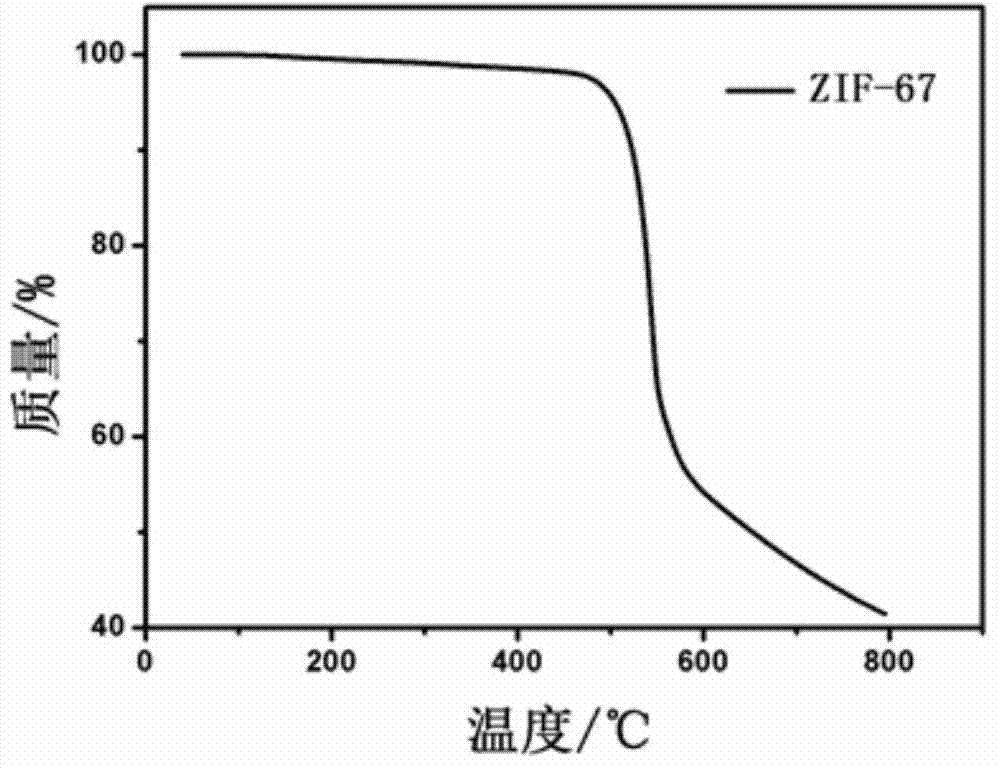

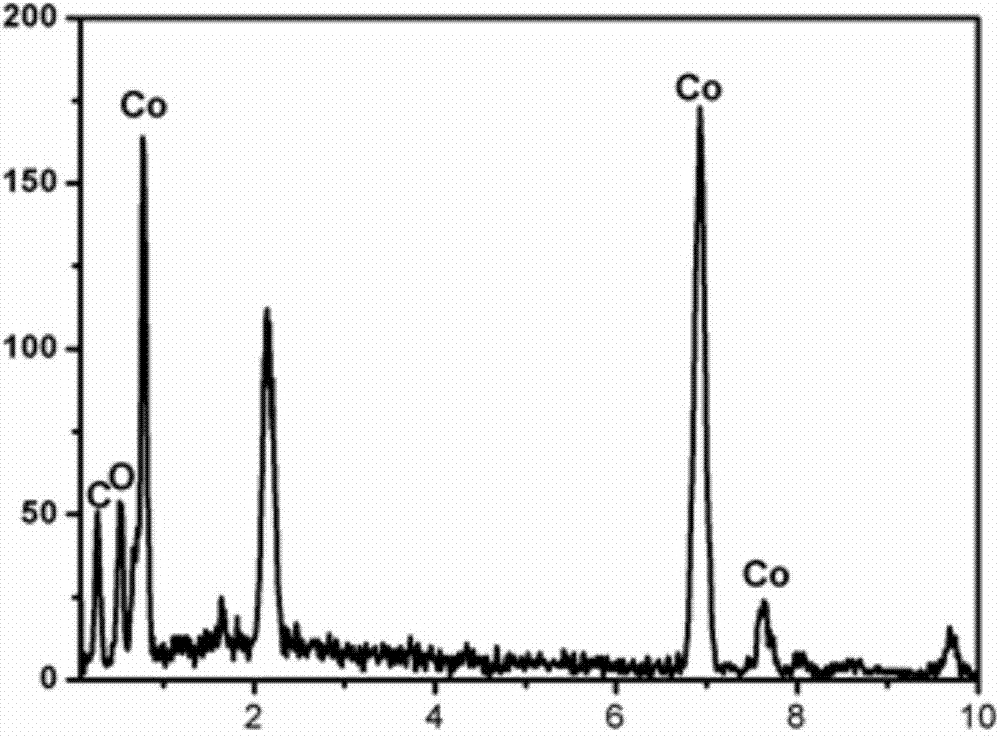

Dye-sensitized solar cell counter electrode and production method thereof

InactiveCN104752062AEasy to operateLow costLight-sensitive devicesFinal product manufactureParticulatesPhotochemistry

The invention discloses a dye-sensitized solar cell counter electrode and a production method thereof. The production method thereof includes 1, dissolving cobalt nitrate hexahydrate and 2-methylimidazole with methyl alcohol, then mixing and stirring methanol solutions of the cobalt nitrate hexahydrate and 2-methylimidazole for 20-40 minutes before centrifuging the same, and obtaining ZIF (zeolite imidazole ester skeleton structure structure)-67 by separating, washing and drying the mixture; 2, roasting the ZIF-67 for 2 hs under 600-850 DEG C in the inert gas atmosphere; 3, dissolving the mixture obtained from the step 2 with isopropanol before subjecting the same to ball grinding for 6-8 hs to obtain particulate matters, and spraying and drying the particulate matters on the surface of FTO (fluorine-doped tin oxide) conductive glass. The production method thereof is easy to operate and low in cost, and the dye-sensitized solar cell is high in photoelectric converting efficiency.

Owner:DALIAN UNIV OF TECH

Preparation method of broadband gradient LED (Light-emitting Diode) fluorescent film

InactiveCN103243318AImprove performanceUniform color temperatureSolid/suspension decomposition chemical coatingLuminescent compositionsChemistryBroadband

The invention provides a preparation method of a broadband gradient LED (Light-emitting Diode) fluorescent film. The preparation method is characterized in that broadband gradient LED fluorescent powder serves as a raw material; a uniform multicolour (red, green, blue and the like) fluorescent material film is deposited on an LED device or an LED lampshade gasket by a suspension method or a sol-gel method; and the broadband gradient LED fluorescent film prepared by the method has uniform isotropic color temperatures. The preparation method can be used for manufacturing and massively producing high-performance white LEDs with same performance, and can be used for preparing white LED devices, which can emit light approximating to sunlight, with high photoelectric conversion rates and high color rendering indexes. The broadband gradient LED fluorescent powder has a special structure and composition, and is good in dispersity, high in stacking density, great in scattering intensity and high in light-emitting efficiency.

Owner:HUNAN SCI & TECH RES & DEV CENT

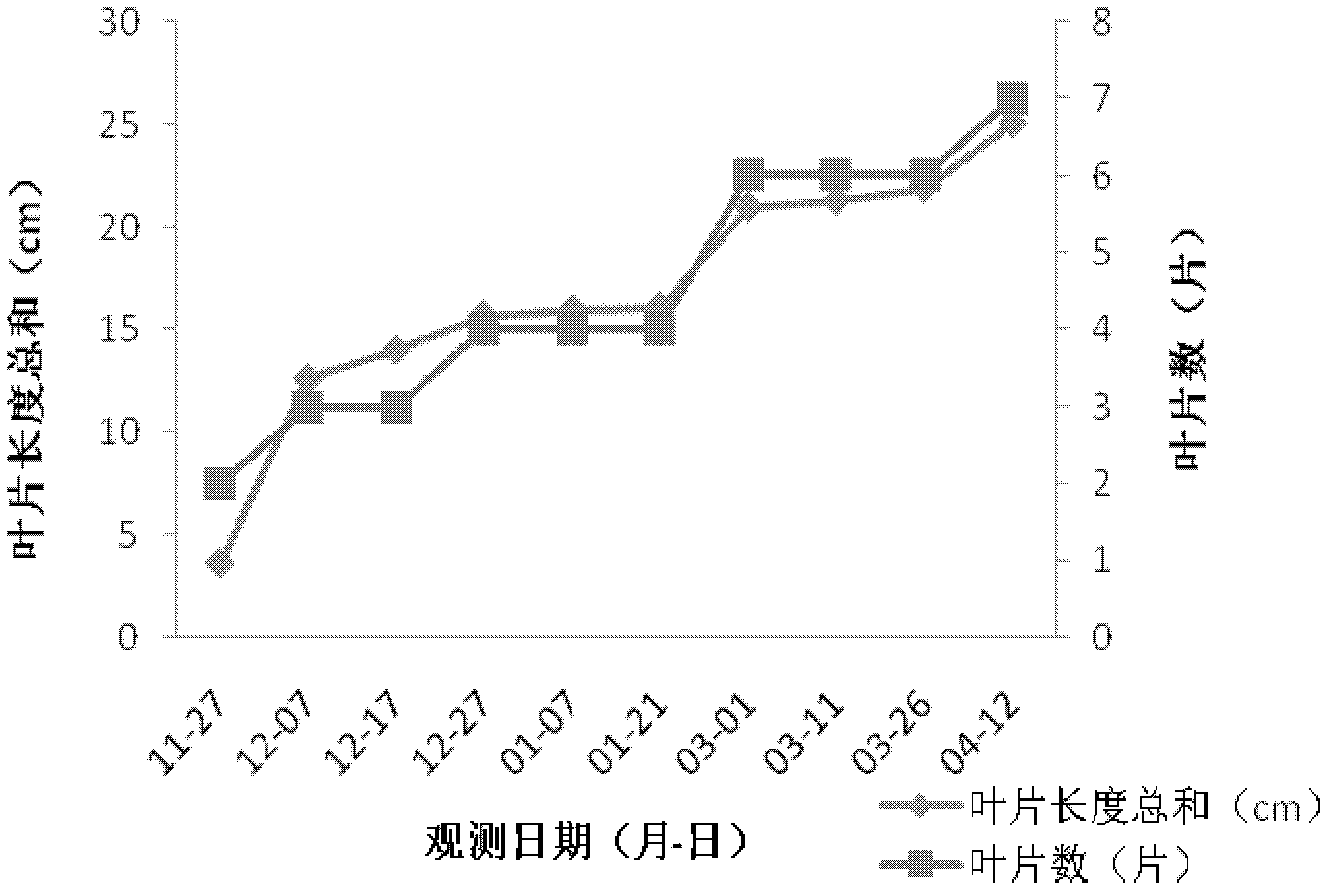

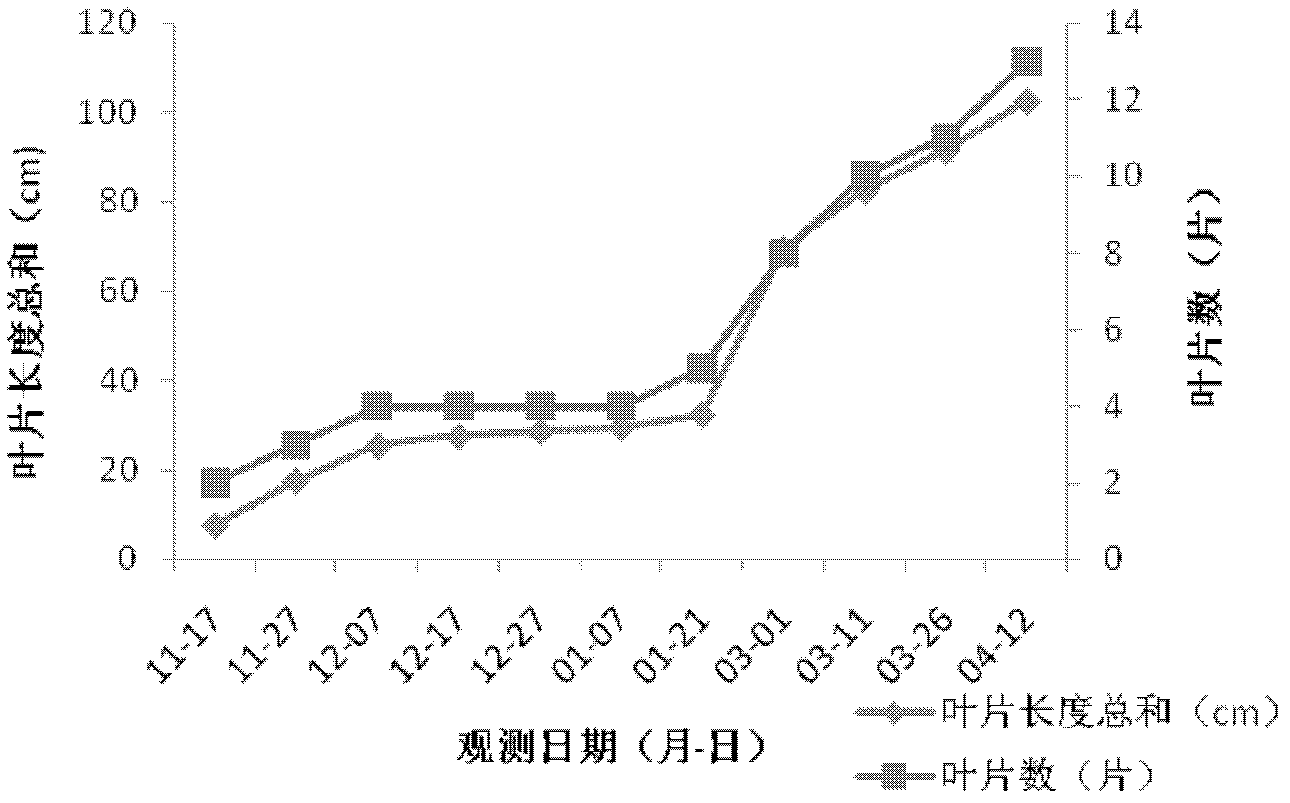

Application of LED (Light Emitting Diode) in plant cultivation

InactiveCN102415300AImprove photoelectric conversion rateIncrease effective lightPoint-like light sourceLighting support devicesEngineeringLED lamp

The invention provides application of an LED (Light Emitting Diode) in plant cultivation, in particular application of a lamp tube type LED as a light source in plant cultivation. According to the invention, the utilization rate of a light source can be further determined to be improved by adopting a specific mixture ratio of red light to blue light and the growth amount of plants can be effectively improved by adopting specific illumination intensity through research. The lamp tube type LED used as the light source can be widely used for cultivating the plants, in particular for greenhouse plants and can be used for improving the growth efficiency of the plants and reducing energy consumption. The LED is a cold light source, so that the LED can be closed to the plants without burning the plants. The invention further provides a lamp tube type LED light supplementing rack. The height of the light supplementing rack can be adjusted. In addition, the height of each LED lamp can be adjusted according to the heights of the plants. The lamp tube type LED light supplementing rack can be used for supplementing light to the plants from the front side or the side.

Owner:BEIJING FORESTRY UNIVERSITY

Preparation method of aluminum conductive paste of high-performance environment protection solar cell

InactiveCN101752459AImprove photoelectric conversion rateReduce stressFinal product manufactureNon-conductive material with dispersed conductive materialSilicon chipLinear expansion coefficient

The invention discloses a preparation method of aluminum conductive paste of a high-performance environment protection solar cell. The aluminum conductive paste produced by the method is free of lead and solves the problem of environment pollution. The linear expansion coefficient of lead-free glass powder obtained in the preparation process is close to that of a silicon chip, and the success rate after burning is improved. The preparation method of the paste comprises the following steps: (1) preparing glass powder; (2) preparing inorganic adhesive glass metal powder; (3) manufacturing organic carriers; (4) adopting carbon powder of 2-5 mu m for later use; and (5) preparing the aluminum conductive paste: taking the following components by mass percent: 75-85% of aluminum powder coated by aluminum nitride, 9-20% of organic carrier, 3-4% of inorganic adhesive glass metal powder and 1-3% of C powder, wherein the total amount is 100%, and after mixing, grinding with a three-roller mill to particle size of 15-30 mu m to obtain the product with the viscosity of 25000-35000 mpa.s.

Owner:广东鑫皇冠新材料有限公司

Nitride light emitting diode and manufacturing method thereof

InactiveCN103647009AReduce entryReduce refluxPolycrystalline material growthFrom chemically reactive gasesQuantum wellPhysical chemistry

The invention discloses a nitride light emitting diode and a manufacturing method thereof. The structure at least comprises a substrate, an n type nitride layer, an active area and a p type nitride layer. The active area comprises M pairs of AlxIn1-x-yGayN / GaN quantum wells and N pairs of InGaN / GaN quantum wells. Electronic reflux and a polarization effect are improved. Composite efficiency of a quantum well area and a density of two-dimension electron gas at an interface are increased. Photoelectric conversion efficiency of the light emitting diode is increased too. Simultaneously, an endurance capacity of the LED to static electricity is enhanced and an electrical property of the LED is improved.

Owner:TIANJIN SANAN OPTOELECTRONICS

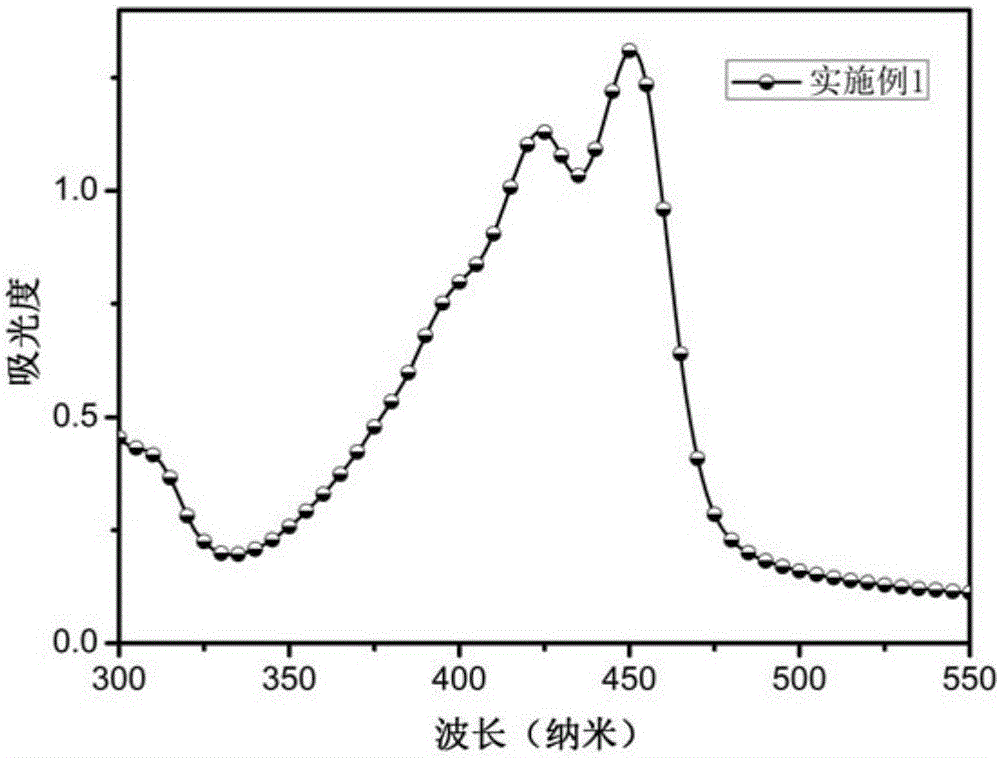

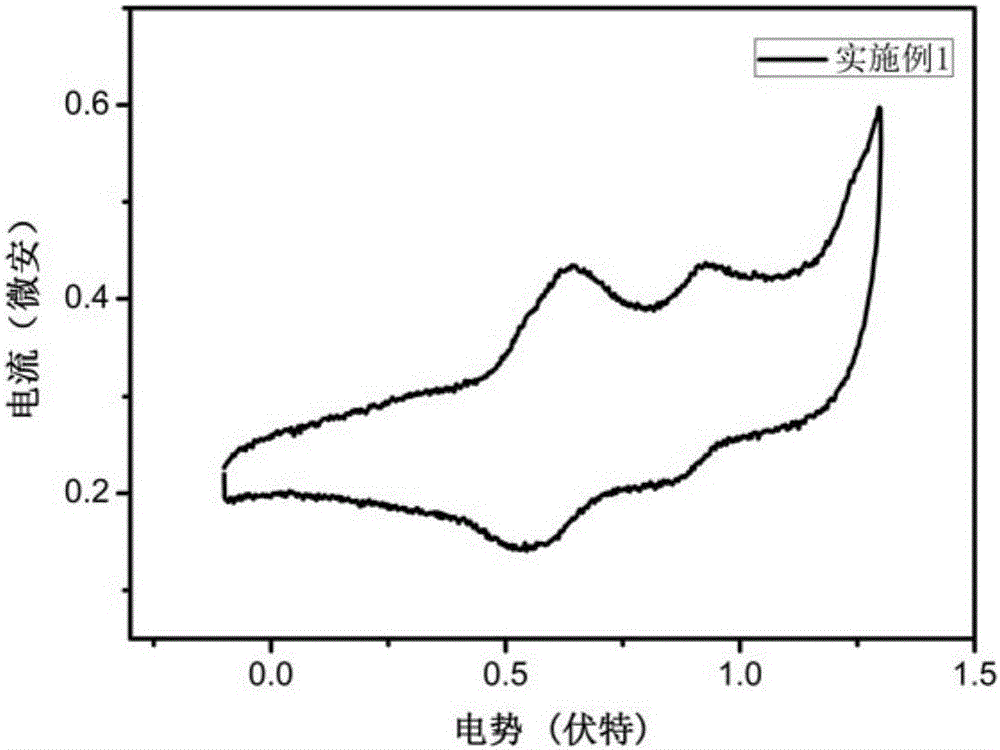

Triphenylamine-benzothiophene organic small-molecule hole transporting material and application thereof

InactiveCN105753883AEasy transferLarge planar delocalized structureOrganic chemistrySolid-state devicesHigh current densitySolubility

The invention discloses a triphenylamine-benzothiophene organic small-molecule hole transporting material and an application thereof.The material has a specific heterocycle conjugated system and triphenylamine structural units with alkyl chains, and the solubleness and the hydrophobicity are good in an organic solvent; as the hole mobility can be effectively improved through a large two-dimensional conjugate plane structure, the material is applied to a perovskite solar cell, the stability of a device can be improved, the current density and the high photoelectric conversion rate are increased, and the material has the broad application prospects.

Owner:CENT SOUTH UNIV

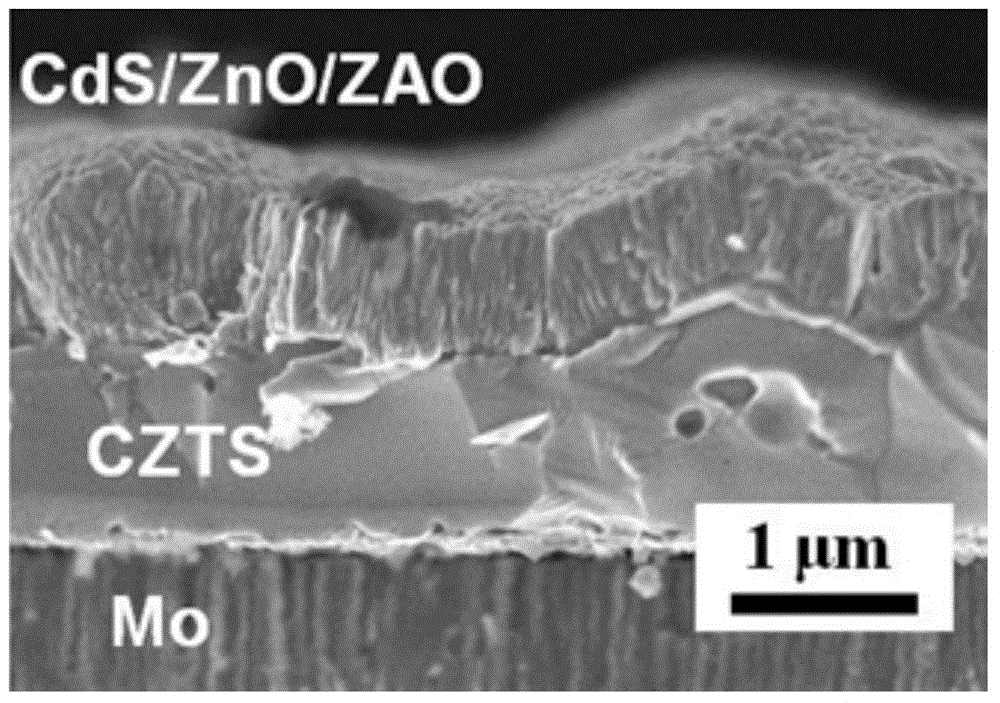

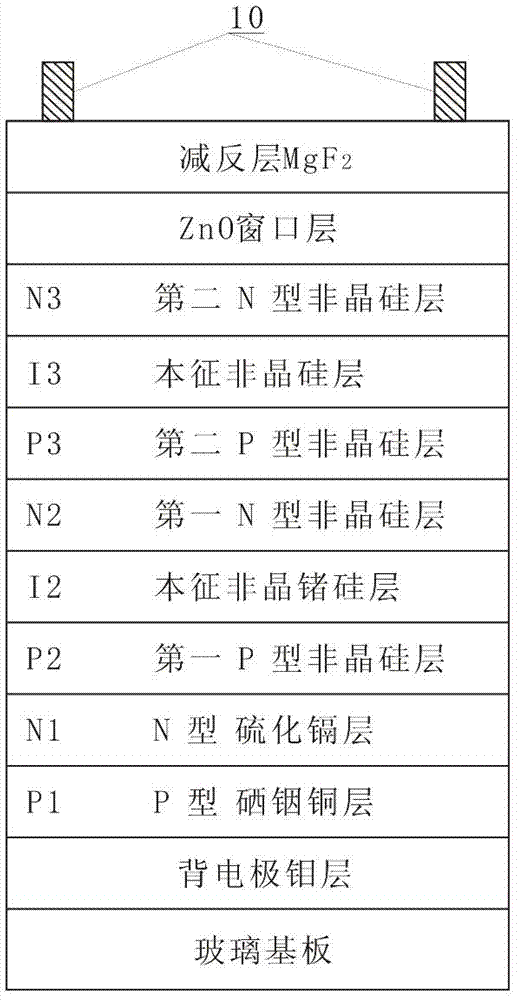

Novel three-junction thin-film solar cell and production method thereof

InactiveCN102856421AImprove photoelectric conversion rateLow manufacturing costFinal product manufacturePhotovoltaic energy generationIndiumSelenium

The invention discloses a novel three-junction thin-film solar cell, which comprises a glass substrate, a back electrode molybdenum layer, a multi-junction cell unit, a window layer and a reflection reducing layer arranged in sequence from bottom to top. The reflection reducing layer is provided with a gate electrode; the multi-junction cell unit consists of the following cell layers arranged in sequence from bottom to top: a P-type selenium-indium-copper layer, an N-type cadmium sulfide layer, a first P-type amorphous silicon layer, an intrinsic amorphous germanium-silicon layer, a first N-type amorphous silicon layer, a second P-type amorphous silicon layer, an intrinsic amorphous silicon layer and a second N-type amorphous silicon layer. The invention also discloses a production method of the novel three-junction thin-film solar cell, and the cell layers are manufactured respectively by magnetron sputtering, vacuum selenide annealing or vacuum evaporation. The characteristics of an a-Si / a-SiGe solar cell technology and a CuInSe2 thin-film solar cell are combined by the solar cell, the scope of the wavelength of solar light to be absorbed can be expanded to 500-1100nm, the rate of photoelectric conversion can be increased to 20 percent, and the manufacturing cost is low.

Owner:四川汉能光伏有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com