Semiconductor electrode, manufacture method thereof and solar cell containing same

A technology for solar cells and semiconductors, applied in the field of dye-sensitized solar cells, which can solve the problems of low porosity of porous semiconductor layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

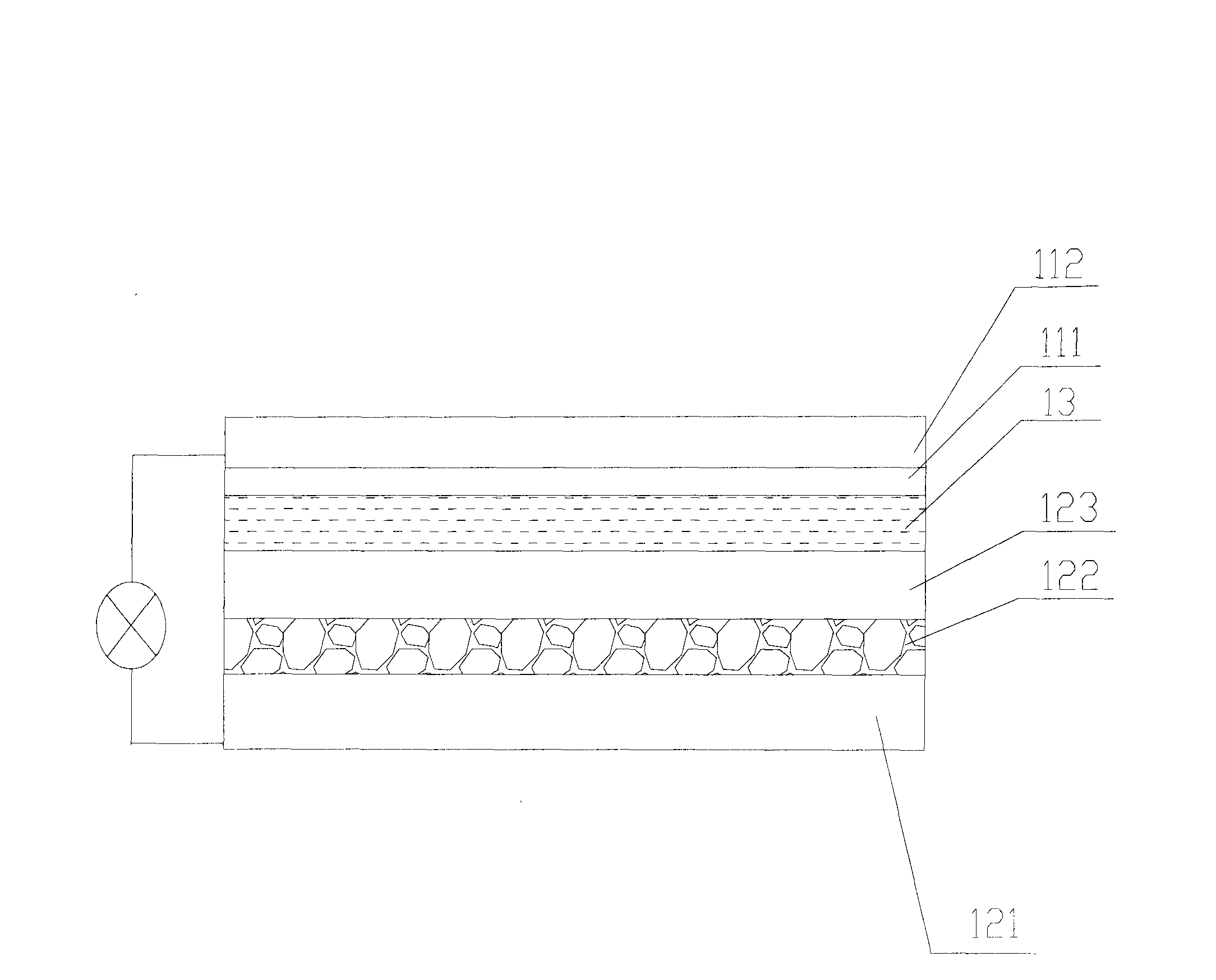

[0016] A method for preparing a semiconductor electrode, the method comprising forming a porous semiconductor layer containing semiconductor particles on a conductive bottom layer, and then forming a dye layer on the porous semiconductor layer, wherein, the method for preparing the porous semiconductor layer includes comprising semiconductor nanoparticles, The slurry of pore-forming agent and dispersant is coated on the conductive bottom layer, and after a period of calcination, during the calcination process, a three-dimensional network porous skeleton with interconnected semiconductor crystal grains is formed, and at the same time, the dispersant is fully volatilized during calcination, and sintered The time is 10-120 minutes, the sintering temperature is 300-600°C, the slurry layer is calcined for a period of time to obtain a solid film, and the conductive bottom layer with the solid film is immersed in a solution that can dissolve the porogen but not dissolve the semiconduct...

Embodiment 1

[0033] This example is used to prepare the semiconductor electrode for a dye-sensitized solar cell provided by the present invention and the dye-sensitized solar cell containing the semiconductor electrode.

[0034] (1) Preparation of semiconductor crystal film precursor solution

[0035] 25 g TiO 2 Granules (particle diameter 30 nm), 0.8 g of CaCO 3 Pore former (pore former and TiO 2 The volume ratio is 1:90), joins in 0.54 gram polyethylene glycol, is configured into slurry, and slurry is put into ball mill (Nanjing University Instrument Factory, model QM-3SP2), is ball milling time 0.5 hour in process condition, ball milling temperature At 25°C, slurry P1 was prepared.

[0036] (2) Preparation of semiconductor electrodes

[0037] The slurry P1 is uniformly coated on a conductive glass coated with a fluorine-doped tin dioxide film with a size of 5 × 2.5 cm (FTO conductive glass with a square resistance of 15 ohms manufactured by Qinhuangdao Yaohua Glass Co., Ltd., and ...

Embodiment 2

[0046] This example is used to prepare the semiconductor electrode for a dye-sensitized solar cell provided by the present invention and the dye-sensitized solar cell containing the semiconductor electrode.

[0047] The dye-sensitized solar cell R2 was prepared in the same manner as in Example 1, except that the slurry P1 was replaced by the slurry P2 prepared as follows, and the volume ratio between the porogen and the semiconductor particles in P2 was 1: 14.

[0048] 25 g TiO 2 Granules (particle diameter 30 nm), 3.2 g of CaCO 3 Pore-forming agent, add 0.58 gram of polyvinylpyrrolidone to be configured into a slurry, the slurry is put into a ball mill (Nanjing University Instrument Factory, model QM-3SP2), and the process conditions are 0.5 hours of ball milling time, and the ball milling temperature is 25°C to obtain a precursor slurry P2.

[0049] The first-stage calcination time is 30 minutes, the calcination temperature is 400°C, the solution used is 200mL, pH=2 nitri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com