Patents

Literature

245 results about "Porous semiconductors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

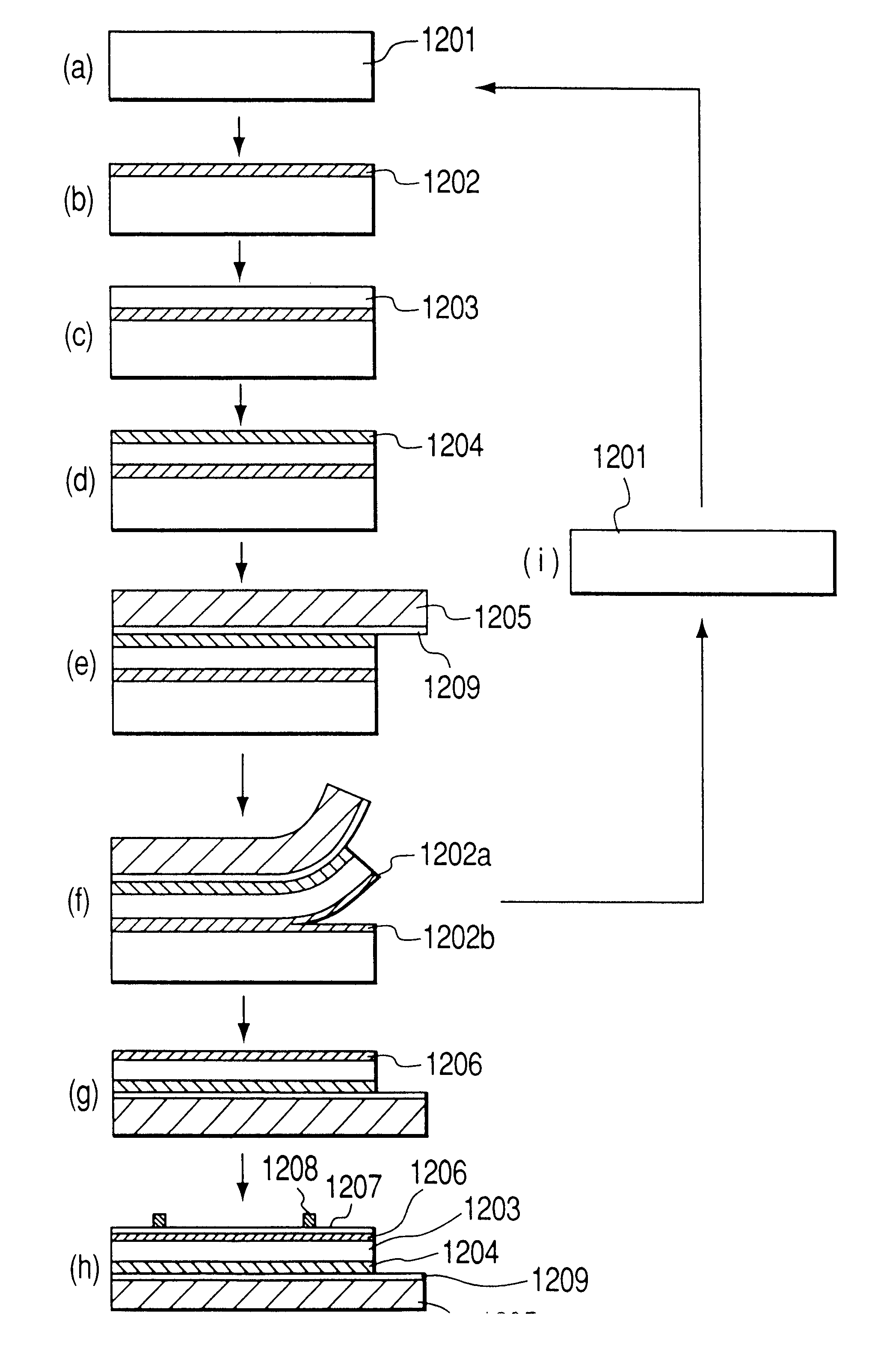

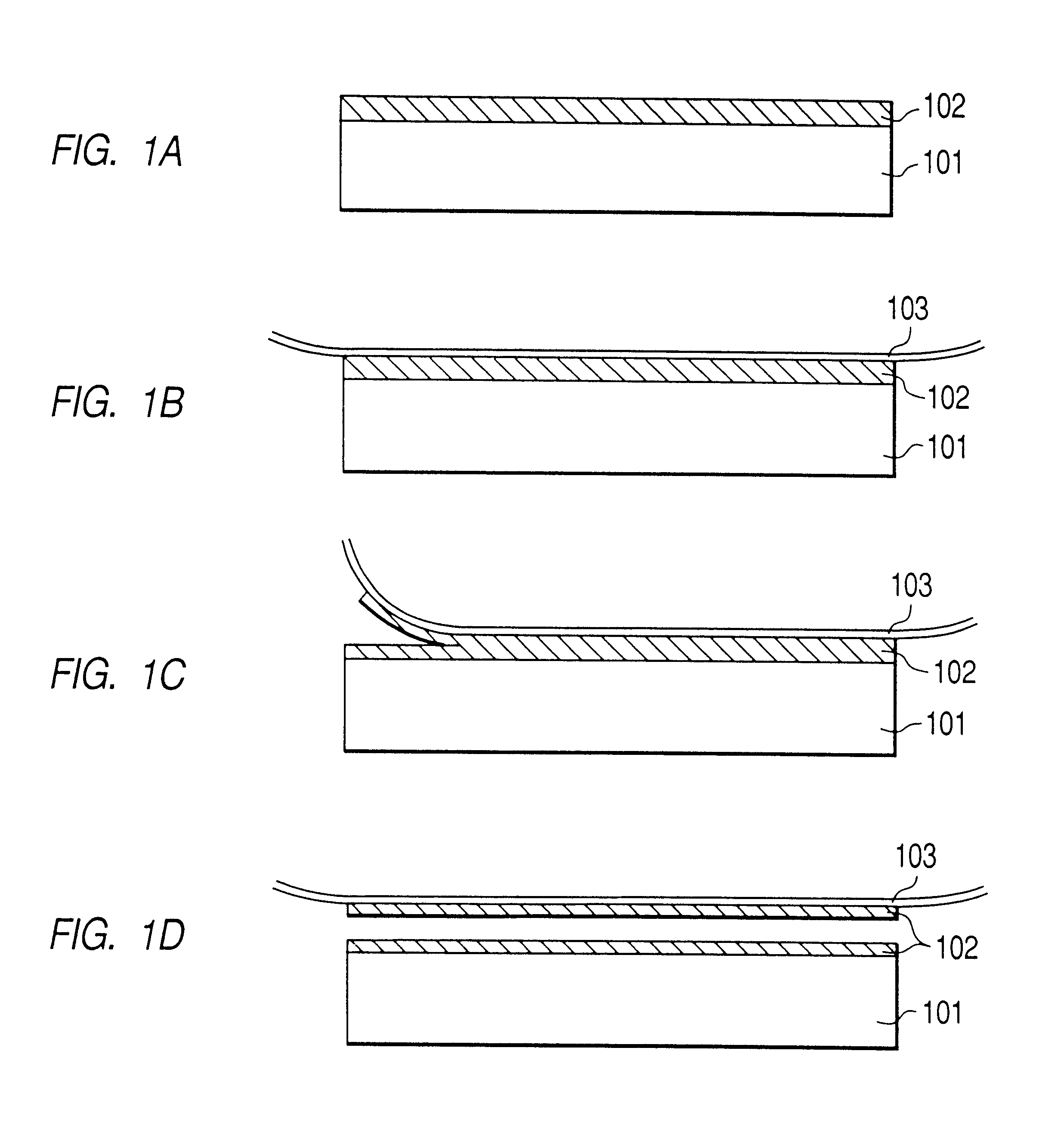

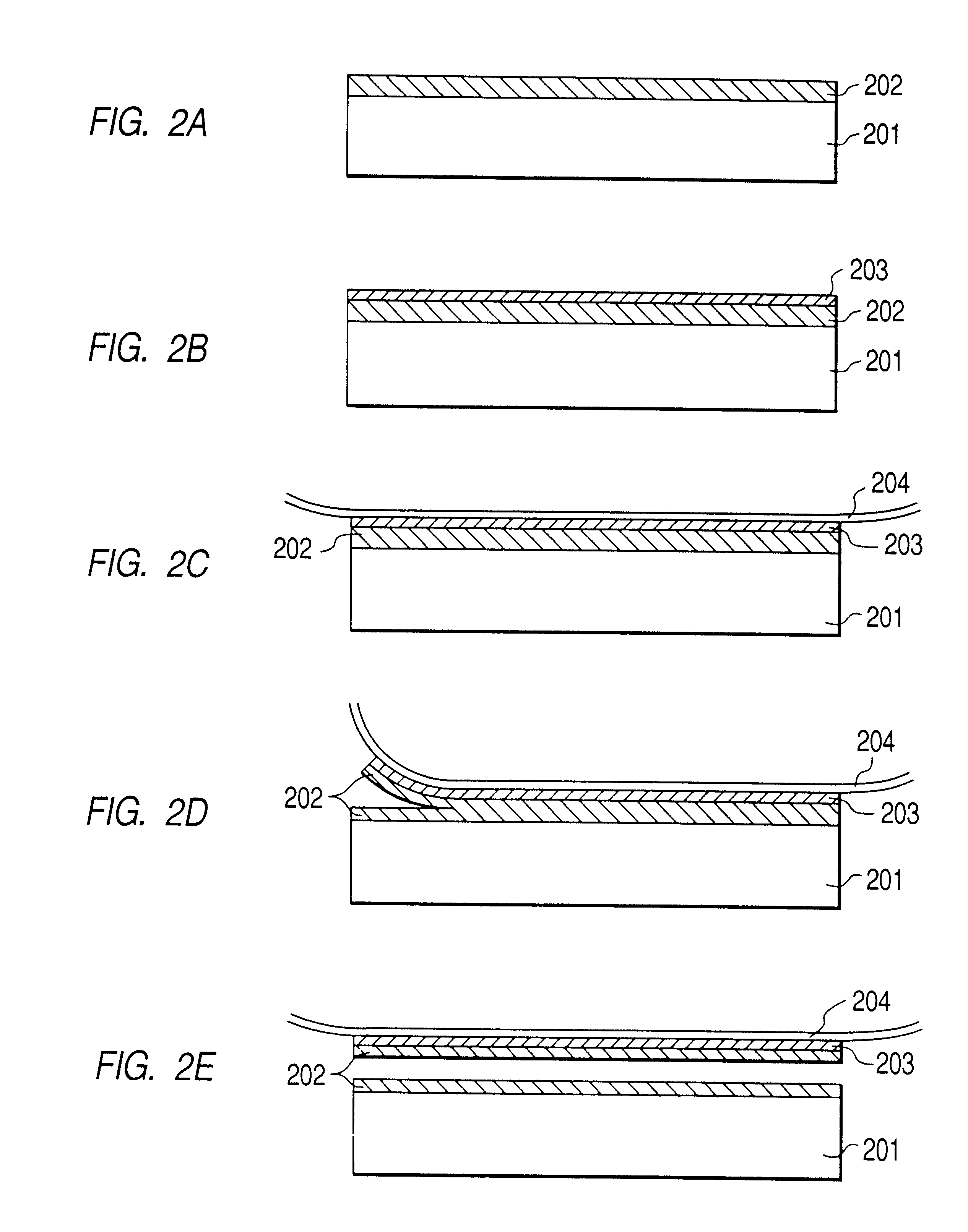

Process for producing semiconductor article

InactiveUS6534382B1Guaranteed high speed operationReduce power consumptionSemiconductor/solid-state device testing/measurementFinal product manufacturePorous semiconductorsSemiconductor

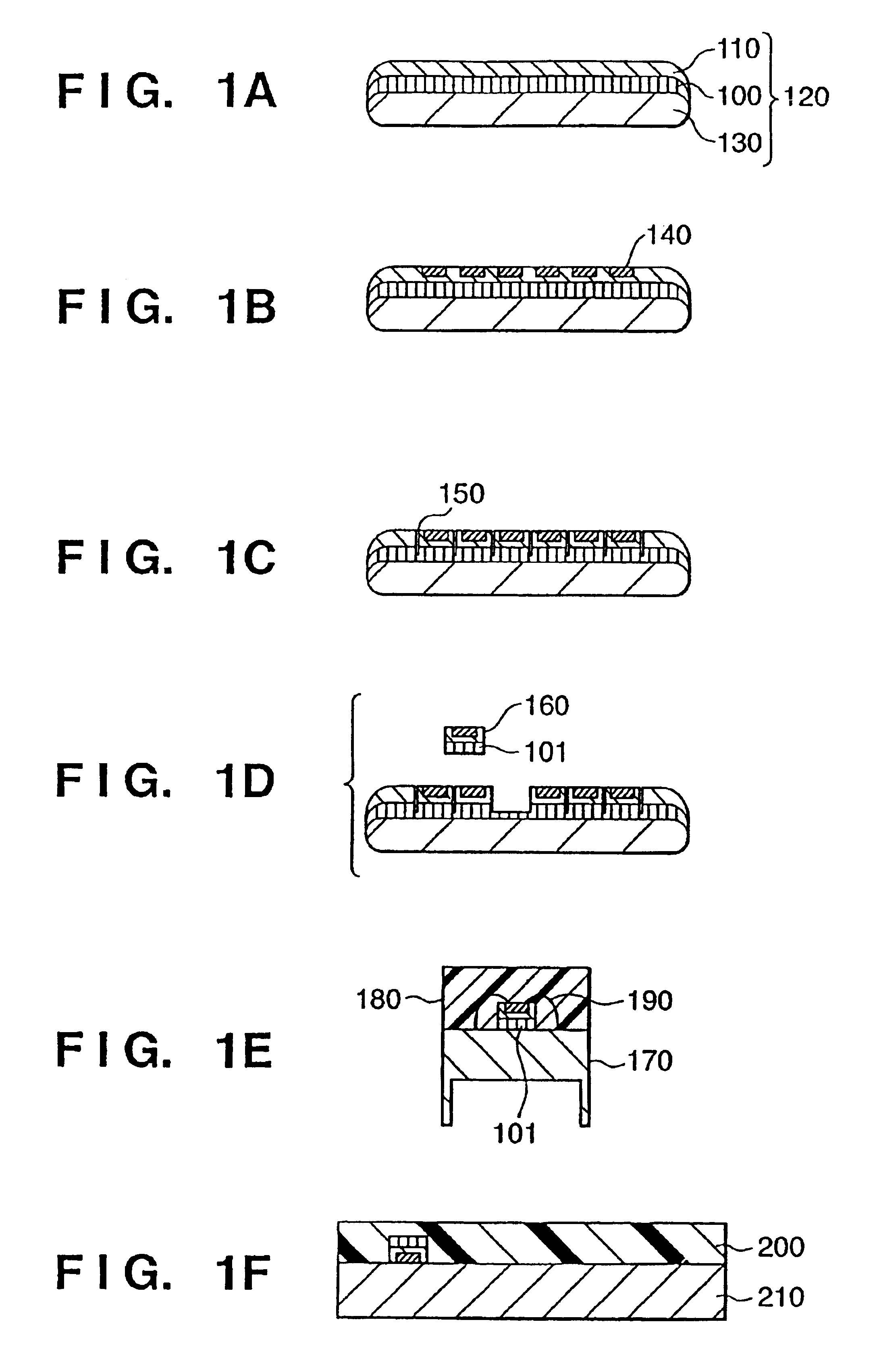

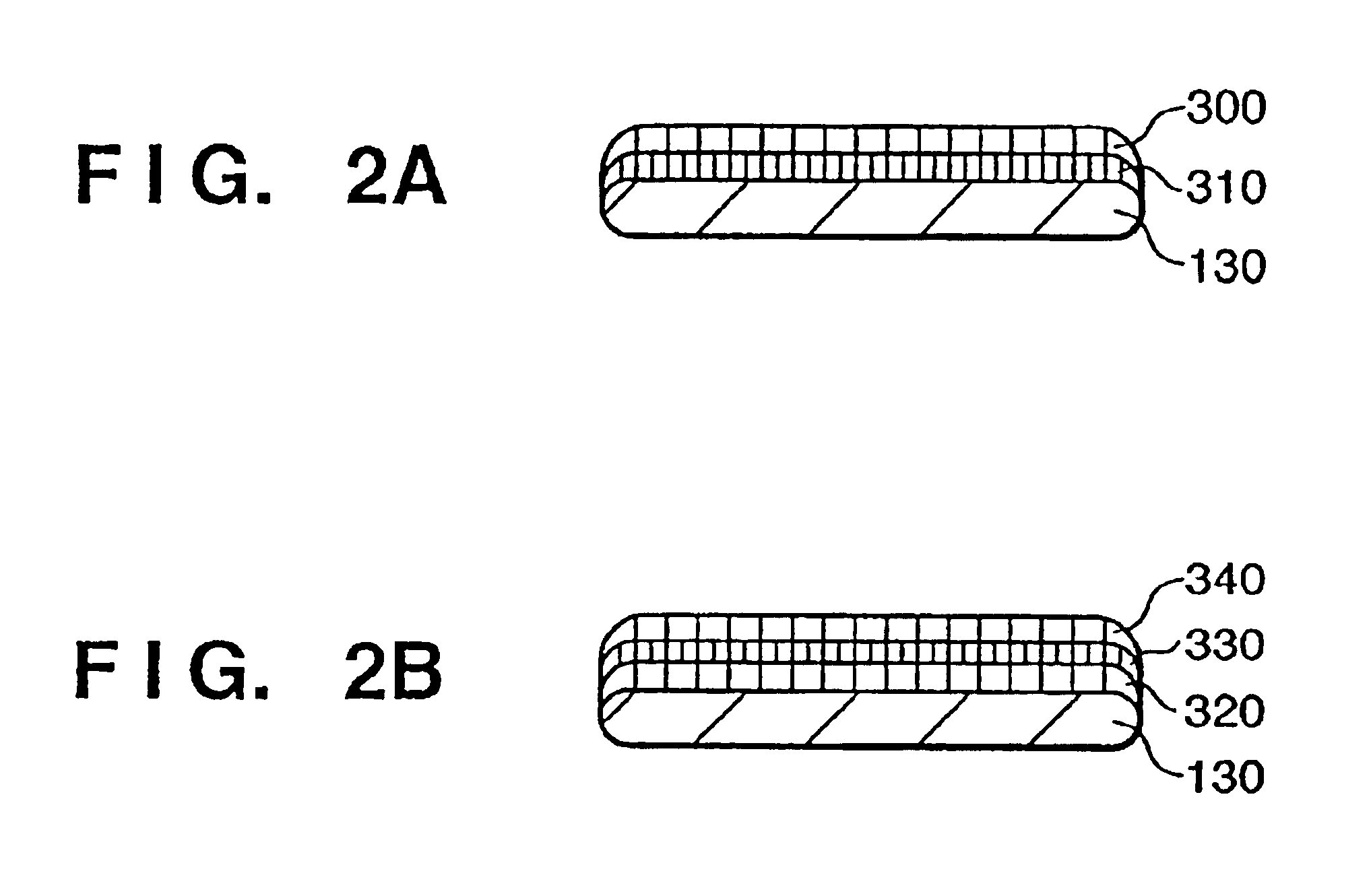

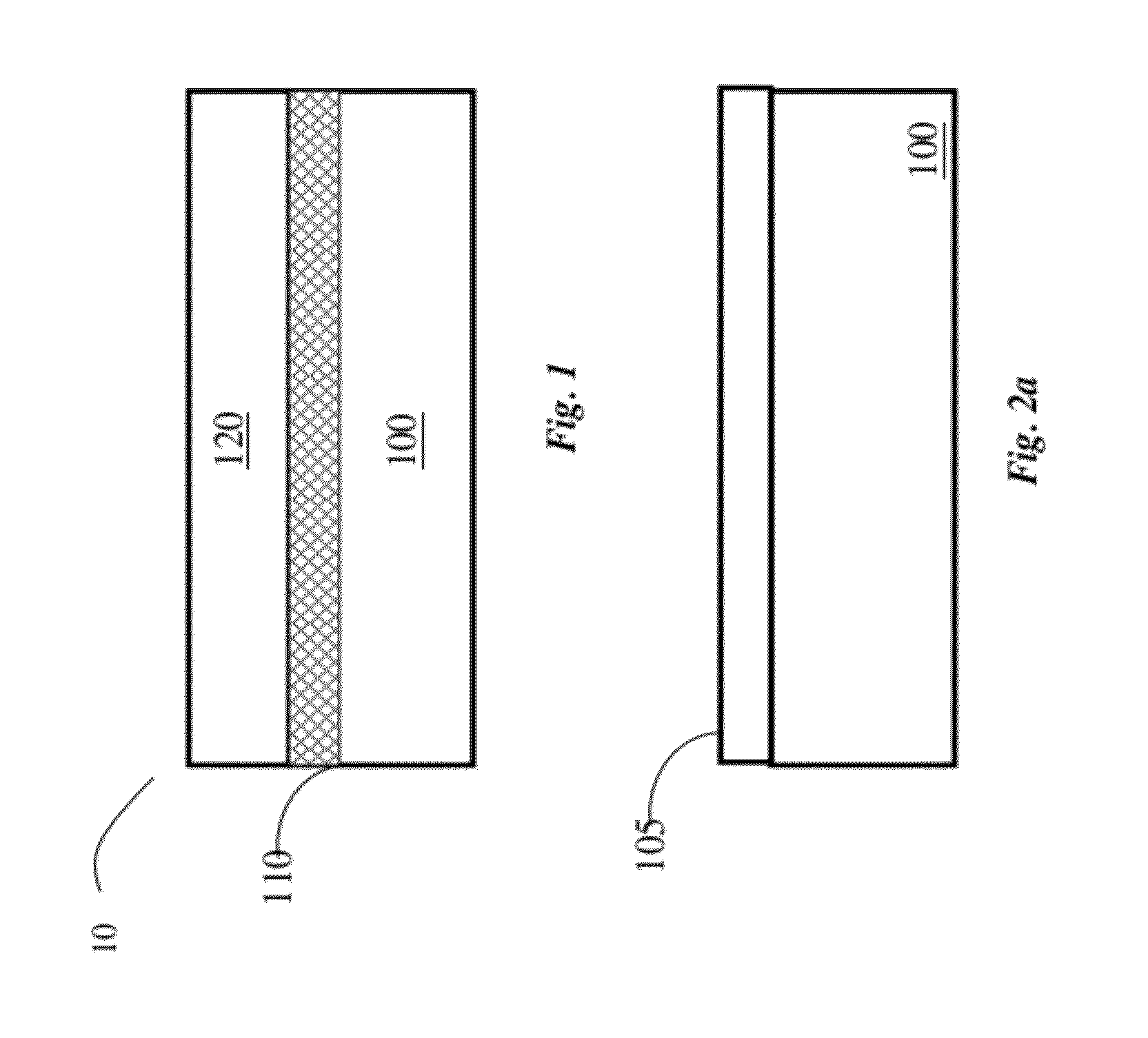

A process for producing a semiconductor article is provided which comprises the steps of bonding a film onto a substrate having a porous semiconductor layer, and separating the film from the substrate at the porous semiconductor layer by applying a force to the film in a peeling direction.

Owner:CANON KK

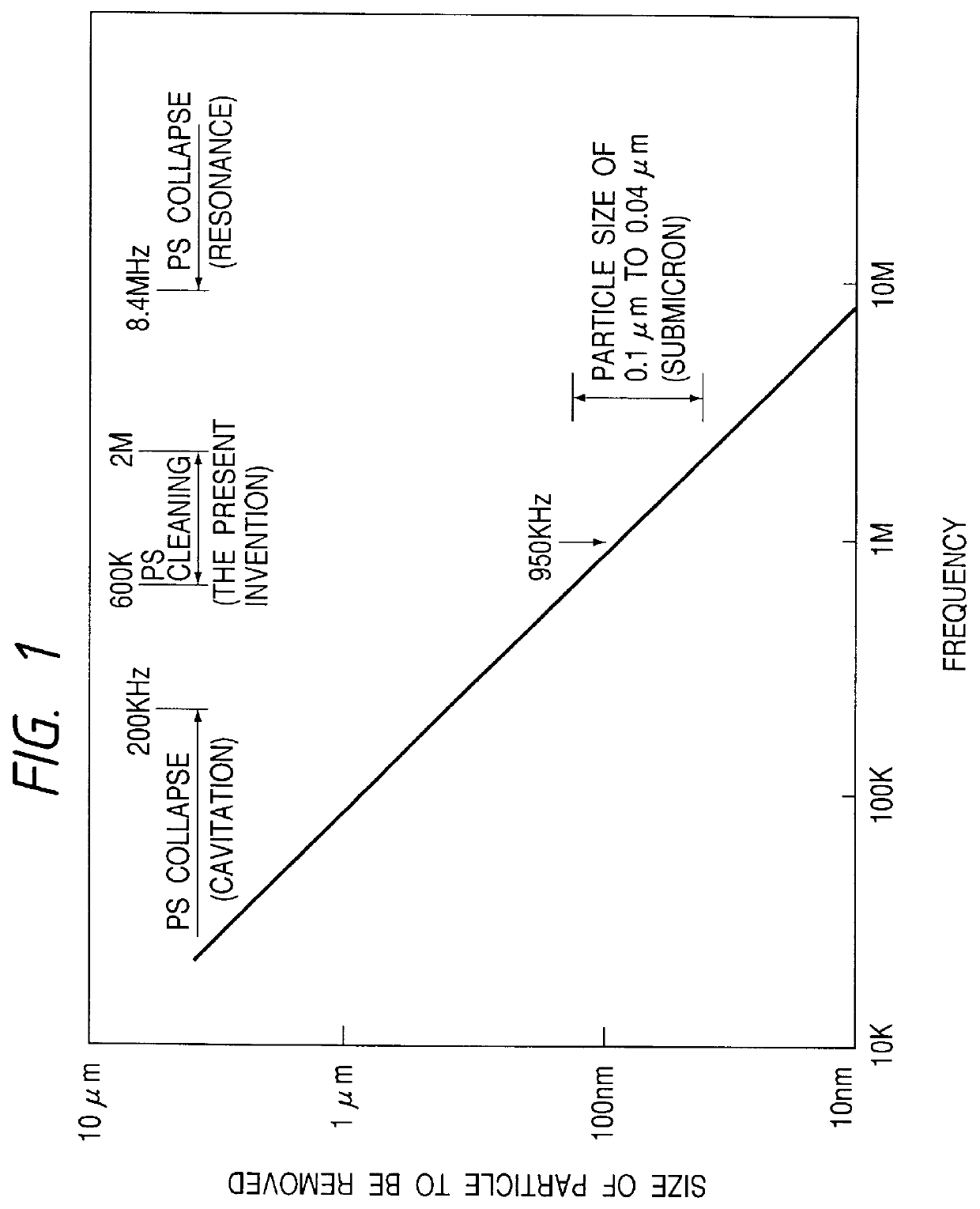

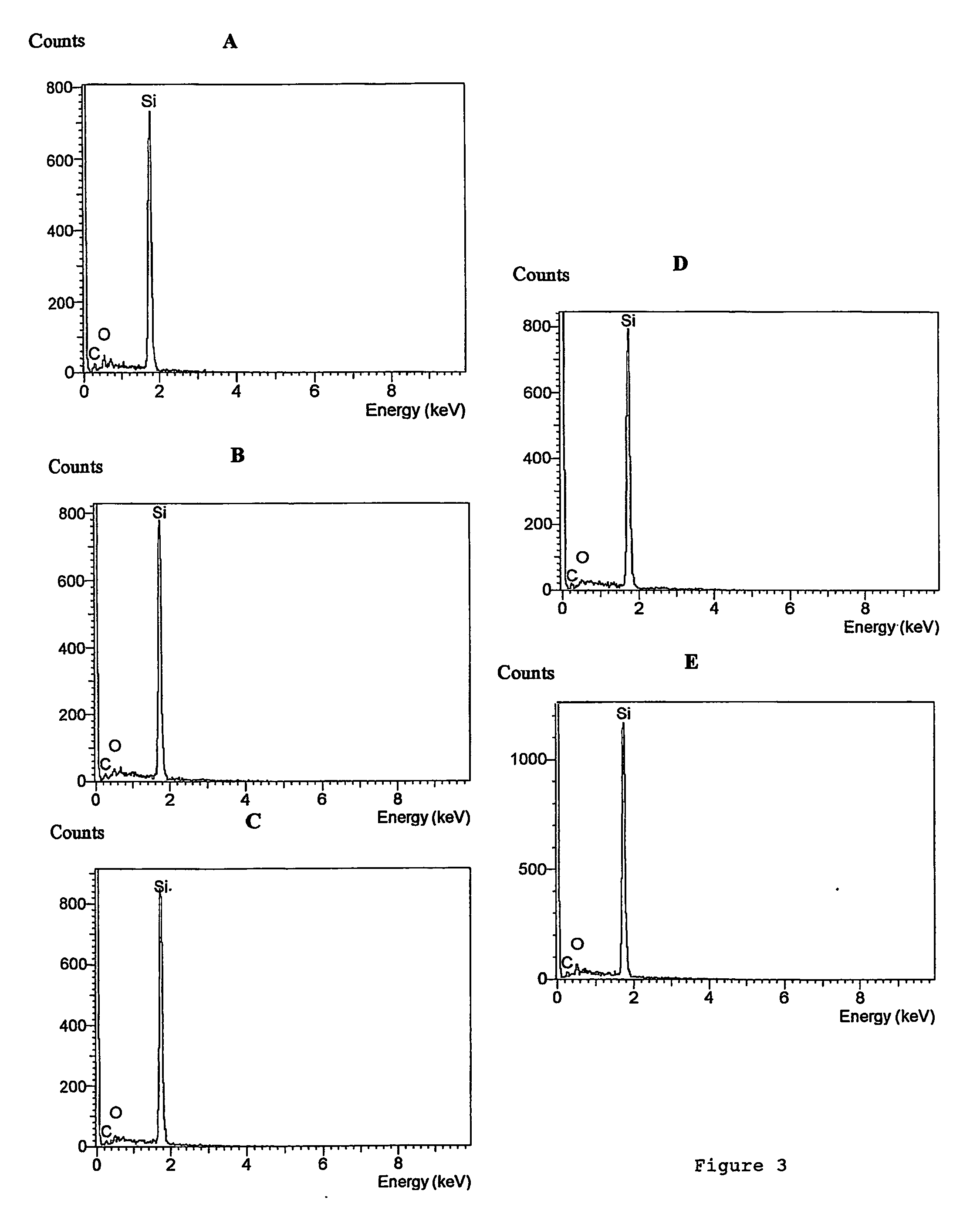

Cleaning methods of porous surface and semiconductor surface

InactiveUS6058945AEfficient removalImprove stabilityElectrostatic cleaningSemiconductor/solid-state device manufacturingCavitationResonance

Provided is a suitable cleaning method of a porous semiconductor substrate without collapse of the porous structure due to cavitation or resonance. In a cleaning method of a porous surface of a semiconductor substrate having the porous structure at least in the surface, cleaning for removing dust particles adhering to the porous surface of the substrate takes place with pure water on which a high-frequency wave with a frequency in the range of from 600 kHz to 2 MHz is superimposed.

Owner:CANON KK

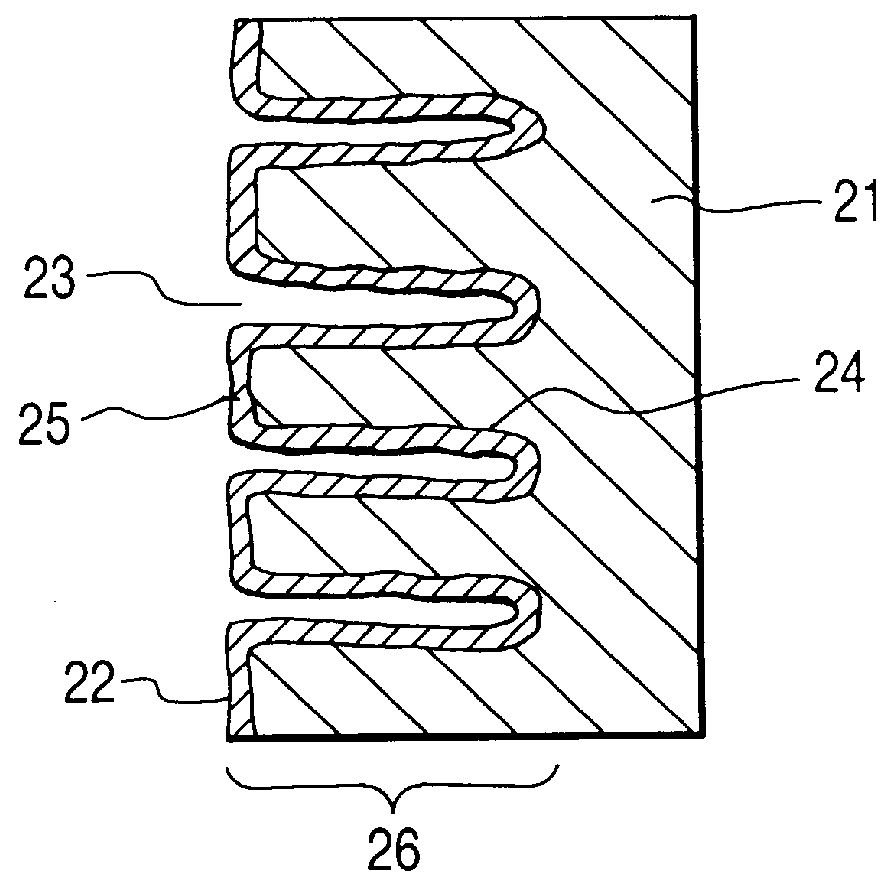

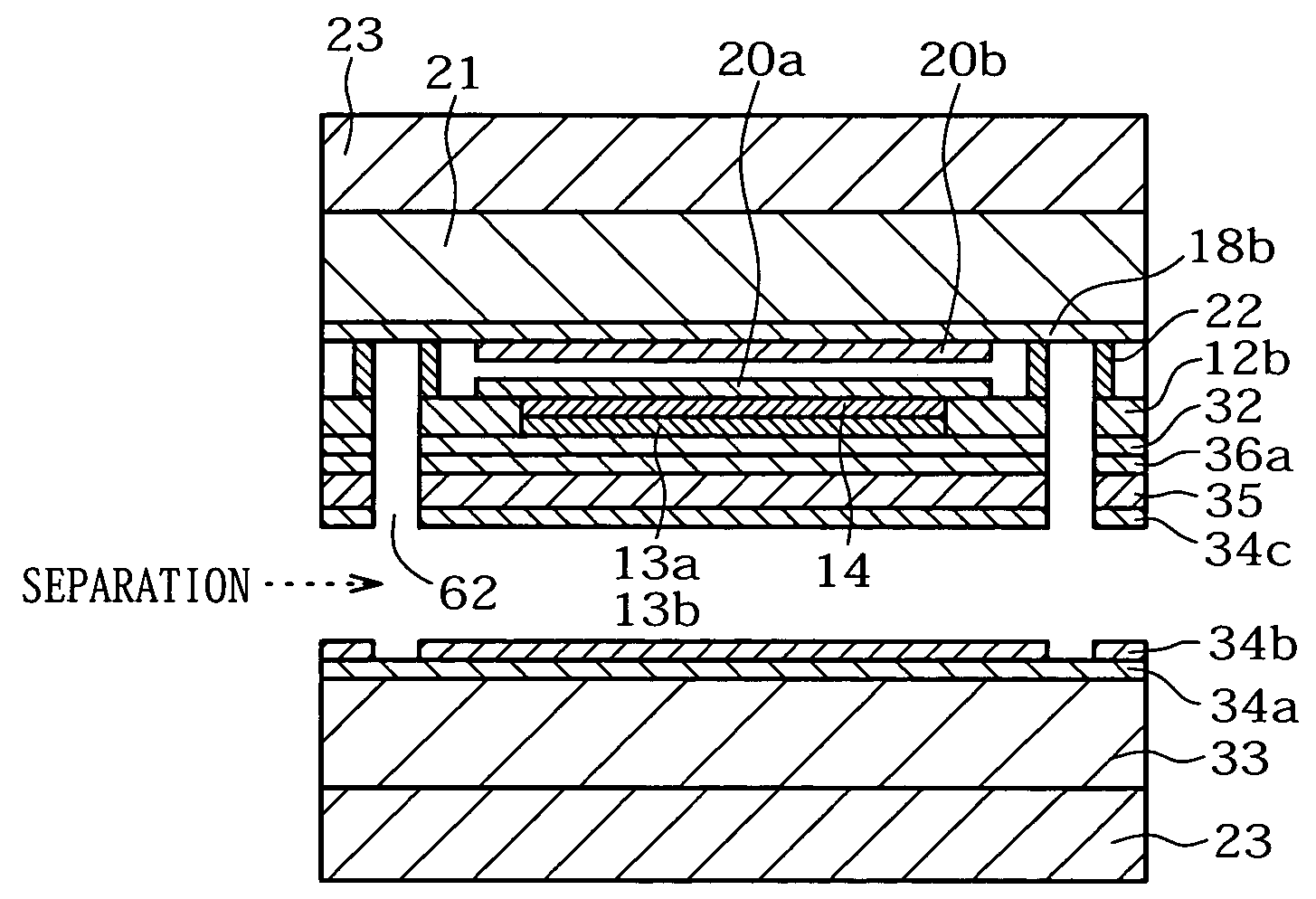

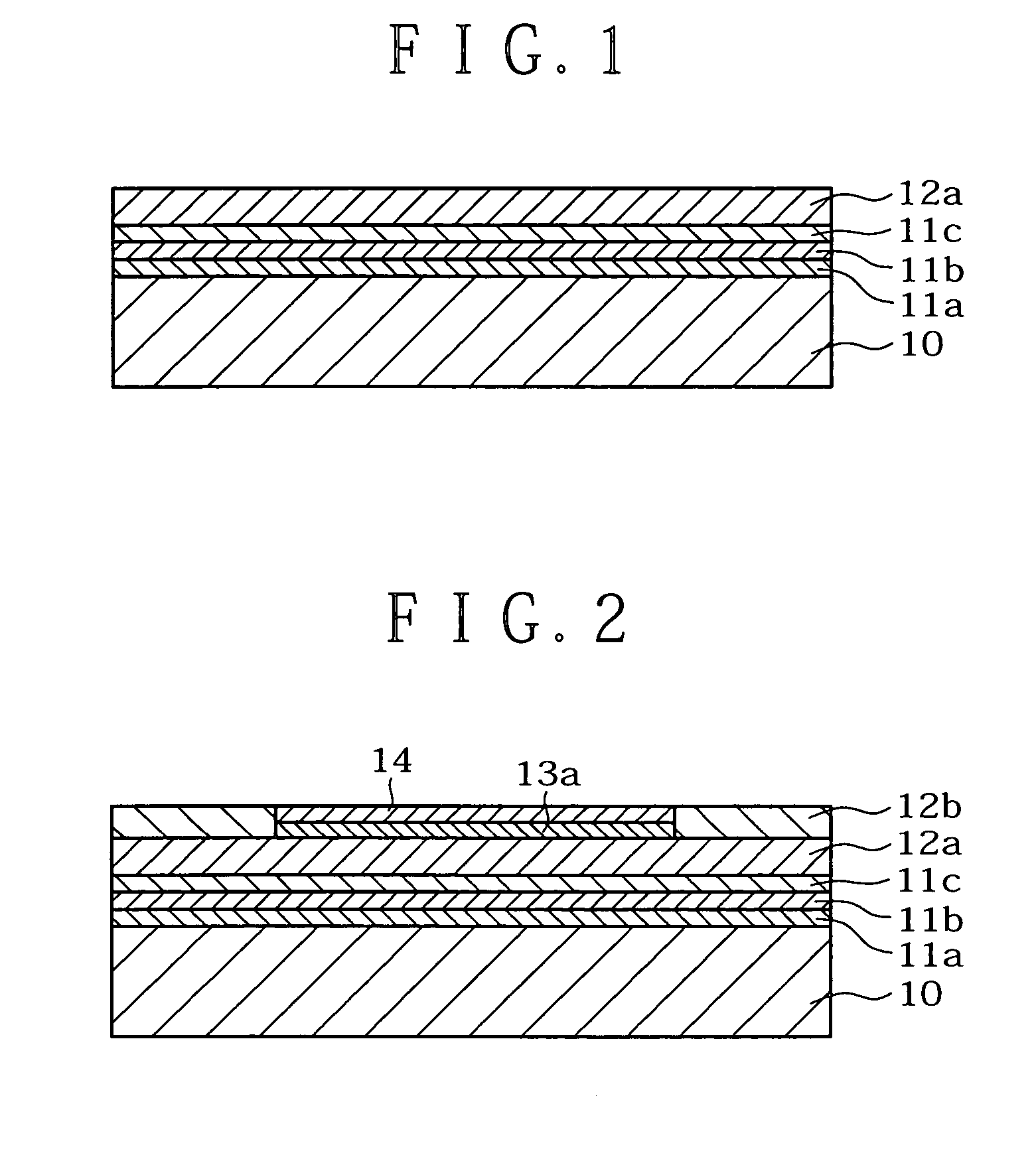

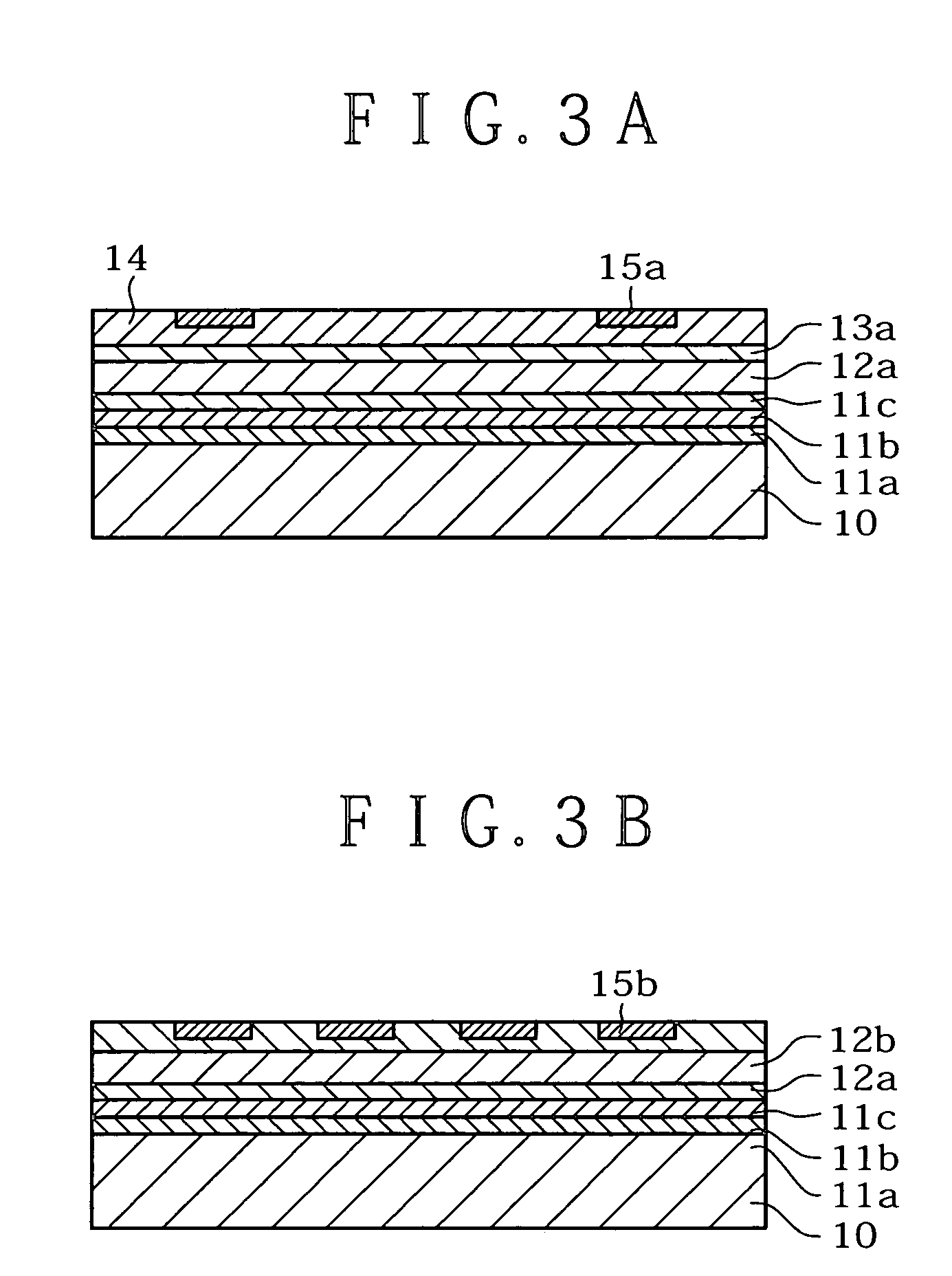

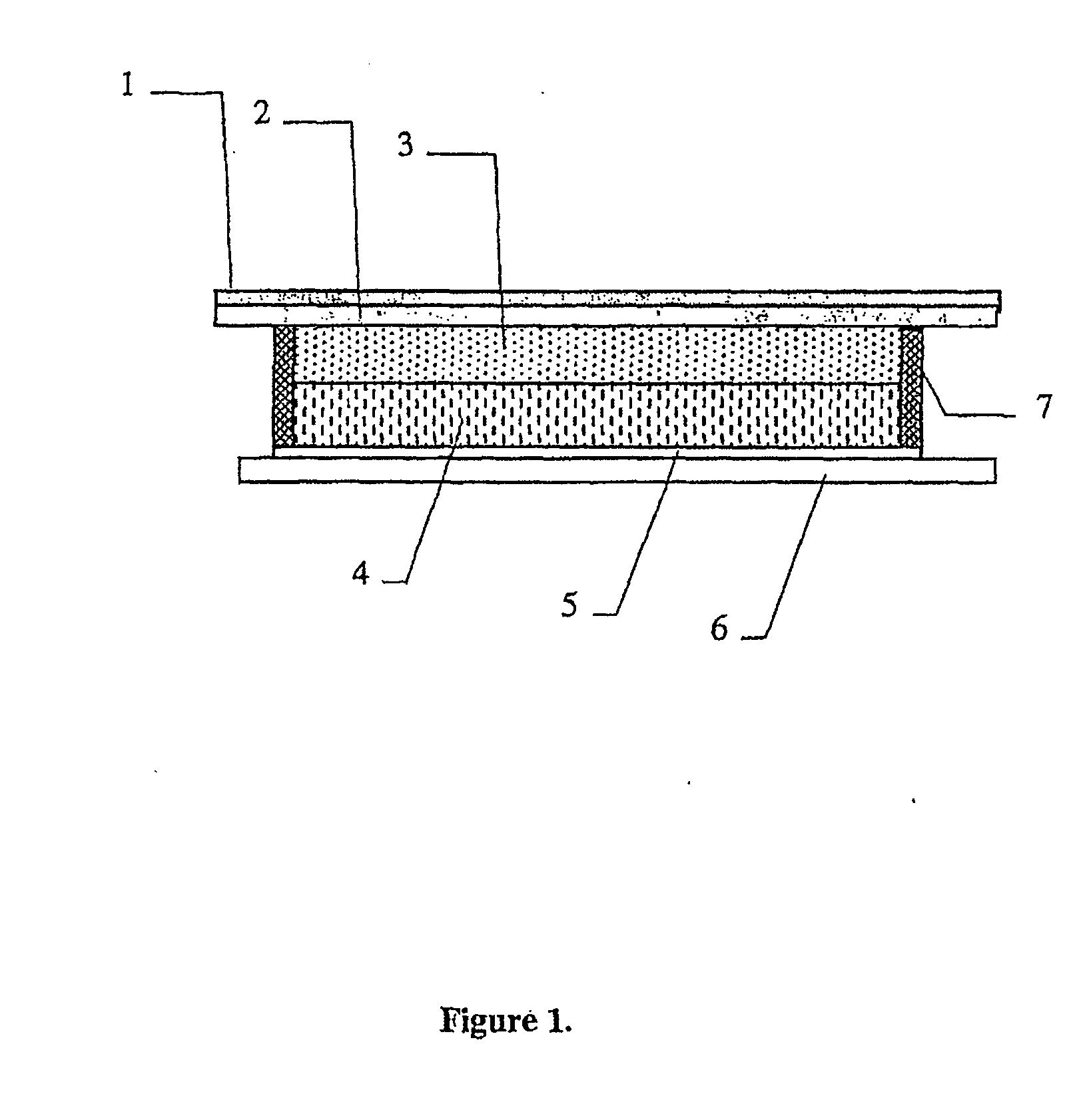

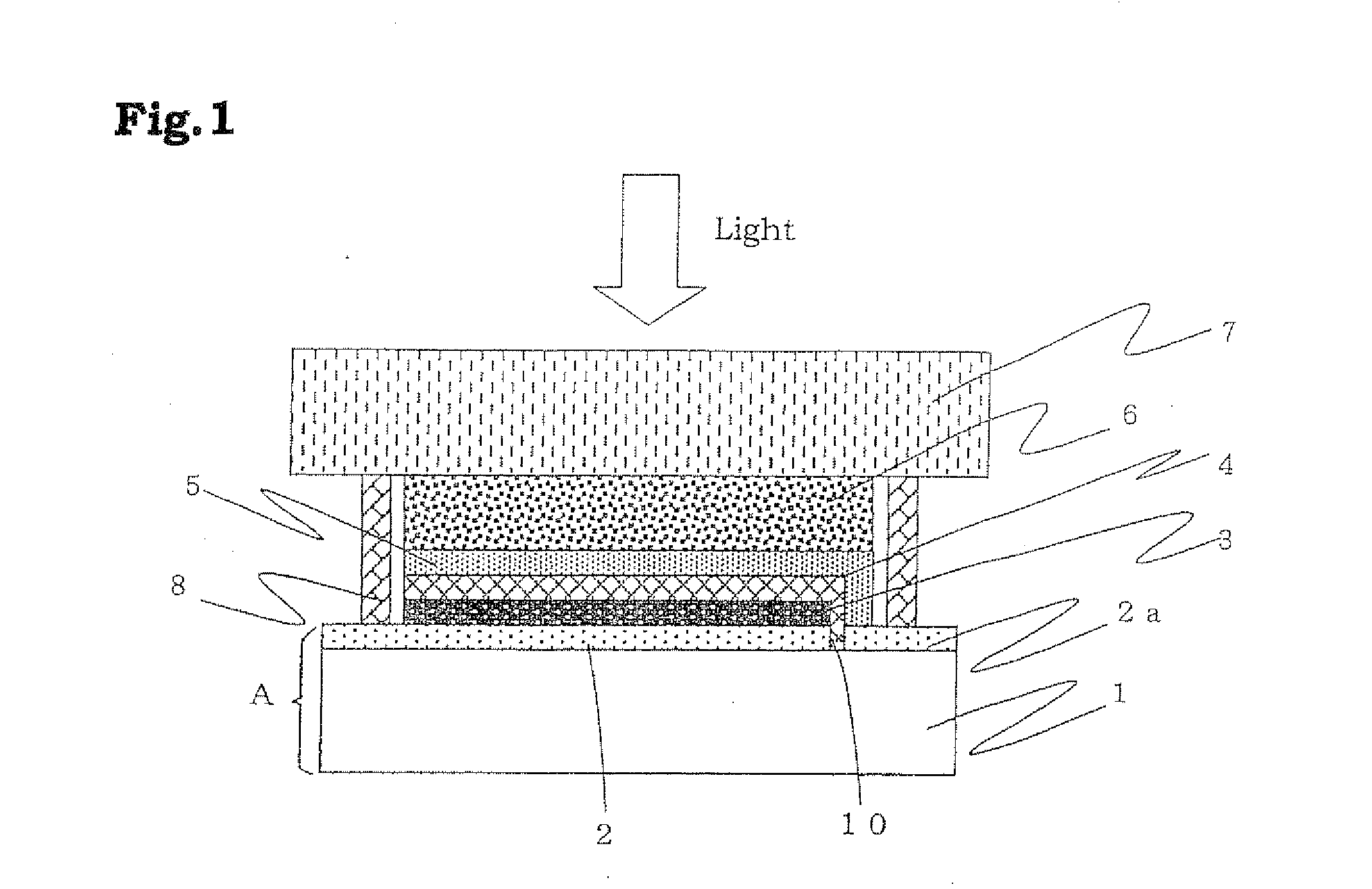

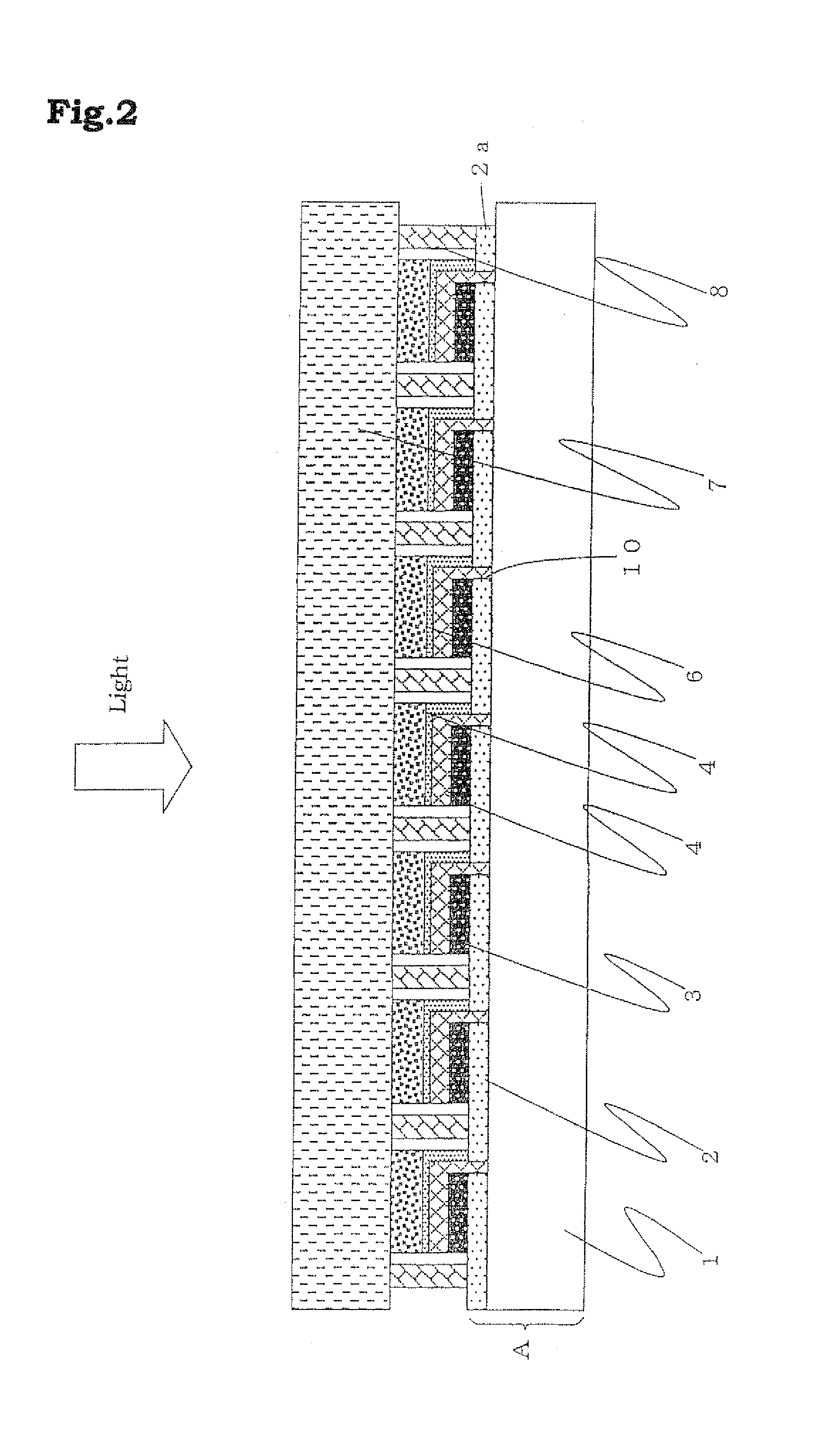

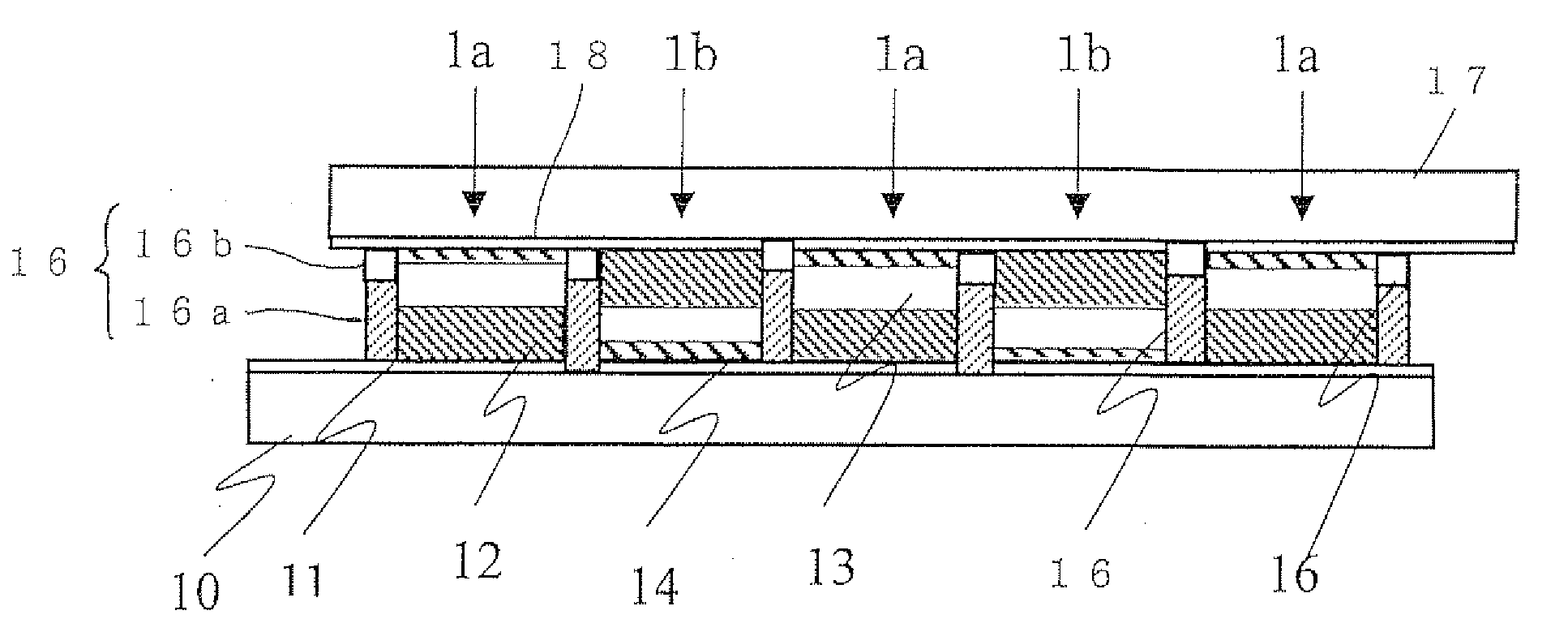

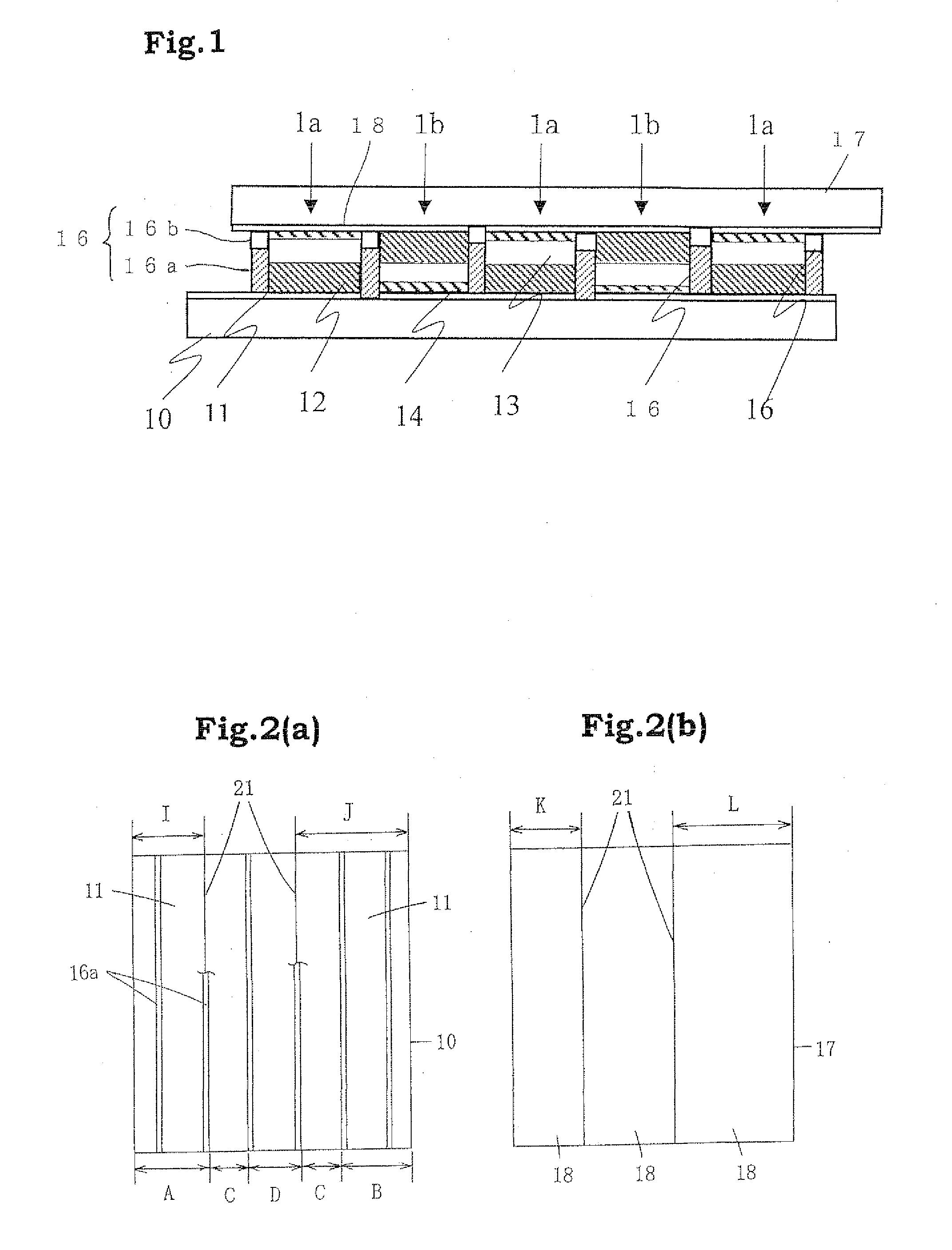

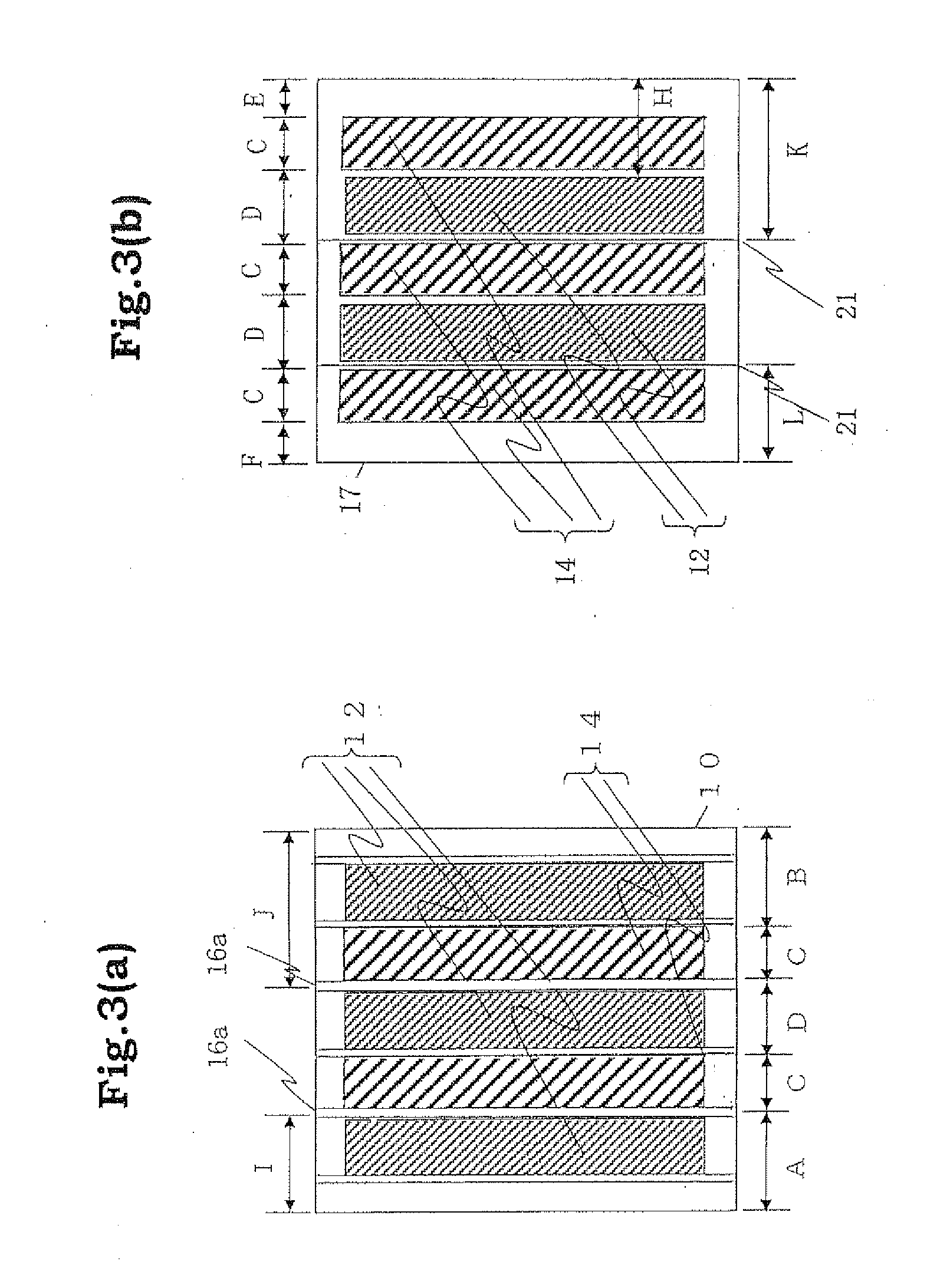

Manufacturing process for ultra slim electrooptic display device unit

To obtain a high intensity, high definition and sophisticated electrooptic display device unit such as transmissive type LCD, a semi-transmissive type LCD, a reflective type LCD, a surface emitter type organic EL, or an underside emitter type organic EL, etc. which has high electron and positive hole mobility and low leak electric current qualities.A porous semiconductor layer (low porous Si layer 11a / high porous Si layer 11b / low porous Si layer 11c), a monocrystalline Si layer12a, and the Si O2 layer 13a are formed on a monocrystalline Si substrate 10. The Si O2 layer 13a of the peripheral circuit area is removed, leaving the Si O2 layer 13a in the display area. The poly Si layer 14a is formed in the display area by semiconductor epitaxial growth, and a monocrystalline Si layer 12b is formed in the peripheral circuit area. Then, the display element section is formed in the poly Si layer 14 of the display area and the peripheral circuitry section is formed in the monocrystalline Si layer 12b of the peripheral circuit area. The assembly is divided into each ultra slim electrooptic display device unit after separation from the backing, and after the process of separating the Si substrate 10 from the porous Si layer 11b and by attaching the backing to the ultra slim electrooptic display element substrate after its separation. Each ultra slim electrooptic display device unit is divided after attaching the backing.

Owner:SONY CORP

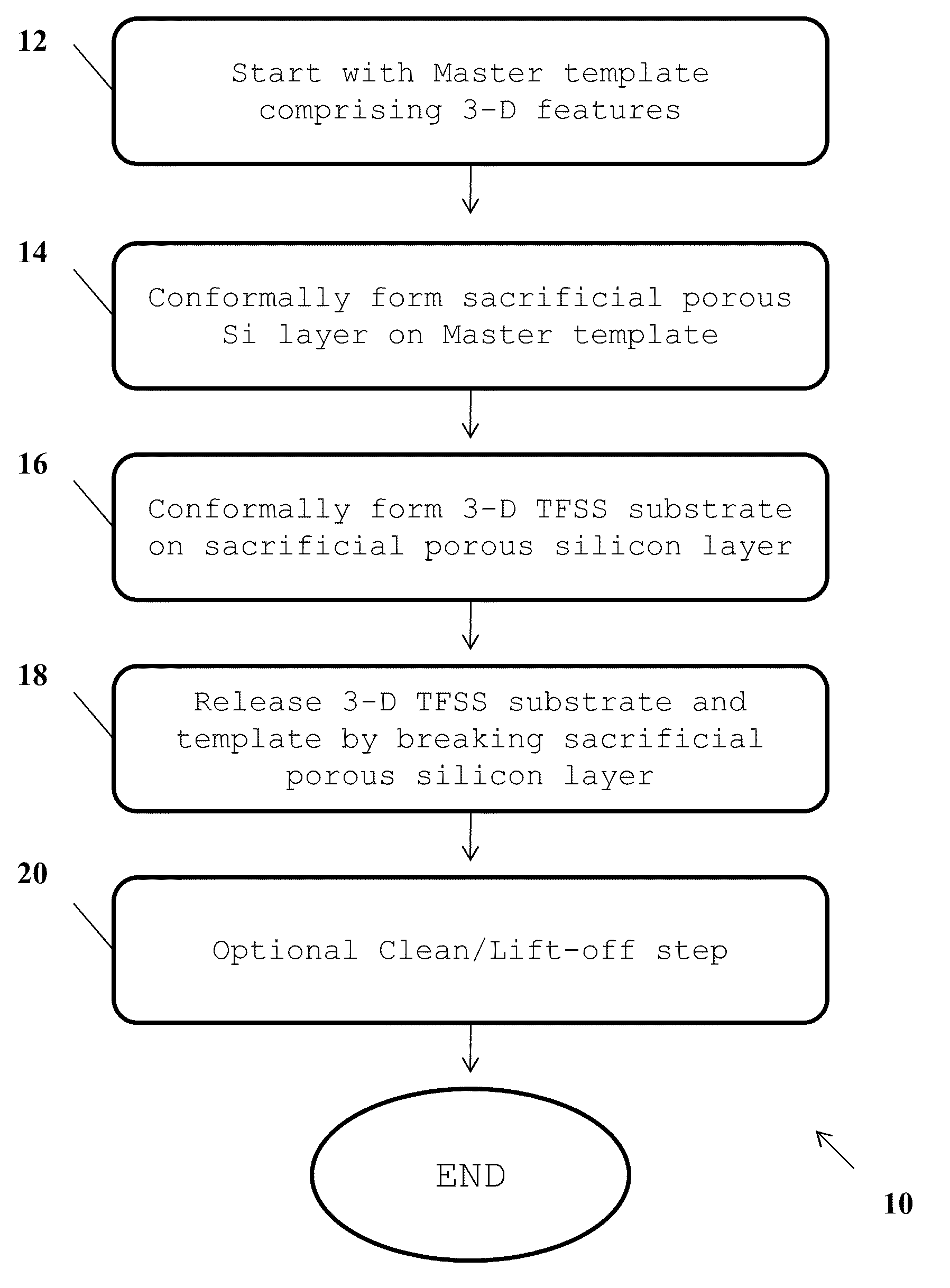

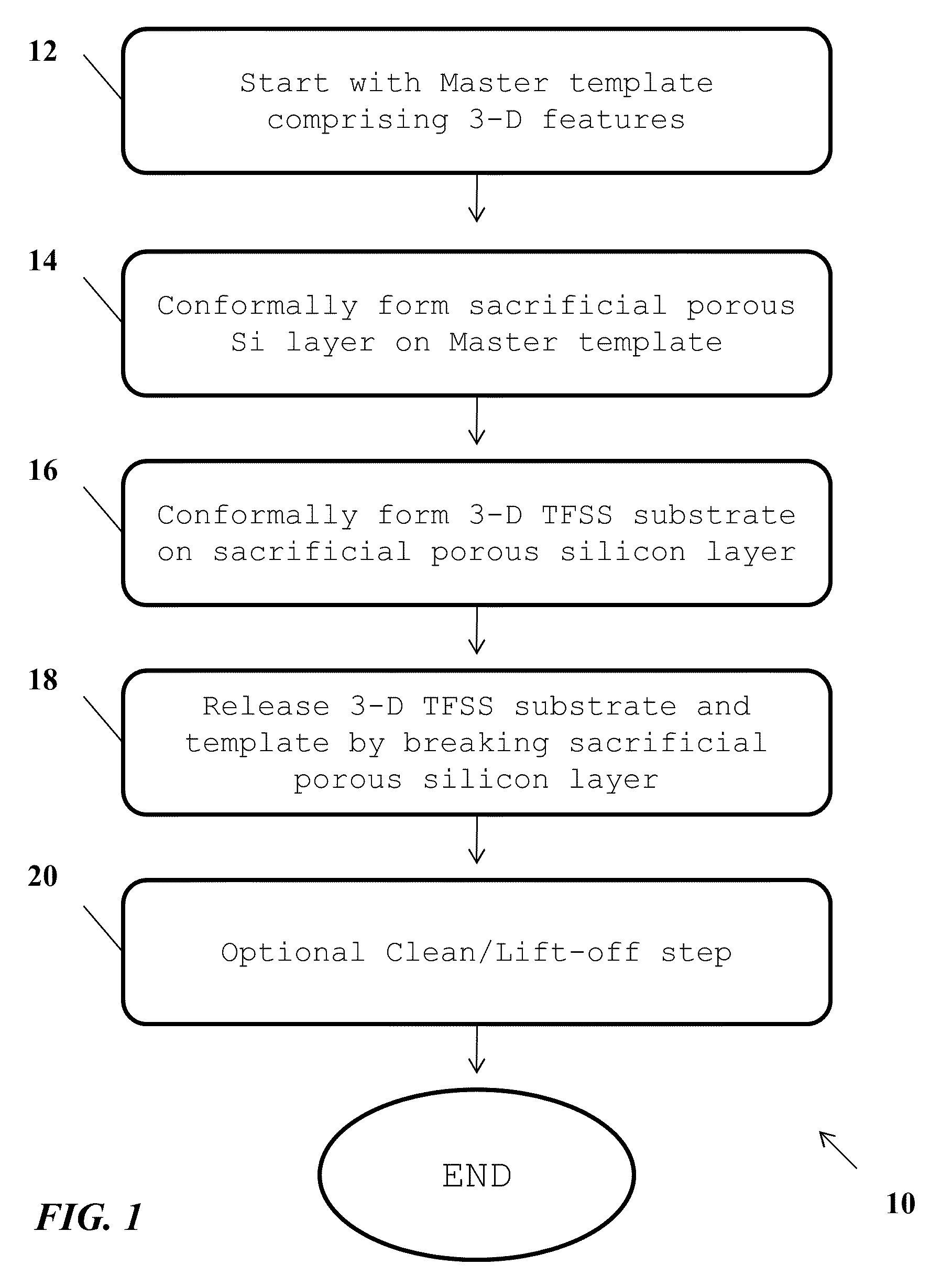

Substrate release methods and apparatuses

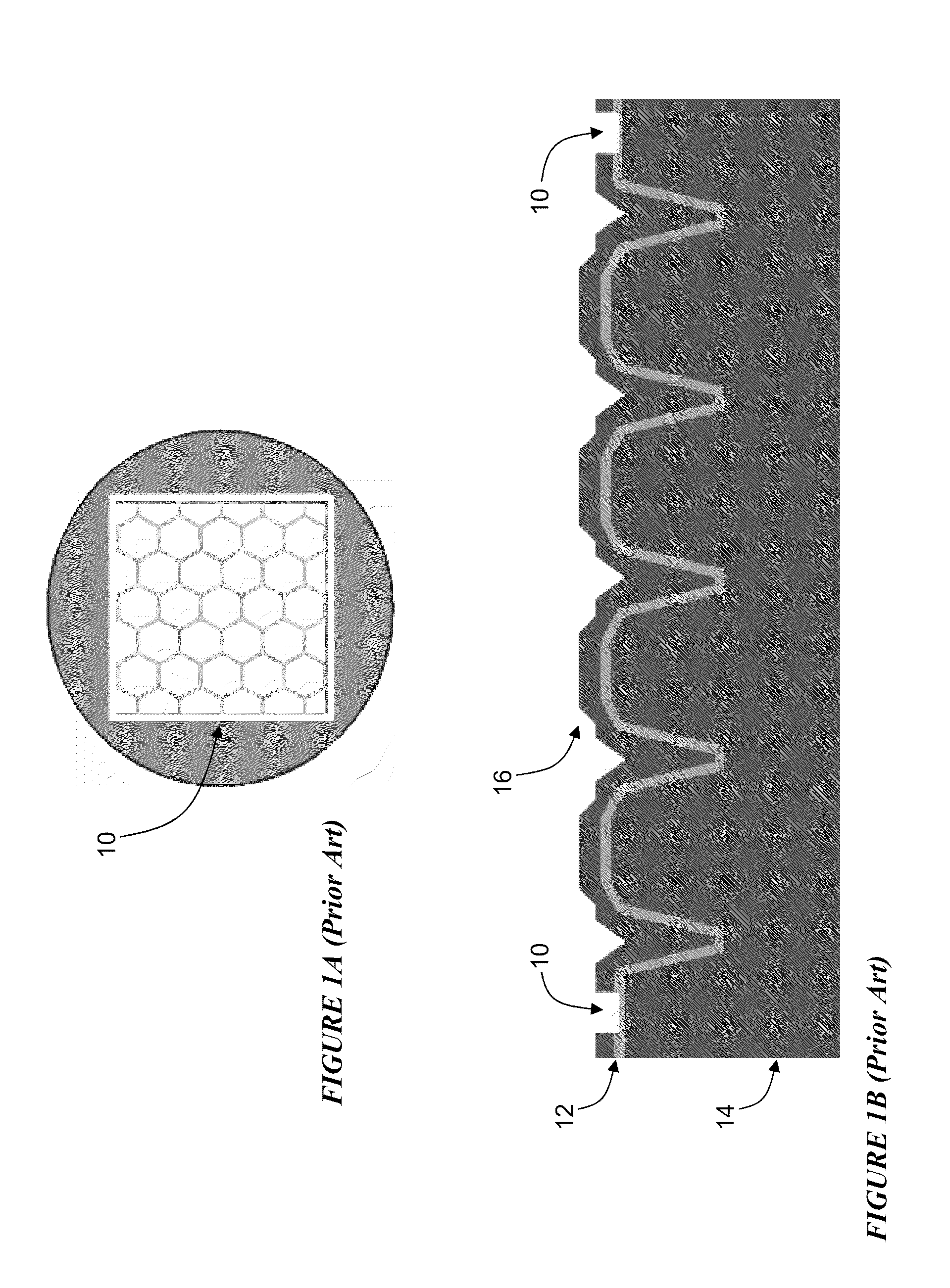

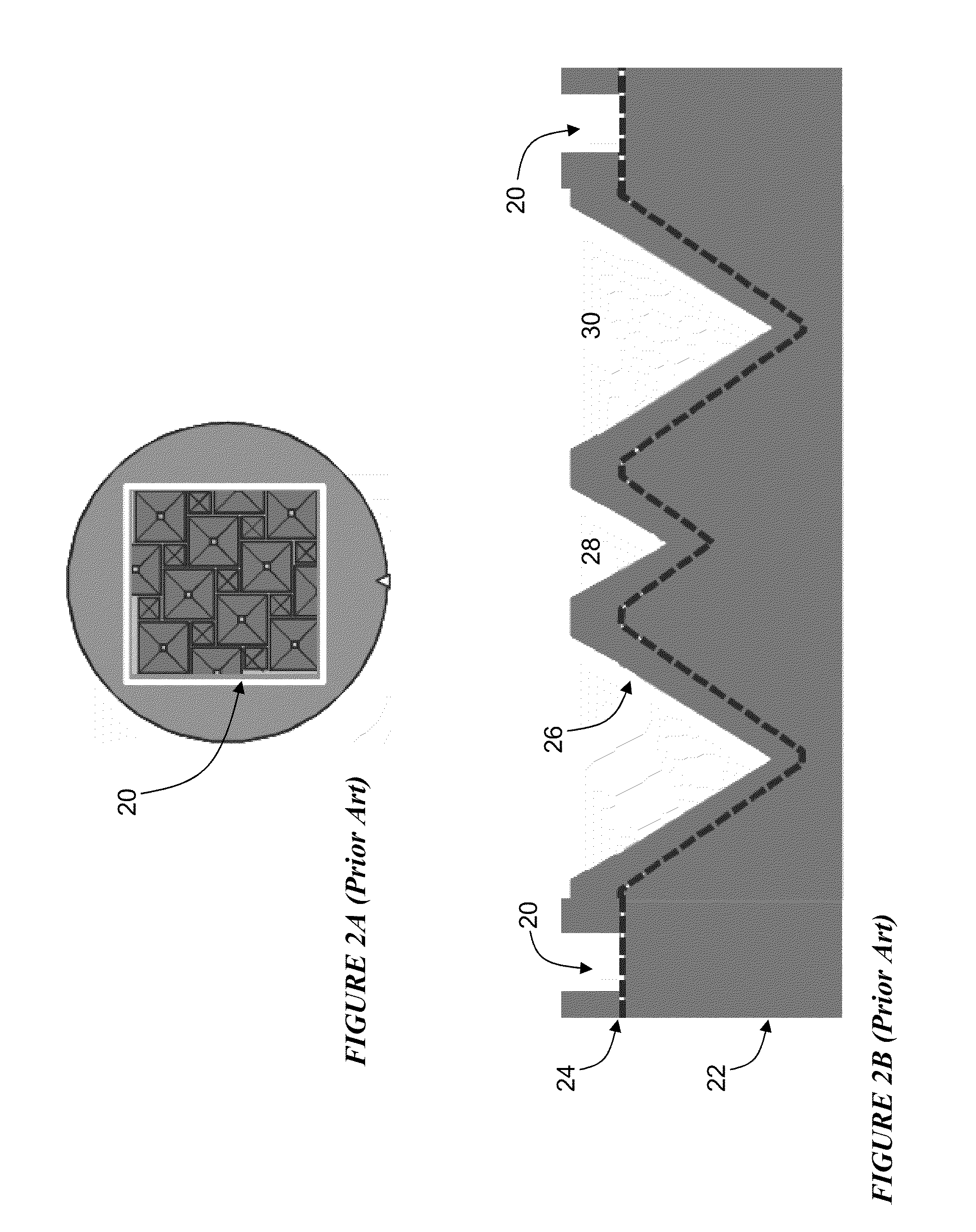

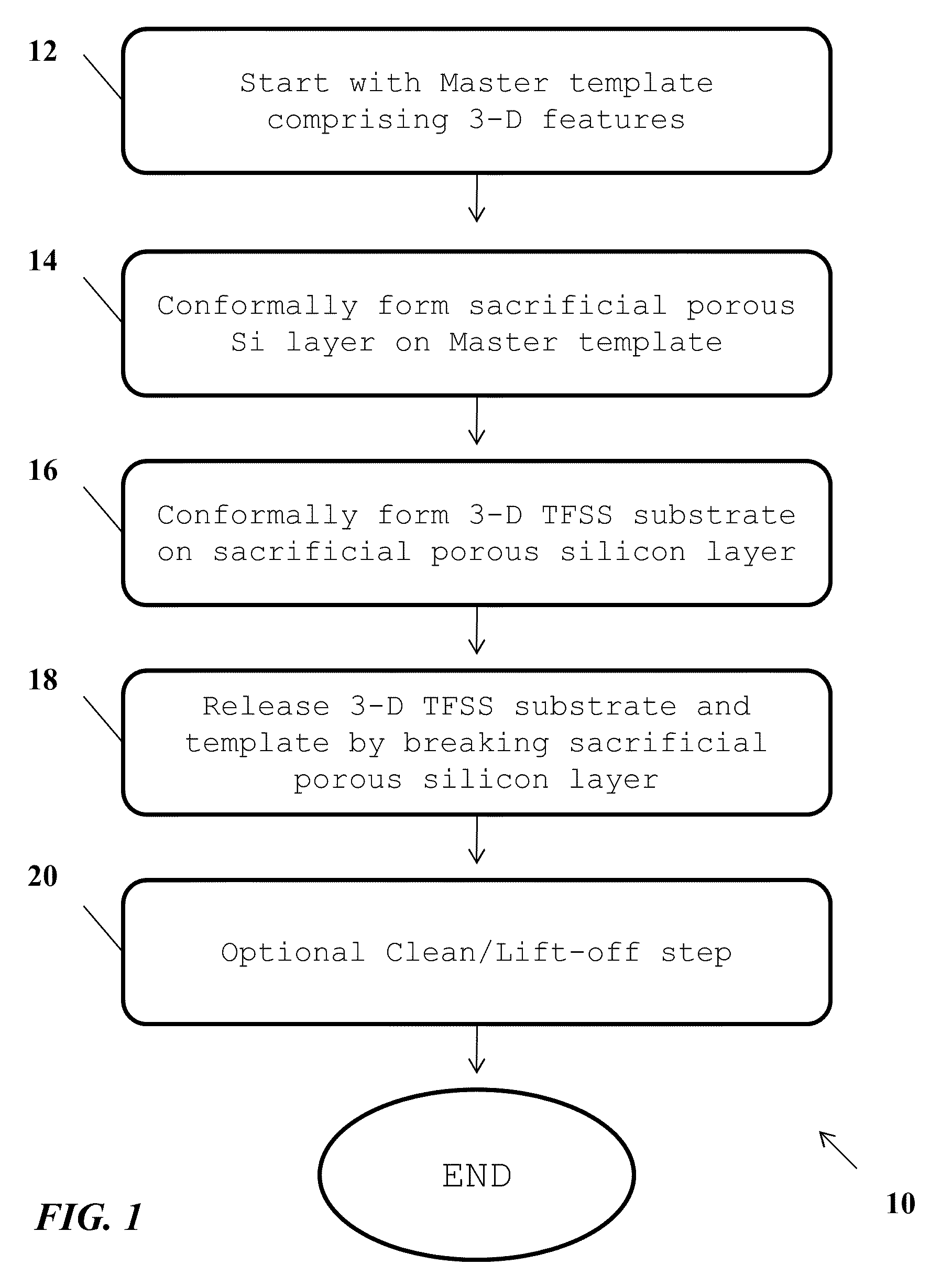

InactiveUS20100022074A1Reduce harmMinimize complexitySemiconductor/solid-state device manufacturingSemiconductor devicesPorous semiconductorsCrystalline semiconductor

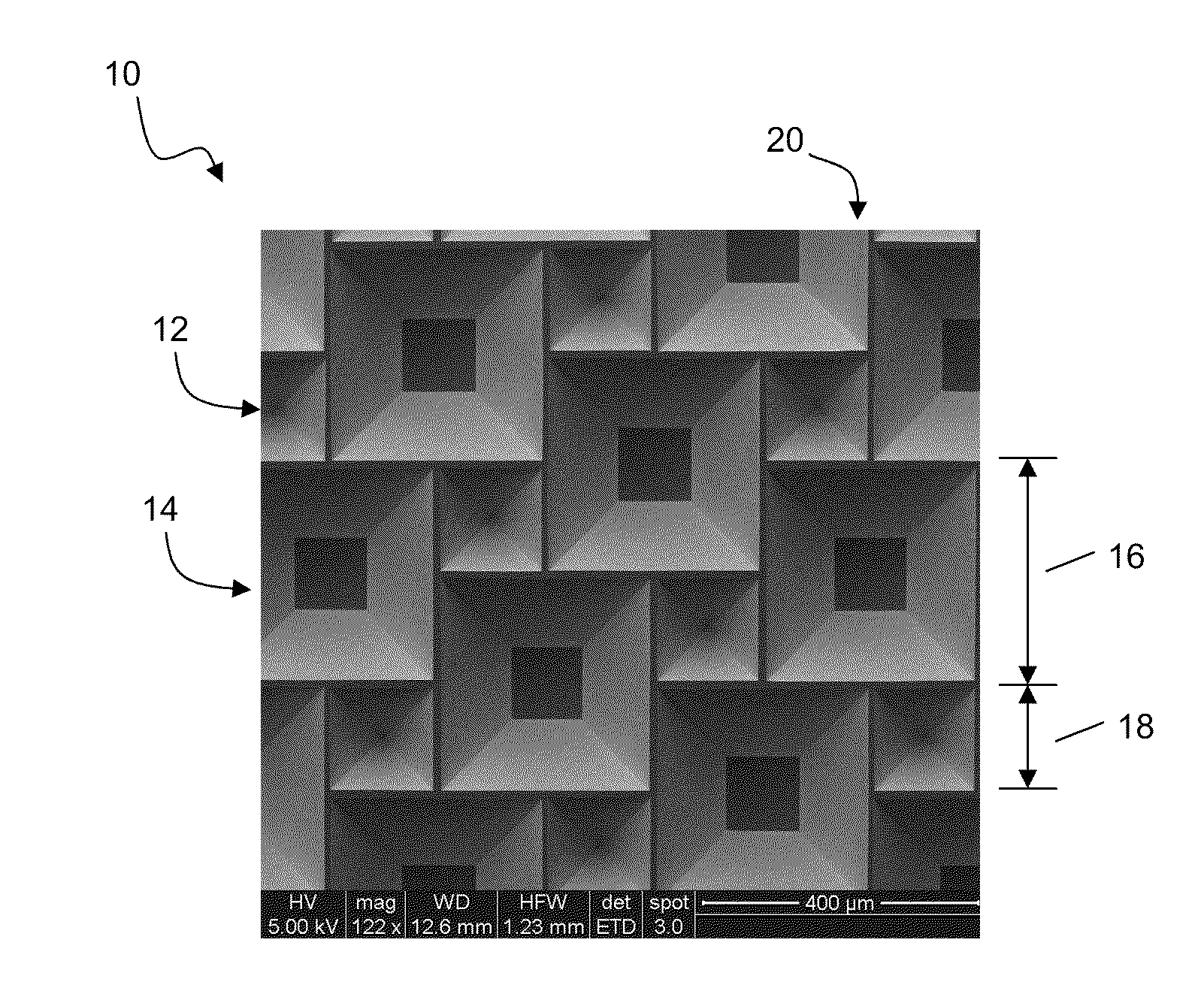

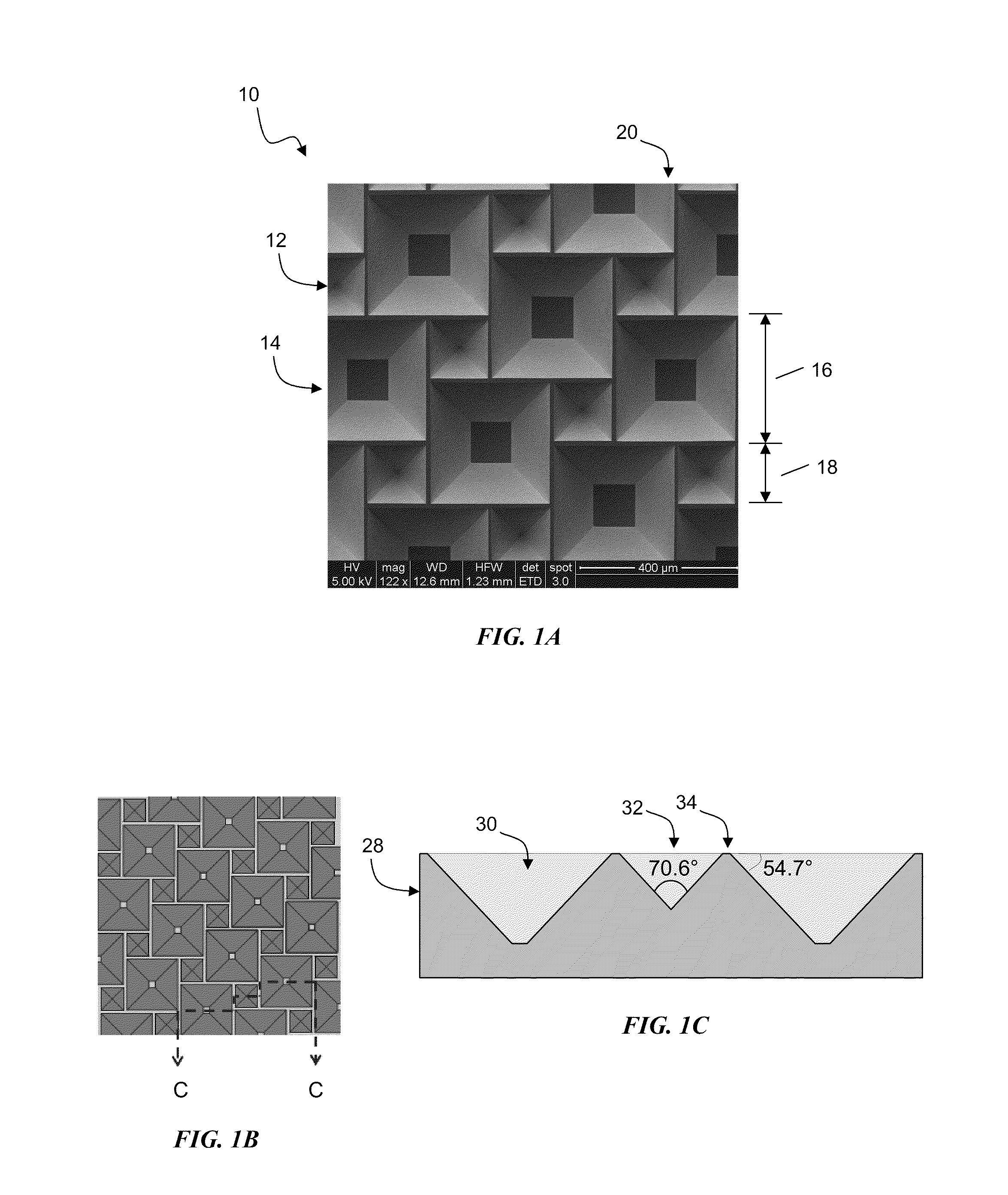

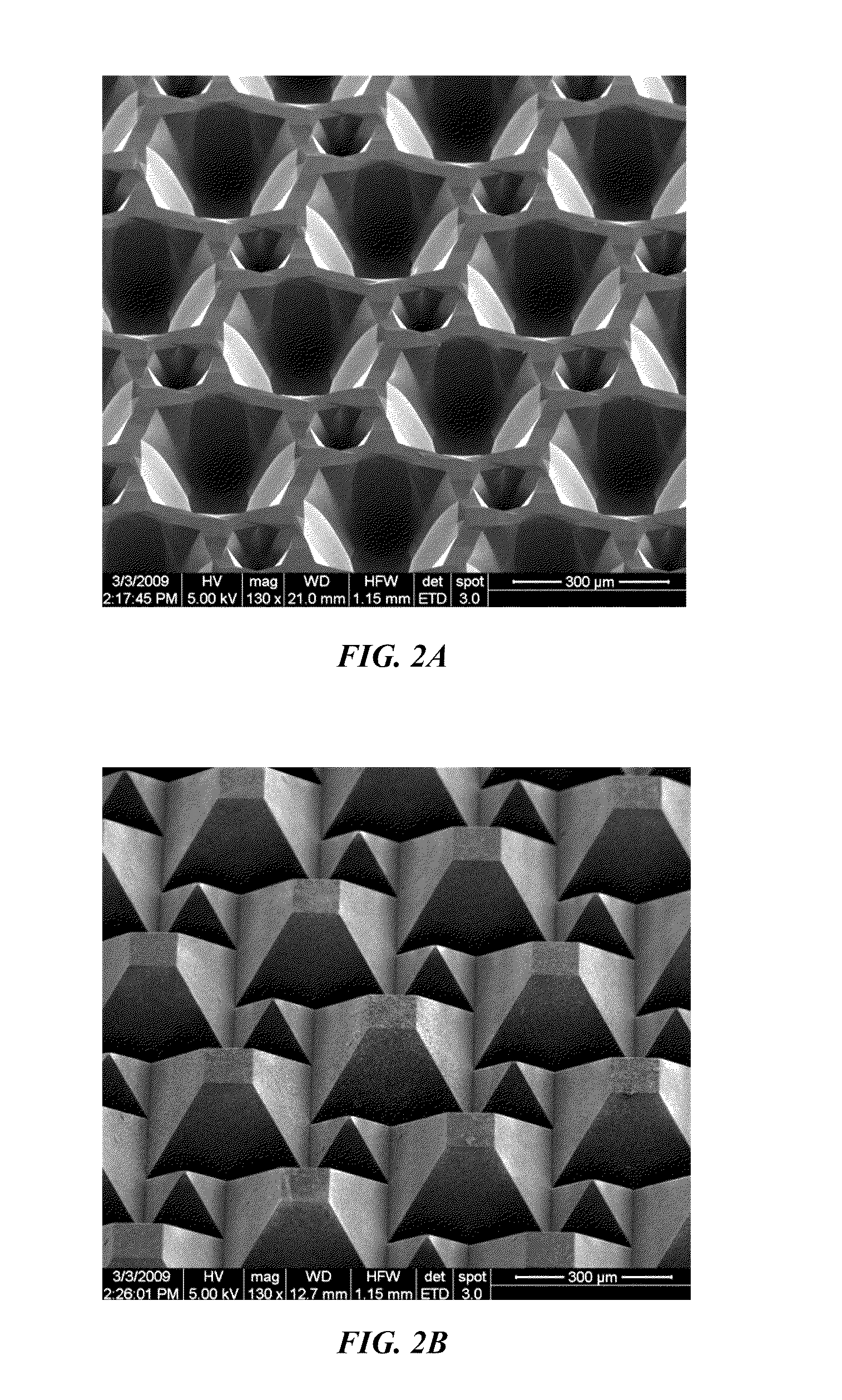

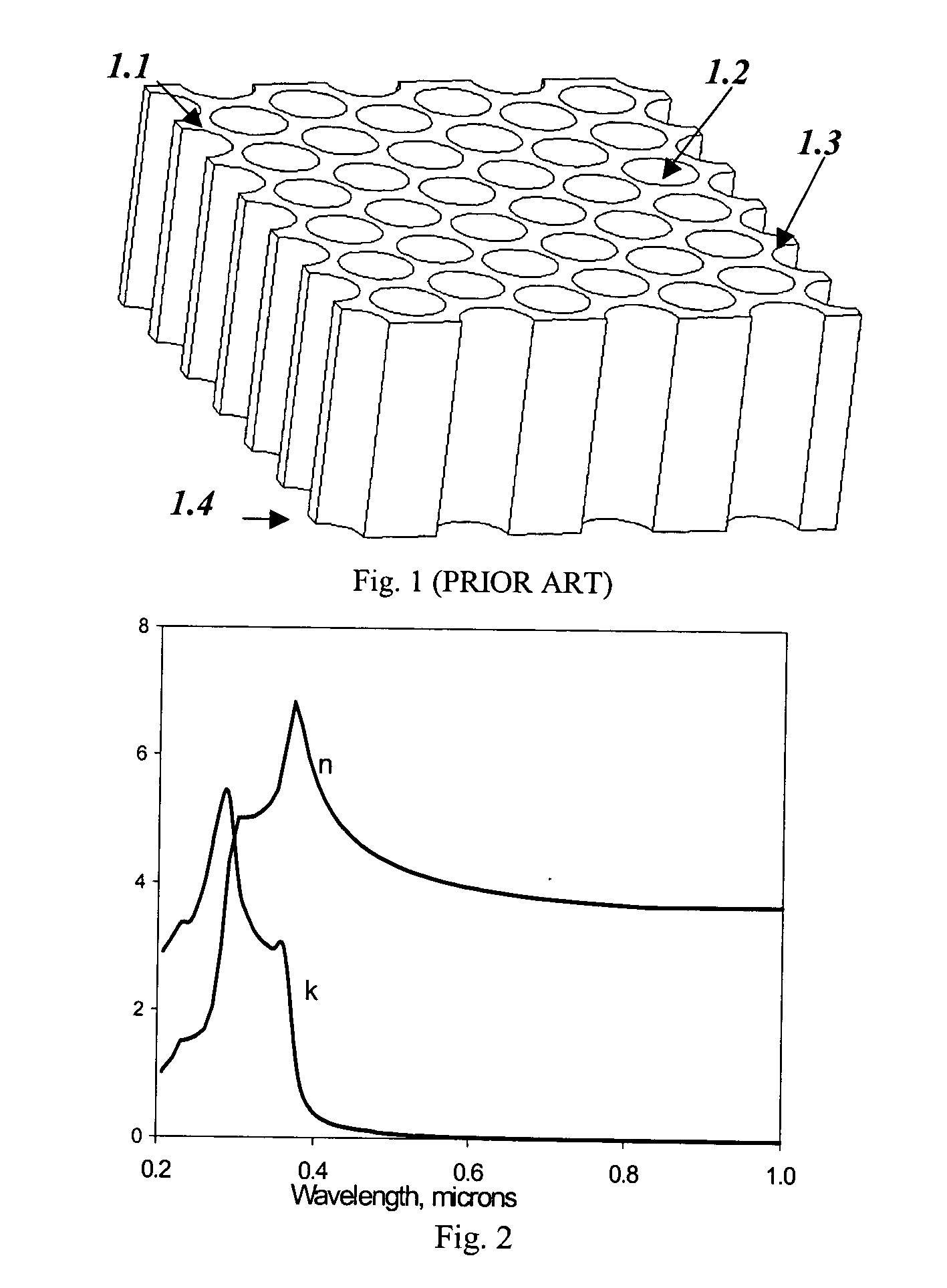

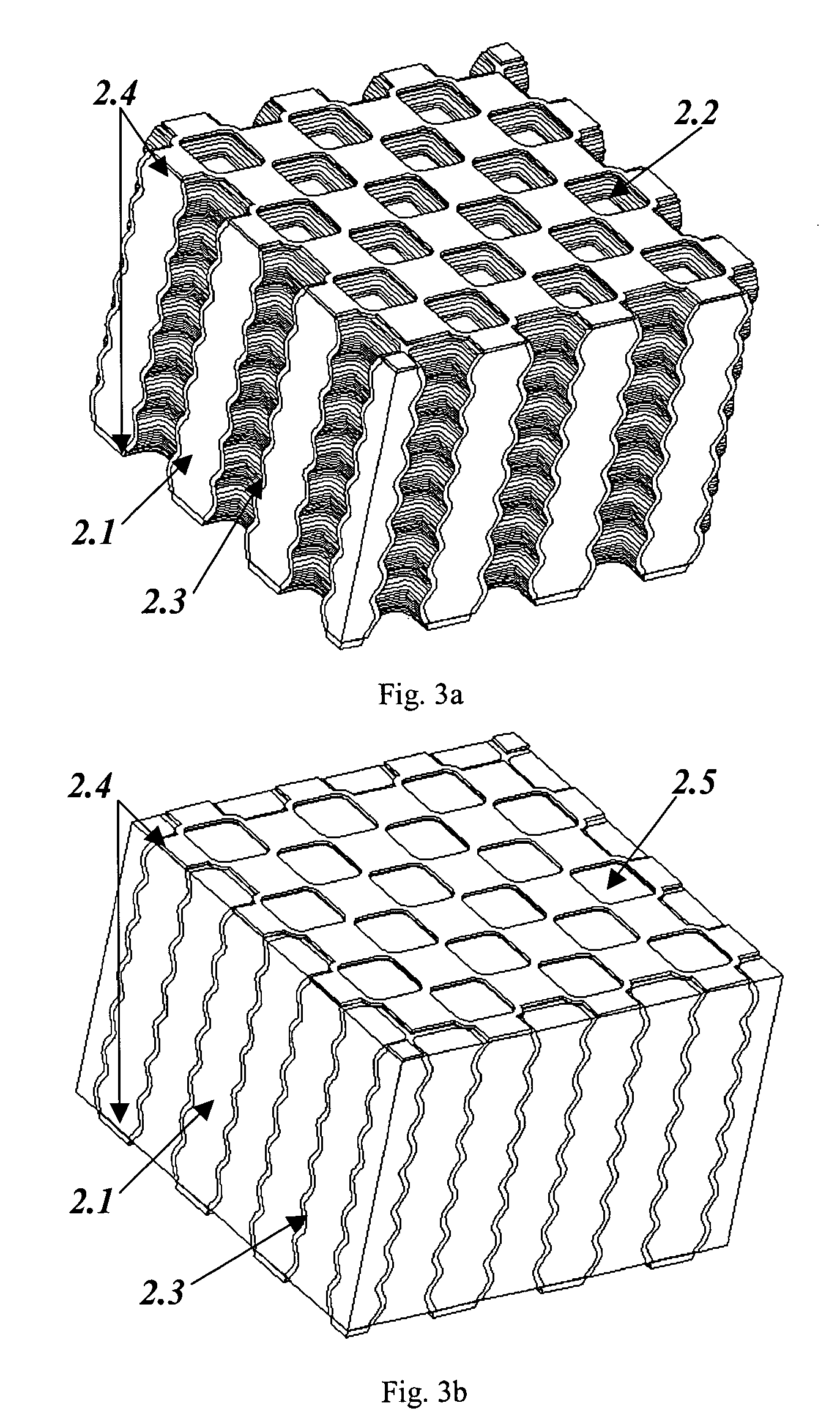

The present disclosure relates to methods and apparatuses for fracturing or breaking a buried porous semiconductor layer to separate a 3-D thin-film semiconductor semiconductor (TFSS) substrate from a 3-D crystalline semiconductor template. The method involves forming a sacrificial porous semiconductor layer on the 3-D features of the template. A variety of techniques may be used to fracture and release the mechanically weak porous semiconductor layer without damaging the TFSS substrate layer or the template layer such as pressure variations, thermal stress generation, and mechanical bending. The methods also allow for processing three dimensional features not possible with current separation processes. Optional cleaning and final lift-off steps may be performed as part of the release step or after the release step.

Owner:BEAMREACH SOLAR INC

Three-dimensional thin-film semiconductor substrate with through-holes and methods of manufacturing

InactiveUS20100300518A1Eliminate and reduce disadvantageEliminate and reduce and problemFinal product manufactureSemiconductor/solid-state device manufacturingOptoelectronicsPorous semiconductors

A method for the fabrication of a three-dimensional thin-film semiconductor substrate with selective through-holes is provided. A porous semiconductor layer is conformally formed on a semiconductor template comprising a plurality of three-dimensional inverted pyramidal surface features defined by top surface areas aligned along a (100) crystallographic orientation plane of the semiconductor template and a plurality of inverted pyramidal cavities defined by sidewalls aligned along the (111) crystallographic orientation plane of the semiconductor template. An epitaxial semiconductor layer is conformally formed on the porous semiconductor layer. The epitaxial semiconductor layer is released from the semiconductor template. Through-holes are selectively formed in the epitaxial semiconductor layer with openings between the front and back lateral surface planes of the epitaxial semiconductor layer to form a partially transparent three-dimensional thin-film semiconductor substrate.

Owner:BEAMREACH SOLAR INC

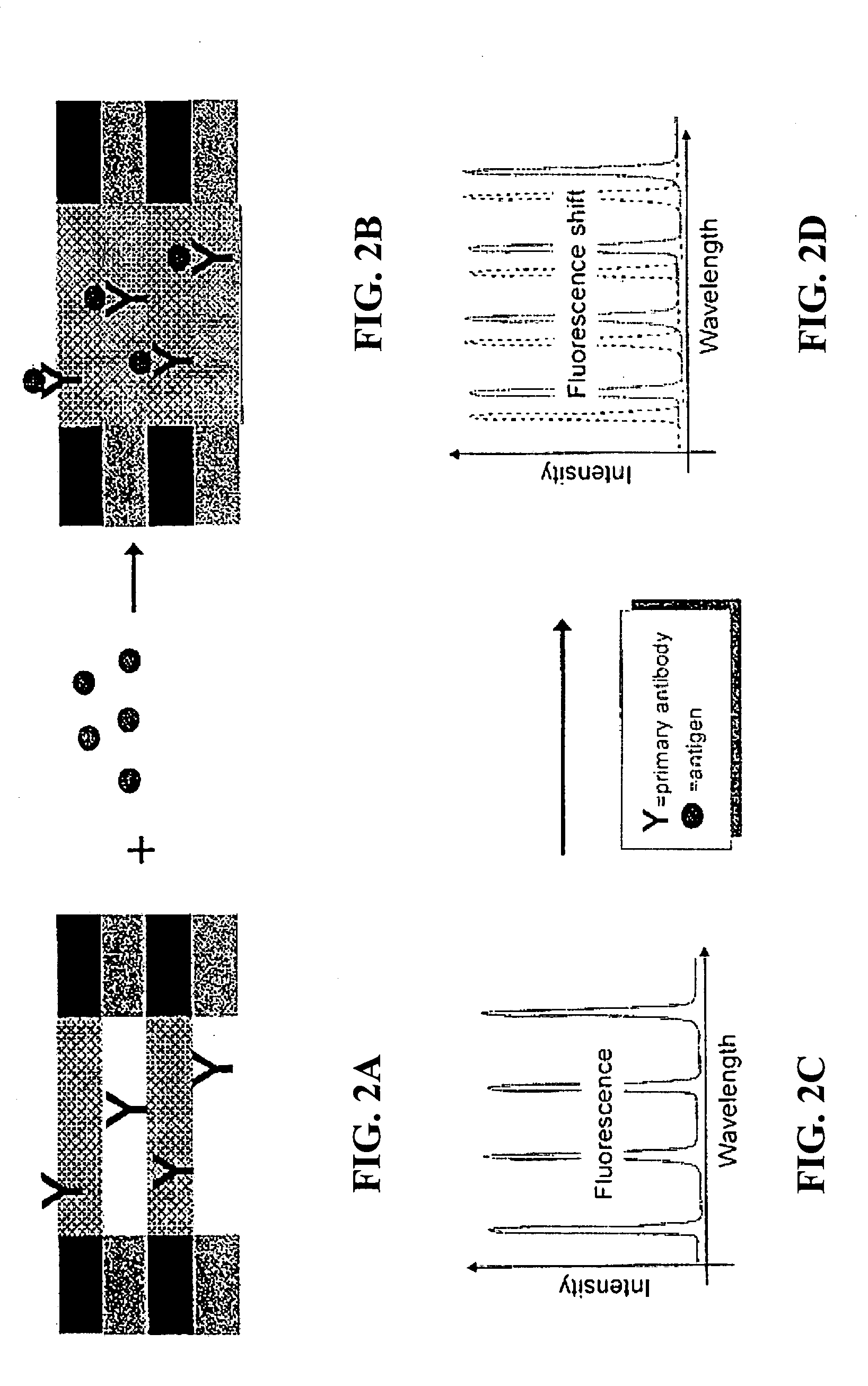

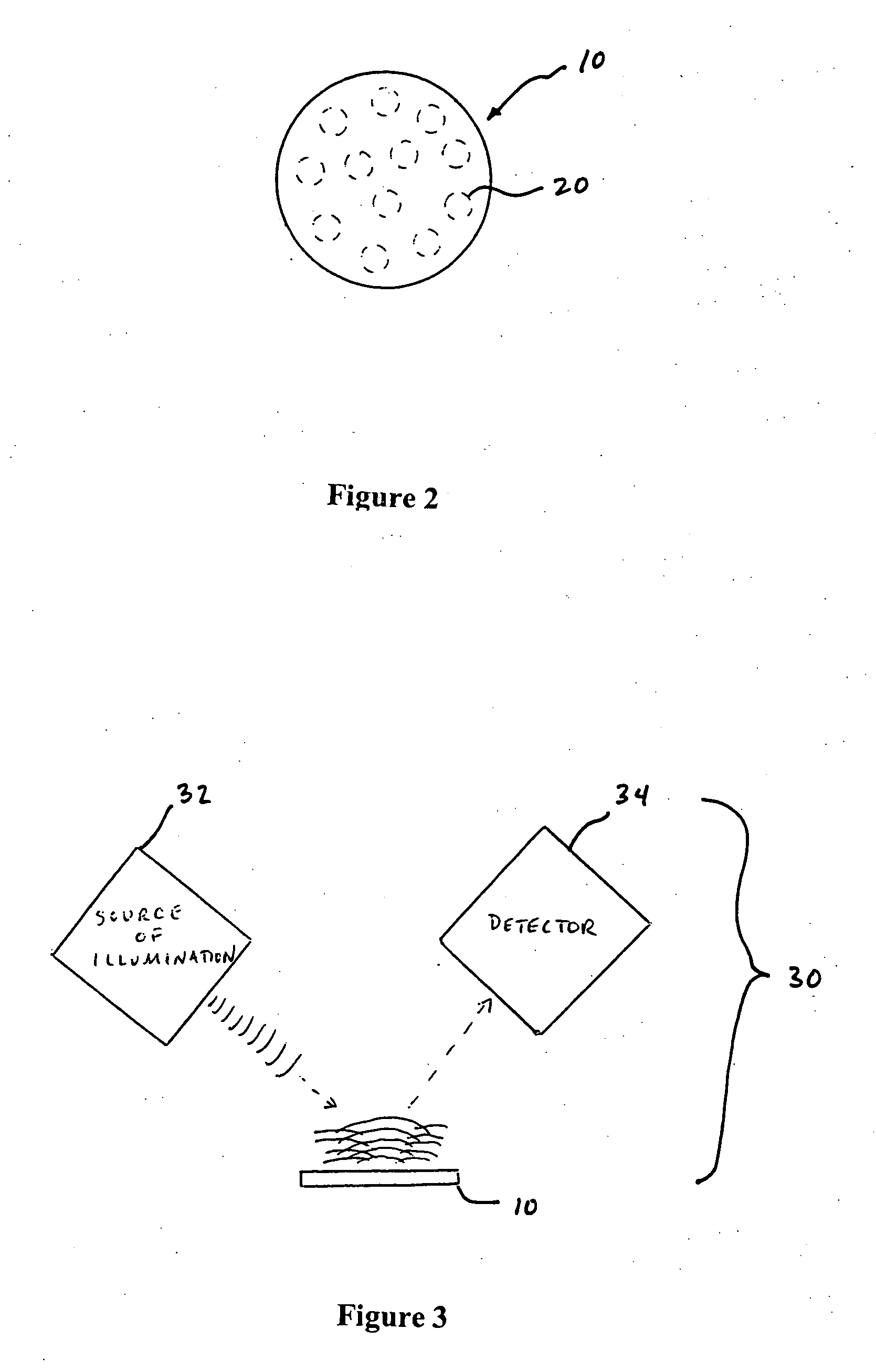

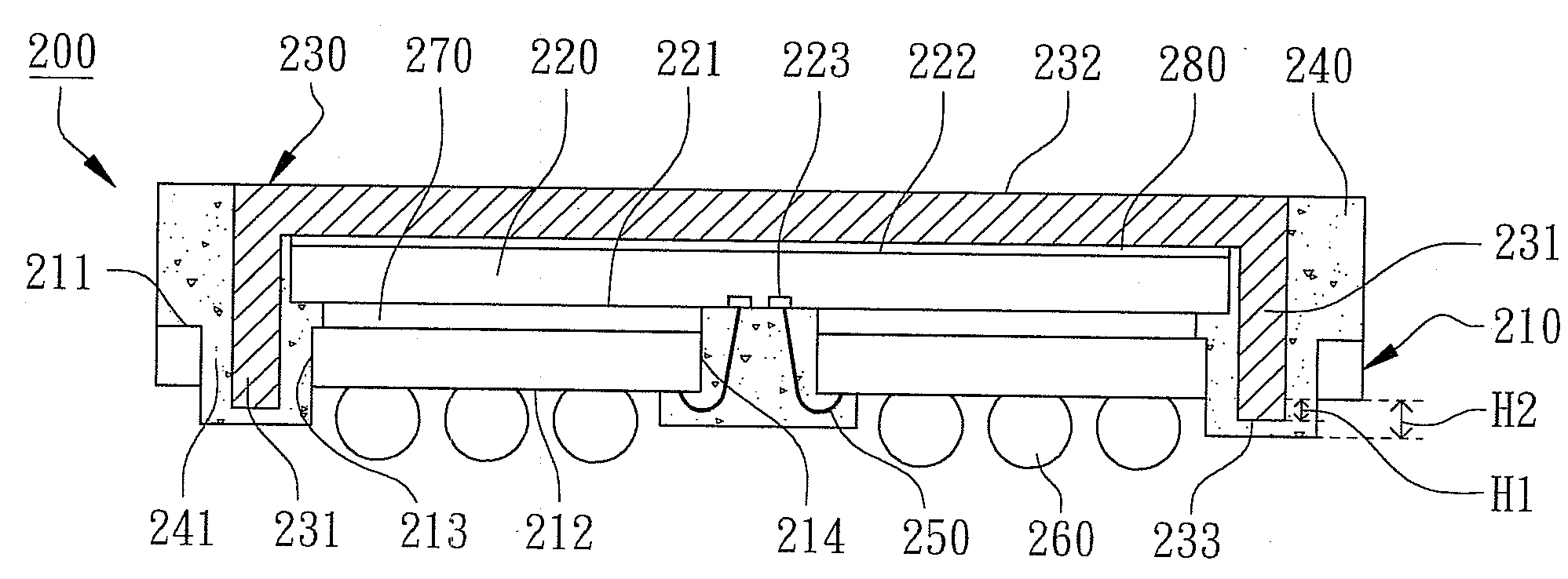

Detection of biomolecules using porous biosensors and Raman spectroscopy

ActiveUS20050196876A1Bioreactor/fermenter combinationsRadiation pyrometryProtein profilingFluorescence

The invention provides methods used to analyze the contents of a biological sample, such as blood serum, with cascade Raman sensing. A fluorescence producing nanoporous biosensor having probes that bind specifically to known analytes is contacted with a biological sample and one or more bound complexes coupled to the porous semiconductor structure are formed. The bound complexes are contacted with a Raman-active probe that binds specifically to the bound complexes and the biosensor is illuminated to generate fluorescent emissions from the biosensor. These fluorescent emissions generate Raman signals from the bound complexes. The Raman signals produced by the bound complexes are detected and the Raman signal associated with a bound protein-containing analyte is indicative of the presence of the protein-containing compound in the sample. The invention methods are useful to provide a protein profile of a patient sample. The invention also provides detection systems useful to practice the invention methods.

Owner:INTEL CORP

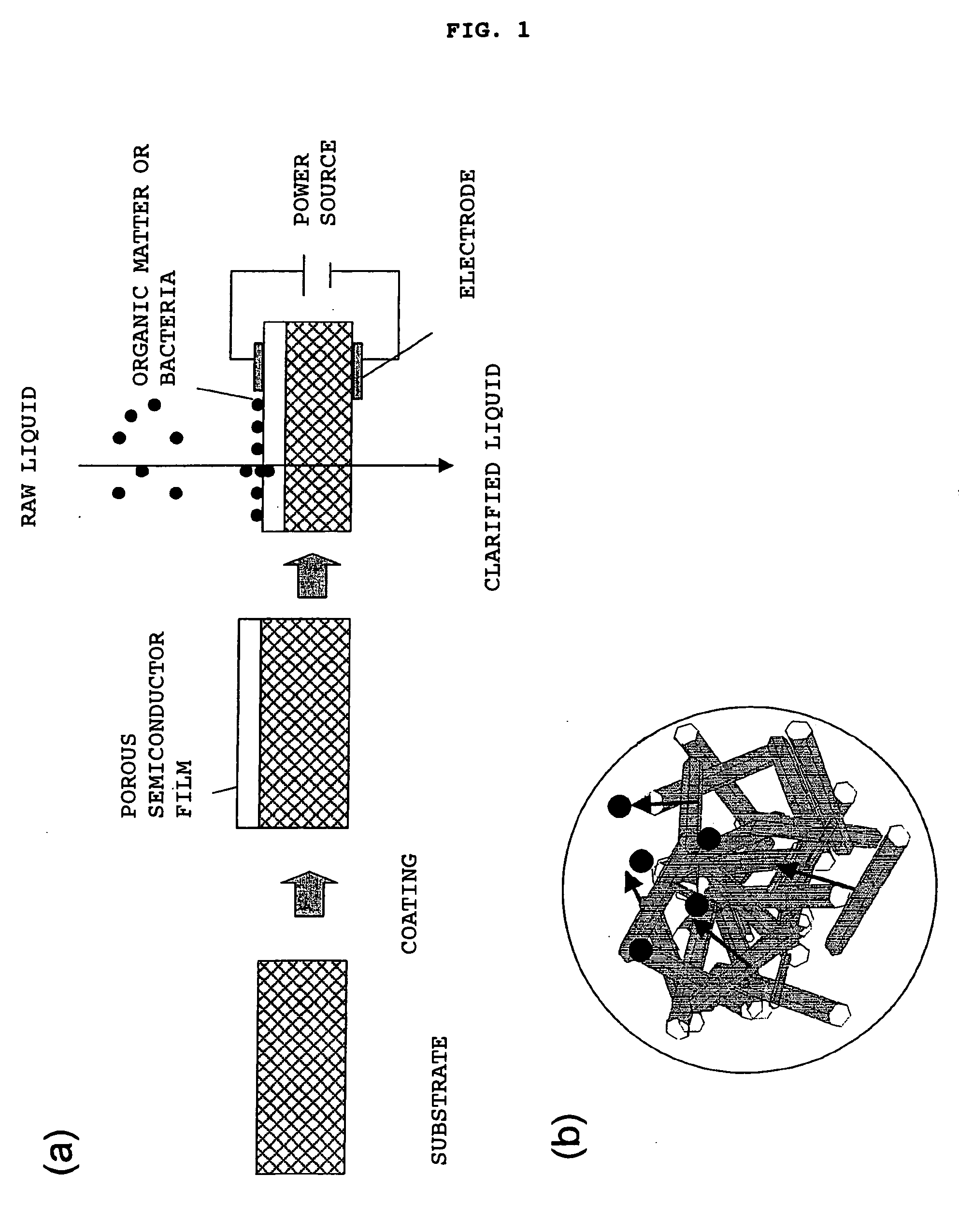

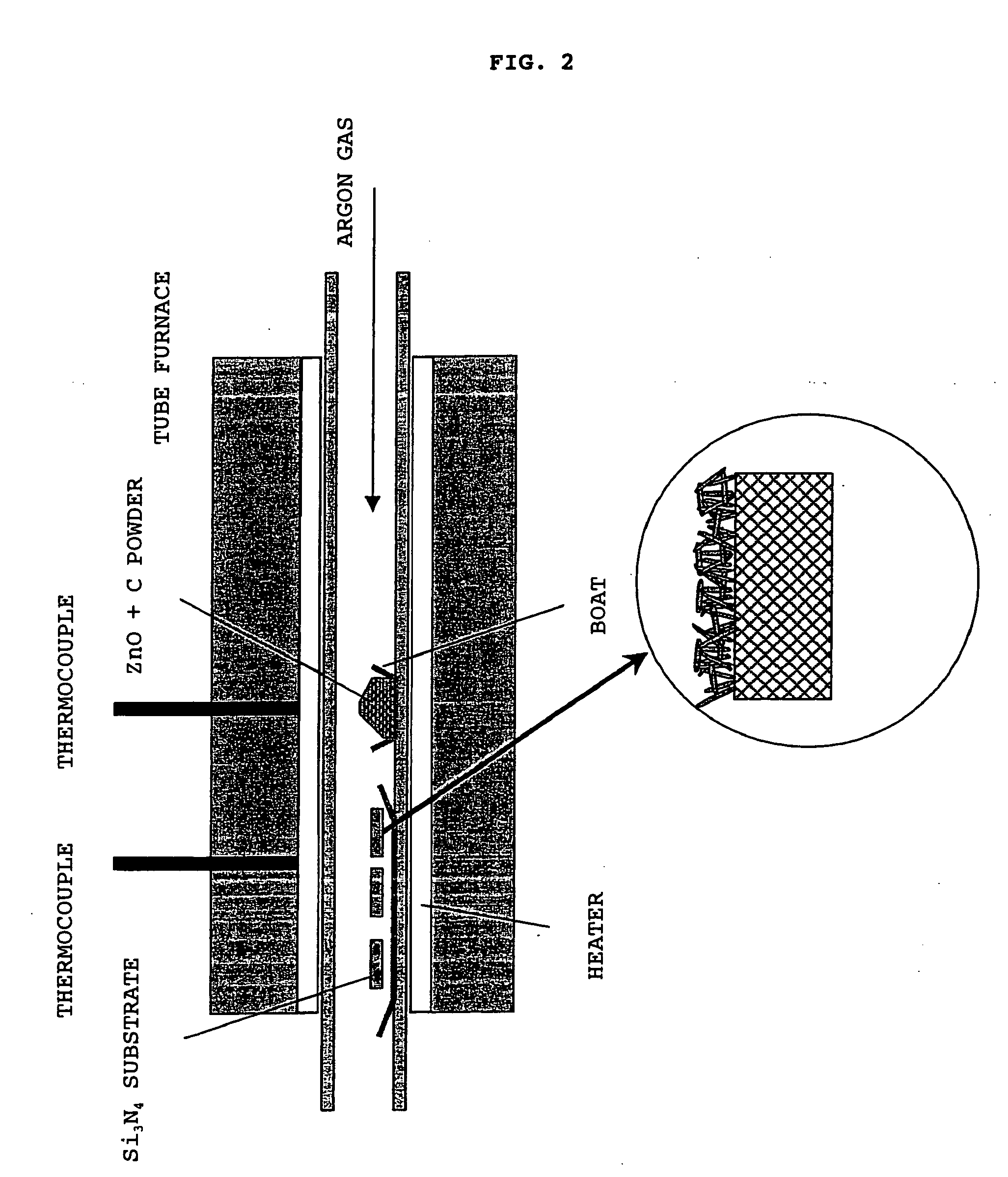

Porous semiconductor and process for producing the same

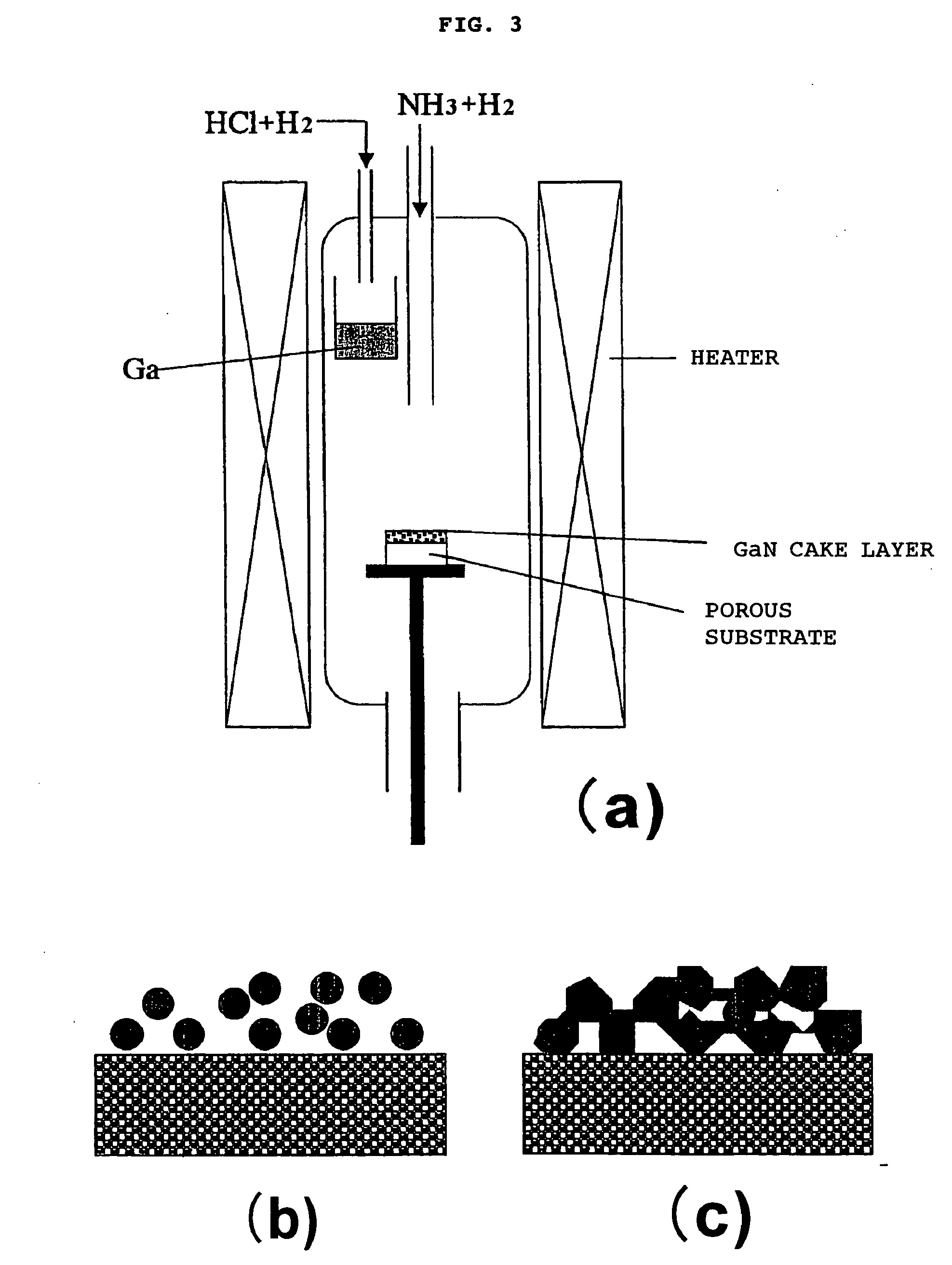

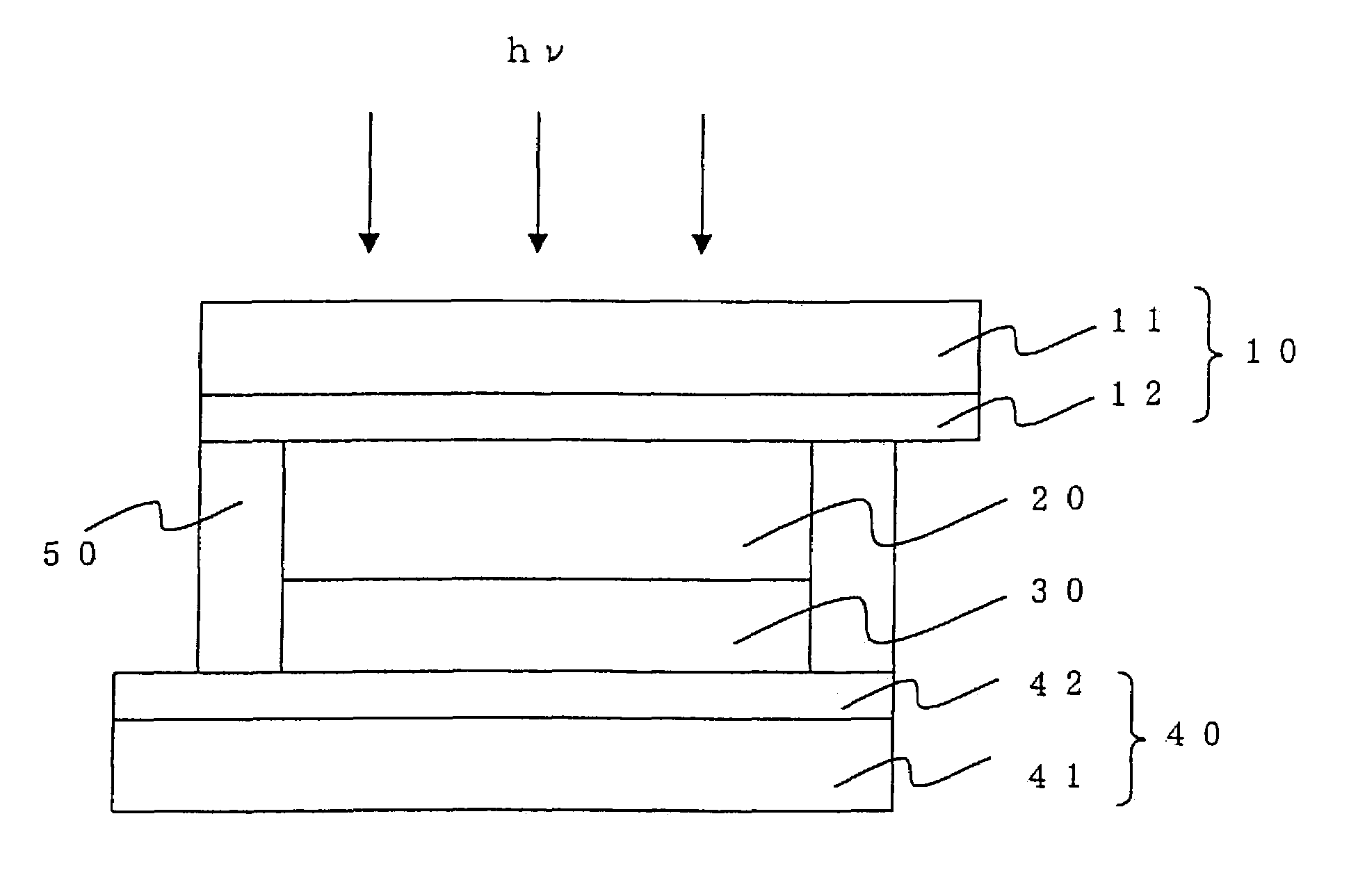

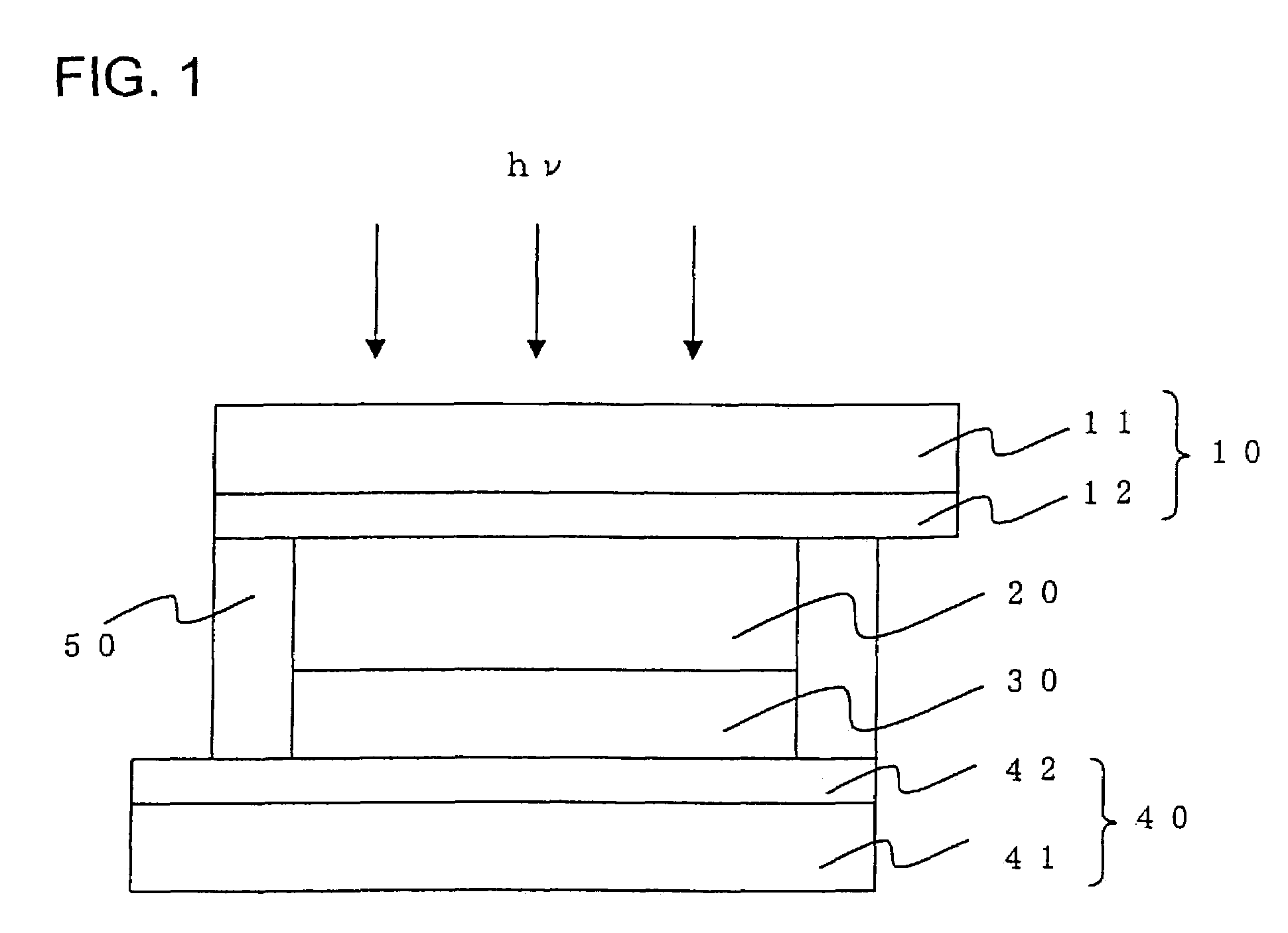

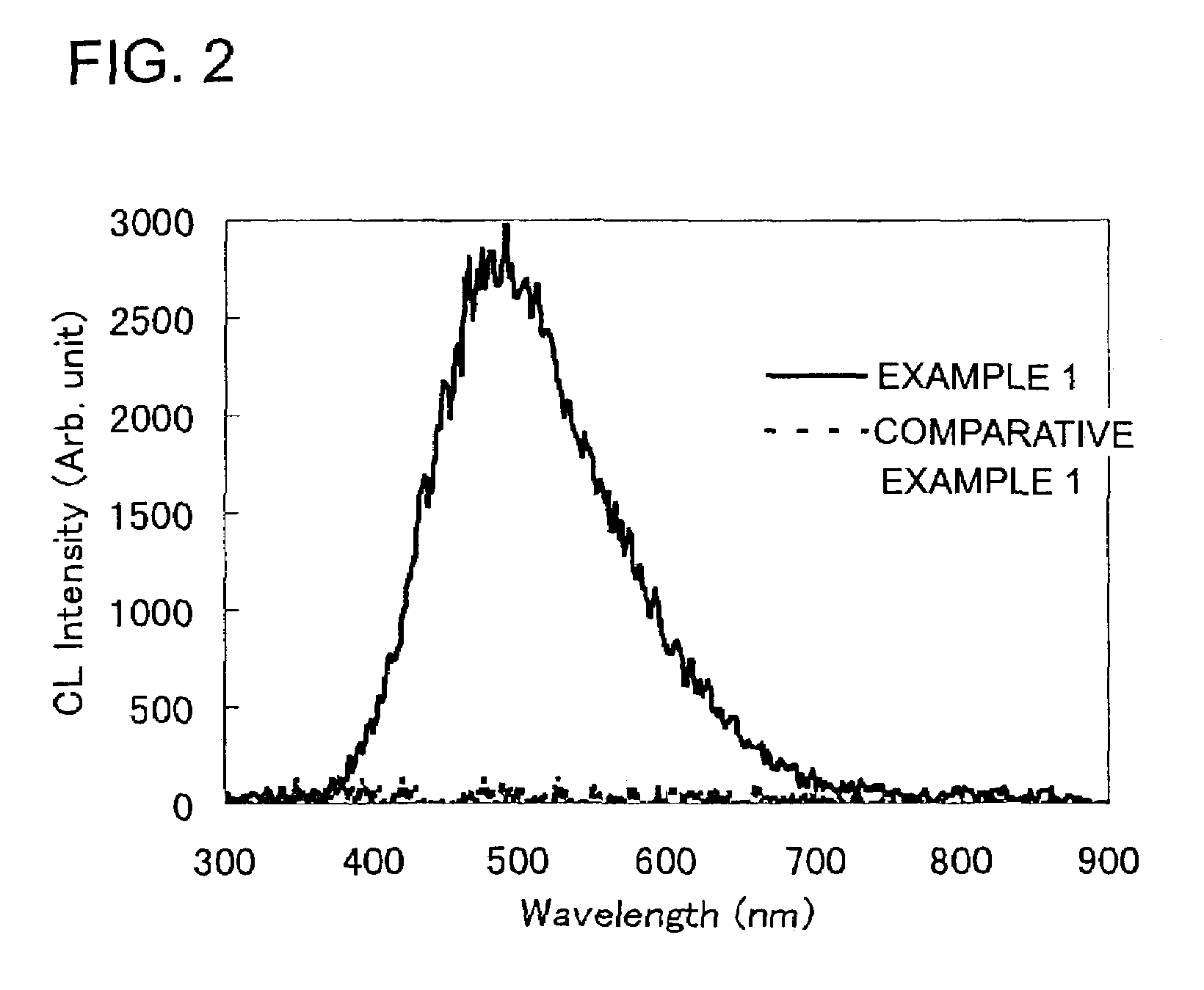

InactiveUS20050042743A1Increase brightnessLow costBioreactor/fermenter combinationsBiological substance pretreatmentsPorous substrateRare-earth element

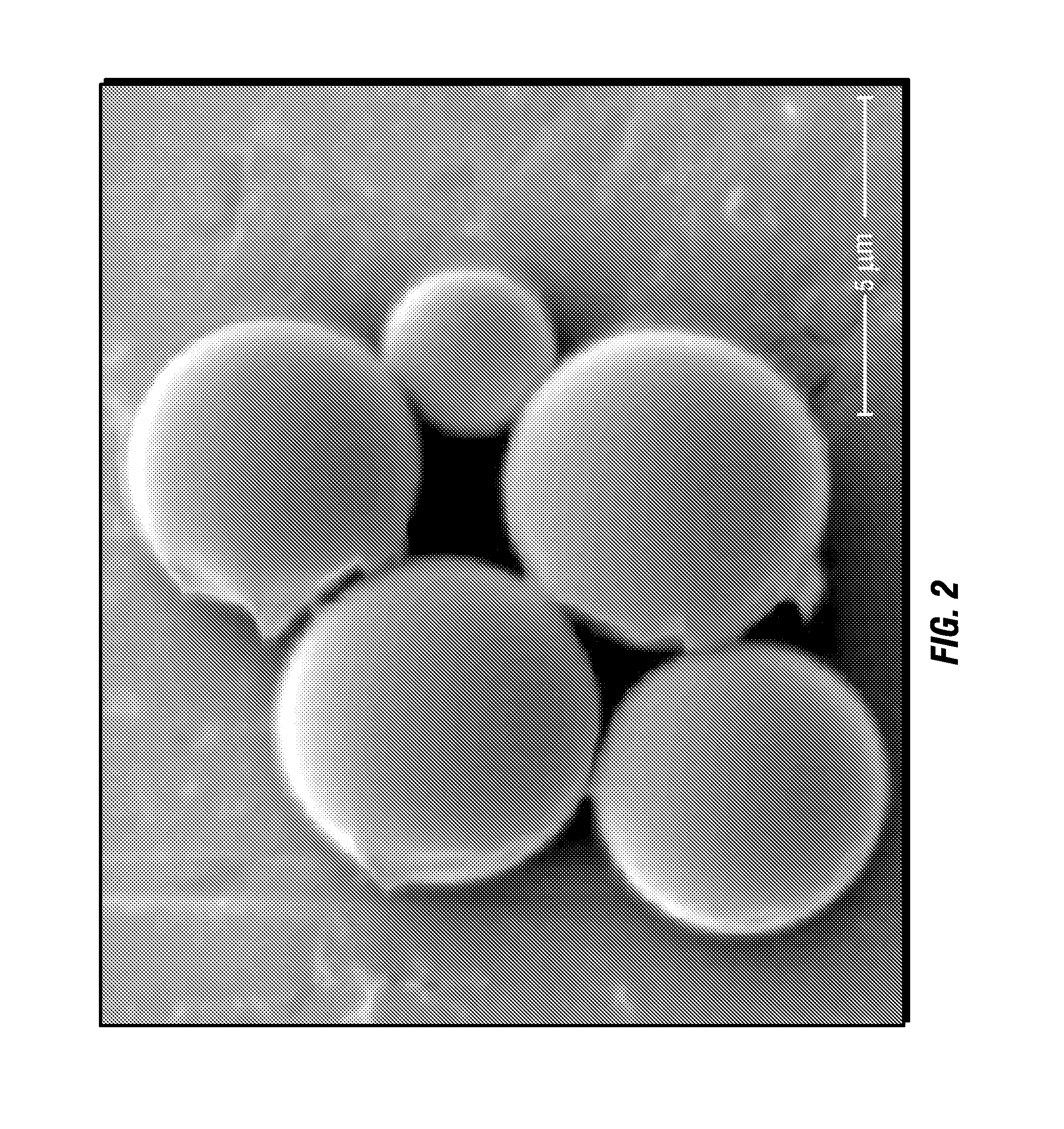

The present invention provides a filter with which organic matter, bacteria, viruses, and other harmful substances can be trapped, and the trapped material can be sterilized and decomposed, at low cost and extremely high efficiency. A porous ceramic or metal is used as a substrate, and a porous semiconductor composed of a semiconductor material having a light emitting function is formed in the interior or on the surface of this substrate. An electrode is provided to this product to serve as a filter, voltage is applied so that ultraviolet light is emitted while a fluid is being filtered, and any harmful substances are filtered and simultaneously sterilized and decomposed. The porous semiconductor layer is preferably composed of columns grown perpendicular to the substrate plane, and has the function of emitting ultraviolet light with a wavelength of 400 nm or less. The pores in the porous substrate column are through-holes perpendicular to the substrate plane, and the average size of these pores is preferably from 0.1 to 100 μm. The distal ends of the columns preferably have a pointed shape. To manufacture, a suspension of semiconductor particles having a light emitting function is filtered through the porous substrate serving as a filter medium so as to form a deposited layer of semiconductor particles on the porous substrate surface. A deposited layer of p-type semiconductor particles and a deposited layer of n-type semiconductor particles may also be formed so that these form a pn junction. Further, the present invention is characterized in that an insulating layer is formed on the top and bottom surfaces of the porous semiconductor layer, and semiconductor particles are dispersed in the insulating layer, with the bandgap of the semiconductor particles in the porous light emitting layer or the porous semiconductor layer being at least 3.2 eV, and being doped with gadolinium, which is the light emitting center. In addition, the porous semiconductor layer may be made of porous silicon nitride composed of columnar Si3N4 particles with an average aspect ratio of at least 3 and an oxide-based binder phase containing at least one of rare earth element, and emit visible light or ultraviolet light.

Owner:SUMITOMO ELECTRIC IND LTD

Photovoltaic cell including porous semiconductor layer, method of manufacturing the same and solar cell

InactiveUS7202412B2Jsc is improvedHigh yieldLight-sensitive devicesDeferred-action cellsTransport layerPeak value

A photovoltaic cell comprises: an anode electrode including a conductive support and a porous semiconductor layer; a photosensitive dye; a charge transport layer; and a counter electrode support, wherein the anode electrode has the property of causing cathode luminescence having a luminous peak wavelength in a visible region and shows a haze rate H of 60% or more at a wavelength in the visible region.

Owner:SHARP KK

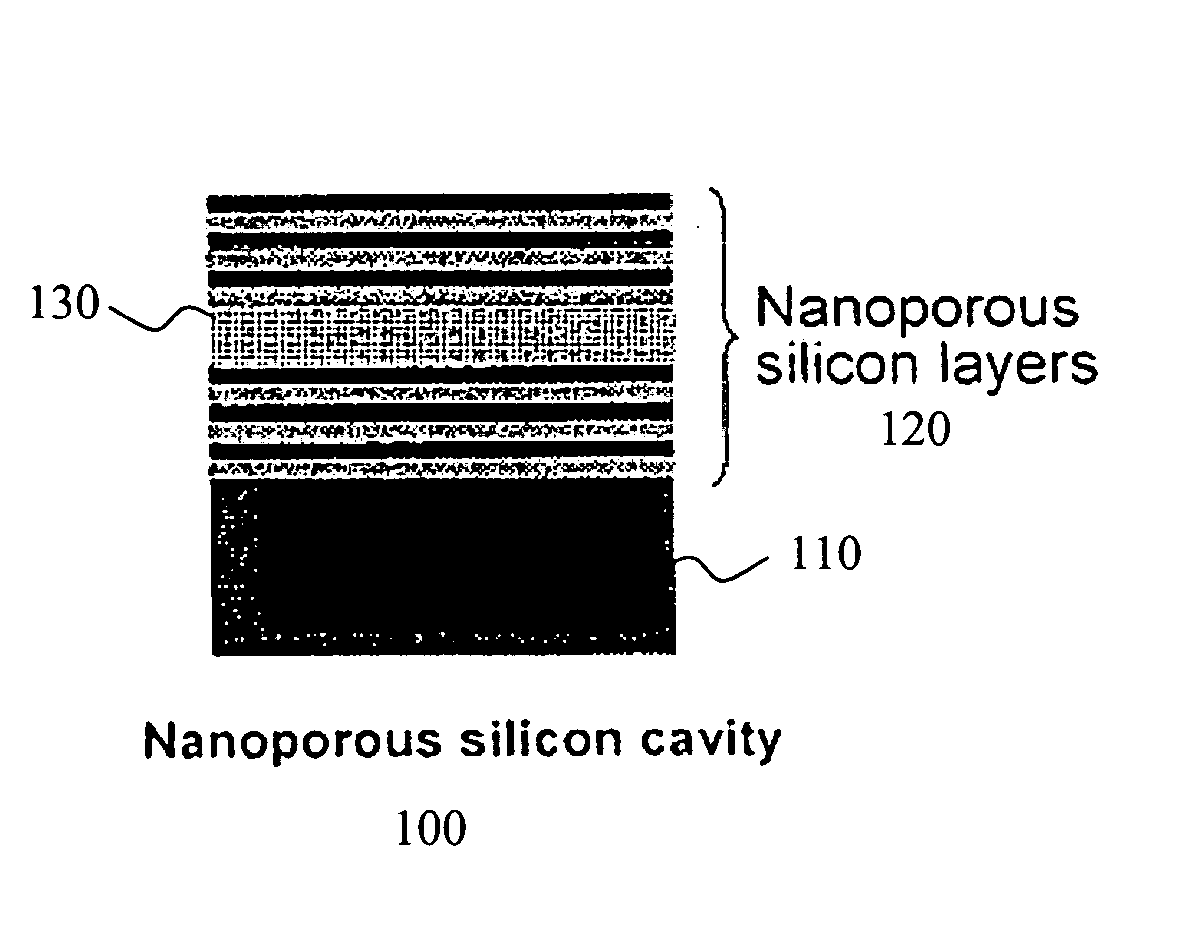

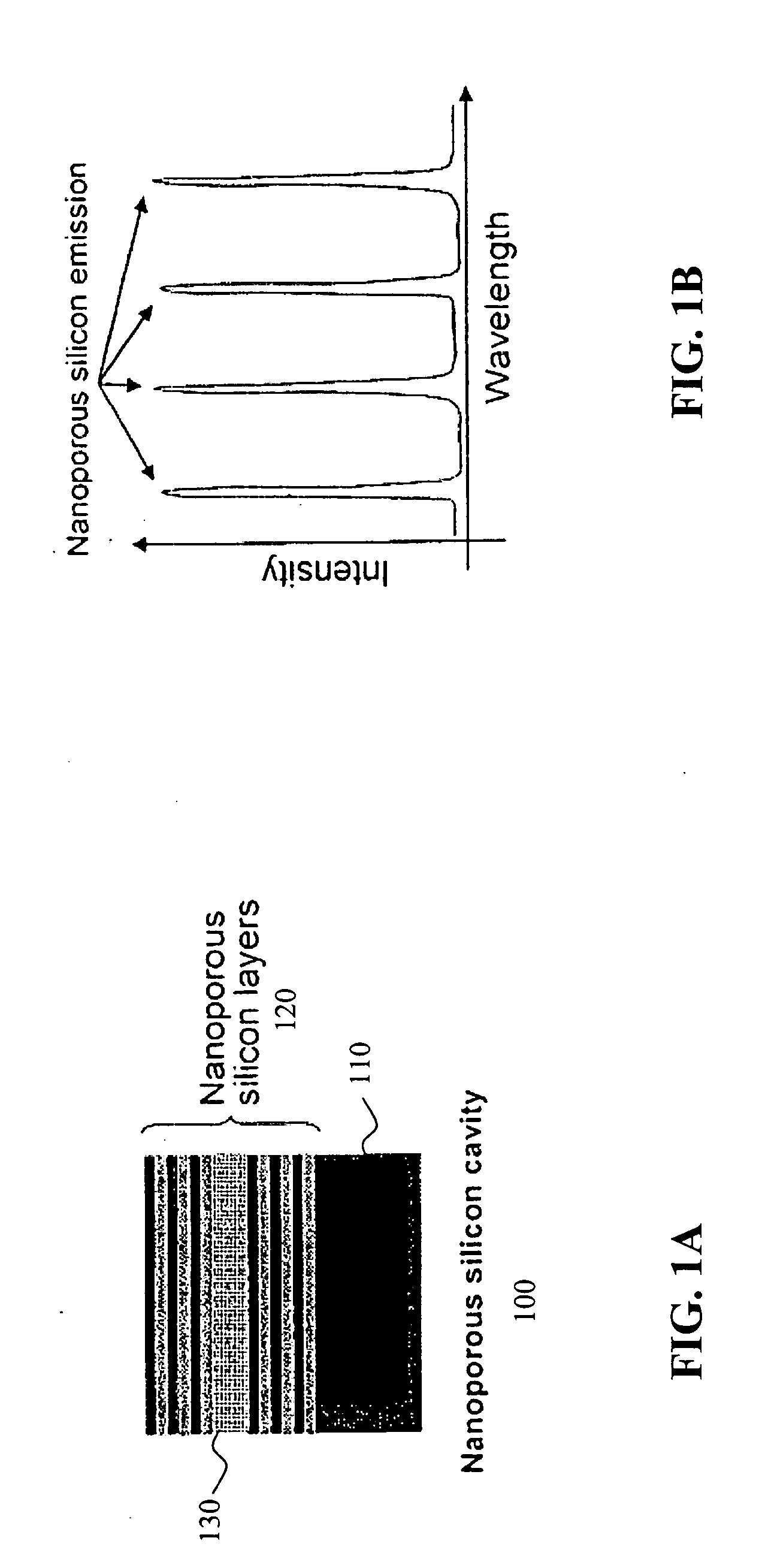

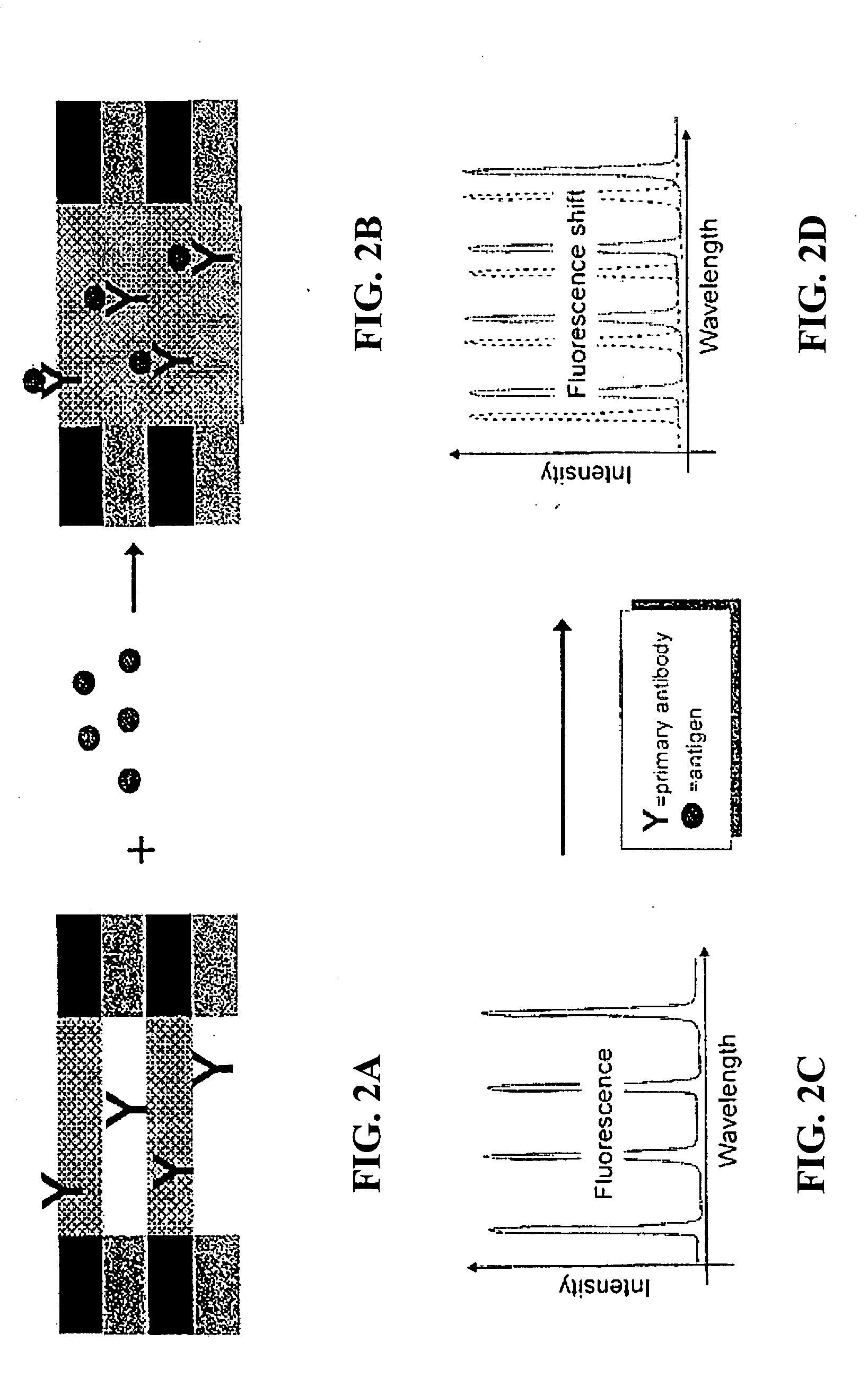

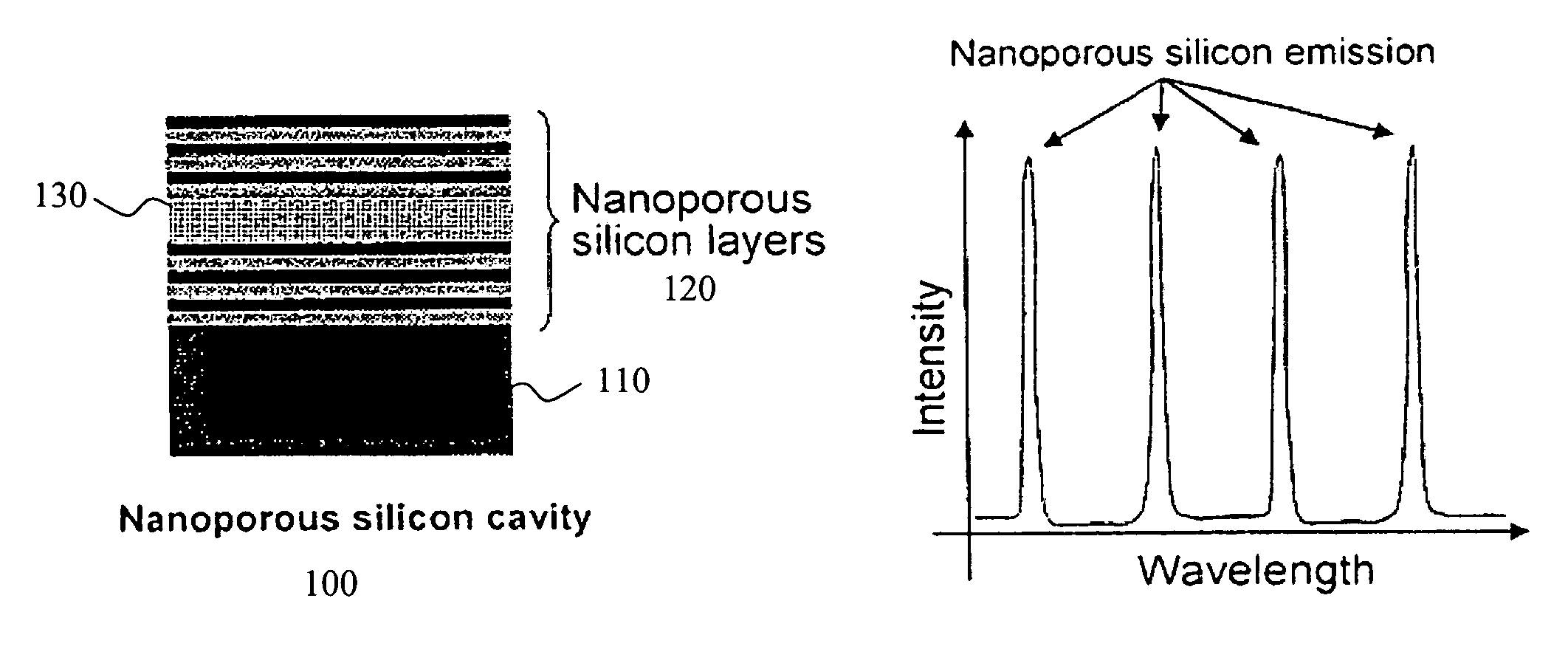

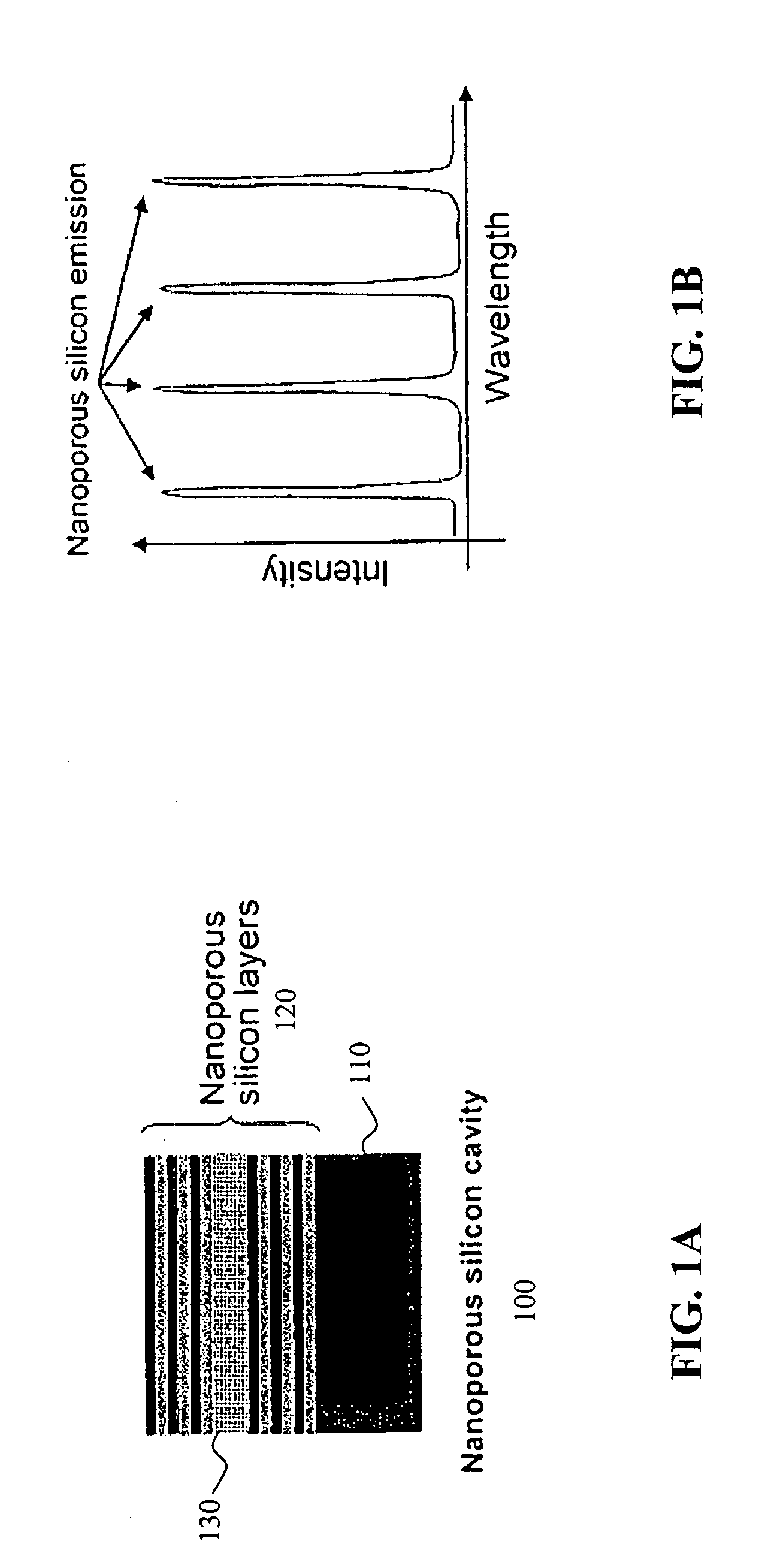

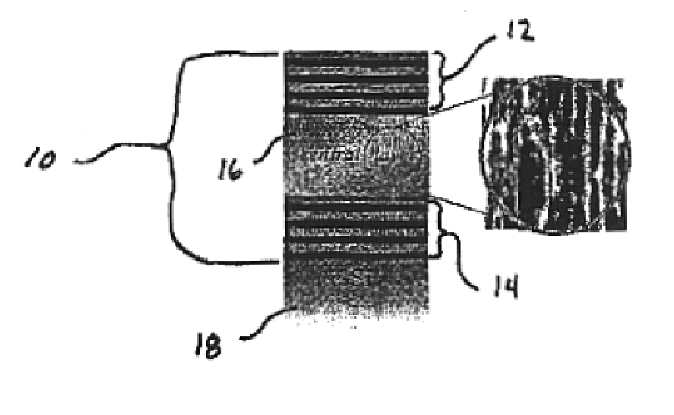

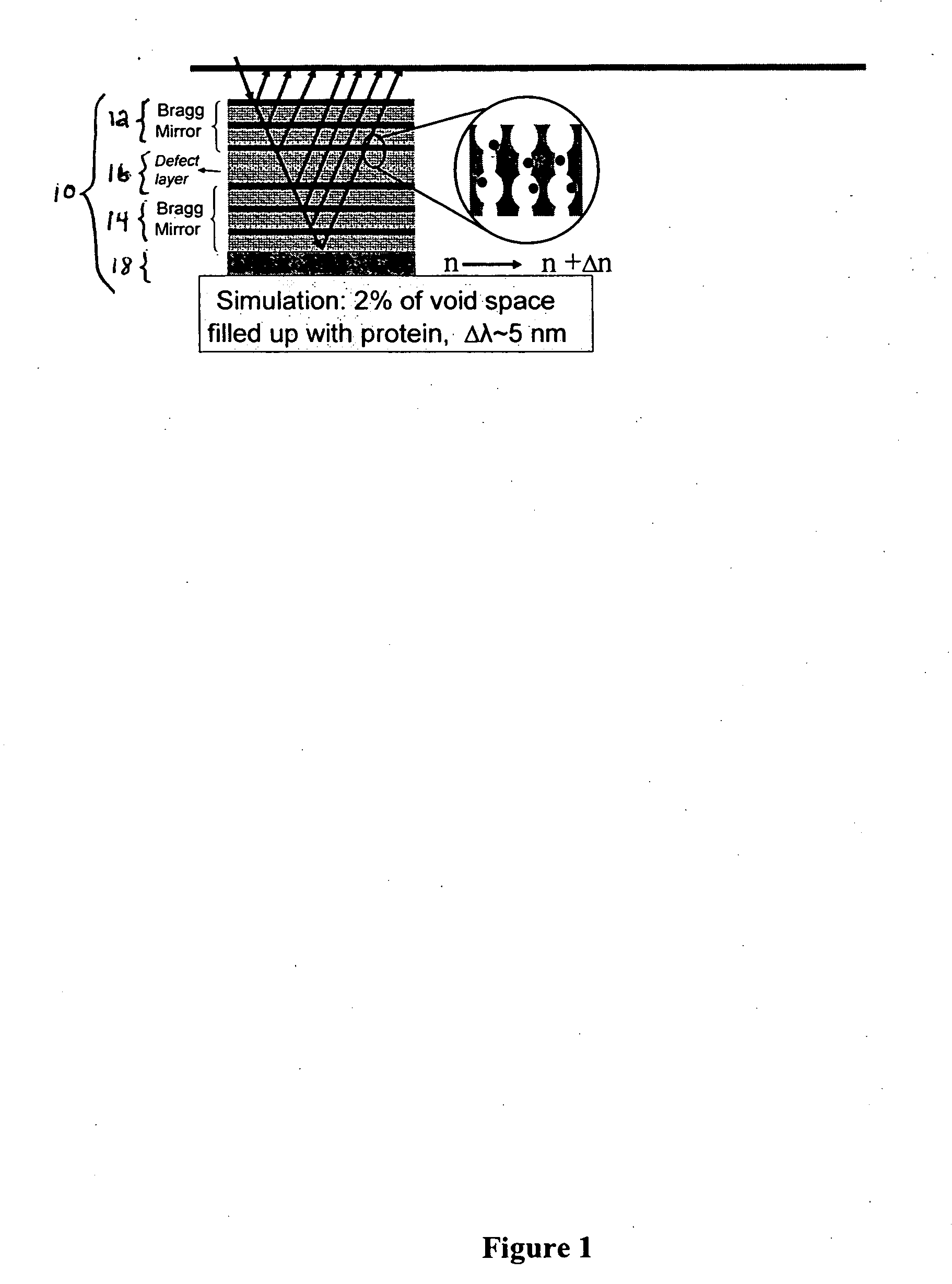

Microcavity biosensor and uses thereof

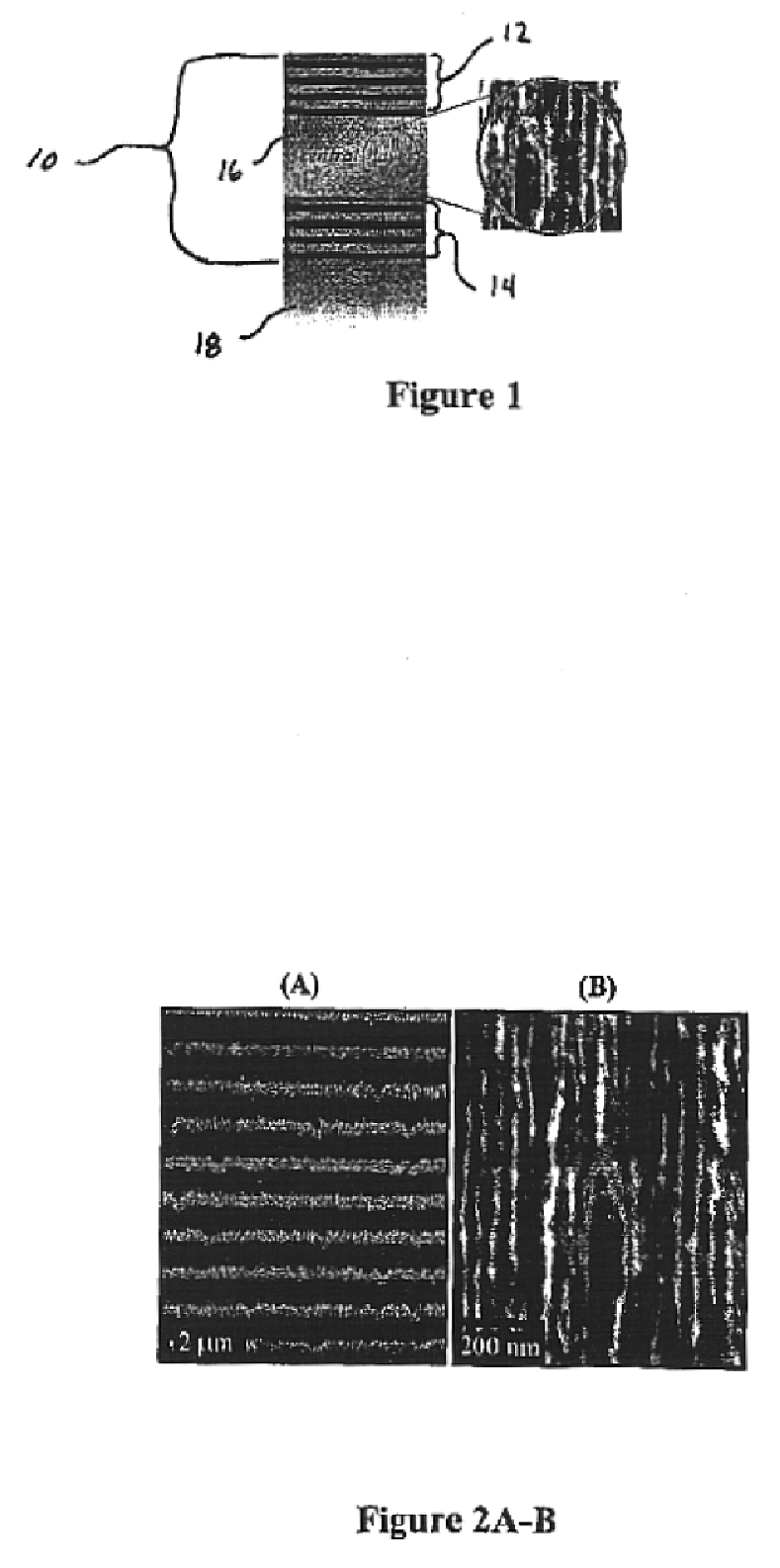

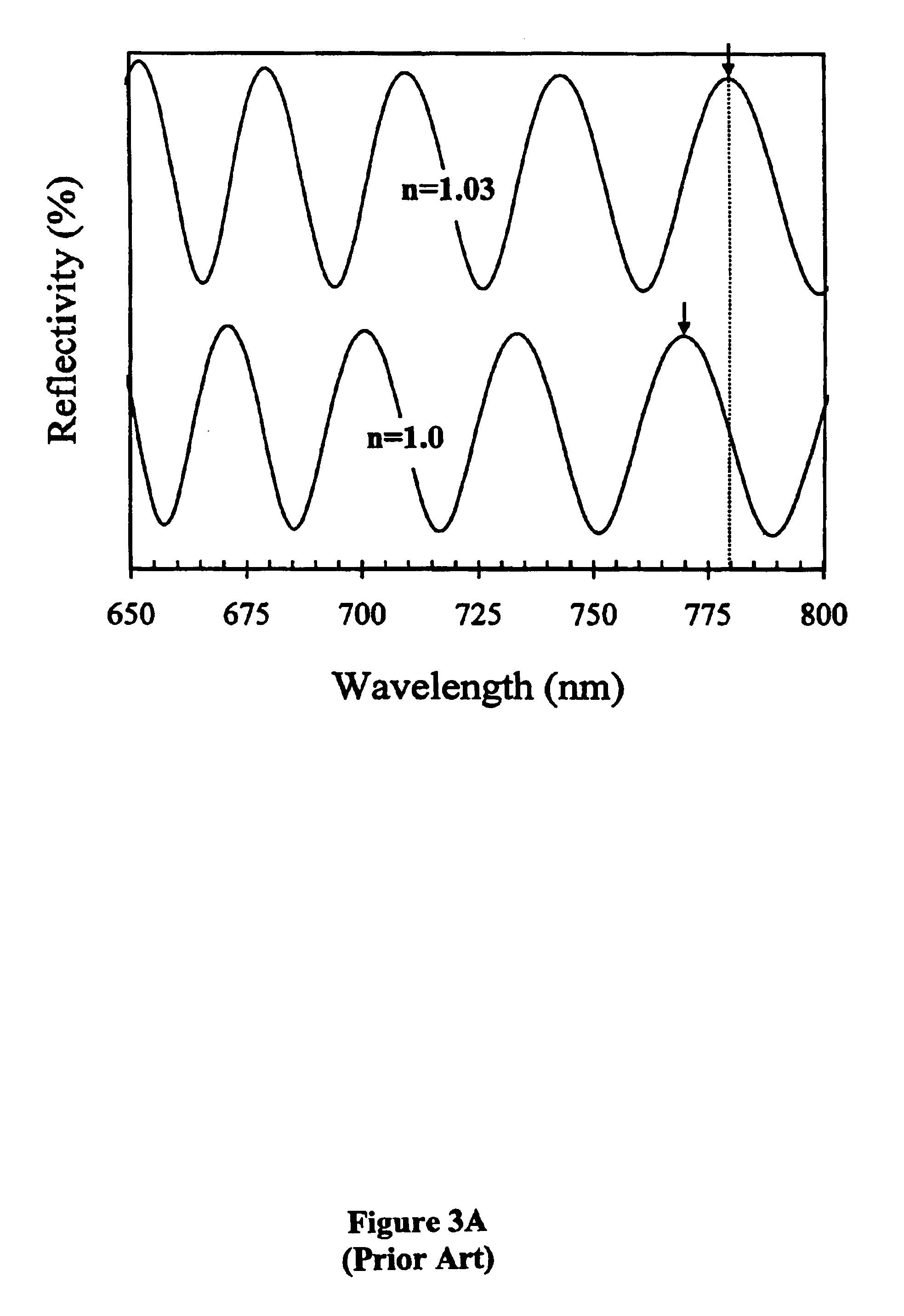

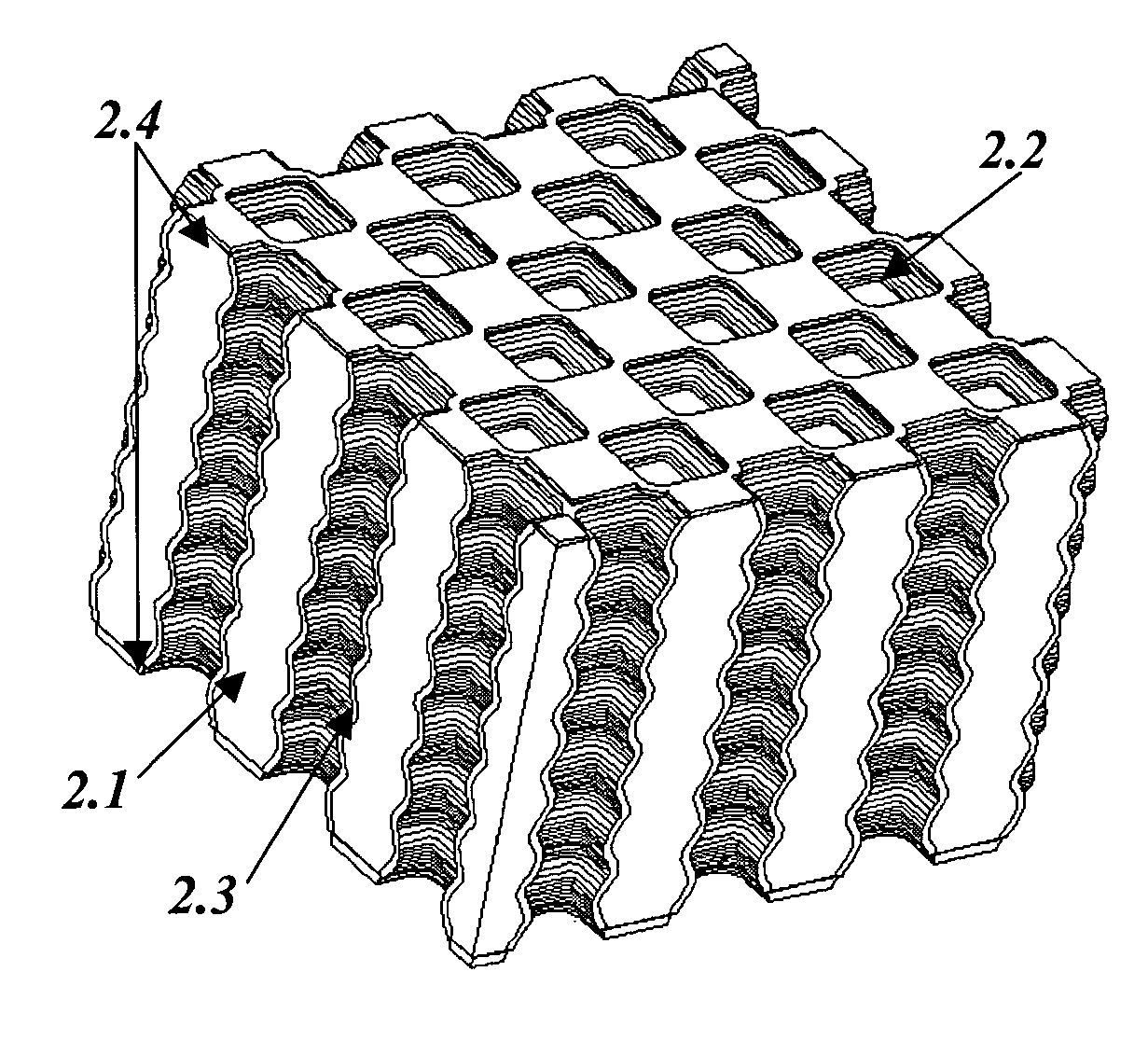

InactiveUS7226733B2High sensitivityLarge signalImmobilised enzymesBioreactor/fermenter combinationsPorous semiconductorsCentral layer

A biological sensor which includes: a porous semiconductor structure comprising a central layer interposed between upper and lower layers, each of the upper and lower layers including strata of alternating porosity; and one or more probes coupled to the porous semiconductor structure, the one or more probes binding to a target molecule, whereby a detectable change occurs in a refractive index of the biological sensor upon binding of the one or more probes to the target molecule. Methods of making the biological sensor and methods of using the same are disclosed, as is a detection device which includes such a biological sensor.

Owner:UNIVERSITY OF ROCHESTER

Method of manufacturing a spectral filter for green and longer wavelengths

InactiveUS20040134879A1Low level of lossIncrease the sectionElectrolysis componentsPaper/cardboard articlesBandpass filteringElectrochemistry

A method of manufacture for optical spectral filters with omnidirectional properties in the visible, near IR, mid IR and / or far IR (infrared) spectral ranges is based on the formation of large arrays of coherently modulated waveguides by electrochemical etching of a semiconductor wafer to form a pore array. Further processing of said porous semiconductor wafer optimizes the filtering properties of such a material. The method of filter manufacturing is large scale compatible and economically favorable. The resulting exemplary non-limiting illustrative filters are stable, do not degrade over time, do not exhibit material delamination problems and offer superior transmittance for use as bandpass, band blocking and narrow-bandpass filters. Such filters are useful for a wide variety of applications including but not limited to spectroscopy, optical communications, astronomy and sensing.

Owner:LAKE SHORE CRYOTRONICS INC

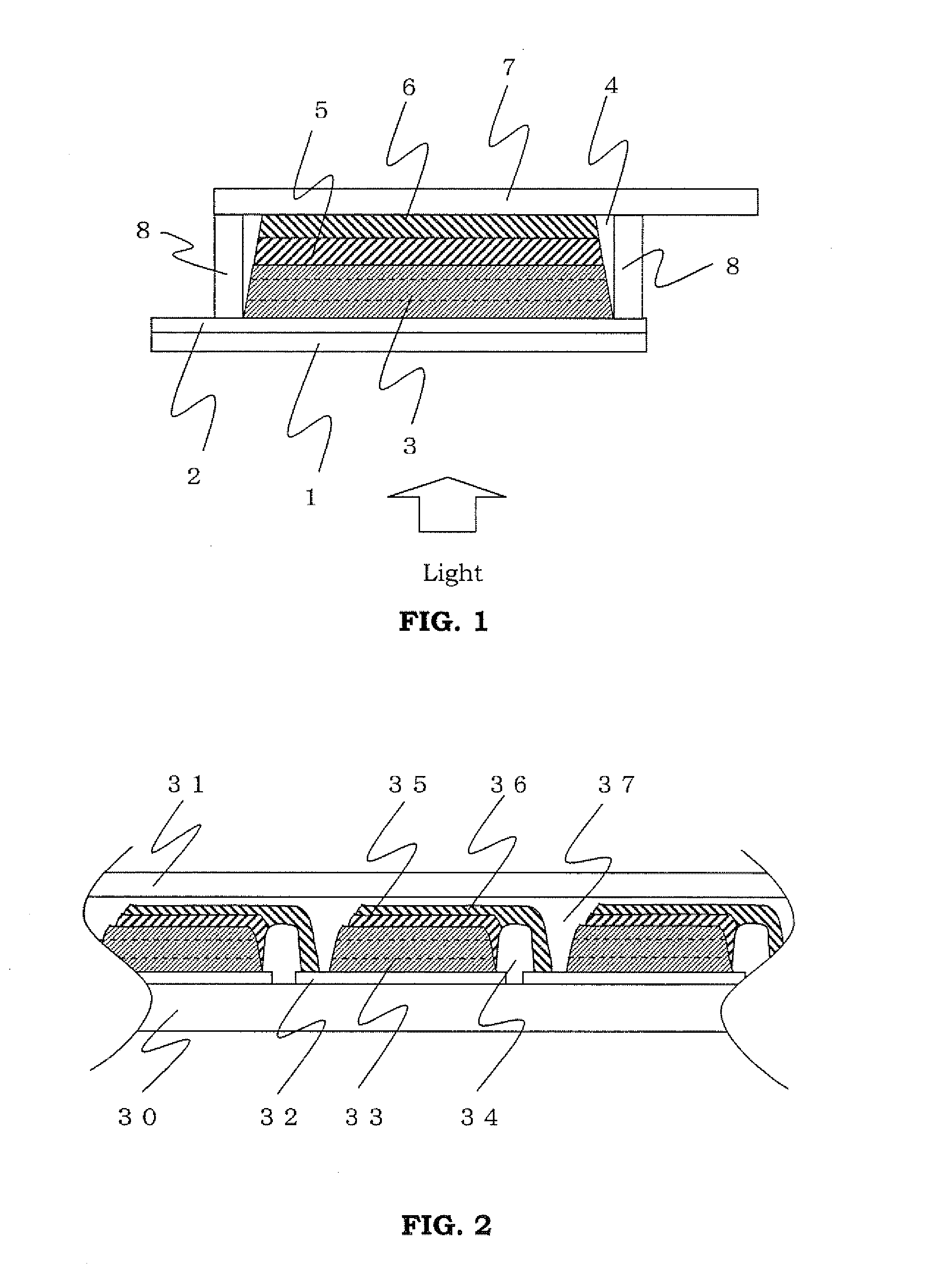

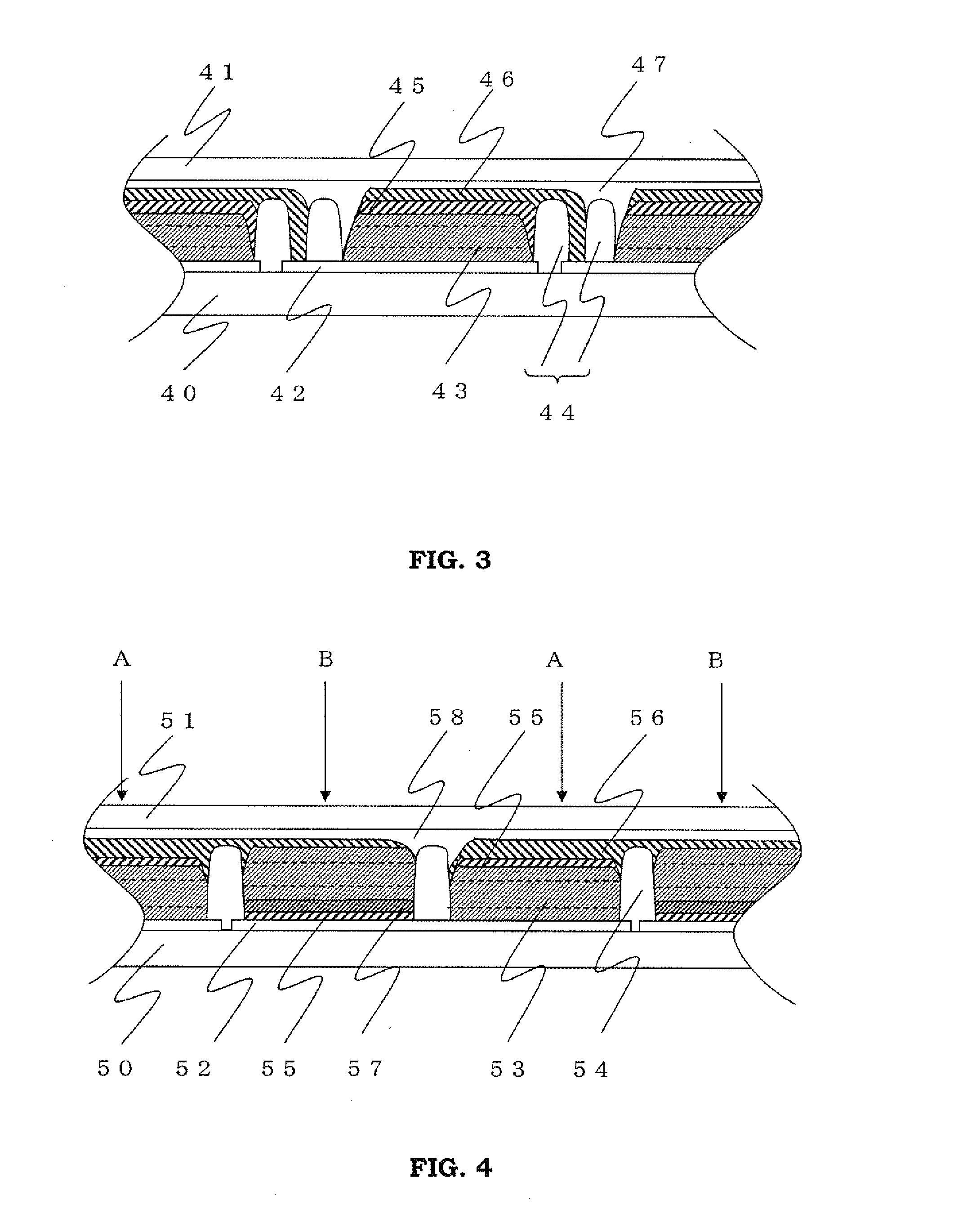

Dye sensitized solar cell and dye-sensitized solar cell module

InactiveUS20100012166A1Low costImprove performancePV power plantsCell component detailsCharge carrierPhotoelectric conversion

A dye-sensitized solar cell formed by layering a conductive layer; a photoelectric conversion layer in which a dye is adsorbed in a porous semiconductor layer and the layer is filled with a carrier transporting material; and a counter electrode including only a counter electrode conductive layer or including a catalyst layer and a counter electrode conductive layer on a support made of a light transmitting material,in which the photoelectric conversion layer is brought into contact with the counter electrode; the porous semiconductor layer forming the photoelectric conversion layer has two or more layers with different light scattering properties; and the two or more porous semiconductor layers are layered in an order of from a layer with lower light scattering property to a layer with higher light scattering property from a light receiving face side of the dye-sensitized solar cell.

Owner:SHARP KK

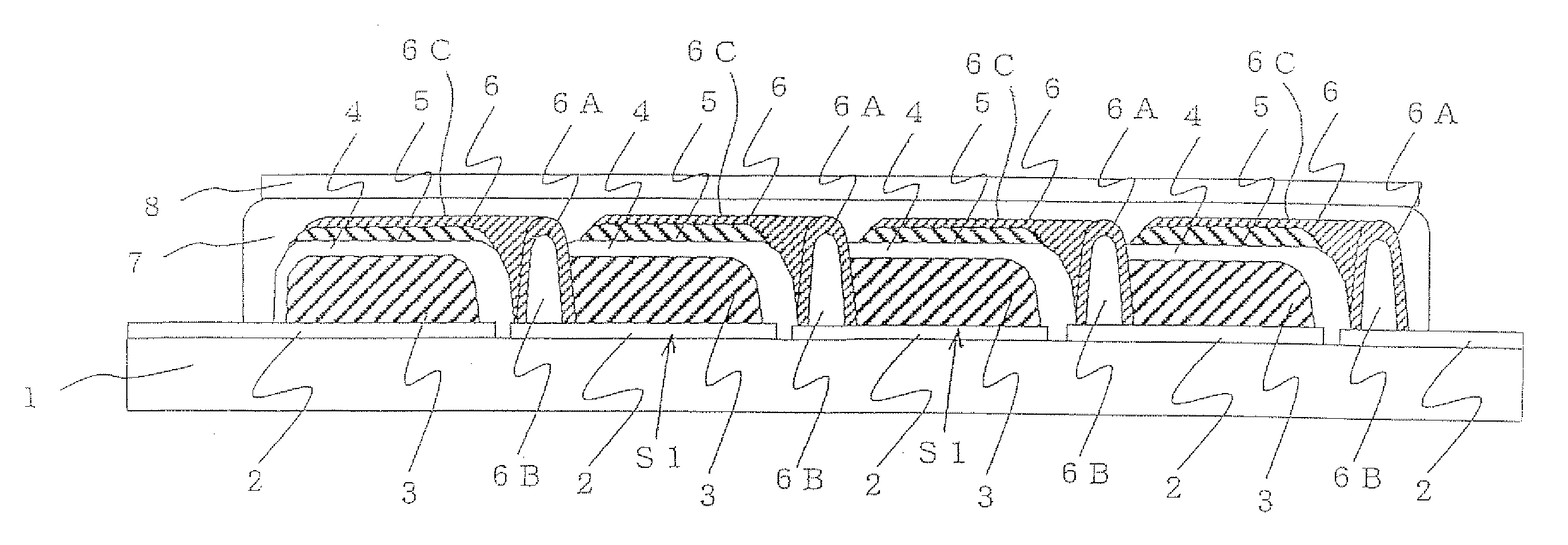

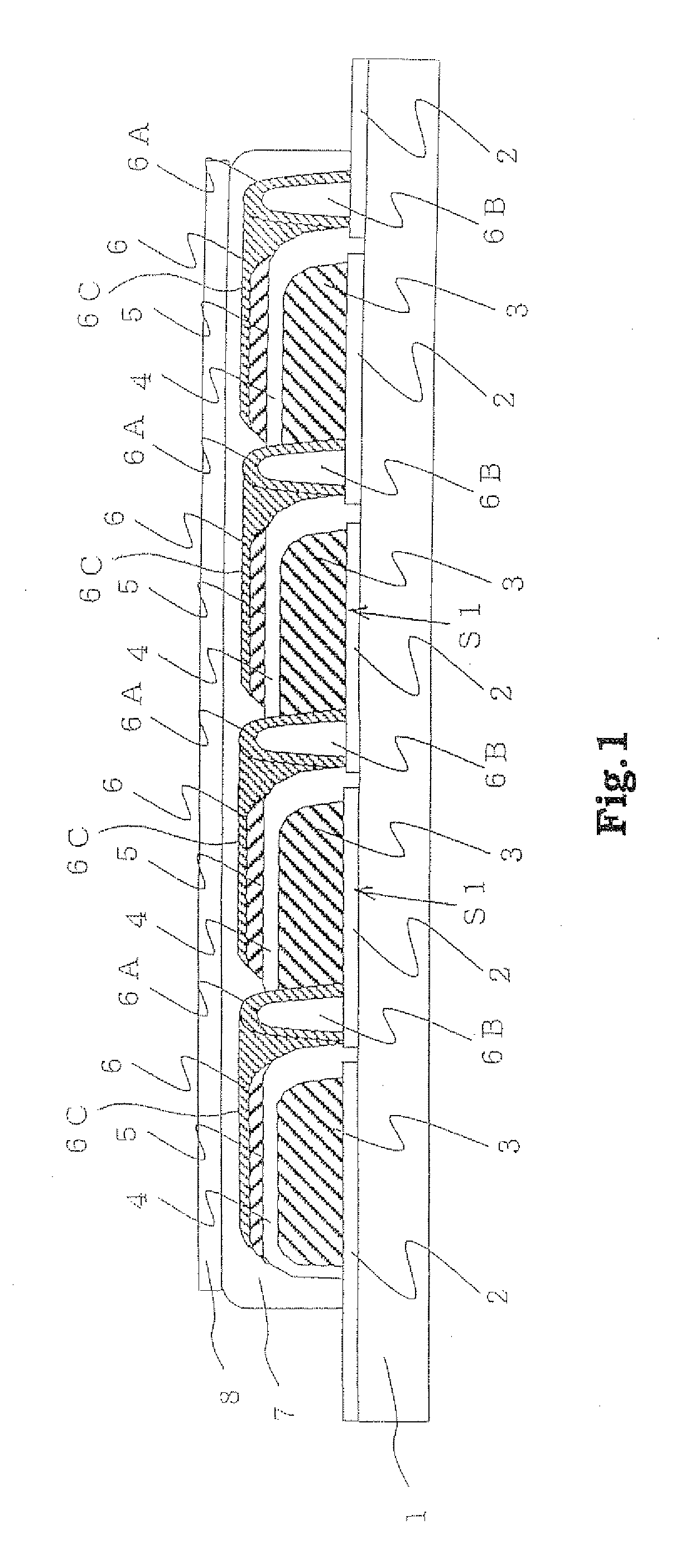

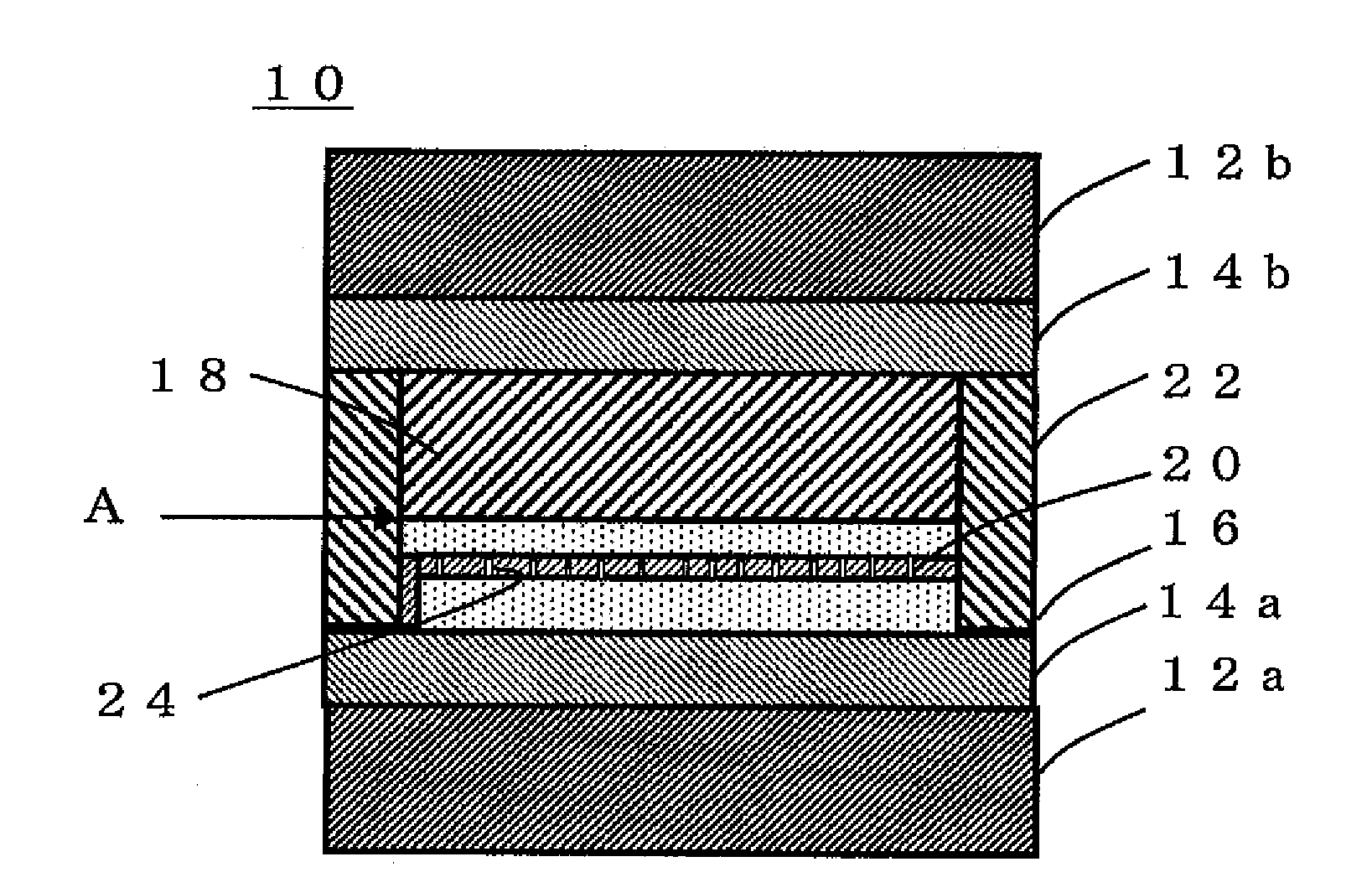

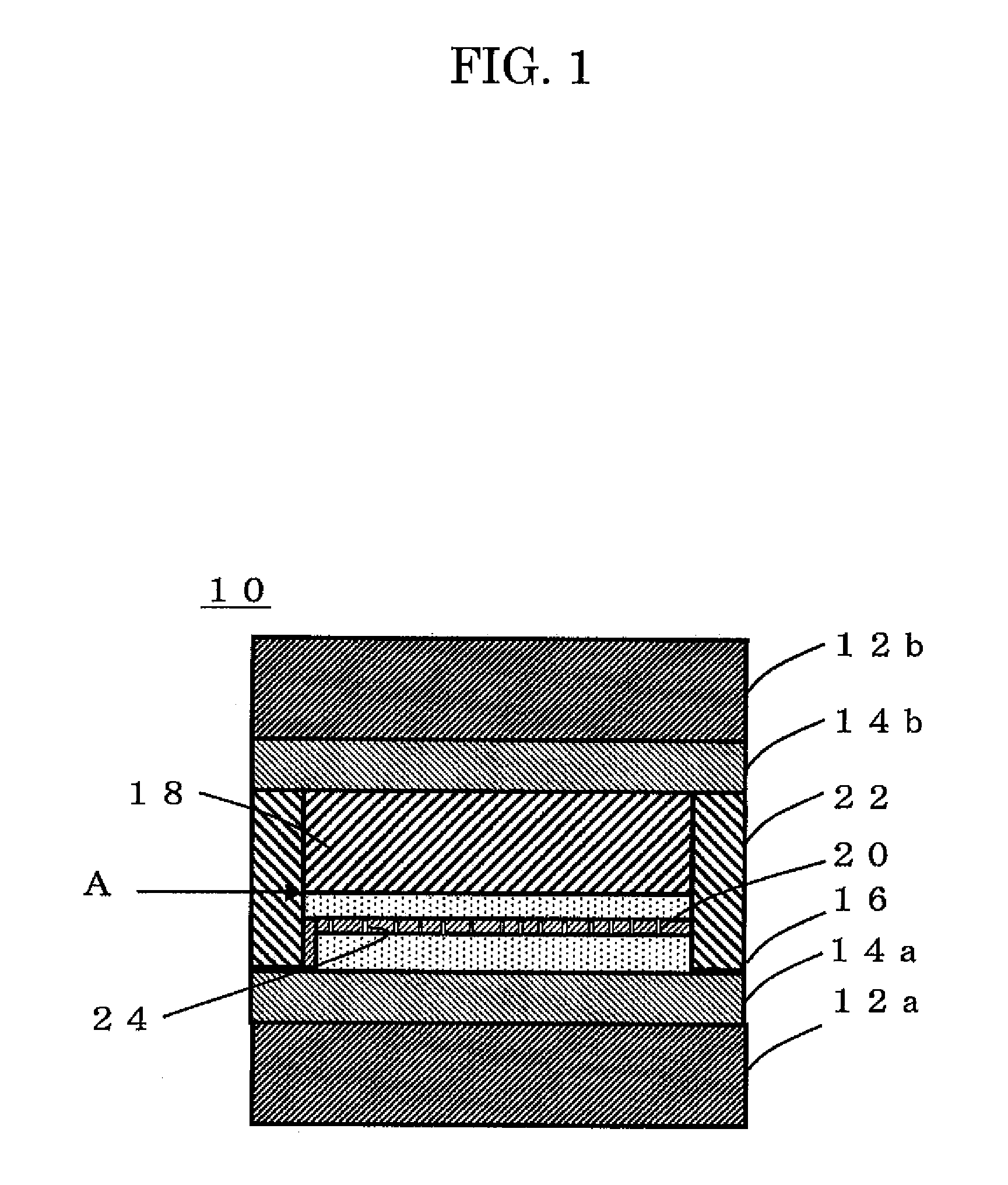

Thin-film semiconductor device and method of manufacturing the same

InactiveUS6972215B2Cheap to prepareImprove efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringPorous semiconductors

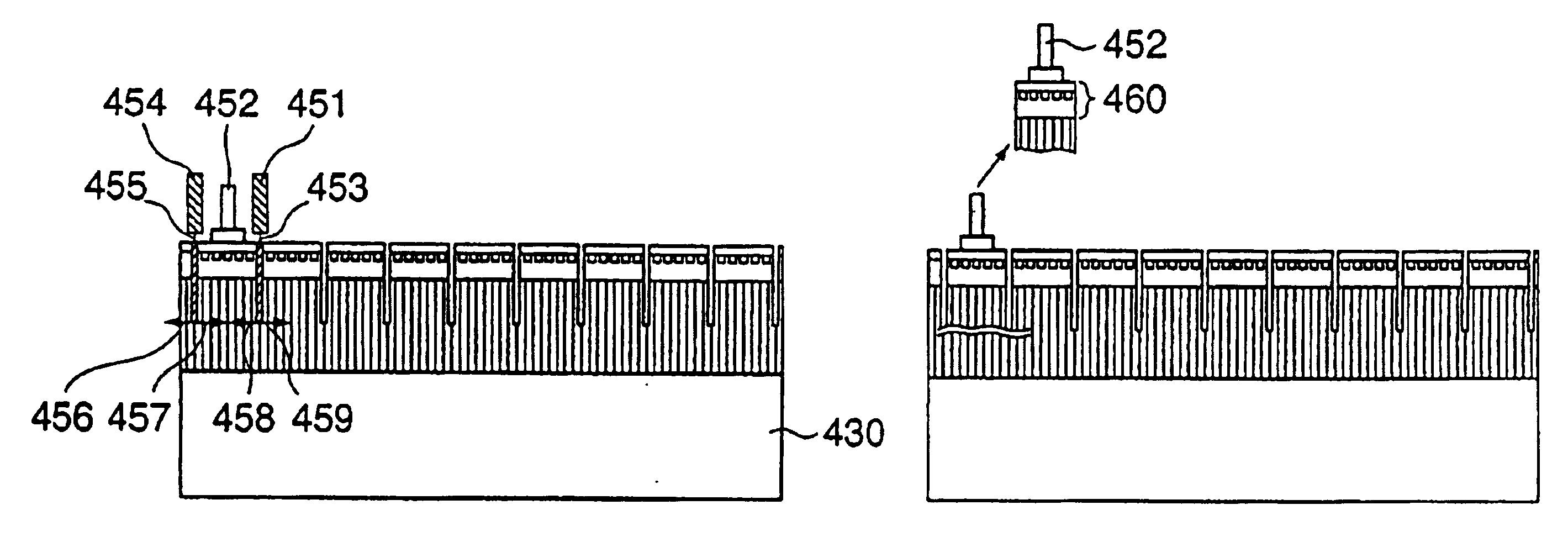

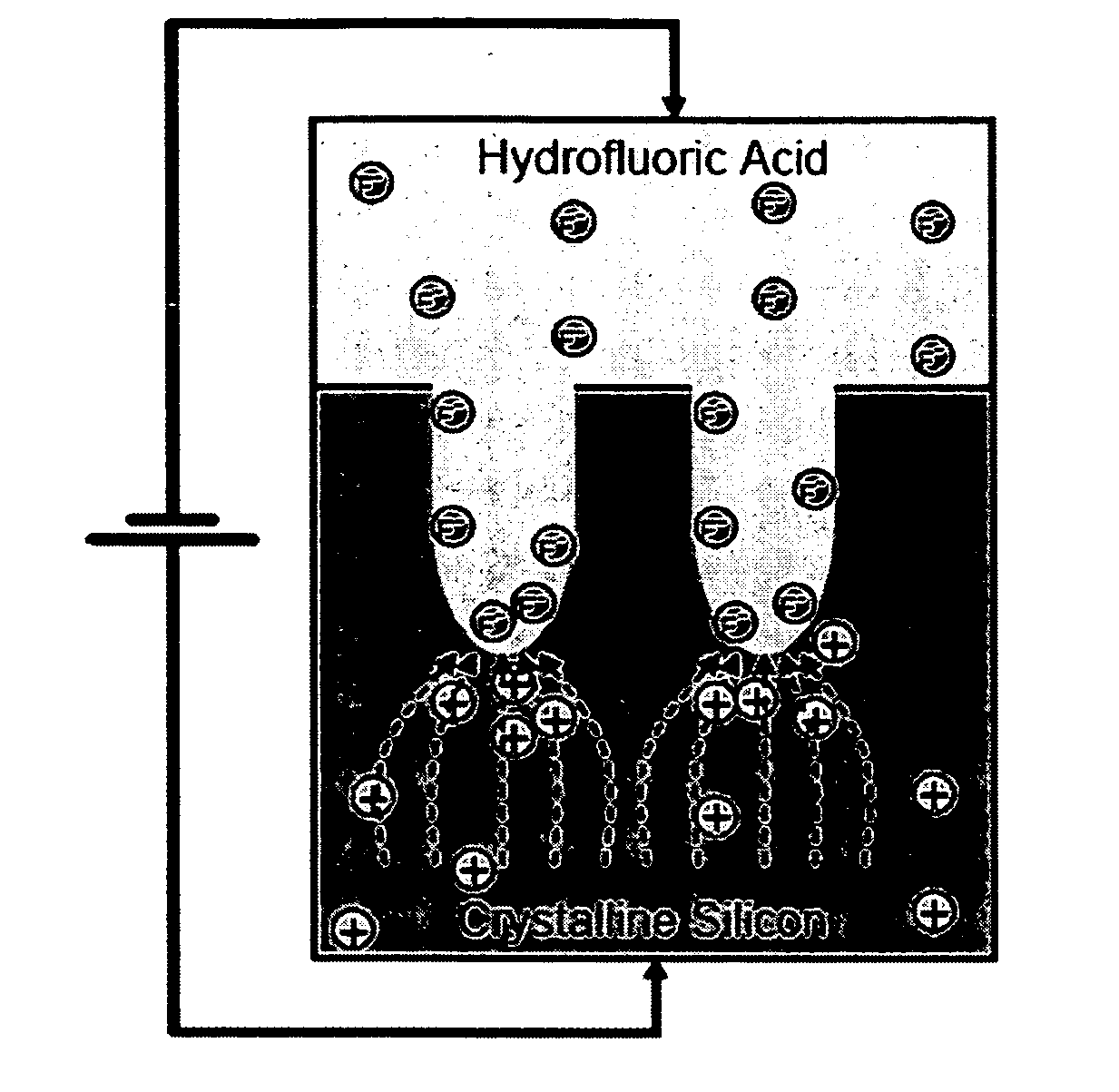

A semiconductor device is manufactured using the method including the steps of anodizing a semiconductor substrate to form a porous semiconductor layer on a semiconductor region of the semiconductor substrate; forming a non-porous semiconductor layer on the porous semiconductor layer; forming a semiconductor element and / or semiconductor integrated circuit in the non-porous semiconductor layer; forming kerfs from a surface side of the non-porous semiconductor layer toward the semiconductor region; and applying a pressure of a fluid to the porous semiconductor layer such that the desired region of the semiconductor element and / or semiconductor integrated circuit is separated from the semiconductor substrate.

Owner:CANON KK

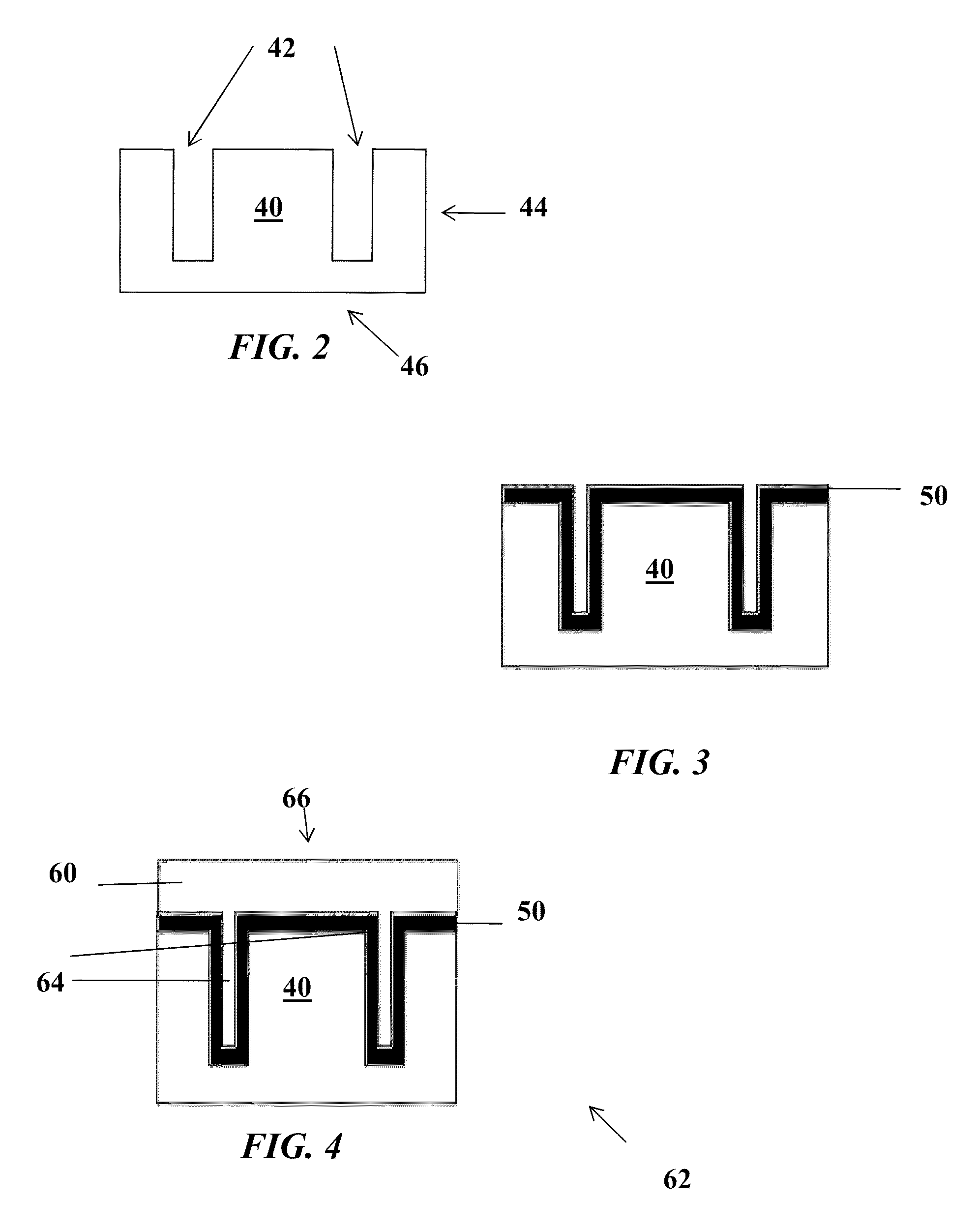

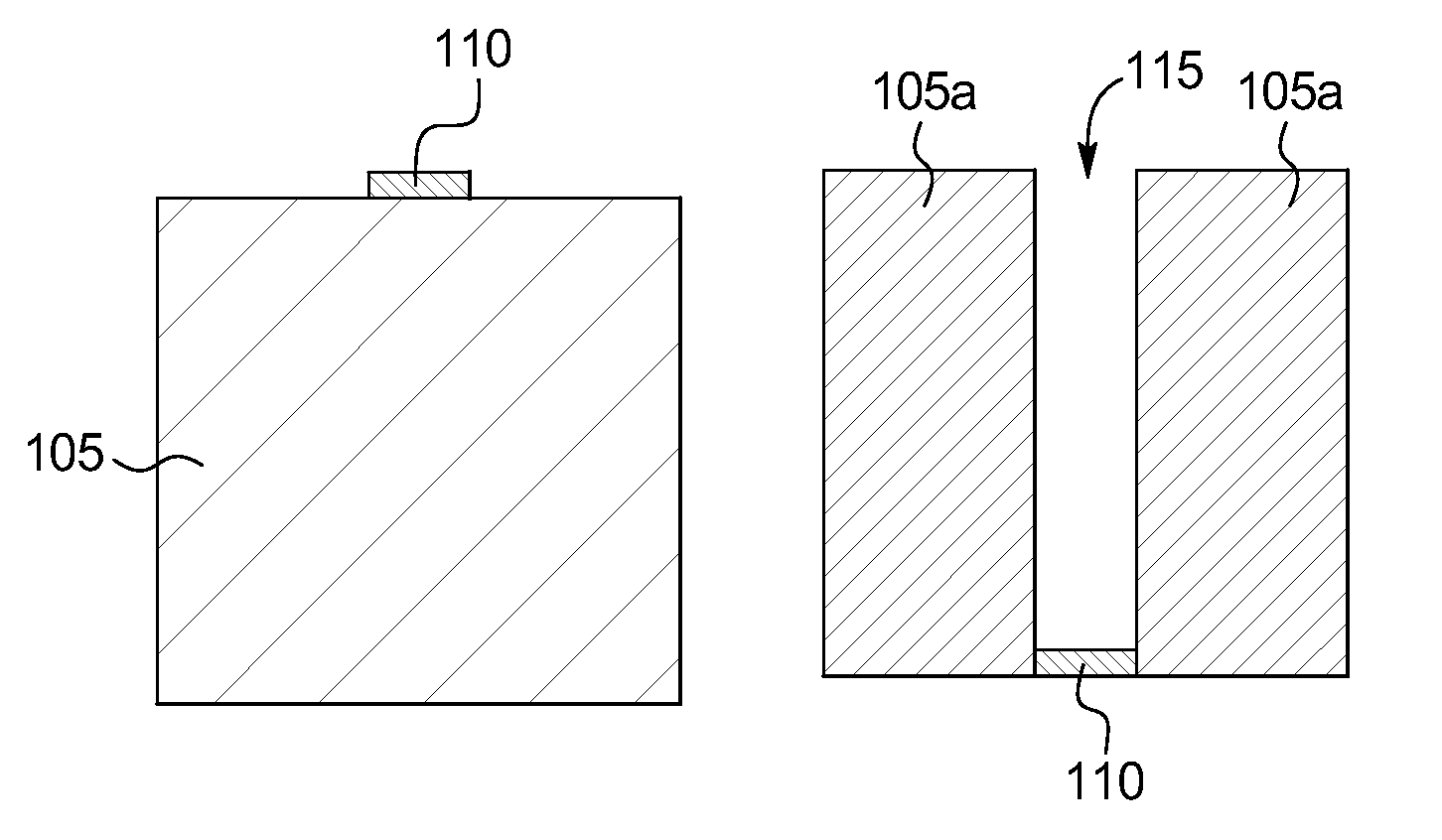

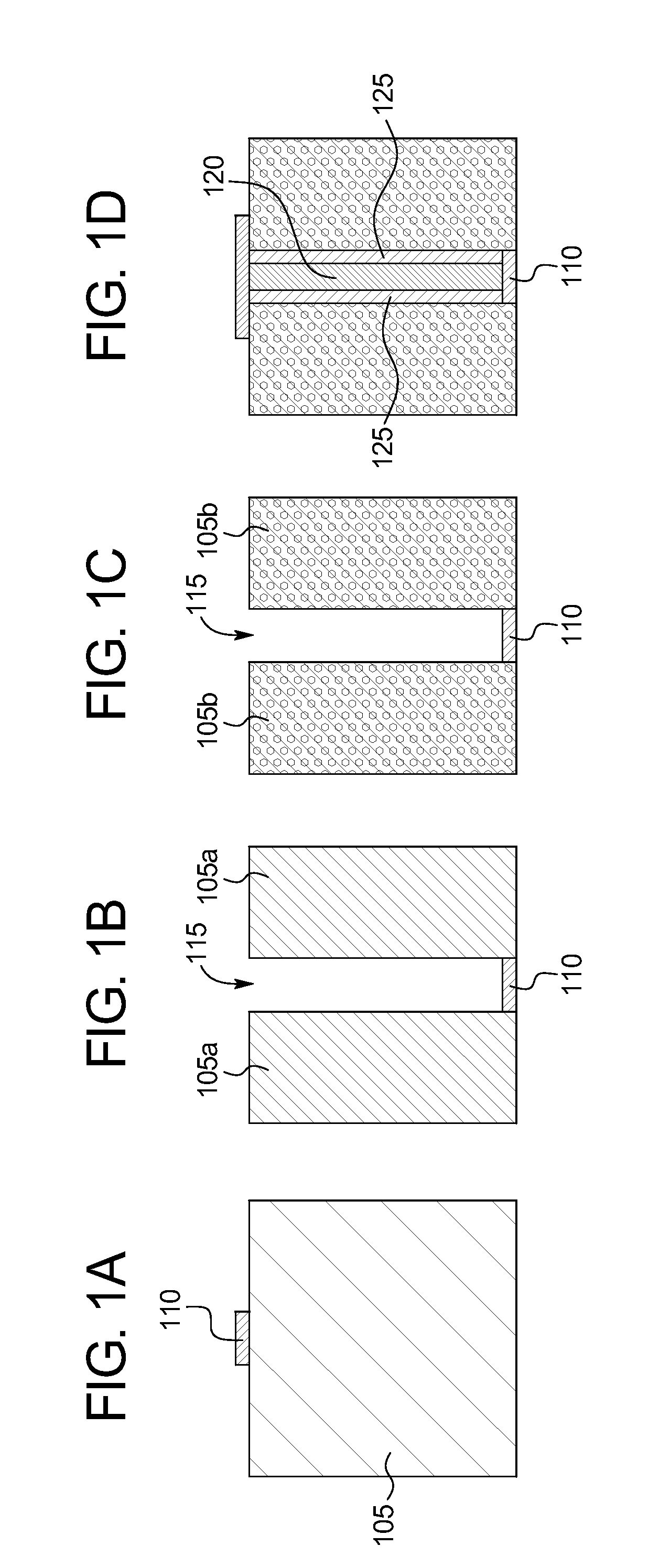

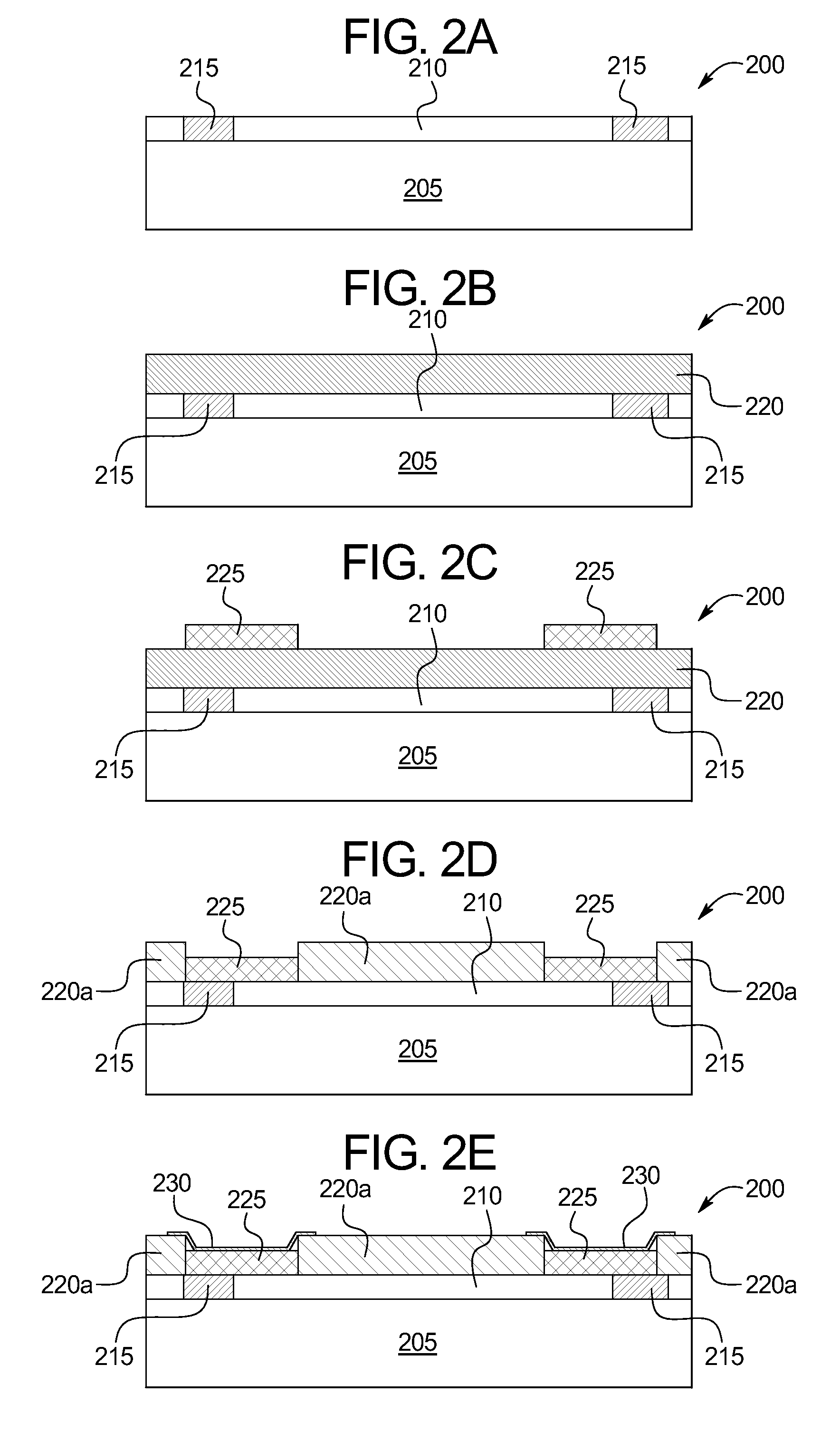

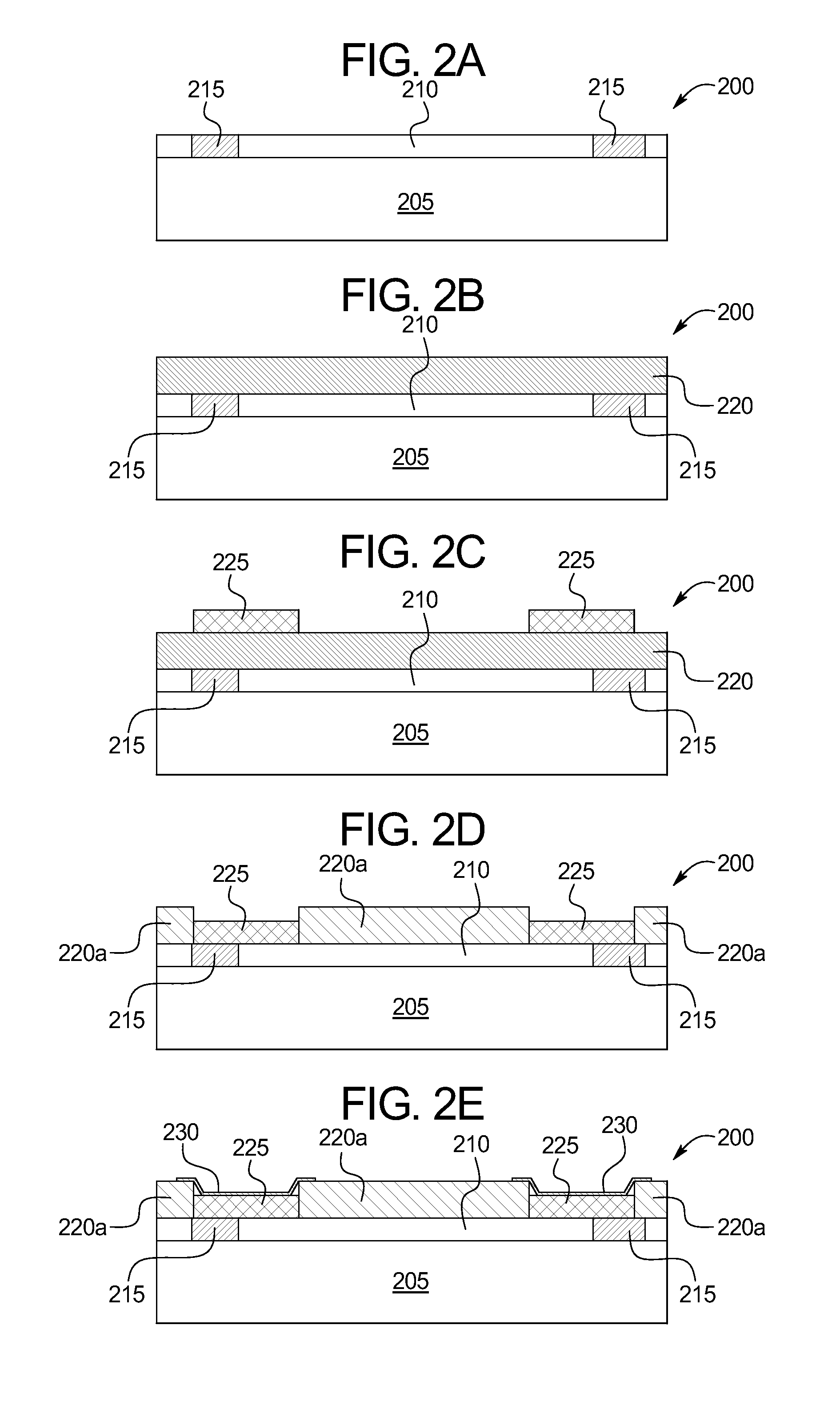

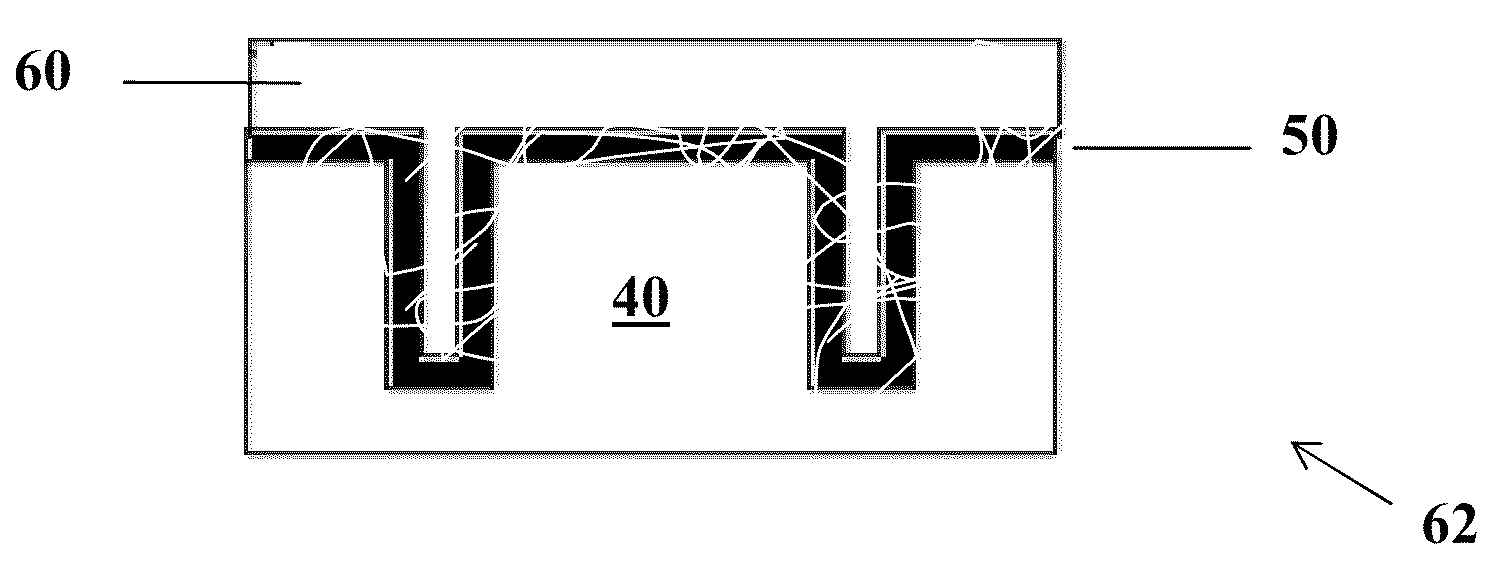

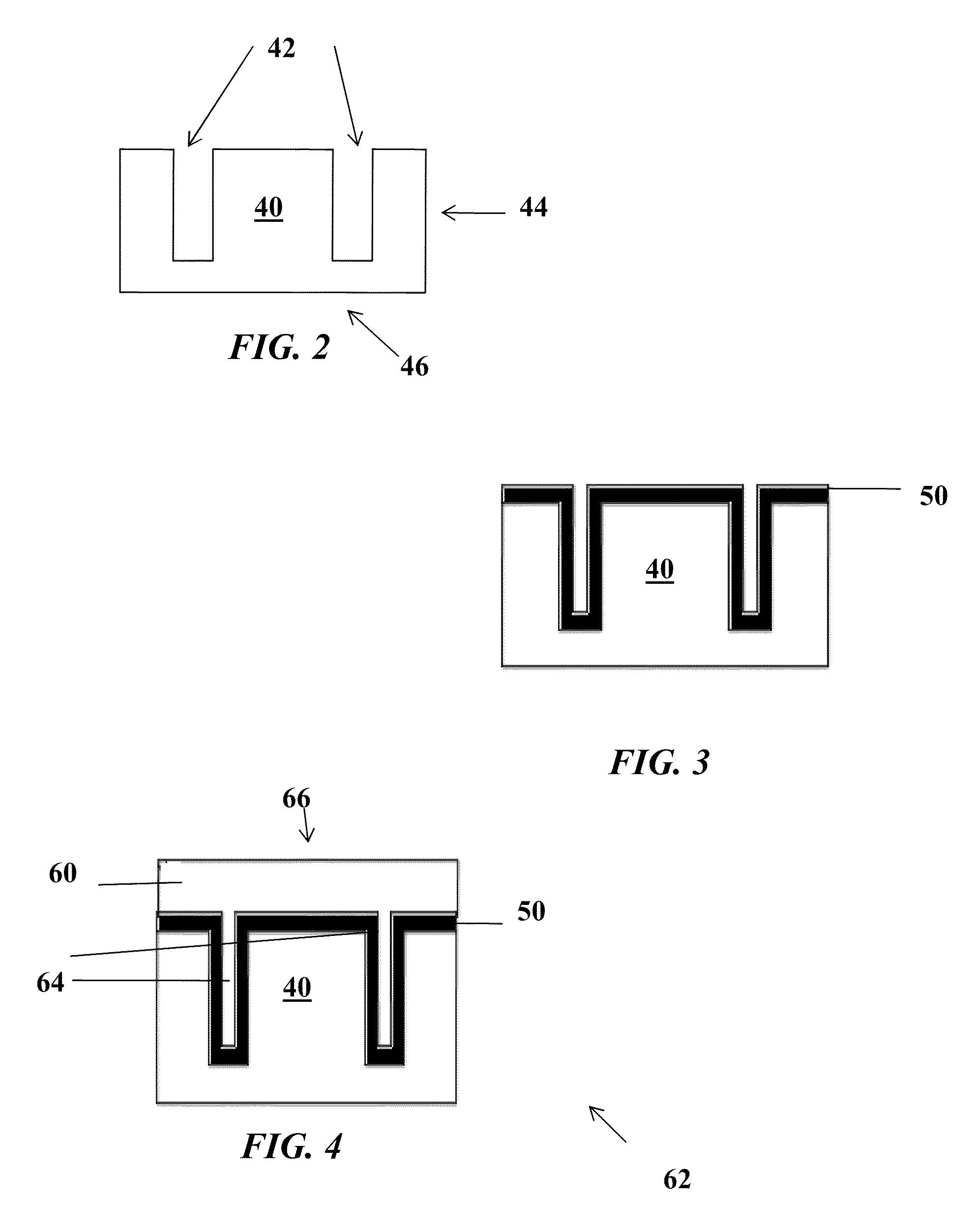

Trench Formation Method For Releasing A Thin-Film Substrate From A Reusable Semiconductor Template

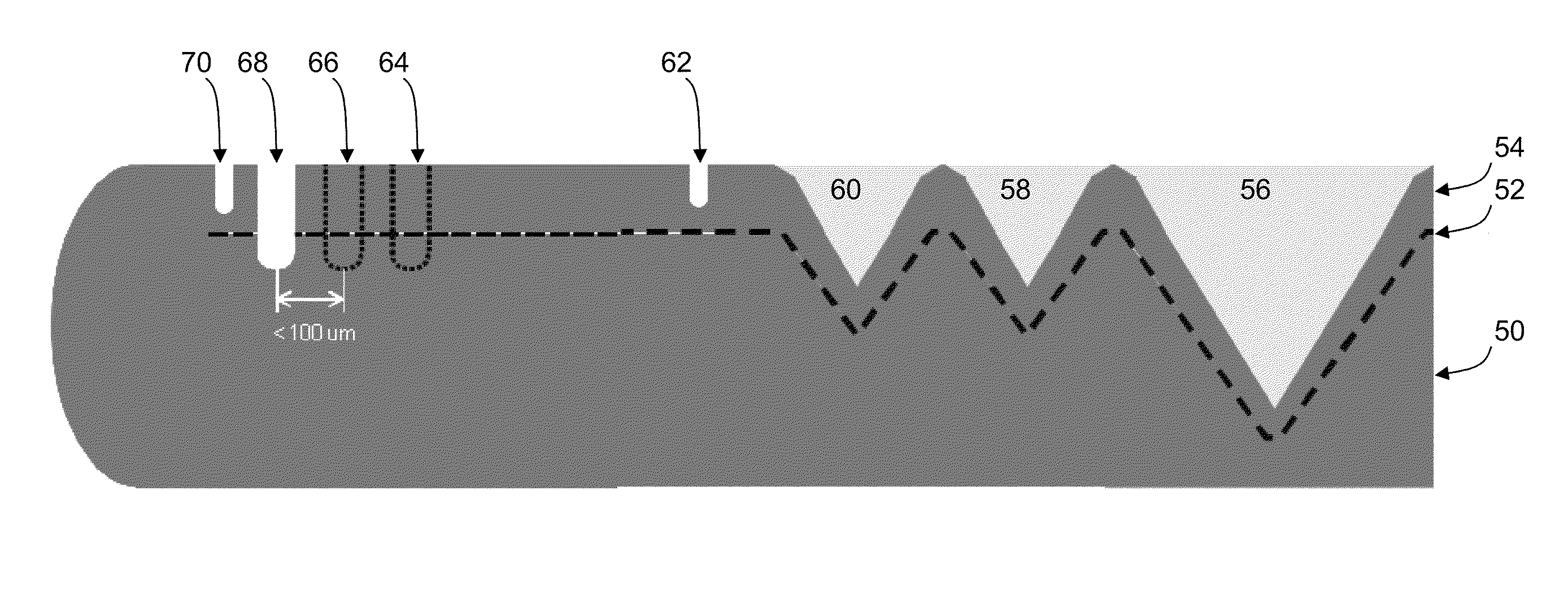

ActiveUS20100203711A1Process controlEliminates and reduces disadvantage and problemFinal product manufactureSemiconductor/solid-state device manufacturingPorous semiconductorsPellicle membrane

A method is provided for fabricating a thin-film semiconductor substrate by forming a porous semiconductor layer conformally on a reusable semiconductor template and then forming a thin-film semiconductor substrate conformally on the porous semiconductor layer. An inner trench having a depth less than the thickness of the thin-film semiconductor substrate is formed on the thin-film semiconductor substrate. An outer trench providing access to the porous semiconductor layer is formed on the thin-film semiconductor substrate and is positioned between the inner trench and the edge of the thin-film semiconductor substrate. The thin-film semiconductor substrate is then released from the reusable semiconductor template.

Owner:BEAMREACH SOLAR INC

Method of forming nanoscale three-dimensional patterns in a porous material

ActiveUS8486843B2Improve the level ofSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectSemiconductor materials

A method of forming a nanoscale three-dimensional pattern in a porous semiconductor includes providing a film comprising a semiconductor material and defining a nanoscale metal pattern on the film, where the metal pattern has at least one lateral dimension of about 100 nm or less in size. Semiconductor material is removed from below the nanoscale metal pattern to create trenches in the film having a depth-to-width aspect ratio of at least about 10:1, while pores are formed in remaining portions of the film adjacent to the trenches. A three-dimensional pattern having at least one nanoscale dimension is thus formed in a porous semiconductor, which may be porous silicon. The method can be extended to form self-integrated porous low-k dielectric insulators with copper interconnects, and may also facilitate wafer level chip scale packaging integration.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Dye-sensitized solar cell module and method of producing the same

A dye-sensitized solar cell module comprising: a plurality of electrically series-connected solar cells having a first conductive layer formed on an insulating substrate; a photoelectric conversion device formed on the first conductive layer; and a second conductive layer formed on the photoelectric conversion device, wherein the photoelectric conversion device has a photoelectric conversion layer having a porous semiconductor layer adsorbing a dye, a carrier transporting layer and a catalyst layer and the dye-sensitized solar cell module is characterized in that the second conductive layer of the above-described one solar cell contacts the first conductive layer of an adjacent another solar cell and the photoelectric conversion device of the above-described adjacent another solar cell contacts the second conductive layer of the above-described one solar cell.

Owner:SHARP KK

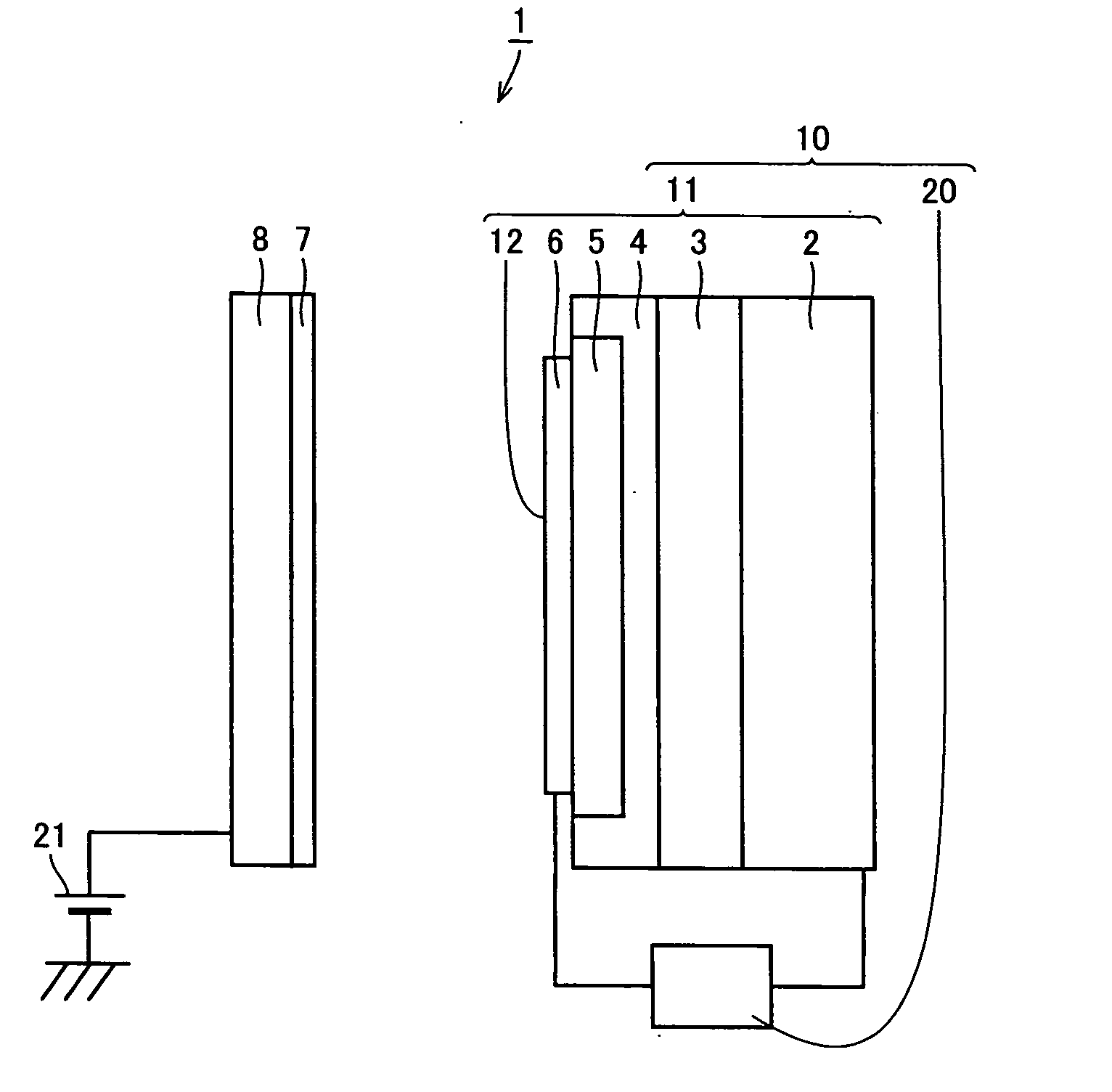

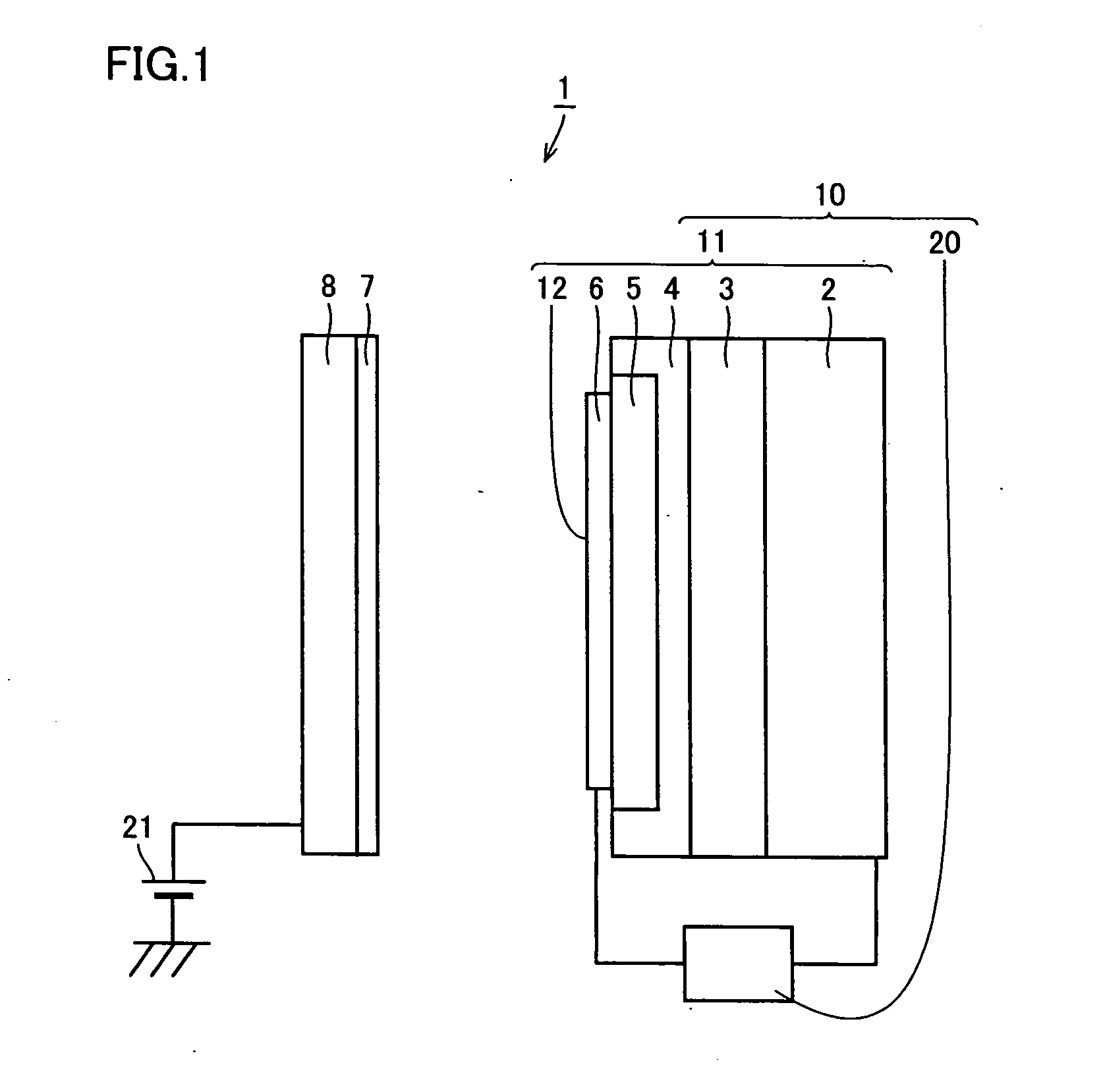

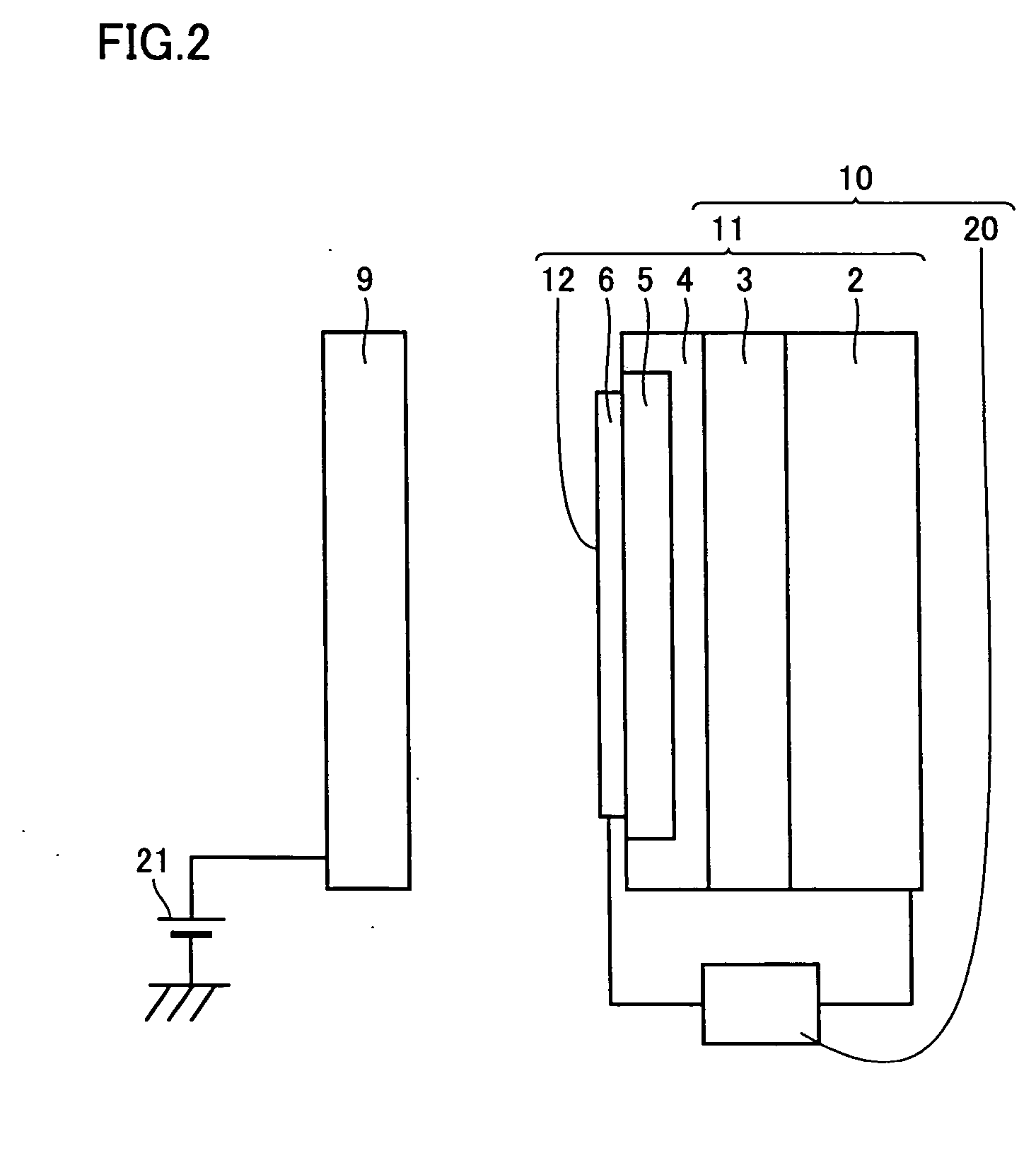

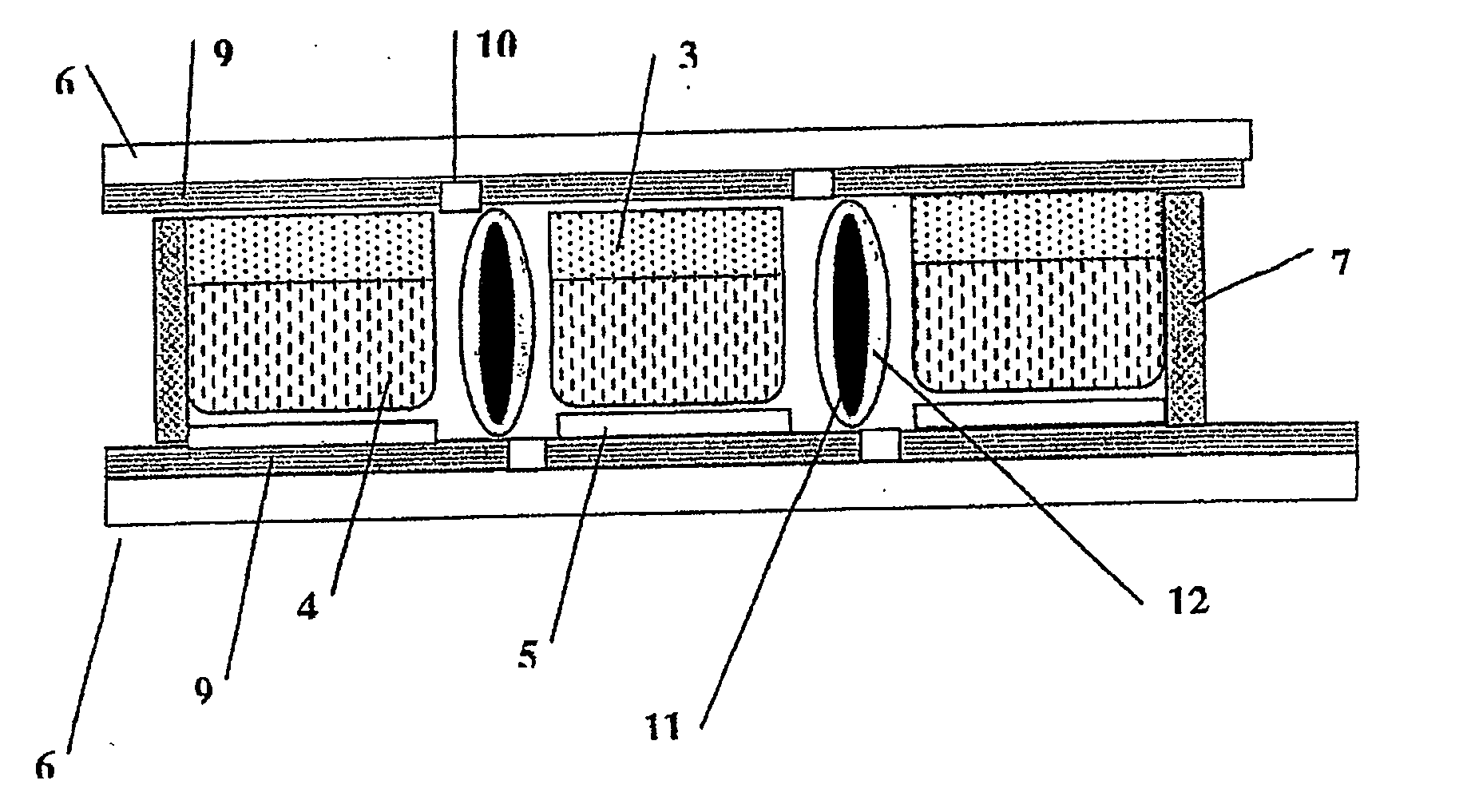

Electron emitter, charger, and charging method

InactiveUS20060291905A1Drive stabilityCathode ray tubes/electron beam tubesStatic indicating devicesElectrical polarityPorous semiconductors

Provided are an electron emitter continuously emitting electrons stably even in the atmosphere, a charger using the electron emitter, and a charging method using the charger. The electron emitter includes a electron emitting element consisting of a first electrode, a second electrode, and a semiconductor layer formed therebetween, and a power supply for alternately applying a positive voltage enabling electron emission and a negative voltage having a polarity opposite to the positive voltage. At least a part of the surface on the first electrode side of the semiconductor layer is formed of a porous semiconductor layer. Electrons captured in the porous semiconductor layer in the course of electron emission with application of a positive voltage disturb electron emission from the electron emitting element. Such electrons, however, are removed by application of a negative voltage.

Owner:SHARP KK +1

Photoelectrochemical device

InactiveUS20060243587A1Overcome lack of conductivityIrreversible damageCellsElectrolytic capacitorsElectrical conductorMetallic materials

A photoelectrochemical (PEC) device comprising two substrates, wherein: at least one substrates is transparent and coated with Transparent Electronic Conductor (TEC); a working electrode comprising dye sensitised porous semiconductor is formed on one substrate; a counter electrode comprising catalytic layer is formed on another substrate; electrolyte is placed between the two substrates; metallic conductor are utilized to conduct electrical current within and from the device; a protective layer of non-metallic material, with sufficient electrical conductivity to enable viable electrical output from the PEC device, is used to protect the metallic conductors from the electrolyte of the device.

Owner:DYESOL IND

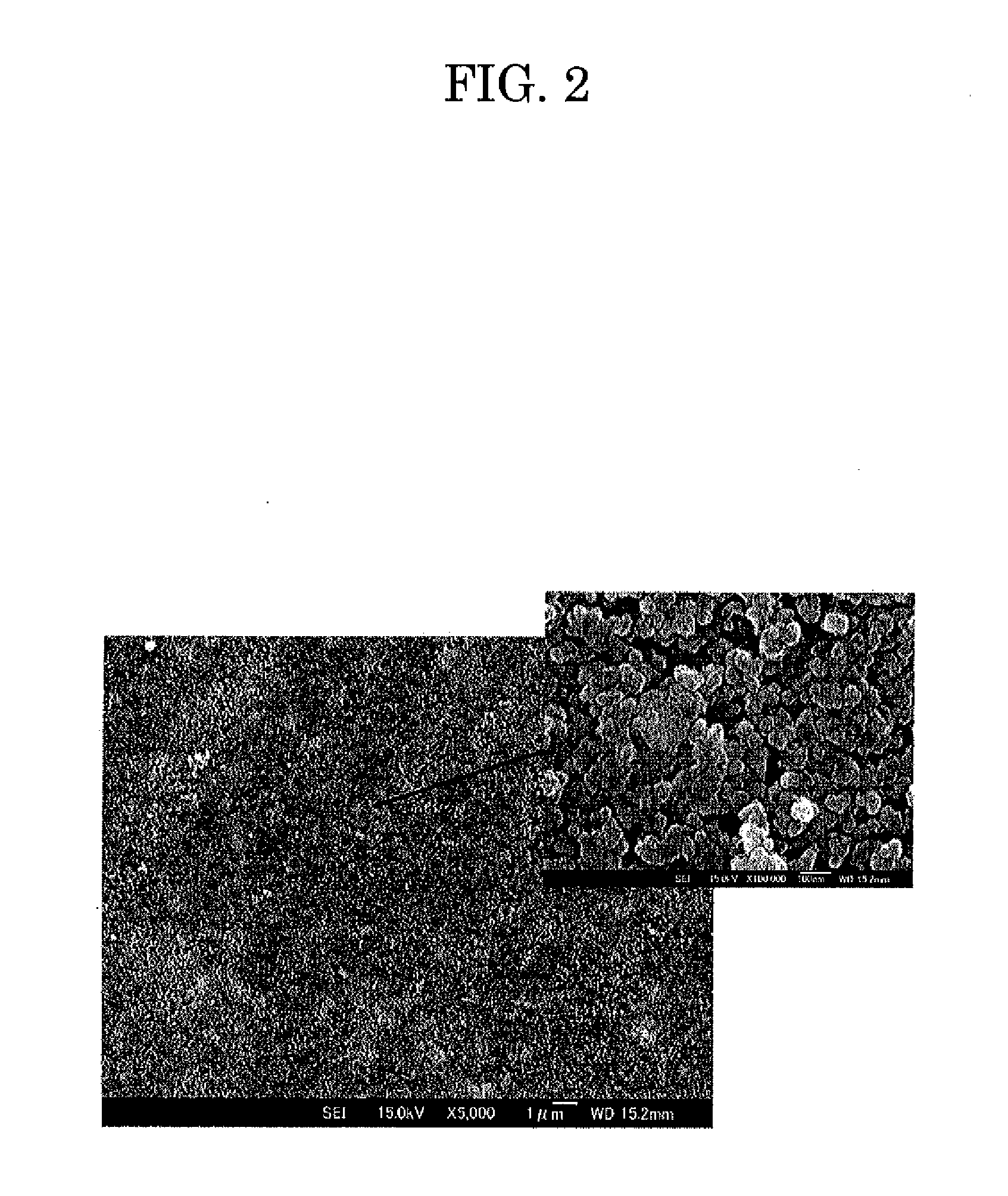

Method for forming semiconductor film and use of semiconductor film

InactiveUS7511298B2Improve adhesionMaintain good propertiesLight-sensitive devicesSolid-state devicesMetallurgySpray coating

The present invention provides a process for forming a semiconductor film, comprising the steps of applying a semiconductor particle dispersion liquid to a substrate surface by spray coating in such a manner that the atomized droplets of the dispersion liquid discharged from the spray coater have a mean diameter of about 30 μm or less, and drying the coating to form a porous semiconductor film; and use of the semiconductor film obtained by the process.

Owner:KANSAI PAINT CO LTD

Composite material comprising a porous semiconductor impregnated with an organic substance

ActiveUS20070071787A1Suitable for formulatingPowder deliveryImpression capsOrganic matterPorous semiconductors

The invention provides a composite material comprising a porous semiconductor impregnated with at least one beneficial organic substance, wherein the beneficial organic substance is present in an amount of at least 15% by weight, based on the weight of the material. Also provided are methods for the preparation of such materials, pharmaceutical compositions comprising them and their use in methods of treatment.

Owner:PSIMEDICA

Method of forming nanoscale three-dimensional patterns in a porous material

ActiveUS20110263119A1Facilitate wafer level packaging integrationImprove the level ofSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectSemiconductor materials

A method of forming a nanoscale three-dimensional pattern in a porous semiconductor includes providing a film comprising a semiconductor material and defining a nanoscale metal pattern on the film, where the metal pattern has at least one lateral dimension of about 100 nm or less in size. Semiconductor material is removed from below the nanoscale metal pattern to create trenches in the film having a depth-to-width aspect ratio of at least about 10:1, while pores are formed in remaining portions of the film adjacent to the trenches. A three-dimensional pattern having at least one nanoscale dimension is thus formed in a porous semiconductor, which may be porous silicon. The method can be extended to form self-integrated porous low-k dielectric insulators with copper interconnects, and may also facilitate wafer level chip scale packaging integration.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Dye-sensitized solar cell and process for producing the same

InactiveUS20090314339A1Easy to produceImprove conversion efficiencyElectrolytic capacitorsFinal product manufactureMicroparticleSolvent

Owner:NIPPON STEEL CHEMICAL CO LTD +1

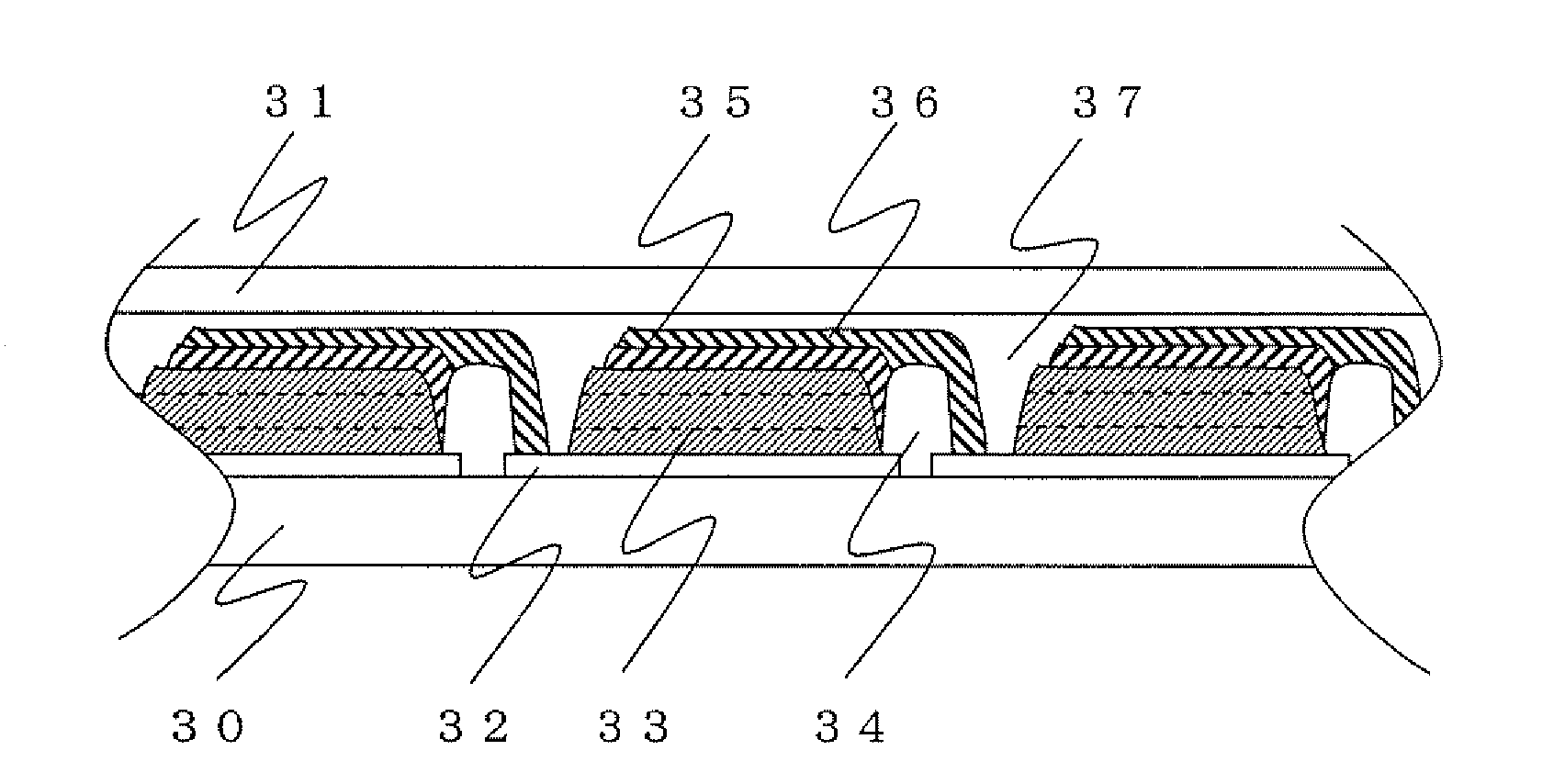

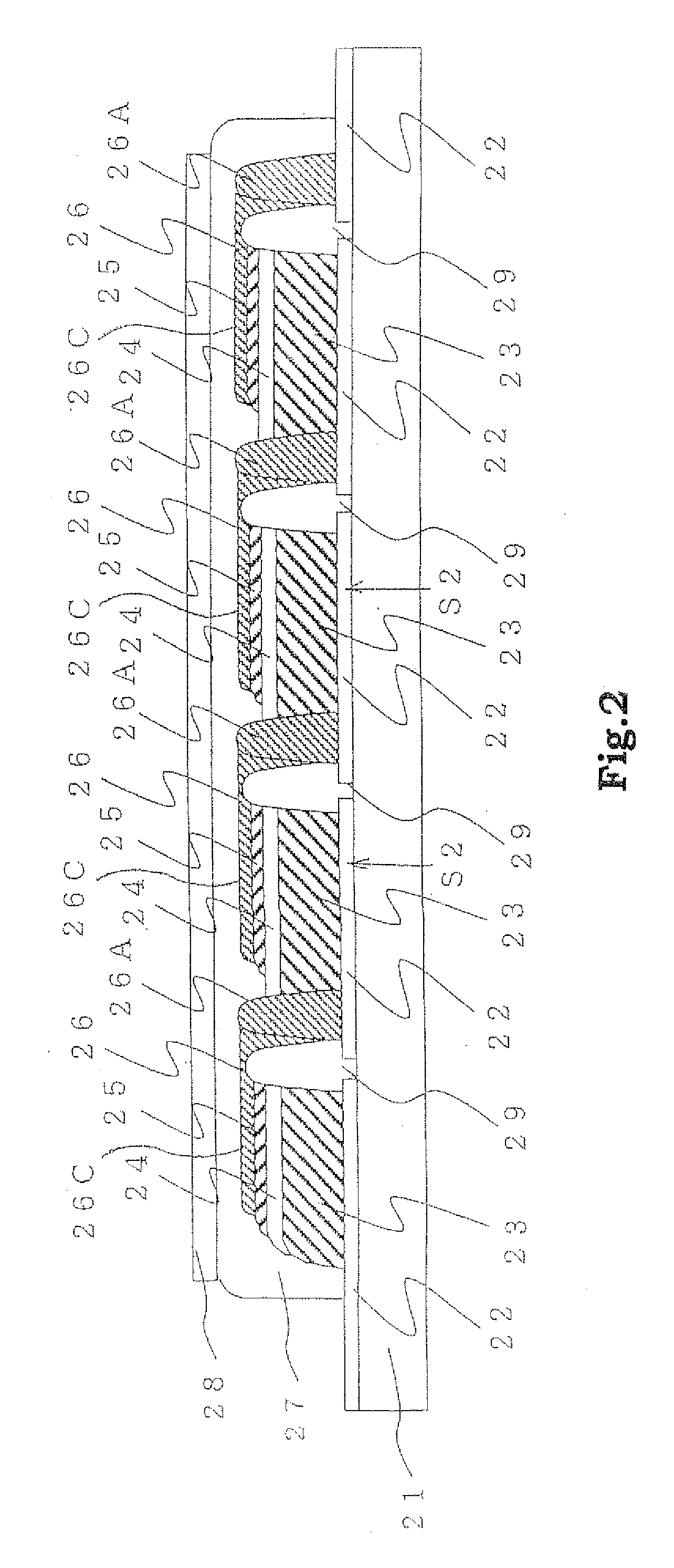

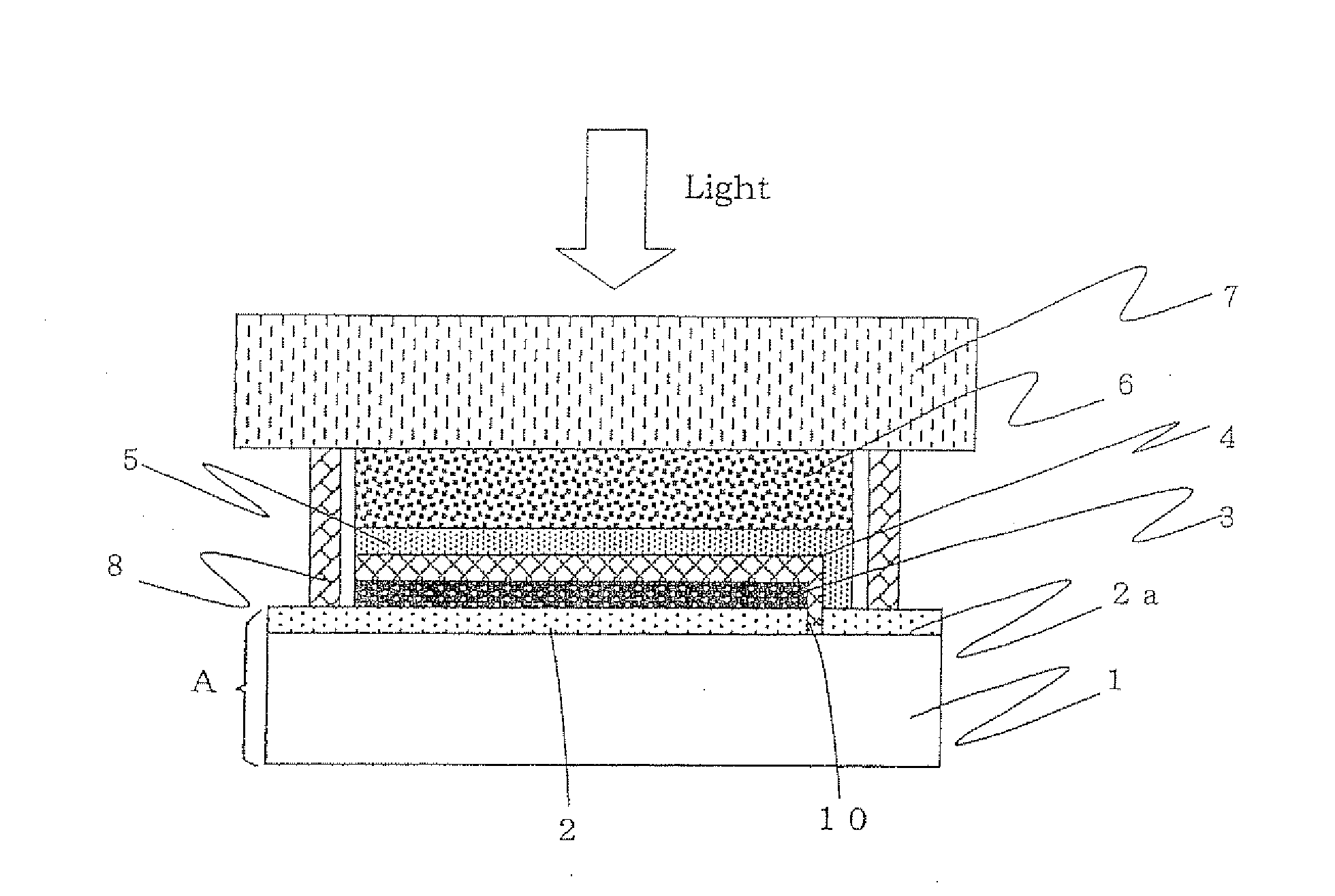

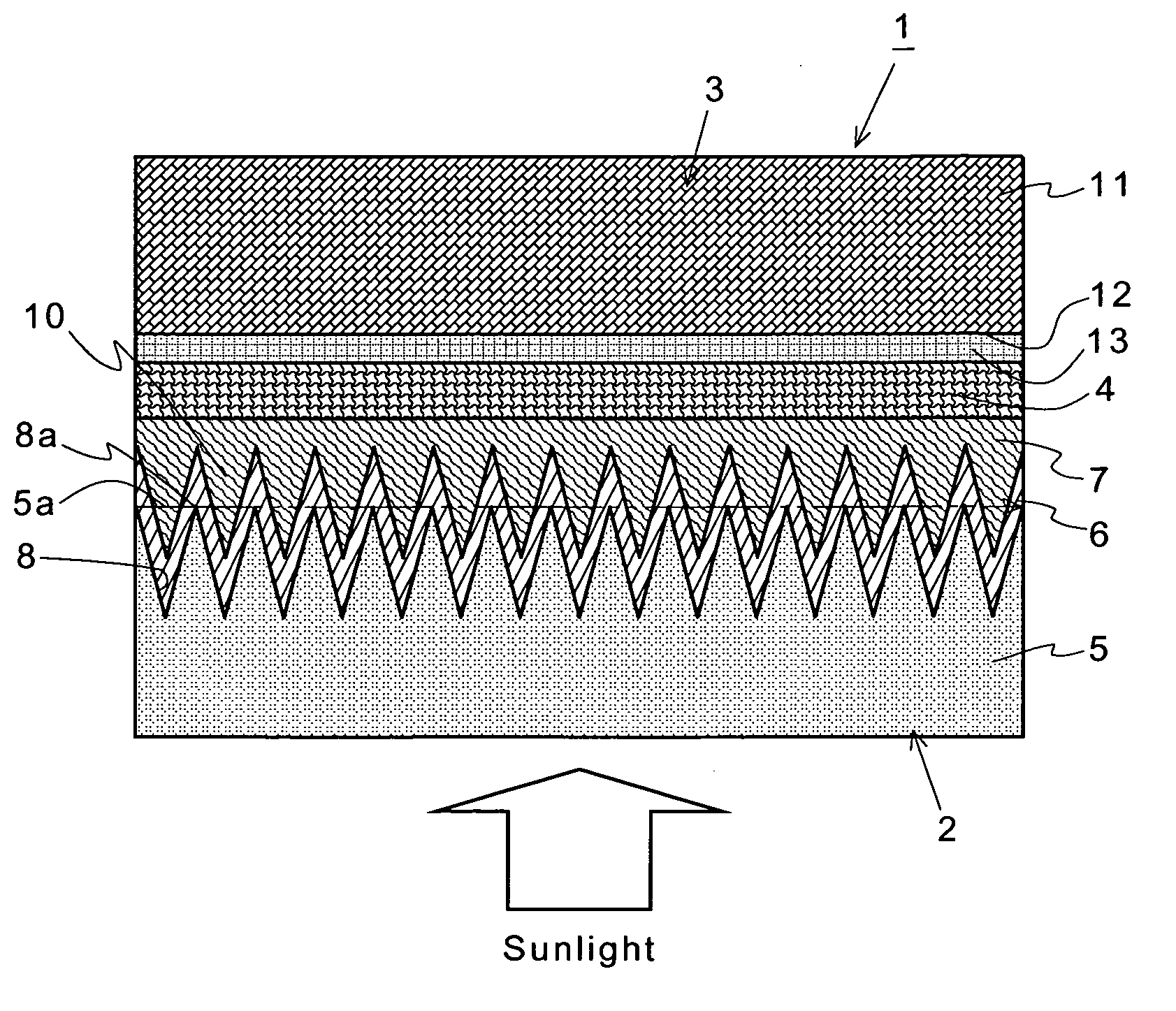

Photosensitized solar cell, production method thereof and photosensitized solar cell module

InactiveUS20110023932A1Reduce weightImprove featuresElectrolytic capacitorsFinal product manufacturePhotosensitizerEngineering

A photosensitized solar cell characterized in that at least a catalyst layer 3, a porous insulating layer 4 internally containing an electrolyte, a porous semiconductor layer 6 with a photosensitizer adsorbed thereon, internally containing the electrolyte, and a translucent cover member 7 are laminated in this order on a conductive substrate.

Owner:SHARP KK

Macroporous silicon microcavity with tunable pore size

InactiveUS20060276047A1High sensitivitySolid-state devicesSemiconductor/solid-state device manufacturingPorositySemiconductor structure

A biological sensor which includes: a macroporous semiconductor structure comprising a central layer interposed between upper and lower layers, each of the upper and lower layers including strata of alternating porosity; and one or more probes coupled to the porous semiconductor structure, the one or more probes binding to a target molecule, whereby a detectable change occurs in a refractive index of the biological sensor upon binding of the one or more probes to the target molecule. Methods of making the biological sensor and methods of using the same are disclosed, as is a detection device which includes such a biological sensor.

Owner:UNIVERSITY OF ROCHESTER

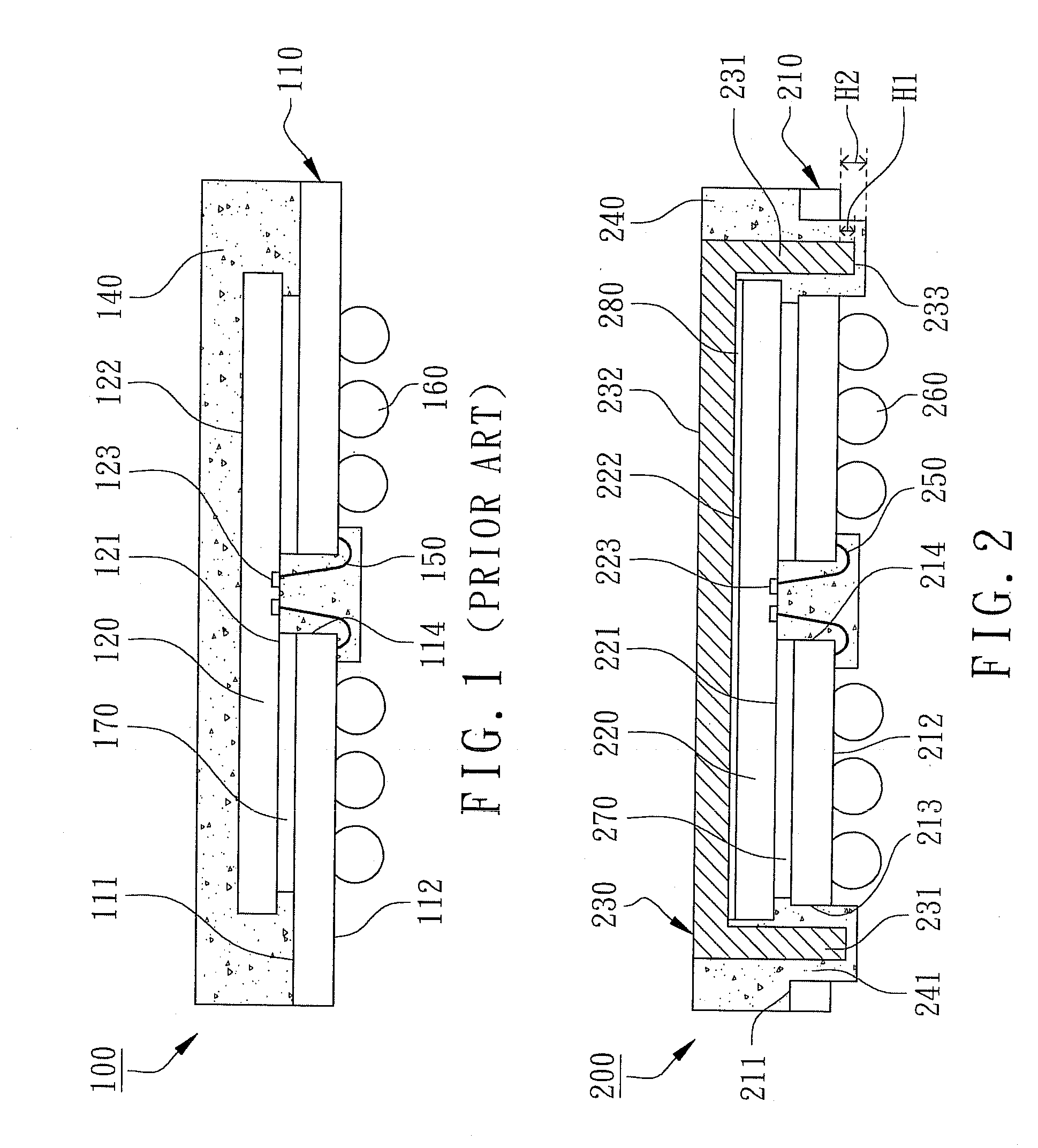

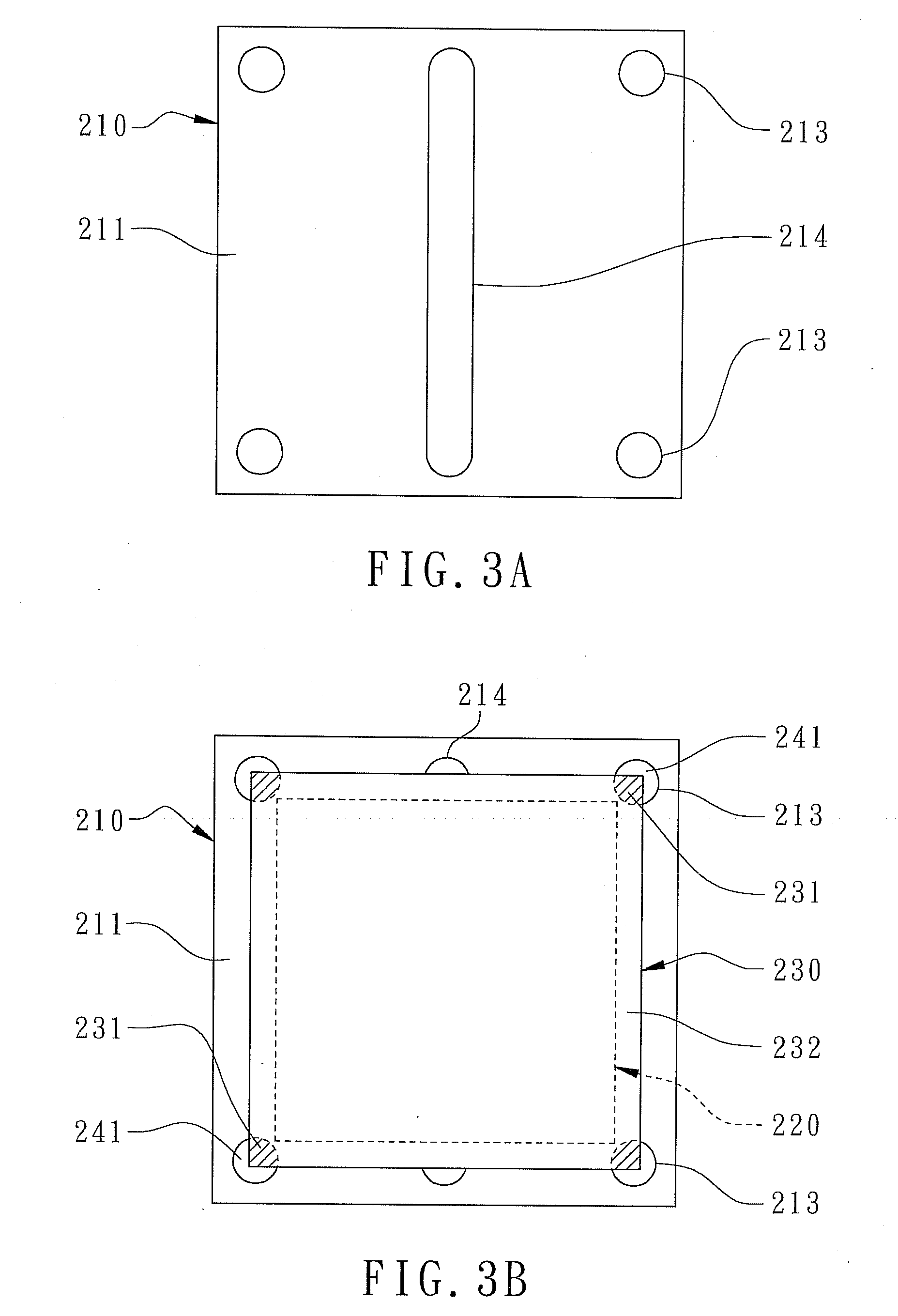

Thermally-enhanced multi-hole semiconductor package

InactiveUS20090236732A1Prevent peelingThermal-enhanced multi-holeSemiconductor/solid-state device detailsSolid-state devicesAdhesiveSemiconductor package

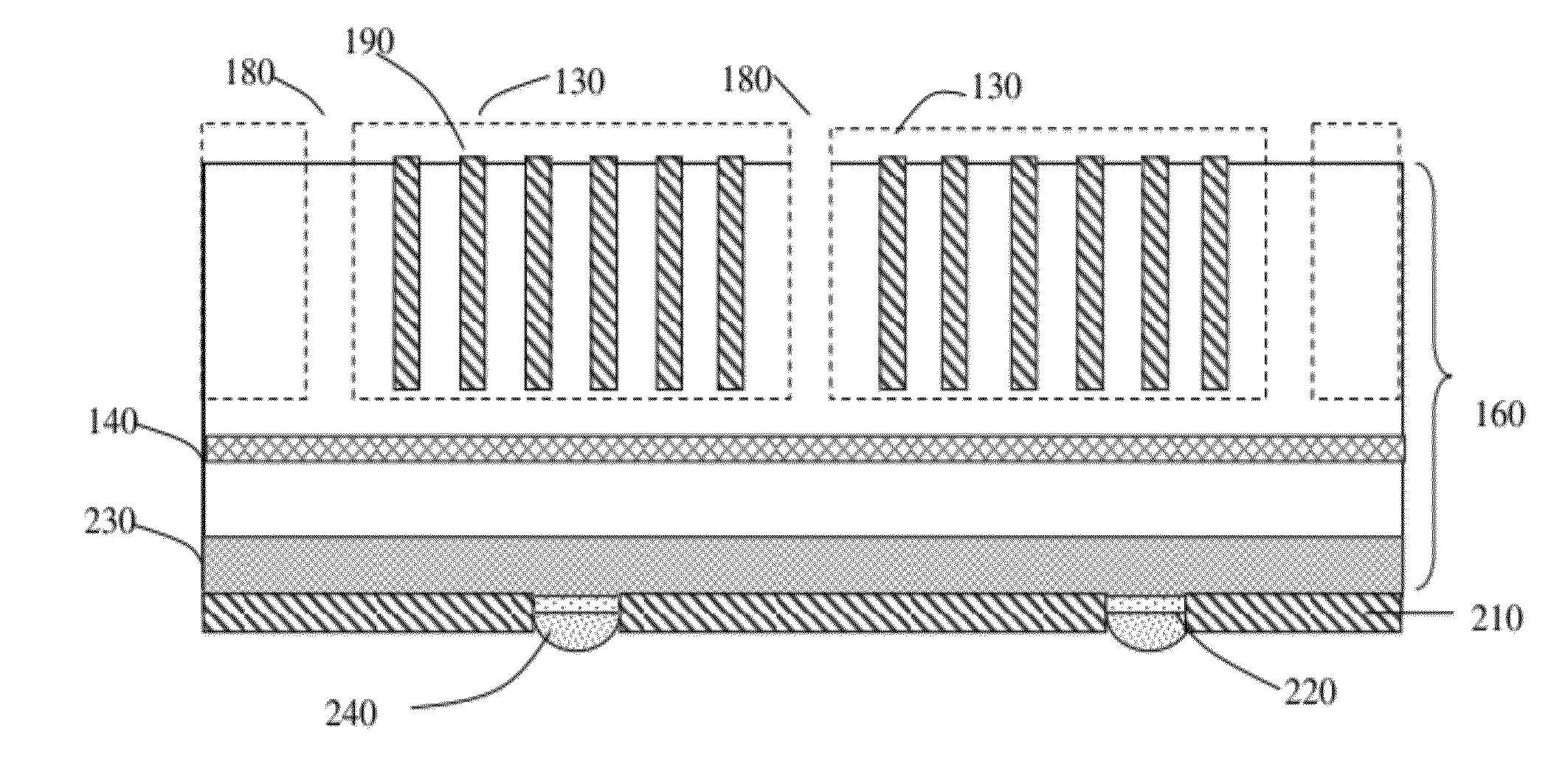

A thermal-enhanced multi-hole semiconductor package is revealed, primarily comprising a substrate with a plurality of alignment holes, a chip disposed on the substrate, an internal heat sink attached to the chip, and an encapsulant. The internal hear sink has a plurality of alignment bars and a heat dissipation surface. The alignment bars are inserted into the alignment holes, but not fully occupying the alignment holes to provide a plurality of flowing channels therein. The encapsulant completely encapsulates the alignment bars through filling the flowing channels. Therefore, the internal heat sink can be aligned to the substrate and is integrally connected with the chip and the substrate utilizing a small amount of adhesive or without any adhesive to form a composite having high rigidity and strong adhesion.

Owner:POWERTECH TECHNOLOGY

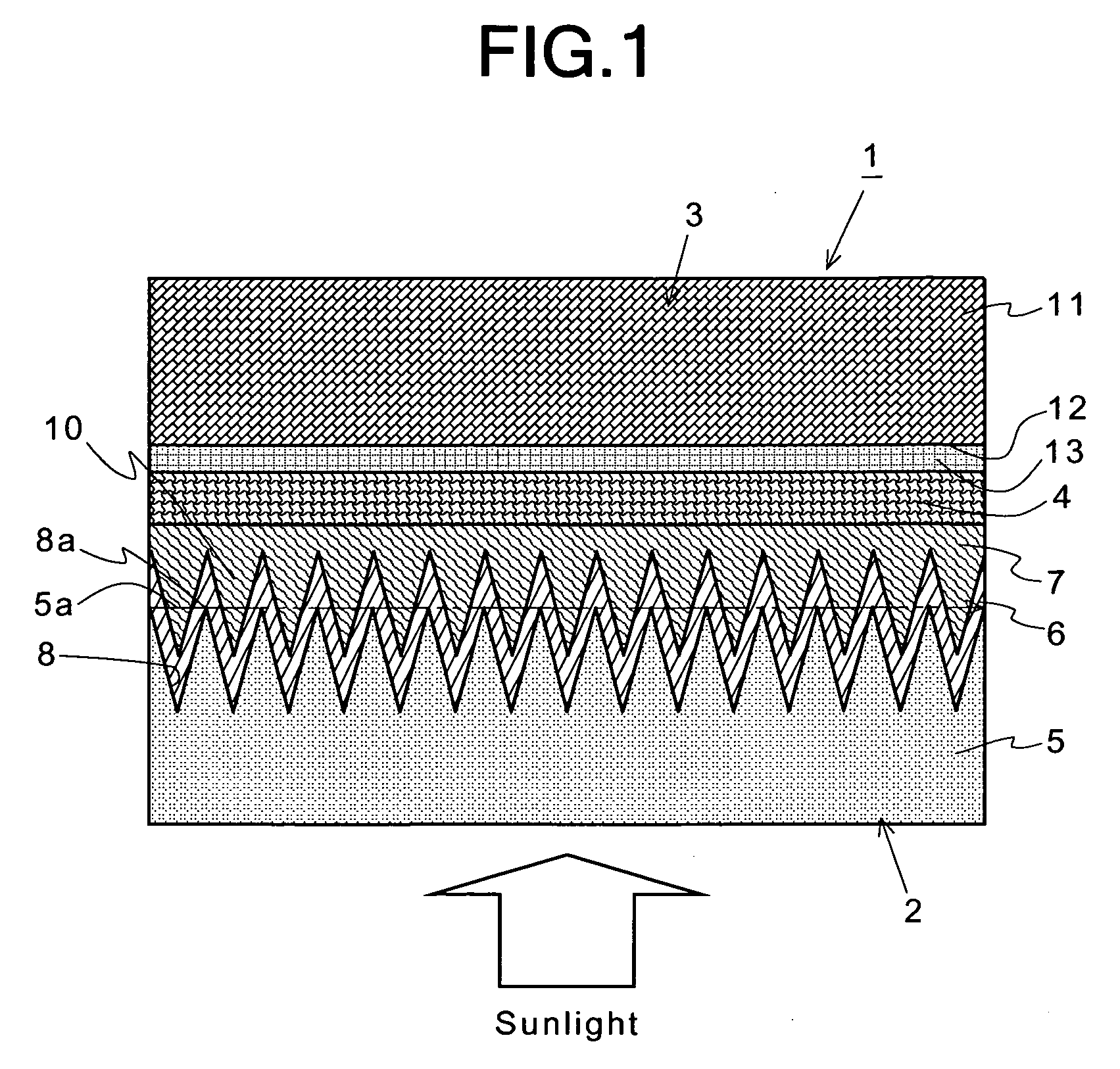

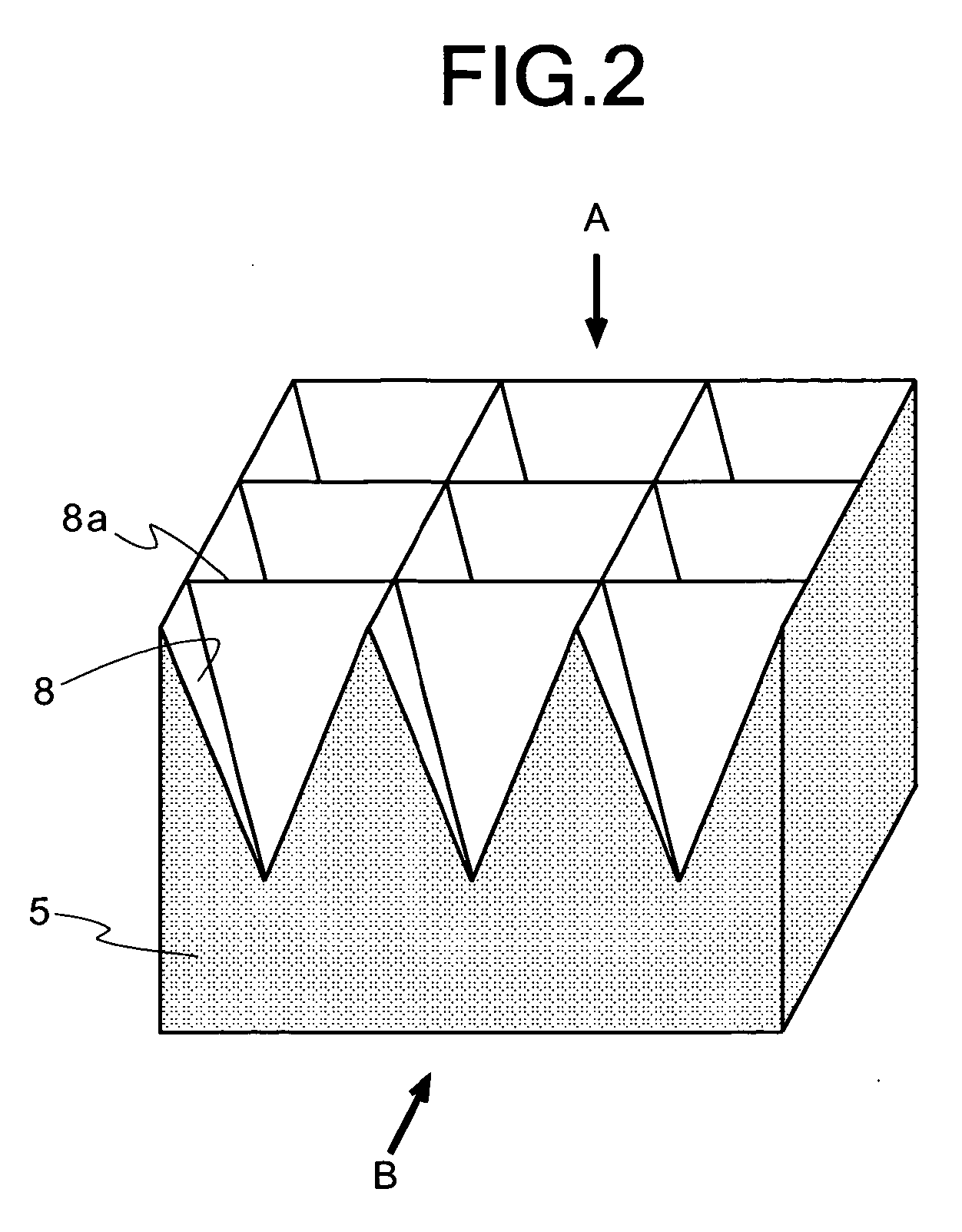

Photoelectrode for dye sensitizing solar cell or organic solar cell, and dye sensitizing solar cell having same

InactiveUS20060065301A1Enhance photoelectric transfer efficiencyIncrease the amount of lightElectrolytic capacitorsPhotovoltaic energy generationSemiconductor electrodeOrganic solar cell

In a dye sensitizing solar cell 1 wherein an electrolyte 4 is filled in a space between a photoelectrode 2 and a counter electrode 3, recesses 8 are formed in the surface 5a of a substrate member 5 of the photoelectrode 2, and a transparent electrode film 6 is formed on the surface of the substrate member 5 to form recessed portions 10 in the transparent electrode film 6. On the transparent electrode film 6 of the photoelectrode 2 with this construction, a porous semiconductor electrode film 7 is formed, and a sensitizing dye is absorbed and carried on the porous semiconductor electrode film 7.

Owner:ENPLAS CORP

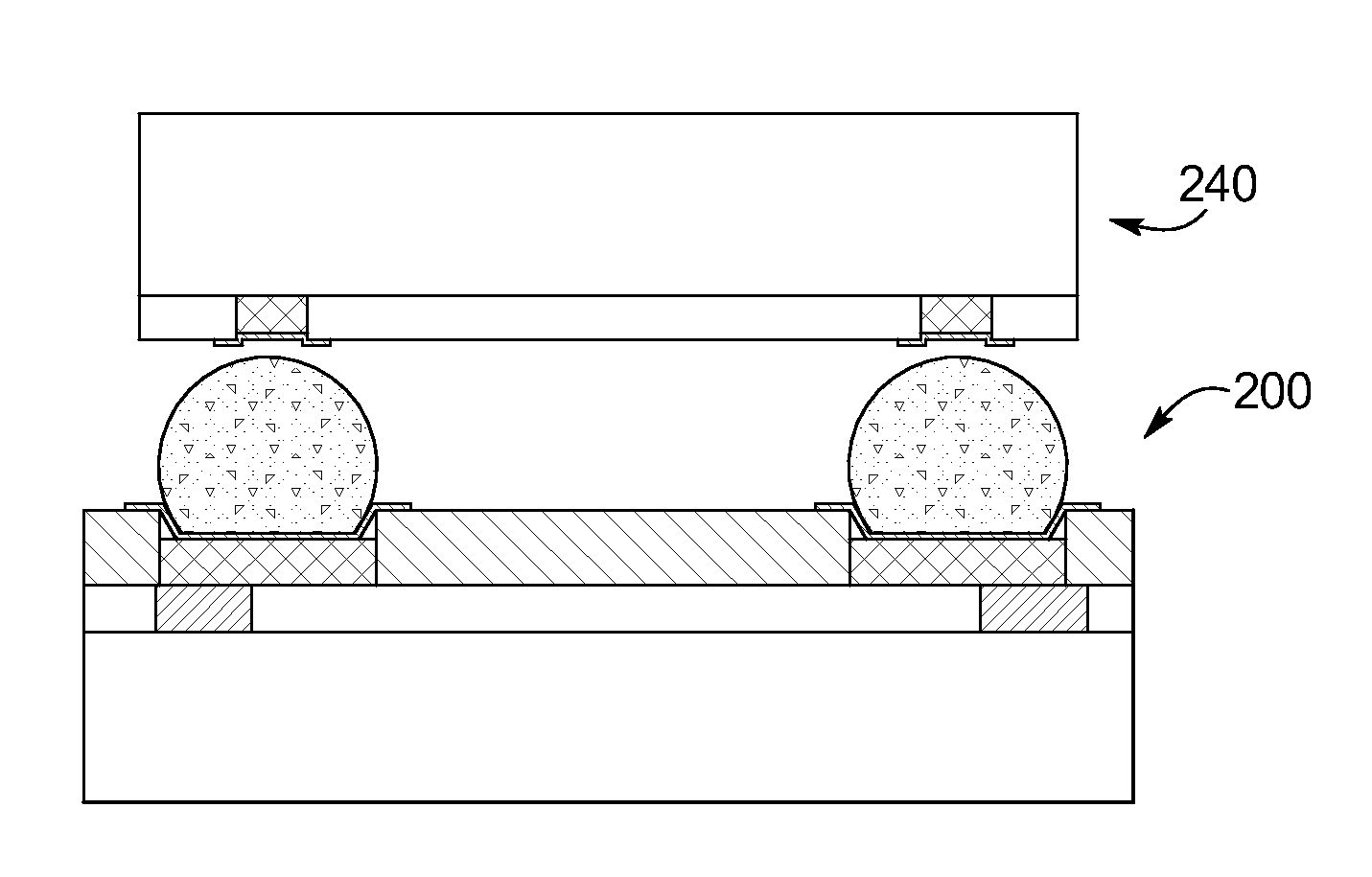

Substrate release methods and apparatuses

InactiveUS7745313B2Reduce harmMinimize complexitySemiconductor/solid-state device manufacturingSemiconductor devicesPorous semiconductorsCrystalline semiconductor

The present disclosure relates to methods and apparatuses for fracturing or breaking a buried porous semiconductor layer to separate a 3-D thin-film semiconductor semiconductor (TFSS) substrate from a 3-D crystalline semiconductor template. The method involves forming a sacrificial porous semiconductor layer on the 3-D features of the template. A variety of techniques may be used to fracture and release the mechanically weak porous semiconductor layer without damaging the TFSS substrate layer or the template layer such as pressure variations, thermal stress generation, and mechanical bending. The methods also allow for processing three dimensional features not possible with current separation processes. Optional cleaning and final lift-off steps may be performed as part of the release step or after the release step.

Owner:BEAMREACH SOLAR INC

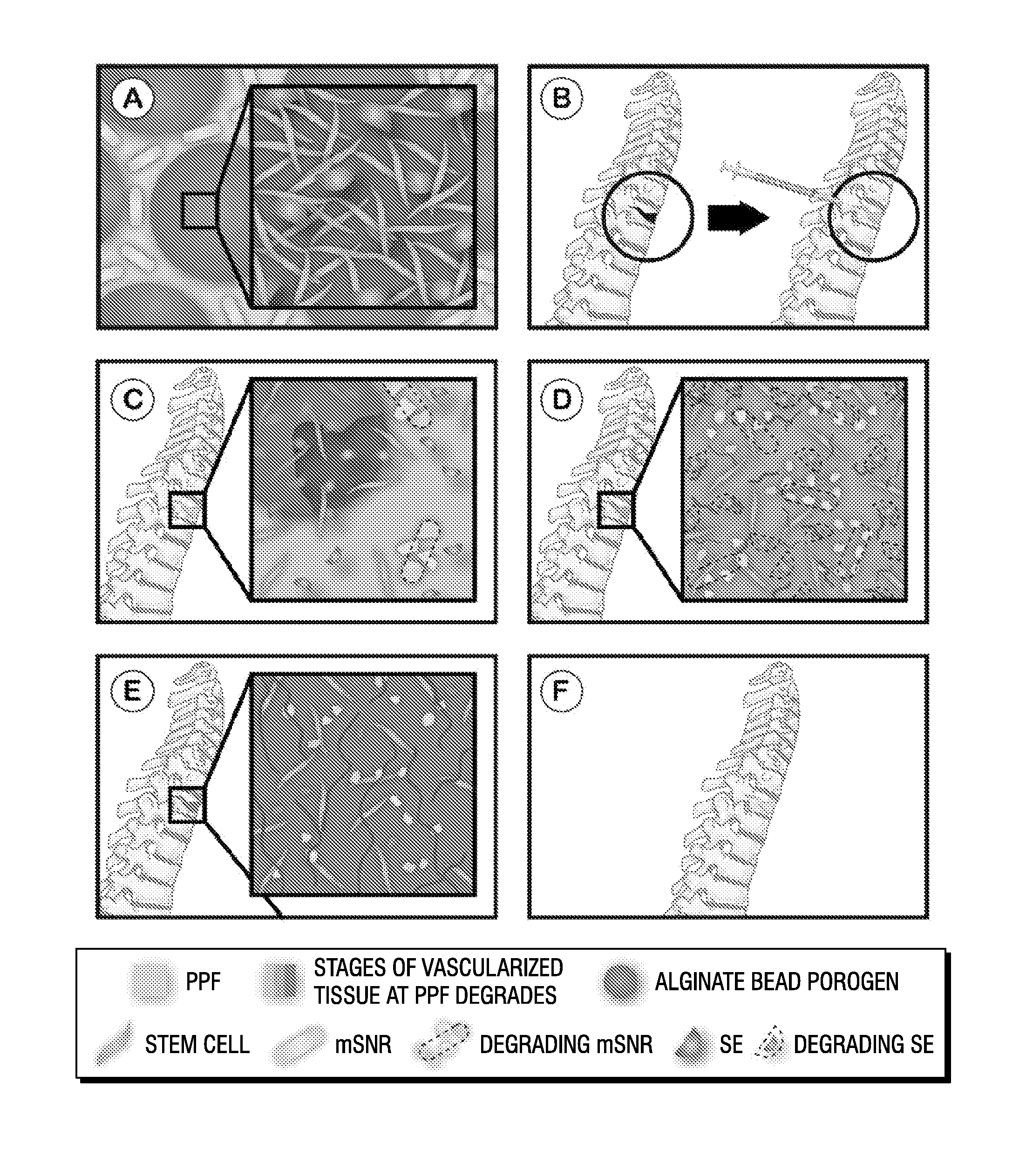

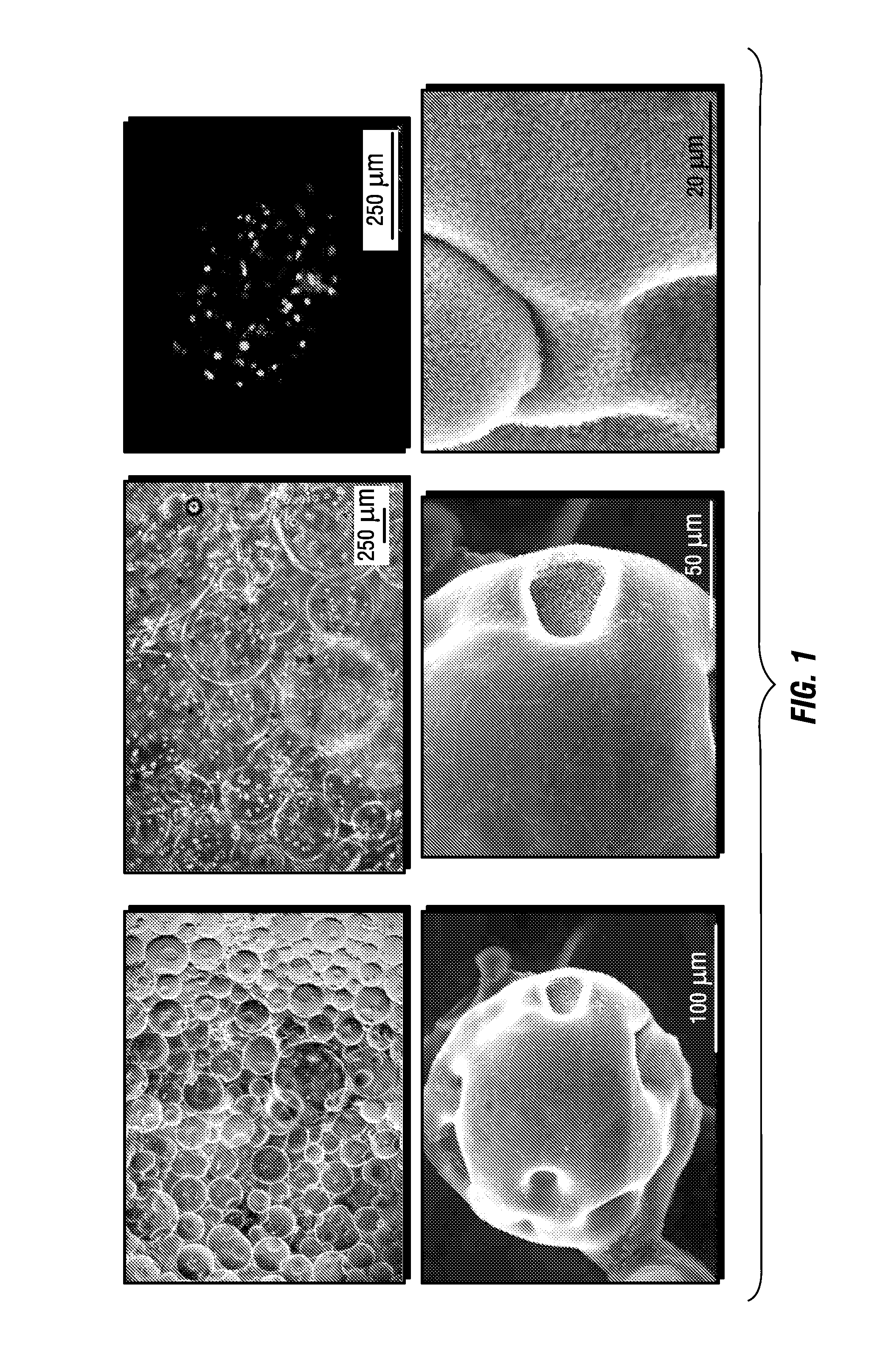

Biodegradable scaffolds

InactiveUS20130184835A1Optimal mechanical characteristicEnhance healing processBiocidePowder deliveryActive agentBiodegradable scaffold

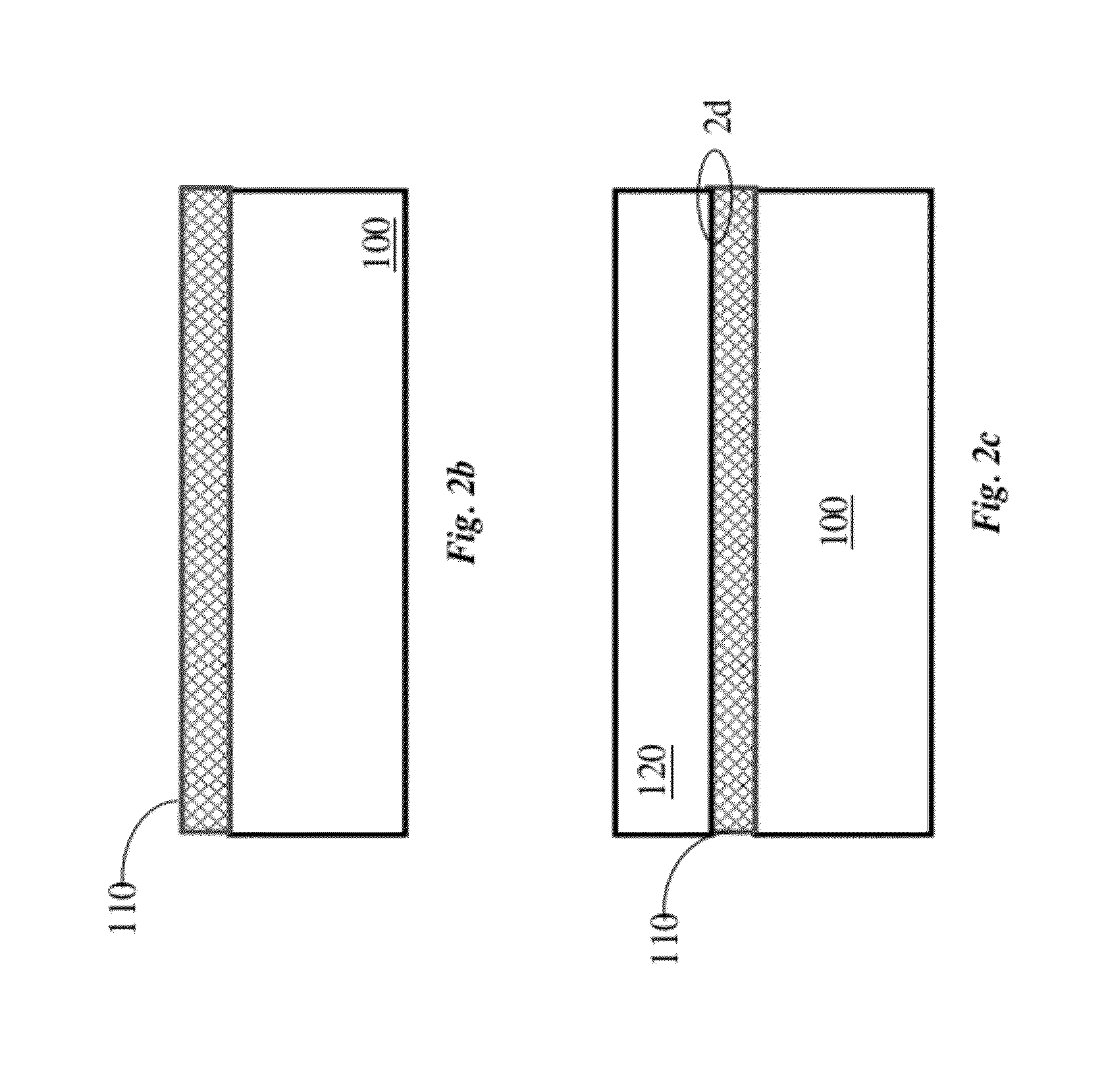

In some embodiments, the present invention provides compositions that comprise: (1) a biodegradable polymer matrix; and (2) at least one biodegradable reinforcing particle that is dispersed in the matrix. In some embodiments, the biodegradable reinforcing particle is selected from the group consisting of porous oxide particles and porous semiconductor particles. In additional embodiments, the compositions of the present invention further comprise a (3) porogen particle that is also dispersed in the matrix. In further embodiments, the compositions of the present invention are also associated with one or more active agents. In various embodiments, the active agents are associated with the biodegradable polymer matrix, the biodegradable reinforcing particle, and / or the porogen particle. In various embodiments, the compositions of the present invention may be utilized as scaffolds, such as scaffolds for treating bone defects. Further embodiments of the present invention pertain to methods of making the compositions of the present invention.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

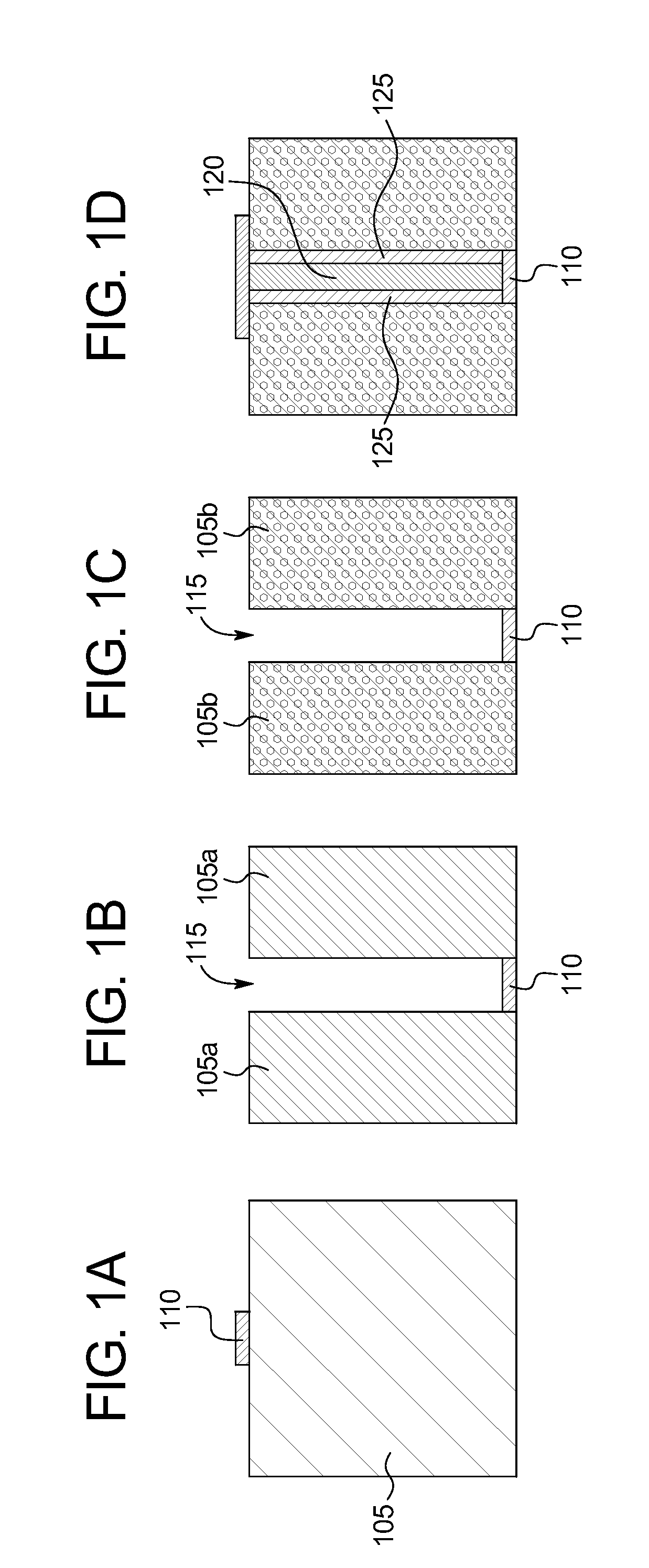

Semiconductor Devices and Methods of Manufacturing Thereof

ActiveUS20120080686A1Semiconductor/solid-state device manufacturingSemiconductor devicesPorous semiconductorsSemiconductor

In one embodiment, a method of forming a semiconductor device includes forming a first porous semiconductor layer over a top surface of a substrate. A first epitaxial layer is formed over the first porous semiconductor layer. A circuitry is formed within and over the first epitaxial layer. The circuitry is formed without completely oxidizing the first epitaxial layer.

Owner:INFINEON TECH AG

Dye-sensitized solar cell module and method of manufacturing the same (as amended)

ActiveUS20100024875A1Increase the effective areaDeterioration of performance of W-type can be avoidedElectrolytic capacitorsFinal product manufacturePhotoelectric conversionEngineering

A dye-sensitized solar cell module which is characterized by providing a pair of opposed substrates 10 and 17 in which at least one of the substrates is transparent and a plurality of conductive layers 11 and 18 are formed in parallel with one another on the each opposed surface of the substrates, a plurality of adjacent photoelectric conversion devices 1a and 1b formed in a state of being electrically connected in series between the pair of conductive substrates 11 and 17, and insulating layers 16 formed between the adjacent photoelectric conversion devices 1a and 1b, wherein the photoelectric conversion devices 1a and 1b have a porous semiconductor layer 12 adsorbing a dye, an electrolyte layer 13 and a catalyst layer 14 and the insulating layer 16 is formed by dividing into two or more times in the direction of a substrate thickness.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com