Dye sensitized solar cell and dye-sensitized solar cell module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

production example 1

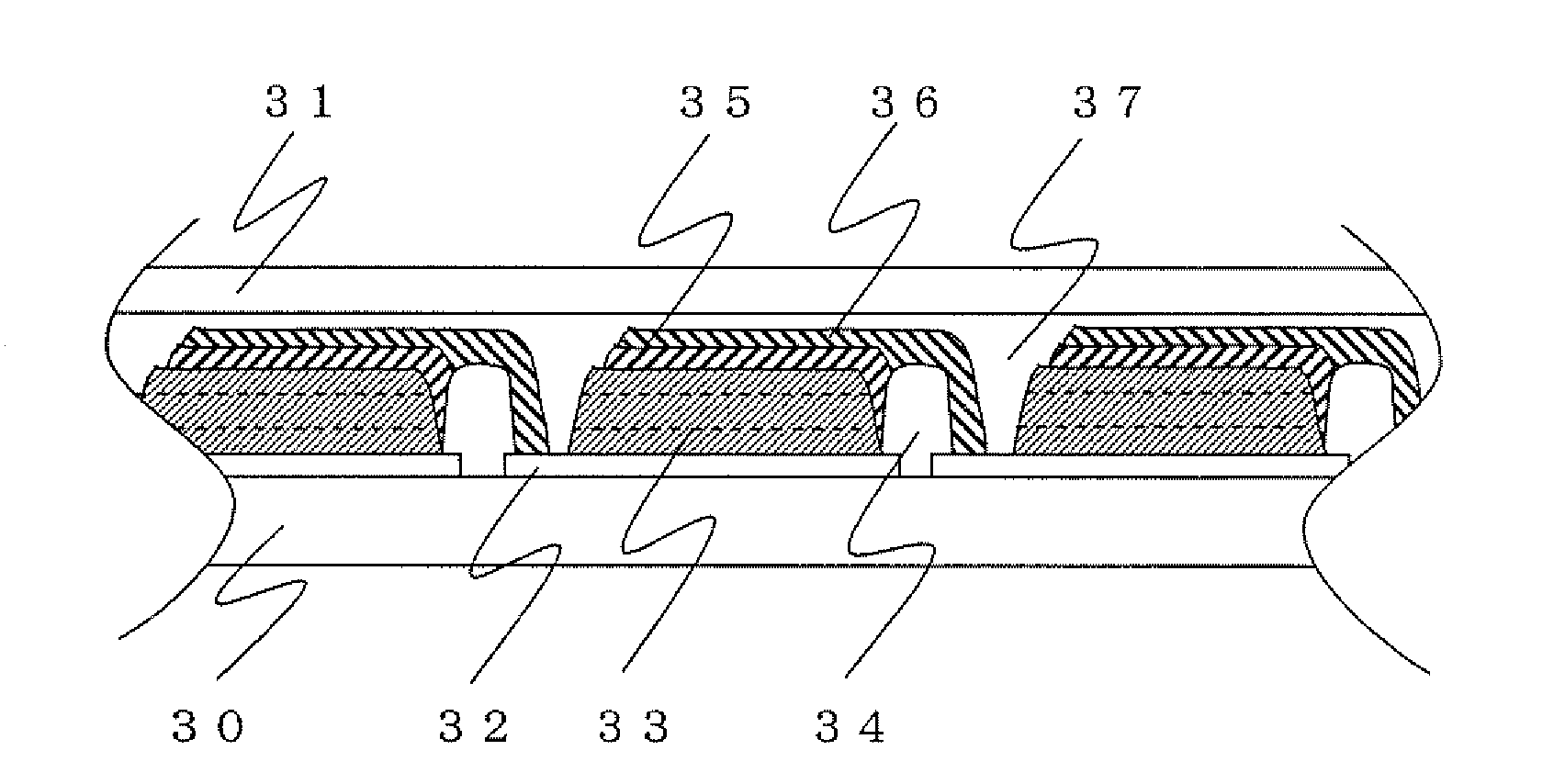

[0170]A solar cell (unit cell) shown in FIG. 1 was produced.

[0171]FIG. 1 is a schematic cross-sectional view of a main part showing the layer structure of a solar cell of the present invention.

[0172]In FIG. 1, a reference numeral 1 denotes a support: a reference numeral 2 denotes a conductive layer: a reference numeral 3 denotes a photoelectric conversion layer filled with a carrier transporting material: a reference numeral 4 denotes a carrier transporting material: a reference numeral 5 denotes a catalyst layer: a reference numeral 6 denotes a counter electrode conductive layer: a reference numeral 7 denotes an output electrode: and a reference numeral 8 denotes a sealing material.

[0173]A glass substrate (trade name: SnO2 film-bearing glass, manufactured by Nippon Sheet Glass Co., Ltd.) obtained by forming a conductive layer 2 of a SnO2 film on a glass support 1 was used. A commercialized titanium oxide paste (trade name: Ti-Nanoxide T / SP, average primary particle diameter of tita...

production example 2

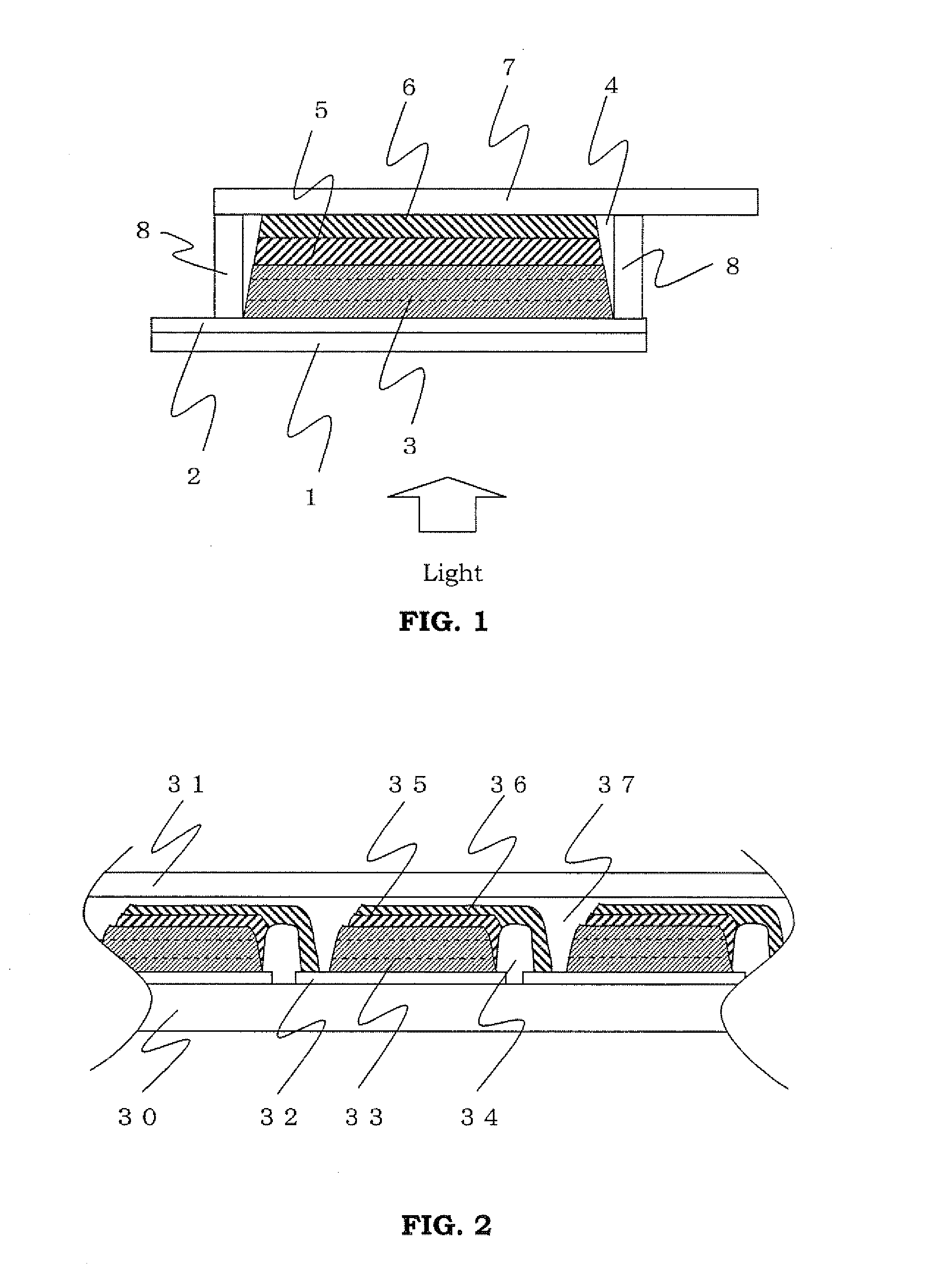

[0185]A solar cell module shown in FIG. 2 was produced.

[0186]FIG. 2 is a schematic cross-sectional view of a main part showing a layer structure of a solar cell module of the present invention. In the drawing, a reference numeral 30 denotes a support: a reference numeral 31 denotes a cover: a reference numeral 32 denotes a conductive layer: a reference numeral 33 denotes a photoelectric conversion layer filled with a carrier transporting material: a reference numeral 34 denotes an inter-cell insulating layer: a reference numeral 35 denotes a catalyst layer: a reference numeral 36 denotes a counter electrode conductive layer: and a reference numeral 37 denotes an insulating layer.

[0187]A glass substrate (trade name: SnO2 film-bearing glass, manufactured by Nippon Sheet Glass Co., Ltd.) obtained by forming a conductive layer 32 of a SnO2 film on a glass support 1 was used. A scribe line was formed in a prescribed site of the conductive layer 32 of the glass substrate by radiating lase...

production example 3

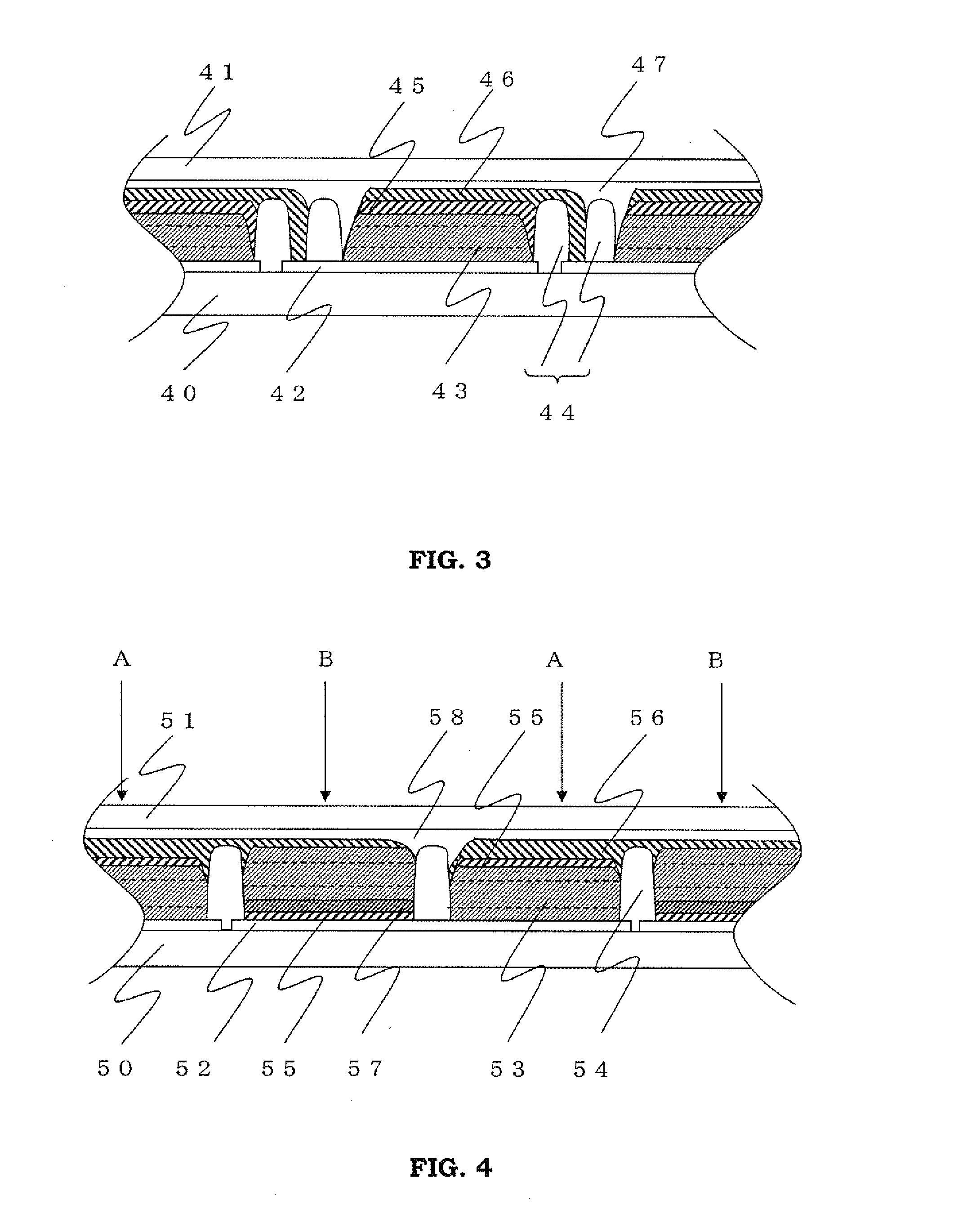

[0191]A solar cell module shown in FIG. 3 was produced.

[0192]FIG. 3 is a schematic cross-sectional view of a main part showing a layer structure of a solar cell module of the present invention. In the drawing, a reference numeral 40 denotes a support: a reference numeral 41 denotes a cover: a reference numeral 42 denotes a conductive layer: a reference numeral 43 denotes a photoelectric conversion layer filled with a carrier transporting material: a reference numeral 44 denotes an inter-cell insulating layer: a reference numeral 45 denotes a catalyst layer: a reference numeral 46 denotes a counter electrode conductive layer: and a reference numeral 47 denotes an insulating layer.

[0193]A solar cell module was completed in the same manner as in Production Example 2, except that after the porous semiconductor layers were formed, two rows of the inter-cell insulating layers 44 were formed an thereafter, the counter electrode conductive layer 46 was formed between the inter-cell insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com