Patents

Literature

32results about How to "Improve FF" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

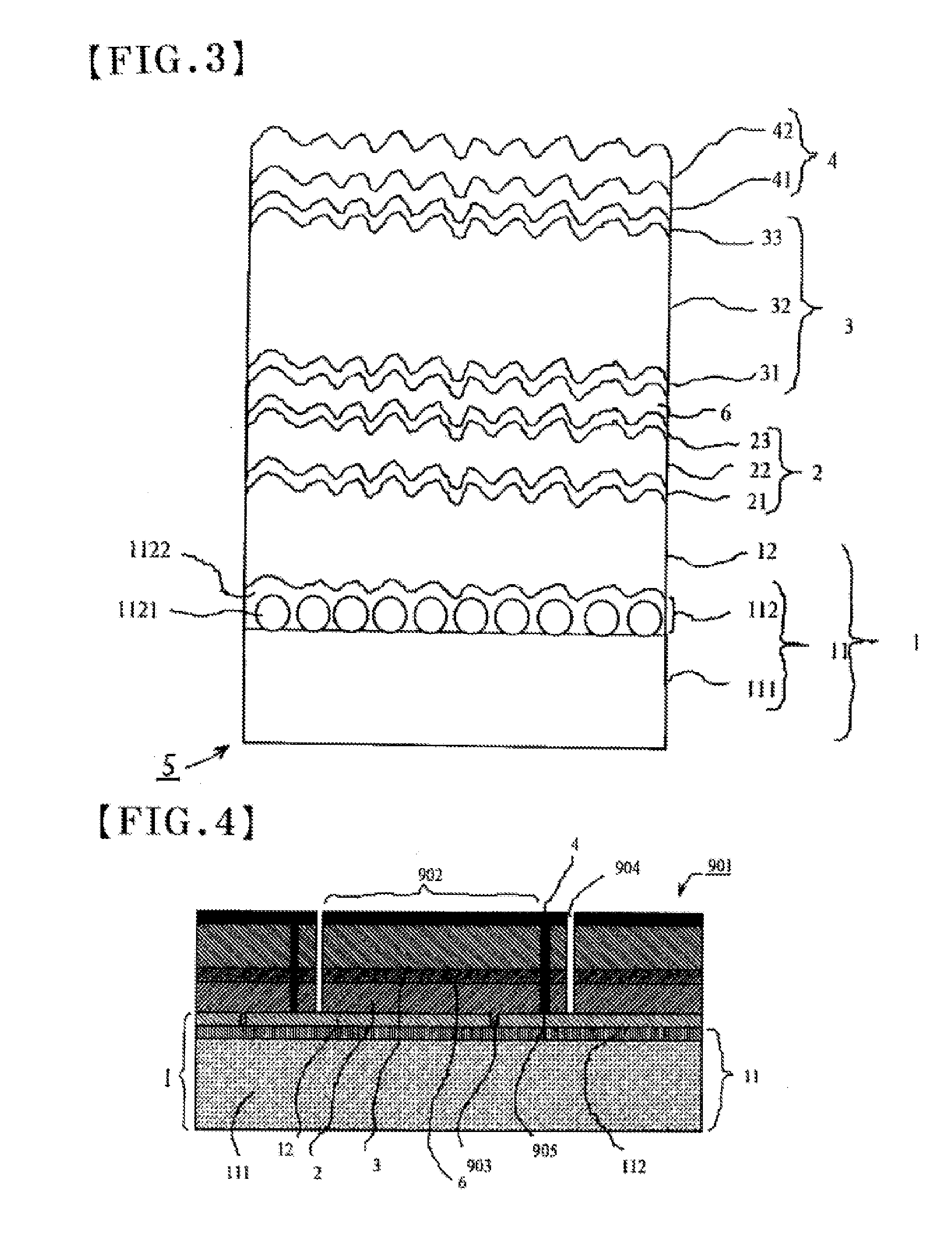

Silicon-based thin-film photoeclectric converter and method of manufacturing the same

InactiveUS20090133753A1Low resistivityImprove propertiesFinal product manufactureSolid-state devicesElectrical resistance and conductanceHydrogen concentration

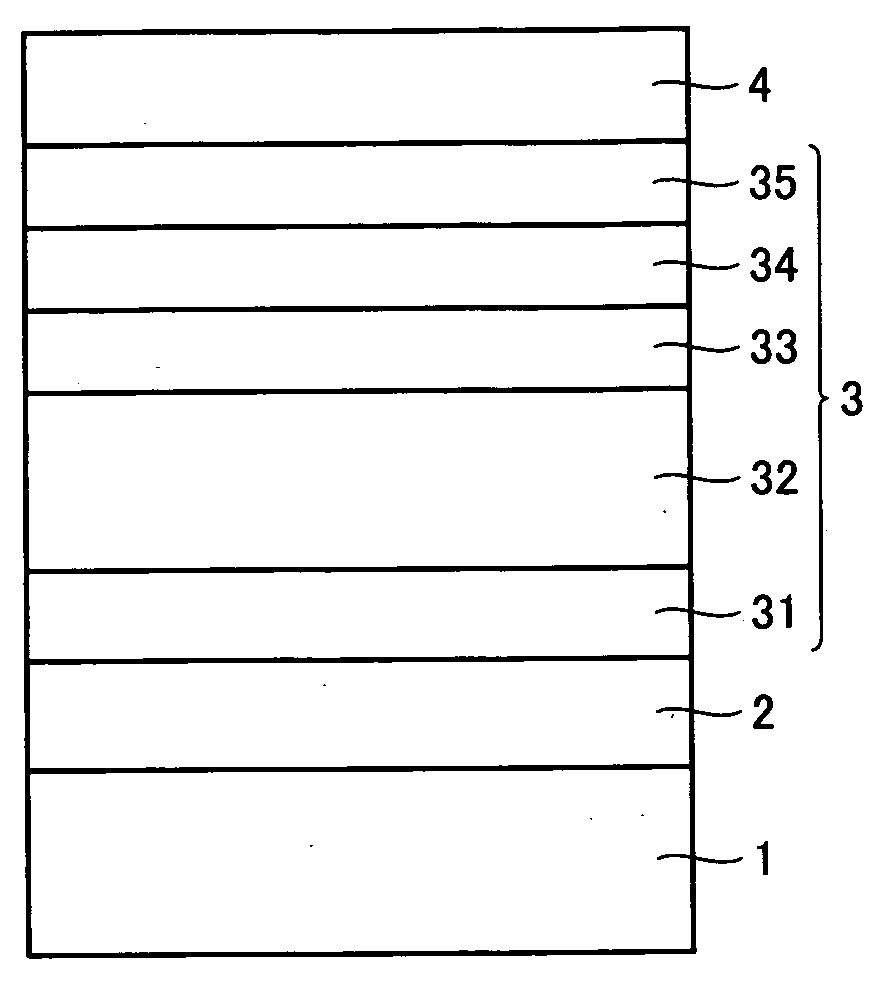

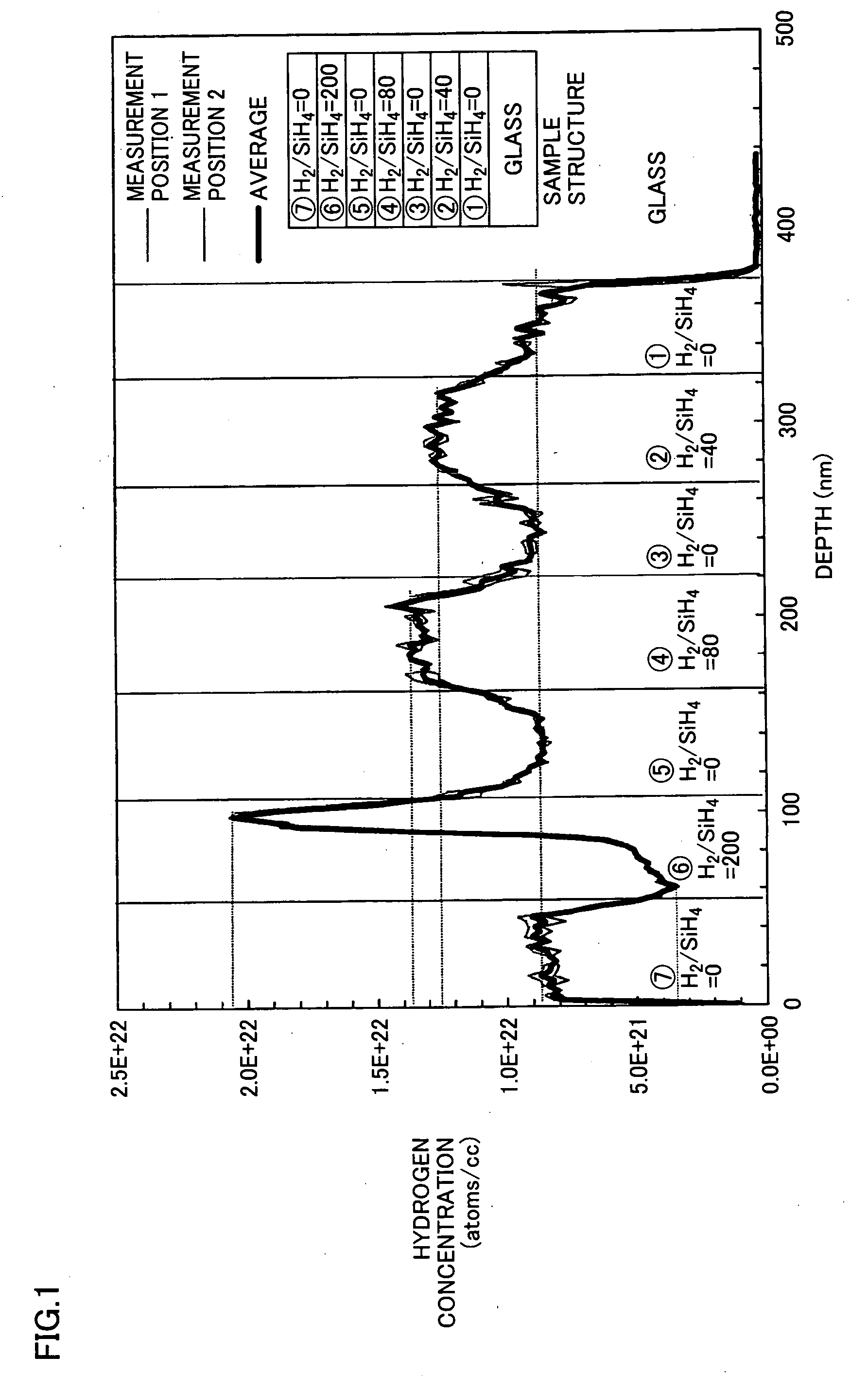

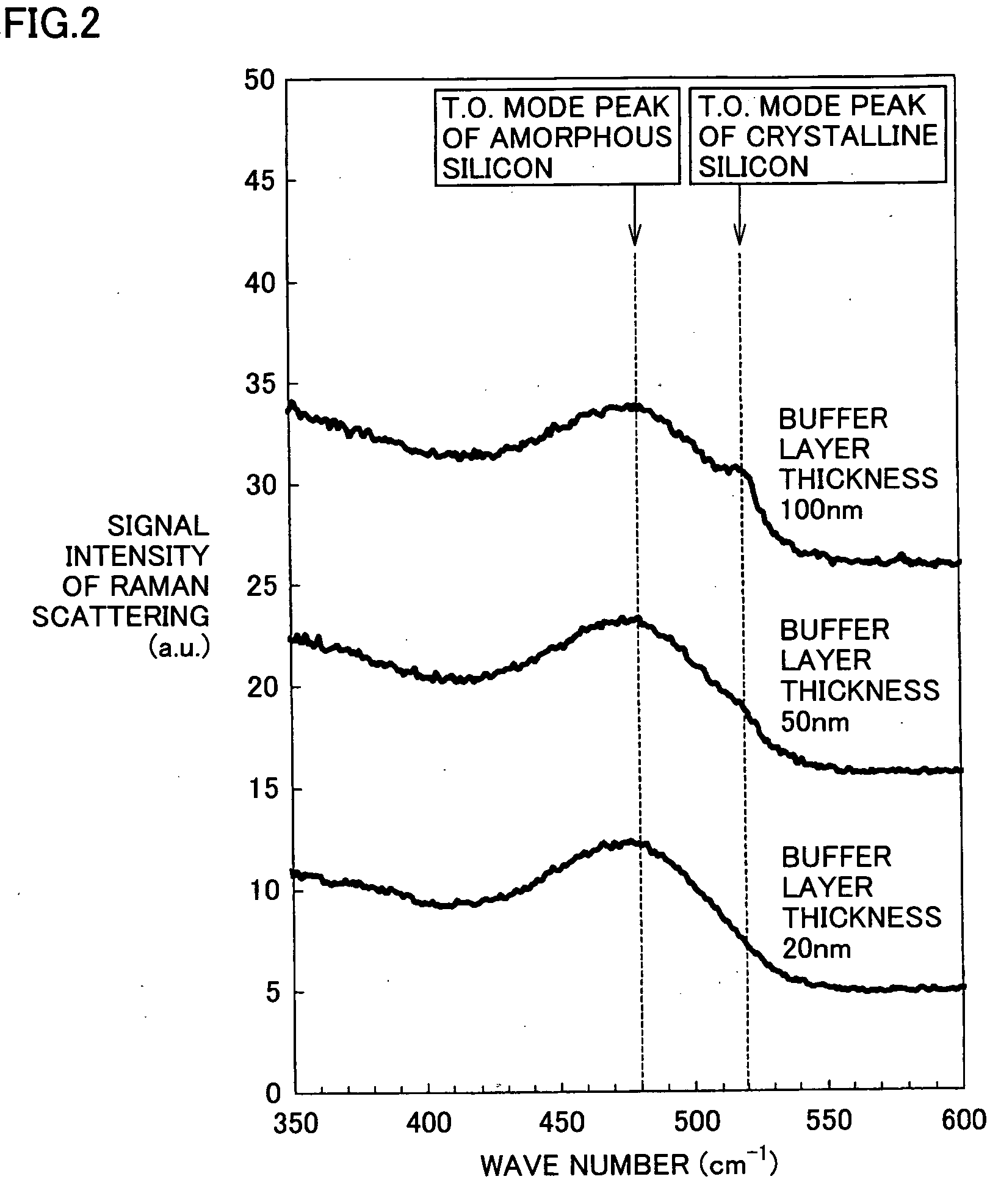

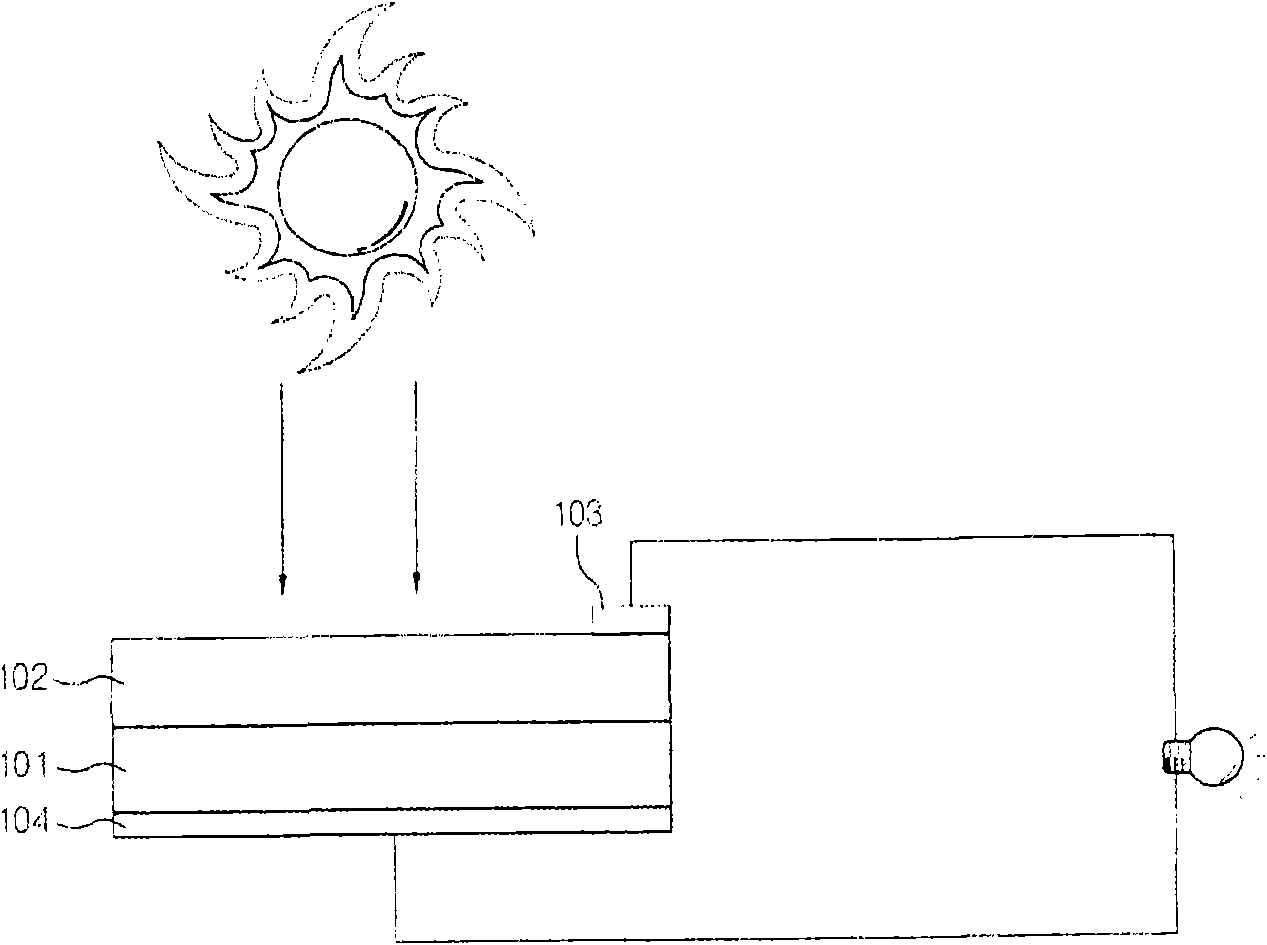

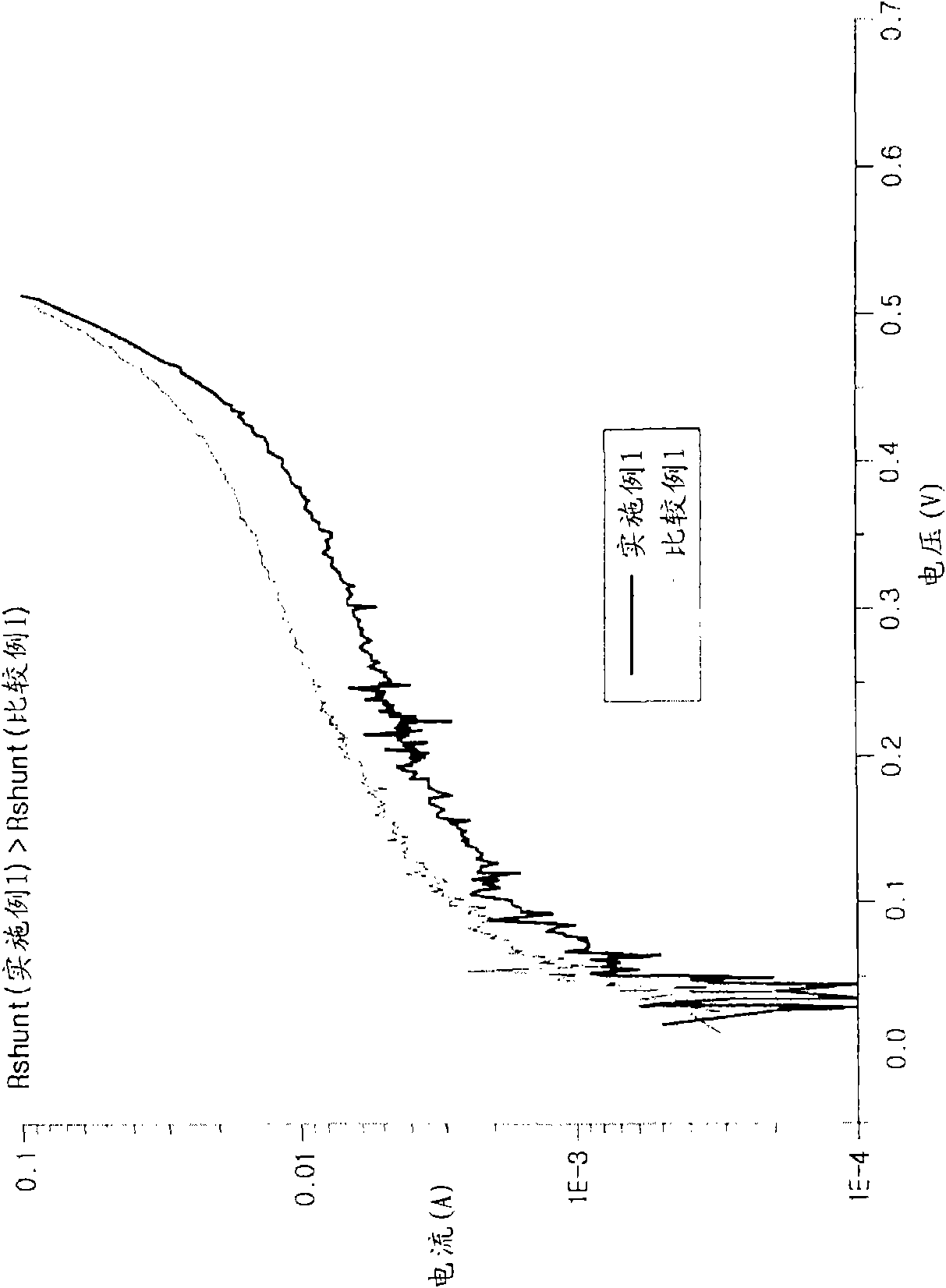

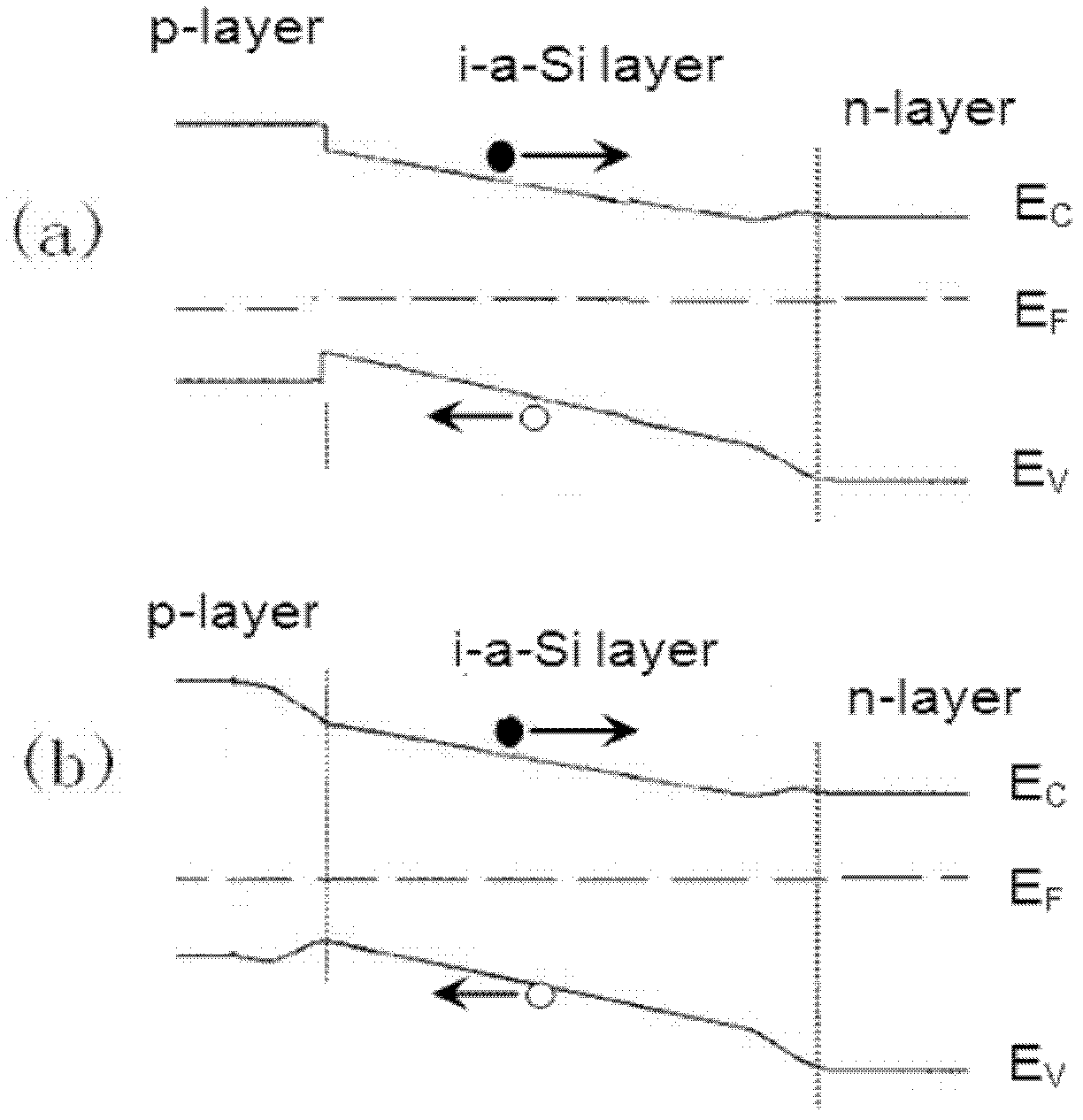

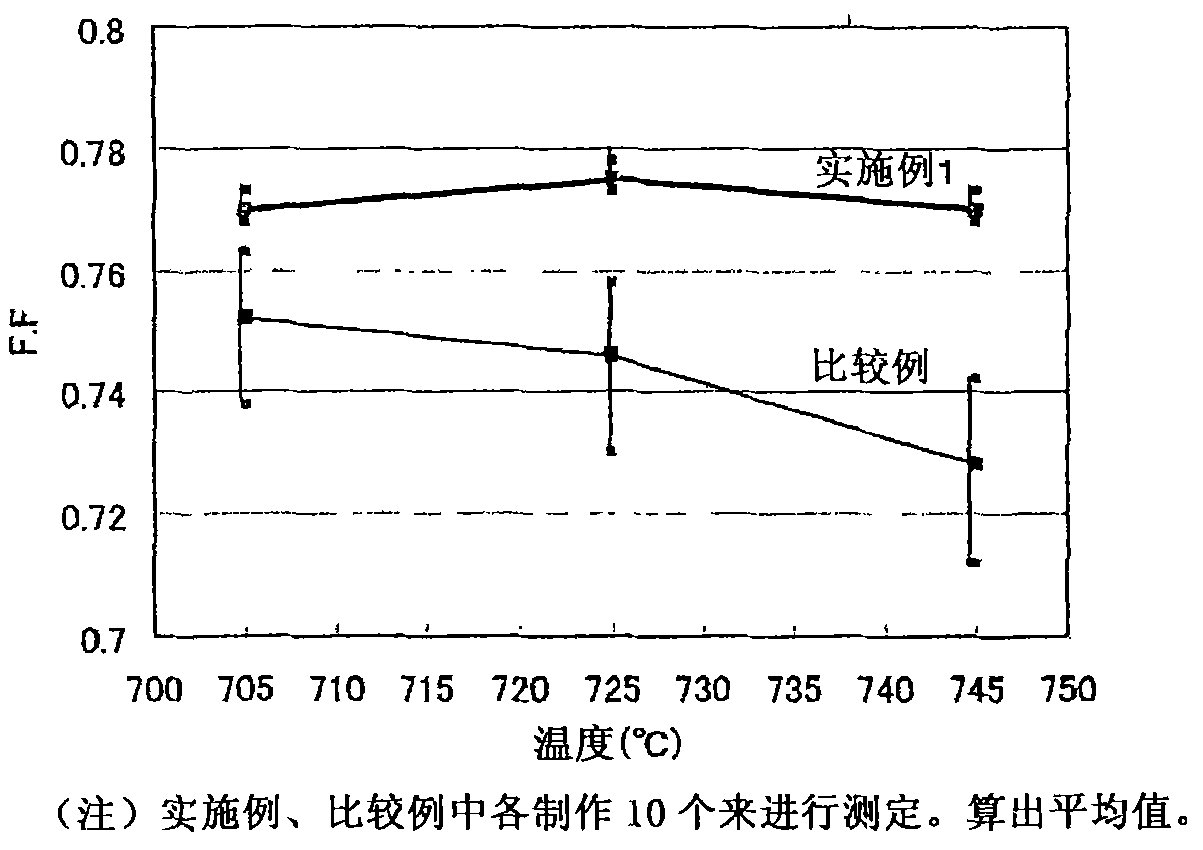

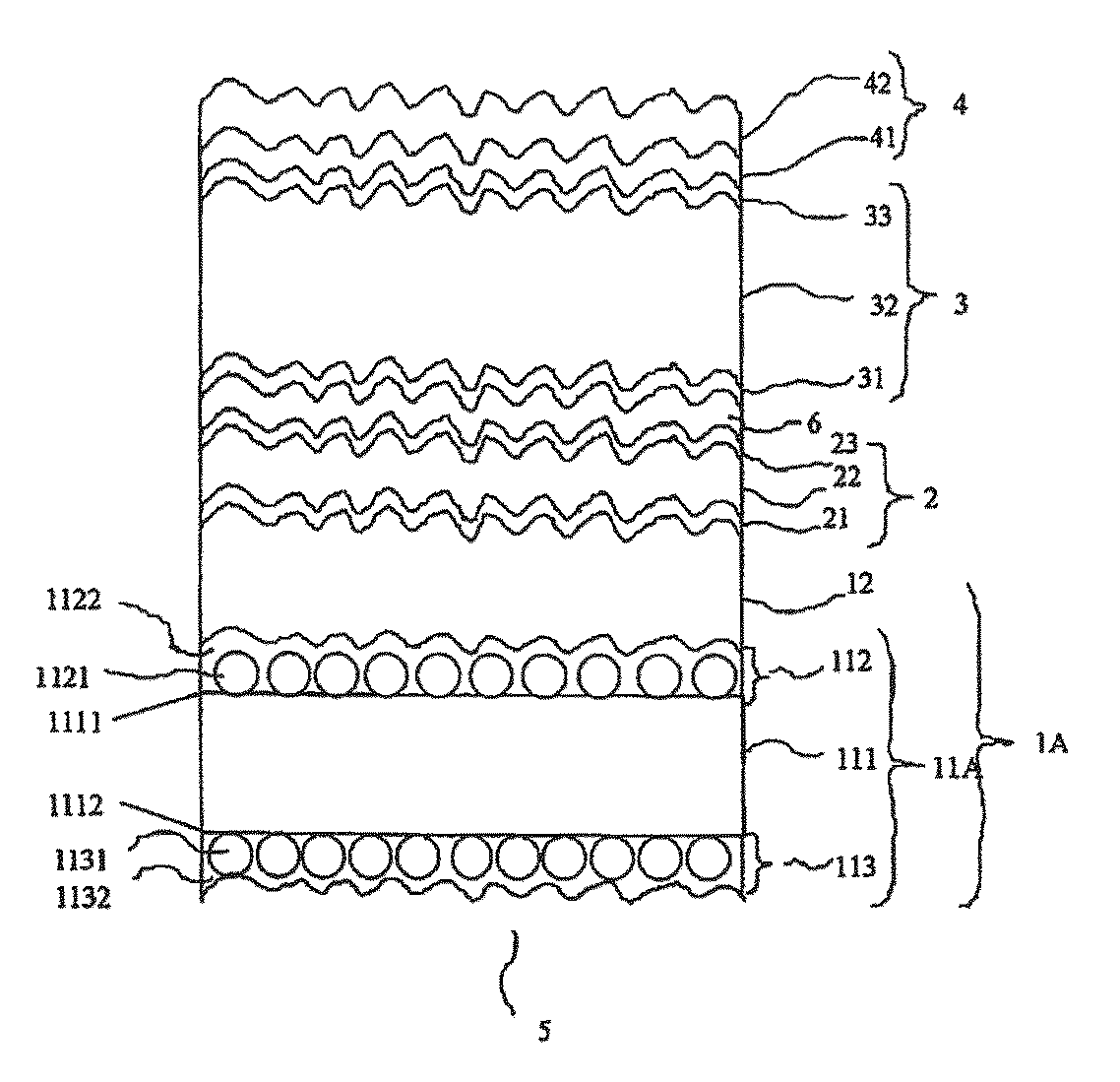

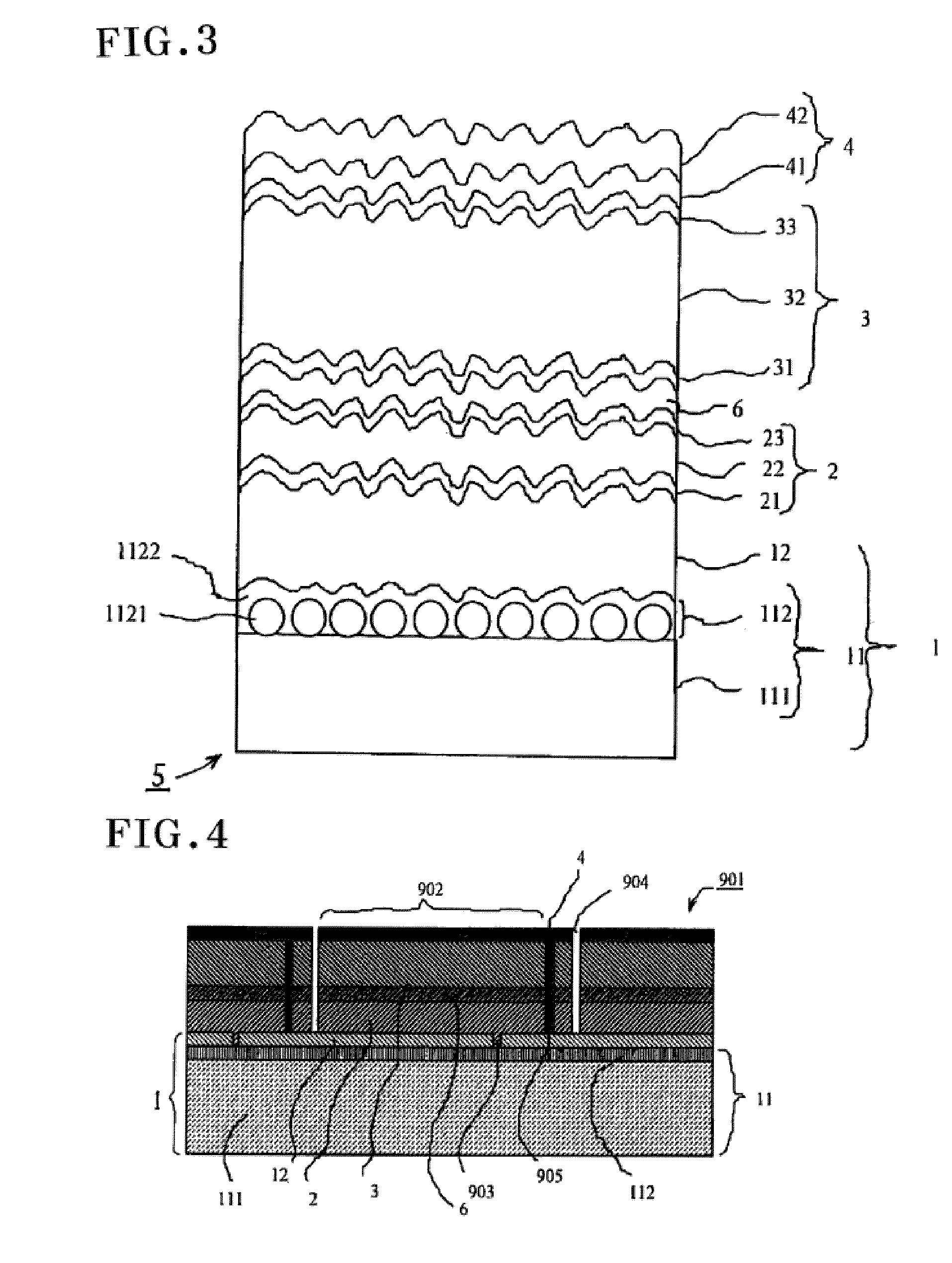

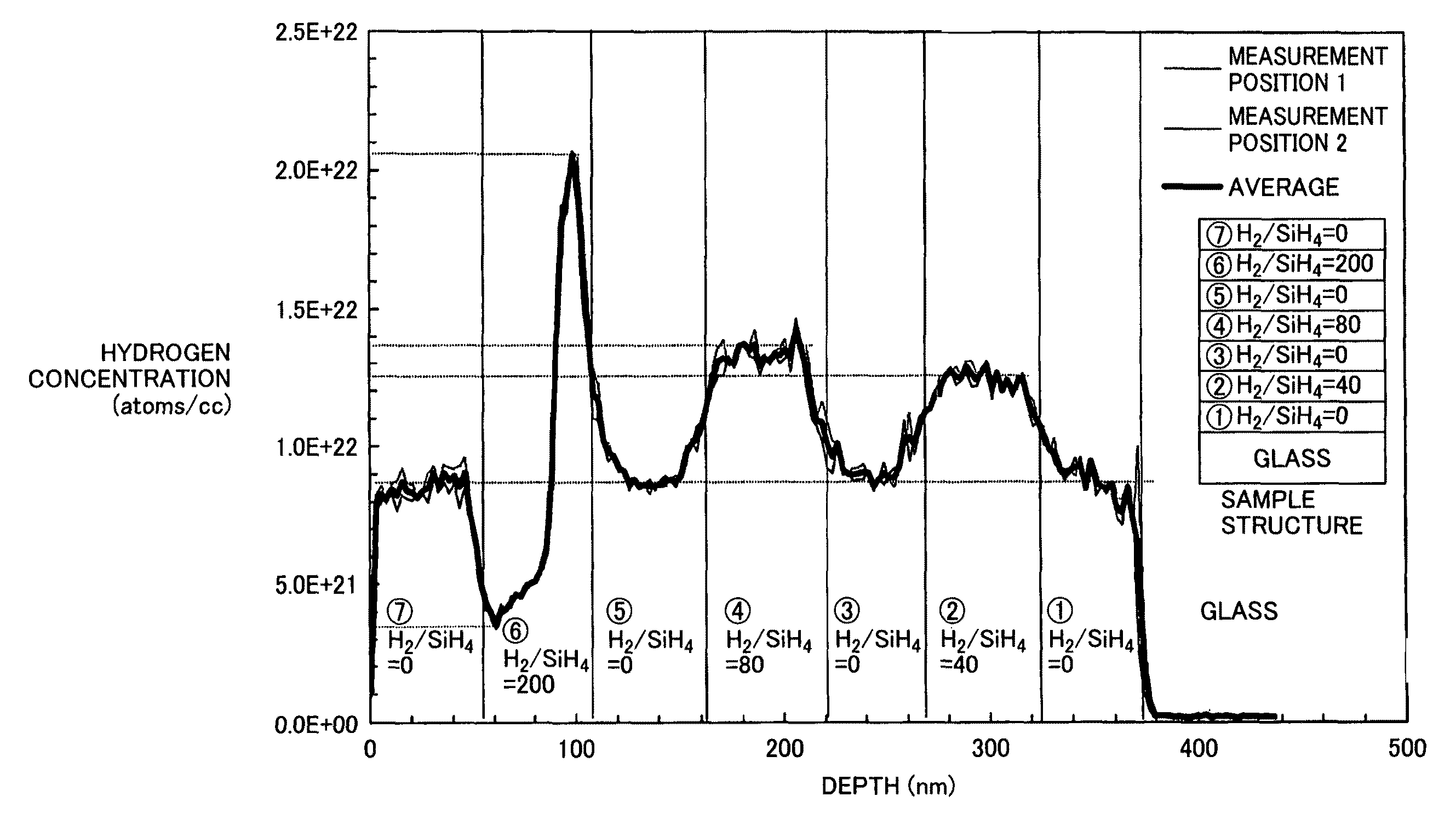

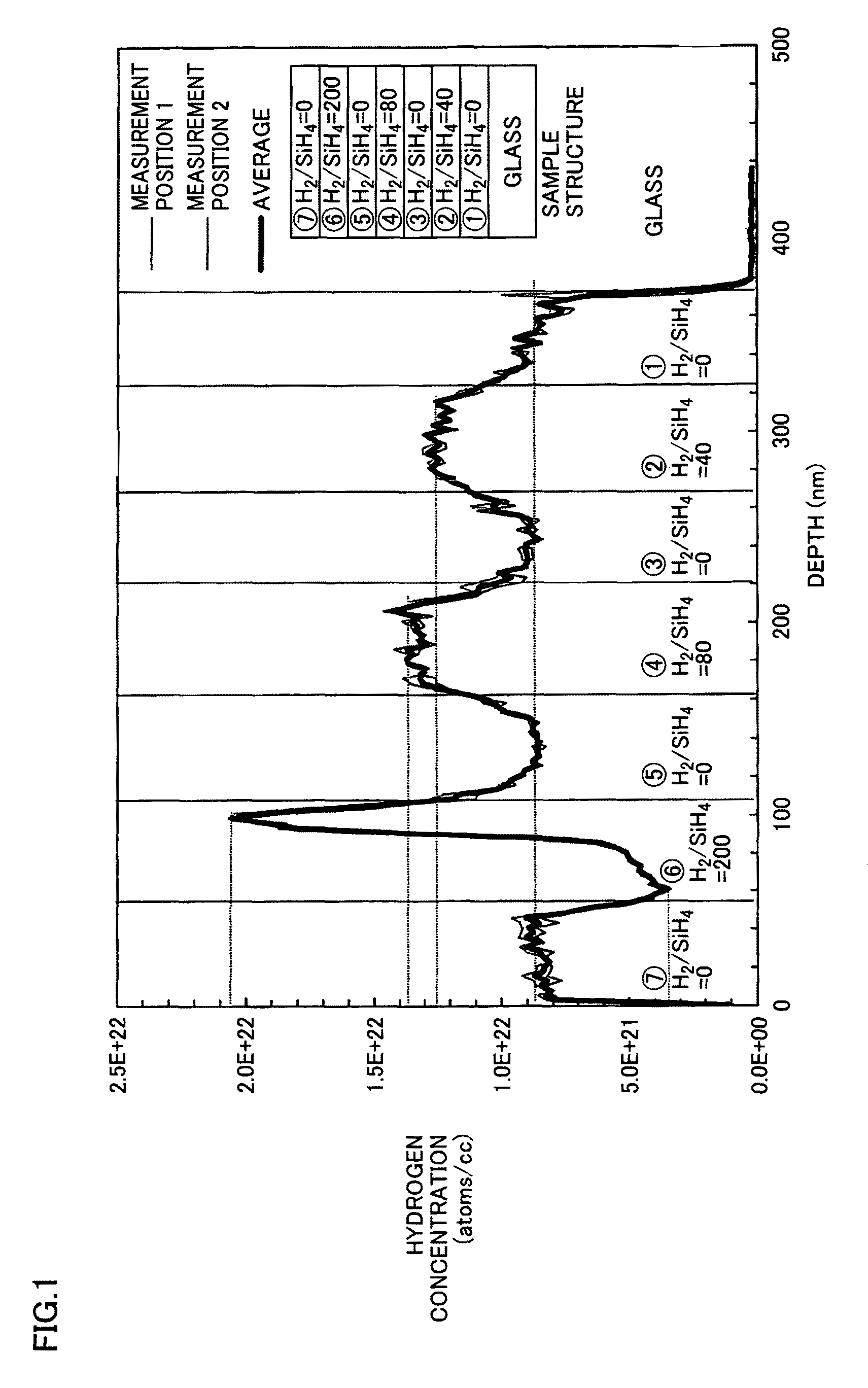

In order to improve photoelectric conversion properties of a silicon-based thin-film photoelectric converter to which a conductive SiOx layer is inserted to obtain an optical confinement effect, the silicon-based thin-film photoelectric converter according to the present invention includes an i-type photoelectric conversion layer of hydrogenated amorphous silicon or an alloy thereof, an i-type buffer layer made of hydrogenated amorphous silicon, and an n-type Si1-xOx layer (x is 0.25-0.6) stacked successively, wherein the buffer layer has a higher hydrogen concentration at its interface with and as compared with the photoelectric conversion layer and has a thickness of at least 5 nm and at most 50 nm. Accordingly, generation of silicon crystal phase parts and reduction of resistivity are promoted in the n-type Si1-xOx layer, contact resistance at the interface is reduced, and FF of the photoelectric converter is improved, so that the photoelectric converter achieves improved properties.

Owner:KANEKA CORP

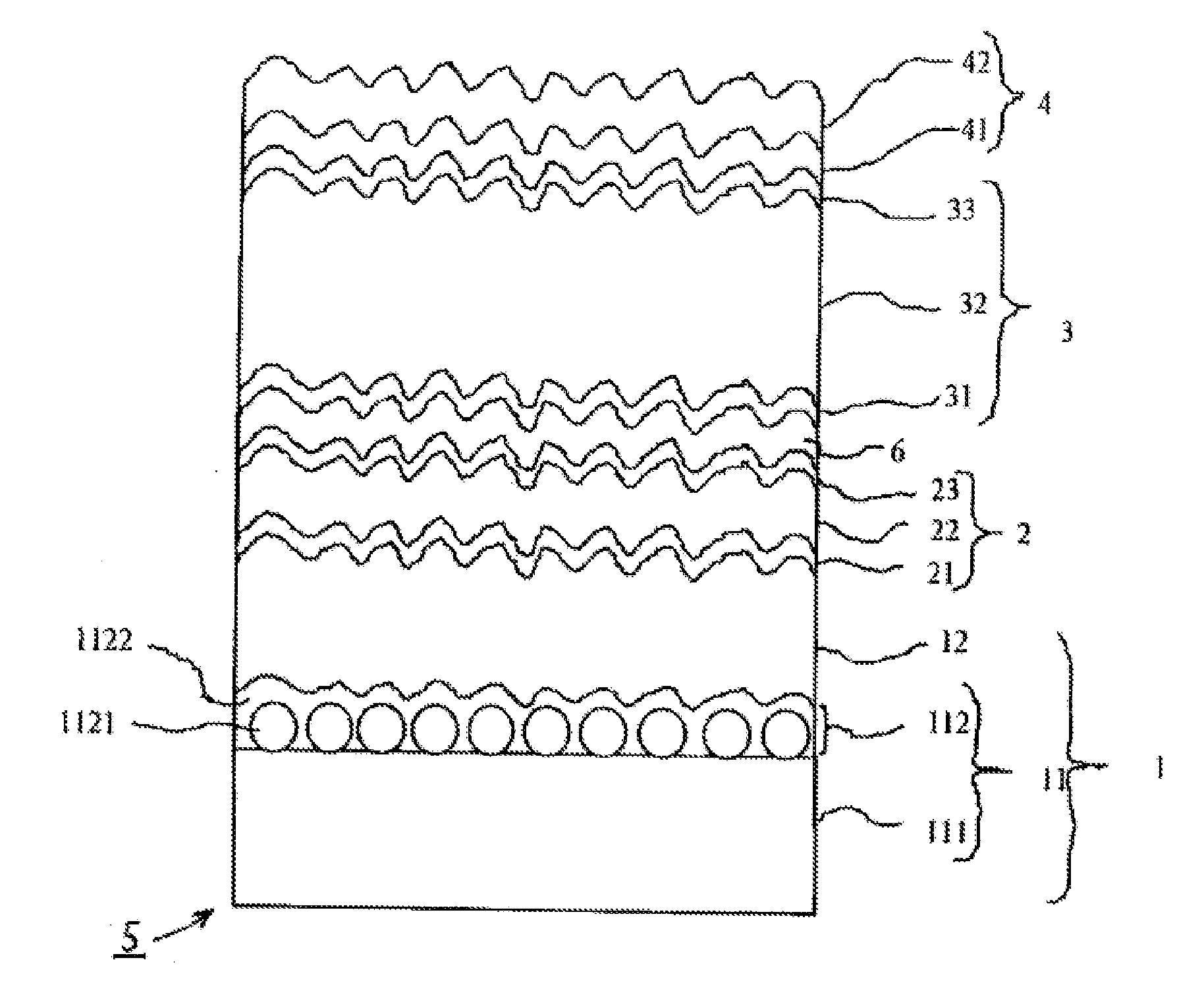

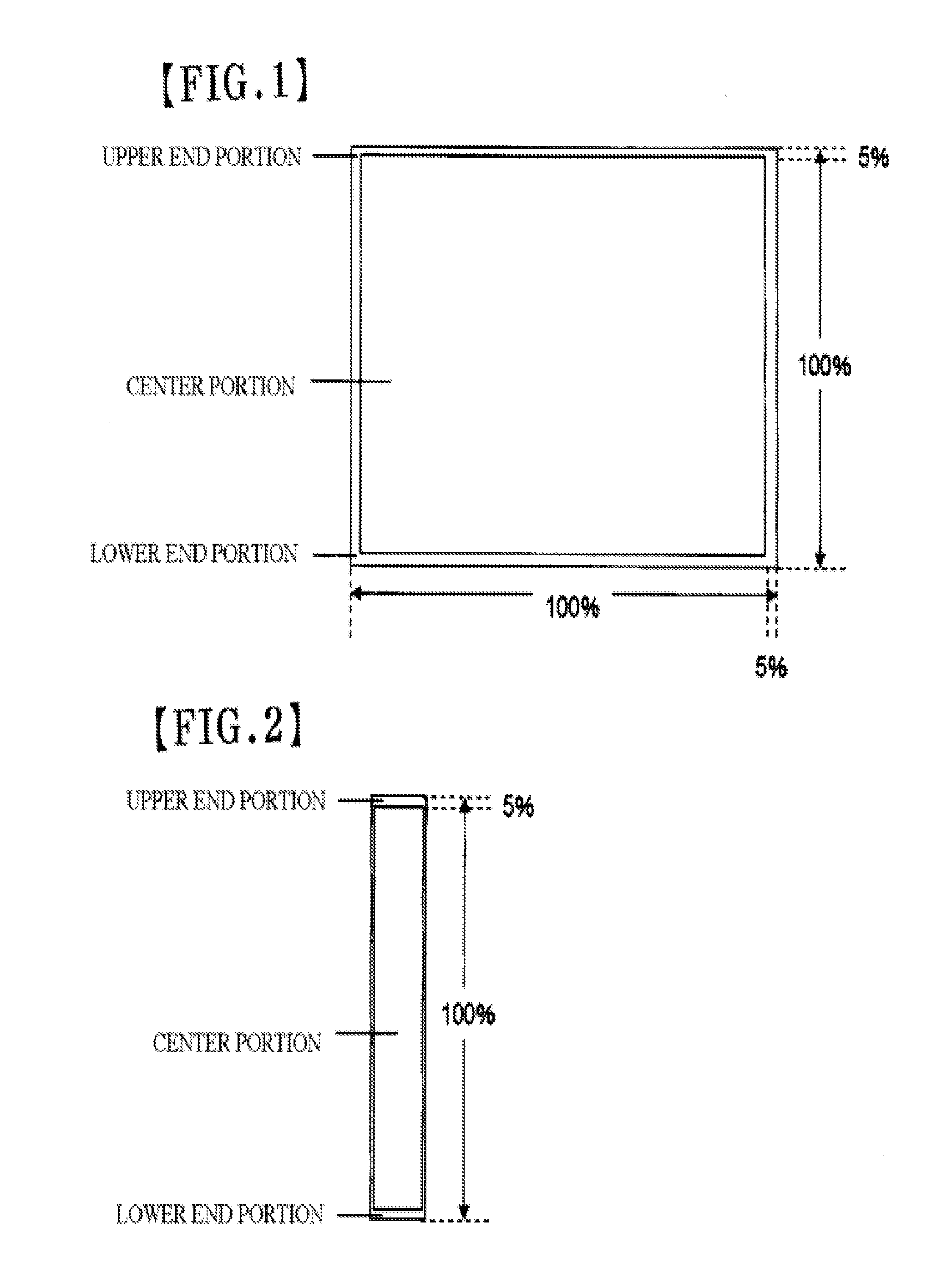

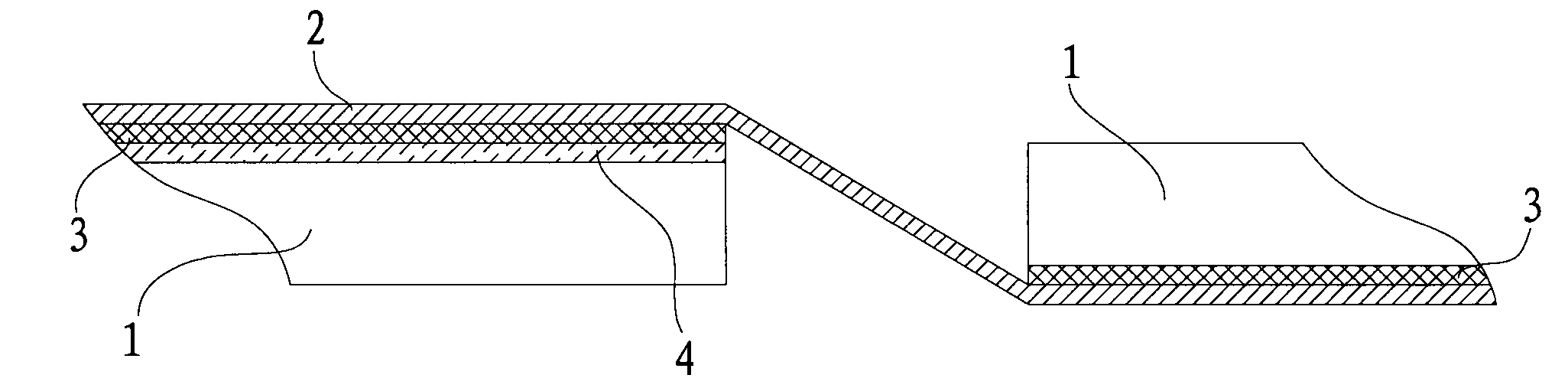

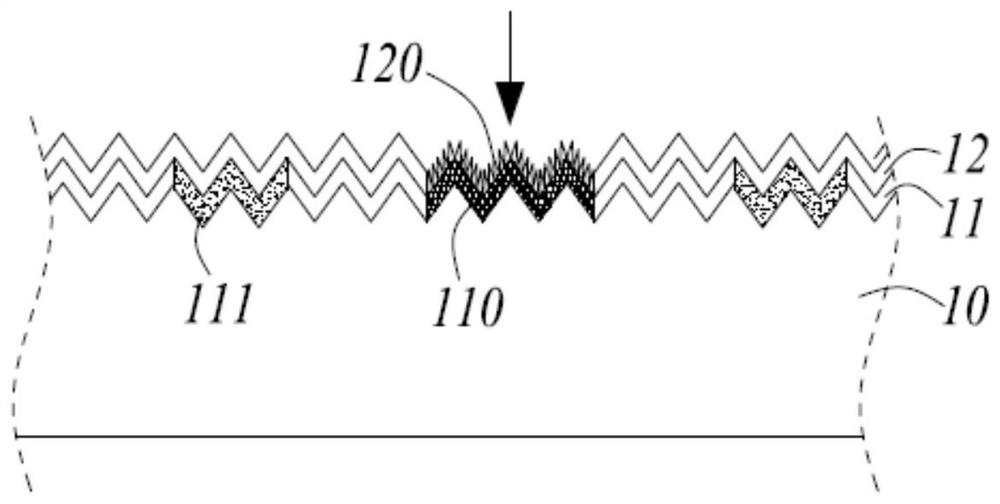

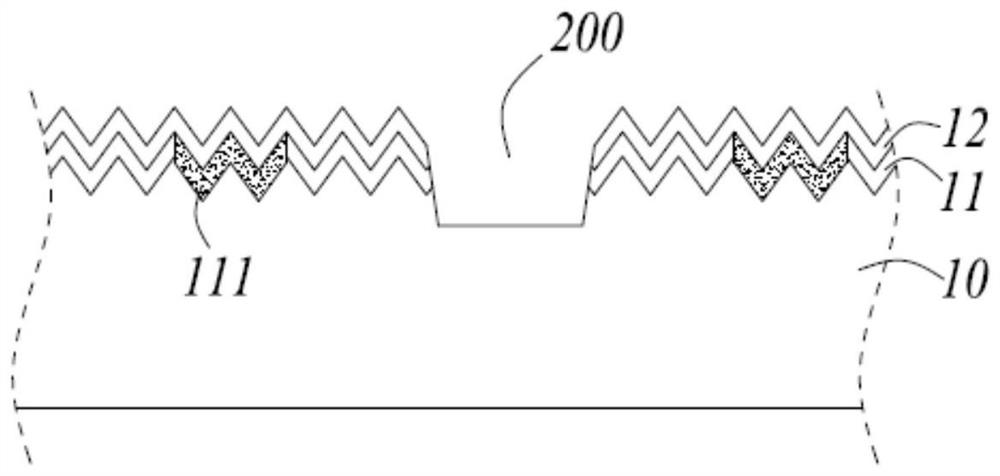

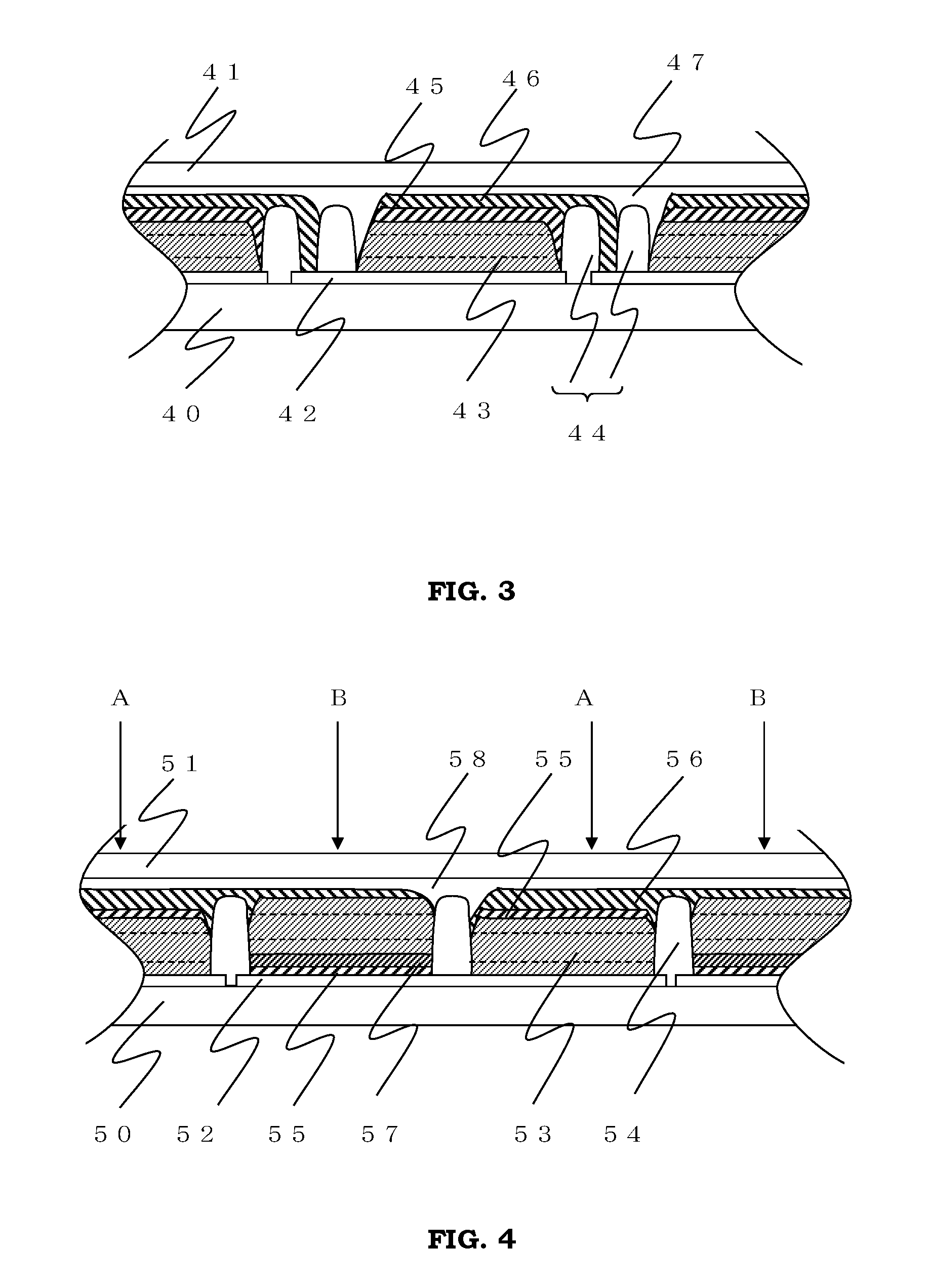

Substrate for thin-film photoelectric conversion device, thin-film photoelectric conversion device including the same, and method for producing substrate for thin-film photoelectric conversion device

InactiveUS20110073162A1Improve adhesionImprove FFFinal product manufacturePV power plantsProduction ratePhotoelectric conversion

Provided is a substrate for a thin-film photoelectric conversion device which makes it possible to produce the device having improved characteristics at low cost and high productivity. The substrate includes a transparent base member, with a transparent underlying layer and a transparent electrode layer successively stacked on one main surface of the transparent base member. The underlying layer includes transparent insulating fine particles and transparent binder, and the particles are dispersed to cover the one main surface with a coverage factor of particles—ranging from 30% or more to less than 80%. An antireflection layer is provided on the other main surface of the transparent base. The antireflection layer includes transparent insulating fine particles and transparent binder, and the particles are dispersed to cover the other main surface with a coverage factor greater than the underlying layer. The transparent electrode layer contains zinc oxide deposited by low-pressure CVD method.

Owner:KANEKA CORP

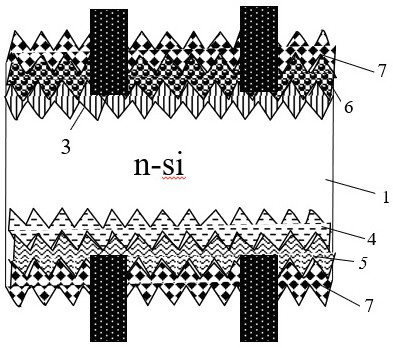

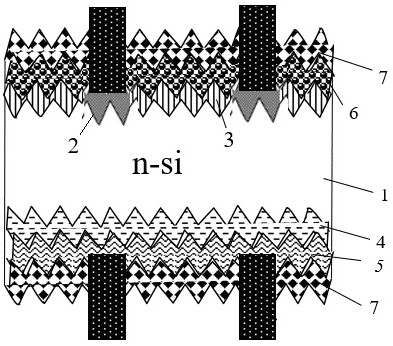

N-type fragmented solar cell structure and manufacturing method thereof

InactiveCN111326606AImprove FFIncrease VOCFinal product manufacturePhotovoltaic energy generationCrystallographyElectrical battery

The invention discloses an N-type fragmented solar cell structure and a manufacturing method thereof. The manufacturing method comprises: providing an n-type solar cell substrate, and processing at least one side surface of the substrate to form a cutting groove for cracking; at least forming a continuous passivation layer on the surface of one side of the substrate, and enabling the grooving wallof the grooving to be covered by the passivation layer; splitting the substrate along the cutting groove to form a fragmented battery, and forming a natural oxide layer on the quasi-neutral region, which is not covered by the passivation layer, of the edge of the fragmented battery; and passivating the quasi-neutral region, which is not covered by the passivation layer, of the edge of the fragmented battery and the natural oxide layer by using hydrogen plasma. According to the invention, the first passivation structure and the second passivation structure are formed on the edge of the fragmented cell after slicing, the first passivation structure covers the exposed space charge region, and the second passivation structure covers the quasi-neutral region, so that the fragmented cell with the edge full-area passivation structure is obtained.

Owner:苏州光汇新能源科技有限公司

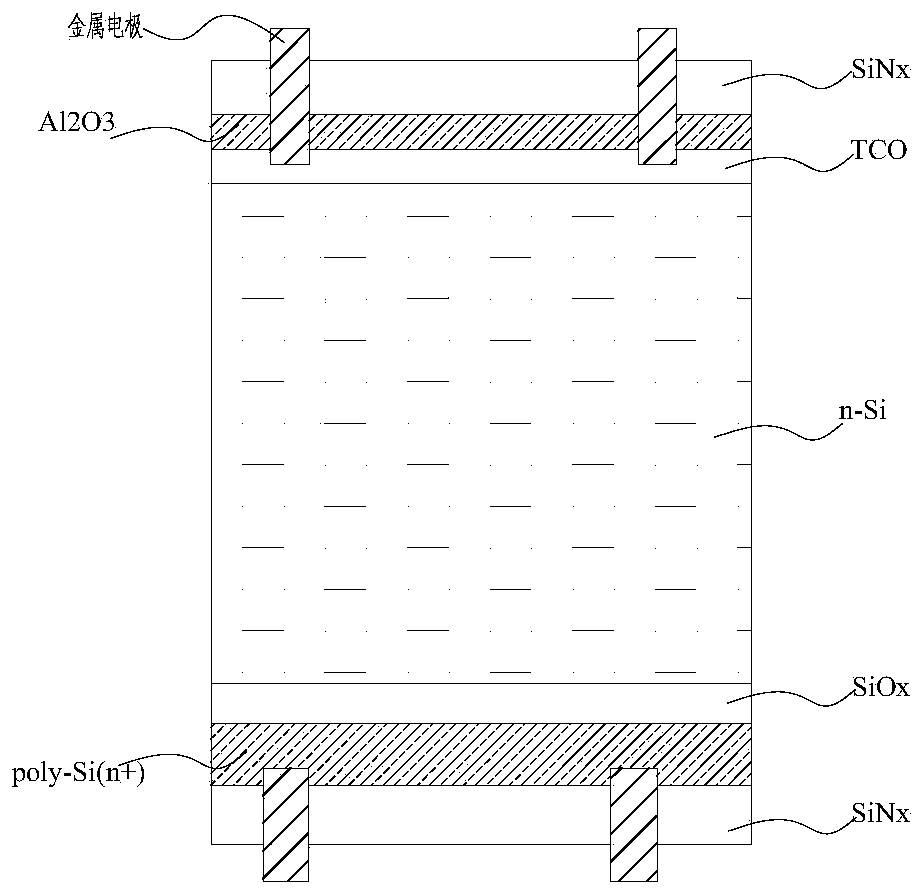

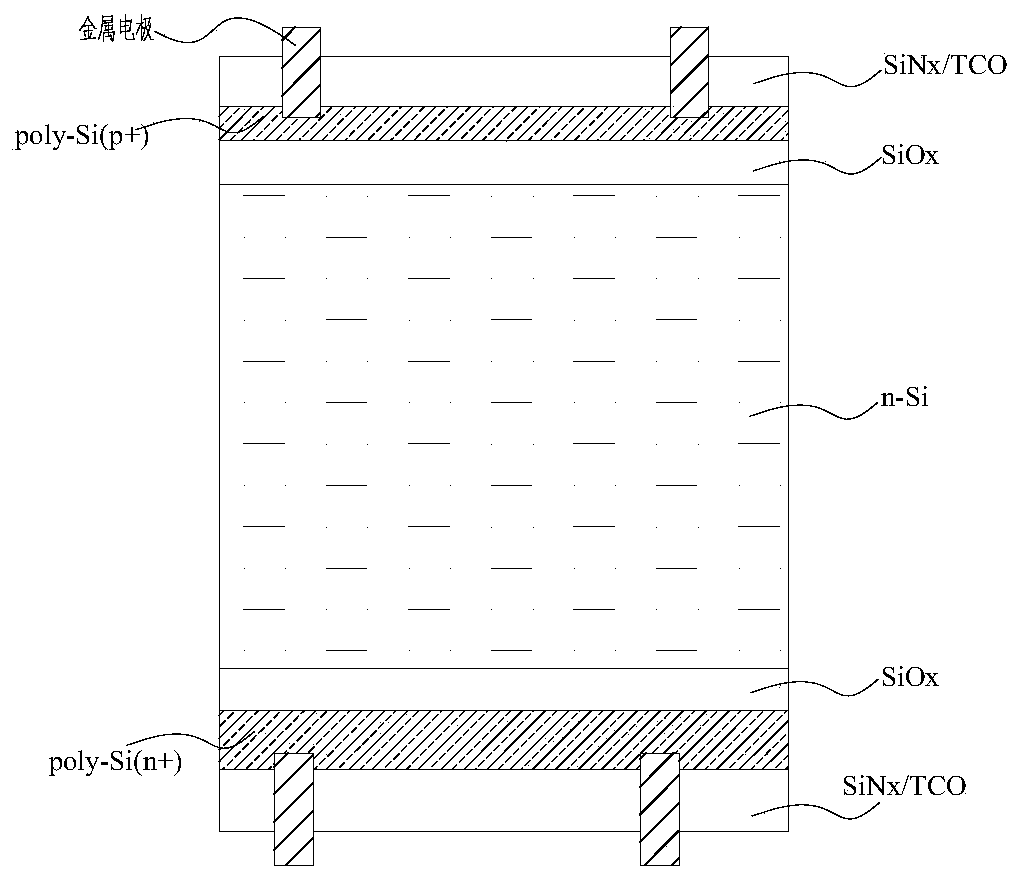

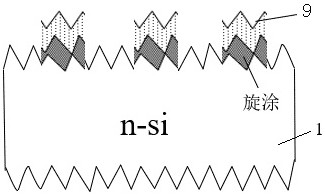

Manufacturing method of N-type TOPCon solar cell

ActiveCN111628047AReduce the amount of investmentAvoid damageFinal product manufacturePhotovoltaic energy generationPhysical chemistrySilicon oxide

The invention relates to a manufacturing method of an N-type TOPCon solar cell. The manufacturing method comprises the following steps: a, double-sided texturing; b, single-sided spin coating; c, single-sided oxidation: forming a boron-containing silicon oxide layer on a spin coating surface; d, forming a heavily doped region substrate and a lightly doped region substrate: forming an organic masklayer for protecting a heavily doped region at a position corresponding to the metal gate line by using a mask mode, completely removing the boron-containing silicon oxide layer and the boron source outside the coverage area of the organic mask layer by using HF, and then removing the organic mask layer; and e, heavy doping and light doping: specifically, completely pushing the spin-coated boron source into the silicon substrate through a tubular low-pressure diffusion method, forming a heavy doping region is formed, carrying out whole-surface source-through deposition to form a lightly dopedregion, and finally, carrying out high-temperature oxidation to form a BSG layer with the thickness of 80-100nm, and then carrying out normal subsequent processes. According to the invention, a boronselective emitter can obtain higher photoelectric conversion efficiency, so that the conversion efficiency of the solar cell is improved.

Owner:常州顺风太阳能科技有限公司

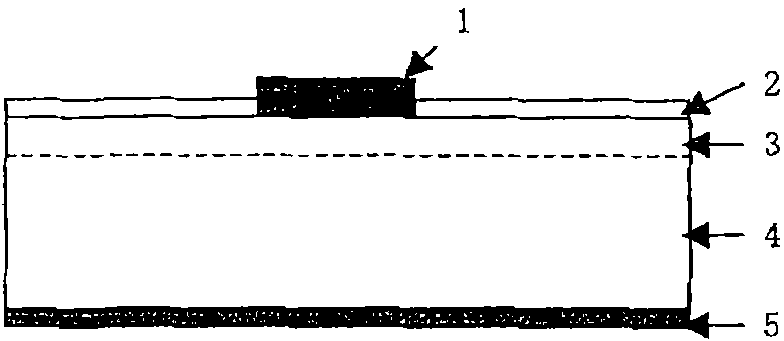

Solar cell

InactiveCN101611497AImprove efficiencyDecline in physical propertiesFinal product manufacturePhotovoltaic energy generationRefractive indexSolar cell

A solar cell includes a p-n structure having a first conductive semiconductor substrate, a second conductive semiconductor layer formed on the first conductive semiconductor substrate and having a conduction opposite to the first conductive semiconductor substrate, and a p-n junction formed at an interface between the first conductive semiconductor substrate and the second conductive semiconductor layer; a passivated layer formed on the second conductive semiconductor layer and composed of silicon oxynitride with a refractive index of 1.45 to 1.70; an anti-reflection film formed on the passivated layer and composed of silicon nitride; a front electrode connected to the second conductive semiconductor layer with passing through a part of the passivated layer and the anti-reflection film and exposed outward; and a rear electrode formed at an opposite side to the front electrode with the first conductive semiconductor substrate being interposed therebetween to be connected to the first conductive semiconductor substrate.

Owner:LG ELECTRONICS INC

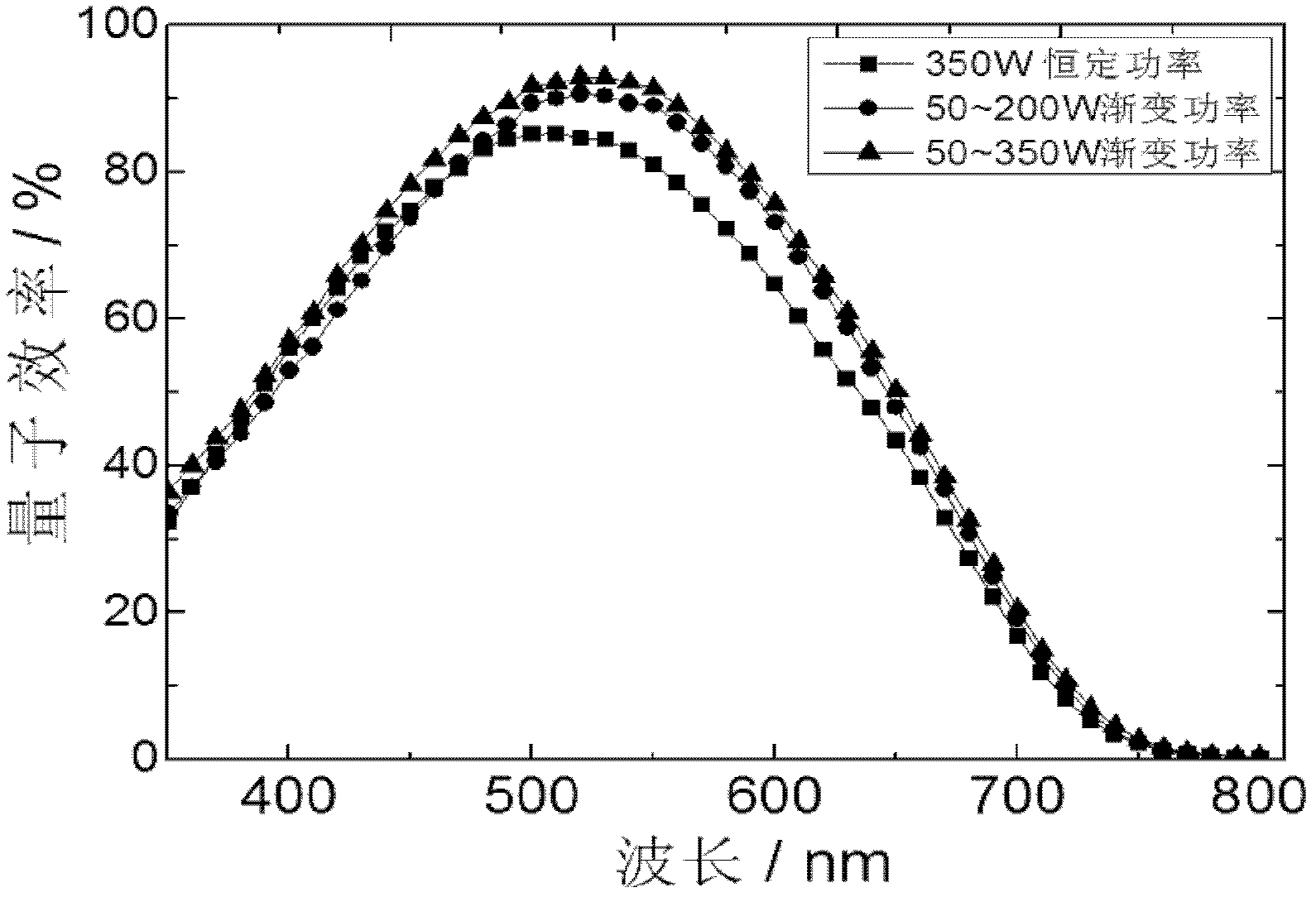

Nano silicon window layer with gradient band gap characteristic and preparation method thereof

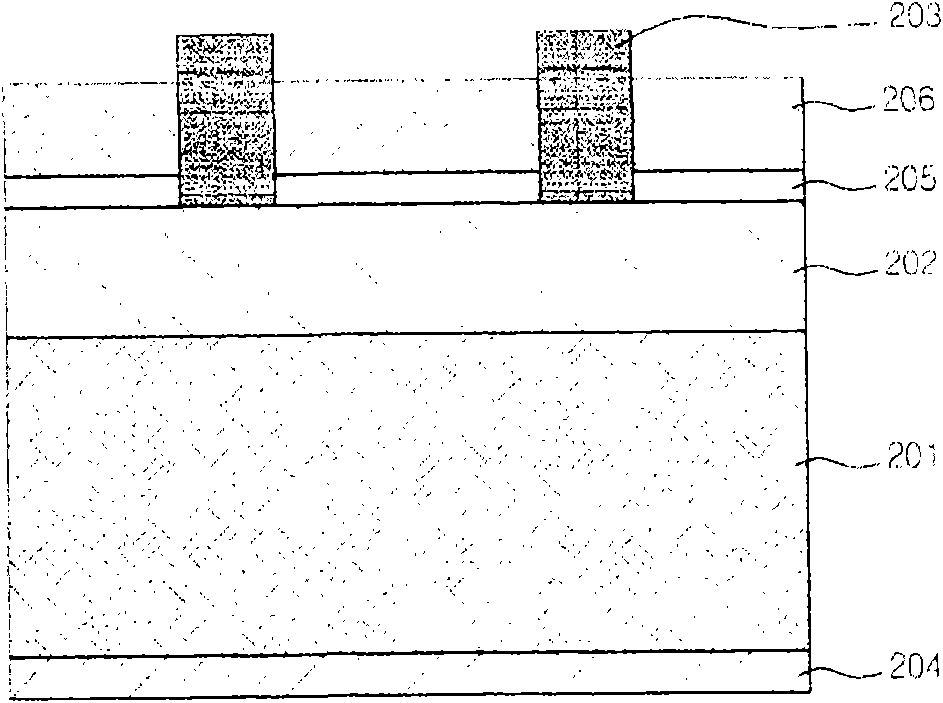

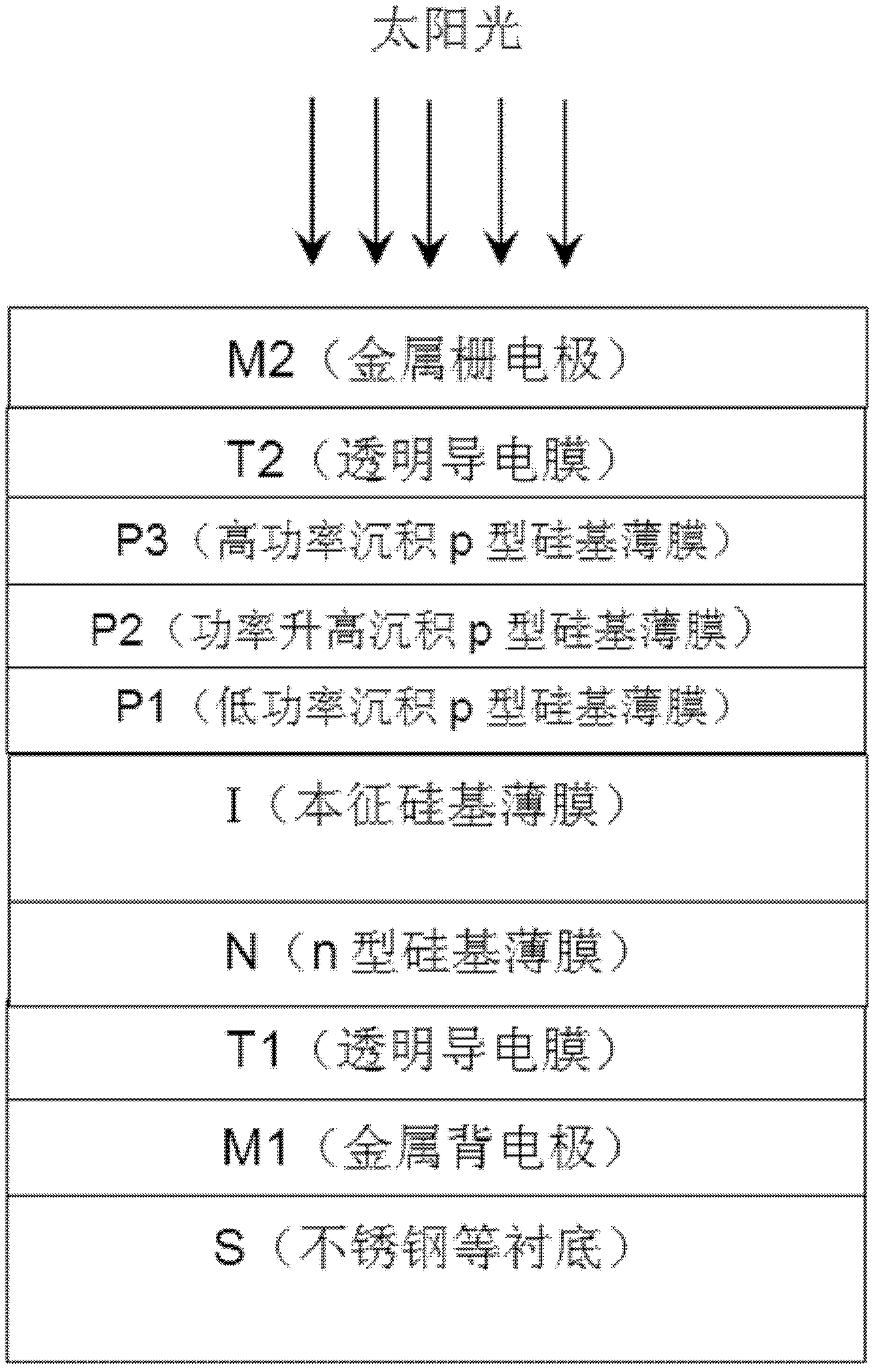

InactiveCN102569481ALittle bombardmentReduce compoundingFinal product manufactureNanoopticsSpectral responseP type silicon

The invention relates to a nano silicon window layer with the gradient band gap characteristic, which is formed by depositing on the surface of a sample to be processed, wherein the surface of the sample to be processed is sequentially stacked with a metal back electrode M, a transparent conductive back electrode T1, an n-type Si-based thin film N and an intrinsic Si-based thin film I. The nano silicon window layer is formed by sequentially stacking a silicon thin film P1, a silicon thin film P2 and a silicon thin film P3. A preparation method of the nano silicon window layer comprises the following steps: depositing the p-type silicon thin film P1 with small thickness under a low glow power; then gradually raising the power and depositing the thin film P2; and finally, and completing the window layer P3 under a high power. The nano silicon window layer has the advantages that when the nano silicon window layer is applied to the window layer of an n-i-p-type silicon-based thin film solar cell, high electric conductance and wide band gap can be acquired, the bombardment of a solar cell i / p interface can be effectively reduced, the band gap matching between an intrinsic layer and the window layer can be implemented and the filling factor, the open-circuit voltage and the spectral response of the solar cell are obviously improved, so that the silicon-based thin film solar cell with high photoelectric conversion efficiency is obtained.

Owner:NANKAI UNIV

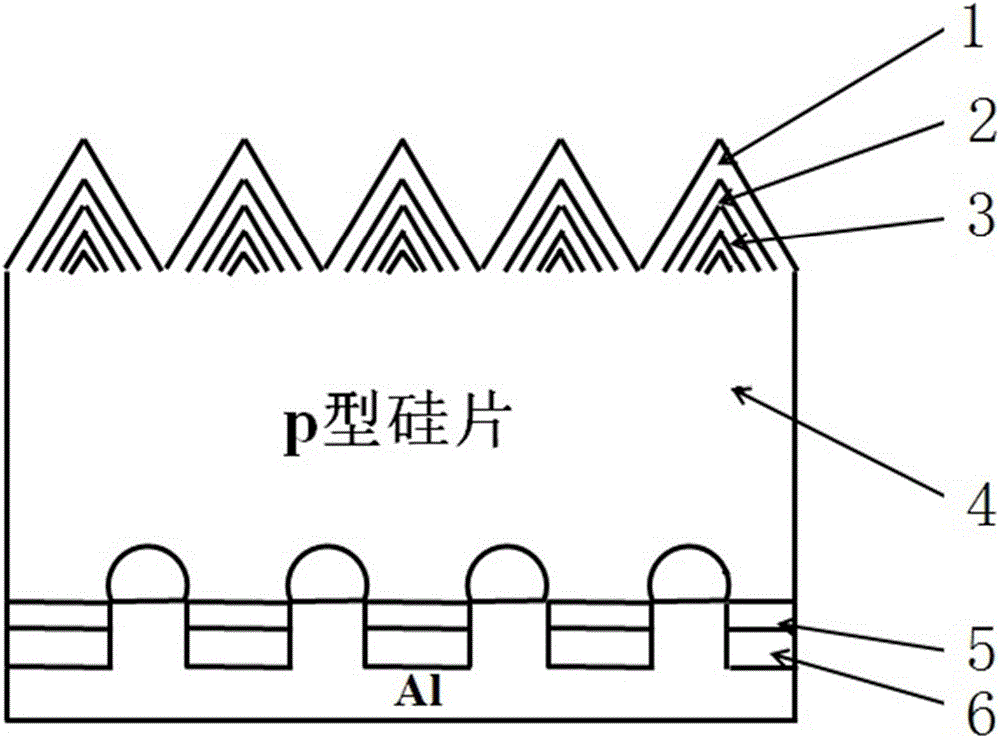

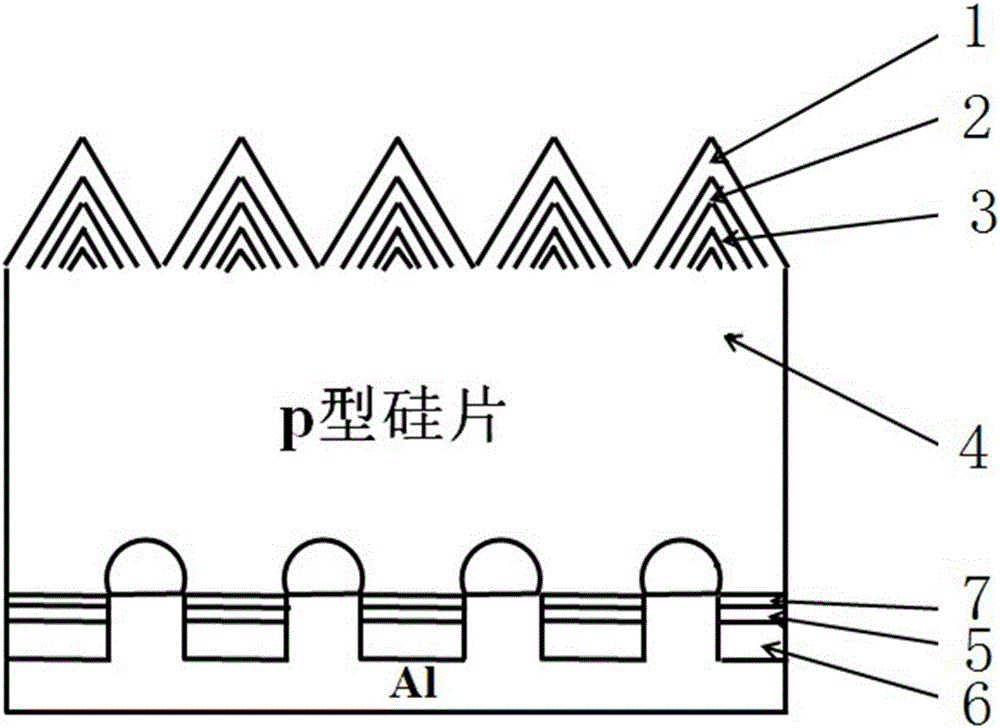

A process for preparing passivated emitter rear contact (PERC) solar cells

ActiveUS20170294545A1Simple processLow production costFinal product manufacturePhotovoltaic energy generationScreen printingCatalytic metal

A process for preparing a passivated emitter rear contact solar cell, which includes the steps as follows: removing the damaged layer on the surface of the silicon wafer and at the same time polishing both surfaces, texturing, forming PN junction, etching, removing the glass impurity, depositing a passivation film on the back surface, depositing a passivating antireflective layer on the front surface, making local openings on the back surface, screen printing of metal paste on both the front surface and the back surface and sintering, in which the texturing step employs a catalytic metal etching approach, and the textured structure is a nanometer-level textured structure. The present invention has combined removing the damaged layer on the surface of the silicon wafer and polishing both the front and back surfaces into one single step, and thus has simplified the production process and reduced the production cost.

Owner:CSI CELLS CO LTD

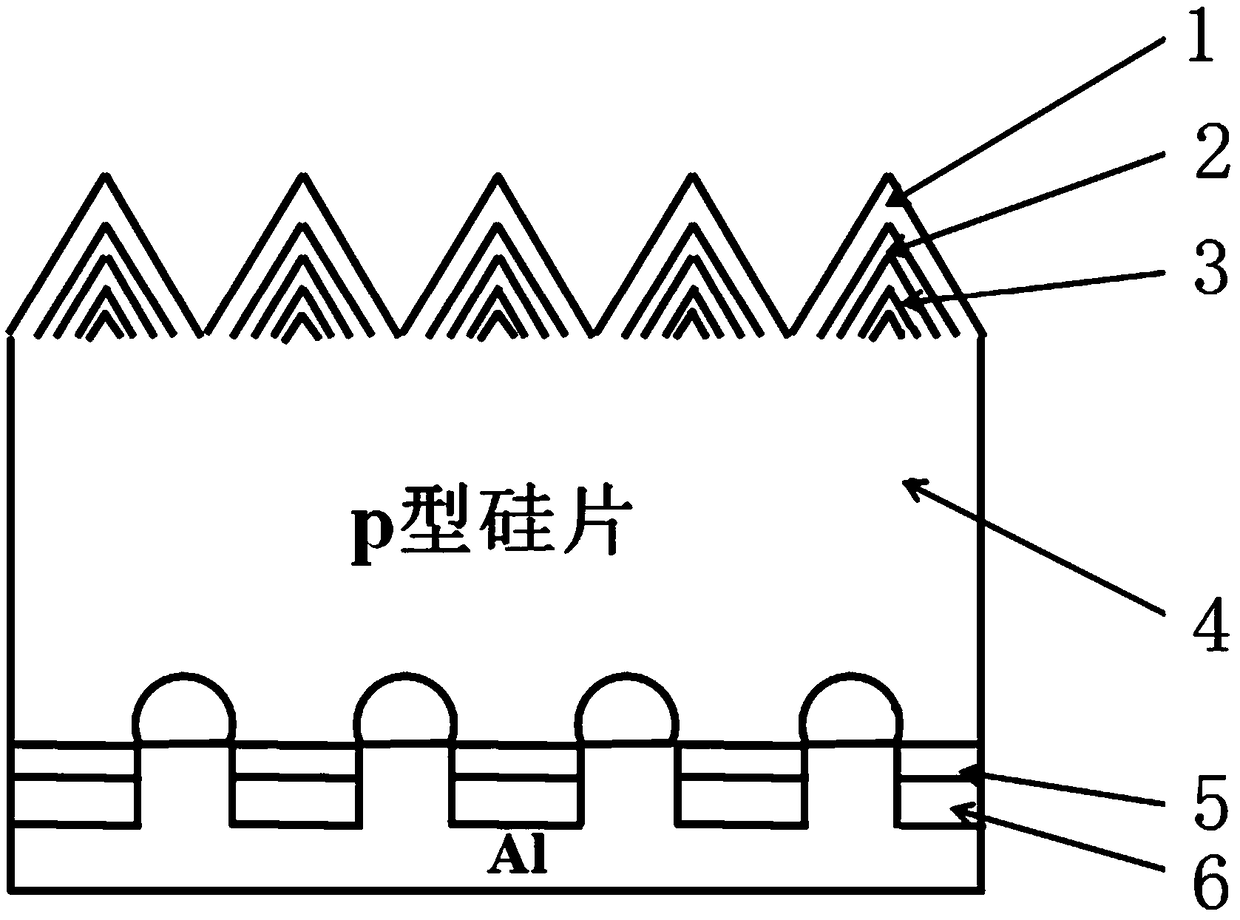

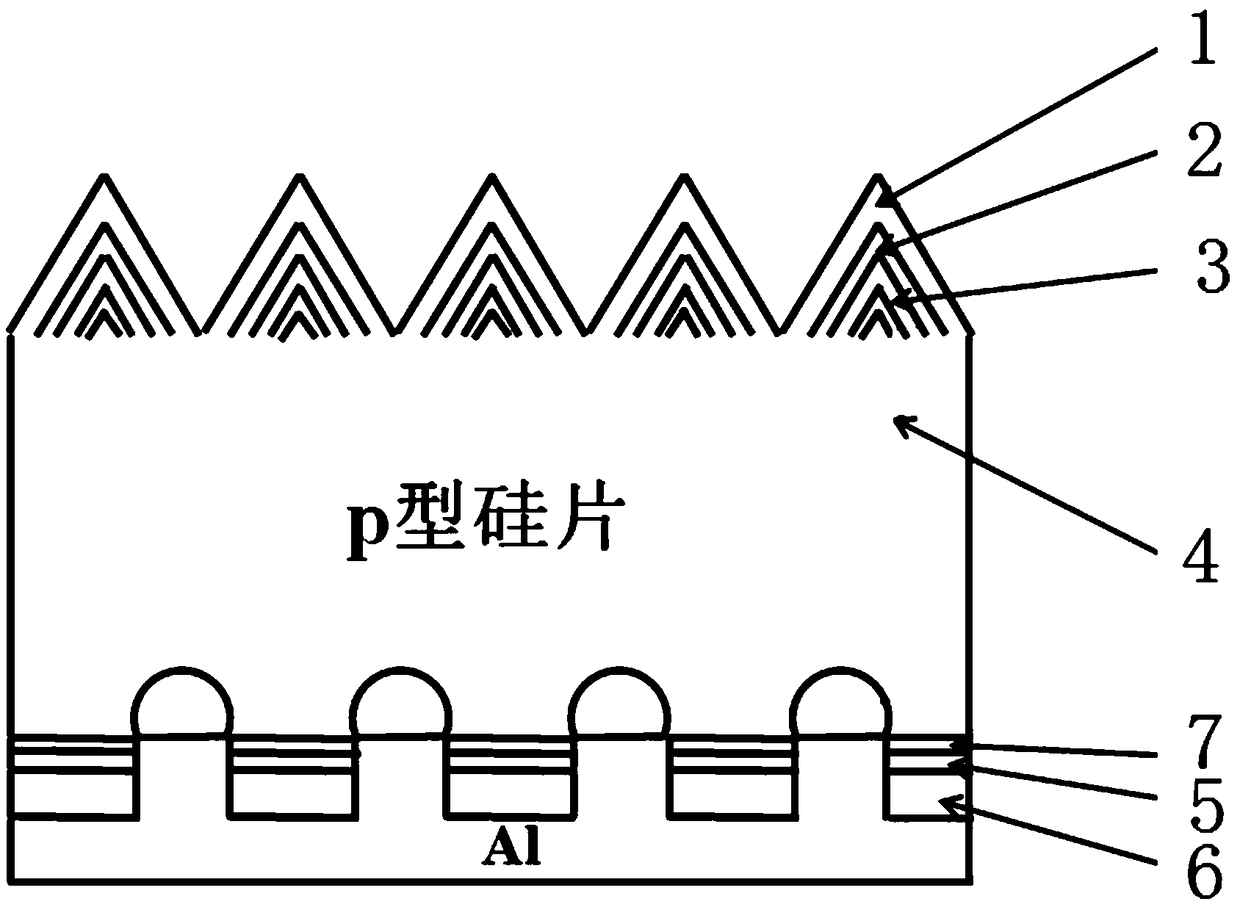

PERC solar cell structure and preparation process thereof

ActiveCN106653871AIncrease impurity concentrationImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationElectrical batteryEngineering

The invention discloses a PERC solar cell structure and a preparation process thereof. The PERC solar cell structure comprises a cell piece body. A SiO2 layer, an anti-reflection layer and an AlOx layer are successively deposited / grown on the front surface of the cell piece body. An AlOx layer and a SiNx layer are successively deposited on the back surface of the cell piece body. On the basis of a conventional PERC cell preparation process, a surface oxidation doping process is used. In addition, the PERC battery process is adjusted. A unique surface passivation layer deposition process is also used. The beneficial effect of the preparation process is that effective doping in an oxidation process improves the surface impurity concentration of the cell, improves the FF of the cell, compensate the deterioration of the FF due to the local contact on the back surface; and the adjustment of the PERC cell process solves edge electric leakage due to doping process so as to simply the process, thereby improving the conversion efficiency of the cell and providing a better hydrogenation effect for the subsequent photonic recovery process of the PERC battery so as to achieve anti-LID.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

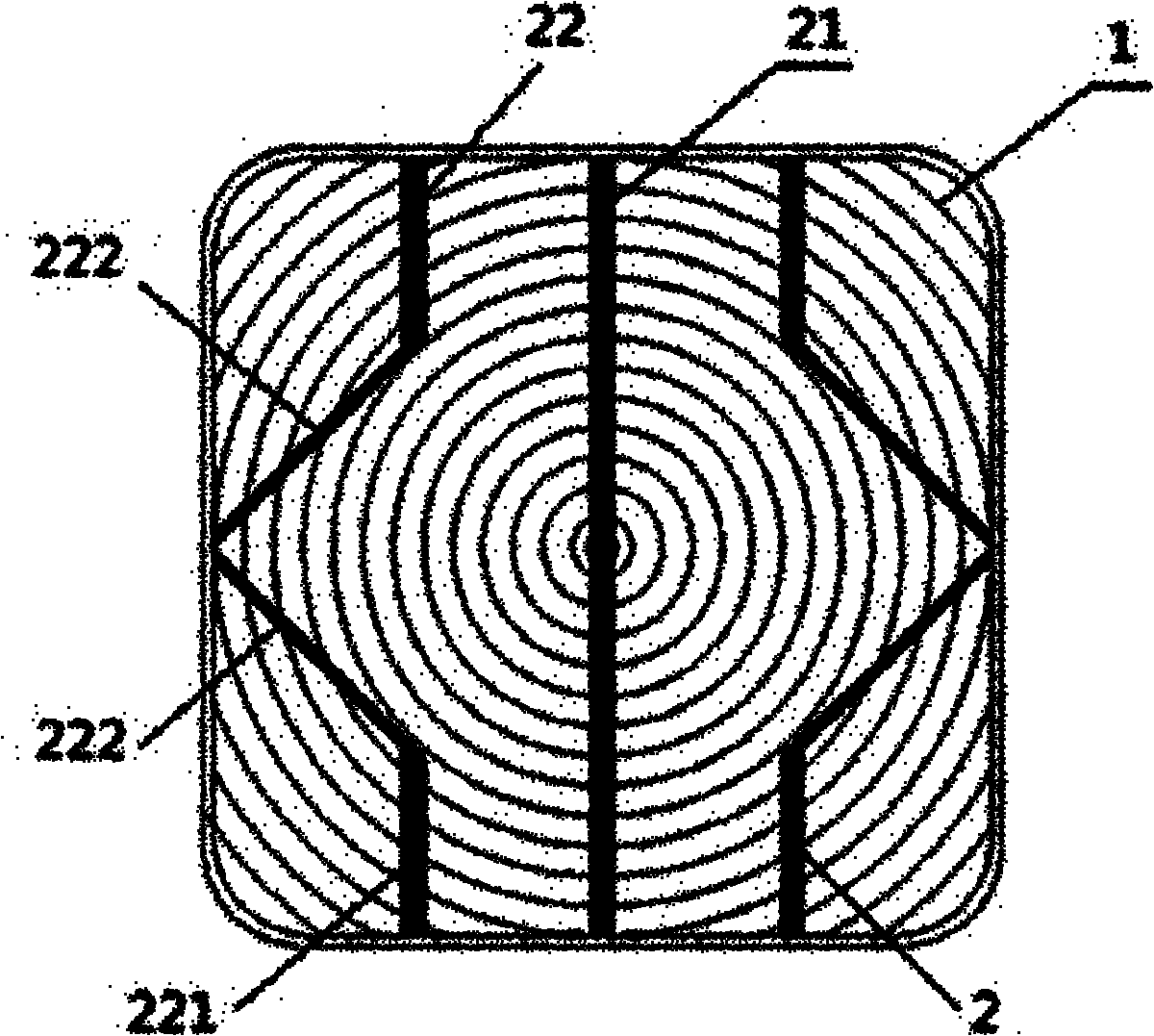

Positive electrode of silicon solar cell designed according to topology principle

ActiveCN102130193AReduce collectionEasy to collectPhotovoltaic energy generationSemiconductor devicesEngineeringSilicon solar cell

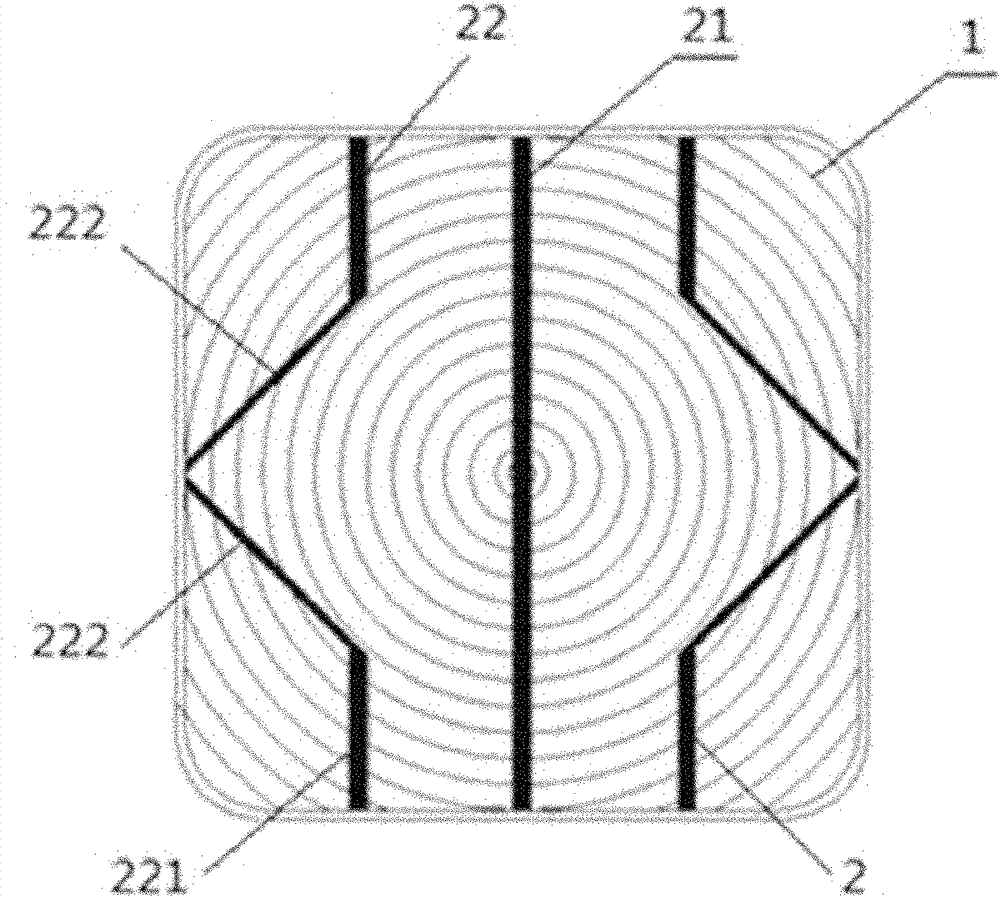

The invention relates to the field of the design of positive electrodes of silicon solar cells, in particular to a positive electrode of a silicon solar cell designed according to the topology principle. The positive electrode comprises fine grid lines and main grid lines, wherein a plurality of fine grid lines on the front side of a cell film are in concentric circles and concentric circular arcs; and the distance between the adjacent fine grid lines is 2-3mm. In the grid line conduction structure of the silicon solar cell, which is designed by the invention, the topology rule is applied, and thus the distribution condition of the grid line conduction structure is changed, the transmission speed of electrons on the surface of the cell film is improved and the effective conduction of the electrons is improved.

Owner:TRINA SOLAR CO LTD

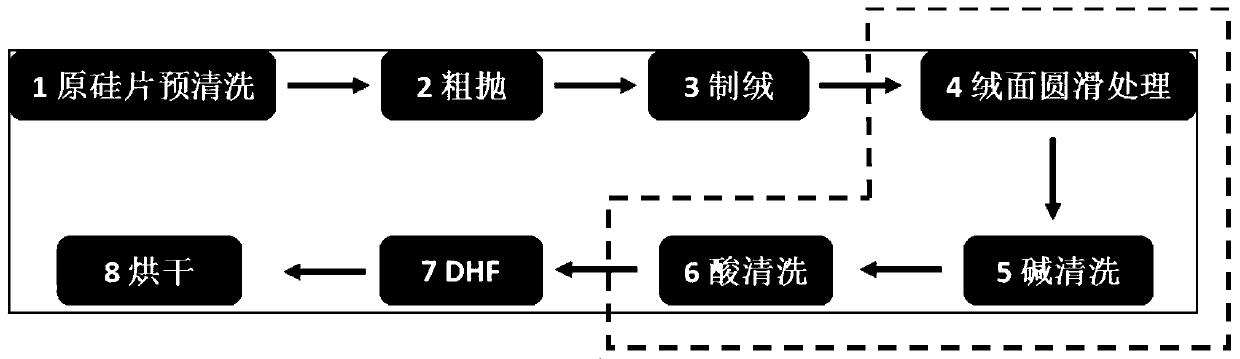

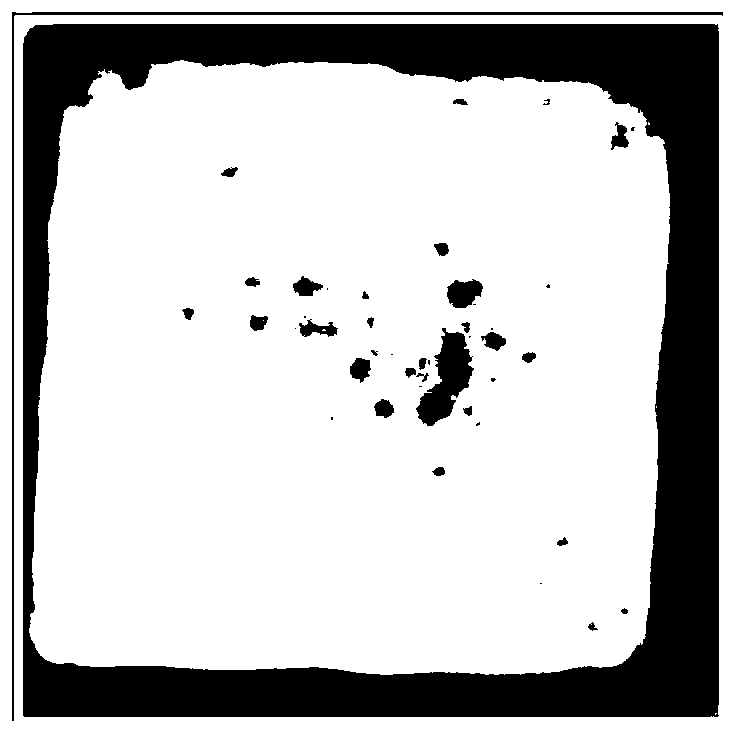

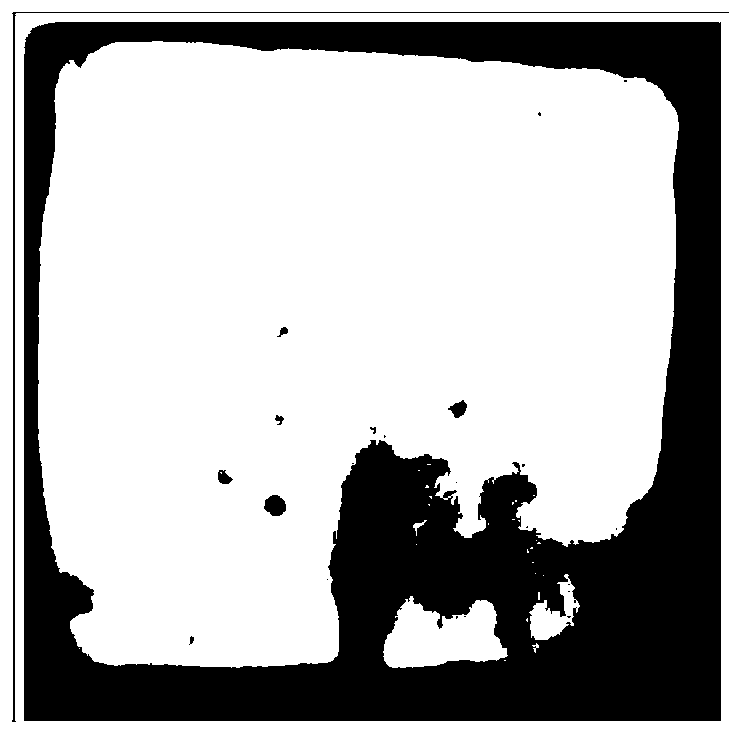

Texturing and cleaning method of heterojunction solar cell

InactiveCN110993724ARound shapeReduce defective rateFinal product manufactureSemiconductor/solid-state device manufacturingHeterojunctionMetallurgy

The invention discloses a texturing and cleaning method for a heterojunction solar cell. The texturing and cleaning method sequentially comprises the following steps: pre-cleaning a silicon wafer, roughly polishing and texturing the silicon wafer, carrying out texturing surface smoothing treatment, carrying out alkali cleaning, carrying out acid cleaning, and carrying out DHF cleaning and drying.According to the cleaning method, after alkali cleaning is adjusted to smoothing treatment, due to the fact that acid cleaning is adopted for smoothing treatment, alkali cleaning is added after acid cleaning, residual acid cleaning liquid before cleaning can be neutralized, and marks formed before cleaning can be removed in a slight corrosion mode. Through the optimized texturing process, the optimal cleaning effect can be achieved, an EL reject ratio is effectively reduced, and the Voc and FF of the heterojunction cell are improved.

Owner:JINENG CLEAN ENERGY TECH LTD

Solar cell module and interconnecting strips thereof

InactiveCN103811576AIncrease light receiving areaReduce power outputPhotovoltaic energy generationSemiconductor devicesSquare MillimeterEngineering

The invention discloses a solar cell module and interconnecting strips thereof. The solar cell module comprises a plurality of crystalline silicon solar cell pieces, the solar call piece is provided with a main grid line, the main grid line is provided with a conductive film, the interconnecting strips are bonded on the conductive film, the interconnecting strips are made of conductive metal, the volume resistivity of the interconnecting strip is smaller than or equal to 1.9ohm*square millimeter / m, the interconnecting strip has the yield strength of smaller than or equal to 90MPa, and the tensile strength of more than or equal to 130MPa, and the coefficient of elongation of the interconnecting strip is more than or equal to 15%. According to the solar cell module and the interconnecting strips thereof, the fragmentation of the cell piece is effectively reduced, the volume resistivity of the interconnecting strip is lowered, the serially connected resistors of the cell and the module are reduced, the filling factor FF of the module is improved, the width of the interconnecting strip is reduced, and the light receiving area of the cell is increased.

Owner:WUXI SUNTECH POWER CO LTD

A kind of perc solar cell structure and preparation technology thereof

ActiveCN106653871BIncrease impurity concentrationImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationElectrical batteryEngineering

The invention discloses a PERC solar cell structure and a preparation process thereof. The PERC solar cell structure comprises a cell piece body. A SiO2 layer, an anti-reflection layer and an AlOx layer are successively deposited / grown on the front surface of the cell piece body. An AlOx layer and a SiNx layer are successively deposited on the back surface of the cell piece body. On the basis of a conventional PERC cell preparation process, a surface oxidation doping process is used. In addition, the PERC battery process is adjusted. A unique surface passivation layer deposition process is also used. The beneficial effect of the preparation process is that effective doping in an oxidation process improves the surface impurity concentration of the cell, improves the FF of the cell, compensate the deterioration of the FF due to the local contact on the back surface; and the adjustment of the PERC cell process solves edge electric leakage due to doping process so as to simply the process, thereby improving the conversion efficiency of the cell and providing a better hydrogenation effect for the subsequent photonic recovery process of the PERC battery so as to achieve anti-LID.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Graphene solar HJT cell front silver paste and preparation method thereof

ActiveCN114023494ARealize the effect of low temperature curingGood lookingNon-conductive material with dispersed conductive materialPhotovoltaic energy generationHeterojunctionSilver paste

The invention discloses graphene solar HJT cell front silver paste and a preparation method thereof. The front silver paste is prepared from the following raw materials in percentage by weight: 5-20% of nano silver powder, 70-90% of flake silver powder, 2-10% of an organic carrier, 0.1-5% of an organic auxiliary agent and 0.1-1% of graphene. The front silver paste has the beneficial effects that (1) the nano silver powder with a specific size and the flake silver powder are mixed for use, and the graphene is added, so that the morphology of a silver network is improved, the densification is increased, and the resistivity during low-temperature curing is reduced; (2) on the basis of not changing the thixotropy of the front silver paste, the nano silver powder and the graphene are modified to increase the dispersity of substances, so that the stability of the silver paste is improved; and meanwhile, through surface modification, the printability of the silver paste is improved, the heterojunction quality of a solar cell is improved, and the photoelectric conversion efficiency is improved.

Owner:南通俊丰新材料科技有限公司

Full-back-contact high-efficiency crystalline silicon cell metal graphical making method

InactiveCN106549066AReduce alignment accuracy requirementsReduce manufacturing costSemiconductor devicesMetallurgyBack surface field

The invention relates to a full-back-contact high-efficiency crystalline silicon cell metal graphical making method. First, back high-temperature boron diffusion is carried out on a full-back-contact crystalline silicon cell to form an emitter junction, back phosphorus diffusion is carried out to form a back surface field, front phosphorus diffusion is carried out to form a front surface field, and front / back passivation anti-reflection layer deposition treatment is carried out. Then, an electrode pattern and metallization process is carried out to complete full-back-contact high-efficiency crystalline silicon cell metal graphical making. Compared with the prior art, there is no need for expensive lithography equipment, PVD equipment, sputtering equipment or other large metal deposition equipment in the subsequent metallization process, the method is compatible with conventional production screen printing equipment, and the preparation cost of full-back-contact crystalline silicon cells is reduced significantly.

Owner:SHANGHAI SHENZHOU NEW ENERGY DEV

Conductive paste for solar cell electrode

ActiveCN101432890BImprove FFImprove performanceSemiconductor/solid-state device manufacturingNon-conductive material with dispersed conductive materialConductive pasteFrit

A conductive paste for solar cell electrodes with which high FF value can be obtained stably, and a method for producing a solar cell using the same are provided. The conductive paste is a conductive paste for solar cell electrodes which includes an organic binder, a solvent, conductive particles, glass frits, and (A) a substance which changes into a gas at a temperature in the range of 150 to 800 DEG C, and a metal oxide, (B) an organometallic compound and a metal oxide, or (C) a compound containing Al, Ga, In or Tl.

Owner:SHARP KK +1

Substrate for thin-film photoelectric conversion device, thin film photoelectric conversion device including the same, and method for producing substrate for thin-film photoelectric conversion device

InactiveUS8658885B2Improve adhesionImprove FFFinal product manufacturePV power plantsProduction ratePhotoelectric conversion

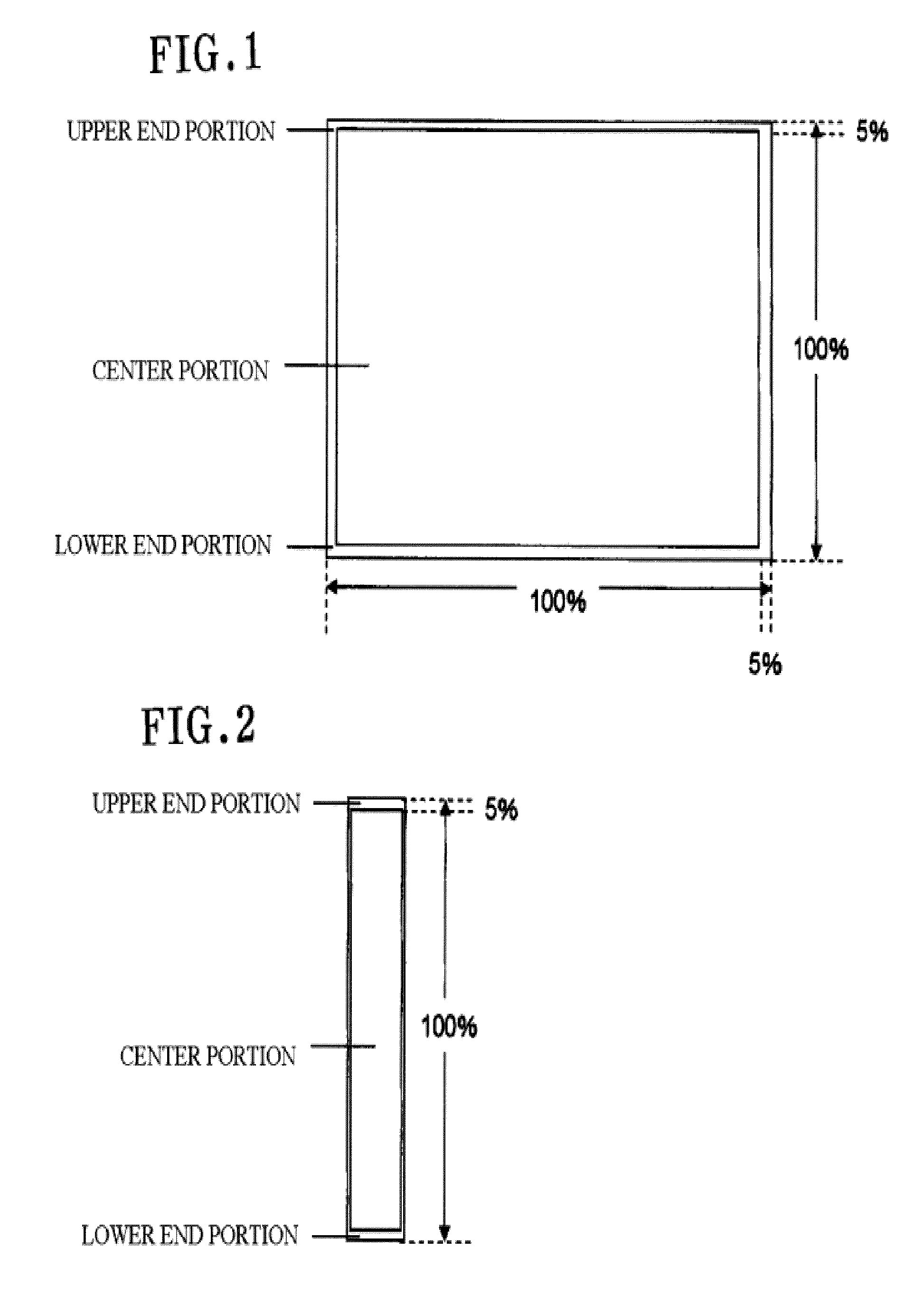

Provided is a substrate for a thin-film photoelectric conversion device which makes it possible to produce the device having improved characteristics at low cost and high productivity. The substrate includes a transparent base member, with a transparent underlying layer and a transparent electrode layer successively stacked on one main surface of the transparent base member. The underlying layer includes transparent insulating fine particles and transparent binder, and the particles are dispersed to cover the one main surface with a coverage factor of particles ranging from 30% or more to less than 80%. An antireflection layer is provided on the other main surface of the transparent base. The antireflection layer includes transparent insulating fine particles and transparent binder, and the particles are dispersed to cover the other main surface with a coverage factor greater than the underlying layer. The transparent electrode layer contains zinc oxide deposited by low-pressure CVD method.

Owner:KANEKA CORP

Solar cell diffusion deep junction preparation method

InactiveCN112164733AIncrease junction depthIncrease concentrationFinal product manufacturePhotovoltaic energy generationChemical physicsPhysical chemistry

The invention relates to the field of solar cell production. The invention discloses a method for preparing a solar cell diffusion deep junction. The method comprises the following steps of: 1, preparing a SiO2 layer; 2, preparing a constant impurity phosphorus source on the surface of the silicon wafer through twice deposition; 3, pushing phosphorus atoms into the silicon wafer to form a PN junction; 4, carrying out supplementary diffusion; 5, preparing a rear oxide layer; and 6, depositing an impurity phosphorus source on the surface of the silicon wafer again. The antireflection suede is prepared before the first step. The method has the beneficial effects that under the condition of not changing the overall sheet resistance and the process time, the PN junction depth and the junction region phosphorus concentration difference are effectively increased, and the Uoc and the FF of the battery piece are improved, so that the battery conversion efficiency is improved.

Owner:山西潞阳光伏科技有限公司

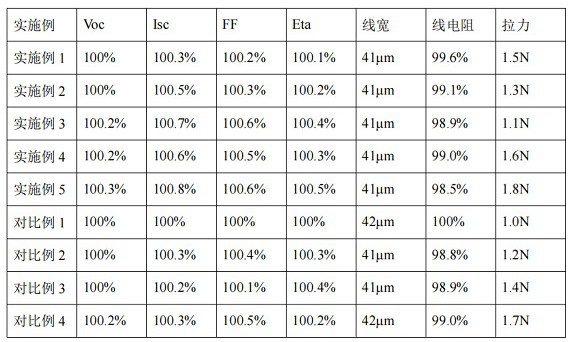

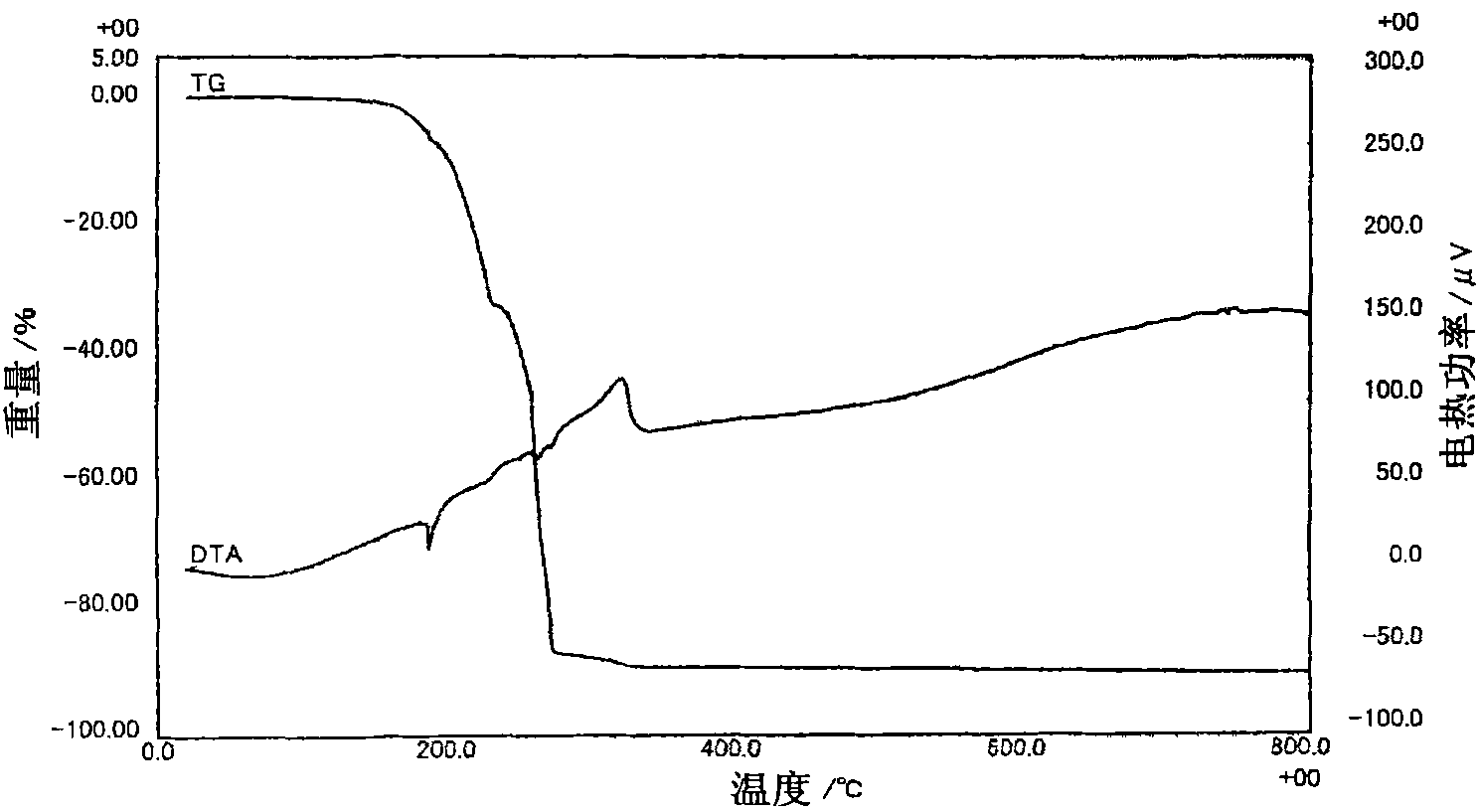

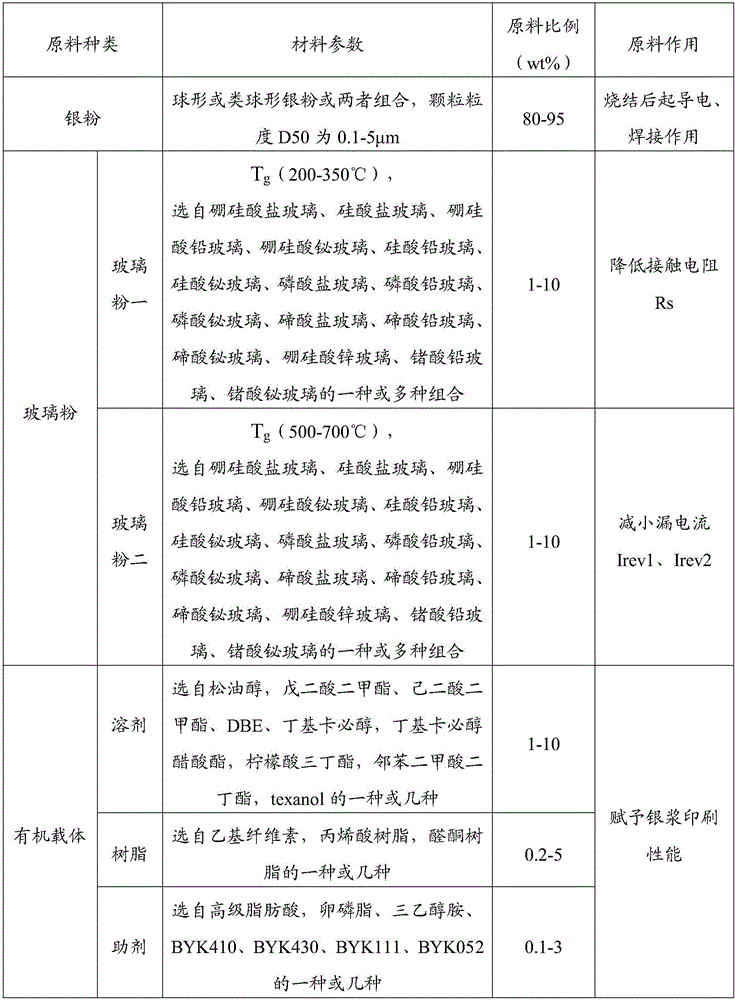

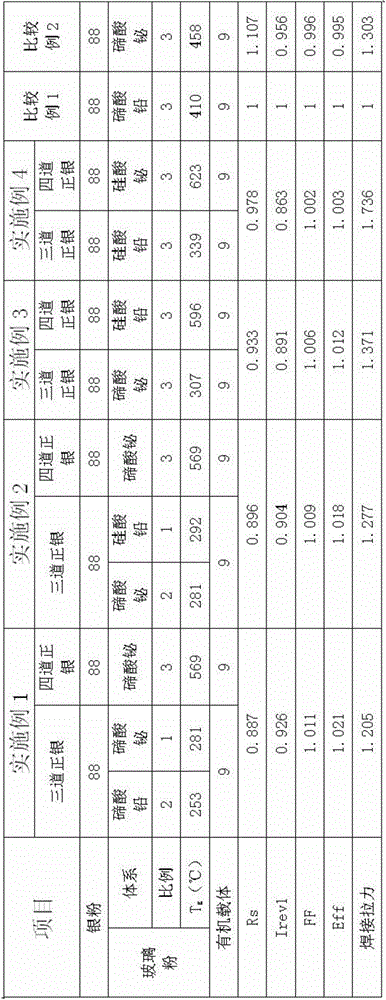

Silver paste combination for secondary printing of crystalline silicon solar cell

InactiveCN105957580AIncrease opening ratioControl corrosion depthNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteMetallurgy

The invention discloses a silver paste combination for secondary printing of a crystalline silicon solar cell. The silver paste combination comprises third positive silver paste and fourth positive silver paste, wherein the third positive silver paste is mainly prepared from silver powder I, an organic carrier I and glass powder I; the fourth positive silver paste is mainly prepared from silver powder II, an organic carrier II and glass powder II; Tg of the glass powder I is 200-350 DEG C; and the Tg of the glass powder is 500-700 DEG C. The silver paste combination for secondary printing of the crystalline silicon solar cell comprises special third positive silver paste and special fourth positive silver paste. The contact resistance of the cell can be reduced; and the leakage current Irev1 and Irev2 can be reduced, so that FF is improved and the photoconversion efficiency Eff of the cell is improved.

Owner:CHANGZHOU JUHE NEW MATERIAL CO LTD

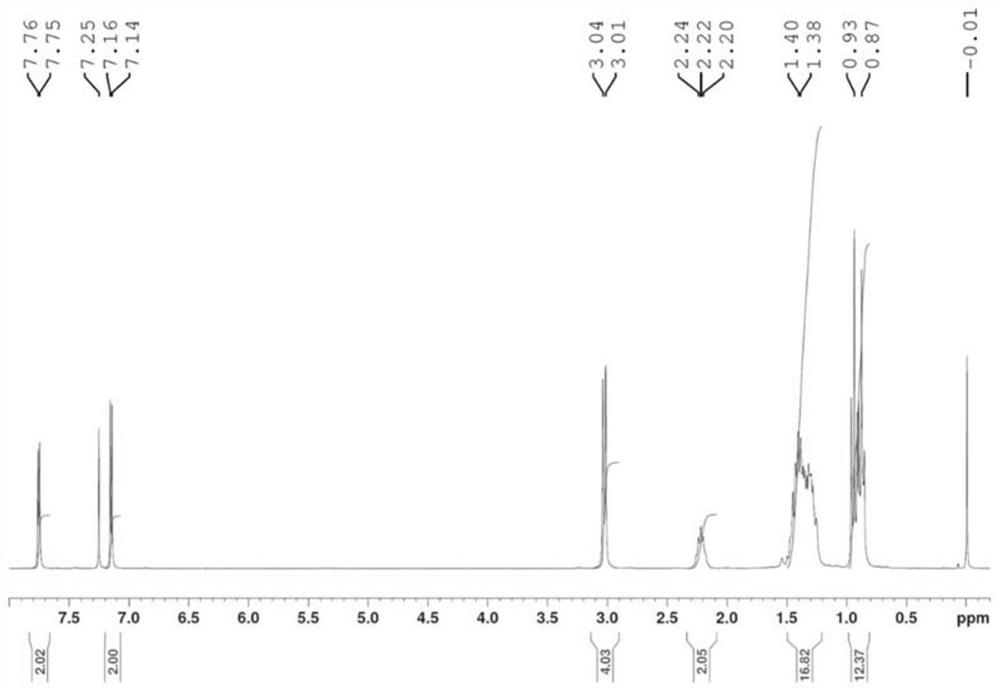

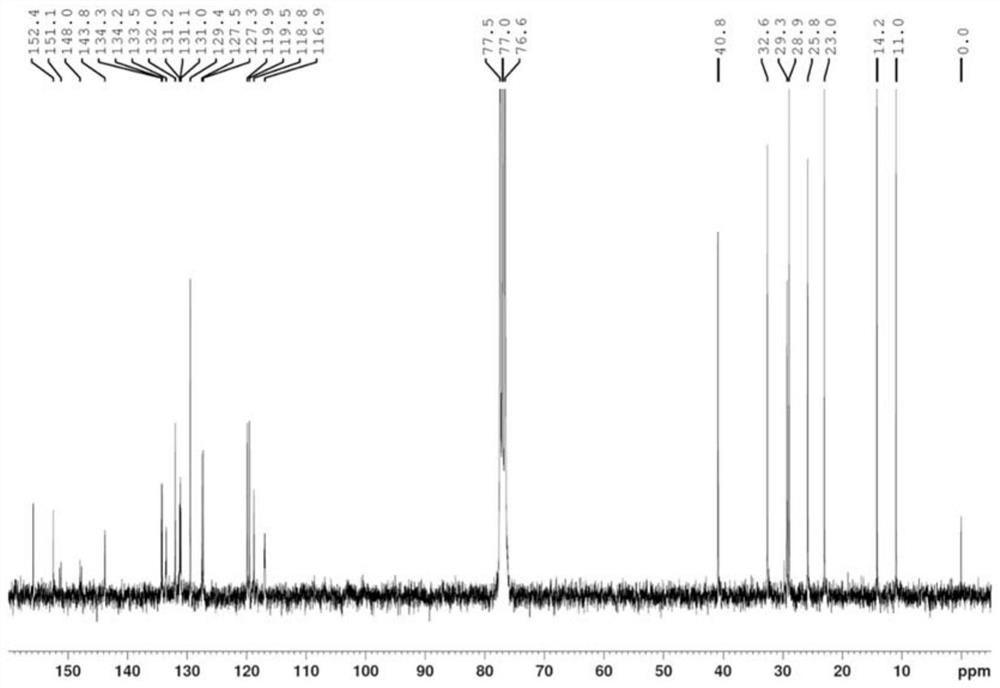

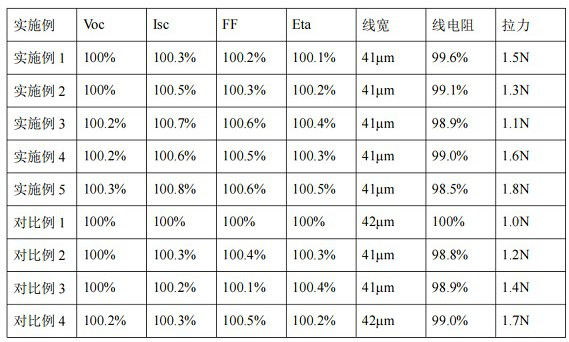

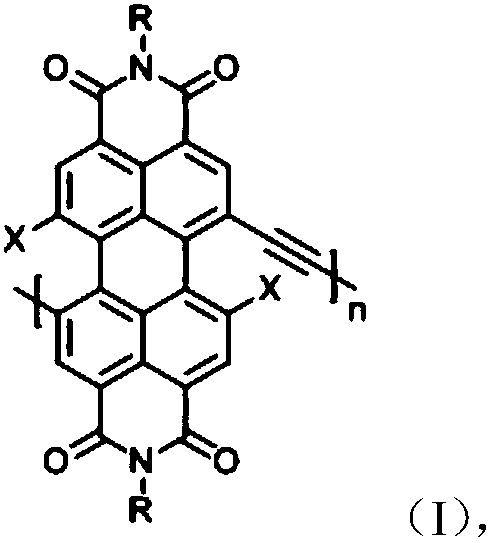

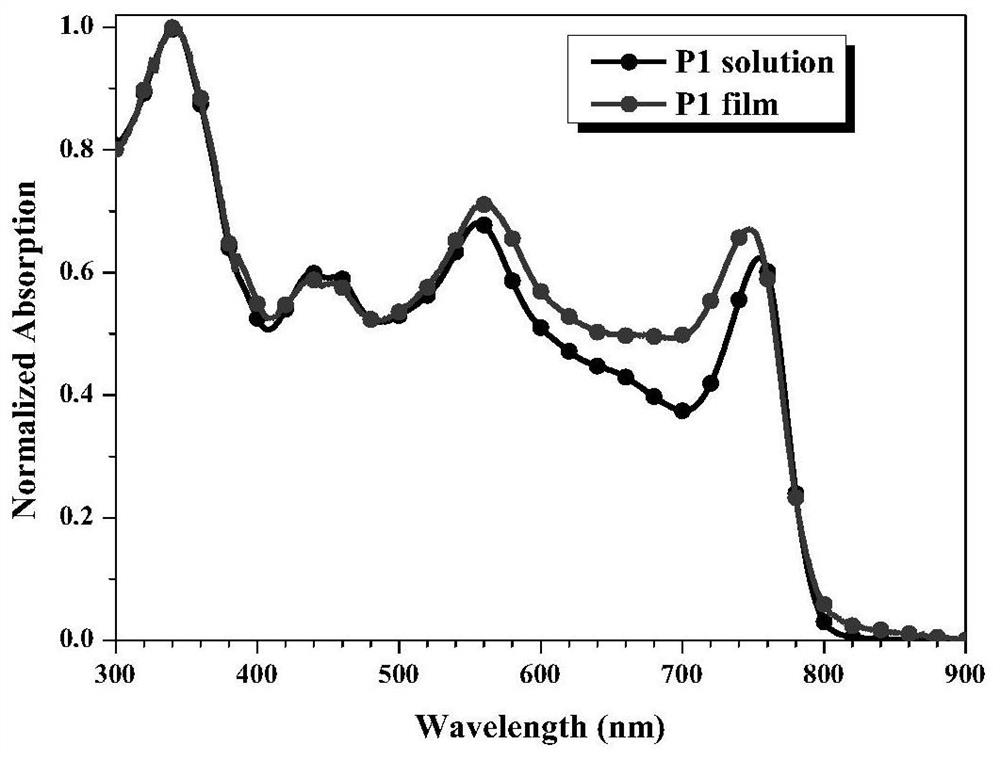

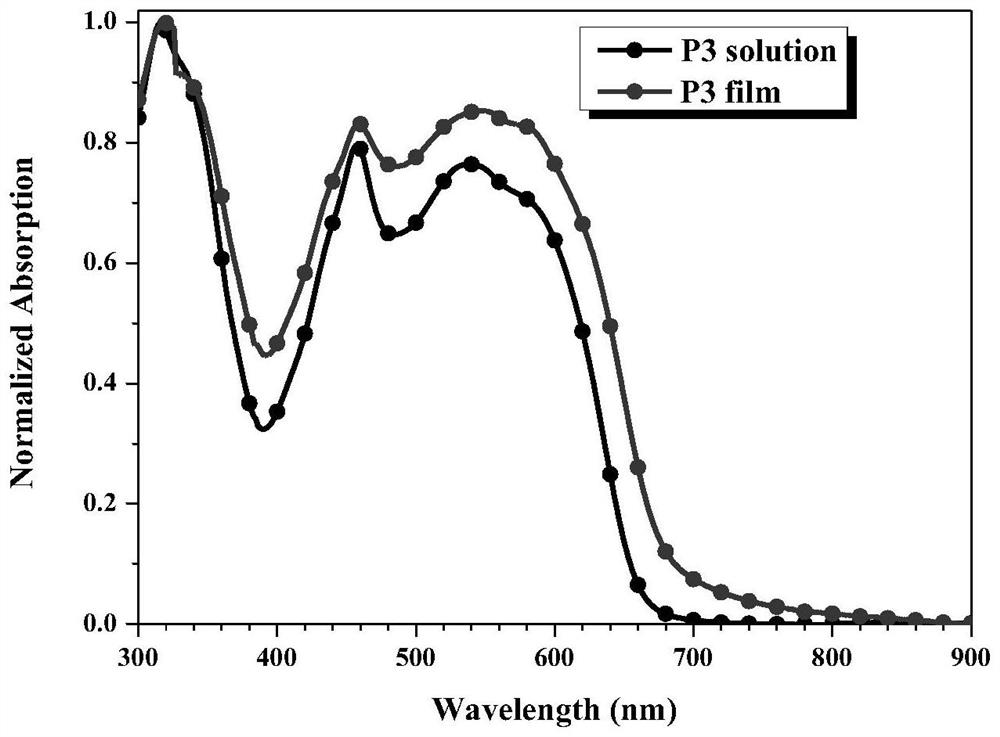

Application of p-type D-A copolymer containing quinoxaline unit in efficient organic and perovskite solar cell

PendingCN113024779AChange planarityEasy to processSolid-state devicesSemiconductor/solid-state device manufacturingQuinoxalinePerovskite solar cell

The invention discloses application of a p-type D-A copolymer containing a quinoxaline unit in an efficient organic and perovskite solar cell. The structure of the copolymer is a quinoxaline conjugated polymer as shown in a formula I or a formula II. Different types of side chains are introduced to a quinoxaline structure, so that the planarity of polymer molecules is changed, the electron energy level of a material is adjusted, and meanwhile, molecular accumulation after polymer film formation is changed, which is beneficial to solution processing in a solar cell preparation process; Therefore, the mobility of the donor-acceptor blended film is improved, a contribution is made to the improvement of short-circuit current (Jsc), meanwhile, the fill factor (FF) of the blended material in a photovoltaic device is also improved, and the solubility, the energy level and the ultraviolet-visible spectrum absorption of the polymer can be further adjusted so as to obtain better photoelectric conversion efficiency.

Owner:INST OF CHEM CHINESE ACAD OF SCI

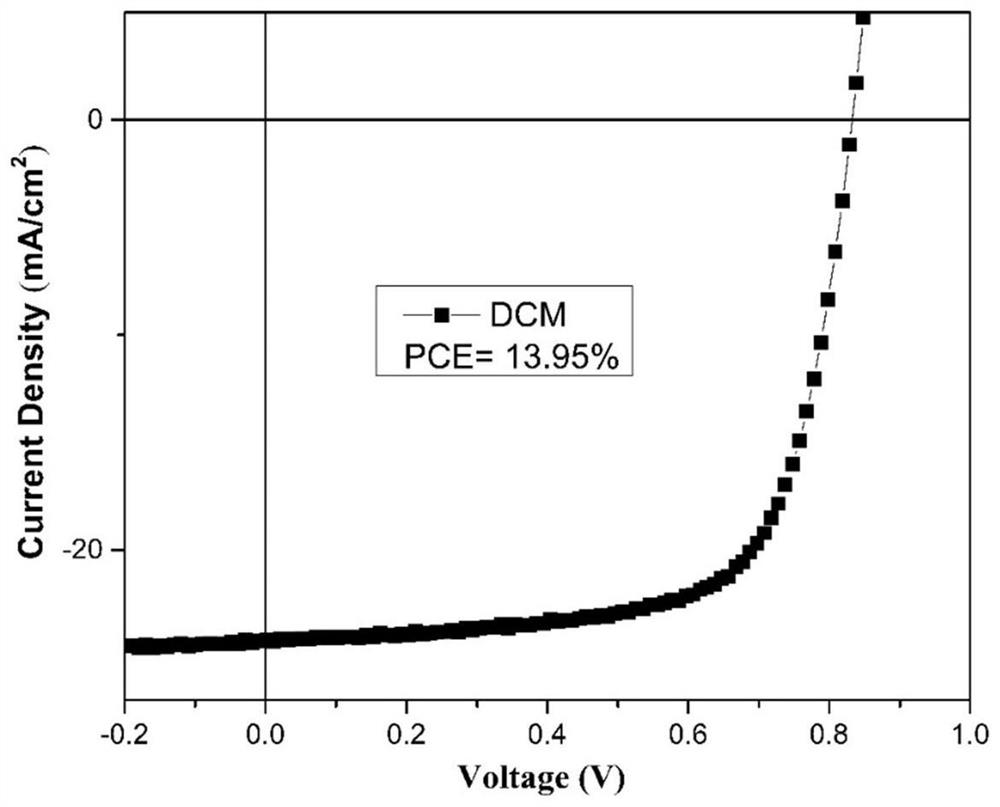

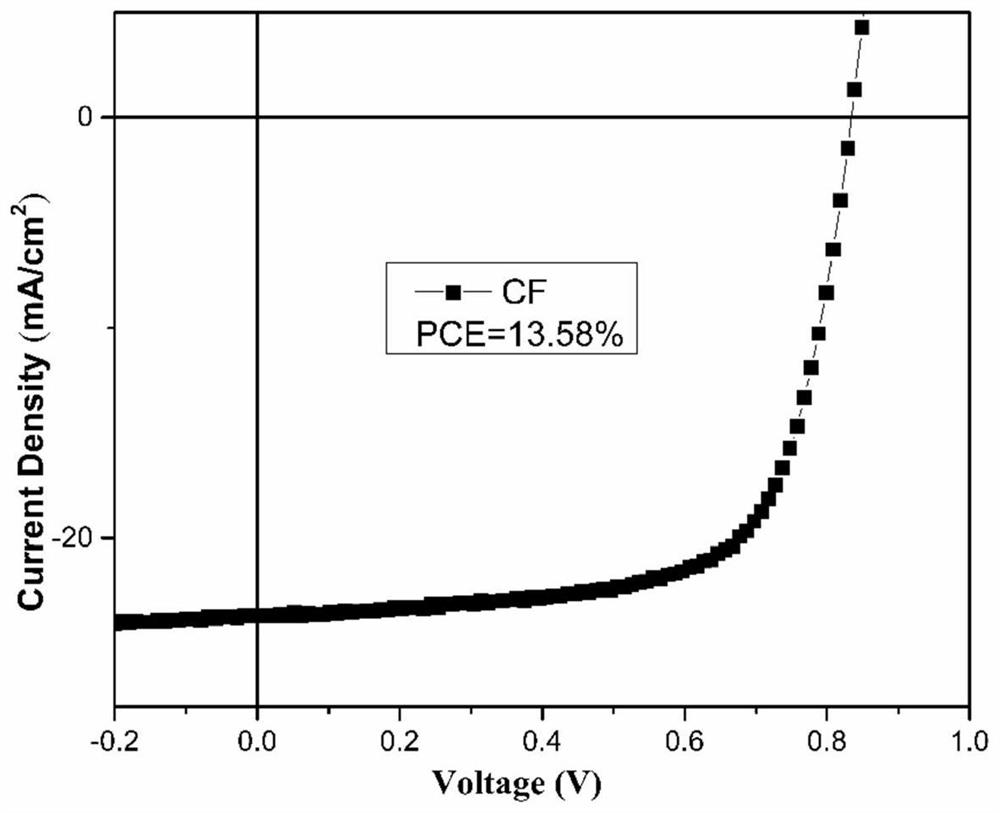

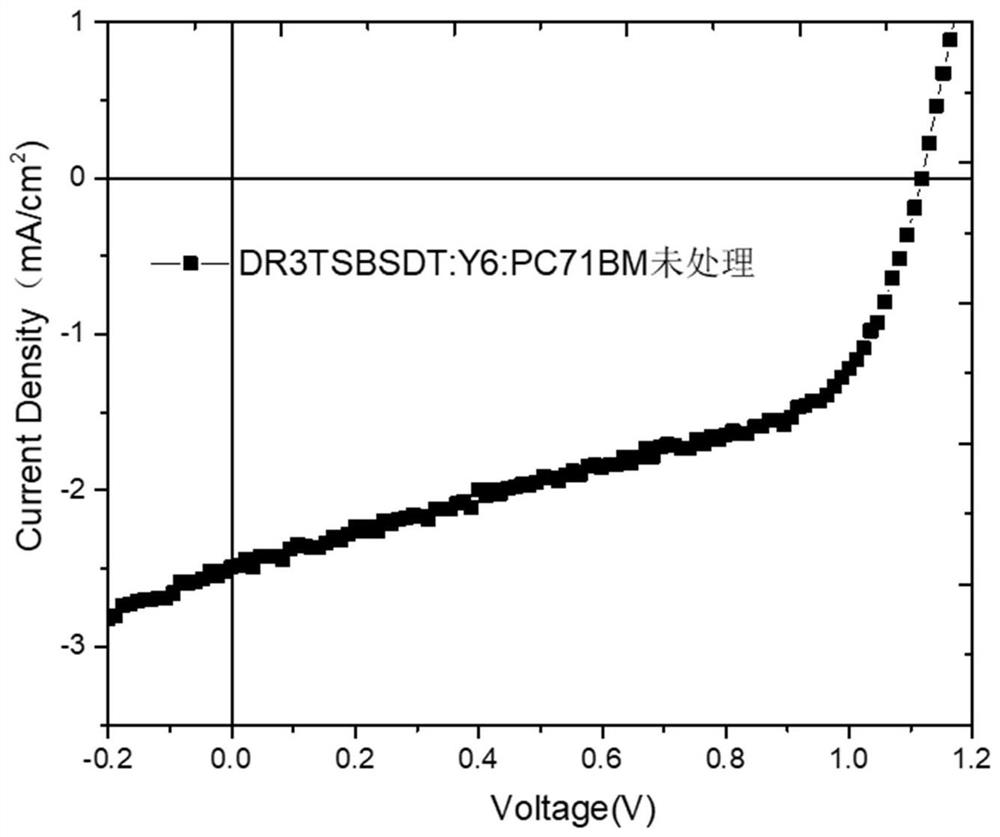

Method for regulating and controlling longitudinal morphology of organic solar cell through solvent annealing post-treatment

PendingCN114744127ASimple manufacturing methodImprove efficiencyFinal product manufactureSolid-state devicesHeterojunctionElectron donor

The invention discloses a method for regulating and controlling the longitudinal morphology of an organic solar cell through solvent annealing post-treatment. The invention belongs to the field of solar cells. The organic solar cell device is composed of a bottom substrate, a conductive anode, a hole transport layer, an organic photoactive layer, an electron transport layer and a metal cathode, wherein the photoactive layer is a bulk heterojunction formed by blending an organic electron donor material and an organic electron acceptor material. The method is characterized in that the longitudinal morphology of the active layer is regulated and controlled through solvent annealing treatment by adopting solvent steam treatment, so that all components in the active layer are reasonably and longitudinally separated. According to the method, the short-circuit current and the filling factor of the solar cell can be remarkably improved, and the photoelectric conversion efficiency of the full-small-molecule organic solar cell is improved.

Owner:SOUTH CHINA UNIV OF TECH

Silicon-based thin-film photoelectric converter and method of manufacturing the same

InactiveUS7960646B2Improve FFImproved propertySolid-state devicesSemiconductor/solid-state device manufacturingHydrogen concentrationAmorphous silicon

In order to improve photoelectric conversion properties of a silicon-based thin-film photoelectric converter to which a conductive SiOx layer is inserted to obtain an optical confinement effect, the silicon-based thin-film photoelectric converter according to the present invention includes an i-type photoelectric conversion layer of hydrogenated amorphous silicon or an alloy thereof, an i-type buffer layer made of hydrogenated amorphous silicon, and an n-type Si1-xOx layer (x is 0.25-0.6) stacked successively, wherein the buffer layer has a higher hydrogen concentration at its interface with and as compared with the photoelectric conversion layer and has a thickness of at least 5 nm and at most 50 nm. Accordingly, generation of silicon crystal phase parts and reduction of resistivity are promoted in the n-type Si1-xOx layer, contact resistance at the interface is reduced, and FF of the photoelectric converter is improved, so that the photoelectric converter achieves improved properties.

Owner:KANEKA CORP

Positive electrode of silicon solar cell designed according to topology principle

ActiveCN102130193BReduce collectionEasy to collectPhotovoltaic energy generationSemiconductor devicesSilicon solar cellEngineering

The invention relates to the field of the design of positive electrodes of silicon solar cells, in particular to a positive electrode of a silicon solar cell designed according to the topology principle. The positive electrode comprises fine grid lines and main grid lines, wherein a plurality of fine grid lines on the front side of a cell film are in concentric circles and concentric circular arcs; and the distance between the adjacent fine grid lines is 2-3mm. In the grid line conduction structure of the silicon solar cell, which is designed by the invention, the topology rule is applied, and thus the distribution condition of the grid line conduction structure is changed, the transmission speed of electrons on the surface of the cell film is improved and the effective conduction of the electrons is improved.

Owner:TRINA SOLAR CO LTD

Graphene solar HJT battery positive silver paste and preparation method thereof

ActiveCN114023494BRealize the effect of low temperature curingGood lookingNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteHeterojunction

The invention discloses a front silver paste of a graphene solar HJT battery and a preparation method thereof. The raw materials of the front silver paste include the following components: by weight percentage, 5-20% nano-silver powder, 70-90% flake silver powder, 2-10% organic vehicle, 0.1-5% organic additive, 0.1~1% graphene. Beneficial effects: (1) Nano-silver powder of a specific size is mixed with flake-shaped silver powder, and graphene is added to improve the morphology of the silver network, increase densification, and reduce resistivity during low-temperature curing. (2) On the basis of not changing the thixotropy of the front silver paste, modify the nano-silver powder and graphene to increase the dispersion of the substance, thereby increasing the stability of the silver paste; at the same time, through surface modification, the printability of the silver paste is improved, Increase the quality of the heterojunction of the solar cell and improve the photoelectric conversion efficiency.

Owner:南通俊丰新材料科技有限公司

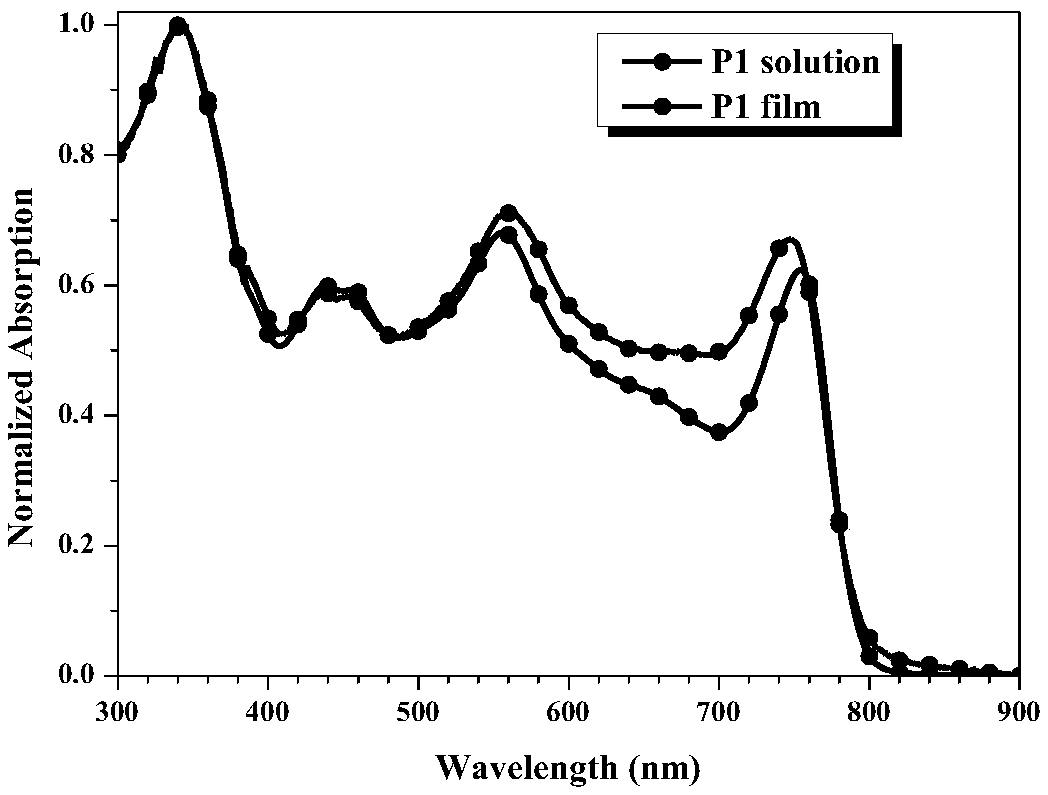

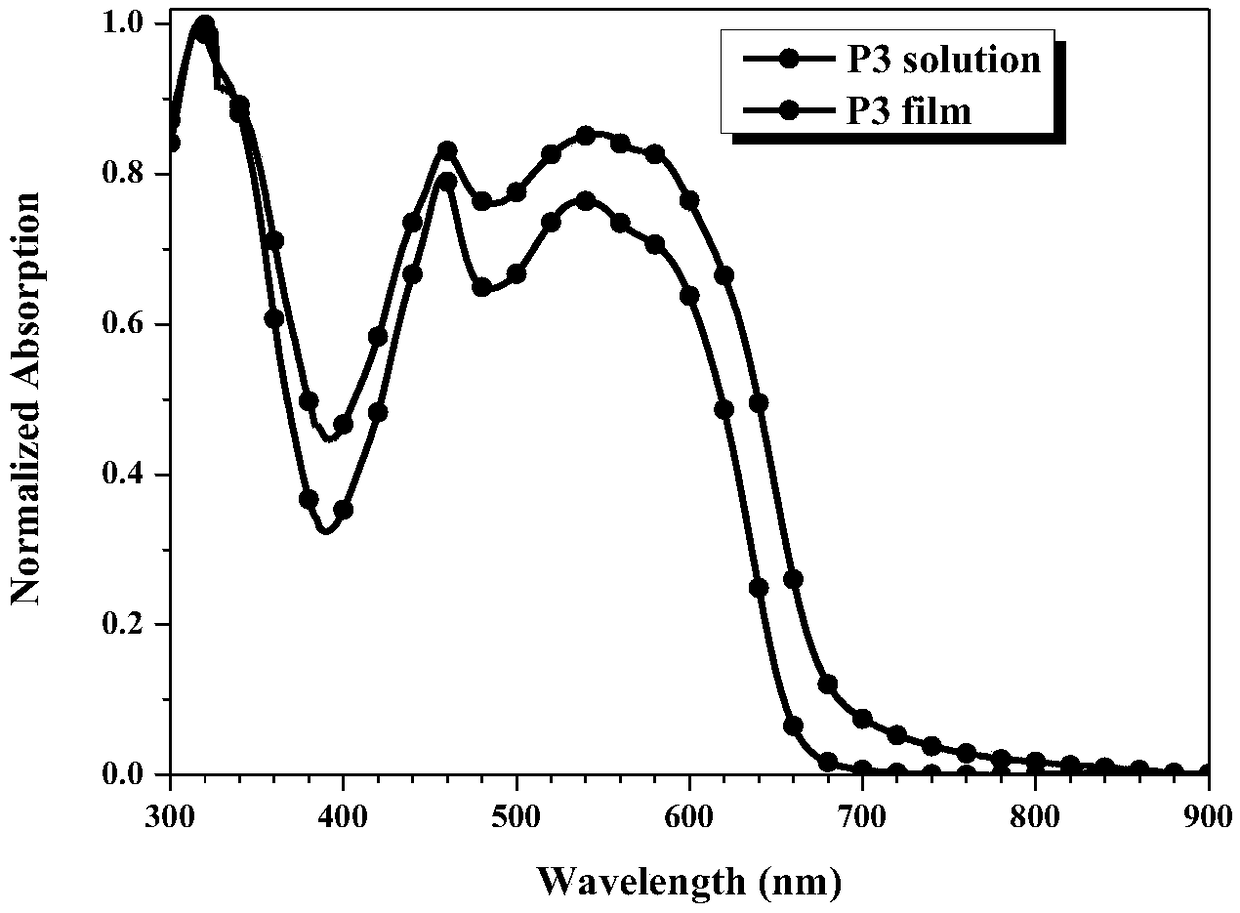

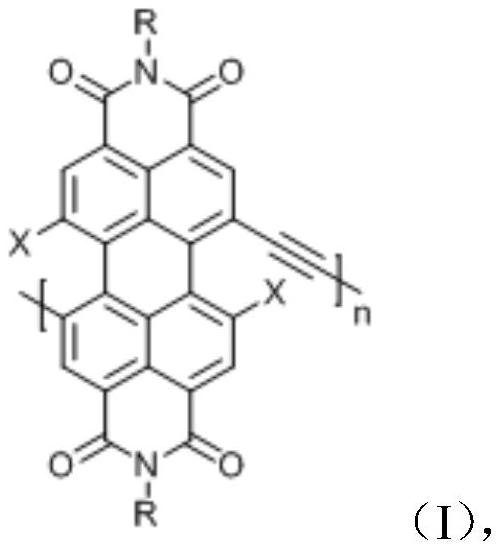

Perylene bisimide polymer as well as preparation method and application thereof

ActiveCN109180911AReduce steric effectAvoid damageSolid-state devicesSemiconductor/solid-state device manufacturingSolubilityPolymer science

The invention discloses a perylene bisimide polymer. The structural formula is as shown in the specification. In the formula, R is alkyl, and X is one of H and F atoms. The perylene bisimide polymer provided by the invention is prepared by taking perylene bisimide and carbon-carbon triple bonds as repetitive units and carrying out a Stille coupled reaction. The carbon-carbon triple bond serving asa conjugated micro unit exists in the polymer chain, so that the pi system of polymer molecules can be effectively enlarged, and the content of the perylene bisimide in the polymer chain can be positioned at a high status. Therefore, on one hand, the electronic mobility is improved; and on the other hand, aggregation of the molecules can be weakened, and fill factor improvement is caused. Compared with a common D-A molecule, the molecule in the invention has wide absorption spectrum, and due to introduction of the atom F, the band gap of the polymer is narrowed, and the absorption range is widened; and the polymer has wide and strong absorption in a visible region, has higher short-circuit current than a non-fluorinated polymer, and has excellent solubility, and the solution is easy to process.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

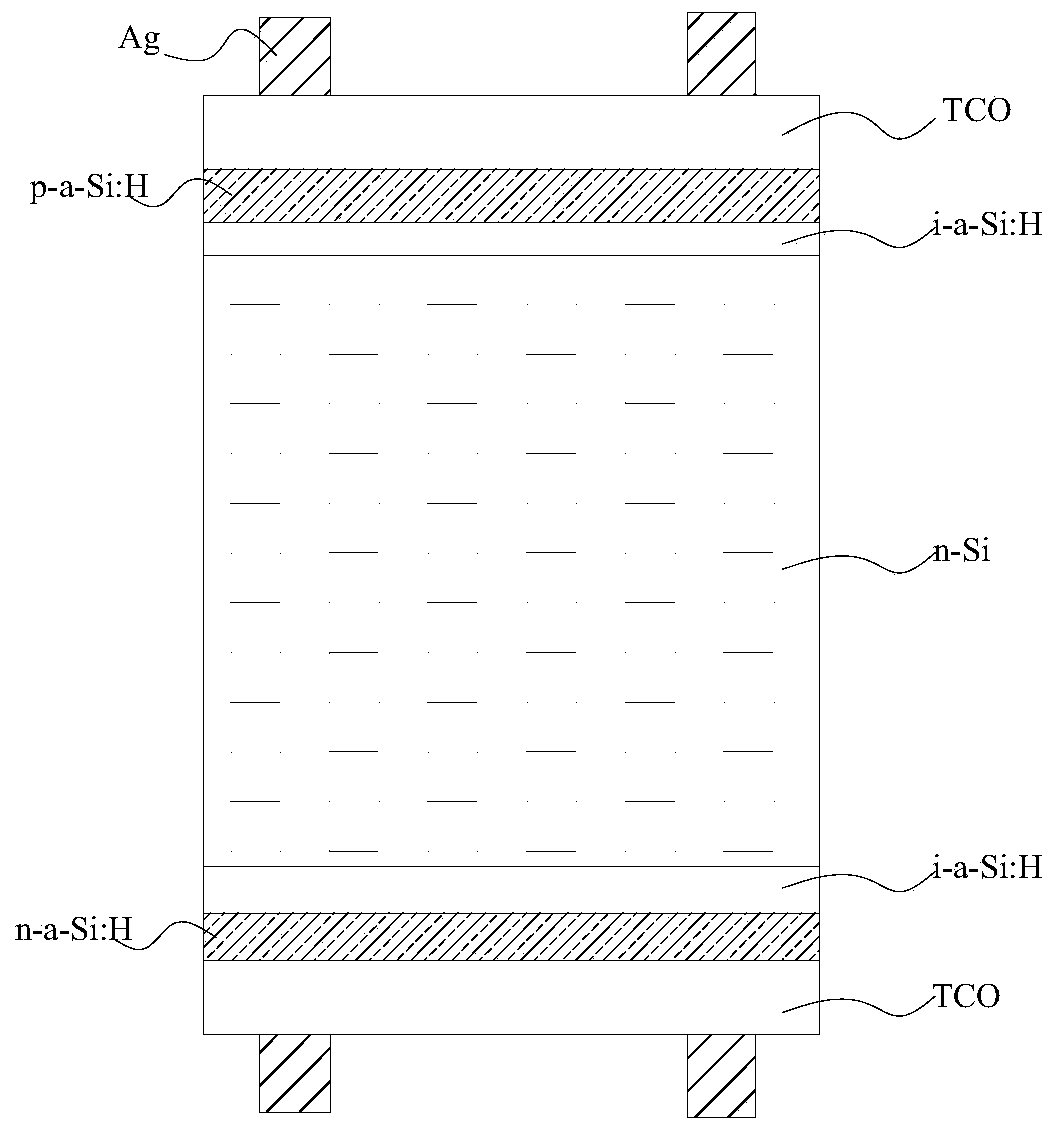

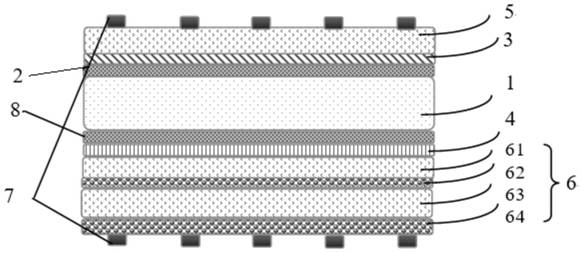

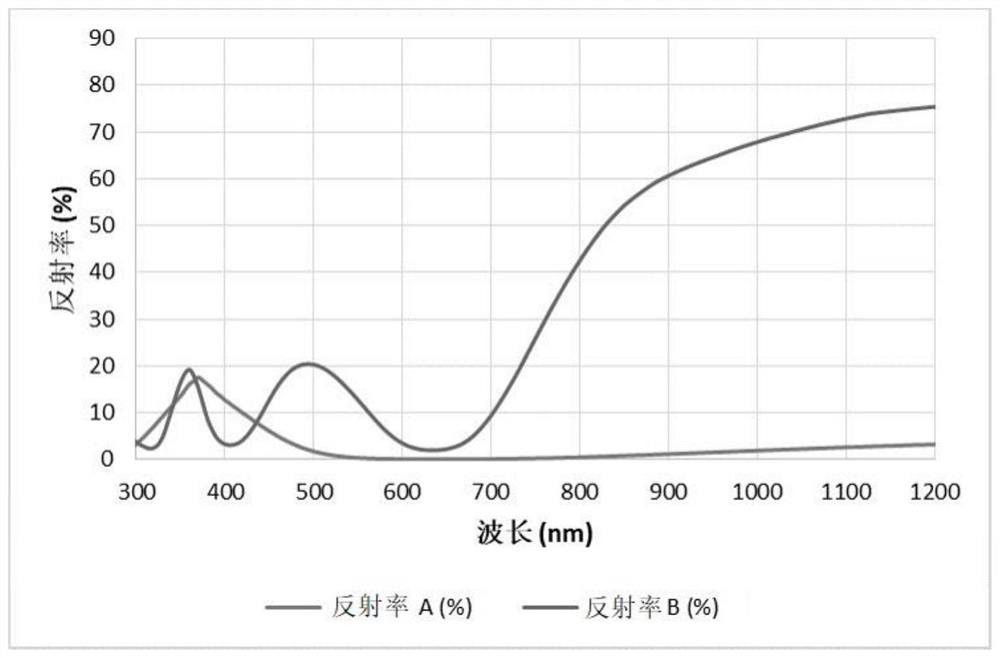

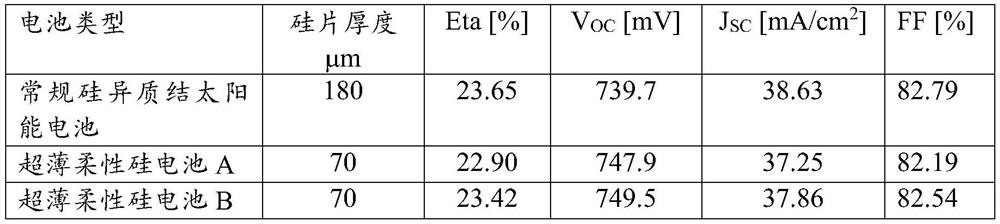

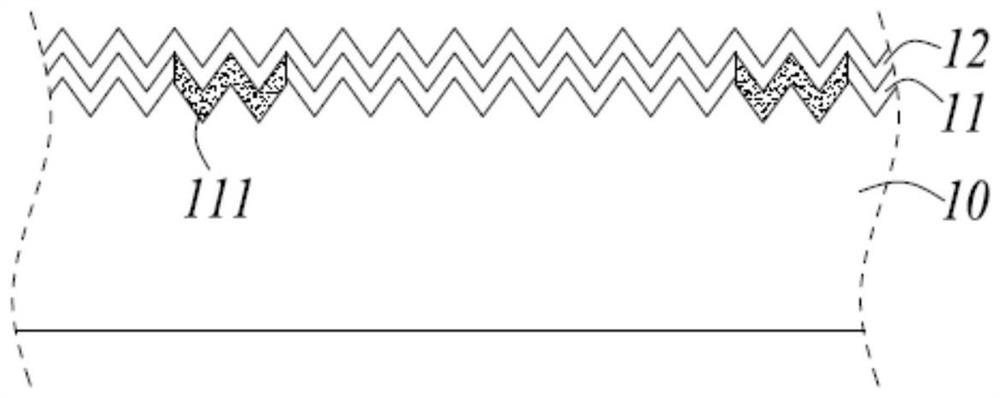

Ultrathin flexible silicon solar cell

PendingCN111916504AIncrease short circuit current densityImprove FFPhotovoltaic energy generationSemiconductor devicesEngineeringSilicon solar cell

The invention relates to an ultrathin flexible silicon solar cell which comprises a transparent conductive layer, an n-type doped layer, a first intrinsic passivation layer, a monocrystalline siliconwafer, a second intrinsic passivation layer, a p-type doped layer and a semi-transparent and semi-reflective functional layer which are sequentially stacked, wherein the semi-transparent and semi-reflective functional layer comprises at least one TCO material layer and at least one metal layer. According to the ultrathin flexible silicon solar cell provided by the invention, by arranging the semi-transparent and semi-reflective functional layer, the short-wave transmittance is greater than 80%, the long-wave reflectivity is greater than 60%, the long-wave band light reaching the back surface of the silicon wafer is reflected and utilized again, and the short-circuit current density of the cell is improved. The semi-transparent and semi-reflective functional layer comprises a metal layer, so that the transverse collection capability of photo-generated holes on the back electrode is improved, the resistance loss is reduced, the FF of the cell is improved, and the flexible ultrathin silicon cell with the cell efficiency of 23.4% is finally obtained. The weight of the cell is 5.38 g, and the gram weight of each watt of cell is 0.95 g / W.

Owner:德运创鑫(北京)科技有限公司

Photovoltaic cell and preparation method thereof

PendingCN114765231ASuppress edge recombinationImprove FFLaser beam welding apparatusSemiconductor devicesLaser scribingBattery cell

The invention discloses a photovoltaic cell and a preparation method thereof, and the preparation method of the photovoltaic cell comprises a diffusion junction preparation step, a laser scribing step, a grooving step, an impurity glass removal step, a front and back passivation step, an electrode forming step and a splitting step. When the fragmented battery is obtained, the edge junction region, corresponding to the pn junction, at the fragmentation position of the fragmented battery is covered by the first passivation layer and is not directly exposed to the external environment, so that the edge recombination of the fragmented battery can be effectively inhibited, and the FF, VOC, JSC and efficiency of the fragmented battery are further improved.

Owner:CSI CELLS CO LTD +1

A kind of perylene imide polymer and its preparation method and application

ActiveCN109180911BReduce steric effectAvoid damageSolid-state devicesSemiconductor/solid-state device manufacturingPerylenemonoimideImide

The invention discloses a perylene imide polymer, the structural formula of which is as follows: wherein R is an alkyl group; X is one of H and F atoms. The peryleneimide polymer provided by the present invention takes peryleneimide and carbon-carbon triple bond as repeating units, and is prepared by Stille coupling reaction; the carbon-carbon triple bond exists in the polymer as a conjugated microunit In the chain, the π system of the polymer molecule can be effectively increased, and the content of peryleneimide in the polymer chain can be at a higher position; this is conducive to improving the electron mobility on the one hand, and on the other hand can weaken the molecular The aggregation leads to the increase of the fill factor; the molecule has a wider absorption spectrum than the ordinary D-A type molecule, and the introduction of the F atom also leads to the narrowing of the band gap of the polymer and broadens the absorption range; the polymer is in It has wide and strong absorption in the visible light region, and has higher short-circuit current than unfluorinated polymers, and has better solubility and is easy to process in solution.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

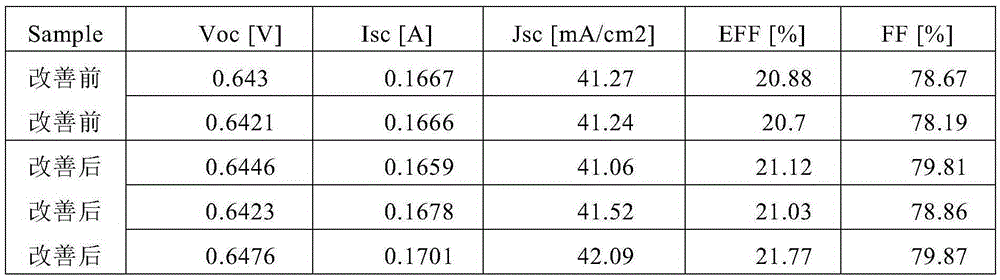

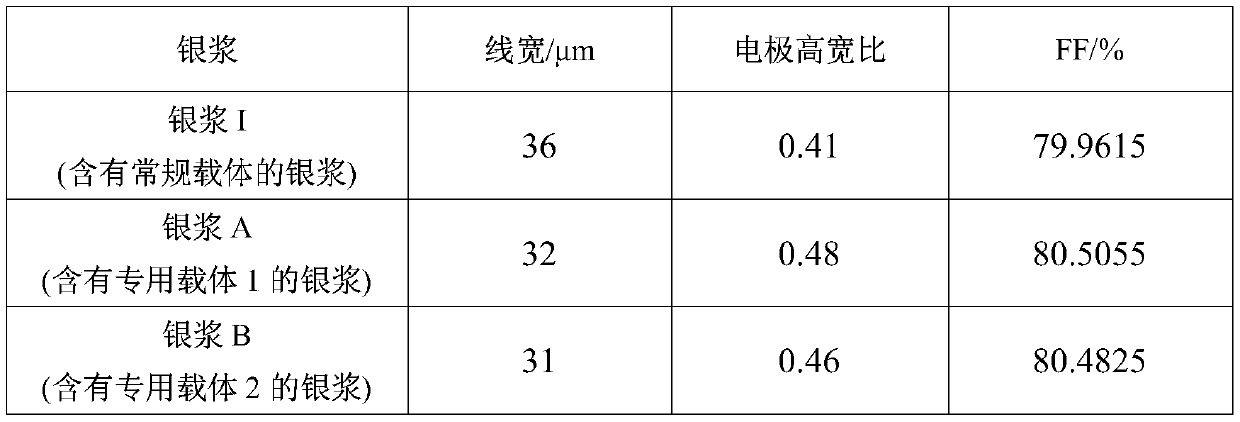

Carrier special for front silver paste for printing fine lines step by step and preparation method

ActiveCN110880377AImprove adhesion performanceSolving Line Width IssuesNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteElectronic materials

The invention relates to the technical field of electronic materials, and discloses a carrier special for front silver paste for printing fine lines step by step. The carrier consists of two organic carriers and is a binary mixed carrier. A conventional carrier cannot meet the requirement of step-by-step printing for a first layer of film, so that the carrier special for the front silver paste forprinting fine lines step-by-step is prepared and can satisfy the strength and connectivity of the first layer of film and the grabbing force of the film to a silicon substrate in the step-by-step printing. The front silver paste prepared by the method can reduce the unit consumption, has good linetype after being sintered, and has higher filling factor and high photoelectric conversion efficiency. The invention also discloses a preparation method of the special carrier.

Owner:上海银浆科技有限公司

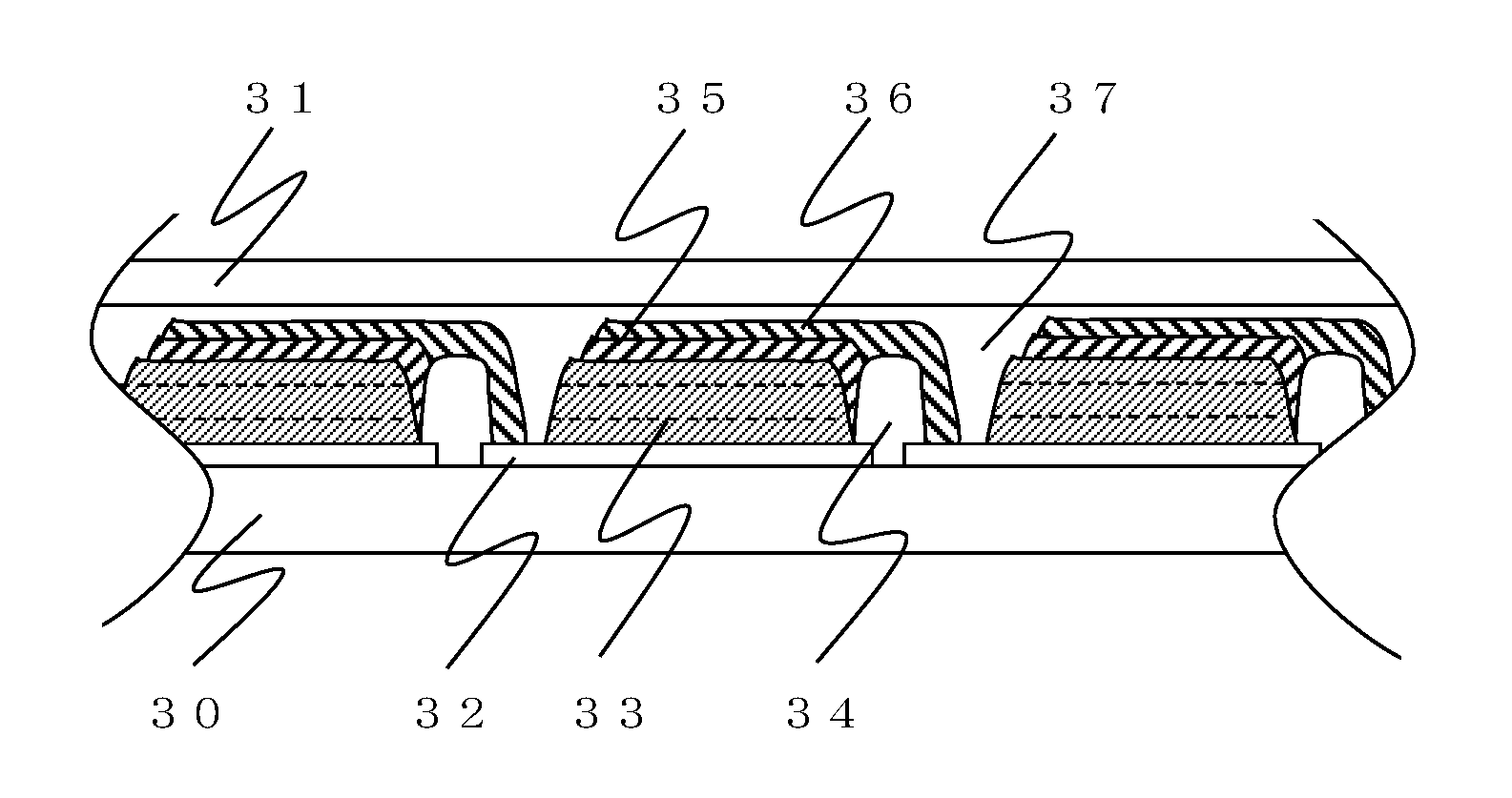

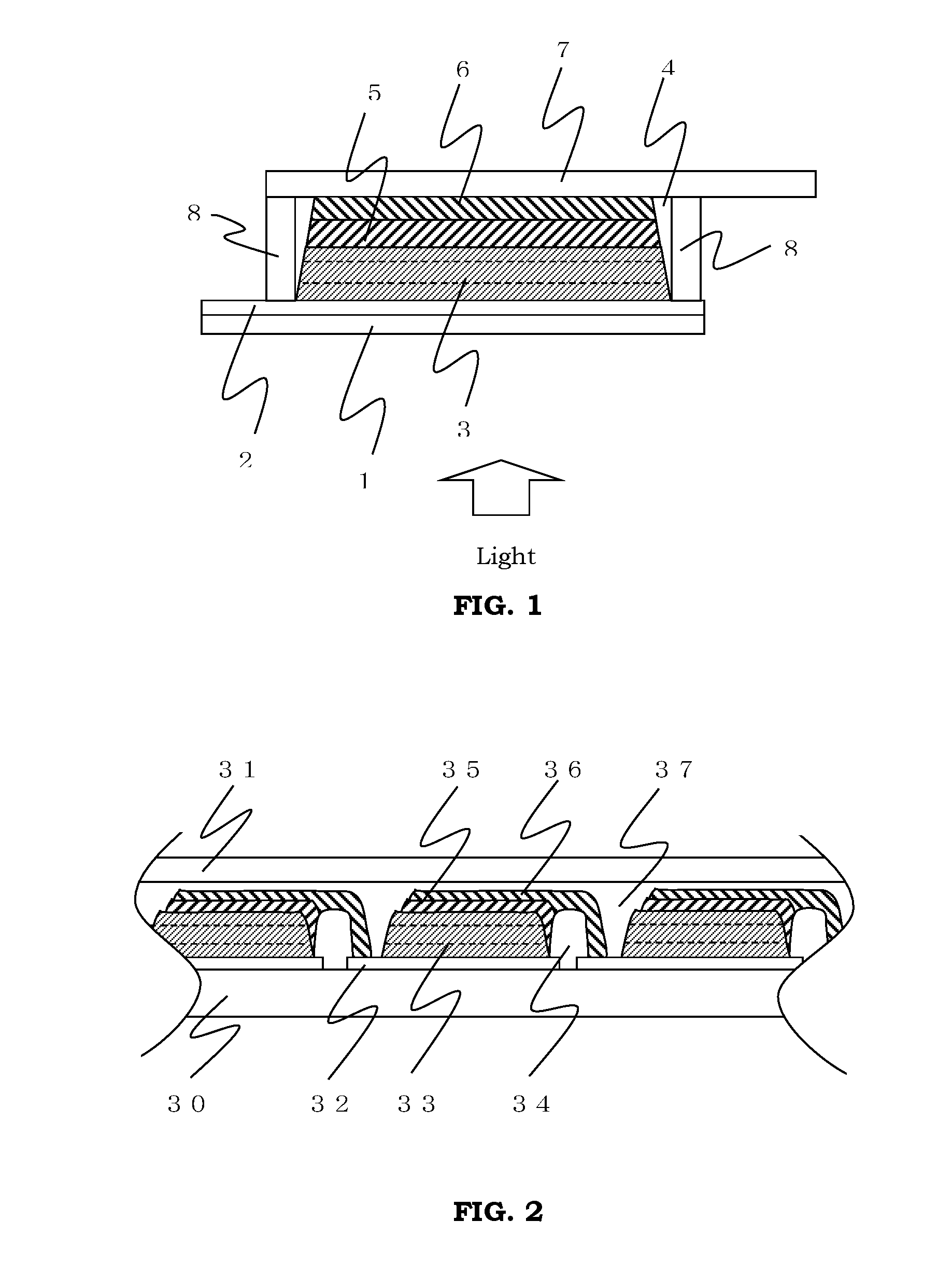

Dye-sensitized solar cell and method for manufacturing thereof

ActiveUS20160343517A1Low costImprove performanceLight-sensitive devicesCell component detailsCharge carrierEngineering

A dye-sensitized solar cell formed by layering a conductive layer; a photoelectric conversion layer in which a dye is adsorbed in a porous semiconductor layer and the layer is filled with a carrier transporting material; and a counter electrode including only a counter electrode conductive layer or including a catalyst layer and a counter electrode conductive layer on a support made of a light transmitting material, in which the photoelectric conversion layer is brought into contact with the counter electrode; the porous semiconductor layer forming the photoelectric conversion layer has two or more layers with different light scattering properties; and the two or more porous semiconductor layers are layered in an order of from a layer with lower light scattering property to a layer with higher light scattering property from a light receiving face side of the dye-sensitized solar cell.

Owner:SHARP KK

Process for preparing passivated emitter rear contact (PERC) solar cells

ActiveUS9966484B2Simple processLow production costFinal product manufacturePhotovoltaic energy generationScreen printingCatalytic metal

A process for preparing a passivated emitter rear contact solar cell, which includes the steps as follows: removing the damaged layer on the surface of the silicon wafer and at the same time polishing both surfaces, texturing, forming PN junction, etching, removing the glass impurity, depositing a passivation film on the back surface, depositing a passivating antireflective layer on the front surface, making local openings on the back surface, screen printing of metal paste on both the front surface and the back surface and sintering, in which the texturing step employs a catalytic metal etching approach, and the textured structure is a nanometer-level textured structure. The present invention has combined removing the damaged layer on the surface of the silicon wafer and polishing both the front and back surfaces into one single step, and thus has simplified the production process and reduced the production cost.

Owner:CSI CELLS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com