Manufacturing method of N-type TOPCon solar cell

A solar cell and manufacturing method technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of polluted cells and diffusion furnace tubes, difficult adjustment of diffusion processes, etc., achieve high photoelectric conversion efficiency, reduce investment quota, and improve short circuit. effect of current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

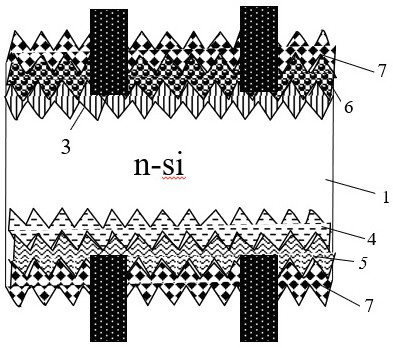

[0038] The manufacture method of the N-type TOPCon solar cell that the present embodiment relates to, comprises the steps:

[0039] a. Double-sided texturing: use the N-type silicon wafer substrate 1 with a minority carrier life > 10ms, perform double-sided pretreatment, reduce the thickness to 6 μm, and perform alkali texturing to form a pyramid textured surface, and the thinning amount is controlled at 0.40g;

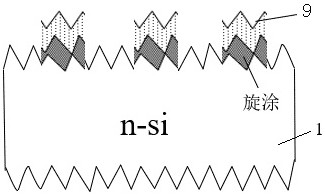

[0040] b. Single-sided spin coating: use a spin coating liquid with a volume ratio of boron source: pre-wetting liquid of 1:1.6, and use a speed of 2000r / m to spin evenly and distribute it on the textured silicon wafer surface, as Preconditions for forming a heavily doped region; among them, boric acid: water: propylene glycol monomethyl ether is 1: 2.8: 6.8 in volume ratio: propylene glycol monomethyl ether in pre-wetting liquid: water in volume ratio The ratio is 1:1.5, so as to ensure that the boron source can be mixed evenly and can be easily and evenly spin-coate...

Embodiment 2

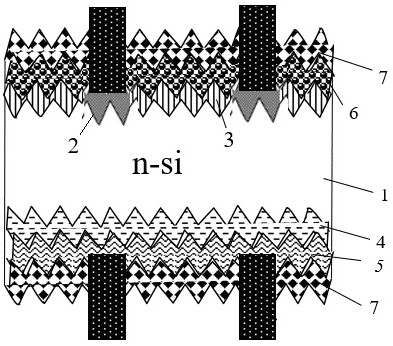

[0053] This embodiment relates to a method for fabricating an N-type TOPCon solar cell based on selective emitter technology, including the following steps: using an N-type silicon chip, the resistivity is 1Ω.cm, and the minority carrier lifetime is >10ms.

[0054] 1) Double-sided texturing: In the slot machine, pre-treatment polishing is performed first, and the polishing thickness is about 6 μm; potassium hydroxide is used: the volume ratio of additives for model TS52 is 8:1, the temperature is maintained at 80 ° C, and the time is about 6 minutes Carry out rapid texturing; the amount of thinning is controlled at 0.42g;

[0055] 2) Single-side spin coating, single-side oxidation, using a spin coating solution with a mass ratio of boron source: pre-wet solution = 1:1.8, in an atmosphere with a nitrogen:oxygen volume ratio of 1:2.8, and controlling the temperature at 700°C for 1 hour Using tubular oxidation to form boron-containing silicon oxide layer to solve the problem of b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com