Bars reducing and sizing mill

A technology for reducing sizing mills and bars, which is applied in the direction of metal rolling stands, metal rolling mill stands, metal rolling, etc., can solve the problems of low product grade, poor quality and stability, and achieve compact machine structure, Lightweight and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

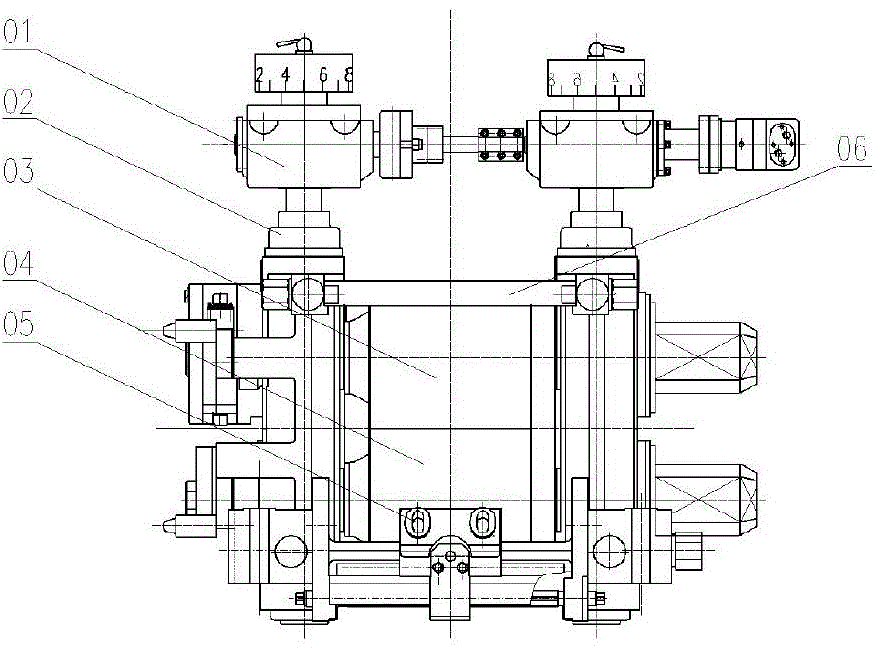

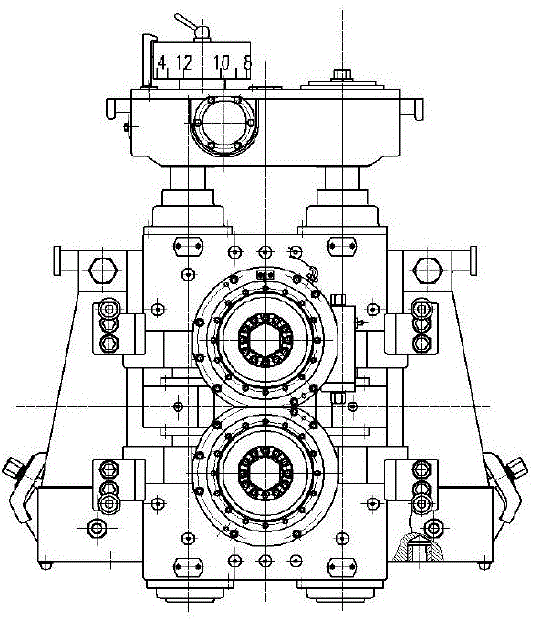

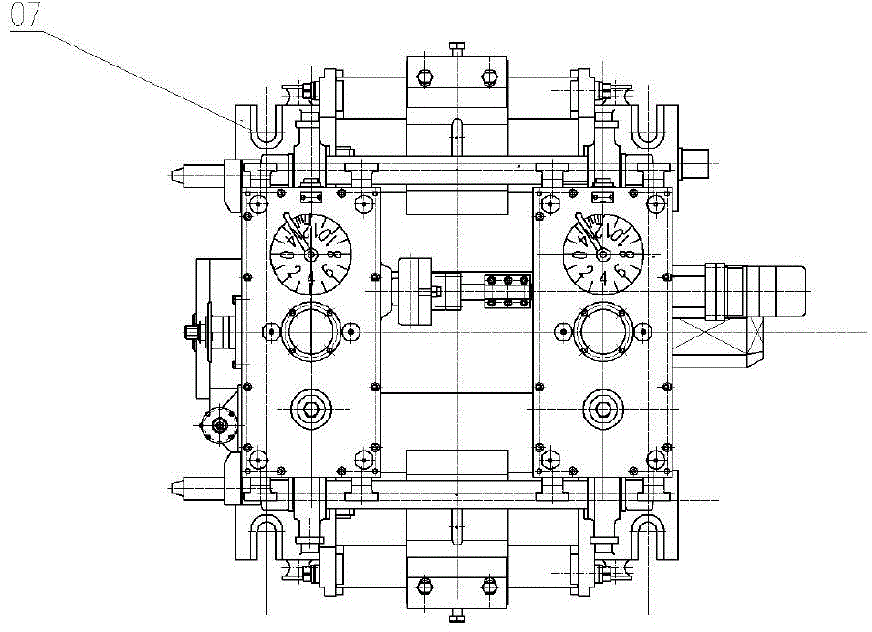

[0025] Such as Figures 1 to 7 As shown, the bar reducing and sizing machine in this embodiment is a short stress line model, including a roll gap adjustment device 01, a tie rod assembly 02, a frame 07 and a beam 06, a roll assembly, and a guide beam device 05. The roll assembly includes the upper roll assembly 03 and the lower roll assembly 04. The special structure of the tie rod assembly makes the change scale of the center distance between the upper and lower rolls of the bar reducing and sizing machine 0.1 mm, which meets the accuracy requirement of the opening of the reducing and sizing machine. The butterfly spring shock absorber is used in the tie rod assembly to eliminate the gap between the tie rod and the copper nut. The figure shows the copper nut 53 installed on the side of the upper roll box. At the same time, a spherical anti-axial movement device is ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com