Patents

Literature

182results about How to "Eliminate axial play" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

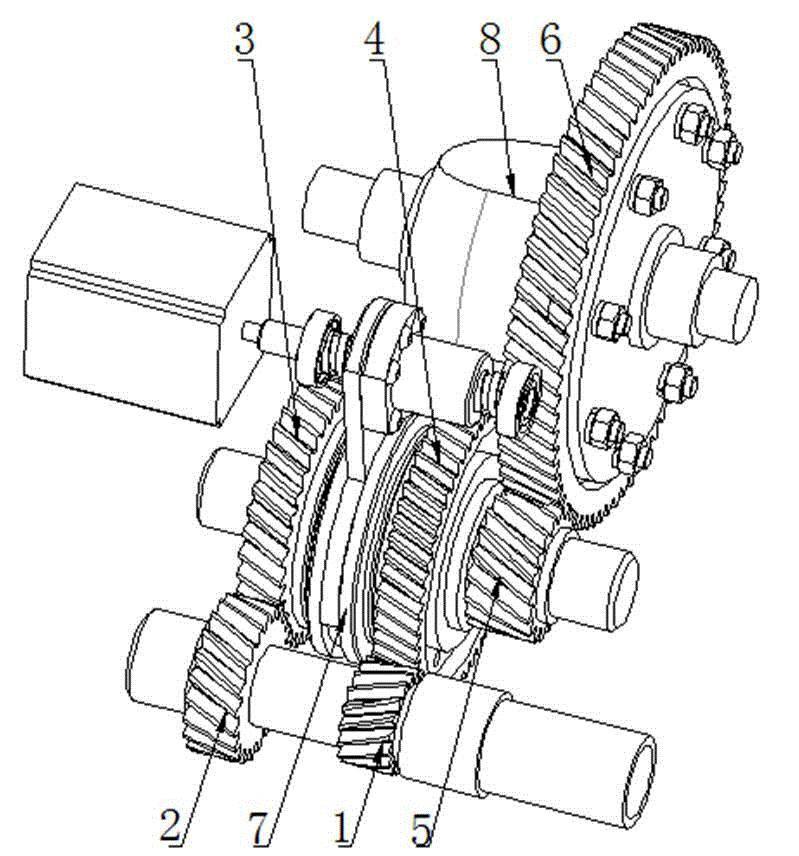

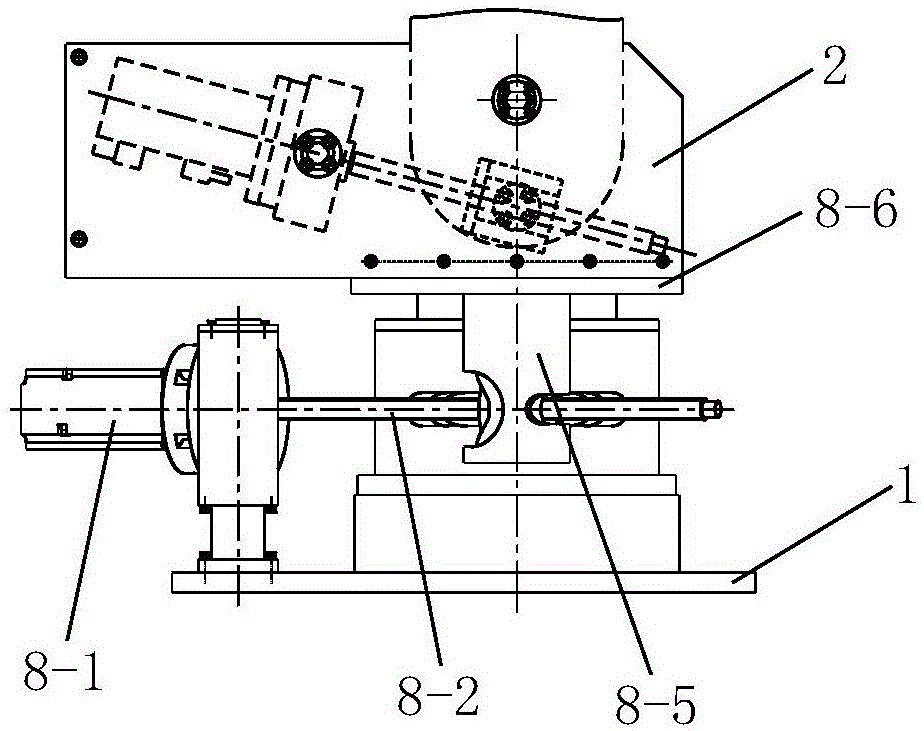

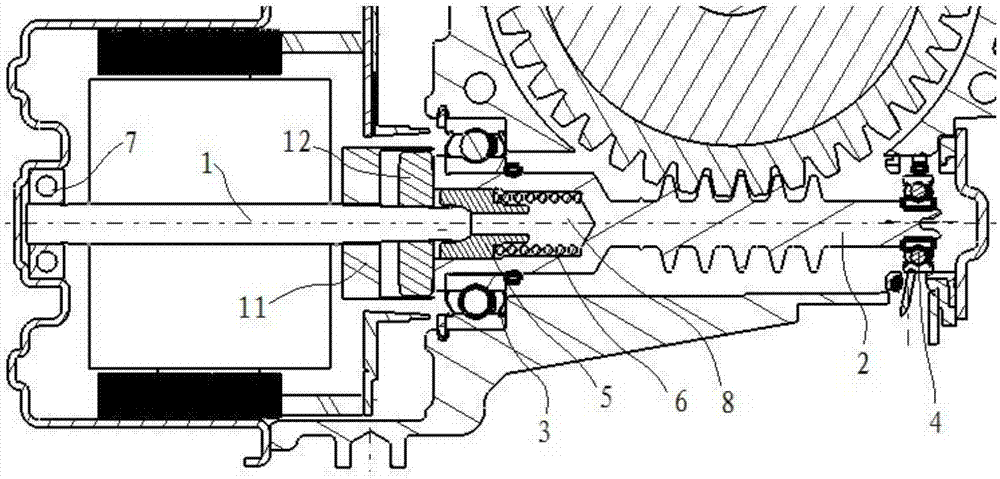

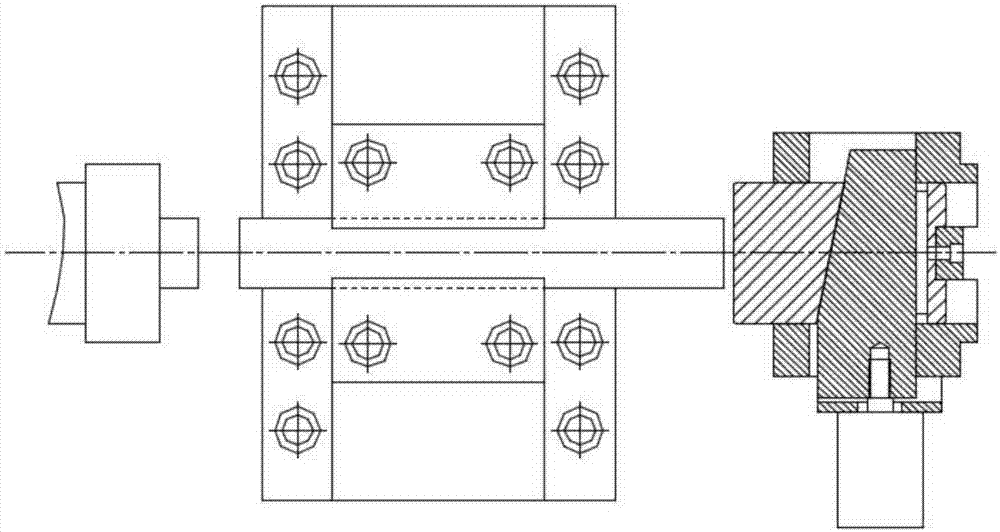

Screw-nut gear-shifting mechanism for automatic two-gear transmission of electric car

InactiveCN103557316AImprove transmission efficiencyEliminate axial playGearingGearing controlGear driveAutomatic transmission

The invention relates to a screw-nut gear-shifting mechanism for an automatic two-gear transmission of an electric car. The mechanism comprises an input shaft, an intermediate shaft and a fork gear-shifting mechanism, wherein the input shaft and the intermediate shaft are parallel to each other; a first-gear driving gear and a second-gear driving gear are fixedly arranged on the input shaft respectively; a second-gear driven gear, a first-gear driven gear, a main reduction driving gear and a synchronizer are sequentially arranged on the intermediate shaft respectively; the first-gear driving gear and the first-gear driven gear are normally engaged, and the second-gear driving gear and the second-gear driven gear are normally engaged; a main reduction driven gear is arranged to be matched with the main reduction driving gear, and during installation for usage, the main reduction driven gear is fixed on a differential mechanism flange plate through bolts; and a fork of the fork gear-shifting mechanism is sleeved with a joint sleeve of the synchronizer. According to the mechanism, a screw and screw-nut mechanism is adopted, so that the accuracy and the reliability of gear shifting are improved; and the mechanism is simple in structure, convenient to install and small in size, has a self-locking function and can prevent gears from loosening.

Owner:HEFEI UNIV OF TECH

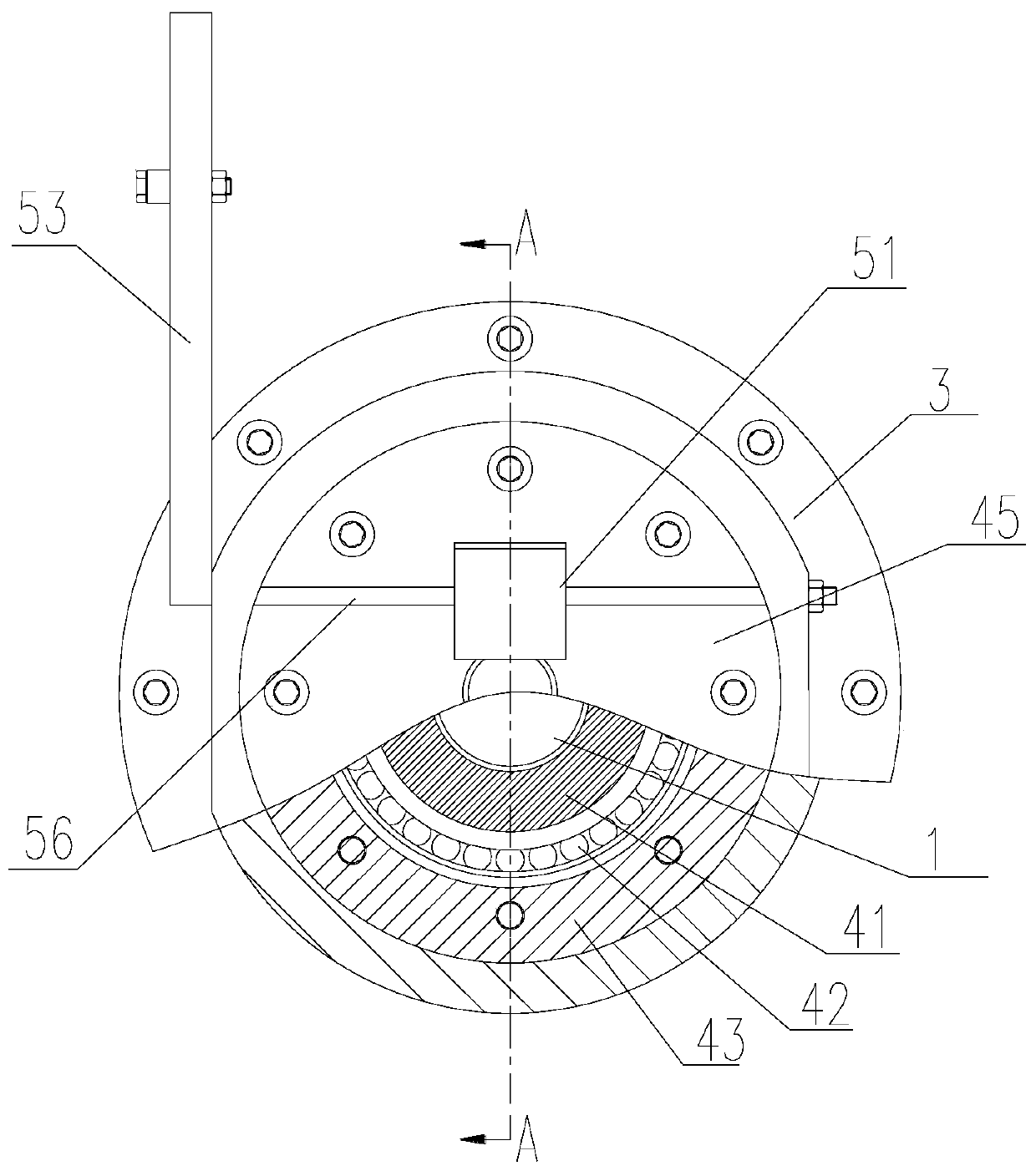

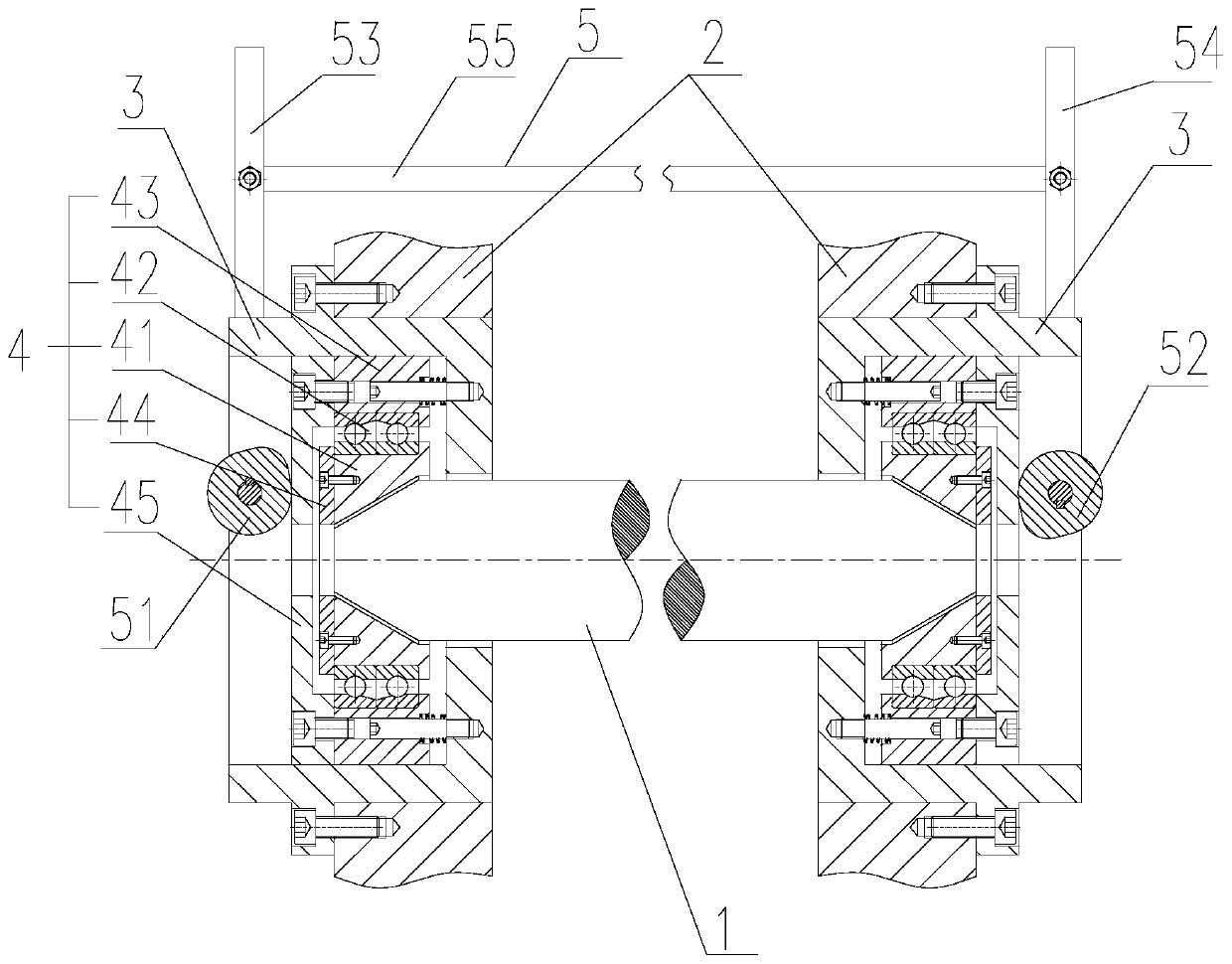

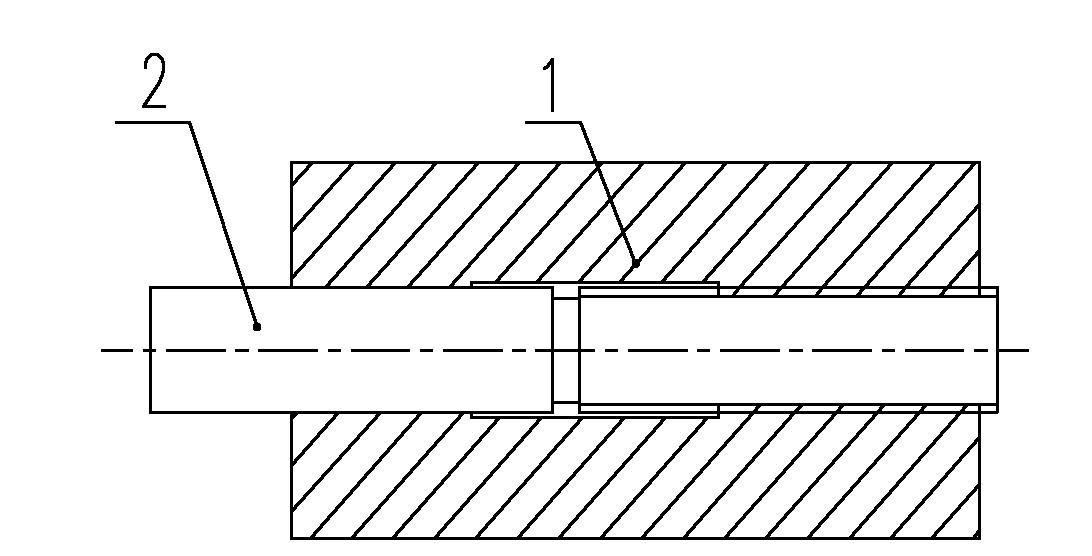

Manual type bearing protection device

The invention relates to a magnetic levitation bearing system, in particular to a manual type bearing protection device. The manual type bearing protection device comprises a rotor, two bearing seats,two groups of bearing protection assemblies and a manual driving assembly; two ends of the rotor are in a circular truncated cone shape; the two bearing seats are arranged at the two ends of the rotor, and the two ends of the rotor extend into the bearing seats; the two groups of the bearing protection assemblies are symmetrically and slidably arranged in the bearing seats, cone-shaped holes which are matched with the ends of the rotor are formed in the bearing protection assemblies; and the manual driving assembly drives the bearing protection assemblies to axially move close to each other until the bearing protection assemblies are in contact with the rotor. The manual type bearing protection device can temporarily support the rotor when a magnetic bearing system fails, can manually protect the rotor, prevents damage caused by falling of the high-speed rotor, and improves the security of the system.

Owner:JIANGSU UNIV OF TECH

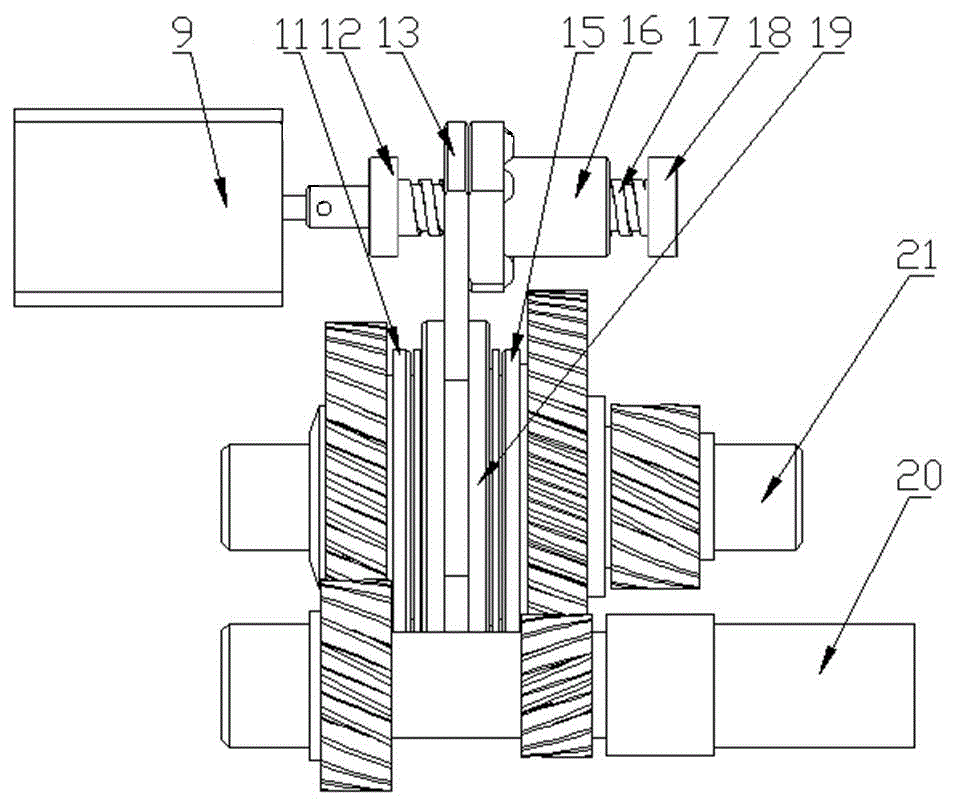

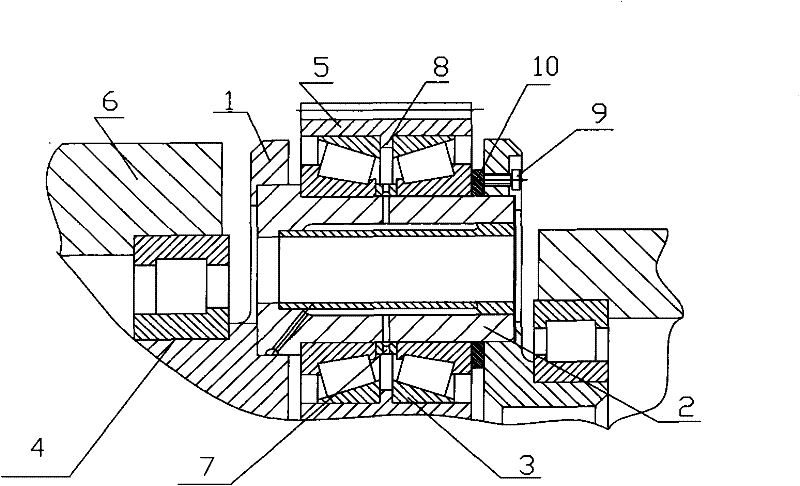

Planetary transmission structure of wind power gear box

InactiveCN102518787AAvoid shock loadsImprove operational reliabilityRolling contact bearingsToothed gearingsElectricityGear wheel

The invention relates to a planetary transmission structure of a wind power gear box, which comprises a sun gear, a planetary bracket, a mandrel, planetary gear bearings, planetary bracket bearings and a planetary gear. The planetary bracket is mounted on a box through the planetary bracket bearings, the planetary gear is mounted on the mandrel through the planetary gear bearings, and the planetary gear bearings are a pair of tapered roller bearings and are mounted back to back. The planetary transmission structure is capable of bearing bending moment generated by axial force of the planetary gear more effectively, load impact from paddles is prevented, running reliability of the gear box is improved, and the working requirement of the wind power gear box is met.

Owner:HARBIN DONGAN ENGINE GRP

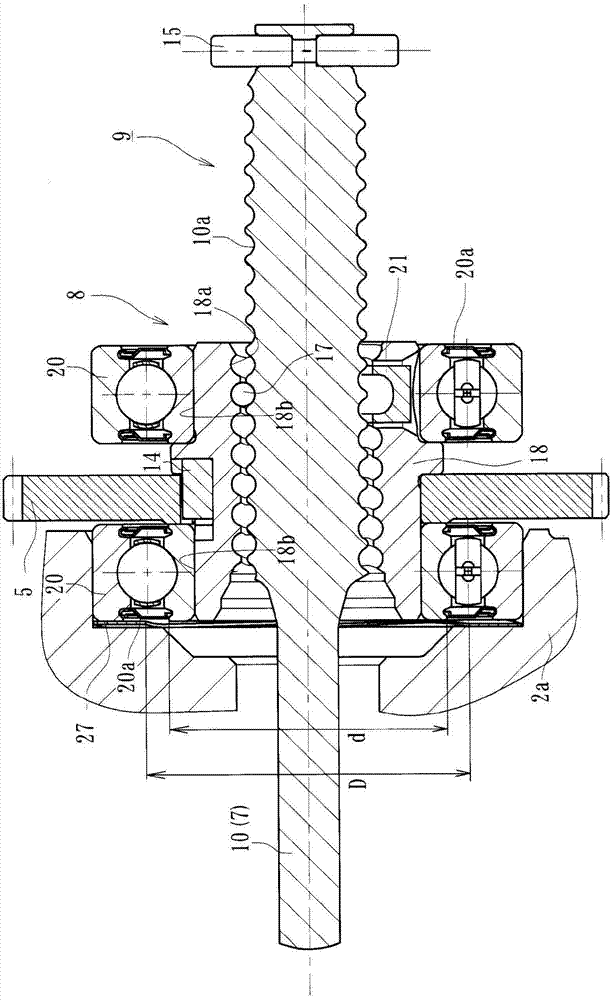

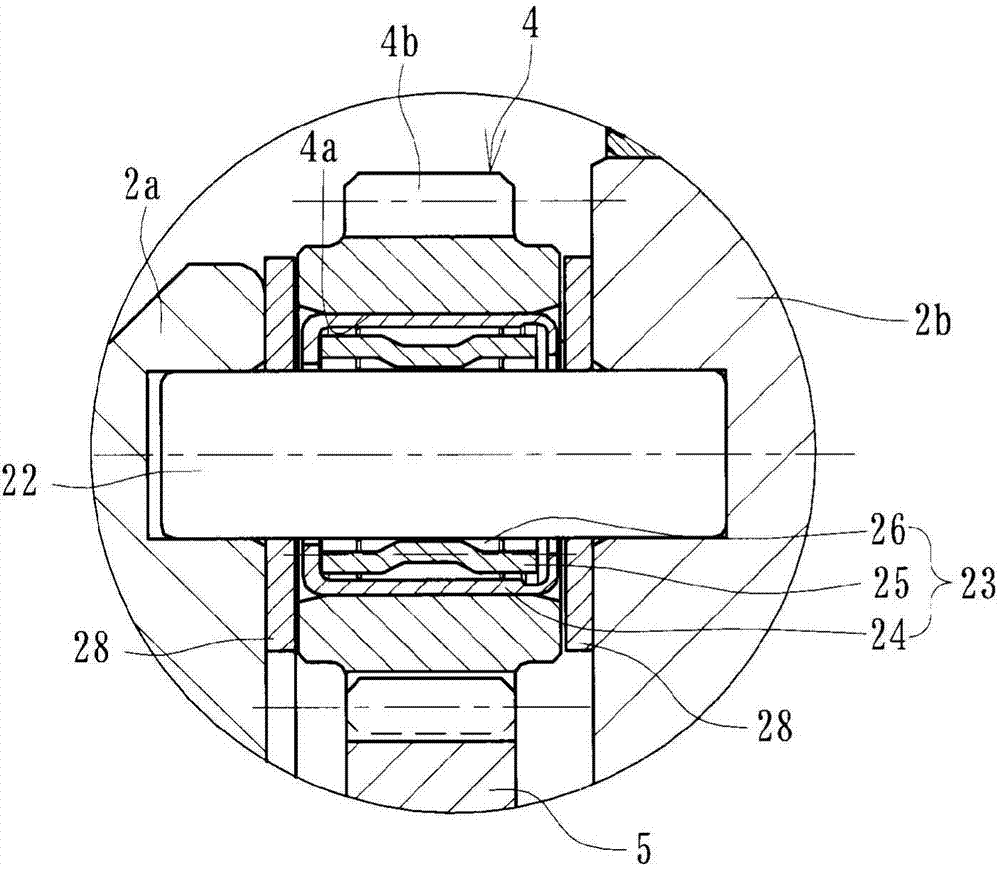

Electrically powered linear actuator

Provided is an electrically powered linear actuator, which averts ball screw lock up, is inexpensive and has excellent rotation performance. An output gear (5) configuring a deceleration mechanism (6) is fixed to a nut (18). Support bearings (20, 20) are disposed on both sides of the output gear (5) and the pair of support bearings (20, 20) are configured from a pair of roller bearings of the same specifications that can bear both thrust loads from the drive shaft (7) and radial loads applied through the output gear (5). The support bearings are installed in a housing (2a) via a washer (27), which is obtained from a ring-shaped elastic member. The internal diameter (D) of the washer (27) is formed to be larger than the external diameter (d) of the inner ring of the support bearing (20).

Owner:NTN CORP

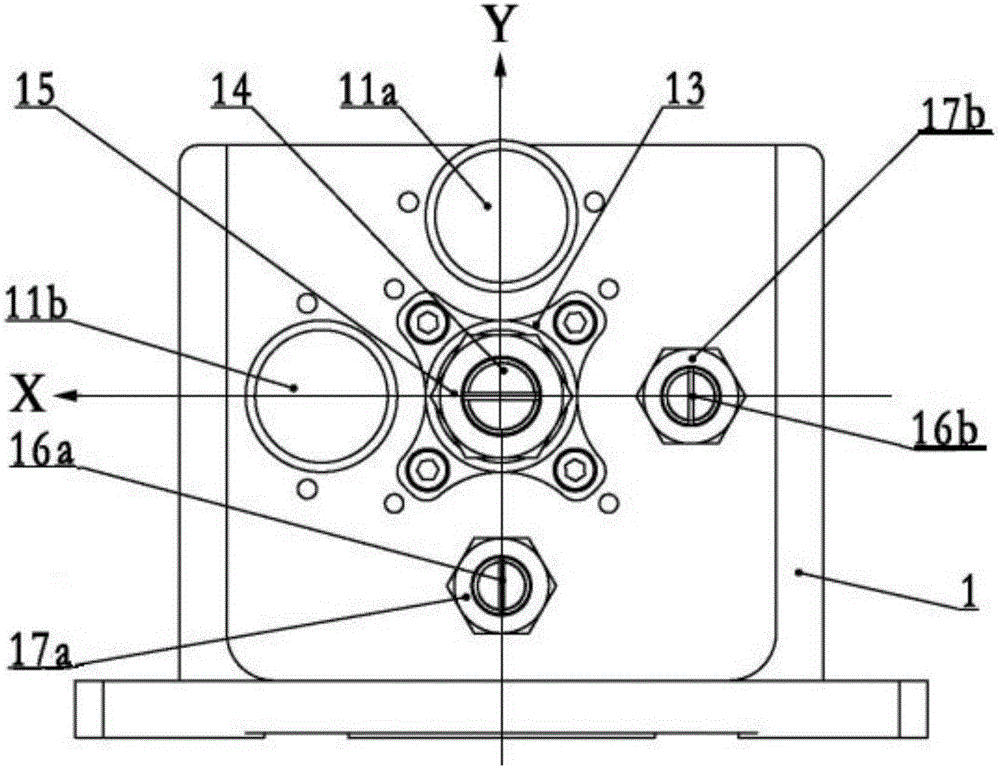

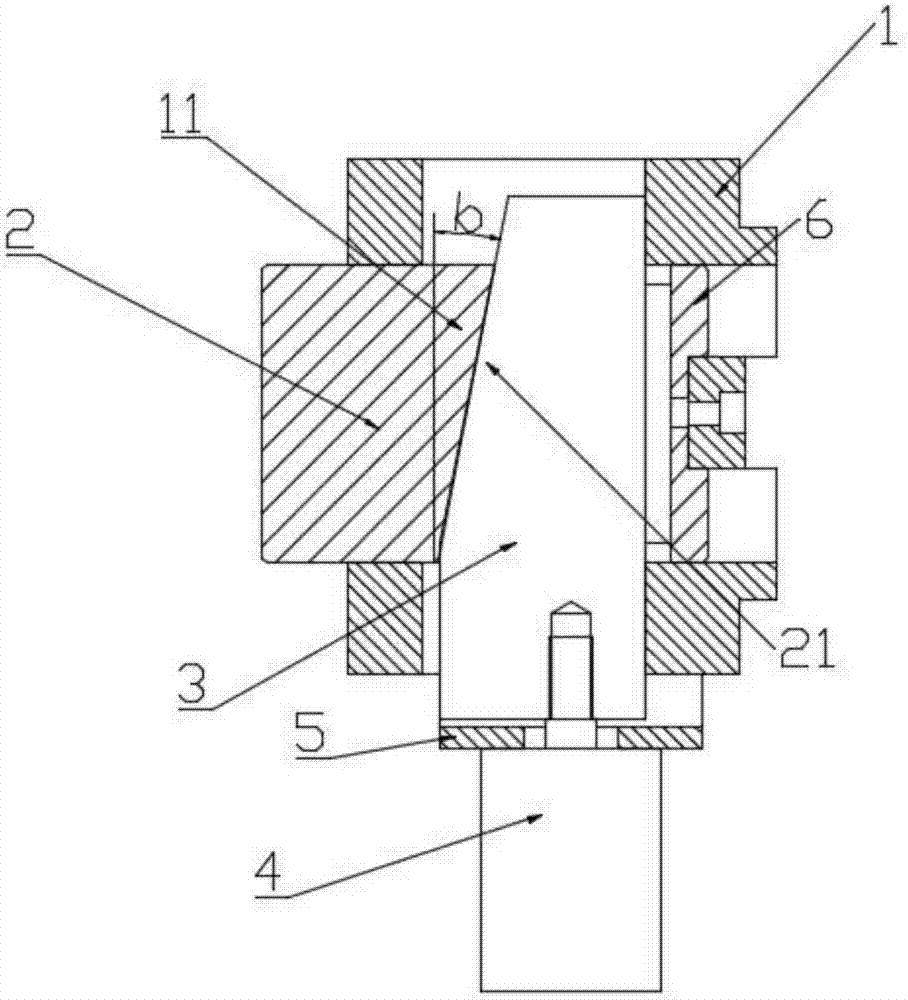

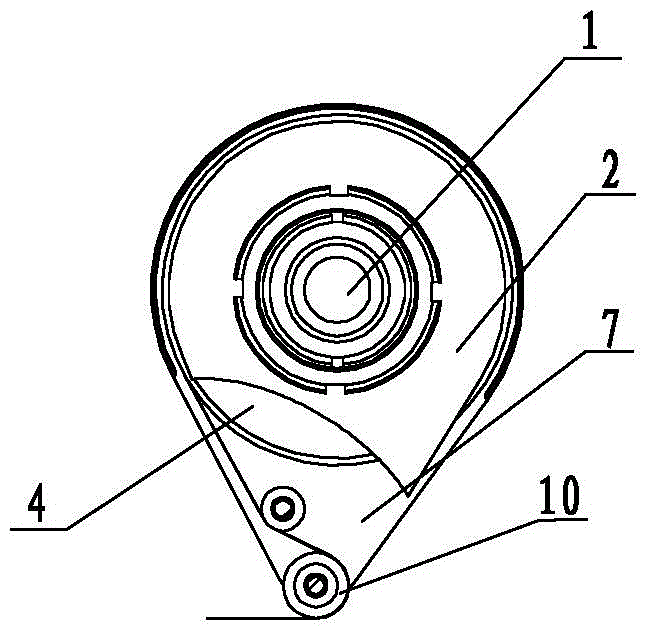

Two-dimensional electric mirror adjustment device

ActiveCN106773022AReduce manufacturing costIncrease the itineraryOptical elementsLight beamEngineering

The invention discloses a two-dimensional electric mirror adjustment device, relates to the technical field of beam control and overcomes defects that an existing fast steering mirror has a small rotation angle range and is high in manufacturing cost to realize automatic two-dimensional adjustment of a planar mirror. The device comprises a support base, a mirror seat, a planar mirror, a central shaft, a bearing press ring, a lens press block, two telescopic sliders, two slider guide seats, a knuckle bearing, two stepping motors, a backlash spring, an adjusting screw seat, an adjusting screw, two reset spring seats and two reset springs. Through threaded connection of the stepping motors and the telescopic sliders and limited guide of the slider guide seats, rotation movement of the stepping motors is converted into linear movement, further, the mirror seat and the mirror are directly driven by balls at the end parts of the telescopic sliders to deflect at a small angle, the cost is low, the two-dimensional electric mirror adjustment device can realize angle adjustment in a range of plus or minus 5-degree level through travel increase of a driver, and the adjustment range is increased by almost a hundred times than that of plus or minus 5' level of the fast steering mirror.

Owner:长春长光精密仪器集团有限公司

Ring-disk electrode

InactiveCN1789996AGuaranteed coaxialityReduce runoutMaterial electrochemical variablesCurrent noiseDiffusion

The invention discloses a ring-disk electrode body in the electrochemical analysis measuring electrode domain, which is characterized by the following: setting the ring and disk electrode at the axle and two bottoms at the same plane with macromolecular material insulating ring and adhesion layer between them; embedding the ring electrode in the end part of ring union body; connecting the ring union body with the screw of ring guide rod with guide matching face; contacting the disk electrode roof and the probe in the hole of disk guide rob bottom stickly; setting the ring and disk guide rod at the same axle with insulation sleeve and compacting by nut; setting the protection lid and sealing ring on the bottom of electrode body. The invention is applied to detect the diffusion coefficient and electrochemical parameter with large insulation resistance between ring and disk and small contact resistance in the signal guide system, which reduces the current noise and utility lifetime.

Owner:JIANGSU JIANGFEN ELECTROANALYTICAL INSTR

One-way braking device for wind power pitch system

InactiveCN102287332ASafe parkingPrevent lockWind motor controlMachines/enginesTransmission brakeEngineering

A unidirectional braking device for a wind power pitch system, the end cover is fixed on the shell, the mandrel passes through the shell and the end cover, and the mandrel is fitted between the mandrel and the shell and between the mandrel and the end cover Bearing; the mandrel gear is fixed on the mandrel, and the outer teeth of the mandrel gear mesh with the inner teeth of the transmission disc; one end of the brake spring is on the housing and the other end is on the brake pad, and the braking surface of the brake pad is in contact with the transmission disc. The disc surfaces of the discs match each other, the electromagnetic coil is fixed on the casing and the direction of its electromagnetic force is aligned with the brake pad, and the electromagnetic coil is electrically connected to the main power supply circuit. The invention utilizes brake springs, brake pads and electromagnetic coils to cooperate with one-way clutches to control the pitch system. When the main power supply circuit is powered off and the backup power supply fails, the fan blades can be safely returned. The paddle can prevent the motor braking device from locking up, and can return the blade to a safe position, so that the wind turbine can run and stop safely.

Owner:BEIJING WENCHUANG YOULIKE NEW ENERGY TECH

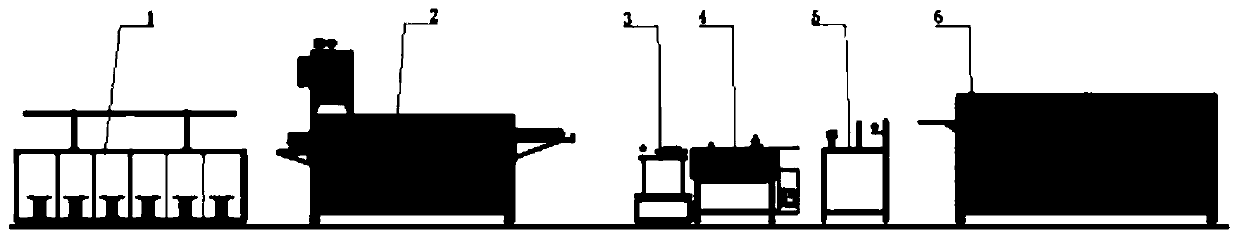

Micro-wire annealing tin plating machine production line

PendingCN109929971AProduction standardizationHigh speed productionHot-dipping/immersion processesFurnace typesFine lineProduction line

The invention discloses a micro-wire annealing tin plating machine production line and belongs to the field of cable machining. The micro-wire annealing tin plating machine production line comprises apay-off frame. A base is arranged at the lower end of the pay-off frame. An annealing furnace, a pickling bath, a tin furnace, a wire passing guide wheel set and a take-up machine. The pay-off frameis provided with a wire shaft. A first wire passing guide wheel is arranged on the surface of the pay-off frame. According to the production line, the special pay-off frame, the annealing furnace, thepickling bath, the tin furnace and the wire passing guide wheel set are arranged to be combined with the take-up machine, thus production of microwires is not troublesome any more, a user only needsto thread wires into the whole production line one by one like that of a traditional machine mode, the equipment can carry out the annealing technology and the tin plated technology automatically, allthe machined wires can be rolled and wound attractively with the standard and at a high speed, the defect that in the current wire industry, the microwires cannot be manufactured in batches is overcome, and the microwires can be produced with the standard and at a high speed.

Owner:鹰潭毅鹏智能科技有限公司

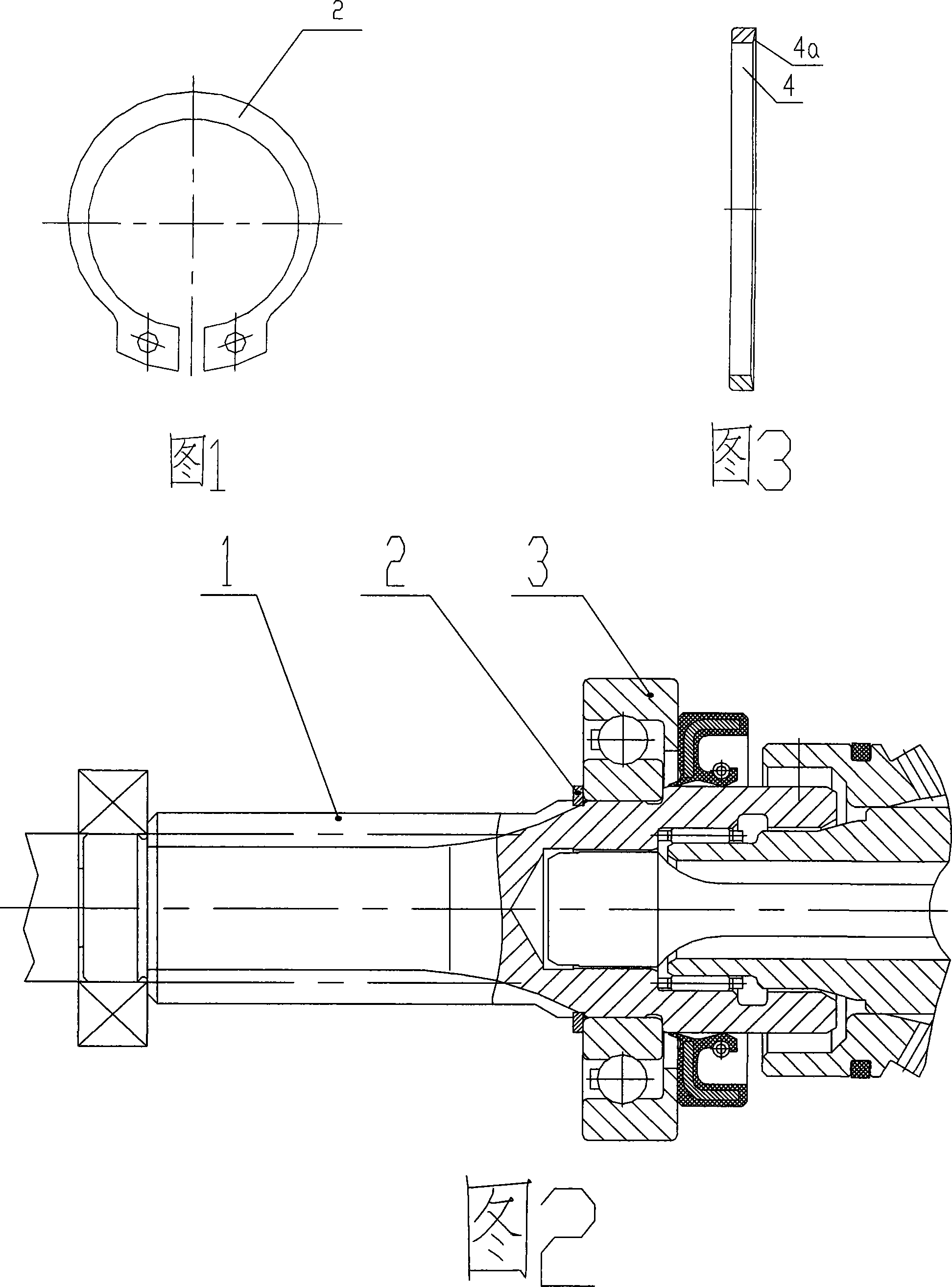

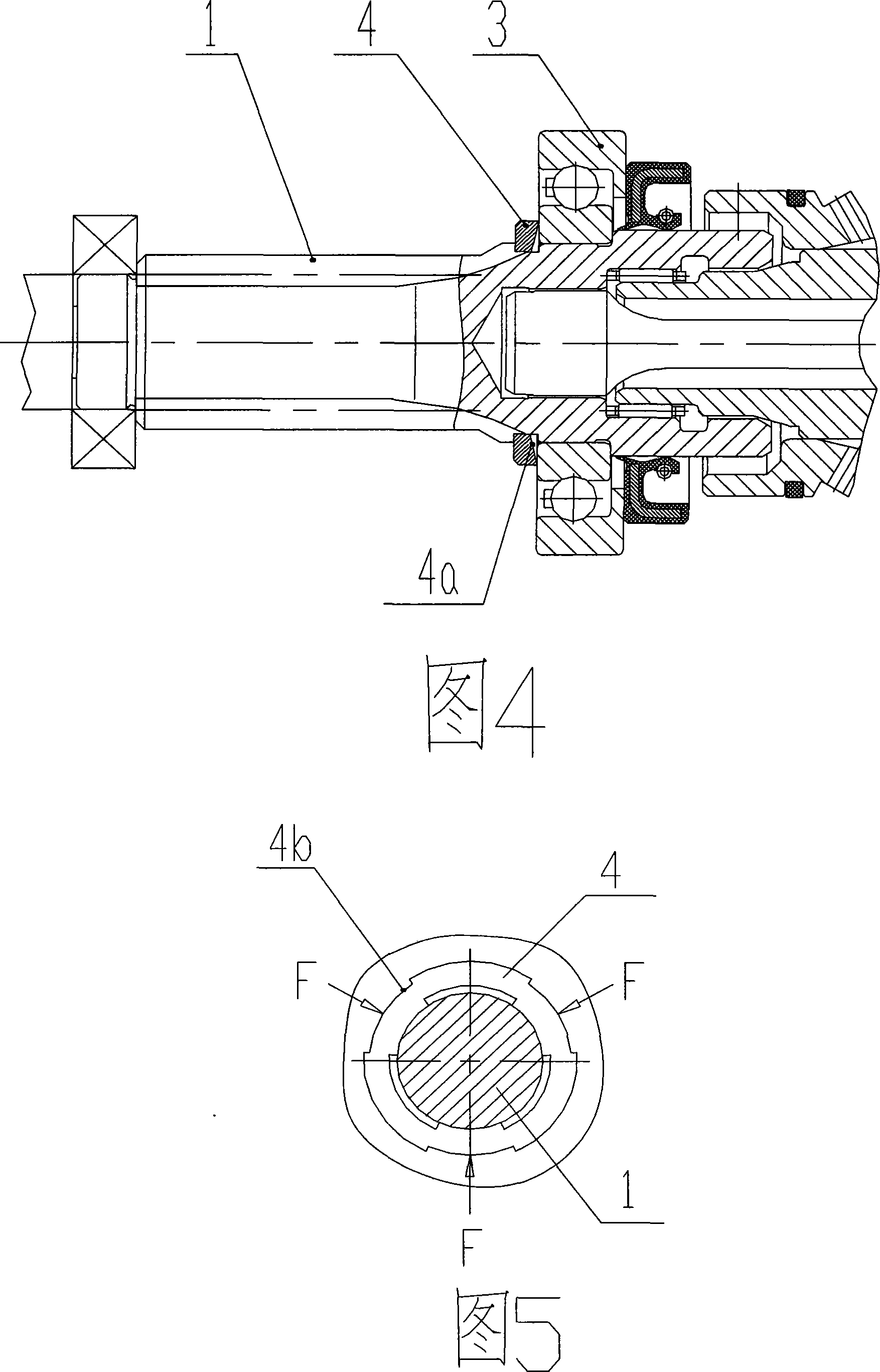

Method for fixed upper bearing of axial parts

InactiveCN101182864AQuick assemblyEliminate axial playFastening meansBearing unit rigid supportSpring steelCarbon steel

A method of fixing a bearing at axis parts is that a low carbon steel closed-ring retainer ring is adopted and designed; the retainer ring, a bearing and other relevant parts are installed at the axis parts according to the assembling sequence; the circle of the retainer ring is pressed uniformly and synchronously along the radial direction to ensure that the retainer ring is extruded and transmuted inside a retainer ring installing slot to be filled in an actually existent axial gap at the position. The present invention solves the problem that the usual method adopts a clasp-type spring steel retainer ring to position the bearing, so the axial gap caused by the error accumulation of an assembling chain results in the axial move of the bearing to influence the product performance. The present invention is especially conducive to the prompt assembly of the axis parts with compact structure and relevant parts and can reduce the axial size precision requirement to other relevant parts.

Owner:荆州恒隆汽车零部件制造有限公司

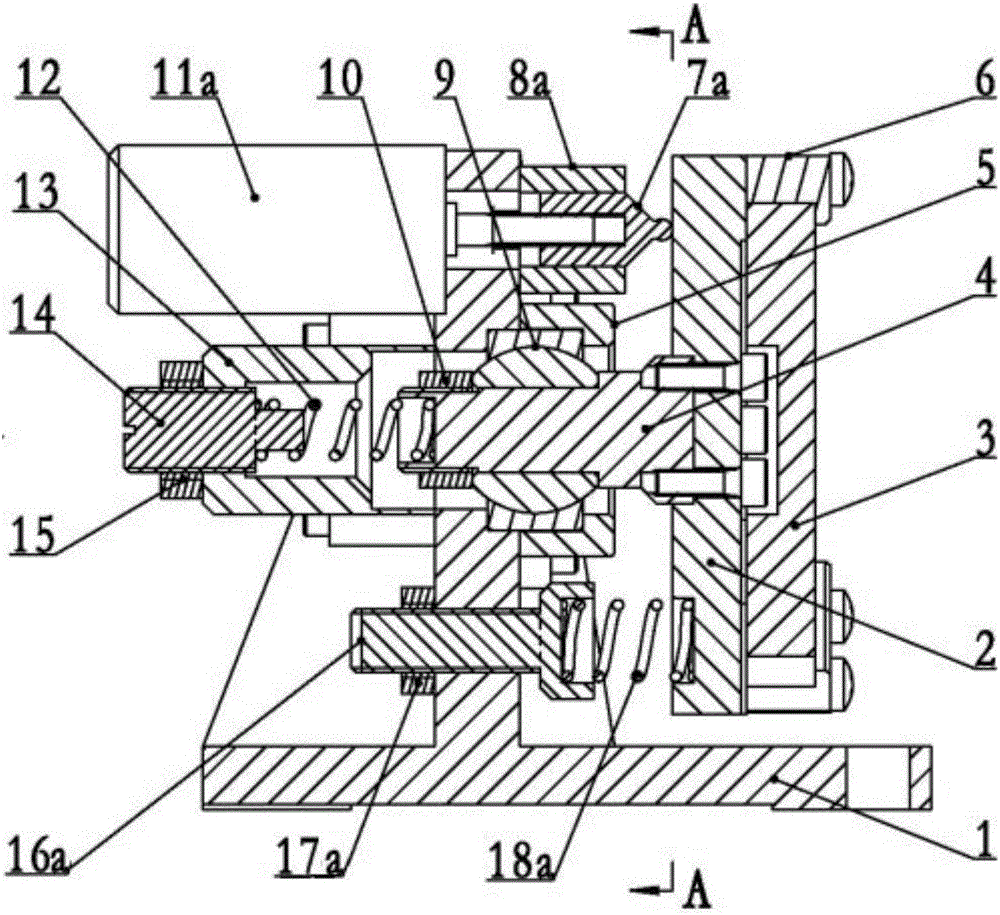

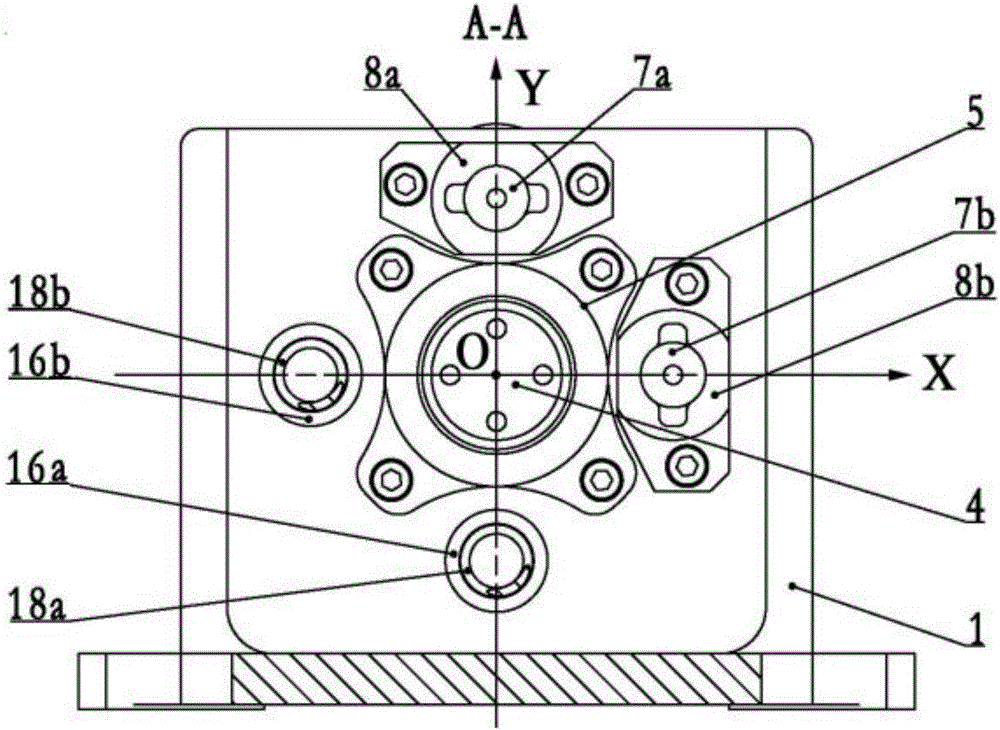

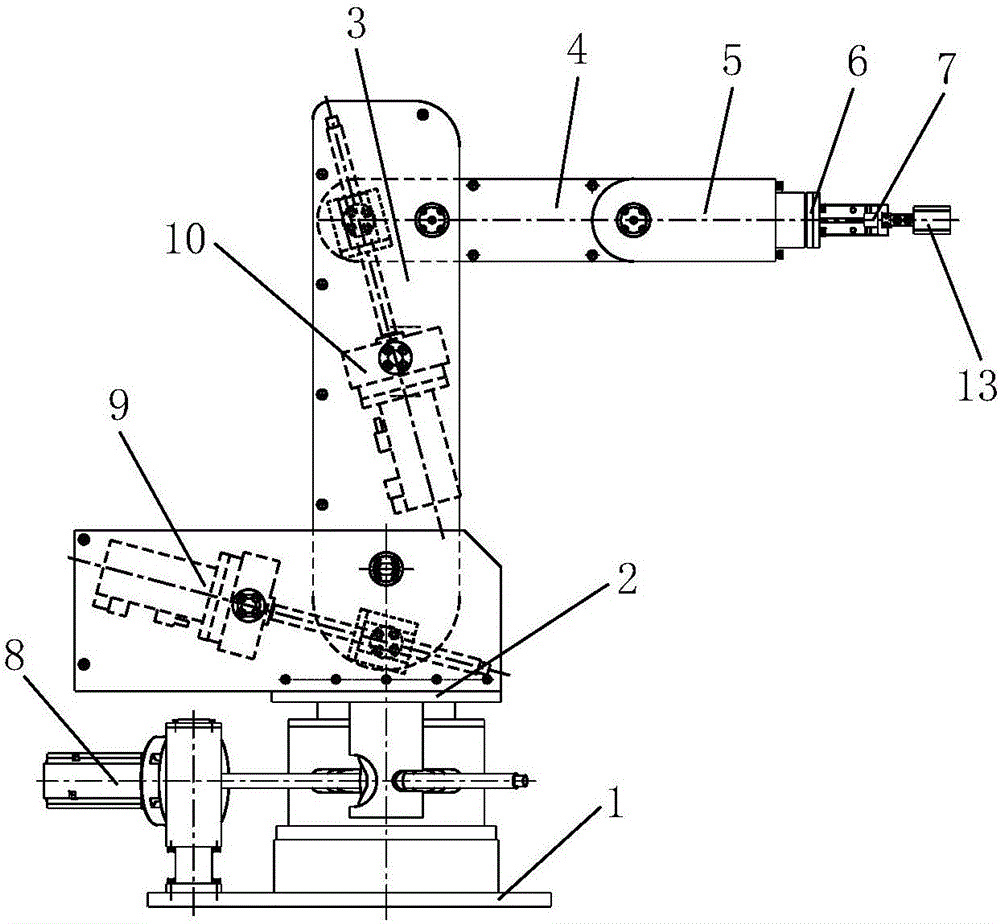

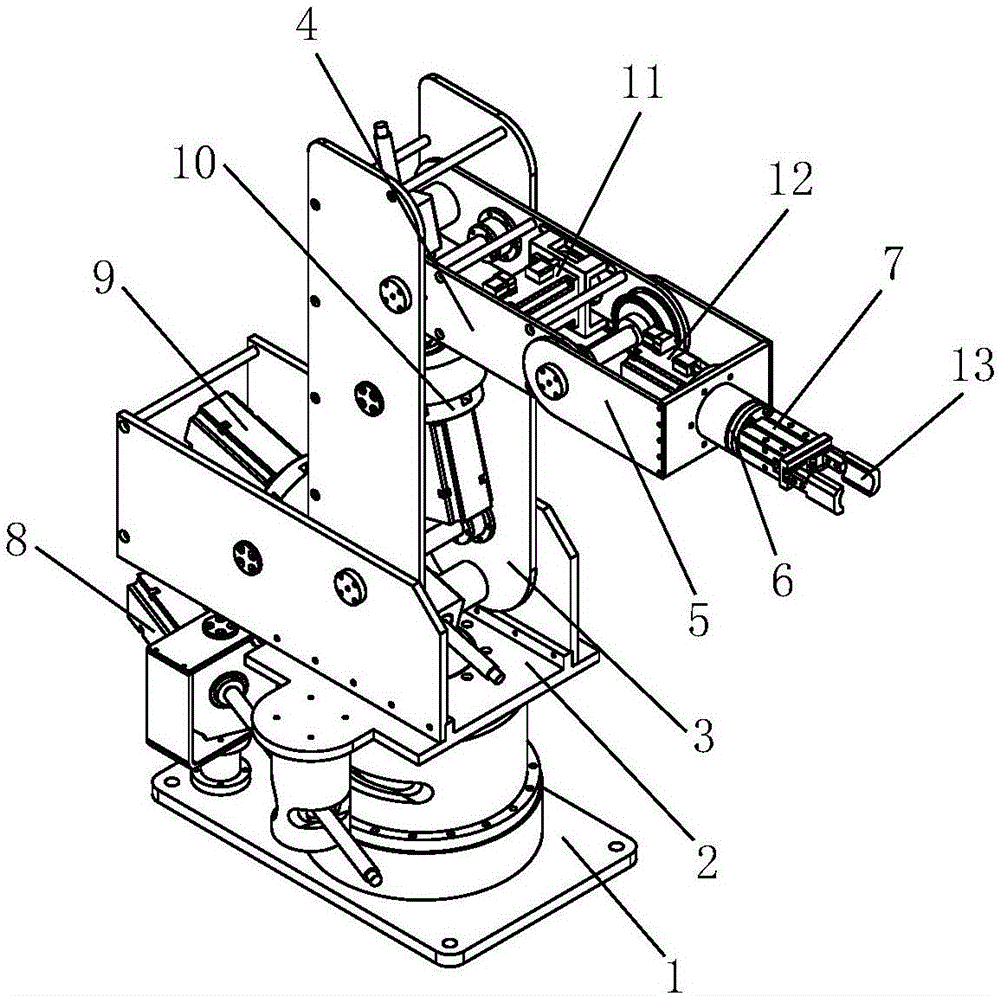

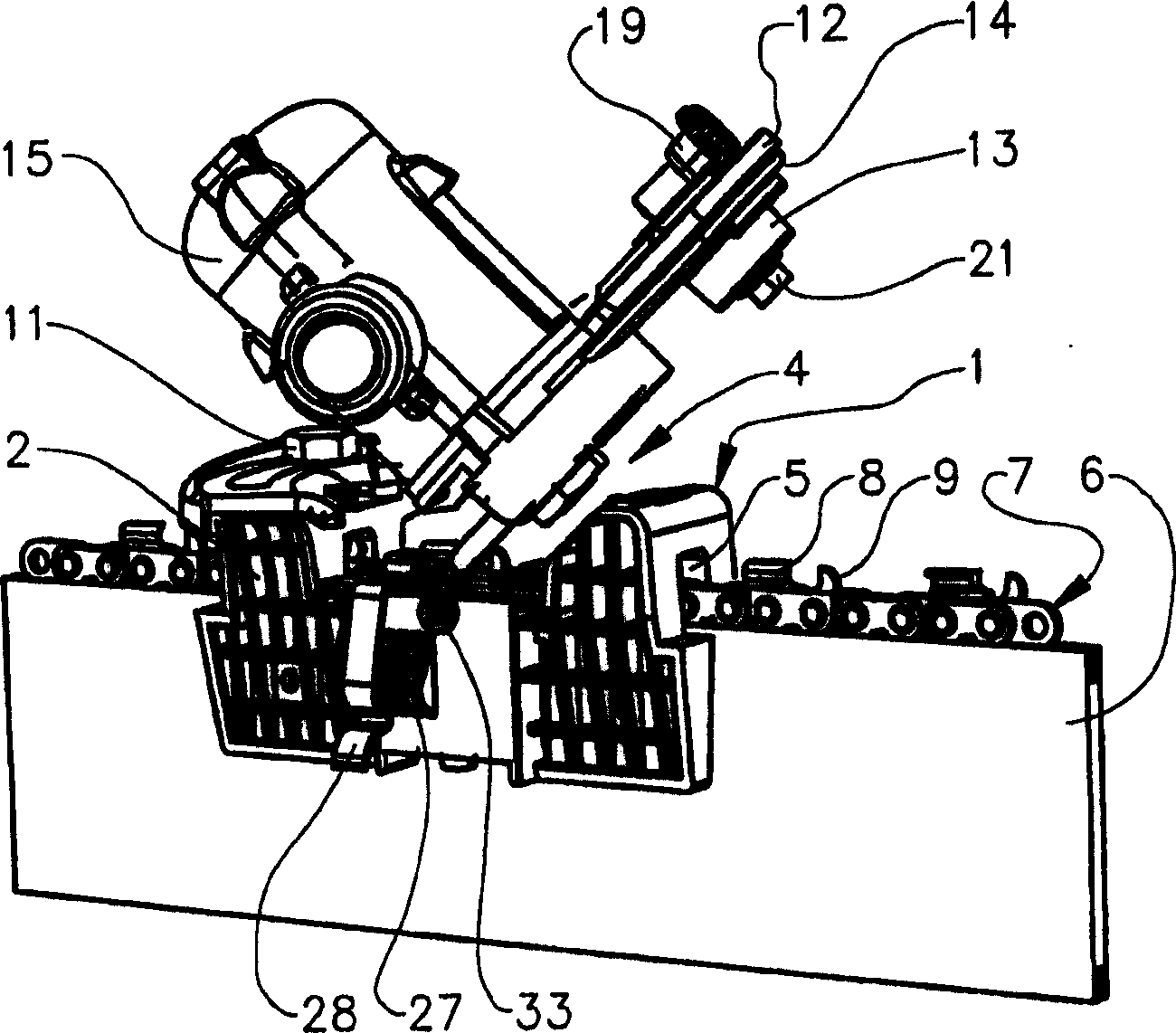

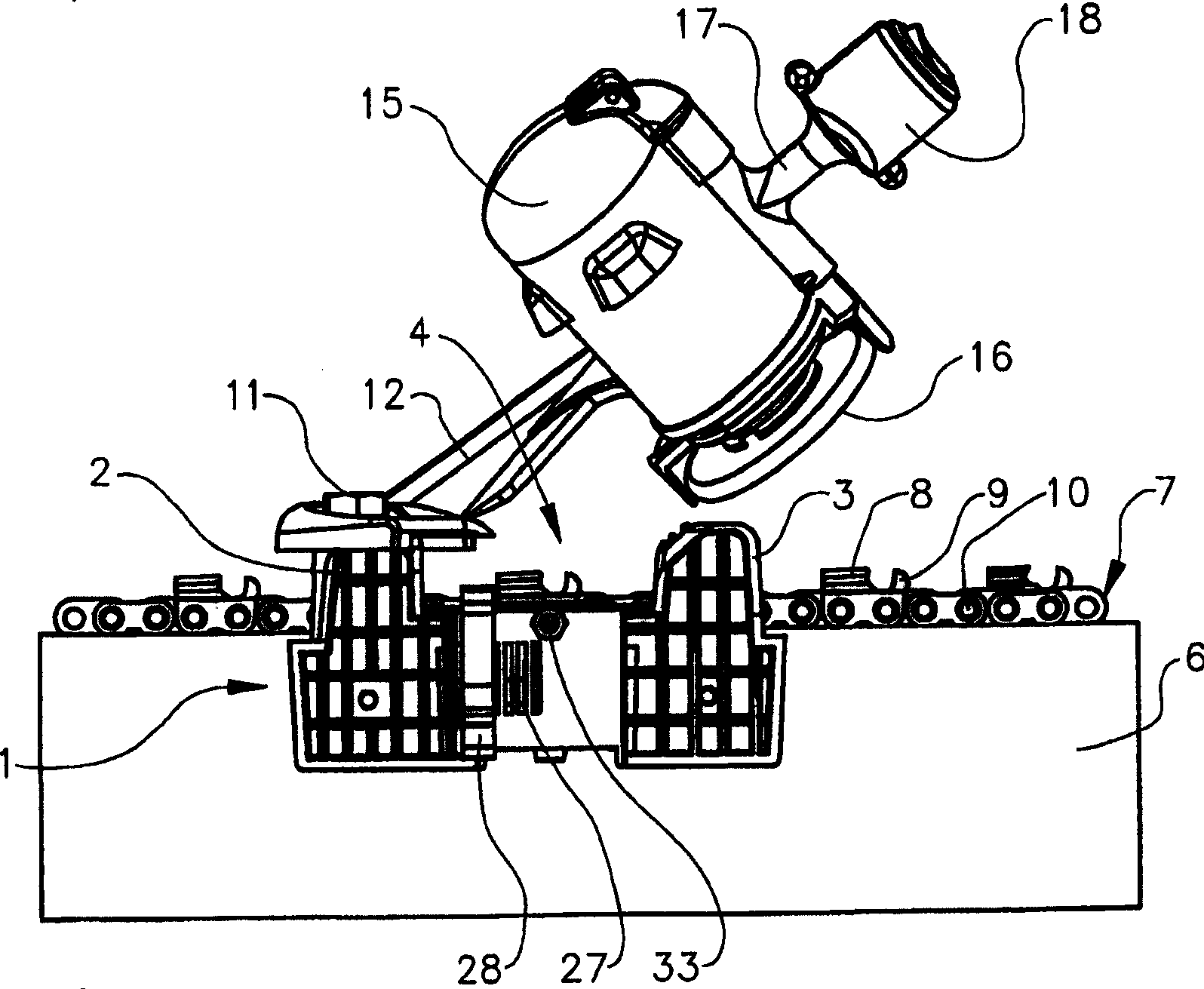

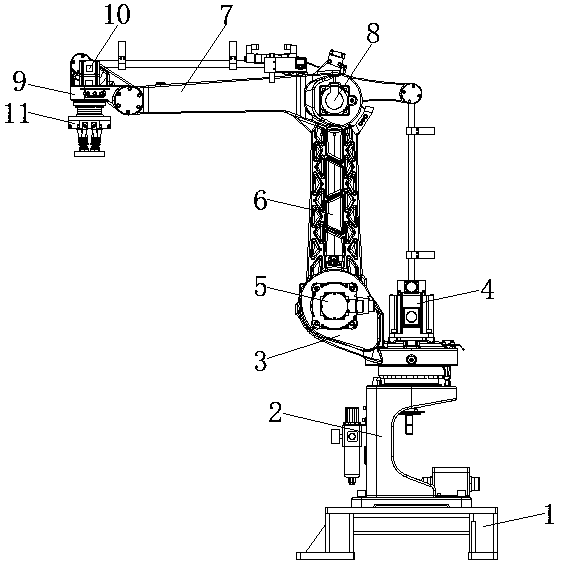

Robot for precise assembling

ActiveCN106426177ALess varietyReasonable structureProgramme-controlled manipulatorGripping headsBall screw driveEngineering

The invention discloses a robot for precise assembling. The robot for precise assembling comprises a base, a rotary table, a large arm, a small arm, a wrist joint, a front end rotational joint and a pneumatic clamping device. The rotary table is rotationally installed on the base. One end of the large arm is hinged to the rotary table, and the other end of the large arm is hinged to one end of the small arm. The other end of the small arm is hinged to one end of the wrist joint, and the front end rotational joint is rotationally installed at the other end of the wrist joint. The pneumatic clamping device is installed at the outer end of the front end rotational joint. A rotary table ball screw driving mechanism used for driving the rotary table to rotate is installed on the base, a large arm ball screw driving mechanism used for driving the large arm to rotate is installed on the rotary table, a small arm ball screw driving mechanism used for driving the small arm to rotate is installed on the large arm, a wrist joint driving mechanism used for driving the wrist joint to rotate is installed on the small arm, and a front end joint driving mechanism used for driving the front end rotational joint to rotate is installed on the wrist joint. The robot for precise assembling is stable in transmission, high in positioning precision and production efficiency, long in service life and wide in application range.

Owner:THE NORTHWEST MACHINE

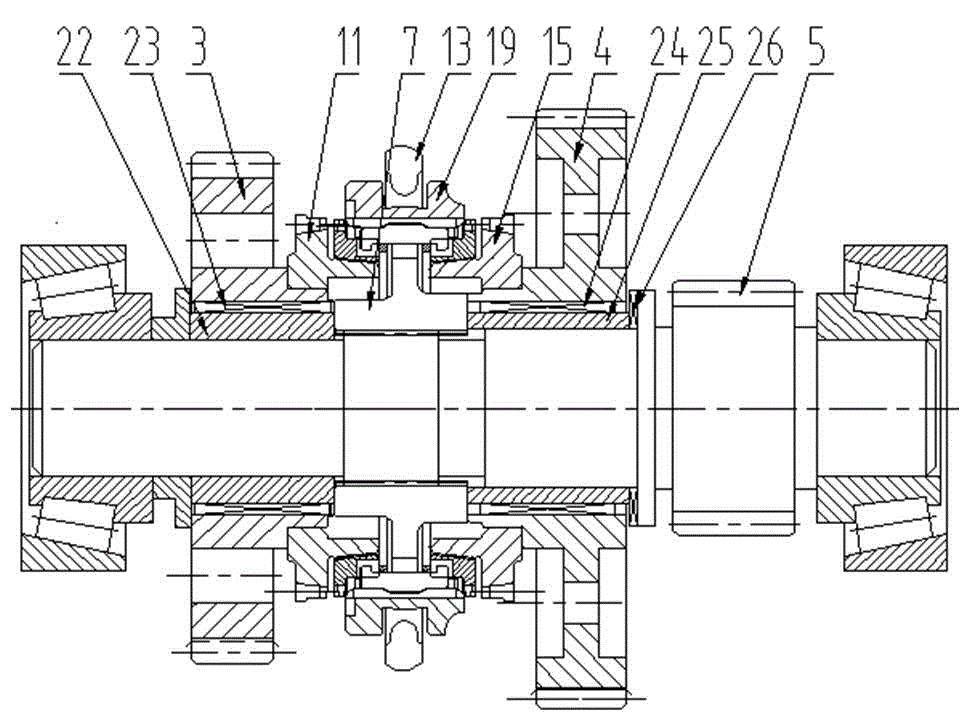

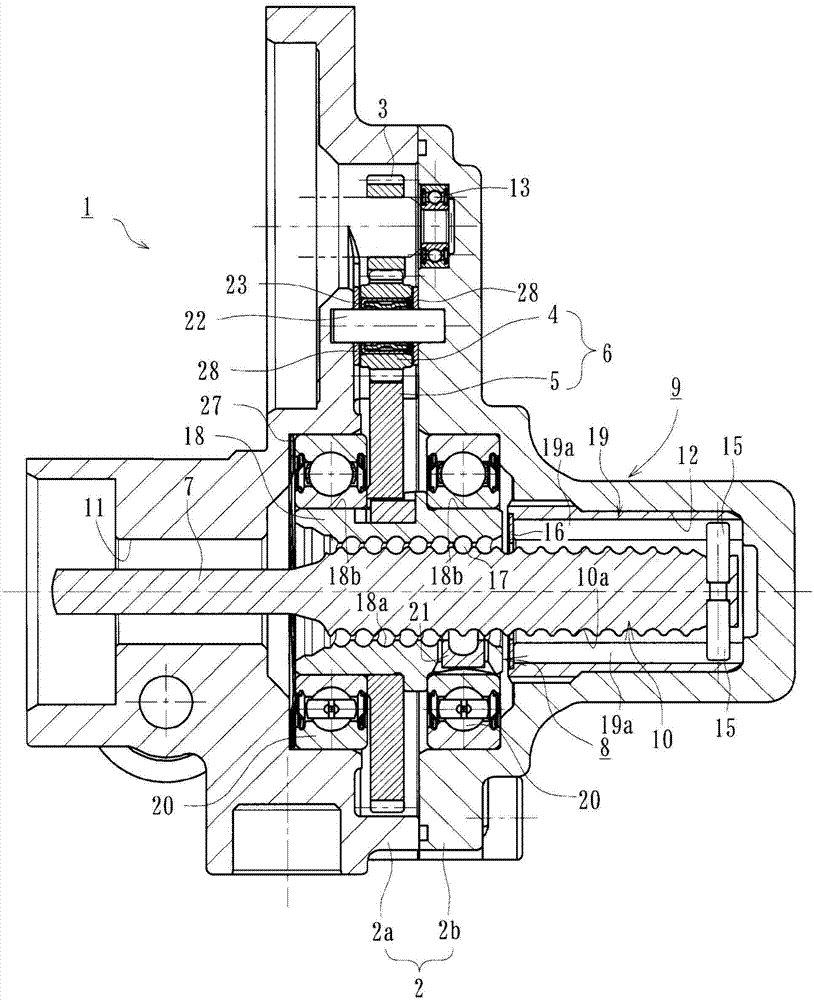

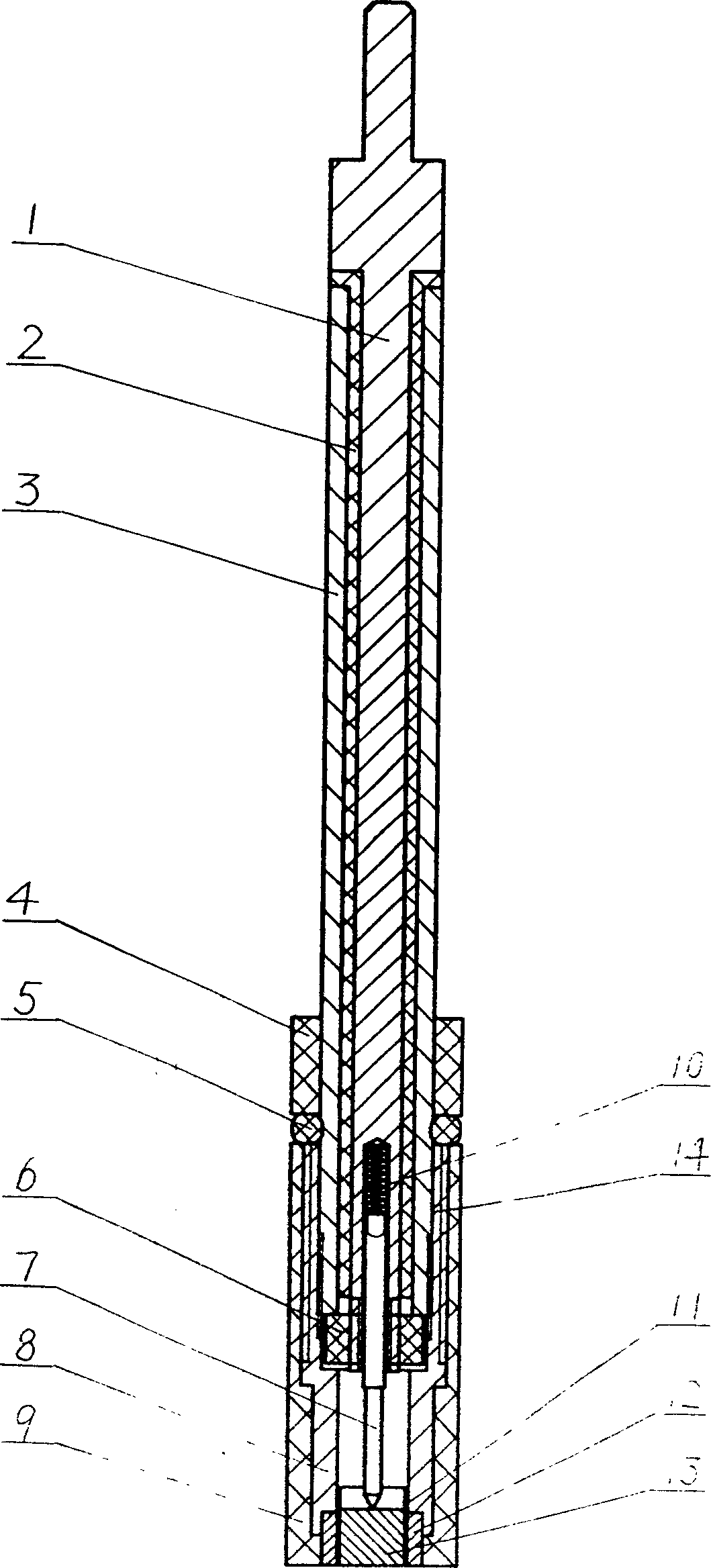

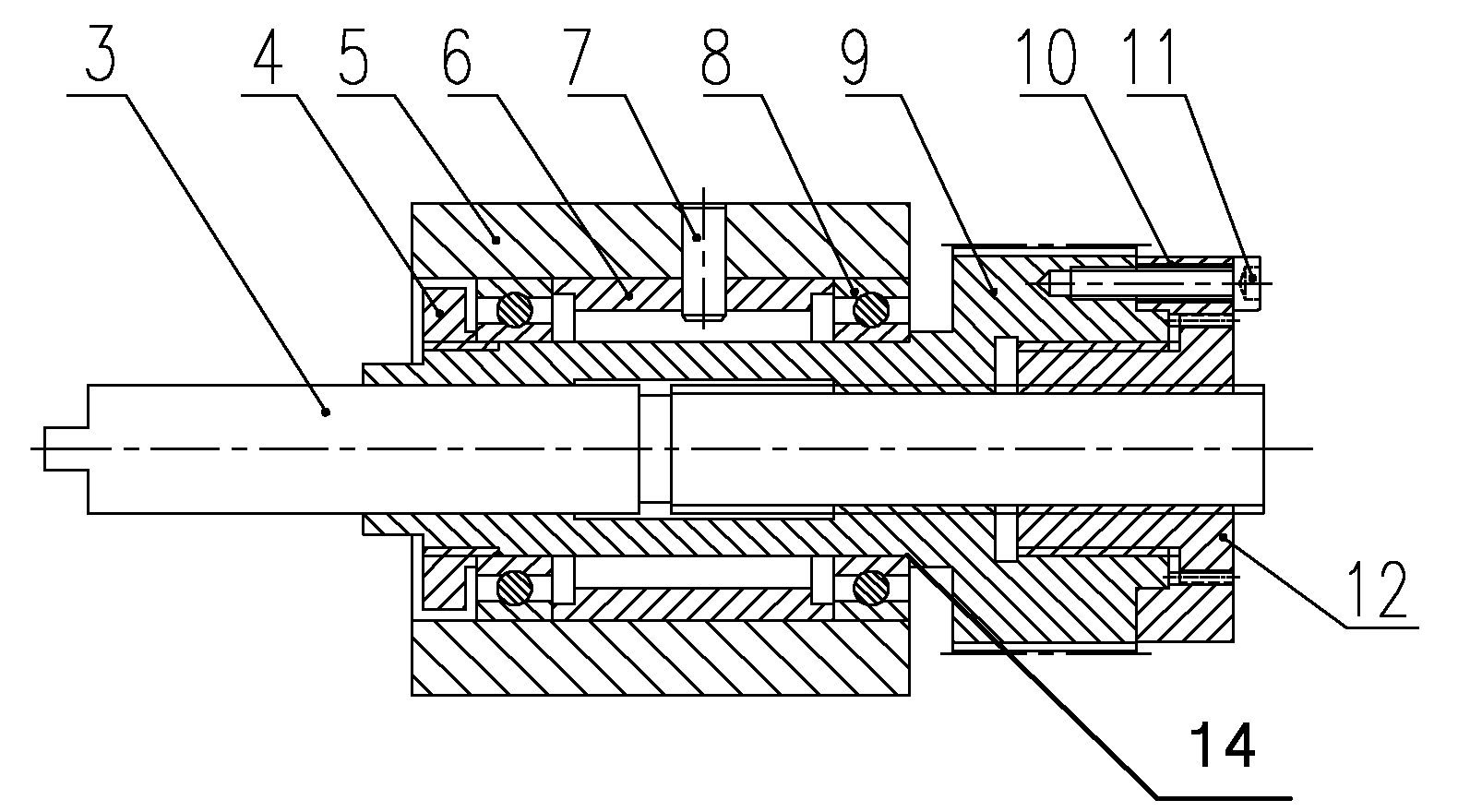

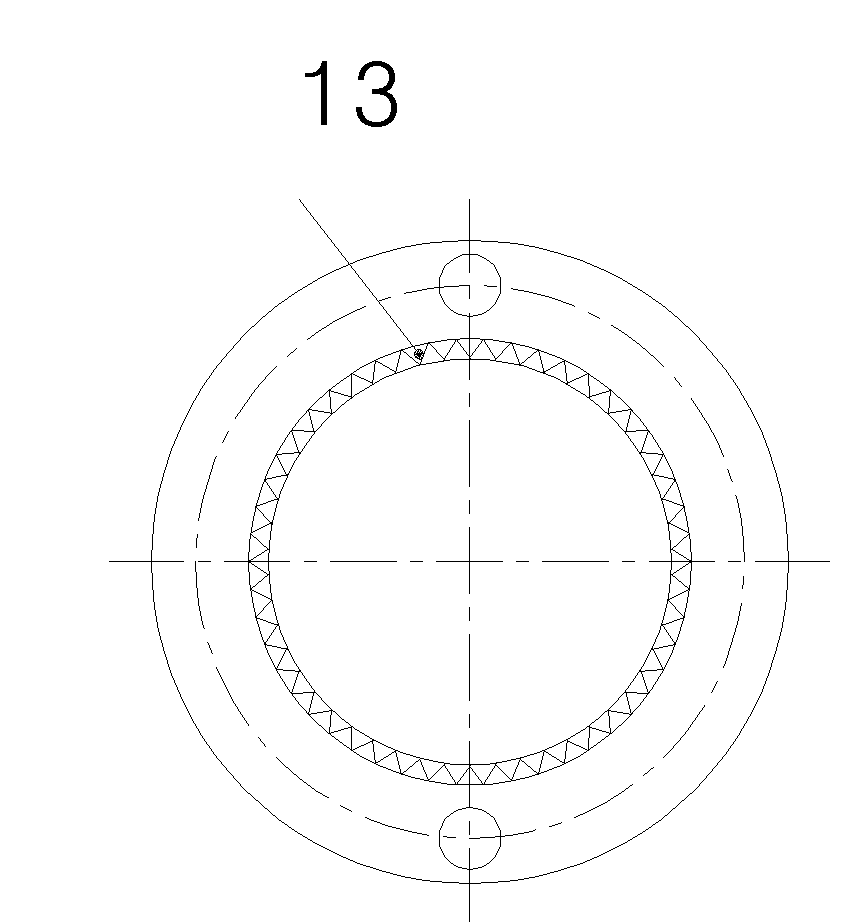

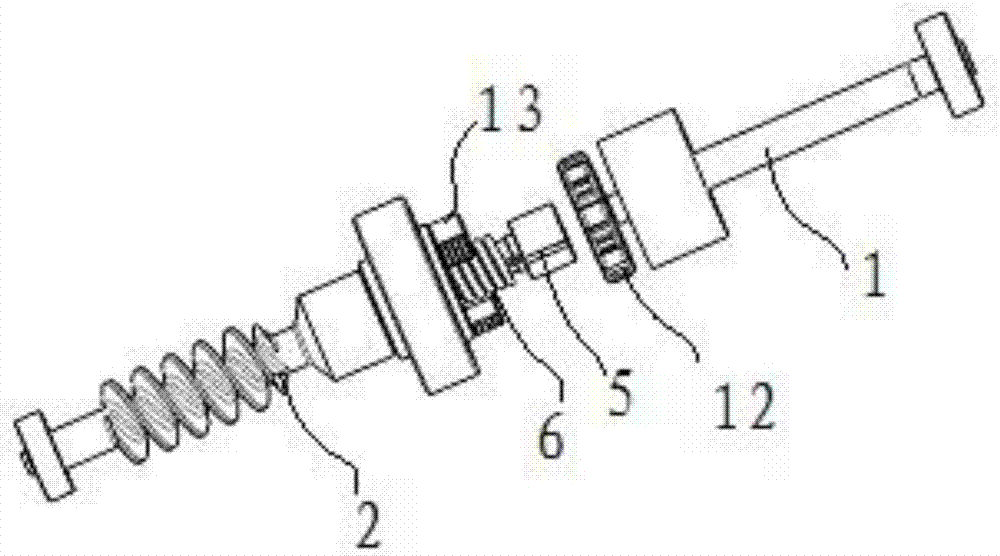

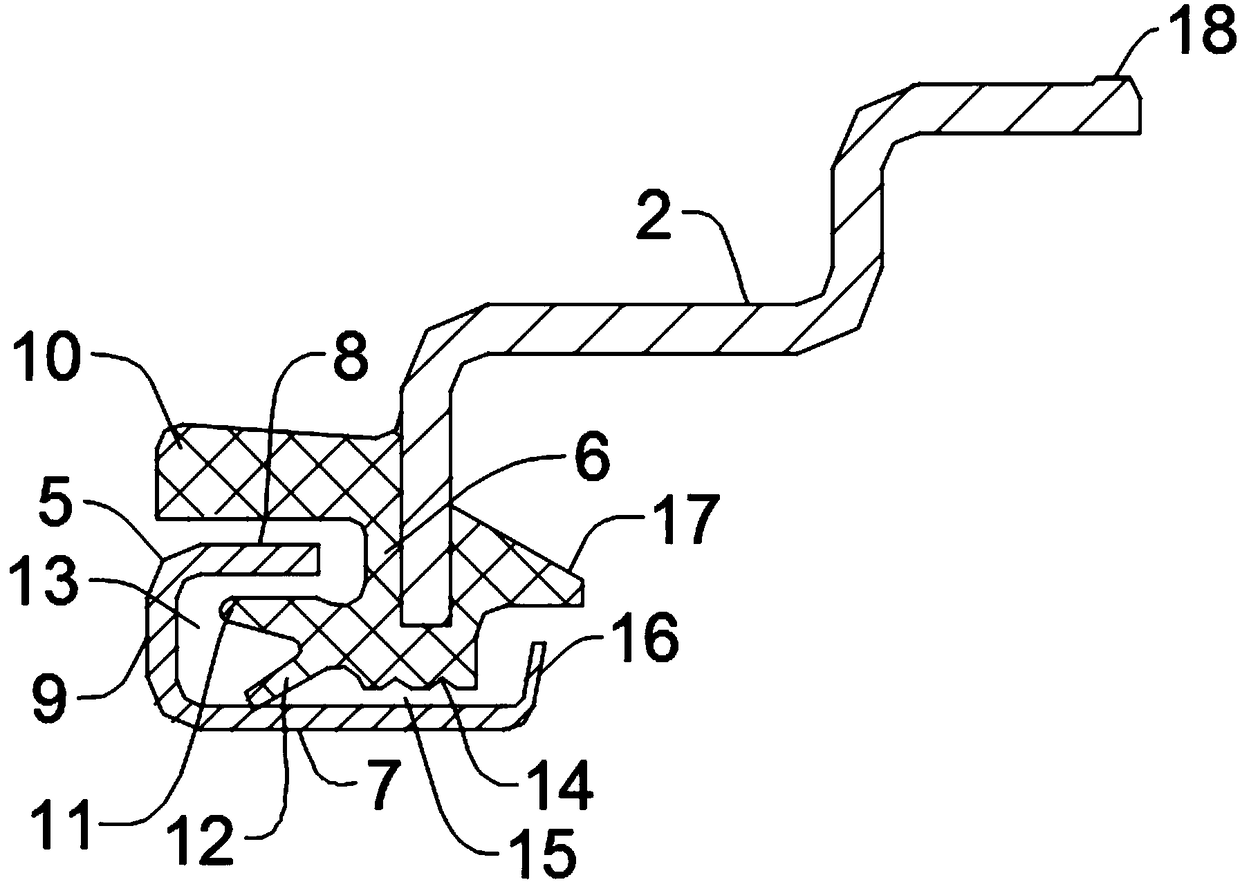

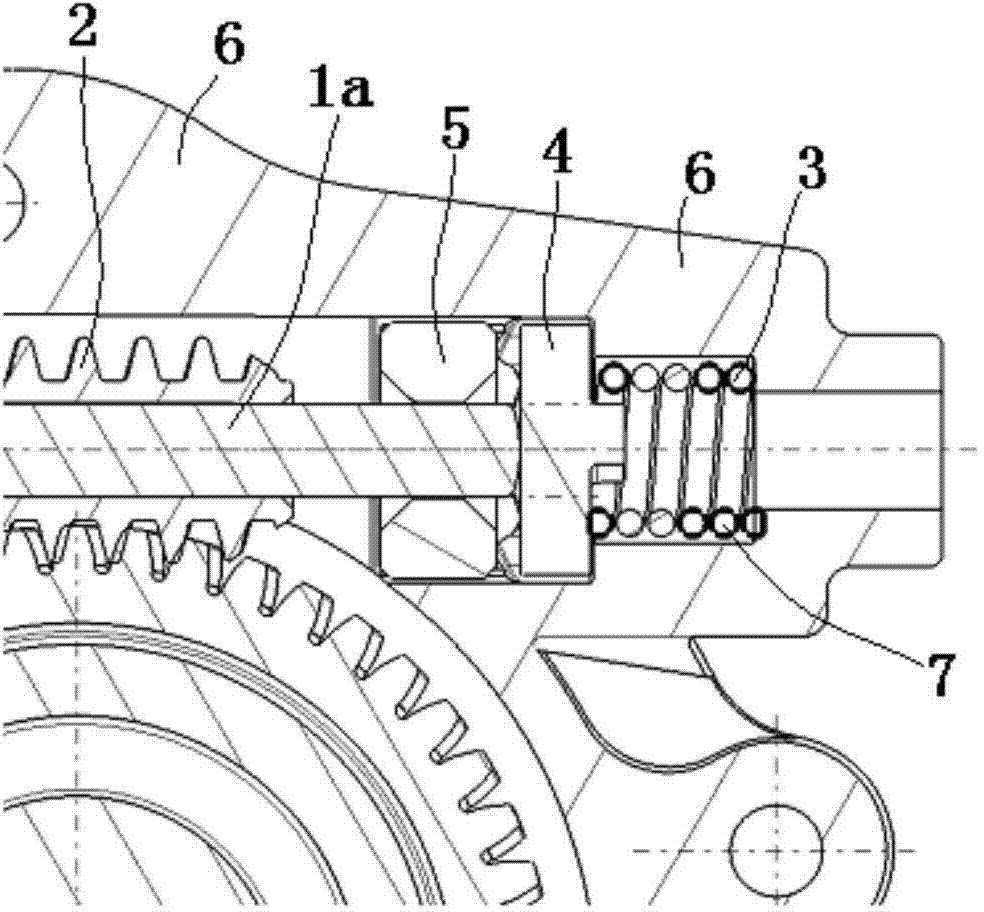

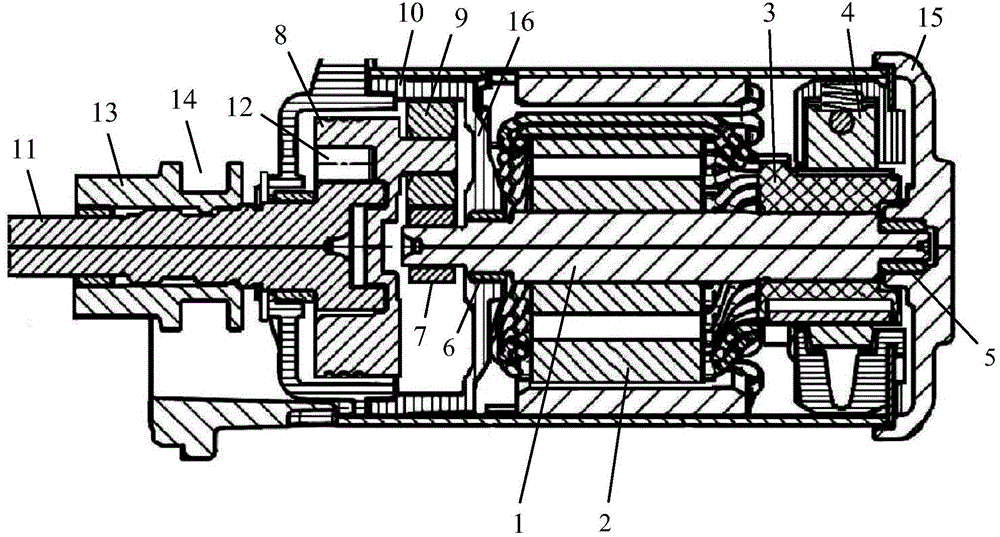

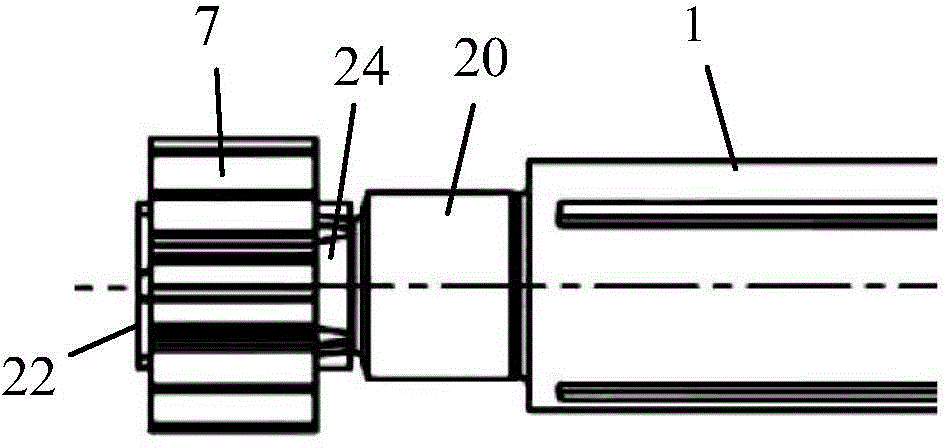

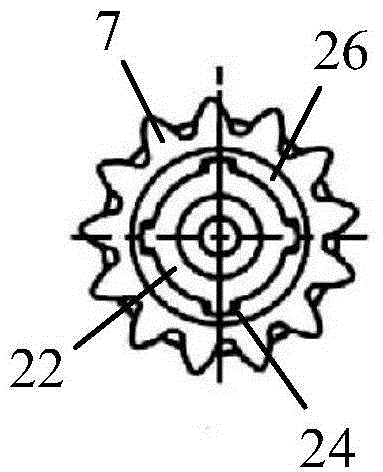

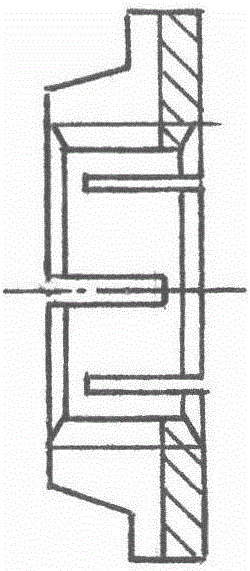

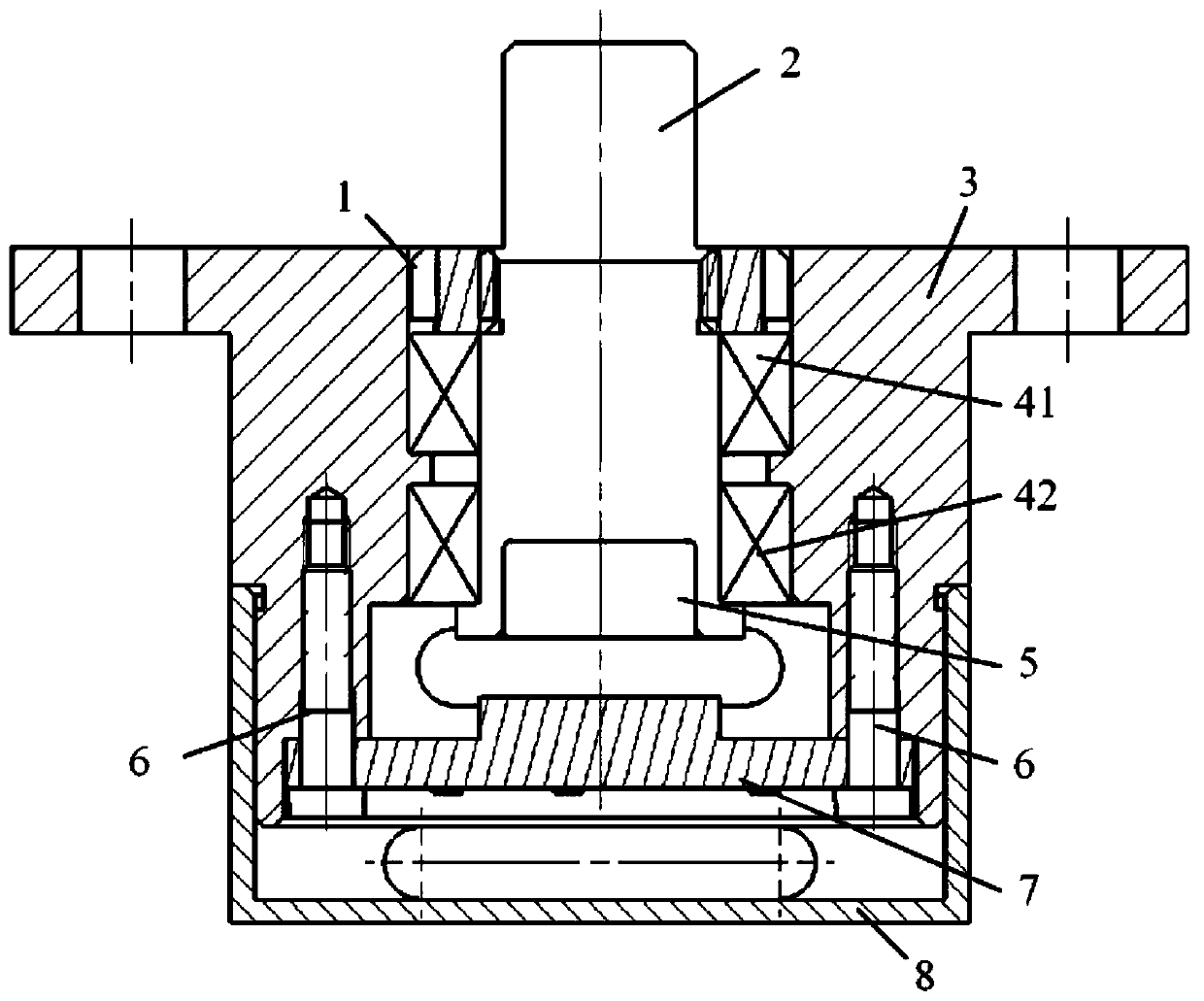

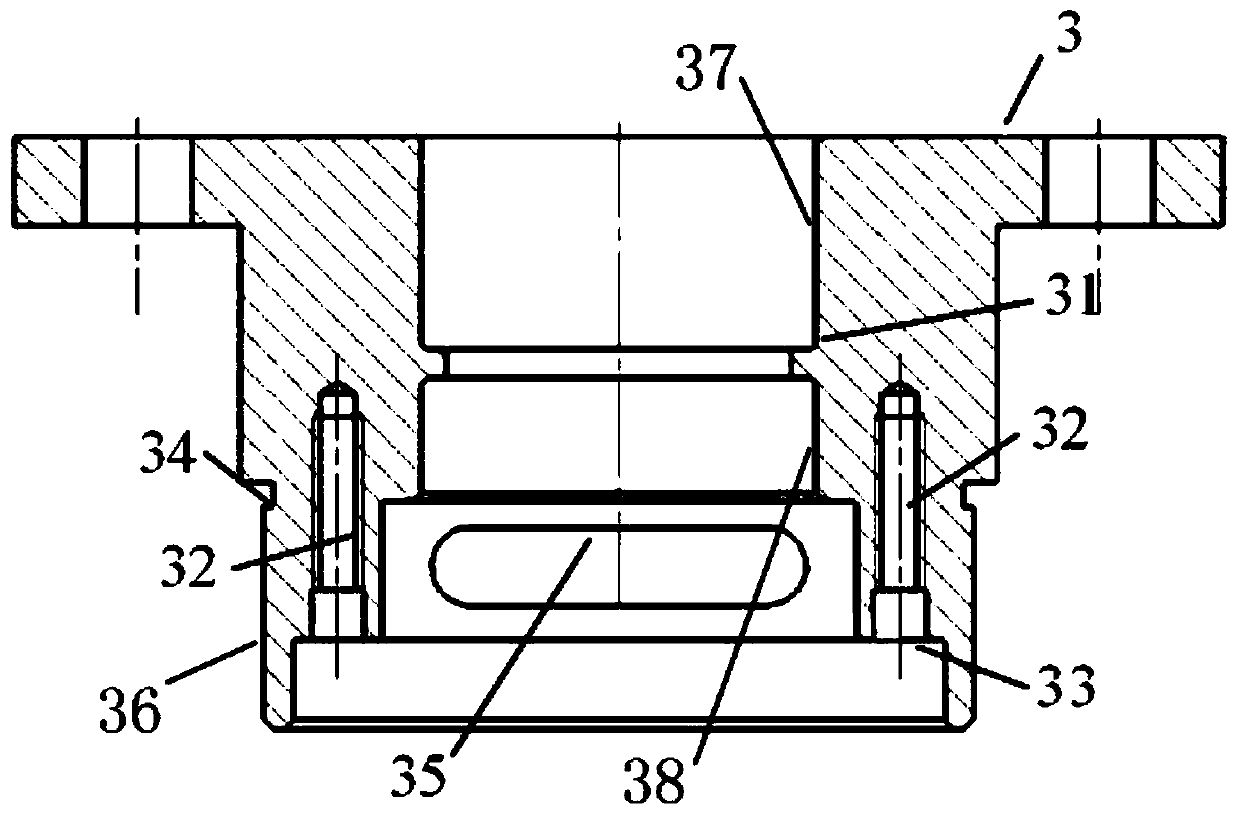

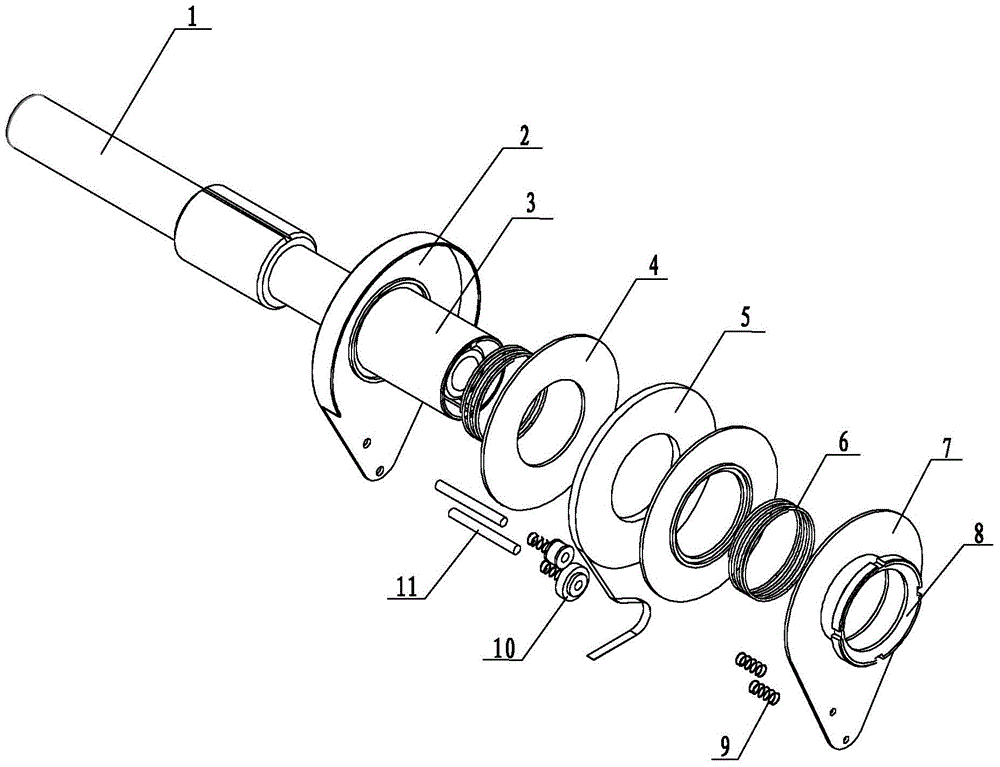

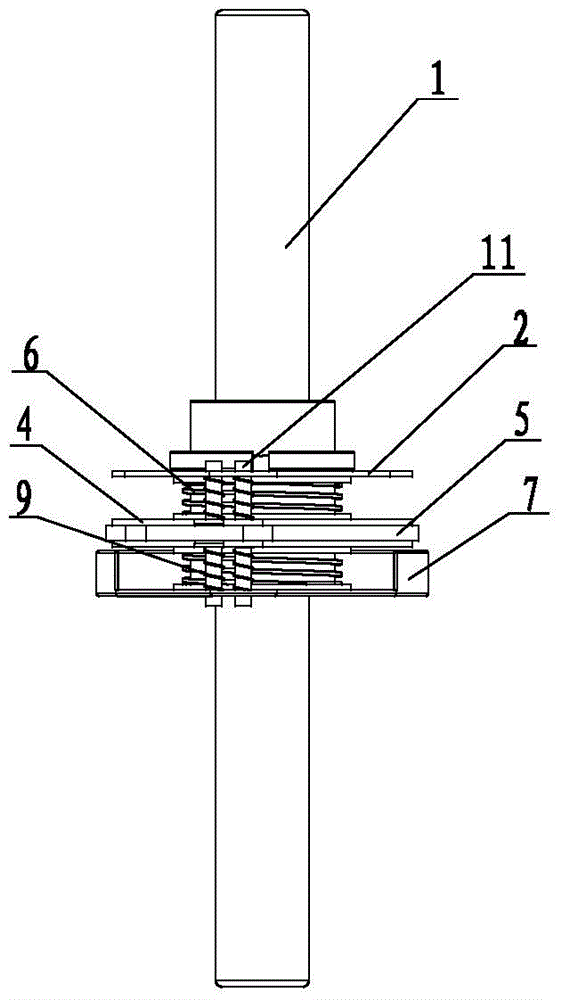

Planetary roller screw with clearance eliminating nut

The invention discloses a planetary roller screw with a clearance eliminating nut. The planetary roller screw with the clearance eliminating nut is used for eliminating the axial clearance between a roller and a nut and the axial clearance between a roller and a screw at the same time. According to the technical scheme, on the basis that elastic elements (7 and 9) are added to half nuts (6 and 10) respectively for pretightening, the clearance eliminating nut (8) is used in cooperation, pretightening force is generated through the combined action of elastic deformation of the elastic elements (7 and 9) and elastic deformation of an elastic thin-wall radial plate A in the clearance eliminating nut (8), and therefore the effect of eliminating the axial clearance between the roller and the nut and the axial clearance between the roller and the screw is achieved. The planetary roller screw with the clearance eliminating nut is simple in structure, convenient to manufacture and high in practicability.

Owner:姚琴

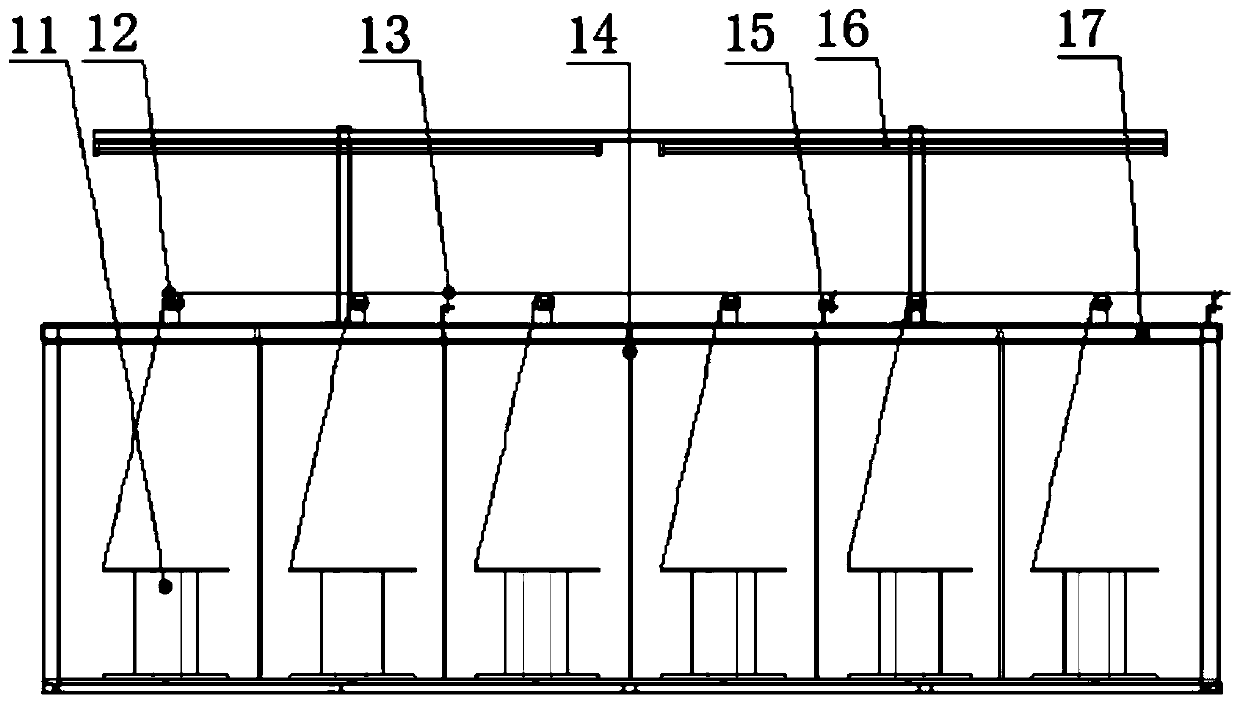

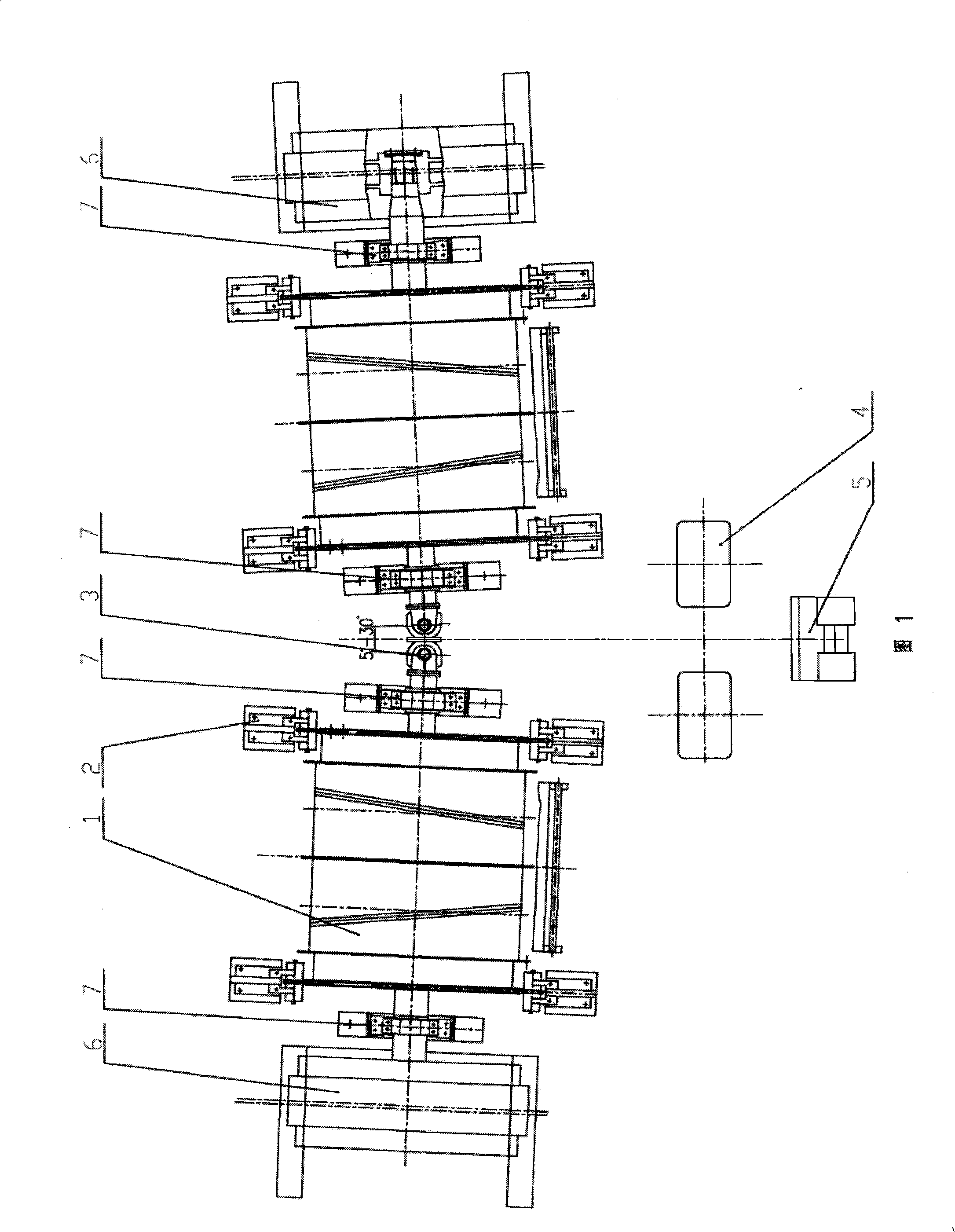

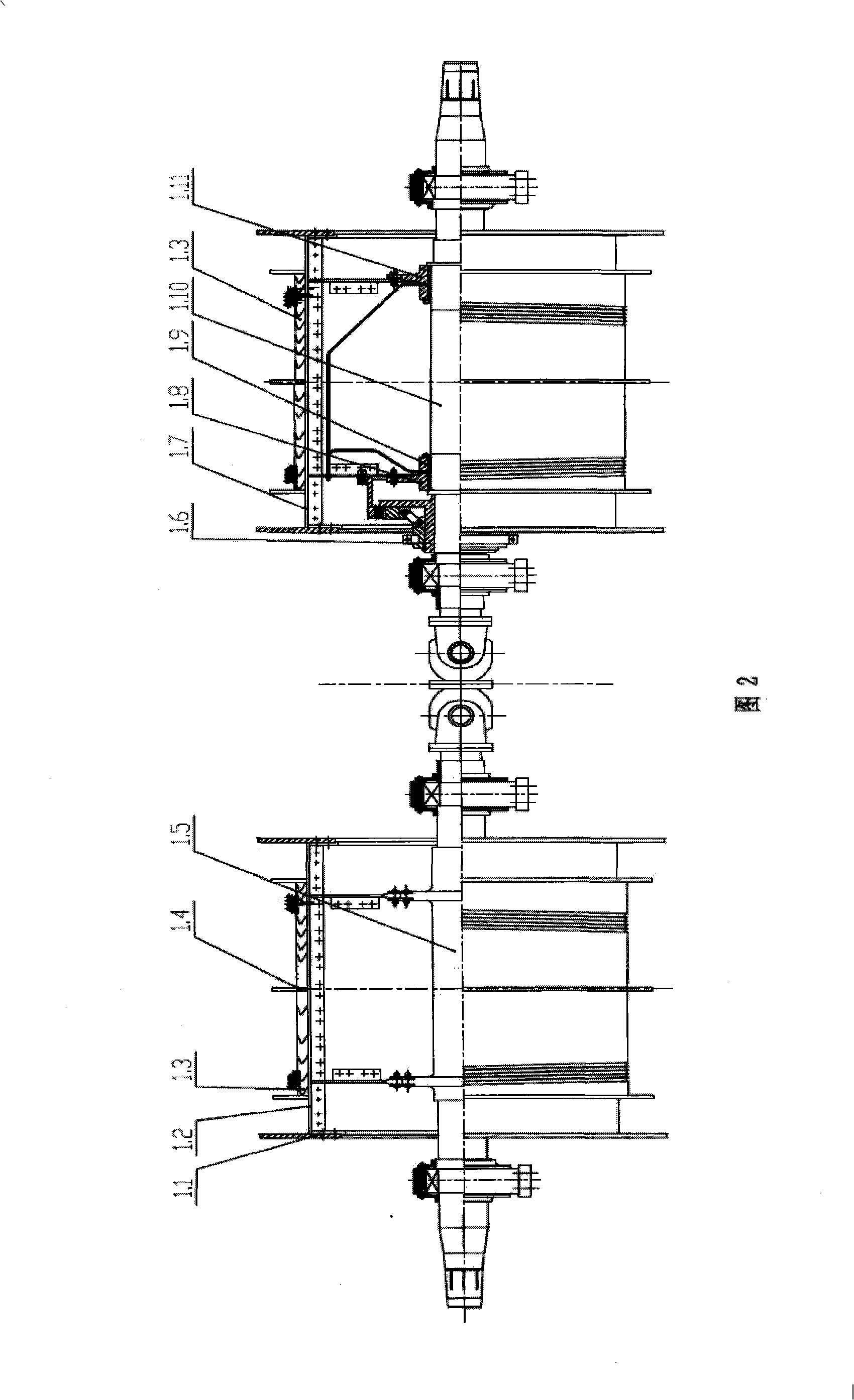

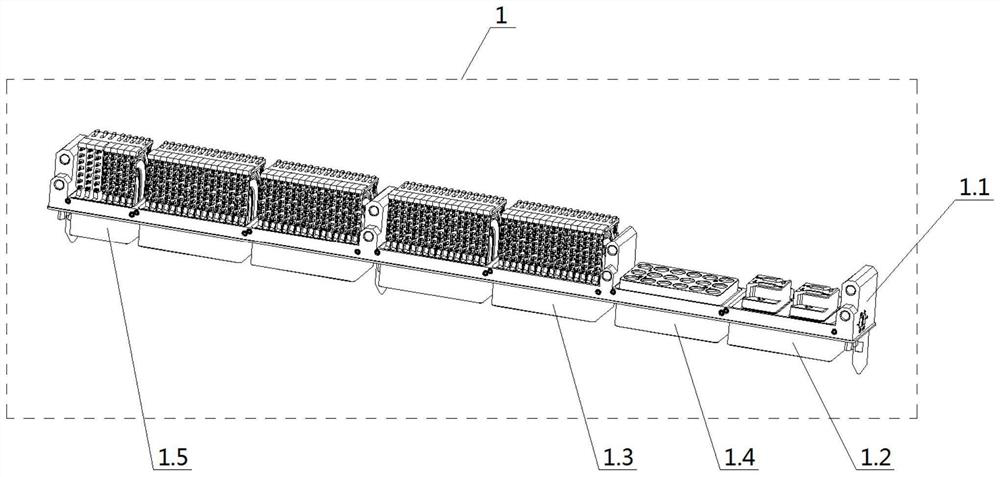

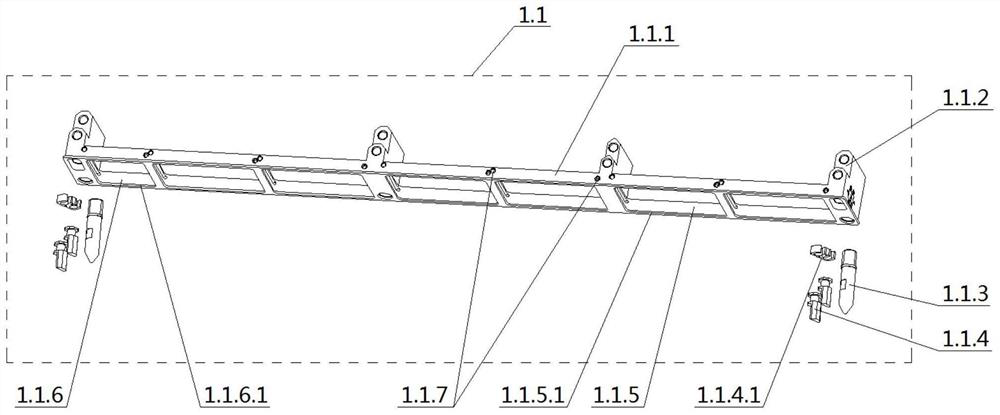

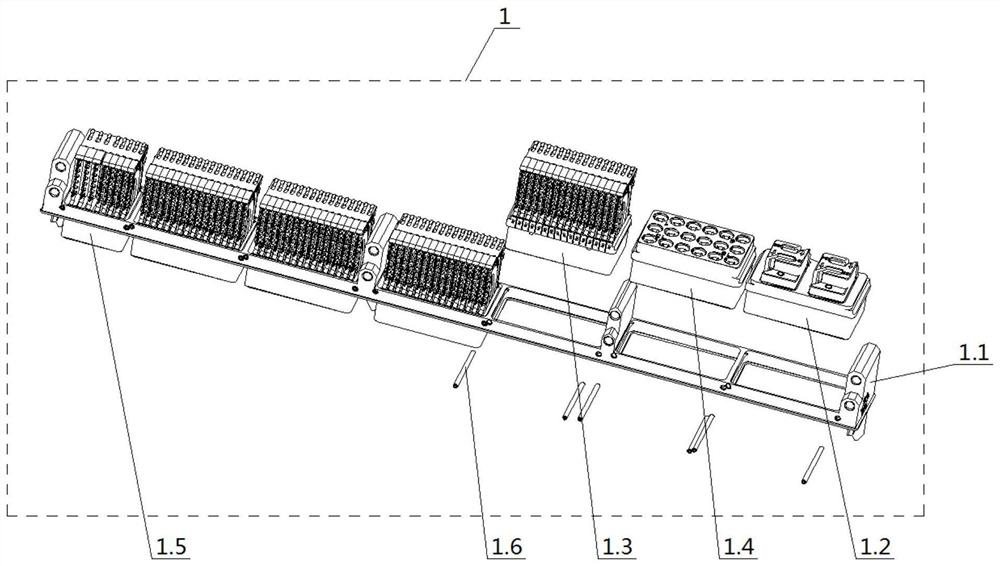

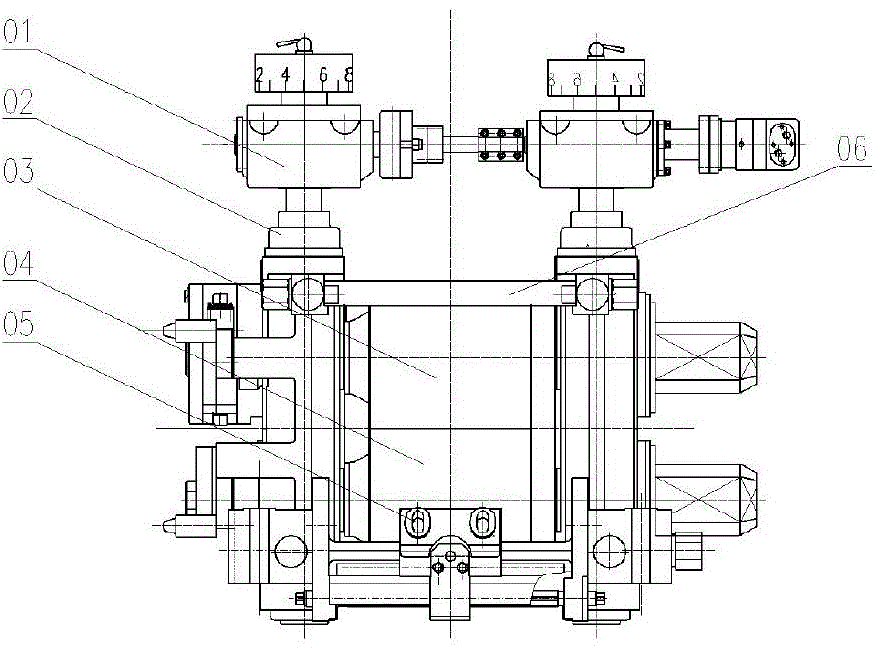

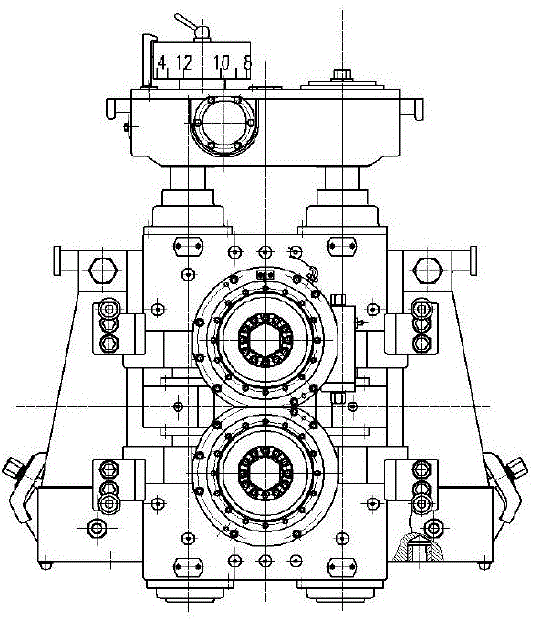

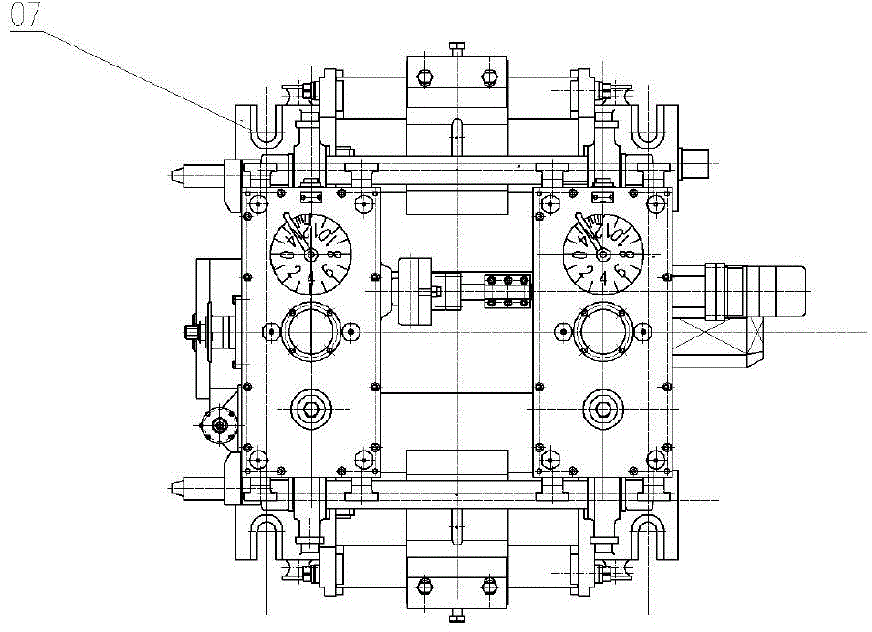

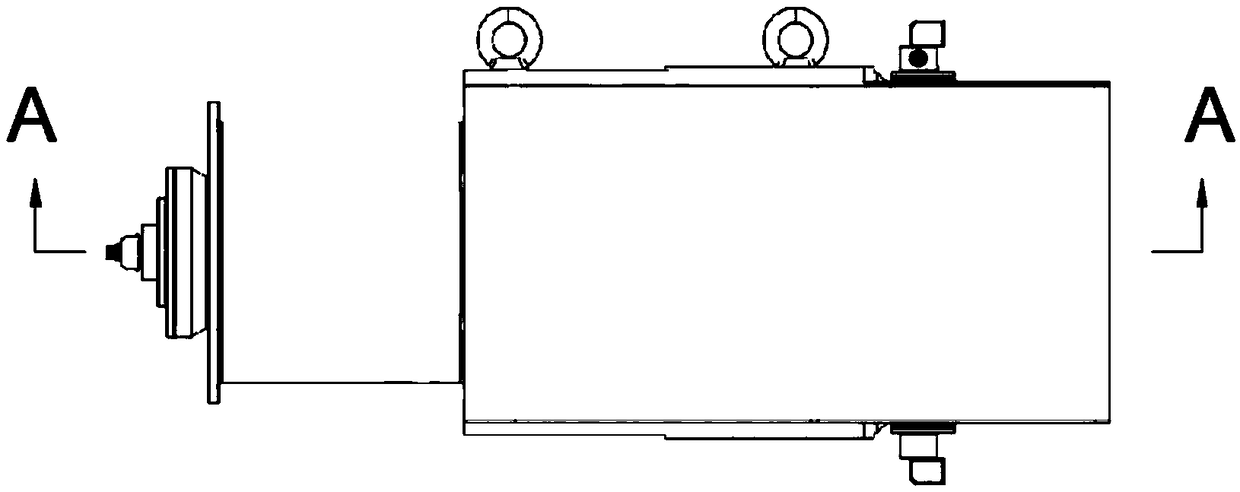

Double-cylinder articulated multi-rope winding type hoist

ActiveCN101407299ASmall diameterIncrease the lifting loadElevatorsMine liftsCouplingElectric machinery

The invention discloses a dual-drum articulated multirope winding hoisting machine, which mainly consists of a main shaft unit 1, a disc brake 2, a universal coupling 3, a hydraulic station 4, an operation desk 5 and motors 6. The main shaft unit is arranged on and respectively fixed with a bearing support 7, and articulated by the universal coupling, other ends thereof are linked with the motor for carrying out synchronous direct connection drag, the two ends of an assembled braking disc 1.1 are provided with the symmetrical disc brake, the hydraulic station is used for providing brake pressure, and the two motors and the hydraulic station are controlled by the operation desk. The main shaft unit consists of the assembled braking disc, a fixed wound roll 1.2, a plastic lining board 1.3, a rope-retaining board 1.4, the main shaft 1.5 of the fixed wound roll, a rope-adjusting clutch 1.6, a nomadic wound roll 1.7, a left hub 1.8, two halves of brasses 1.9, the main shaft 1.10 of the nomadic wound roll and a right hub 1.11, wherein, the main shafts of the fixed wound roll and the nomadic wound roll are not in the same center line and have an included angle of 5 to 10 degrees. When in working, a container is lifted by two cable wires, thus effectively meeting the lifting needs.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

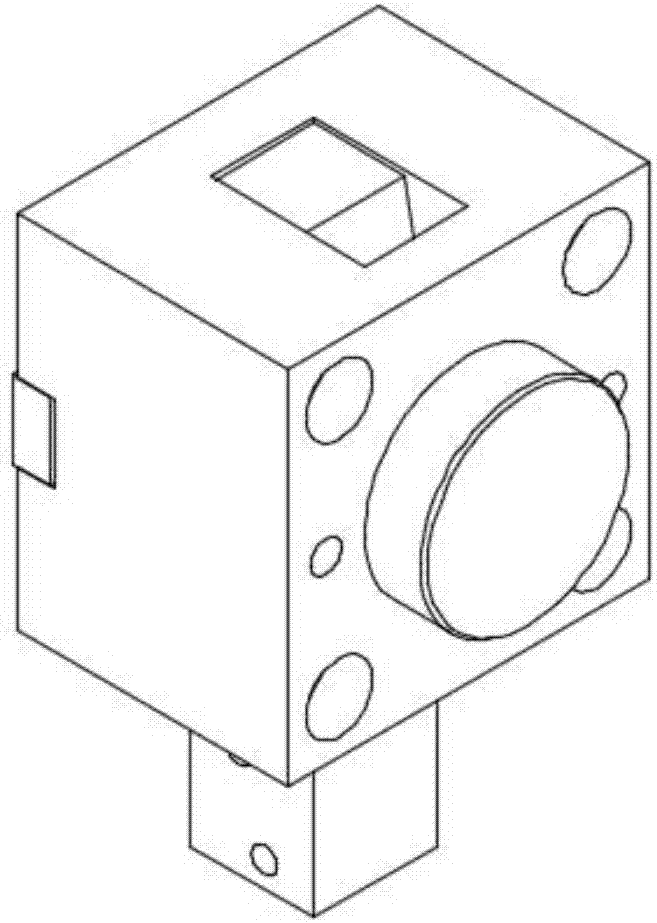

LRM photoelectric radio frequency integrated connector compatible with VPX standard

ActiveCN111969376AEliminate radial playEliminate axial playIncorrect coupling preventionTwo-part coupling devicesRadio frequencyMechanical engineering

The invention provides an LRM photoelectric radio frequency integrated connector compatible with VPX standard. The LRM photoelectric radio frequency integrated connector comprises a plug and a socket,wherein the plug comprises a plug shell provided with an optical fiber plug module, a plurality of high-speed plug modules, a radio frequency plug module and a mixed plug module, the socket comprisesa socket shell fixedly provided with an optical fiber socket module, a plurality of high-speed socket modules, a radio frequency socket module and a mixed socket module, and the plug and the socket are matched and inserted to form the LRM photoelectric radio frequency integrated connector compatible with the VPX standard. According to the invention, different types of connectors meeting the VPX standard requirements are integrated on the same connector shell, and through structural optimization design, the connector has the advantages of being small in occupied total space, light in weight, highly uniform in connector installation height and accurate in connector relative position, the reliability of signal transmission between components or systems meeting the VPX standard is guaranteed,and the increasingly complex and precise signal connection requirements between hardware components and systems compatible with the VPX standard are met.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

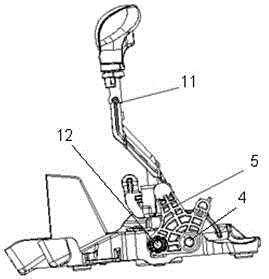

Selection arm neck bush of gear-shifting control assembly and installation structure thereof

InactiveCN105840803AEliminate axial playEliminate radial playGearing controlBearing componentsRetainerEngineering

The invention discloses an installation structure of a selection arm neck bush of a gear-shifting control assembly. The installation structure comprises a base body, a selection arm, a shaft pin, the selection arm neck bush and a fixing retainer ring. The base body is rotatably arranged on the shaft pin in a sleeving mode. The selection arm is fixedly arranged on the shaft pin in a sleeving mode. A bush main body of the selection arm neck bush is an elastic neck bush with an axial opening. The shaft pin is sleeved with the bush main body. The bush head of the selection arm neck bush radially extends to form flangings. Splay convex corners are arranged on the flangings circumferentially. The bush main body is pressed between the selection arm and the shaft pin, and the splay convex corners are pressed and padded between the sidewall of the selection arm and the fixing retainer ring. Certain elasticity is produced in the radial direction and the axial direction of the selection arm neck bush, and backlashes of the selection arm after installation are eliminated.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

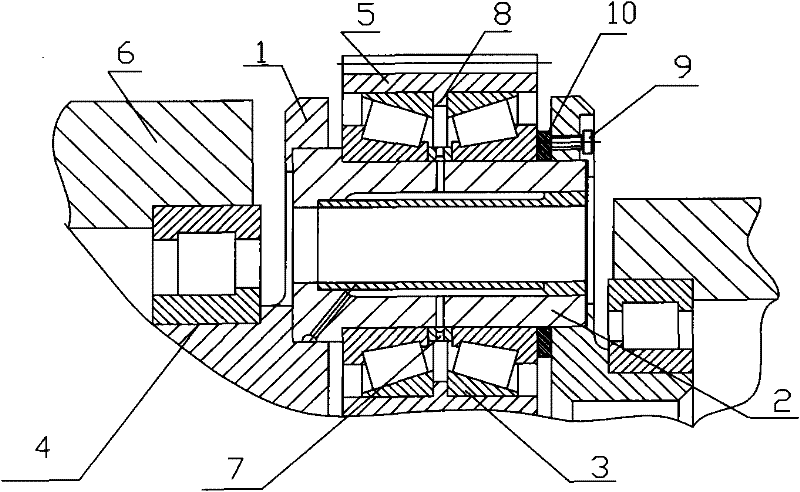

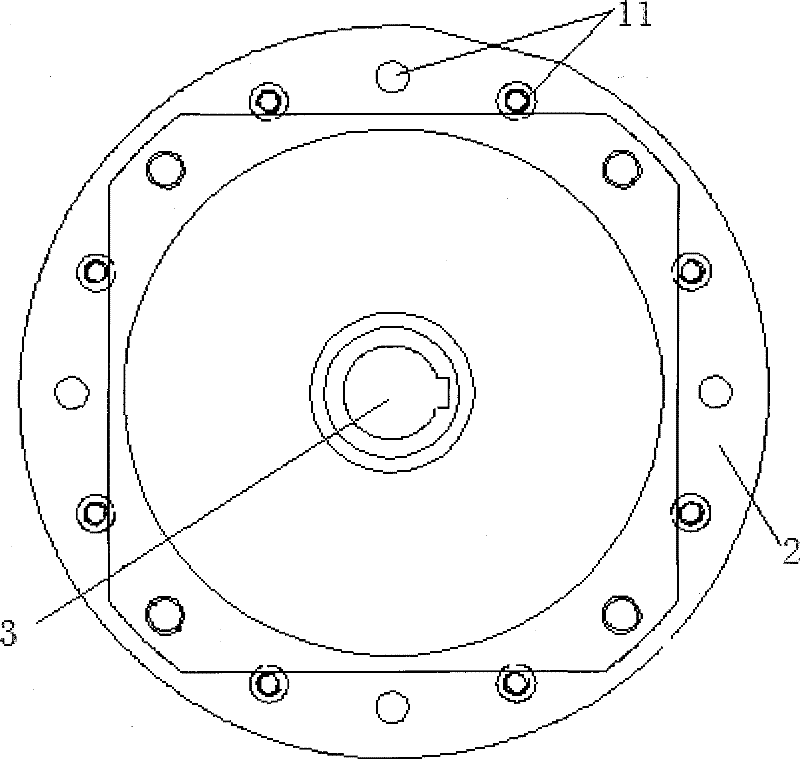

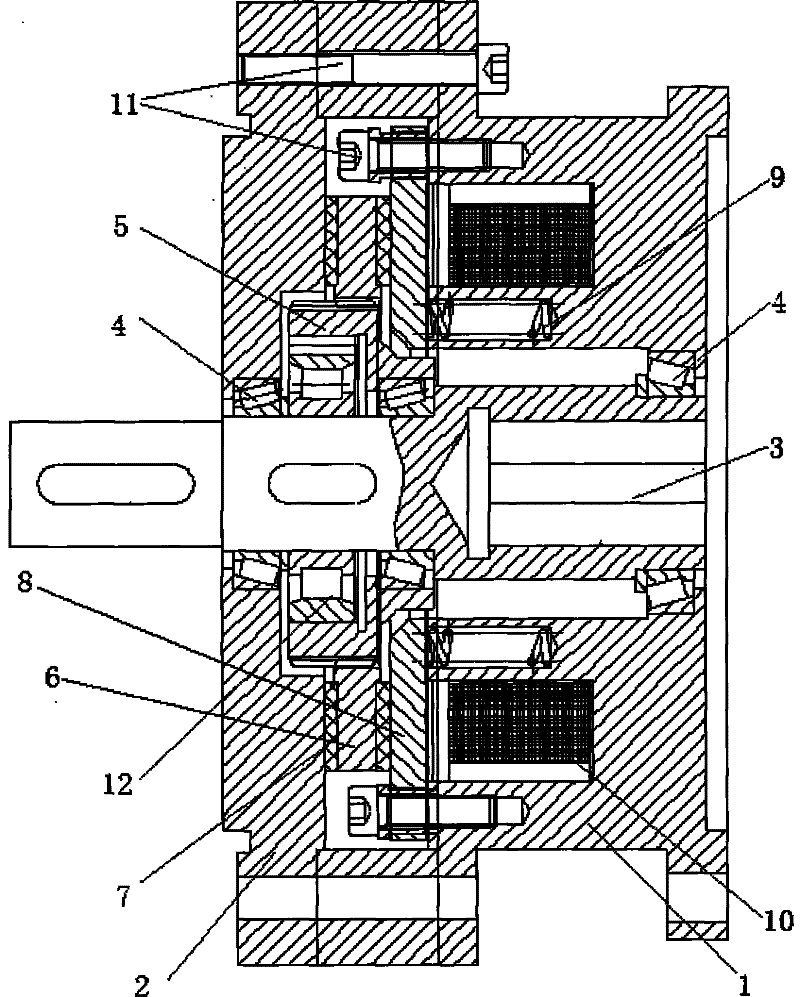

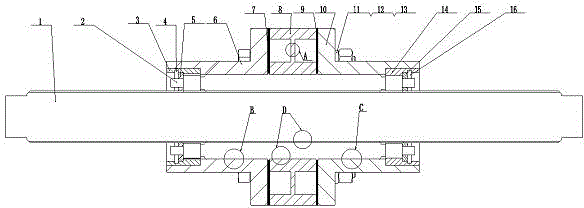

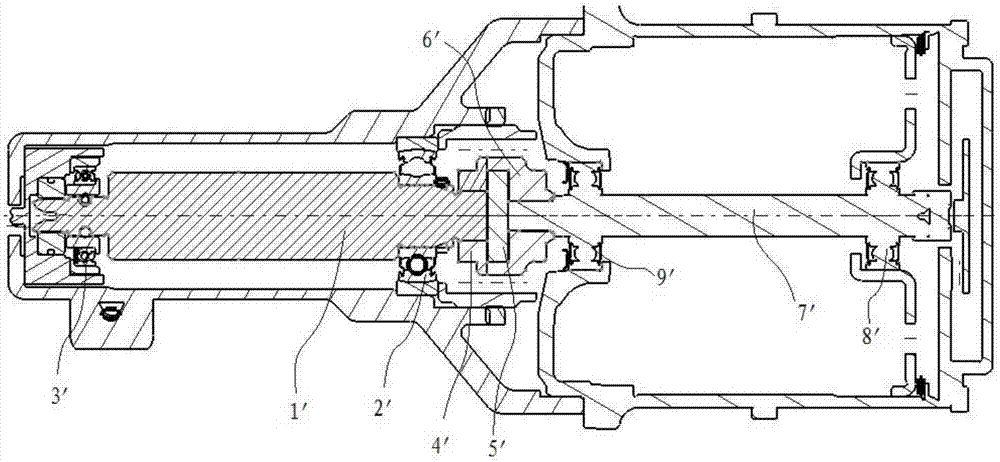

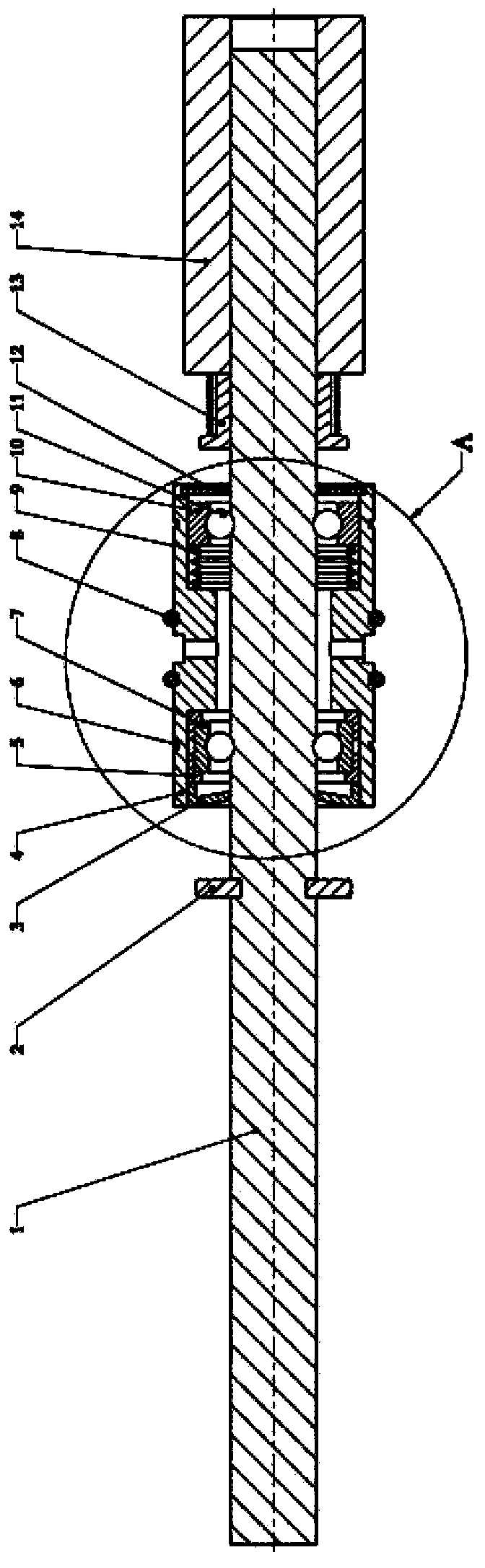

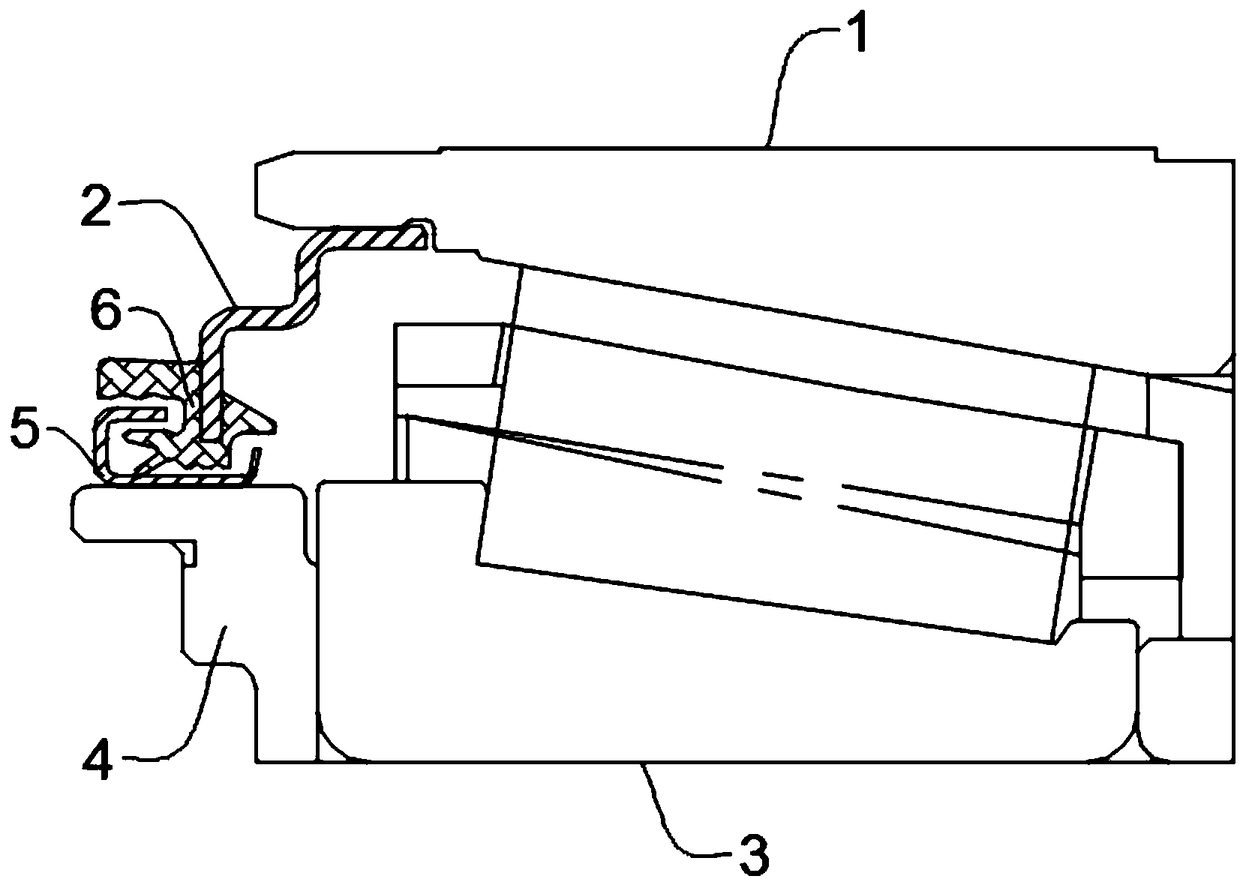

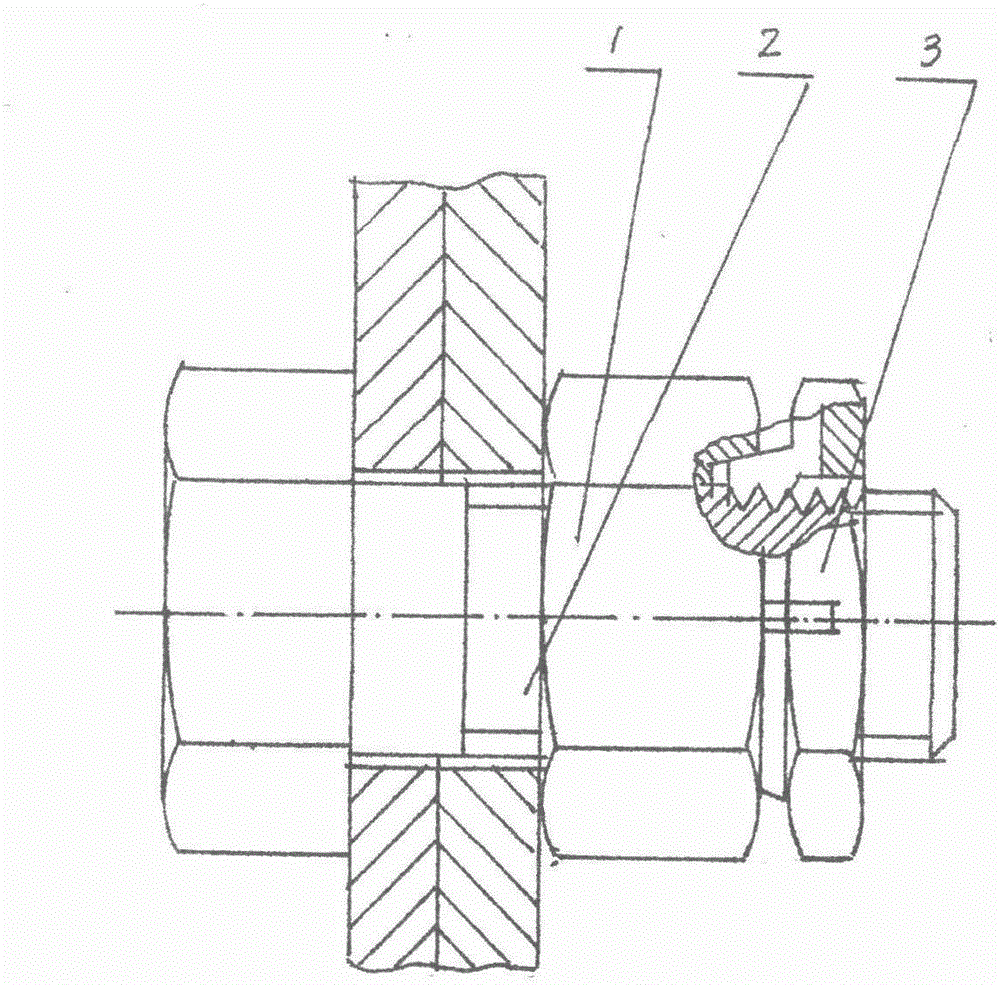

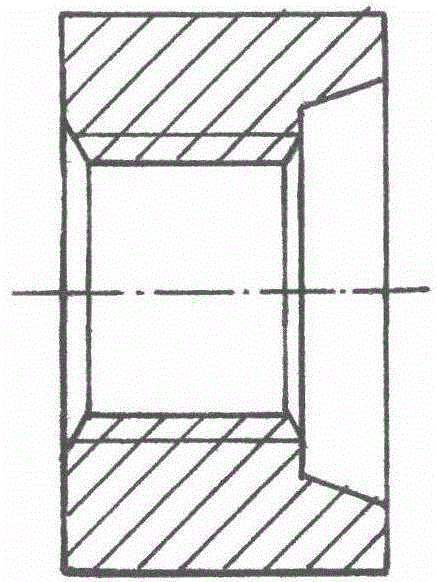

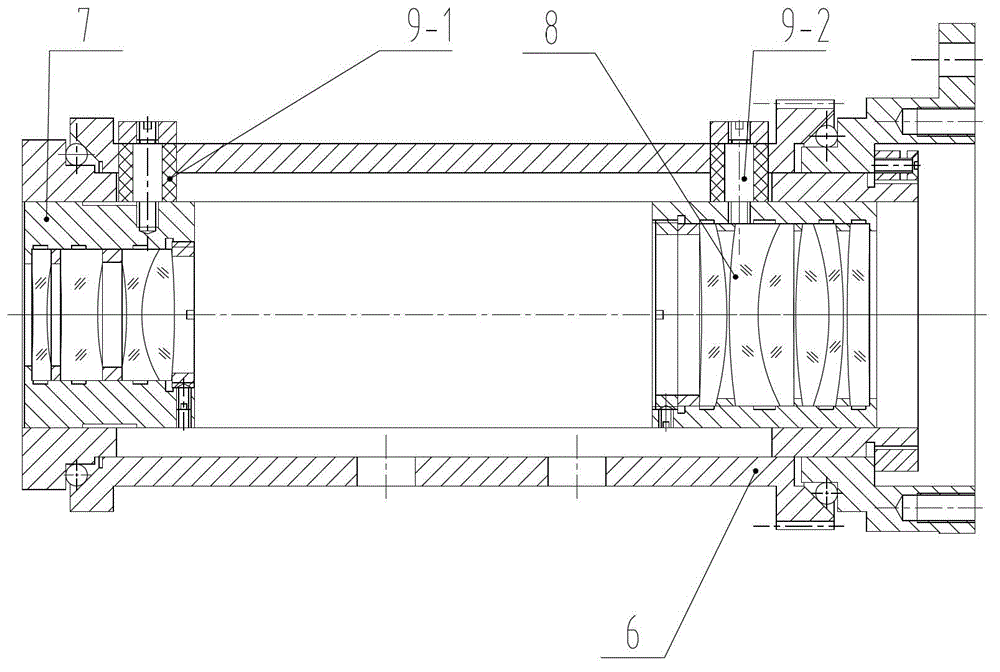

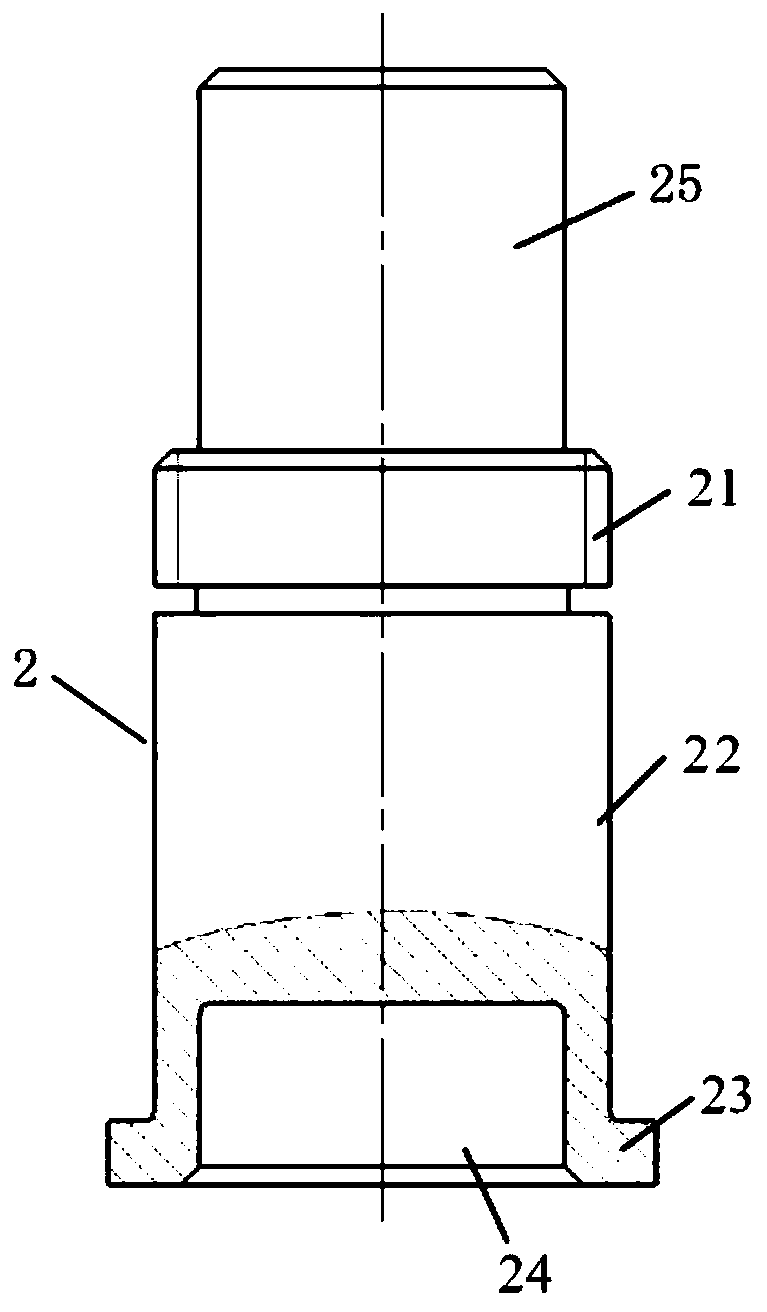

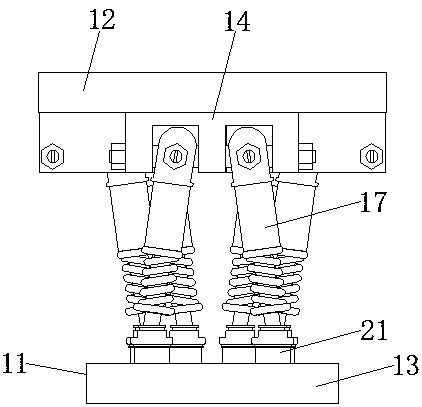

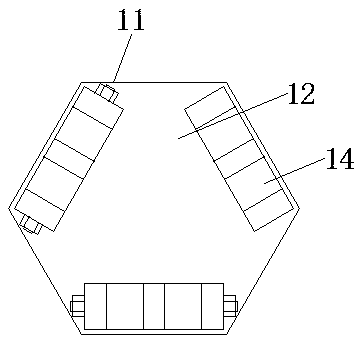

Transmission device of precise displacement actuator

InactiveCN102094951AEliminate axial playEliminate axial backlashGearingGearing detailsRolling-element bearingEngineering

The invention relates to a transmission device of a precise displacement actuator. The transmission device is characterized in that a transmission pair consists of a swivel nut and a screw; the swivel nut is supported in a supporting shell through a bearing piece; the bearing piece comprises a bearing inner clamping ring nut, a bearing outer retainer ring and two rolling bearings, wherein the tworolling bearings are respectively arranged at both sides of the bearing outer retainer ring; one of rolling bearing inner rings forms axial limit through a circular bead positioned on the swivel nut;and the bearing inner clamping ring nut is connected with the swivel nut through internal threads and acts on the other rolling bearing inner ring along a reverse axial direction to form the axial limit.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

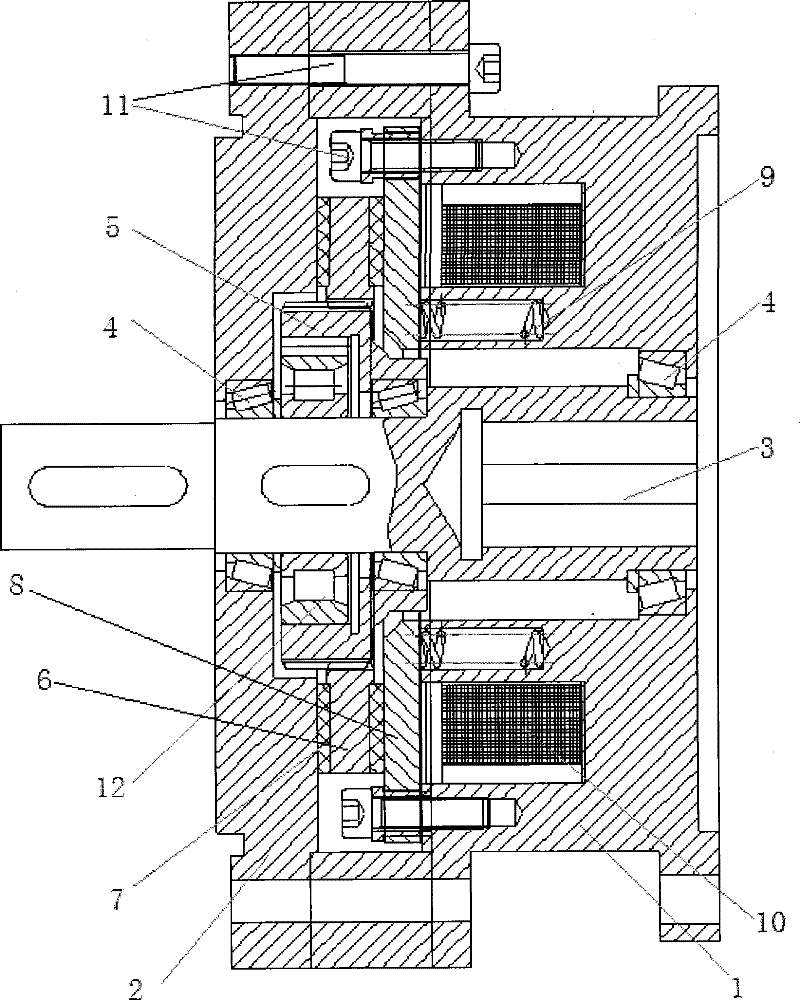

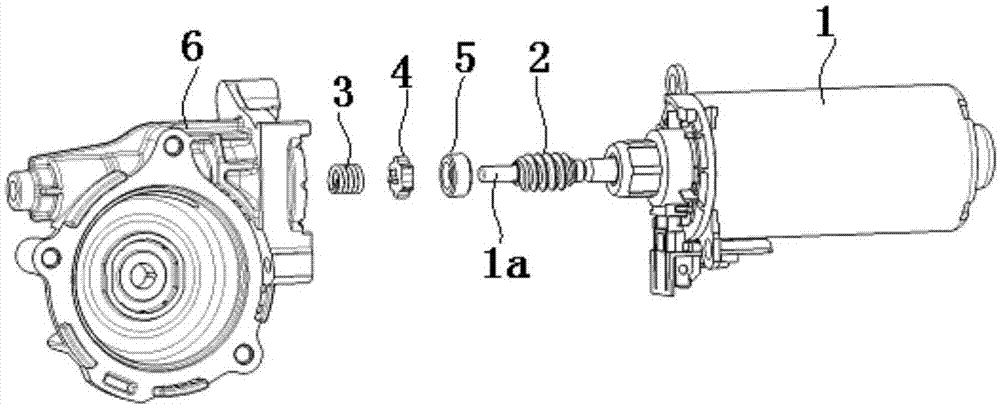

Steering power-assisted motor

InactiveCN107253492AEliminate axial playNo axial playElectrical steeringMechanical energy handlingControl theory

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

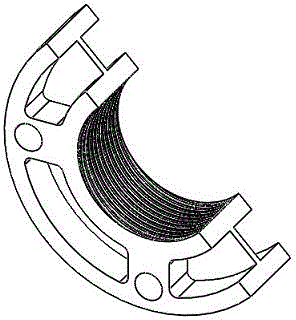

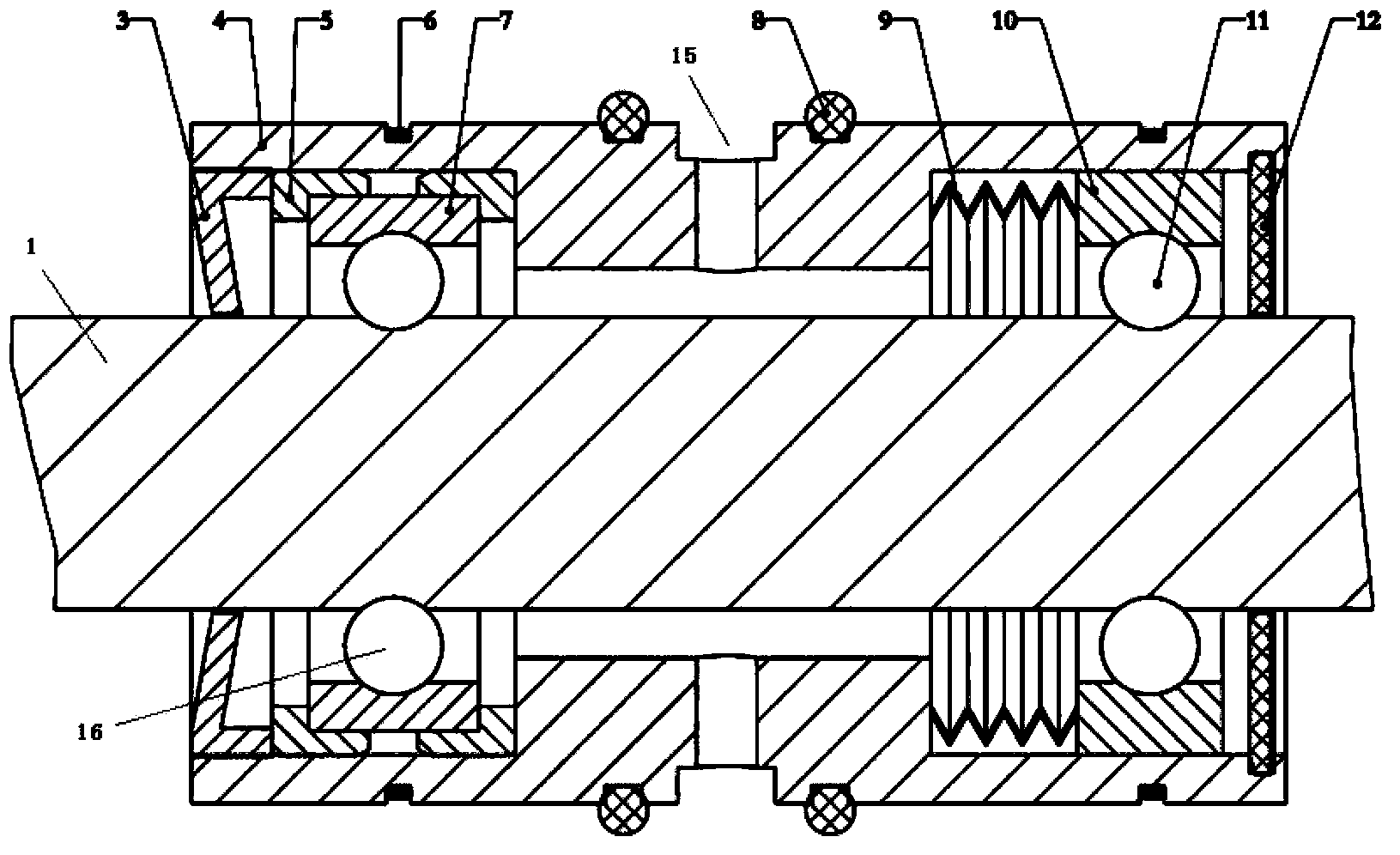

High-speed elastic damping false twister spindle based on sensor technology

ActiveCN103409868AReduce radial and axial vibrationsEliminate axial playTextiles and paperYarnExternal circuit

The invention discloses a high-speed elastic damping false twister spindle based on the sensor technology. The high-speed elastic damping false twister spindle based on the sensor technology comprises a mandrel, two sets of steel balls which are arranged on the radial outer side of the mandrel, and a big outer ring which is used for fixing the steel balls on the mandrel, wherein a small outer ring is arranged between each set of steel balls and the big outer ring, all the steel balls are fixed in the big outer ring through the small outer rings, a spring is arranged between one small outer ring and the big outer ring in the axial direction, and the spring axially and tightly presses the small outer rings. Due to the facts that the small outer rings are arranged between the steel balls and the big outer ring, plastic damping sleeves are arranged between the small outer rings and the big outer ring in an embedded mode to reduce radial vibration and axial vibration, and the spring which is arranged between the small outer ring and the big outer ring in a connected mode is arranged in the axial direction to eliminate the axial clearance, stable working of the high-speed elastic damping false twister spindle is ensured, and stability of spinning products is ensured. Due to the fact that a vibration sensor is in cooperation with an external circuit to carry out real-time online detection on vibration parameters of a false twister, the faults of the high-speed elastic damping false twister spindle can be predicted, and the spinning technology can also be adjusted according to the vibration parameters to achieve optimization of quality of yarn.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

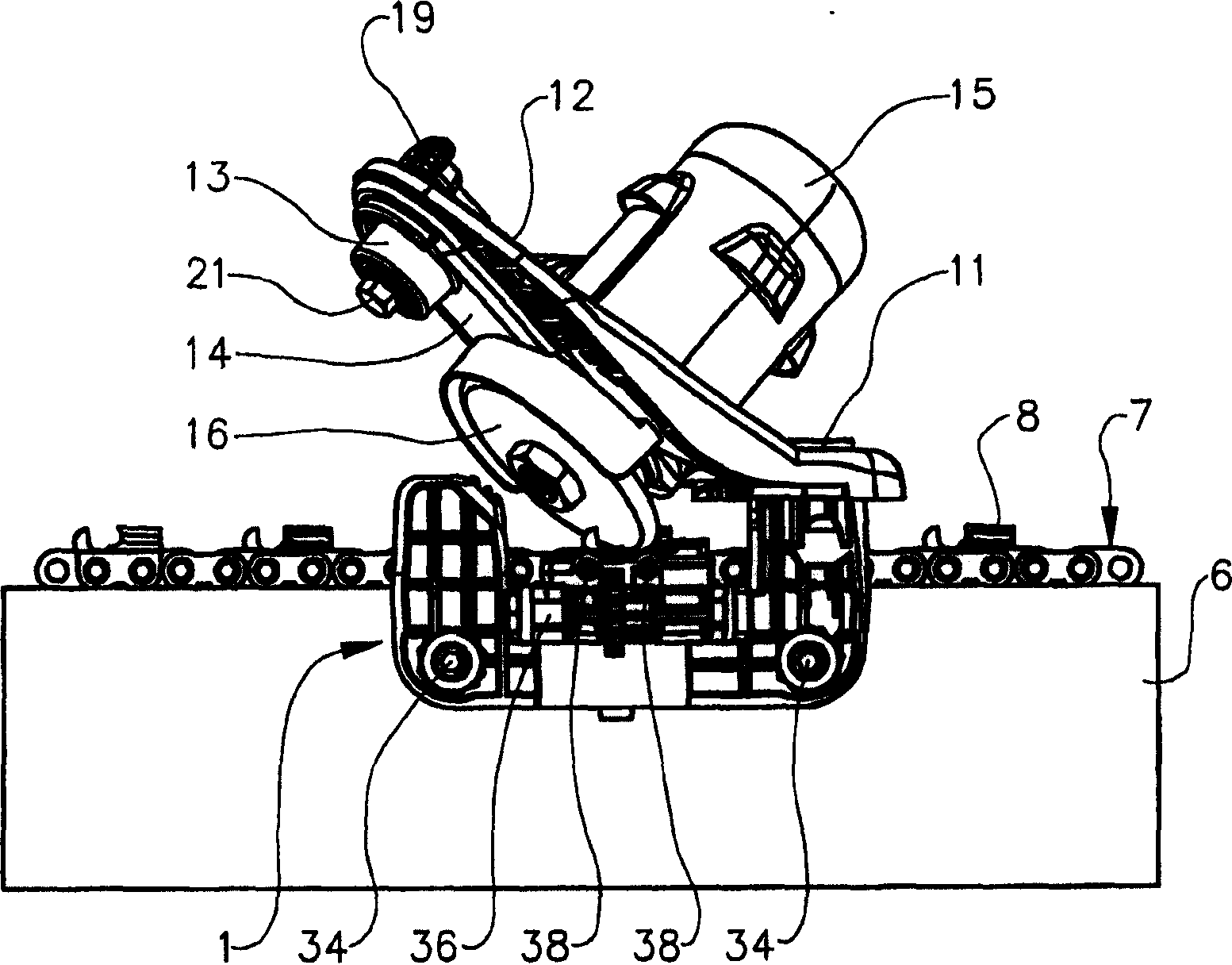

Device for sharpening chain saw teeth

InactiveCN1886224AEliminate axial playIncrease additional sizeSawing tools dressing arrangementsElectricityIn plane

A device for sharpening chain saw teeth, in particular of a chain saw which is portable and applicable in the field, and where the chain is not to be taken off the chain saw blade when sharpened enables swinging of a grinding wheel (16) transversaly to each tooth (8) of a chain (7) resulting in plane cutting faces of each tooth (8). The grinding wheel (16) of the relatively small diameter is rotated by an actuator (15) of the suitably small power and high number of the revolutions resulting in high cutting speed. Said actuator (15) can be either electric motor, supplied with electricity from electric mains or a battery, a pneumatic motor or a hydraulic motor.

Owner:德拉戈·岑达克

Sealing device for large bearing

Owner:CHENGDU TIANMA RAILWAY BEARING

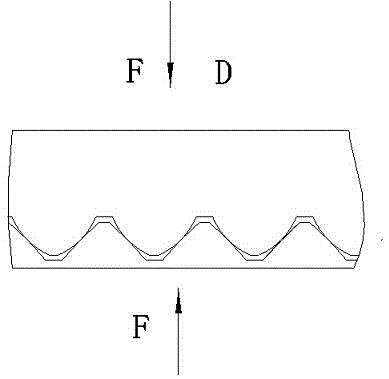

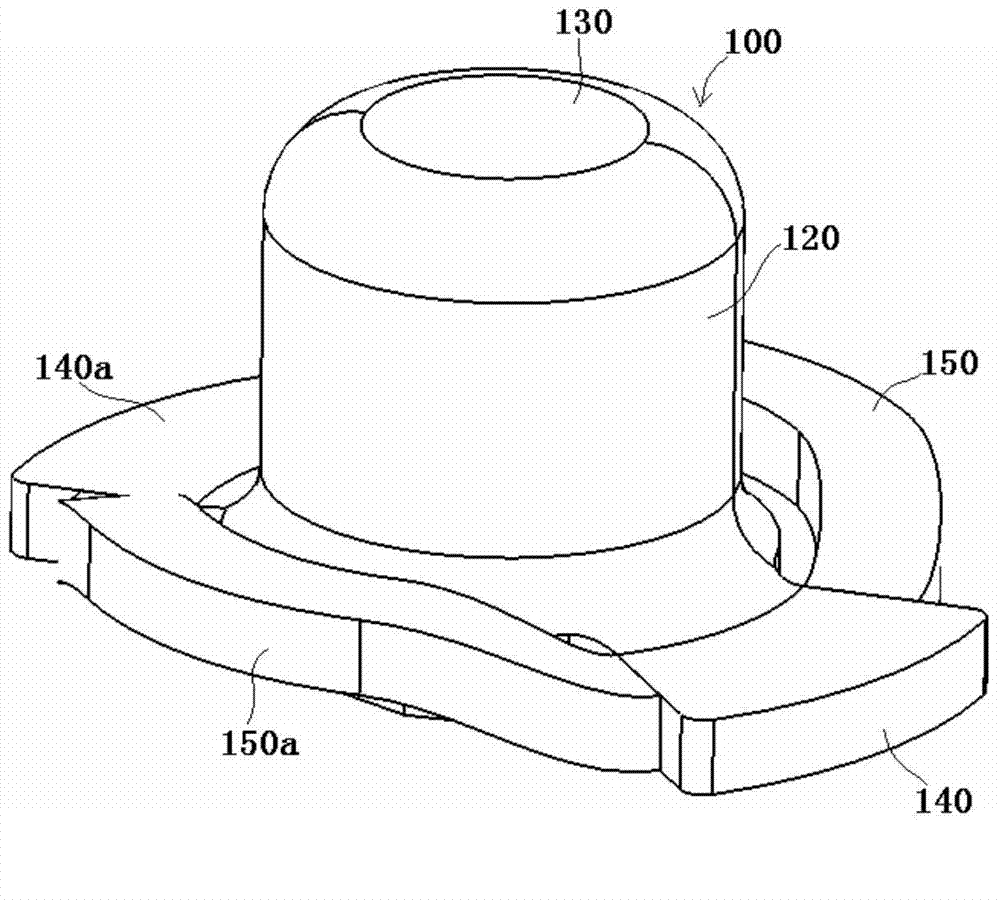

Gap adjusting component and electric lifting adjusting device of automobile seat with gap adjusting component

ActiveCN104842827AReduce in quantityEliminate axial playMechanical energy handlingMovable seatsWear resistantEngineering

The invention discloses a gap adjusting component which is a plastic piece and comprises a cylinder part with an inner cavity. A first end of the cylinder part is opened, and a second end of the cylinder part is provided with an axial limiting end wall. An axial gap adjusting corrugated edge is arranged at the first end of the cylinder part. The corrugate fluctuating direction of the axial gap adjusting corrugated edge is parallel to the axial direction of the cylinder part. After the gap adjusting component is applied to an electric lifting adjusting device of an automobile seat, the axial gap of an output shaft for driving a motor is eliminated through the deformation of the axial gap adjusting corrugated edge of the gap adjusting component, and the tolerance requirement of a reduction gearbox body and a worm is lowered. The gap adjusting component has the advantage that by means of the gap adjusting component, an adjusting spring, a wear-resistant gasket and an oil-contained bearing in the prior art are replaced to eliminate the axial gap, the number of parts is decreased, assembling is simplified, and cost is reduced. In addition, the gap adjusting component can be designed in a modularized mode.

Owner:KEIPER (CHANGSHU) SEATING MECHANISMS CO LTD

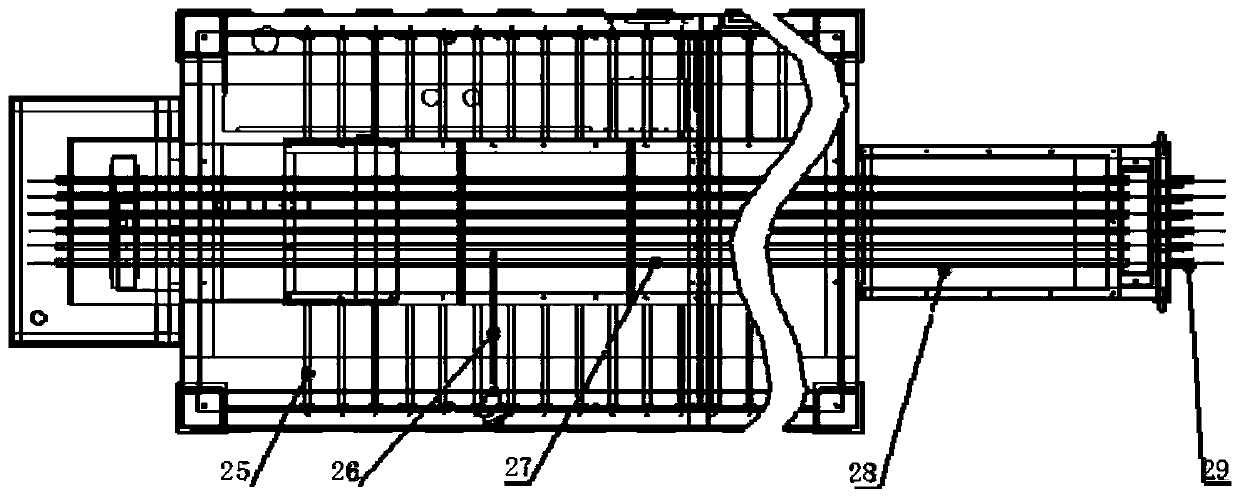

Bars reducing and sizing mill

InactiveCN104889156ACompact structureReduce weightMetal rolling stand detailsRolling equipment maintainenceEngineeringCopper

The invention discloses a bars reducing and sizing mill which is of a short stress line type. The bars reducing and sizing mill comprises a roll-gap adjuster, a pull rod assembly, a frame, a beam, a roll assembly and a guide beam. The roll assembly comprises an upper roll assembly and a lower roll assembly and further comprises a pull rod, butterfly spring absorbers and a spherical anti-axial play device; the butterfly spring absorbers are disposed at upper and lower ends of the pull rod and used for eliminating a gap between the pull rod and a copper nut; the spherical anti-axial play device is used for eliminating an axial gap between the pull rod and a bearing block; the butterfly spring absorbers surround the pull rod; the pull rod assembly allows a central distance of upper and lower rolls of the mill to change by 0.1mm.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

Motor assembly and vehicle starter

InactiveCN105680619AEliminate axial playAvoid wear and tearPower operated startersElectric motor startersControl theory

The invention discloses a motor assembly, in particular a motor assembly of a vehicle starter. The motor assembly comprises a motor and a speed change mechanism, wherein the motor comprises an armature shaft; the speed change mechanism comprises an input gear; the input gear is arranged on the armature shaft through a spline; the spline comprises outer spline teeth and inner spline teeth; the outer spline teeth are formed on the armature shaft; the inner spline teeth are formed in the input gear and engaged with the outer spline teeth; and at least one of a pair of tooth side surfaces of each spline tooth inclines relative to the central axis of the armature shaft. The invention further discloses the vehicle starter comprising the motor assembly. A commutator and an electric brush of the motor can be prevented from being worn due to axial endplay of the armature shaft.

Owner:SEG AUTOMOTIVE GERMANY GMBH

Elastic cone wedge-caulking type anti-disengagement nut

The invention provides an elastic cone wedge-caulking type anti-disengagement nut mainly formed by combining a thick nut body with a conical hole in the right end and a thin nut body with an outer cone boss at the left end. At least two blind grooves with one ends closed and the other ends closed are evenly distributed in each of the two ends of the thin nut body. During use, because of the wedge-caulking of a cone and the tightening effect of the blind grooves, the axial clearance and the radial clearance between the elastic cone wedge-caulking type anti-disengagement nut and a thread of a bolt can be effectively eliminated, and the anti-disengagement and retreating stopping effects of the elastic cone wedge-caulking type anti-disengagement nut are achieved. According to the elastic cone wedge-caulking type anti-disengagement nut, the plane wedge-caulking principle is ingeniously applied in the three-dimensional cone and is combined with the blind groove elastic shrinkage principle, the structure is simple, the anti-disengagement and retreating stopping effects are stable and reliable, installation and detachment are convenient, and the elastic cone wedge-caulking type anti-disengagement nut can be widely applied to various occasions, having strict anti-disengagement requirements for thread tightening pieces, especially occasions where air planes, automobiles and high-speed trains have special requirements for disengagement prevention of the tightening pieces.

Owner:华和平

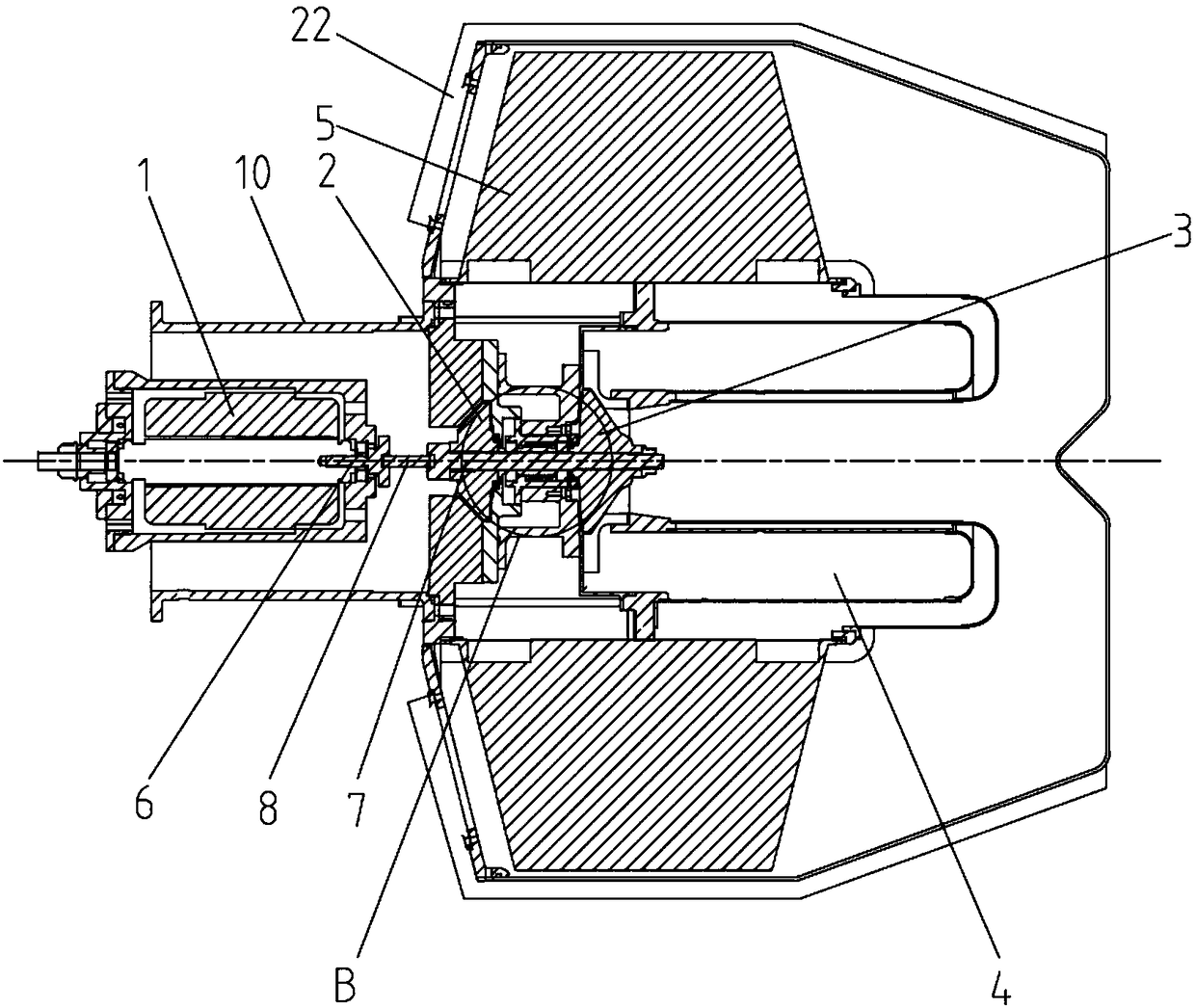

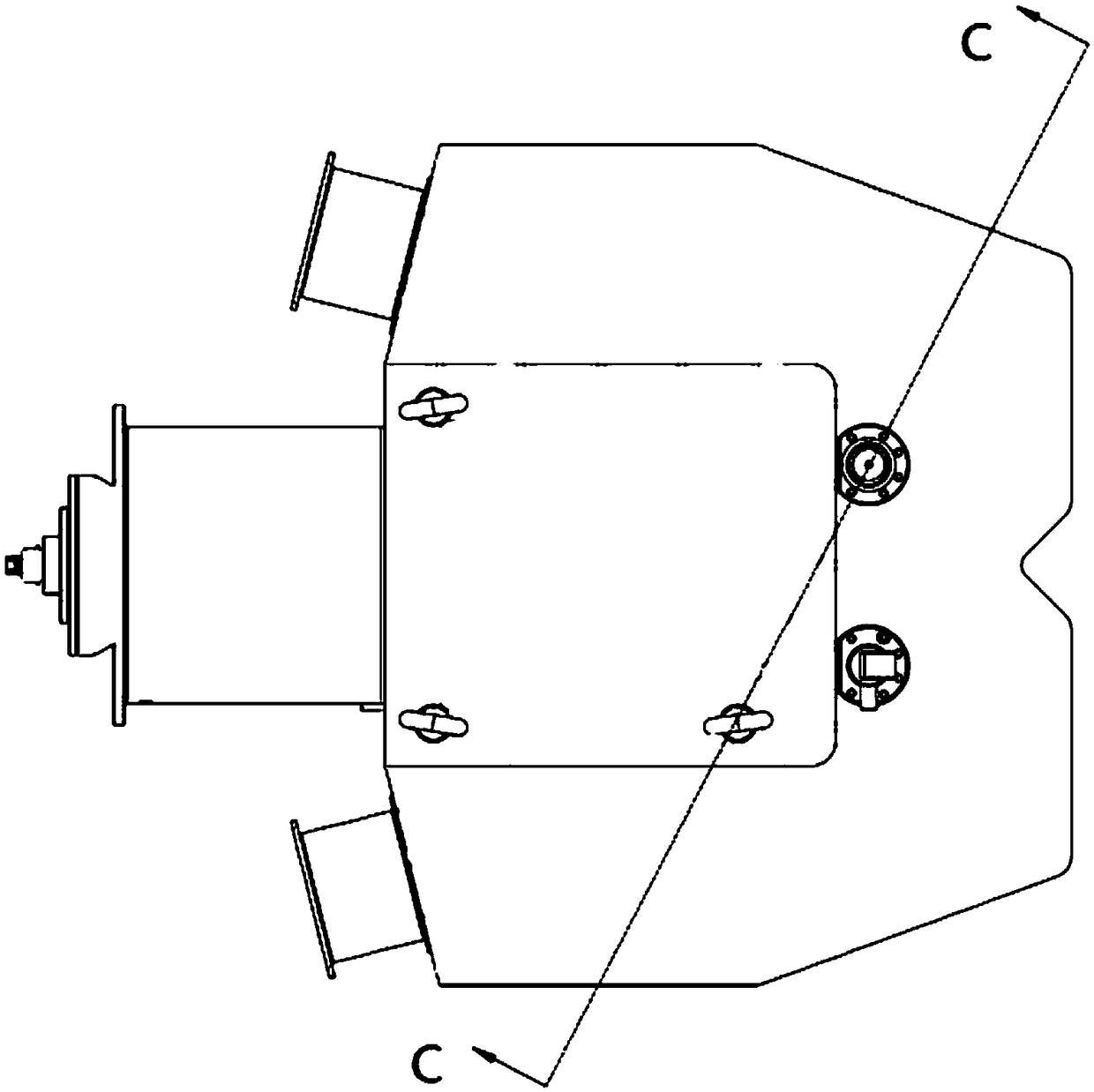

Micro gas turbine generator set

InactiveCN109057968AAchieving a modular designIncrease temperatureTurbine/propulsion fuel supply systemsGas turbine plantsCombustion chamberGas compressor

The invention relates to the technical field of engine equipment, in particular to a micro gas turbine generator set, which comprises an electric generator, a gas compressor and a turbine, a combustion chamber and a nozzle. The electric generator, the gas compressor and the turbine are mounted on a rotating shaft; an outlet end of the nozzle is inserted into the combustion chamber; an exhaust endof the gas compressor is in communication with the combustion chamber; and an exhaust end of the combustion chamber is in communication with the turbine. The micro gas turbine generator set further comprises a heat regenerator; the heat regenerator is provided with a first channel and a second channel that are isolated and in close contact with each other; an inlet of the first channel is in communication with the exhaust end of the gas compressor; the outlet of the first channel is in communication with the combustion chamber; and the inlet of the second channel communicates with the exhaustend of the turbine. The air entering the combustion chamber can be preheated through the heat regenerator, thereby improving the temperature of the air entering the combustion chamber and further improving the combustion efficiency, reducing the content of pollutants in the exhaust gas and reducing the temperature of the exhaust gas at the same time.

Owner:靳普

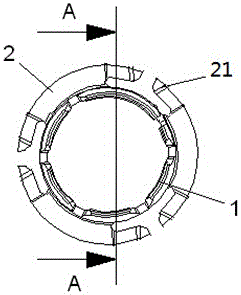

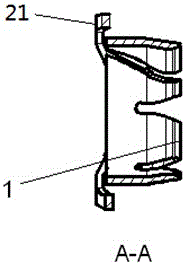

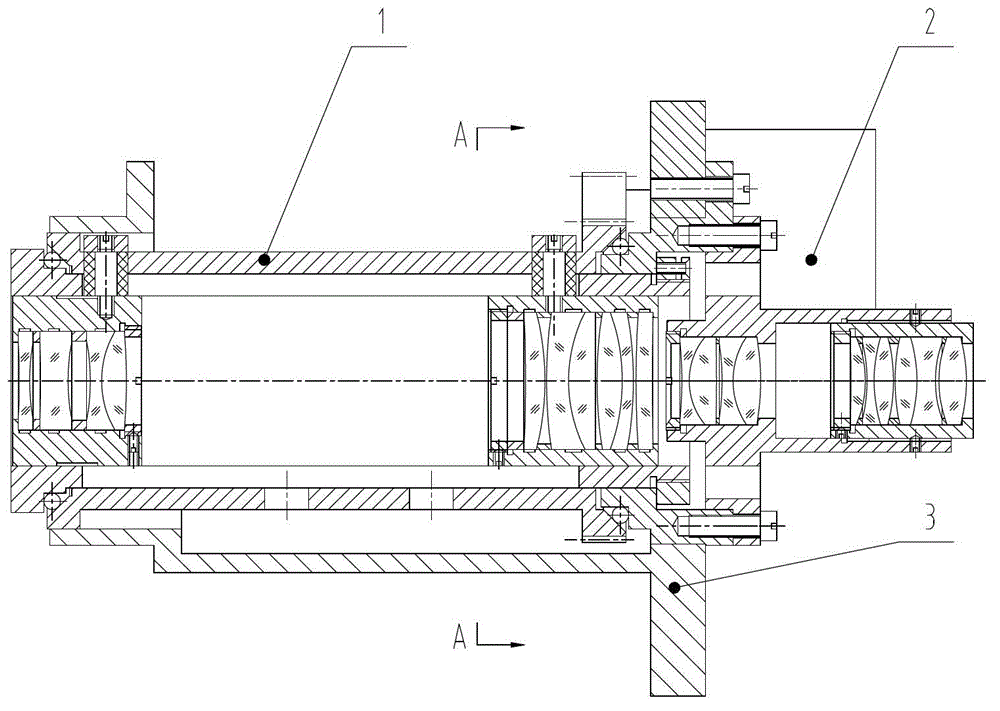

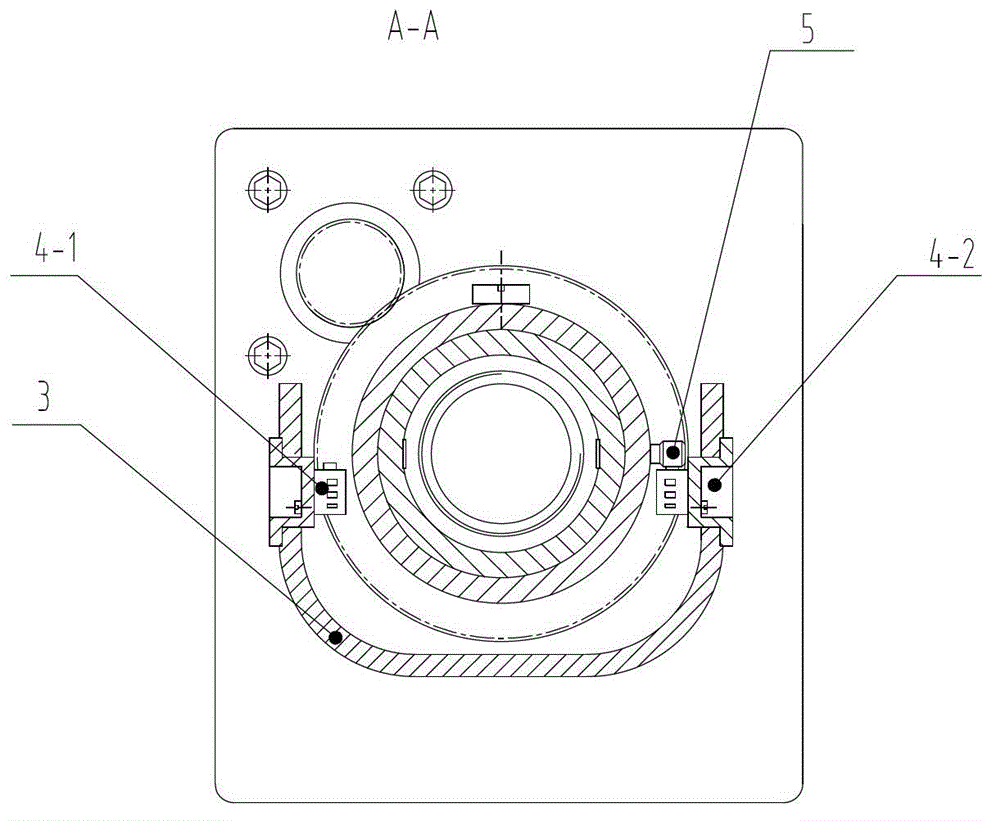

Electric continuous zooming mechanism with high-stability image surface

The invention discloses an electric continuous zooming mechanism with a high-stability image surface. The electric continuous zooming mechanism comprises a zoom lens group, a motor group, a shell, a first limit switch, a second limit switch and a contact, wherein the zoom lens group, the motor group, the first limit switch and the second limit switch are respectively fixed on the shell, the zoom lens group comprises a zoom guide rail group, a zoom light group, a compensating light group, a first cam group and a second cam group, the zoom guide rail group is a gapless rolling guide rail, and comprises an inner zoom barrel, an outer zoom barrel, a bearing seat, an opened pressing ring, a key, a first ball and a second ball. According to the invention, stability of the image surface during continuous zoom in specific environment such as temperature, impact and vibration can be realized, and imaging quality of a zoom system is improved.

Owner:NANJING NORTH OPTICAL ELECTRONICS

Small high-dynamic and high-precision digital output magneto-electricity encoder and mounting control method thereof

InactiveCN110006336AImprove performanceHigh rotation accuracyProgramme controlComputer controlElectricityMicrocontroller

The invention discloses a small high-dynamic and high-precision digital output magneto-electricity encoder and a mounting control method thereof. The digital output magneto-electricity encoder comprises a main shaft, a main body, a signal processing circuit board and a shell; the main shaft and the main body are in dual-bearing support mechanism; a radial magnetizing circular magnet is arranged ina main shaft counter bore; the signal processing circuit board is a wafer shape, and a Hall sensor chip is arranged at the center of the front, and a microcontroller and a CAN bus interface circuit are arranged at the back, and the signal processing circuit board is fixed on a step surface of the main body through bolts; a magnetic field signal is tested by adopting a diameter differential way, and a closed-loop tracking segmentation algorithm is used for quickly converge a measurement angle to input two orthogonal cosine signal corresponding angle values. Through the small high-dynamic and high-precision digital output magneto-electricity encoder and the mounting control method thereof disclosed by the invention, the interference resistance is improved, and the measurement angle precision and the response speed are improved.

Owner:CHINA AIR TO AIR MISSILE INST

Friction welding machine limiting rod clearance-eliminating device

PendingCN107414282AEliminate axial playClearance is reliableWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingMechanical engineering

The invention provides a friction welding machine limiting rod clearance-eliminating device, which comprises a shell, an ejector rod, a wedge block and a power device. The ejector rod is horizontally arranged in the shell; the wedge block is vertically arranged in the shell; a first inclined surface of the ejector rod and a second inclined surface of the wedge block overlap together; the power device is connected with the wedge block; upward movement of the wedge block is transformed into horizontal movement of the ejector rod; and through arranging a sliding chute or a spring, automatic reset can be realized after use. According to the friction welding machine limiting rod clearance-eliminating device provided by the invention, the ejector rod is pushed through the wedge block so as to move axially, so that an axial clearance generated during welding piece clamping is eliminated; and the inclined surfaces are self-locked, so that the friction welding machine limiting rod clearance-eliminating device is reliable in eliminating the clearance, simple and effective in structure, and more accurate in abrasion value measurement.

Owner:SUZHOU XIYAN MACHINERY TECH CO LTD

Tape spool centering, positioning and clamping device

InactiveCN103935793AGuaranteed positivityEliminate axial playWebs handlingEngineeringMechanical engineering

The invention discloses a tape spool centering, positioning and clamping device, and belongs to clamping tools. An existing tape spool centering, positioning and clamping device has the defects that a tape spool is prone to axially moving, and a tape-shaped article is prone to damage. The tape spool centering, positioning and clamping device comprises a fixing shaft, a fixing pipe, a left supporting baffle, a right supporting baffle, two clamping plates, two guiding wheels, first elastic pieces and second elastic pieces. The fixing pipe is provided with a nut stop ring limiting piece, the two clamping plates are located between the left supporting baffle and the right supporting baffle, clamping space is formed between the two clamping plates, the first elastic pieces are arranged between one clamping plate and the left supporting baffle and between the other clamping plate and the right supporting baffle respectively, the two first elastic pieces are the same in performance, the guiding wheels are arranged on the radial outer side of the clamping space, a supporting shaft between one guiding wheel and the left supporting baffle and a supporting shaft between the other guiding wheel and the right supporting baffle are respectively provided with one second elastic piece, and the second elastic pieces are the same in performance. According to the tape spool centering, positioning and clamping device, the two sides of the two clamping plates and the two sides of the guiding wheels are provided with the elastic pieces with the same performance to provide clamping force, and centering and positioning in the adjusting process are achieved.

Owner:浙江天时光电科技有限公司

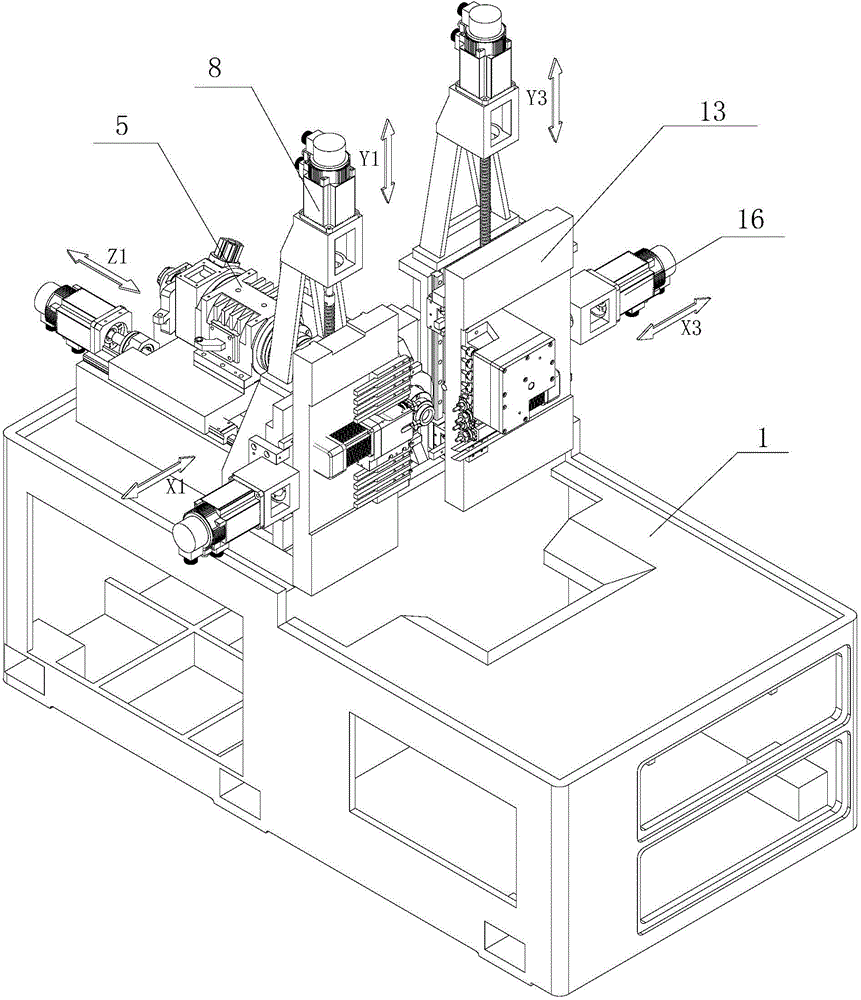

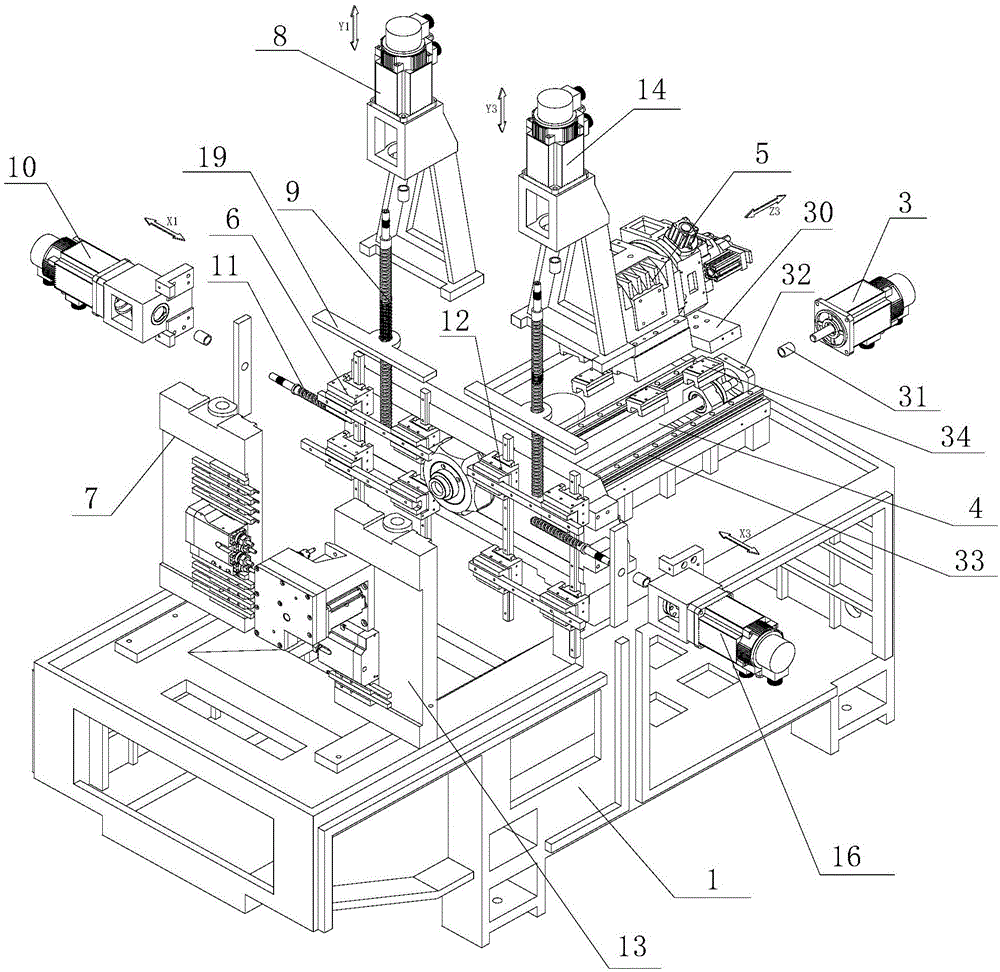

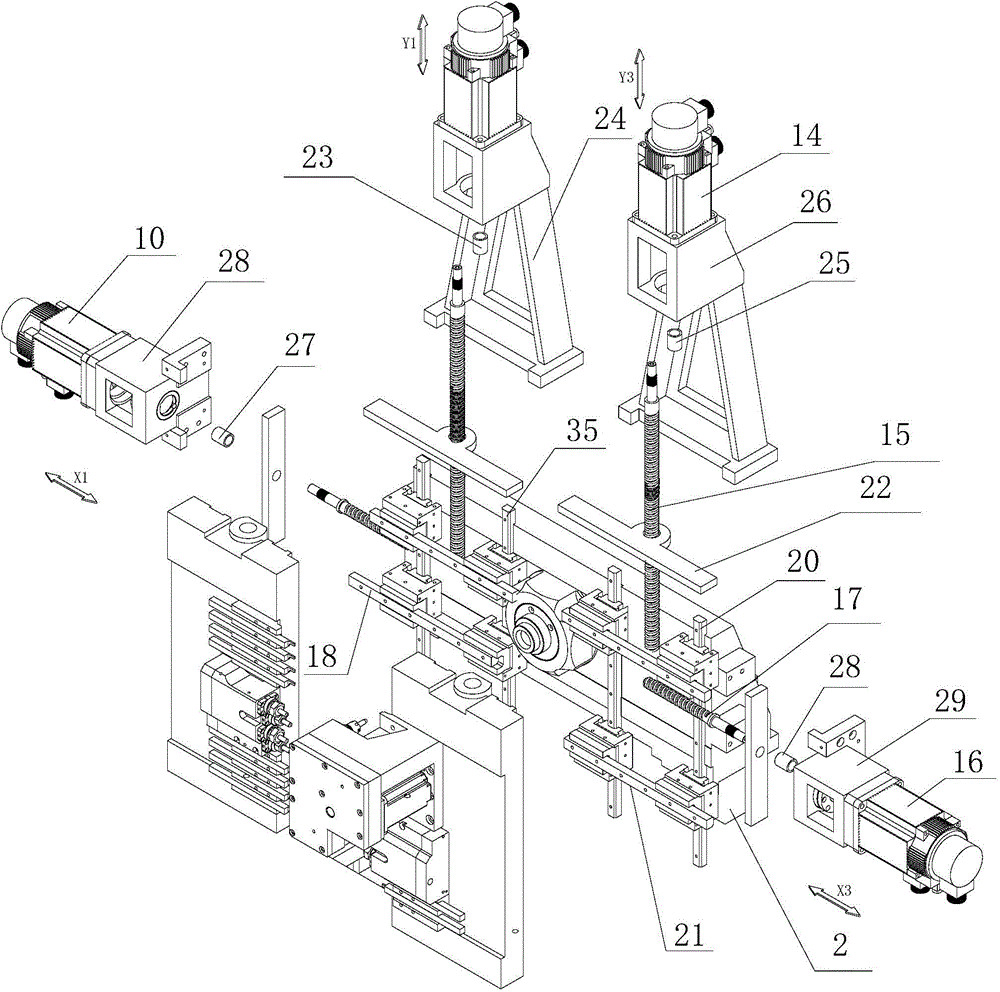

Decentring type turn-milling machine tool provided with positive axis with five-axis structure

InactiveCN104551719AReduce frictionReduce wearFeeding apparatusOther manufacturing equipments/toolsMachine tool

The invention discloses a decentring type turn-milling machine tool provided with a positive axis with a five-axis structure. The decentring type turn-milling machine tool comprises a tool body, upright columns, a Z1-axis assembly, a Y1-axis assembly, an X1-axis assembly, a Y3-axis assembly and an X3-axis assembly. The Z1-axis assembly comprises a Z1-axis servo motor, a Z1-axis lead screw and a positive spindle of the machine tool; the Y1-axis assembly comprises first cross blocks, a Y1-axis servo motor, first slide seats and a Y1-axis lead screw; the X1-axis assembly comprises a first tool mounting plate, an X1-axis servo motor and an X1-axis lead screw; the Y3-axis assembly comprises second cross blocks, a Y3-axis servo motor, second slide seats and a Y3-axis lead screw; the X3-axis assembly comprises a second tool mounting plate, an X3-axis servo motor and an X3-axis lead screw. The decentring type turn-milling machine tool has the advantage that technical shortcomings that tools on a decentring type turn-milling machine tool in the prior art are mounted on the same component, each tool only can carry out machining after machining is completed by the corresponding front tool during work, the tools are constrained by one another, the workpiece forming time cannot be effectively optimized and the workpiece forming efficiency is affected can be overcome.

Owner:NANJING JIANKE MACHINERY

Four-axis stamping robot

PendingCN108297072ACompact structureNo gapProgramme-controlled manipulatorStacking articlesControl theoryRobot

The invention discloses a four-axis stamping robot which comprises a base, a first shaft seat, a second shaft seat, a first servo motor, a second servo motor, a first shaft arm, a second shaft arm, athird servo motor, a four-axis fixing part and a fourth servo motor. The first shaft seat is fixedly connected to the top of the base. The second shaft seat is rotationally connected to the top of thefirst shaft seat. The first servo motor is fixedly connected to the top of the second shaft seat. The second servo motor is fixedly connected to the front face of the second shaft seat. The lower endof the first shaft arm is rotationally connected with the back face of the second shaft seat. One end of the second shaft arm is rotationally connected with the upper end of the first shaft arm. Thethird servo motor is fixedly connected to the front face of the second shaft arm. The four-axis fixing part is rotationally connected to the other end of the second shaft arm. According to the four-axis stamping robot, through cooperation of the above structures, a mechanical gripper connecting part in the four-axis stacking robot is improved, a mechanical gripper can be adjusted in the six freedom degree directions, and the adjusting precision is high.

Owner:FOSHAN POLYTECHNIC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com