Patents

Literature

66results about How to "No axial play" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

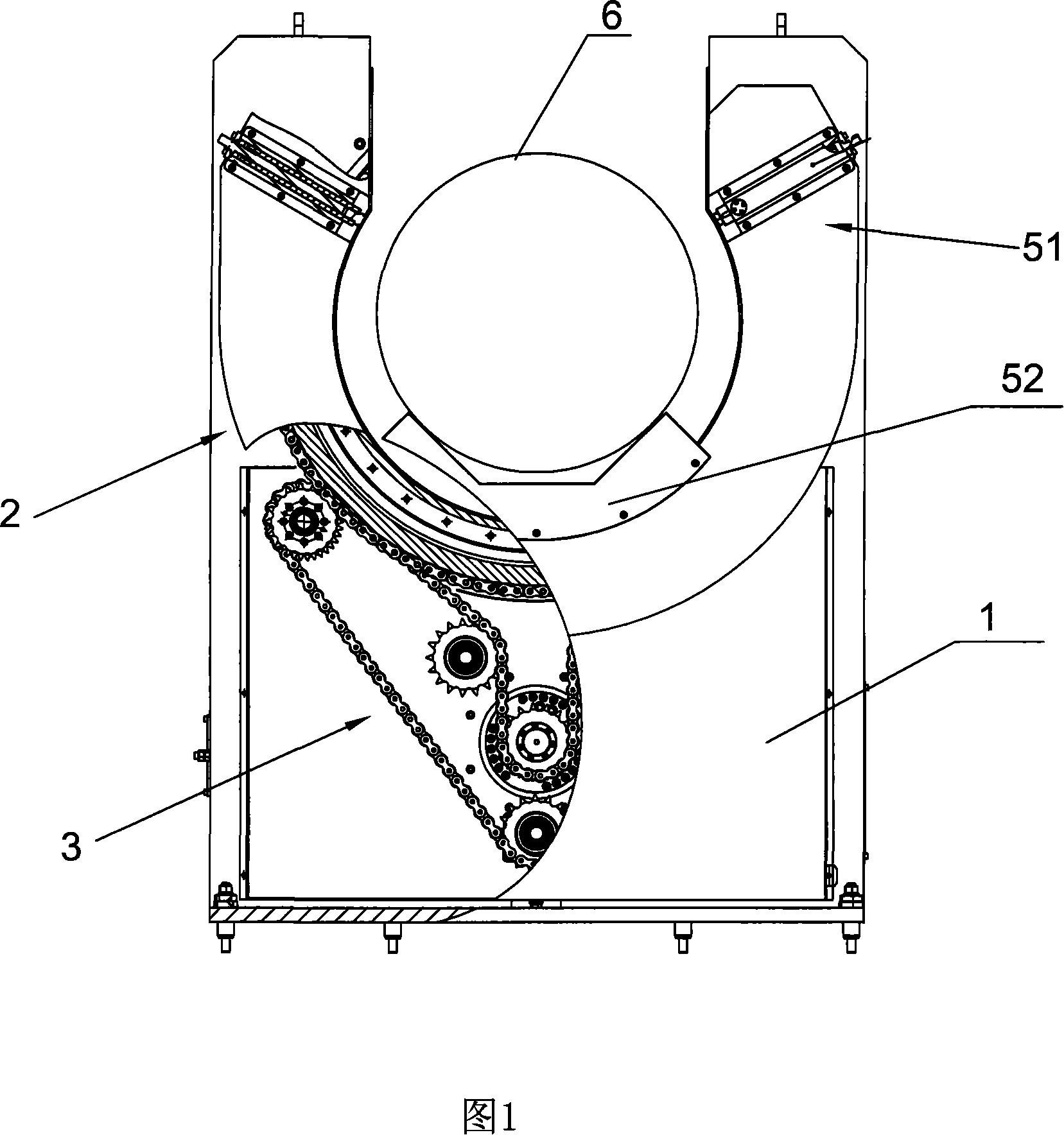

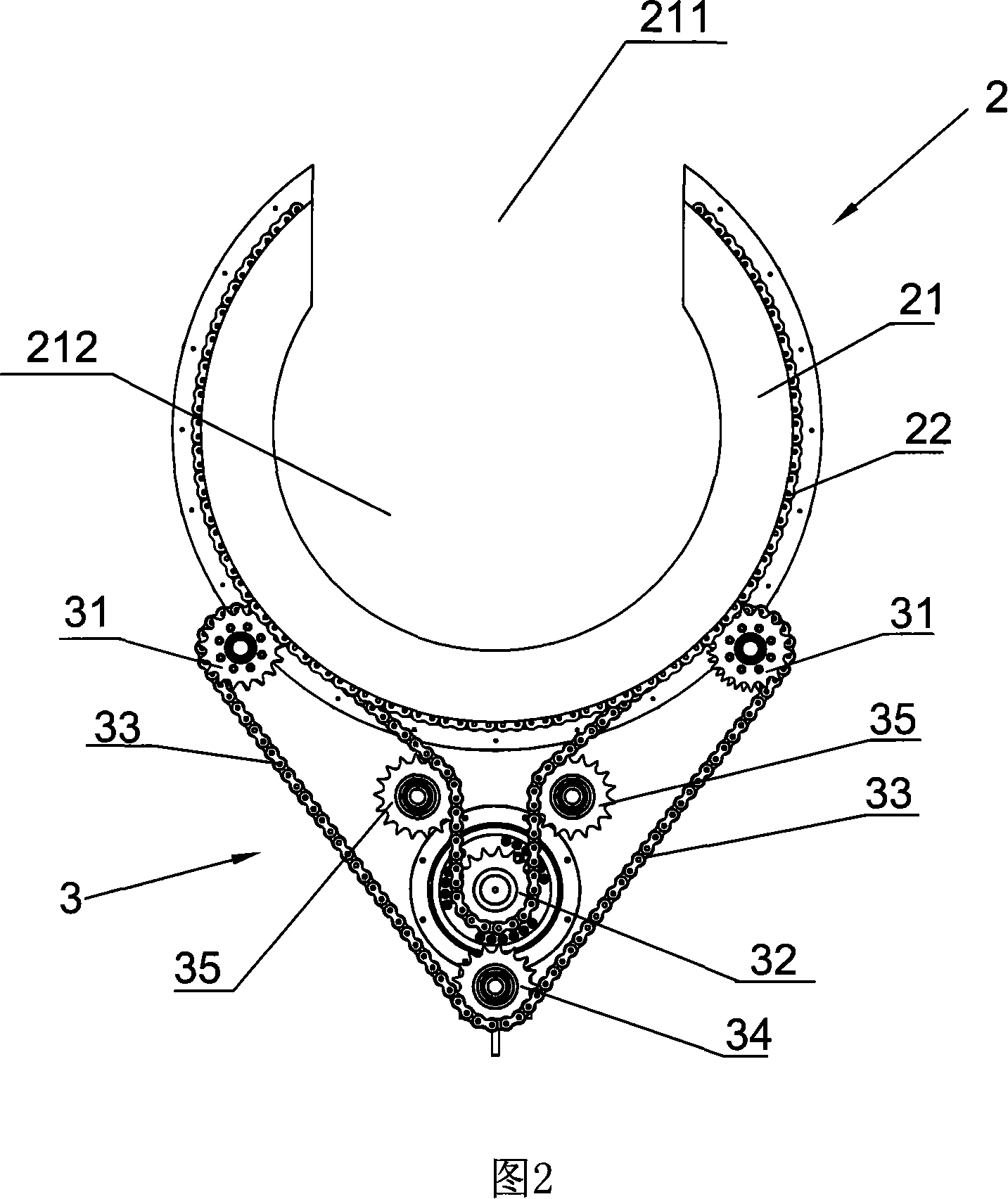

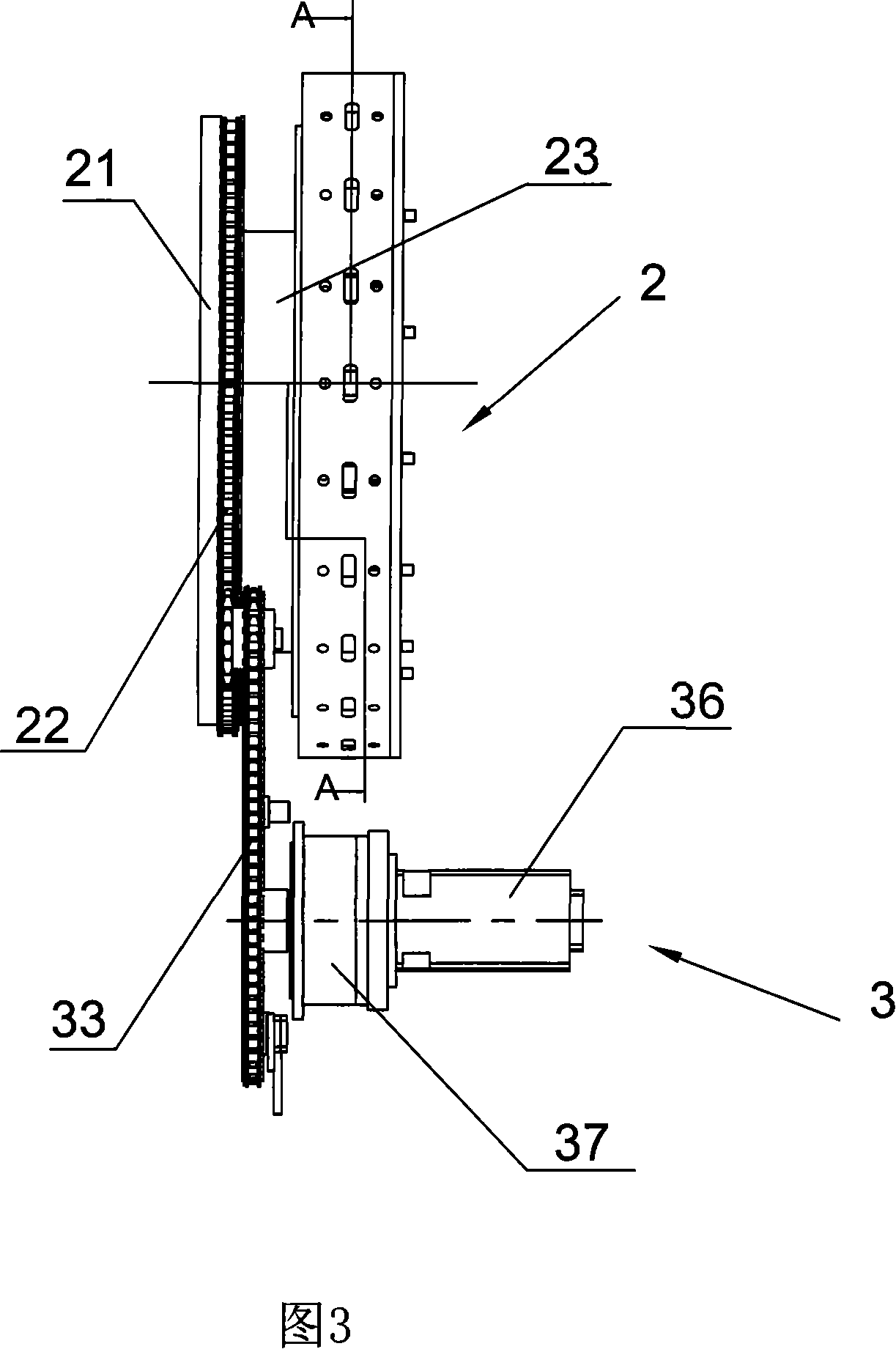

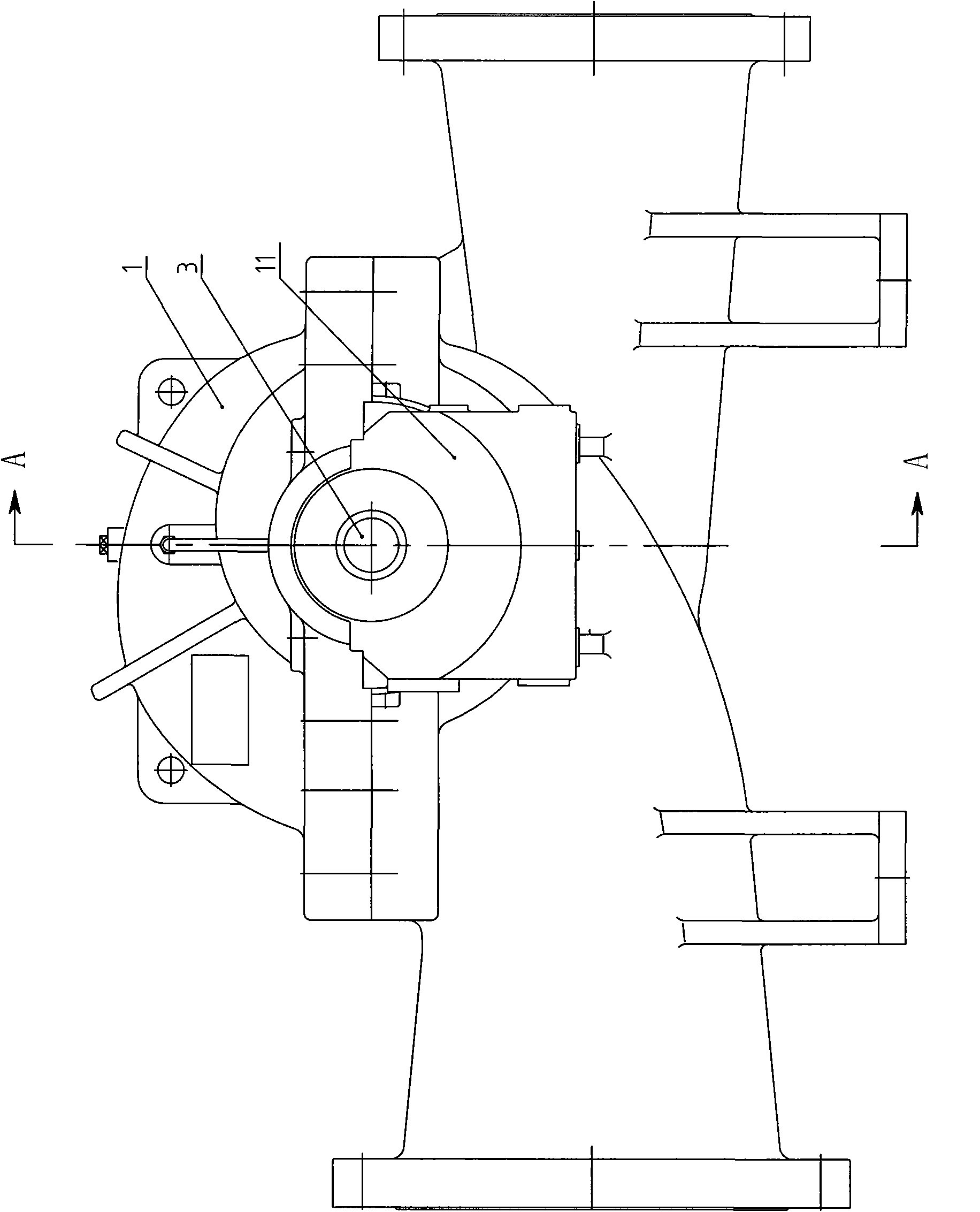

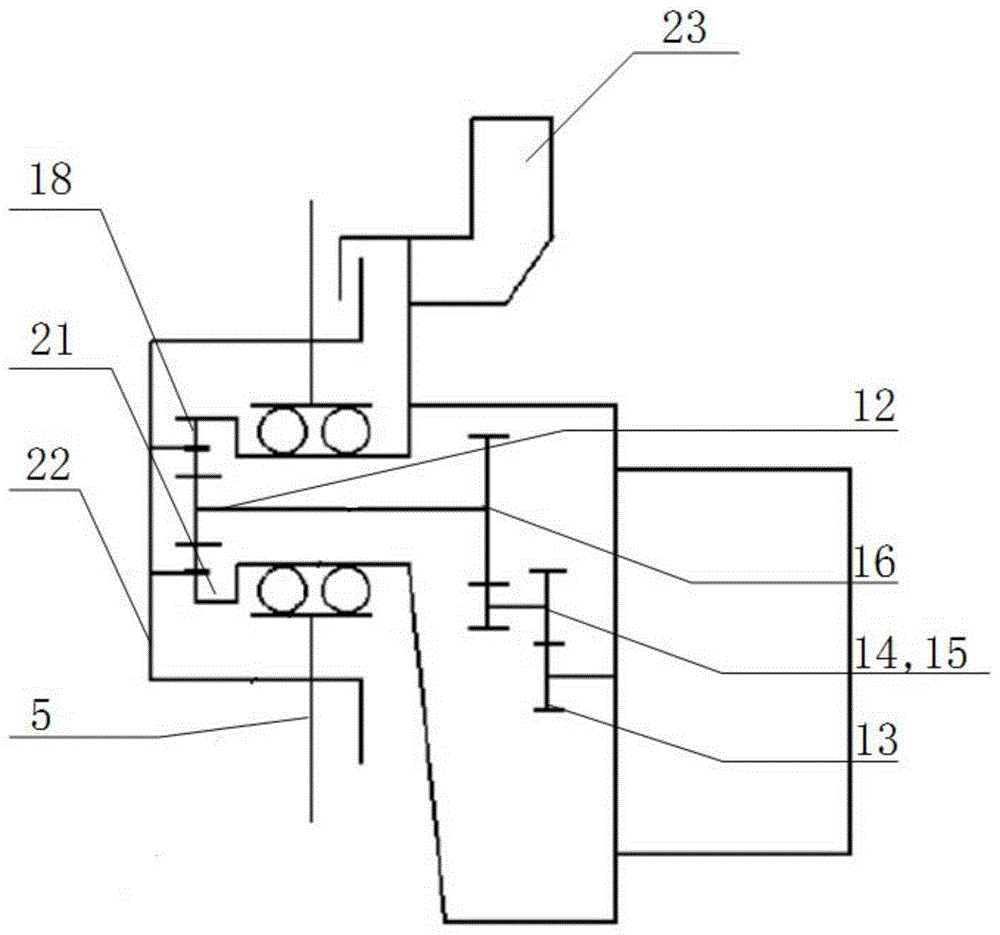

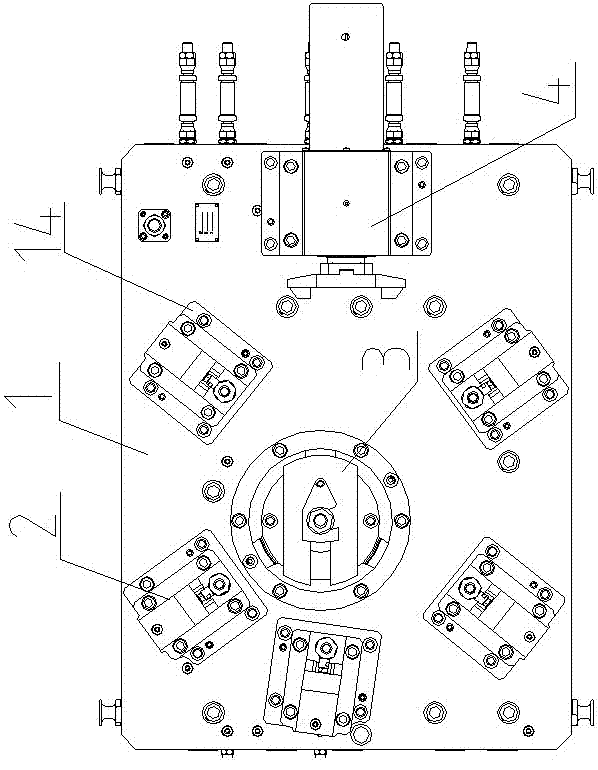

Pipe cutting positioner

ActiveCN101112742AGuaranteed stabilityRealize synchronous linkageWelding/cutting auxillary devicesAuxillary welding devicesSprocketLinkage concept

The invention provides a cutting positioning machine which includes a frame body, a rotary positioning mechanism rotatablely arranged on the frame body, and a transmission mechanism driving the rotary positioning mechanism to rotatablely position; the rotary positioning mechanism includes a rotary disc with a chamber, a chain fixedly circled on the external circumference of the rotary disc, and a clamp positioning mechanism arranged at the chamber close to the rotary disc for clamping the pipes; the transmission mechanism includes at least one transmission chain wheel engaged with the chain; as the diameter of the rotary disc of the rotary positioning mechanism on the positioning machine is not restricted by the process, the large rotary disc can be added and meanwhile be matched with the clamp positioning mechanism, tightly clamping the pipes to be cut with different types, in particular to the large types; furthermore, the chain wheel is adopted for transmission, which ensures the stability of the rotation of the rotary disc, thus no skidding or axial movement occurring in the cutting process, and sequentially implementing the synchronous linkage between the cutting equipment and the positioning machine.

Owner:KUSN HUAHENG ENG TECH CENT

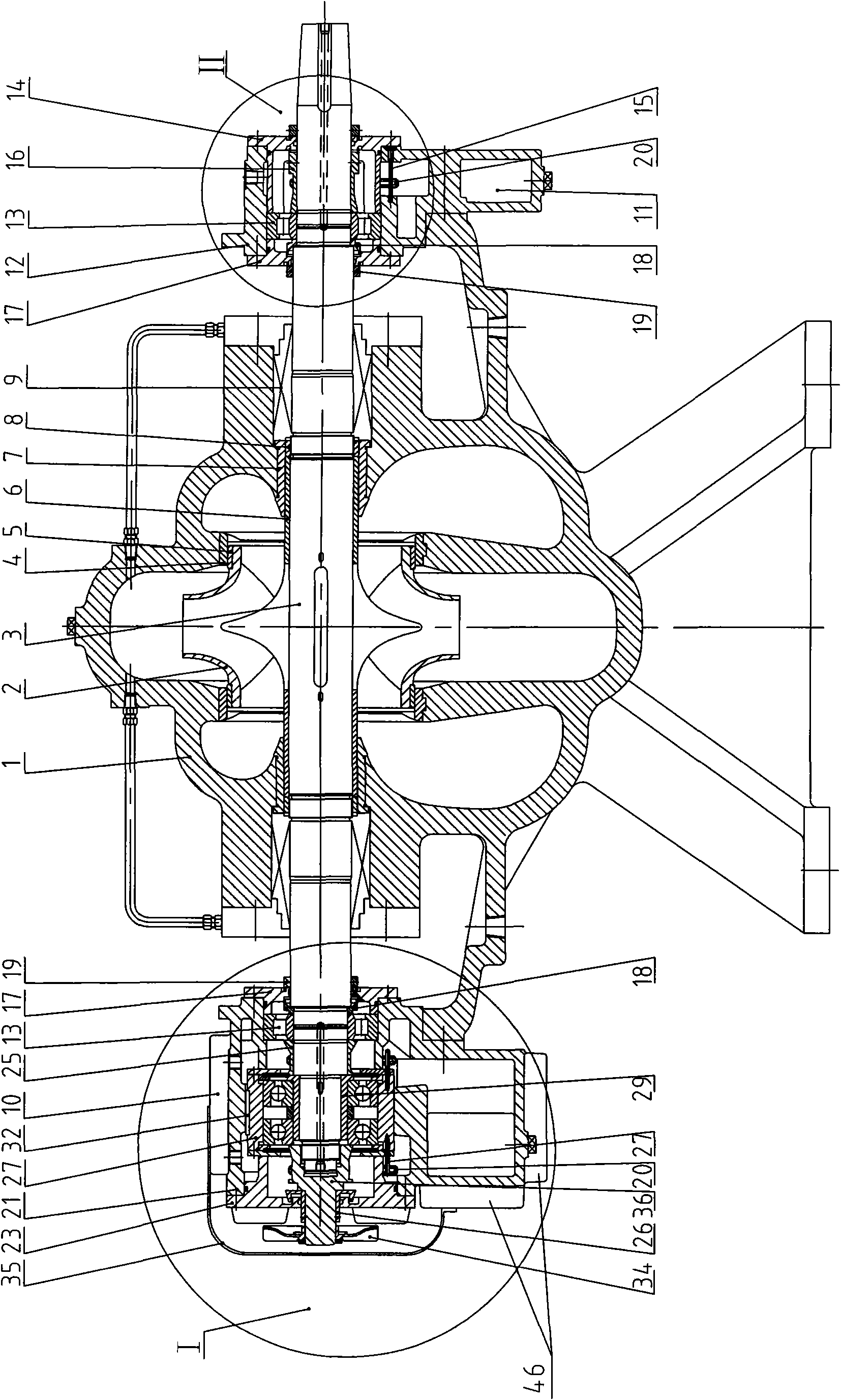

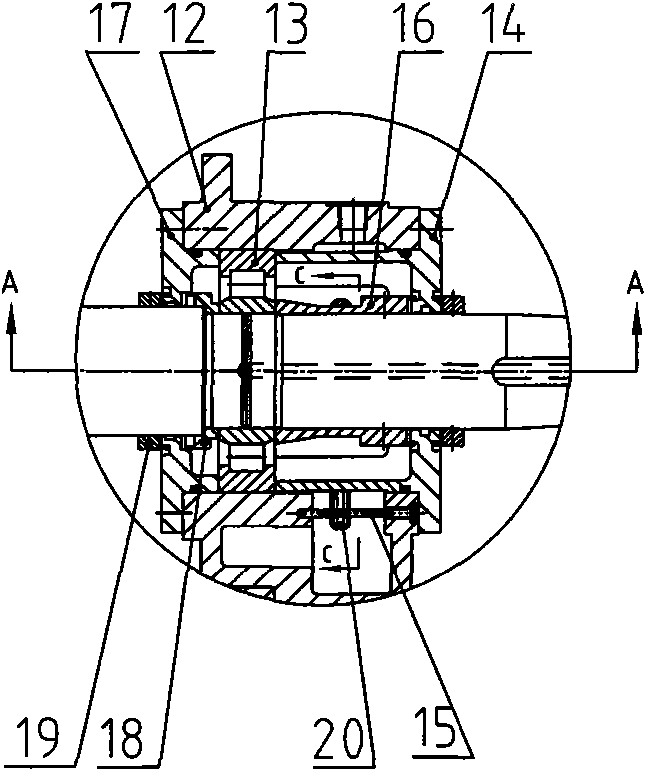

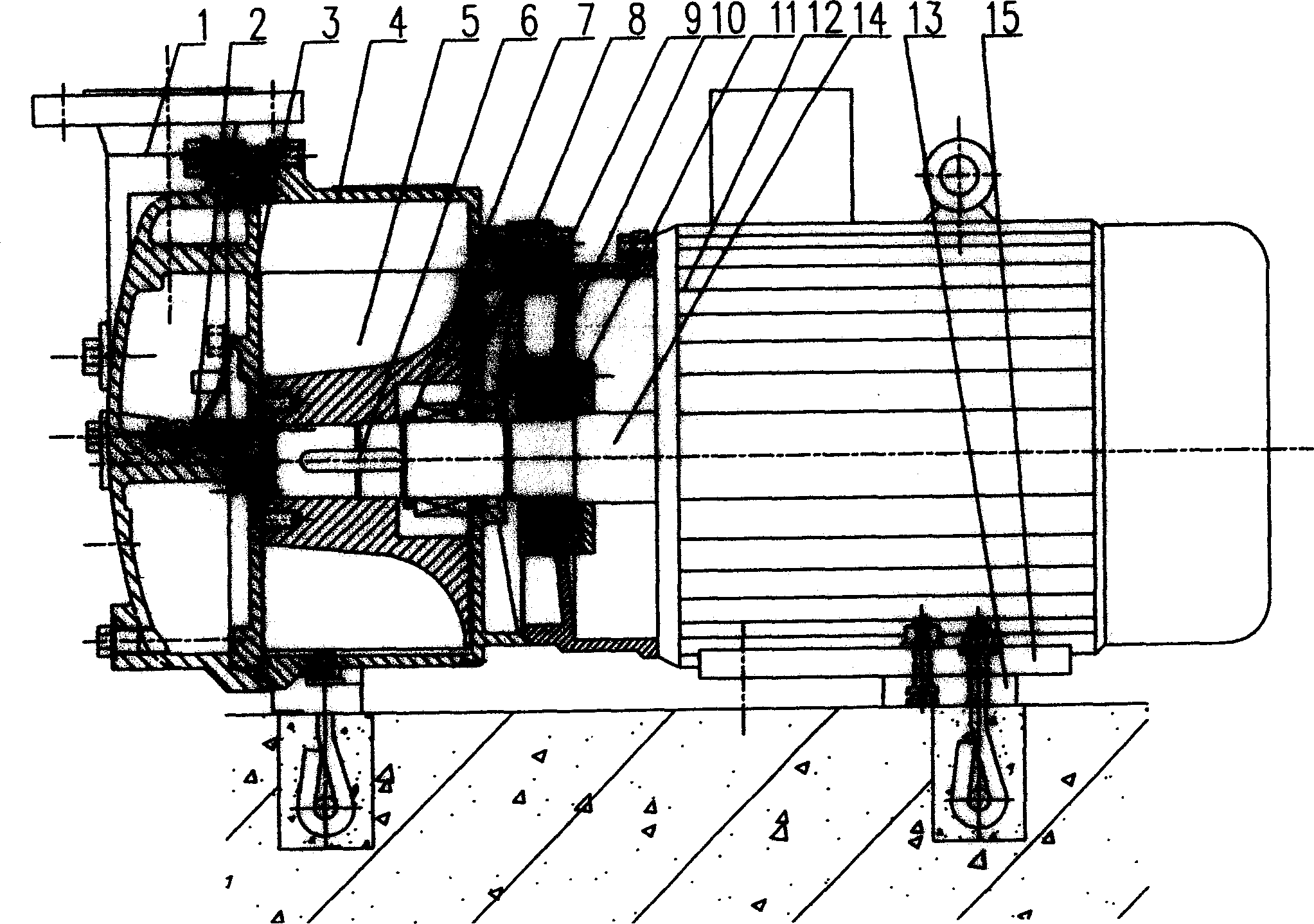

Pipeline delivery pump

ActiveCN101994701AEasy to disassembleShorten maintenance timePump componentsRadial flow pumpsImpellerDesalination

The invention relates to a pipeline delivery pump, which is suitable for the pipeline delivery of crude oil and natural gas and the sea water transportation in long distance in the field of desalination of sea water. The pump comprises a pump body, an impeller, a shaft, a left bearing device and a right bearing device; the impeller is arranged on the shaft in the pump body; two ends of the shaft extending out of the pump body are respectively provided with the left and right bearing devices which are connected with the pump body; the shaft end of the right bearing is connected with the outputshaft of a motor; two ends of the shaft are respectively provided with an axial hole; a shaft platform is arranged on the shafts of the first bearings of the left and right beating devices; and a circular groove is arranged in the middle of the shaft platform; and any part of the circumference of the circle groove is provided with a radial hole communicated with the axial hole. In the invention, the problems of difficult disassemble of the pipeline delivery pump bearing and unbalanced axial force are solved, and the bearing is extremely convenient and rapid to disassemble and maintain, a great amount of time is saved, and the work efficiency is greatly improved; and in addition, the impact of the axial force to the bearing is reduced and the service life of the bearing is improved by improving the structure of the bearing device.

Owner:辽宁恒星泵业有限公司

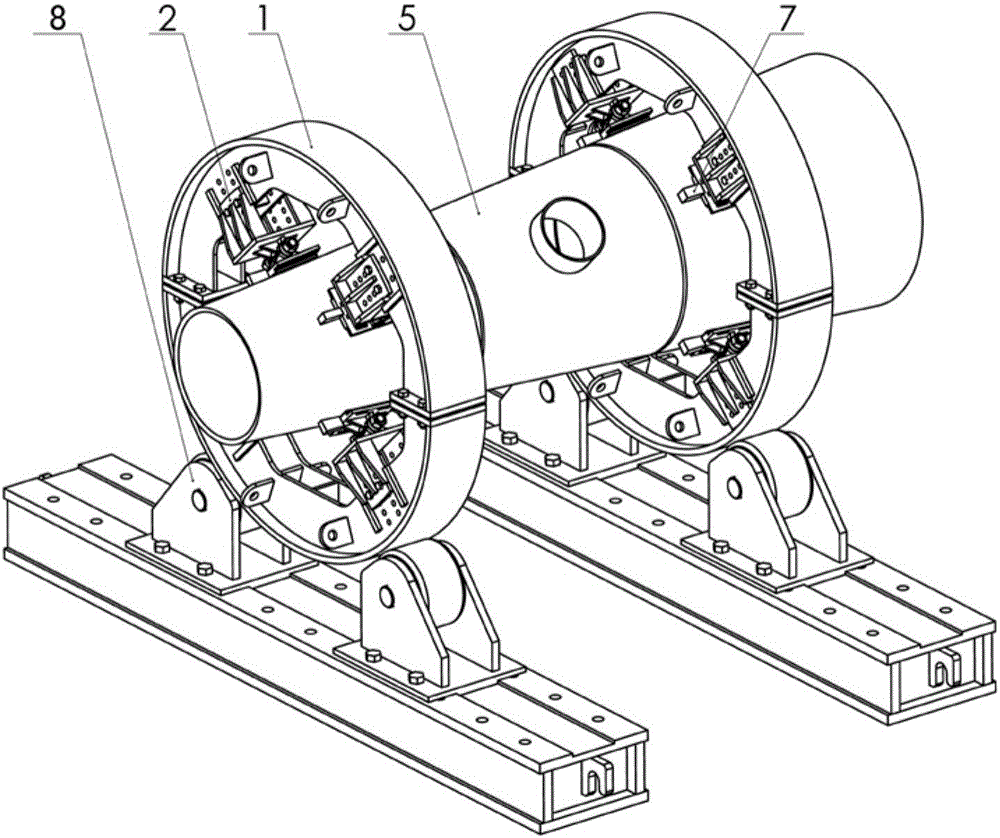

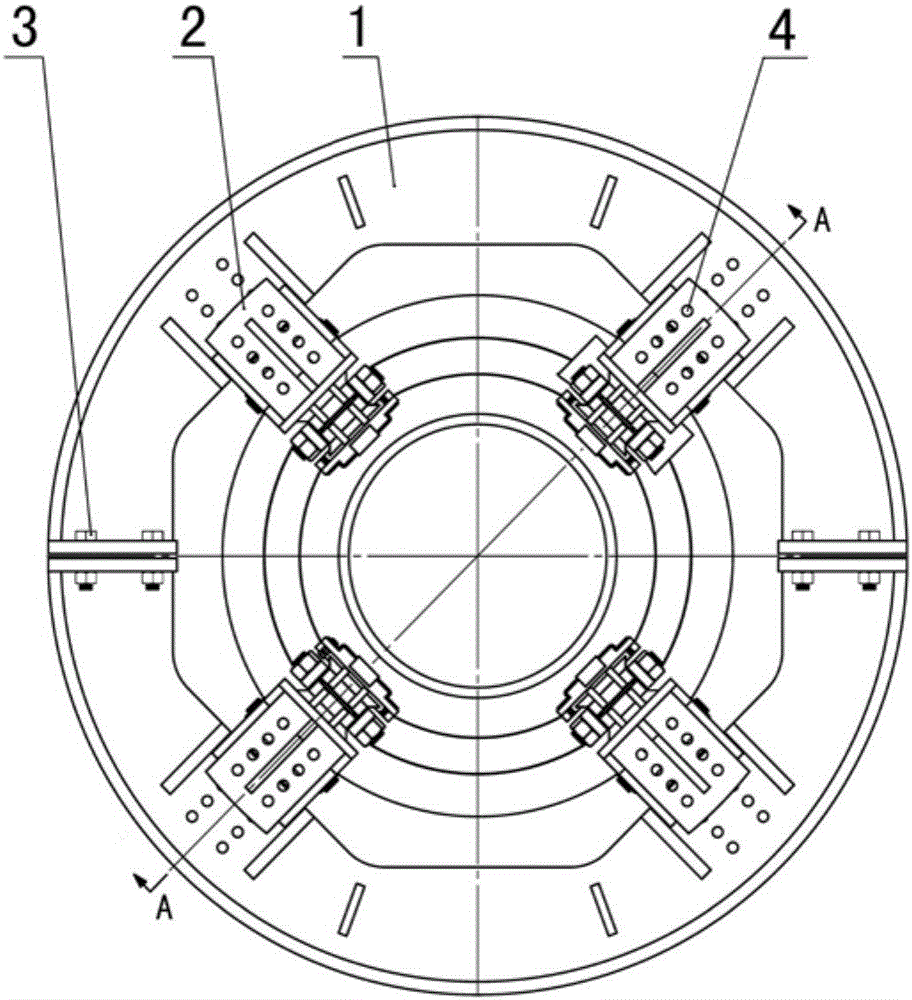

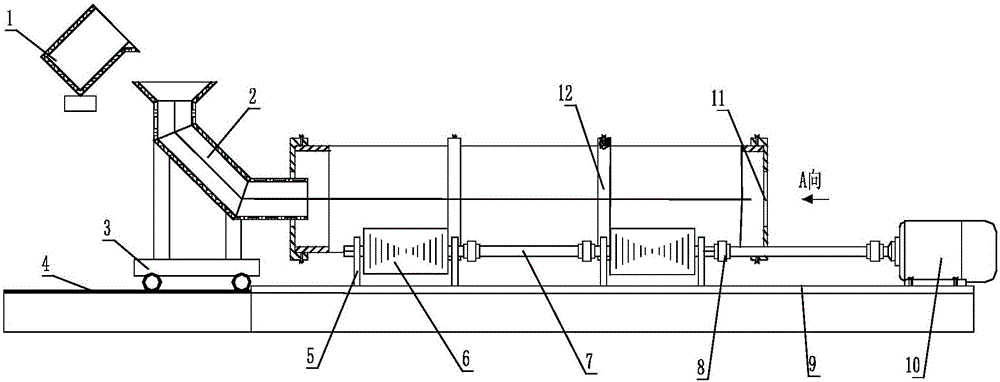

Horizontal rotating device for conical barrel body

ActiveCN106624576ASmooth horizontal rotationReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesCircular coneEngineering

The invention discloses a horizontal rotating device for a conical barrel body. The horizontal rotating device comprises support rings and hinged supports installed on the support rings, each support ring is a disc-shaped member, through holes are evenly distributed at the periphery of each support ring, and each group of through holes comprises a plurality of pairs of equidistant through holes distributed radially along the support ring. The support surfaces of lower hinged supports are uniformly in contact with the periphery of the outer circular conical surface of the conical barrel body at the same time, the horizontal rotating device is guaranteed to clamp the conical barrel body coaxially, the connection positions of upper hinged supports and the radial through holes of the support rings are adjusted, and then the distances from the lower hinged supports to the axes of the support rings are changed to adapt to clamping of the conical barrel bodies of different diameters. The horizontal rotating device is novel and simple in structure, and when the rotating device clamps the conical barrel body to roll on an idler wheel, the various operations like automatic welding for the butted joint of the long conical barrel body, multi-directional mounting on a cone body, and welding parts inside and outside the cone body are completed.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

Process for rolling large-scale rails into miniature type rails and rollers therefor

InactiveCN1546247ALow powerLow running costRollsMetal rolling arrangementsEngineeringMechanical engineering

Owner:周燕雄 +1

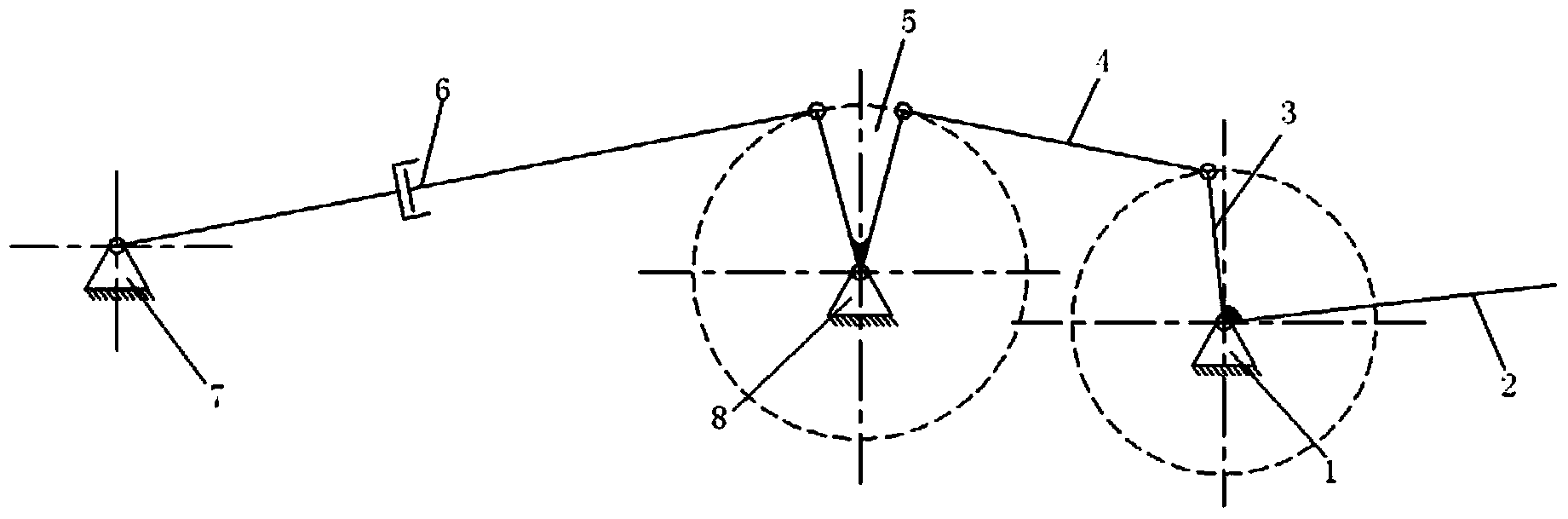

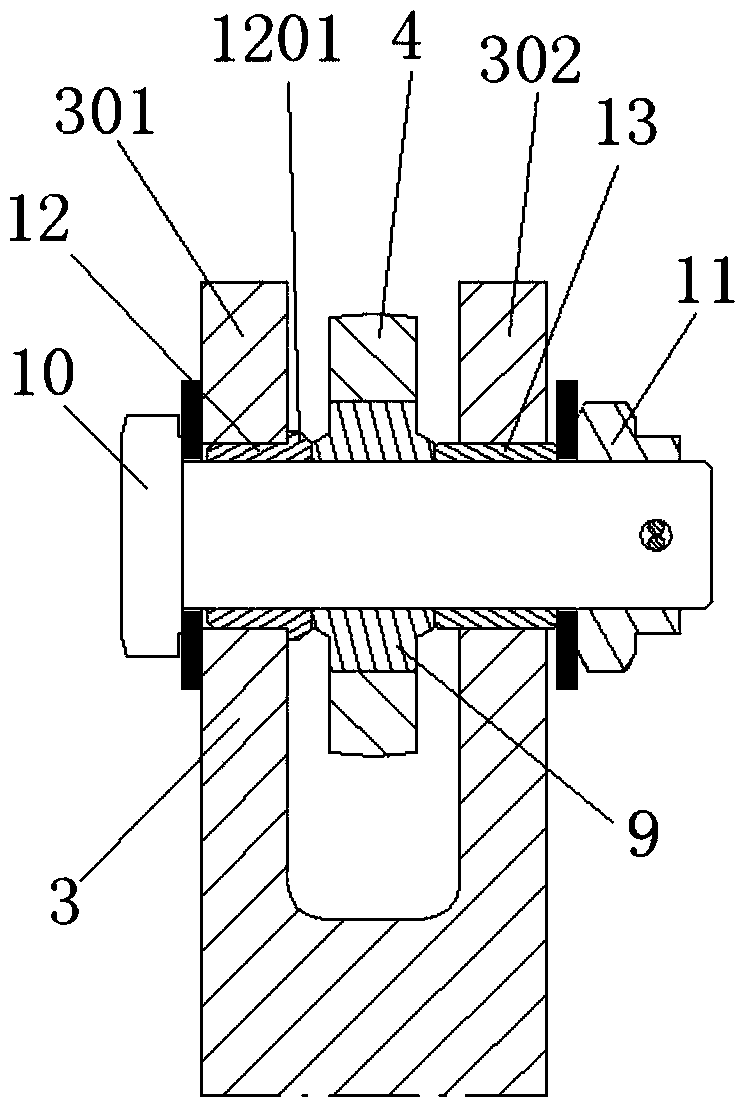

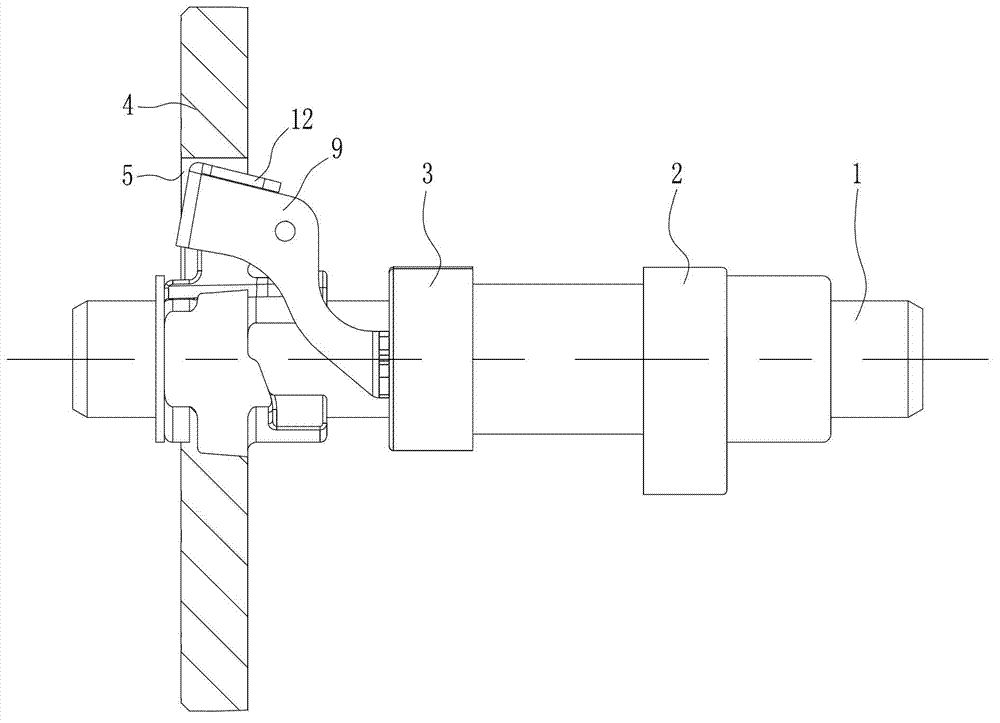

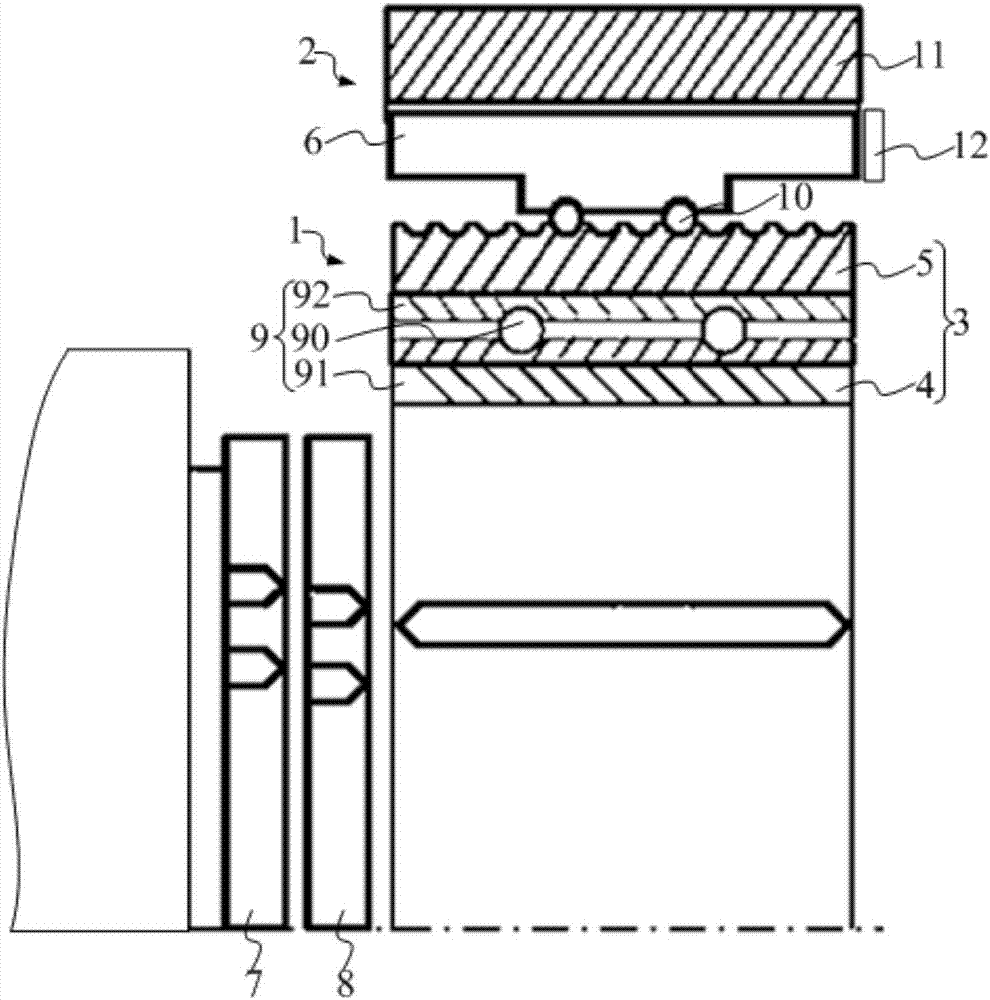

Double-rocker transmission mechanism applicable to movable control surface of aerial vehicle

ActiveCN104290901AHigh movement reliabilityImprove connection stiffnessWithout power ampliicationServo actuatorFlight vehicle

The invention relates to a double-rocker transmission mechanism applicable to a movable control surface of an aerial vehicle. A first hinged joint pair is formed between a rocker and a connecting bar, a second hinged joint pair is formed between the connecting bar and an auxiliary rocker, a third hinged joint pair is formed between the auxiliary rocker and a linear servo actuator, a fourth hinged joint pair is formed between the linear servo actuator and a first base, and a fifth hinged joint pair is formed between the auxiliary rocker and a second base; in each hinged joint pair, the axial movement of a hinge bearing is prevented by the way that a bush 12 and a sleeve 13 arranged on corresponding connecting lugs are in abutted connection with two sides of an inner ring of a hinge bearing 9 on a connector between two connecting lugs. The double-rocker transmission mechanism applicable to a movable control surface of an aerial vehicle provided by the invention can avoid exposure of a driving part of the mechanism to external high-temperature environments, so that the movement reliability of the mechanism is improved.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

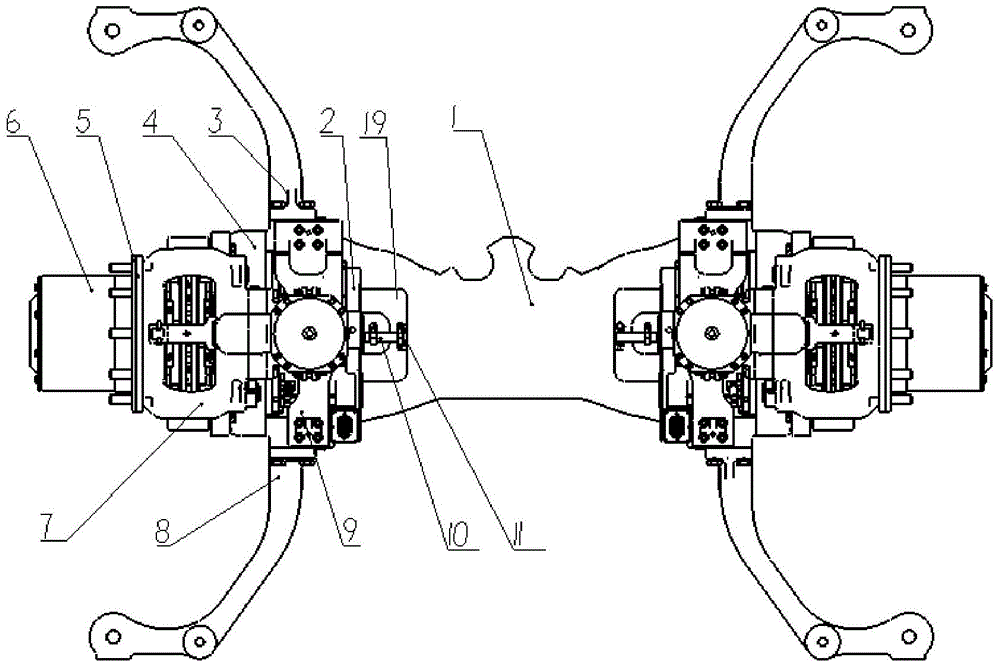

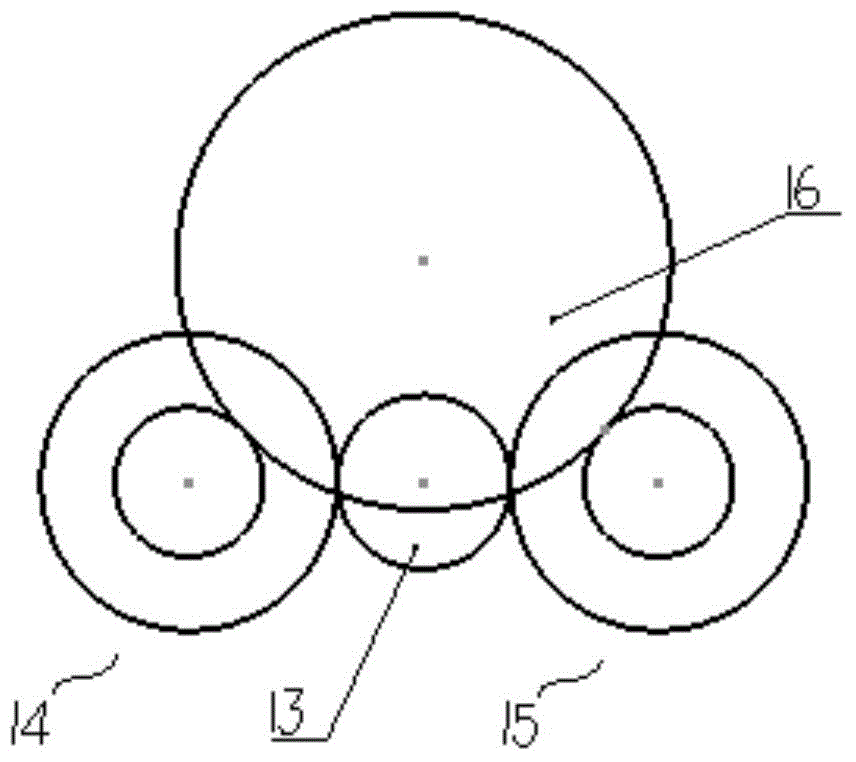

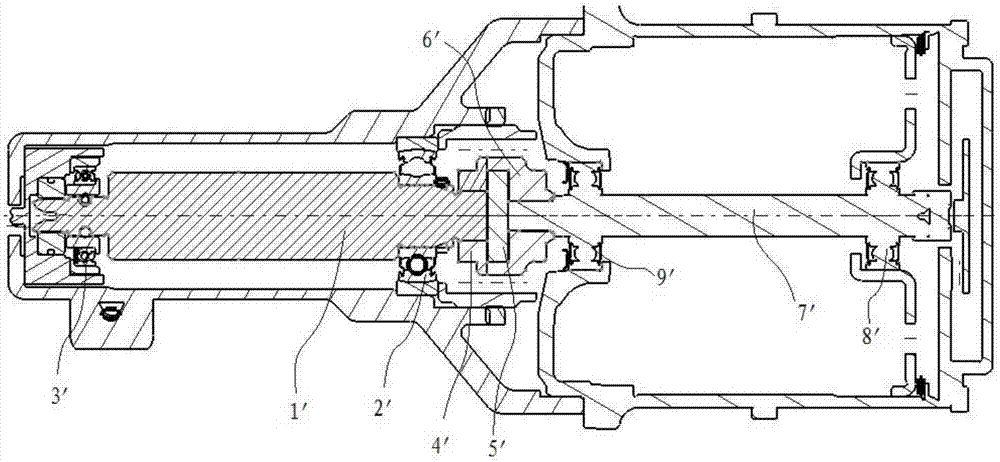

Wheel rim motor driving system and wheel rim motor driving axle

ActiveCN104908579AReduce axial sizeIncrease powerMotor depositionControl devicesMotor driveElectric machine

The invention relates to a wheel rim motor driving system and a wheel rim motor driving axle. The wheel rim motor driving system comprises a driving motor assembly (2) and a main reducer assembly (4), wherein the main reducer assembly (4) comprises a driving gear, at least two intermediate gear shaft assemblies and an output gear (16); each intermediate gear shaft assembly is provided with a driving intermediate gear and a driven intermediate gear that are connected in a jointly rotating manner; a motor output shaft of the driving motor assembly (2) is connected with a driving gear (13); the driving gear (13) is engaged with each driving intermediate gear in each intermediate gear shaft assembly; each driven intermediate gear in each intermediate gear shaft assembly is engaged with the output gear (16); and the driving gear (13) and the output gear (16) are arranged eccentrically. The wheel rim motor driving axle comprises the wheel rim motor driving system. The wheel rim motor driving system and the wheel rim motor driving axle have the advantages of high motor power, large torque and large middle passage width.

Owner:JASMIN INT AUTO RES ANDDEV BEIJING CO LTD

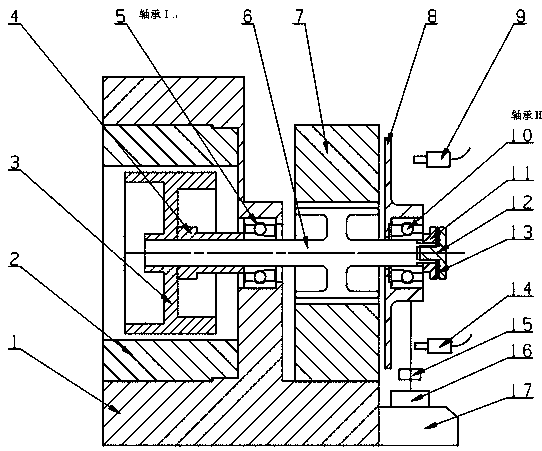

On-line testing device for dynamic friction performance of paired angular contact ball bearings

ActiveCN109959514AOvercoming Disadvantages of InterferenceGuaranteed free rotationMachine bearings testingAir bearingBall bearing

The invention relates to an on-line testing device for the dynamic friction performance of paired angular contact ball bearings. On the basis of the principle of air suspension, the non-contact axialloading of a tested bearing II is obtained while the ultra-low friction support of the high-speed rotating spindle is realized by combining the measurement and adjustment technologies of precision displacement; and the friction torque of the tested bearing II is measured by using a friction torque measuring device put forward by the patent named as "high-speed miniature bearing dynamic friction torque measuring instrument" with the application number of 201610639490.9 in the research group, thereby realizing simultaneous on-line measurement of the friction torque, vibration, temperature and wearing amount of a single precision bearing. Since the outer ring of a partner tested bearing I is fixed on a base, right movement of the shafting is limited and when the shafting is in a static stateand does not work, the shafting, together with non-working faces of the radial-axial air bearing and the thrust disc, bears the shafting torque balancing after careful balance weight, thereby protecting the non-working surface of the high-precision radial-axial air bearing from being in contact for long time and being damaged.

Owner:SHANGHAI UNIV +1

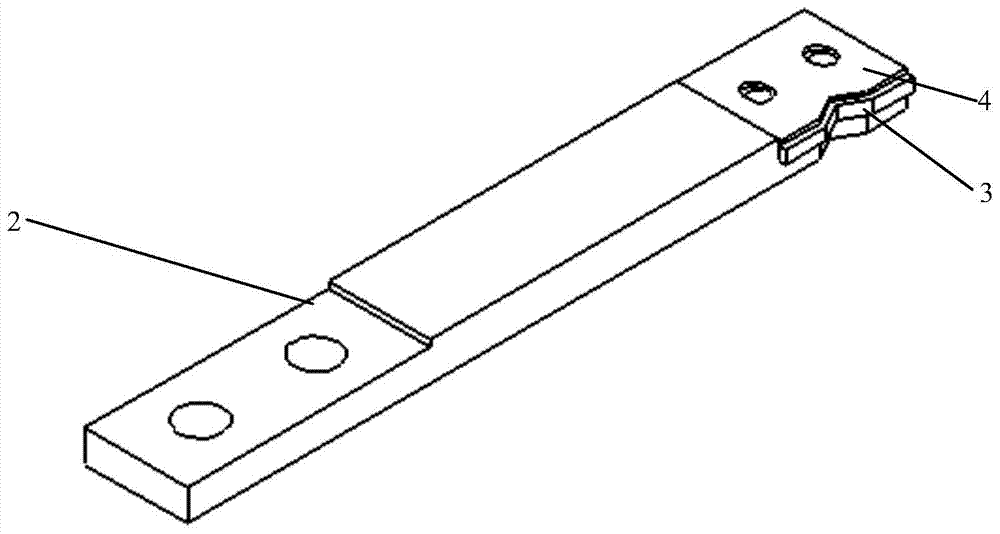

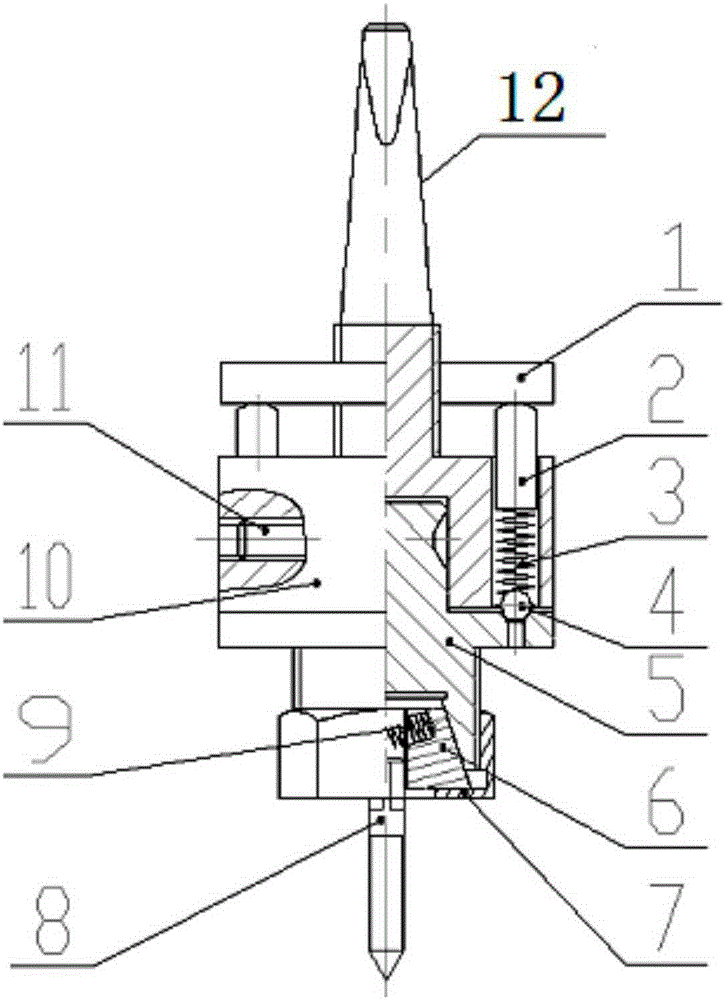

Clamping head of blanking machine

InactiveCN101362217AGuaranteed Dimensional ConsistencyNovel structureAutomatic conveying/guiding stockChucksElastic componentEngineering

The invention discloses a chuck of a blanking machine, and the structure of the chuck consists of a spring chuck, a movable component, and a clamping sleeve; taper is arranged at the outer side of the left end of the spring chuck and is provided with an external locking sleeve which is installed on a main axle; a clamping sleeve carrier is arranged at the inner side of the spring chuck; one end of the clamping sleeve carrier extends out of the spring chuck; a plurality of rolling chutes are arranged on the clamping sleeve carrier; an elastic component and the movable component are movably arranged in the rolling chute; the clamping sleeve is arranged at the inner side of the movable component; by the arrangement of the movable component, axial play produced by the fraction force of the chuck can be transformed into the rolling force of a rolling component; that is, the clamping sleeve only receives compaction force transmitted by the rolling component; the compaction force clamps the workpiece, without producing the axial play, thus guaranteeing the consistency of the size of cutting workpiece.

Owner:钟树平

Trimming and burr clearing device for orifice

The invention discloses a trimming and burr clearing device for an orifice. The trimming and burr clearing device comprises a handle, a rocker arm, a connecting rod, a spindle, a chamfering countersink and a casing. The casing is of a hollow structure, and the spindle is arranged in the casing. One end of the spindle extends out of the casing and is connected with the connecting rod in a transmission mode, and the other end of the spindle extends out of the casing and is connected with the chamfering countersink in a detachable mode. A first through hole is formed in one end of the connecting rod, the spindle penetrates the first through hole and is connected with the connecting rod through a first nut, and the connecting rod can drive the spindle to rotate. A second through hole is formed in the other end of the connecting rod, and one end of the rocker arm penetrates the second through hole and is fixedly connected with the connecting rod through a second nut. The other end of the rocker arm is connected with the handle. The trimming and burr clearing device for the orifice has fewer parts, is simple in structure, small in weight and light in hand holding and can achieve trimming and burr clearing of a screw hole in a deep long shaft hole easily by lengthening the countersink.

Owner:慈溪汇丽机电股份有限公司

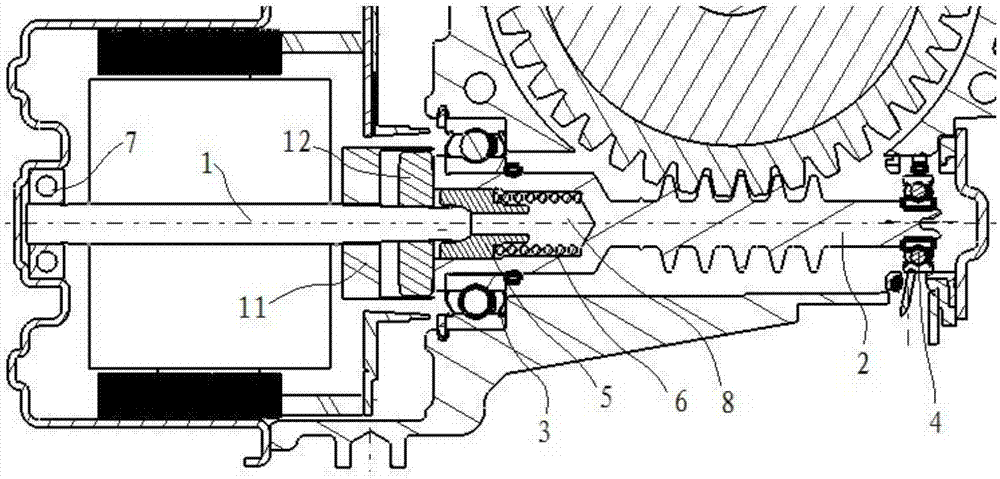

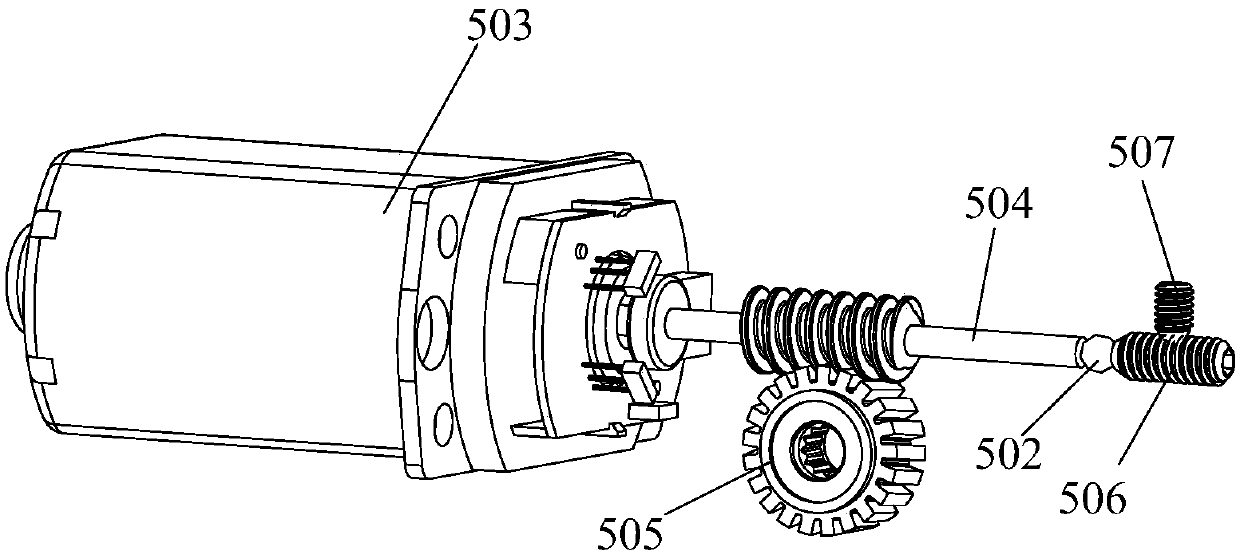

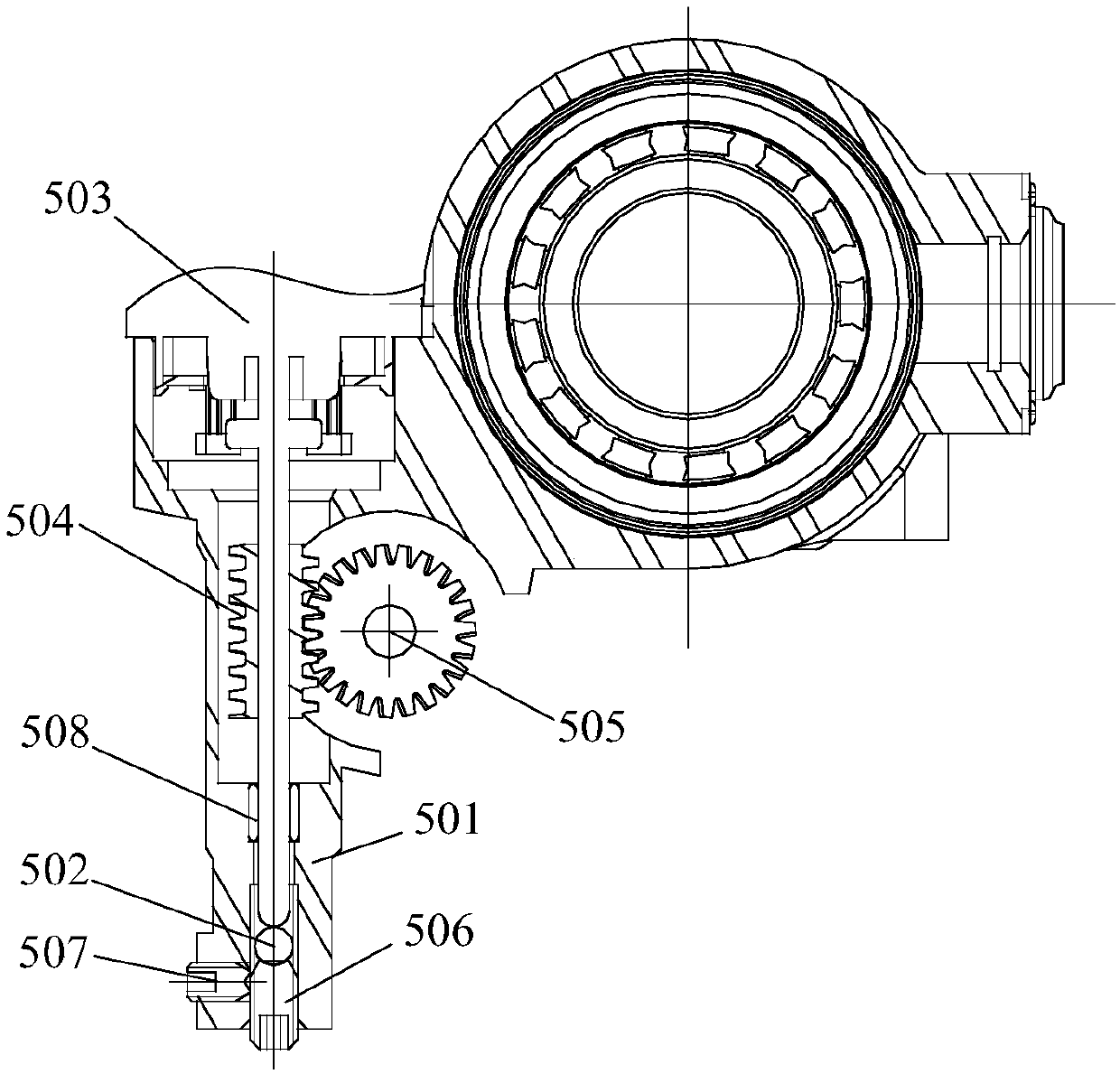

Steering power-assisted motor

InactiveCN107253492AEliminate axial playNo axial playElectrical steeringMechanical energy handlingControl theory

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

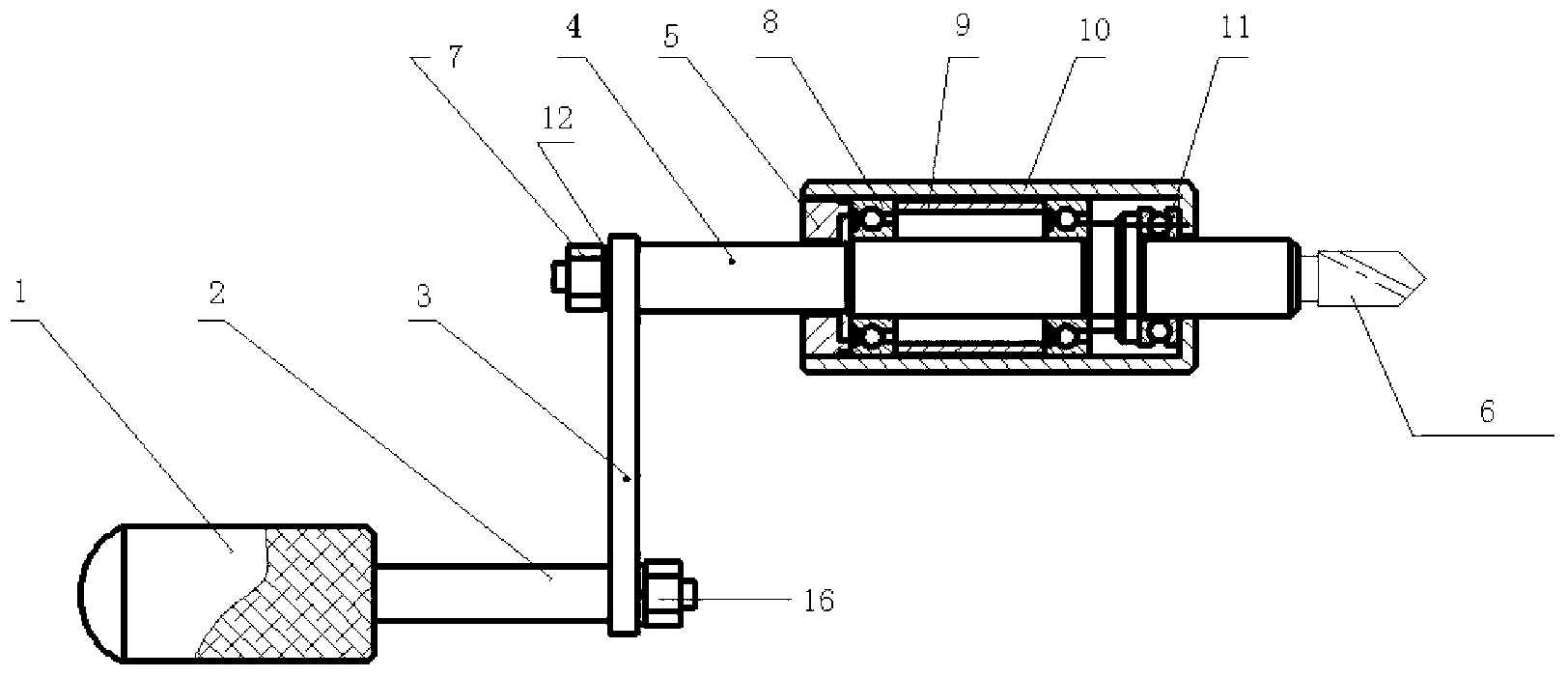

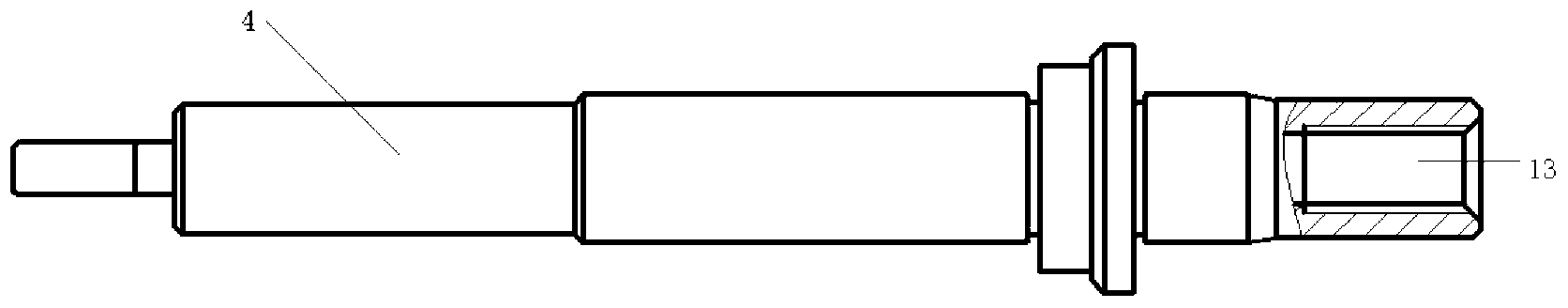

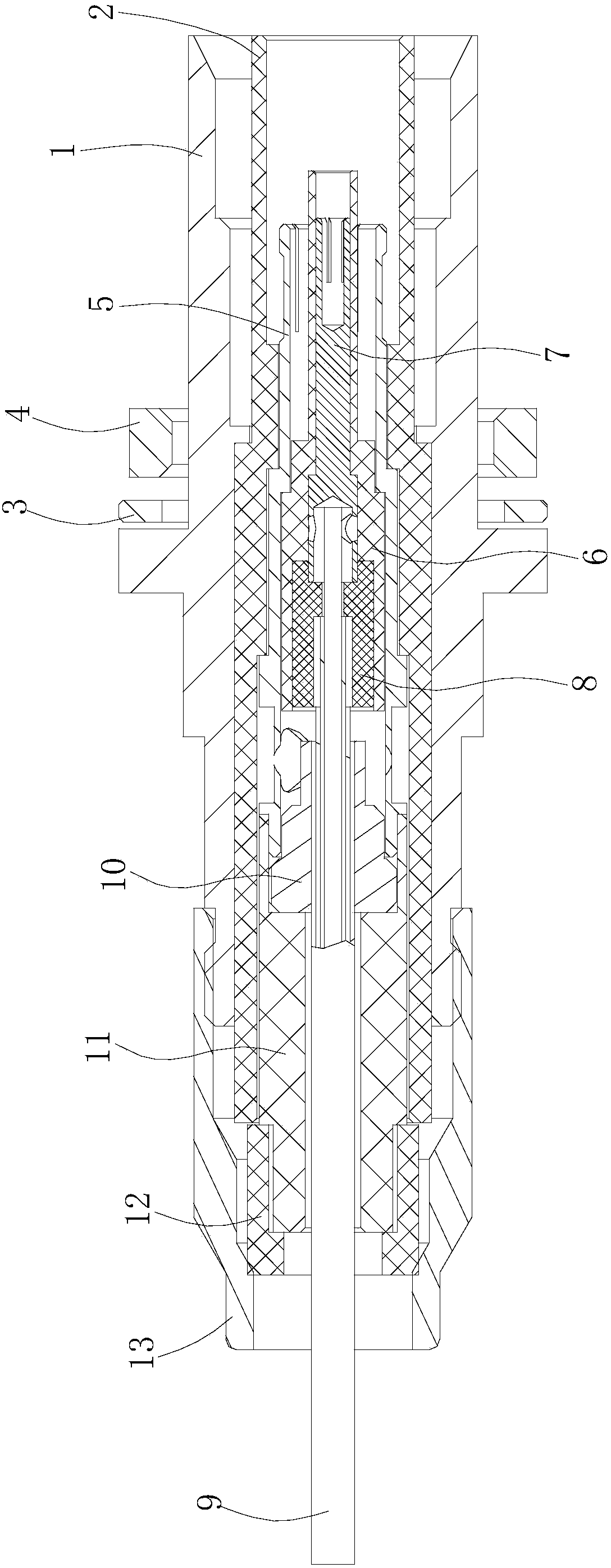

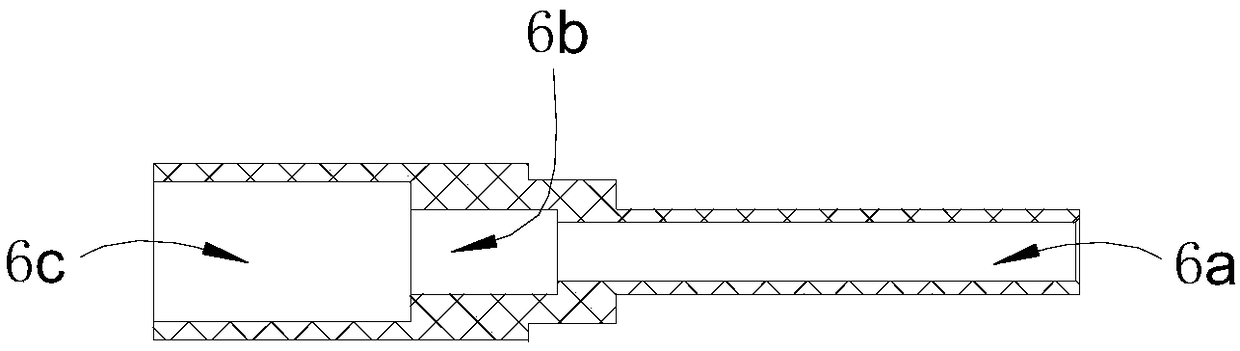

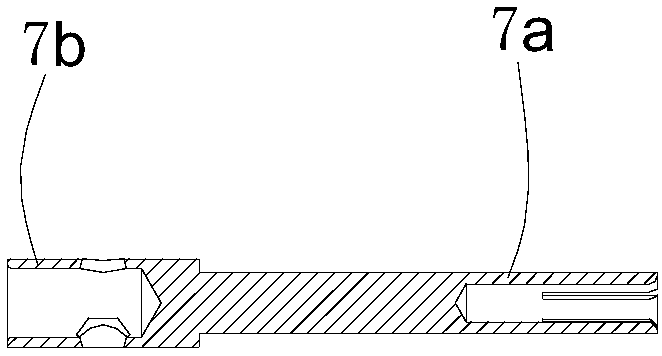

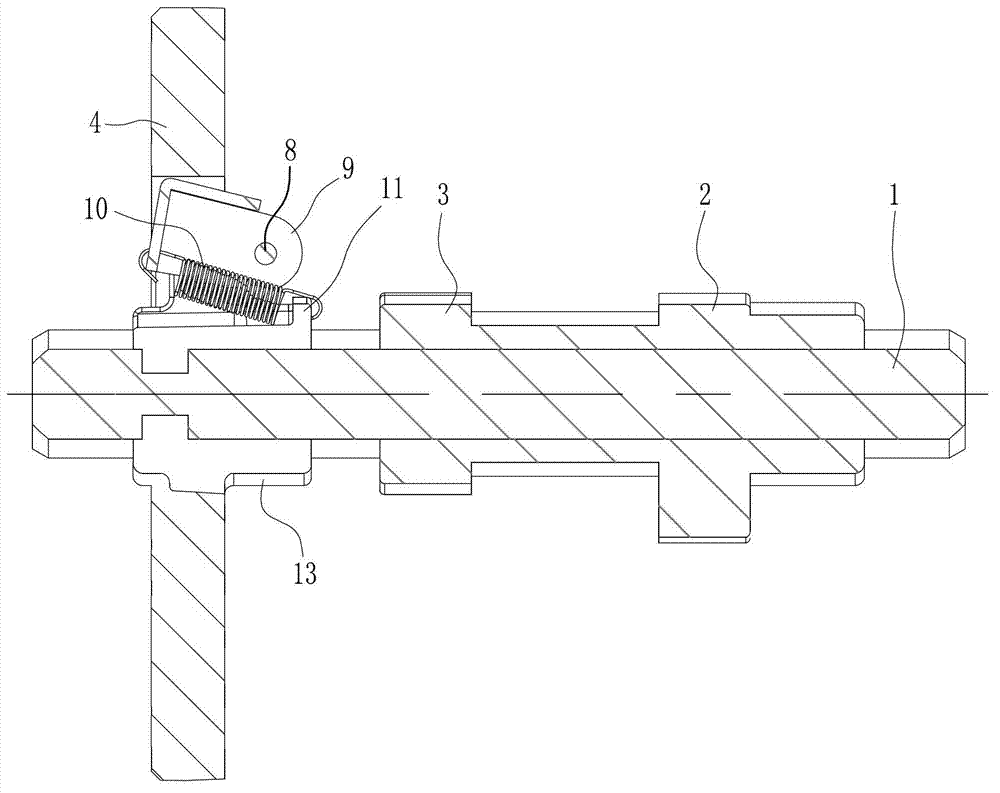

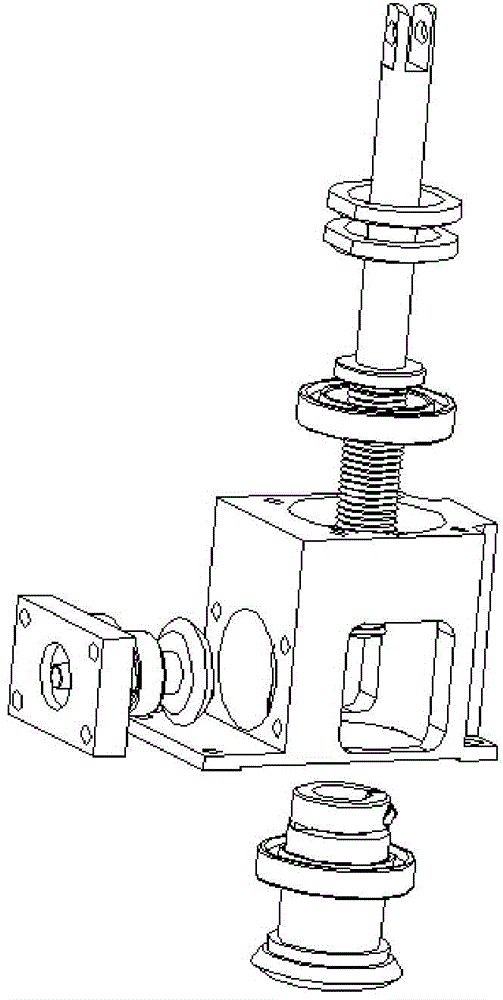

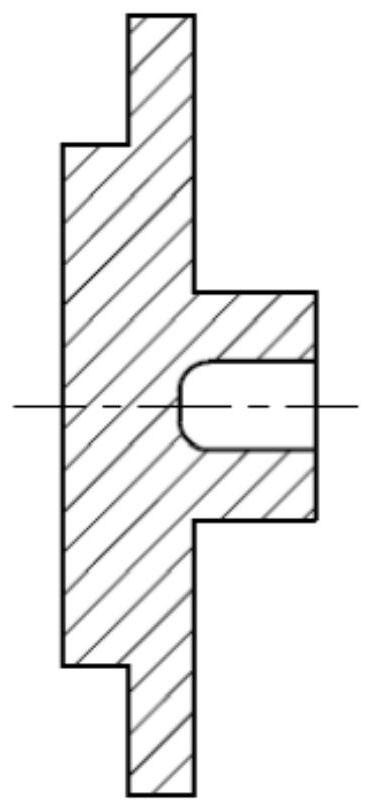

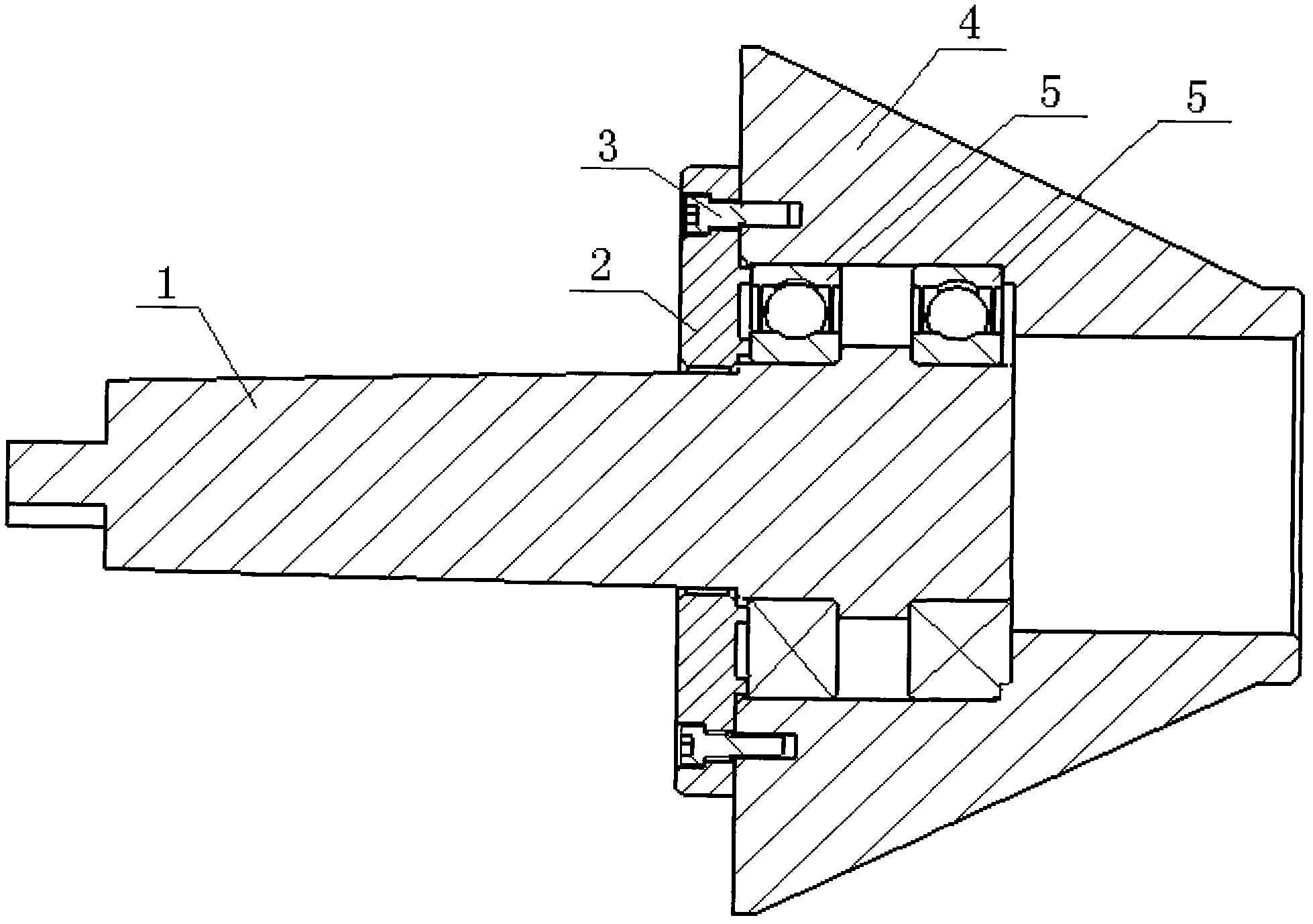

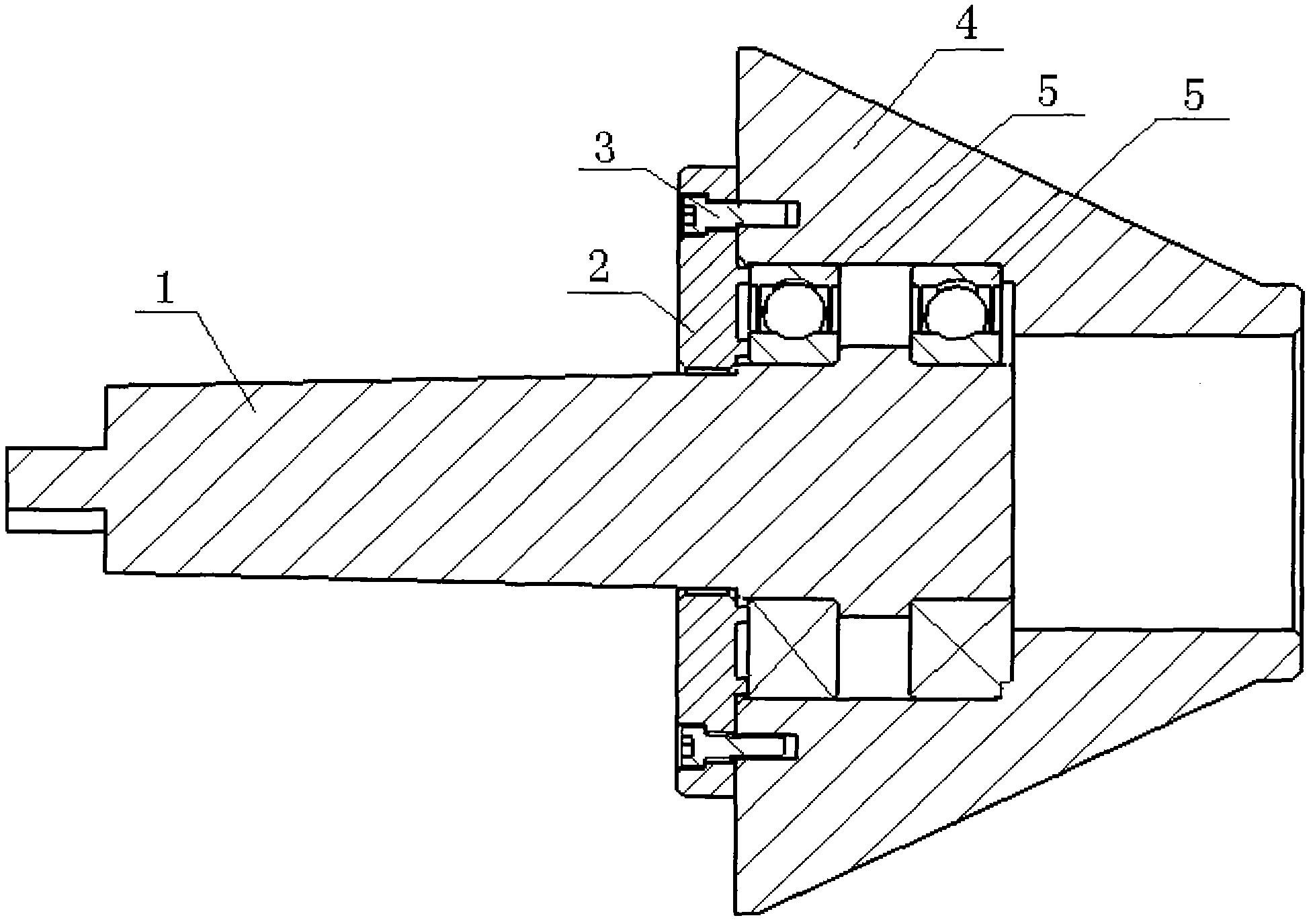

Conveniently mounted and adjusted high-precision ball screw supporting structure

The invention discloses a conveniently mounted and adjusted high-precision ball screw supporting structure which comprises a rear support (1), wherein a ball screw (4) is fixed on the rear support (1) through a rear locking nut (2) and a rear bearing (3); the front end of the ball screw (4) is fixed on a front support (7) through a front locking nut (5) and a front bearing (6); the structure is characterized in that: an external thread is arranged on one side of the ball screw (4) close to the front bearing (6); a locking nut (8) is in threaded connection with the external thread; a spacing sleeve (9) is sleeved between the front support (7) and the ball screw (4); and one end of the spacing sleeve (9) is butted against the front bearing (6) while the other end is butted against the locking nut (8). The ball screw supporting structure has the advantages of simple structure, smart design, convenience and quickness in mounting and adjusting, and capability of ensuring mounting precision.

Owner:通用技术集团大连机床有限责任公司

Clamping finger for clamping shaft part

The invention relates to a clamping finger for clamping a shaft part. The clamped rear end face of the shaft part can be made to be tightly attached to a positioning end face, and it is guaranteed that positioning is reliable. According to the clamping finger, a pneumatic claw is controlled by a pneumatic valve to be opened and closed through compression air, one end a clamping finger rod is fixedly installed on the pneumatic claw through a screw, and a V-shaped groove is machined in the other end of the clamping finger rod; a rubber gasket and a fixed thin sheet are respectively fixed above the V-shaped groove; a V-shaped groove is formed in the rubber gasket in a cutting mode, and when the rubber gasket is fixed to the clamping ringer rod, the rubber gasket is exposed out of the V-shaped groove; when the clamping finger is adopted for clamping the shaft part, because of stressed deformation of the rubber gasket, the fixed thin sheet can be pressed to deform; due to deformation, the shaft part is pushed upwards, the end face of the shaft part is made to be tightly attached to the positioning end face, and the end face positioning purpose is achieved.

Owner:DALIAN UNIV OF TECH

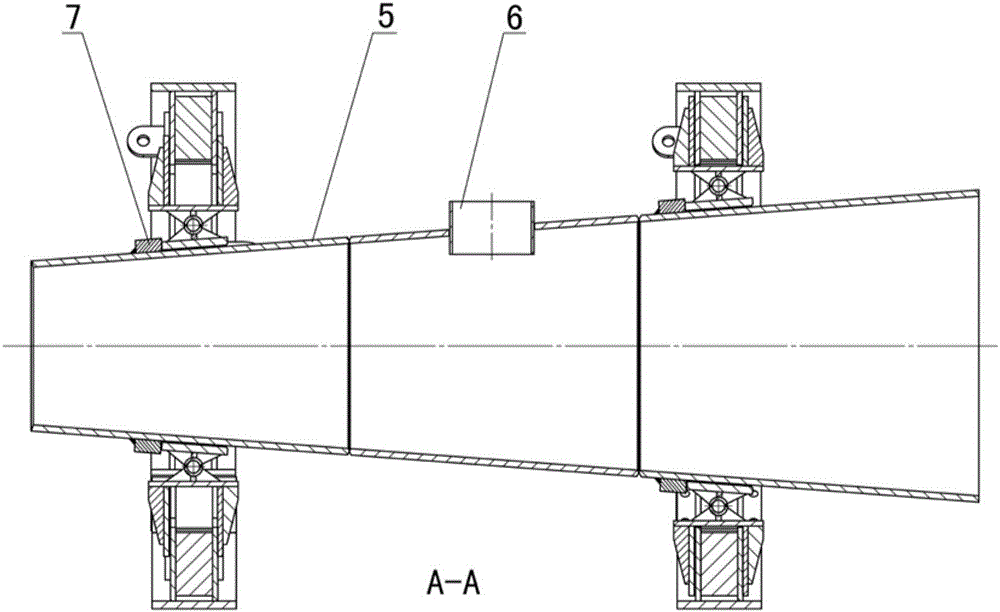

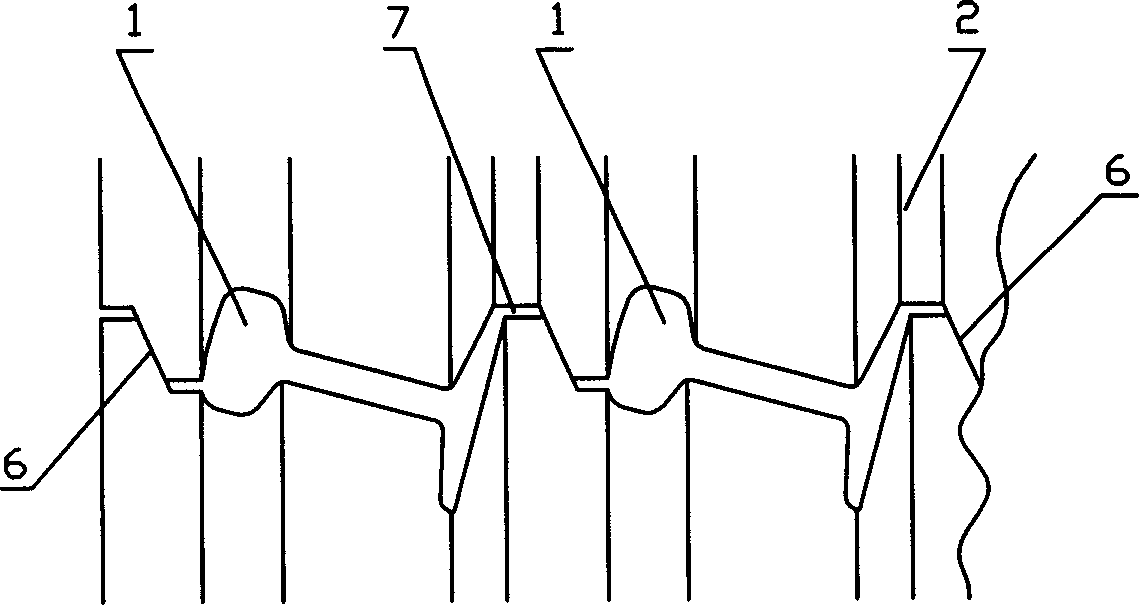

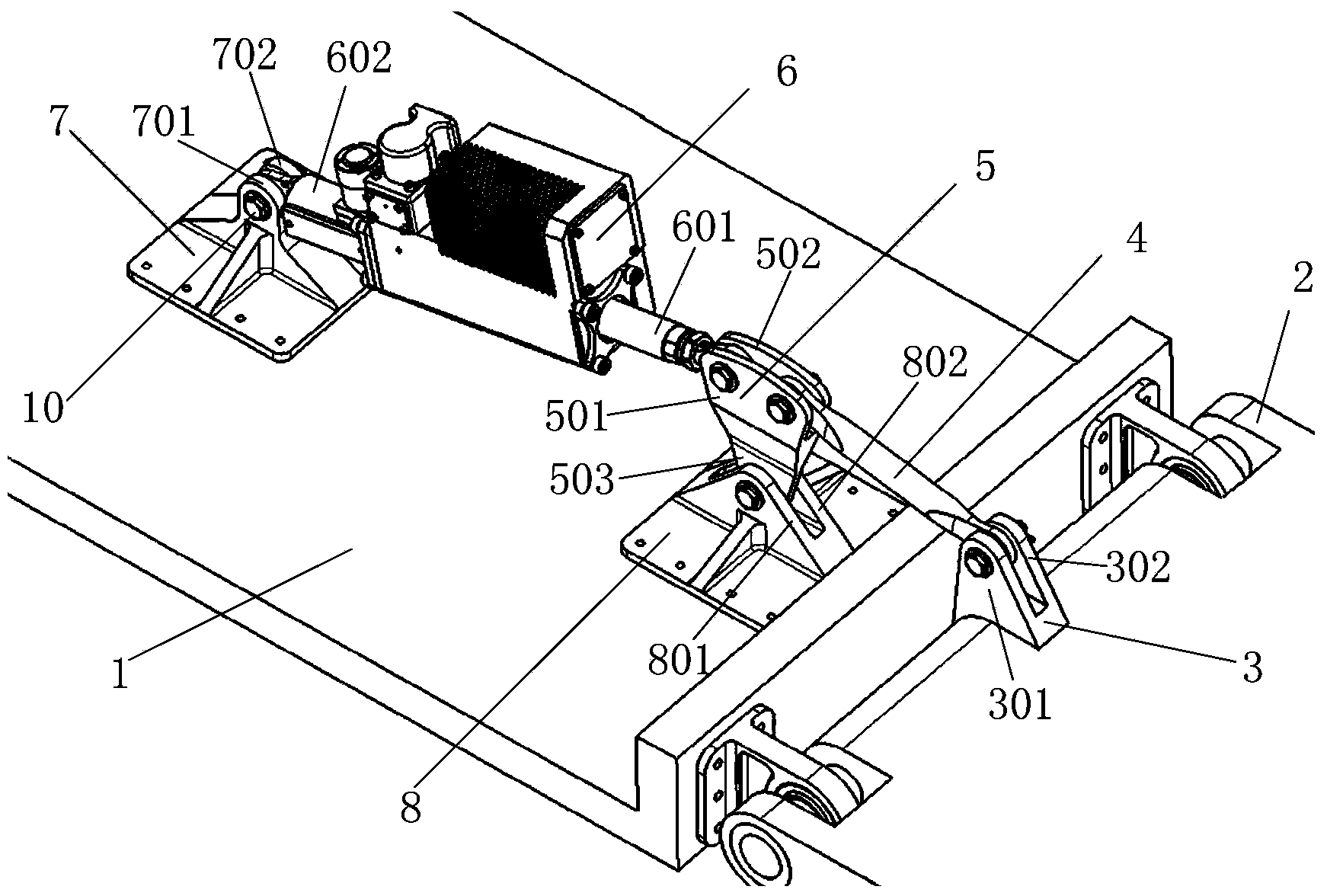

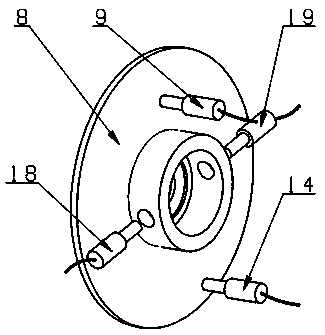

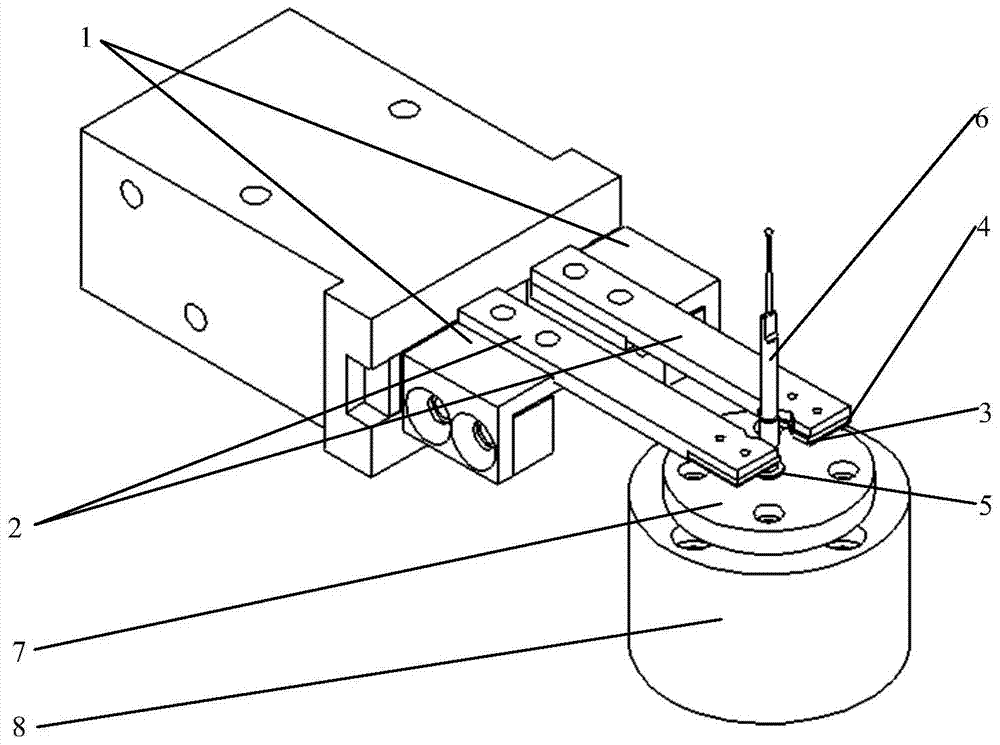

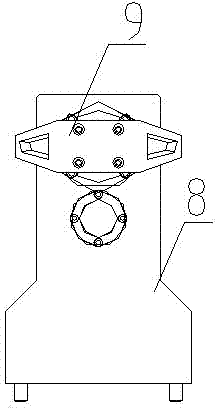

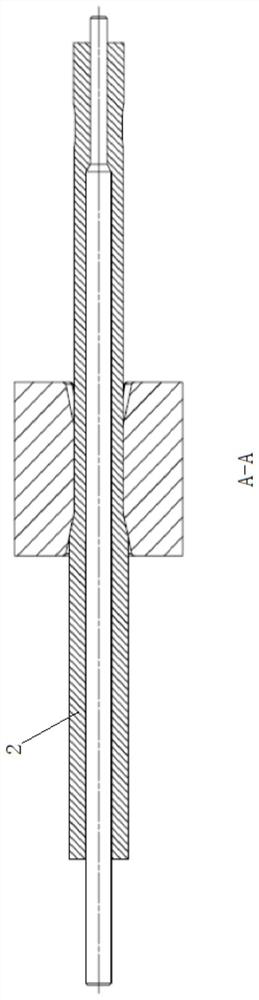

Axial play positioning device of bi-metal composite wear resisting pipe during centrifugal casting

The invention discloses an axial play positioning device of a bi-metal composite wear resisting pipe during centrifugal casting. The device comprises two parts of a front end positioning wheel and a back end thrust positioning wheel; the front end positioning wheel and the back end thrust positioning wheel are respectively mounted on the outer sides of pipe end blockage plates at two ends of a carbon steel outer pipe for axial positioning; rolling bearings are adopted as the front end positioning wheel and the back end thrust positioning wheel, so that the carbon steel outer pipe can axially adjust the length, and the carbon steel outer pipes with different diameters can be adapted to in the vertical direction; and because of elastic support of a spring, the back end thrust positioning wheel is always located in an axial play contact state in the casting period, the combined surfaces are stable in contact without generating axial movement and vibration, the positioning is reliable, and the defects in the prior art can be effectively solved.

Owner:ANSHAN TAIYUAN IND

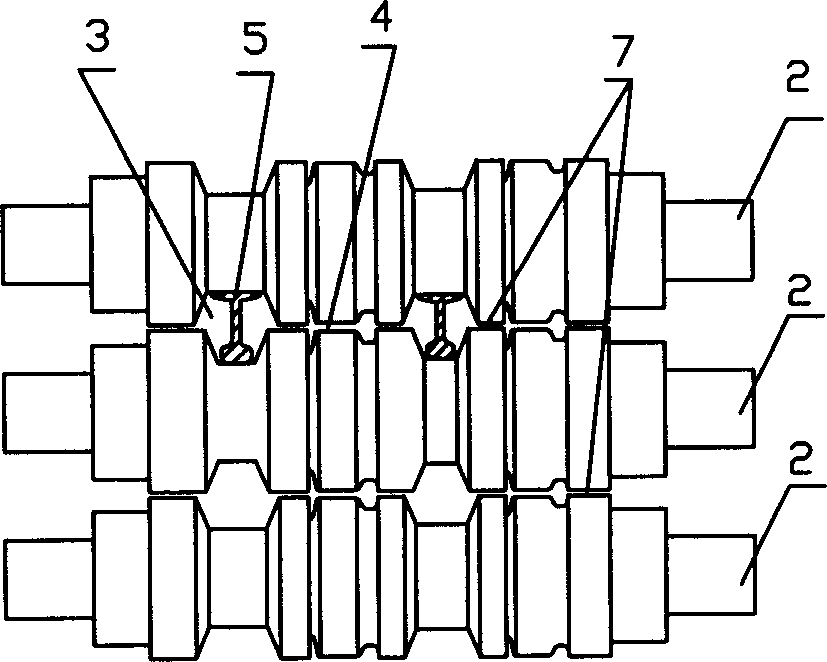

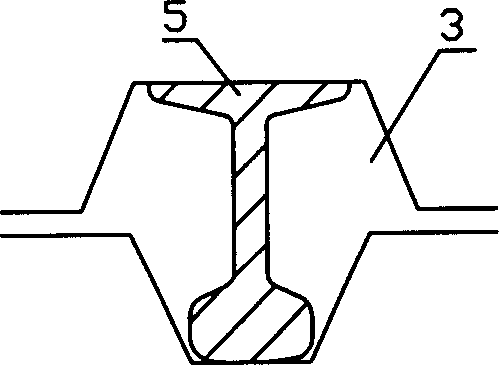

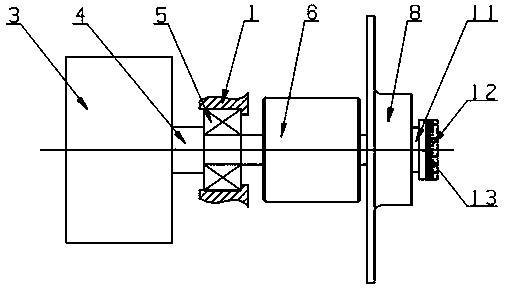

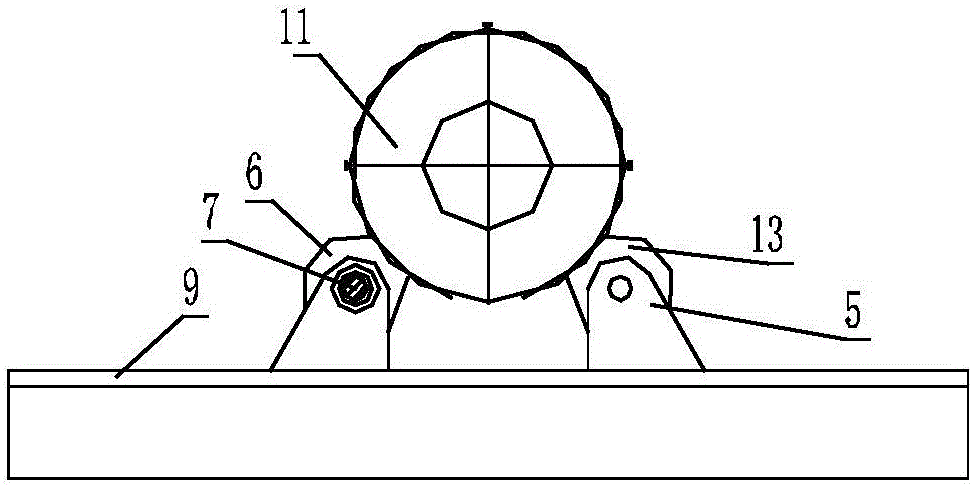

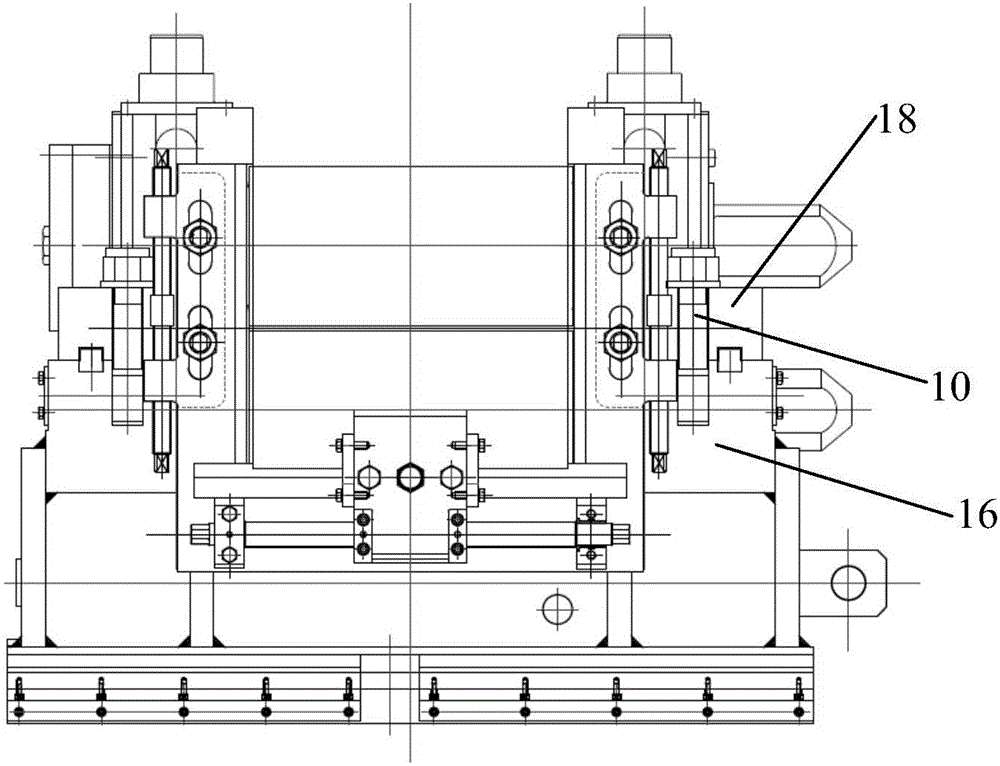

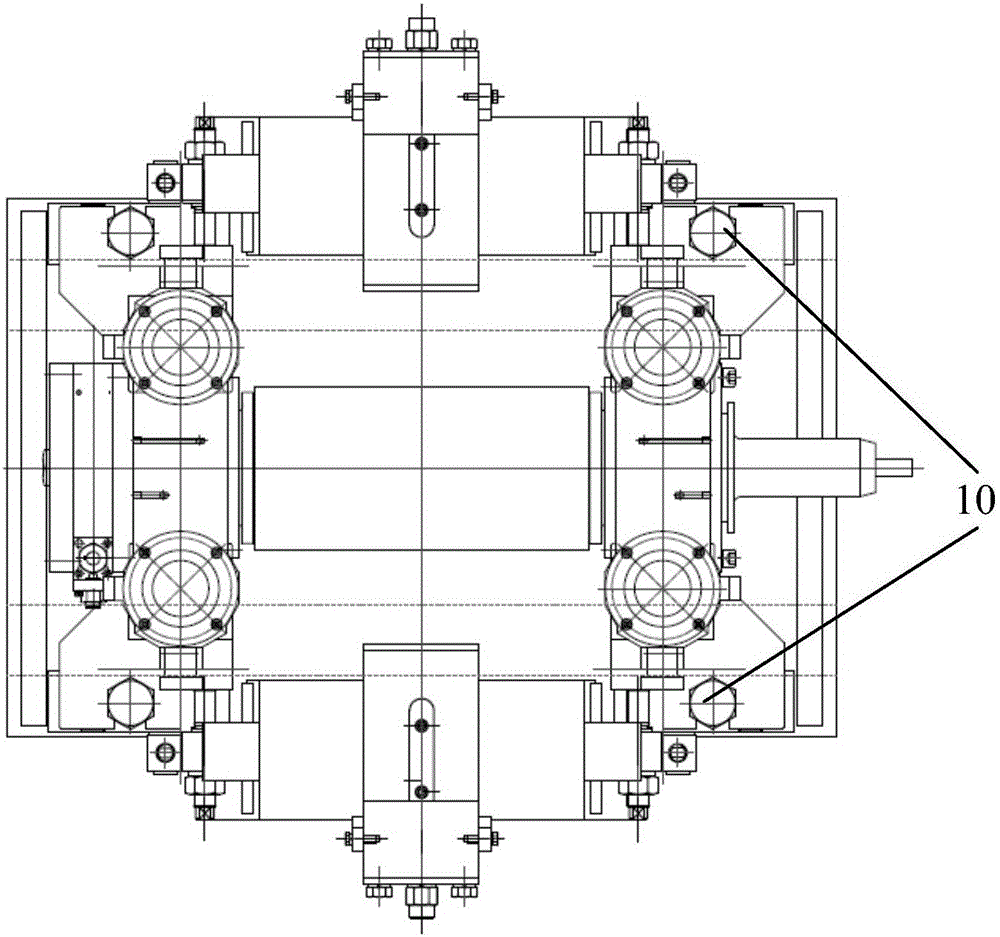

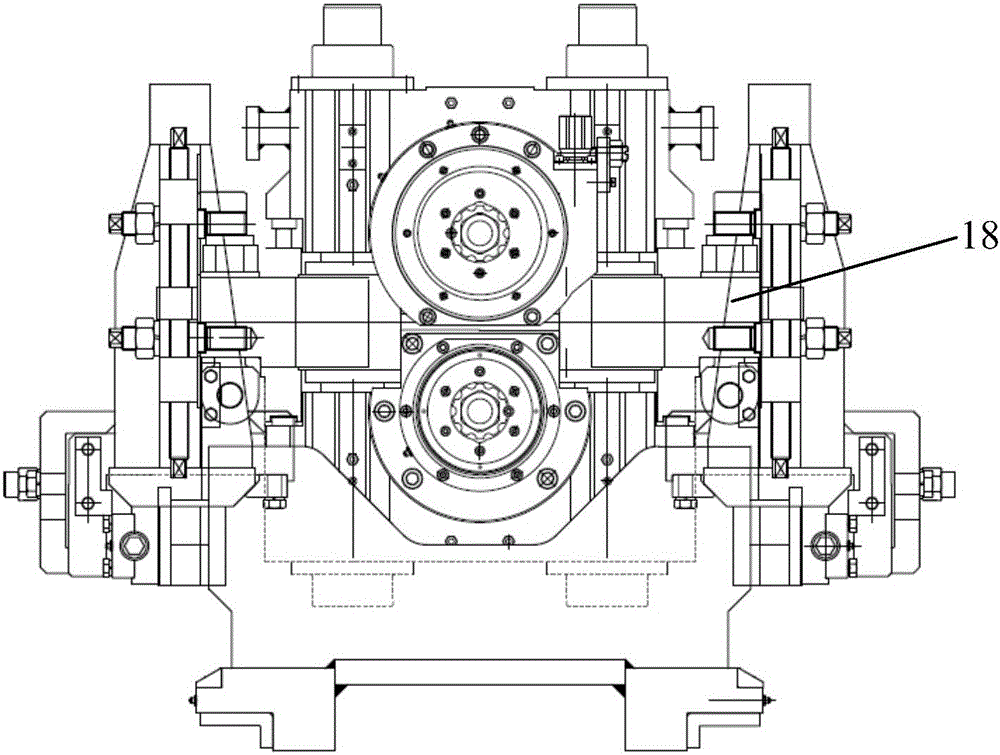

High-precision bar rolling mill

ActiveCN106180204ACompact structureEasy to disassembleMetal rolling stand detailsMetal rolling arrangementsSocial benefitsAxial displacement

The invention provides a high-precision bar rolling mill. The high-precision bar rolling mill comprises a base and a roller system. The roller system and the base are mounted and fixed through a roller system support. A conical hole and four grooves are formed in each stand column of the base of the rolling mill. Adjusting liner plates are arranged in the grooves. Vertical boss structures matched with the four grooves in each stand column of the base of the rolling mill are arranged on the four sides of the roller system support. An assembly gap between the roller system support and the stand columns of the base can be adjusted by tightly pressing screws through the adjusting liner plates. Semi-conical holes are formed in the middles of bosses of the roller system support and matched with the conical holes in the stand columns of the base of the rolling mill. The roller system support and the base of the rolling mill are locked through conical drift bolts. The high-precision bar rolling mill is compact in structure, easy to dismount and mount, high in rigidity, small in bounce value and free of axial displacement; round bar products rolled through the high-precision bar rolling mill are high in section size precision, small in ovality and especially suitable for production of bars; and domestication and batch manufacturing of the high-precision bar rolling mill can completely replace an import mode, and great economic and social benefits are achieved.

Owner:JIANGSU XIHU SPECIAL STEEL

Single-core triaxial high-voltage plug connector

PendingCN108233124AImprove reliabilityImprove insulation performanceSecuring/insulating coupling contact membersTwo-part coupling devicesElectrical conductorEngineering

The invention discloses a single-core triaxial high-voltage plug connector. A mounting sleeve is sleeved in an inner hole of a plug shell; a gap is reserved between the front-end outer wall of the mounting sleeve and the front-part inner wall of the plug shell; the rear end of the mounting sleeve extends out of the rear side of the plug shell; an inner conductor is sleeved in an inner hole of themounting sleeve; the front end of the inner conductor extends to the front part of the inner hole of the mounting sleeve; a gap is reserved between the front-end outer wall of the inner conductor andthe front-part inner wall of the mounting sleeve; a second insulating sleeve is sleeved in an inner hole of the inner conductor; the front end of the second insulating sleeve extends out of the frontside of the inner hole of the inner conductor; a mounting hole is formed in the second insulating sleeve; a jack piece is mounted at the front part of the mounting hole; a high-temperature wire extends into the mounting hole from the rear side of the mounting hole; a core wire of the high-temperature wire is connected with the jack piece; and the first insulating sleeve is sleeved between the rear-part inner wall of the mounting hole and the high-temperature wire. The single-core triaxial high-voltage plug connector disclosed by the invention has the following beneficial effects: the insulating performance is good, the equipment space and cost can be remarkably saved, and the reliability of a farming system is greatly improved.

Owner:中国电子科技集团公司第四十研究所

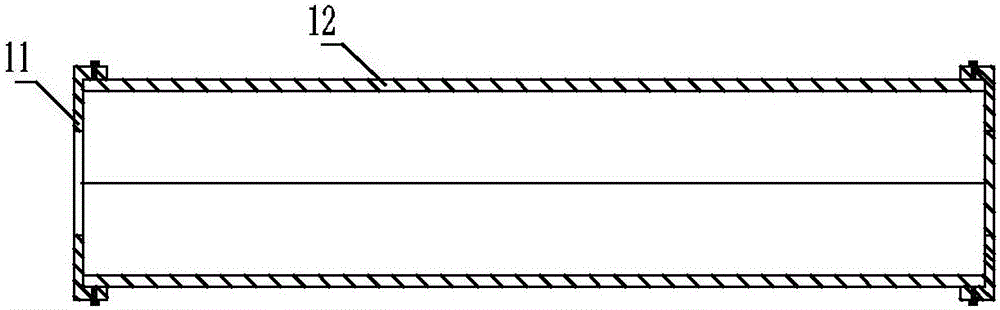

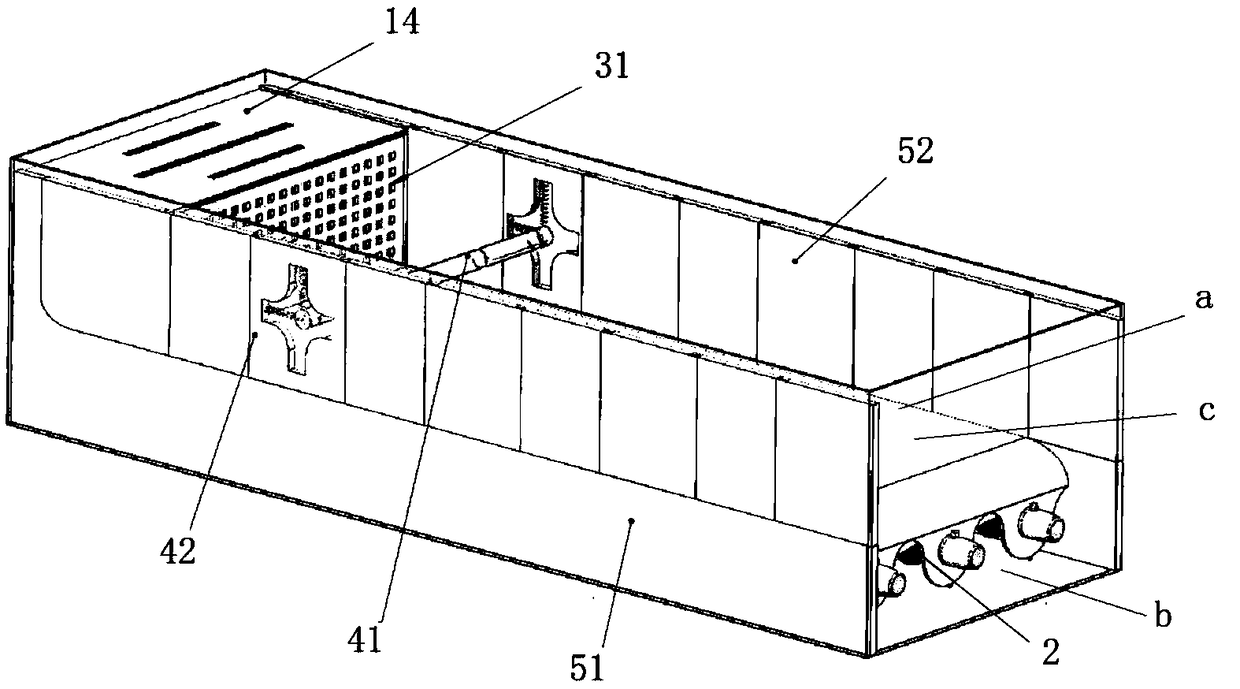

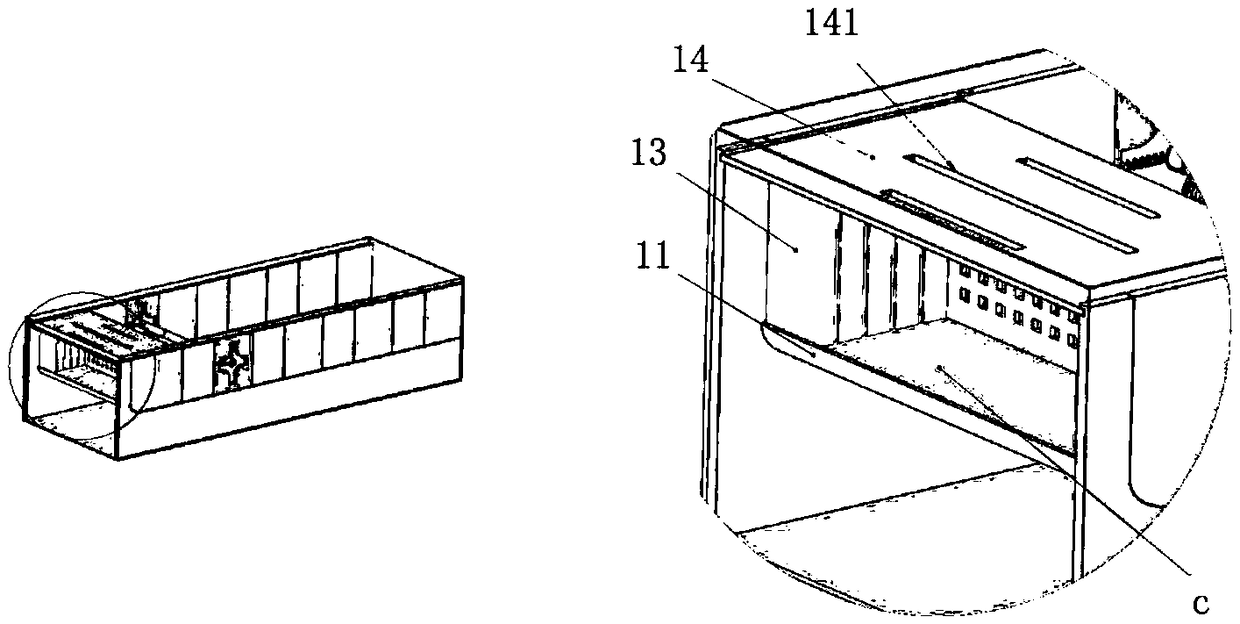

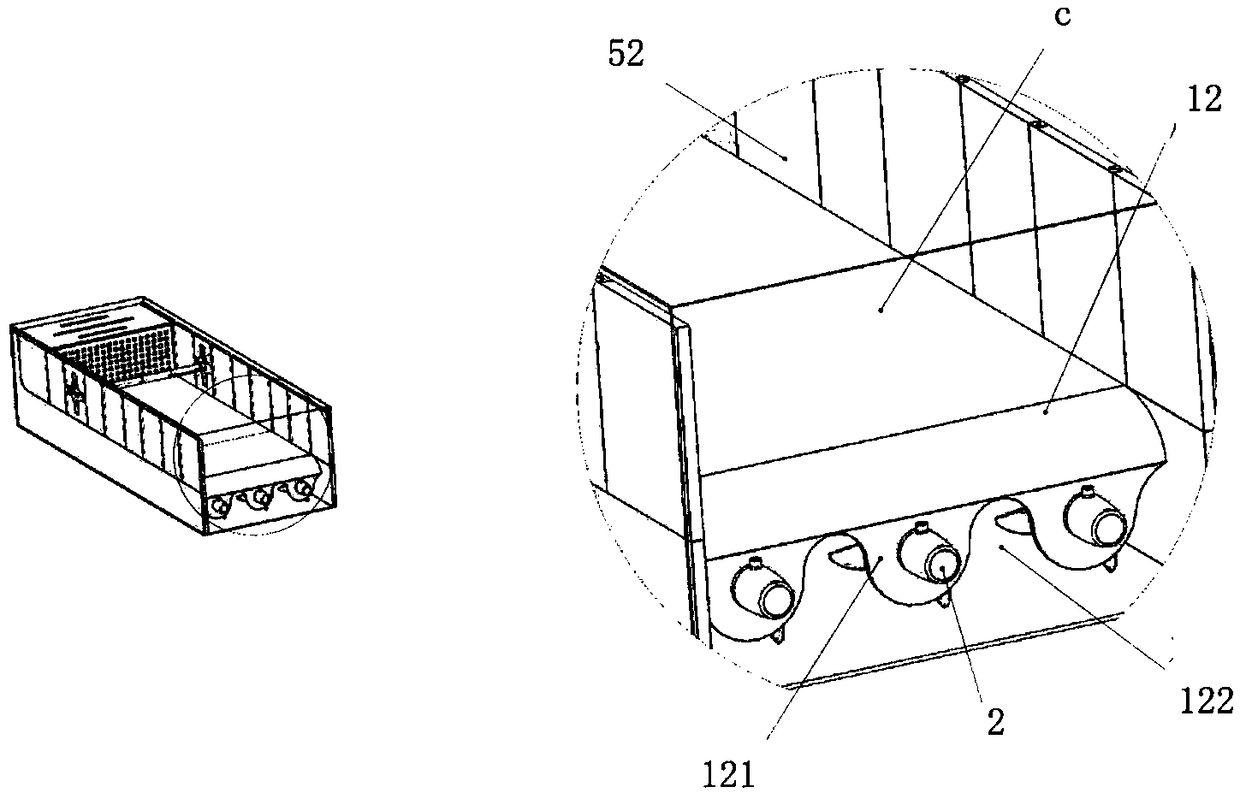

Test water tank for vortex-induced vibration test of suspended spanning pipeline

The invention discloses a test water tank for a vortex-induced vibration test of a suspended spanning pipeline. The test water tank is a cuboid with an opening formed in the upper end surface, and isdivided into a test section and a drainage section by means of a water flow partition plate. The test water tank is provide with a flow direction diversion device, a power adjustable device, a stablewater flow device, a suspended spanning pipeline suspending device, a position adjusting device and a data acquisition device. In the test water tank disclosed by the invention, an upper flow straightener can be moved equidistantly, a flat flow plate is installed in a slot manner, the slot can achieve the anti-collision effect, a thin and long hole is formed to achieve a buffering effect, the disassembly and assembly test is facilitated, the structural installation is reasonable, the suspended spanning pipeline has multiple pipe diameters for the tests of different pipe diameters, lateral andforward springs are convenient for installation and disassembly, a cylindrical suspension plate and a splicing plate are movable and replaceable, tests of water flows in different flow directions canbe conducted, and the test water tank is simple and compact in structure.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

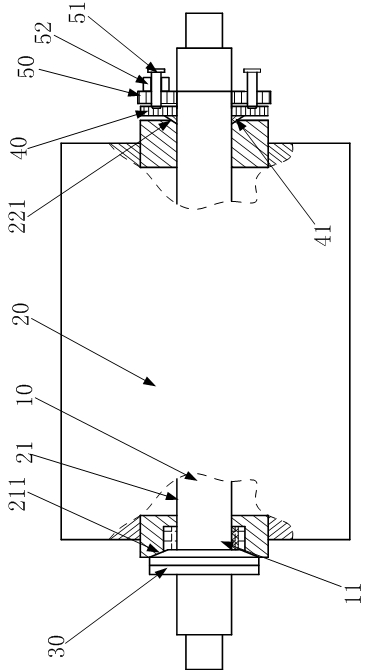

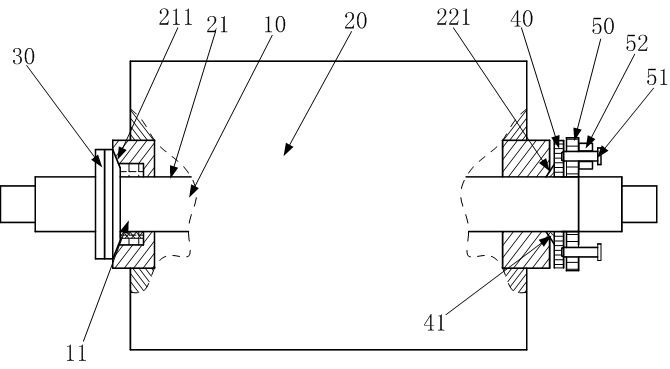

Fixing mechanism for brush roller of circuit board grinding machine

ActiveCN102581724AAvoid influenceGuaranteed uptimeGrinding machine componentsGrinding machinesDrive shaftEngineering

A fixing mechanism for a brush roller of a circuit board grinding machine comprises a transmission shaft (10) and a brush roller (20) sleeved on the transmission shaft (10). A positioning conical disk (30) is disposed at a positioning end (11) of the transmission shaft (10), and a first conical hole (211) matching with the positioning conical disk (20) in taper is disposed at a positioning end of a center hole (21) of the brush roller (20). The fixing mechanism further comprises a moving pressure disk (40) and a nut pressure disk (50), wherein the moving pressure disk (40) is movably sleeved to a fixed end (12) of the transmission shaft (10), the nut pressure disk (50) is in threaded connection with the fixed end (12) of the transmission shaft (10), and the nut pressure plate (5) jacks the moving pressure disk (4) to press the brush roller (20). According to the technical scheme, impact of opposite force of the brush roller upon the fixing mechanism is avoided, the brush roller is stable in operation without jumping and axial play, and quality of a ground board is guaranteed.

Owner:博罗县精汇电子科技有限公司

Small size single stage single water suction ring vacuum pump

InactiveCN1904379ASmall footprintSave ground areaPump componentsRadial flow pumpsImpellerSingle stage

The invention relates to a small single-stage water-ring vacuum pump, which includes a pump cover, a pump body, an impeller, a mechanical seal, a bearing support and a motor member. One end of the bearing support is firm-jointed with the motor by a bolt and the other end of the bearing support is firm-jointed with the pump body by a bolt. On the bearing support is mounted a bearing, which is sleeved on the mainshaft of the motor. The impeller and the mechanical seal in the pump body are direct mounted on the mainshaft of the motor.

Owner:SHANGHAI KAIQUAN PUMP IND GROUP

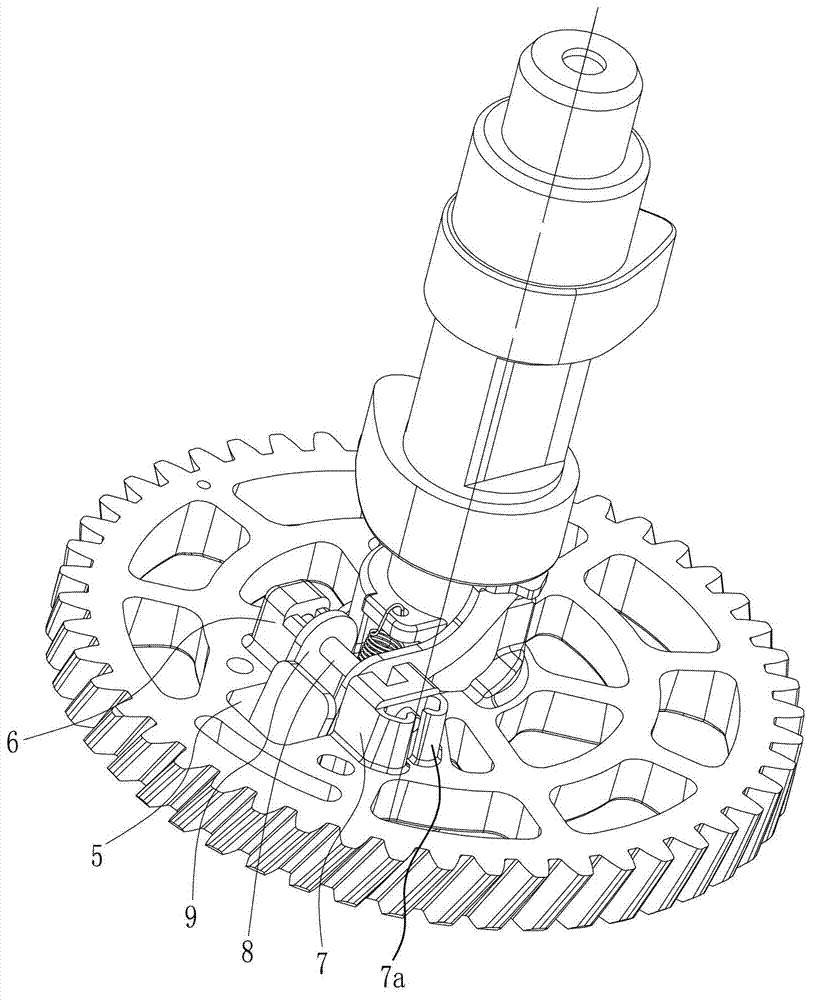

Engine starting cam shaft assembly

ActiveCN102777228ALow costGood torque stabilityValve arrangementsMachines/enginesBatch productionCam

The invention discloses an engine starting cam shaft assembly. A first pin base (6) and a second pin shaft (7) are arranged on the end face of a driving gear (4); a centrifugal flyweight (9) is hinged between the first pin base (6) and the second pin base (7) through a pin shaft (8); the pin shaft (8) is a steel straight round pin; a resetting tension spring (10) is arranged between the pin shaft (8) and a cam shaft (1); and one end of the resetting tension spring (10) is connected with the centrifugal end of the centrifugal flyweight (9), and the other end of the resetting tension spring (10) is connected with a hole base (11) arranged on the driving gear (4). The engine starting cam shaft assembly provided by the invention has the advantages of simple and compact structure, less parts, and convenience and rapidness of assembly. Not only can space and materials be saved, but also the controllability in batch production is good; and the operation reliability can be effectively improved. According to the engine starting cam shaft assembly provided by the invention, the centrifugal flyweight is mounted by using the steel straight round pin, so that not only can the pin shaft be prevented from deformation or damage, but also the friction resistance between the pin shaft and the centrifugal flyweight can be reduced.

Owner:重庆澳强工贸股份有限公司

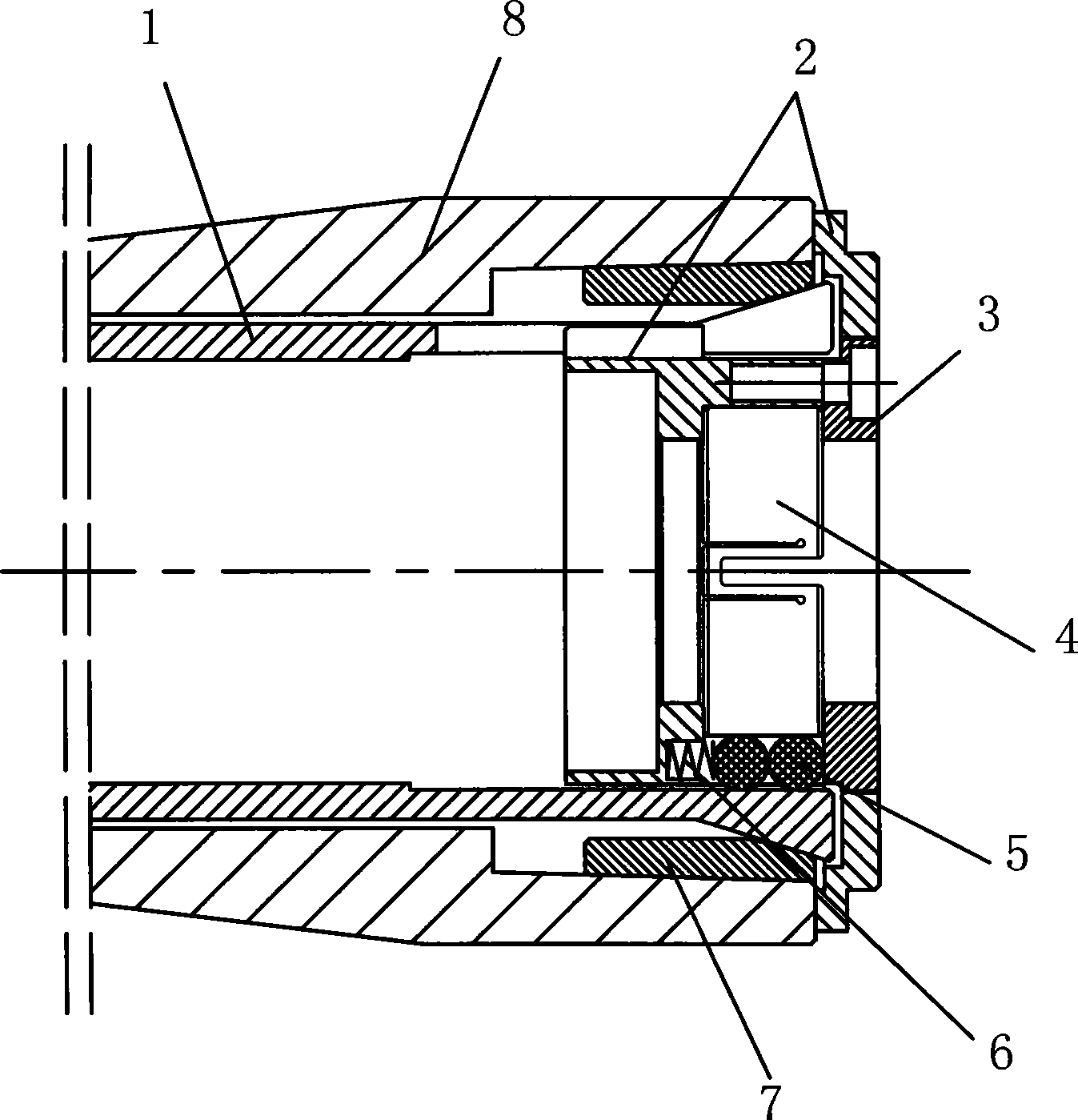

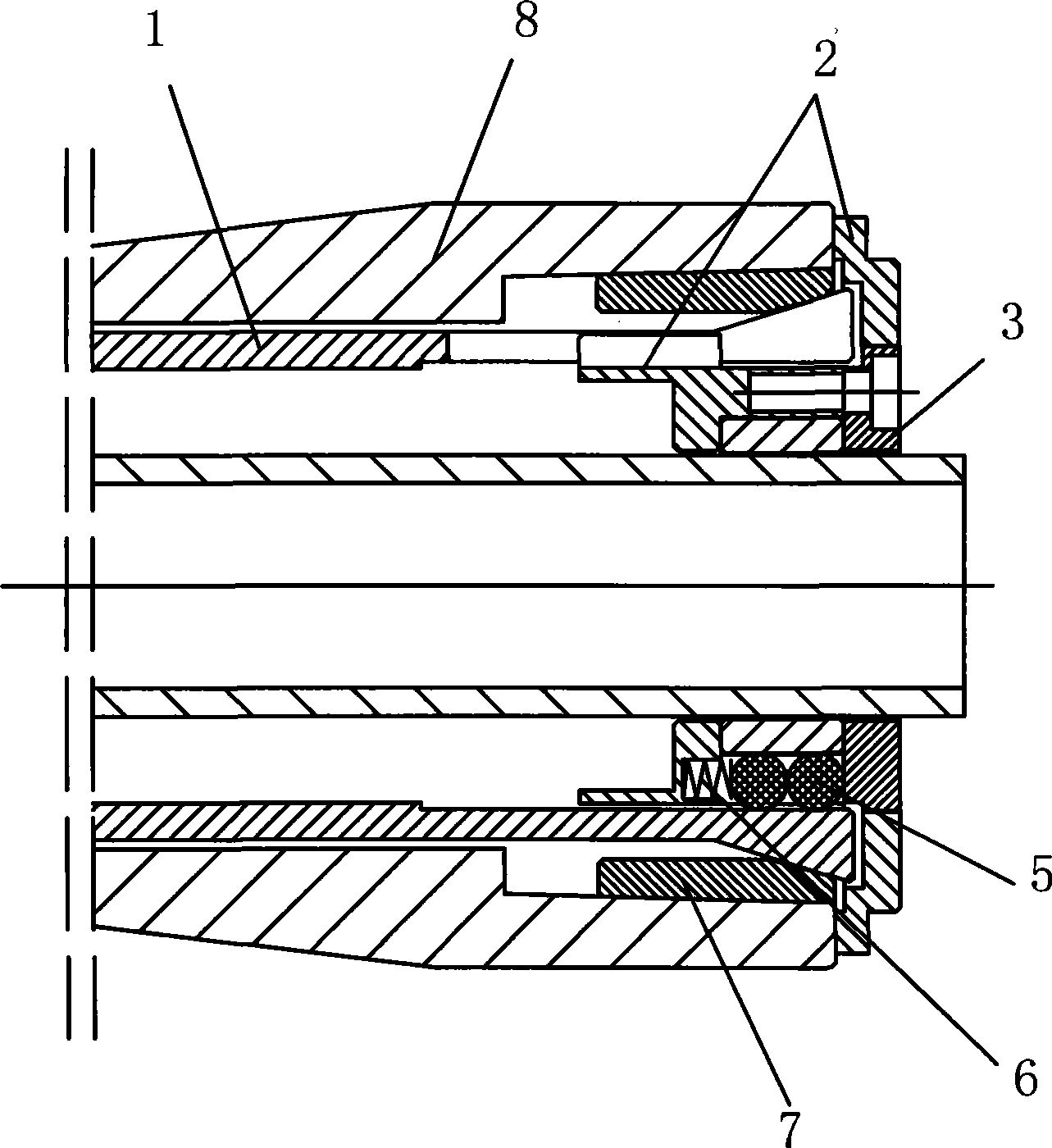

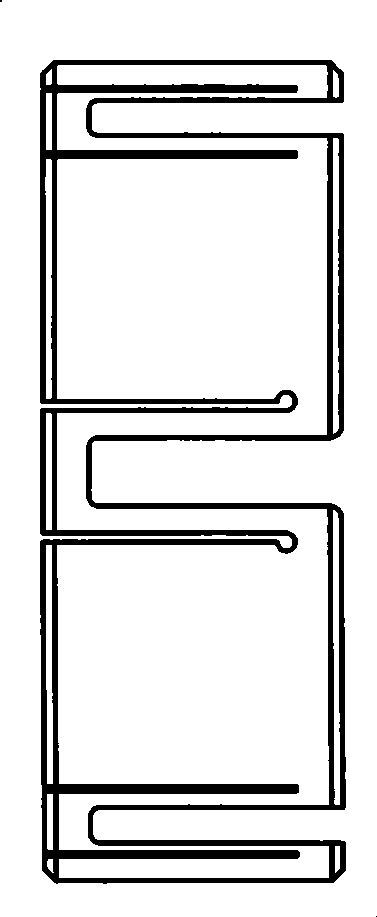

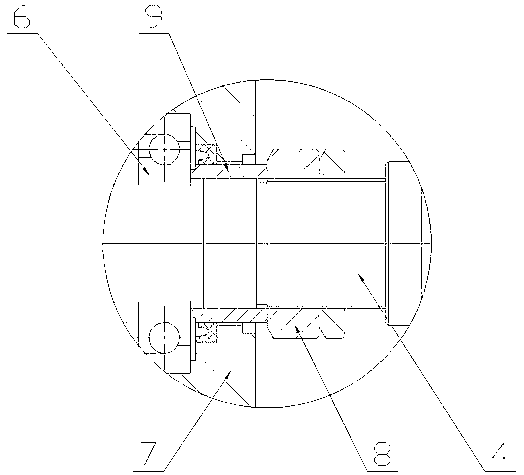

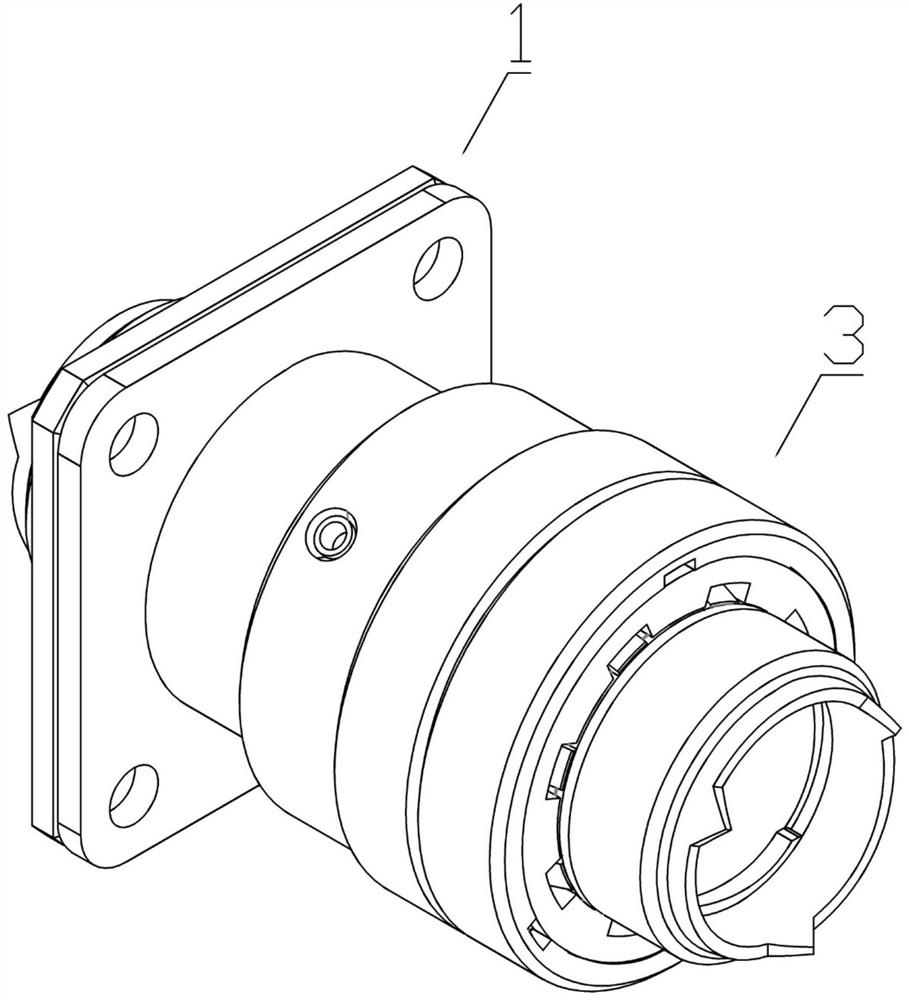

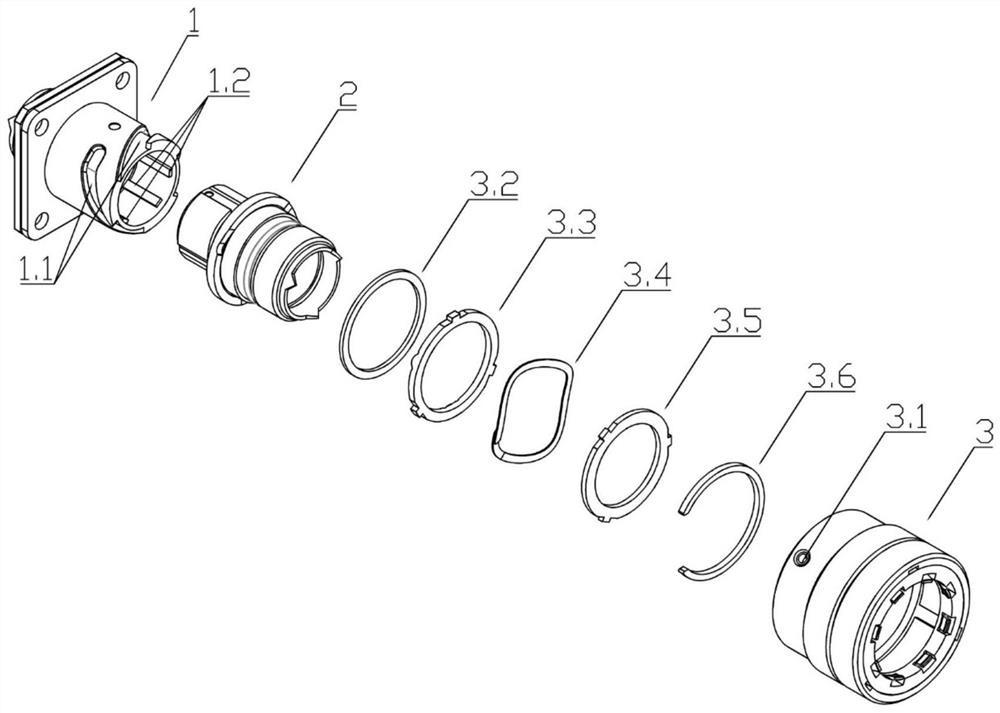

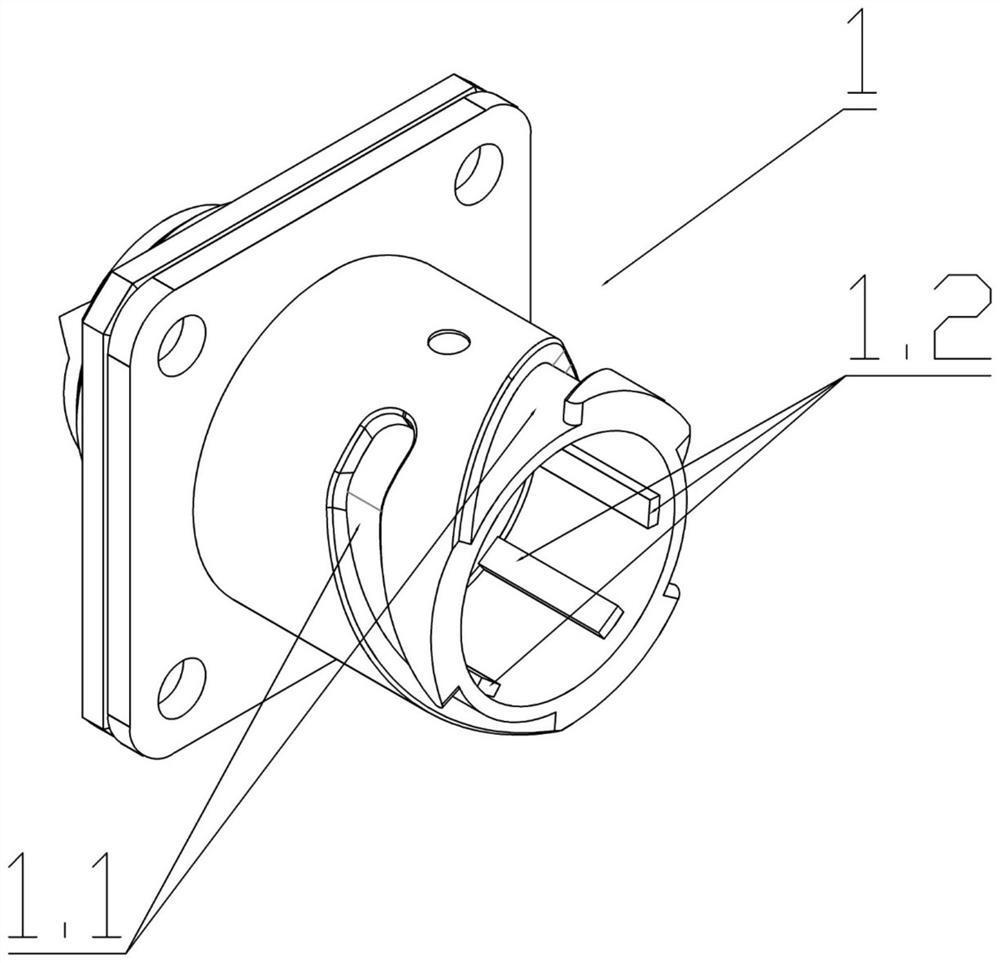

Plug self-locking connector

InactiveCN111682357ANo axial playOvercoming elasticityCoupling device detailsCircular discStructural engineering

The invention discloses a plug self-locking connector. The plug self-locking connector comprises a plug and a socket, wherein the socket is a square plate shell, a curved groove is formed in the outerwall of a cylindrical part, inserted with the plug, of the square plate shell, and an internal spline is arranged on the inner wall of the cylindrical part; the plug comprises a shaft-shaped spline shell and a cylindrical connecting nut, and the spline shell sleeves the connecting nut; an outer key groove is formed in the left end of the spline shell, and a protruding disc is further arranged inthe axial middle of the spline shell; a clamping nail is arranged in the left end of the connecting nut, a stepped hole is formed in the middle, and a key groove is formed from the stepped position tothe right end of the connecting nut; a disc of the spline shell is located on the right side of a middle stepped hole of the connecting nut. A locking washer, a corrugated spring and a clamping spring are sequentially arranged on the right side of the disc of the spline shell. A groove is formed in the right face of the spline shell disc, a protrusion corresponding to the groove in the spline shell disc face is arranged on the left end face of the locking washer, and a key is further arranged on the circumferential face of the locking washer. Self-locking of the internal structure of the plugcan be realized, and safe operation of high-precision equipment is facilitated.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

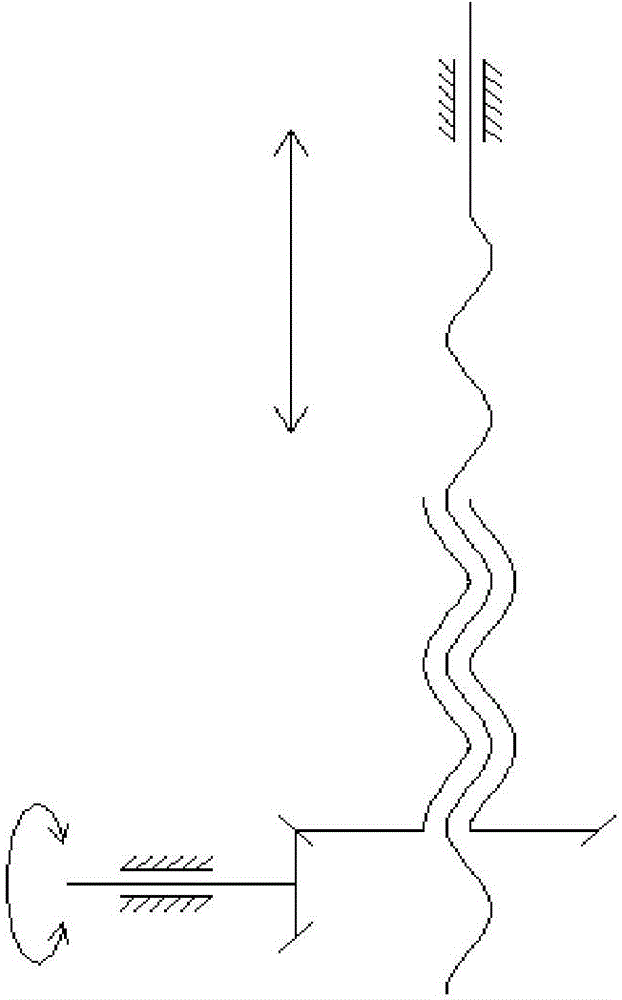

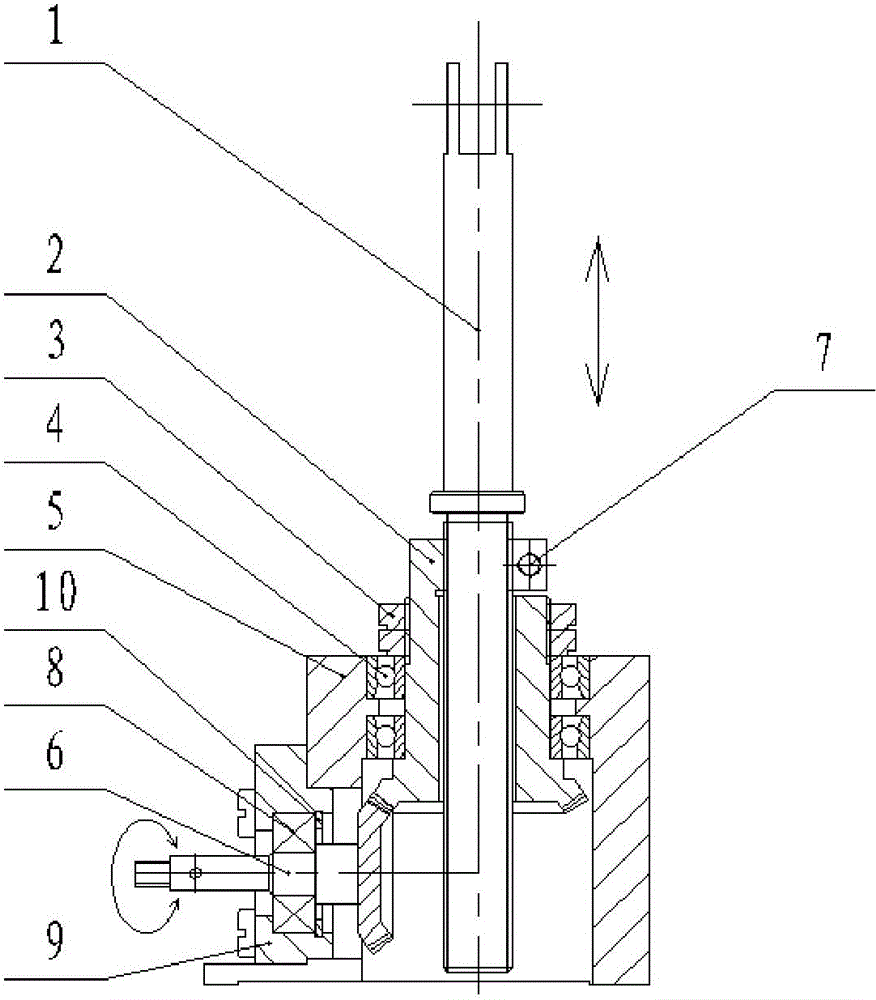

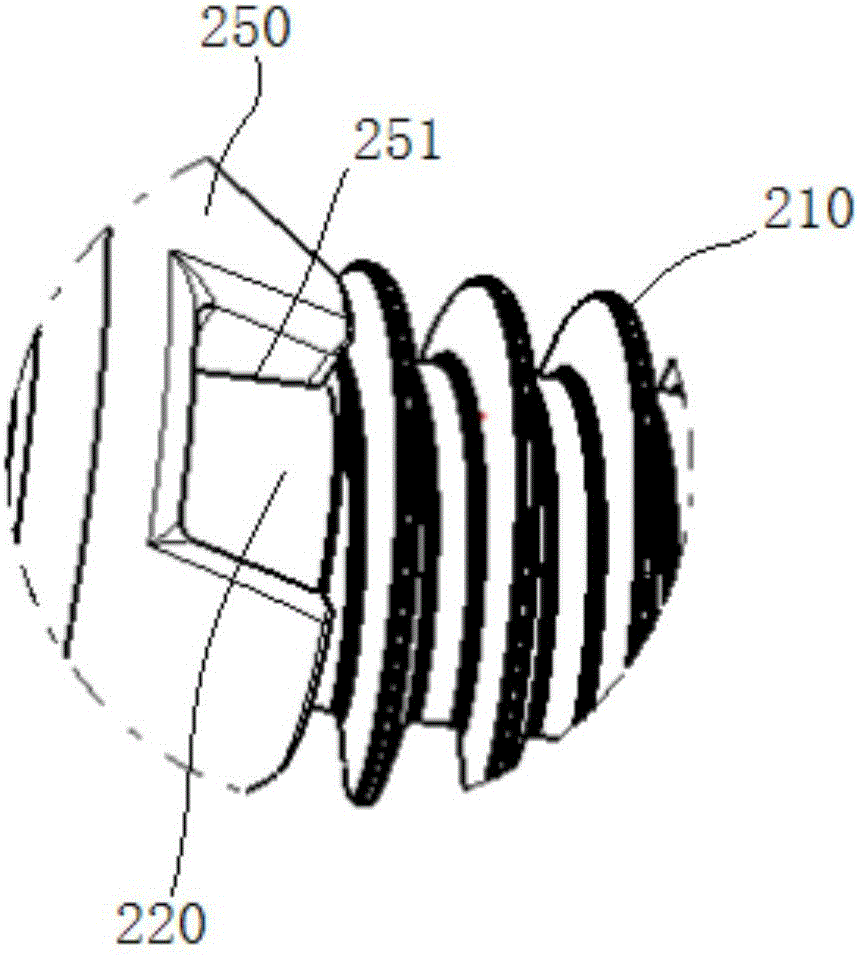

Spiral lifting mechanism

The invention discloses a spiral lifting mechanism which is applied to the industries of precise machines, automobiles, precise machine tools and the like. The set of precise spiral lifting mechanism is composed of a transmission bevel gear, a lifting lead screw, a gear nut, a machine base, bearings and other mechanical parts. The spiral lifting mechanism has the advantages of being compact in structure, low in part machining precision, simple in assembling method and capable of achieving accurate spiral lifting. In addition, the spiral lifting mechanism is low in machining cost, capable of being applied to multiple precise machine industries and convenient to apply and popularize.

Owner:北京兴华机械厂有限公司

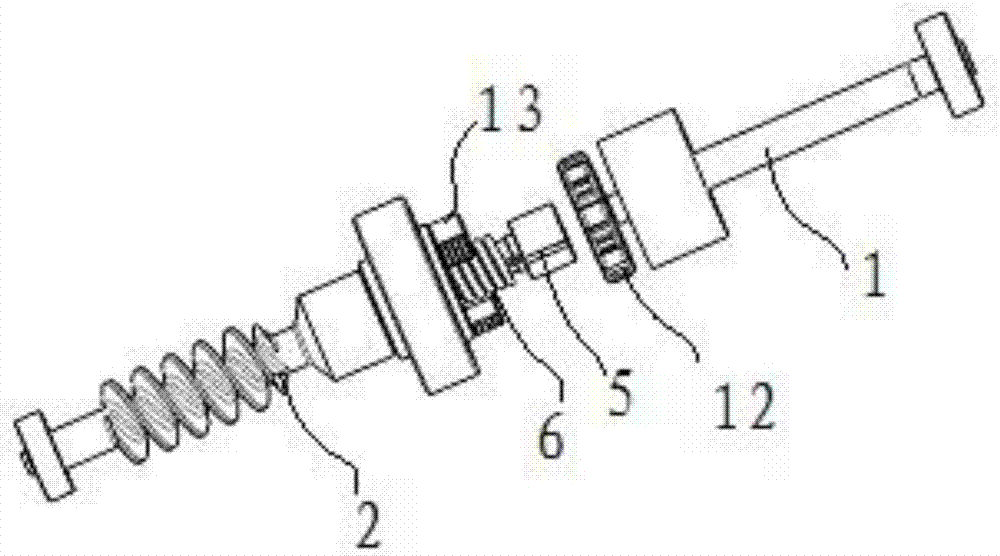

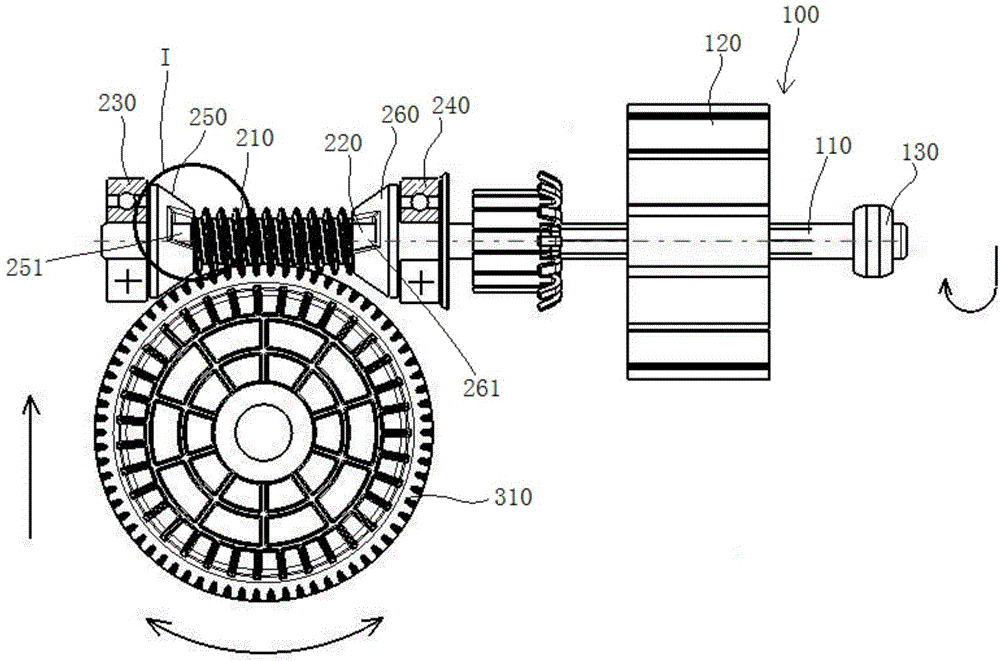

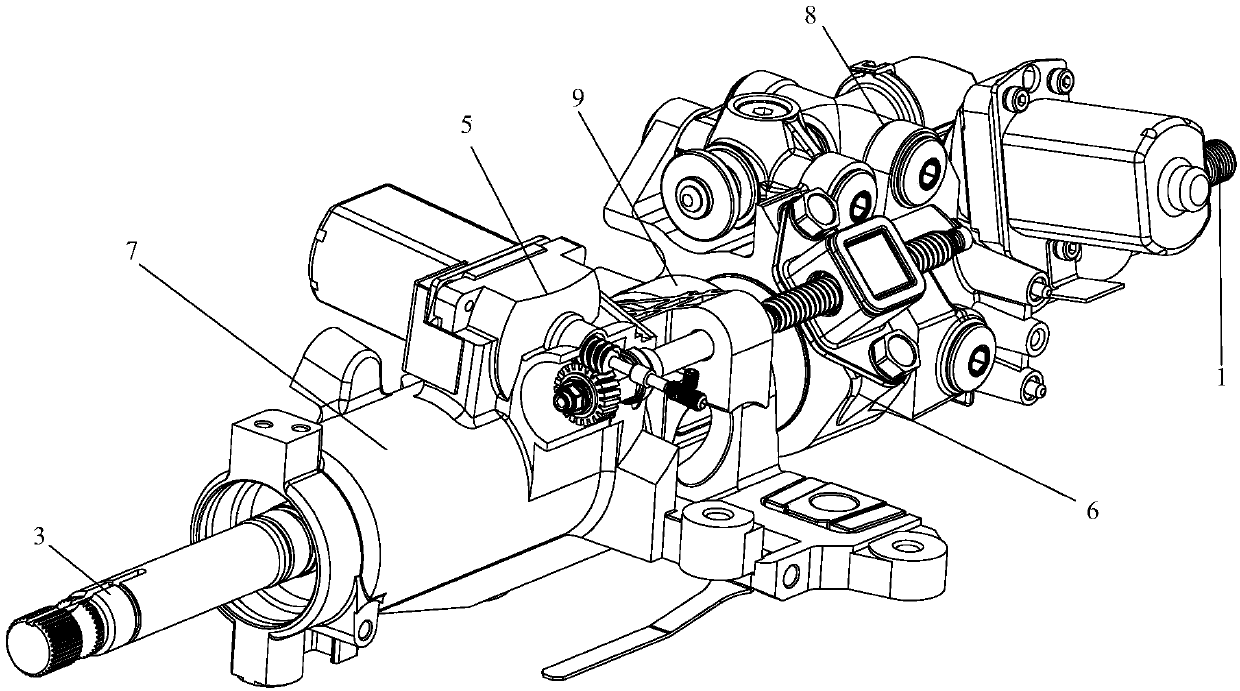

Speed changer and automatic gear-shifting executor

InactiveCN107575571AControl Axial Movement DisplacementEliminate axial playMechanical actuated clutchesGearing controlActuatorVariator

The invention relates to a speed changer and an automatic gear-shifting executor. The automatic gear-shifting executor comprises a synchronizer and a driving unit. The synchronizer comprises a joiningsleeve including a body ring and a driving ring. The body ring and the driving ring are coaxially arranged. The driving ring sleeves outside the body ring. The driving ring is connected with the bodyring in a relatively rotating manner and a synchronous axial-moving manner. The driving unit is provided with an output part sleeving outside the driving ring and used for outputting rotary motion rotating around a central axis of the driving ring through the output part. Lead-screw driving is achieved between the driving ring and the output part. The lead-screw driving is used or converting rotary motion of the output part into axial motion of the driving ring and the body ring. The automatic gear-shifting executor in the technical scheme has high mechanical driving efficiency and short dynamic response time.

Owner:SCHAEFFLER TECH AG & CO KG

Automobile motor assembly with double rolling bearing structure

InactiveCN106505792AEasy to fixHigh strengthMechanical energy handlingSupports/enclosures/casingsElectric driveEngineering

The invention discloses an automobile motor assembly with a double rolling bearing structure. The automobile motor assembly comprises a motor, a worm, a worm gear, and a reducing box for assembling the worm and the worm gear, wherein the motor comprises a motor output shaft and an electric drive component; the electric drive component drives the motor output shaft to rotate; the worm is arranged at a worm end of the motor output shaft; the worm gear and the worm are in drive connection; and the worm end of the motor output shaft is supported in the reducing body through two rolling bearings. The two rolling bearings are adopted and the radial clearance is very small, so that the worm and the worm end of the motor output shaft do not bend when the worm gear bears very high radial force, and the worm and the worm gear are always meshed on a node, thereby ensuring the transmission efficiency and improving the strength of the worm gear and the worm.

Owner:上海胜华波汽车电器有限公司

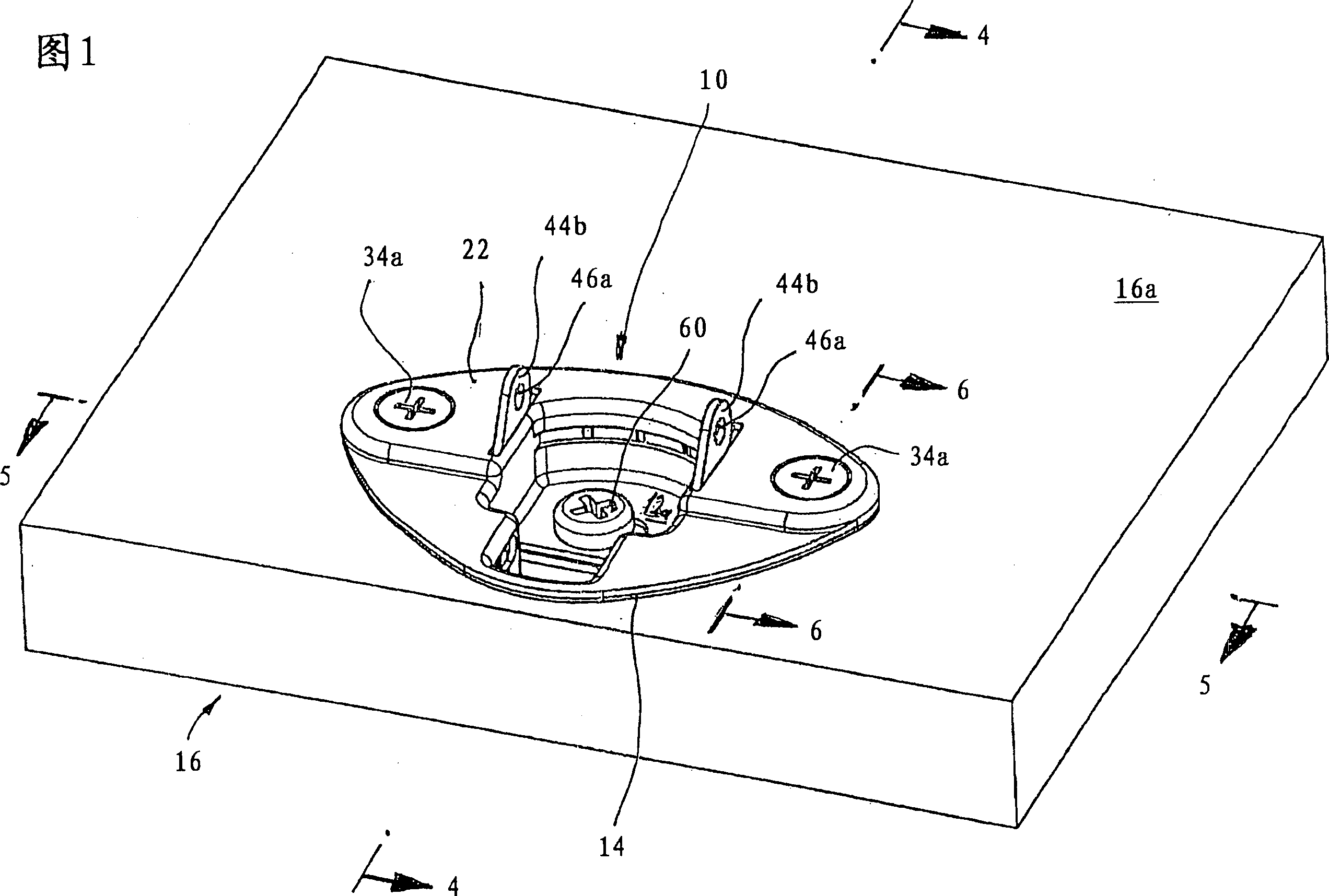

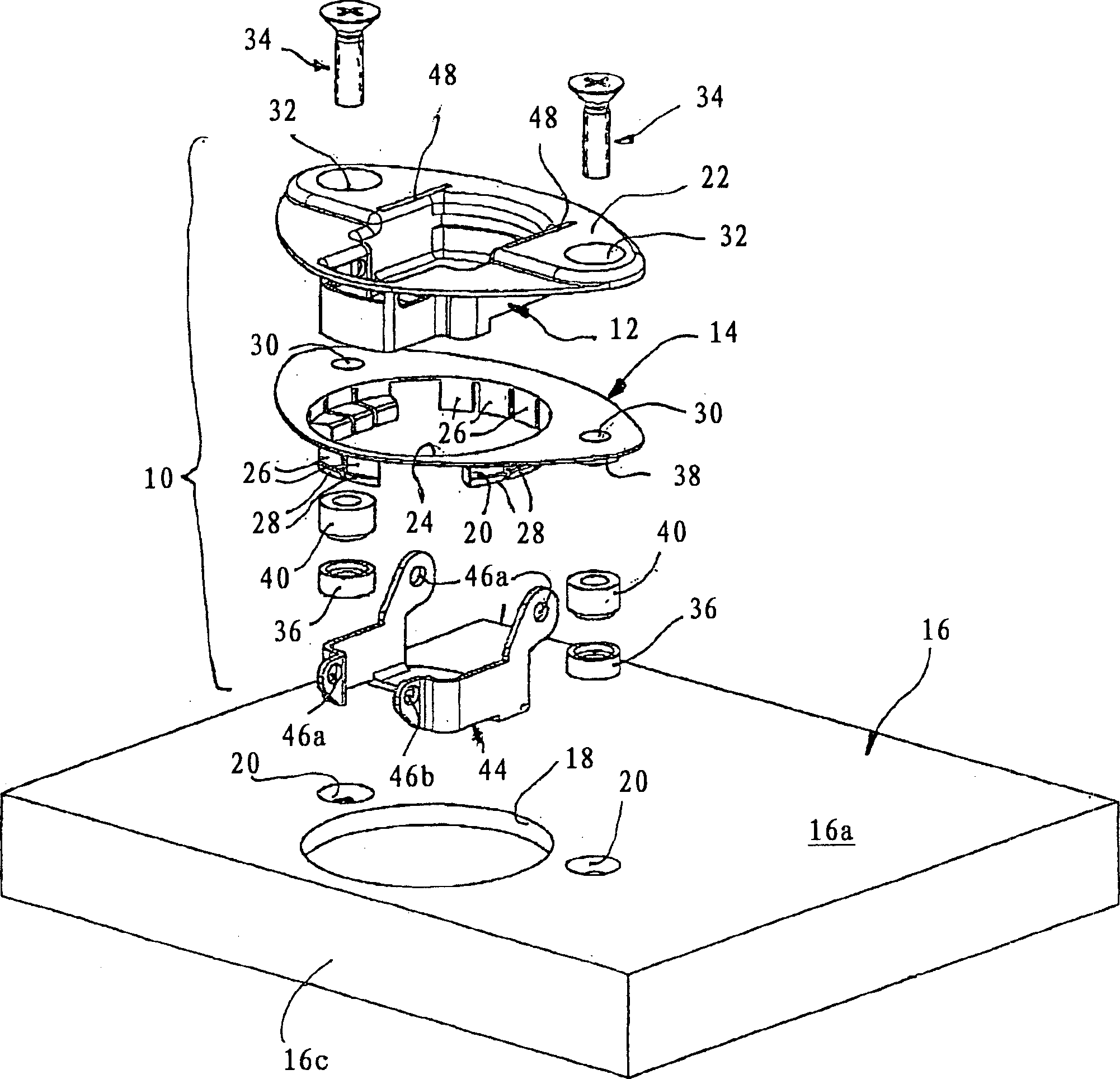

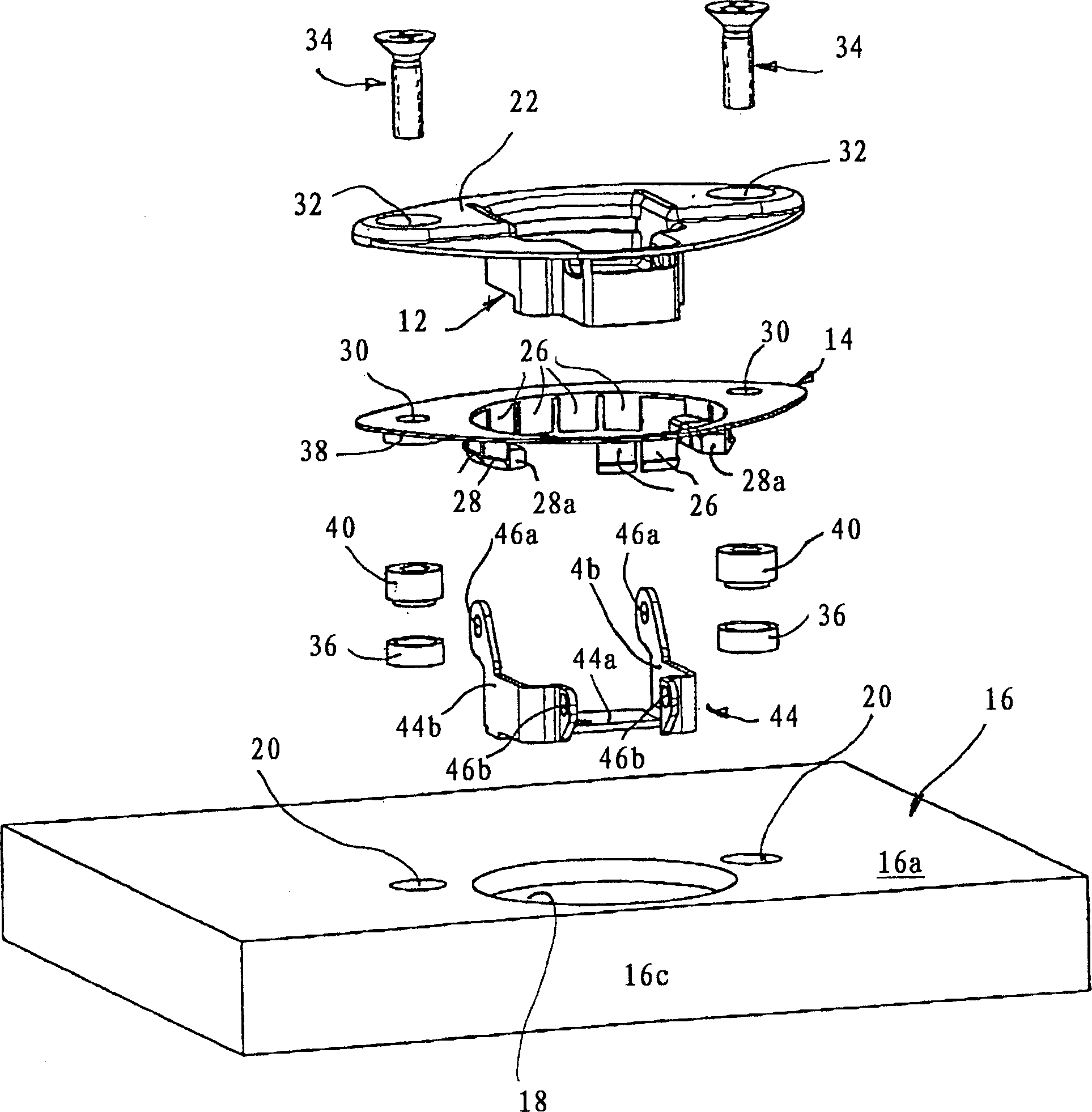

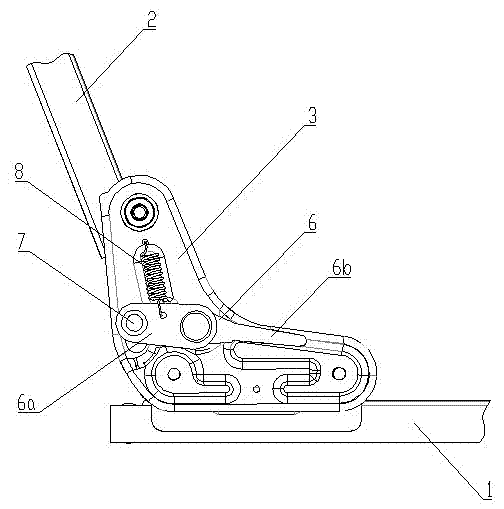

Hinge housing for a door leaf at least by areas made of a thin-walled metal or hollow metal profile

The invention relates to a hinge housing (10) which is flushly mounted in a recess (18) inside the wall (16a) of a door leaf (16) which is made of a thin-walled metal and provided with a metal pot-shaped part (12) whose top edge is projected and forms in single-piece a fixing flange (22) and a guard plate (14) disposed between the fixing flange (22) and the internal part of the door leaf. Said guard plate (14) comprises elastic snap-in pins (26) which are disposed in the a recess (24) thereof corresponding to the recess (18) of the door leaf (16) and which, in the fixed position thereof, encompass the edge area of the recess (18) of the door leaf (16) on the internal part of the wall. Said guard plate (14) comprises at least two through holes which are (30) remote from each other in the direction of an opening (20) associated with each of them and embodied in the wall (16a) of the door leaf (16) and two through openings (32) which are embodied in the fixing flange (22) and are crossed by the butt-joints (34b) of fastening screws (34) whose ends are screwed into a clamping plate (36). Elastically deformable fixing bodies (40) crossed by the butt-joints (34b) of the fastening screws (34) are arranged between the flat faces of the guard plate (14) oriented towards the wall (16a) of the door leaf (16) and the limiting faces of the clamping plates (36) opposite thereto and in the undistorted form thereof produce an external limitation of the openings (20) in the wall (16a) of the door leaf and of the clamping plate 36.

Owner:KARL LAUTENSCHLAGER GMBH & CO KG

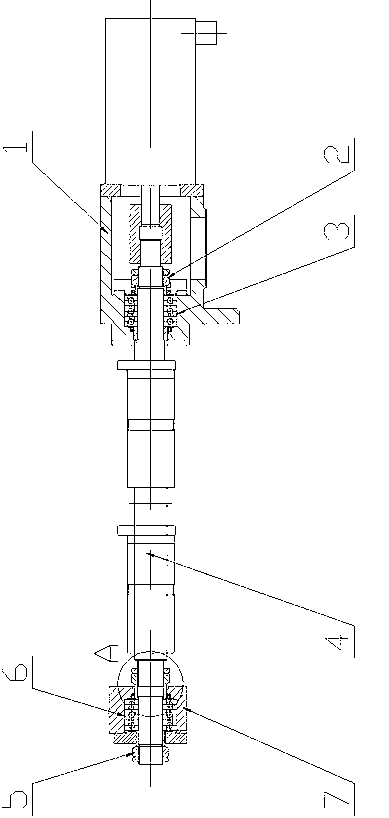

Axial adjusting device of electric four-way adjustable steering column

InactiveCN109572798AAvoid height adjustment failureEliminate axial playSteering controlsSteering columnEngineering

The invention discloses an axial adjusting device of an electric four-way adjustable steering column. The axial adjusting device of the electric four-way adjustable steering column includes a telescopic motor, a worm connected to the telescopic motor, a first limiting piece for applying a load to the worm, and a force transmitting piece positioned between the first limiting piece and the worm androtatable in the circumferential direction with the worm, and the force transmitting piece is in point contact with the first limiting piece and the worm. According to the axial adjusting device of the electric four-way adjustable steering column, the axial clearance of the telescopic motor is eliminated by arranging the force transmitting piece and the limiting piece, so that the axial movement of the telescopic motor and the worm does not occur in the running process, the failure of the height adjustment of the steering column caused by sticking of the motor is effectively avoided, the reliability is improved, and the comfort and safety of driving and riding are also improved.

Owner:WUHU STERLING STEERING SYST

Use method of tapping clamp

InactiveCN105215485AAvoid it happening againImprove processing qualityThread cutting machinesEngineeringDrilling machines

The invention discloses a use method of a tapping clamp. The use method comprises the following steps: a suitable screw tap (8) and matched clamping blocks (6) are selected according to the size of the hole diameter of a hole to be tapped; the screw tap (8) is arranged in the clamping blocks (6); the clamping blocks (6) are arranged below a clutch (5); a clamping nut (7) is screwed up to lock the screw tap (8); the clutching torque of the clutch (5) is controlled through an adjustment device, so that the tapping clamp can be applicable to tapping of screw holes with different hole diameters; and the end of an assembly post (12) is connected onto a drilling machine, and tapping and drilling can be performed at a preset position. The tapping clamp can be used on an ordinary bench drill; the machining quality is good; the efficiency is high; the phenomenon that the tip of the screw tap (8) is broken can be effectively avoided; almost no rejected product is produced; and the tapping clamp has good application prospect.

Owner:WUHU HENGLONG AUTO STEERING SYST

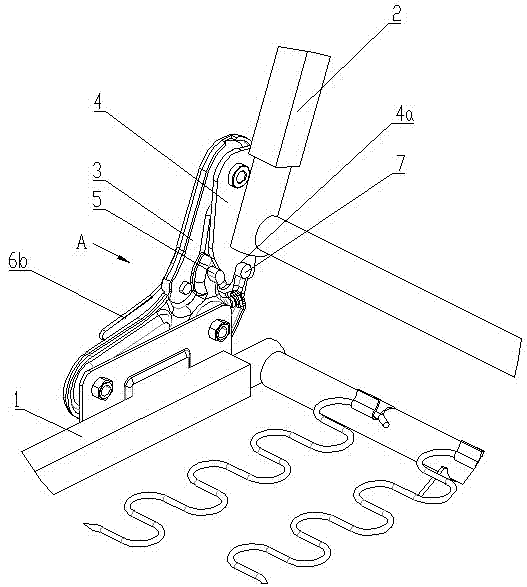

Automobile backrest folding mechanism

ActiveCN102275529BEasy to controlSimple structureMovable seatsManufacturing cost reductionEngineering

The invention discloses an automobile backrest folding mechanism comprising a connection plate fixed on a cushion framework, wherein the backrest framework is rotatably matched with the connection plate by a locking plate, the locking plate is provided with a limitation pin for limiting the backward turning of a backrest, a locking assembly is used for locking the locking plate when the seat is normally used, or unlocking the locking plate when the backrest needs to be laid down, one end of a locking pin of the locking assembly, which extends into a slot of the locking plate, is cylindrical, and the end face of the locking pin extends out of the side of the locking plate. Because the limiting slot of the locking pin is canceled, the manufacturing process is simplified, the external diameter size can be efficiently ensured, the production efficiency is efficiently enhanced, the production cost is lowered, and the problem of abnormal sound generated by no interval between the automobilebackrest folding mechanism and the slot of the locking plate is solved. In addition, through arranging an axial limiting structure to the locking pin and improving the limitation pin and reinforcing ribs, the product quality, the performance, and the production efficiency can be further enhanced, and the manufacturing cost is reduced.

Owner:CHONGQING YANFENG ADIENT AUTOMOTIVE COMPONENTS CO LTD

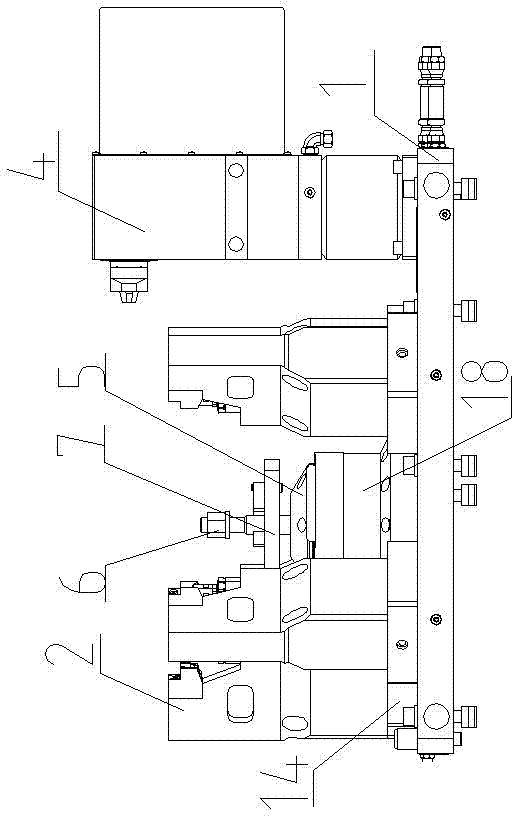

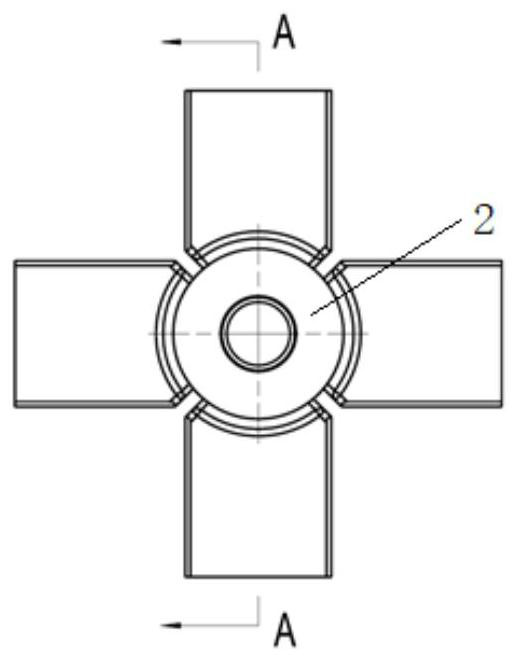

Work fixture for installation plane and tile lid combination face of main reducing gear housing of passenger car

InactiveCN103934710AEnsure consistencySmall sizePositioning apparatusMetal-working holdersReduction driveEngineering

The invention belongs to the field of vertical machining devices of a main reducing gear housing of a passenger car, and particularly relates to a work fixture for an installation plane and a tile lid combination face of the main reducing gear housing of the passenger car. The work fixture comprises a bottom board, an angular locating device, five or more auxiliary supporting and compressing devices and a main compressing device, wherein the angular locating device, the auxiliary supporting and compressing devices and the main compressing device are fixedly arranged on the bottom board. The auxiliary supporting and compressing devices are distributed in the circumferential direction. The main compressing device is arranged in the circumferential line where the auxiliary supporting and compressing devices are distributed. The angular locating device is arranged outside the circumferential line where the auxiliary supporting and compressing devices are distributed. The work fixture is simple in structure and high in machining accuracy, and main reducing gear housings of various types can be machined under the situation of replacing a locating block of the angular locating device.

Owner:ZHENGZHOU JINGYIDA AUTO PARTS

Manufacturing method of hollow half shaft of heavy-load automobile and hollow half shaft

The invention relates to a manufacturing method of a hollow half shaft of a heavy-load automobile and the hollow half shaft. The manufacturing method comprises the following steps: a steel bar is forged to form a flange plate blank; a seamless steel pipe is subjected to rotary swaging to be machined into a variable-cross-section hollow pipe; the hollow pipe and the flange plate blank are welded; machining and heat treatment are conducted on the welded hollow pipe and the flange plate blank to form the hollow half shaft. By the adoption of the rotary swaging process, the machined hollow pipe ishigh in precision, uniform in wall thickness and good in straightness, and meanwhile due to the fact that precision rotary swaging belongs to cold forming, the inner surface and the outer surface ofthe hollow pipe obtained through the process are good in quality, decarburization is basically avoided, a metal flow line is complete, and strength is high.

Owner:DONGFENG COMML VEHICLE CO LTD

Lathe center

InactiveCN102319911AImprove general performanceNo axial playTailstocks/centresEngineeringMachine tool

The invention discloses a lathe center, which comprises an assembly shaft, a jacking head and a gland, wherein the jacking head is a cone, the top of the jacking head is a flat end face, one end of the assembly shaft is inserted into a step hole at the large end of the jacking head and connected with the jacking head through a bearing, the other end of the assembly shaft is arranged on a lathe, and the gland is arranged at the outer side of the bearing; as a preferably scheme, the jacking head is connected with the assembly shaft through two bearings arranged in interval; and the step hole in the jacking head is a through hole. The lathe center is convenient for installation and easy to realize and has strong generality; and the general center of the lathe is replaced by using the conical jacking head with planar top, the jacking head is connected with the assembly shaft through the two bearings, and the jacking head is matched with a chuck of the lathe, so that effective clamping of steel pipes of multiple specification is realized, and the production efficiency and the product quality are improved.

Owner:WUXI DAJIN HIGH PRECISION COLD DRAWN STEEL TUBE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com