Patents

Literature

279results about How to "No deflection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

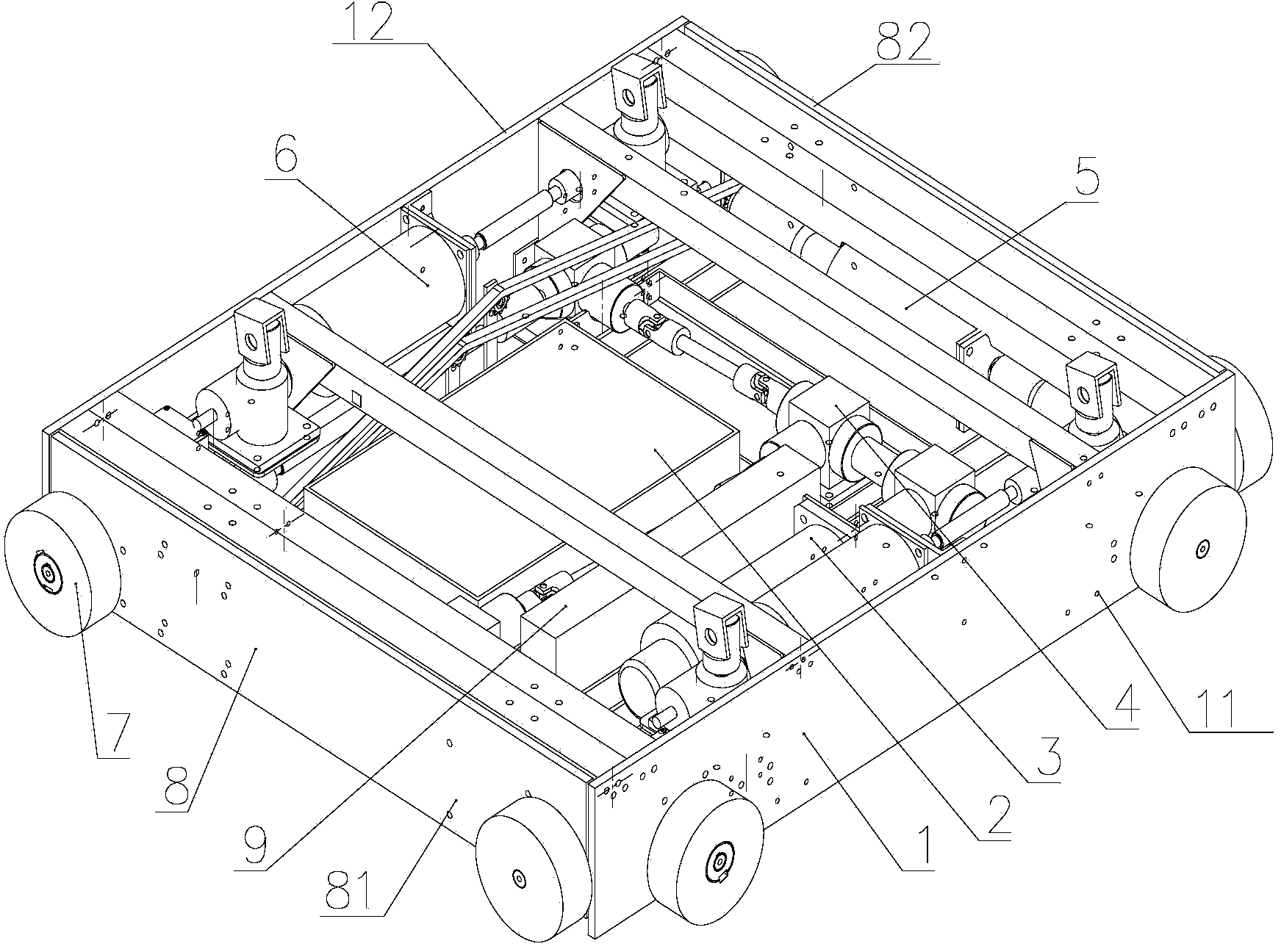

Intelligent shuttle capable of running in three-dimensional way and control method thereof

ActiveCN103818672ANo deflectionImprove space utilizationStorage devicesWireless transceiverTransceiver

The invention provides an intelligent shuttle capable of running in a three-dimensional way. The intelligent shuttle comprises a shuttle body, a power system, a driving system, a speed-reducing system, a reversing system and a control system, wherein the power system, the driving system, the speed-reducing system, the reversing system and the control system are fixed to the shuttle body; the power system is electrically connected with the control system and the driving system respectively through cables to supply power; the control system is electrically connected with the driving system, the speed-reducing system and the reversing system respectively; the four sides of the bottom of the shuttle body are provided with two wheels respectively; the driving system is in transmission connection with the wheels through the speed-reducing system to supply power to the wheels. The invention further provides a control method of the intelligent shuttle capable of running in a three-dimensional way. The method comprises the following step: receiving a task command through a wireless transceiver by an industrial personal computer, namely, driving the intelligent shuttle capable of running in a three-dimensional way to a goods receiving point for carrying goods and run to a goods unloading point for unloading goods. The intelligent shuttle has the beneficial effects of high running efficiency, high storing capacity and reduction of the investment cost.

Owner:安徽哥伦布智能科技有限公司

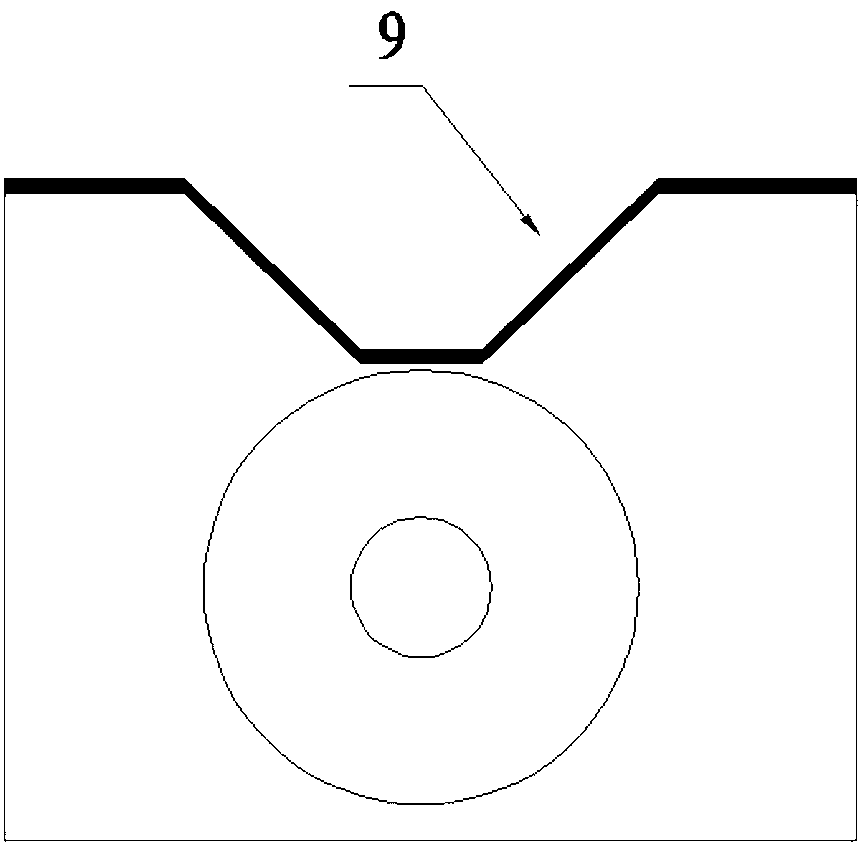

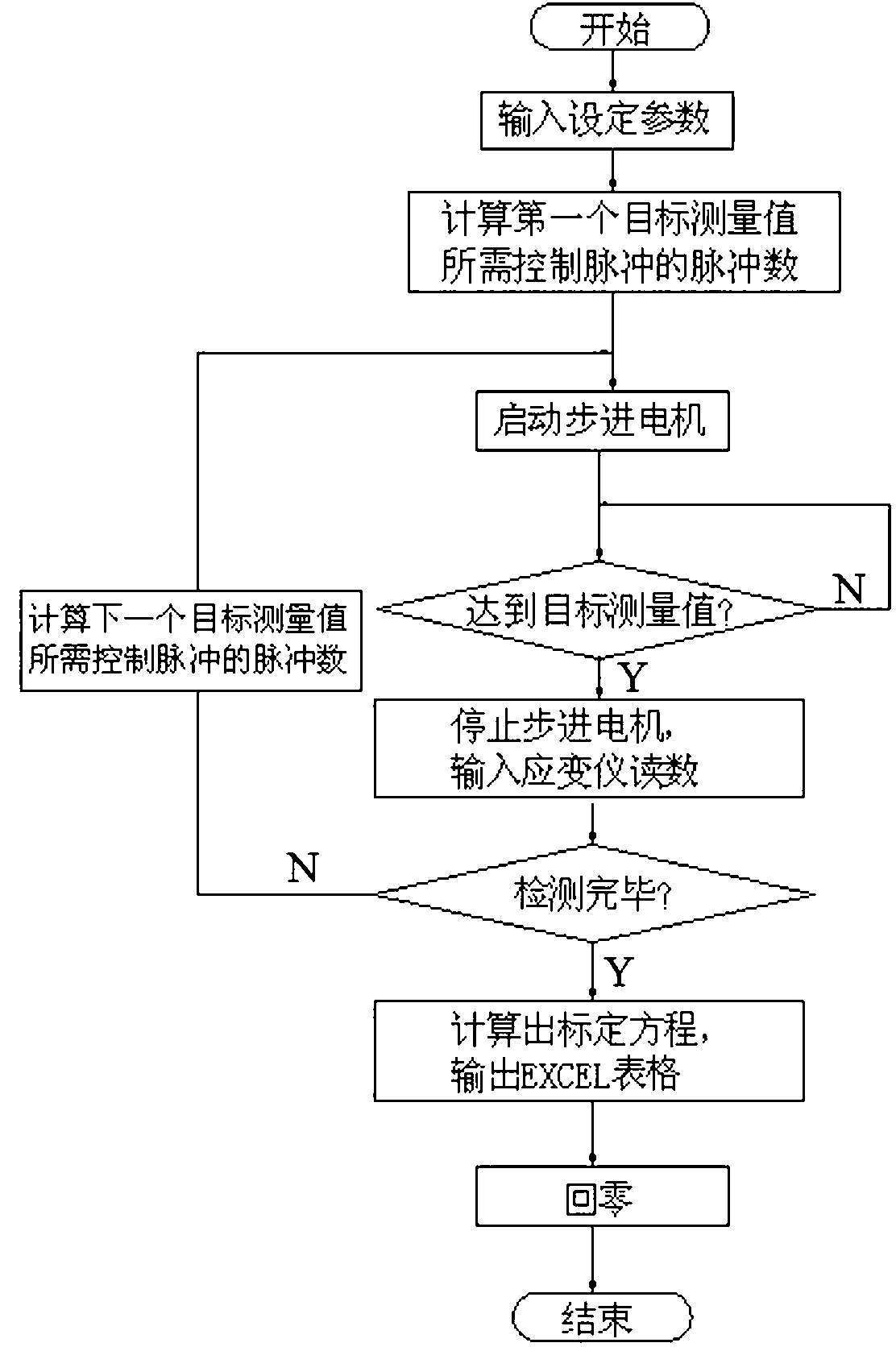

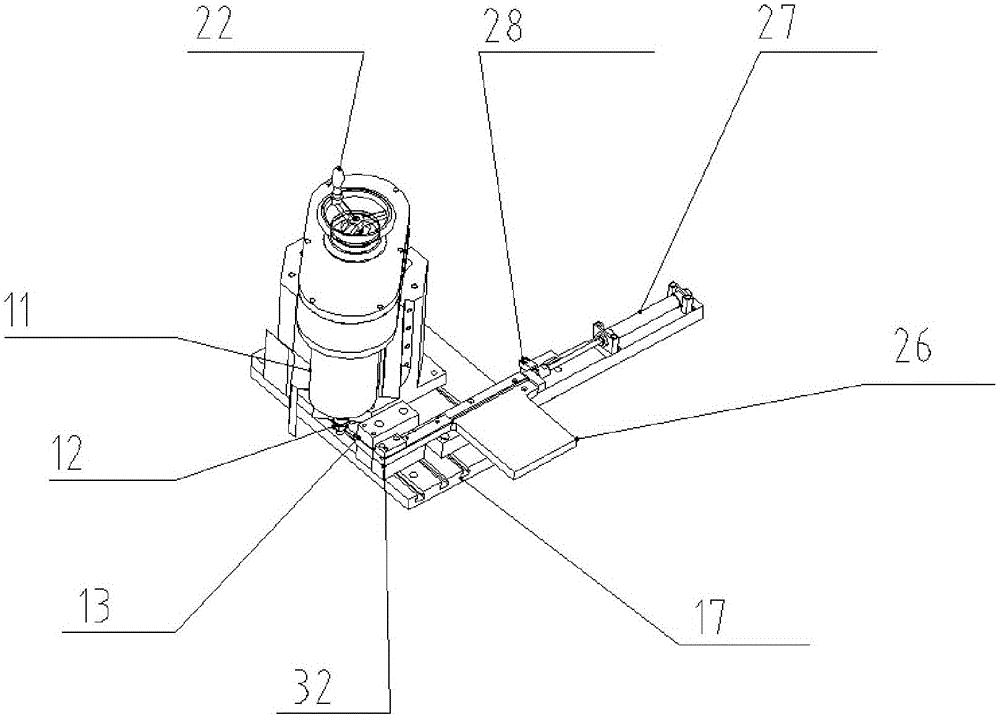

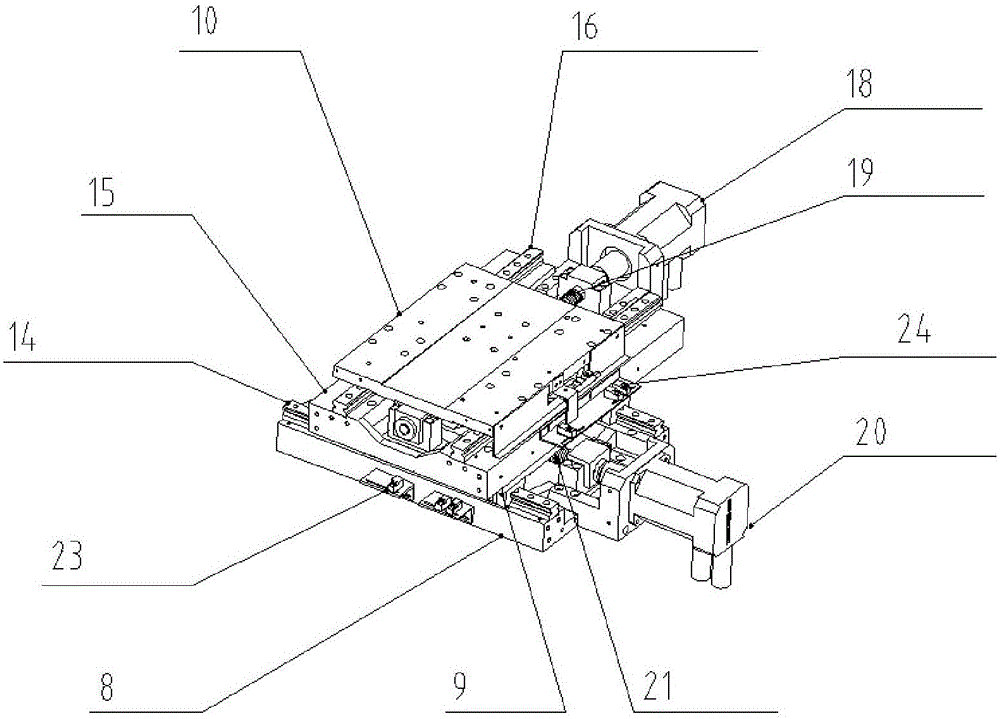

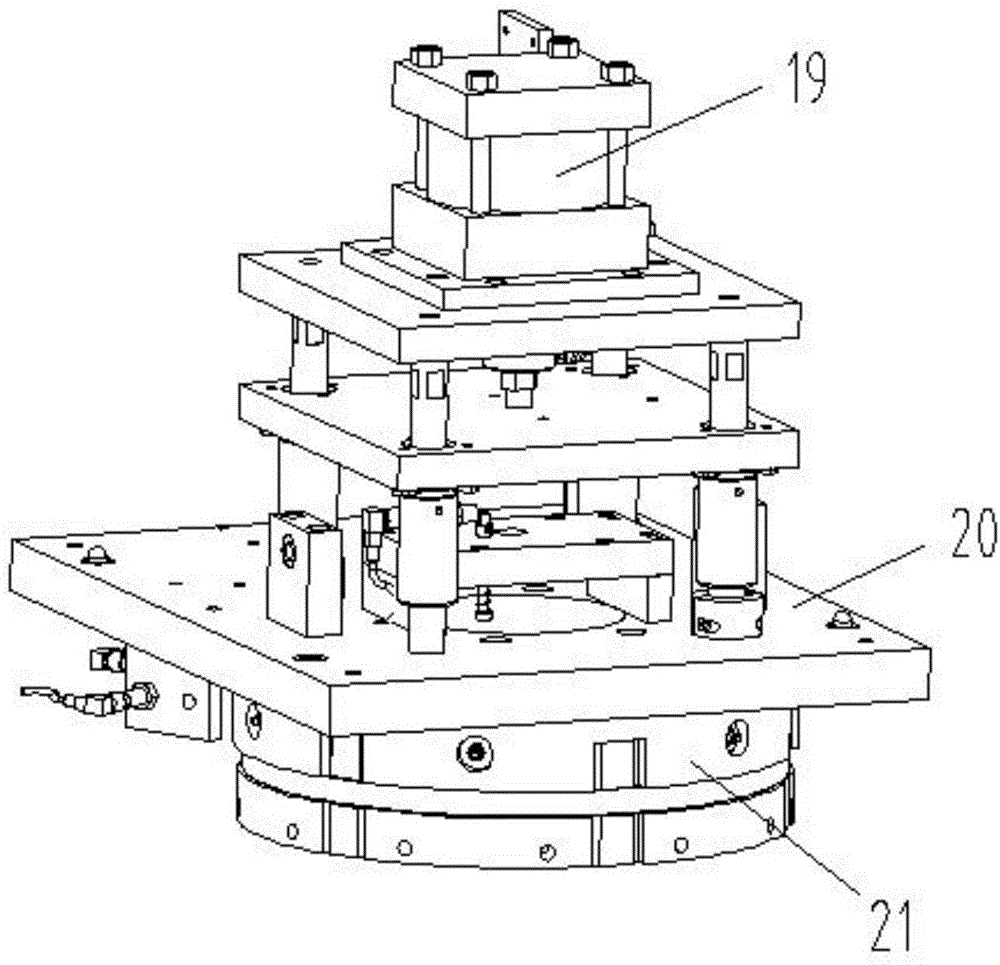

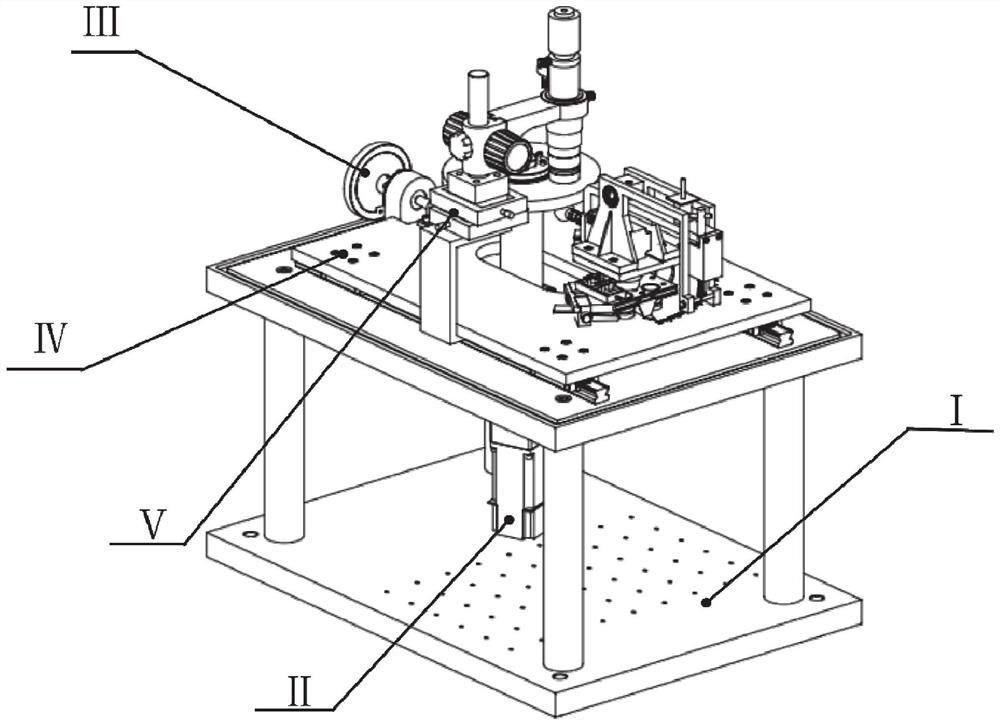

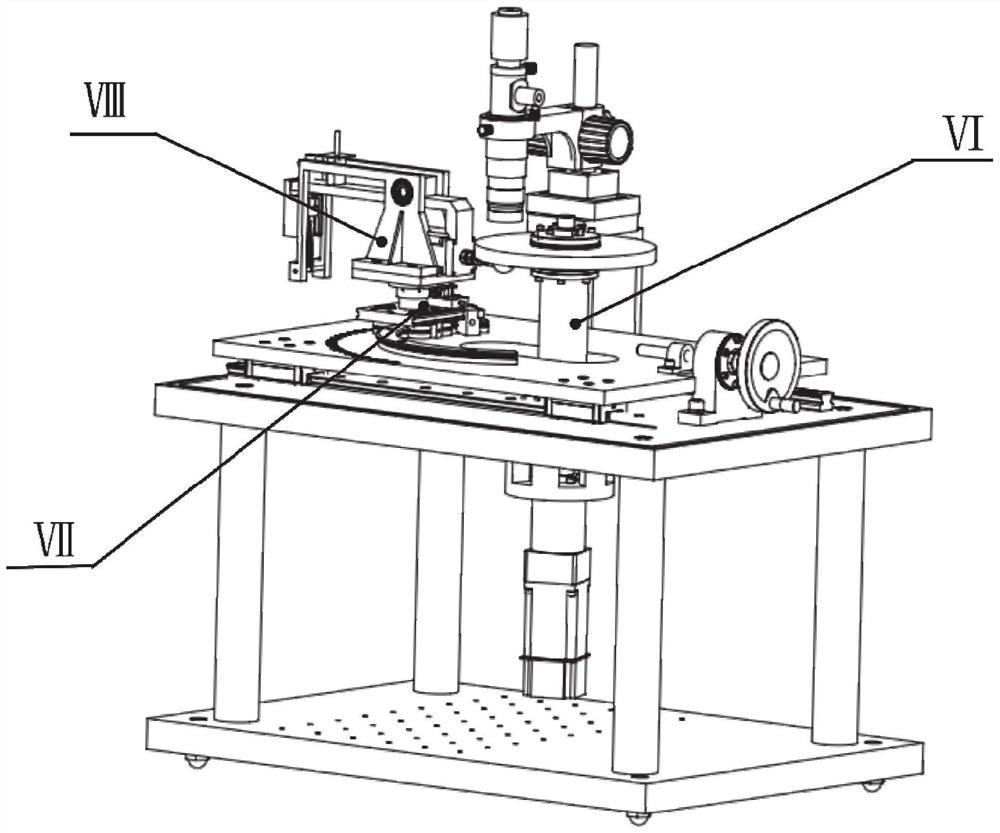

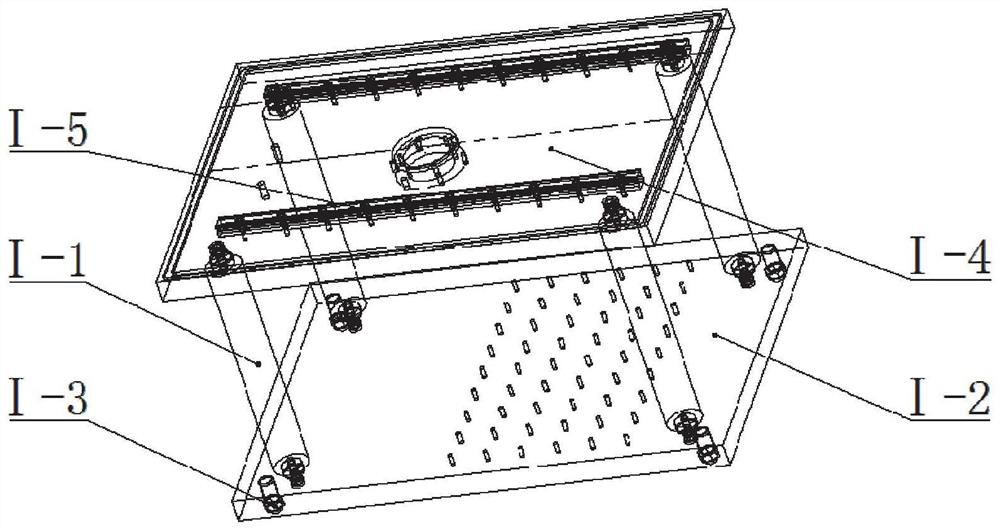

Automatic calibration device and calibration method for strain gauge

InactiveCN102927959AFully automatic calibrationFully automatic detectionMeasurement devicesContinuous measurementGrating

The invention provides an automatic calibration device and calibration method for a strain gauge. The automatic calibration device adopts a grating displacement sensor as a standard, a stepper motor for driving, a controller for controlling, reading and processing data, and a closed-loop system is completely adopted, so that full-automatic calibration and detection are realized for the strain gauge, wherein the output accuracy of the grating displacement sensor is 3 mum, so the detection accuracy is guaranteed; a horizontal base is provided with two V-shaped guide rails which are parallel to each other, so that a movable flame can not deflect or tilt when running with load, and the loading capacity and the application range can be improved; and a high-precision ball screw can be guaranteed to transfer enough torsion accurately during the movement process. With the adoption of the method, continuous measurement for multiple positions can be realized, the work efficiency of measurement can be improved, a calibration equation adopts a simple cubic equation, so that the calibration process is greatly simplified, a zero-returning step eliminates an accumulated error caused by long-term work of a controller, and further, the detection accuracy of the method is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

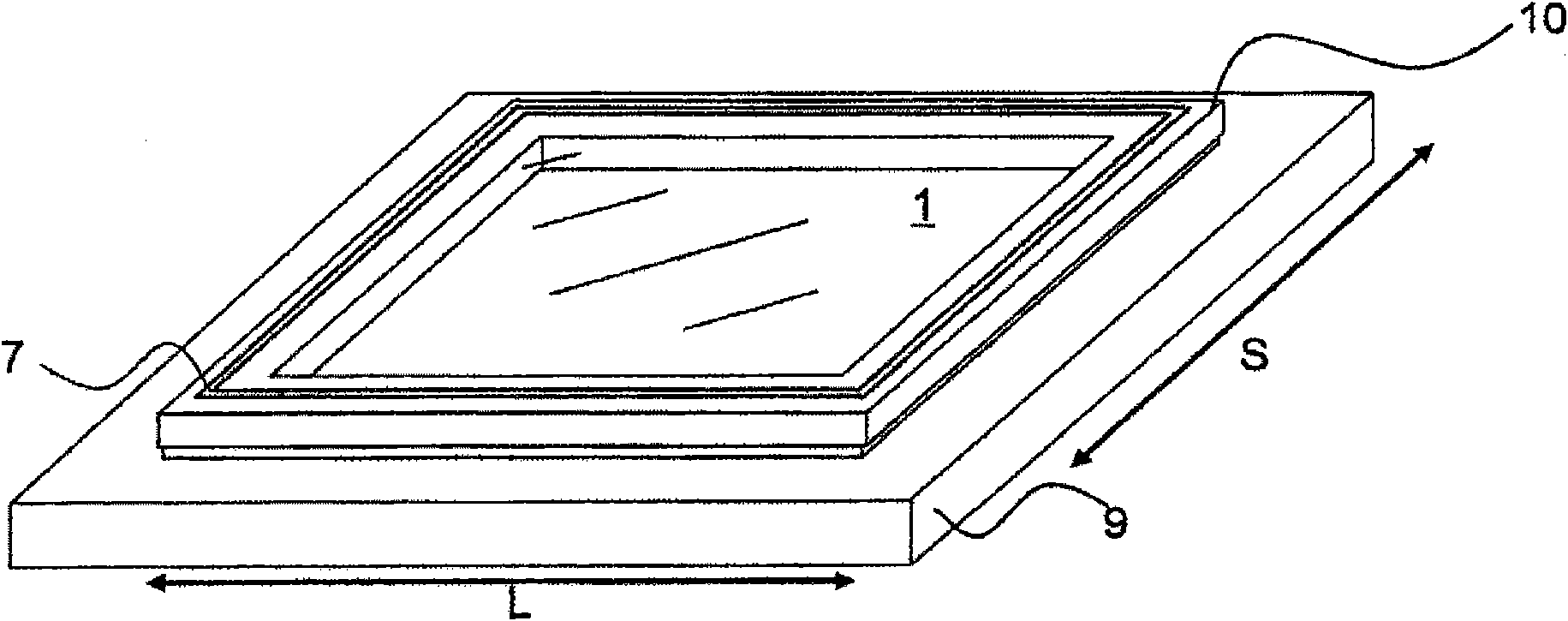

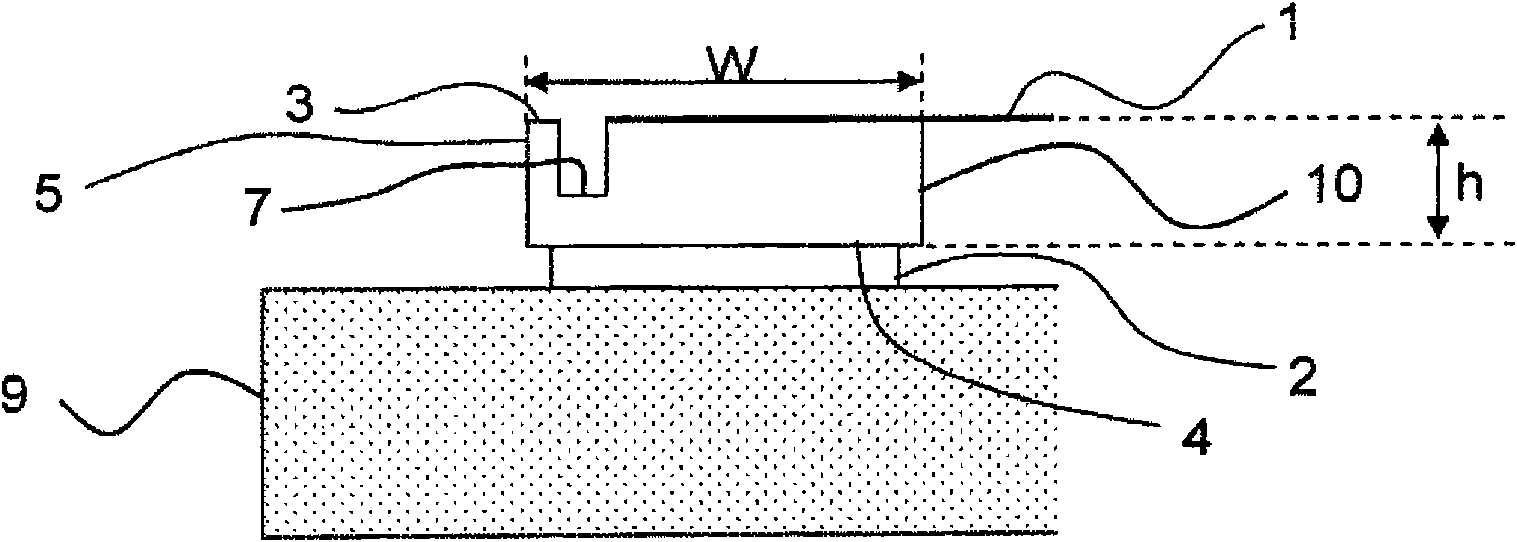

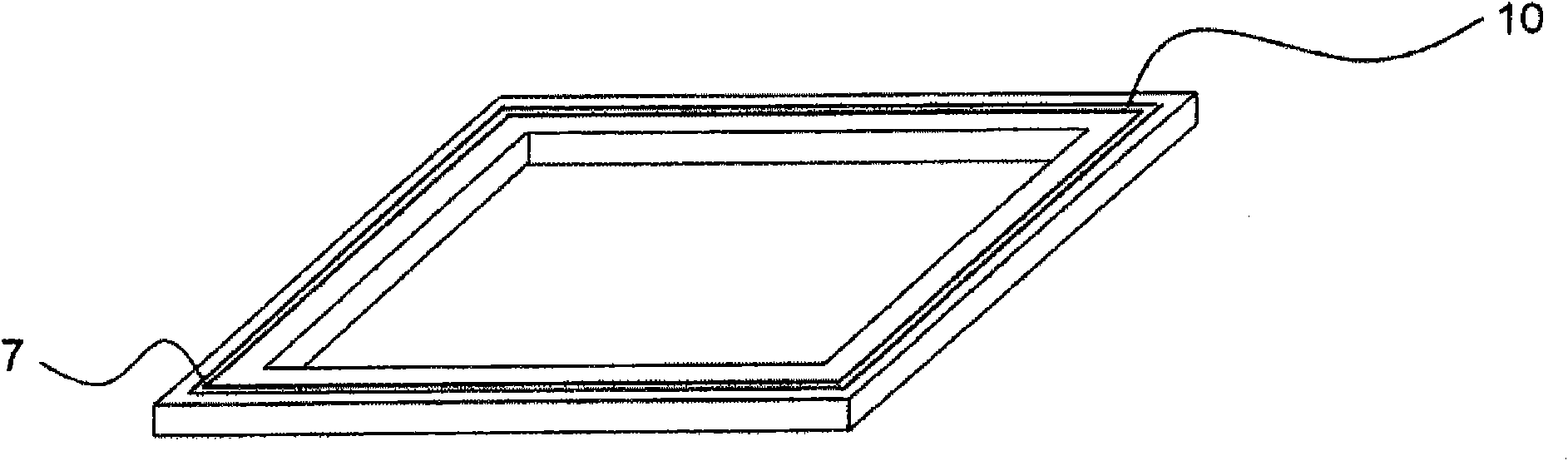

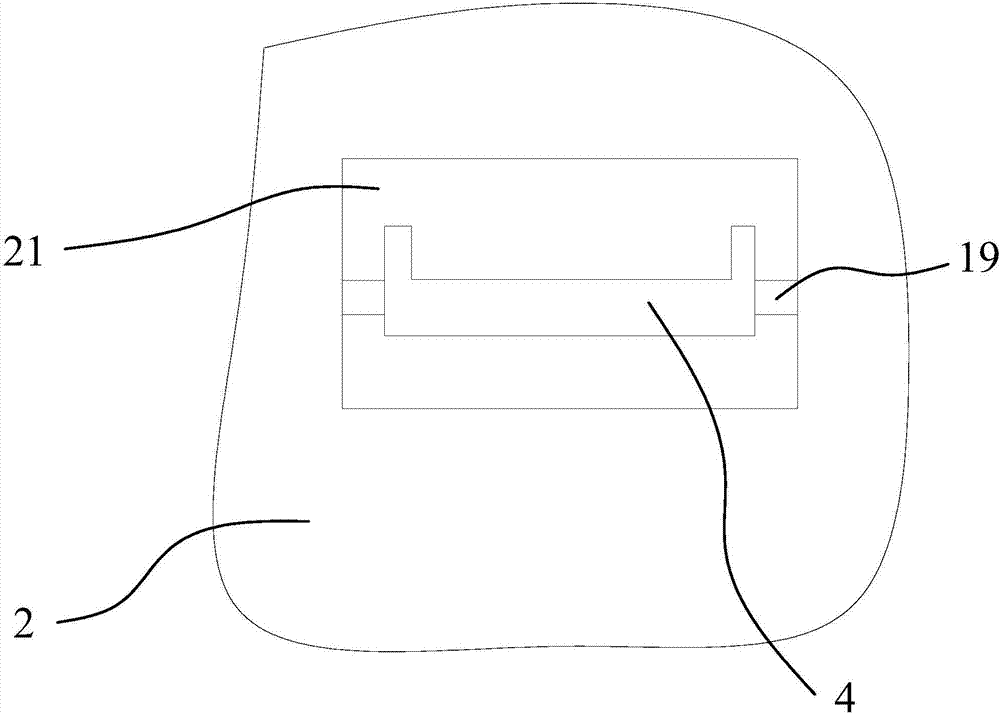

Frame of large pellicle and grasping method of frame

ActiveCN101689018AEasy to take outReliable controlPhotomechanical apparatusOriginals for photomechanical treatmentEdge surfaceAdhesive materials

A frame of large pellicle comprising a polygonal frame having a plurality of sides, a pellicle film bonded to the upper edge surface of the frame, and an adhesive material applied on the lower edge surface of the frame wherein upon grasping the frame of a large-sized pellicle the longest side of which frame is 1m or longer, the frame has protrusions or recesses for grasping on all sides of the frame. The frame is grasped surely by grasping the protrusions or recesses for grasping at at least one position or more on each side of the frame simultaneously, and the pellicle can be taken out easilyfrom a container without causing distortion or flexure when it is stuck on a photomask, or the like.

Owner:ASAHI KASEI KK

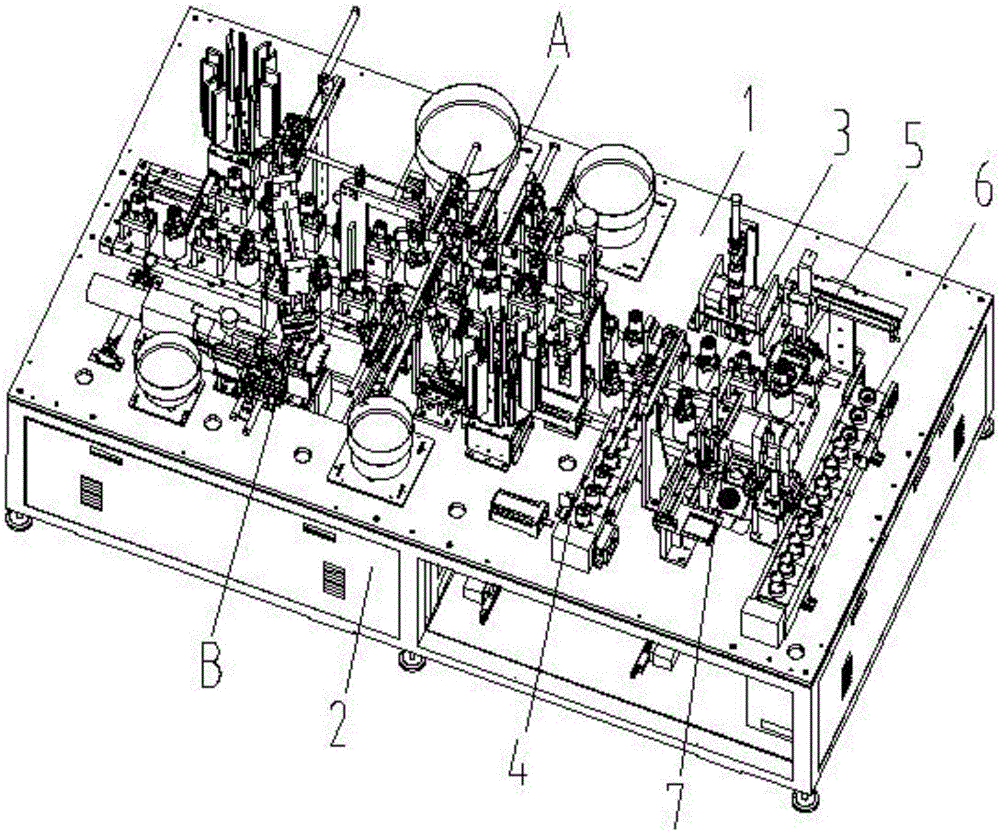

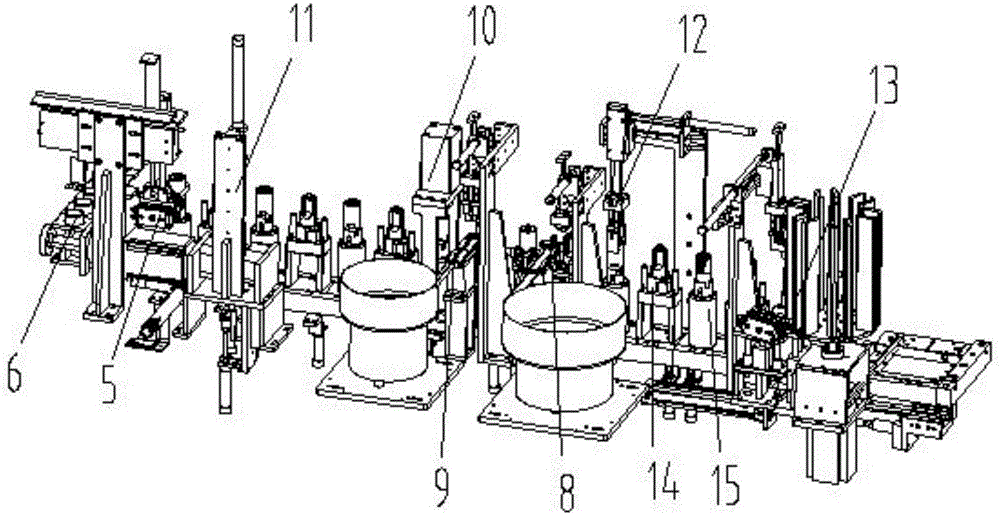

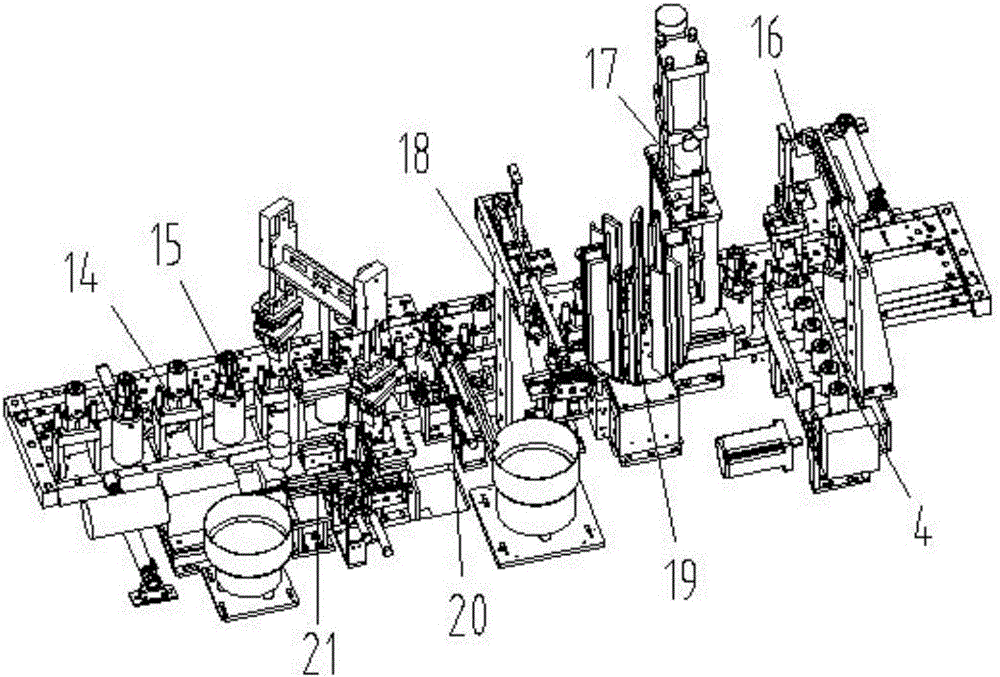

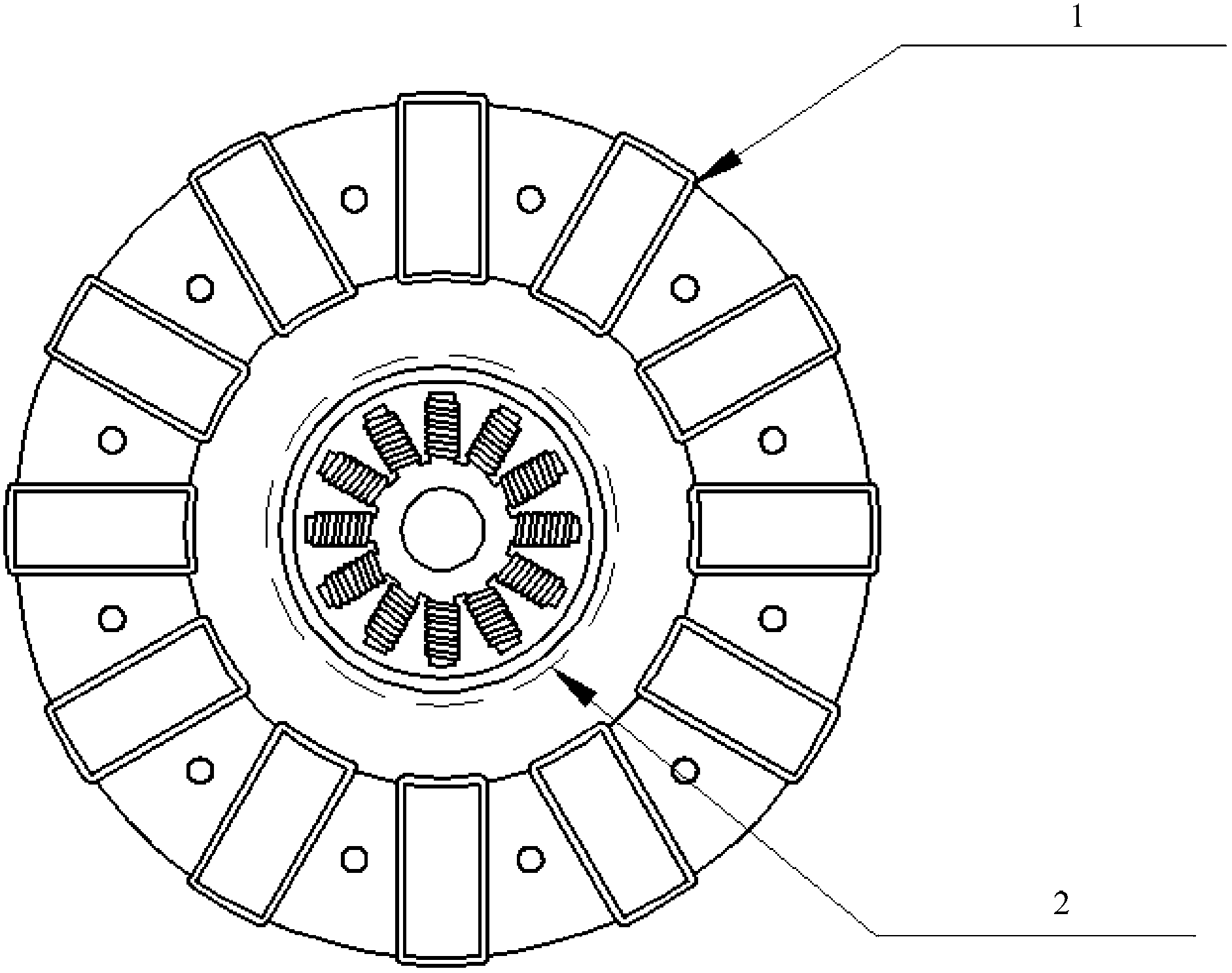

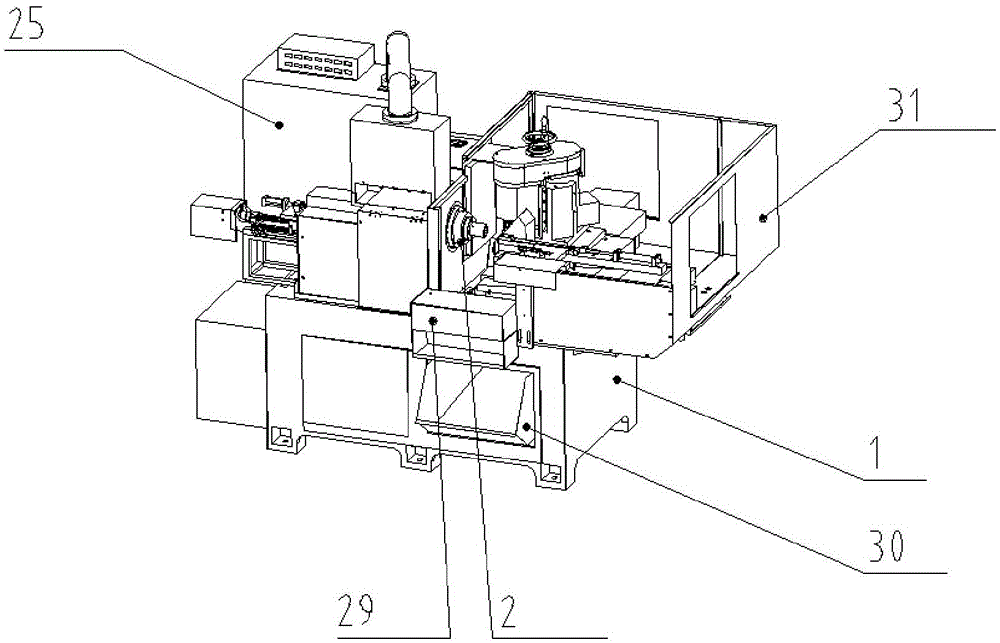

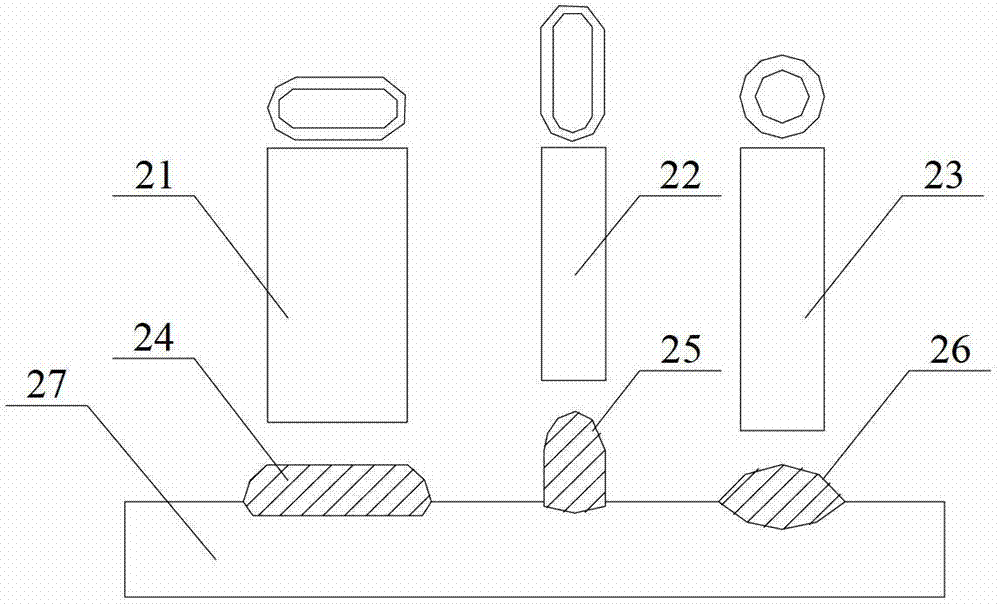

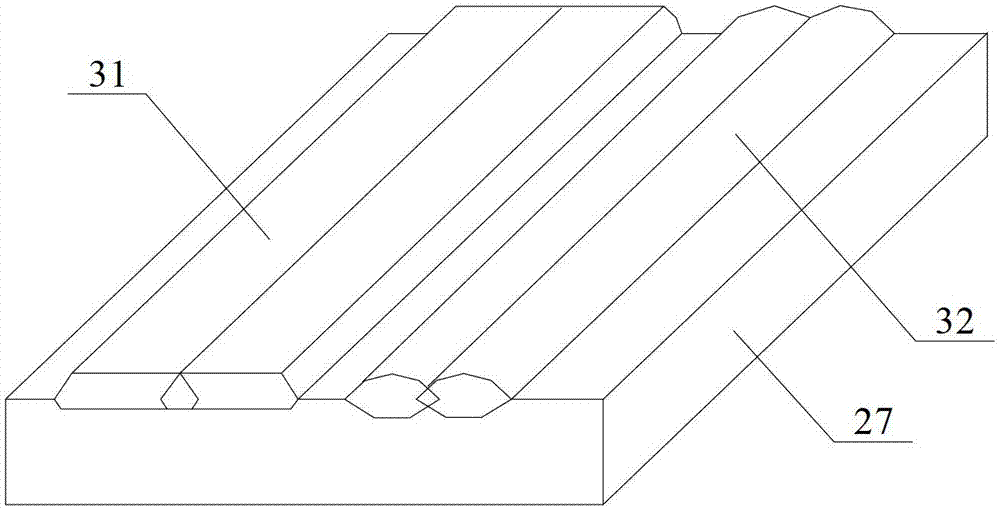

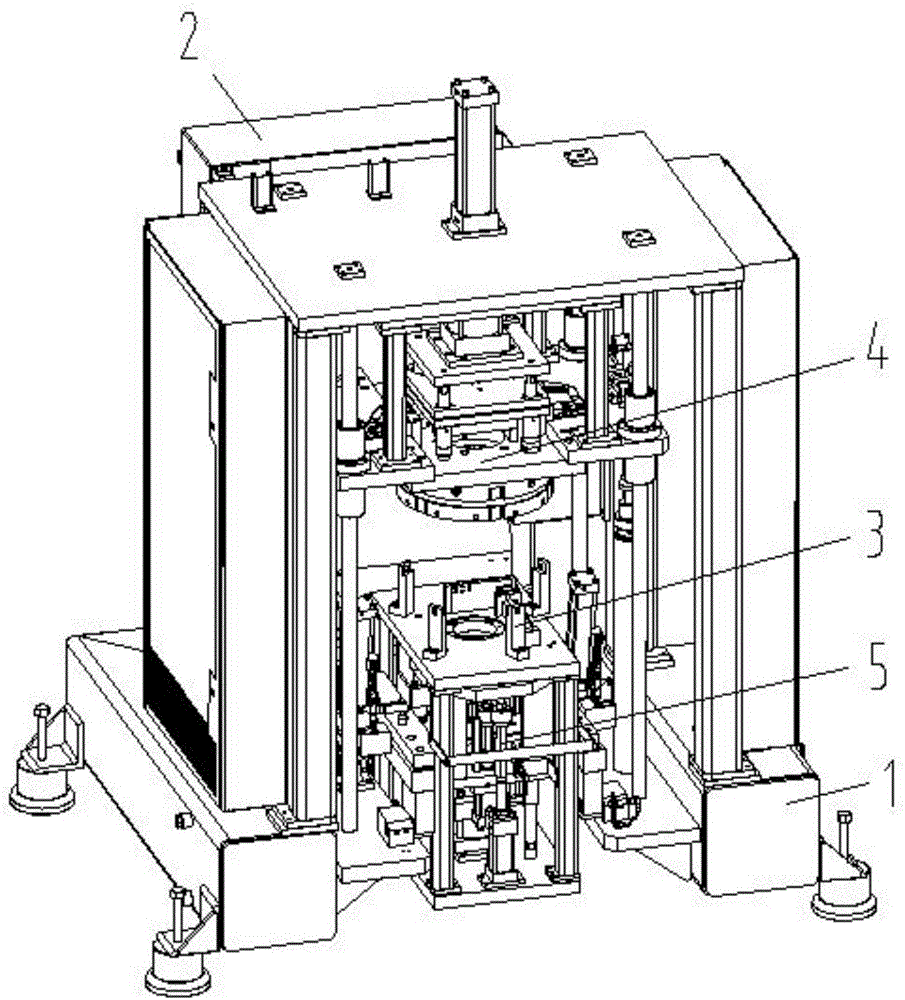

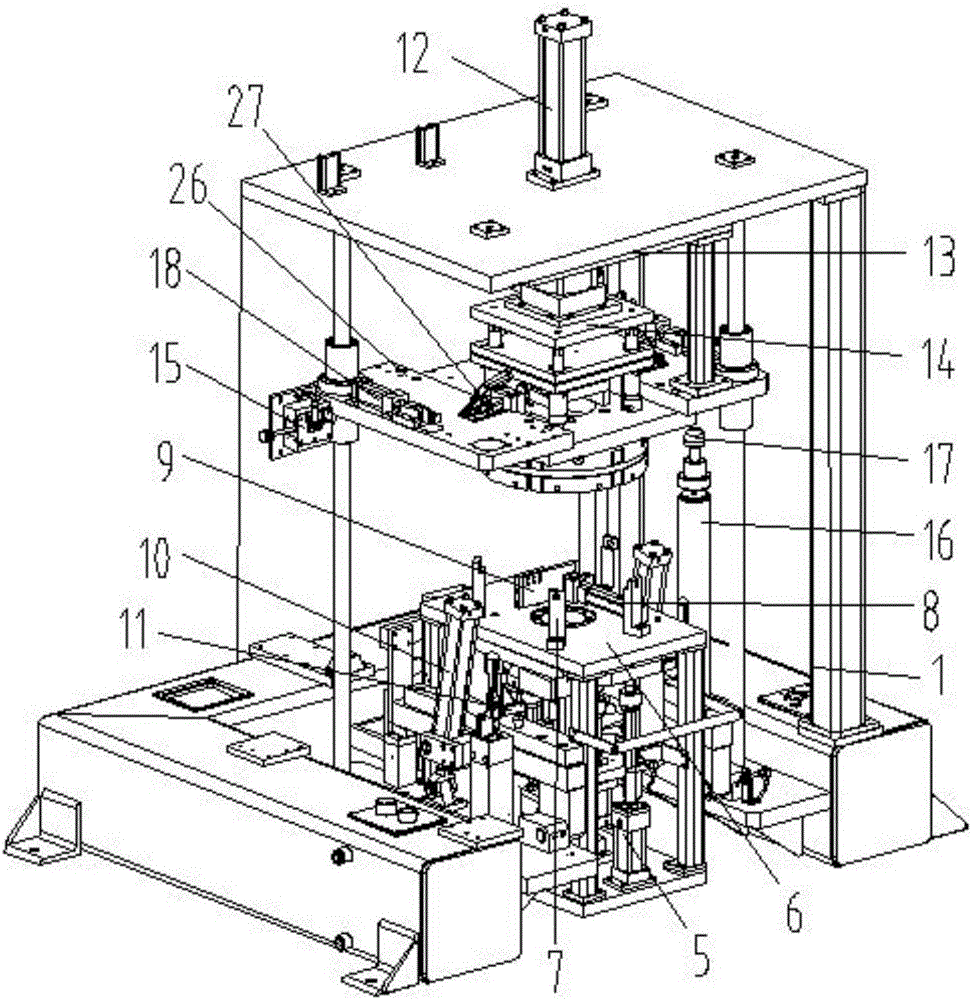

Full-automatic assembly production machine for motor stator

ActiveCN106787494AImprove efficiencySimple structureManufacturing stator/rotor bodiesManipulatorStator

The invention relates to a full-automatic assembly production machine for a motor stator. The full-automatic assembly production machine comprises a frame and a distribution control box, a conveying device is arranged on the frame and comprises two feeding devices, feeding blocks are arranged on the feeding devices, transposition cylinders are arranged at ends of the two feeding devices, shell assembly carriers and magnetic tile assembly carriers are arranged on the feeding blocks, a clamp spring feeding device, an oil bearing feeding device, a shell feeding manipulator, a riveting device, a grounding terminal assembly device, a left magnetic tile feeding device, a magnetic tile spring piece feeding device, a right magnetic tile feeding device, a sleeving manipulator, a compression device, a magnetizer and a turnover discharging device are arranged on the frame, the shell feeding manipulator is matched with a shell conveying belt on the frame, and the turnover discharging device is matched with a discharging conveying belt on the frame. Integrated automatic assembly is realized, and assembly efficiency is greatly improved.

Owner:ANHUI DALAI MOTOR CO LTD

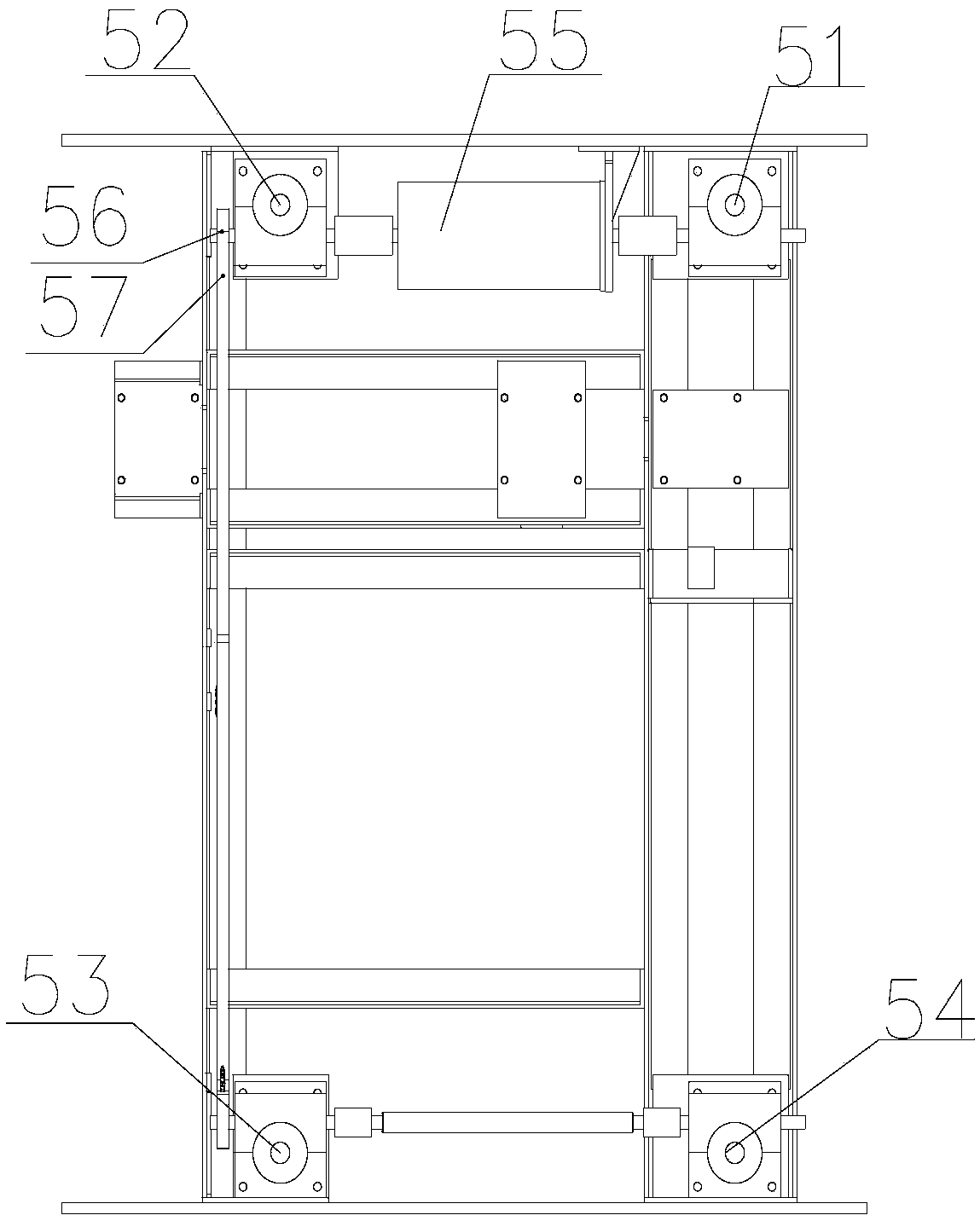

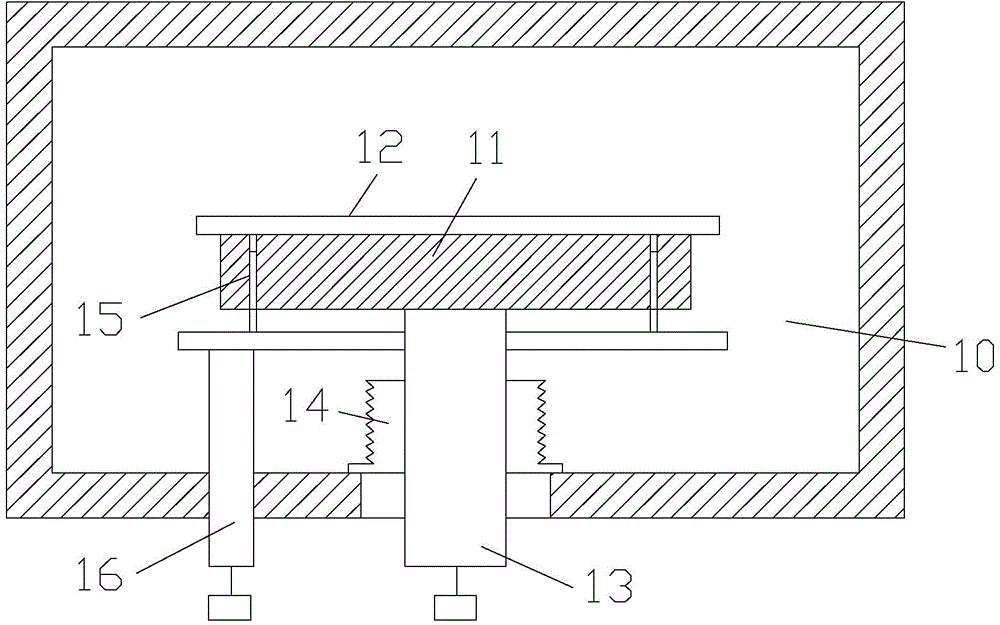

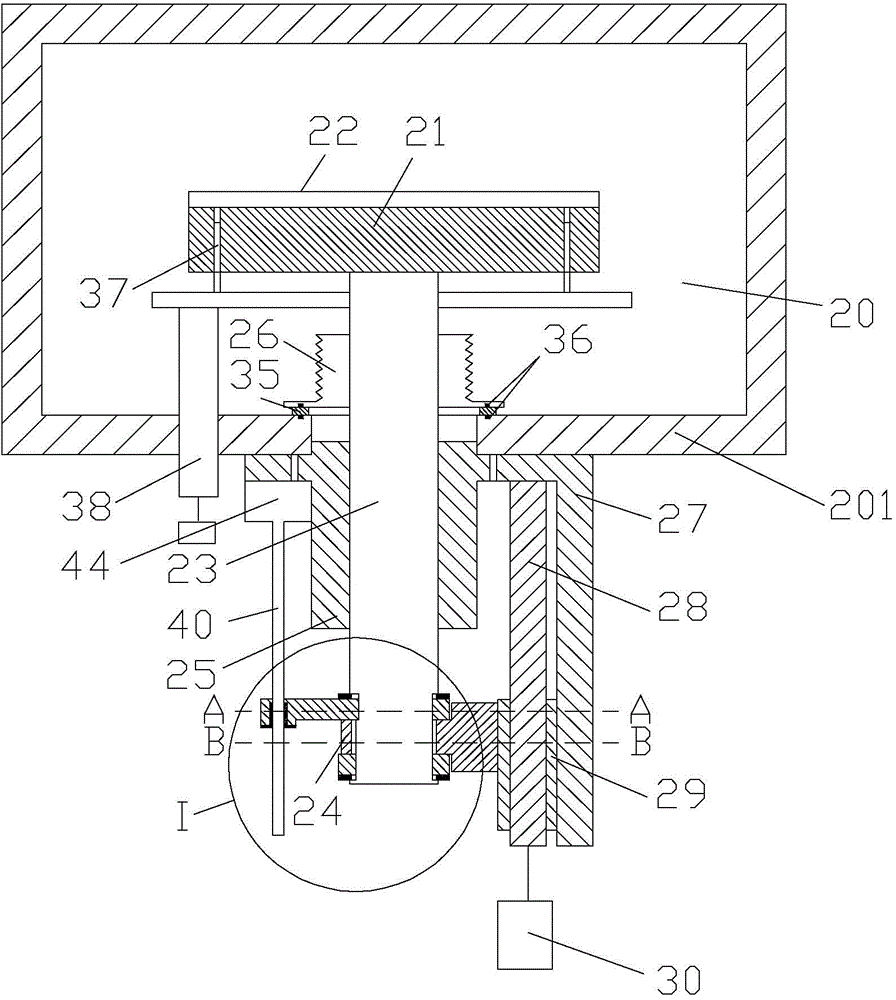

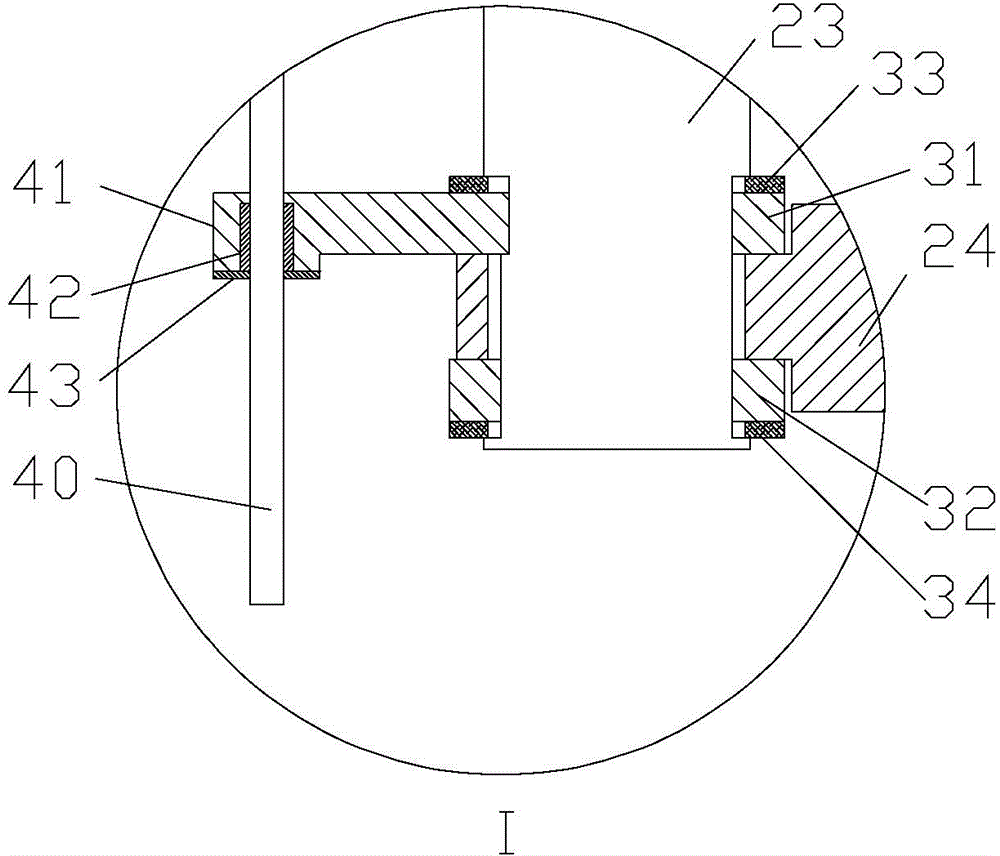

Carrying platform elevating gear, reaction cavity, and plasma processing device

ActiveCN104465447AGuaranteed levelnessEliminate redundant constraintsElectric discharge tubesVacuum evaporation coatingRotational degrees of freedomEngineering

The invention provides a carrying platform elevating gear, a reaction cavity, and a plasma processing device. A bracket driving source drives a shaft lifting bracket to do lifting motion. A bellows shaft passes through the shaft lifting bracket and is fixedly connected with the shaft lifting bracket, so as to do lifting motion with the shaft lifting bracket in a linear bearing, thereby realizing lifting motion of the carrying platform which is fixed on the bellows shaft. In the carrying platform elevating gear, a guiding mechanism is used to limit axial rotation of the bellows shaft in a lifting process. The bellows shaft passes through the linear bearing, a guiding shaft installing assembly, and a shaft lifting bracket in sequence. The guiding shaft installing assembly tightly holds the bellows shaft. The upper end of the guiding shaft is fixed on the cavity wall of the reaction cavity. The lower end of the guiding shaft passes through the guiding shaft installing assembly, so that the guiding shaft installing assembly does lifting motion with the shaft lifting bracket along the guiding shaft. The carrying platform elevating gear can limit rotation degree of freedom of a connecting rod, so as to ensure a carrying device from deflecting.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

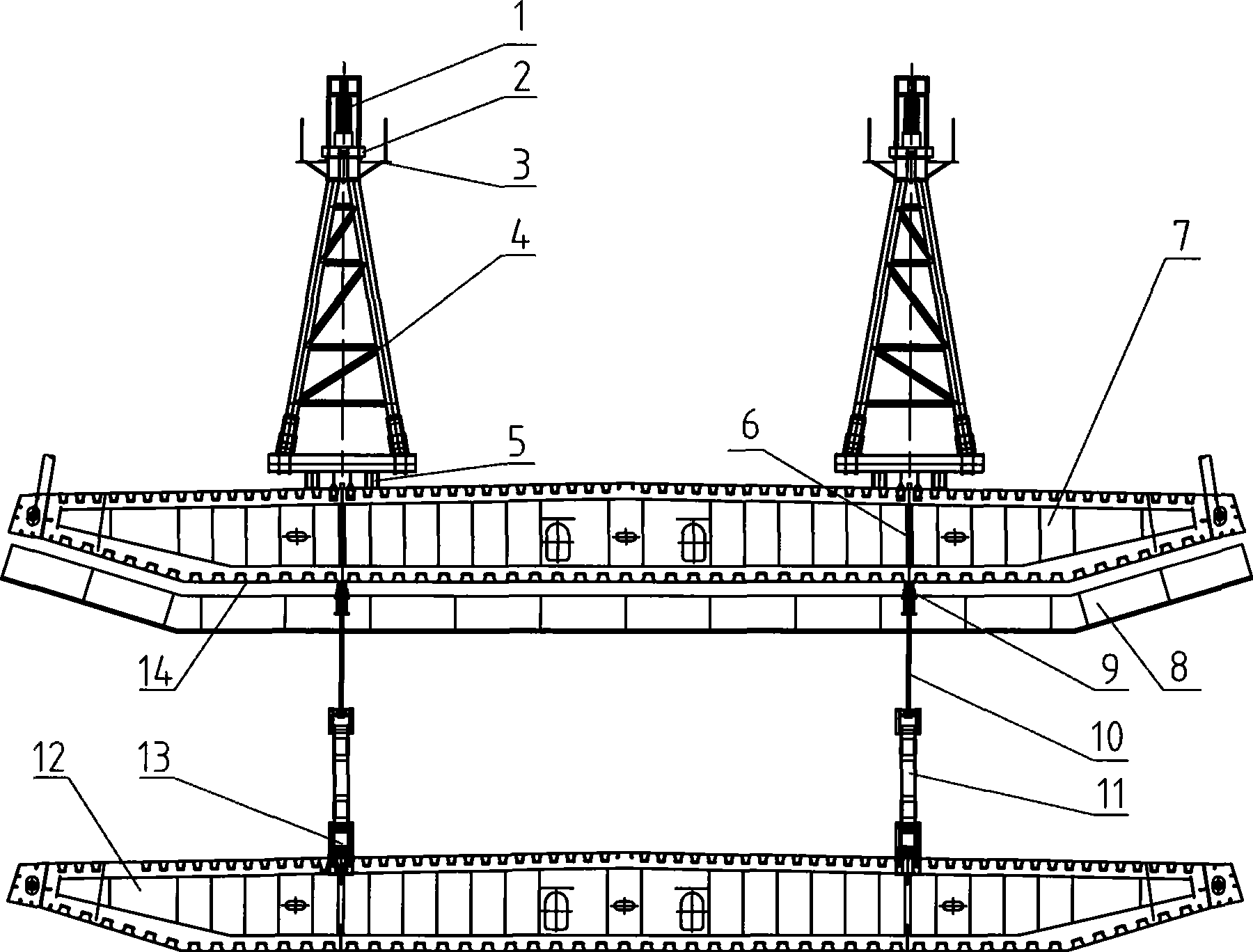

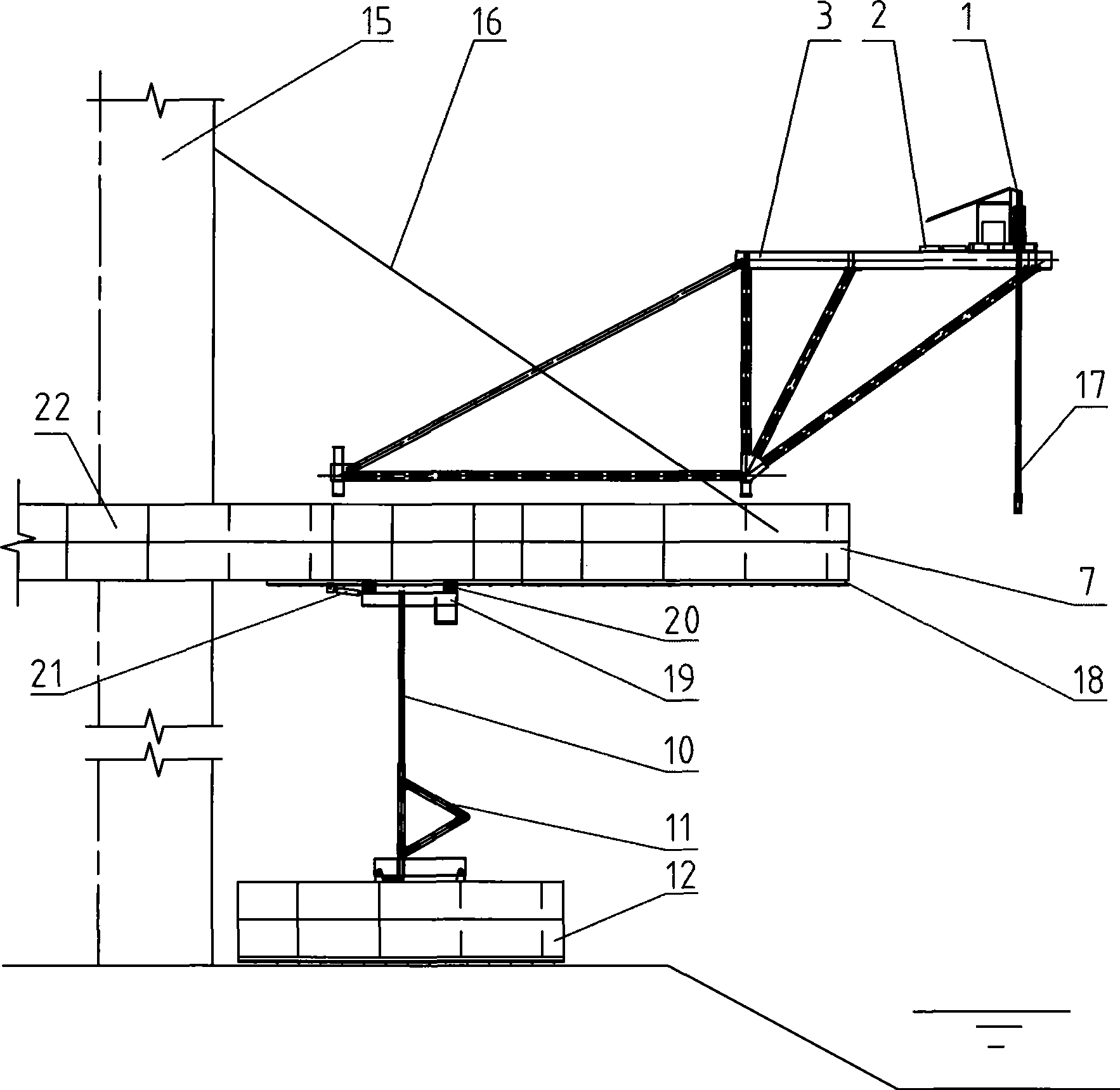

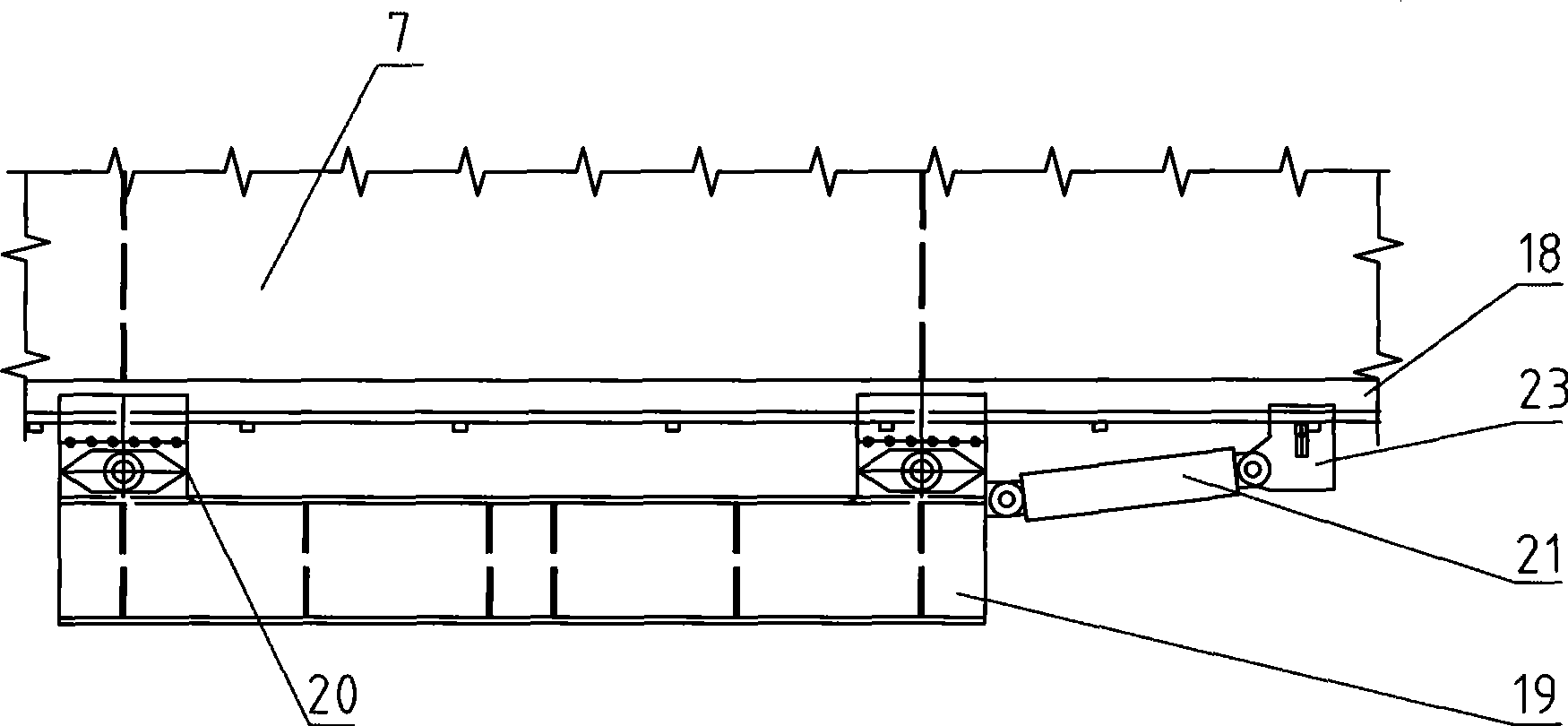

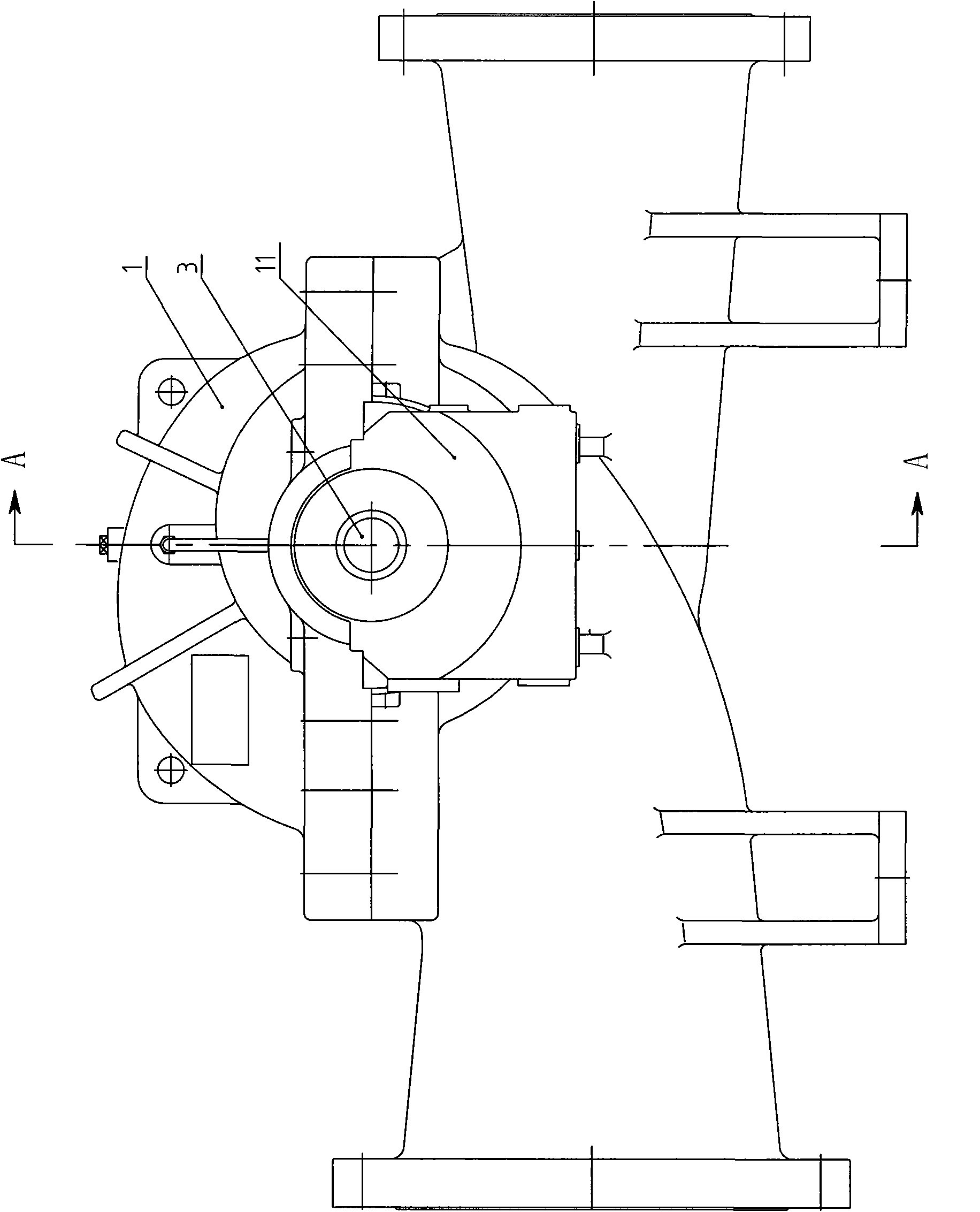

Construction methods of hanging beam and assembling cantilever in the bottom of steel case beam

ActiveCN101377072AReduce lossNo deflectionBridge erection/assemblyBridge materialsCantileverSteel box girder

The present invention discloses a construction method in which a steel box girder is hung on a girder bottom to be transported and is assembled by cantilevers. The construction method includes the following steps: a track is arranged on the bottom of a steel box girder; below the steel box girder, a hydraulic creeping formwork mechanism arranged under the steel box girder is utilized to transport a steel box girder to be assembled; and meanwhile, triangular hanging frames are adopted to change hanging points. The present invention provides the method for assembling the steel box girders of a low-cost bridge, which is generally used for the construction of bridges in wide and shallow rivers without navigation conditions and mountainous areas as well as the construction of bridges in rivers with ordinary navigation conditions, and the efficiency of the whole construction process is high.

Owner:SHANDONG LUQIAO GROUP

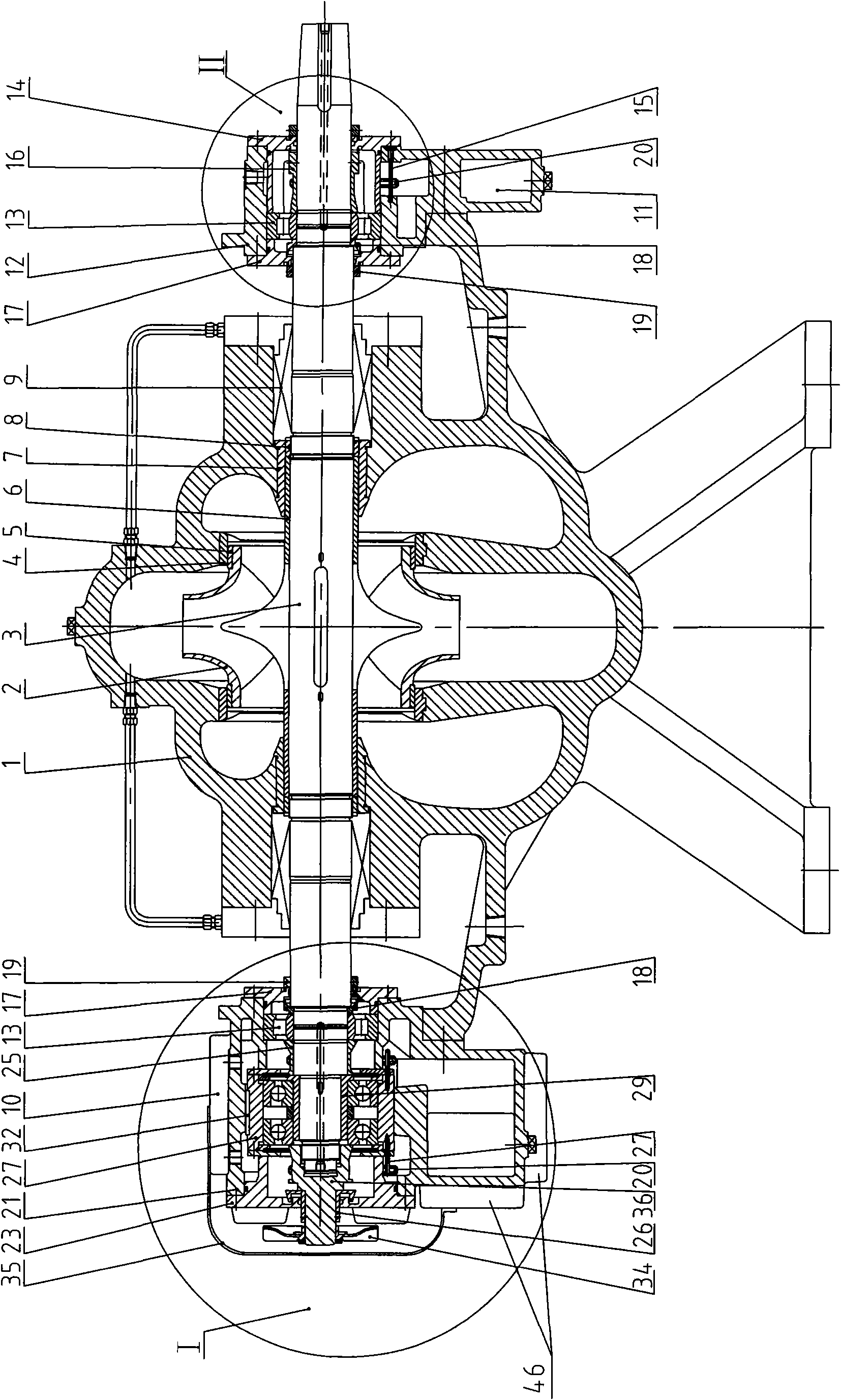

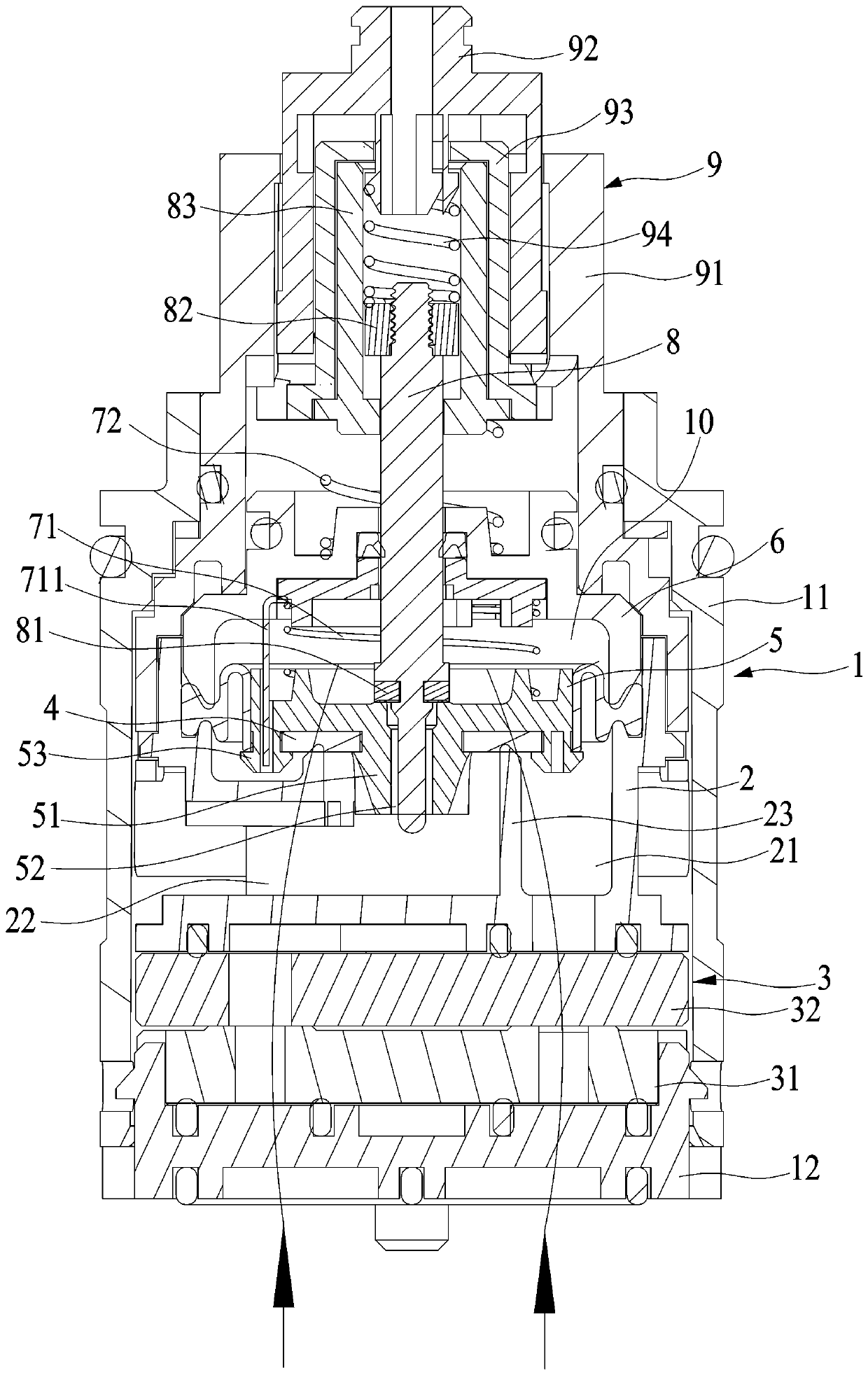

Pipeline delivery pump

ActiveCN101994701AEasy to disassembleShorten maintenance timePump componentsRadial flow pumpsImpellerDesalination

The invention relates to a pipeline delivery pump, which is suitable for the pipeline delivery of crude oil and natural gas and the sea water transportation in long distance in the field of desalination of sea water. The pump comprises a pump body, an impeller, a shaft, a left bearing device and a right bearing device; the impeller is arranged on the shaft in the pump body; two ends of the shaft extending out of the pump body are respectively provided with the left and right bearing devices which are connected with the pump body; the shaft end of the right bearing is connected with the outputshaft of a motor; two ends of the shaft are respectively provided with an axial hole; a shaft platform is arranged on the shafts of the first bearings of the left and right beating devices; and a circular groove is arranged in the middle of the shaft platform; and any part of the circumference of the circle groove is provided with a radial hole communicated with the axial hole. In the invention, the problems of difficult disassemble of the pipeline delivery pump bearing and unbalanced axial force are solved, and the bearing is extremely convenient and rapid to disassemble and maintain, a great amount of time is saved, and the work efficiency is greatly improved; and in addition, the impact of the axial force to the bearing is reduced and the service life of the bearing is improved by improving the structure of the bearing device.

Owner:辽宁恒星泵业有限公司

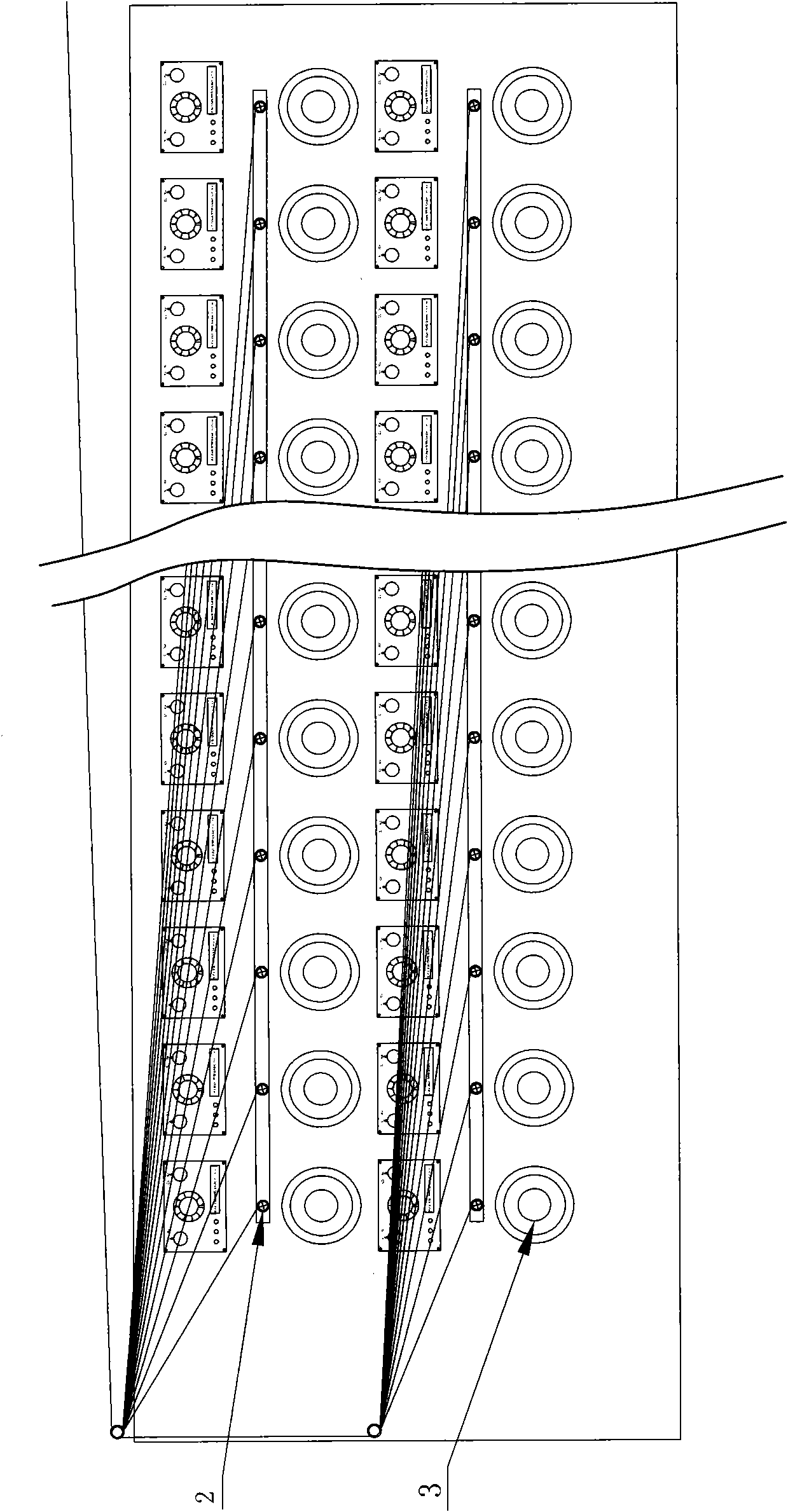

Wire-arranging mechanism of multi-head wire-rewinding machine and numerical control wire-arranging method

InactiveCN101863398AReduce distractionsReduce production capacityFilament handlingManufacturing cost reductionNumerical control

The invention relates to the field of wire-arranging technology of a multi-head wire-rewinding machine, in particular to a wire-arranging mechanism of the multi-head wire-rewinding machine and a numerical control wire-arranging method. The wire-arranging mechanism of the multi-head wire-rewinding machine comprises a stander, a PLC controller, a screw rod driving device, wire-arranging guide wheels, a reversing guide wheel and a wire-arranging guide wheel driving device, wherein the wire-arranging guide wheel driving device is connected with the wire-arranging guide wheels; the screw rod driving device comprises a screw rod, a screw rod nut, an approach switch, two screw rod bearing seats, two synchronous belt pulleys, a synchronous belt and a constant speed motor, wherein the screw rod nut is connected with the wire-arranging guide wheel driving device; the PLC controller is connected with the approach switch and the constant speed motor; and the PLC controller is provided with a forward rotation monitoring timer, a reverse rotating monitoring timer, a millisecond-level reversing timer and a speed increasing and reducing timer. The invention not only reduces the interference amongwires and the production accidents and improves the wire-arranging quality and finished product wire quality, but also simplifies the structure, is easy for operation and reduces the manufacturing and maintaining costs.

Owner:东莞市康汇聚线材科技有限公司

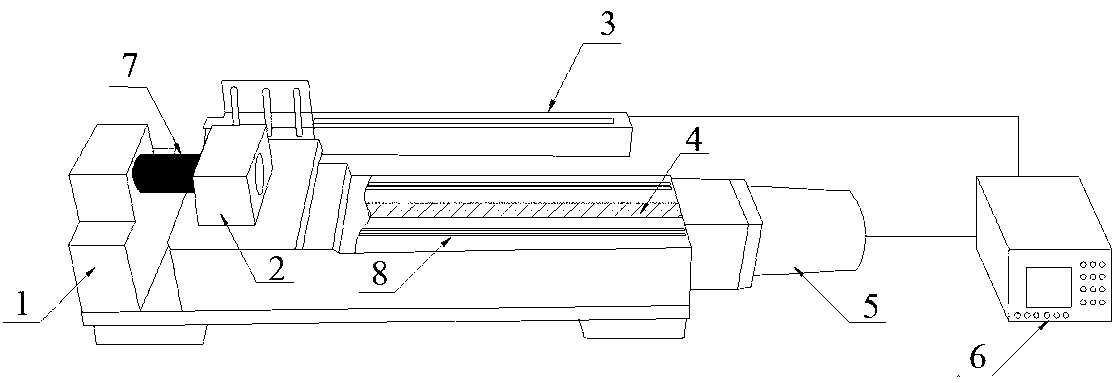

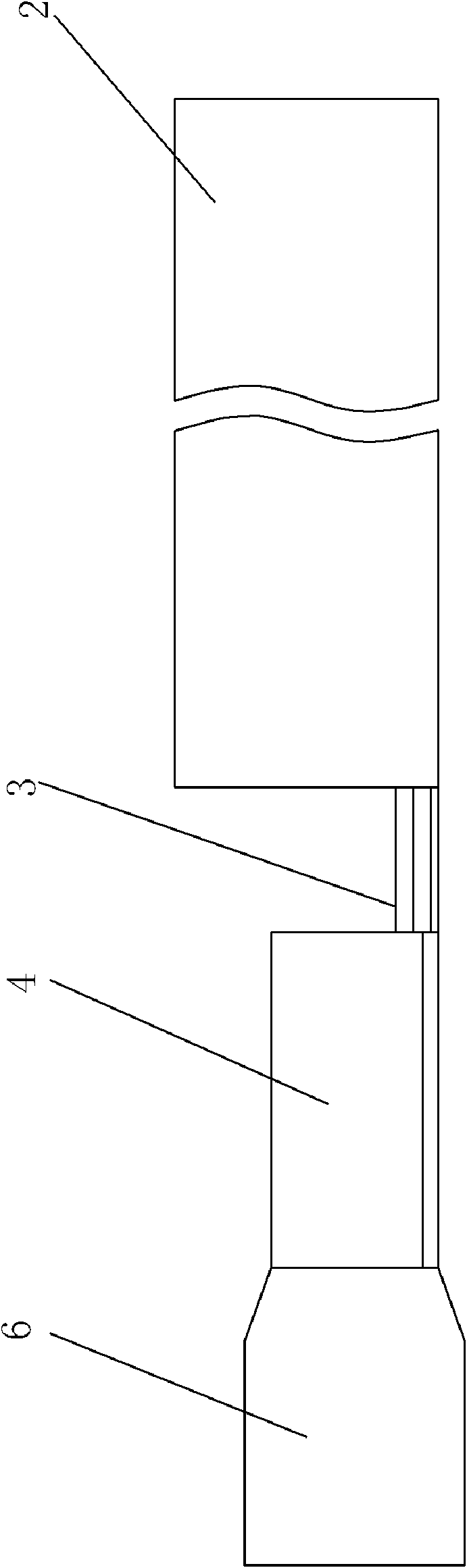

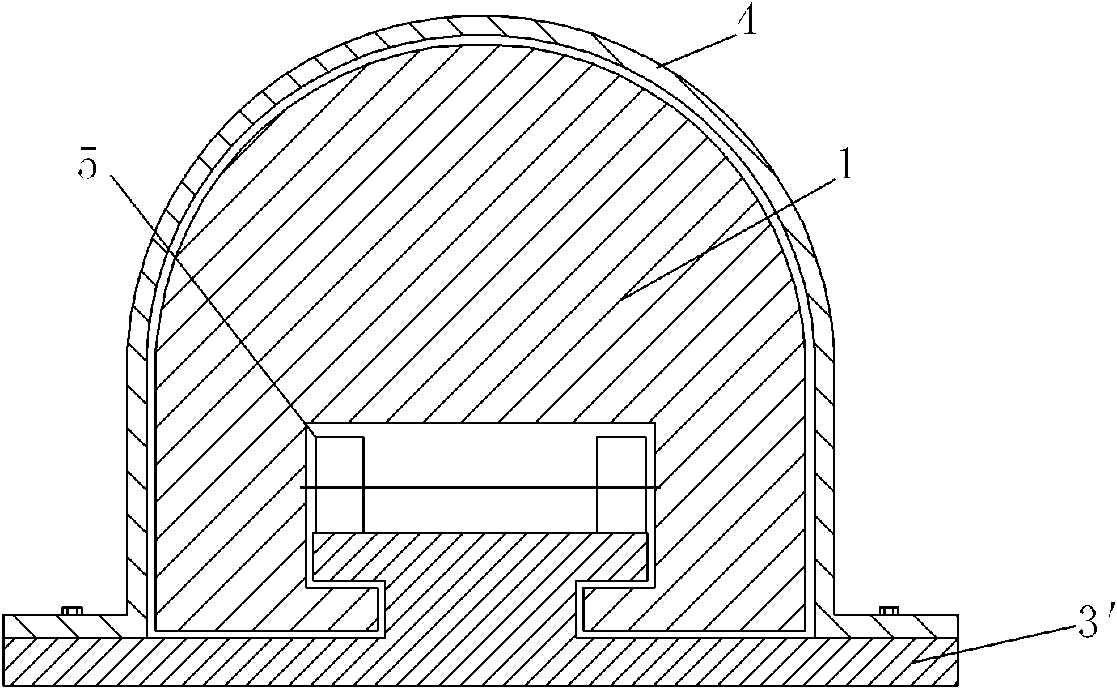

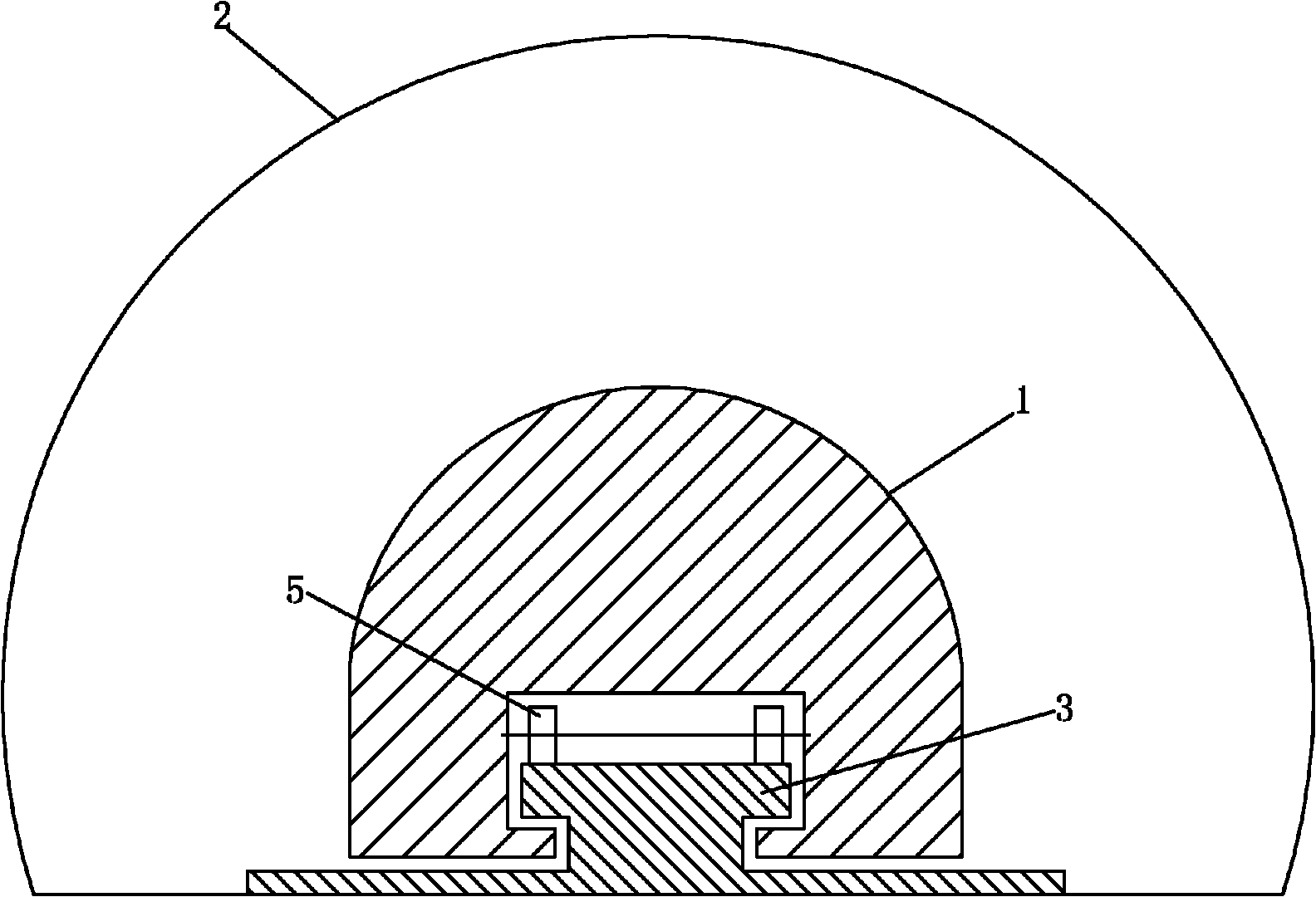

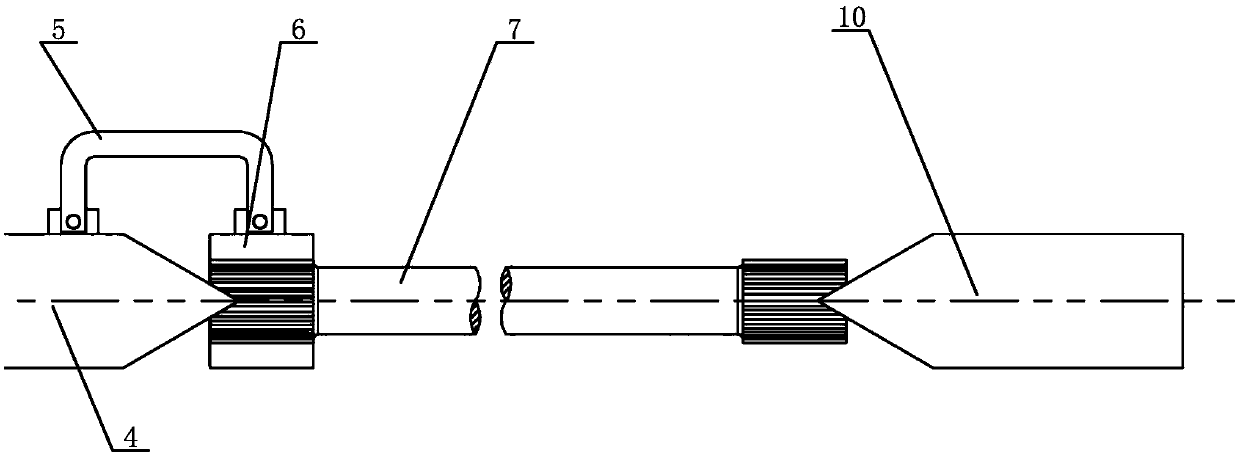

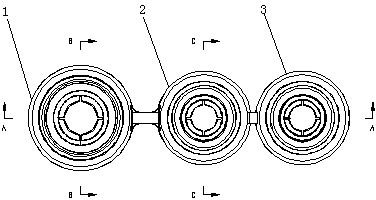

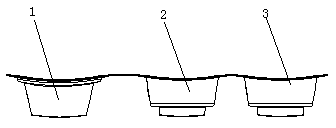

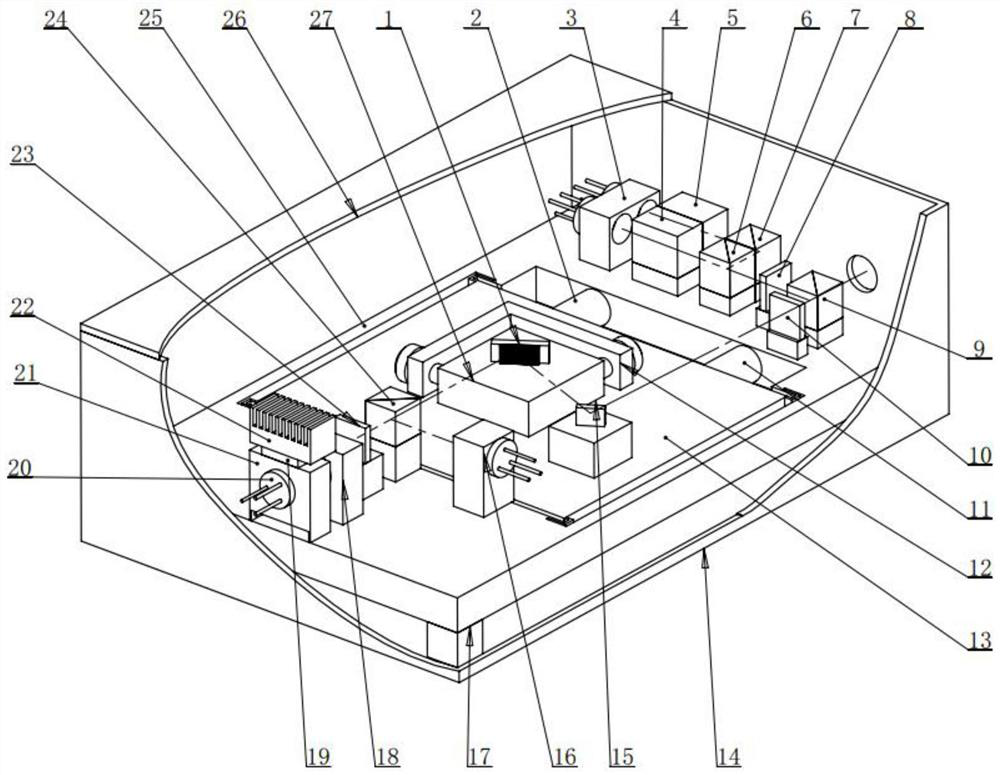

High-speed train-tunnel aerodynamic characteristic movable model experiment system

InactiveCN101852672AThe experimental data is realHigh strengthAerodynamic testingEngineeringHigh speed train

The invention relates to a high-speed train-tunnel aerodynamic characteristic movable model experiment system which comprises an air cannon launching device (6), a train model (1), a tunnel model (2) and a guide rail (3) in the tunnel model (2); the section of the cannon tube (4) of the air cannon launching device (6) is in the shape of a gate arch, the shape of the bottom (3') thereof is the same with the shape of the guide rail (3) in the tunnel model (2), and the bottom (3') and the guide rail (3) in the tunnel model (2) are connected into an integrated structure; and the section of the guide rail (3) is in an I-shaped structure, the middle at the bottom of the train model (1) is matched with the I-shaped structure of the guide rail (3), and the train model (1) is embedded on the guide rail (3) in a sliding mode. Through the system, the train model stably runs on the guide rail, the train model has large size and is more approximate to the real state of train running, and the aerodynamic characteristic of a train running in a tunnel can be better simulated and researched.

Owner:SOUTHWEST JIAOTONG UNIV

Axial actuating device with elastic coupling part

InactiveCN1992483ANo deflectionLimit displacement effectProjector focusing arrangementCamera focusing arrangementRelative displacementAxial displacement

This invention is an axial actuating device with flexible link part, and it can be used to carry objects and make the objects moving along the bearing, which including: the fixed part, the movement part, and the link part. The link part is used to combine the fixed part and the movement part to make the two parts forming mutual axial link state, and the fixed part and the movement part respectively fix the magnet and the coil, so when imposing the current to the movement part, the movement part can generate a relative displacement according to the current size and position, to achieve the purpose of providing the axial displacement, and meanwhile, since the mobile energy comes from the mutually exclusive force of the magnetic field, so it also has shockproof effect.

Owner:IND TECH RES INST

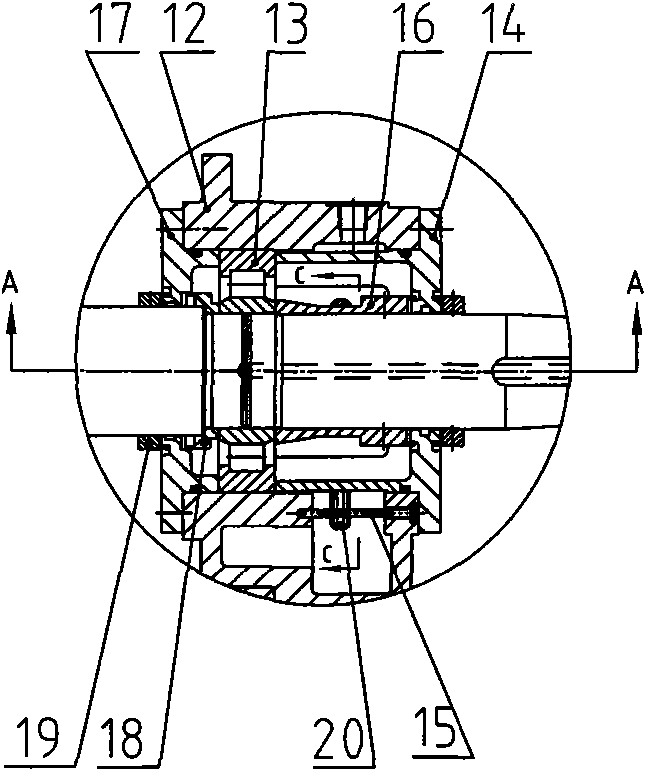

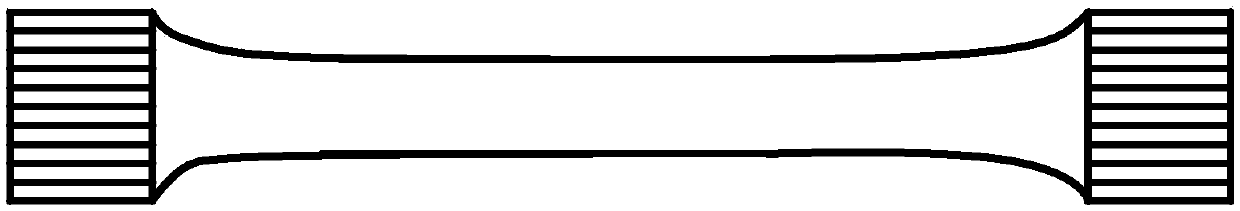

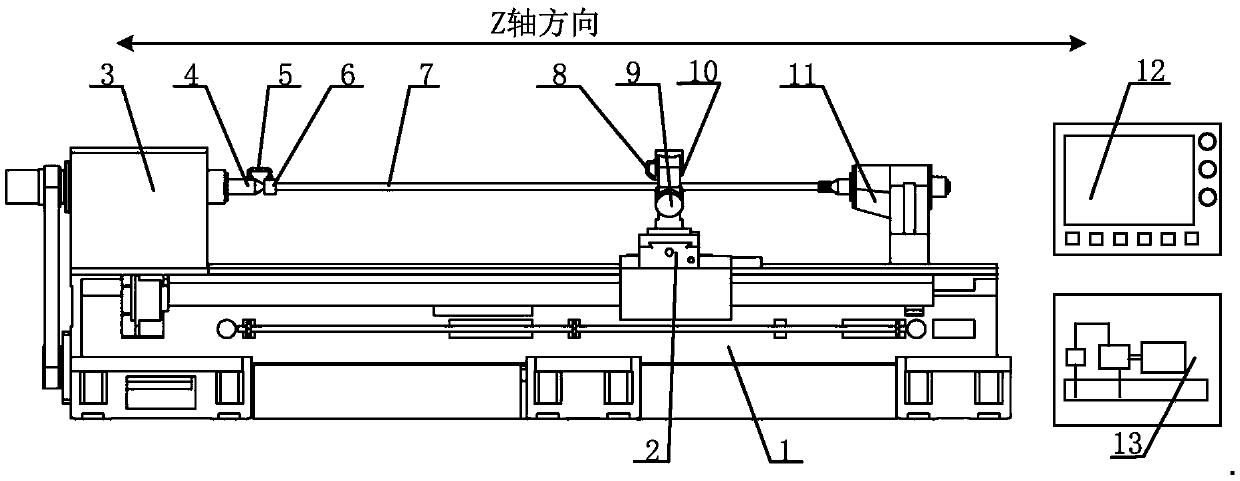

Numerical control rolling machine tool for outer circle rolling of torsion shaft

ActiveCN108673051AFastenedHigh speedWork clamping meansPositioning apparatusHydraulic cylinderEngineering

The invention provides a numerical control rolling machine tool for outer circle rolling machining of a torsion shaft. The numerical control rolling machine tool comprises a machine tool body, an outer circle rolling head, a dual centre locating device, a shifting fork connecting part, an internal spline clamp sleeve, a full closed protection cover, a displacement measurement system, a precise oilmist cooling system, a numerical control system and a hydraulic system. The outer circle rolling head of the machine tool adopts a multi-rolling-wheel symmetric rolling device structure, and when outer circle rolling machining of the torsion shaft is carried out, a workpiece bears multiple equal pressures in the radiation direction; a displacement sensor is mounted in a hydraulic cylinder of theouter circle rolling head, the change value of the rolling diameter in the outer circle rolling process is worked out through the rolling cylinder displacement value fed back by the displacement sensor, and intelligent judgment on the limiting position of the outer circle rolling arc end can be achieved; and the shifting fork connecting part replaces a traditional chuck, a transmission structure is optimized, meanwhile, worker operation is more convenient, the machine tool is more suitable for streamlined production operation, and the rolling machining efficiency is higher.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

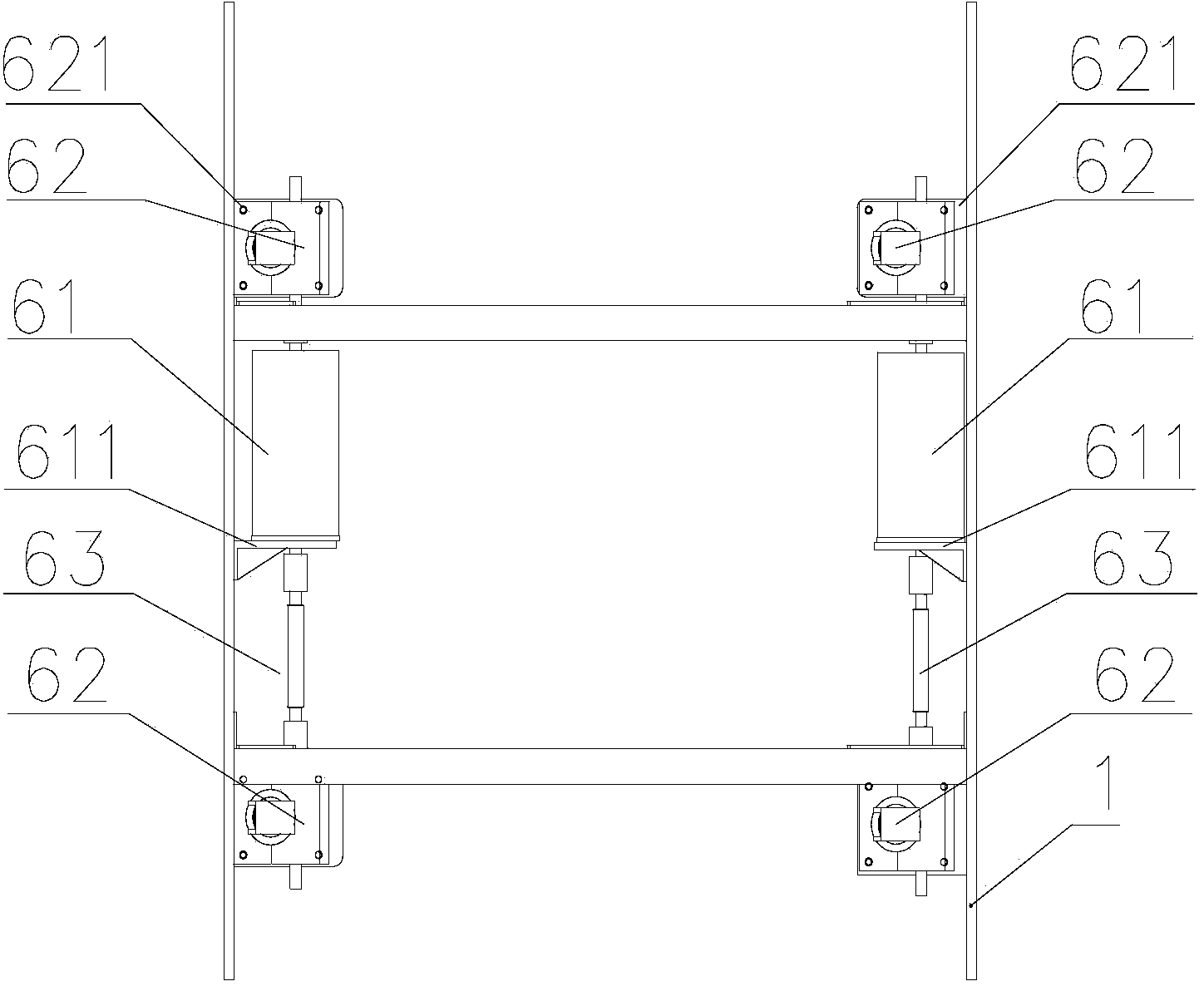

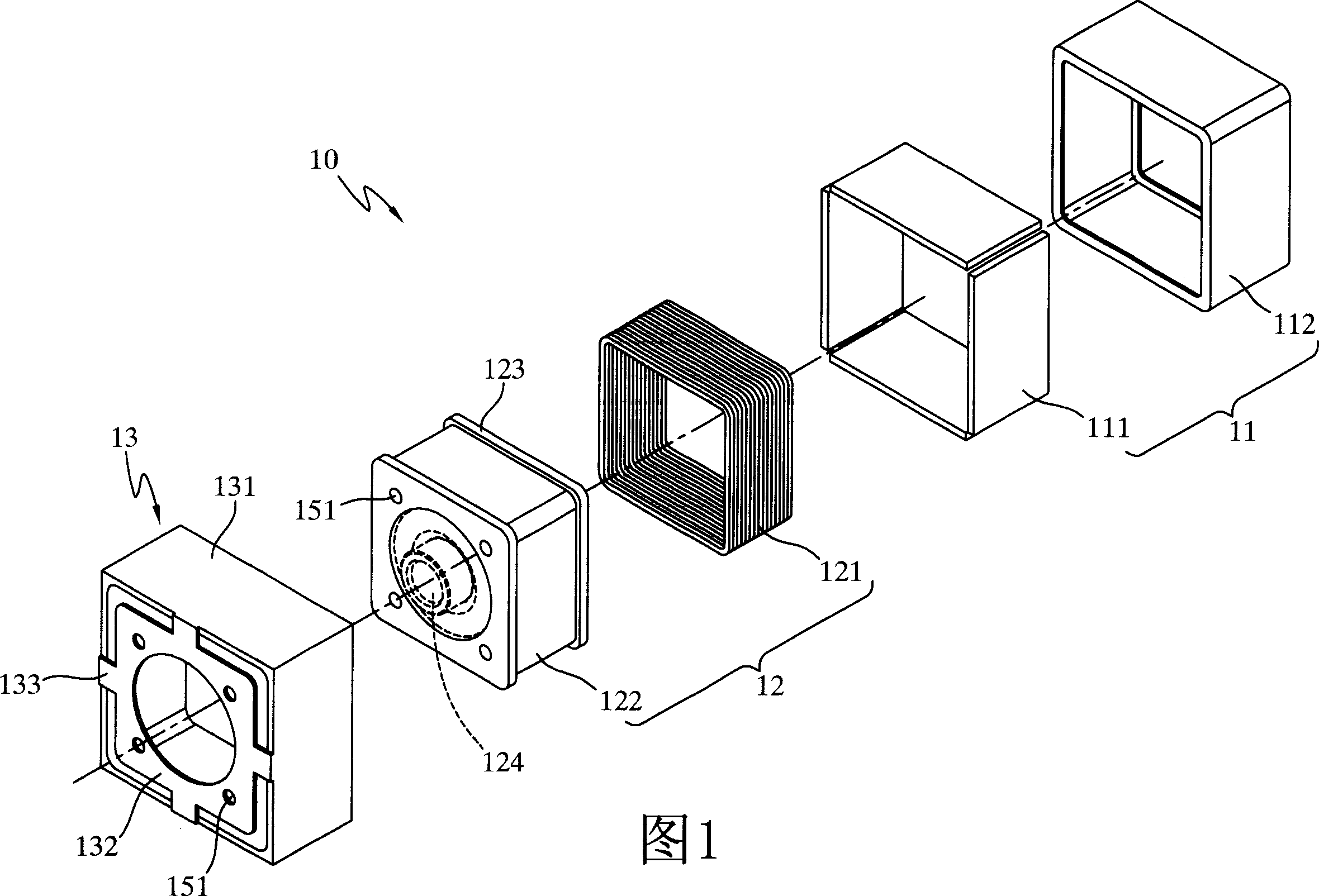

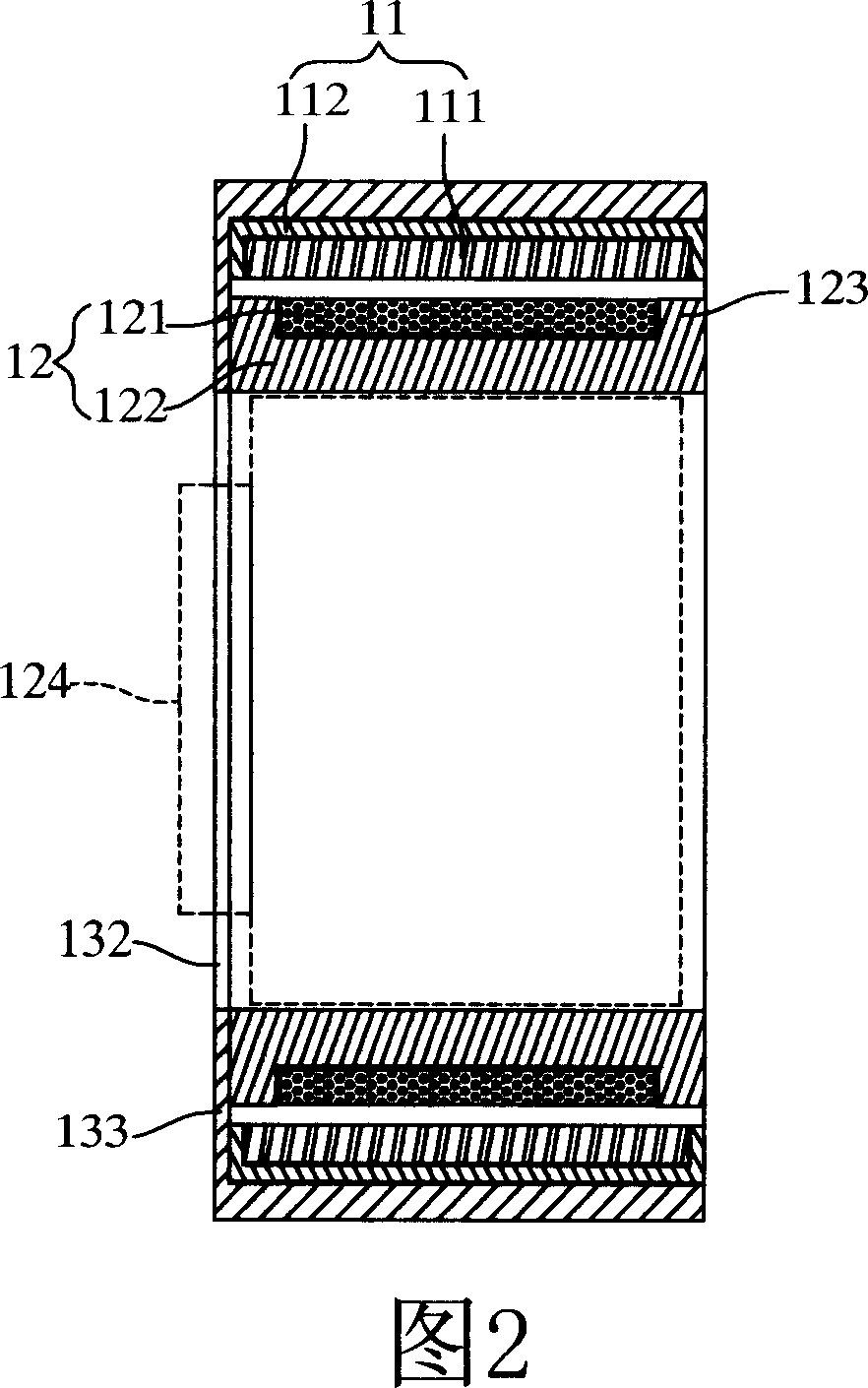

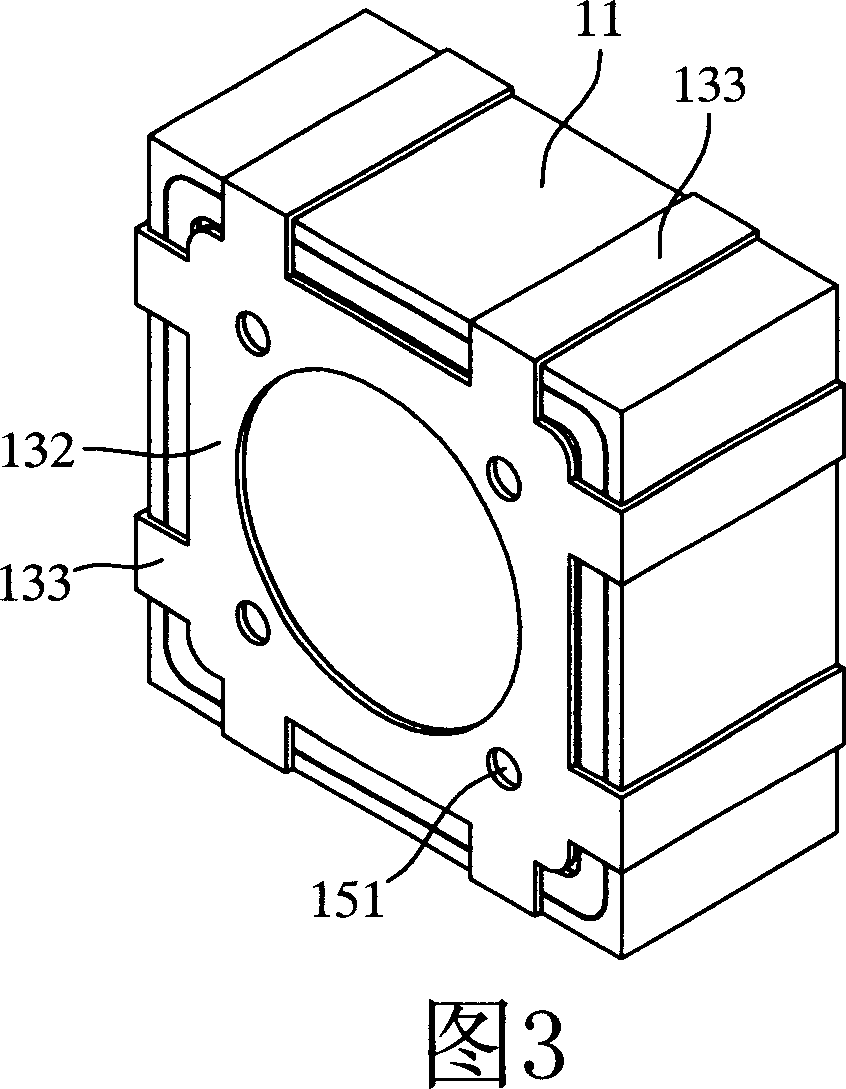

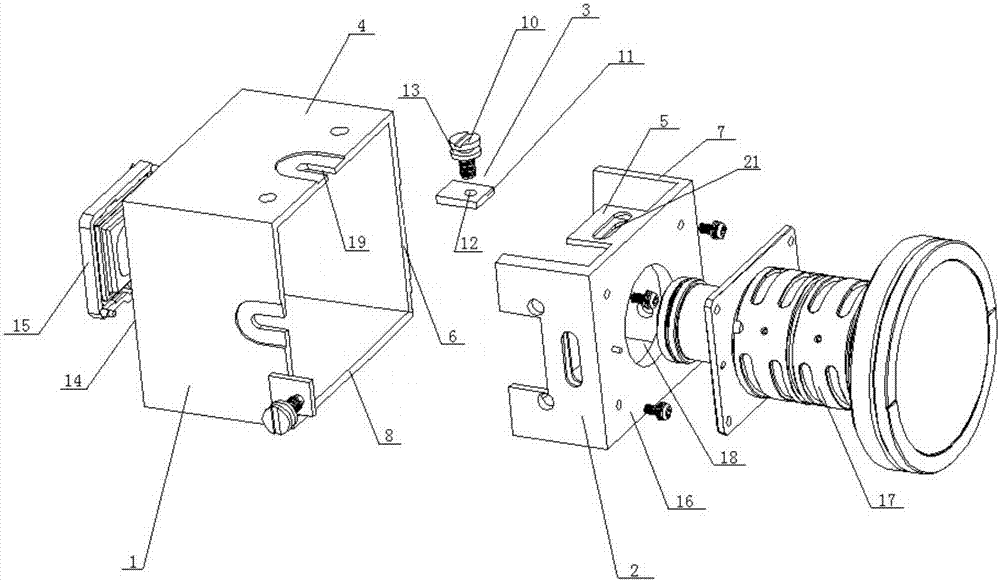

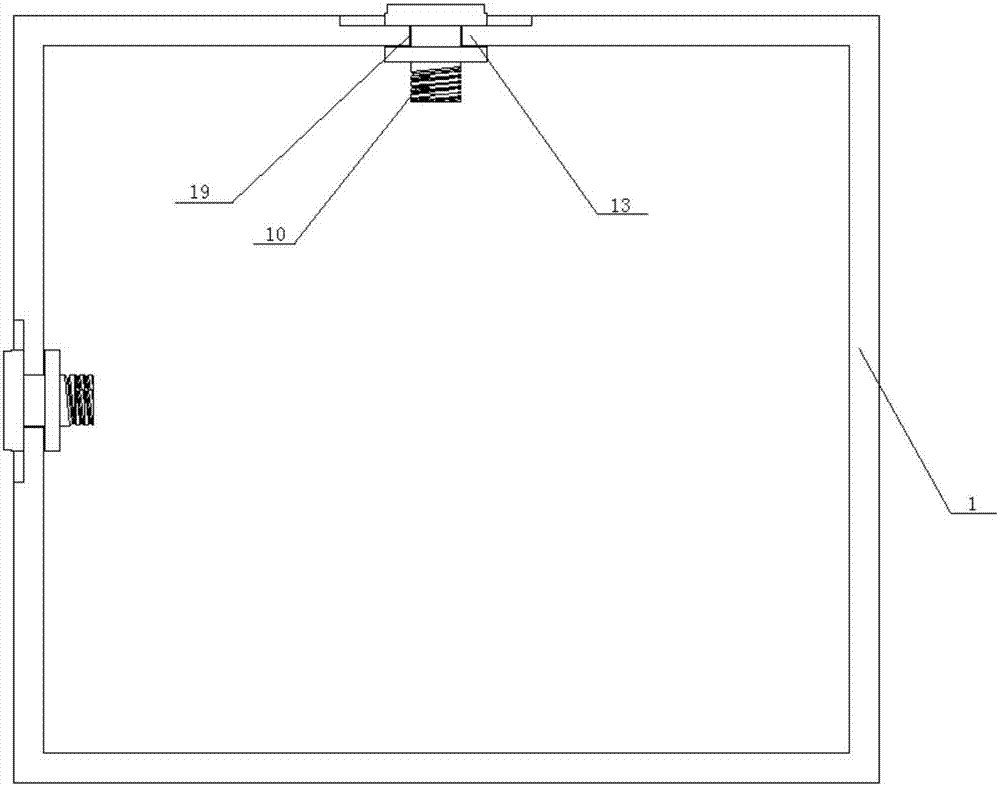

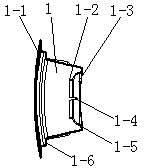

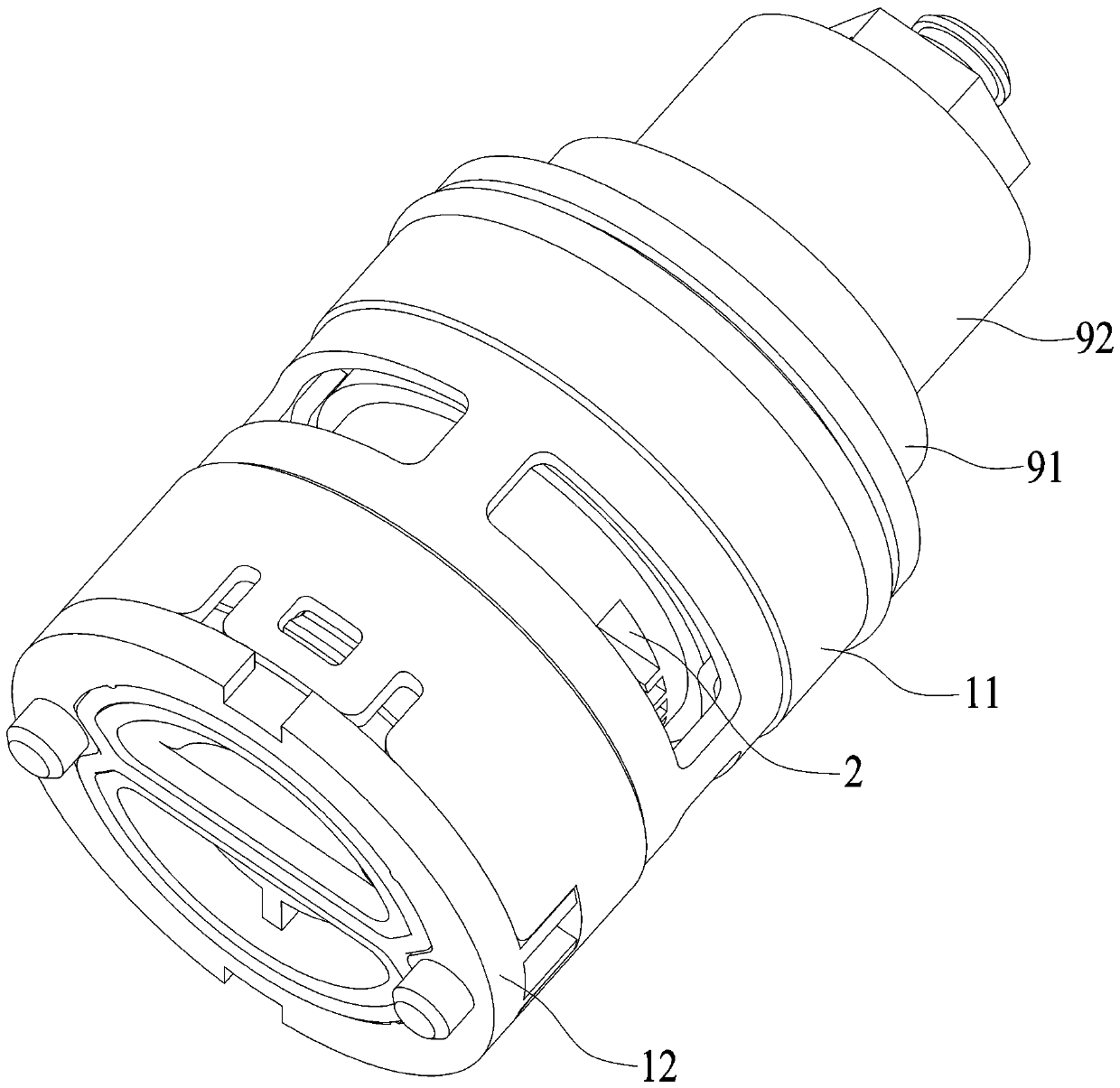

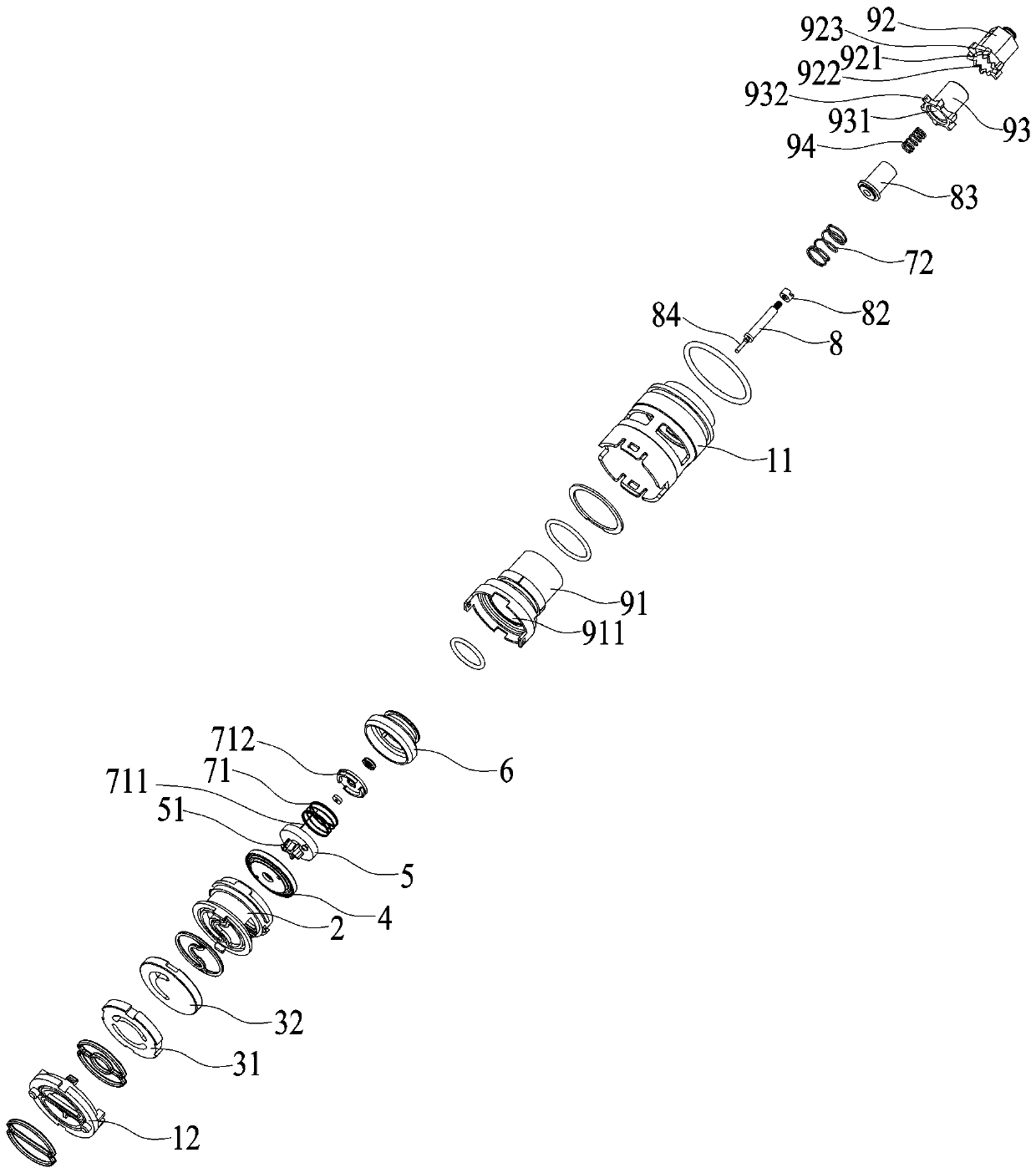

Lens adjusting device

ActiveCN107092154ANo deflectionHigh adjustment accuracyProjectorsCamera lensDigital micro mirror device

The invention discloses a lens adjusting device which comprises a light machine shell, a lens bracket and a sliding adjuster. The sliding adjuster includes at least two horizontal adjusting rods, at least two vertical adjusting rods, at least two horizontal rails parallel to each other and at least two vertical sliding rails parallel to each other. Each of the horizontal rails is equipped with a horizontal adjusting rod, and each of the vertical sliding rails is equipped with at least one vertical adjusting rod. One end of each of the horizontal adjusting rod is fixedly installed at a side wall of one side of the lens bracket, and the other end is fixedly installed to a side wall of the other side of the lens bracket. One end of each of the vertical adjusting rod is fixedly installed at a top wall of the light machine shell, and the other end is fixedly installed to the bottom wall of the light machine shell. When the lens adjusting device is used to adjust a deviation between a lens and a digital micro mirror device of an optical engine, the lens adjusting device can not deflect by itself, the adjusting precision is more accurate, and the applicability is better.

Owner:HISENSE VISUAL TECH CO LTD

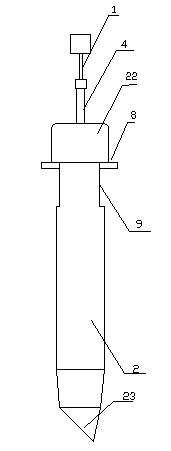

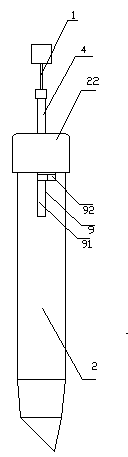

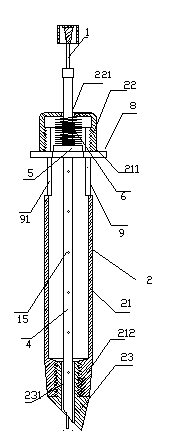

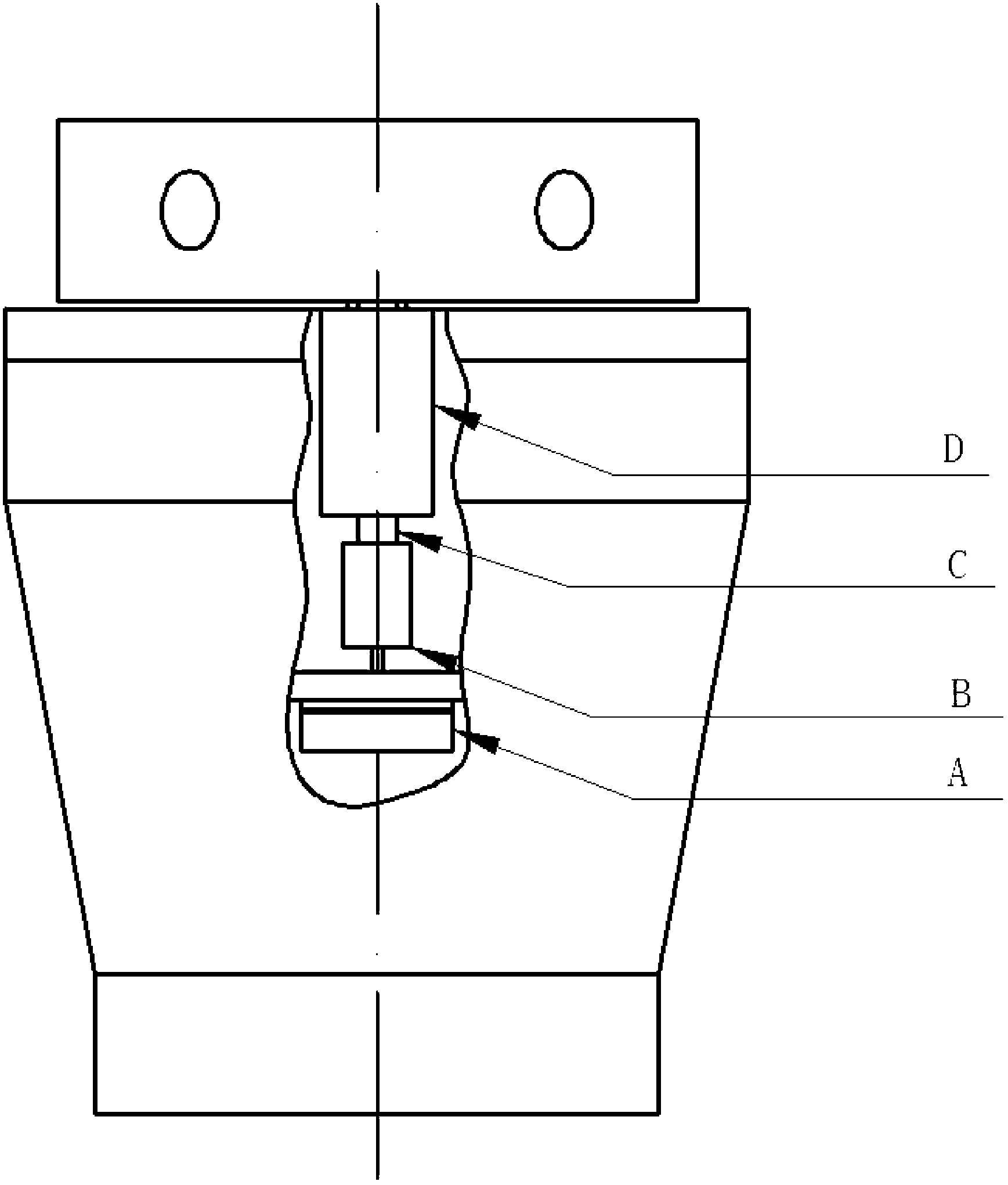

Rapid needle inserting acupoint embedding tool

The invention provides a rapid needle inserting acupoint embedding tool and belongs to the technical field of medical apparatus and instruments. The rapid needle inserting acupoint embedding tool comprises a catgut embedding pushing and burying needle core and is characterized by further comprising a syringe. A catgut-embedding inserting needle which is provided with a through hole is arranged in the syringe and is capable of rapidly penetrating through the head portion of a retraction syringe. The structure includes that a spring is arranged between the catgut embedding needle and the syringe, the catgut embedding needle is provided with a inserting needle ring, stirring rods are arranged on one side of the embedding needle or two symmetrical sides of the embedding needle, L-shaped or reverse-L-shaped guide grooves are formed on one side of the embedding needle ring or two symmetrical sides of the embedding needle ring. The stirring rod penetrates out of the L-shaped or reverse-L-shaped guide grooves which are formed on one side of the embedding needle ring or two symmetrical sides of the embedding needle ring. In a surgery, rapid needle embedding is achieved through the spring, an operator can stably control the needle after the needle is embedded, no scratching is produced, therefore the rapid needle inserting acupoint embedding tool is capable of effectively avoiding pain caused by manual needle embedding, is capable of cancelling the procedure of injecting anesthetic, not only reduces side effects caused by the anesthetic on a patient, but also reduces surgery cost.

Owner:卢振中

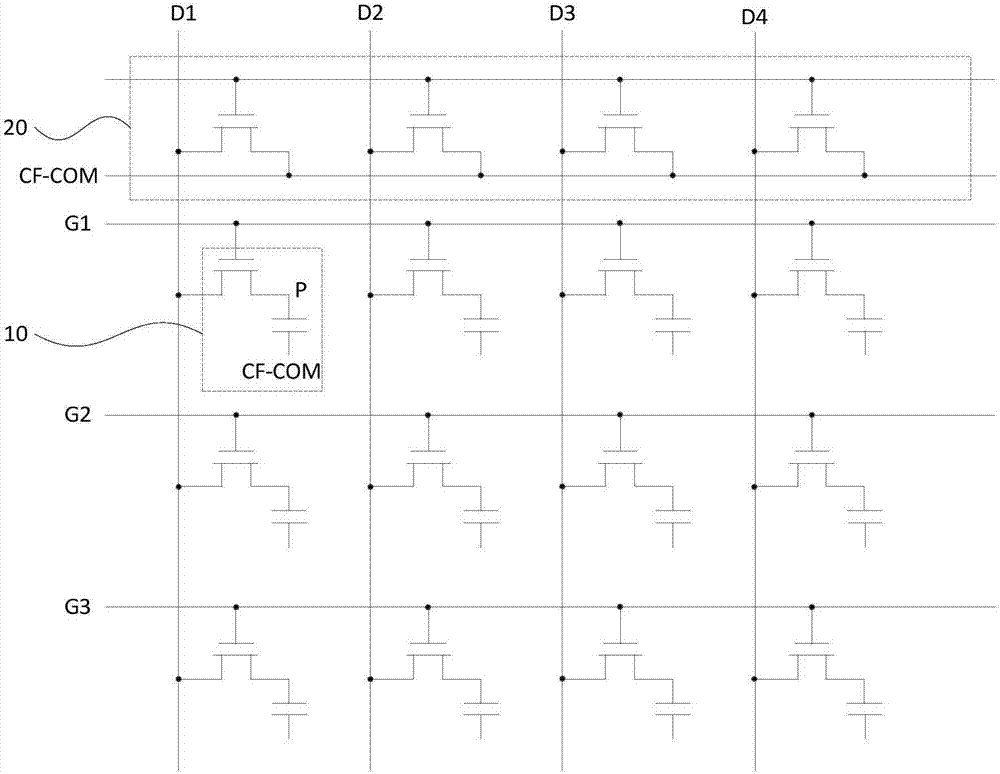

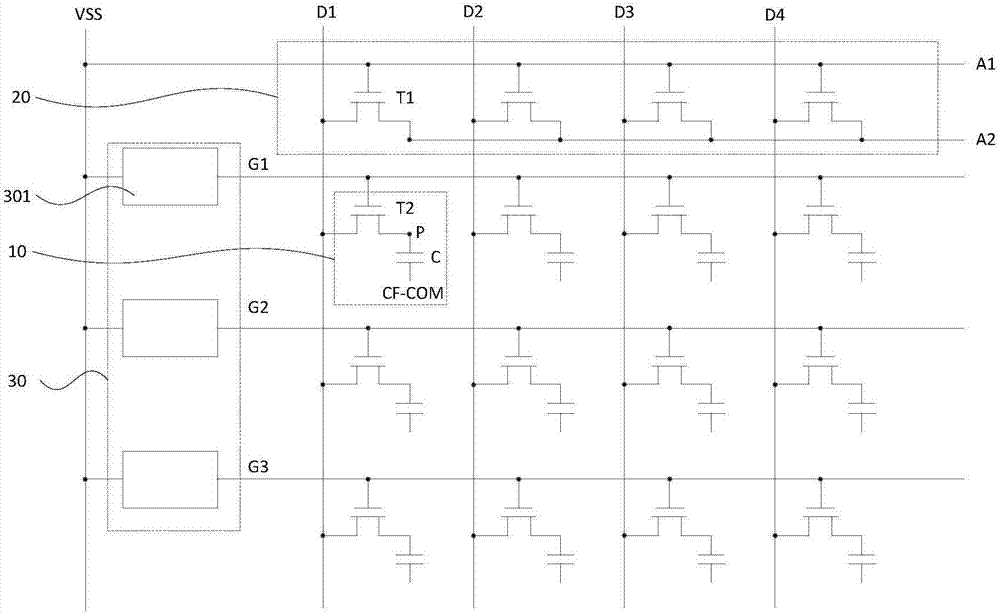

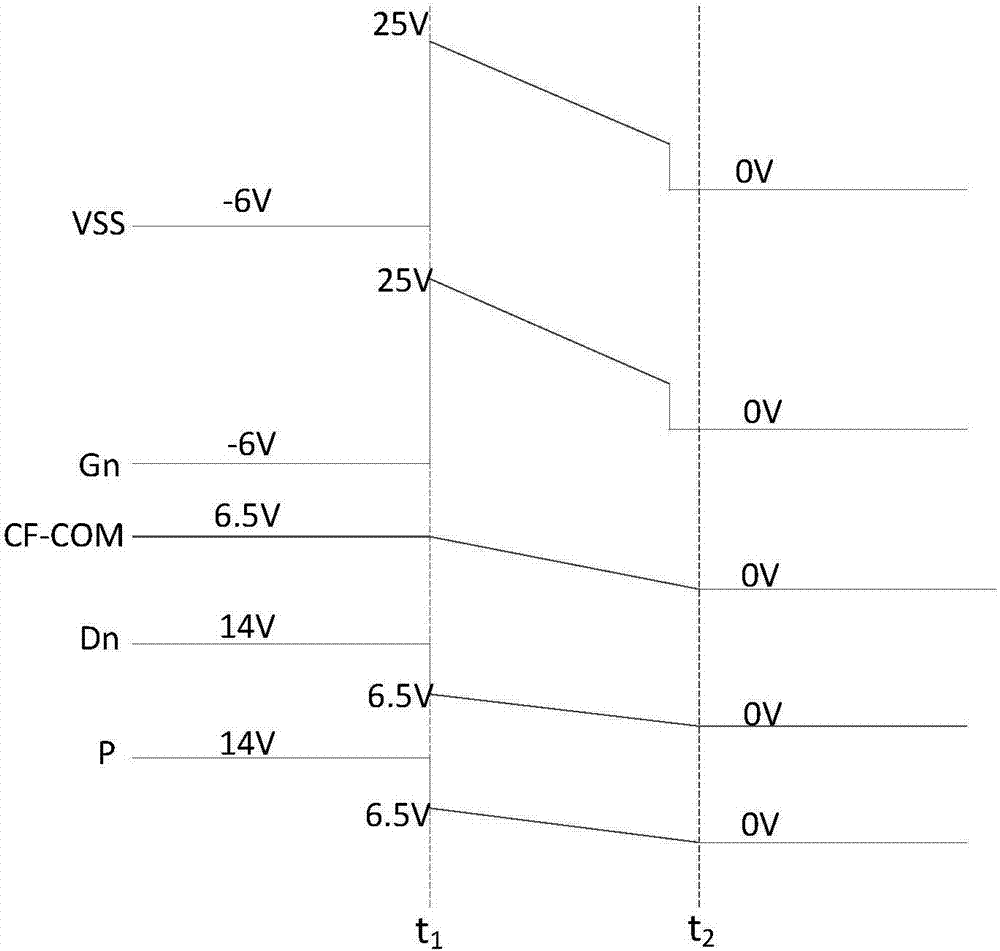

Array substrate and display panel

InactiveCN107193168AAvoid whiteningNo deflectionStatic indicating devicesNon-linear opticsControl circuitLiquid crystal

The invention discloses an array substrate and a display panel. The array substrate comprises multiple scanning lines, data lines arranged to be crossed with the scanning lines so as to define multiple pixel areas and a control circuit which is connected with multiple data lines and used for making voltage on the data lines equal to that of a common electrode during shutdown and making voltage of pixel electrodes in the pixel areas equal to that of the data lines. Accordingly, the voltage difference between the pixel electrodes in the pixel areas and the common electrode during shutdown can be balanced, liquid crystals do not deflect, and white ghosting of a screen is avoided.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

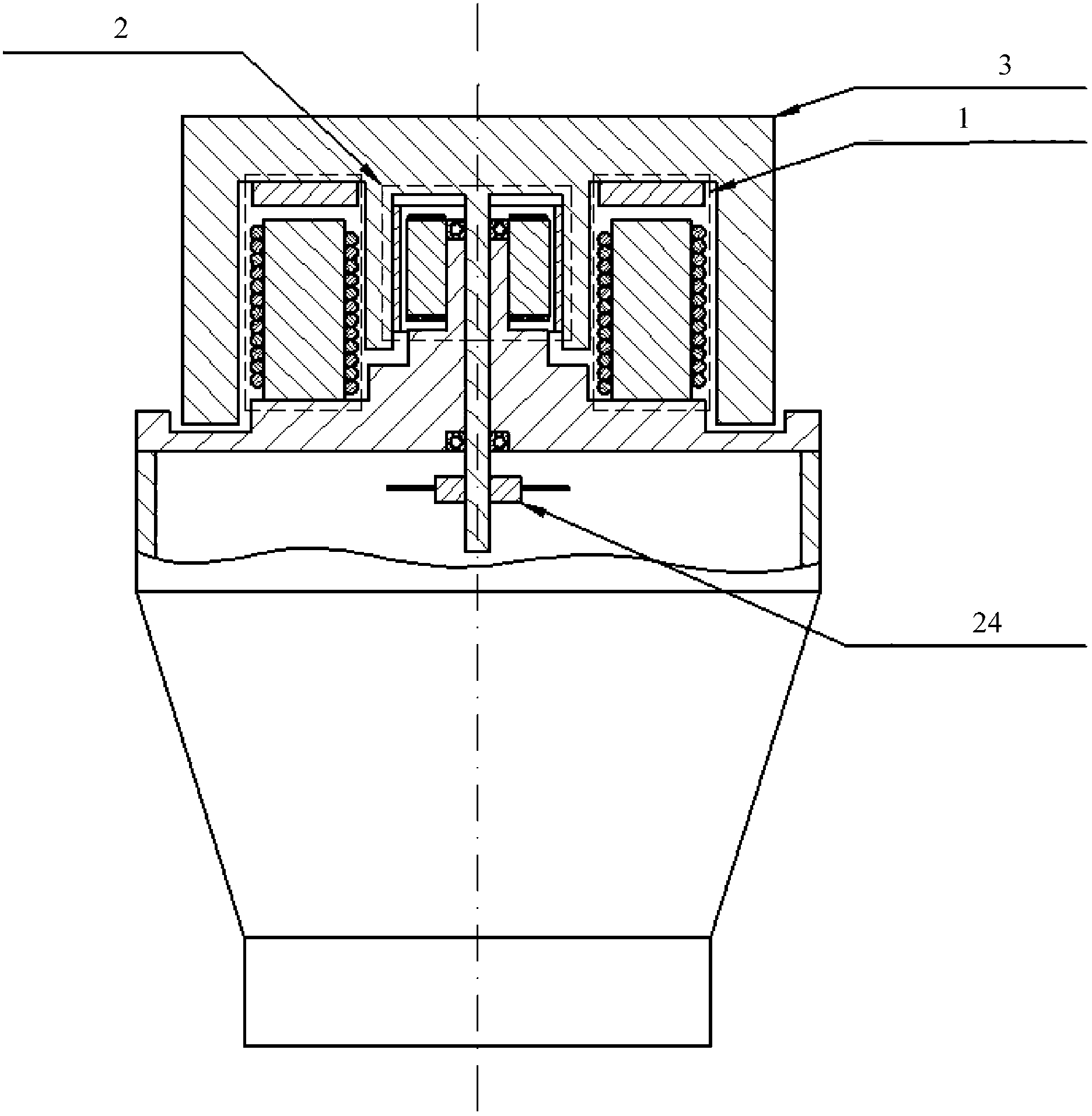

Electromagnetic drive type magnetic suspension rotating platform

ActiveCN102710181ASolve wear and tearSolve the carrying capacityMagnetic holding devicesPermanent magnet rotorEngineering

The invention discloses an electromagnetic drive type magnetic suspension rotating platform which comprises an electromagnetic suspension structure positioned on an outer ring and an electromagnetic drive structure positioned on an inner ring, wherein a rotating platform casing is arranged outside the electromagnetic suspension structure and the electromagnetic drive structure; the electromagnetic suspension structure comprises an annular electromagnetic suspension iron core; a plurality of teeth are symmetrically arranged on the annular electromagnetic suspension iron core along the circumference; an electromagnetic suspension winding is wound on each tooth; a high-precision air gap sensor is arranged at the clearance between every two teeth; an annular suspension conductor plate is arranged above the annular electromagnetic suspension iron core; the electromagnetic suspension structure comprises an annular electromagnetic drive iron core; three groups of teeth are symmetrically arranged on the outer side of the electromagnetic drive iron core along the circumference; the electromagnetic suspension windings are continuously wound on each group of teeth; each group of electromagnetic drive winding is in a link type structure; an annular permanent magnet rotor is arranged outside the annular electromagnetic drive iron core; and a photoelectric encoder is arranged on a rotating shaft of the rotating platform casing. The assembly difficulty is reduced and the manufacturability is improved.

Owner:TIANJIN UNIV

Electric water heater and assembly method of electric water heater using large plastic sleeve

The invention provides an electric water heater and an electric water heater assembly method using a large plastic sleeve. The electric water heater comprises an inner container, an outer shell, a water inlet pipe, a water outlet pipe, a magnesium rod, a water inlet pipe sleeve, a water outlet pipe sleeve and a magnesium rod sleeve. One ends of the various sleeve bodies are narrow-mouthed ends, and the other ends of the various sleeve bodies are flared ends. Each narrow-mouthed end is provided with an inner container follow-shape surface which is characterized that a middle hole edge of the inner container follow-shape surface of each plastic sleeve is provided with a horn-mouth shape elastic cantilever extending inward. The free end of each horn-mouth shape elastic cantilever is a cylindrical installation guide. The water inlet pipe sleeve, the water outlet pipe sleeve and the magnesium rod sleeve are connected into a whole in a sequential and side-by-side mode. The electric water heater is reasonable in structural design, high in installation efficiency and good in tightness. In the electric water heater assembly method using the large plastic sleeve, the separated or integrated large plastic sleeve is firstly clamped on a magnesium rod seat, the water inlet pipe and the water outlet pipe, wherein the magnesium rod seat, the water inlet pipe and the water outlet pipe are arranged outside the inner container. Only once inner container leakage detecting is needed, and thus processing step is simplified, and production efficiency and foaming quality are improved.

Owner:HAIER GRP CORP +1

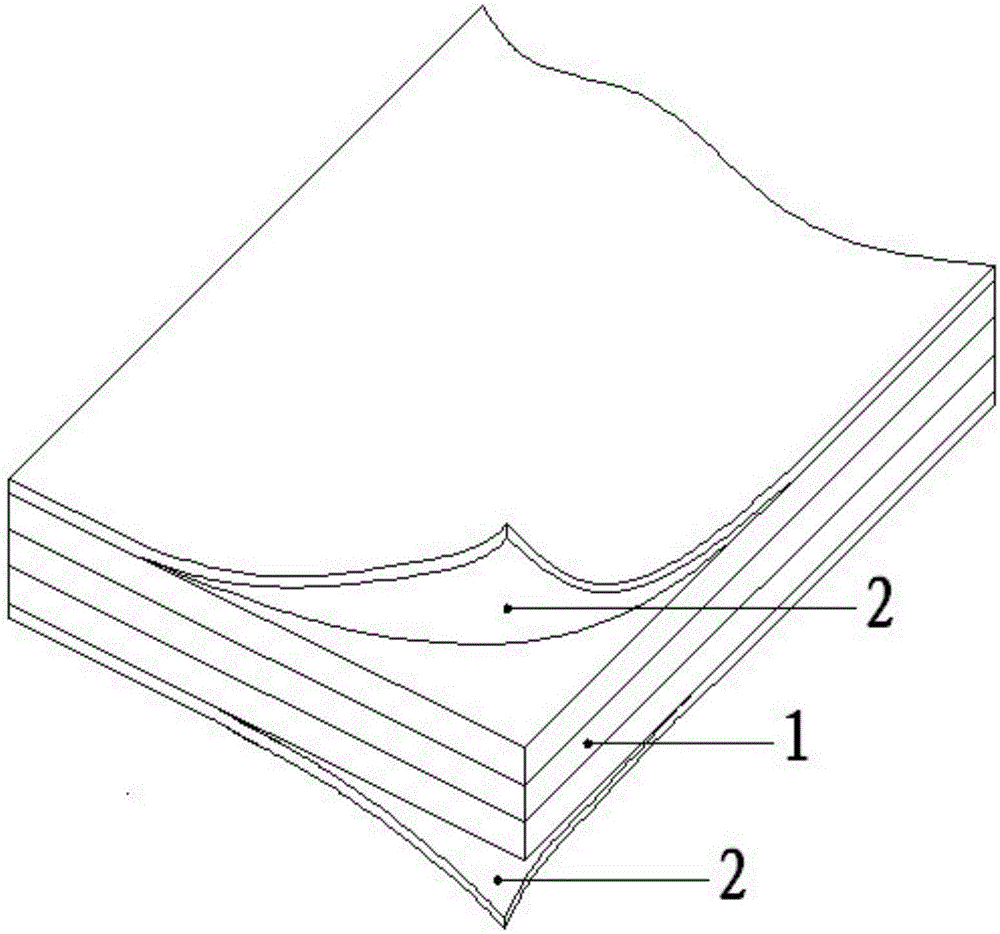

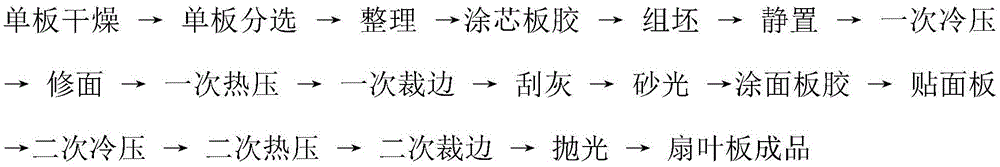

Eucalyptus vane plywood and manufacturing method thereof

InactiveCN105058520AReduce internal stressAvoid deformationAldehyde/ketone condensation polymer adhesivesWood veneer joiningEngineeringResin adhesive

The invention relates to eucalyptus vane plywood and a manufacturing method thereof. The eucalyptus vane plywood comprises a core plate and panels adhering to the two surfaces of the core plate. The core plate is composed of three veneers, and core plate adhesives are smeared between every two adjacent veneers. The veneers are eucalyptus veneers formed by rotationally cutting eucalyptus logs. The core plate adhesives are composed of E0 urea formaldehyde resin adhesives, flour, ammonium chloride and ferrous powder in the ratio of 1:0.4:0.006:0.001. The panels are bintangor panels formed by rotationally cutting bintangor logs. Panel adhesives are smeared between the core plate and the panels and are composed of E0 urea formaldehyde resin adhesives and flour in the ratio of 1:0.5. The eucalyptus vane plywood is simple in structure, good in rigidity, free of deformation and cracking, easy to manufacture and capable of effectively reducing the production cost, improving the quality of vanes and prolonging the service life of the vanes.

Owner:广西万林林产业有限责任公司

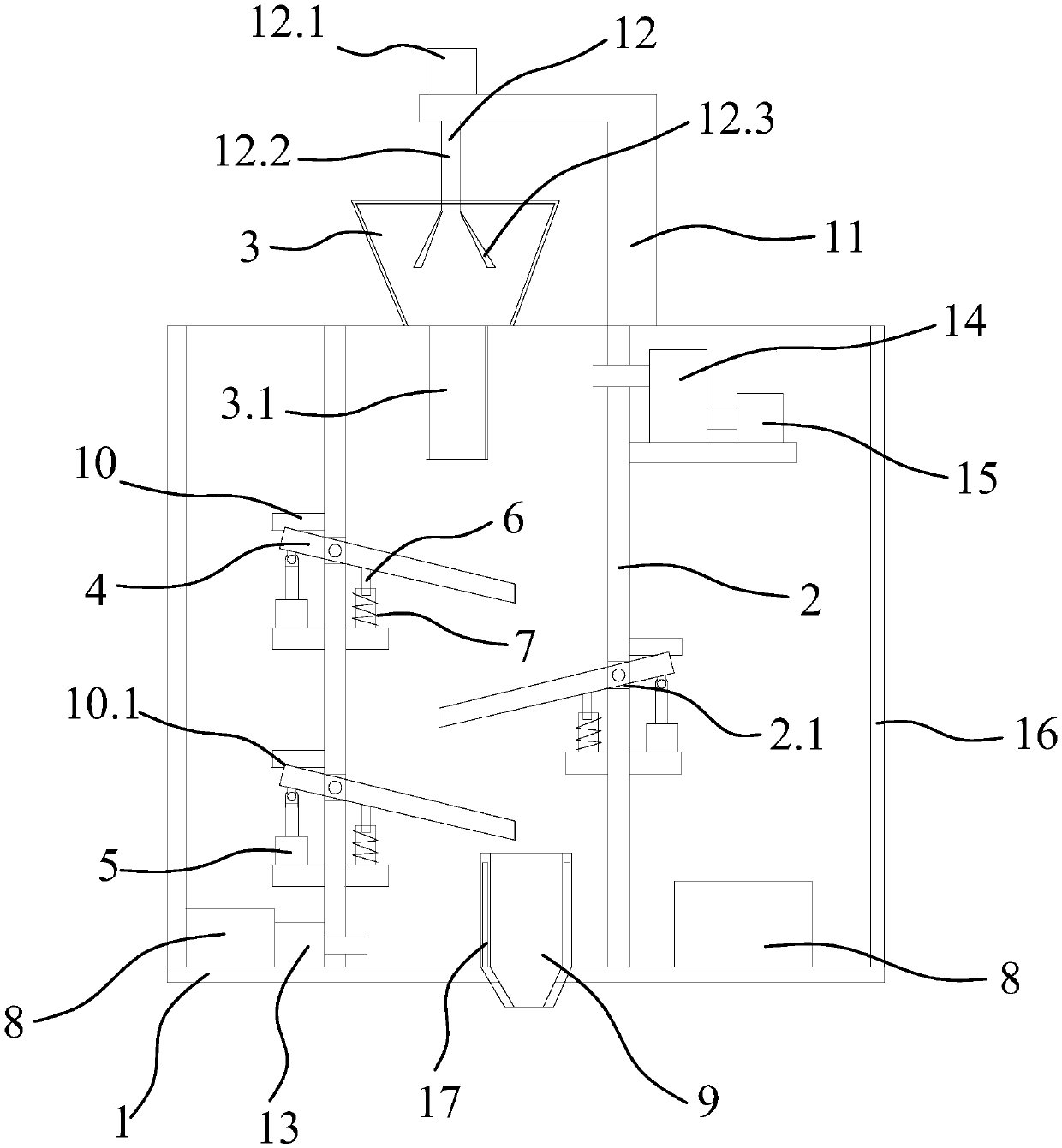

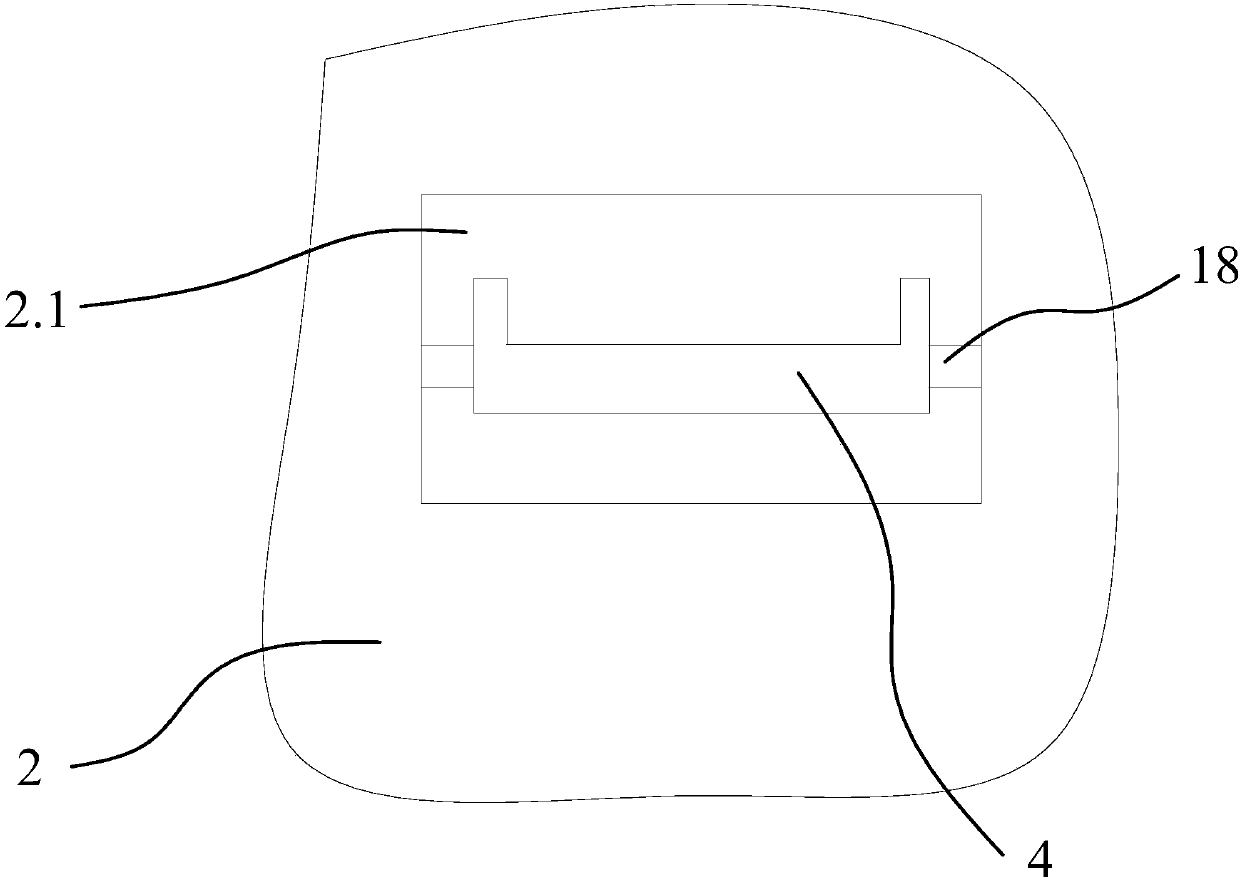

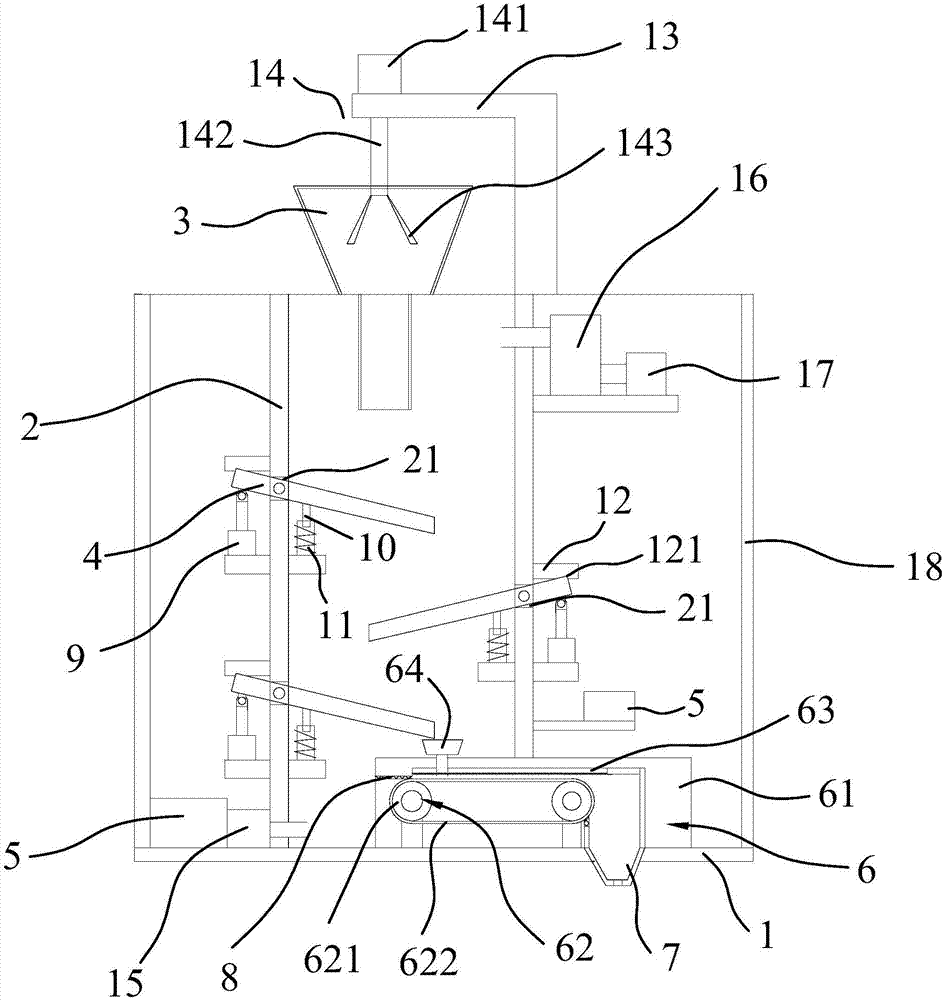

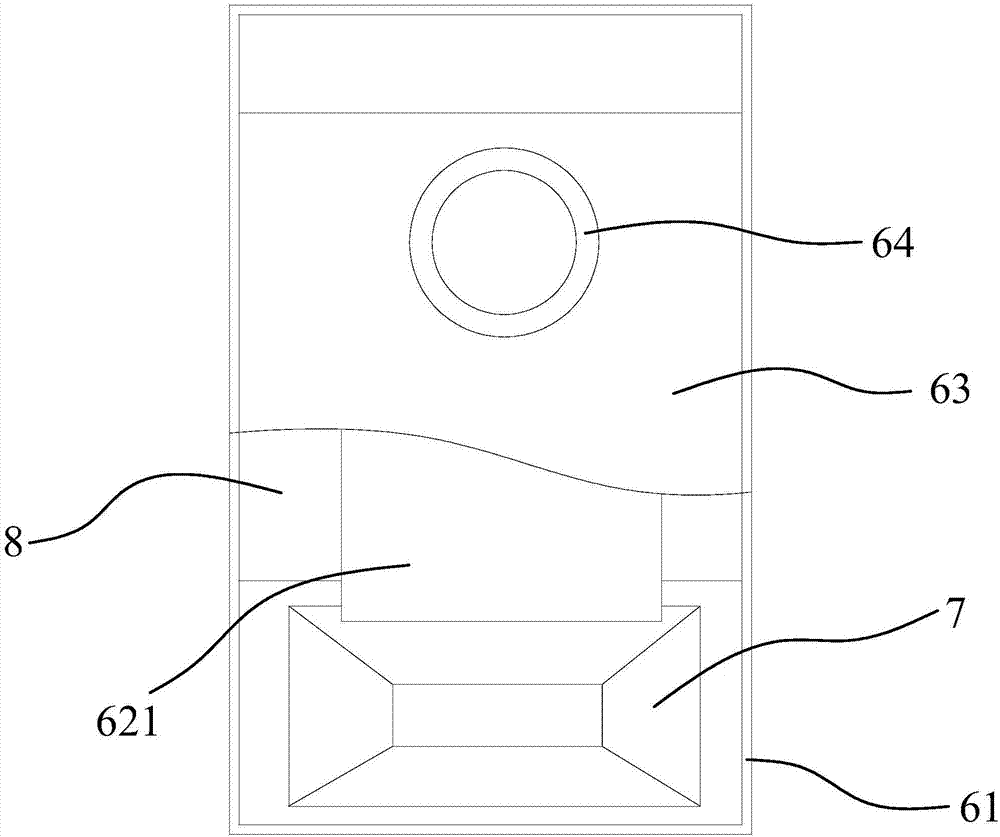

Pretreatment device for fed materials of injection molding machine

The invention discloses a pretreatment device for fed materials of an injection molding machine. The pretreatment device comprises a bottom plate (1), a box body (2) is arranged on the bottom plate, and a feeding hopper (3) is arranged above the box body (2). A plurality of iron-made guiding plates (4) are rotatably arranged on the inner side wall of the box body (2), arranged on the two sides ofthe inner side wall of the box body (2) correspondingly and sequentially distributed in a staggered mode from top to bottom. Structures for iron scrap separation are arranged on the iron-made guidingplates (4). Recycling boxes (8) are arranged on the positions, located on the two sides of the box body (2), of the bottom plate (1), and a discharging pipe (9) is arranged on the position, located atan end opening of the iron-made guiding plate (4) on the lowest position, of the bottom plate (1). According to the pretreatment device for the fed materials of the injection molding machine, iron scraps in the fed materials are automatically removed, iron scrap impurities are prevented from entering an injection molding cavity, the product quality is improved, and meanwhile parts in the injection molding cavity can be protected against being damaged.

Owner:NINGBO HAITAI IND & TRADE

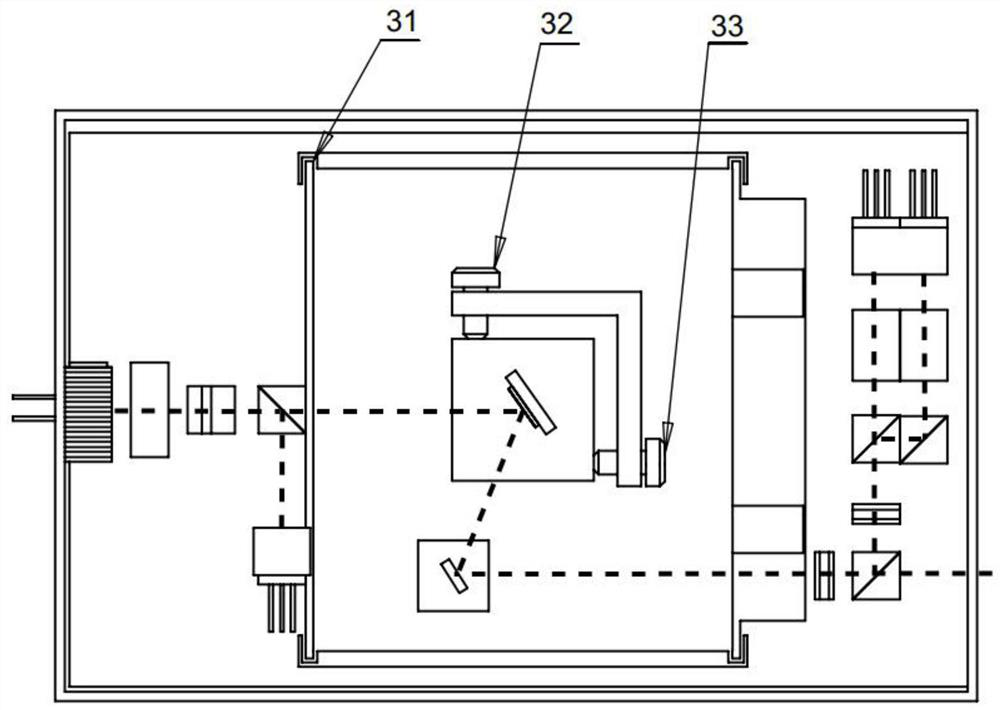

Frequency stabilization and light intensity stabilization dual-piezoelectric ceramic tuning external cavity semiconductor laser

PendingCN111786255AAchieve tuningNo deflectionLaser detailsSemiconductor laser optical deviceFrequency stabilizationGrating

The invention discloses a frequency stabilization and light intensity stabilization dual-piezoelectric ceramic tuning external cavity semiconductor laser. The laser comprises a laser diode module, a collimator, a light intensity stabilizing module, a blazed grating, an output reflector, an output polarization light splitting module, a two-dimensional adjusting module, a flexible adjusting platform, piezoelectric ceramic a, piezoelectric ceramic b, a frequency stabilizing module, a bottom plate, an elastic damper and a shell. The double piezoelectric ceramics are adopted to drive the flexible adjusting platform to achieve blazed grating rotation and translation, the length of the outer cavity can be adjusted when the angle of the grating is adjusted, a fixed longitudinal mode is kept in theouter cavity, and therefore broadband mode-hopping-free tuning is achieved. When atomic absorption spectrum characteristic analysis needs to be carried out, a frequency tuning mode can be adopted, and when a stable laser beam is needed, a light intensity stabilizing mode and a frequency stabilizing mode can be adopted; the output reflector and the blazed grating are placed on the flexible adjusting platform together, and the output light beam does not deflect in the tuning process.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

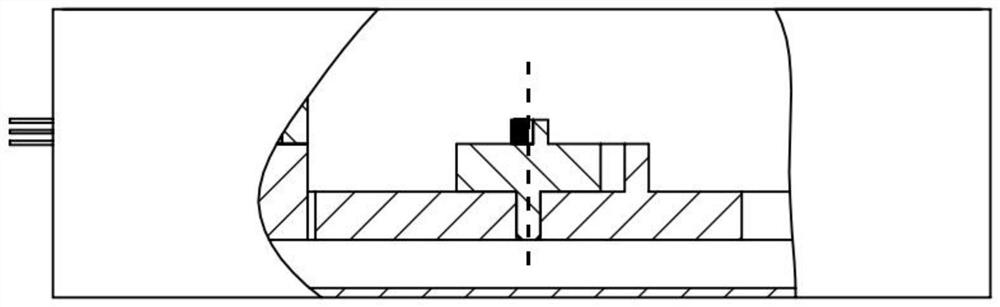

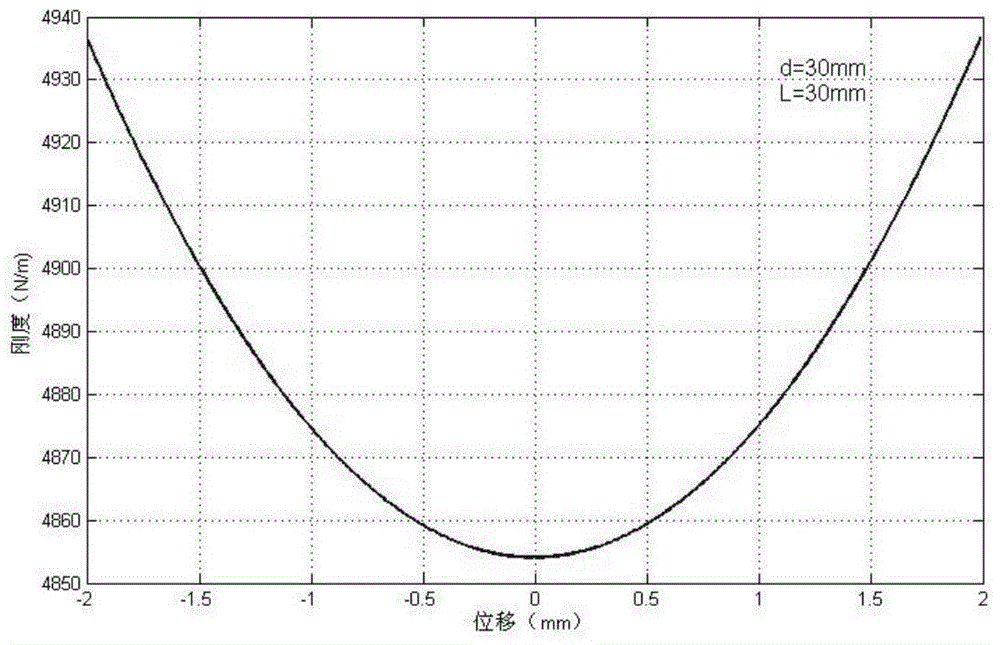

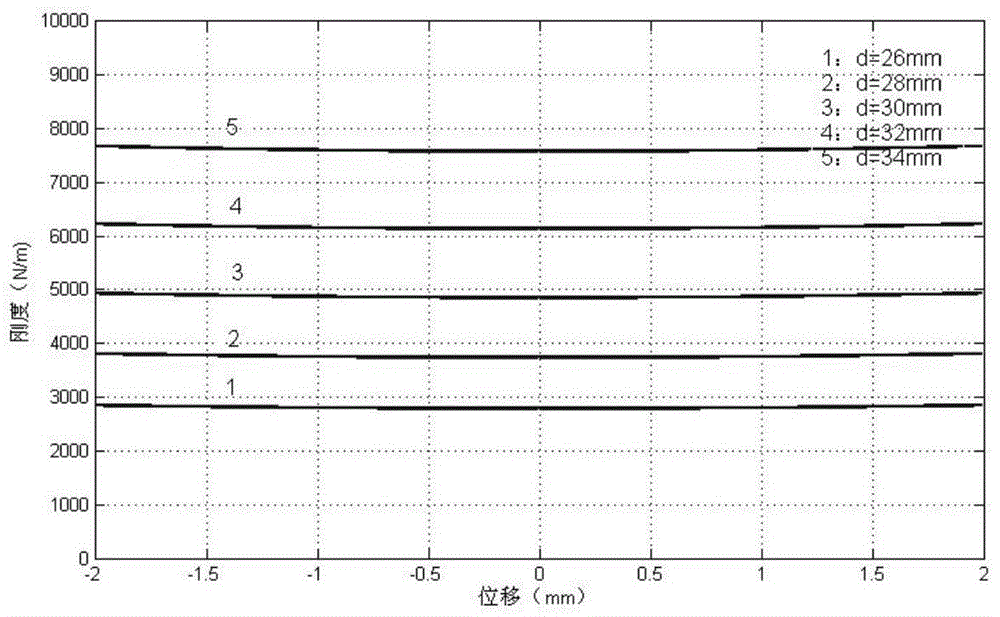

Maglev nonlinear vibration isolator of satellite sensitive load and design method

InactiveCN104879411ANo deflectionMagnetic field stabilizationVibration dampersMagnetic springsNonlinear vibrationDesign methods

The invention provides a maglev nonlinear vibration isolator of satellite sensitive load. The maglev nonlinear vibration isolator comprises an output rod, an outer package, a first magnetic body, a second magnetic body and a third magnetic body, the first magnetic body, the second magnetic body and the third magnetic body are all arranged on the inner side of the outer package, the first magnetic body is fixed at the upper end of the outer package, the third magnetic body is fixed at the lower end of the outer package, and the second magnetic body is arranged between the first magnetic body and the third magnetic body and is opposite to the same in a same-polarity manner. The invention further provides a corresponding system and method. A mode that the magnetic bodies are serially connected is adopted, and the magnetic bodies are coaxial and move axially, so that deflection of angles of the magnetic bodies is avoided; a magnetic field is stable, so that vibration at other frequency can be avoided. The maglev nonlinear vibration isolator is nonlinear in rigidity.

Owner:SHANGHAI SATELLITE ENG INST

Feed pretreatment device for injection molding machine

The invention discloses a feed pretreatment device for an injection molding machine. The feed pretreatment device for the injection molding machine comprises a bottom plate (1), a box body (2) is arranged on the bottom plate, and a feed hopper (3) is arranged above the box body (2); the inner side walls of the box body (2) are provided with a plurality of iron-made guide plates (4) which are sequentially displaced from the top to the bottom, and scrap iron separating devices are correspondingly arranged on the iron-made guide plates (4); and a drying and heating device (6) is disposed, below the iron-made guide plates (4), on the bottom plate (1) and is used for drying and pre-heating injected plastic particles. The feed pretreatment device for the injection molding machine performs pretreatment for the feed of the injection molding machine and drying and preheating for the materials, therefore, the improvement of the efficiency is benefited and the product quality is improved.

Owner:NINGBO HAITAI IND & TRADE

Turning and milling all-in-one machine

ActiveCN106493571AFast processingNo deflectionWork clamping meansFeeding apparatusWire rodEngineering

The invention discloses a turning and milling all-in-one machine. A spindle can rotate around the Y axis. A clamping device arranged at one end of the spindle comprises a chuck, a chuck sleeve, a driving oil cylinder and an elastic piece. The chuck is connected with the chuck sleeve in a sleeved mode through a conical surface. A piston rod of the driving oil cylinder is fixedly connected with the chuck sleeve. The elastic piece can provide axial elastic force for the piston rod of the driving oil cylinder. Feeding of a milling device and a turning device in the X direction and the Y direction can be achieved through a horizontal feeding mechanism, and a longitudinal lifting mechanism can realize rise and fall of the milling device and the turning device in the Z direction. An automatic feeding mechanism can send a linear workpiece into the clamping device in the Y direction and drive the linear workpiece to slide in the Y axis in the clamping device. According to the turning and milling all-in-one machine, turning and milling are integrated on one machine tool, a wire rod can be completely or half clamped by the clamping device, rapid switching between turning and milling is achieved, the machining speed is high, and high-speed full-automatic machining is achieved; and meanwhile, since the clamping device clamps and positions the wire rod to different degrees all the time, deflection deformation of the wire rod is avoided, and the machining precision is guaranteed.

Owner:美事满工具(海安)有限公司

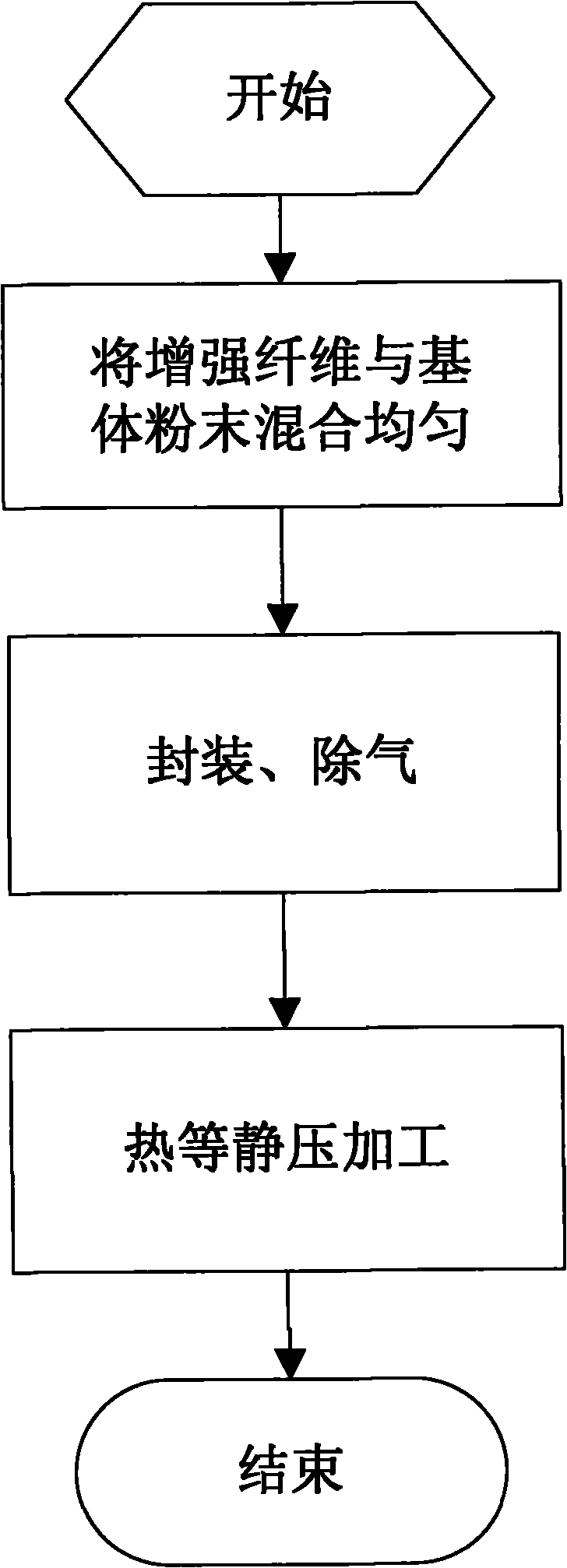

Processing technology for metal composite material

The invention provides a processing technology for a metal composite material. The metal composite material comprises reinforcing fibers and a substrate. The processing technology comprises the following steps of: uniformly mixing the reinforcing fibers and substrate powder; and packaging, degassing, and performing hot isostatic pressing to improve the compactness of the composite material. By the processing technology for the metal composite material, a reinforcing material (the fibers, particles or whiskers) can be mixed with the substrate metal powder in any ratio according to the designed performance requirement of the metal-based composite material.

Owner:CHANGSHU DONGTAO METAL COMPOSITE MATERIAL

Switch valve with temperature adjusting function

PendingCN107620814ANo deflectionImprove sealingDiaphragm valvesOperating means/releasing devices for valvesInlet channelAxial pressure

The invention discloses a switch valve with a temperature adjusting function. An inserting hole is formed in a sealing film of the switch valve, and a clamping jaw is arranged on a film support and inserted in the inserting hole of the sealing film; an axial pressure relief hole is formed in the clamping jaw, and a bearing inner cover is mounted on a valve core body; a first spring is mounted between the bearing inner cover and the film support, and a back-pressure cavity is formed between the bearing inner cover and the sealing film; the back-pressure cavity and a water inlet channel communicate through a through hole or an interval, and the lower end of a sealing guide rod is provided with a plug and inserted into the pressure relief hole; the upper end of the sealing guide rod is provided with a pressing structure, and a second spring is mounted between the upper end of the sealing guide rod and the pressing structure; when the sealing guide rod is driven by the pressing structure to move upwards, the pressure relief hole is unblocked through the plug of the sealing guide rod; or when the sealing guide rod is driven by the pressing structure to move downwards, the pressure relief hole is blocked through the plug of the sealing guide rod. According to the switch valve with the temperature adjusting function, when the valve is driven through pressing to be opened or closed, the sealing guide rod of the switch valve cannot deflect, and the sealing effect is good accordingly.

Owner:XIAMEN PSSIN TECH CO LTD

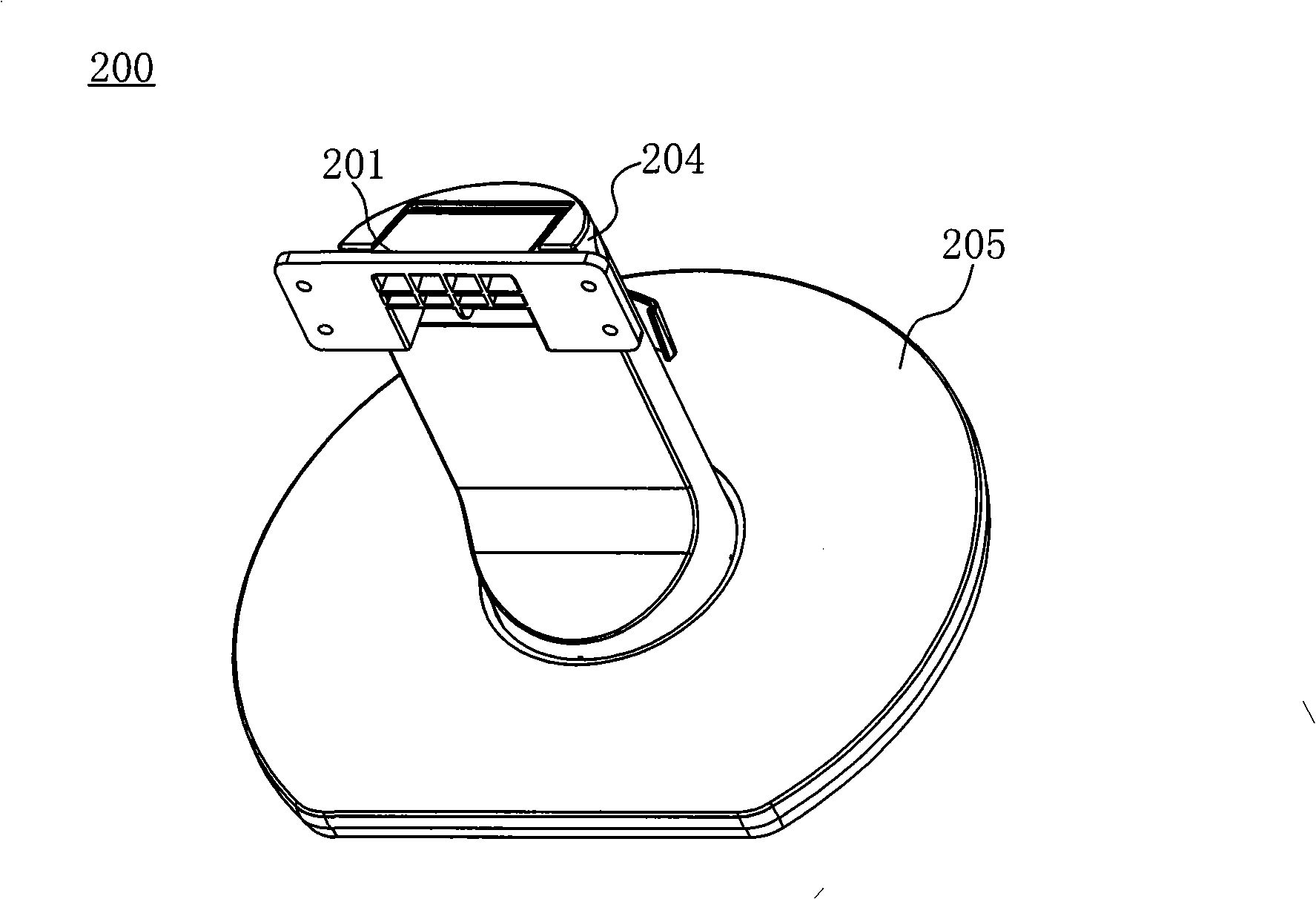

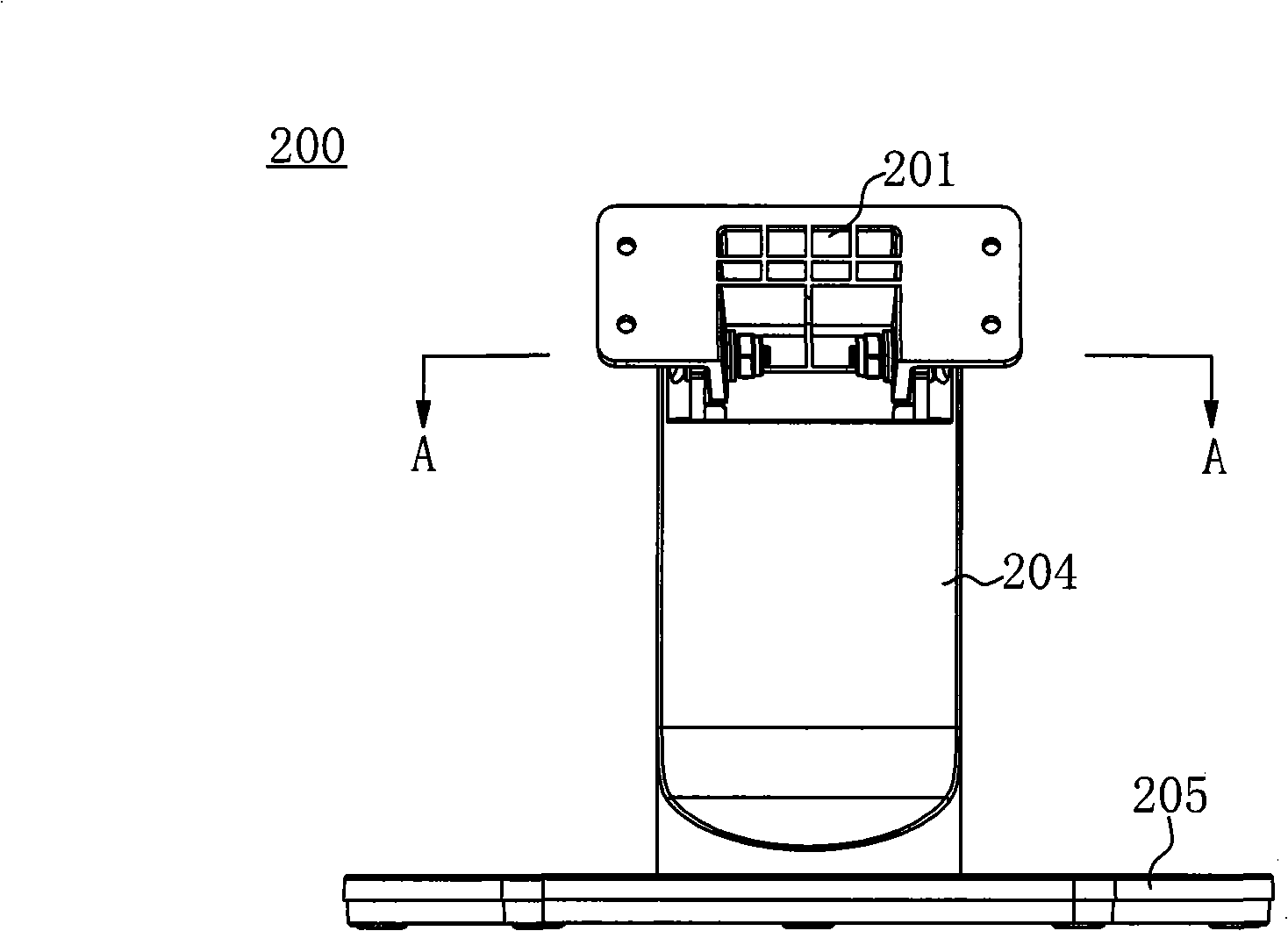

Screen supporting seat

InactiveCN101315145ALow costGuaranteed angle adjustment functionStands/trestlesNon-linear opticsEngineeringUltimate tensile strength

A screen supporting seat comprises a movable connector for connected a screen panel, and is characterized in that the screen supporting seat also comprises a pedestal, the movable connector is directly connected with the pedestal via a hinge to form the screen supporting seat, and the movable connector and the pedestal are both made from polymeric plastic materials. The inventive screen supporting seat, which is assembled by direct hinge connection of the movable connector and the pedestal, replaces polymeric plastic materials for metals as the material for the movable connector and the pedestal, so as to reduce the manufacturing cost of the screen supporting seat by 30-40%, and can still satisfy the connection strength and retain the current angular adjustment function; and no deflection and swinging phenomena take place during service. The inventive screen supporting seat can be used as a bracket for LCD screens with various sizes.

Owner:QISDA SUZHOU +1

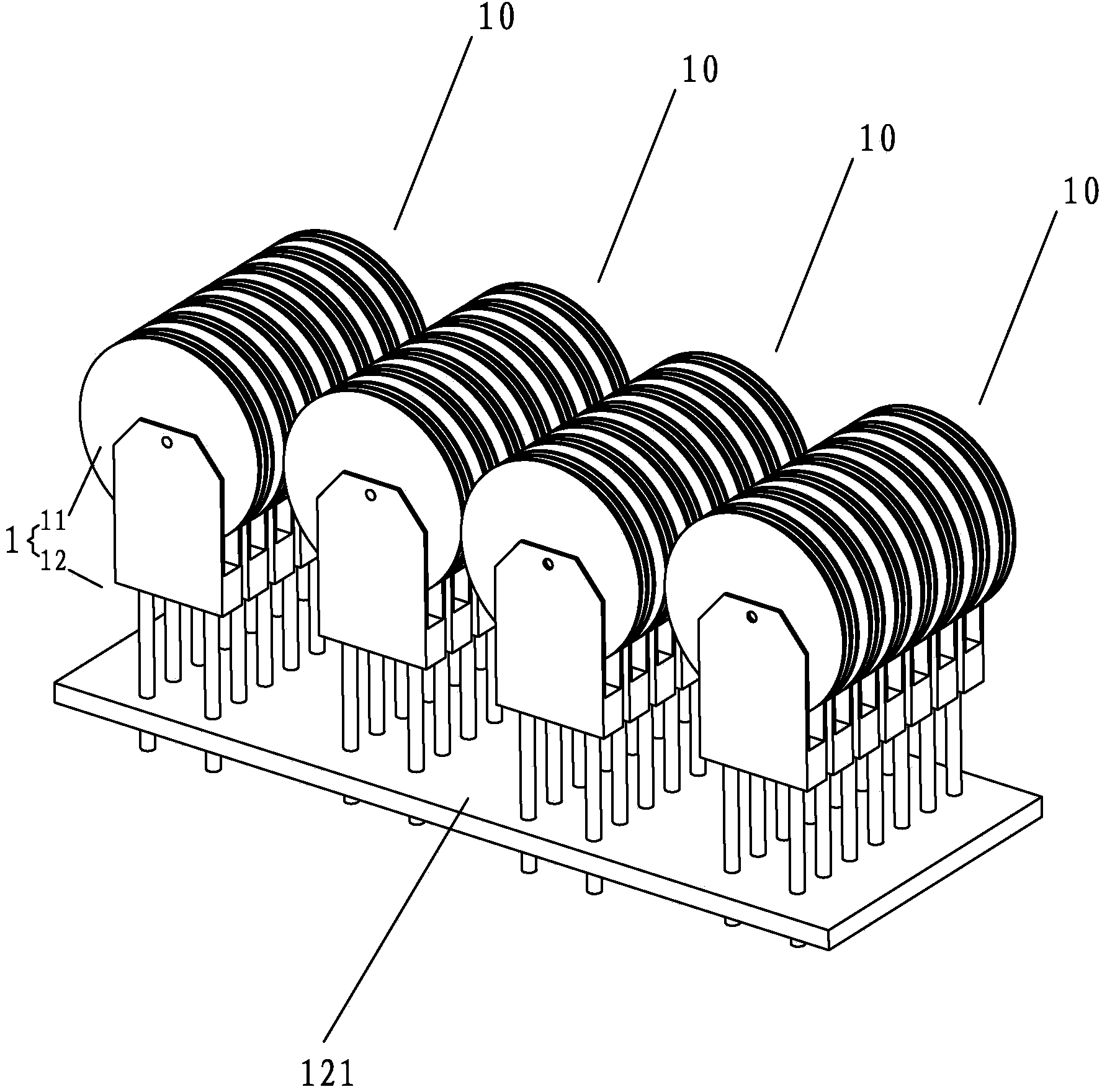

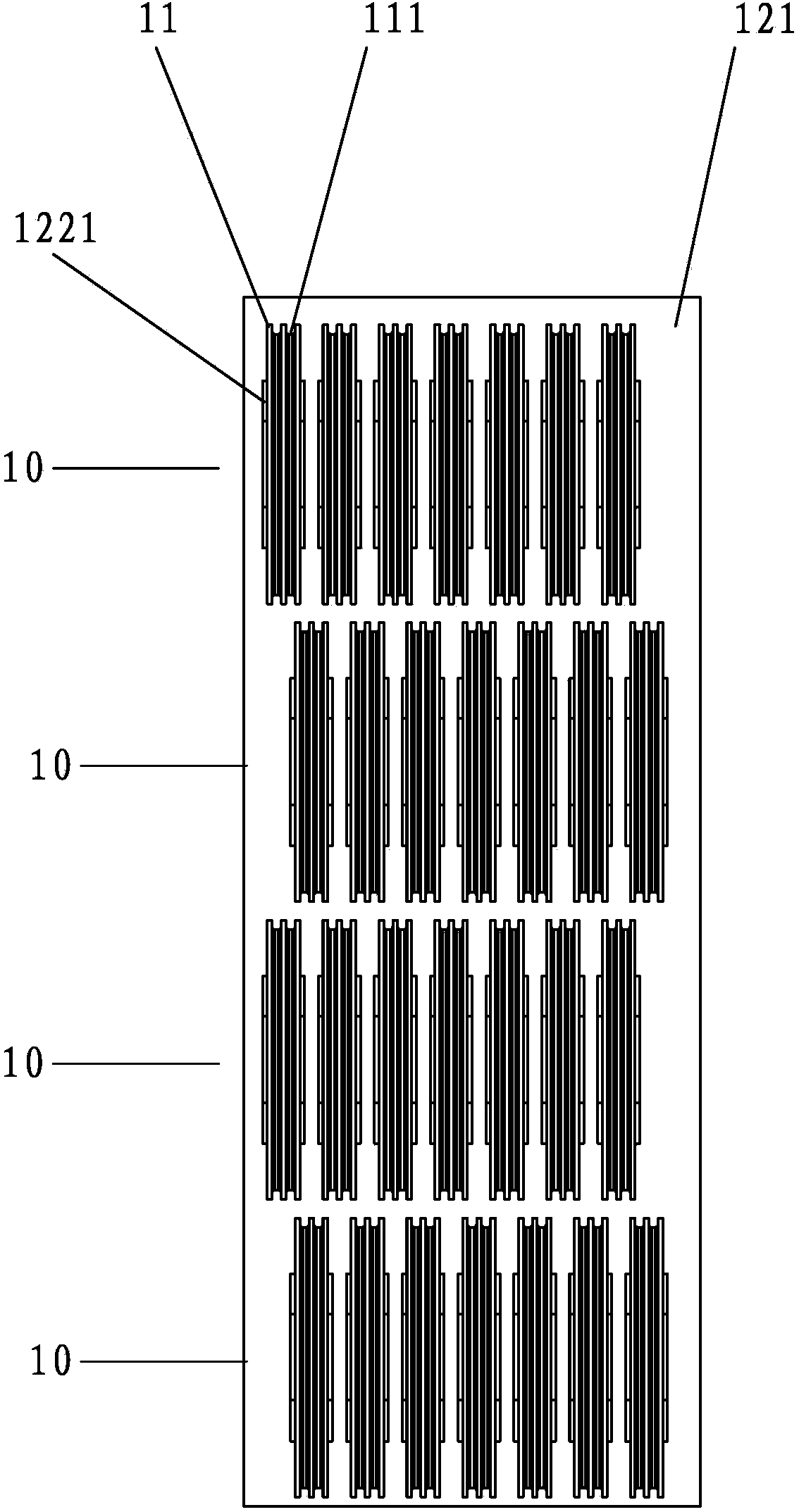

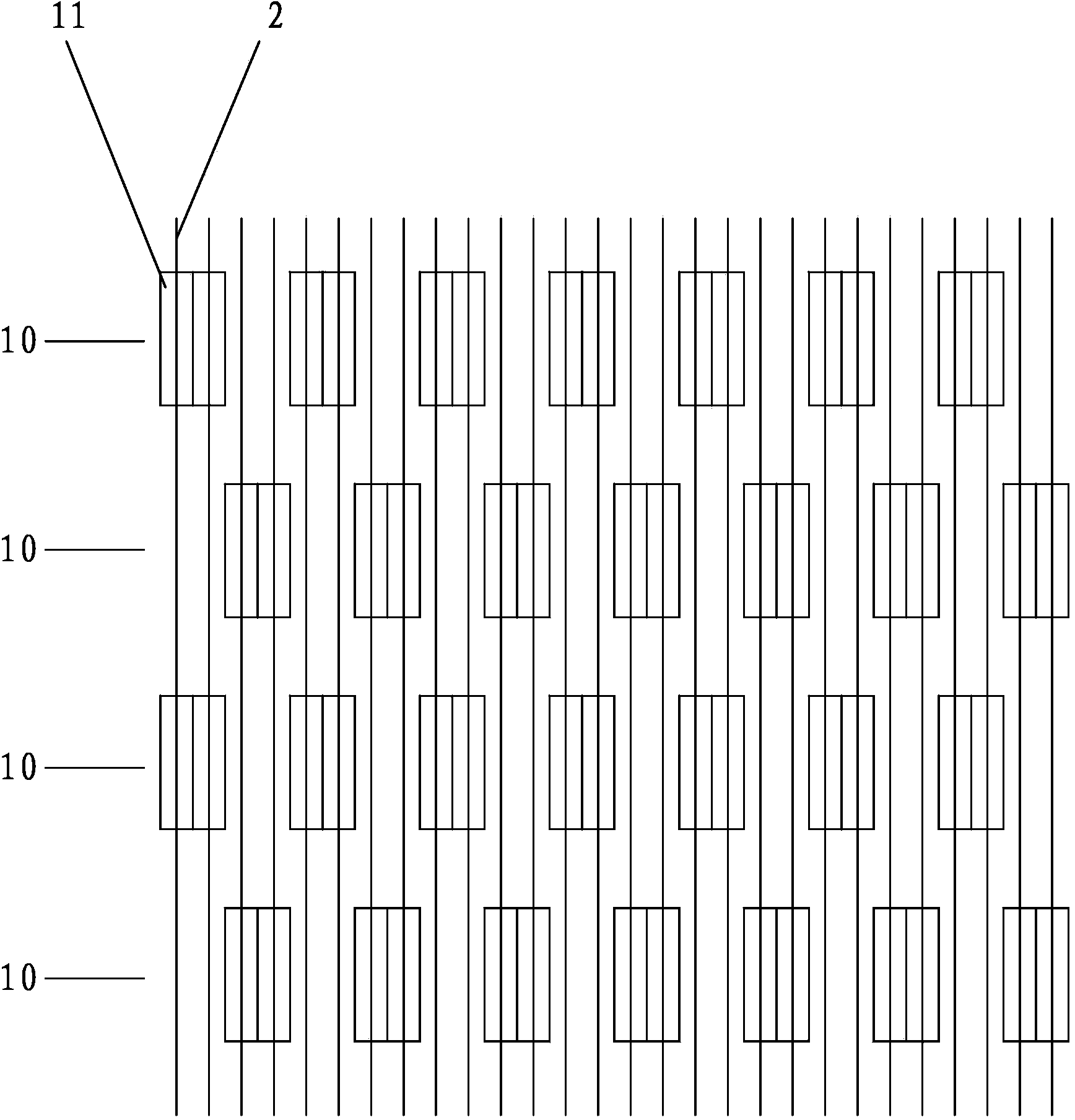

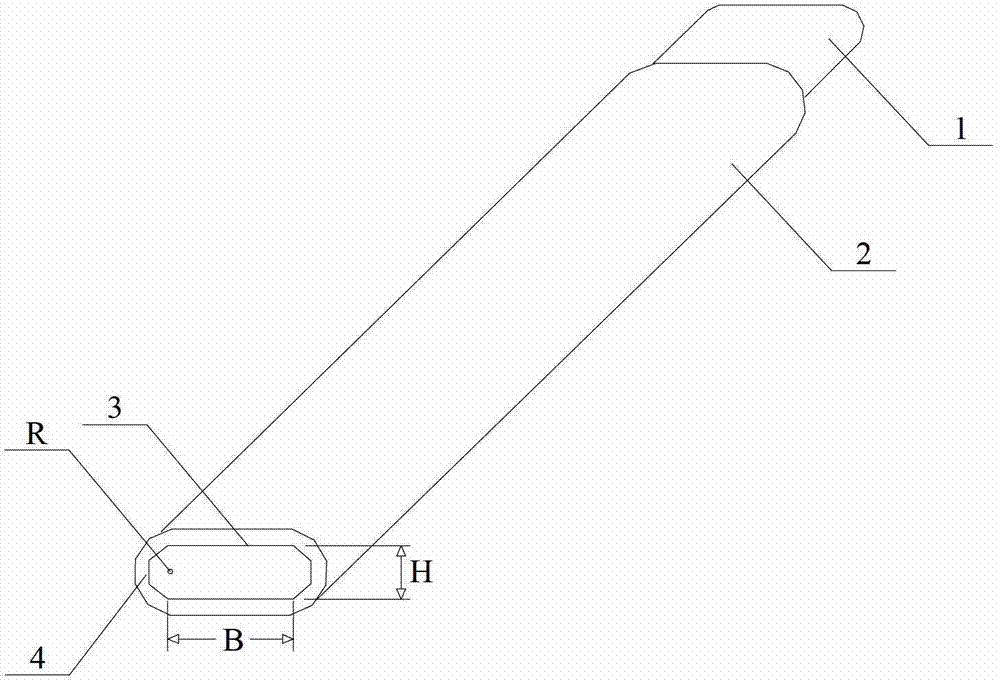

Novel tension adjustment mechanism of multi-wire diamond wire saw

ActiveCN103507176AArrangement rules are reasonableEasy alignmentWorking accessoriesStone-like material working toolsDiamond wire sawEngineering

The invention provides a novel tension adjustment mechanism of a multi-wire diamond wire saw. The novel tension adjustment mechanism comprises a plurality of tension adjustment units, and the tension adjustment units comprise tensioning wheels and tension driving devices. Two wire grooves are evenly formed in each tensioning wheel. Each tension adjustment unit is tabular. The tension adjustment units are arranged in rows, the rows of tension adjustment units are arranged in a staggered mode, tension adjustment units in interval rows are in one-to-one correspondence mutually, and the distances between planes where the adjacent wire grooves are located are equal. Therefore, one or two wire grooves of each tension adjustment unit can be selected and used by people, and the positions of beaded wires can be conveniently adjusted. The tension adjustment units are tabular so as to be conveniently and densely arranged in a regular and reasonable mode, space is saved, and regular beaded wire arrangement and aligning are facilitated. Tension adjustment can be conducted on beaded wires respectively or simultaneously, and therefore the beaded wires are strong in flexibility. The number of the beaded wires can be increased or reduced, beaded wire distribution forms can be changed, and distances between the beaded wires can be adjusted to adapt to all kinds of cutting thicknesses.

Owner:HUAQIAO UNIVERSITY

Flat round-corner-shaped bead welding rod having coatings with different thicknesses

InactiveCN103170755AStable combustionNo deflectionWelding/cutting media/materialsSoldering mediaArc stabilityAlloy

The invention provides a flat round-corner-shaped bead welding rod having coatings with different thicknesses. The section of a welding core is in a flat round corner shape, the width ratio of the welding core and each flat plane is 1;1.5-3, and the radius of each round corner is half of the thickness of the welding core. The sections of coatings are in different thickness shapes, the thicknesses of the coatings coated on the outside of the two flat planes are 1.6-3 mm, and the thicknesses of the coatings coated on the outside of the two round corners are 1.2-2.0 mm. The flat round-corner-shaped bead welding rod can obviously increase the weight ratio of the coatings of welding rods (effective areas of the coatings coated on the flat-round-corner-shaped welding core having the same section are much larger than that of a round-bar-shaped welding core), and much abrasion-resistant alloy is melted and transited into bead welding joints to improve abrasion-resistant performance. Much alloy material having good electrical conductivity is added to improve melting speed and arc stability of the coatings, and the technical problems that two coatings of the two round corners of the welding rod, on two sides, fall off and are melted incompletely because of ultra-thicknesses of the coatings are resolved.

Owner:HARBIN INST OF TECH

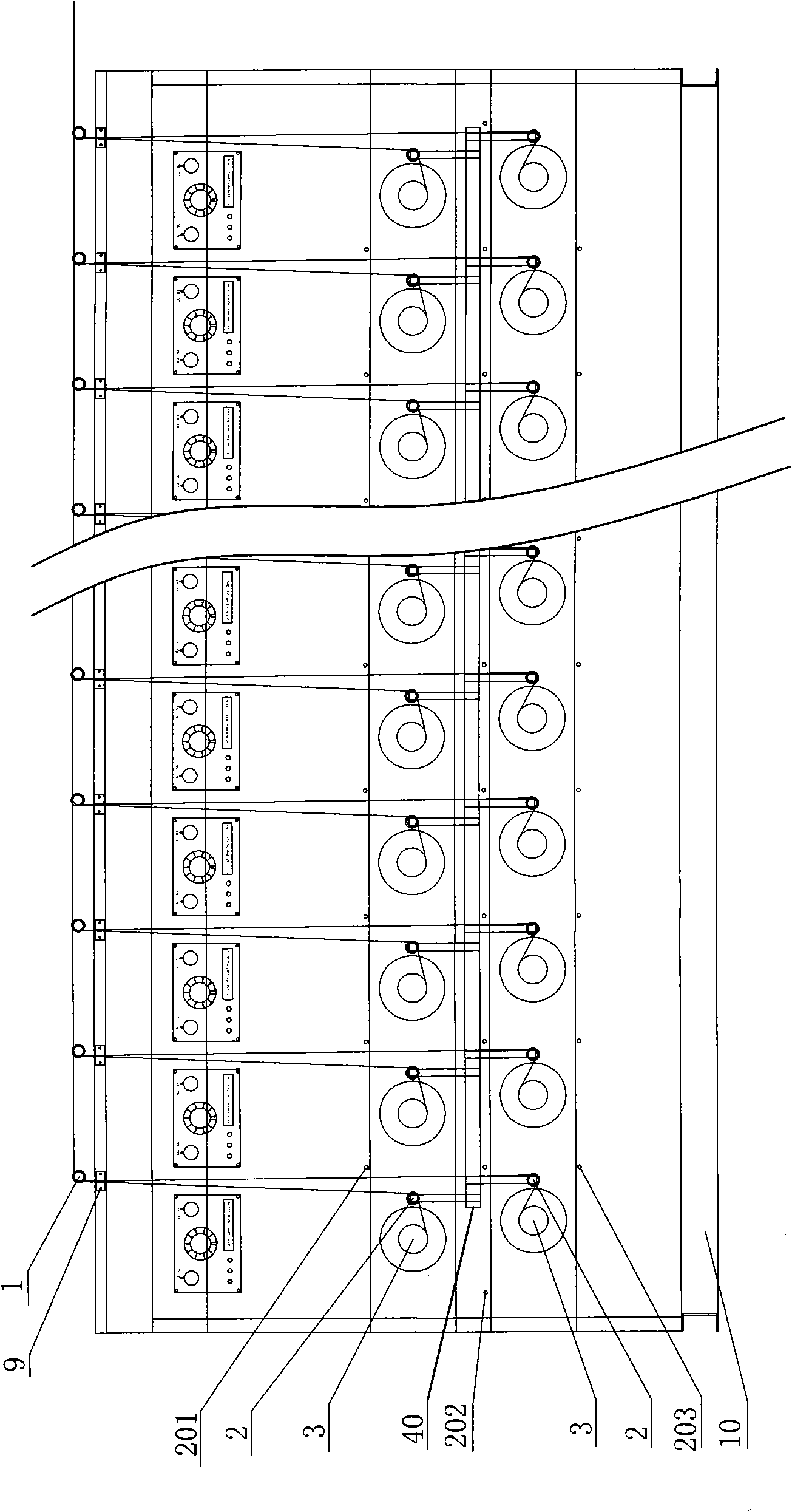

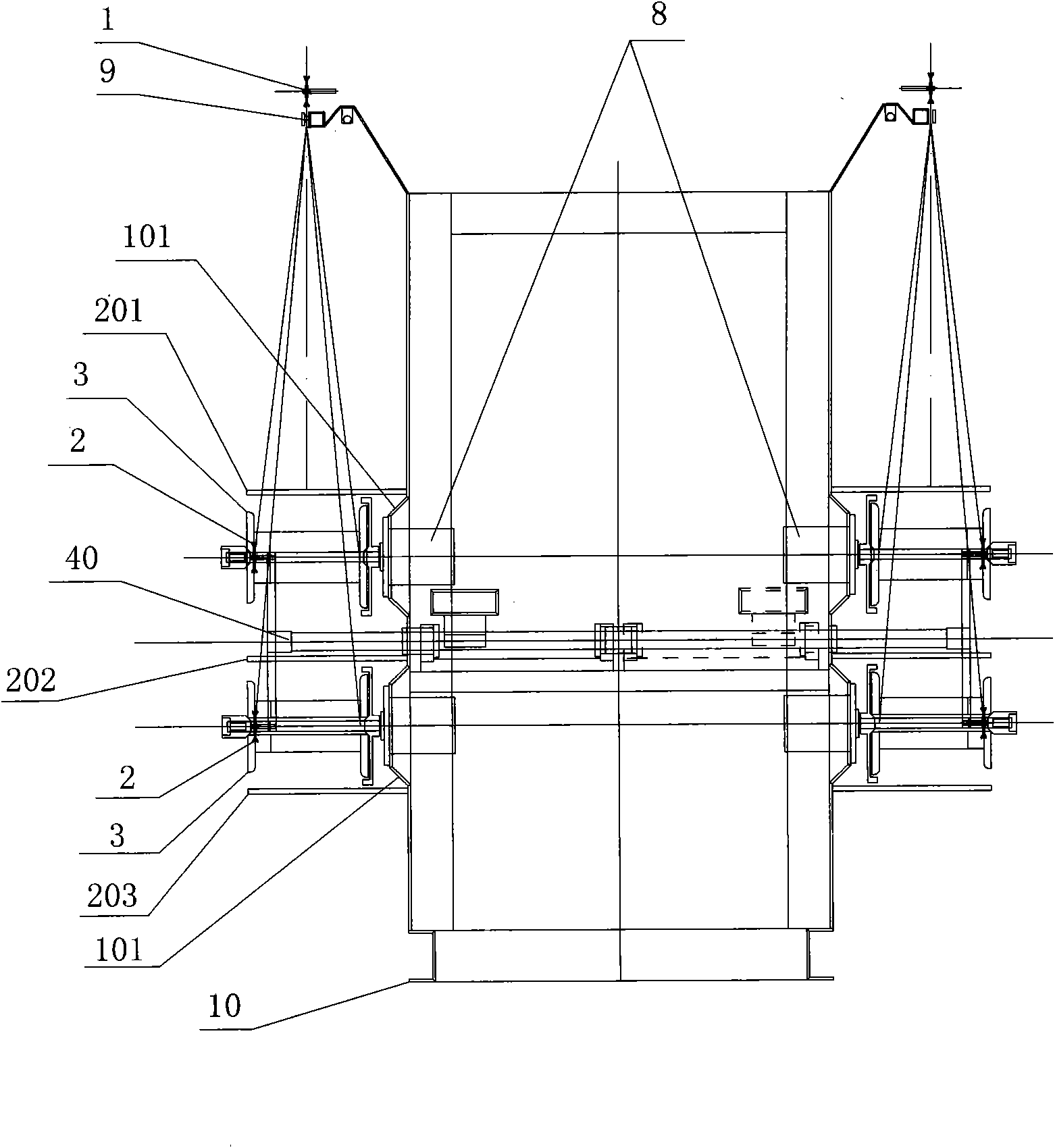

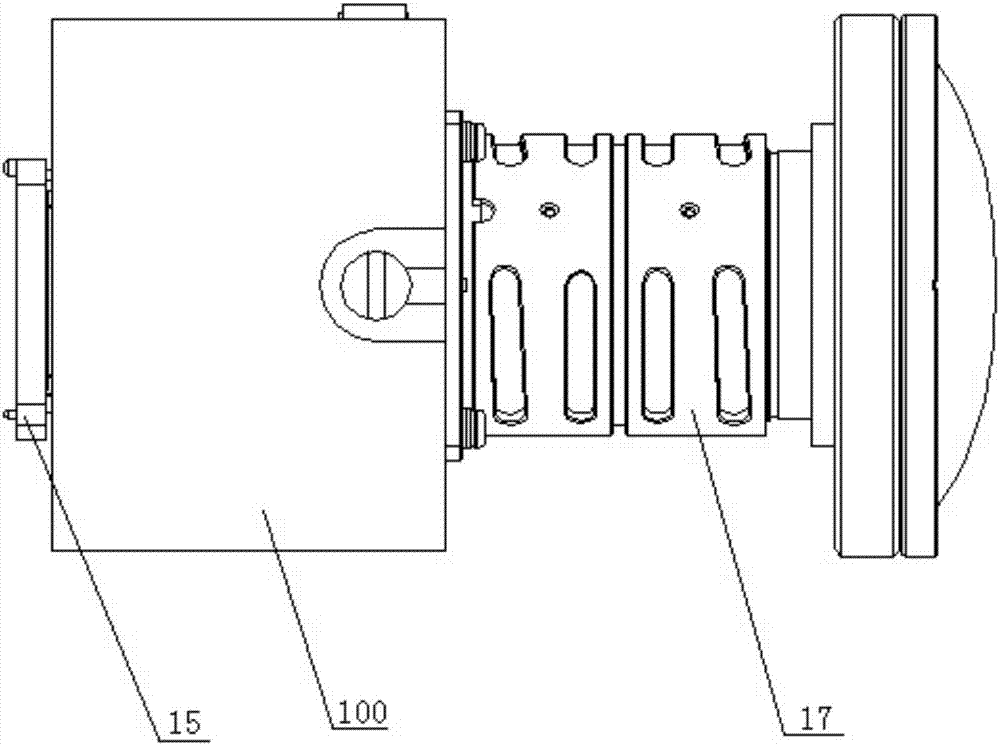

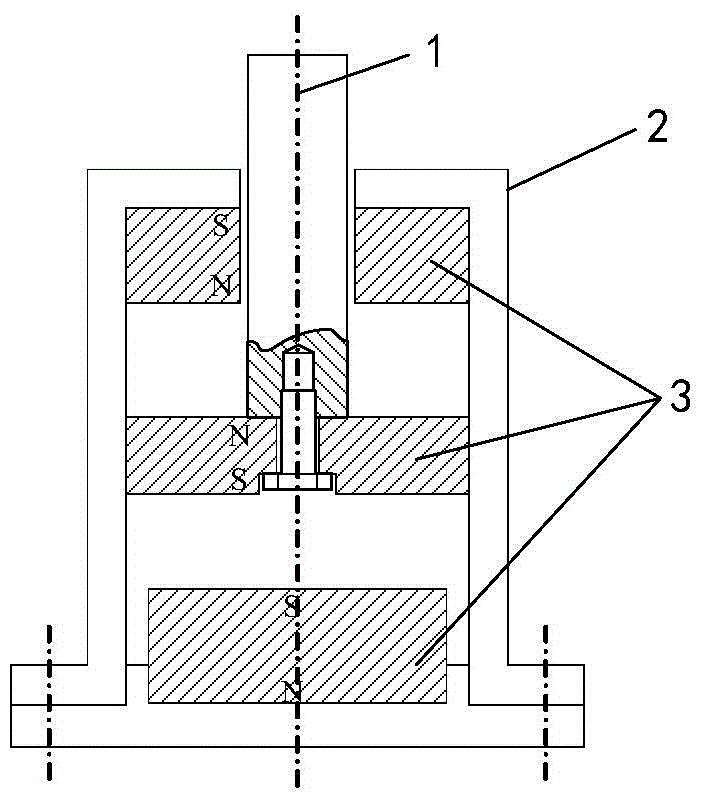

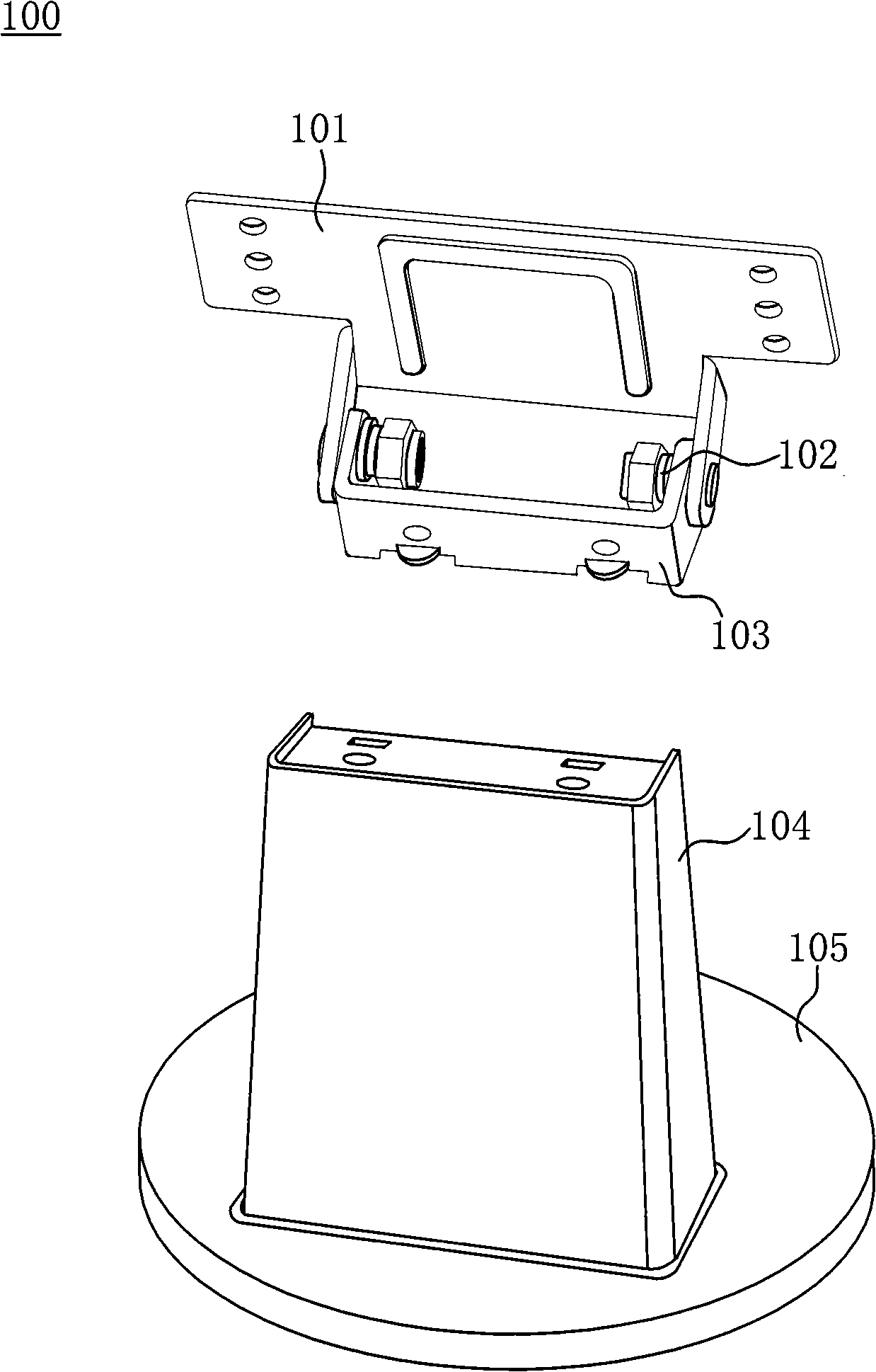

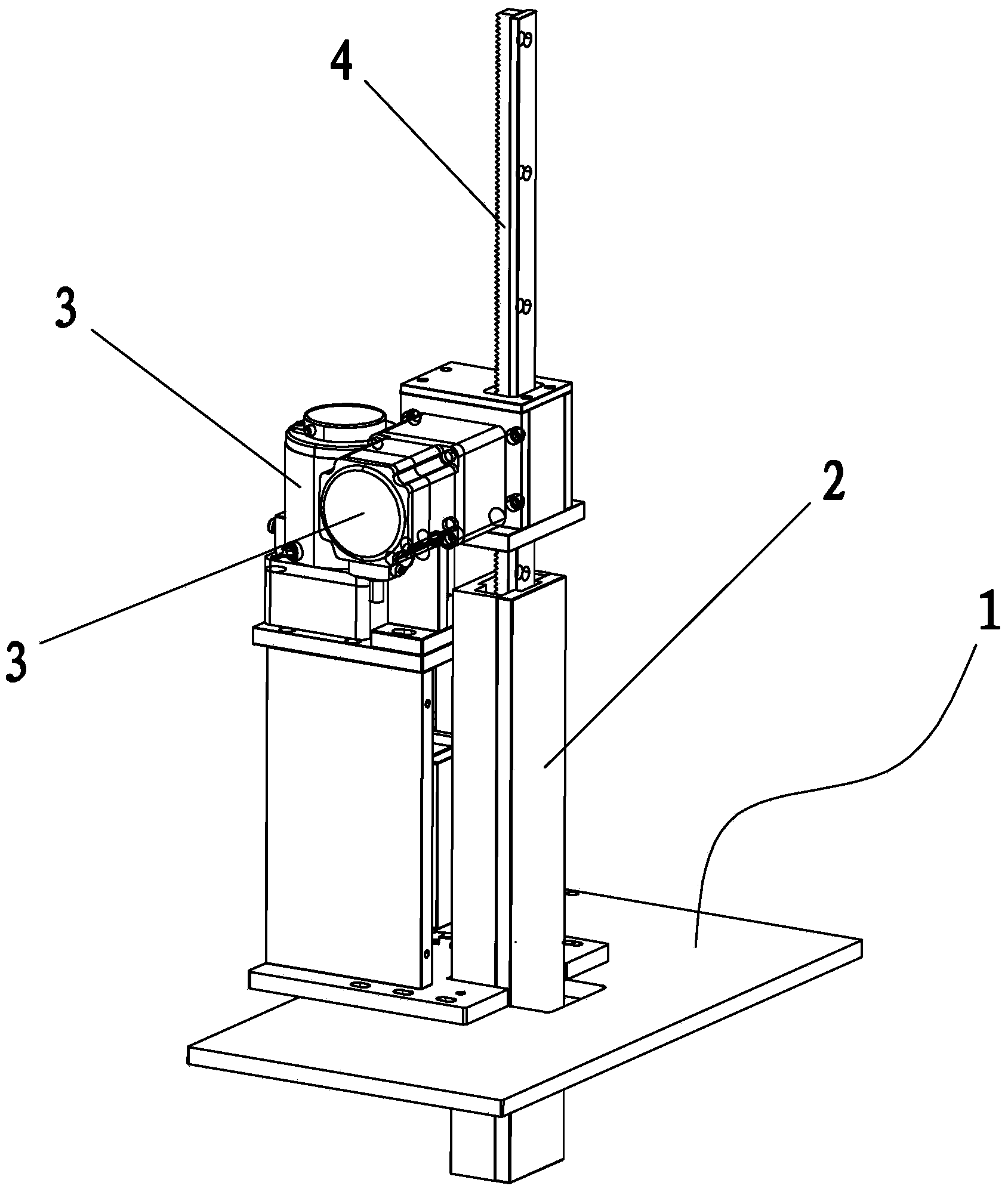

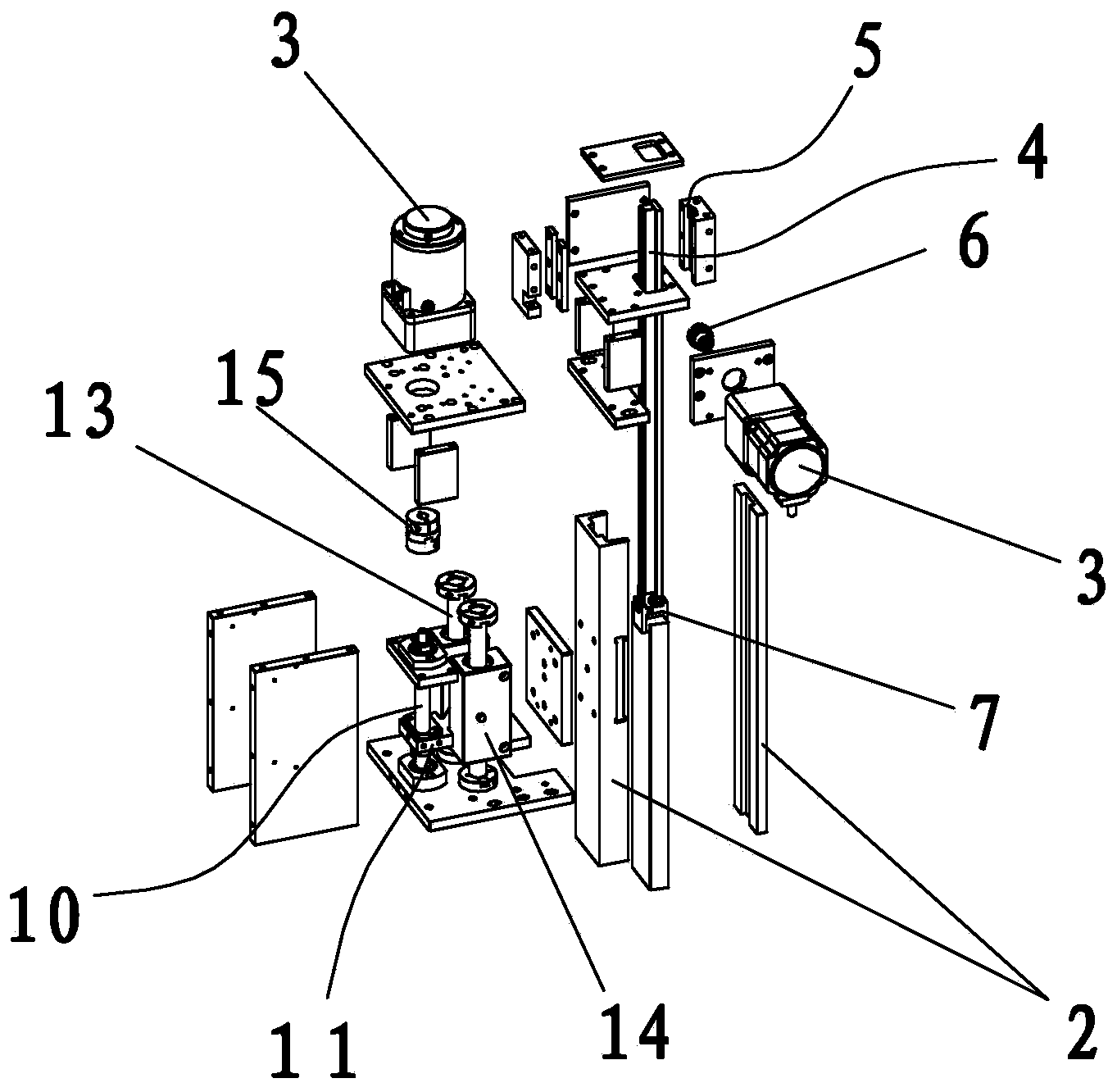

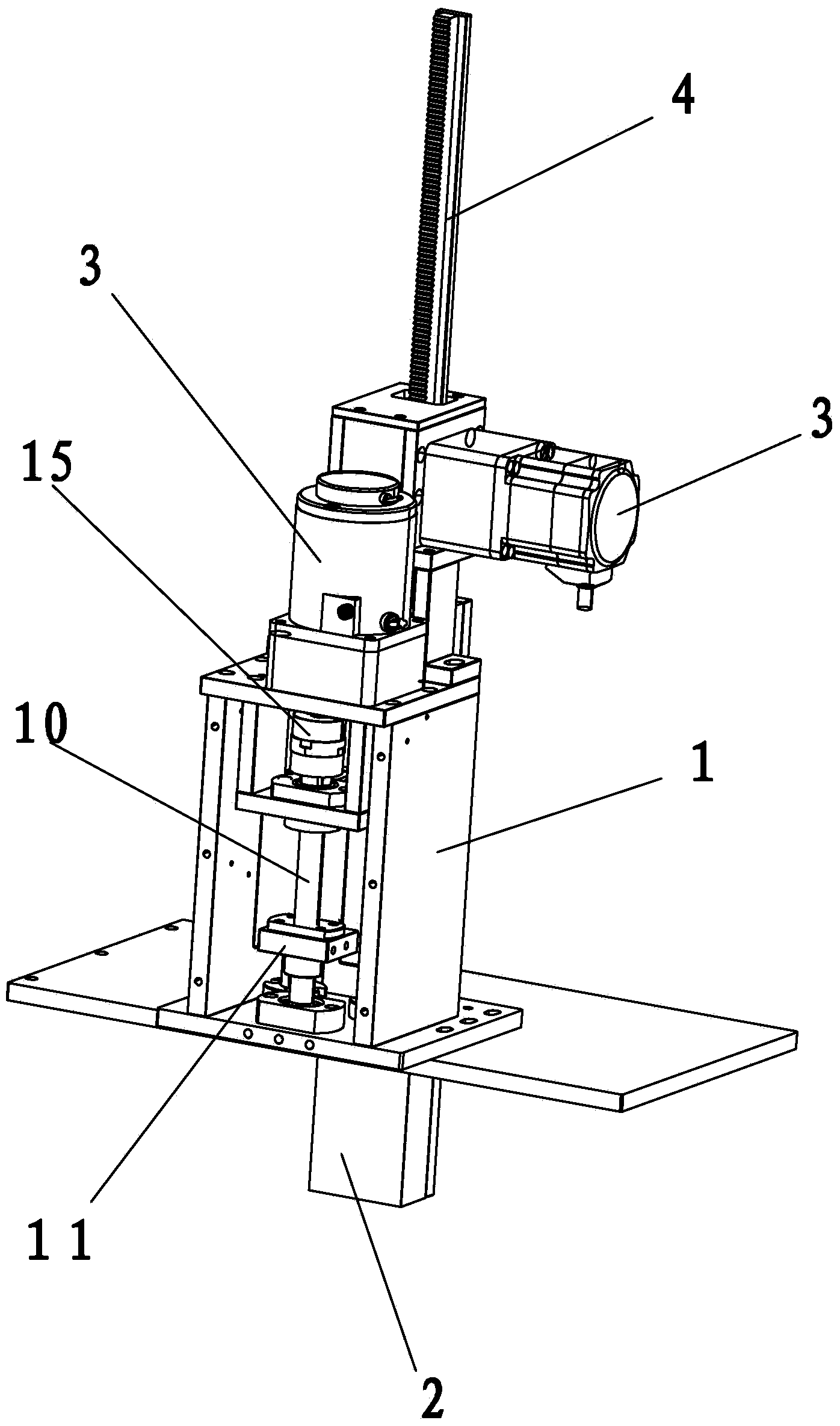

Gear shaft part comprehensive locking assembler

ActiveCN106624785ANo deflectionAvoid damageAssembly machinesWork holdersDistribution controlEngineering

The invention relates to a gear shaft part comprehensive locking assembler. The gear shaft part comprehensive locking assembler comprises a frame and a power distribution control box; the frame is provided with a locking carrier device matched with a gear shaft; the locking carrier device is matched with a gear sleeving mechanism on the upper side and a short shaft inserting device on the lower side; the frame is provided with a carrier base; a hole with the aperture larger than the diameter of the gear shaft is formed in the center of the carrier base; the carrier base is provided with a fixed clamping block and a movable clamping block matched with each other; the movable clamping block is connected with a movable clamping cylinder on the carrier base; the fixed clamping block and the movable clamping block are matched with a middle fixed block on the gear shaft; and the gear sleeving mechanism, the short shaft pressing mechanism and the movable clamping cylinder are connected to the power distribution control box. The gear shaft part comprehensive locking assembler comprehensively clamps the irregular middle fixed block through the fixed clamping block and the movable clamping block, guarantees no deviation of the gear shaft in the assembly process, and meanwhile, prevents a fixed part from directly acting on the gear shaft to prevent damage of the gear shaft so as to improve the assembly effect.

Owner:徐州万旭机械有限公司

Device for measuring friction force and film thickness of lubricating oil film under different surface speeds

InactiveCN111780972AIncrease positive pressureIncrease the maximum frictionMachine bearings testingUsing optical meansRotational axisEngineering

The invention discloses a device for measuring friction force and film thickness of a lubricating oil film under different surface speeds, and the device comprises an experiment bench which is provided with a translation platform, and the translation platform can move linearly under the drive of a drive device. A main shaft system is arranged on the experiment bench, a glass disc is arranged on the main shaft system, and the glass disc can rotate. An arc-shaped guide rail is arranged on the translation platform. The rotating base is installed on the arc-shaped guide rail and can move along thearc-shaped guide rail, the loading system is installed on the rotating base, a steel ball of the loading system and the glass disc move relatively, and a rotating bearing in the rotating base converts friction force generated by relative movement into pressure which can be collected by a pressure sensor on the rotating base.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Wax conveying mechanism for polishing machine

InactiveCN104057399APlay a protective effectCannot interfere with normal movementPolishing machinesWaxEngineering

The invention provides a wax conveying mechanism for a polishing machine. The wax conveying mechanism for the polishing machine comprises a support. A pushing device, a stabilization rack and a power device are arranged on the support, wherein the pushing device is used for pushing rod wax to move to be in friction with a cloth roller, the stabilization rack is used for keeping the rod wax stable, and the power device is used for driving the pushing device and the stabilization rack to be mutually matched. The stabilization rack is connected with the power device through a positioning mechanism and the power device drives the stabilization rack and the rod wax to move in the same direction. The special pushing device is used for fixing the rod wax and making the rod wax continuously be in contact with or abut against the cloth roller, the special stabilization rack is arranged for the rod wax, the rod wax is protected in a reinforced mode and is not prone to breakage, and it is required that the stabilization rack protects the rod wax and cannot block normal movement of the rod wax. When the cloth roller and the rod wax are consumed and shortened, both the rod wax and the stabilization rack move downwards, and it is guaranteed that only a small section of the rod wax is exposed out of the stabilization rack. Thus, the stabilization rack and the pushing device are kept to move in the same direction.

Owner:NINGBO ZHENHE ELECTRICAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com