Patents

Literature

85results about How to "Reduce interface reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

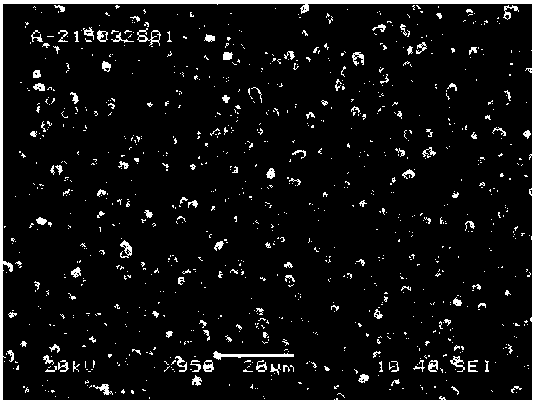

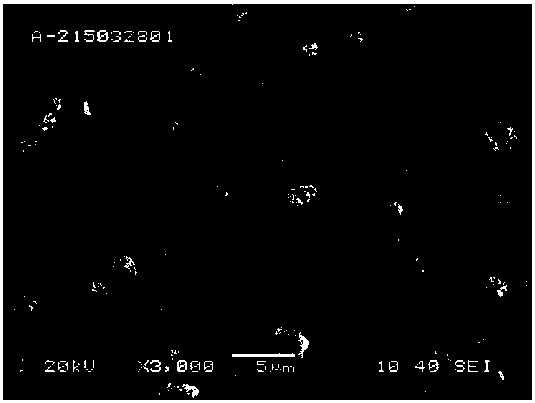

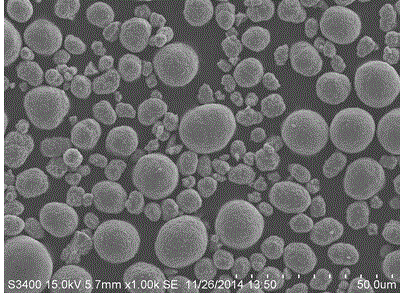

High-density and small-particle size nickel-cobalt-manganese hydroxide and preparation method thereof

InactiveCN107640792AHigh density and small tap densityLow tap densityCell electrodesSecondary cellsHigh densityManganese

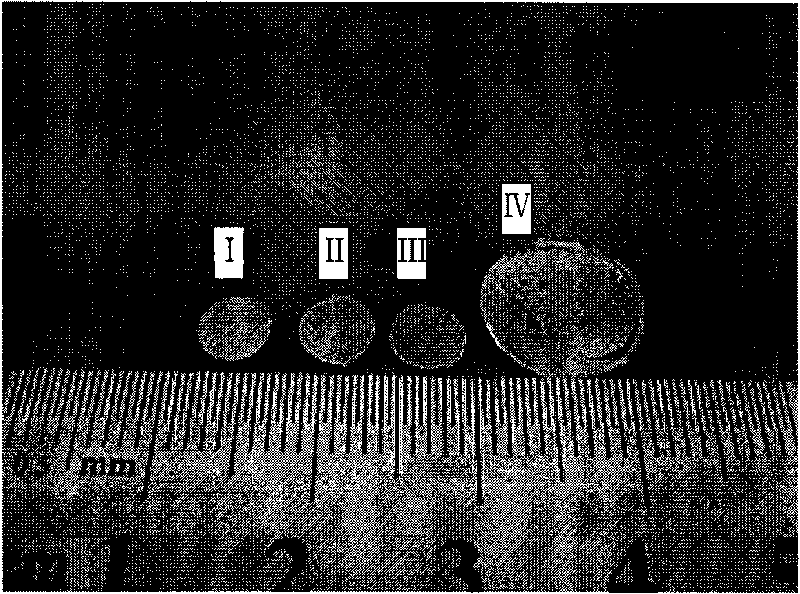

The invention discloses a high-density and small-particle size nickel-cobalt-manganese hydroxide and a preparation method thereof. For the high-density and small-particle size nickel-cobalt-manganesehydroxide provided by the invention, a general chemical formula is NixCoyMnz(OH)2, wherein x+y+z=1, x is larger than or equal to 0.3 and smaller than or equal to 0.8, y is larger than or equal to 0.1and smaller than or equal to 0.4, and z is larger than or equal to 0.1 and smaller than or equal to 0.4; the particle sizes are d10 larger than or equal to 2 microns, d50 equal to 2.5-4 microns and d90 smaller than or equal to 6 microns, the tap density is larger than or equal to 1.4g / cm<3>, the specific surface area is 5-20m<2> / g, and the shape is spherical or spheroidal. The invention also discloses the preparation method of the high-density and small-particle size nickel-cobalt-manganese hydroxide. The preparation method is strong in controllability, can stably control the particle sizes ineach production batch without using a surfactant and is low in production cost, high in efficiency and good in physicochemical index of a final product.

Owner:ZHUJI PAWA NEW ENERGY

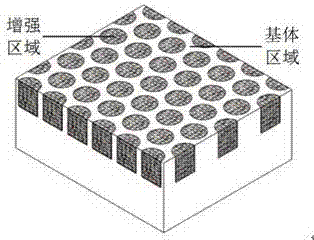

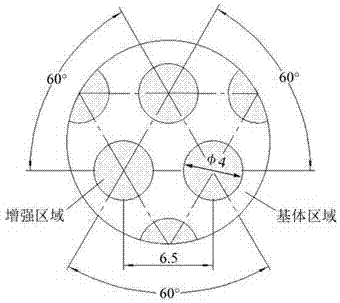

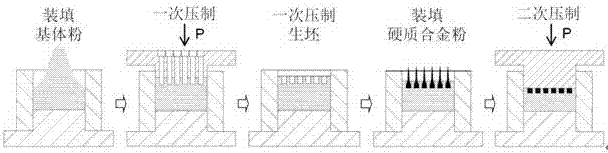

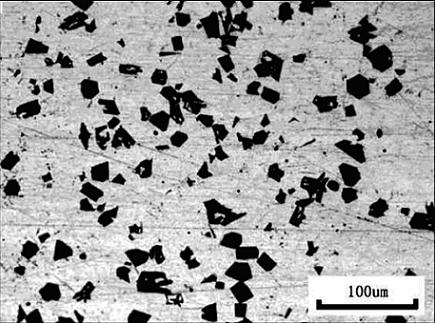

Powder metallurgy preparation method of localization reinforced composite

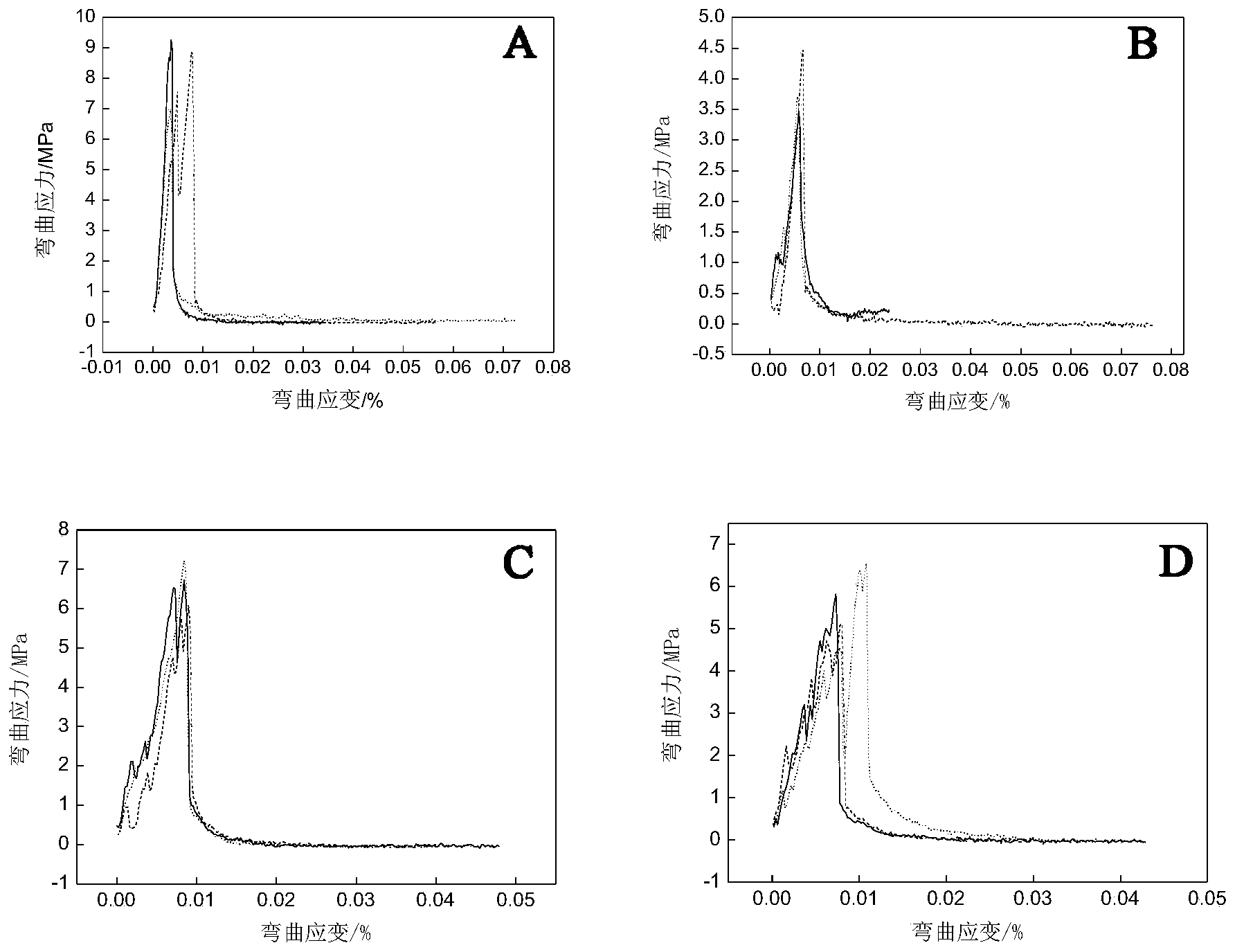

The invention belongs to the technical field of composite preparation, and particularly relates to a powder metallurgy preparation method of a localization reinforced composite for manufacturing wear-resisting quick-wear parts of mining and building machines. The method comprises the following steps that (1) tungsten carbide powder and titanium carbide powder are used as reinforced particles, reduced iron powder and high-speed steel powder are used as a metal binder, and hard alloy powder is prepared according to a certain proportion; (2) the prepared hard alloy powder is put into a ball mill, and a process control agent is added for ball milling and mixing; and (3) a forming agent is added into the hard alloy powder subjected to uniform ball milling and mixing, and then the steps of mixing, prepressing, smashing, sieving particle making and the like are carried out. In a composite layer of the composite prepared through the method, discontinuous reinforcement areas are uniformly distributed in a continuous matrix area, cracks are not prone to being produced and expanding in the service process of the composite, and strength-toughness matching performance of the composite is achieved well; and the wear resistance of the composite can be obviously improved, and the service life of the composite can be obviously prolonged.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Preparation method of oxide doped and modified Y2O3+YSZ high-temperature-resisting shell

InactiveCN103949590AHigh strengthReduce interface reactionFoundry mouldsFoundry coresSlurryDoped oxide

The invention relates to a preparation method of an oxide doped and modified Y2O3+YSZ high-temperature-resisting shell. The preparation method comprises the following steps: preparing mixed powder of yttrium oxide and doped oxide and yttrium sol into slurry; coating, coating, stuccoing and drying; repeating the above steps for many time; then dewaxing so as to prepare a shell, and then sintering so as to form a finished product. The shell or a cruicible is suitable for smelting, precision casting and directional solidification of high-activity alloys and refractory metal at a high temperature of 1500-2000 DEG C, has the characteristics of low interface reaction, good deformability, high intensity, easy forming and capability of selecting types of doped oxides and dopping content according to the actual alloy components, and is more economical and has better technology property and thermal shock resistance as compared with pure yttrium oxide shells.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

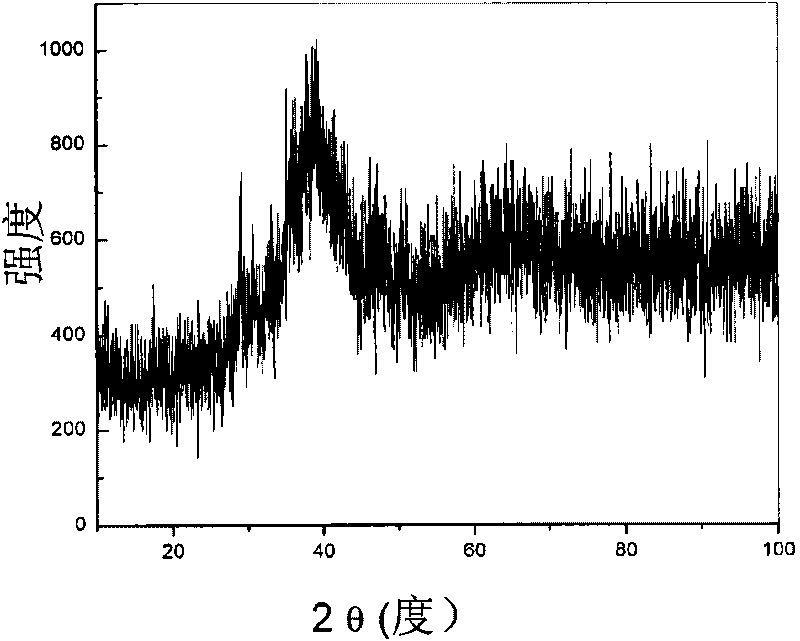

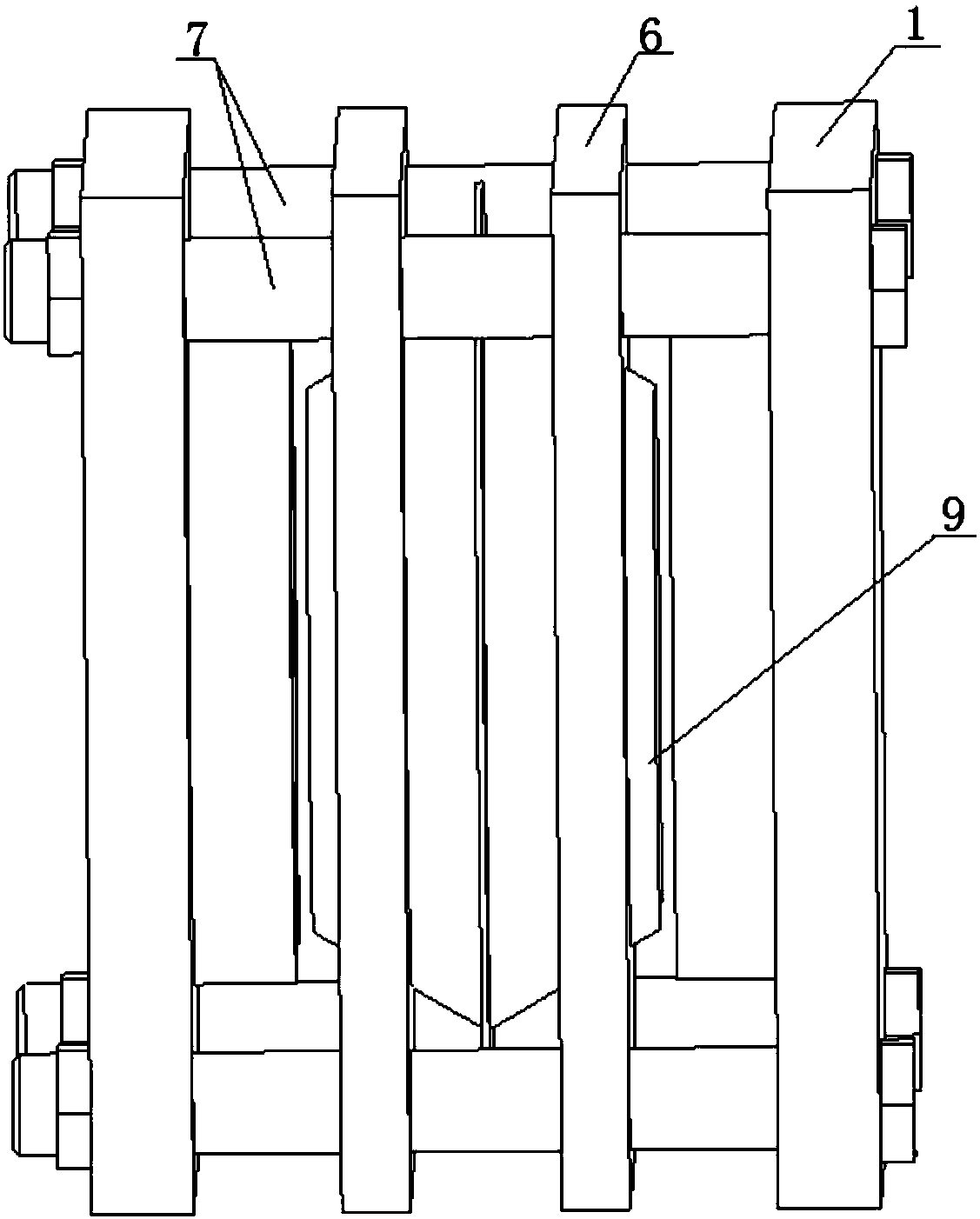

Method and device for preparing large-size bulk amorphous composite materials

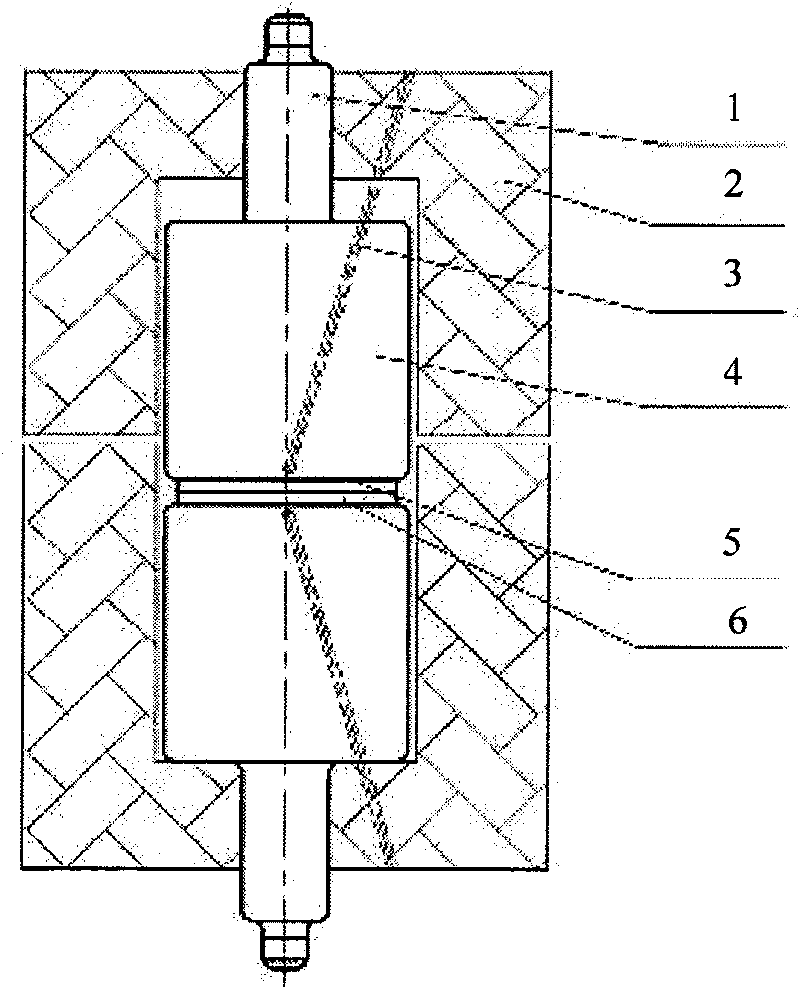

The invention provides a method for preparing large-size bulk amorphous composite materials, which belongs to the field of preparing amorphous alloy (metallic glass) and composite materials thereof. The method applies to superplastic diffusion bonding of bulk amorphous substances and fiber, and is characterized in that the bulk amorphous substances and the fiber are arranged in a certain mode (such as a layered mode and the like), put into a mold, pressurized and thermally insulated under gas protection or vacuum for superplastic diffusion bonding; pressure is released after a certain period of time; and workpieces are taken out of the mold. The invention also provides a novel device for preparing large-size bulk amorphous, fiber / amorphous composite materials through superplastic diffusion bonding. The device consists of a heating system, a heat insulation system, a mold system, a loading system, a gas protection system and a cooling system. The method and the device have the advantages of reinforcing the fiber, enabling the shape of amorphous alloy-base composite materials to be designed, enabling the volume of the fiber in the composite materials to be controlled and enabling the fiber to be used in other various amorphous alloy systems low in amorphous formation capability, and are applicable to armor boards, armor-piercing shells and the like.

Owner:UNIV OF SCI & TECH BEIJING

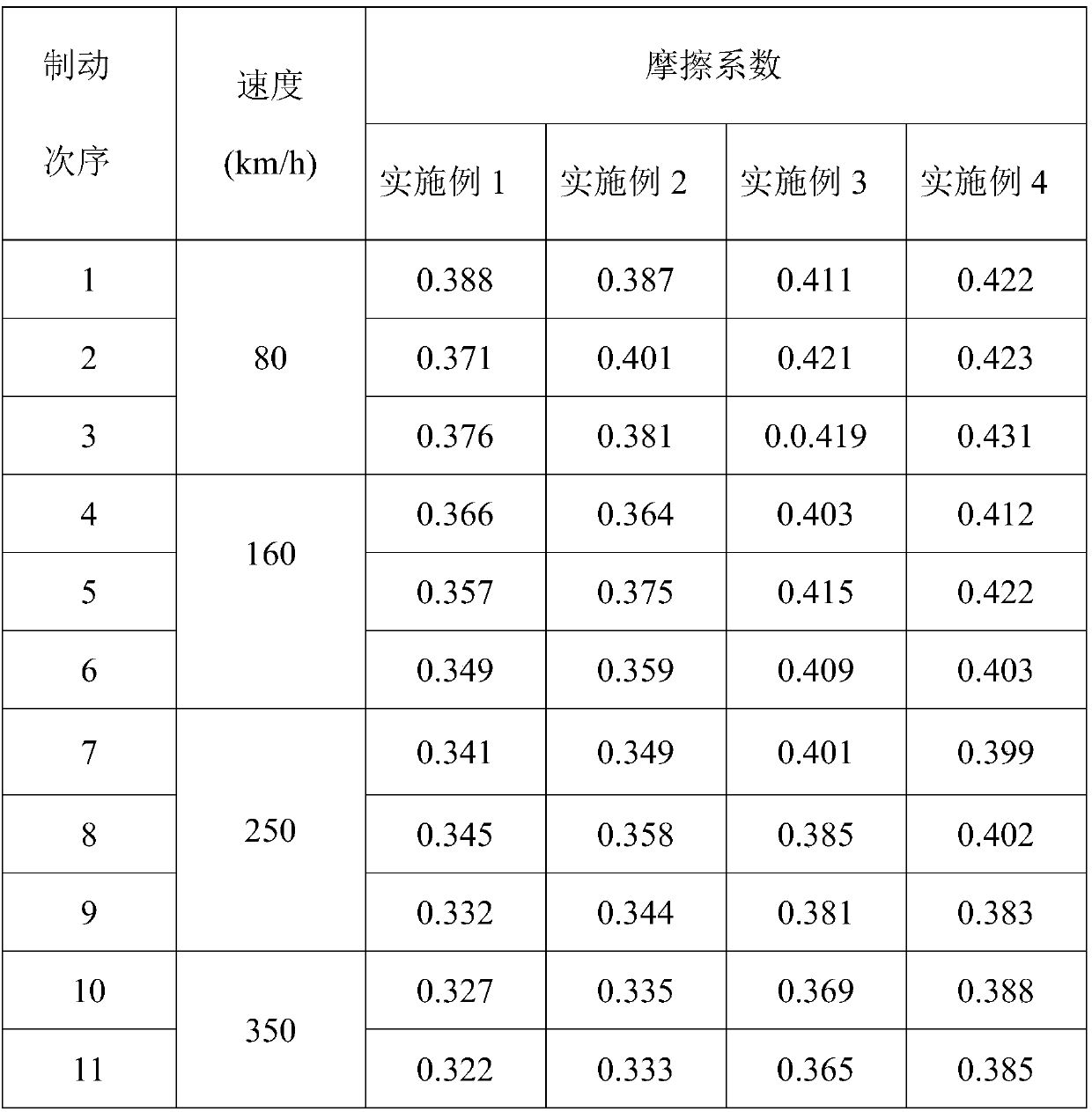

Powder metallurgy friction material for high-speed train braking and preparation method of powder metallurgy friction material

InactiveCN109518100AImprove high temperature friction performanceImprove self-shear strength and compressive strengthPowder metallurgyCopper plating

The invention relates to the technical field of brake materials, in particular to a powder metallurgy friction material for high-speed train braking and a preparation method of the powder metallurgy friction material. The powder metallurgy friction material is prepared from the following raw materials: copper powder, iron powder, copper-plated flake graphite, copper-plated graphite granules, chromium iron powder, molybdenum disulfide powder and alumina fiber through a powder metallurgy process. The powder metallurgy friction material has good mechanical properties, and is stable in friction coefficient, small in abrasion loss and good in thermal failure resistance; through the adopted raw materials and the ratio, the friction material with excellent properties can be prepared at the relatively-low sintering pressure and temperature, energy consumption is saved, a preparing process is simple and easy to control, the performance is excellent, and good application prospects are achieved.

Owner:BEIJING TIANRENDAOHE NEW MATERIAL CO LTD

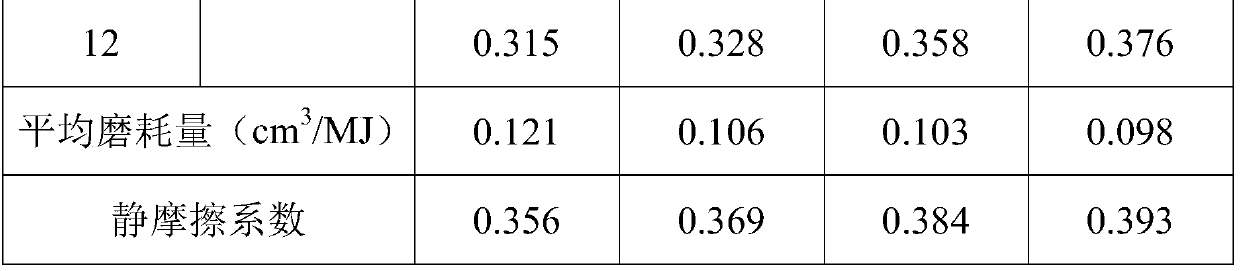

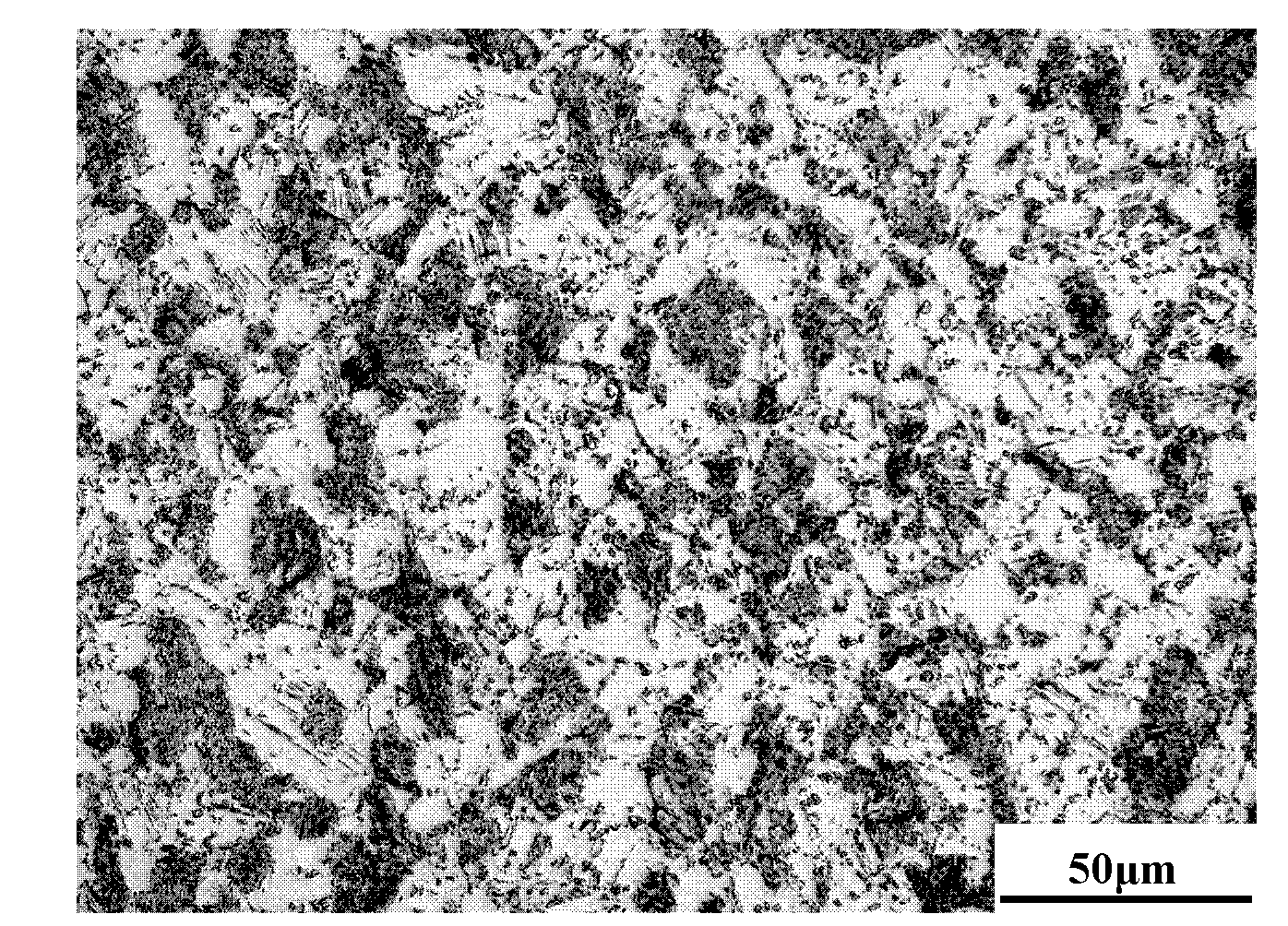

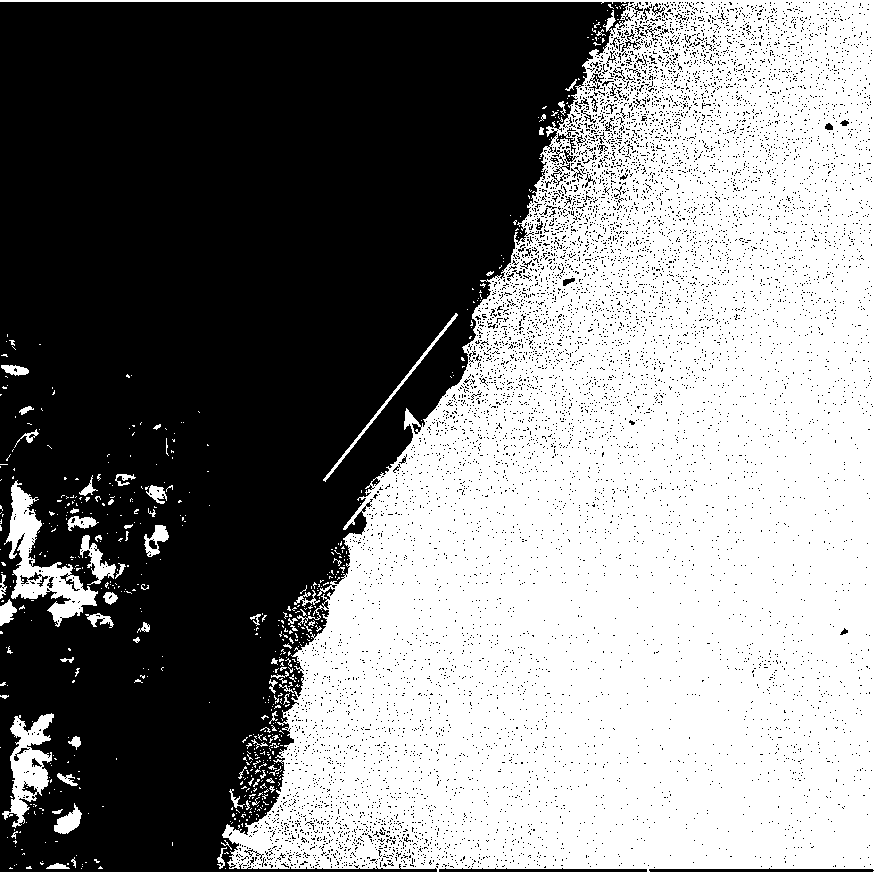

Preparation method of TiAl alloy investment casting shell

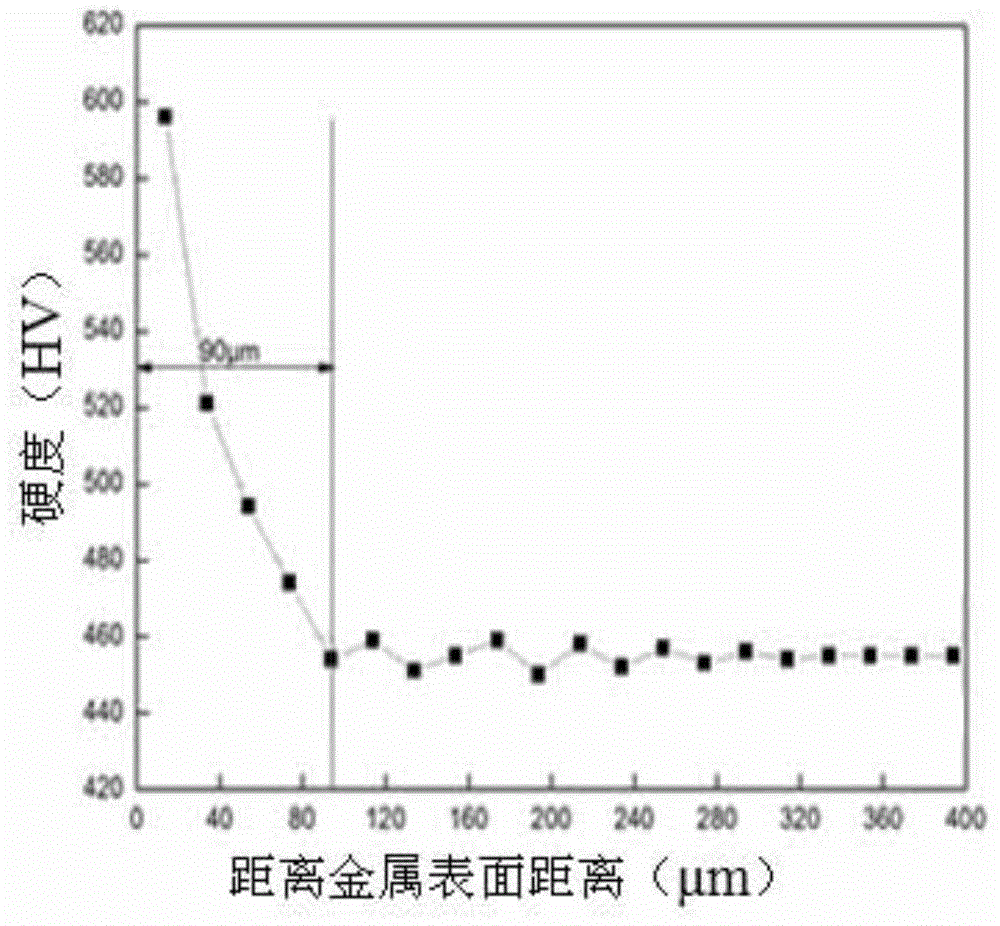

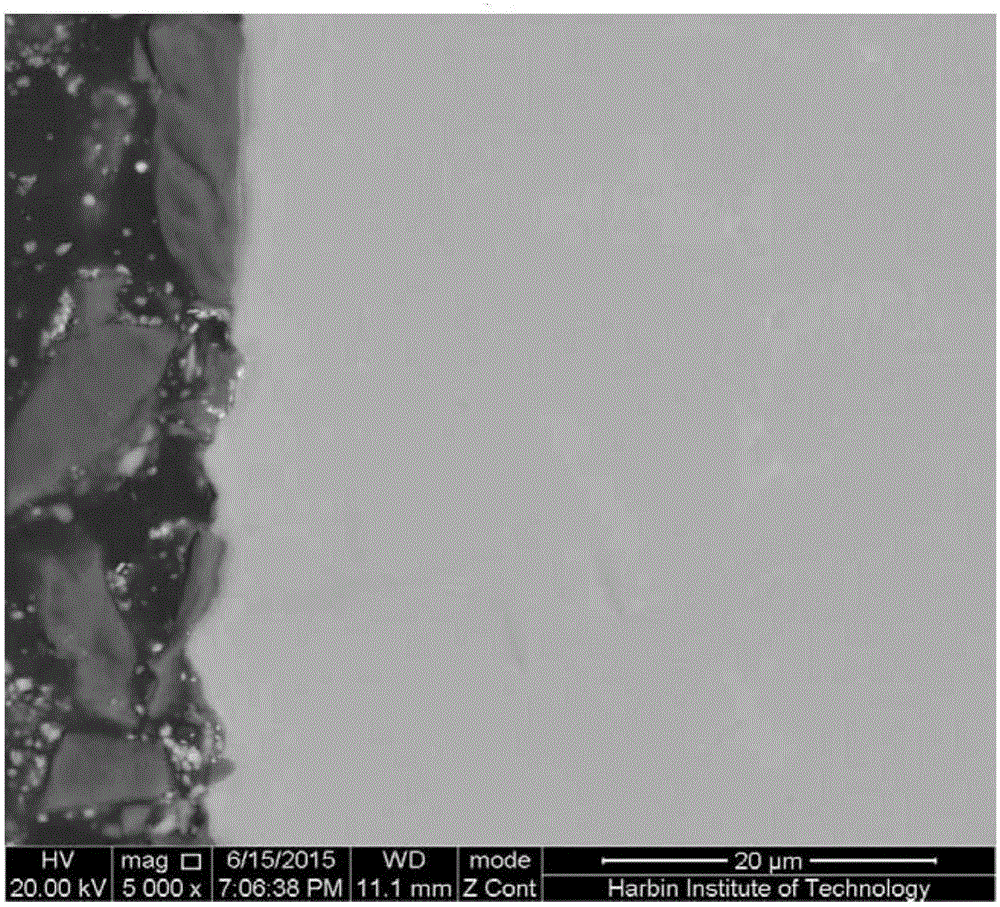

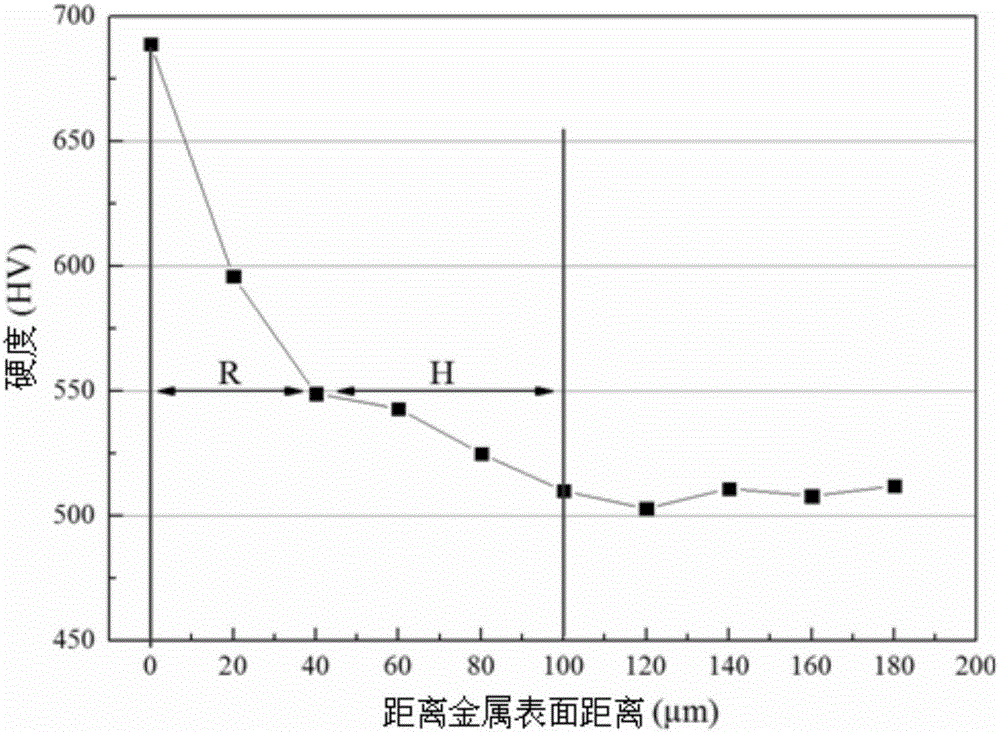

InactiveCN104907495AReduce interface reactionNo obvious sticky sandFoundry mouldsFoundry coresSurface layerInvestment casting

The invention provides a preparation method of a TiAl alloy investment casting shell. The preparation method of the TiAl alloy investment casting shell aims at solving the problems of high cost and heavy interface reaction of the existing TiAl alloy investment casting ceramic shell. The method comprises the steps of 1, preparing the slurry of a surface layer, 2, preparing a surface-layer shell, 3, preparing an impending surface-layer shell, 4, preparing a back-layer shell, 5, sealing, and 6, dewaxing and roasting. The preparation method is used for remarkably reducing the degree of the TiAl alloy investment casting interface reaction and achieving the purposes of reducing the TiAl alloy investment casting cost and reducing the interface reaction. The shell casting is bright in surface without obvious sand burning; the thickness of the interface reaction is about 30 microns and the interface reaction degree is weaker than that of the traditional shell.

Owner:HARBIN INST OF TECH

Preparation method of titanium-steel composite plate

ActiveCN107626764AReduce spreadImprove the bonding strength of the interfaceTitaniumMaterials processing

The invention discloses a preparation method of a titanium-steel composite plate, and belongs to the field of material processing. The preparation method of the titanium-steel composite plate comprises the steps that the surfaces of adopted titanium blanks and the surface of an adopted steel blank are treated, and then the surfaces of the titanium blanks are coated with paint and dried at the roomtemperature; the two titanium blanks with the surfaces being treated and coated with paint are aligned and stacked together, the steel blank is placed between the two titanium blanks, and then the blanks are assembled together symmetrically; the periphery of a composite blank is welded and sealed, and vacuumizing treatment is conducted; and the composite blank is placed in a heating furnace so asto be subject to heat treatment, then multi-pass rolling is conducted, the composite blank is air cooled after being rolled, and edge cutting, tension-straightening and flattening are conducted. According to the preparation method of the titanium-steel composite plate, the surfaces of the titanium blanks are coated with protective coatings, so that the titanium blanks are protected, the situationthat the composite performance is affected due to the fact that titanium with active chemical properties is oxidized and forms compounds with other elements is avoided, and the coatings are preparedfrom isolation paint which can prevent oxidization of titanium and prevent diffusion of harmful elements (such as C and N) at high temperatures.

Owner:KUNMING UNIV OF SCI & TECH

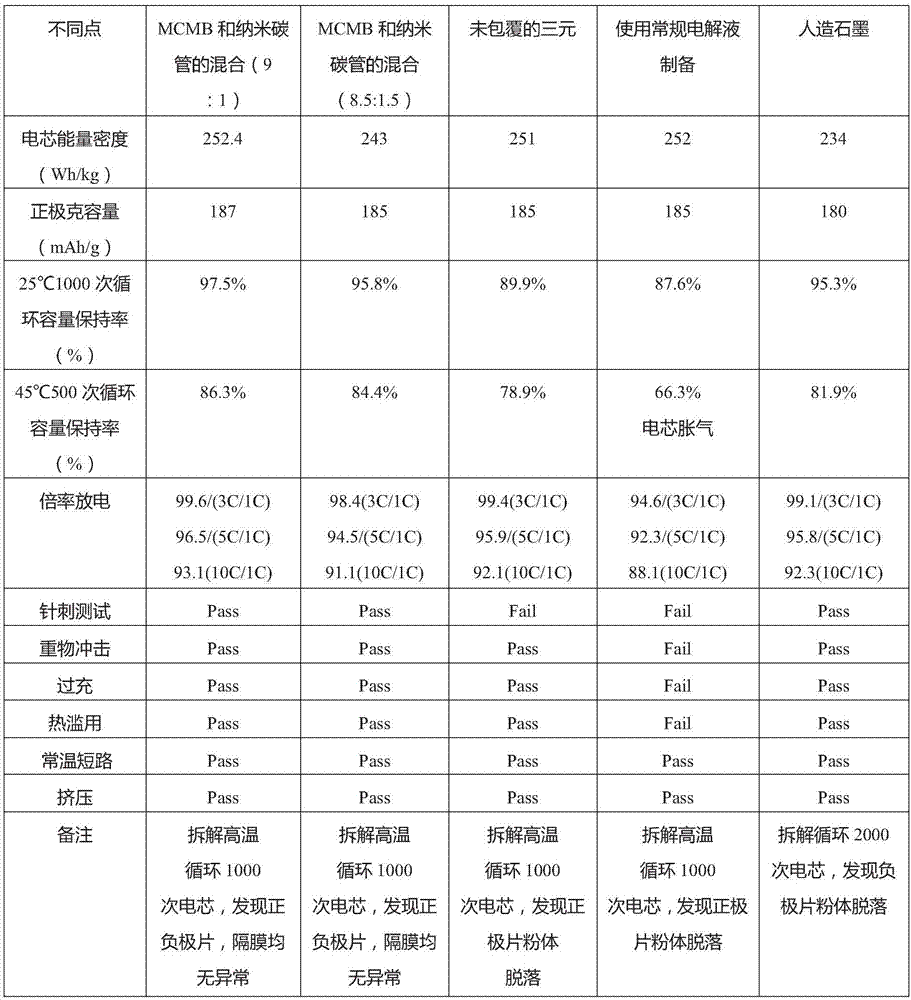

Ternary lithium battery electrolyte and high-temperature resistant, high-capacity and high-safety lithium battery core

InactiveCN107978794AImprove securityImprove high temperature resistanceMaterial nanotechnologyCell electrodesCarbon nanotubeCarbonate

The invention discloses a ternary lithium battery electrolyte and a high-temperature resistant, high-capacity and high-safety lithium battery core. According to the lithium battery core, a high-temperature resistant high-safety electrolyte is prepared by adopting a novel lithium salt of a conductive lithium salt LiBOB (lithium bis(oxalate)borate) and a lithium salt LiFSI (lithium bis(fluorosulfonyl)imide) and adding a proper amount of additive of FEC (fluoroethylene carbonate), MMDS (methylene methanedisulfonate) and TMP (trimethyl phosphate). A novel ternary positive electrode material coatedwith a mixture of nano titanium dioxide and a ternary material (LiNi0.8Co0.1Mn0.1O2) is adopted by a positive electrode, and a mixture of mesocarbon microbeads MCMB and carbon nanotubes is adopted bya negative electrode, thereby preparing the novel high-temperature resistant high-capacity lithium-ion power battery core for an automobile. According to the prepared battery core, the cycle performance is improved, and meanwhile, the problem of high-temperature air expansion is well solved.

Owner:GUANGDONG TEAMGIANT NEW ENERGY TECH CORP

Method for preparing particle-enhanced metal matrix composite

InactiveCN102021357AImprove performanceReduce interface reactionInterfacial reactionMetal matrix composite

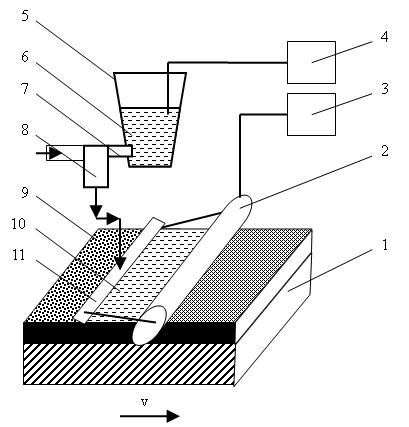

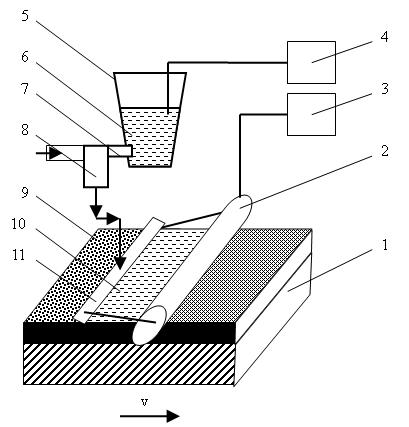

The invention relates to a method for preparing a metal matrix composite, in particular to a method for preparing a particle-enhanced metal matrix composite by laminating technology. In the method, a metal matrix in the metastable state such as a fine-grained, even amorphous state and the like obtained by combining quick cooling technology and the enhancement of ceramic particles is combined with the ceramic particles to achieve higher material performance; molten metal is blown onto surfaces of the ceramic particles under the protection of inert gases, and the ceramic particles are combined with the matrix firmly by rolling compaction; the molten metal blown later is compounded with a metal layer blown earlier, so that the combination of the ceramic particles and the metal matrix during the rolling compaction is improved further; and the processes are performed repeatedly until the particle-enhanced metal matrix composite with specified thickness is obtained. The method is easy and convenient to operate, and the large-scale industrial production is easy to realize; and due to high cooling rate, the matrix metal has high performance, and an interface reaction between the particles and the metal matrix is relieved simultaneously.

Owner:JIANGSU UNIV

Process for preparing orienting-reinforced aluminum ¿Cbased composite material

The present invention relates to preparation process of directional enhanced aluminum-base composite material. The process includes the following steps: mixing metal powder, short fiber ceramic phase and PVA solution to obtain composite material slurry; directionally extruding the composite material slurry in some mold to prepare short fiber ceramic phase directionally enhanced aluminum-base composite material wire; stoving, superposing in the length direction and pressure forming to form aluminum-base composite material block; and final sintering in hydrogen or argon atmosphere or in a vacuum sintering furnace to obtain short ceramic fiber directional enhanced aluminum-base composite material. The composite material has wide ceramic phase content range, less interface reaction to the aluminum alloy base, high directional degree and other advantages.

Owner:SOUTH CHINA UNIV OF TECH

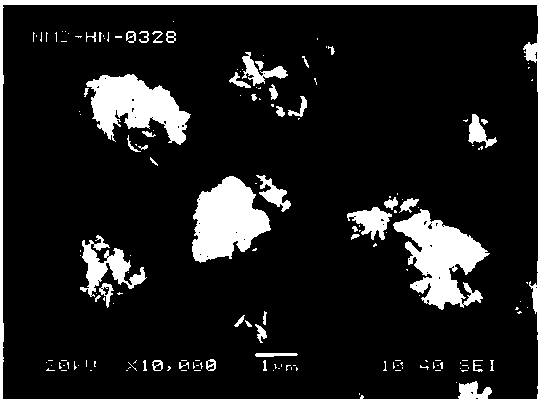

Preparation method of high-nickel ternary material used for lithium ion battery

A preparation method of a high-nickel ternary material used for a lithium ion battery. The ternary material is Li(Ni<0.6>Co<0.2>Mn<0.2>)O<2>, of which gram volume is not less than 180 mAh / g and service life retention rate after 2000 circulations is not less than 80%. The preparation method includes following steps: (1) preparation of a precursor solution; and (2) mix-calcination. During the preparation process, because an organic solution can reduce particle aggregation, a complexing agent can control the appearance and the compatibility between a titanium dioxide enhancing material and electrolyte, the ternary material is high in the gram volume (not less than 180 mAh / g) and is good in the service life retention rate after 2000 circulations (not less than 80%). The ternary material is easy to control in appearance, is simple in process and is suitable for industrialized production.

Owner:JIANGSU LENENG BATTERY INC

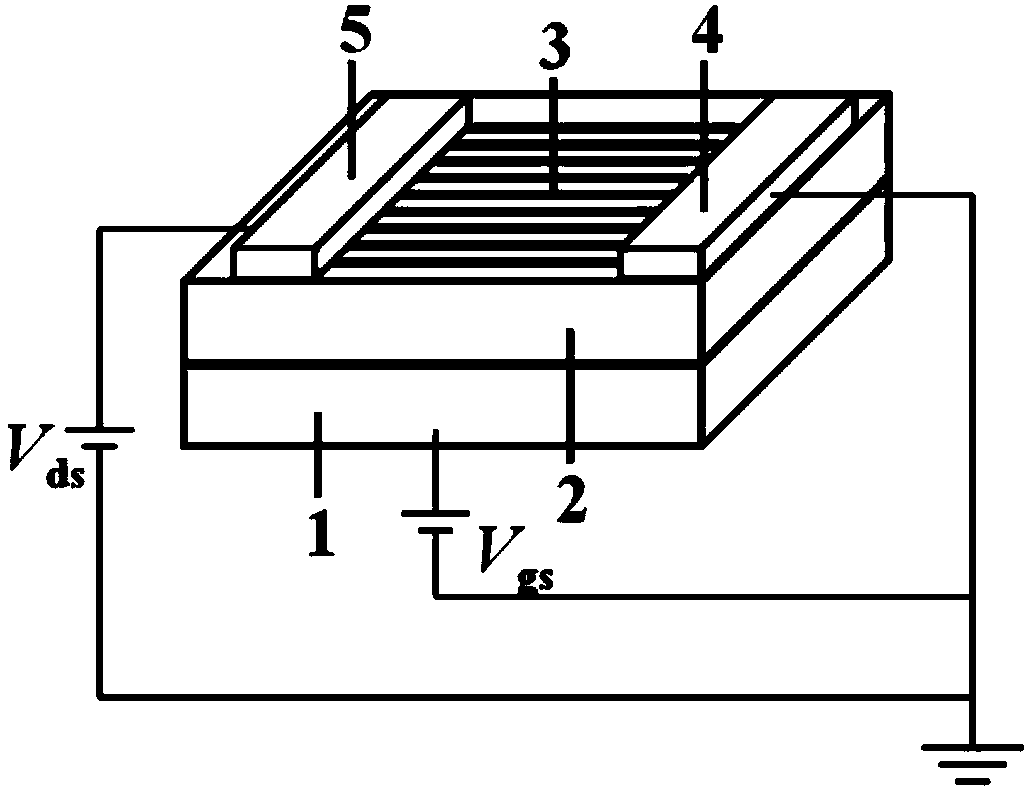

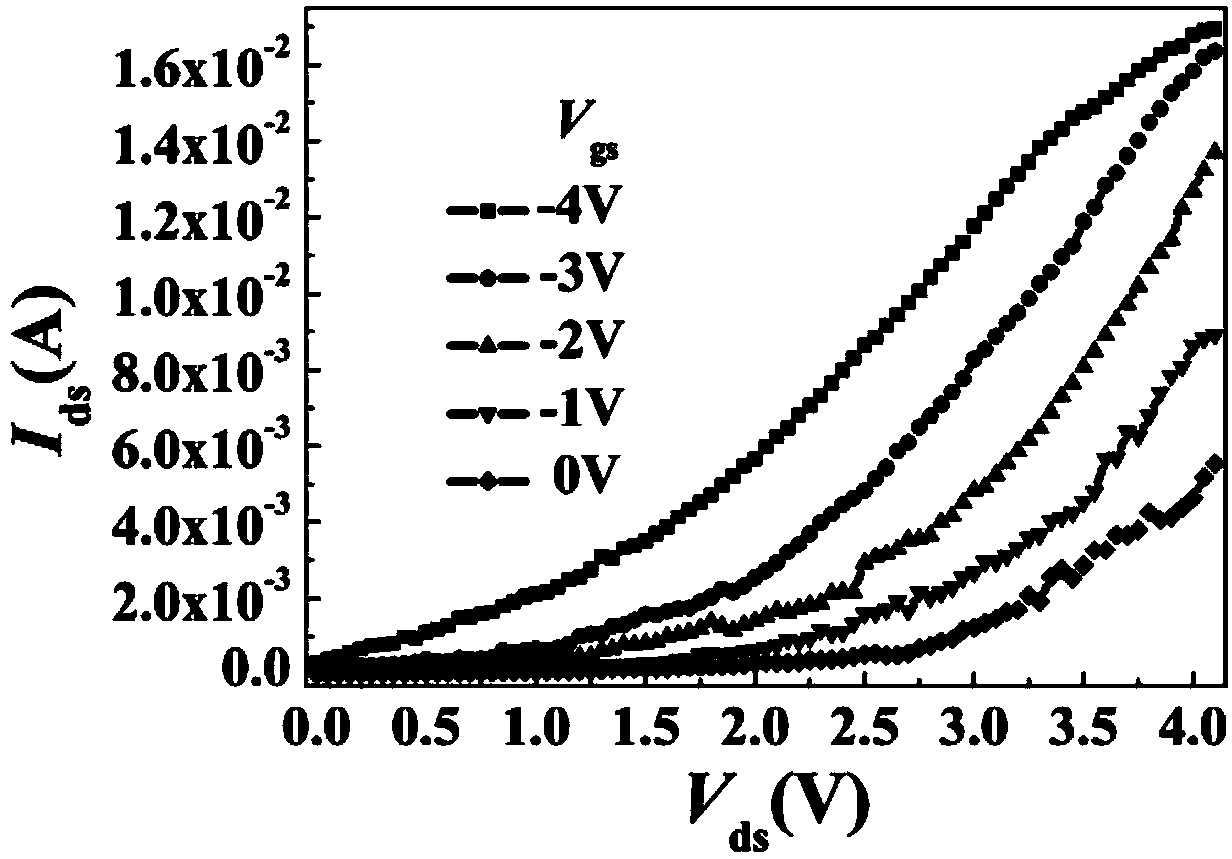

Ferro-electric field effect transistor based on structured carbon nano tube striped array and manufacturing method thereof

InactiveCN104009091AIncrease the on-state currentHigh switching ratioNanoinformaticsSemiconductor/solid-state device manufacturingOrganic field-effect transistorCharge carrier mobility

The invention discloses a ferro-electric field effect transistor based on a structured carbon nano tube striped array and a manufacturing method of the ferro-electric field effect transistor. According to the unit structure of the transistor, a bottom electrode layer (1) is arranged on the bottom layer, a ferro-electric film insulated gate layer (2) and a structured carbon nano tube striped array channel layer (3) are sequentially arranged on the middle layer, and a top layer is arranged on the structured carbon nano tube striped array channel layer (3) and comprises a transistor source electrode (4) and a transistor drain electrode (5); carbon nano tubes are single-walled carbon nano tubes, or double-walled carbon nano tubes or multi-walled carbon nano tubes. According to the ferro-electric field effect transistor, the on-state current and the switch ratio are large, carrier mobility is high, the starting voltage is small, the storage window is wide, and meanwhile the ferro-electric field effect transistor has the advantages of being simple in structure and a buffering layer is not needed, interface contact between a ferro-electric layer and a semiconductor layer is good, and large-area soft devices are easy to obtain. The manufacturing method is simple in technology, convenient to operate and low in cost and dispense with expensive equipment, and large-area and large-scale industrial production is easy to realize.

Owner:XIANGTAN UNIV

Electromagnetic pulse forming device and method for aluminum-based carbon fiber reinforced composite material

The invention discloses an electromagnetic pulse forming device and method for an aluminum-based carbon fiber reinforced composite material. The electromagnetic pulse forming device comprises a crucible container, a crucible fixing device and carbon fiber cloth. The crucible container is fixedly arranged on the crucible fixing device. The carbon fiber cloth is arranged in the middle of the crucible container. Coils are arranged on both sides of the crucible container. An inner cavity of the crucible container is filled with metal aluminum or aluminum alloy melt. The two coils are distributed on the two sides of the carbon fiber cloth. By the adoption of the electromagnetic pulse forming device and method, the formation of the interfacial brittle phase is effectively retarded, the performance of the composite material is improved, the fiber is not easily damaged by pressure, the forming quality of the composite material is improved, the forming period is greatly shortened, the production efficiency is improved, and the composite material is more suitable for mass production.

Owner:WUHAN UNIV OF TECH

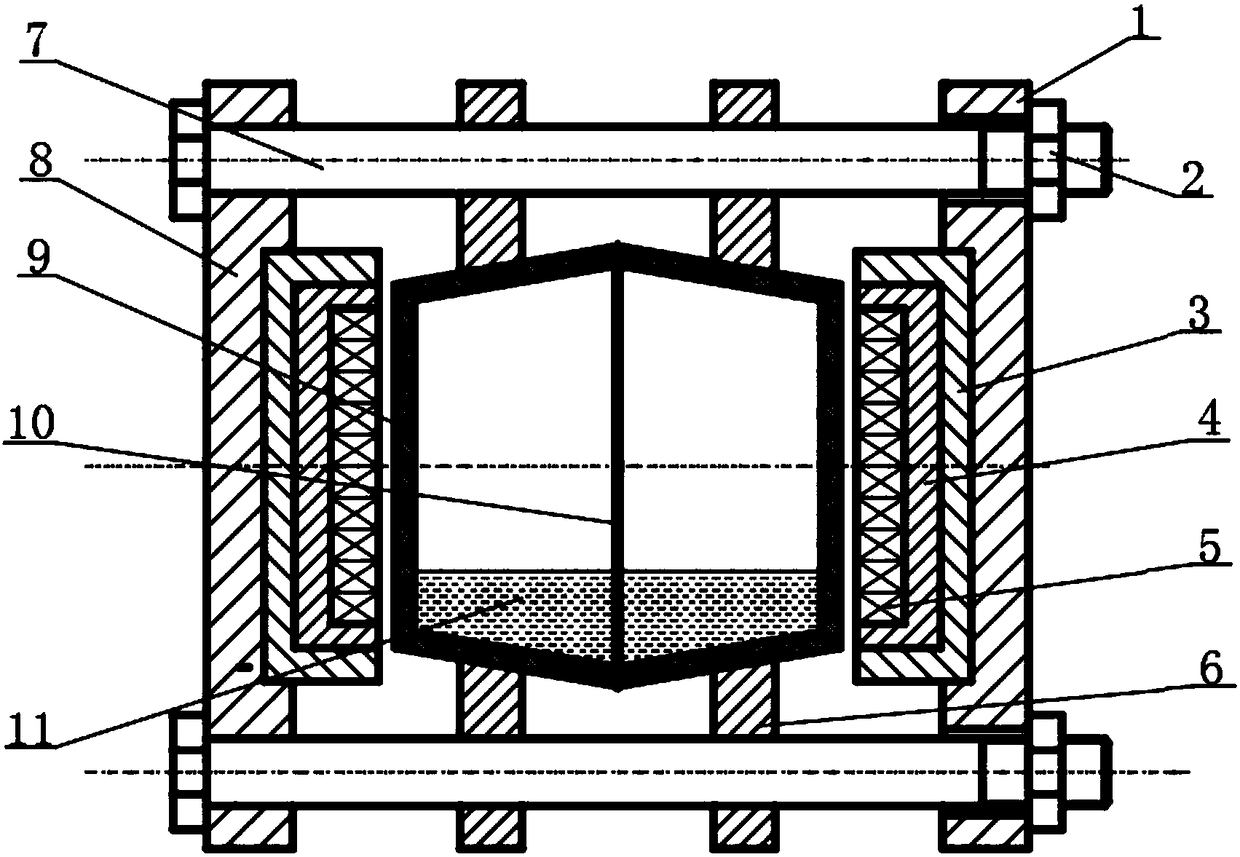

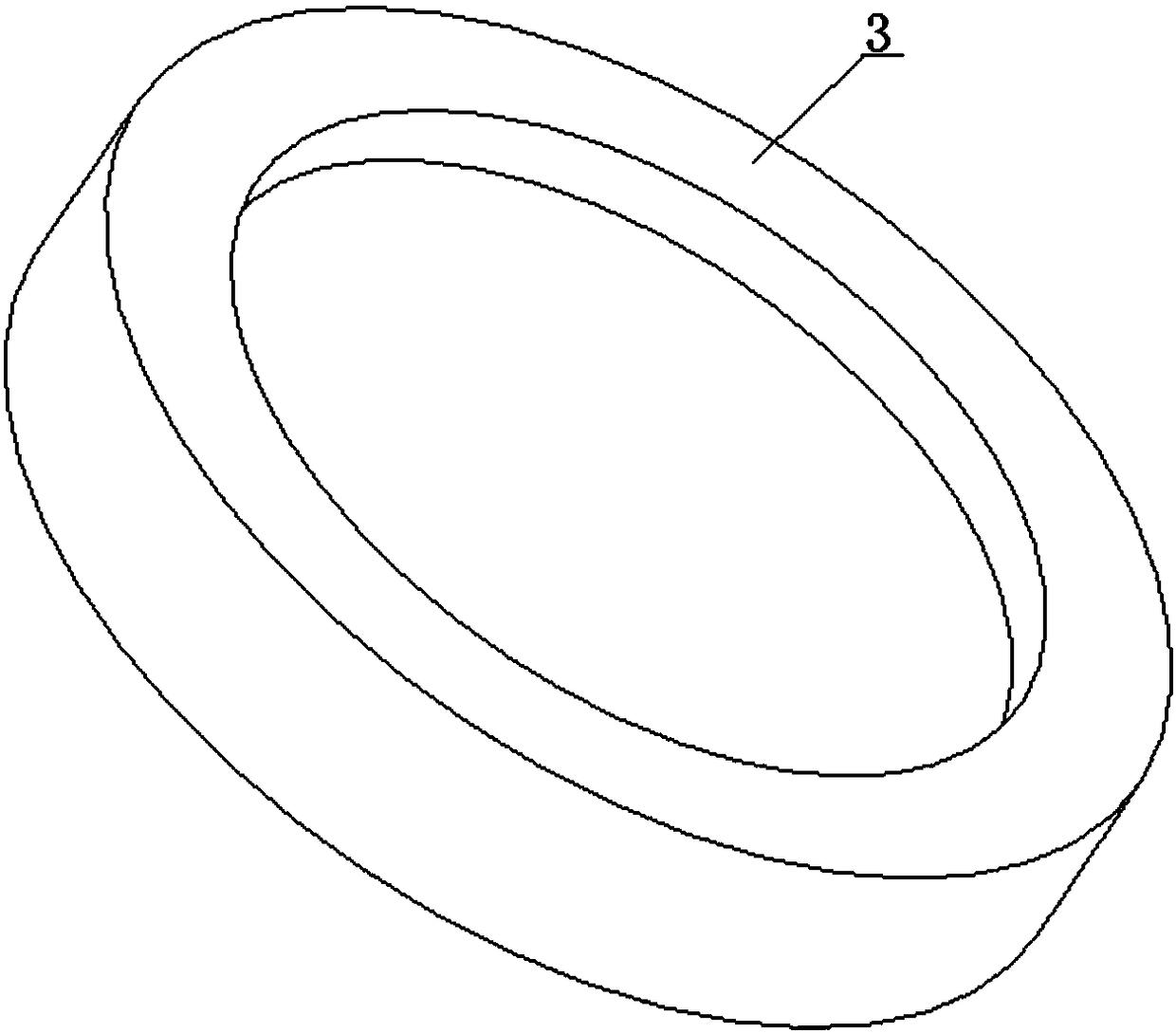

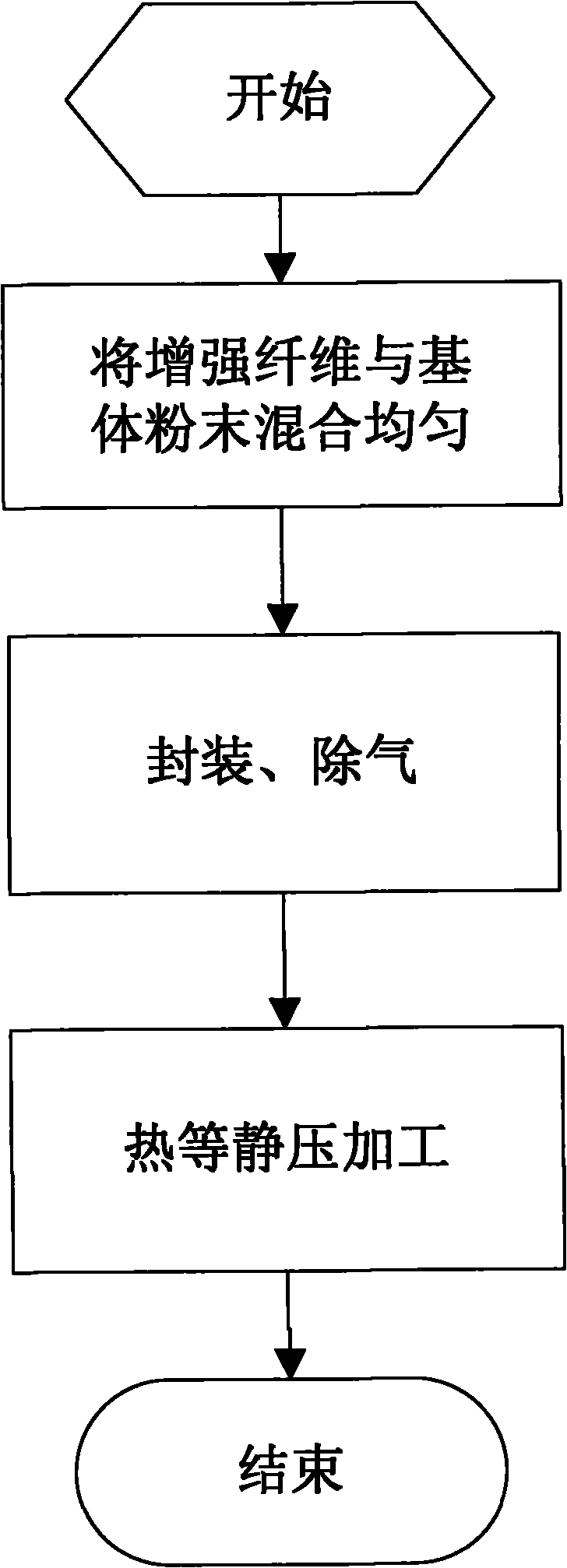

Processing technology for metal composite material

The invention provides a processing technology for a metal composite material. The metal composite material comprises reinforcing fibers and a substrate. The processing technology comprises the following steps of: uniformly mixing the reinforcing fibers and substrate powder; and packaging, degassing, and performing hot isostatic pressing to improve the compactness of the composite material. By the processing technology for the metal composite material, a reinforcing material (the fibers, particles or whiskers) can be mixed with the substrate metal powder in any ratio according to the designed performance requirement of the metal-based composite material.

Owner:CHANGSHU DONGTAO METAL COMPOSITE MATERIAL

Forming method of metal base carbon nanotube composite material part

ActiveCN108080629ALimit reunionGood dispersionAdditive manufacturing apparatusTransportation and packagingSelective laser meltingOxygen

The invention discloses a forming method of a metal base carbon nanotube composite material part. The forming method comprises the following steps: (1) metal powder and a carbon nanotube are preheatedto obtain a metal base carbon nanotube composite material; (2) program files and SLM equipment are prepared; and (3) when the oxygen volume content of a forming chamber is not more than 0.1%, according to the program files and forming process parameters, selective melting is started for gradual stacking to form the needed part. The forming method uses a selective laser melting technology for layer-by-layer melting to improve dispersibility of the carbon nanotube in a metal matrix; due to high cooling speed, the interface reaction of the carbon nanotube and the metal matrix and the element segregation are reduced; through control of core process parameters, the stability of forming the metal base carbon nanotube composite material is improved; the compactness of the formed material can reach above 99.8%; a complicated part can be directly formed; the production period is shortened; the forming efficiency is improved; and higher production and application value is achieved.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

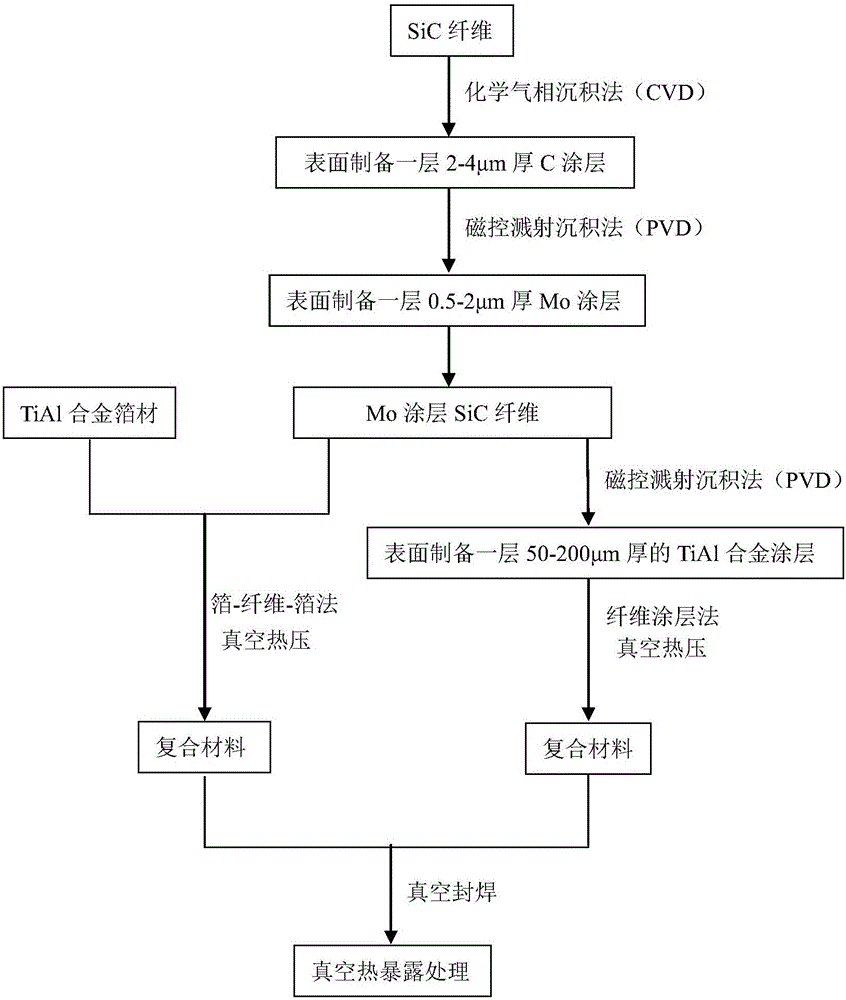

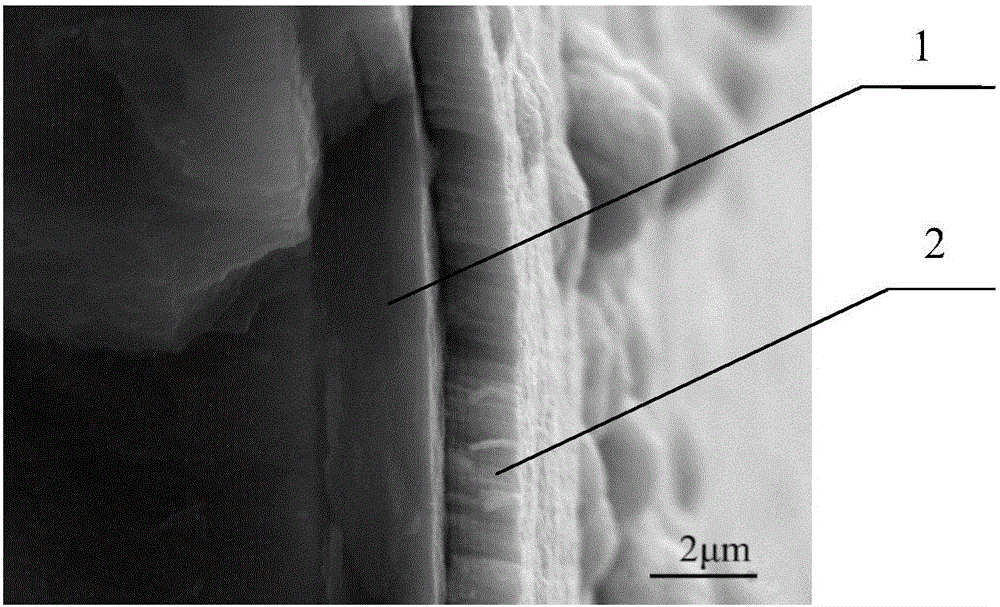

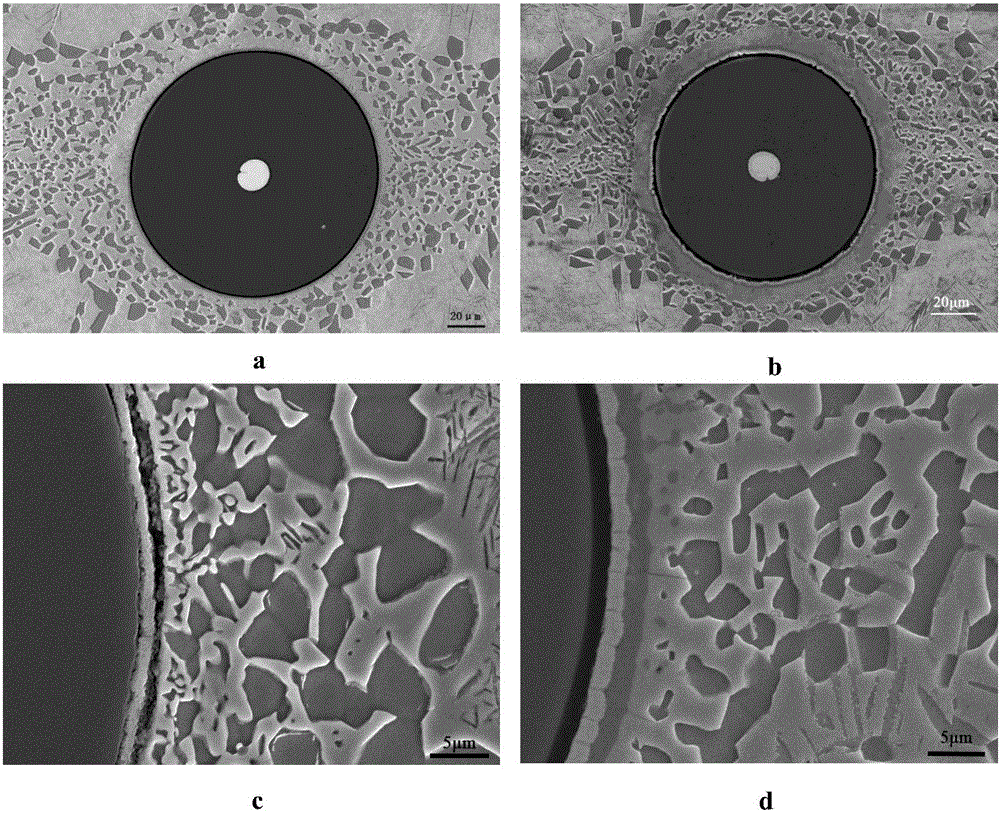

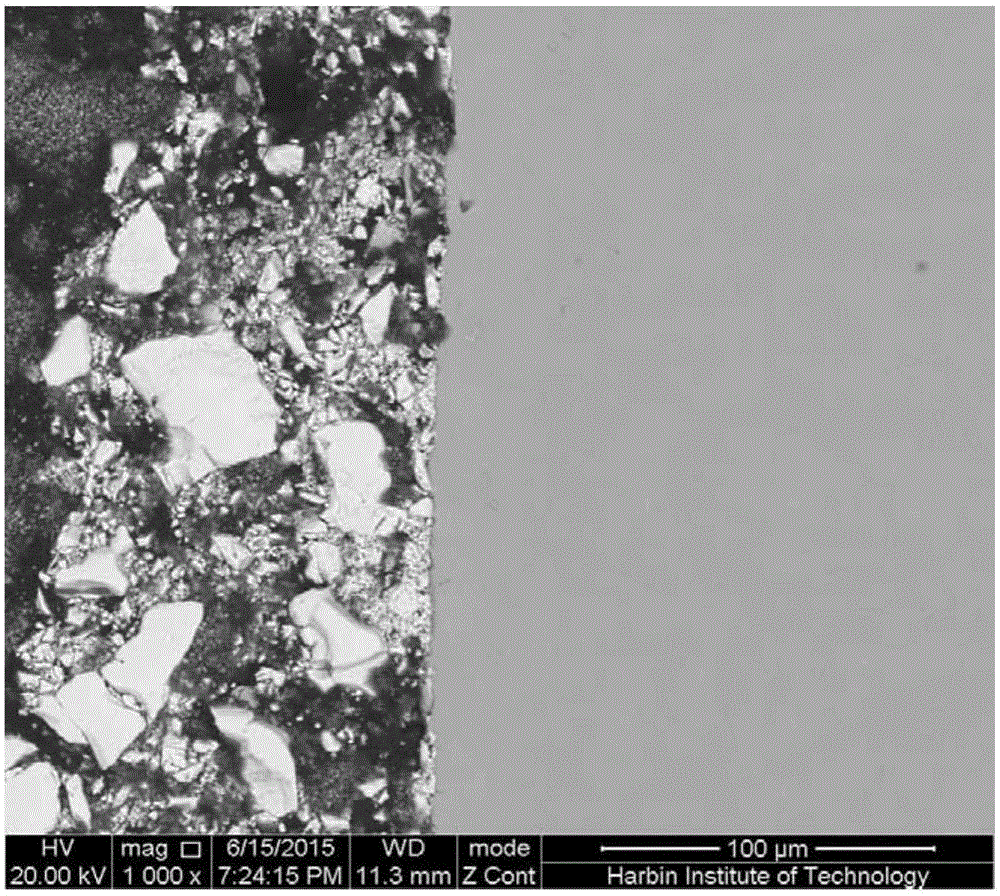

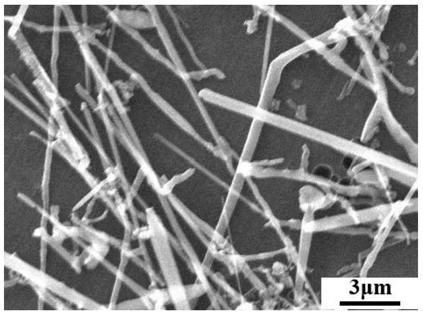

SiC fiber-reinforced TiAl-based composite with Mo coating and preparation method of SiC fiber-reinforced TiAl-based composite

The invention provides an SiC fiber-reinforced TiAl-based composite with an Mo coating and a preparation method of the SiC fiber-reinforced TiAl-based composite. The preparation method comprises the steps of firstly, preparing a layer of C coating with the thickness of 2-4[mu]m on the surface of SiC fiber by using a chemical vapor deposition process; then, uniformly depositing an Mo metal coating with the thickness of 0.5-2[mu]m on the surface of the SiC fiber with the C coating by using a magnetron sputtering deposition process; and finally, preparing the SiC fiber-reinforced TiAl-based composite with the Mo coating by using a foil-fiber-foil process or a fiber coating process. The interface reaction speed of the fiber and a matrix and the consumption speed of the C coating of the fiber under a high-temperature condition are effectively reduced, and the Mo coating is excellent in thermal stability, does not participate in the interface reaction, is not diffused and can be used for effectively relieving the thermal residual stress at the interface of the composite.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

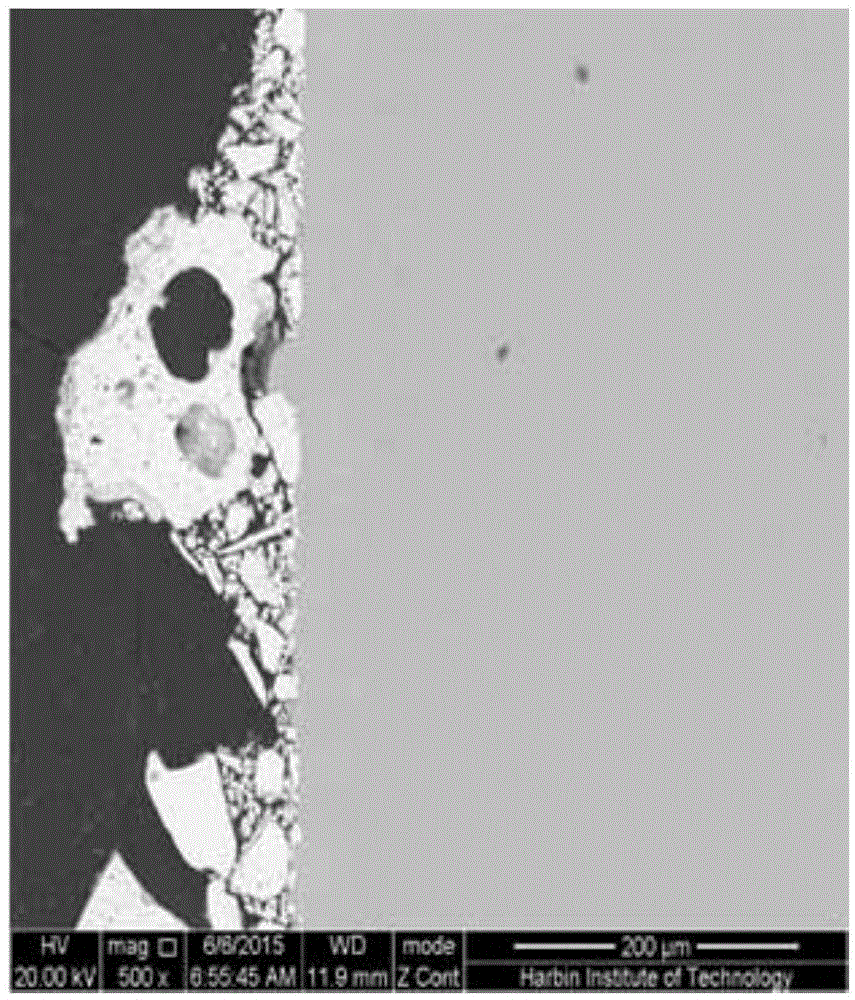

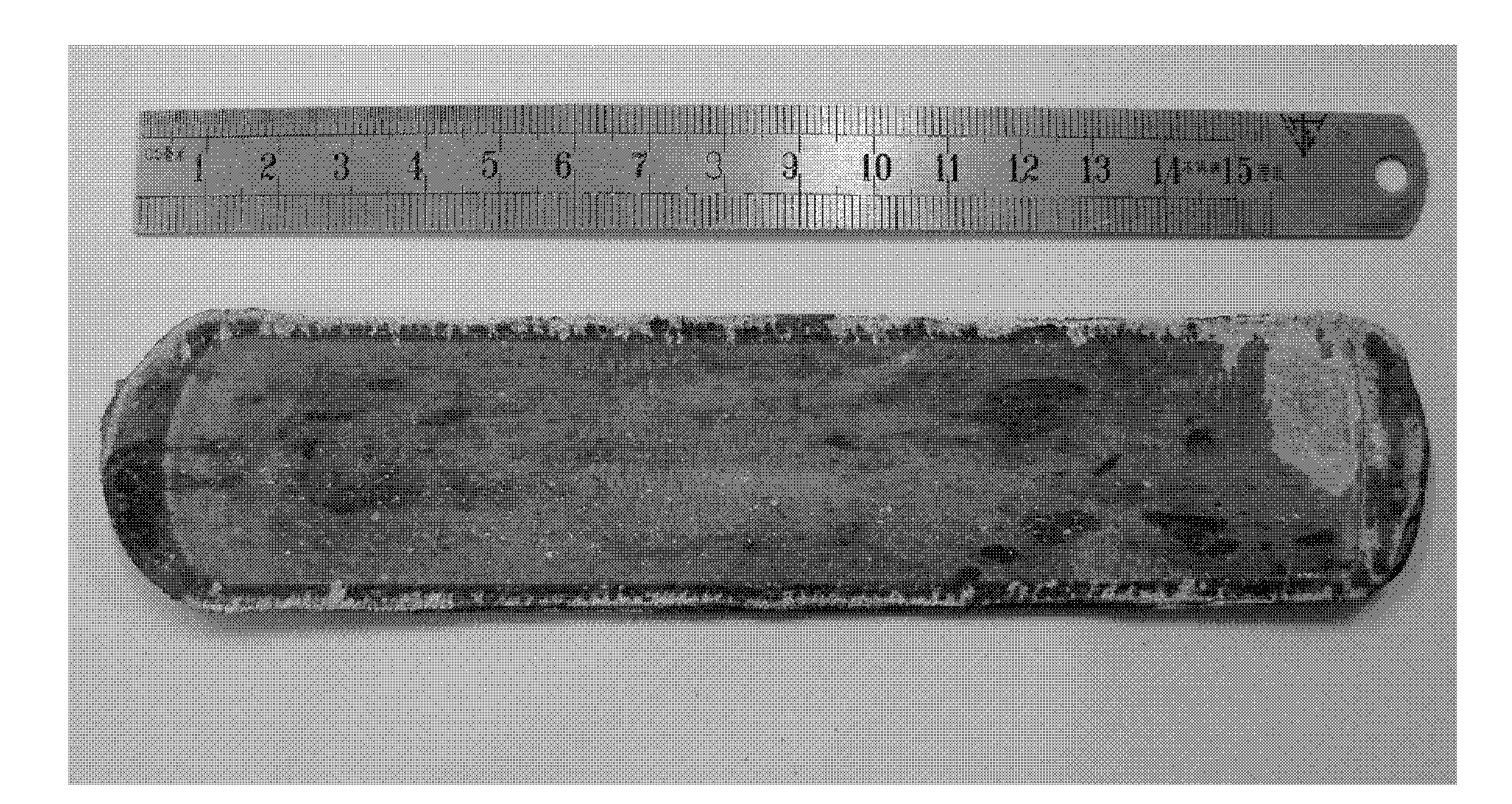

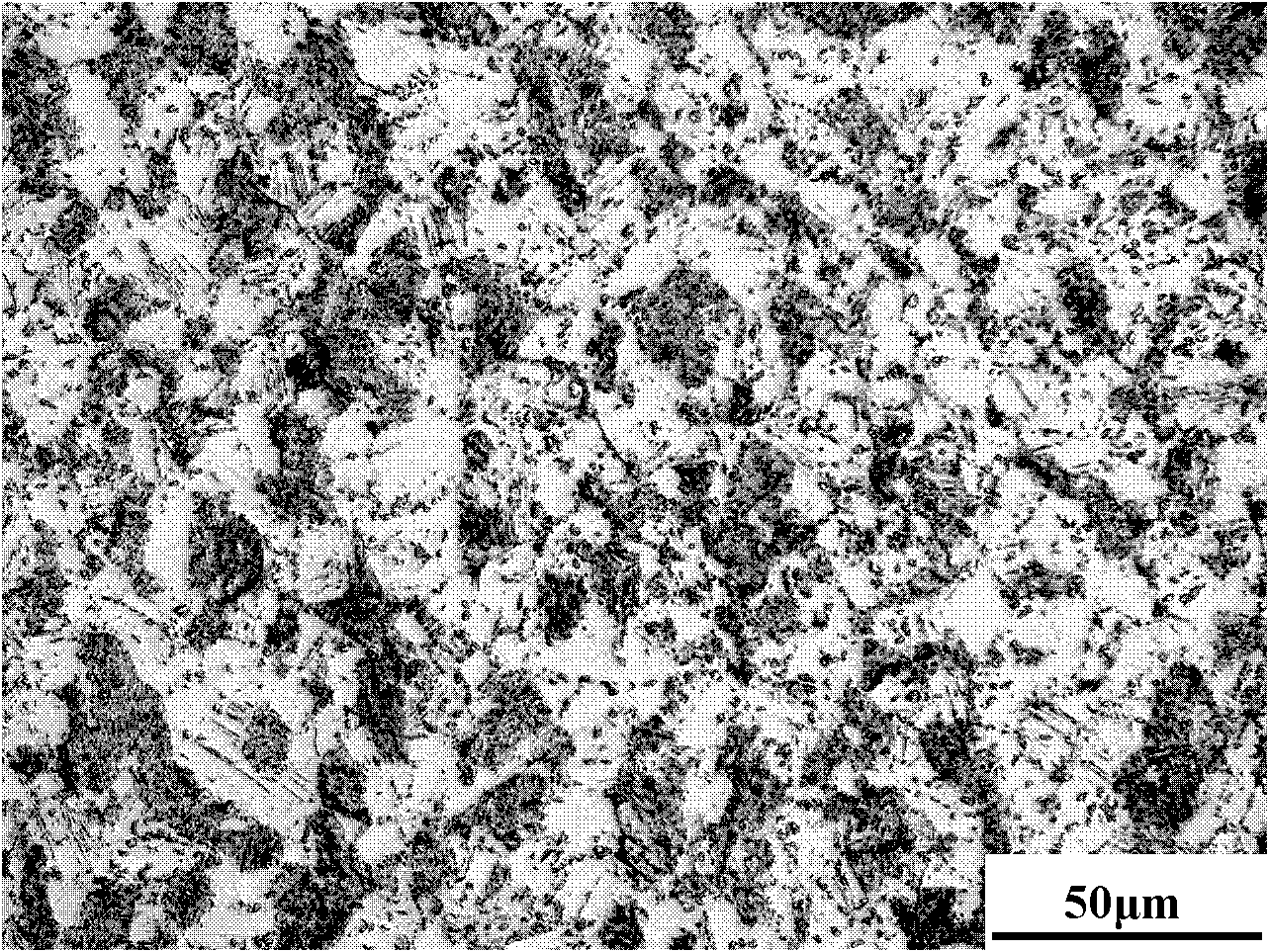

Preparation method of tungsten-containing high-inertia shell through TiAl alloy investment casting

InactiveCN105195674AReduce the degree of investment casting interface reactionReduce interface reactionFoundry mouldsFoundry coresInvestment castingTungsten

The invention relates to a preparation method of a tungsten-containing high-inertia shell through TiAl alloy investment casting and aims to solve the problems of high cost, thicker burnt-on sand layer on the casting surface and a serious interface reaction of an existing TiAl alloy investment cast ceramic shell. The method comprises steps as follows: step one, preparation of surface slurry; step two, preparation of a surface shell; step three, preparation of a back shell; step four, slurry sealing; step five, dewaxing and roasting. According to the method, low-cost Al2O3 powder is added to ammonium tungstate sol, a high-inertia refractory material is generated with a certain roasting technology, the degree of a TiAl alloy investment casting interface reaction is remarkably reduced, and the cost for TiAl alloy investment casting is reduced, and the interface reaction is reduced. The shell has a smooth casting surface, burnt-on sand is remarkably reduced, the thickness of an interface reaction layer is about 20 mu m, and compared with a conventional shell, the shell is greatly improved.

Owner:HARBIN INST OF TECH

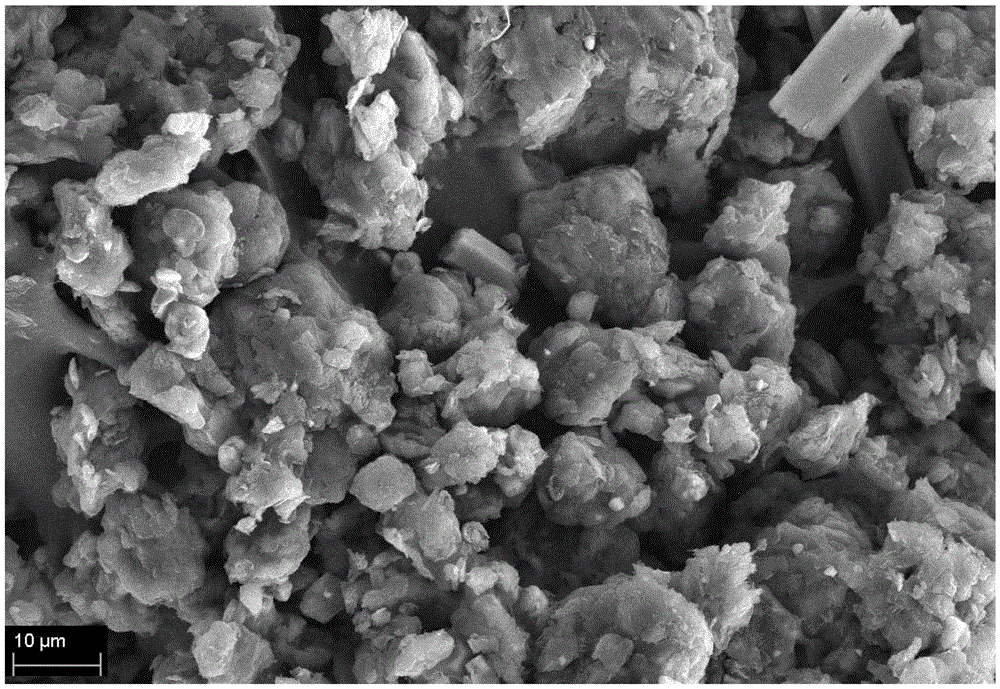

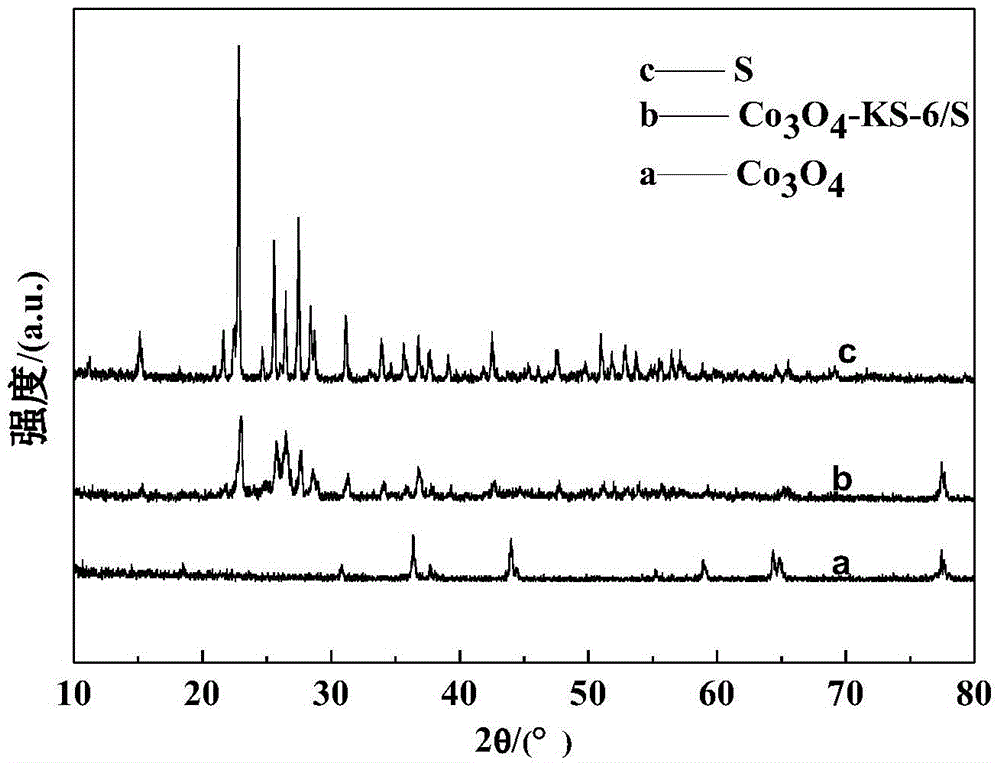

Additive Co3O4-contained lithium-sulfur battery positive electrode material and preparation method

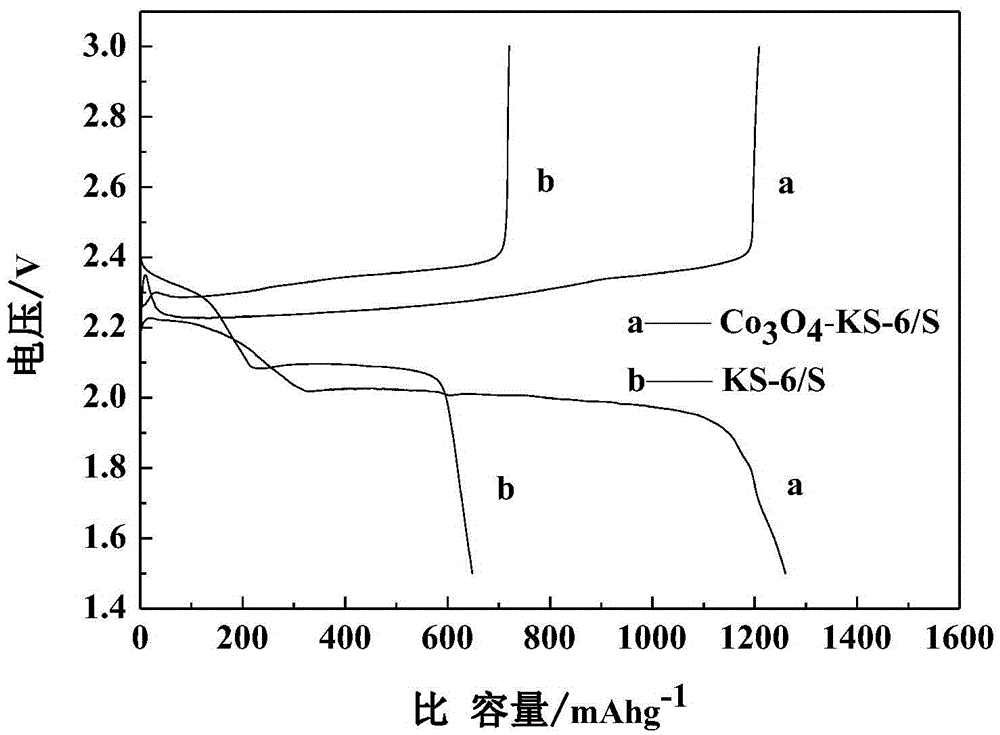

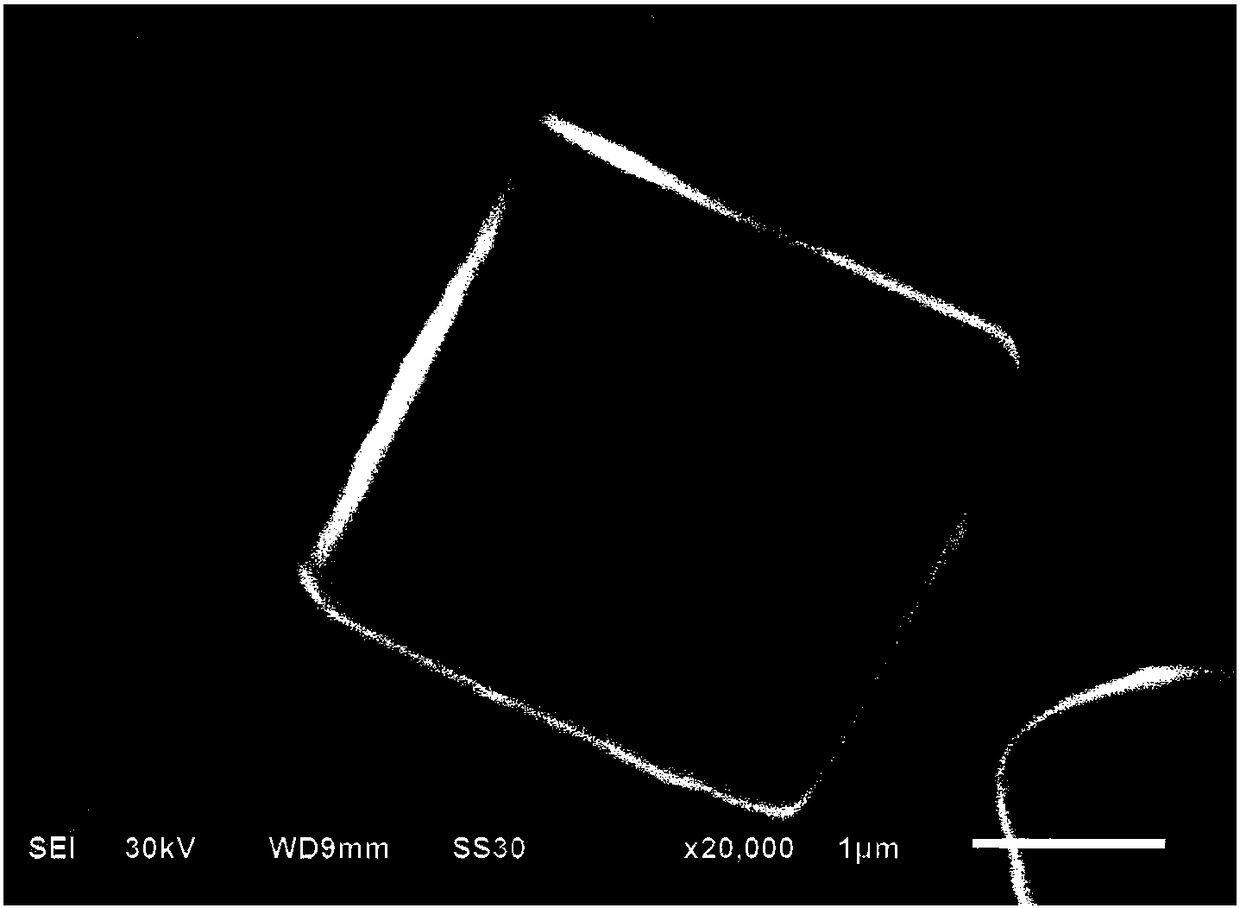

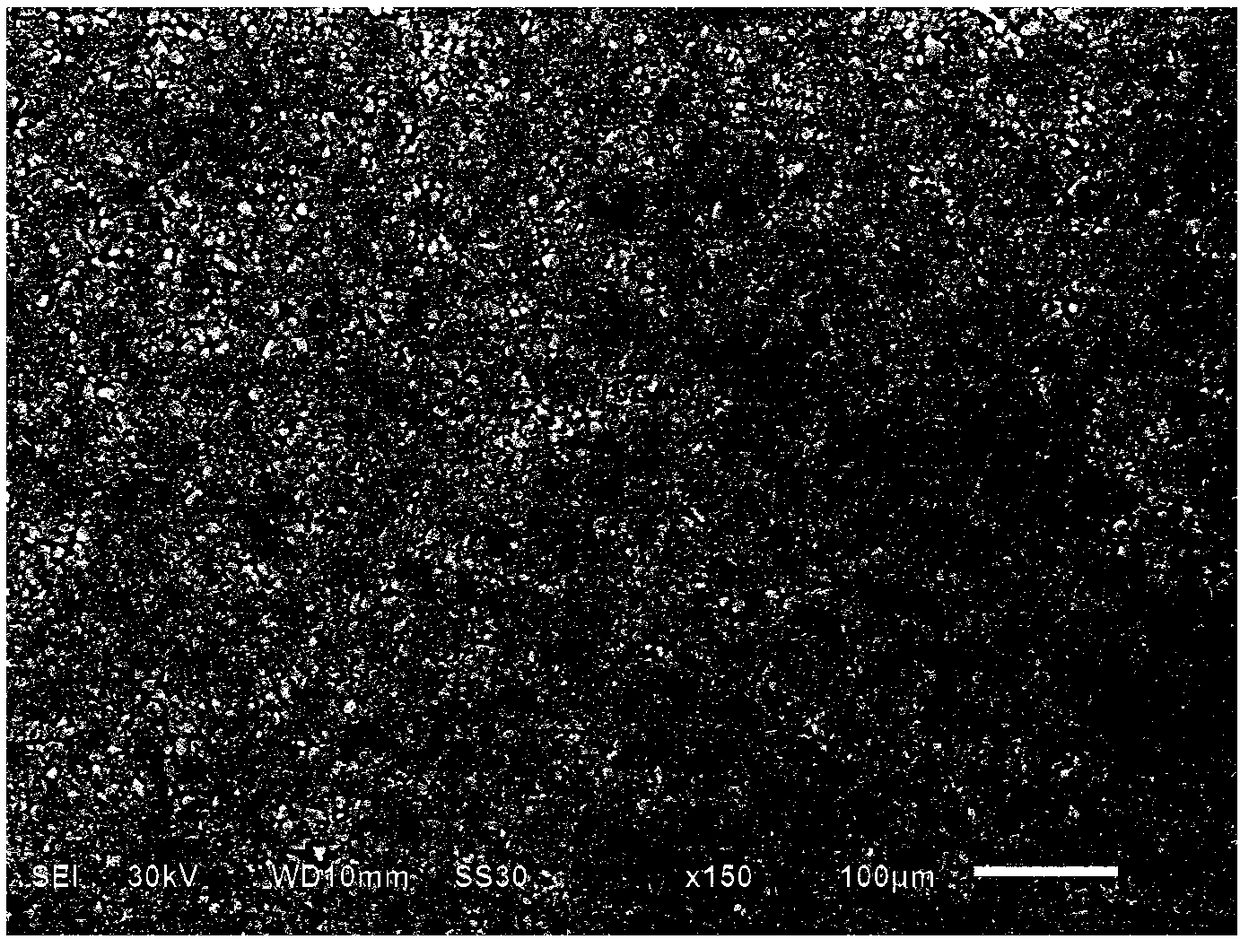

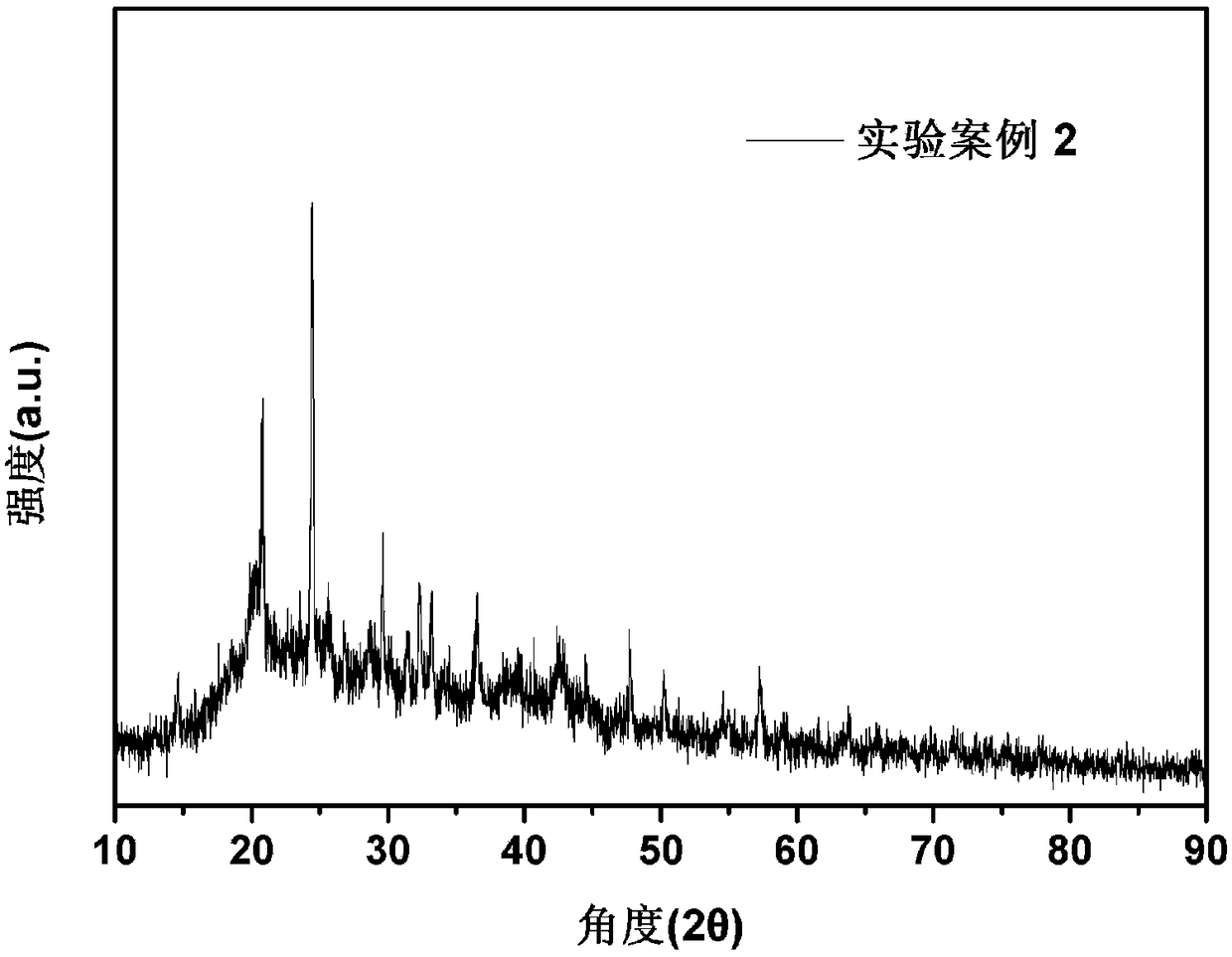

ActiveCN105680016AImprove cycle stabilityHigh specific capacityCell electrodesSecondary cellsMass ratioSulfur

The invention discloses an additive Co3O4-contained lithium-sulfur battery positive electrode material. The positive electrode material is prepared from KS-6, Co3O4 and sulfur in a doping manner, wherein Co3O4 and sulfur are uniformly filled in the KS-6 laminated layer; the mass ratio of KS-6 to Co3O4 is 1:0.1-0.25; and the mass ratio of Co3O4-KS-6 to sulfur is 1:1-2. The invention also discloses a preparation method for the additive Co3O4-contained lithium-sulfur battery positive electrode material; according to the preparation method, the raw materials are subjected to wet mixing and high-temperature calcining to obtain the Co3O4-KS-6 composite product; the obtained product is mixed with sulfur and grinded to obtain the lithium-sulfur battery positive electrode material; the preparation method is low in cost and simple to operate; meanwhile, the production efficiency can be improved easily, and industrial production can be facilitated; and in addition, the prepared positive electrode composite material is high in specific discharge capacity, high in cycling stability and can be widely applied to the energy storage field as the lithium-sulfur battery positive electrode material.

Owner:XIAN UNIV OF TECH

Inorganic/organic polymer composite solid electrolyte film and preparation method thereof

ActiveCN108336398AImprove electrochemical stabilityImprove Interface StabilitySolid electrolytesSecondary cellsSolid state electrolytePolymer science

The invention provides an inorganic / organic polymer composite solid electrolyte film and a preparation method thereof and belongs to the technical field of lithium ion batteries. The inorganic / organicpolymer composite solid electrolyte film is prepared by: mixing inorganic solid electrode, polymer matrix and an organic solvent, and carrying out film casting and drying in sequence. The inorganic / organic polymer composite solid electrolyte film has the advantages of both solid electrode and liquid electrode, has no need for electrolytes with added lithium salts, and is suitable for film casting.

Owner:XIANGTAN UNIV

Method for improving dry-friction wear performance of aluminum-based composite material

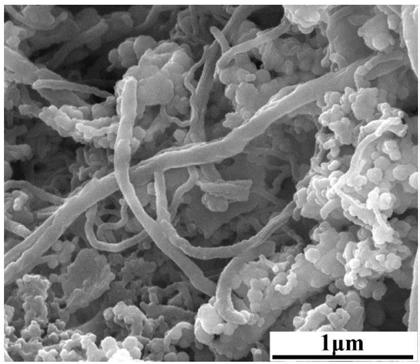

ActiveCN109385552AImproves dry friction and wear performanceAvoid reunionAluminum matrix compositesCarbon nanotube

The invention discloses a method for improving dry-friction wear performance of an aluminum-based composite material, and belongs to the technical field of the aluminum-based composite material. The technical difficulties that the carbon nano-tubes are hard to uniformly disperse in the aluminum matrix and the interface bonding of the carbon nano-tubes and the aluminum matrix is weak are solved. The method comprises the following steps: one, weighing mass of carbon nano-tubes and silicon carbide whiskers by utilizing the formula as shown in description; two, plating nickel on the surfaces of the carbon nano-tubes, then placing in absolute ethyl alcohol, and ultrasonically dispersing to obtain suspension A; three, acid-pickling the silicon carbide whiskers, placing in distilled water, and ultrasonically dispersing to obtain the suspension B; four, dropping the suspension A in the suspension B, pouring the adhesive to press a precast block; five, placing in an extrusion casting mold, heating and keeping temperature, casting the aluminum alloy in molten state, sealing, performing secondary pressing, keeping pressure, cooling and then demolding; six, thermal-extruding; and seven, thermal-treating. The dry-friction wear performance of the aluminum-based composite material is improved.

Owner:HARBIN INST OF TECH

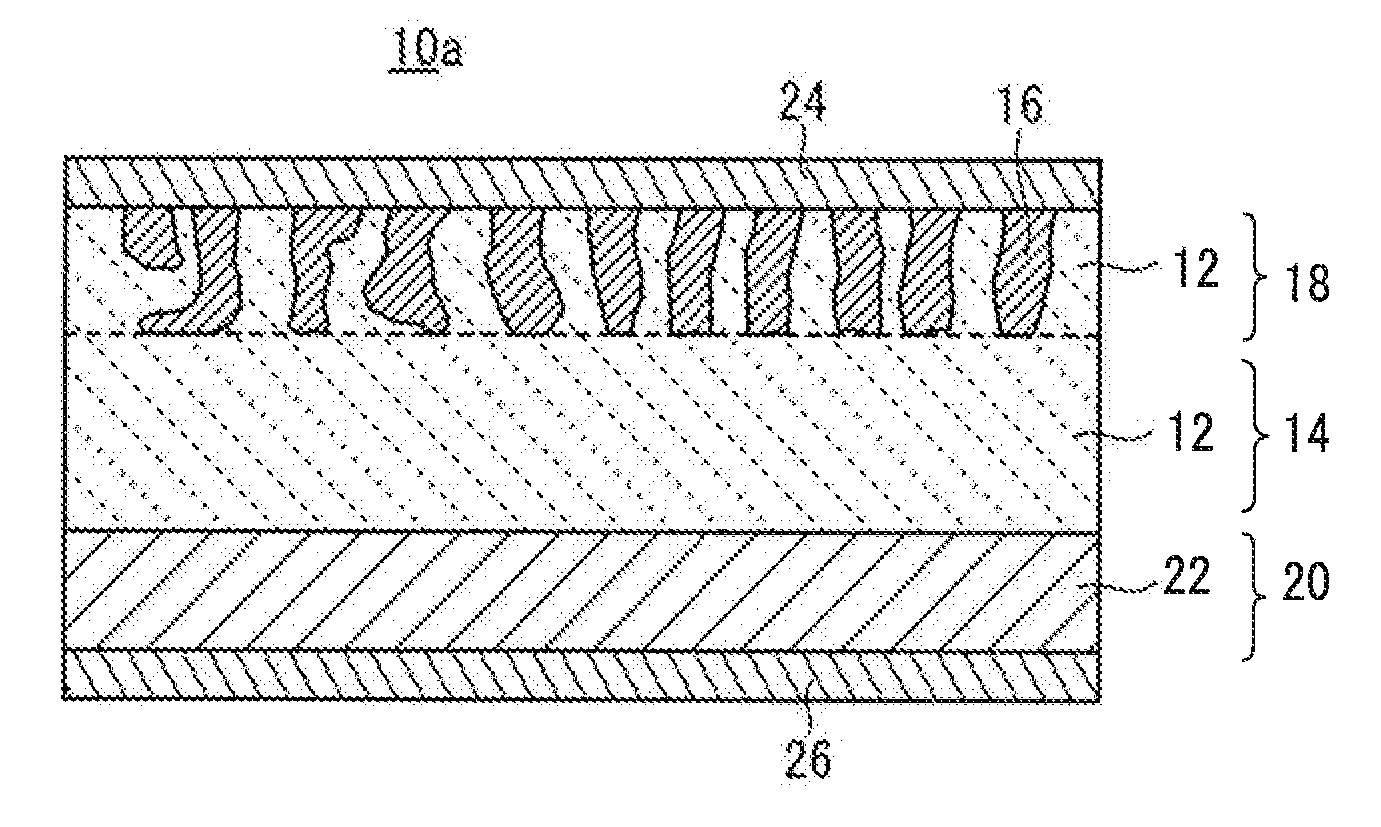

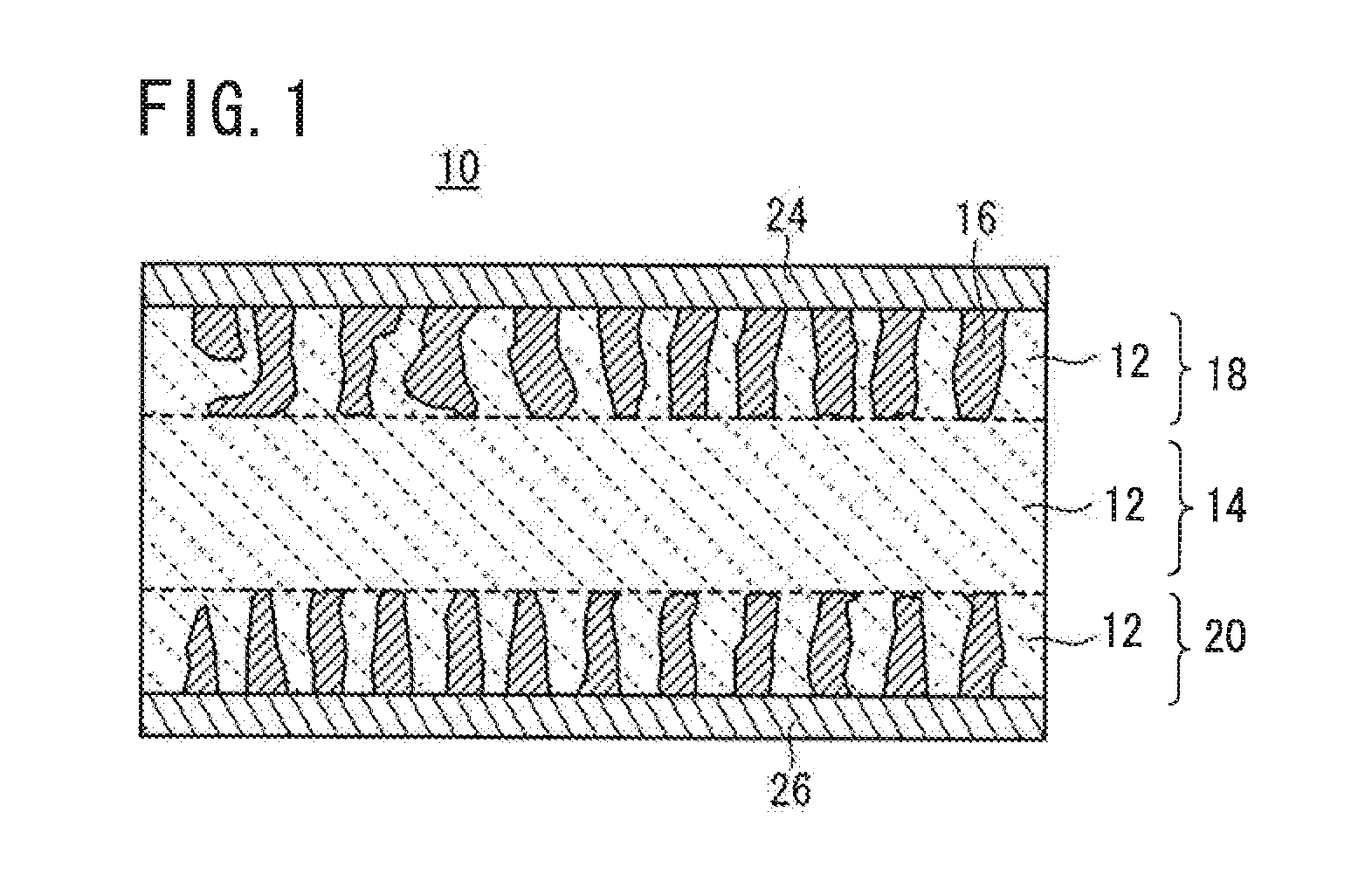

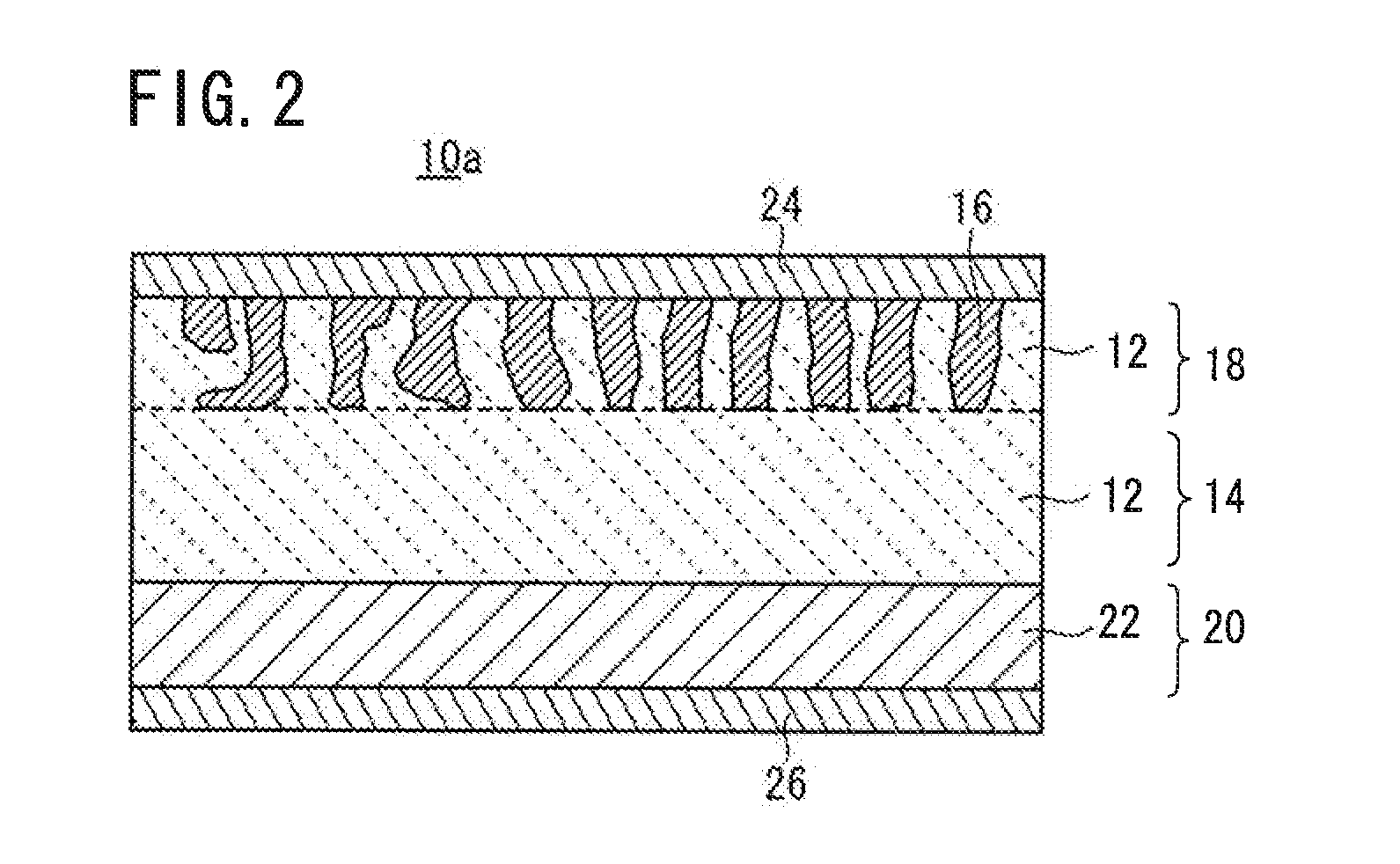

All-solid-state cell

ActiveUS20140205890A1Reduce resistanceReduce interface reactionCell electrodesSecondary cellsAll solid stateElectrolysis

An all-solid-state cell contains a combination of an electrode active material and a solid electrolyte, and has a plate-shaped fired solid electrolyte body of a ceramic containing a solid electrolyte, a first electrode layer (e.g. a positive electrode) integrally formed on one surface of the fired solid electrolyte body by mixing and firing an electrode active material and a solid electrolyte, and a second electrode layer (e.g. a negative electrode) integrally formed on the other surface of the fired solid electrolyte body by mixing and firing an electrode active material and a solid electrolyte. The solid electrolyte materials added to the first electrode layer and the second electrode layer comprise an amorphous polyanion compound.

Owner:KYUSHU UNIV +1

Lithium cobalt oxide precursor with coating structure and preparation method and application thereof

ActiveCN112645390AImprove structural stabilityImprove thermal stabilityZinc oxides/hydroxidesSecondary cellsPhysical chemistryElectrochemistry

The invention provides a lithium cobalt oxide precursor with a coating structure and a preparation method and application thereof. The preparation method comprises the following steps: mixing and stirring a cobalt source doped with metal elements and a metal salt solution, adding alkali liquor, and continuously stirring to obtain a precursor mixture; and sintering the precursor mixture to obtain the lithium cobalt oxide precursor with the coating structure. According to the preparation method, the surface of the lithium cobalt oxide precursor is coated with the metal hydroxide by adopting a liquid-phase synthesis method so that the coating is more uniform, the coating layer can stably exist, and a stable solid solution coating interface is formed in the subsequent multiple sintering processes, and thus the material structure is more stable, and the electrochemical performance is better.

Owner:EVE ENERGY CO LTD

Forming method for continuous fiber reinforced metal matrix composite parts

InactiveCN108048761ASimple processShort cycleTransportation and packagingMetal-working apparatusSlurryMetal matrix composite

The invention discloses a forming method for continuous fiber reinforced metal matrix composite parts. The forming method specifically comprises the following steps that step 1, matrix-containing metal photocurable slurry is prepared; step 2, continuous fibers are pretreated; step 3, blanks of composite parts are subjected to solidification forming; step 4, the blanks are subjected to post-processing; and step 5, degreasing sintering is carried out to obtain the required parts. The forming method for the continuous fiber reinforced metal matrix composite parts solves the problems of complicated process and long cycle time in the prior art.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

Method for preparing nano SiC/Cu-based composite material employing pressureless infiltration technique

ActiveCN103484705AImprove wetting performanceThe process is simple and easy to controlNitrogen gasForming pressure

The invention discloses a method for preparing a nano SiC / Cu-based composite material employing a pressureless infiltration technique. The method comprises the following steps: putting nano SiC powder and nickel powder, which are subjected to surface modification treatment, into a compression moulding press according to the ratio to press and mold, so as to obtain a compact prefabricated part, and then putting the compact prefabricated part into a graphite crucible; putting a pure copper block at the upper part of the compact prefabricated part; carrying out impregnation reaction inside a box-type atmosphere furnace under nitrogen protection; carrying out heat preservation for 4-6 hours at the temperature of 1100-1400 DEG C, and cooling along with the furnace, so as to obtain the nano SiC / Cu-based composite material. The nano SiC / Cu-based composite material disclosed by the invention has the advantages of high strength, high density, excellent wear-resisting property and the like. The technology disclosed by the invention is simple and easy to control. The nano SiC / Cu-based composite material disclosed by the invention is applied to the casting technology of a copper water jacket, a copper chute and a copper cooling wall, and is mainly applied to improvement of the performance of buried pipe copper-casting cooling equipment; the service lives of the copper water jacket, the copper chute and the copper cooling wall are prolonged.

Owner:江西余越科技有限公司

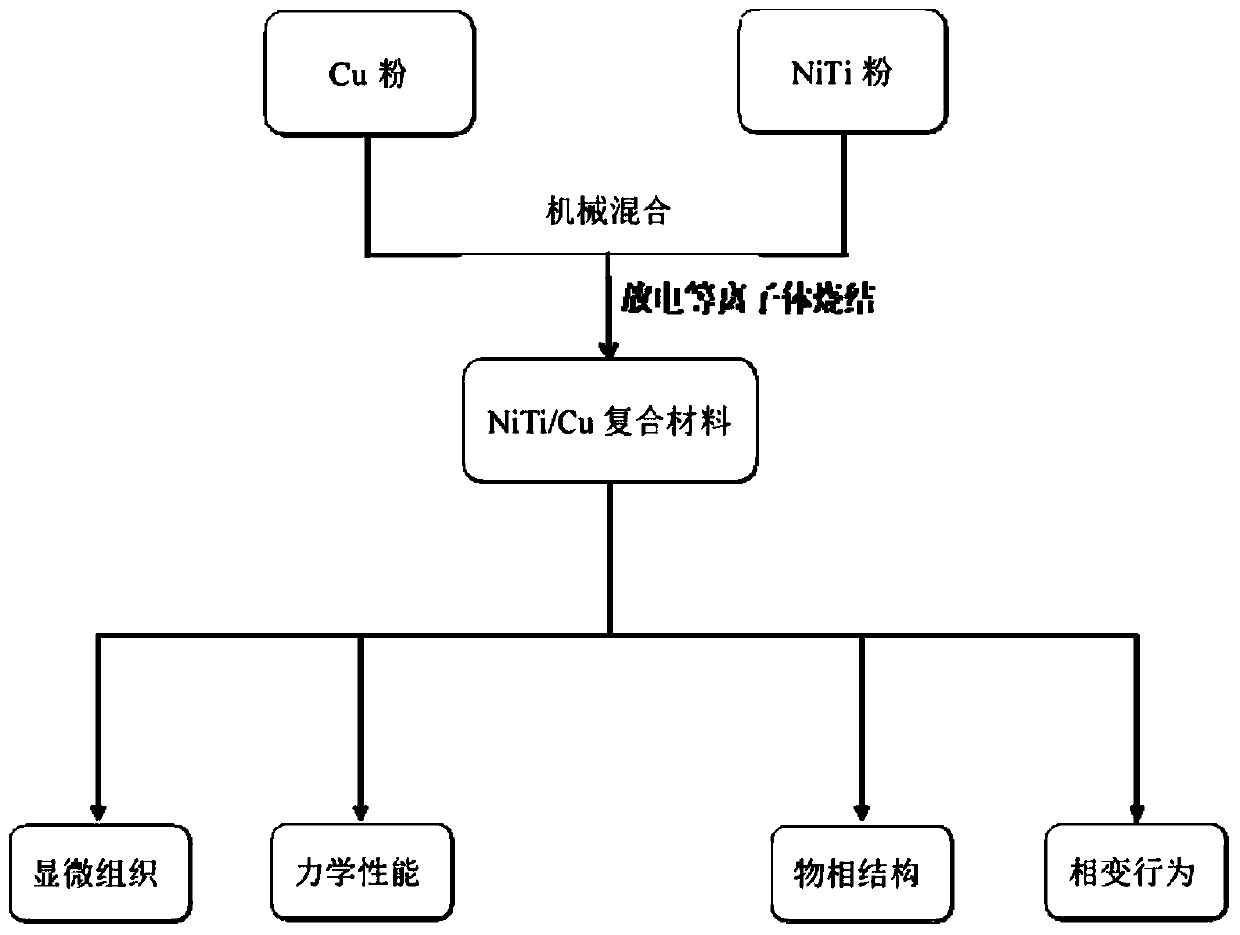

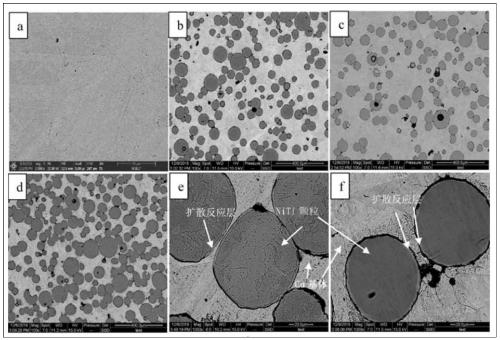

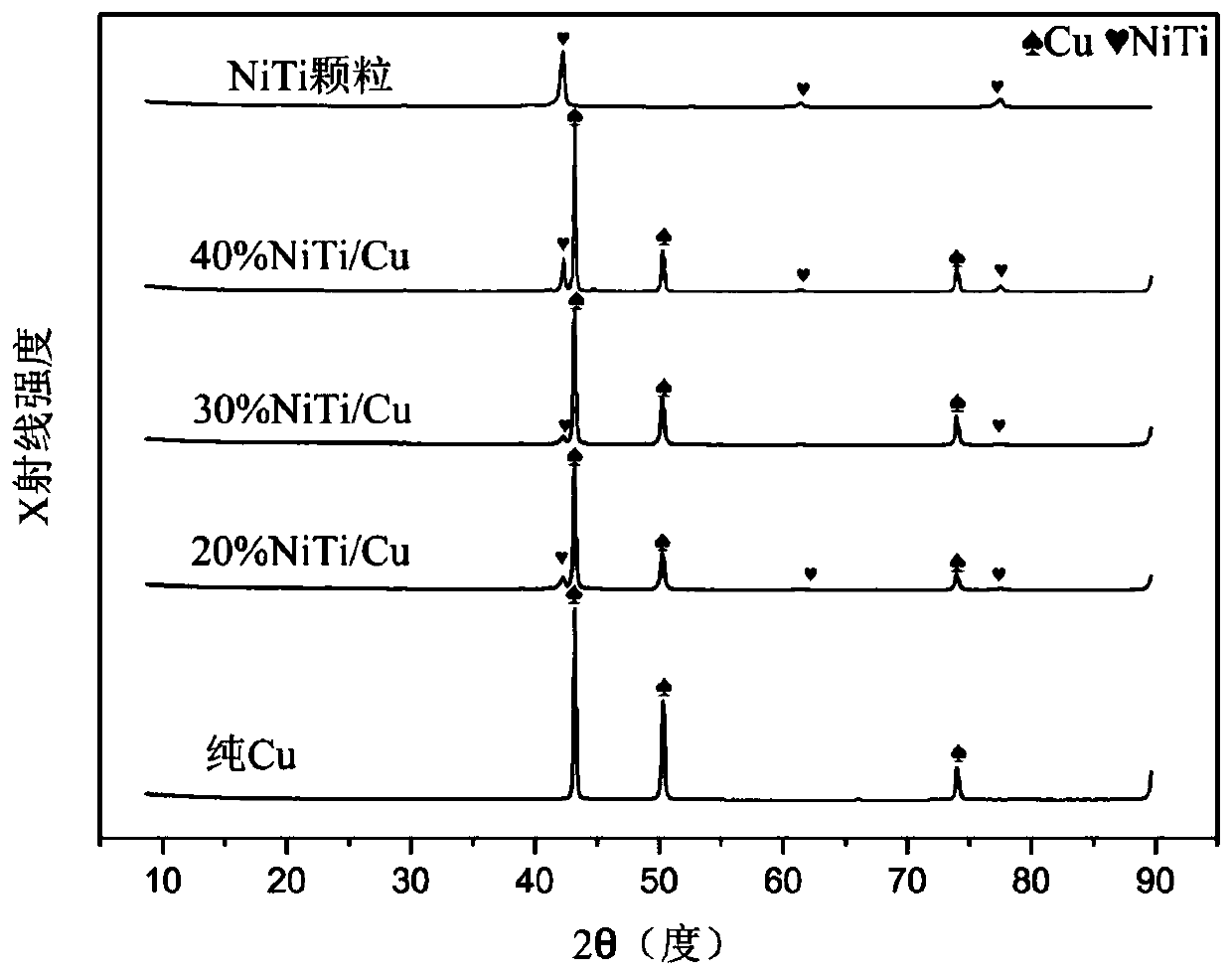

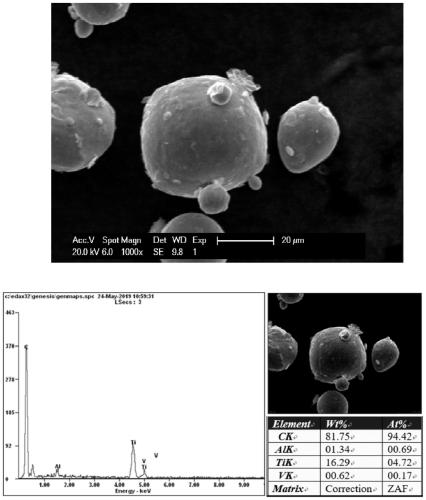

Shape memory alloy particular enhanced copper-based composite material and preparation method

InactiveCN109822095AHigh strengthMaintain large plastic deformationInterfacial reactionMartensite transformation

The invention provides a shape memory alloy particular enhanced copper-based composite material and a preparation method. The shape memory alloy particular enhanced copper-based composite material isprepared by the following steps: S1, selecting micron order shape memory alloy particles and copper power particles (the particle sizes are smaller than 100[mu]m); S2, mechanically mixing the shape memory alloy particles and copper power particles for 20-80 minutes to obtain mixed powder; and S3, putting the mixed powder in a graphite mold to obtain the shape memory alloy particular enhanced copper-based composite material by means of a discharge plasma sintering method. Compared with pure copper, the strength of the shape memory alloy particular enhanced copper-based composite material is improved obviously, and large plastic deformation similar to that of pure copper is kept. The shape memory alloy particular enhanced copper-based composite material has a martensite phase transformationcharacteristic. Compared with a pressureless sintering method, the preparation method of the shape memory alloy particular enhanced copper-based composite material has the advantages of being short insintering time and low in sintering temperature and capable of pressurizing in a sintering process, and the interfacial reaction can be reduced obviously and the production efficiency can be improved.

Owner:HARBIN ENG UNIV

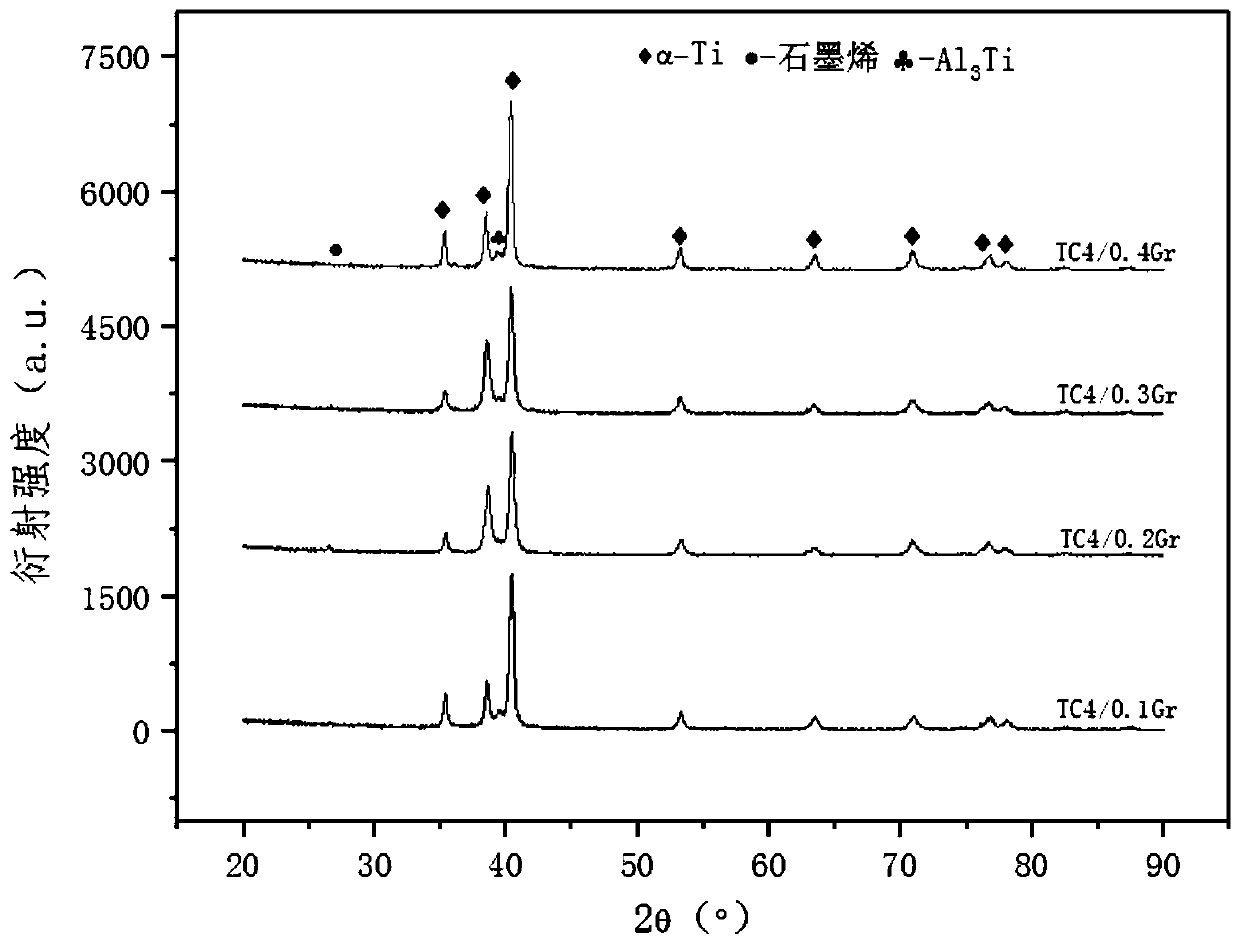

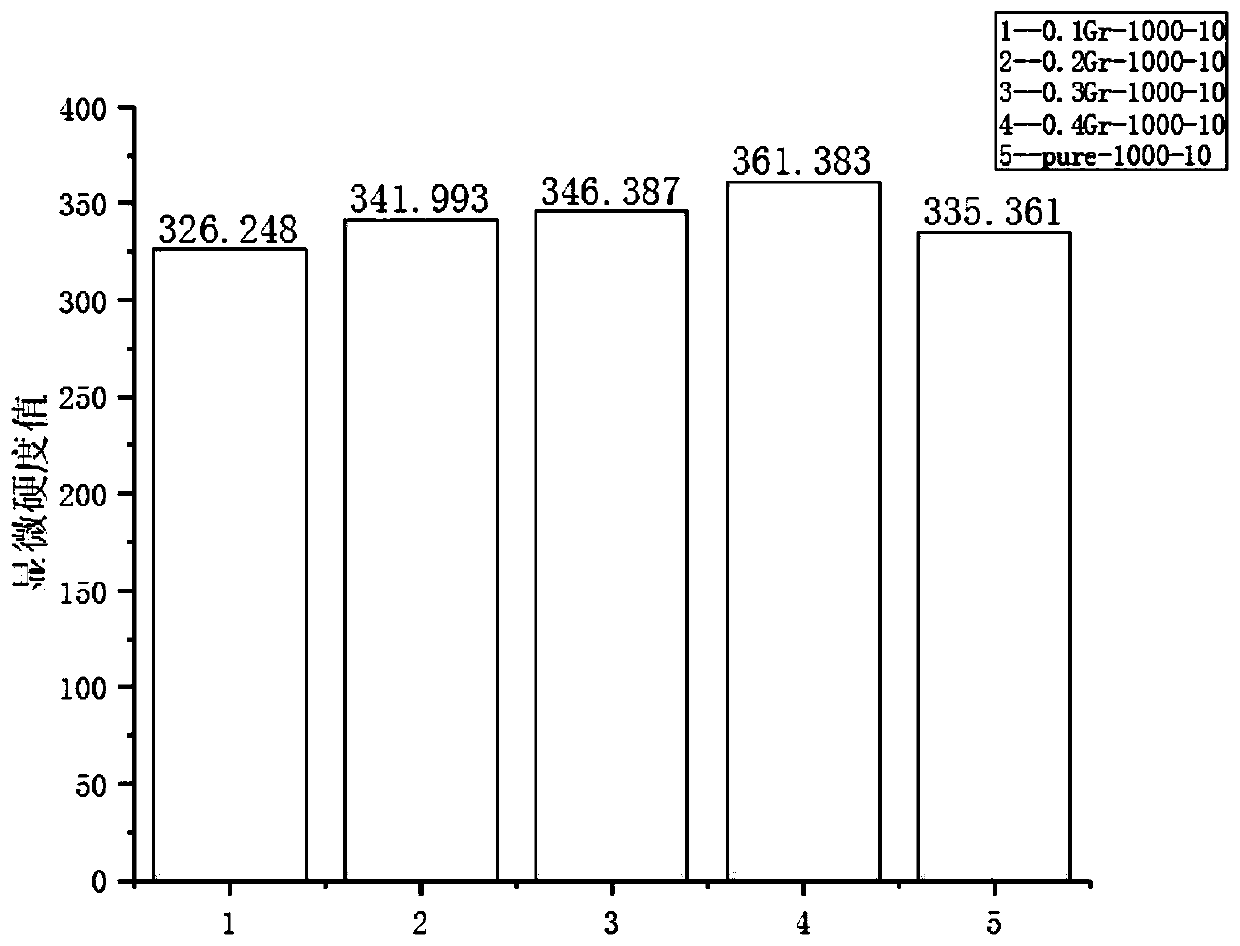

Nanometer TiC modified graphene reinforced titanium-matrix composite material, and preparation method and application thereof

ActiveCN110331314APromote sheddingEasy to fall off and suspendTitanium matrix compositesSurface layer

The invention discloses a nanometer TiC modified graphene reinforced titanium-matrix composite material, and a preparation method and the application thereof. According to the composite material, titanium or titanium alloy serves as a titanium matrix, graphene with surfaced modified with nanometer TiC serves as a reinforced phase, and the modified graphene is evenly distributed around titanium matrix particles to from a network structure. According to the nanometer TiC modified graphene reinforced titanium-matrix composite material, and the preparation method and the application thereof, one layer of nanometer TiC is used for covering the surface of each titanium matrix particle with a three-dimensional mechanical mixing method, then the surface, with one layer of nanometer TiC, of each titanium matrix particle is covered with one layer of graphene, and then a core and shell structure with one titanium particle as the core, the nanometer TiC as the intermediate layer and graphene as the surface layer is obtained. With the preparation method, the problem that according to traditional wet milling, it is difficult to cover the surfaces of titanium particles with graphene evenly is solved. Because of the nanometer TiC, interface reaction between graphene and the titanium matrix in the preparation process is reduced to a certain degree, and the titanium-matrix composite material reinforced with graphene modified with nanometer TiC is obtained through sintering. The composite material is high in strength and plasticity, and good in forming and processing performance, and therebybeing capable of applied to aerospace and the ship and warship manufacturing industry.

Owner:SOUTHEAST UNIV

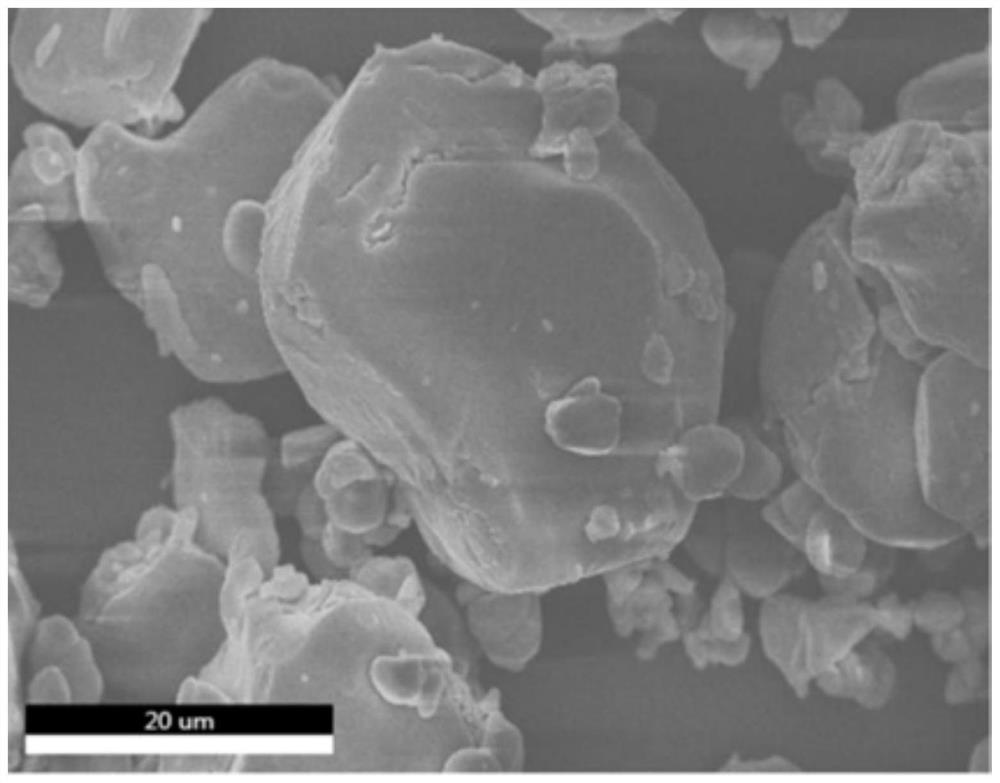

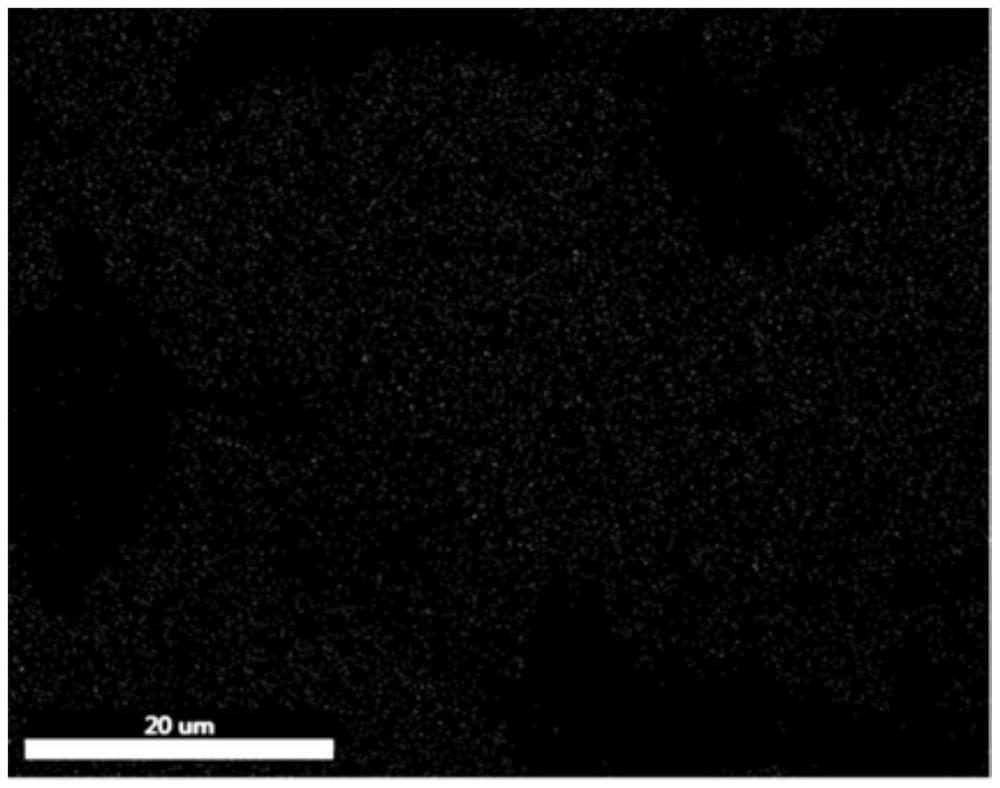

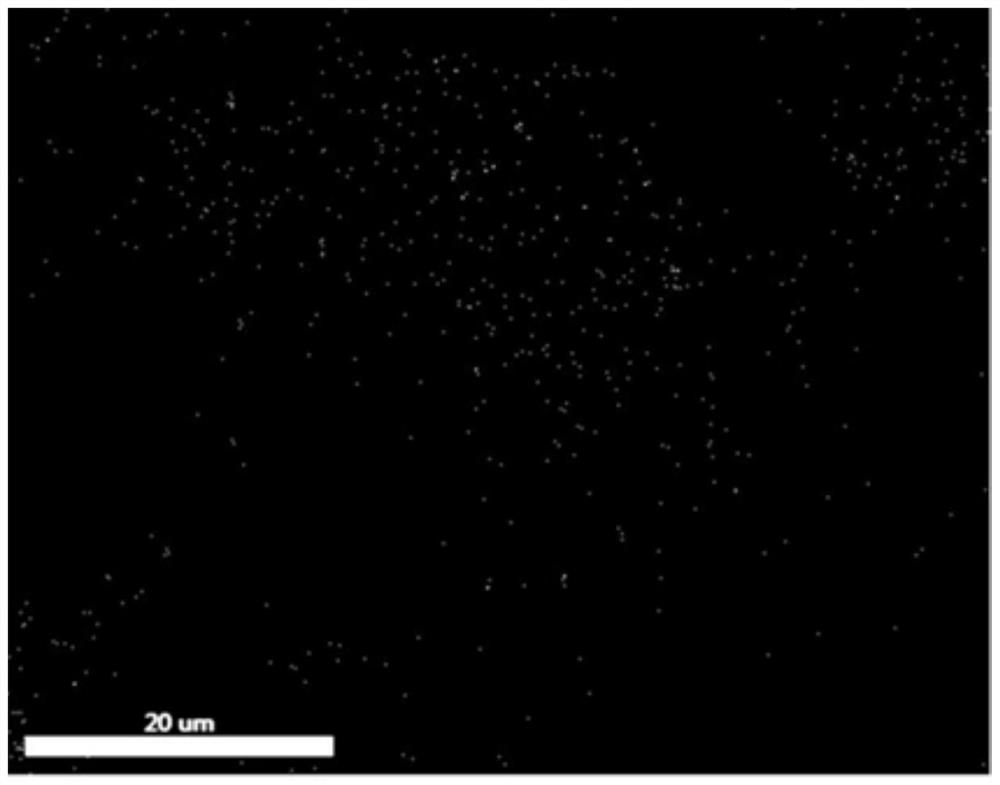

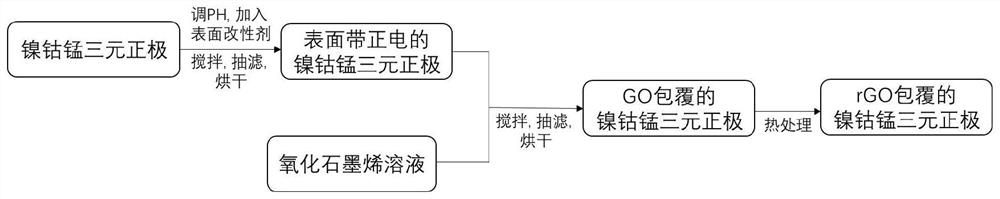

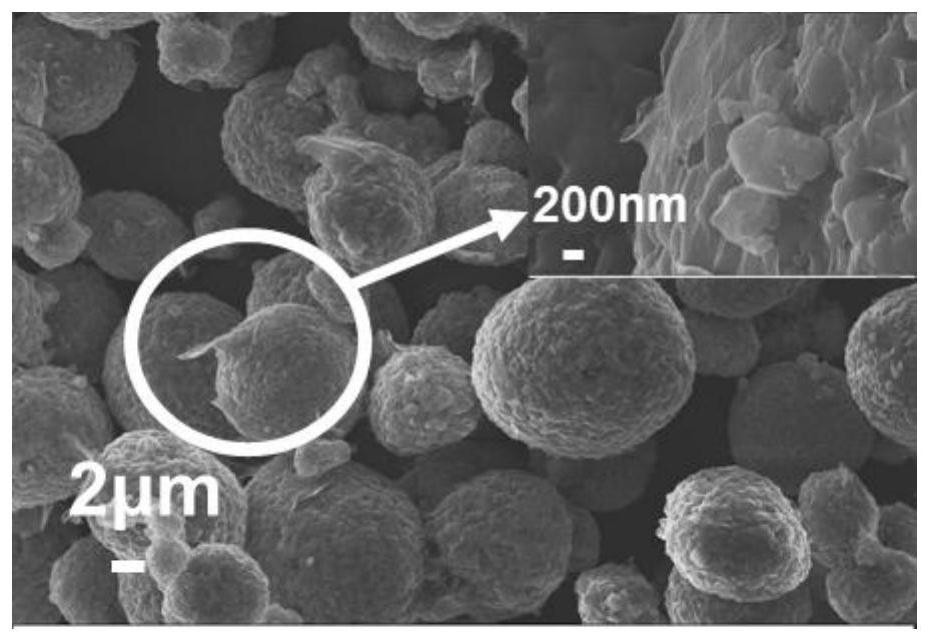

Preparation method of reduced graphene oxide modified nickel-cobalt-manganese ternary positive electrode material

InactiveCN113328075AImprove electronic conductivityIncrease surface areaCarbon compoundsCell electrodesManganeseLithium-ion battery

The invention discloses a preparation method of a reduced graphene oxide modified nickel-cobalt-manganese ternary positive electrode material, which belongs to the technical field of lithium ion batteries. The method comprises the following steps of firstly, carrying out modification treatment on a high-nickel ternary positive electrode material (LiNi0.8Co0.1Mn0.1O2) by utilizing a silane coupling agent, so that the surface of the high-nickel ternary positive electrode material has positive charges, enabling the modified LiNi0.8Co0.1Mn0.1O2 material and a graphene oxide (GO) solution to be subjected to simple solution blending treatment, and achieiving electrostatic self-assembly, and then carrying out heat treatment reduction to obtain a structure of the reduced graphene oxide (rGO) coated high-nickel ternary positive electrode material (LiNi0.8Co0.1Mn0.1O2). The reduced graphene oxide obtained after heat treatment reduction has high electronic conductivity and stable chemical properties and contains a large number of defects, Li<+> can penetrate through the plane of graphene, and high capacity and good recyclability are provided. Through the design of the coating structure, the positive electrode material with relatively high capacity and excellent cycle performance is obtained.

Owner:BEIJING UNIV OF CHEM TECH

Ti-Al-Cr-Mo alloy and preparation method of plate thereof

The invention relates to a Ti-Al-Cr-Mo alloy and a preparation method of a plate thereof. The alloy comprises the following components in percentage by weight: 45-49 Ti, 0.5-5 Al, 0.1-0.3 Cr, and the balance of Mo; and the preparation method of the plate of the alloy comprises the following steps of: 1 preparing the Ti-Al-Cr-Mo alloy by adopting an HIP (Hot Isostatic Pressing) method; 2 cutting to obtain a blank required by rolling from the alloy prepared by adopting the HIP method; 3 putting the blank obtained in the step 2 into a pure titanium plate sheath; 4 putting the Ti-Al-Cr-Mo alloy with the sheath into a heating furnace and preheating; and 5 carrying out multi-pass rolling at small pass and low deformation speed on the Ti-Al-Cr-Mo alloy with the sheath, then putting into an electric furnace and cooling with the furnace; and removing the sheath to obtain the Ti-Al-Cr-Mo alloy plate. The invention solves the difficult problems that the Ti-Al-Cr-Mo alloy is more brittle and difficult to deform at high temperature and prepare the Ti-Al-Cr-Mo alloy plate in a rolling manner. The invention has simple process and method as well as reasonable process parameters; an alloy ingot blank prepared by adopting the HIP method is directly rolled by adopting the sheath; the plate prepared by adopting the rolling manner has even deformation; and the rolled alloy has even and tiny tissue, no edge crack and surface crack and good surface quality and is suitable for industrialized production.

Owner:CENT SOUTH UNIV

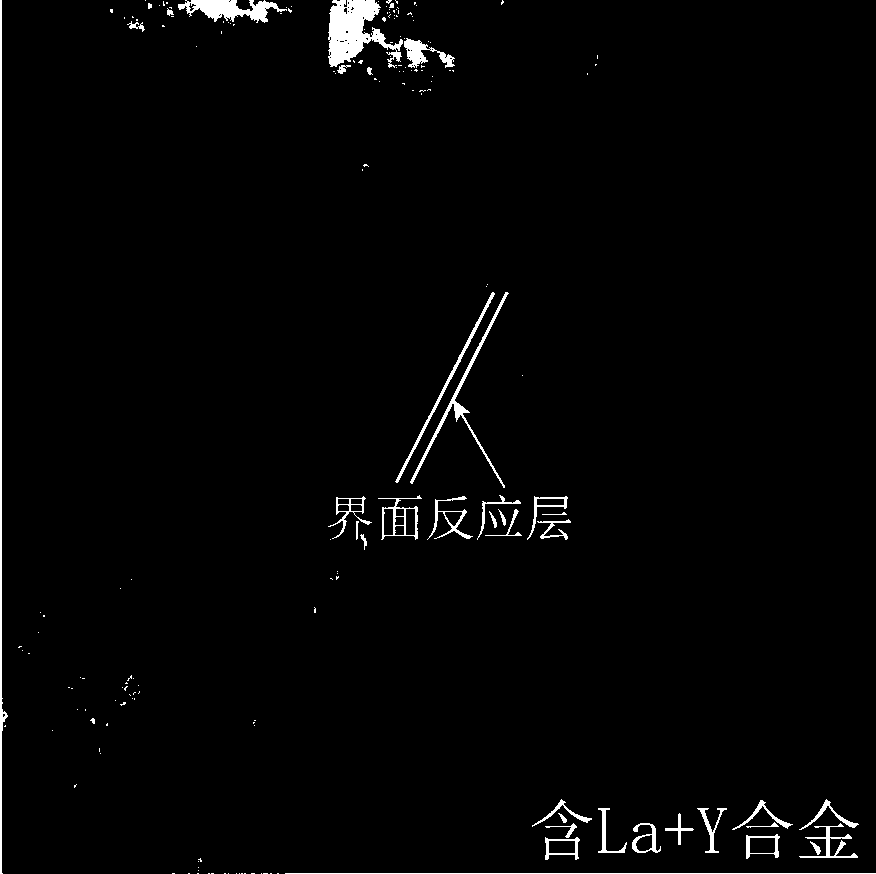

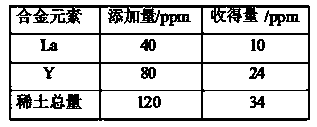

Method for stabilizing rare earth elements in nickel-based single crystal superalloy

ActiveCN107619957AStable contentImprove antioxidant capacityRare-earth elementSingle crystal superalloy

The invention relates to a method for stabilizing rare earth elements in nickel-based single crystal superalloy. Specifically, the mode of complexly adding the rare earth elements to the nickel-basedsingle crystal superalloy is adopted, wherein the content of the rare earth La element is 50+ / -10 ppm, the content of the rare earth Y element is 100+ / -20 ppm, and the content ratio of the rare earthLa element to the rare earth Y element is not lower than 1:3 but not higher than 1:2. The interface reaction between the alloy and a mold shell material is reduced, and the content of the rare earth elements in the nickel-based single crystal superalloy is stabilized. According to the method, the interface reaction between the alloy and the mold shell material is effectively reduced by adding a proper amount of the rare earth La element and the rare earth Y element to the nickel-based single crystal superalloy; and thus the content of the rare earth elements in the nickel-based single crystalsuperalloy is stable, the functions of the rear earth elements are brought into play, and the oxidation resistance, high-temperature creep resistance and the like of the nickel-based single crystal superalloy are improved.

Owner:JIANGXI UNIV OF SCI & TECH

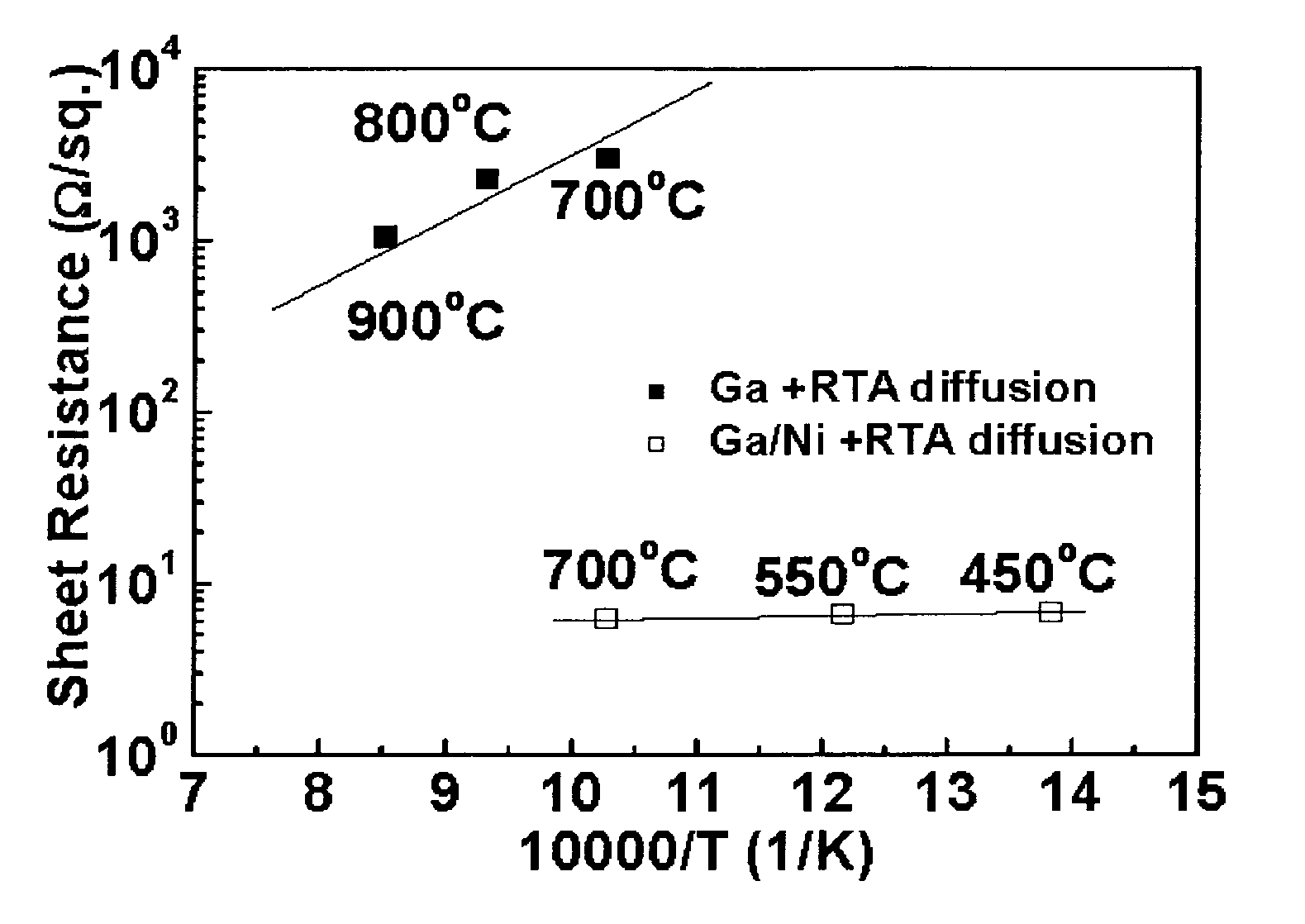

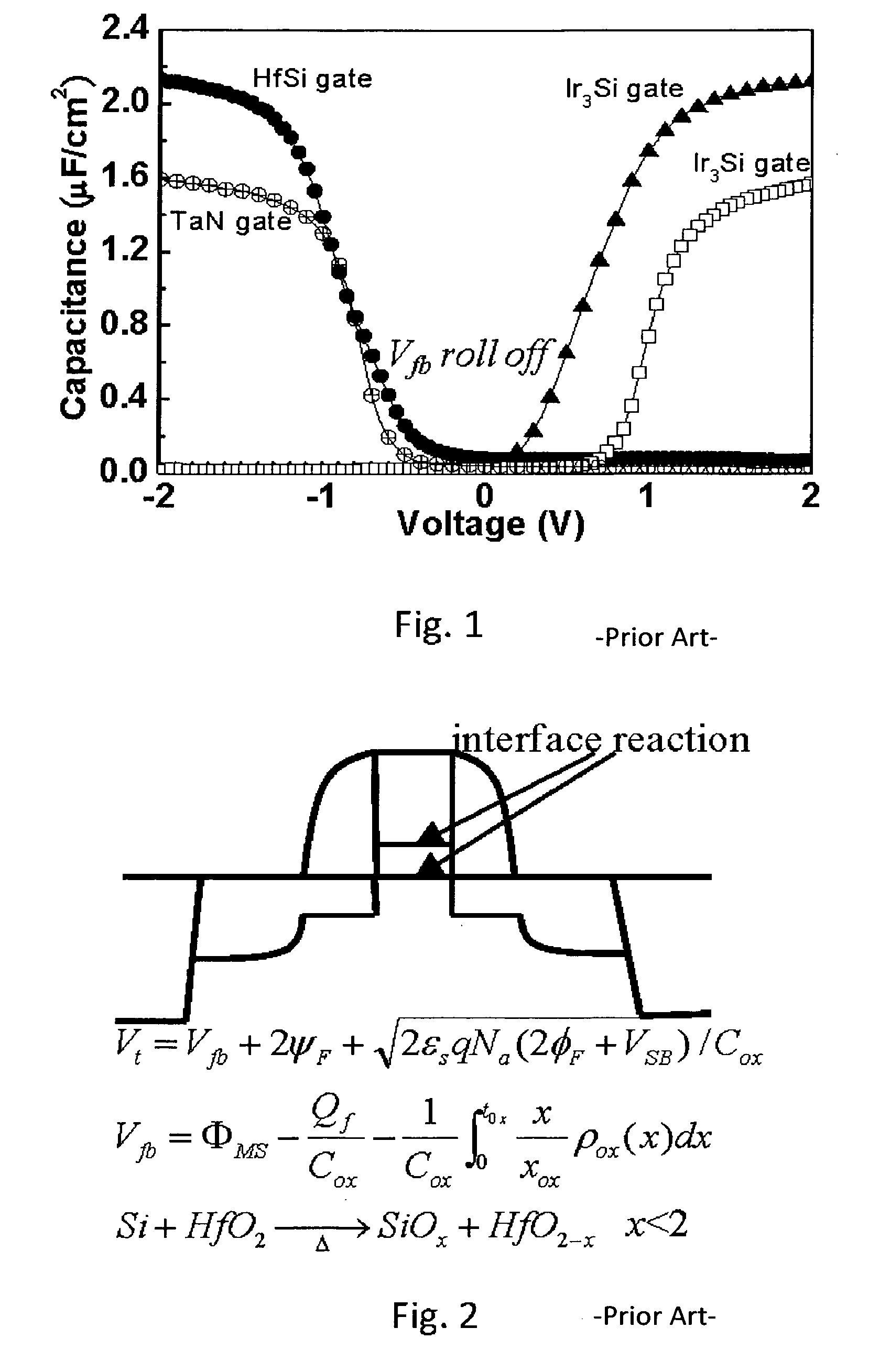

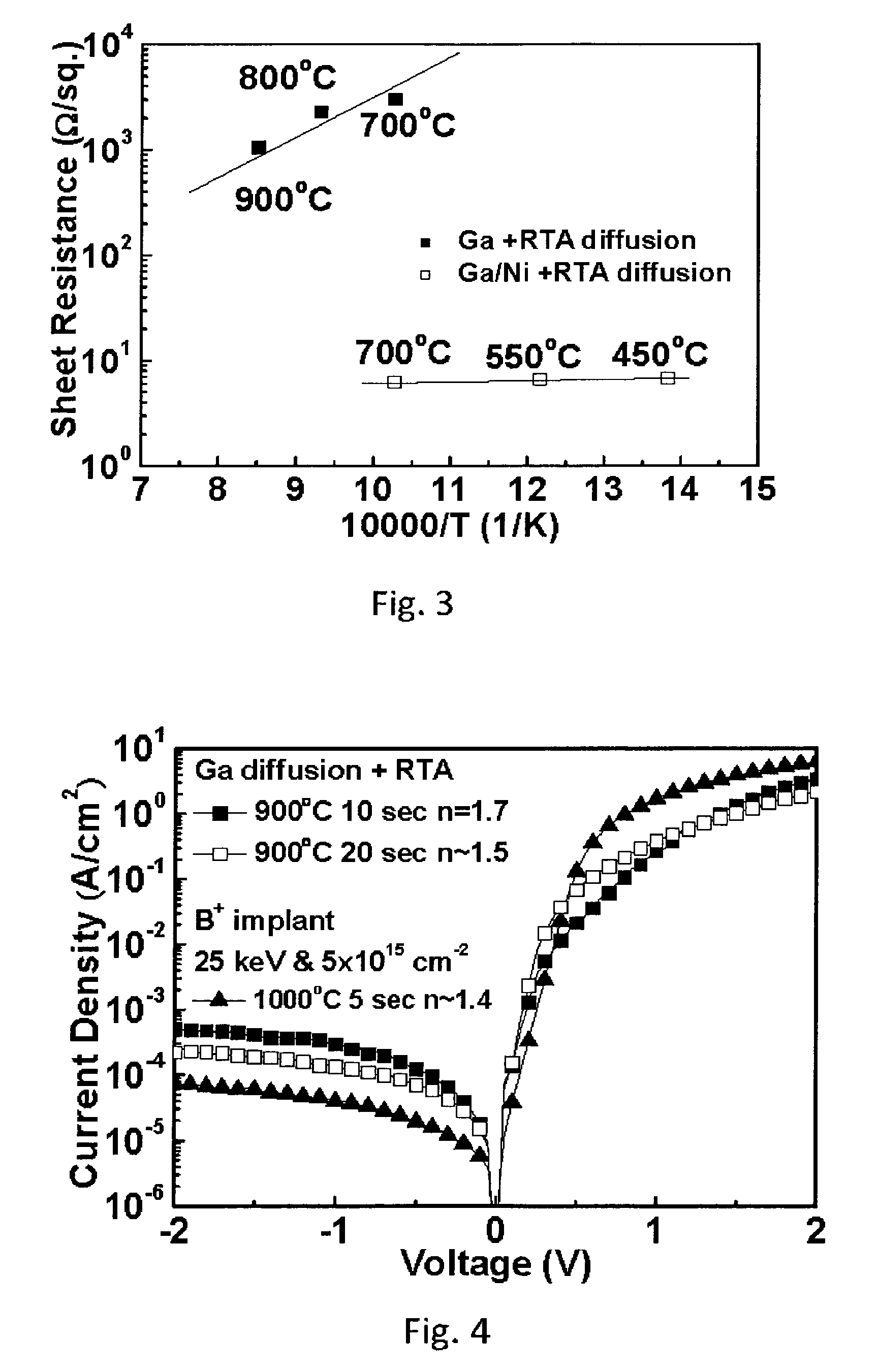

Method for making very low Vt metal-gate/high-k CMOSFETs using self-aligned low temperature shallow junctions

InactiveUS20090280630A1Improve mobilityReduction of defect-assisted diffusionSemiconductor/solid-state device manufacturingSemiconductor devicesEquivalent oxide thicknessInstability

This invention proposes a method for making very low threshold voltage (Vt) metal-gate / high-κ CMOSFETs using novel self-aligned low-temperature ultra shallow junctions with gate-first process compatible with VLSI. At 1.2 nm equivalent-oxide thickness (EOT), good effective work-function of 5.3 and 4.1 eV, low Vt of +0.05 and 0.03 V, high mobility of 90 and 243 cm2 / Vs, and small 85° C. bias-temperature-instability<32 mV (10 MV / cm, 1 hr) are measured for p- and n-MOS.

Owner:NAT CHIAO TUNG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com