Patents

Literature

170results about How to "Increase stirring speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-density and small-particle size nickel-cobalt-manganese hydroxide and preparation method thereof

InactiveCN107640792AHigh density and small tap densityLow tap densityCell electrodesSecondary cellsHigh densityManganese

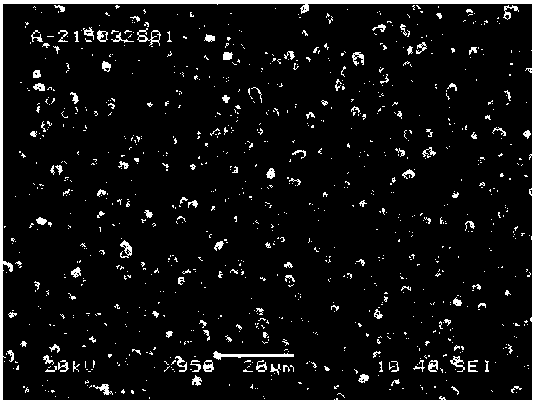

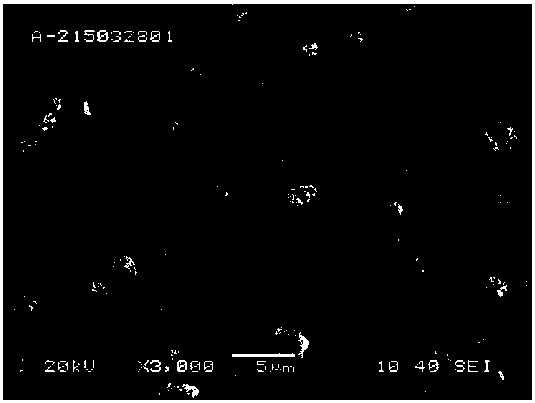

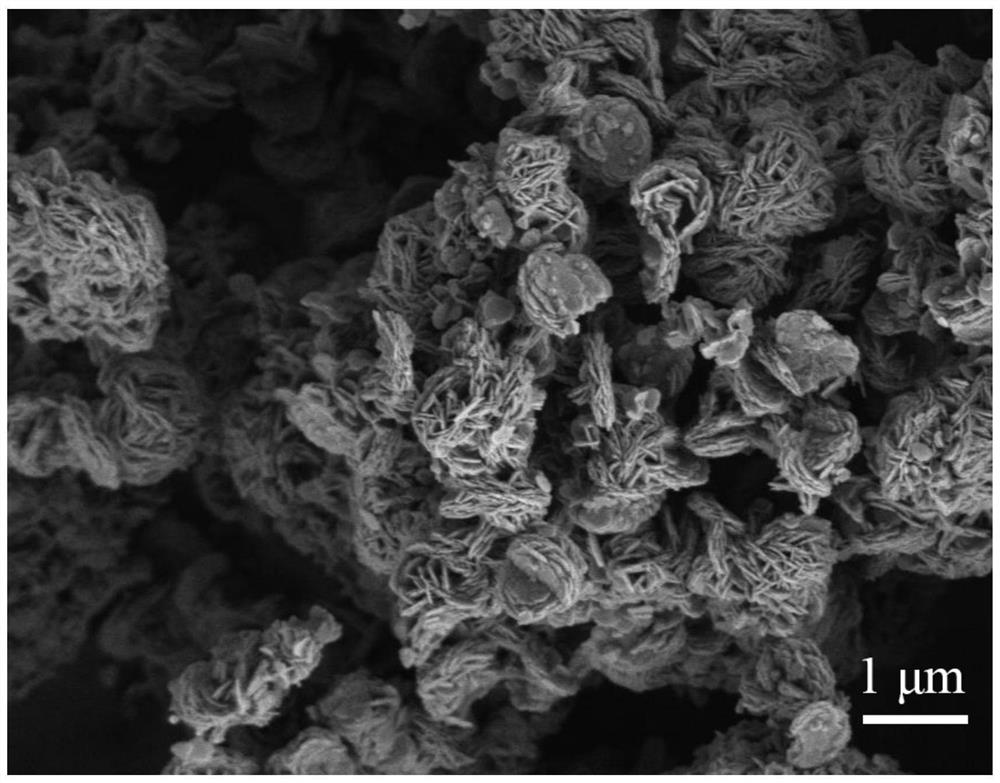

The invention discloses a high-density and small-particle size nickel-cobalt-manganese hydroxide and a preparation method thereof. For the high-density and small-particle size nickel-cobalt-manganesehydroxide provided by the invention, a general chemical formula is NixCoyMnz(OH)2, wherein x+y+z=1, x is larger than or equal to 0.3 and smaller than or equal to 0.8, y is larger than or equal to 0.1and smaller than or equal to 0.4, and z is larger than or equal to 0.1 and smaller than or equal to 0.4; the particle sizes are d10 larger than or equal to 2 microns, d50 equal to 2.5-4 microns and d90 smaller than or equal to 6 microns, the tap density is larger than or equal to 1.4g / cm<3>, the specific surface area is 5-20m<2> / g, and the shape is spherical or spheroidal. The invention also discloses the preparation method of the high-density and small-particle size nickel-cobalt-manganese hydroxide. The preparation method is strong in controllability, can stably control the particle sizes ineach production batch without using a surfactant and is low in production cost, high in efficiency and good in physicochemical index of a final product.

Owner:ZHUJI PAWA NEW ENERGY

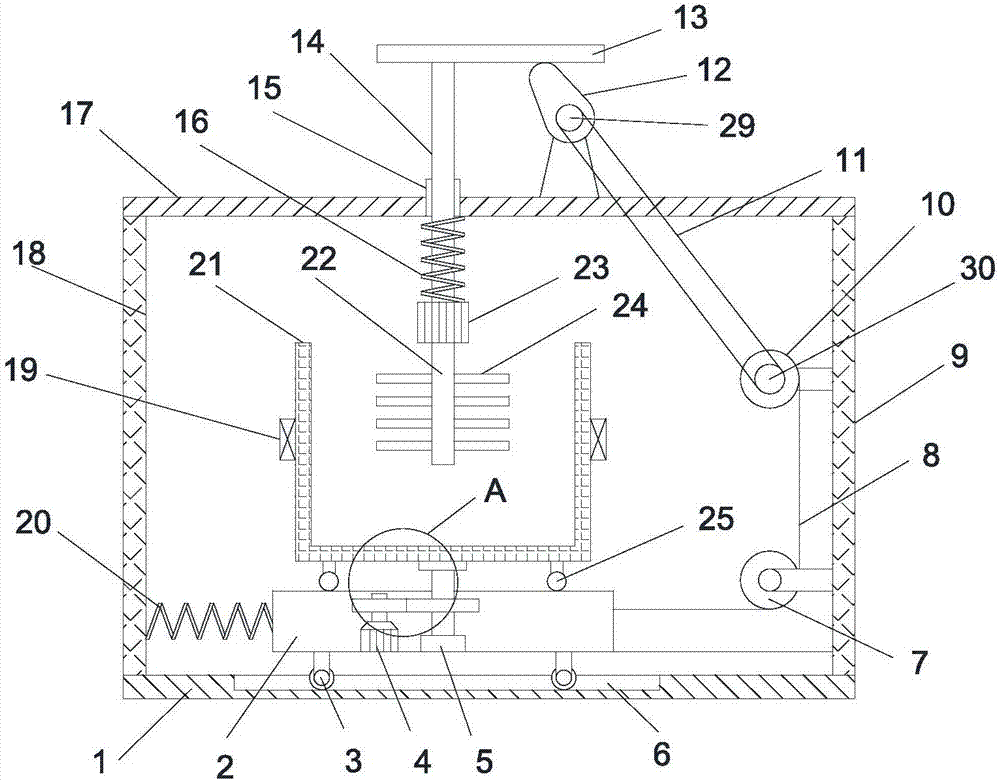

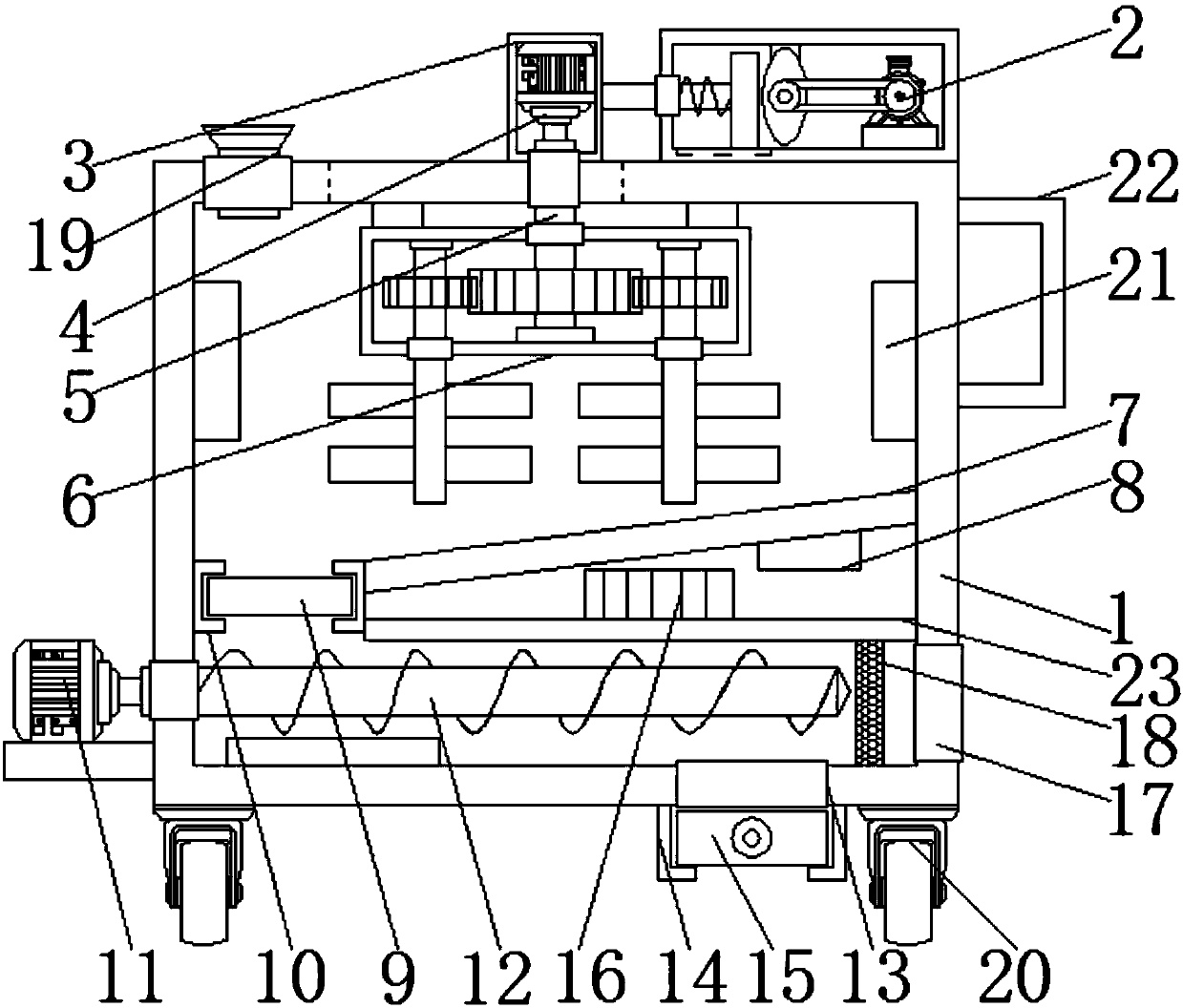

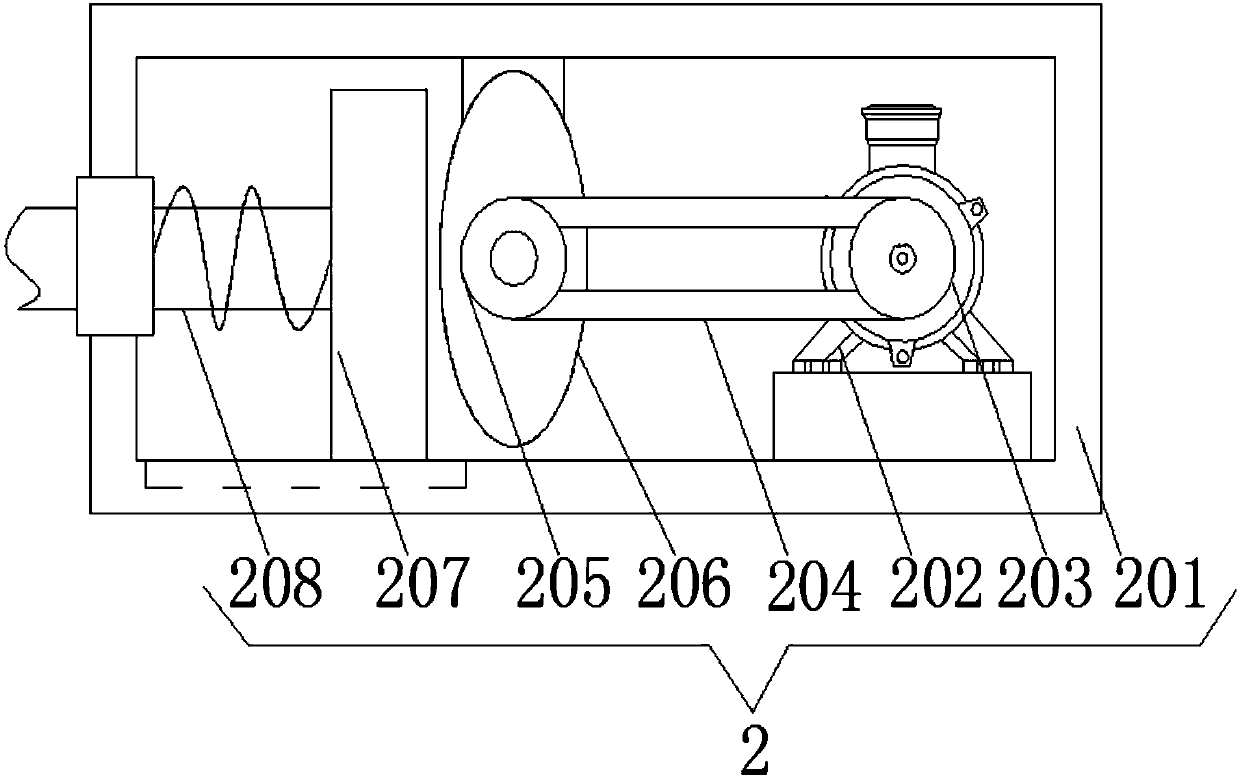

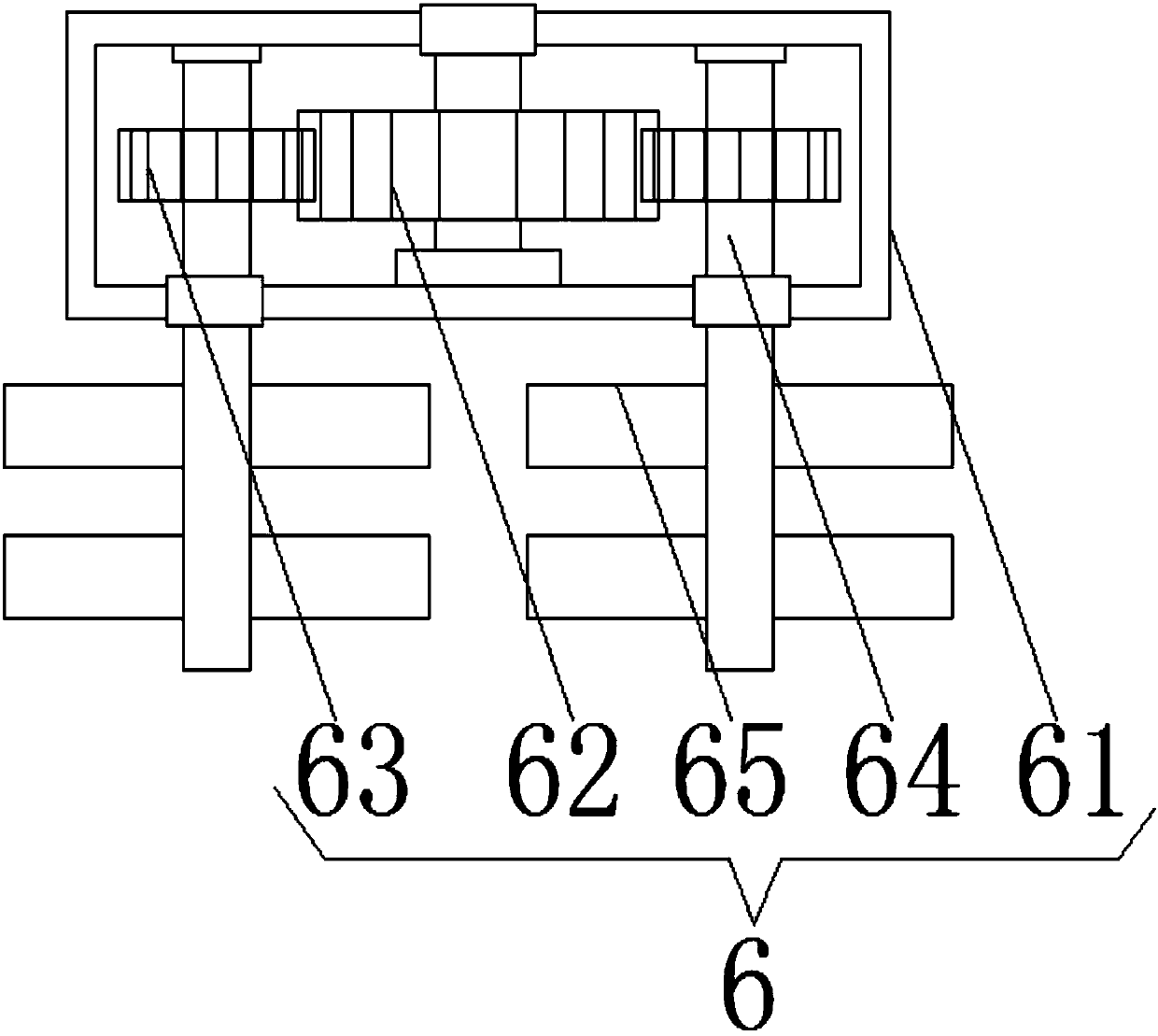

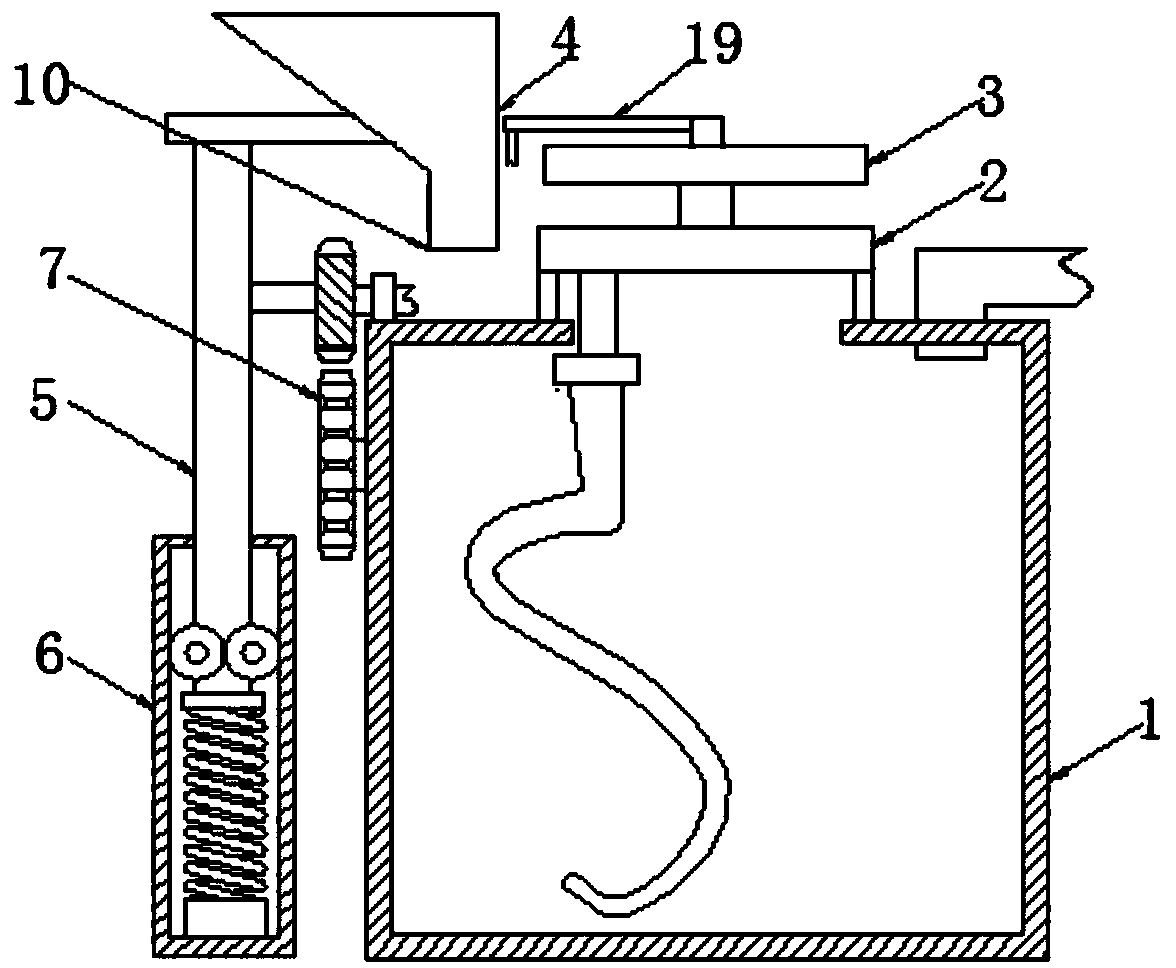

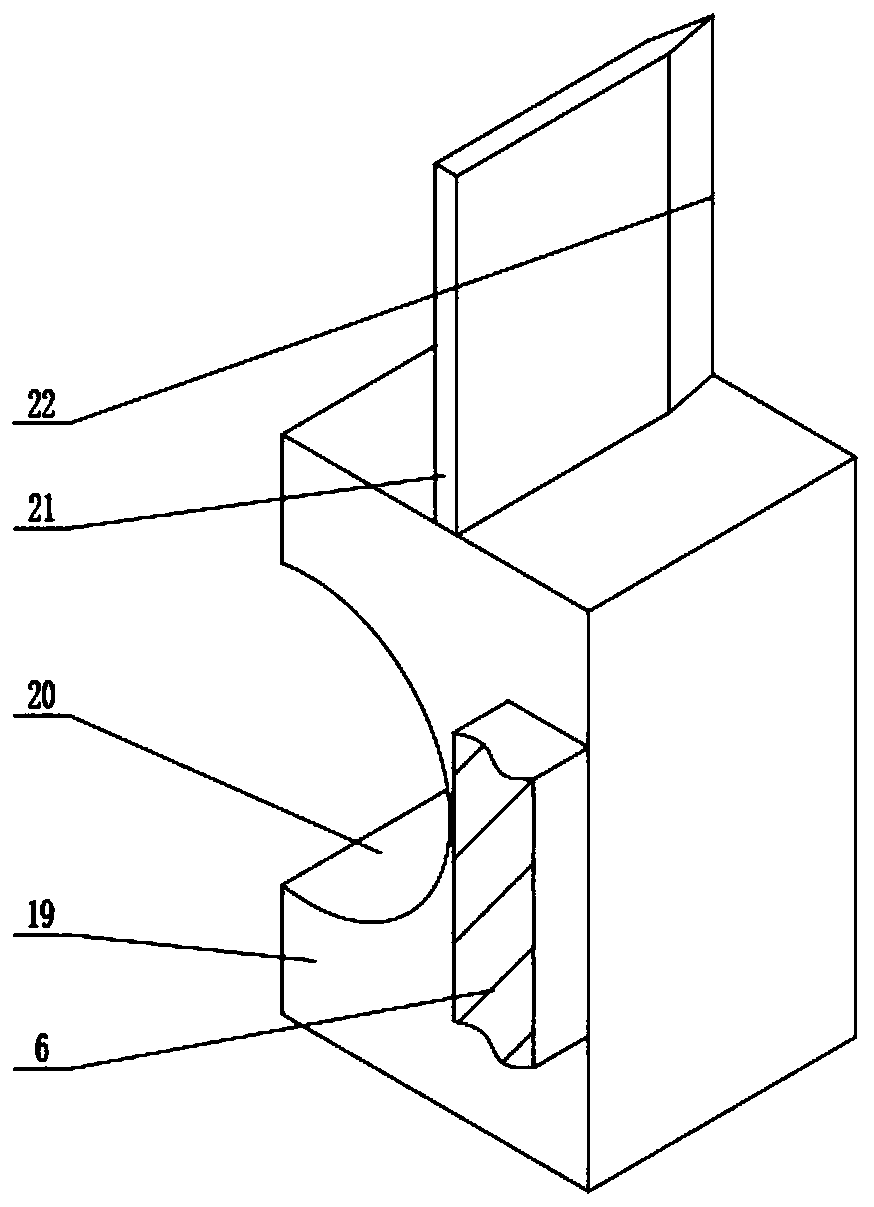

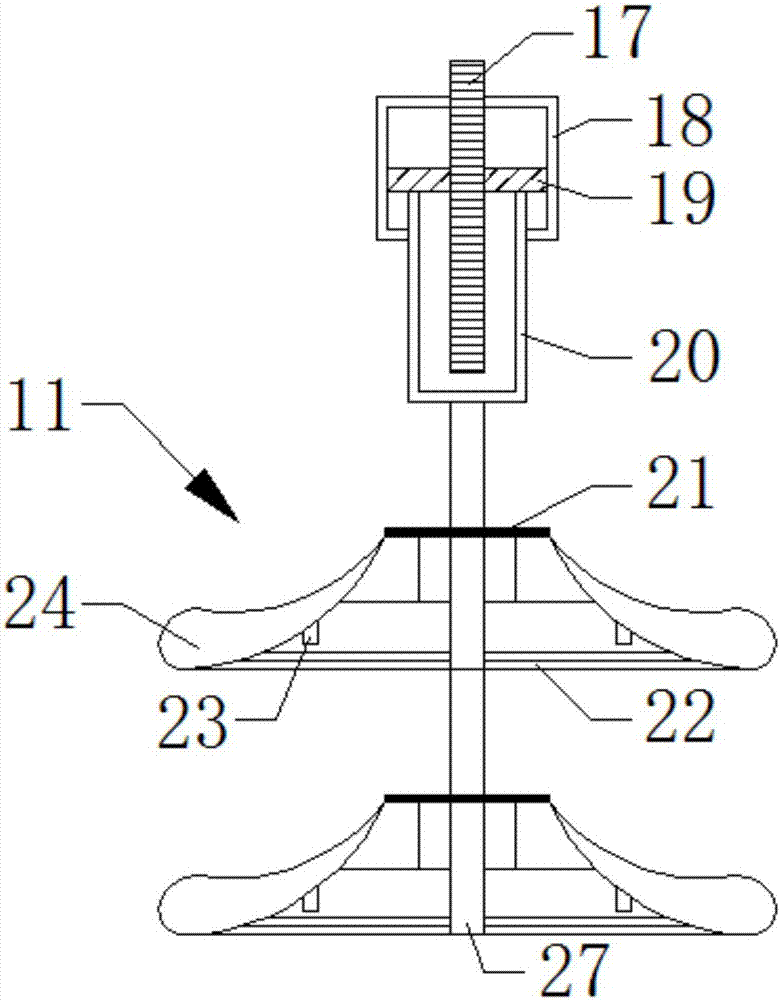

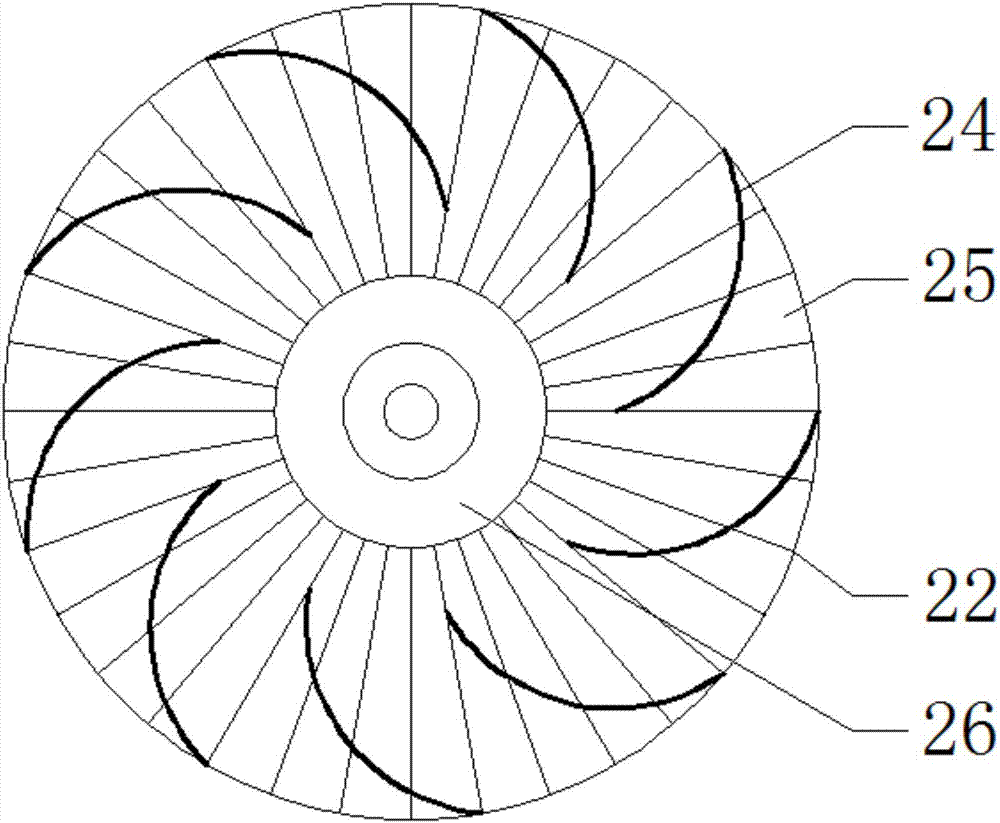

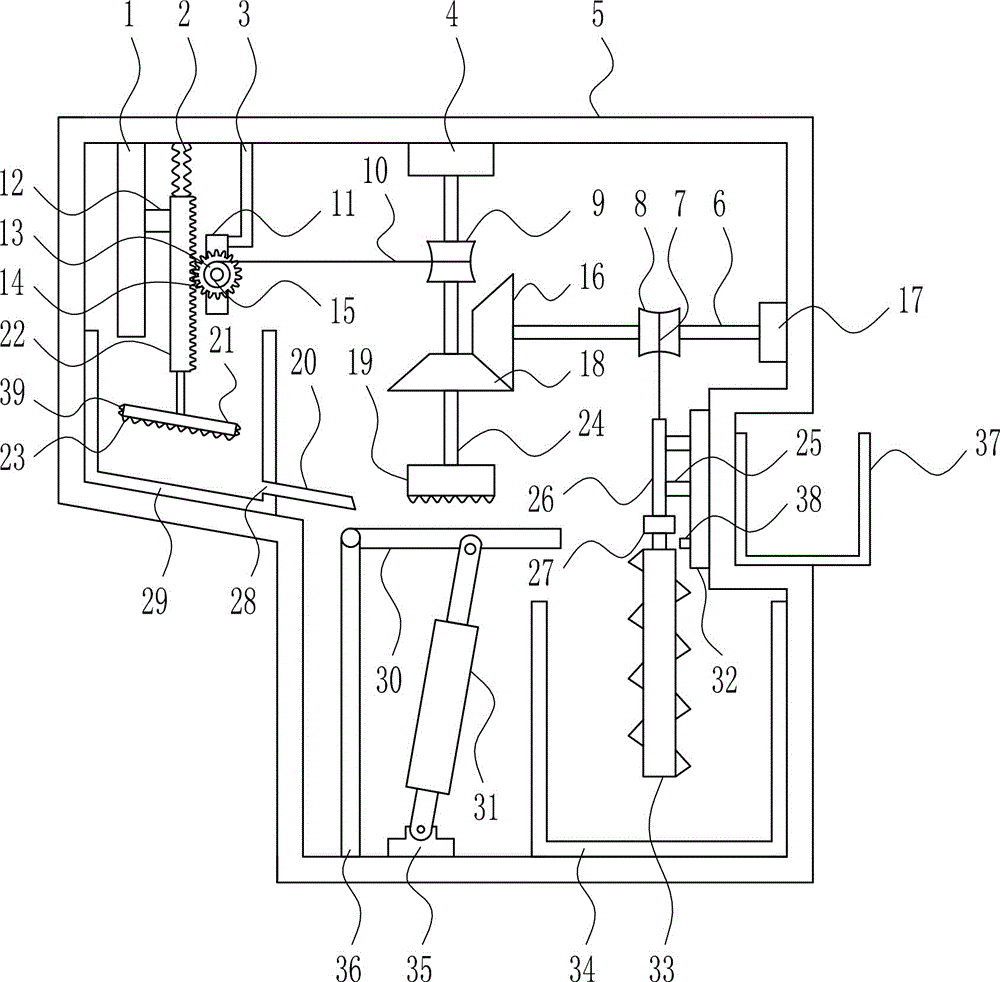

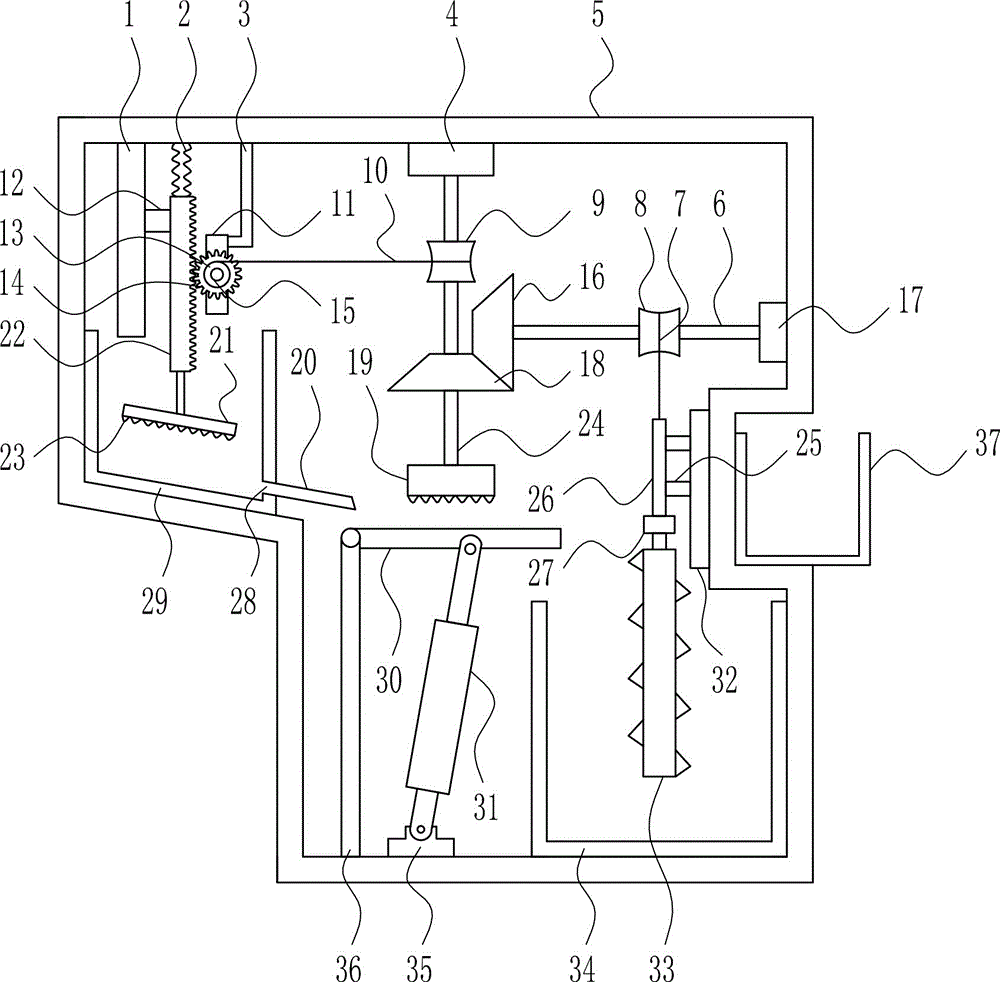

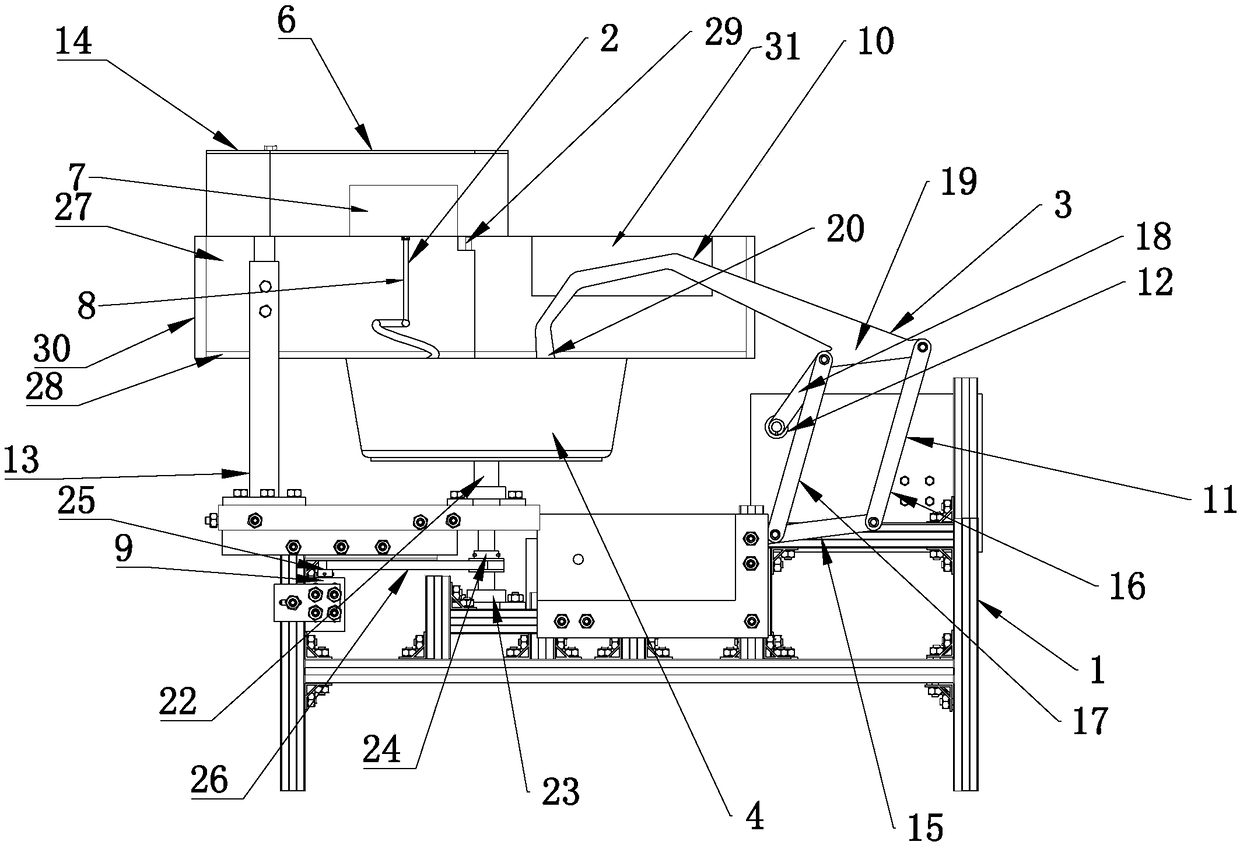

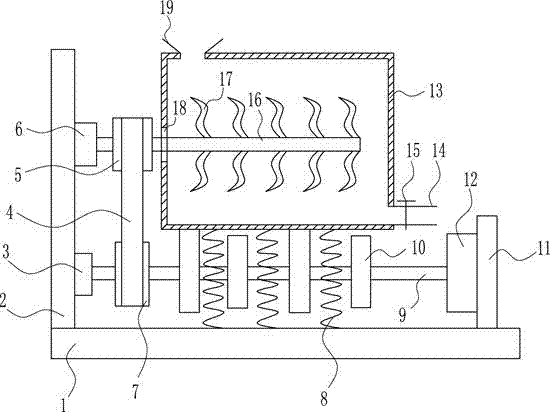

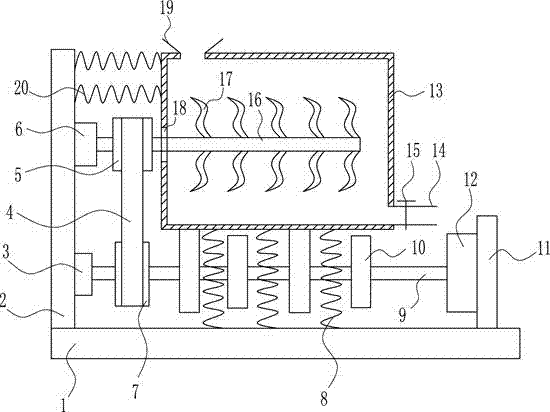

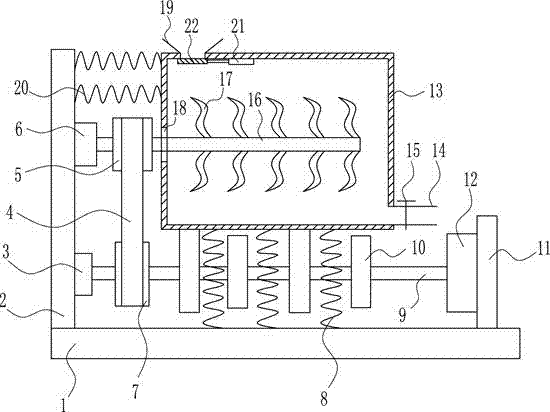

Concrete quick stirring device for municipal construction

The invention discloses a concrete quick mixing device for municipal construction, which comprises a lower base plate, on which a left column and a right column are vertically welded and fixedly installed; a limit spring is arranged between the sliding platform and the left column, and a Rotating motor, the output shaft of the rotating motor is coaxially fixed with a driving gear, the sliding platform is provided with a limit bearing seat, the driven shaft runs through the sliding platform upwards, and the output shaft of the stirring motor is coaxially fixed with a stirring shaft. A number of blades are uniformly arranged on the shaft; a cam is rotated on the upper top plate; The invention can stir the concrete at different depths in the mixing barrel, and the blades can stir the concrete at different lateral positions in the mixing barrel, so that the concrete can be stirred more fully and completely, and the mixing speed and effect are greatly improved.

Owner:苏昭缄

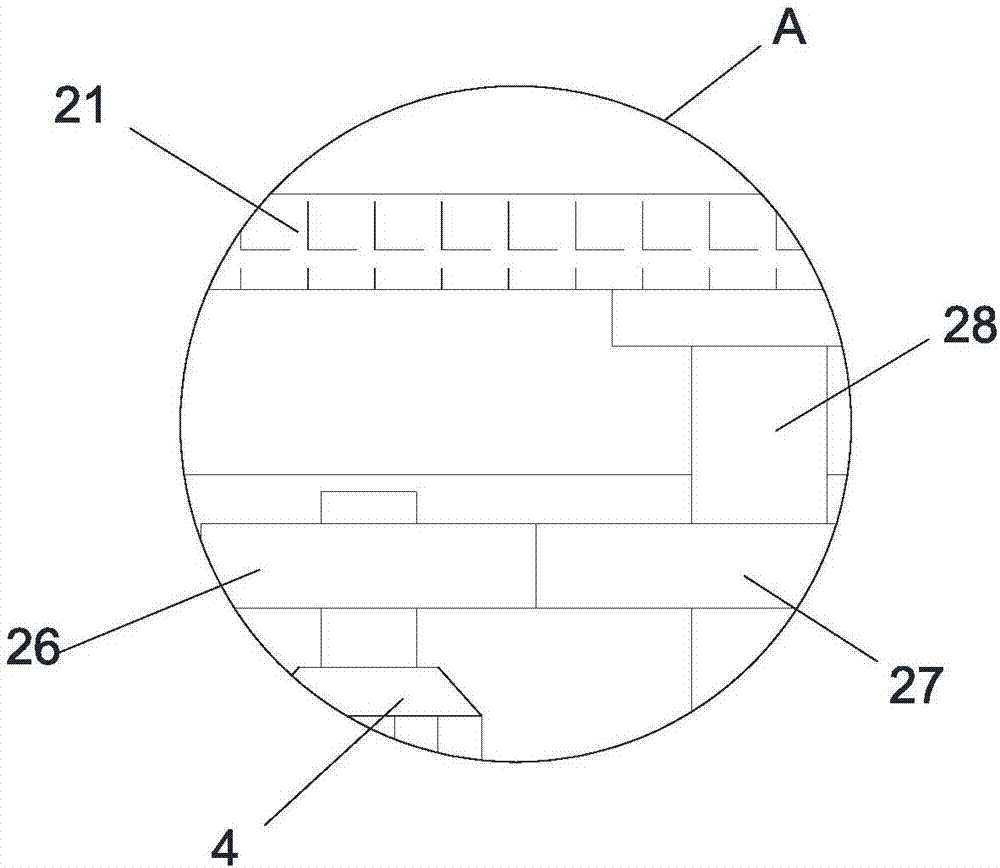

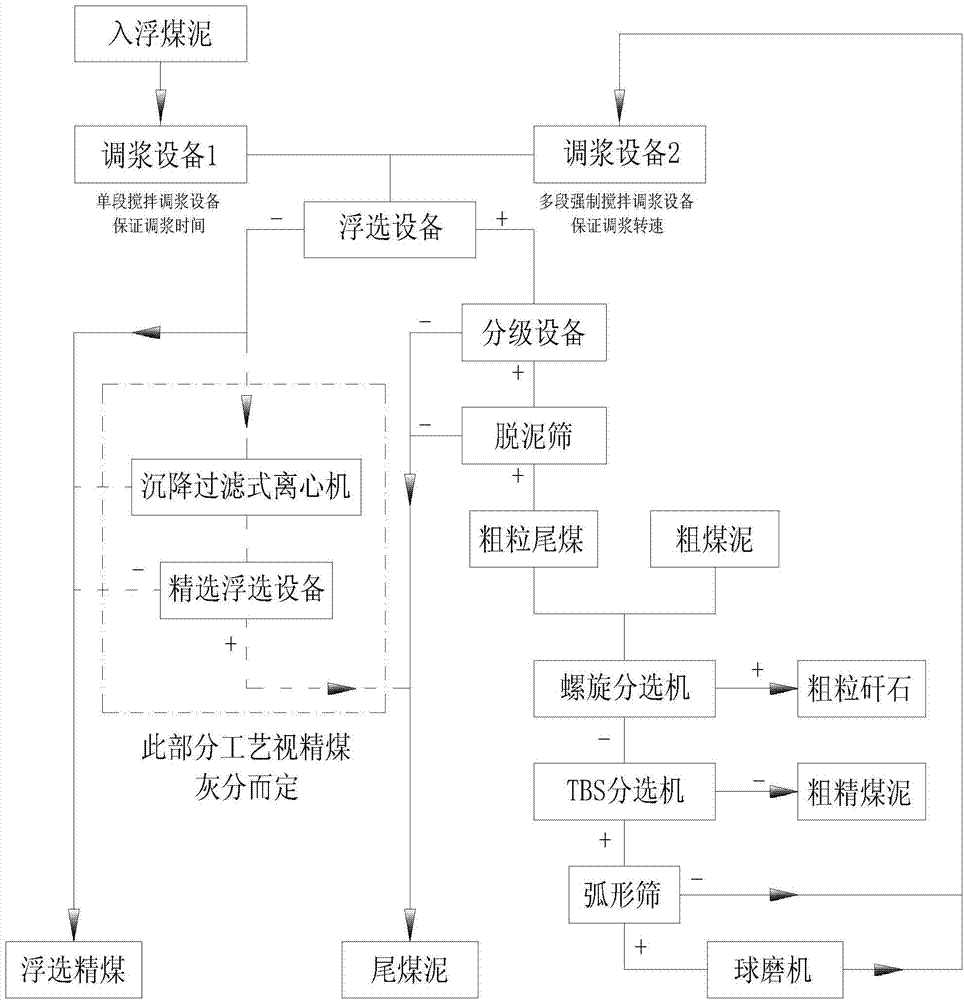

Dissociating, independent slurry mixing and bulk floatation process for fine grain middings

ActiveCN104722389ASolve the rough running problemAvoid energy consumptionWet separationEngineeringSlurry

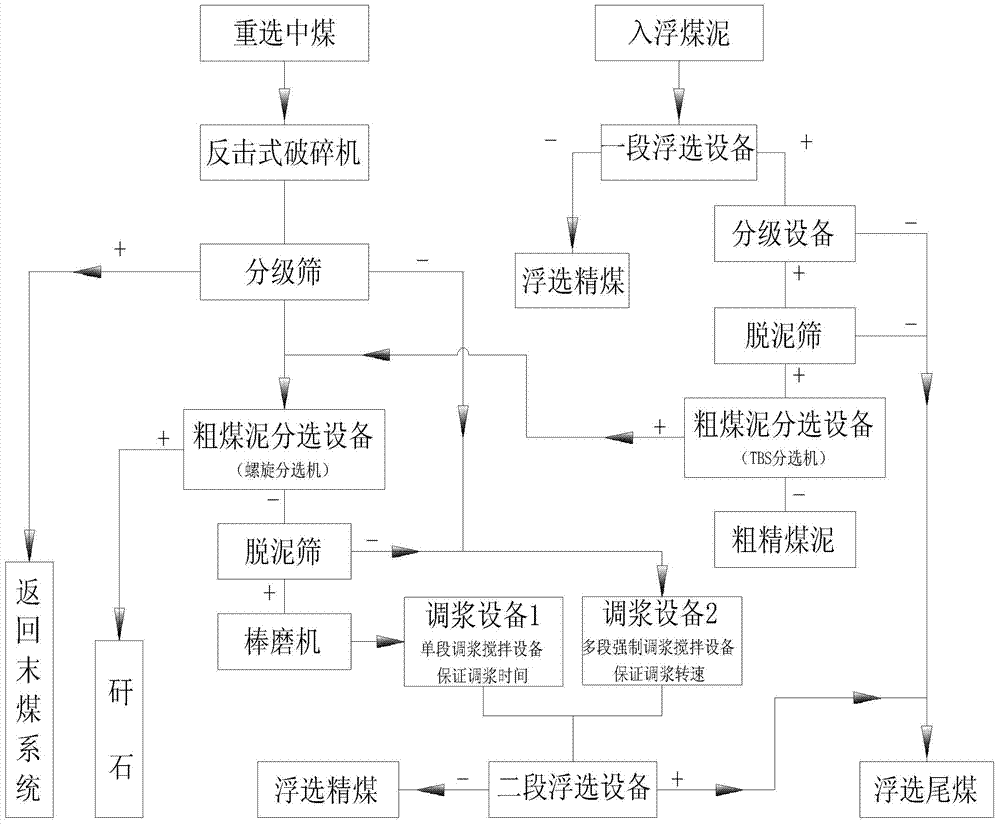

The invention discloses a dissociating, independent slurry mixing and bulk floatation process for fine grain middings and belongs to the technical field of coal slime floatation. The process comprises the first step of slurry mixing operation, the second step of roughing, the third step of dehydration and fine floatation operation, the fourth step of separation and desliming operation, the fifth step of coarse slime separation operation, the sixth step of desliming operation and the seventh step of ore grinding operation. According to the independent slurry mixing bulk floatation process for dissociating the coal from the fine grains, the procedure is simple, investment is small, energy consumption is low, the operation cost is low, the separation efficiency is high, and economical benefits are remarkable.

Owner:CHINA UNIV OF MINING & TECH

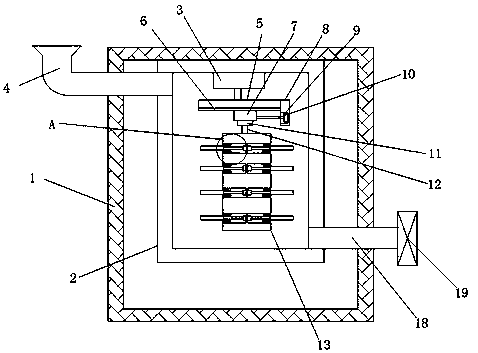

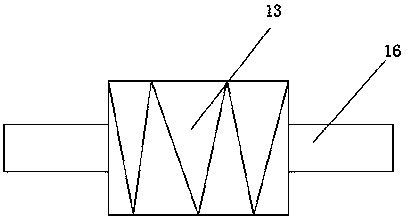

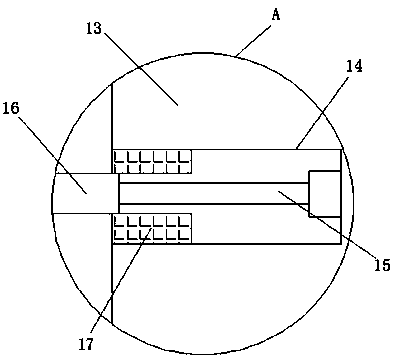

Plastic extruder

The invention discloses a plastic extruder. The plastic extruder comprises a box body. The right side of the top of the box body is fixedly connected to a movable device, and the top of the box body is slidably connected to a motor case; the top of the inner wall of the motor case is fixedly connected to a first motor; the output shaft of the first motor is fixedly connected to a rotating shaft through a coupling; and the bottom end of the rotating shaft successively penetrates through the motor case and the box body to extend into the box body. The plastic extruder disclosed by the inventionrelates to the technical field of plastic processing. The plastic extruder can mix materials fully, so that the utilization ratio of the materials is increased and the manufacturing cost of the materials is lowered; the plastic extruder can drive a stirring device to move, so that the material stirring rate is increased, and the working time of staff is shortened; the plastic extruder can be cooled after use, so that the service life of the plastic extruder is prolonged, and the plastic extruder is conveniently moved; impurities and plastic particles which are not melted can be filtered and discharged, so that the quality of the materials is improved, and processing in the later period is facilitated.

Owner:李庭裕

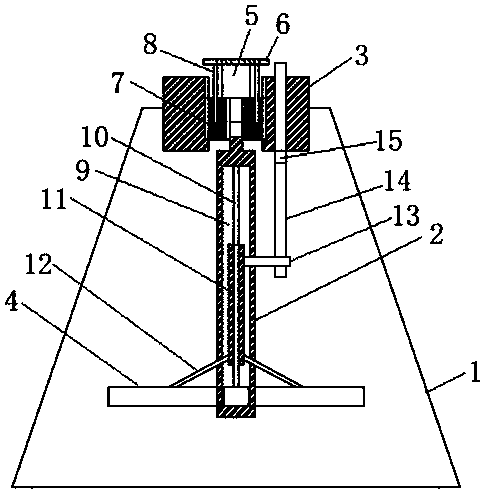

Flour detection equipment capable of quantitatively feeding and automatically stirring by utilizing gravity

InactiveCN110743412AExpand the mixing rangeFast formingTransportation and packagingRotary stirring mixersCircular discElectric machinery

The invention relates to the technical field of flour, and discloses flour detection equipment capable of quantitatively feeding and automatically stirring by utilizing gravity, wherein the flour detection equipment comprises a stirring bin, a rotating disc is movably connected above the stirring bin, and drives a stirring rod to rotate so as to stir flour, and the stirring rod is positioned at the eccentric position of the rotating disc. According to the invention, by increasing the stirring range of the stirring rod, the dough molding is accelerated, and the stirring rate is increased; a moving rod rotates to cause an arc block to approach a disc shell by using a support column as a rotating point, an arc strip synchronously moves, and is clamped with the disc shell to obstacle the rotation of the disc shell, and the rotating of the rotating disc is correspondingly stopped, so that the stirring operation is automatically suspended to conveniently take out the dough, and the reducingof the service life of the motor due to the repeated switching of the power supply is avoided; and a material receiving hopper moves downwards to open a material outlet, and the stirring rod rotates,so that the stirring is performed while the flour is discharged, the occurrence rate of the blocky flour dough is reduced, the stirring effect is good, the linkage among all structures is enhanced, and the operation is convenient and rapid.

Owner:杭州柯宏网络科技有限公司

Antibacterial deodorizing nanometer fiber, and preparation method thereof

ActiveCN109183193ALow priceNo pollution in the processSpinning solutions preparationArtifical filament manufactureFiberManufacturing technology

The invention belongs to the technical field of fiber manufacturing, and more specifically relates to an antibacterial deodorizing nanometer fiber, and a preparation method thereof. The antibacterialdeodorizing nanometer fiber is prepared from, by weight, 22 to 26 parts of nanometer titanium dioxide, 30 to 35 parts of chitosan, 3 to 5 parts of rose flower, 55 to 60 parts of Glacial Acetic Acid, 2to 4 parts of single layer graphene, 2 to 3 parts of bamboo fiber micropowder, 1 to 2 parts of carboxymethylcellulose sodium, and 1 to 2 parts of garlic essential oil. The antibacterial deodorizing nanometer fiber possesses excellent bacteria killing and inhibiting and deodorizing effect; the antibacterial validity and broad spectrum activity of chitosan nanometer fiber are improved; the raw materials are relatively cheap; no high temperature treatment is needed in the preparation process; the preparation process is simple and convenient; cost is low; efficiency is high; no pollution is caused; and energy consumption is low.

Owner:HEYE HEALTH TECH CO LTD

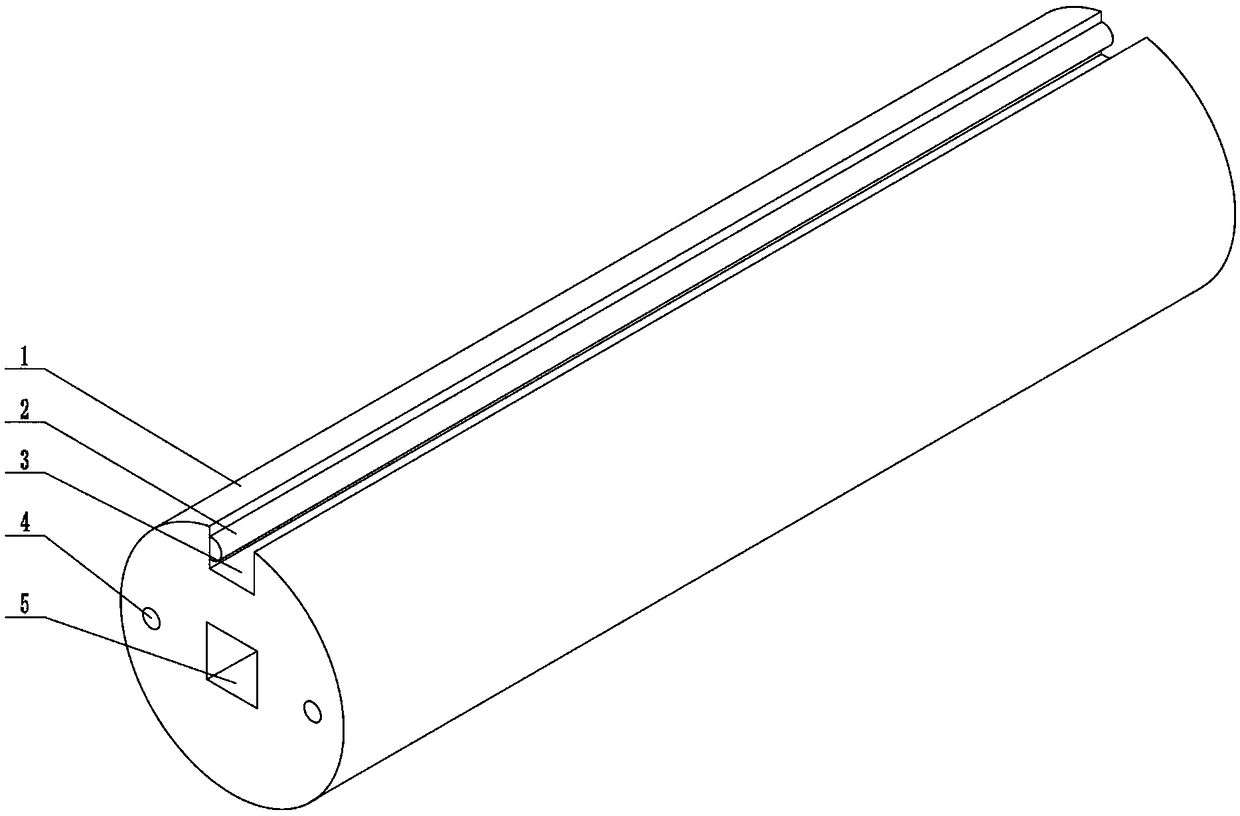

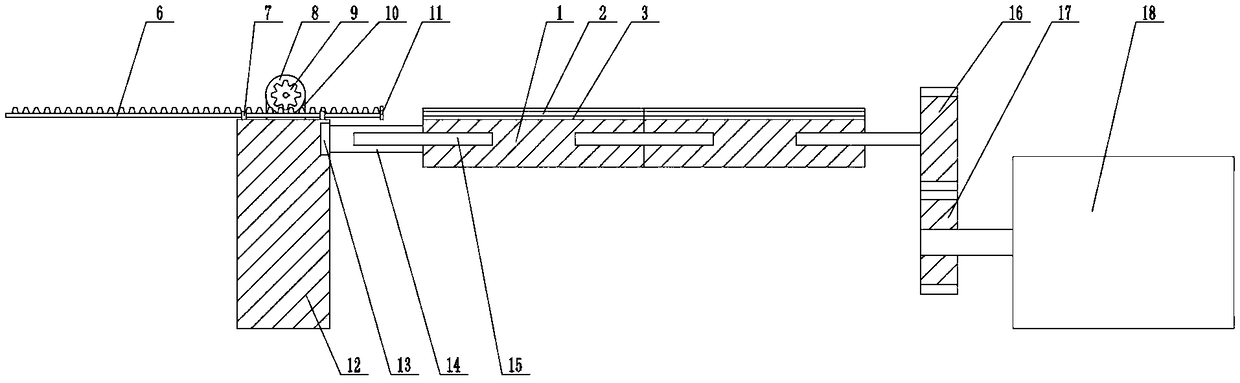

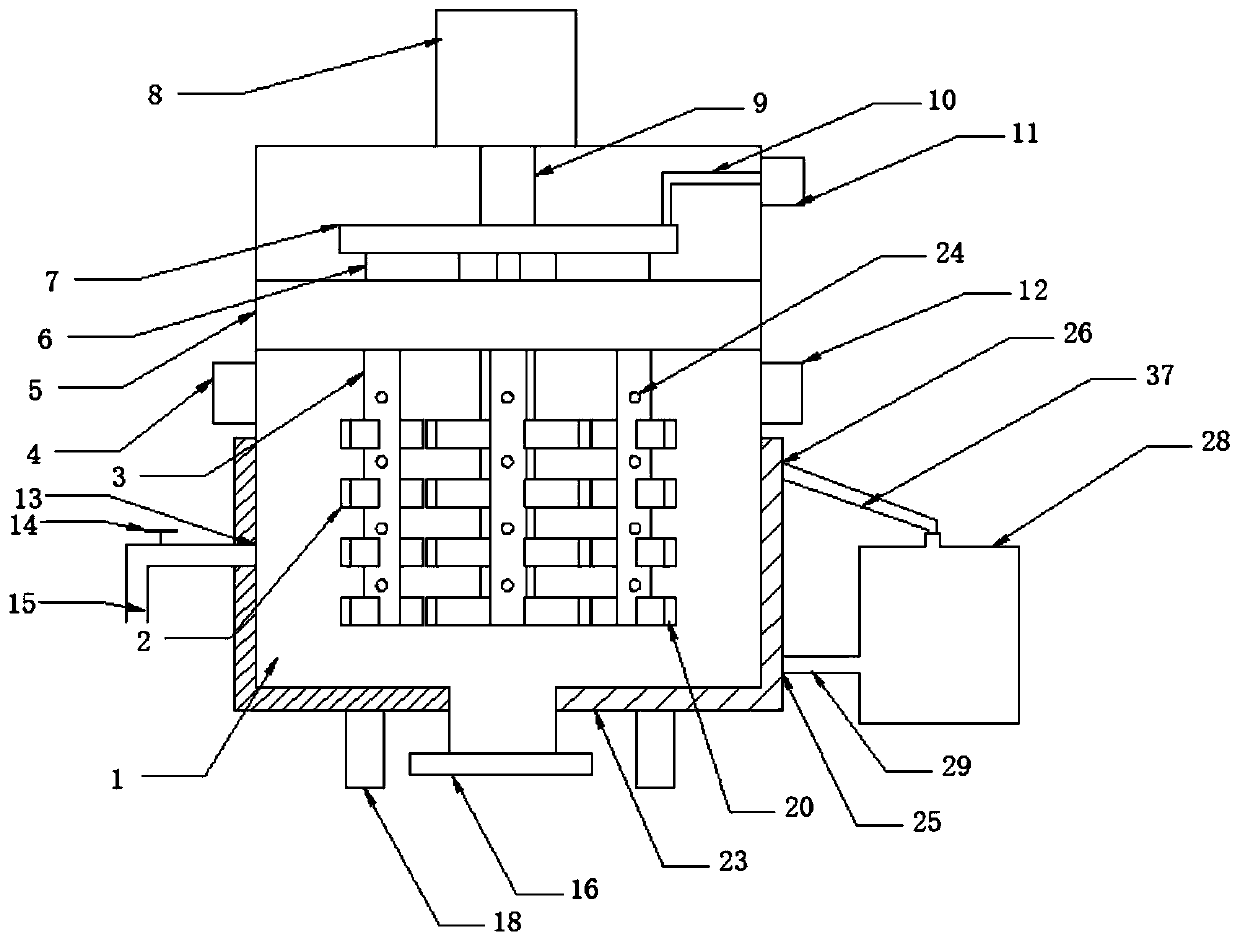

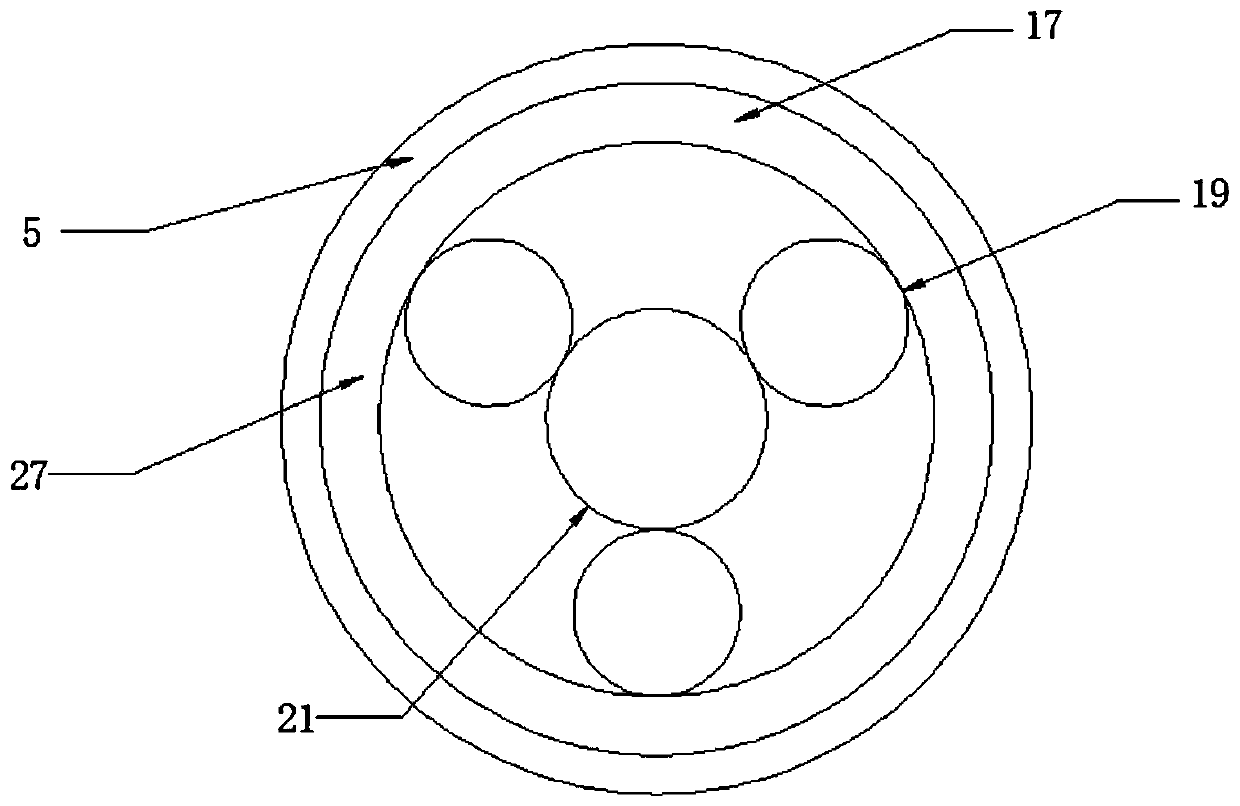

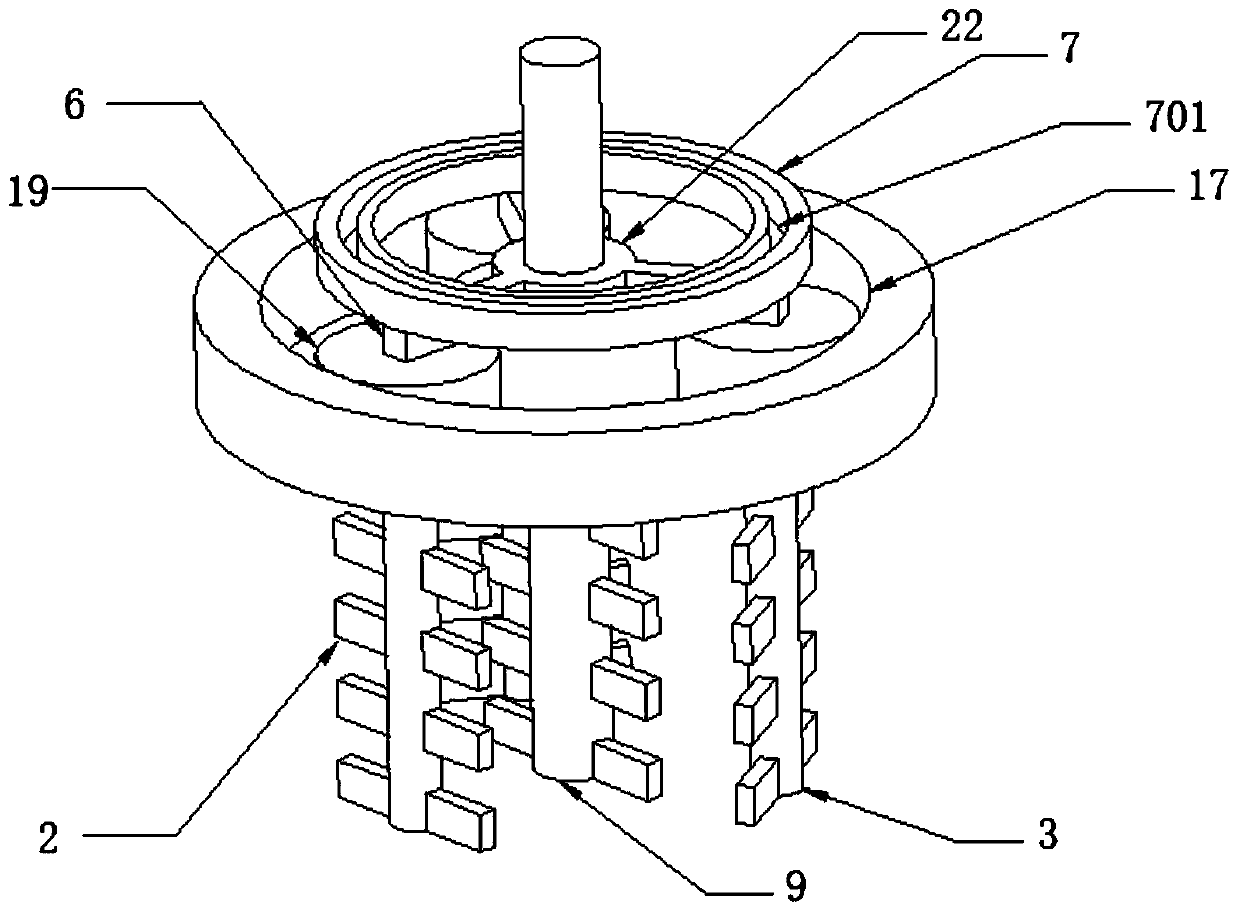

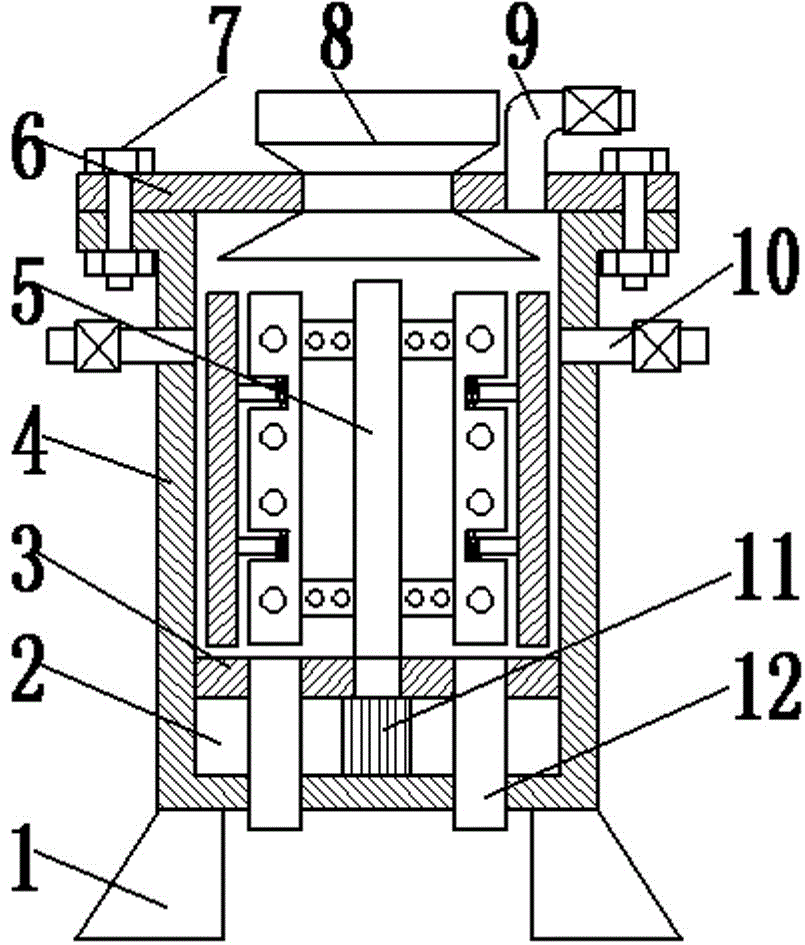

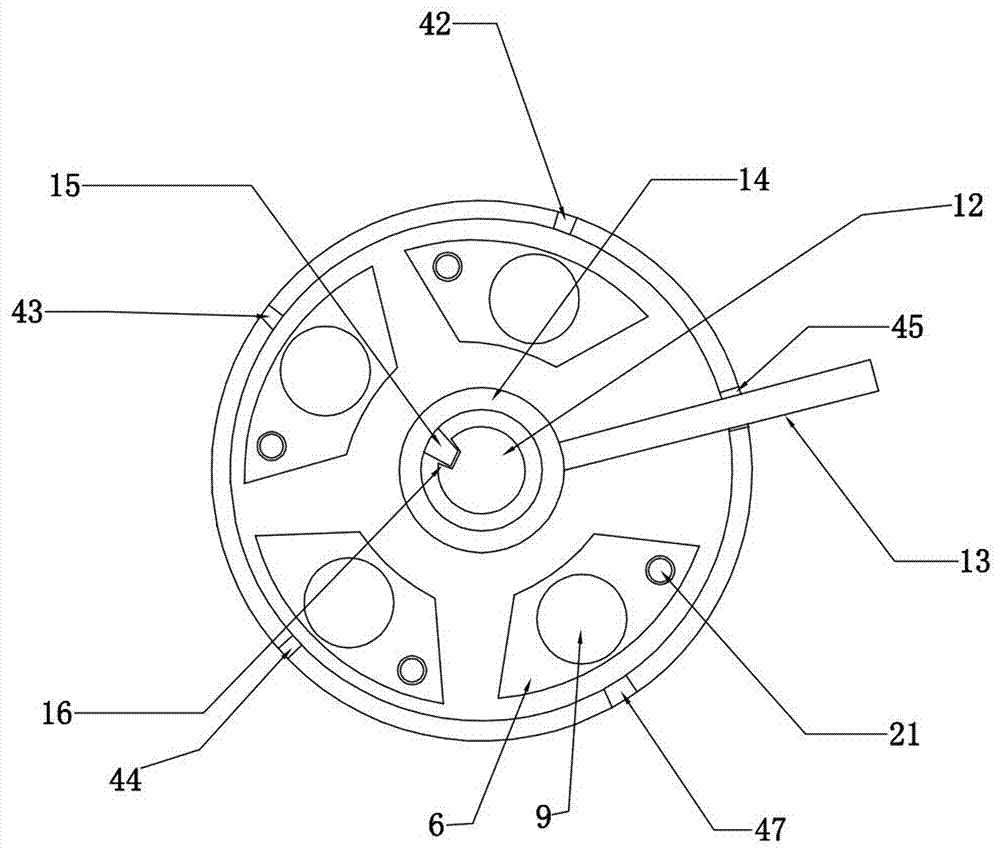

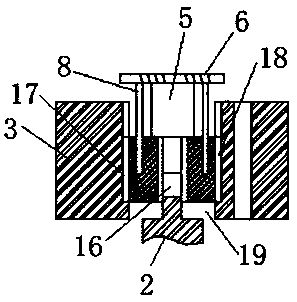

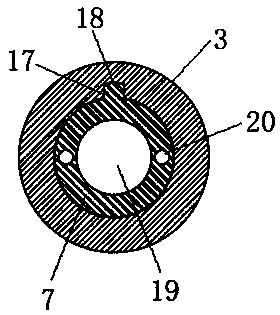

Paper product raw material stirring device

InactiveCN111001349AIncrease stirring speedAvoid mixing unevenlyRotary stirring mixersTransportation and packagingGear wheelElectric machinery

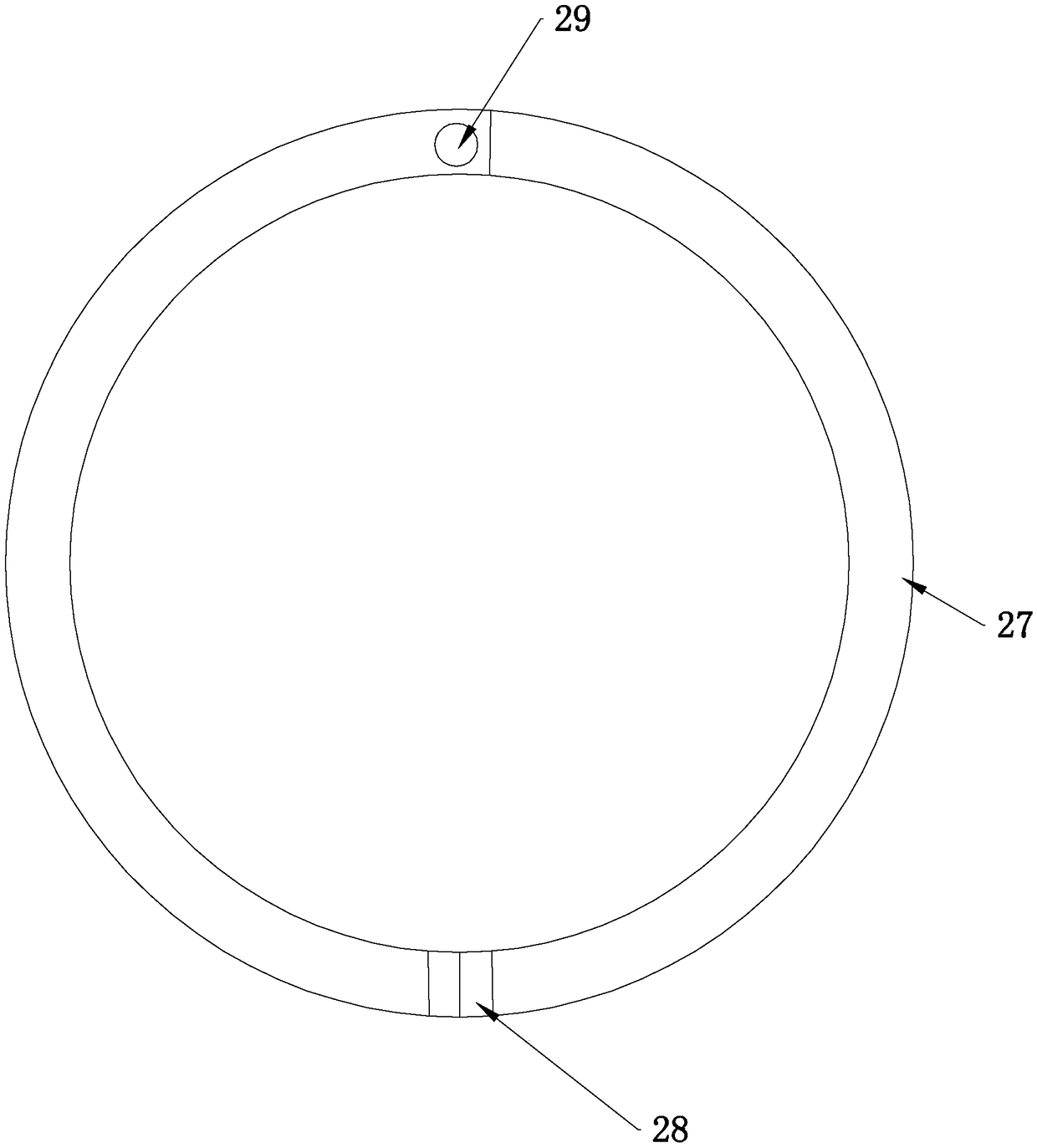

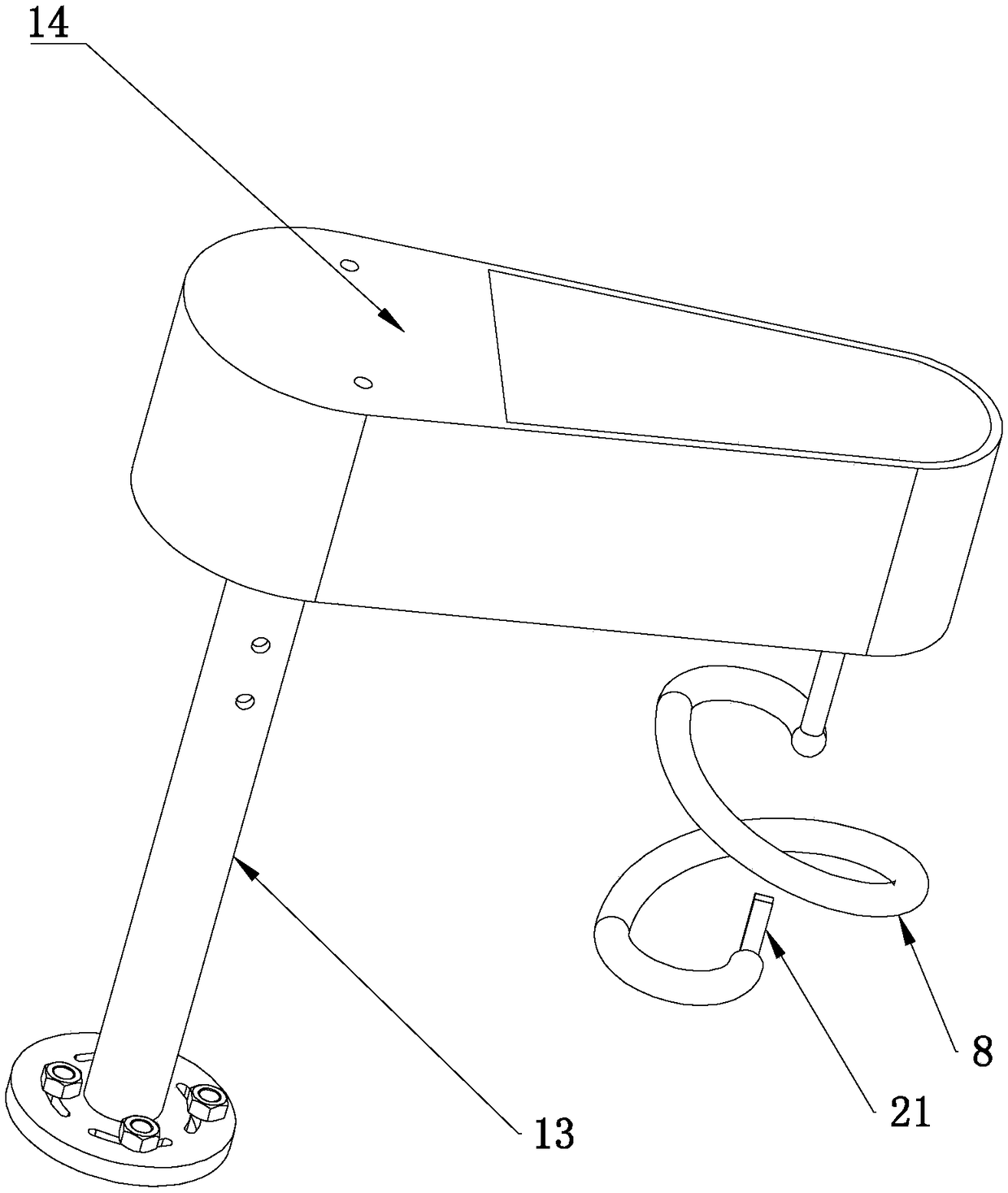

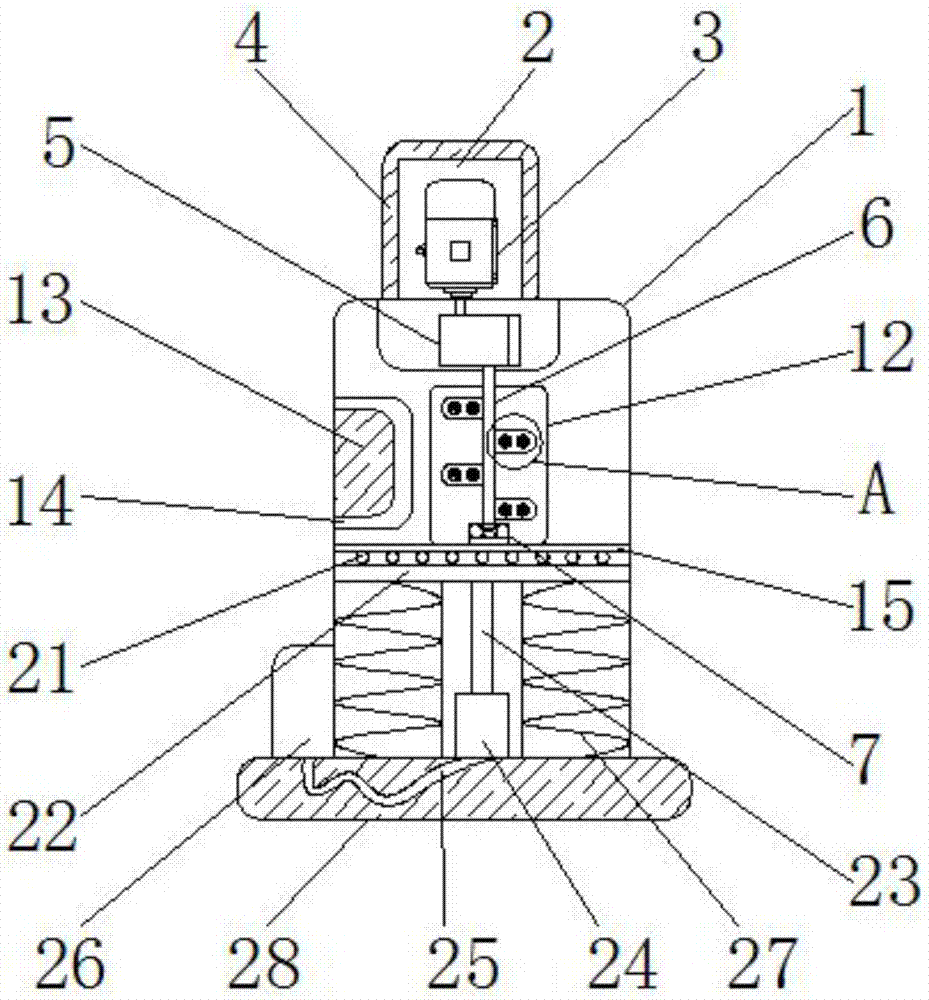

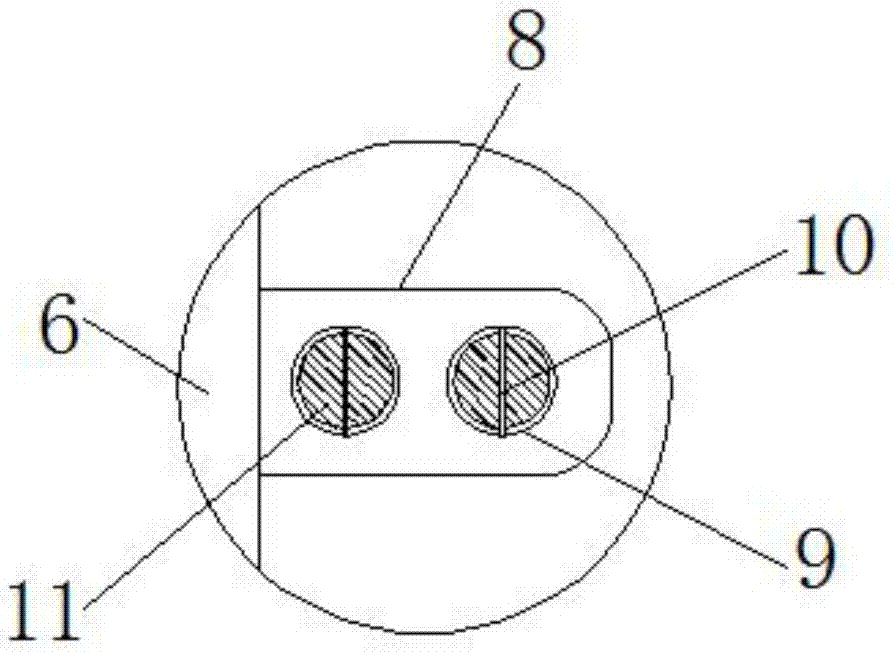

The invention discloses a paper product raw material stirring device which adopts a stirring tank and further comprises a stirrer, a protection disc and a stirring motor. The stirring motor is arranged above the stirring tank; the protection disc is arranged at the top in the stirring tank; the stirrer comprises a gear ring, a stirring shaft, a sun gear and a planetary gear; the gear ring is arranged on the inner wall of the protection disc; a stirring shaft is arranged in the stirring tank; one end of the stirring shaft is connected to the stirring motor, the other end of the stirring shaft is connected with the sun gear in a penetrating manner; the sun gear is arranged in the gear ring in parallel; a planetary ring is arranged on the stirring shaft; three cross rods are uniformly distributed along the circumference of the planetary ring; the number of the planetary gears and the stirring rods is three; one end of each stirring rod is arranged at the tail end of a planet carrier crossrod, the other end is connected to the planetary gear; a plurality of stirring blades are uniformly arranged on the stirring shaft and the stirring rods; a feeding hole is formed in one side of the outer wall of the stirring tank, a liquid inlet is formed in the other side; and a discharge hole is formed in the bottom of the stirring tank. The paper product raw material stirring speed can be effectively increased.

Owner:蚌埠大美印务有限公司

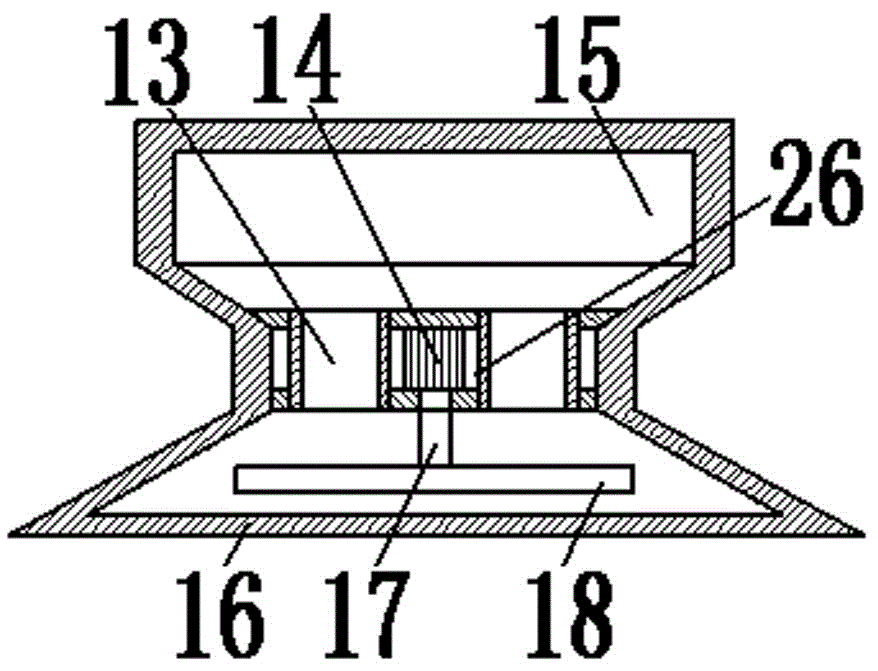

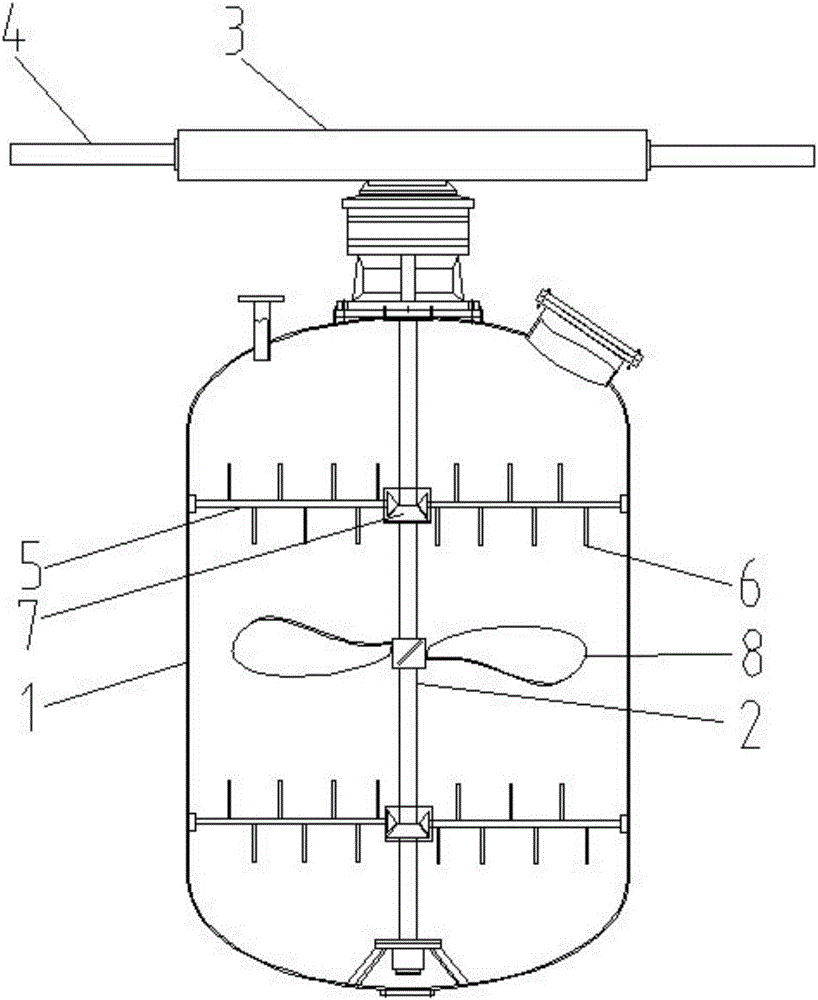

Chemical agitating vessel capable of spreading materials uniformly

InactiveCN106390812AIncrease stirring speedTake advantage ofRotary stirring mixersTransportation and packagingRaw materialExhaust gas

The invention discloses a chemical agitating vessel capable of spreading materials uniformly, comprising a base, wherein an agitating tank is arranged at the top of the base; an agitating device and a motor cavity are arranged in the agitating tank; a support plate is arranged at the top of the agitating tank; a feeding device and an exhaust gas discharge pipe are arranged at the top of the support plate; the feeding device is arranged on the center line of the support plate, and consists of a feeding hopper, a feeding pipe, a second driving motor, a protection cavity, a connecting shaft, a discharging hopper and a material spreading paddle; and the agitating device consists of an agitating shaft, a scraping plate, a vertical rod, an ejector rod, a through hole, a top spring and an agitating paddle. The chemical agitating vessel disclosed by the invention is simple in structure, reasonable in design, and convenient in use; the setting of the feeding device can uniformly spread chemical raw materials into the agitating tank during feeding, thereby greatly increasing the agitating rate; and the setting of the agitating device not only can agitate the chemical raw materials but also can scrape away residues on the inner wall of the agitating tank, so that the chemical raw materials can be fully utilized.

Owner:方渊铭

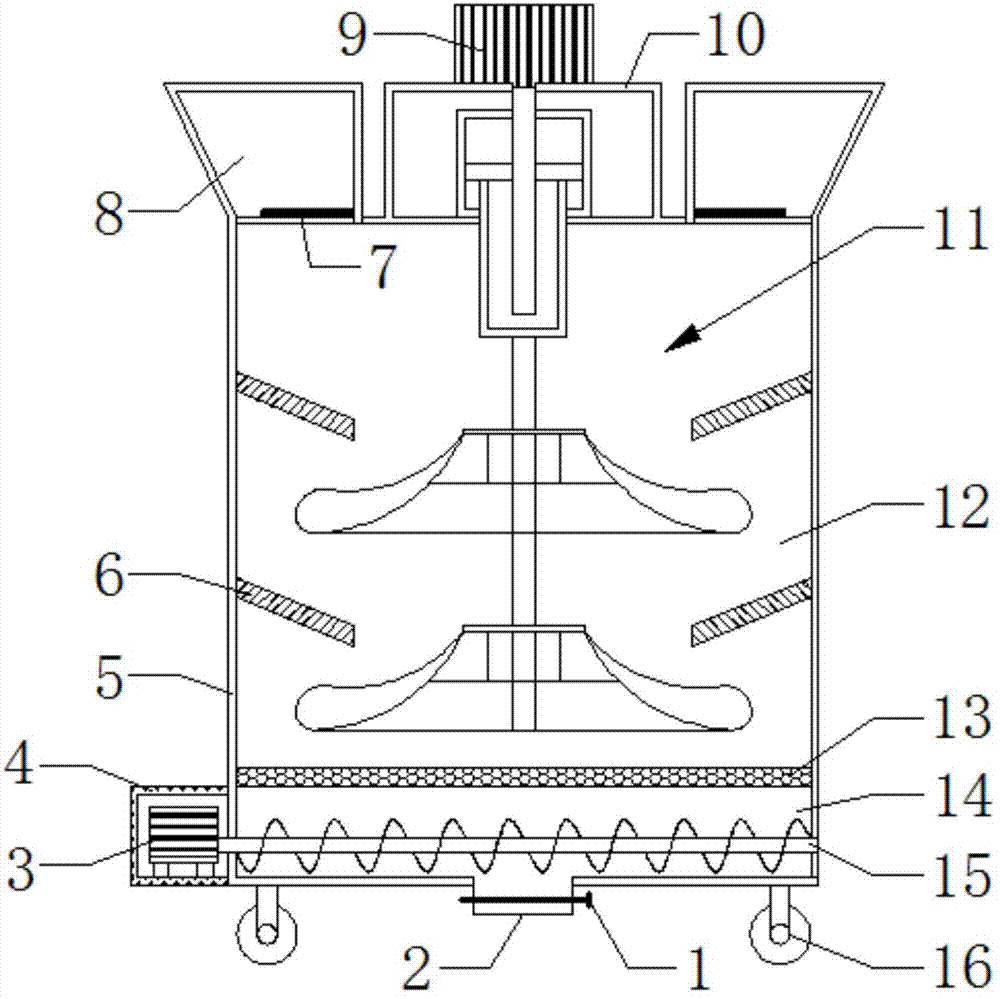

Material mixing device for civil engineering

The invention discloses a mixing and batching device for civil engineering, which comprises a box body, a screw mixer and a vertical mixer. A coarse mixing box is arranged at the inner upper end of the box body, and a fine mixing box is arranged at the lower end of the box body, wherein The screw mixer is fixedly connected to the inside of the fine mixing box, a first stirring motor is fixedly connected to one end surface of the fine mixing box, the lower end of the fine mixing box is provided with a discharge pipe, and the vertical mixer is fixed Connected inside the rough mixing box, the vertical mixer includes a stirring impeller, a stirring shaft and a screw, a feeding funnel is fixedly connected on both sides of the upper end of the box, and the two groups of feeding funnels are fixedly connected. There is a second stirring motor. The mixing and batching device for civil engineering realizes the use of mixing and batching by being provided with a box body, a screw mixer and a vertical mixer, and has high use value.

Owner:FUNAN GAOFUXING INTELLIGENT TECH CO LTD

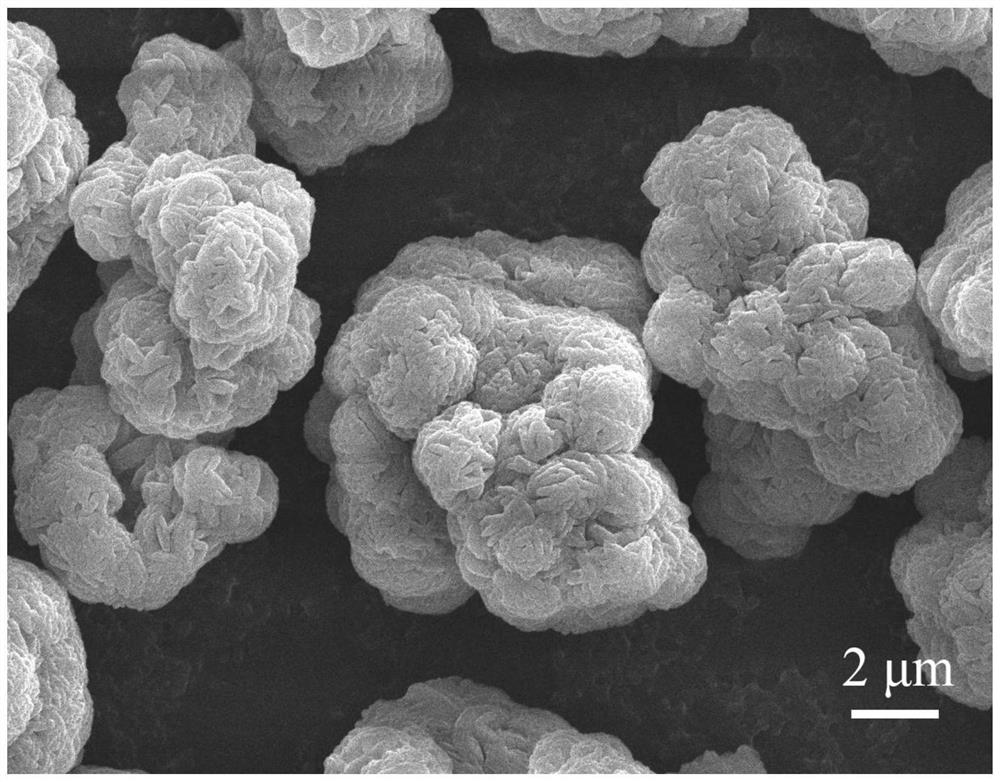

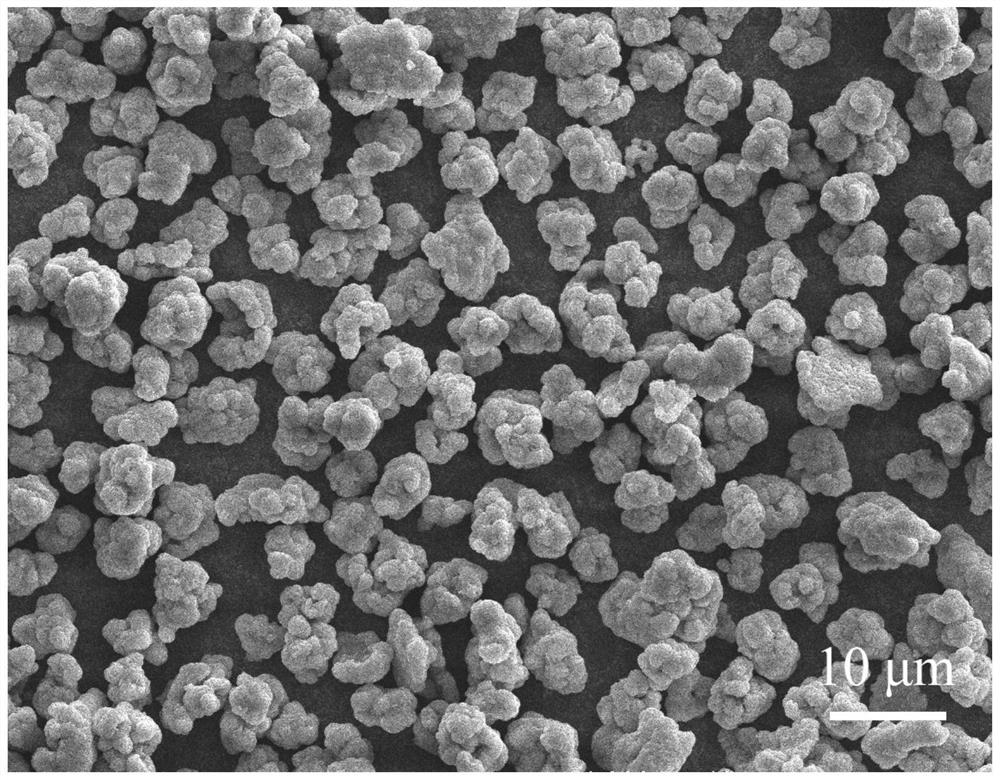

Preparation method of high-tap-density iron phosphate material

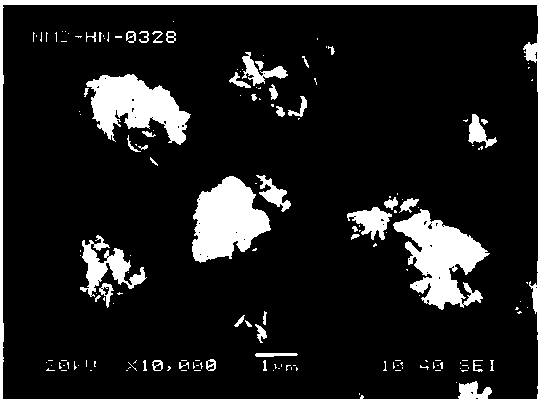

InactiveCN112573496AIncreased chance of collisionStable reunionCell electrodesSecondary cellsHigh concentrationPhysical chemistry

The invention discloses a preparation method of a high-tap-density iron phosphate material. The preparation method comprises the following steps: S1, quickly reacting a high-concentration iron sourcesolution with a high-concentration phosphorus source solution to obtain an iron phosphate seed crystal; and S2, slowly adding a low-concentration iron source solution and a low-concentration phosphorus source solution at a constant speed to realize growth of iron phosphate crystals so as to obtain the high-tap-density iron phosphate material. According to the method, the seed crystal reaction andthe crystallization reaction of iron phosphate are effectively separated, and the sphere-like micron-sized iron phosphate particles are successfully prepared. According to the spheroidic large-particle iron phosphate, primary particles are closely agglomerated, secondary particles are uniform in size, and extremely high tap density (larger than 1.05 g / cm<3>) is shown.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

Method for preparing high-activity high-efficiency polyethylene catalyst

The invention relates to a method for preparing a high-activity high-efficiency polyethylene catalyst for high-density polyethylene production by a tank slurry method, which is characterized by: dispersing magnesium ethylate serving as a carrier in a C6 to C13 straight-chain paraffin serving as an organic solvent and adding titanium tetrachloride which is a transition metal compound under conditions of a temperature of 50 to 180 DEG C and a stirring speed of 10 to 1,000rpm, wherein the mixing weight ratio of the magnesium ethylate to the titanium tetrachloride of 0.1 to 99.0 percent; after thereaction finishes, performing filtration, washing and pre-activation; and improving the technical index of the activity of the catalyst to 58*10<4>gPE / gTi and 3.1*10<4>gPE / gTi. The method adopts highrotating speed to obtain a big shearing force and reduces the particle size of the prepared catalyst to 1 to 2mum.

Owner:PETROCHINA CO LTD

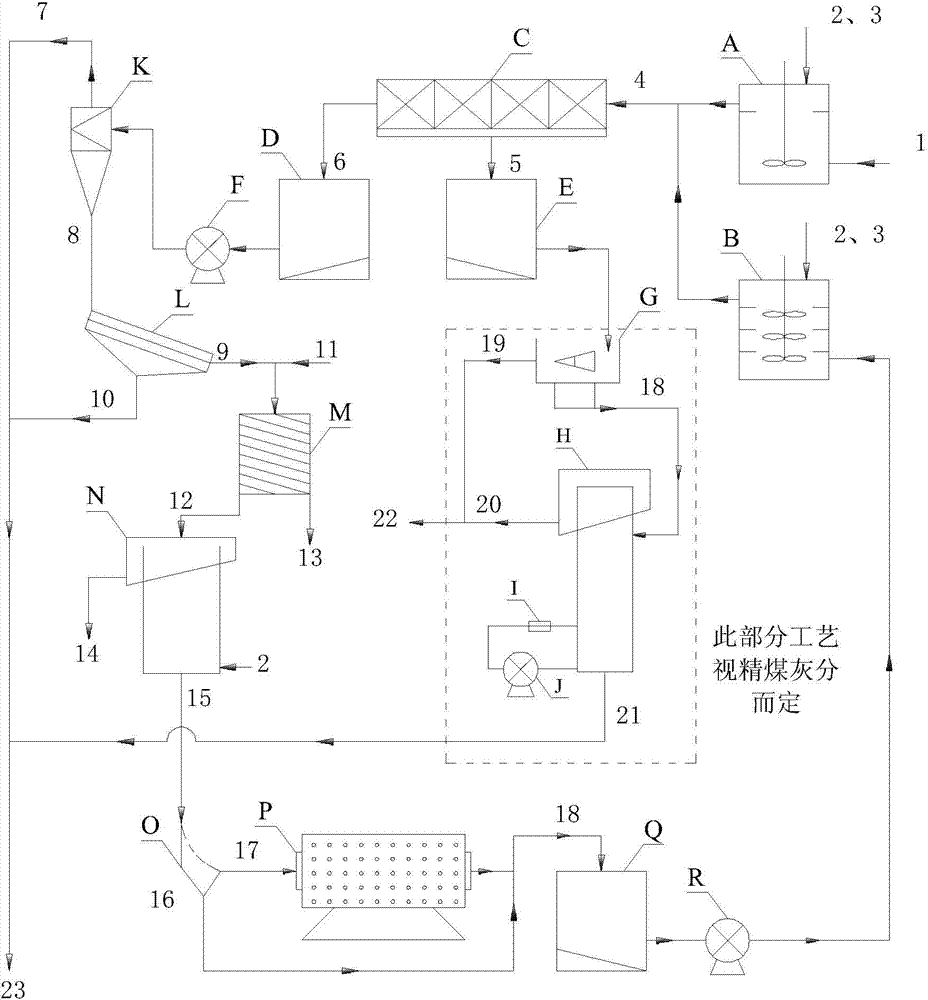

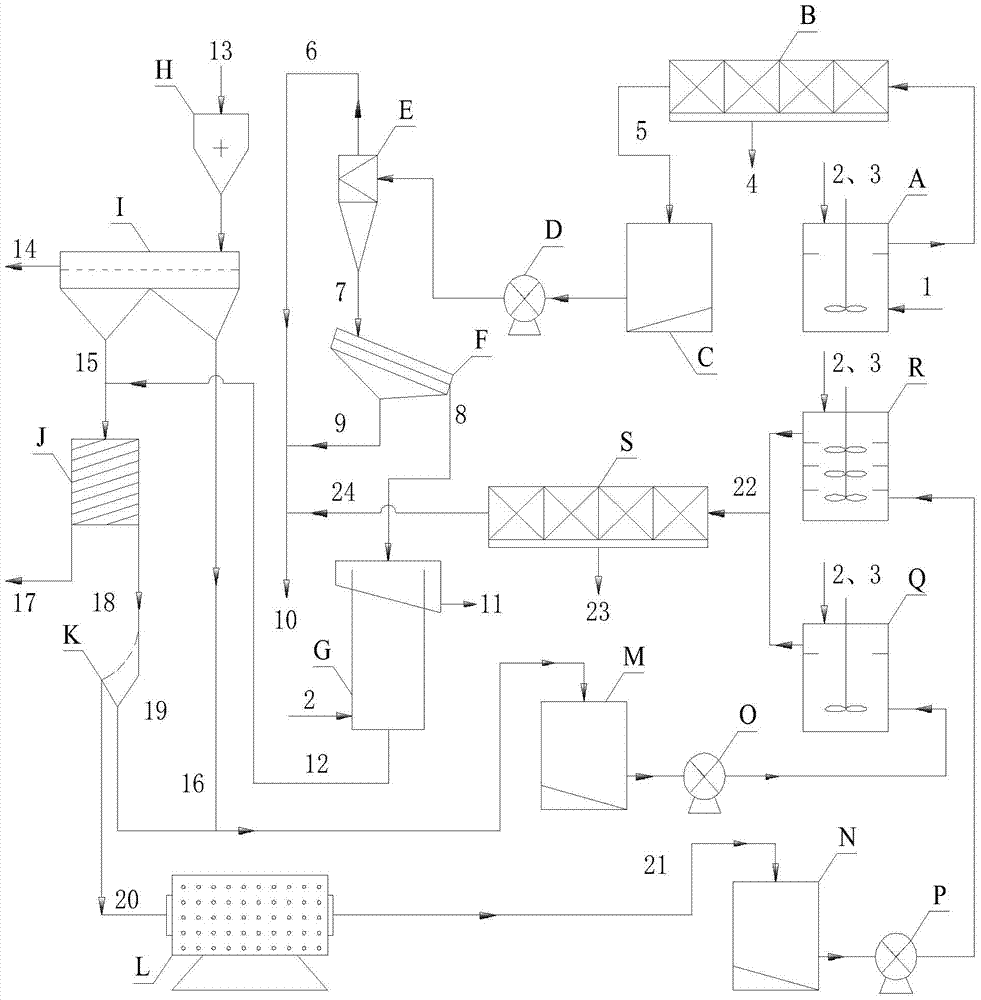

Coking middling coal dms-flotation combined separation process

The invention discloses a coking middling coal dms-flotation combined separation process, and belongs to the technical field of coking middling coal separation. The process comprises the steps of 1, primary size mixing flotation operation, 2, hierarchical dewatering operation, 3, crushing and screening operation, 4, coarse slime separation operation, 5, desliming operation, 6, ore grinding dissociation operation, 7, secondary size mixing operation and 8, secondary flotation operation. The coking middling coal dms-flotation combined separation process is simple in procedure, small in investment, low in energy consumption, little in operation cost, high in separation efficiency and remarkable in economic benefit.

Owner:CHINA UNIV OF MINING & TECH

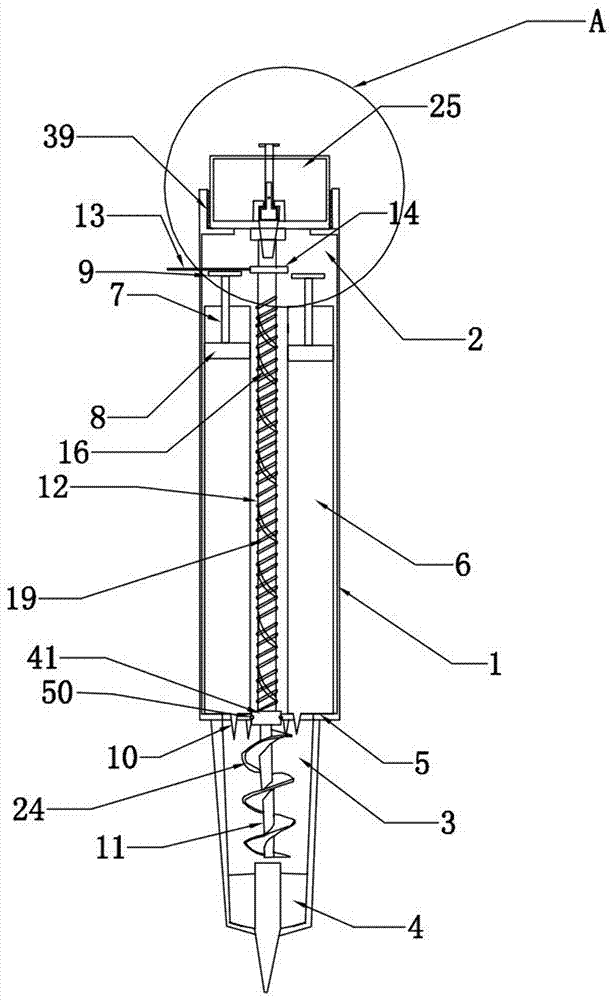

Novel color mixing pen

ActiveCN107097567AFast forwardQuick reverseInk reservoir pensMultiple-point writing implementsPulp and paper industryColor mixing

The invention discloses a novel color mixing pen which comprises a shell. A containing cavity is formed in the shell and comprises a color storage cavity, a color mixing cavity and an output cavity. Four color storage pipes are mounted in the color storage cavity. Pigment different in color is mounted in the color storage pipes and extruded into the color mixing cavity through pistons. A color mixing assembly is mounted in the color mixing cavity and comprises a stirring rod arranged in the color mixing cavity and a stretching-out rod extending upwards from the stirring rod. An adjusting rod repeatedly slides downwards in a straight-strip-shaped rotary fit groove formed in the shell, an integrally-formed ring sleeve of the adjusting rod is driven to slide in a spiral sliding groove of the stretching-out rod, then the stretching-out rod and the stirring rod connected with the lower end of the stretching-out rod are rotated, and a reset spring connected to the stretching-out rod in a sleeving manner enables the stirring rod to rotate in a reciprocating manner; and the stirring rate is greatly increased, and more labor is saved.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

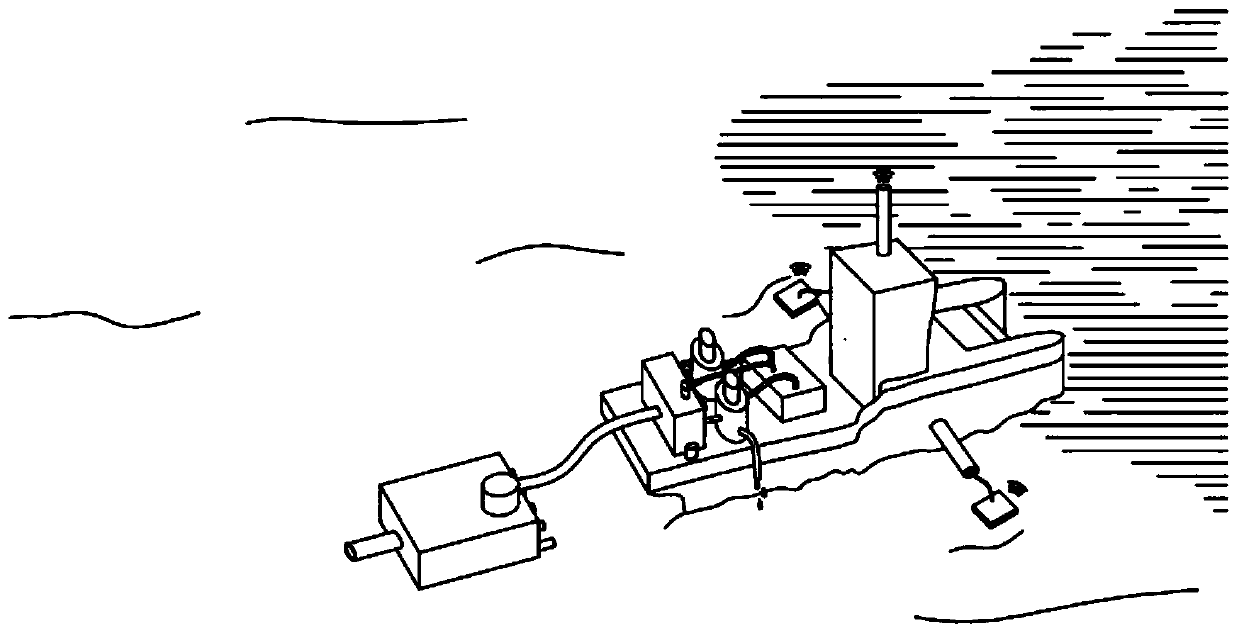

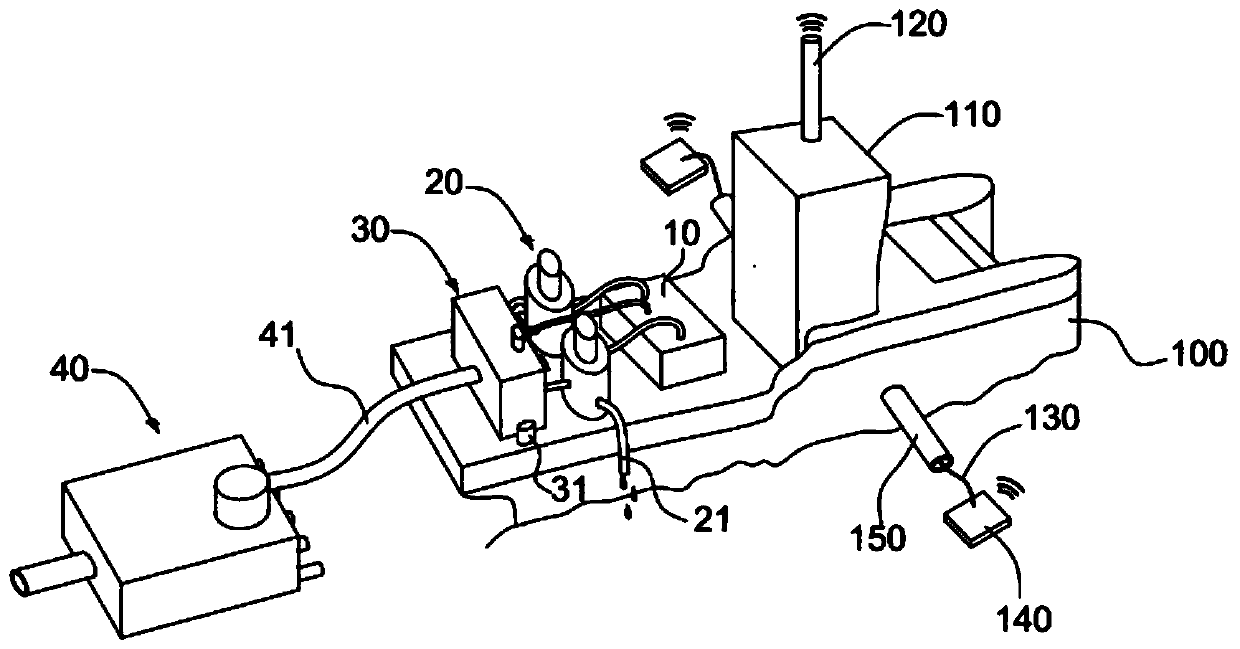

Marine oil spill clearing and recovering device

ActiveCN110422290AEasy to separateIncrease stirring speedWater cleaningWaterborne vesselsFuel tankOil spill

The invention discloses a marine oil spill clearing and recovering device, and belongs to the technical field of marine oil spill pollution treatment. The device comprises a ship body, wherein the twosides of the ship body are fixedly connected with first fixing rods, the end portions of the first fixing rods are connected with monitoring assemblies arranged in water through cable bodies, and themonitoring assemblies are in wireless connection with a processor on the ship body; and the ship body is fixedly provided with an oil collecting tank, a third oil filtering tank and a second oil filtering box, wherein the oil collecting tank is connected with the third oil filtering tank through a first oil discharge pipe, the third oil filtering tank is connected with the second oil filtering tank through a second connecting pipe, and the second oil filtering tank is connected with a first oil filtering tank arranged on the water surface of the rear side of the stern of the ship body througha first connecting pipe. According to the marine oil spill clearing and recovering device, the drift direction of oil films can be effectively detected, so that the sea surface and the oil films areseparated, thus avoiding the sea surface from forming the oil films with a certain coverage range and reducing petroleum leakage sea area pollution and influence on creatures; and in addition, the water content rate of recovered crude oil can be reduced through multi-stage treatment.

Owner:ZHEJIANG OCEAN UNIV

Construction site efficient concrete mixing device

InactiveCN107984623AEasy to changeStir wellCement mixing apparatusControl apparatusEngineeringElectric control

The invention provides a construction site efficient concrete mixing device. The construction site efficient concrete mixing device comprises a device body and an electric control box; a discharge port is formed in one side of the device body; a feed port is formed in the other side of the device body; a storage box is arranged on one side of the feed port; a mixing cylinder is arranged on the surface of the device body; a mixing cylinder inner wall is arranged in the mixing cylinder; a first mixing auxiliary device is arranged on the surface of the mixing cylinder inner wall; a base is arranged at the bottom end of the first mixing auxiliary device; an arc direction changer is arranged at the top end of the base; and a second mixing auxiliary device is arranged on one side of the first mixing auxiliary device. The first mixing auxiliary device and the second mixing auxiliary device are totally the same, but are opposite in direction; and the first mixing auxiliary device and the second mixing auxiliary device are connected end to end to conveniently change the self-weight advancement direction of materials in the mixing cylinder, so that the materials are mixed more sufficiently and quickly, and the mixing speed of the device body is accelerated.

Owner:潘春亮

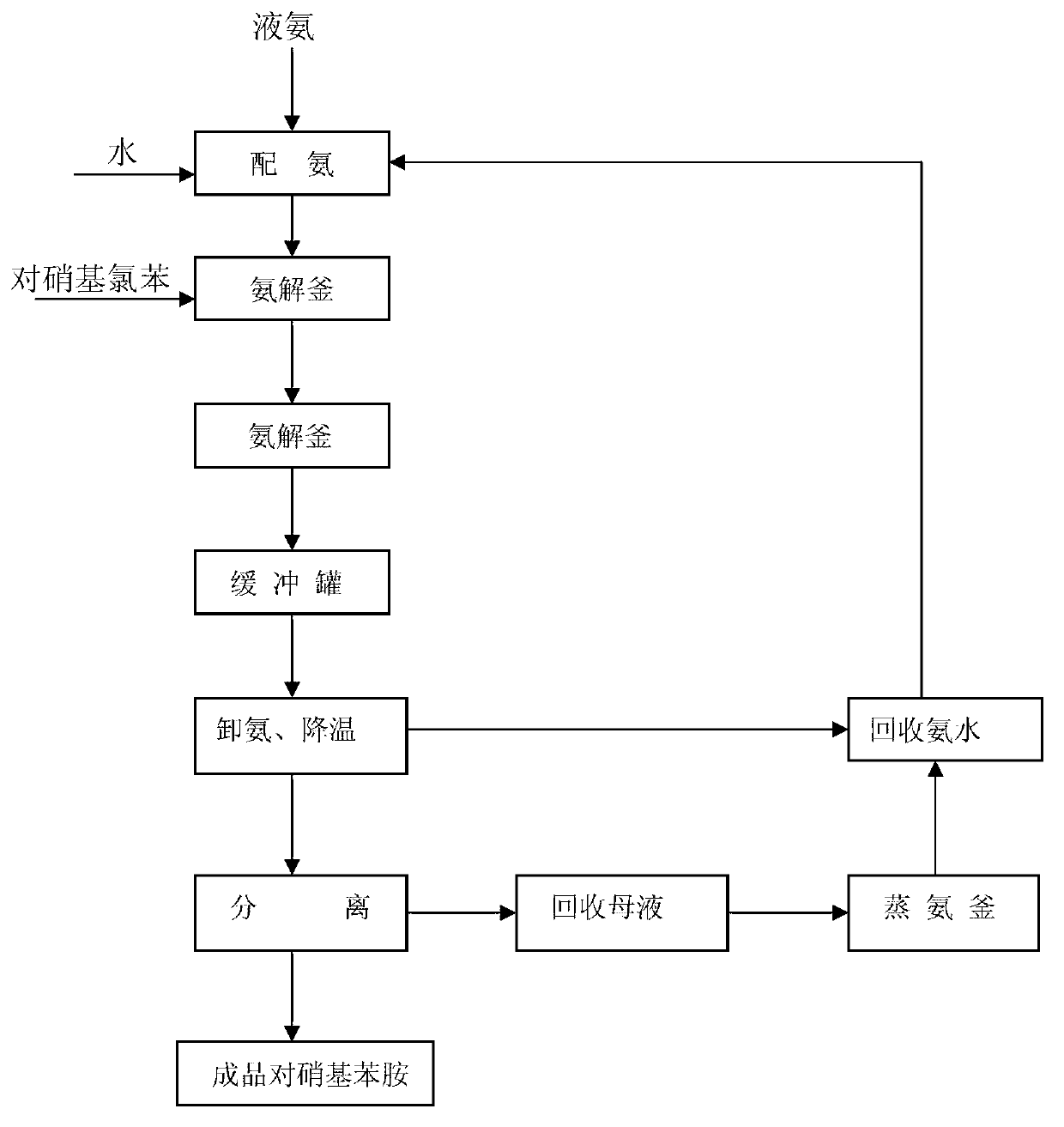

Method for continuous production of paranitroaniline by series-connected kettles

ActiveCN103130655AIncreased chance of collisionGuaranteed pressureOrganic compound preparationAmino compound preparationP-NitroanilineHigh pressure

The invention provides a method for continuous production of paranitroaniline by series-connected kettles. The method comprises the following steps of: adding ammonia water with mass percentage concentration of 20%-50% to two or more than two high-pressure ammonolysis kettles which are connected in series, stopping charging when ammonia water in each ammonolysis kettle accounts for 50% of the volume of the kettle, slowly starting the stirring of the ammonolysis kettle till the speed of the ammonolysis kettle rises to 200-600 r / m, then adding p-nitrchlorobenzene and ammonia water according to a molar ratio of 1: (2-10) to the first high-pressure ammonolysis kettle connected in series for carrying out continuous ammonolysis reaction when the temperature of each ammonolysis kettle is heated to 120-200 DEG C and the pressure of each ammonolysis kettle is increased to 3-9.5MPa, enabling materials reacted in the last ammonolysis kettle to enter a buffering tank for buffering, then entering a pressure relief cooling kettle for pressure relief and temperature reduction, separating the cooled materials to obtain a solid material, and drying to obtain paranitroaniline. The method has the advantages of being capable of improving the working efficiency and reducing the labor intensity and simultaneously solving the problems of unstable quality, potential safety hazards and the like caused by manual operation.

Owner:绍兴齐越化工科技有限公司

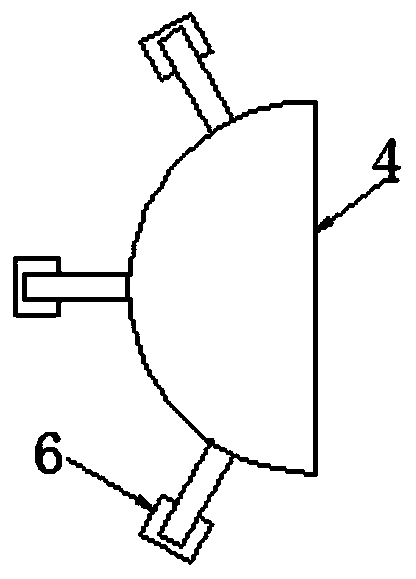

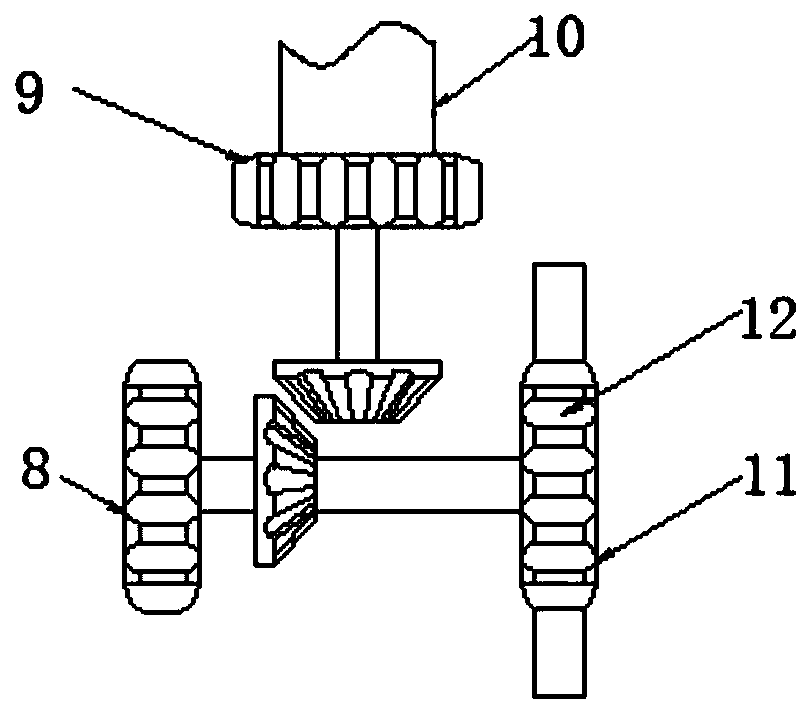

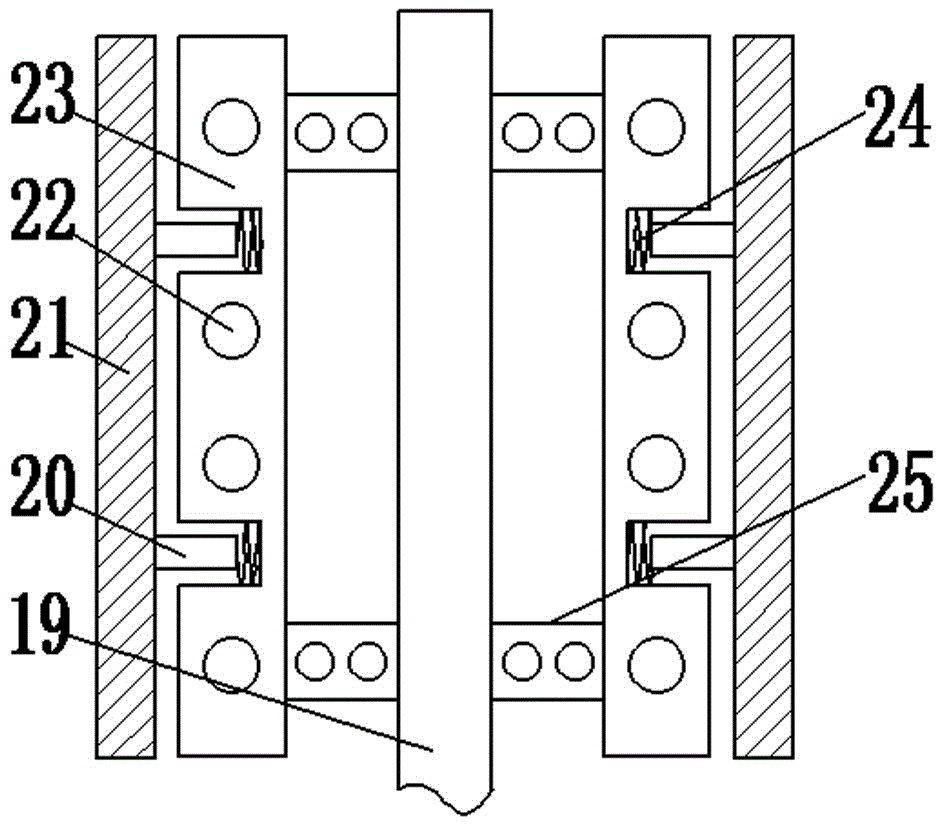

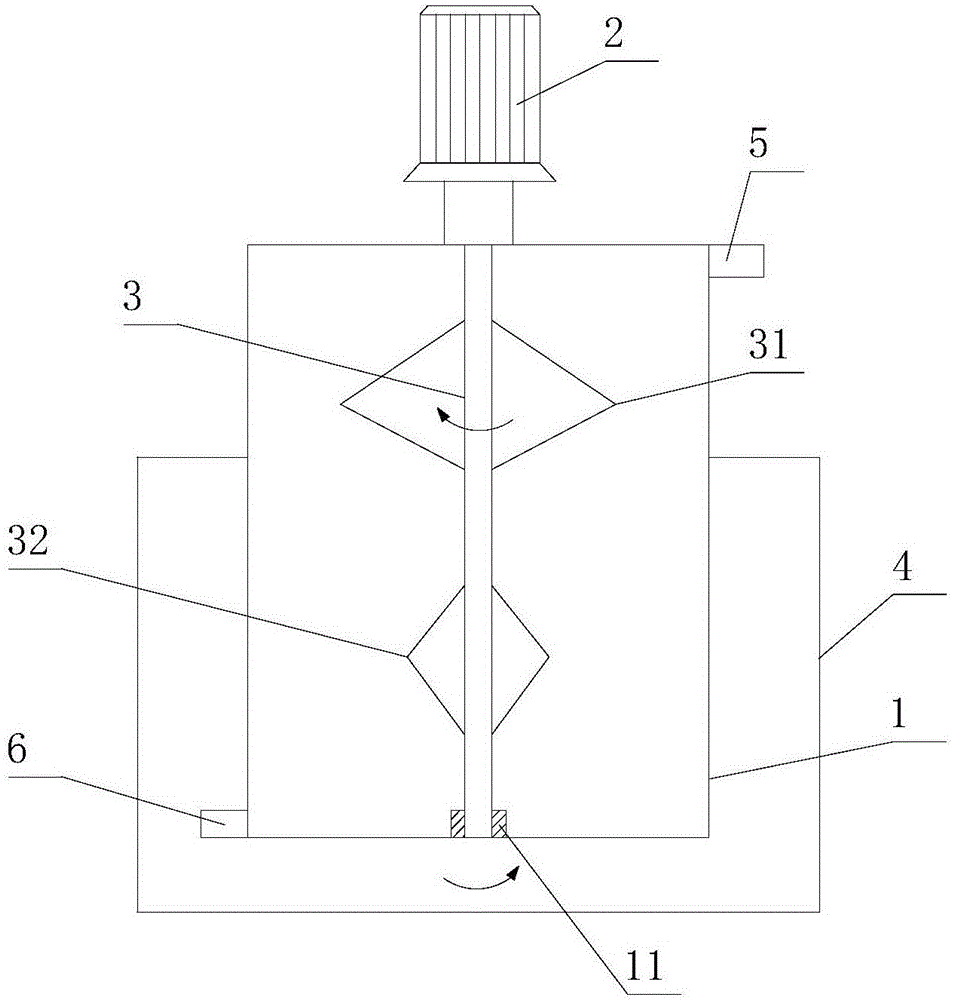

Multidirectional stirring equipment

InactiveCN105771732AIncrease contact timeSimple structureRotary stirring mixersTransportation and packagingImpellerContact time

The invention discloses multidirectional stirring equipment.A stirring shaft perpendicularly goes deeply into a stirring tank body from the top of the stirring tank body, and is driven to rotate by a driving device, the upper end, stretching out of one end of the stirring tank body, of the stirring shaft is connected with a rack in a rack box through a gear, two oil cylinders are connected with the two ends of the rack respectively, two sets of fixing and stirring components are distributed on the stirring shaft, each fixing and stirring component comprises two stirring rods symmetrically arranged on the stirring shaft, a plurality of stirring blades are installed on each stirring rod, one end of each stirring rod is fixed to the stirring shaft through a bevel gear set, and the other end of each stirring rod is installed on a bearing pedestal on the inner wall of the stirring tank body.The multidirectional stirring equipment is simple in structure, materials can be stirred in multiple directions through the rotating stirring rods with the combination of a stirring impeller, the contact time of different materials is further prolonged by means of the back and forth reciprocating stirring mode, the stirring speed is increased, the stirring effect is improved, and the production efficiency is improved; the stirring shaft rotates under driving of the oil cylinders and the rack box, so that the energy consumption is low, and the multidirectional stirring equipment is safe to use.

Owner:XUZHOU BEIER ELECTRIC CO LTD

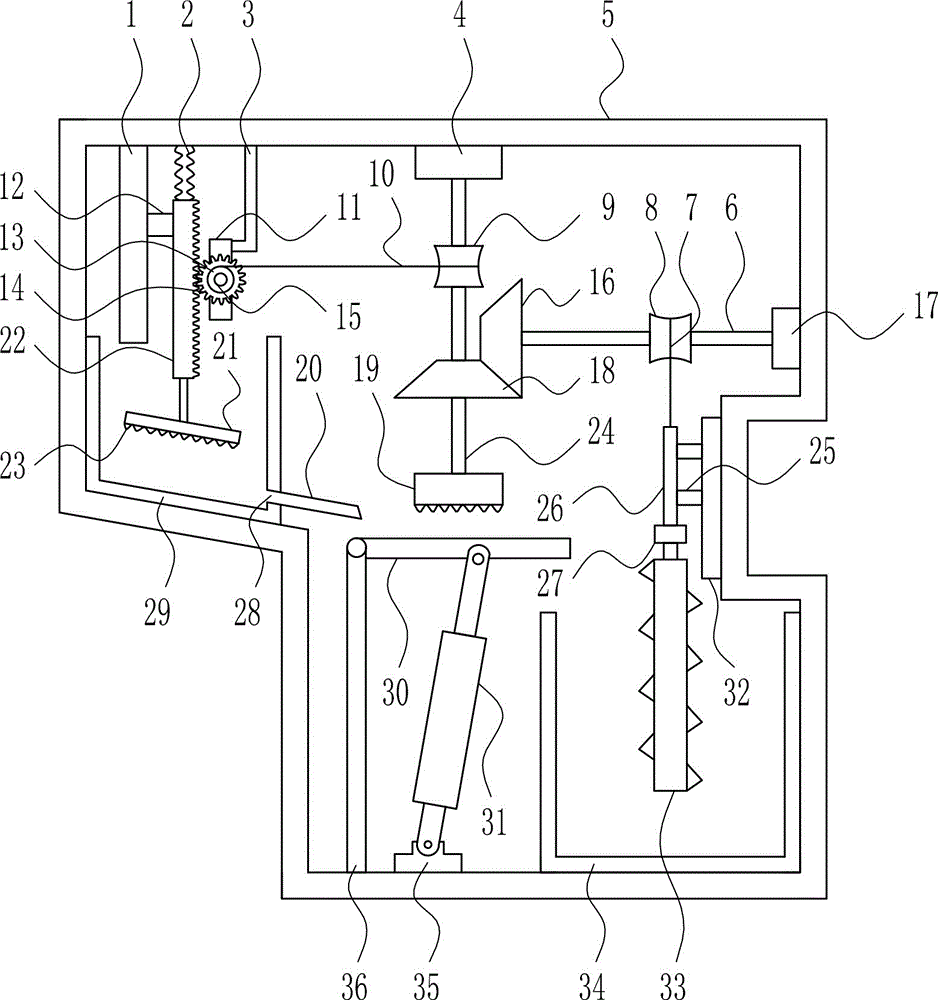

Multifunctional recycling apparatus for building waste

InactiveCN106431045AAvoid litteringIncrease stirring speedSolid waste managementCement mixing apparatusEngineeringConductor Coil

The invention relates to a recycling apparatus, in particular to a multifunctional recycling apparatus for building waste; the technical problem to be solved herein is to provide a multifunctional recycling apparatus for building waste having many functions. In order to solve the above technical problem, the invention provides such a multifunctional recycling apparatus for building waste, comprising a first slide rail, a spring, a first link, a first rotary motor, a support, a second rotary shaft, a second pull wire, a third winding wheel, a second winding wheel, a first pull wire and the like; the first slide rail is provided with a first slider, the right end of the first slider is provided with a rack, the upper end of the rack is connected to the lower end of the spring, the lower end of the rack is connected to breaking stone, and the bottom of the breaking stone is provided with first small tapered teeth. The multifunctional recycling apparatus for building waste has many functions; people may place belongings in a receiving basket provided herein such that littering of articles is prevented.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

Novel agitating-crushing integrated agitation tank for cement

ActiveCN109278188AReduce resistanceIncrease stirring speedCement mixing apparatusGrain treatmentsEngineeringCement

The invention discloses a novel agitating-crushing integrated agitation tank for cement, belonging to the field of cement agitating tanks. In use of the novel agitating-crushing integrated agitation tank, hydraulic lifting rods are started to drive a supporting substrate to move downward after materials are added, so an integral agitating and crushing device is driven to move downwardly into the agitation tank and performs crushing and agitating operation; at the time, rotating rods are driven to move downwardly, so transmission rods are driven to move downwardly, and thus, the agitation tankis maintained in a horizontal state and kept stable and thus better performs crushing and agitating operation; when a material needs to be guided out after completion of agitating or crushing, the hydraulic lifting rods are started to drive the integral agitating and crushing device to move up, so the rotating rods are driven to move up, the transmission rods are driven to move up, and the agitation tank is driven to incline by a certain angle, which allows the materials to be led out from a concrete outlet.

Owner:芜湖腾飞信息科技有限公司

Mixing system for producing color masterbatch

The invention discloses a mixing system for producing color masterbatch. The mixing system comprises a frame. A mixing box is fixedly connected to the middle of the inner wall of the top end of the frame. A hopper-shaped feeding pipe is arranged at the top end of the side wall of one side of the mixing box. A cylinder is fixedly connected to the inner wall of the top end of the mixing box. A support plate is fixedly connected to a piston rod of the cylinder. A sliding rail is fixedly connected to the bottom end of the support plate. A sliding block is slidably connected to the sliding rail. Afirst connecting plate is vertically and fixedly connected to one end of the support plate. A first groove is formed in the side wall of the side, close to the sliding block, of the first connecting plate. A first telescopic rod is arranged in the first groove. The first telescopic rod is fixedly connected with the side wall of the sliding block. A rotary motor is fixedly connected to the bottom end of the sliding block. The output end of the rotary motor is fixedly connected with a rotary shaft. By the adoption of the mixing system, the color masterbatch raw materials can be quickly mixed inan all-round manner, the raw materials left on the surfaces of mixing plates can be removed automatically after mixing is completed, and the mixing speed and quality are increased greatly.

Owner:滁州华美塑业有限公司

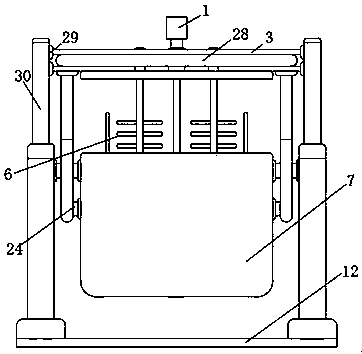

Integrated punching-type automatic dough kneading bowl

InactiveCN109362822ASpeed up kneading efficiencyEven by forceMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsPunchingMotor drive

The invention discloses an integrated punching-type automatic dough kneading bowl. The integrated punching-type automatic dough kneading bowl comprises a frame, a flour blending assembly and a dough kneading assembly; a dough kneading bowl is arranged on the frame; the flour blending assembly and the dough kneading assembly are arranged around the dough kneading bowl; the flour blending assembly comprises a first installation seat, a first driving motor and a stirring rod; the first driving motor is installed above the dough kneading bowl via the first installation seat; the stirring rod is connected onto an output shaft of the first driving motor; the dough kneading bowl is in rotating connection with the frame; a third driving motor is arranged on the frame, and is used for driving the dough kneading bowl to rotate; the dough kneading bowl and the first driving motor are in eccentric arrangement; the dough kneading assembly comprises a push pressure bar, a linkage drive rod and a second driving motor; and the second driving motor drives the linkage drive rod so as to drive the push pressure bar to perform beating and pushing actions inside the dough kneading bowl. Thus, stirringis performed on dough while beating is carried out by a dough kneading machine, so that, multi-direction kneading is synchronously performed so as to accelerate dough kneading efficiency; moreover, the dough kneading machine highly simulates processes of artificial dough kneading, so that, dough is fully kneaded with labor input reduced.

Owner:WENZHOU UNIV OUJIANG COLLEGE

Reaction chamber for producing aluminum oxide

InactiveCN107200341AImprove cooling effectRapid coolingAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium hydroxideAgricultural engineering

The invention discloses a reaction chamber for alumina production, which comprises a reaction chamber outside the reaction chamber and a precipitation cylinder. The upper end of the reaction chamber outside the reaction chamber is provided with an equipment compartment, and a first drive motor is installed inside the equipment compartment. The front end of a drive motor is connected with a reducer, and the front end of the reducer is equipped with a connecting shaft, the outside of the connecting shaft is connected with a stirring blade, and the outer surface of the stirring blade is provided with a fan hole, and the inside of the fan hole is A rotating shaft is connected, and fan blades are installed on the outer surface of the rotating shaft, a bearing is arranged on the inner bottom surface of the precipitation cylinder, and a placement plate is installed on the lower end of the precipitation cylinder. The reaction chamber for alumina production is designed with sound-absorbing boards, reducers, stirring blades, bearings, refrigerators, gear plates, rollers, damping plates and pneumatic devices, which can absorb noise, increase the speed of precipitation, and reduce The cooling time can prevent the balance in the precipitation cylinder from being broken, causing the aluminum hydroxide crystals to dissolve into the solution again.

Owner:青海新高科材料研究院有限公司

Bacillus subtilis and application thereof in production of gamma-polyglutamic acid

ActiveCN110904012AHigh viscosityIncrease dissolved oxygen concentrationBacteriaMicroorganism based processesBiotechnologyGlutamic acid product

The invention discloses bacillus subtilis and an application of bacillus subtilis in production of gamma-polyglutamic acid. Bacillus subtilis NT-11 (Bacillus subtilis) CCTCC NO: M 2019383 is taken asa fermentation strain, and glutamine is taken as a precursor. pH, stirring speed, tank pressure and ventilation quantity are regulated and controlled in the middle stage of fermentation, so that morebeneficial conditions are provided for the fermentation process. Thallus growth is promoted, and ultrahigh molecular weight gamma-polyglutamic acid is synthesized. The fermentation broth is subjectedto alcohol precipitation, redissolution, centrifugation, filtration, alcohol precipitation again, drying and other extraction processes to obtain an ultrahigh molecular weight gamma-polyglutamic acidproduct, and the molecular weight of the ultrahigh molecular weight gamma-polyglutamic acid product is detected to be 3000 to 6000 kDa. According to the invention, the method is simple in process, easy to operate, low in cost and high in yield; the prepared polyglutamic acid is high in purity, clear in molecular weight, ultrahigh, relatively stable and controllable; and industrial large-scale production can be achieved.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD +1

Method for improving hyaluronic acid volume of production of fermentation production by adding oxygen carrier dodecane

InactiveCN101294181AIncrease productionReduce energy consumptionMicroorganism based processesFermentationDodecaneChemistry

A method for increasing the fermentation production of hyaluronic acid by adding an oxygen carrier of dodecane belongs to the technology field of applying the oxygen carrier to the optimization of the fermentation process. The invention adopts the method of adding the oxygen carrier of dedecane (1-5%, v / v) in a certain concentration to a fermentation broth after 8 hours' fermentation, so as to increase the dissolved oxygen concentration, thereby increasing the production of the hyaluronic acid. When the concentration of the dedecane is 5%, the production of the hyaluronic acid increases from 5.0g / L to 6.0g / L by contrast (no oxygen carrier is added). The method is simple, effective and applicable to the industrial production of the hyaluronic acid and has certain significance in guiding the optimization of other high-viscosity fermentation processes.

Owner:JIANGNAN UNIV

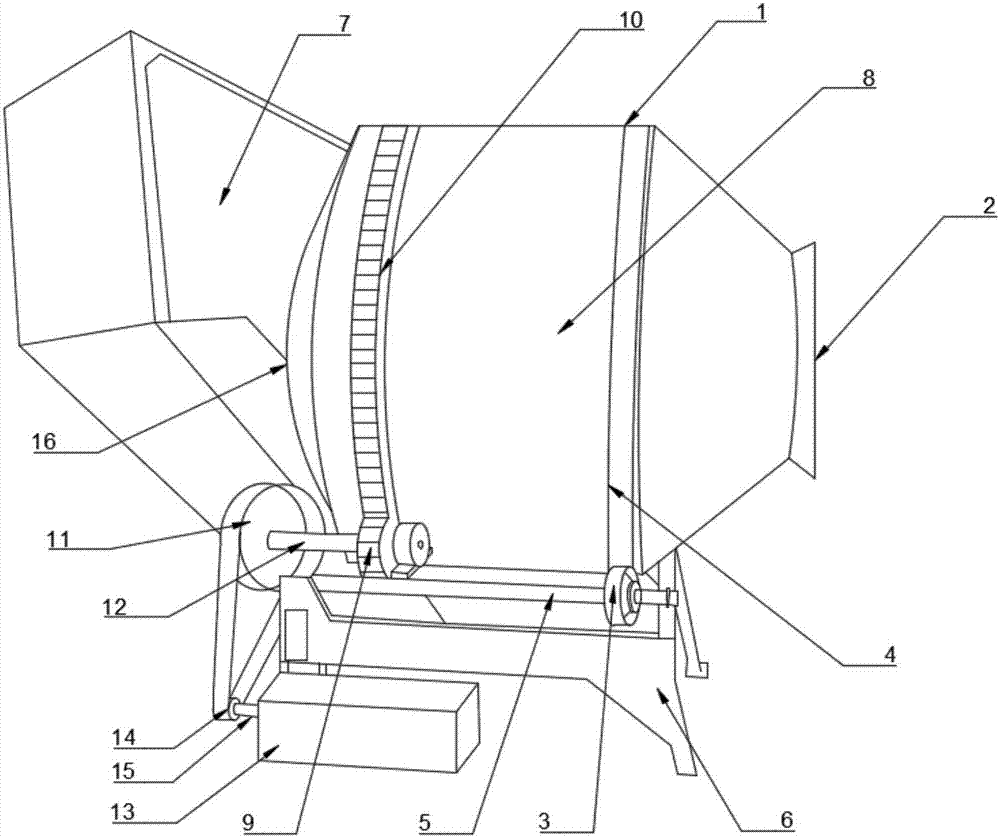

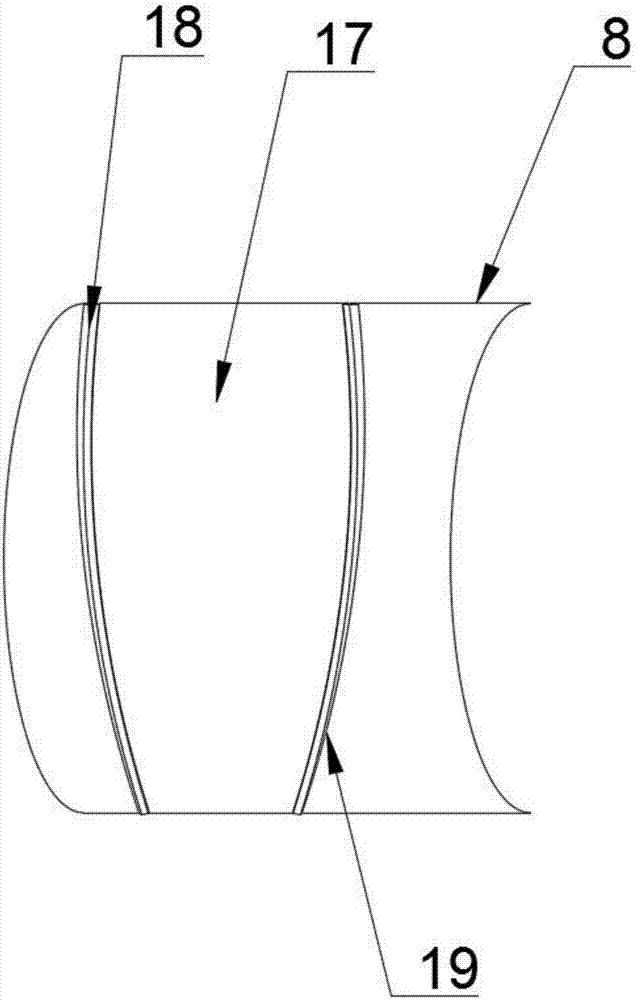

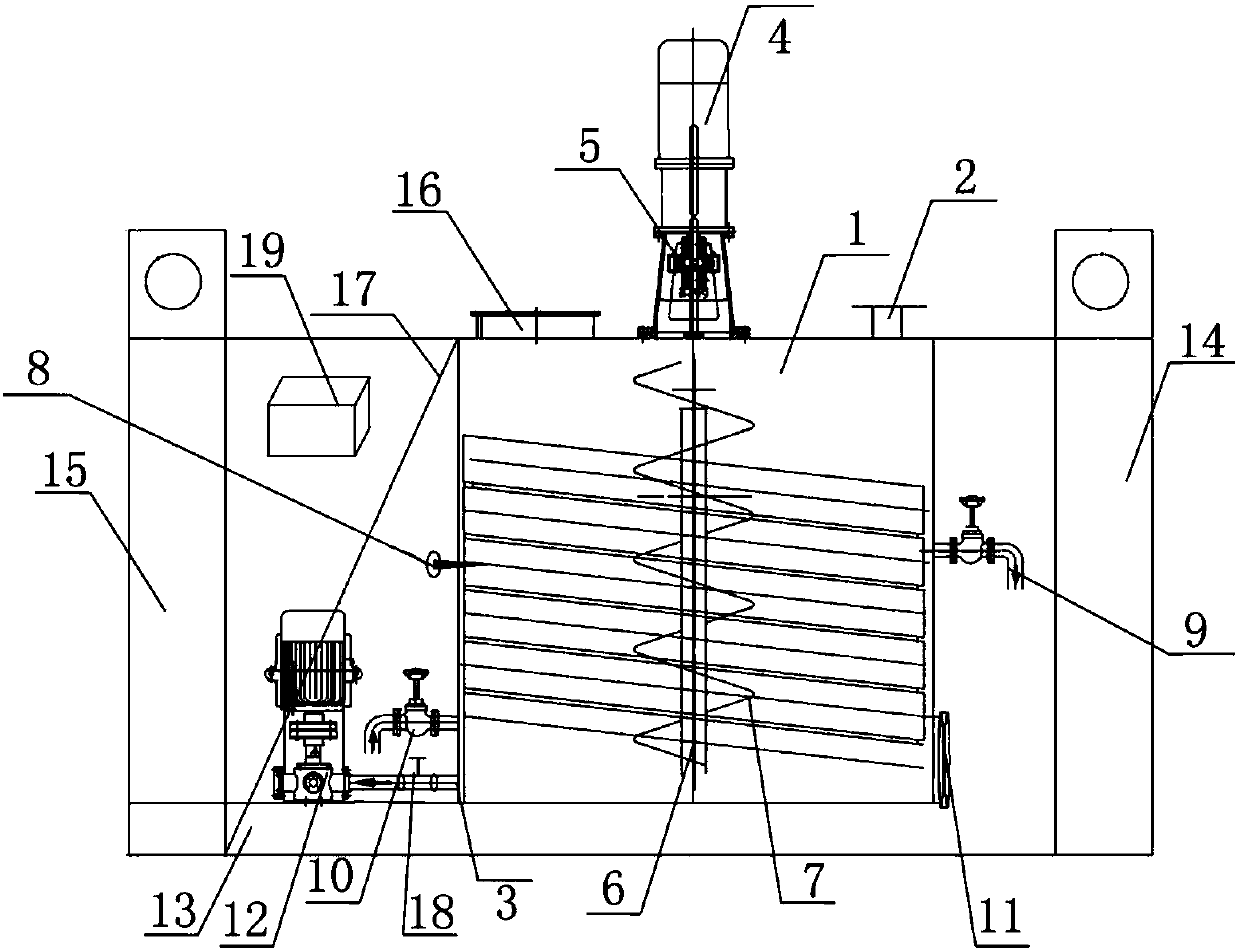

Efficient raw material mixing device for LOW-E glass production

InactiveCN106975403AAvoid spillingPrevent outflowShaking/oscillating/vibrating mixersTransportation and packagingShake upEngineering

The invention relates to a raw material mixing device for glass production. The raw material mixing device comprises a bottom plate, a left side plate, a left bearing seat, a belt, a small pulley, a motor, a large pulley, a first spring, a rotating shaft, a cam, a right side plate, a right bearing seat and a mixing box. The left side of the top of the bottom plate is provided with the left side plate and the right side of the left side plate is provided with the motor and the left bearing seat. The motor is located above the left bearing seat. In stirring, the cam rotates and drives the mixing box to shake up and down. Stirring and shaking are carried out simultaneously so that a material mixing rate is improved.

Owner:安徽万佳节能科技有限公司

Modified asphalt stirring device

PendingCN107670553AIncrease stirring speedImprove mixing uniformityRotary stirring mixersTransportation and packagingBiochemical engineeringReducer

The invention discloses a modified asphalt stirring device which comprises a stirring tank. A feeding port is formed in the top of the stirring tank, a discharging port is formed in the side wall of the bottom of the stirring tank, a stirring motor is arranged in the middle of the top of the stirring tank and connected with a speed reducer, a stirring shaft is connected on a rotating shaft of thespeed reducer and extends into the stirring tank, screw blades are arranged on the stirring shaft, a temperature meter is arranged on the side wall of the stirring tank, a first high-temperature brakevalve and a second high-temperature brake valve are arranged on two opposite side walls of the stirring tank, a access hole is formed in the side wall of the bottom of the stirring tank opposite to the discharging port, and the discharging port is connected with the input end of a finished product conveying pump. By the aid of the high-temperature brake valves, the temperature of the stirring tank can be changed by inputting external heat, mixed and stirred states of asphalt and modifying agents are improved by improving the temperature, stirring of the stirring blades is accelerated, mixed uniformity of the asphalt and the modifying agents are further improved, dead corners in the stirring process are omitted by the aid of the stirring blades, and stirring efficiency and production efficiency are greatly improved.

Owner:湖北正康科技创新有限公司 +1

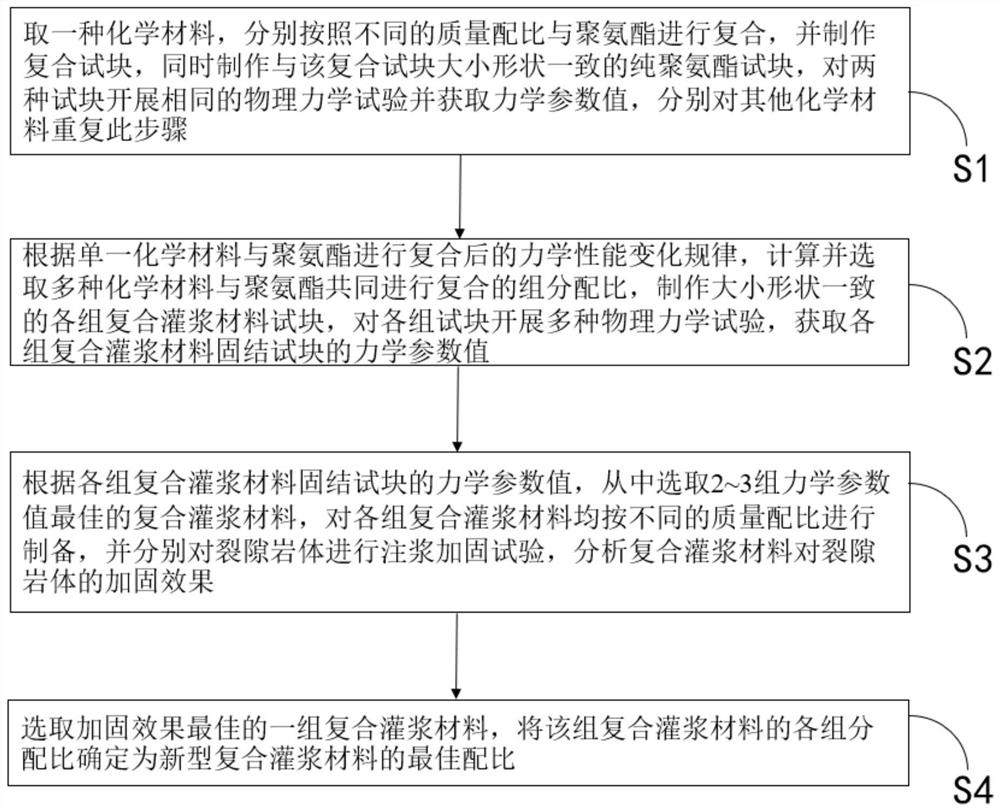

Method for acquiring proportion of composite grouting material for reinforcing fractured rock mass

ActiveCN113640462AEffective reinforcementImprove performanceMaterial analysis using wave/particle radiationPreparing sample for investigationMechanical propertyGrout

The invention provides a method for acquiring the proportion of a composite grouting material for reinforcing fractured rock mass. The method comprises the following steps of compounding a chemical material with polyurethane according to different mass proportions, mastering a mechanical property change rule after each proportion of the chemical material is compounded with polyurethane, selecting a plurality of proper chemical materials and compounding the chemical materials with polyurethane together, researching and developing a plurality of groups of composite grouting materials with different proportions, acquiring mechanical parameter values of the composite grouting materials, adopting the composite grouting materials to carry out grouting reinforcement tests on fractured rock masses, observing the reinforcement effect, selecting a group of composite grouting materials with the best reinforcement effect, and determining the proportion of all the components of the selected group of composite grouting materials as the optimal proportion of the novel composite grouting material. According to the method for acquiring the proportion of the composite grouting material for reinforcing fractured rock mass, the optimal proportion of all the components of the chemical composite grouting material can be obtained, so that the composite grouting material with excellent performance is prepared, and the fractured rock mass is effectively reinforced.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

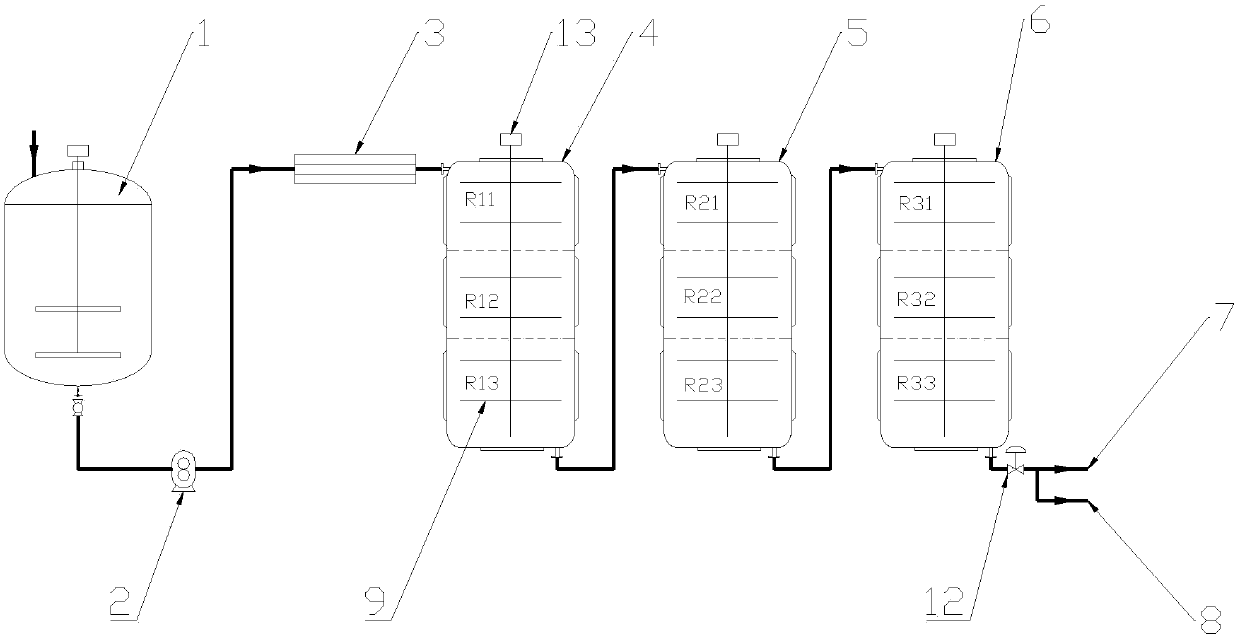

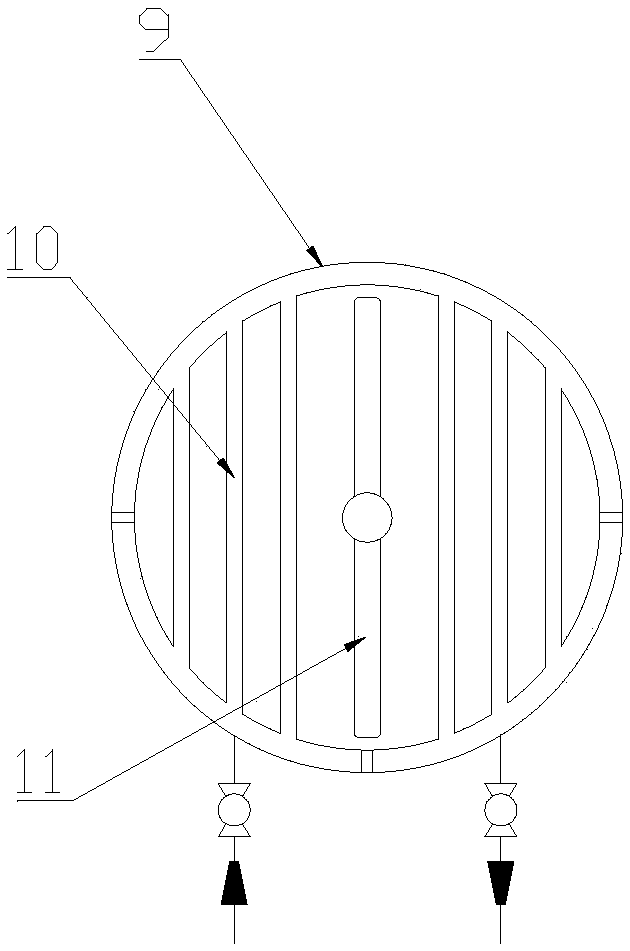

Device for preparing solid acrylic resin and method thereof

PendingCN108671867ARemove in timeIncrease heat transfer areaChemical/physical/physico-chemical stationary reactorsPolymer scienceBulk polymerization

The invention relates to a device for preparing a solid acrylic resin and a method thereof, solving a problem of difficulty of high viscosity conveying, stirring and heat and mass transfer in a continuous bulk polymerization process. The method is based on a process formula, cooperated with a corresponding device, without adding a solvent, mixes acrylic and methacrylic monomers, vinyl monomers andfunctional monomer mixtures in the presence of organic peroxides and molecular weight regulators, through a plurality of plug flow reactors connected in series and independently controlling temperature, and performs copolymerization reaction. An obtained product has uniform color and a small molecular weight distribution.

Owner:BOLIER CHEM YANGZHOU

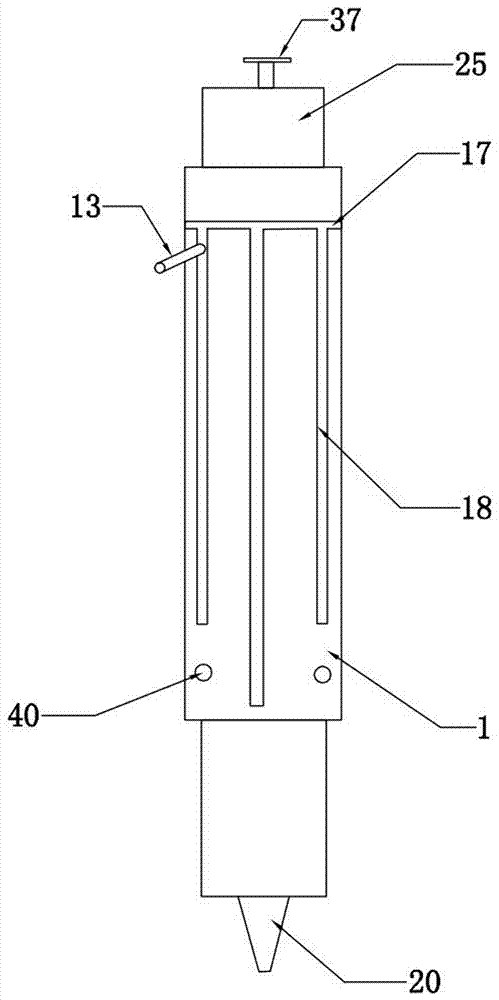

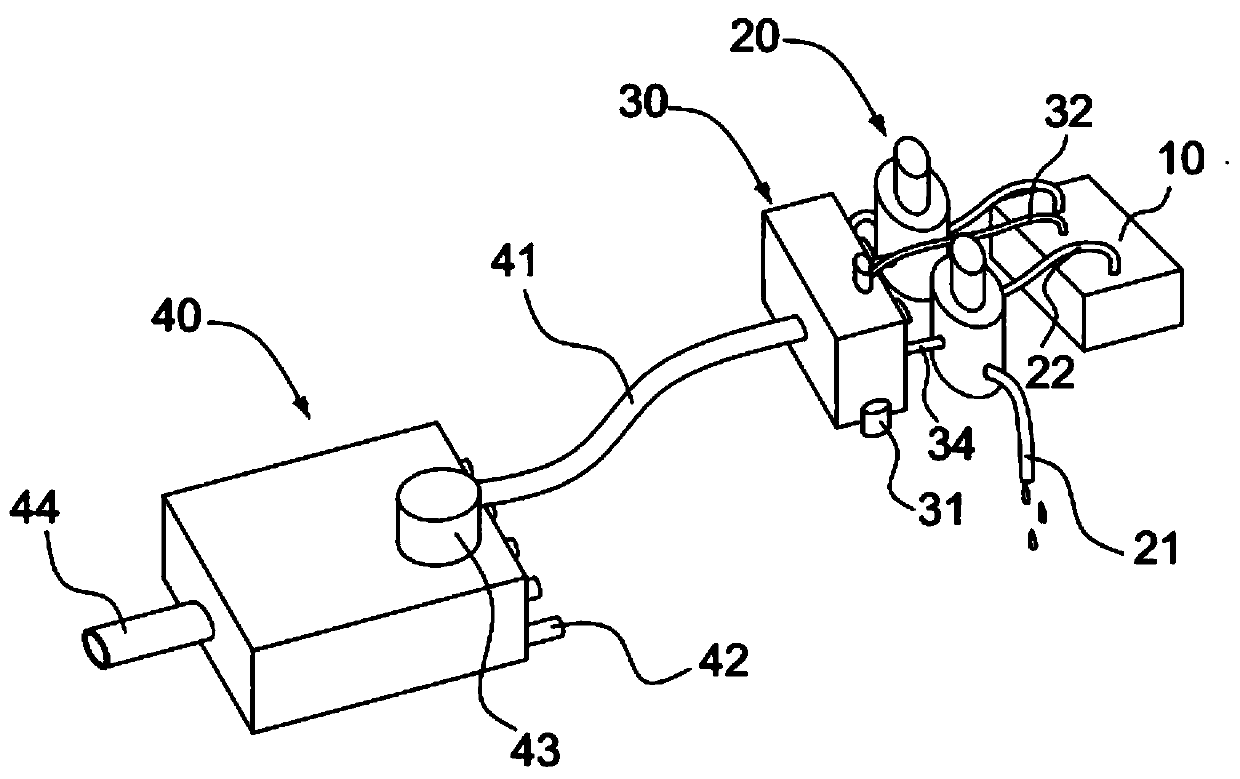

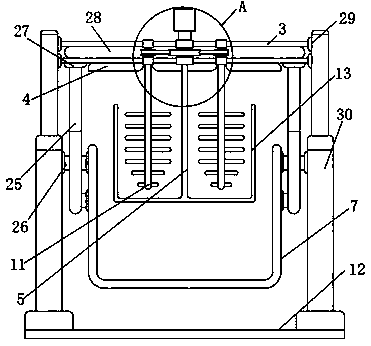

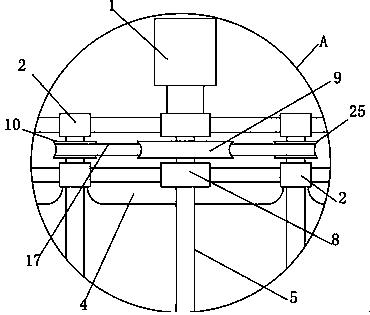

Method and device for culturing edible fungi after inoculation

PendingCN109699401AAvoid risk of carryover to culture flasksImprove cultivation efficiencyMixersCultivating equipmentsBiotechnologyBottle

The invention relates to the technical field of edible fungi culture, particularly relates to a method for culturing edible fungi after inoculation and also relates to a device used in the culture method. The method comprises the following steps of: inoculating solid strain blocks to a culture bottle, stirring and crushing solid strain blocks by using a stirring device, continuing culturing, or after inoculating and growing for a period of time, stirring and crushing solid strain blocks, continuing culturing, or after the culture bottle is well cultured, stirring and crushing by adopting the stirring device before solid strain blocks are inoculated to a next-stage seed tank, and inoculating the seed tank. According to the method and device, the telescopic stirring device is adopted to achieve the purpose of stirring and crushing strain blocks or materials in the culture bottle and preventing strain blocks or materials from being infected by miscellaneous bacteria. The stirring device is convenient to take and place, the operation is convenient, and the problem in the prior art that a stirring paddle cannot be matched with a triangular bottle because the size of the stirring paddleis not proper is solved.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

A kind of white carbon black mixing device

The invention discloses a white carbon black stirring device which comprises a tank body with the hollow interior, wherein a stirring shaft is arranged in the tank body; a plurality of first vanes, which are centrosymmetric about the axis of the stirring shaft, are arranged at the upper section of the stirring shaft; a plurality of second vanes, which are centrosymmetric about the axis of the stirring shaft, are arranged at the lower section of the stirring shaft; the outer diameters of the first vanes are larger than those of the second vanes; a bracket is also arranged outside the tank body; a groove is formed in the bracket; the tank body is rotatably arranged in the groove; a turntable is arranged at the bottom of the groove and drives the tank body to rotate on the bracket; during stirring, the rotation direction of the bracket is opposite to that of the stirring shaft. The white carbon black stirring device is high in stirring efficiency and stable in stirring.

Owner:WUXI HENGCHENG SILICON IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com