Coking middling coal dms-flotation combined separation process

A sorting and flotation technology, which is applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of energy consumption, entrainment, and high-fine mud in tailing coal running and coarse crushing, so as to save crushing energy consumption, High sorting efficiency and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

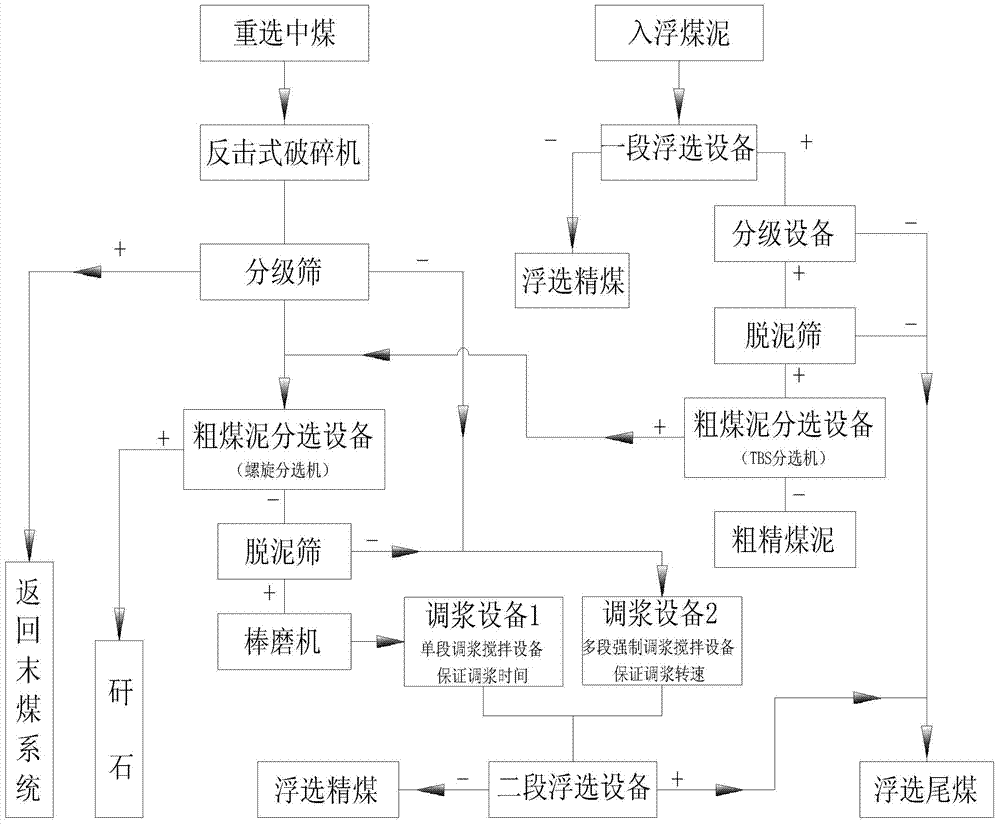

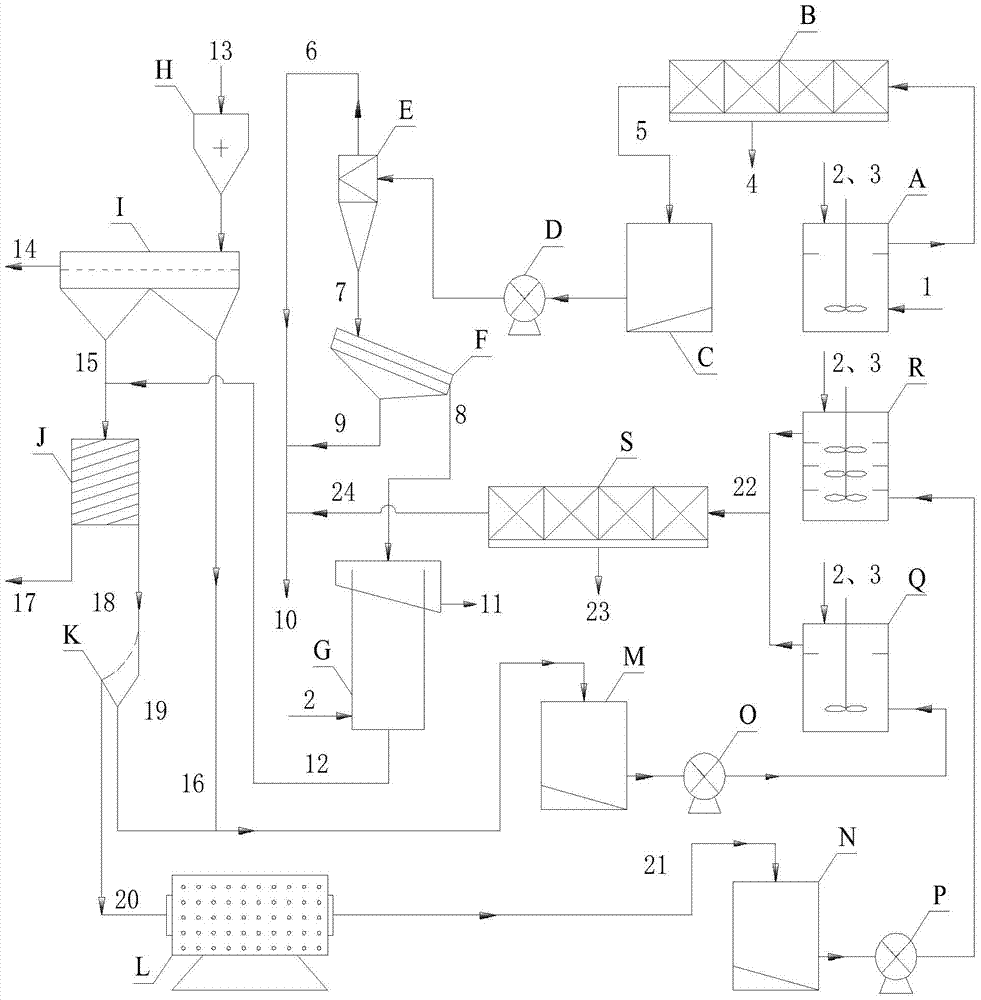

[0038] Example: such as figure 1 Shown, a kind of coking middling coal refloating combined separation process of the present invention. After slurry adjustment, the floating coal slime flows into the first-stage flotation machine for separation to obtain flotation clean coal and tailing coal. The tailing coal of the first stage of flotation is concentrated and dehydrated through the grading cyclone and the desliming screen. The overflow of the grading cyclone and the desliming sieve are used as the flotation tailings together with the subsequent flotation tailings, which are deslimed and dehydrated through the desliming screen. The final coarse coal tailings are fed into the first-stage coarse coal slime separator for gravity separation to obtain coarse fine coal slime and a first-stage heavy product. The crushed coal (including lump medium coal and fine medium coal) is crushed by the impact crusher, and the crushed products are sent to the grading sieve to obtain +2mm coarse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com