Patents

Literature

76 results about "Steam coal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steam coal, also known as thermal coal, is suitable for electric power production. Steam coal is ground into a fine powder that burns quickly at high heats and is used in power plants to heat water in boilers that run steam turbines. It also may be used to provide space heating for homes and businesses.

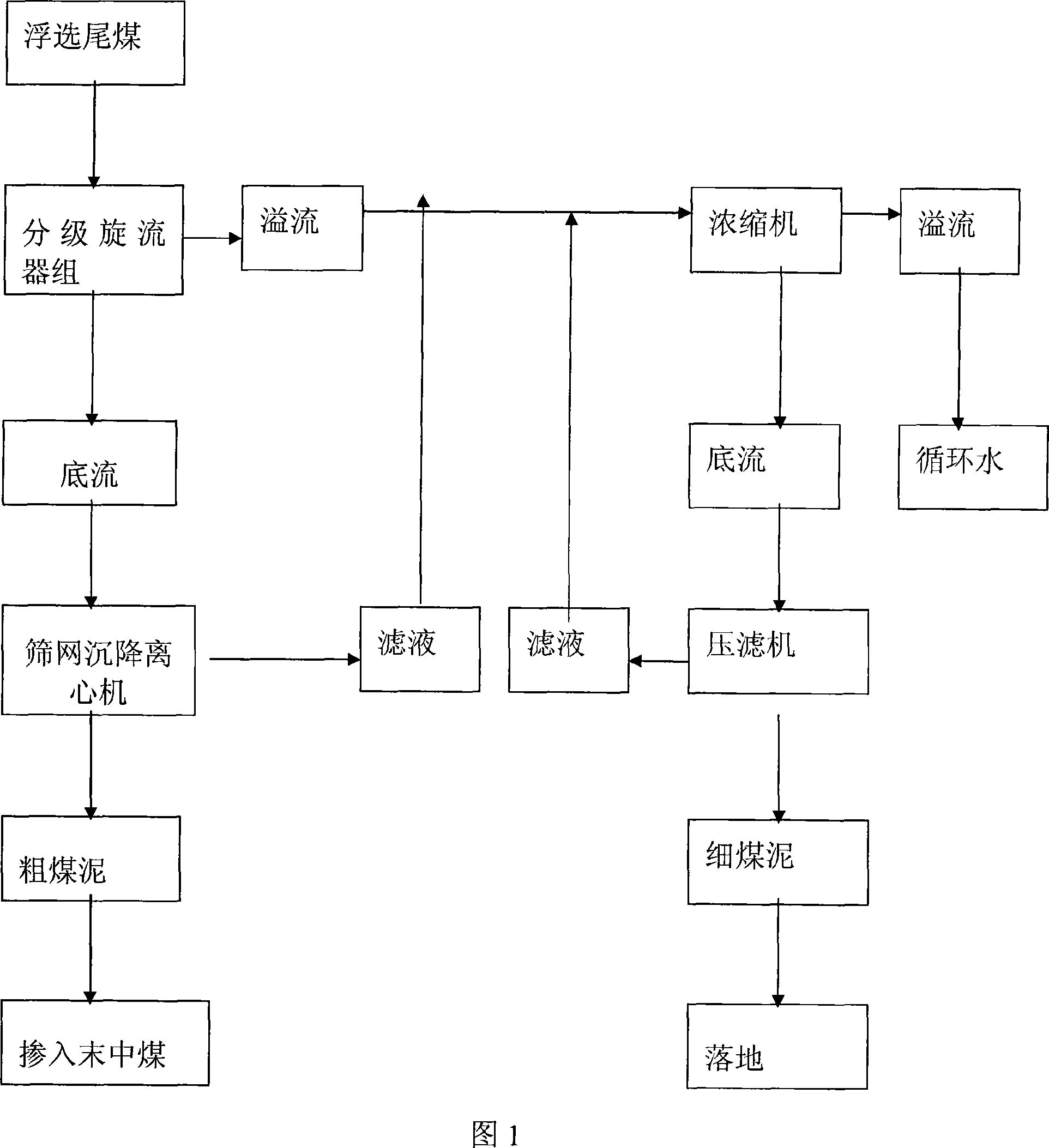

Floating tail-coal graded recovering process

The invention relates to a technology method of flotation tailings classification recovery process, belongs to solid-liquid separation technology area, used to solve maximize recovery of flotation tailings issue. It uses classification Cyclone group to grade flotation tailings, the products moisture after dehydration is 14-18%, the particle size of recovery is 0.045-3mm, it occupy55-60% of floatation tailings quantity; the pressure filter recover fine fuel, the product after dehydration occupy 40-45% of floatation tailings quantity. The invention method filled the flotation tailings bank of use the technology at home and abroad, supplies a low input, high efficiency, simple process, a high degree automation of flotation tailings recovery method, has a simple system, low-moisture products, a bulk materials, can into the coal or other late Medium steam coal advantages. Six months can recover the investment, with good economic and social benefits.

Owner:开滦(集团)有限责任公司煤业分公司

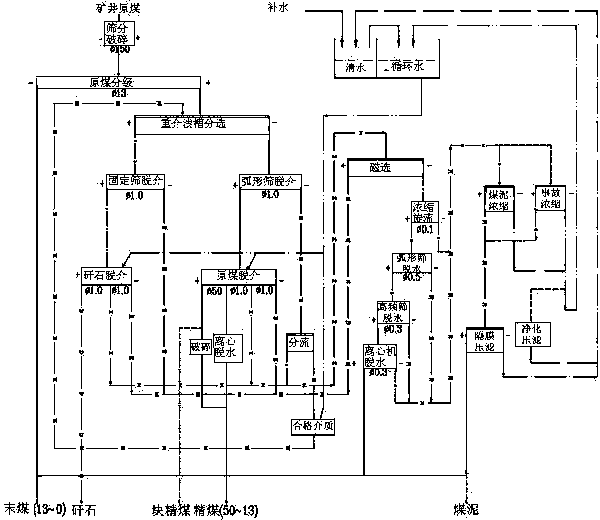

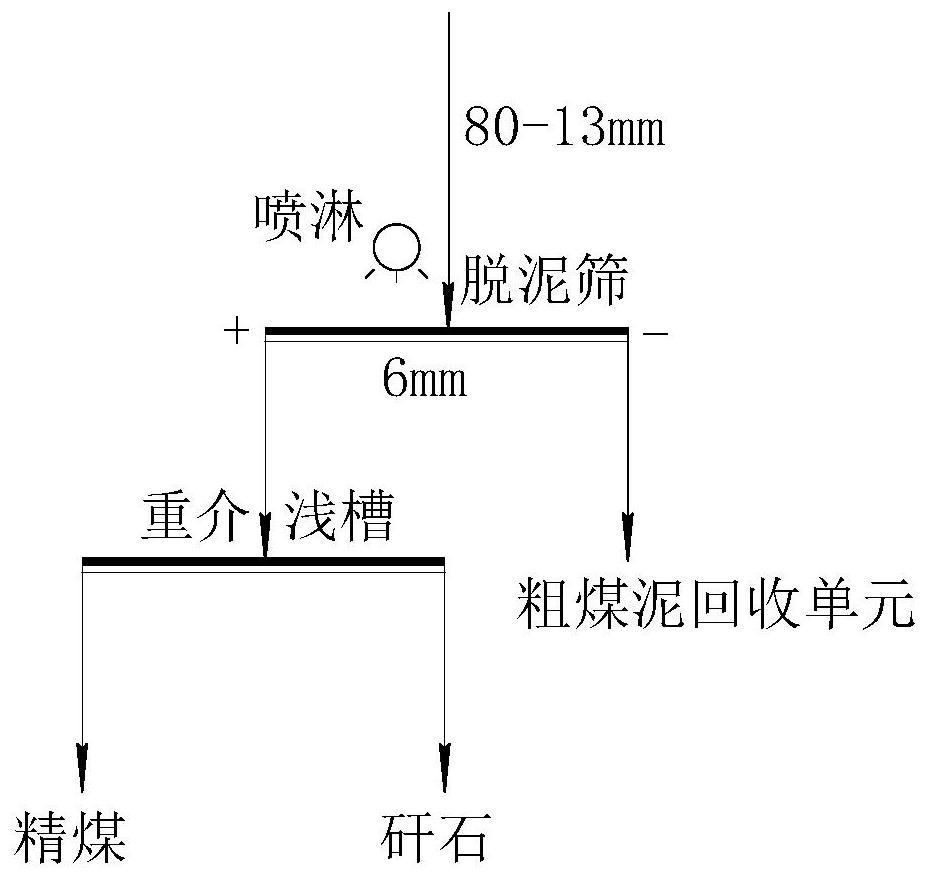

Steam coal washing processing method for easy-to-argillization gangues

The invention belongs to the field of coal dressing of steam coal and particularly relates to a steam coal washing processing method for easy-to-argillization gangues. The steam coal washing processing method for the easy-to-argillization gangues is a coal preparation process which specifically comprises the following steps: carrying out 13-mm dry screening after crushing raw coal and adopting a dense-medium shallow slot to separate coal blocks with the size of 150mm-13mm, wherein powder coal with the size which is less than 13mm is not selected; recycling coarse slime, filter-pressing fine slime and carrying out closed cycle of washing water. The steam coal washing processing method adopts the dry screening so that the argillization of the gangues is reduced to the greatest extent, and the load of a slime water system is relieved; meanwhile, a product is flexible in structure and strong in adaptability and can be adapted to possible changes of coal quality and markets in the future.

Owner:COAL IND JINAN DESIGN & RES

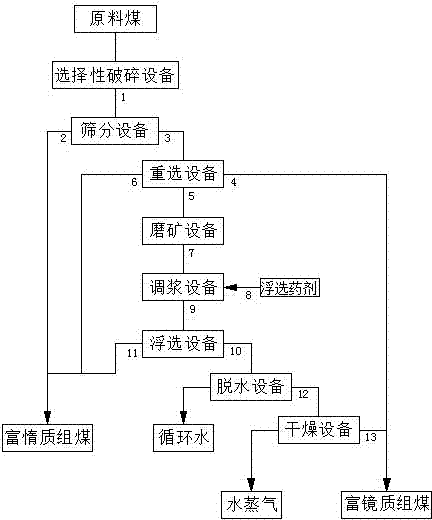

Deep preparation technology of coal for direct coal liquefacation

The invention discloses a deep preparation technology of coal for direct coal liquefacation. Feed coal is selectively crushed and then is sieved with a 0.5 mm particle size to grade; products passing through the sieving are separated through gravity concentration equipment, so as to obtain gravity treated cleaned coal, gravity treated middlings and gravity treated tailings; the gravity treated middlings is ground and fed into size mixing equipment; flotation reagent is added to the size mixing equipment, size mixing is performed, and then products are pumped into flotation equipment to perform separation, so as to obtain flotation cleaned coal and flotation tailings; the flotation cleaned coal is filtered and dried and then mixed with the gravity treated cleaned coal to form rich-vitrinite coal which is served as coal for direct coal liquefacation; and the products of the feed coal not passing through the sieving after crushing and sieving, the gravity treated tailings and the flotation tailings are mixed into rich-inertinite coal which can be served as high-quality steam coal, coal for gasification and the like. The technology is based on coal petrography maceral, adopts the differences in terms of densities and surface natures of different coal petrography maceral, and adopts the method of the combination of gravity concentration and flotation, so as to realize the large-scale separation and enrichment of coal maceral, increase the hydrogen-to-carbon ratio of coal for liquefacation, greatly improve the oil yield of direct liquefacation of coal, and obviously increase the economic benefit of direct liquefacation of coal.

Owner:CHINA UNIV OF MINING & TECH

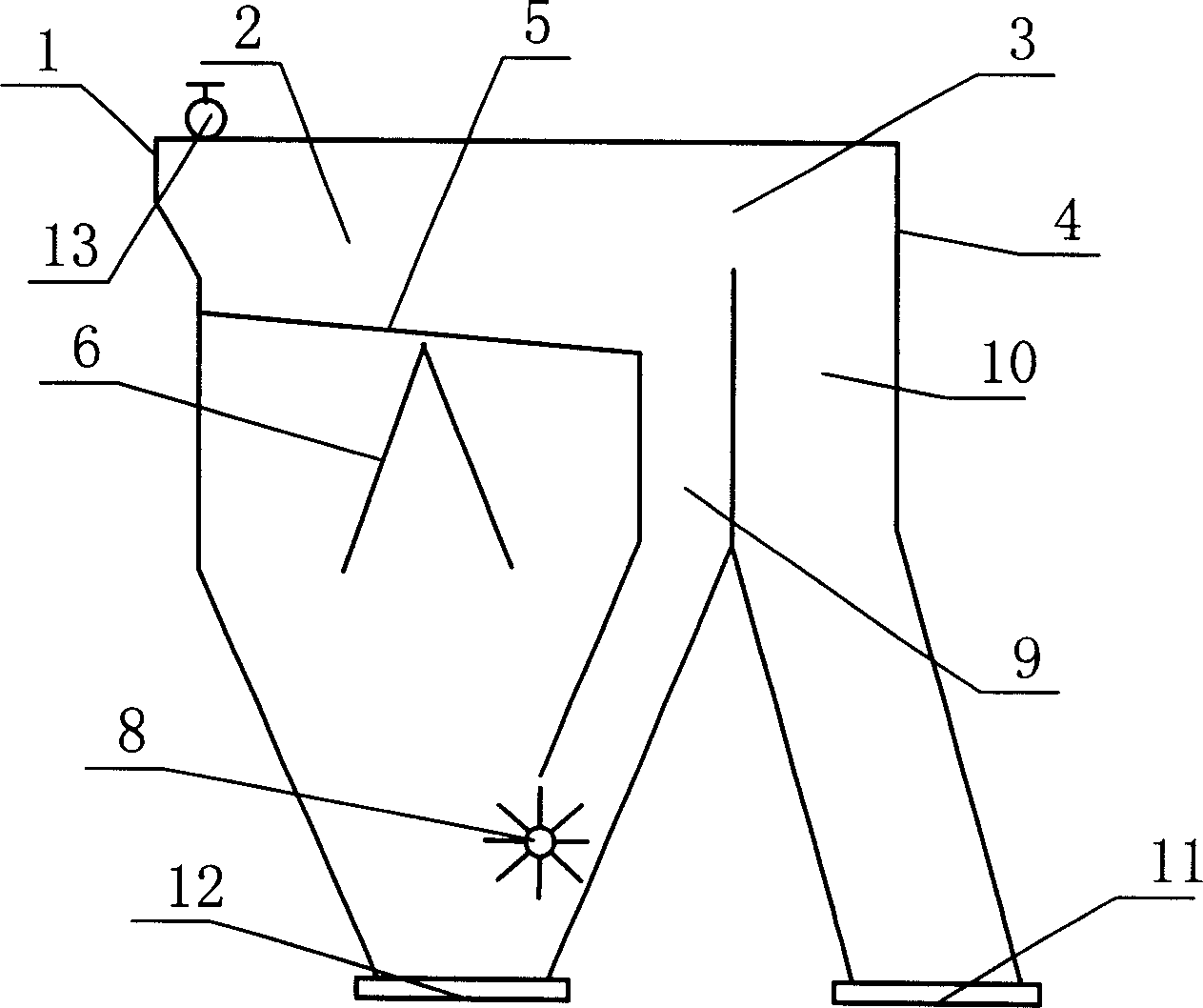

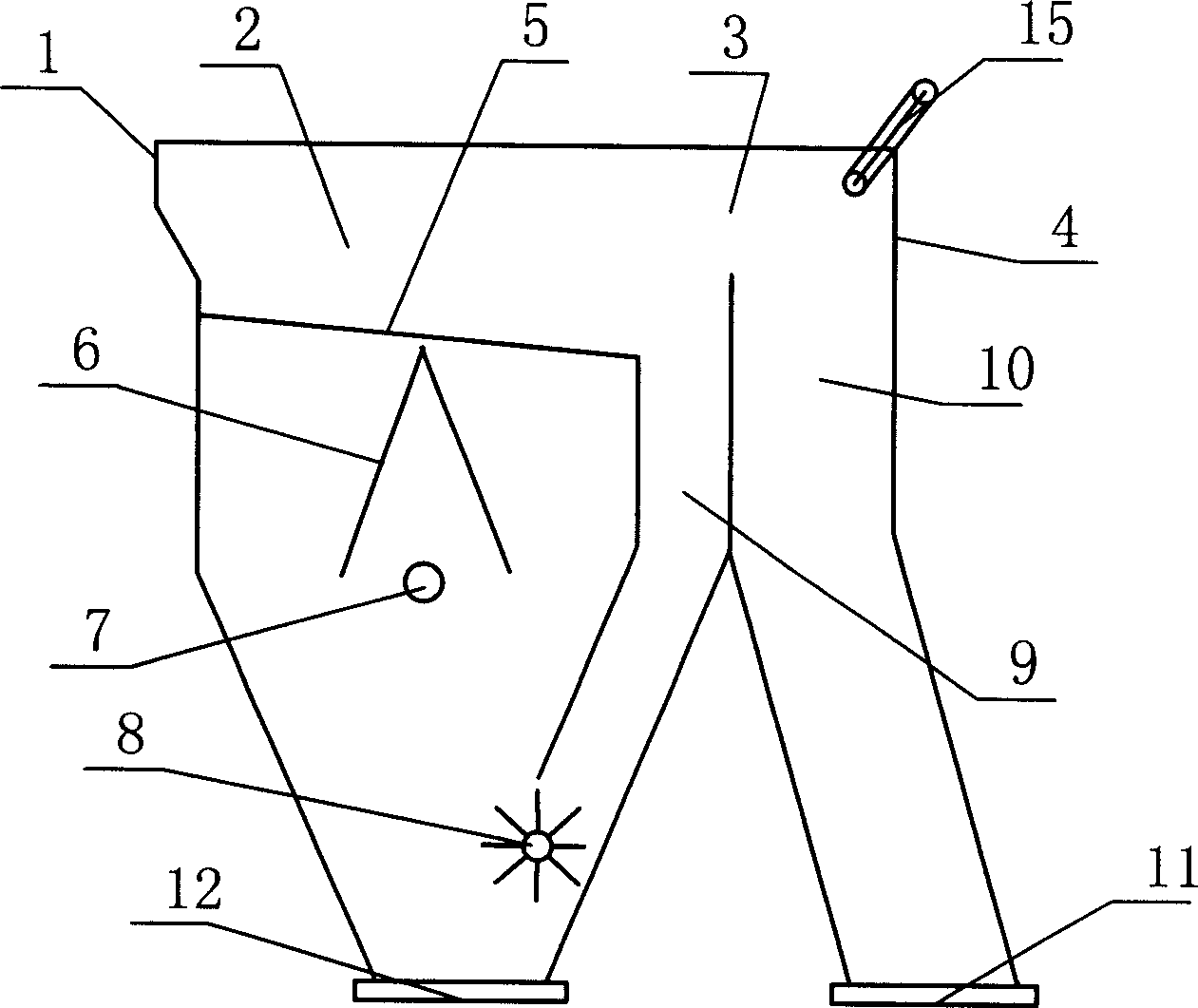

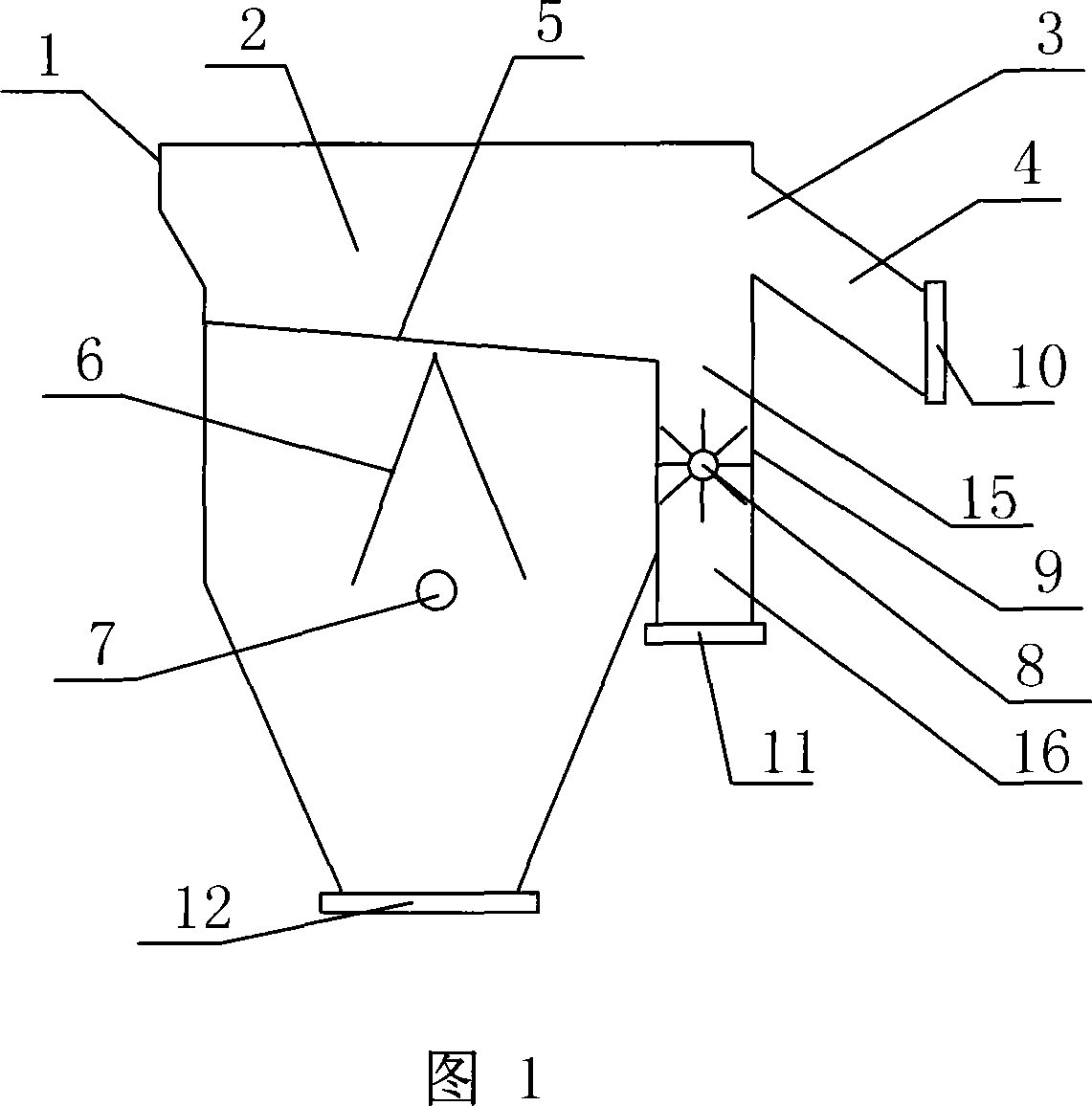

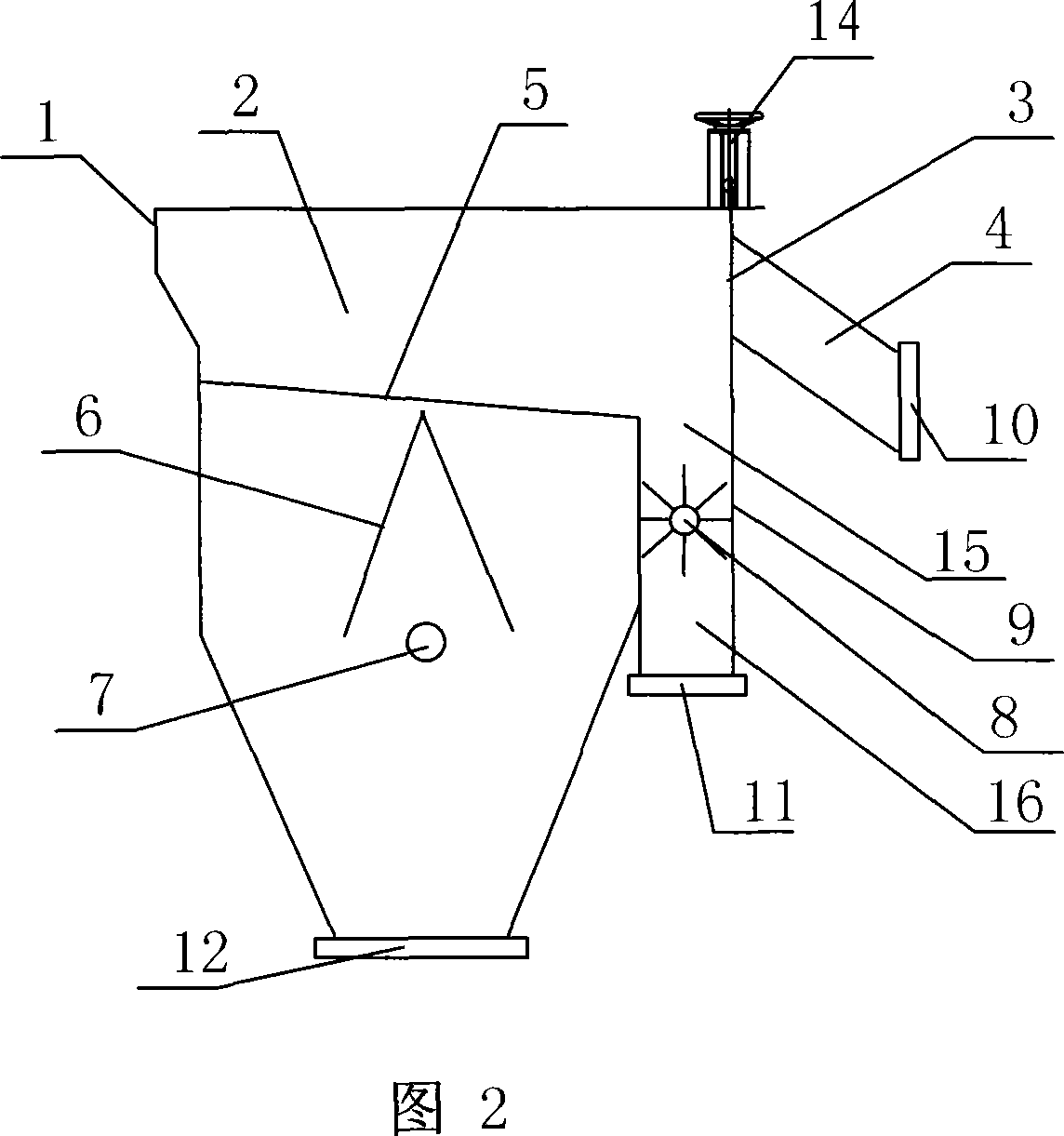

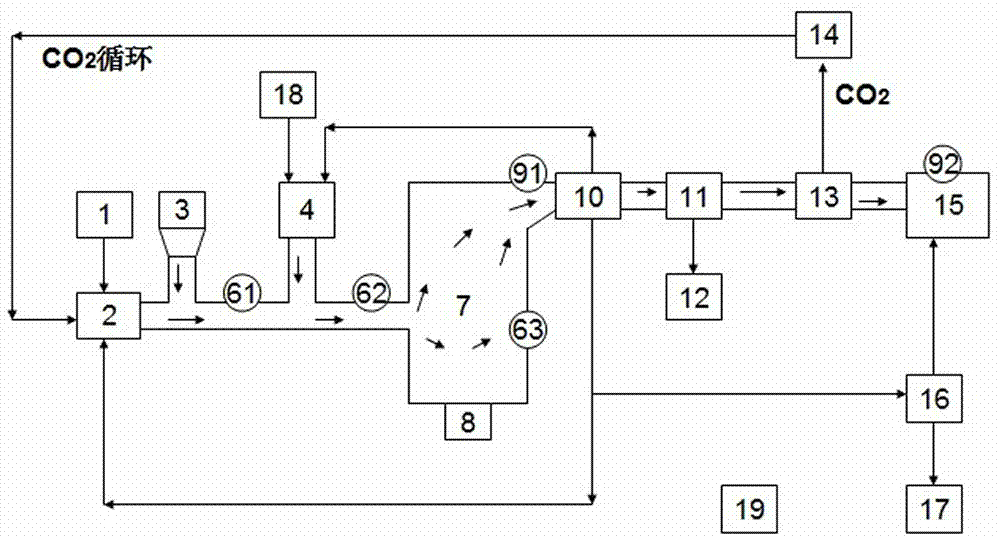

Coal pyrolysis gasification poly-generation device and process based on circulating fluidized bed

InactiveCN103881761ARealize hierarchical optimization utilizationTo solve the purpose of efficient purificationFluidized bed combustionCombustible gas productionElectricityCombustion

The invention discloses a coal pyrolysis gasification poly-generation device and process based on a circulating fluidized bed. A circulating fluidized bed boiler is organically coupled with a moving bed coal pyrolysis reactor and a moving bed gasification furnace, the high temperature circulation ash of the circulating fluidized bed boiler is used as a carrier for pyrolyzing high volatile coal steam coal from a coal funnel in the moving bed coal pyrolysis reactor, the semicoke generated in pyrolysis is separated out from the pyrolysis reactor and is fed into the moving bed gasification furnace for gasification, and at the same time the moving bed gasification furnace is used as a device for purifying a pyrolysis coal gas, thereby achieving the function of on-line dust collection of the pyrolysis coal gas. The gasified activated coke as a byproduct is discharged outside the reaction system. Therefore, through organic combination of three procedures, including pyrolysis, gasification and combustion, graded optimized utilization of the coal resource is achieved, joint production of heat, electricity, tar, coal gas and activated coke is achieved, and meanwhile the purposes of gasifying the coal gas and efficiently purifying the pyrolysis coal gas are achieved.

Owner:SHANXI LUAN MINING GRP +1

Steam coal preparation technique with low coal slime yield

The invention relates to a steam coal preparation technique with low coal slime yield, comprising the following steps of: (1) storing the raw coal of steam coal in a horizontal cabin, wherein the height of coal storage is less than 10 m; (2) crushing the raw coal less than 200 nm by using a grading crusher; (3) feeding the raw coal into a bolting mill for milling after crushing, wherein the coal with big screening size enters a lump coal washing system for washing, the fine coal powder with small size is then sieved, and the fine powder less than 6 nm after sieving directly enters a product cabin; and the remaining slack coal enters a non-pressure dense media swirler for washing and de-liming. The technique can wash all the steam coal with relatively lower cost; the coal slime yield is reduced; and the calorific value of washed steam coal product is increased.

Owner:CHINA SHENHUA ENERGY CO LTD

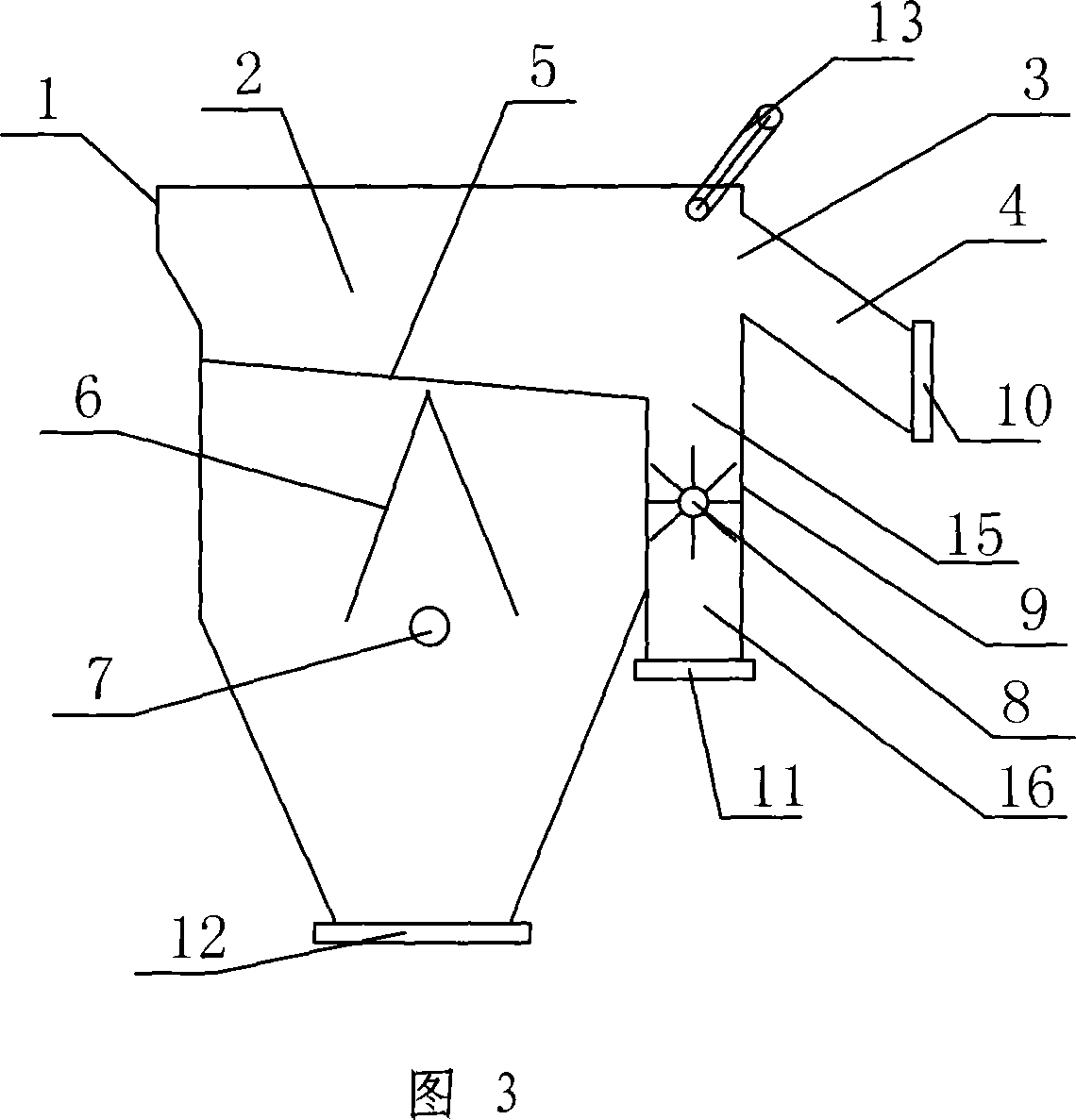

Torbanite washbox, coal separation system and coal separation method thereof

InactiveCN101185912AUse less waterReduce or eliminate top waterWet separationWater savingProcess engineering

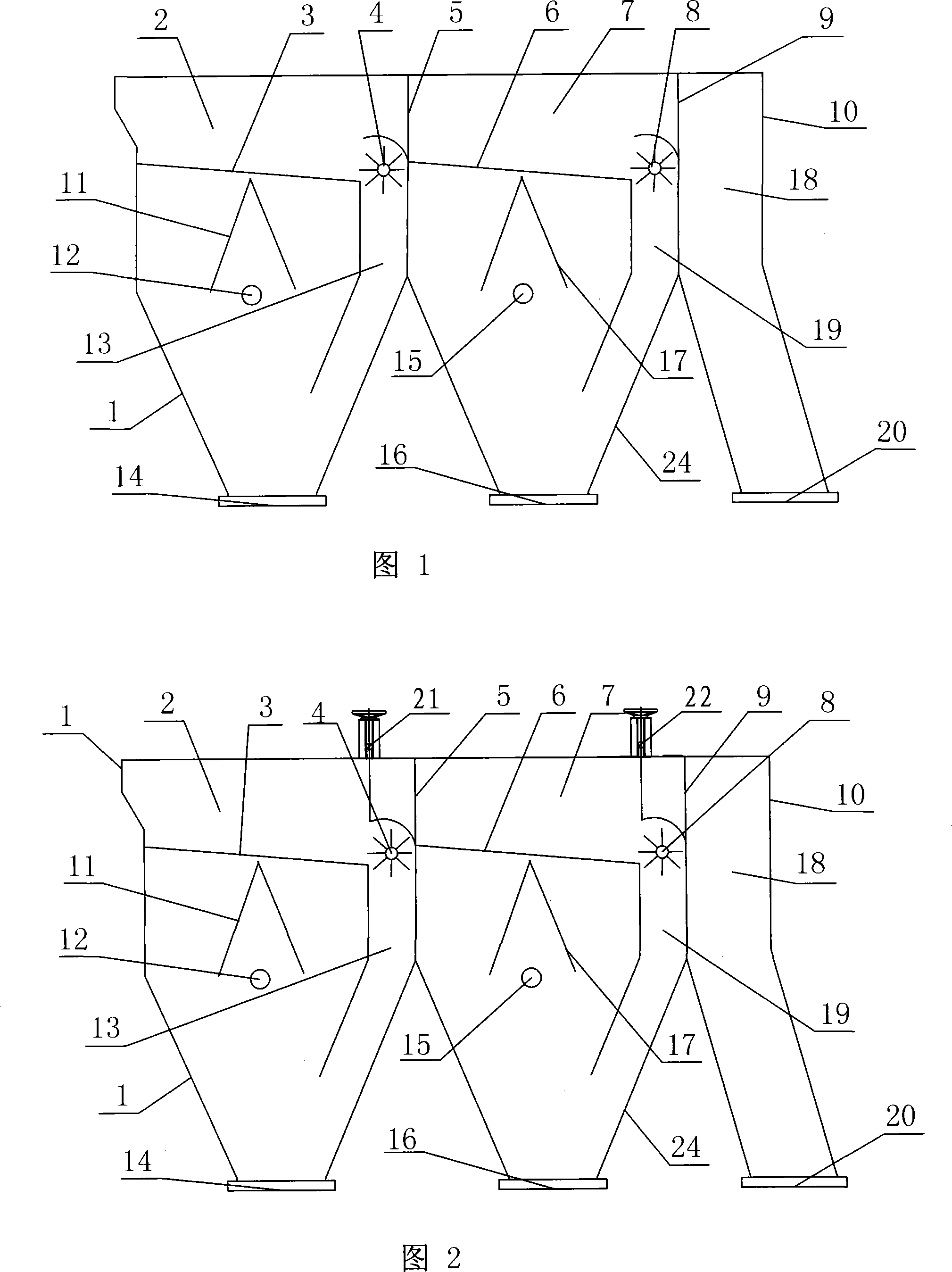

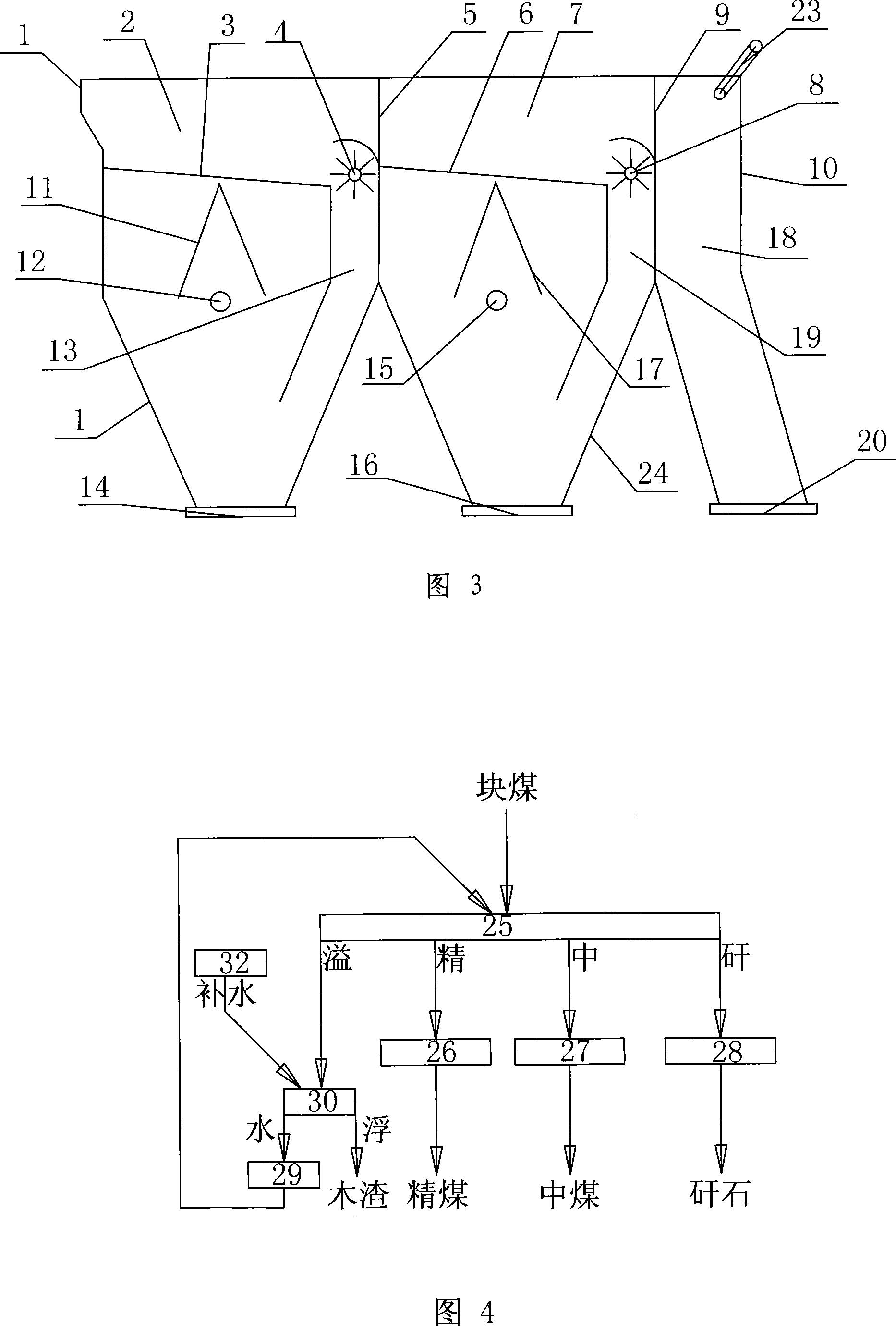

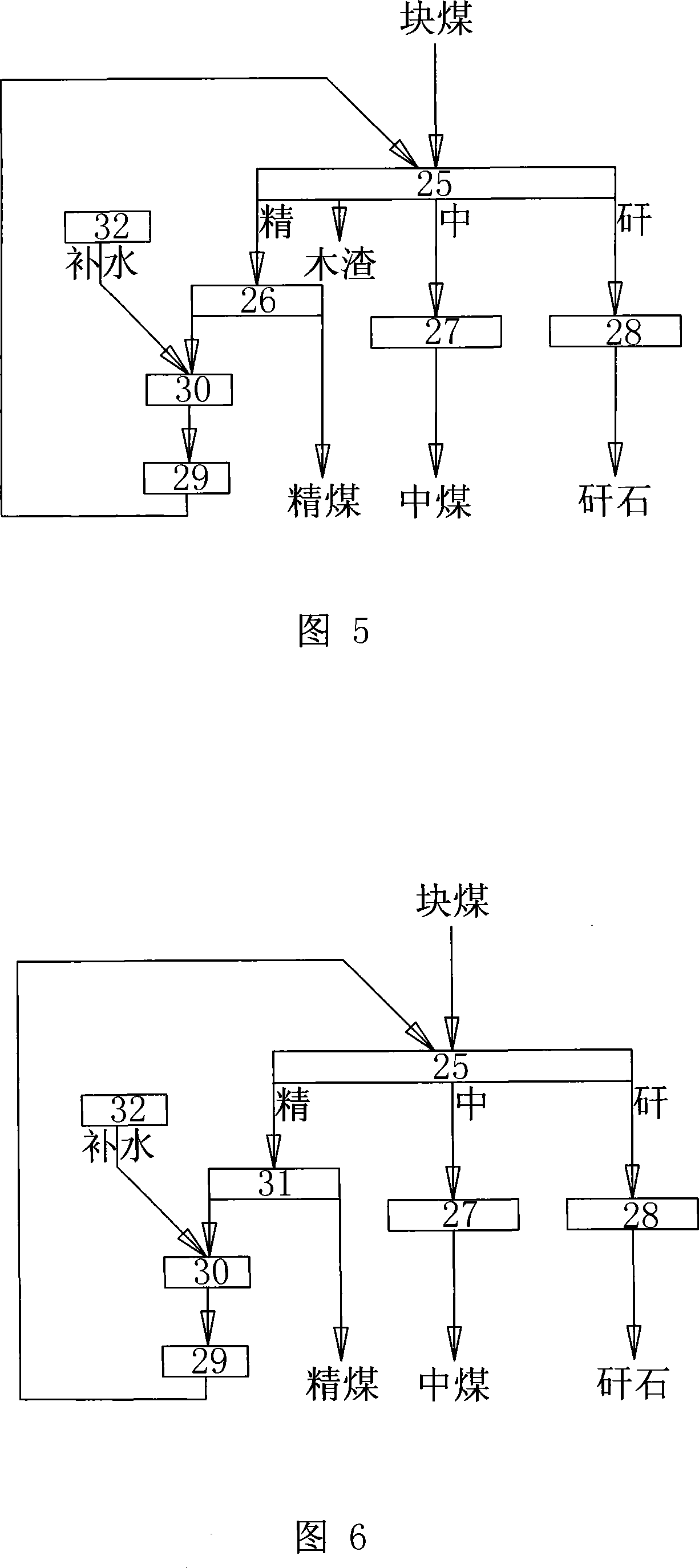

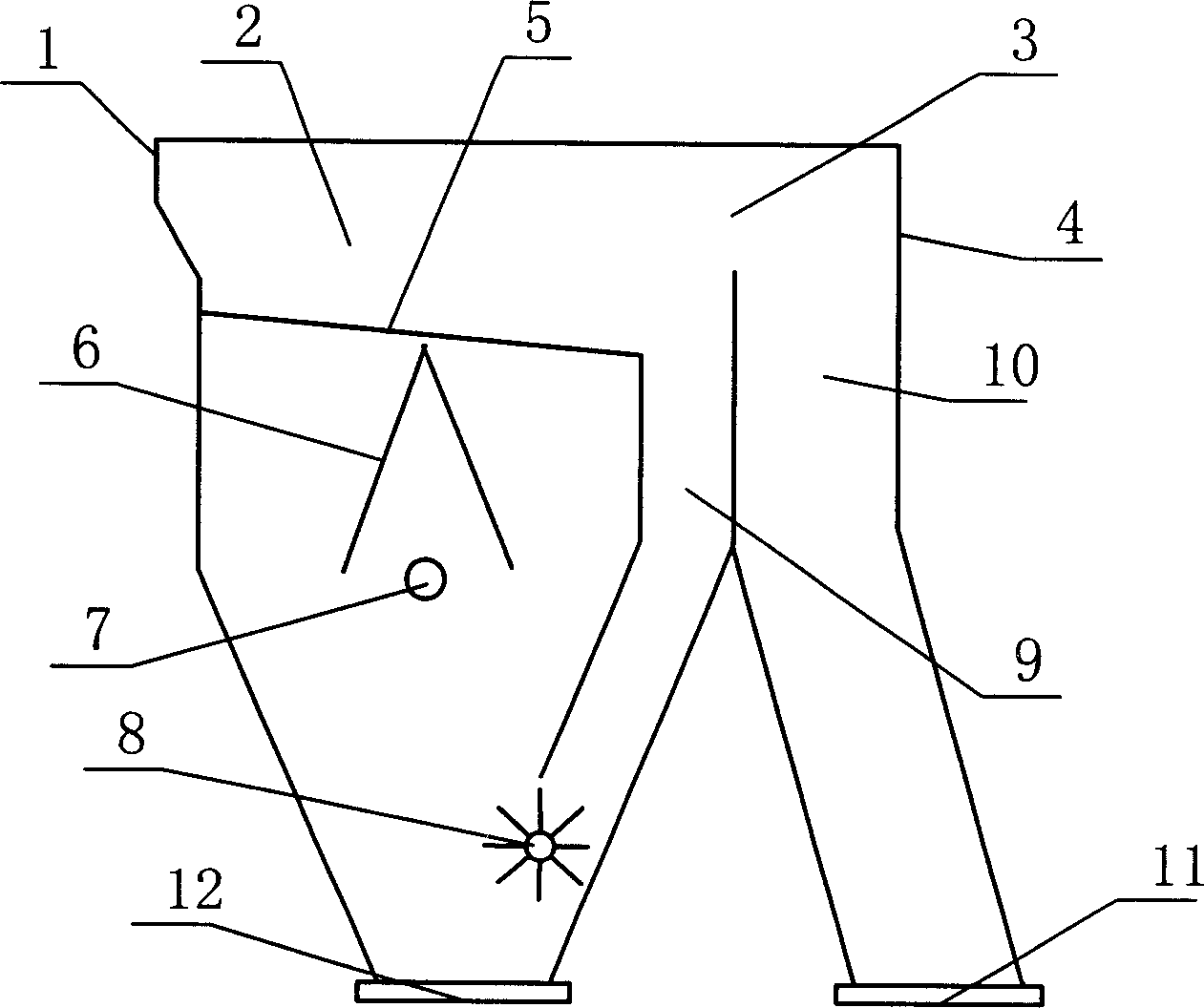

The invention discloses a coal block jigger, a coal selection system and a coal selection method, which belongs to coal jigging selection field and is more particularly suitable for select coal blocks. The coal block jigger of the invention is formed by multiplying the inclined angle of a filter board of the existing multi-section jigger and changing a overflow spillway into a clean coal outlet passage; the coal selection system of the coal block jigger comprises the coal block jig, a rock refuse bucket elevator, a middling bucket elevator, a clean coal bucket elevator, a recycling water bucket, a recycling water pump, a water supply device and so on; and the coal selection of the coal block jigger can one-time select rock refuse, middlings, clean coal and a plurality of other products, and the water supply amount in selection is small. By adopting the invention to select coal blocks, processing amount can be increased, a great deal of water can be saved, washing and cleaning cost can be lowered, system steps can be simplified and system overall investment is reduced, thus achieving the effect that can not be achieved by the existing multi-section jigger. The invention is a brand new coal blocks selection jigger, a coal selection system and a coal selection method, which can be used for selecting steam coal and can also substitute dense medium vertical wheelers and inclined wheelers for coal block selection.

Owner:唐山易通科技开发有限公司

Apparatus and method for wash separating coal by jump separation

A jig washing method and its apparatus for removing coal gangue feature that the overflow channel of existing single-segment jig washer is reformed for only discharging light product, the inclination of sieving board is increased, the water supplementing unit is additionally used, and the depth of bed layer is increased. Its advantages are high effect to separate 3 products at same time, and less consumption of water and electric energy.

Owner:唐山易通科技开发有限公司

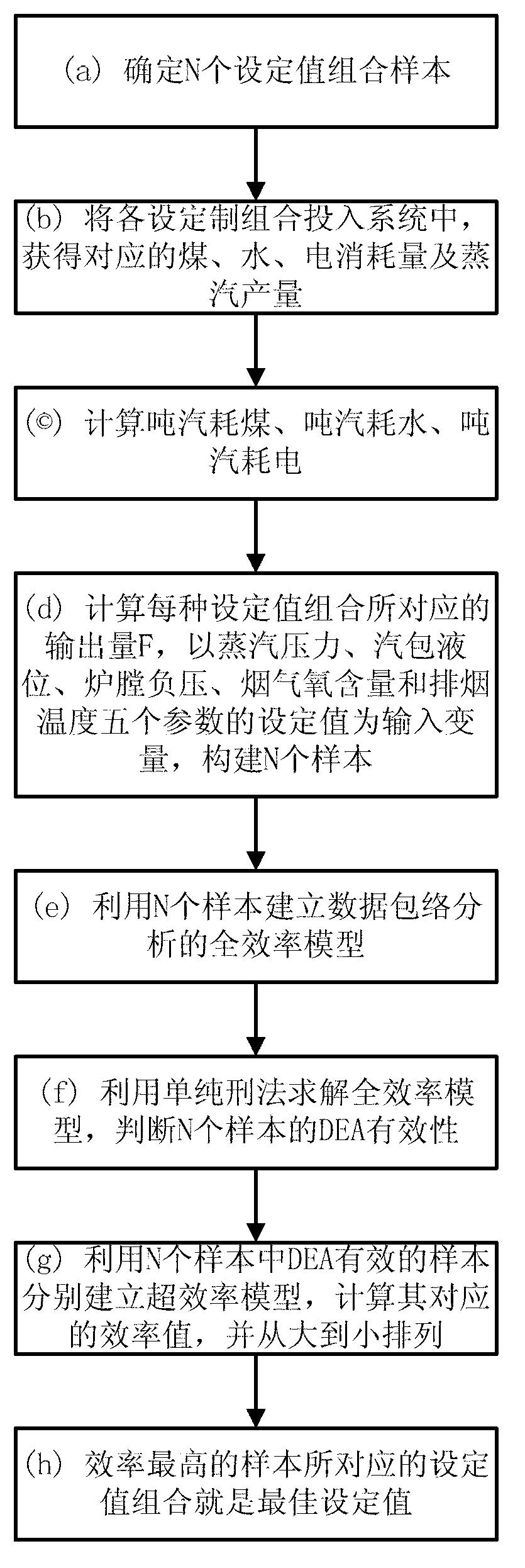

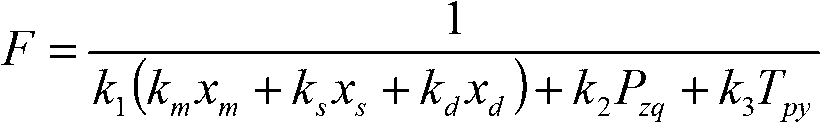

Method for determining best setting value of chain furnace control system

InactiveCN102997216ARealize economical energy savingGuaranteed uptimeBoiler controlSolid fuel combustionElectricitySteam pressure

Disclosed is a method for determining a best setting value of a chain furnace control system. The device is characterized by comprising steps of determining a plurality of setting value combinations of steam pressure, the boiler level, the hearth negative pressure, the fume oxygen content and the fume discharging temperature in accordance with experience; sequentially placing the setting value combinations to the chain furnace control system, and obtaining the coal consumption, the water consumption, the electricity consumption and the generated steam quantity by using all monitoring points; calculating the tons of steam coal consumption, tons of steam water consumption, tons of steam power consumption and the production cost corresponding the setting value combinations, regarding the reciprocal value of the weighted sum of the production cost, the steam pressure and the fume discharging temperature, establishing the full-efficiency module, finding a solution, obtaining the detection number corresponding to samples, and regarding the samples corresponding to non-negative detection number as the Data Envelopment Analysis (DEA) validness; and substituting the non-negative detection number to the full-efficiency module, finding the efficiency values corresponding to DEA effective samples, wherein the setting value combinations corresponding to DEA effective samples of high effective values are the best setting value of the steam pressure, the boiler level, the hearth negative pressure, the fume oxygen content and the fume discharging temperature.

Owner:BEIHUA UNIV

Method for producing form coke from Jurassic steam coal

Method for producing form coke from Jurassic steam coal comprising the steps of, coal disintegrating, washing, drying, dry distillation so as to obtain high temperature coal tar and half-tar or refined gluing coal, disintegrating to below 0.4mm, obtaining powdered coal binding agent, distilling into pitch binding agent, preparing shaped coal by mixing 8-15% of pitch binding agent, 15-25% of powdered coal binding agent, charring the molded coal to obtain molded coke.

Owner:葛立凯 +1

Separation technique for difficult-to-separate steam coal

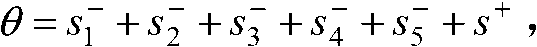

The invention discloses a separation technique applicable to difficult-to-separate steam coal, and belongs to a coal separation method. The separation technique comprises the steps that A, drying-method separation is adopted for coal with the particle sizes larger than 50 mm, middling coal is broken and then subjected to re-separation operation; B, wet-method separation is adopted for coal with the particle sizes of 13-50 mm, and middling coal is broken is subjected to re-separation operation; C, wet-method separation is adopted for coal with the particle sizes of 3-13 mm, and middling coal isbroken and subjected to re-separation operation; and D, wet-method separation is adopted for coal with the particle sizes of 1-3 mm, and coal with the particle sizes of 0-1 mm is subjected to pressing filtering operation for obtaining coal slime. Dry-method classification is adopted for raw coal; classification equipment comprises a bohou screen and an air-stream classification machine; the coalis not in contact with water before separation; the argillization degree is lowered; generation of secondary coal slime is reduced; affection of the argillization degree on the separation process is overcome; clean coal is recycled; the recycling rate of clean coal is improved, so that maximum resource utilization of steam coal is ensured; different separation modes are adopted according differentparticle sizes of coal; coarse particles are subjected to intelligent dry-separation machine separation; middle-size particles are subjected to dense-medium shallow slot separation; and fine particles is subjected to three-product dense-medium hydrocyclone separation; and while the highest separation precision is ensured, the separation cost is the lowest.

Owner:CHINA UNIV OF MINING & TECH +2

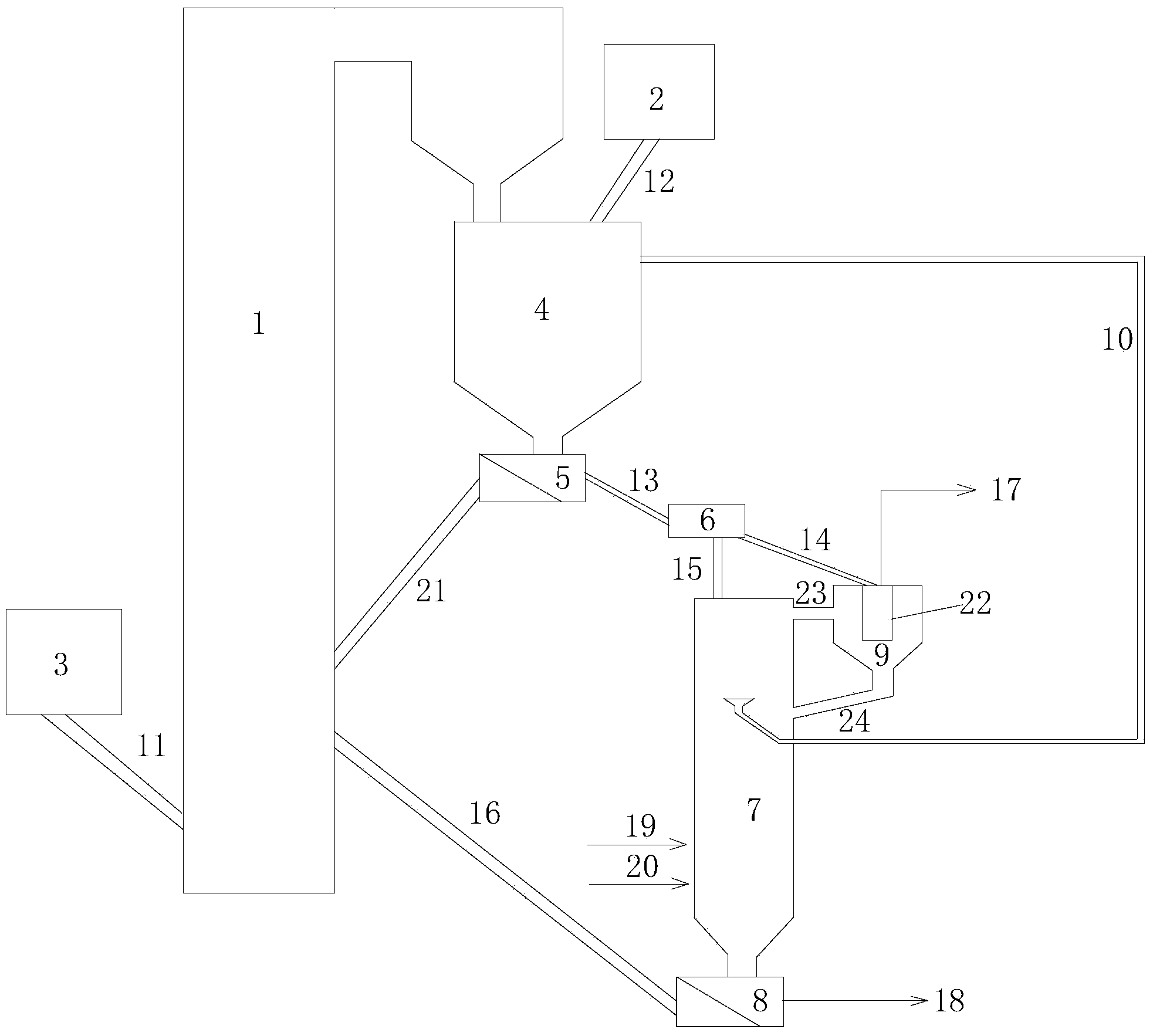

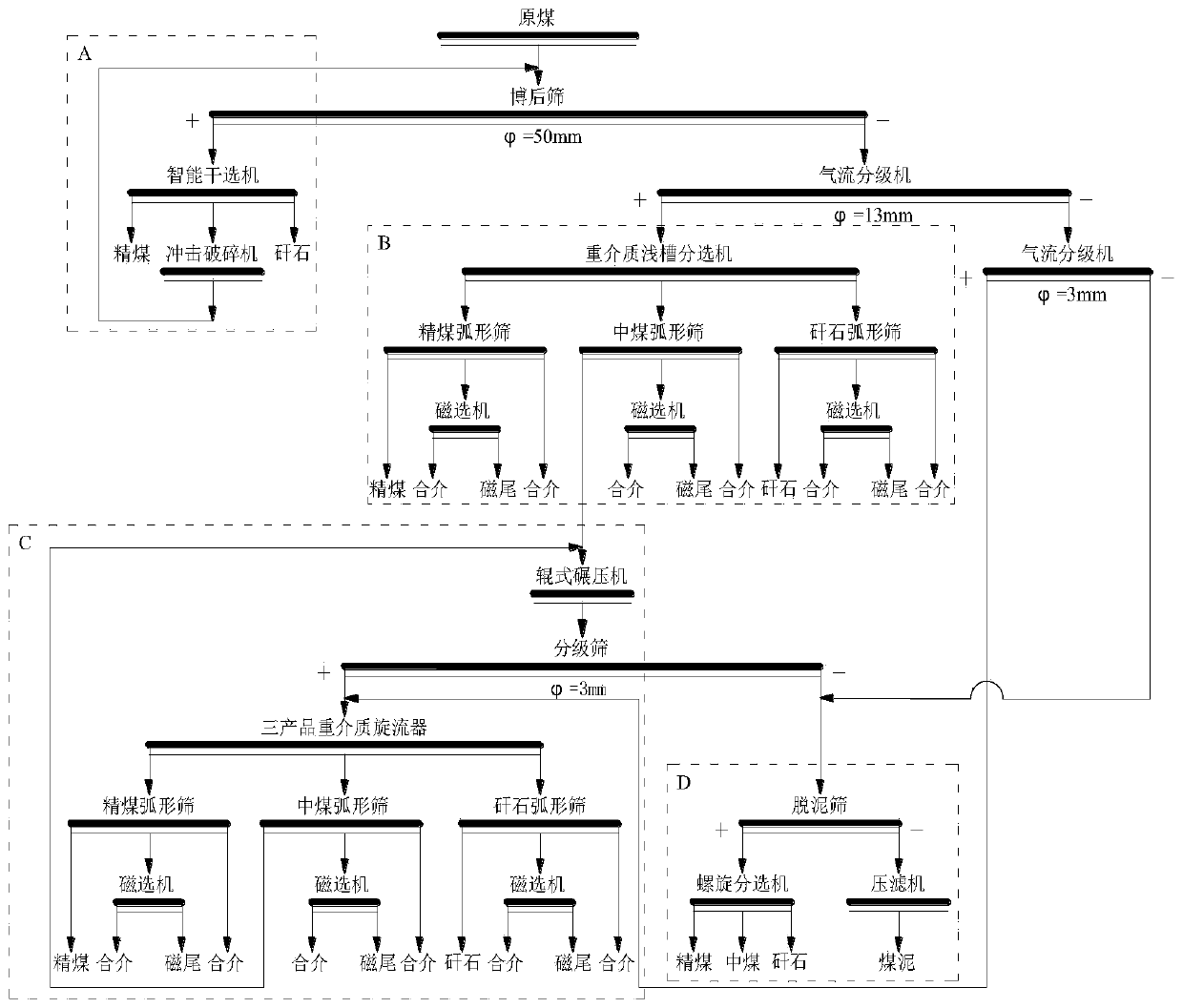

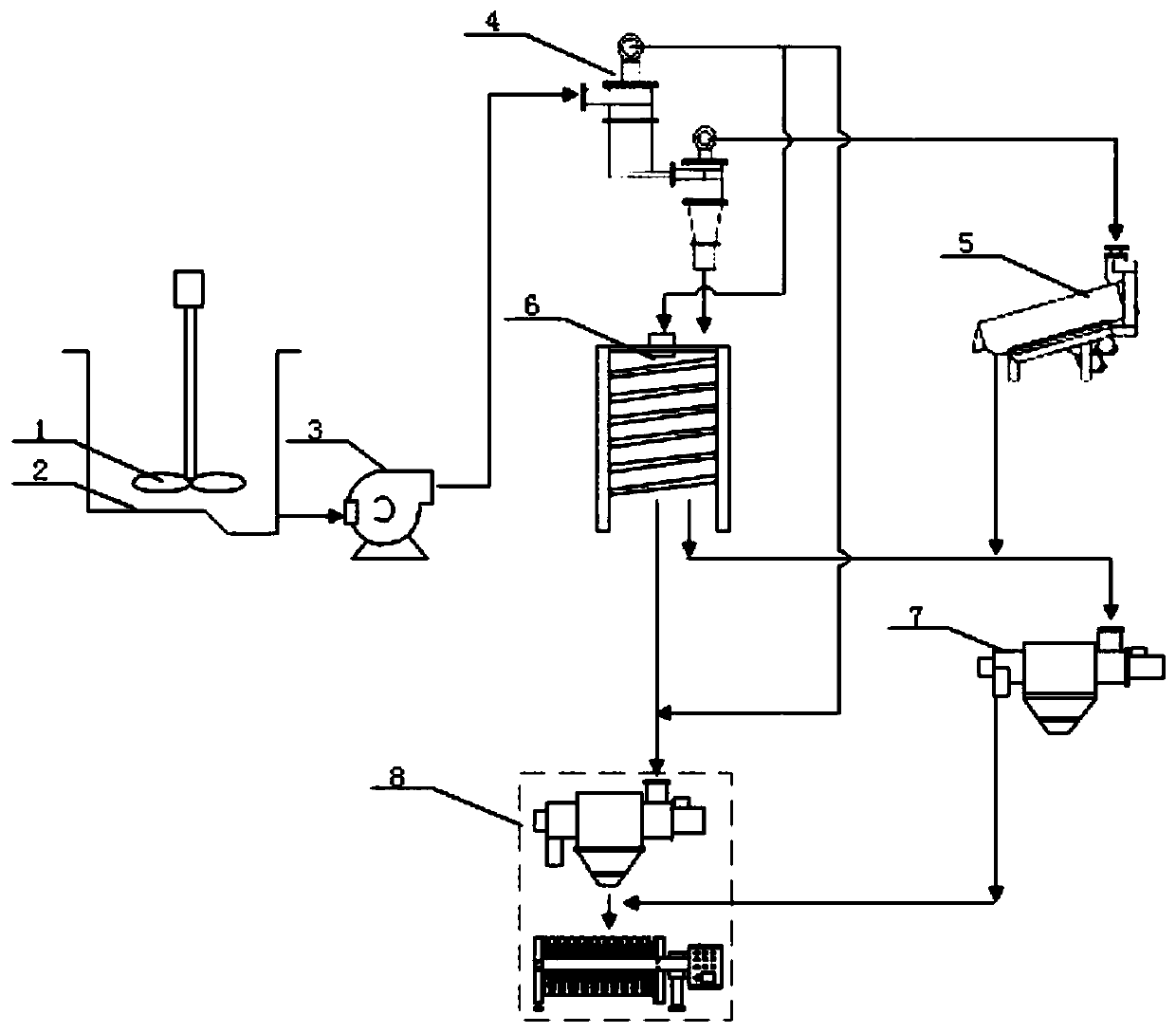

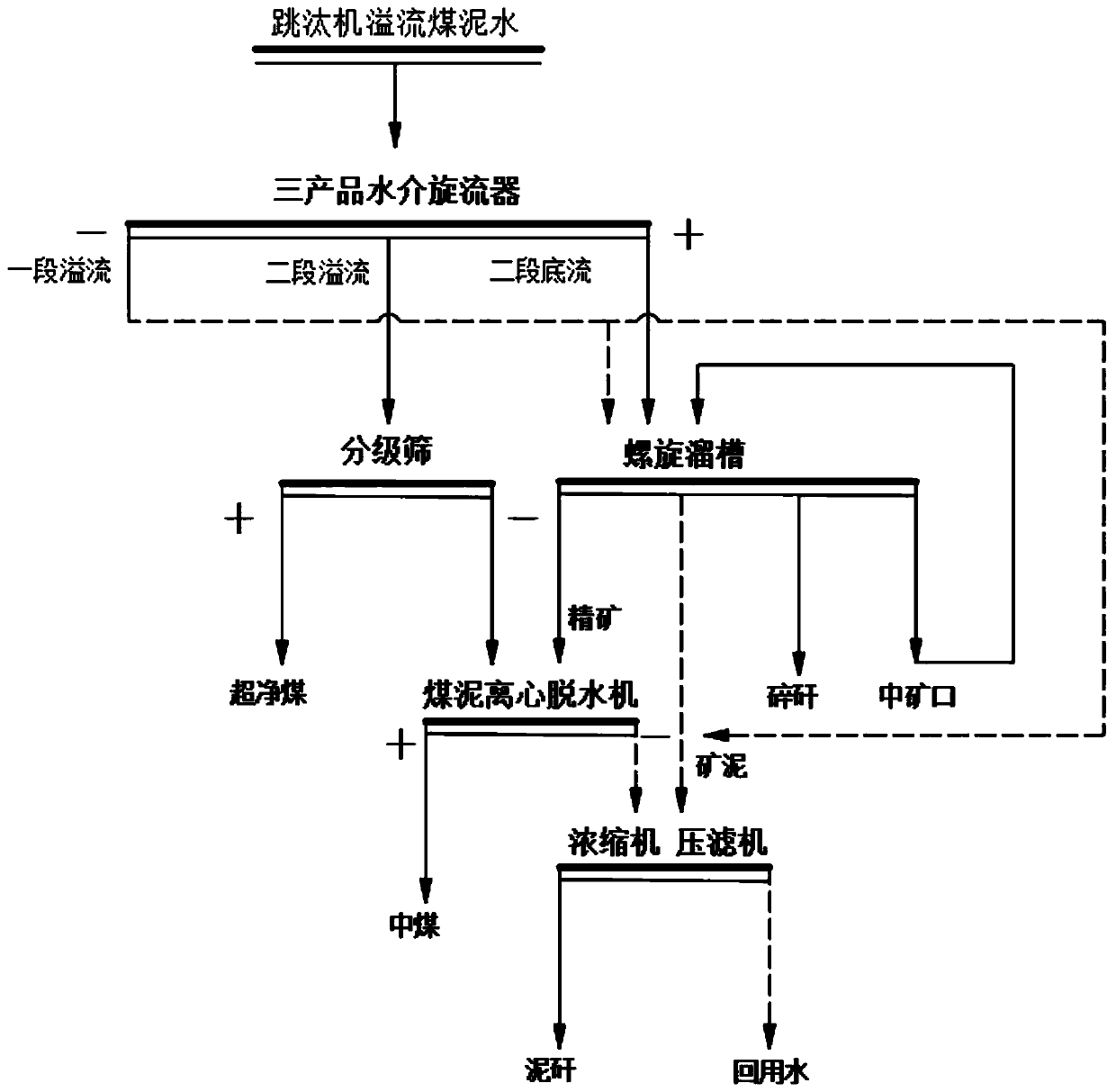

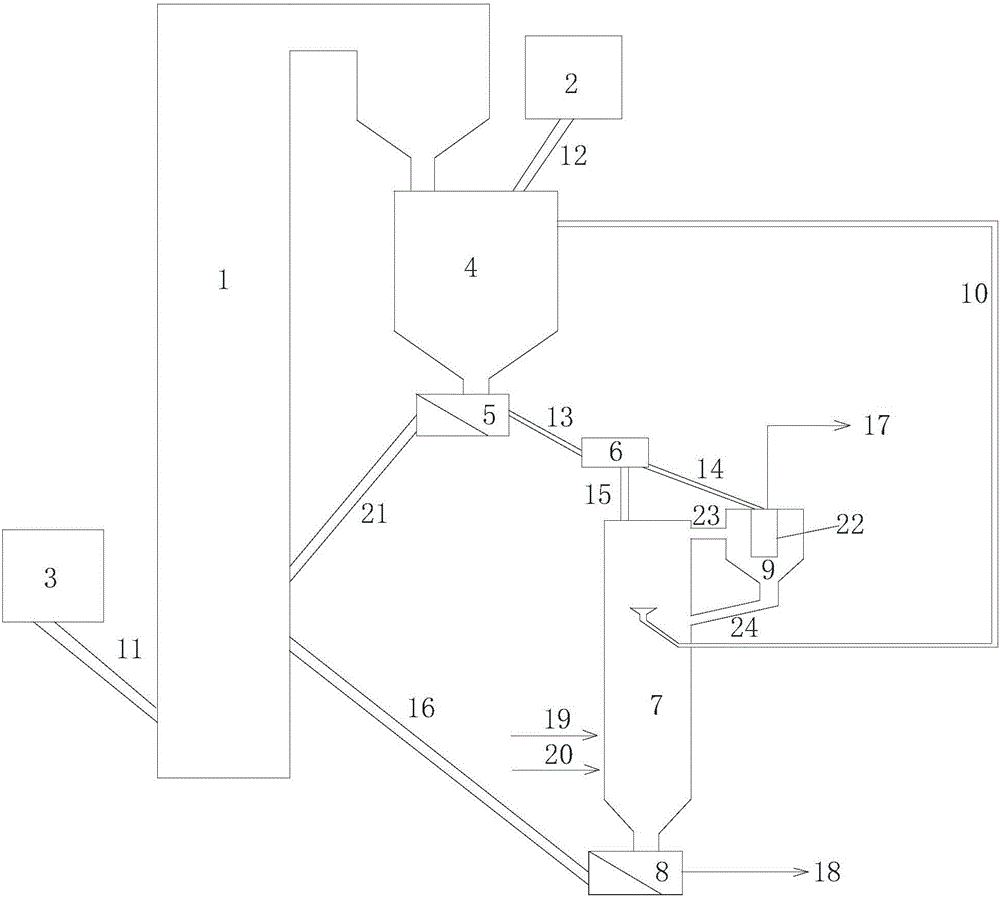

Device and process for recovering jigging overflow coal slime to separate ultra-clean coal through physical cyclone flow

ActiveCN110560258ANo pollution in the processInnovative ideasSolid separationThermodynamicsIron powder

The invention discloses a device and process for recovering jigging overflow coal slime to separate ultra-clean coal through physical cyclone flow. The ultra-clean coal separation device comprises a cyclone separation device, a spiral chute and a screening and dehydrating device. The cyclone separation device comprises a first-section flat bottom classifying cyclone device and a second-section large-cone-angle sorting cyclone device. The first-section flat bottom classifying cyclone device and the second-section large-cone-angle sorting cyclone device are each provided with a first overflow port, a second overflow port and a base flow port, and ultra-clean coal products can be obtained through screening at the second overflow ports. The spiral chute comprises four discharge ports for ore concentrate and the like. The screening and dehydrating device comprises a classifying screen, a coal slime centrifugal dehydrator, a pressure filter and other desliming and dehydrating devices. The spiral chute is arranged below the base flow port and can recover middling coal products. Part of ore pulp at the first overflow ports serves as make-up water of the chute. Water dehydrated from the dehydrating device in the system can serve as coal washing reuse water of a jigging machine. The invention further discloses an ultra-clean coal separation process. The device and process for separatingthe ultra-clean coal through the physical cyclone flow is novel and unique in idea, simple in process, free of addition of a fine iron powder medium to pure water and free of pollution to the environmental and products. Moreover, after the ultra-clean coal is separated, middling coal power coal products can be produced from other byproducts, and water resources can be cyclically utilized.

Owner:SHANDONG UNIV OF SCI & TECH

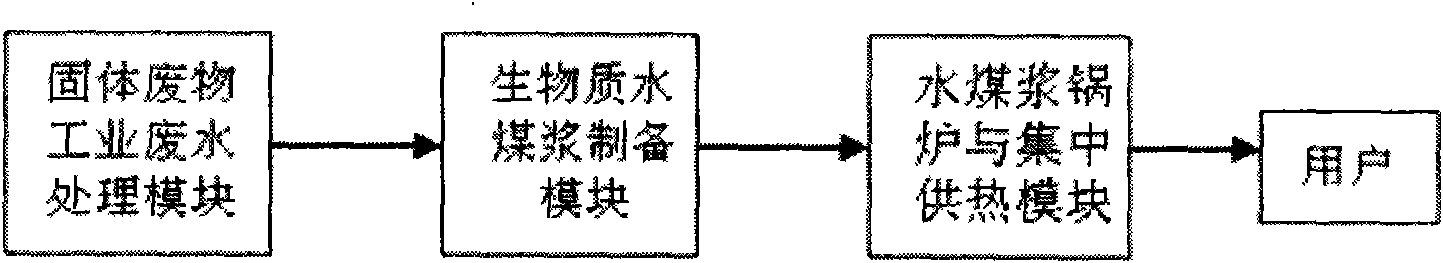

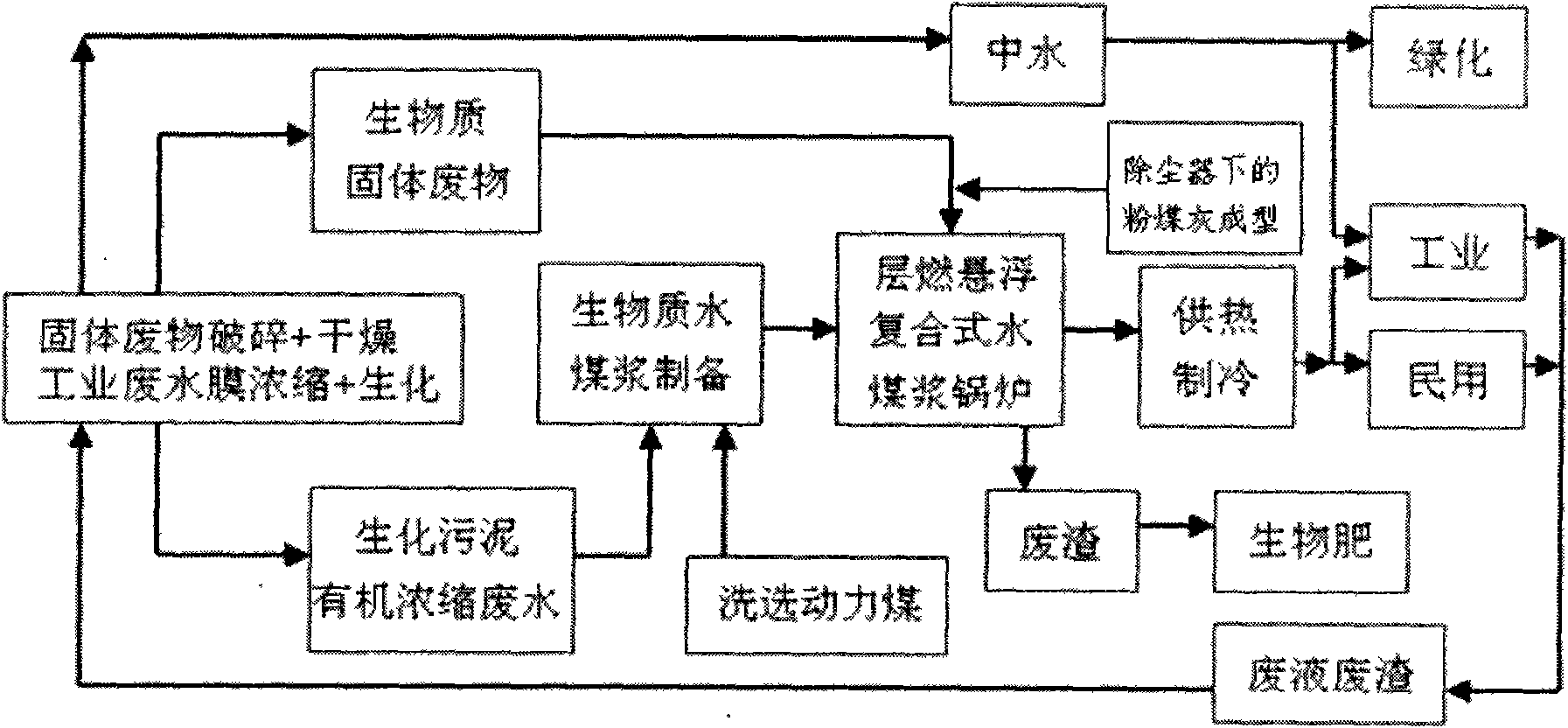

Biomass water-coal-slurry slurring and combustion method and integrated system

InactiveCN101639225AChange processing philosophyEasy to handleWater/sewage treatment by centrifugal separationFluidized bed combustionIndustrial waste waterSludge

The invention relates to a biomass water-coal-slurry slurring and combustion method and an integrated system. The integrated system is provided with a solid waste and industrial waste water processingmodule, a biomass water-coal-slurry slurring module and a water-coal-slurry boiler and integrated heating system and is characterized in that firstly, solid combustible waste and waste water are putinto the solid waste and industrial waste water processing module for being processed; and then film concentrate which takes biochemical sludge and organic concentrated waste water as main and is processed by film concentration and 30-40% of film concentrate of washing steam coal processed according to 60-70% of film concentration processing of the washing steam coal are matched and put in the biomass water-coal-slurry slurring module for blending to prepare biomass water-coal-slurry; and the prepared biomass water-coal-slurry is put in the water-coal-slurry boiler and integrated heating system for grate firing suspension combined type or circulating fluid-bed suspension combined type combustion; and during the combustion, crushed and dried solid combustible waste is added in batch type mode.

Owner:贵州蓝宇环保能源服务有限公司

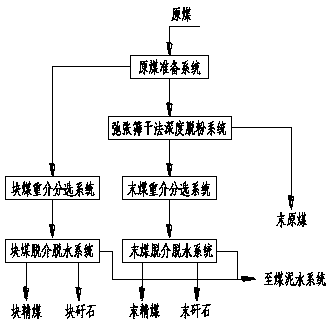

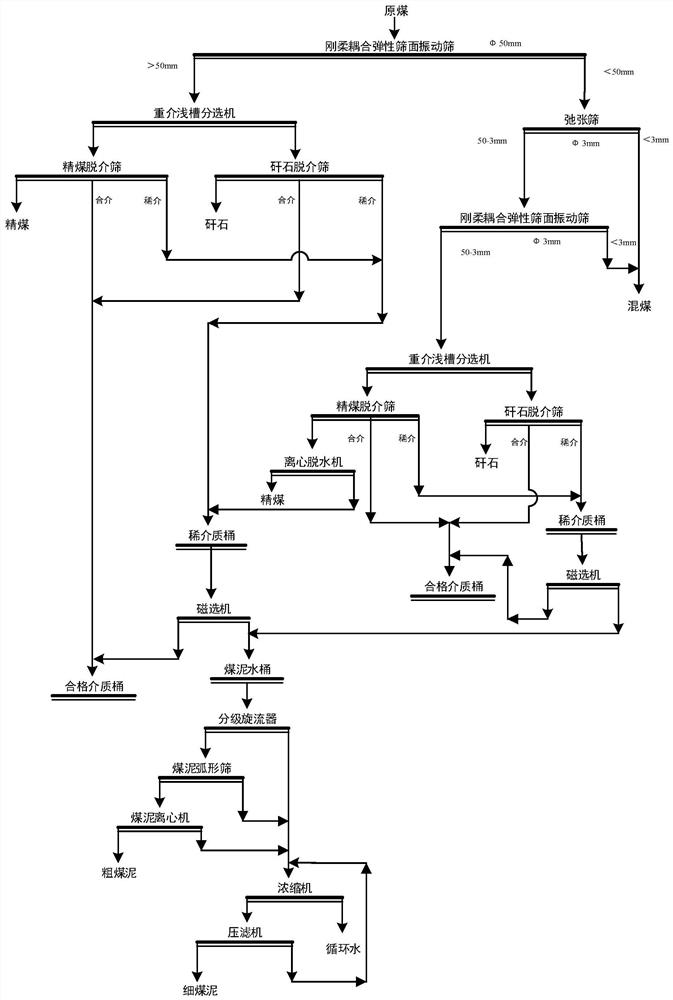

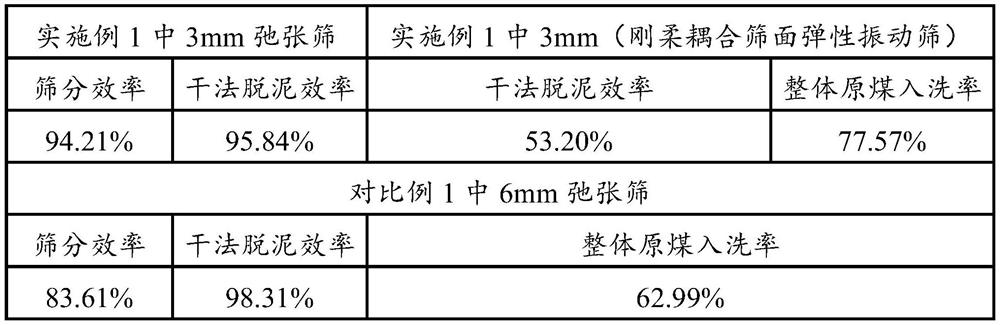

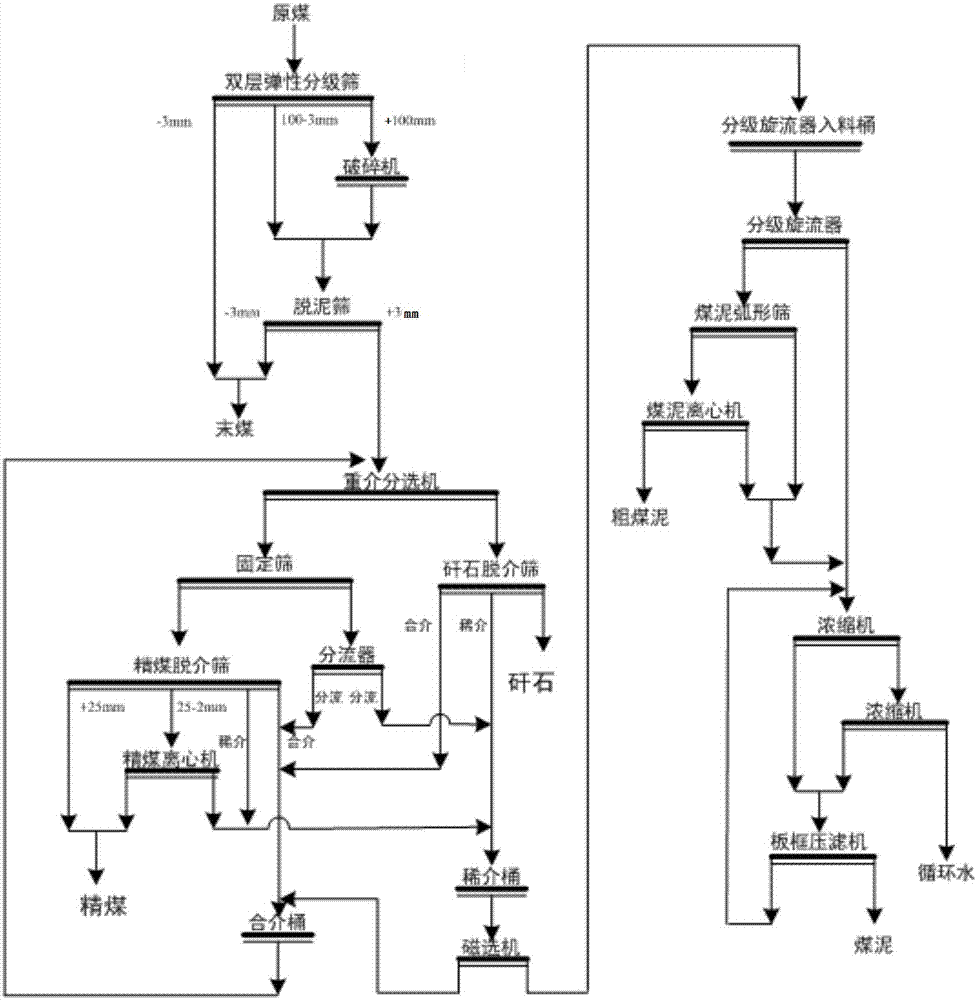

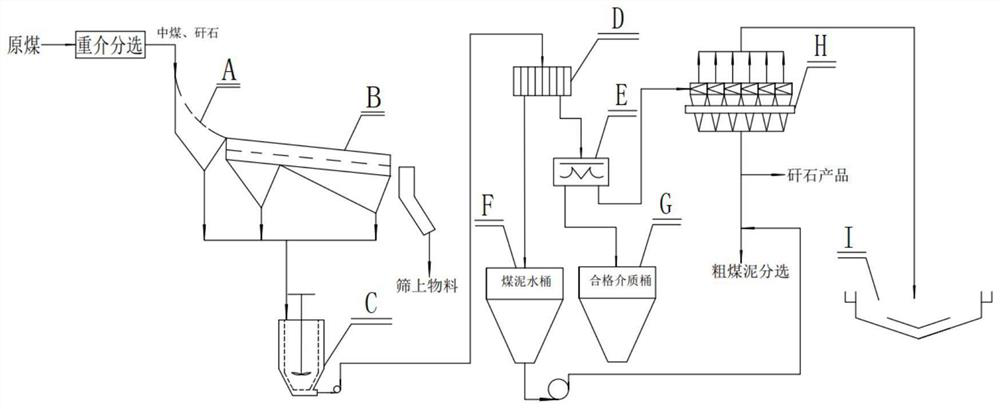

Steam coal dense medium separation process capable of effectively reducing slime content

InactiveCN109999991AReduce the number of running unitsReduce operating loadWet separationWater treatment systemSeparation system

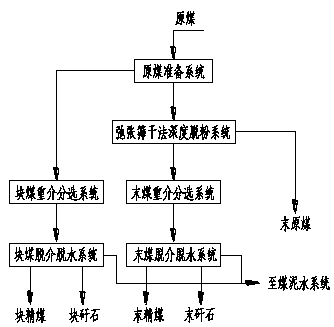

The invention discloses a steam coal dense medium separation process capable of effectively reducing slime content. The process comprises a raw coal preparing system, a fine coal dry method deep finesremoval system, a block coal dense medium separation system, a fine coal dense medium separation system, and a slime water treatment system. The relaxation sieving dry method deep fines removal process is adopted in 3 mm raw coal grading, the fine-particle-size dry method screening is adopted for enabling the slime amount in the subsequent fine coal washing process link is greatly reduced, the running load of the slime water system is effectively relieved, the secondary slime amount is reduced, the clean coal water is reduced, the commercial coal quality is further improved, meanwhile, due toreduction of the slime content, stability of the fine coal medium circular system is ensured, medium consumption is reduced, the running number of slime water treatment devices is reduced, and production cost is reduced.

Owner:COAL IND JINAN DESIGN & RES

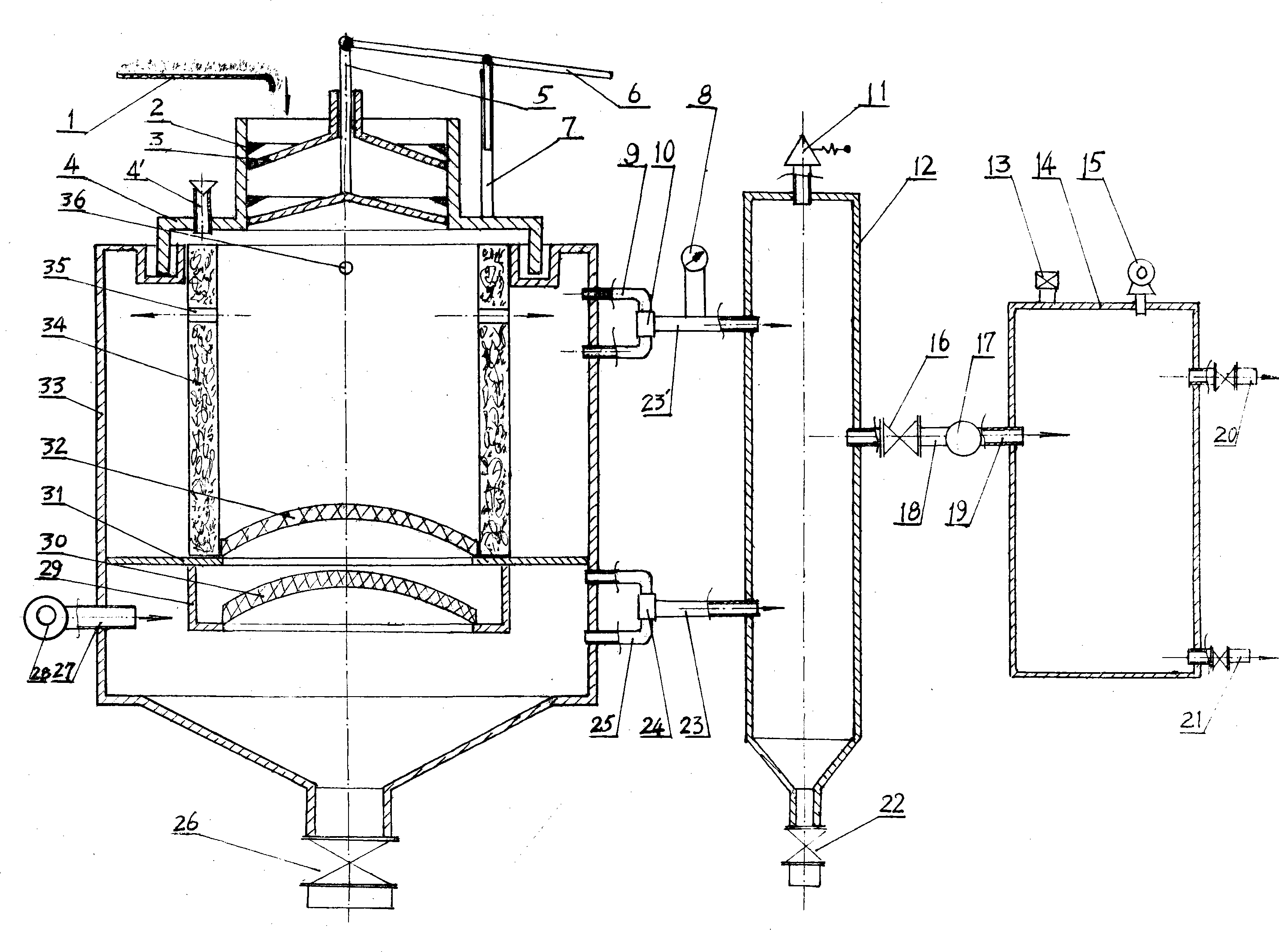

Mechanical stream-handing gasification furnace and used raw material

The invention discloses a mechanical continuous feeding gasification furnace which uses spherical or rod lump material products which are mixed and compacted by humic acid soil or mixed split coal or washing coal rock refuse which takes up 80 to 89 percent of the total weight, a combustion improver which takes up 1 to 5 percent of the total weight, a catalyst which takes up 4 to 9 percent of the total weight and water which takes up about 5 to 10 percent of the total weight as raw materials; separators and supported slabs of an inner cavity of a furnace body are provided with an arc flame bridge with rough holes and pores, a tube which can be flexibly replaced is put on the separator, a flume on the top of the furnace body is provided with an explosion proof cover which is provided with a double-layer bell in the middle, a filtering bucket beside the furnace body is connected with an air inlet pipe, and a valve and connecting pipe are used for connecting the filtering bucket and a pressurizing tank, a gas piping of which can send the produced flammable gas to users. The method uses humic acid soil or mixed split coal in coal mines or washing coal rocks which are left after steam coal or melting coal being washed by coal washers as raw materials to produce civil gas, which fully utilizes natural resources and has great economical and environment-protection benefit and popularization value.

Owner:戴太才

Jigging method for discharging waste rock through independent paths for discharging waste rock, and coal preparation method

InactiveCN101049581AReduce intermediate product lossHigh recovery rateWet separationCoal gangueSieve

A cangue-discharging jig washer with individual coal gangue discharging channel features that the gangue discharge way of existing jig washer is separated from the sieve and an additional coal gangue discharging channel is used. Its dressing method features that the material passing through sieve is separated from the heavy material and then respectively discharged. It has high recovery rate.

Owner:唐山易通科技开发有限公司

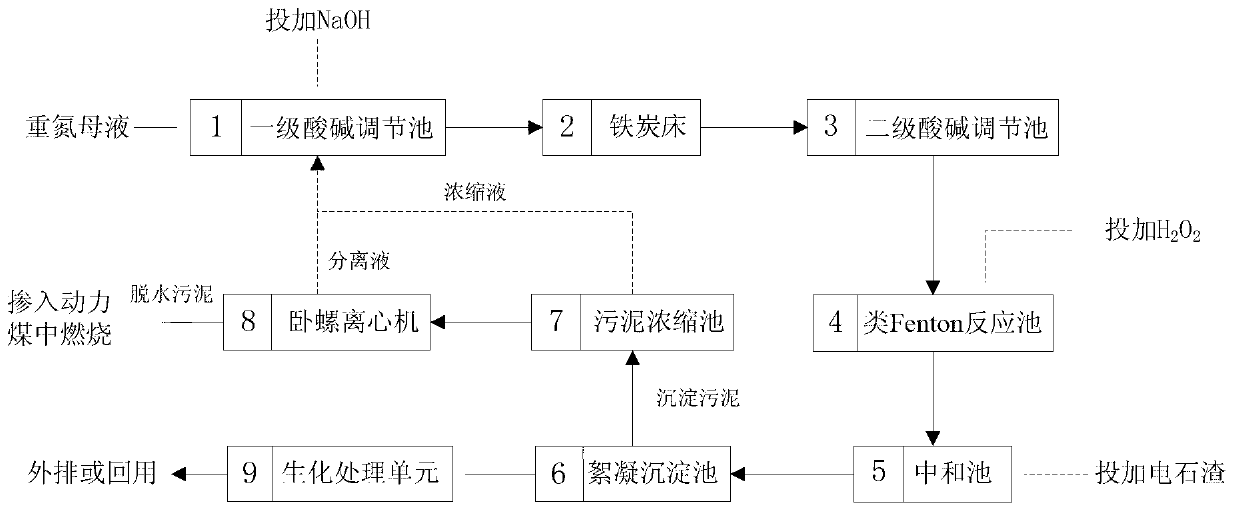

Method for treating heavy-nitrogen mother solution generated from production of dinitrodiazophenol

InactiveCN102992542AImprove conductivityLess one-time investmentMultistage water/sewage treatmentNature of treatment waterSlagSludge

The invention relates to a method for treating the heavy-nitrogen mother solution generated from production of dinitrodiazophenol, comprising the following steps of: collecting the heavy-nitrogen mother solution into a primary acid-base regulation pool, mixing, adjusting the pH value to 3, lifting onto an iron-carbon bed, making the effluent flow into a secondary acid-base regulation pool, adjusting the pH value to 3-4, feeding into a Fenton-like reaction pool for reaction, making the mother solution flow into a neutralization pool, adding carbide slag to adjust the pH to 7-8, filing nitrogen in the mother solution at the same time, making the mother solution flow into a flocculation and sedimentation pool, feeding the supernatant obtained by settling into a subsequent biological treatment unit, treating until the supernatant reaches the standard, discharging or recycling, lifting the sludge obtained by precipitating into a sludge concentration pool, making the supernatant obtained by concentrating reflow into the primary acid-base regulation pool, feeding the concentrated sludge into a horizontal helical centrifuge for centrifugal dehydrating, mixing the dehydrated sludge into steam coal for combustion and utilization, and making a centrifugal separation solution reflow into the primary acid-base regulation pool. The method provided by the invention has the advantages of low investment and stable effect, adopts the carbide slag and waste the scrap iron as the materials for treatment and achieves the purpose of treating the wastes by the wastes.

Owner:CHANGZHOU UNIV

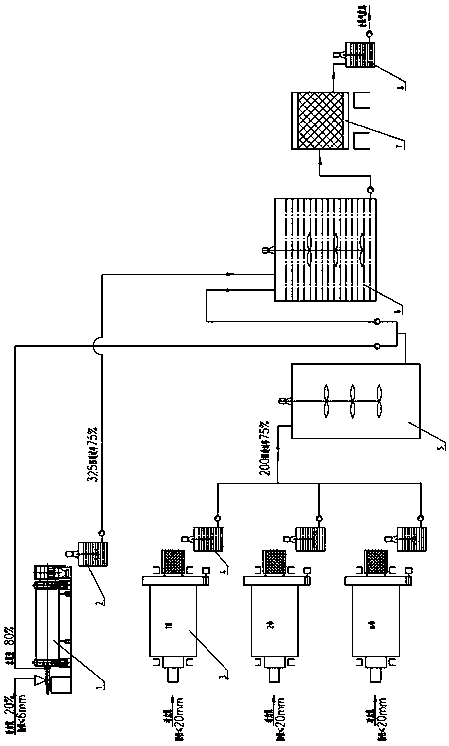

Production process for concentrating water coal slurry by gasification in coal chemical industry and used device

PendingCN108410527AIncrease concentrationImprove stacking efficiencyLiquid carbonaceous fuelsGrain treatmentsPass rateCoal conversion

The invention discloses a production process for concentrating water coal slurry by gasification in coal chemical industry and a used device. The production process comprises the following steps of: (1) putting steam coal with the particle size being less than or equal to 20mm into a plurality of rod grinder for grinding to obtain coarse water coal slurry, then entering rod-grinder buffering tanksafter carrying out primary sieving, and pumping to a slurry accumulating groove; (2) drawing 10%-20% of the coarse water coal slurry entering the slurry accumulating groove, conveying the drawn coarse water coal slurry and the steam coal with the particle size being less than or equal to 6mm into a ball grinder for grinding to obtain 325-mesh fine water coal slurry with the passing rate being 75%, then leading the fine water coal slurry to enter a ball-grinder buffering tank, and pumping to a mixing stirrer; pumping the other coarse water coal slurry entering the slurry accumulating groove tothe mixing stirrer; (3) mixing and stirring the fine water coal slurry and the coarse pumped into the mixing stirrer; (4) leading the water coal slurry after primary sieving into the buffering tank,pumping into a gasifying furnace as a coal gasifying material to carry out gasification. The production process disclosed by the invention has the beneficial effects that the concentration of the water coal slurry is increased by 2%-3%, and the gasifying efficiency and the coal conversion efficiency of the gasifying furnace are greatly improved.

Owner:JIANGSU QIULIN HEAVY IND

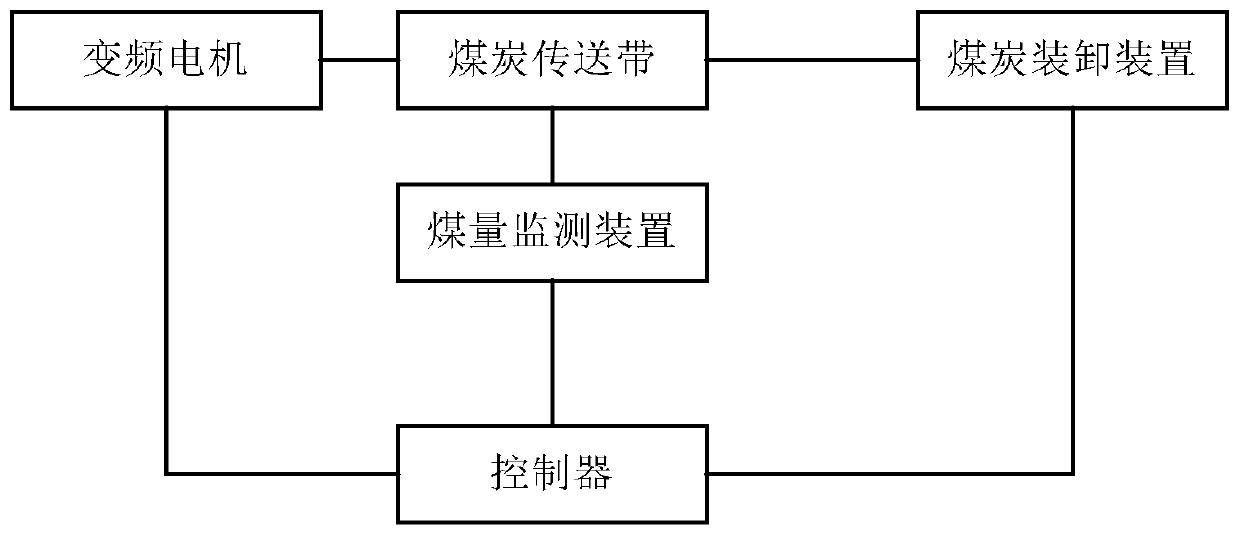

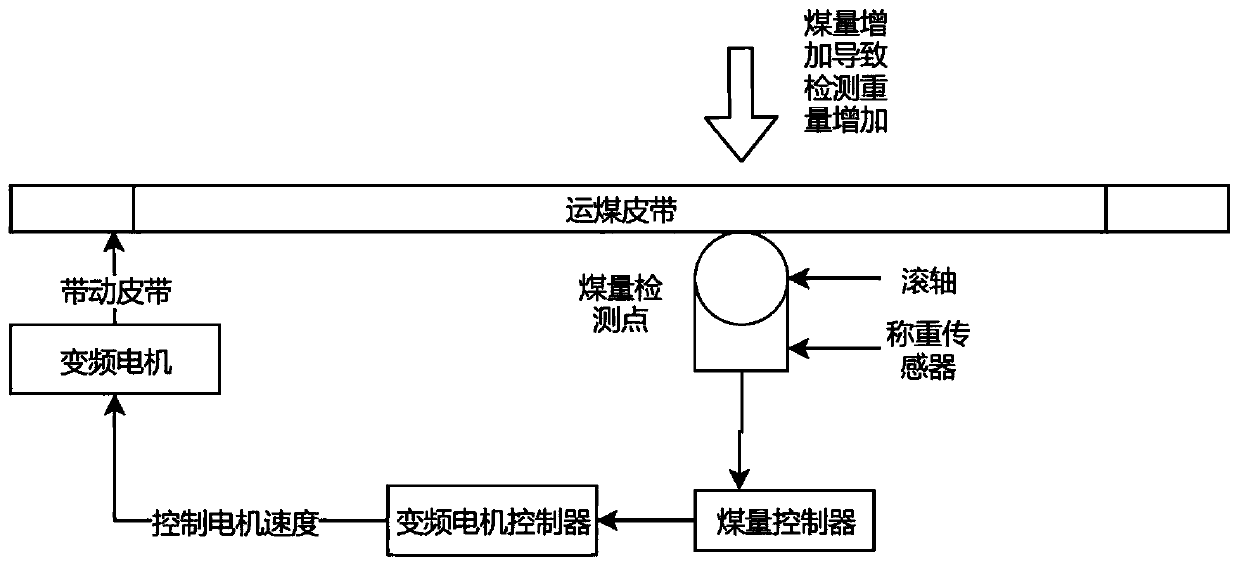

Mining coal transportation system

InactiveCN111086851AGuaranteed transportation efficiencyReduce consumptionConveyorsControl devices for conveyorsMining engineeringElectric machinery

The invention provides a mining coal transportation system. The mining coal transportation system comprises a coal loading and unloading device, a coal conveyor belt, a variable frequency motor, a coal quantity monitoring device and a controller, wherein the coal loading and unloading device is used for loading coal collected by a coal mining machine onto the coal conveyor belt; the coal conveyorbelt is used for transporting the coal in a conveying manner; the variable frequency motor is used for providing conveying power for the coal conveyor belt; the coal quantity monitoring device is usedfor monitoring the coal quantity on the coal conveyor belt; the controller is in communication connection with the coal loading and unloading device, the coal quantity monitoring device and the variable frequency motor; and the controller is used for monitoring the coal quantity on the coal conveyor belt through the coal quantity monitoring device and controlling the operation speed of the variable frequency motor according to the coal quantity on the coal conveyor belt. According to the technical scheme provided by the invention, the coal quantity monitoring device is arranged and is used for monitoring the coal quantity on the coal conveyor belt, so that the operation speed of the system is adjusted in real time according to the coal quantity on the coal conveyor belt; the power energyconsumed by the transportation system is reduced while the coal transportation efficiency is ensured.

Owner:QINGDAO CCS ELECTRIC CORP

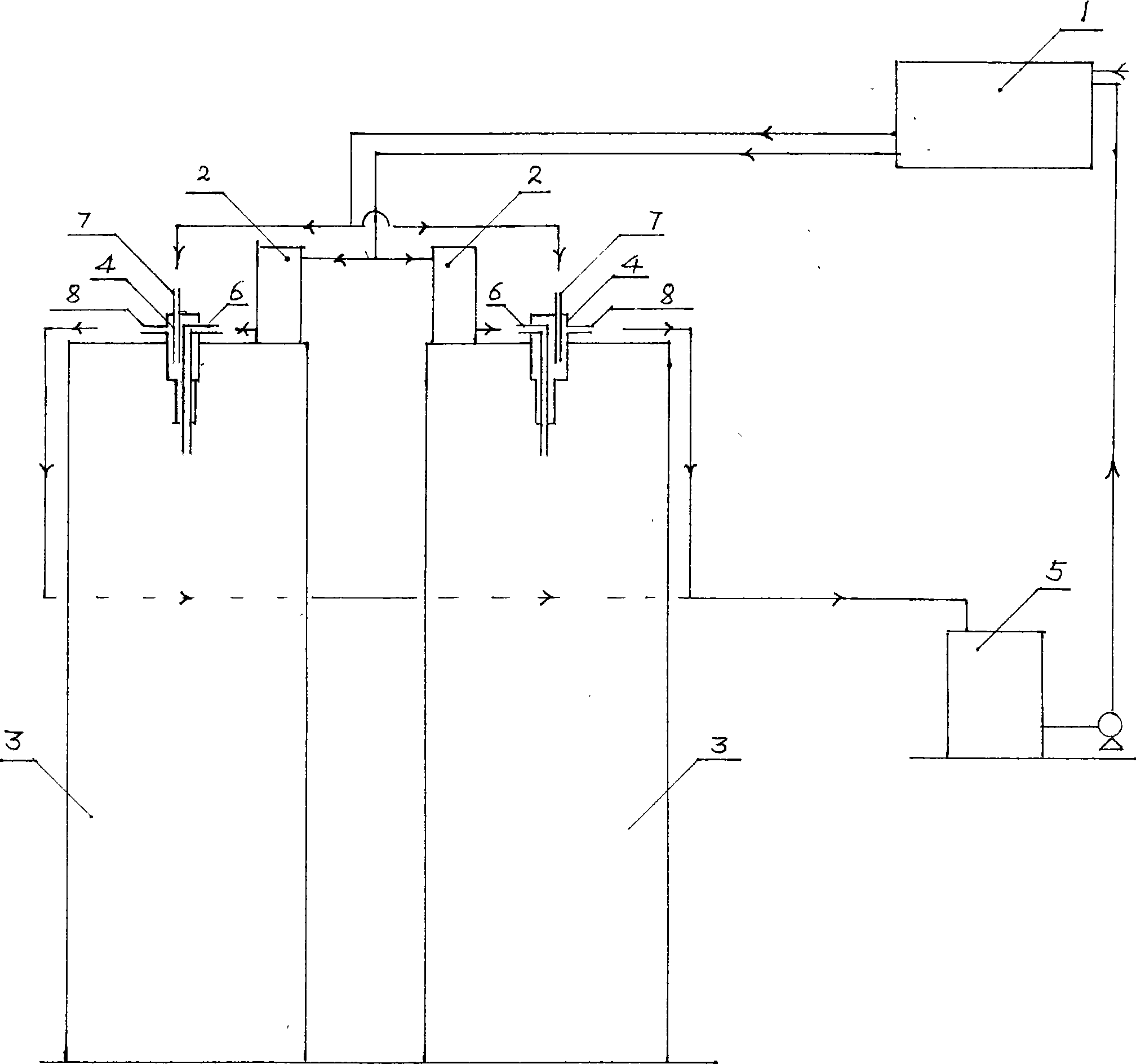

Energy-saving apparatus of active carbon activation furnace

The invention relates to an energy-saving device of an active carbon activation furnace, which comprises an elevated water tank (1), water storage tanks (2), regenerators (3), water jackets (4) and a low water tank (5). The device is provided with two regenerators (3) in parallel, the tops of the regenerators (3) are respectively provided with two water jackets (4), the external top ends of the regenerators (3) are respectively provided with two water storage tanks (2), the elevated water tank (1) is respectively connected with the water storage tanks (2) and the water jackets (4) by pipes, the water jackets (4) are connected with the low water tank (5) which is connected with the elevated water tank (1), a water inlet pipe (6) is respectively arranged inside the water jackets (4), one end of the water inlet pipe (6) is connected with the water storage tanks (2) and the other end of the water inlet pipe (6) is connected with the regenerators (3), one end of a water inlet pipe (7) arranged on the top of the water jackets (4) is connected with the elevated water tank (1) and the other end of the water inlet pipe (7) is connected with the water jackets (4), one end of a water outlet pipe (8) is connected with the water jackets (4) and the other end of the water outlet pipe (8) is connected with the low water tank (5). The device has the advantages of reducing the steam coal by 90%, lowering energy consumption and reducing pollution, and reducing the manufacturing cost of the active carbon.

Owner:山西华青环保股份有限公司

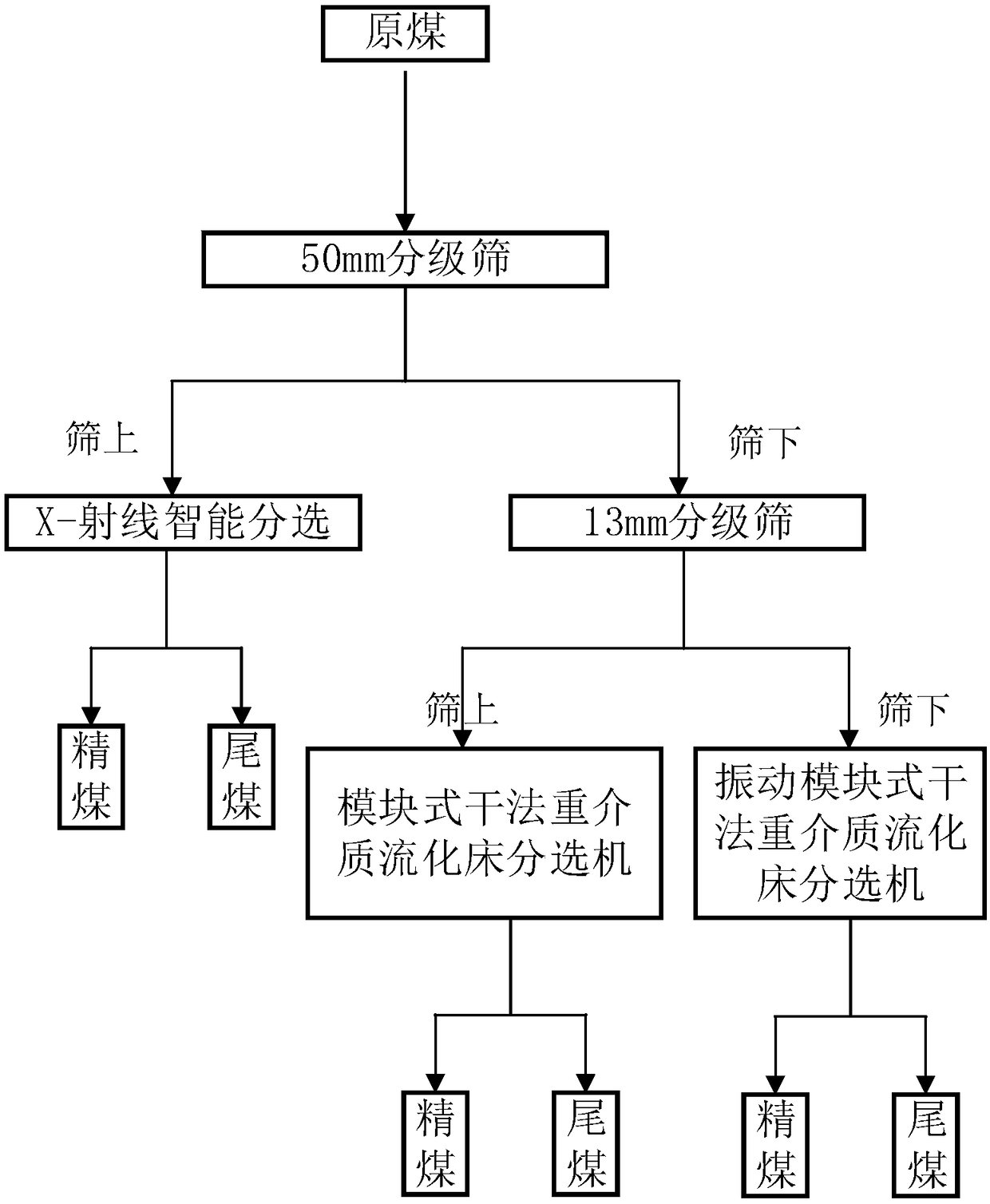

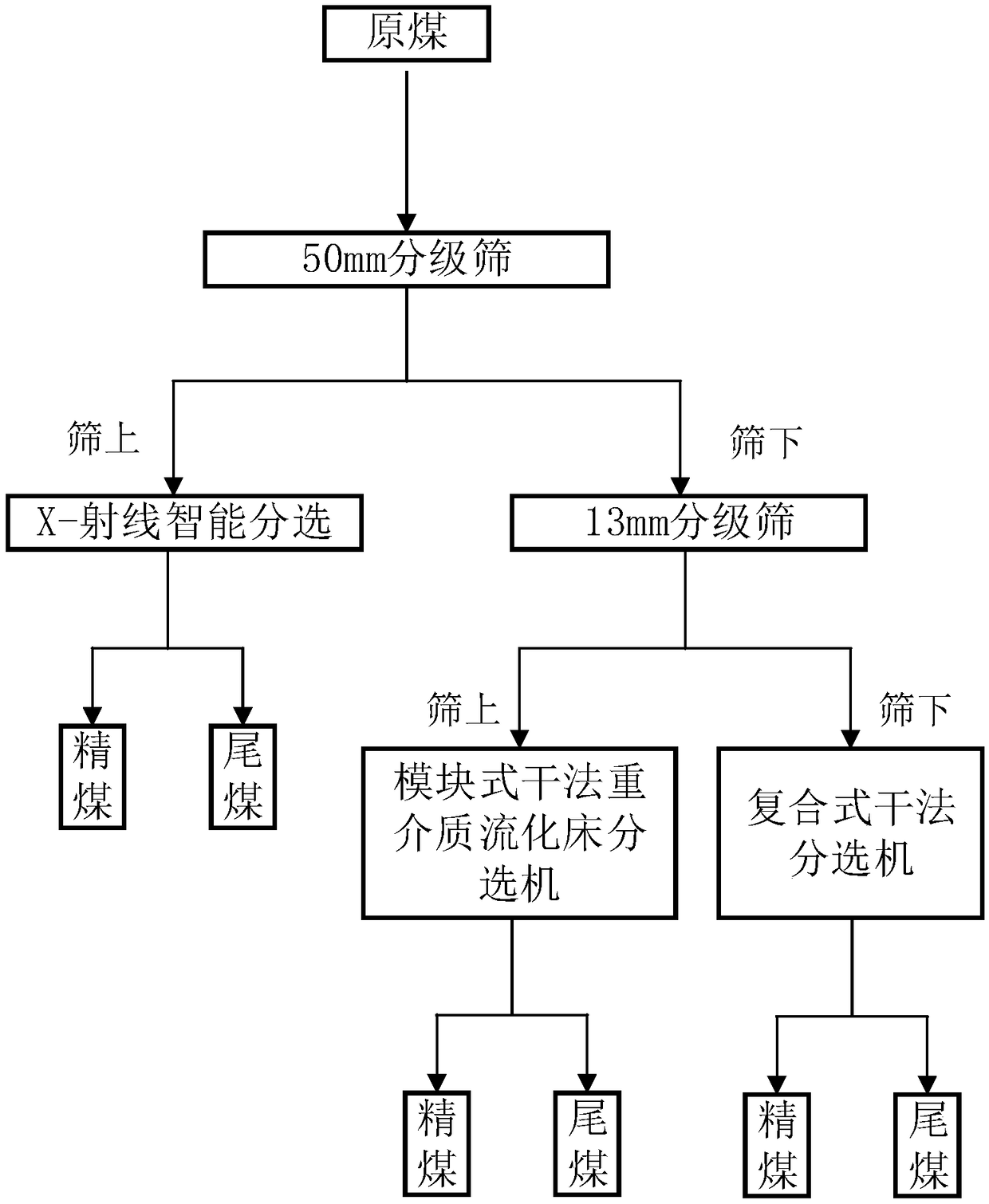

Steam coal full-grained dry upgrading gangue-discharging process

ActiveCN109482494ARealize sortingGuaranteed sorting accuracyGas current separationFluidized bedX-ray

The invention discloses a steam coal full-grained dry upgrading gangue-discharging process. A method adopts a full dry process. The process is mainly divided into three parts, namely X-ray intelligentseparation, coarse-grained coal dry separation and fine-grained coal dry separation. To-be-separated raw coal is screened and then divided into three granular grades, and screened products with the three granular grades of plus 50 mm, 13-50 mm and minus 13 mm enter an X-ray intelligent separator, a modular dry heavy medium fluidized bed dry separator and a fine-grained dry separator to obtain cleaned coal and tailings. The process flow is simple, the separation efficiency is high, energy consumption is low, no water is used, the production cost is low, and economic benefits are good.

Owner:CHINA UNIV OF MINING & TECH

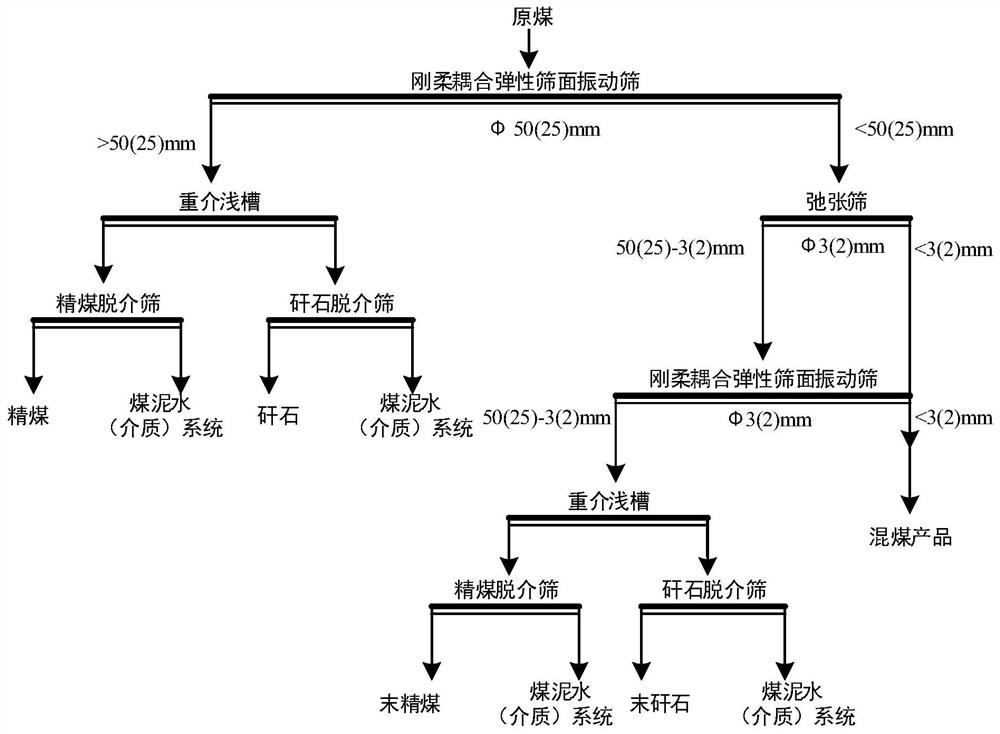

Multi-stage screening and fine coal removal type preparation method of sized raw coal of power coal

The invention discloses a multi-stage screening and fine coal removal type preparation method of sized raw coal of power coal. The method comprises the following steps that dry grading of one of 50mm, 25mm and 13mm is conducted on raw coal through a first rigid-flexible coupling elastic screen surface vibrating screen, oversize materials larger than 50 (25 / 13) mm are fed into a dense medium shallow slot sorting machine for sorting, and medium drainage and dewatering are conducted on light products and heavy products obtained after sorting to obtain clean coal and gangue products; undersize materials enter a flip-flow screen of 3 mm or 2 mm to be subjected to dry grading; the oversize material of the flip-flow screen enters a second rigid-flexible coupling elastic screen surface vibrating screen of 3mm or 2mm for dry fine coal removal, and the undersize material of second rigid-flexible coupling elastic screen surface vibrating screen of the 3mm or 2mm and the undersize material of the flip-flow screen of the 3mm or 2mm are used as a mixed coal product; and the light and heavy products obtained after the 50 (25 / 13)-3 (2) mm oversize materials are sorted by the dense medium shallow slot sorting machine are subjected to medium drainage and dewatering to obtain the clean coal and the gangue products. According to the multi-stage screening and fine coal removal type preparation method of sized raw coal of the power coal, the raw coal selection rate is high, the sorting precision is high, the load of a slime water system is small, and the method has the remarkable effect on treating viscous and wet power coal prone to argillization.

Owner:SHENHUA BAOTOU ENERGY CO LTD

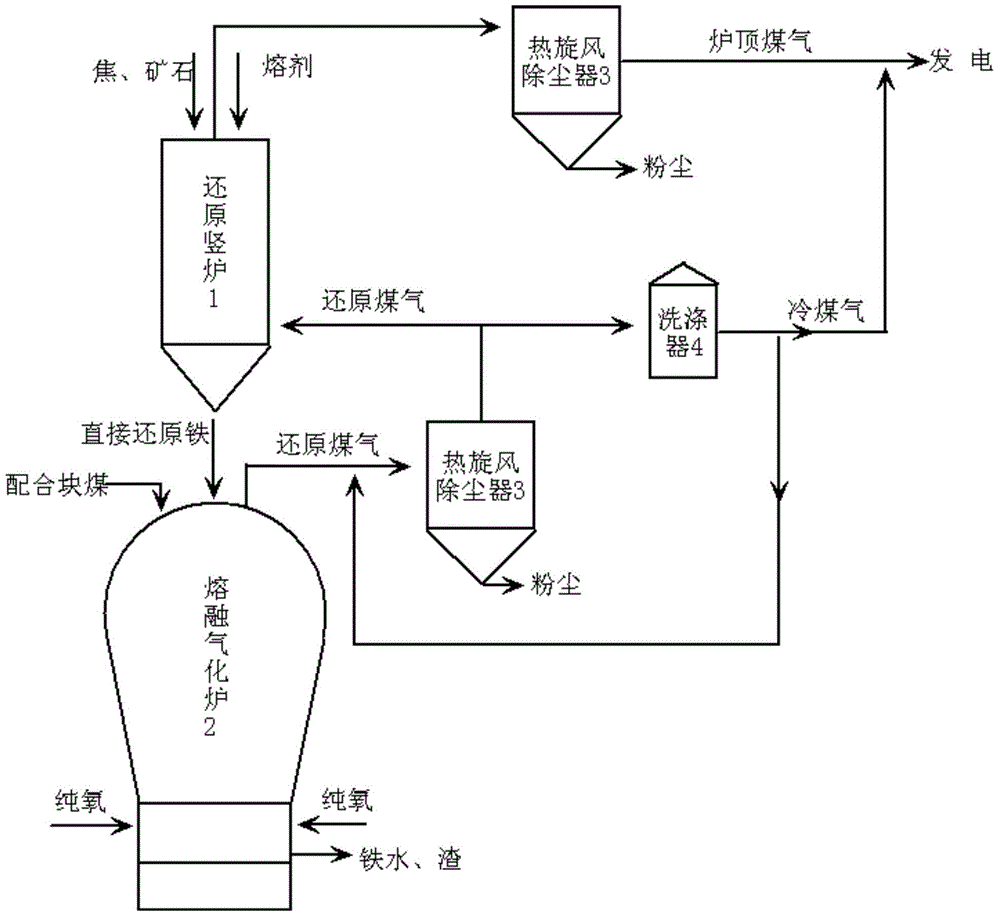

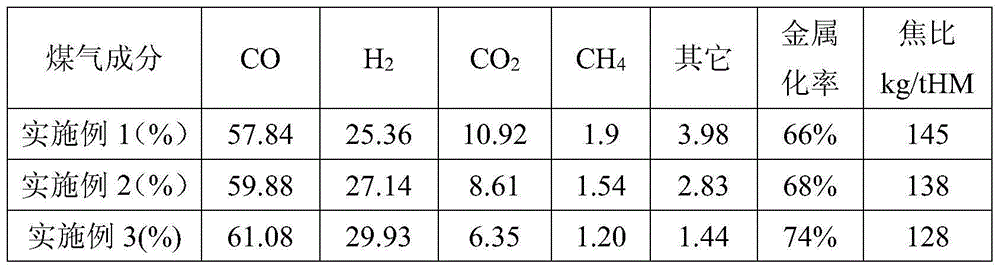

COREX method for reducing coal gas components through coal gas blending adjustment

The invention discloses a COREX method for reducing coal gas components through coal gas blending adjustment. The COREX method comprises the following steps: step I, coal blending, wherein the types of several kinds of lump coal are gas coal (Ad=4-5, Vd=37-42), steam coal 1 (Ad=5-6, Vd=26-30) and steam coal 2 (Ad=2-3, Vd=24-26); the particle size of the three kinds of coal is 0-60 mm; the supplying amount of the gas coal takes up 38-42% of the weight of the whole matching coal; the supplying amount of the steam coal 1 takes up 18-21% of the weight of the whole matching lump coal; the supplying amount of the steam coal 2 takes up 37-44% of the weight of the whole matching lump coal. According to the COREX method, through the cooperation of different lump coal, the effective components in reduced coal gas are increased, the reduction metallization ratio of ore is increased, the coke consumption during the COREX reduction process is reduced, and the production cost is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

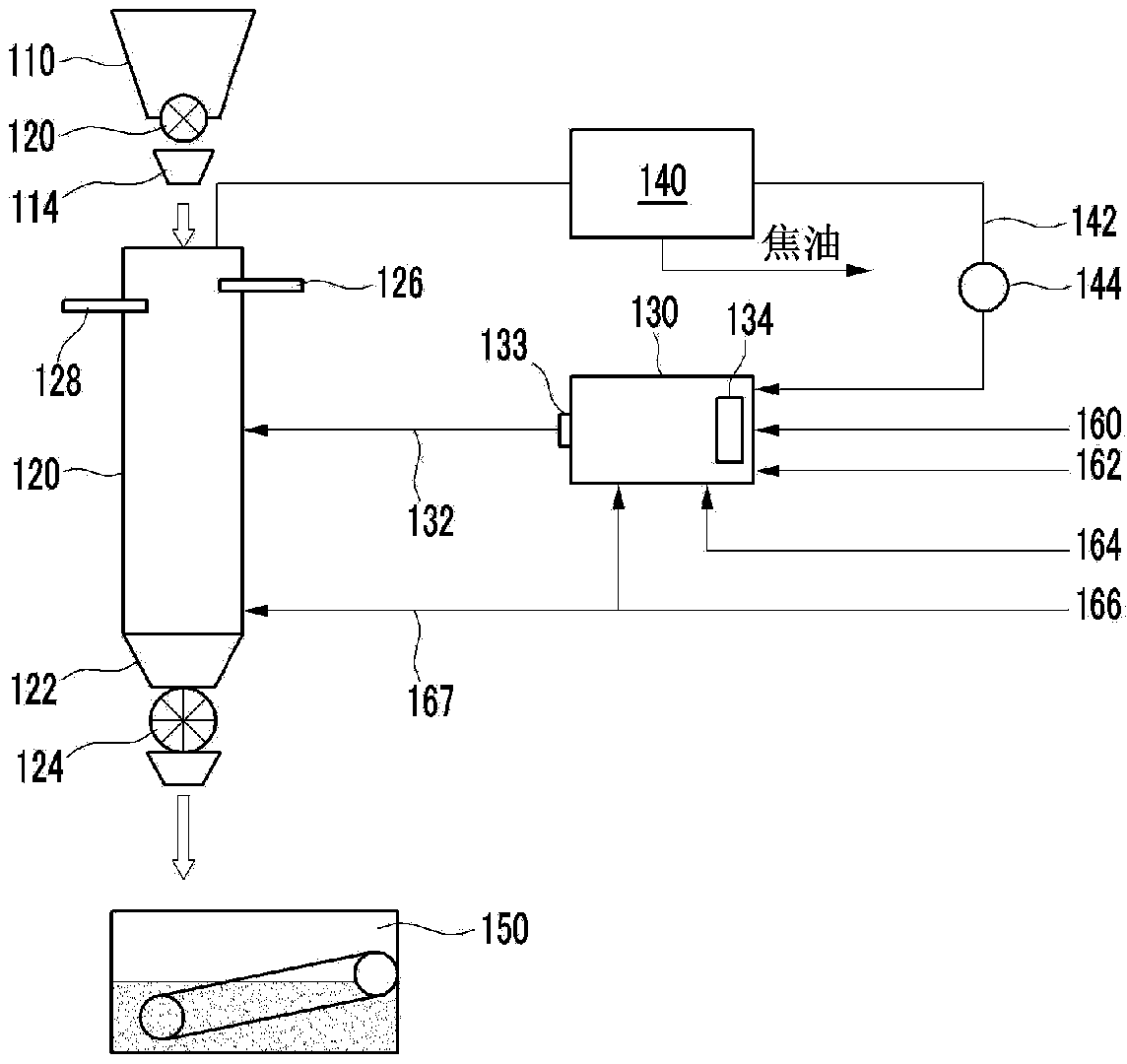

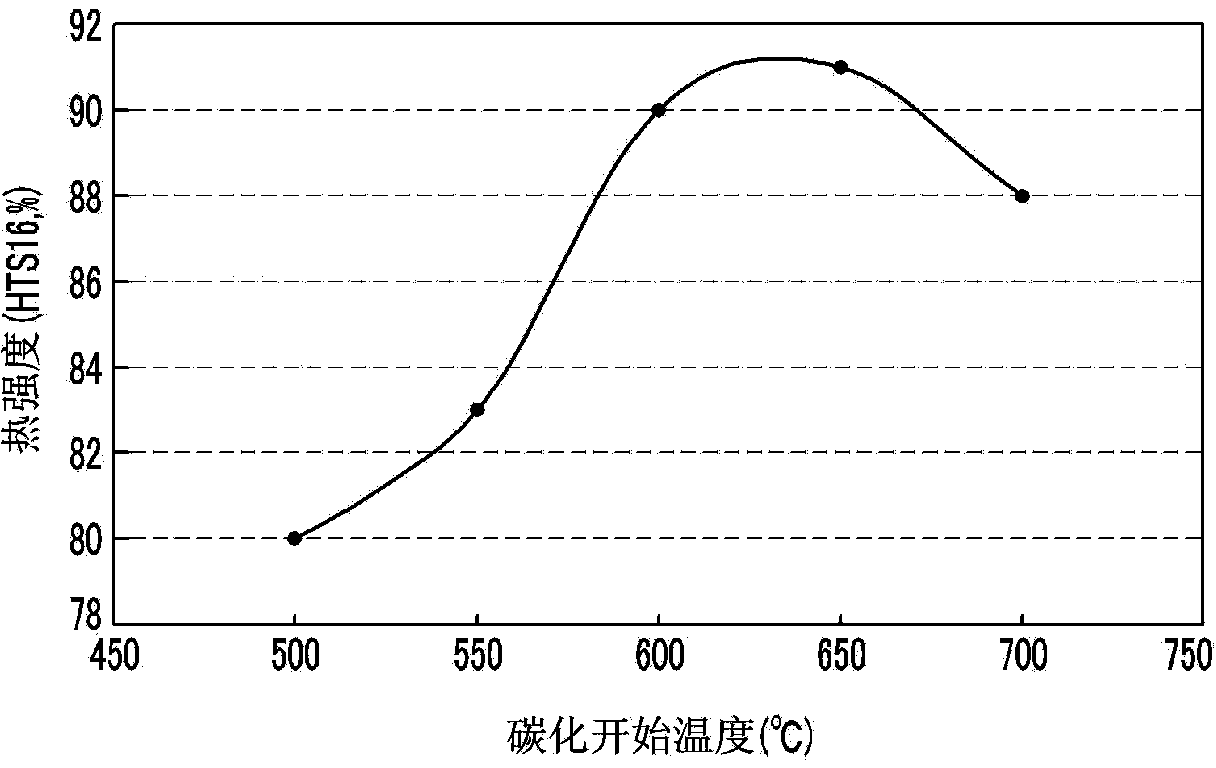

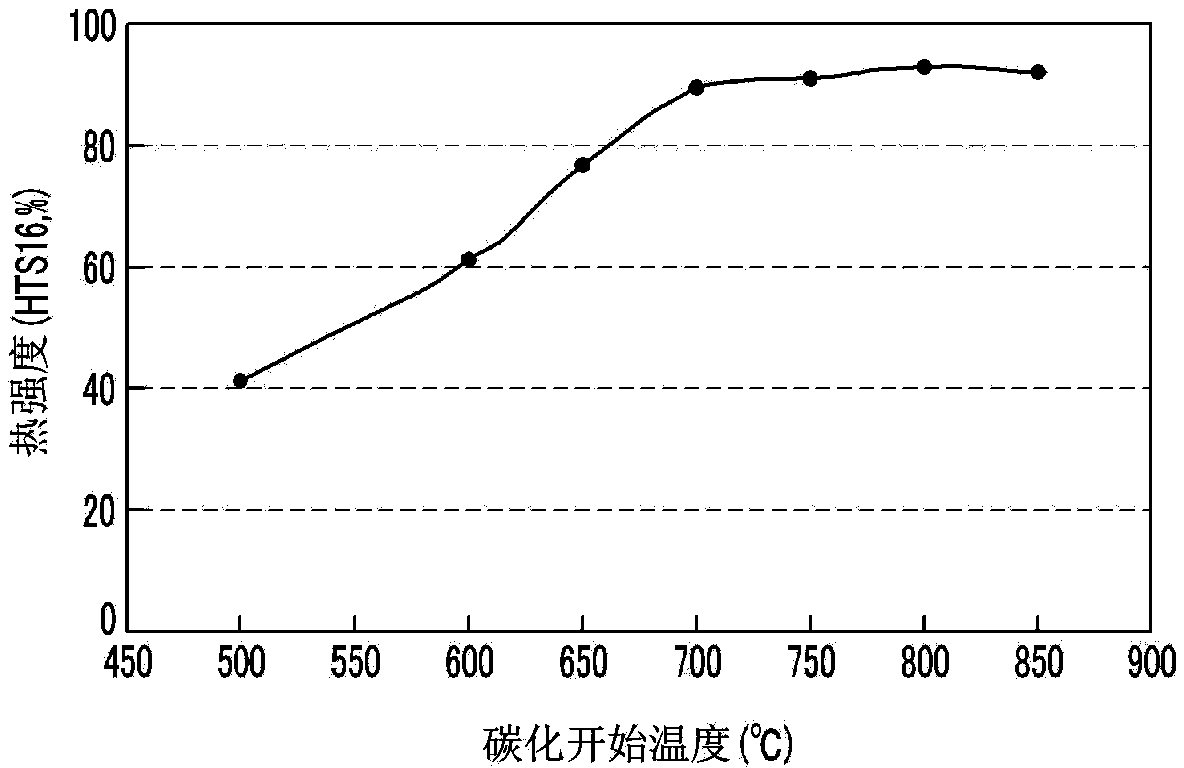

Method for manufacturing partially carbonized coal briquettes, apparatus for manufacturing partially carbonized coal briquettes, and apparatus for manufacturing molten iron

InactiveCN103370396AHigh heat intensityDirect heating destructive distillationBiofuelsCoal briquetteIron powder

Disclosed are an apparatus and a method for manufacturing molten iron. The apparatus for manufacturing molten iron according to the present invention includes: a multi-stage fluidization furnace for converting a fine iron ore into a fine direct reduced iron by reduction; at least one high temperature agglomerating apparatus for pressing the fine direct reduced iron to manufacture a high temperature agglomerate; at least one pulverizing apparatus for pulverizing the high temperature agglomerate to a predetermined particle size; a first transporting apparatus for transporting the pulverized high temperature agglomerate; and a melting furnace for melting the transported high temperature agglomerate by combusting a powder-type or agglomerate-type steam coal and supplying a reduced gas generated in the furnace to a fluidization reduction furnace. Further, at least one agglomerate storing bath for storing a portion of the pulverized high temperature agglomerate is further included. The molten iron can be stably and efficiently manufactured by applying the present invention.

Owner:POHANG IRON & STEEL CO LTD

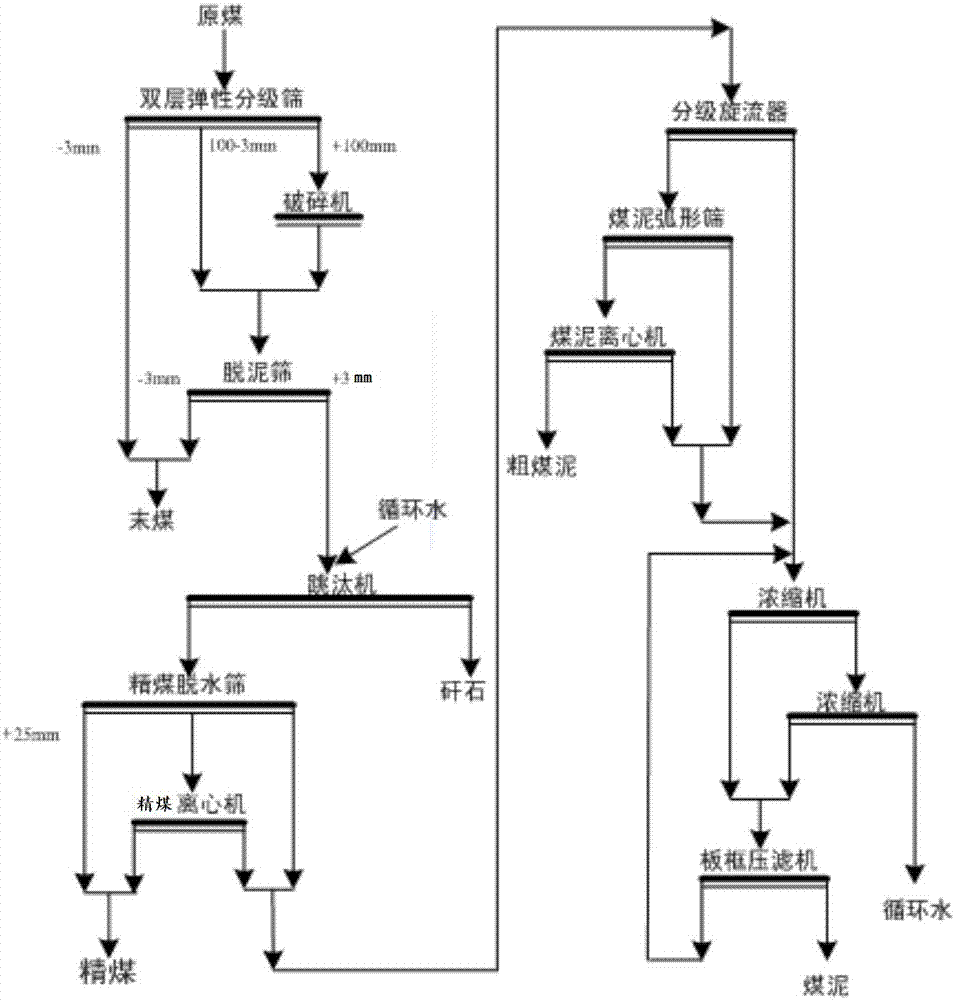

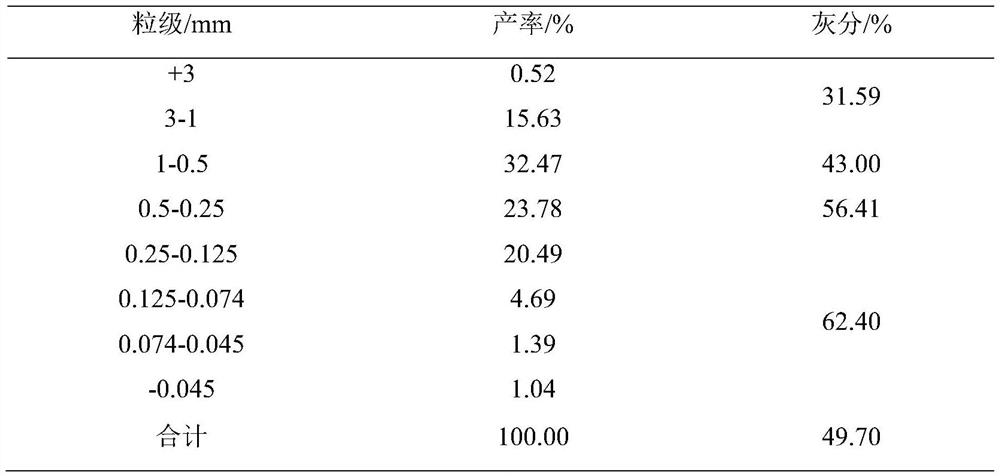

Steam coal separation method

ActiveCN109731674AImprove sorting conditionsHigh recovery rateWet separationCycloneProcess engineering

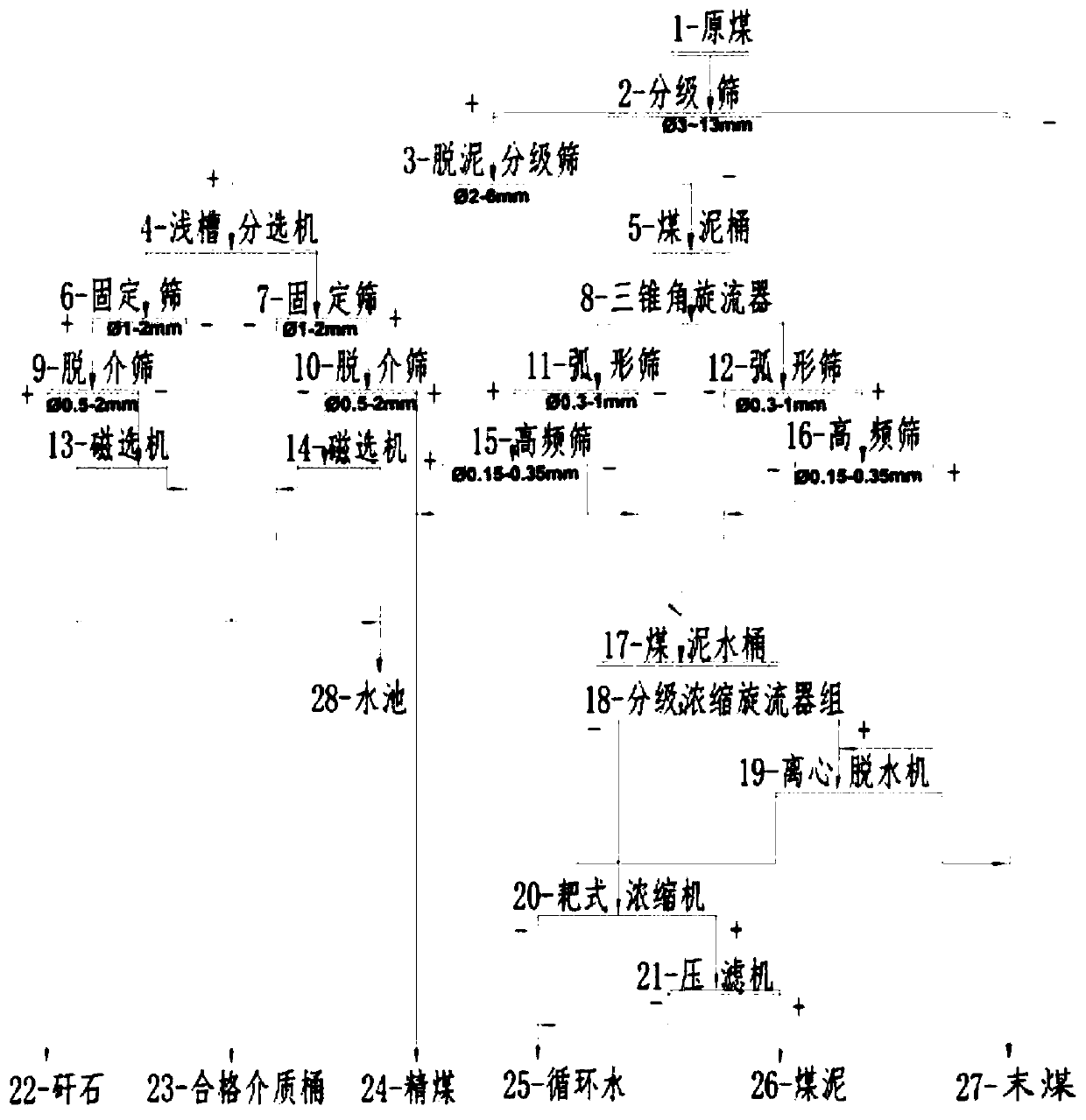

The invention provides a steam coal separation method, and belongs to the technical field of coarse coal slime separation. The steam coal separation method comprises the following steps that (1), rawsteam coal is classified through a classifying screen, and classifying screen oversize products are obtained; (2), the classifying screen oversize products obtained in the step (1) are de-slimed through a de-sliming classifying screen, and de-sliming classifying screen oversize products and coal slime are obtained; (3), the de-sliming classifying screen oversize products obtained the step (2) areseparated through a dense-medium separator, and coarse clean coal is obtained; (4), the coarse clean coal obtained in the step (3) sequentially passes through a fixed screen and a medium removing screen, and clean coal I is obtained; and (5), the coal slime obtained in the step (2) is separated through a tri-cone angular cyclone, obtained overflow sequentially passes through an arc-shaped screen and a high-frequency screen, and clean coal II is obtained. According to the steam coal separation method, the coal slime is separated again through the tri-cone angular cyclone to produce the clean coal, the problem that the clean coal is mixed in de-sliming classifying screen undersize coal slime is solved, the recovery rate of the steam coal clean coal is increased, and meanwhile the separationprecision and the hour treatment capability are improved.

Owner:SHANDONG UNIV OF SCI & TECH

Non-quantitative washing method for low-quality coal slime

PendingCN112871441AReduce the phenomenon of cementingReduce the amount of slimeWaste processingSolid separationEconomic benefitsProcess engineering

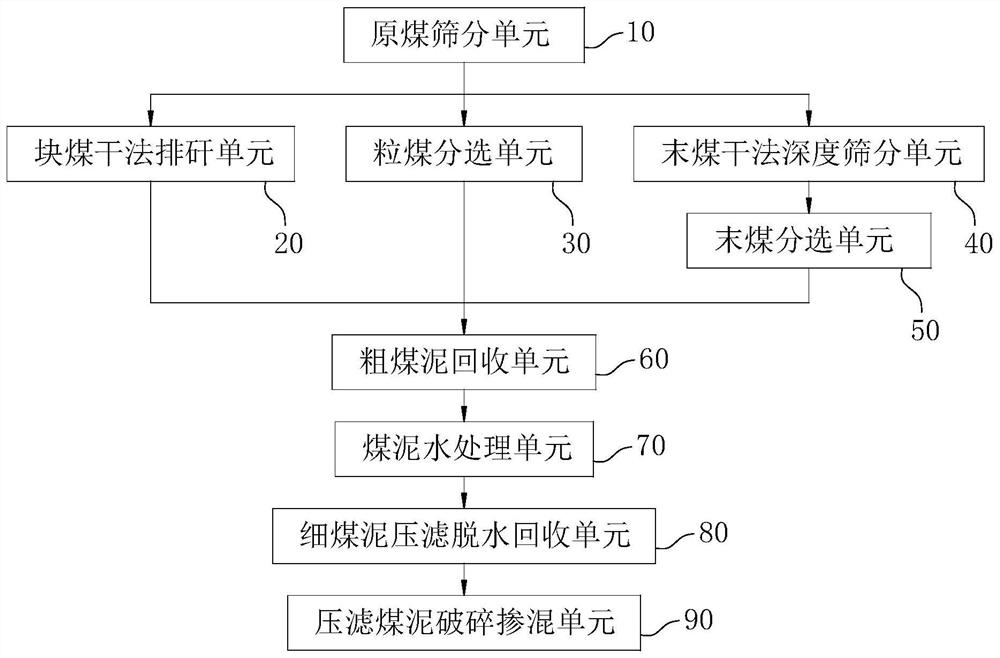

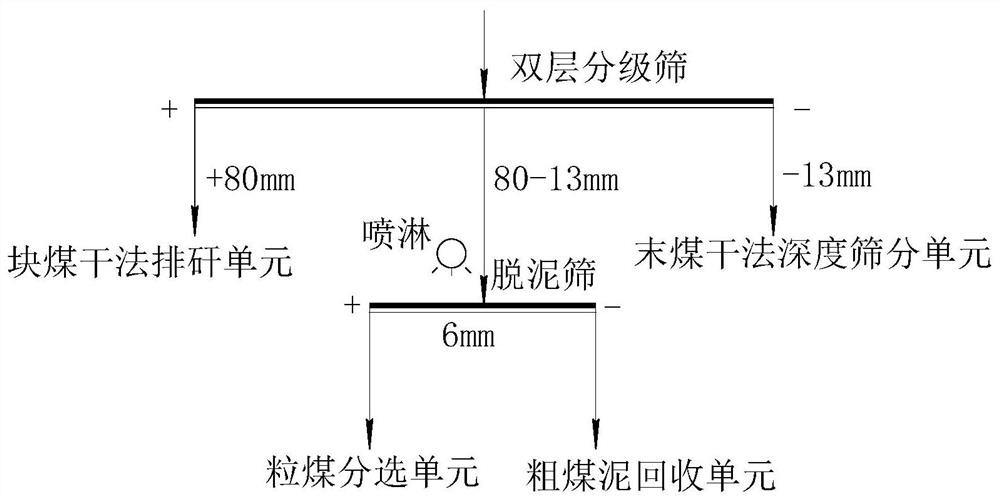

The invention belongs to the technical field of coal slime recovery of power coal preparation plants, and particularly relates to a non-quantitative washing method for low-quality coal slime. The method comprises a raw coal screening unit, a lump coal dry-method gangue discharging unit, a pea coal sorting unit, a slack coal dry-method deep screening unit, a slack coal sorting unit, a coarse slime recycling unit, a slime water treatment unit, a fine slime filter-pressing dehydration recycling unit and a filter-pressing slime crushing and mixing unit which are sequentially arranged along the washing process. According to the method, coal slime non-landing operation can be achieved, the links of forklift transfer, automobile transportation and the like are omitted, the environmental protection problem caused by coal slime sales is thoroughly solved, the effects of coal slime landing non-quantification, commercial coal yield maximization, water resource utilization saving and economic benefit noticing are achieved, the utilization limitation of coal slime products is broken through, effective resource configuration is optimized, and the actual economic benefits of enterprises can be effectively improved.

Owner:ANHUI UNIV OF SCI & TECH

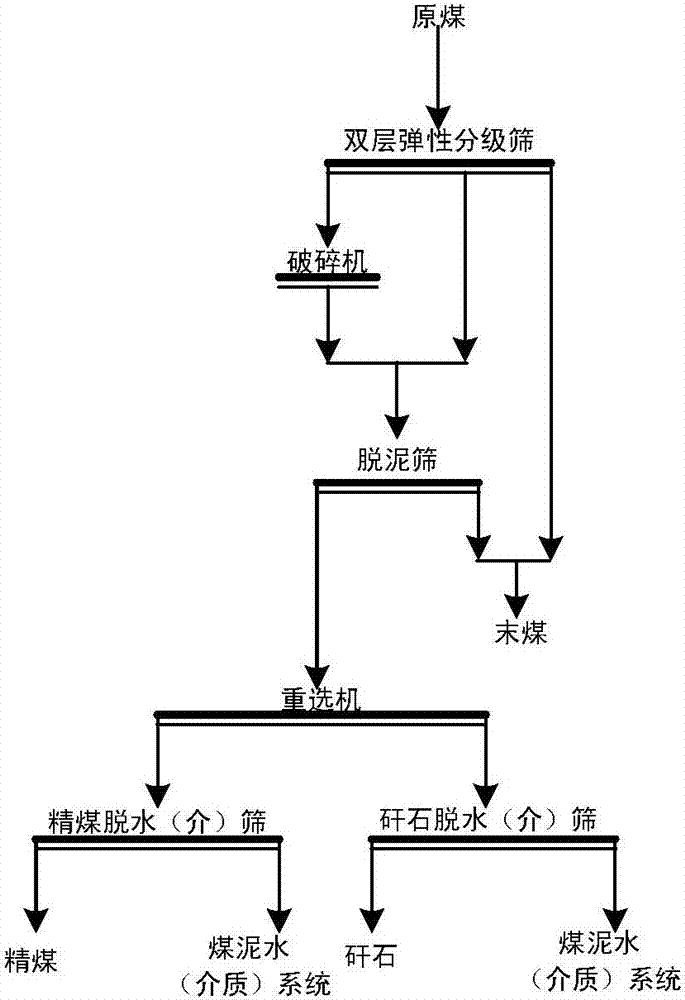

Steam coal separation process

ActiveCN107008566AWiden the proportion of selectedIncrease the proportion of selectedSievingScreeningWater treatment systemProcess engineering

The invention discloses a steam coal separation process. The steam coal separation process comprises the steps that raw coal is subjected to dry method deep classification through a double-layer elastic classifying screen, first-layer plus sieve materials of the double-layer elastic classifying screen enter a crusher, the first-layer plus sieve materials after crushing and second-layer plus sieve materials of the double-layer elastic classifying screen enter a desliming screen together to be subjected to dry desliming, and minus sieve materials of the double-layer elastic classifying screen and minus sieve materials of the desliming screen serve as slack coal products; plus sieve materials of the desliming screen enter a gravity separator for separation, light products and heavy products after separation are subjected to medium removal and dehydration, then clean coal and gangue products are obtained, minus sieve materials after medium removal and dehydration enter a slime water treatment system to be treated, and washing water closed cycle of the system is realized. The steam coal separation process is simple, production is steady and efficient, the steam coal separation has the advantages that the preparation proportion is high, the feed size range is wide, separation precision and adaptability are high, production cost is low and the like, and good economical and practical benefits are achieved.

Owner:CHINA UNIV OF MINING & TECH

Preparation method of composite pulverized coal added with cold-rolled waste emulsion residues, and composite pulverized coal

The invention discloses a preparation method of composite pulverized coal added with cold-rolled waste emulsion residues, and the composite pulverized coal. The preparation method of the composite pulverized coal added with the cold-rolled waste emulsion residues comprises the following steps of firstly placing the cold-rolled waste emulsion residues and economizer fallout ash into a stirrer according to a certain weight proportion, fully stirring uniformly to obtain a mixture; placing the mixture and steam coal into the stirrer according to a certain weight proportion, stirring, and then placing into a coal pulverizer, and powdering to obtain the composite pulverized coal. The preparation method of the composite pulverized coal added with the cold-rolled waste emulsion residues provided by the invention is simple in preparation process, simple and convenient to operate, and low in preparation cost, the cold-rolled waste emulsion residues are recycled, and the production cost of the pulverized coal is reduced.

Owner:MAANSHAN IRON & STEEL CO LTD

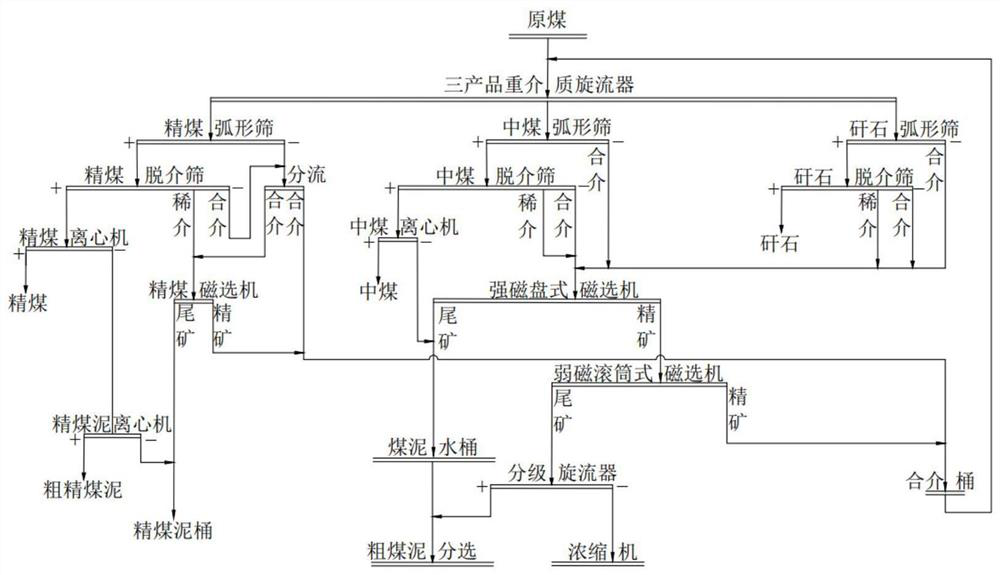

Complete magnetic separation technology for intermediate gangue qualified media of power coal prone to argillization

ActiveCN112138856AReduce yieldGuaranteed disengagementWet separationThermodynamicsMagnetic separator

The invention provides a complete magnetic separation technology for intermediate gangue qualified media of power coal prone to argillization. The technology includes the following steps that a middling coal and gangue suspension liquid subjected to dense medium separation is subjected to medium removal screening to form oversize materials, qualified media and dilute media; the qualified media andthe dilute media are merged and enter an intermediate gangue magnetic tail barrel; the intermediate gangue magnetic tailing barrel is fed into a strong magnetic disc type magnetic separator for roughing and is divided into concentrates and tailings; the magnetic separation tailings enter a coal slime bucket, and the magnetic separation concentrates enter a drum-type magnetic separator for concentration and are divided into concentrates and tailings; the magnetic separation concentrates return to a qualified medium barrel, and the magnetic separation tailings are divided into underflow and overflow through a grading cyclone; the underflow of the grading hydrocyclone is fed into coarse slime separation equipment or is doped with a gangue product, and the overflow of the grading hydrocycloneenters a thickener. According to the technology, high-ash fine silt in the intermediate gangue qualified media is completely discharged through two times of magnetic separation, the situations that repeated circulation of the high-ash fine silt intensifies gangue argillization and deteriorates the medium recovery and slime water treatment effects are avoided, and an effective means is provided for sufficient medium recovery and slime water treatment pressure reduction.

Owner:CHINA UNIV OF MINING & TECH

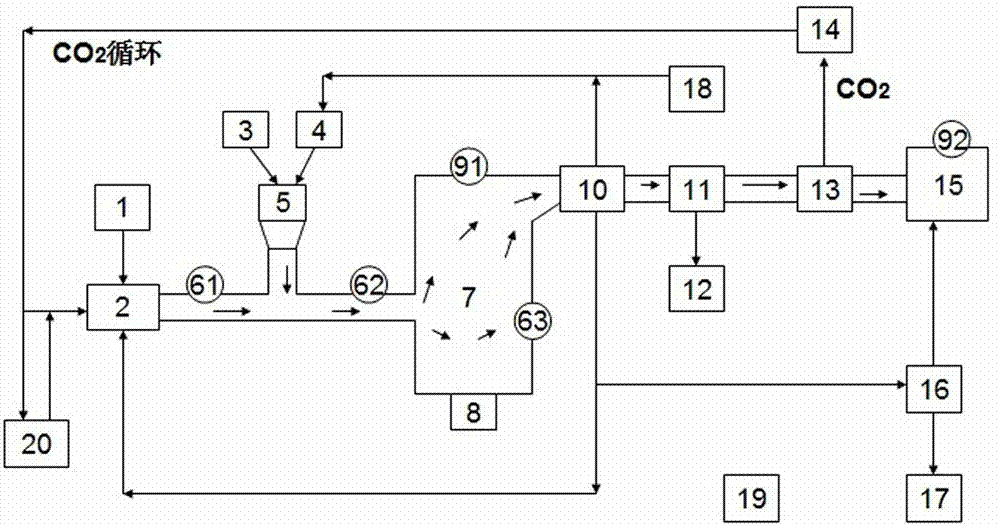

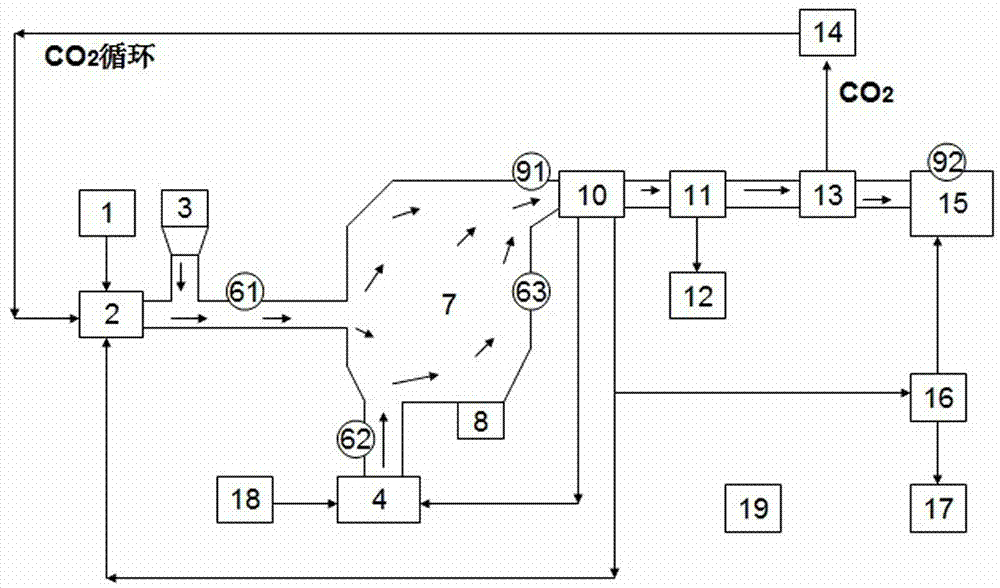

Coal pyrolysis gasification polygeneration device and process based on circulating fluidized bed

InactiveCN103881761BRealize hierarchical optimization utilizationTo solve the purpose of efficient purificationFluidized bed combustionCombustible gas productionElectricityCombustion

The invention discloses a coal pyrolysis gasification poly-generation device and process based on a circulating fluidized bed. A circulating fluidized bed boiler is organically coupled with a moving bed coal pyrolysis reactor and a moving bed gasification furnace, the high temperature circulation ash of the circulating fluidized bed boiler is used as a carrier for pyrolyzing high volatile coal steam coal from a coal funnel in the moving bed coal pyrolysis reactor, the semicoke generated in pyrolysis is separated out from the pyrolysis reactor and is fed into the moving bed gasification furnace for gasification, and at the same time the moving bed gasification furnace is used as a device for purifying a pyrolysis coal gas, thereby achieving the function of on-line dust collection of the pyrolysis coal gas. The gasified activated coke as a byproduct is discharged outside the reaction system. Therefore, through organic combination of three procedures, including pyrolysis, gasification and combustion, graded optimized utilization of the coal resource is achieved, joint production of heat, electricity, tar, coal gas and activated coke is achieved, and meanwhile the purposes of gasifying the coal gas and efficiently purifying the pyrolysis coal gas are achieved.

Owner:SHANXI LUAN MINING GRP +1

Remote explosion-proof hydrogen production device for recycling coalified carbon dioxide and technology thereof

The invention relates to the field of hydrogen production, and particularly relates to a remote explosion-proof hydrogen production device for recycling coalified carbon dioxide and a technology thereof. The technology comprises the following steps: 1) turning on a power switch; 2) turning on a solar steam generator valve, feeding the water vapor to a steam coal slurry spray machine and carrying out coal slurry treatment on the coal fed by an intelligent coal feeder; 3) turning on a spare CO2 tank valve, so that the CO2 reacts with coal slurry after passing through a plasma torch generator; 4) feeding a reaction gas to a vapor generating set and the formed vapor to the vapor tank; 5) feeding the cooled gas to a purifier to purify; and 6) feeding the purified gas to a separator to separate. The remote explosion-proof hydrogen production device has the beneficial effects that 1, the remote explosion-proof hydrogen production device is simple and variable in structure, 2, zero pollution discharge is achieved, and CO2 is recycled, 3, the additional value is increased, and an integrated chain of hydrogen production, oxygen production and byproducts is built; 4, energy consumption is reduced by using solar energy in comparison with the traditional technology; and 5, the safety of a production line is effectively ensured.

Owner:程礼华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com