Steam coal full-grained dry upgrading gangue-discharging process

A full-grain, steam coal technology, applied in chemical instruments and methods, solid separation, separation of solids from solids by air flow, etc. Guaranteed sorting accuracy and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

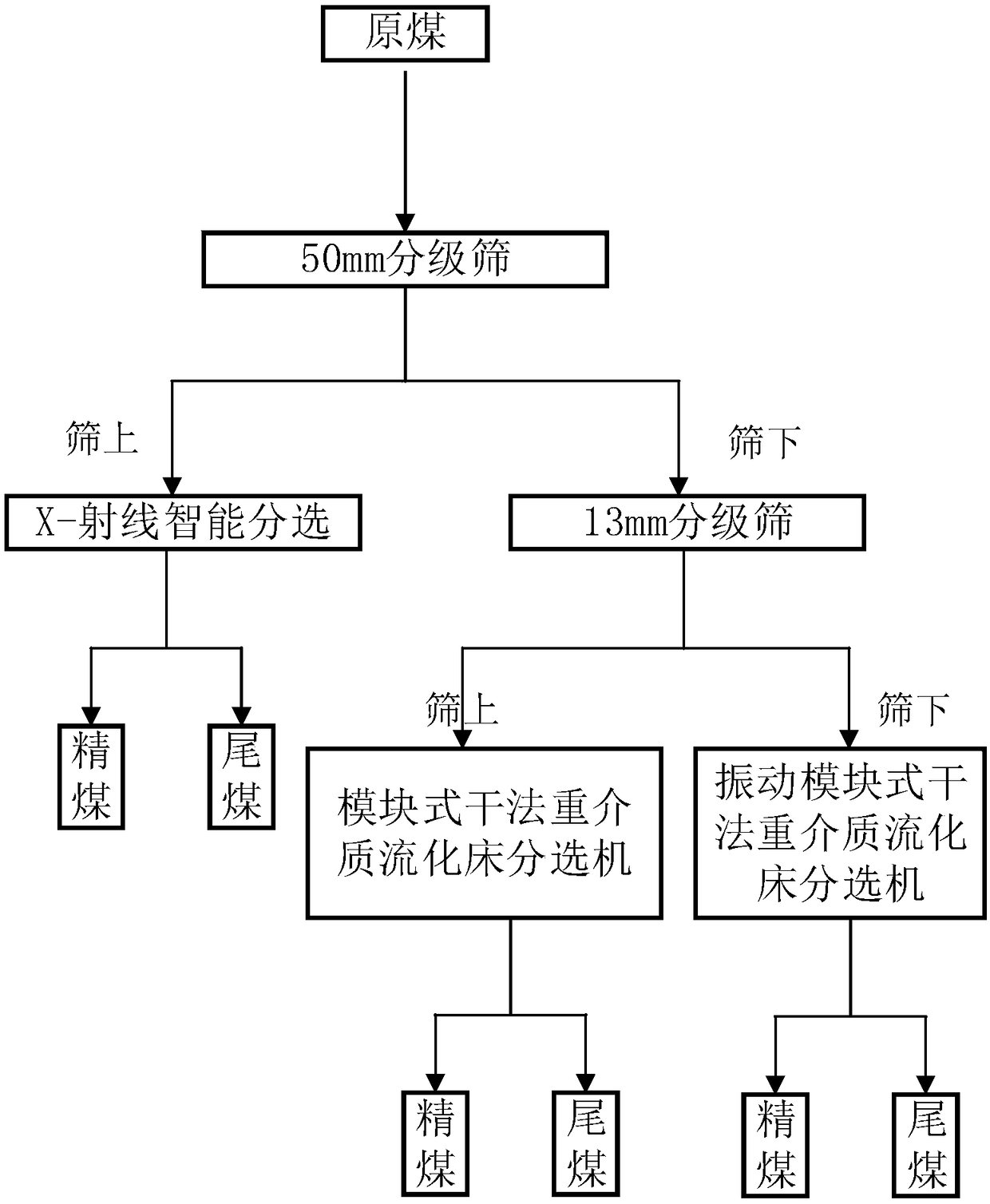

[0026] Such as figure 1 As shown, the process of this embodiment is suitable for coal with low raw coal moisture (less than 6%). Raw coal preparation: the incoming coal from the mine or coal storage yard is first classified through a 50mm grading sieve, and the +50mm raw coal on the sieve is sent to the X-ray intelligent sorting system for sorting through the conveyor belt to obtain large gangue and clean coal; -50mm raw coal enters The hole diameter is 13mm grading sieve for classification, and the +13mm raw coal on the sieve enters the dry separation of the modular dry heavy medium fluidized bed dry separation machine to obtain clean coal and tailing coal; the -13mm raw coal enters the fine-grained dry separation The machine is used for separation to obtain clean coal and tailing coal. In this embodiment, the fine-grained dry separation machine is a vibration module type dry heavy medium fluidized bed dry separation machine.

Embodiment 2

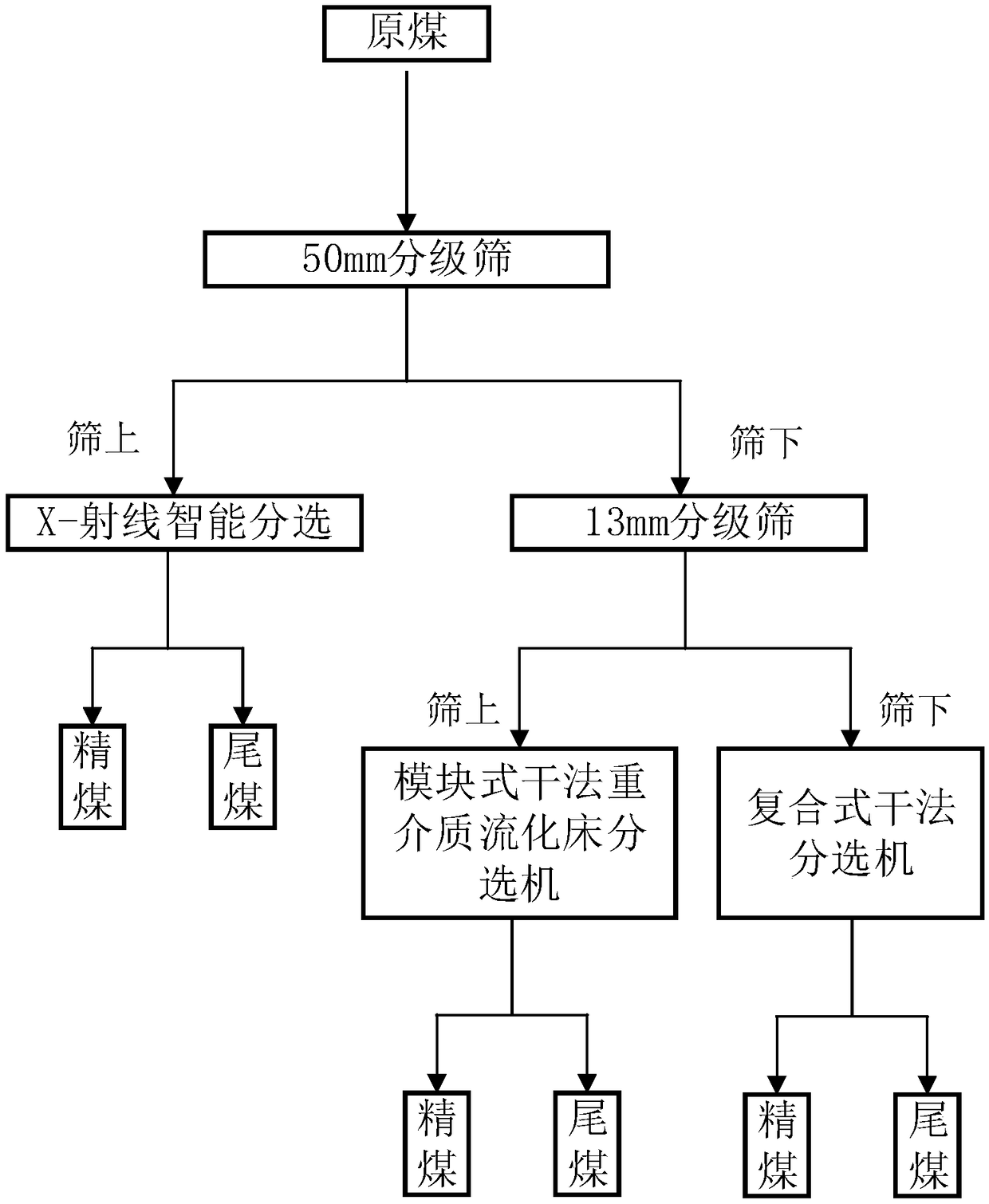

[0028] Such as figure 2 As shown, the process of this embodiment is suitable for coal with raw coal moisture higher than 6%. Raw coal preparation: the incoming coal from the mine or coal storage yard is first classified through a 50mm grading sieve, and the +50mm raw coal on the sieve is sent to the X-ray intelligent sorting system for sorting through the conveyor belt to obtain large gangue and clean coal; -50mm raw coal enters The hole diameter is 13mm grading sieve, and the +13mm raw coal on the sieve enters the modular dry heavy medium fluidized bed dry separator or the composite dry separator for dry separation to obtain clean coal and tailing coal; -13mm The raw coal enters the composite dry separator for separation to obtain clean coal and tailing coal. In this embodiment, the fine-grained dry separator selects the composite dry separator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com