Patents

Literature

1047results about How to "Improve sorting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

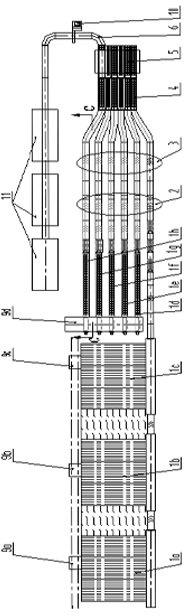

Comprehensive treating system for domestic wastes

InactiveCN102527701AIncrease productionImprove qualityBio-organic fraction processingWaste processingSludgeOrganic manure

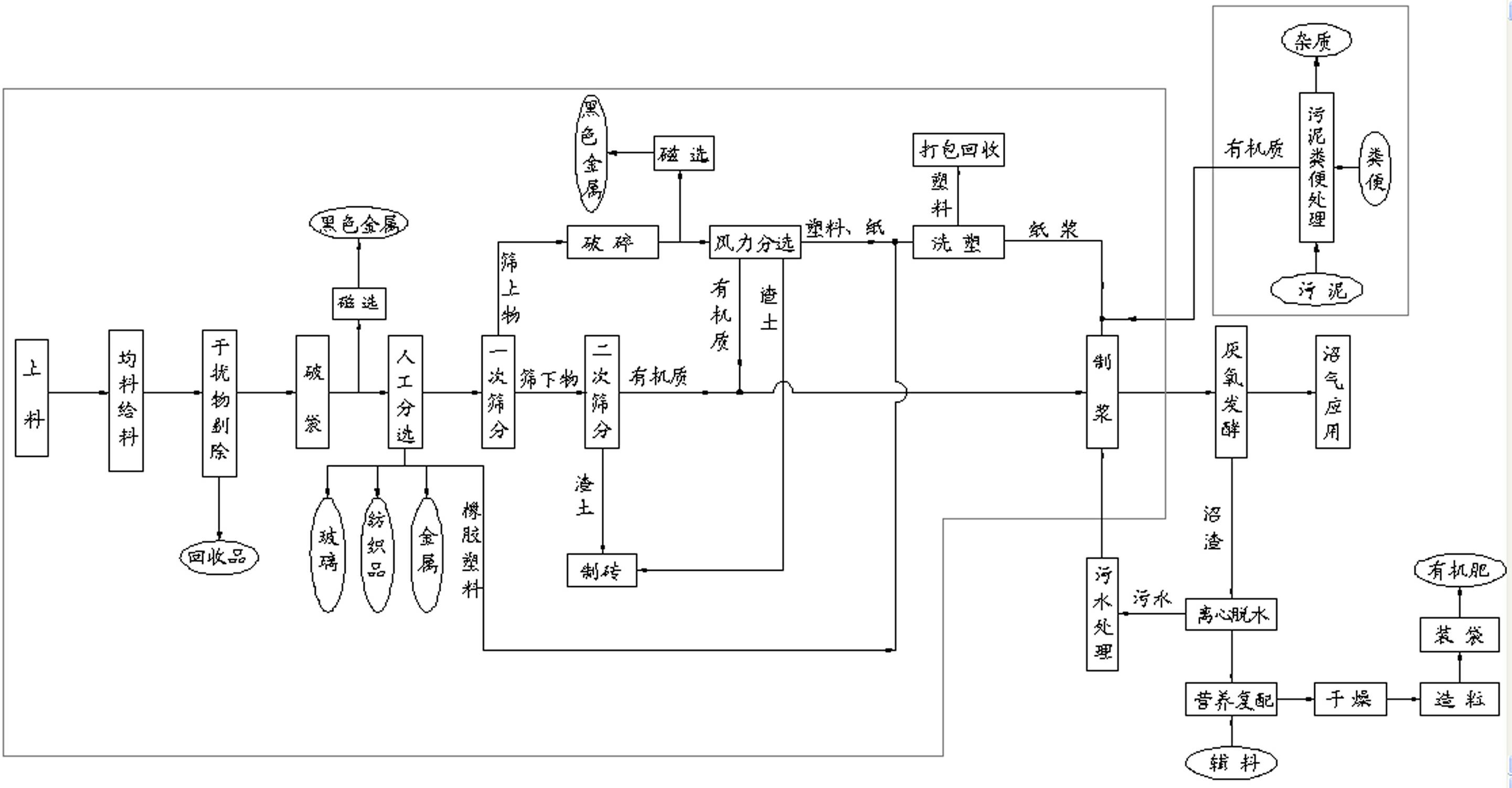

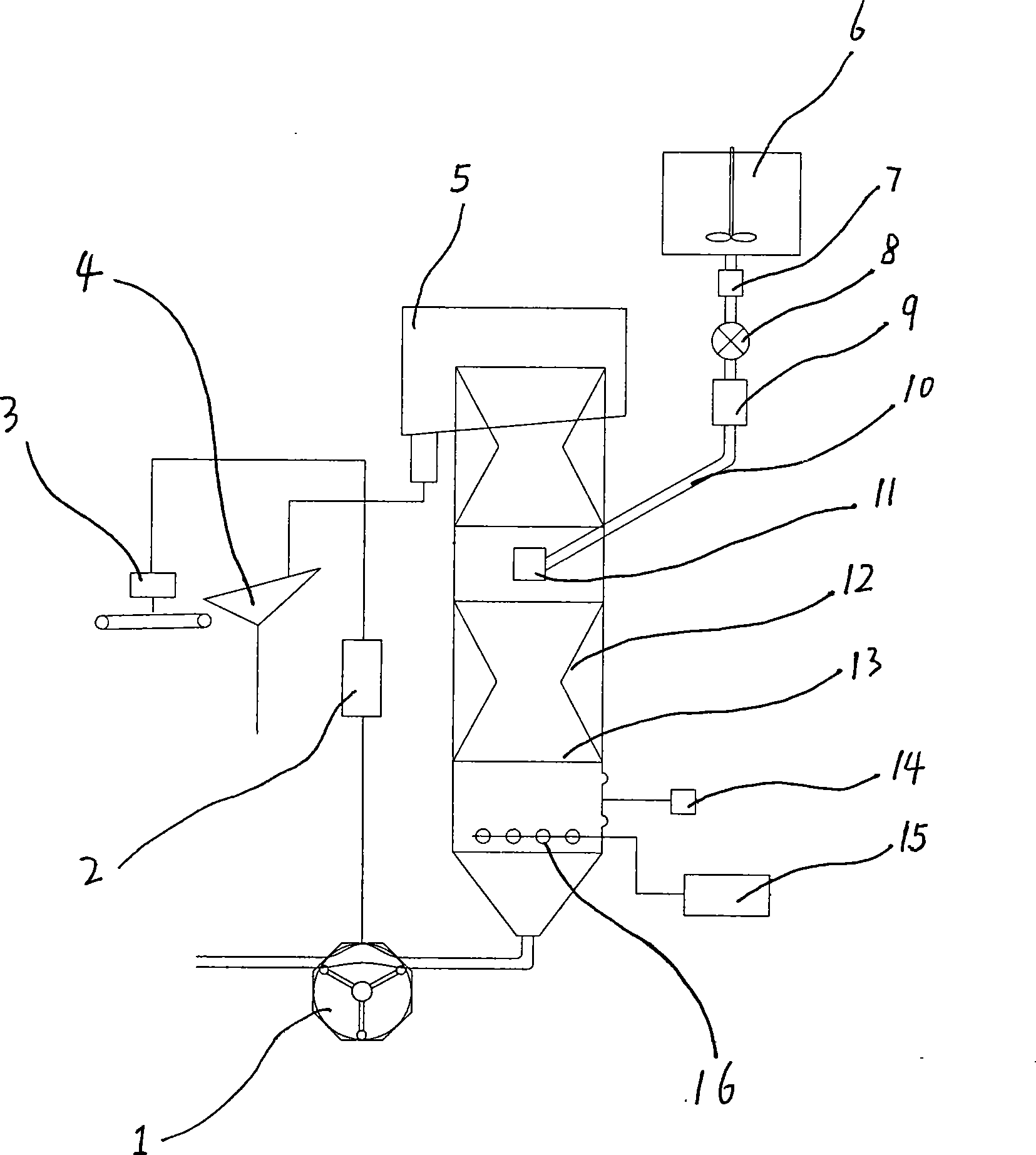

The invention discloses a comprehensive treating system for domestic wastes. Reutilizing comprehensive treatment for mixed wastes is realized by the system according to a comprehensive sorting technology and a combined anaerobic fermentation technology, wherein the advanced sorting techniques, such as, crushing, magnetic separating, sieving, air classifying, and the like, are adopted in the comprehensive sorting technology; reutilized products, such as metal, plastics, organic matters, and the like, are screened out; the screened organic matters are prepared into slurry together with sludge and excrements and are then subjected to the combined anaerobic fermentation; the reutilized products, such as methane, organic fertilizer, and the like, can be produced under the action of anaerobic fermentation; and after the methane is purified, the methane is used for generating power, domestic fuel or vehicle-mounted fuel. According to the technology, the intensified treatment for organic wastes, such as domestic wastes, sludge, excrements, kitchen wastes, and the like, can be realized. The comprehensive treating system is high in mechanical and automated degree. Compared with the prior art, the comprehensive treating system has the advantages of simplification, effectiveness, less labor power, and the like.

Owner:BEIJING HAOHAI TIANJI TECH +1

Method for placenta mesenchyma stem cell separation and in vitro amplify cultivation

InactiveCN101270349AImprove sorting effectImprove purification rateSkeletal/connective tissue cellsBiological testingCD34Decidual tissue

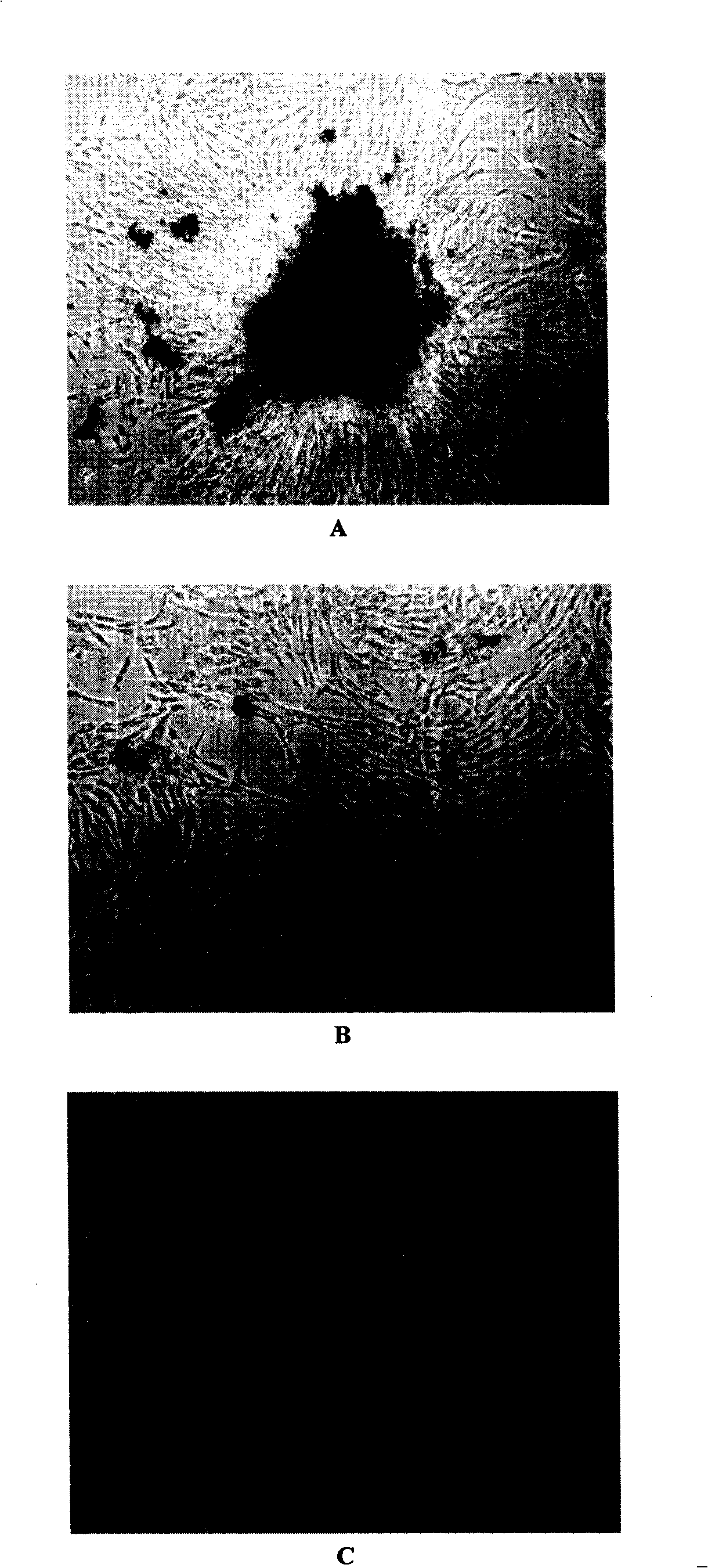

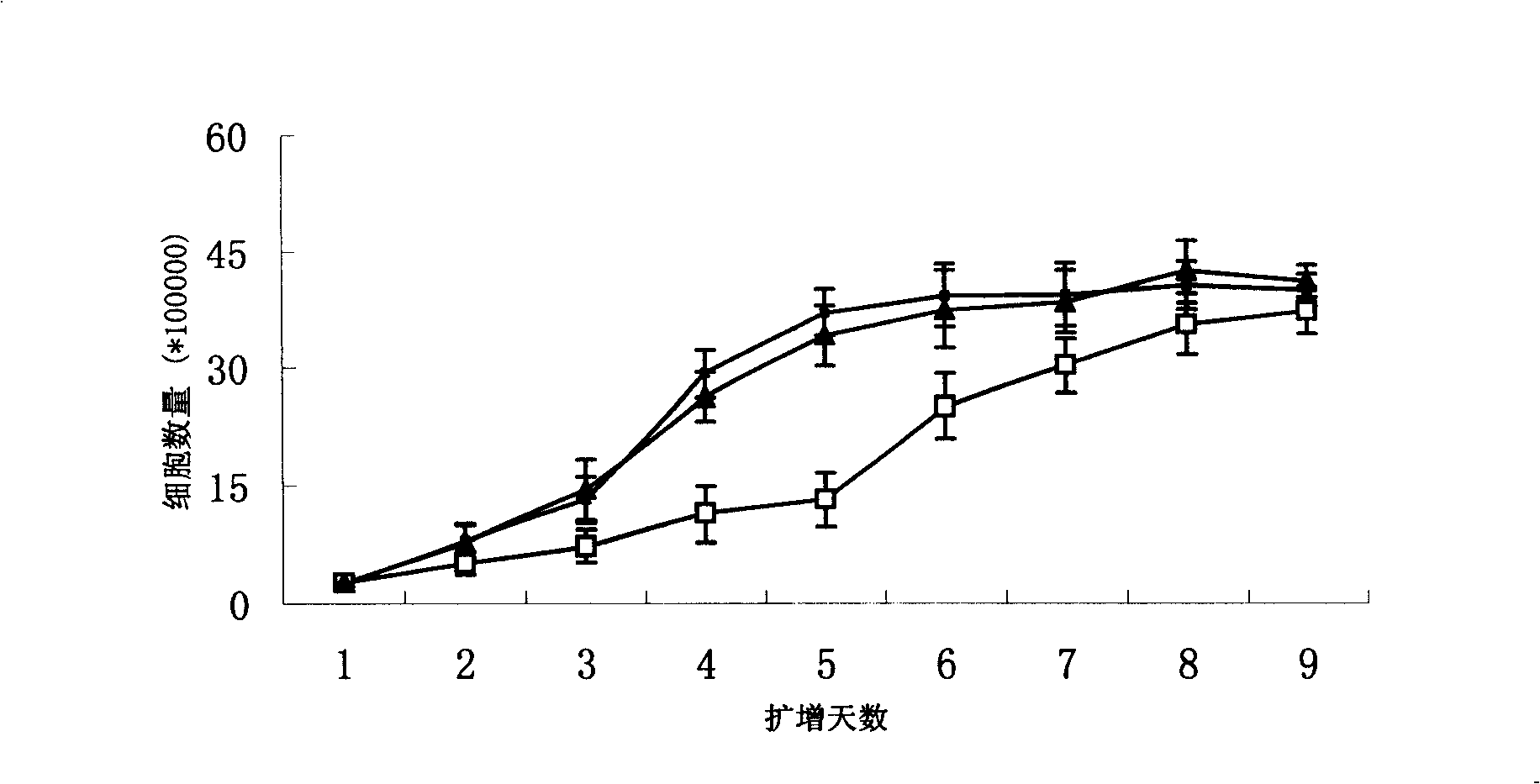

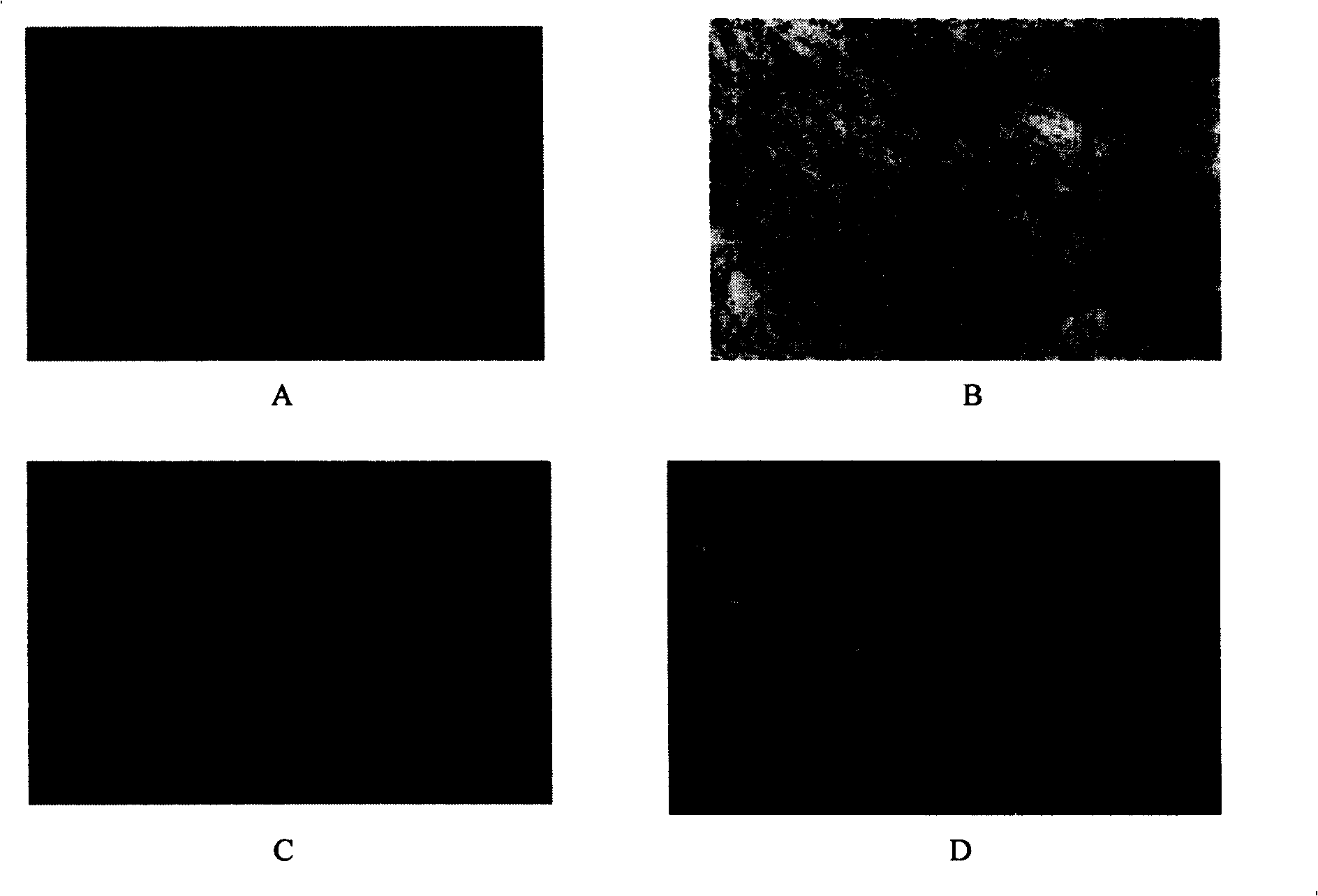

The invention provides a method for separation of placenta-derived mesenchymal stem cells, and for amplification and culture in vitro. After decidual tissue cells on the side of a placenta matrix are adopted and collected, primary culture cells are amplified by adhering to wall; the placenta-derived mesenchymal stem cells are purified by adopting positive and negative immunological sorting and combination method to get CD34<->CD105<+> cells which are secondarily amplified and cultured in a serum-free culture system in vitro. By adopting the method provided by the invention, just few primary culture cells (1X10<5> cells) are needed every time to produce a good sorting result; and the purification rate of the placenta-derived mesenchymal stem cells is further improved. Not only the culture system used has significant advantage of amplification over placenta-derived mesenchymal stem cells, but also the amplified cells have multiplex differentiation potential. The method can be applied for purification of placenta-derived mesenchymal stem cells and amplification and culture in vitro.

Owner:ZHEJIANG UNIV

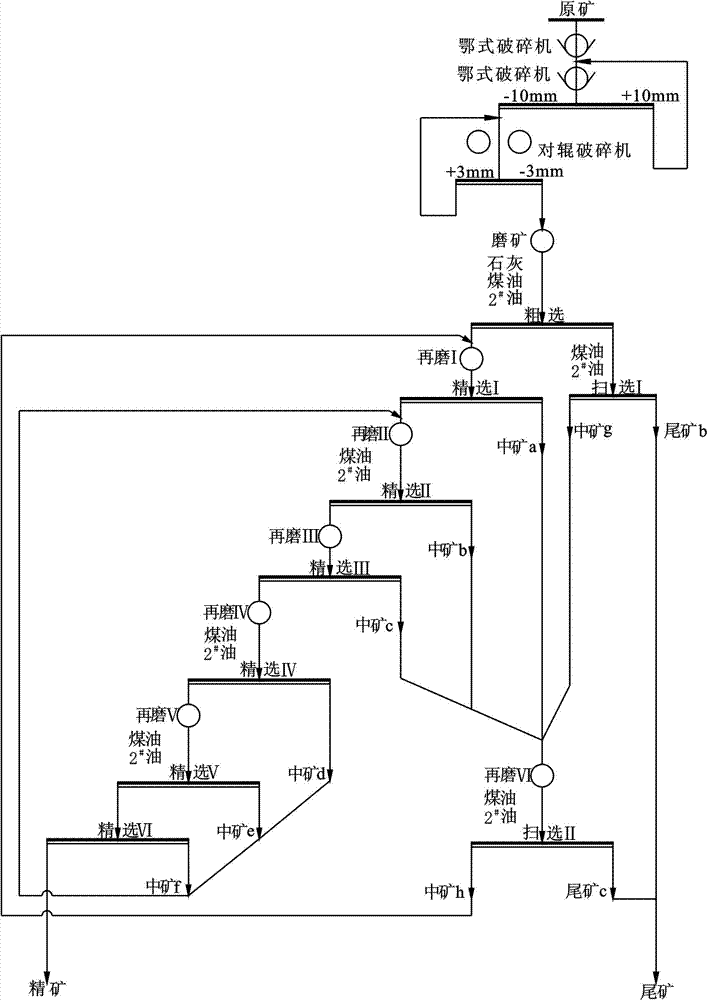

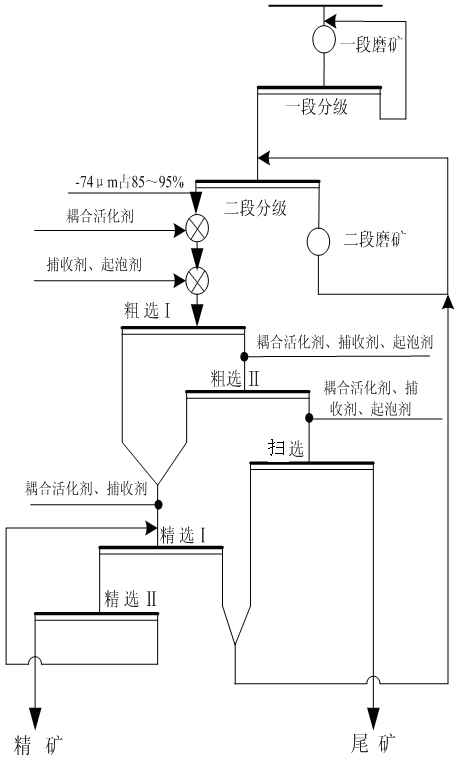

Fine flaky-cryptocrystalline mixed graphite separation technique

The invention discloses a fine flaky-cryptocrystalline mixed graphite separation technique which comprises the following steps: primary rough grinding and rough separation, quintic regrinding and sextic concentrating, and middling centralized processing. According to the technique, in the rough separation step, the grinding fineness is -0.074mm, and the content is 90-95%; in the concentrating step, the regrinding fineness is -0.045mm, and the content is 90-95%; and thus, the graphite monomer is sufficiently dissociated, thereby sufficiently ensuring the fixed carbon content and recovery rate of the concentrated concentrate. The technique adopts gradually decreased low concentrating concentrations in multiple concentrating process to ensure the dispersity of ore slurry, thereby solving thesevere problem of entrapped impurities in floatation foam; and thus, in the final concentrate, the fixed carbon content is 91.35%, and the recovery rate is 91.30%, thereby solving the problems of lowtechnical indexes, low grade, low recovery rate and high cost in the fine flaky-cryptocrystalline mixed graphite concentrate separation, so that the fine flaky-cryptocrystalline mixed graphite ores are utilized in an efficient, economical and reasonable way.

Owner:SICHUAN PILOT GRAPHITE PROD

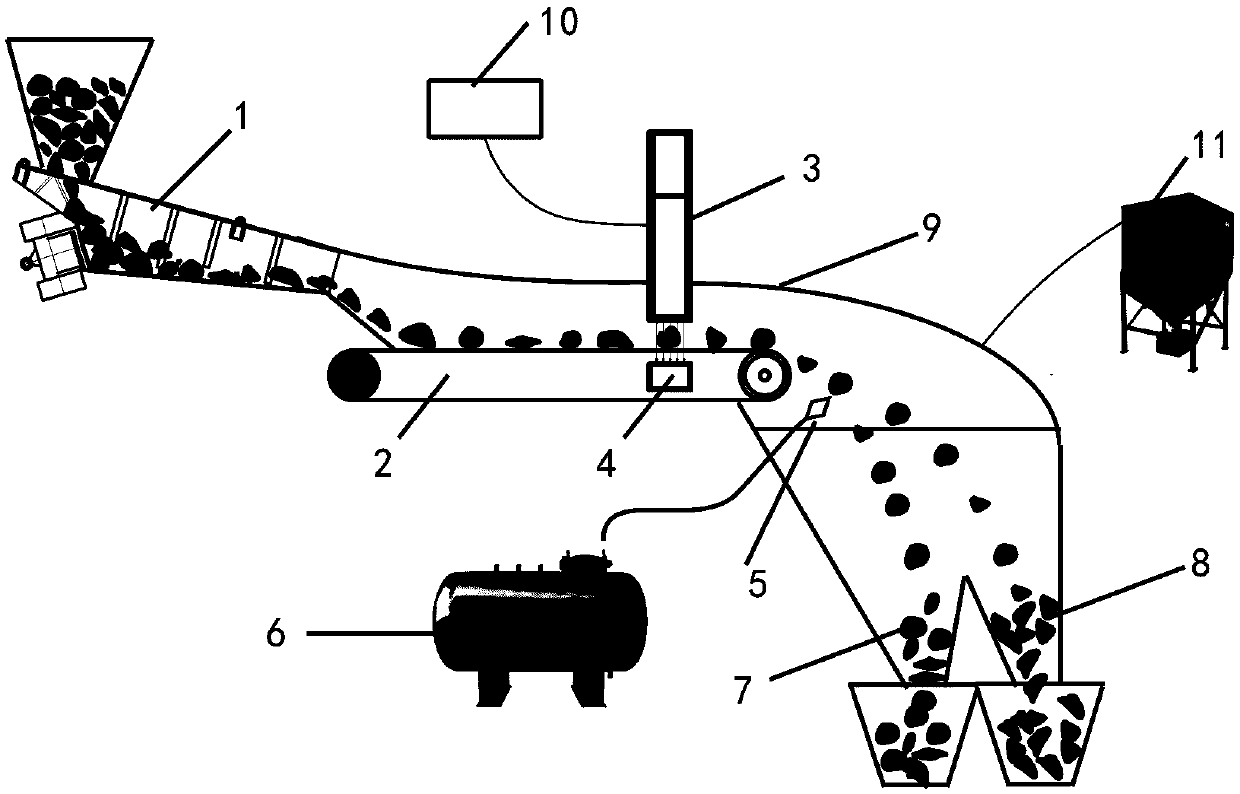

Telligent dry separator (TDS)

InactiveCN105499154AReduce in quantityLess-associative articulation pointSortingDust controlElectric control

The invention discloses a telligent dry separator (TDS). The telligent dry separator is characterized in that an intelligent identification method is adopted for establishing corresponding analysis models according to different characteristics of coal quality, through big data analysis, digitalized identification is conducted on coal and gangue, and finally the gangue is discharged through an intelligent execution system. The telligent dry separator (TDS) comprises four major systems, namely a feeding system, a material distribution system, an identification device and an execution mechanism, and three auxiliary systems, namely an air supplying system, a dedusting system and an electric control system. By means of the telligent dry separator (TDS), separation precision can be improved, the lower separation limit can be further lowered, and a condition is created for achieving the effect that all block raw materials ranging from 3mm to 300 mm adopt the intelligent dry separation process. Compared with traditional cleaning equipment, the telligent dry separator (TDS) has the advantages that on the aspect of construction investment, a system can be simplified, investment can be reduced, and the construction period can be shortened; on the aspect of separation effects, precision can be guaranteed, the heat value can be raised, and no coal slime is generated; on the aspect of production cost, consumption can be lowered, maintenance can be reduced, and manual work can be decreased.

Owner:TIANJIN MEITENG TECH CO LTD

Reverse/direct flotation technology of collophanite

The invention discloses a reverse / direct flotation technology of collophanite. The technology comprises the following steps of: performing ore reduction, ore grinding and size mixing on the silicon calcium type collophanite; adding a carbonate gangue mineral flotation regulator and fatty-acid soap respectively to perform size mixing; performing reverse flotation on the material after the size mixing, wherein the product in the tank is reverse flotation concentrate; dehydrating the reverse flotation concentrate and adding sodium carbonate so as to adjust the pH value to 8-10; performing closed-loop ore grinding and grading on the base flow; enabling the grading overflow to enter a direct flotation stirring tank, and adding water glass and fatty acid soap into the tank respectively to perform size mixing; performing direct flotation on the material subjected to the size mixing, wherein the direct flotation foam product is direct flotation concentrate; and performing concentration, filtration and drying to obtain the finished product of phosphate concentrate. After dehydration (reagent removal), the technology disclosed by the invention can be used for remarkably reducing the amount of sodium carbonate for neutralizing acid water; the sodium carbonate has a dispersion and grinding aid function, and the over-grinding of the material of direct flotation can be reduced; and the fresh surface and proper size composition generated by the ore grinding are favorable for improving the sorted behavior of the direct flotation and improving the sorting efficiency.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

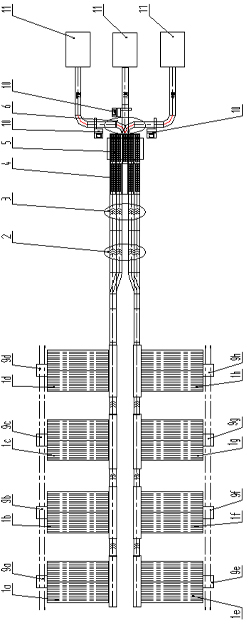

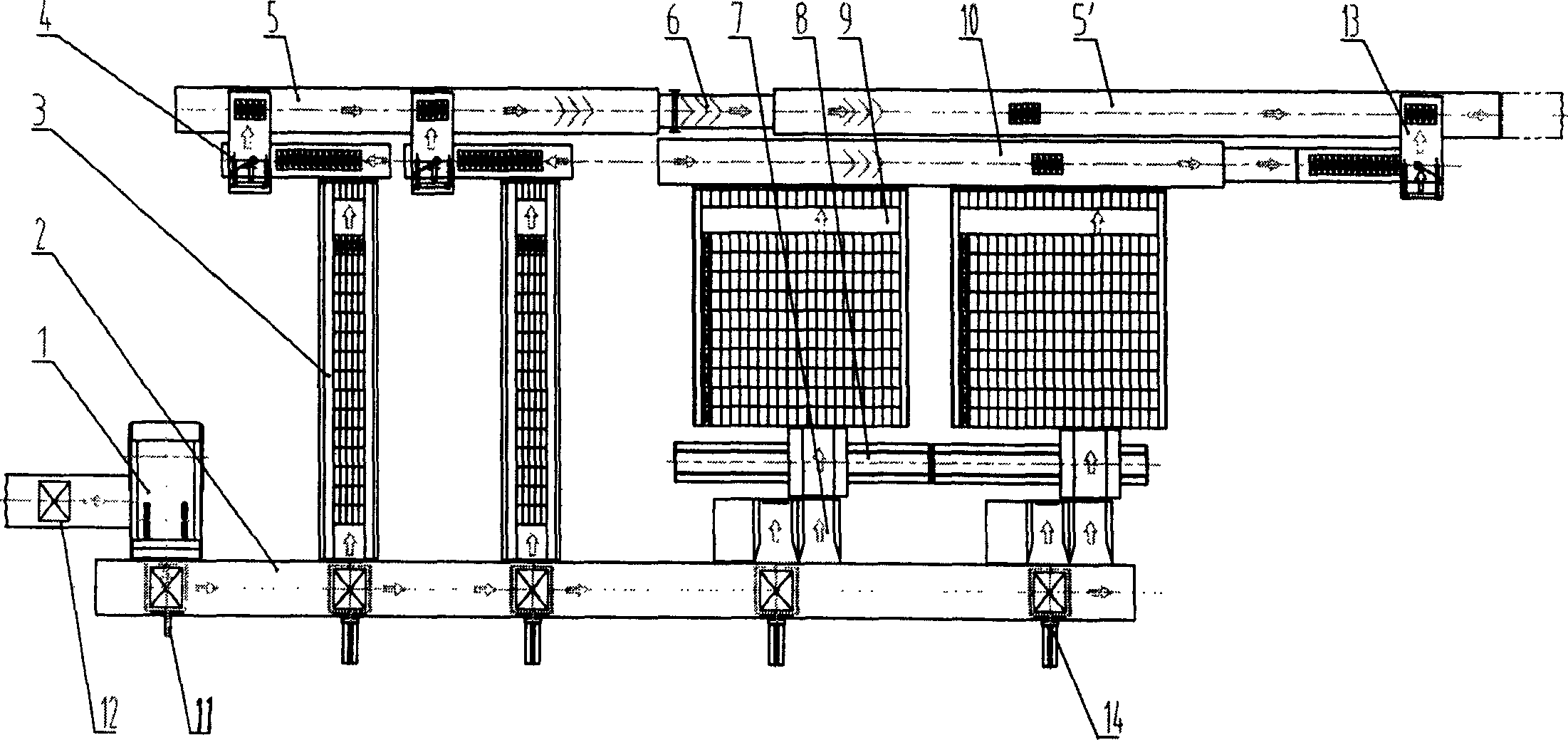

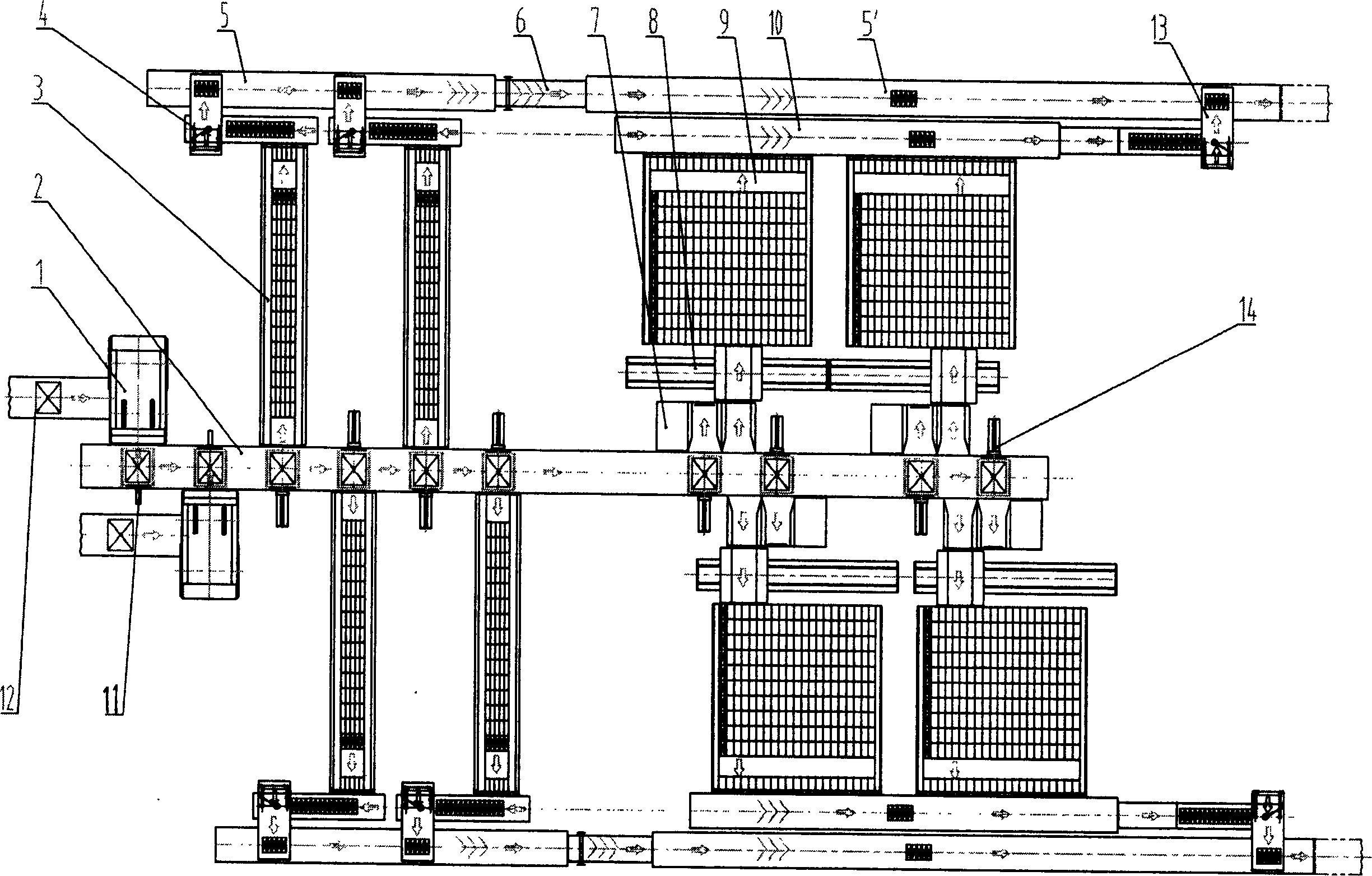

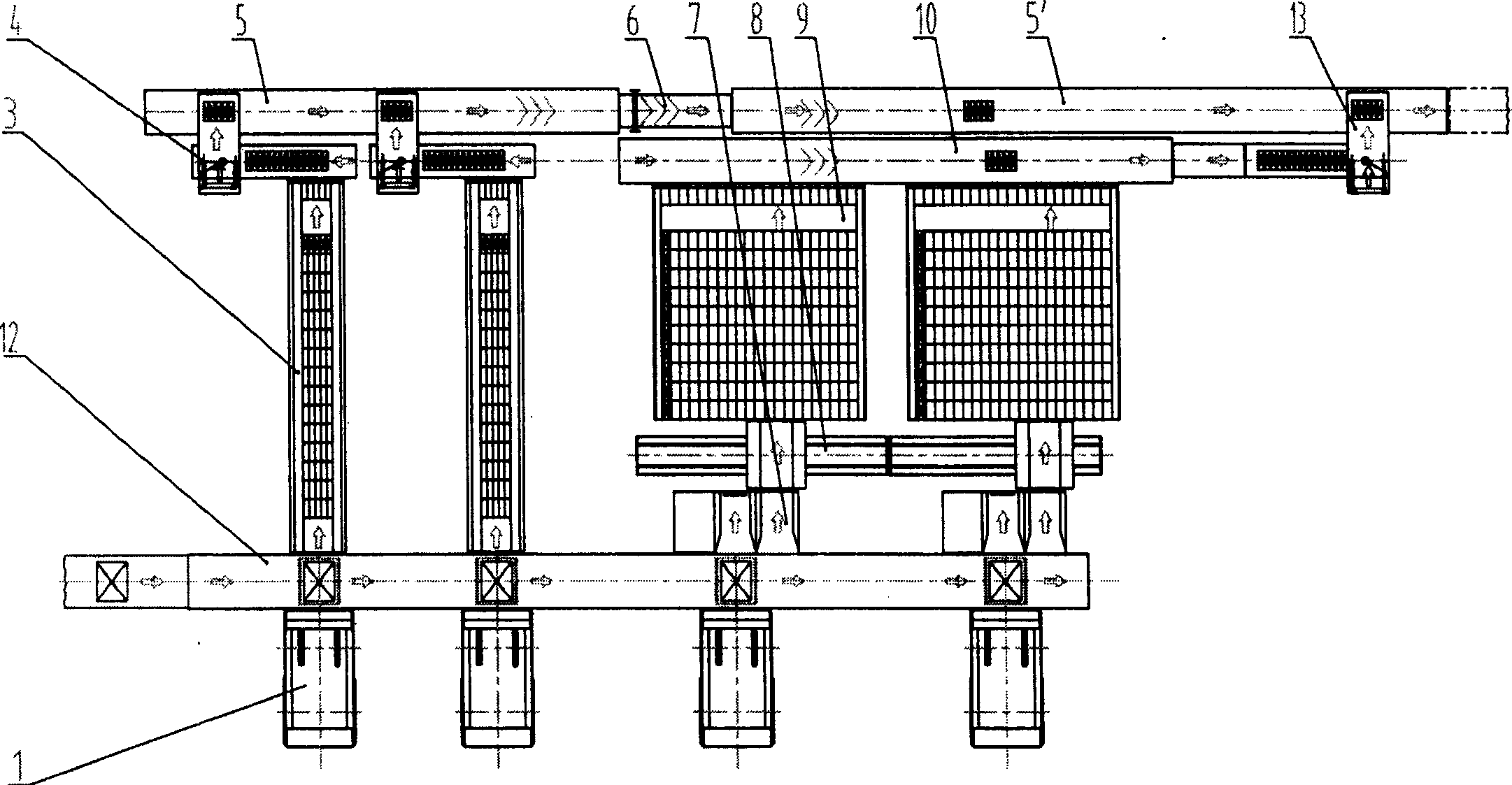

High-speed cigarette sorting system

InactiveCN101948017ASorting high speedHigh degree of automationPackagingConveyor partsEngineeringHigh velocity

The invention discloses a high-speed cigarette sorting system. The system comprises a plurality of sorting units (1), parallel conveying lines (2), a flow dividing unit (3), a caching unit (4), a flow combining unit (5) and an outlet conveyer (6), wherein the parallel conveying lines consist of at least two conveying lines which are sequentially arranged on the downstream of the sorting unit; the flow dividing unit is a rocker conveyer of which the tail end can rotate to different heights; the caching unit consists of at least two layers of conveyors; the rocker conveyer can rock to be connected with conveyer of each layer of the caching unit; the flow combining unit has a passage type structure comprising at least two layers, of which each layer is connected with a corresponding hierarchy of the caching unit; each layer of the flow combining unit is provided with a plurality of feed passages and one discharge passage; and the number of the conveying lines, the number of passages of the flow dividing unit and the number of passages at each layer of the flow combining unit are the same. The system can simultaneously sort and convey the cigarettes and divide and combine the flow in parallel, so that high-speed sorting of the cigarettes is realized, the sorting capacity of the system is greatly improved, and the automation degree of the sorting system is improved.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

Cigarette automatic sorting process

InactiveCN1803559AFlexible configurationMeet the requirements of the orderArticle unpackingConveyor partsEngineeringTransmission equipment

The invention discloses a bar-cigarette self-picking craft, which is characterized by the following: opening the cigarette box automatically; fetching cigarette pile from box; feeding material automatically through over two picking equipments; picking different kinds of bar-cigarette on respective transmission equipment according to the need of order. The invention can improve material-supplement and picking efficiency and system disposal ability, which reduces the labor strength.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

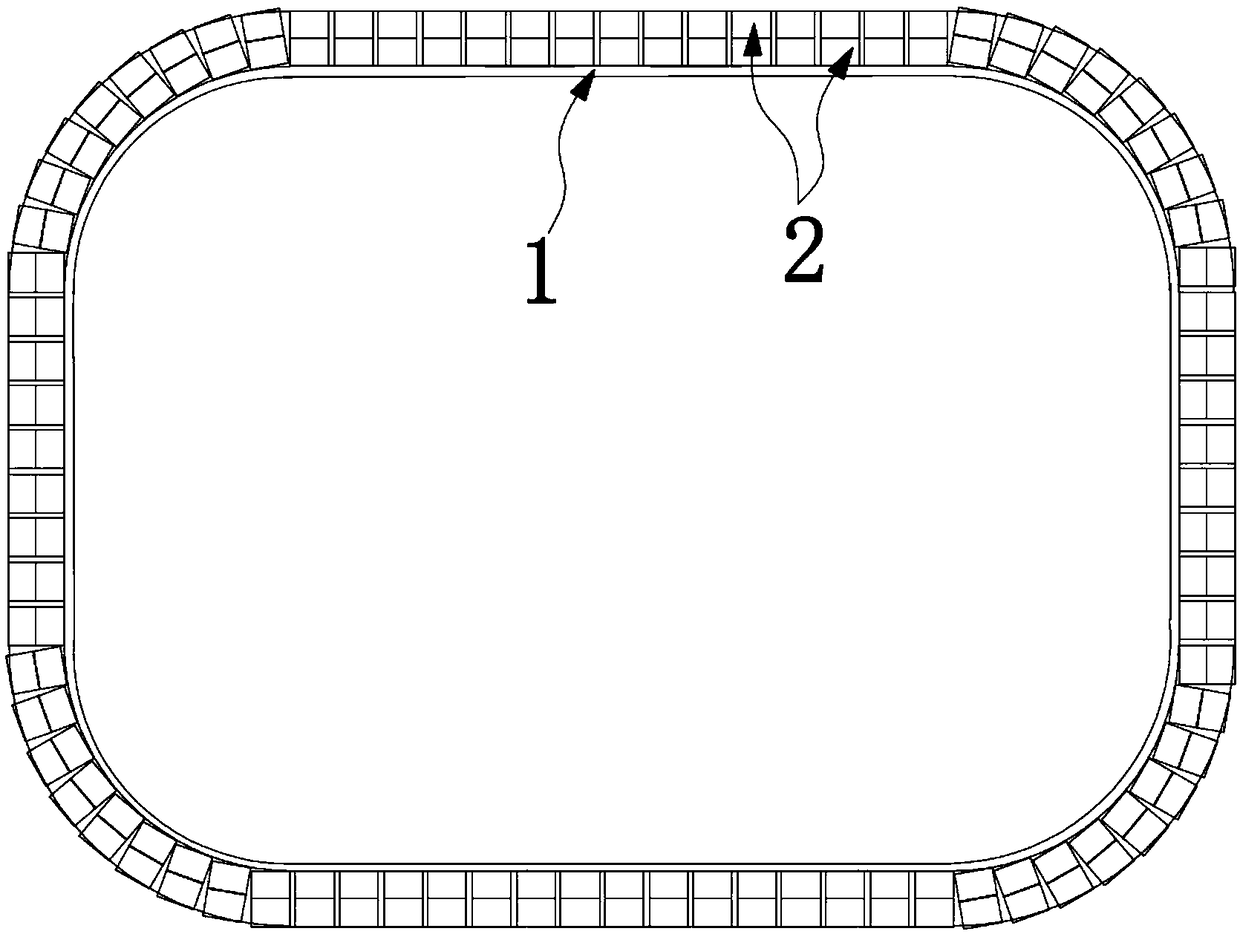

Cross-belt logistic sorting system

The invention discloses a cross-belt logistic sorting system. The cross-belt logistic sorting system comprises a conveying line, a sorting line, distributing tables, a plurality of sorting carts, a cycling rail and an upper computer, wherein the conveying line is used for conveying to-be-sorted packages or cargoes to the sorting line from the lower portion; the sorting line is used for conveying the packages or the cargoes conveyed by the conveying line to corresponding sorting sliding grooves according to the preset classification rule; the distributing tables are used for measuring volumes and weights of the packages or the cargoes conveyed by the sorting line; the sorting carts are used for conveying the packages or the cargoes conveyed by the distributing tables to corresponding sorting openings to be output; the cycling rail is used for guiding the sorting carts to convey and sort the packages or the cargoes through cycling moving; the upper machine is used for controlling sortingand conveying of the packages or the cargoes. According to the cross-belt logistic sorting system, the structure is simpler, sorting efficiency is remarkably improved, transportation and assembling are convenient, and automation of logistic sorting is achieved.

Owner:SHENZHEN YUZHI EQUIP TECH CO LTD

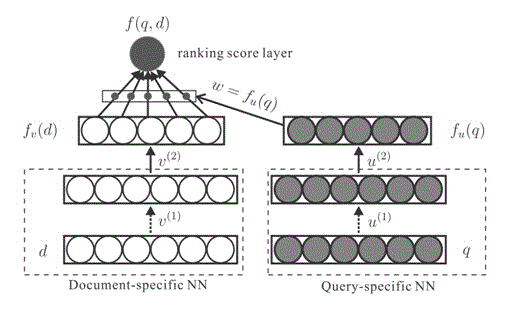

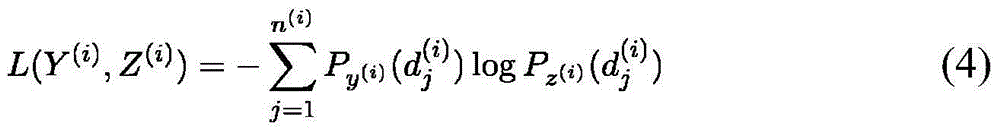

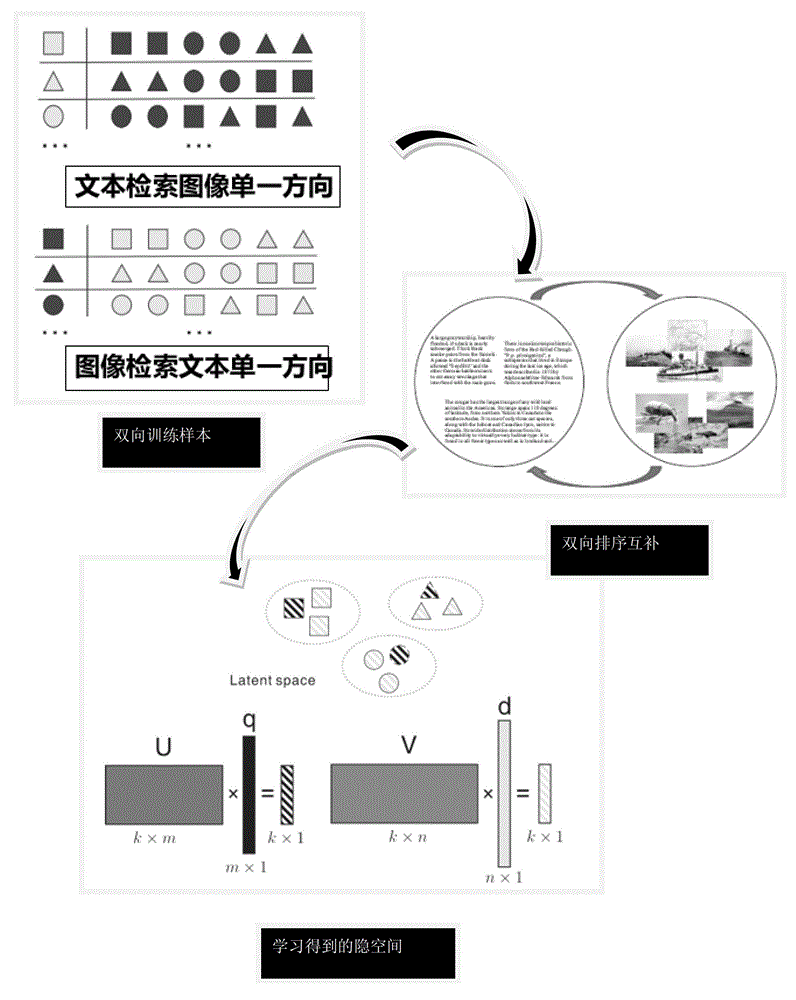

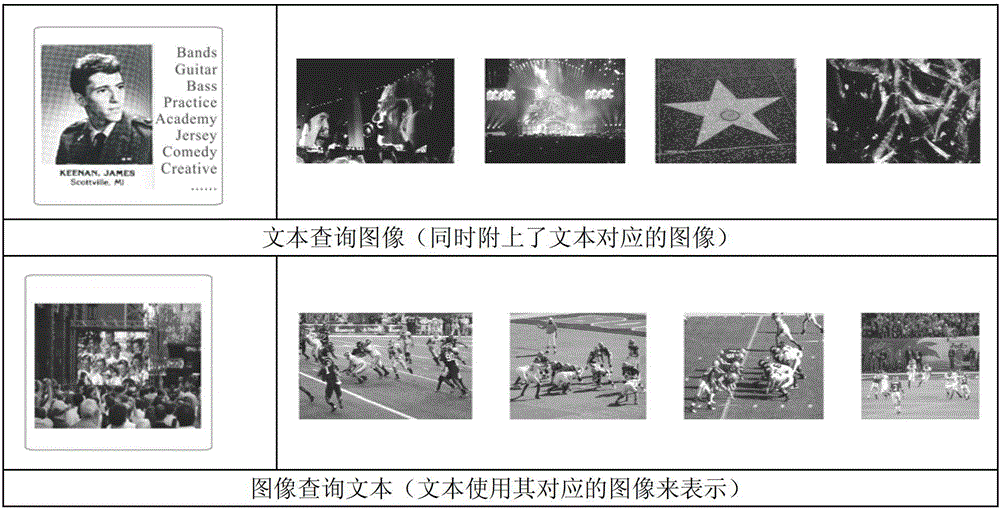

Cross-media sorting method based on deep neural network

InactiveCN104317834AImprove sorting effectGood feature expressionCharacter and pattern recognitionSpecial data processing applicationsPattern recognitionModel method

The invention discloses a cross-media sorting method based on a deep neural network. The method comprises the following steps that (1) a sorting sample of using a text to retrieve an image or a sorting sample of using the image to retrieve the text is constructed as a training sample; (2) cross-media sorting study based on the deep neural network is conducted to the constructed training sample, and multimedia semantic space and a cross-media sorting model are obtained; (3) the studied cross-media sorting model is adopted to conduct cross-media retrieval. Due to the use of the deep neural network driven by cross-media sorting data, the semantic comprehensive ability of the obtained retrieval model is stronger, and using the text to retrieve the image or using the image to retrieve the text to obtain a superficial model method with a traditional performance is better.

Owner:ZHEJIANG UNIV

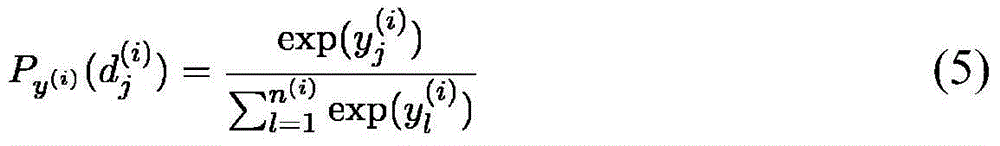

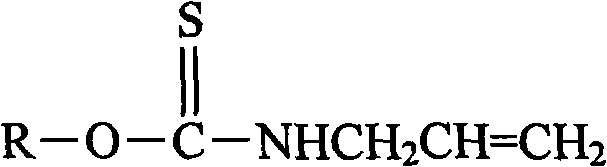

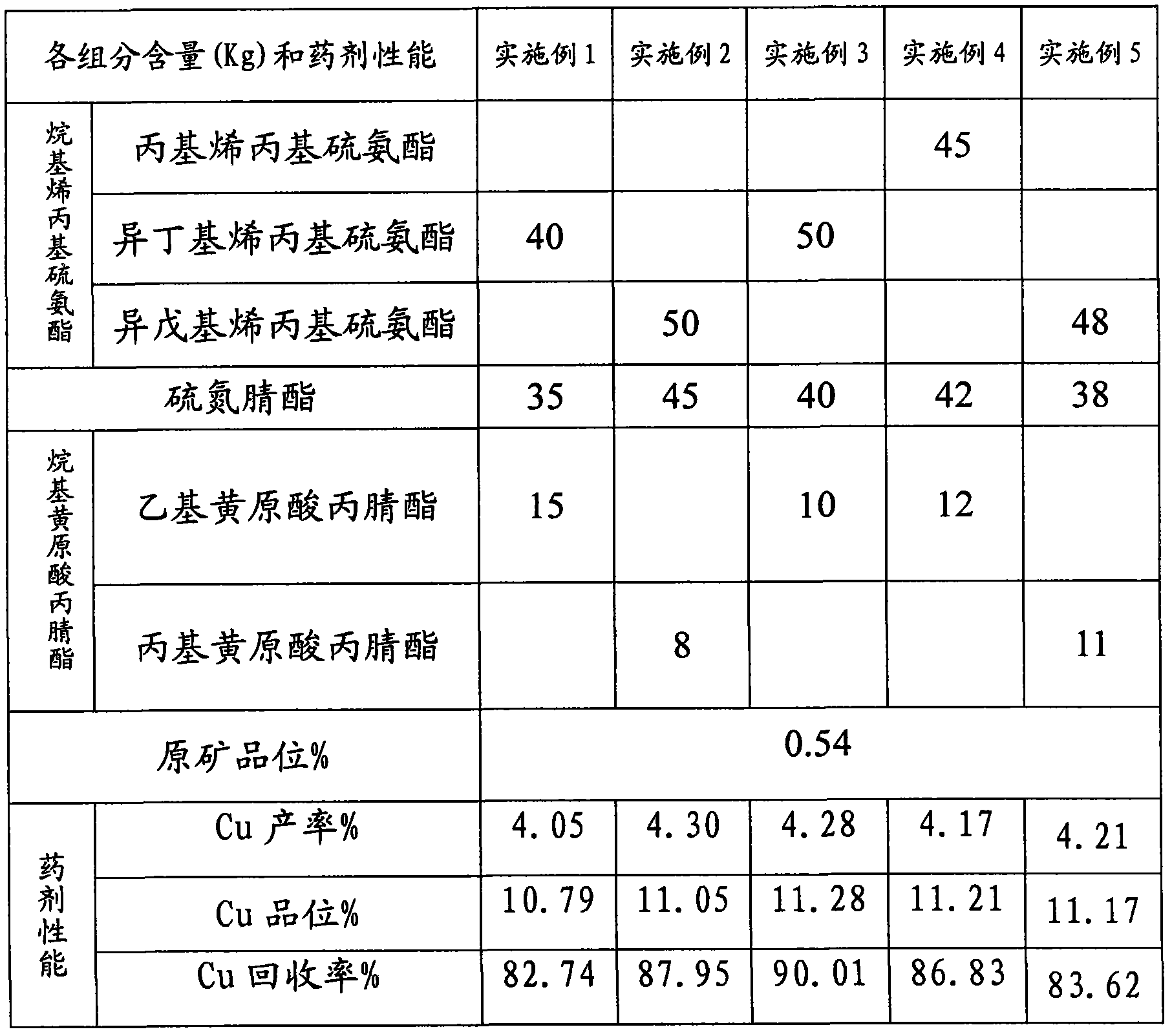

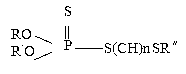

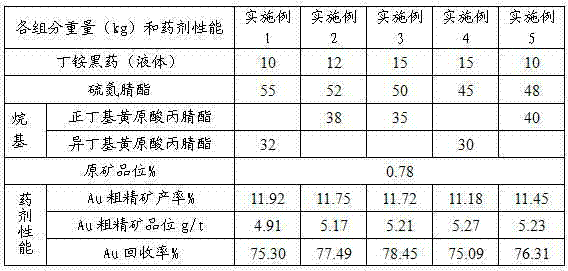

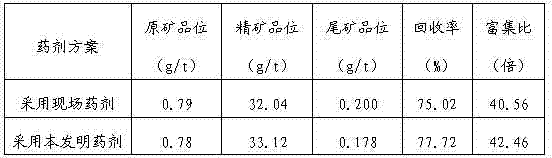

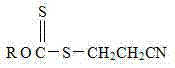

High sulfur copper ore collecting agent

The invention relates to a high sulfur copper ore collecting agent, which is characterized by consisting of the following materials in part by weight: 40 to 50 parts of alkyl allyl thionocarbamate, 35 to 45 parts of sulfur nitrogen nitrile ester and 8 to 15 parts of alkyl xanthonic acid propionitrile ester. The collecting agent has double properties of collecting and foaming, high selectivity and high collecting capacity, can realize high-efficiency separation of copper and sulfur when the pH value is in a range from 7 to 10, can effectively improve the concentrate grade and the recovery rate, and has a wider application range.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Garbage classifying, recycling and treating system and garbage classifying and recycling method

InactiveCN103240157ARealize sortingGood sorting effectGrain treatmentsMechanical material recoveryGarbage disposalTreatment system

The invention relates to a garbage classifying, recycling and treating system and a garbage classifying and recycling method. The garbage classifying, recycling and treating system comprises a garbage crushing device and a garbage separation pool, wherein the crushing device comprises a first crushing device and a second crushing device; the output of the first crushing device corresponds to the feeding port of the second crushing device; and the output of the second crushing device is connected with the feeding port of the garbage separation pool. The garbage treatment method comprises the following steps of: firstly, extruding and crushing the garbage at the first crushing device, tearing the garbage in bags so as to expose the liquid or solid in the bags; secondly, smashing, grinding and extruding the garbage through the second crushing device; and finally discharging the garbage from the second crushing device and feeding the garbage into the separation pool to be separated. Through separation according to different proportions, the system and the method require less equipment and are low in cost and good in separation effect.

Owner:长春奥瑞投资管理有限公司

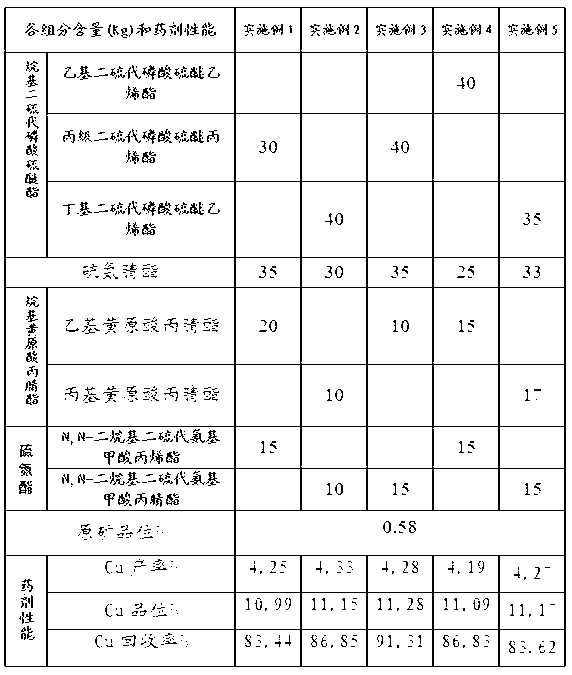

Collecting agent for high-sulfur copper mine

The invention relates to a flotation agent for a copper mine and discloses a high-efficiency collecting agent for a high-sulfur copper mine. The collecting agent comprises the following materials in parts by weight: 30-40 parts of alkyl phosphorodithioic acid thioether ester, 25-35 parts of cyanoethyl diethyl dithionocarbamate, 10-20 parts of alkyl xanthic acid propionitrile ester and 10-15 parts of sulfur-nitrogen ester. The collecting agent for the high-sulfur copper mine has double functions of collecting and foaming, is good in selectivity and high in collecting ability, can realize high-efficiency separation of copper from sulfur in a low pH value (approximately 5) range, can effectively reduce the consumption of lime in the floatation process, can effectively increase the grade and recovery rate of concentrate, and has a wider application scope.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Ammonium-amine coupling activation method based on copper mineral sulfurization floatation system

Owner:KUNMING UNIV OF SCI & TECH

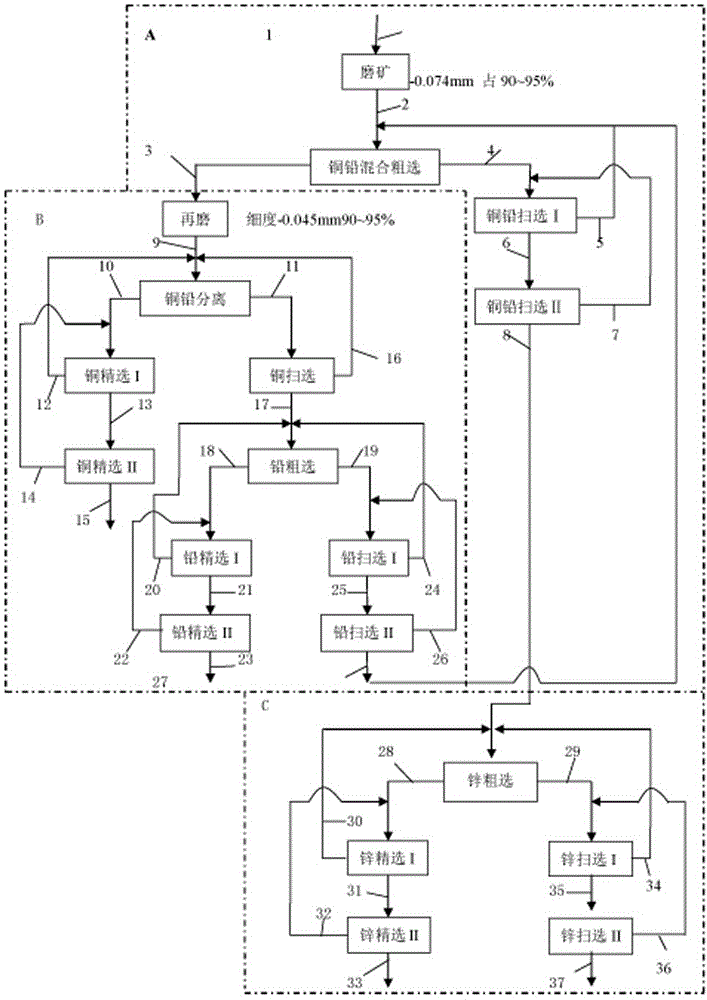

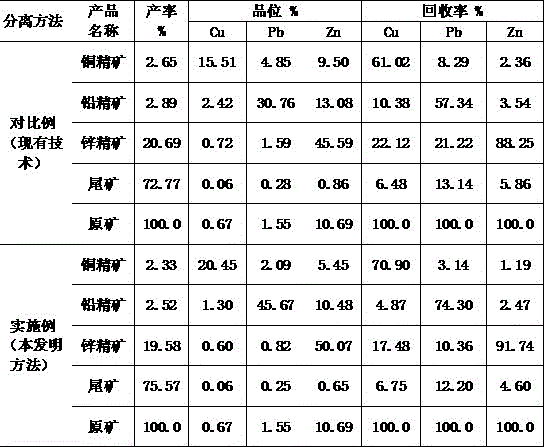

Pollution-free flotation separation method for copper-lead-zinc polymetallic ore

Owner:ZIJIN MINING GROUP

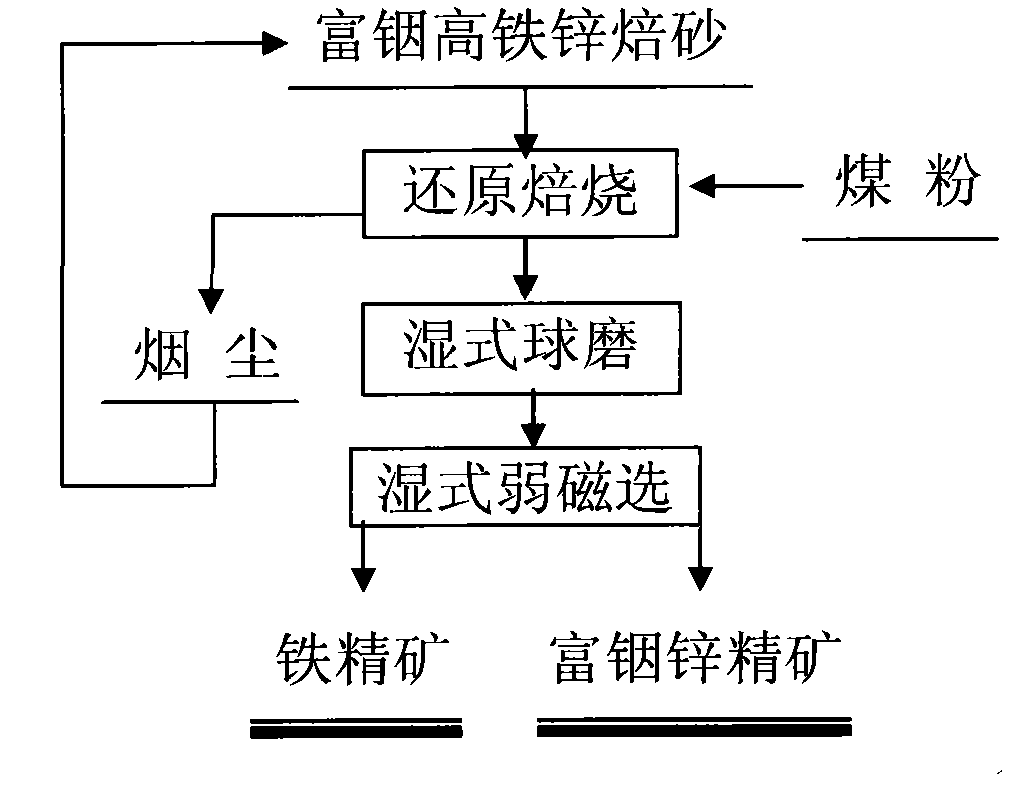

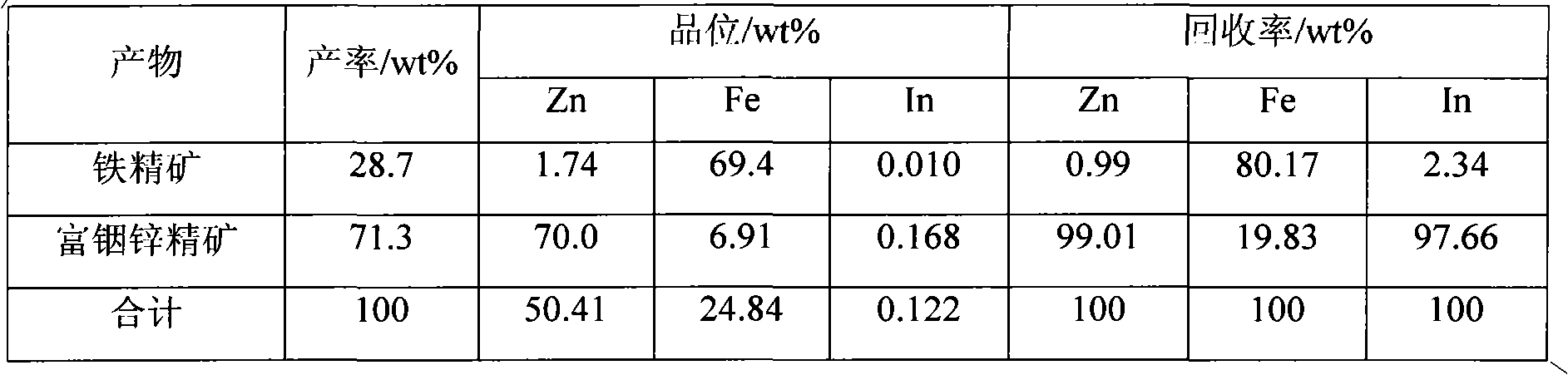

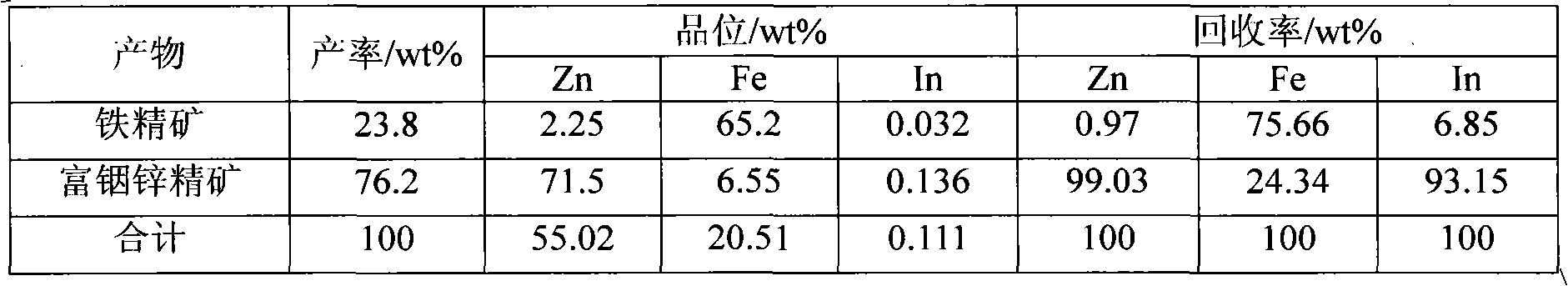

Method for separating zinc and indium and iron from indium-enriched high-iron high-zinc calcine through reduction-magnetic separation

InactiveCN102134655AReduce dosageReduce energy consumptionMagnetic separationReduction treatmentIndium

The invention relates to a method for separating zinc and indium and iron from indium-enriched high-iron high-zinc calcine through reduction-magnetic separation, belonging to the technical field of mineral processing. The invention is characterized in that the method adopts the technical means that mineral dressing is combined with smelting and performs smelting firstly and mineral dressing secondly; and the method is as follows: the waste heat of the indium-enriched high-iron zinc calcine obtained through fluidized roasting is utilized, the indium-enriched high-iron zinc calcine is introduced to perform low-temperature weak reduction treatment at below 570 DEG C and ensure that zinc ferrite is decomposed and reduced to ZnO, Fe3O4 and iron, the reduced calcine is levigated to prepare slurry, and zinc and indium and iron is separated through wet-type magnetic separation to obtain iron ore concentrates and indium-enriched zinc- enriched ore concentrates. The method has low energy consumption and low dosage of a reducing agent, is simple in operation, easy in control and high in metal recovery rate. Therefore, the indium embedded and distributed in zinc ferrite can be released, the loss caused by the high temperature volatilization of indium can be avoided, and the zinc and indium and iron of the indium-enriched high-iron high-zinc calcine can be separated in an ore dressing manner before leaching.

Owner:KUNMING UNIV OF SCI & TECH

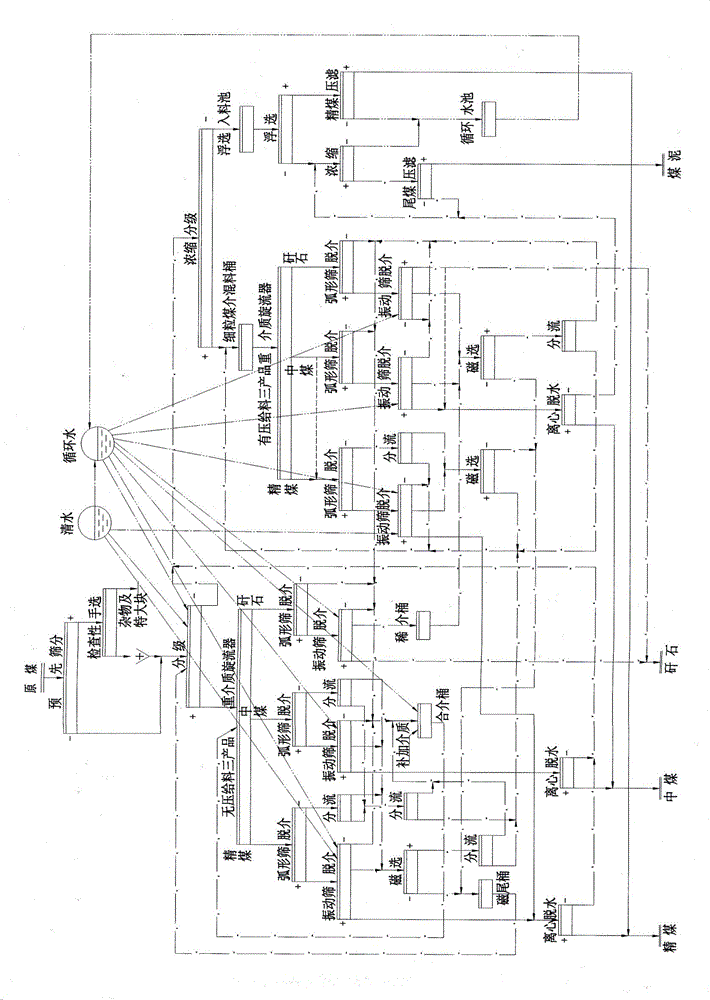

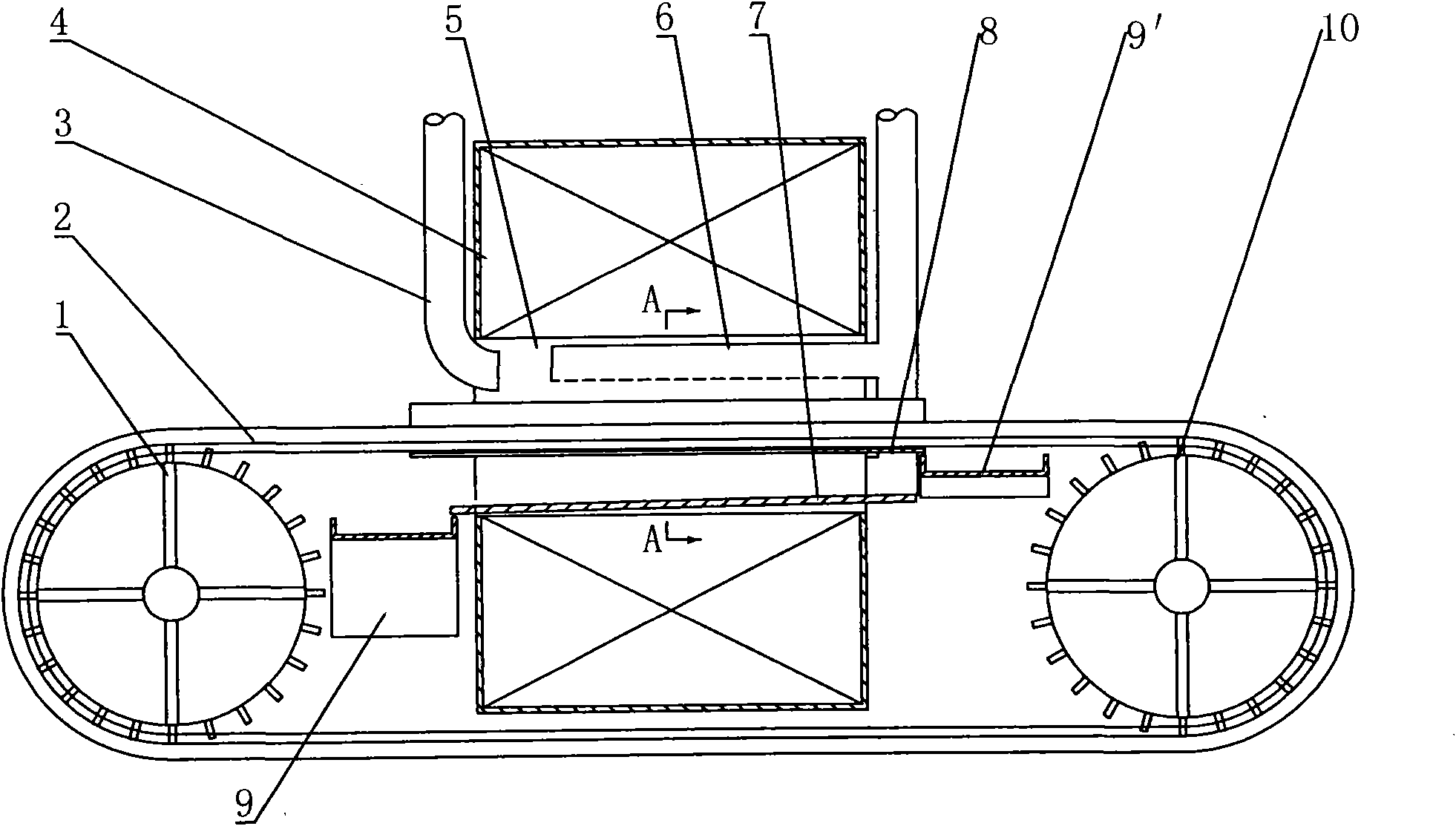

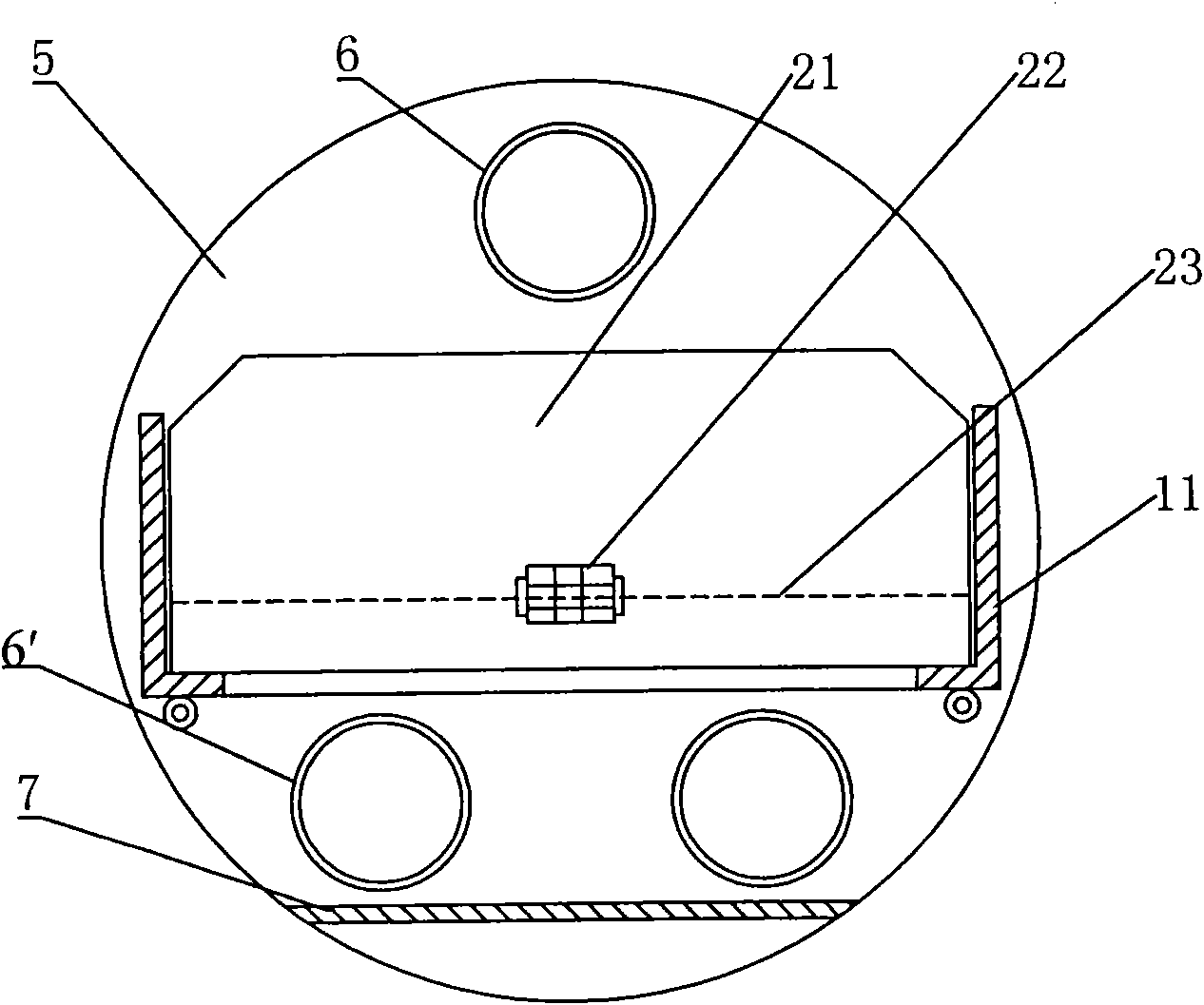

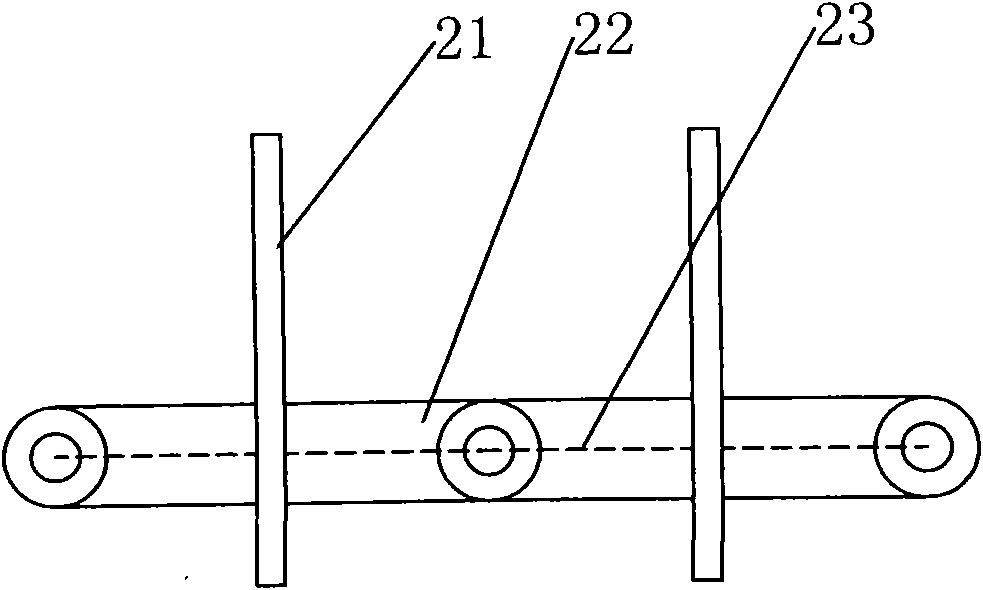

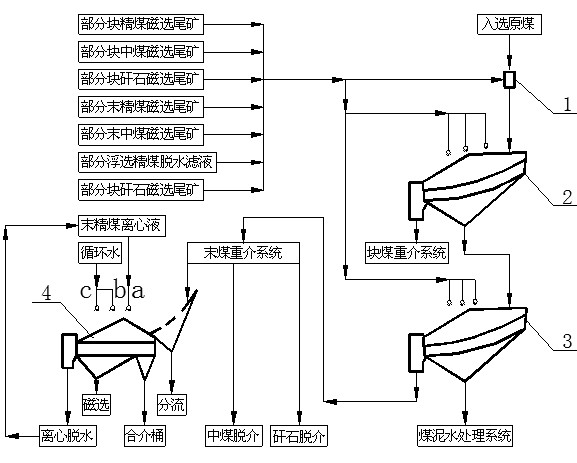

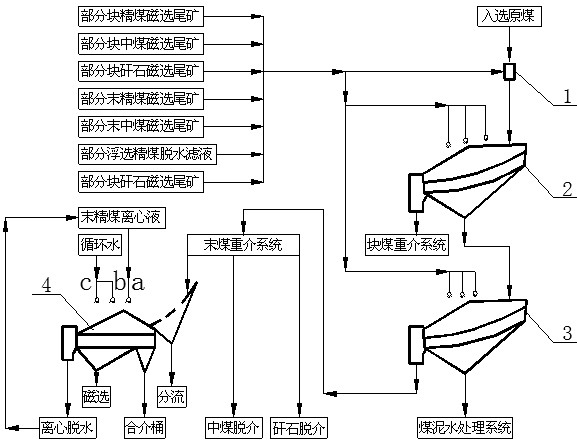

Wide-grain-grade double-dense-medium process for separating all coarse coal slime

The invention discloses a wide-grain-grade double-dense-medium process for separating all coarse coal slime. The wide-grain-grade double-dense-medium process includes that raw coal is preliminarily sieved, manually picked and graded, then oversize products can be used as coarse grain coal, the coarse grain coal is fed into a non-pressure tri-product dense-medium cyclone to be separated, undersize products are concentrated and graded and then are dehydrated in an underflow manner to be used as fine grain coal, the fine grain coal is fed into a pressure tri-product dense-medium cyclone to be separated, and excess flow is fed into a flotation filter-press system, so that the coal slime can be separated; qualified suspension liquid of a fine grain coal dense-medium separating system is provided by coarse grain clean coal of a coarse grain coal separating system, lower branches of coarse grain middling coal primary-section medium removing equipment and branches of coarse grain clean coal and coarse grain middling coal magnetic separation concentration; dilute suspension liquid of coarse grain gangue products and dilute suspension liquid of middling coal and gangue products of a fine grain coal system are treated together; magnetic separation tailings are used as wetting water or primary spray water for grading screens. The wide-grain-grade double-dense-medium process has the advantages that the fine grain coal dense-medium system has a medium automatic generating function, all the coarse coal slime can be efficiently separated by dense media, the suspension liquid is circulated in a closed-loop manner, the separation efficiency is high, the products are flexible in structure, and the production and operation costs are low.

Owner:TANGSHAN BRANCH COAL SCI ACAD

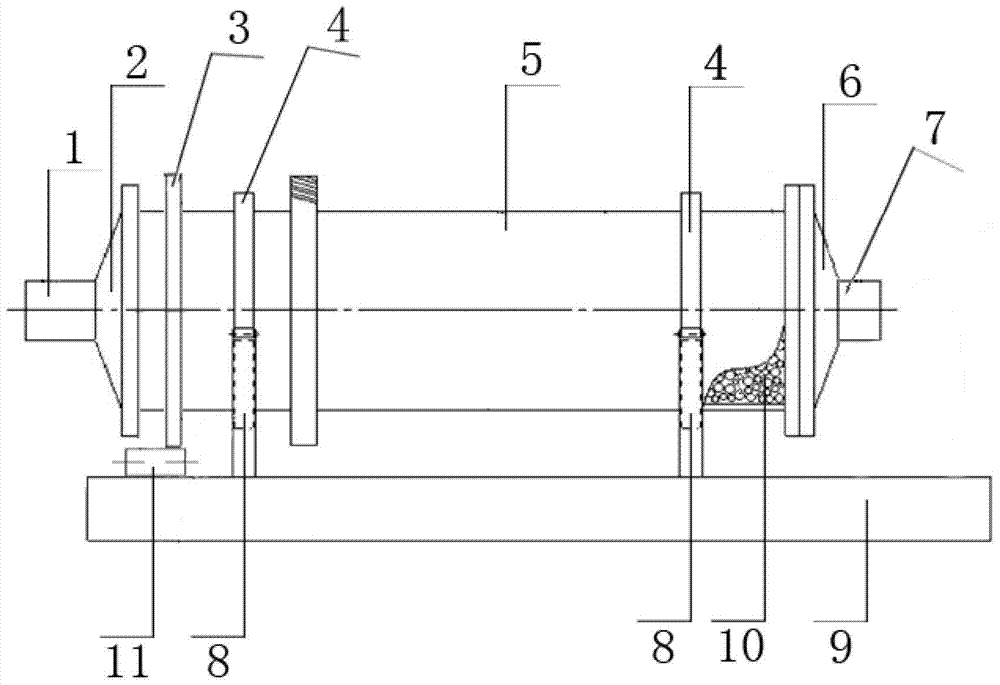

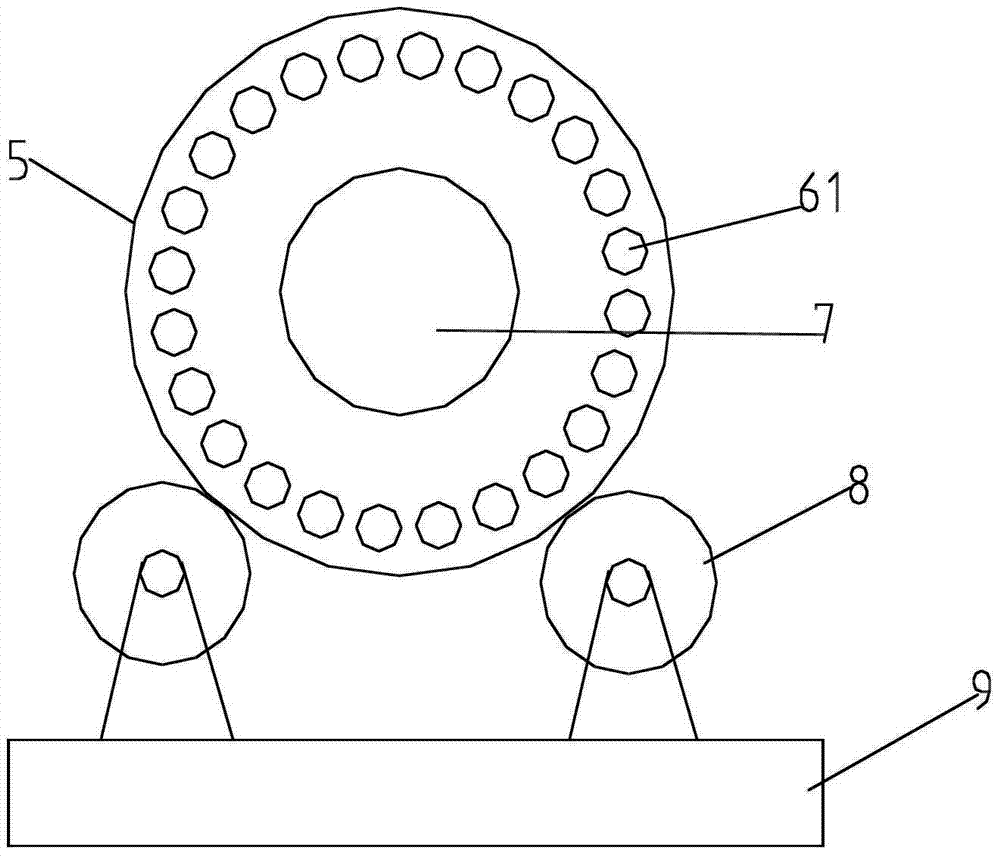

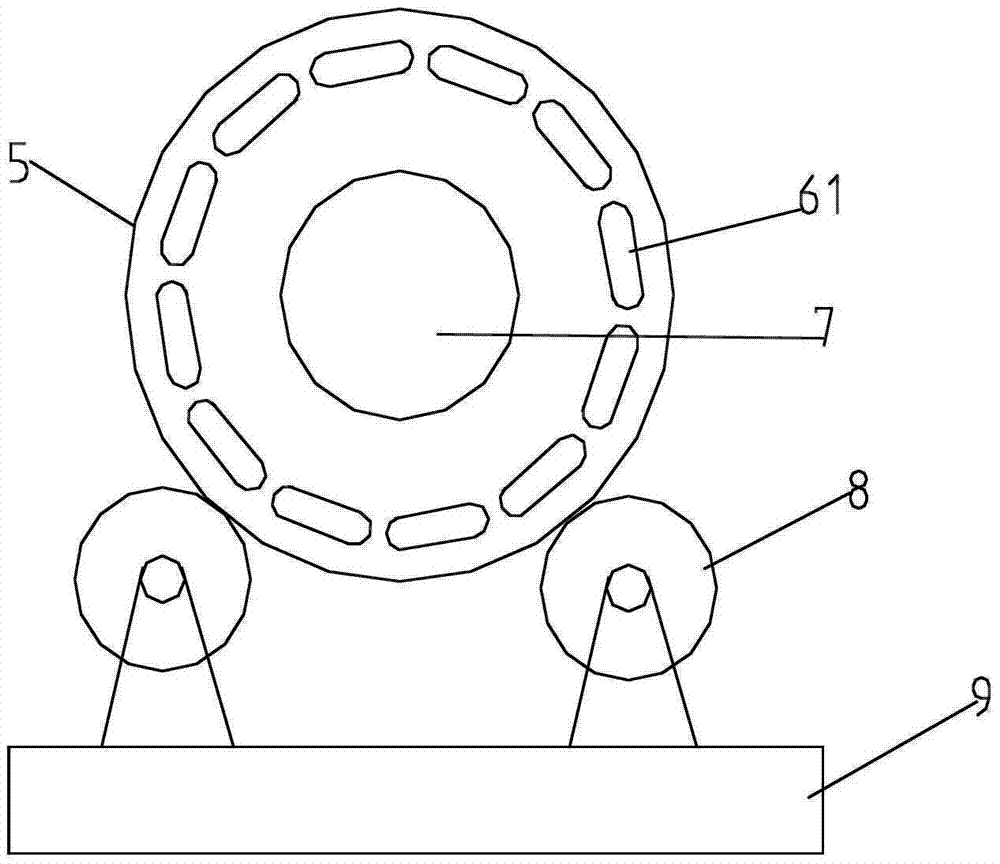

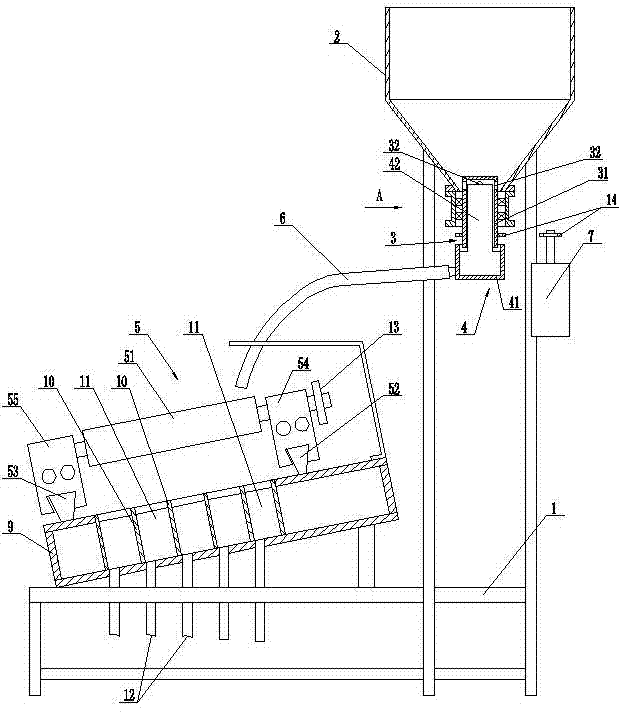

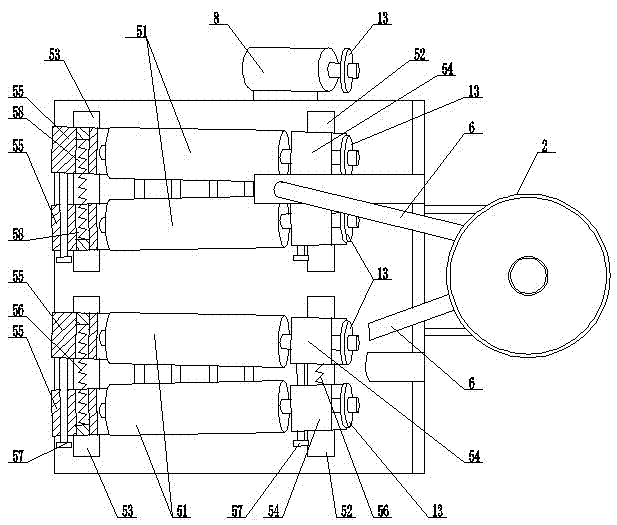

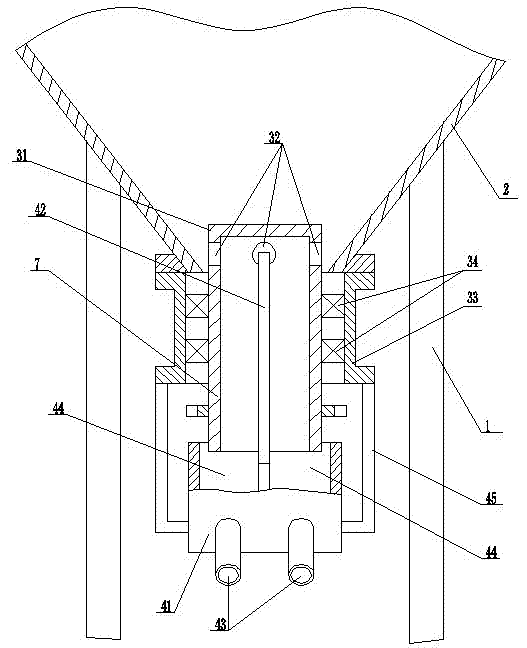

Steel ball sorting machine

The invention discloses a steel ball sorting machine. The steel ball sorting machine comprises a hopper, a rotary type ball taking device, a steel ball distributing device and at least one group of steel ball sorting devices, wherein the hopper is arranged on a stander, the rotary type ball taking device is arranged at the bottom of the hopper, the steel ball sorting devices are arranged on the stander, and steel ball delivery pipes are connected on the steel ball distributing device; the rotary type ball taking device and the steel ball sorting devices are respectively driven by a ball taking power device and a sorting power device, each steel ball sorting device comprises two rotating rollers, one ends (close to the steel ball delivery pipes) of the rotating rollers are high and the other ends of the rotating rollers are low, the two rotating rollers are both connected with the sorting power device in a power manner, two ends of each rotating roller are respectively and rotatably connected on two slide blocks capable of sliding on the stander, and gap adjusting devices capable of adjusting the size of a gap between the two rotating rollers are arranged on the two slide blocks at the same end; and a ball receiving groove is formed below the steel ball sorting devices, a plurality of ball receiving regions sequentially arrayed along the length directions of the rotating rollers are arranged in the ball receiving groove. The steel ball sorting machine is simple in structure, high in production efficiency, high in sorting quality and good in sorting effect.

Owner:WULIAN DADI PRECISION STEEL BALL CO LTD

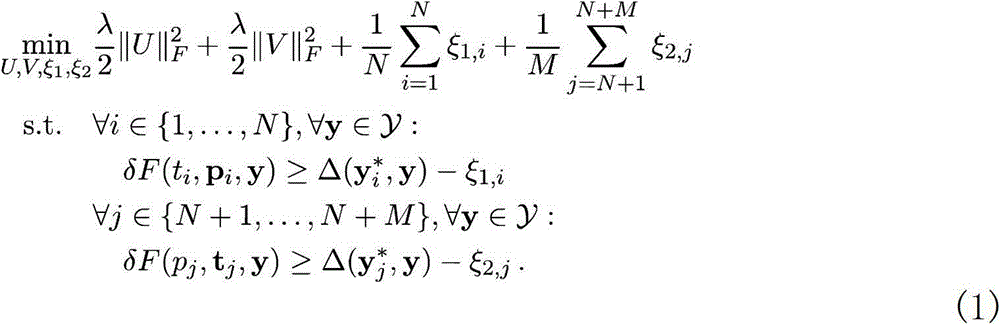

Cross-media sorting method based on hidden space learning and two-way sorting learning

InactiveCN103559191AImprove sorting effectMultimedia data retrievalSpecial data processing applicationsLearning basedImage retrieval

The invention discloses a cross-media sorting method based on hidden space learning and two-way sorting learning. The method includes 1, centrally constructing sorting samples of text retrieval images and sorting samples of image retrieval texts into a training sample; 2, performing cross-media sorting learning based on the hidden space learning and the two-way sorting learning on the constructed training sample, and acquiring a multimedia semantic space and a cross-media sorting model; 3, using the learned cross-media sorting model to performing cross-media sorting. The method can be applied in the text retrieval images and the image retrieval texts, and modeling is performed on two retrieval directions simultaneously, the acquired semantic understanding capacity of a retrieval model is stronger, and retrieval accuracy is higher as compared with the method considering one-way sorting learning only.

Owner:ZHEJIANG UNIV

Method for preparing fatty hydroximic acid collecting agent and application

The invention discloses a method for preparing a fatty hydroximic acid collecting agent, which is characterized by comprising the following steps of: stirring alkyl hydroximic acid having more than or equal to 5 to 9 carbon atoms, fatty acid having 5 to 22 carbon atoms and mixed solvent oil having 4 to 30 carbon atoms for reaction at room temperature and then separating an oil phase from a water phase, wherein the oil phase is the fatty hydroximic acid collecting agent. The collecting agent of the invention has good selectivity, high collectivity, proper foaming characteristic and easy dissolution in water. Rare earth metal concentrate is obtained by the following steps of: grinding crude rare earth metal oxide ore; adding sodium hydroxide, water glass, sodium fluorosilicate and sodium sulphide into the grinded ore; adding the fatty hydroximic acid collecting agent of the invention into the mixture; then adding modified starch into the mixture; and finally performing flotation. The collecting agent of the invention is a flotation collecting agent for the rare earth metal oxide which is suitable for industrial production and has simple process and high separation efficiency.

Owner:广东省资源综合利用研究所

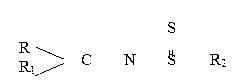

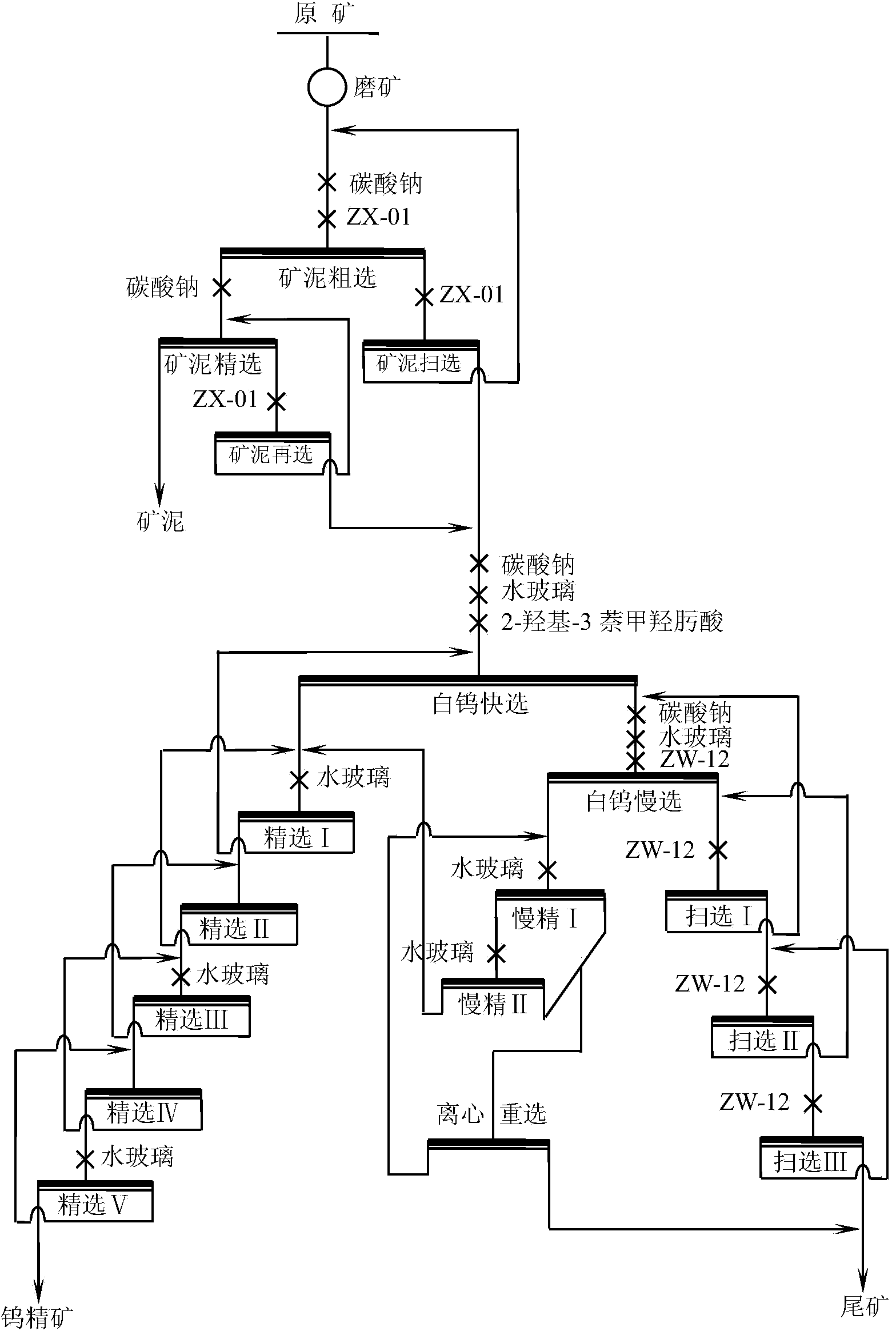

Beneficiation method of refractory low-grade scheelite

ActiveCN104226462AAddressing the Effects of SortingImprove sorting effectFlotationWet separationHydroxamic acidLower grade

The invention provides a beneficiation method of refractory low-grade scheelite. The method adopts slurry collecting agent ZX-01, slurry collecting agent 2-hydroxy-3 naphthoyl hydroxamic acid and slurry collecting agent ZW-12 which have high selective collecting capability; the method comprises the steps of finely grinding raw ore, carrying out slurry flotation, carrying out rapid beneficiation on scheelite, selecting the scheelite, carrying out slow beneficiation on scheelite, slowly selecting the scheelite, carrying out centrifugal reselection on middlings, and the like to finally obtain the scheelite concentrate. The low-grade scheelite sorted by the method is good in sorting indexes; the scheelite concentrate is higher in grade and yield; the beneficiation method of the refractory low-grade scheelite is stable, efficient, good in sorting effect, high in adaptability, high in recovery index and low in production cost, thus being suitable for popularization and application.

Owner:JIANGXI UNIV OF SCI & TECH

Sorting technology for coarse coal slurry damping pulsation interference bed

InactiveCN101543802AImprove loose stateReasonable flow distributionWet separationPeristaltic pumpEngineering

The invention discloses sorting technology for a coarse coal slurry damping pulsation interference bed. The sorting technology is formed by the mutual connection of an interference bed sorter, a feeding system, a peristaltic pump, a cleaned coal recovering system, and a water pump, and is characterized in that the inside of the interference bed sorter is added with a plurality of damping blocks and screens; the middle part of the interference bed sorter is connected with the feeding system to form a stable fluid bed; simultaneously, a diaphragm is additionally arranged on the lower part of the interference bed sorter and the upper part of a heavy product discharge port to generate a pulsating flow, so that particles with different densities gain the accelerating effect and retarding effect, and the leading action of the density on the separation effect is strengthened; the peristaltic pump is used for discharging heavy products, so that the processing capability of the equipment is improved; under the conditions of wide particle size range of the coarse coal slurry and heavy processing load, the good separation effect and high separation efficiency can also be achieved by the separation process.

Owner:HENAN POLYTECHNIC UNIV

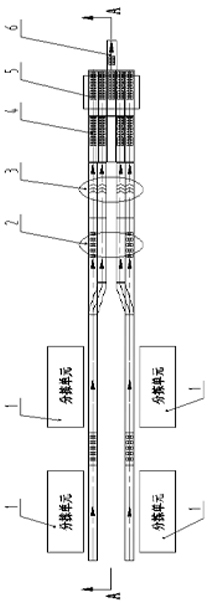

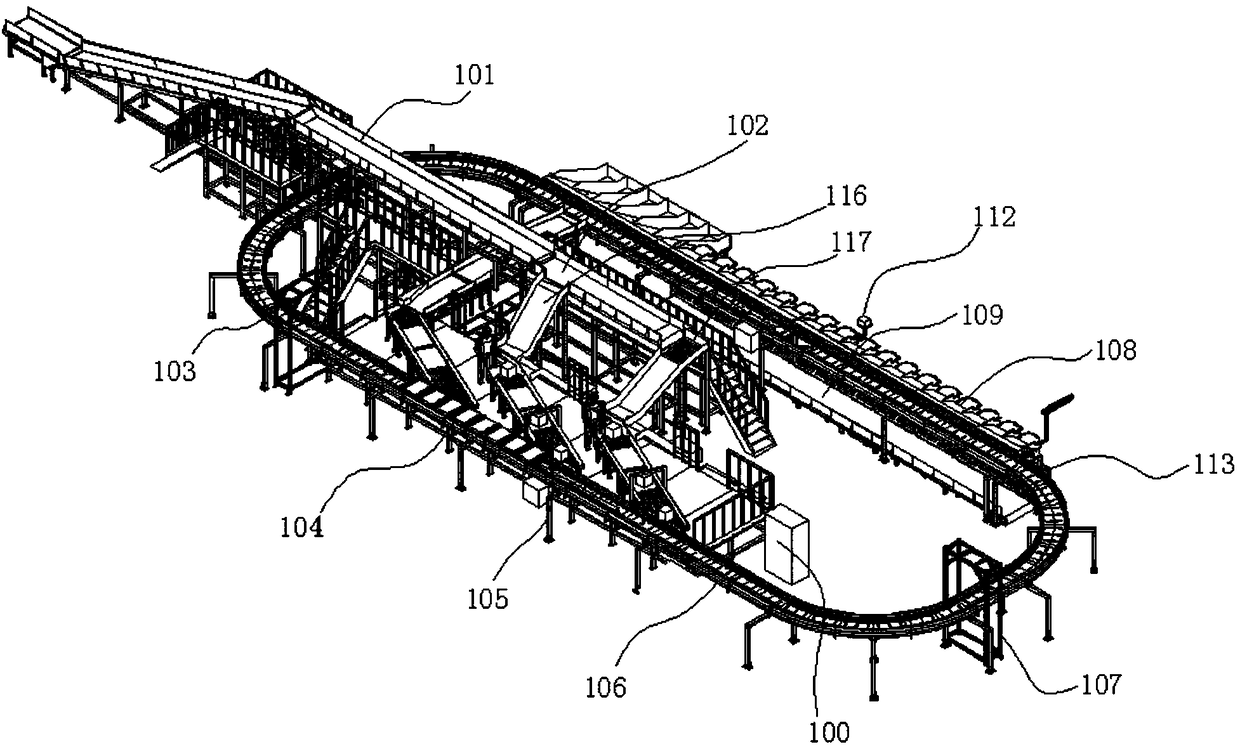

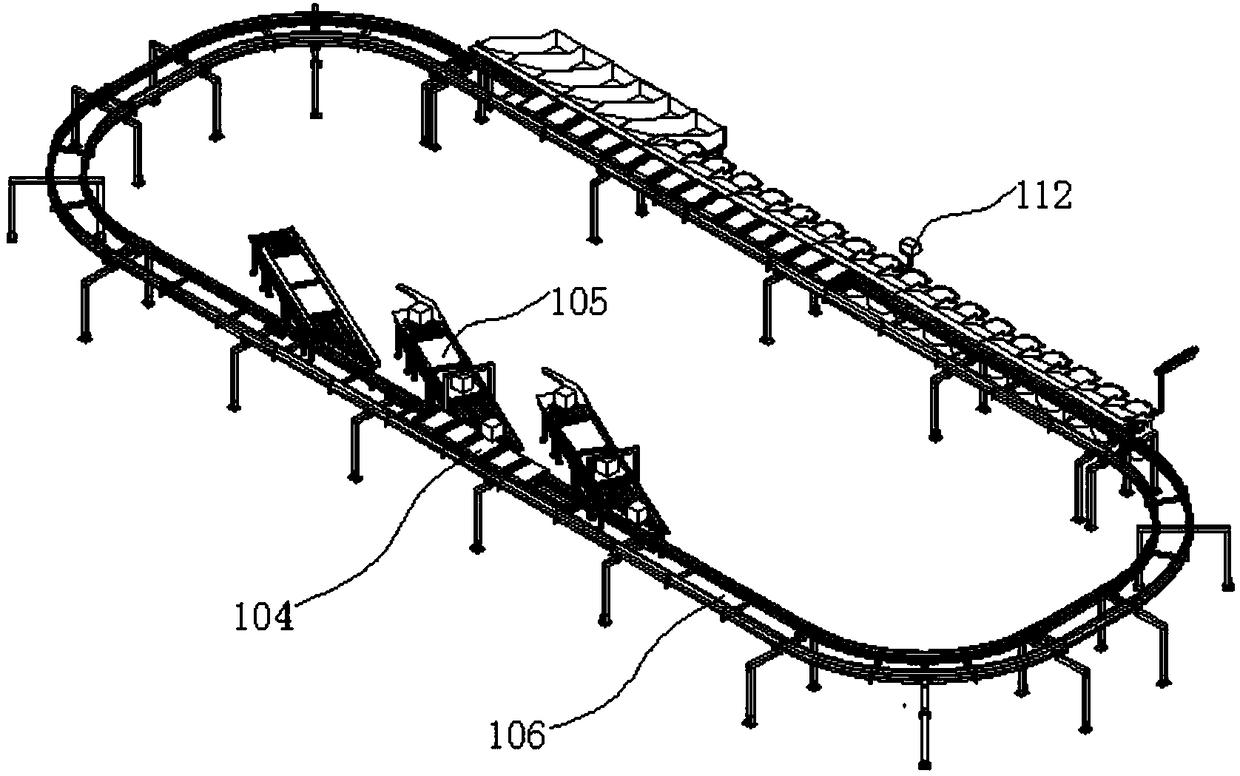

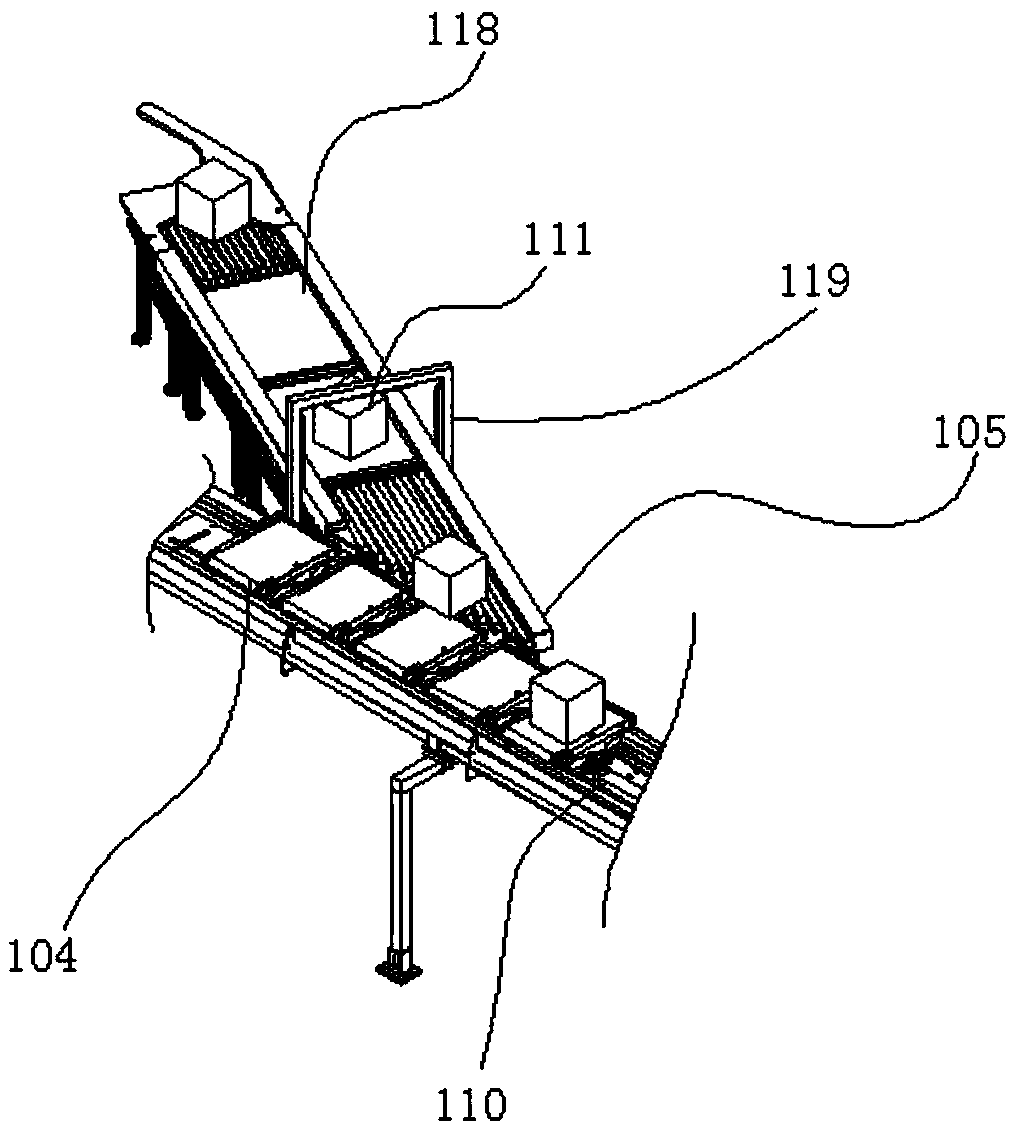

Double-loop-line intersected belt sorting machine, intersected belt sorting system and sorting method thereof

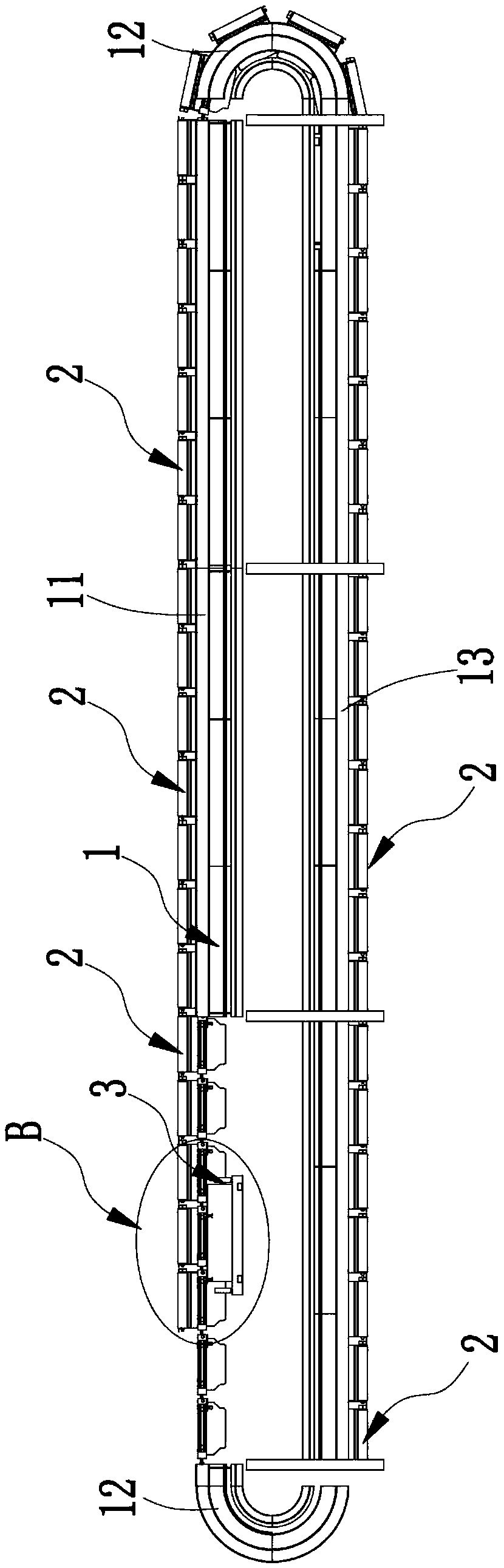

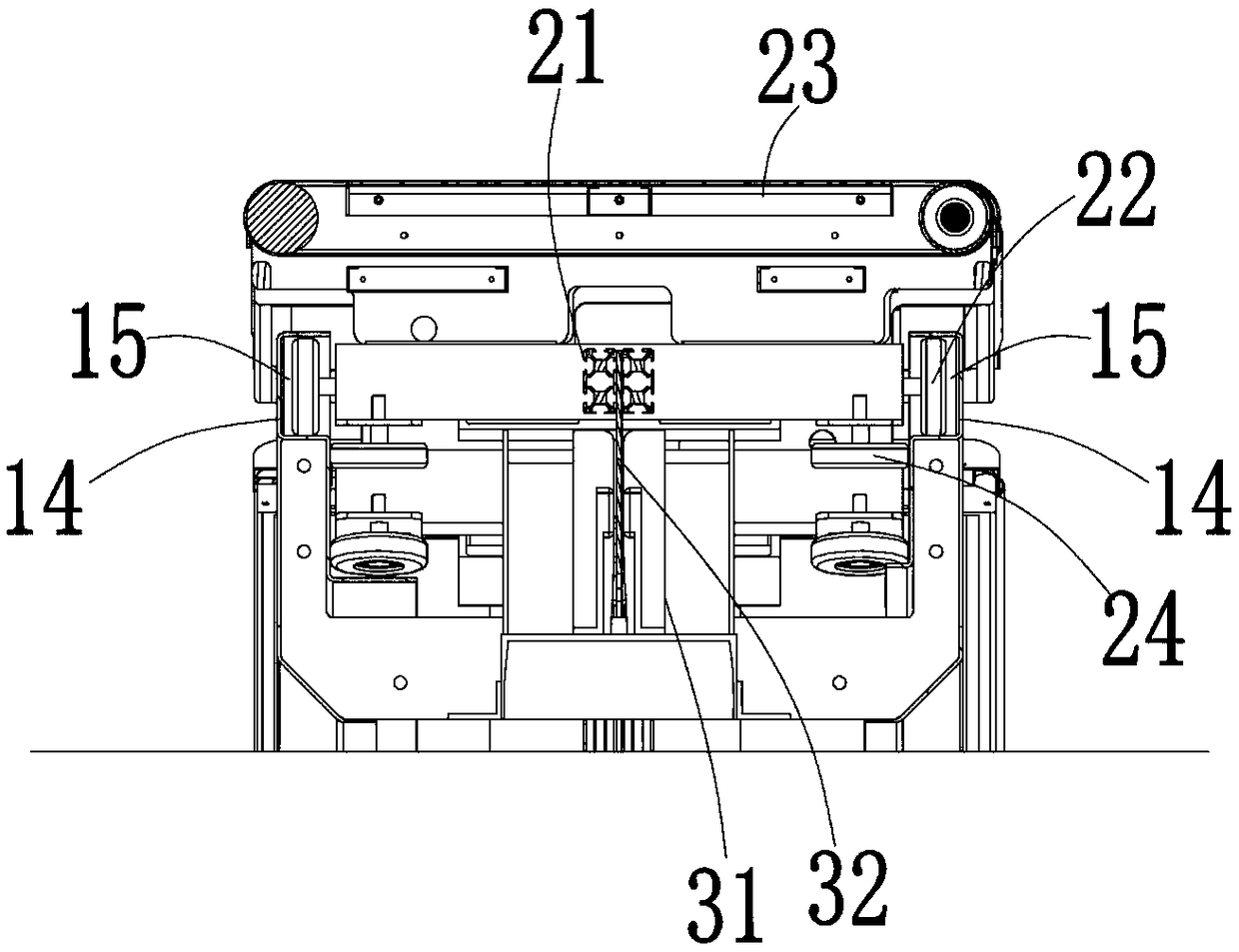

PendingCN109335538AReduce vacancy rateIncrease the number ofPackagingConveyor partsEngineeringMechanical engineering

The invention discloses a double-loop-line intersected belt sorting machine, an intersected belt sorting system and a sorting method thereof. The double-loop-line intersected belt sorting machine comprises at least one annular rail, two sets of intersected belt cars for forming two conveying loop lines circularly rotated on the annular rails side by side, and a power device for driving the two sets of intersected belt cars to move along the annular rails. The double-loop-line intersected belt sorting machine is delicate in design and simple in structure; as two sets of cars are used in one annular rail, the number of the intersected belt cars is increased by using internal space of the loop lines under the precondition of not increasing the floor area to multiply the sorting capacity, theuse efficiency of the sorting machine is improved, and the equipment cost is reduced; and meanwhile, parcels can be transferred between two conveying annular intersected belt cars, so that the idlingrate of the cars can be reduced, meanwhile, the parcel loading flexibility is improved, and the arrangement requirements and the occupied space of a particle loading line are reduced.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

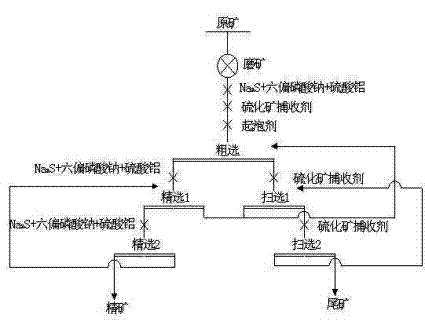

Method for beneficiating high-peat copper sulphide ore

The invention discloses a method for beneficiating high-peat copper sulphide ore and relates to a method for beneficiating nonferrous metals, which specifically relates to a method for beneficiating high-peat copper sulphide ore; regulating agent and composite inhibitor are added before floating ore pulp and after graining raw ore; flotation environment and mineral surface state in ore pulp are improved in the method disclosed by the invention; the inhibition capacity of inhibitor on easily-floated gangue mineral and selective collection of collecting agent on mineral are enhanced; compared with the traditional method for beneficiating pre-deslimed peat, a technical procedure is simplified by the invention; the loss of available mineral caused by pre-deslimed peat is avoided; and the recycle rate of copper is increased by about more than 18%.

Owner:HUNAN RES INST FOR NONFERROUS METALS

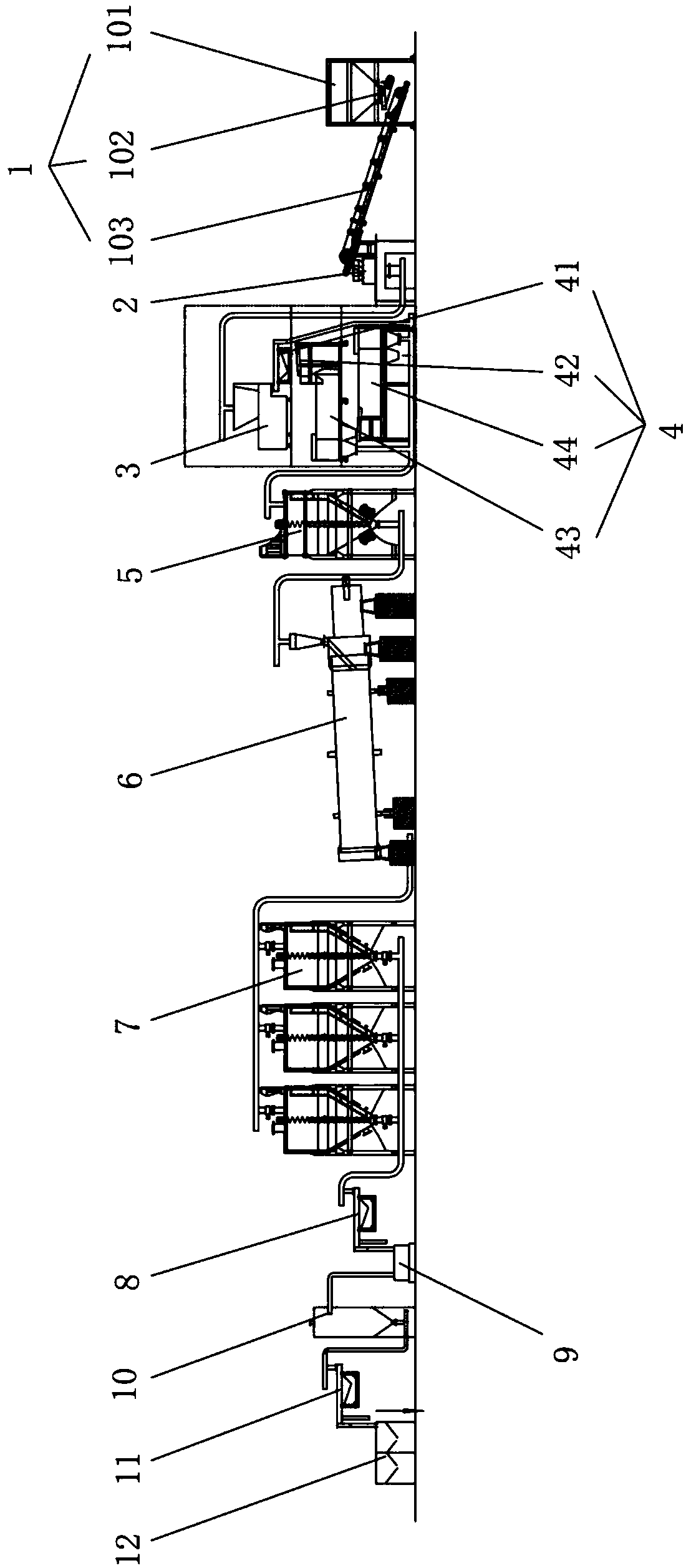

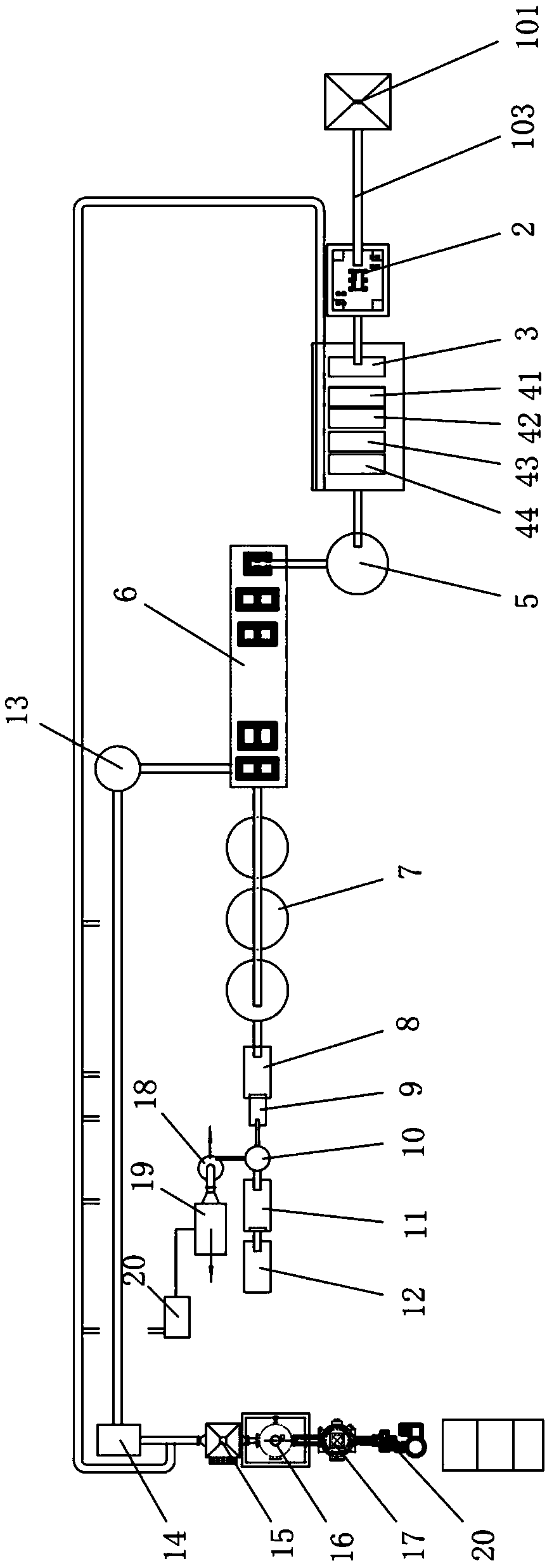

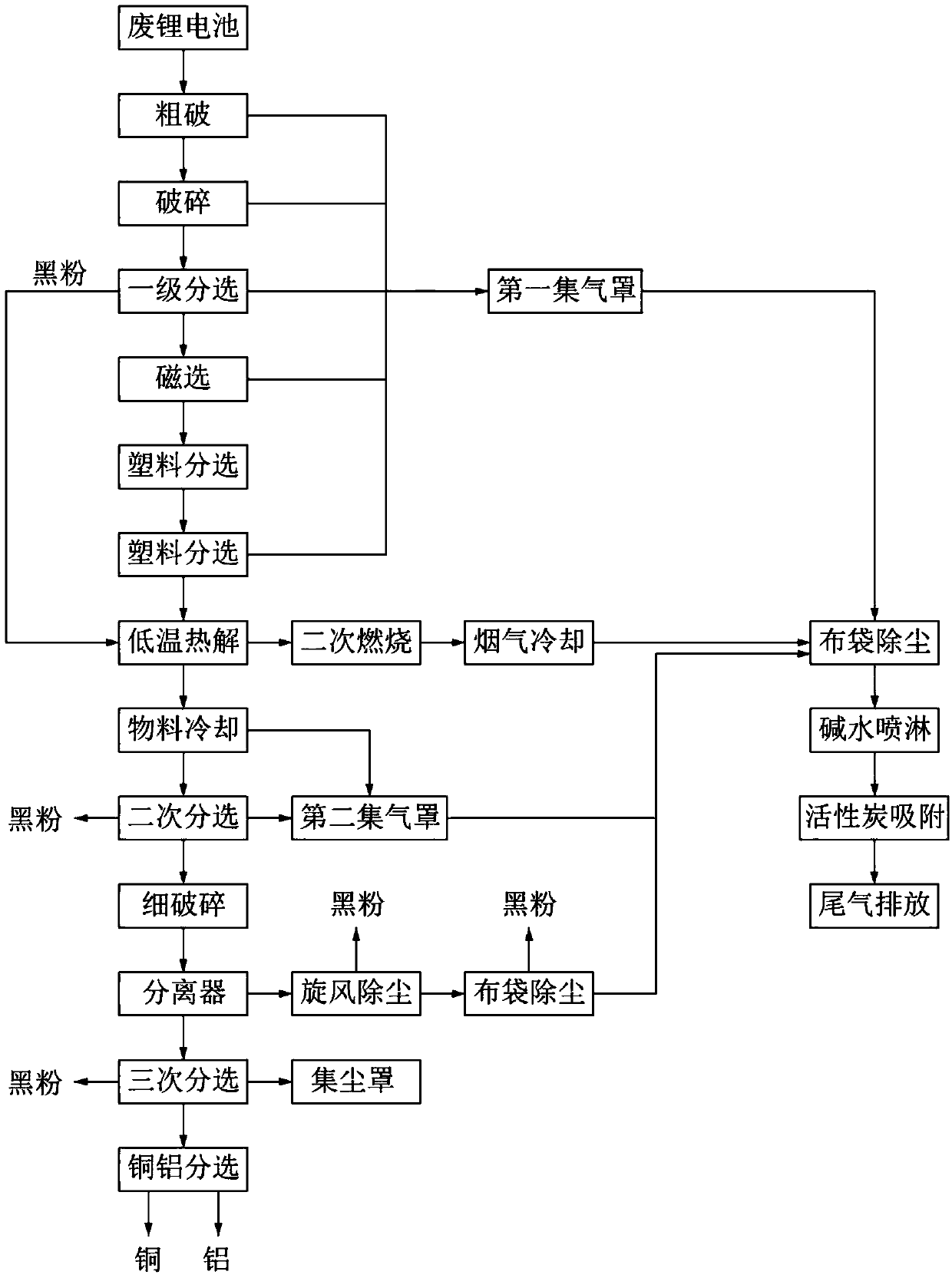

Waste lithium ion battery crushing and sorting device and method

PendingCN109604024AFull play to recycling valueImprove sorting effectWaste accumulators reclaimingGrain treatmentsElectrical batteryEngineering

The invention discloses a waste lithium ion battery crushing and sorting device and method. The crushing and sorting device comprises a feeding device; a rough crushing machine of which the feeding end is connected with the discharging end of the feeding device; a crushing machine of which the feeding end is connected with the discharging end of the rough crushing machine; a multistage sorting device of which the feeding end is connected with the discharging end of the crushing machine; a pyrolyzing furnace of which the feeding end is connected with the discharging end of the multistage sorting device; a material cooling bin of which the feeding end is connected with the discharging end of the pyrolyzing furnace; a second vibrating screen of which the feeding end is connected with the discharging end of the material cooling bin; a fine crushing machine of the feeding end is connected with the discharging end of the second vibrating screen; a third vibrating screen of which the feedingend is connected with the discharging end of a separator; and a jigging machine of which the feeding end is connected with the discharging end of the third vibrating screen. According to the waste lithium ion battery crushing and sorting device and method, high-efficiency recovery of valuable components in a lithium ion battery can be achieved; and the sorting effect is good, and the recovery rateof black powder is high.

Owner:ZHUZHOU DINGDUAN EQUIP CO LTD

Vortex magnetic separator

InactiveCN101104156ABounce farHigh frequency of alternationMagnetic separationElectrical polarityMetallic materials

The invention relates to a magnetic separation device, in detail is a bow wave type magnetic separation machine. The magnetic separation machine includes an outer rolling drum with the inner and outer wall being conical surfaces, the outer rolling drum is the non-magnetic and non-metallic material; an inner rolling drum is arranged in the outer rolling drum, the inner rolling drum has a male cone near the inner wall of the outer rolling drum, magnetic units with opposite polarities are alternatively disposed on the male cone of the inner rolling drum; the inner and outer rolling drum have the same vertical rotary axis and are driven by different rotor axes respectively; blanking ports are arranged at the upper part of the inner and outer rolling drum, and annular material-receiving ports are arranged on the periphery at the lower part of the inner and outer rolling drum. The invention can improve the selection effect of non-magnetic metal energy.

Owner:镇江电磁设备厂有限责任公司

Collecting agent for low-grade refractory gold ores

The invention discloses a collecting agent for low-grade refractory gold ores. The collecting agent comprises the following materials by weight: 45-55 parts of cyanoethyl diethyl dithionocarbamate, 30-40 parts of allyl alkyl xanthate, and 10-15 parts of liquid ammonium dibutyl dithiophosphate. The collecting agent has dual attributes, such as collecting and bubbling, the selectivity is good, the collecting capacity is strong, and the concentrate grade and the recovery rate can be effectively improved in a pH value range of from 8 to 8.5, thereby being the high-efficiency collecting agent for low-grade refractory gold ores.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

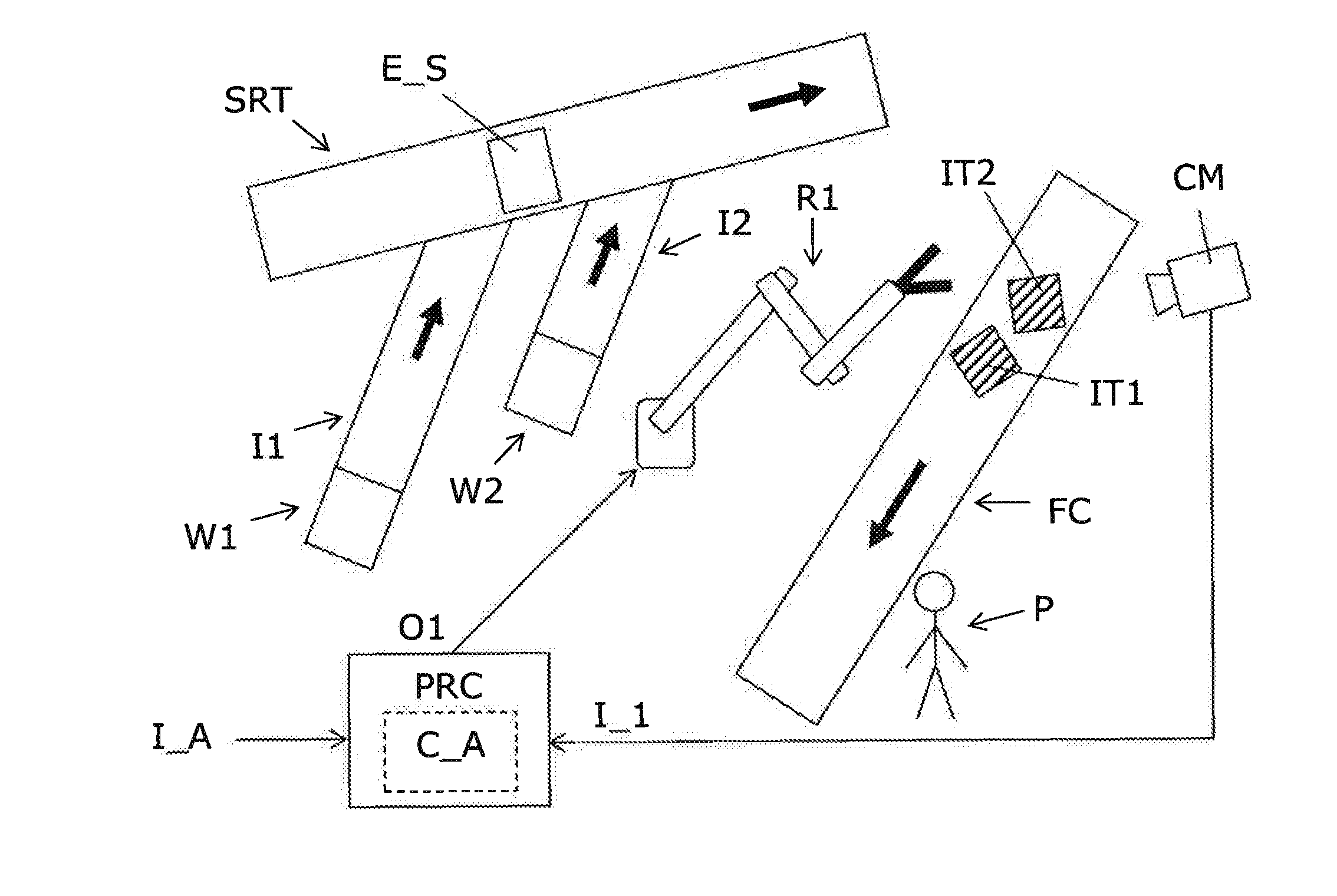

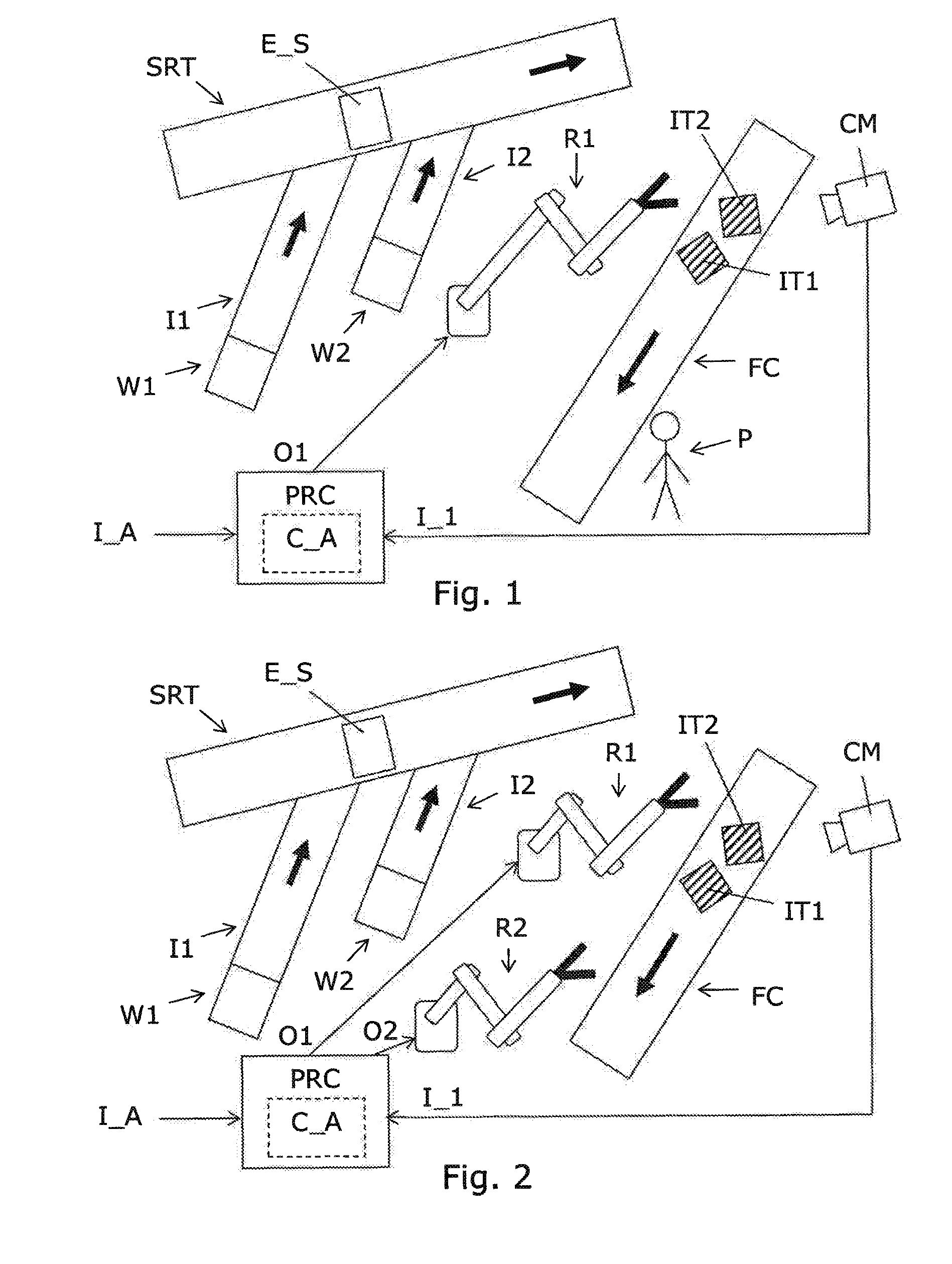

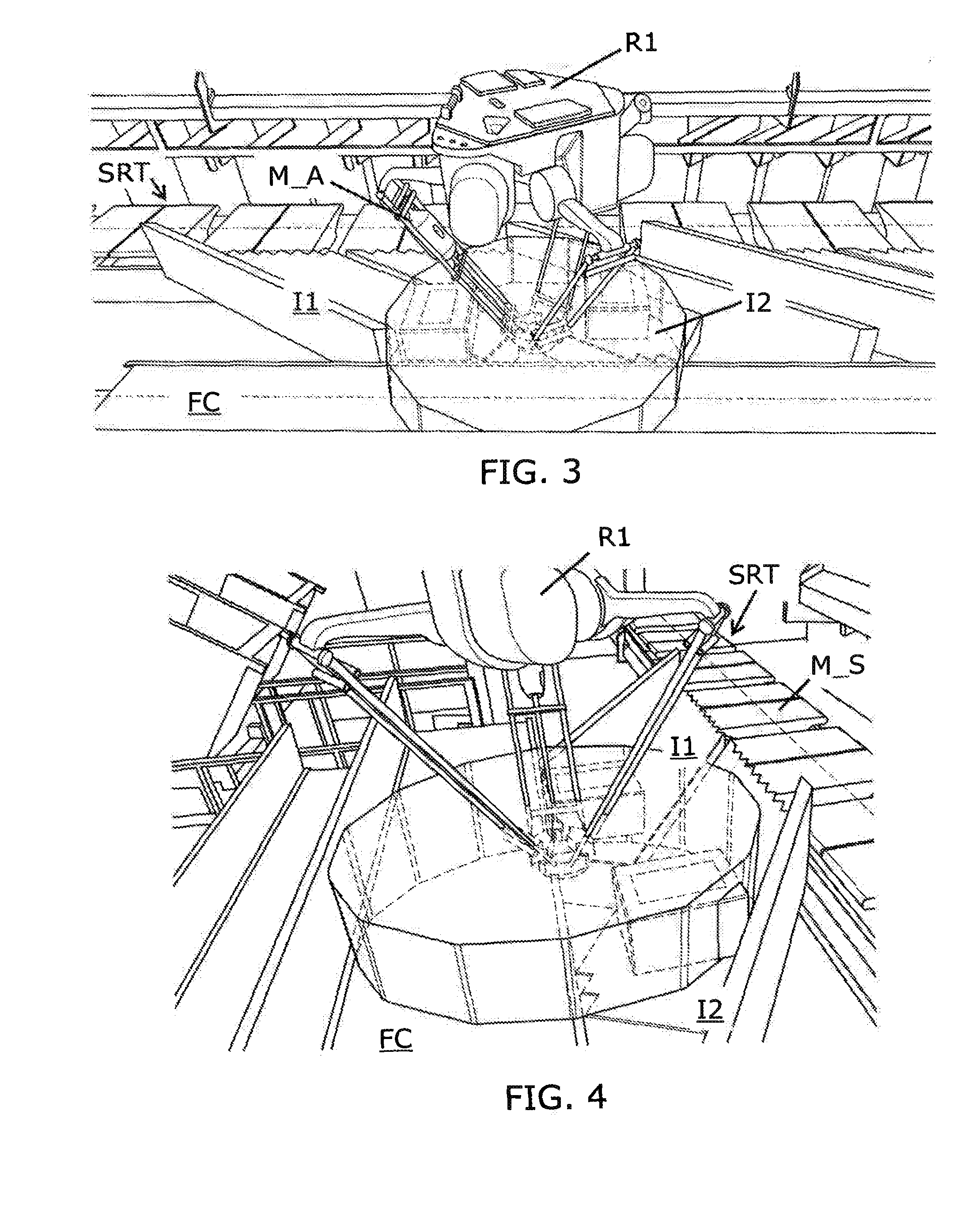

Method for inducting and singulating items to a sorter

ActiveUS9555447B2Improve sorting effectProgramme-controlled manipulatorSortingManual handlingComputer science

Owner:BEUMER GRP AS

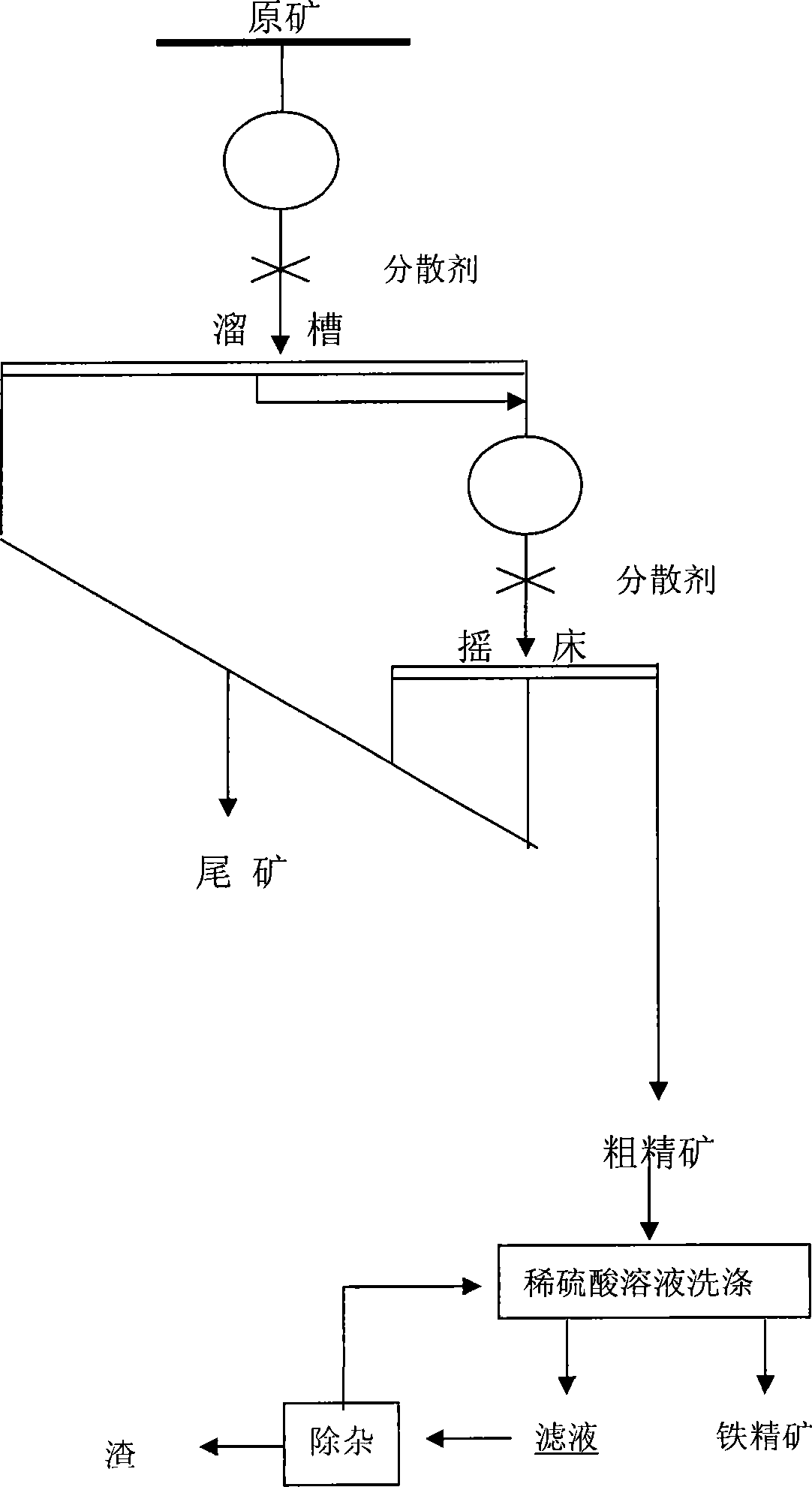

Method forpreparing iron concentrate for making iron from phosphorus-containing oolitic hematite

InactiveCN101054625AAvoid muddyingRaise the gradeProcess efficiency improvementGranularityRoom temperature

The invention discloses a method of producing iron ore concentrate containing roe - like phosphorus hematite for iron manufacture, comprising crashing the roe - like ore, wet grinding until the hematite of granularity < 0.074mm are 40-60 mass% of whole hematite, adjusting the pulp mass percent concentration to 20%-30%, adding the water glass as dispersant of 0.5-1.0kg / t, agitating adequately, selecting by helix shoot, grinding produced ore concentrate until the one with the granularity < 0.074mm are more than 80 mass%, having the water glass as dispersant of 0.2-0.5kg / t, agitating to disperse uniformly, then selecting by shaking table, washing produced iron ore concentrate in room temperature by 0.5%-1.5% dilute sulfuric acid solution for 5-15 minutes, centrifugal separation, in which the solid are iron ore concentrate. The invention treats the roe - like phosphorus hematite to obtain the iron ore concentrate with a tenor of 62%, P content less than 0.06%. The invention can fully and reasonably apply rich roe - like phosphorus hematite resource in our country, has a good effect of dephosphorization and a low cost. And produced iron ore concentrate have a high recovery ratio.

Owner:CENT SOUTH UNIV

Superconductive magnetic separating device

ActiveCN101920223ASmall granularityImprove separation efficiencyMagnetic separationDrive wheelGranularity

The invention relates to a superconductive magnetic separating device which comprises a solenoid superconductive magnet, a driving wheel and a driven wheel, wherein an annular closed screen type conveyer belt is wound on the driving wheel and the driven wheel, and the bearing surface of the screen type conveyer belt is a screen; and a part of the screen type conveyer belt passes through a room temperature hole of the superconductive magnet, and another part is positioned outside the superconductive magnet. The superconductive magnetic separating device can realize continuous production and greatly improve the separating efficiency; and meanwhile, the solenoid superconductive magnet is adopted, thus the background magnetic field intensity is high, and the separating effect is good; and the superconductive magnetic separating device can be used for treating weakly magnetic materials and fine mineral powder, extracting and separating high-grad iron ore deposits, low-grid iron ore deposits and tainings from iron ore and iron ore from red mud and has high separating efficiency and small separable mineral powder granularity.

Owner:江苏旌凯中科超导高技术有限公司

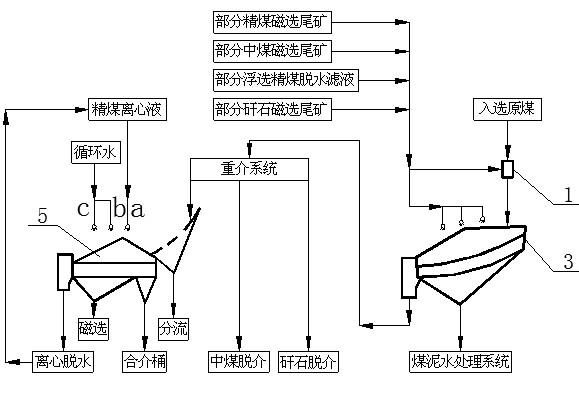

Coal slime treatment process for deslimed dense-medium coal separation

Disclosed is a coal slime treatment process for deslimed dense-medium coal separation. In the process, part of coal slime including magnetically separated clean coal tailings, magnetically separated middling coal tailings, magnetically separated gangue tailings and dehydrated filtrate of floatation separated clean coal is used as flush water for a wet-process classifying screen or a desliming screen and used as spray water for the same, and clean coal centrifugate is used as the primary spray water for a clean coal medium drainage screen. On the premise of guaranteeing feed concentration in floatation separation, work load of a concentrator can be lowered (by 20-40%), higher separation precision in gravity separation operation is maintained, better separation effect can be achieved in thecrude slime separation link and the fine slime flotation link, the recovery rate of crude particles in centrifugate is increased while medium consumption of coal separation plants is reduced, primaryinvestment, floor area and processing cost for deslimed dense-medium coal separation plants are decreased, product quality is improved, and higher economic benefit can be achieved.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com