Beneficiation method of refractory low-grade scheelite

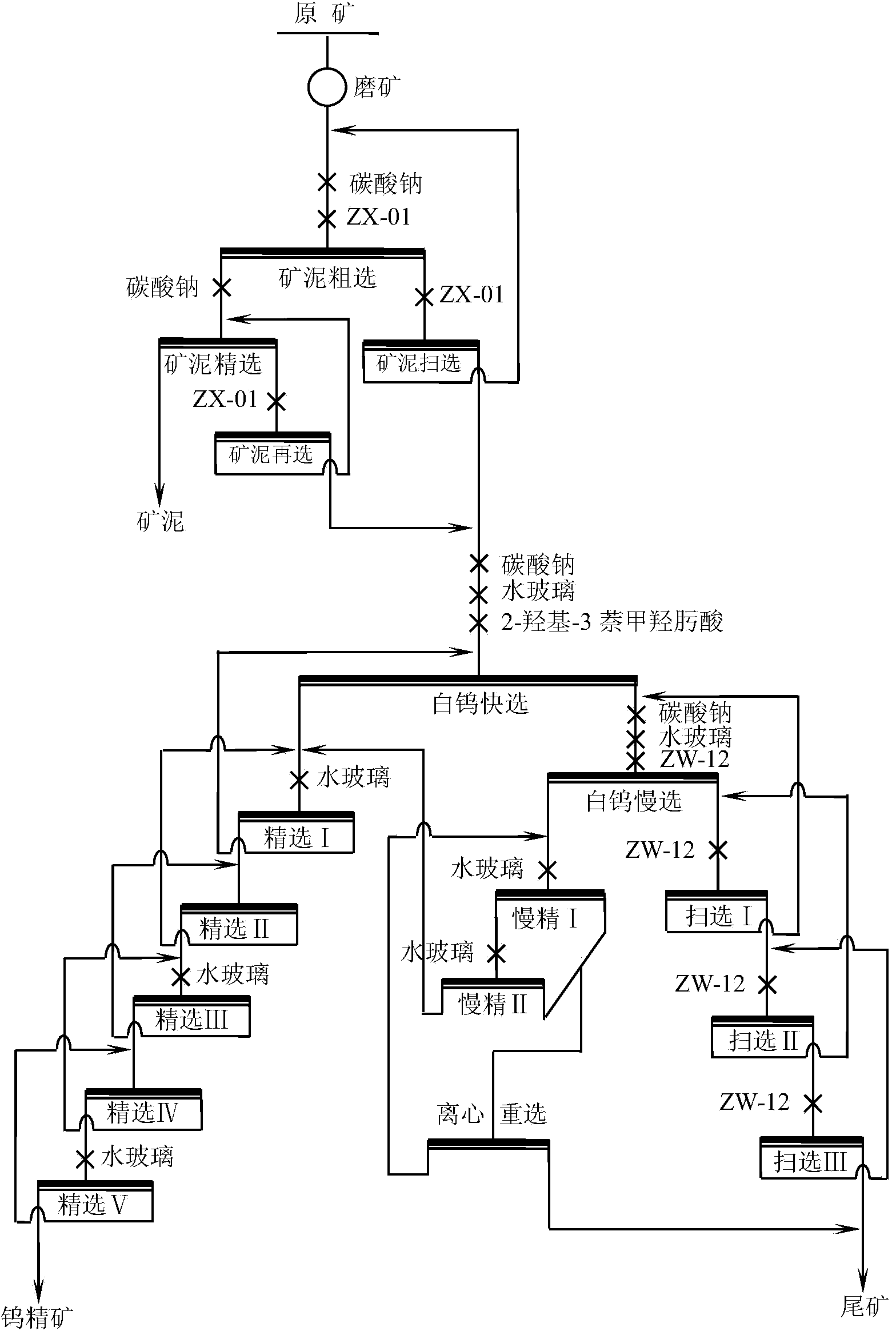

A beneficiation method and scheelite technology, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of large influence of gangue minerals, poor flotation collection effect, and low comprehensive recovery rate, etc. The recovery index is high, the sorting effect is good, and the effect of avoiding mechanical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Mix 150g of dimethyl dicocoyl ammonium chloride, 100g of lauryl ether amine, and 100g of sodium laurylamine acetate, and stir at normal temperature and pressure for 100-120min to obtain collector ZX-01.

[0044] Mix 150g of 8-hydroxyquinoline, 100g of dodecanal, 200g of medilan, and 100g of 1,1,2-octyltricarboxylate, stir evenly at normal temperature and pressure to obtain collector ZW-12.

Embodiment 2

[0046] Mix 250g of dimethyl dicocoyl ammonium chloride, 100g of lauryl ether amine, and 100g of sodium laurylamine acetate, and stir at normal temperature and pressure for 100-120min to obtain collector ZX-01.

[0047] Mix 250g of 8-hydroxyquinoline, 100g of dodecanal, 200g of medilan, and 100g of 1,1,2-octyltricarboxylate, stir evenly at normal temperature and pressure to obtain collector ZW-12.

Embodiment 3

[0049] Mix 200g of dimethyl dicocoyl ammonium chloride, 100g of lauryl ether amine, and 100g of sodium laurylamine acetate, stir at normal temperature and pressure for 100-120min to obtain collector ZX-01.

[0050] Mix 200g of 8-hydroxyquinoline, 100g of dodecanal, 200g of medilan, and 100g of 1,1,2-octyltricarboxylate, stir evenly at normal temperature and pressure to obtain collector ZW-12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com