Coal slime treatment process for deslimed dense-medium coal separation

A technology for dense medium coal preparation and coal slime water, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of poor working environment, large amount of dust, increase of primary investment cost and floor space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

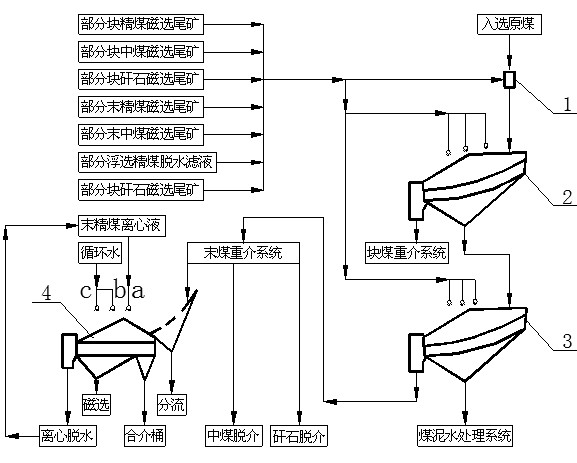

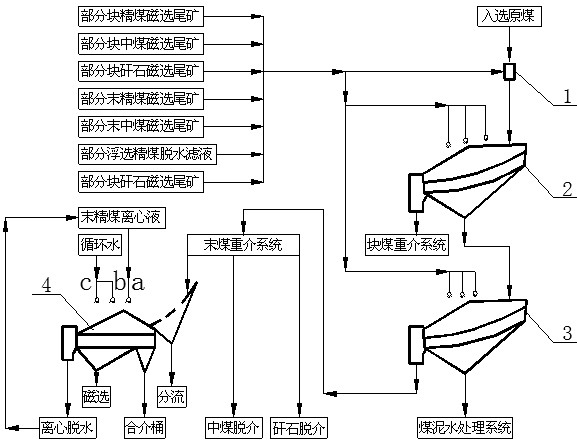

[0025] like figure 1 As shown, in the raw coal classification and desliming heavy medium process, the magnetic separation tailings and the flotation clean coal dewatering filtrate are used as the flushing water of the wet grading sieve and the flushing of the wet grading sieve and the desliming sieve. Water spraying, the order of priority is: lump clean coal magnetic separation tailings, lump coal magnetic separation tailings, lump gangue magnetic separation tailings, final clean coal magnetic separation tailings, final medium coal magnetic separation tailings, flotation Clean coal dehydration filtrate, waste rock magnetic separation tailings. The specific process is as follows:

[0026] First, set the water consumption per hour for the wet classification and desliming of the selected raw coal according to the routine, because the screening efficiency of the wet classification screen 2 and the desliming efficiency of the desliming screen 3 are related to the particle size cha...

Embodiment 2

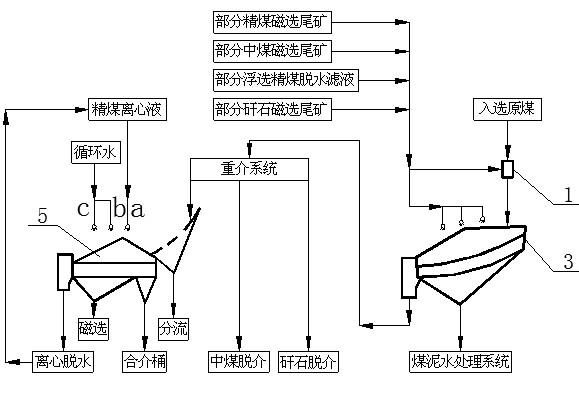

[0029] like figure 2 As shown, in the process of mixing raw coal into the desliming heavy medium process, using magnetic separation tailings and flotation clean coal dewatering filtrate as the feed water of the desliming screen to flush the chute and the water spraying of the desliming screen, the priority order The order is: clean coal magnetic separation tailings, medium coal magnetic separation tailings, flotation clean coal dehydration filtrate, gangue magnetic separation tailings. The specific process is as follows:

[0030] Firstly, set the hourly water consumption of selected raw coal desliming operation, because the desliming efficiency of the desliming screen 3 is related to the particle size characteristics of the selected raw coal, equipment performance and the selected water injection volume, the value range of the water injection volume Usually 1.0m3 / h~2.5m3 / h. In this embodiment, the processing capacity of the selected raw coal is 430t / h, and the flushing volume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com